Patents

Literature

801results about "Overturning articles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

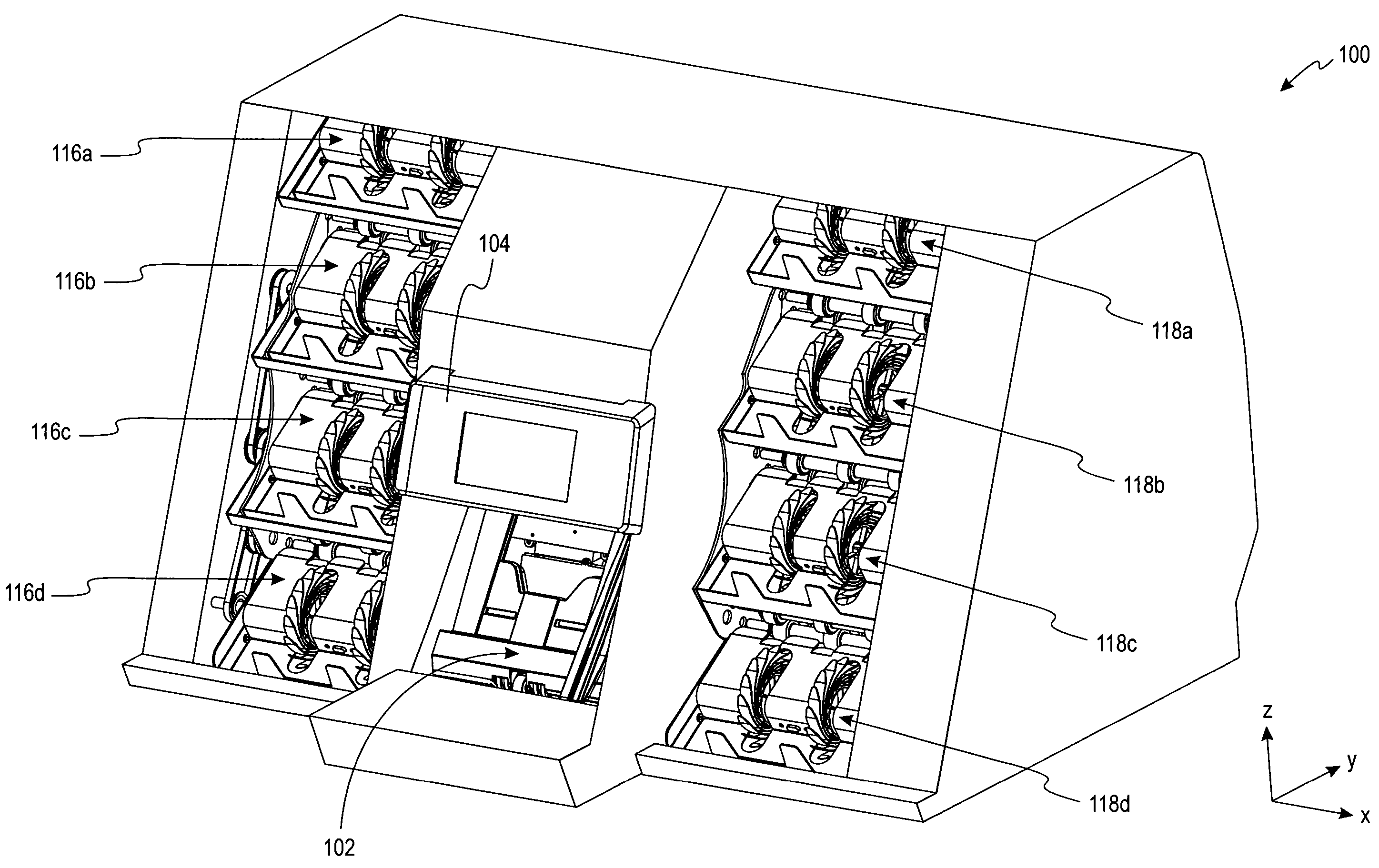

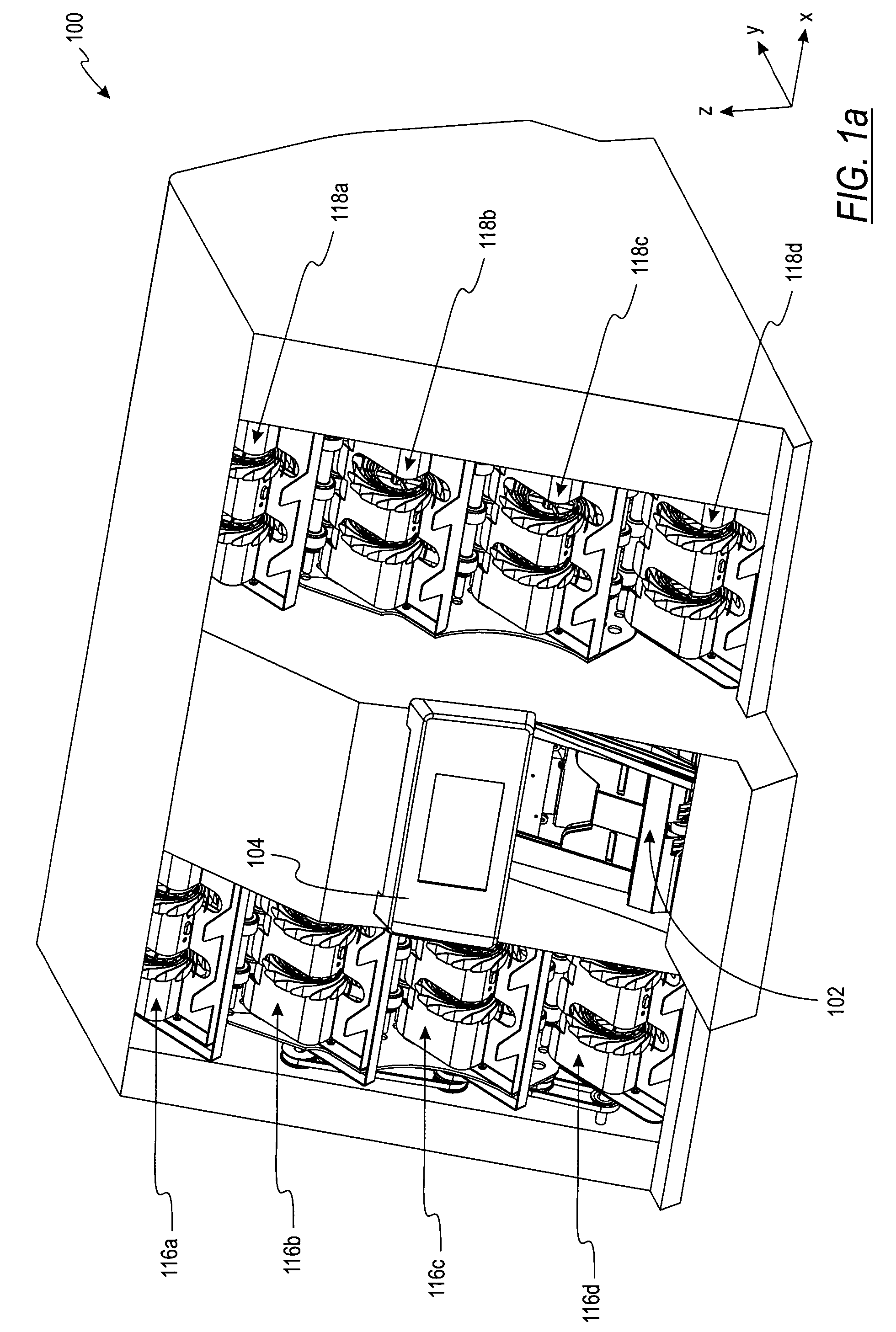

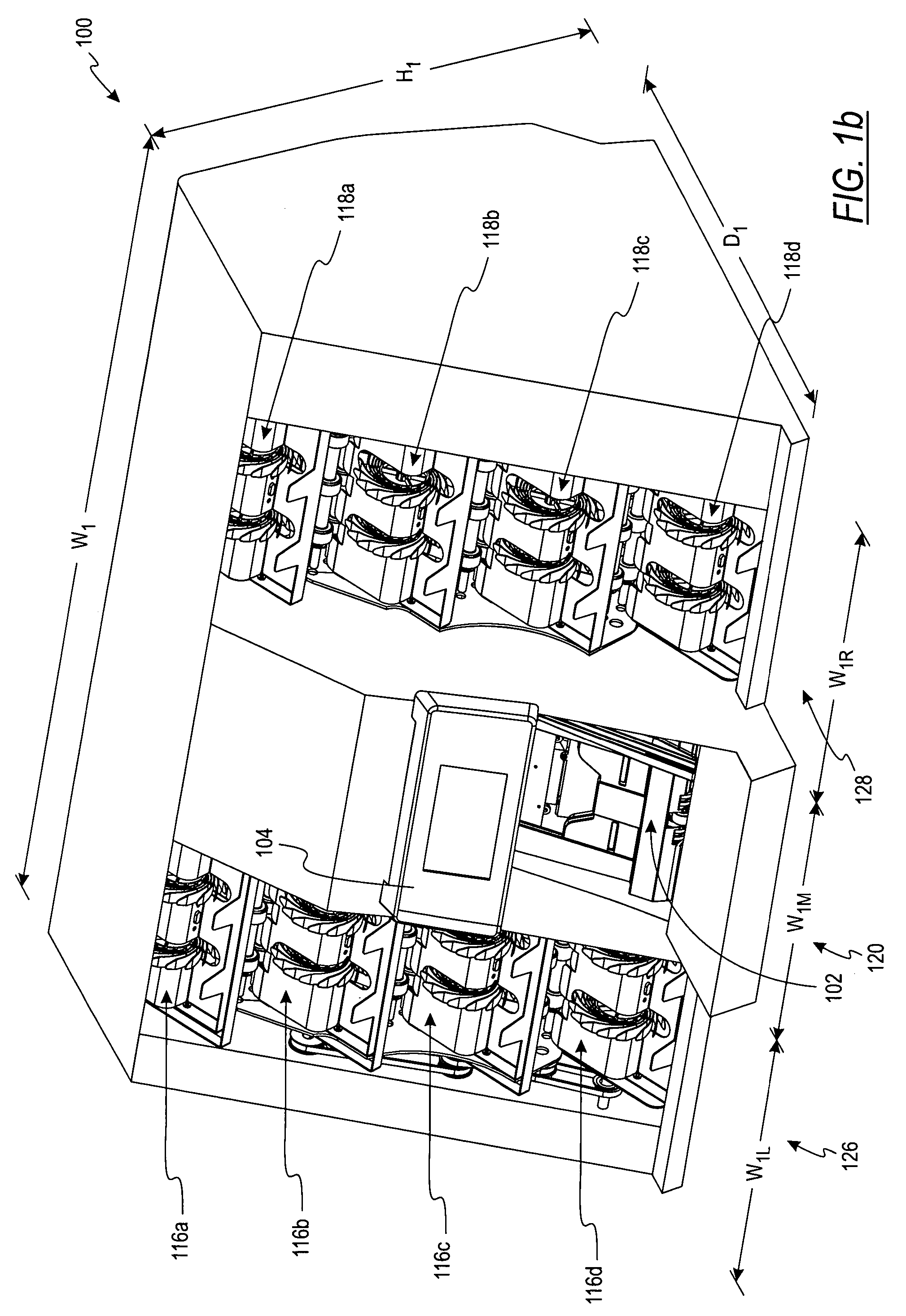

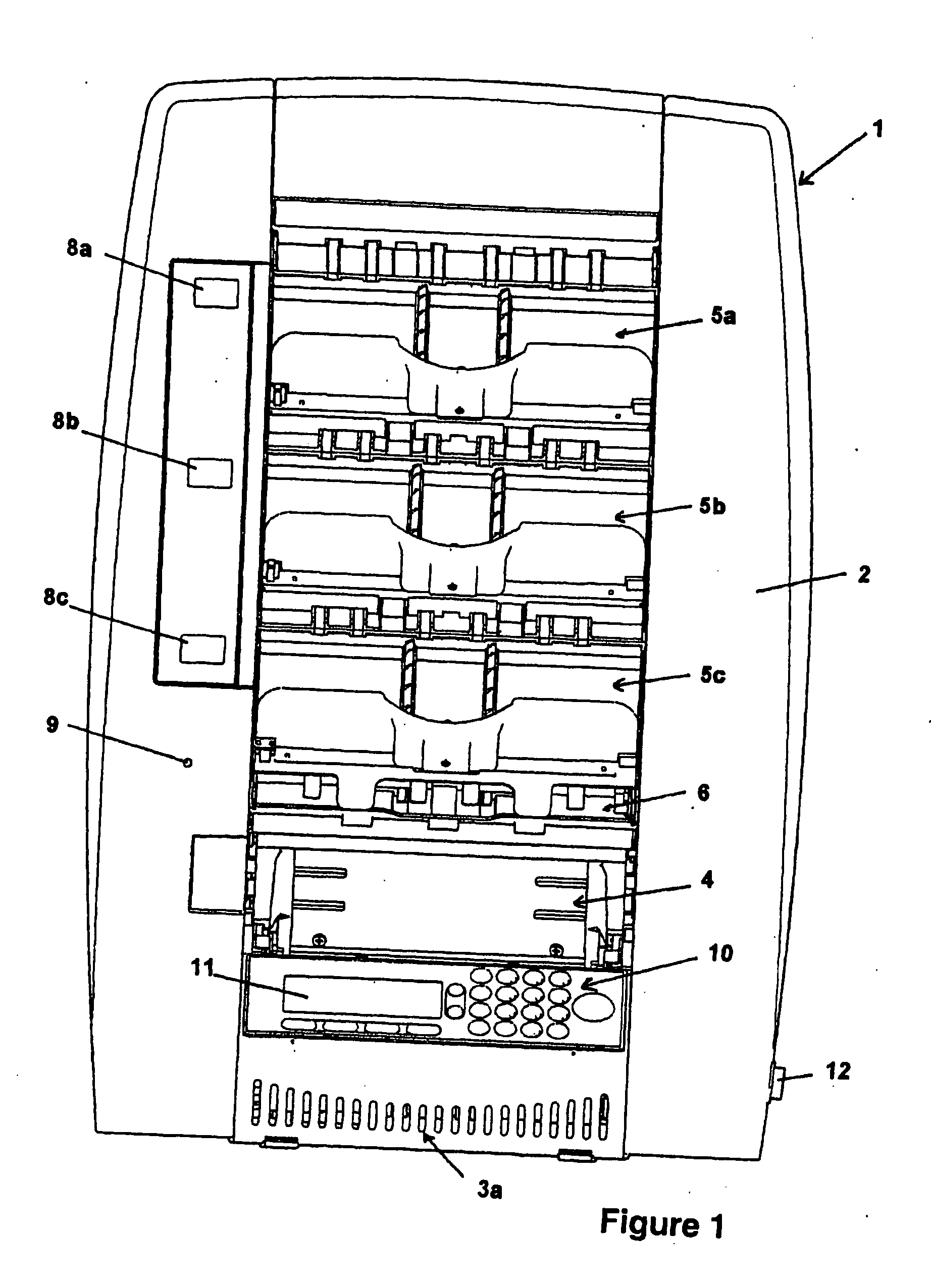

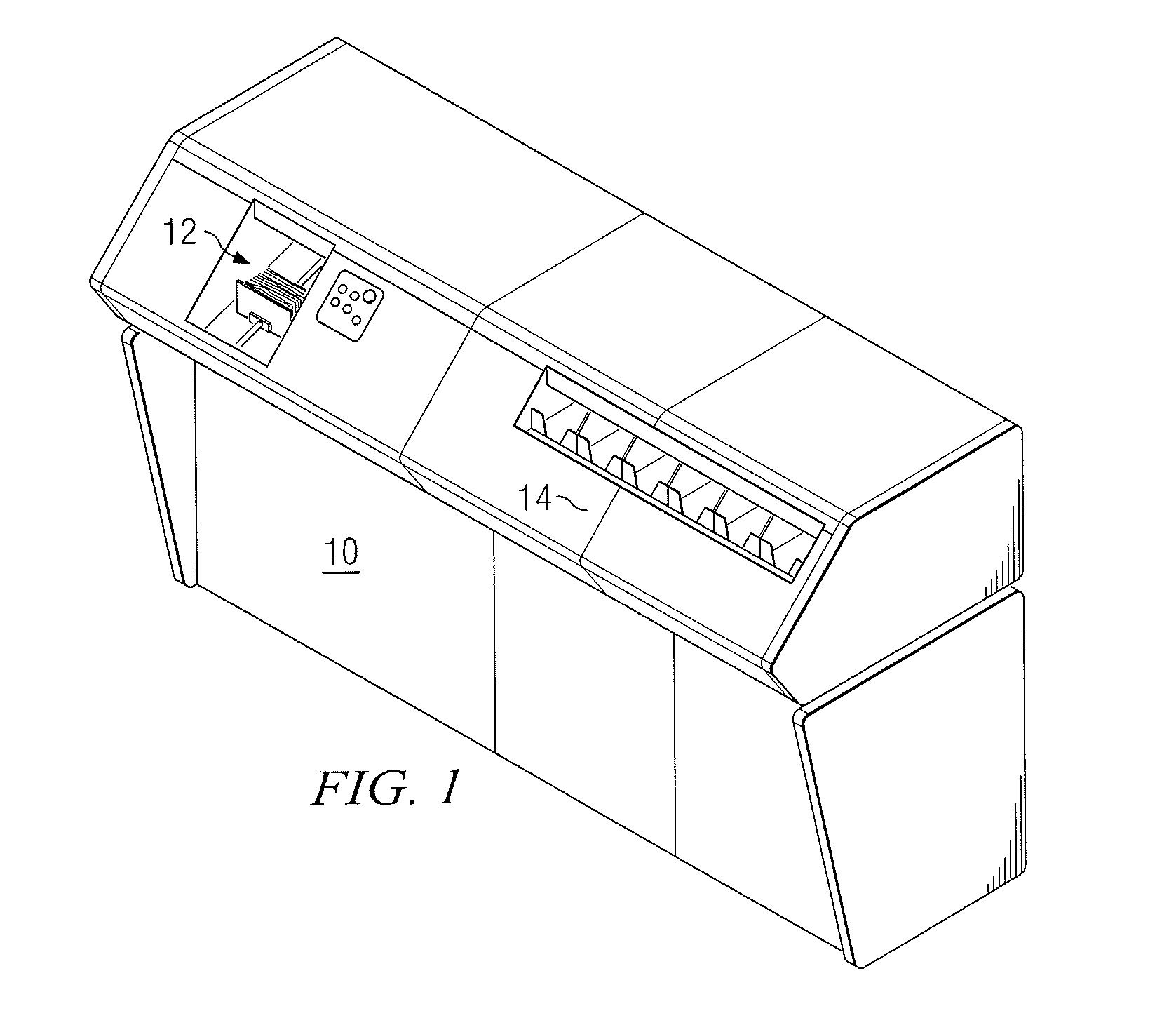

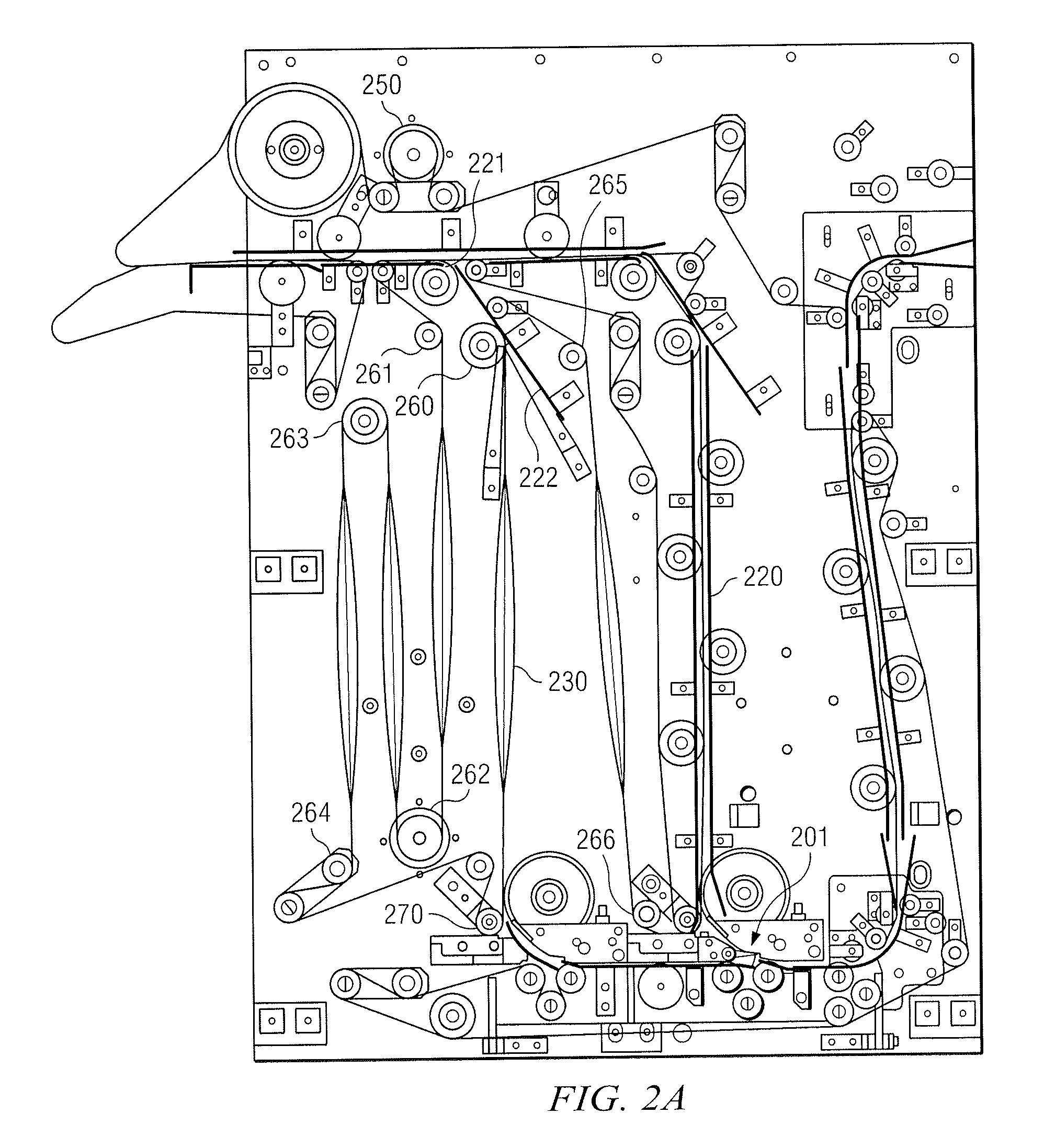

Currency processing device, method and system

InactiveUS20050029168A1Rapid assessmentClose proximityOverturning articlesCoin/currency accepting devicesEngineering

