Patents

Literature

116results about How to "Efficient flip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

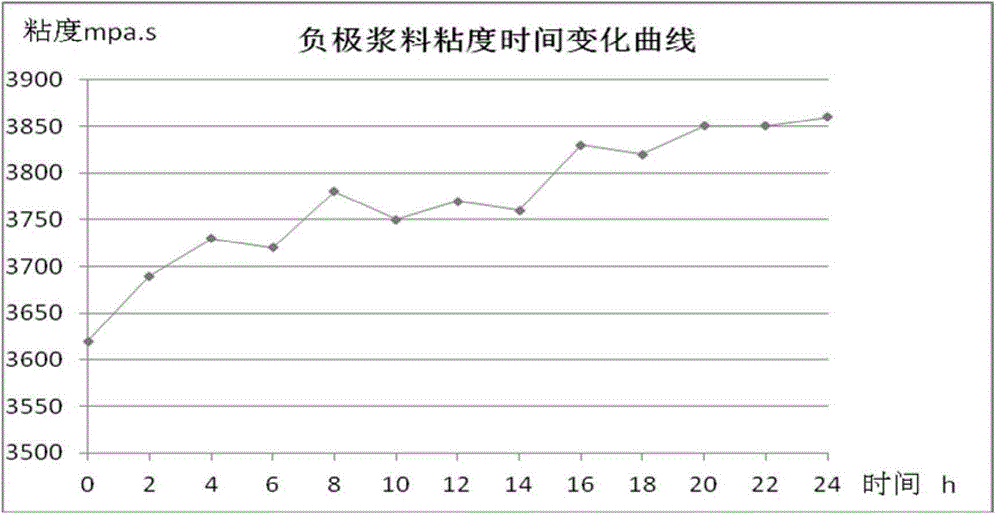

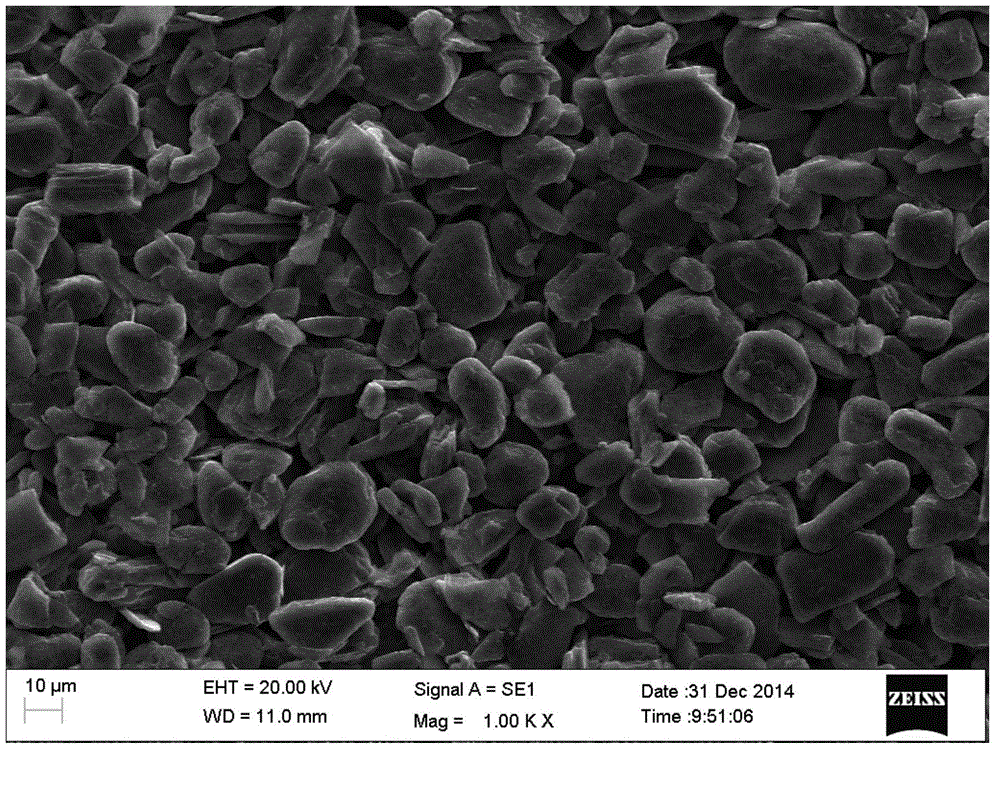

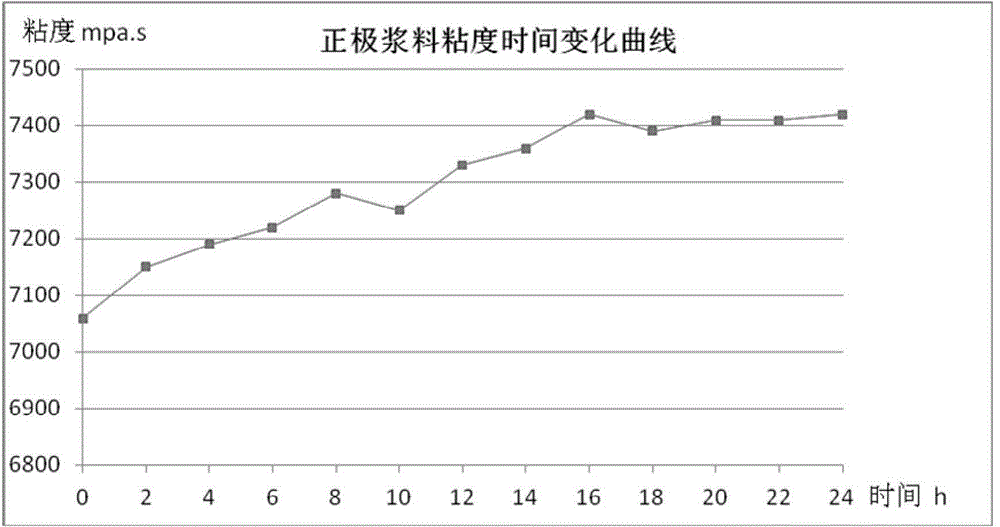

Dry-powder pulping method of lithium-ion battery

InactiveCN104577071AIncrease productivityShorten pulping timeCell electrodesSecondary cellsHigh humidityPulp and paper industry

The invention relates to a dry-powder pulping method of a lithium-ion battery. The dry-powder pulping method comprises the following steps: mixing materials according to the adding sequence, i.e., active matters, a conductive agent, a bonding agent and / or a thickening agent and active matters; then adding with a solvent by different times to carry out high-speed stirring, the temperature, the revolution speed, the auto-rotational speed and the vacuum degree of the pulping machine are controlled in the process of high-speed stirring, and thus obtaining high-temperature and high-humidity pulp; stirring the high-temperature and high-humidity pulp with reduced speed, cooling, screening by a 80-200-mesh sieve, and discharging, thus preparing pulp for a positive electrode or a negative electrode of the lithium-ion battery. The dry-powder pulping method has the characteristics that the prepared pulp is good in uniformity and stability, the operation is simple and convenient, the fund investment and energy consumption are saved, the pulping period is short, and at least three barrels of pulp are prepared by each piece of equipment every day.

Owner:SHANDONG QIXING NEW ENERGY SCI & TECH CO LTD

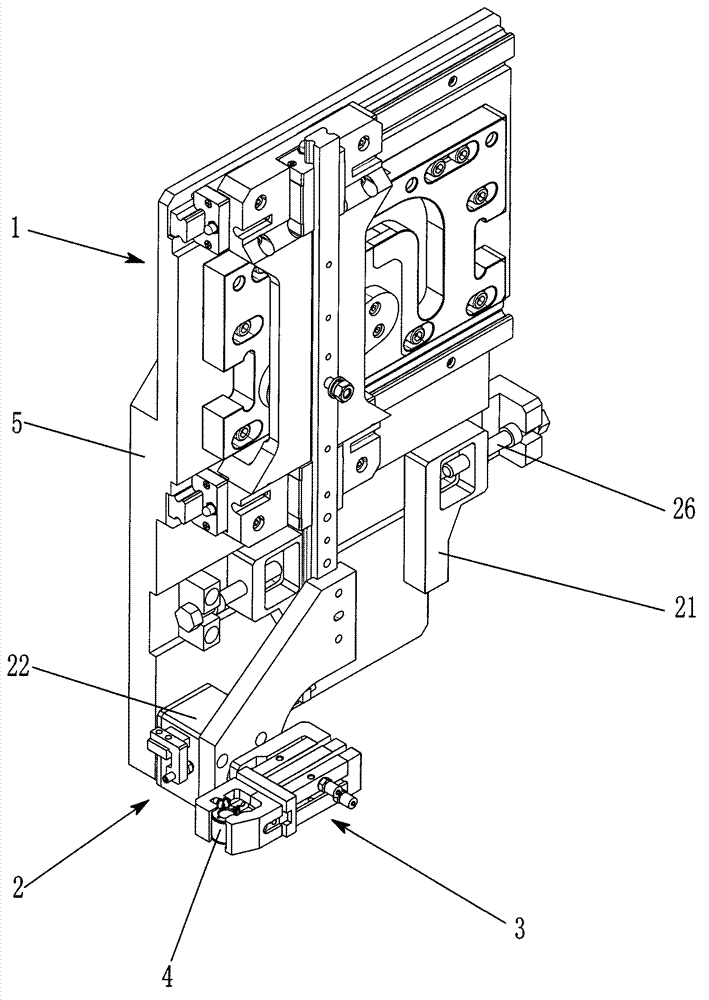

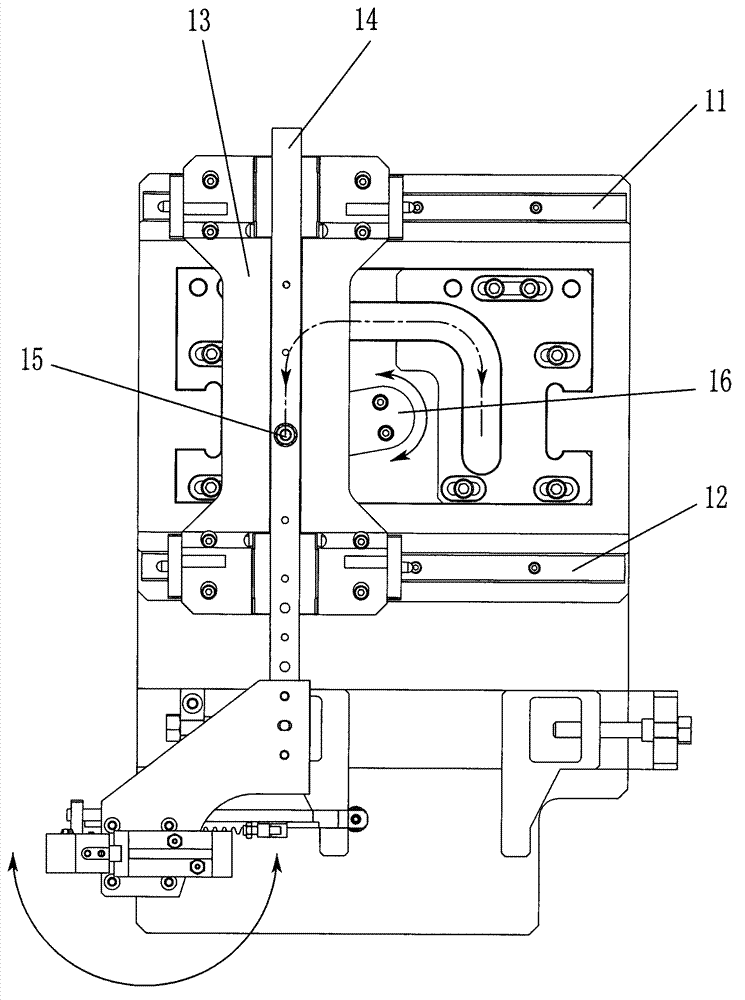

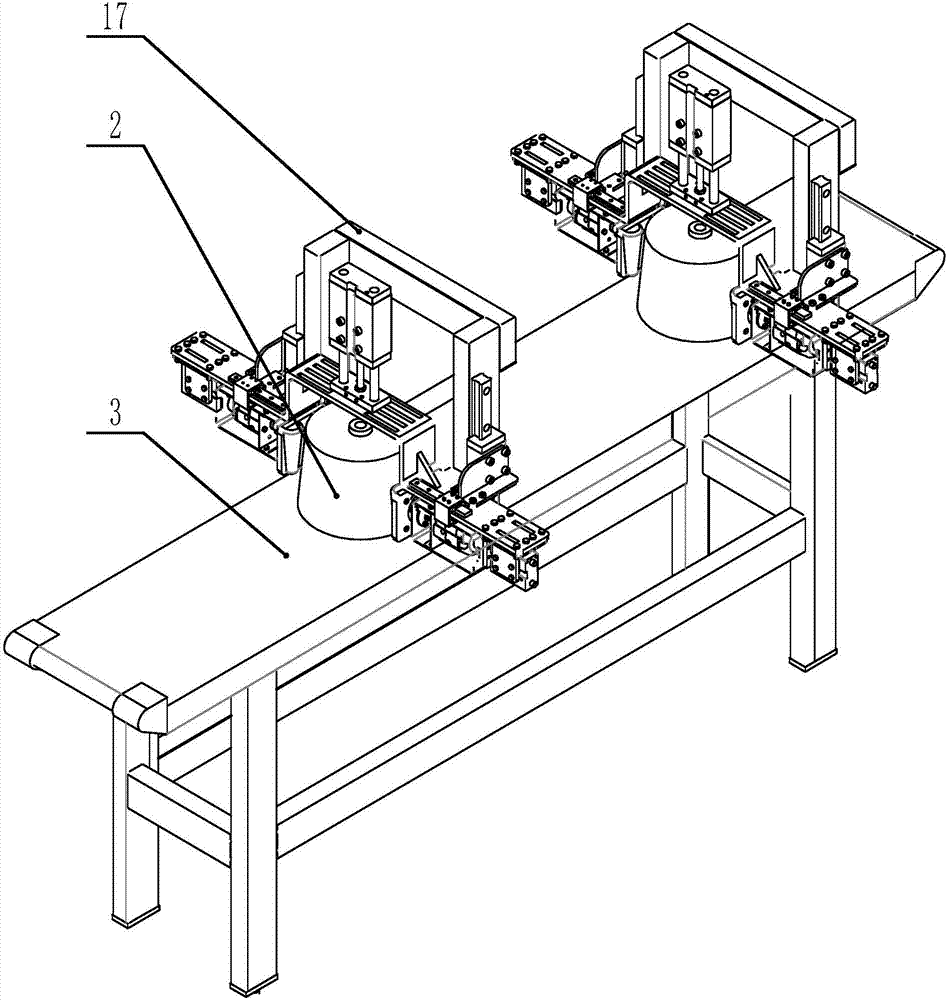

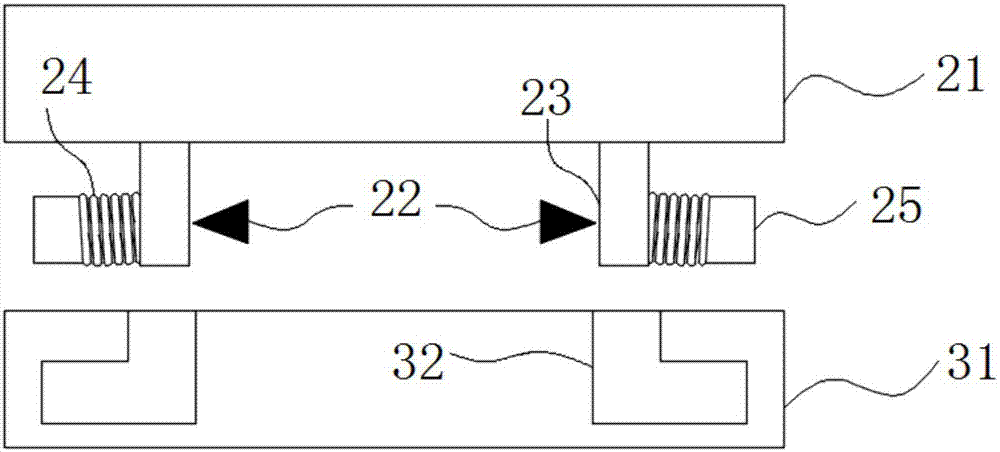

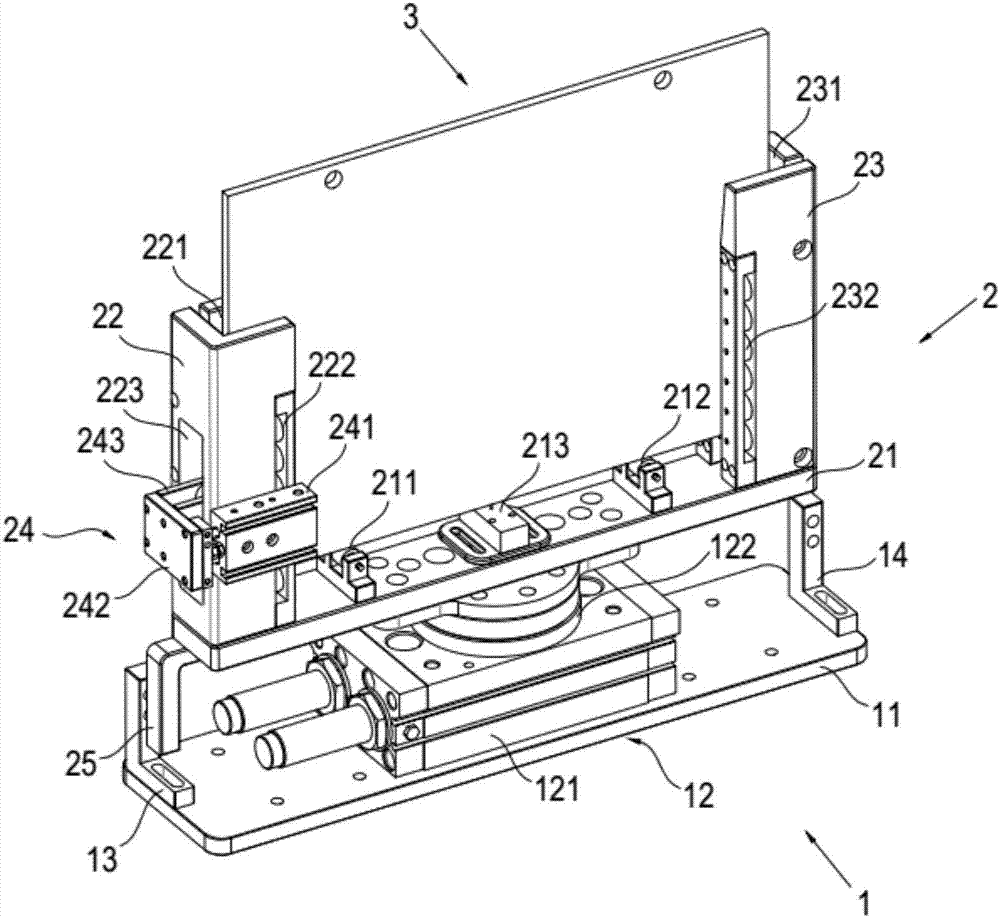

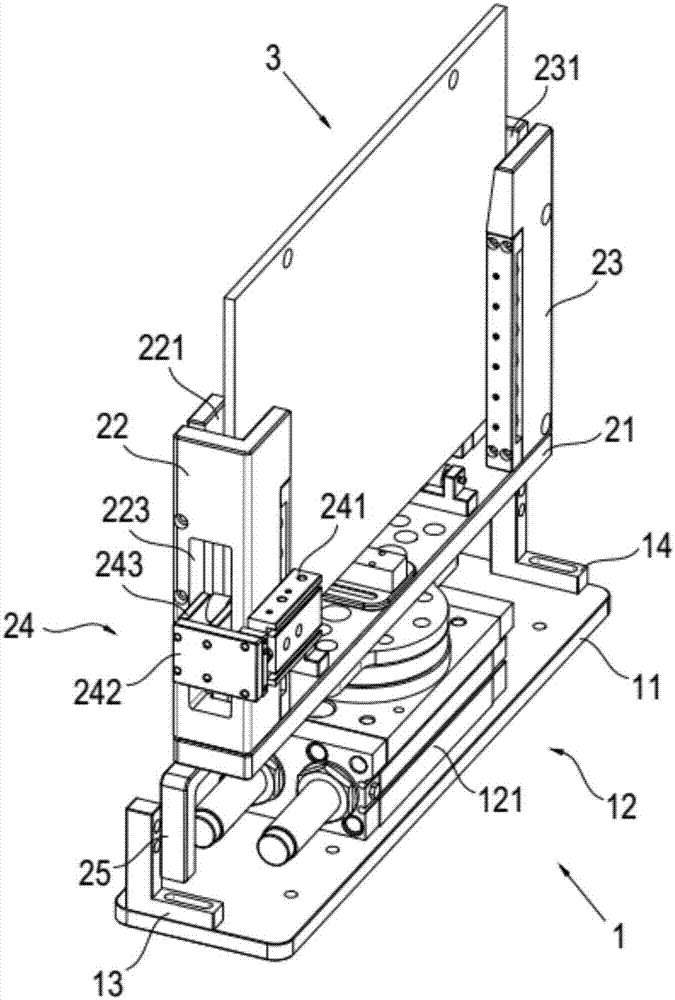

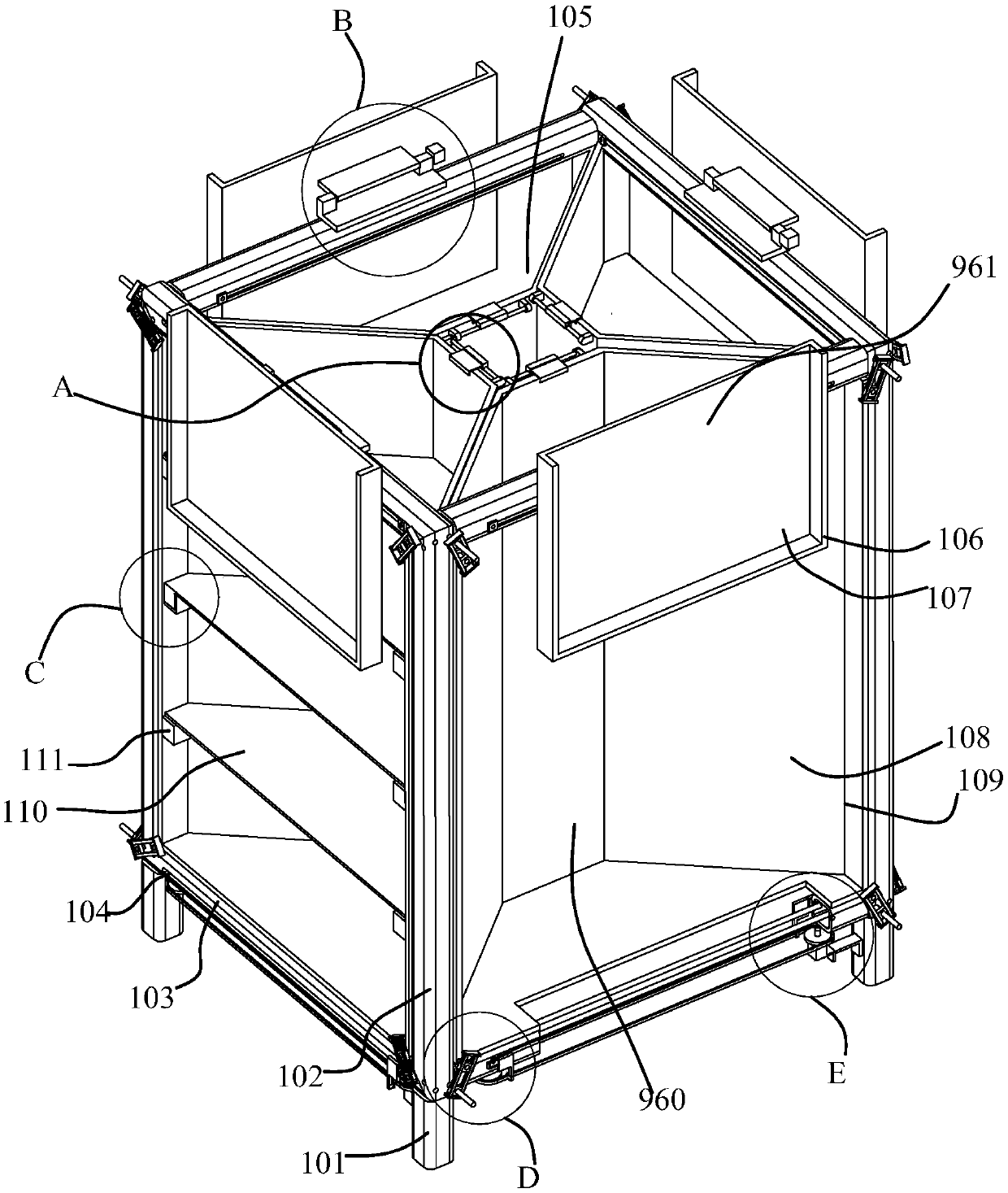

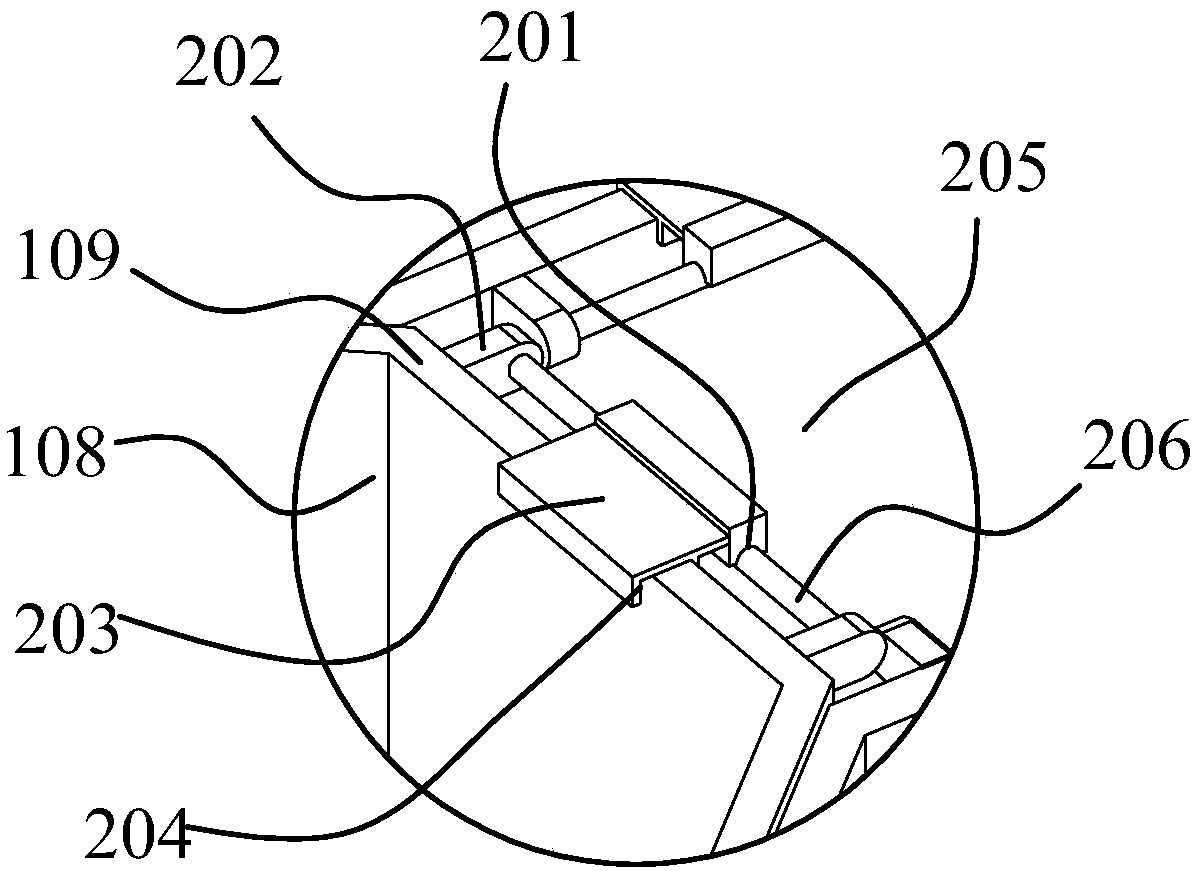

Material translation and turnover device

The invention discloses a material translation and turnover device which comprises a material translation device and a material turnover device. Material translation and turnover are achieved only by adopting a power source. The device can transfer material efficiently at a high speed in an accurate positioning manner, can overturn the material during the material translation process, and causes the material to be overturned to the required direction. The device is especially suitable for transferring the material on the automatic production line.

