Patents

Literature

179results about How to "Improve tapping efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Screw

Owner:BI MIRTH CORP

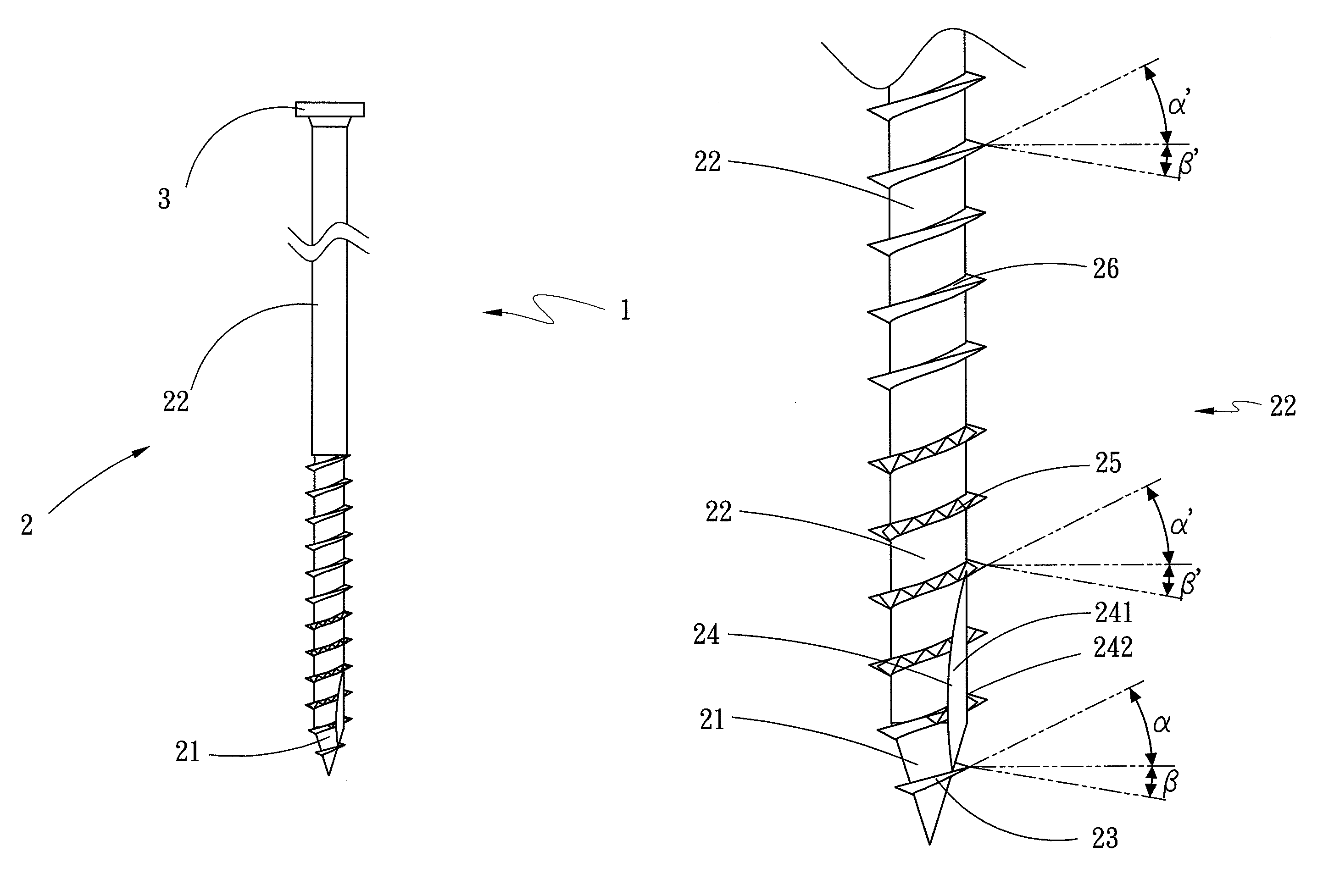

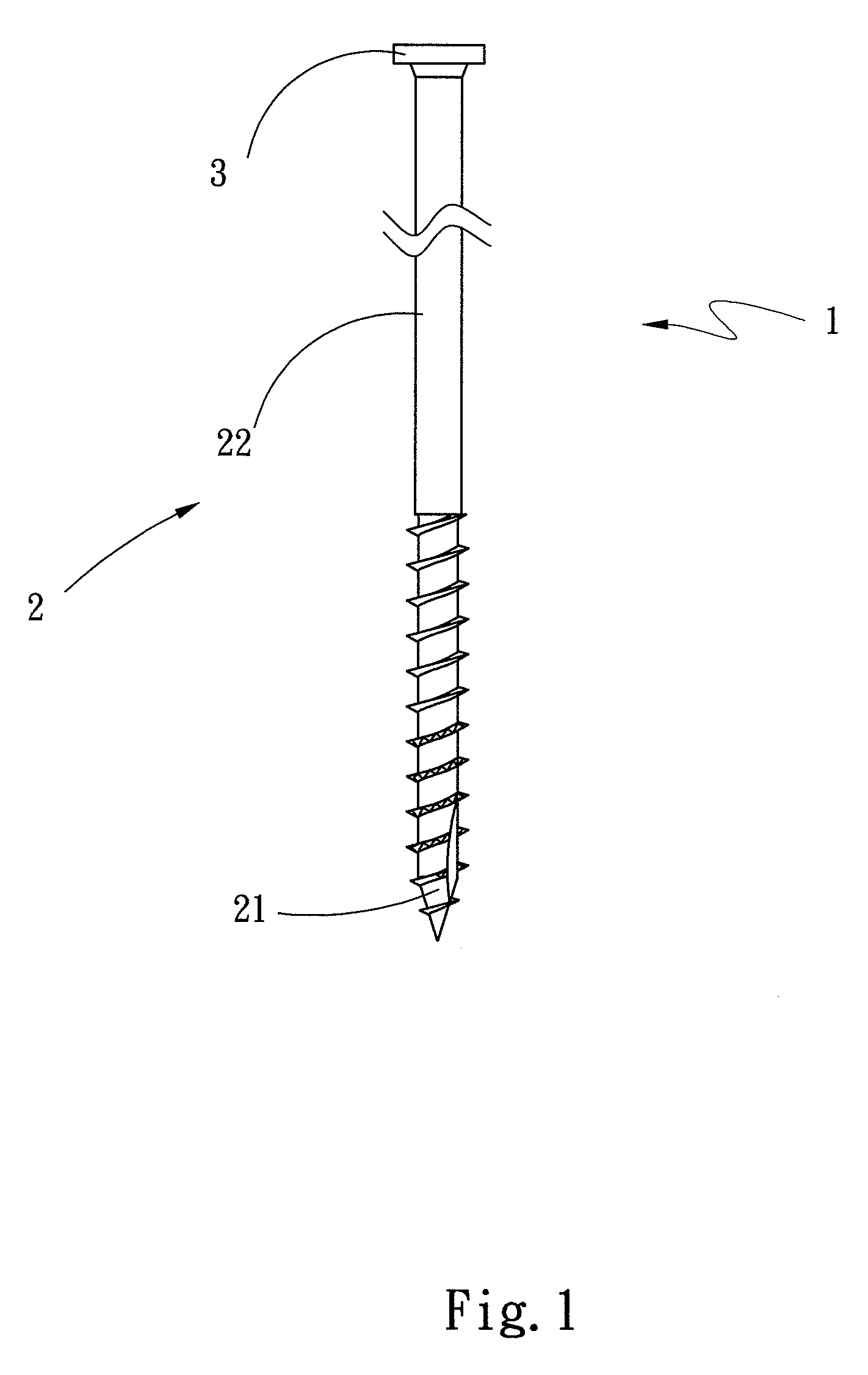

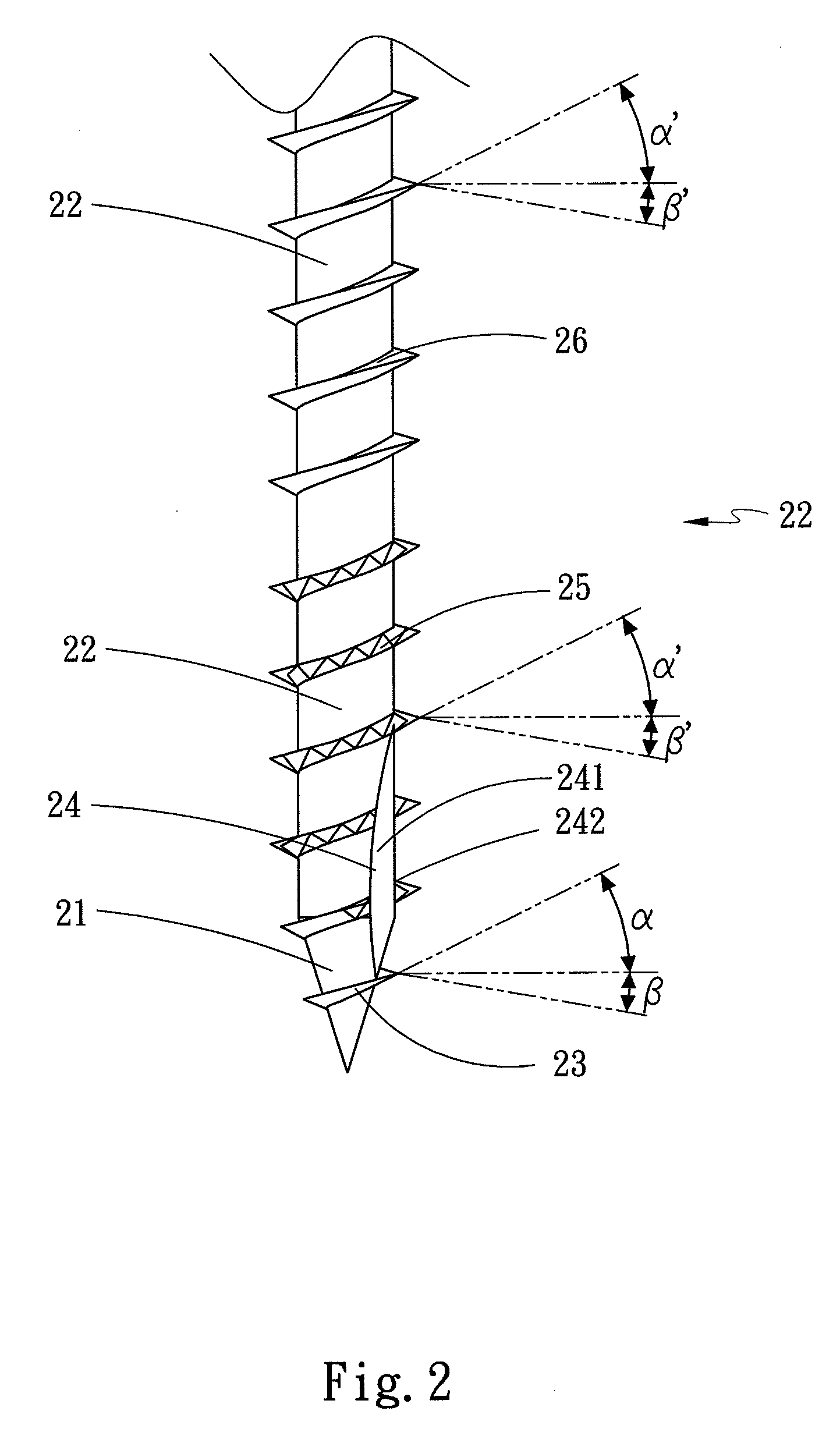

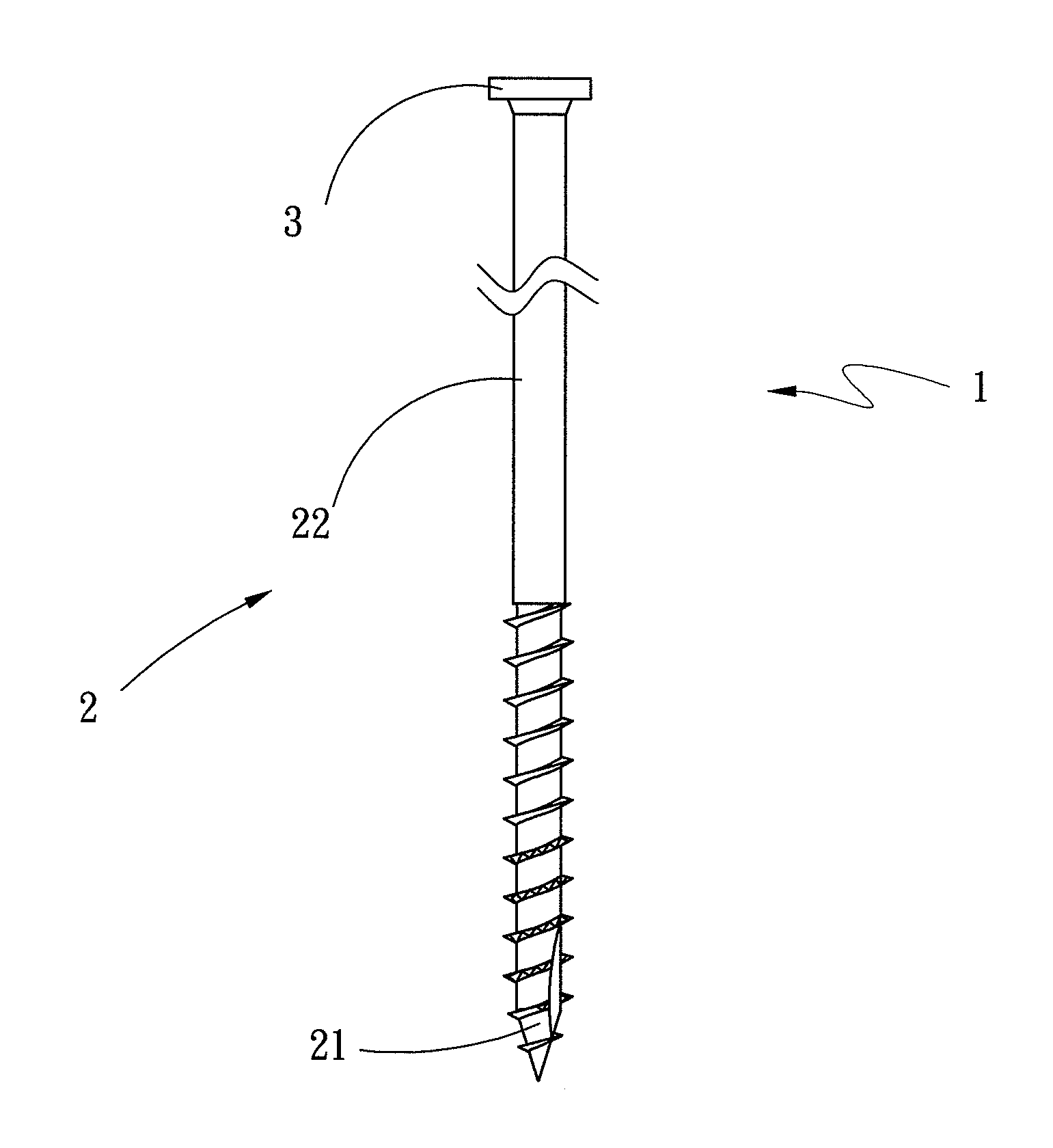

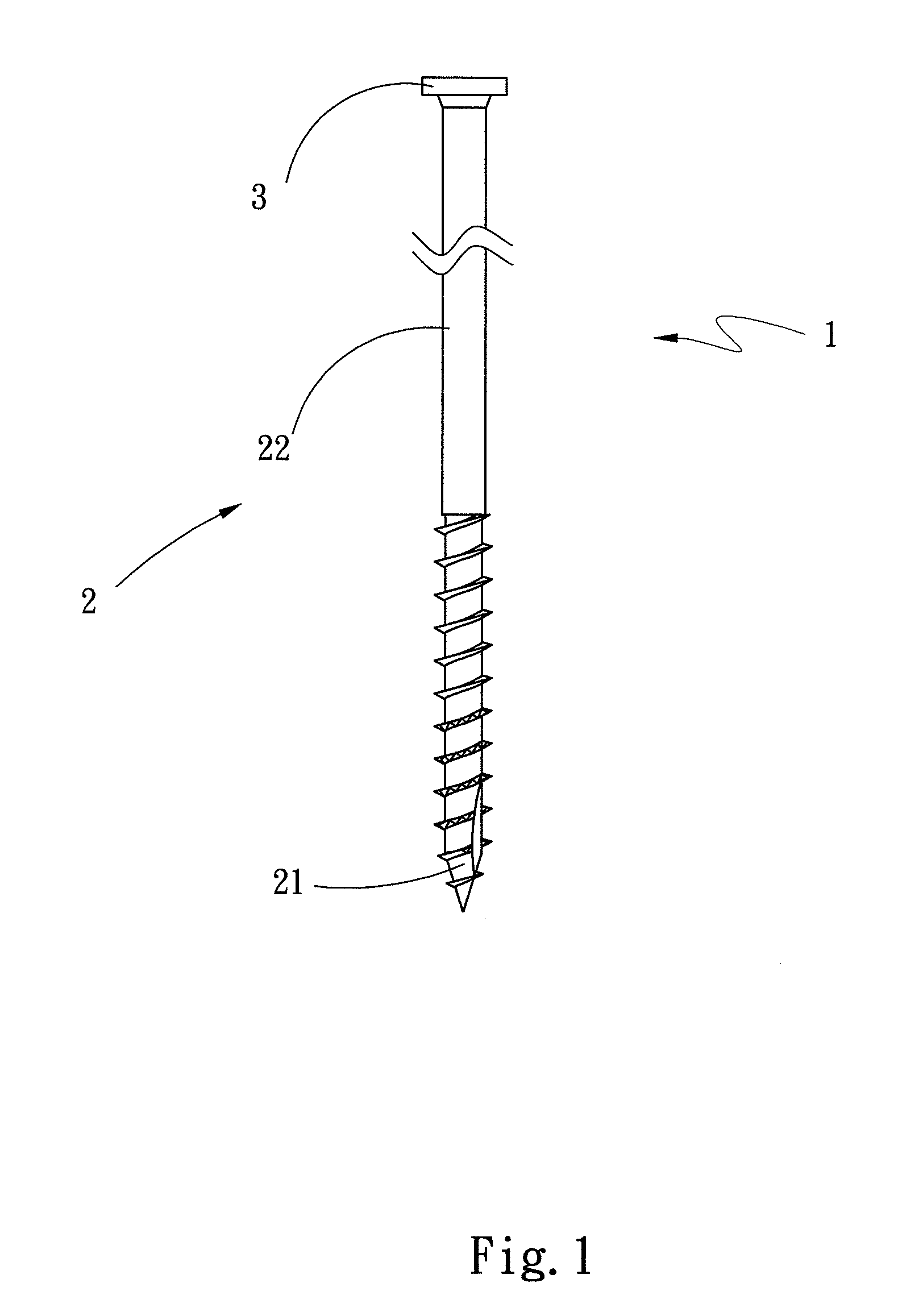

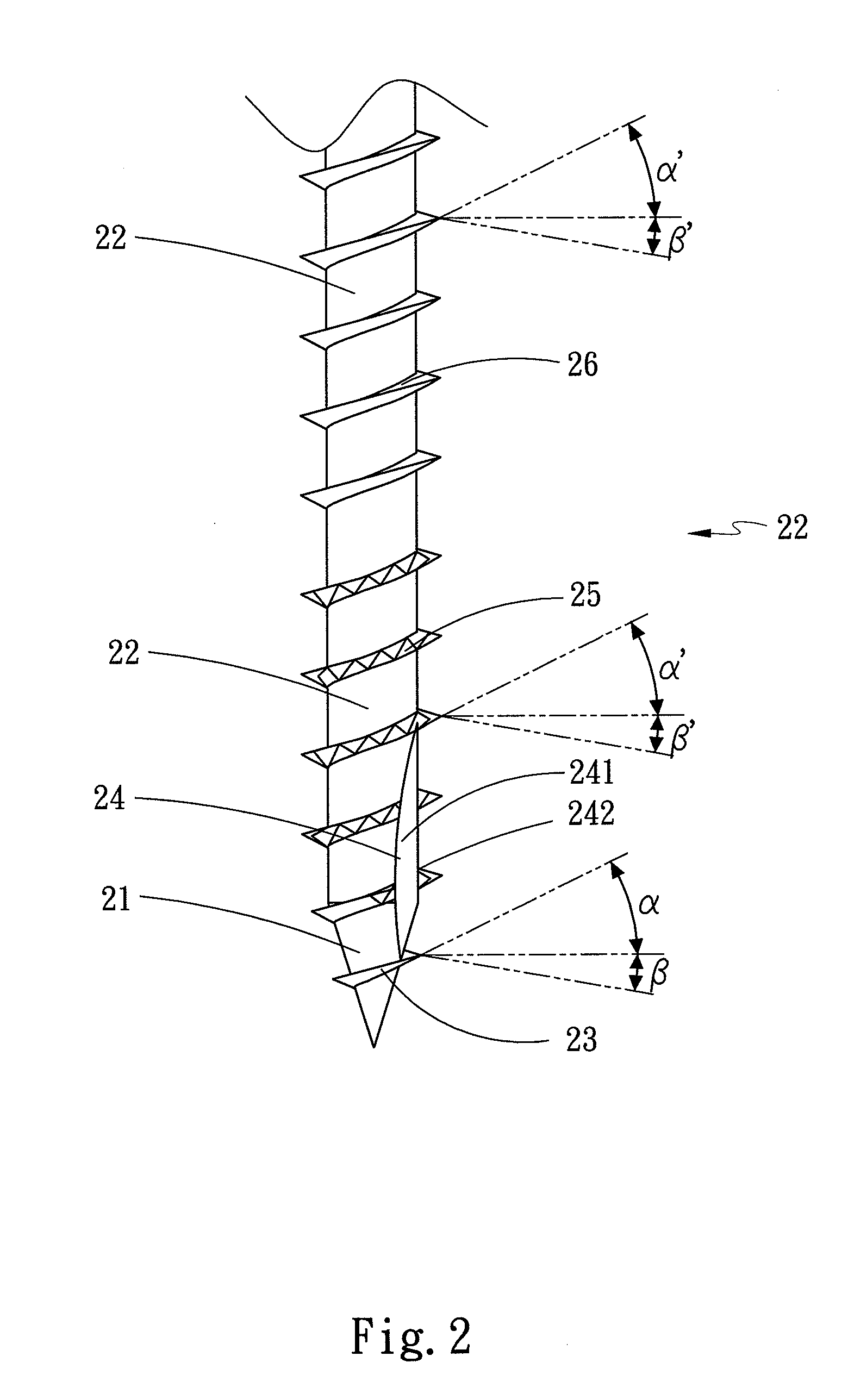

Screw

A screw has a screw head and a shank. The screw head has a square cavity, a hexagonal cavity or a hexagonal boss to be wedged by a screw driver for wrenching. The shank has four sections of threads on the periphery. A first thread is asymmetrical to facilitate drilling holes and spaced with a first threaded pitch. A second thread has a carved V-shaped tail end extended in a direction of the shank at a length larger than one of the first threaded. A third thread has asymmetrical saw-type threads, and a fourth tread is asymmetrical. The screw thus formed can rapidly perform thread tapping and debris dispelling, and reduce friction and expand drilling holes and achieve fast fastening.

Owner:BI MIRTH CORP

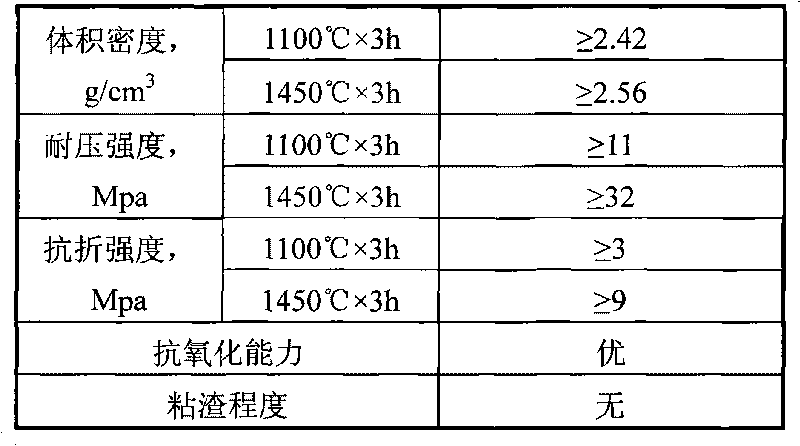

Ramming material for blast-furnace tapping channel and preparation method thereof

InactiveCN101723694ALow costSolve sticky residueBlast furnace componentsBlast furnace detailsSlagAluminum silicate

The invention relates to a ramming material for a blast-furnace tapping channel and a preparation method thereof. The preparation method comprises the following steps of: mixing 0 to 25 percent of brown aluminum oxide by weight, 45 to 70 percent of aluminum silicate material by weight, 5 to 15 percent of silicon carbide by weight, 3 to 5 percent of high-temperature asphalt by weight, 3 to 6 percent of Si powder by weight, 2 to 4 percent of alumina micropowder by weight and 1 to 10 percent of titanium-containing blast-furnace slag, adding 4 to 7 percent of thermosetting phenolic resin in mixture by weight, mixing and grinding for 5 to 10min, evenly stirring, and packaging for later use. The ramming material has the advantages of easily-obtained material, low cost, baking avoidance, convenient construction, high tapping efficiency and comprehensively-utilized titanium-containing blast-furnace slag; and the ramming material solves the problems of serious adherent slag and poor oxidation resistance in the tapping process of the tapping channel at the same time of obtaining better high-temperature strength, ensures that the service life is prolonged by 30 to 50 percent, and is particularly suitable for the tapping channel of the blast furnace for melting vanadium titano-magnetite.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method for aluminum silicon carbide compound material IGBT (Insulated Gate Bipolar Translator) substrate and method for inlaying aluminum alloy

The invention relates to a preparation method for an aluminum silicon carbide compound material IGBT (Insulated Gate Bipolar Translator) substrate and a method for inlaying an aluminum alloy. The method comprises the following steps of: (1) designing a framework mould; (2) pressing a mould; (3) microwave sintering; and (4) vacuum pressure aluminizing, wherein the step of designing a framework mould comprises: designing punched or tapped parts on two opposite sides or four sides as male moulds, and designing non-punched or non-tapped parts as female moulds, thereby forming a convex-concave shape of a cavity of the framework mould; and convex-concave joints are transited by using R10-R20mm arcs; and the step of vacuum pressure aluminizing comprises: placing a part having a convex-concave side of a silicon carbide framework into an aluminizing mould vertical to an opening direction, and loading the aluminizing mould into a vacuum pressure steeping furnace while keeping an opening to be upward; and the aluminizing is performed under a 8MPa aluminizing pressure, thereby filling the silicon carbide framework and a concave part with aluminum alloys. By adopting the method, the inlaid aluminum alloys and the aluminum alloy in the silicon carbide framework are simultaneously condensed and crystallized, the connection is tight, and the aluminum alloys are inlaid in the punched or tappedparts, thereby promoting the punching or tapping efficiency.

