Preparation method of bio-based fiber degradable fabric

A bio-based and fabric technology, applied in the field of fabric production, can solve problems such as cotton catching machine winding, achieve the effect of preventing cotton from running around, preventing clogging, and improving the effect of catching cotton

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

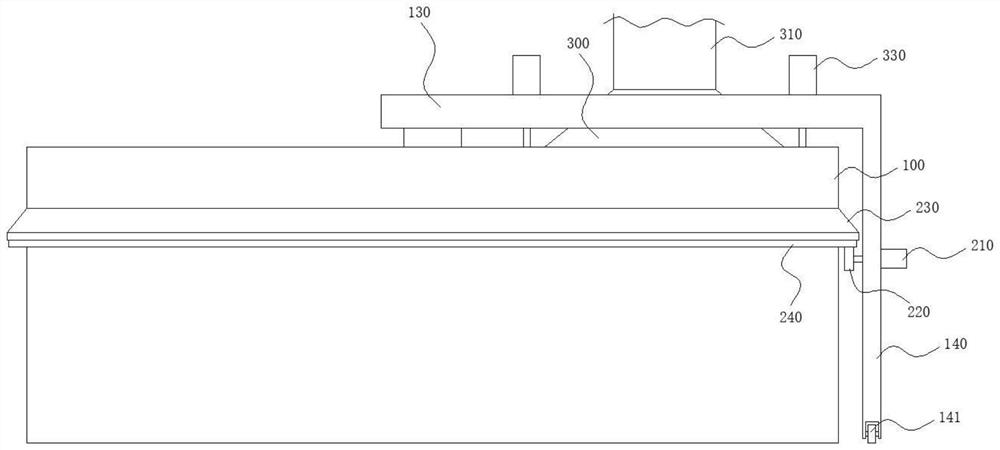

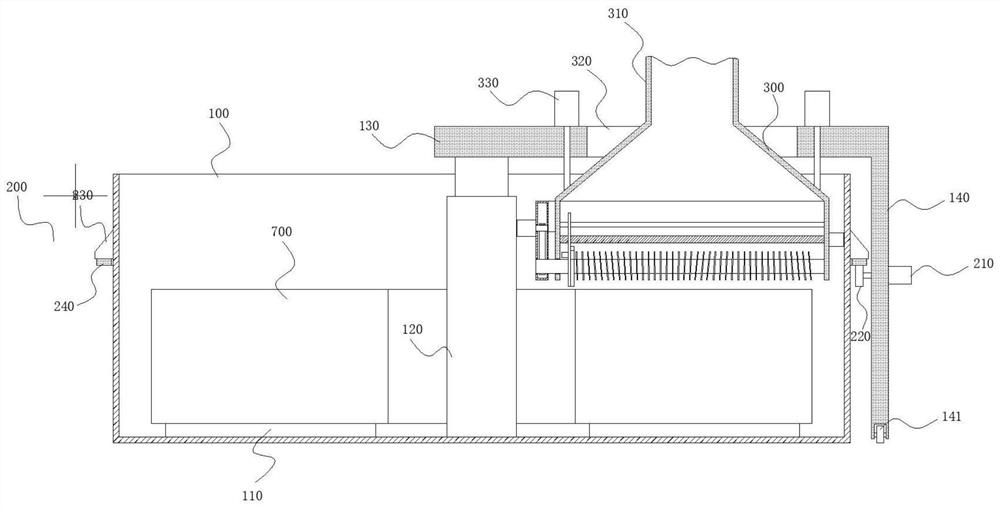

[0041] Such as Figure 1-8 , in the first embodiment, a method for preparing a bio-based fiber degradable fabric, including a cotton picking machine, the cotton picking machine includes