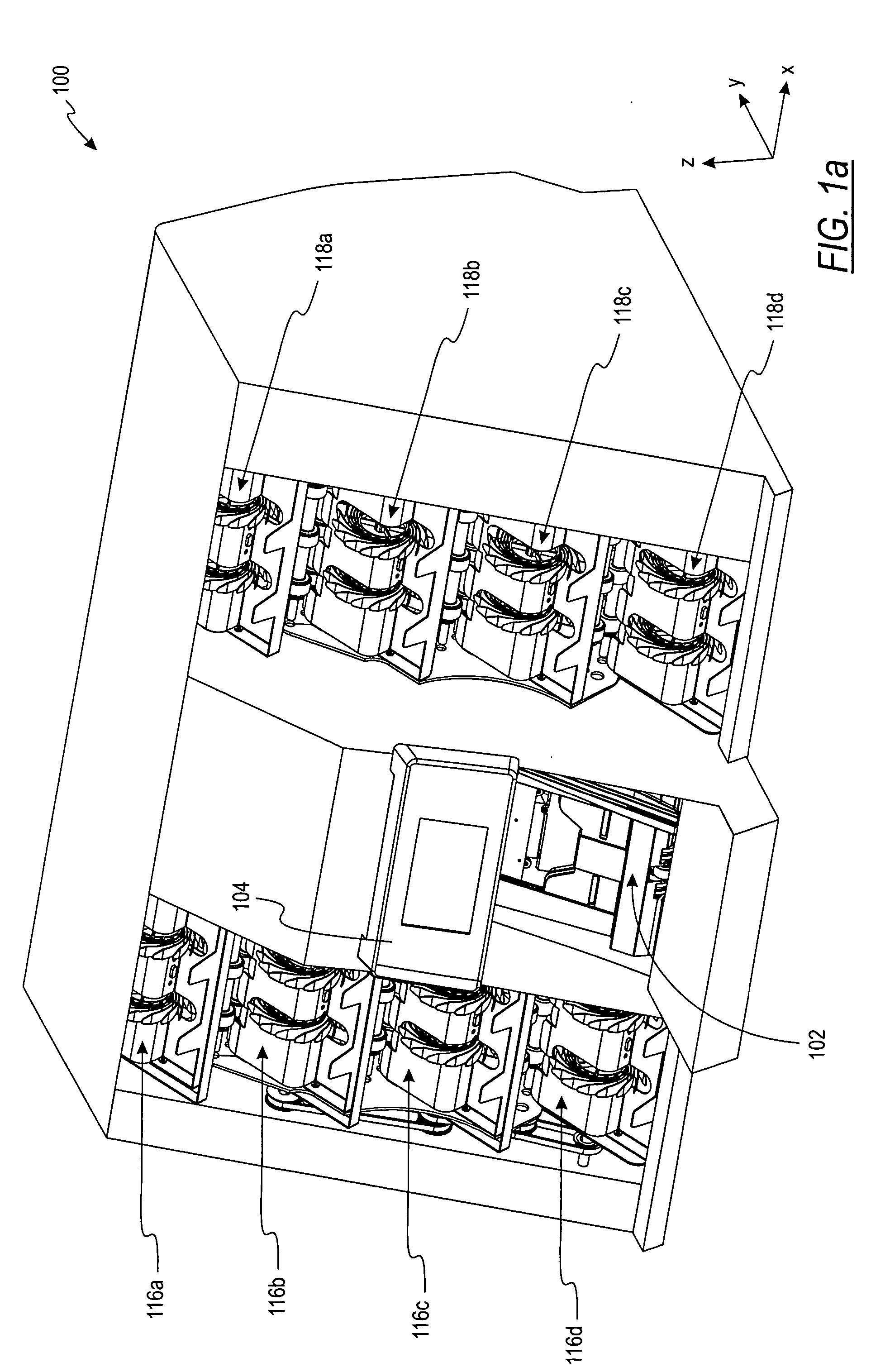

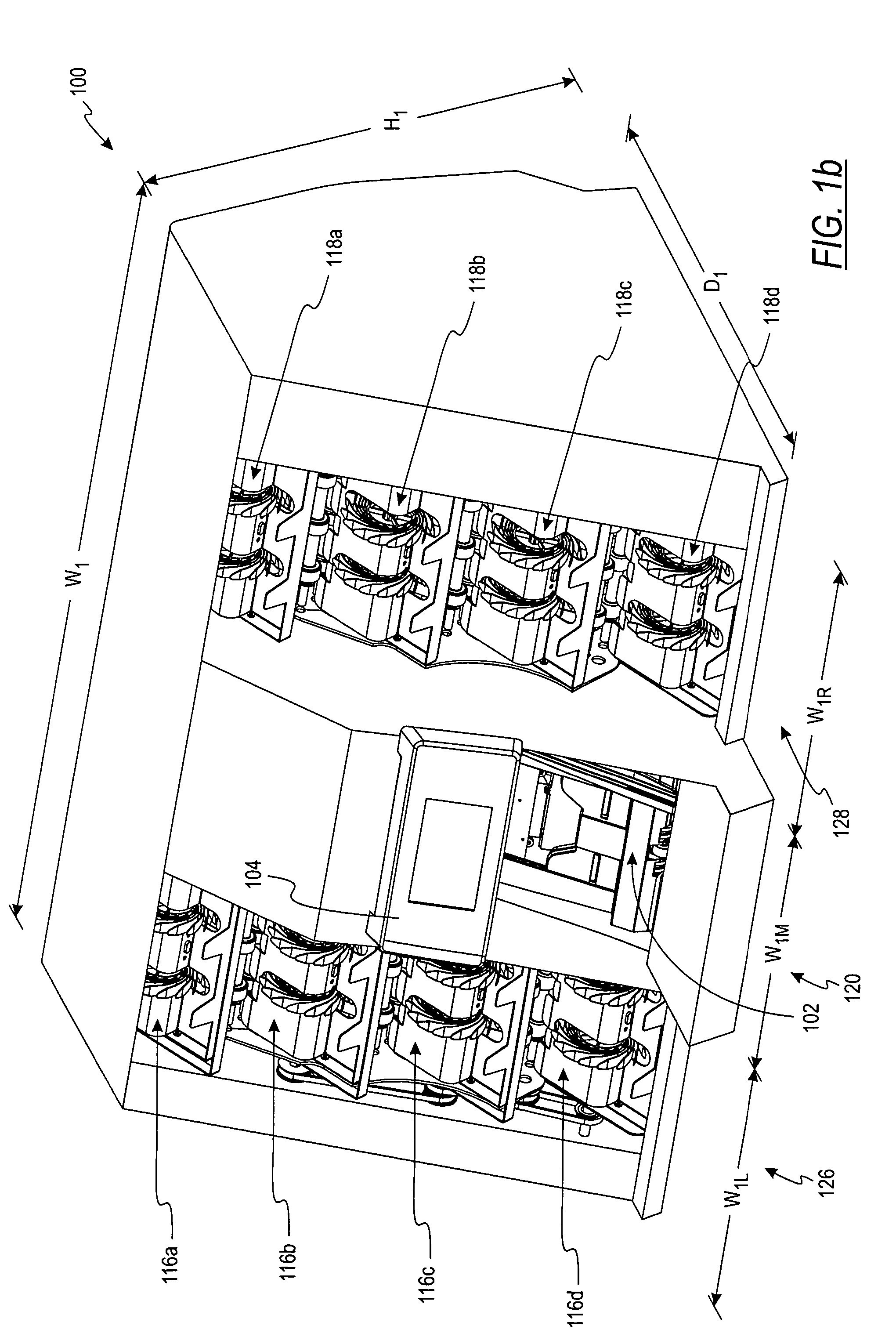

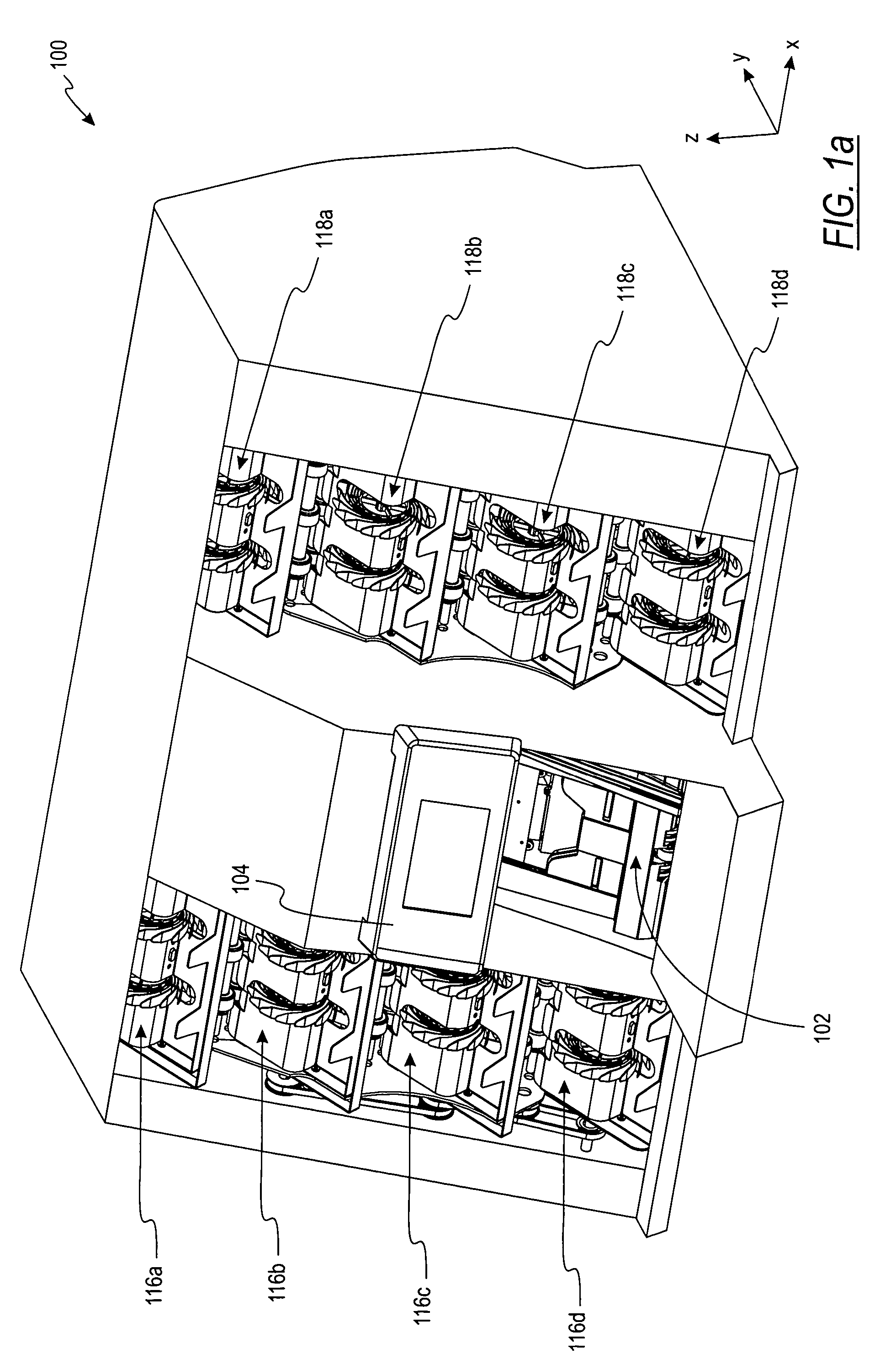

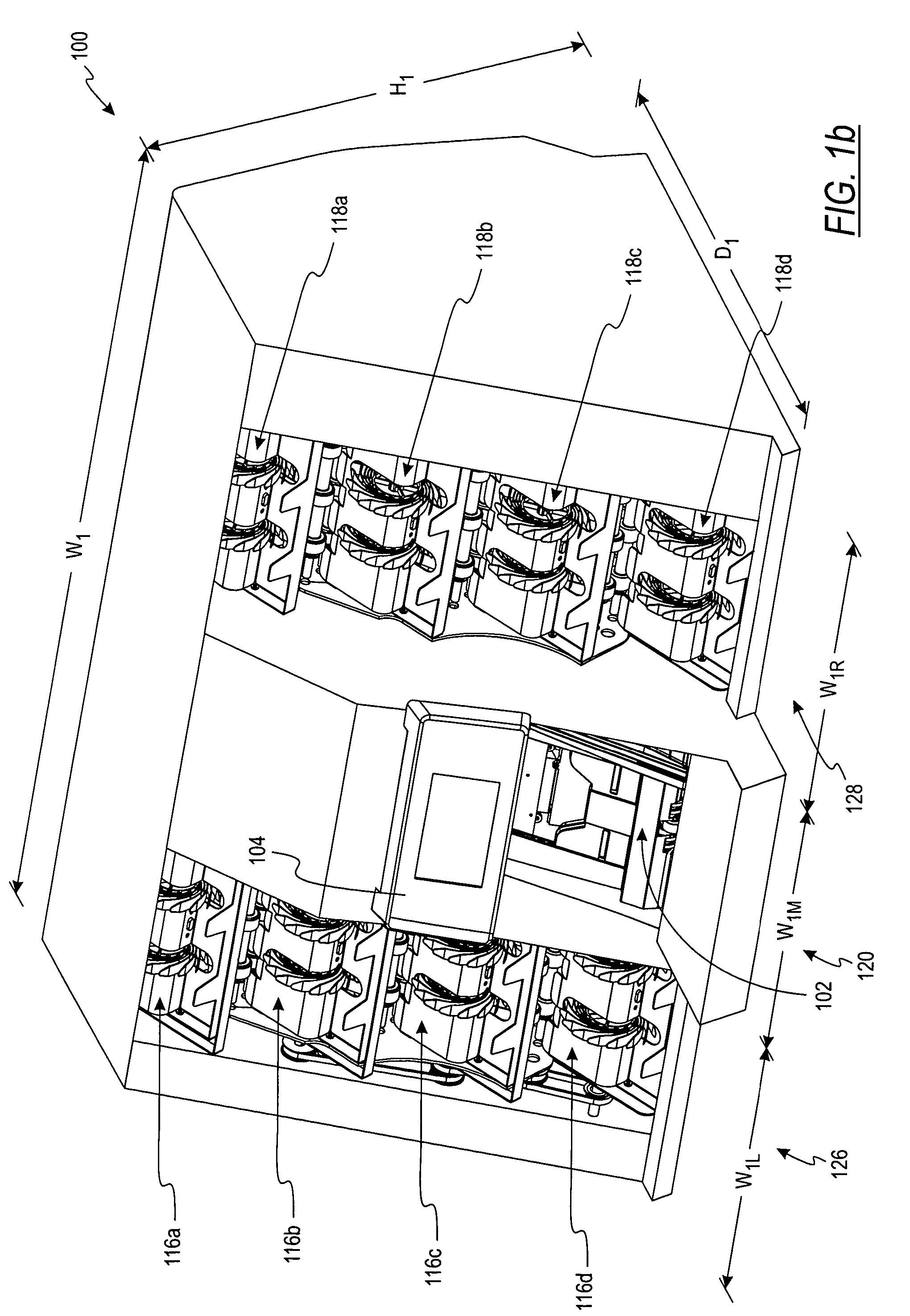

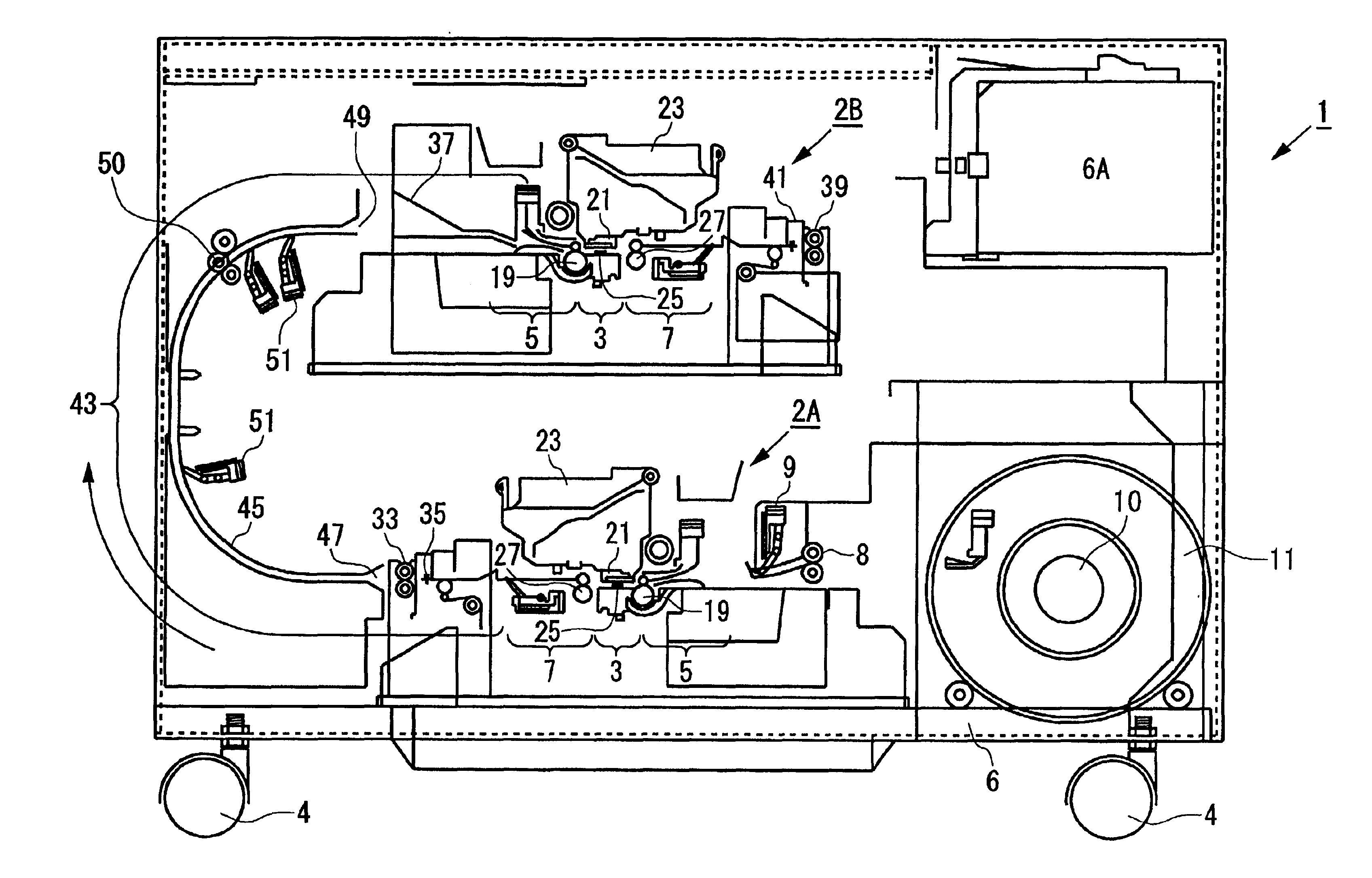

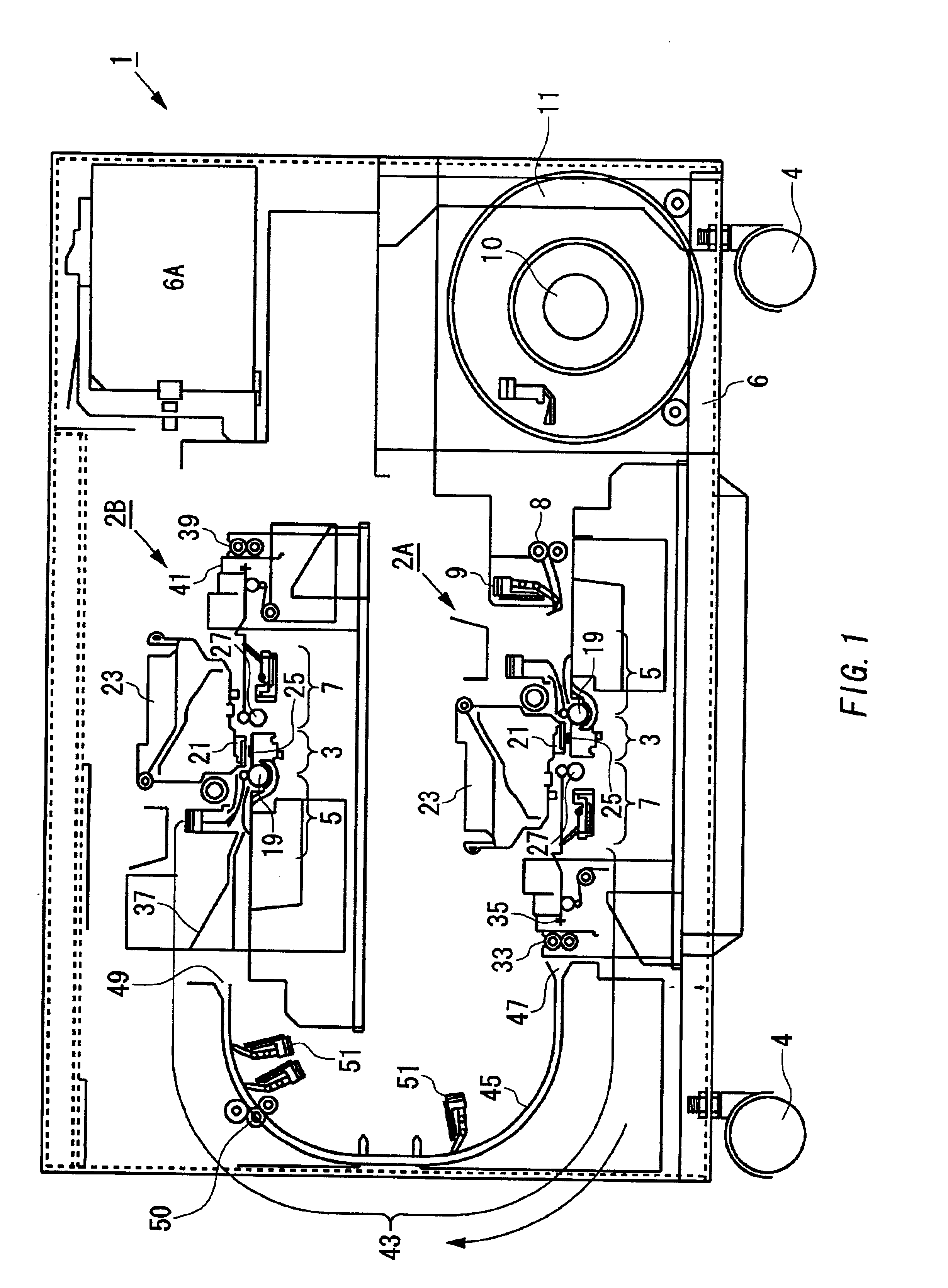

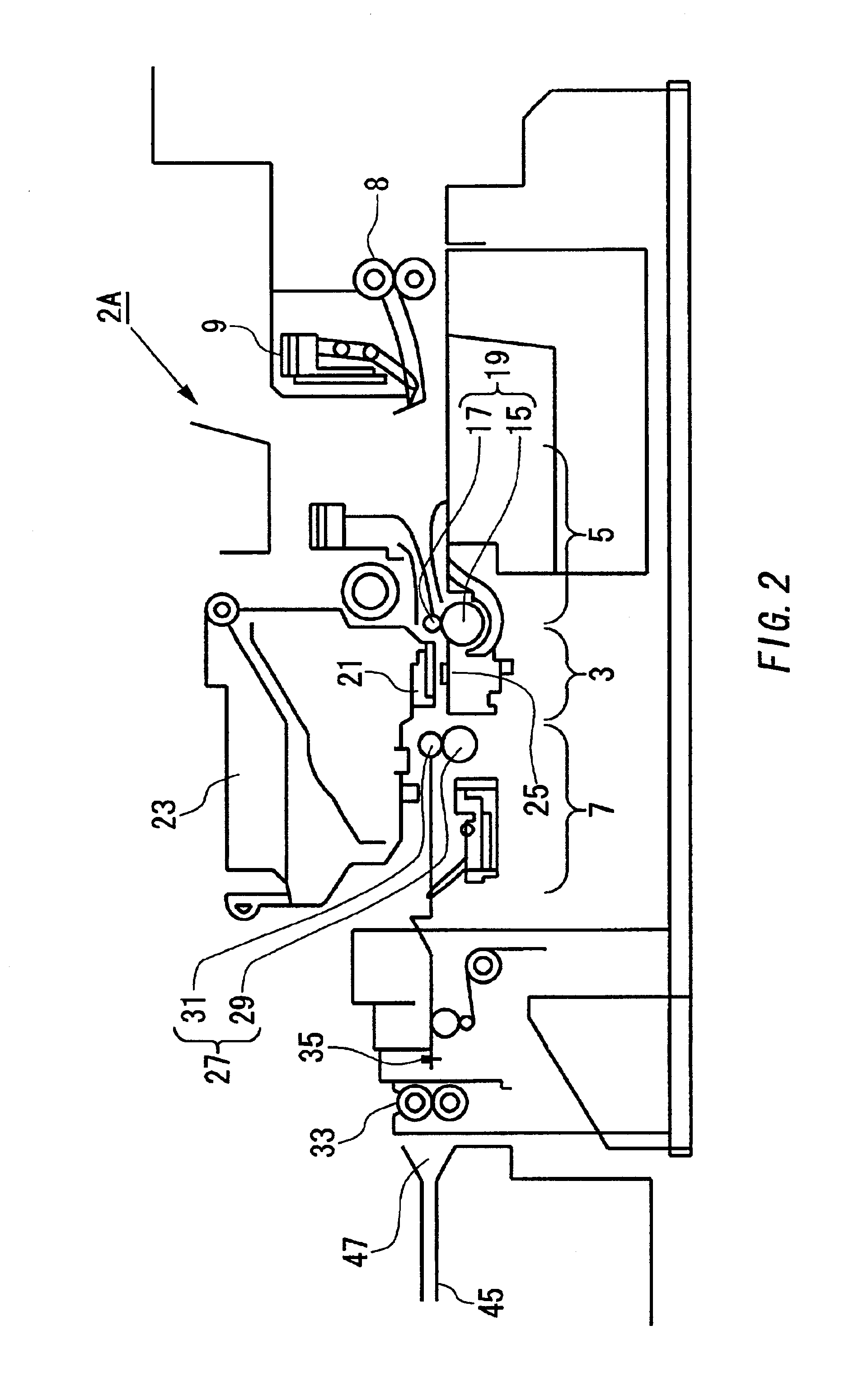

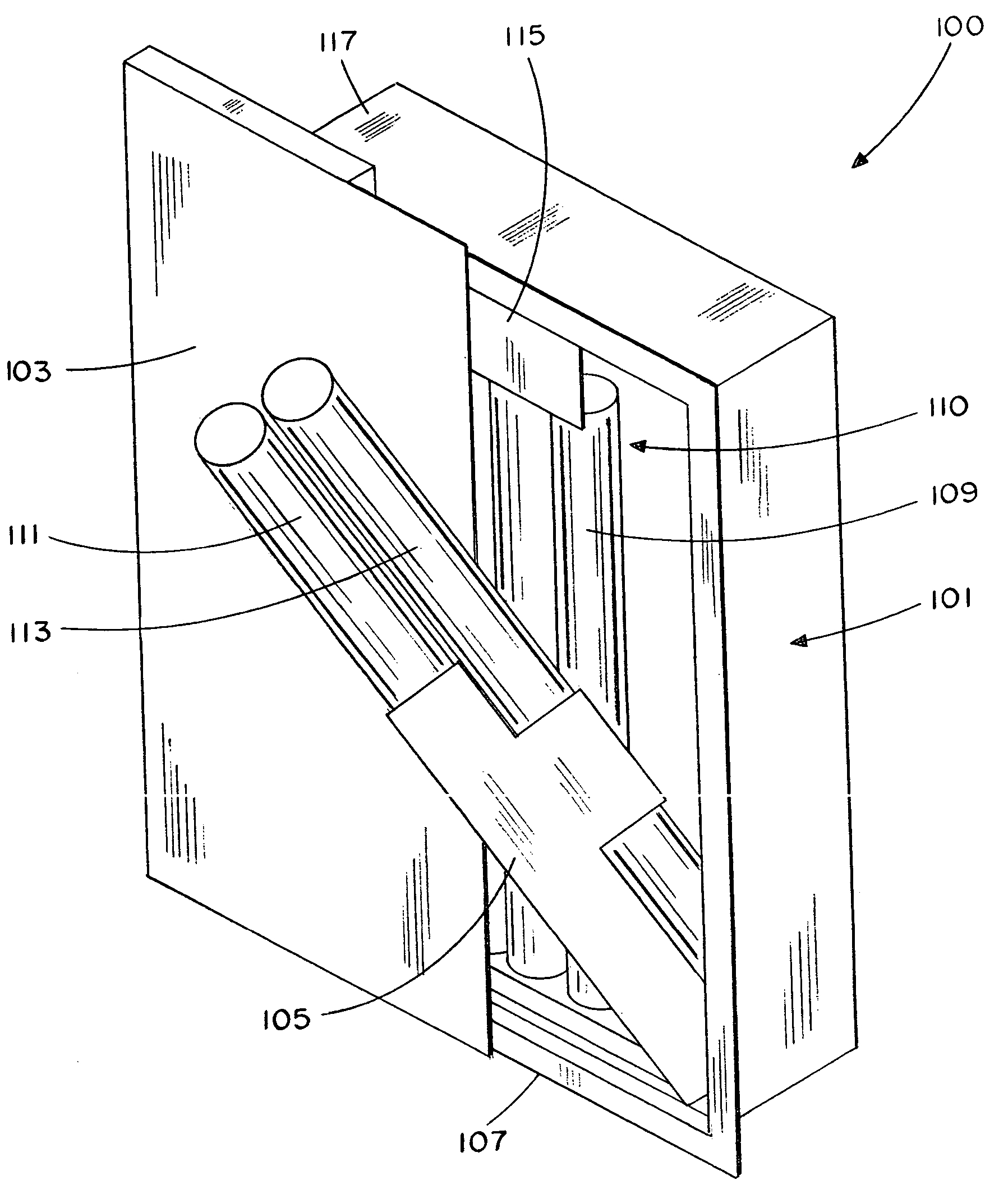

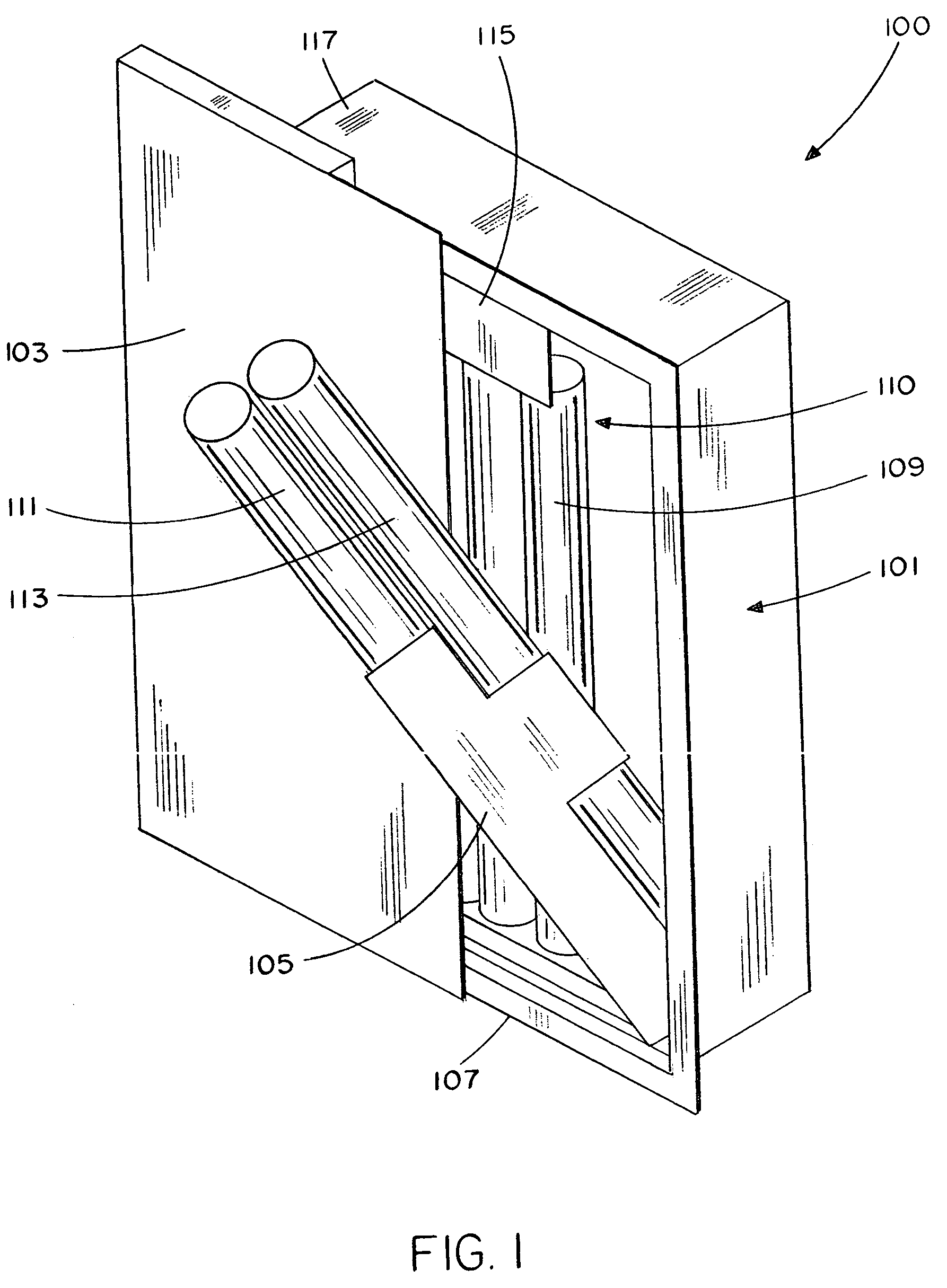

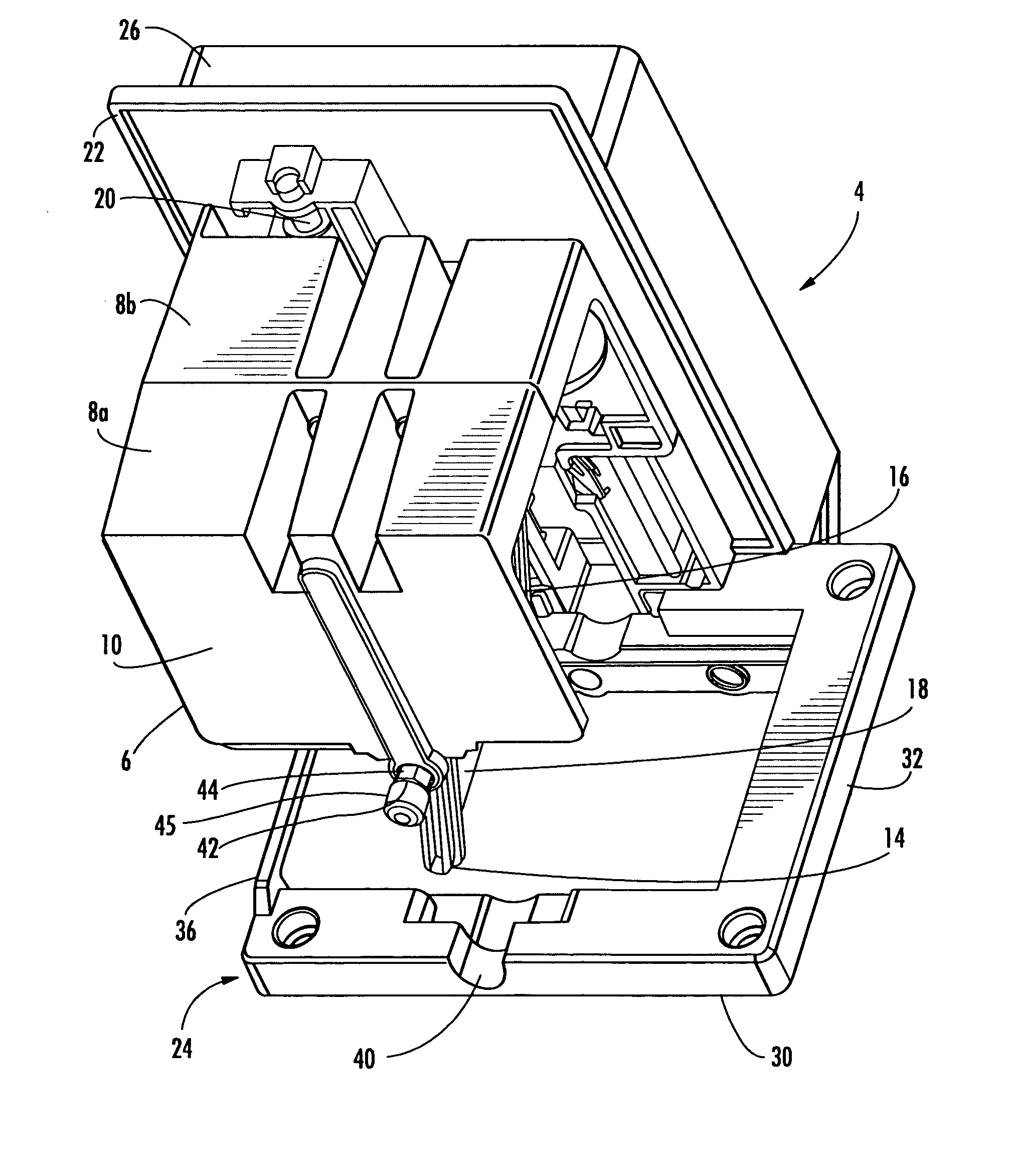

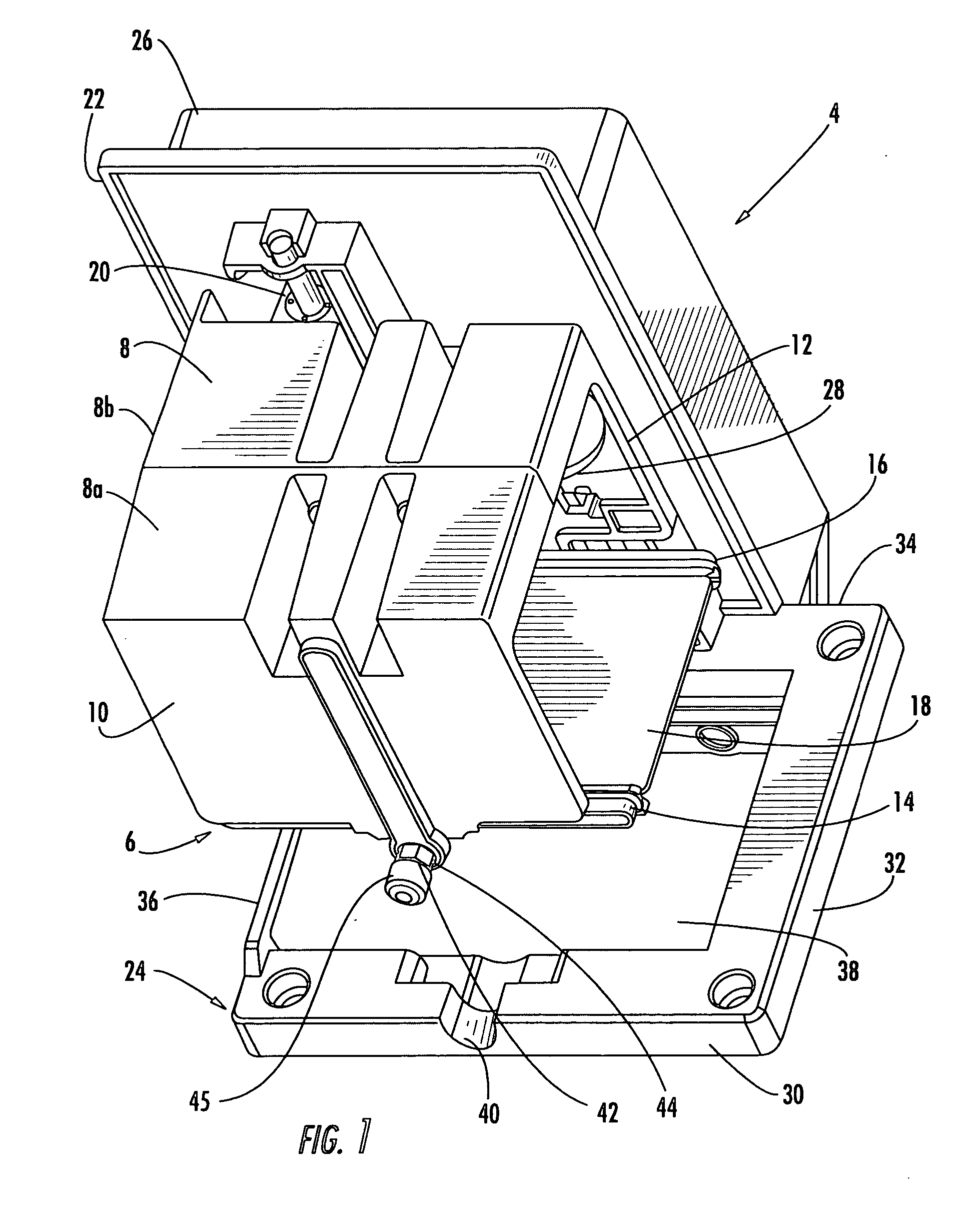

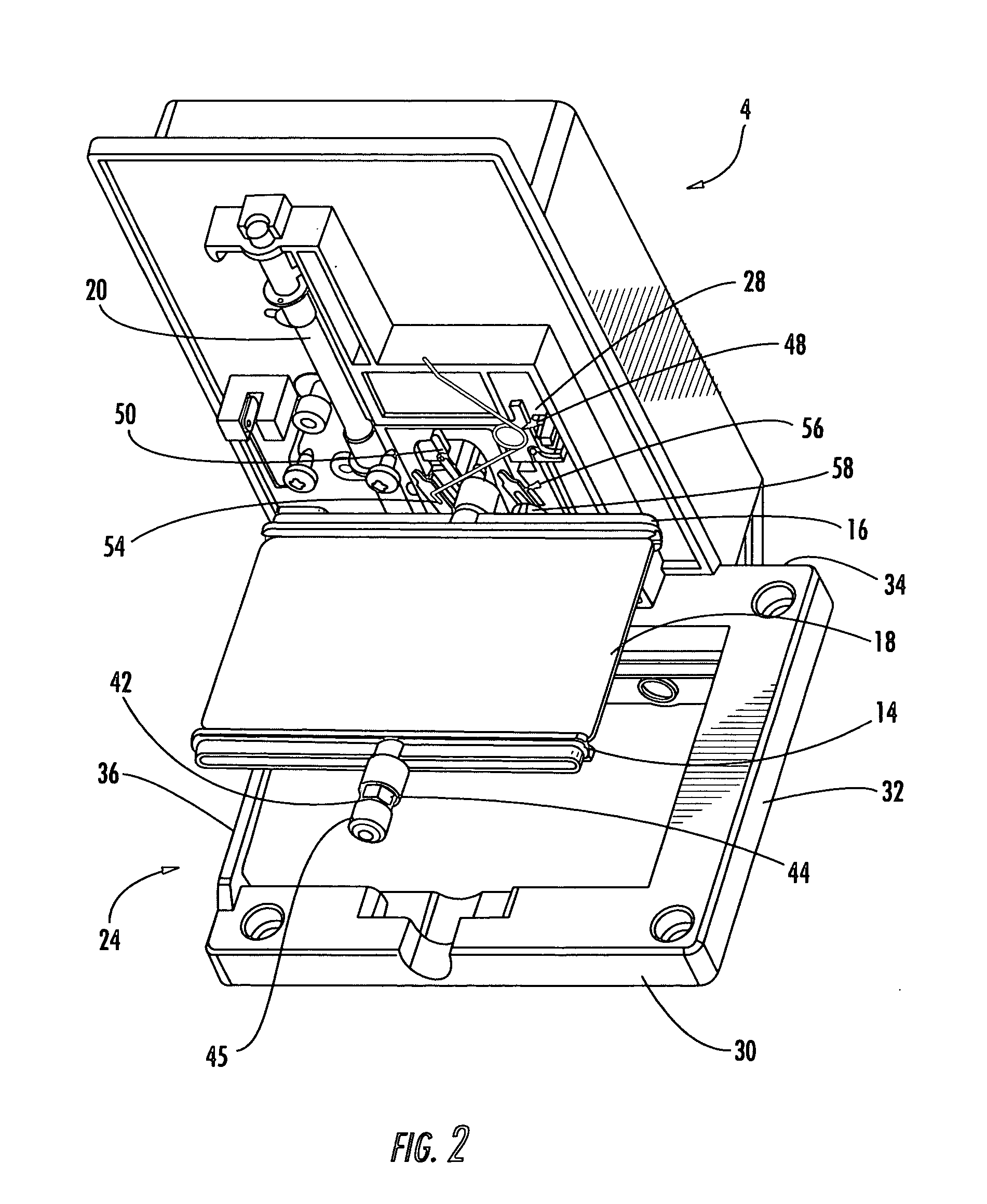

According to one embodiment of the present invention, a currency processing device for receiving and processing a stack of currency bills is disclosed. The currency processing device comprises an input receptacle for receiving a stack of bills to be processed, a plurality of output receptacles for receiving bills after the bills have been processed, a transport mechanism for transporting the bills from the input receptacle to the output receptacles, and a discriminating unit for examining the bills. The output receptacles are arranged such that a center of at least one output receptacle is laterally offset from a center of the input receptacle. The discriminating unit includes a detector positioned between the input receptacle and the output receptacles and is adapted to determine the denomination of bills.

Owner:CUMMINS-ALLISON CORP

Currency processing device, method and system

InactiveUS20050183928A1Rapid assessmentClose proximityPaper-money testing devicesOverturning articlesEngineeringComputer science

According to one embodiment of the present invention, a currency processing device for receiving and processing a stack of currency bills is described. The currency processing device comprises an input receptacle for receiving a stack of bills to be processed, a plurality of output receptacles for receiving bills after the bills have been processed, a transport mechanism for transporting the bills from the input receptacle to the output receptacles, and a discriminating unit for examining the bills. The output receptacles are arranged such that a center of at least one output receptacle is laterally offset from a center of the input receptacle. The discriminating unit includes a detector positioned between the input receptacle and the output receptacles and is adapted to determine the denomination of bills.

