Patents

Literature

42results about "Fibre breaking by toothed members" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

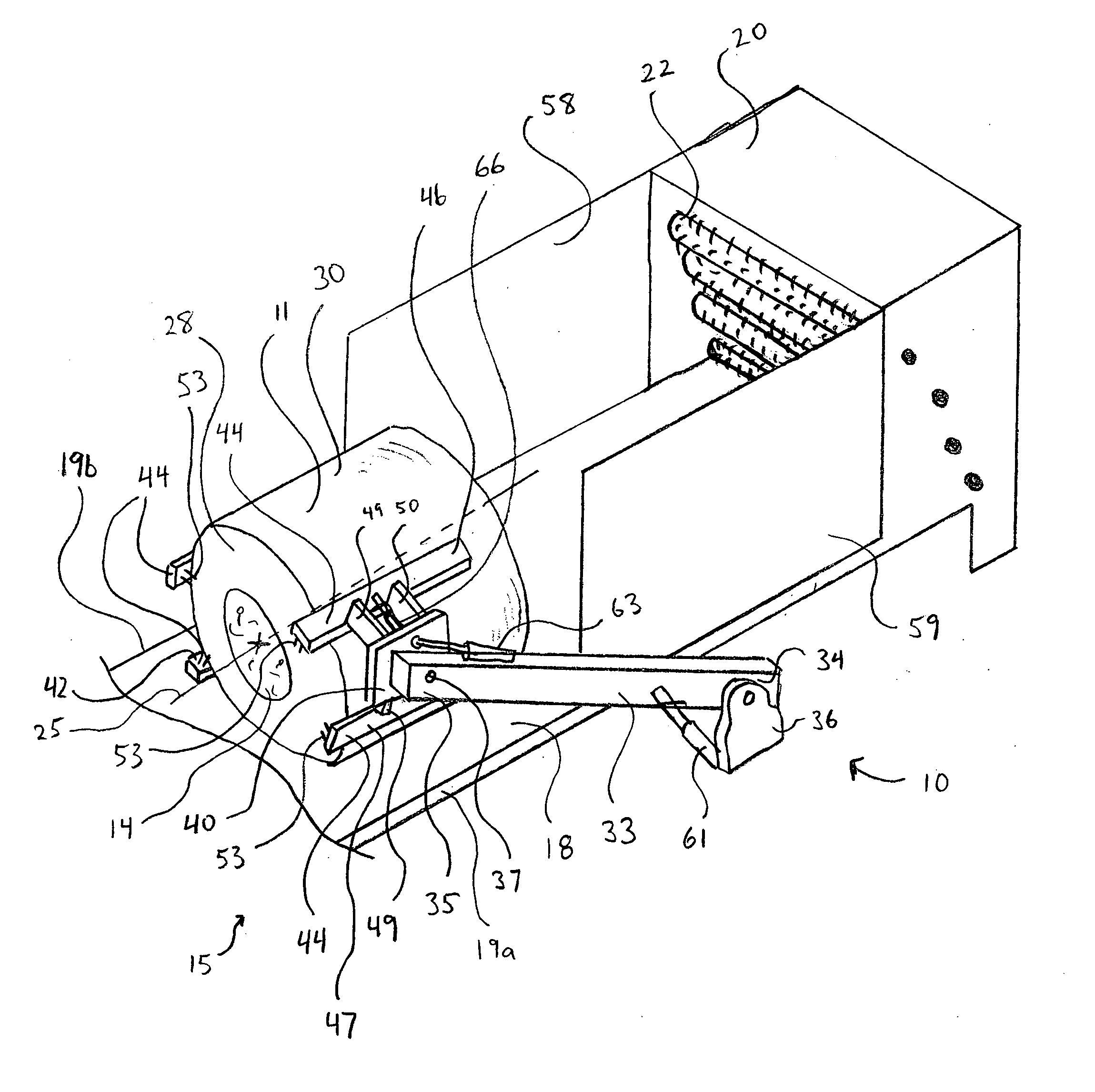

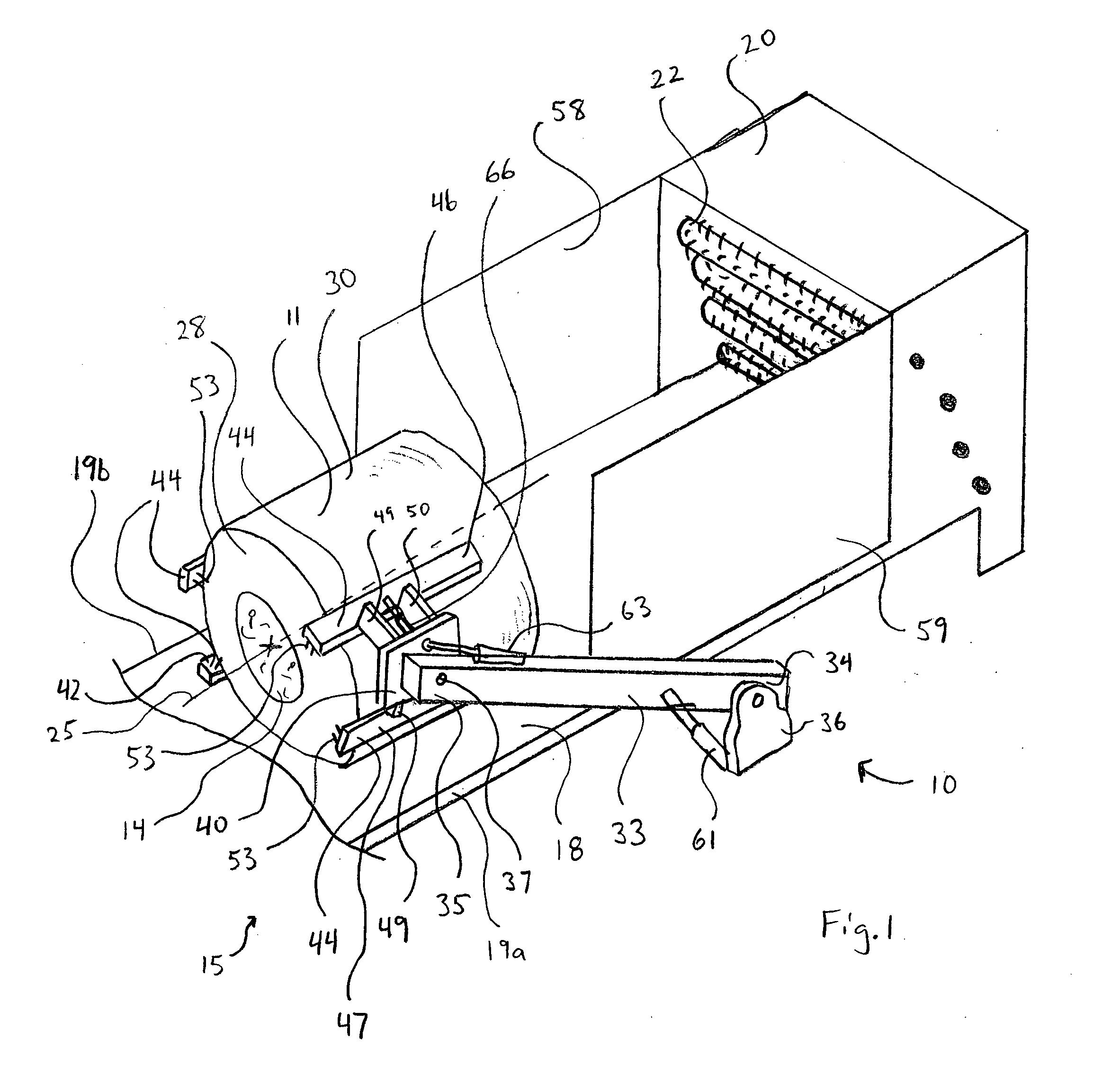

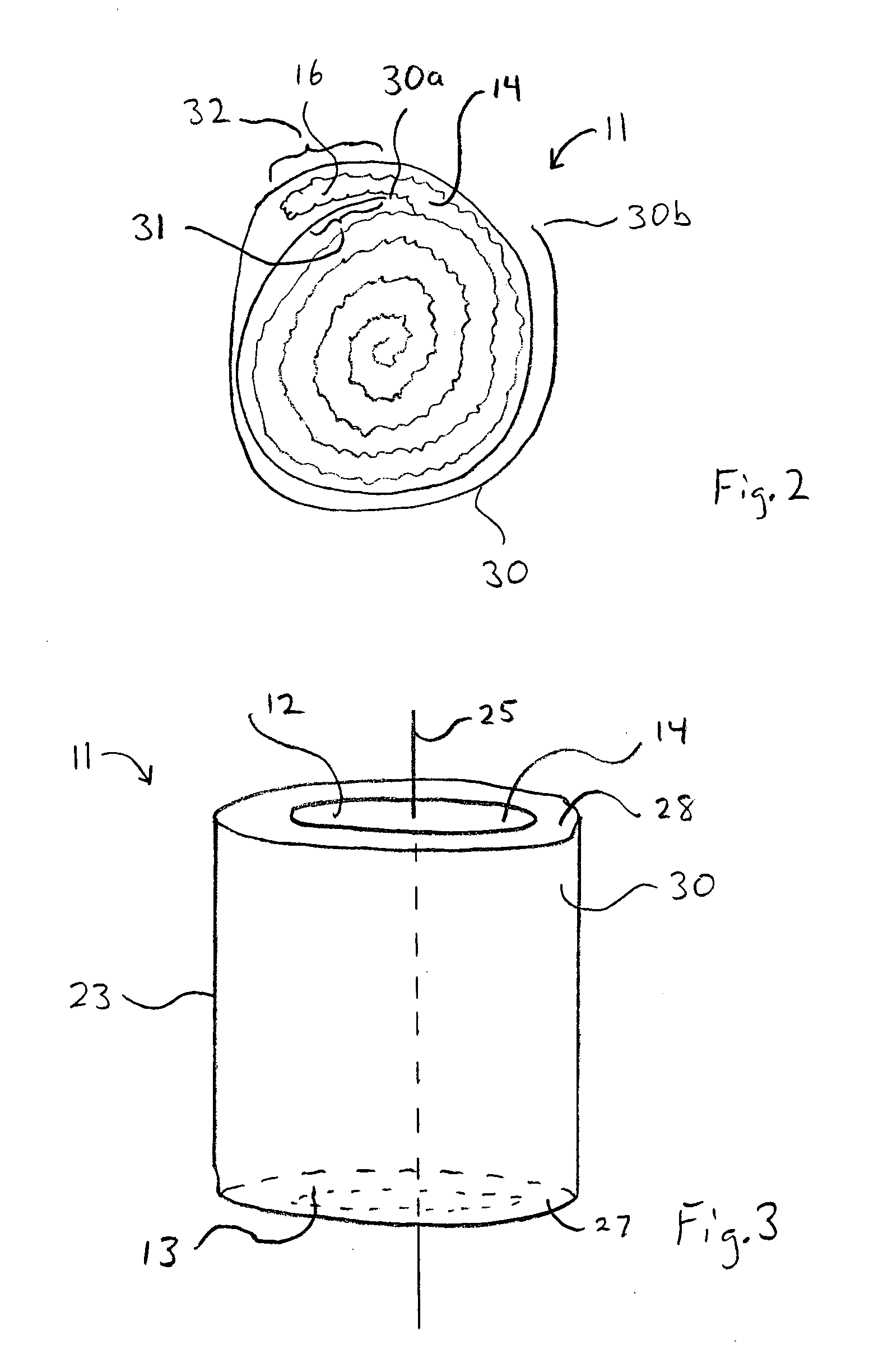

Cylindrical module unwrapping device and method

InactiveUS20090202327A1Avoid pollutionEasy to disassembleOverturning articlesPackaging bottlesFiberEngineering

Owner:CHEROKEE FABTION

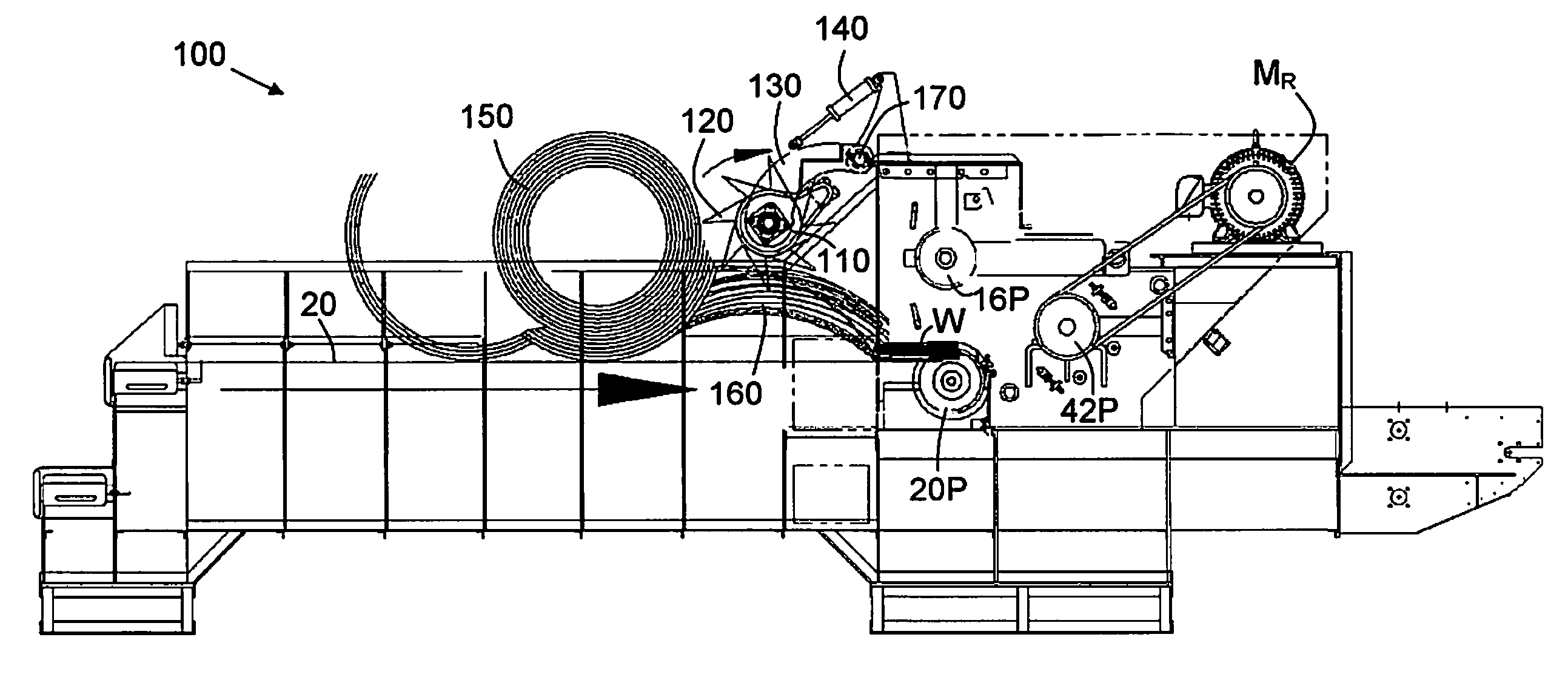

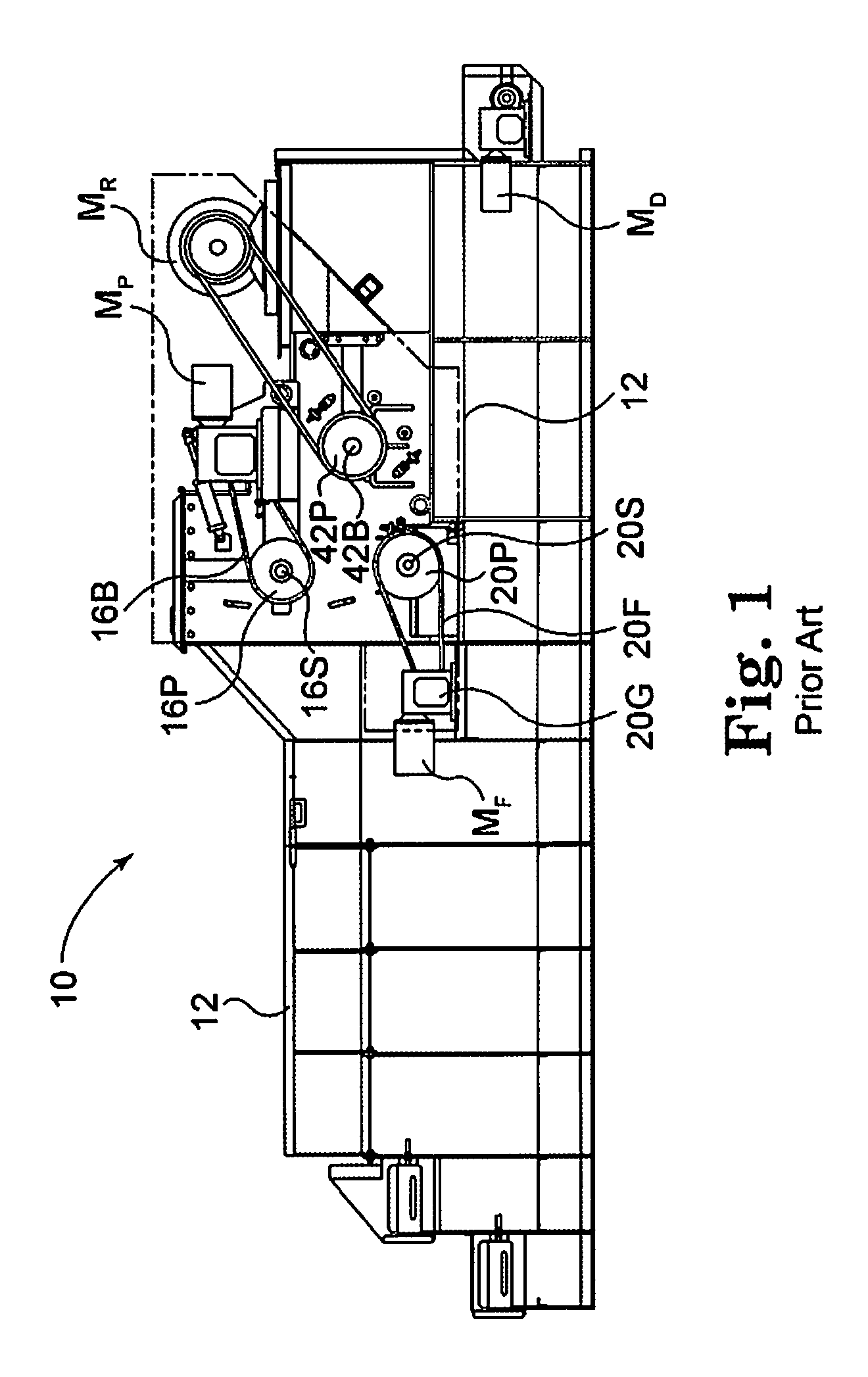

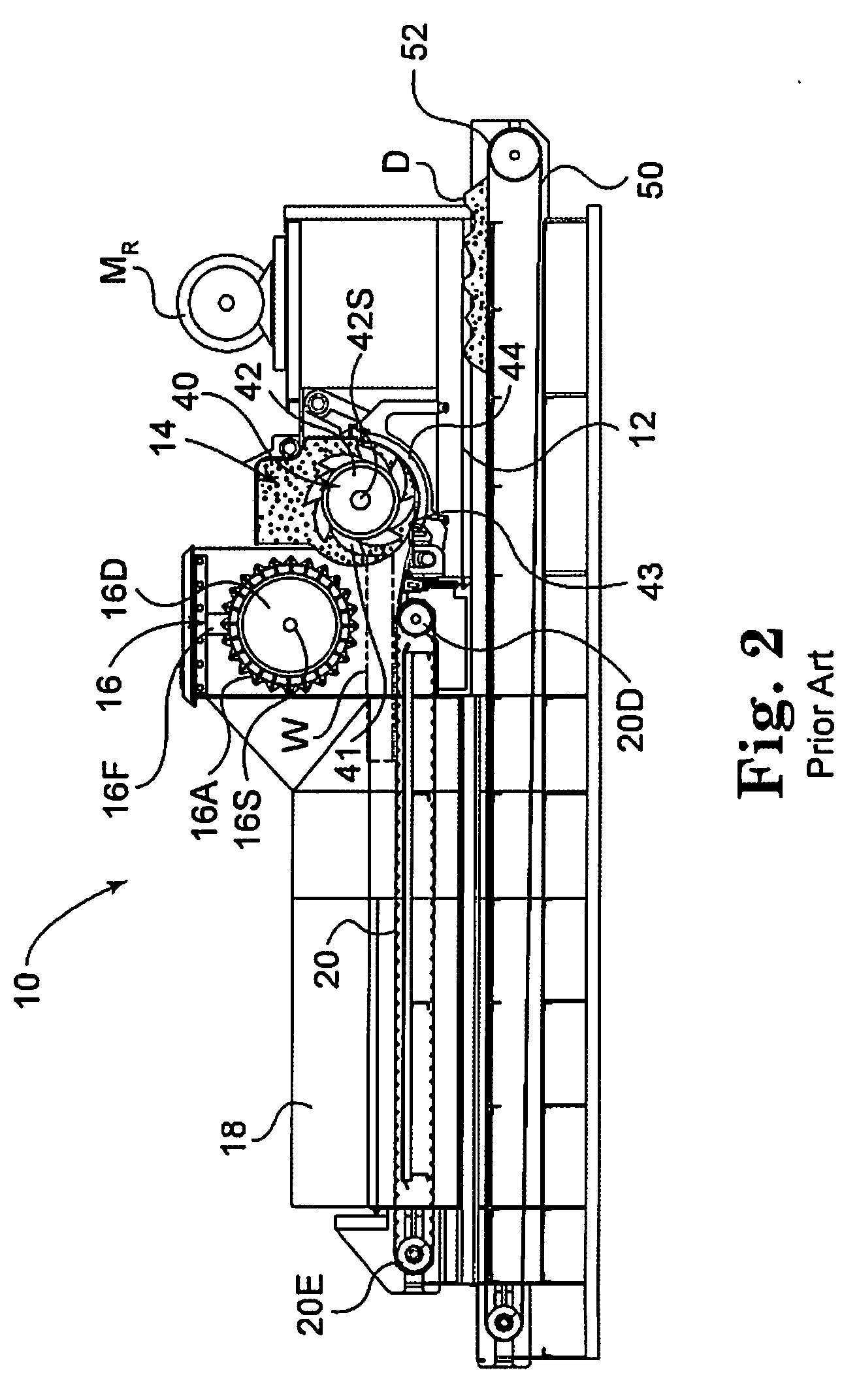

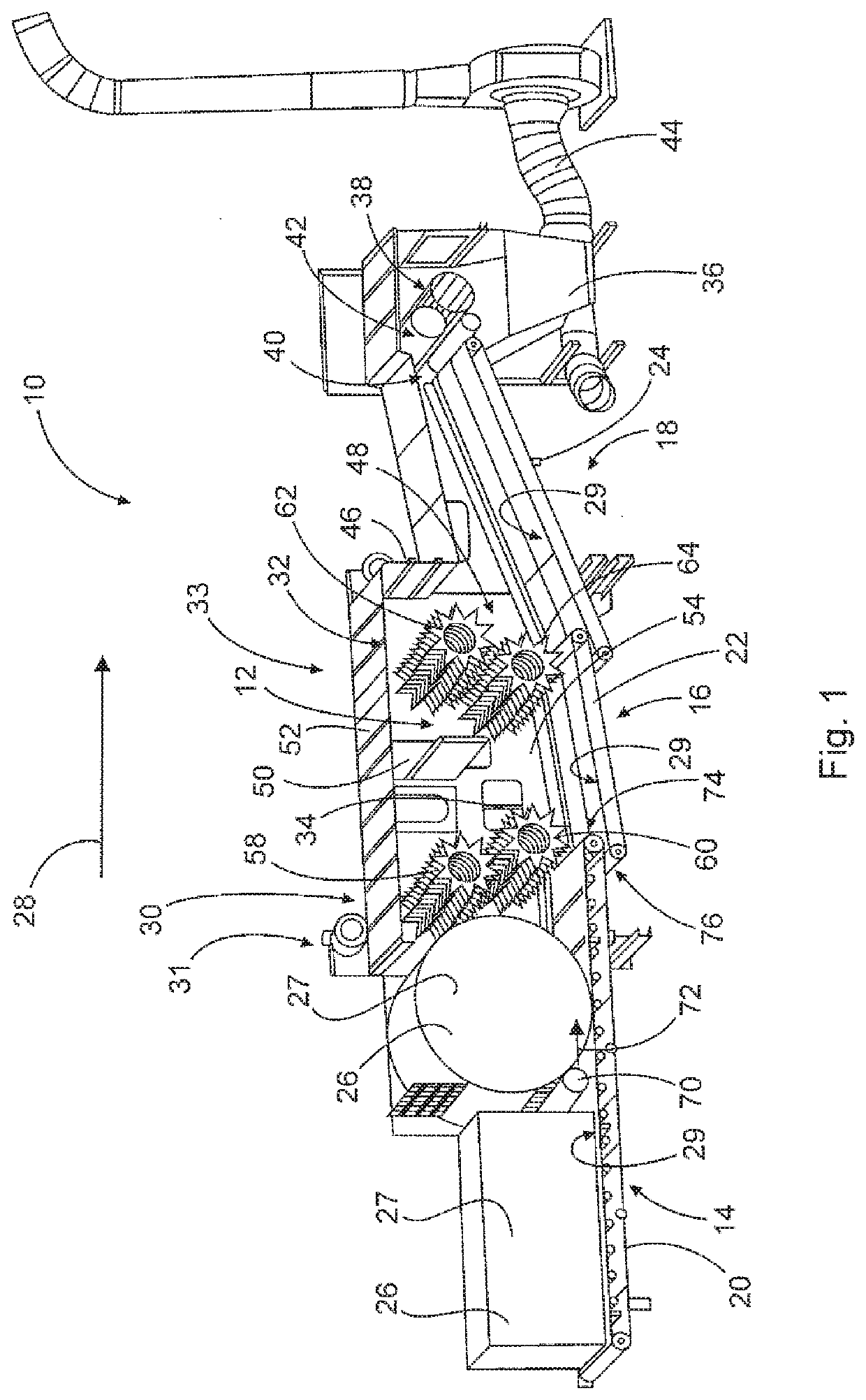

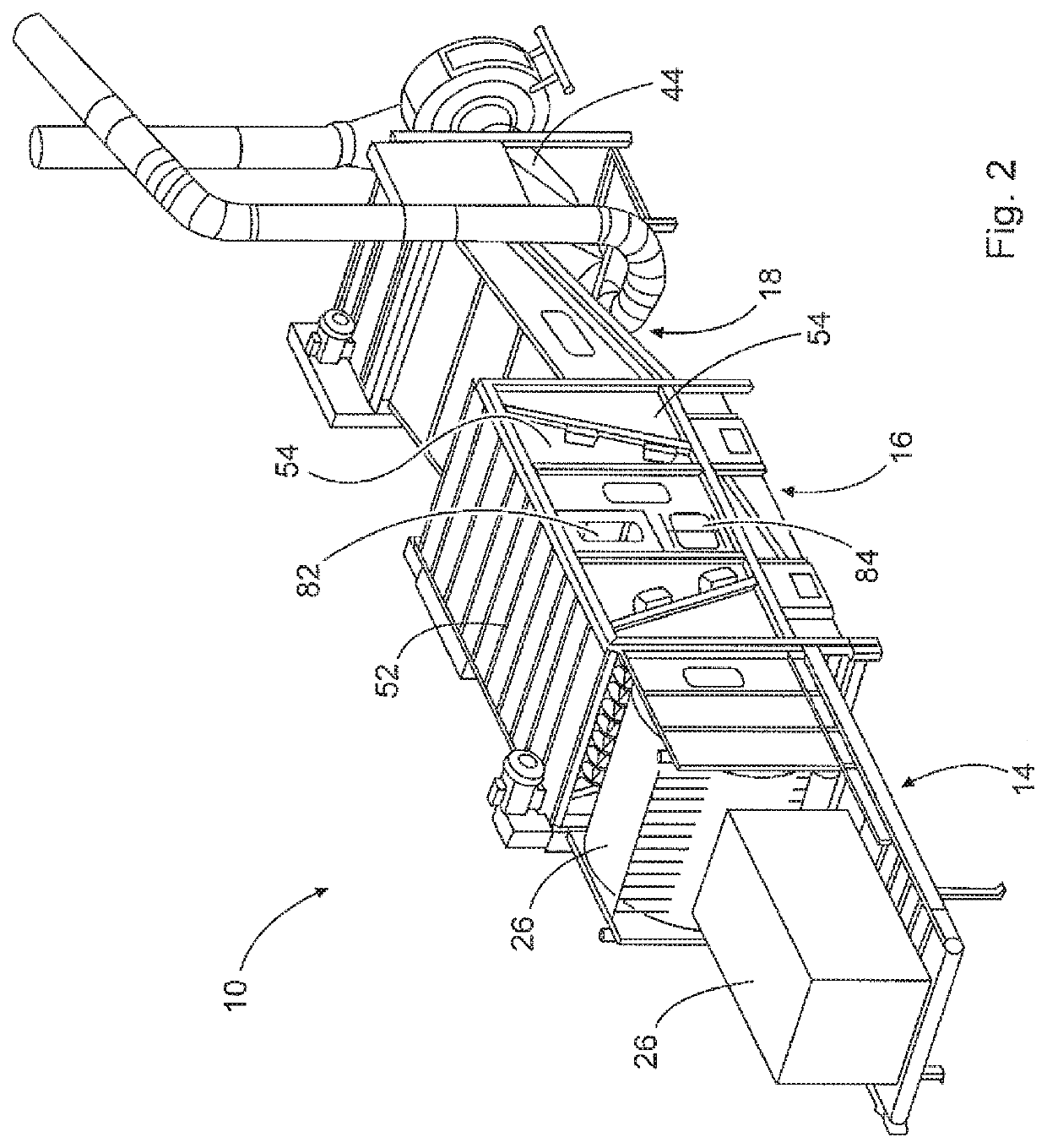

Bale breaker apparatus and method

An auxiliary powerfeed is disclosed, which is designed to work in conjunction with other feeding devices found on a horizontal grinder, which typically include a horizontal feed conveyor and a powerfeed drum. The auxiliary powerfeed features a rotating drum on which are mounted rigid tines (or teeth) arranged in a staggered pattern. The drum is rotationally mounted within a pivotally mounted lift arm. The lift arm holds the axial shaft of the drum at each end. A set of hydraulic cylinders is mounted to the lift arm, one on each end of the drum. During operation, as a bale or other object comes into contact with the auxiliary powerfeed, the drum automatically lifts until it reaches the top of the object, the limit of its lift path, or a predetermined height that optimizes efficacy for a particular application. In some cases, the auxiliary powerfeed automatically operates differently with different feedstock consistencies. In other cases, the auxiliary powerfeed is set to operate on a predetermined sequence based on feedstock consistency.