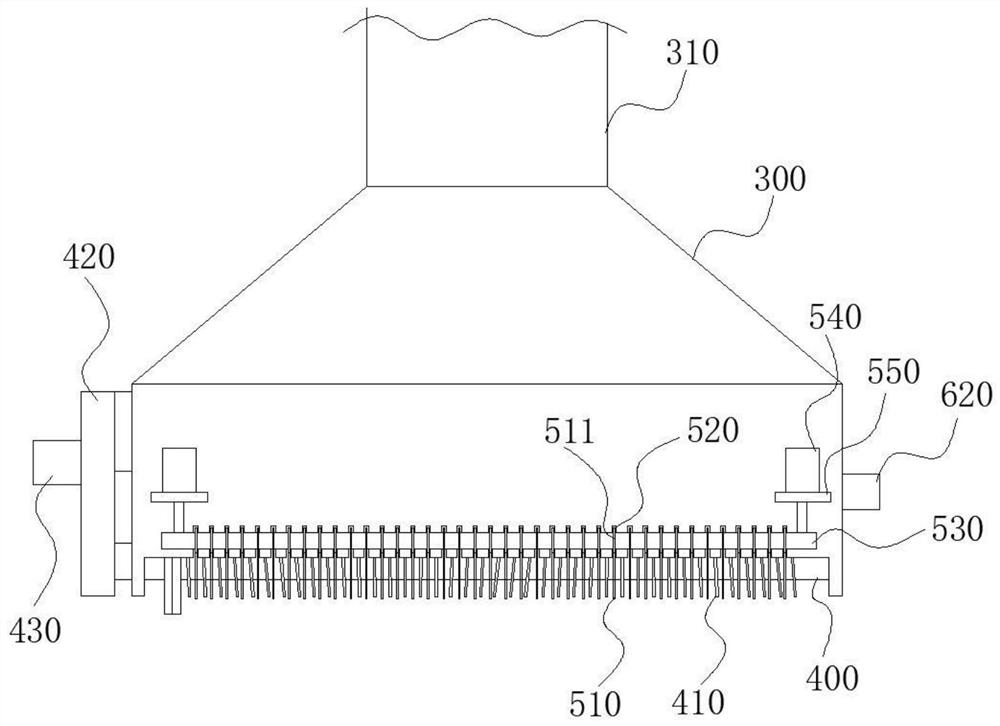

[0042] The positioning cover 300 is liftably connected to the rotating arm 130, and the upper port of the positioning cover 300 is connected with a cotton suction tube 310;

[0043] The rotating roller 400 is rotatably connected to the lower port of the positioning cover 300, and one end of the rotating roller 400 passes through the side wall of the positioning cover 300 and is connected to the first drive assembly;

[0044] A plurality of grasping blades 410 are set obliquely on the outer peripheral wall of the rotating roller 400, and the adjacent cotton grasping blades 410 are not parallel to each other; wherein, the outer circumferential wall of the grasping cotton blades 410 has several cotton grasping openings 411 , a plurality of grasping cotton openings 411 on the plurality of graspi...

Embodiment 2

[0060] As an optimized solution of Embodiment 1, the second drive assembly includes a second gear ring 650 sleeved on the outer wall of the rotating ring 630, and a second servo motor 670 connected to the moving plate 600. The output of the second servo motor 670 The end meshes with the second gear ring 650 through the second gear 660.

[0061] This embodiment is implemented in such a way that the second servo motor 670 drives the second gear ring 650 to rotate, and the second gear 660 drives the rotating ring 630 to rotate on the moving plate 600 through the second gear ring 650 to improve the precision of rotation.

[0062] As an optimized solution of this embodiment, the moving plate 600 is provided with an annular shield 680, and the shield 680 is used to shield the second gear 660 and the second gear ring 650, so as to prevent the cotton from being entangled.

[0063] This optimization scheme: the second gear 660 and the second gear ring 650 can be covered by the provided...

Embodiment 3

[0065] As an optimized solution of Embodiment 1, at least two slide bars 610 and a ball screw module 620 are connected in the positioning cover 300, the slide bar 610 slides through the moving plate 600, and the ball screw of the ball screw module 620 The nut runs through the moving plate 600 and is fixedly connected with the moving plate 600 .

[0066] This embodiment is implemented in such a way that the moving plate 600 is driven to move on the slide bar 610 by the ball screw module 620 provided, so that the moving precision of the moving plate 600 is improved.

[0067] As an optimized solution of this embodiment, the opposite sides of the moving plate 600 are respectively connected to the opposite sides of the positioning cover 300 through bellows sleeves 621, and the ball screw of the ball screw module 620 is mounted on the bellows sleeves. Inside 621.

[0068] This optimization solution: the bellows sleeve 621 can cover the ball screw of the ball screw module 620 to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com