Owner:CUMMINS-ALLISON CORP

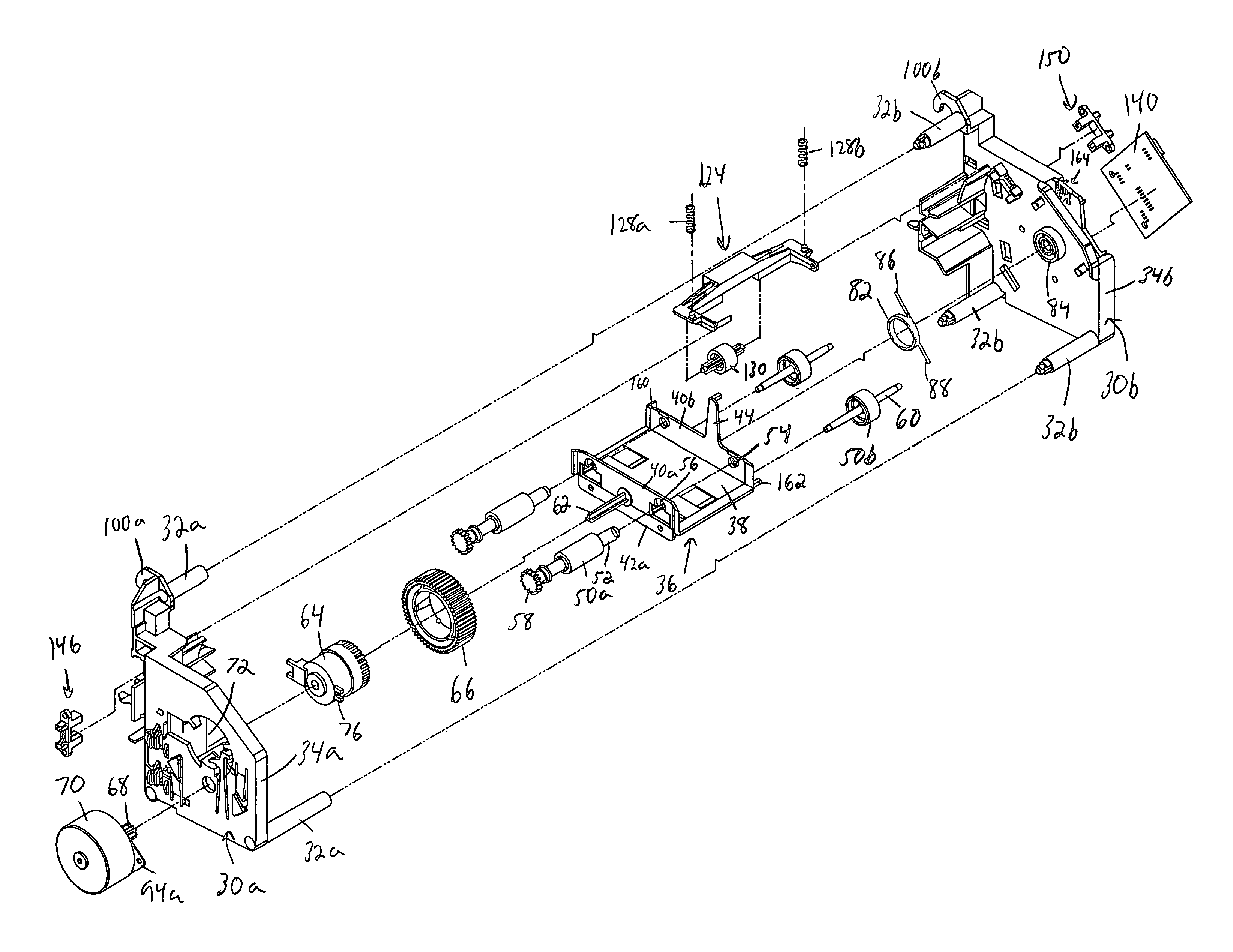

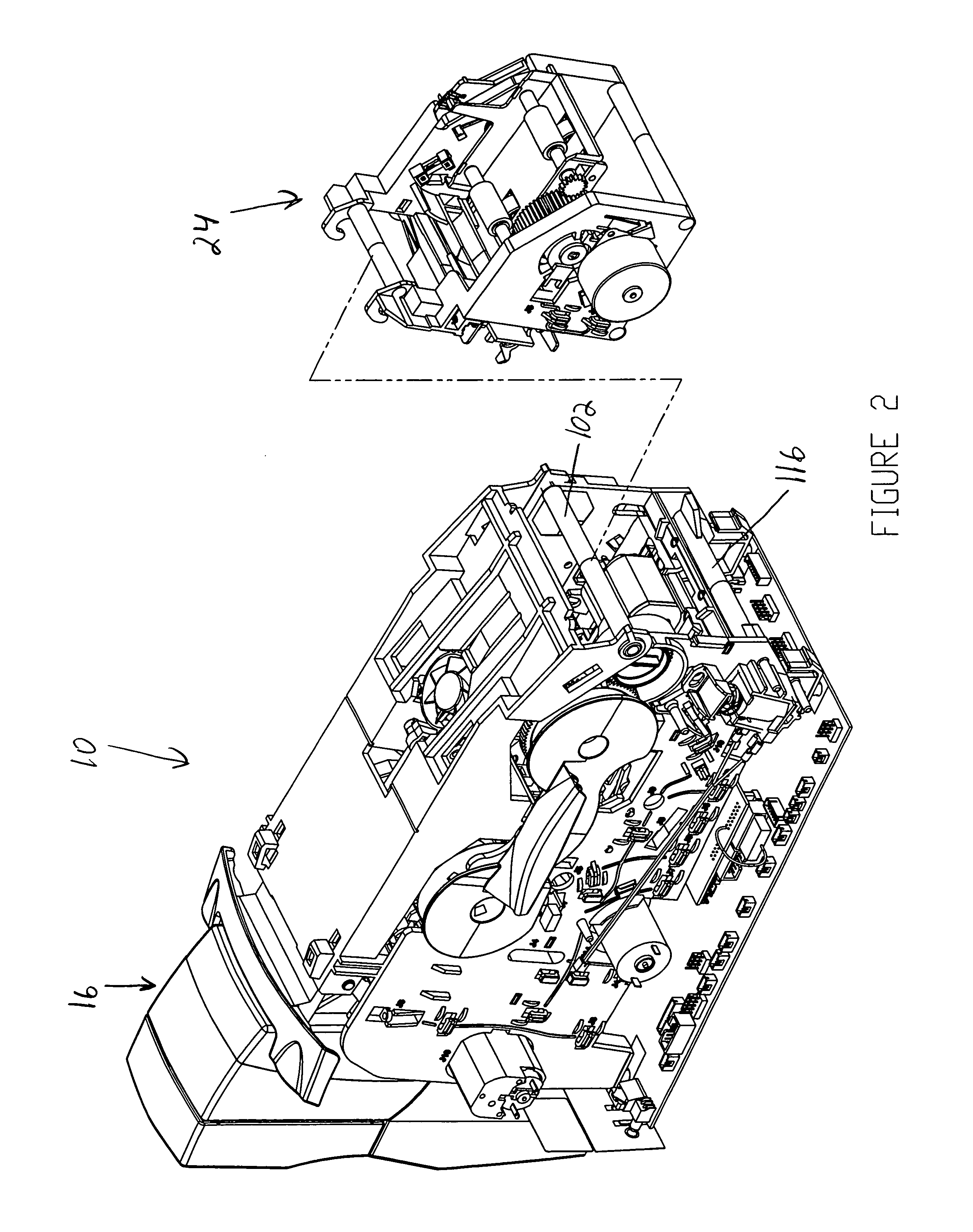

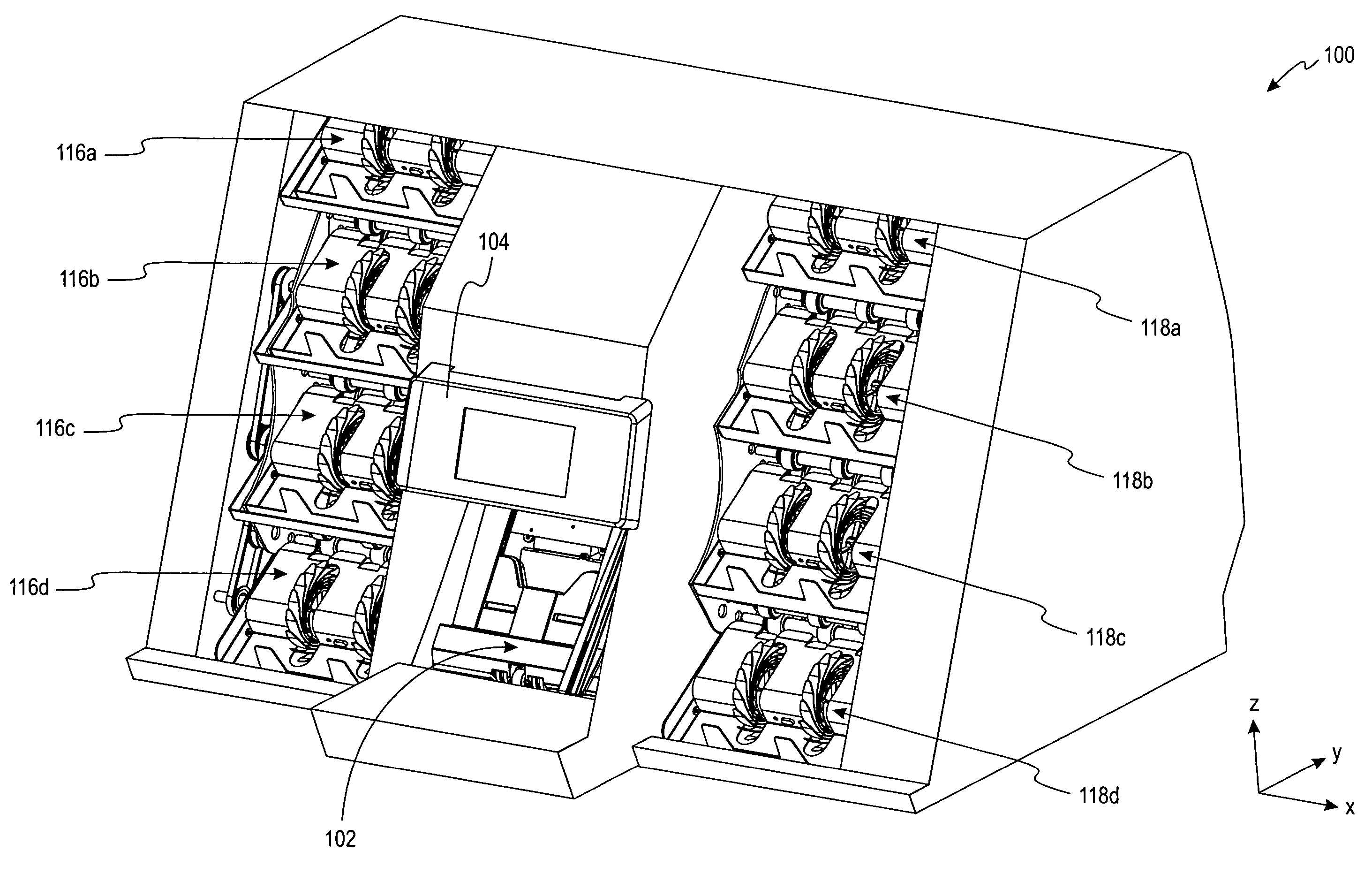

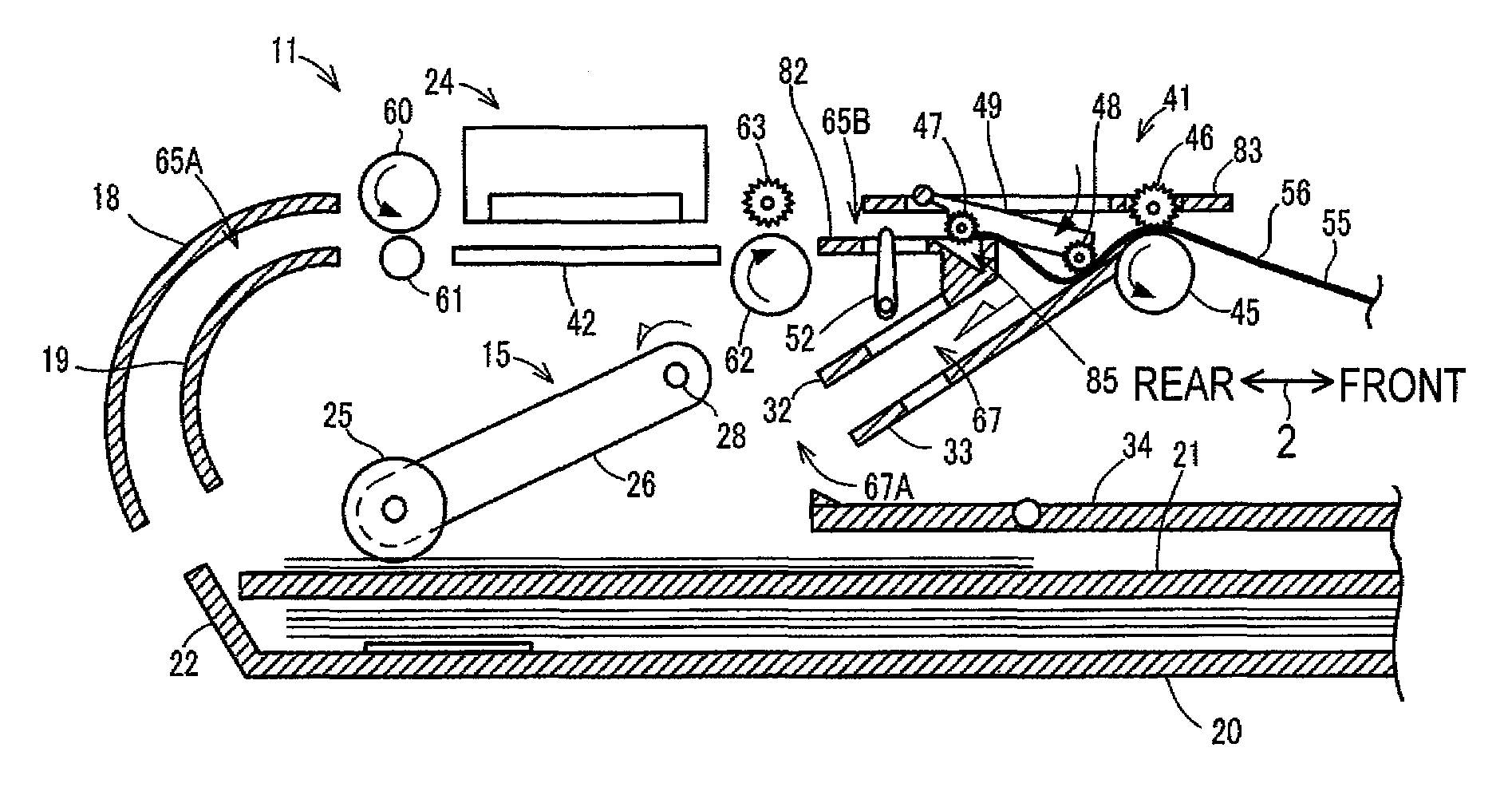

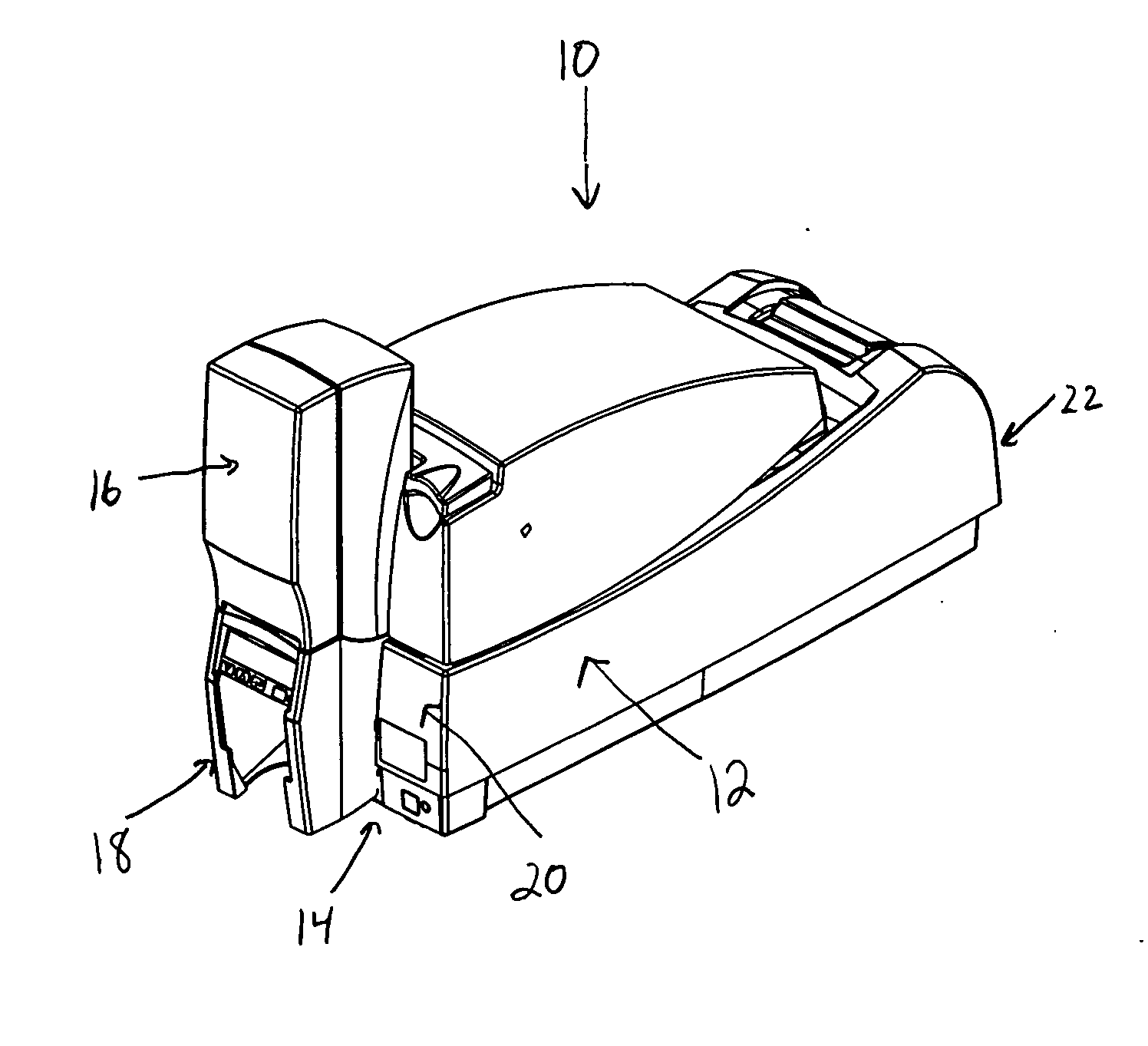

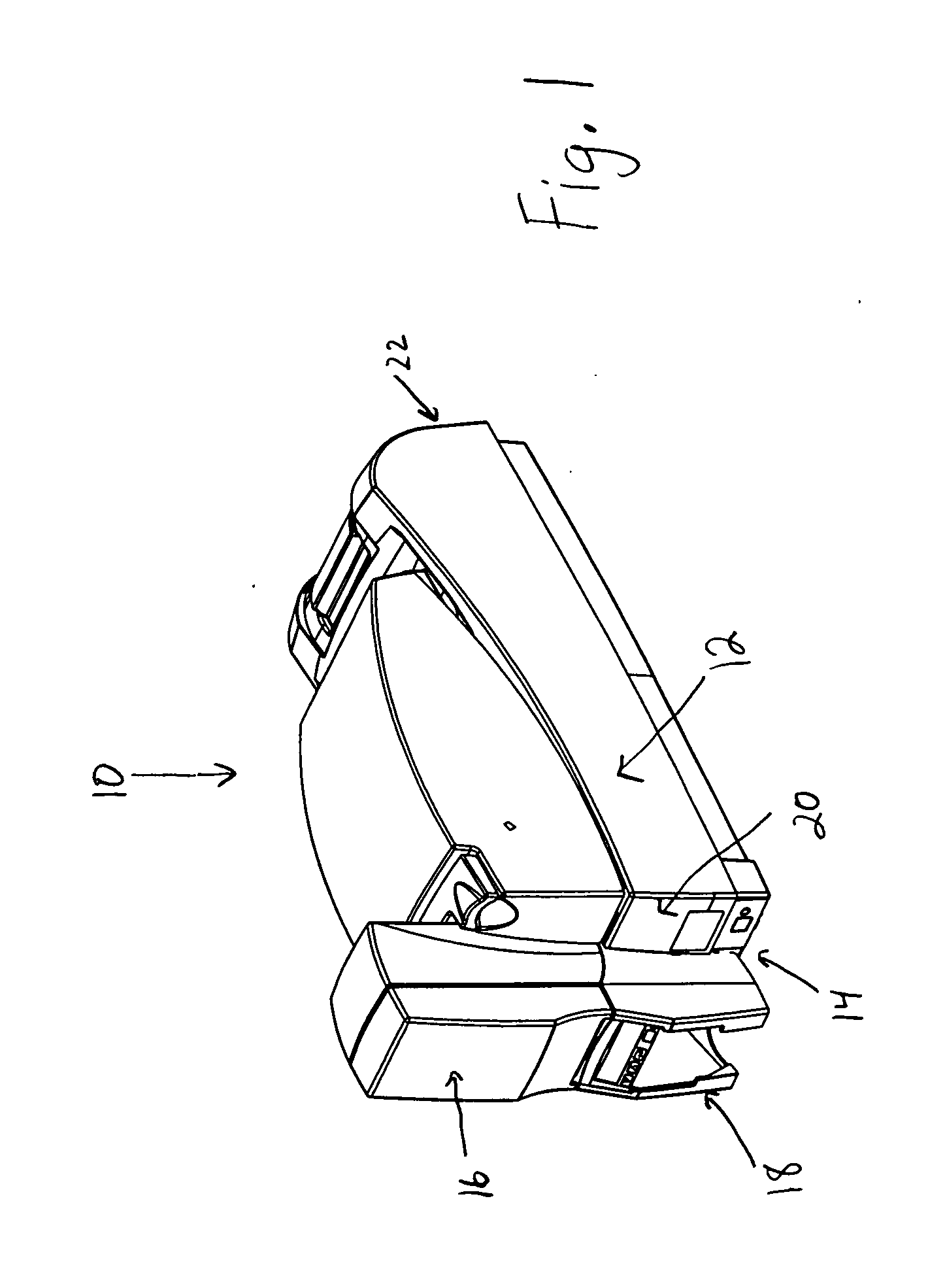

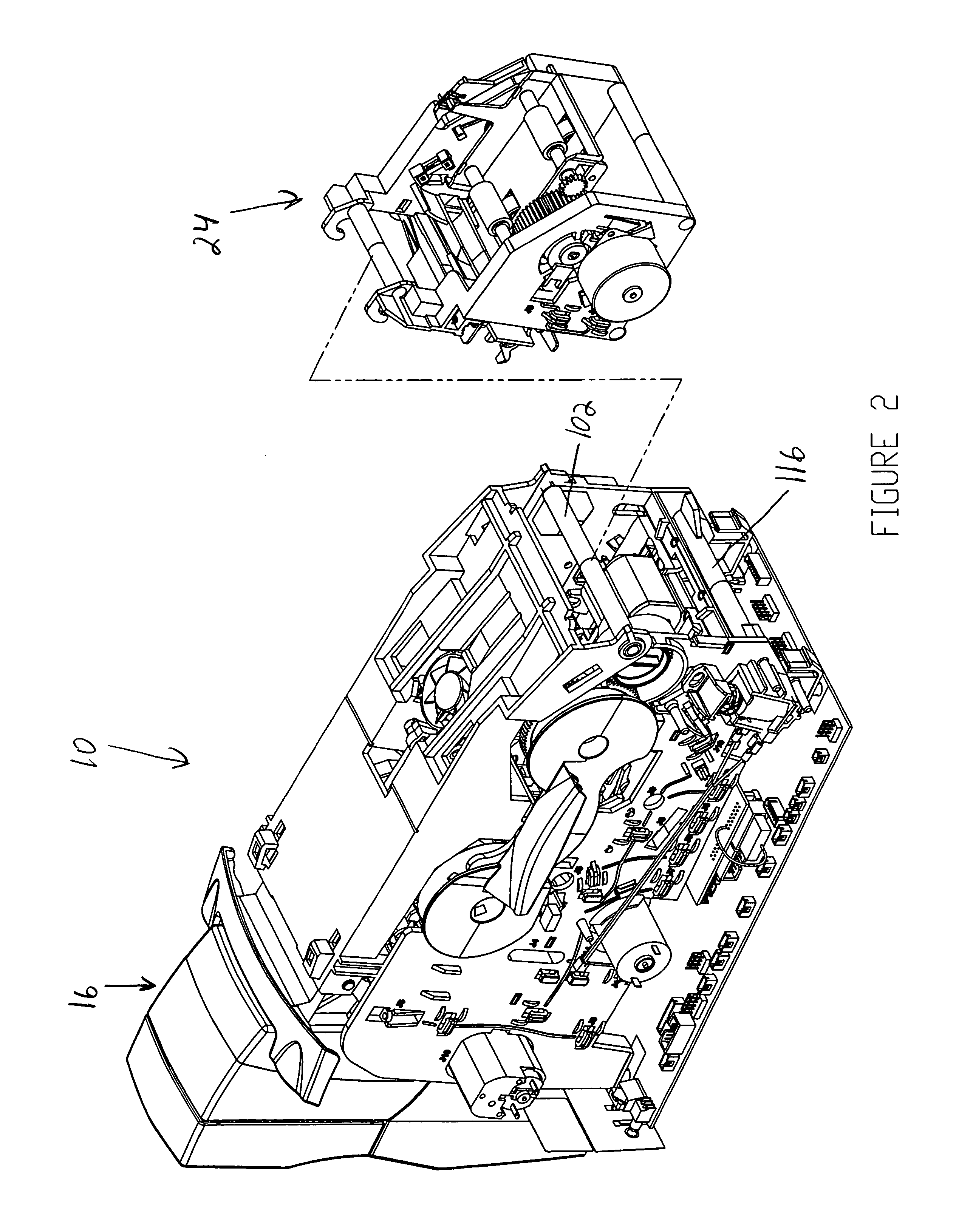

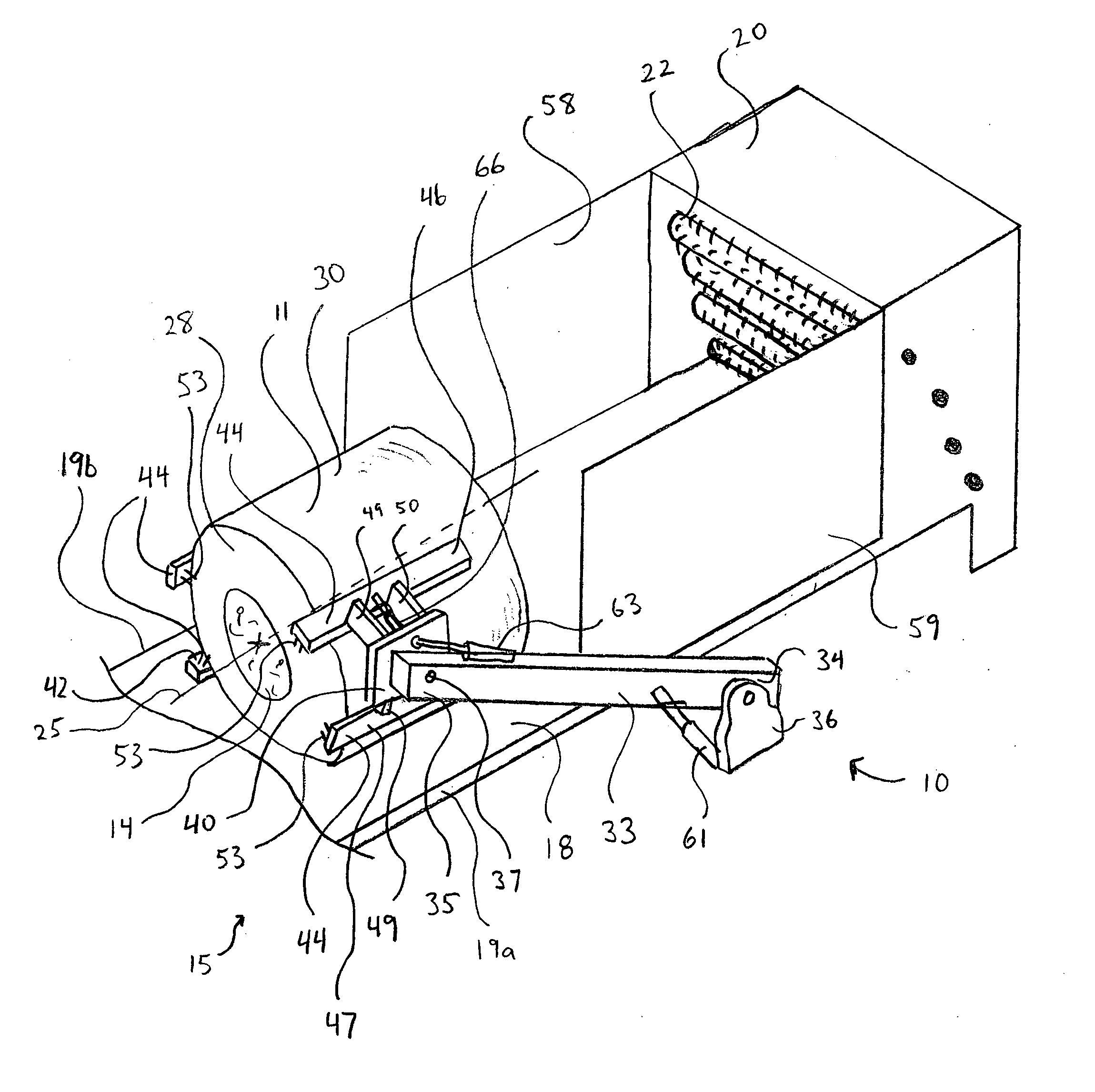

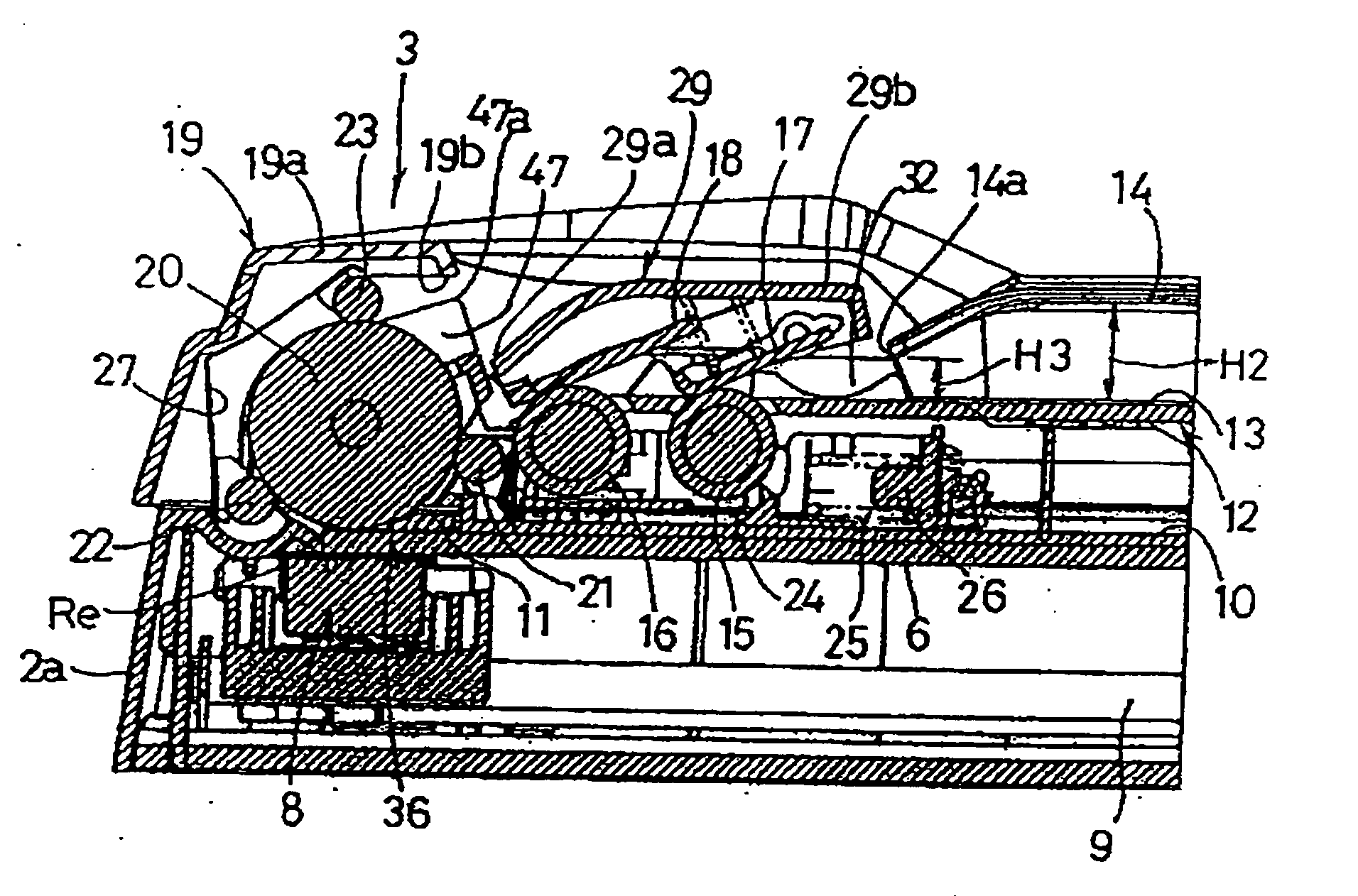

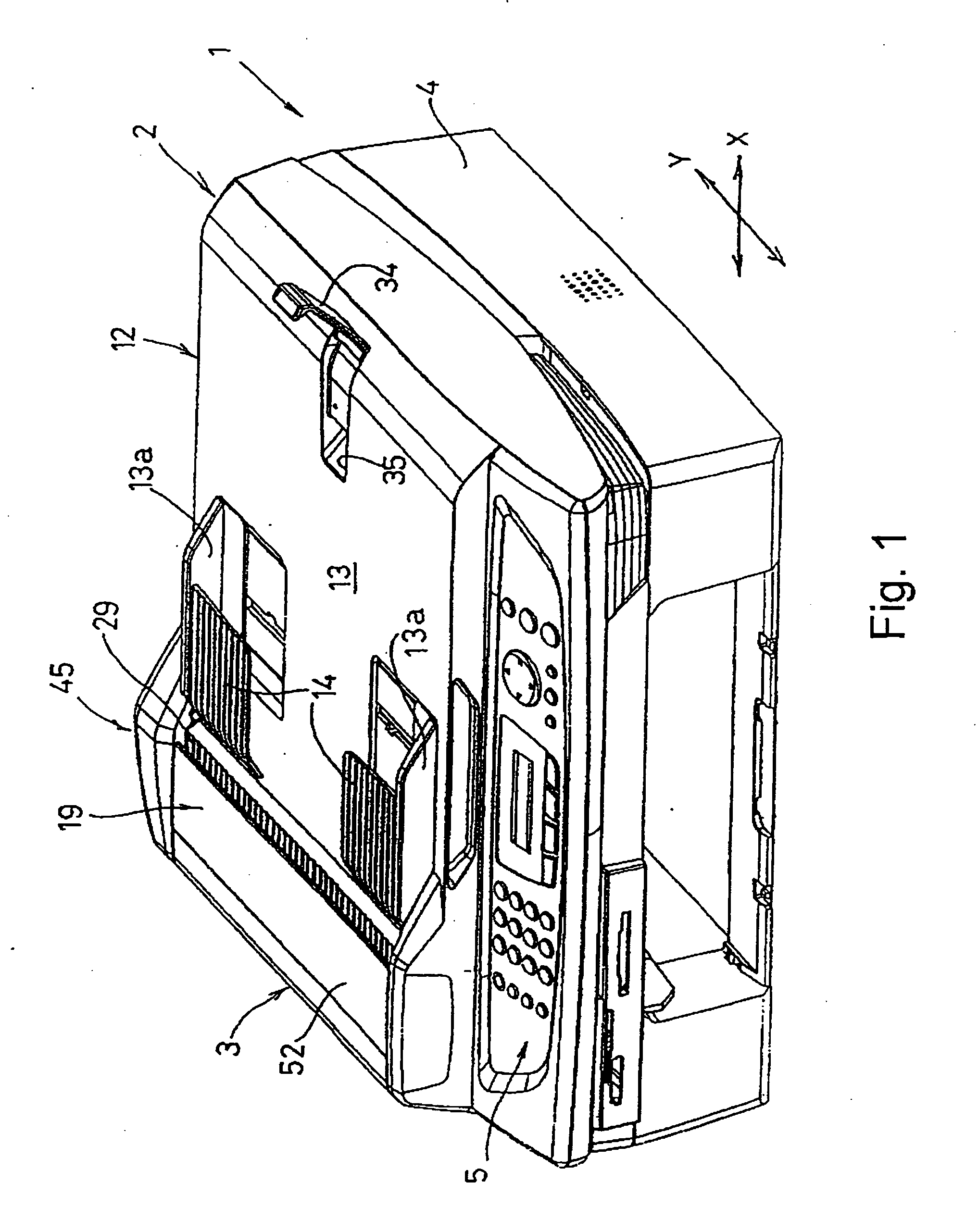

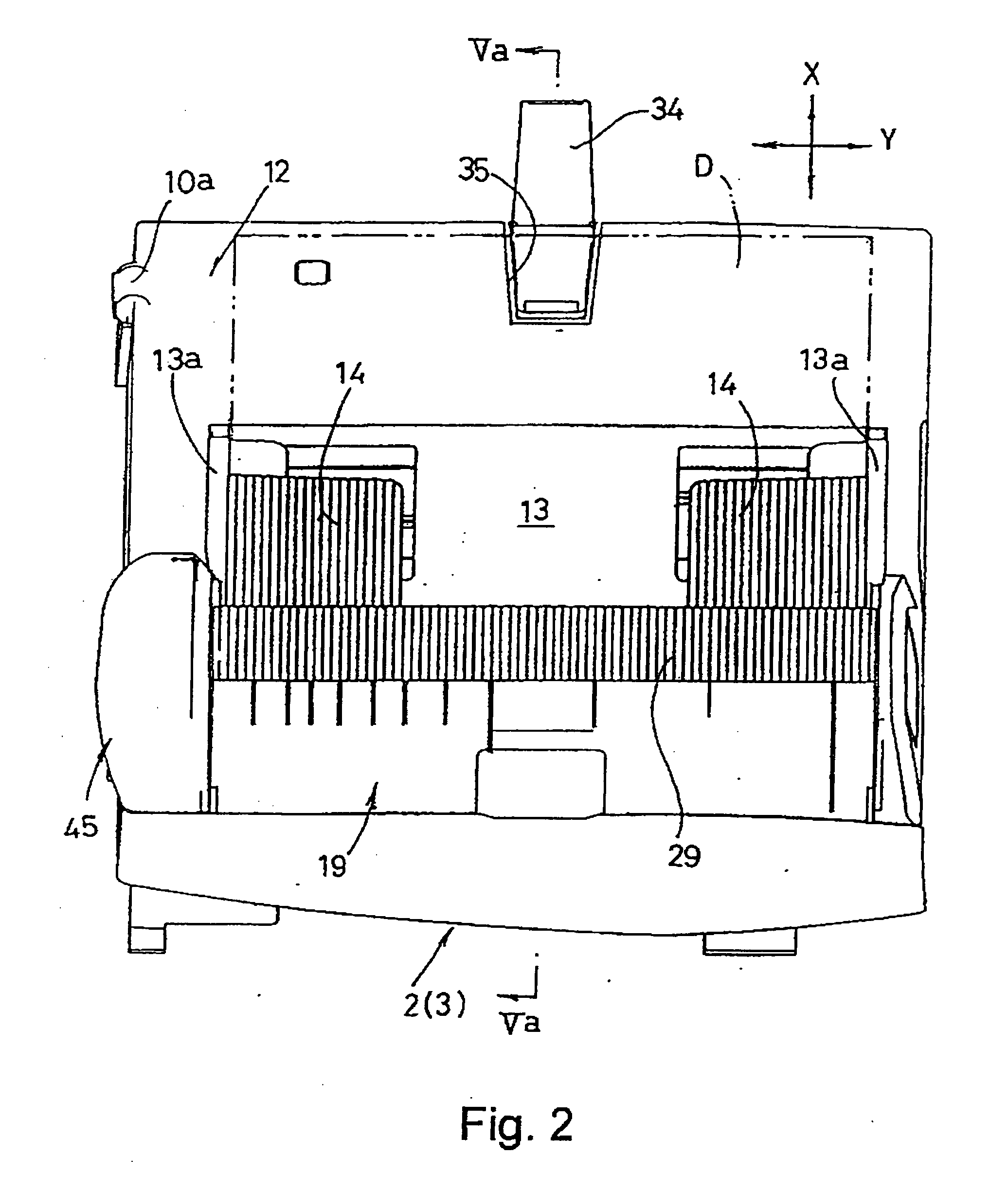

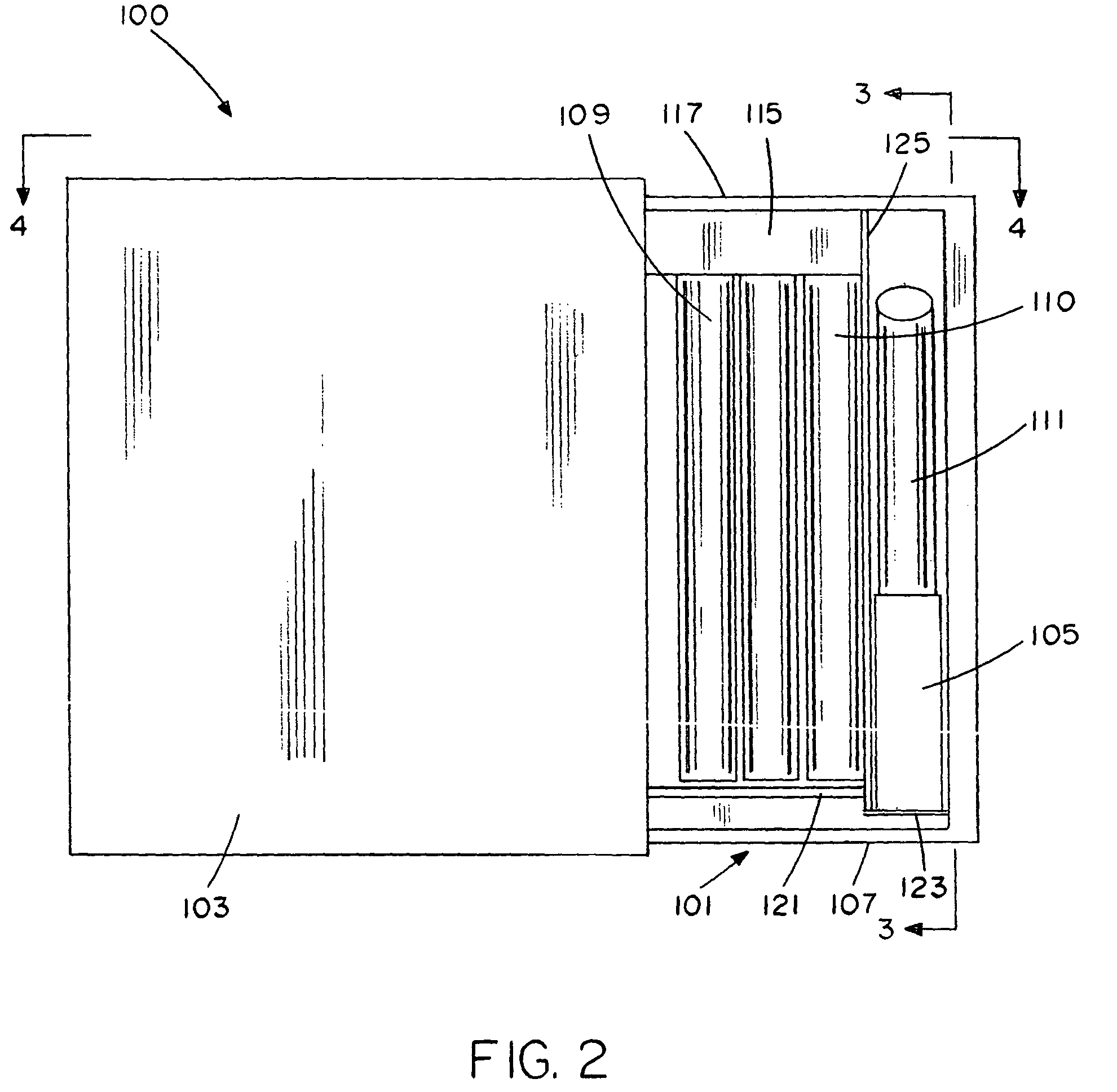

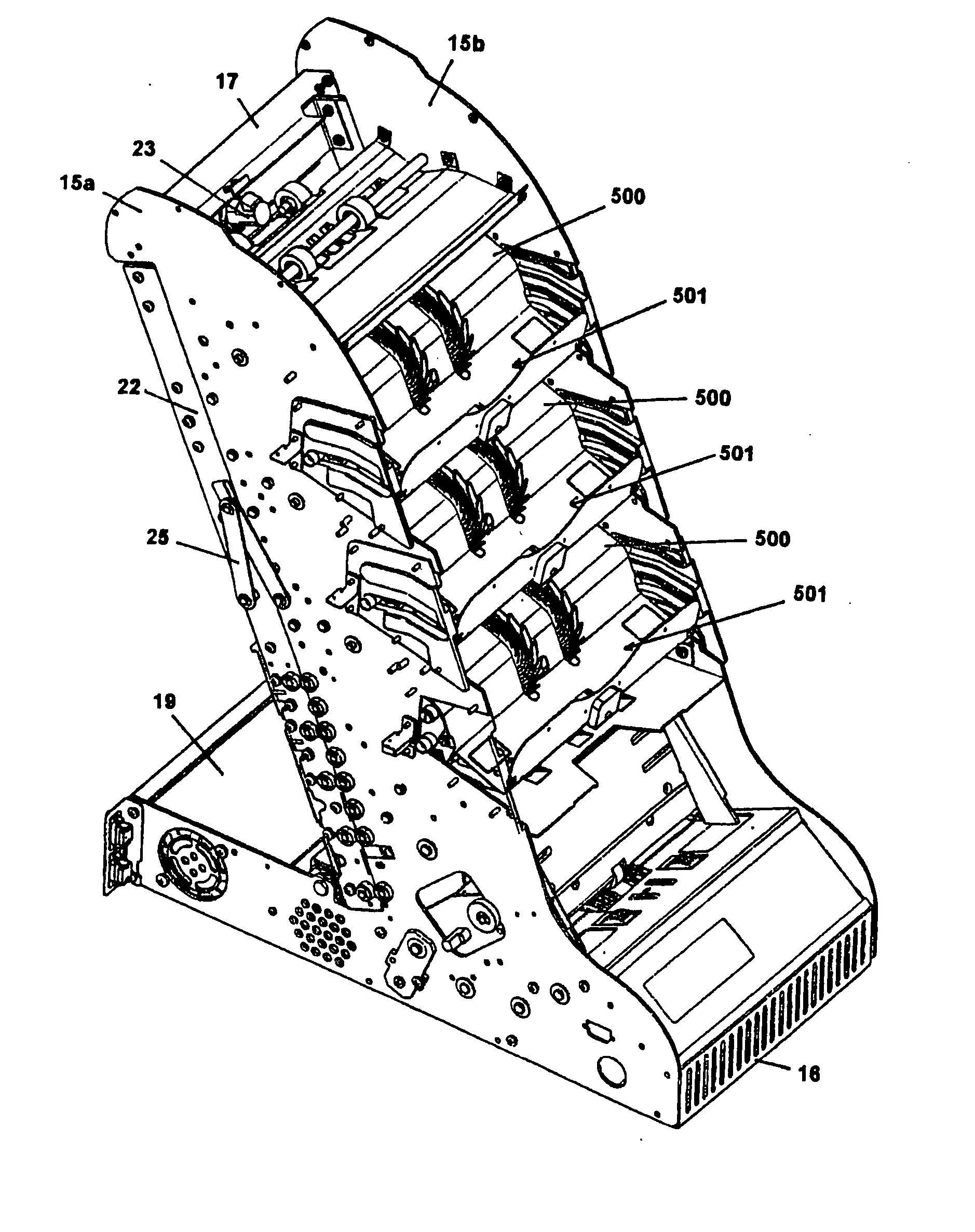

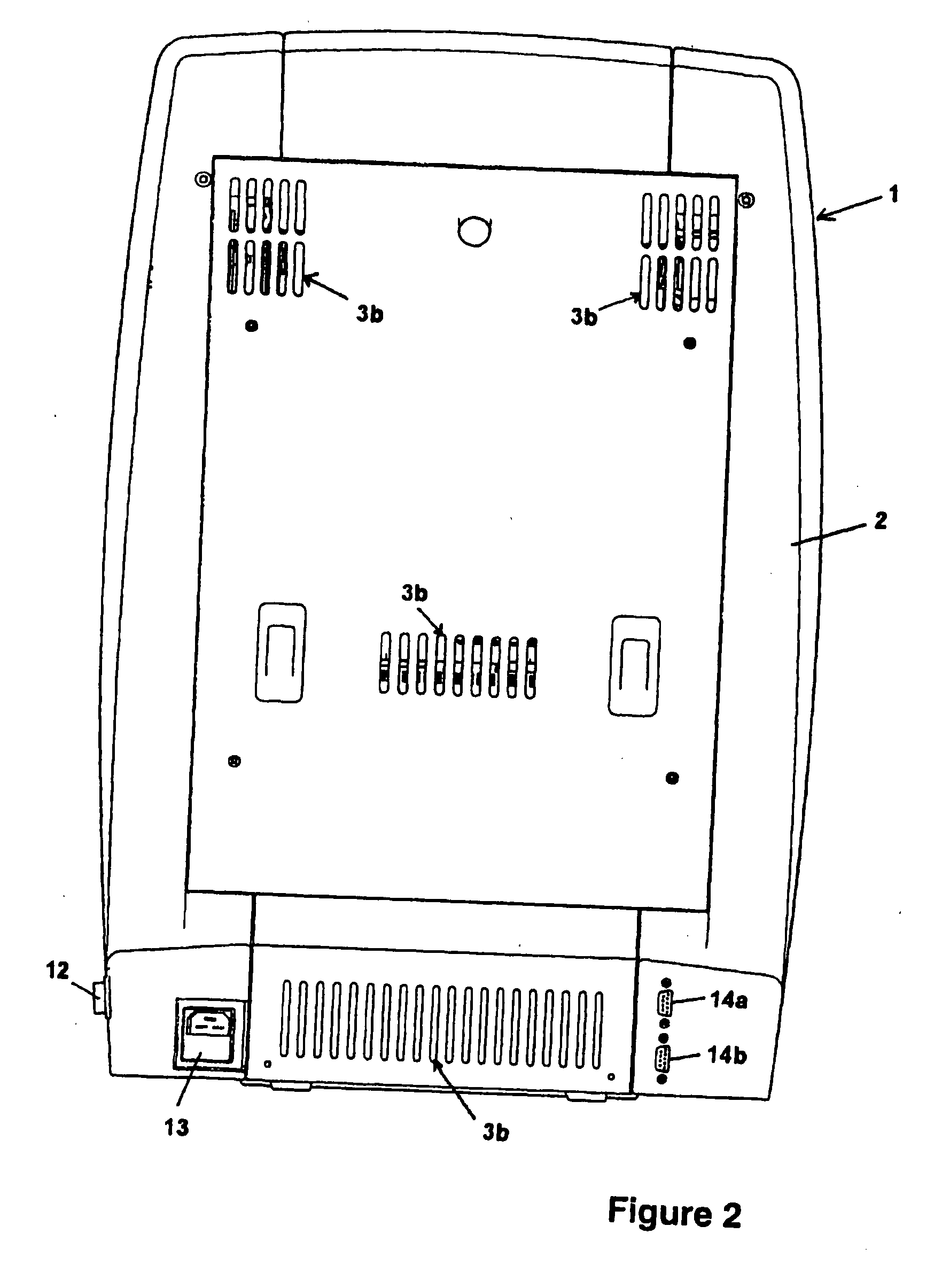

Plastic card reorienting mechanism and interchangeable input hopper

InactiveUS7398972B2Easy and quick connectionEasy to assembleOverturning articlesTypewritersModular unitModularity

A card reorienting mechanism and an input hopper of plastic card processing equipment, for example a desktop plastic card printer. The card reorienting mechanism is a modular unit that permits the entire mechanism to be inserted or removed as a single unit from the printer. In addition, the input hopper is designed as an interchangeable system that permits alteration in the card capacity of the hopper.

