Patents

Literature

247results about How to "Prevent heat radiation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water super-thin steel structure fire-proof paint and preparation method thereof

InactiveCN101125980AHigh strengthImprove fire performanceFireproof paintsPentaerythritolDiammonium phosphate

The invention relates to a waterborne super thin steel structure fireproof coating and a preparation method Which is evidently different from the solvent-typed expansion foam fireproof coating, the invention solves the problems of environmental pollution, resource waste and high cost in prior solvent-typed super thin steel structure fireproof coating. The invention takes water as solvent and comprises the components with certain weight portions: water of 5-25 weight portions, waterborne resin or mixed waterborne resin of 10-30 weight portions, waterborne expansion additive of 25-50 weight portions, pentaerythritol or dipentaerythritol or starch of 5-15 weight portions, one or two components among urea, melamine and dicyano diammonium with 6-15 weight portions, ammonium dihydrogen phosphate, ammonium polyphoste or diammonium phosphate of 15-30 weight portions, expansion regulator of 3-18 weight portions, titanium dioxide of 3-12 weight portions, dispersion agent of 0.1-1.0 weight portions.

Owner:应急管理部四川消防研究所

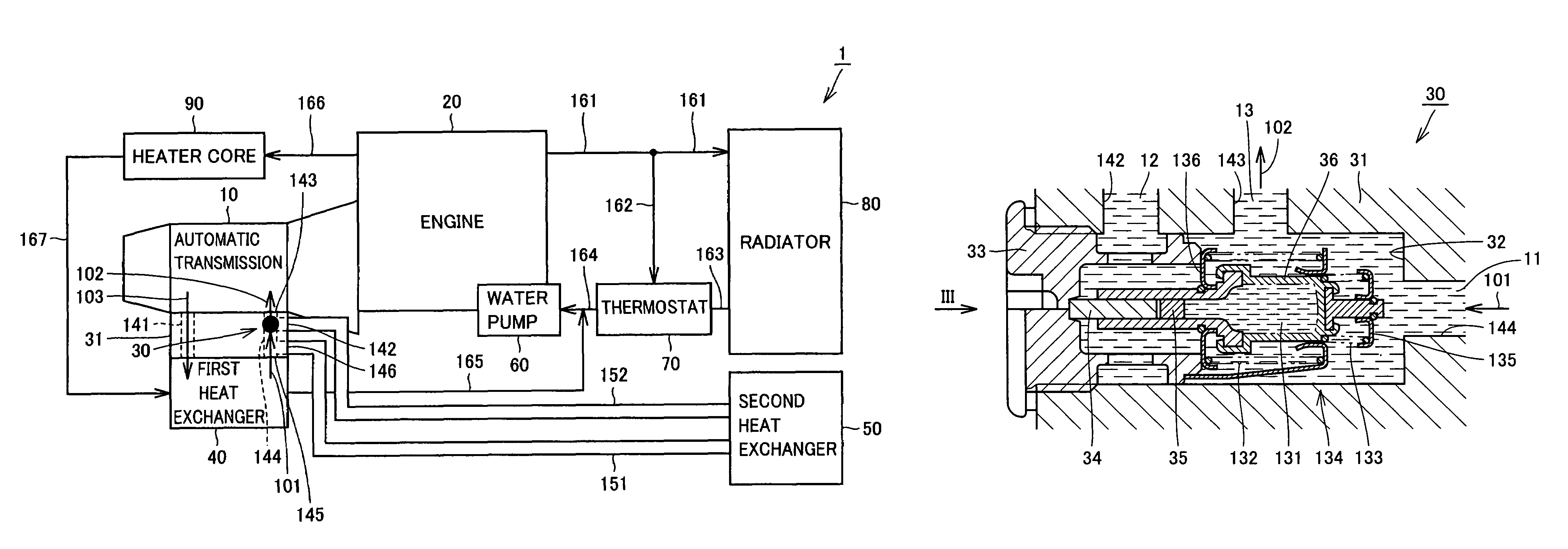

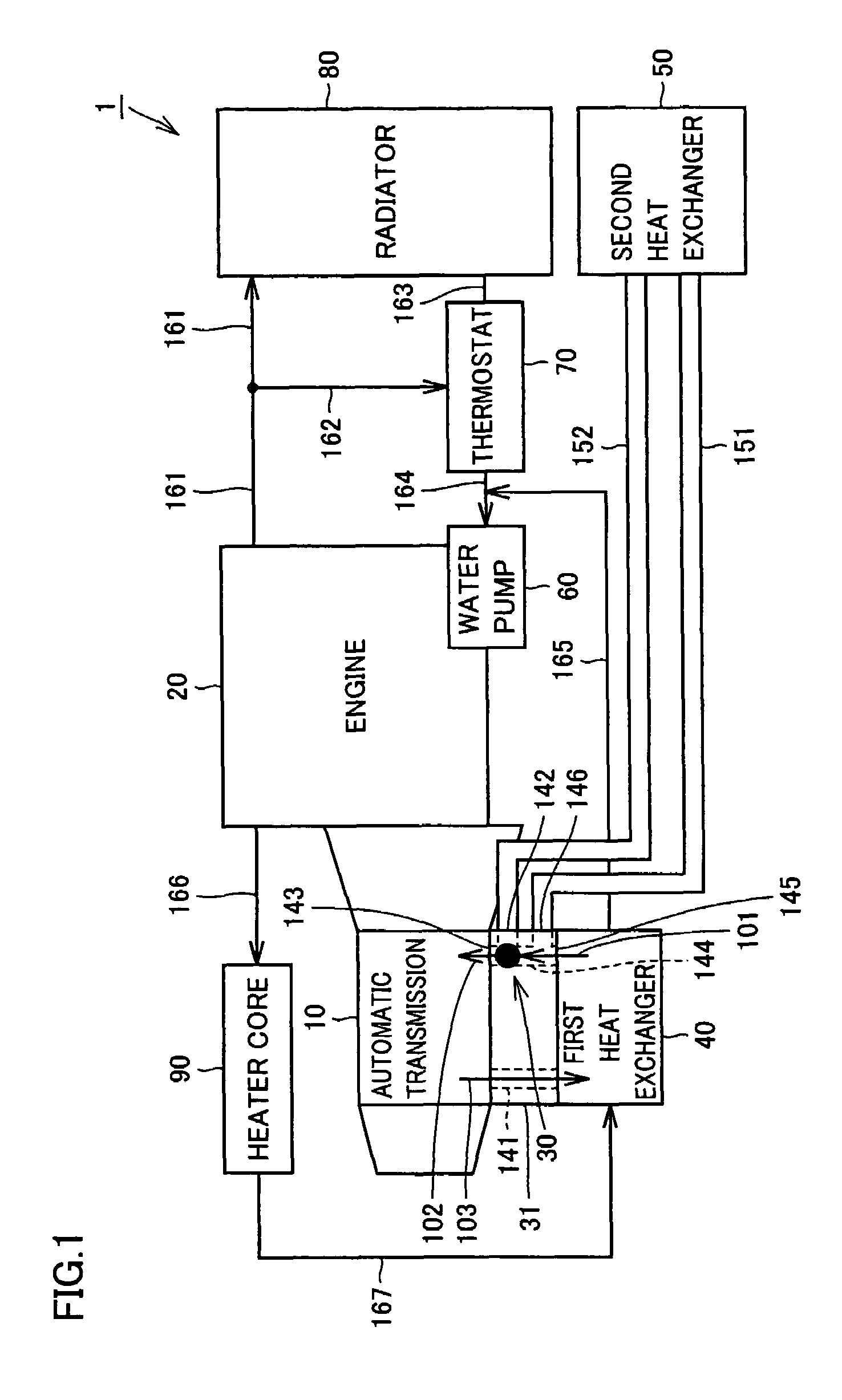

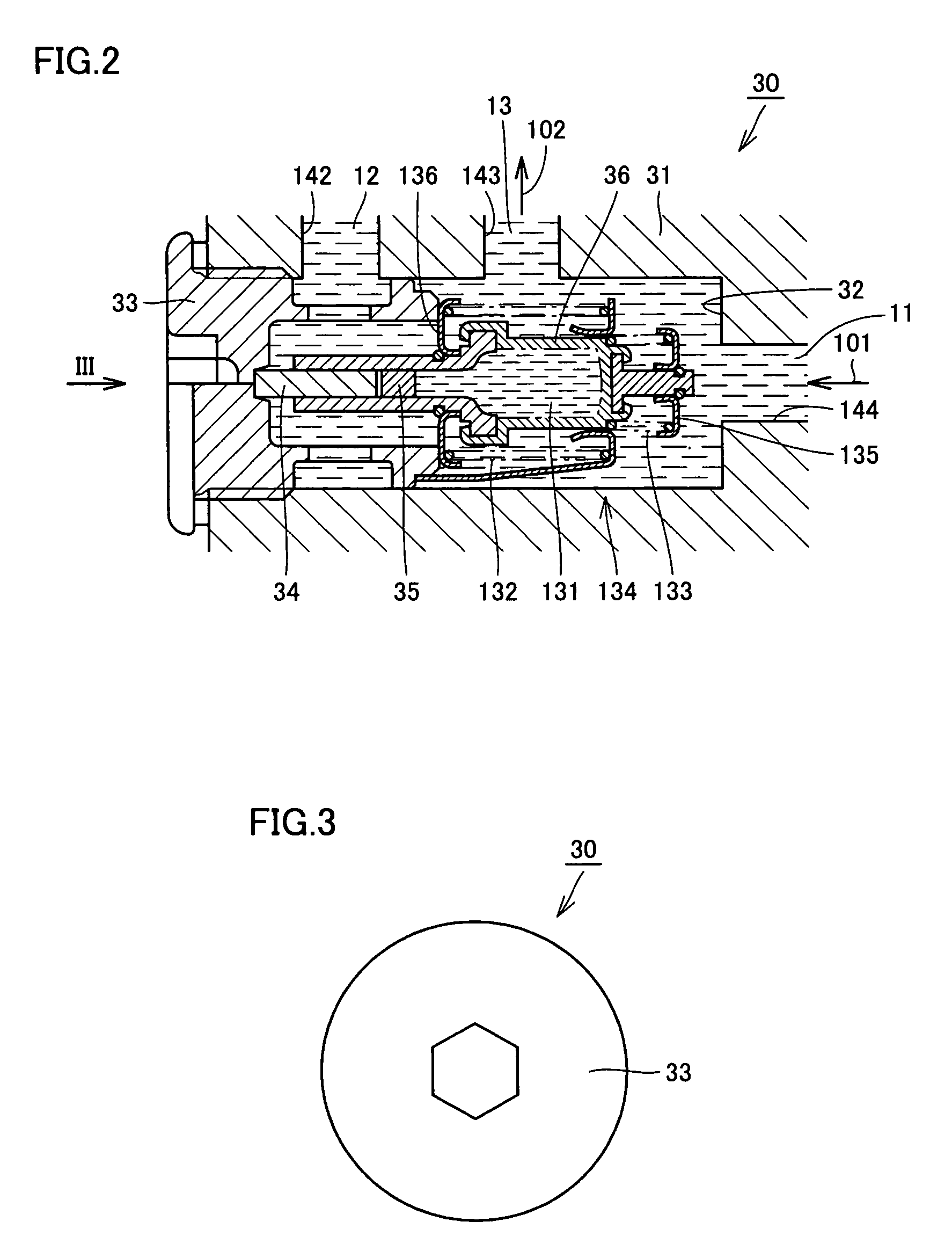

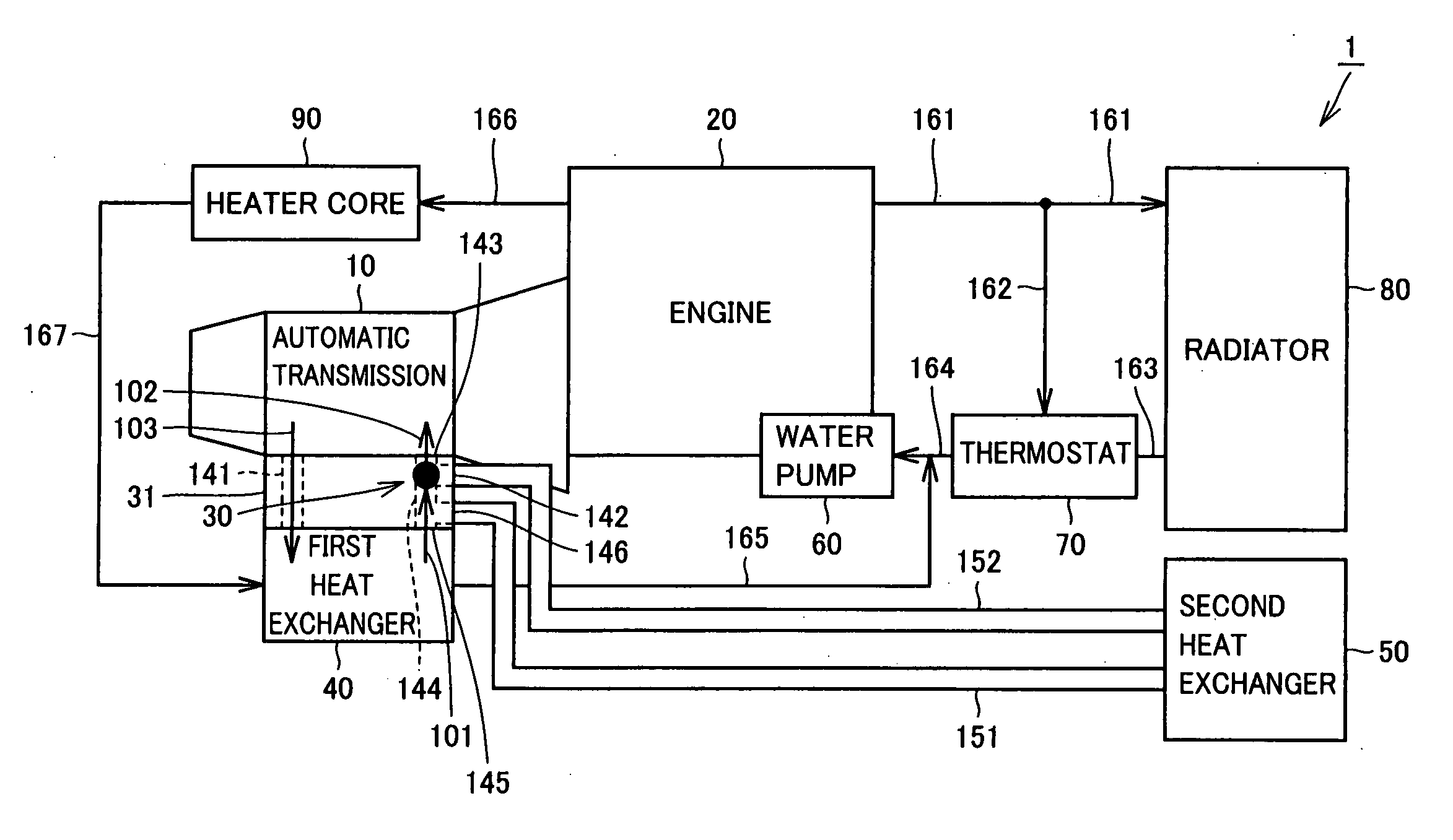

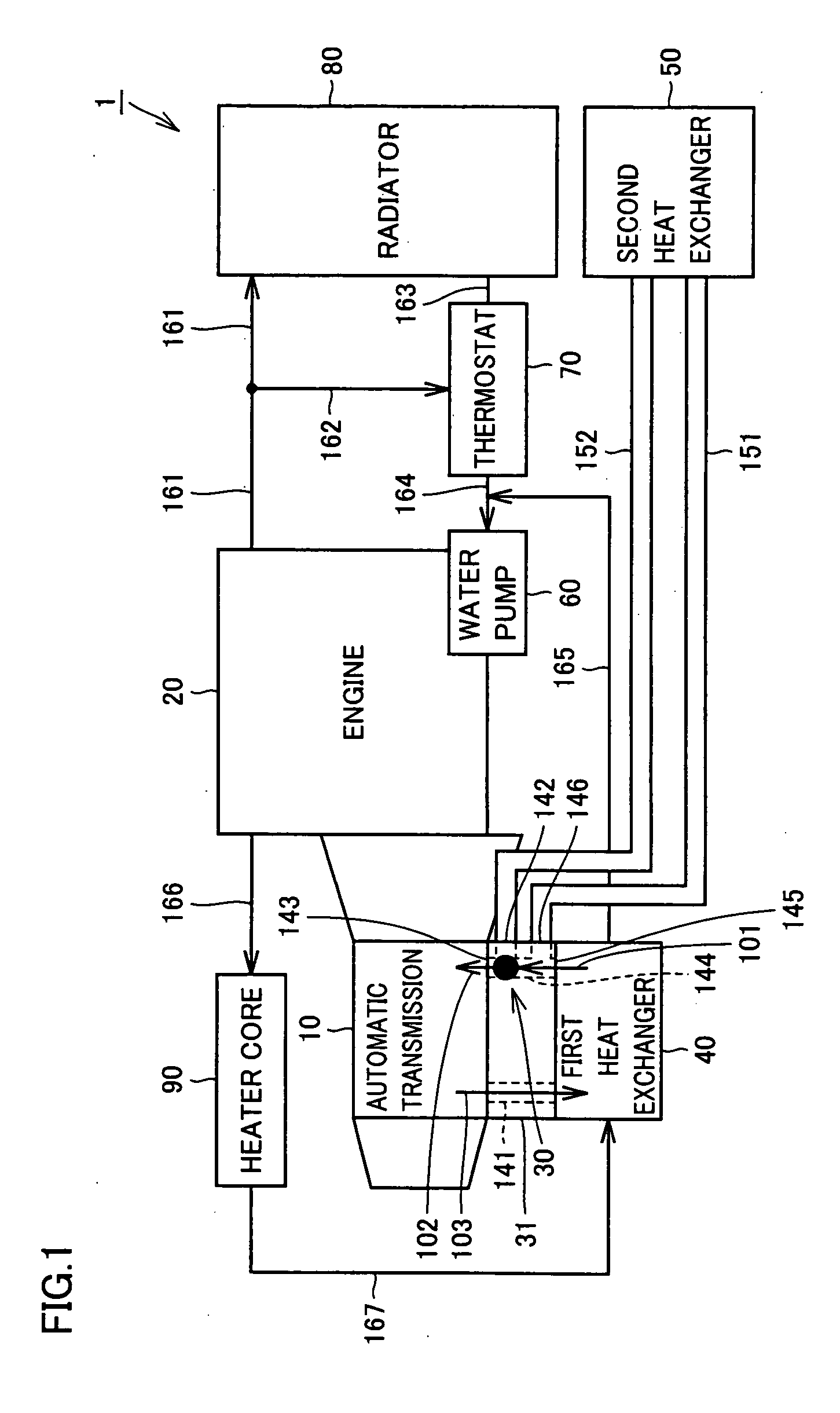

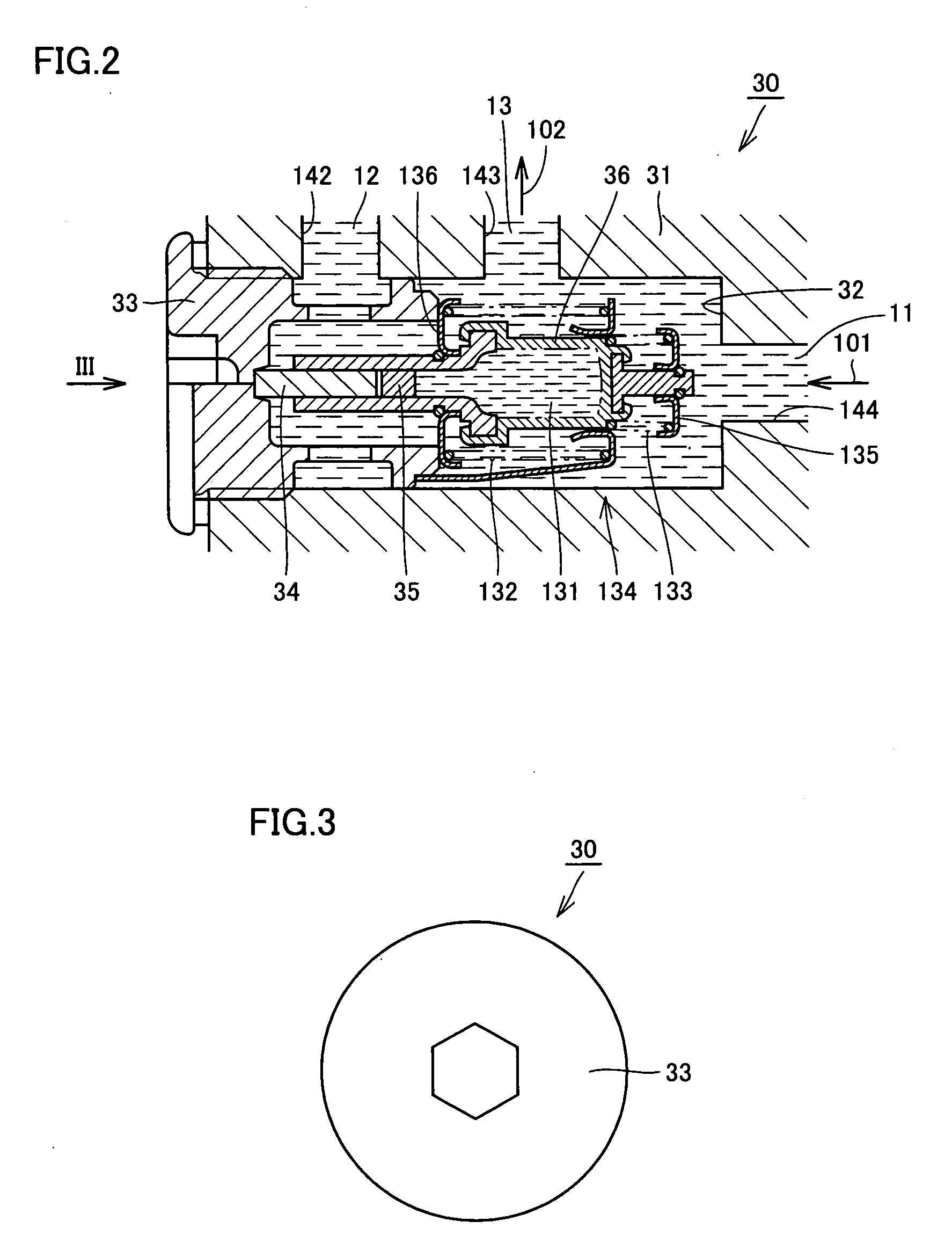

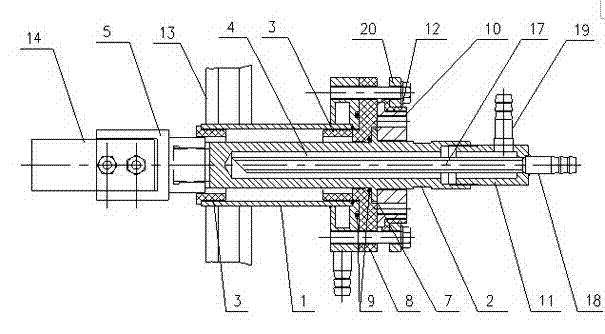

Heat exchanger structure of automatic transmission

InactiveUS7665513B2Heat radiationRapid temperatureTemperature control without auxillary powerGearboxesAutomatic transmissionEngineering

A heat exchanger structure of an automatic transmission stabilizing a temperature of oil is provided. A heat exchanger structure of an automatic transmission includes an automatic transmission, a first heat exchanger provided on an upstream side and a second heat exchanger provided on a downstream side, each capable of cooling oil ejected from the automatic transmission, and a thermo valve capable of supplying oil subject to heat exchange by at least one of first and second heat exchangers to the automatic transmission. When a temperature of the oil is relatively low, the thermo valve supplies oil passed through the first heat exchanger to the automatic transmission and shuts off a flow of oil from the second heat exchanger to the automatic transmission. When a temperature of the oil is relatively high, the thermo valve supplies oil passed through first and second heat exchangers to the automatic transmission.

Owner:TOYOTA JIDOSHA KK

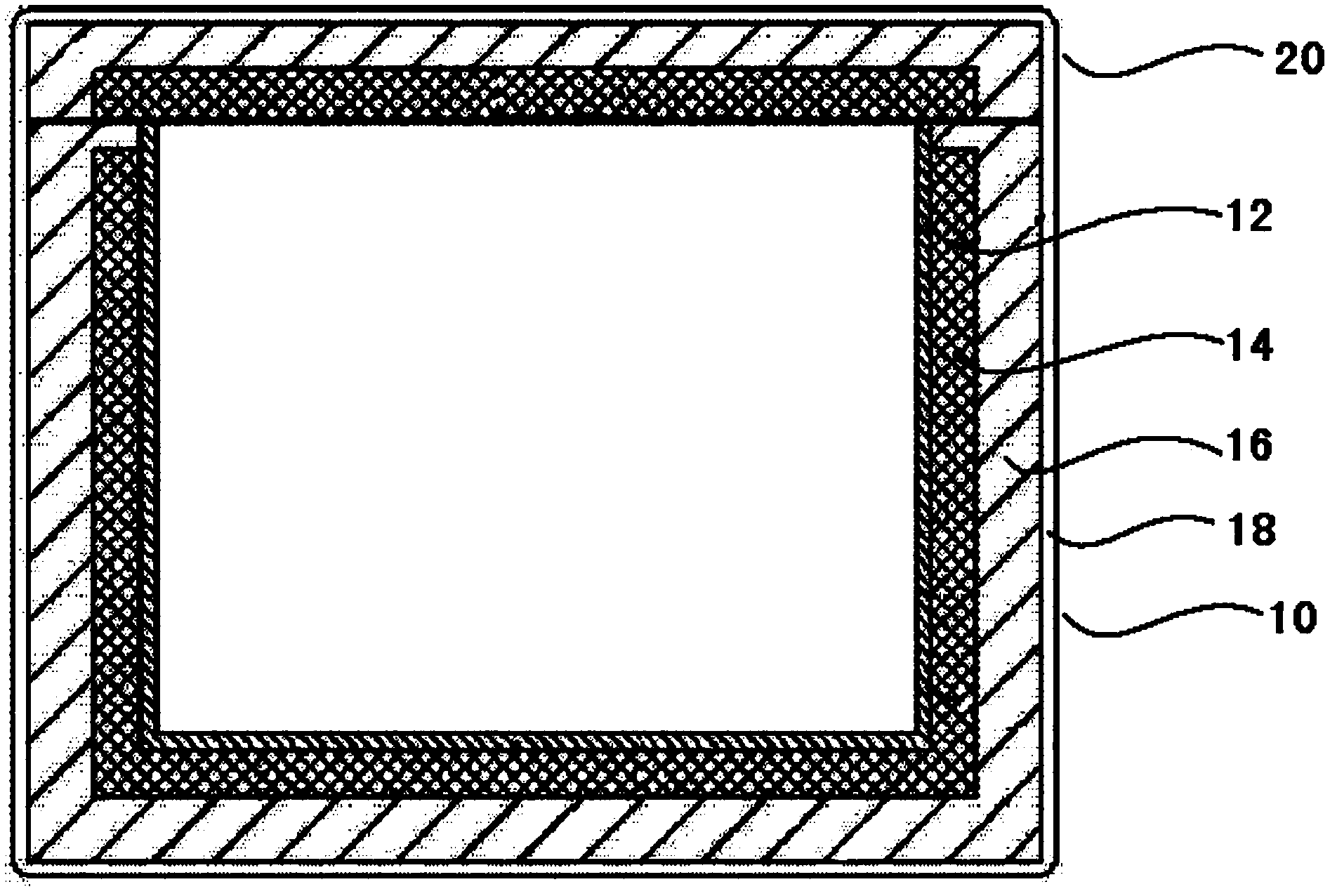

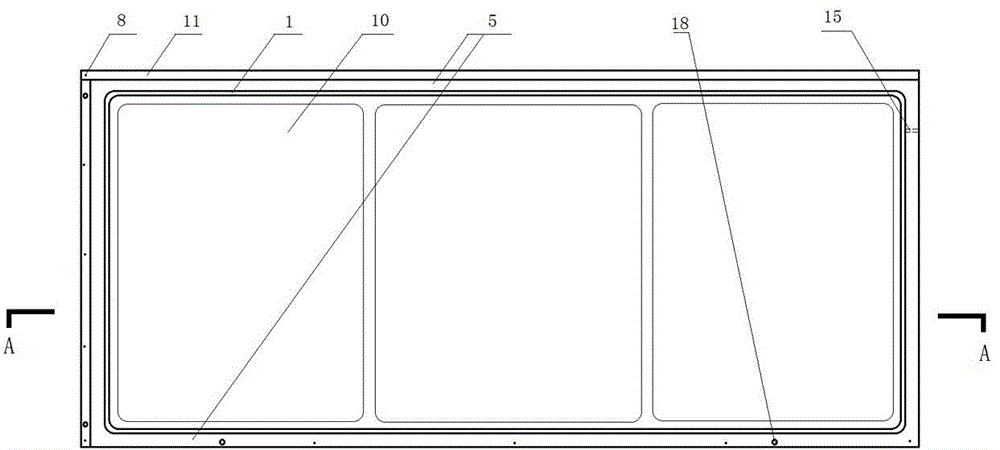

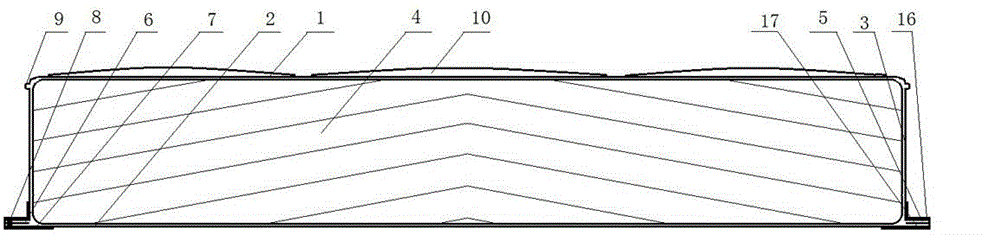

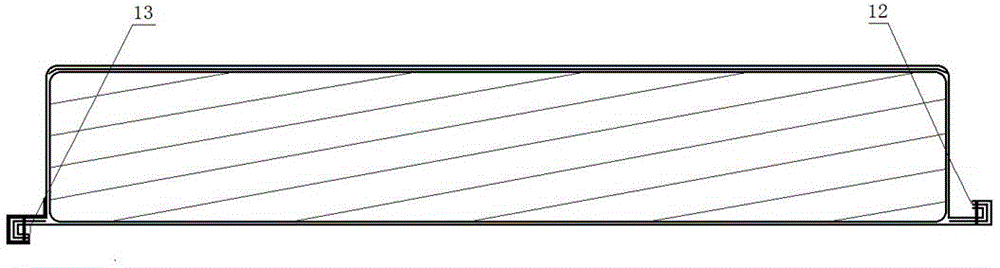

Heat insulation cold closet for medical supplies

ActiveCN103723379AReduce thicknessIncrease effective volumeLighting and heating apparatusInsulation for cooling apparatusEngineeringEffective volume

The invention discloses a heat insulation cold closet. According to the heat insulation cold closet, due to the fact that a vacuum heat insulation panel layer and a rigid polyurethane layer are arranged in a polyurethane foamed plastic layer to form a composite head insulation structure, the thickness of the heat insulation cold closet is reduced so that the effective volume of a heat insulation closet in the same shape can be greatly increased; furthermore, the coefficient of heat insulation of the heat insulation cold closet is smaller than or equal to 0.004W / mK, heat radiation, heat conduction and heat convection between the interior of the closet body and the outside environment can be effectively prevented, and the heat insulation closet can guarantee that the interior temperature is controlled below 2-8 DEG C for more than 120 hours. The heat insulation cold closet is mainly used for cold storage and refrigeration during transportation and storage of medicine such as vaccine, insulin, blood products, biological products and reagents.