Owner:ROTOCHOPPER

Apparatus for stripping fibre material from textile fibre bales of spinning material, for example cotton, synthetic fibres and the like

InactiveUS20060207064A1Reduce light lossNo wearFibre cleaning/openingCarding machinesTextile fiberEngineering

An apparatus for stripping fiber material from textile fiber bales has a tower, which can be moved to and fro in relation to the fiber material by means of a carriage having a travel motor or the like, and has at least one boom, which is provided with the stripping apparatus. The boom together with the stripping apparatus can be moved in the height direction of the tower by means of a lifting motor or the like. A movable distance sensor is provided for determination of the location in the length direction. In order to make possible, by simple means, an exact determination of location in the length and / or height direction, a movable distance sensor scans, for location determination in the length and / or height direction, the distances to a counterpart element and calculates from those distances the location.

Owner:TRUETZSCHLER GMBH & CO KG

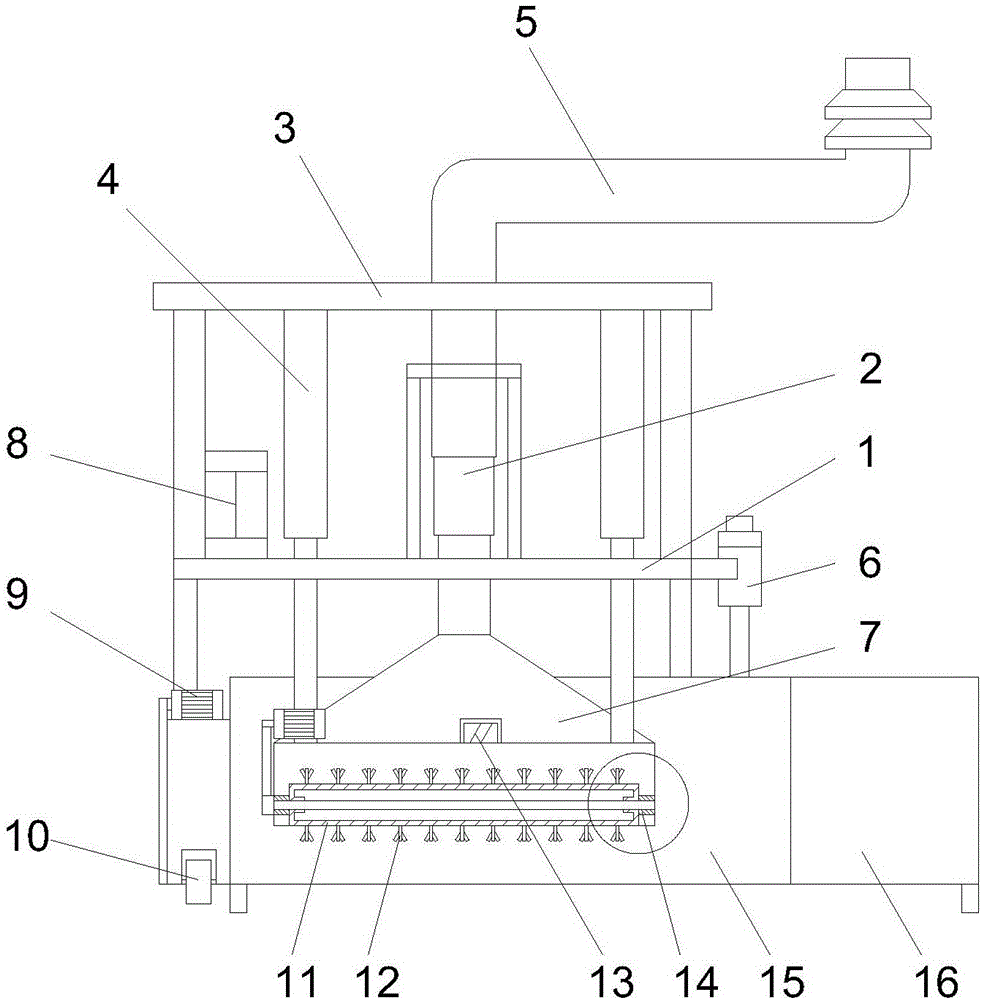

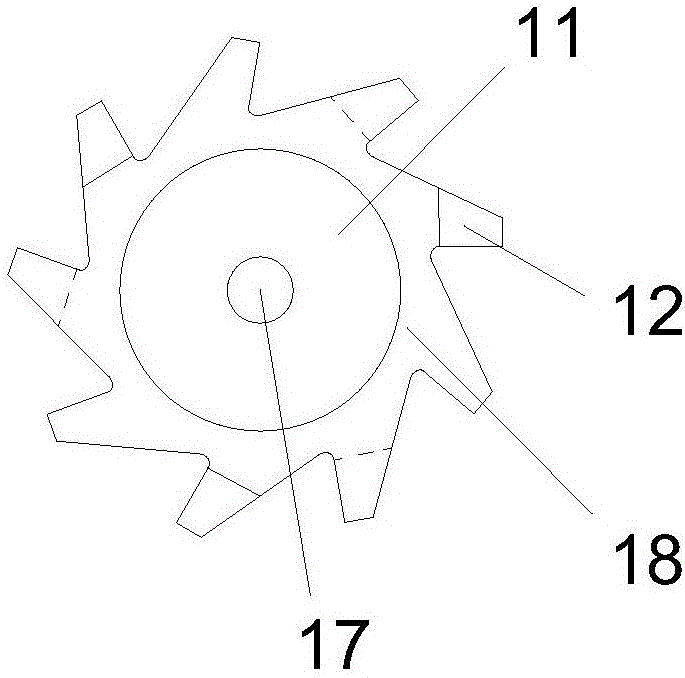

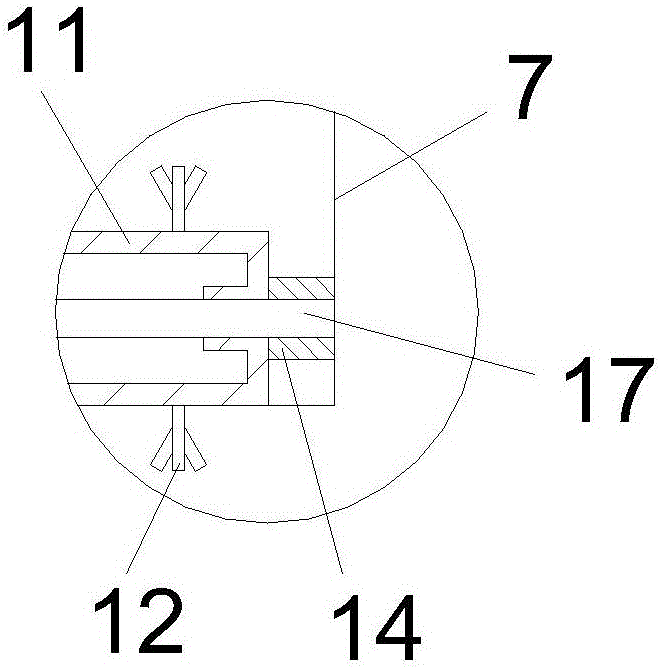

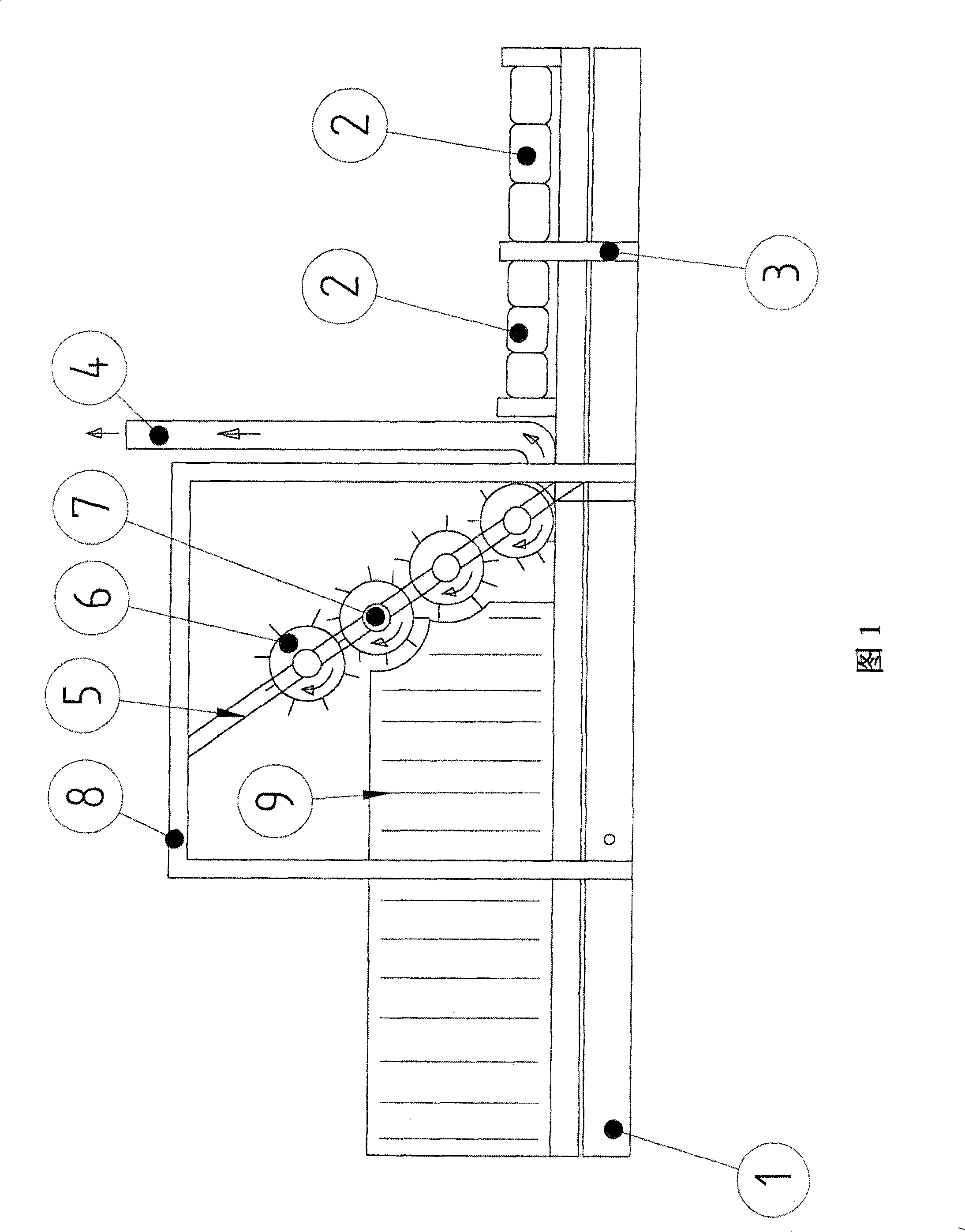

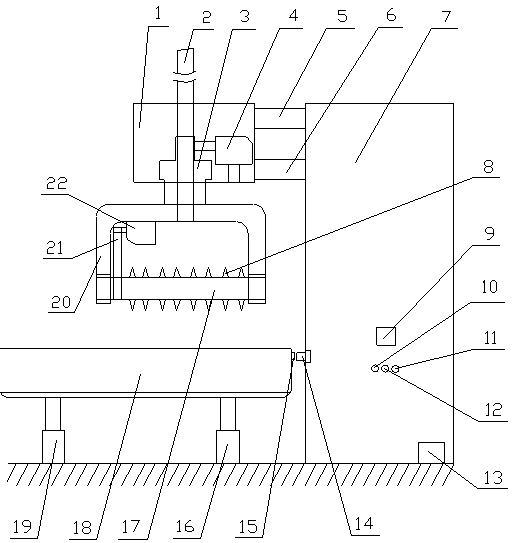

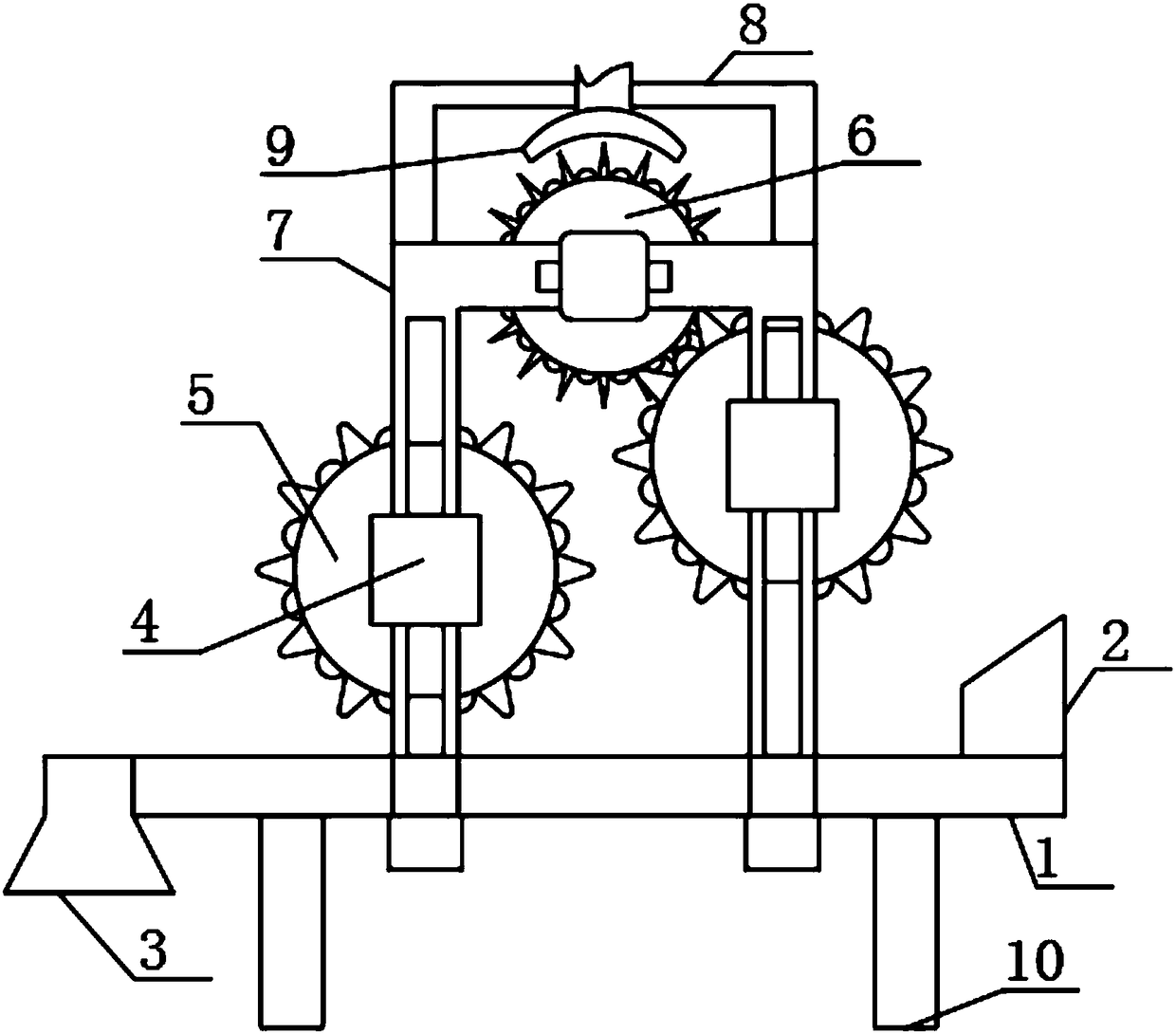

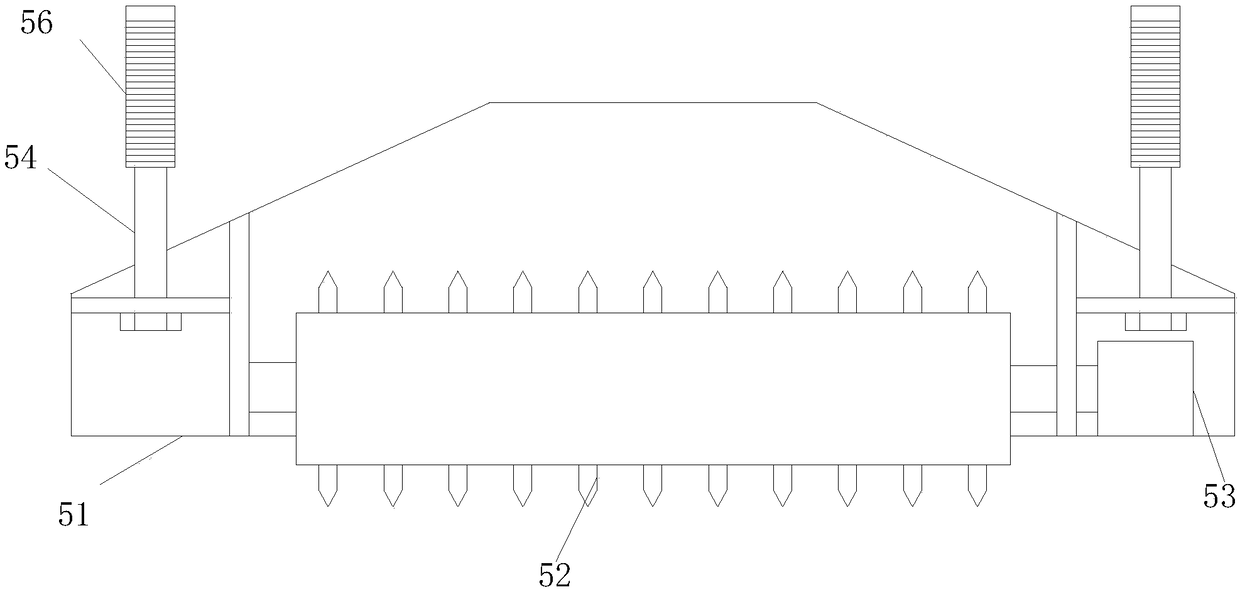

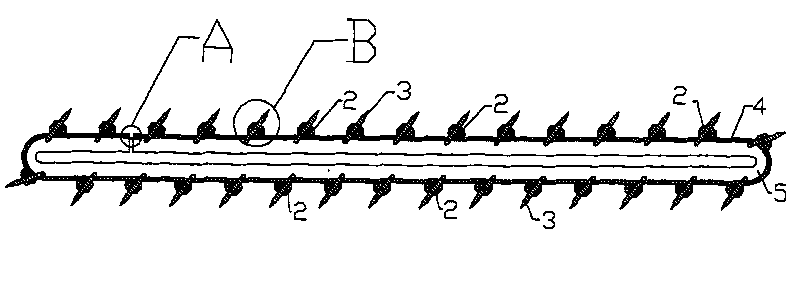

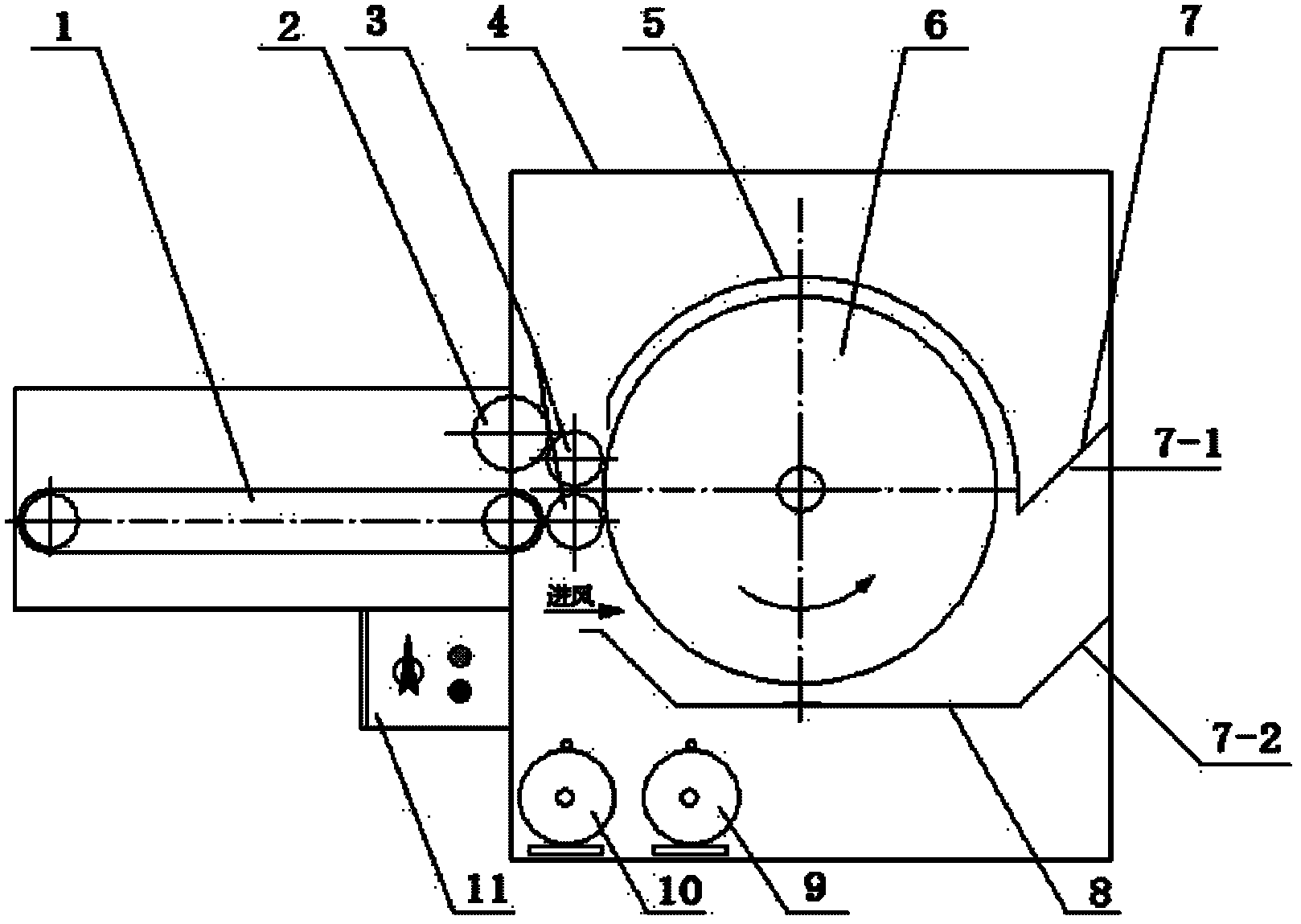

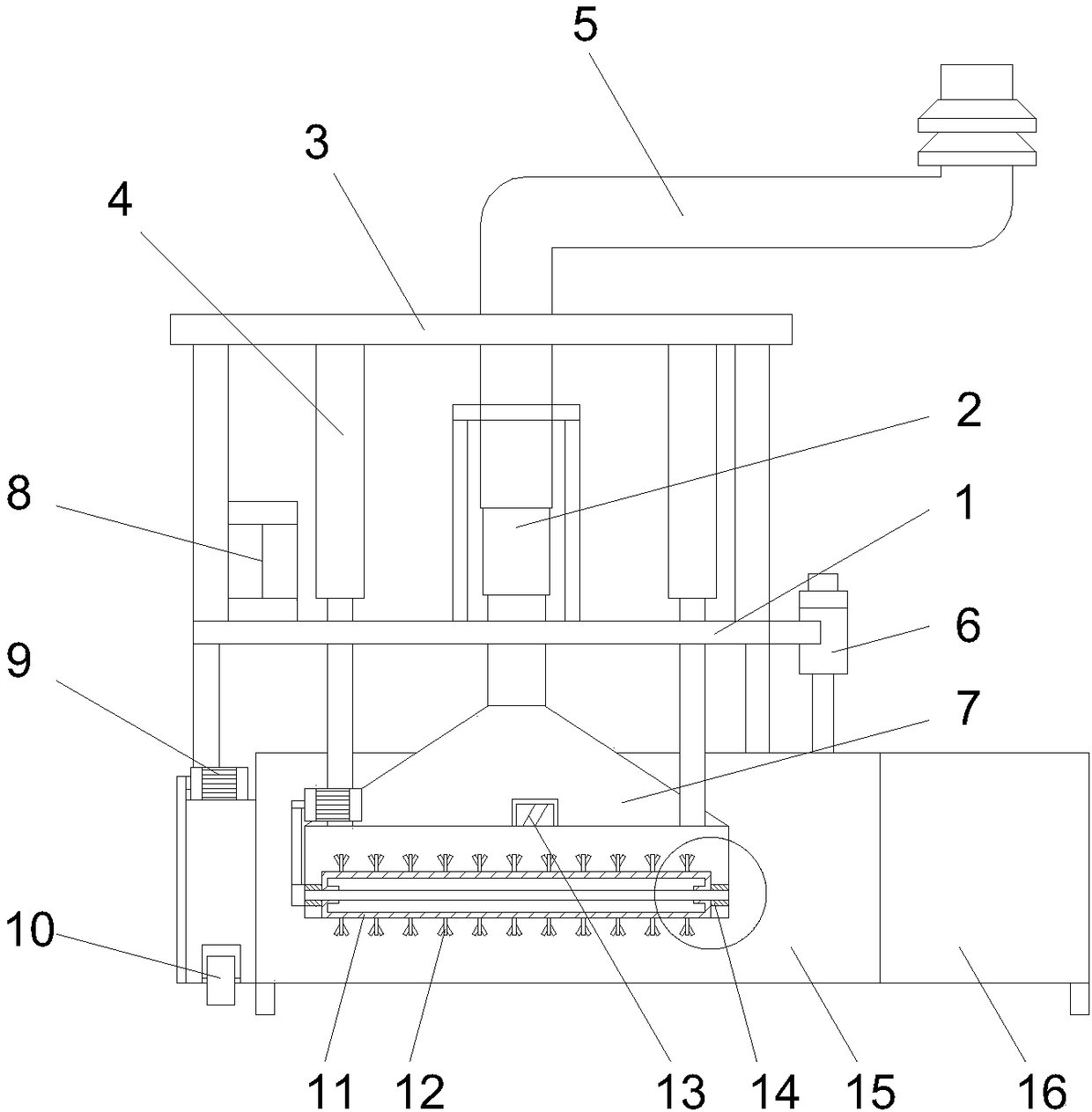

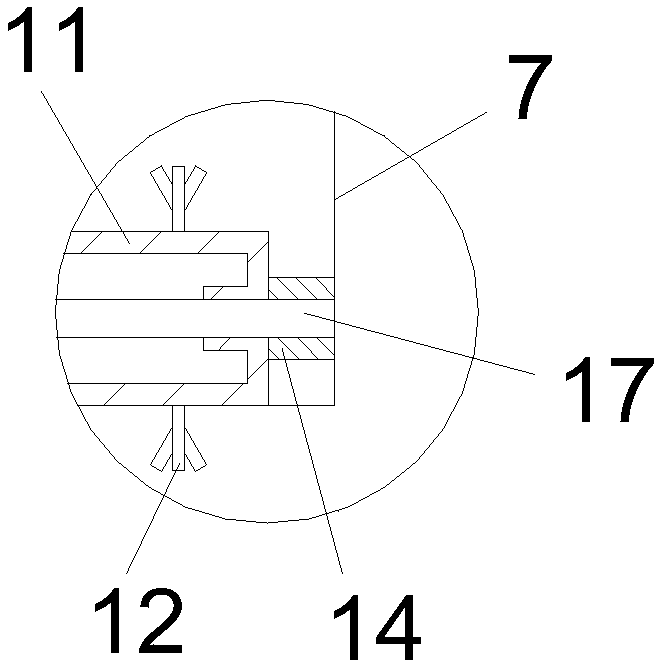

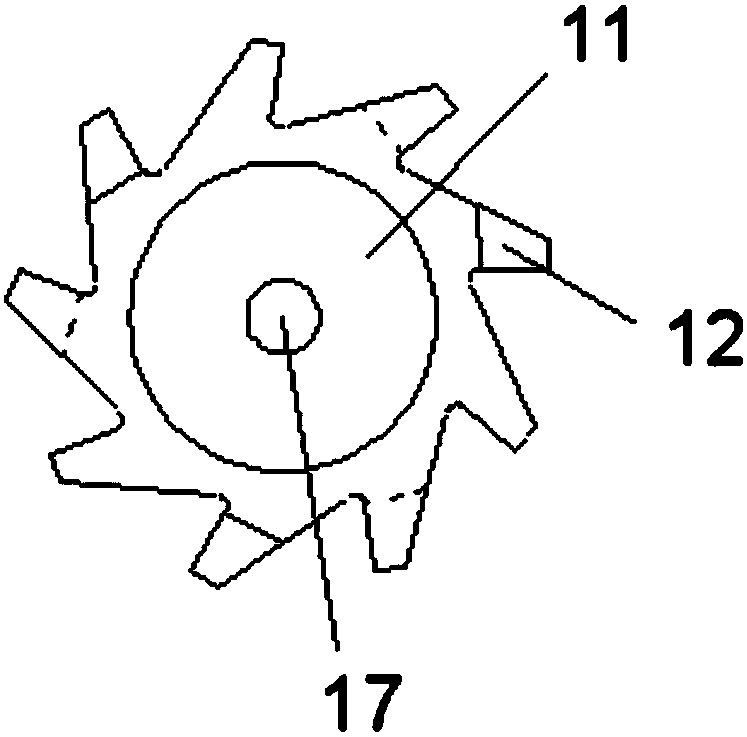

Anti-twisting automatic bale plucker

ActiveCN106167927AStop stalkingPrevent stalking situationsFibre breaking by toothed membersDrive motorEngineering

The invention discloses an anti-twisting automatic bale plucker which comprises a cotton conveying pipe, a stretchable pipe, a suction bin hopper, a bale plucking roller, a supporting plate, a top plate, a trolley, a sliding ring, an inner ring wallboard and an outer ring wallboard. The cotton conveying pipe is connected with the top of the stretchable pipe. The lower end of the stretchable pipe is connected with the top of the suction bin hopper. A material sensing sensor is arranged on the side wall of the suction bin hopper. A bale plucking roller is installed inside the suction bin hopper. A plurality of bale plucking fluted discs are evenly distributed on the bale plucking roller in the axial direction. The number of plucking teeth arranged on the bale plucking fluted discs is the multiple of 3, one third of the plucking teeth and the bale plucking fluted discs are on the same plane, the other two plucking teeth adjacent to the plucking teeth on the same plane of the bale plucking fluted discs are bent towards the two sides of the axial direction respectively, and a driving motor for driving the bale plucking roller is installed on the suction bin hopper. The anti-twisting automatic bale plucker is simple in structure, uniform in peeling cotton suction, capable of achieving intelligent motion cotton suction, capable of effectively preventing the bale plucking roller from being twisted by cotton, and capable of improving the working efficiency.

