Cone yarn overturning device and working method

A technology of turning device and bobbin yarn, applied in the field of textile machinery and automation, can solve the problems of short service life of cylinder, poor overall stability, unreasonable structure, etc., and achieve the effects of prolonging service life, easy disassembly and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

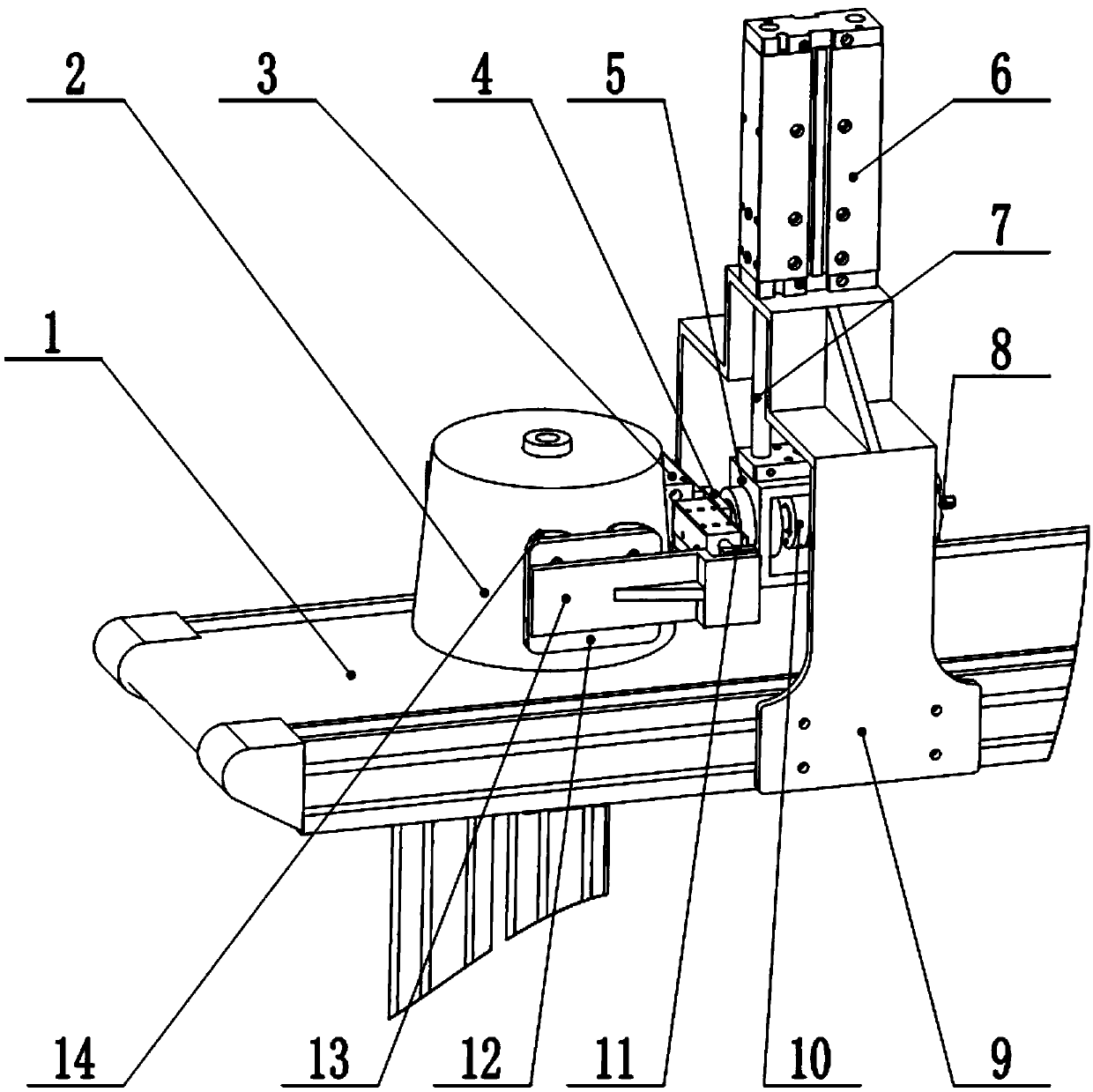

