Bobbin yarn clamping, overturning and lifting device and working method

A clamping and bobbin technology, applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of short service life of the cylinder, poor overall stability, unreasonable structure, etc., to prolong the service life, easy to disassemble, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

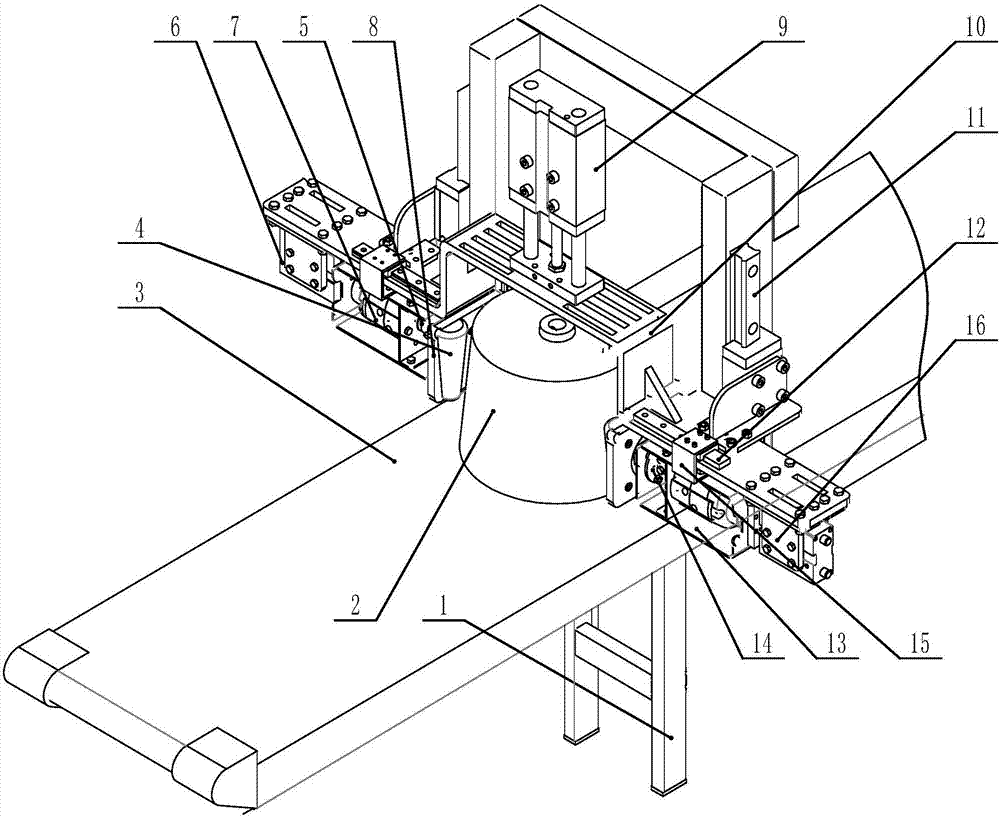

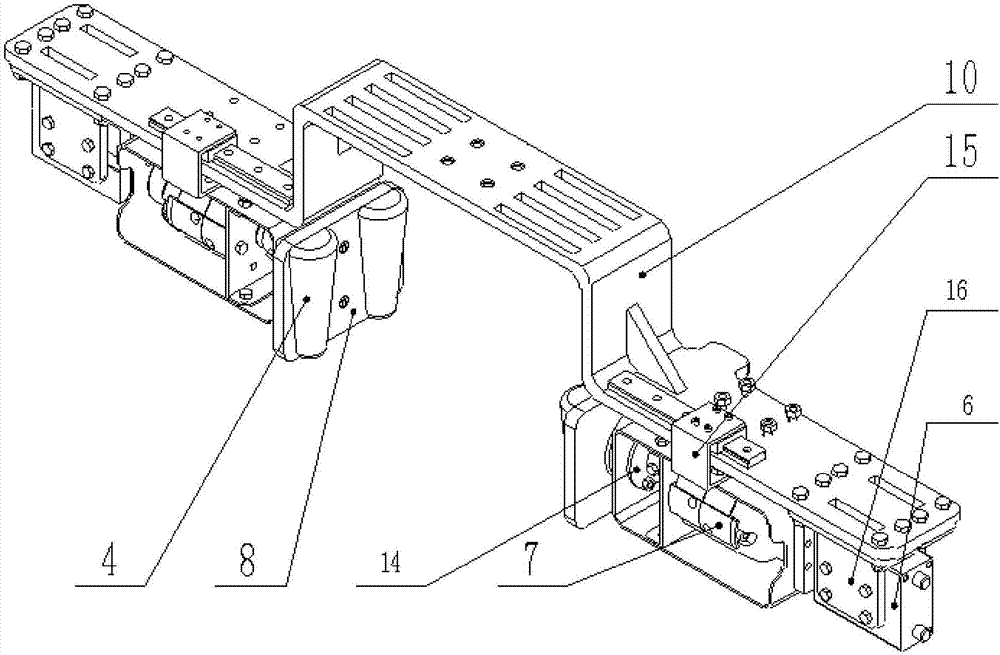

[0028] A bobbin clamping and turning lifting device, comprising a mounting frame 1, on which a conveyor belt 3 and a turning and clamping device 17 are arranged; the turning and clamping device 17 includes a column frame and a turning lifting plate 10, and the column frame is provided with Vertical motion guide rail 11 and lifting cylinder 9, flip lifting plate 10 links to each other with vertical motion guide rail 11 by slide block, and lifting cylinder 9 links to each other with flipping lifting plate 10; Turning lifting plate 10 is a convex plate, and its vertical plane projection is "Several" shape, a clamping cylinder 6, a horizontal motion guide rail 12 and a rotating cylinder fixing frame 13 are respectively provided at both ends of the flipping lifting plate 10, and the