Owner:HUNAN HANGTIAN CHENGYUAN PRECISION MACHINERY

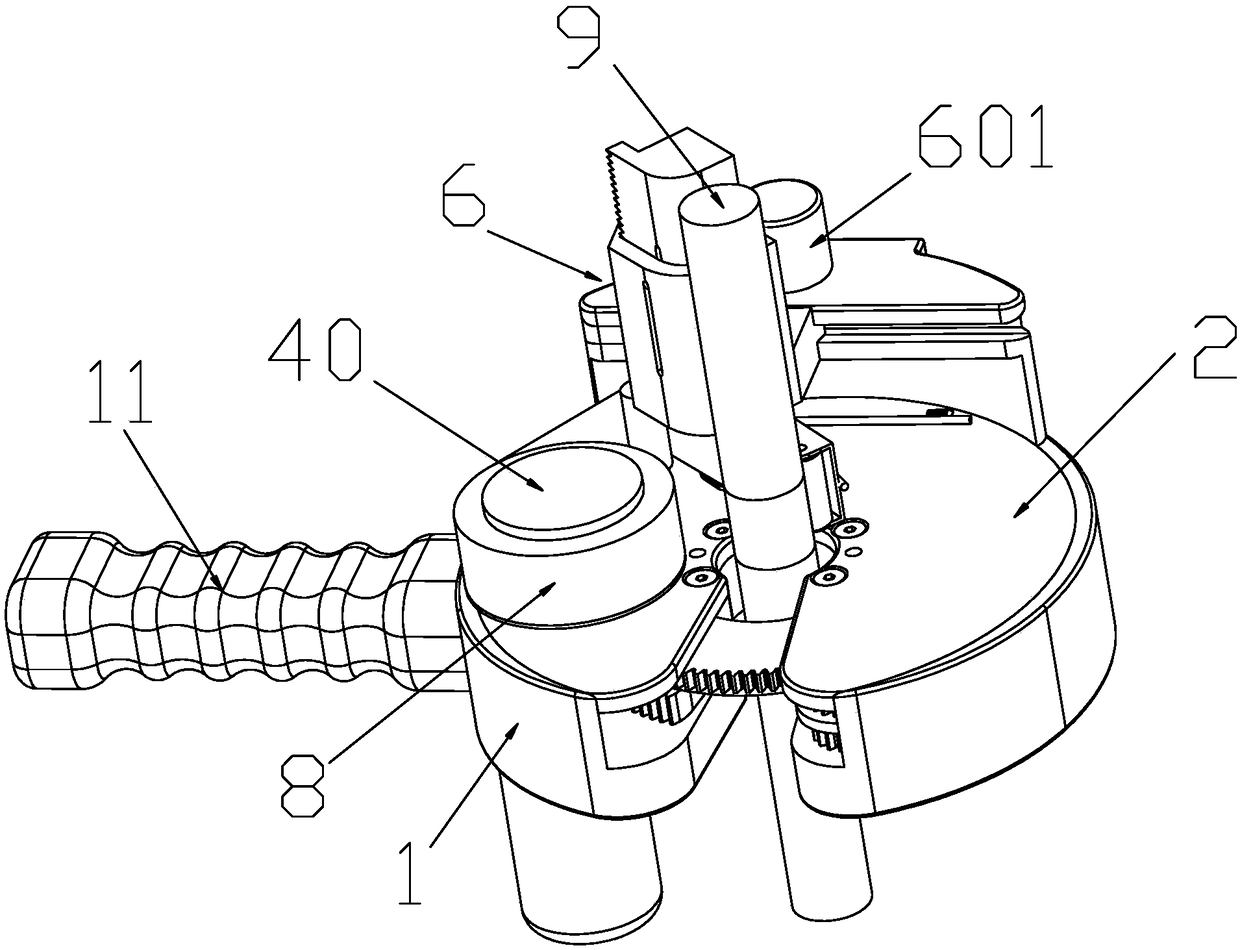

Portable automatic adhesive tape winding device

ActiveCN108455356ARealize the initial windingRealize automatic windingArticle deliveryAdhesive beltEngineering

The invention discloses a portable automatic adhesive tape winding device which comprises a housing, a mounting plate rotatably arranged in the housing, a wire harness penetrating hole, an adhesive tape supply device and an adhesive tape winding driving device, wherein the wire harness penetrating hole is of a through hole structure penetrating through the housing and the mounting plate simultaneously and is formed in the rotating center of the mounting plate; the adhesive tape supply device comprises an adhesive tape mounting base for placing an adhesive tape roll and a hold-down mechanism capable of extruding the adhesive tape towards the wire harness; the adhesive tape mounting base and the hold-down mechanism are positioned on the mounting plate; and the adhesive tape winding driving device is used for driving the mounting plate to rotate to enable the adhesive tape supply device to do circular motion around a to-be-wound wire harness so as to wind the adhesive tape on the wire harness. With adoption of the structure, the adhesive tape is automatically wound and is compressed, so that the adhesive tape winding quality is improved; after the adhesive tape is wound, the adhesivetape is automatically and completely cut off; the end parts of the adhsive tape are clamped and pulled to a wire harness winding station, so that the initial end of the adhesive tape is wound on the wire harness, the manual operating steps are reduced, the adhesive tape winding efficiency is greatly improved to facilitate improvement of the production efficiency and reduce the manual labor intensity.

Owner:伯朝平 +1

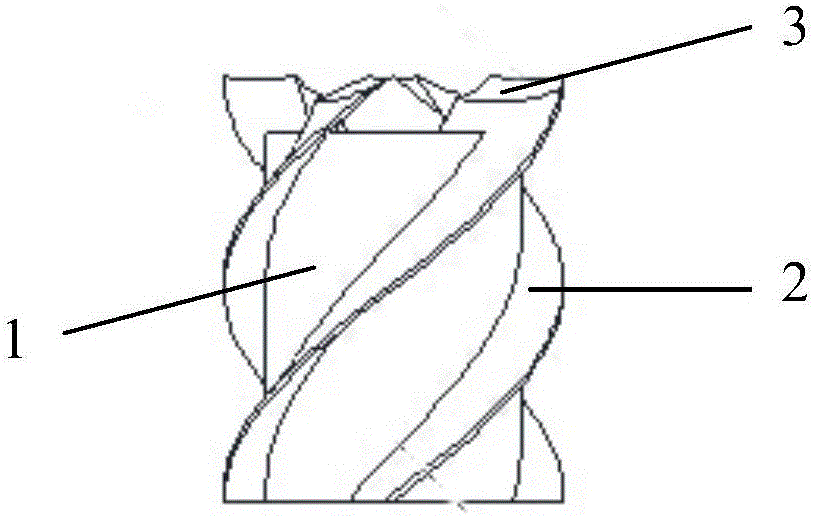

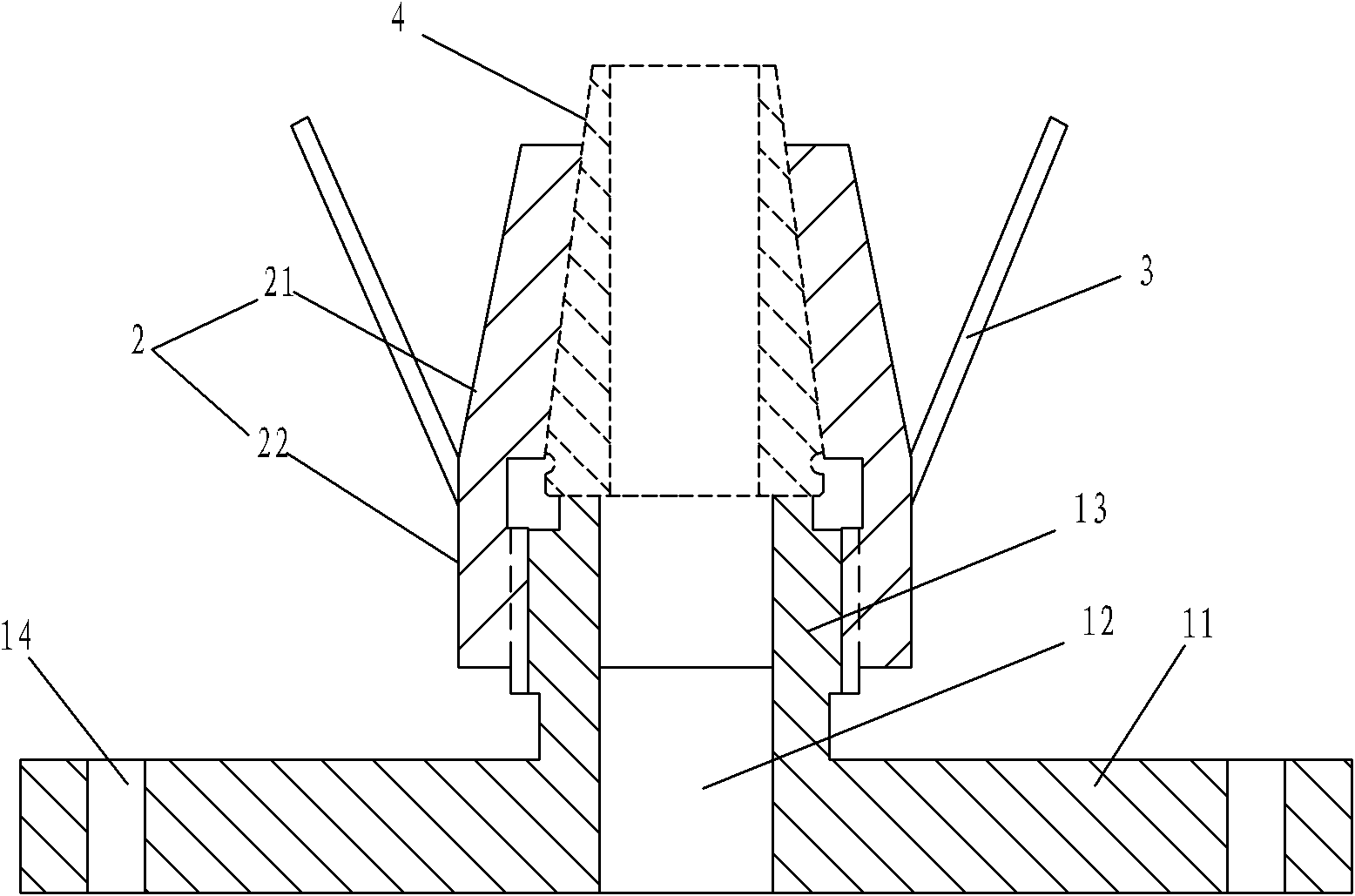

Electric rubber tapping knife

ActiveCN104620937AImprove efficiencyTapping is quick and easyForestryEngineeringUltimate tensile strength

The invention discloses an electric rubber tapping knife. The electric rubber tapping knife comprises a motor, a guide device and a rotating knife head. The guide device is connected with an outer shell of the motor through a fixing screw, and the rotating knife head is arranged in the guide device. The guide device is composed of a plurality of arc-shaped trapezoidal guide sheets. Each guide sheet is composed of an outer arc face, an inner arc face and two waist faces. A notch is formed between every two adjacent guide sheets. Limiting faces on the same plane are formed by the adjacent waist faces between every two adjacent guide sheets and are parallel to the axis. A screw blade is arranged at the rotating knife head. The electric rubber tapping knife is used for replacing traditional manual rubber tree bark tapping and traditional V-shaped-knife rubber tree bark tapping, rubber tapping is easily, conveniently, rapidly and efficiently carried out, the labor intensity is reduced, the requirement for the rubber tapping technology is reduced, the labor cost is saved accordingly, and the benefits of the natural rubber industry is accordingly improved.

Owner:曹建华 +3

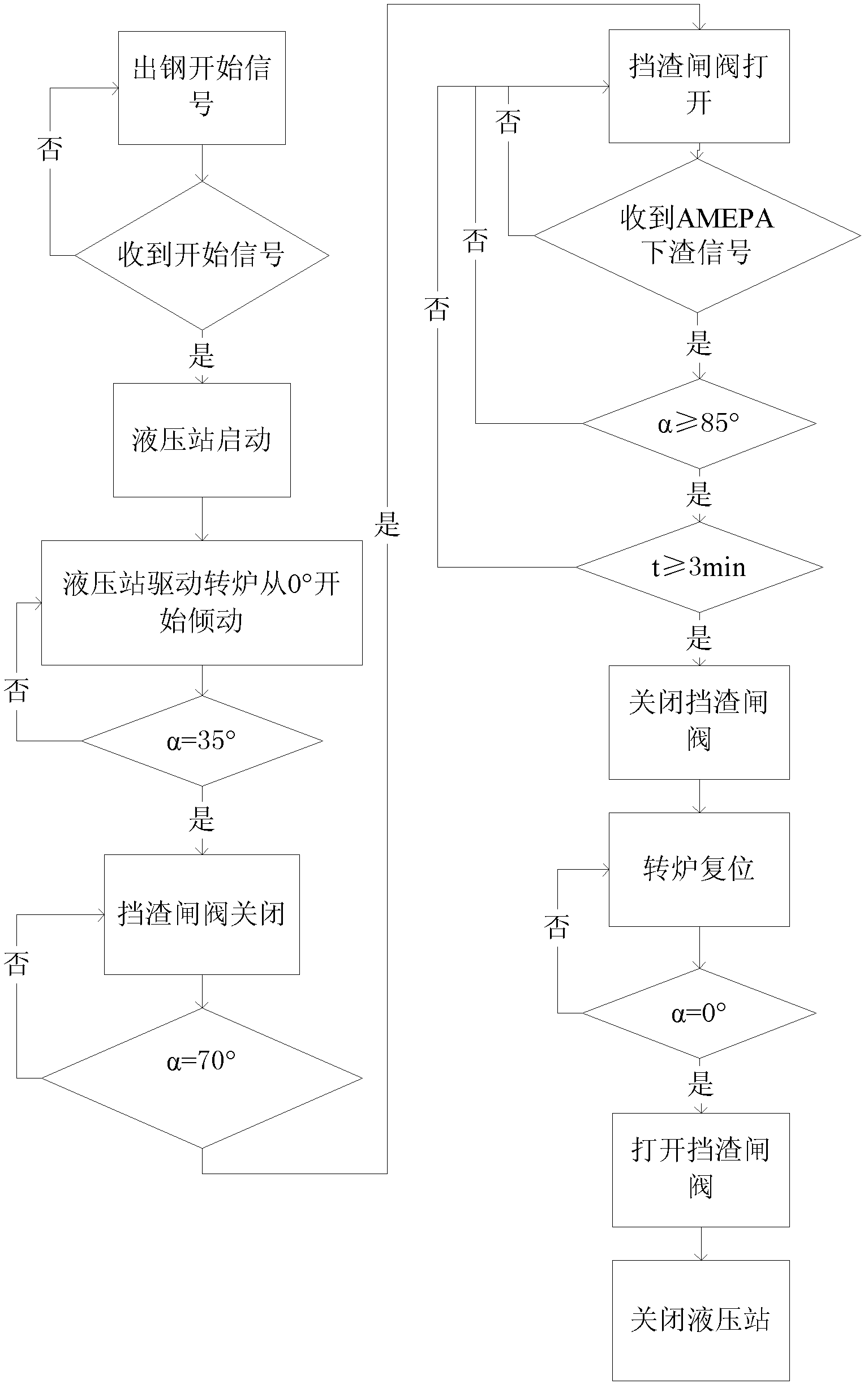

Converter tapping hole sliding gate slag-stopping process

ActiveCN103255261AQuality improvementReduce processing costsManufacturing convertersProcess efficiency improvementSlagStart signal

The invention discloses a converter tapping hole sliding gate slag-stopping process. The process comprises the following steps that: (1) a hydraulic station is started when a tapping start signal is received; (2) the converter starts to tilt, and a tilting angle signal is sent to a PLC on a real-time basis, and when the converter tilting angle reaches a first critical value, the PLC controls the close of a slag-stopping gate valve; (3) when the converter tilting angle reaches a second critical value, the PLC controls the opening of the slag-stopping gate valve; (4) when tapping molten steel is close to the end and slagging begins, the PLC immediately controls close of the slag-stopping gate valve if the following conditions are satisfied simultaneously: a. the PLC detects a slagging signal sent by an infrared slagging detection system aligning at the tapping molten steel to the PLC; b. the converter tilting angle is no less than 85DEG; and c. the tapping time is no less than 3min; (5) after tapping, the converter is reset, and when the PLC detects that the converter is returned to the starting position, the PLC controls opening of the slag-stopping gate valve; and (6) hydraulic station is closed.