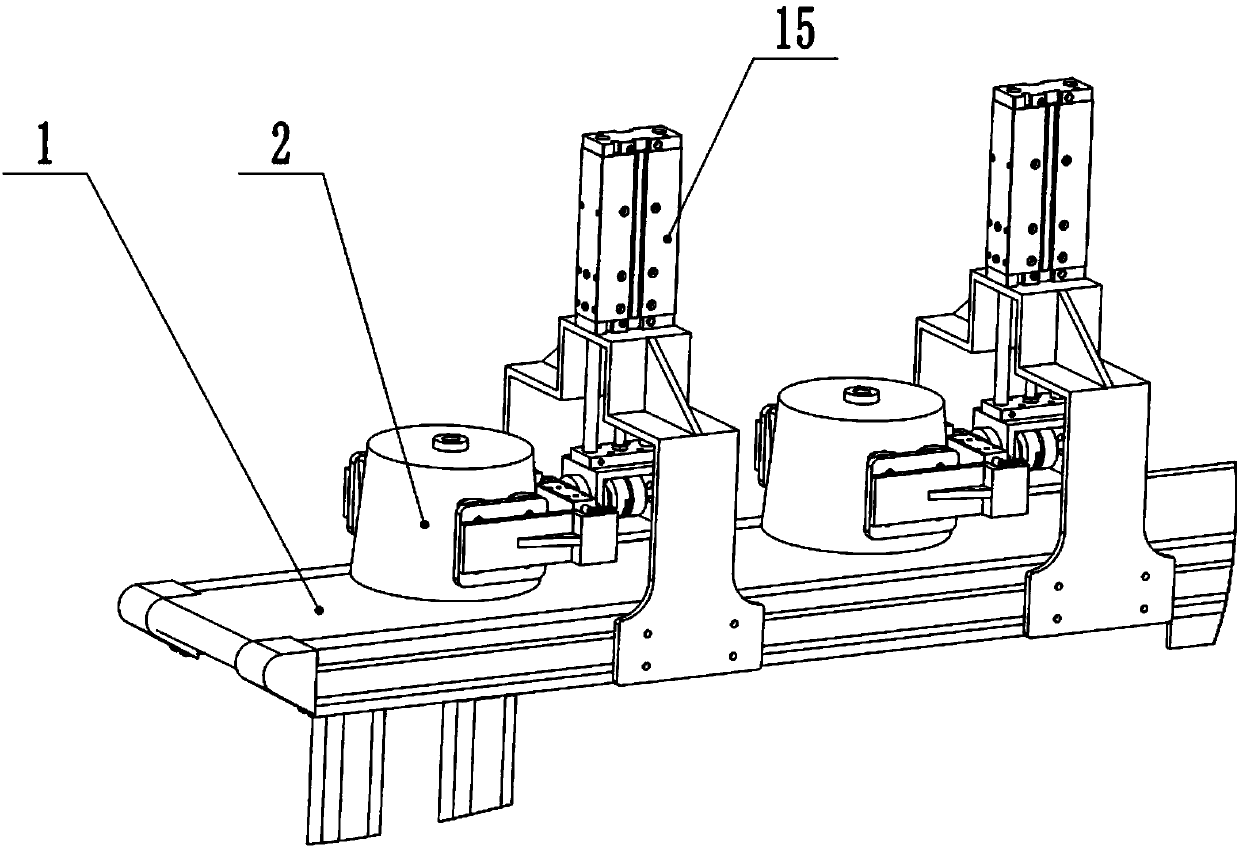

[0031] A kind of bobbin reversing device, comprises conveyor belt 1 and a reversing device 15, such as figure 1 As shown; the overturning device 15 includes an overturning mounting frame 9, which is a convex frame, and the material of the overturning mounting frame is a steel alloy structural plate. Bolt connections are installed on both sides of the conveyor belt 1 .