Owner:SUZHOU ANTEK INDAL

Heat exchanger structure of automatic transmission

InactiveUS20060060346A1Temperature stabilityHeat radiationGearboxesTemperatue controlAutomatic transmissionEngineering

A heat exchanger structure of an automatic transmission stabilizing a temperature of oil is provided. A heat exchanger structure of an automatic transmission includes an automatic transmission, a first heat exchanger provided on an upstream side and a second heat exchanger provided on a downstream side, each capable of cooling oil ejected from the automatic transmission, and a thermo valve capable of supplying oil subject to heat exchange by at least one of first and second heat exchangers to the automatic transmission. When a temperature of the oil is relatively low, the thermo valve supplies oil passed through the first heat exchanger to the automatic transmission and shuts off a flow of oil from the second heat exchanger to the automatic transmission. When a temperature of the oil is relatively high, the thermo valve supplies oil passed through first and second heat exchangers to the automatic transmission.

Owner:TOYOTA JIDOSHA KK

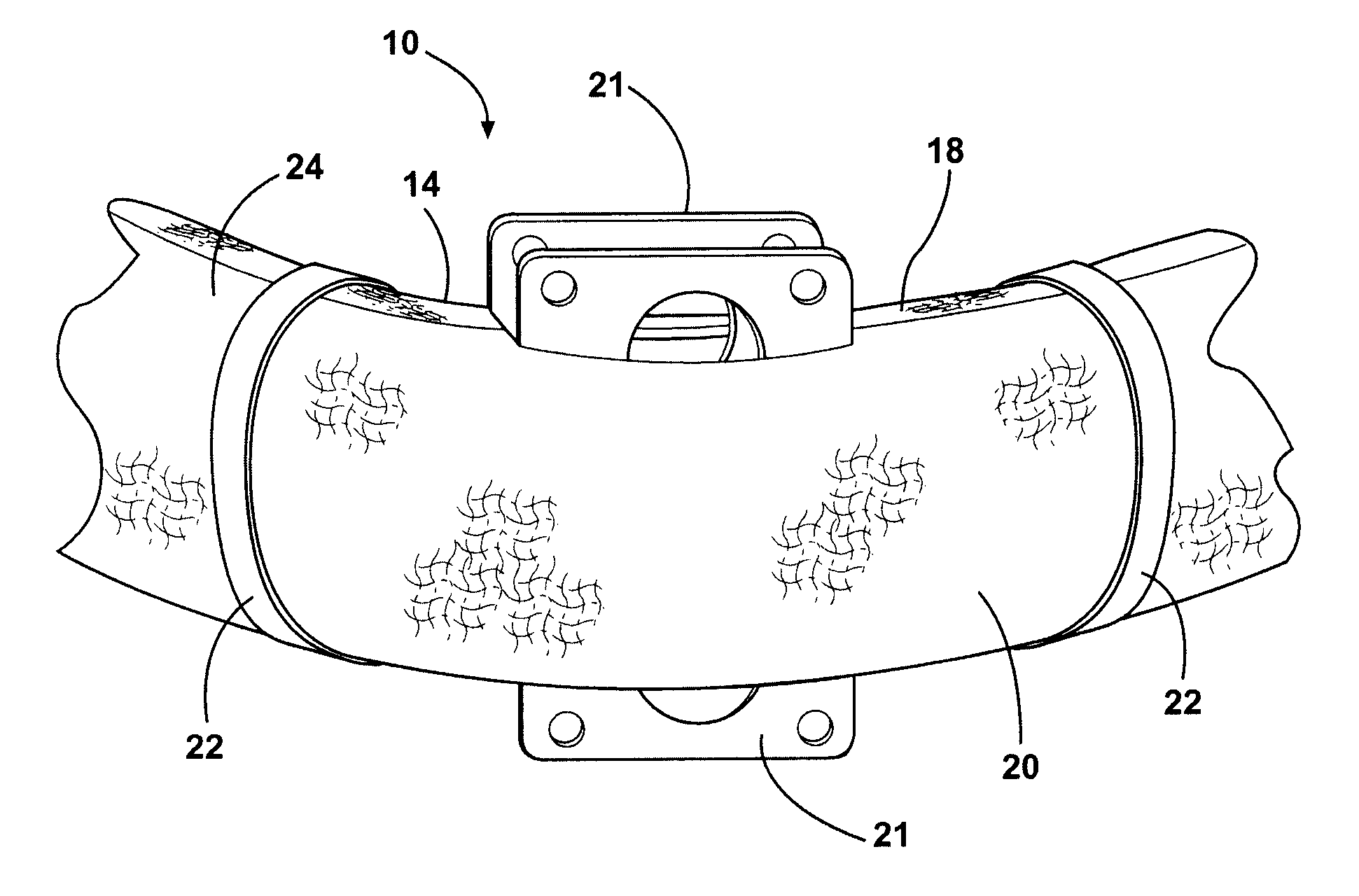

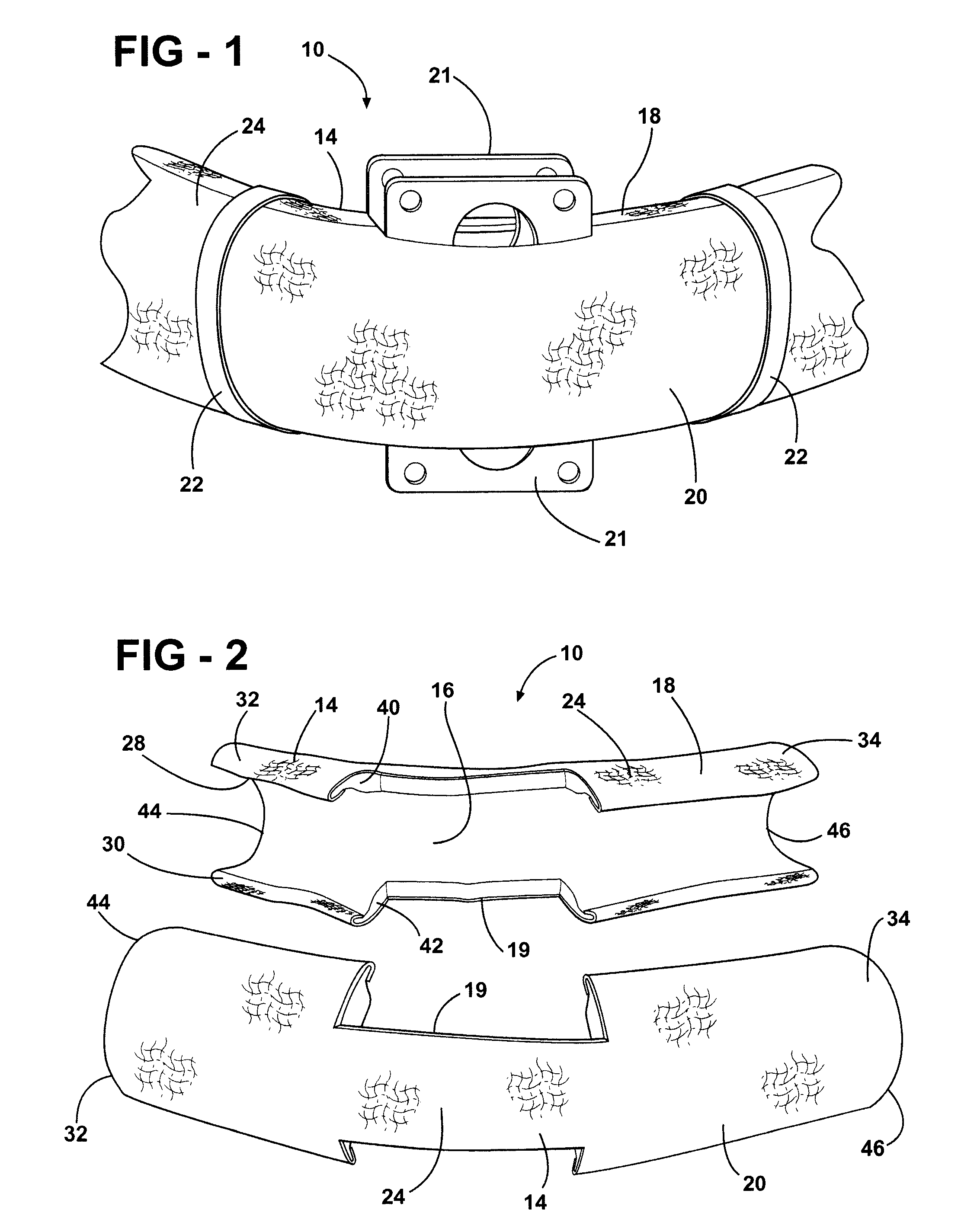

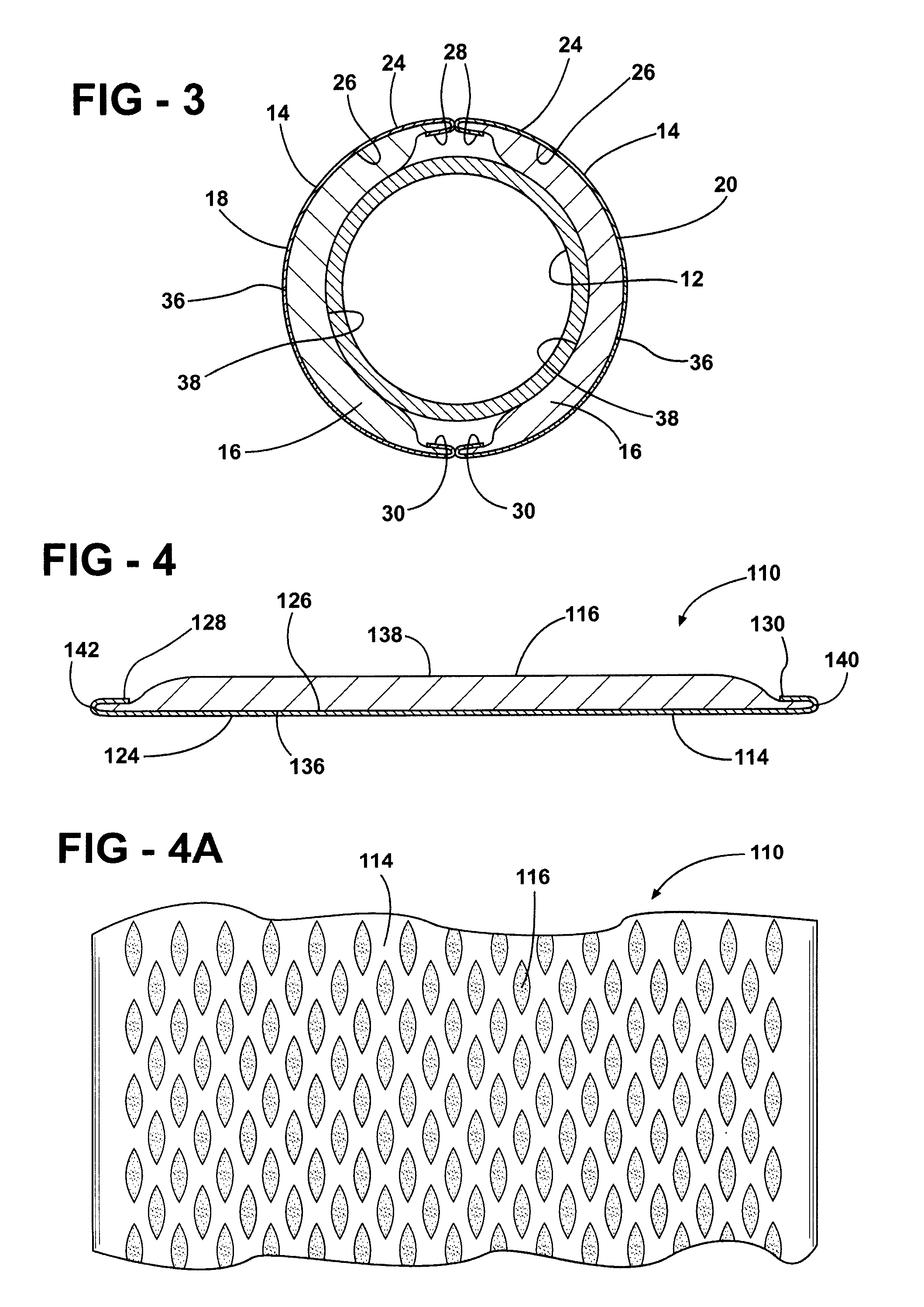

Thermal shield and methods of construction and installation

InactiveUS20080169038A1Easily instalEconomical to manufacture and installThermal insulationExhaust apparatusMetalArchitectural engineering

A wrappable heat shield for an exhaust pipe and methods of construction and installation thereor includes an outer layer of metal having opposite inner and outer faces extending between opposite sides. An inner layer of non-woven insulation is attached to the the outer layer by a crimped portion extending along one of the opposite sides of the outer layer. The inner layer has a width sufficient to extend completely about a circumference of the exhaust pipe and is arranged in continuous contact with the exhaust pipe about its circumference while the outer layer remains spaced therefrom.

Owner:FEDERAL MOGUL POWERTAIN LLC

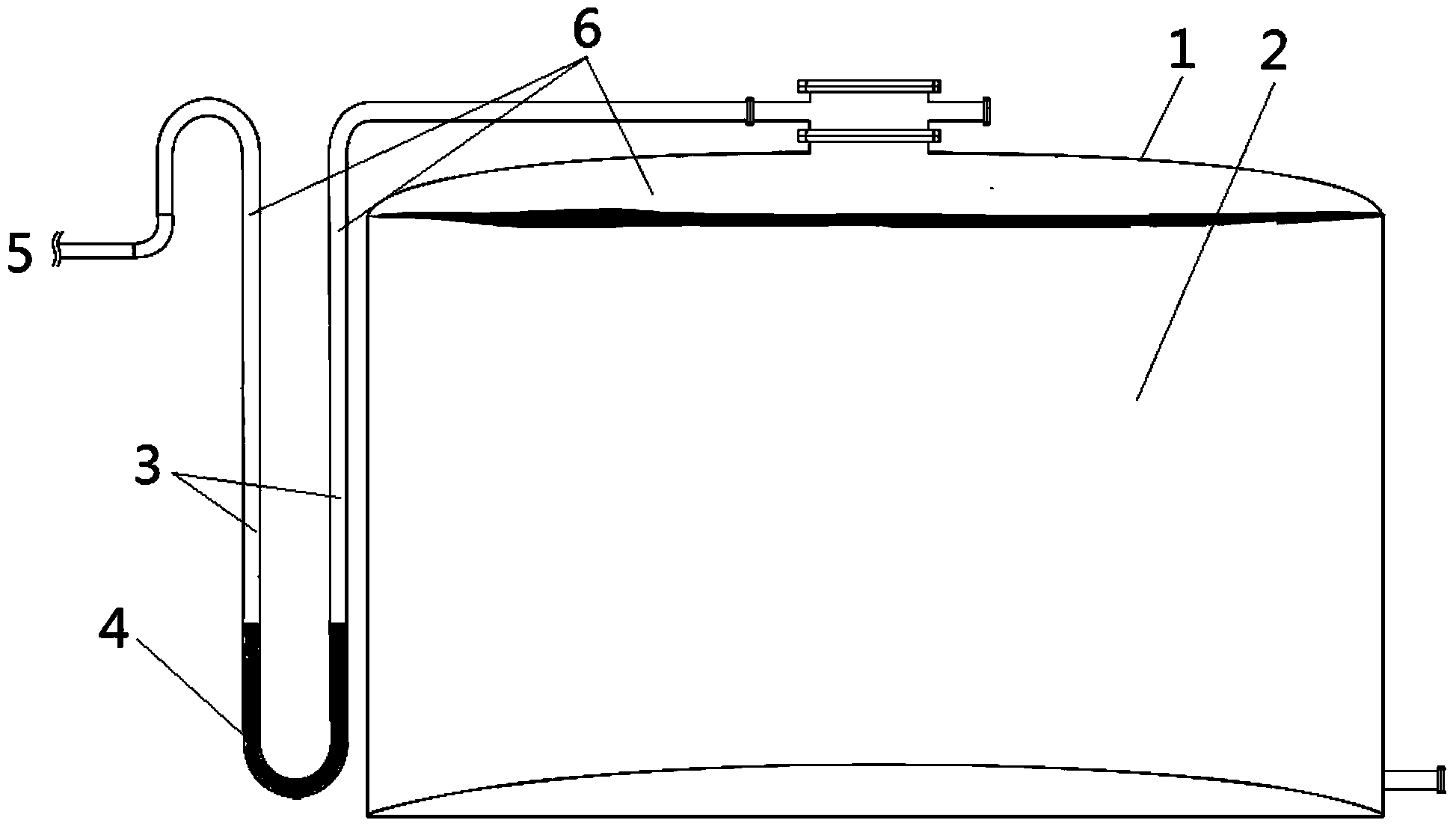

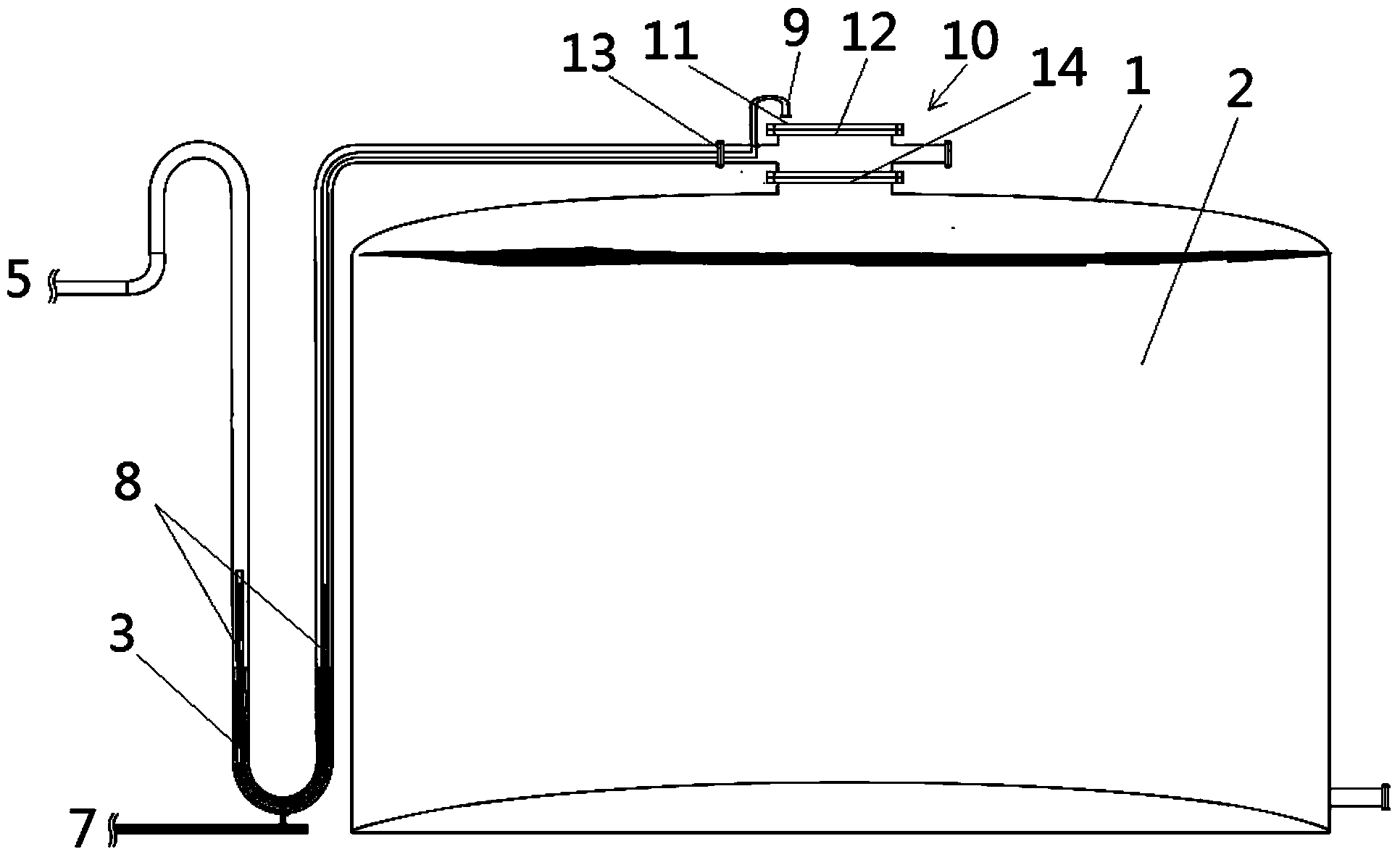

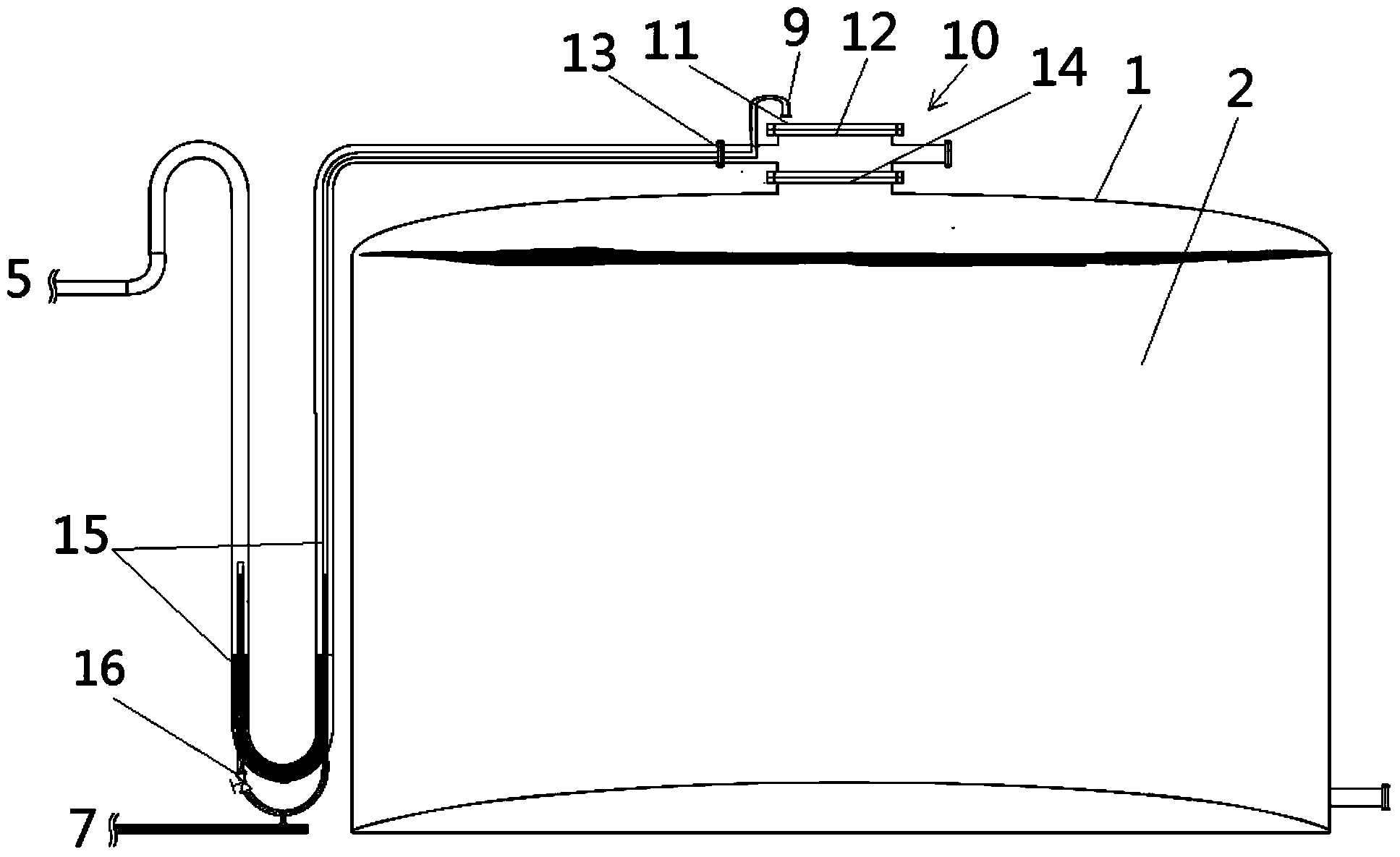

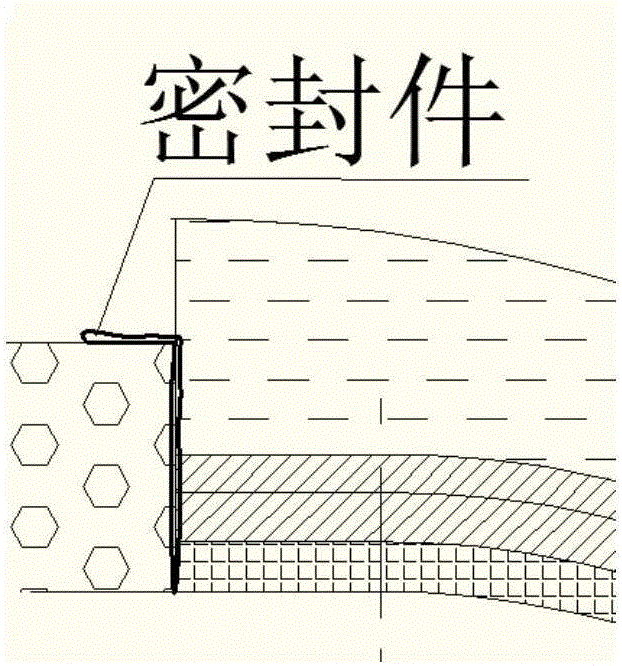

Idle sealing and explosion suppression device used for dangerous chemical containers and defense method

ActiveCN103922051AEliminate volatilizationEliminate fugitiveLarge containersPackaging under vacuum/special atmosphereFire protectionCombustion

The invention relates to an idle sealing and explosion suppression device used for dangerous chemical containers, and a defense method which responds to multistage shaped charge and aims at conducting sympathetic detonation on oxygen-contained hydrocarbon gas in gas-phase space of the container in a mode of entering the payload containers at any time. The device comprises idle sealing devices arranged on the dangerous chemical containers. Each idle sealing device comprises a U-shaped sleeve, wherein a Y-shaped penetrating pipe is arranged inside the U-shaped sleeve, one upper port of the U-shaped sleeve is communicated with the gas-phase of a gas idle sealing medium source, the other upper port of the U-shaped sleeve is communicated with the gas-phase of the corresponding container through an idle sealing disc on the top of the corresponding container, the port on the gas distribution side of the Y-shaped penetrating pipe is hung in a vertical pipe on the gas distribution side of the U-shaped sleeve, the port on the corresponding container side of the Y-shaped penetrating pipe is connected with a spraying pipe on the top of the corresponding container, the bottom port of the U-shaped sleeve is connected and communicated with a liquid-state fire protection medium source after penetrating out of a bottom connection pipe of the U-shaped sleeve, a liquid valve of the sleeve can serve as a large-breath and small-breath valve, a liquid valve of the penetrating pipe can serve as a safety relief valve, the atmosphere can be isolated in a systemic mode, and the combustion explosion condition of the gas-phase space of the corresponding container and pipelines can be permanently restrained.