Owner:BAOSHAN IRON & STEEL CO LTD

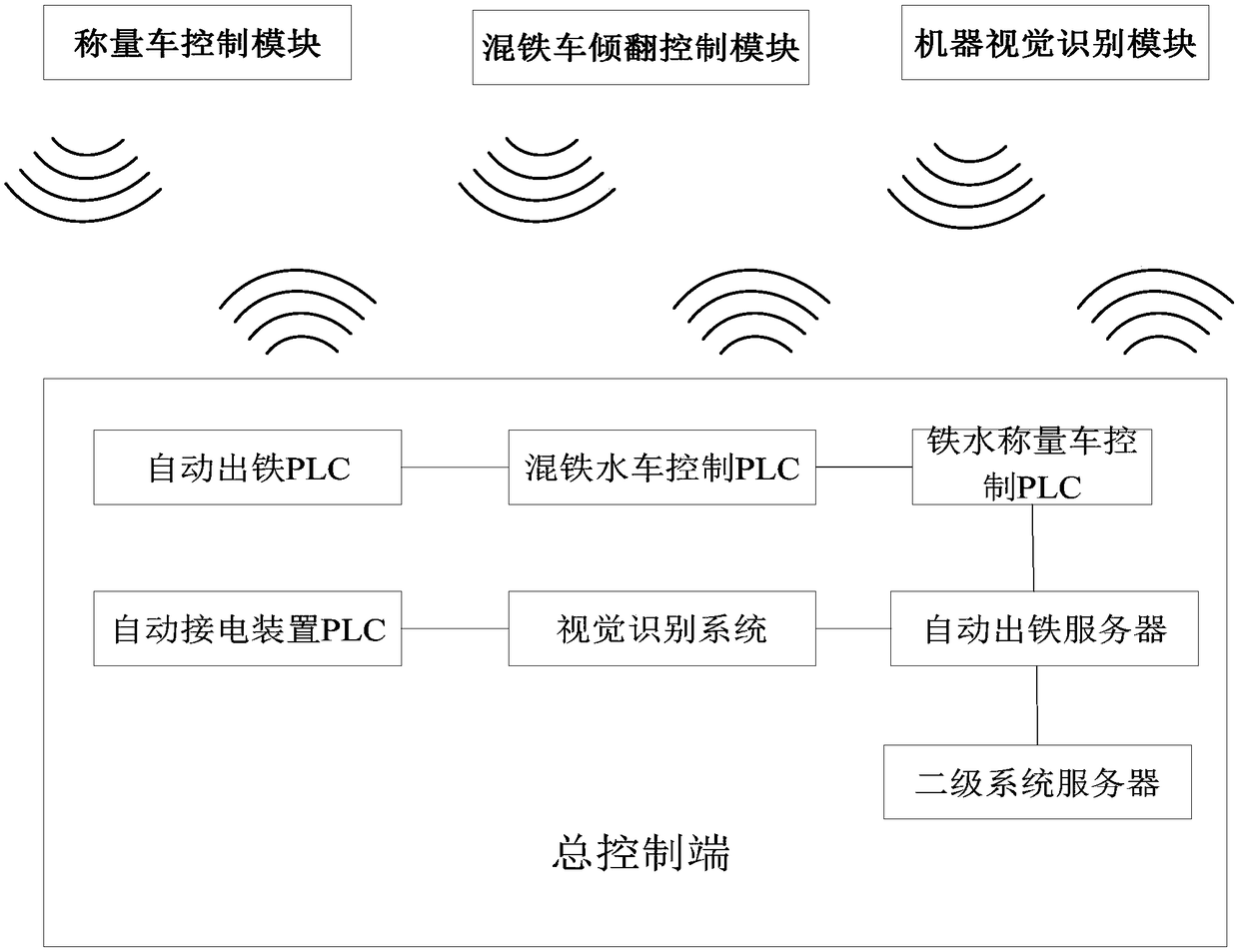

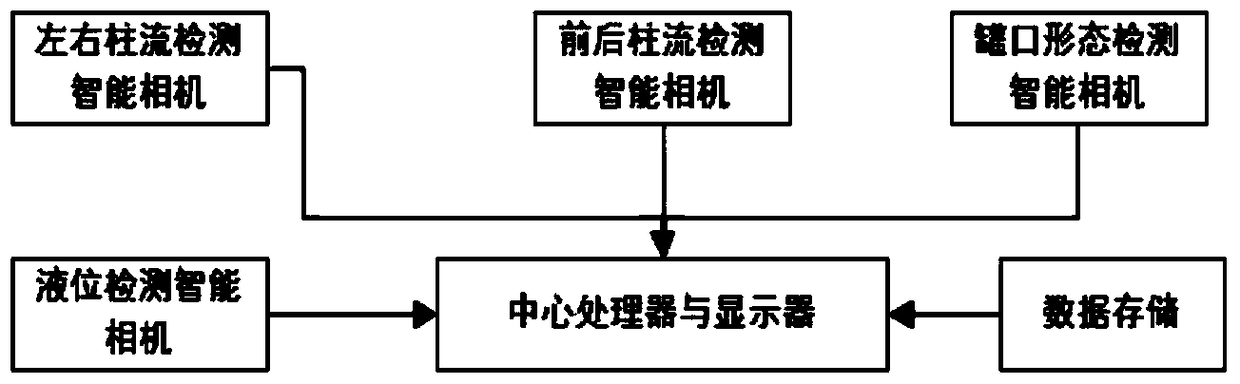

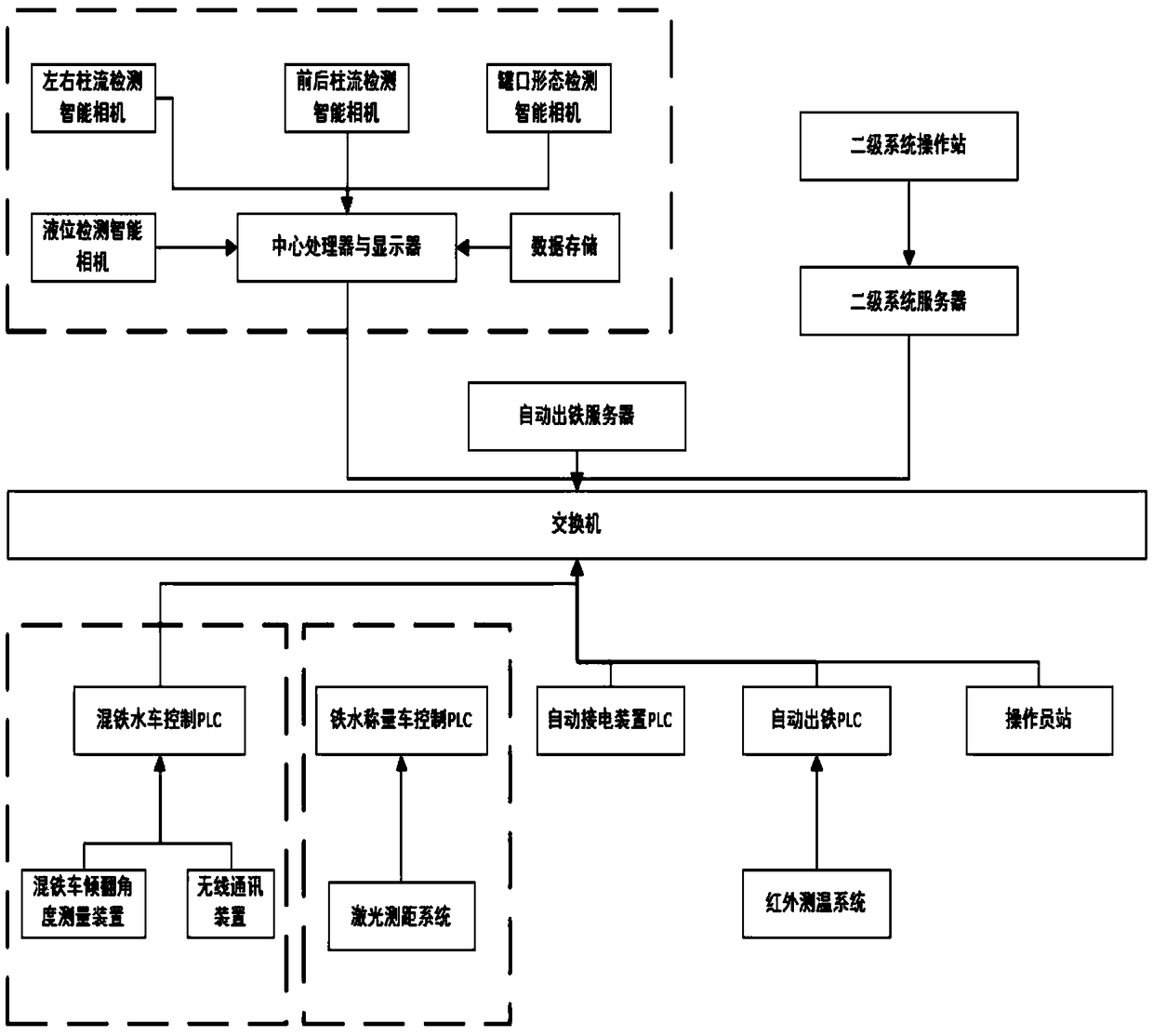

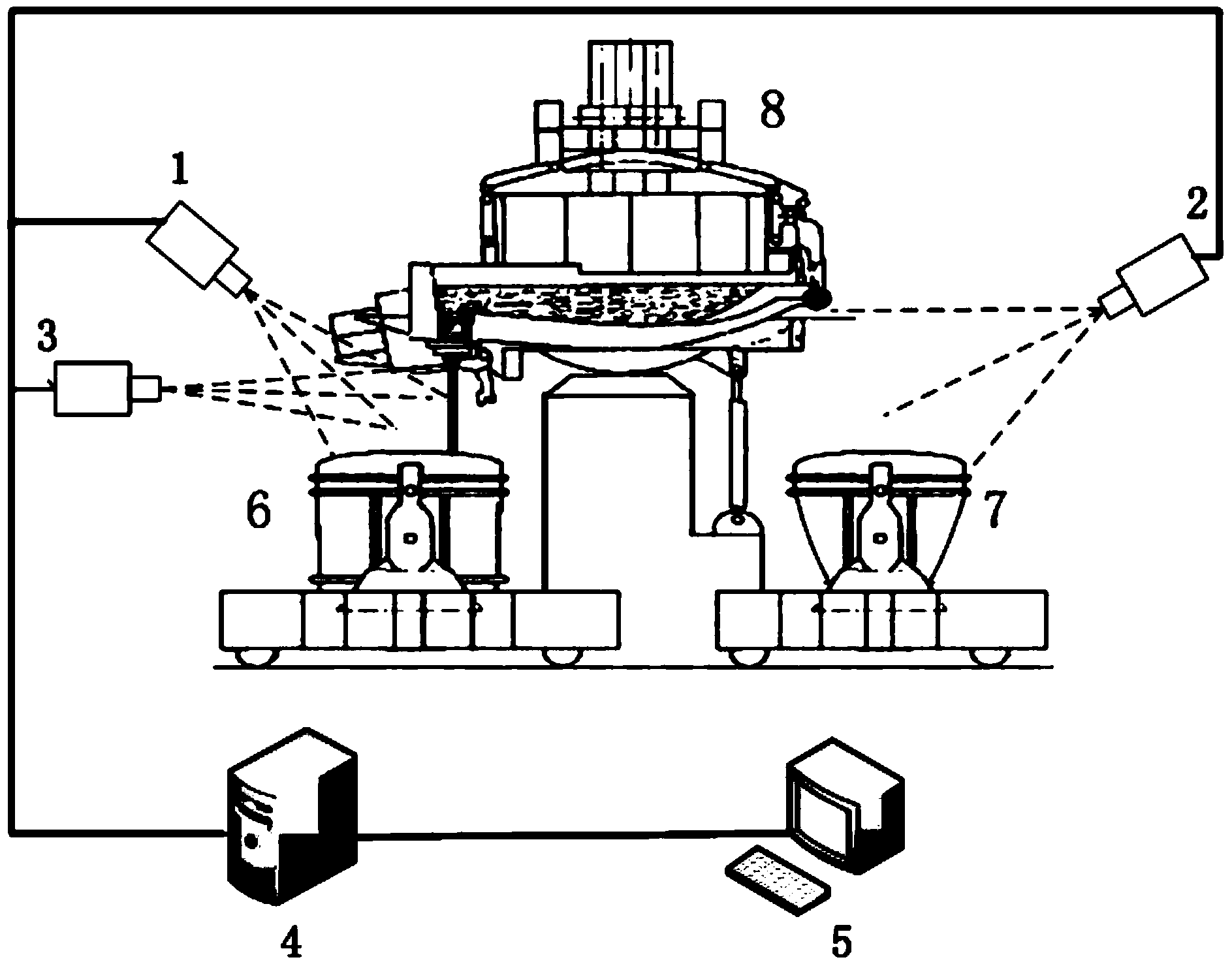

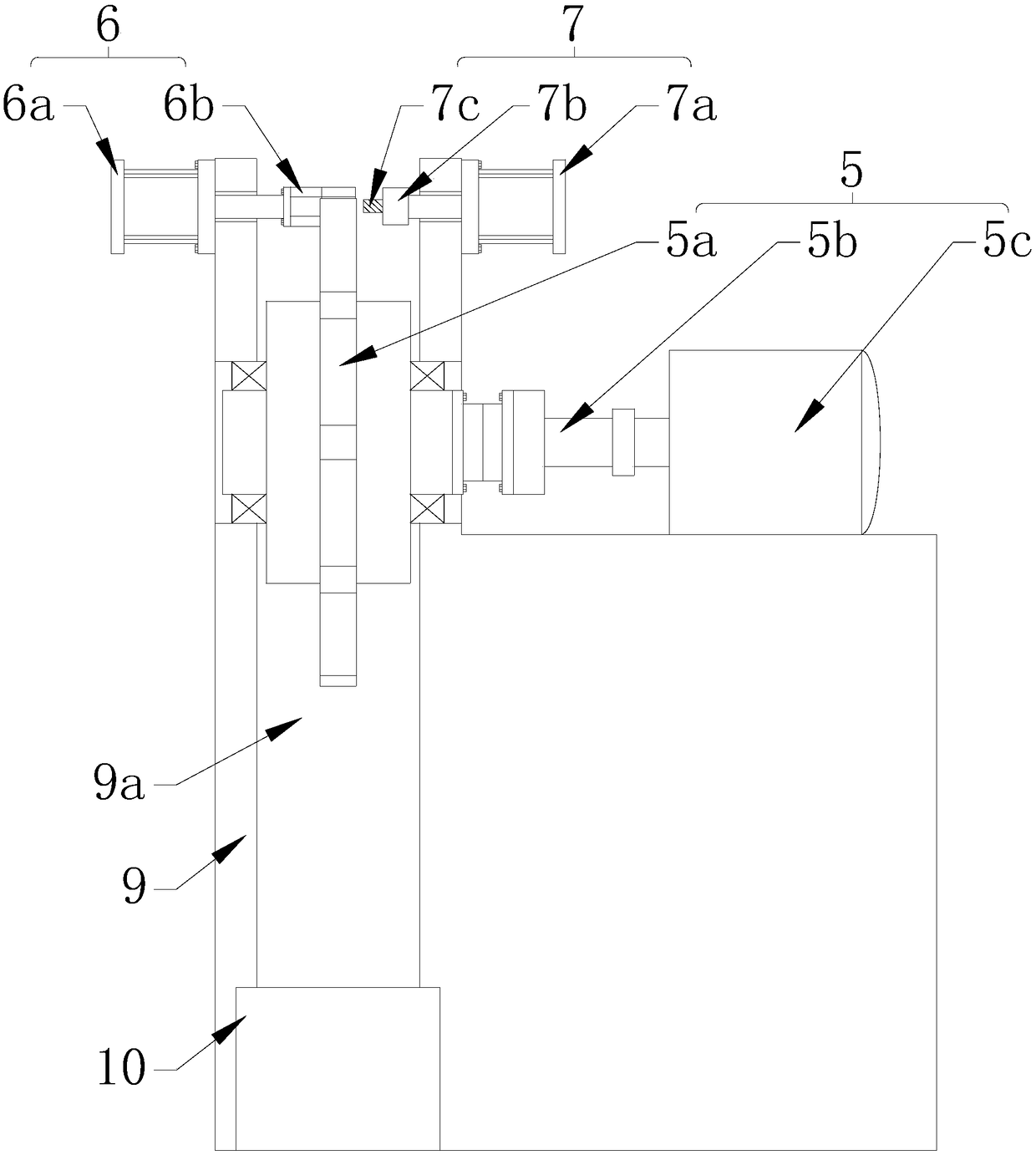

Automatic tapping control system of inverted pouring station

ActiveCN109062161AEasy to operateIncreased level of controlTotal factory controlProgramme total factory controlElectricityAutomatic control

The invention discloses an automatic tapping control system of an inverted pouring station. The system automatically analyzes the shape of a tank port via the visual recognition technology, automatically detects and analyzes the molten iron column flow and automatically measures a molten iron liquid level and a temperature so as to complete automatic tipping of a molten iron mixing vehicle and automatic weighing of a molten iron weighing vehicle; the location of the molten iron weighing vehicle is detected by the laser positioning technology in real time, so that the automatic operation of themolten iron weighing vehicle is completed; by positioning and plugging of an automatic power connection device of the molten iron mixing vehicle, automatic power-on and power-off of the molten iron mixing vehicle are achieved; and the communication integration of each control unit is completed via a communication system, and the automation and unmannedization of the tapping of the inverted pouring station are achieved at last via gathering parts into a whole plus reasonable programming and algorithms.

Owner:大连重工环保工程有限公司 +1

Monitoring device for tapping of converter/electric furnace and control method

ActiveCN104232837ARealize all-round monitoringEliminate potential safety hazards in tappingFurnace componentsManufacturing convertersSteelmakingElectric arc furnace

The invention relates to the technical field of metallurgical steelmaking, and aims to provide a monitoring device of the tapping of a converter / an electric furnace, and a control method. The monitoring device of the tapping of the converter / electric furnace comprises an infrared detector A, an infrared detector B, a camera, a central server and a monitoring terminal, wherein the infrared detector A is mounted on the tapping side of the furnace; the infrared detector B is mounted on the deslagging side of the furnace; the camera is mounted above a bale tapping position; and the infrared detector A, the infrared detector B and the camera are respectively connected with the central server. The monitoring device disclosed by the invention can comprehensively monitor the tapping of the converter / electric furnace, to be specific, monitor whether a slag ladle is in the position, monitor whether the bale is in the position, monitor the deslagging destination before tapping, monitor whether steel slag is discharged after tapping, monitor whether the bale is emptied , and the like, the potential safety hazard of the tapping caused by the fact that the slag ladle and the bale are not in the position can be avoided, the tapping efficiency is improved, the quantity of the steel slag flowing into the bale is reduced, and the molten steel quality is improved.

