High-low frequency compound torsional vibration tapping device

A technology of torsional vibration and tapping device, which is used in tangent devices, metal processing equipment, manufacturing tools, etc., can solve the problems of strict restrictions on workpiece shape and geometric size, complicated operation, and difficult to ensure the coaxiality of processing holes. The effect of improving tapping processing efficiency, simplifying device structure and improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below in conjunction with the accompanying drawings.

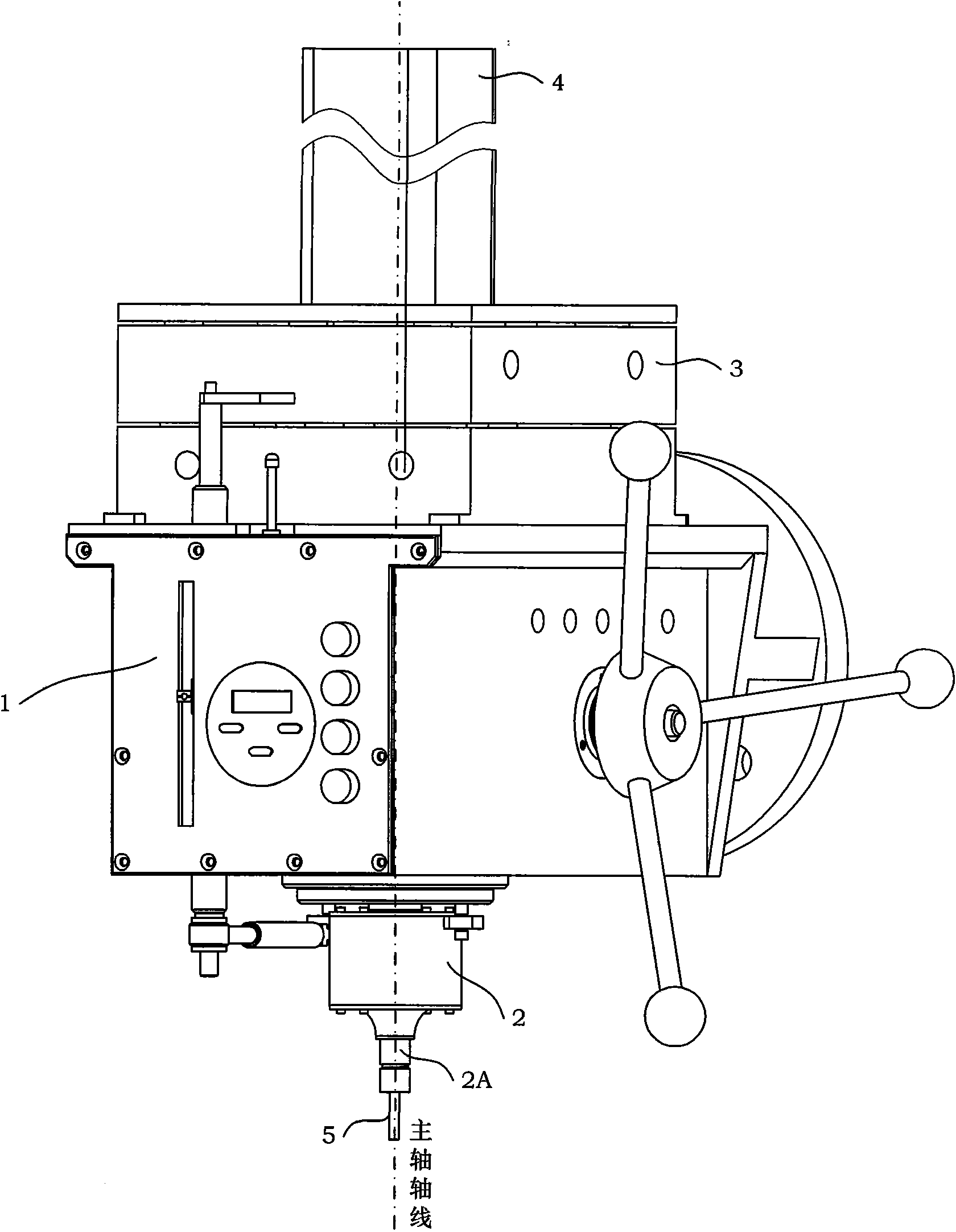

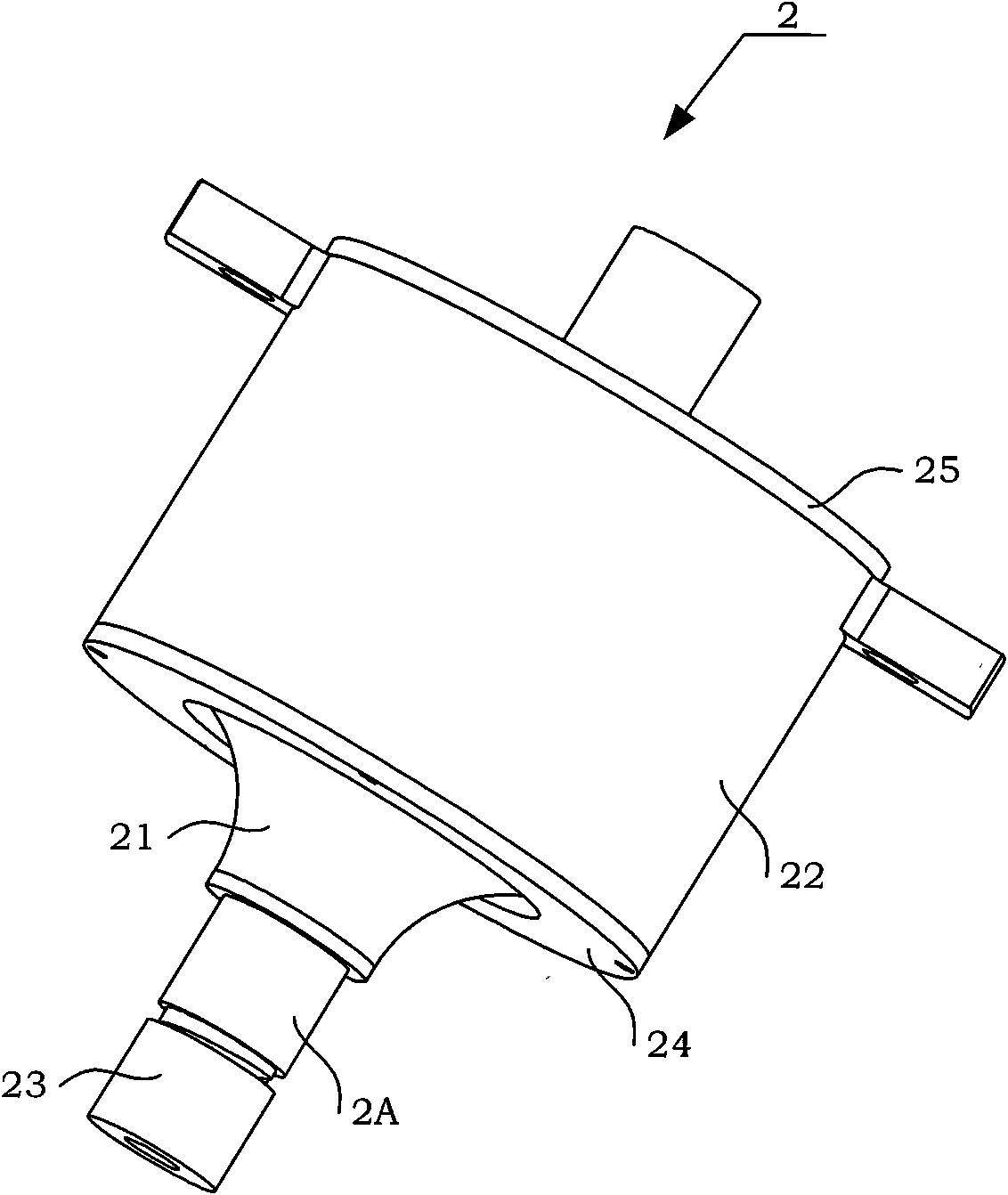

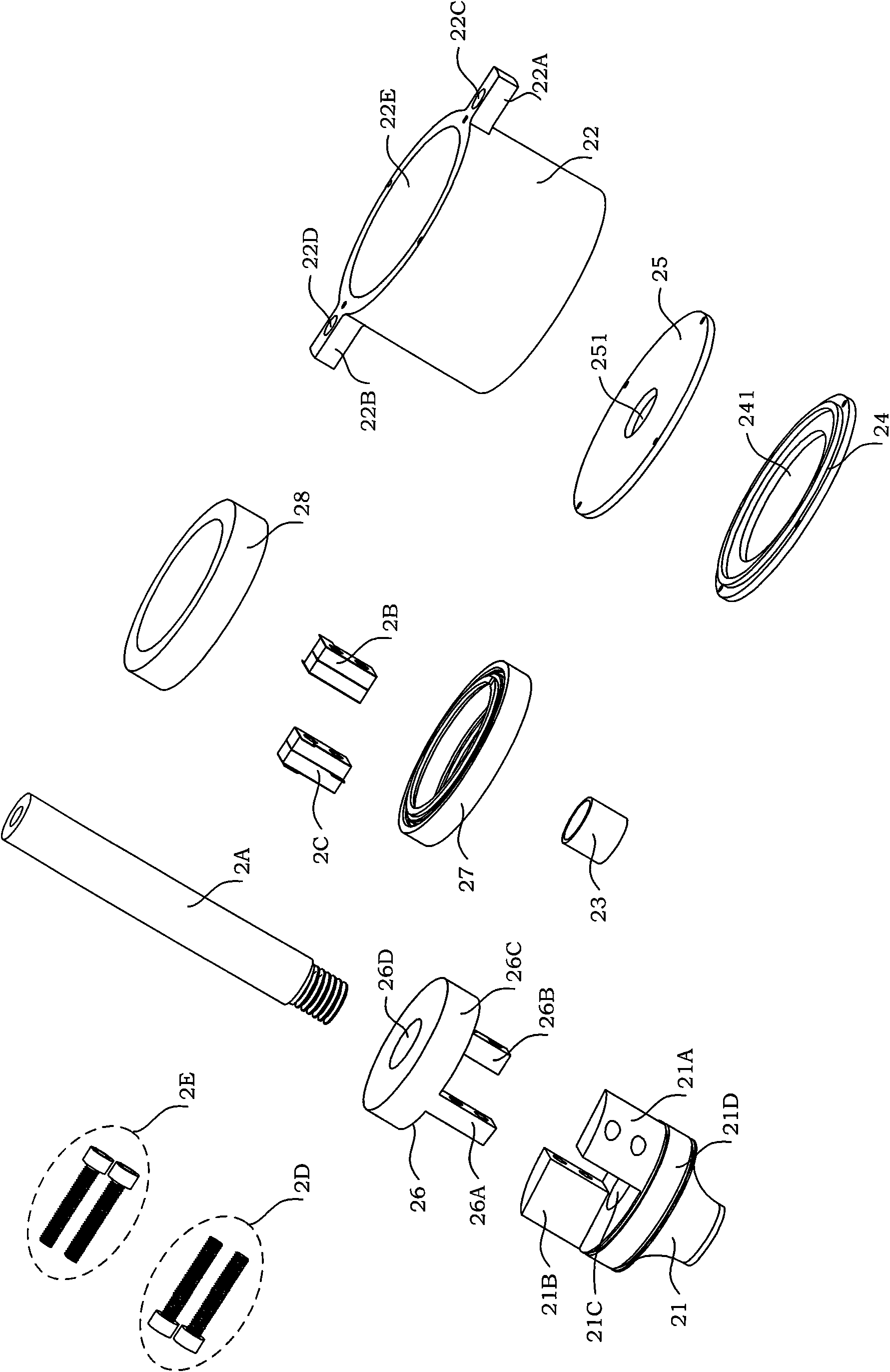

[0059] A high-low frequency composite torsional vibration high-efficiency tapping device suitable for low frequency below 60 Hz and high frequency above 16 kHz of the present invention includes a spindle mechanism 1 , an ultrasonic transducer vibration assembly 2 , a floating assembly 3 and a servo motor 4 .

[0060] (1) Spindle mechanism 1

[0061] see figure 1 , Figure 4 , Figure 4A ~ Figure 4F As shown, the spindle mechanism 1 includes a spindle box 11 , an auxiliary feed assembly 12 , a spindle sleeve 13 , an operation panel 14 , a spline assembly 15 , a gland 16 , and a telescopic connector 17 .

[0062] The center of the mounting plate surface 11a of the spindle box 11 is provided with an A through hole 11d, and the A through hole 11d is used to place the rack sleeve 12a; four corners of the mounting plate surface 11a are provided with four threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com