Owner:国铠特种流体机械制造(青岛)有限公司

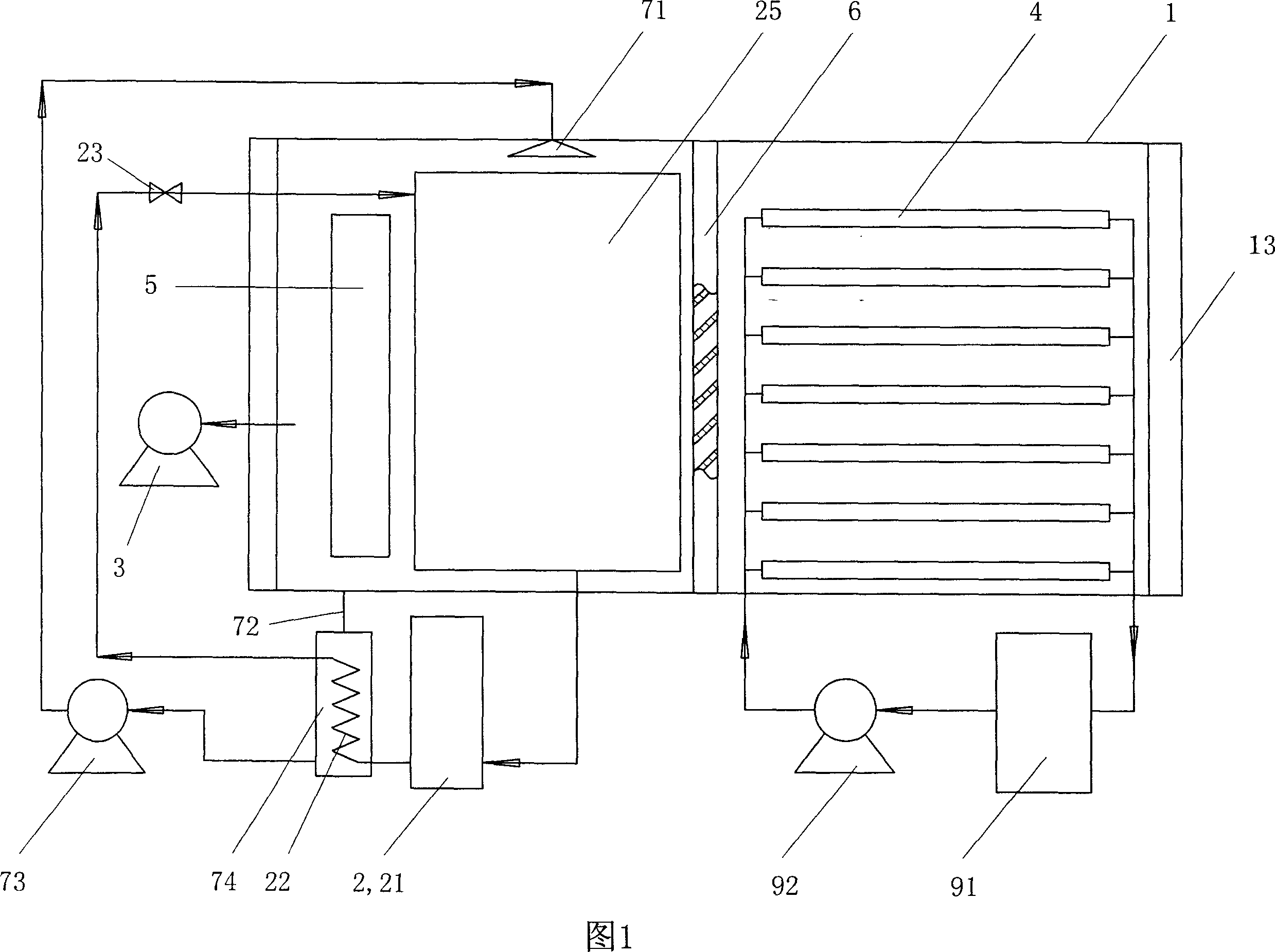

Freezing drying machine

InactiveCN101025329ADoes not affect circulationIncrease contact areaDrying solid materials without heatDrying machines with local agitationFreeze-dryingEngineering

This invention is about a kind of freeze-drying set, composing of case; freezing engine set vacuum pump and hot plate. The freezing engine set composes of compressor, heat exchanger, expansion valve and evaporator; the hot plate is set in front of the case, and the evaporator of the freezing engine set is set in rear of the case; there are louver interboards between the evaporator and hot plate, and fan in rear of the evaporator. The invention consumes less energy and be manipulated conveniently.

Owner:李志平 +1

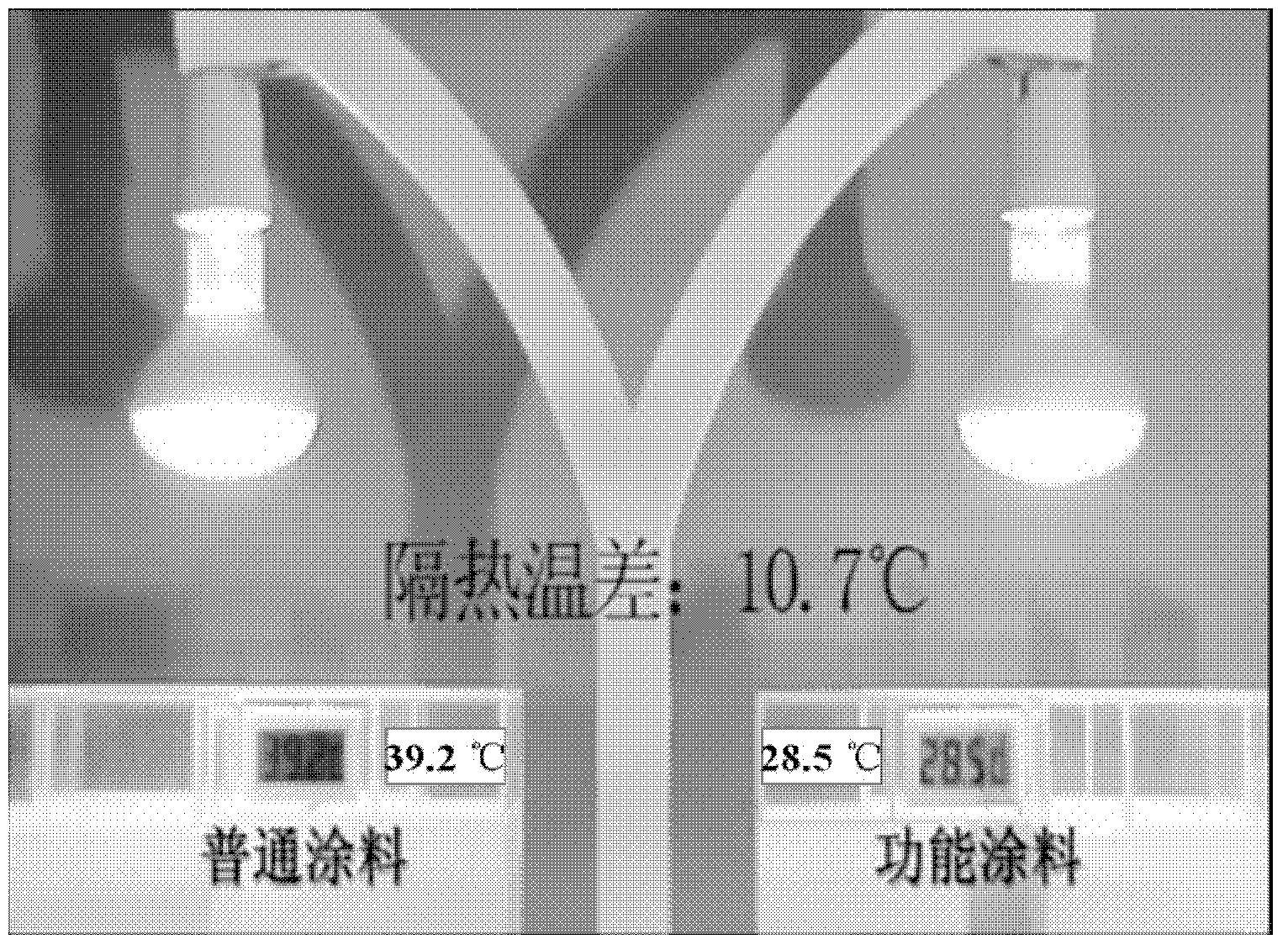

Water-based nano reflection and heat insulation transparent coating and preparation method thereof

ActiveCN105505060AReduce energy consumptionAchieve integrity and water resistanceAntifouling/underwater paintsChemical industryEmulsionNano dispersion

The invention discloses a water-based nano reflection and heat insulation transparent coating and a preparation method thereof. The formula of the coating comprises the followings in percentages by weight: 35%-50% of a water-based acrylic emulsion, 5%-15% of water-based lithium silicate, 5%-15% of a water-based polyurethane emulsion, 5%-10% of a water-based heat insulation nano dispersion sizing agent, 5%-10% of a water-based heat insulation and heat preservation nano dispersion, 2%-12% of a wetting dispersant, 0.2%-0.5% of a flatting agent, 0.2%-1% of a thickener, 0.1%-0.2% of an antifungus and anti-mildew agent, 0.5%-2.5% of a coalescing agent, 0.5%-2% of a silane coupling agent and 5%-25% of deionized water. According to the water-based nano reflection and heat insulation transparent coating disclosed by the invention, under the precondition of without influencing lighting, heat radiation is blocked and infrared heat energy is prevented from being conducted into the interior of a base material through effective reflection and heat energy conduction, and thus the effects of heat insulation and heat preservation are reached. Heat energy, entering the room through the base material, generated by an outdoor heat source can be effectively blocked in summer, and indoor heat can be effectively blocked from being dispersed in winter, so that the application of refrigeration and heat preservation equipment can be effectively reduced, and the energy-saving effect is obvious.

Owner:CHANGSHA MINDE FIRE ENG PAINT CO LTD

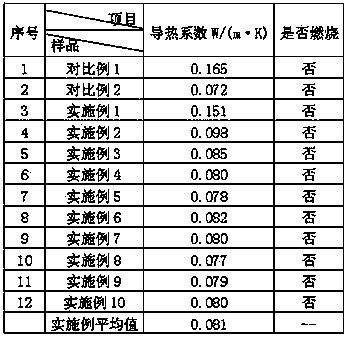

Carbon aerogel thermal insulation material and preparation method thereof

ActiveCN103466998ALow thermal conductivityImprove insulation effectThermal insulationIndustrial equipment

Aiming at the problems in the prior art that the silica aerogel is high in price and the heat conductivity coefficient of an ordinary thermal insulation material is large, the invention particularly relates to a carbon aerogel thermal insulation material and a preparation method thereof. The carbon aerogel thermal insulation material consists of the following components in parts by weight: 100 parts of a man-made inorganic fiber, 0-200 parts of a carbon material, 0.5-2.0 parts of a dispersing agent and 0.5-2.0 parts of an adhering agent. The carbon aerogel thermal insulation material provided by the invention can be a powder material, a slurry material, a felt material or a plate material in state. The carbon aerogel thermal insulation material has the advantages of small heat conductivity coefficient and moderate price, is easy to construct and popularize, and can be widely applied to insulation of buildings, industrial equipment and pipelines; and the preparation method is low in cost and simple and easy to operate.

Owner:CHENGDU SOLVER TECH

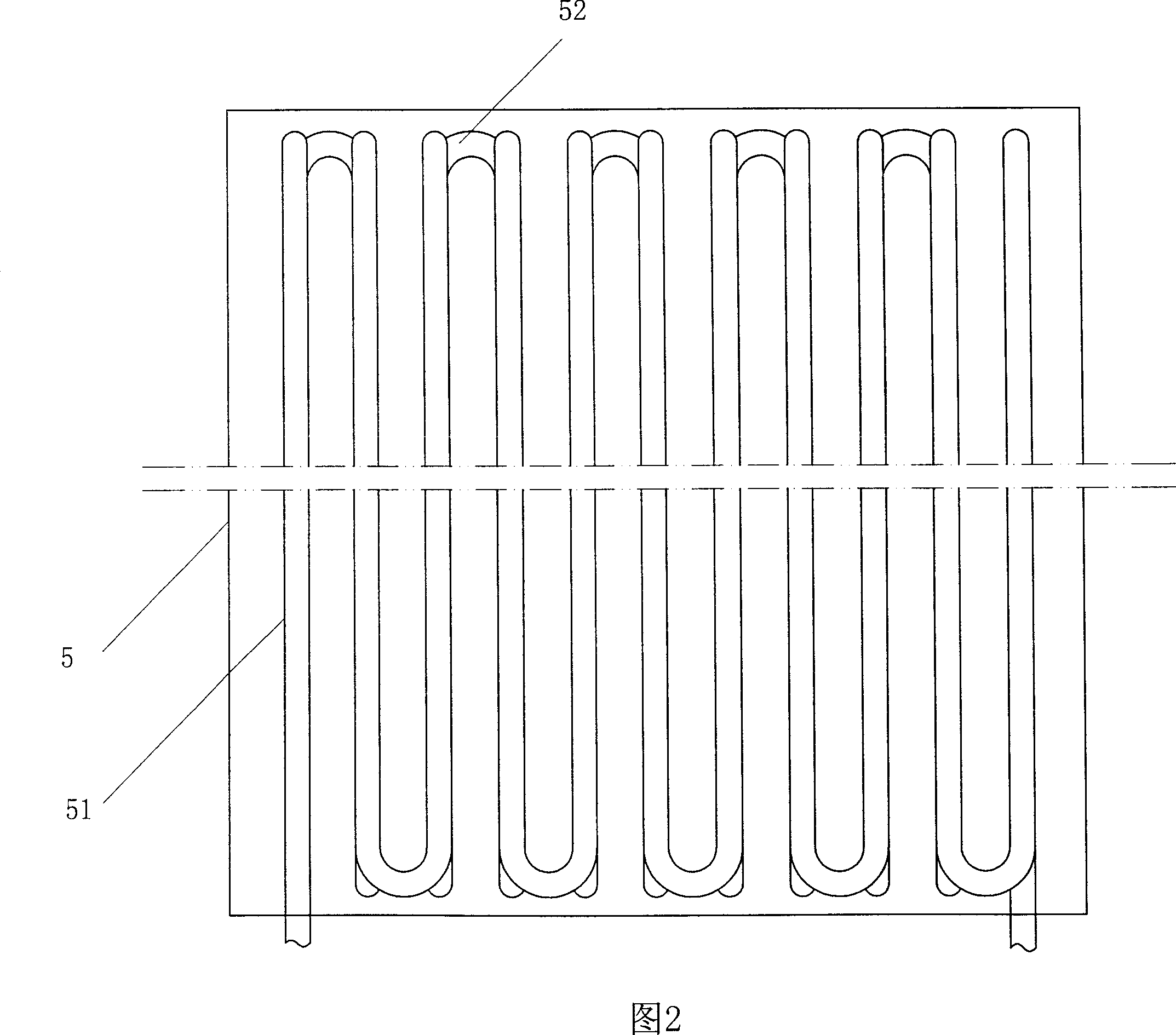

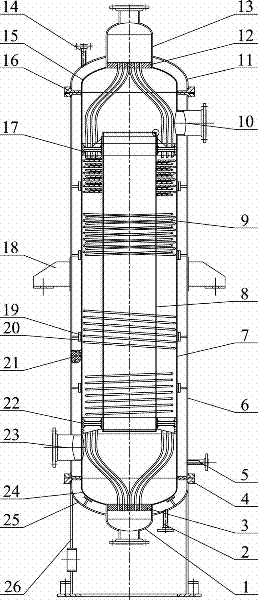

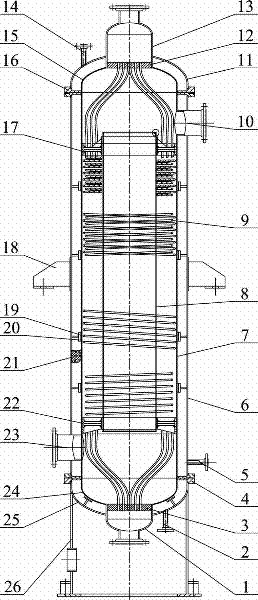

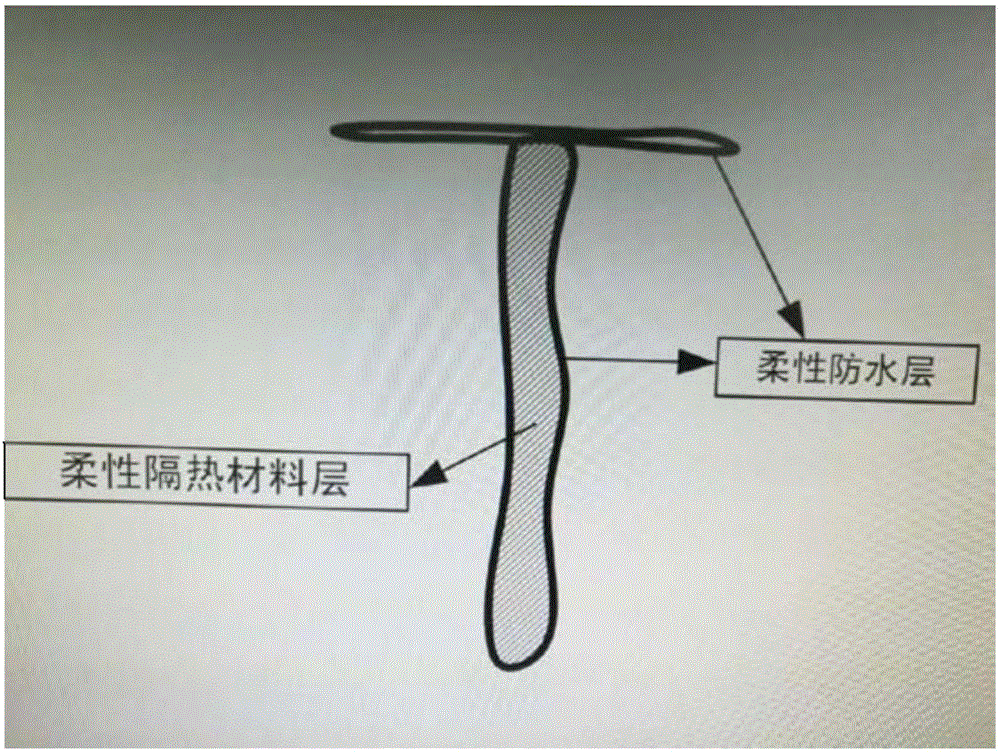

Single-flow low-temperature spiral winding tube type heat exchanger with vacuum heat-insulation effect

InactiveCN102564167AAvoid heat conductionHas low temperature heat transfer characteristicsStationary tubular conduit assembliesMathematical modelEngineering

A single-flow low-temperature spiral winding tube type heat exchanger with a vacuum heat-insulation effect mainly comprises a spiral winding tube bundle and a vacuum shell. A winding equation of a novel spiral tube bundle theory is applied, a mathematical model is built and applied to a numerical simulation process of a flow field, accordingly, a computation method of the tube bundle winding theory is obtained, and the spiral winding tube type heat exchanger is designed and manufactured. The vacuum heat-insulation technology is applied to the single-flow low-temperature spiral winding tube type heat exchanger, a vacuum structure consisting of an upper gland, a lower gland and a barrel which are independent from each other is adopted, and shortcomings that a traditional vacuum structure and a tube nest bundle are combined difficultly and inconvenient in manufacture, installation, detachment and maintenance and the like are overcome. The single-flow low-temperature spiral winding tube type heat exchanger is applicable to technical fields of gas purification and liquefaction separation including natural gas low-temperature liquefaction at the temperature of minus 161 DEG C, air low-temperature liquefaction separation at the temperature of minus 197 DEG C, low-temperature liquid-nitrogen washing at the temperature of minus 197 DEG C, low-temperature methanol washing at the temperature of minus 70 DEG C and the like, low-temperature heat exchange efficiency can be improved, and the single-flow low-temperature spiral winding tube type heat exchanger has the advantages that the single-flow low-temperature spiral winding tube type heat exchanger is compact in structure, heat transfer area of unit volume is large, heat expansion can be automatically compensated, the heat exchanger can be enlarged easily, the quantity of heat exchange equipment can be reduced, and the like.

Owner:张周卫

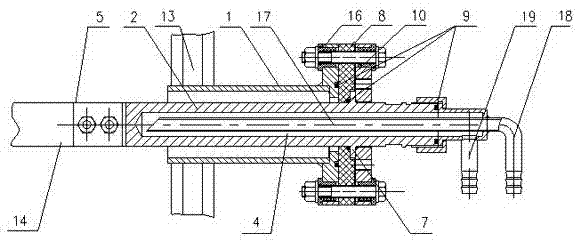

Water-cooled electrode of high temperature vacuum furnace

ActiveCN102519266AEffective lockingWill not age and failElectric heating for furnacesCopperWater cooling

The invention discloses a water-cooled electrode of high temperature vacuum furnace. The water-cooled electrode comprises an electrode seat having a through hole arranged in the center, an electrode bar arranged to penetrate through the electrode seat, an annular mounting boss arranged on the electrode bar, an insulating flange arranged between the electrode seat and the annular mounting boss, a copper flange arranged on the other side of the annular mounting boss, a cooling cavity arranged in the electrode bar, a cooling water pipe arranged in the cooling cavity, a water inlet pipe arranged at the end of the electrode bar close to the copper flange and communicated with the cooling water pipe, a water outlet pipe arranged also at the end of the electrode bar close to the copper flange and communicated with the cooling cavity, a molybdenum connection block arranged at the other end of the electrode bar and connected with a heater, a flange ring arranged on the copper flange and connected with the insulating flange and the electrode seat via bolts, and an insulating sleeve arranged between the flange ring and the copper flange. The invention is suitable for high-temperature high-vacuum environments, and has reliable and effective insulation and long service life.

Owner:CSSC SHENGHUI EQUIP

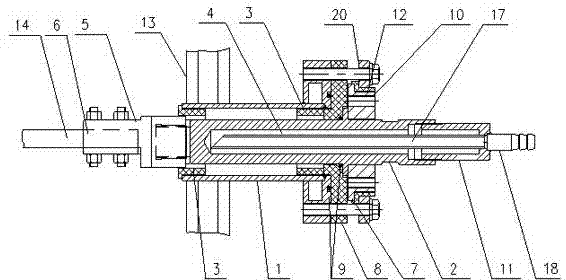

Flexible heat preservation assembly

ActiveCN105909918AImprove insulation effectInsulate from heatThermal insulationPipe protection by thermal insulationInsulation layerMetal foil

The invention relates to a flexible heat preservation assembly. The flexible heat preservation assembly is characterized in that the flexible heat preservation assembly comprises one or more layer of heat insulation reflecting component and heat insulation layers, wherein the heat insulation reflecting component comprises metal foil pieces and flexible heat insulation mats, and the flexible heat insulation mats are clamped between the metal foil pieces; and the number of the flexible heat insulation layers is more than one. The flexible heat preservation assembly is good in heat preservation performance, and heat emitted by high-temperature equipment can be effectively isolated; and in addition, the flexible heat preservation assembly is flexible in arrangement and economical, and the number of layers of the stacked structure can be set according to requirements.

Owner:BEIJING HAORUISEN TRADE +1

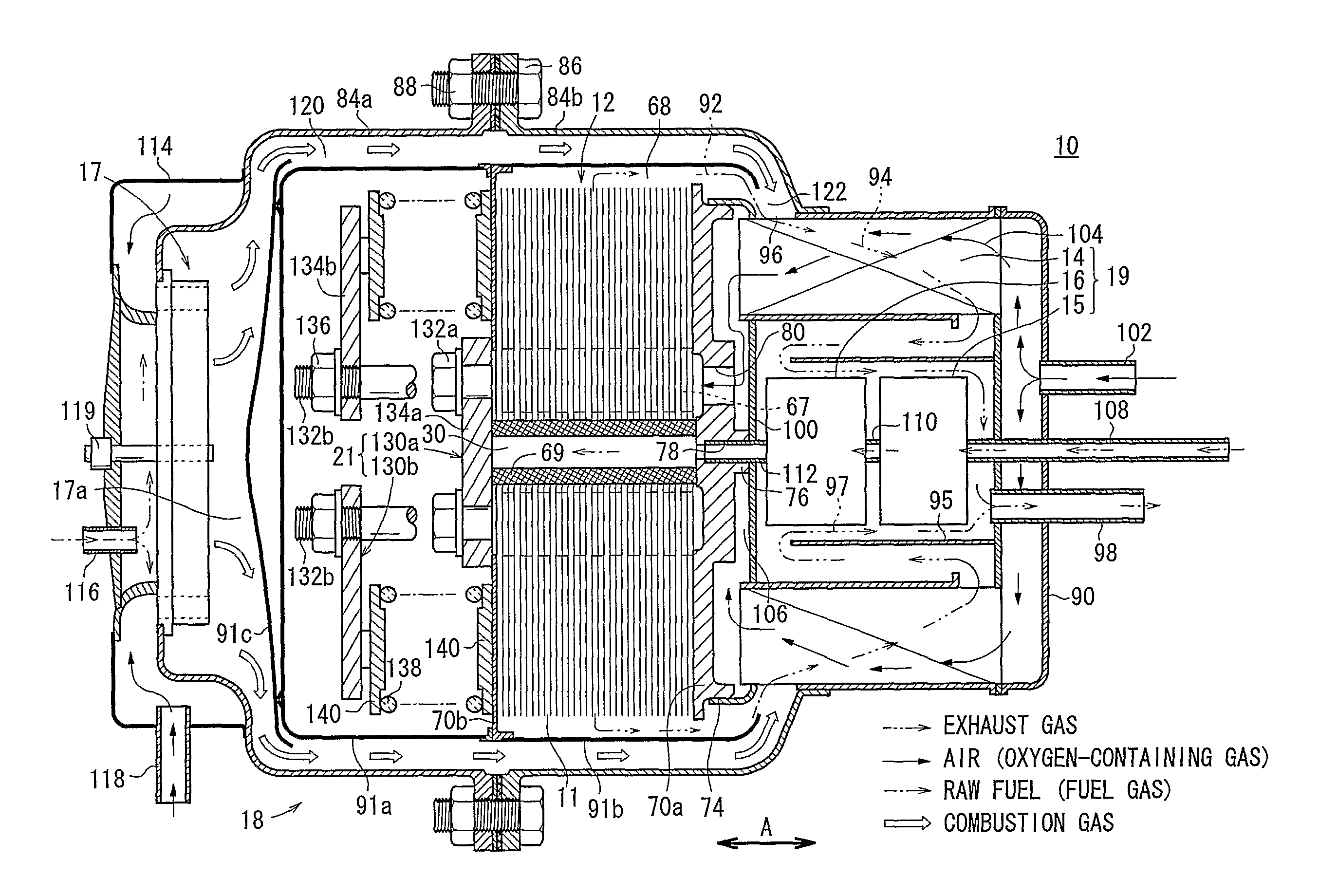

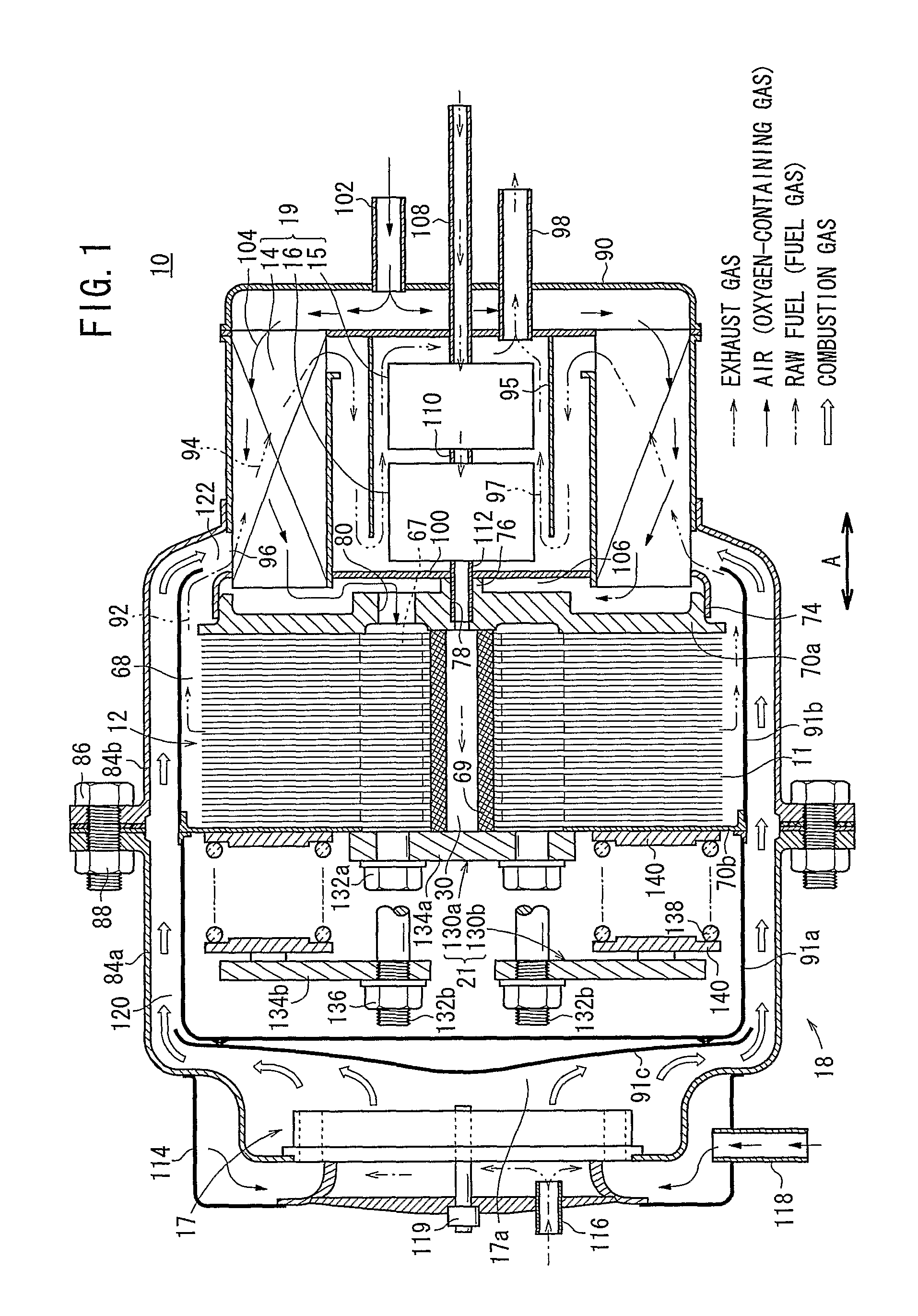

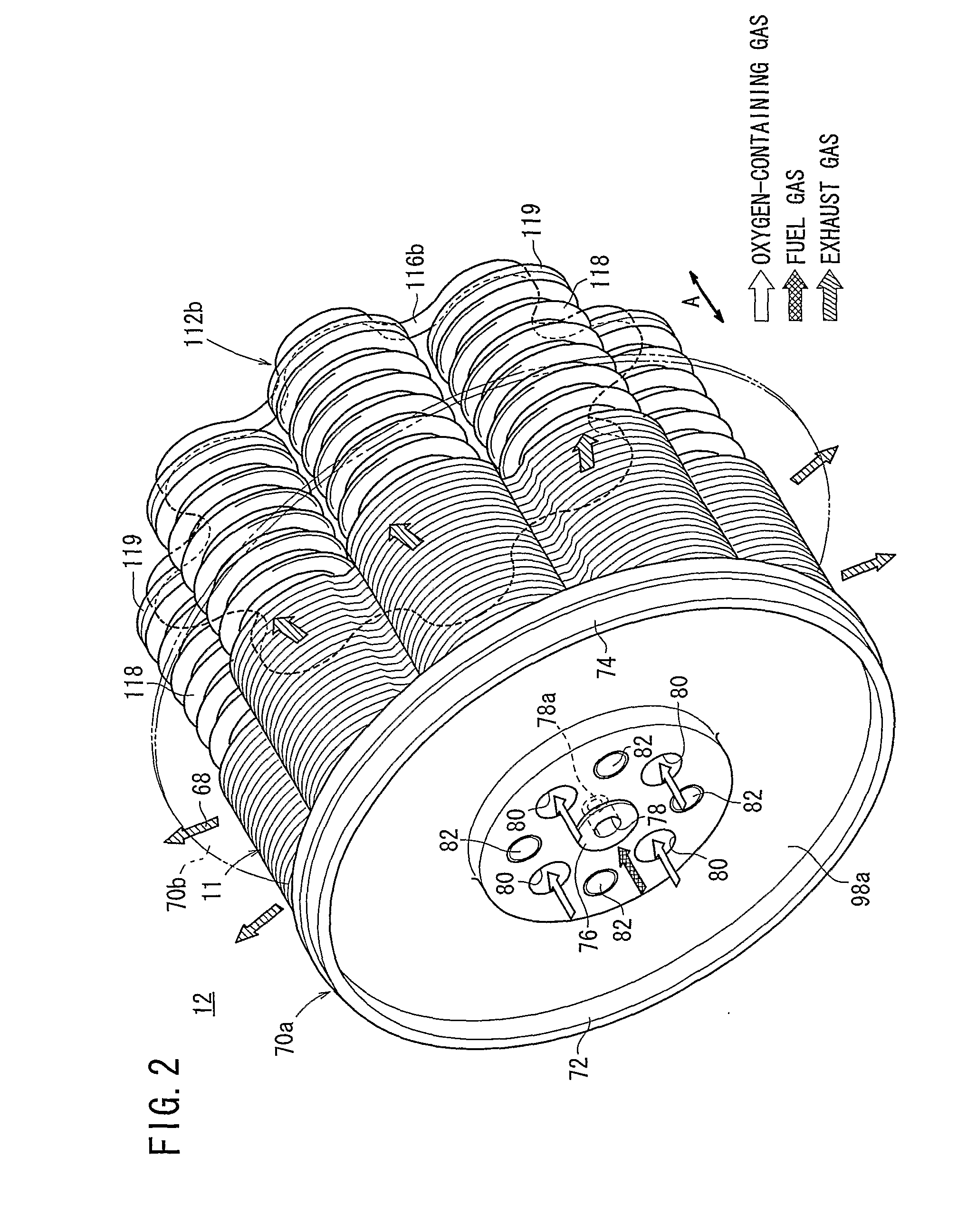

Fuel cell system

ActiveUS20090263689A1Simple structureIncreased durabilityFuel cells groupingFuel cell auxillariesCombustorFuel cells