Owner:GUANGDE TIANYUN NEW TECH

Apparatus for stripping fibre material from textile fibre bales of spinning material, for example cotton, synthetic fibres and the like

InactiveUS7506410B2Reduce light lossMounting of the optical distance sensors is simpleCarding machinesMechanical fibre separationTextile fiberTower

Owner:TRUETZSCHLER GMBH & CO KG

Bale breaker

InactiveCN101289773ALow costIncrease power valueCarding machinesFibre breaking machinesFiberEngineering

Owner:胡贝特·赫格特

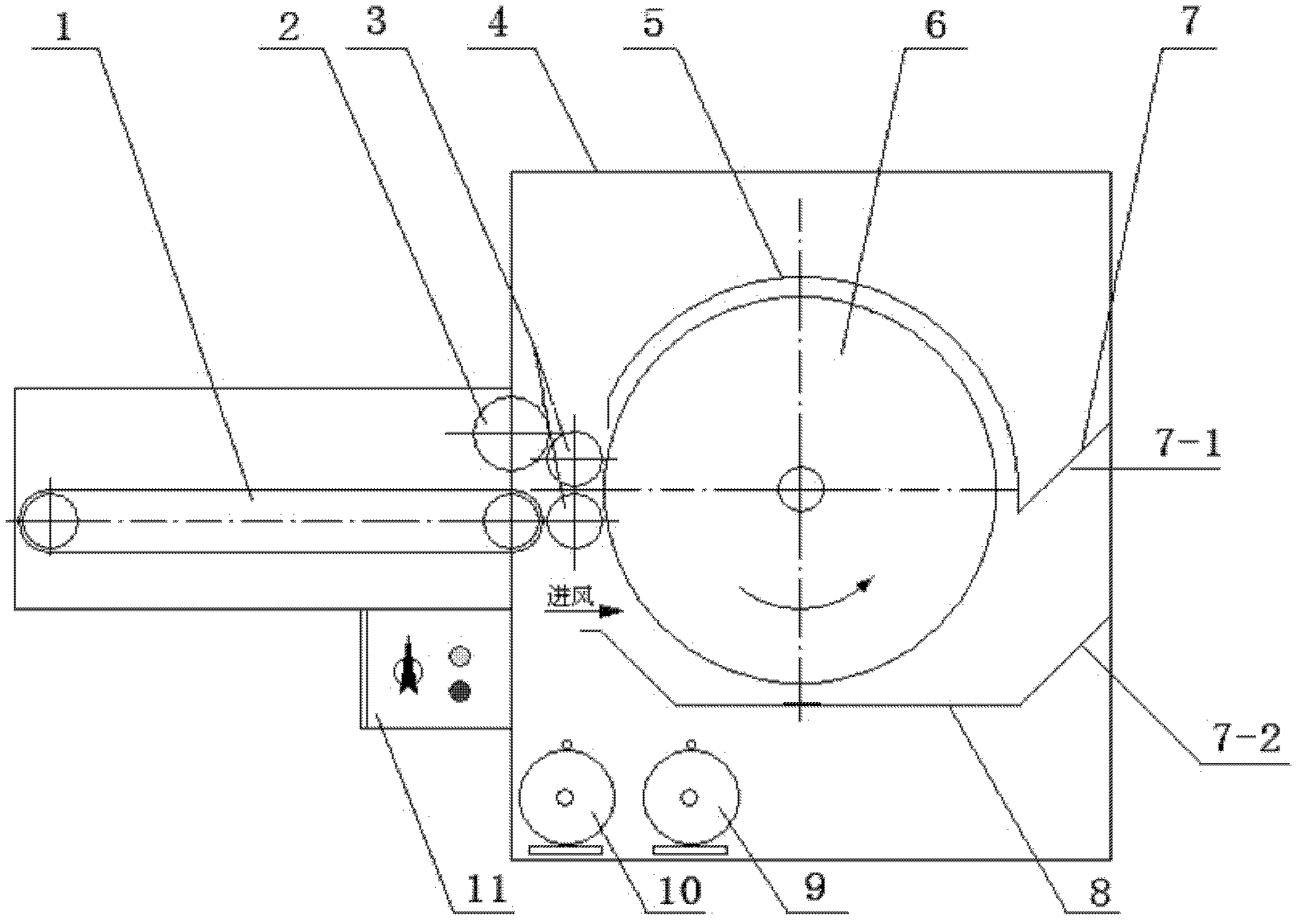

Plucker for cotton thread processing

InactiveCN110616475AReduce processing costsAchieve processing benefitsFibre breaking machinesFibre breaking by toothed membersHydraulic cylinderTransmission belt

A plucker for cotton thread processing comprises a plucker head, a conveying pipe, a rotating shaft, a rotating motor, a first supporting rod, a second supporting rod, a plucker body, a plucking blade, a plucking switch, a rotating switch, a lifting switch, a first hydraulic cylinder, a plucking wheel, a cotton batt tank, a second hydraulic cylinder, a plucking wheel platform, a transmission coverand a plucking motor. The plucker head is mounted on the side face of the plucker body through the first supporting rod and the second supporting rod, the cotton batt tank is mounted on the first hydraulic cylinder and the second hydraulic cylinder and positioned on the lateral side of the plucker body, the plucking wheel is mounted on the lower portion in the plucking wheel platform, the plucking blade is arranged on the plucking wheel, the plucking motor is mounted on the upper portion in the plucking wheel platform, a transmission belt is arranged in the transmission cover, one end of thetransmission belt in the transmission cover is connected with the plucking motor while the other end of the same is connected with the plucking wheel, and the rotating shaft is arranged on the upper portion of the plucking wheel platform. The plucker is simple in structure and convenient for plucking operation, cotton thread processing cost is lowered, and cotton thread processing benefit is realized.

Owner:余庆县鸿祥棉纺有限责任公司

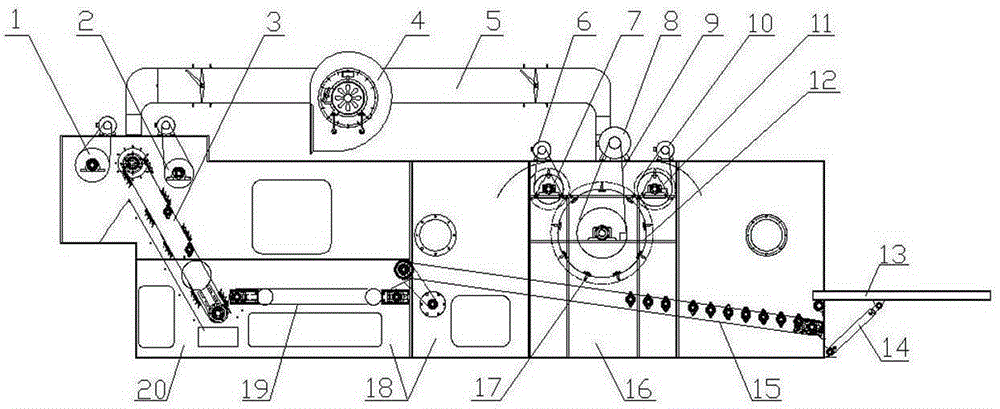

Automatic cotton plucker

InactiveCN107557916AEasy to absorbEasy to grabFibre breaking machinesFibre breaking by toothed membersElectric machineryPlucker

The invention discloses an automatic cotton plucker which comprises a supporting plate, a suction bin bucket and an air suction box. A supporting column is fixed at each of two ends of the supportingplate, the bottom end of a top plate is fixedly connected with two electric extensible rods, the bottom ends of the electric extensible rods are fixedly connected with the suction bin bucket, a rotating shaft at one end of a cotton plucking roller is fixedly connected with an output shaft of a speed reducing motor, a plurality of plucking teeth are arranged on the cotton plucking roller, the middle of the top end of the suction bin bucket is communicated with a cotton conveying pipe, and an extensible hose is arranged on one section of the cotton conveying pipe. Cotton is stripped and pluckedthrough the plucking teeth, so that convenience is brought to the cotton conveying pipe to absorb the cotton; by arranging the electric extensible rods, height of the suction bin bucket can be adjusted, and convenience is brought to plucking and sucking in the cotton no matter the cotton is more or less; by arranging a shaft sleeve on the rotating shaft of the cotton plucking roller, the shaft sleeve is fixed on the inner wall of the suction bin bucket to prevent the cotton from being close to the rotating shaft, and the circumstance that the rotating shaft of the cotton plucking roller is entangled is prevented.

Owner:湖州世韩进出口有限公司

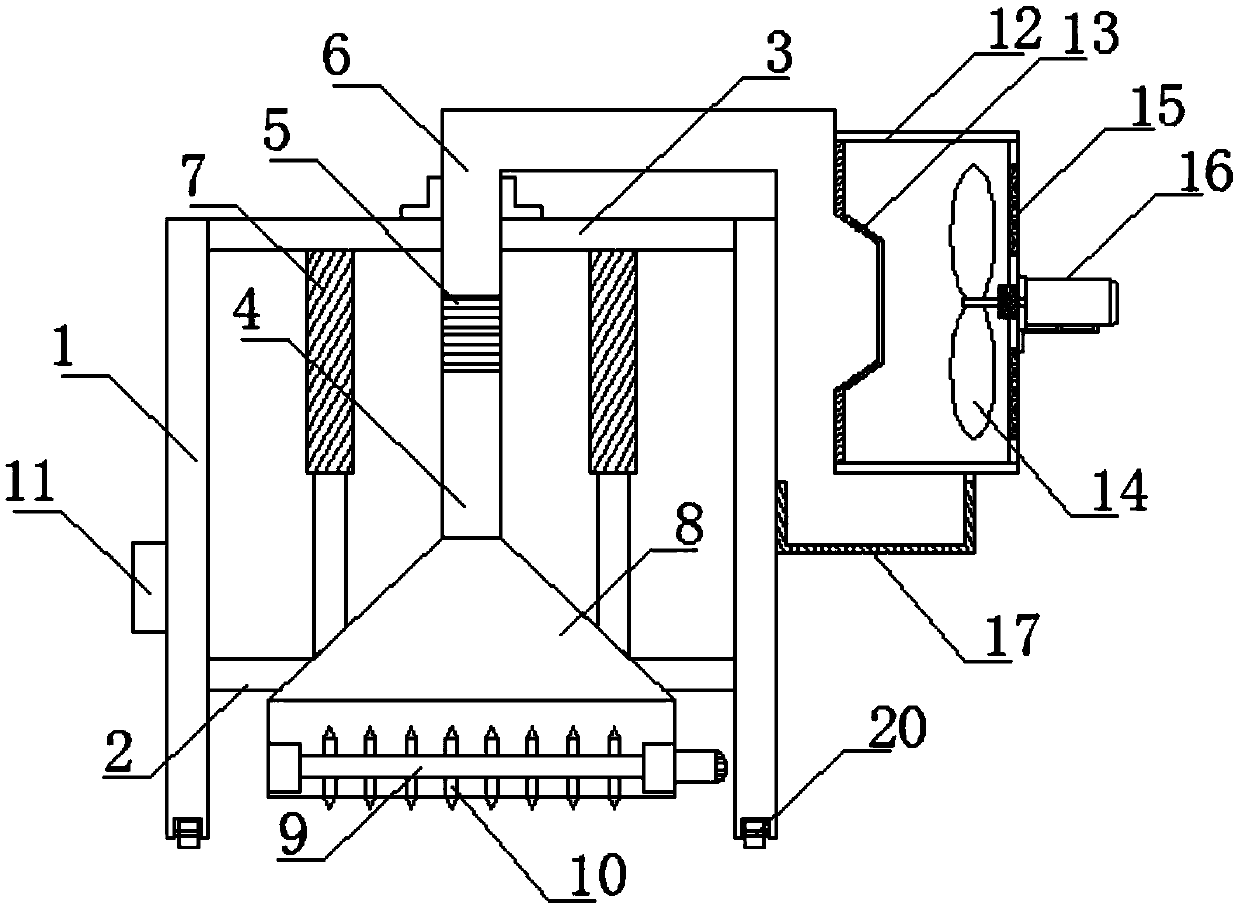

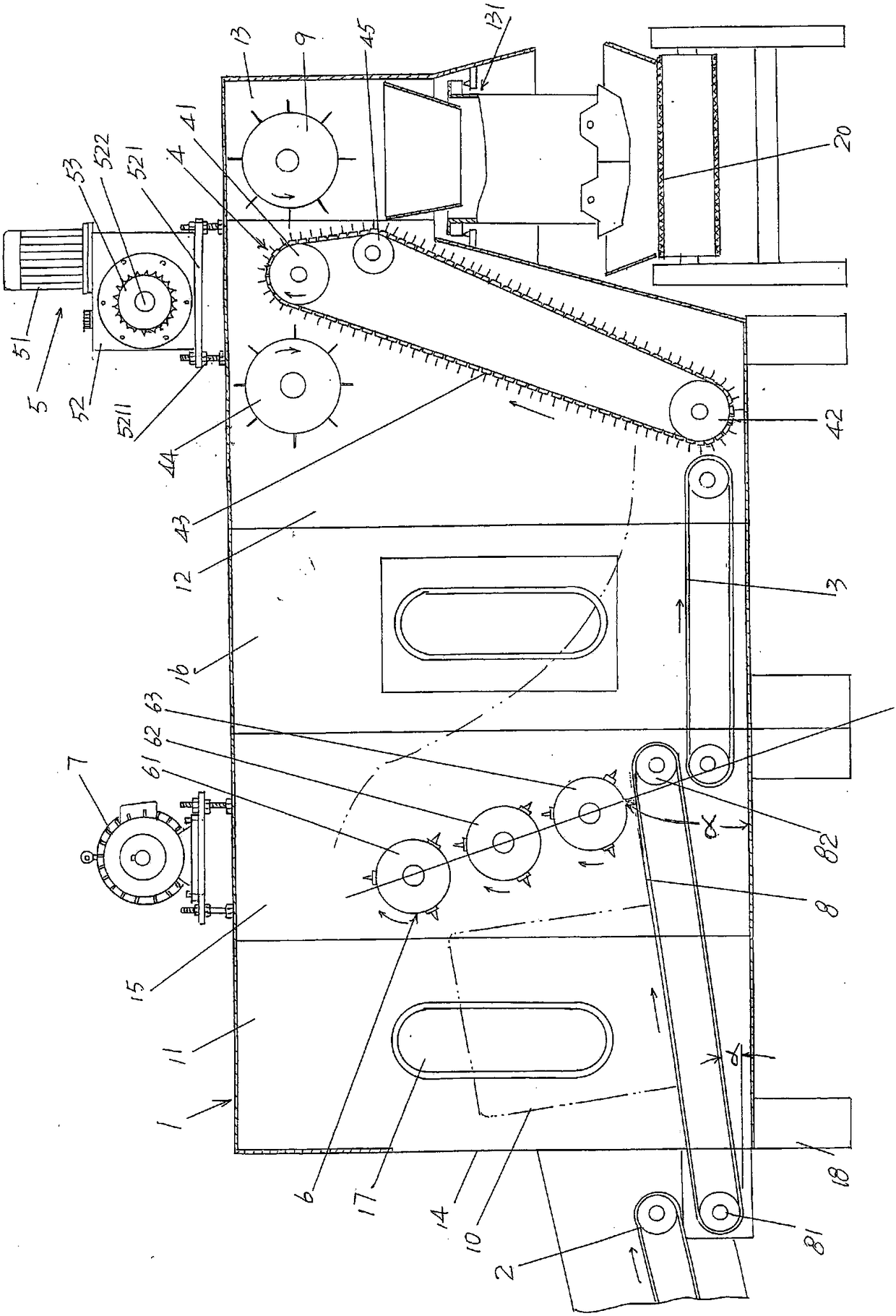

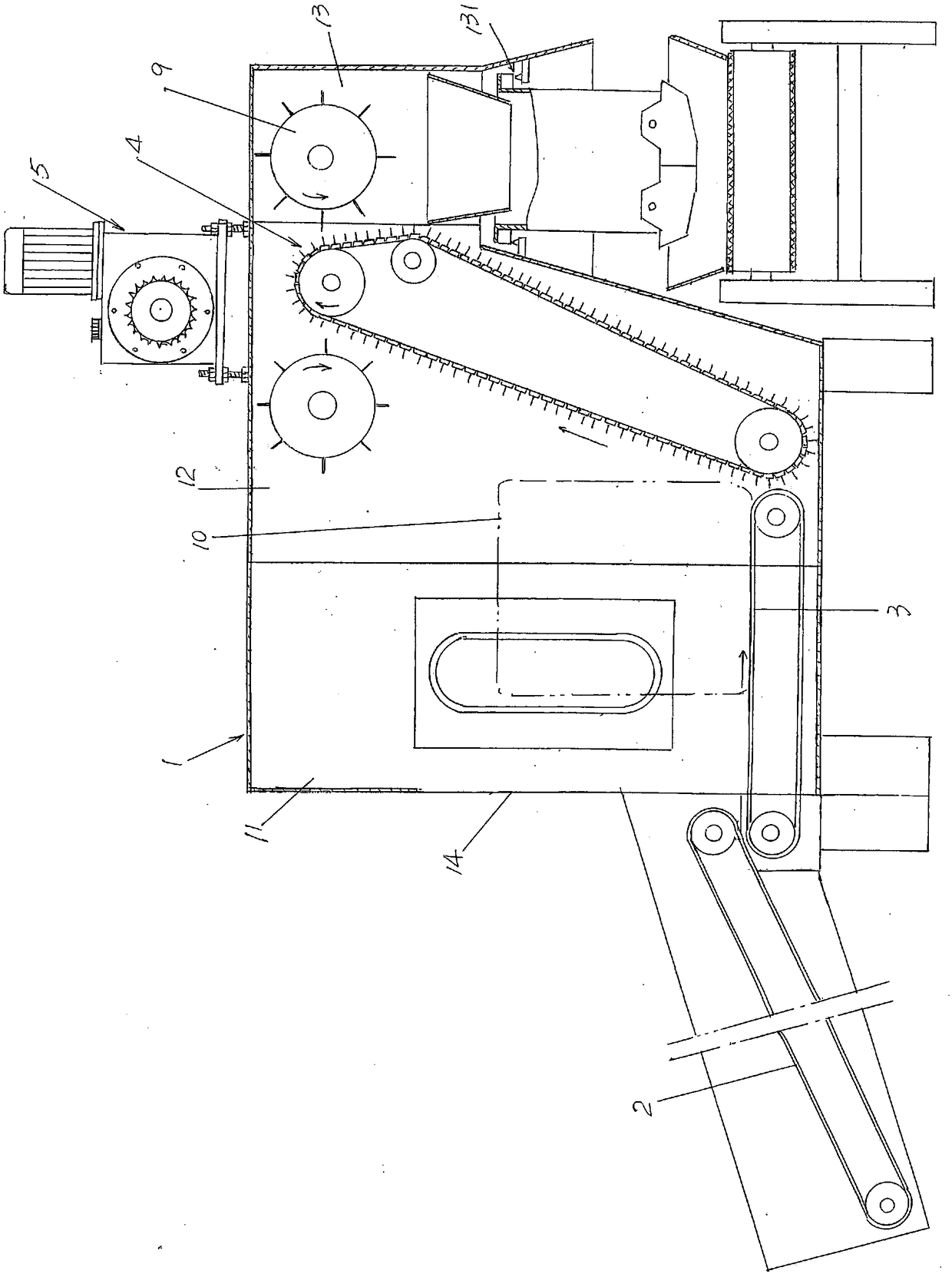

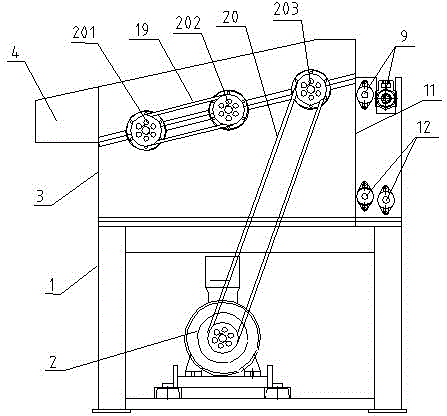

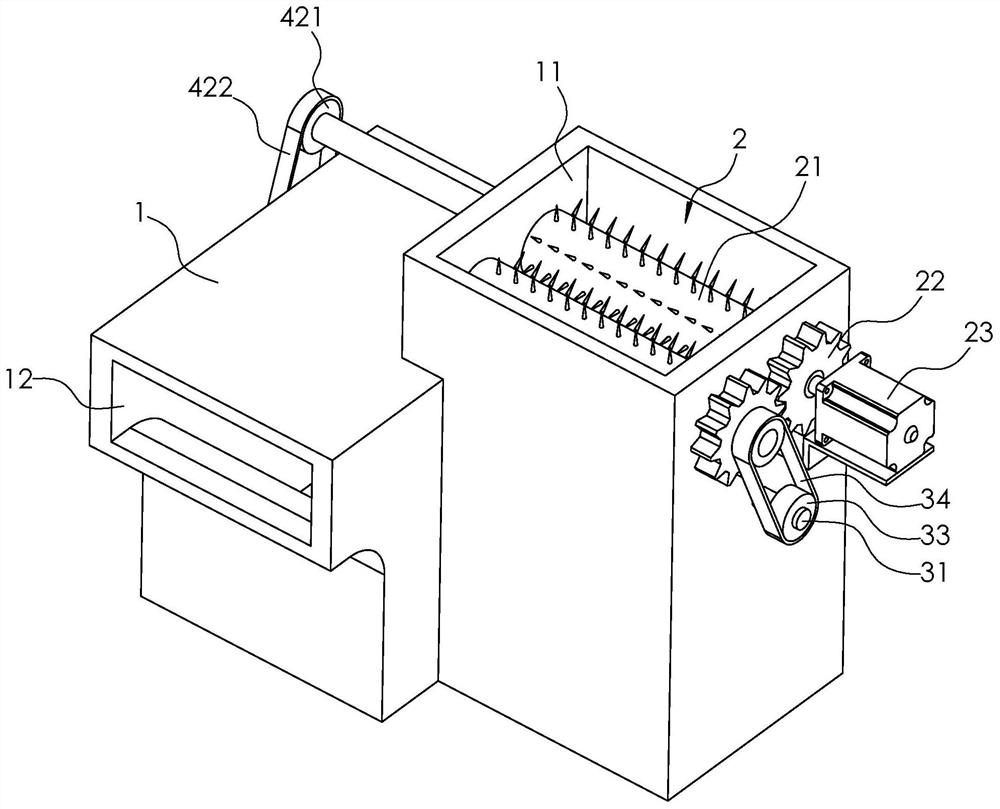

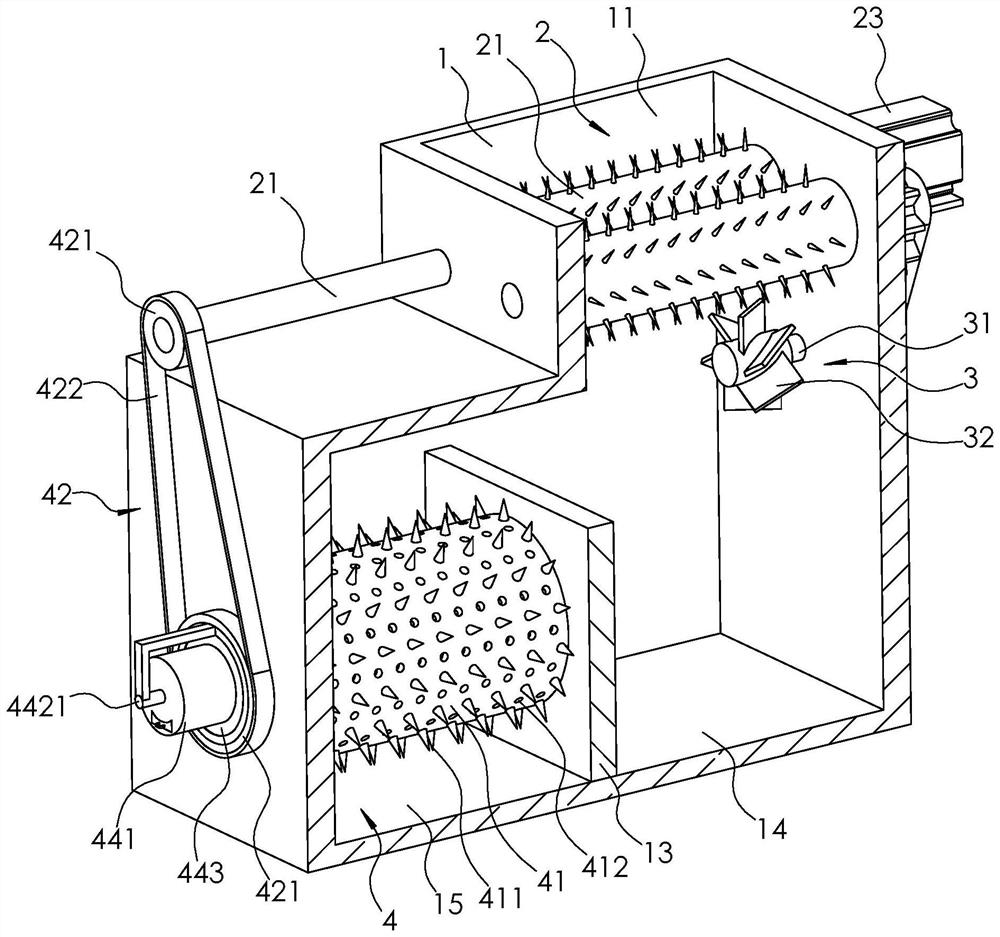

Bale opener

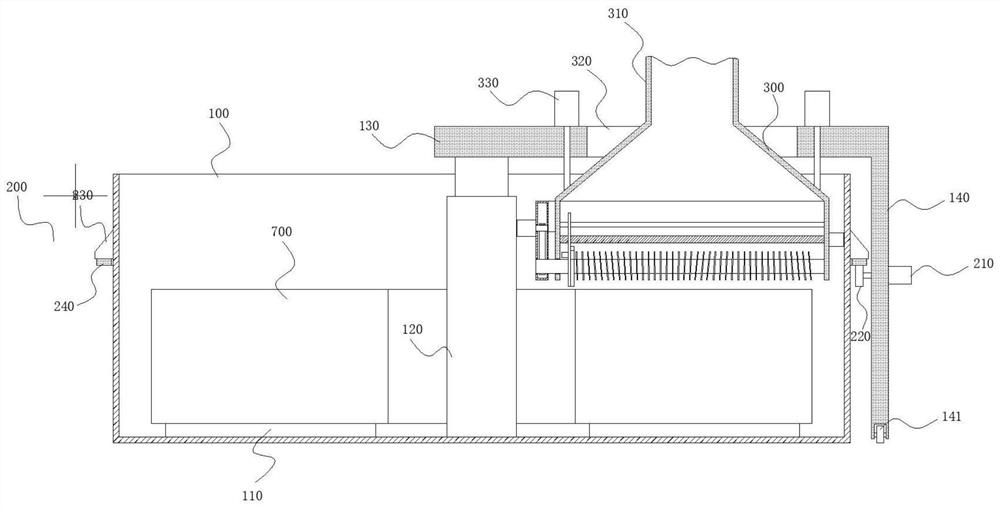

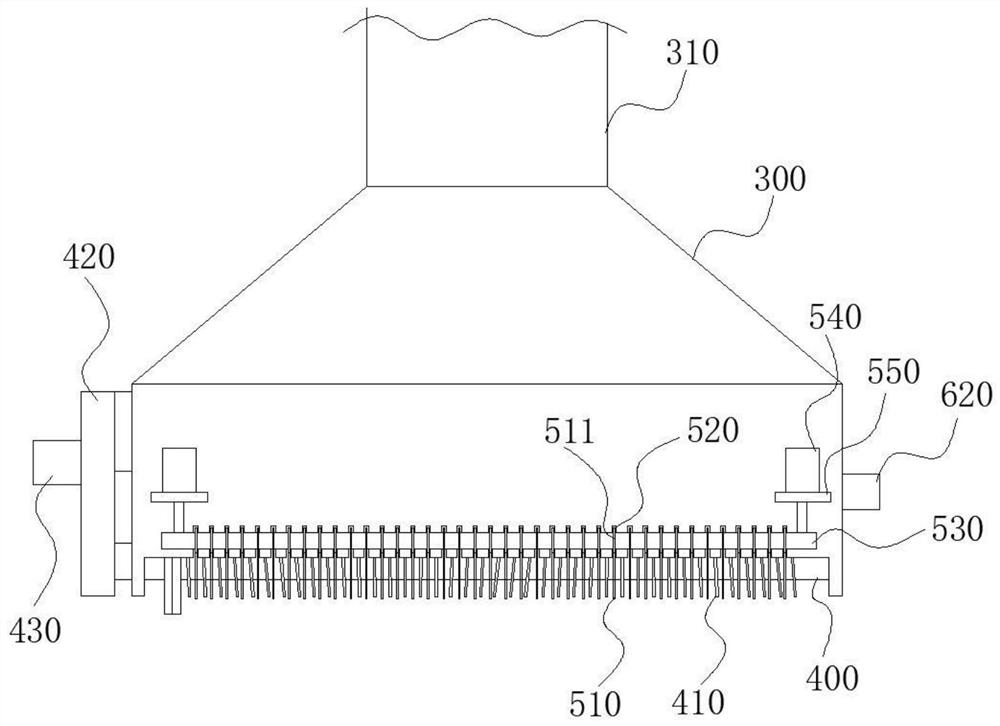

ActiveCN106435842AImprove cotton leveling efficiencyImprove protectionFibre breaking machinesFibre breaking by toothed membersFiberEngineering

The invention provides a bale opener and belongs to the technical field of non-woven machinery. The bale opener comprises a box body, the box body includes a feeding chamber, a cotton trimming cavity and a metering cotton discharge chamber. A feeding curtain is arranged at the left side of the box body, a cotton trimming mechanism is arranged in the cotton trimming cavity, a cotton stripping roller is arranged inside the metering cotton discharge chamber, a weighing metering discharge device is below the metering cotton discharge chamber, and a cotton trimming power mechanism is arranged at the top of the box body. The bale opener is characterized in that the box body further includes a front unpacking release chamber and a fiber transition cavity, a front unpacking release mechanism is arranged inside the front unpacking release chamber, the top of the box body is provided with an unpacking release power transmission unit, a conveying curtain is arranged inside the fiber transition cavity, the left end of the conveying curtain extends to the inside of the front unpacking release chamber, and the right end of the conveying curtain extends to the inside of the cotton trimming cavity; a raw cotton conveying belt is arranged at the position corresponding to the lower portions of the feeding chamber and the front unpacking release chamber, the left end of the raw cotton conveying belt corresponds to the lower portion of the right end of the feeding curtain through a feeding hole of the box body, and the right end of the raw cotton conveying belt corresponds to the upper portion of the left end of the feeding curtain through the feeding hole of the box body. The cotton trimming efficiency of the cotton trimming mechanism is improved, and the protection of the cotton trimming mechanism is facilitated.

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

Opener with scutching function

PendingCN108441990ASolve wear and tearSolve the problem of the influence of the sticky fabric on the pine roller on the pineCleaning using toolsMagnetic separationMetal impuritiesEngineering

The invention discloses an opener with a scutching function, and relates to the field of textile articles. The opener comprises two opening mechanisms, a cleaning mechanism and a supporting rod, lifting mechanisms are arranged on two fixed legs of the supporting rod, the opening mechanisms are connected between a left supporting rod body and a right supporting rod body through the lifting mechanisms, a feeding plate is fixedly connected with the fixed legs of the supporting rod, and a cleaning mechanism is arranged in the center of the top of the supporting rod. Through the arrangement of theopening mechanisms, when one opening mechanism conducts opening, the other opening mechanism lifts through the corresponding lifting mechanism to be meshed with the cleaning mechanism and attracts metal impurities through first electromagnets, and when meshed with the cleaning mechanism, the cleaning mechanism cleans away fabric adhering to the opening mechanism, and cleans away the metal impurities at the same time. The problems that the metal impurities in raw cotton wear a machine and the fabric adhering to a loosening roller has influence on loosing are solved, and the opener has the advantages of being high in practicability and simple in structure.

