Lint cotton pretreatment device

A pretreatment device, lint technology, applied in the direction of unpacking with toothed tools, unpacking machines, etc., can solve the problems of inability to identify foreign fibers, difficult to loosen clumps, damage to fiber length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

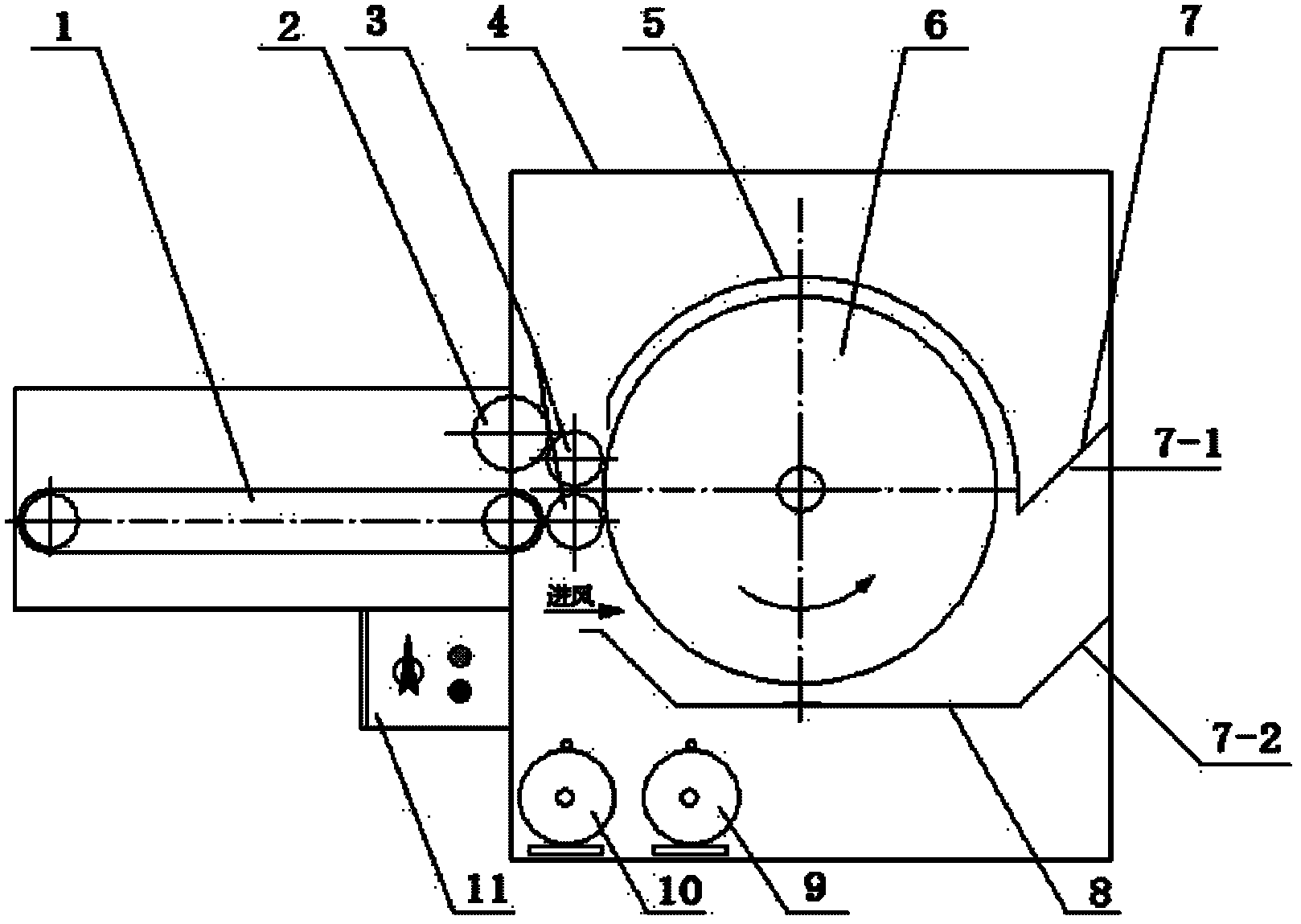

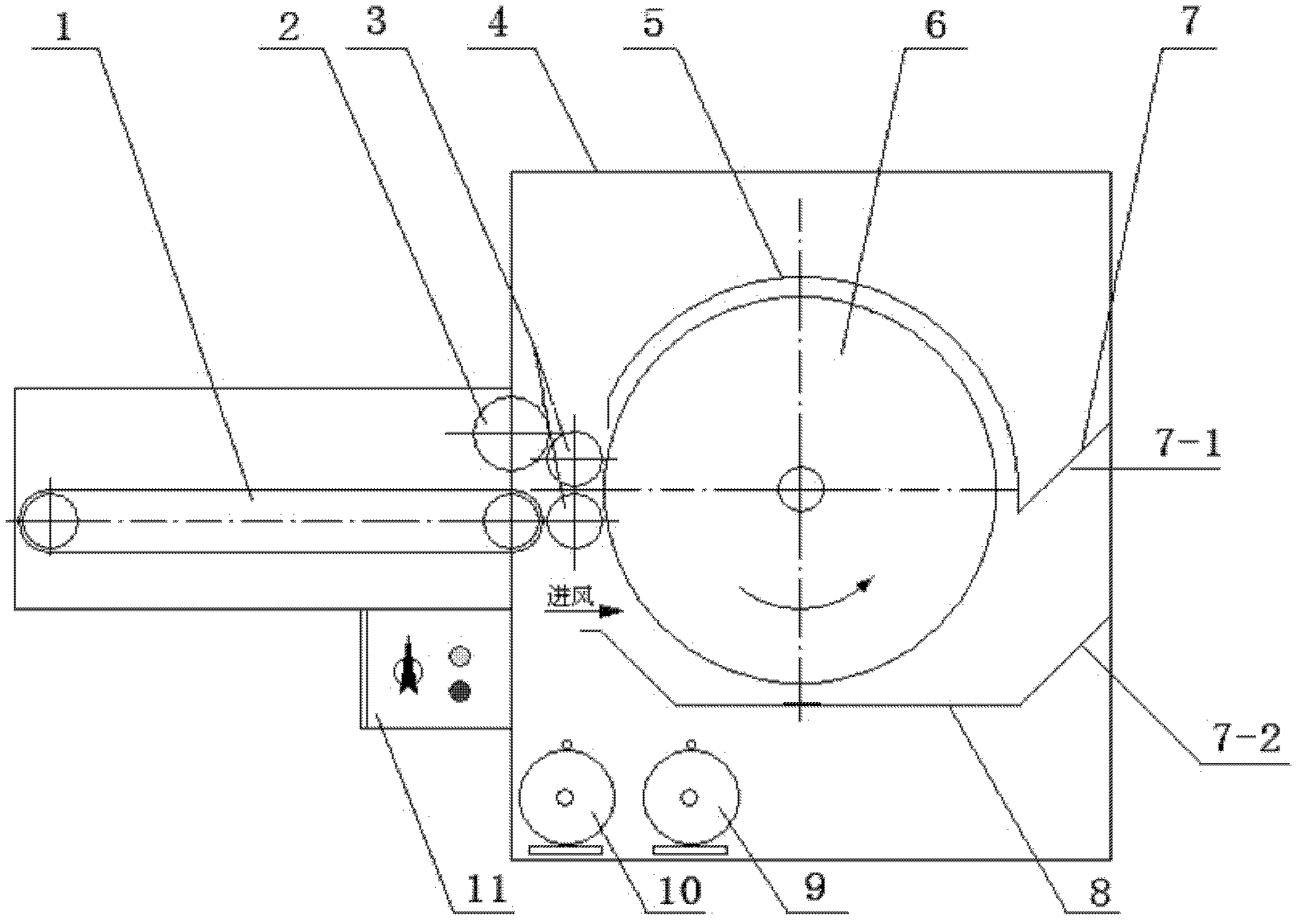

[0020] The lint pretreatment device proposed by the present invention is described in detail as follows in conjunction with the accompanying drawings and embodiments.

[0021] As shown in the figure, the lint pretreatment device according to one embodiment of the present invention includes: a transmission mechanism, a casing 4, an upper arc plate 5, a rack roller 6, a windshield 7, a bottom plate 8, and a control mechanism.

[0022] Wherein, in the device of this embodiment, the conveying mechanism consists of a conveying belt 1, a pressing roller 2 and two cotton-feeding barbed rollers 3 . The conveyor belt 1 is used to transport the lint to be processed to the rack cylinder 6 . The pressing roller 2 is located directly above the conveyor belt 1, and rolls the unprocessed lint conveyed on the conveyor belt 1, so that the lint is fed into the two cotton-feeding barbed rollers 3 at a stable and uniform speed. Two cotton-feeding barbed rollers 3 are arranged between the pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com