Owner:SUZHOU HANCHUAN CO LTD AKA HARMONTRONICS

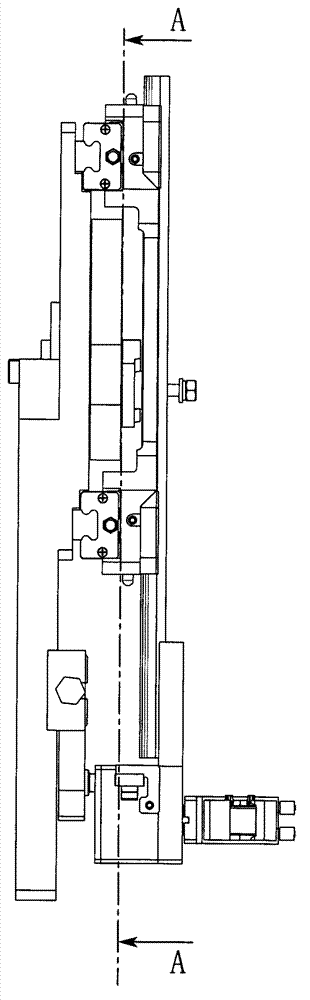

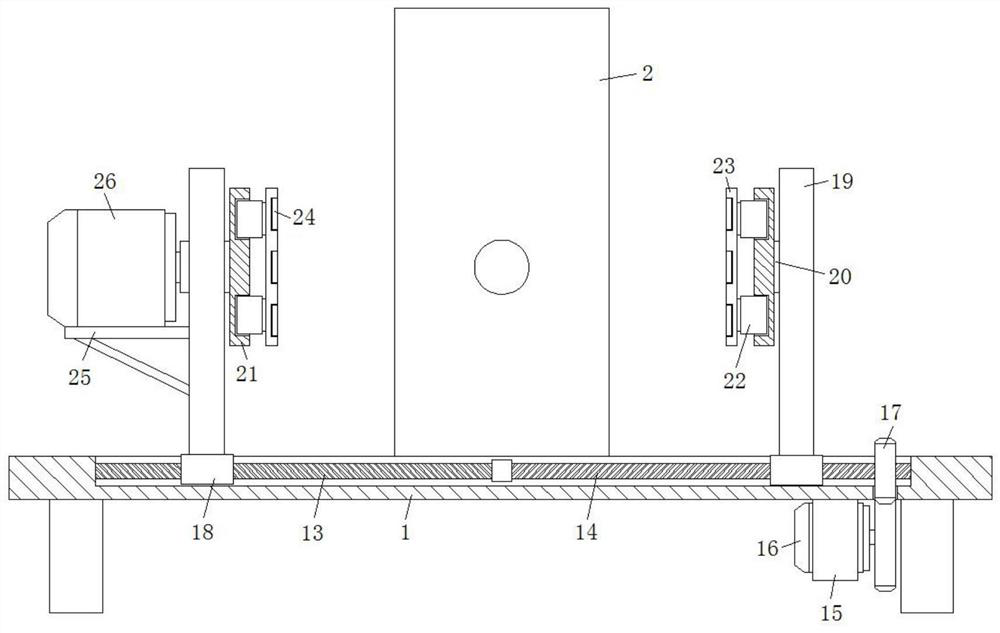

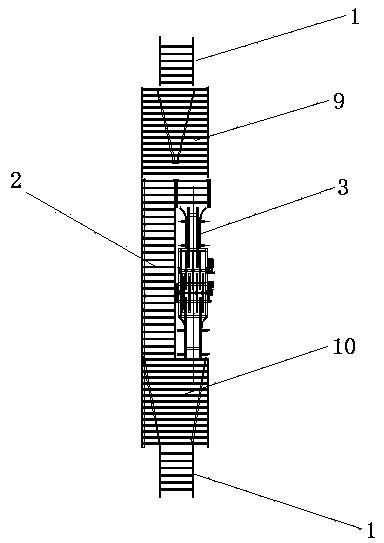

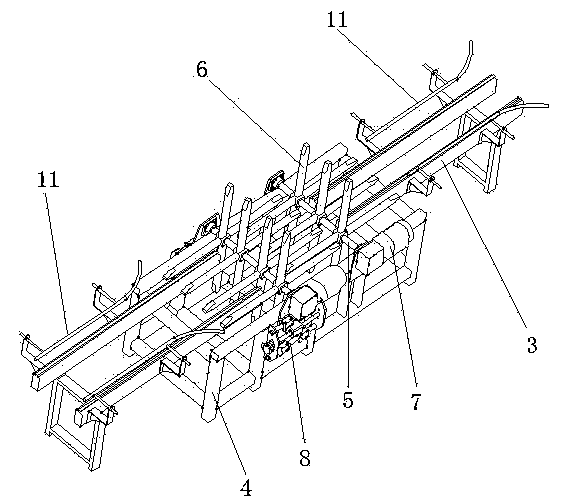

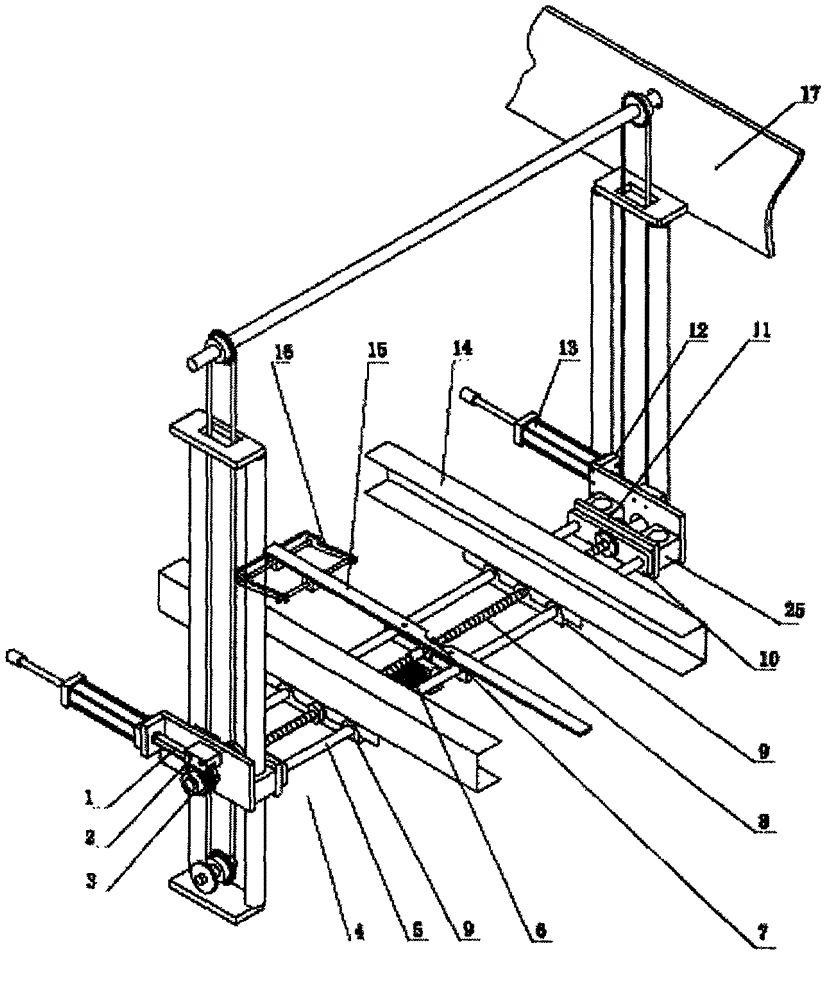

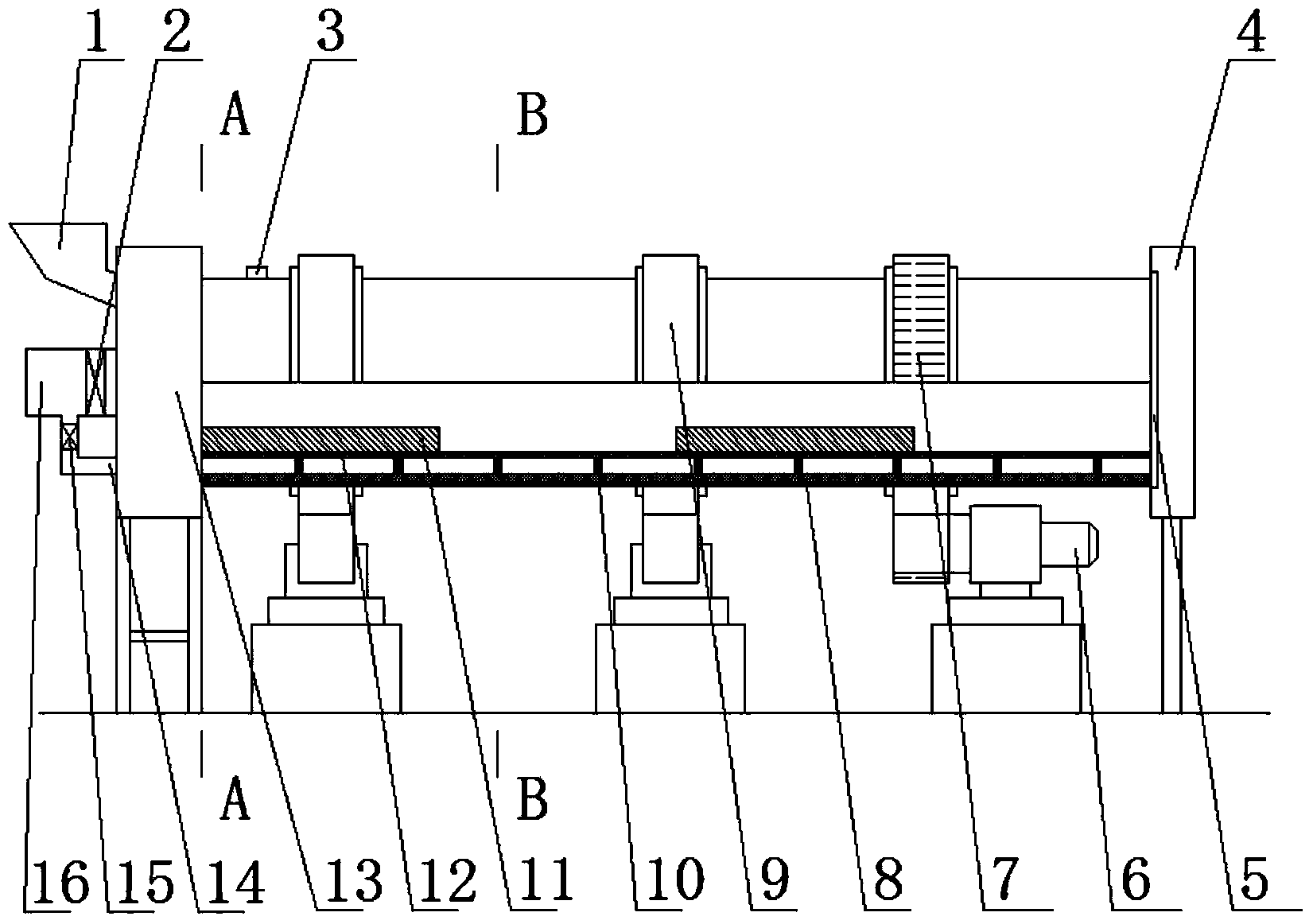

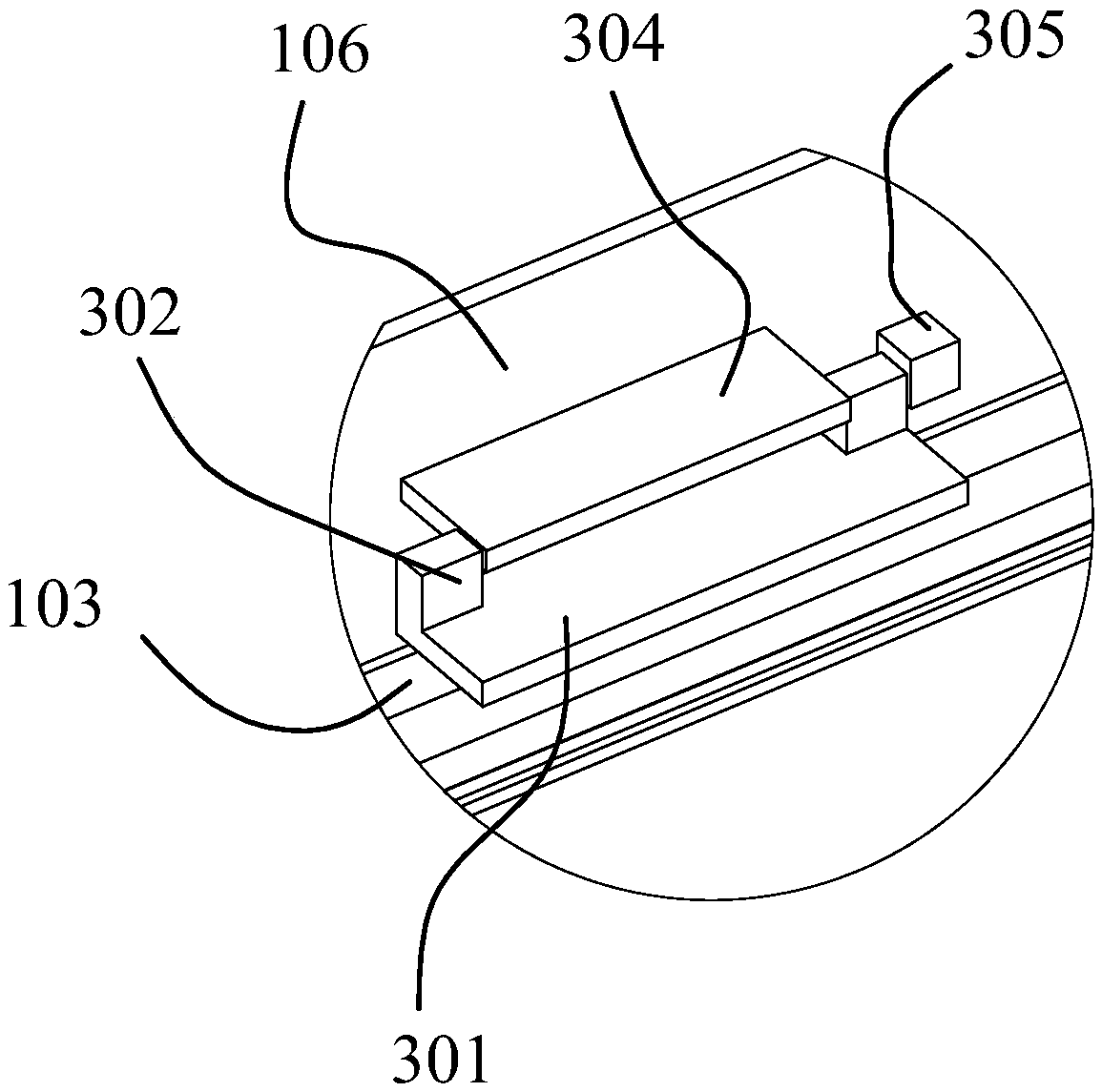

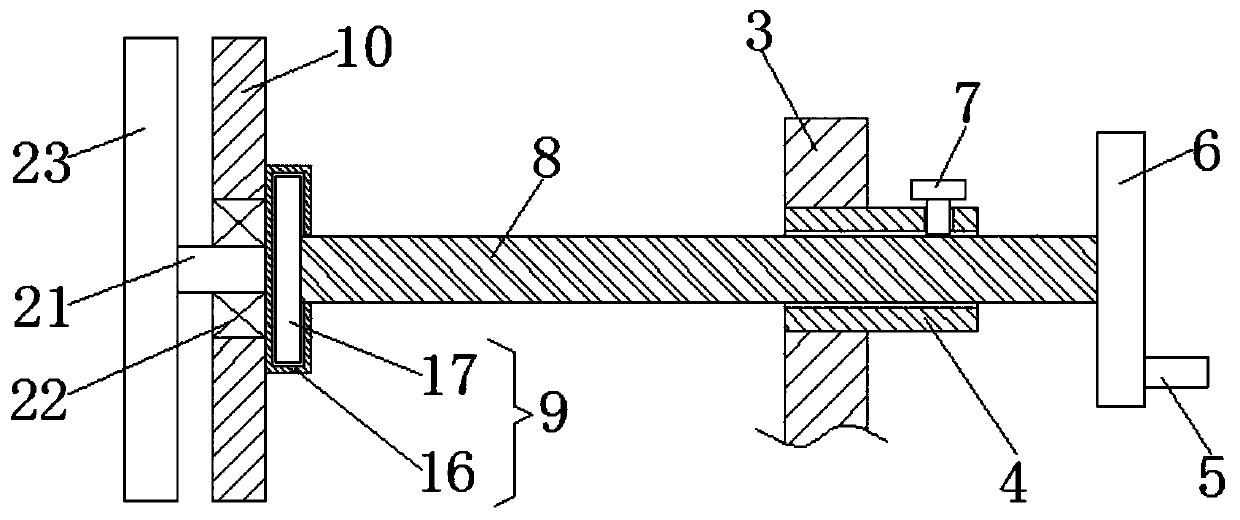

Bobbin yarn clamping, overturning and lifting device and working method

The invention relates to a bobbin yarn clamping, overturning and lifting device and a working method, and belongs to the field of textile machinery and automation. The device comprises a mounting frame; the mounting frame is provided with a conveyor belt and an overturning and clamping device; the overturning and clamping device comprises a stand column frame and an overturning and lifting plate,and the stand column frame is provided with a vertical movement guide rail and a lifting air cylinder; the lifting air cylinder is used for controlling and lifting the overturning and lifting plate; the overturning and lifting plate is a convex plate, the two ends of the overturning and lifting plate are symmetrically provided with clamping air cylinders, horizontal movement guide rails and rotaryair cylinder fixing frames respectively, rotary air cylinders are arranged in the rotary air cylinder fixing frames, clamping plates are arranged on the sides, opposite to each other, of the rotary air cylinder fixing frames, the clamping plates are used for clamping bobbin yarn, and the clamping air cylinders control the rotary air cylinder fixing frames to move horizontally. By means of the device, automatic overturning of the bobbin yarn can be achieved, the workload of workers is reduced, and the productivity is improved.