Owner:阜阳恒泰纺织有限公司

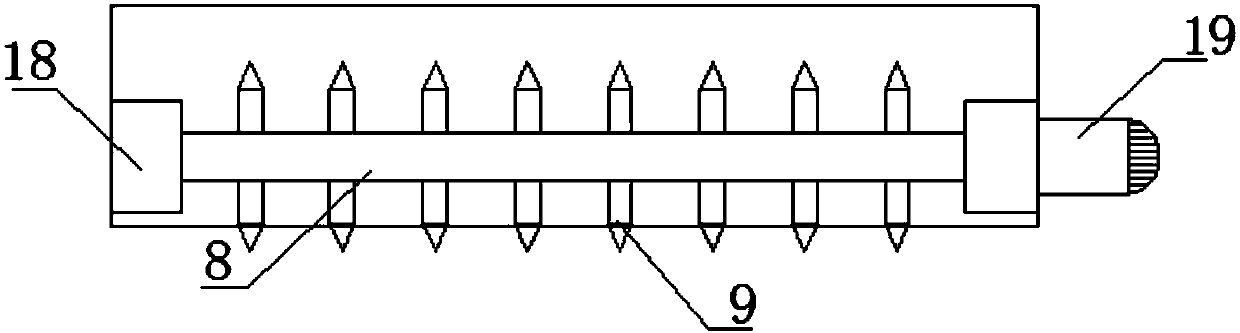

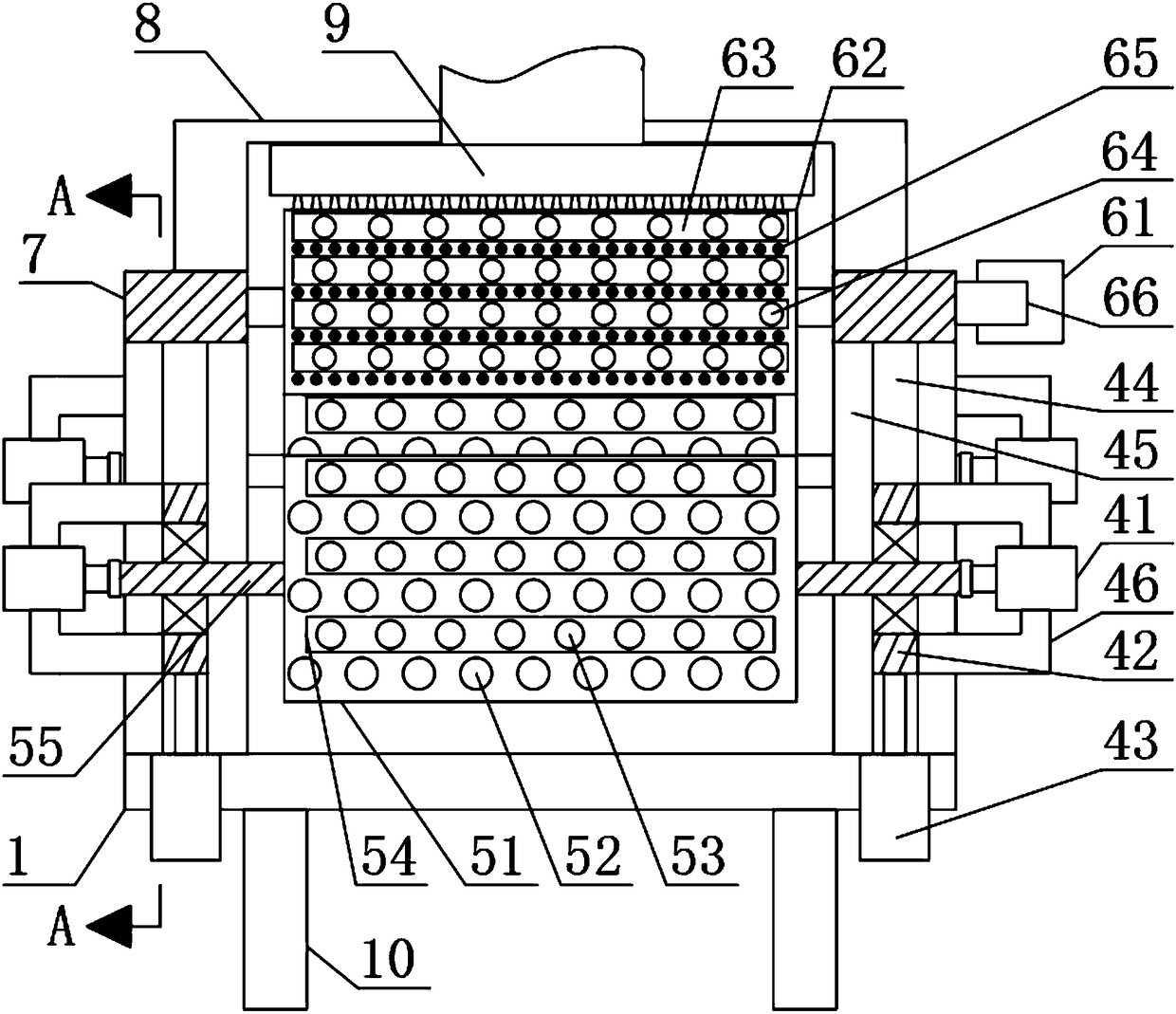

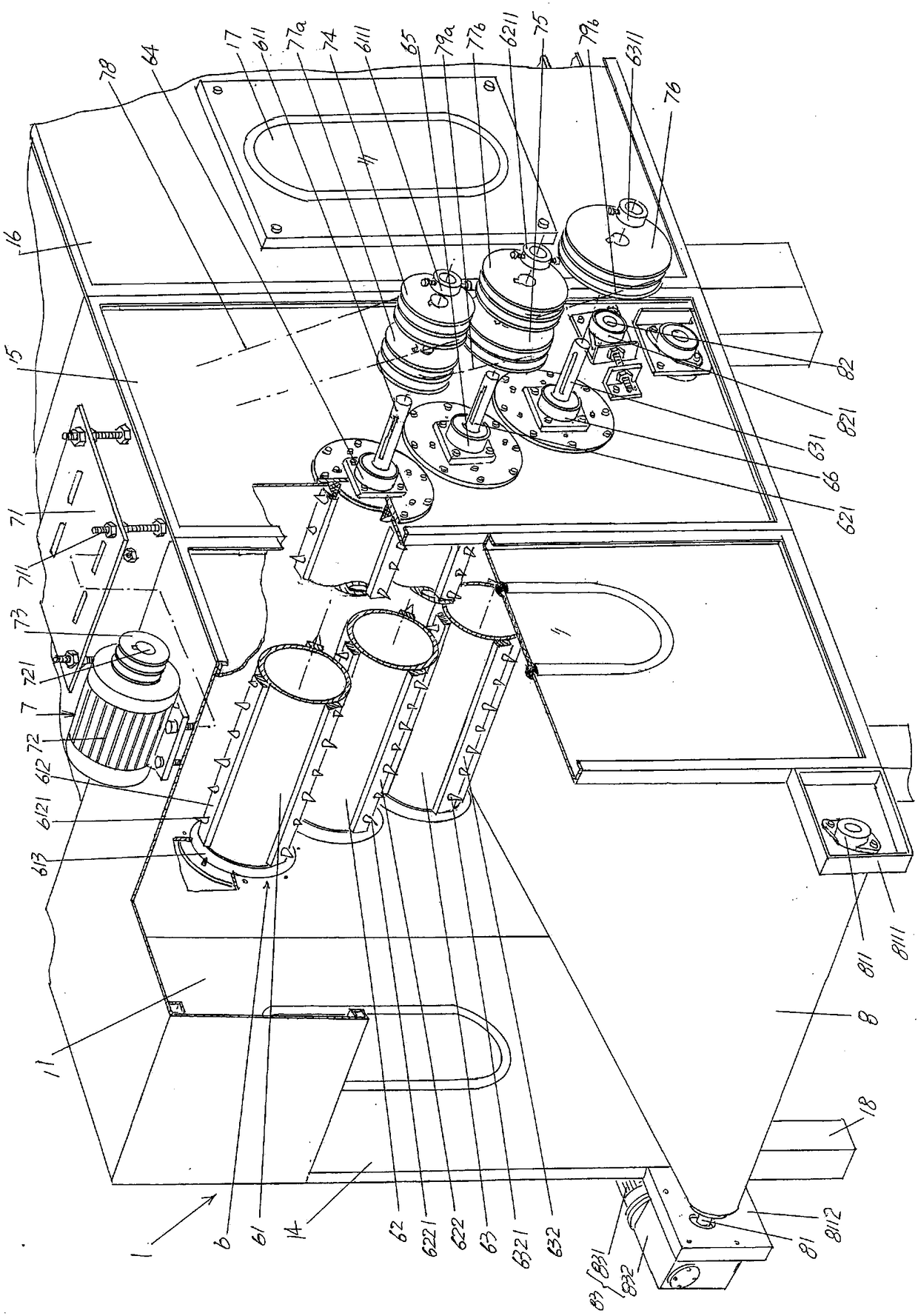

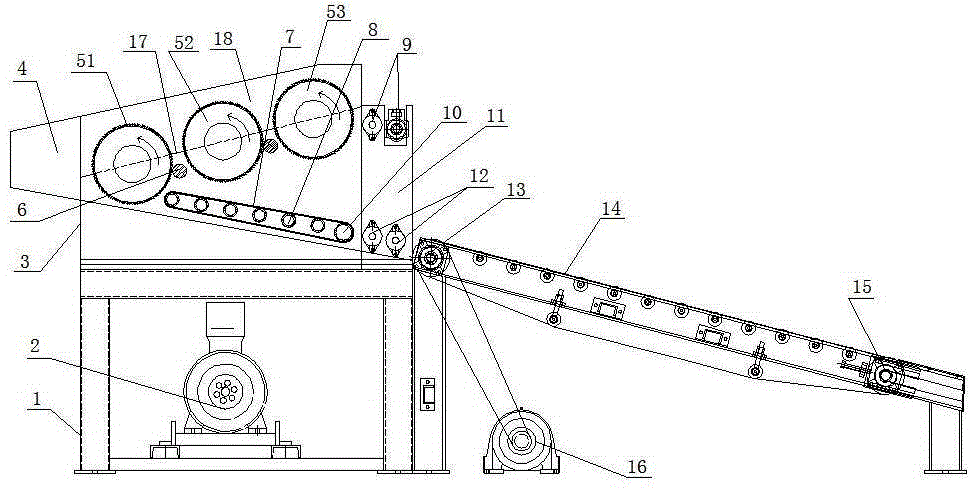

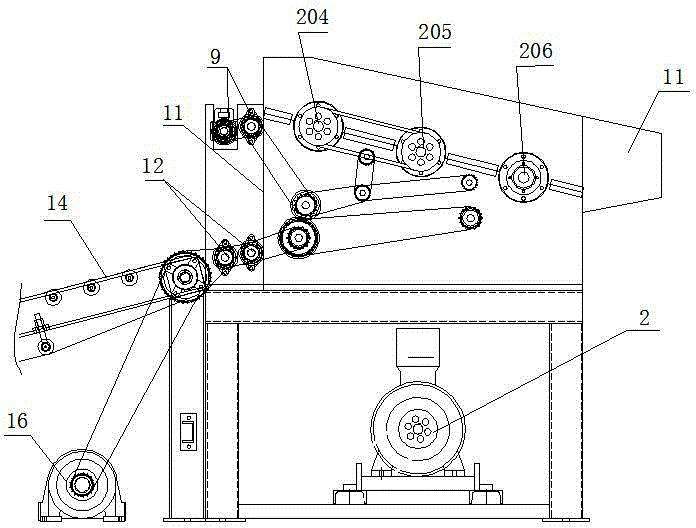

Energy-saving loose fiber cake opener

InactiveCN105316800AAvoid hurting handsReduce labor intensityFibre breaking machinesFibre breaking by toothed membersElectricityYarn

The invention discloses an energy-saving loose fiber cake opener which comprises an opening unit, a cotton bin unit and a feeding unit. The opening unit and the cotton bin unit are communicated, and the cotton bin unit and the feeding unit are communicated. The opening unit, the cotton bin unit and the feeding unit are provided with an opening bin, a cotton bin and a feeding bin respectively. A first belt type conveyor and an opening mechanism are arranged in the opening bin. A second belt type conveyor is arranged in the cotton bin. A third belt type conveyor is arranged in the feeding bin. A conveying belt on the third belt type conveyor is provided with a steel nail for conveying. The energy-saving loose fiber cake opener is characterized in that the opening mechanism comprises a first opening roller, a second opening roller and a third opening roller, the outer circles of the first, second and third opening rollers are provided with radial steel nails respectively, and one ends of the first, second and third opening rollers are connected with first, second and third power mechanisms through a transmission mechanism respectively. By the adoption of the opener, the processed loose fiber is good in quality, the spinning requirement for high-quality cotton yarn can be met, and the opener saves electricity, does not injure hands, and is low in labor intensity, high in production efficiency and suitable for opening dehydrated cotton loose fiber cakes.

Owner:WUXI QIANZHOU YAODA MACHINERY FACTORY

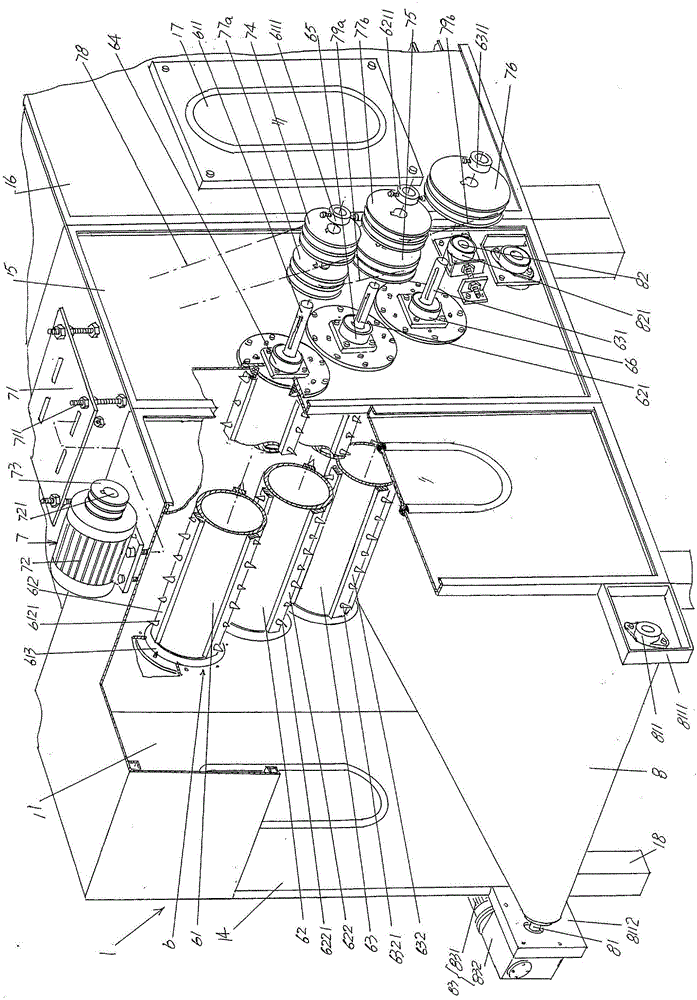

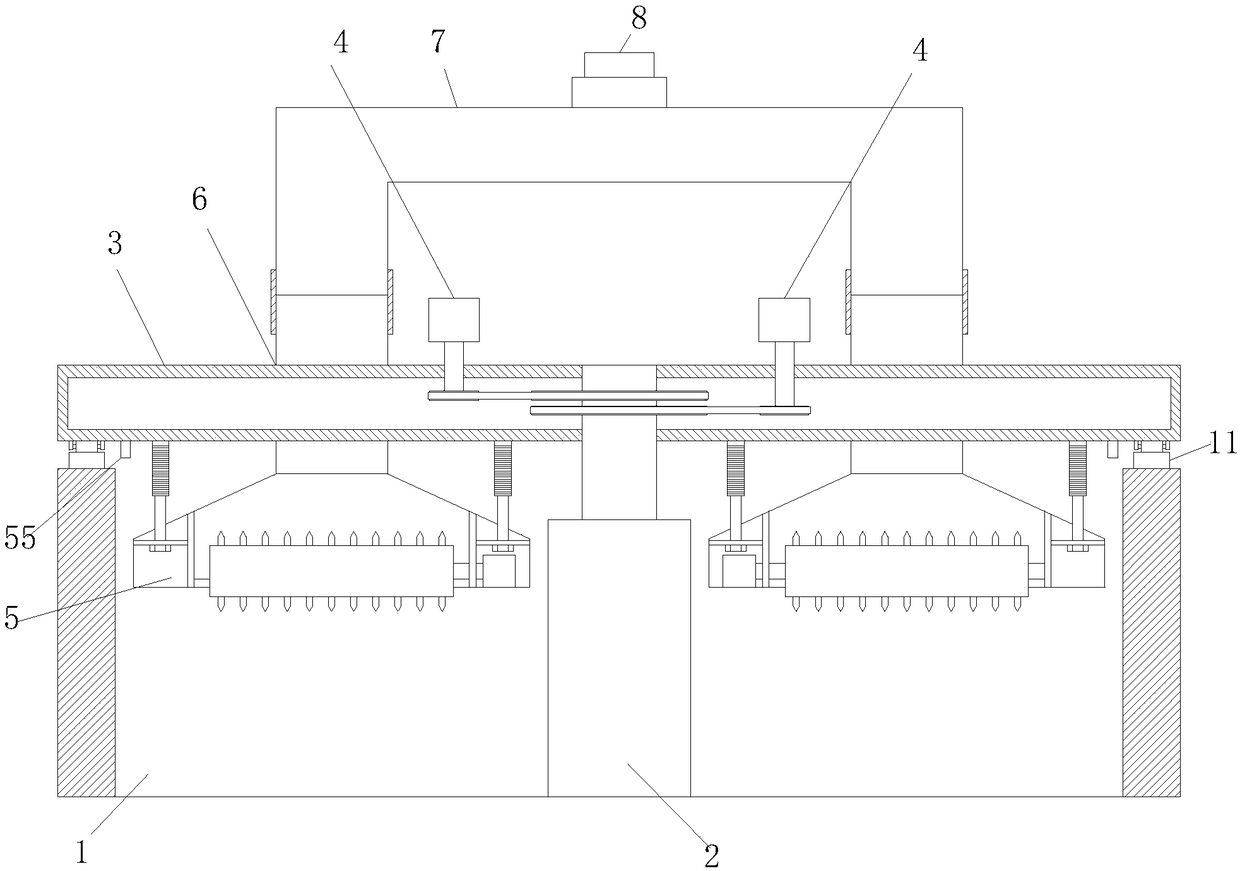

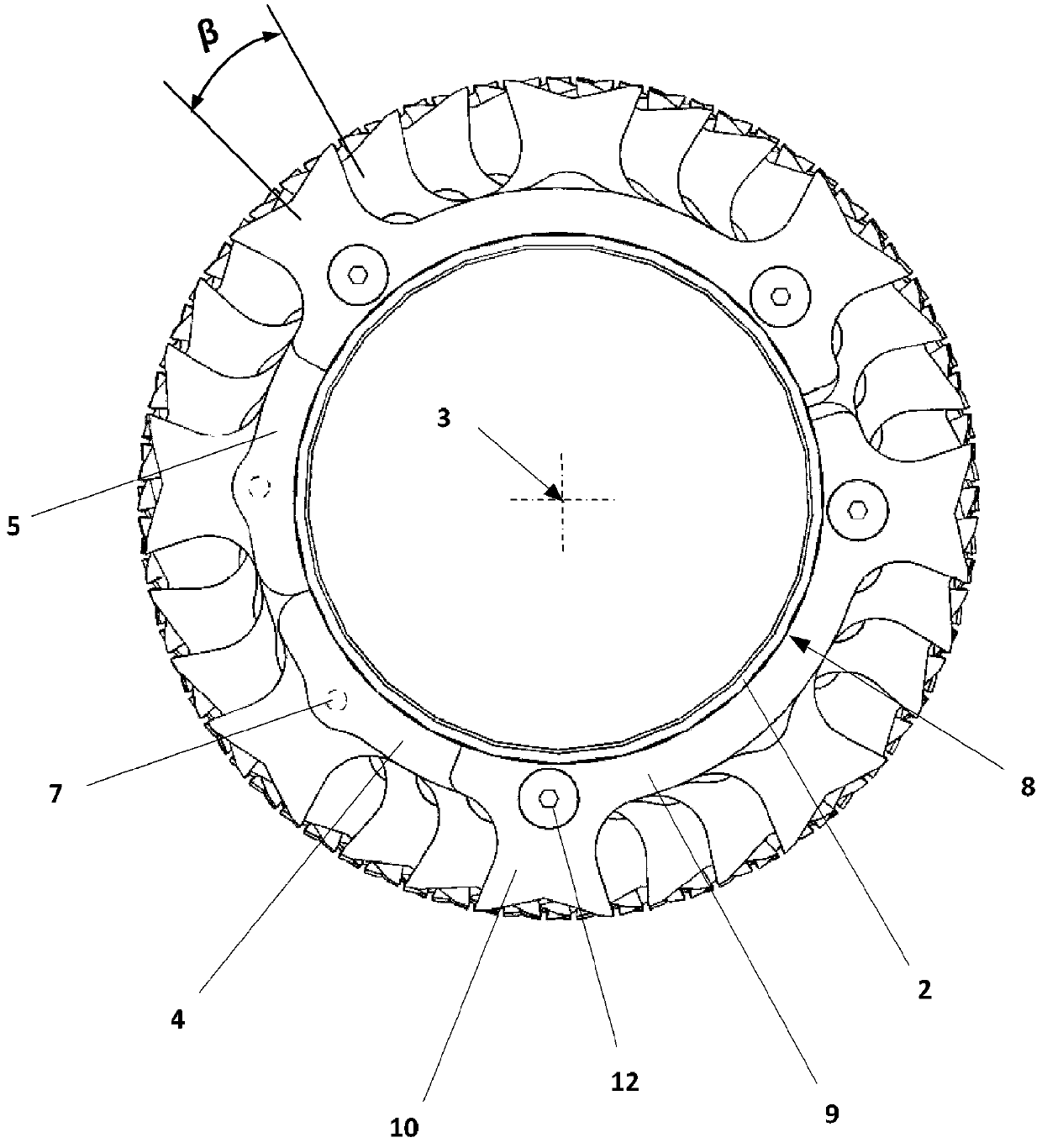

Disc plucker

InactiveCN108441989ASmall footprintRunning balanceFibre breaking machinesFibre breaking by toothed membersCircular discEngineering

The invention discloses a disc plucker which comprises a bin. A stand column is vertically installed in the middle of the bin and connected and provided with a driving frame through a bearing. The twoends of the driving frame both extend to the upper side of the bin and are slidingly connected with the upper edge of the bin. Driving motors for driving the driving frame to work are arranged on thedriving frame. Cotton collecting devices are symmetrically arranged on the driving frame with the middle as the axis. Telescopic cotton conveying pipes are installed on the upper sides of the cottoncollecting devices respectively. The upper portions of the telescopic cotton conveying pipes converge into a main pipeline. The main pipeline is rotationally connected with and installed on a fixed pipeline. The occupied space of the plucker is reduced; due to the symmetrical cotton collecting devices, the plucker keeps balance during operation, the stability of the plucker is increased, and the cotton suction work efficiency is improved; due to the two driving motors, the failure shutdown time of the plucker is shortened; due to an infrared distance measuring sensor and an electric telescopicrod, the distance between a material suction bin hopper and a cotton material is automatically adjusted.

Owner:阜阳恒泰纺织有限公司

Open charter

ActiveCN106435842BImprove cotton leveling efficiencyImprove protectionFibre breaking machinesFibre breaking by toothed membersFiberEngineering

