Overturning conveying device

A conveying device and conveying line technology, which is applied in the direction of conveying objects, transportation and packaging, etc., can solve the problems of high use cost and maintenance cost, expensive manipulator equipment, complex structure, etc., achieve simple structure, fast work, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

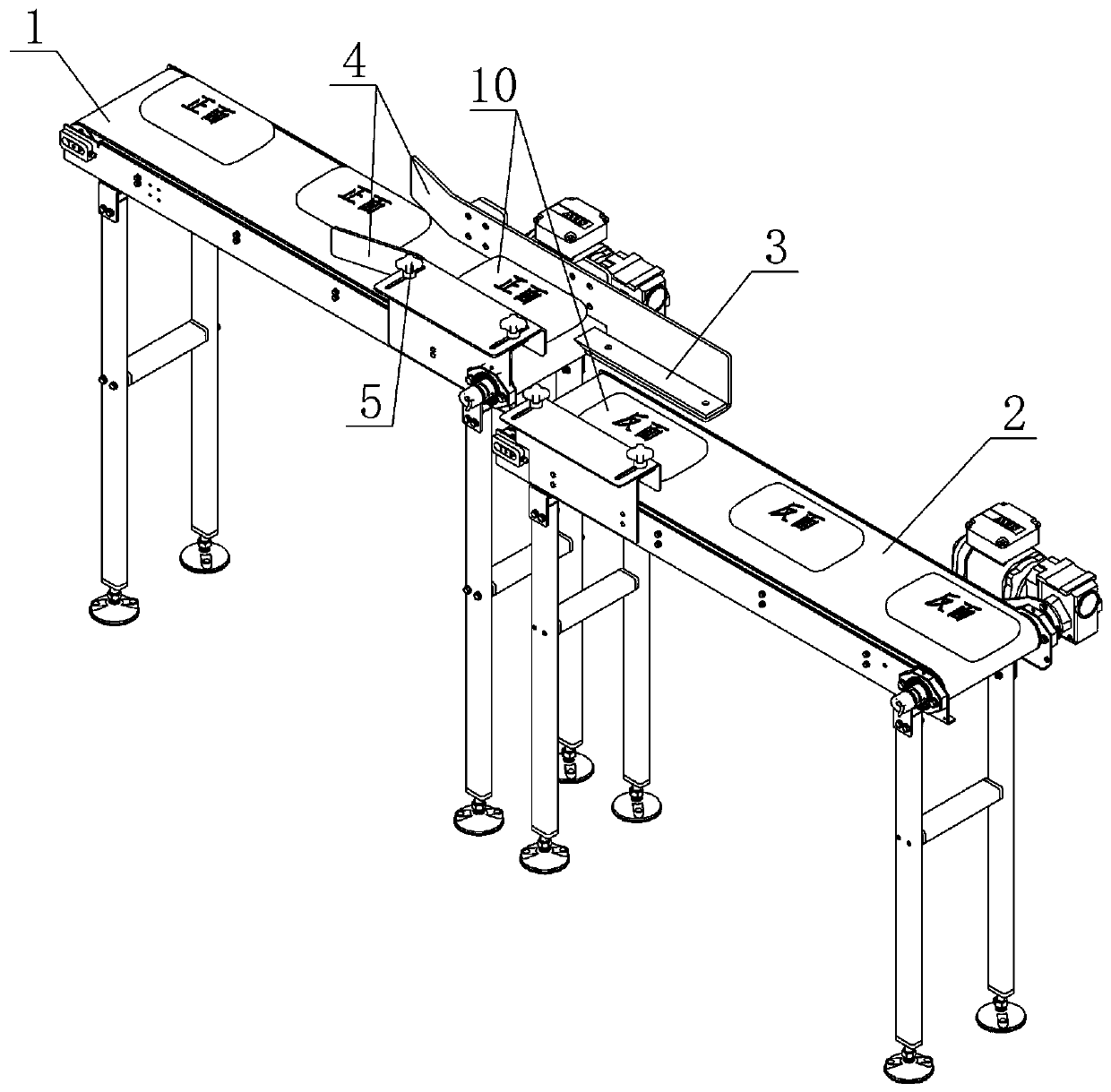

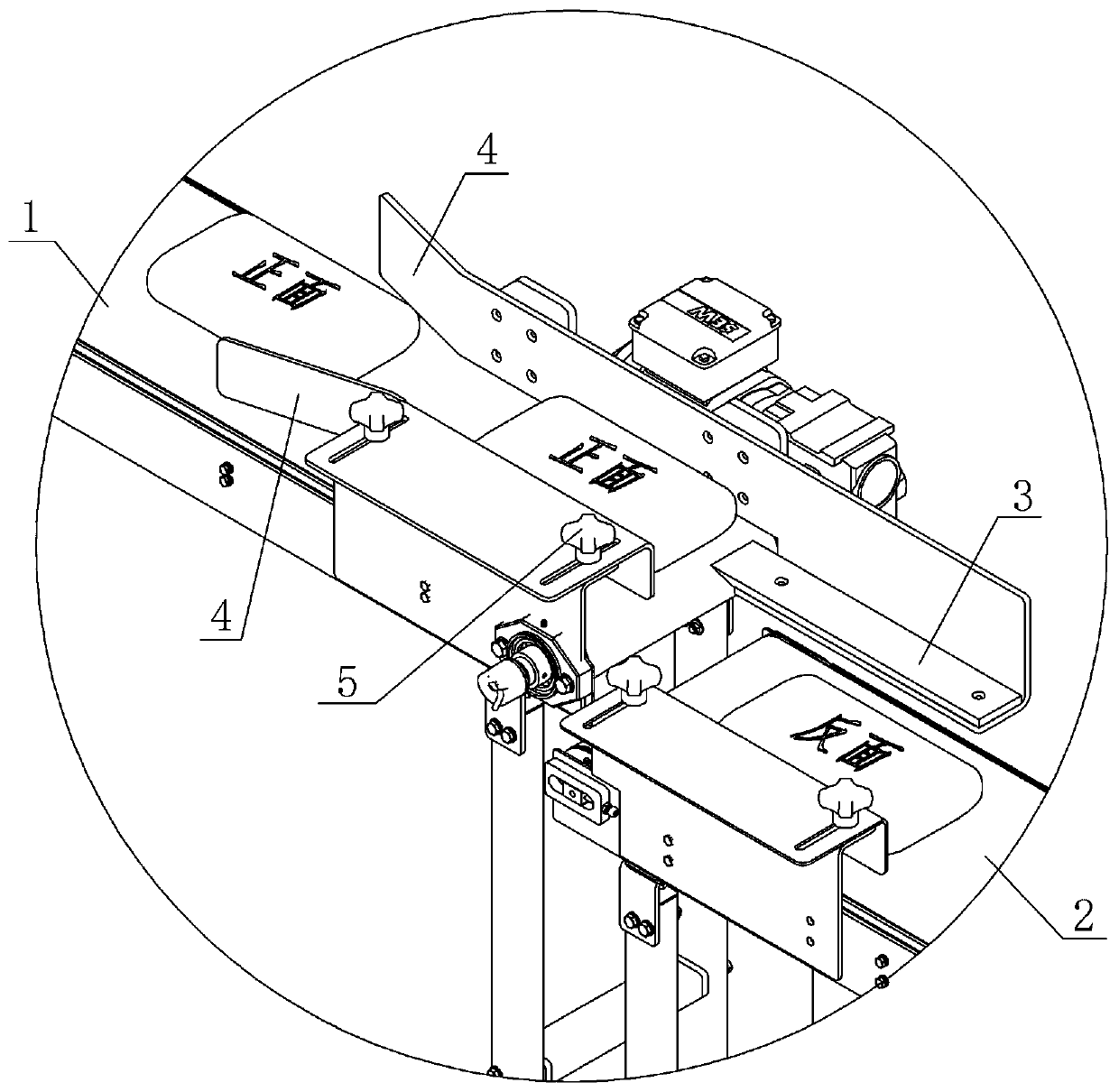

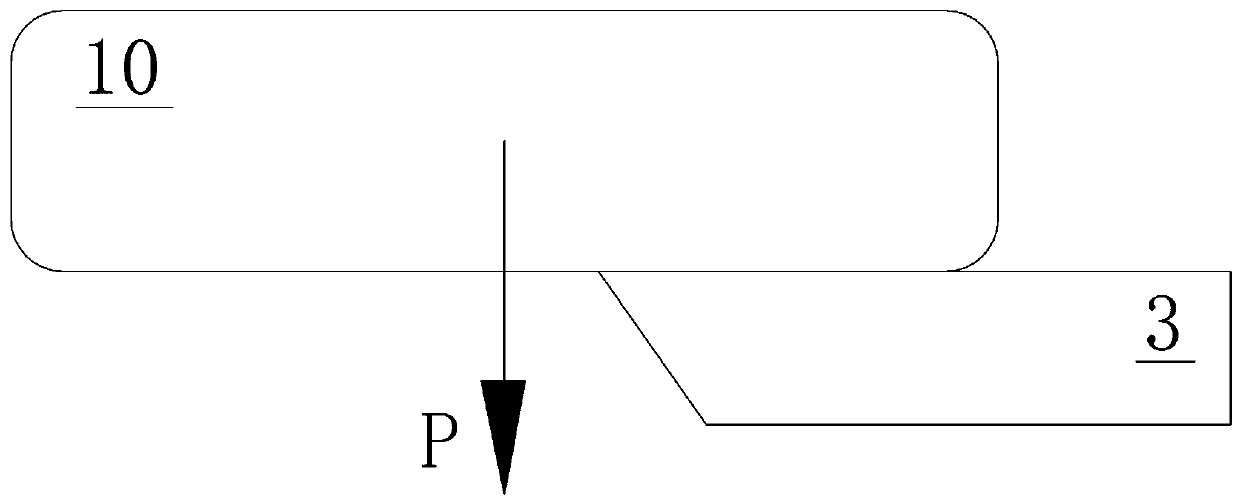

[0009] A reversing conveying device, comprising an upper conveying line 1 and a lower conveying line 2, the lower conveying line is located below the output end of the upper conveying line, a reversing plate 3 is fixedly installed outside the output end of the upper conveying line and above the lower conveying line, and the reversing The plate extends from one side above the lower conveying line to the middle, and the end of the turning plate extension does not exceed the center of gravity of the position where the conveyed object 10 is output from the upper conveying line, and the top surface of the turning plate is parallel to the conveying surface of the upper conveying line And the height is not higher than the conveying surface of the conveying line.

[0010] Such as Figure 1-3 As shown, the conveyed object falls into the top surface of the turning plate along the upper conveying line, and the lateral end of the turning plate does not exceed the center of gravity line P ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com