Owner:SHANDONG UNIV

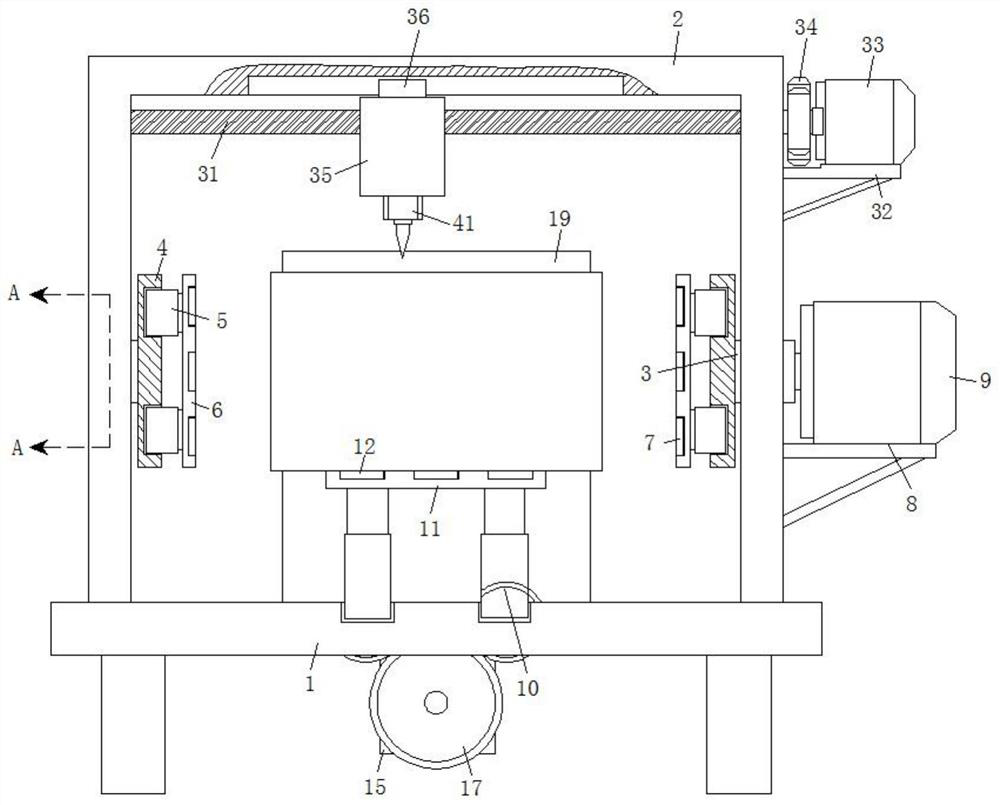

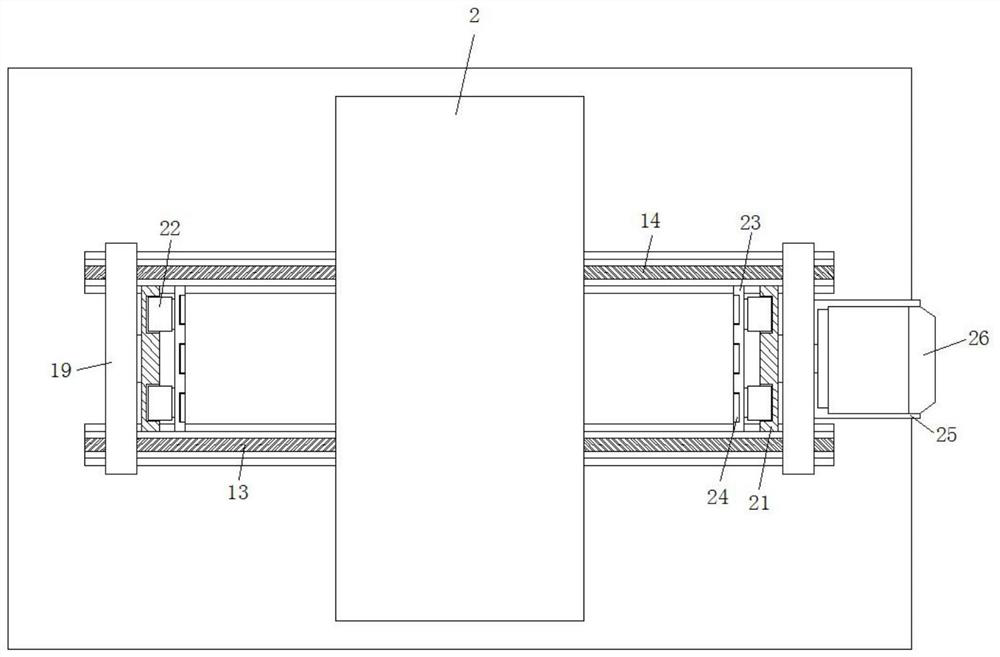

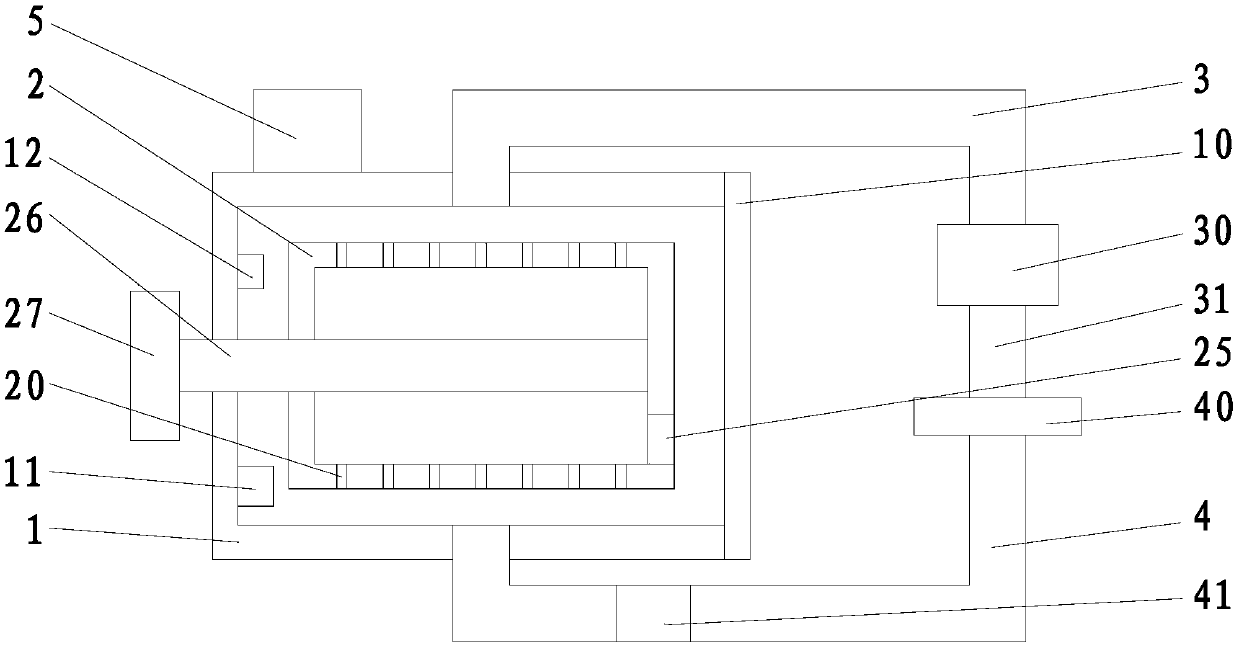

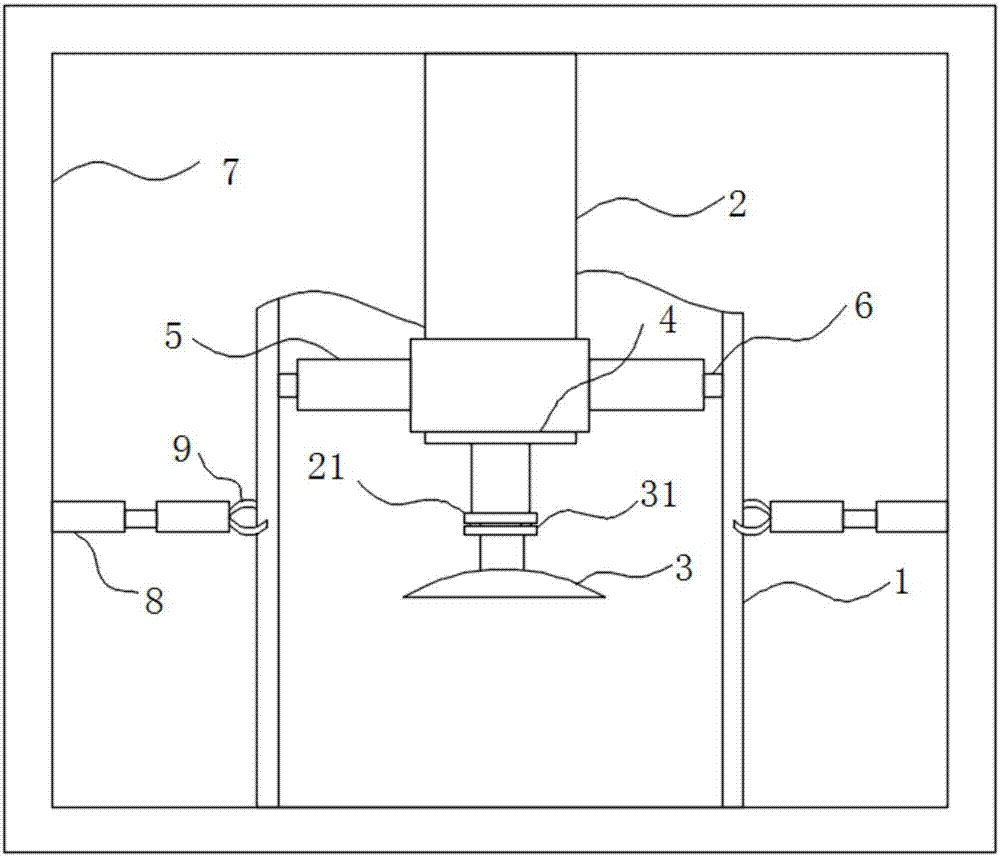

Dead-corner-free efficient drilling equipment for power distribution cabinet production

PendingCN112139542AImprove work efficiencyGuaranteed uptimeFeeding apparatusPositioning apparatusRolling-element bearingStructural engineering

The invention discloses dead-corner-free efficient drilling equipment for power distribution cabinet production. The equipment comprises a working table. An installing frame is fixed to the middle ofthe top face of the working table through screws. First installing columns are connected to the inner walls of the two sides of the installing frame through rolling bearings correspondingly. First installing plates are fixed to the ends of the first installing columns correspondingly. First grooves are formed in the upper sides and the lower sides of the ends, away from the first installing columns, of the first installing plates. First electric telescopic rods are fixedly connected to the inner walls of the first grooves through screws. First adsorption plates are fixedly connected to the output ends of the first electric telescopic rods through screws. First electromagnetic blocks are fixed in the other ends of the first adsorption plates correspondingly. First horizontal frames are fixedly connected to the sides of the first installing frames through screws. First servo motors are fixedly connected to the top faces of the first horizontal frames through screws. The equipment is stable in operation, reasonable in design and high in automation degree, dead-corner-free drilling operation on the six faces of an electric control cabinet can be achieved after one-time feeding, and theworking efficiency of drilling of the electric control cabinet is greatly improved.

Owner:ANHUI LANRUN AUTOMATION INSTR

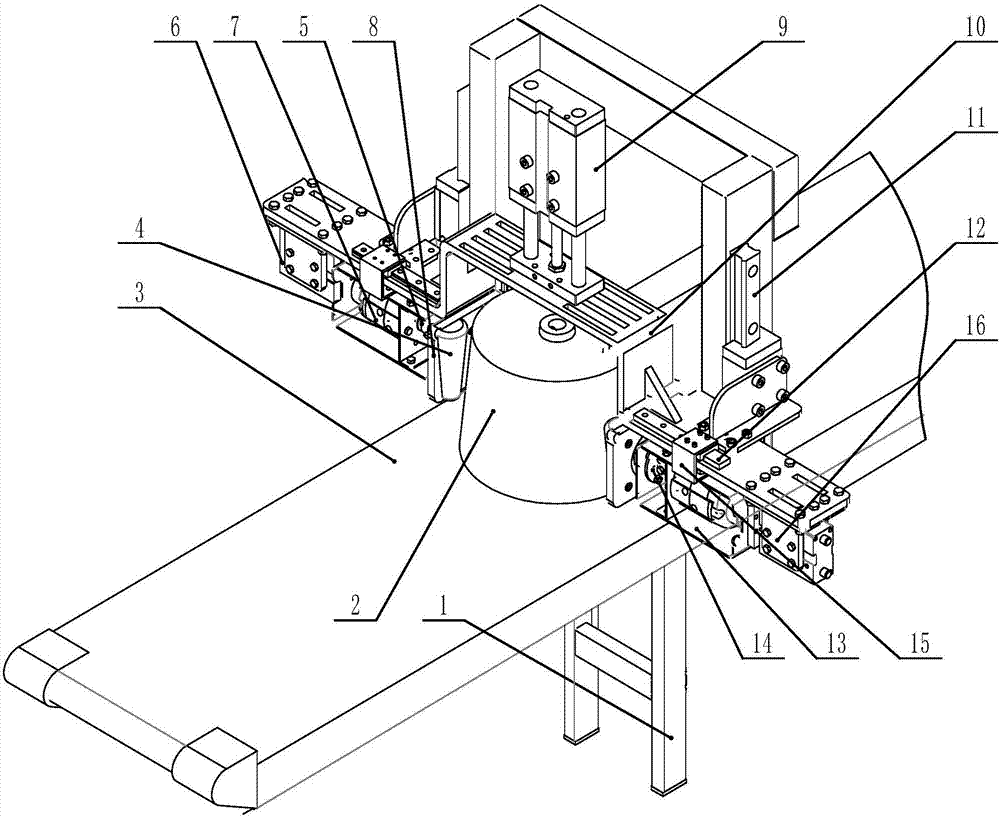

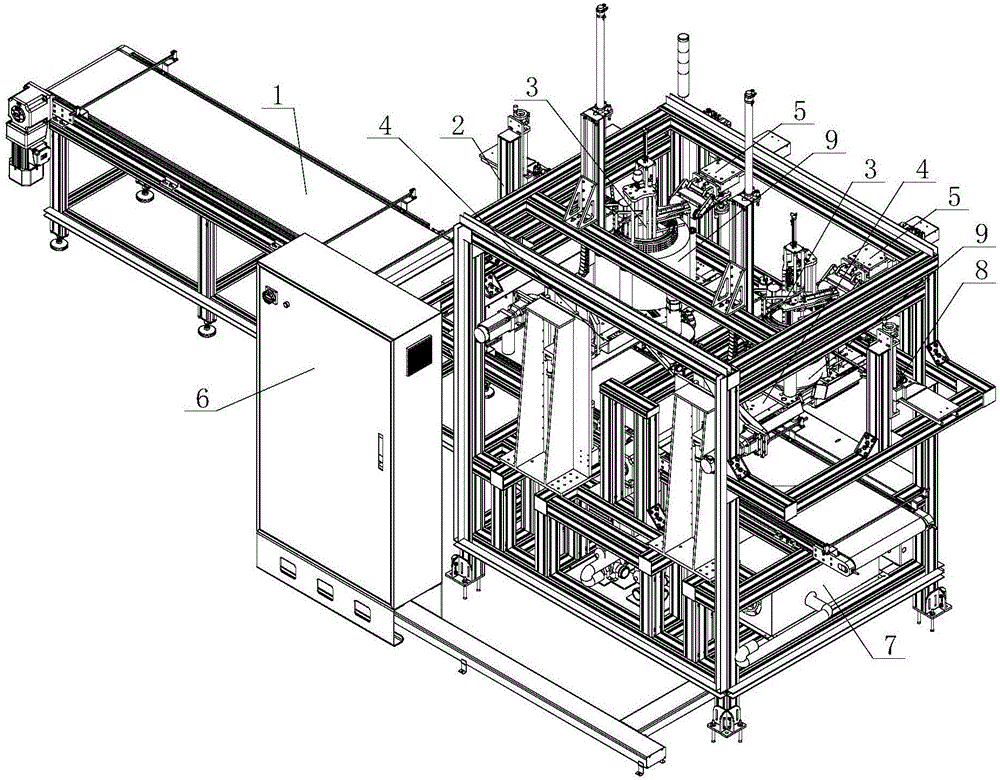

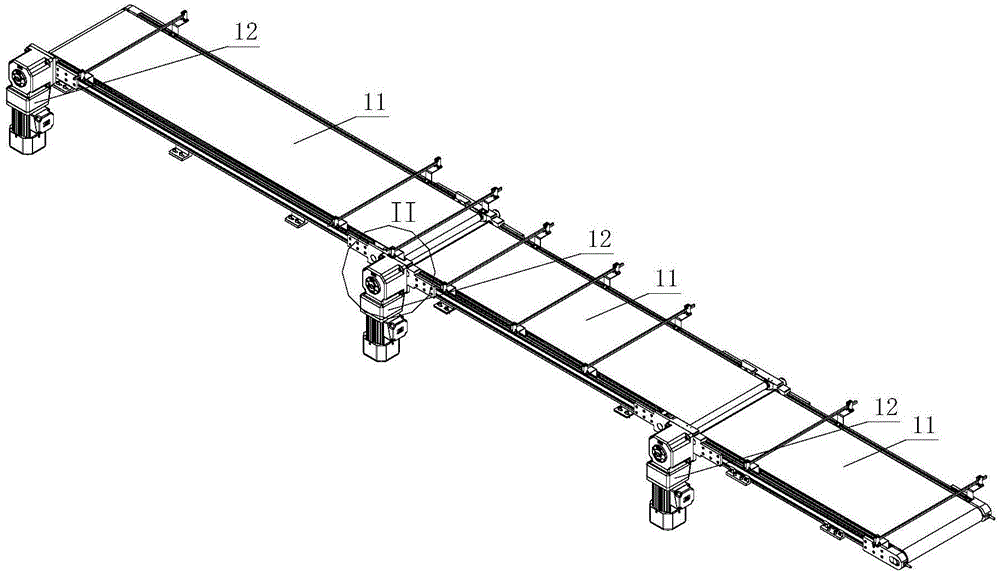

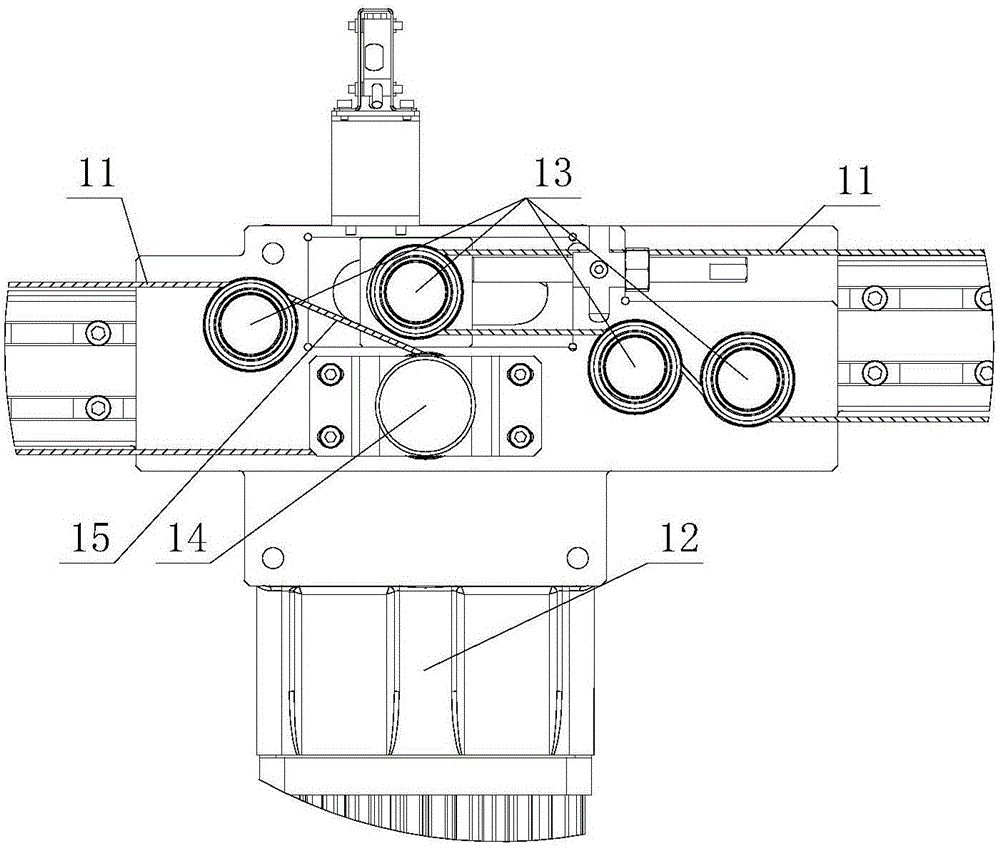

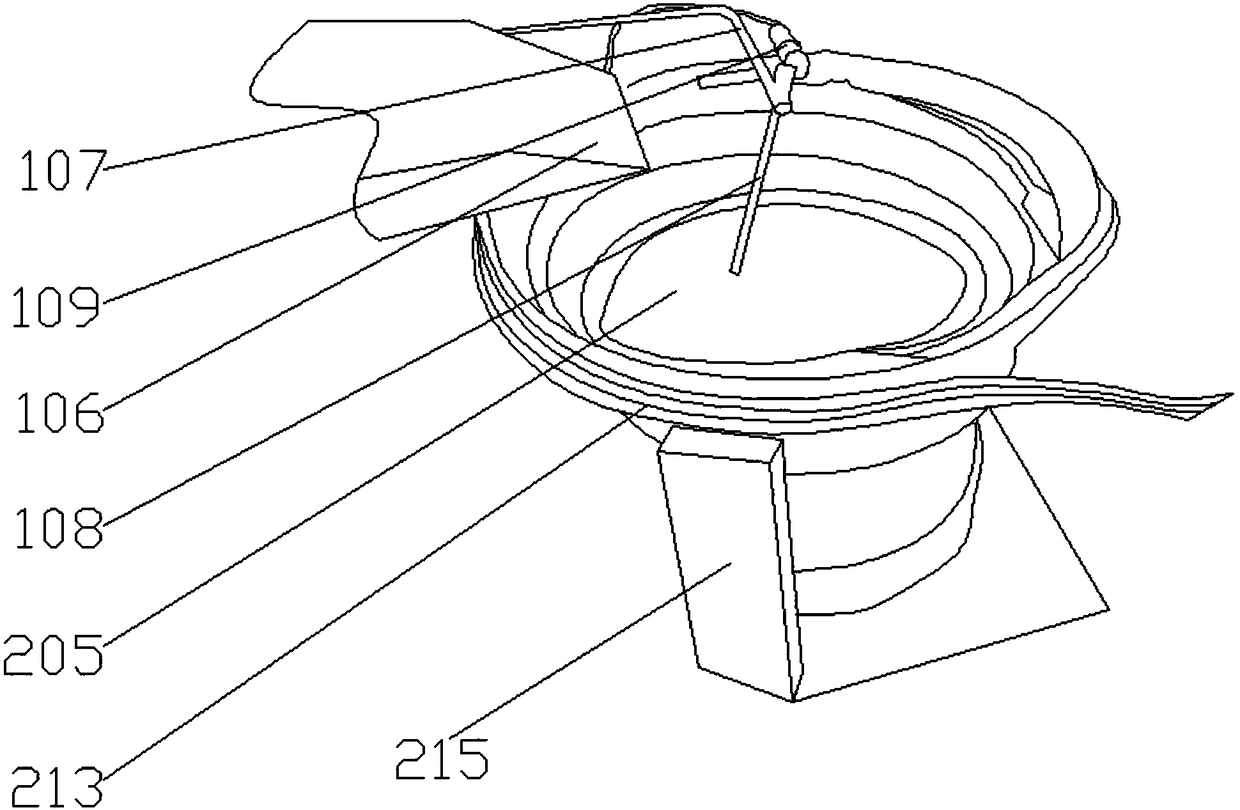

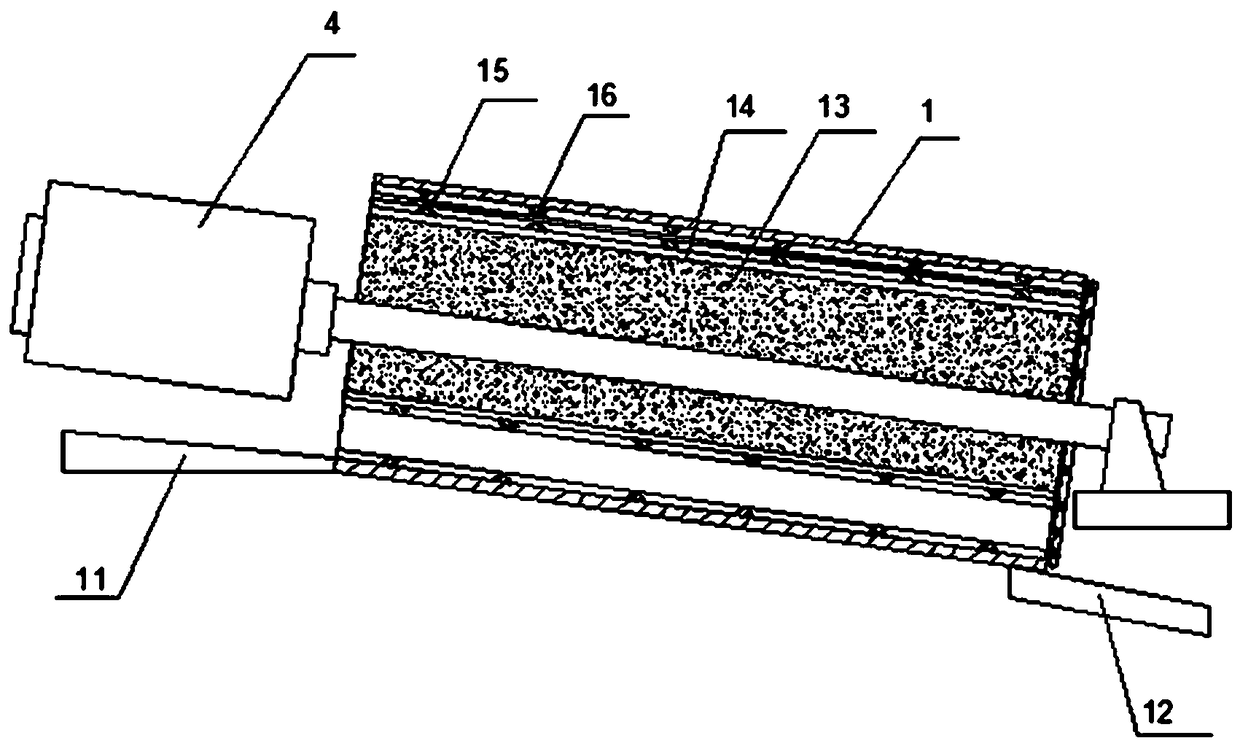

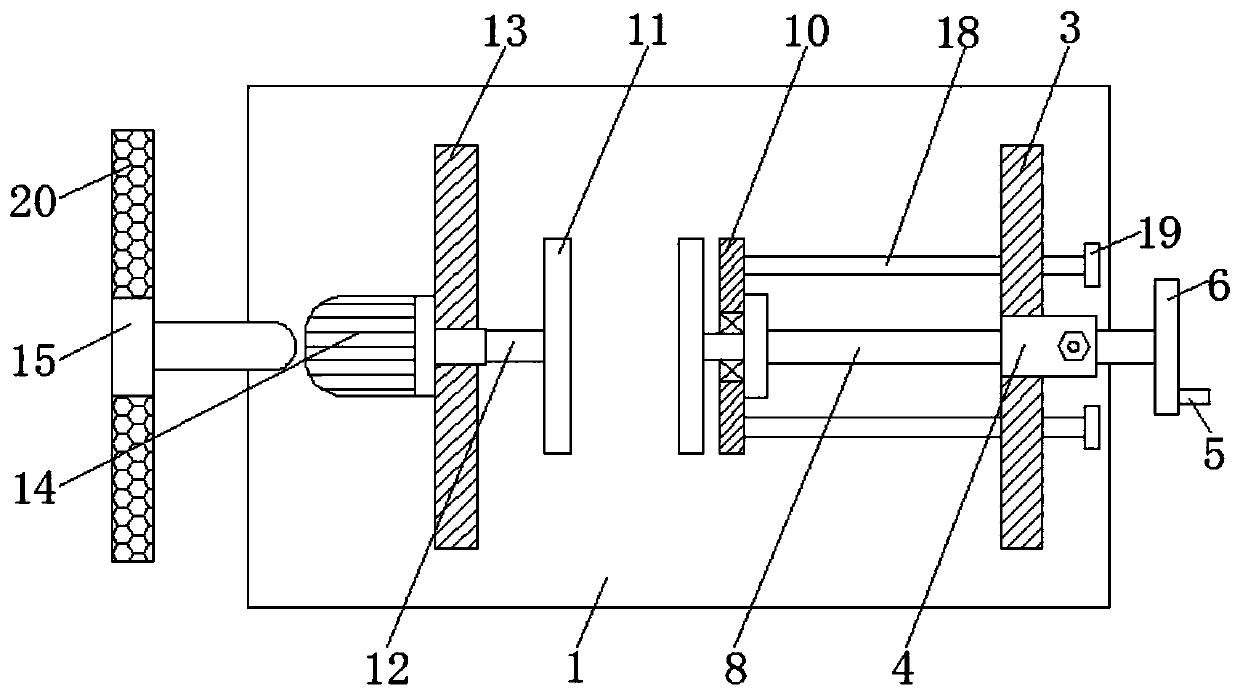

Glass fiber yarn roll membrane coating machine

ActiveCN106697366ATransport impactImprove coating efficiencyPackaging by pressurising/gasifyingWrapping with article rotationYarnGlass fiber

The invention discloses a glass fiber yarn roll membrane coating machine, and belongs to the technical field of glass fiber production equipment. The glass fiber yarn roll membrane coating machine is good in coating effect and high in membrane coating efficiency. The glass fiber yarn roll membrane coating machine comprises a conveying device used for conveying yarn rolls and preventing scattered yarns of the yarn rolls from getting stuck, clamping turnover devices used for grabbing, overturning, lifting and rotating the yarn rolls, a membrane conveying device used for placing coating membranes, attaching the coating membranes onto the yarn rolls and cutting off the coating membranes, a membrane pressing device used for tightly pressing the yarn rolls, membrane pushing devices used for pushing level the coating membranes exceeding the end faces of the yarn rolls onto the end faces of the yarn rolls, and a control system used for controlling the clamping turnover devices, the membrane conveying device, the membrane pressing device and the membrane pushing devices to achieve linkage. The glass fiber yarn roll membrane coating machine is suitable for a membrane coating machine coating a layer of membrane outside glass fiber yarn rolls.