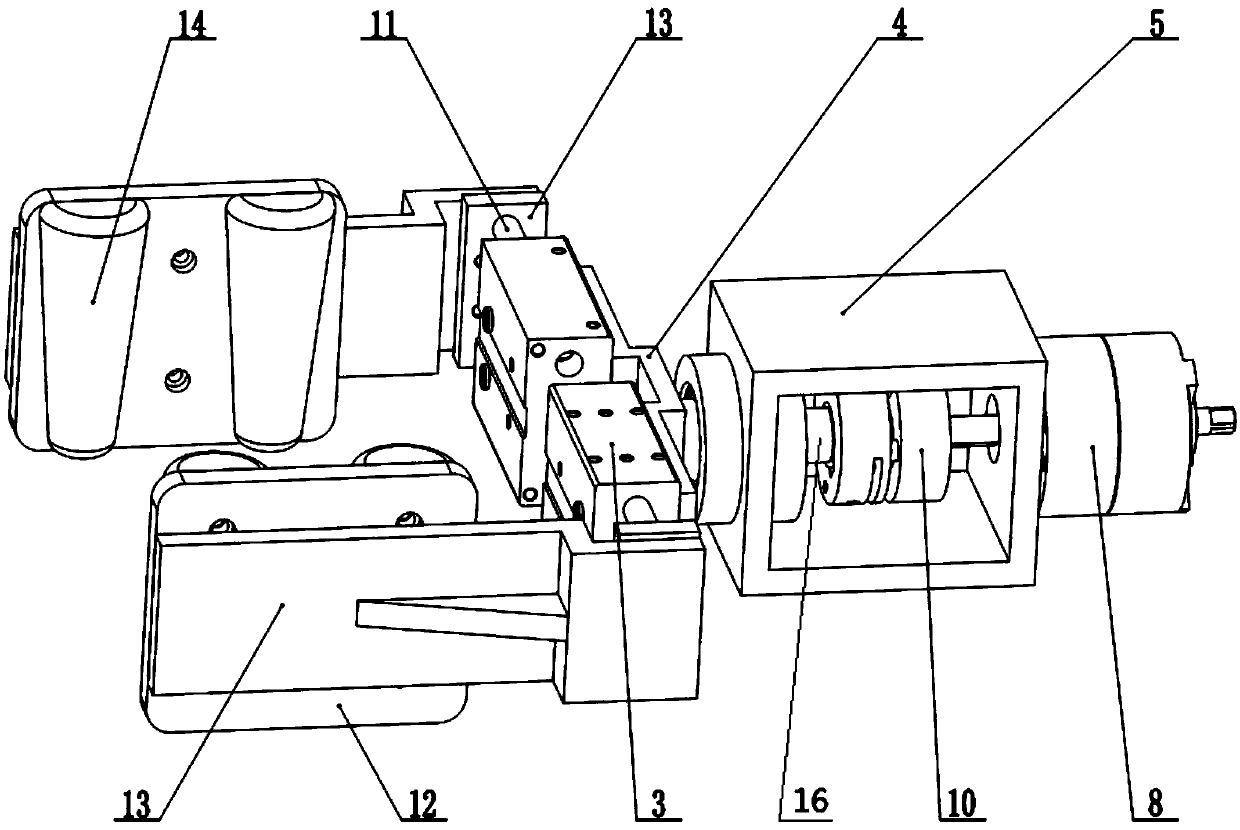

[0032] The top of the overturn mounting frame 9 is provided with a lifting cylinder 6 and a vertical guide rail 7, and one end of the lifting cylinder 6 is connected with a lifting mounting frame 5, and the lifting mounting frame 5 is connected with the vertical rail 7 by a slide block; Hold the mounting plate 4, two clamping cylinders 3 are symmetrically arranged on the clamping mounting plate 4, and the two clamping cylinders 3 are respectively connected to a clamping connecting plate 13 through the horizontal clamping guide rail 11, and the two clamping connecting plates 13 face each other One side is provi...

Embodiment 2

[0035] A bobbin turning device, the structure of which is as described in Embodiment 1, the difference is that the lifting mounting frame 5 is a rectangular frame, the top of the lifting mounting frame 5 is connected to the lifting cylinder 6, and the coupling 10 is arranged on the lifting mounting frame 5 In the internal rectangular space, the clamping mounting plate 4 and the rotating cylinder 8 are symmetrically arranged on the outer sides of the two ends of the lifting mounting frame 5 .

Embodiment 3

[0037] A bobbin reversing device, its structure is as described in Embodiment 2, the difference is that the vertical guide rail 7 includes two guide rails parallel to each other. The two guide rails are conducive to maintaining stability during ascent and fall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com