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

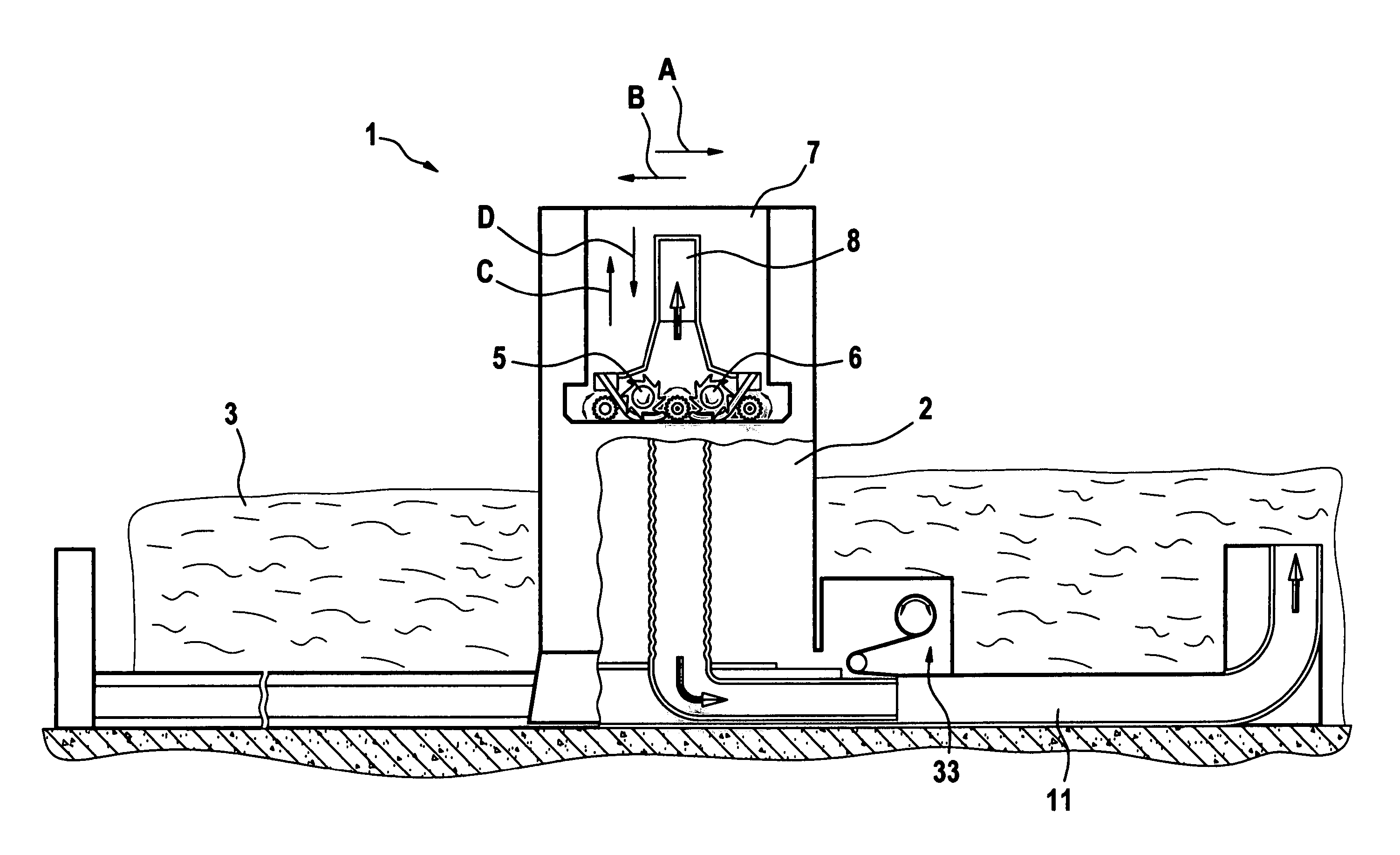

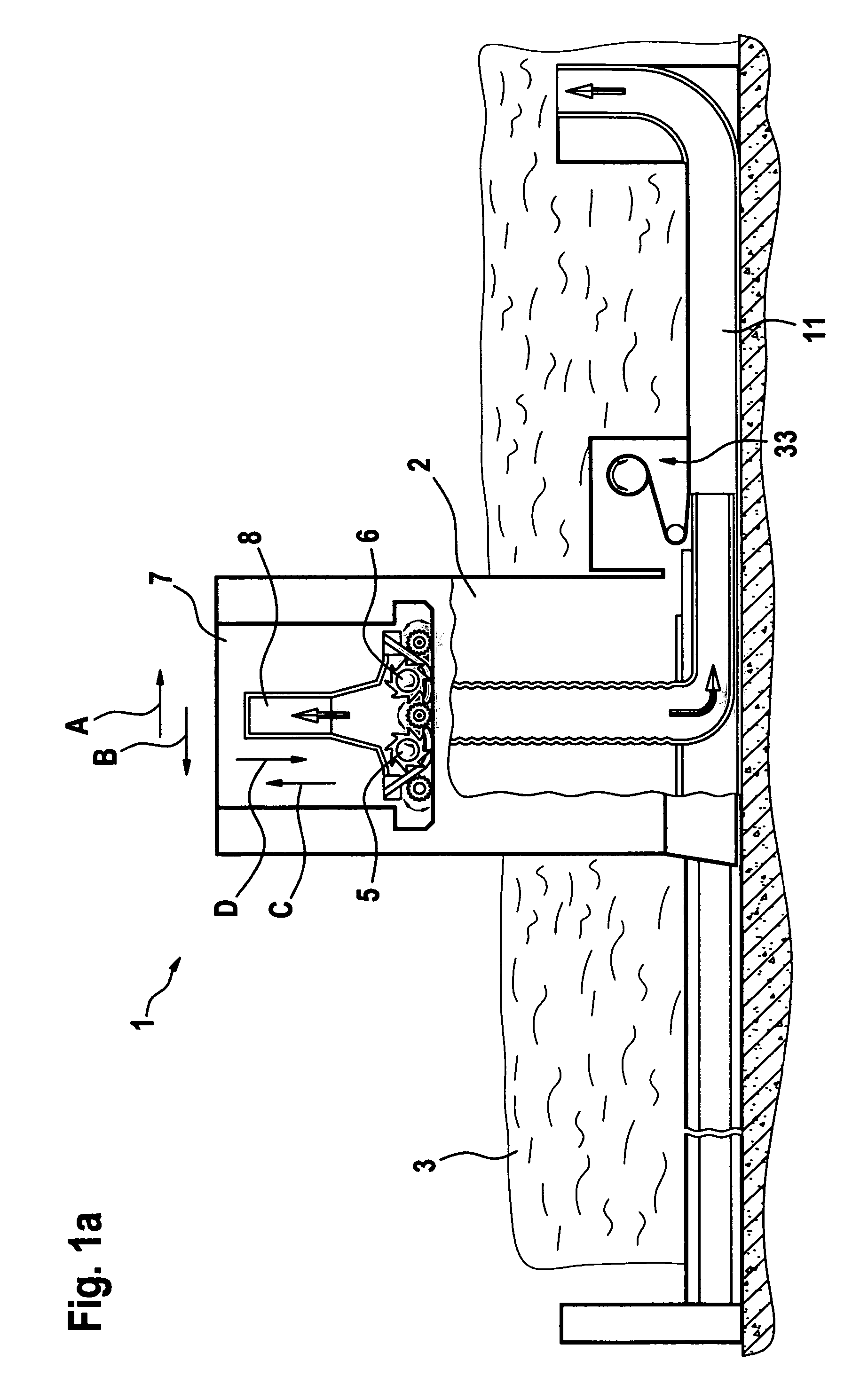

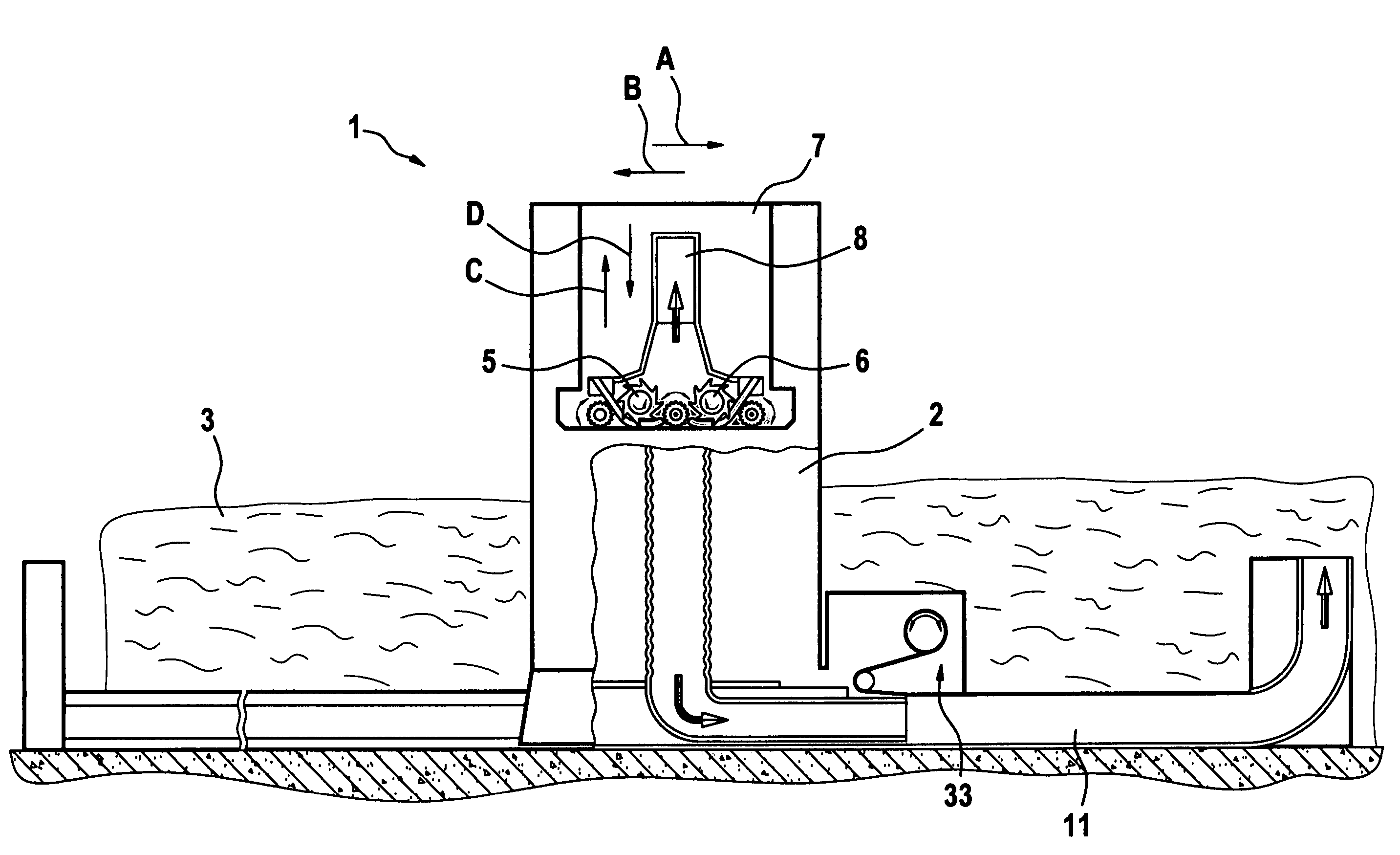

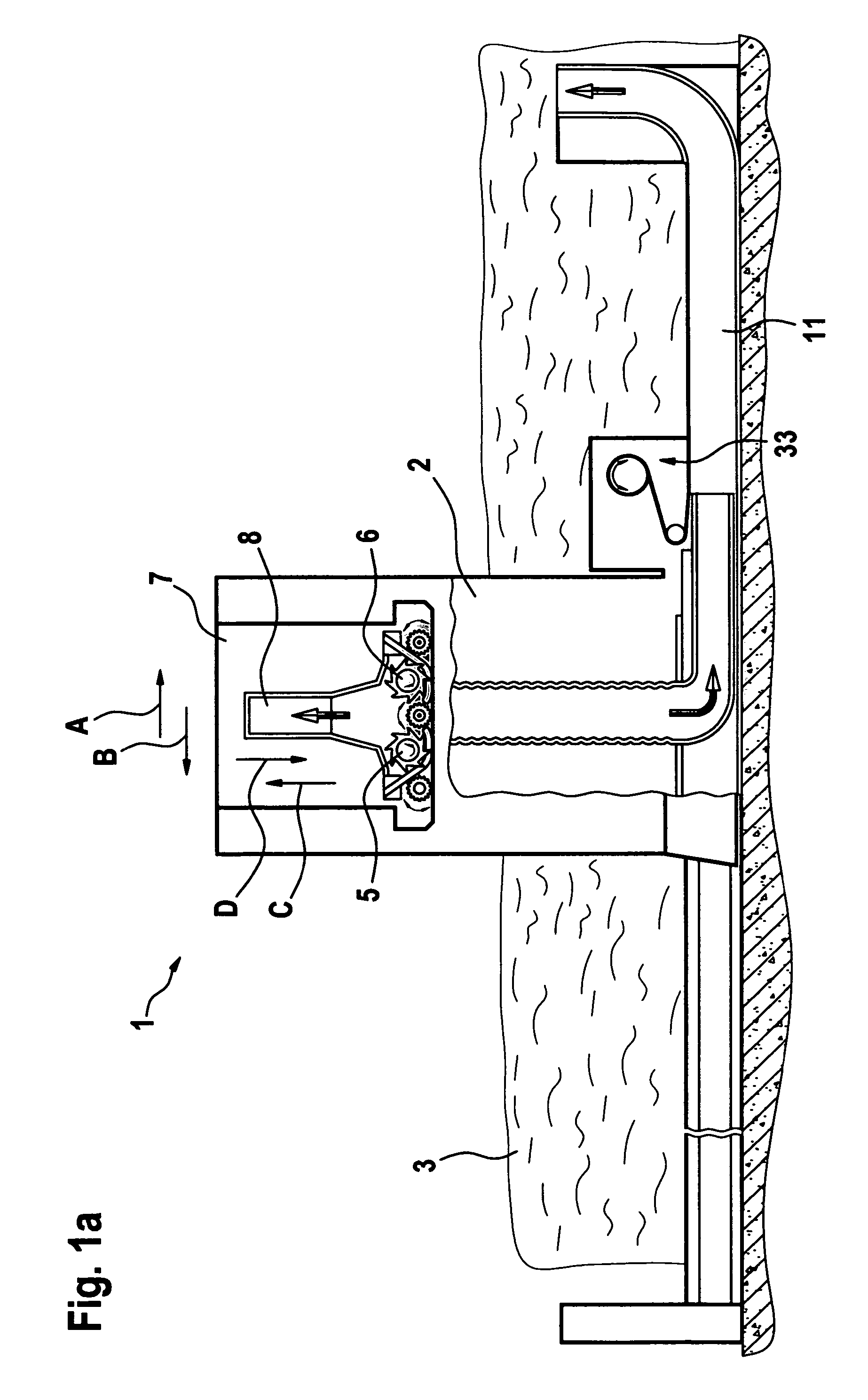

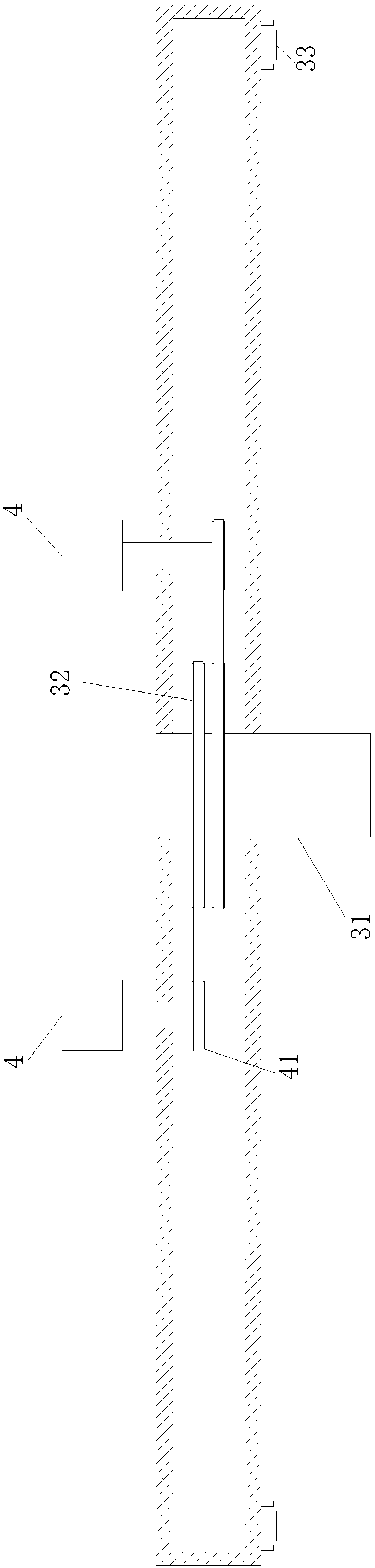

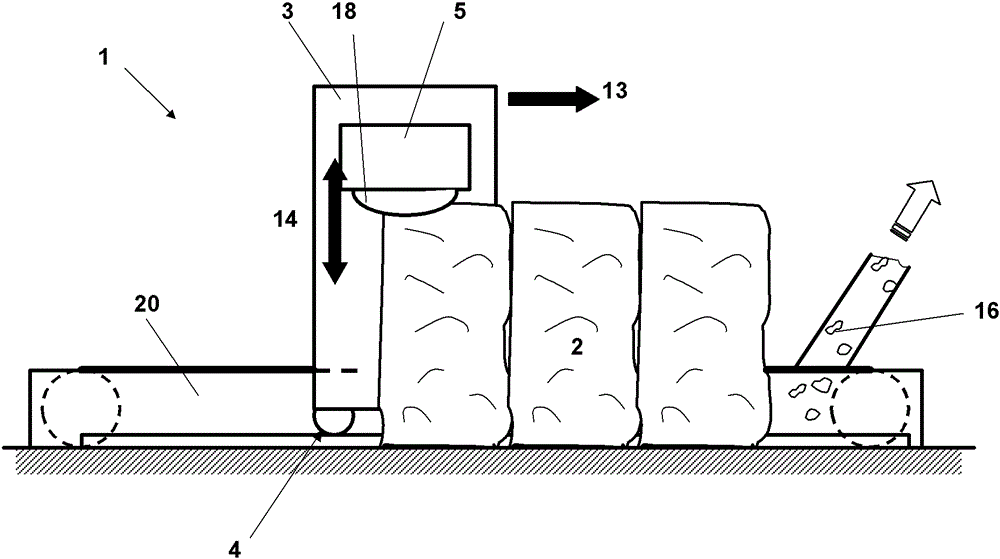

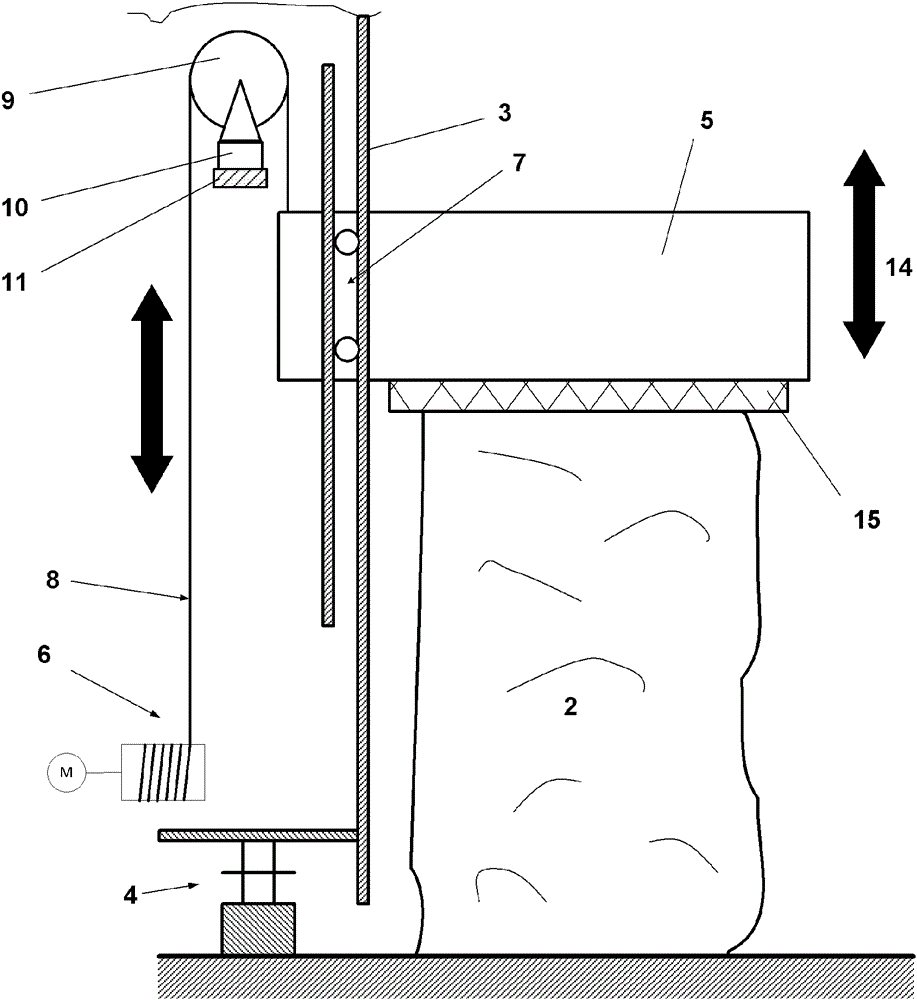

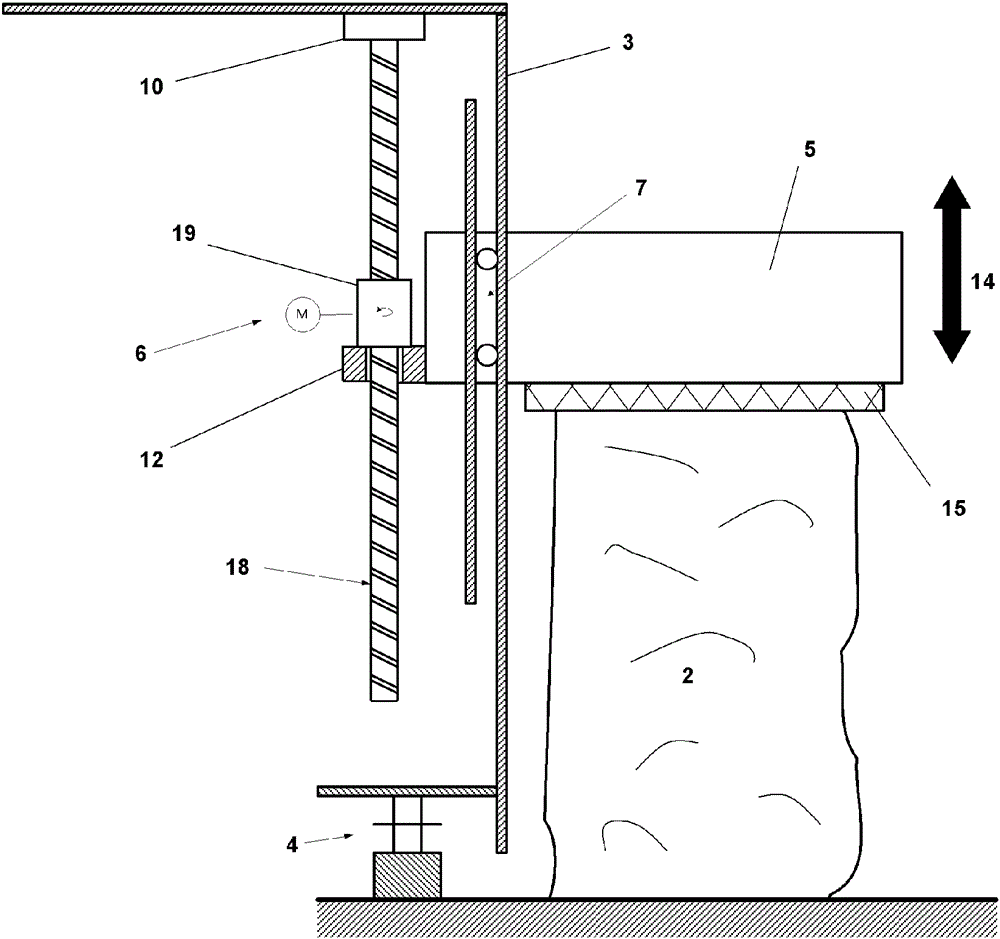

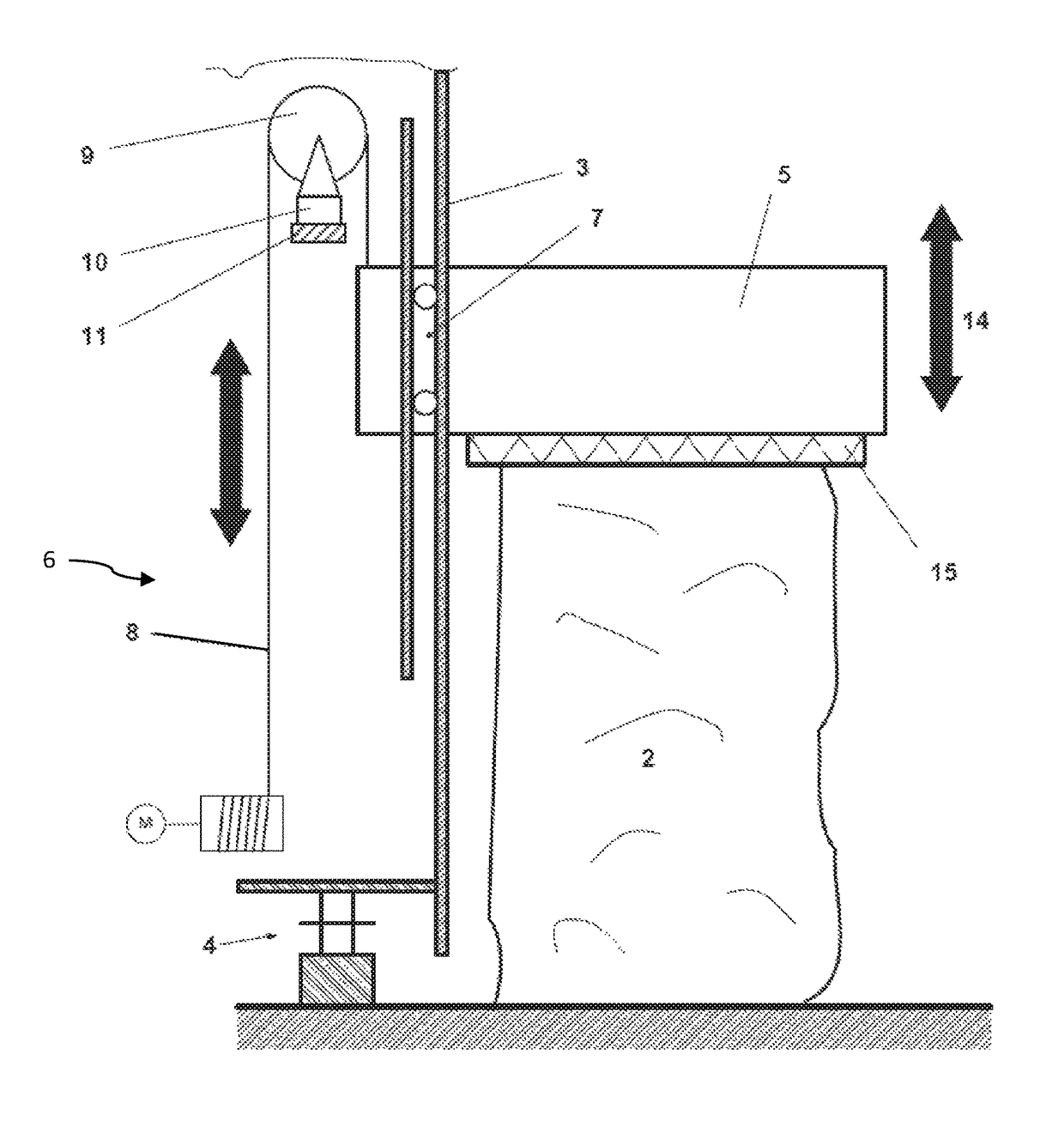

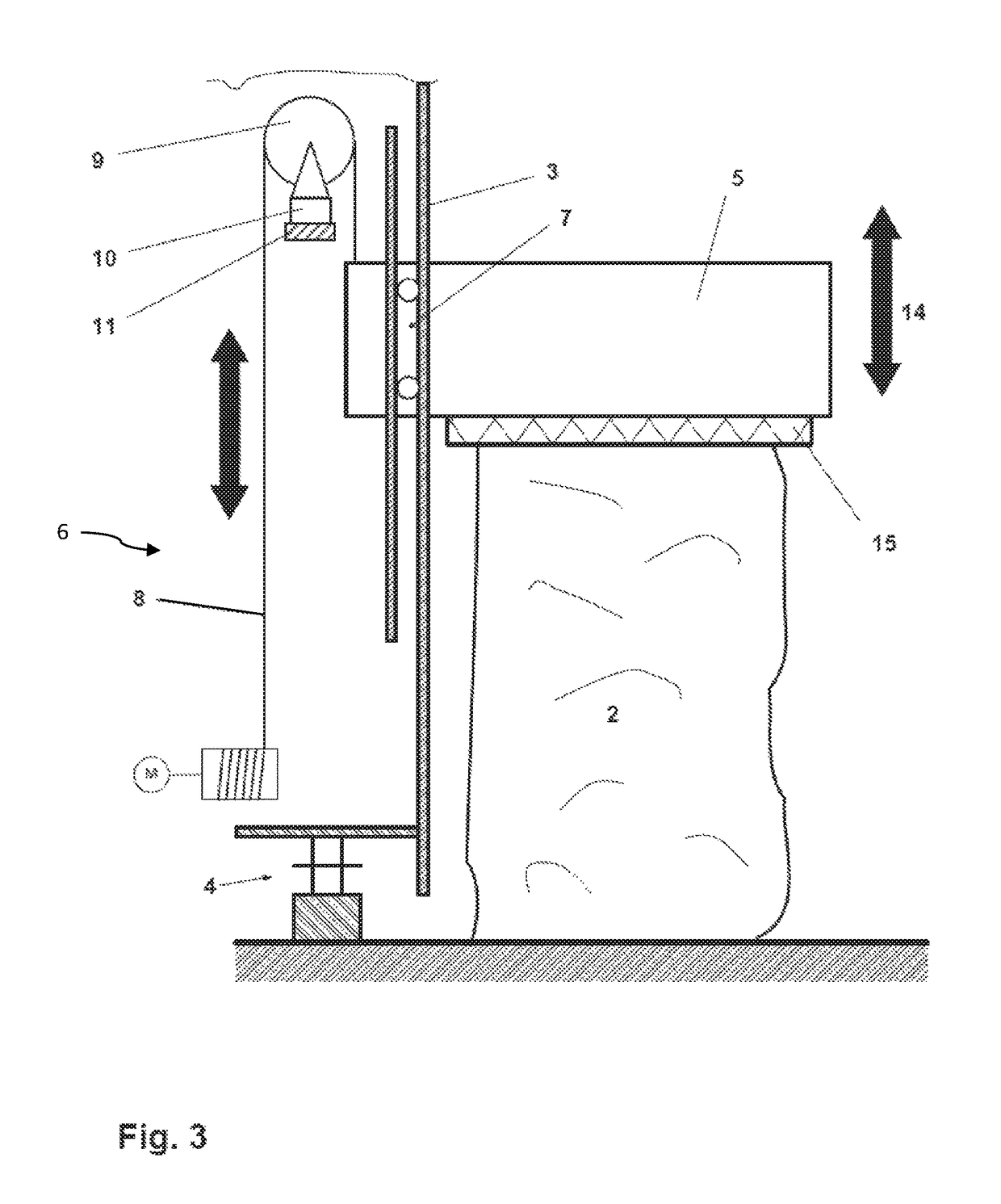

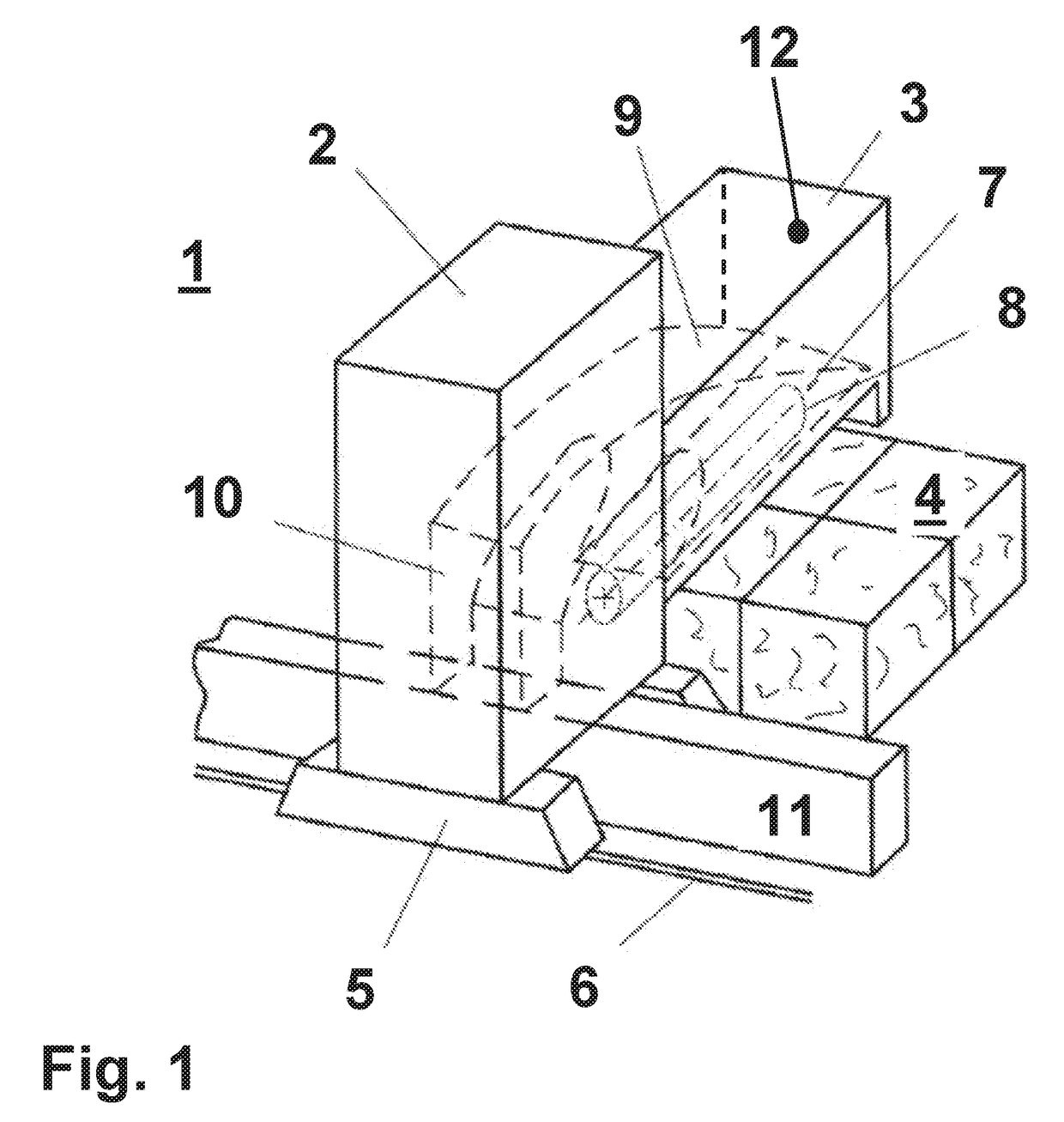

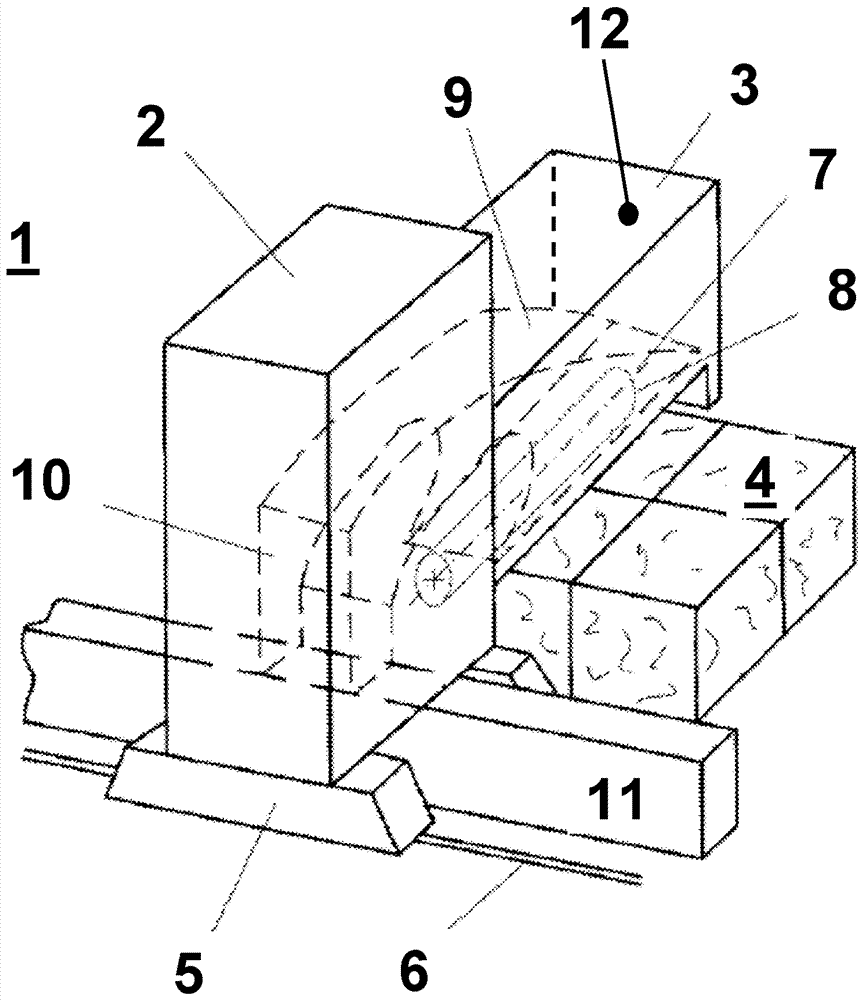

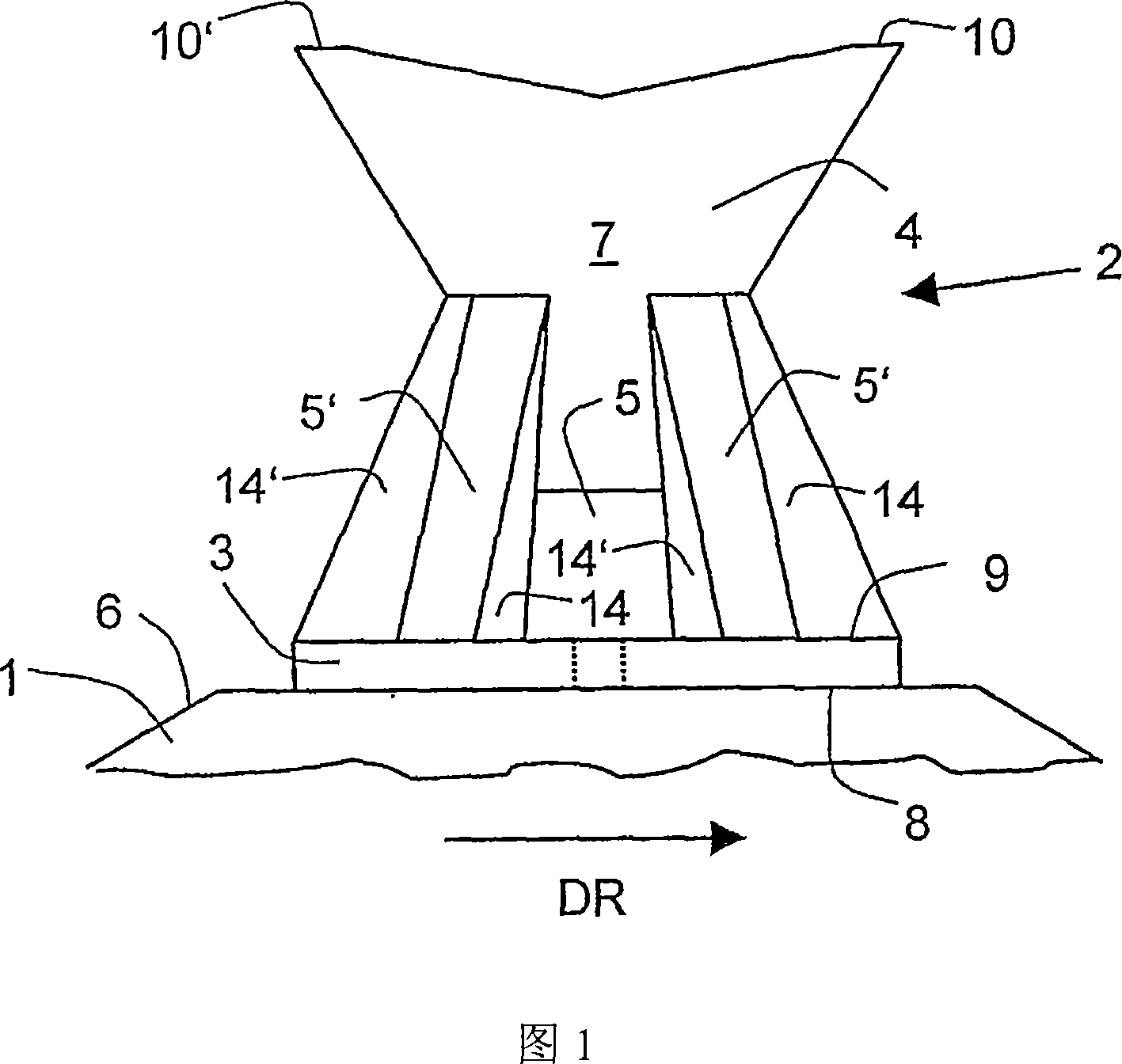

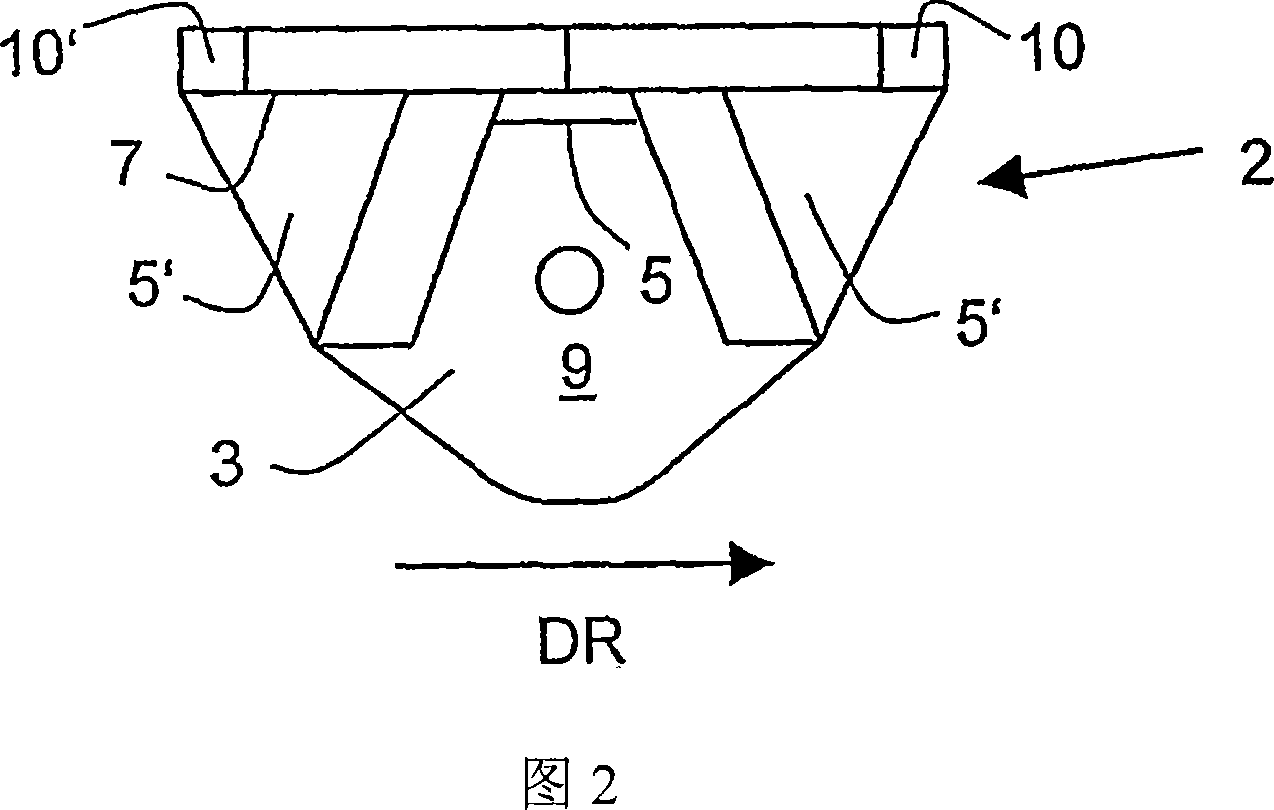

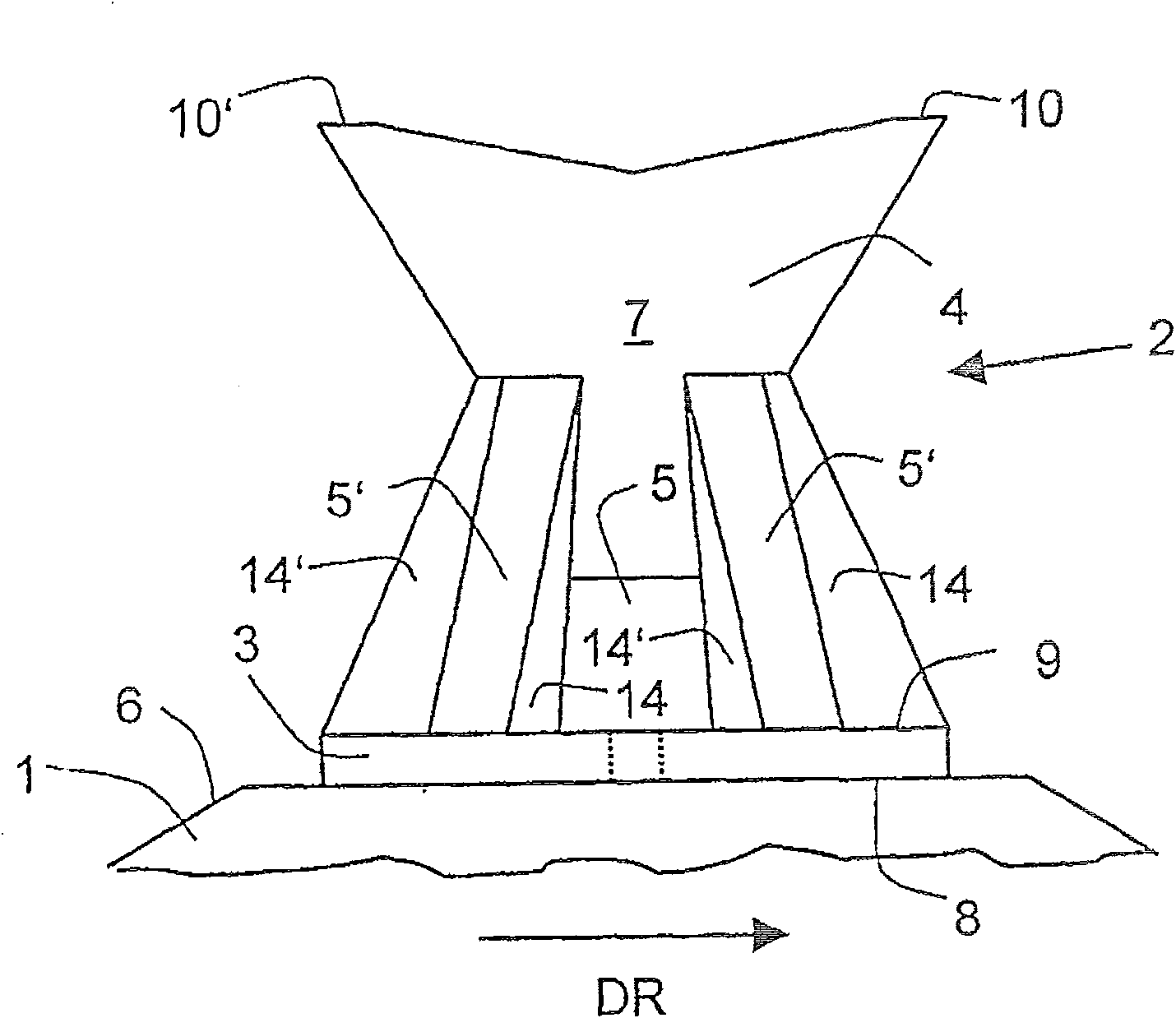

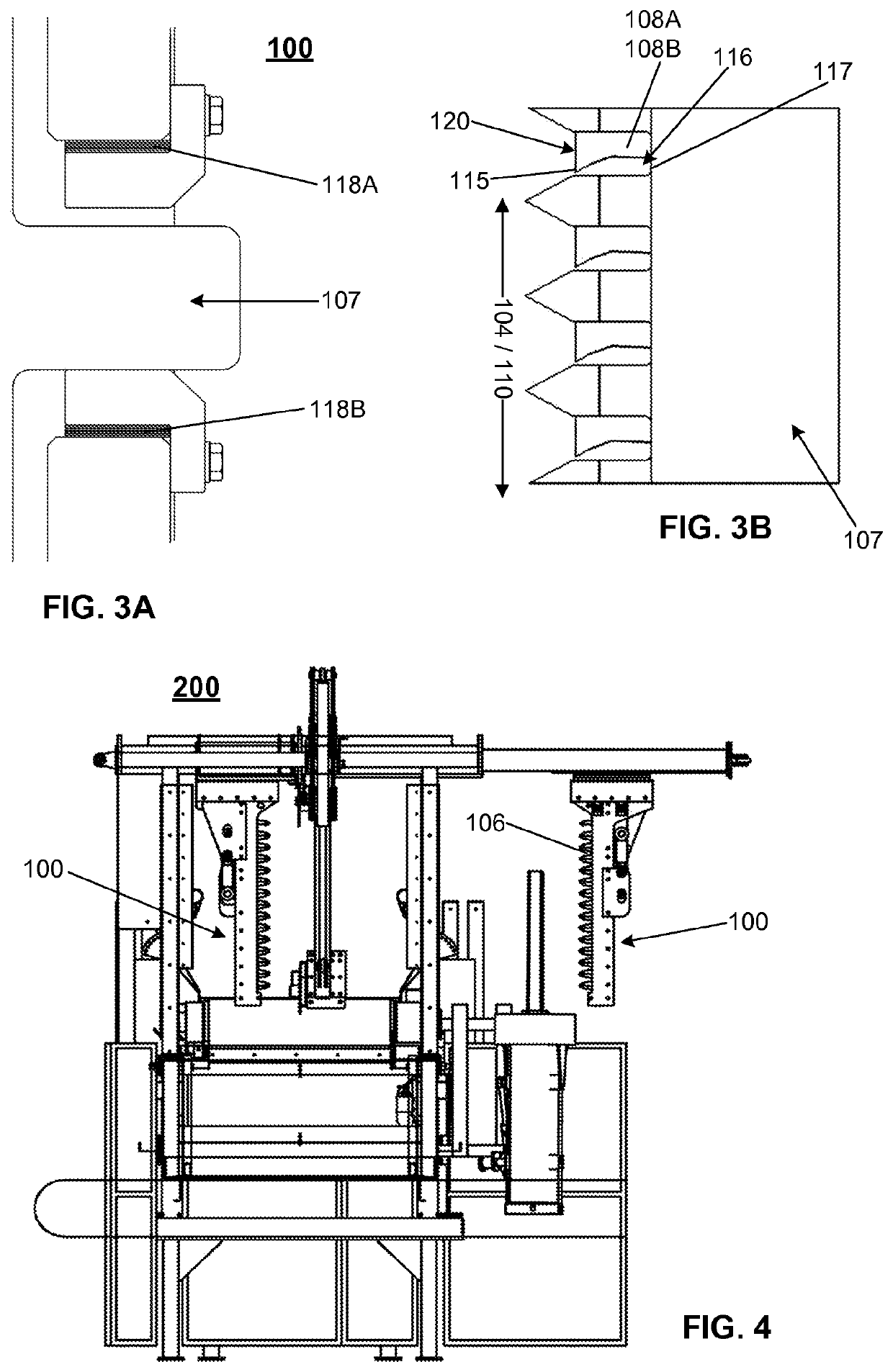

Bale Opener

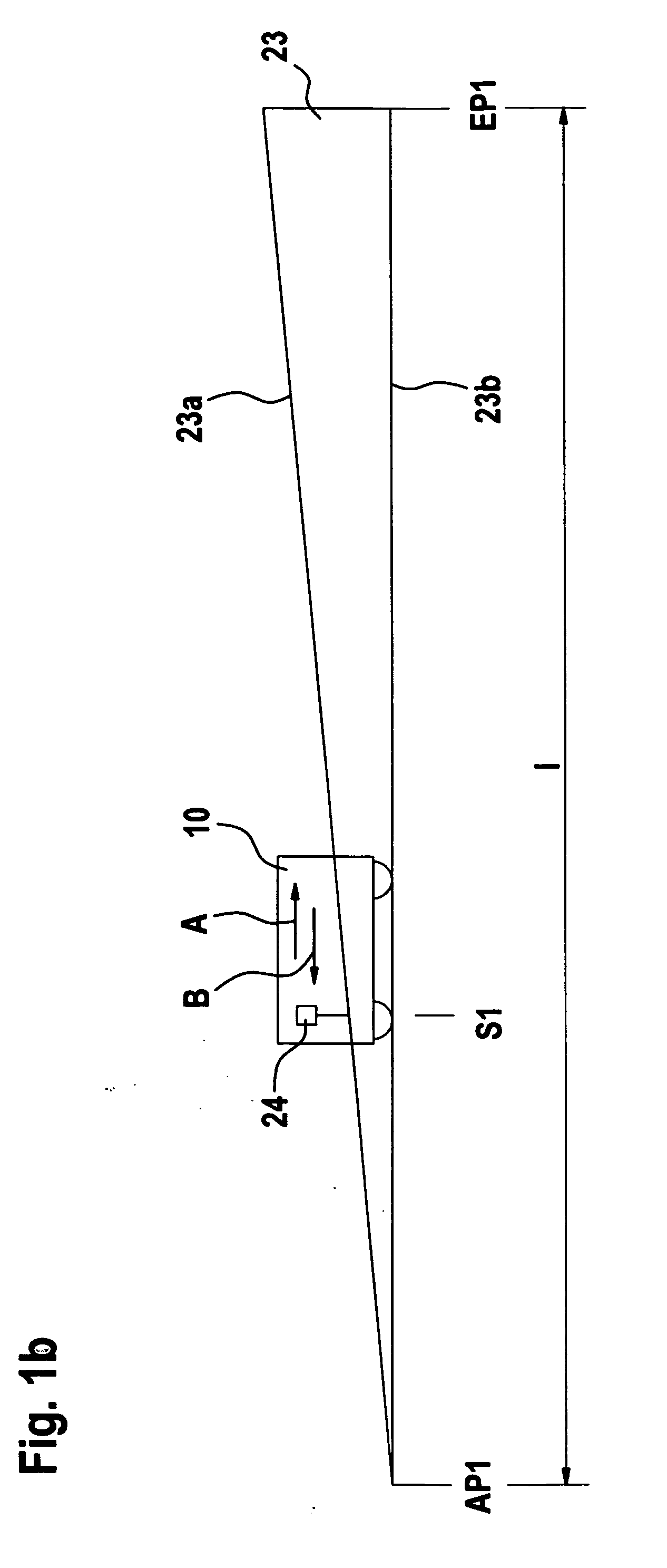

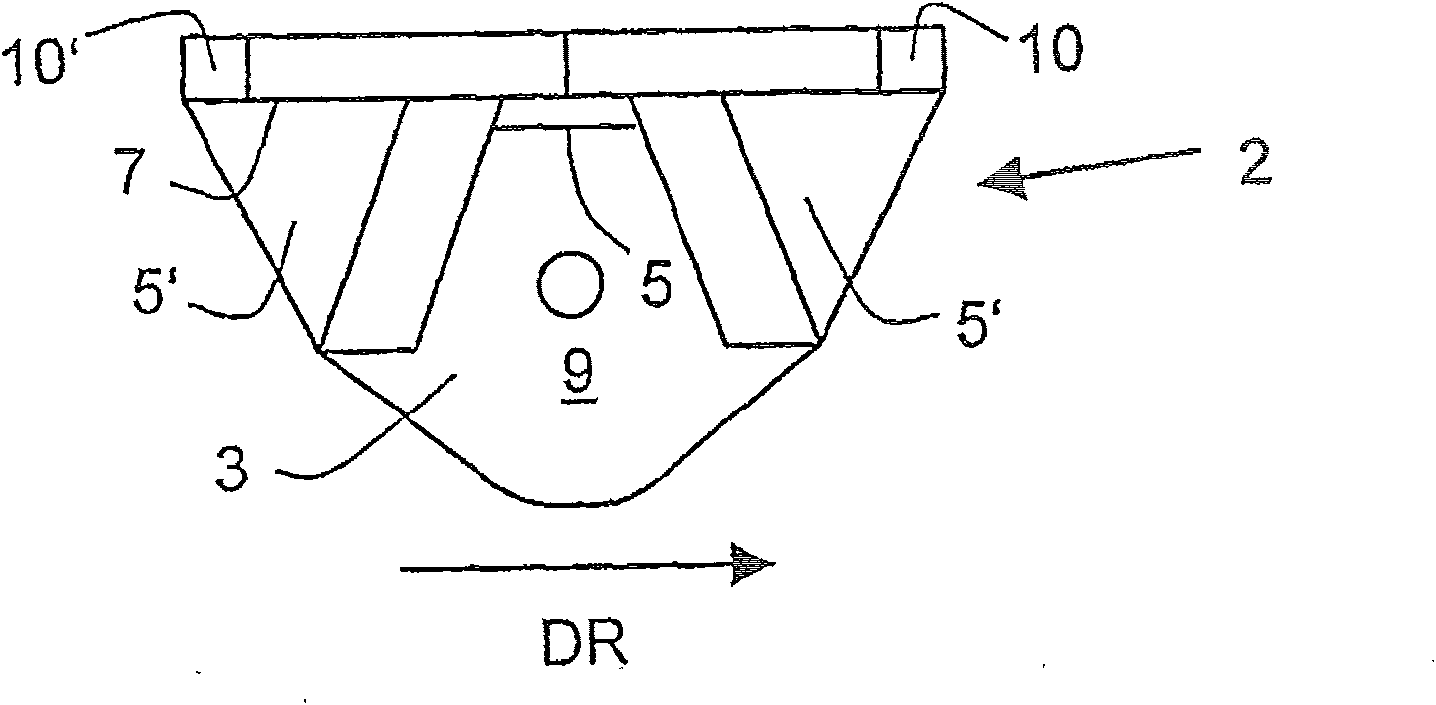

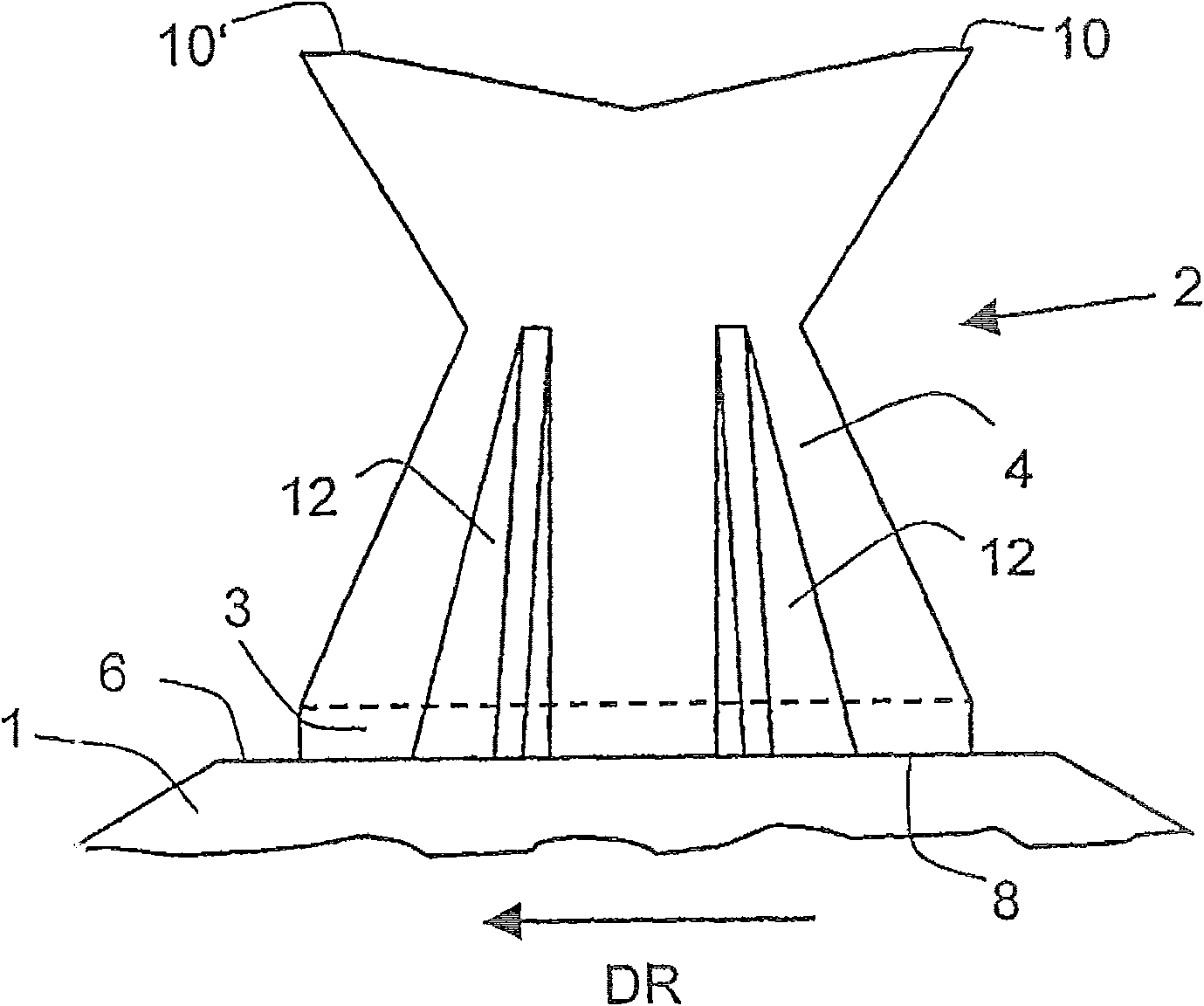

The invention relates to be opener (1) for stripping fiber flocks from fiber bales (2), having a stripping tower (3) arranged on a running gear (4) or a bogie and having a stripping arm (5). The stripping arm (5) is mounted in a height-adjustable mount in a guide (7) on the stripping tower (3). A lifting gear (6) is provided for the height adjustment of the stripping arm (5), wherein the lifting gear (6) is mounted on the stripping arm (5) and on the stripping tower (3), and the lifting gear has at least one load cell (10).

Owner:MASCHINENFABRIK RIETER AG

Preparation method of bio-based fiber degradable fabric

InactiveCN113604909APrevent scurryingMovement restrictionsFibre breaking machinesFibre breaking by toothed membersYarnPolymer science

The invention discloses a preparation method of a bio-based fiber degradable fabric, and relates to the technical field of fabric production. The preparation method comprises the steps of firstly, grabbing piled bio-based fiber cotton through a bale plucker; putting the bio-based fiber cotton grabbed by the bale plucker into a cotton blending machine; making the bio-based fiber cotton in the cotton blending machine into cotton rolls by using a lapper; carrying out opening, carding and impurity removal on the cotton rolls in the third step through a carding machine, preparing fiber cotton card slivers, and then carrying out pre-drawing treatment on the fiber cotton card slivers to obtain fiber cotton drawn slivers; performing first to fourth treatments on cotton made of other