Owner:福德机器人(成都)有限责任公司

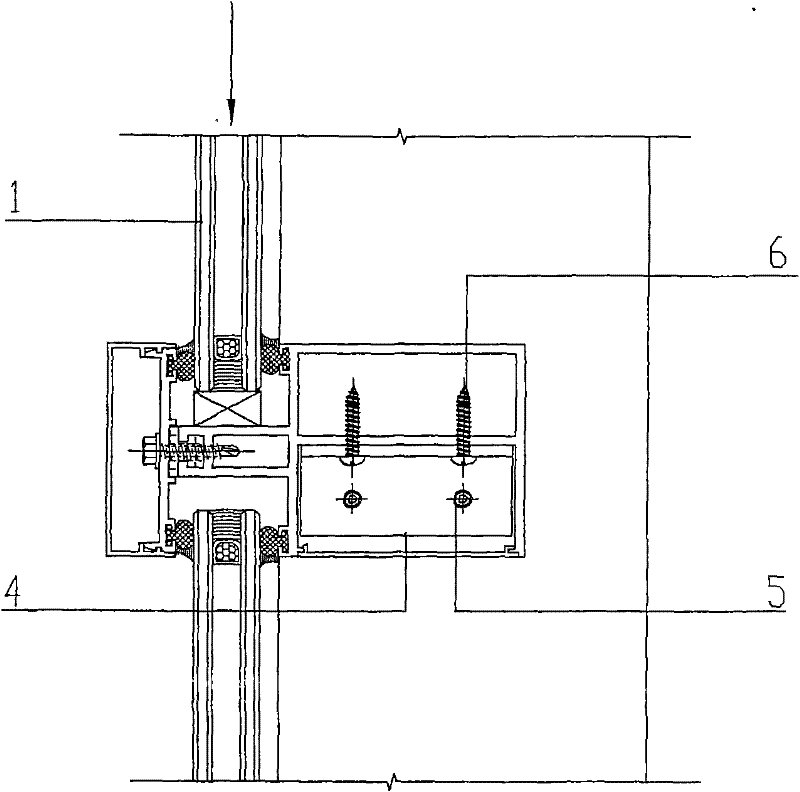

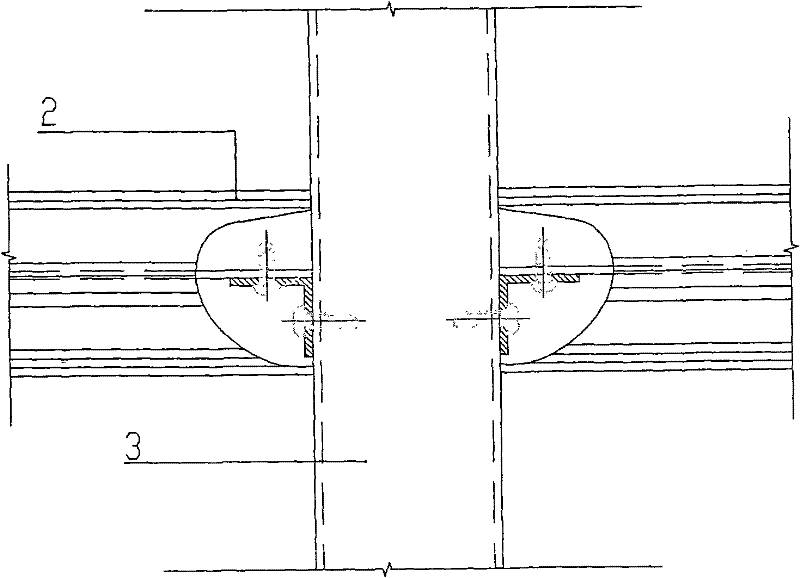

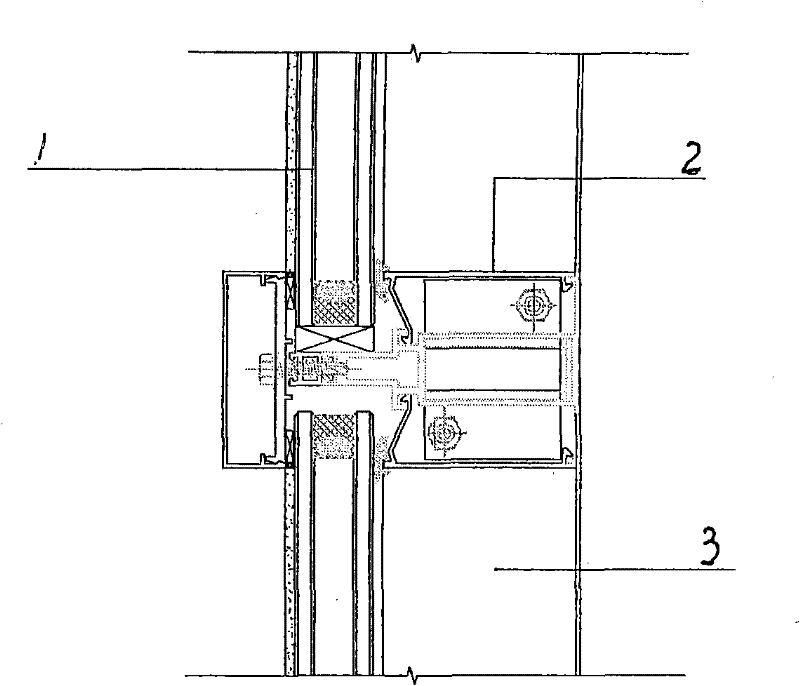

Four-bit embedded glass curtain window system

The invention provides a four-bit embedded glass curtain window system. The system consists of a section frame, glass and an open window, wherein an upright column and a cross beam are embedded in a cross beam through a double T-shaped cross beam supported bracket to form the section frame of the curtain wall, and the section frame is connected with a main structure through a steel switching part; the cross beam and the upright column section are separated into a plurality of separated components; the double T-shaped embedded cross beam supported bracket is embedded in a cross beam cavity, and is fixed on the upright column; an open hinge slot is arranged on an opening frame, and a hinge shaft on an opening sash is embedded in the hinge slot; the opening sash is separated into an opening sash body which is subject to surface spray treatment and a glass adhesive stick which is subject to surface anodic oxidation treatment; and the glass adhesive stick is embedded and clamped in a section slot of the opening sash body. By the adoption of the four-bit embedded glass curtain window system, the assembly quality of a curtain wall plate and the safety of a curtain wall component are improved; inside assembly of glass can be realized, dependency on scaffolds, construction baskets and other devices and facilities is reduced, and the glass can be changed conveniently in assembling and daily maintaining processes.

Owner:TIANJIN SHENGFANG CURTAIN DECORATION ENG

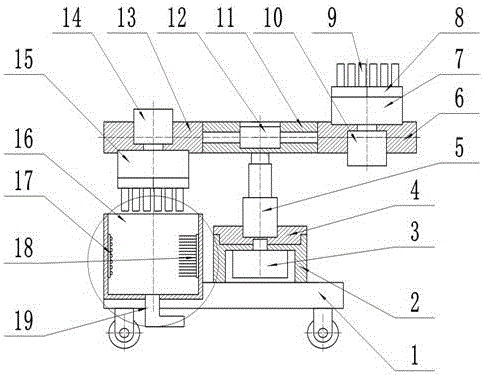

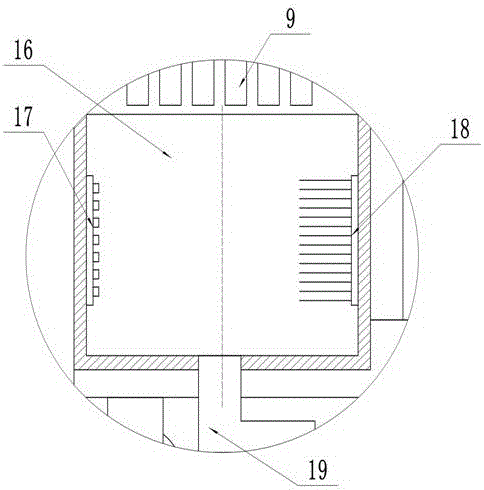

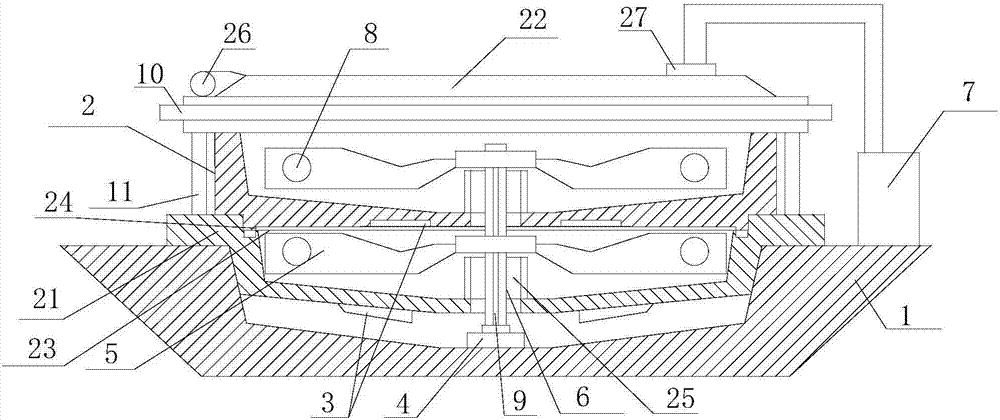

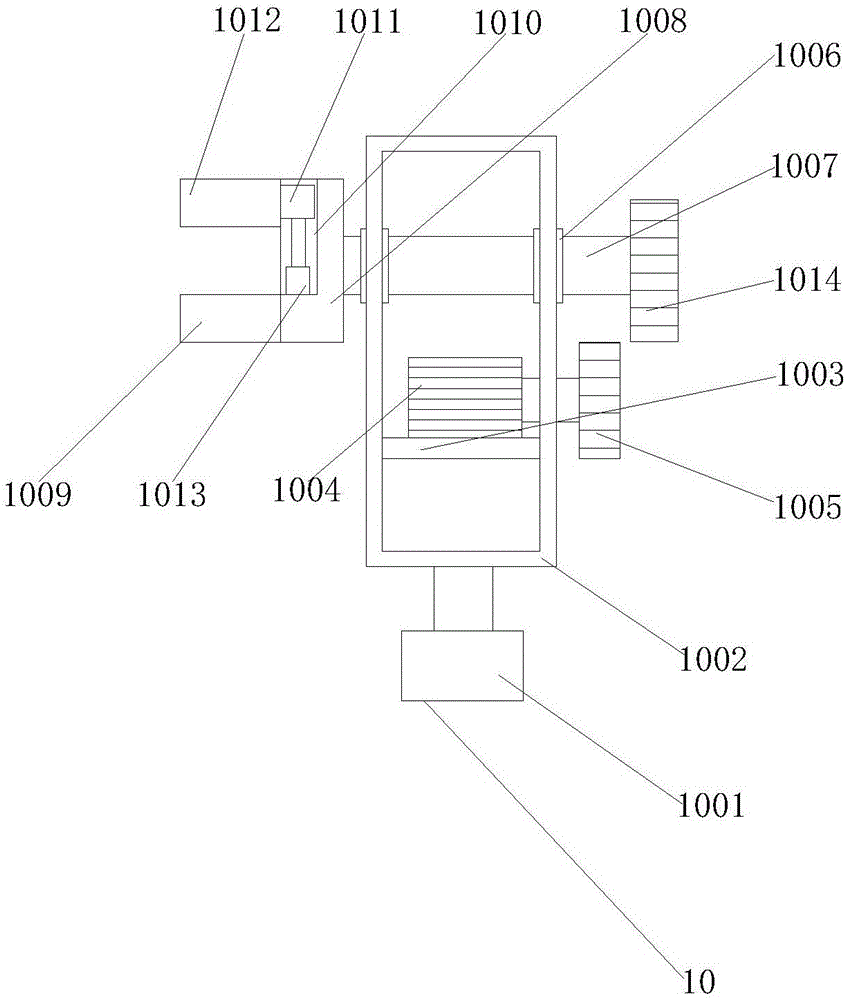

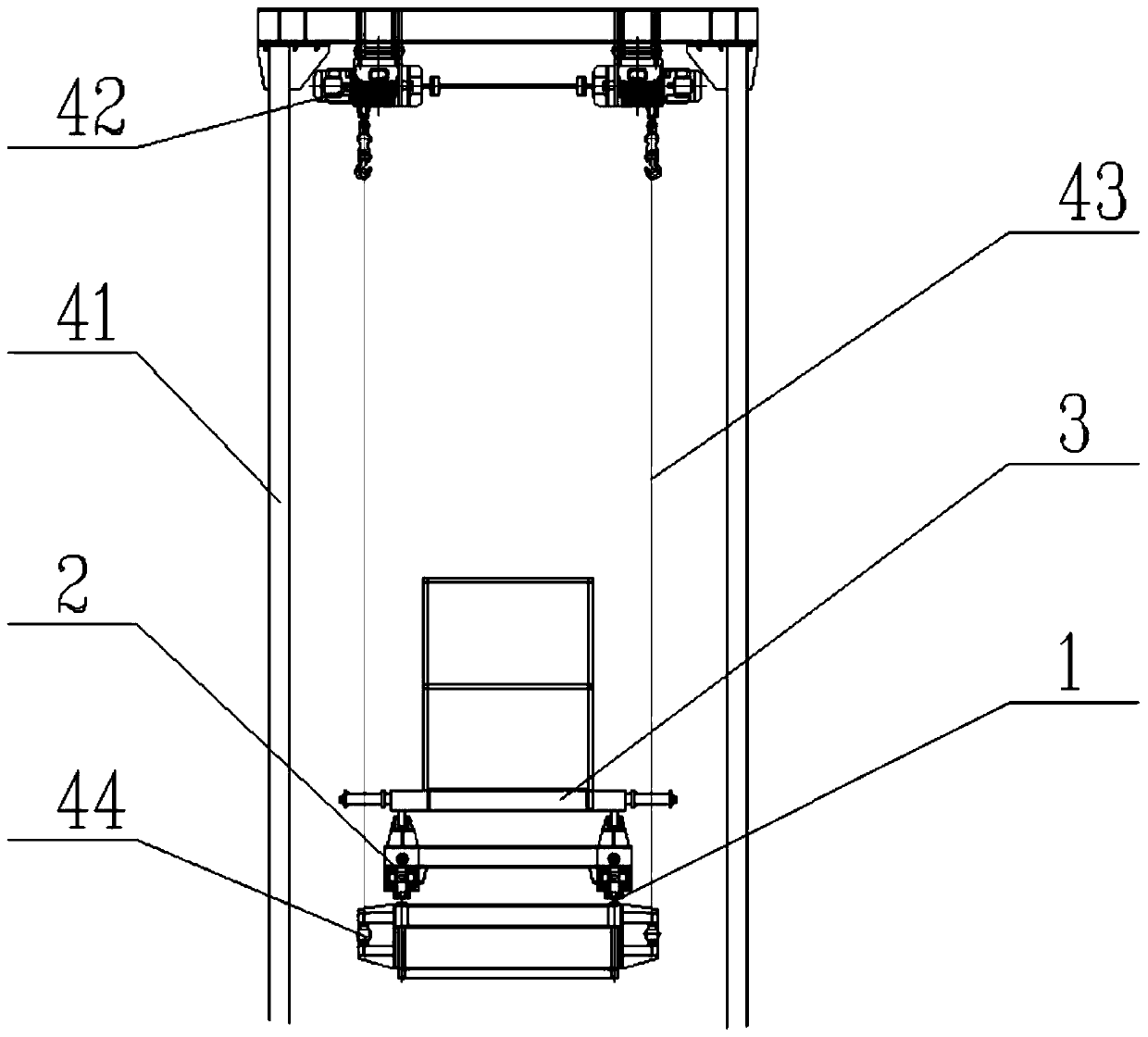

Under beam device used for irradiation processing accelerator and capable of automatically turning over goods

InactiveCN104355098AEfficient flipEffective turning over and overturning operationConveyor partsEngineeringIrradiation

The invention discloses an under beam device used for an irradiation processing accelerator and capable of automatically turning over goods. The under beam device includes a conveying roller table and a manual turnover roller table on the conveying roller table, wherein an automatic turnover device is arranged on one side of the manual turnover roller table side by side; the automatic turnover device includes a goods conveying mechanism, a fixing support and two turnover mechanisms; each turnover mechanism includes a rotating shaft penetrating through the goods conveying mechanism and a plurality of turnover brackets fixed in sequence on the rotating shaft. Compared with the prior art, the under beam device used for the irradiation processing accelerator and capable of automatically turning over goods, provided by the invention, has the advantages that personnel can control goods to reach the device at will and selectively by arranging the automatic turnover device on one side of the manual turnover roller table; the automatic turnover device automatically turns over goods, and goods reach the irradiation zone; as the all-manual turning over operation is eliminated, the working efficiency is improved, and labor input is reduced.

Owner:JIANGSU ZHONGKE HI WITS TECH DEV

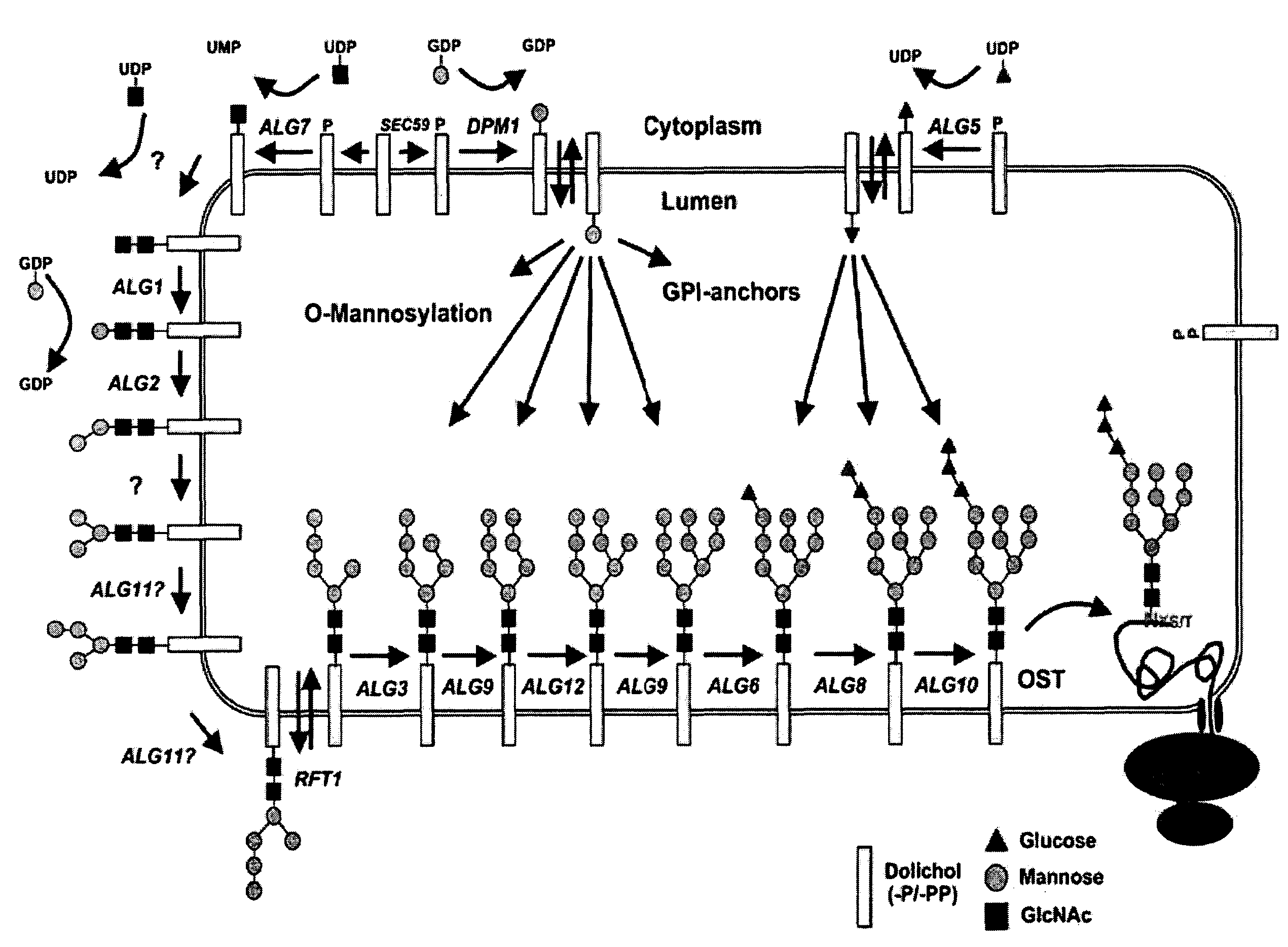

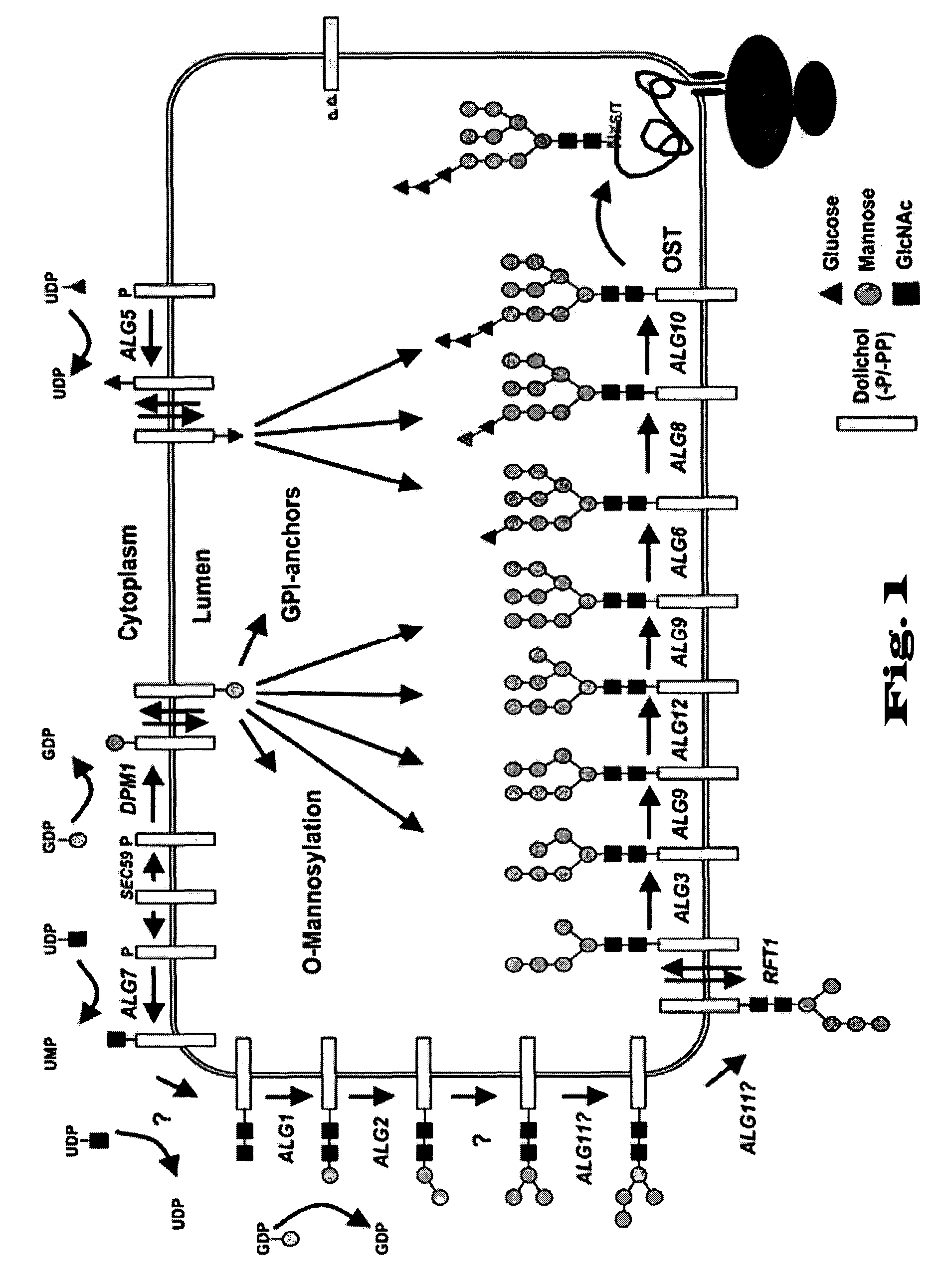

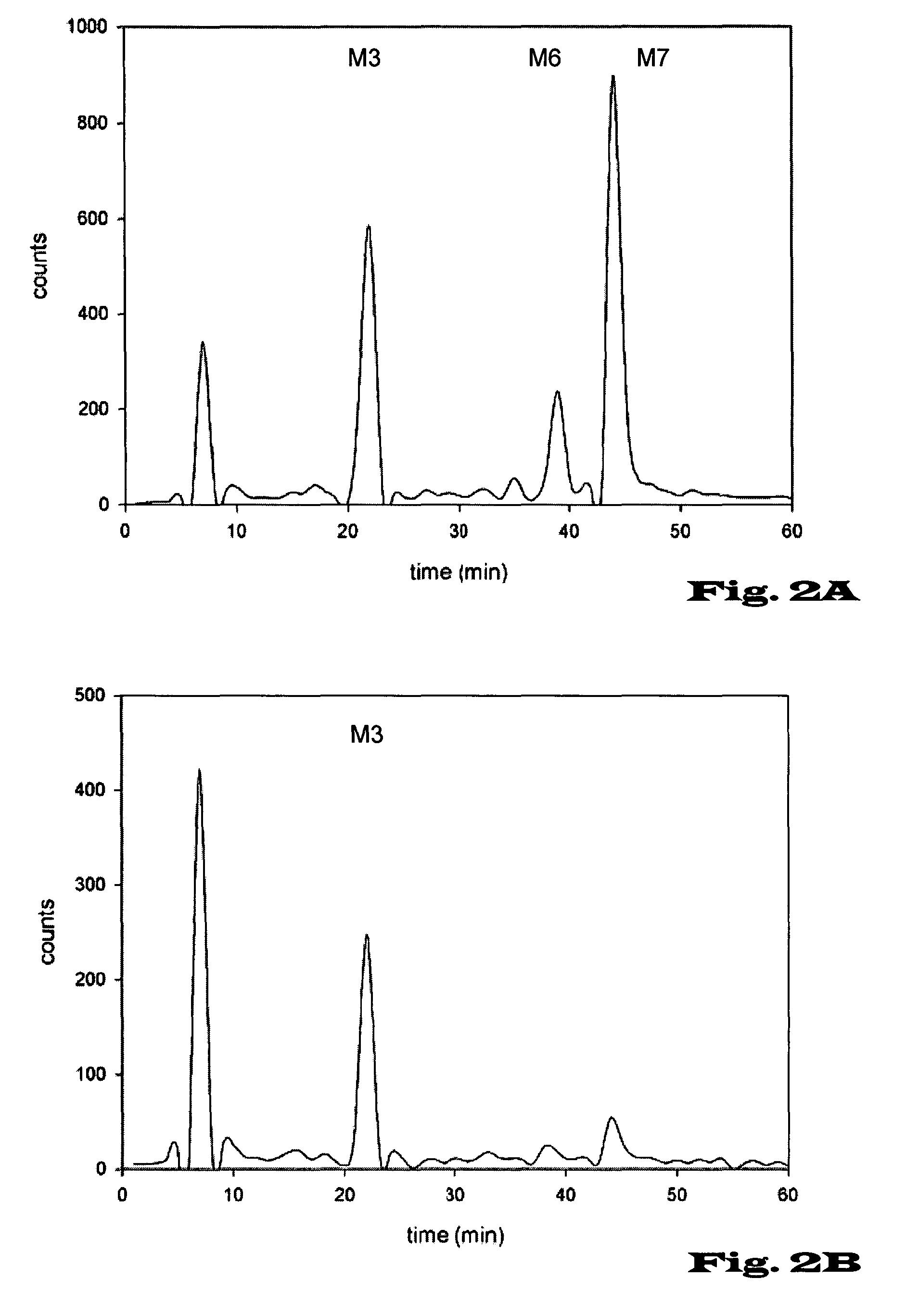

Novel tools for the production of glycosylated proteins in host cells

InactiveUS20110207214A1Good curative effectWithout triggering unwanted side effectAnimal cellsFungiYeastTherapeutic protein

The invention improves glycoprotein production and protein glycosylation engineering in eukaryotes, specifically the production of human-like complex or hybrid glycosylated proteins in lower eukaryotes such as yeasts. The invention provides glycosylation modified eukaryotic host cells capable of producing glycosylation optimized proteins useful as immunoglobulins and other therapeutic proteins, and provides cells capable of producing glycoproteins having glycan structures similar to glycoproteins produced in human cell. The invention further provides proteins with human-like glycan structures and novel compositions thereof producible by these cells.

