Patents

Literature

98results about How to "Avoid radial force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

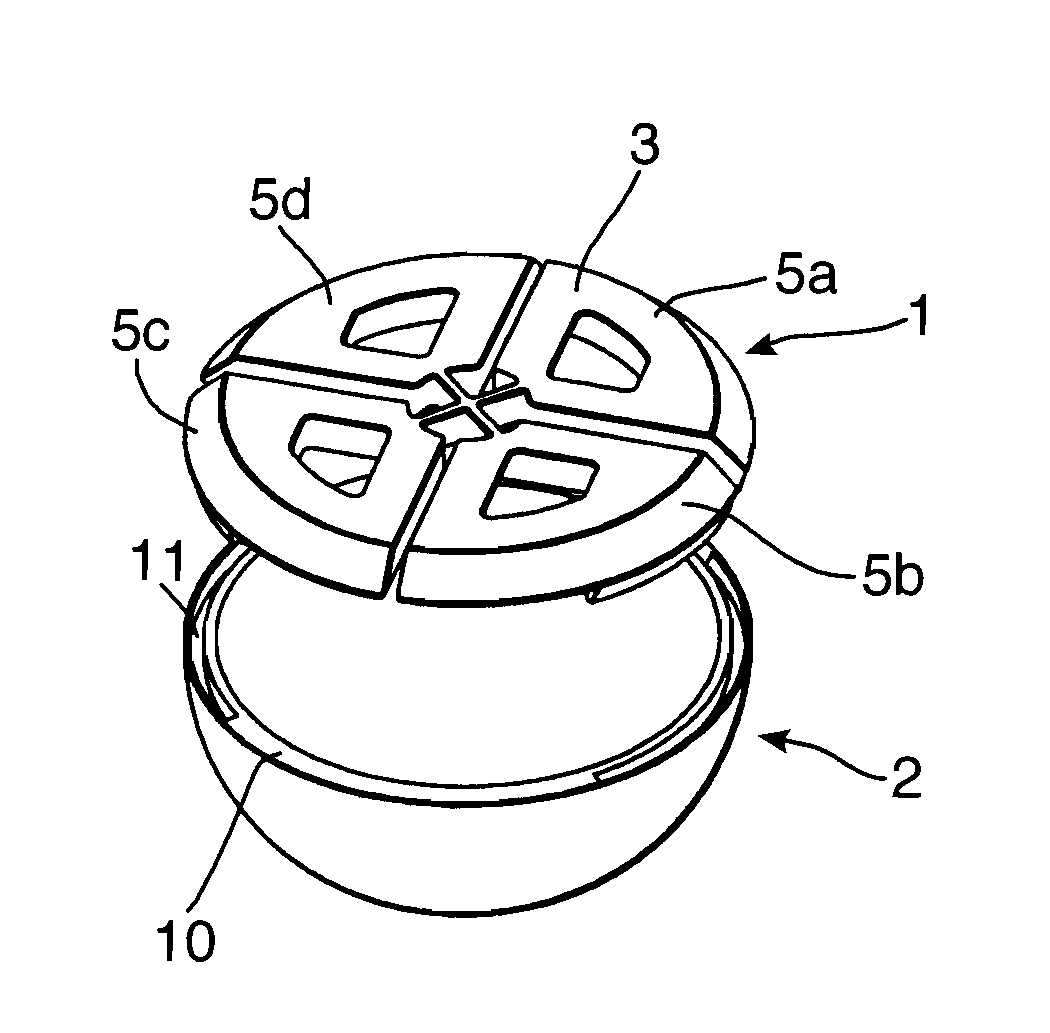

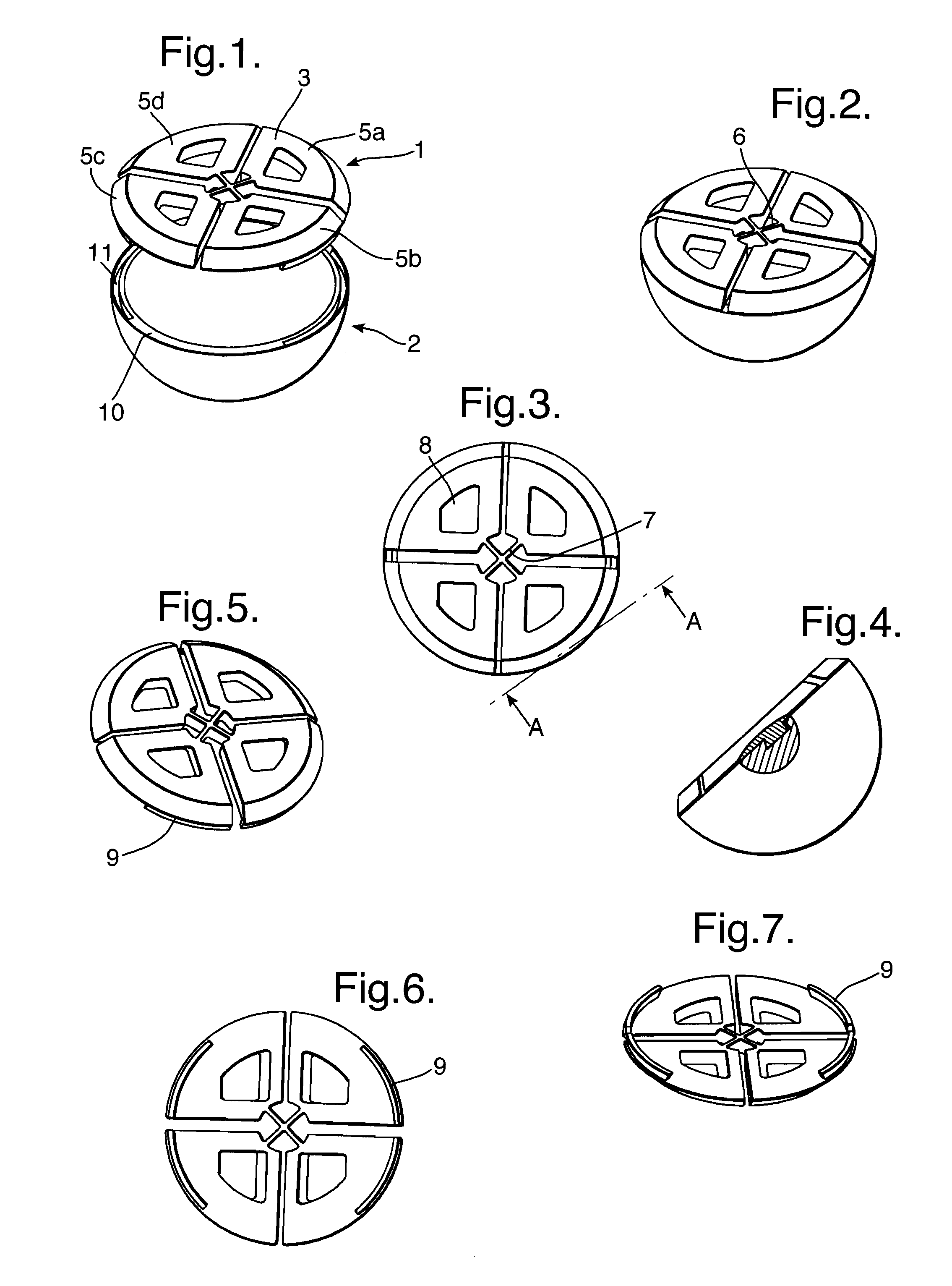

Cap and activation tool

ActiveUS8500744B2Firmly connectedMinimize movementJoint implantsAcetabular cupsProsthesisEngineering

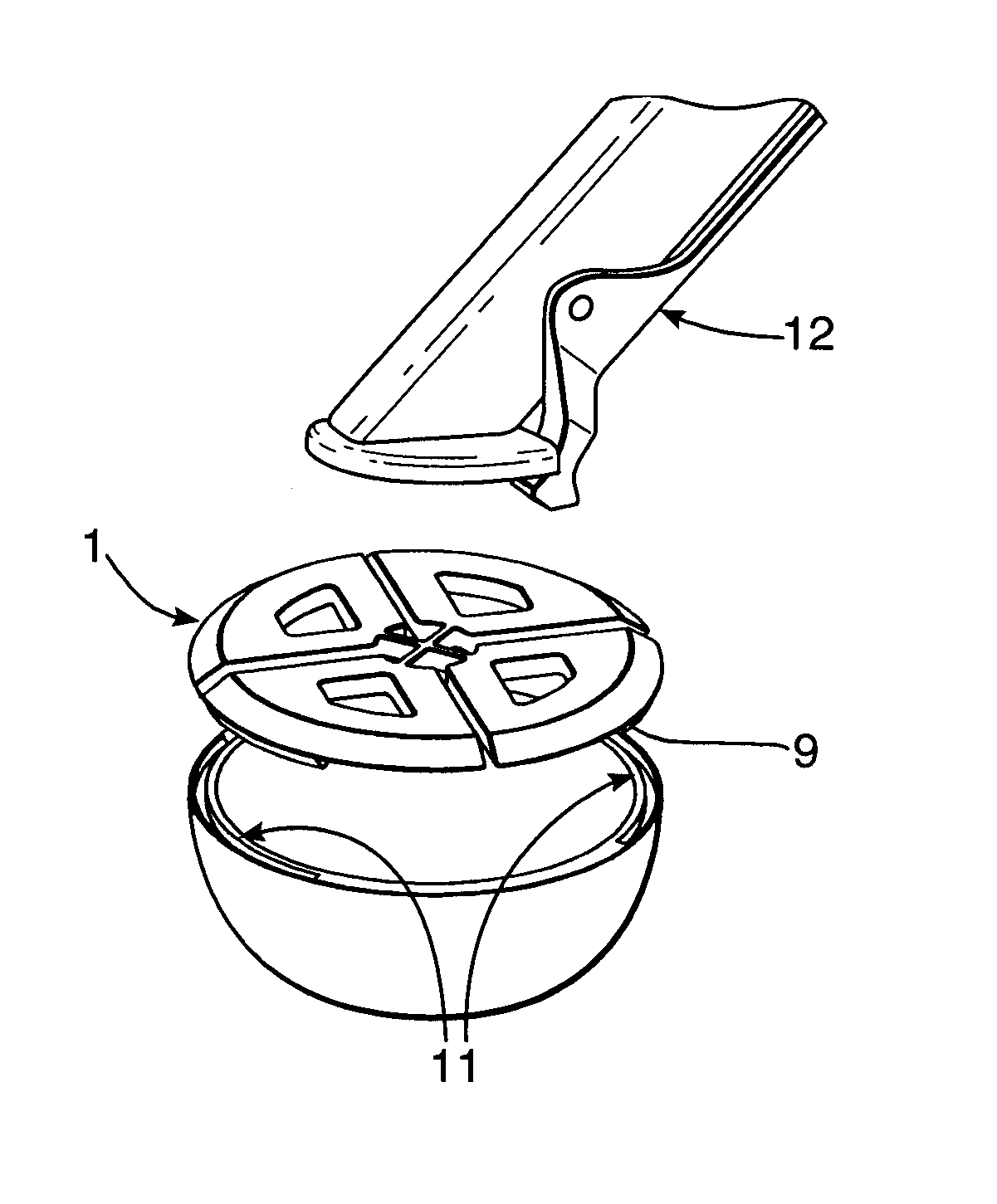

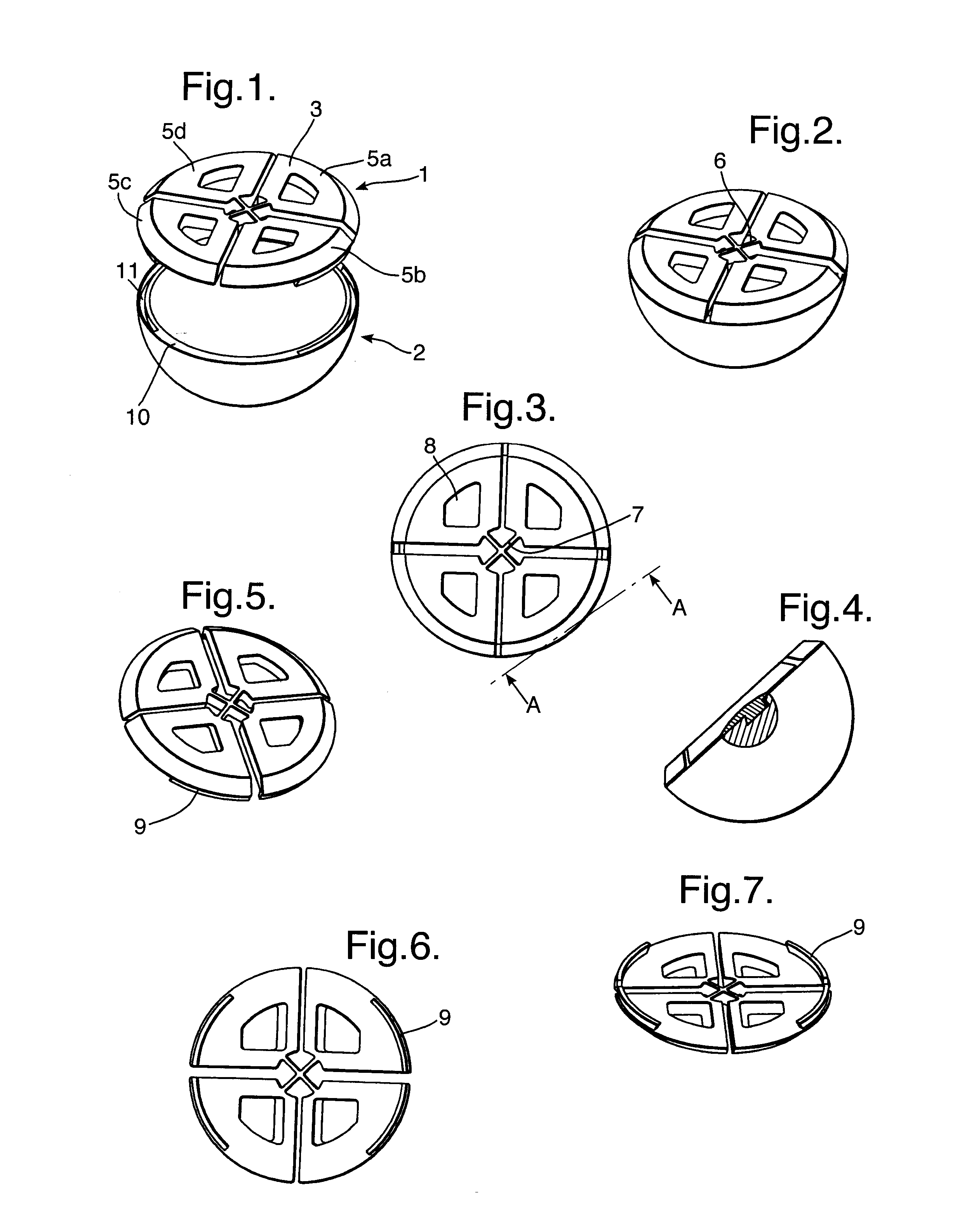

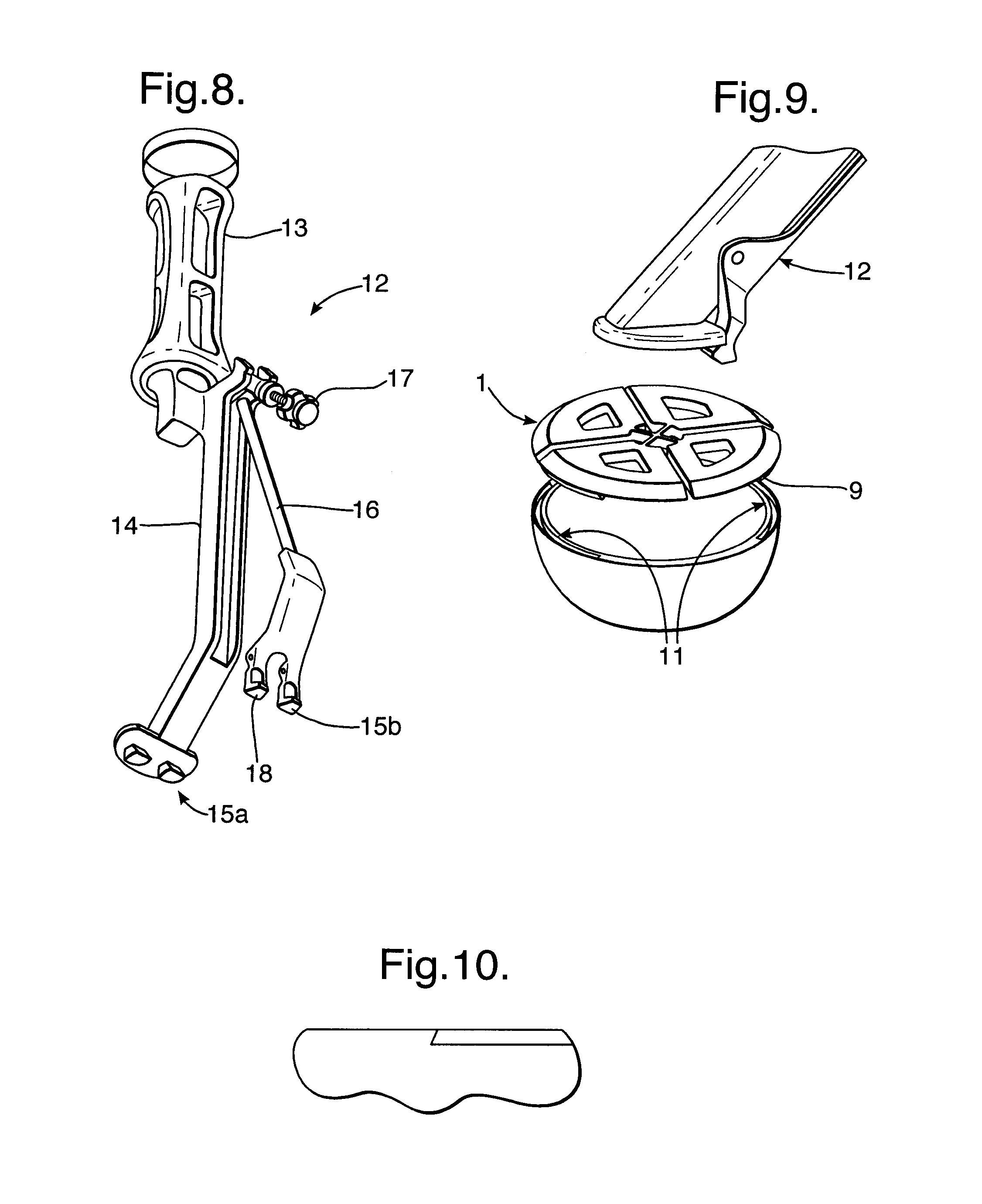

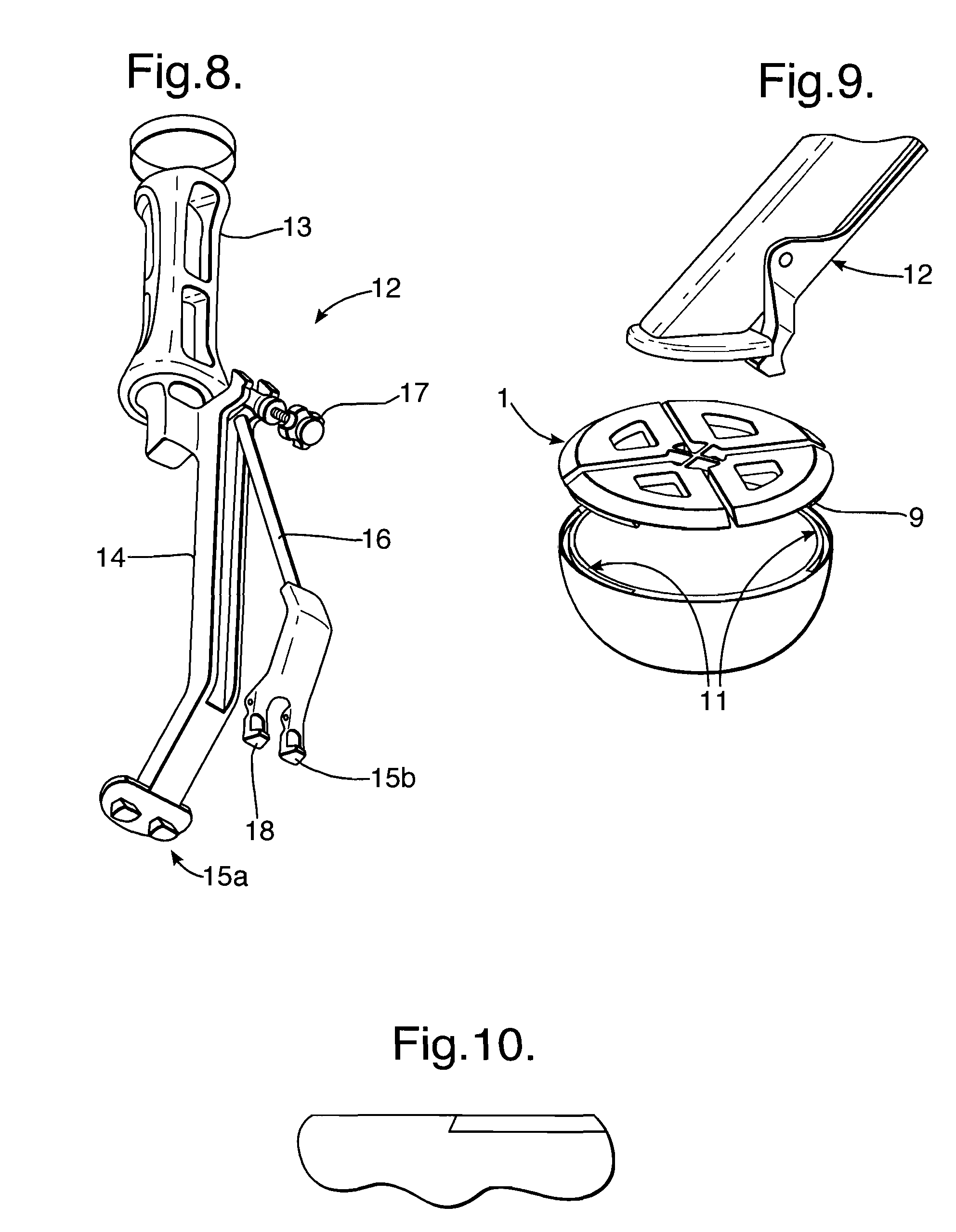

A cap used during the insertion of an acetabular cup prosthesis. The cap includes impaction plate having an upperside and an underside. The impaction plate includes a plurality of separate sectors mutually connected at a connection point on the impaction plate by flanges. Each sector includes interlocking elements which in use enable the impaction plate to be connected to an introduction tool. The cap also includes at least one lug extending downwardly from the underside of each sector. The lug is located at the portion of the underside of the impaction plate which will in use enable the lug to be interconnected with a corresponding recess on an internal wall, an external wall or a rim of a prosthesis.

Owner:FINSBURY DEV

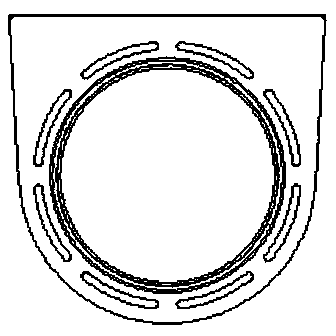

Main case water-cooling tungsten alloy triangle belt wheel motor

ActiveCN104485778AIncrease flow rateImprove cooling effectMechanical energy handlingSupports/enclosures/casingsEngineeringScrew thread

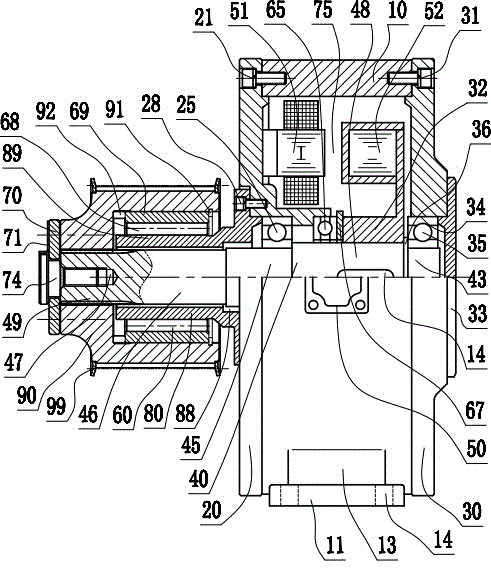

The invention relates to a motor special for a motor train locomotive and provides a main case water-cooling tungsten alloy triangle belt wheel motor. The motor comprises a motor case, a front end cover, a rear end cover, a motor spindle, a stator, a rotor and triangle belt wheels. According to the improvement, a cooling interlayer is arranged between the outer wall and the inner wall of the motor case and arranged by bypassing a lead window, the two periphery isolated two ends of the cooling interlayer are provided with a water inlet penetrating hole and a water outlet penetrating hole respectively, the water inlet penetrating hole and the water outlet penetrating hole are spaced through an isolating rib, a front end flow guide rib arranged on the inner side of the front end face of the case and a rear end flow guide rib arranged on the inner side of the rear end face of the case are arranged in a misplaced mode, a water outlet taper thread is arranged on a water outlet lug, the bottom of the water outlet taper thread leads to the water outlet penetrating hole, a water inlet taper thread is arranged on a water inlet lug, the bottom of the water inlet taper thread leads to the water inlet penetrating hole, component force members are fixed to the front end cover, inner-ring-free bearings are arranged between the component force members and the triangle wheels, and a tungsten alloy hard wearing layer is arranged on the surface of the supporting circle of each outer bearing of each component force member in a compositing mode.