Owner:杭州谱诚泰迪实业有限公司

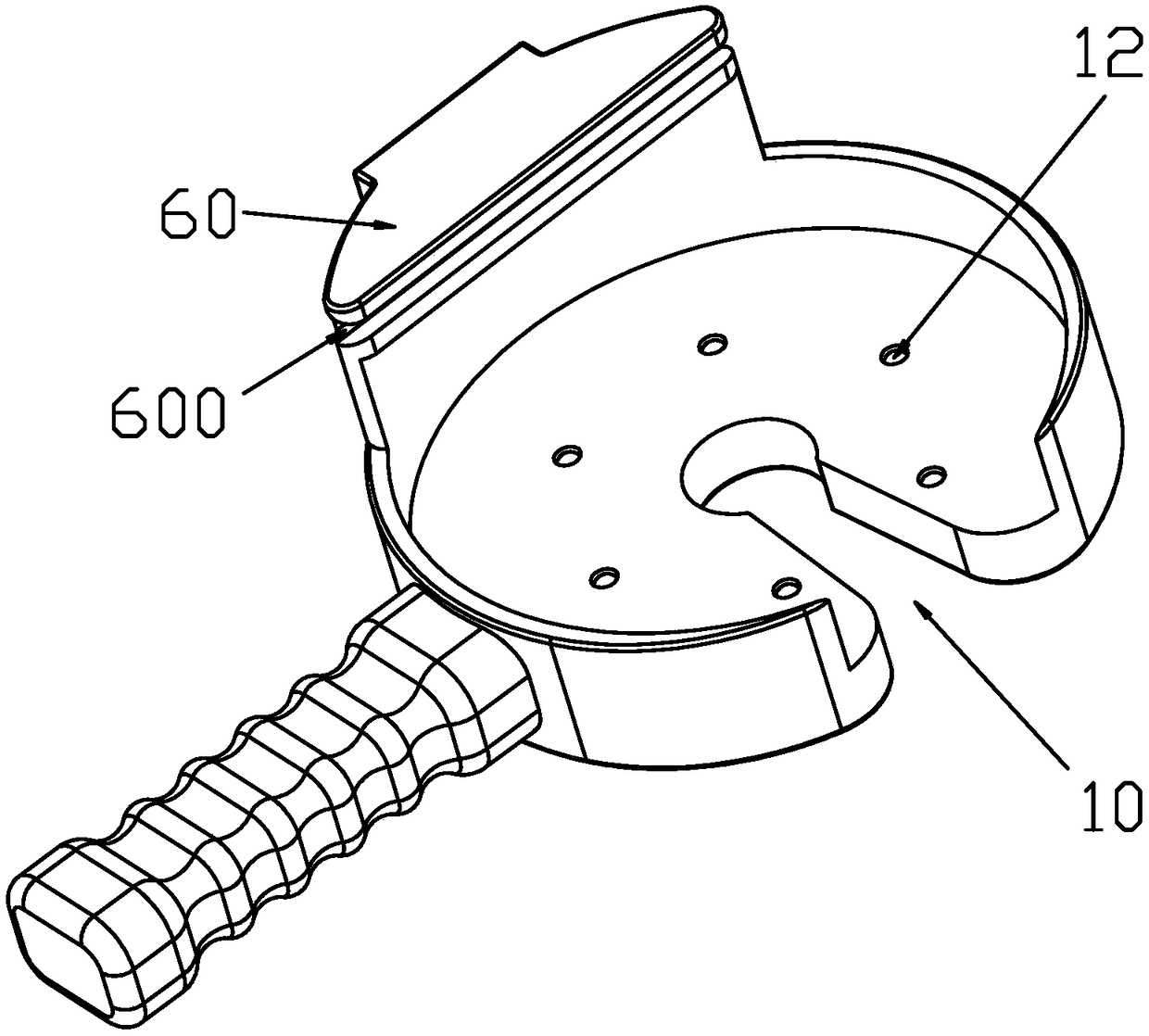

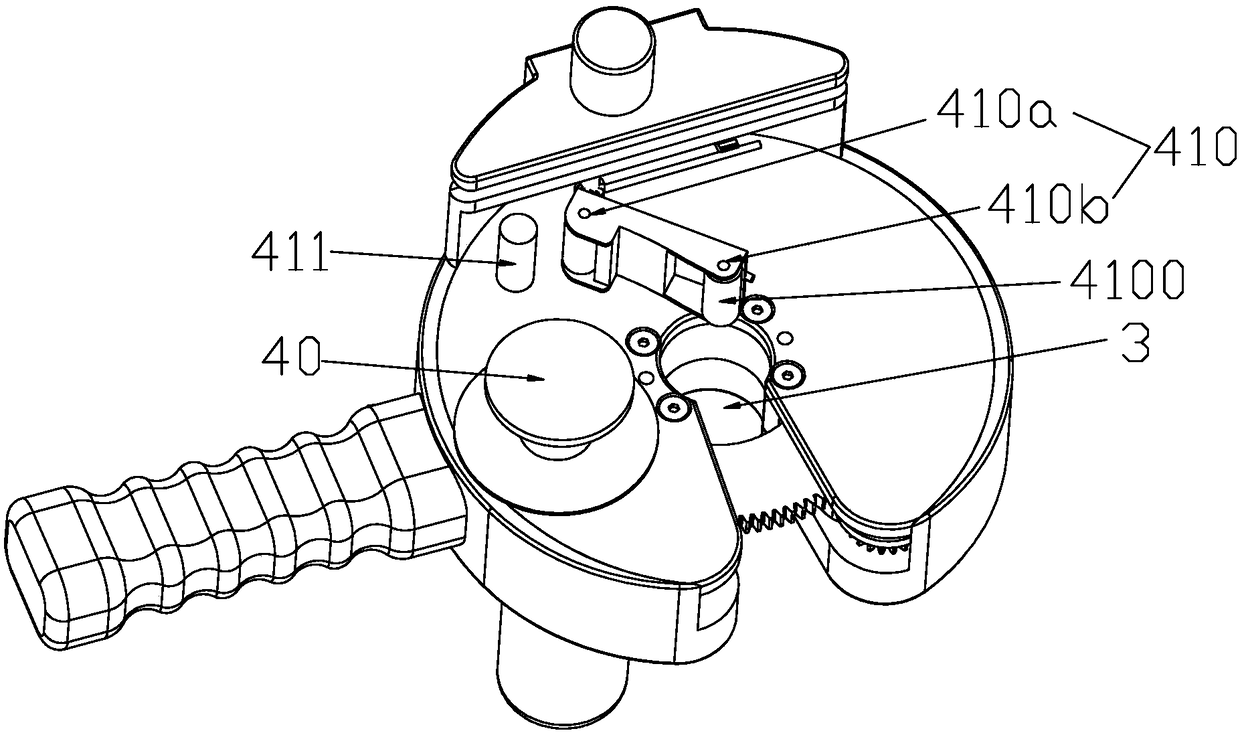

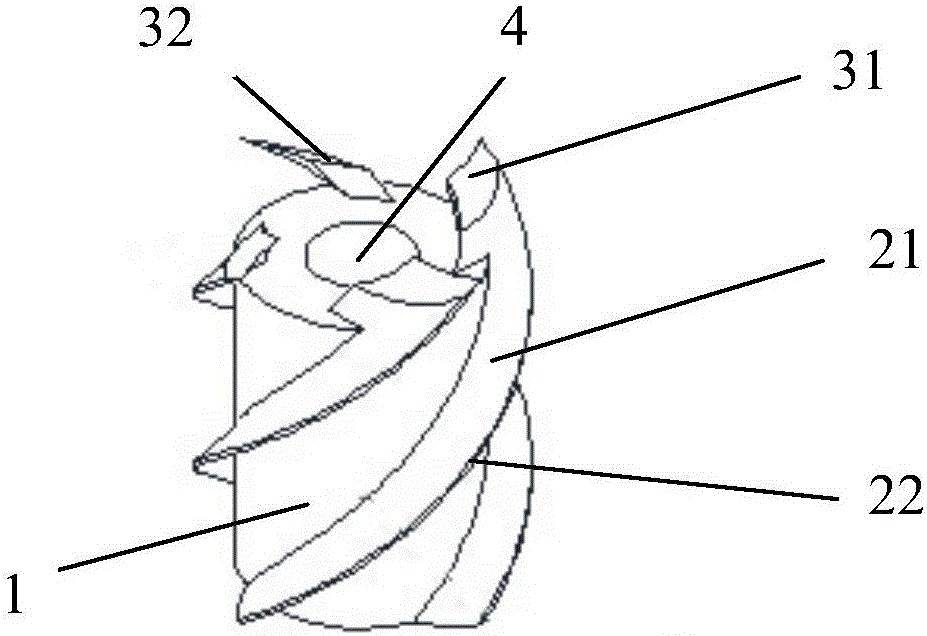

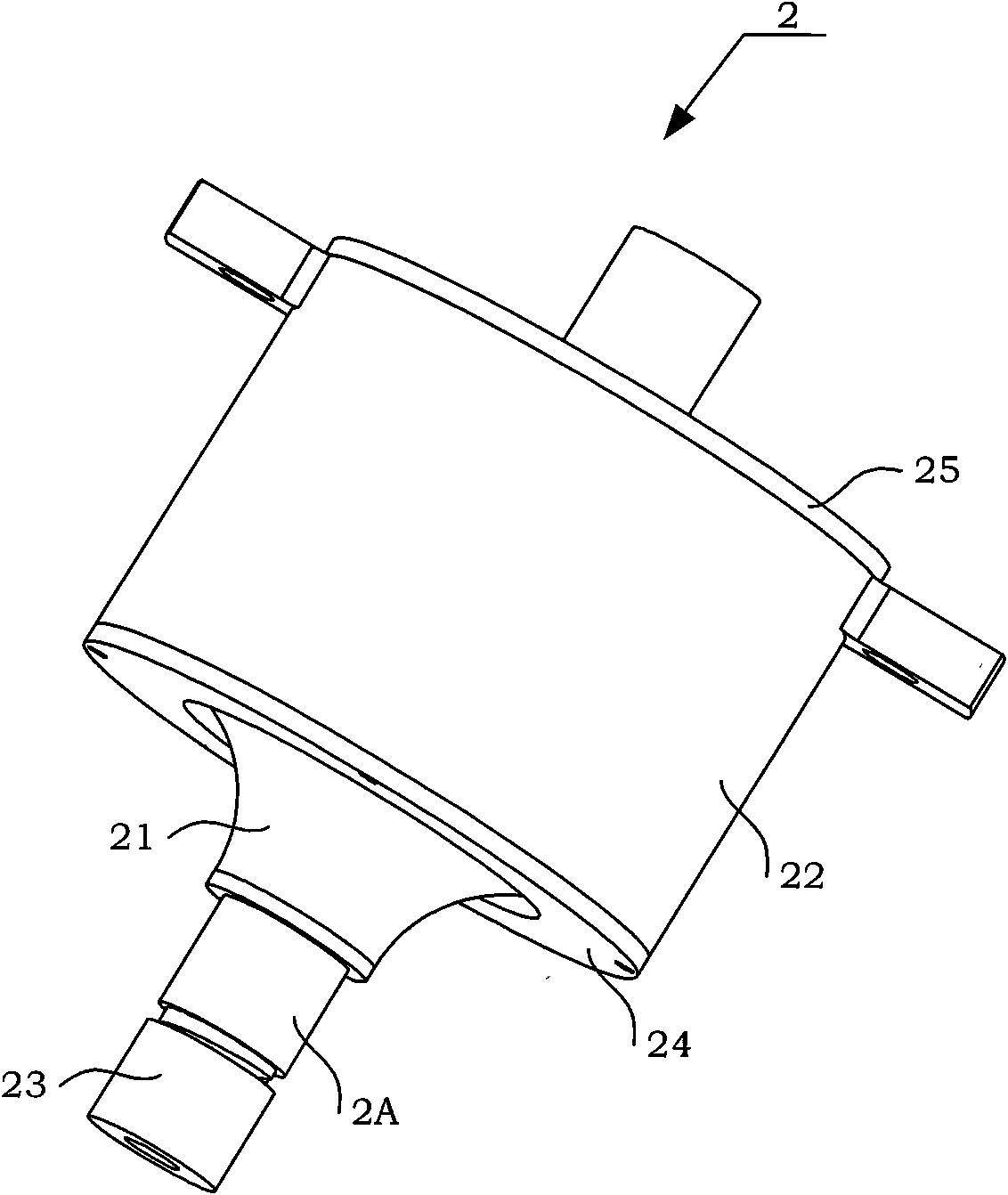

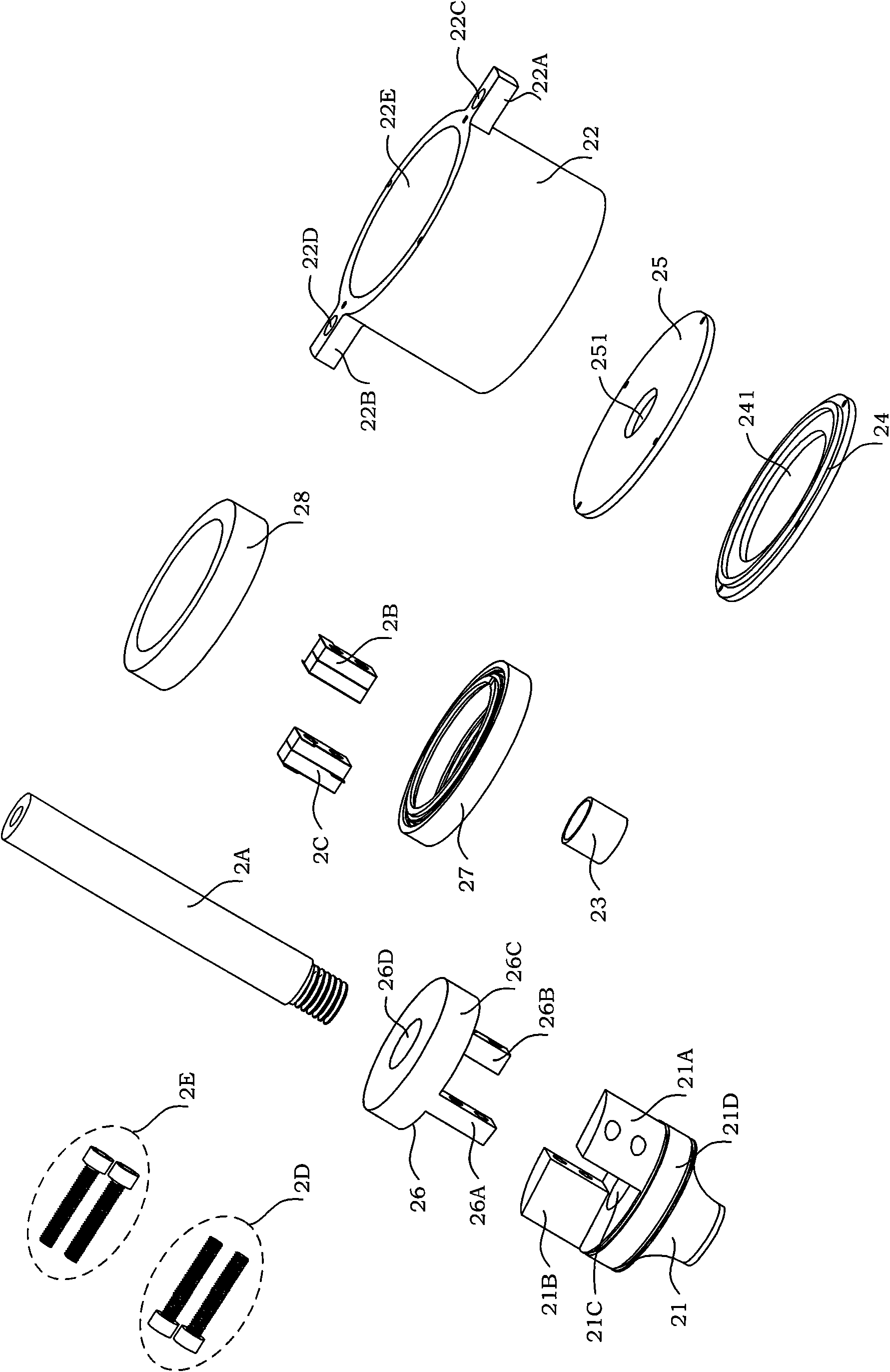

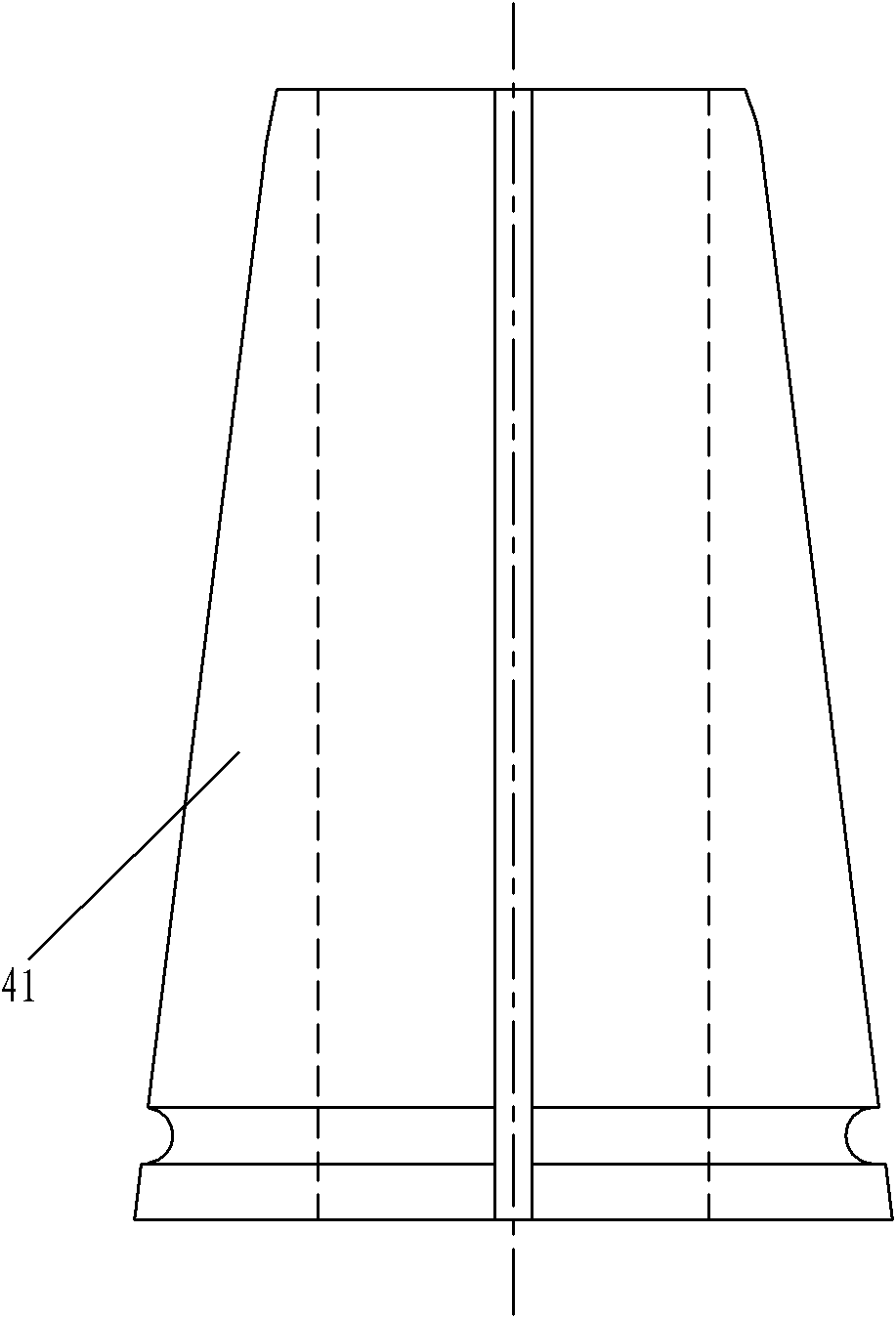

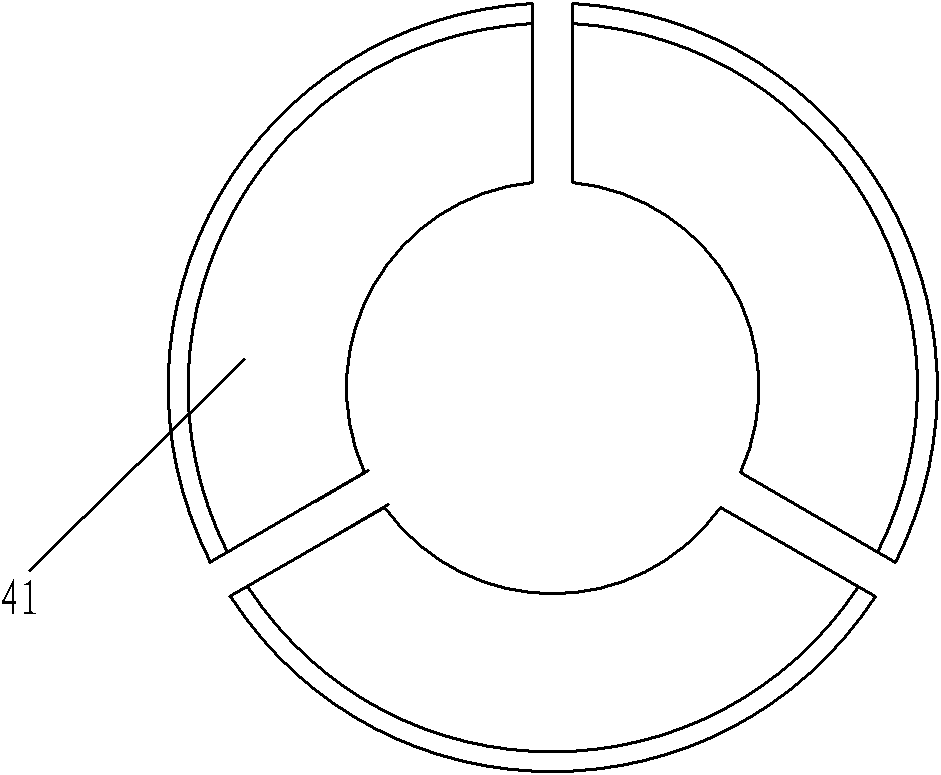

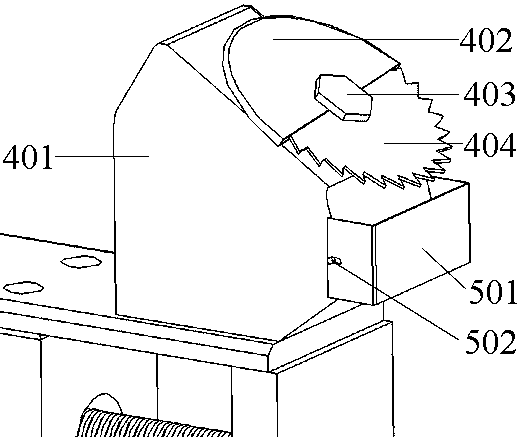

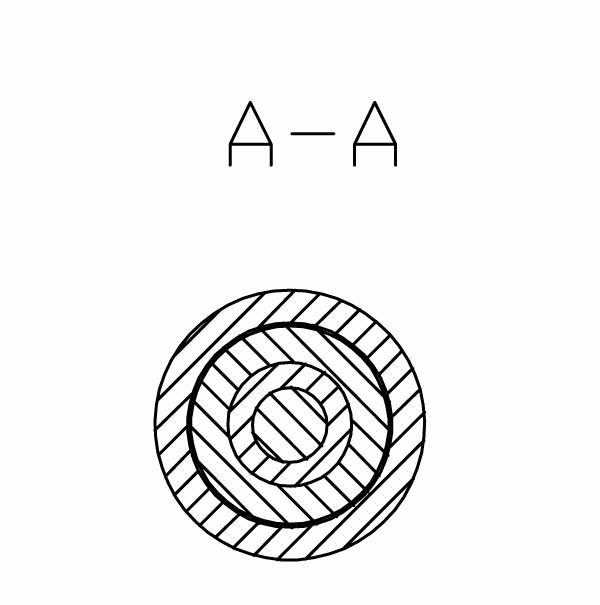

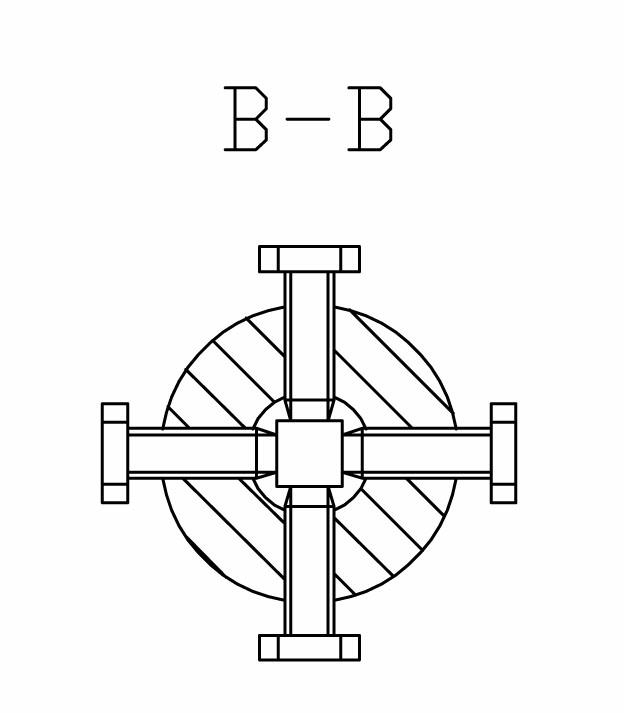

Rotary tool bit of electric rubber tapping knife

InactiveCN105075799AReduce the intensity of manual tappingImprove tapping efficiencyForestryMechanical forceMotor shaft

The invention discloses a rotary tool bit of an electric rubber tapping knife. The rotary tool bit is composed of a cylindrical knife body, an axial spiral blade set, a radial spiral blade set and a motor shaft fixing hole. The radial spiral blade set is arranged at the top end of the axial spiral blade set. The diameter of the cylindrical knife body is 9-10 mm. The height of the portions, outside the cylindrical knife body, of axial spiral blades is 1-2 mm. The included angle between the axial spiral blades and the axis is 30-35 degrees. The axial spiral blade set comprises 4-6 blades. Each axial spiral blade is composed of an axial blade bevel and an axial blade knife edge. Each radial spiral blade is composed of a radial blade bevel and a radial blade knife edge. The axial blade knife edges and the radial blade knife edges are all spiral. The rotary tool bit is simple in structure, convenient to use and capable of being driven by mechanical force to efficiently rotate at high speed and meanwhile cut rubber tree bark in the longitudinal direction and the transverse direction.

Owner:HAINAN ZHENGNONGGAOKE TECH CO LTD

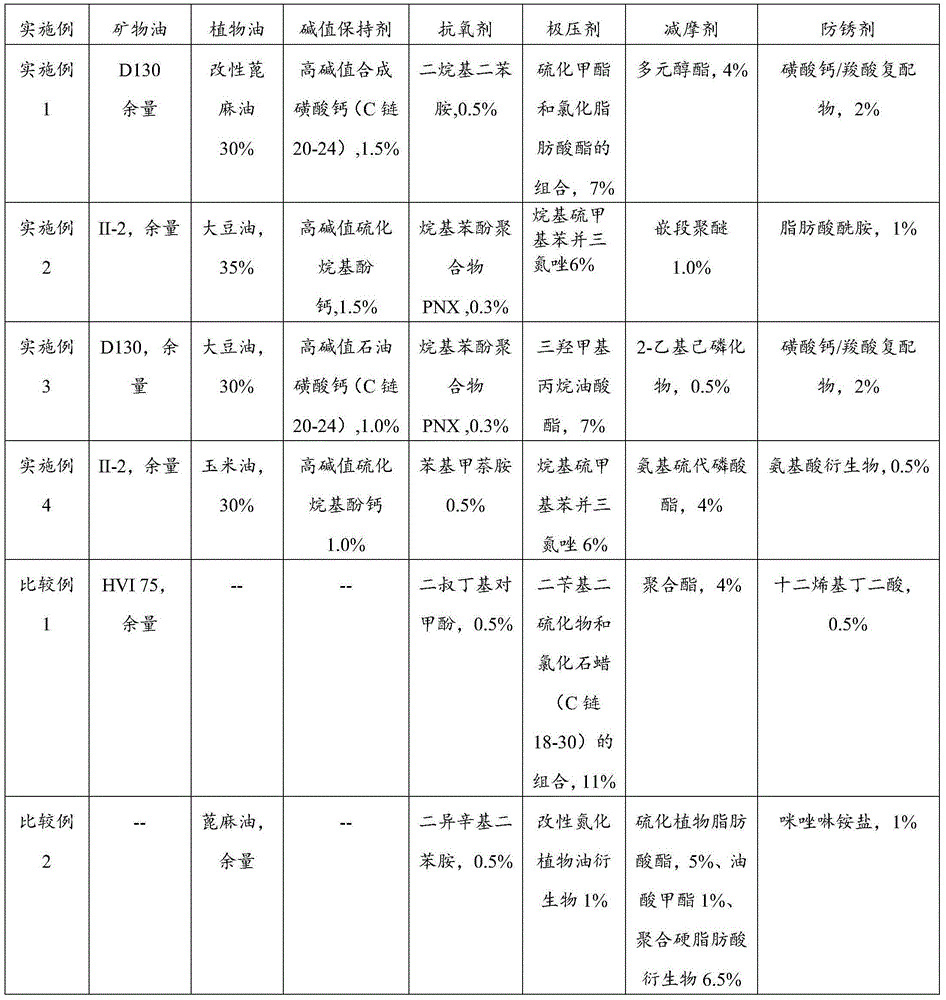

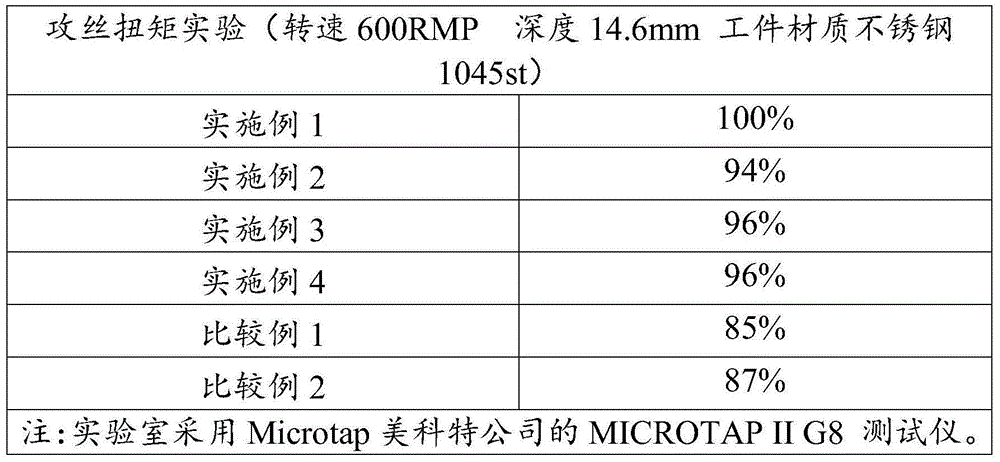

Half-plant type pure-oil-based cutting oil and application thereof

The invention relates to half-plant type pure-oil-based cutting oil and application thereof. The half-plant type pure-oil-based cutting oil mainly solves the problems that in the prior art, oxidation is prone to occurring, high-temperature oil mist is heavy, and low-temperature storage application is inconvenient. The half-plant type pure-oil-based cutting oil is prepared from, by weight, 45-60 parts of mineral oil, 30-45 parts of vegetable oil, 1-2 parts of base number retention agents, 0.2-0.5 part of antioxidants, 3-10 parts of extreme-pressure agents, 1-10 parts of anti-friction agents and 1-3 parts of antirust agents. According to the half-plant type pure-oil-based cutting oil and the application thereof, the problems are better solved, the higher tapping efficiency is achieved, and the half-plant type pure-oil-based cutting oil can be applied to a titanium alloy and stainless steel metal processing technology.

Owner:CHINA PETROLEUM & CHEM CORP

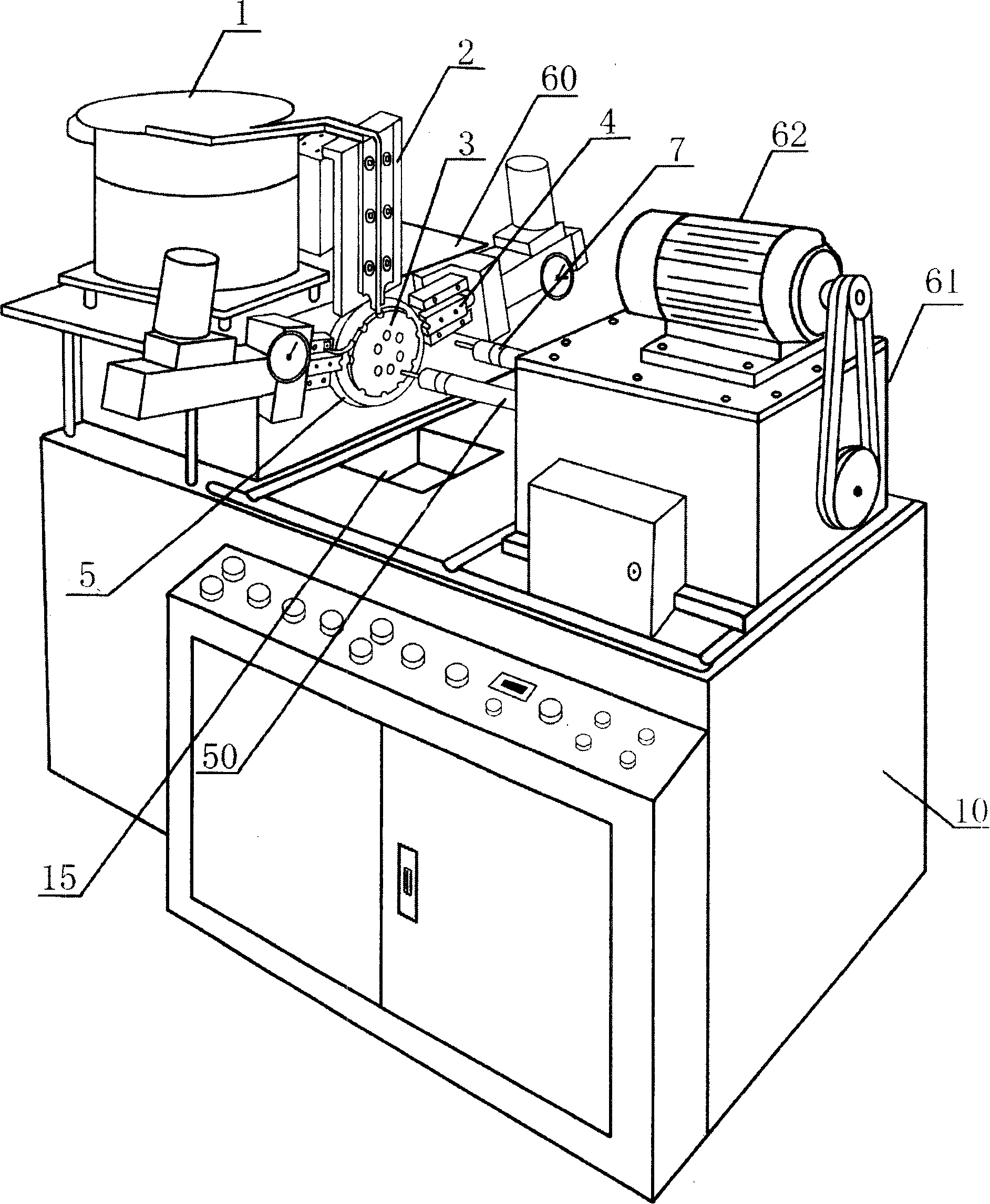

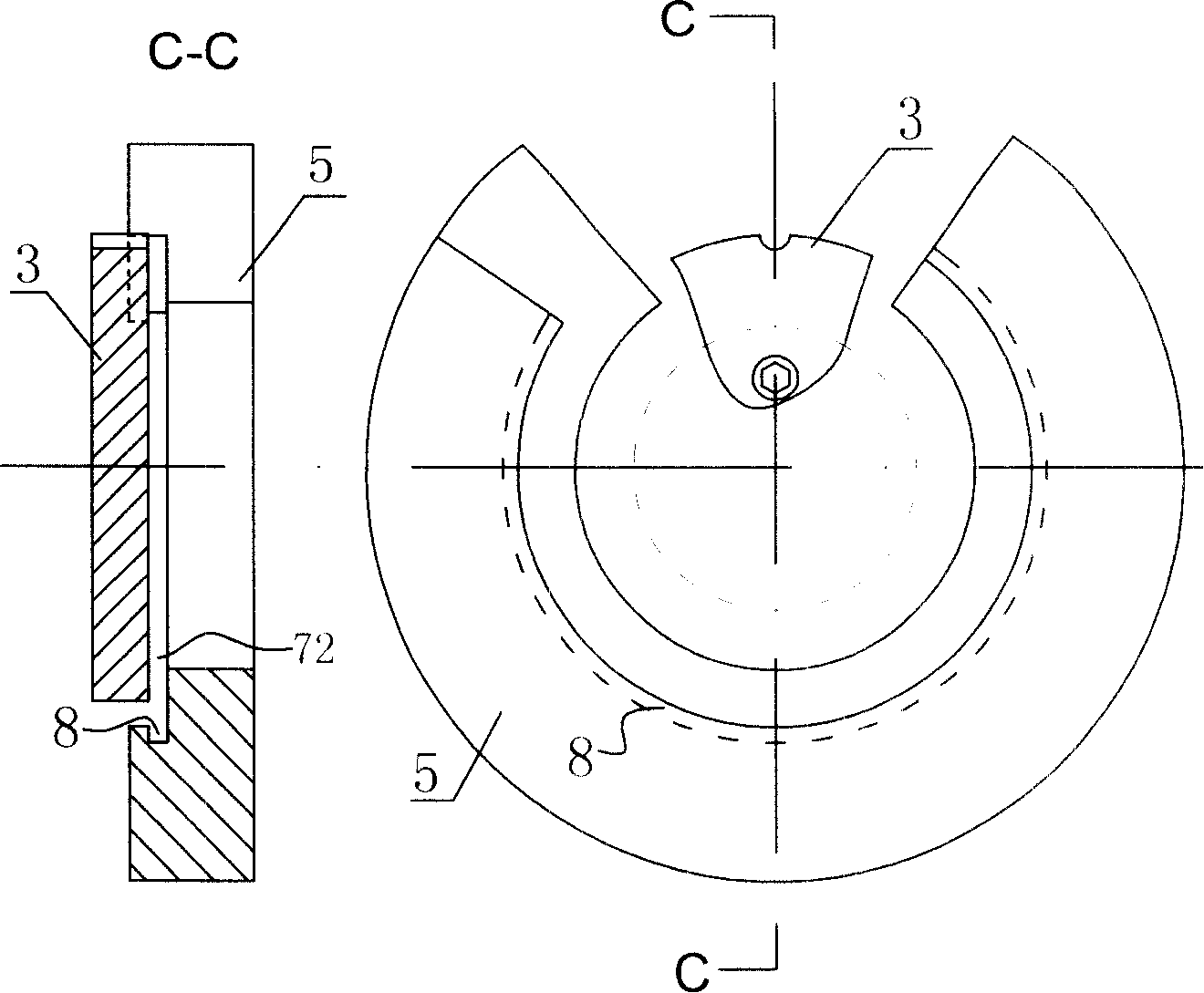

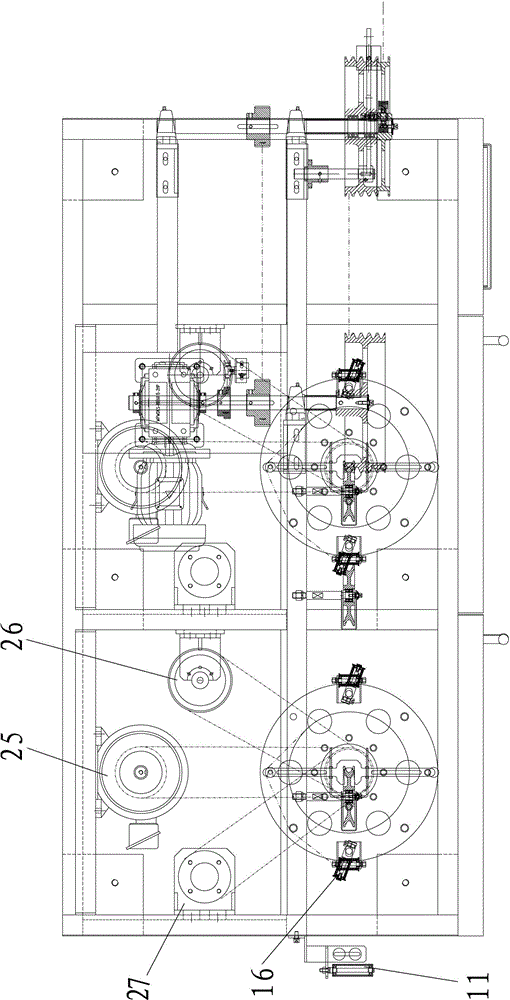

Clamping mechanism for double end threading machine

InactiveCN101190495ASafe and stable jobSolve key technologiesPrecision positioning equipmentThread cutting machinesEngineeringChassis

The invention relates to a dual-head tapping machine holding mechanism, comprising a rotatable chuck with blocking position and clamps arranged at the two sides of the chuck; the external circumference of the chuck is provided with 9 blocking positions used for positioning workpiece; a guide chassis with internal troughs is arranged between a workbench and the chuck; the guide chassis is arranged in parallel with the chuck; the clamps are symmetrically arranged at the two sides of the chuck. The clamping head of the clamp is provided with an opening trough corresponding to the blocking position of the chuck. The rotation of the chuck is controlled by a positioning mechanism; a positioning wheel is coaxial with the chuck; the number of blocking positions on the position wheel is the same with that on the chuck. The invention is fully automatically controlled and has the advantages of high working efficiency, safely saving energy, wide processing range, and convenient maintenance.