Owner:LONZA LTD

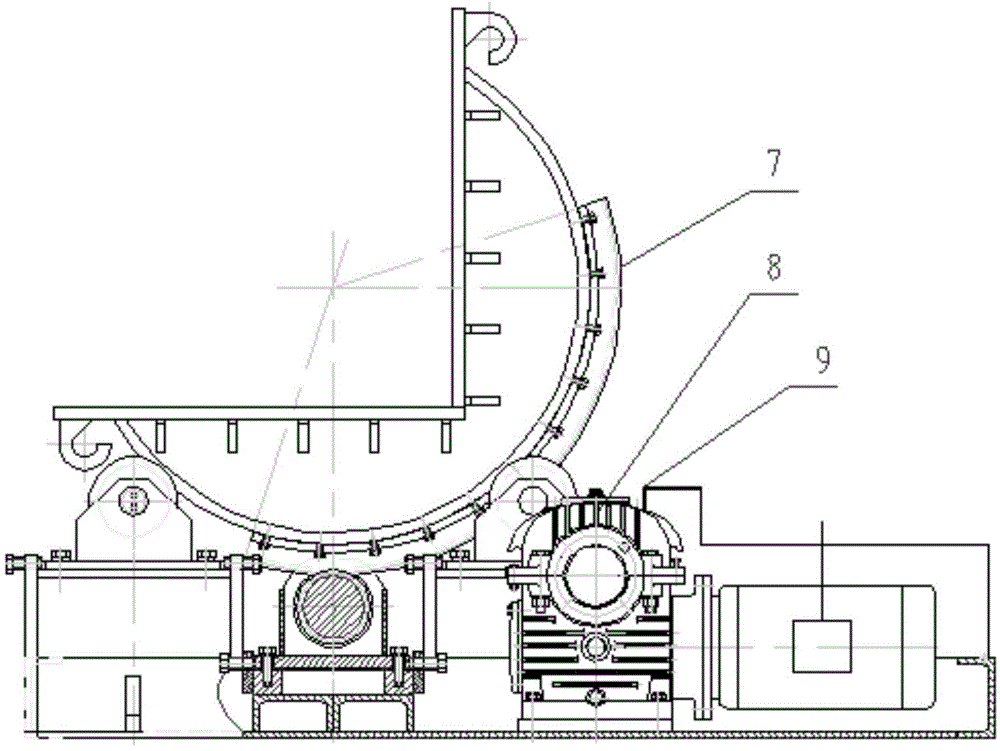

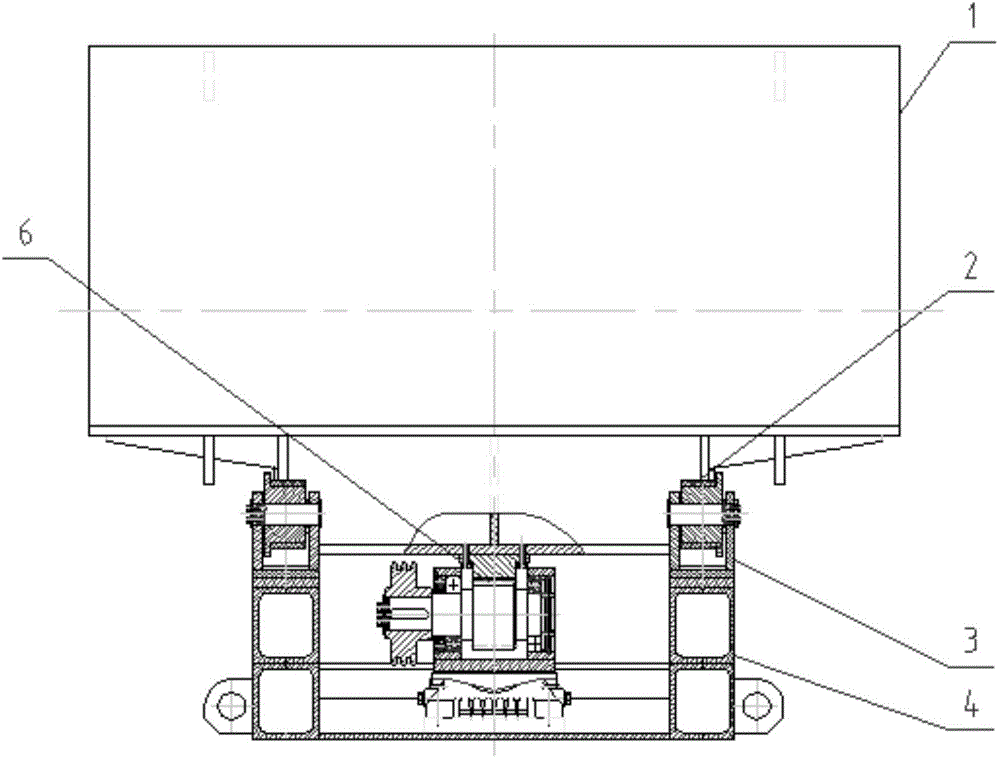

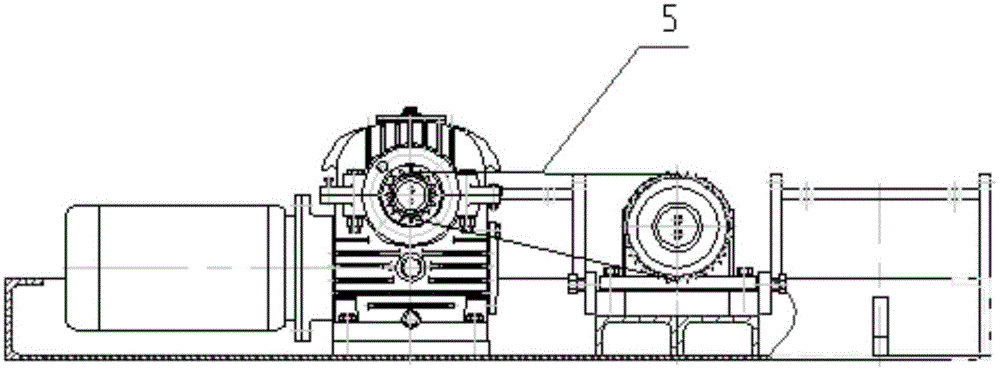

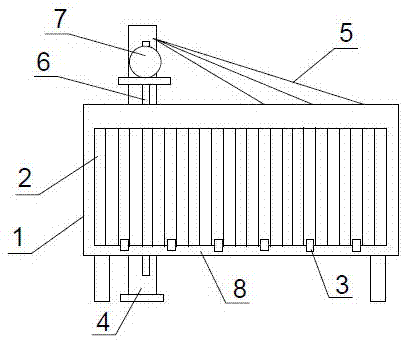

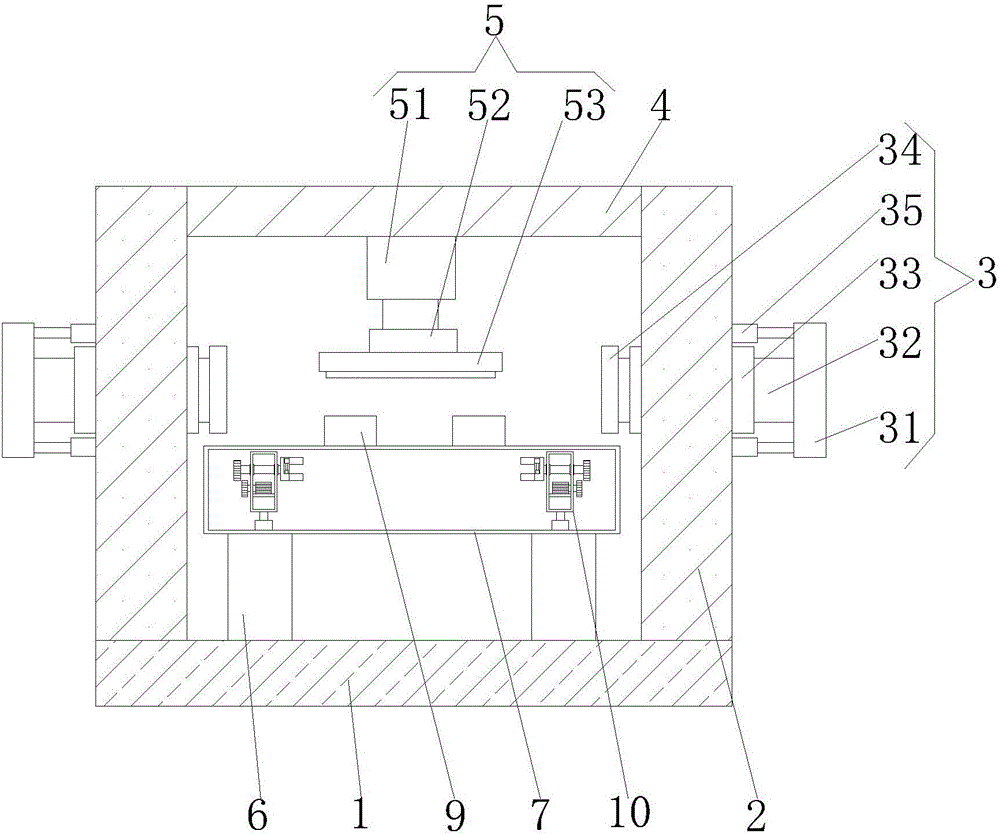

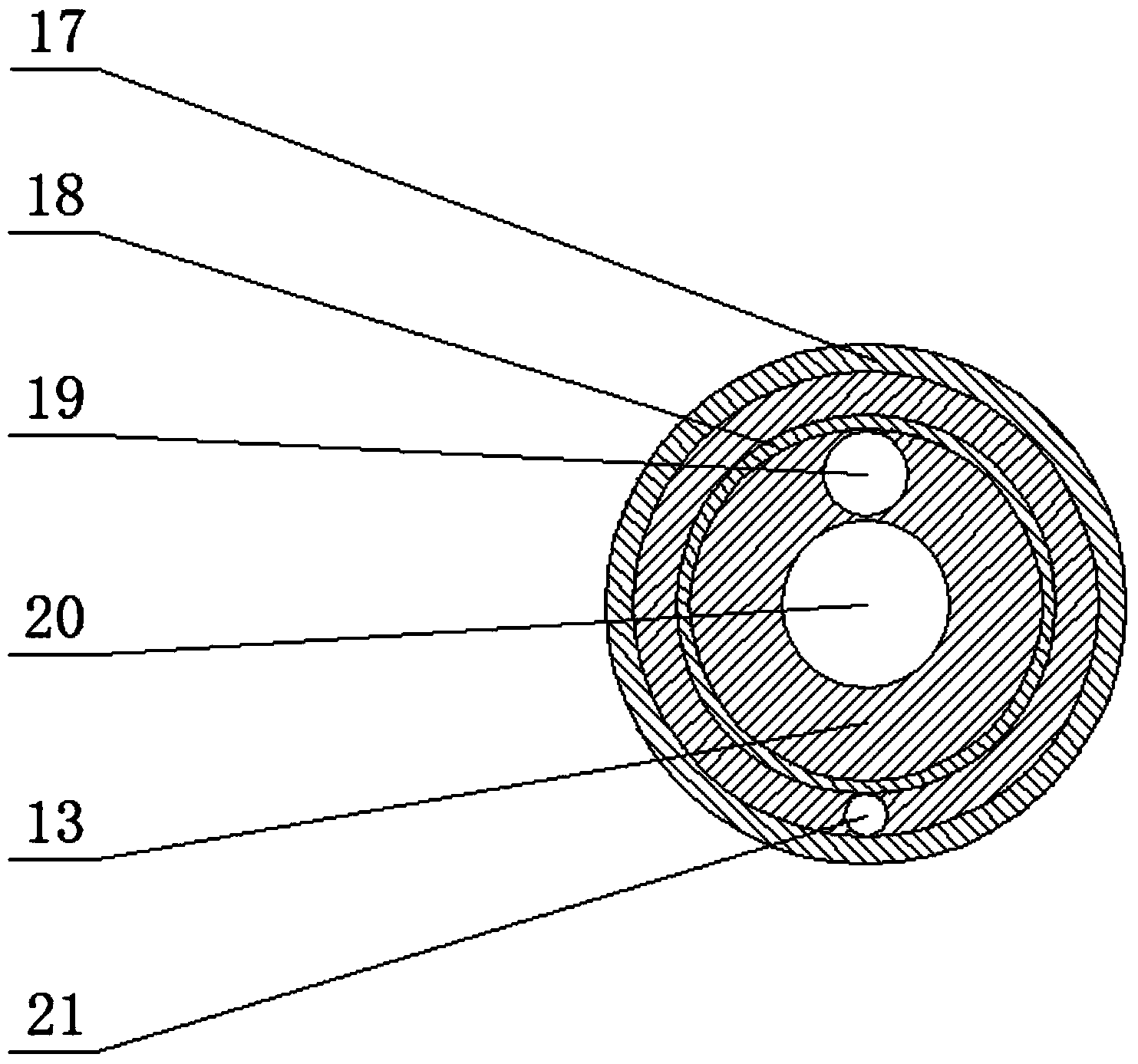

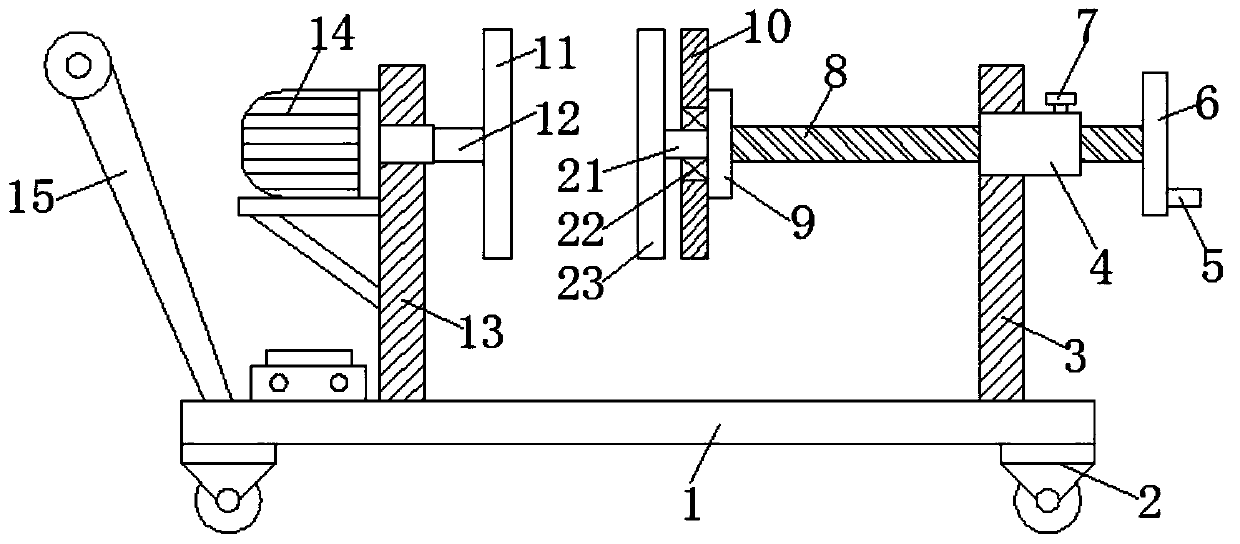

Workpiece overturning device

InactiveCN105364611AEfficient flipSimple structureMetal working apparatusThrough transmissionReducer

The invention provides a workpiece overturning device which comprises an overturning table, a base, four supports, four carrier rollers, a worm reducer, a motor, a gear shaft and a gear ring. The four supports are fixed to the base. The four carrier rollers are installed on the four supports and support the overturning table. The motor and the worm reducer are connected and fixed to the base. The gear shaft is fixed to a bearing seat on the base. The worm reducer is connected with the gear shaft through three rows of chains. The gear ring is installed at the bottom of the overturning table. The gear shaft is meshed with the gear ring. The overturning table is rotated to another plane level from one plane level through transmission in the overturning process, the overturning table walks in a circumferential track, and thus the workpiece overturning device can be effectively used for overturning parts subjected to machining and especially overturning parts with the weight being about 4 tons. The workpiece overturning device has the beneficial effects of being simple in structure, small in size, convenient to carry, stable in operation and the like.

Owner:TIANJIN WANXIN TRANSMISSION EQUIP

Mechanical device for washing workpieces

ActiveCN106733855AEfficient flipEasy to cleanCleaning using toolsCleaning using liquidsWorking environmentEngineering

Owner:蓝海天

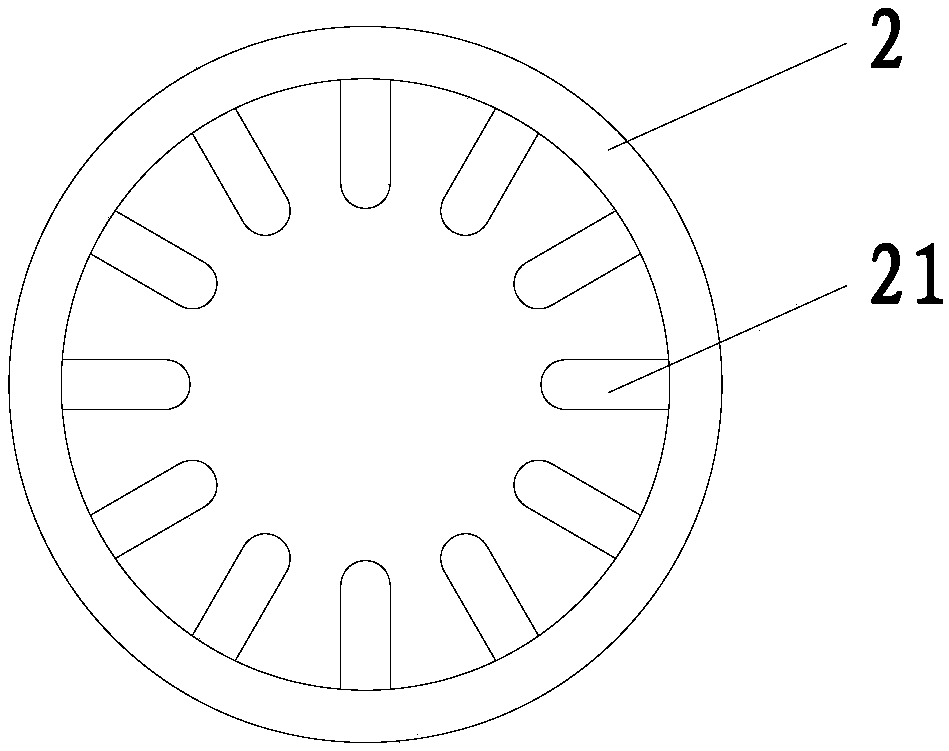

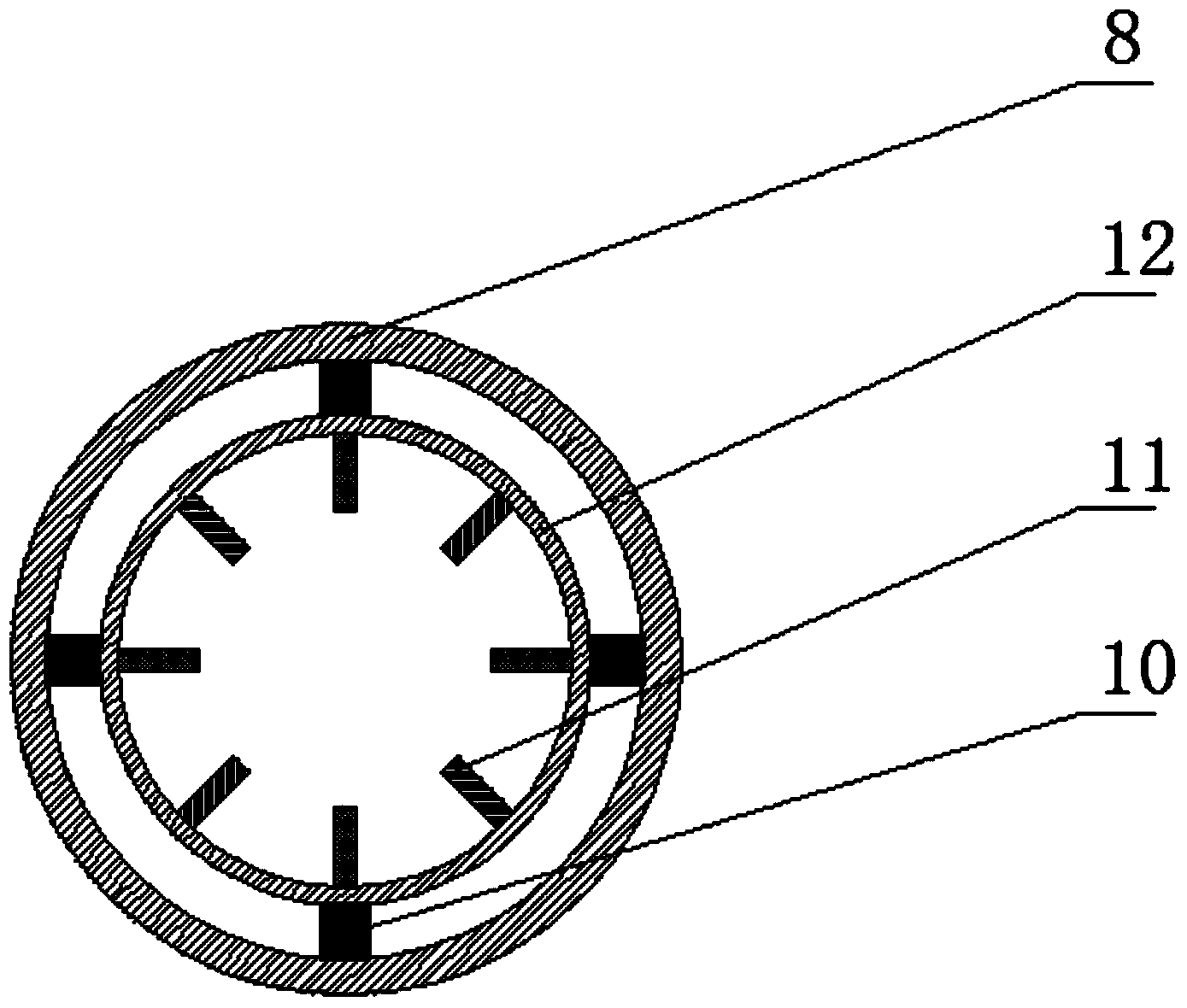

Rotating type blueberry baking equipment

The invention discloses rotating type blueberry baking equipment. The rotating type blueberry baking equipment comprises a baking oven, a rotating drum, a rotating shaft, an air inlet pipe, an air exhaust pipe, a heating device, a drying device, a circulating fan and a control device, wherein the rotating drum which is horizontally arranged is arranged in the baking oven; a plurality of ventilation holes are formed in the drum wall of the rotating drum; the rotating shaft is fixed on the rotating drum, and penetrates through one side wall of the baking oven to be connected with a motor locatedoutside the baking oven; the top of the baking oven is connected with the air exhaust pipe; the detachable drying device is fixed to the tail end of the air exhaust pipe; the bottom of the baking oven is connected with the air inlet pipe; the start end of the air inlet pipe is connected with the circulating fan; the heating device is arranged in the air inlet pipe; and the drying device is connected with the circulating fan through a connection pipe. According to the rotating type blueberry baking equipment disclosed by the invention, the rotating drum is arranged in the baking oven, so thatblueberries can be effectively overturned during baking, and can be evenly baked; and besides, tiny sundries mixed with the blueberries can be sifted out.

Owner:王荣忠

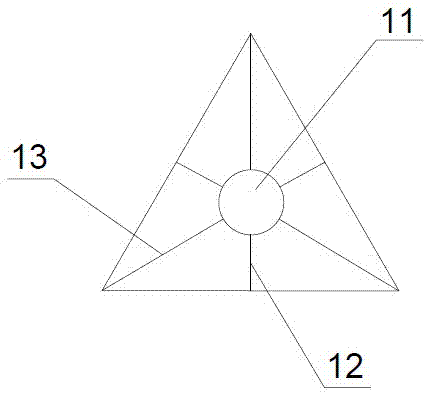

Three-side turning billboard

InactiveCN105448208AImprove stabilityImprove visual effectsIdentification meansAir filterEngineering

The invention relates to a three-side turning billboard, which belongs to the field of billboards. The three-side turning billboard comprises a support frame, a plurality of triangular prisms, a driving device, a transmission device, a lighting device and a controller, wherein the plurality of triangular prisms are arranged on the support frame; a reinforcing support column is fixedly connected to one side of the back of the support frame, and the top end of the reinforcing support column is connected with one end, which is far from the reinforcing support column, of the support frame through a plurality of chains; an air filter port is formed in the reinforcing support column; each triangular prism comprises a central column, a triangular frame and a plurality of support plates and connecting plates which are used for connecting the central column with the triangular frame; the support plates are vertically arranged between the side surface of the triangular frame and the central column and are vertically arranged in the middle of the side surface of the triangular frame. According to the three-side turning billboard, the reinforcing support column is arranged, and the structure of the triangular prisms is improved, so that the strength and stability of the whole billboard are increased.