Owner:ENTRUST DATACARD

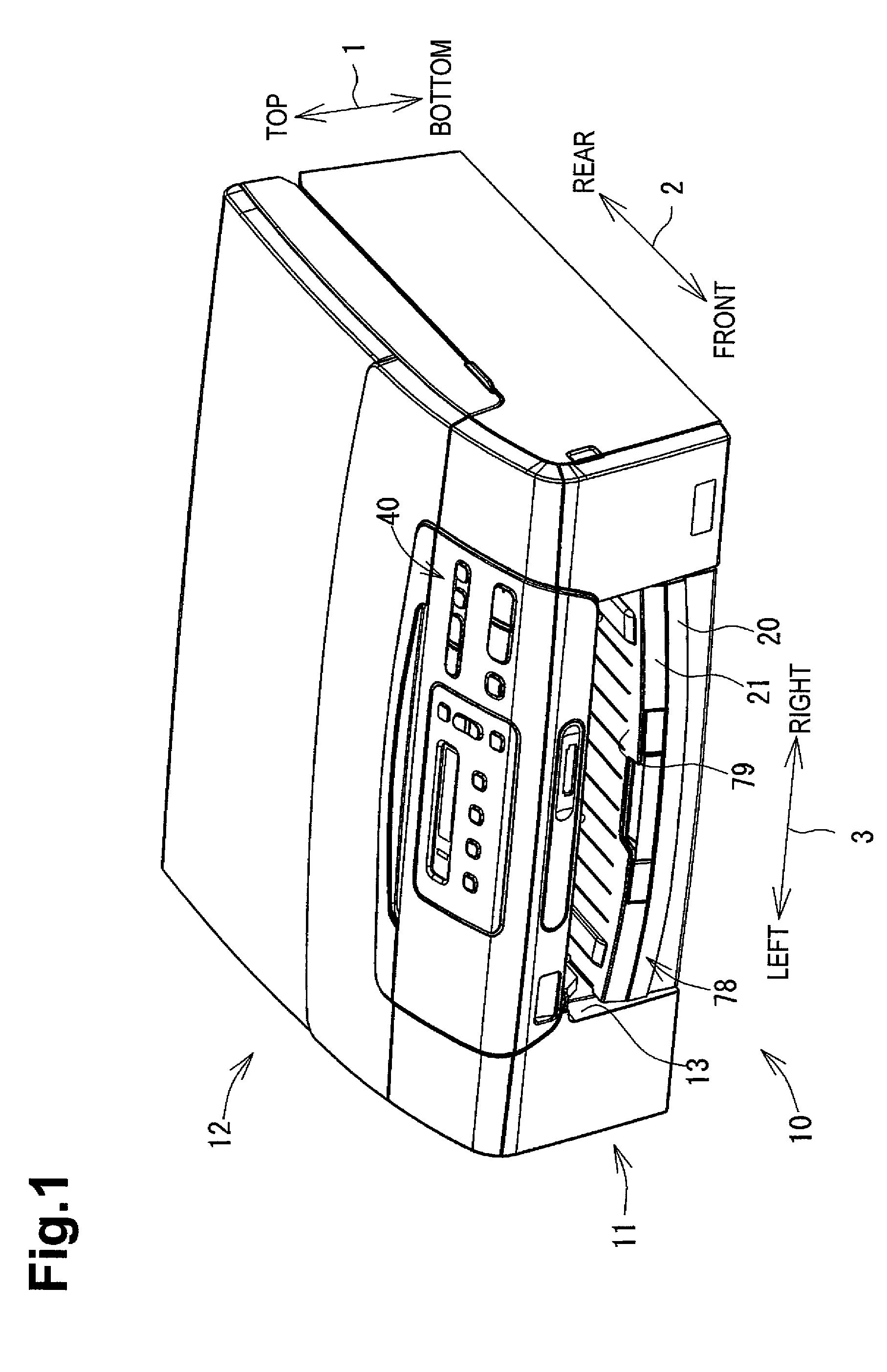

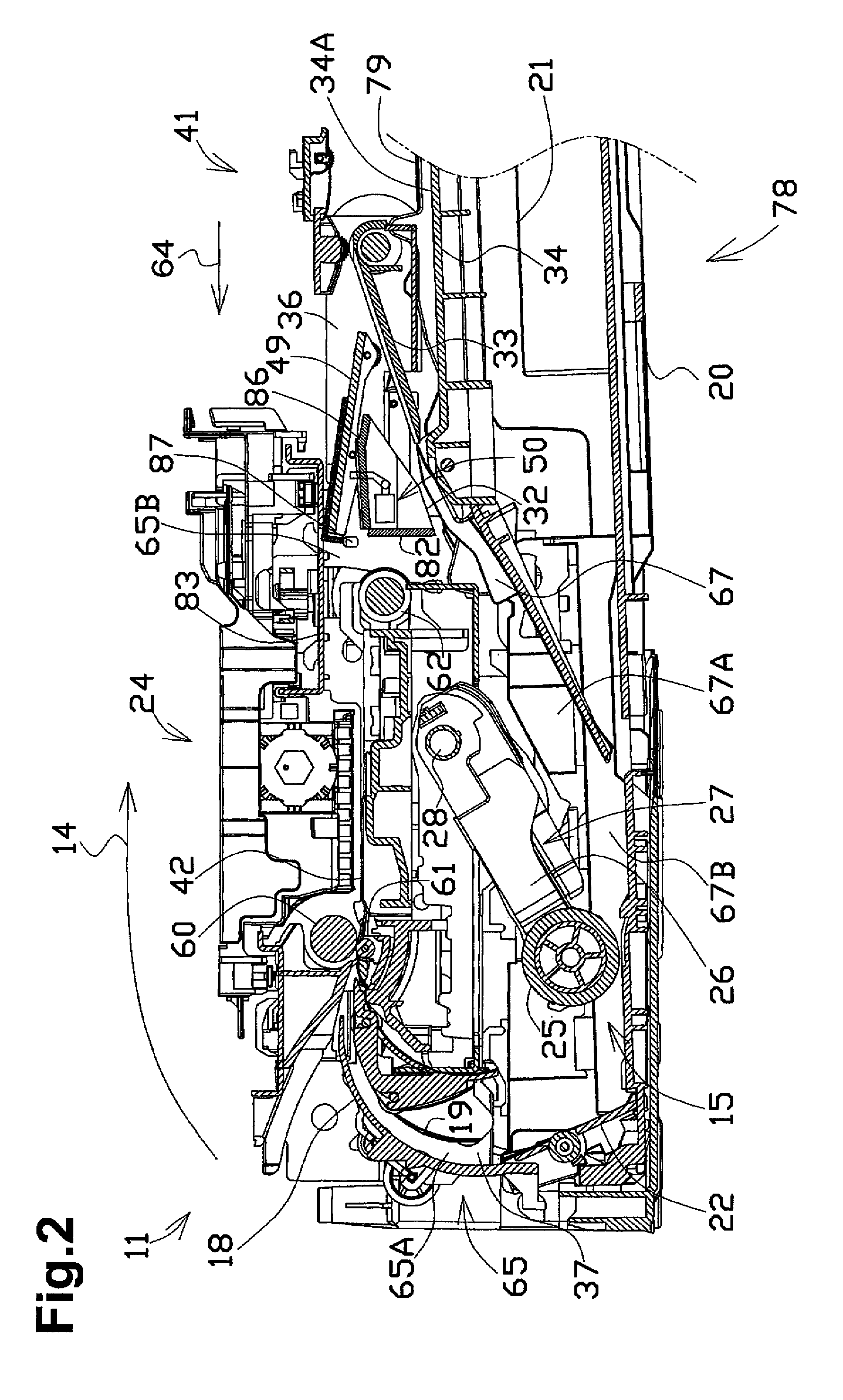

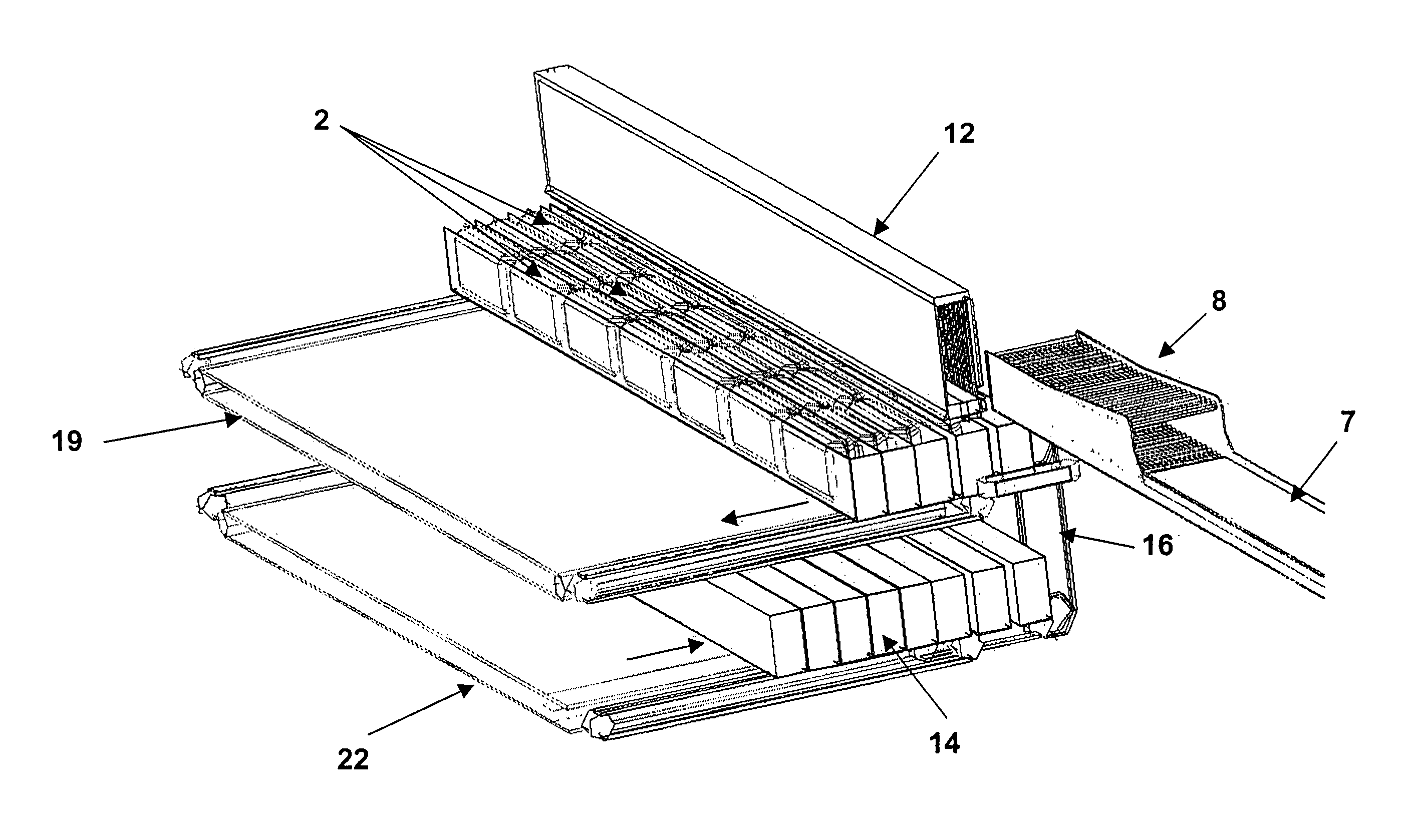

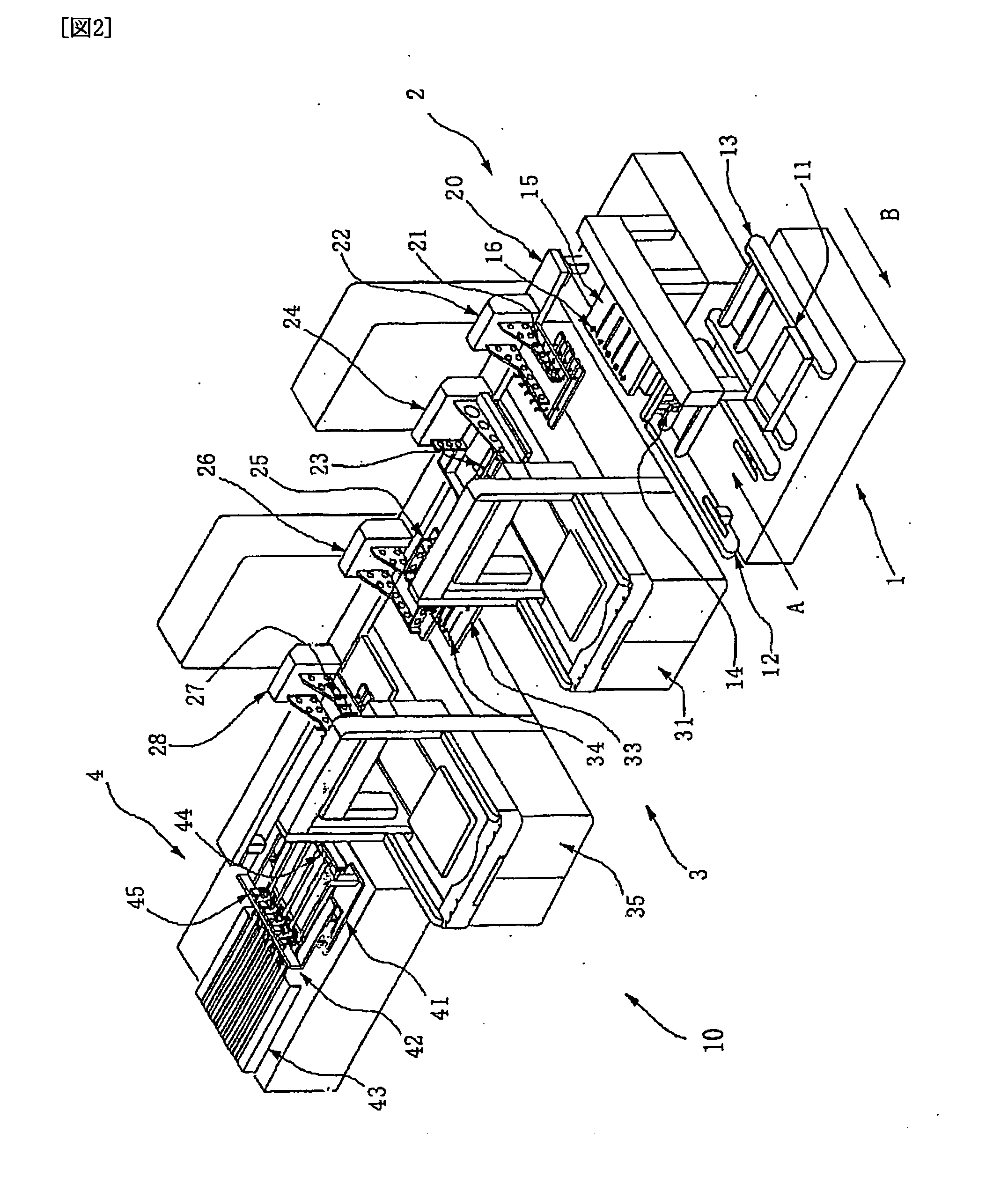

Currency processing device, method and system

InactiveUS7726457B2Rapid assessmentClose proximityOverturning articlesCoin/currency accepting devicesEngineering

According to one embodiment of the present invention, a currency processing device for receiving and processing a stack of currency bills is disclosed. The currency processing device comprises an input receptacle for receiving a stack of bills to be processed, a plurality of output receptacles for receiving bills after the bills have been processed, a transport mechanism for transporting the bills from the input receptacle to the output receptacles, and a discriminating unit for examining the bills. The output receptacles are arranged such that a center of at least one output receptacle is laterally offset from a center of the input receptacle. The discriminating unit includes a detector positioned between the input receptacle and the output receptacles and is adapted to determine the denomination of bills.