A fuel cell system includes a fuel cell stack, a heat exchanger, a reformer, and a combustor. A combustion gas path for supplying the combustion gas produced in the combustor to the heat exchanger as the heat medium is provided. The combustion gas path is provided between a space of dual walls comprising a first inner plate and a second inner plate and a first case unit and a second case unit accommodating a load applying mechanism and the fuel cell stack.

Owner:HONDA MOTOR CO LTD

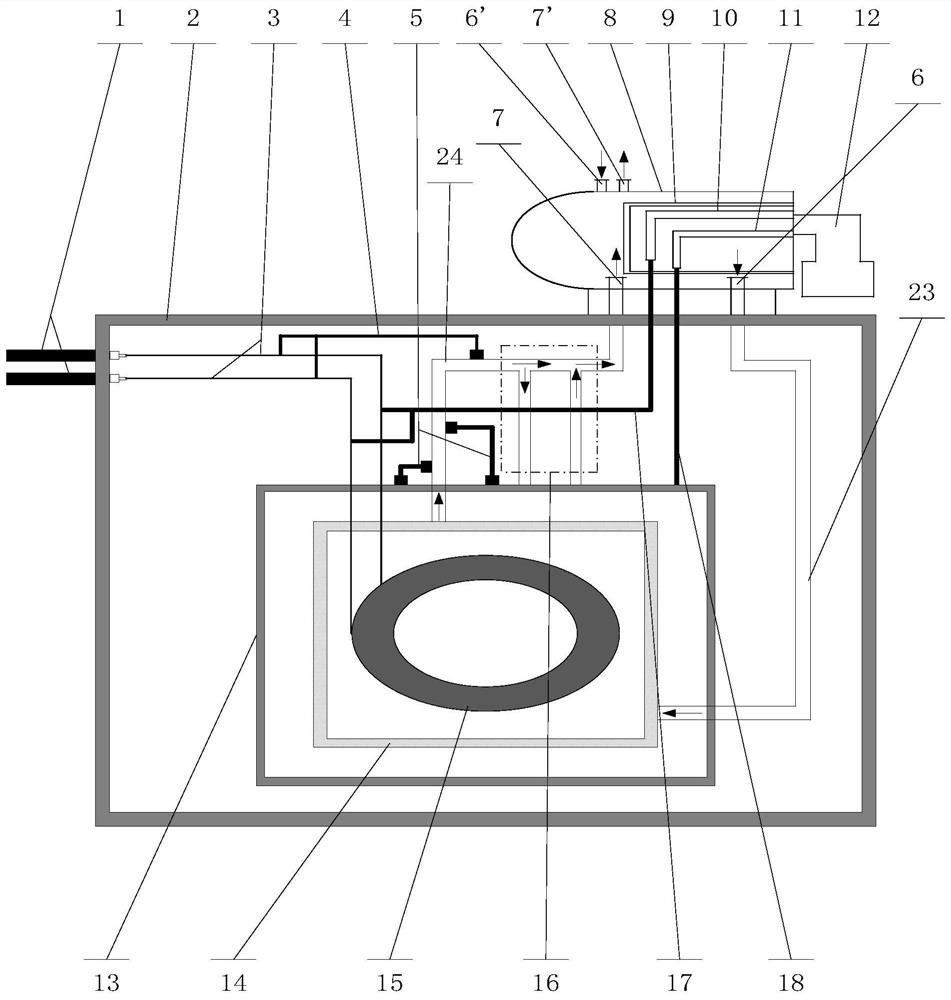

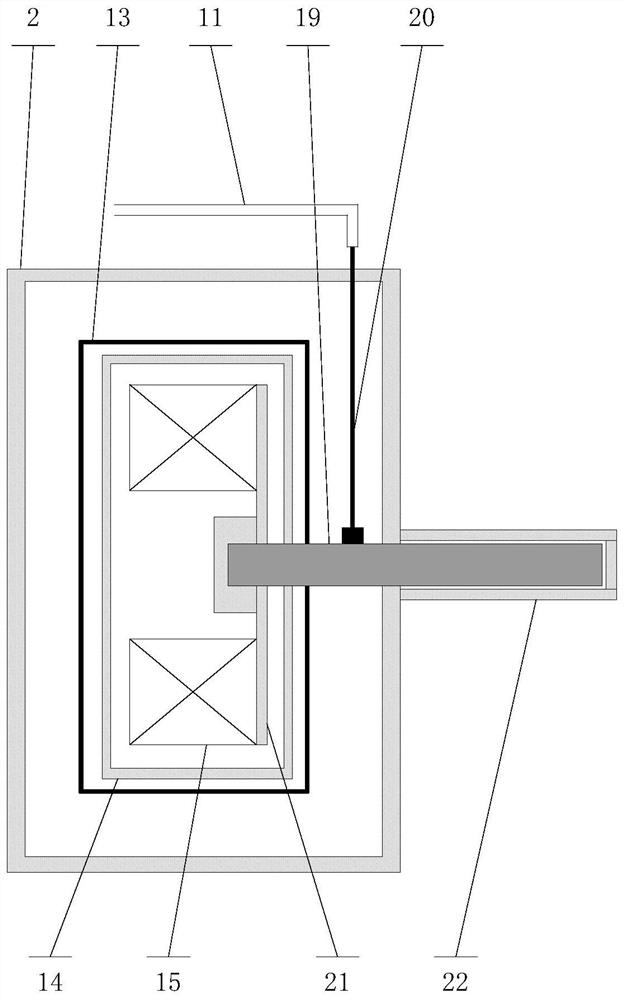

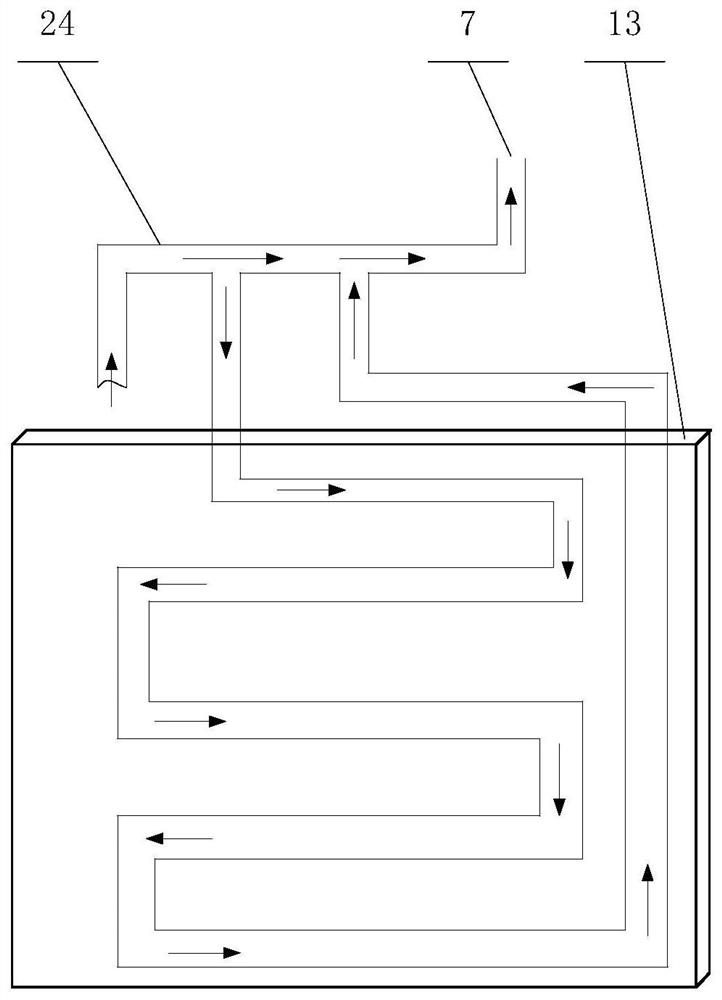

Refrigerating system of low-temperature superconducting magnet

ActiveCN113035486APrevent heat leakagePrevent heat radiationSuperconducting magnets/coilsSustainable buildingsPower applicationSuperconducting Coils

The invention belongs to the technical field of superconducting power application, and discloses a refrigerating system of a low-temperature superconducting magnet. The refrigerating system comprises a cold shield, a lead cooling channel, a cold shield cooling channel, a first liquid helium input opening, a first helium output opening, a helium tank, a liquid helium input pipe and a helium output pipe; the cold shield is arranged outside a low-temperature superconducting coil; the helium tank is arranged between the cold shield and the low-temperature superconducting coil and does not make contact with the cold shield and the low-temperature superconducting coil; the liquid helium input pipe and the helium output pipe are both connected with the helium tank; liquid helium is injected into the helium tank from the first liquid helium input opening through the liquid helium input pipe; helium volatilized from the helium tank is output from the first helium output opening through the helium output pipe; the lead cooling channel is connected between the helium output pipe and a superconducting current lead and is used for guiding cold to cool the superconducting current lead; the cold shield cooling channel is connected between the helium output pipe and the cold shield and is used for conducting cold to cool the cold shield. Therefore, volatilization of liquid helium can be effectively reduced, and the risk of quenching of the low-temperature superconducting magnet is reduced.

Owner:HIWING TECH ACAD OF CASIC

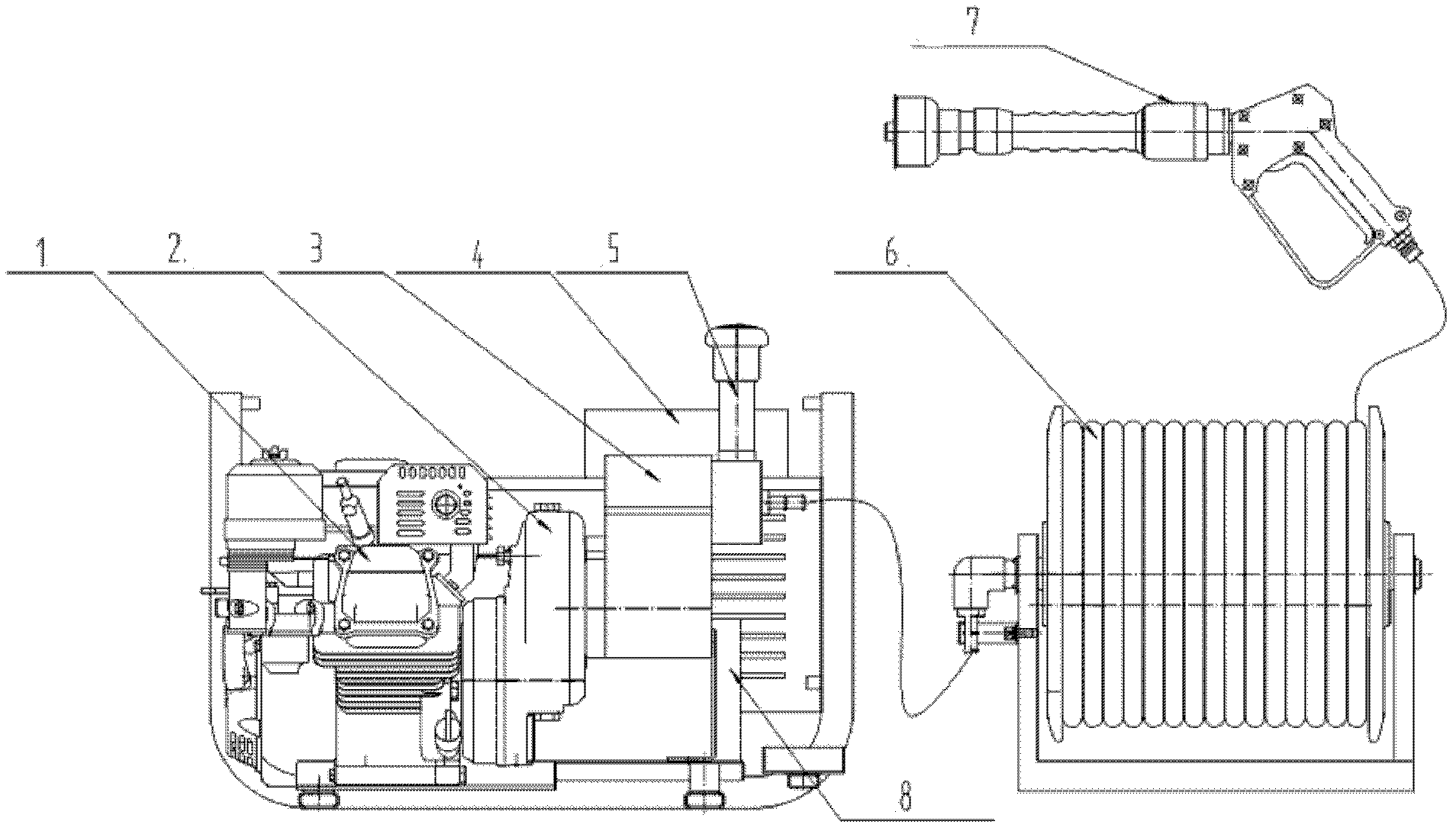

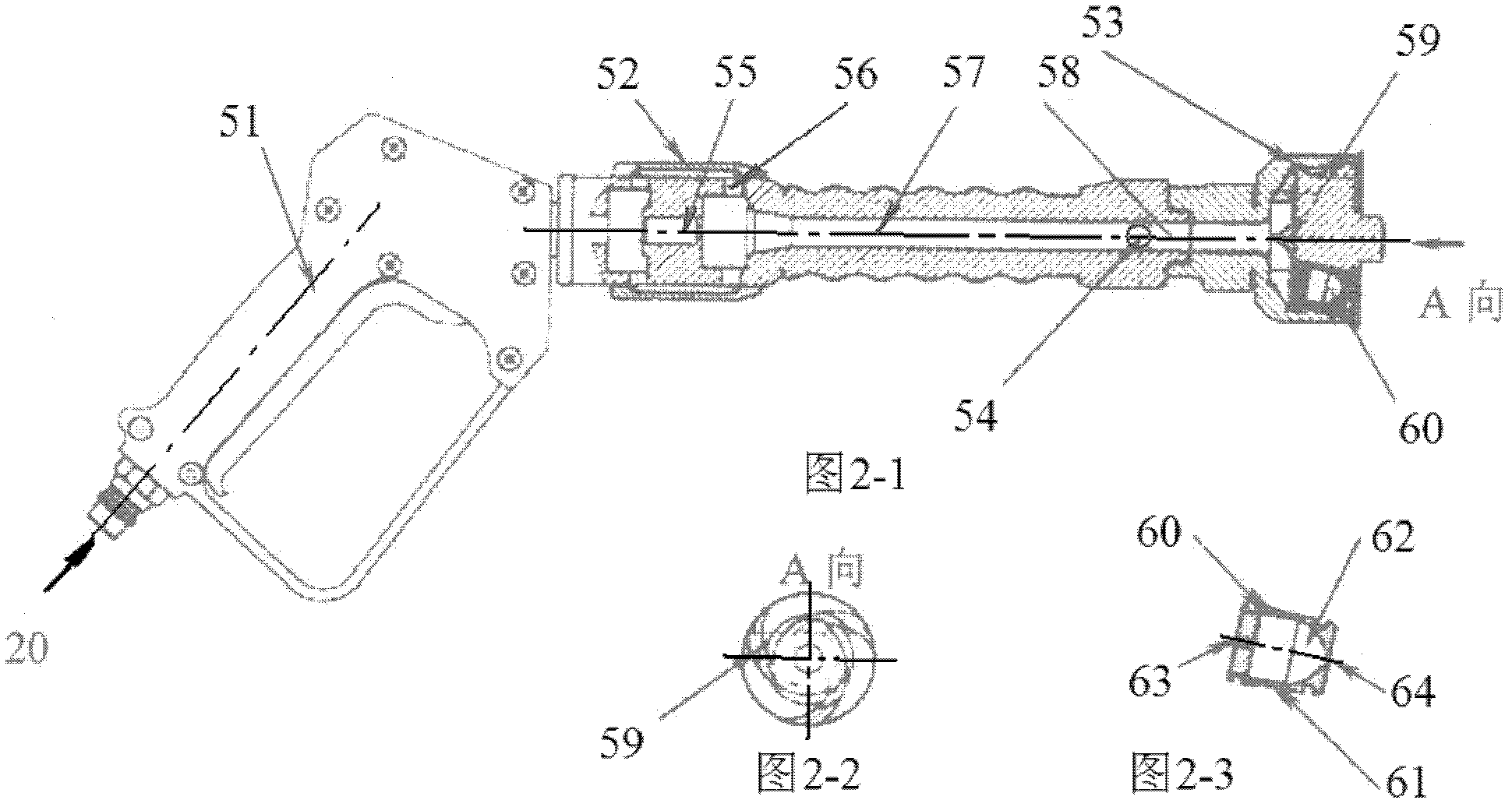

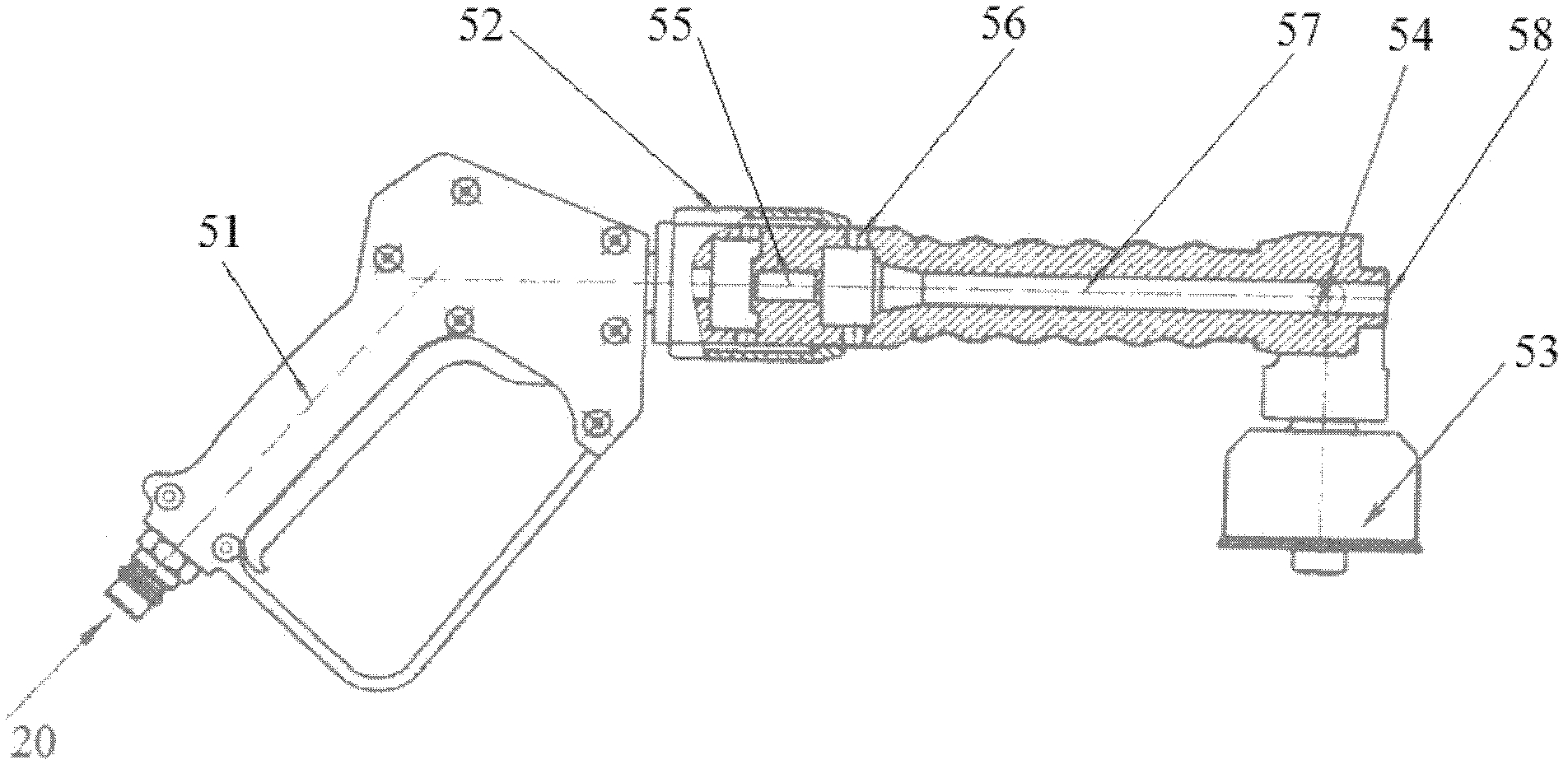

Automatic control clutch type water mist fire extinguishing device

InactiveCN102302834ARealize automatic controlReduce wasteFire rescueControllers with discontinuous output signalAutomatic controlAgricultural engineering

The invention belongs to the field of fire extinguishing and rescue equipment and provides an automatic control clutch type water mist fire extinguishing device. The automatic control clutch type water mist fire extinguishing device comprises an engine, a water pump, a pressure adjusting valve, a hose reel and a water mist spray gun and is characterized by also comprising a clutch type reduction box, an automatic control system and a foam adding system, wherein the engine is connected with the water pump through the clutch type reduction box; the pressure adjusting valve is arranged at a water outlet of the water pump; the hose reel is connected with the pressure adjusting valve; the water mist spray gun is connected with the hose reel; the automatic control system controls the engine and the foam adding system; and the foam adding system is connected with an inlet of the water pump. The automatic control clutch type water mist fire extinguishing device realizes automatic control of a machine set so as to realize unmanned management after the device is started, save unnecessary waste of fuel oil and water, effectively prolong service life of equipment and save labor.

Owner:TIANJIN TIMELYRAIN IND & TRADING

Laminated insulator of low-temperature thermal-insulative composite nanometer material

InactiveCN1895885AIncrease the average reflectanceReduce heat transferLaminationLamination apparatusCalcium silicatePolyester

A multi-layer heat isolator used as the low-temp heat-insulating surface layer of LNG ship or tank is prepared through plating zirconium oxide or zirconium oxide-aluminum oxide film on both surfaces of polyester or polyamide film by sol-gel method to form a reflecting screen, preparing the composite SiO2 aerogel-calcium silicate nanoparticles by sol-gel method, solvent replacing and surface modifying to obtain an isolating substance, and alternatively in-situ sticking to obtain a (3-50)-layer heat isolator (reflecting screen-isolating substance-reflecting screen-isolating substance).

