Cylindrical module unwrapping device and method

a cylindrical module and unwrapping technology, which is applied in the direction of transportation and packaging, unpacking by cutting, and packaged goods type, etc., can solve the problems of contaminated cotton, contaminated cotton is undesirable, and the tail of the wrap material remains in the cotton and enters the gin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

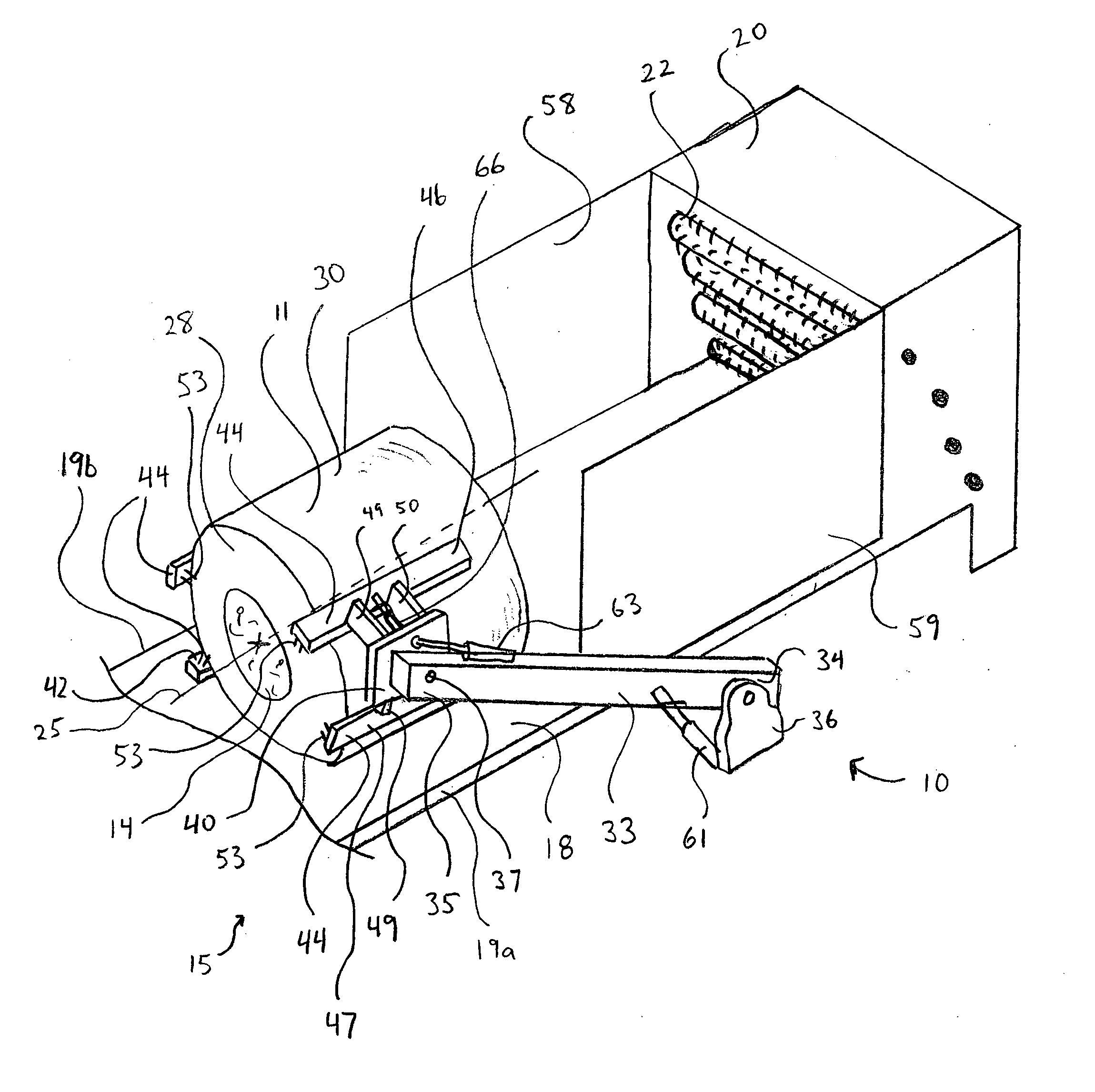

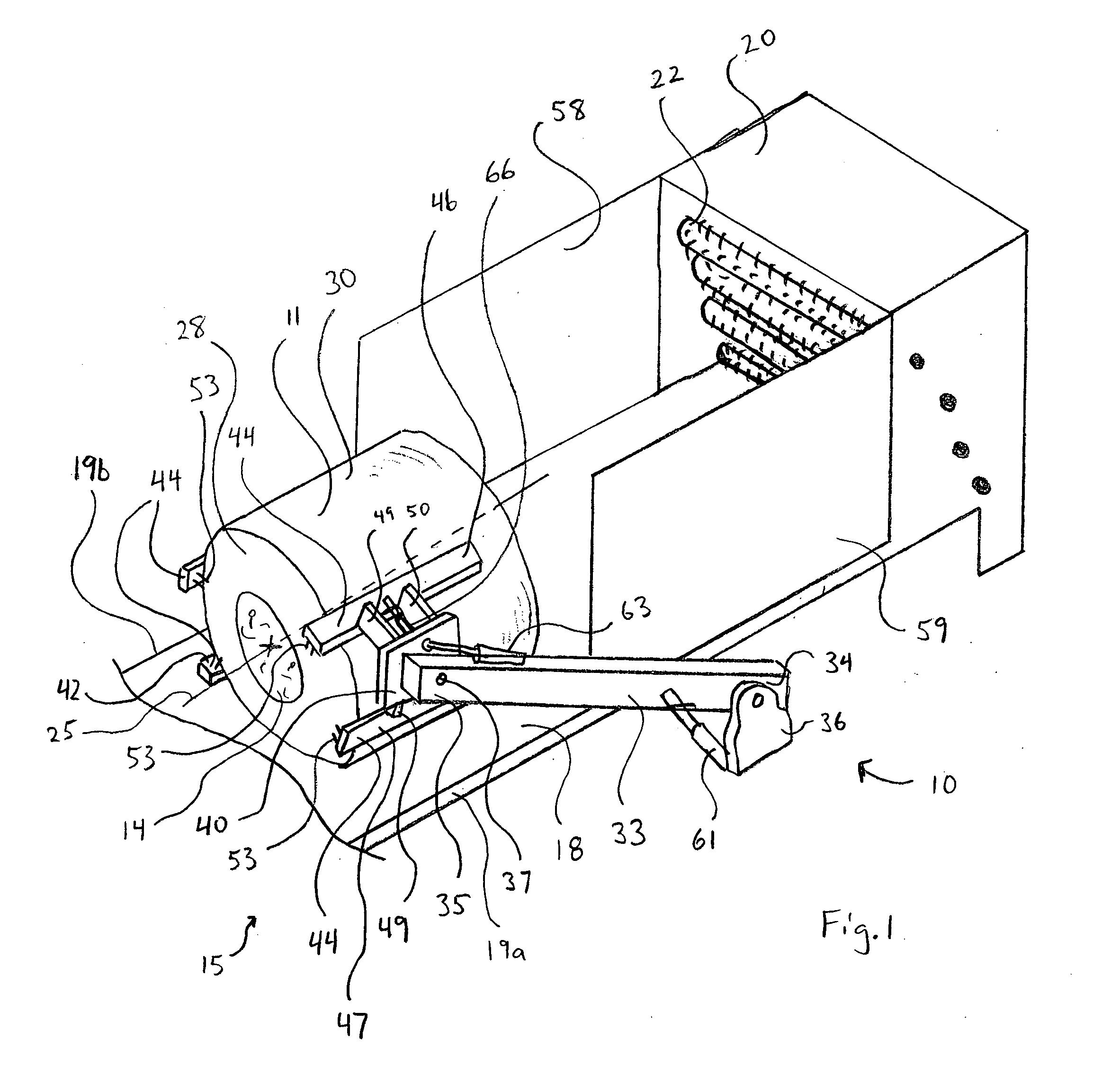

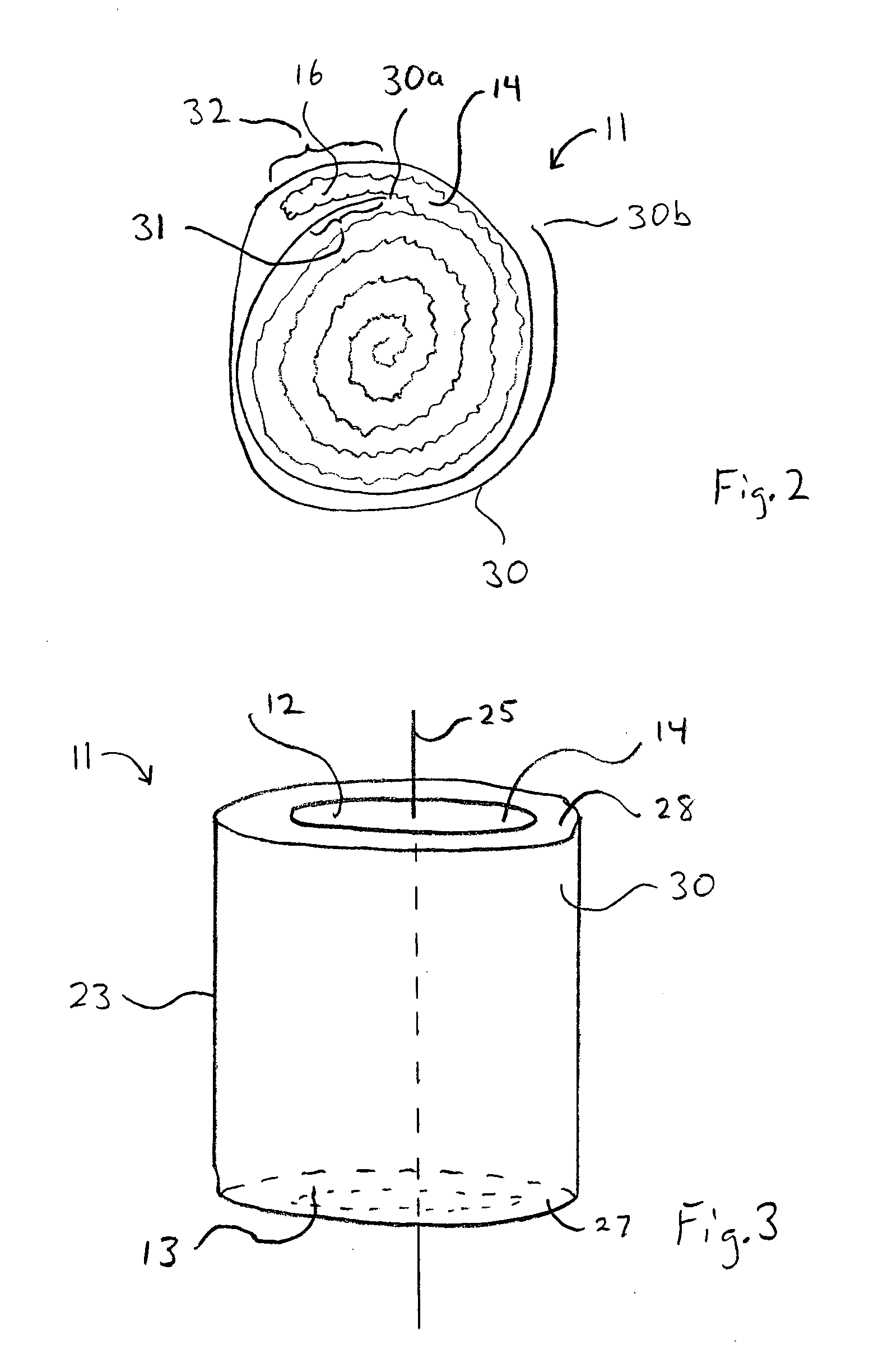

[0023]As illustrated in FIG. 1, a module-receiving area 15 of a crop processing facility such as a cotton gin is shown. A plurality of wrapped bales, also called round modules 11, of fibrous material, such as seed cotton 14, are delivered by truck or other suitable transport vehicle (not shown) to a horizontal receiving conveyor 18. Cylindrical modules 11 are typically loaded on the conveyor 18 on their lateral or rounded side, i.e., the curved surface of the cylinder, with the vertical axis 25 of the cylindrical module 11 roughly parallel to the conveyor 18. The conveyor 18 moves the modules 11 laterally away from the transport vehicle towards the first component of the gin system such as disperser 20. A disperser 20 is typically the first element of a cotton gin line as its spiked, spinning, disperser cylinders 22 function to break up seed cotton modules 14.

[0024]The cylindrical module unwrapping device 10 of the present invention is located upstream of the disperser 20, preferabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com