Owner:CUMMINS-ALLISON CORP

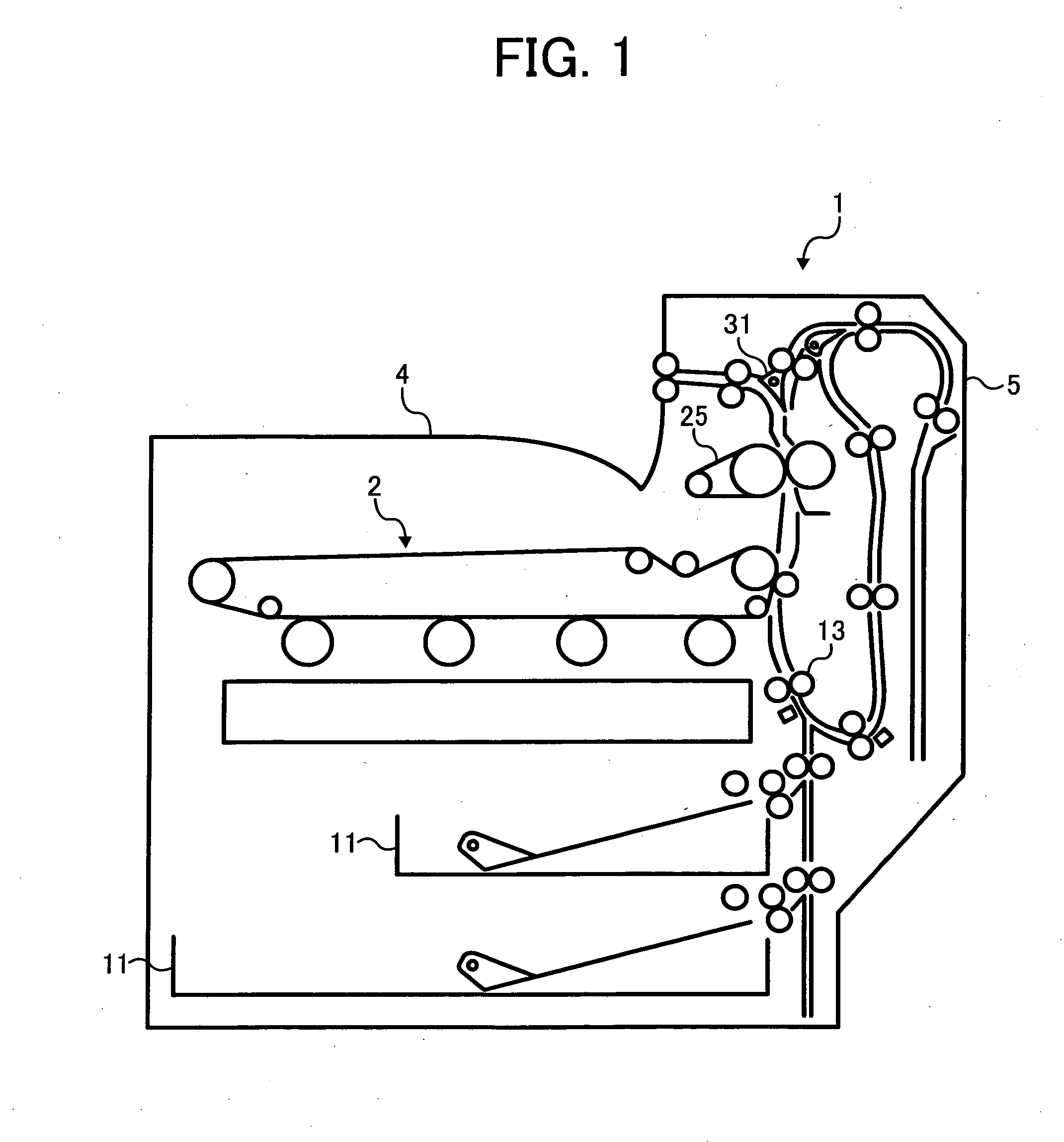

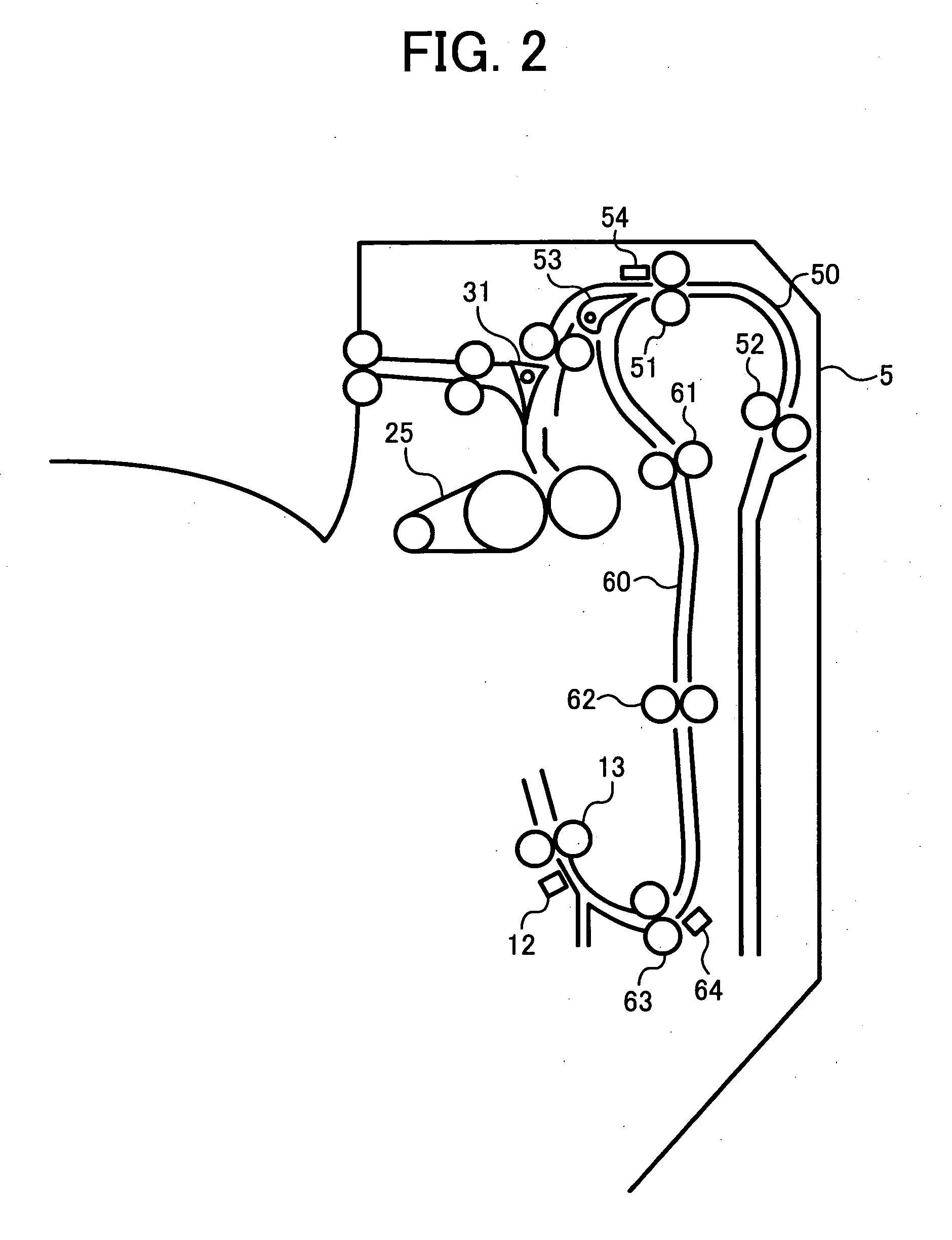

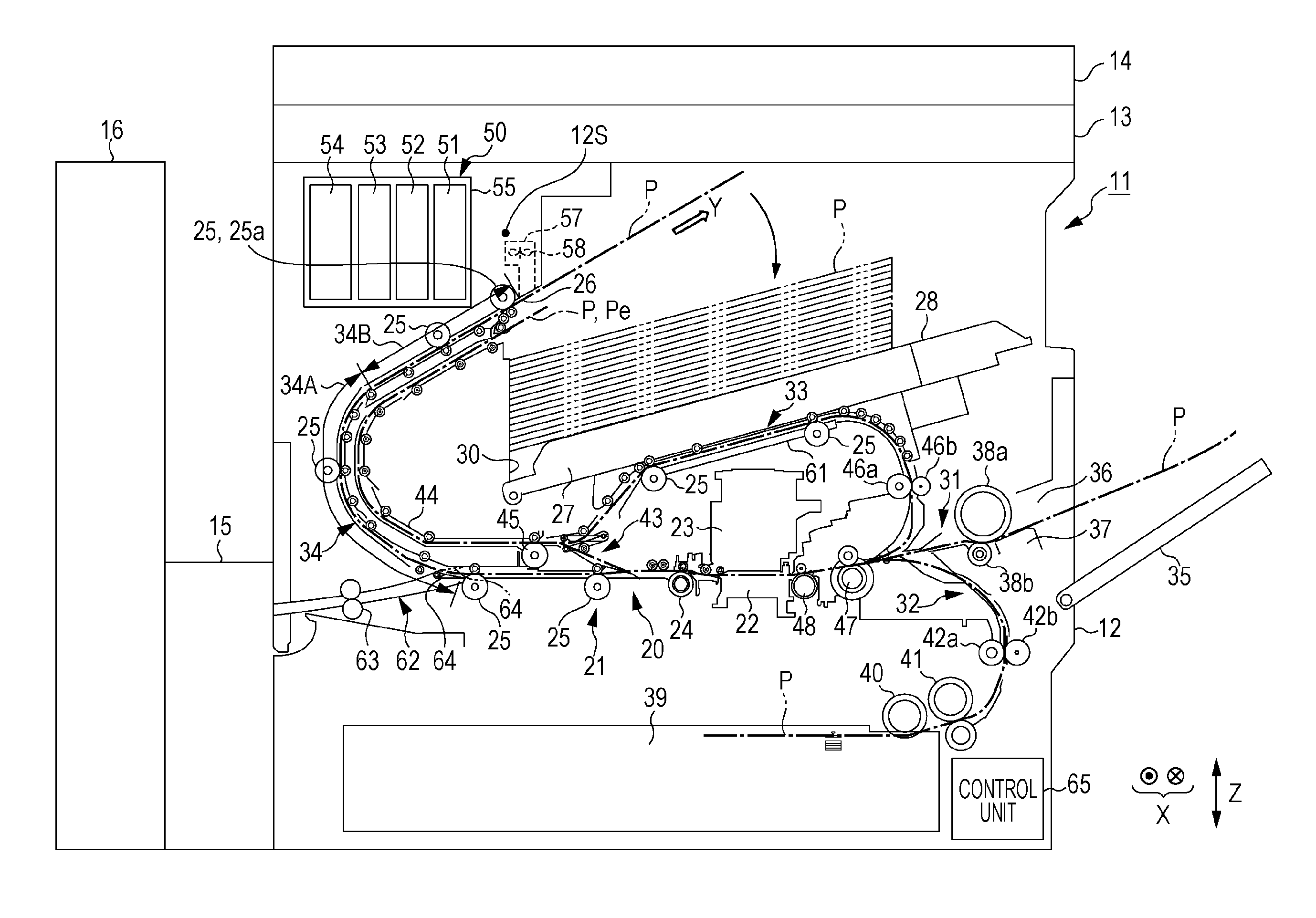

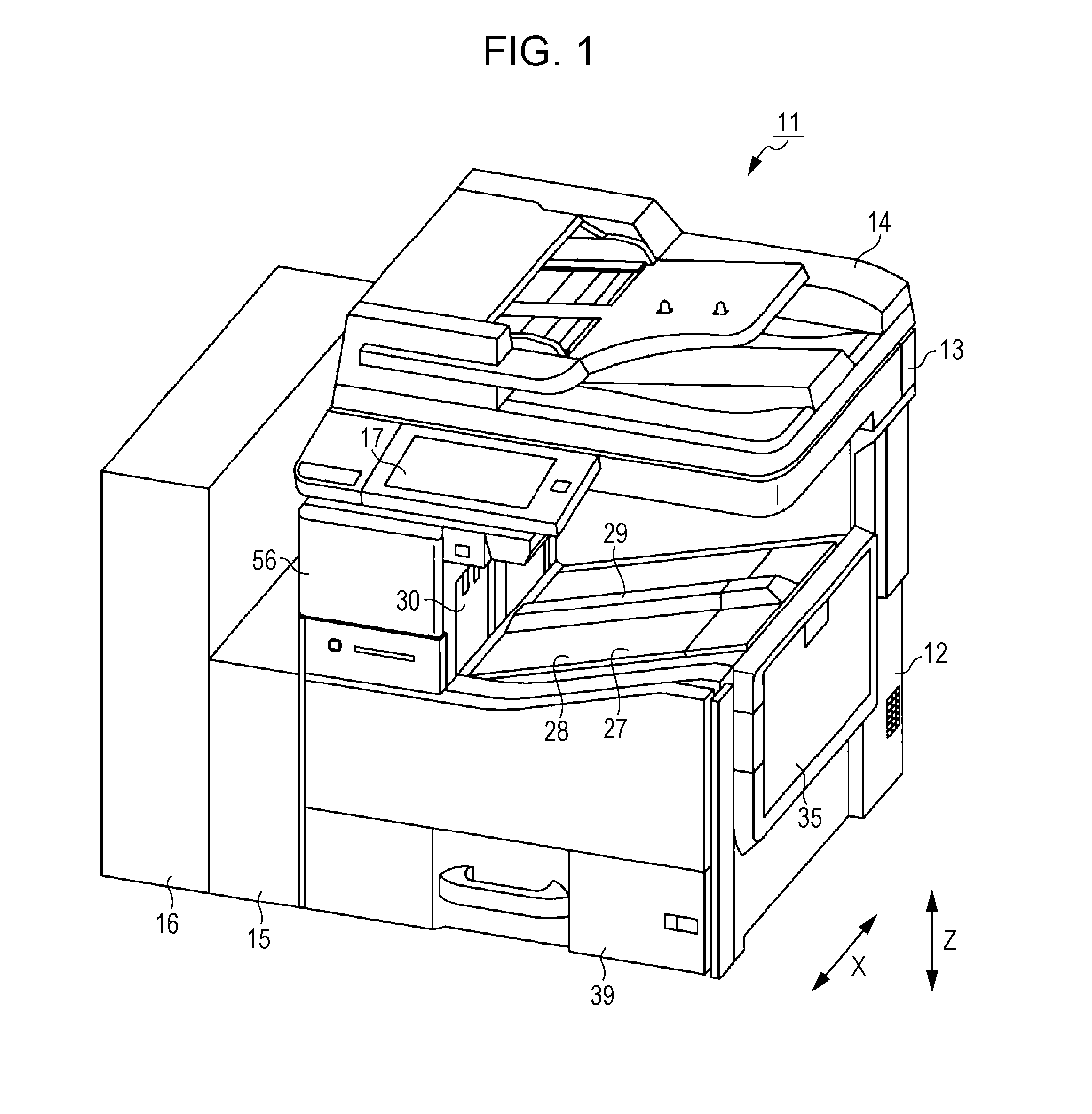

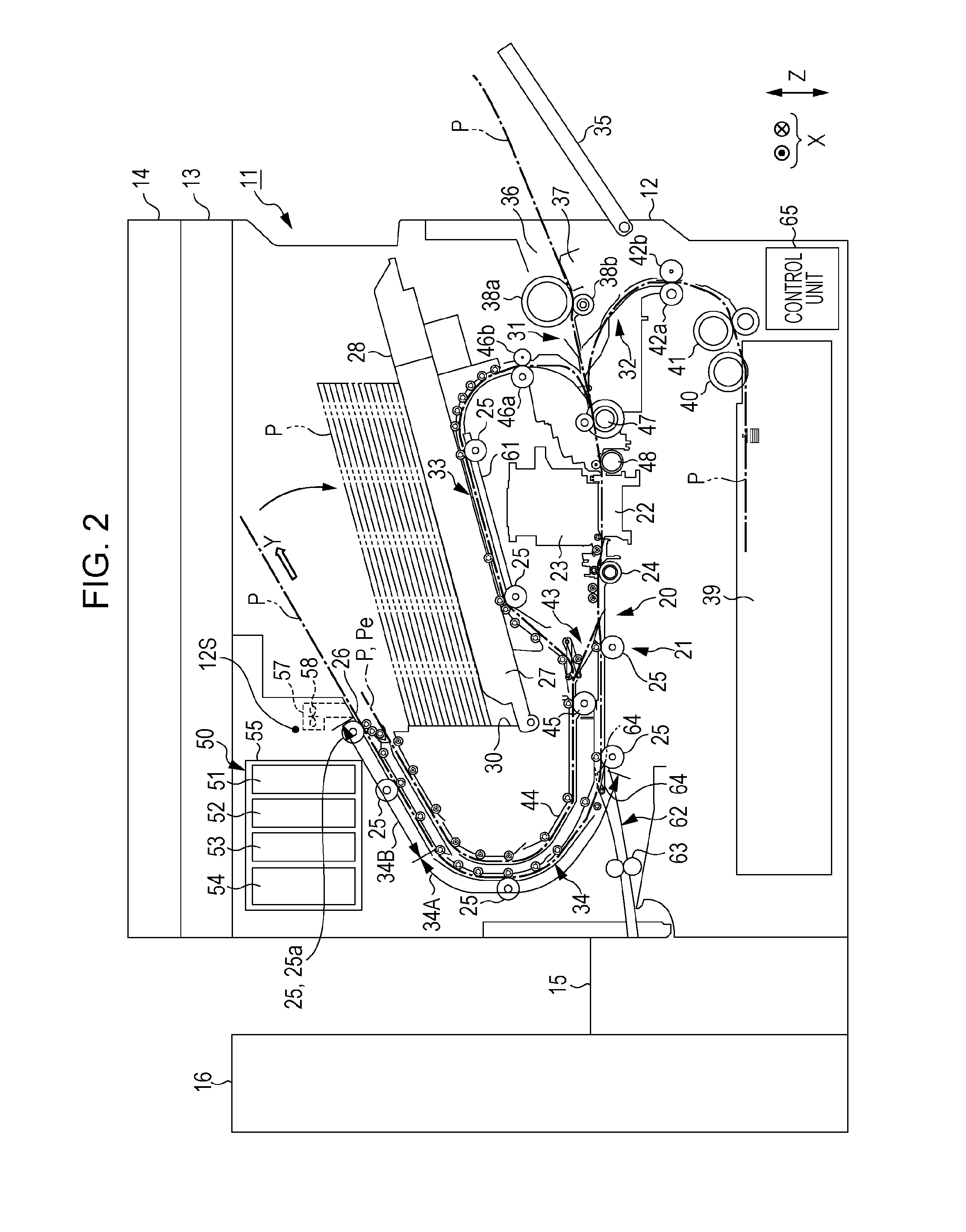

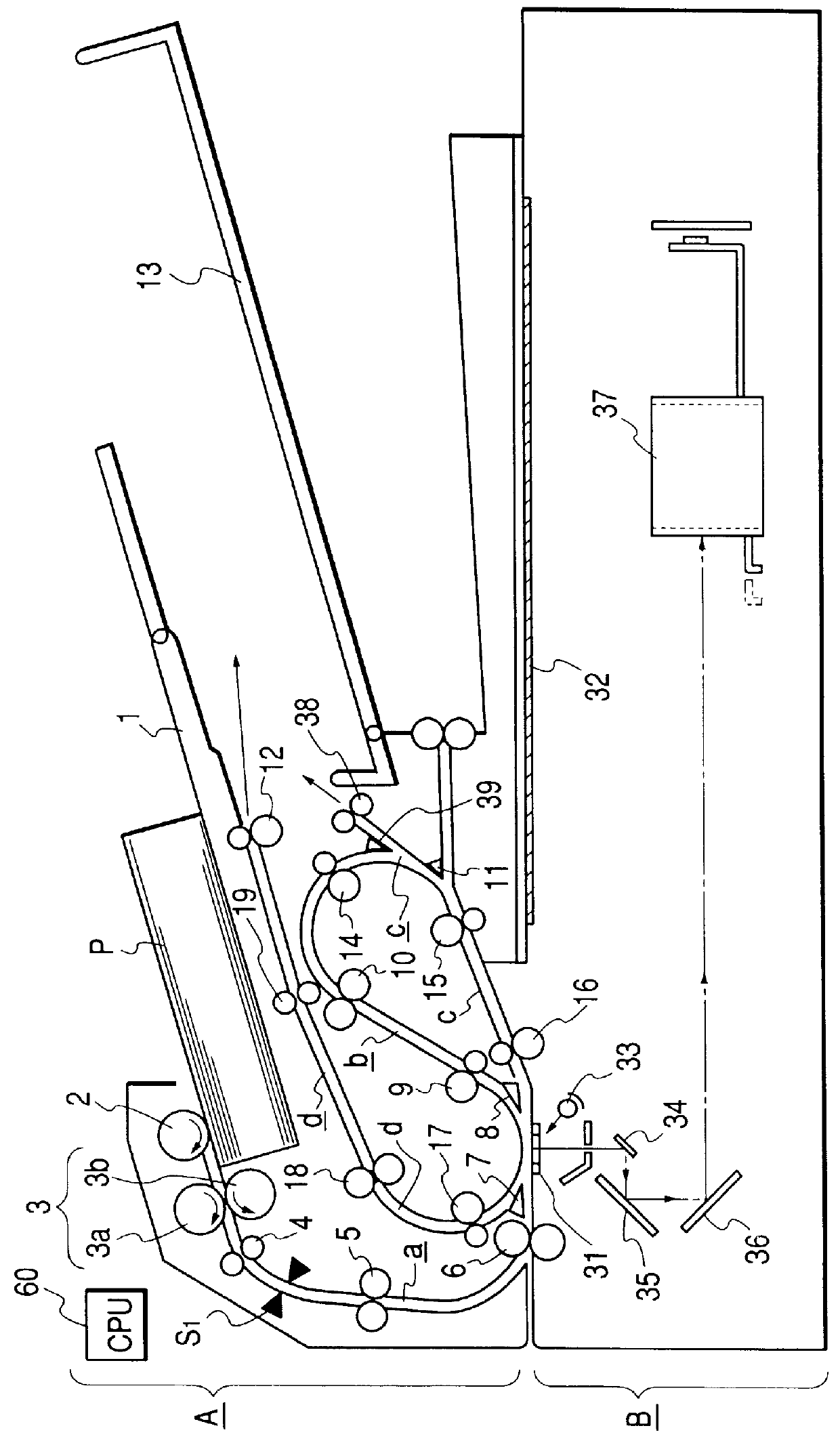

Image forming apparatus and method

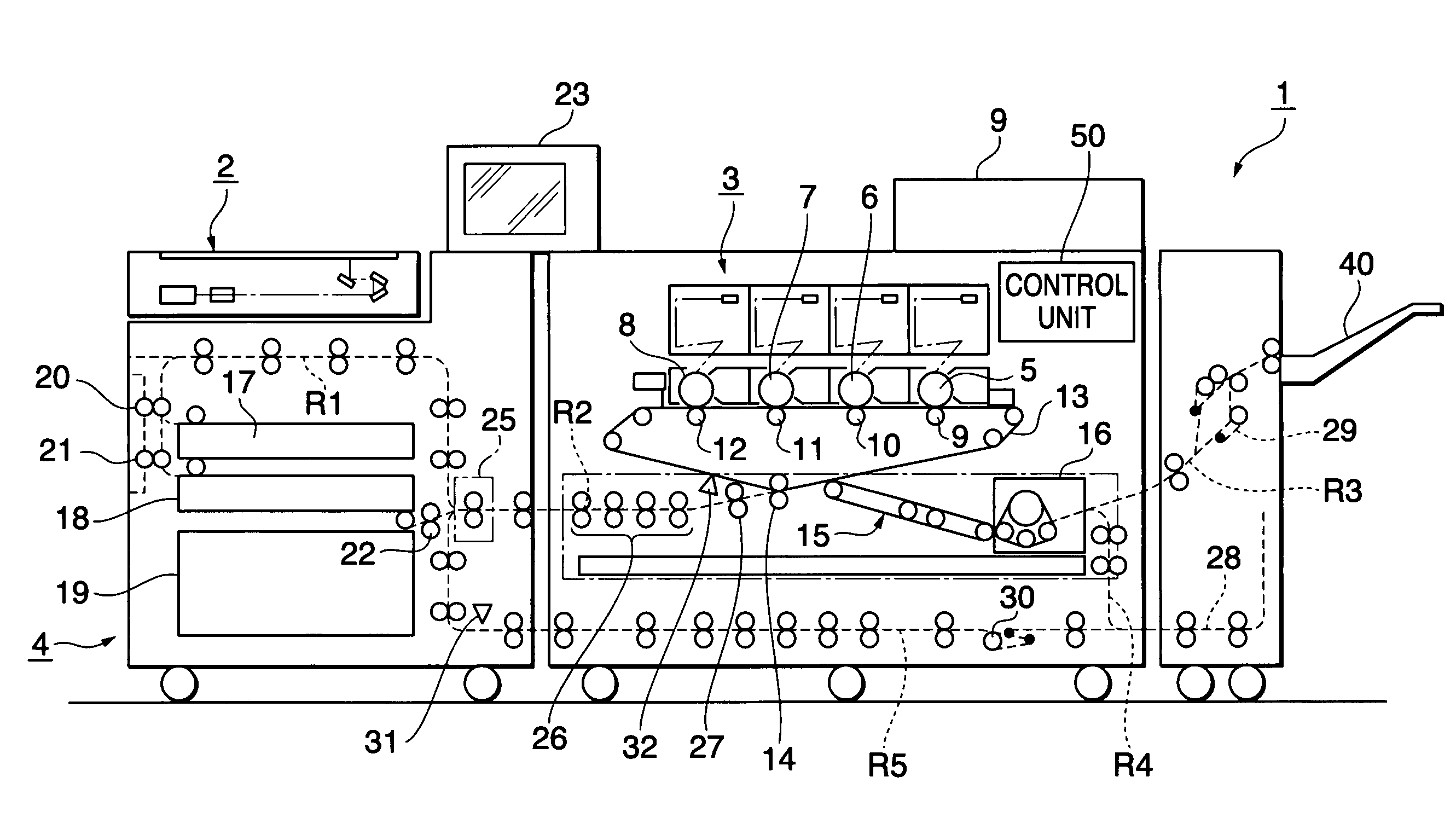

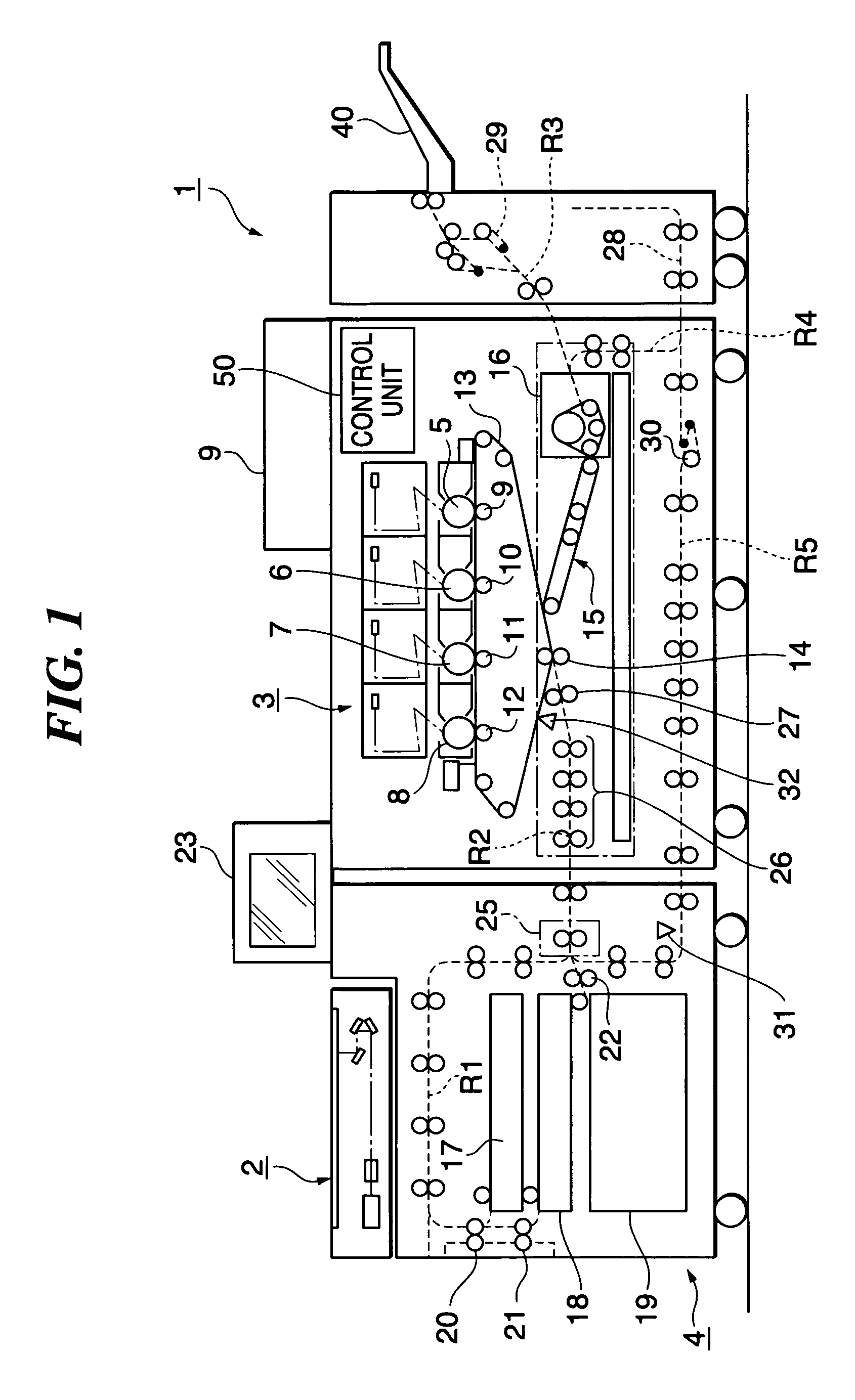

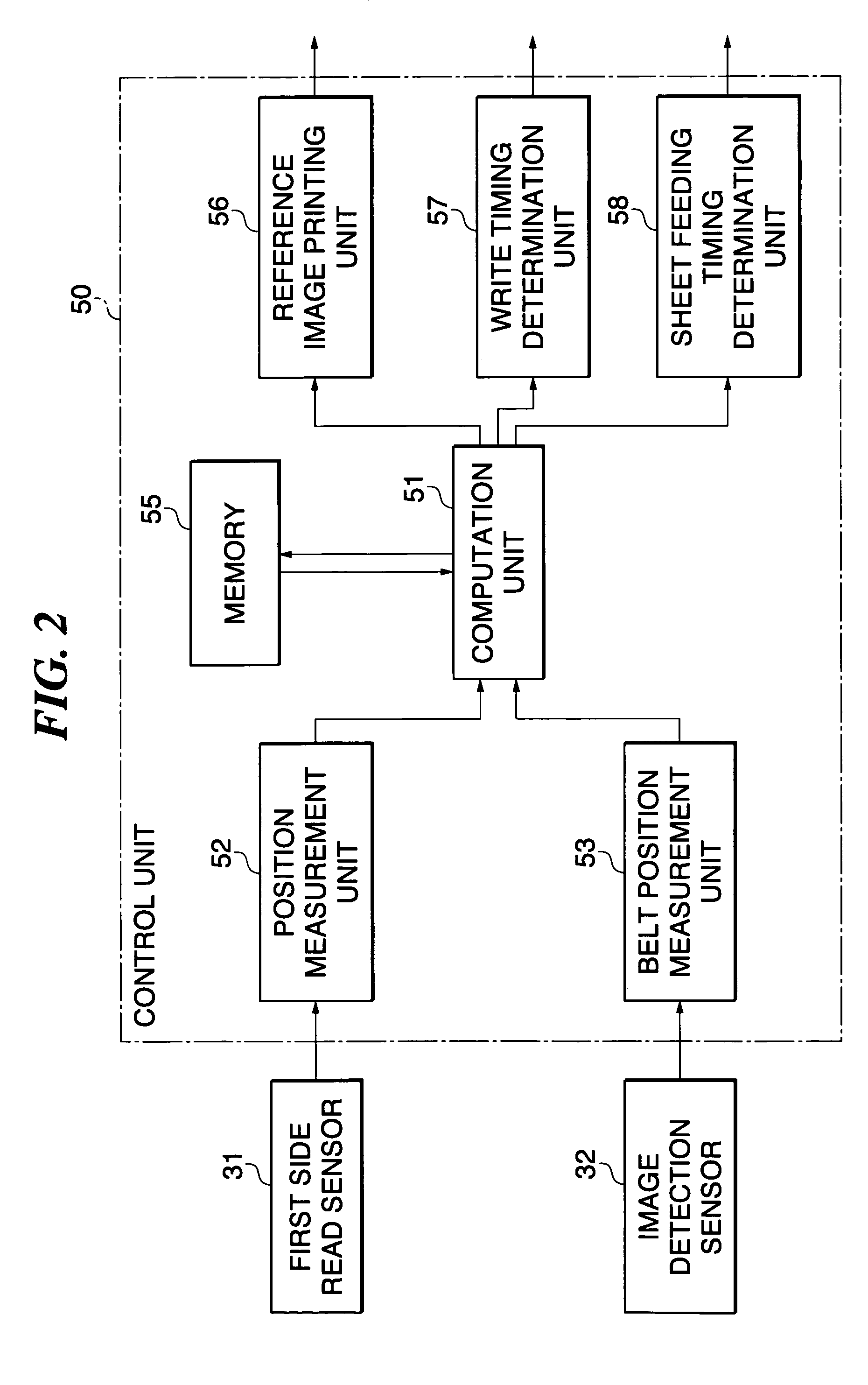

InactiveUS7177585B2Long distanceTimely controlRegistering devicesOverturning articlesImage transferImage formation

An image forming apparatus registers both sides of sheets with great precision in a sheet transportation direction in both-side image formation. The image forming apparatus includes: photoconductive drums holding toner images; an intermediate transfer belt temporarily holding the toner images; a secondary transfer roll that transfers the toner images to a sheet in a transfer unit; a registration roll rotating toward the transfer unit being in sheet feeding timing; a fixing unit fixing the toner images transferred to a first side of the sheet; reversion transportation paths reversing the sheet and again transporting the sheet to the transfer unit; a first sensor detecting the image of the first side of the sheet; and a second sensor that detects the toner images held in the intermediate transfer belt.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Currency processing device, method and system

InactiveUS7753189B2Rapid assessmentClose proximityPaper-money testing devicesOverturning articlesEngineering

According to one embodiment of the present invention, a currency processing device for receiving and processing a stack of currency bills is described. The currency processing device comprises an input receptacle for receiving a stack of bills to be processed, a plurality of output receptacles for receiving bills after the bills have been processed, a transport mechanism for transporting the bills from the input receptacle to the output receptacles, and a discriminating unit for examining the bills. The output receptacles are arranged such that a center of at least one output receptacle is laterally offset from a center of the input receptacle. The discriminating unit includes a detector positioned between the input receptacle and the output receptacles and is adapted to determine the denomination of bills.

Owner:CUMMINS-ALLISON CORP

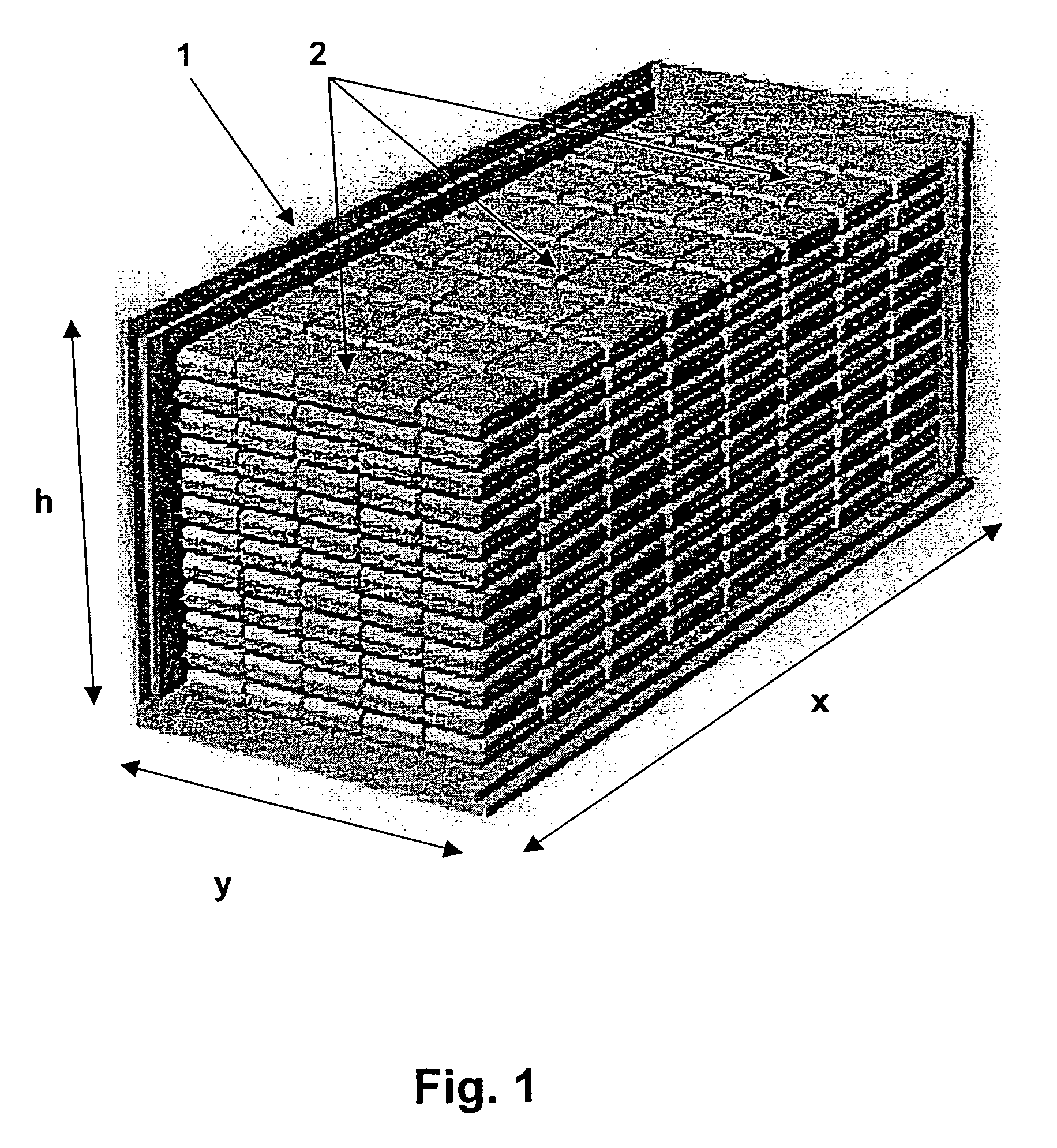

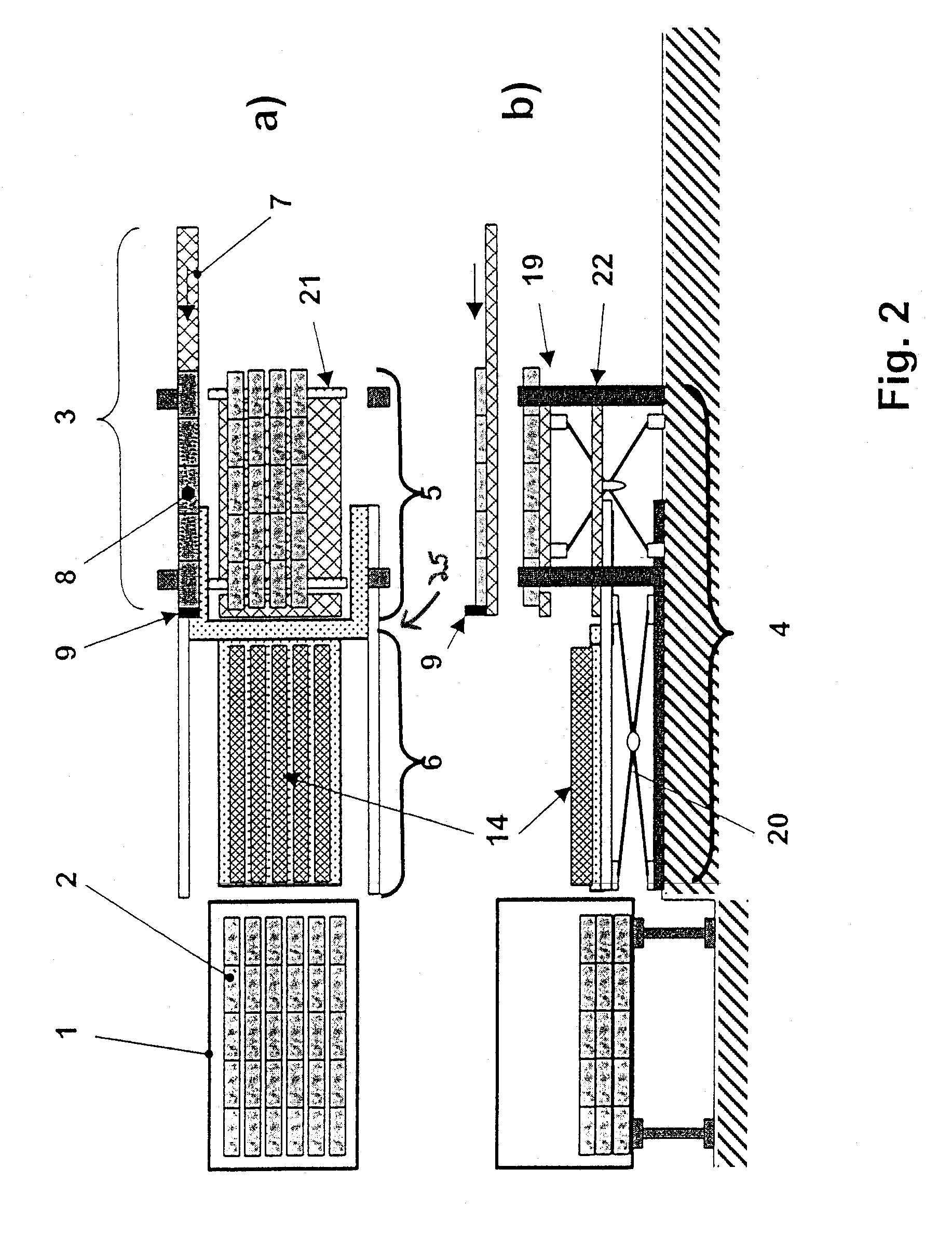

Device for processing mail items in bundles

InactiveUS20090269173A1Processing bundles of mail items easily, reliably and cheaplyPaper article packagingOverturning articlesMechanical engineeringDelivery system

A device for processing mail items, having: at least one stacking device for forming a bundle of superimposed mail items and moving it from a forming position to a loading position; one or more robots for removing the bundles in the loading position and moving them into a covering position; one or more covering devices for placing upside down containers over the bundles in the covering position, so the bundles of mail items are housed inside the containers; a conveying system supplied by the covering devices with bundles of mail items covered with respective upside down containers; and a turnover device for turning the containers over through 180°, so the containers are positioned with their respective openings facing upwards.

Owner:ELSAG DATAMAT SPA

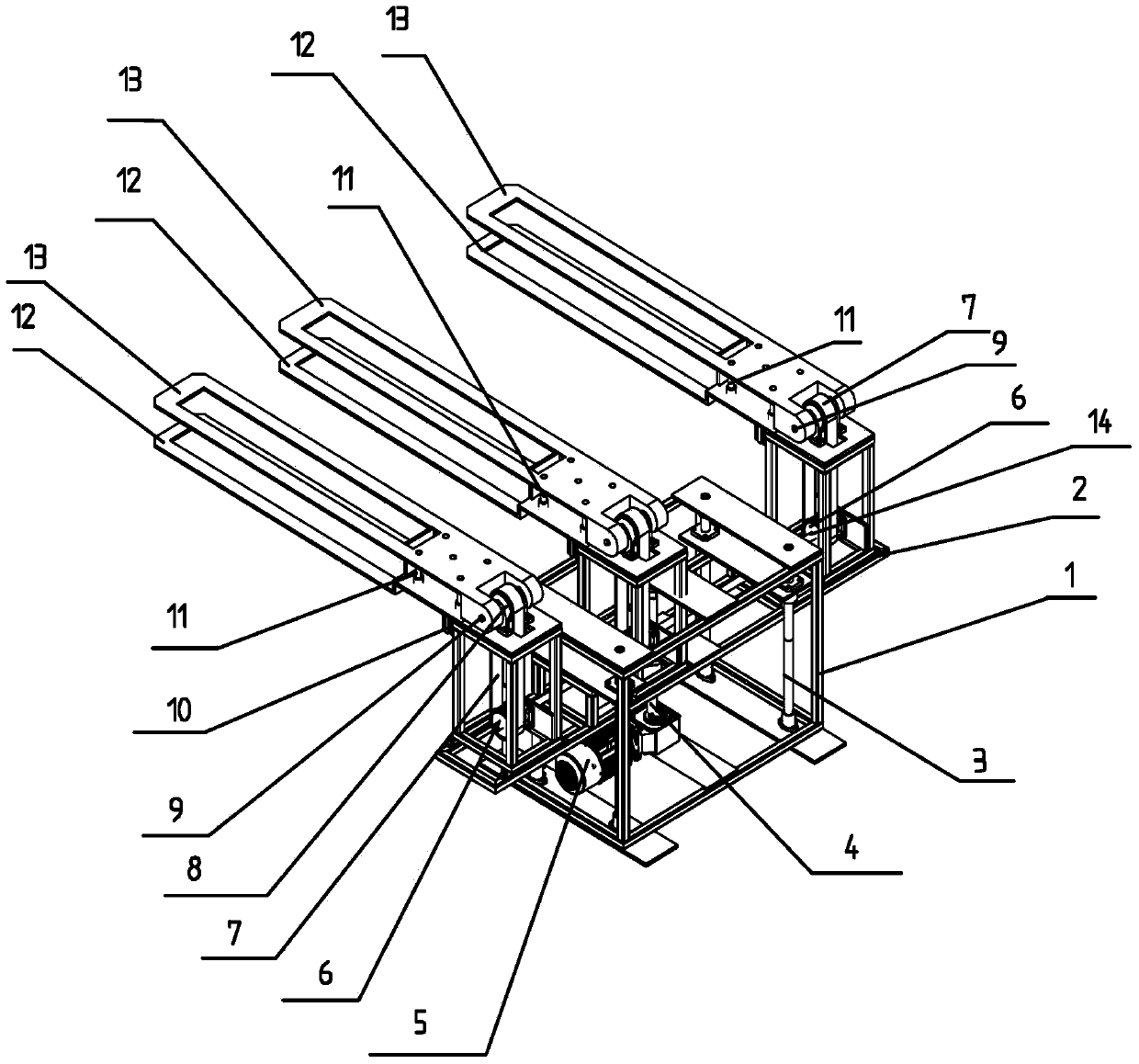

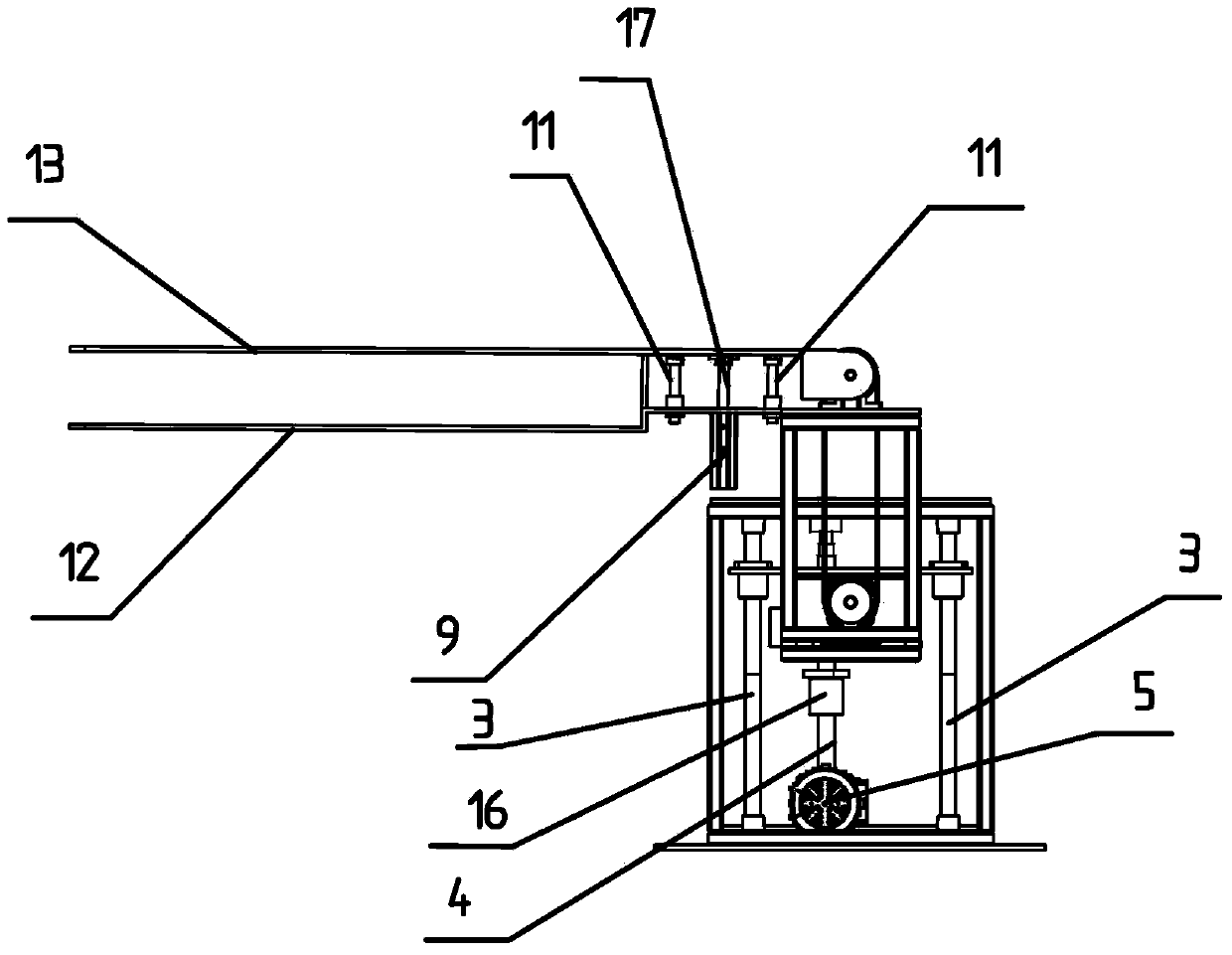

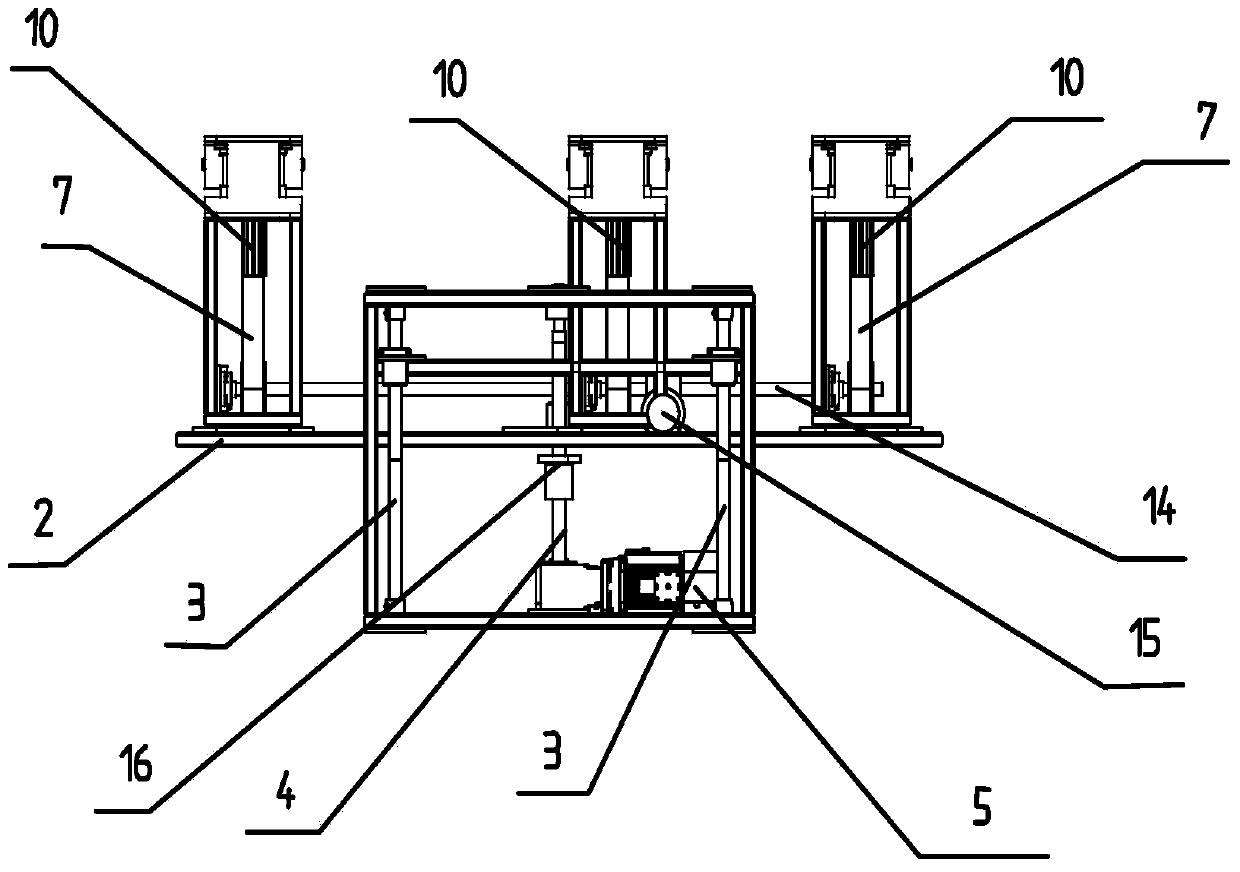

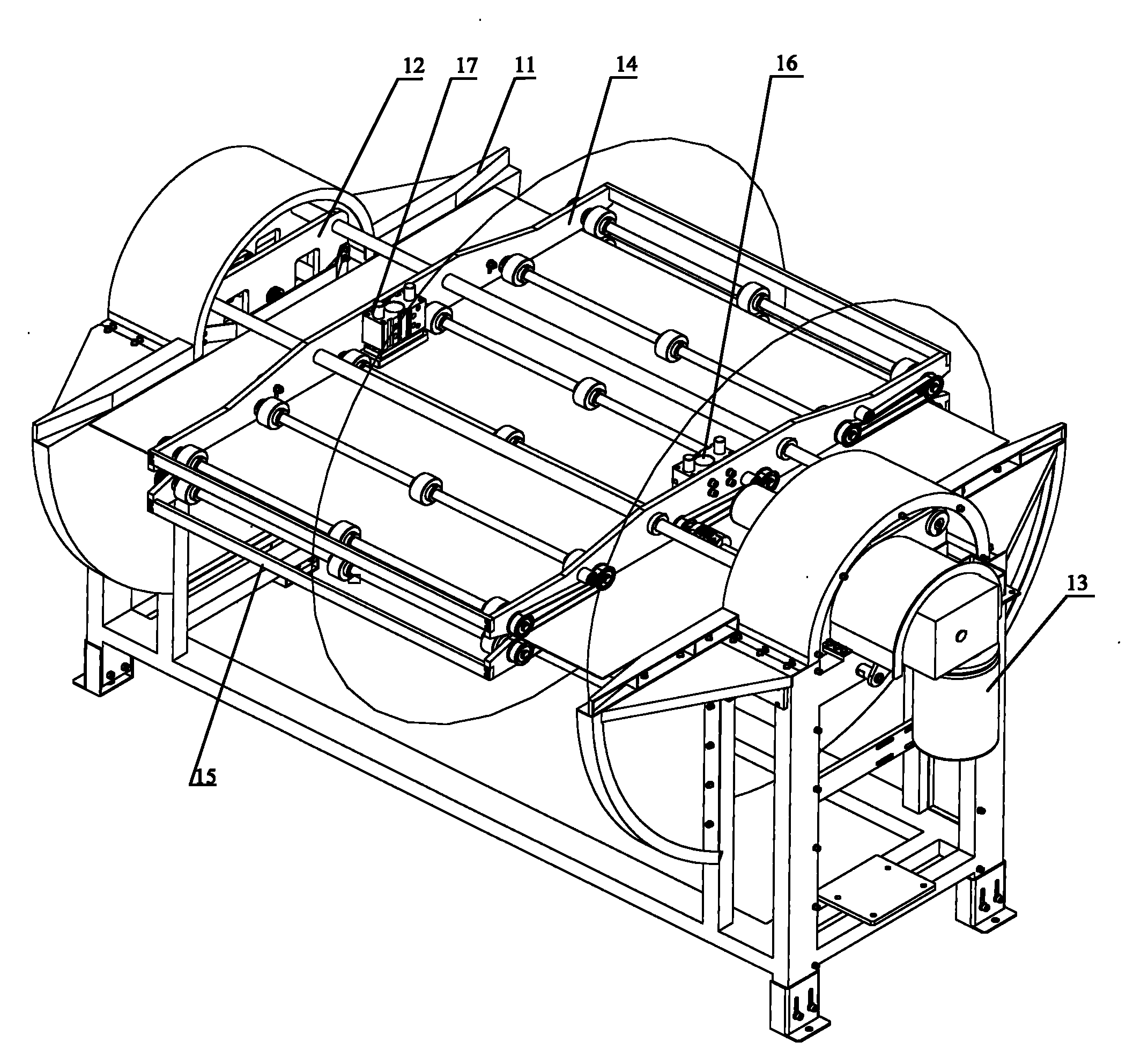

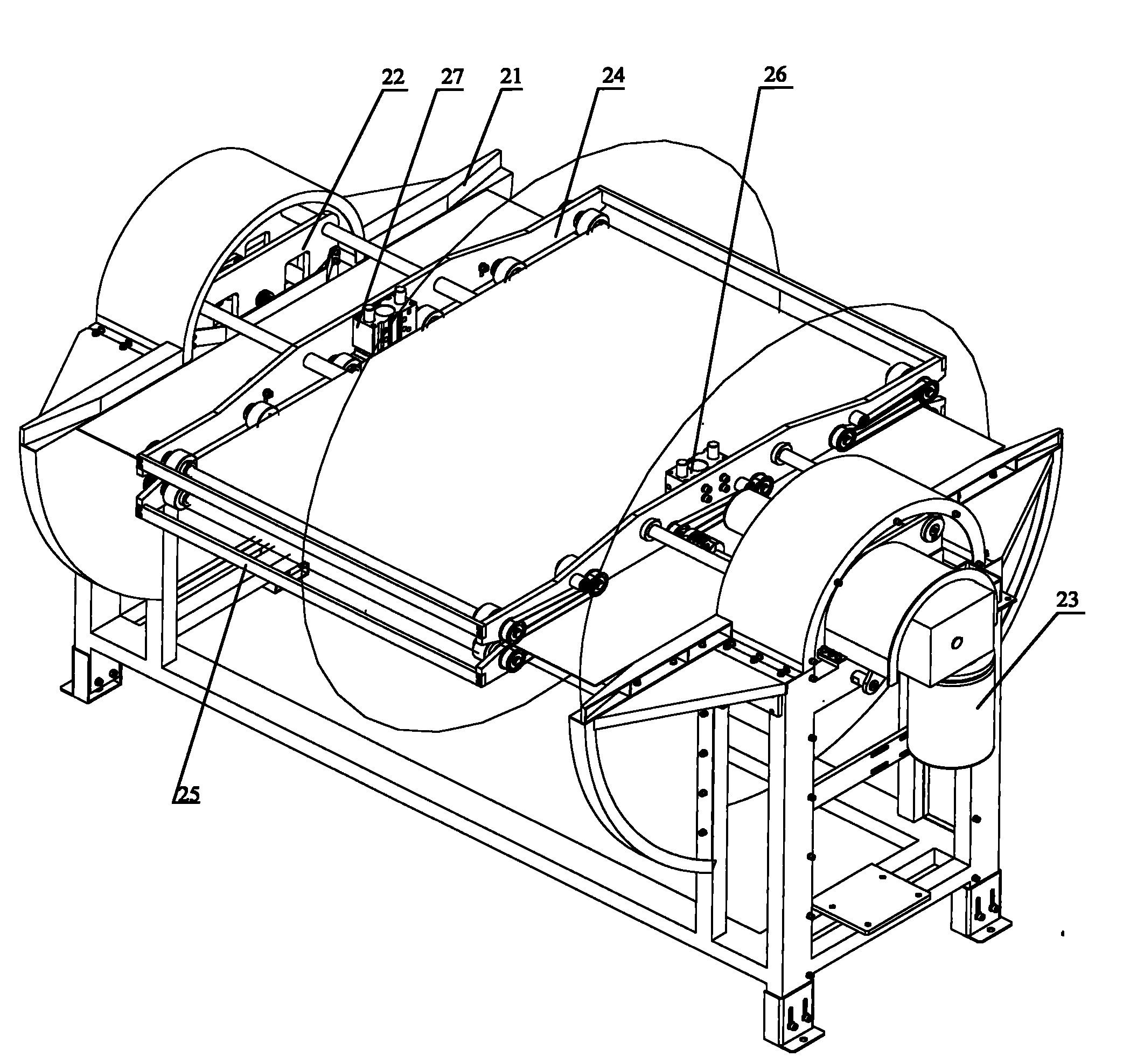

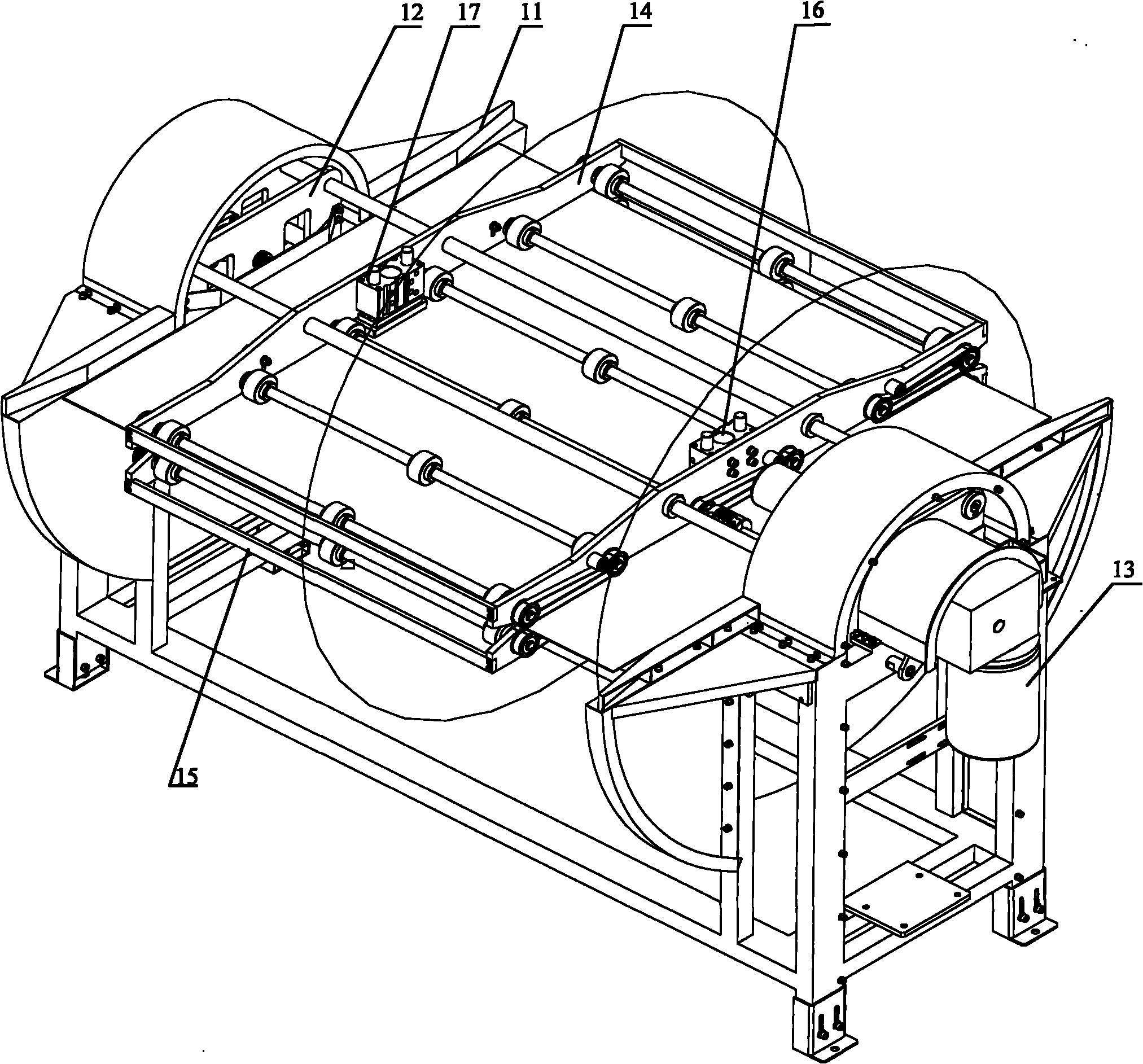

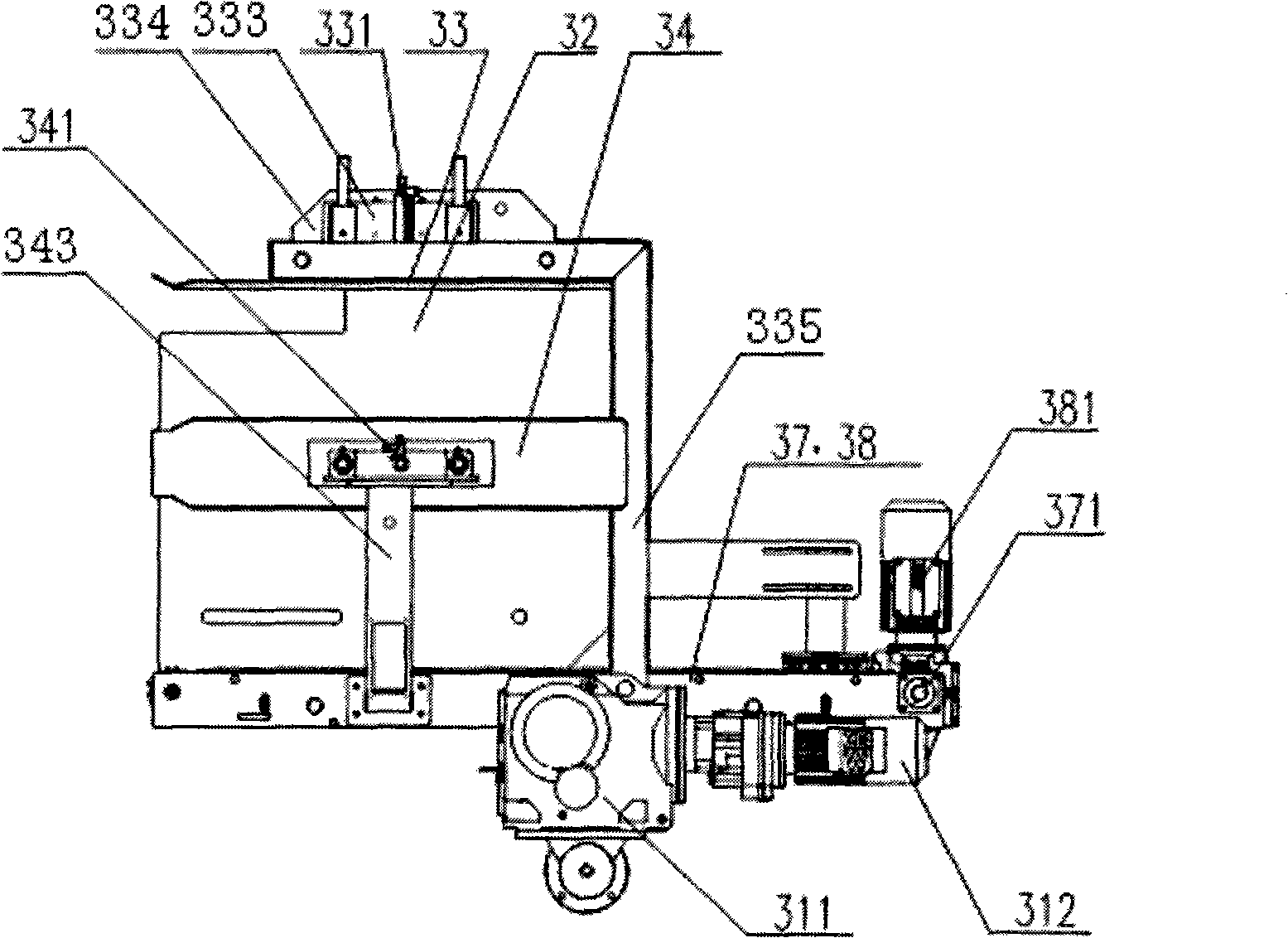

Adjustable full-automatic tilter and method thereof

The invention discloses an adjustable full-automatic tilter and a method thereof. The tilter comprises a base and a baseboard arranged on the bottom end of the base, wherein a plurality of guiding shafts are arranged on the baseboard of the base; a lifting device is arranged among the guiding shafts; a motor for lifting used for controlling the lifting device to move in the direction of the guiding shafts is arranged on the base, and is connected with the lifting device through a screw rod; one or more clamping plate devices for clamping objects to be overturned are arranged on the top part of the lifting device, and are connected with the lifting device through a rotary shaft. The adjustable full-automatic tilter is simple in structure and wide in use, and not only can be applied to single-faced corrugated paper paperboards, but also can be applied to corrugated paper stacks with different thicknesses; when the adjustable full-automatic tilter is in use, the group quantity of work clamping plates can be adjusted according to the corrugated paper (stacks) length specifications so as to realize the overturning process of the corrugated paper (stacks) with different length specifications. In addition, the overturning and reversing of products can be finished without manual operation, and the regularity and the completeness of the products can be ensured.