Owner:上海暄能工程材料有限公司

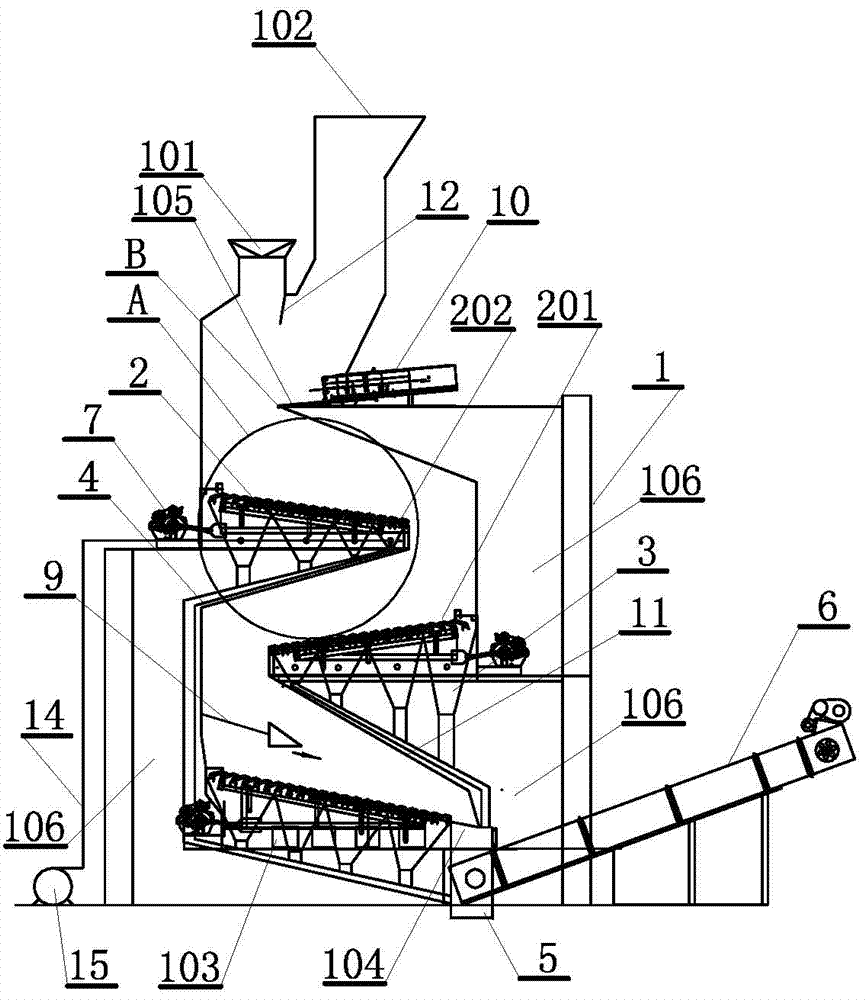

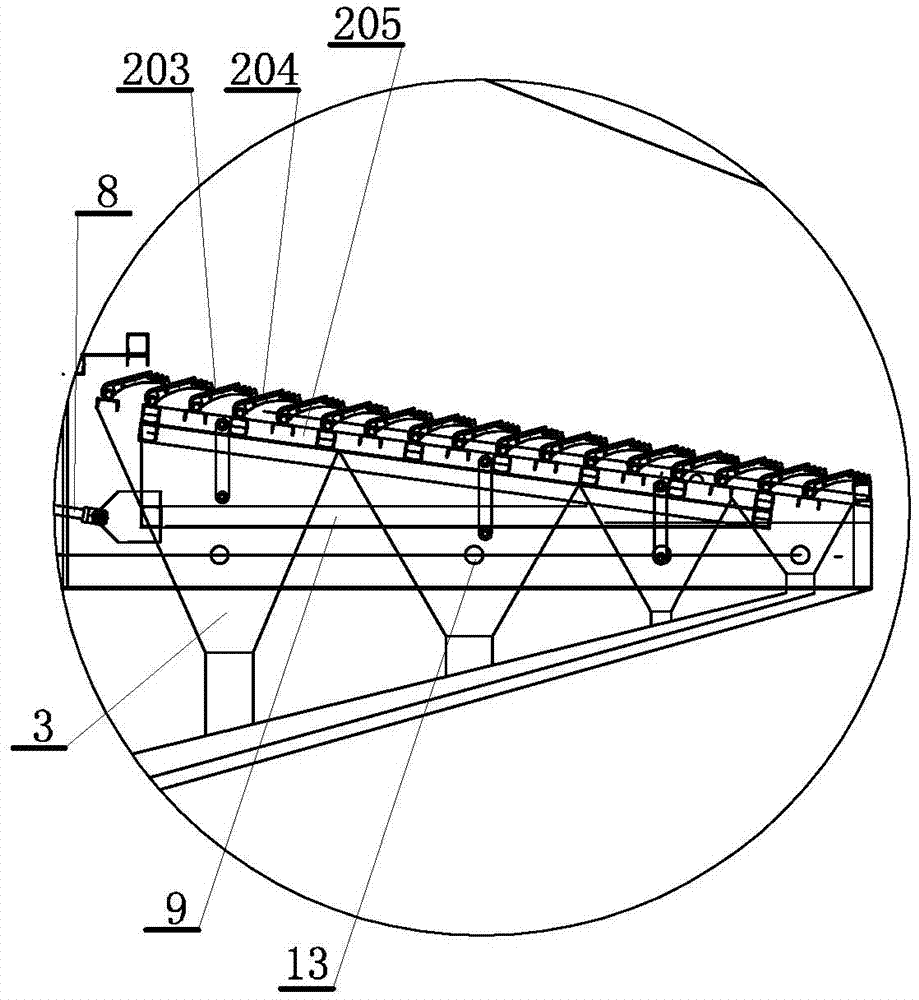

Multi-layer reciprocating type gasified combustion furnace

PendingCN107131503ASmall sizeLarge amount of disposalInclined grateIncinerator apparatusCombustionSlag

The invention discloses a multi-layer reciprocating type gasified combustion furnace comprising a combustion furnace body. A gasified fume discharging outlet and a gasified raw material garbage feeding inlet are formed in the upper end of the combustion furnace body, and a combustion gas inlet and a slag tapping outlet after combustion of gasified raw material garbage are formed in the lower end side of the combustion furnace body; a hearth in the furnace body is vertically provided with multiple layers of furnace rows from top to bottom; each layer of furnace row is arranged in a downward-inclining mode; the high end sides of the furnace rows at the lower layers stretch out of the low end sides of the furnace rows at the upper layers to enable the gasified raw material garbage on the furnace rows at the upper layers to fall into the high end sides of the furnace rows at the lower layers from the low end sides of the upper layers along the inclining gradient; and dust receiving funnels are arranged on the bottom face of the furnace row at each layer and connected with a dust discharging pipeline to output dust from the bottom side of the combustion furnace body. Because the garbage is fully dried and dehydrated through the multiple layers of furnace rows in the hearth, the heat value is increased, the combustion effect is more full, the structure is simple, the size of the combustion furnace is decreased greatly, investment is reduced, thermal decomposition gasified combustion of the furnace row at each layer can be achieved, and the application range of raw materials is wide.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

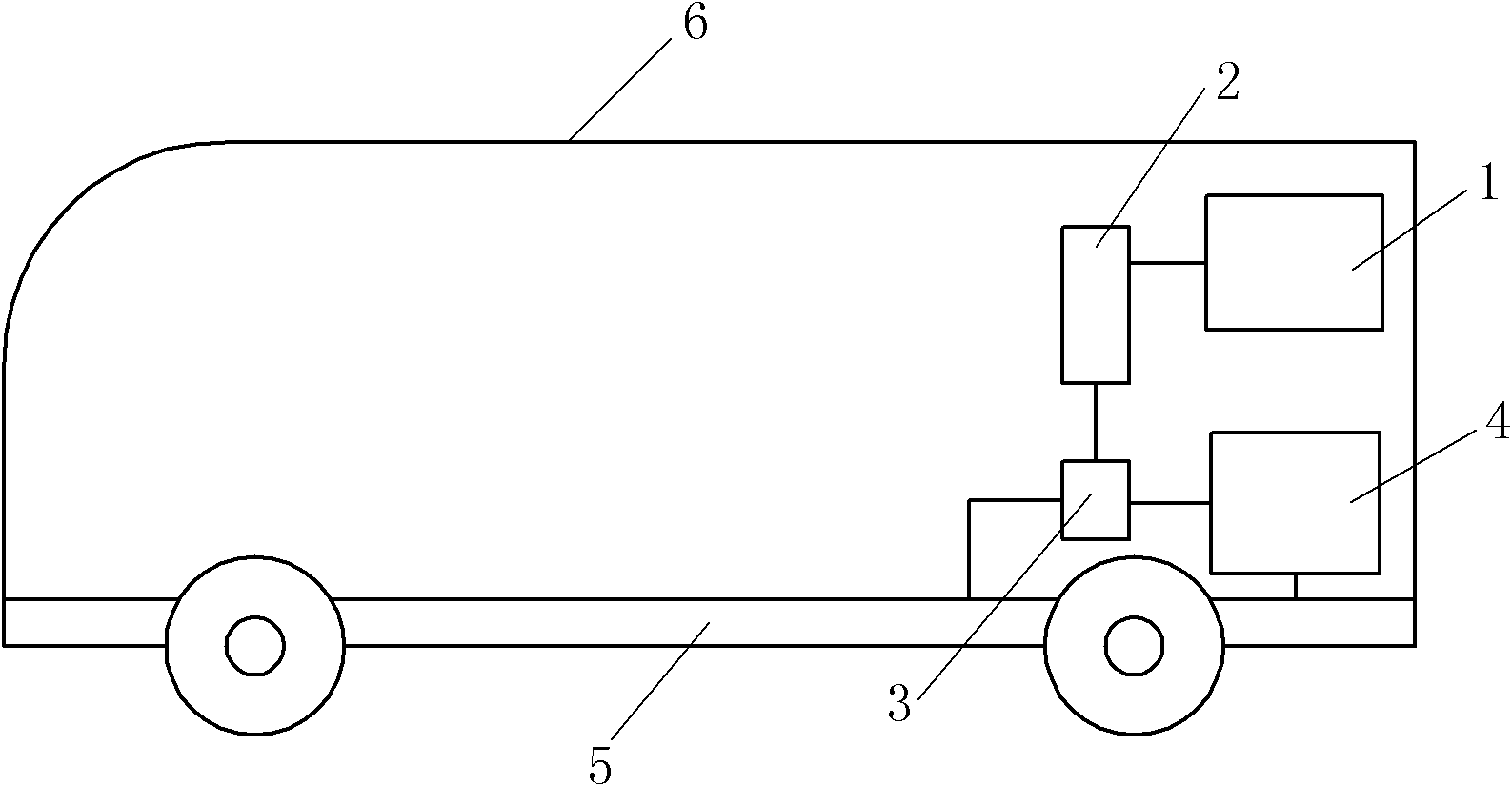

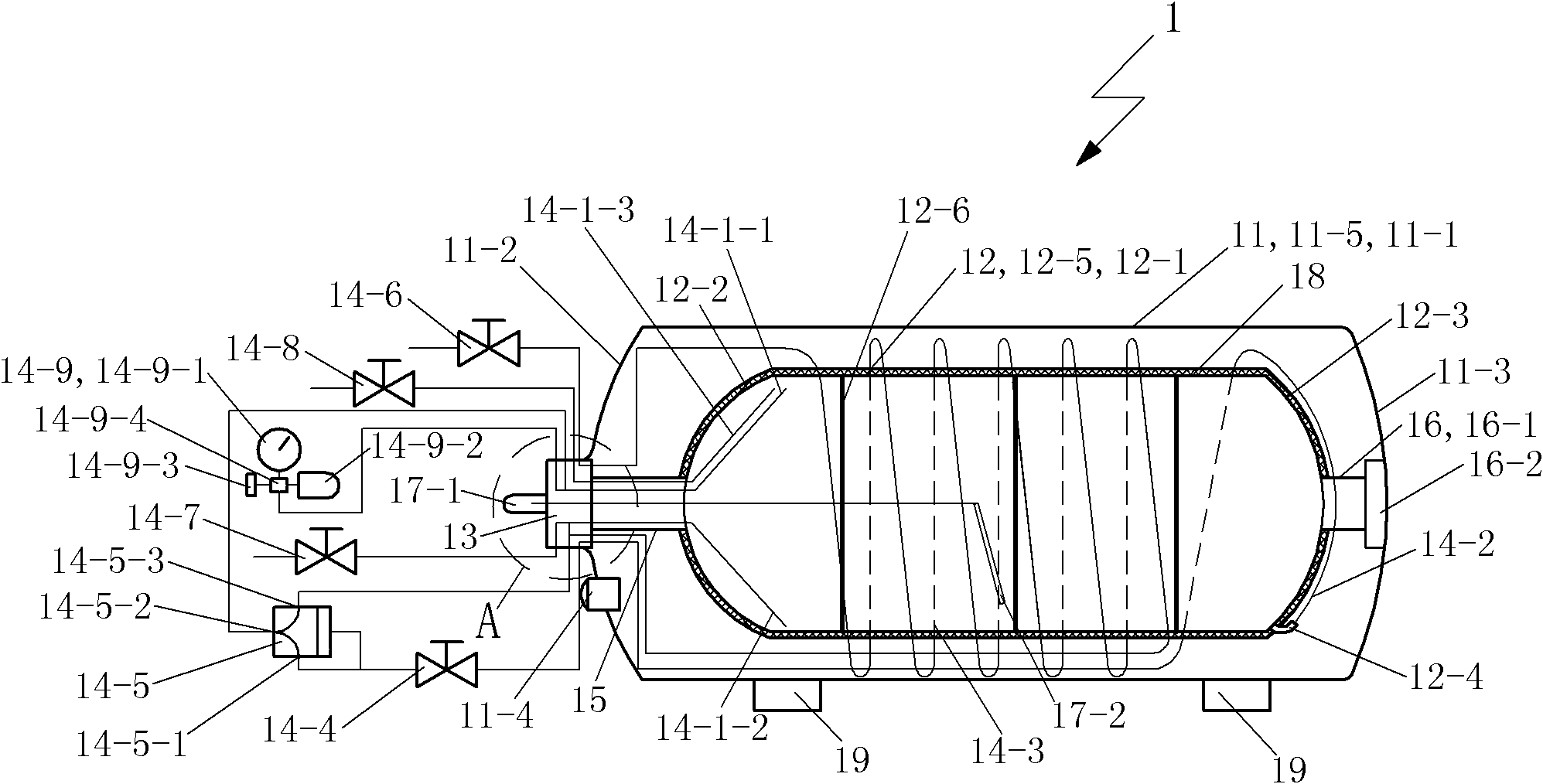

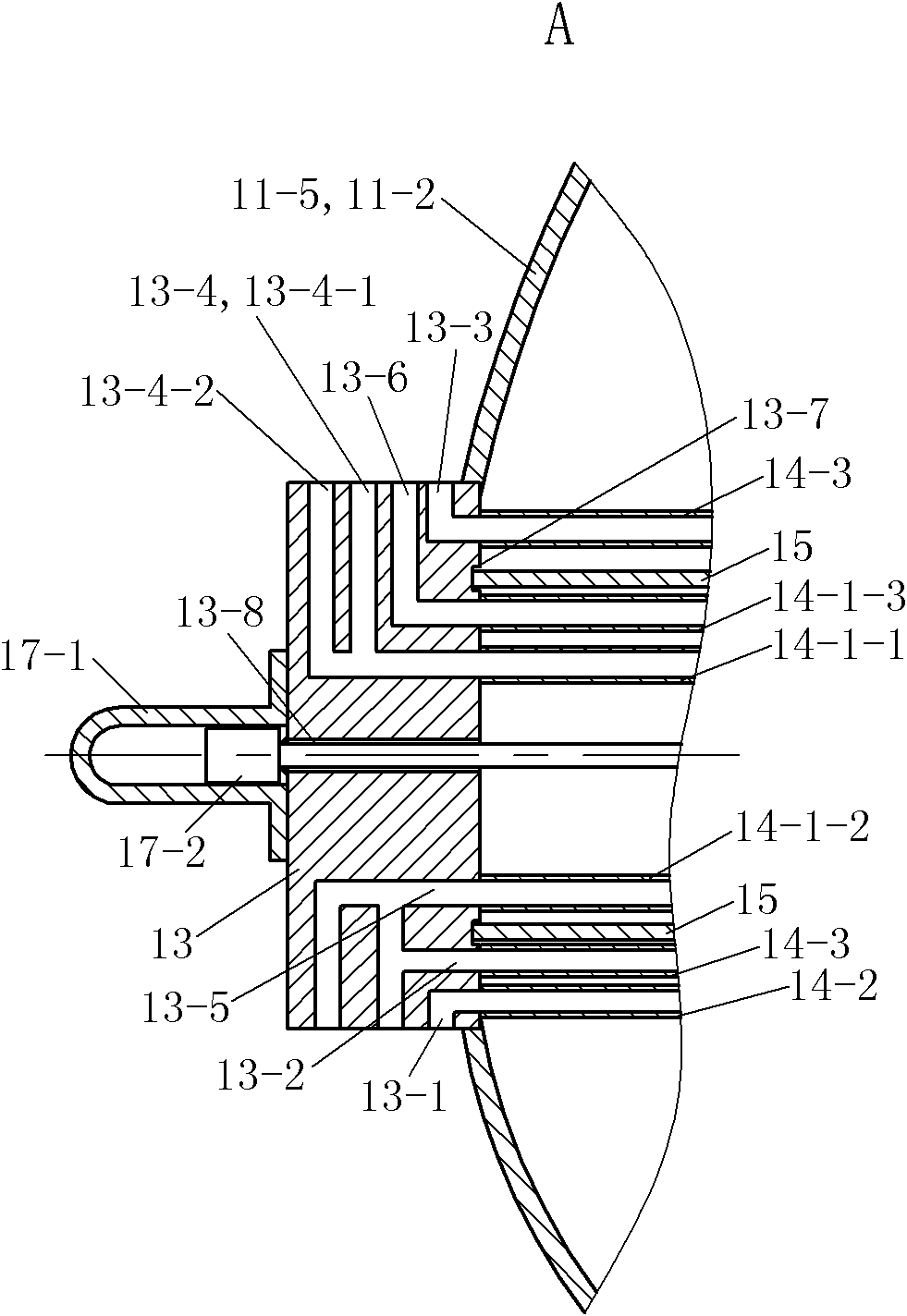

Horizontal low-temperature insulating air cylinder and vehicle power system taking gas as power source

InactiveCN102147049AGood insulation performanceIncrease storage capacityContainer filling methodsPressure vesselsTransmission systemEngineering

The invention relates to a horizontal low-temperature insulating air cylinder which comprises a casing, an internal cylinder, a distributor, a cylinder pipeline of a pipeline control system, a neck tube, a supporting piece and an insulating layer. The invention further relates to a vehicle power system taking gas as a power source, which comprises the horizontal low-temperature insulating air cylinder, a gasifier, a pressure regulating tank, an air engine, an operation and control mechanism, a power source control pedal, a chassis and a vehicle body; the power source control pedal is connected with a power input part of the operation and control mechanism; a power output part of the operation and control mechanism is connected with a control rod of a control valve of the pressure regulating tank; a gas outlet of the horizontal low-temperature insulating air cylinder is connected with a gas inlet of the gasifier through a connecting pipe; a gas outlet of the gasifier is connected with a gas inlet of the pressure regulating tank through a connecting pipe; a gas outlet of the pressure regulating tank is connected with a gas inlet of the air engine through a connecting pipe; a power output part of the air engine is connected with a power input part of a transmission system of the chassis; and the power source control pedal is connected with the control end of the control valve of the pressure regulating tank through the operation and control mechanism.