Owner:平湖市金兔实业有限公司

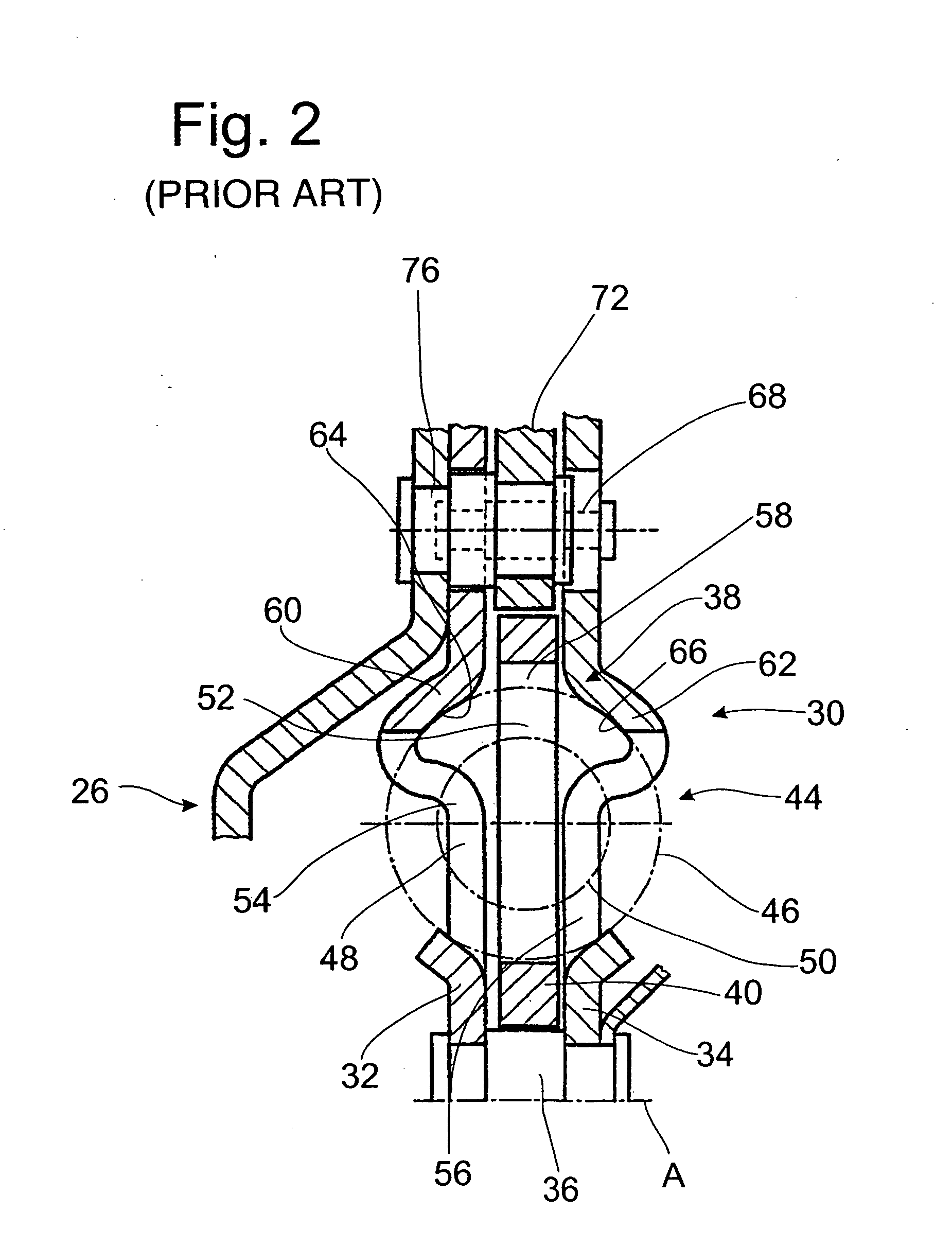

Cap and activation tool

ActiveUS20060293686A1Trend downEasy to disassembleJoint implantsAcetabular cupsProsthesisEngineering

A cap used during the insertion of an acetabular cup prosthesis. The cap comprises an impaction plate having an upperside and an underside. The impaction plate comprises a plurality of separate sectors mutually connected at a connection point on the impaction plate by means of flanges. Each sector includes interlocking means which in use enable the impaction plate to be connected to an introduction tool. The cap also comprises at least one lug extending downwardly from the underside of each sector. The lug is located at the portion of the underside of the impaction plate which will in use enable the lug to be interconnected with a corresponding recess on an internal wall, an external wall or a rim of a prosthesis.

Owner:FINSBURY DEV

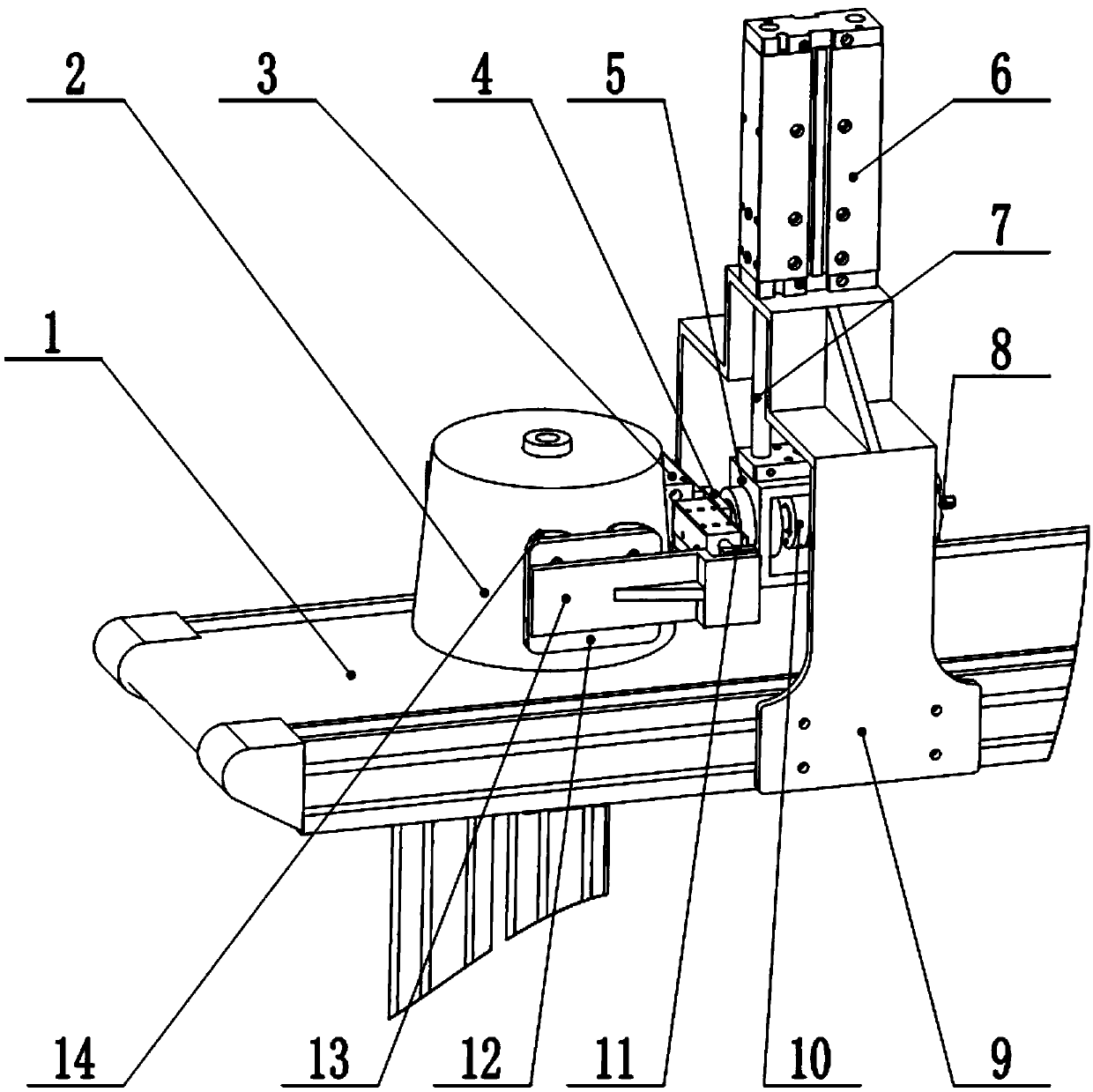

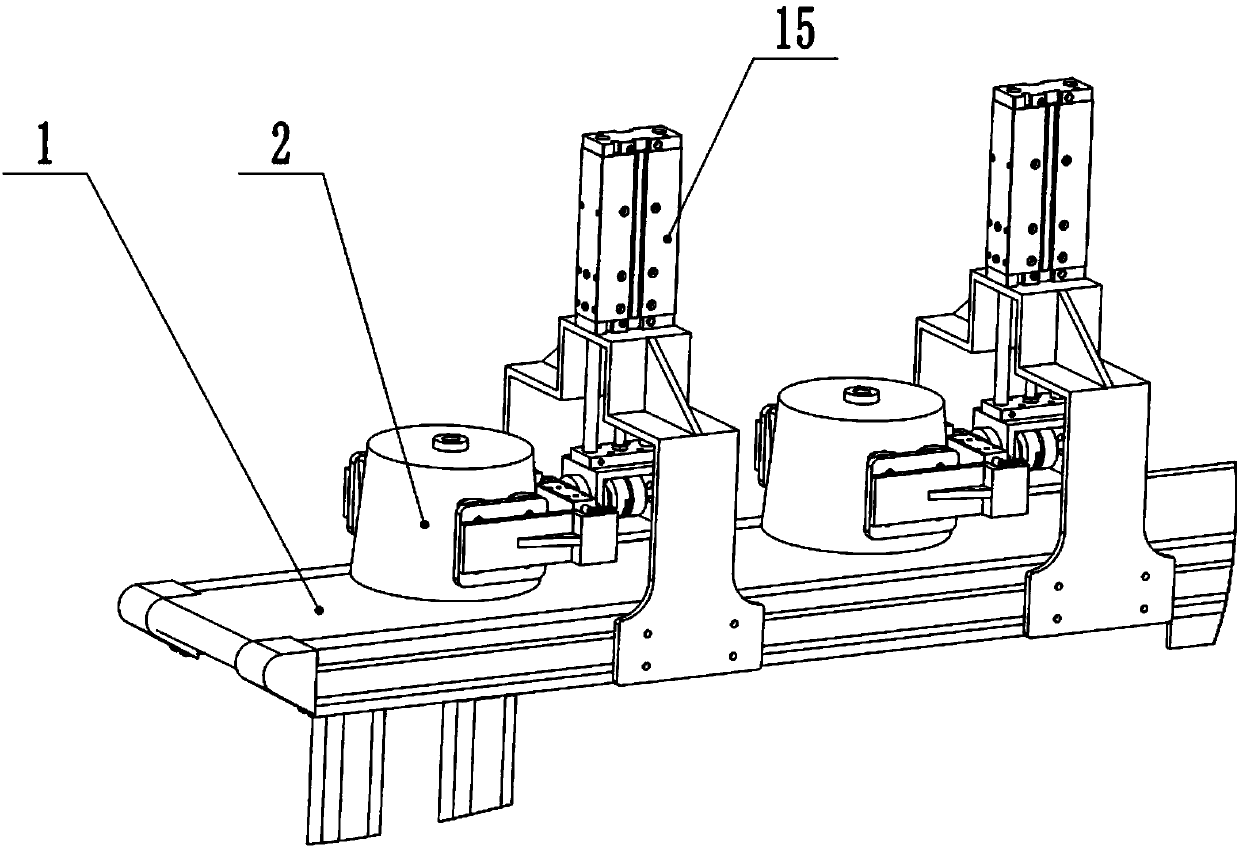

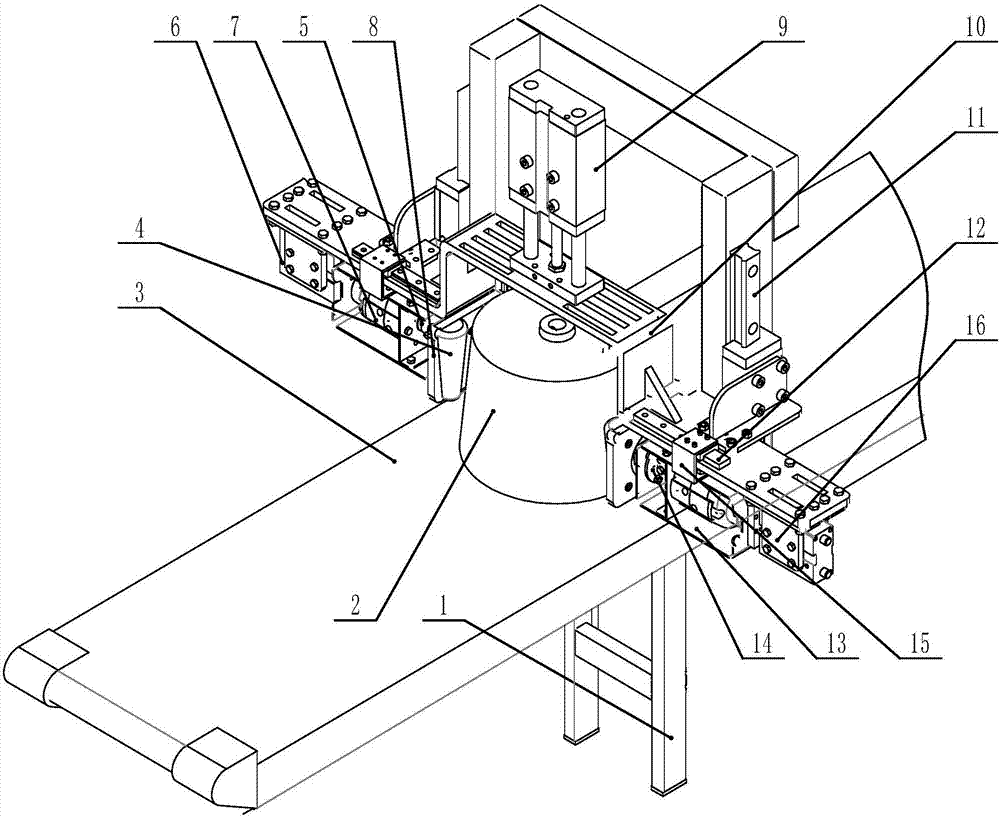

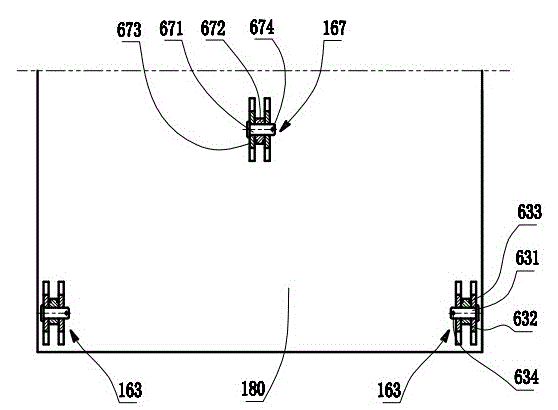

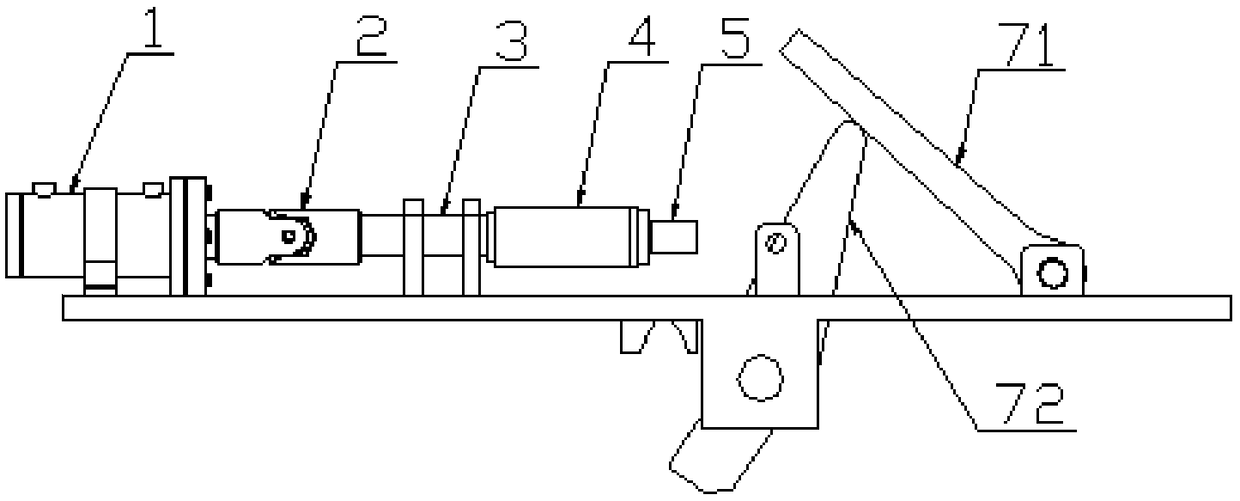

Cone yarn overturning device and working method

PendingCN107867552AExtended service lifeEliminate vibrationProgramme-controlled manipulatorGripping headsYarnStructural engineering

The invention relates to a cone yarn overturning device and a working method and belongs to the field of automation of textile machines. The device comprises a conveying belt and an overturning devicebody; the overturning device body comprises an overturning installing frame which is an inverted-T-shaped frame and is arranged above the conveying belt in a striding manner; a lifting cylinder and avertical guide rail are arranged at the top end of the overturning installing frame; one end of the lifting cylinder is connected and provided with a lifting installing frame; the lifting installingframe is connected with the vertical guide rail through a slider; a clamping installing plate is arranged at one end of the lifting installing frame and is symmetrically provided with two clamping cylinders; the two clamping cylinders are each connected with a clamping connection plate through a horizontal clamping guide rail; the two clamping connection plates are connected with a clamping plate;a rotating cylinder is arranged at the other end of the lifting installing frame; and one end of the rotating cylinder is connected with the clamping installing plate. The clamping cylinders achieveclamping of cone yarn, the lifting cylinder drives overall lifting, overturning of the cone yarn is achieved through the rotating cylinder, the structure is simple, adjustable adaptability is high, and the stable efficiency of operation is high.

Owner:SHANDONG UNIV

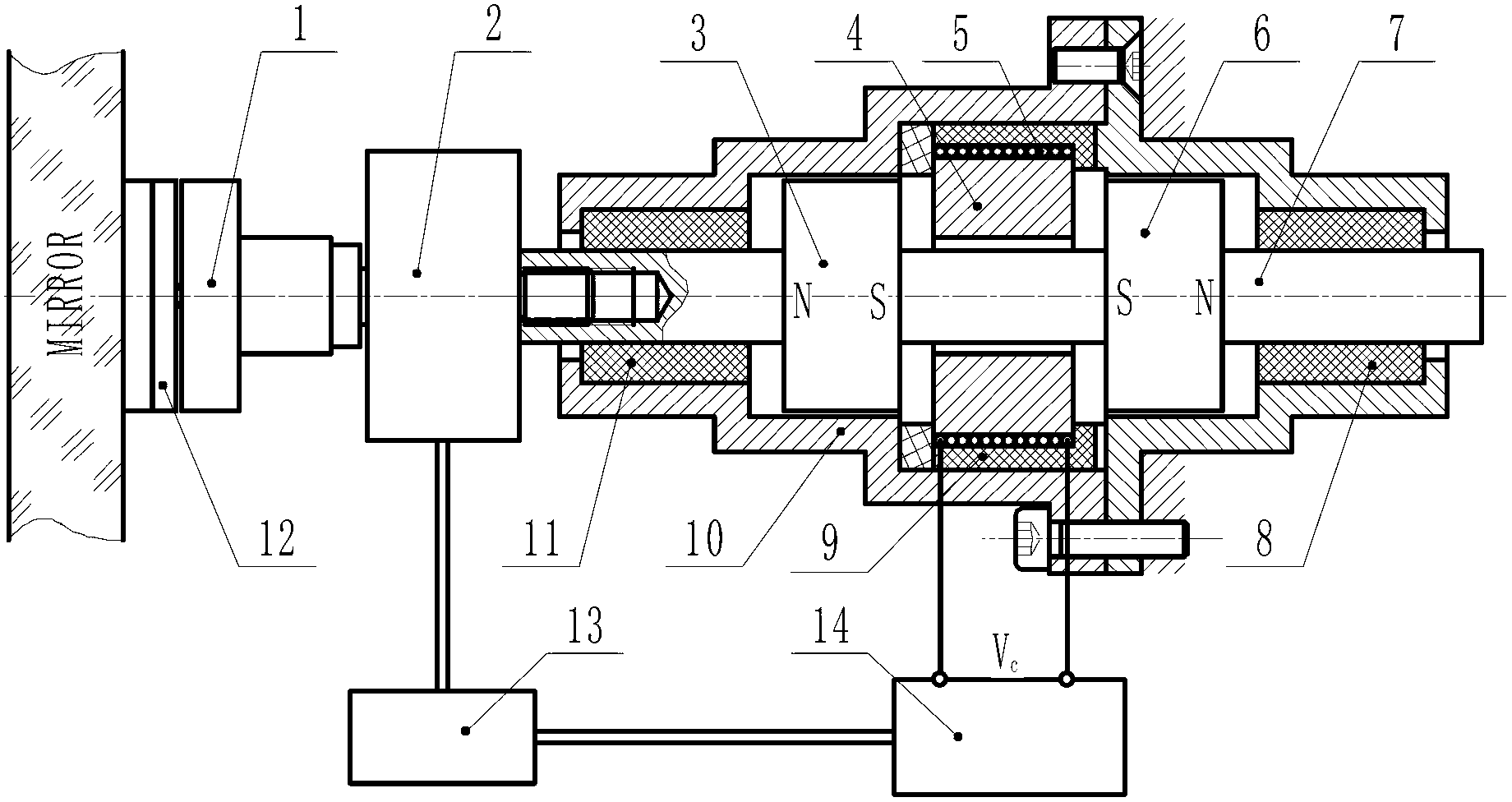

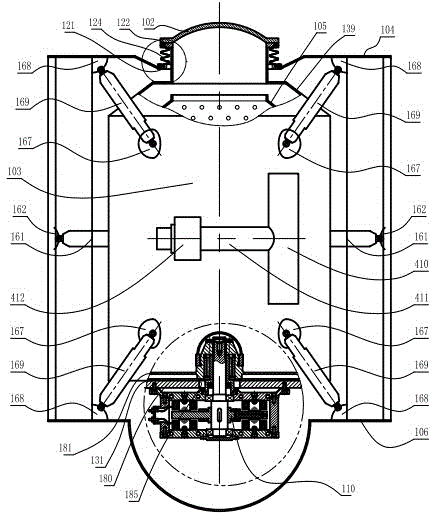

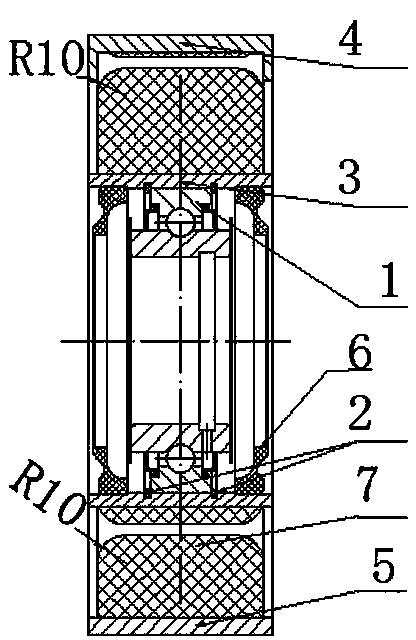

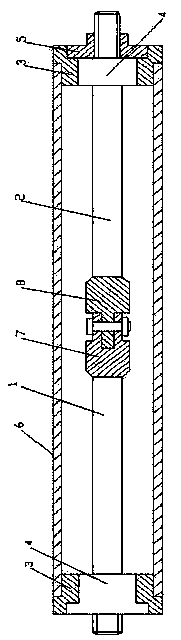

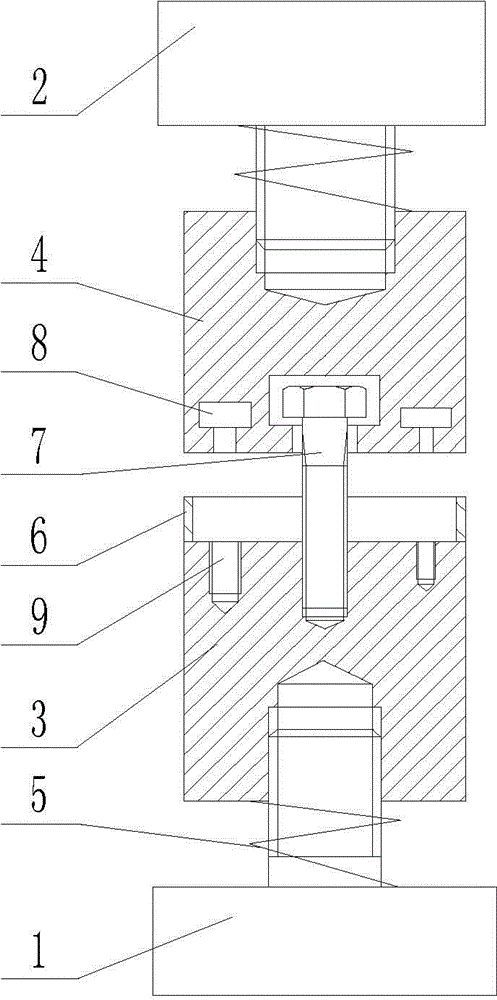

Electromagnetic force actuator for active support of astronomical telescope mirror face

InactiveCN103178685AHigh outputSimple structureTelescopesDynamo-electric machinesControl systemActive support

The invention relates to an electromagnetic force actuator for active support of an astronomical telescope mirror face. One end of the force actuator is connected with a supported mirror face through a force sensor, and the other end of the force actuator is fixed in a mirror cell. The electromagnetic force actuator is characterized in that a force output end of the force actuator is arranged on an axle at the center of the force actuator; two permanent magnets with strong magnetism are arranged on the center axle of the force actuator; a coil with an iron core is fixed on a shell of the force actuator; and the output of the force actuator is connected with a control system, and the control system is connected with the coil with the iron core. The electromagnetic force actuator for the active support of the astronomical telescope mirror face has the advantages that structure is simple, mass is low, energy consumption is low, control accuracy of input force is high, response speed is high, stroke of the force actuator is large, force adjusting range is wide, environment requirements are low, and the force actuator can be used in South Pole and even in space special environment. Connection of the force actuator and the mirror face is facilitated.