Owner:ZHEJIANG WANJIA CULTURE TECH CO LTD

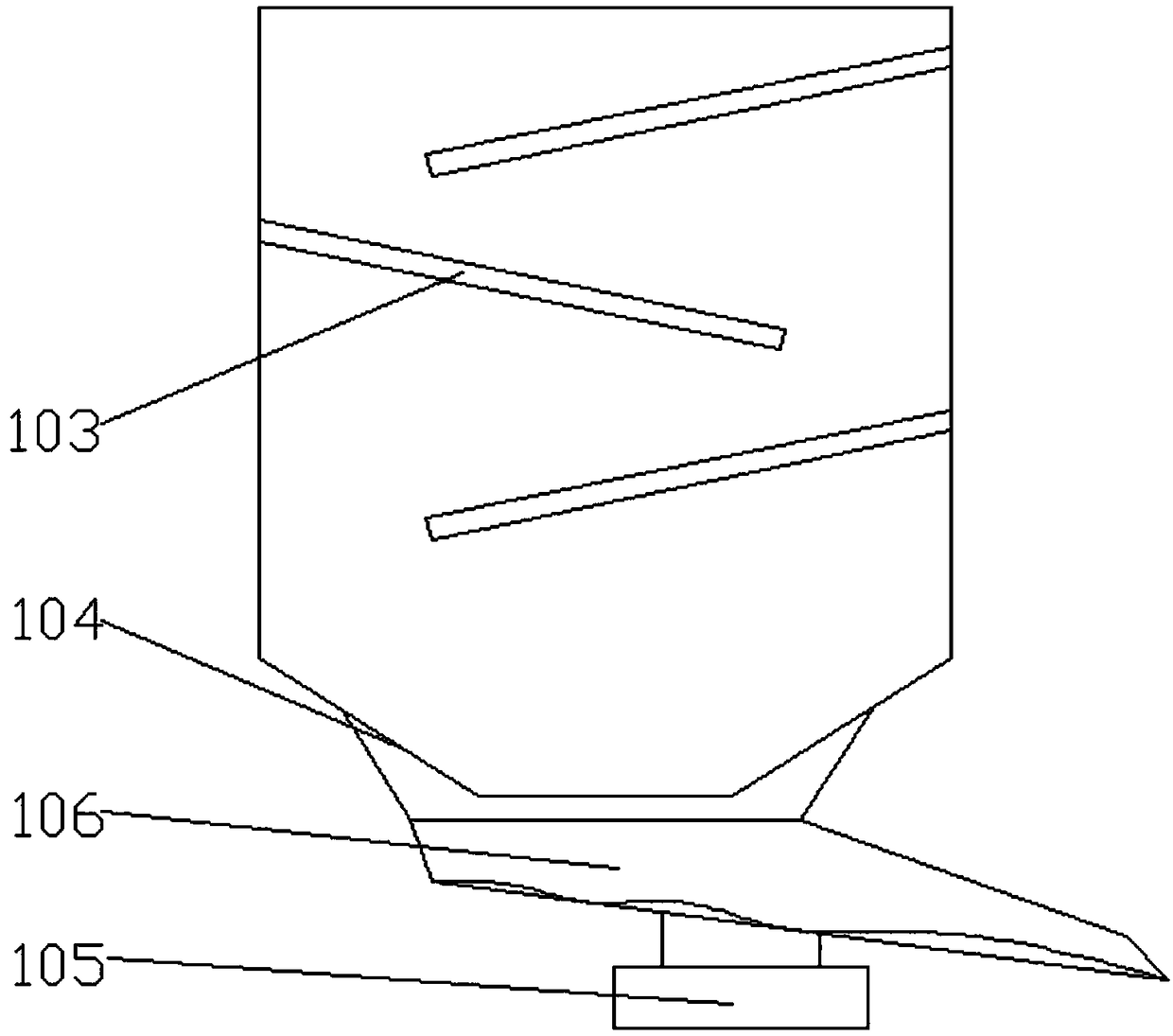

Novel adjustable multistage hotpot seasoning stir-frying and stirring device

A novel adjustable multistage hotpot seasoning stir-frying and stirring device relates to hotpot seasoning processing equipment and comprises a support frame, a stir pan, heating devices, a stir-frying and driving motor, a stir-frying and stirring sheet, a stir-frying driving shaft and a tail gas recycling device, wherein the stir pan, the stir-frying driving motor and the tail gas recycling device are arranged on the support, the stir pan comprises a pan body and a sealing cover, the outer surface of the bottom of the pan body is provided with a positioning groove, the top is provided with a connecting groove, the axis of the pan body is provided with a driving hole, the side surface of the top of the pan body is provided with a ratchet mechanism, the bottommost part of the pan body is connected with the support, the uppermost part of the pan body is connected with the sealing cover through the ratchet mechanism, the heating devices are embedded into the outer surface of the bottom of the pan body by surrounding the axis of the pan body of the stir pan and are distributed uniformly, and the sealing cover is provided with a blow vent and is communicated with the tail gas recycling device through the blow vent. By adopting the device provided by the invention, on one hand, one or more types of materials can be simultaneously stir-fried, on the other hand, the stir-fried materials can be effectively overturned and tail gas during the stir-frying is recycled.

Owner:重庆市凯鸿食品有限公司

Mechanical machining surface finishing equipment

InactiveCN106271993AEasy flipSpeed up the processGrinding carriagesGrinding machinesSurface finishMechanical equipment

The invention discloses mechanical machining surface finishing equipment. The mechanical machining surface finishing equipment comprises a base, the top of the base is fixedly connected with support frames, one side of each support frame is fixedly connected with a fixing device, each fixing device comprises a push plate, one side of each push plate is fixedly connected with one end of a push rod, and the other end of each push rod penetrates through a limiting sleeve to be fixedly connected with one side of a fixing plate. According to the machining surface finishing equipment, by cooperatively using second electric telescopic rods, support blocks, motors and first gears, mechanical equipment can be automatically turned over in the finishing process, the problem that the mechanical equipment cannot be automatically turned over when the mechanical equipment surface is finished is solved, and the manual turnover condition is avoided; by cooperatively using mobile rods, fixed blocks, fixed extrusion blocks, movable extrusion blocks, third electric telescopic rods and second gears, the mechanical equipment can be better turned over in the finishing process, and then the working progress is improved.

Owner:张庆荣

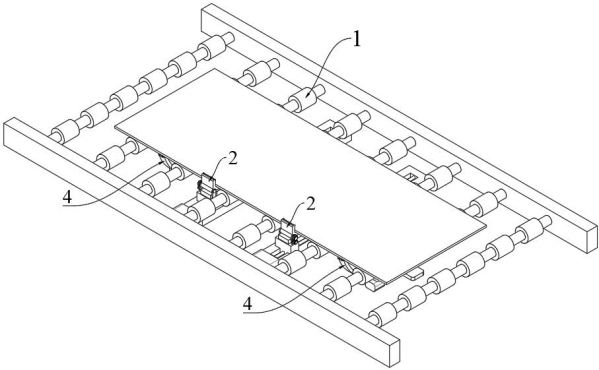

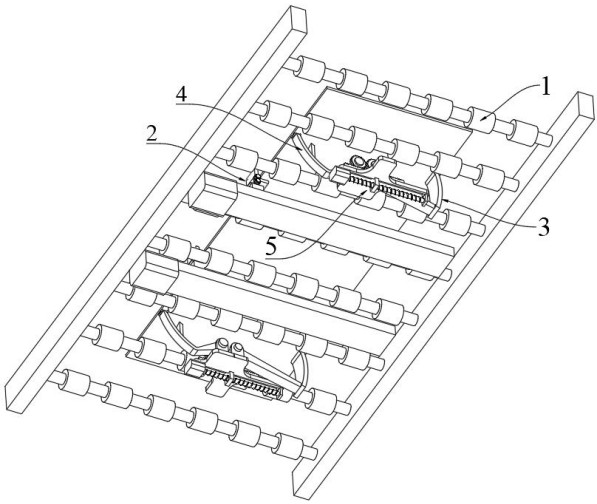

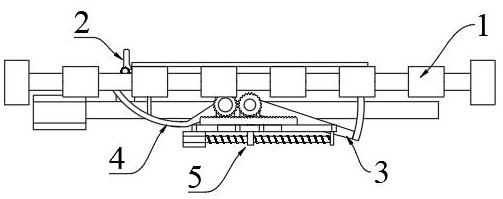

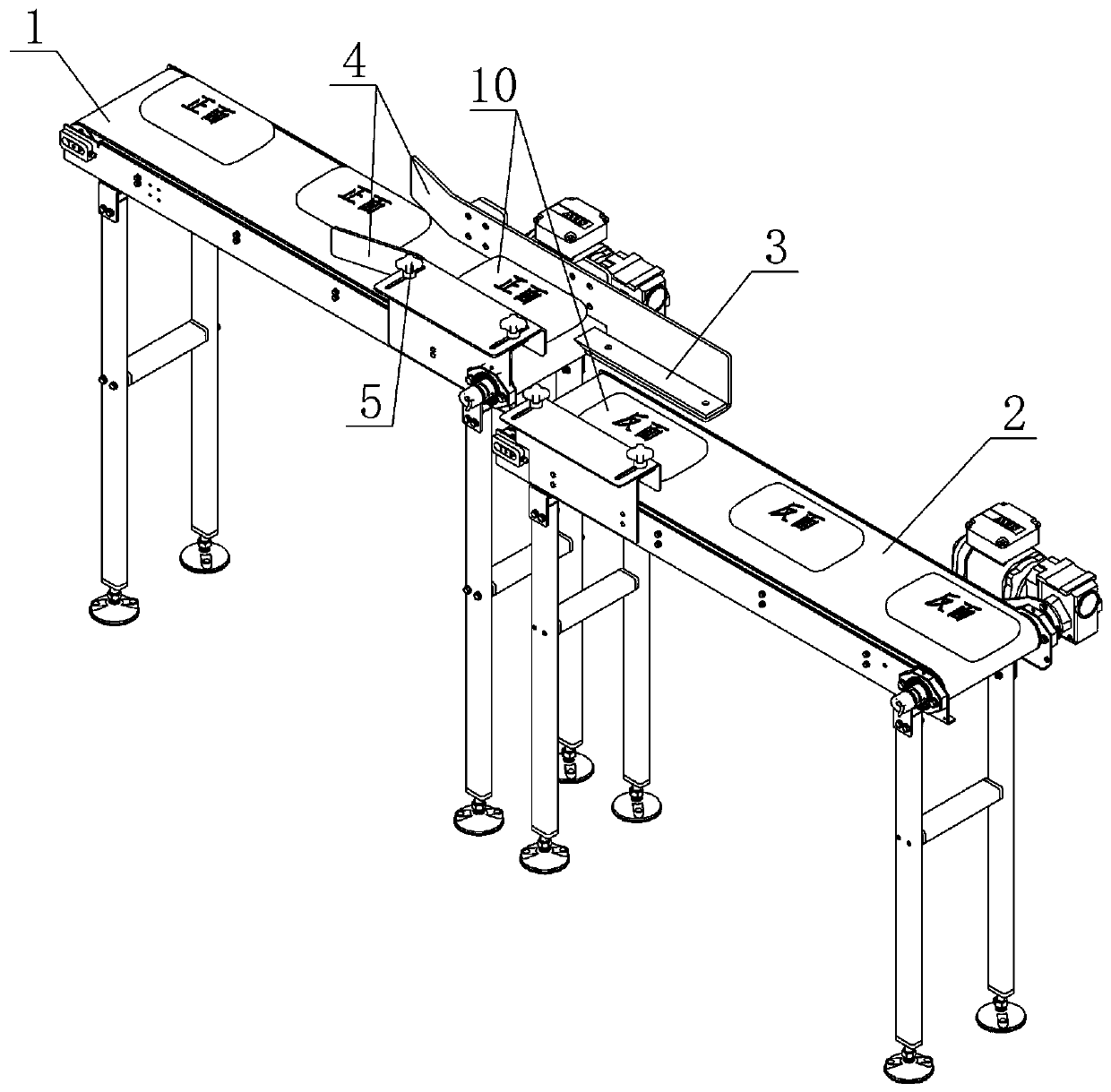

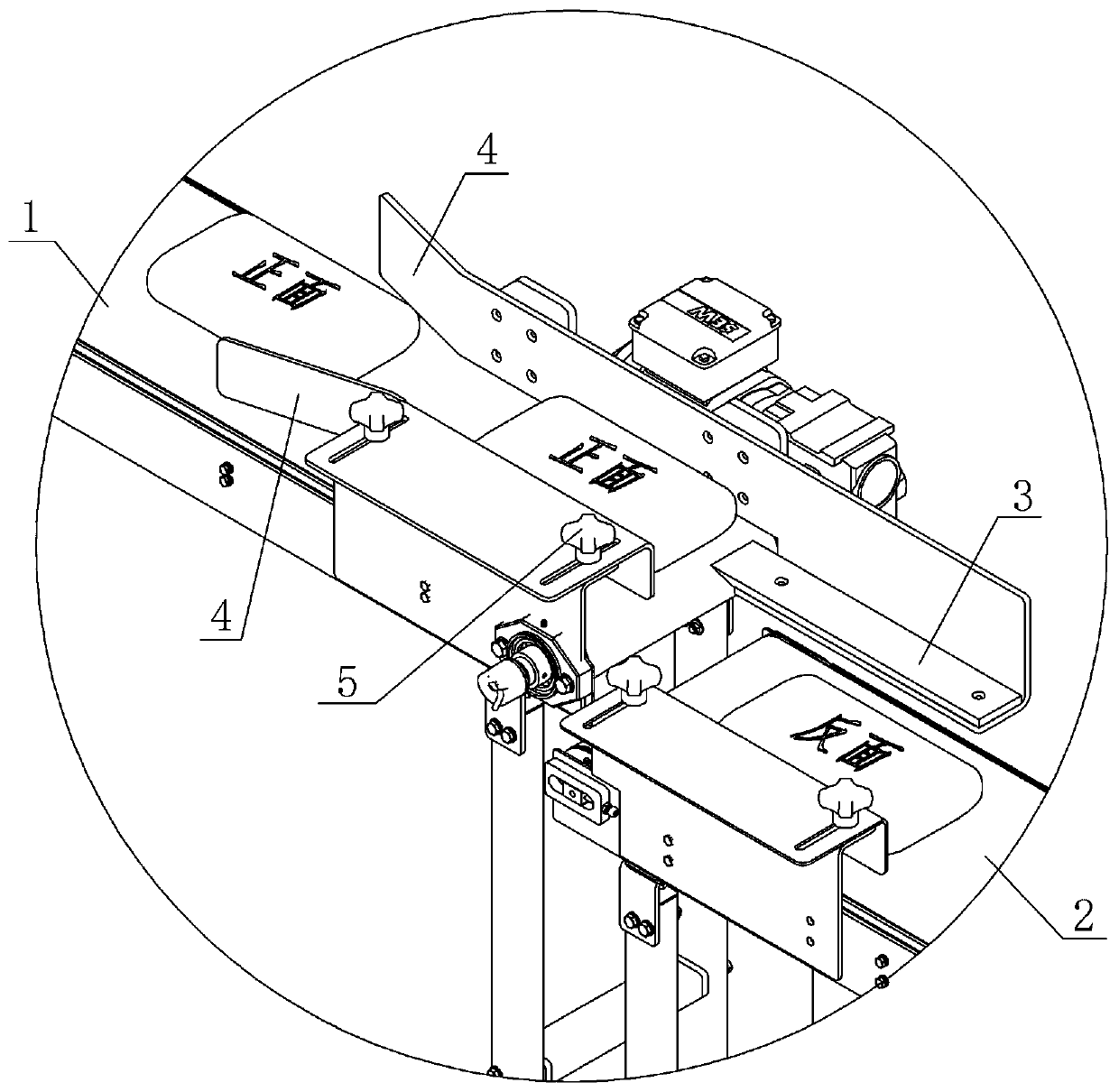

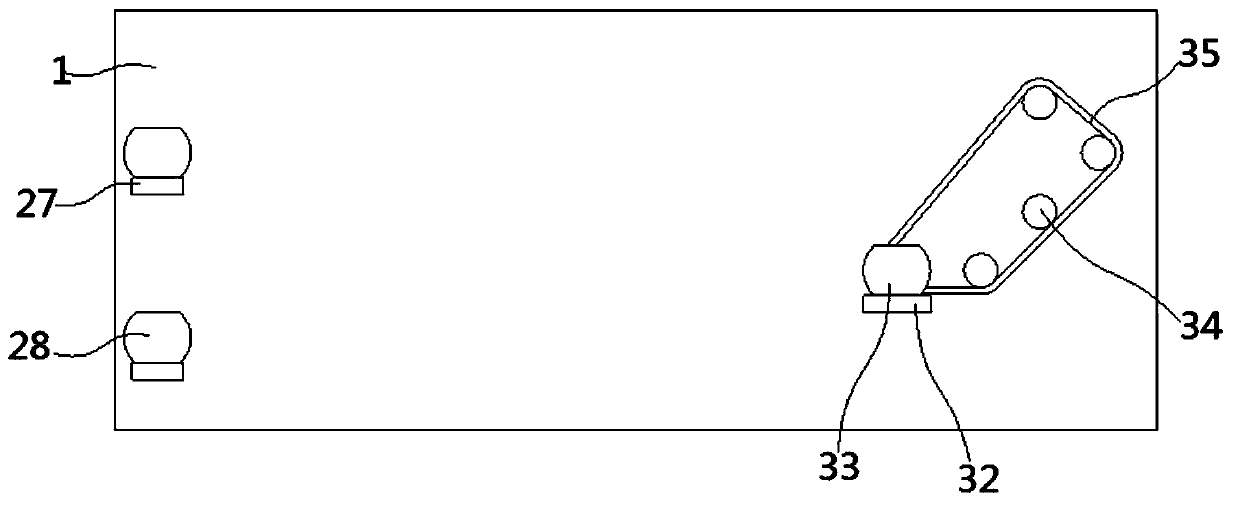

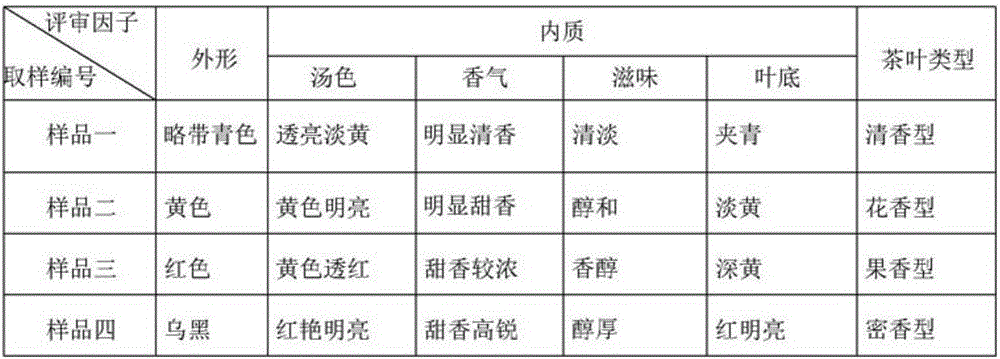

Printed circuit board conveying and overturning device and method

ActiveCN114313925AShorten footprintAvoid bloatingPrinted circuit manufactureConveyor partsProduction lineEngineering

The invention provides a printed circuit board conveying and overturning device and method. The device comprises a plurality of conveying rollers arranged at intervals; the fulcrum mechanism comprises a linear assembly, a rotating assembly and an L-shaped plate; the upward jacking and slow descending mechanism comprises a driving assembly, an upward jacking assembly and a slow descending assembly. When the L-shaped plate limits the circuit board from one side edge of the circuit board, the jacking assembly jacks up the other side of the circuit board, the linear assembly synchronously drives the rotating assembly to move, and the rotating assembly synchronously drives the L-shaped plate to rotate; when the circuit board is jacked and turned over to incline towards one side of the slow descending assembly by a preset angle under the action of the jacking assembly and the L-shaped plate, the slow descending assembly rotates upwards to make contact with the circuit board, and after contact, the slow descending assembly is used for rotating downwards under the action of the driving assembly. According to the scheme, the circuit board can be automatically turned over from the side face, the size of the device is reduced, and too long conveying line and production line equipment is avoided.