Owner:丁雨福

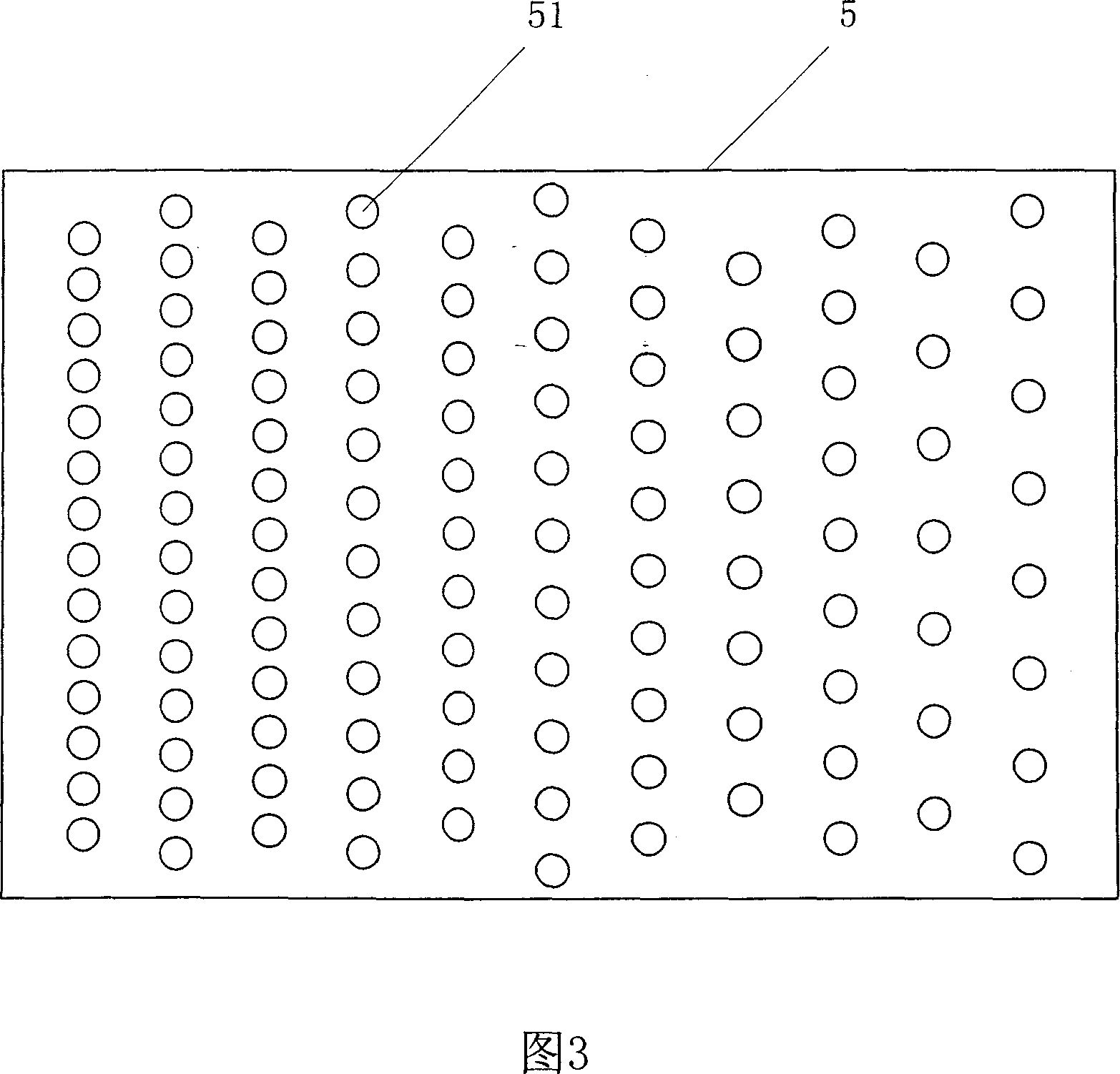

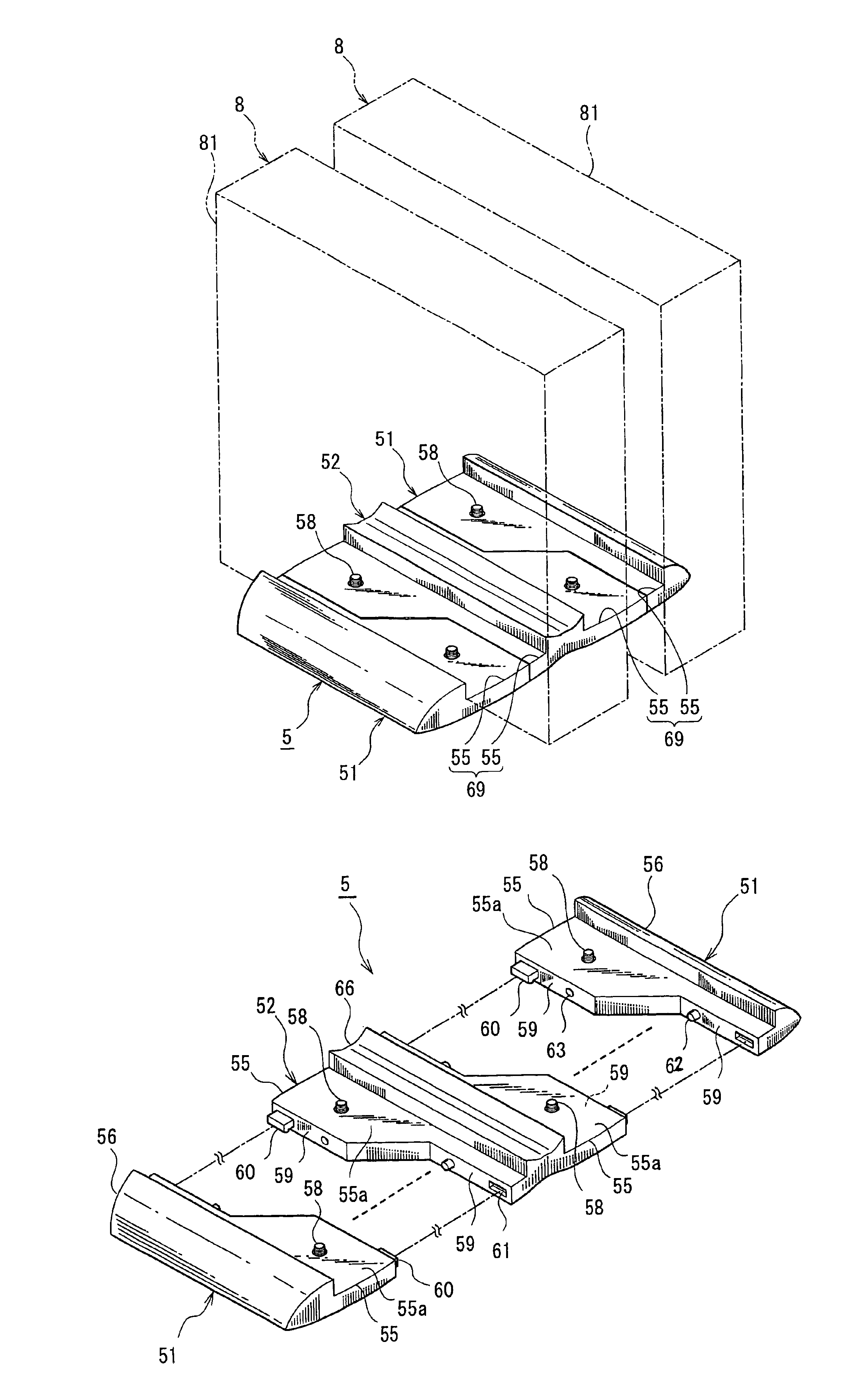

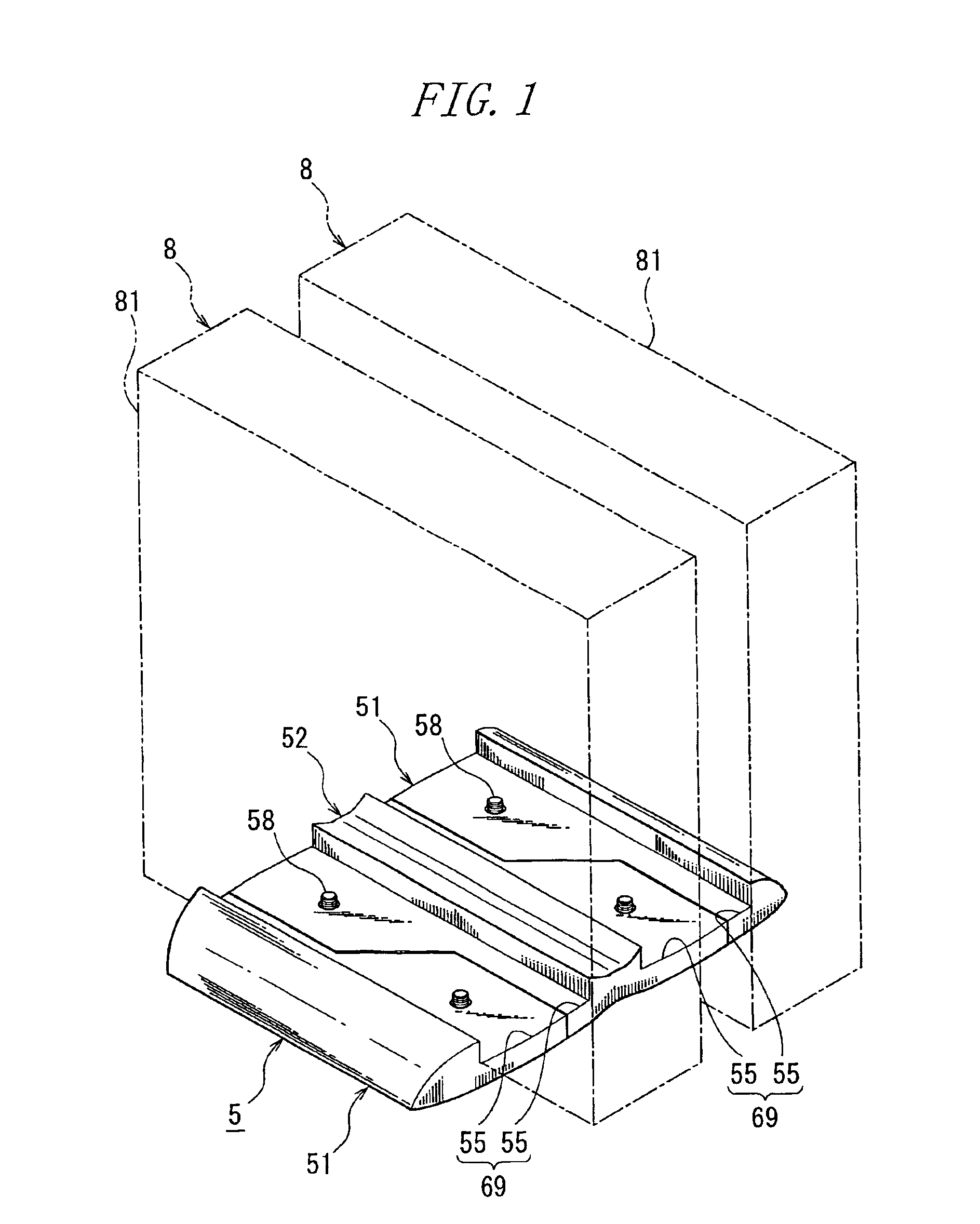

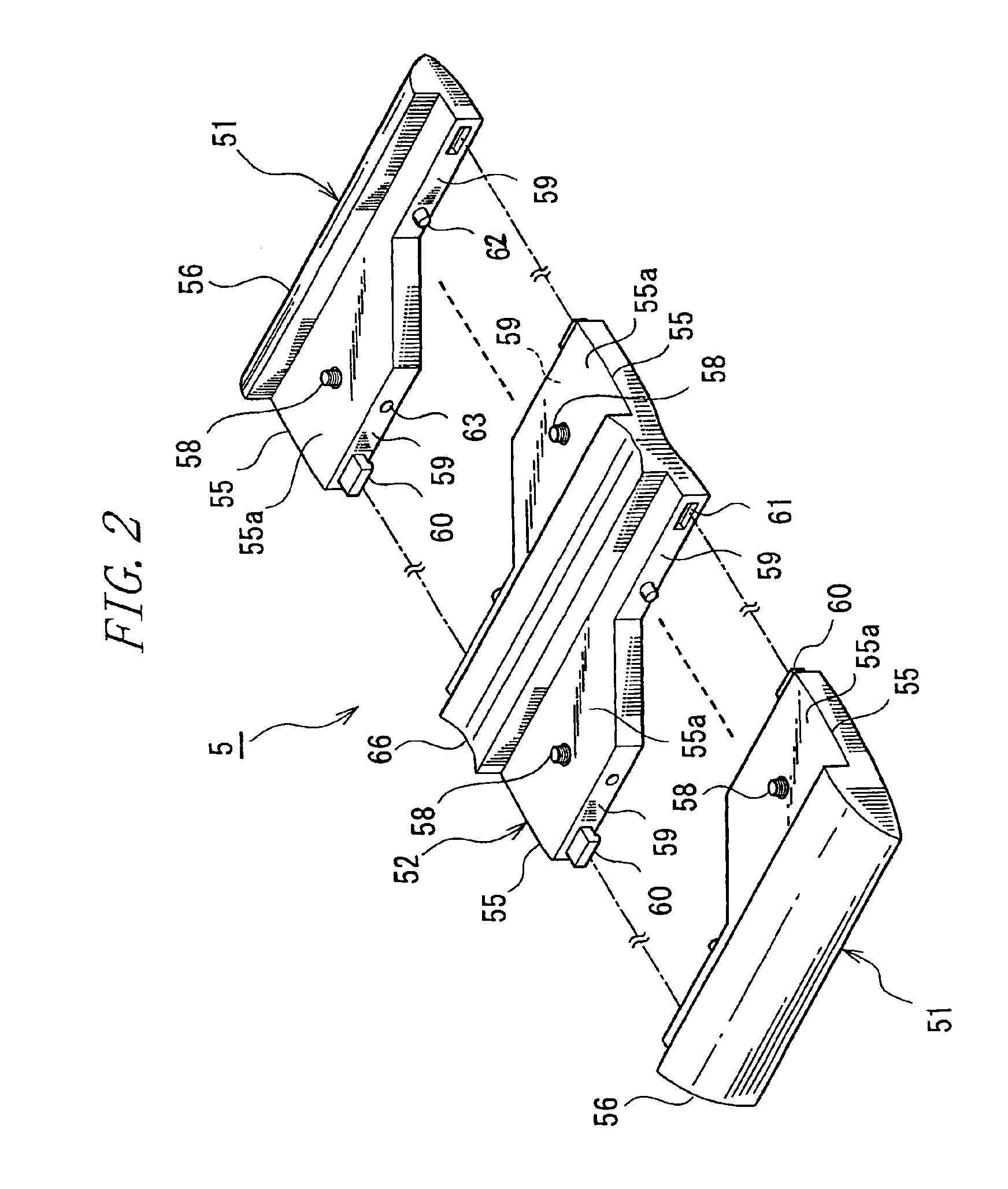

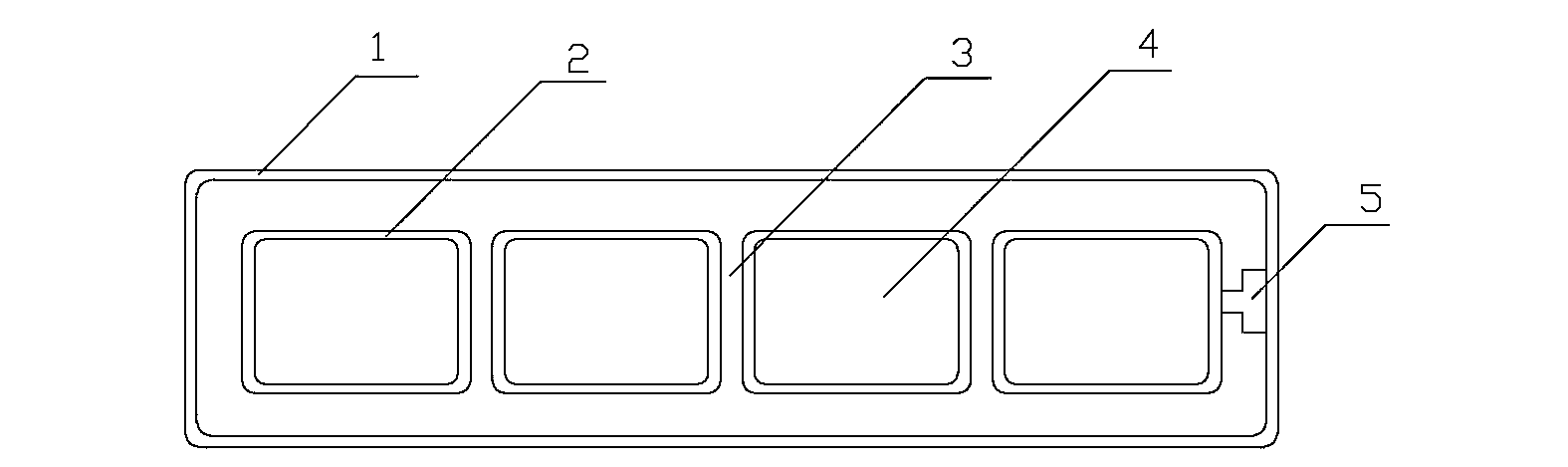

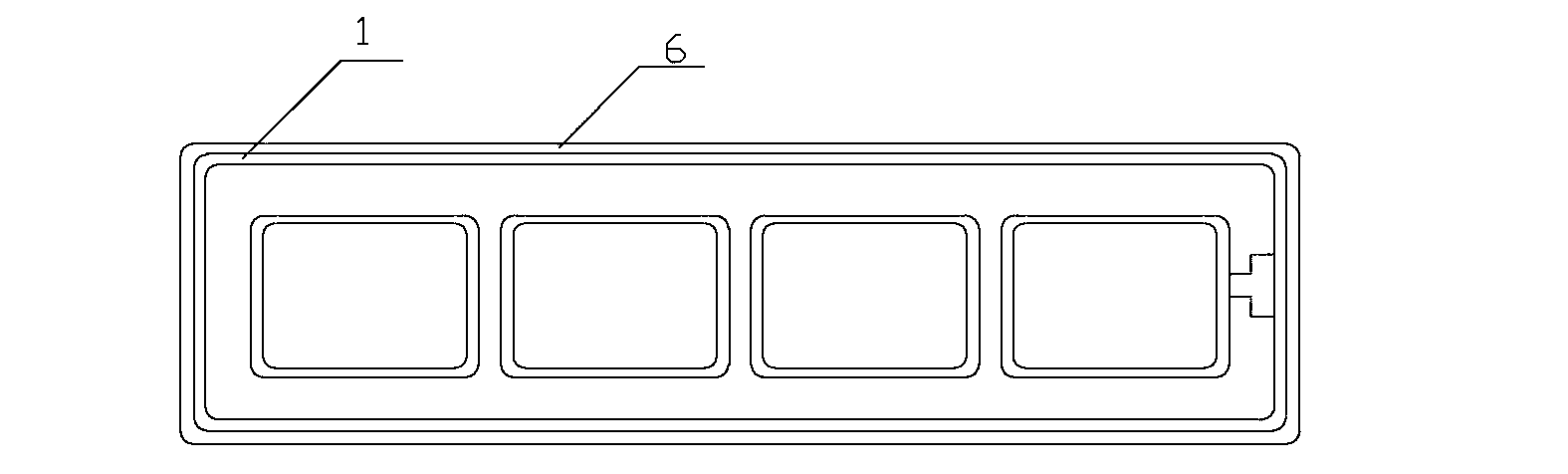

Stand for installing plurality of box bodies

InactiveUS6923414B2Avoid radiation interferenceReduce excess spacePortable framesCasings/cabinets/drawers detailsEngineeringMechanical engineering

A stand for installing a plurality of box bodies is capable of reducing a space needed for installing the plurality of box bodies in parallel and preventing interference with heat radiation of each box body. A stand 5 for installing a plurality of each box bodies 81 in parallel includes a pair of outer stands 51, 51 holding the box bodies 81 disposed on the outer sides from the sides of outer surfaces of the box bodies 81, a middle stand 52 disposed between these outer stands 51, 51 and holding both of the box bodies 81, 81 adjacent to each other from the face-to-face sides thereof, and a connection mechanism detachably connecting the stands 51 52.

Owner:FUJITSU LTD

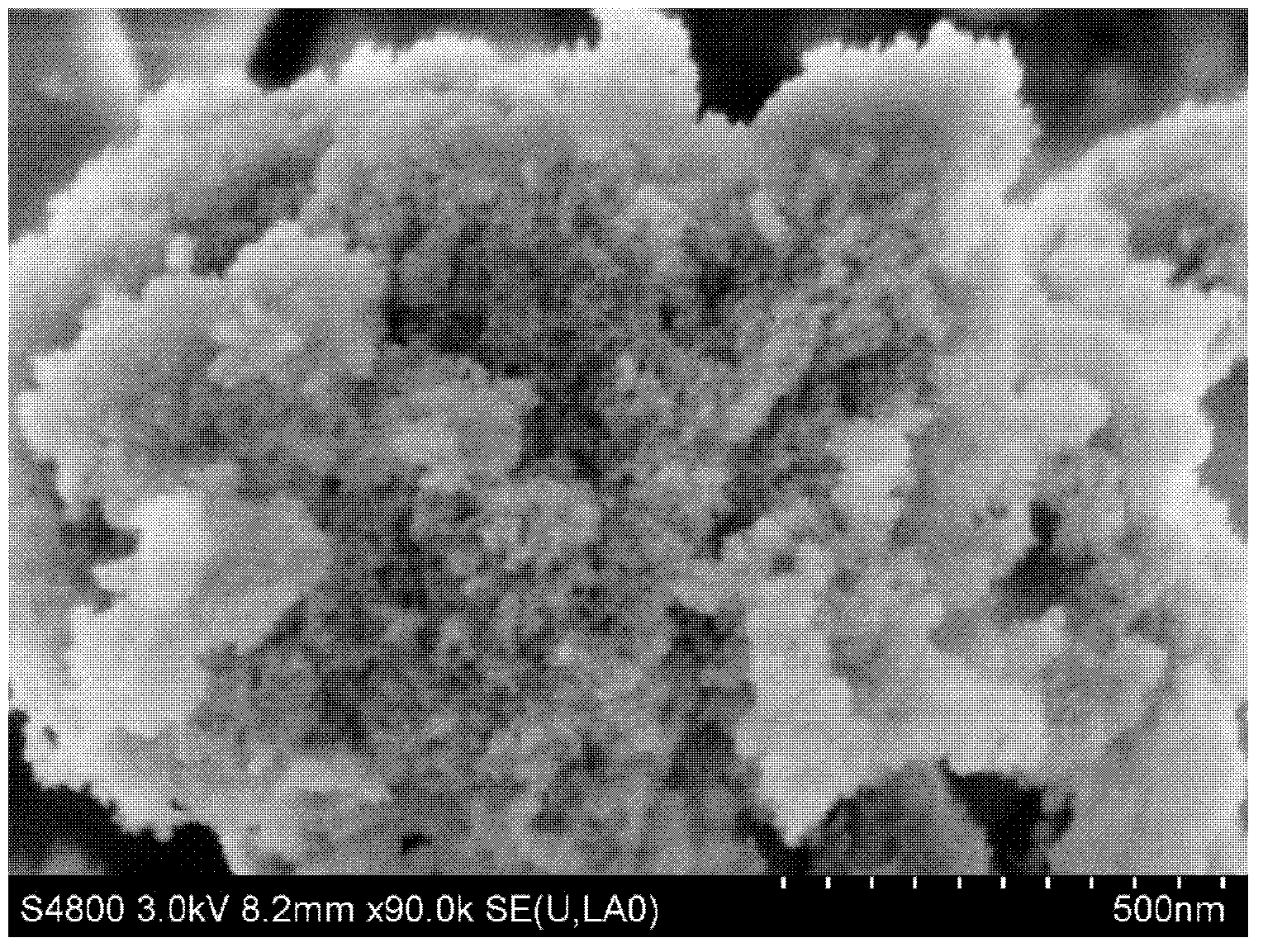

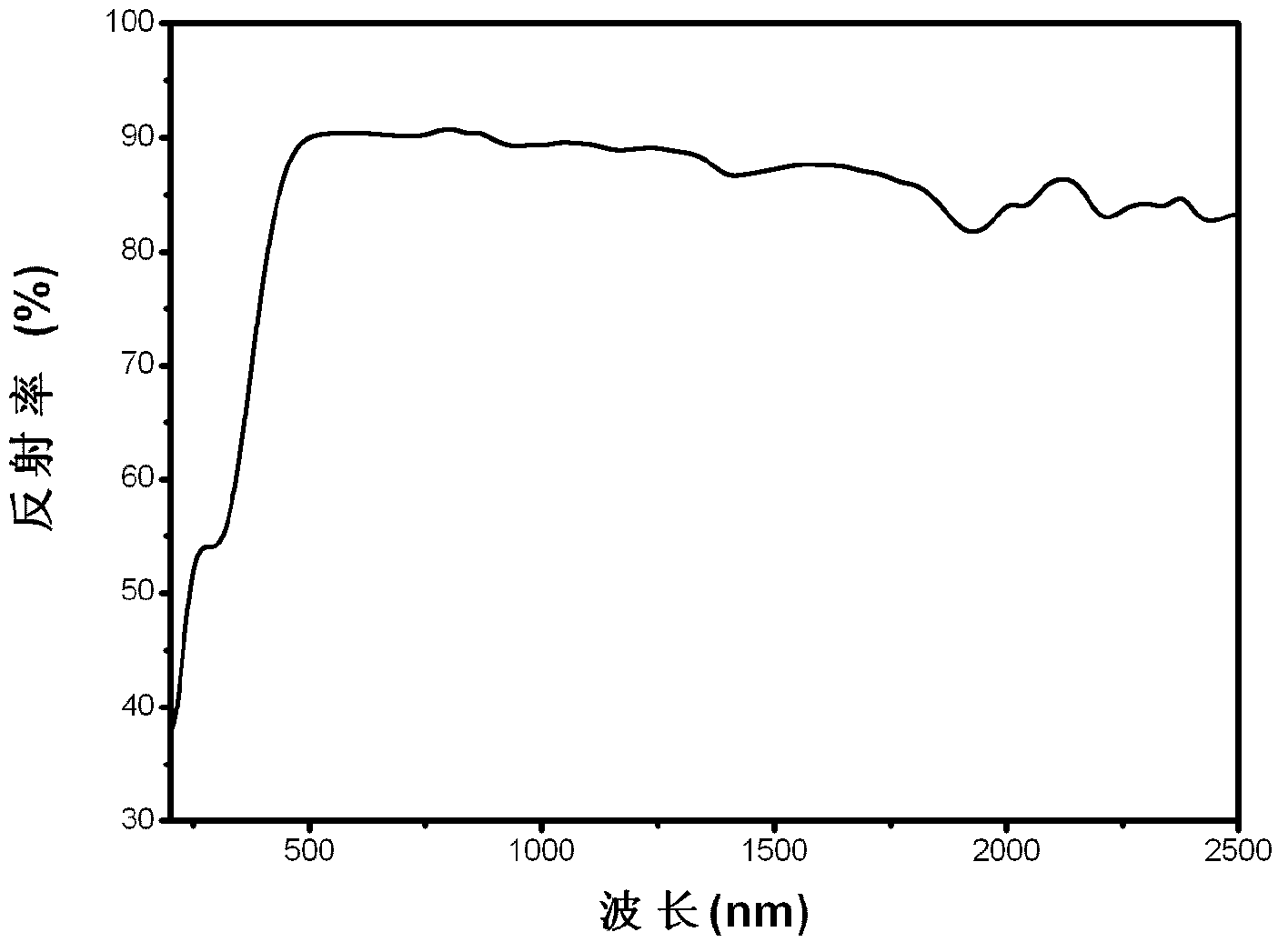

Heat-reflecting heat-insulation inorganic composite material as well preparation method and application thereof

InactiveCN102585572APrevent heat radiationHas anti-ultraviolet damage functionFibre treatmentRadiation-absorbing paintsMicro nanoThermal insulation

The invention discloses a heat-reflecting heat-insulation inorganic composite material as well a preparation method and an application thereof. The heat-reflecting heat-insulation inorganic composite material is a micron / nano composite material which takes alumina, titanium oxide and silicon oxide as substrates and is doped with one or a plurality of rare-earth elements such as yttrium, cerium and lanthanum. The inorganic composite material prepared by using a liquid phase method, a liquid phase coating method and a solid phase mixing method can be used for preparing a heat-reflecting thermal-insulation heat-insulation coating. The heat-reflecting heat-insulation inorganic composite material has the beneficial effects that 1) the reflectivity of the heat-reflecting heat-insulation inorganic composite material on a heat ray can be above 90%, the thermal radiation of sun and thermal radiation of other thermal radiation sources can be effectively prevented, ultraviolet ray can be absorbed, and the heat-reflecting heat-insulation inorganic composite material has an ultraviolet ray harm resistant function; 2) the heat-reflecting heat-insulation inorganic composite material is an inorganic solid material which does not contain an organic solvent and has the beneficial effects that is the material is safe and non-toxic, has stable chemical property and stable heat reflecting thermal insulation performance, is easy to store for a long term, and the like; and 3) the preparation technology is simple and easy to operate, the raw material is easy to obtain and cheap, the reaction process is almost free from industrial three wastes, thus the preparation technology has the characteristics of green production and environment-friendly application and is suitable for industrial production.