Owner:NANJING INST OF ASTRONOMICAL OPTICS & TECH NAT ASTRONOMICAL OBSE

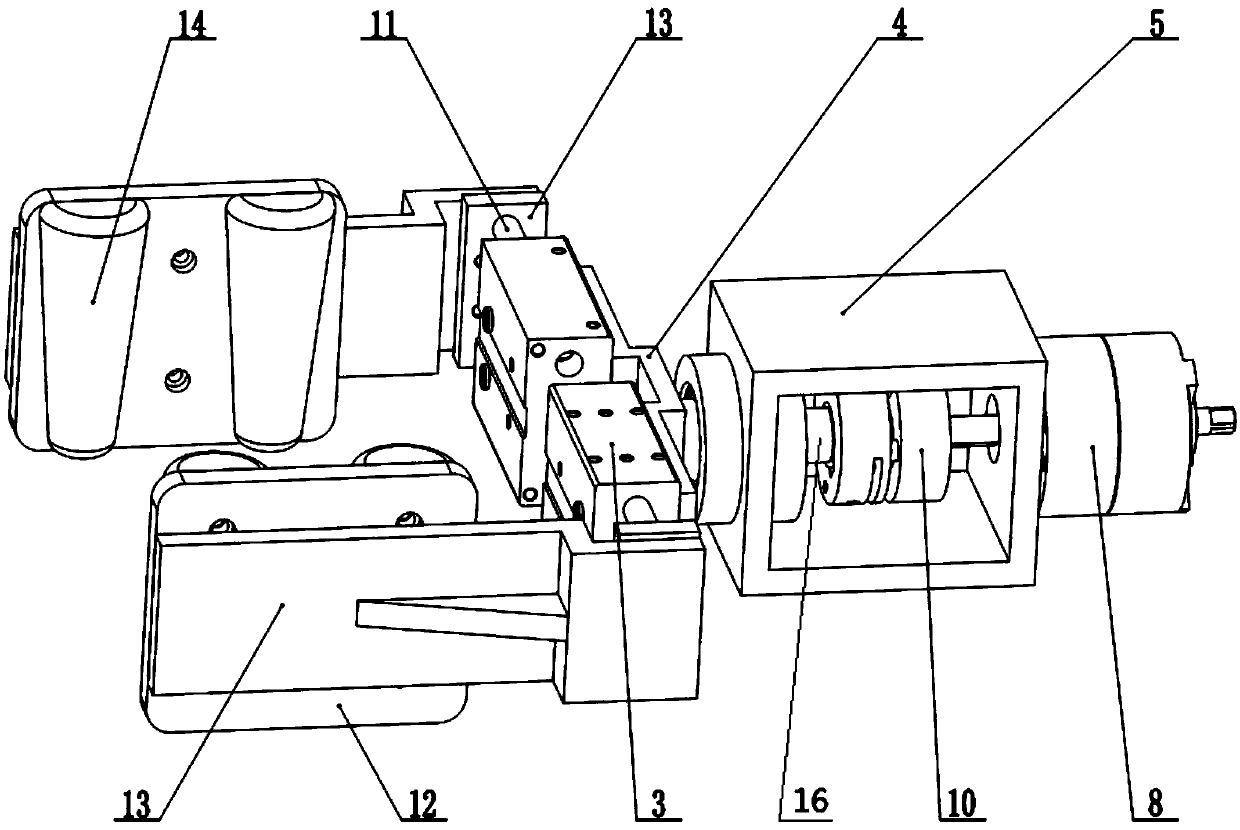

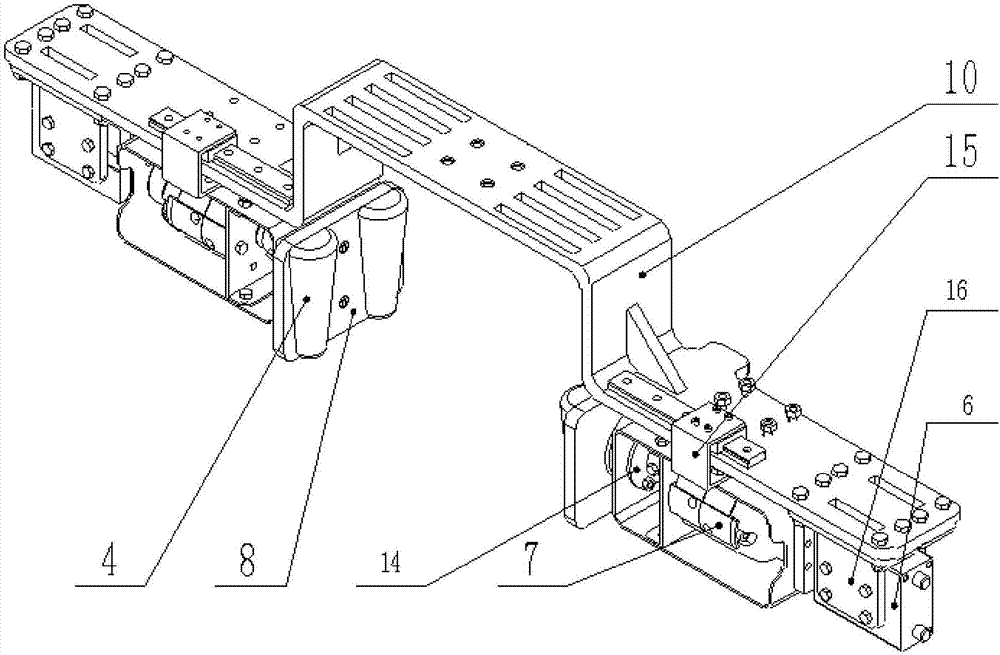

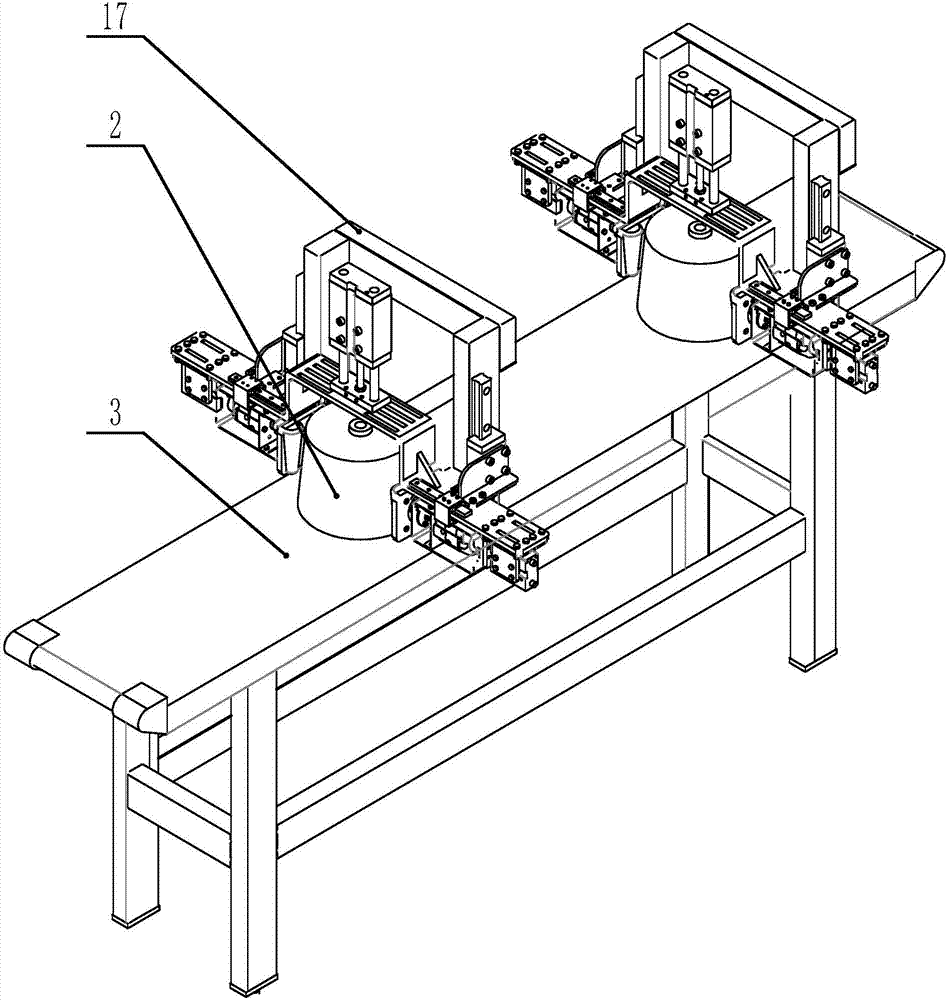

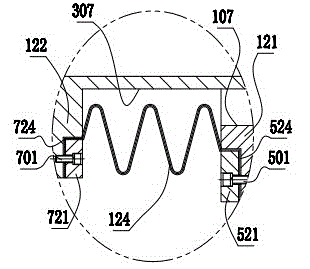

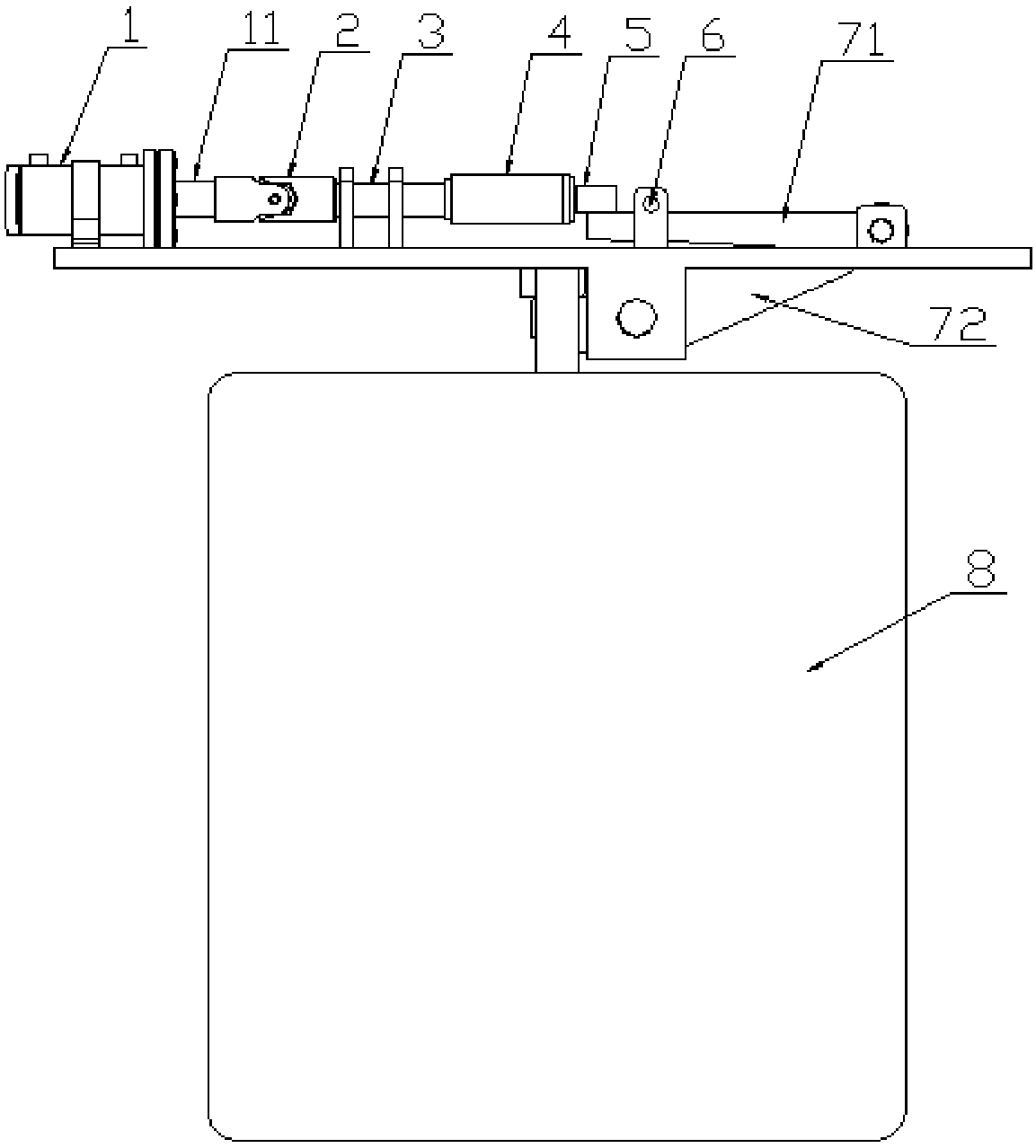

Bobbin yarn clamping, overturning and lifting device and working method

The invention relates to a bobbin yarn clamping, overturning and lifting device and a working method, and belongs to the field of textile machinery and automation. The device comprises a mounting frame; the mounting frame is provided with a conveyor belt and an overturning and clamping device; the overturning and clamping device comprises a stand column frame and an overturning and lifting plate,and the stand column frame is provided with a vertical movement guide rail and a lifting air cylinder; the lifting air cylinder is used for controlling and lifting the overturning and lifting plate; the overturning and lifting plate is a convex plate, the two ends of the overturning and lifting plate are symmetrically provided with clamping air cylinders, horizontal movement guide rails and rotaryair cylinder fixing frames respectively, rotary air cylinders are arranged in the rotary air cylinder fixing frames, clamping plates are arranged on the sides, opposite to each other, of the rotary air cylinder fixing frames, the clamping plates are used for clamping bobbin yarn, and the clamping air cylinders control the rotary air cylinder fixing frames to move horizontally. By means of the device, automatic overturning of the bobbin yarn can be achieved, the workload of workers is reduced, and the productivity is improved.

Owner:SHANDONG UNIV

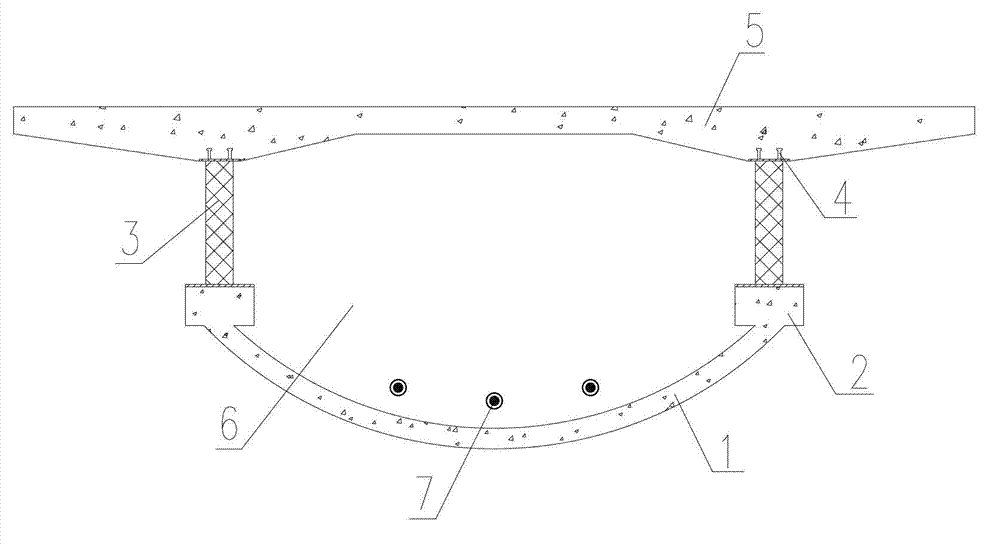

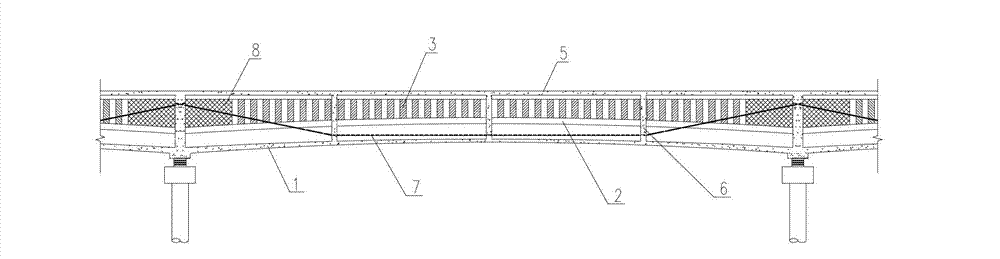

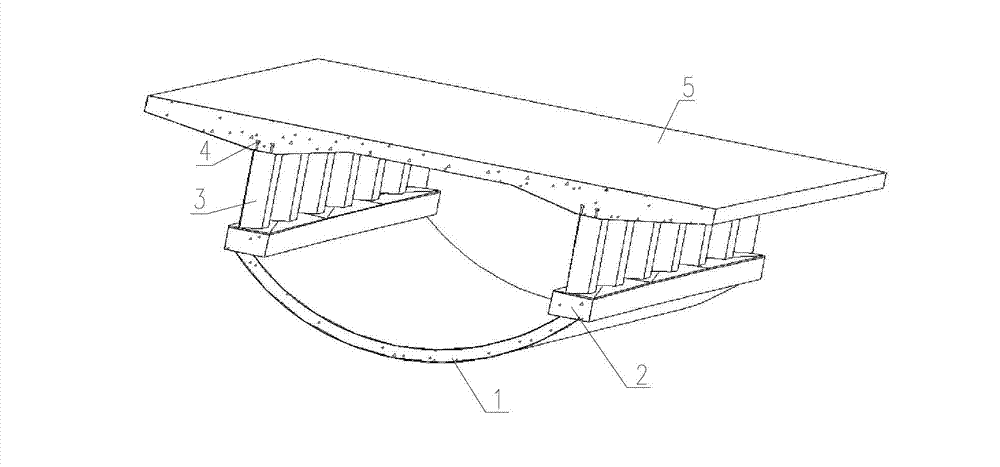

Assembly type saddle-shell-shaped bottom plate continuous box girder bridge and construction method thereof

InactiveCN103046463ANo constructionFast assembly and constructionBridge erection/assemblyFalseworkPre stress

The invention provides an assembly type saddle-shell-shaped bottom plate continuous box girder bridge. A construction method of the assembly type saddle-shell-shaped bottom plate continuous box girder bridge includes utilizing a pretensioned prestress concrete saddle shell plate as a bottom plate of the continuous box girder bridge and a corrugated steel web plate as a web plate of the continuous box girder bridge, casting a prestress concrete top plate of the continuous box girder bridge sectionally on site, and tensioning anchorage top plate prestress reinforcing ribs in batch to form a novel integral assembly type continuous box girder bridge. The preformed pretensioned concrete saddle shell plate is utilized to substitute for a cast flat bottom plate of the concrete box girder bridge, a bottom wood formwork and a support scaffold are omitted during construction of the concrete box girder bridge, and the box girder bridge can be used as a temporary construction platform, so that construction load of on-site concrete casting is reduced, and prestress tension anchorage construction process of the lower portion of the continuous box girder bridge is simplified. The novel assembly type saddle-shell-shaped bottom plate continuous box girder bridge has the advantages of high construction speed, no support construction, good structural integrity, attractive modeling, low manufacturing cost and the like, and is particularly applicable to a rail transit viaduct with large standard span and long mileage.