Owner:诸暨斯通机电设备制造有限公司

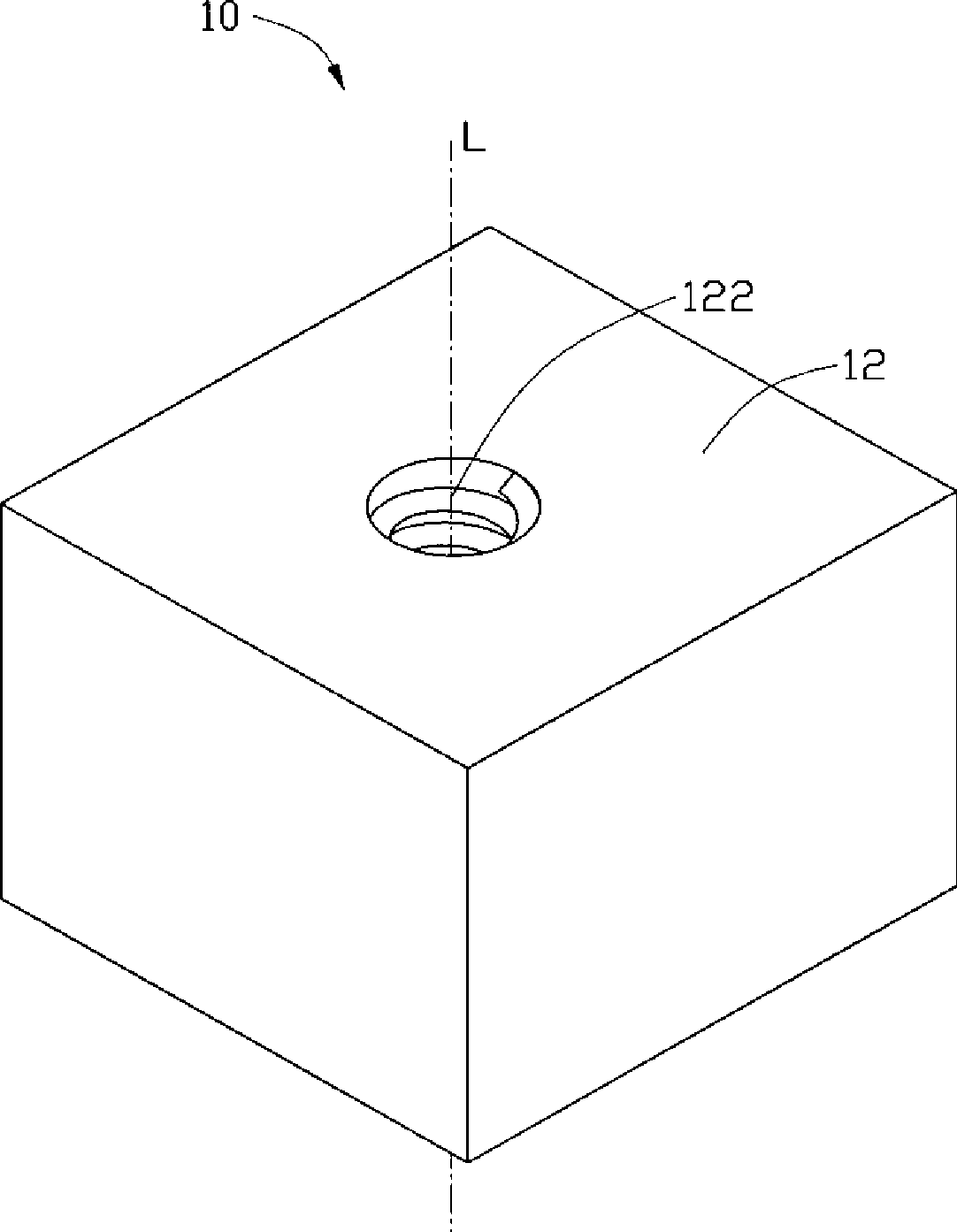

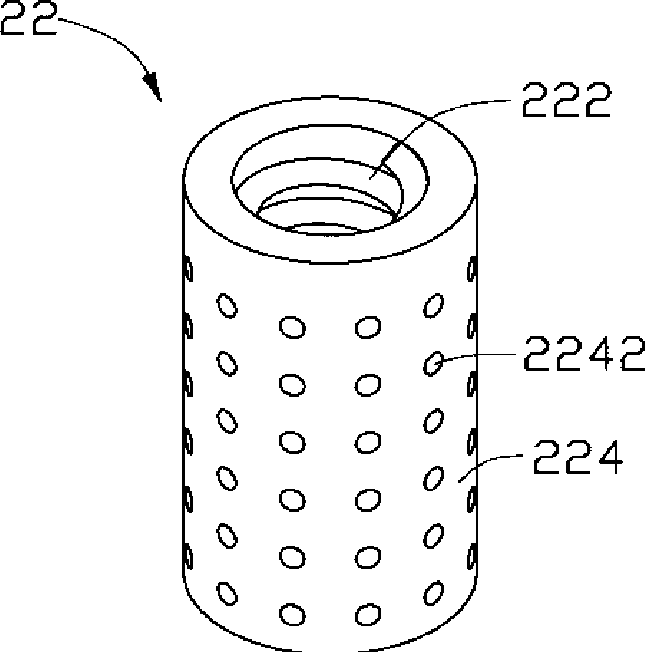

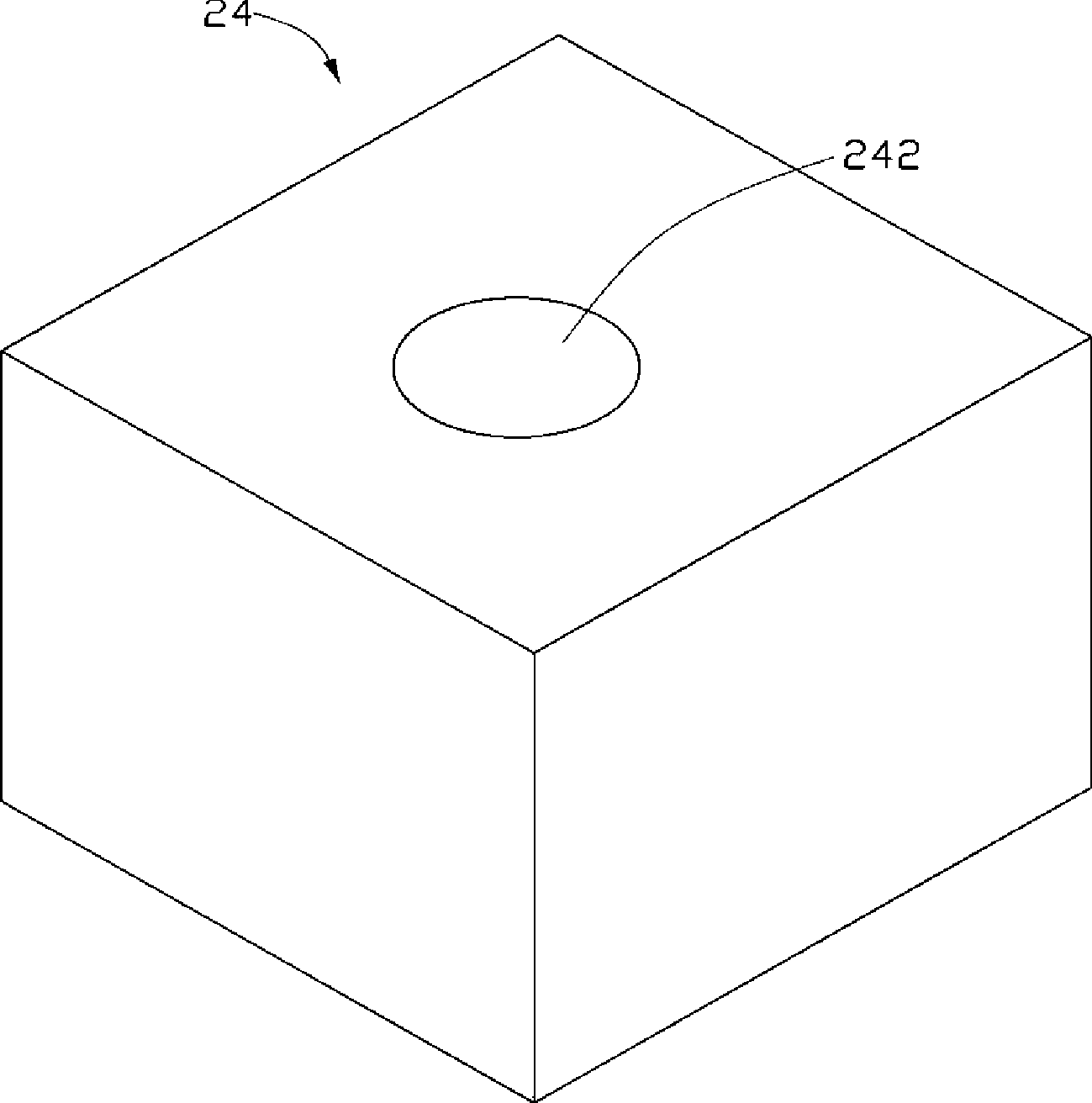

Metal injection molding product and manufacturing method thereof

The invention provides a method for manufacturing a metal injection molding product, which comprises the following steps: providing a screw stud of which the inside is provided with a threaded hole; uniformly mixing metal powder and a binder into a feeding material; manufacturing the feeding material into granules of 2 to 15 micrometers; heating the granules to a plasticization state, and filling the granules into a die cavity of an injection mould to mold a blank which is provided with a matching hole of which the shape and the size are equivalent to that of the screw stud; arranging the screw stud in the matching hole of the blank so as to form a premolding product; degreasing the premolding product so as to remove the binder in the blank; and sintering the degreased premolding product. The invention also provides a metal injection molding product manufactured by the manufacturing method.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

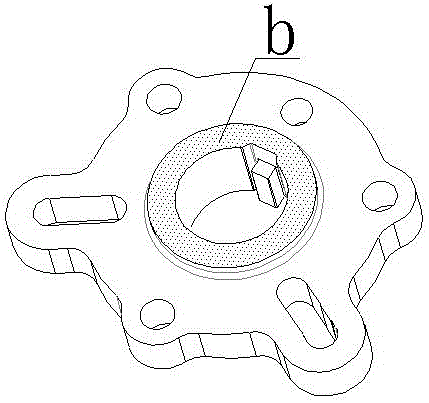

Camshaft toothed wheel hub for automobile engine and powder metallurgical preparation method for camshaft toothed wheel hub

ActiveCN106041094AReduce the amount of processingImprove shift outputTransportation and packagingMetal-working apparatusCamMachining

The invention discloses a camshaft toothed wheel hub for an automobile engine and a powder metallurgical preparation method for the camshaft toothed wheel hub. The method comprises the following steps: S101, preparing materials; S102, pressing and forming; S103, sintering blank; S104, refining and processing; S105, performing steam treatment; and S106, detecting and packaging. The method is linked up orderly, is fewer in processes, and has a material utilization rate higher than 95%. The camshaft toothed wheel hub obtained by the method is less in machining amount, is high in output per shift and is good in consistency, so that the product manufacturing cost is reduced by 50% when various performance requirements of the camshaft toothed wheel hub are met.

Owner:马鞍山市华东粉末冶金厂

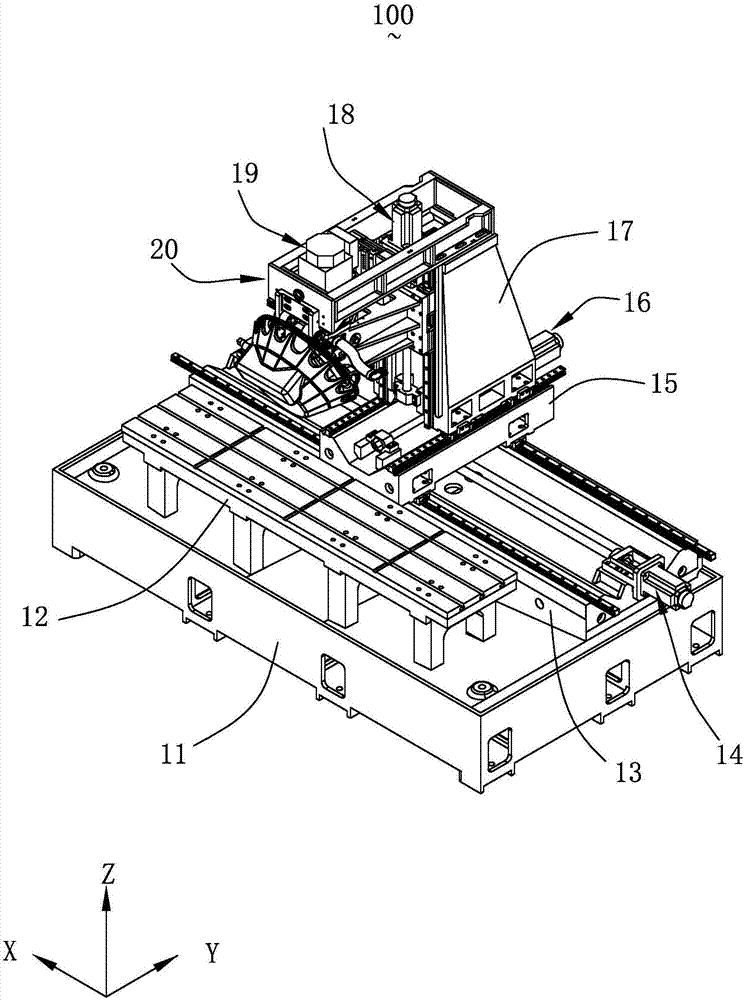

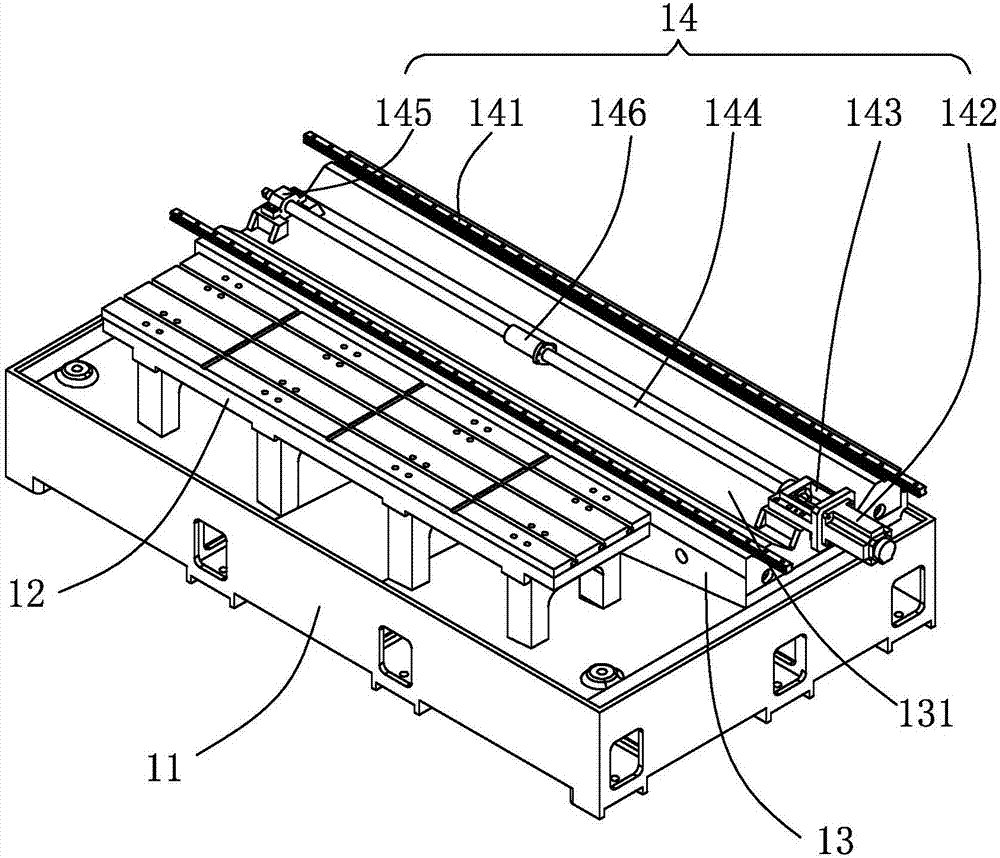

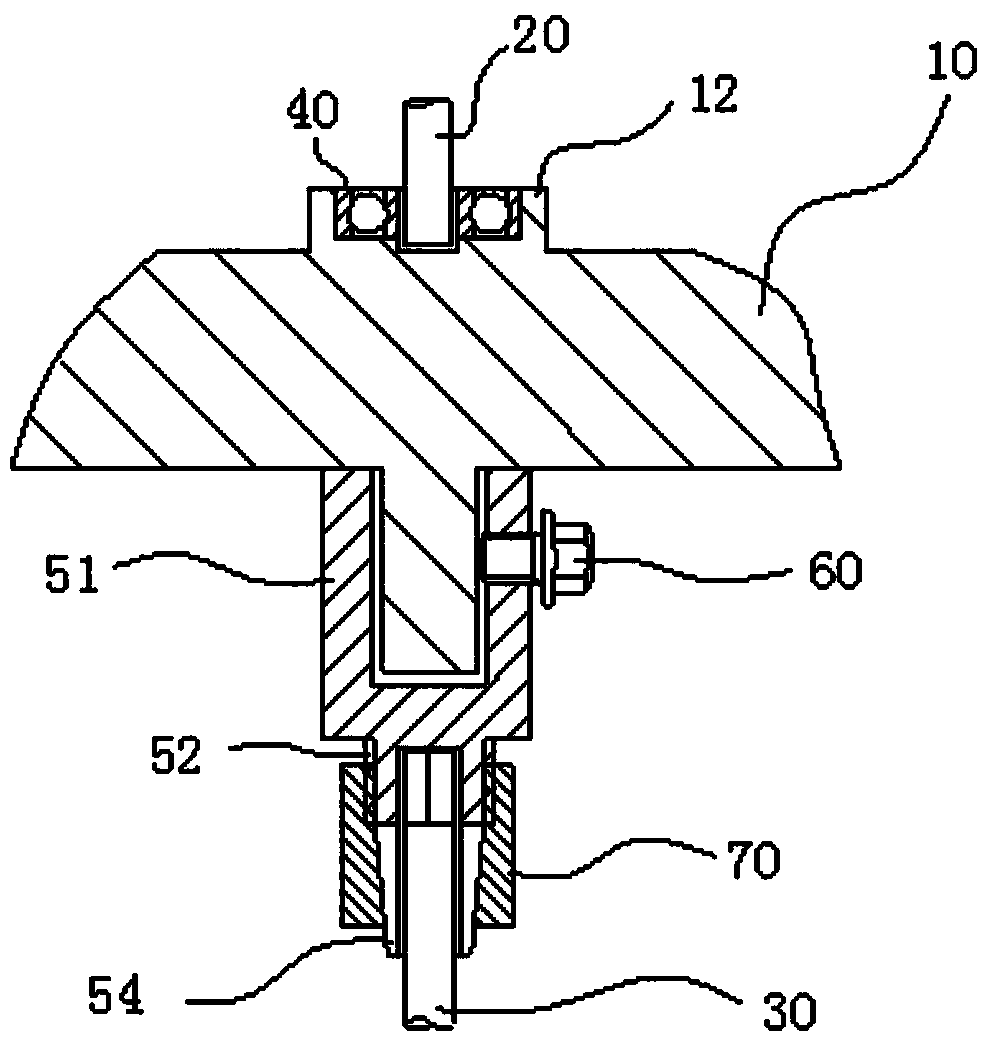

Drilling-milling tapping machine

PendingCN107138967ASmall footprintNot easy to wearLarge fixed membersPositioning apparatusMachineWorkbench

The invention discloses a drilling-milling tapping machine. The drilling-milling tapping machine comprises a base, a workbench fixed to the base, an installation table arranged on the base and located on one side of the workbench, an X-axis driving mechanism arranged on the installation table, a saddle erected on the installation table and driven by the X-axis driving mechanism, a Y-axis driving mechanism arranged on the saddle, a stand column arranged on the saddle and driven by the Y-axis driving mechanism, a Z-axis driving mechanism arranged on one side of the stand column, a main shaft box arranged on one side of the stand column and driven by the Z-axis driving mechanism, a tool changing system fixedly connected with the top of the stand column, and a protective cover arranged on the edge of the base. The main shaft box and the tool changing system are located above the workbench. The drilling-milling tapping machine is constant in load and good in stability.

Owner:中山长准机电有限公司

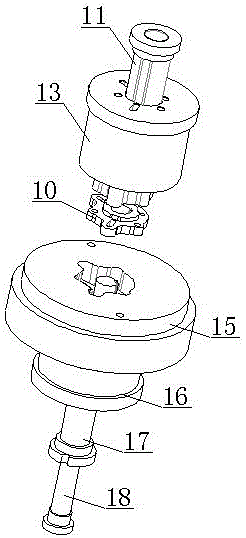

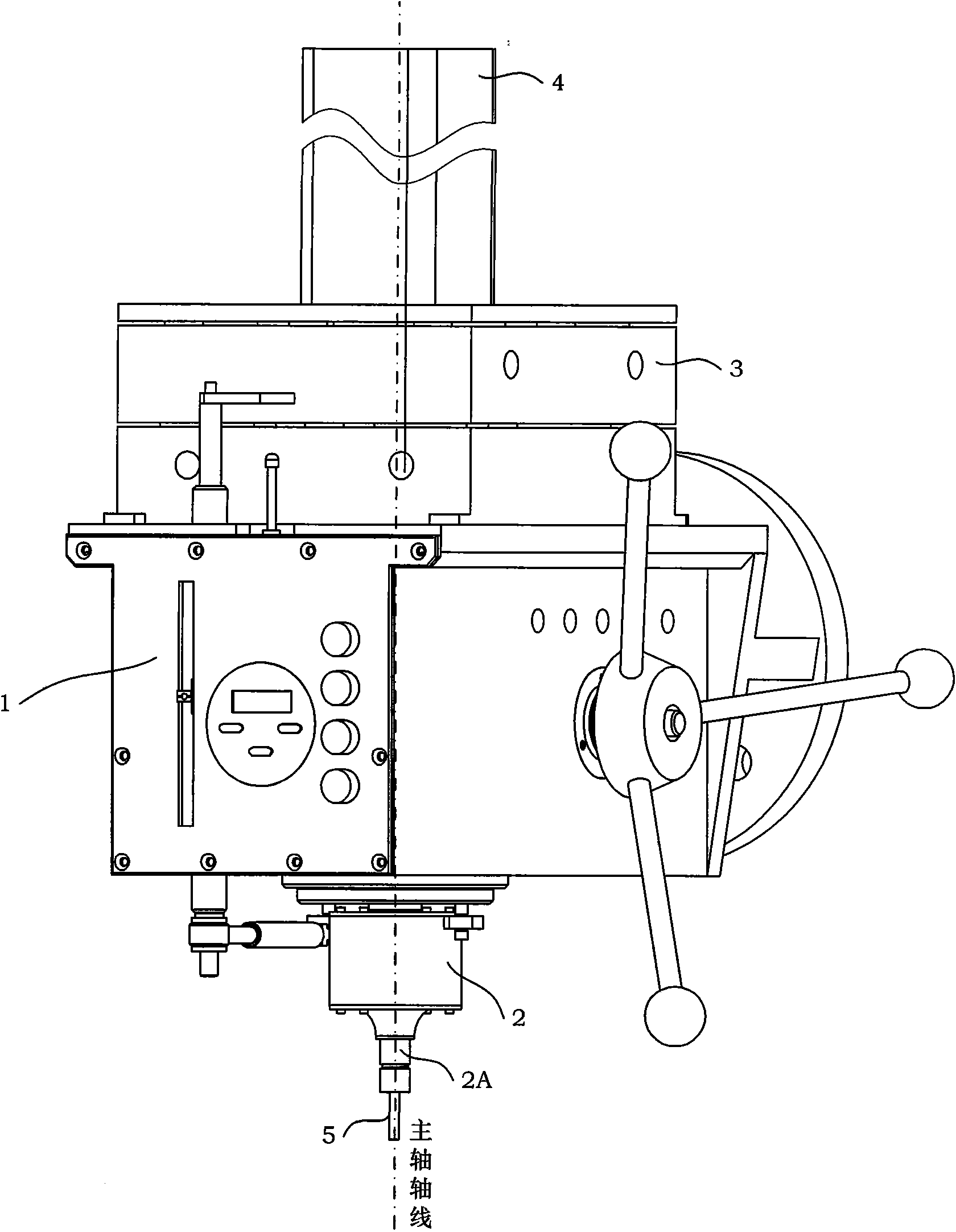

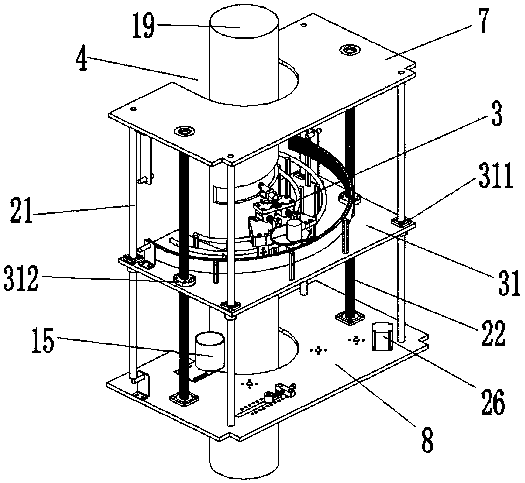

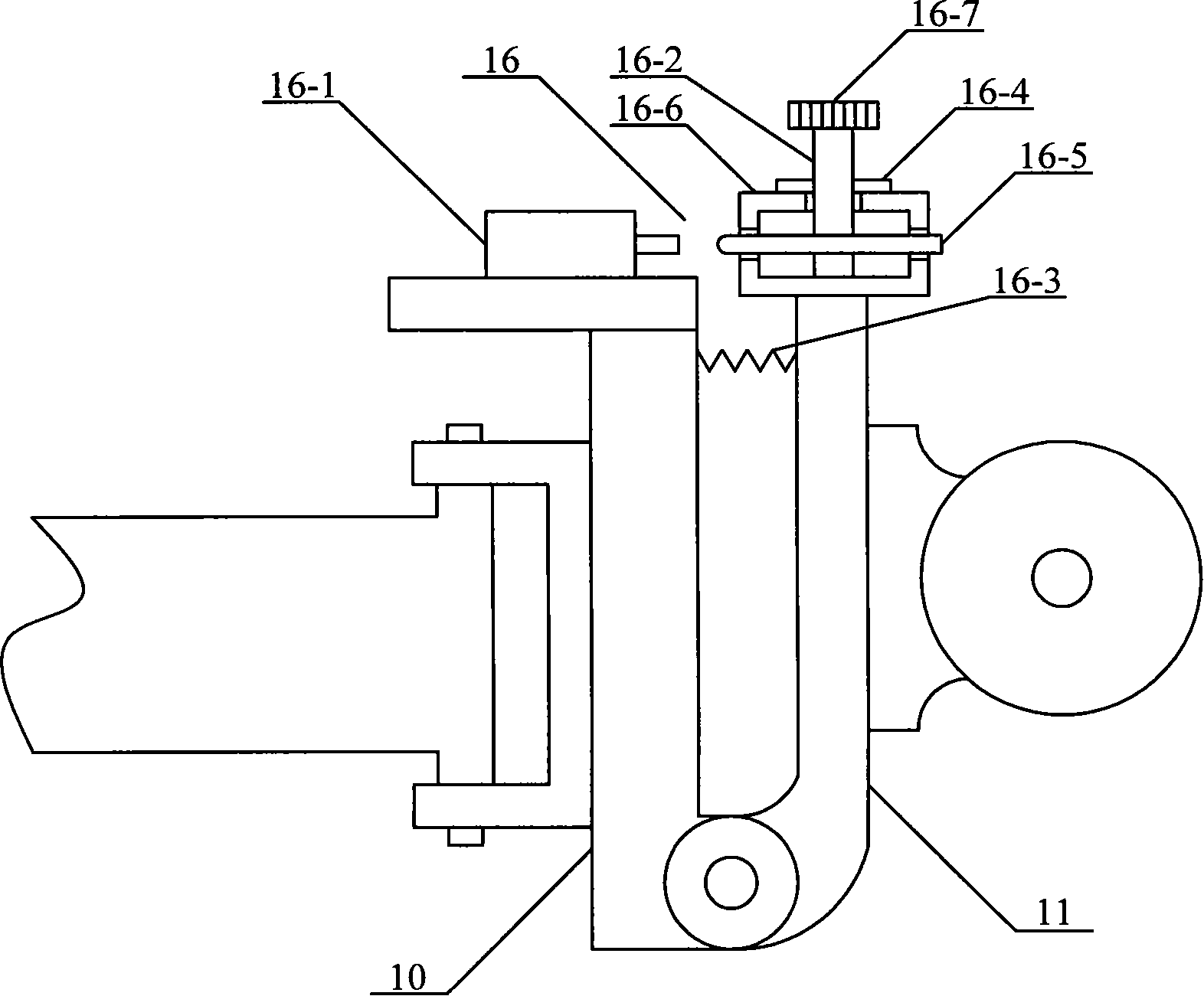

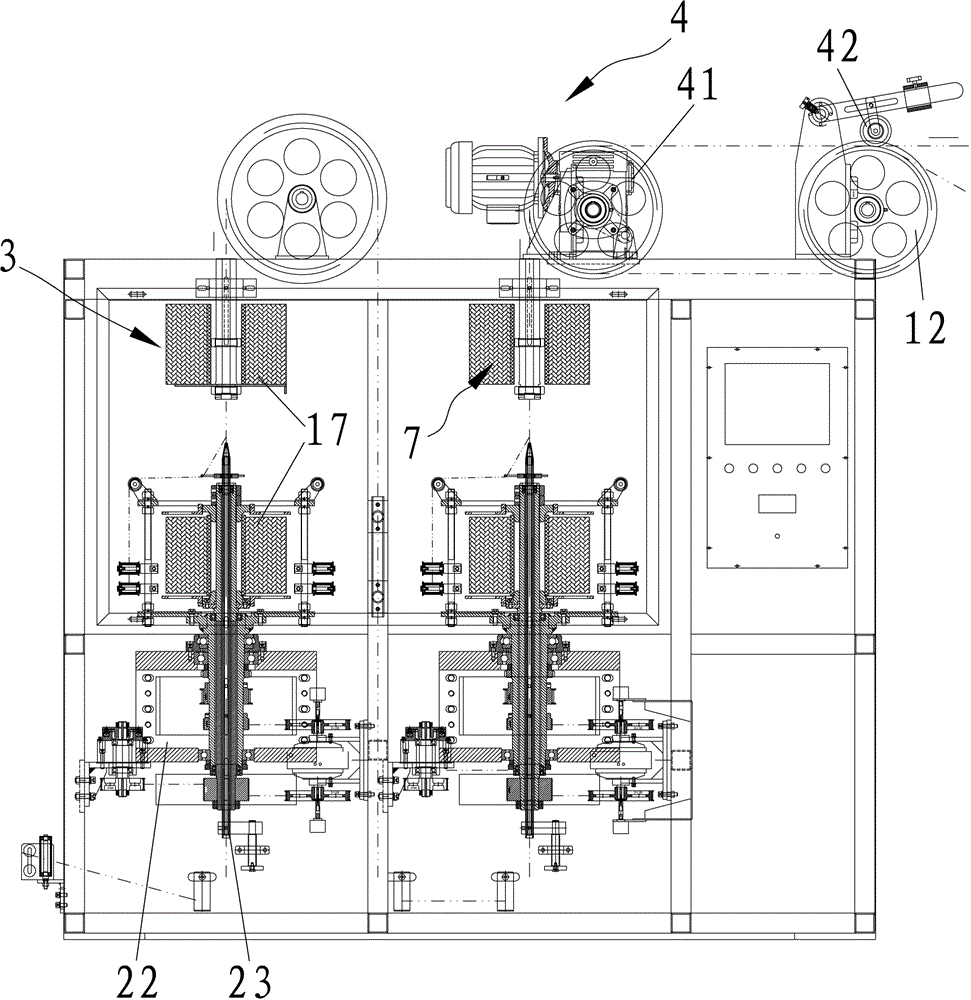

High-low frequency compound torsional vibration tapping device

InactiveCN101633064AExtended service lifeIncrease flexibilityThread cutting machinesEngineeringTorsional vibration