Owner:FOSHAN NANHAI FUCHENG BELTING IND +2

Double-sided printing apparatus

InactiveUS6916132B2Low costSimplifying transportation pathPrinting mechanismsOverturning articlesEngineeringRecording media

Owner:AVAYA TECH CORP +1

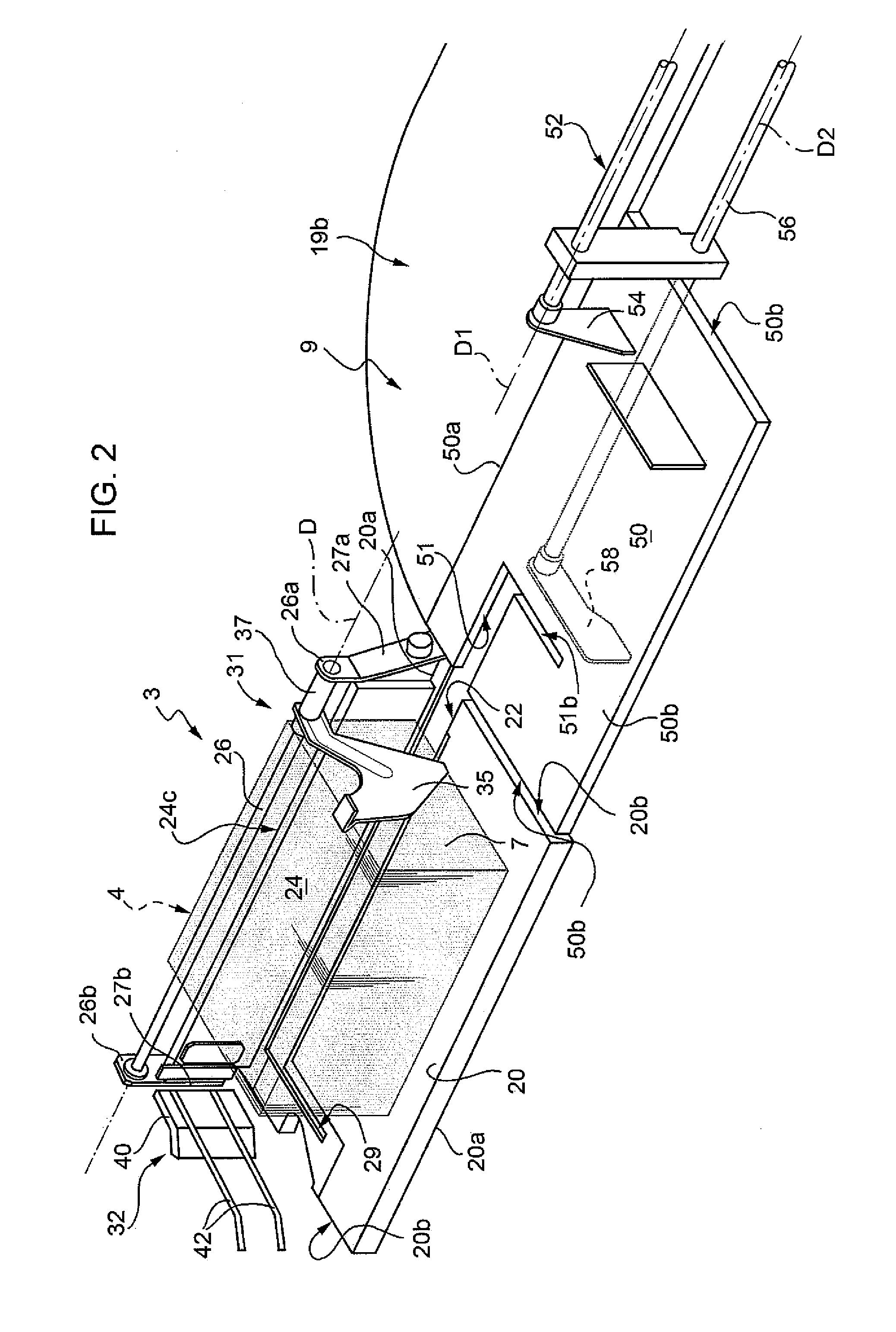

Feeding device and image recording apparatus with the feeding device

Owner:BROTHER KOGYO KK

Plastic card reorienting mechanism and interchangeable input hopper

InactiveUS20050104281A1Quick and easy changeEasy and quick connectionOverturning articlesTypewritersModular unitComputer printing

A card reorienting mechanism and an input hopper of plastic card processing equipment, for example a desktop plastic card printer. The card reorienting mechanism is a modular unit that permits the entire mechanism to be inserted or removed as a single unit from the printer. In addition, the input hopper is designed as an interchangeable system that permits alteration in the card capacity of the hopper.

Owner:ENTRUST DATACARD

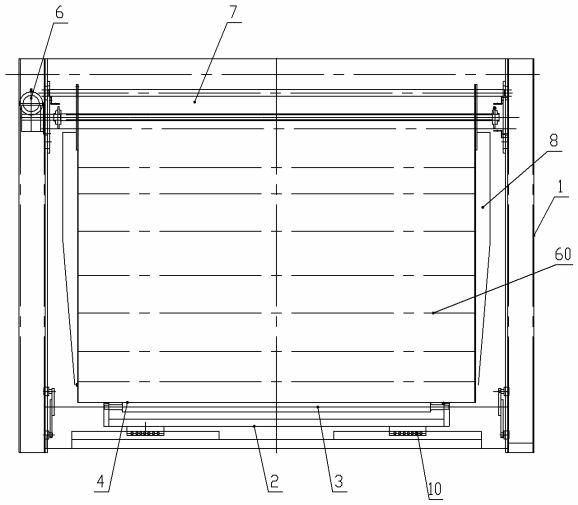

Panel turnover machine

The embodiment of the invention discloses a panel turnover machine which comprises a stand, a motor, a first mounting panel, a second mounting panel, a first transmission component, a second transmission component and an anti-falling component, wherein the motor is fixed at one end of the stand; the first mounting panel is fixed on an output shaft of the motor; the second mounting panel is articulated on the other end of the stand and rotates in the same direction as the rotary motor; the first transmission component and the second transmission component are arranged between the first mounting panel and the second mounting panel and used for transmitting a turnover panel, and the distance between the first transmission component and the second transmission component is larger than the thickness of the turnover panel; and the anti-falling component for preventing the turnover panel from falling off is arranged between the first transmission component and the second transmission component. It can be seen from the technical scheme that because the two transmission components are arranged between the first mounting panel and the second panel, when the turnover panel is transmitted to a specified position by the first turnover panel and when the motor drives the first mounting panel and the second mounting panel to turn over 180 degrees, the turnover panel and the two transmission components simultaneously turn over.

Owner:南通水山环保设备有限公司

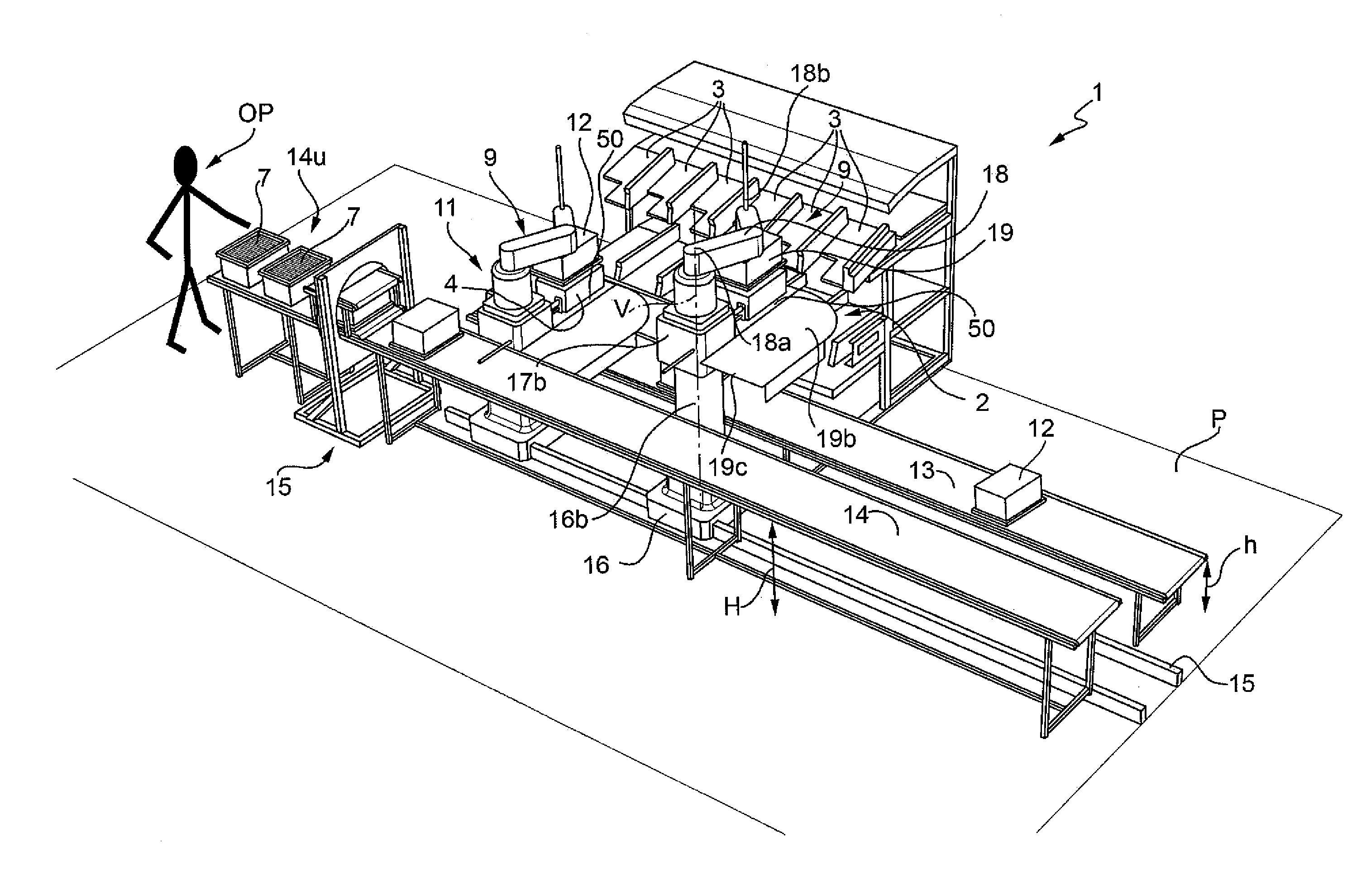

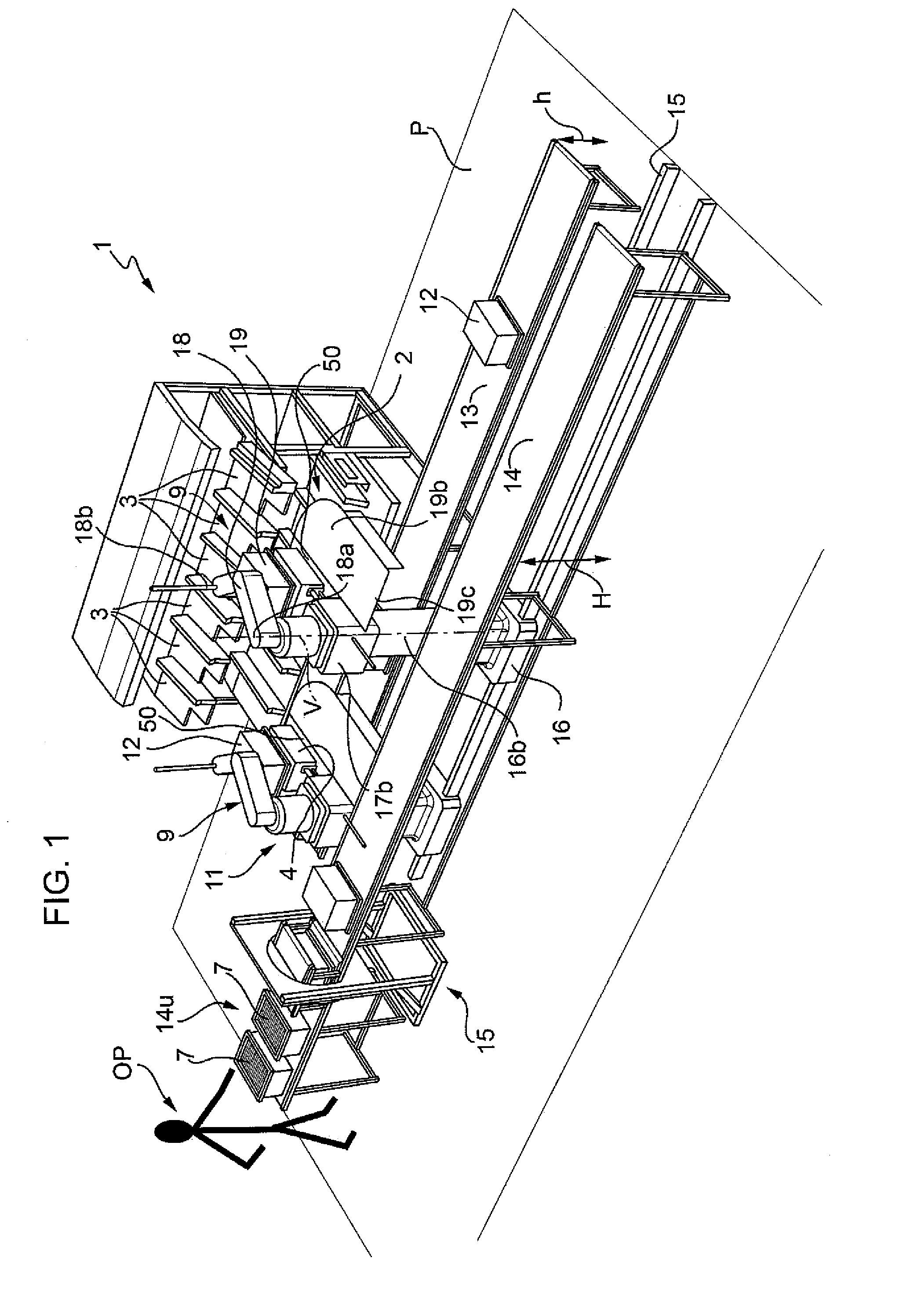

System and method for loading a cargo space with piece goods

InactiveUS7210280B2Avoid damage and lossImprove loading timeCharge manipulationSolid materialEngineeringMachining system

A machining system and unit, especially a welding cell, is provided for use for the machining of workpieces (2), especially body parts of vehicles. The machining system has one or more machining stations (15, 16) with robots (18, 19, 20) and at least one rotation or turning station (5), which has at least two work stations (6, 7) for carrying out different operations simultaneously. The turning station (5) has at least two multiaxially movable turning units (8, 9) arranged next to one another with said gripping tools (11, 12, 13). The working areas (10) intersect each other at the work stations (6, 7).

Owner:KUKA INNOTEC

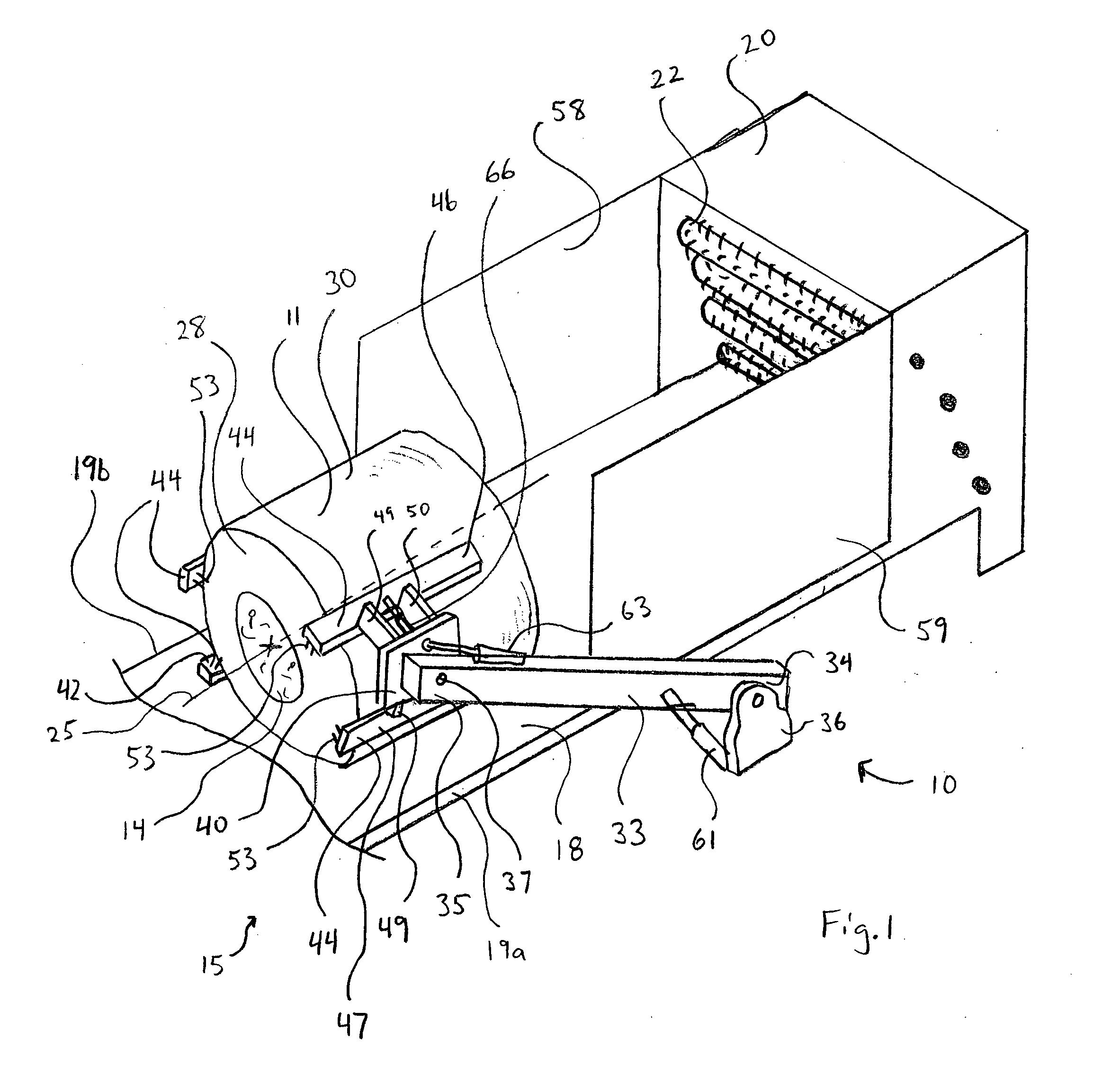

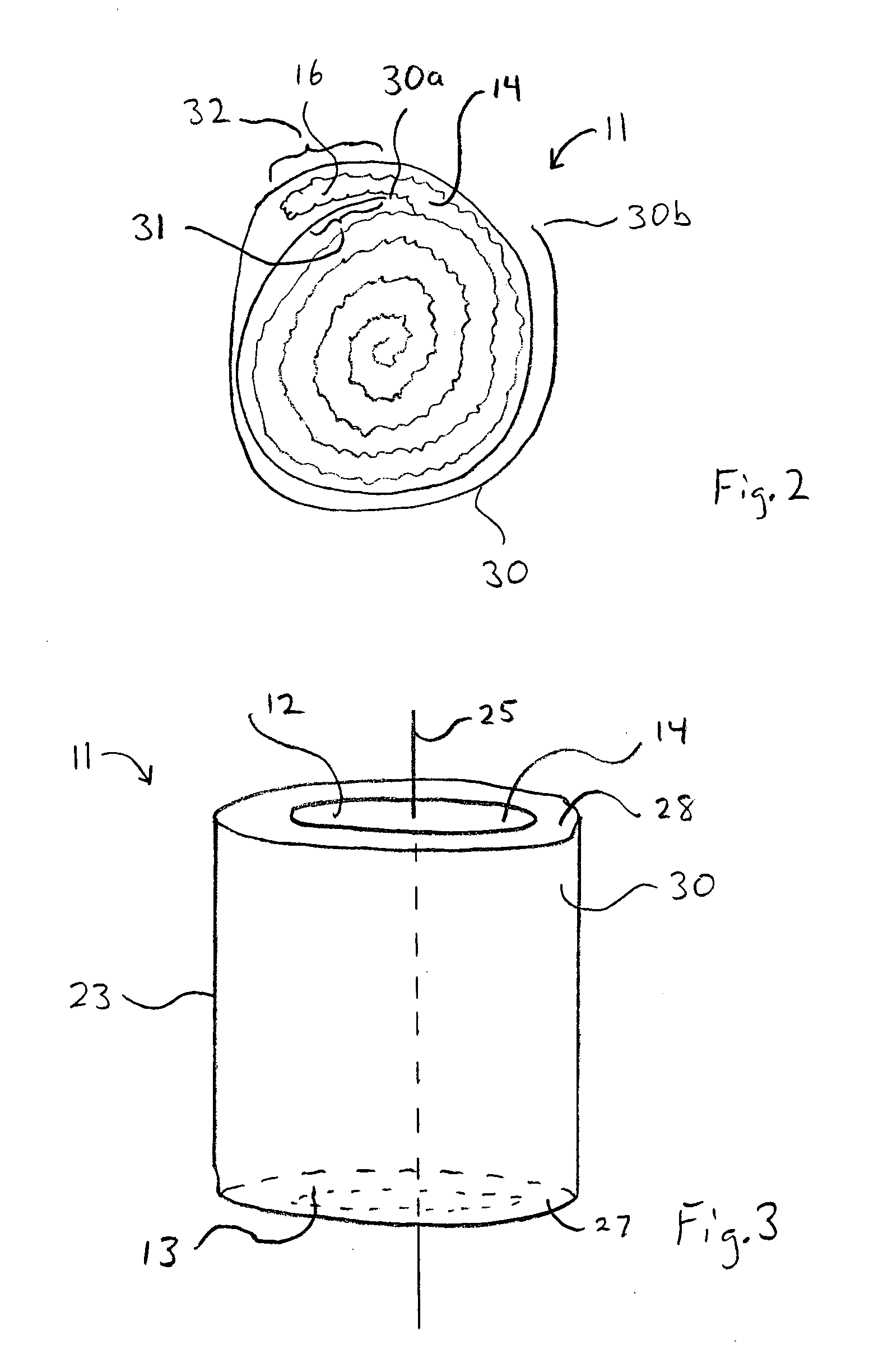

Cylindrical module unwrapping device and method

InactiveUS20090202327A1Avoid pollutionEasy to disassembleOverturning articlesPackaging bottlesFiberEngineering

Owner:CHEROKEE FABTION

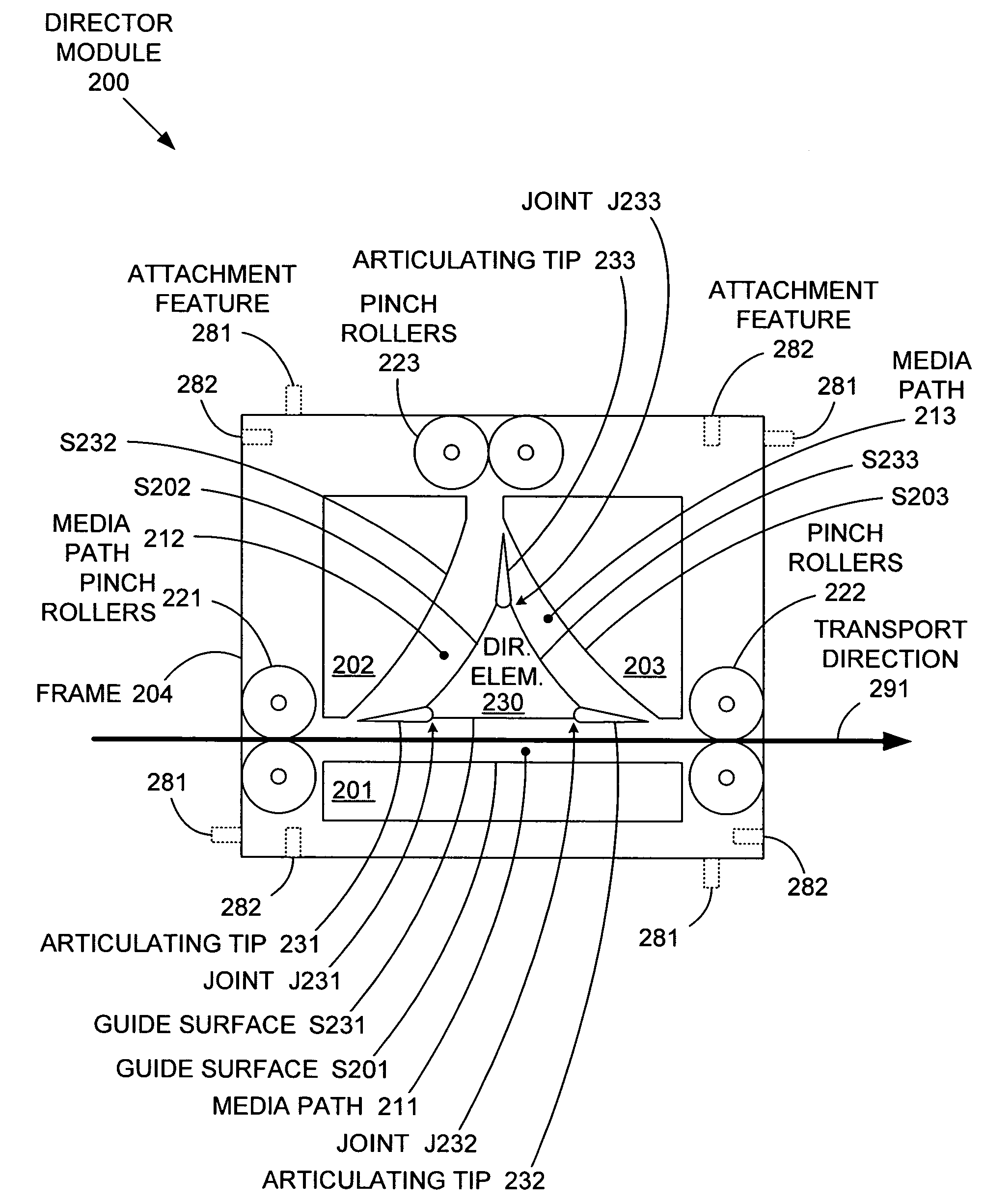

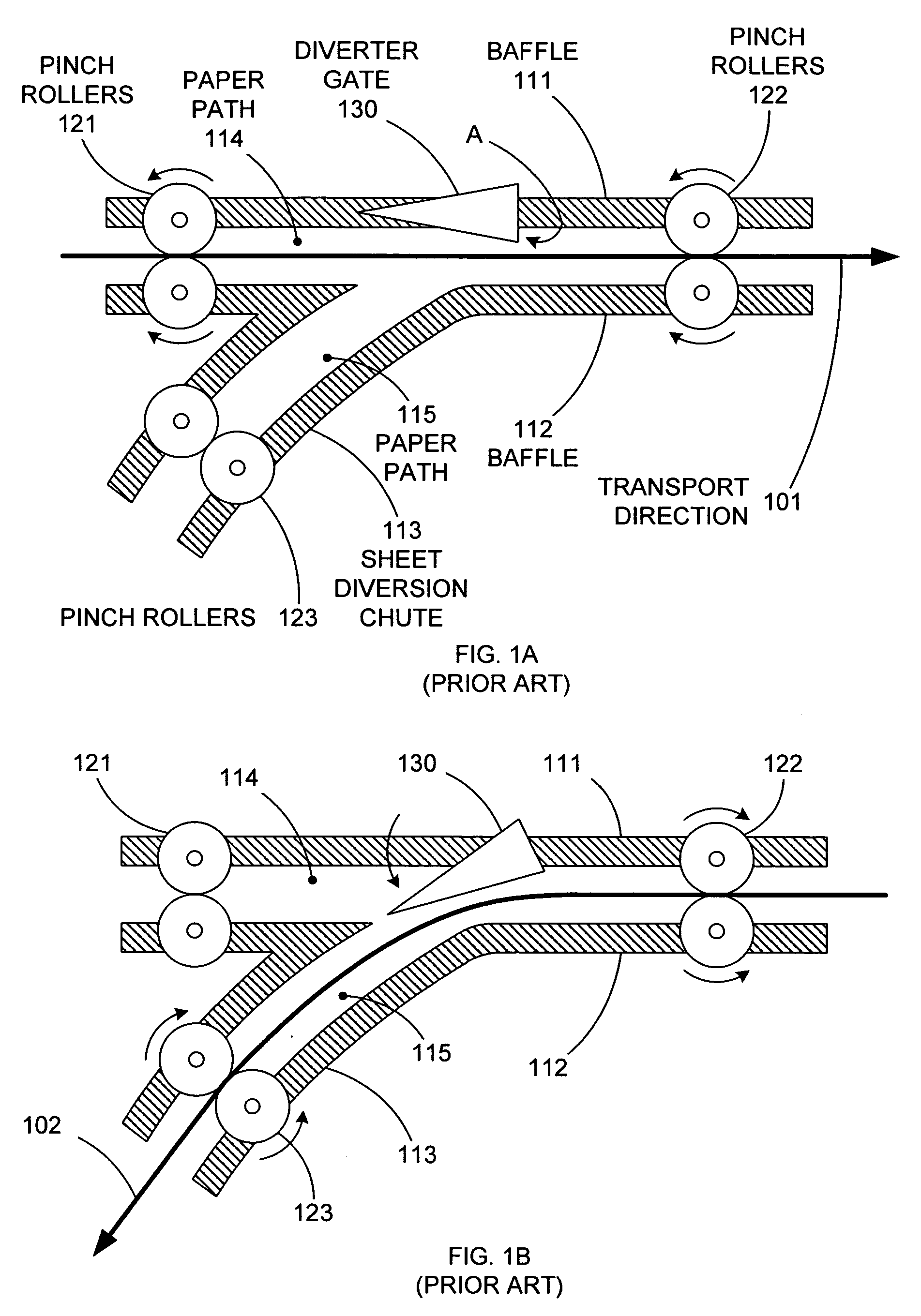

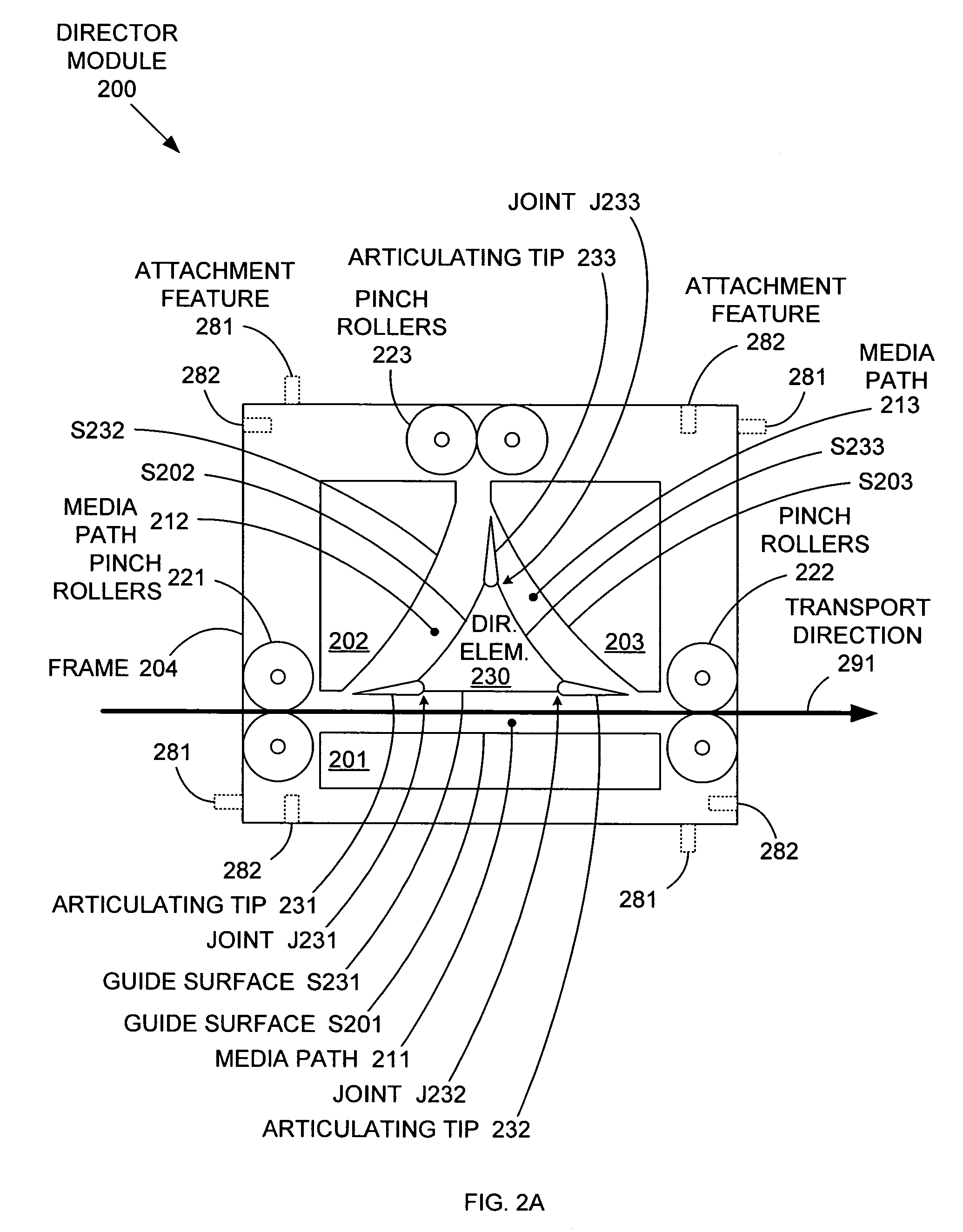

Flexible director paper path module

InactiveUS7108260B2Highly configurableImprove system flexibilityOverturning articlesArticle deliveryTransport systemEngineering

A flexible media transport system includes a director element having articulating tips that provide access to selected media paths. The director element(s) can be incorporated into a director module. Multiple director modules can then be combined into a highly flexible and reconfigurable media transport system. By implementing the joints between the articulating tips and the body of the director element such that a continuous surface is provided in the path of the flexible media, stubbing of the moving media can be avoided. The continuous-surface joint interface can be provided via flexible skins, monolithic articulating tip-director element structures, and preconfigured resilient plate structures, among others.

Owner:PALO ALTO RES CENT INC

Document feeder

ActiveUS20050194731A1Large heightSimple and compact structureOverturning articlesElectrographic process apparatusPaper documentDocument preparation

Owner:BROTHER KOGYO KK

Cigarette package

InactiveUS7823731B2Promote sportsImprove abilitiesPackaging cigaretteCigar manufactureEngineeringMechanical engineering

A cigarette package, in some embodiments, can comprise a tray, a cover coupled to the tray, and a cigarette holder secured to the tray and adapted to move between a first position substantially inside the tray and a second position substantially outside the tray. In some embodiments, a cigarette package can comprise a tray, a cover adapted to slide on the tray between a closed position and an open position, and a cigarette holder coupled to a first wall of the tray and adapted to move between a first position and a second position as the cover slides on the tray. In some embodiments, a consumer can operate a cigarette package of the present application with one hand to dispense at least one cigarette.

Owner:R J REYNOLDS TOBACCO COMPANY

Sheet conveyance apparatus having mechanism for flexibly controlling interval between sheets and image forming apparatus

Owner:RICOH KK

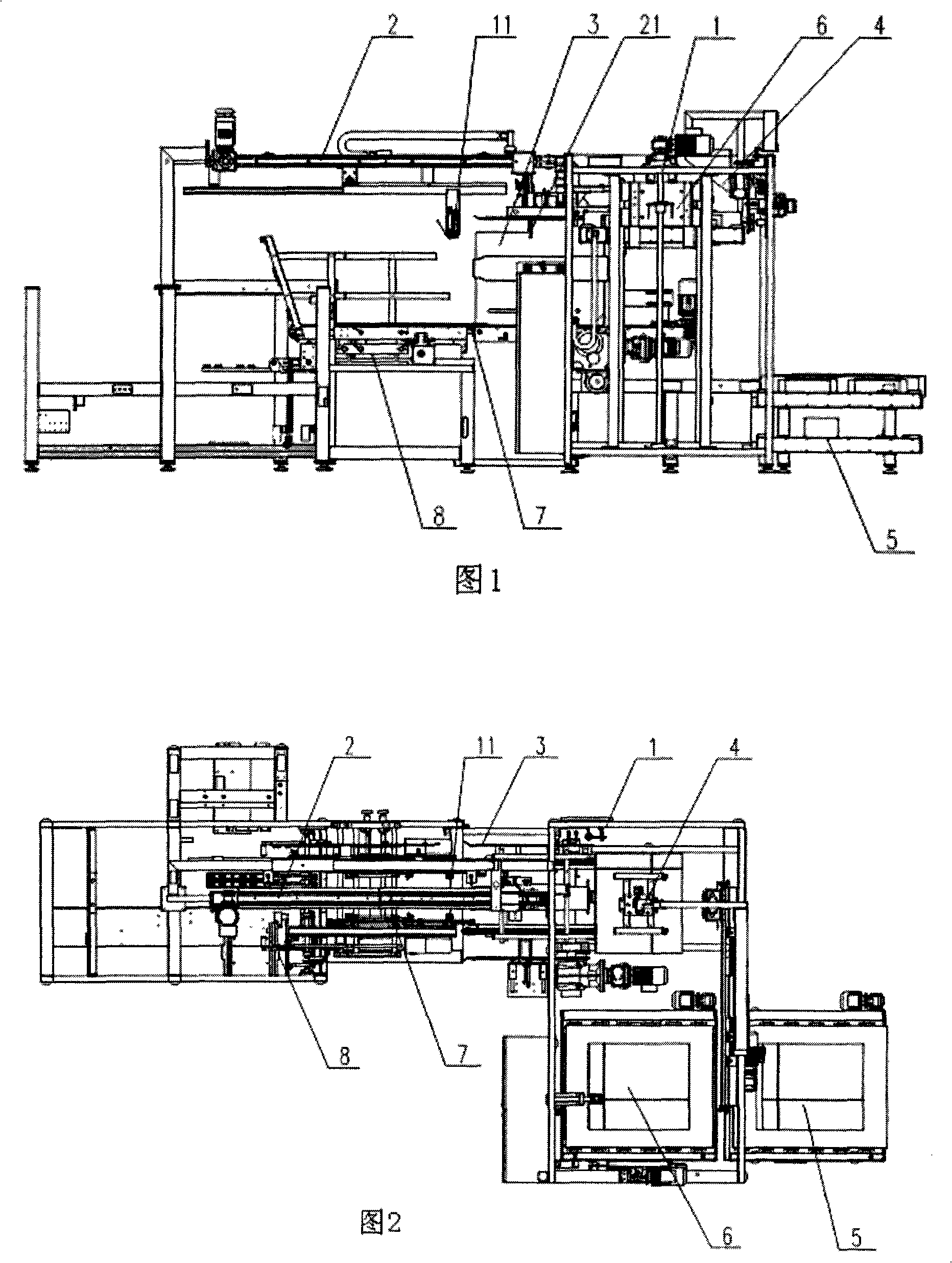

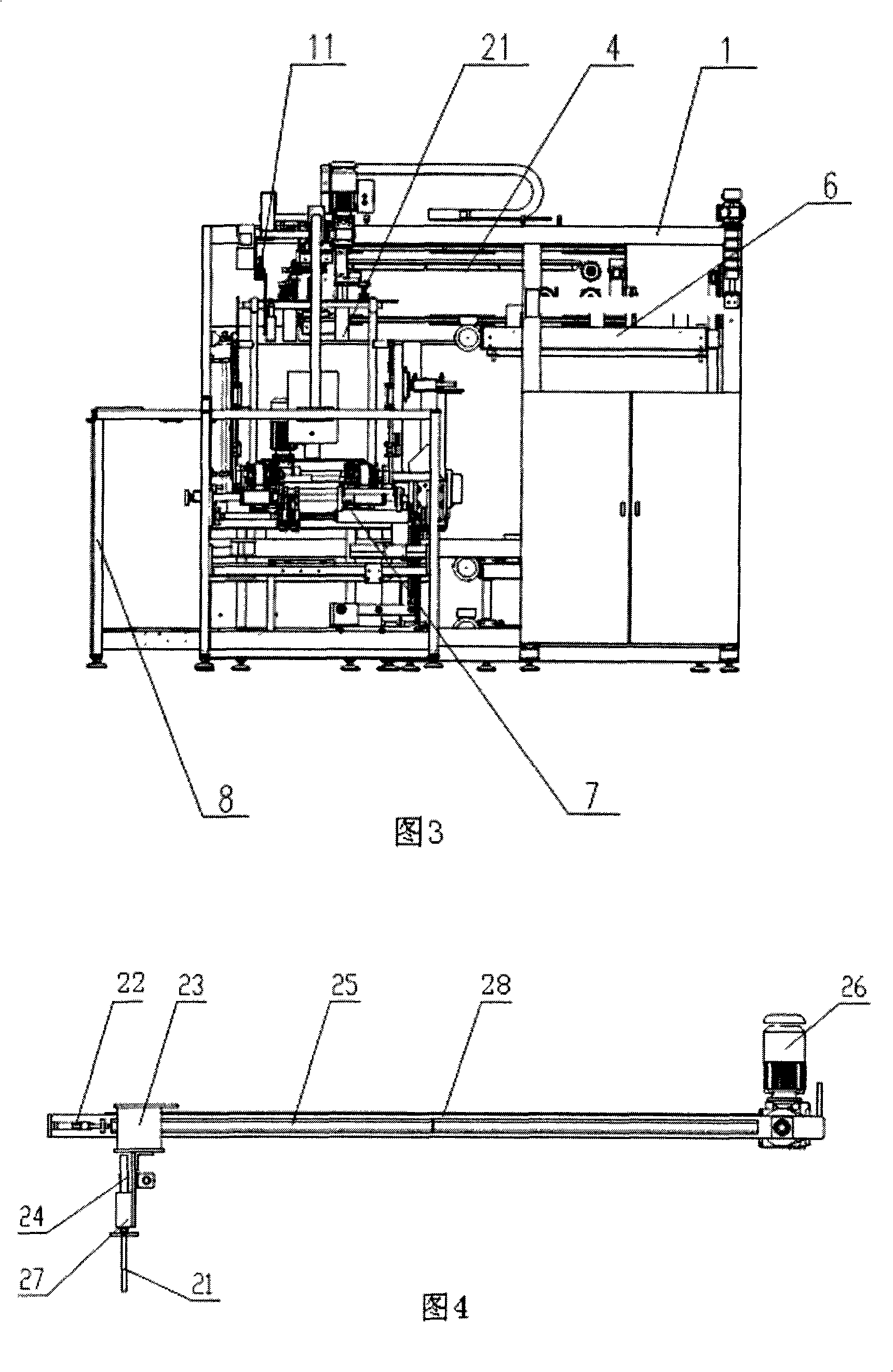

Automatic box feeding machine

ActiveCN101492104ARealize fully automated operationSolve the problems of high labor intensity and low work efficiencyOverturning articlesPackagingCartonFully automatic

The invention provides an automatic box feeding machine, which comprises a machine frame provided with a box inlet and a box outlet. The automatic box feeding machine is characterized in that the machine frame is provided with a lifting device which is connected with the box inlet; and the upper side of the lifting device is provided with a moving and rotating device, and the lower side of the moving and rotating device on one side of the lifting device is provided with a paper box aligning and stacking device which is connected with the box outlet. The automatic box feeding machine can completely achieve automatic box feeding, and overcome the defects of high labor intensity, low work efficiency, and the like, brought by feeding boxes by workers in the prior art. The automatic box feeding machine has the advantages of compact structure, reasonable layout and accurate and quick automatic box feeding, and does not occupy more production spaces. Proper automatic box feeding machine models can be selected according to different box sealing machine layouts of the prior art, so that the automatic box feeding machine also has the advantages of wide application range, convenient installation and investment conversation, and can provide guarantee for cigarette packing to achieve fully-automatic operation.