Owner:SOUTHEAST UNIV

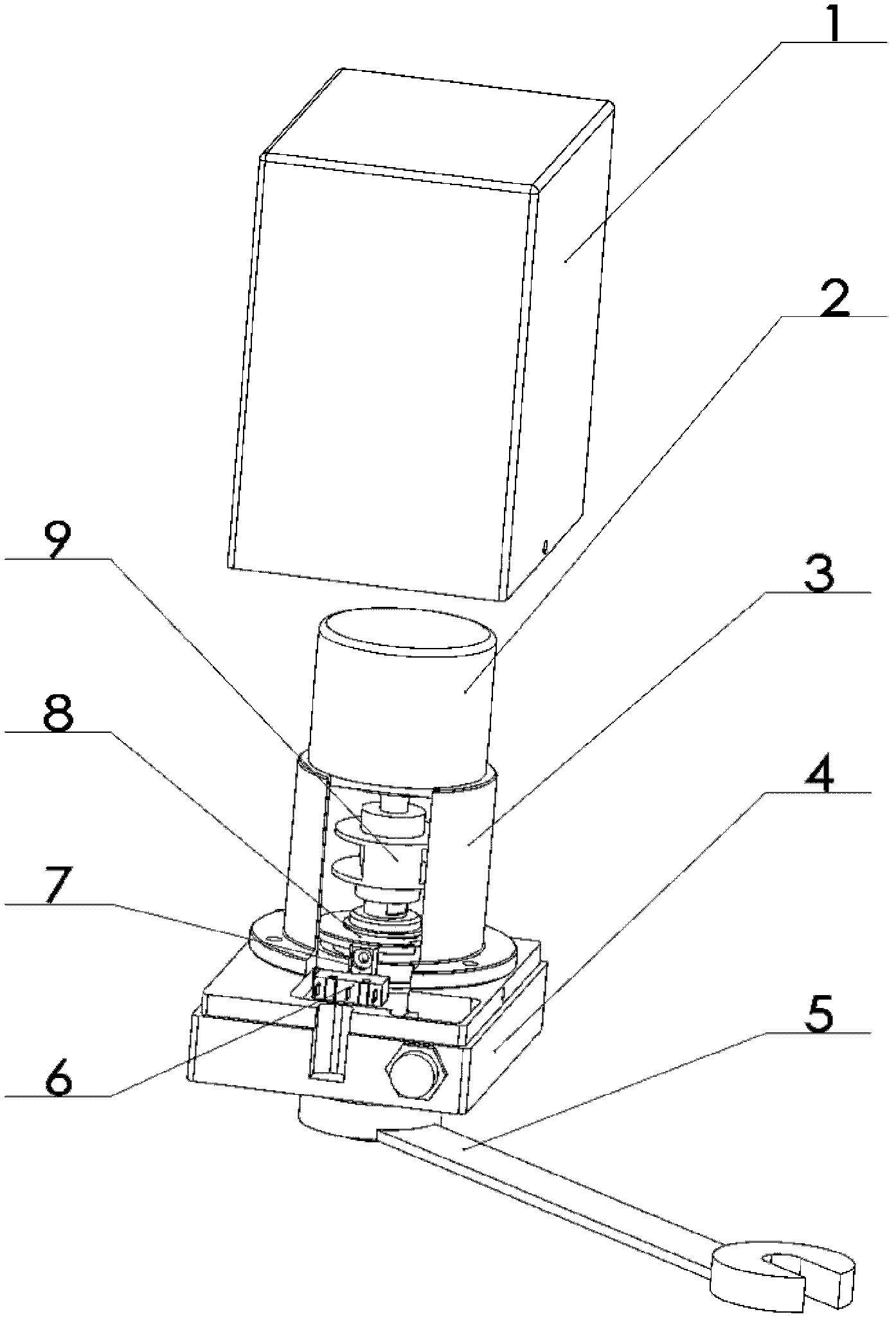

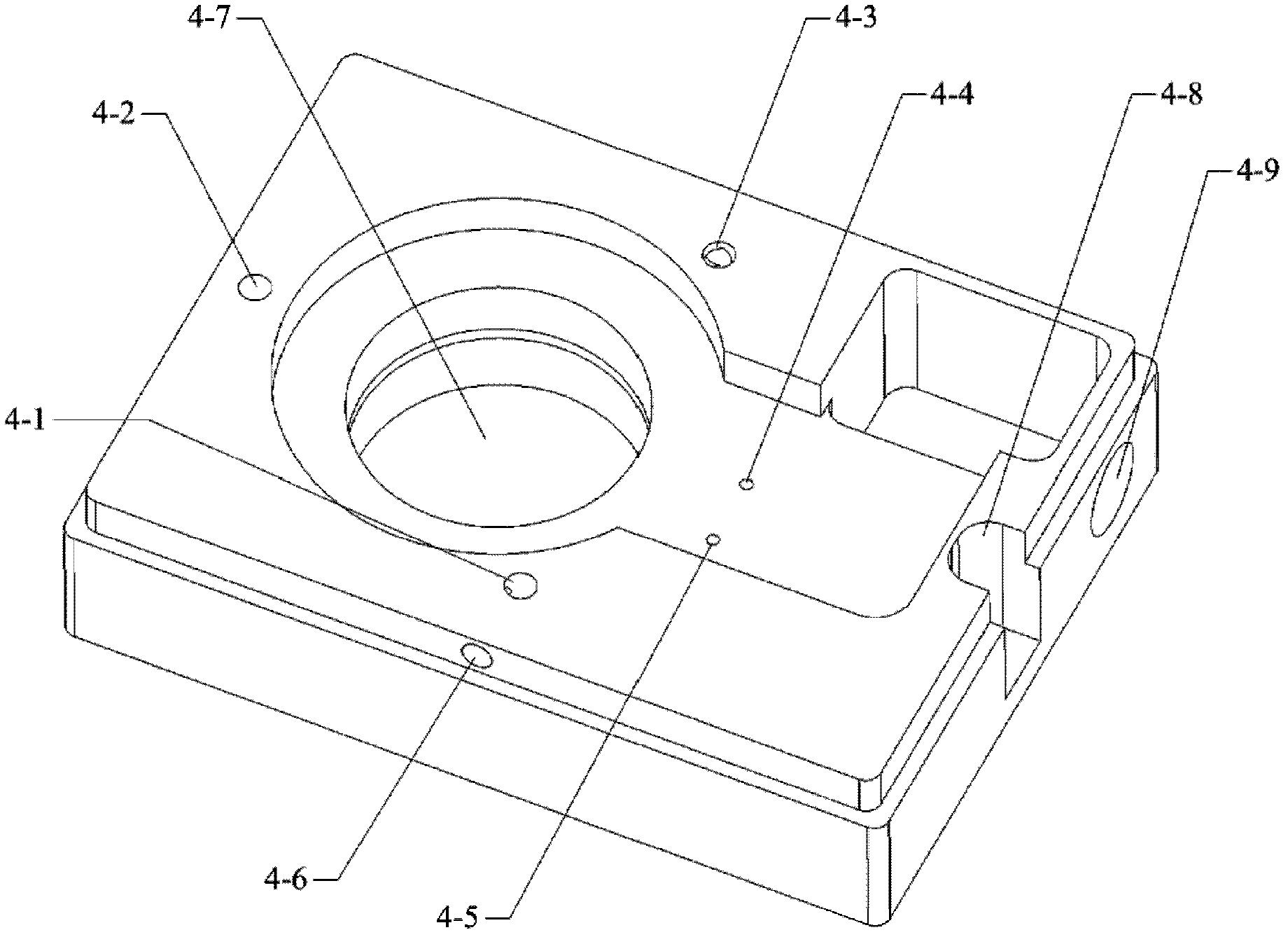

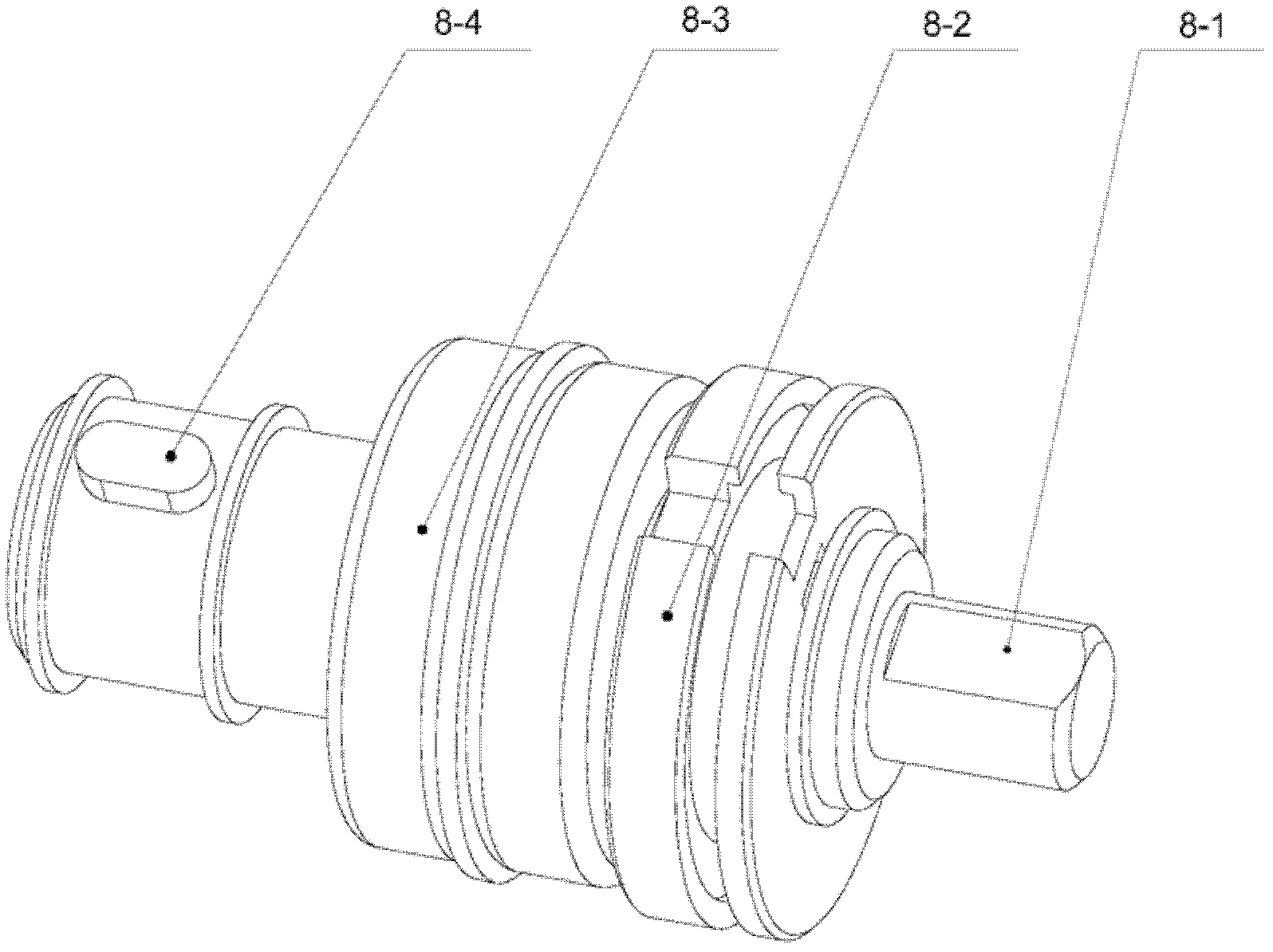

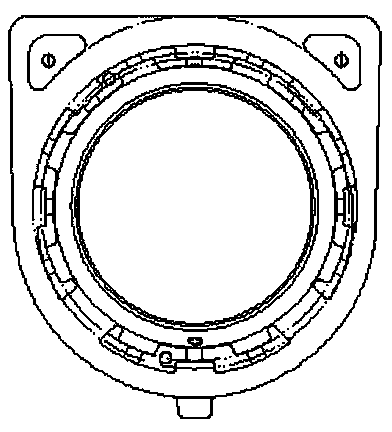

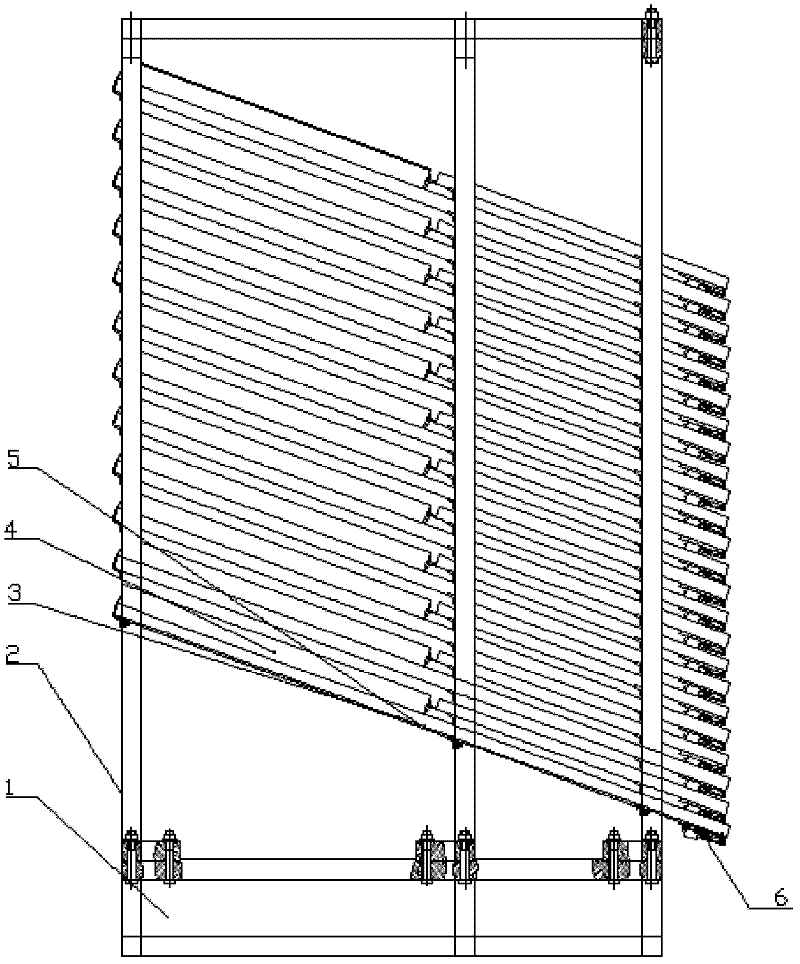

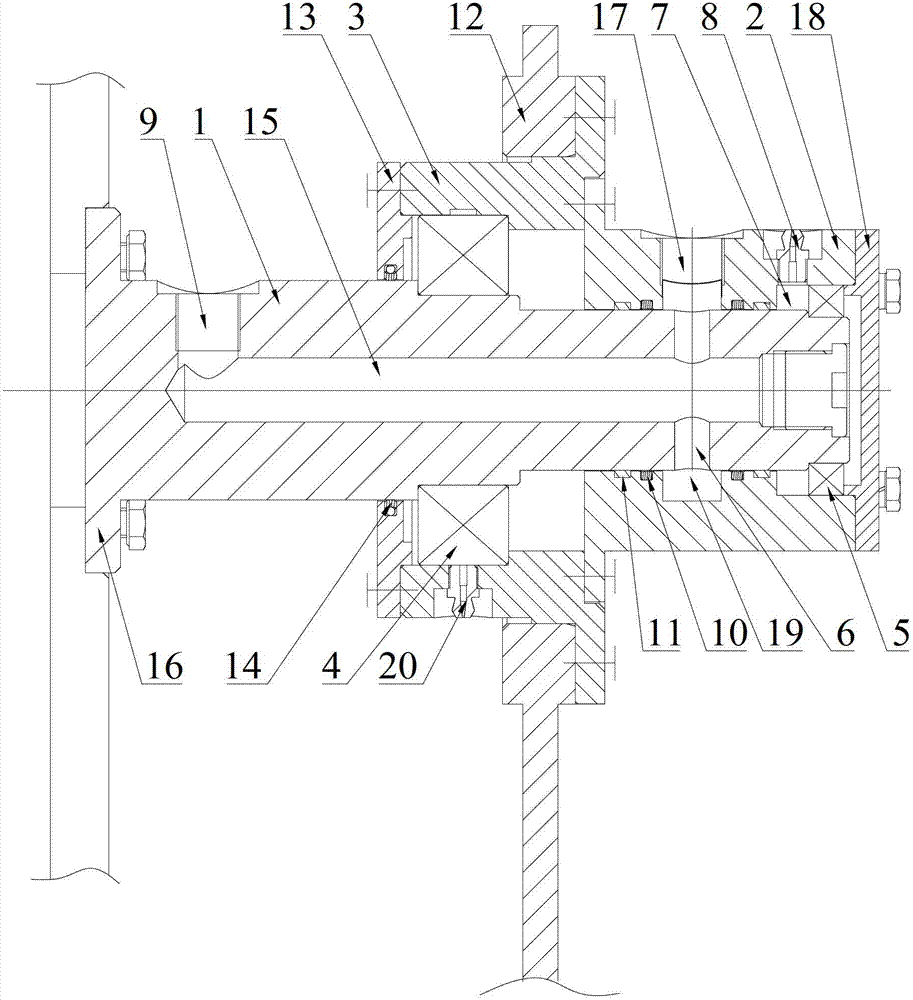

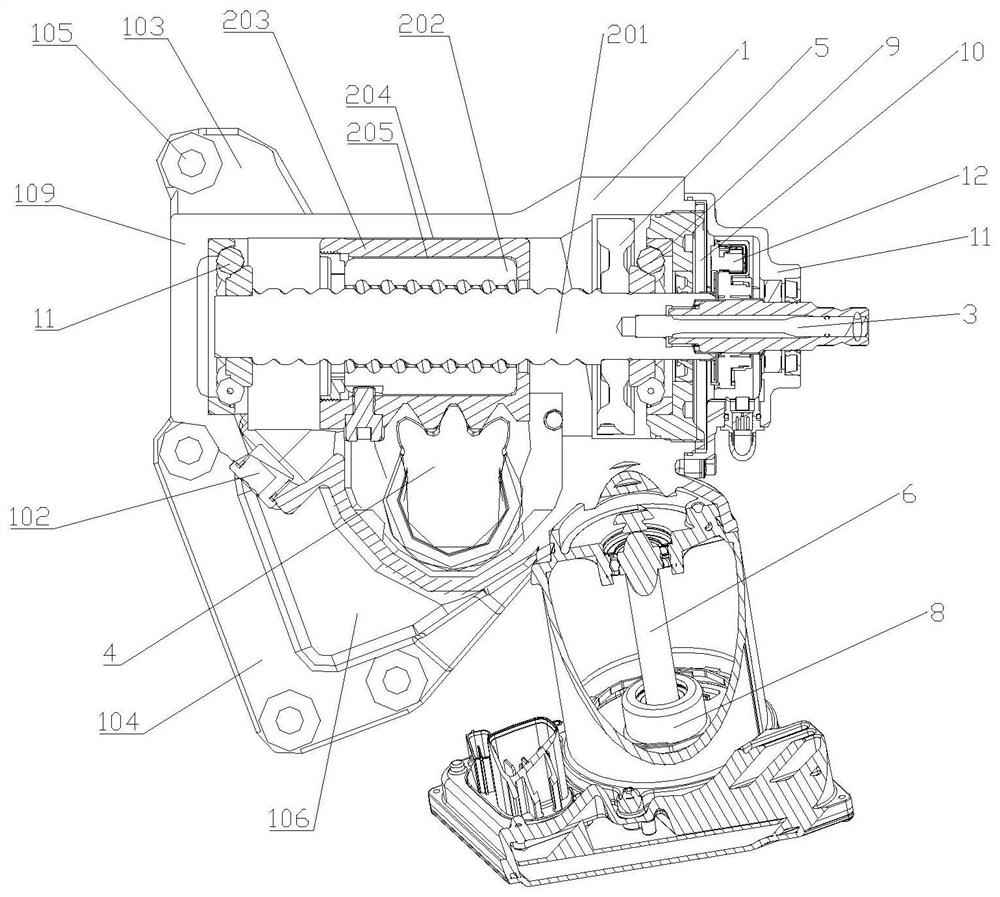

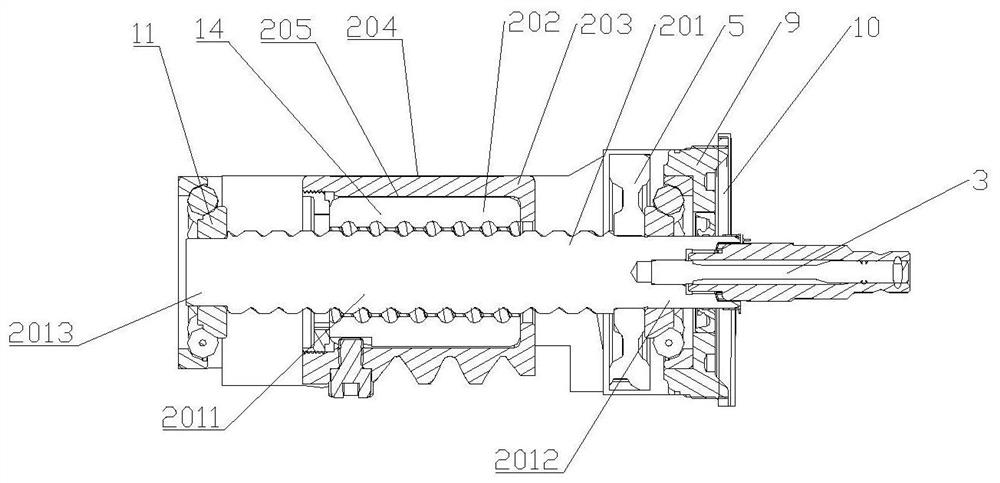

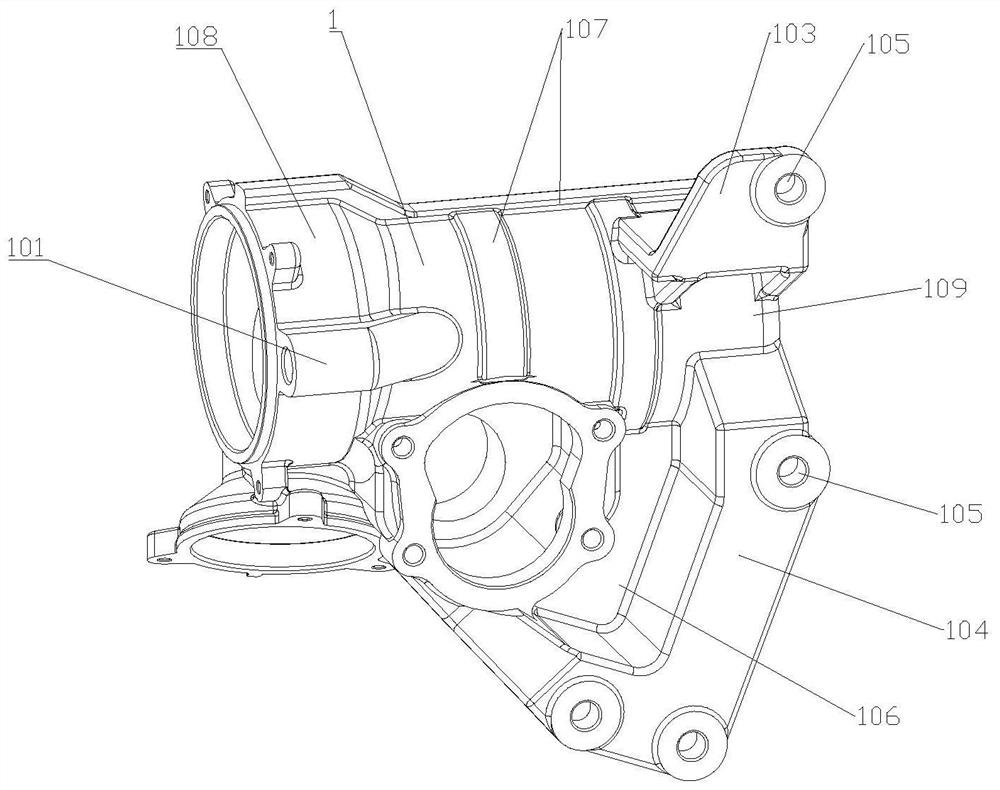

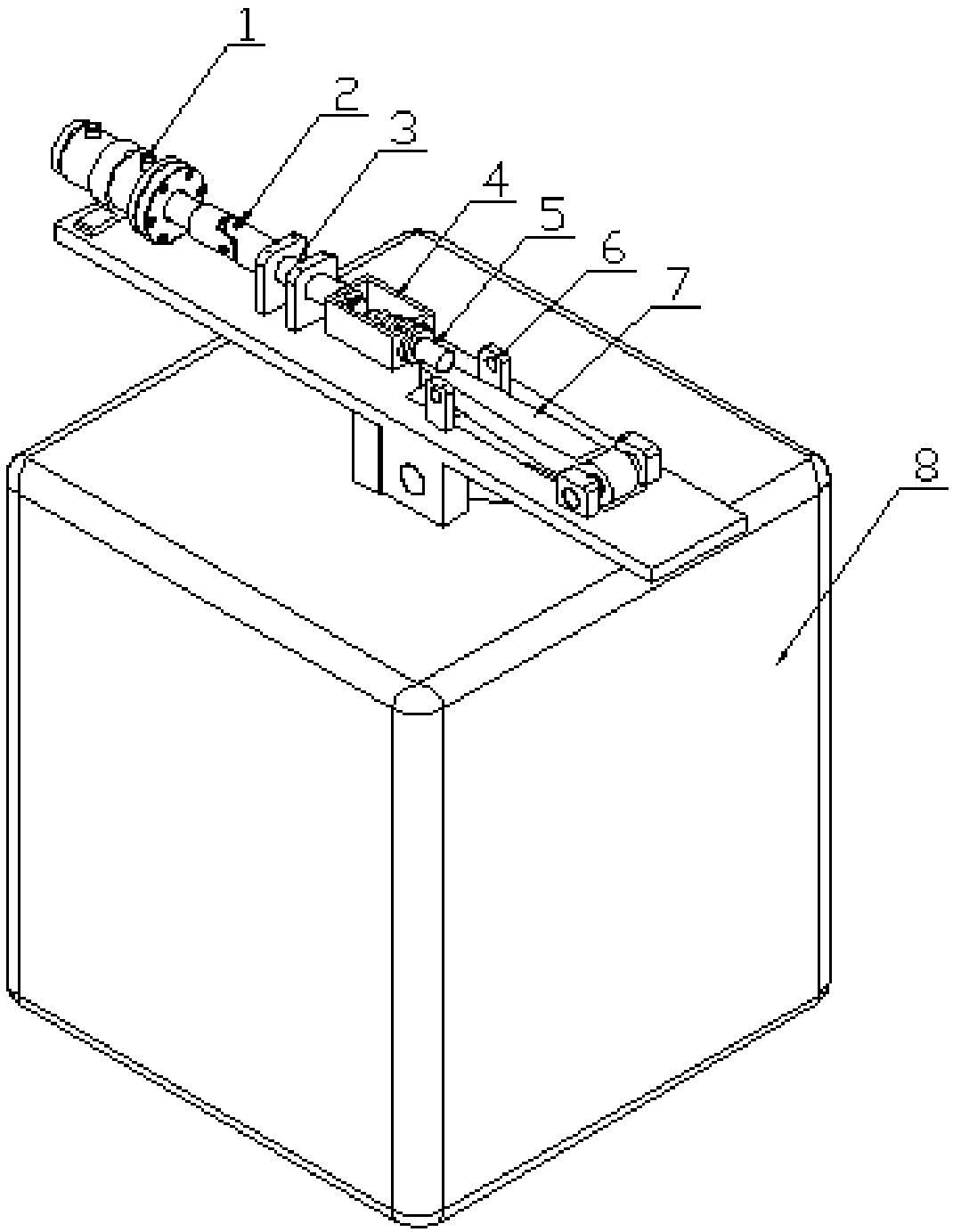

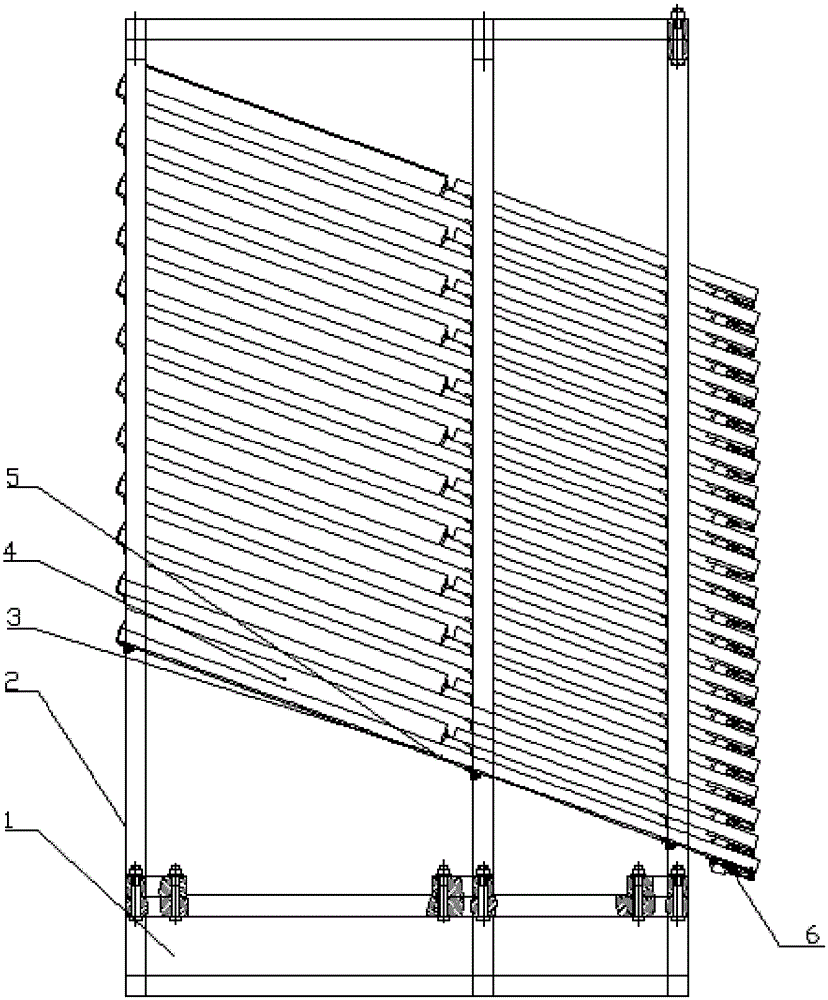

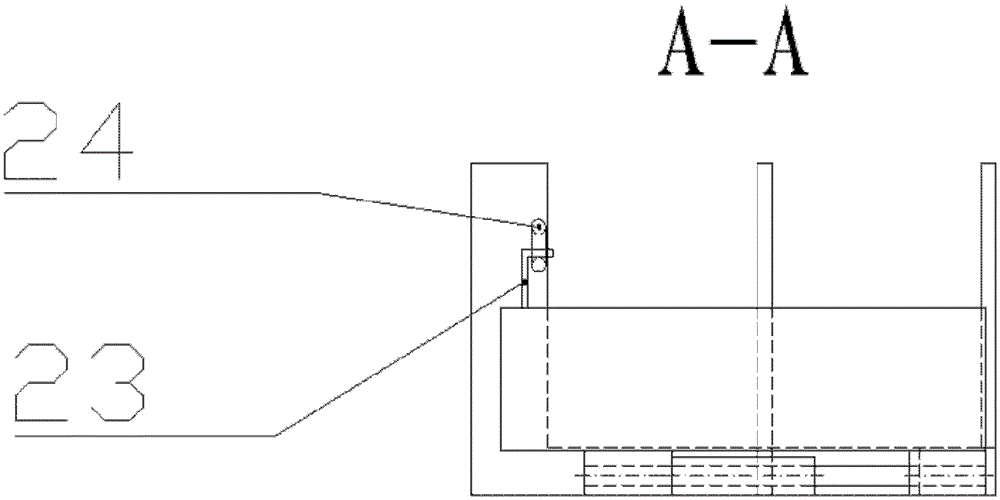

Solar photovoltaic tracking system angle position feedback module

ActiveCN102289232AHigh concentricityGuaranteed concentricityControl using feedbackCouplingEngineering