The invention discloses a high-low frequency compound torsional vibration tapping device comprising a main shaft mechanism, an ultraphonic transduction vibration assembly, a floating assembly and a servo motor, wherein the ultraphonic transduction vibration assembly is arranged in the main shaft mechanism; the servo motor is arranged on a supporting plate of the floating assembly; and the floating assembly is arranged on the surface of a mounting plate of a main shaft box of the main shaft mechanism. The torsional vibration tapping device can be suitable for high-low frequency compound torsional vibration tapping with low frequency less than 60 Hz and high frequency more than 16 kHz and combines low frequency torsional vibration provided by the servo motor and high frequency torsional vibration provided by the ultraphonic transduction vibration assembly, thereby realizing the high-low frequency compound torsional vibration tapping of a cutter, simplifying the structure of the device and enhancing the precision of equipment; in addition, the invention realizes the radial floating of the cutter by installing an X-directional floating assembly and a Y-directional floating assembly, prevents larger radial force from being generated during processing and realizes the flexible processing of the torsional vibration tapping device in such a way that the axial floating of a main shaft of the cutter is provided by a spline part assembly.

Owner:BEIHANG UNIV

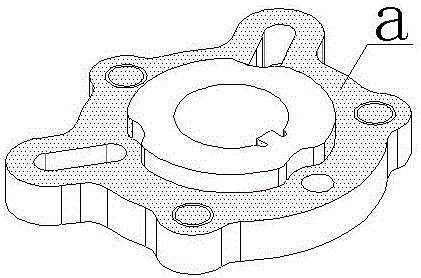

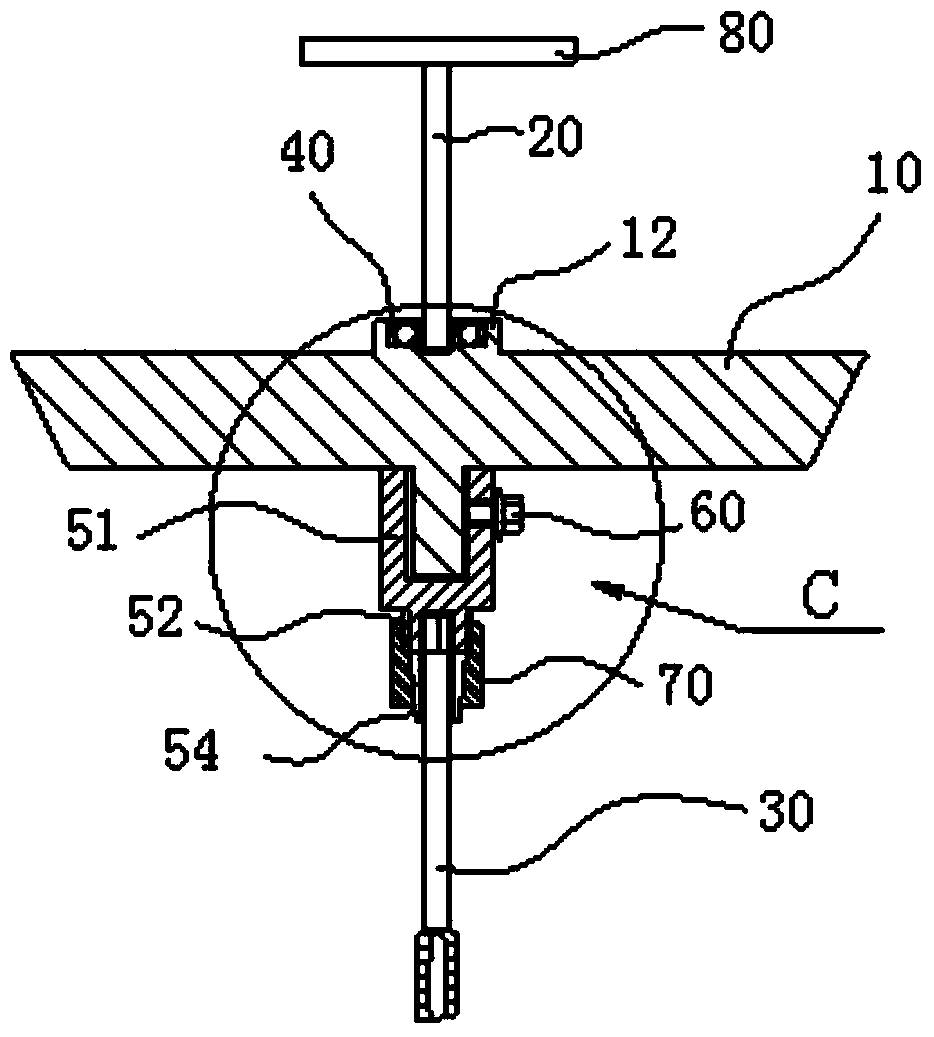

Concealed clamp device

InactiveCN102152143AFast and accurate card alignmentImprove quality and efficiencyPositioning apparatusMetal-working holdersEngineeringMechanical engineering

Owner:ANHUI RUIDA MACHINERY

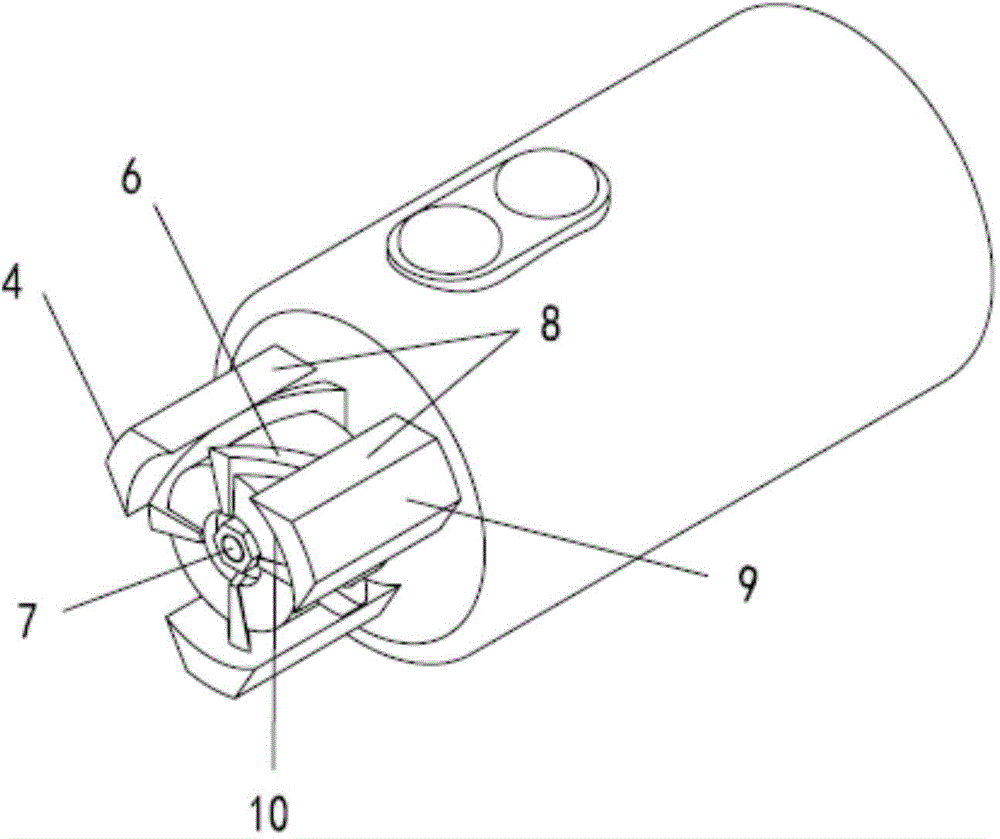

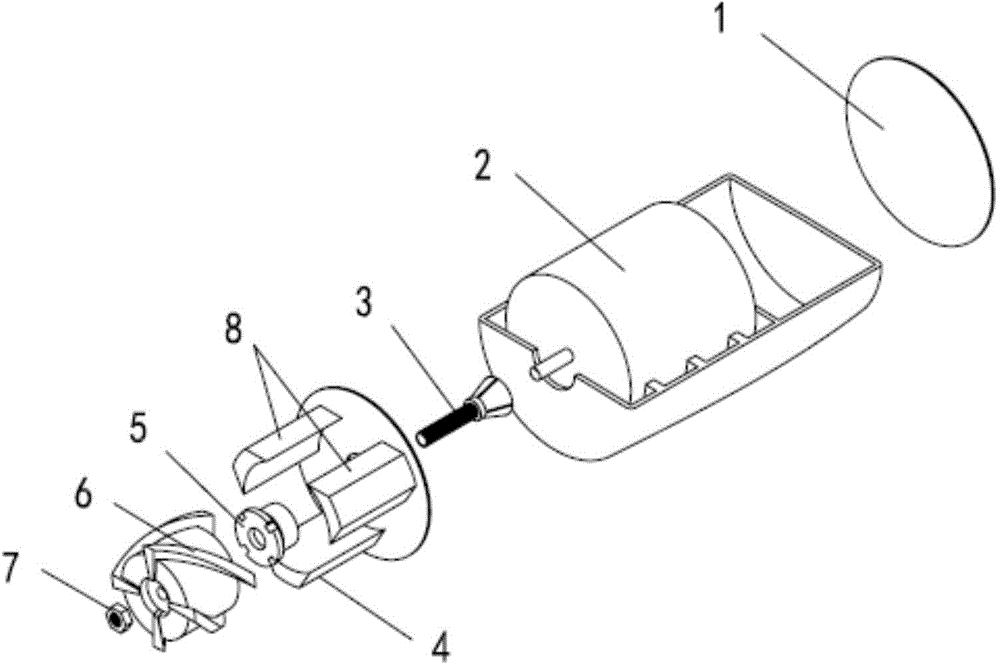

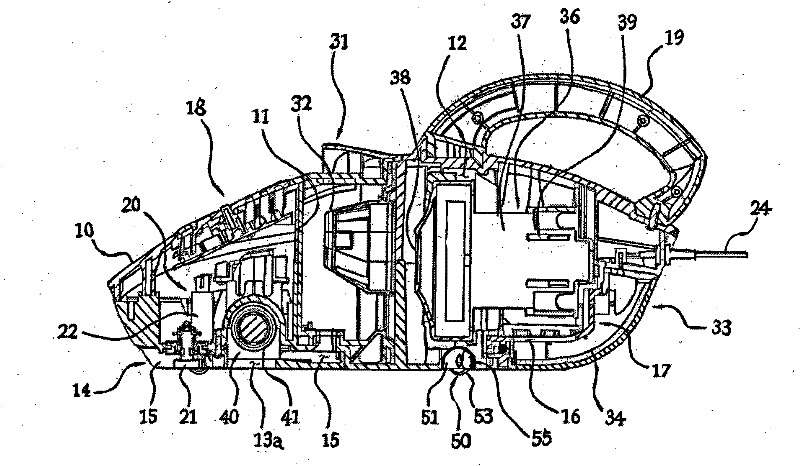

Hitting component and vacuum cleaner using the hitting component

InactiveCN102217915AImprove tapping efficiencyIncrease the percussion areaSuction cleanersEngineeringMechanical engineering

The invention relates to a hitting component for making dust fly and then absorbed in a vacuum manner by hitting articles to be cleaned (bedding articles, carpets, curtains, clothes, sofas and mattresses, etc.) and a vacuum cleaner using the hitting component. Especially, the invention relates to a hitting part amplifying the overall amplitude by supporting a vibratory rod through a flexible support part and making the vibratory rod not only vertically swing but so vertically vibrate, and a vacuum cleaner using the hitting component.

Owner:SUZHOU HAAN TECH +1

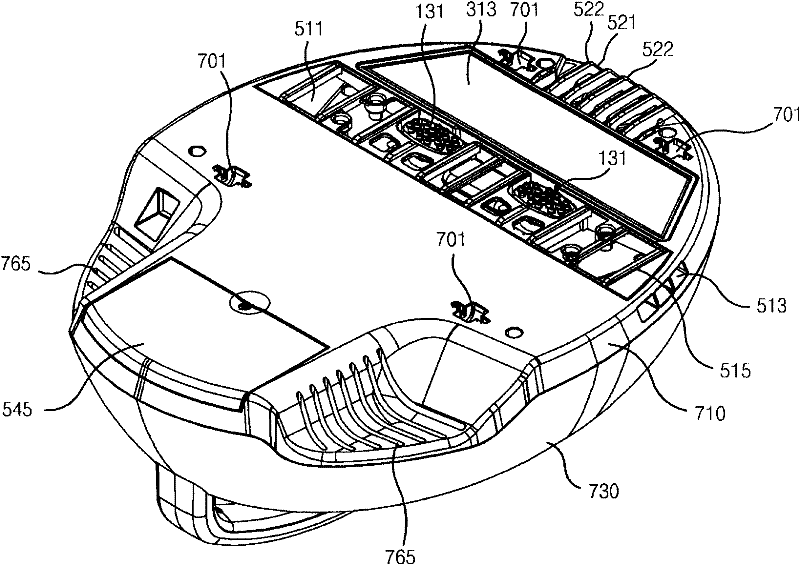

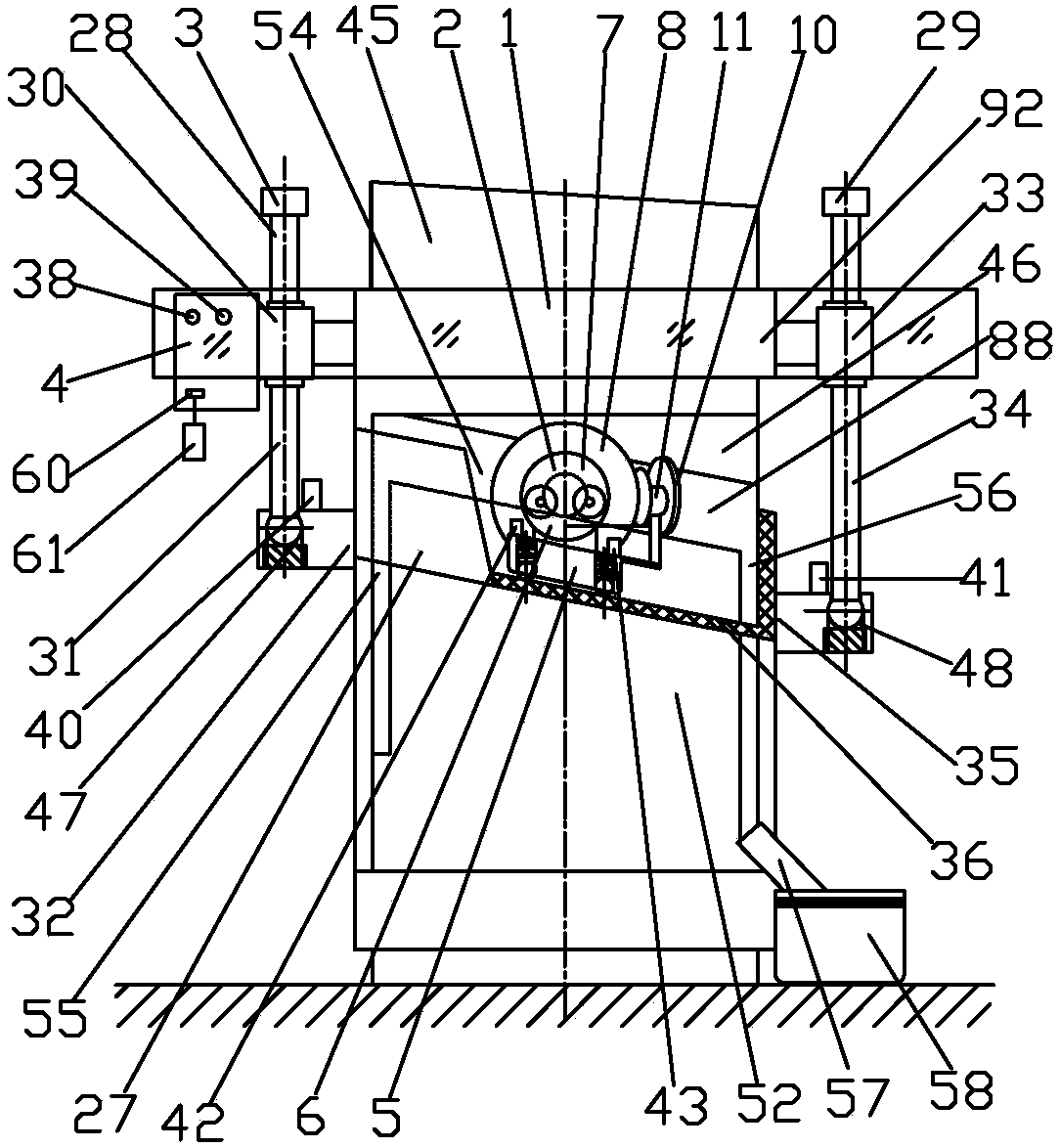

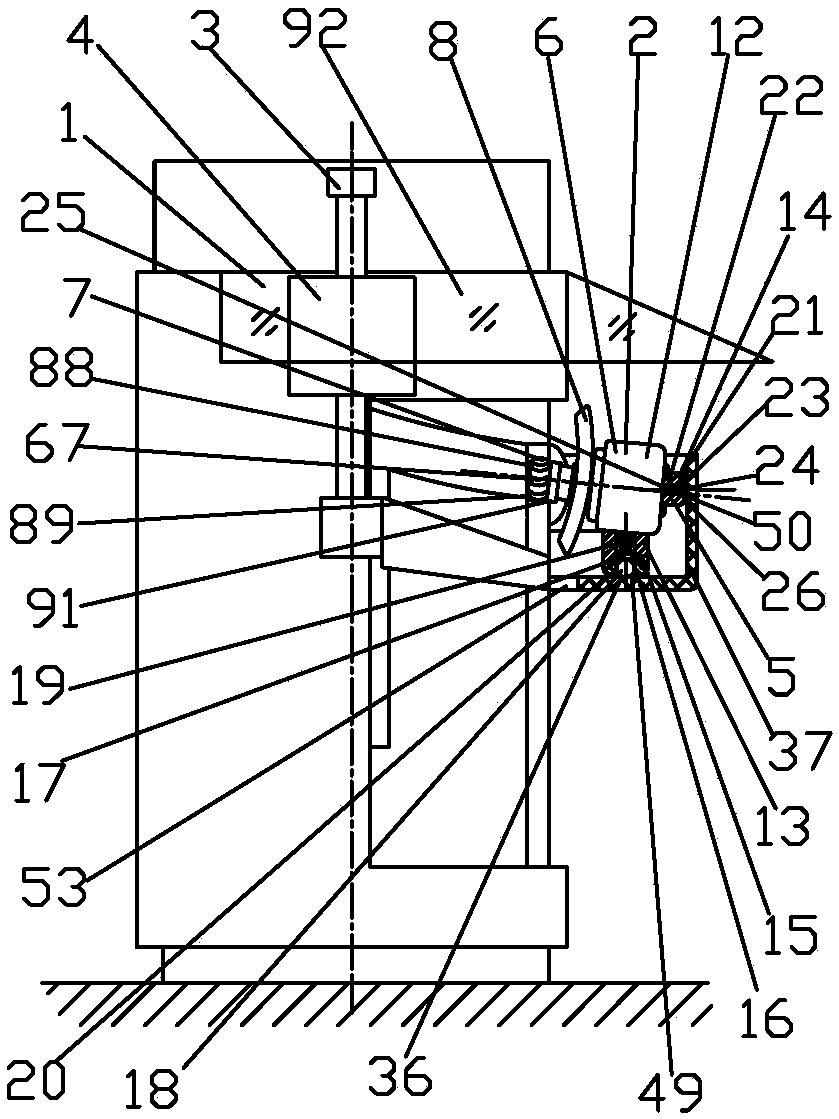

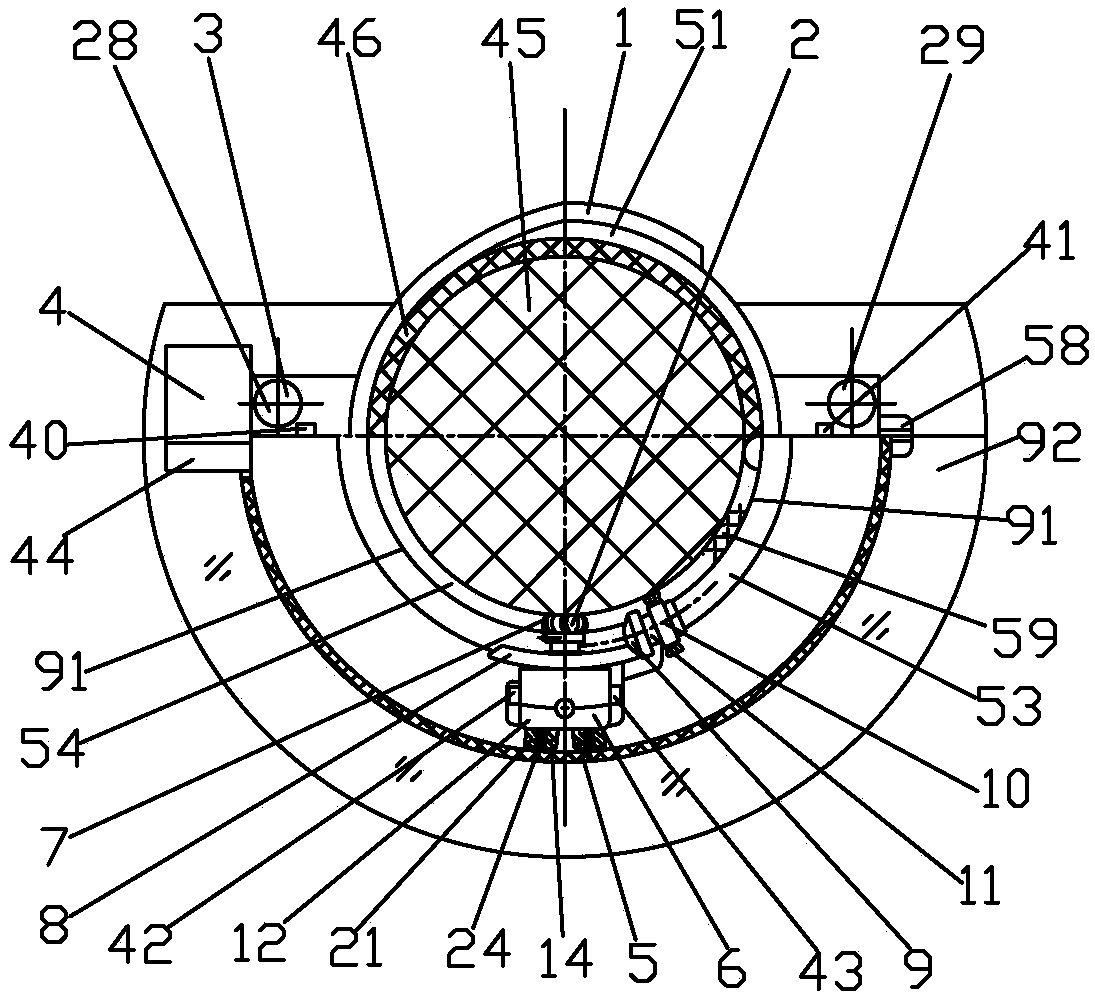

Rubber tapping equipment with double-knife-edge structure

PendingCN108432590AComplete lift movement wellAvoid the disadvantages of unbalanced transmissionForestryRenewable energy machinesControl systemTree trunk

The invention provides rubber tapping equipment with a double-knife-edge structure. The equipment comprises an outer frame, a vertical lifting work feeder arranged on the outer frame and a spiral rubber-tapping device arranged on the vertical lifting work feeder and capable of vertical lifting along the vertical lifting work feeder; and the spiral rubber-tapping device is provided with a rubber-tapping knife with an adjustable extending distance and a double-sided knife edge, the outer frame is provided with a tree trunk fixing position used for accommodating a tree trunk of a rubber tree, theposition, corresponding to the tree trunk fixing position, of one side of the outer frame is provided with a detachable movable baffle, the top end of the outer frame is provided with a solar panel and a control system, the vertical lifting work feeder and the spiral rubber-tapping device are connected with the solar panel and the control system, and the part, located at the edge position of thetree trunk fixing position, of the bottom of the outer frame is provided with a rubber collecting barrel. The equipment provided by the invention can replace manual rubber tapping, not only improves rubber tapping efficiency, but also improves rubber tapping quality; and the equipment is provided with the rubber tapping knife with a front knife edge and back knife blade structure, so that the equipment facilitates effective and high-efficiency cutting of the rubber tree.