Owner:四川英创力电子科技股份有限公司

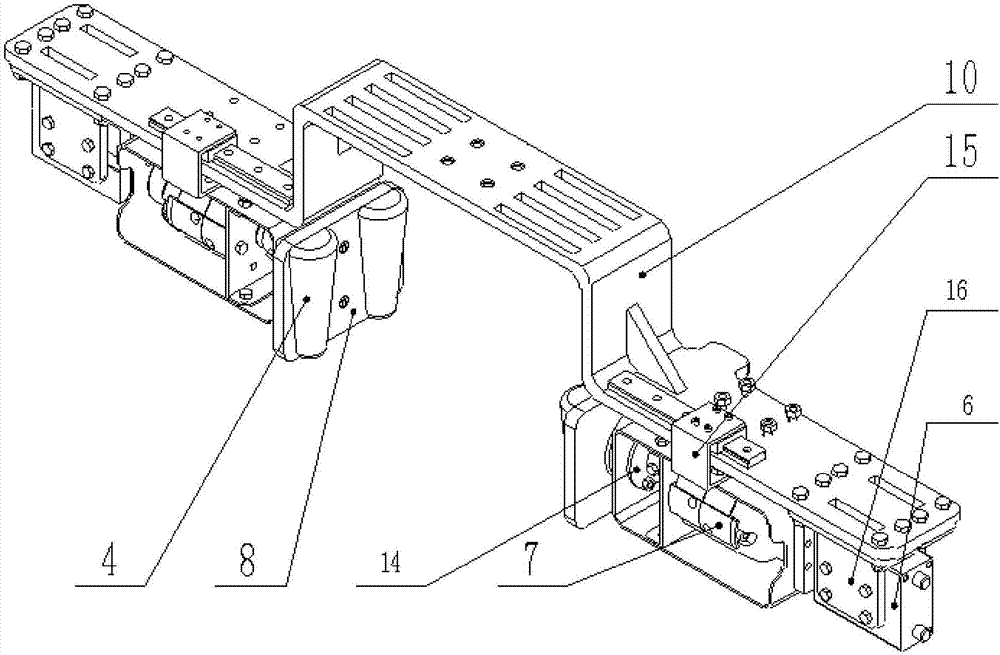

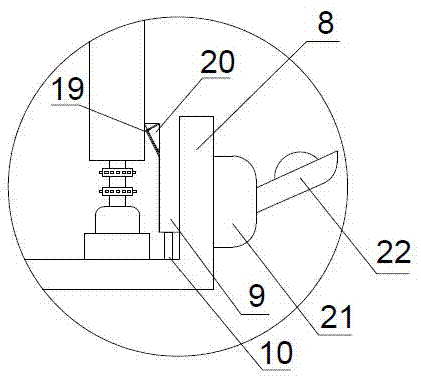

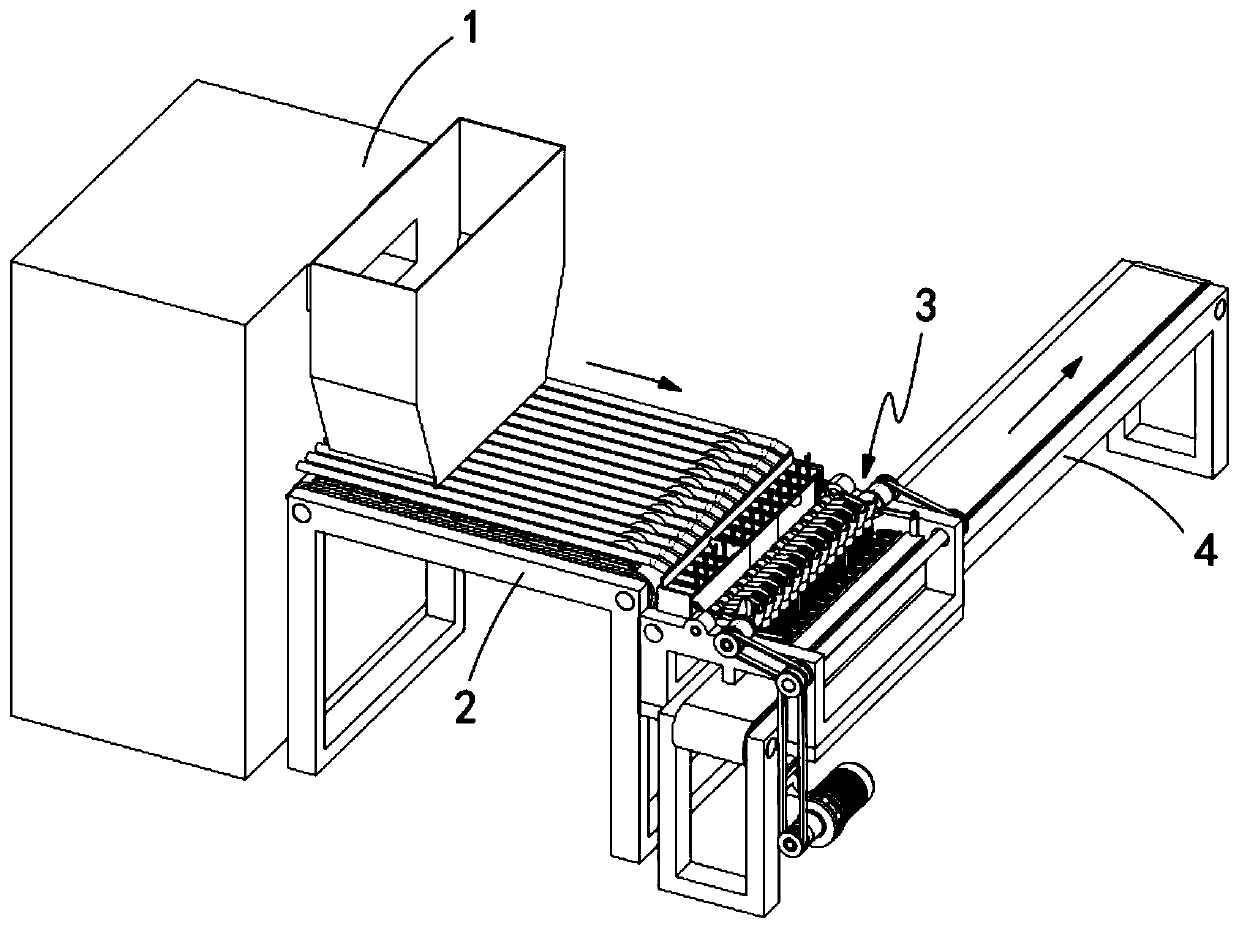

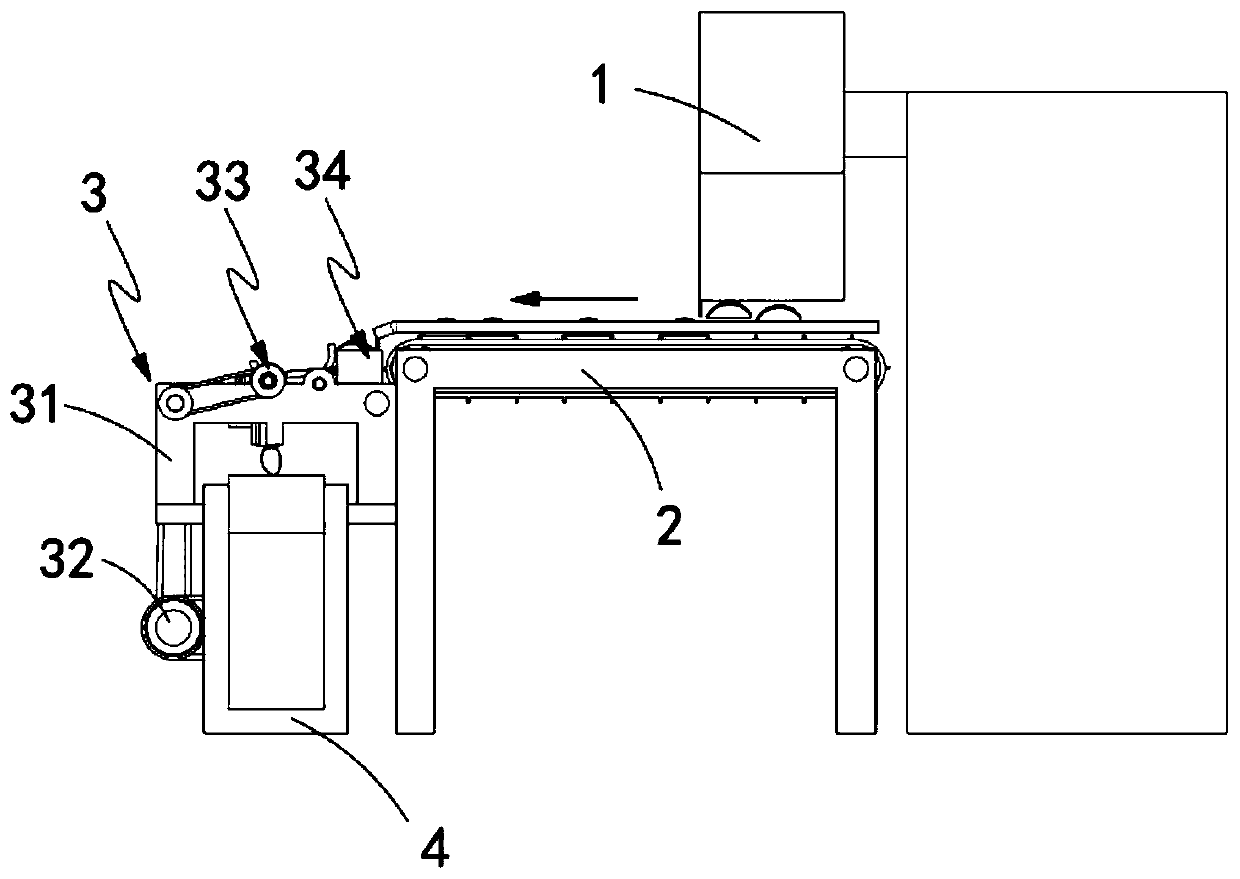

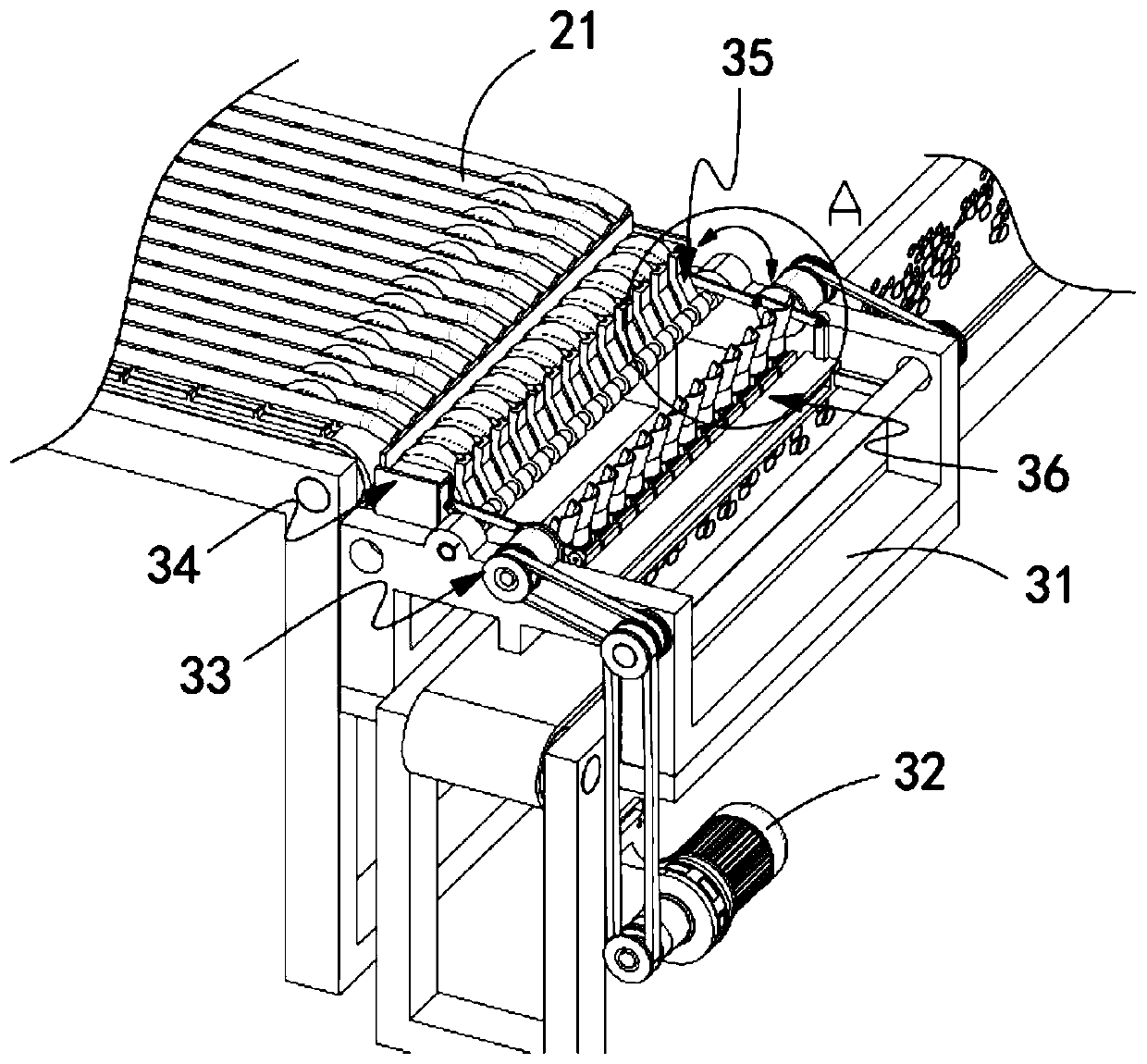

Automatic positioning and rapid slicing device for garlic cloves

ActiveCN111070261ASlice accuratelyMaximize the area on one sideMetal working apparatusAgricultural engineeringDrive motor

The invention relates to an automatic positioning and rapid slicing device for garlic cloves. The automatic positioning and rapid slicing device comprises a garlic clove feeding machine, a feeding conveying device and a discharging conveying device, wherein the garlic clove feeding machine is arranged at the head end of the feeding conveying device, and the discharging conveying device is transversely arranged at the tail end of the feeding conveying device; and the automatic positioning and rapid slicing device further comprises a slicing device, wherein the slicing device comprises a fixingframe, a driving motor, transmission assemblies, an overturning assembly, a transferring assembly and a slicing assembly, the fixing frame is erected at the head part of the transmission direction ofthe discharging conveying device, and the transmission assemblies are arranged at the two ends of the length direction of the fixing frame. According to the automatic positioning and rapid slicing device for the garlic cloves, a positioning barrel is used for positioning the garlic cloves, then the garlic cloves are accurately sliced by the slicing assembly, the device effectively achieves the single-sided area maximization of the garlic cloves, and meanwhile, the overturning assembly is matched to overturn the garlic cloves, so that the tips of the garlic cloves are effectively matched with the transferring assembly, and the garlic cloves can enter the positioning barrel to be accurately positioned.

Owner:临泉县松鹤脱水蔬菜有限公司

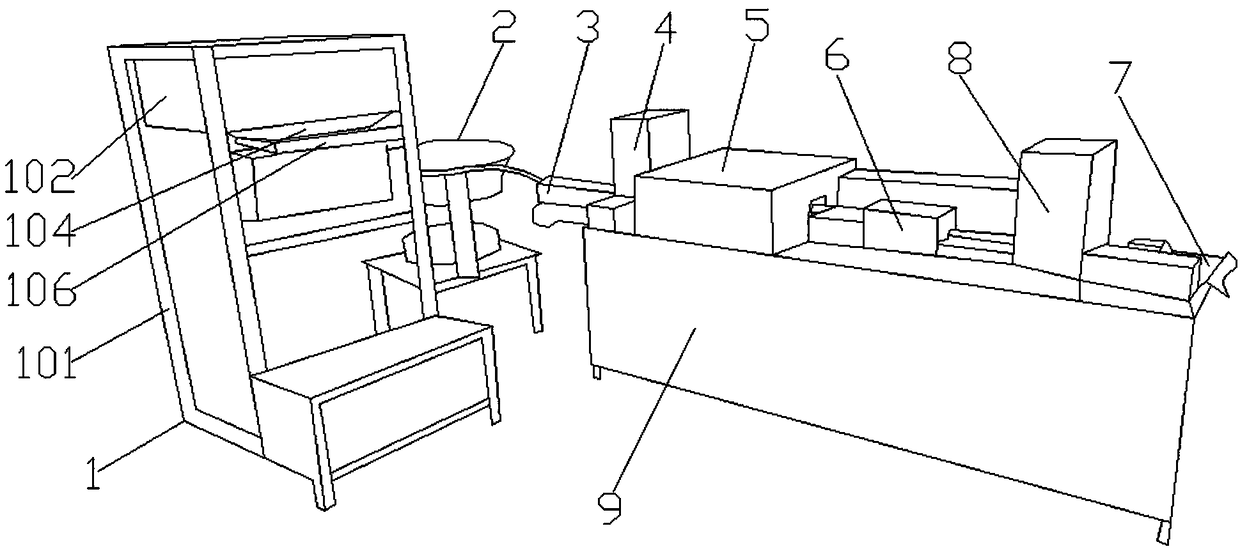

Automatic antibiotic bottle cap detection equipment

PendingCN108489991APrevent influxDoes not produce excessive outputOptically investigating flaws/contaminationInductorEngineering

The invention relates to the technical field of medical instruments, and particularly discloses an automatic antibiotic bottle cap detection device, comprising a feeding mechanism, a vibration mechanism, a first conveying mechanism, a first detecting mechanism, a second detecting mechanism, a turning mechanism, a second conveying mechanism and a third detecting mechanism, wherein the feeding mechanism comprises a buffer plate, a vibration motor, a vibration plate, a contact rod and an inductor; the vibration mechanism comprises a first spiral conveying plate, a second spiral conveying plate, athird spiral conveying plate, a first steering track, a second steering track and a third steering track; the first detecting mechanism comprises a first light source and a first camera; the second detecting mechanism comprises a square fixed frame, a second light source, a fixed rod and a second camera; and the third detecting mechanism comprises a three camera and a third light source; the turning mechanism comprises a semi-closed sleeve, a torsion bar and a U-shaped buckle. The automatic antibiotic bottle cap detection device has the characteristics that the output can be adjusted, the positive and negative adjustments are unified, the transportation is not disturbed, the equipment cost is low, and the detection efficiency is high.

Owner:浙江冠利新材料股份有限公司

Automatic paper overturning and coating machine

The invention discloses an automatic paper overturning and coating machine. The automatic paper overturning and coating machine comprises an overturning frame which is rotationally connected with a machine body; the overturning frame is provided with paper holding arms and paper blocking arms and is in transmission connection with a driving device; the overturning frame is a frame type overturning frame; the frame type overturning frame comprises two guiding rods arranged in parallel and connection shaft end plates arranged at the two top ends of the guiding rods; the connection shaft end plates and the guiding rods are combined together to form an overturning frame body; one lead screw is arranged between the two guiding rods in parallel; threads arranged on the two sides of the lead screw are opposite in turning direction, and the lead screw is in rotational connection relative to the overturning frame body; the at least two paper blocking arms are hinged to and supported by one end of a paper blocking arm connection frame which is fixedly arranged on the middle portions of the guiding rods; the two paper holding arms are made from steel channels and fixedly connected to sliding blocks which are in sliding connection with the guiding rods; and the center positions of the sliding blocks are each correspondingly provided with a screw hole with the same turning direction as the lead screw. The automatic paper overturning and coating machine has the beneficial effects of being high in production efficiency and good in paper overturning quality.

Owner:YANCHENG HONGJING MACHINERY SCI & TECH CO LTD

Bag overturning device for mushroom cultivation

PendingCN107371791AReasonable structureFunctionalCultivating equipmentsMushroom cultivationMushroomUltimate tensile strength

The invention discloses a bag overturning device for mushroom cultivation. The bag overturning device comprises a cultivation bag body and a single acting cylinder; the top of the single acting cylinder is fixed on the outer frame and the end of the single acting cylinder extends to an inner cavity of the cultivation bag body, telescopic rods are fixedly arranged on two inner sides of the middle part of an outer frame, and clamps are fixedly arranged on the two ends of the telescopic rods, the clamps are clamped on two sides of the cultivation bag body, and the bottom of the cultivation bag body is fitted with the bottom of the outer frame, the single acting cylinder is connected flexibly with a rubber suction disc, and the end of the single acting cylinder is fixedly provided with a first fixing block. According to the bag overturning device for mushroom cultivation, the surface of the rubber suction disc is coated with a latex layer for absorbing the bottom of the cultivation bag body, and the latex layer is not easy to fall off; the bottom of the cultivation bag body is effectively overturned, the device is simple in structure and easy to use, the cultivation bag can be overturned and are not be damaged, the labor intensity of workers is reduced, and the working efficiency is improved.

Owner:重庆市永川区佳诚食用菌种植专业合作社

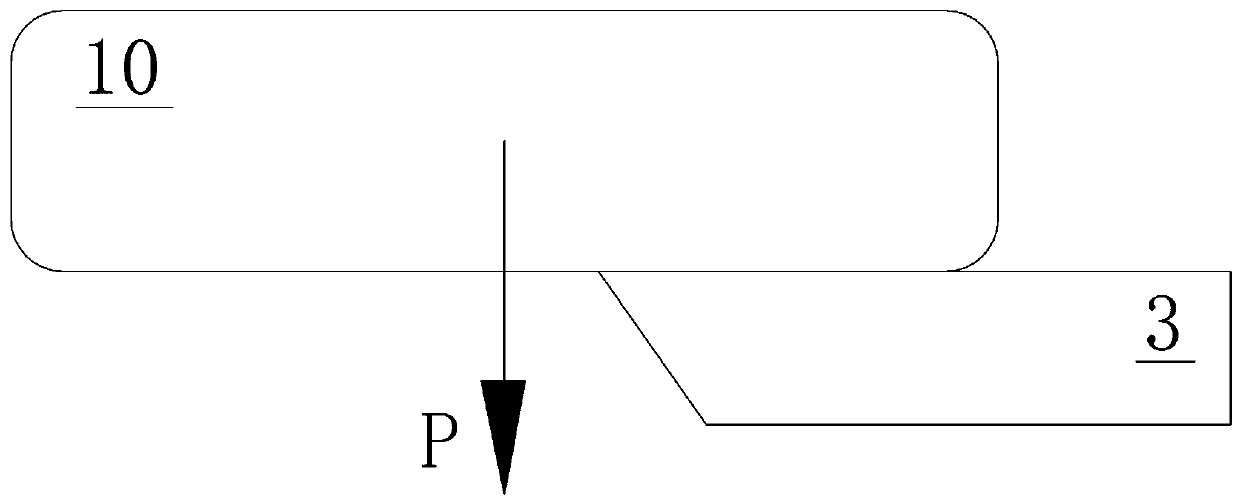

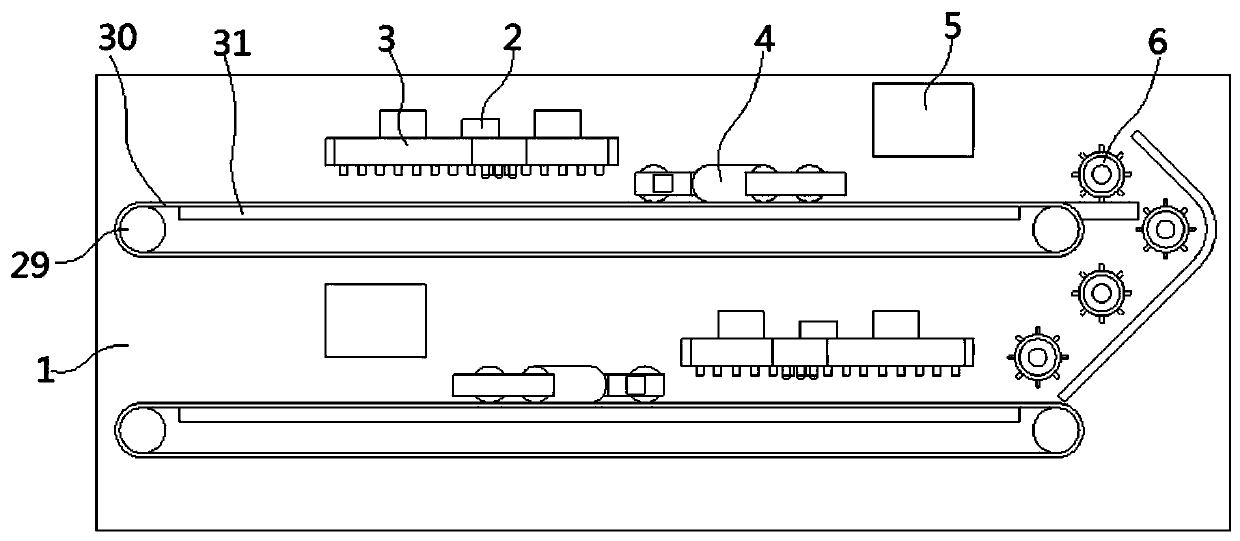

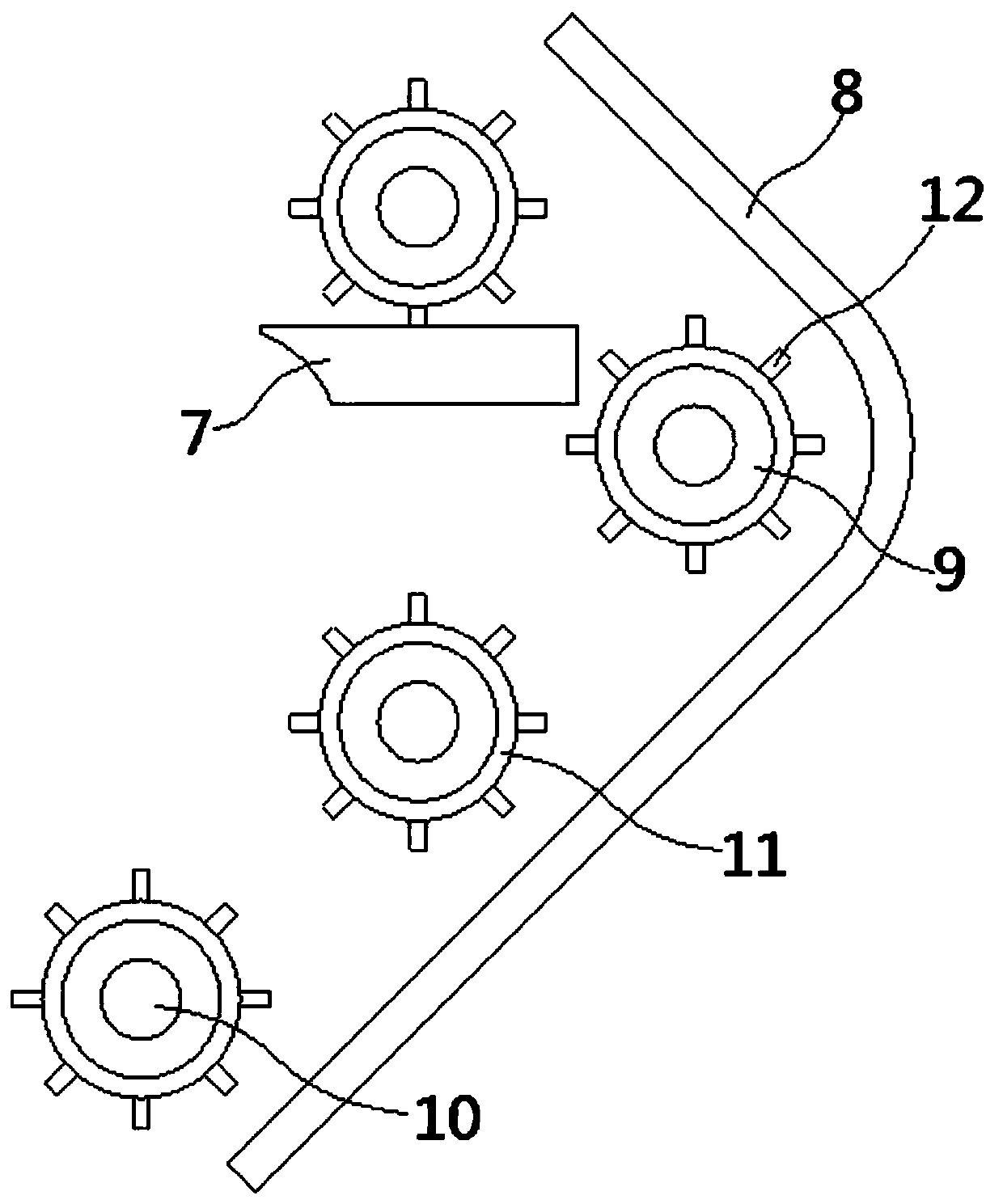

Overturning conveying device

The invention discloses an overturning conveying device. An upper conveying line and a lower conveying line with different heights are arranged. An overturning plate is fixedly mounted outside the output end of the upper conveying line and above the lower conveying line. The tail end in the transverse direction of the overturning plate only extends to the side of the gravity line of the conveyed object and does not exceed the gravity line. The conveyed object rotates around the part supported by the overturning plate under action of gravity after falling onto the overturning plate. The conveyed object rotates at 180 degrees and falls onto the lower conveying line below, and then is continuously conveyed along the lower conveying line. The overturning conveying device is simple in structurebut can effectively overturn the object, so that the production time of conveying equipment is effectively shortened. Working is quick, and production efficiency can be improved.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

Turnover mechanism used for automatic production line

PendingCN107380977APrevent back and forth shakingImprove positional accuracyConveyor partsTotal factory controlPhysicsEngineering

The invention discloses a turnover mechanism used for an automatic production line. The turnover mechanism comprises a control system, a turnover assembly comprising an installing base and a rotating air cylinder arranged on the installing base, and a clamping assembly used for clamping a product to be turned over; the clamping assembly is arranged over the turnover assembly; and the rotating air cylinder is electrically connected with the control system and is controlled by the control system to drive the clamping assembly to do reciprocated rotation motion. According to the turnover mechanism, the product yield can be improved while the turnover efficiency is improved.

Owner:SUZHOU RS TECH

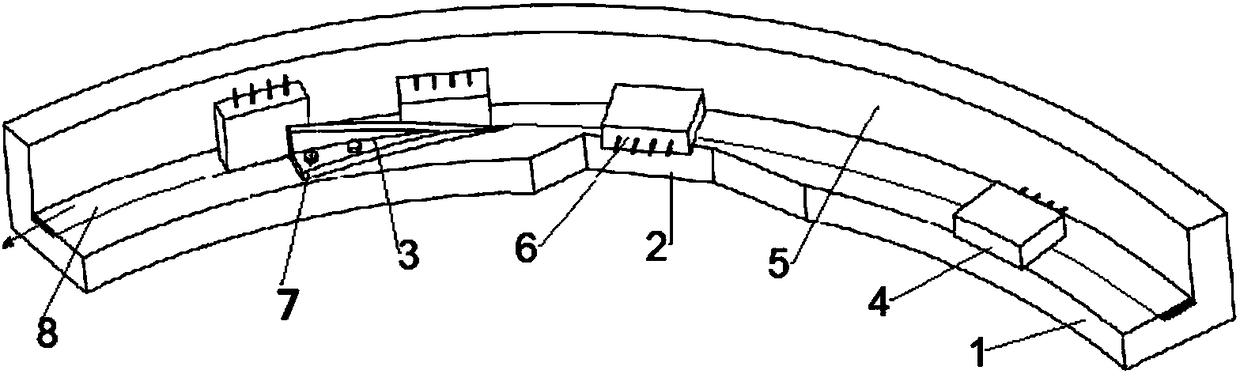

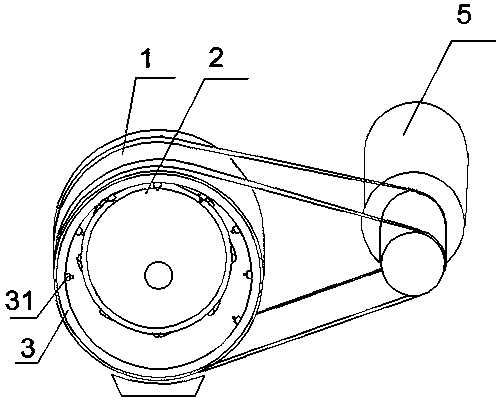

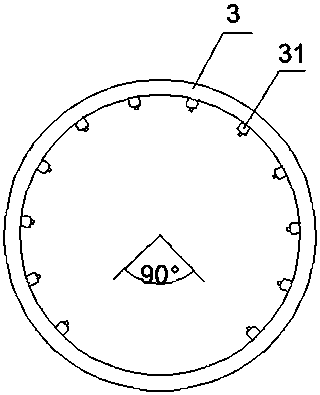

Directional arrangement device for rectangular workpieces

InactiveCN108584376AReduce workloadIncrease productivityConveyorsWelding/cutting auxillary devicesEngineeringNotching

The invention discloses a directional arrangement device for rectangular workpieces. The directional arrangement device comprises a track and a disc wall, wherein the track is horizontally arranged inan arc-shaped mode, and the disc wall is vertically and fixedly connected with the outer side of the track; an arc-shaped conveying belt which circularly moves from the feeding side to the discharging side is arranged on the side, close to the disc wall, of the upper part of the track, and the conveying belt is driven by a driving device; and an inclined surface lifting plate which is used for directionally arranging the rectangular workpieces and is arranged adjacent to the conveying belt is arranged on the side, far away from the disc wall, of the upper part of the track, and a dischargingnotch is formed in the front of the feeding side of the inclined surface lifting plate. According to the directional arrangement device, under the driving of the conveying belt, the rectangular integrated circuit elements needing to be welded are reversed and arranged orderly through the inclined surface lifting plate, weld legs can face upwards, and then the rectangular integrated circuit elements are sequentially conveyed to a welding machine for later welding. The directional arrangement device is simple in structure, reasonable in design, convenient to operate, stable in performance, goodin reliability, capable of reducing the workload of workers, high in production efficiency, low in production cost, wide in market prospect, and capable of being popularized and applied in the technical field of circuit element welding.