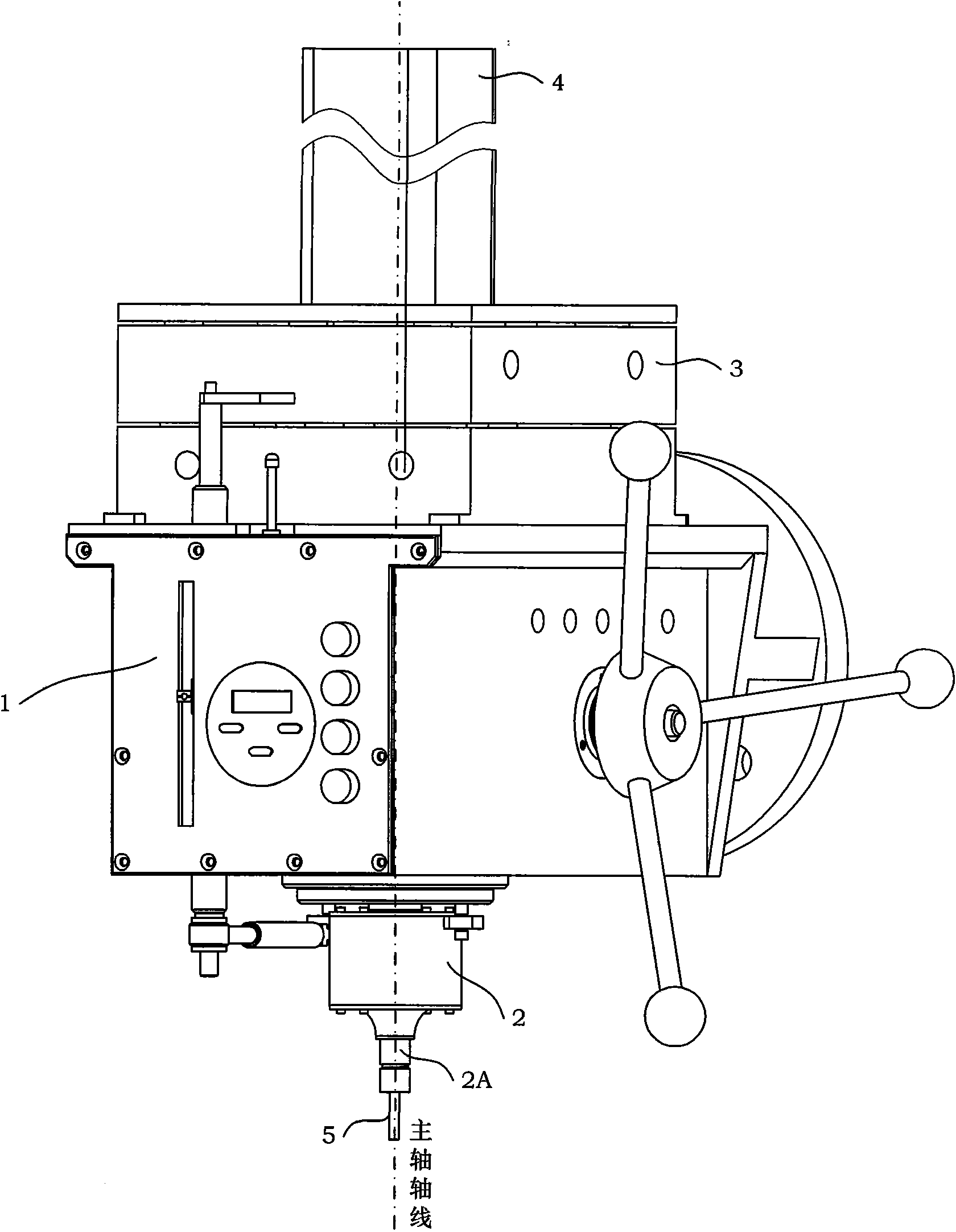

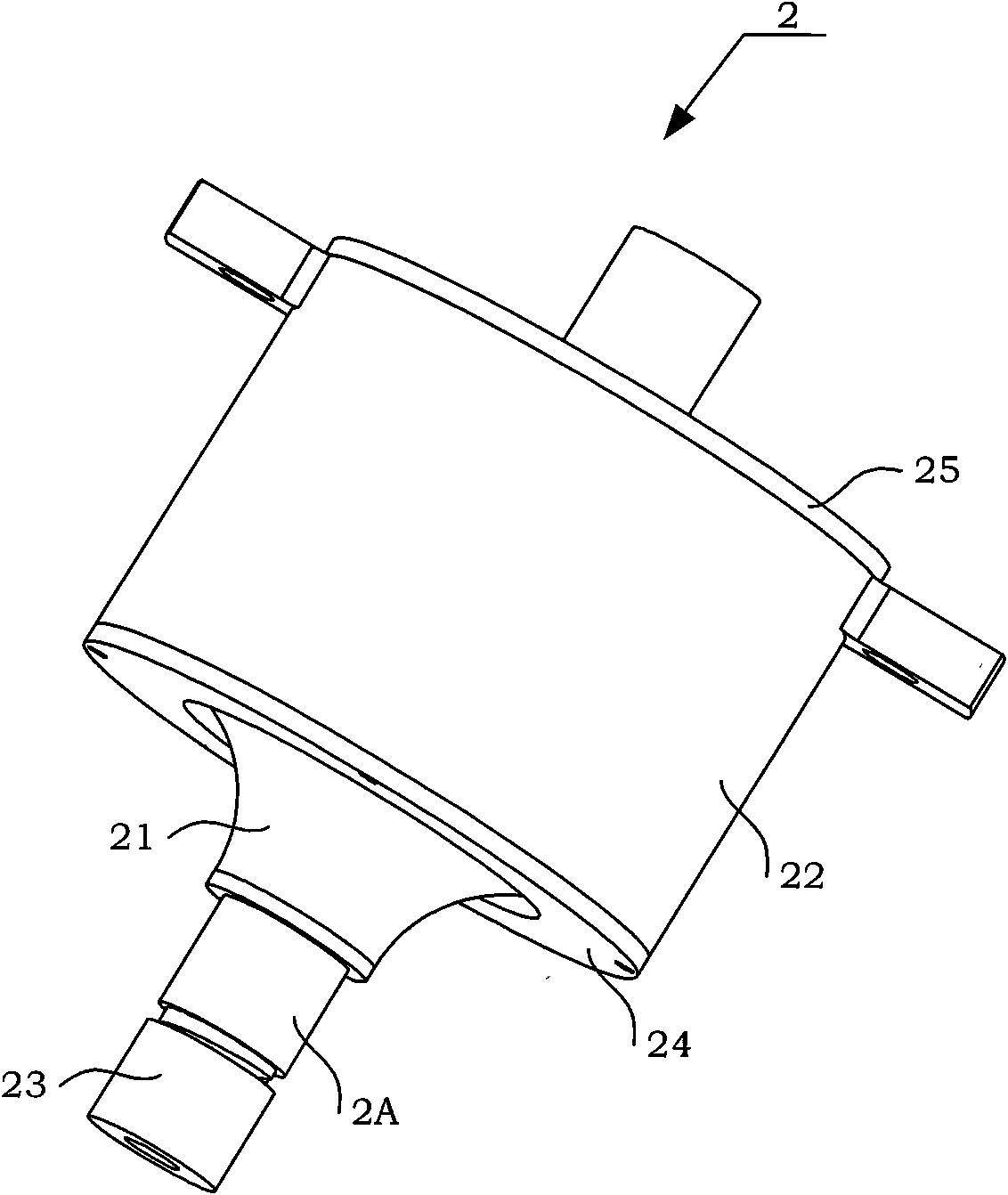

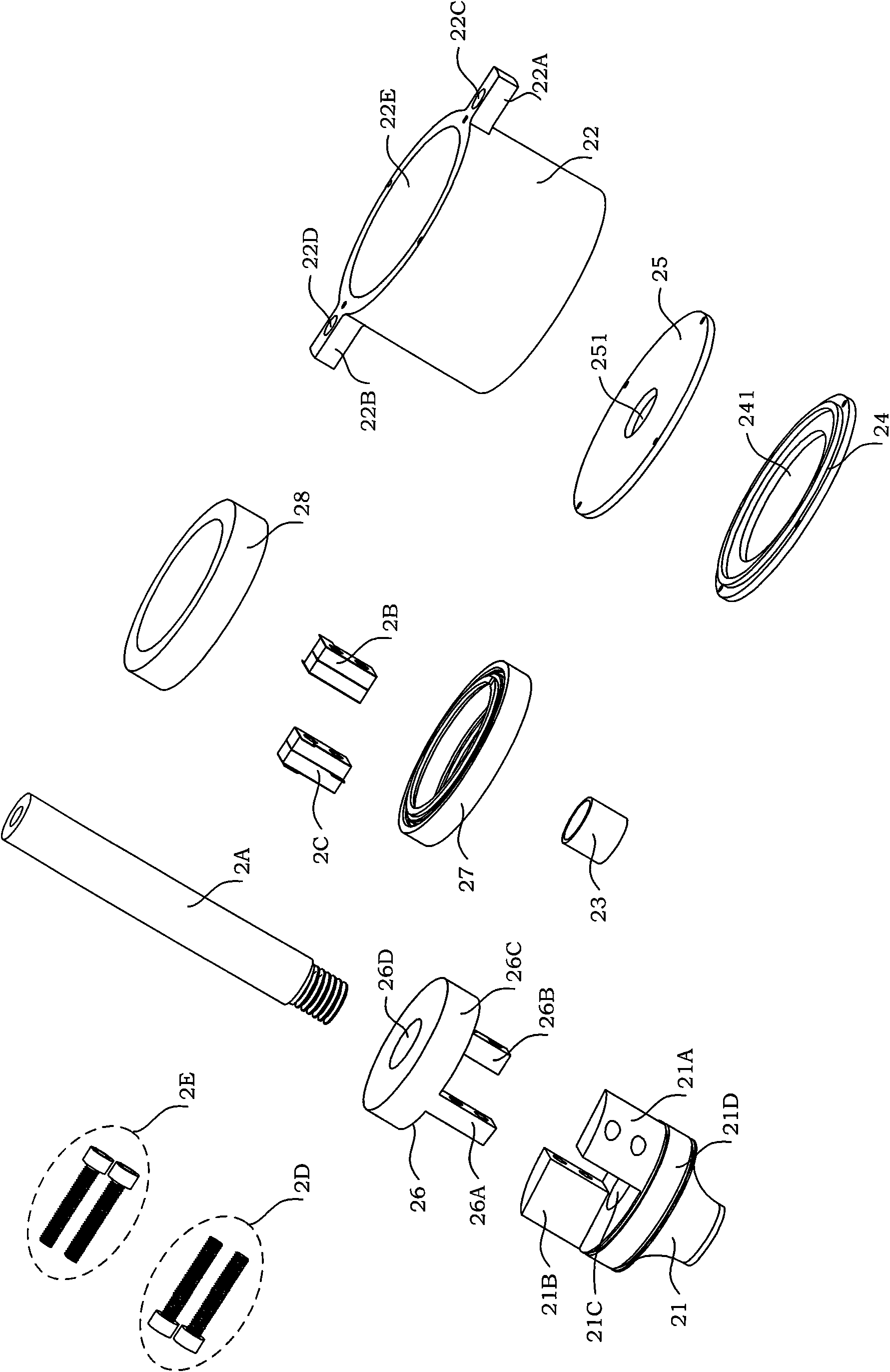

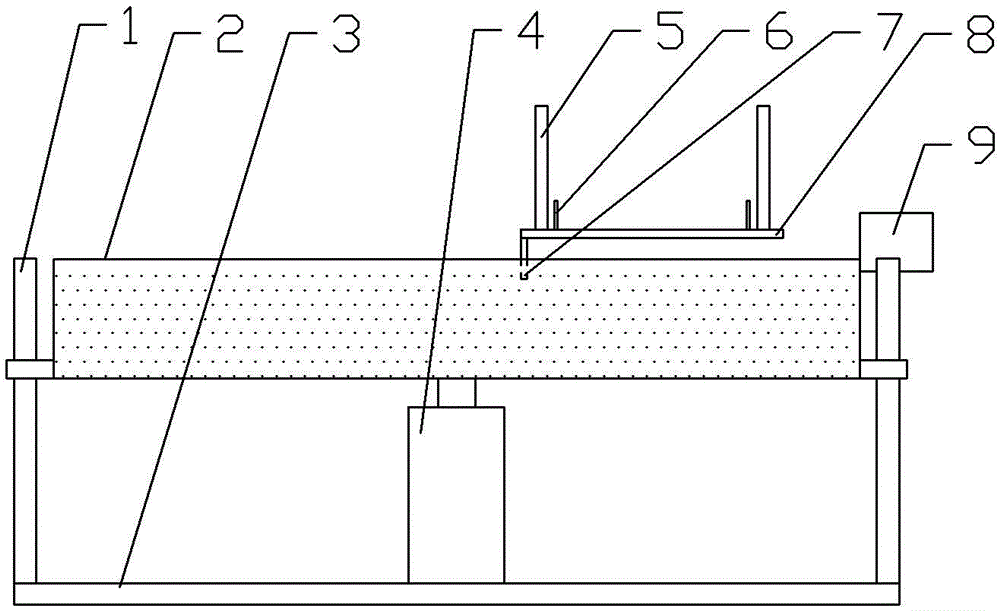

The invention discloses an angular position feedback module of a sun photovoltaic tracking system. The angular position feedback module is composed of a shell (1), a rotary encoder (2), a coded disc installation rack (3), a module base (4), a connecting rod (5), a limiting switch (6), a sliding block, a central shaft combination (8) and a flexible coupling (9). The shell (1) covers the module base (4), the rotary encoder (2), the coded disc installation rack (3), the limiting switch (6), the sliding block (7), the upper half part of the central shaft combination (8) and the flexible coupling (9) are sealed in a seal cavity consisting of the shell (1) and the module base (4). By integrating two functions of angular size feedback and extreme position alarming, the angular position feedback module provided by the invention has high integral protection level in comparison with the way of using independent components; meanwhile, the protection design for a sensor is added, a limiting angleis convenient for adjusting, the transport and installation are convenient; therefore, the angular position feedback is more stable and reliable.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

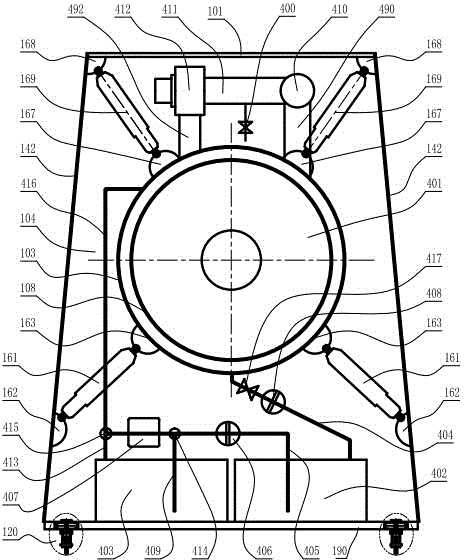

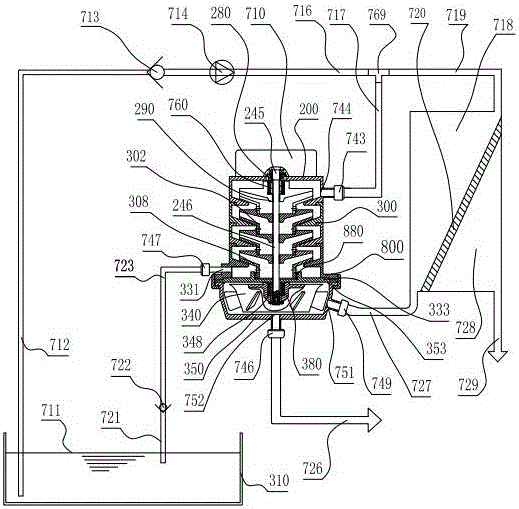

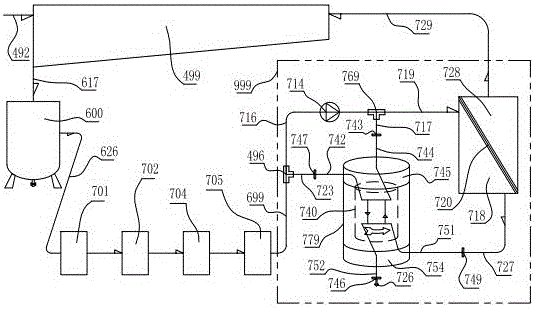

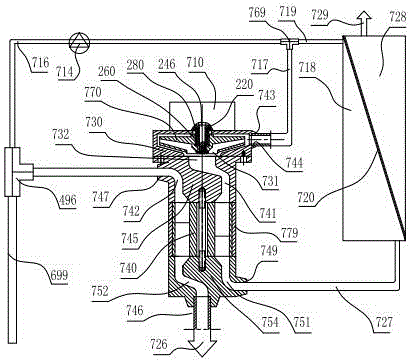

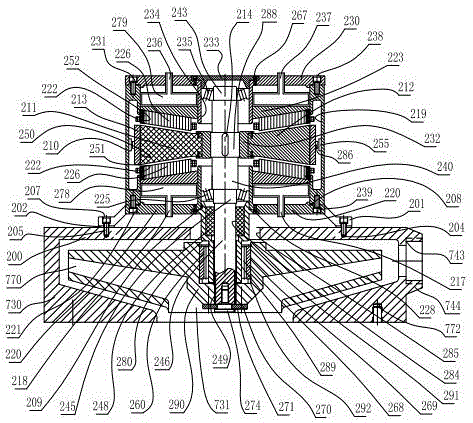

Disc-type motor clamp spring shock absorption nickel alloy dry-cleaning equipment

ActiveCN104947389AAvoid the problem of cross-contamination of germsGuaranteed uptimeNon-rotating vibration suppressionDry-cleaning apparatusEngineeringNickel alloy

The invention relates to a washing machine, and discloses disc-type motor clamp spring shock absorption nickel alloy dry-cleaning equipment which comprises a machine shell, a washing drum, a heat pump drying system, a solvent recovery system, an inner shock absorption assembly part, an outer shock absorption wheel set and a disc-type water-cooling motor assembly. The inner shock absorption assembly part comprises hauling clamp spring shock absorbers and support clamp spring shock absorbers; the disc-type water-cooling motor assembly comprises a motor shell, a motor front cover plate, a motor rear cover plate, a rotor support, a motor rotating shaft, a front bearing, a rear bearing, a permanent magnet, second stators and first stators; according to the disc-type water-cooling motor assembly, the inner end faces of the motor front cover plate and the motor rear cover plate are fixedly connected with the first stators and the second stators respectively, the first stators and the second stators are located on the two sides of the rotor support respectively, on the circumstance of original single stator and single rotor, the stator assemblies are additionally arranged, a two-stator motor is achieved, that is to say, two motors work in parallel, and therefore the power is increased by multiple times without enlarging the diameter.