Owner:AGRI MACHINERY INST CHINESE TROPICAL ACAD OF SCI

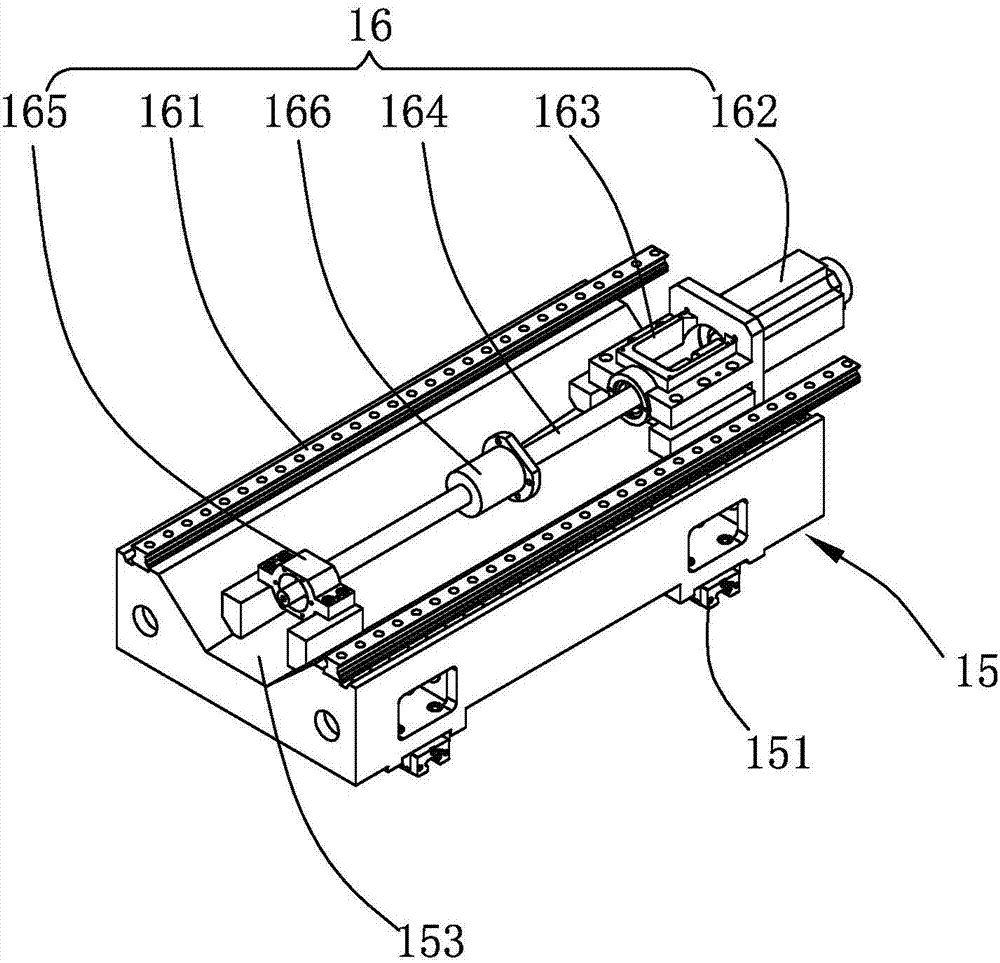

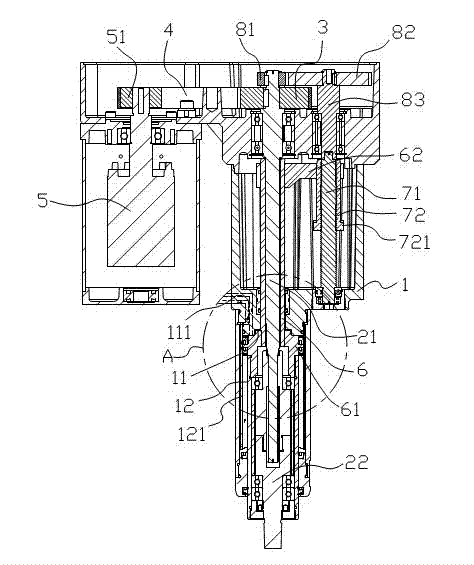

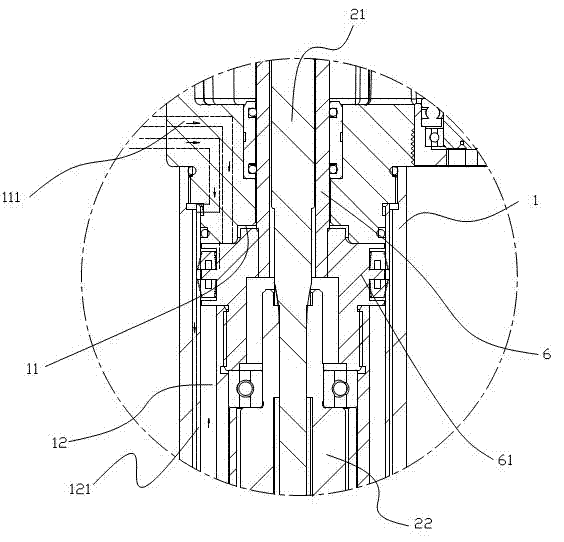

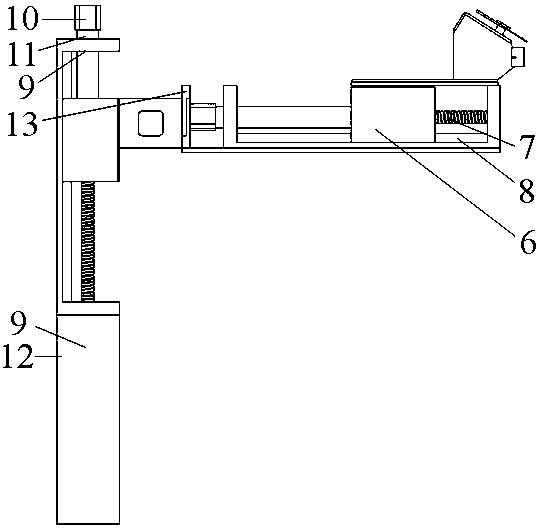

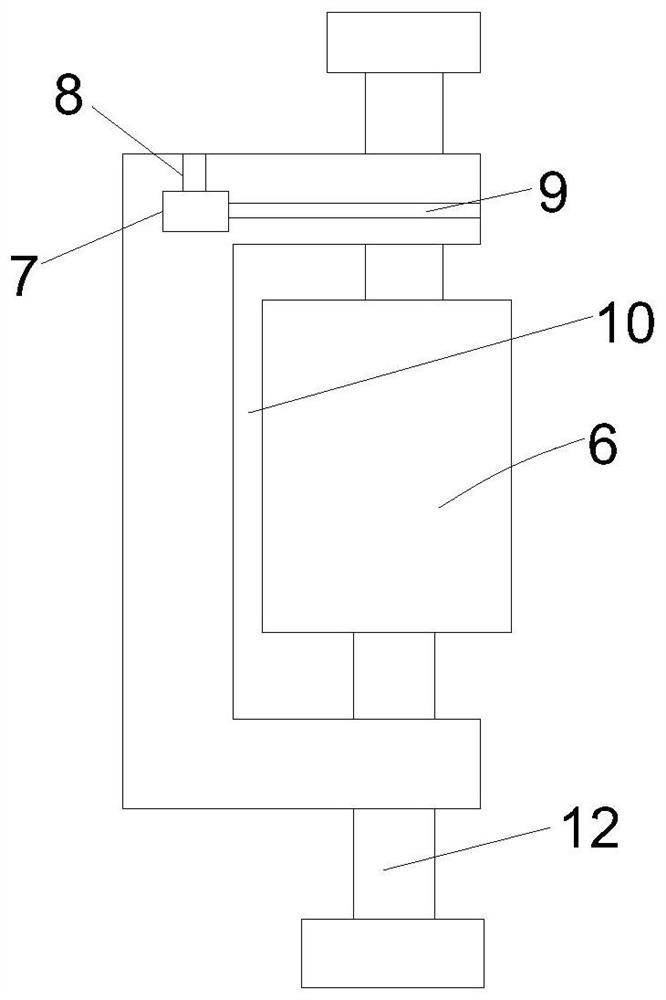

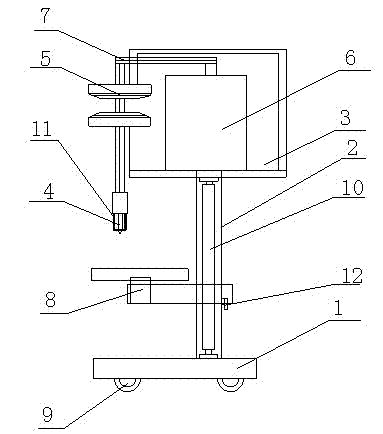

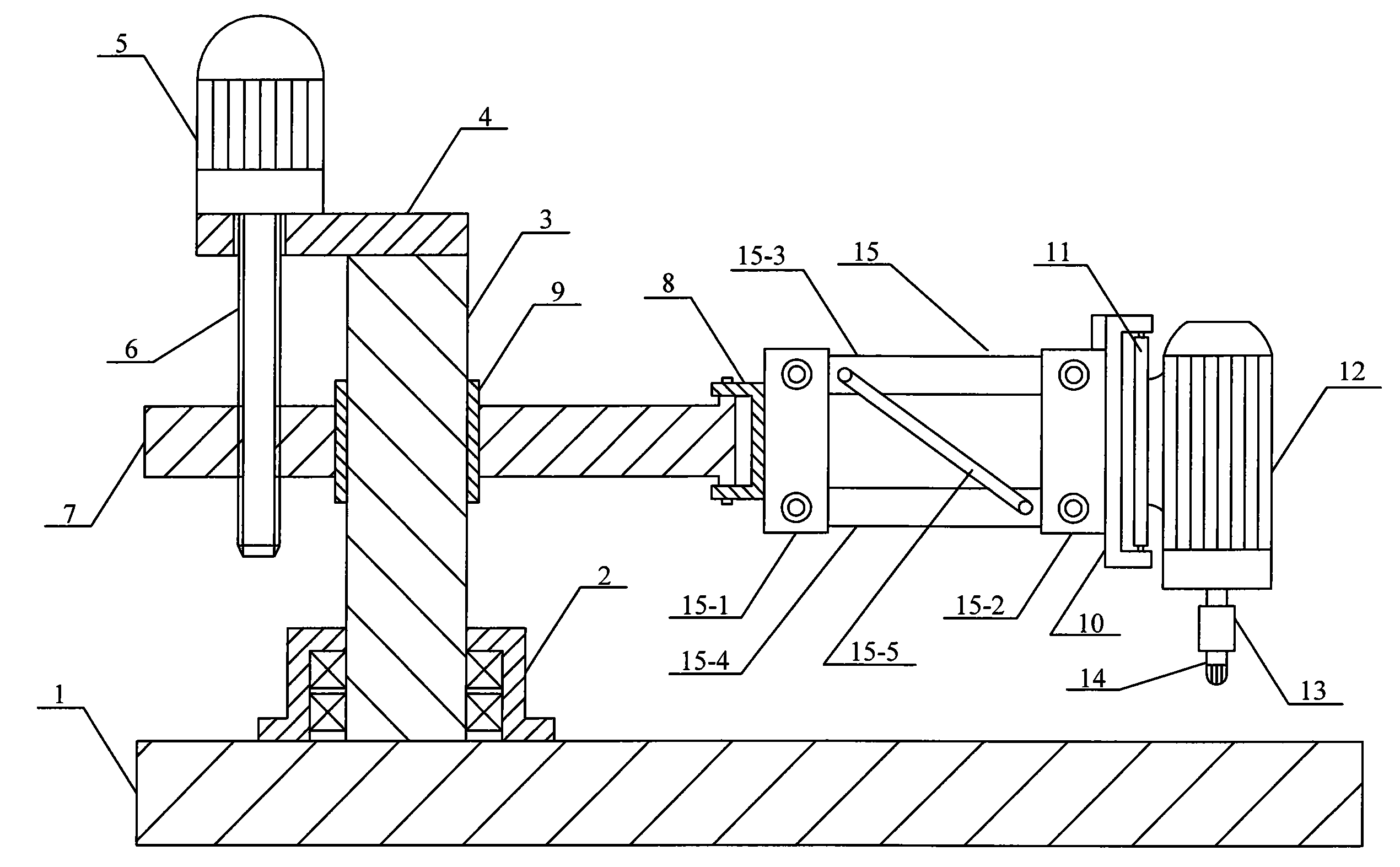

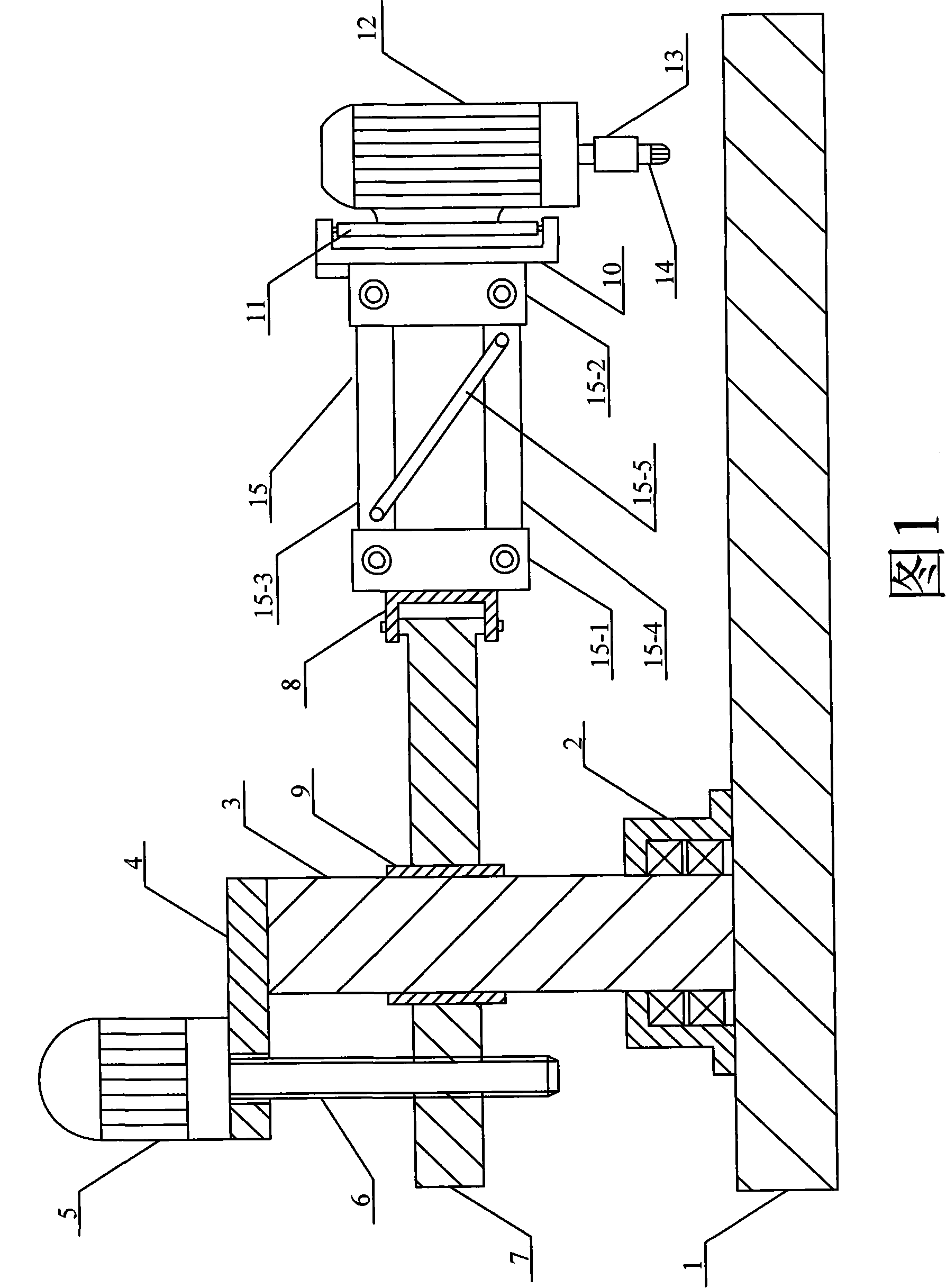

Automatic tapping machine power head capable of fast feed and fast return

InactiveCN103170686AFast feedRetract the knife quicklyThread cutting machinesFeeding apparatusEngineeringMechanical engineering

An automatic tapping machine power head capable of fast feed and fast return comprises a main shaft box and a main shaft disposed in the main shaft box. The main shaft comprises an outer spline shaft and an inner spline shaft, wherein the head of the outer spline shaft extends into the tail of the inner spline shaft, and the inner spline shaft and the outer spline shaft are connected through an inner spline and an outer spline between the shafts. A guide shaft is sleeved outside the outer spline shaft, the inner spline shaft is connected into the head of the guide shaft through a bearing, a piston is installed in the middle of the outer side of the guide shaft, the piston completely isolates a sealed cavity axially formed on the main shaft box into an upper cavity and a lower cavity, and the upper cavity and the lower cavity are respectively connected with an air source through respective air channels. A limit support is connected with the upper portion of the outer side of the guide shaft, the limit support can be connected with a main shaft tapping feed mechanism in a clamping mode, and a movement gap slightly smaller than the idle stroke of the tapping machine is reserved at the position of the clamping connection between the limit support and the main shaft tapping feed mechanism. The automatic tapping machine power head capable of fast feed and fast return is capable of achieving fast feed and fast return of the power head in the idle stroke, and the tapping efficiency of the tapping machine can be greatly improved.

Owner:WENLING GUOBANG ELECTRIC

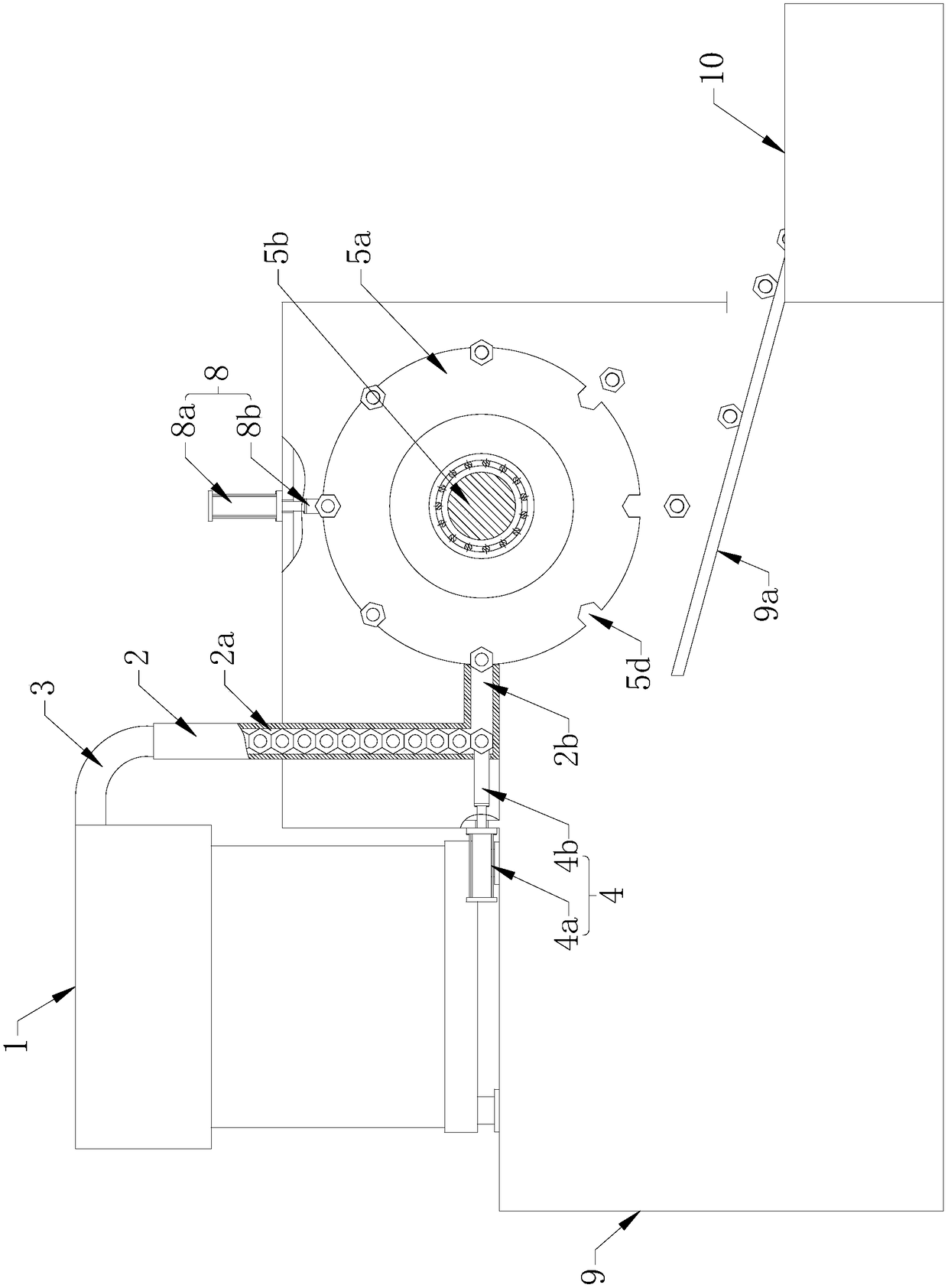

Automatic rubber tapping machine profiling and cutting mechanism for rubber trees

PendingCN108377876AAvoid destructionRealize the function of three-dimensional profiling in spaceForestryNumerical controlAutomation

The invention belongs to the field of agricultural or forestry machines, and relates to an automatic rubber tapping machine profiling and cutting mechanism for rubber trees. The mechanism comprises aprofiling mechanism and a cutting mechanism, the profiling mechanism is composed of a numerical control three-axis sliding table, and the spatial three-dimensional profiling function is achieved by controlling rotation of a stepping motor. The cutting mechanism is installed on the profiling mechanism and is composed of a cutting device and a limiting device, the cutting device achieves cutting bycontrolling rotation of the motor, the limiting device achieves control over the cutting depth through bolt fixation, and therefore synchronous profiling and cutting of the whole rubber tapping process are achieved. The mechanism has the advantages of being simple in structure, convenient and reliable to control and the like, rubber tapping automation is achieved, the rubber tapping efficiency andquality are effectively improved, the defect existing in a traditional rubber tapping mode is overcome, and the requirement for the market can be met.

Owner:HAINAN UNIVERSITY

Machine tool for easy tapping of tube body

InactiveCN107350579AHigh precisionImprove tapping efficiencyThread cutting machinesDrive motorMachine tool

The invention provides a machine tool for pipe body tapping, which relates to the electromechanical field. The machine tool for pipe body tapping includes a bed body, the bottom of the bed body is fixedly connected with support legs, the top of the bed body is fixedly connected with two fixed blocks, and the sides of the two fixed blocks are provided with push screws The threaded ends of the two push screw rods both pass through the fixed block and extend between the two fixed blocks. Two clamping blocks are arranged between the two fixing blocks, and the sides of the two clamping blocks that are far away from each other are fixed The first bearing is connected, and the threaded ends of the two push screw rods are located between the two fixing blocks and are fixedly sleeved with the first bearing. This machine tool is convenient for pipe body tapping. The transmission motor drives the rotation of the main gear and the transmission gear, so that the slider can move horizontally to the left inside the chute. Carry out positioning tapping, effectively improve the accuracy of tapping and improve the tapping efficiency.