Owner:SUZHOU INST OF INDAL TECH

Overturning and flattening device for image recognition ready-made clothes damage detection

InactiveCN110823903AGood flattening efficiencyGood flattening effectOptically investigating flaws/contaminationEngineeringImage identification

The invention discloses an overturning and flattening device for image recognition ready-made clothes damage detection, which relates to the technical field of ready-made clothes detection. The overturning and flattening device comprises a set of supporting plates, wherein a set of first fixing plates is fixed between every two supporting plates, a first flattening mechanism is fixed to one surface of each first fixing plate, and a set of second flattening mechanisms, a set of image recognition and detection mechanisms and a turnover mechanism are fixed between every two supporting plates. Through cooperation of the first flattening mechanisms and the second flattening mechanisms, clothes conveyed on a conveying belt can be effectively flattened, thus the flattening efficiency is better and the flattening effect is better when the clothes are subjected to damage detection; a plurality of round rollers in the turnover mechanism are driven by means of a second motor to rotate, so that rubber columns on the round rollers turns over the clothes quickly and effectively with cooperation of the supporting plates and the overturning plates, thereby improving the clothes detection efficiency, reducing the manpower consumption in the clothes detecting process, meanwhile, improving the clothes detection precision, and being conductive to later selling of the clothes.

Owner:安徽红爱实业股份有限公司

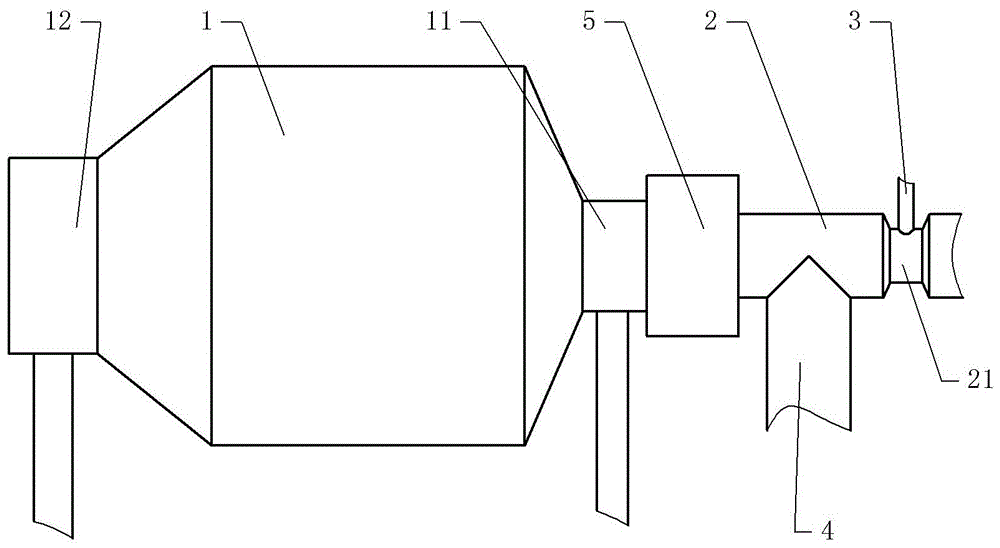

Low-temperature twisting device for tea leaves

The invention discloses a low-temperature twisting device for tea leaves. The low-temperature twisting device comprises a driving device, a twisting drum and a twisting roller, wherein the twisting roller is arranged in the twisting drum and does eccentric circular motion along the axis of the twisting drum; a feed opening and a discharge opening are formed in two ends of the twisting drum; an annular air supply pipeline connected with a nitrogen making machine externally is arranged on one end close to the discharge opening, of the twisting drum; multiple nozzles inclining towards the inner part of the twisting drum are arranged on the air supply pipeline; and the twisting drum is arranged in an inclined manner. According to the low-temperature twisting device for tea leaves, disclosed bythe invention, nitrogen is inflated into the twisting drum capable of performing continuous twisting, heat generated in the twisting process of the tea leaves is removed, and the oxidation of oxygenon tea liquor in the twisting process is eliminated, so that the tea leaves are better in chromaticness, taste and fragrance; and besides, the tea twisting efficiency is improved.

Owner:成都兆丰斯诺科技有限公司

Drying cylinder for waste slurry

InactiveCN103759526ADry fastGuaranteed drying uniformityDrying gas arrangementsDrying chambers/containersPulp and paper industrySlurry

The invention relates to a drying cylinder for waste slurry. The drying cylinder comprises an inner cylinder body, an outer cylinder body, a feeding end and a discharging end, wherein the outer cylinder body is coaxially and fixedly arranged outside the inner cylinder body, one end of the outer cylinder body and one end of the inner cylinder body on the same side are rotatably arranged at the feeding end, the other end of the outer cylinder body and the other end of the inner cylinder body on the same side are rotatably arranged at the discharging end, the positon, in the inner cylinder body, of the feeding end is provided with a waste slurry inlet and a hot air main inlet, and a hot air auxiliary inlet is disposed in the position, between the inner cylinder body and the outer cylinder body, of the feeding end. The waste slurry is quickly dried through hot air of the main inlet, and meanwhile waste slurry attached to the inner cylinder wall is quickly dried through hot air of the auxiliary inlet, so that drying evenness and drying efficiency are guaranteed.

Owner:TIANZI ENVIRONMENTAL PROTECTION EQUIP MFG TIANJIN

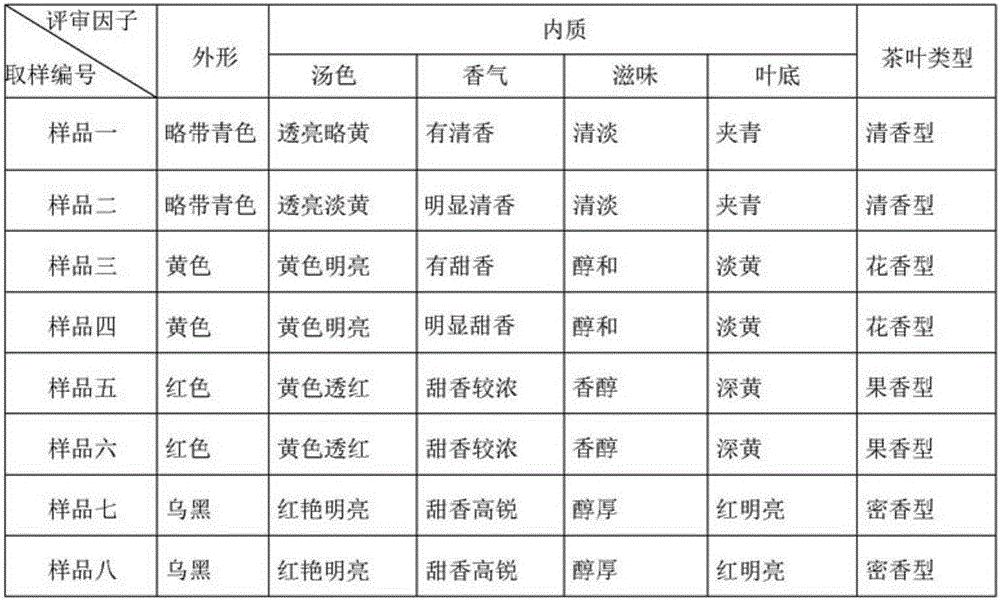

Nitrogen-charging black tea fermenting method

InactiveCN106417723AUniform fermentationHelps control oxygen contentPre-extraction tea treatmentNitrogenBlack tea

The invention discloses a nitrogen-charging black tea fermenting method and relates to a tea production method. The method comprises five steps including a preparation stage, a green tea adding state, a fermentation stage, a nitrogen charging state and a fermentation stopping stage, wherein at the nitrogen charging stage, nitrogen is charged into a fermentation tank, so that the nitrogen content of the fermentation tank is gradually increased from 70% to 90%; at the fermentation stopping stage, tea in the fermentation tank is sampled once every 2-5 minutes, the color and the aroma of the tea are compared, and air introduction is stopped after the tea aroma meets the requirements. The content of nitrogen in the air can be increased and the oxygen content can be reduced through nitrogen charging, so that the fermentation time can be prolonged, and sampling analysis is facilitated.

Owner:贵州黔茗茶业销售有限公司

Convenient tool box used for debridement

The invention discloses a convenient tool box used for debridement. A structure of the convenient tool box used for debridement comprises bottom supporting legs which are arranged circlewise in an array mode, wherein transverse supporting legs which are vertically symmetric and form rectangular frames are fixedly arranged above the bottom supporting legs, a plurality of vertical supporting rods are fixedly arranged among the transverse supporting rods, a sliding box device which is used for placement of scalpels and surgical equipment and has a garbage collecting function is arranged among thetransverse supporting rods, the equipment adopts the sliding box device, a placement platform device and a sliding box driving device, the sliding box driving device is used for driving the sliding box device to move at the same time, by means of relative structures arranged in the sliding box device, loading of a chemical protective garbage bag and placement of relative surgical items are achieved, a folding turn-over working mode is used by the placement platform device, therefore, biological waste in a surgical process is efficiently loaded in the chemical protective garbage bag, and by adopting the folding mode, efficient folding is achieved.

Owner:贾韩静

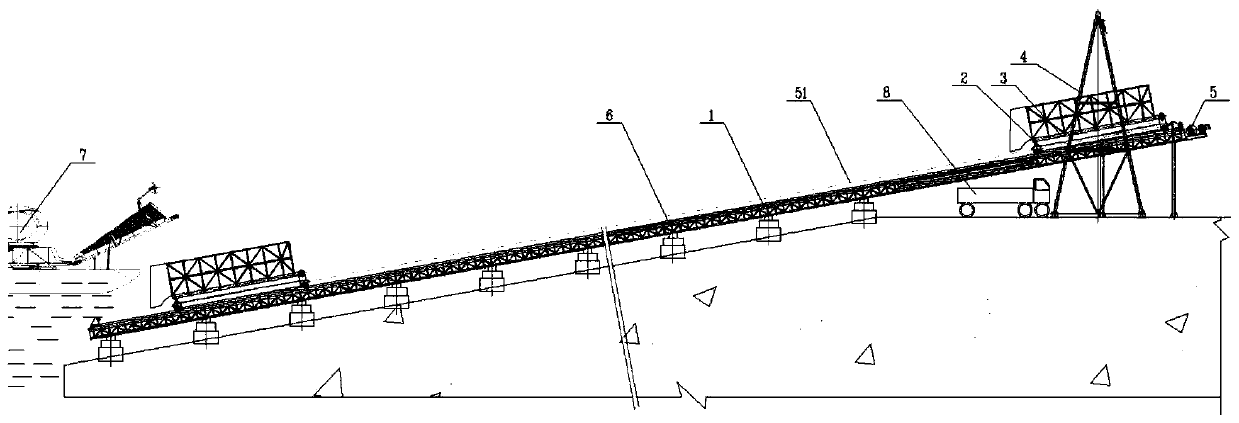

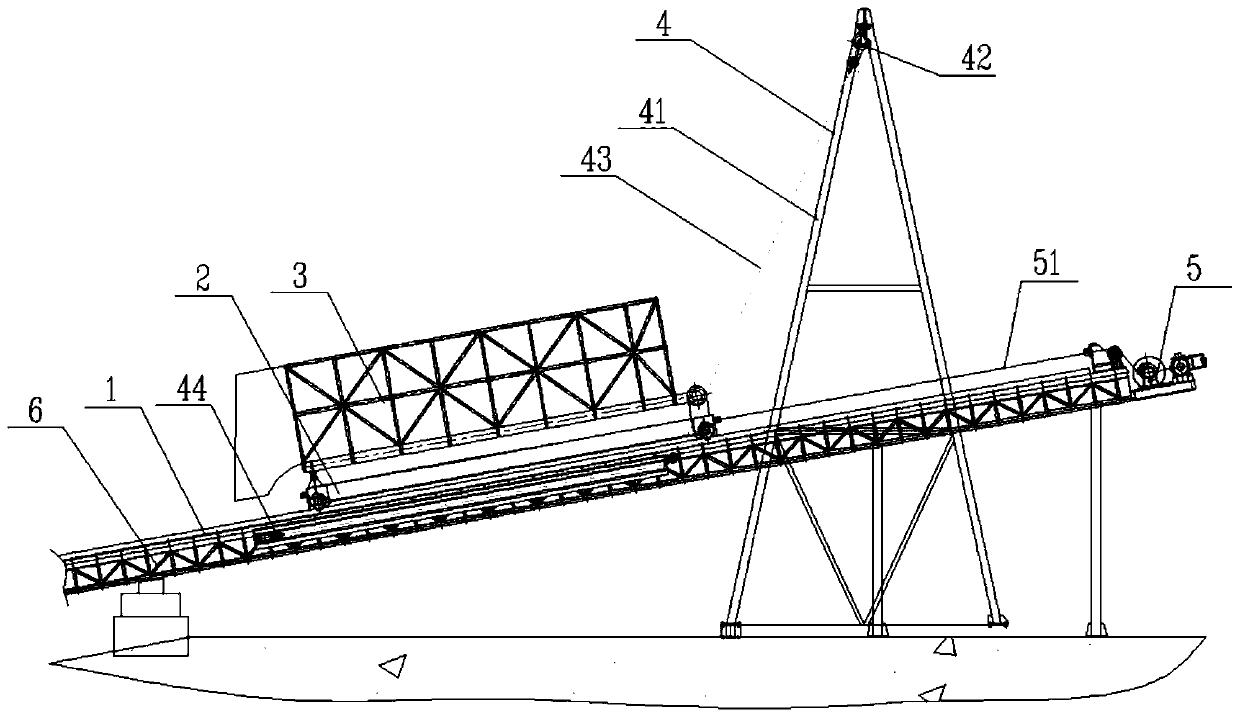

Turnable discharging device for ashore conveying of floating objects on water

PendingCN111332974AEfficient flipNo need for long distance shippingWater cleaningWinding mechanismsWinchIndustrial engineering

The invention discloses a turnable discharging device for ashore conveying of floating objects on water. The turnable discharging device comprises a conveying rail, a conveying bin trolley, a turnoverdevice, a winch and a controller, wherein the conveying rail is fixed to a supporting frame; the conveying bin trolley is connected to the conveying rail in a sliding mode, and a conveying bin is placed on the conveying bin trolley; the conveying bin trolley is further connected with the winch, the winch is fixed to the conveying rail and used for pulling the conveying bin trolley; and the turnover device is connected with the conveying rail and the conveying bin trolley and used for enabling the conveying bin to be turned over, and the controller is used for controlling the turnover device and the winch to work. The turnable discharging device for the ashore conveying of the floating objects on the water is simple in structure, the conveying bin can be effectively turned over through theconveying rail, the winch and the turnover device, and the floating objects inside the conveying bin are dumped out; and meanwhile, the dumping steps are synchronously optimized, so that the efficiency of the turnable discharging device is obviously improved, the labor cost also is reduced, and the floating objects do not need to be conveyed over long distances by manpower.

Owner:SICHUAN ORIENT HYDROELECTRIC ENG

Turnover device for steel structure welding

InactiveCN110315270AEfficient flipEffectively fixedWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThreaded rod

The invention relates to the technical field of steel structures, in particular to a turnover device for steel structure welding. The device comprises a bottom plate, a first supporting plate is fixedly arranged on one side of the upper surface of the bottom plate, one end of an output shaft of a motor penetrates through a second supporting plate and is fixedly provided with a rotating shaft, oneend of the rotating shaft is fixedly provided with a second fixing plate, a threaded sleeve pipe is fixedly arranged at the upper part of the first supporting plate in a penetrating mode, the threadedsleeve pipe is in threaded connection with a threaded rod, one side of the rotating mechanism is fixedly provided with a first fixing plate, guiding rods are fixedly arranged at the two ends of one side of the first fixing plate, the other end of the threaded rod extends to the other side of the threaded sleeve pipe and is fixedly provided with a rotating disc, a rotating handle is fixedly arranged on one side of the rotating disc, a fastening nut is fixedly arranged on one side of the upper surface of the threaded sleeve pipe, and a pushing rod is fixedly arranged on one side of the upper surface of the bottom plate. The turnover device for steel structure welding has the advantages of being used for conveniently fixing and turning over steel structure welded parts, and being simple to operate, convenient to use and high in practicability.

Owner:HUBEI XINSUO CONSTR

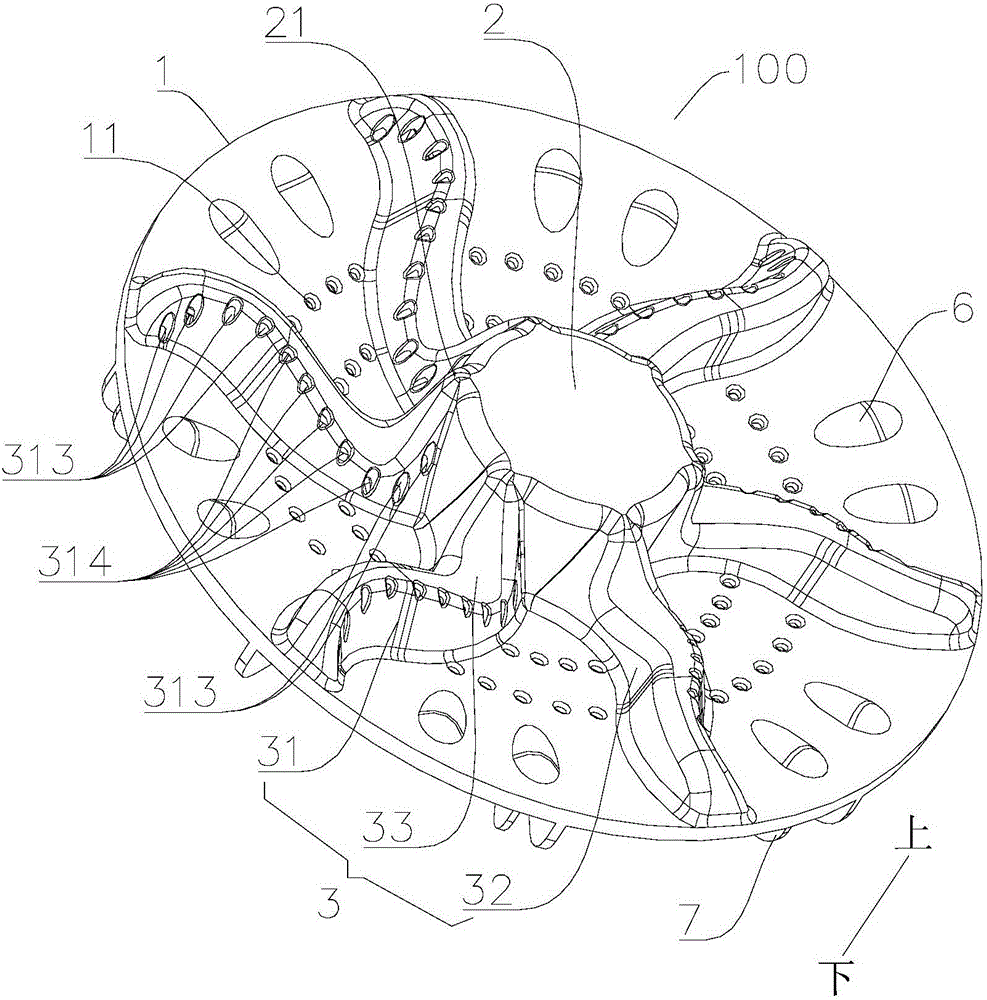

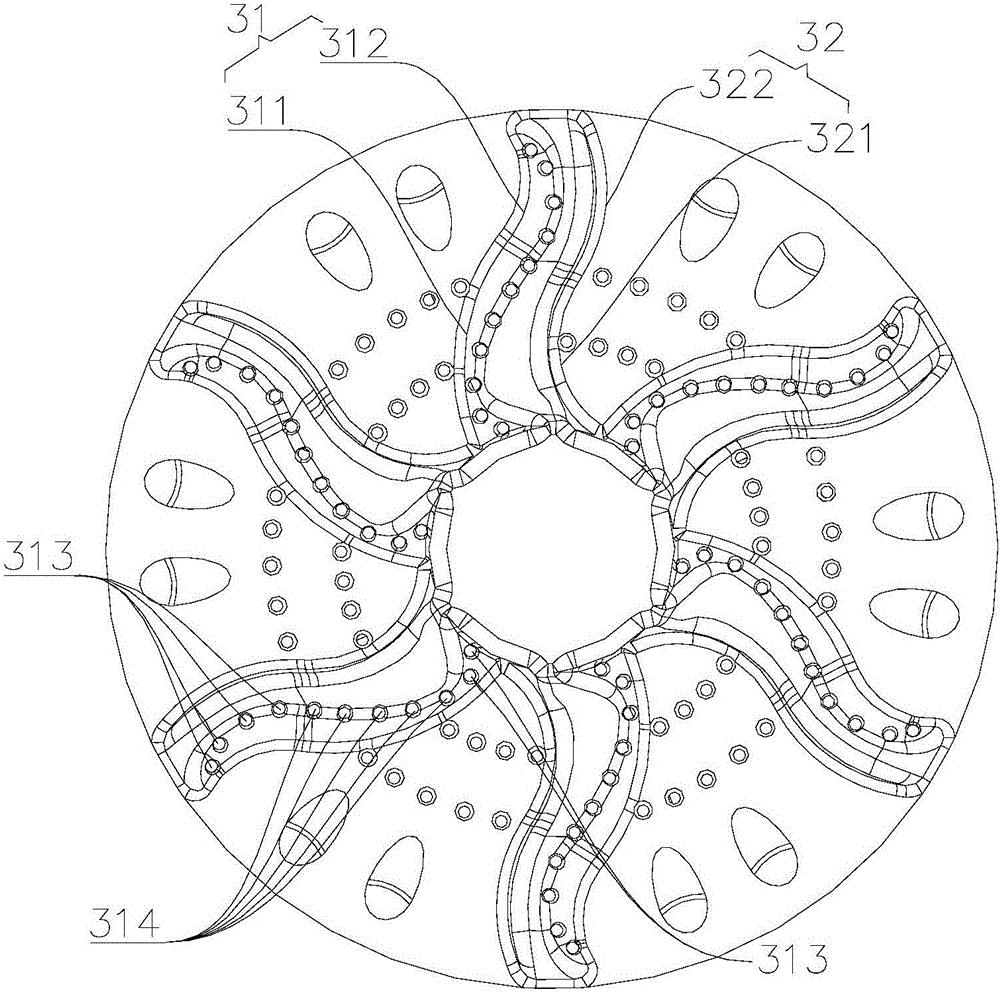

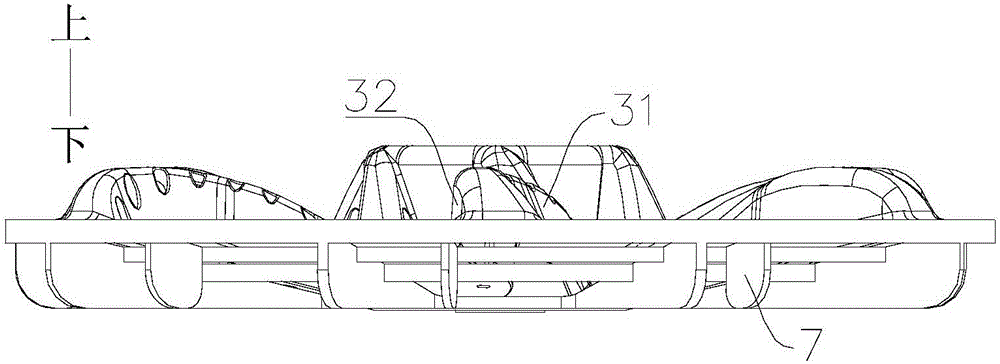

Pulsator washing machine

ActiveCN105088615AEfficient flipAvoid wrinklesWashing machine with receptaclesTextiles and paperEngineeringWater spray

The invention discloses a pulsator washing machine which comprises a pulsator and an inner drum. The pulsator is rotationally arranged in the inner drum, and a washing space is commonly defined by the pulsator and the inner drum. The pulsator comprises a pulsator disc, a central boss and a plurality of lifting ribs. The central boss is arranged on the side, close to the washing space, of the pulsator disc, the lifting ribs are distributed in the circumferential direction of the central boss at intervals, at least part of the lifting ribs are arranged on one side of the pulsator disc and extend in the radial direction of the pulsator disc, in the rotating direction of the pulsator, each lifting rib comprises a rotating upstream face and a rotating backwater face, and at least one water spraying hole for leading water on the other side of the pulsator disc into the washing space is formed in each lifting rib. According to the pulsator washing machine, clothes can be effectively overturned, the clothes are prevented from being wound and crumpled, and the washing effect is stronger.

Owner:HEFEI MIDEA WASHING MACHINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com