Owner:康丽莱(山东)环境科技有限公司

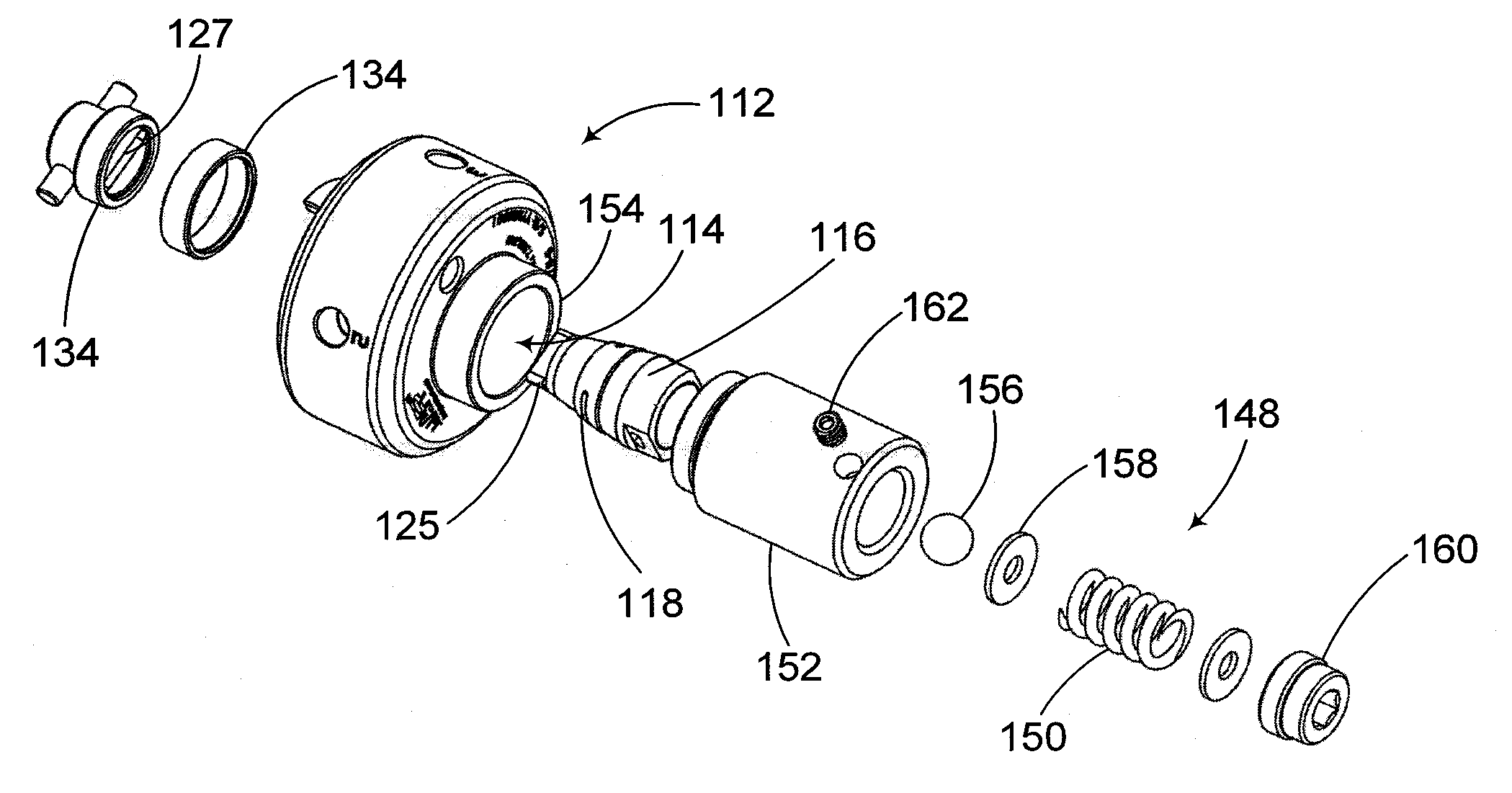

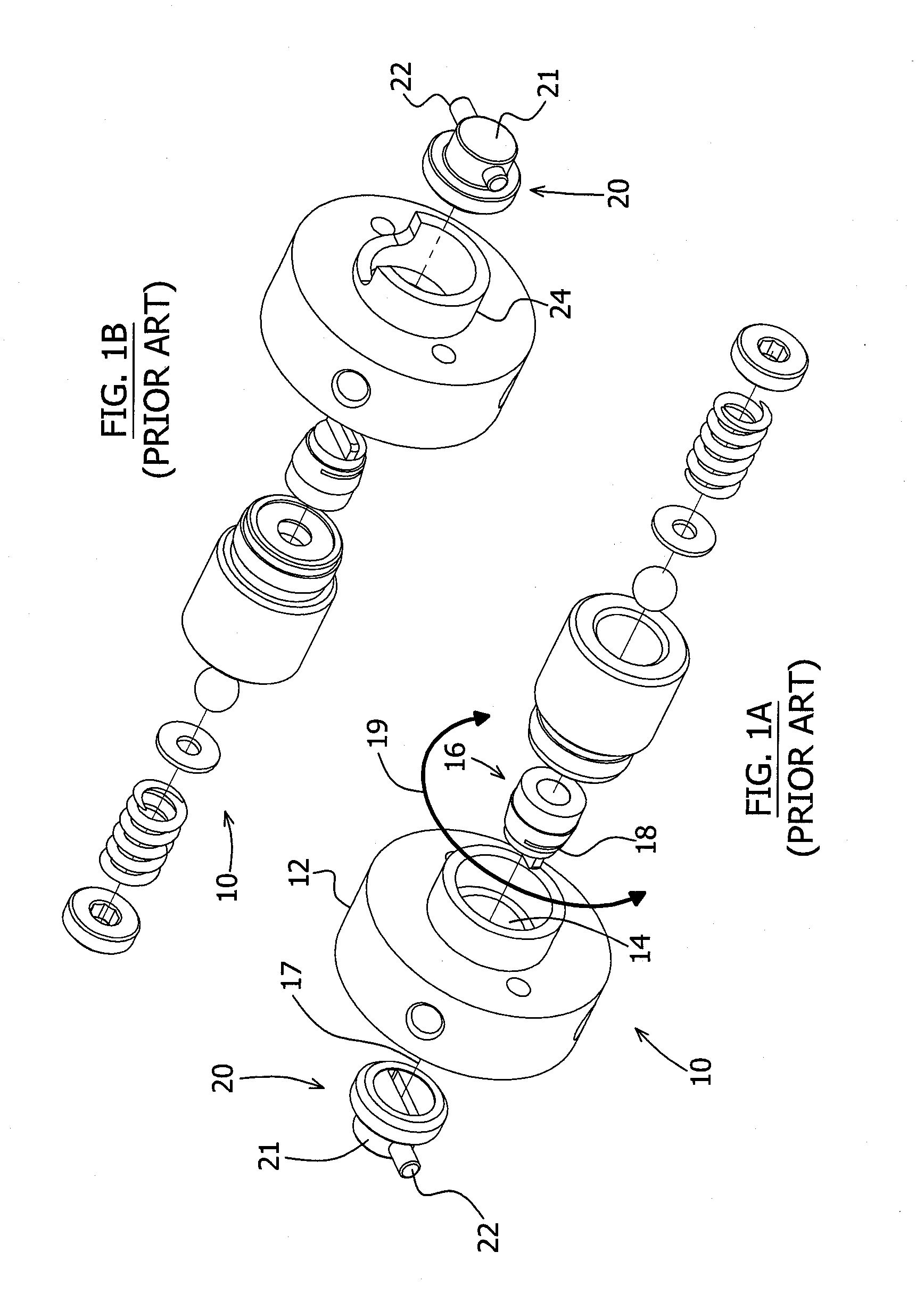

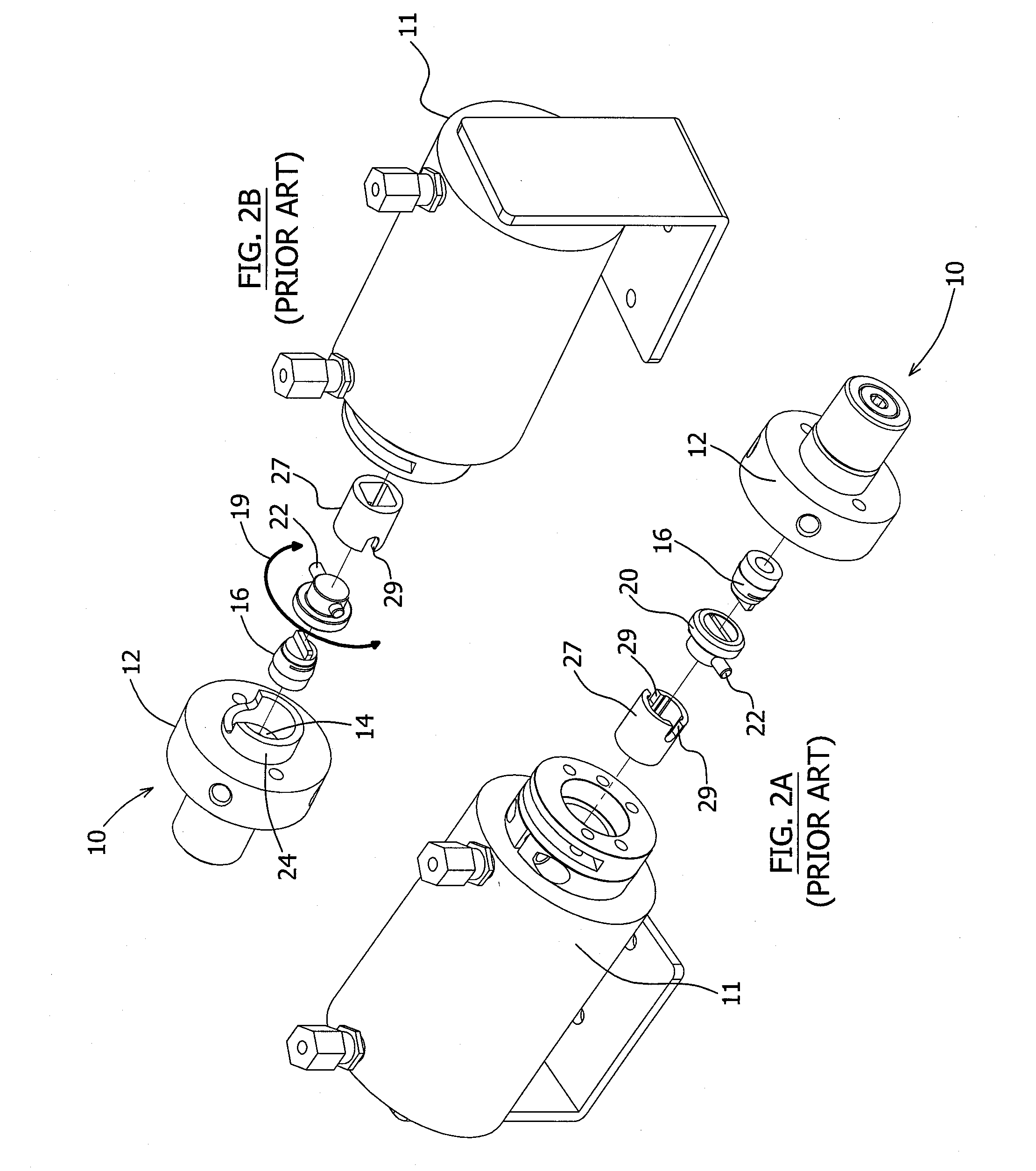

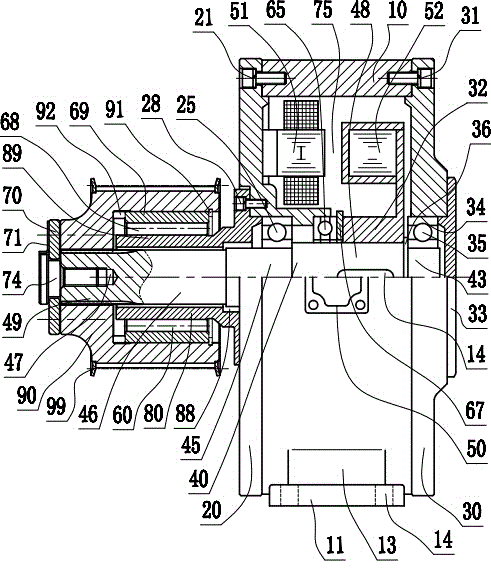

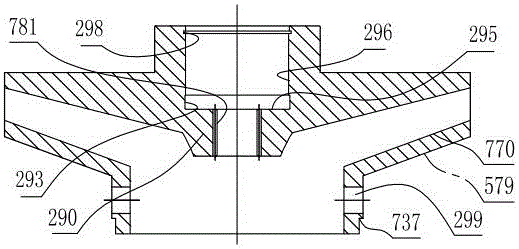

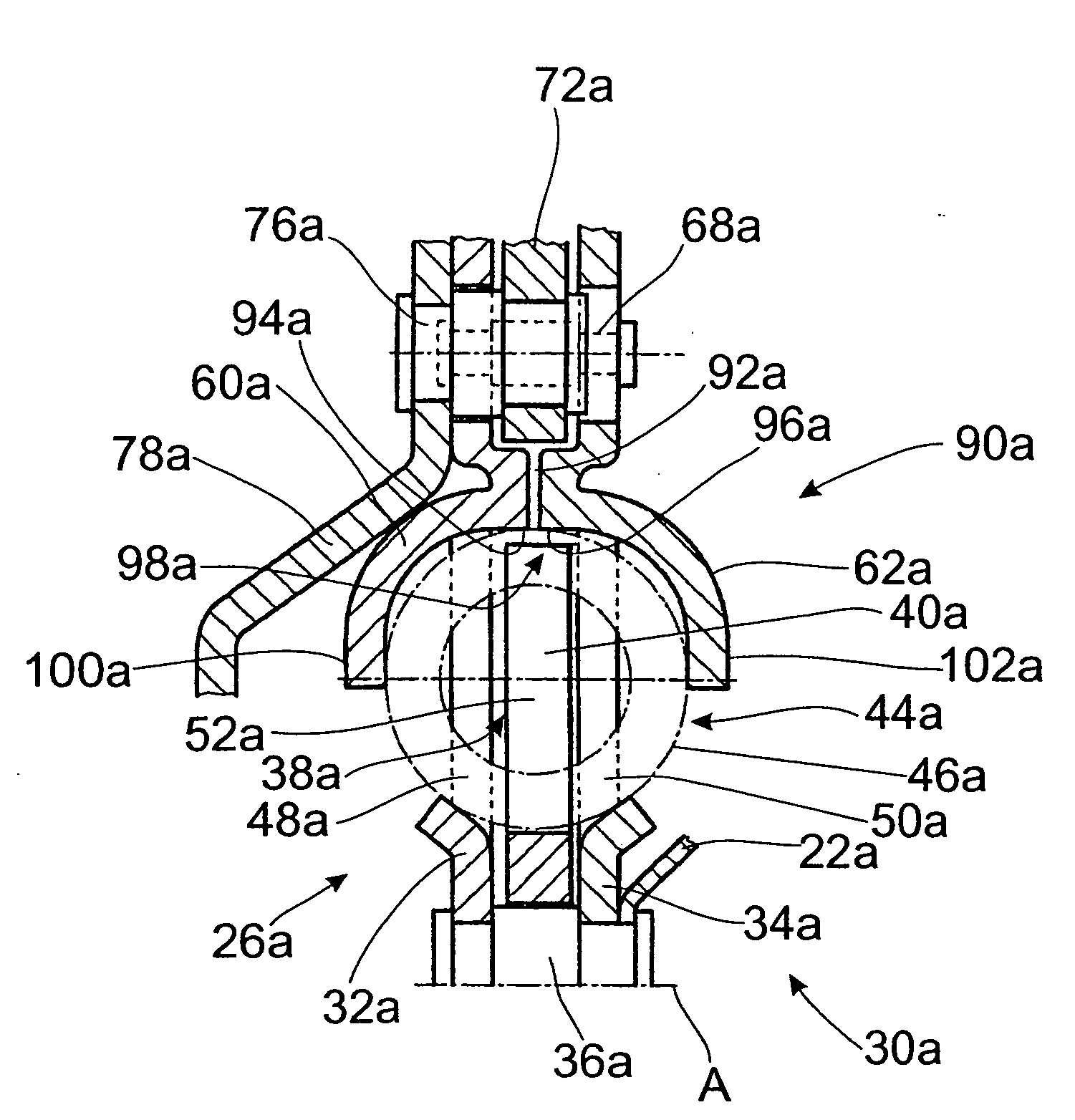

Conical rotary valve for chromatographic applications

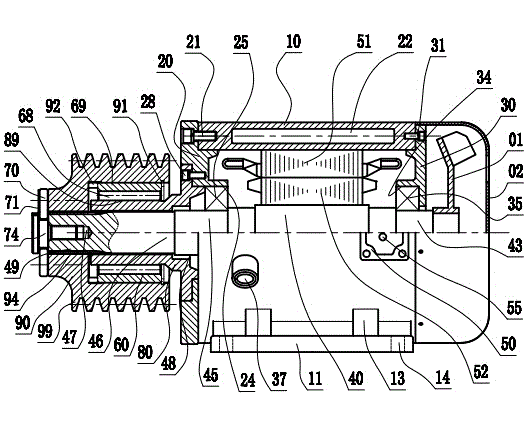

ActiveUS20120181466A1Restraint torsionAvoid radial forcePlug valvesOperating means/releasing devices for valvesRotary valveStator

A conical rotary valve for chromatographic applications is provided, including a valve stator, a valve rotor, a drive adaptor and a pair of stoppers each mounted to the stator. The drive adaptor is rotatable and coupled to the valve rotor for transmitting a rotating force thereto. The drive adaptor has a body and a pair of radial arms projecting from the body radially outward from the axis of rotation on opposite sides thereof. Each of the pair of radial arms is movable along a respective arcuate travelling course with respect to the stator. The stoppers are each positioned to obstruct one of the radial arms at an end of the corresponding travelling course. The stoppers are positioned to simultaneously engage the radial arms, thereby balancing the reaction forces created within the valve when the radial arms reach the ends of their travelling courses.

Owner:APN INC

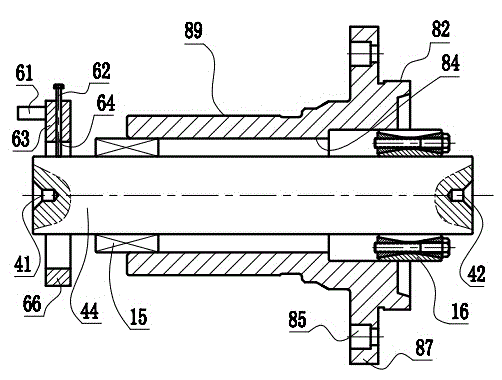

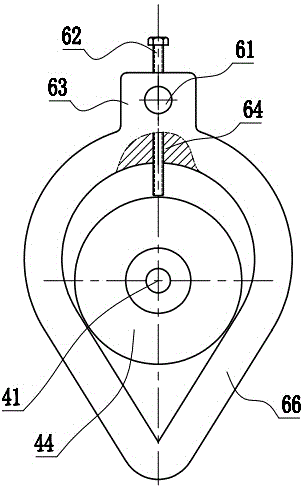

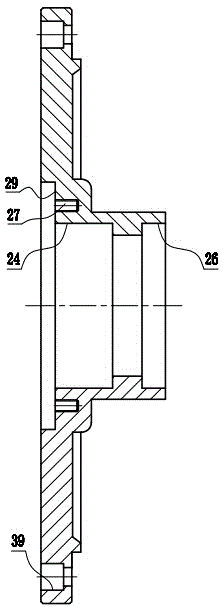

Intermediate support assembly of heavy vehicle drive shaft

InactiveCN103832272ASet strength goodReasonable static and dynamic stiffnessControl devicesDrive shaftEngineering

The invention relates to an intermediate support assembly of a heavy vehicle drive shaft. A bearing is assembled in an inner frame through clamp springs on two sides, sealing rings are arranged on two sides of the bearing, the inner frame is externally vulcanized with an outer cover into a whole through a rubber damping pad, the rubber damping pad is hollowed out internally to form an 'n'-shaped damping groove I which forms a semi-surrounded structure, the rubber damping pad on the upper portion of the inner frame and the inner frame are both covered in an 'n'-shaped empty space, clearances are formed at two side edges of the inner frame, and the lower portion of the rubber damping pad and the inner bottom of the outer cover are connected to form a connecting rib. After the assembly is subjected to complete vehicle trial assembly, the 'n'-shaped semi-surrounded structure of the rubber damping pad can absorb large axial movement of the intermediate support assembly, the angle of the intermediate support assembly is radially adjustable, the radial direction of the intermediate support assembly is ensured to be perpendicular to the axial direction of a center line of the drive shaft, and the intermediate support assembly is simple and feasible and remarkable in benefit, and has promotional value in the automobile industry.

Owner:湖北省丹江口丹传汽车传动轴有限公司

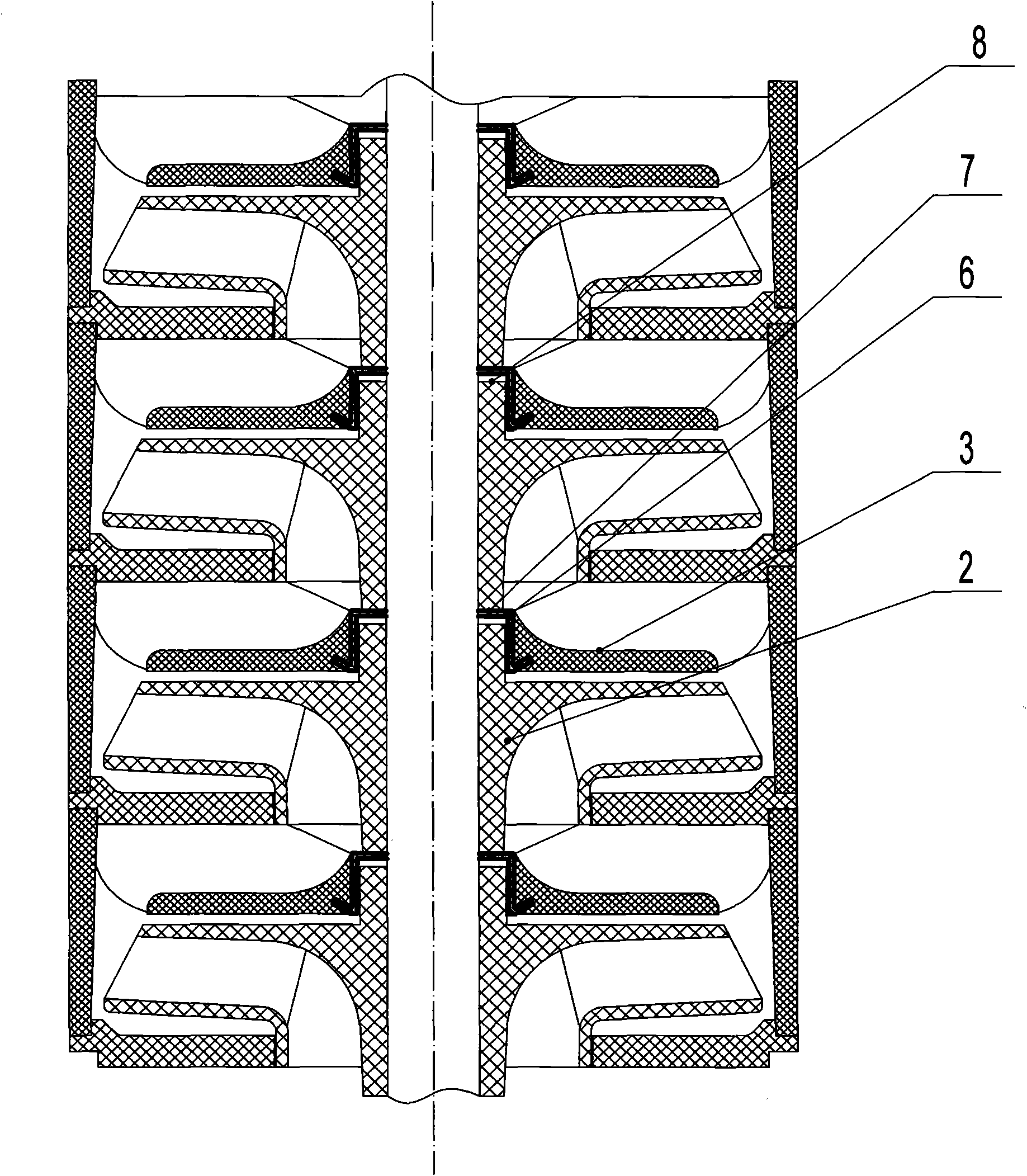

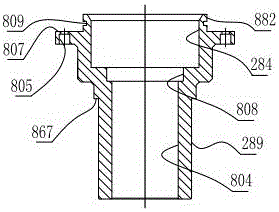

Disc type titanium alloy synchronous belt wheel motor

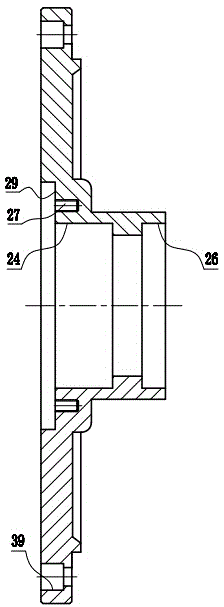

InactiveCN104485772AReduce axial sizeImprove power densityManufacturing dynamo-electric machinesMechanical energy handlingThrust bearingEngineering

The invention relates to a special motor for a locomotive of a motor train unit and a disc type titanium alloy synchronous belt wheel motor. The disc type titanium alloy synchronous belt wheel motor comprises a stator, a rotor, a motor rotary shaft, a motor housing, a front end cover, a rear end cover and a synchronous belt wheel, the stator is fixed on the inner side of the front end cover, and the rotor is fixed on the motor rotary shaft. As improvement, one end face of a thrust bearing is fixed on the front end cover; the other end face of the thrust bearing is tightly attached to the outer end face of one side of an inner hole of a rotor frame; the rear end cover is provided with a bearing rear cover; the bearing rear cover is fixed on the rear end cover through a screw; the inner end of the bearing rear cover extends into a rear cover bearing hole in the rear end cover and abuts against a rear bearing; a supporting component is fixed on the front end cover through a screw; the inner end of a component adjusting ring on the supporting component extends into a front cover bearing hole in the front end cover and abuts against a front bearing; a bearing without an inner ring is arranged between the outer end of the supporting component and the synchronous belt wheel; a thick titanium alloy hard wear-resisting layer is compounded on the surface of the supporting circle of an outer bearing of the supporting component.

Owner:张志雄

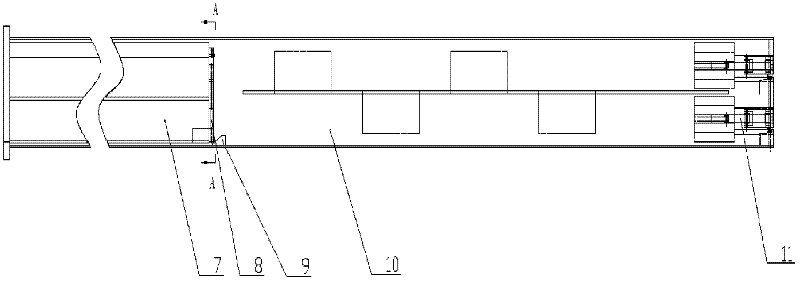

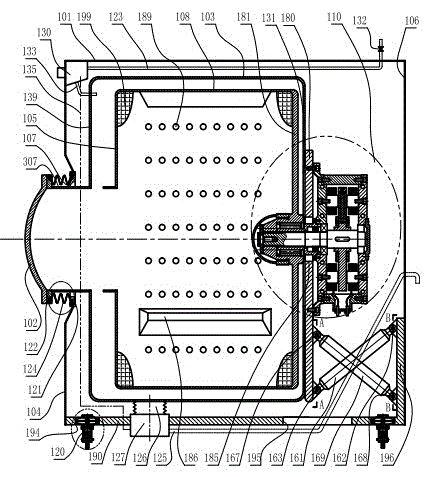

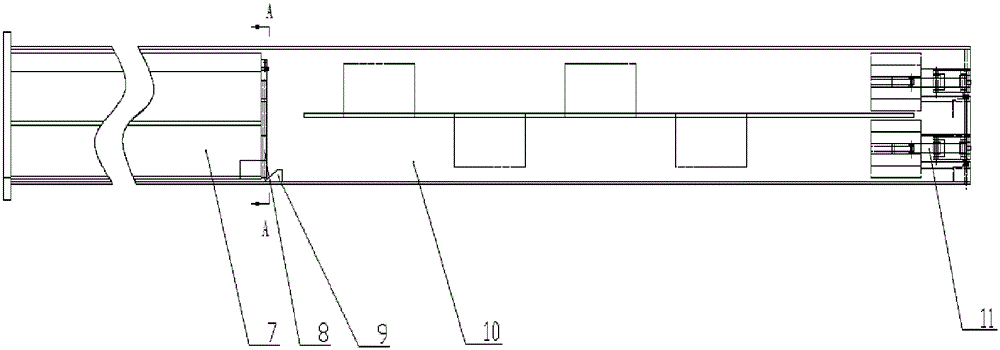

Automatic medicine discharging mechanism of rapid medicine dispensing system using box-type medicine feeding method

ActiveCN102673929ARealize automatic dockingHigh-speed medicineStorage devicesBiomedical engineeringMedicine cabinet

The invention relates to an automatic medicine discharging mechanism of a rapid medicine dispensing system. According to the specifications and the shape characteristics of medicine boxes, vertical and horizontal medicine tanks and medicine cases are designed and placed in a medicine cabinet shown as an accompanying drawing 1. The medicine tanks and the medicine cases have gradually increasing tank widths according to the thickness of the medicine boxes and are used for storing the medicine boxes with different thicknesses shown in an accompanying drawing 2. The front half parts of the medicine tanks are guide grooves of the medicine boxes and the rear half parts of the medicine tanks are used for bearing the medicine cases. The length of the medicine cases is half of the length of the medicine tanks. When the medicine boxes are at the front half parts of the medicine tanks, a medicine feeding mechanism fills the medicine boxes into the medicine cases and guides the medicine boxes into the medicine tanks, so as to continuously supplement new medicine boxes for the medicine tanks. The automatic medicine discharging mechanism of the rapid medicine dispensing system has the characteristics that since the automatic medicine discharging mechanism is matched with a dual-box-type medicine feeding mechanism, the automatic joint of the medicine cases and the medicine tanks is realized and the effect of synchronization of high-speed medicine discharging and high-speed medicine feeding is realized; since the storage capacity of a main medicine cabinet is great and a synchronous medicine discharging method is adopted, the medicine discharging speed is high; and a sliding block and connecting rod medicine discharging mechanism and a photoelectric detection device at a medicine outlet guarantee the working reliability of the medicine discharging system.