Owner:SHANGHAI NORMAL UNIVERSITY

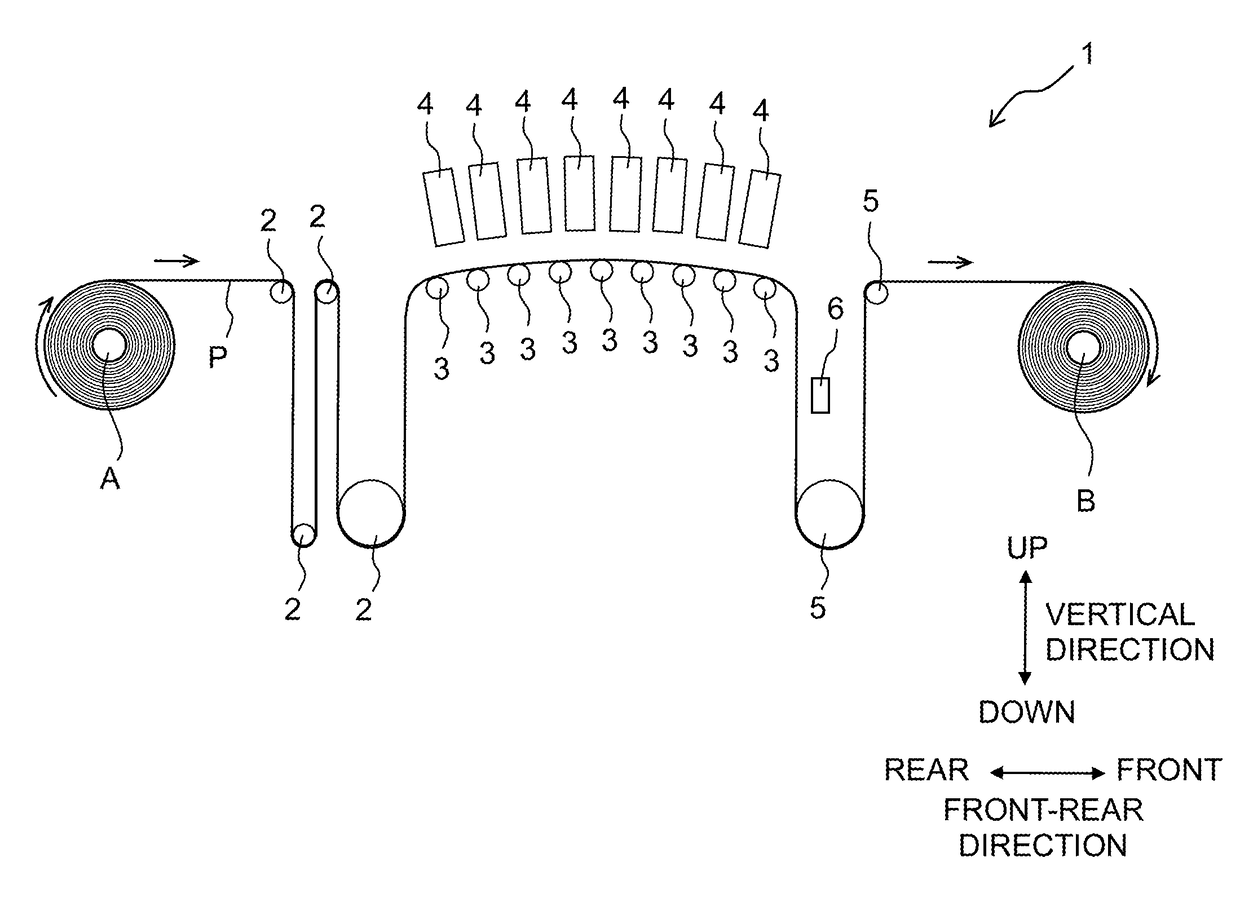

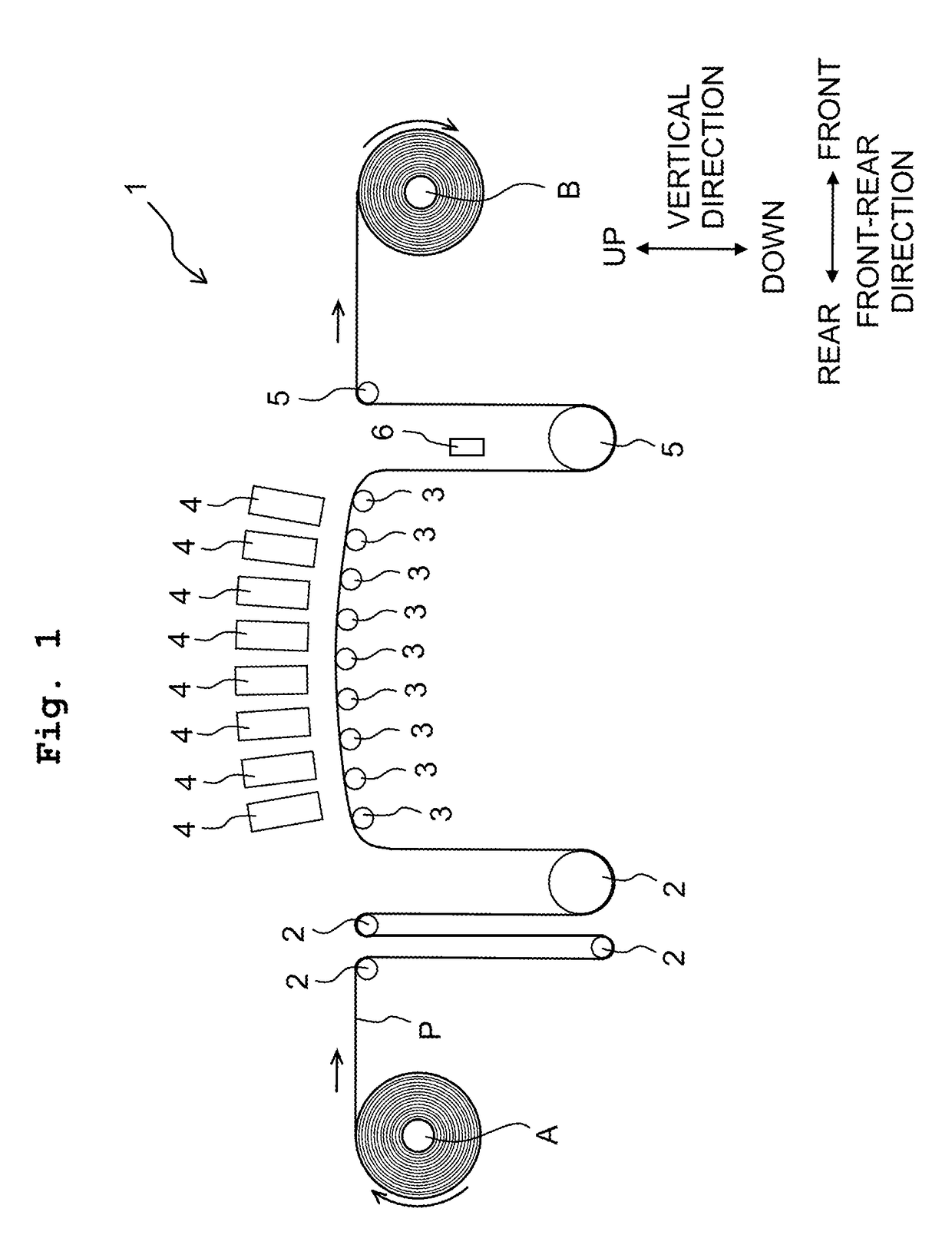

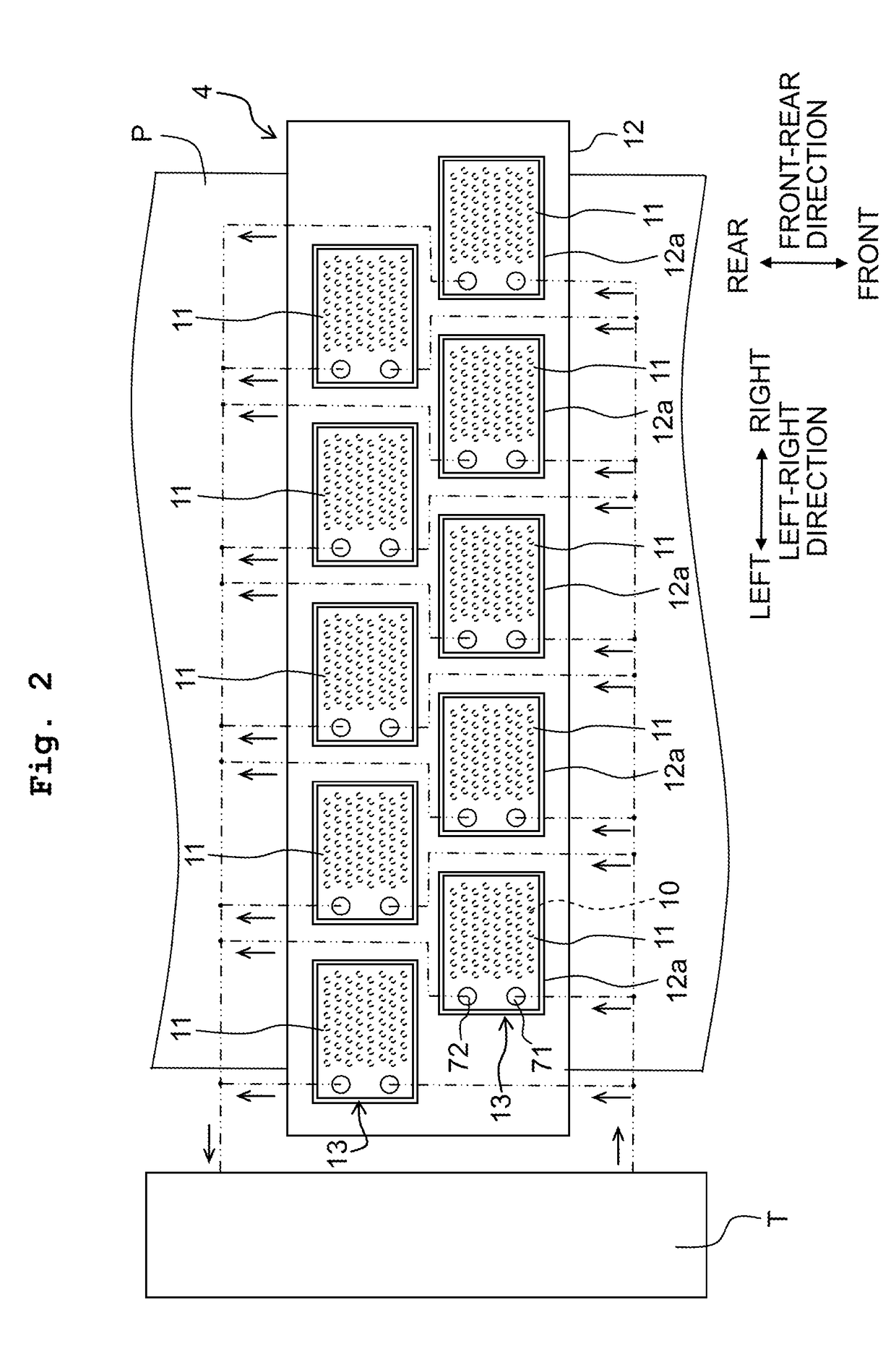

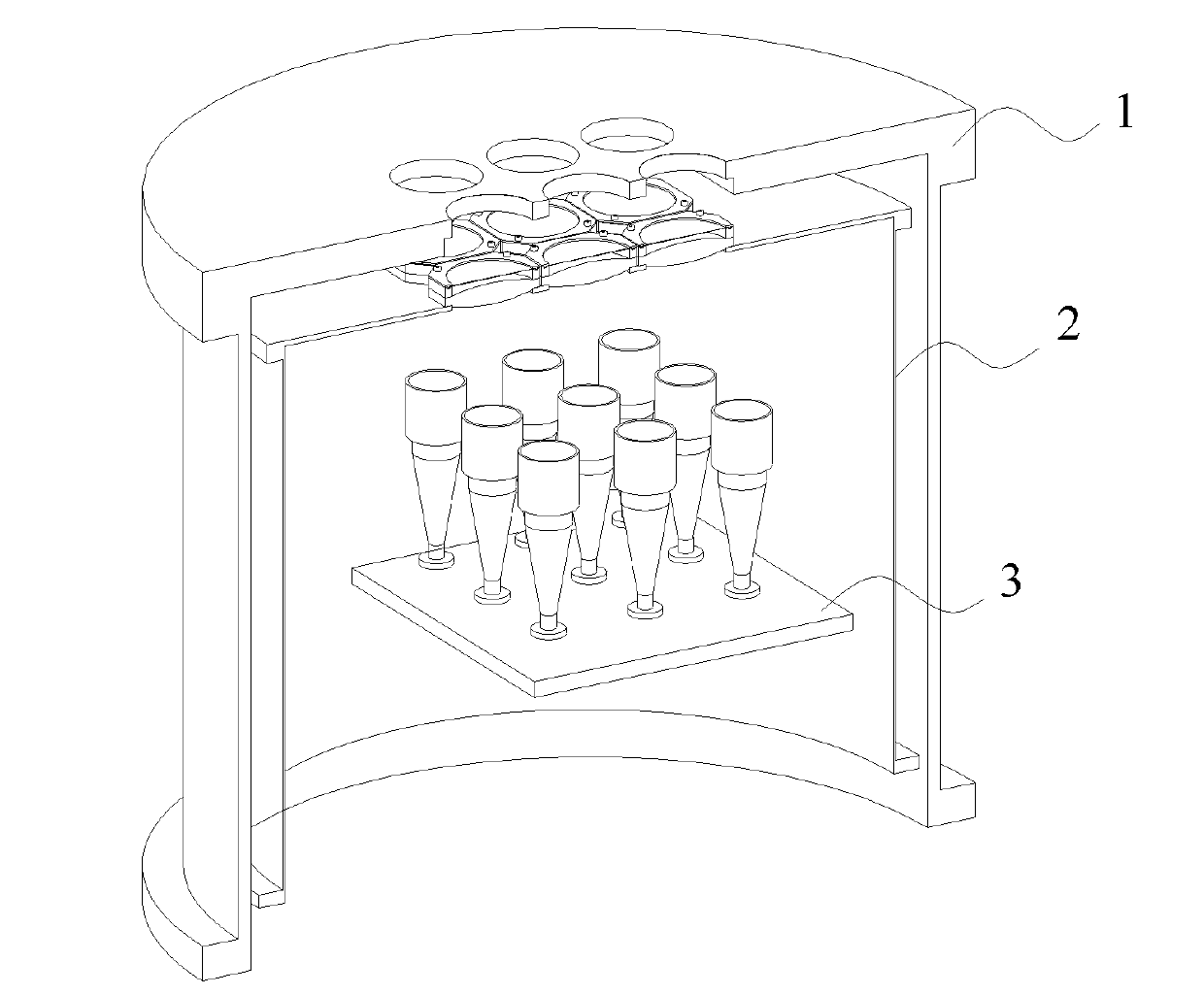

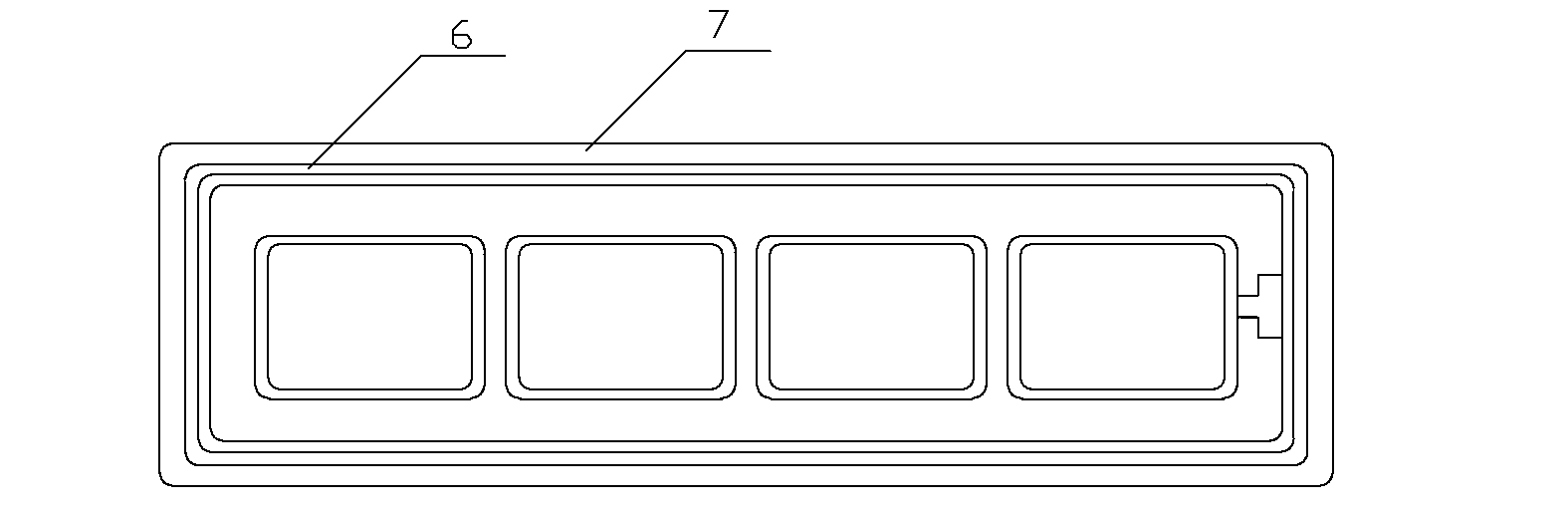

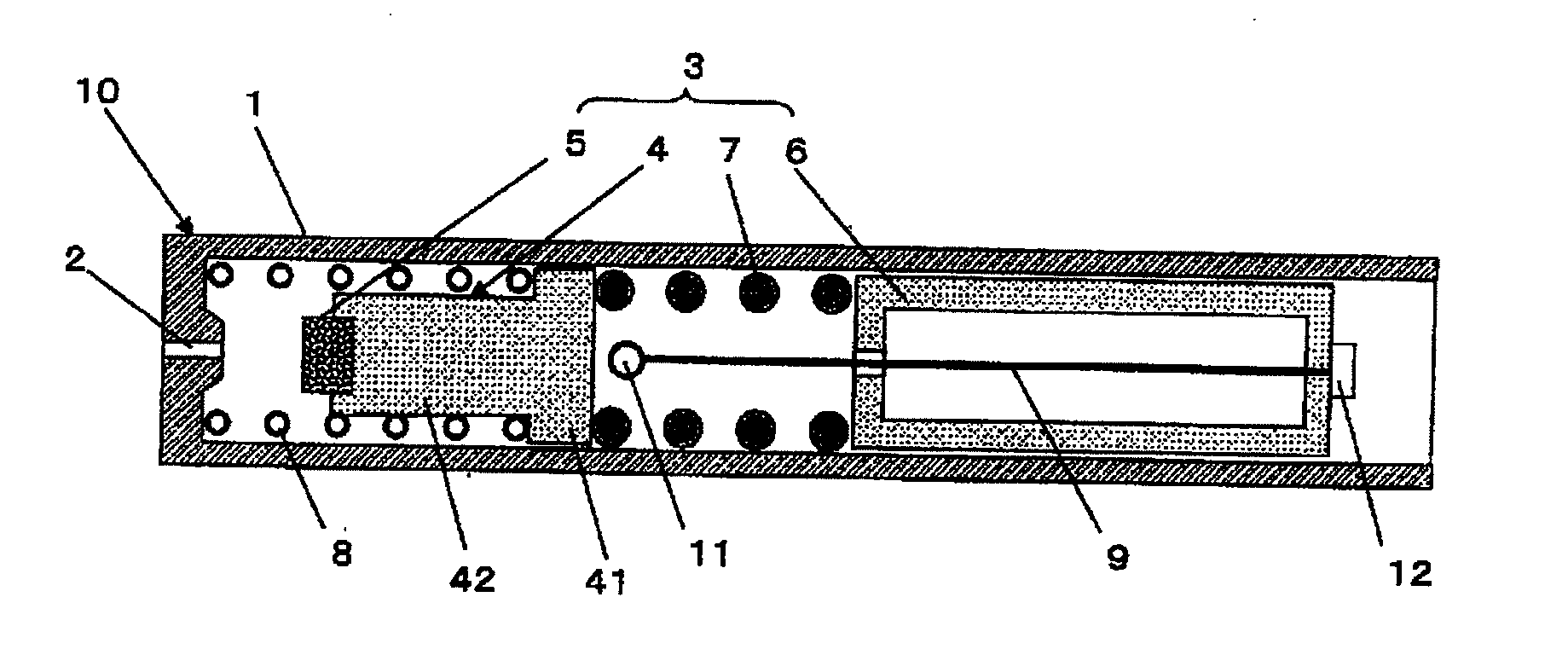

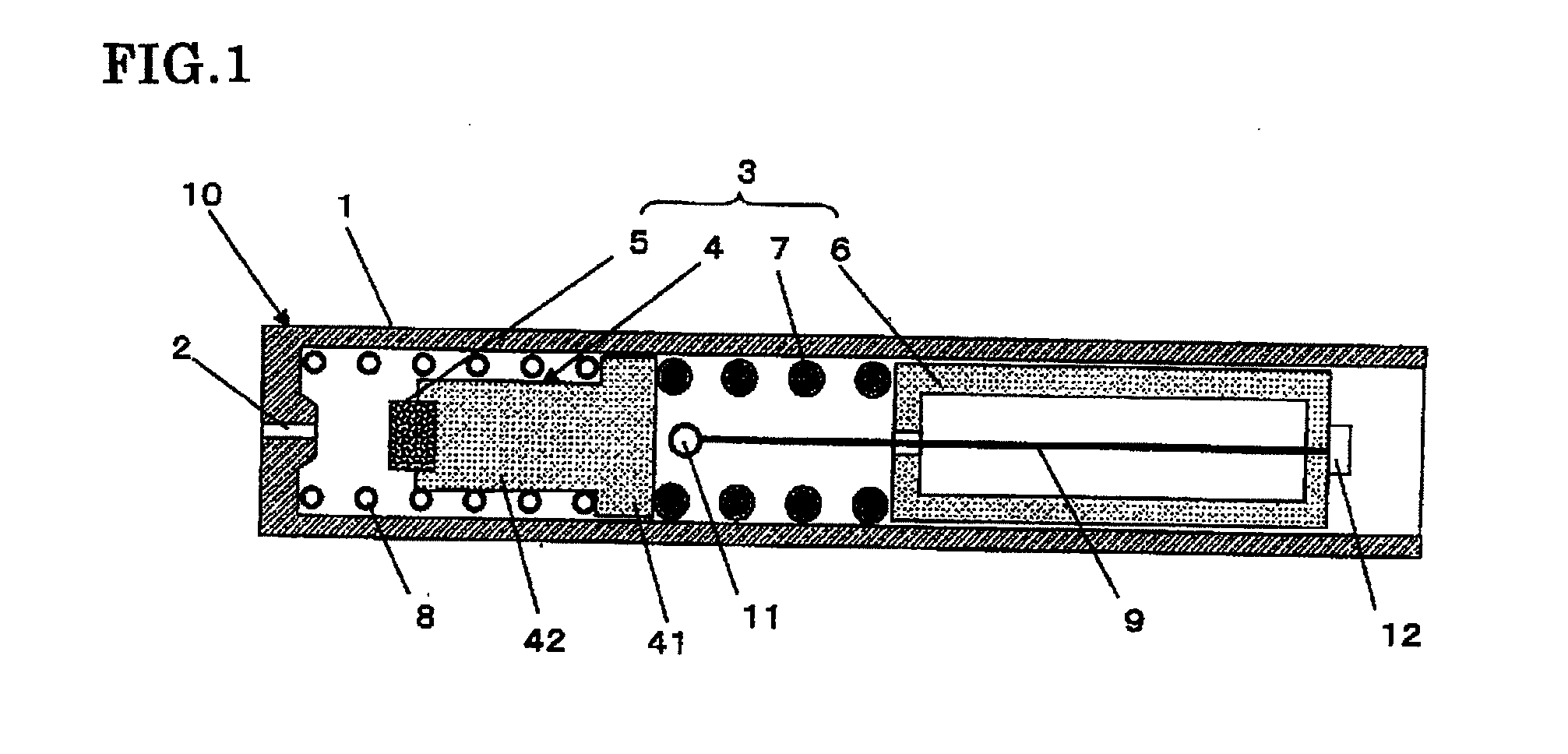

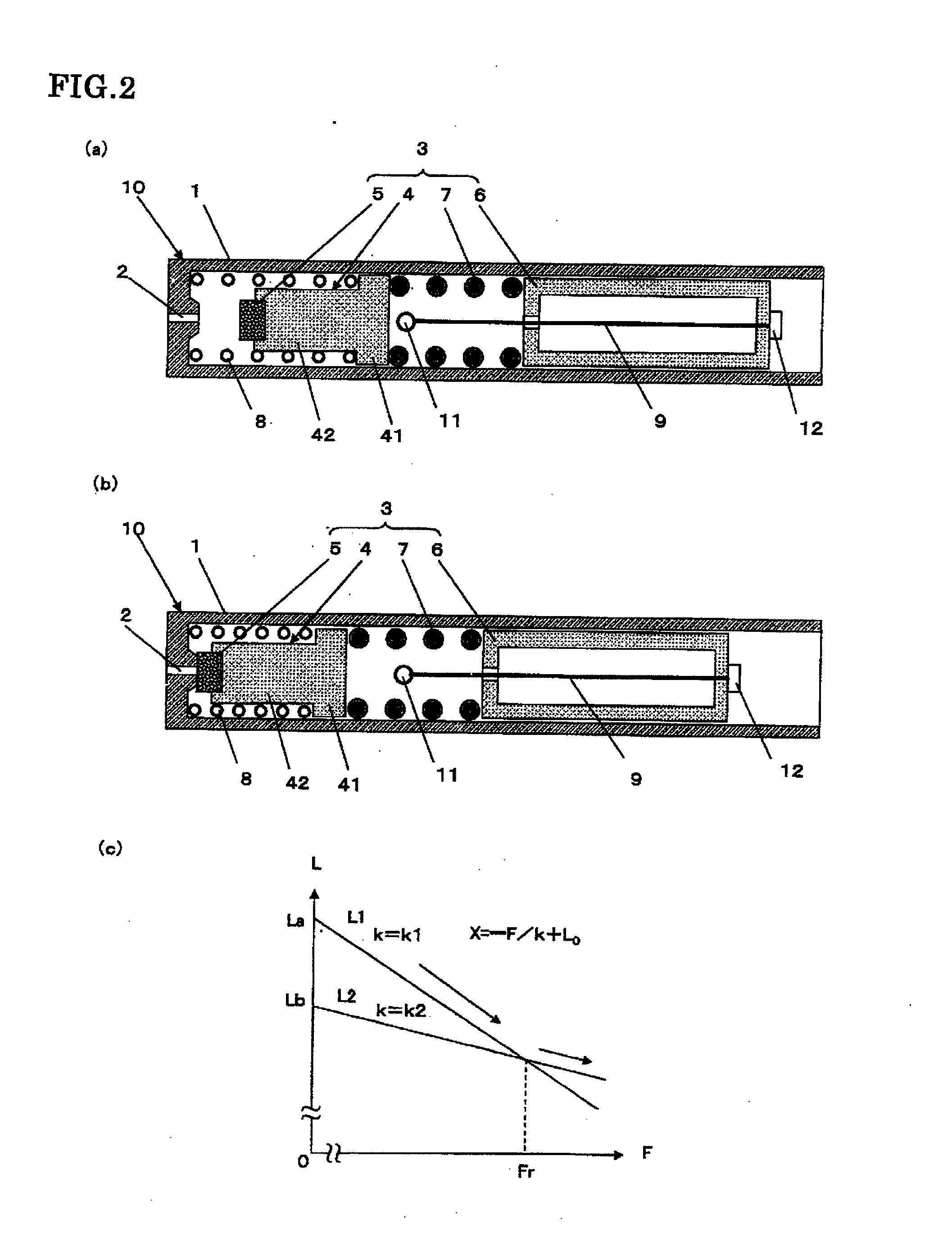

Head module and liquid jetting apparatus including the same

ActiveUS20180022085A1Prevent heat radiationInking apparatusOther printing apparatusLiquid jetComputer module

There is provided a head module including: a head which has an inlet, a plurality of nozzles, and a plurality of driving elements, and in which the nozzles are aligned in rows in a longitudinal direction of a nozzle surface orthogonal to a attaching / detaching direction of the head module; a plurality of driver ICs; a heat spreader; a flexible substrate; and a rigid substrate. In the attaching / detaching direction, the driver ICs are arranged between the head and the heat spreader; the rigid substrate and the head are arranged side by side in the attaching / detaching direction; the rigid substrate and the heat spreader are arranged side by side in a short direction of the nozzle surface; and the rigid substrate has a thickness along the short direction of the nozzle surface.

Owner:BROTHER KOGYO KK

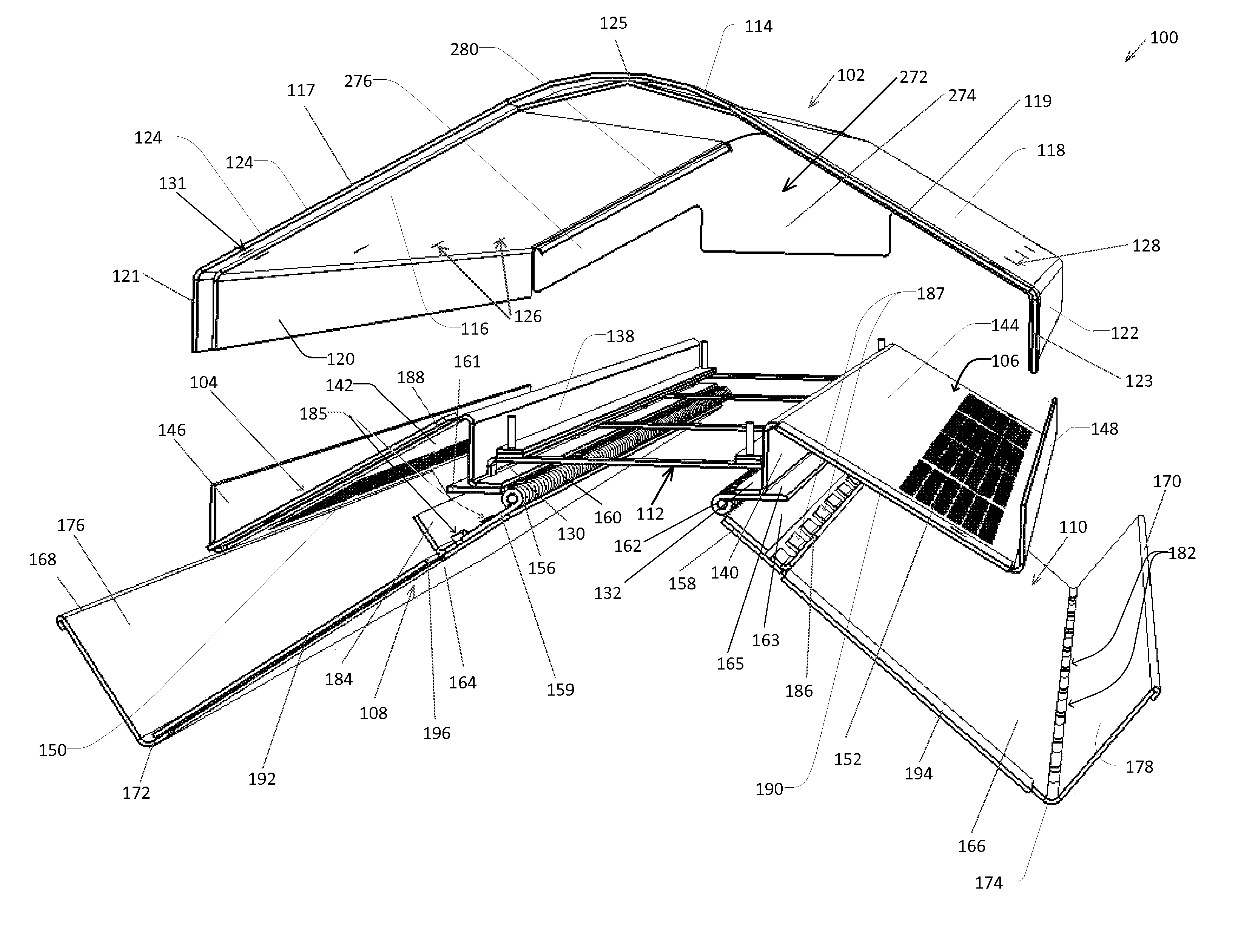

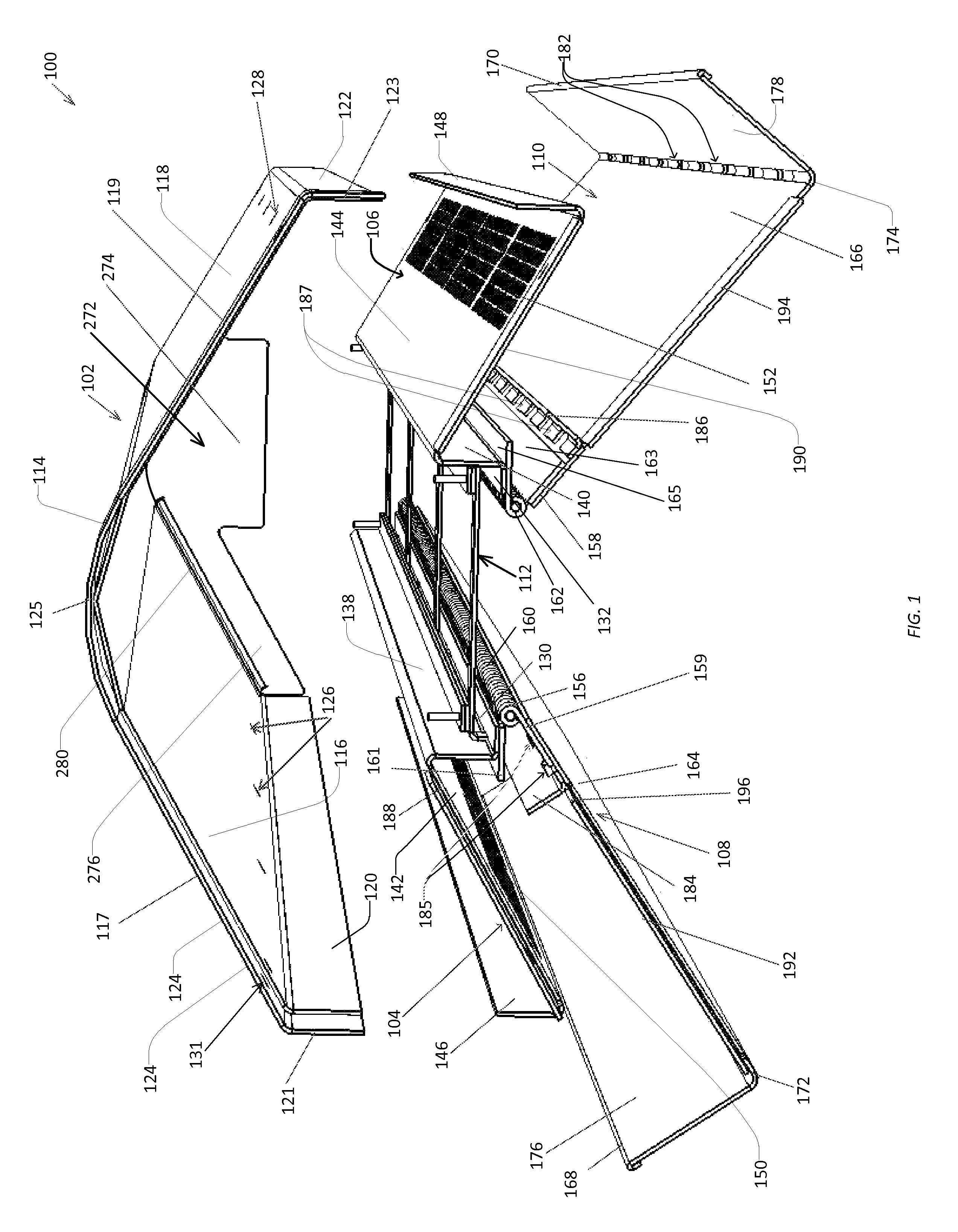

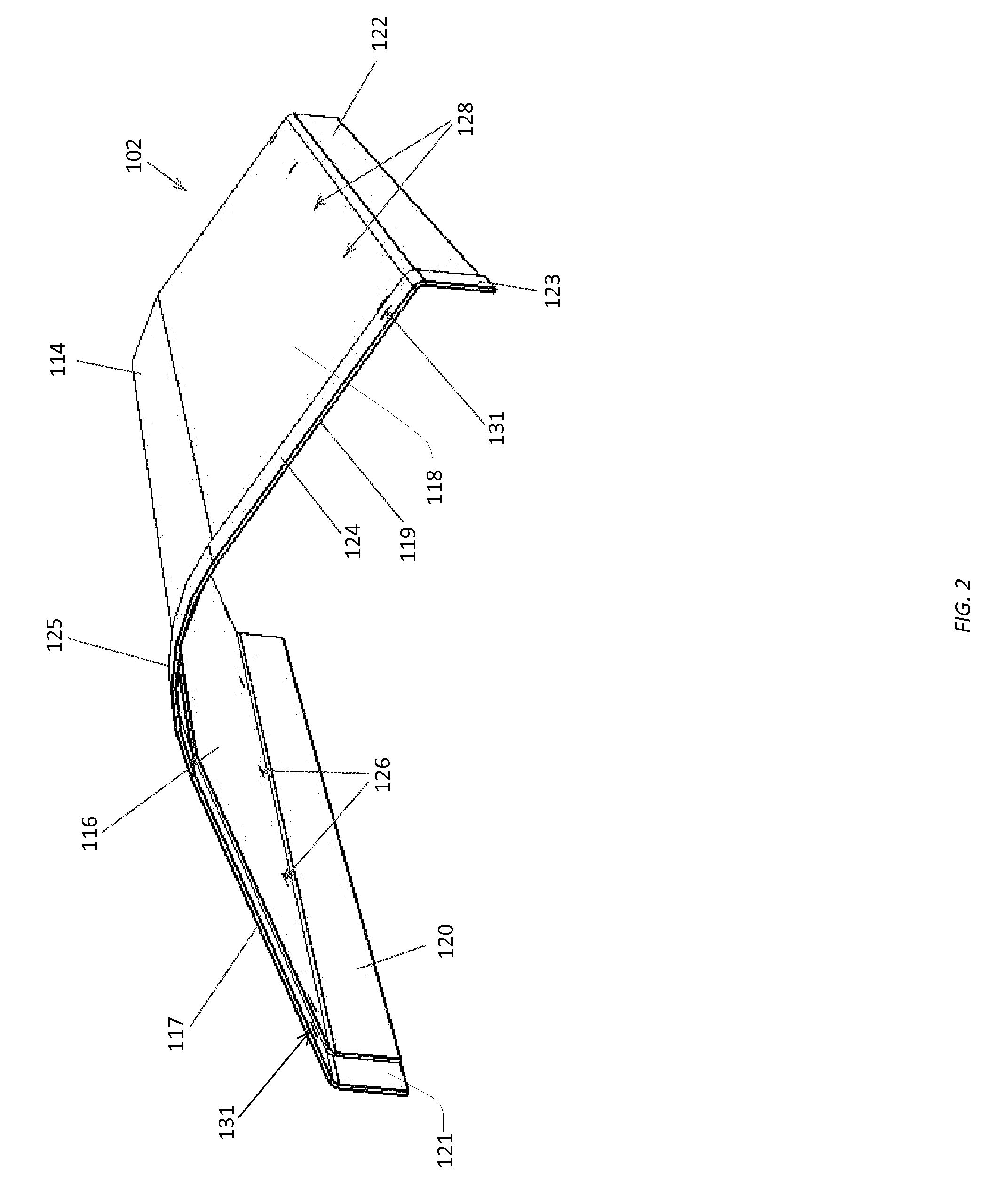

Roof ridge ventilation system

Roof ridge vent system adapted for housing a plurality of fans in a central airflow channel positioned directly over the opening in a ridge portion of a roof for ventilating a plurality of vent chutes or attic space comprising: a hood member engaged with outer edge portions of vent members having air-passageway holes defined therein and inner edge portions preferably being hinged respectively to inner edge portions of base members so as to be adapted for installation on variously-pitched roofs, each base member also having outer edge portions defining a wall adapted for blocking wind from being blown into the vent and for causing airflow over the top of the vent to encourage airflow through the vent system. Vent member sections may be installed end-to-end to define an elongated airflow channel adapted for ventilating with or without assistance from the fans.