Owner:东方机器制造(昆明)有限公司

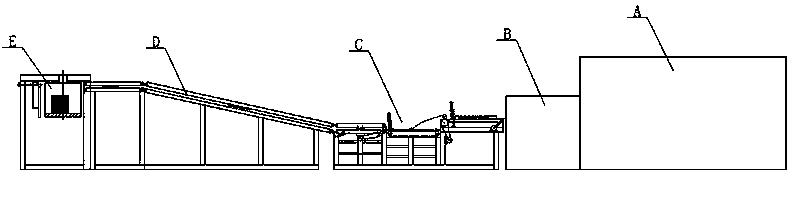

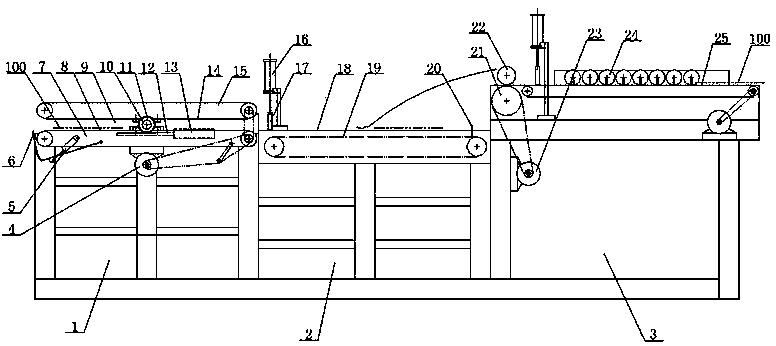

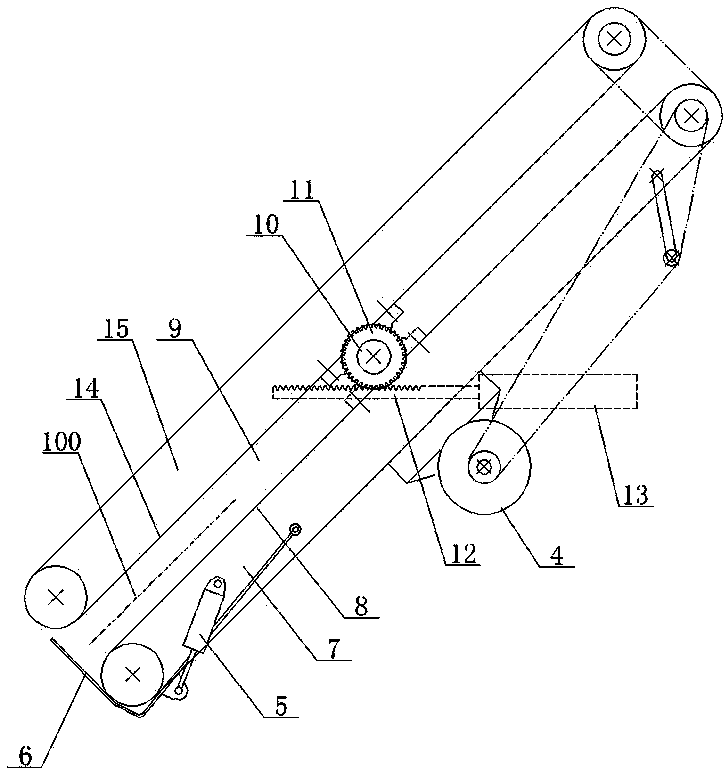

Compound hard paperboard production line with automatic overturning and paper collecting functions

InactiveCN104139999ARaise the output heightMeet the requirements of automatic stackingOverturning articlesPile receiversPaperboardManufacturing line

The invention discloses a compound hard paperboard production line with automatic overturning and paper collecting functions. The compound hard paperboard production line comprises a compound machine, a paper cutting machine, a paper feeding platform and a paper collecting table, and is characterized in that a paperboard overturning mechanism is arranged between the paper cutting machine and the paper feeding platform and comprises a paperboard overturning and conveying assembly, the paperboard overturning and conveying assembly comprises an overturning rack, an upper conveying belt, a lower conveying belt and a paper stop board, the overturning rack can perform 180-degree reciprocating overturning motion, the overturning of the overturning rack is pushed by an overturning pushing part, the upper conveying belt is arranged at the upper part of the overturning rack, the lower conveying belt is arranged at the lower part of the overturning rack, a material passing channel allowing stacked paperboards to pass is reserved between the upper conveying belt and the lower conveying belt, the paper stop board is movably arranged at an outlet of the material passing channel, and when the overturning rack performs forward turning action, the paper stop board blocks the outlet of the material passing channel. According to the compound hard paperboard production line with the automatic overturning and paper collecting functions, not only is automatic production of compound hard paperboards realized, but also the hard paperboards are automatically and flatly stacked and collected with high quality, the flatly stacked and collected hard paperboards can directly meet requirements of mechanical packaging, and the labor intensity of a worker is greatly reduced.

Owner:瑞安市荣庆包装机械厂

Sheet guide device with sheet position adjusting mechanism and image forming apparatus using the same device

InactiveUS6279900B1Easy to adjustSave spaceRegistering devicesOverturning articlesEngineeringMechanical engineering

Owner:RICOH KK

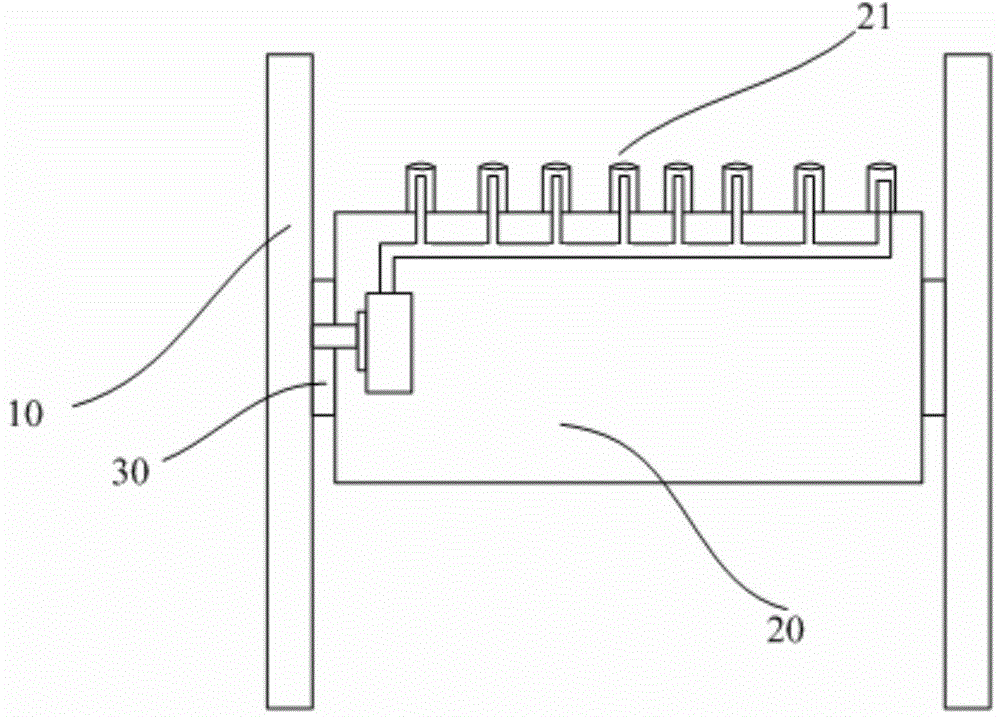

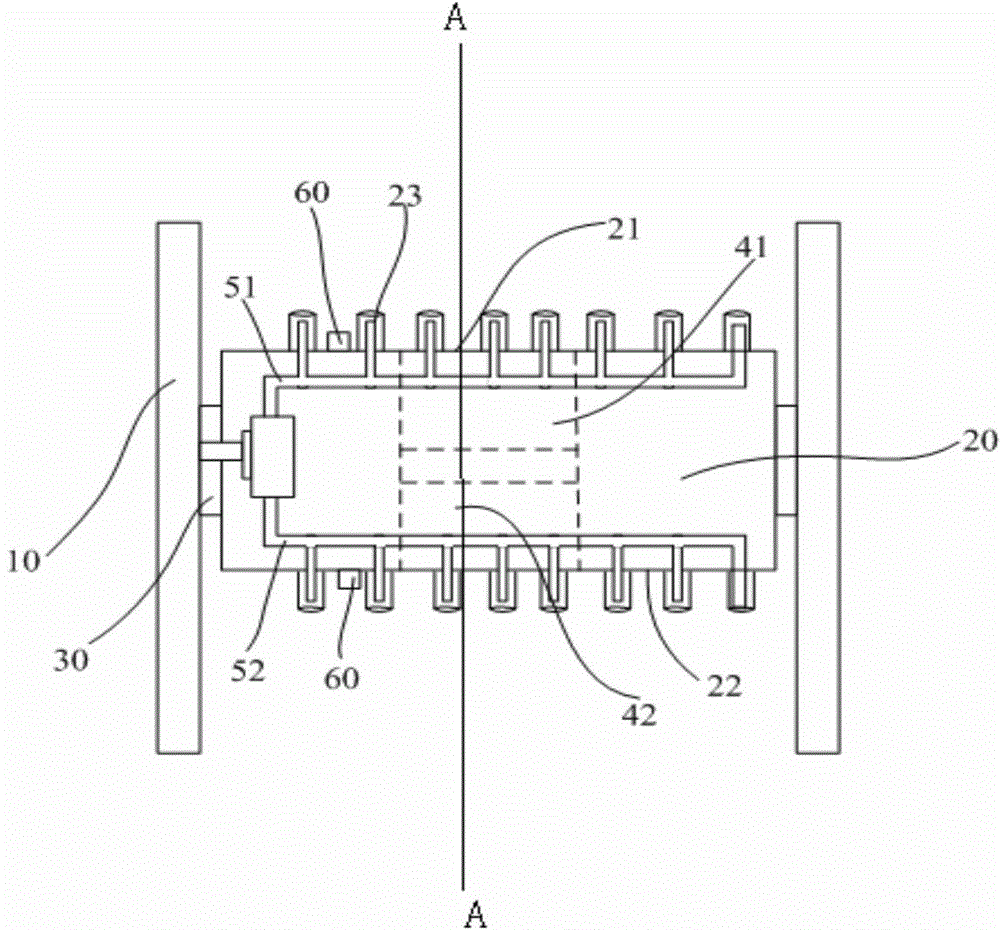

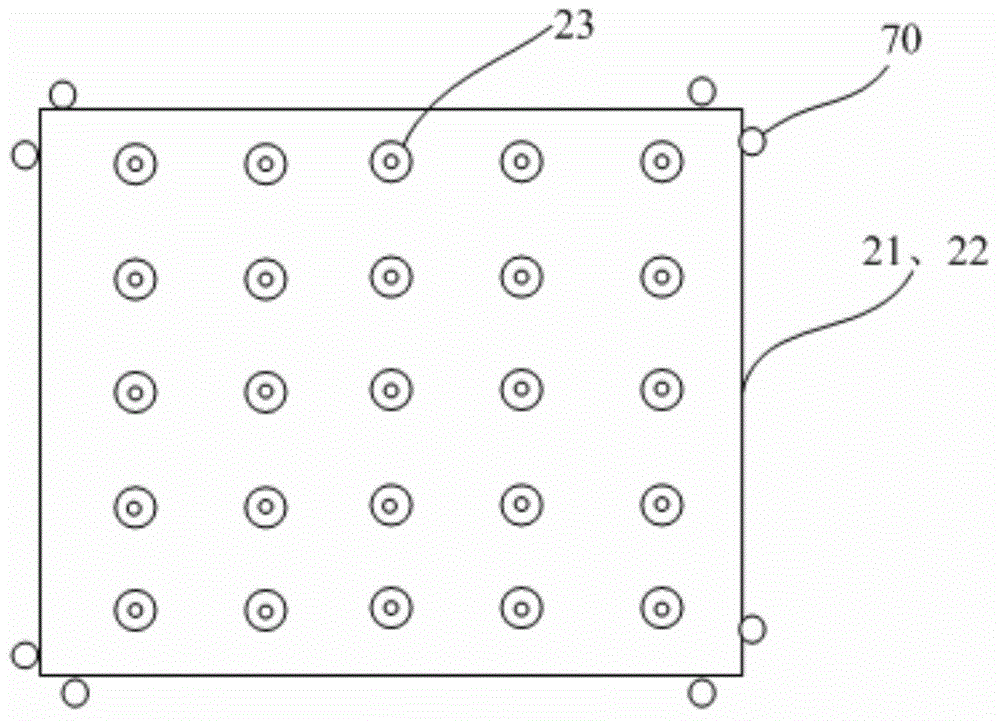

Turning device, base plate box aligning system and base plate box aligning method

ActiveCN104360507AImprove turnover efficiencyReduce consumptionOverturning articlesNon-linear opticsEngineeringMechanical engineering

The invention relates to a turning device, a base plate box aligning system and a base plate box aligning method, and belongs to the technical field of a box aligning process. The problem of low work efficiency of the existing turning device can be solved. The turning device provided by the invention comprises a fixing support frame and a turning platform, wherein the turning platform is connected with the fixing support frame through a vertical rotating shaft, the turning platform is provided with a first adsorption surface and a second adsorption surface which are in opposite arrangement and are used for driving the adsorption base plate, the turning device also comprises a first horizontal rotating shaft, a second horizontal rotating shaft, a vacuum adsorption unit and a control unit, the first horizontal rotating shaft and the second horizontal rotating shaft are respectively used for enabling the first absorption surface and the second absorption surface to rotate in the horizontal direction, the control unit is used for controlling the vacuum adsorption unit to adsorb a base plate through the first adsorption surface and the second adsorption surface, and the turning platform turns the adsorbed base plate through a vertical rotating shaft. The turning device provided by the invention has the advantages that the pre-alignment function can be realized, and meanwhile, the work efficiency can be greatly improved.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

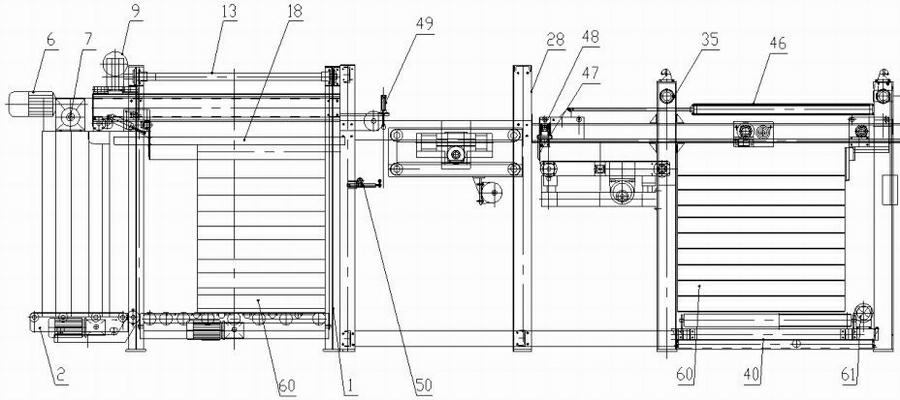

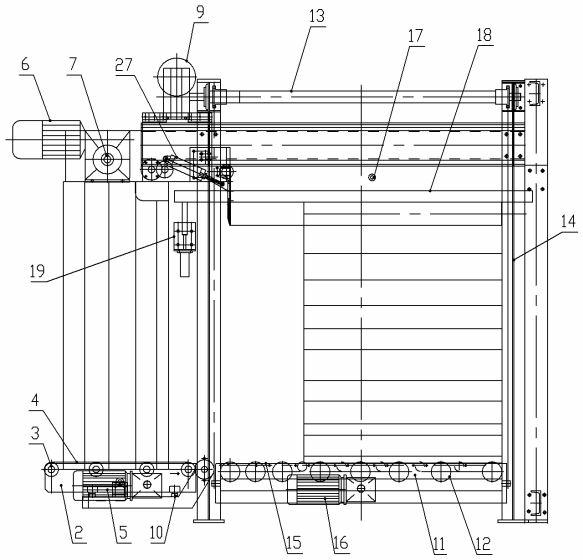

Full-automatic counting board-turning stack aligner

InactiveCN102583072AResolve dependenciesSolve efficiency problemsPaper article packagingOverturning articlesProduction lineCardboard

The invention discloses a full-automatic counting board-turning stack aligner, which comprises an arrangement counting conveying system, a board turning system and a rear conveying accumulation arrangement system. An output end of the arrangement counting conveying system is connected with an input end of the board turning system, an output end of the board turning system is connected with an input end of the rear conveying accumulation arrangement system, and a packing device is arranged between the output end of the arrangement counting conveying system and the input end of the board turning system. The full-automatic counting board-turning stack aligner is certainly well received by enterprises in the packaging industry for improving automation level, precision, intelligence and the like, and also solves the problems that online manual paper board counting, board turning, packing and stack alignment of a corrugated paper board production line greatly rely on manual operation for a long period, and production efficiency is restricted. According to huge market demands, successful development of efficient energy-saving equipment such as the full-automatic counting board-turning packing stack aligner and the like can become the development trend of the efficient equipment in nationwide and global packaging industries.

Owner:河南远航包装机械有限公司

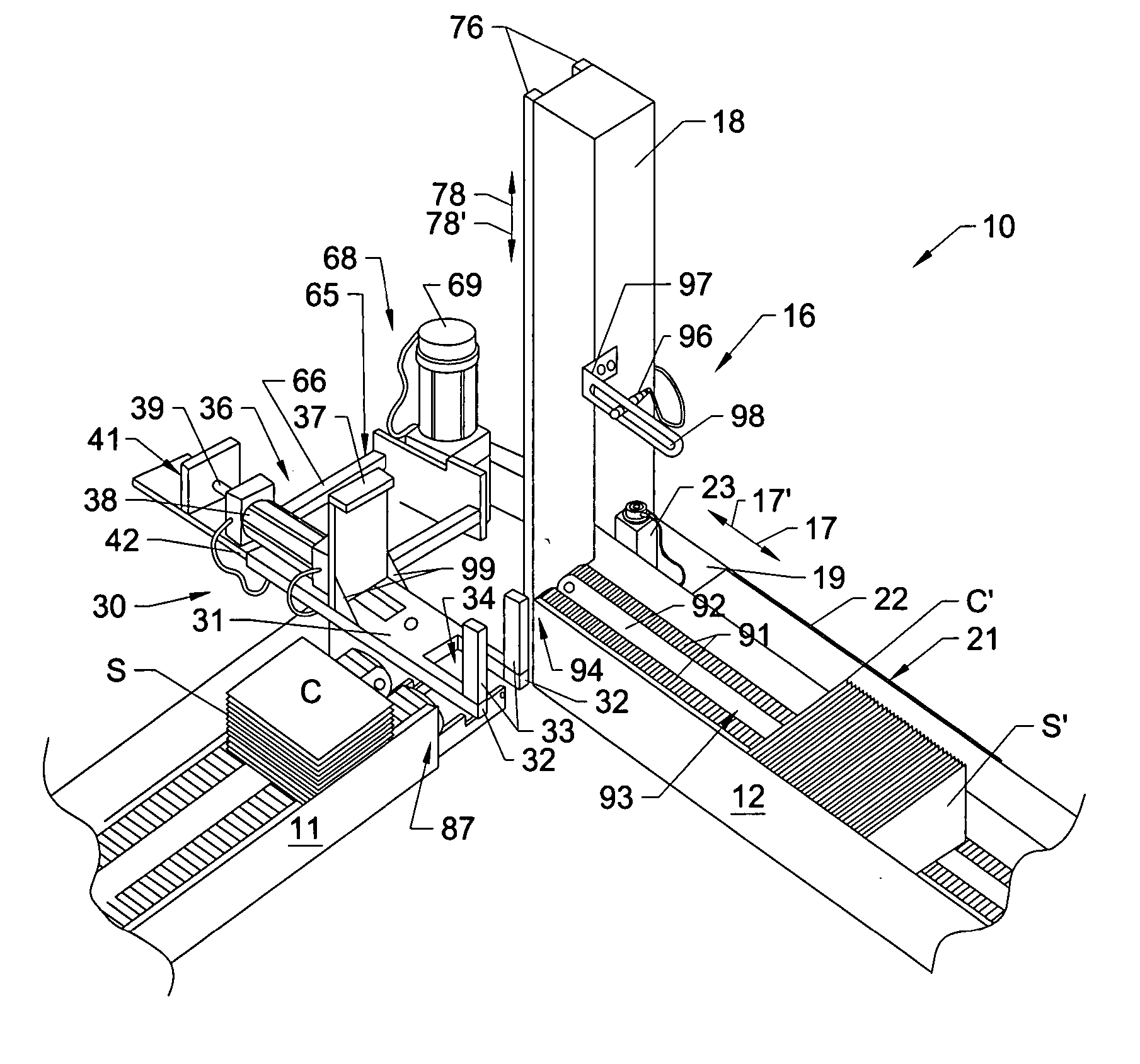

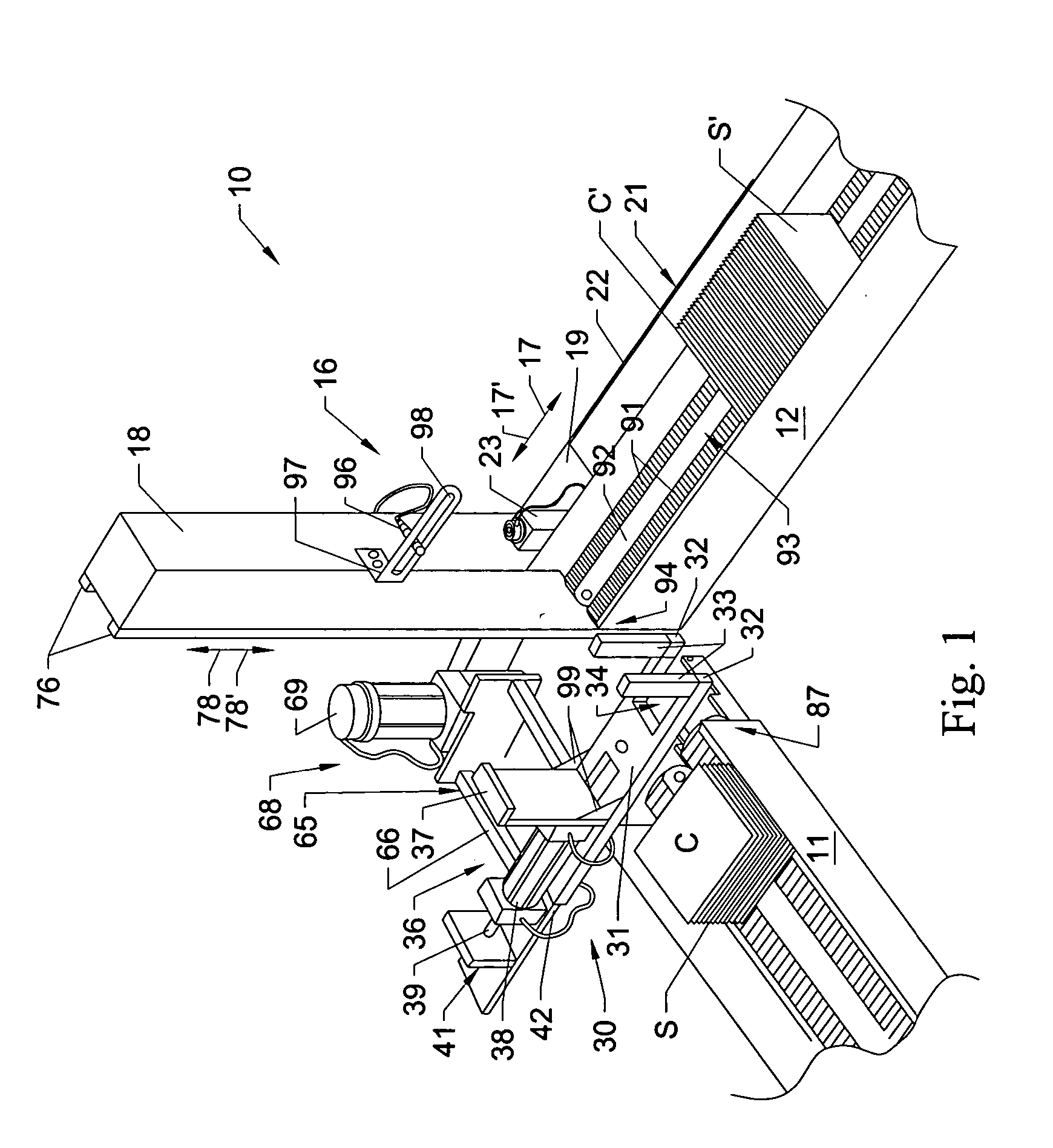

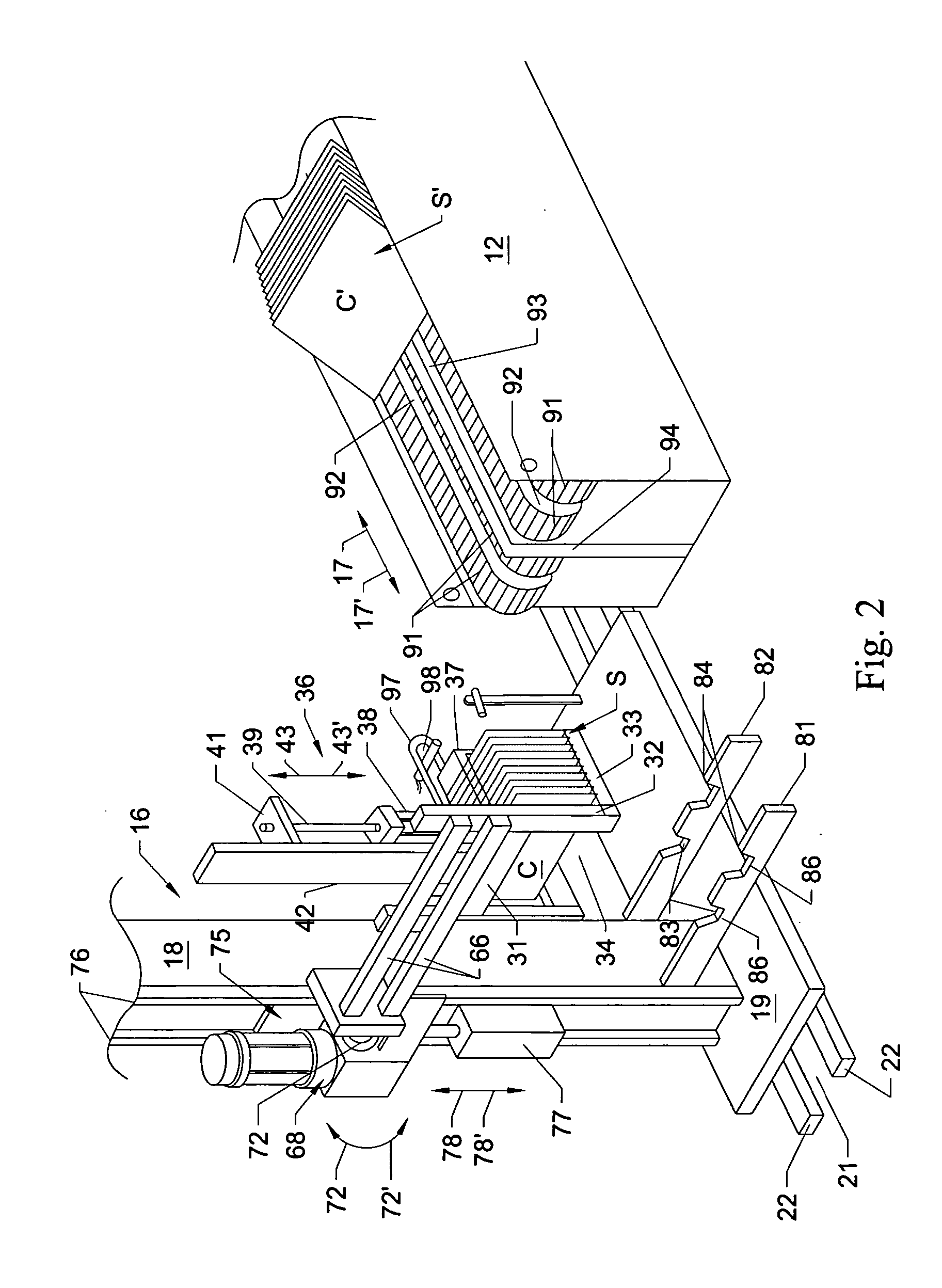

Automatic carton magazine loading system

A magazine loader for automatically loading stacks of cartons onto a magazine of a mass feeder for supplying cartons to a packaging machine, includes a loader in which stacks of cartons are received and held, and a carriage on which the loader is pivotally mounted. The cartons are received loaded in the loader, after which the loader is pivoted from a loading position to a stacking position. The loader is then moved along a feeder conveyor for the packaging machine toward a magazine or supply of previously stacked cartons, until the stack of cartons is received and stacked against the previously loaded cartons to maintain a supply of cartons for feeding into the packaging machine.

Owner:GRAPHIC PACKAGING INT

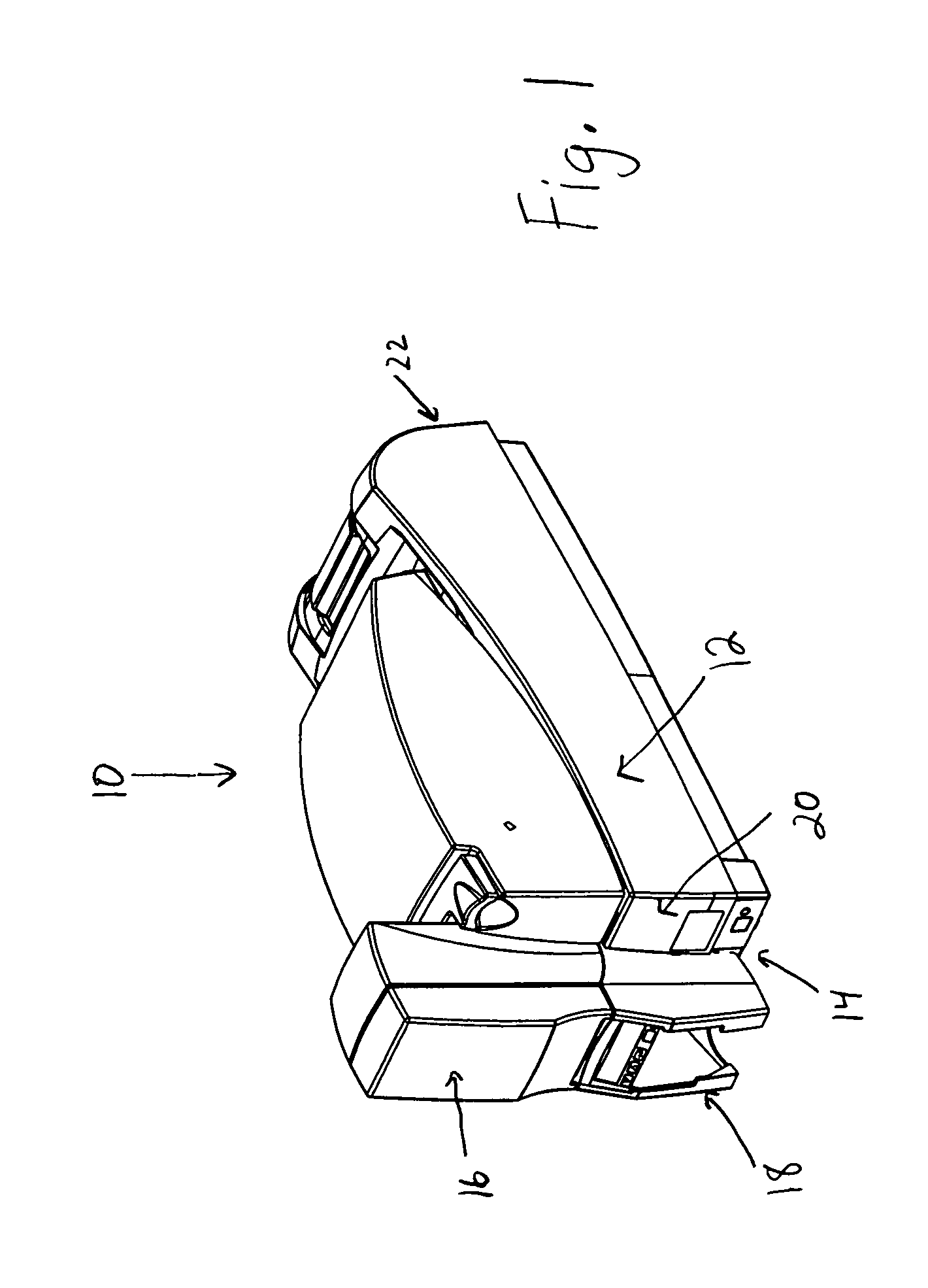

Card-flipping device for use in card printers

A card-flipping device for a card printing apparatus is provided. The card-flipping device comprises a card-carrier unit for transporting the card in a vertical direction, a motor drive means for moving the unit in the vertical direction, and an actuator assembly including a rotatable cam arm for flipping the card over. The card-flipping device is particularly suitable for use in thermal dye printers that print images on card substrates such as driver's licenses, employee badges, student cards, and the like. After one surface of the card has been printed, the card is conveyed to the card-flipping device, where the card is flipped over so that the reverse, unprinted side of the card can be printed thereon.

