Automatic paper overturning and coating machine

An automatic turning and covering technology, which is applied in the direction of turning objects, pile separation, thin material handling, etc., can solve the problems of uneconomical, low production efficiency, poor quality of turning paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

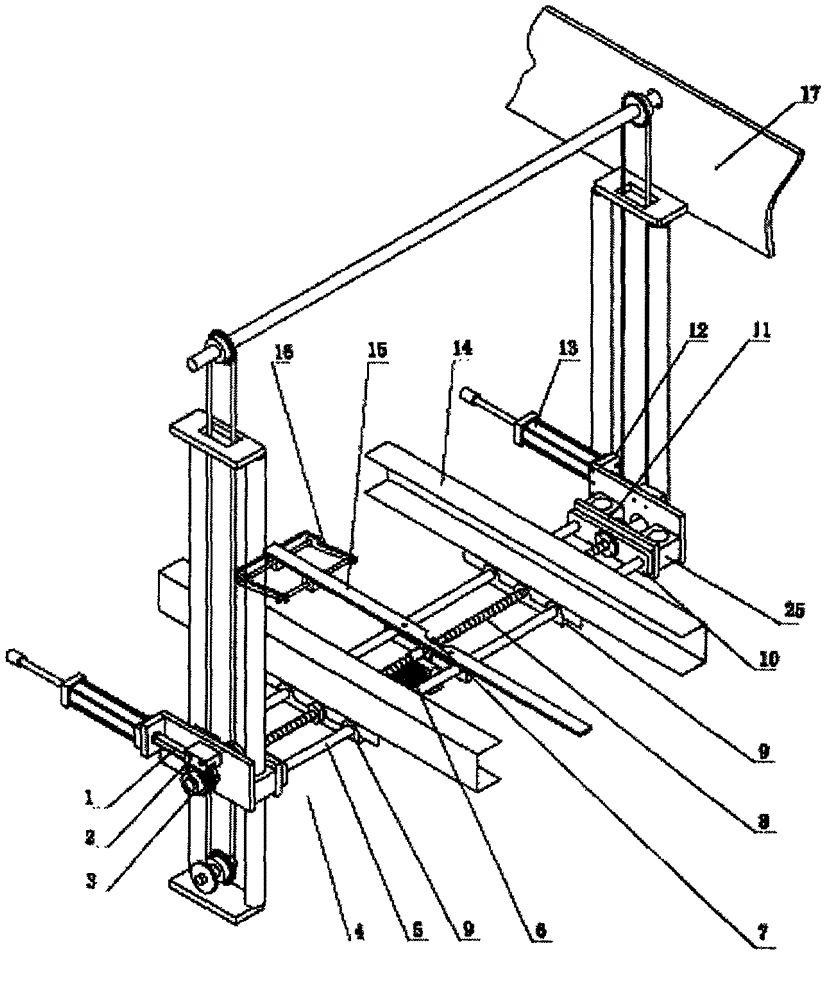

[0011] In the automatic paper turning and laminating machine shown in the figure, the reversing frame 4 is a frame-type reversing frame, which can rotate relative to the fuselage 17. The frame-type reversing frame includes two guide rods 5 arranged in parallel. The connecting shaft end plates 10 at the two tops of the guide rods 5, the connecting shaft end plates 10 and the guide rods 5 are combined together to form an overturning frame body, and a screw mandrel 8 is arranged in parallel between the two guide rods 5, and the screw mandrel 8 It is one, and the direction of rotation of the threads on both sides of the screw mandrel 8 is opposite. The opposite two screw rods are combined through a coupling. In the middle of the guide rods 5 arranged in parallel, a paper stop arm connecting frame 15 is fixedly arranged, and a paper stop arm 16 is hinged on the paper stop arm connecting frame 15. There are two paper stop arms 16, and the paper stop arms 16 are opposite to each othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com