Owner:SHANGHAI VIEW VALLEY TECH +1

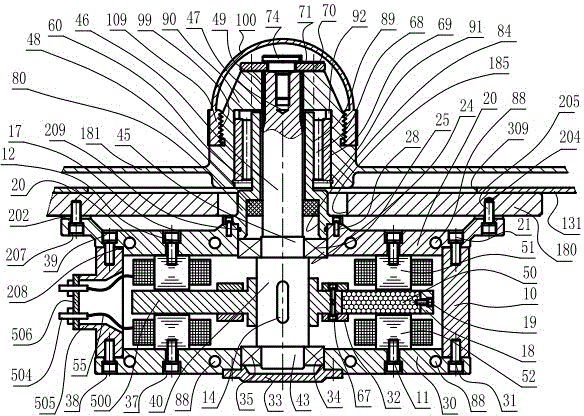

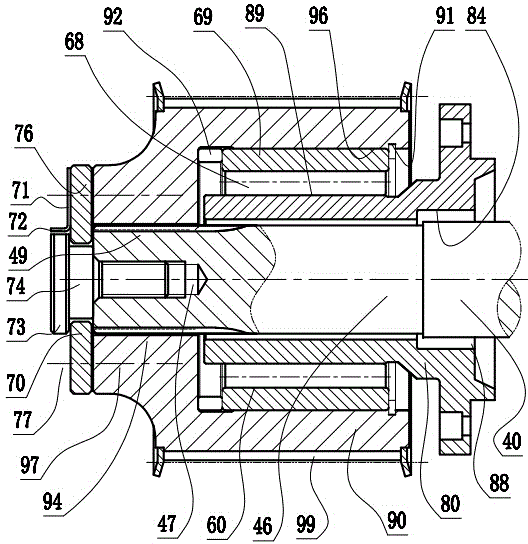

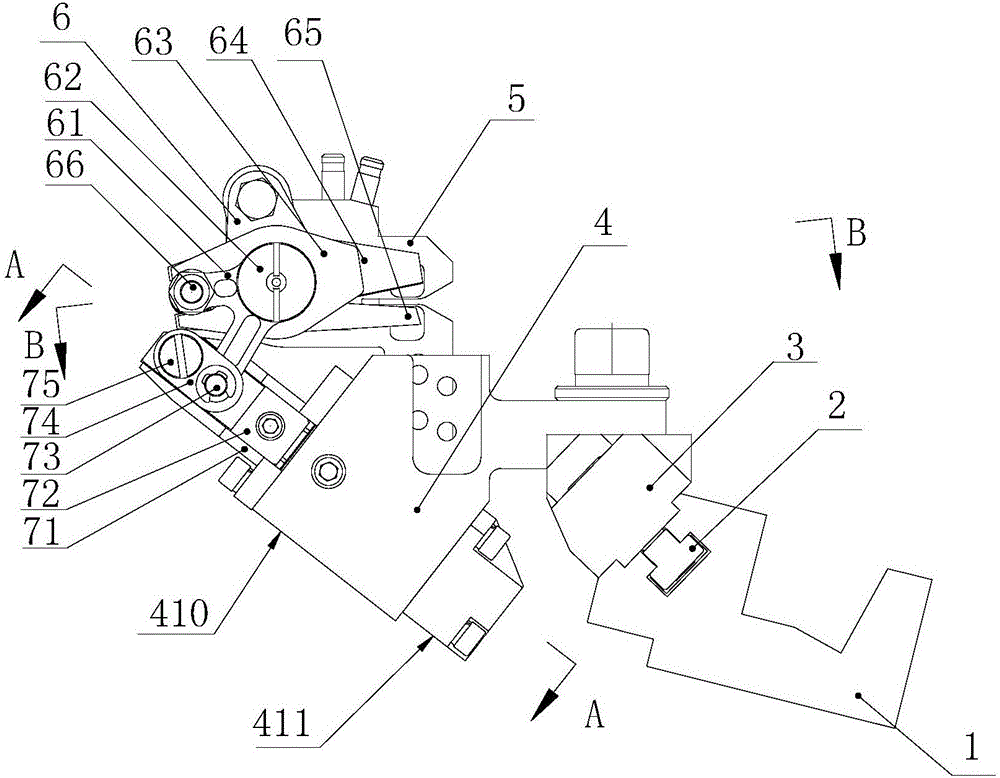

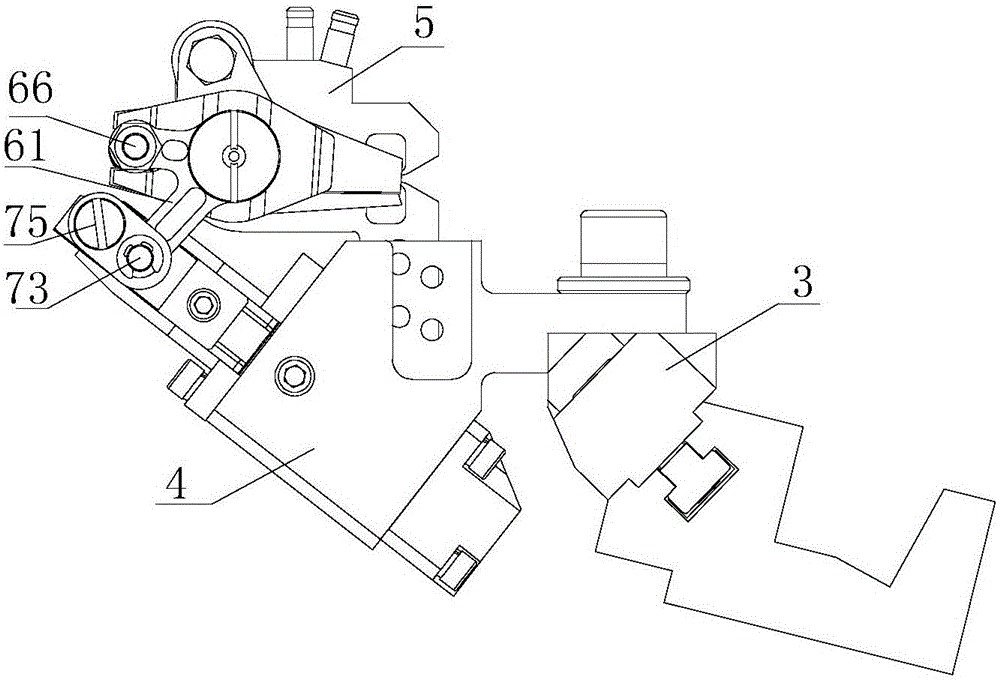

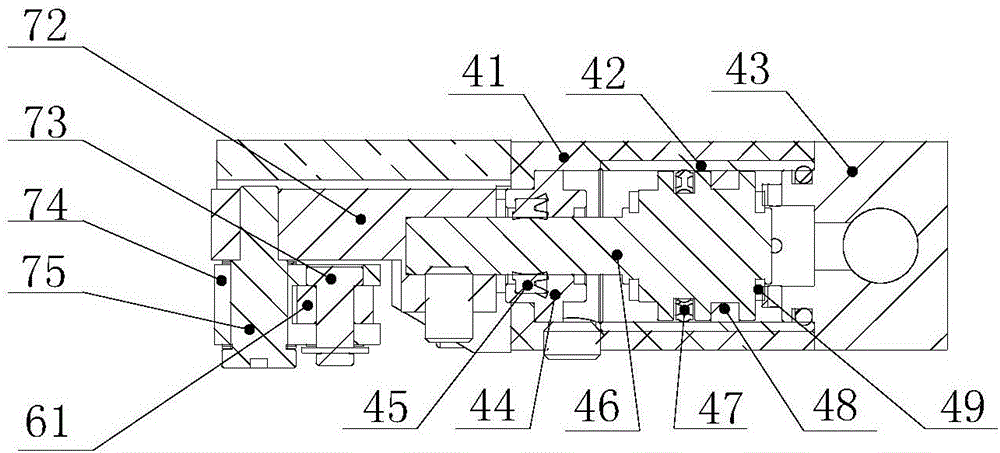

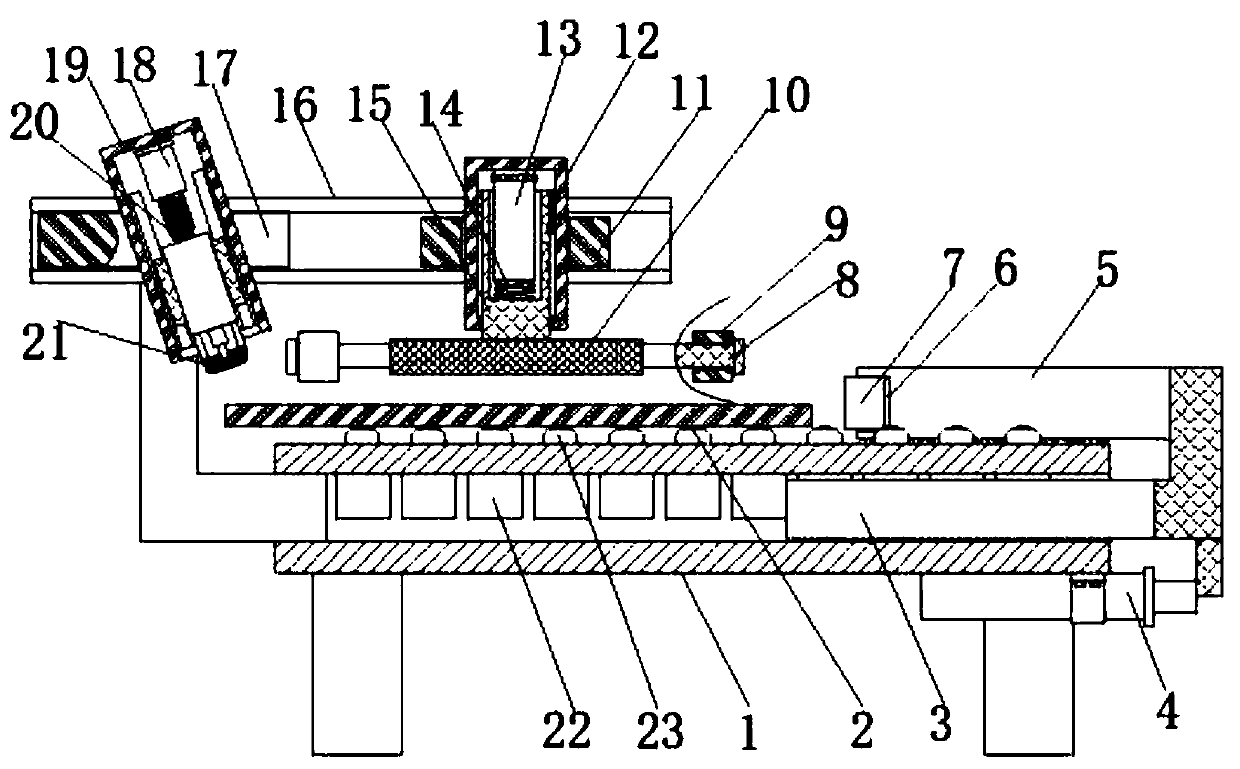

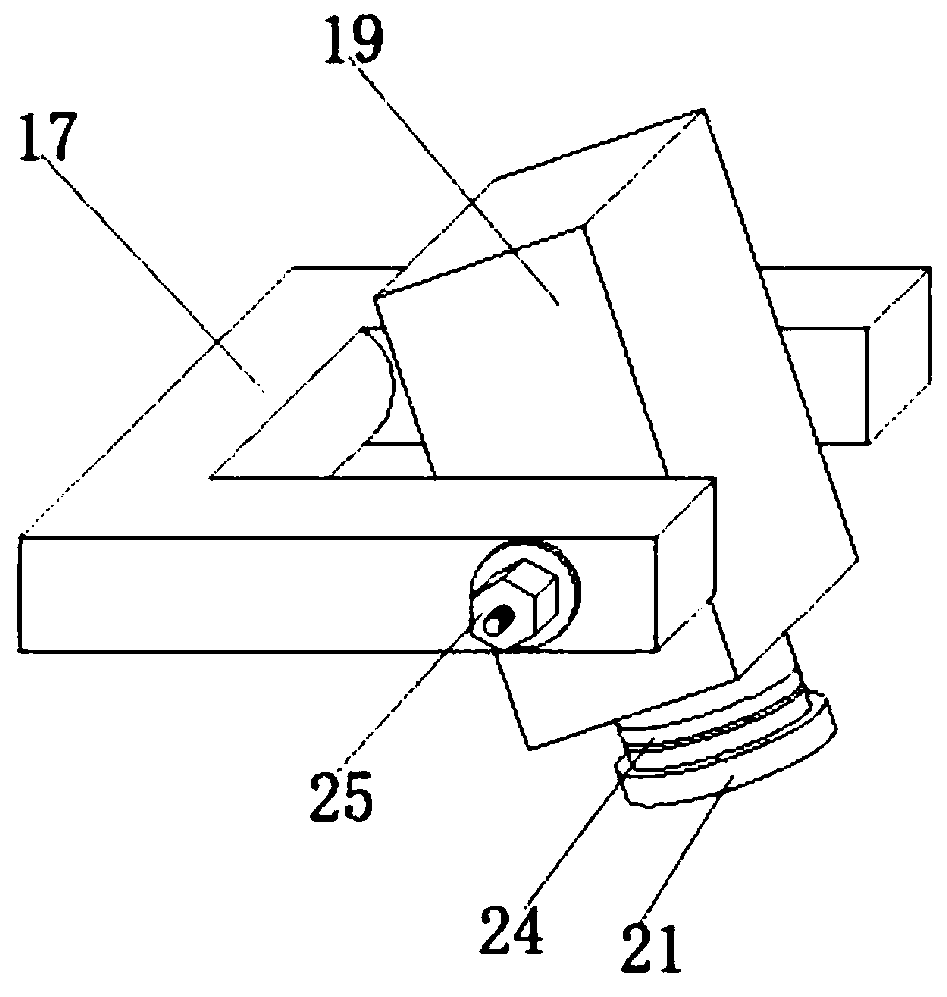

High-low frequency compound torsional vibration tapping device

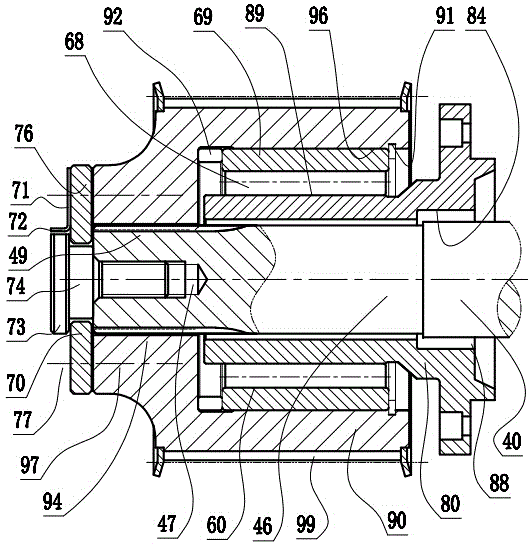

InactiveCN101633064AExtended service lifeIncrease flexibilityThread cutting machinesEngineeringTorsional vibration

The invention discloses a high-low frequency compound torsional vibration tapping device comprising a main shaft mechanism, an ultraphonic transduction vibration assembly, a floating assembly and a servo motor, wherein the ultraphonic transduction vibration assembly is arranged in the main shaft mechanism; the servo motor is arranged on a supporting plate of the floating assembly; and the floating assembly is arranged on the surface of a mounting plate of a main shaft box of the main shaft mechanism. The torsional vibration tapping device can be suitable for high-low frequency compound torsional vibration tapping with low frequency less than 60 Hz and high frequency more than 16 kHz and combines low frequency torsional vibration provided by the servo motor and high frequency torsional vibration provided by the ultraphonic transduction vibration assembly, thereby realizing the high-low frequency compound torsional vibration tapping of a cutter, simplifying the structure of the device and enhancing the precision of equipment; in addition, the invention realizes the radial floating of the cutter by installing an X-directional floating assembly and a Y-directional floating assembly, prevents larger radial force from being generated during processing and realizes the flexible processing of the torsional vibration tapping device in such a way that the axial floating of a main shaft of the cutter is provided by a spline part assembly.

Owner:BEIHANG UNIV

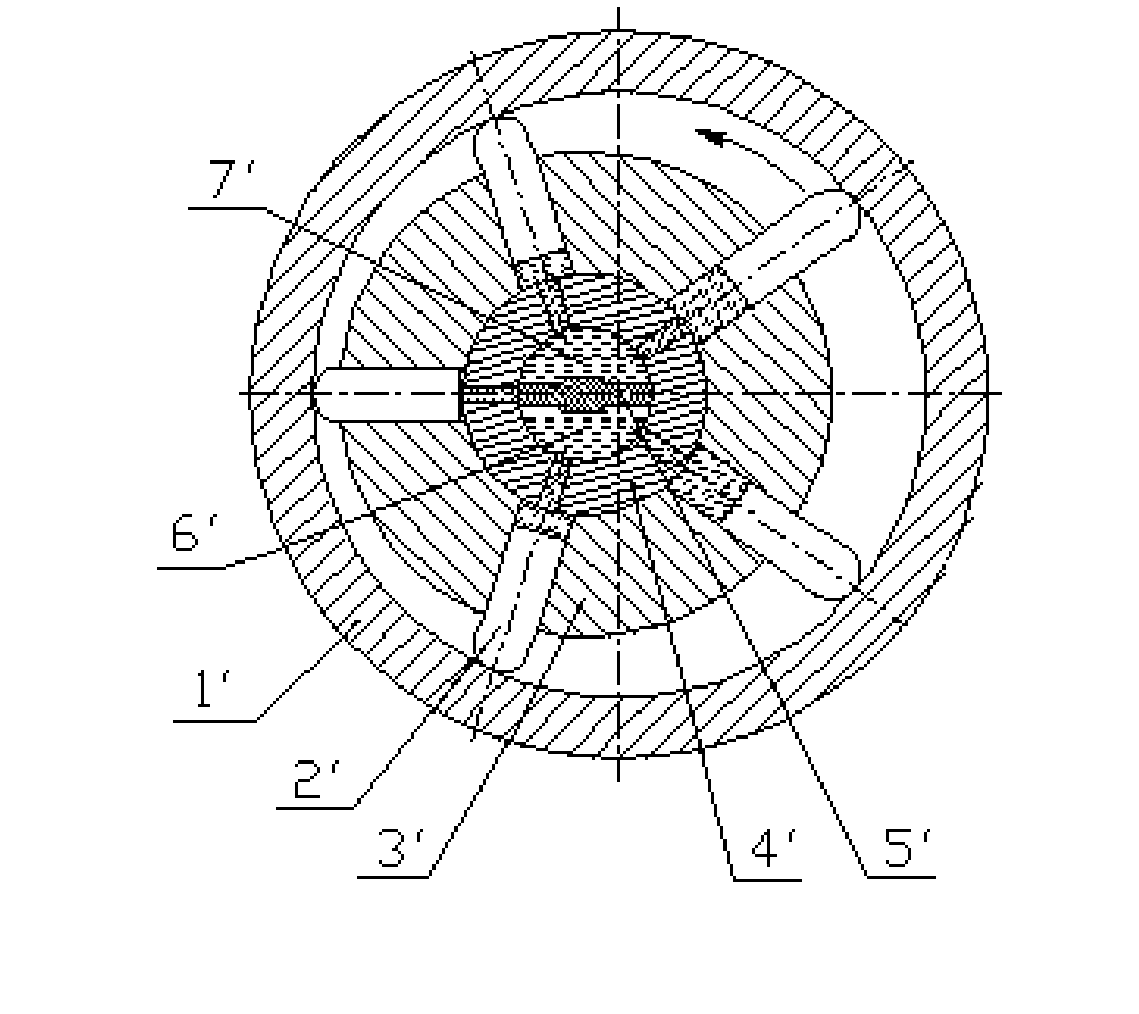

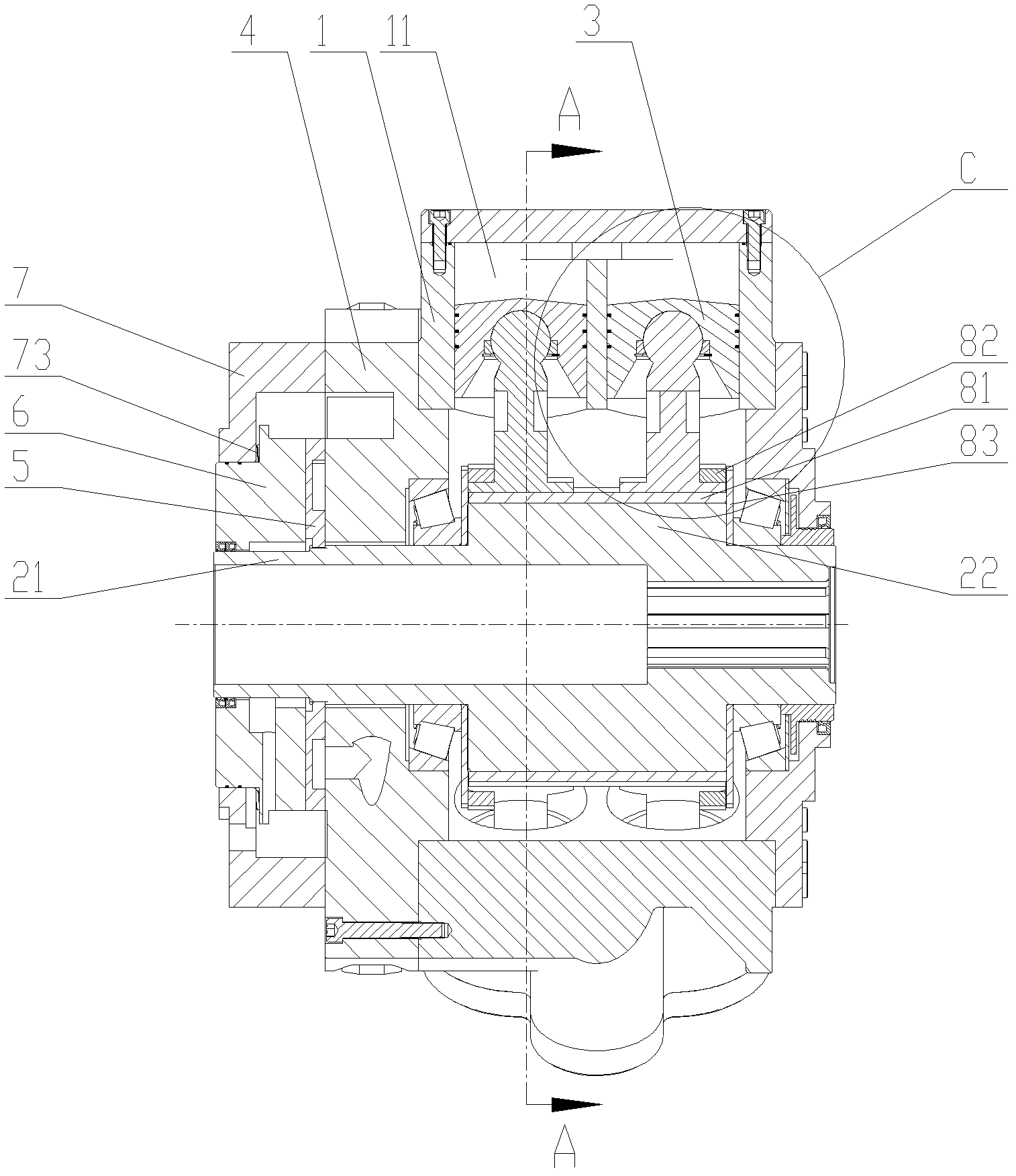

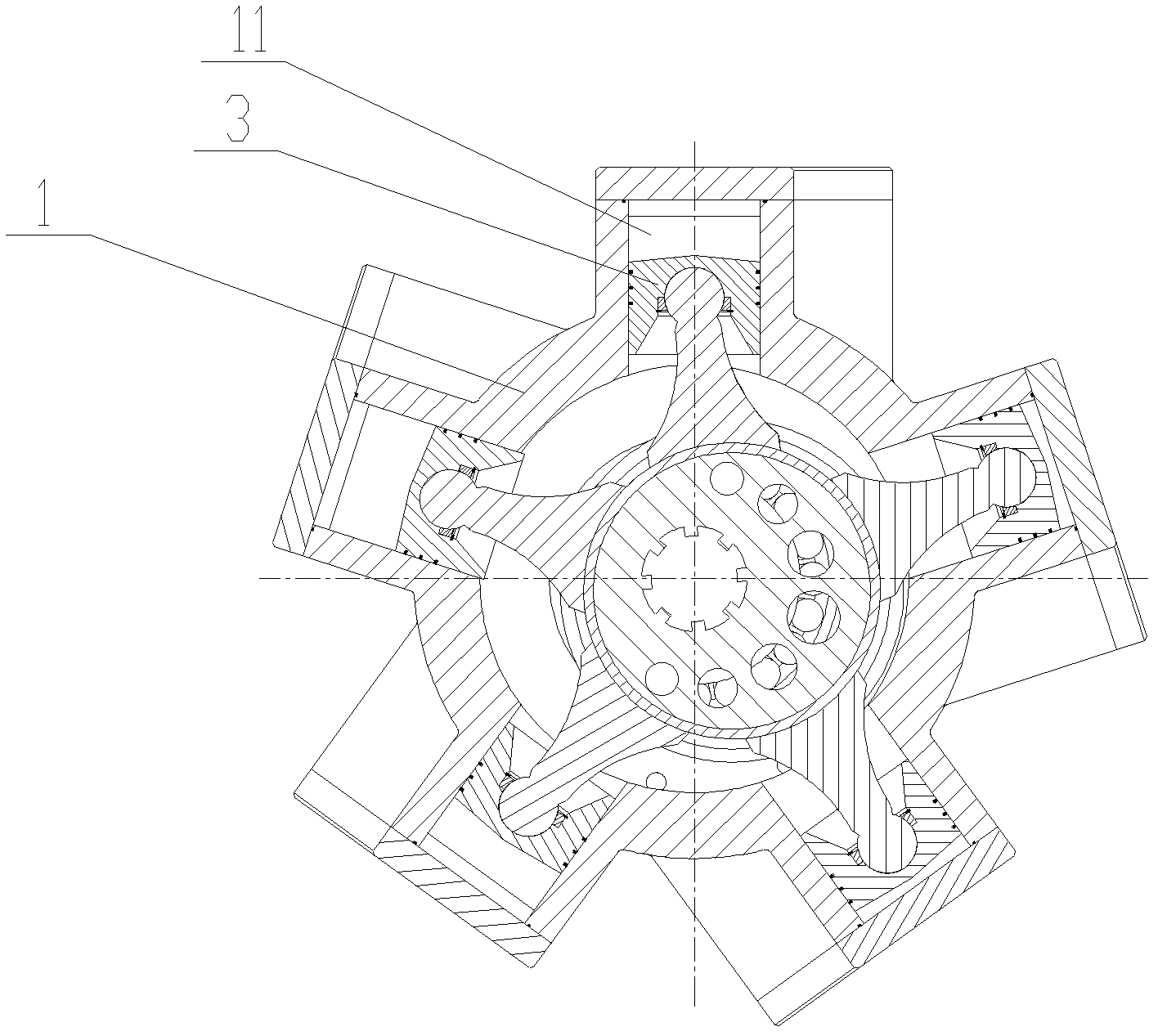

Wind generating set and hydraulic motor thereof

InactiveCN102562475AAvoid radial forceReduce wearWind motor combinationsWind energy generationHydraulic motorHigh pressure

The invention discloses a hydraulic motor. A symmetrical shaft (21) rotationally penetrates through a middle end cap (4), the middle end cap (4) is provided with a plurality of middle end cap oil passages (41) which are communicated with different plunger cavities (11) respectively. A valve plate (5) rotating along with the symmetrical shaft (21) is fixed to the outside of the symmetrical shaft (21) and is provided with a first oil cavity (51) and a second oil cavity (52), and the first oil cavity (51) and the second oil cavity (52) are communicated with the middle end cap oil passages (41) and alternated to form a high-pressure oil inlet cavity and a low-pressure oil return cavity. Any one of plunger components (3) moves to extend into the limit position, then the plunger cavity (11) with the plunger component begins to be communicated with the high-pressure oil inlet cavity, and when the plunger component (3) continues to move to extend out of the limit position, the plunger cavity (11) with the plunger component begins to be communicated with the low-pressure oil return cavity. The hydraulic motor with the structural design has the advantages that unbalanced radial force applied to the valve plate thereof can be avoided, abrasion of the hydraulic motor can be reduced, and the service life thereof can be prolonged. In addition, the invention discloses a wind generating set comprising the hydraulic motor.

Owner:SANY ELECTRIC CO LTD

Slay direct connection type pneumatic trimming device

The invention discloses a slay direct connection type pneumatic trimming device. The slay direct connection type pneumatic trimming device includes a weft beating-up slay, an air cylinder, a pneumatic hemmer, and a weft yarn scissors mechanism; the air cylinder is connected to the weft beating-up slay; the pneumatic hemmer is arranged on the air cylinder; the weft yarn scissors mechanism is arranged on the pneumatic hemmer; and the air cylinder, the pneumatic hemmer, and the weft yarn scissors mechanism swing with the weft beating-up slay. The air cylinder, the weft yarn scissors mechanism, and the pneumatic hemmer are integrally arranged on an air cylinder positioning base to form a unit, the air cylinder positioning base is connected to a T-shaped groove of the weft beating-up slay, and then the air cylinder, the weft yarn scissors mechanism, and the pneumatic hemmer can swing with the weft beating-up slay; and the convenience of a weft beating-up operation is improved, abrasion is reduced, and the service life is prolonged.

Owner:QINGDAO TIANYI GROUP RED FLAG TEXTILE MACHINERY

Rotating connector, pipe winder and engineering machine

The invention discloses a rotating connector, a pipe winder and an engineering machine. The rotating connector comprises a jacket and a core; the jacket is used for being fixedly arranged on a support and is provided with a liquid inlet hole; the core is rotatably embedded in the jacket and is provided with a first end, a second end and a liquid flowing cavity; the first end is provided with a liquid inlet hole, and the liquid inlet hole of the core corresponds to the liquid inlet hole of the jacket; a liquid outlet hole is arranged at the second end; the liquid inlet hole of the core is communicated with the liquid outlet hole via the liquid flowing cavity; and the liquid inlet hole of the core is a through hole transversely penetrating through the core, and an annular cavity is arranged between the liquid inlet hole of the jacket and the liquid inlet hole of the core and is arranged on the jacket and / or the core. The liquid inlet hole of the core of the rotating connector is the through hole, fluid is prevented from exerting radial acting force on the core, and the rotating connector is fixedly arranged on the support firmly and stably via the jacket directly. Accordingly, the rotating connector is not easy to deform, and the service life of the rotating connector is prolonged. Besides, the rotating connector is an independent module, and accordingly is easy to assemble.