Owner:ZEBRA TECH CORP

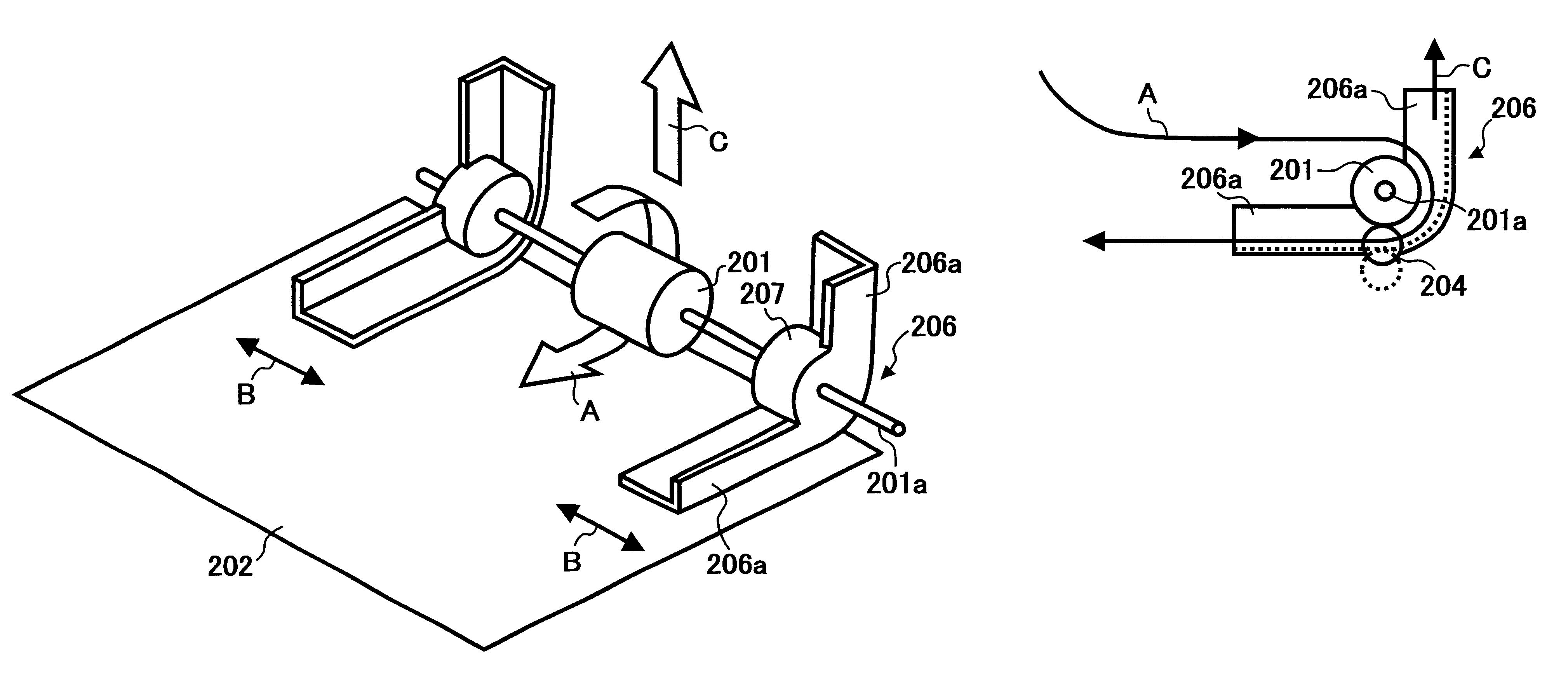

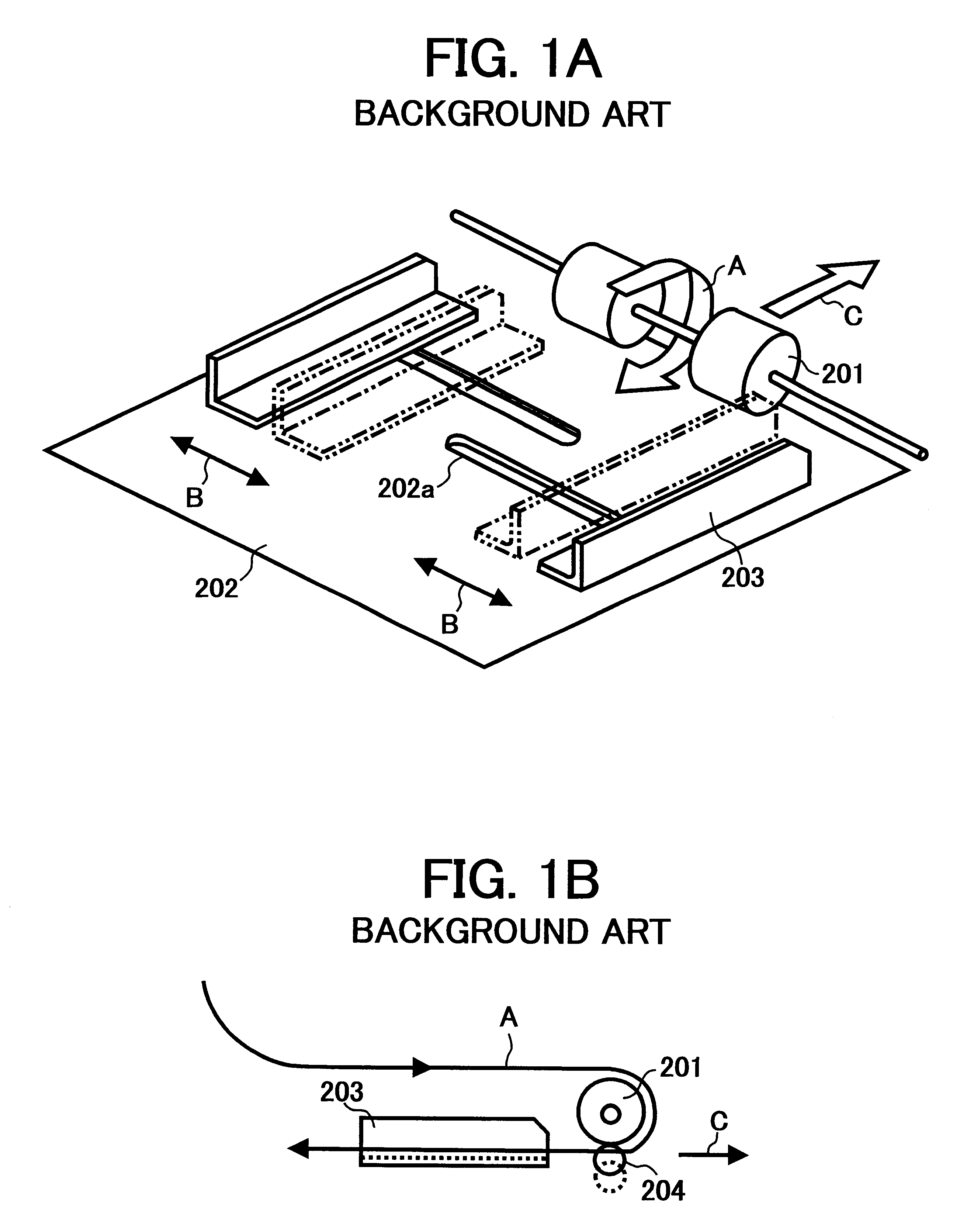

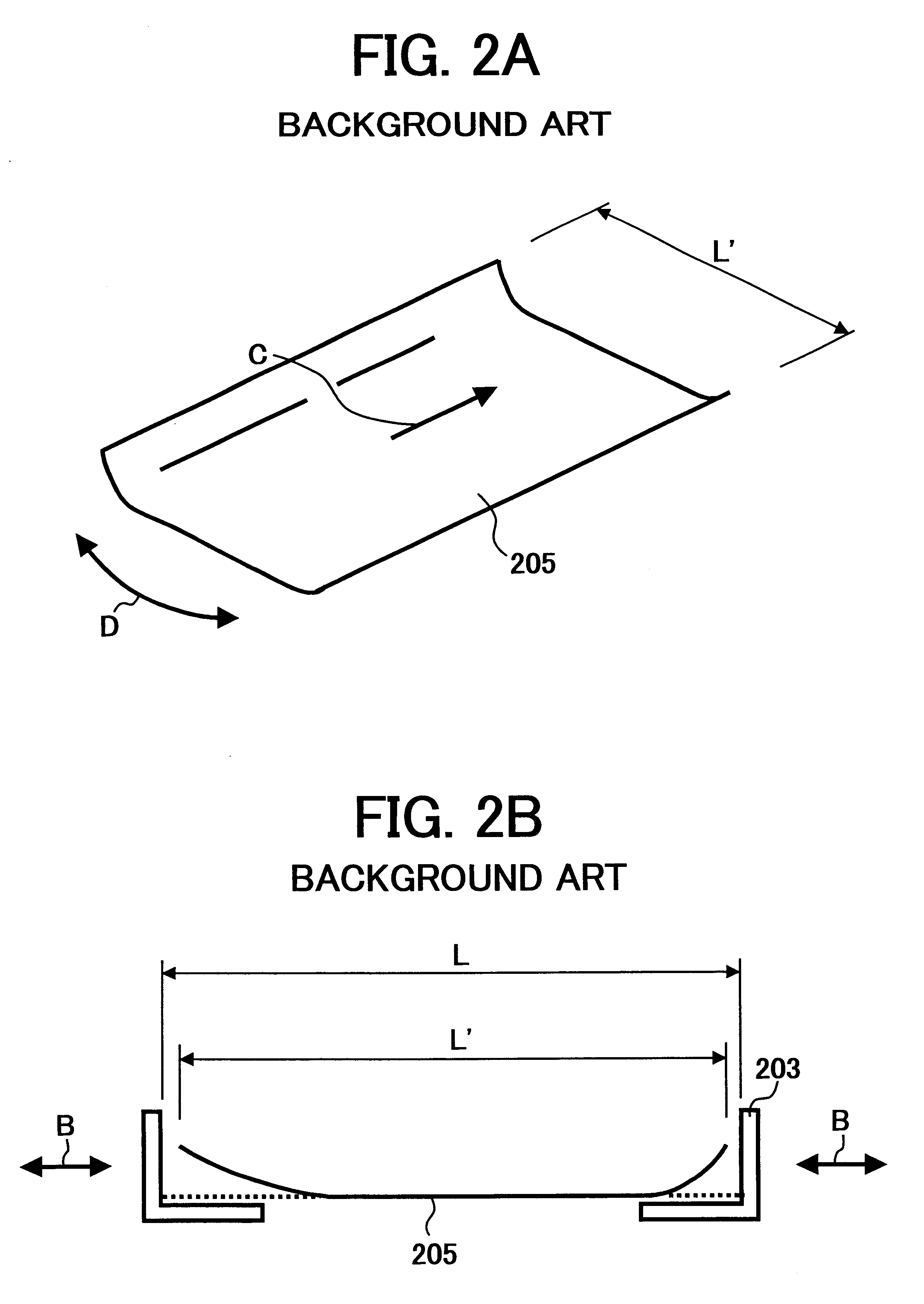

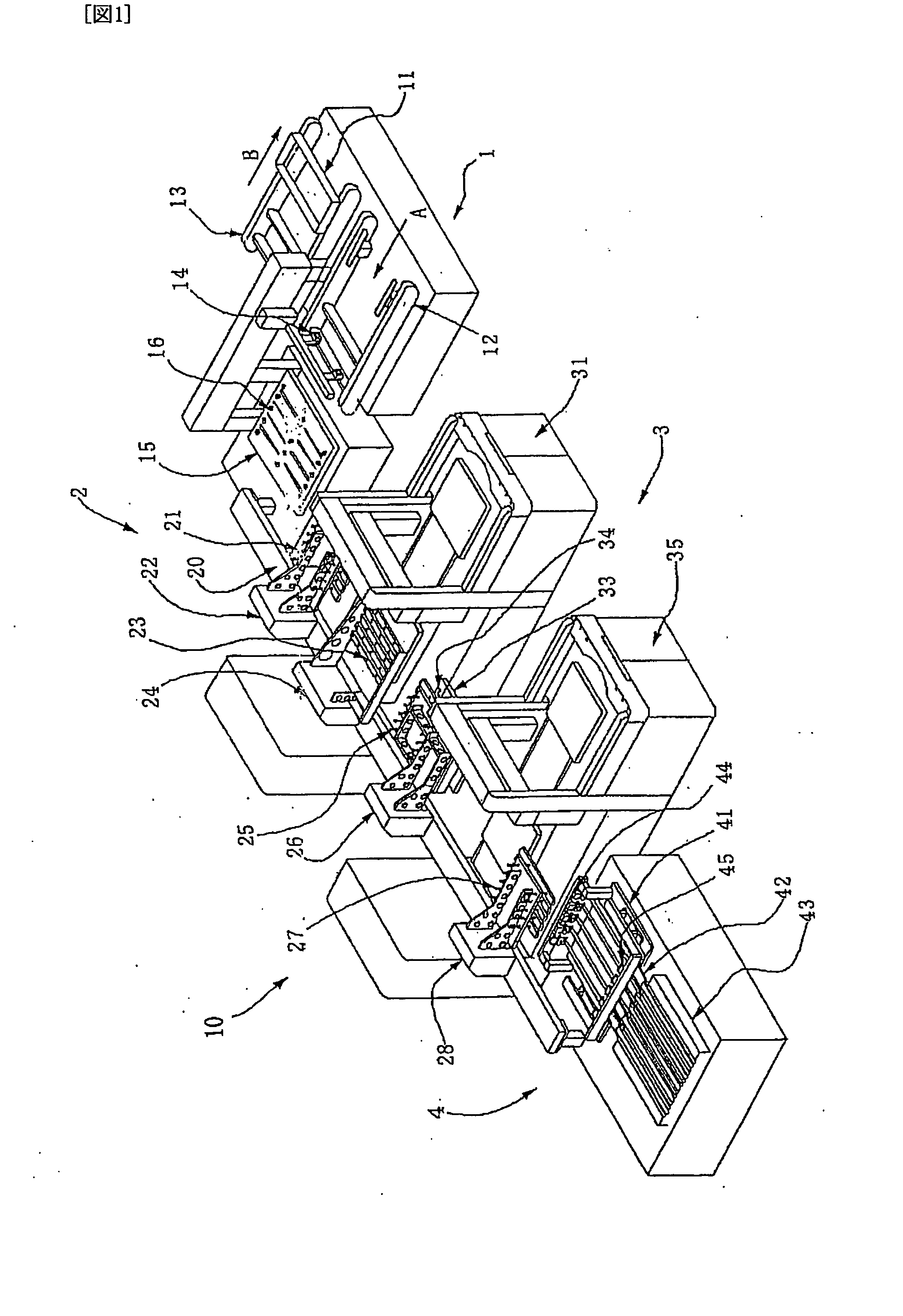

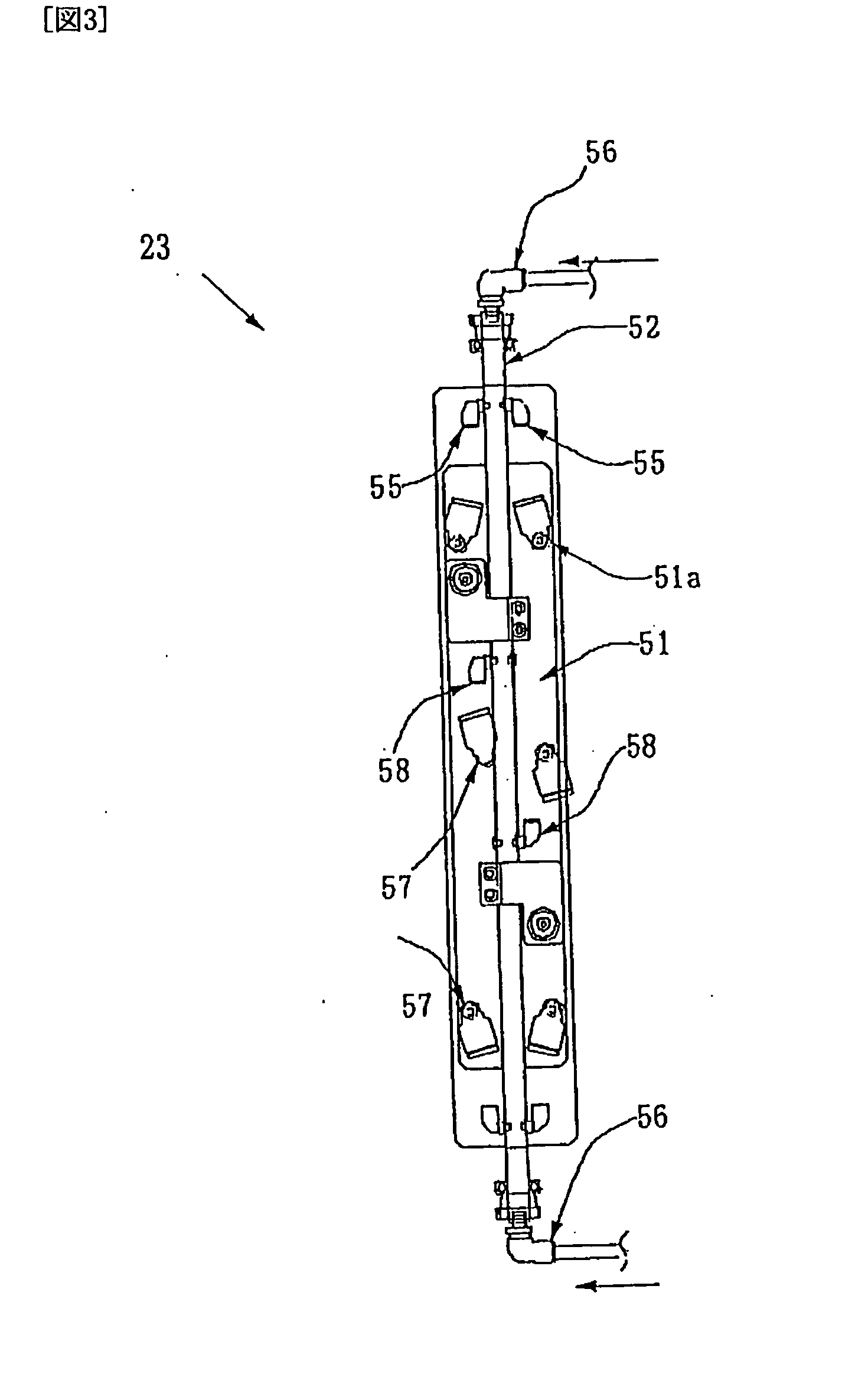

Method for Processing Substrate, Apparatus for Processing Substrate, Method for Conveying Substrate and Mechanism for Conveying Substrate

InactiveUS20080190981A1Short timeAvoid unevennessConveyorsOverturning articlesRotational axisEngineering

A method for processing a substrate and an apparatus for processing a substrate are provided, where a substrate can be prevented from being damaged during conveyance of the substrate, including turning over of the substrate, and the apparatus for processing a substrate having this mechanism for conveying a substrate is miniaturized, so that the area for installment can be reduced.[Means for Achieving Object] An apparatus for processing a substrate which divides a mother substrate into unit substrates is provided with a scribing portion 3 for drawing a scribe line on a mother substrate, a breaking portion 4 for breaking a mother substrate along the formed scribe line, and a portion for conveying a substrate 2 for conveying a mother substrate or a unit substrate at least between the above described respective portions, wherein portion for conveying a substrate 2 has a number of rotational supports 51 and 73 with a suction surface for sucking and holding each substrate from a main surface, rotational supports 51 and 73 have rotational axes 52 and 72, respectively, as well as means for respectively sucking and rotating a substrate which rotates substrates around rotational axes 52 and 72, approximately simultaneously in a state where the substrates are sucked and held in such a manner that at least two main surfaces of each substrate are turned over in the upward and downward direction.

Owner:MITSUBOSHI DIAMOND IND CO LTD

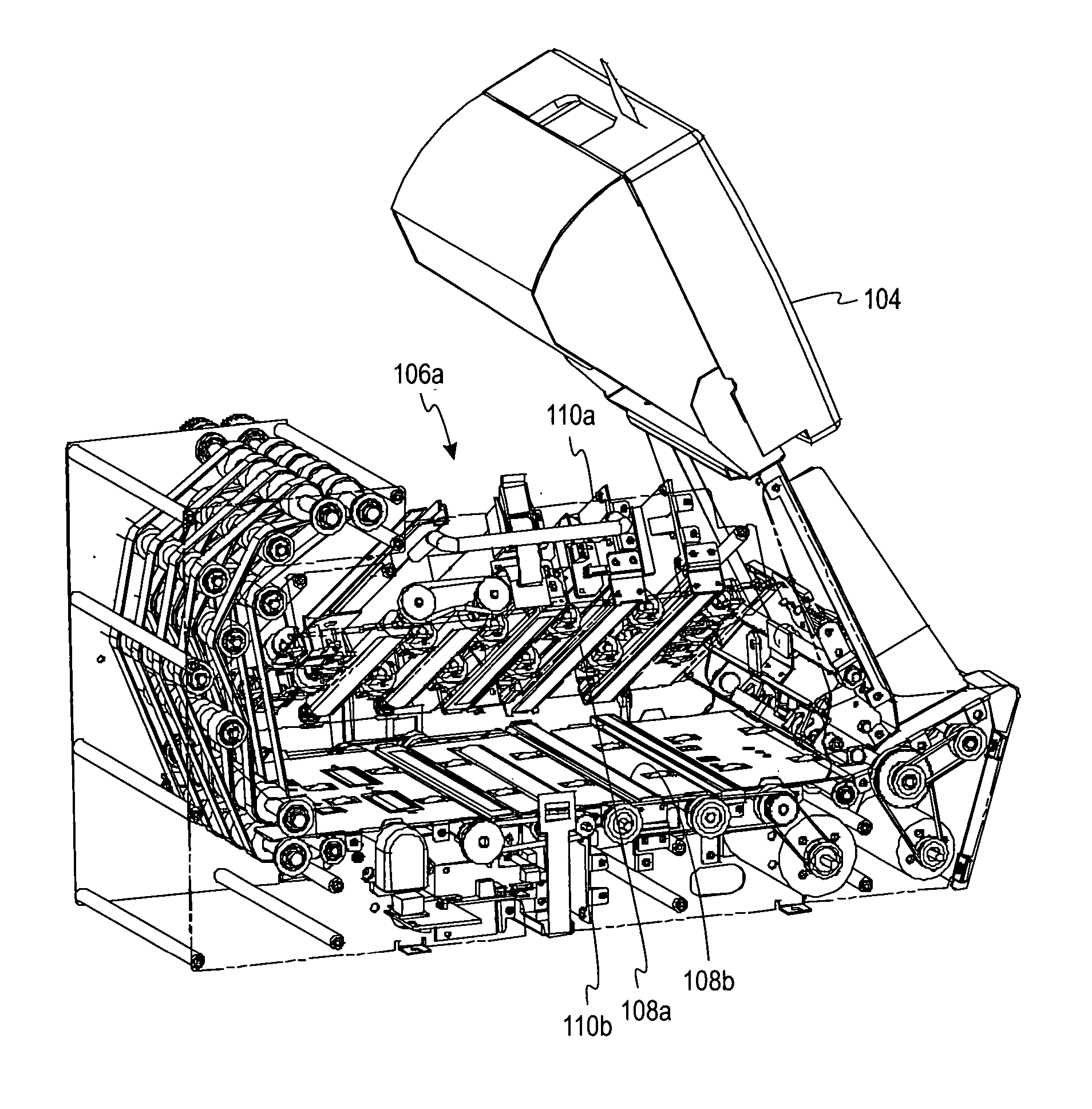

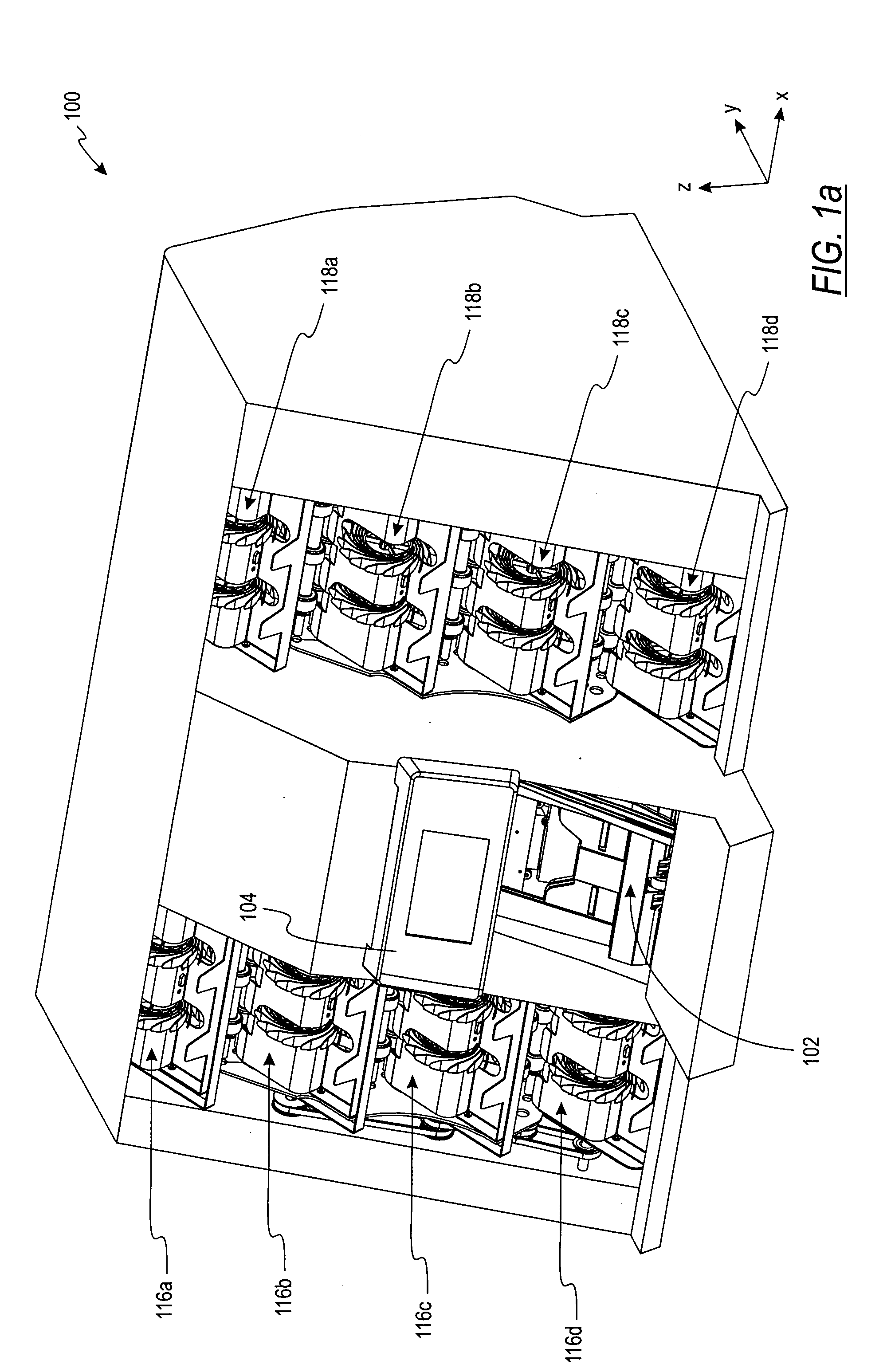

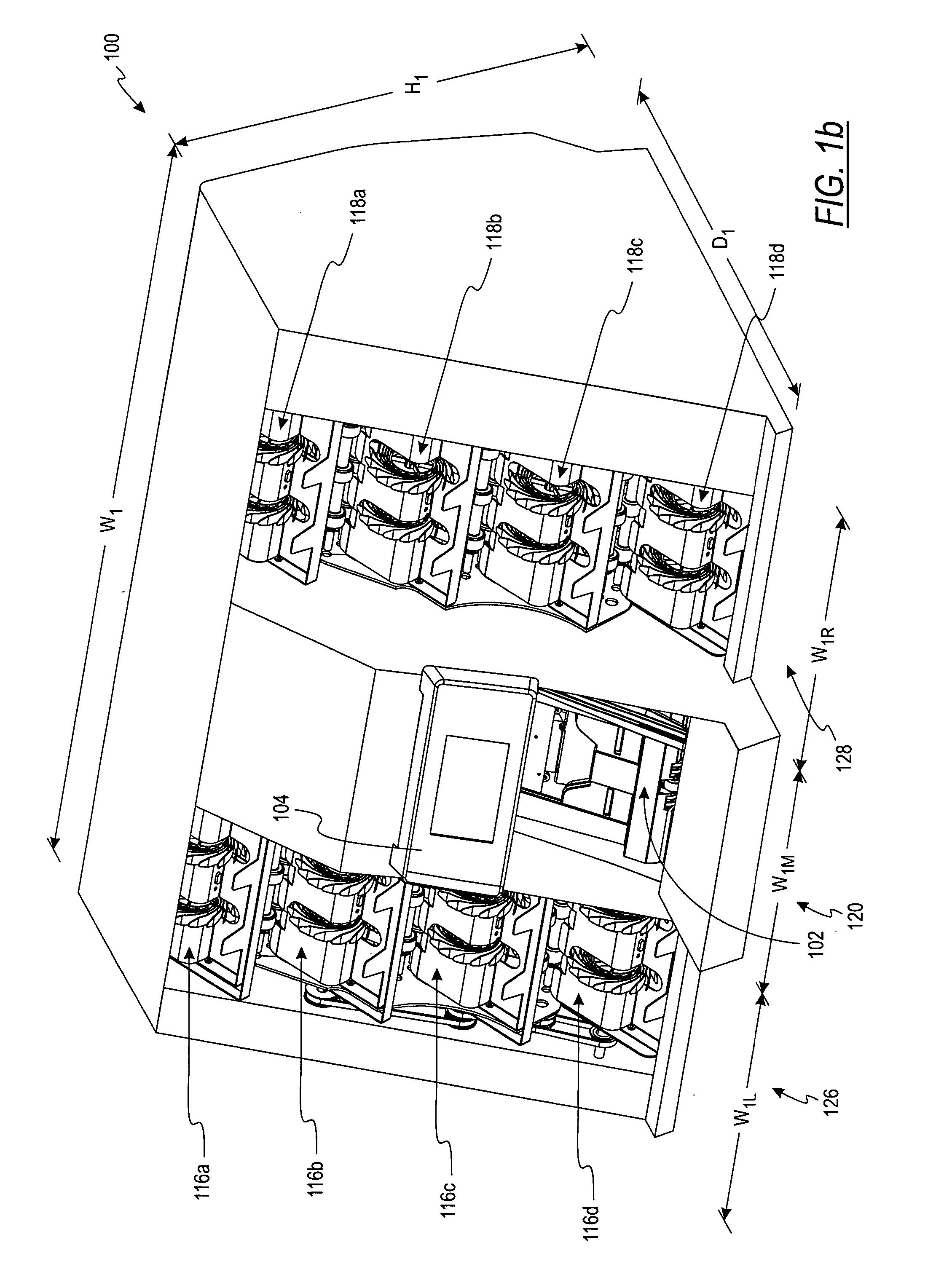

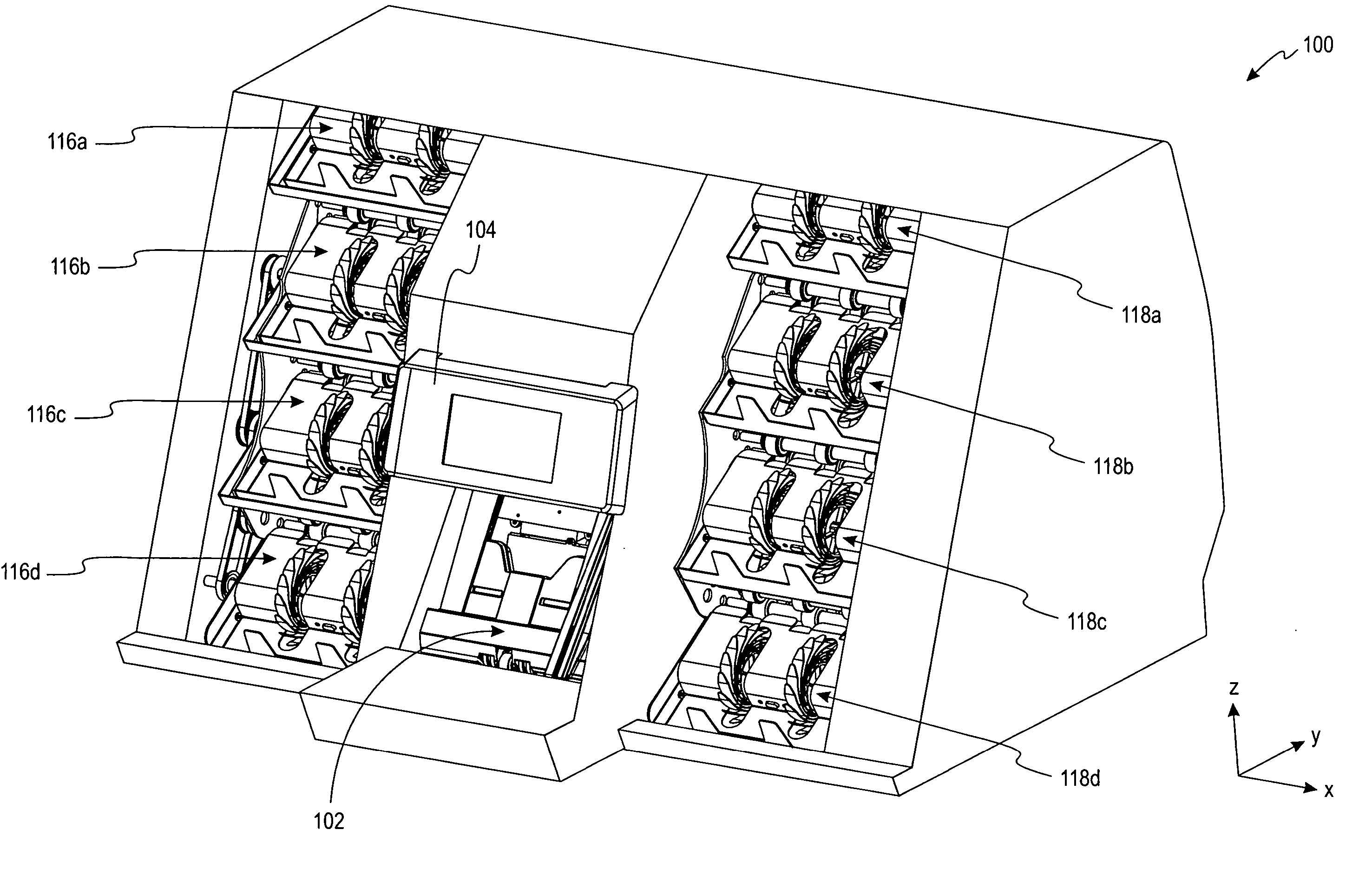

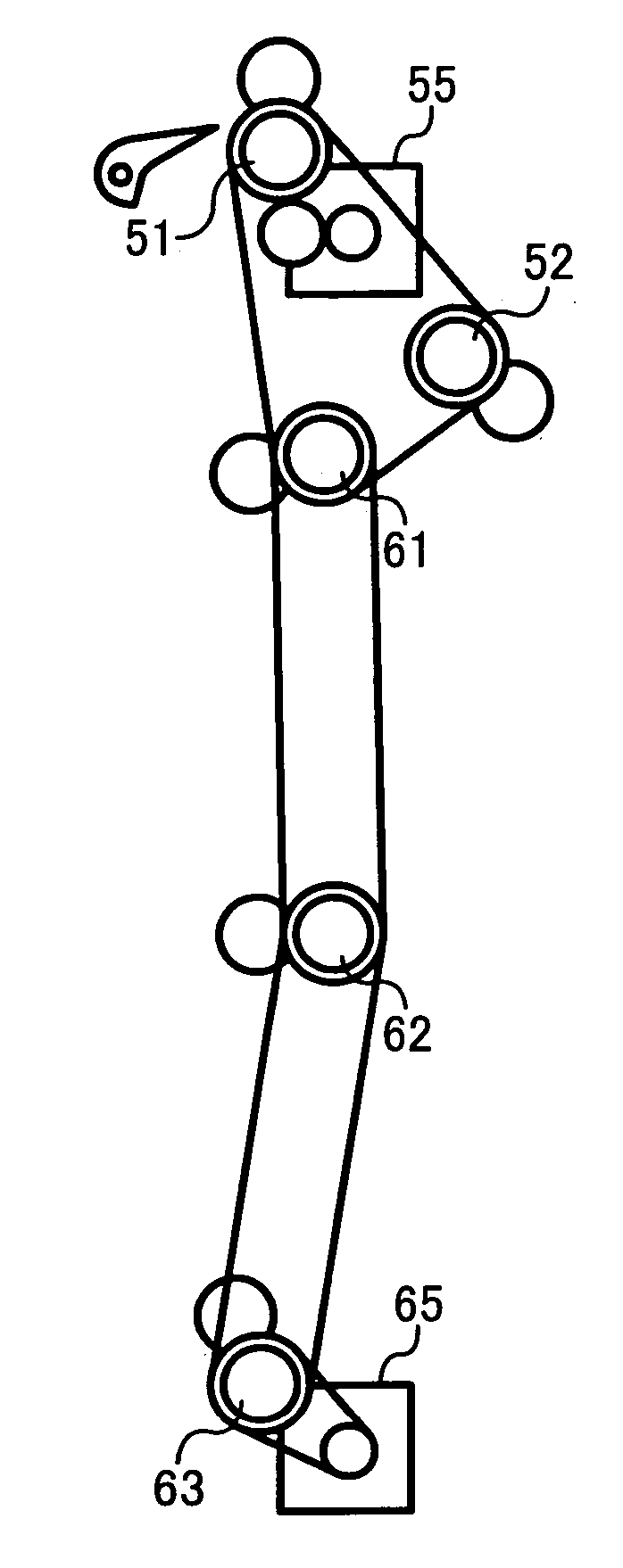

Document sorting machine

InactiveUS20080054544A1Prevent misfeedingOverturning articlesPaper-money testing devicesPaper documentDocument preparation

A document feeder system for use in a document sorting apparatus is disclosed. The document feeder system comprises upper and lower portions, each having respective feeder elements for feeding documents from a hopper, the upper and lower portions being movable relative to one another between, a feeding position, in which the feeder elements of the upper and lower portions are engageable with a document to be fed, and a jam clearance position, in which a document between the feeder elements of the upper and lower portions may be retrieved, wherein the upper and lower portions are urged into the feeding position by a constant force spring.

Owner:DE LA RUE INT LTD

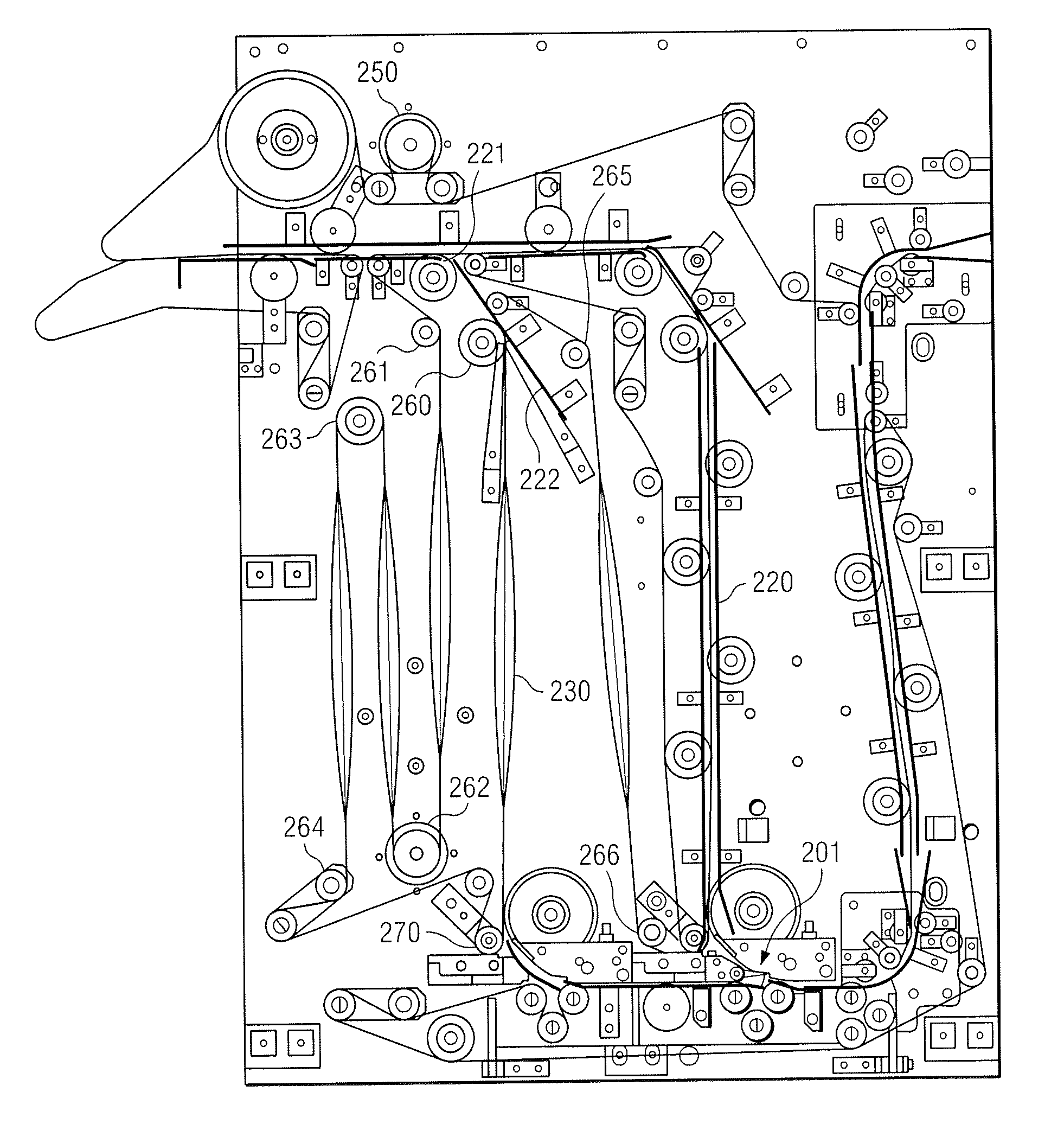

Medium transport unit, recording apparatus, and image reading apparatus

ActiveUS20160116881A1Small sizeReduce device sizeOverturning articlesElectrographic process apparatusElectrical and Electronics engineering

A medium transport unit includes an upstream route in which a print sheet is transported, a first switchback route, a second switchback route, a first guide route, a second guide route, a guide flap configured to switch the route so that the print sheet in the upstream route is transported either toward the first guide route or toward the second guide route, a first discharge route from which the print sheet in the first switchback route is discharged, a second discharge route from which the print sheet in the second switchback route is discharged, and a downstream route passing between the first switchback route and the second switchback route and having an upstream end connected to a junction of downstream ends of the first discharge route and the second discharge route.

Owner:SEIKO EPSON CORP

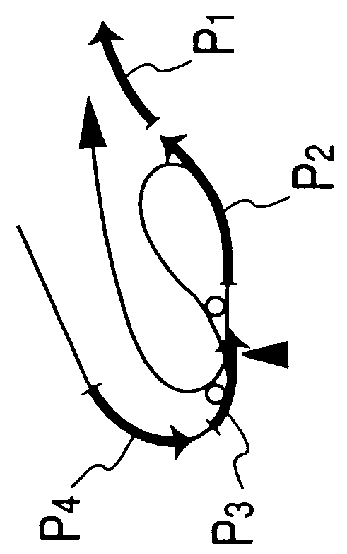

Sheet conveying apparatus with interval control

A sheet material conveying apparatus has a conveying path for directing sheet materials supported on a supporting portion one by one to an image processing position and also directing them to a discharging portion after the completion of image processing, and a reversing path for containing a predetermined number of sheet materials therein, and reversing the sheet materials and directing them to the image processing position. When the interval between the predetermined number of sheet materials to be directed into the reversing path widens to such an extent that the sheet materials cannot be contained in the reversing path, preceding one of the sheet materials is decelerated or stopped in conformity with the widening to enable the predetermined number of sheets to be contained in the reversing path.

Owner:CANON KK

Note facing apparatus for high speed processing

InactiveUS20080116628A1High speed machiningOverturning articlesFunction indicatorsTransmission beltPaper document

The present invention provides an apparatus for facing documents during high speed processing. The present invention employs at least one sensor to scan the documents individually as they are fed sequentially through a processing machine. The sensor determines the direction the documents are facing. Depending on the direction the documents are facing, a path selector directs the documents to one of two equal length paths within the processing machine. If a document is facing up, the path selector directs the document along a first path that leads directly to a collection point. If a document is facing down, the path selector directs the document along a second path that includes a twisted conveyor belt which turns the document about the longitudinal axis to face up. The second path meets with the first path, wherein the conveyor belt reinserts the faced documents back into the same sequential position that the document was in relative to the other documents before being diverted by the path selector.

Owner:DE LA RUE NORTH AMERICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com