materials to obtain cotton drawn slivers; drawing the cotton drawn slivers obtained in the step 5 and the fiber cotton drawn slivers obtained in the step 4 by using a drawing frame, firstly spinning into rough yarns, then spinning into spun yarns, and then stranding and twisting through a spooling to prepare plied yarns; and making the plied yarns into a fabric by using a loom. The preparation method of the bio-based fiber degradable fabric provided by the invention has the advantages of convenience in use, high bale plucking efficiency of the bale plucker, difficulty in blockage of a bale plucking blade and the like.

Owner:安徽宜民服饰股份有限公司

Opener for purified cotton

ActiveCN105986338AHigh porosityIncrease profitFibre breaking by toothed membersElectric machineryEngineering

The invention discloses an opener for purified cotton. Upper and lower rollers are arranged at a feeding hole, and various taker-in rollers are arranged inside a shell; a connecting line of centers of the taker-in rollers is on the same inclined straight line, and intervals between the centers of adjacent taker-in rollers are the same; an inner roller is arranged on the shell among the taker-in rollers; a main conveyer belt is backward and upward arranged at the front end of the feeding hole in an inclined manner; an inner conveyer belt is backward and upward arranged in the shell at the lower end of the taker-in rollers in an inclined manner, the interval between the inner conveyer belt and the lower end of the taker-in roller close to the feeding hole is less than a ratio, namely one to the number of the taker-in rollers, of the whole thickness of a cotton bag, and the rear end face of the inner conveyer belt is close to and slightly higher than the lower end of the taker-in roller at the feeding hole; a negative pressure cotton discharging region is kept between the taker-in rollers and the upper wall of the shell; and a conveyor motor supplies power to the main conveyor belt, the inner conveyer belt, the upper and lower rollers and the inner roller, and a main motor supplies power to the taker-in rollers. The opener for the purified cotton has the advantages that the cotton bag does not need to be manually broken up into multiple layers, continuous feeding can be realized, the energy consumption is low, the production efficiency is high, the yield is high, and opened cotton blocks are small.