Owner:王之韵

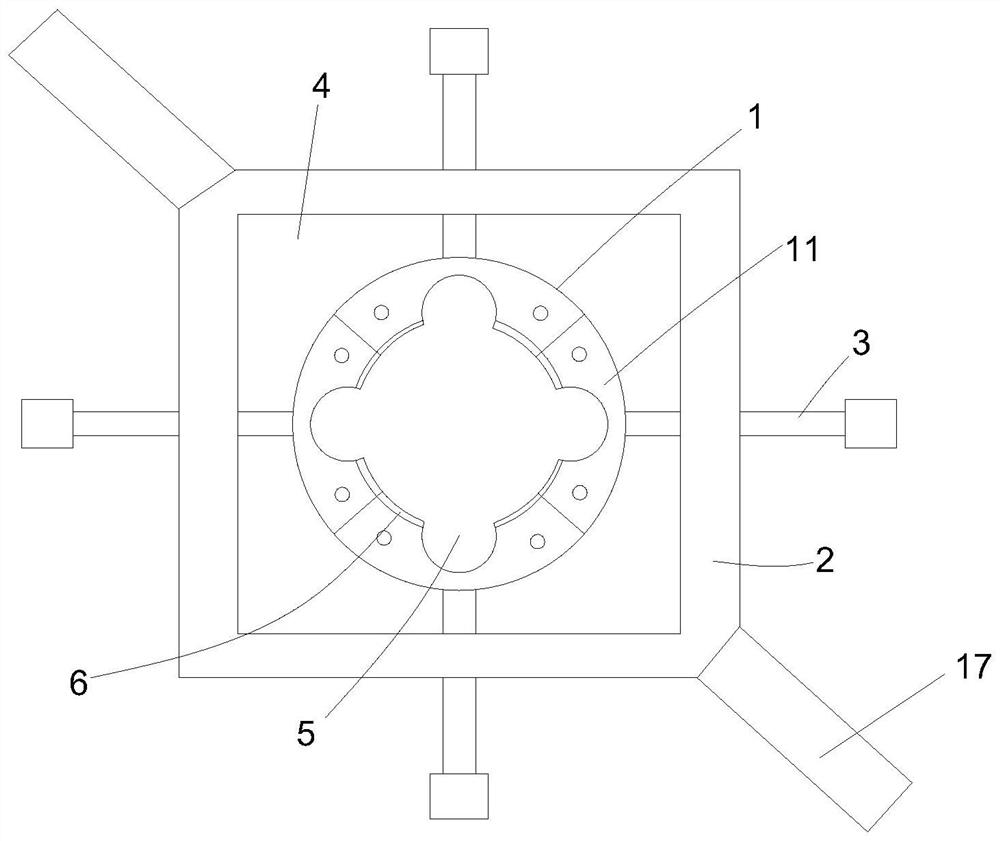

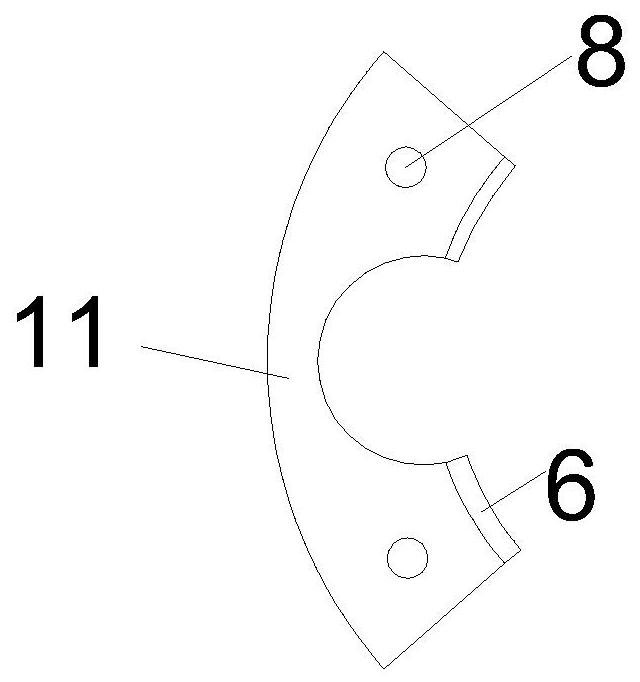

Adjustable circular die

The invention relates to the technical field of circular dies, in particular to an adjustable circular die. The adjustable circular die comprises a circular die body, a fixing frame and first adjusting bolts, the circular die body is formed by splicing four arc-shaped circular die components, mounting holes are formed in the middle of the circular die body, chip removal holes are formed in the middles of the arc-shaped circular die components, adjustable threading die tapping bodies are arranged on the two sides of the chip removal holes, the fixing frame is of a square structure, and each arc-shaped circular die component is arranged on a frame edge of the fixing frame through the corresponding first adjusting bolt. The arc-shaped circular die components can be adjusted to adapt to a to-be-machined part through the first adjusting bolts, threads are machined on the to-be-machined part, generated waste is discharged into the chip removal holes, and therefore tapping efficiency can be improved.

Owner:东台市双厦工具有限公司

Tapping device

InactiveCN104368883AAvoid offsetSelf-fixing performance is strongThread cutting machinesMechanical engineeringEngineering

Owner:ANHUI HONGLU STEEL CONSTR (GROUP) CO LTD

Modified electric tapper

Owner:JIANGSU BOGU ELECTROMECHANICAL

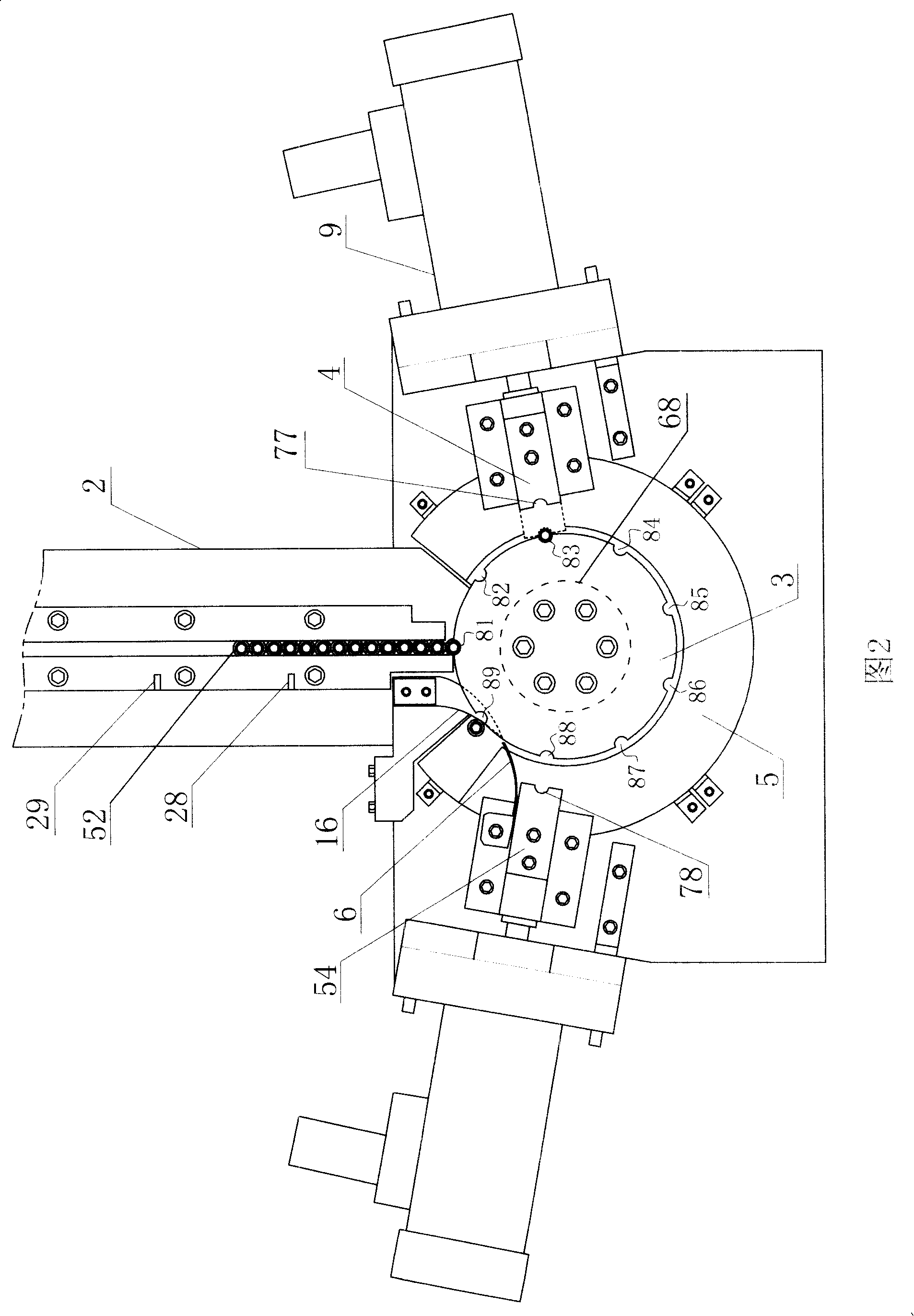

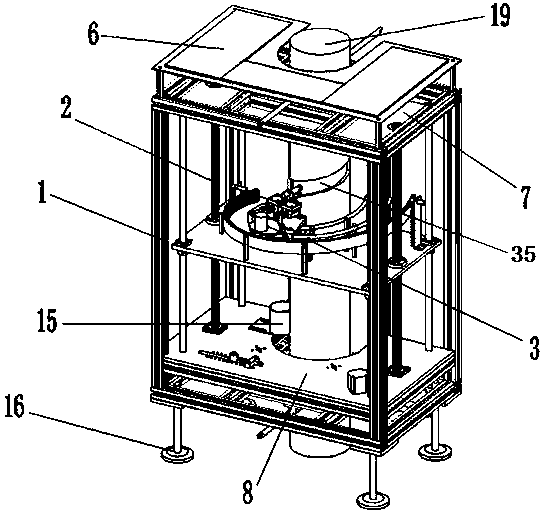

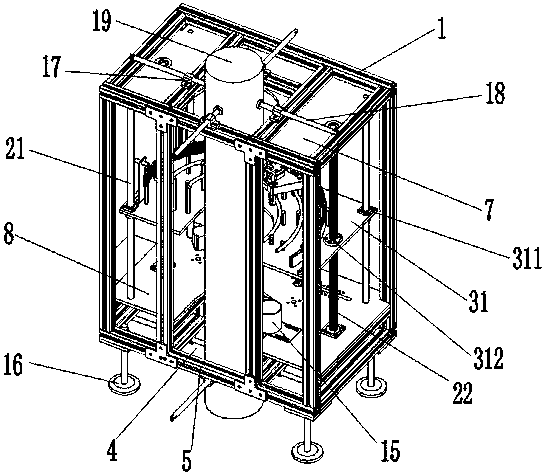

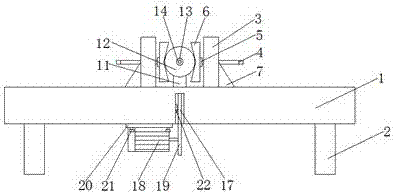

Tapping machining device of hexagon nut

PendingCN109158715AImprove tapping efficiencyImprove product qualityThread cutting feeding devicesThread cutting machinesEngineeringMachining process

The invention discloses a tapping machining device of a hexagon nut. The device comprises a vibration disc, an L-shaped feeding rail, a discharging port, a conveying guide rail, a material pushing mechanism and a material receiving turntable mechanism, wherein the vibration disc is used for conveying a hexagon blank of the thread to be machined, the discharging port is connected with the vibrationdisc, the conveying guide rail is arranged at the upper end of the L-shaped feeding rail, the material pushing mechanism is arranged on the right side of the bottom of the L-shaped feeding rail, andthe material receiving turntable mechanism is arranged on the left side of the bottom of the L-shaped feeding rail; the material pushing mechanism can push the hexagon blank at the bottom of the L-shaped feeding rail to be connected with the right side of the material receiving turntable mechanism, a material ejecting mechanism and a tapping mechanism are arranged in the front and back part of thematerial receiving turntable mechanism correspondingly, wherein the material ejecting mechanism is used for ejecting the hexagon blank in a tapping machining process, the tapping mechanism is used for tapping; and a material pressing mechanism used for pressing the hexagon blank is further arranged above the material receiving turntable mechanism. According to the device, feeding, tapping and discharging are realized, a continuous machining production is realized at the same time, and the tapping efficiency is improved, all-directional fixation is realized in the tapping process, the stability of the tapping is guaranteed, and the production quality of the hexagon nut is improved.

Owner:ZHEJIANG RONNIE PRECISION MACHINE

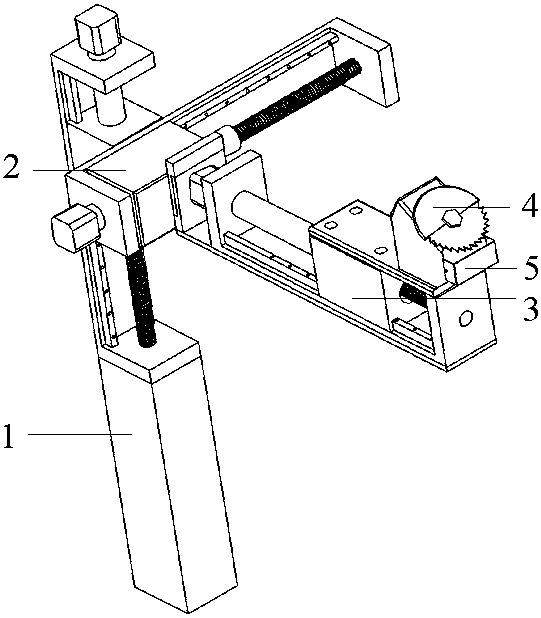

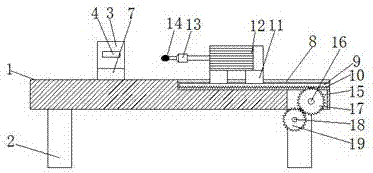

Threading apparatus

ActiveCN101318239BImprove tapping efficiencyIncrease the lengthThread cutting machinesEngineeringSeparation angle

The invention discloses a tapping machine with high tapping efficiency in the technical field of tapping devices, the tapping machine can make all directional tapping for work pieces under the condition of not moving the work pieces. The tapping machine comprises a base, an upright column, a cross arm, a tapping device and a connecting arm; wherein, the lower end of the upright column which is horizontally connected with the cross arm is connected with the base by a bearing; one end of the connecting arm is articulated with one end of the cross arm so as to change the horizontal separation angle between the connecting arm and the cross arm; the other end of the connecting arm is connected with the tapping device.

Owner:展静

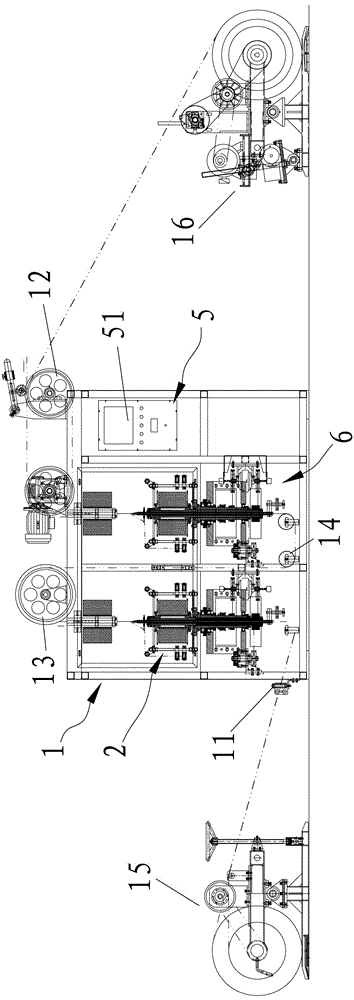

Automatic vertical numerically-controlled wire taping machine

InactiveCN106298100AReduce labor intensityImprove Taping EfficiencyCable/conductor manufactureEngineeringUltimate tensile strength

The present invention relates to the technical field of taping machines, and discloses an automatic vertical numerically-controlled wire taping machine. The automatic vertical numerically-controlled wire taping machine comprises a frame, wherein the frame is sequentially provided with a wire incoming roller set, a first tape rotating device, a first tape storage mechanism, a wire leading mechanism and an unwinding wheel along a wire incoming direction, the first tape rotating device is provided with a containing cavity for containing tape rolls, the containing cavity is provided with an upper end cover which can be detachably connected, and the first tape storage mechanism is provided with a limiting component which is used for limiting stored tape rolls from moving down; and the frame is also provided with a control device which is used for controlling the wire leading mechanism and the first tape rotating device. When the taping machine works, the tape rolls placed in the containing cavity are firstly used, and if the current tape rolls are completely used, new tape rolls can be directly put in the containing cavity from the first tape storage mechanism, wires are in wireless disconnection, tapes can be directly replaced, and thus the labor intensity of operators can be reduced, the taping efficiency can also be increased, a plurality of equipment can be guarded by a single person, and the labor can be reduced.

Owner:DONGGUAN ZHI HAN ELECTRICAL MACHINERY

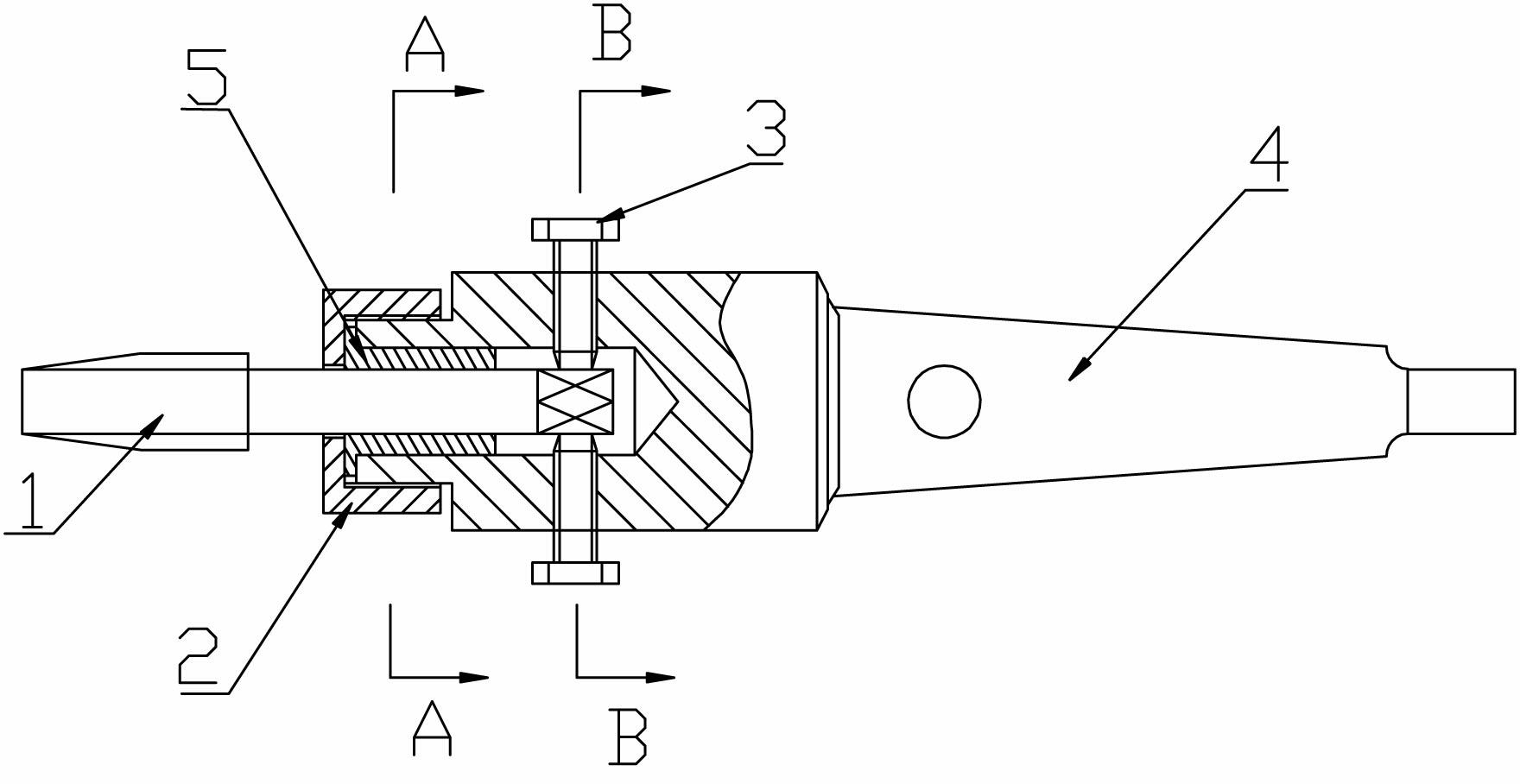

Mechanical thread tapper

InactiveCN102463398ATapping torque is not largeImprove coaxialityThread cutting machinesAccuracy classIndustrial engineering

The invention discloses a mechanical thread tapper. A conical rod is arranged at one end of a clamping body; a clamping surface is formed at one end of the conical rod; a clamping hole is formed at the other end of the clamping body; a positioning sleeve is arranged in the clamping hole by a clamping sleeve; and a plurality of positioning bolts are arranged at positions on the same section of the clamping hole. The mechanical thread tapper can improve tapping efficiency; the adopted four positioning bolts can conveniently adjust the coaxiality of a screw tap; meanwhile, the positioning sleeve has a smaller volume and can be processed to higher accuracy class conveniently, so that the tapping accuracy is improved; and the high-precision positioning sleeve is also favorable for the coaxiality of the screw tap such as the coaxiality and perpendicularity with a drilling machine, so that the vibration of the screw tap at work is reduced, and the instantaneous stress of the screw tap is reduced. After the specification of the screw tap is changed, only the corresponding positioning sleeve is required to be installed. In the invention, the coaxiality and perpendicularity can ensure that the tapping torque of the screw tap is small, so a standard screw tap can be used for processing on the drilling machine, the cost is saved, and the tapping efficiency is greatly improved.

Owner:长航集团宜昌船厂有限公司

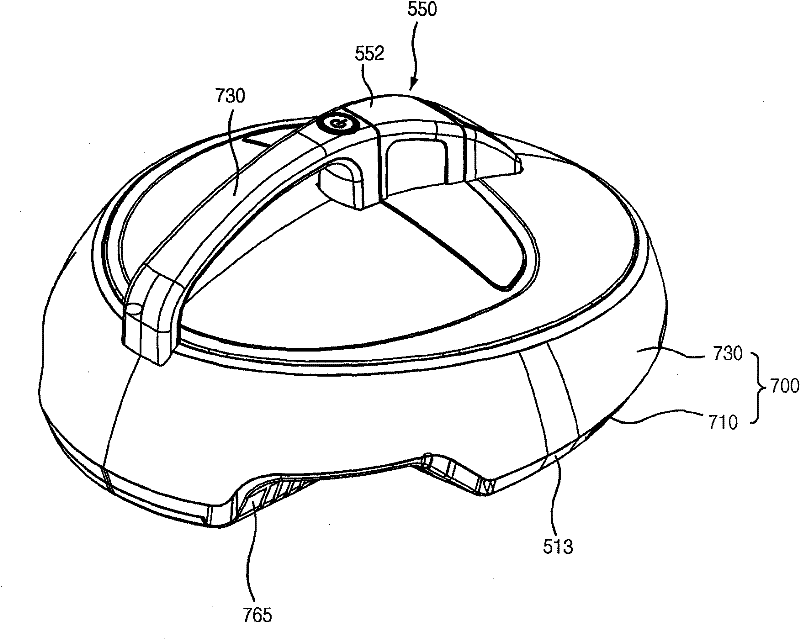

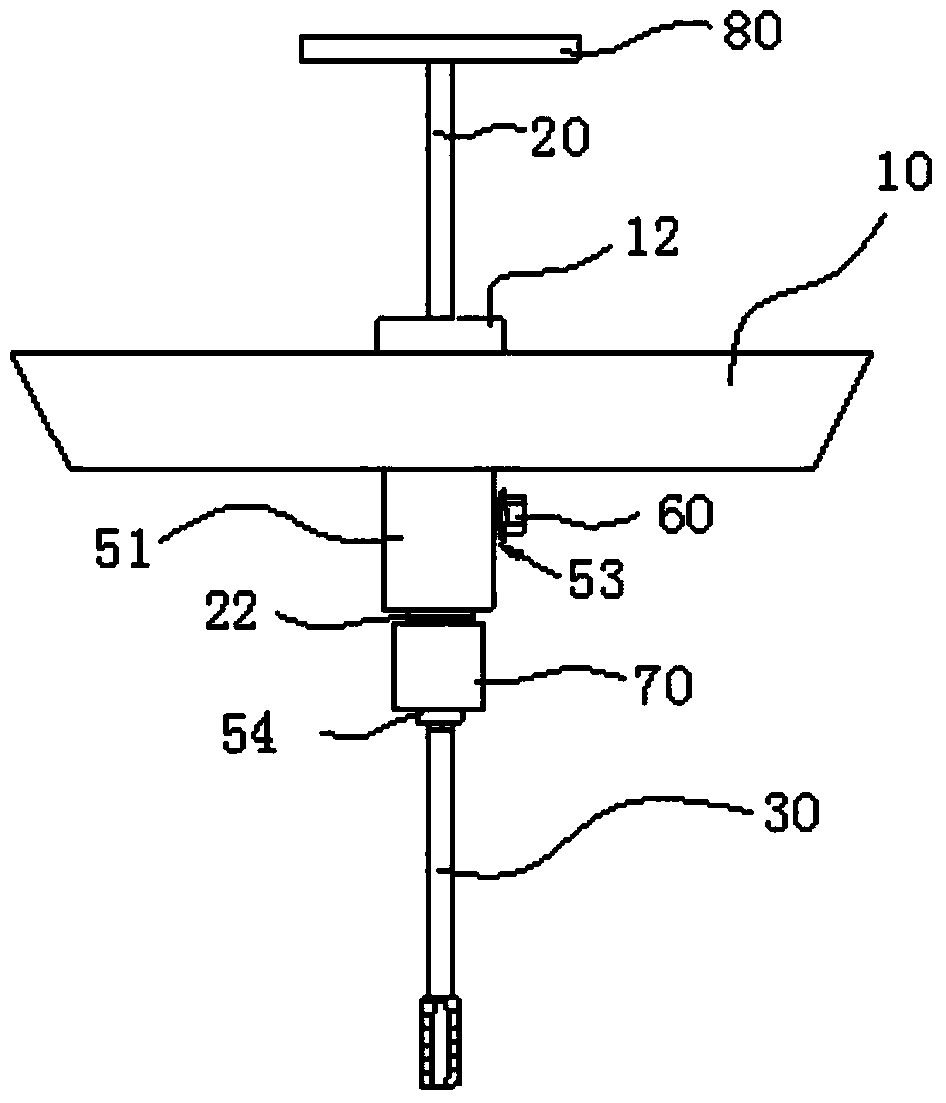

Automatic rubber-tapping robot

The invention provides an automatic rubber-tapping robot. The automatic rubber-tapping robot comprises a tree-wrapping belt, a rubber-tapping mechanical arm, a lifting device and a controller, whereinthe lifting device is connected with the tree-wrapping belt; and the rubber-tapping mechanical arm is connected with the lifting device. When the automatic rubber-tapping robot is in use, an arc-shaped guide rail with a corresponding size is arranged on a rubber tree by utilizing the tree-wrapping belt according to the size of the rubber tree and the position of the to-be-tapped bark of the rubber tree, and an oblique rubber groove and a rubber guide groove are opened in the bark of the rubber tree; every day, the controller controls a cutter disk of a rubber-tapping cutter device to cut andflake along the oblique rubber groove of the bark and then reset, and a cleaning wheel of a rubber-sludge cleaning device moves with the rubber-tapping cutter device to clean rubber sludge on the oblique rubber groove and then reset; every day, rubber glue of the oblique rubber groove tapped by the cutter disk flows into a rubber receiving bag along the oblique rubber groove, and the controller controls the lifting device to reduce the position of the arc-shaped guide rail; the rubber-tapping mechanical arm is utilized for automatic rubber-tapping before dawn every day, and a worker collects the rubber glue in the rubber receiving bag after dawn every day; thus, the problem of large rubber-tapping labor intensity of the worker in the morning is solved, and rubber-tapping efficiency is improved.

Owner:东莞市皓奇企业管理服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com