Owner:SANY HEAVY IND CO LTD (CN)

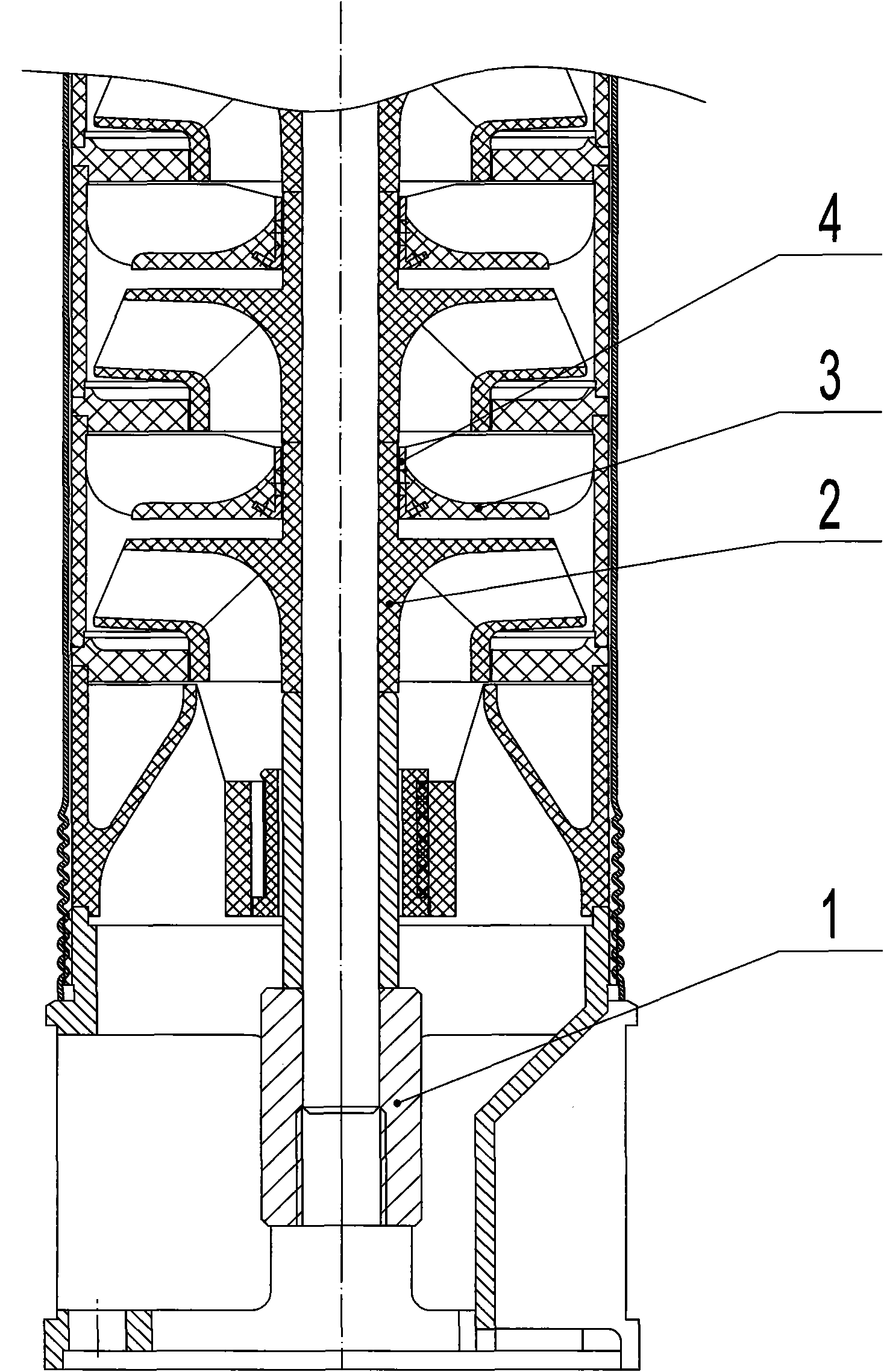

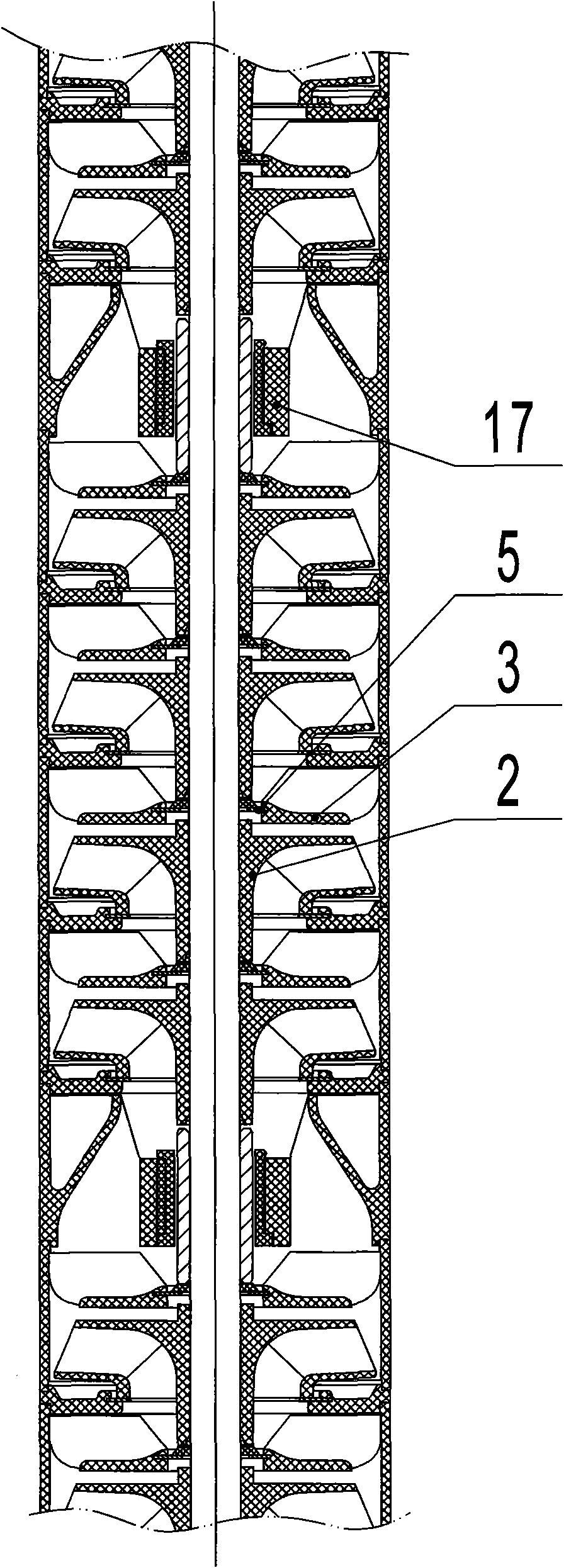

Bearing insert to be inserted in inner hole part of plastic flow deflector shell of engineering plastic well pump

InactiveCN101936304AAvoid radial forceOvercome the downward axial forcePump componentsPumpsImpellerPunching

The invention discloses a bearing insert to be inserted in the inner hole part of the plastic flow deflector shell of an engineering plastic well pump, which is formed by punching a stainless steel plate and is matched with an engineering plastic impeller hub to form a sliding radial bearing and a sliding thrust bearing for bearing the radial force and axial force of the impeller. The upper side of the top part of the insert and the lower end of the impeller hub on the upper side form a lower plain thrust bearing for bearing the downward axial force of the impeller; the downside of the top part of the insert and the upper end of the impeller hub on the down side form an upper plain thrust bearing for bearing the upward axial force applied when the well pump starts; and the inner wall of the cylinder of the insert and the external circle of the impeller hub form a radial sliding bearing for bearing the radial force of the impeller. As a bearing pair with high performance is made of stainless steel and the engineering plastic, the reliability of the engineering plastic multi-stage well pump is improved greatly. The shape of the bearing insert is very suitable to be formed by punching and is also very suitable to be connected with the plastic flow deflector shell into a whole firmly, so material and labor can both be saved.

Owner:JIANGSU UNIV

Nickel alloy disc-type motor welding spring buffer washing machine

ActiveCN104928880AGood cooling effectReduce vibrationOther washing machinesWashing machine with receptaclesBall (bearing)Materials science

The invention relates to a washing machine, and discloses a nickel alloy disc-type motor welding spring buffer washing machine which comprises a machine shell, a drum door, a water containing drum, a rotating drum body, a vertical plate, a bed plate, a disc-type water-cooling motor assembly, an external water supply pipe and a drainage external pipe. As an improvement, a buffer assembly is arranged on the back faces of the rotating parts such as the water containing drum, and the gravity centers of the rotating parts such as the water containing drum are lowered; by means of the two-spring composite action of tension-compression welding spring buffers and a compression-tension welding spring buffer, the pressure or the tension is alternatively reduced; the vibration amplitude is decreased. The drum door is installed on the front face of a water drum flange of an opening of the water containing drum, a corrugated seal ring is connected between the front face of a shell flange of a front panel opening of a shell of the machine shell and the back face of the water drum flange in a sealed mode, static sealing is achieved, and vibration with a certain swing amplitude can be born. According to the nickel alloy disc-type motor welding spring buffer washing machine, under the combination action of upper springs and lower springs of the two-spring buffer assembly and plane bearing balls, the nickel alloy disc-type motor welding spring buffer washing machine can randomly move on bumpy ground.

Owner:平湖市金兔实业有限公司

Electric power steering device

ActiveCN112026914AAvoid deformationAvoid radial forceElectrical steeringElectric power steeringSteering wheel

The invention discloses an electric power steering device, and relates to the technical field of power transmission. The device comprises a shell, a nut and screw rod assembly, an input shaft, an output shaft, a worm gear, a worm, a torque sensor and a motor, one end of the nut and screw rod assembly is installed in the shell, and the other end of the nut and screw rod assembly extends out of theshell and is connected with an input shaft; the input shaft is used for connecting a steering wheel; the worm is obliquely installed in the shell, one end of the worm is meshed with the worm gear, andthe other end of the worm is connected with the motor; and the torque sensor is arranged at the joint of the input shaft and the nut and screw rod assembly. The steering wheel is connected with the input shaft, the torque sensor transmits a force applied to the steering wheel to the motor, the motor applies the force to the worm, the worm drives the worm gear to rotate, then the worm gear transmits a steering force to the nut and screw rod assembly, and the nut and screw rod assembly drives the output shaft assembly to move repeatedly so that a power assisting function is achieved.

Owner:HANGZHOU SHIBAO AUTO STEERING GEAR

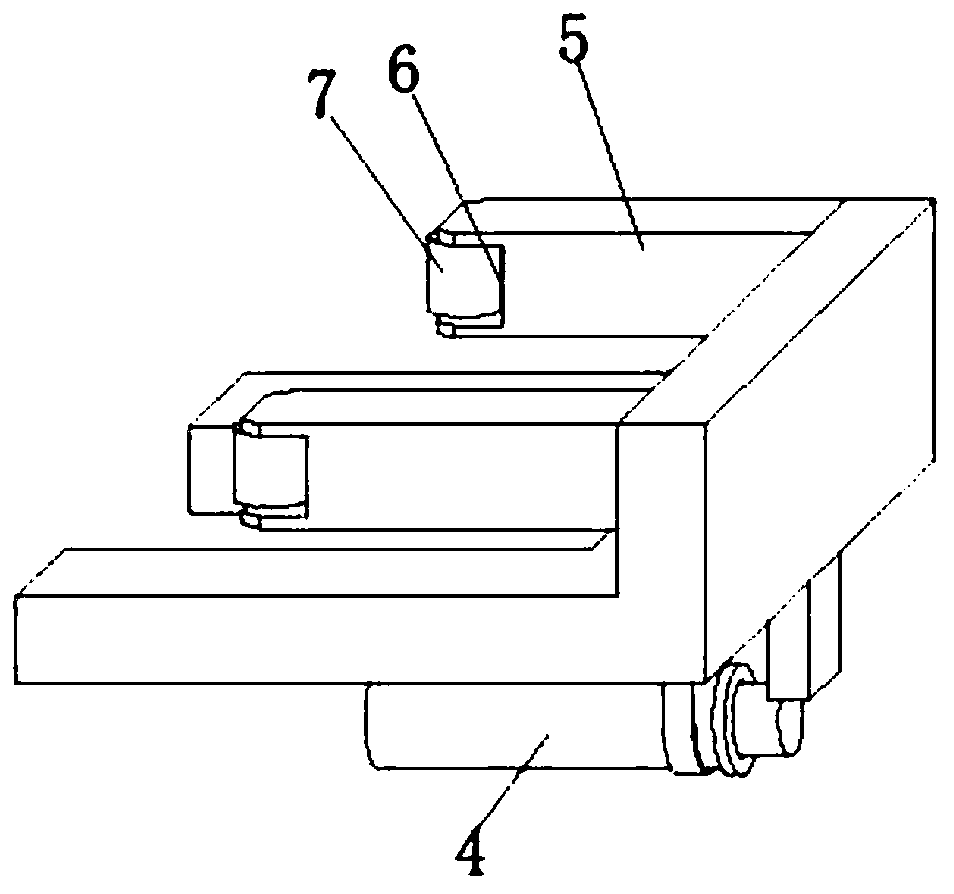

Plate edge grinding device for machining

InactiveCN111482860AImprove convenienceAvoid radial forceEdge grinding machinesGrinding work supportsEngineeringMachining

The invention belongs to the technical field of grinding devices, particularly relates to a plate edge grinding device for machining, and provides the following scheme for solving the problem that anexisting edge grinding device cannot adjust a grinding position and angle in time according to actual conditions. The plate edge grinding device comprises a base in which a cavity is of a flat squaretube structure; two symmetrical L-shaped supporting frames are inserted into one end of the base, two parallel channel steel cross beams with opposite openings are fixed to top ends of the two L-shaped supporting frames, and a C-shaped clamping block and a rectangular fixing frame are clamped to the positions, close to the two ends, between the two channel steel cross beams correspondingly; and amotor box with a downward opening is clamped in the middle of the C-shaped clamping block. According to the plate edge grinding device disclosed by the invention, when the edge of a plate needs to beground in the using process, the edge of the plate only needs to be moved to the position above the edge of the base, then the pressing plate is controlled to descend so as to rapidly press the plate,and meanwhile, the plate can be pushed to advance while being ground, and the grinding convenience is improved.

Owner:程宏剑

Fixing device used for machining long-cylinder thin-walled parts

InactiveCN105014399AReliable positioning and clampingReduce distortionPositioning apparatusGrinding work supportsEngineeringScrew thread

A fixing device used for machining long-cylinder thin-walled parts comprises a pull rod I, a pull rod II and positioning blocks. One end of the pull rod I and one end of the pull rod II are provided with threads respectively. Connectors are arranged at the threaded end of the pull rod I and the threaded end of the pull rod II respectively. The pull rod I and the pull rod II are connected with the connectors through the threads. The positioning blocks are arranged at the connectors of the pull rod I and the pull rod II respectively. A fixing screw sleeve is arranged at the right end of the connector of the pull rod II. The pull rod I and the pull rod II are fixedly connected. According to the fixing device, the positioning blocks are tensioned through the pull rods, the positioning blocks and the parts are in clearance fit, and therefore the fixing device can be conveniently clamped and detached, time and labor are saved when the fixing device is used, and meanwhile the manufacturing cost is saved. Traditional inner hole pressing is replaced with end face pressing, the part deformation is reduced, and the percent of pass of the parts is greatly increased.

Owner:成都九龙柜业有限公司

Tensile testing clamp for bolts

InactiveCN104483190AAvoid radial forcePrecise positioningStrength propertiesEngineeringTensile testing

The invention discloses a tensile testing clamp for bolts. The tensile testing clamp comprises a lower fixing base, an upper fixing base, a lower mold plate and an upper mold plate, wherein the lower mold plate and the lower fixing base are detachably connected; the upper mold plate and the upper fixing base are detachably connected; threaded holes of many different models are formed in the lower mold plate; threaded holes in the lower mold plate are uniformly distributed in one circumference; grooves of many different of models are formed in the bottom of the upper mold plate; the grooves are uniformly distributed in one same circumference; the diameter of the circumference with the grooves is identical to that of the circumference with the threaded holes in the lower mold; the grooves in the upper mold plate correspond to the threaded holes in the lower mold plate. By adopting the tensile testing clamp, the defects of a conventional bolt detection device for detecting the tensile strength of bolts that the operation is tedious and the efficiency is low as a screw nut corresponding to a bolt to be detected needs to be mounted on the lower fixing base each time when a bolt of one model is detected are overcome.

Owner:CHONGQING YINGRUISHENG DIE CASTING

Device for hanging and discarding heavy object in deep sea

InactiveCN108529416AVarious drive methodsImprove reliabilityLoad-engaging elementsEngineeringDriving mode

The invention discloses a device for hanging and discarding a heavy object in deep sea, and relates to the field of deep sea equipment. The device comprises a hydraulic cylinder, a universal coupling,an intermediate shaft, a connector, an explosive bolt, safety pin holes and a two-level lever labor saving mechanism; the hydraulic cylinder and the intermediate shaft are fixedly connected through the universal coupling; the intermediate shaft and the explosive bolt are fixedly connected through the connector; oil is supplied to the hydraulic cylinder by an outboard hydraulic source; the two-level lever labor saving mechanism comprises a first lever and a second lever; the tail end of the first lever is subjected to the contact constraint of the explosive bolt; the tail end of the second lever is used for fixing a lifting lug of the heavy object; and a safety pin is inserted into each safety pin hole when the device is maintained. The problem that a traditional device for hanging and discarding the heavy object is single in driving mode and is only suitable for discarding a heavy object not heavy in weight in shallow water is solved; the effect that the heavy object is discarded by contraction motion of the hydraulic cylinder and by detonating the explosive bolt, and the device is suitable for a deep sea environment is achieved.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

Titanium alloy disc type cooling tube motor union connector fresh water extractor

InactiveCN106082481AReduce operating loadCompact structureSeawater treatmentSpecific water treatment objectivesReverse osmosisFresh water

The invention belongs to a special machine for extracting fresh water from seawater, and discloses a titanium alloy disc type cooling tube motor union connector fresh water extractor which comprises a seawater pretreatment tank, a pretreatment seawater sucking tube, a start sucking tube, a high-pressure start pump, a pipeline tee joint, a reverse osmosis membrane and a union pressure exchange pressurizer pump; as improvement, a pressurizing union connector comprises a volute outlet union check ring, conversion high-pressure union outer threads and a volute union outer ring; a volute outlet sealing spherical surface is arranged on the volute outlet union check ring; a conversion high-pressure sealing concave conical surface is arranged on the conversion high-pressure union outer threads; an outer-ring step surface and outer-ring inner threads are arranged on the volute union outer ring; the volute outlet union check ring is limited by the outer-ring step surface; the outer-ring inner thread is matched with the conversion high-pressure union outer threads to achieve hard sealing between the volute outlet sealing spherical surface and the conversion high-pressure sealing concave conical surface, and thus a pressurizing union connector can be formed. The union connection structure is capable of sealing and fixing a distorted pipeline and is compact in structure and remarkable in energy conservation effect.

Owner:张志雄

Aluminum alloy disc-shaped trapezoidal magneto thread kitchen sewage treatment equipment

InactiveCN106277508AMany purchasing channelsLow costWater/sewage treatment by irradiationPump componentsBiofilmThreaded pipe

The invention relates to domestic sewage treatment equipment and discloses aluminum alloy disc-shaped trapezoidal magneto thread kitchen sewage treatment equipment. The equipment comprises a kitchen washing pool, a three-stage barrier set, oil removal equipment, centrifugal equipment, a salt-tolerant anaerobic biofilm reactor, a salt-tolerant aerobic biofilm reactor and a thread energy recovery reverse osmosis system as improvements: an internal thread on a volute outlet boss is fixedly connected with an external thread on a switching high-pressure tube in a sealed manner so as to form a pressurization screwed joint; a thread energy recovery booster pump is composed of a pressure increase threaded pump part and a threaded pressure switch part; the pressure increase threaded pump part is driven by a disc-shaped trapezoidal magneto; a booster pump suction port and an overall fixed screw hole are respectively formed in the front end face of the threaded booster pump body; a through hole is formed in a pressurization flange plate and corresponds to the overall fixed screw hole; a fastening screw penetrates through the through hole in the pressurization flange plate and is matched with the overall fixed screw hole; and a pressurization center drain hole is aligned at the booster pump suction port. The equipment disclosed by the invention is of a threaded pipeline connecting structure and is simple in structure.

Owner:张志雄

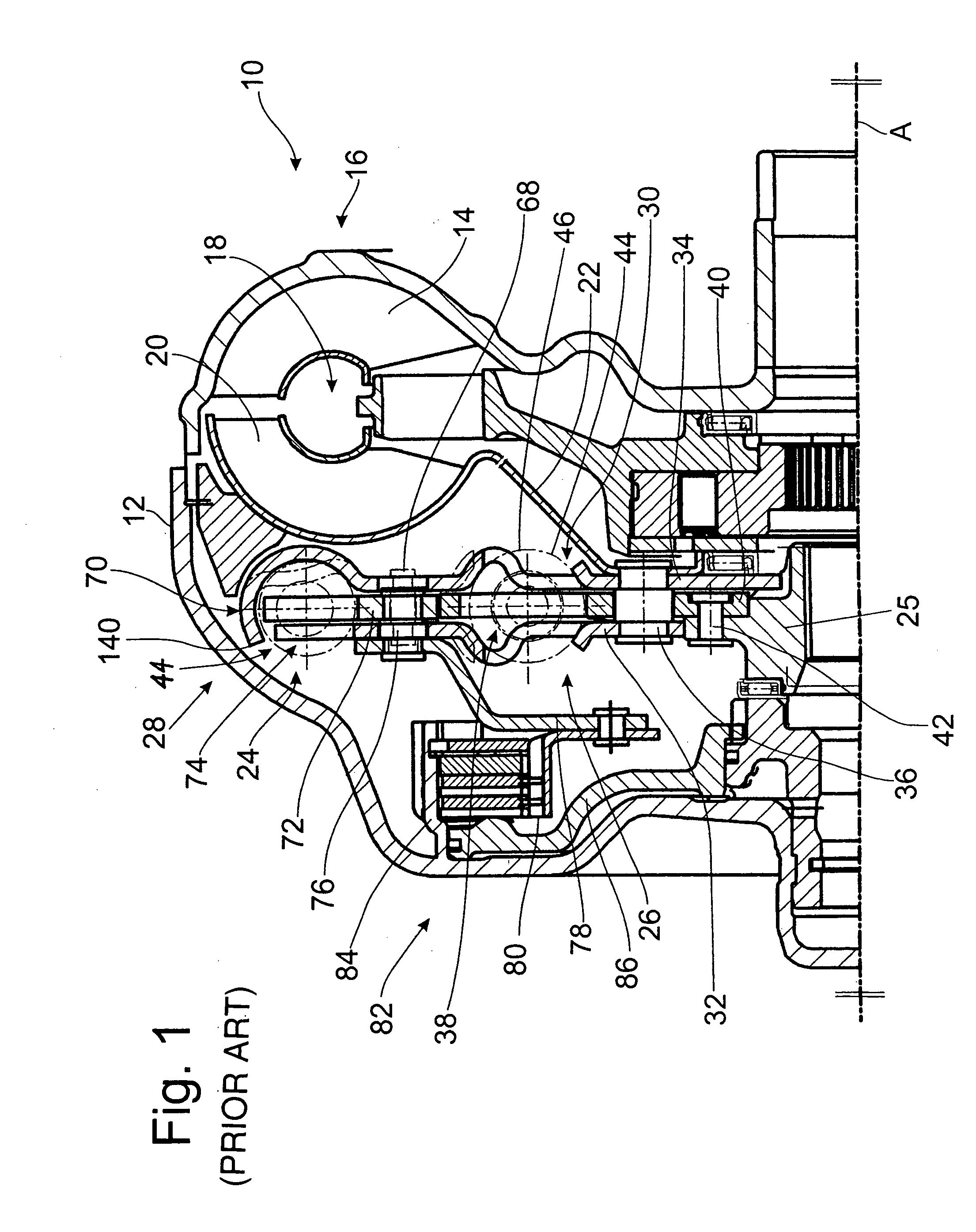

Torsional vibration damper

InactiveUS20080261706A1Load moreAvoid radial forceYielding couplingFluid gearingsEngineeringTorsional vibration

A torsional vibration damper includes a primary side having a pair of axially spaced cover disk elements which are fixed to each other, and a central disk element axially between the cover disk elements, wherein each disk element has a like plurality of circumferentially arranged openings, and each opening has a pair of circumferential support areas. A like plurality of damping element units are arranged in respective sets of openings, and are supported against the circumferential support areas. A radial support surface supports each damping element unit in a radially outward direction, each radial support surface extending without curvature in the axial direction.

Owner:ZF FRIEDRICHSHAFEN AG

A rapid medicine dispensing system adopting a box-type medicine feeding method

ActiveCN102673929BRealize automatic dockingHigh-speed medicineStorage devicesBiomedical engineeringMedicine cabinet

The invention relates to an automatic medicine discharging mechanism of a rapid medicine dispensing system. According to the specifications and the shape characteristics of medicine boxes, vertical and horizontal medicine tanks and medicine cases are designed and placed in a medicine cabinet shown as an accompanying drawing 1. The medicine tanks and the medicine cases have gradually increasing tank widths according to the thickness of the medicine boxes and are used for storing the medicine boxes with different thicknesses shown in an accompanying drawing 2. The front half parts of the medicine tanks are guide grooves of the medicine boxes and the rear half parts of the medicine tanks are used for bearing the medicine cases. The length of the medicine cases is half of the length of the medicine tanks. When the medicine boxes are at the front half parts of the medicine tanks, a medicine feeding mechanism fills the medicine boxes into the medicine cases and guides the medicine boxes into the medicine tanks, so as to continuously supplement new medicine boxes for the medicine tanks. The automatic medicine discharging mechanism of the rapid medicine dispensing system has the characteristics that since the automatic medicine discharging mechanism is matched with a dual-box-type medicine feeding mechanism, the automatic joint of the medicine cases and the medicine tanks is realized and the effect of synchronization of high-speed medicine discharging and high-speed medicine feeding is realized; since the storage capacity of a main medicine cabinet is great and a synchronous medicine discharging method is adopted, the medicine discharging speed is high; and a sliding block and connecting rod medicine discharging mechanism and a photoelectric detection device at a medicine outlet guarantee the working reliability of the medicine discharging system.

Owner:SHANGHAI VIEW VALLEY TECH +1

Water tank type directed sorting device for bottle caps

InactiveCN105381863AReduce labor intensityReduce resistanceWet separationWater tanksHydraulic cylinder

The invention discloses a water tank type directed sorting device for bottle caps. The water tank type directed sorting device for bottle caps comprises a bottom board. A vertical guide rod is arranged on the bottom board and fixedly connected with the bottom board. A water tank is arranged on the guide rod and is in sliding fit with the guide rod. A vertical hydraulic cylinder is arranged between the water tank and the bottom board. An axial flow fan is arranged at the right end of the water tank. A fixing support is arranged above the water tank, and a transversely arranged bearing board is arranged on the support and fixedly connected with the support. The water tank type directed sorting device for bottle caps has the beneficial effect of improving the bottle cap sorting efficiency.

Owner:CHONGQING HESHUTANG BIOTECH CO LTD

Manufacturing method of disc type synchronous belt wheel motor

InactiveCN104485786AEnsure coaxial relationshipHave a coaxial relationshipManufacturing dynamo-electric machinesMechanical energy handlingThrust bearingEngineering

The invention relates to a special motor for a locomotive of a motor train unit and a manufacturing method of a disc type synchronous belt wheel motor. The disc type synchronous belt wheel motor comprises a stator, a rotor, a motor rotary shaft, a motor housing, a front end cover, a rear end cover and a synchronous belt wheel, wherein a lead window is formed in the outer wall of the motor housing; the front end cover and the rear end cover are fixedly connected to the front end face and the rear end face of the motor housing respectively; the stator is fixed on the inner side surface of the front end cover; the rotor is fixed on the motor rotary shaft; the motor rotary shaft is supported on the front end cover and the rear end cover through a front bearing and a rear bearing; one end face of a thrust bearing is fixed on the front end cover; the other end face of the thrust bearing is tightly attached to the outer end face of one side of an inner hole of a rotor frame. The manufacturing method comprises the following steps of preparation of a special clamp, rough machining, thermal treatment and accurate grinding, wherein a supporting component is arranged on the front end cover of the motor, a copper alloy hard wear-resisting layer is arranged on the surface of the supporting circle of an outer bearing of the supporting component, rough machining and laser spraying are carried out before accurate grinding, and the ultra-strong wear resistance is achieved.

Owner:张志雄

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com