clamping cylinder 6 is installed on the flipping lifting plate 10 through the clamping cylinder mounting plate 16. Above, the rotating cylinder fixing frame 13 is connected with the horizontal motion gui...

Embodiment 2

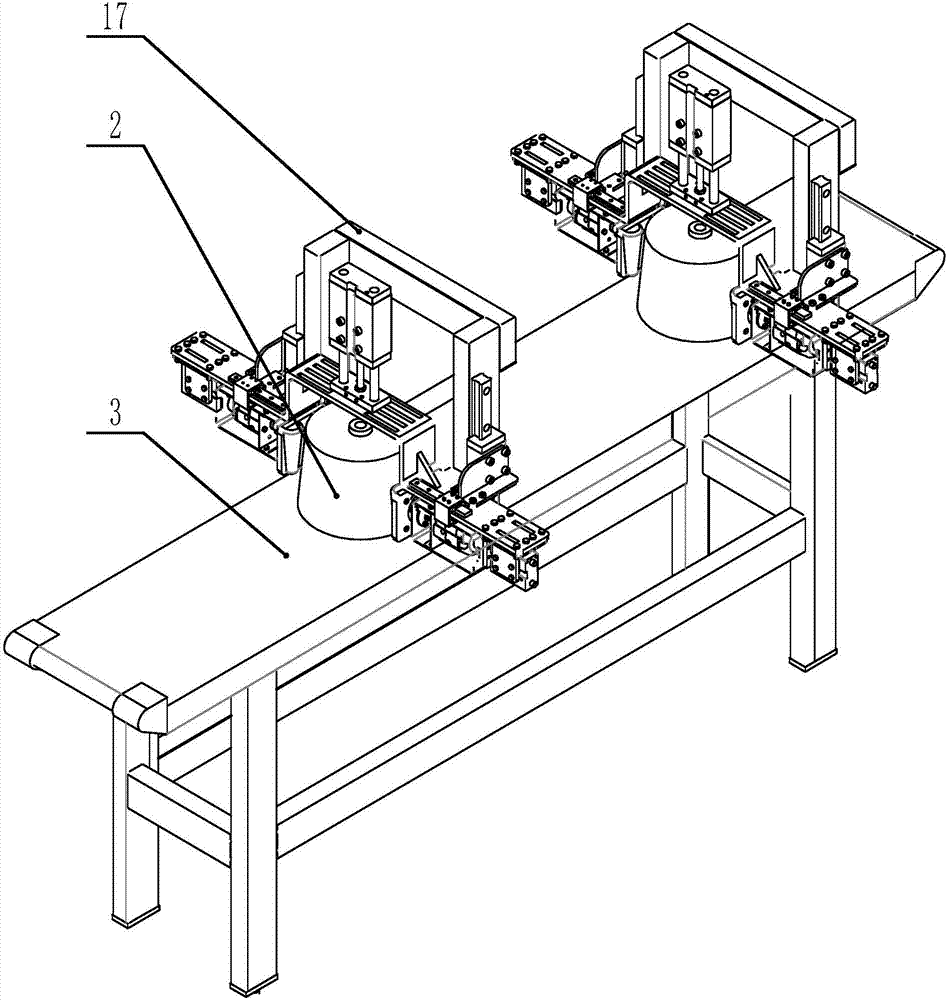

[0031] A bobbin clamping and turning lifting device, the structure of which is as described in Embodiment 1, the difference is that the column frame includes a beam, and columns are provided at both ends of the beam, and the columns are connected to the mounting frames 1 on both sides of the conveyor belt 3, Both columns are provided with vertical motion guide rails 11 . Adding a guide rail structure on both sides of the device can eliminate the vibration caused by the swing torque of the cylinder during the vertical upward movement.

Embodiment 3

[0033] A bobbin clamping and turning lifting device, the structure of which is as described in Embodiment 2, the difference is that a semi-conical glue stick 4 is provided on the opposite side of the clamping plate 8, and two clamping plates 8 are provided with two Semi-cone glue stick 4, the taper of half-cone glue stick 4 is consistent with bobbin yarn 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com