Owner:BAODING CHENQIANG GEOPHYSICAL PROSPECTING CONTROLS CO LTD

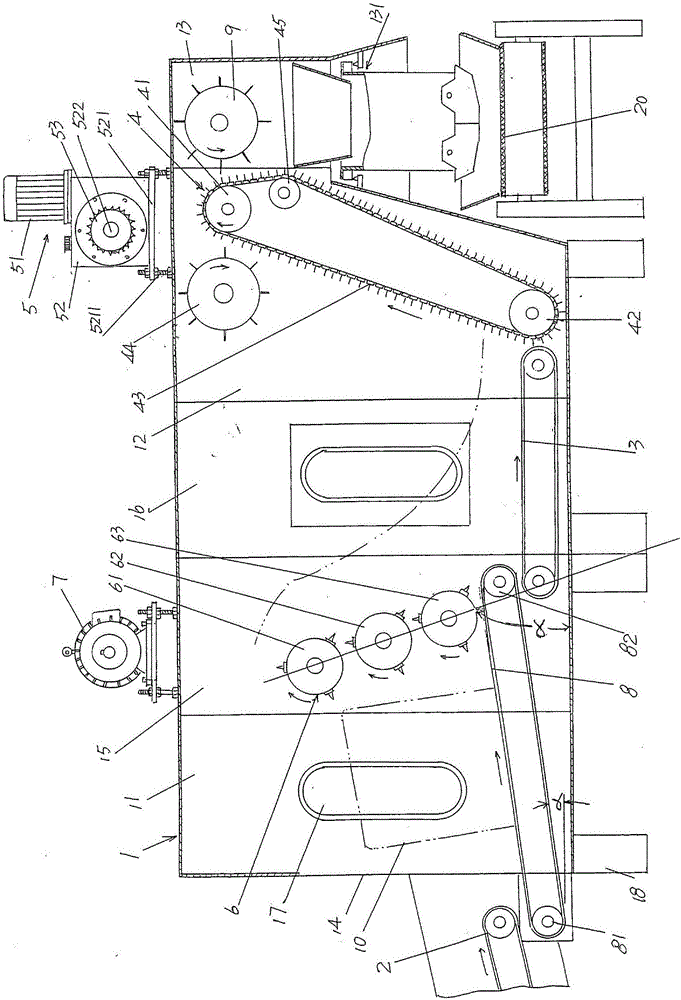

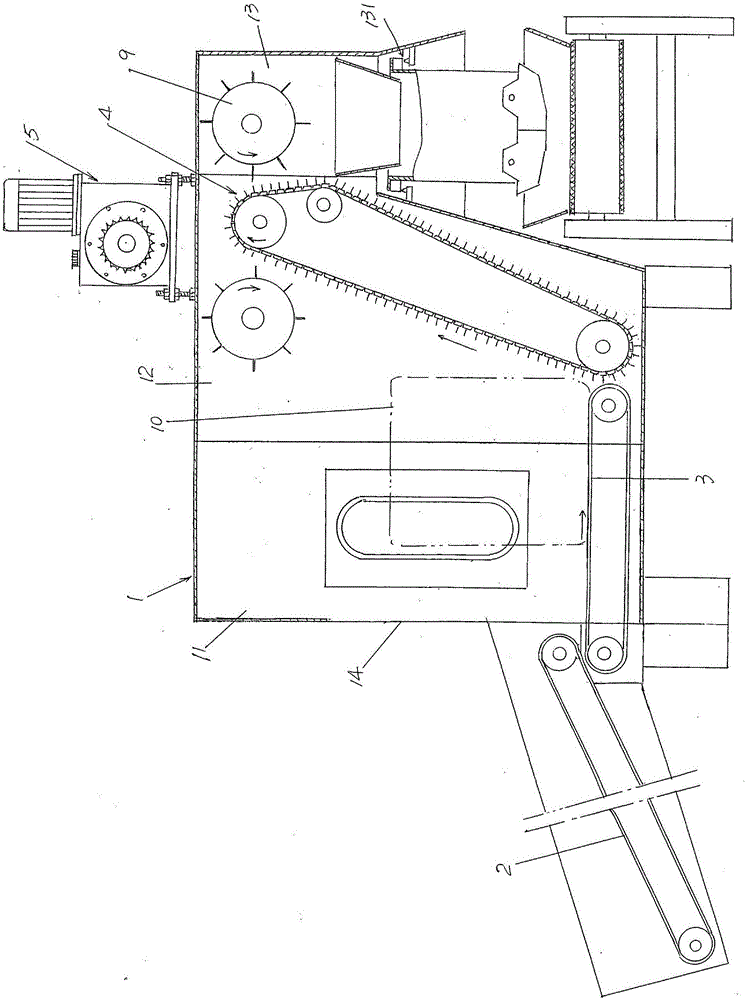

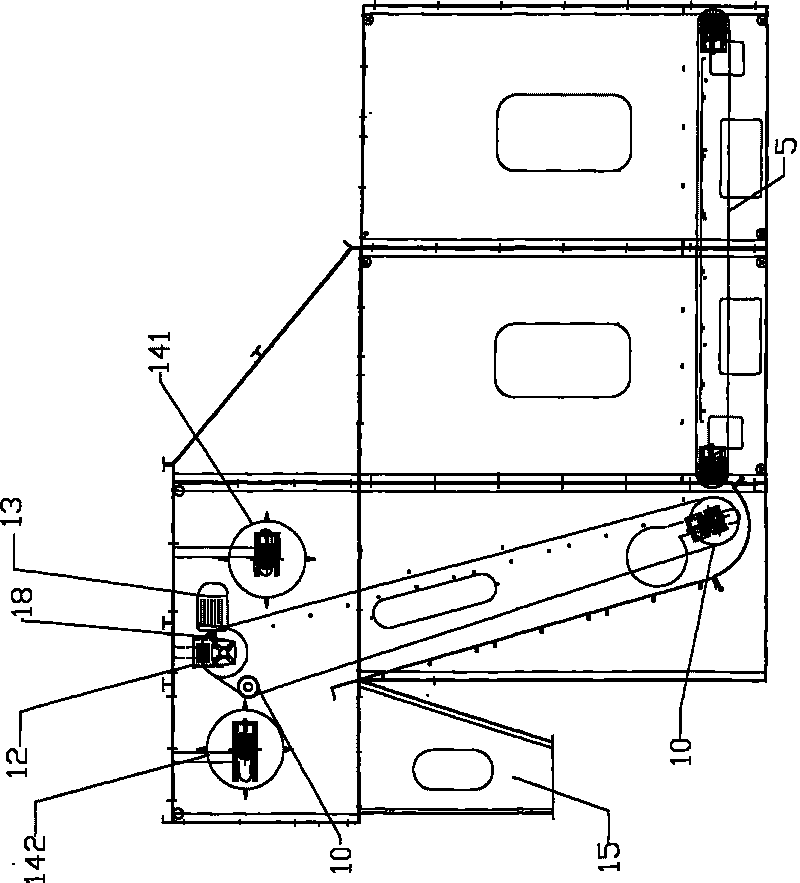

Bale opener and creeping nail curtain thereon

ActiveCN101705530AIncrease profitImprove work efficiencyFibre breaking machinesFibre breaking by toothed membersEngineeringFiber transmission

The invention discloses a bale opener and a creeping nail curtain thereon. The creeping nail curtain comprises a leather curtain body capable of being encircled into a ring along the longitudinal direction, leather laces arranged on the external surface of the leather curtain body along the transverse direction of the leather curtain body, and a plurality of brads passing through the leather curtain body and the leather laces from inside to the outside, wherein the nail points of the brads are exposed outside the leather laces; a plurality of the leather laces are arranged at intervals along the longitudinal direction of the leather curtain body; and on each leather lace, a plurality of the brads are arranged at intervals along the transverse direction of the leather curtain body. The creeping nail curtain adopts the leather curtain body and the leather laces, and the surfaces of leather prices are usually much smoother than those of wooden curtains, so in the fiber transmission process, the creeping nail curtain is difficult to become hairy, improves the utilization ratio of fibers and can be used for a long time without cleaning, and the bale opener containing the creeping nail curtain has a high working efficiency.

Owner:常熟万龙机械有限公司

Lint cotton pretreatment device

InactiveCN102534872AEasy to identifyEasy to detectFibre breaking machinesFibre breaking by toothed membersFiberEngineering

The invention discloses a lint cotton pretreatment device, which relates to the technical field of foreign fiber detection and classification system matched devices. The device comprises a rack roller (6), wherein a plurality of bulges are distributed on the outer surface of the rack roller (6) and are used for hooking and pulling lint cotton to be treated in the rotating process of the rack roller (6). The cotton can be loosened through the loosening treatment of the device provided by the invention, and the elasticity can be recovered, so the foreign fiber can be totally or partial exposed onto the surface of the cotton as much as possible, and the identification, the detection and the metering of the cotton foreign fiber are favorably realized.

Owner:CHINA AGRI UNIV

Cotton grabbing and feeding device for yarn

InactiveCN107245773AReasonable structureInnovative designFibre breaking by toothed membersYarnDrive shaft

The invention discloses a cotton grabbing and feeding device for yarn. The cotton grabbing and feeding device comprises a supporting seat, two sides of the lower end of the supporting seat are connected with supporting legs, the right end of the supporting leg on the left side is connected with a mounting plate, the upper end of the mounting plate is connected with a driving motor, the upper end of the driving motor is connected with a driving shaft, the upper end of the driving shaft is connected with a driving belt wheel, the middle of the upper end of the supporting seat is connected with a fixing barrel, the middle of the fixing barrel is connected with a rotating shaft which is connected with a rotating plate, the middle of the lower end of the rotating plate is connected with a limiting frame, the middle of the limiting frame is connected with a transmission shaft, the middle of the transmission shaft is connected with a drum, the left end of the transmission shaft is connected with a driven belt wheel, the middle of the rotating plate is connected with a cotton suction cover, the upper end of the cotton suction cover is connected with a cotton suction pipe, the right side of the lower end of the rotating plate is connected with a traveling frame, and the outer side of the upper end of the supporting seat is connected with a fixing ring. Rotating of the drum in the horizontal direction is realized, a cotton layer inside the traveling frame is avoided being wound on the drum when the drum rotates for material grabbing, and uniform feeding of the cotton suction cover is realized.

Owner:洪飞飞

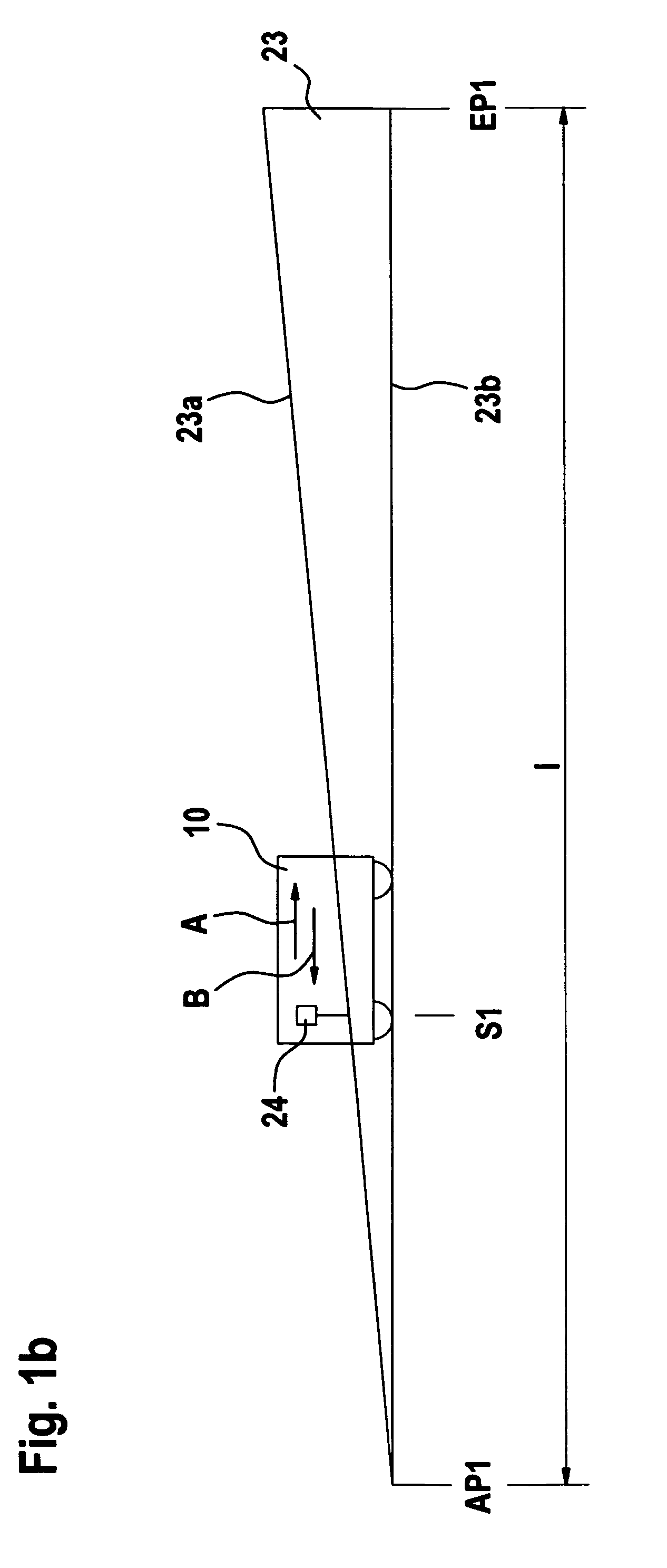

Bale opener

ActiveUS9745672B2Reduce frictionMovement can be somewhat impreciseArticle unpackingHorticulture methodsBogieEngineering

A bale opener for stripping fiber flocks from fiber bales, including a stripping tower arranged on a running gear or a bogie and having a stripping arm. The stripping arm is mounted in a height-adjustable mount in a guide on the stripping tower. A lifting gear is provided for the height adjustment of the stripping arm, wherein the lifting gear is mounted on the stripping arm and on the stripping tower, and the lifting gear has at least one load cell.

Owner:MASCHINENFABRIK RIETER AG

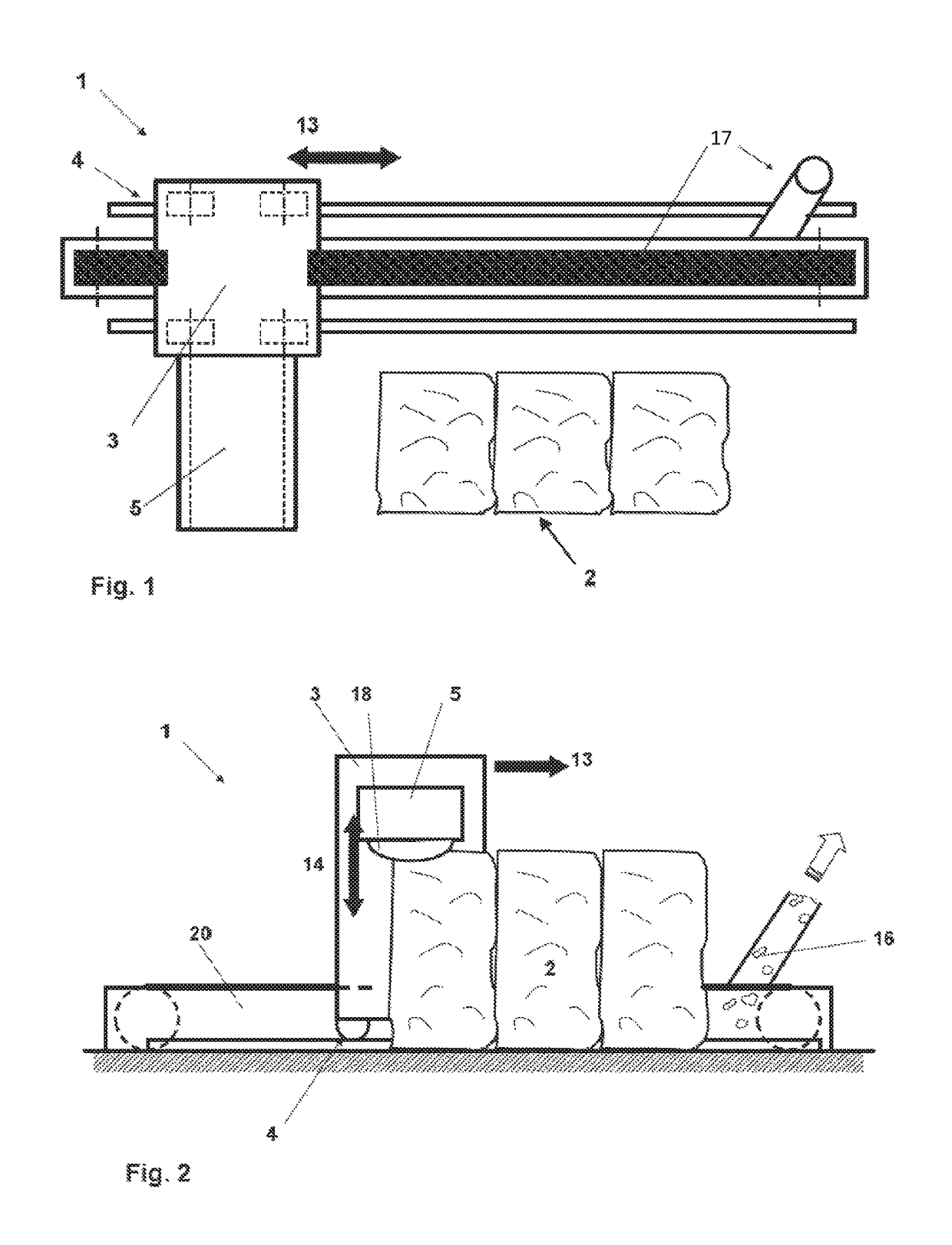

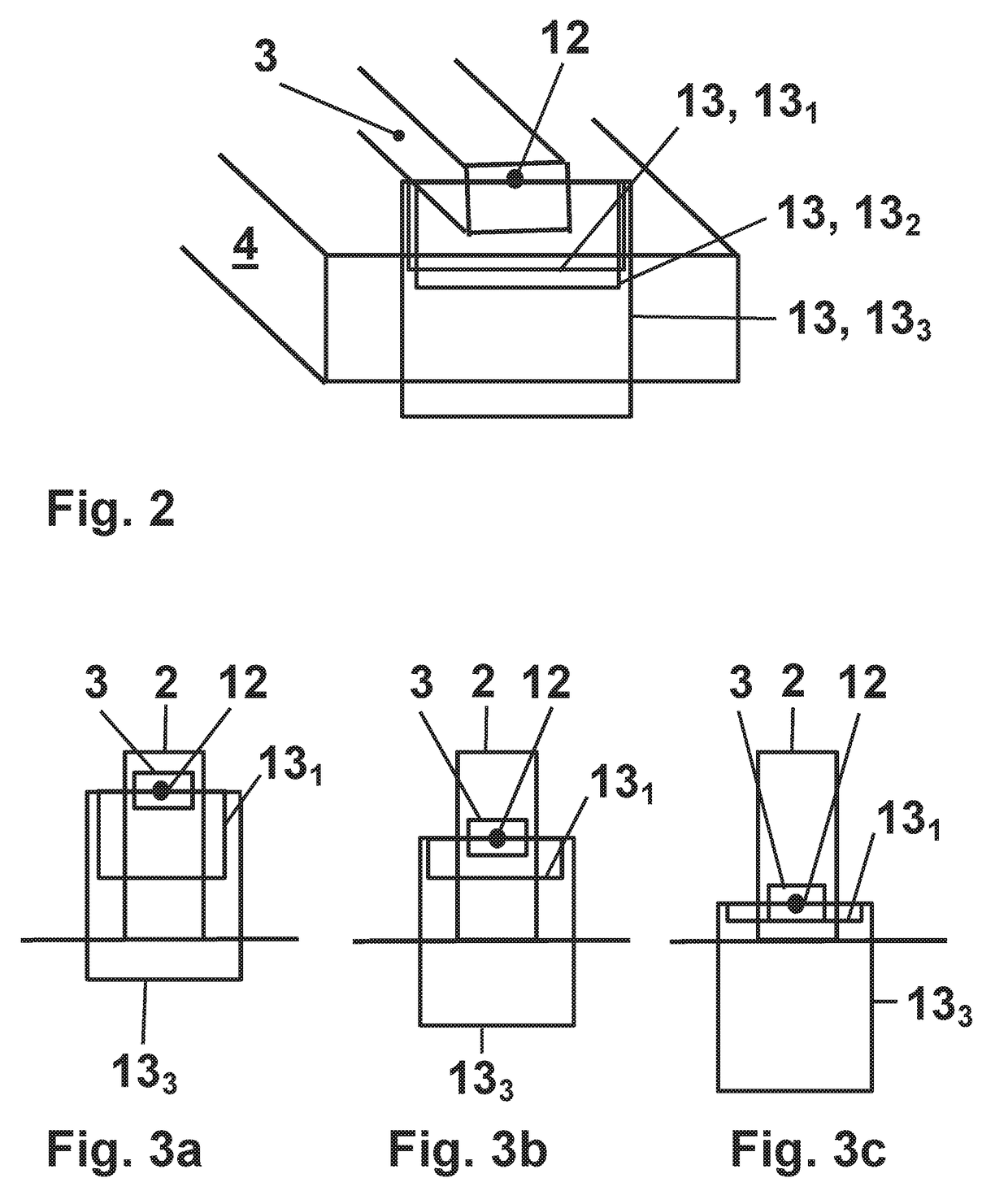

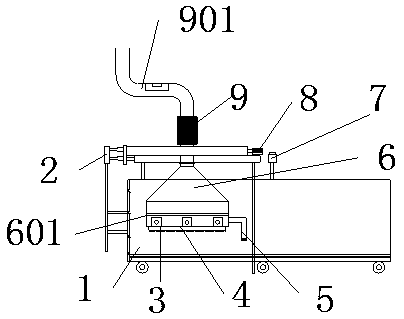

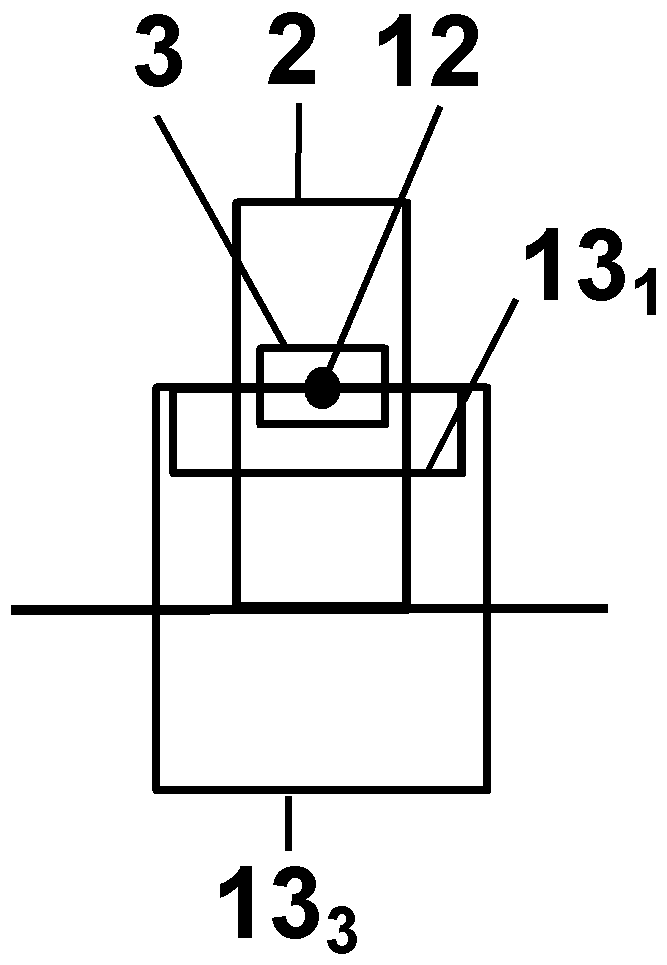

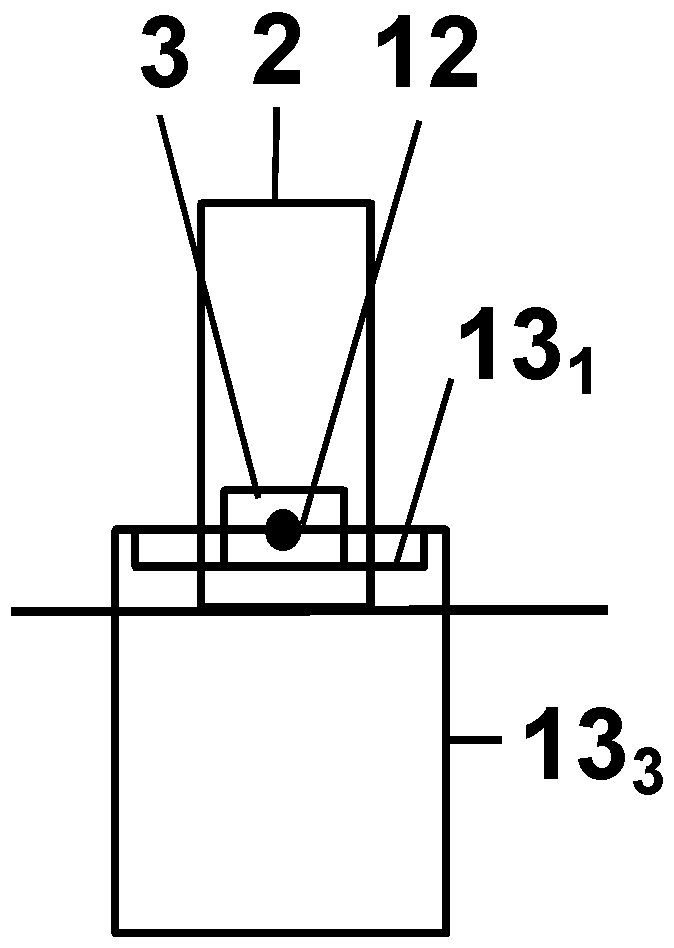

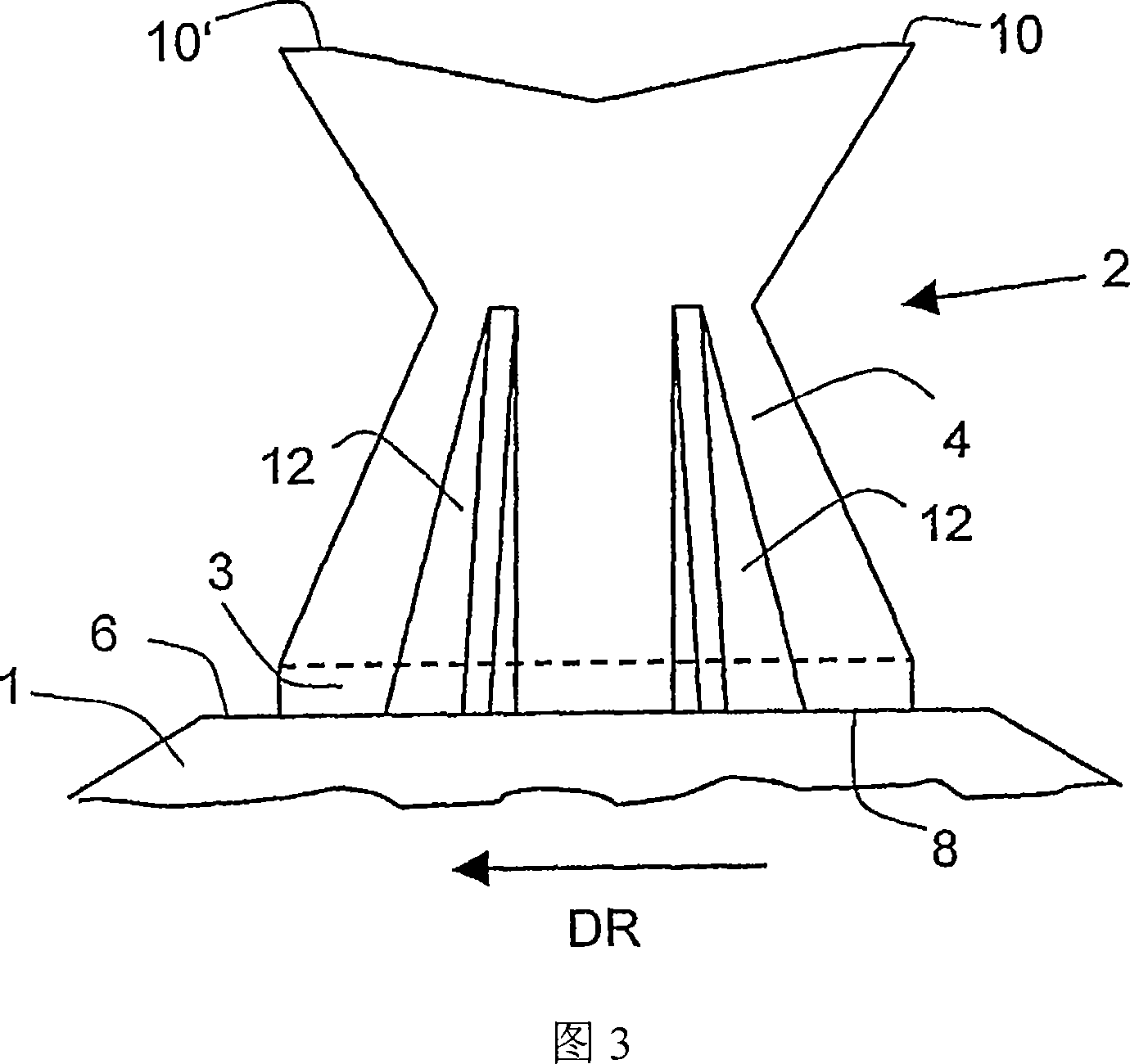

Method for Operating a Bale Opener and Such a Bale Opener

InactiveUS20170298540A1Less susceptibleMore reliableSafety devices for fibre treatmentArticle unpackingEngineeringLaser

The invention relates to a method for operating a bale opener (1) having a stripping element (3) and a safety device for protection against penetration into a hazardous zone of the stripping element (3), said safety device consisting of sensory safety means, wherein a monitoring region (13, 131, 132, 133) at the front beneath the stripping element is detected and wherein the stripping element (3) is mounted on a stripping tower (2). According to the invention the safety device is at least one two-dimensional laser scanner (12), on which at least one monitoring region (13, 131, 132, 133), which is adjustable and variable over time, is monitored. The invention also relates to a corresponding bale opener (1).

Owner:MASCHINENFABRIK RIETER AG

Fully automatic bale plucker for textile

InactiveCN108425161AFully automatedAvoid Manual Box PushingFibre breaking machinesFibre breaking by beater armsEngineeringFully automatic

The invention discloses a fully automatic bale plucker for textile. The fully automatic bale plucker includes a sliding cotton box and a horizontal sensor. The inner surface of the sliding cotton boxis provided with the horizontal sensor, the horizontal sensor is fixedly mounted in the sliding cotton box, the inner surface of the sliding cotton box is provided with a longitudinal sensor, the longitudinal sensor is closely bonded to the sliding cotton box, and the upper end of the longitudinal sensor is provided with an engine. The fully automatic bale plucker for textile is provided with a horizontal laser emitter. If a signal emitted by the horizontal sensor is not received, it is indicated that a cotton wool is not removed completely, a cotton picking beating hand continues to operate;when the signal is received by the horizontal sensor, if the longitudinal sensor does not receive the signal, a hydraulic device is started, and the sliding cotton box moves horizontally until the signal is blocked again; when the horizontal sensor and the horizontal sensor receive the signal, the hydraulic device retracts, a telescopic plug starts to descend, the process is repeated until the cotton wool is removed completely, and full automation is achieved.

Owner:SUZHOU CHENCAI TEXTILE RES & DEV

Method for operating a bale opener and such a bale opener

ActiveCN107298216AImprove securityImprove robustnessSafety devices for fibre treatmentArticle unpackingEngineeringTower

The invention relates to a method for operating a bale opener (1) having a stripping element (3) and a safety device for protection against penetration into a hazardous zone of the stripping element (3), said safety device consisting of sensory safety means, wherein a monitoring region (13, 131, 132, 133) at the front beneath the stripping element is detected and wherein the stripping element (3) is mounted on a stripping tower (2). According to the invention the safety device is at least one two-dimensional laser scanner (12), on which at least one monitoring region (13, 131, 132, 133), which is adjustable and variable over time, is monitored. The invention also relates to a corresponding bale opener (1).

Owner:MASCHINENFABRIK RIETER AG

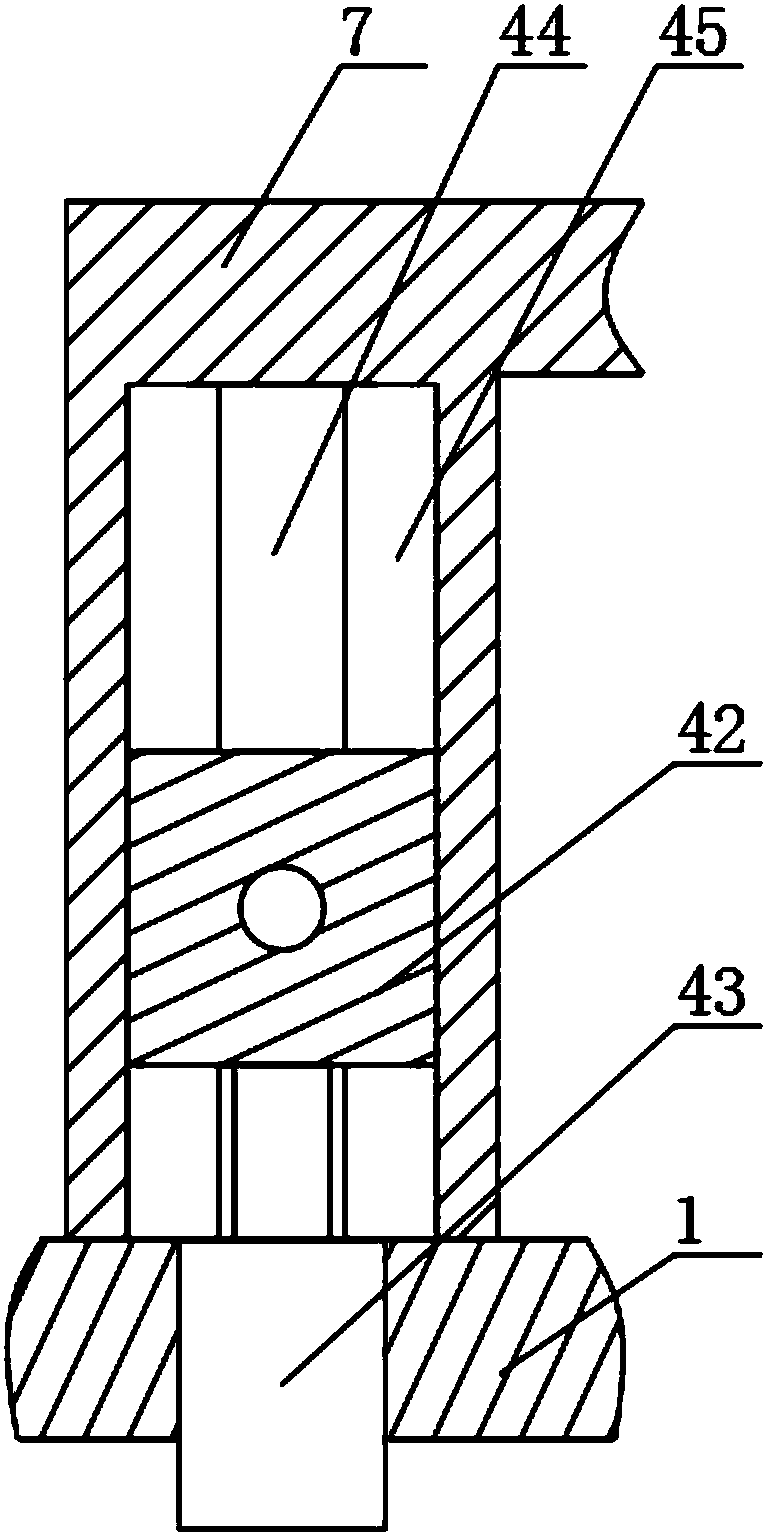

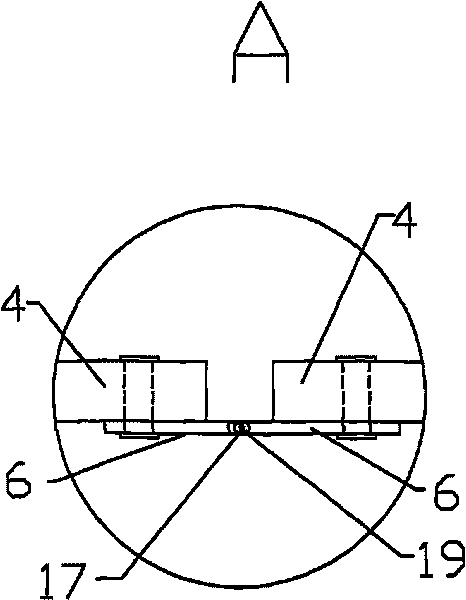

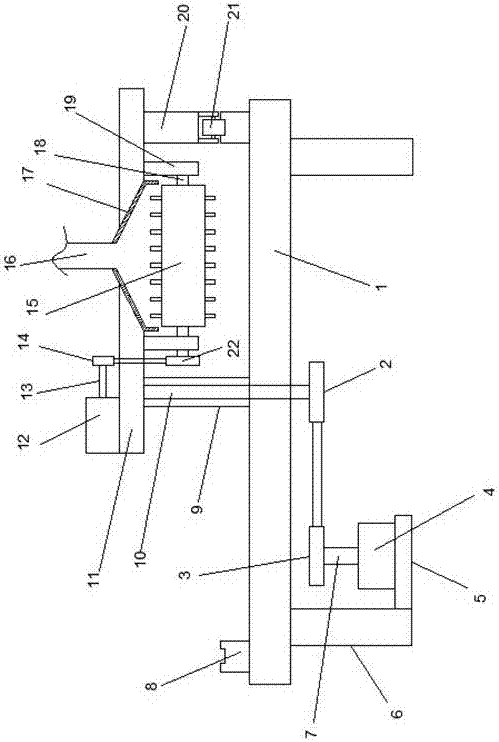

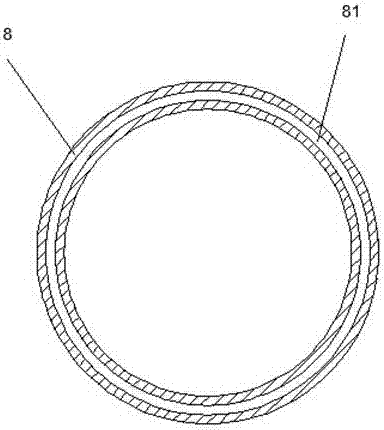

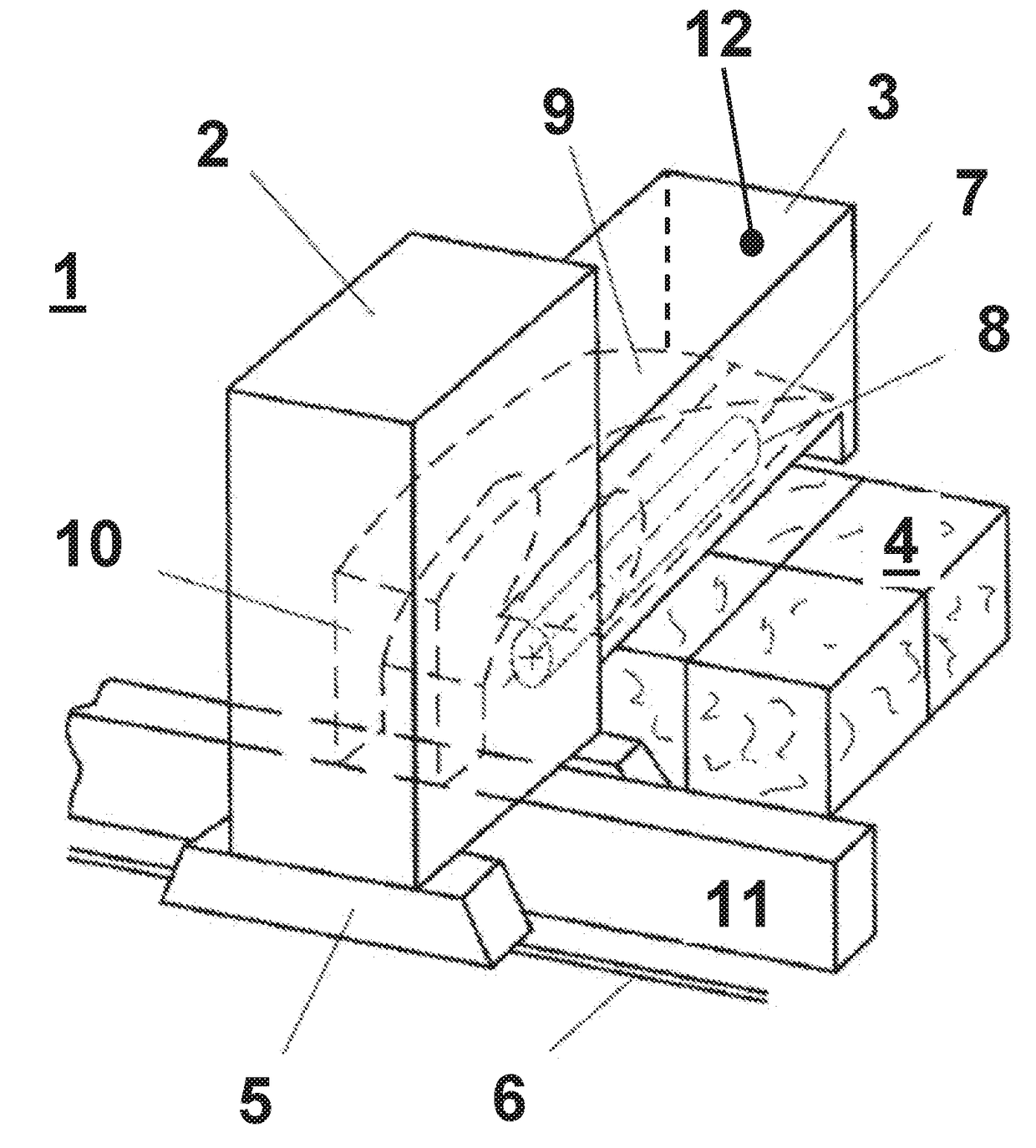

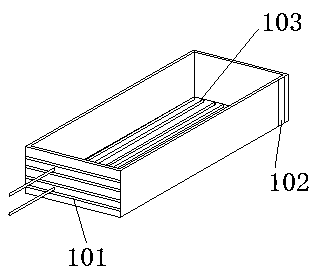

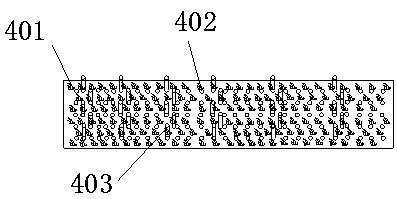

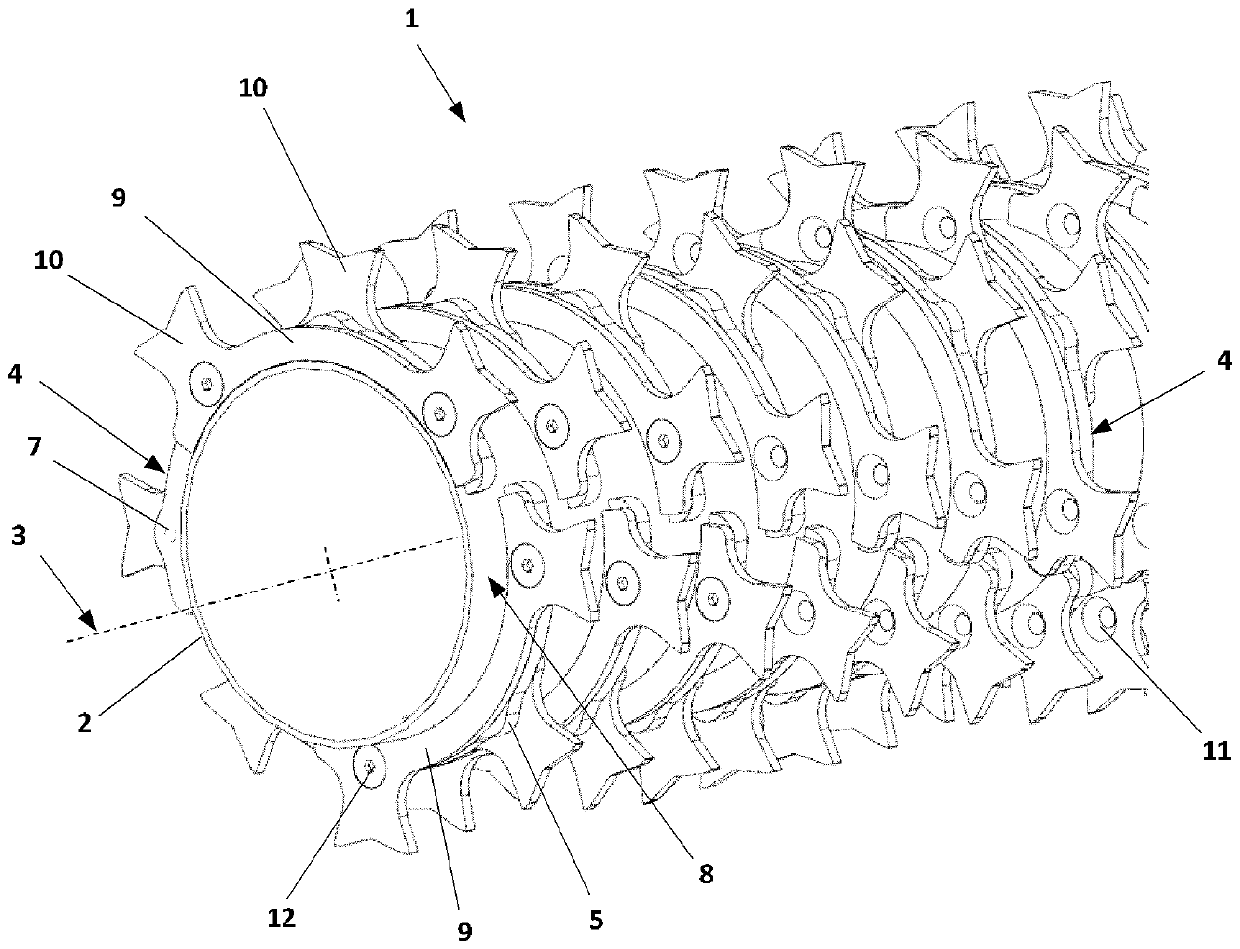

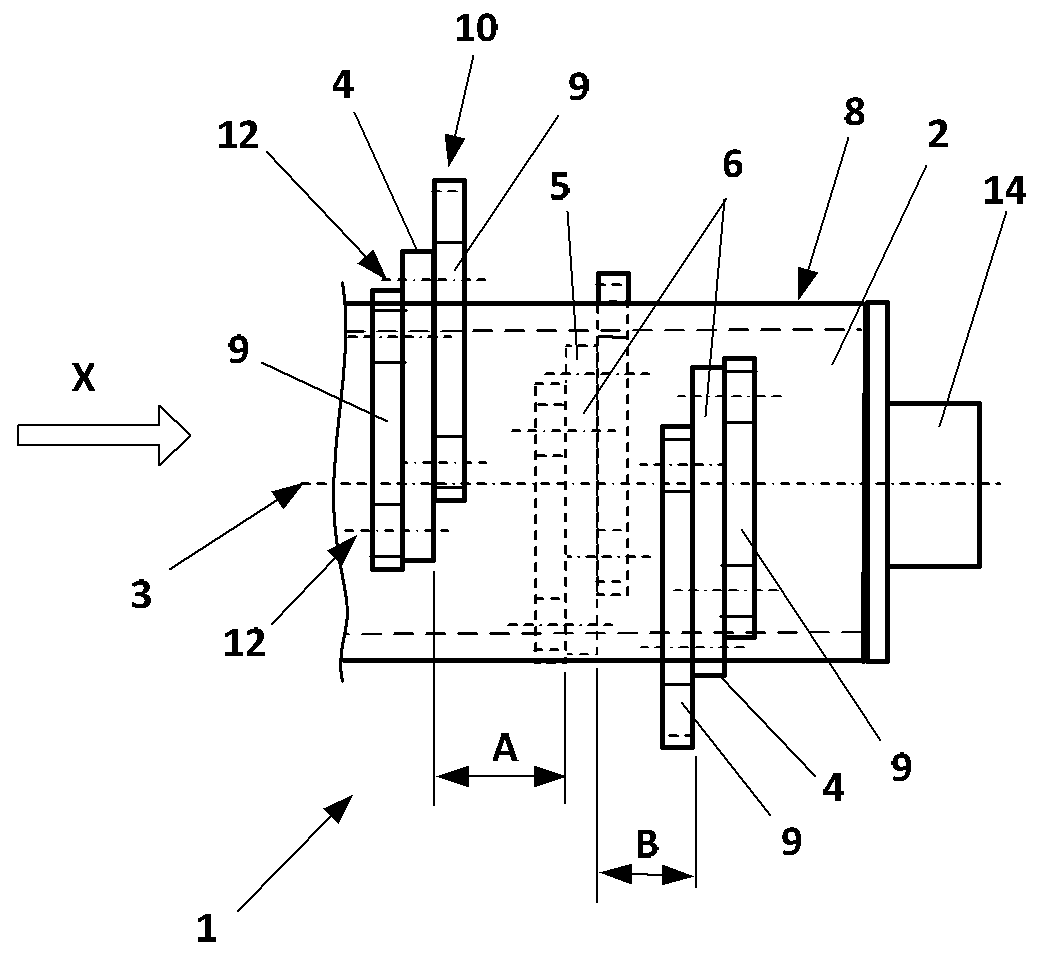

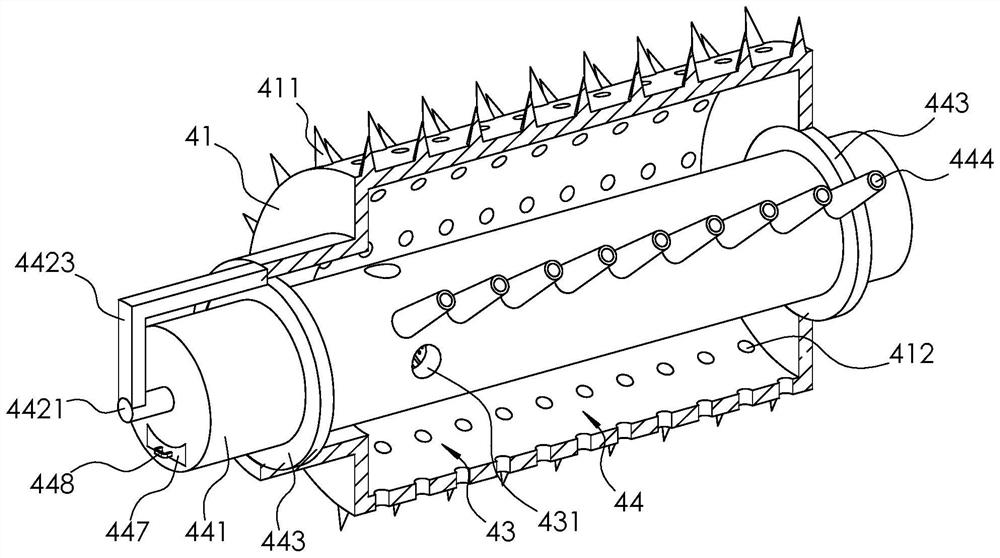

Extraction roller

ActiveCN111254525AImprove running characteristicsReduce deliveryGrain treatmentsFibre breaking machinesFiberClassical mechanics

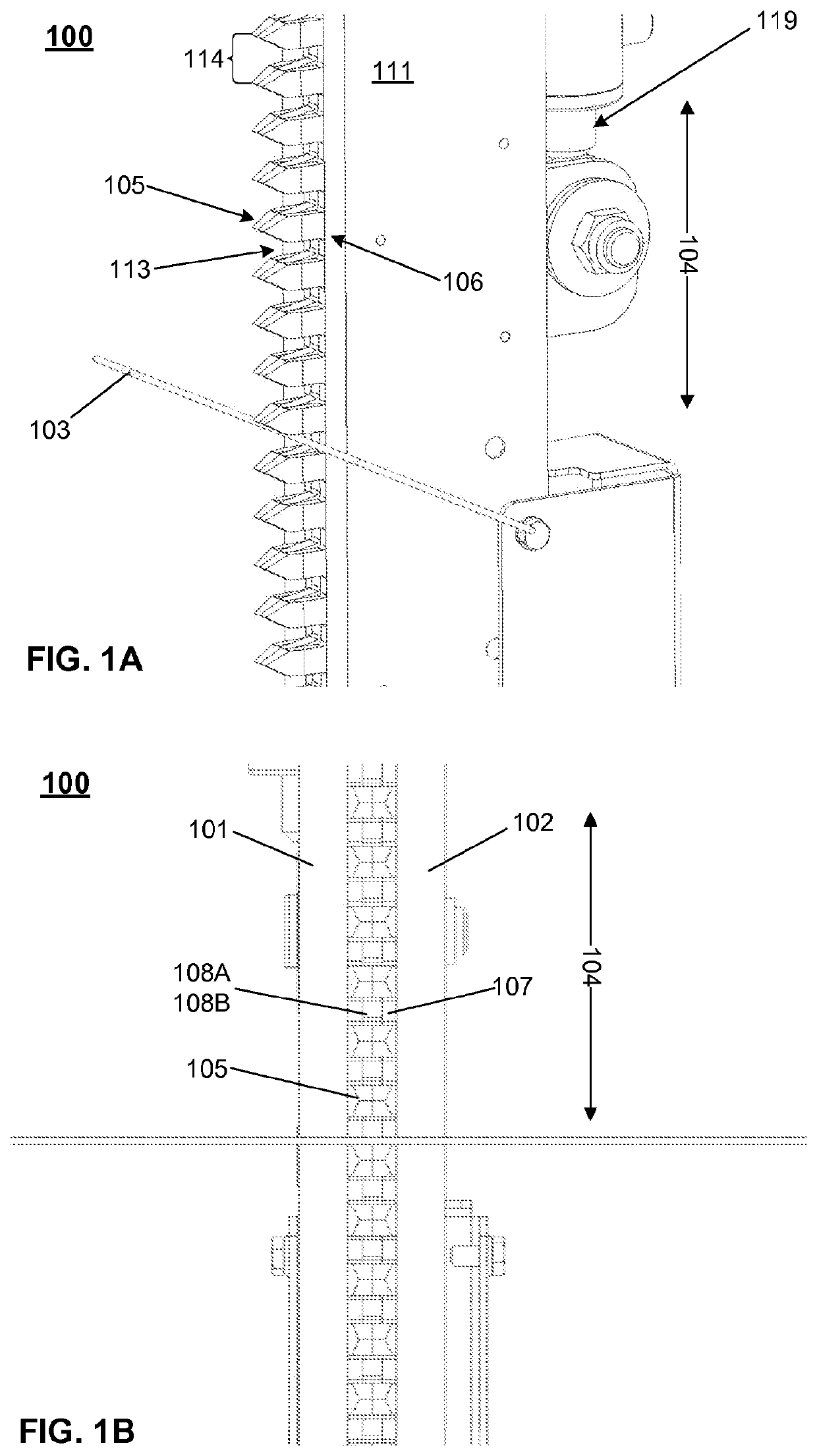

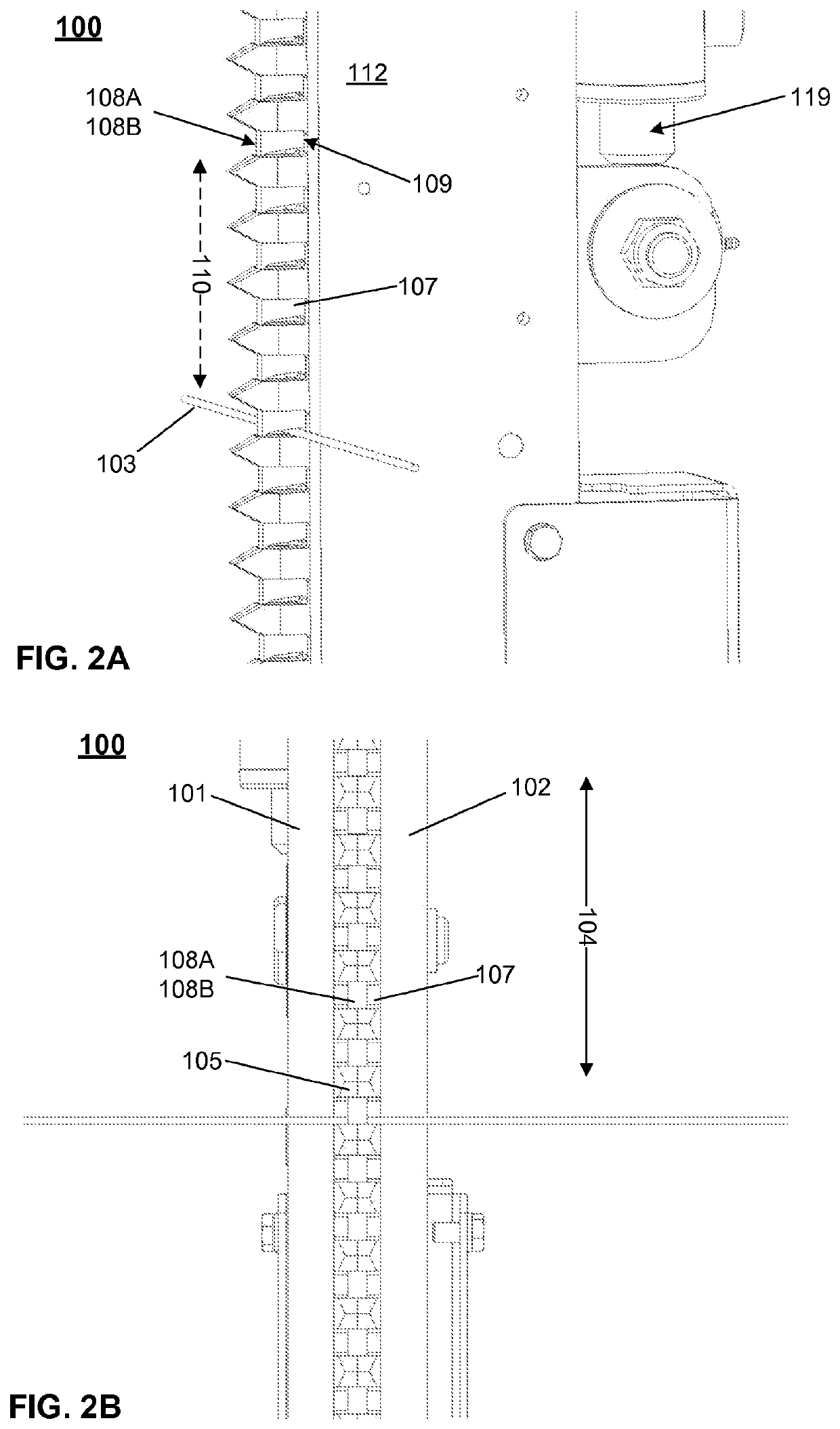

The invention relates to an extraction roller (1) for mechanically opening fiber bales, having a base body (2) designed as a tube, a roller axis (3), and fastening elements (4, 5) situated on the basebody (2) along the roller axis (3). The fastening elements (4) protrude perpendicularly from a surface (6) [sic; (8)] of the base body (2), and each fastening element (4) has at least one through opening (7), parallel to the roller axis (3), for fastening tooth elements (9). Two tooth elements (9) in each case, having at least two teeth (10) in each case, are mounted on each fastening element (4). The two tooth elements (9) are situated at the particular fastening element (4) on opposite sides thereof. The tooth elements (9) are arranged in a circumferential direction of the base body (2) insuch a way that the teeth (10) of the respective tooth elements (9) fastened to a fastening element (4) are offset relative to one another in the circumferential direction.

Owner:MASCHINENFABRIK RIETER AG

Apparatus for loosening fiber material packed in bales

ActiveUS20210010167A1Easy to separateImproved looseningLoadersSolid waste disposalFiberProcess engineering

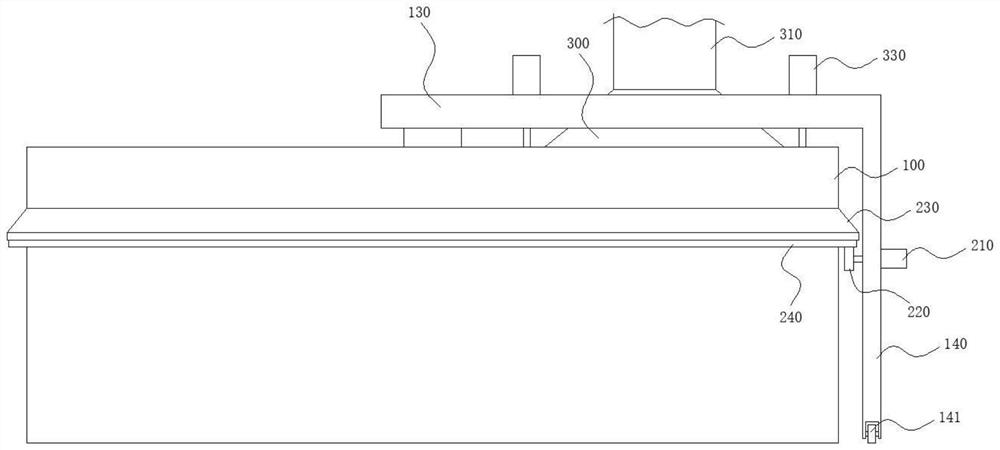

The present invention concerns an apparatus for loosening fiber material packed in bales, comprising a conveyor region for conveying the fiber material along a conveyor direction. The conveyor region includes a feed portion, a buffer portion and a discharge portion. A first roller arrangement is arranged in the transitional region between the feed portion and the buffer portion and a second roller arrangement is arranged in the transitional region between the buffer portion and the discharge portion.

Owner:ROESS NATURE GRP

An anti-tangle automatic cotton picking machine

ActiveCN106167927BStop stalkingPrevent stalking situationsFibre breaking by toothed membersEngineeringDrive motor

Owner:GUANGDE TIANYUN NEW TECH

Tooth element for a removing roller

Owner:MASCHINENFABRIK RIETER AG

Tooth element for removing roller

Owner:MASCHINENFABRIK RIETER AG

A gripping device for gripping a binding material from an object

Owner:CROSS WRAP OY

a cotton opener

ActiveCN113062016BAchieve brokenAchieve separationFibre breaking machinesFibre breaking by toothed membersDust controlEngineering

The present application relates to the technical field of textile equipment, in particular to a cotton opener, which includes a housing with a material inlet and a material outlet, and the housing is provided with a crushing mechanism, a blowing mechanism and a dust removal mechanism sequentially arranged from top to bottom. Mechanism; there is a partition in the shell, and the partition divides the interior of the shell into a cotton seed cavity and a cotton ball cavity arranged in sequence along the horizontal direction; the crushing mechanism is located below the feeding port and directly above the cotton seed cavity, and the cotton ball cavity and the cotton ball cavity The crushing mechanism is set in a misplaced position; the blowing mechanism is located in the cotton seed cavity and faces the cotton ball cavity; the dust removal mechanism is located in the cotton ball cavity and at the discharge port. The dust removal mechanism includes a rotating roller and a driving component. The outer wall of the roller is provided with a number of air holes connected to the inside of the rotating roller; the rotating roller is equipped with a dust suction assembly and a blowing assembly, and the blowing assembly is rotated through one end of the rotating roller and connected to the housing, and the blowing assembly faces the discharge mouth. The application can improve the processing efficiency of cotton bales.

Owner:杭州永信纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com