Owner:DIGITAL CONTROL SYST

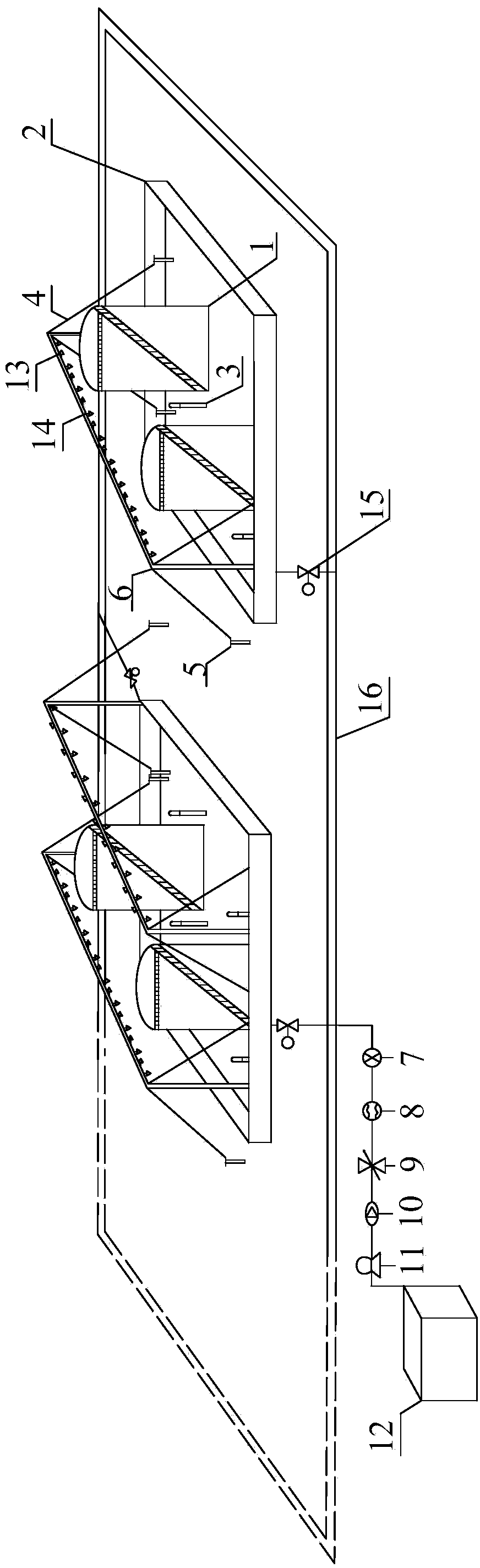

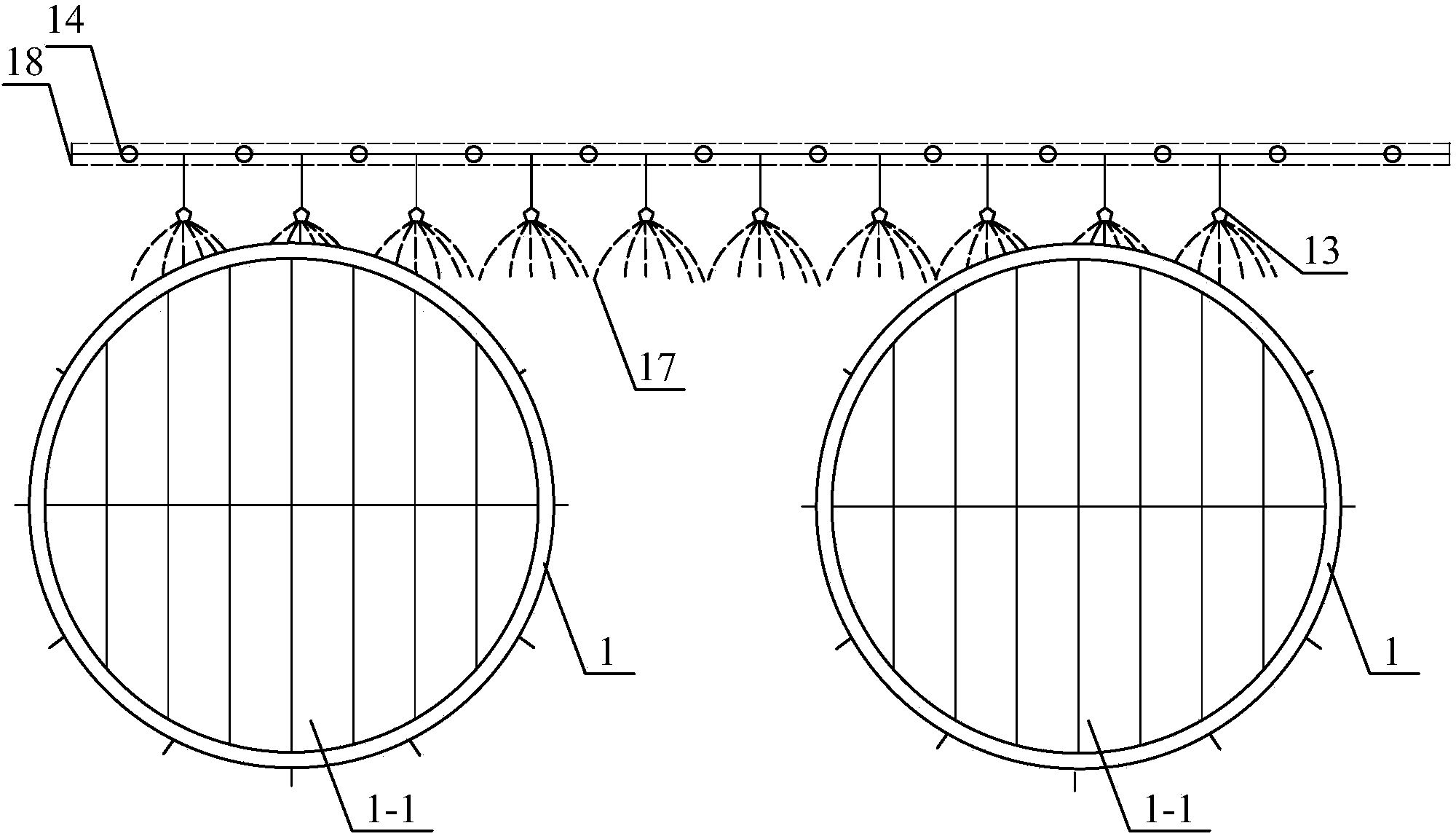

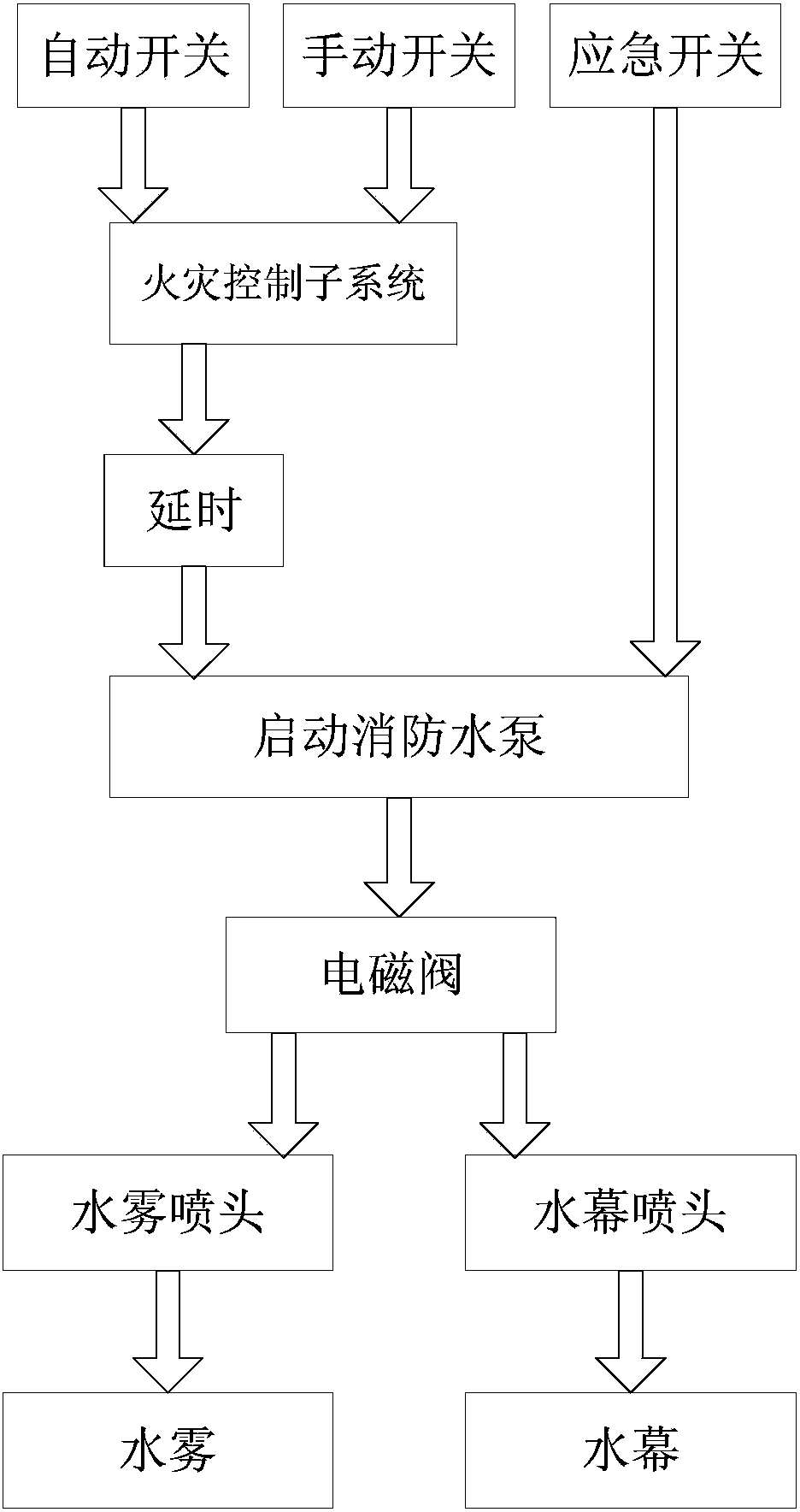

Storage tank fire hazard water curtain spraying protecting system for large-size tank area

The invention relates to a tank area fire-fighting device and belongs to a storage tank fire hazard water curtain spraying protecting system for a large-size tank area. According to the device, when fire hazard happens in one storage tank in the tank area, the water curtain spraying system can be automatically started, then thermal radiation can be effectively blocked, and the tank is sprayed so as to be cooled, and thus the purposes that the tank in accident is prevented from failure of temperature increasing and adjacent storage tanks are protected are achieved. The system consists of a fire hazard sensing subsystem, a fire-fighting water supply subsystem, a tank area spraying tube net subsystem, a water curtain spraying subsystem and a control subsystem, wherein the water curtain spraying subsystem takes the shape of a door and is separated from the storage tanks by a certain distance; the height of a door-shaped horizontal water supply pipeline is identical to the height of a tank body; a plurality of water curtain nozzles and mist nozzles are respectively arranged vertically downward on the pipeline and are arranged at the positions which face to the positions of the tanks and are vertical to the pipeline. The storage tank fire hazard water curtain spraying protecting system has three starting modes, namely, a manual starting mode, an automatic starting mode and an emergency starting mode.

Owner:CHANGZHOU UNIV

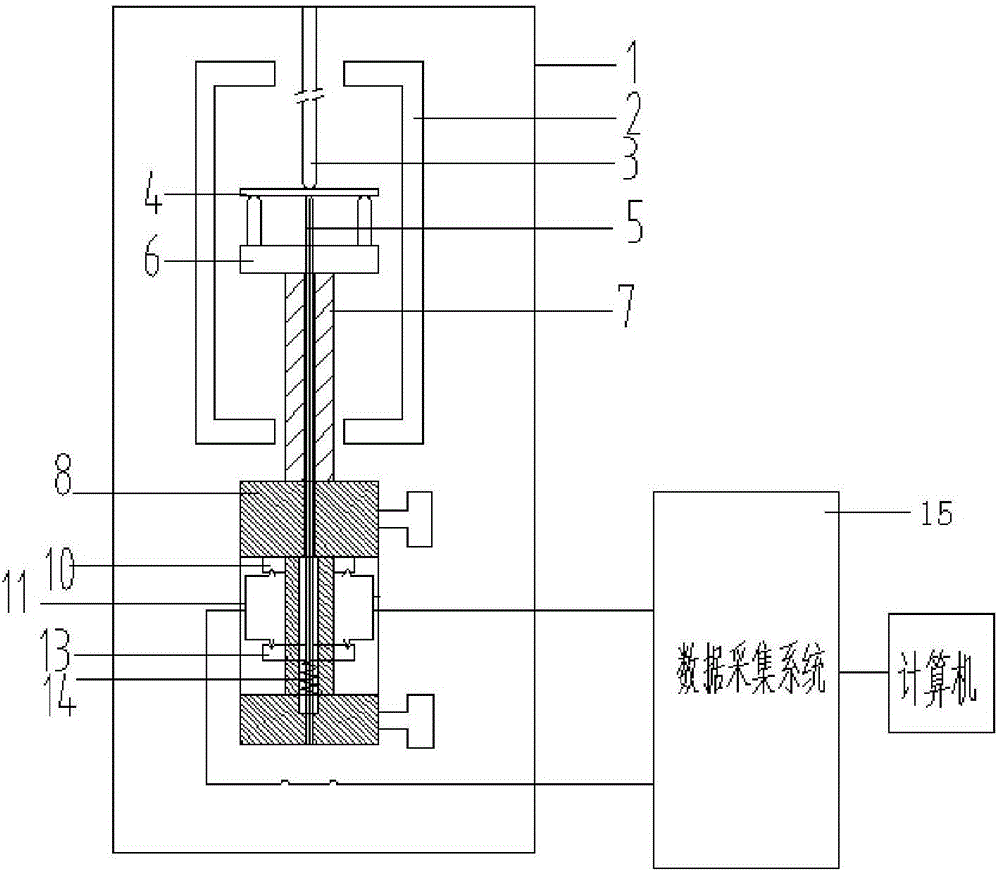

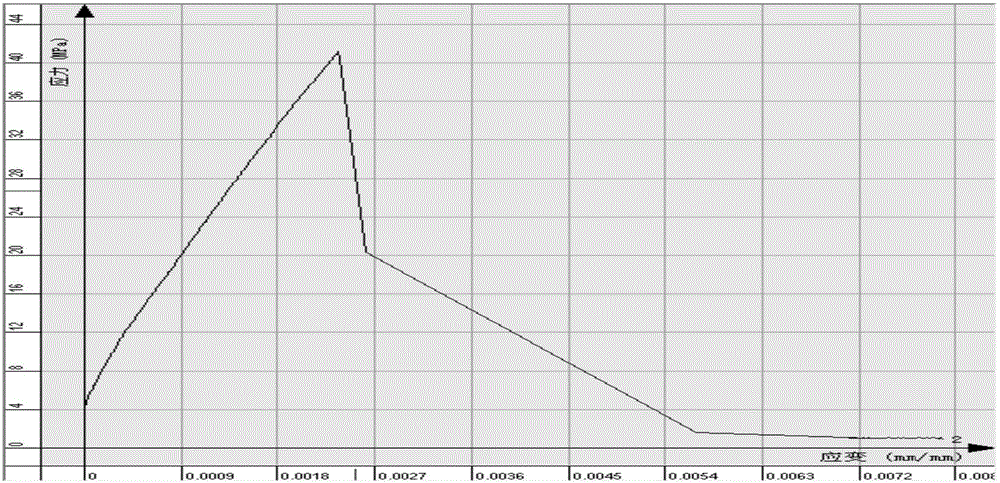

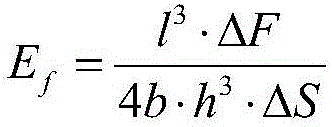

Device and method for measuring superhigh temperature flexure elasticity modulus and fracture strain of material

ActiveCN106053250AReduce the temperaturePrevent heat radiationMaterial strength using steady bending forcesEngineeringWater cooling

The invention discloses a device for measuring superhigh temperature flexure elasticity modulus and fracture strain of a material. The device comprises a load transmitting structure, a deformation transmitting structure and a deformation sensor. The problem that in the test environment with the temperature of 1500 DEG or above, temperature of the environment where a traditional deformation sensor is located exceeds service temperature, and measurement cannot be carried out through the traditional deformation sensor is solved. A water cooling protective sleeve is connected to a hot end pressing rod, heat conduction and heat radiation to the deformation sensor by the outside can be effectively blocked, which is beneficial for reducing the temperature of the deformation sensor, the temperature deformation sensor is made to be 50 DEG C or below, and then the deformation sensor can measure flexure elasticity modulus and fracture strain of the material in the superhigh temperature environment.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Metal vacuum warming plate and manufacturing method for same

InactiveCN104975661AImprove rigidityIncreased resistance to deformationCovering/liningsClimate change adaptationAlloyCavity wall

The invention discloses a metal vacuum warming plate. A vacuum cavity is formed by sealed cooperative connection between an upper metal plate and a lower metal plate; a supporting core is disposed in the vacuum cavity; a vacuumizing hole is formed in the cavity wall of the vacuum cavity; metal with melting point ranging from 90 to 350 DEG C or related alloy sealing bars are arranged between sealing sides for the sealed cooperative connection between the upper metal plate and the lower metal plate; and the sealing bars are bonded with the upper metal plate and the lower metal plate and sealed with the same. The metal vacuum warming plate is advantaged by high vacuum degree durableness in bad natural environments, excellent sealing property, strong anti-deformation capabilities, great corrosion and rust resisting performance and long service life as long as buildings; fireproof performance is A-level; the metal vacuum warming plate is integrated functions of warming, decoration and construction; the construction period can be obviously shortened; installation cost can be reduced; various shapes can be formed; special demands for building outer wall surface corners and arcs can be met; and the metal vacuum warming plate is suitable for various building outer wall warming and roof insulation.

Owner:许浒

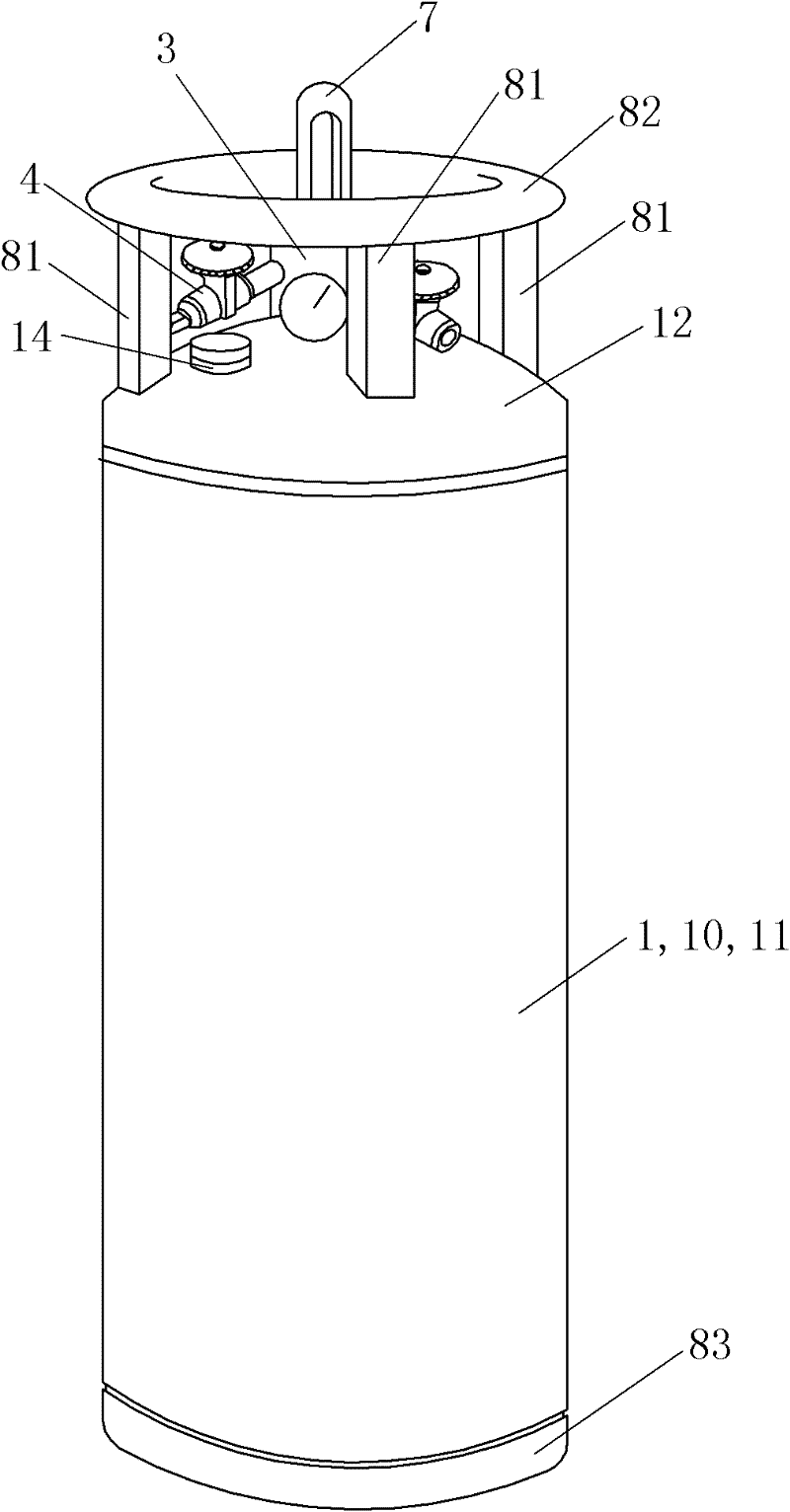

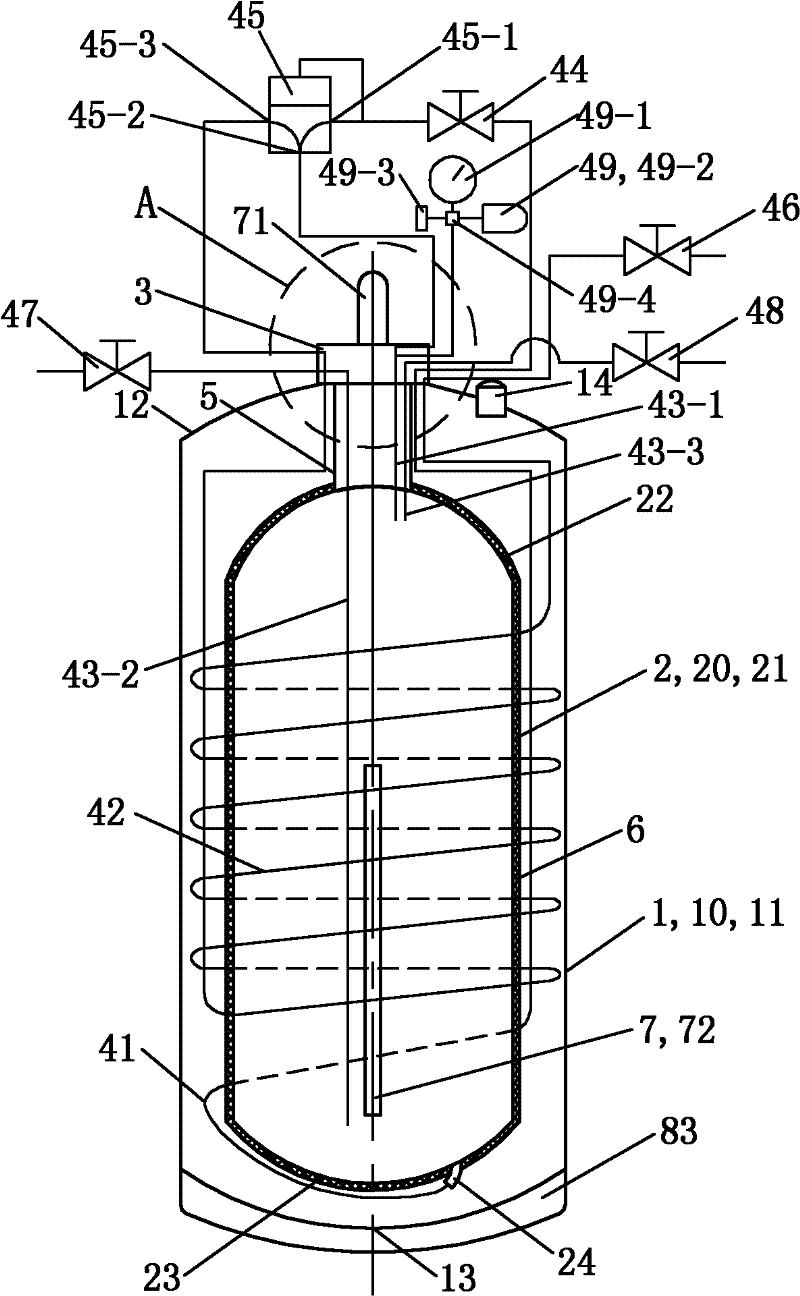

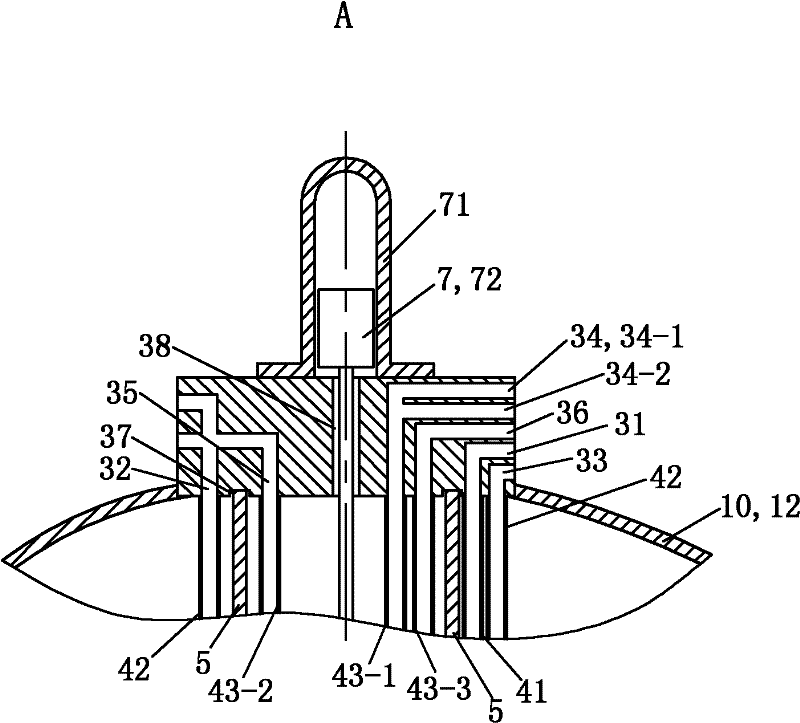

Vertical-type low-temperature heat-insulation gas cylinder

InactiveCN102174983ABlock heat radiationGood insulation effectContainer filling methodsPressure vesselsEngineeringInsulation layer

The invention relates to a vertical-type low-temperature heat-insulation gas cylinder which comprises a shell, a liner, a distributor, an in-cylinder pipeline of a pipeline control system, a neck pipe and an insulation layer; the shell comprises a shell body and a vacuumizing connector which is connected with the shell body in a sealed mode; the liner comprises a liner body and a coil pipe connector which is connected with the liner in a sealed mode and is positioned at the bottom of the liner body; the heat insulation layer is arranged on the outer wall of the liner body; the distributor is a steel integrated component which is provided with an internal channel; the liner is positioned in the inner cavity of the shell body; the distributor is fixed on the shell body in a sealed mode; the upper end of the neck pipe is fixed on the distributor in a sealed mode; the lower end of the neck pipe is arranged at the periphery of the liner body and is fixed on the liner body in a sealed mode, thus the liner body is suspended in the shell body; the in-cylinder pipeline of the pipeline control system comprises a supercharging coil pipe, a vaporization coil pipe and a seal plate assembly; and the seal plate assembly comprises an inner cavity first pipe, liquid inlet and outlet pipes, a gas discharging pipe and a seal plate. The vertical-type low-temperature heat-insulation gas cylinder provided by the invention has the advantages of good heat insulation effect, is convenient to use and is safe and reliable.

Owner:丁雨福

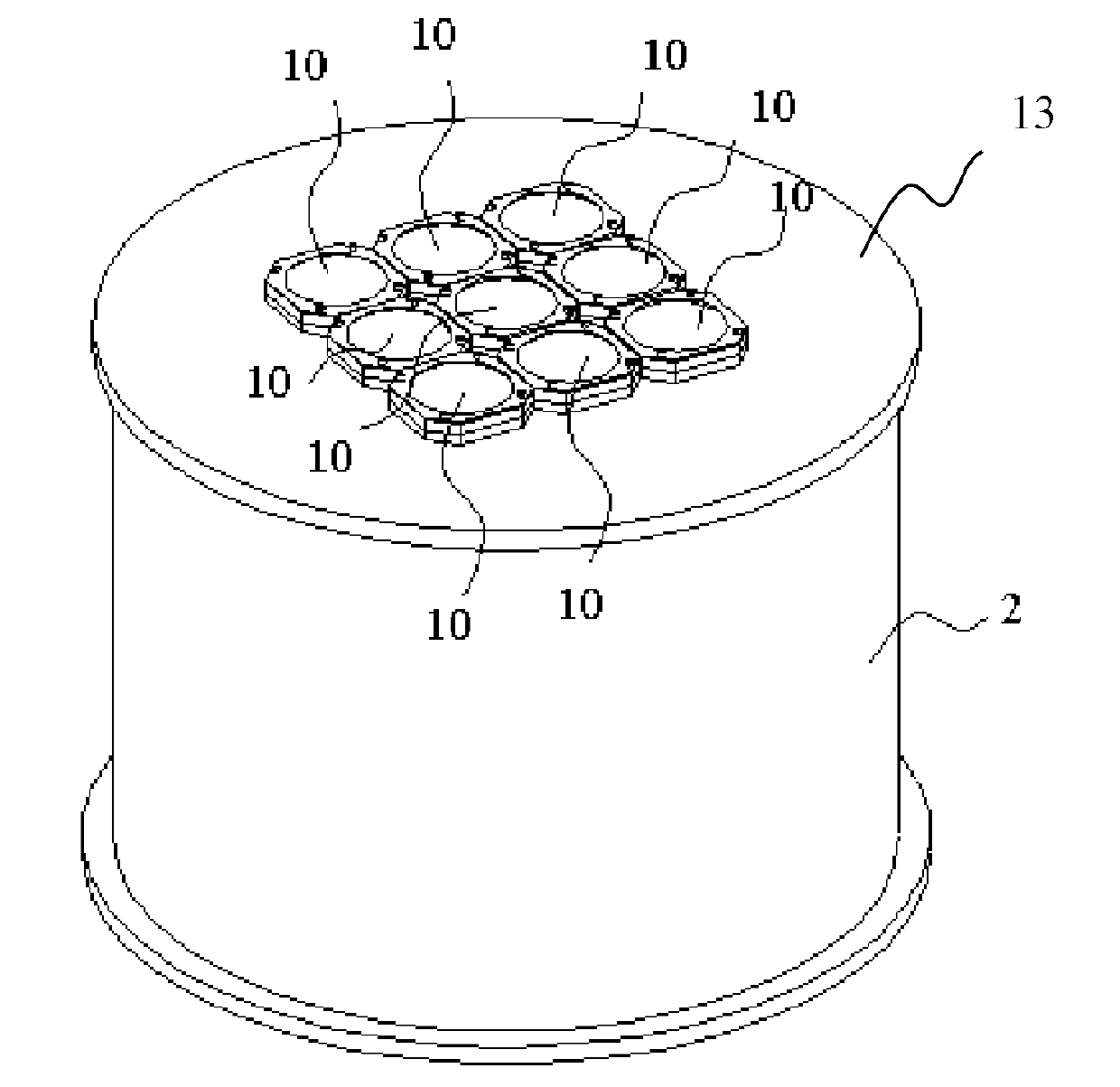

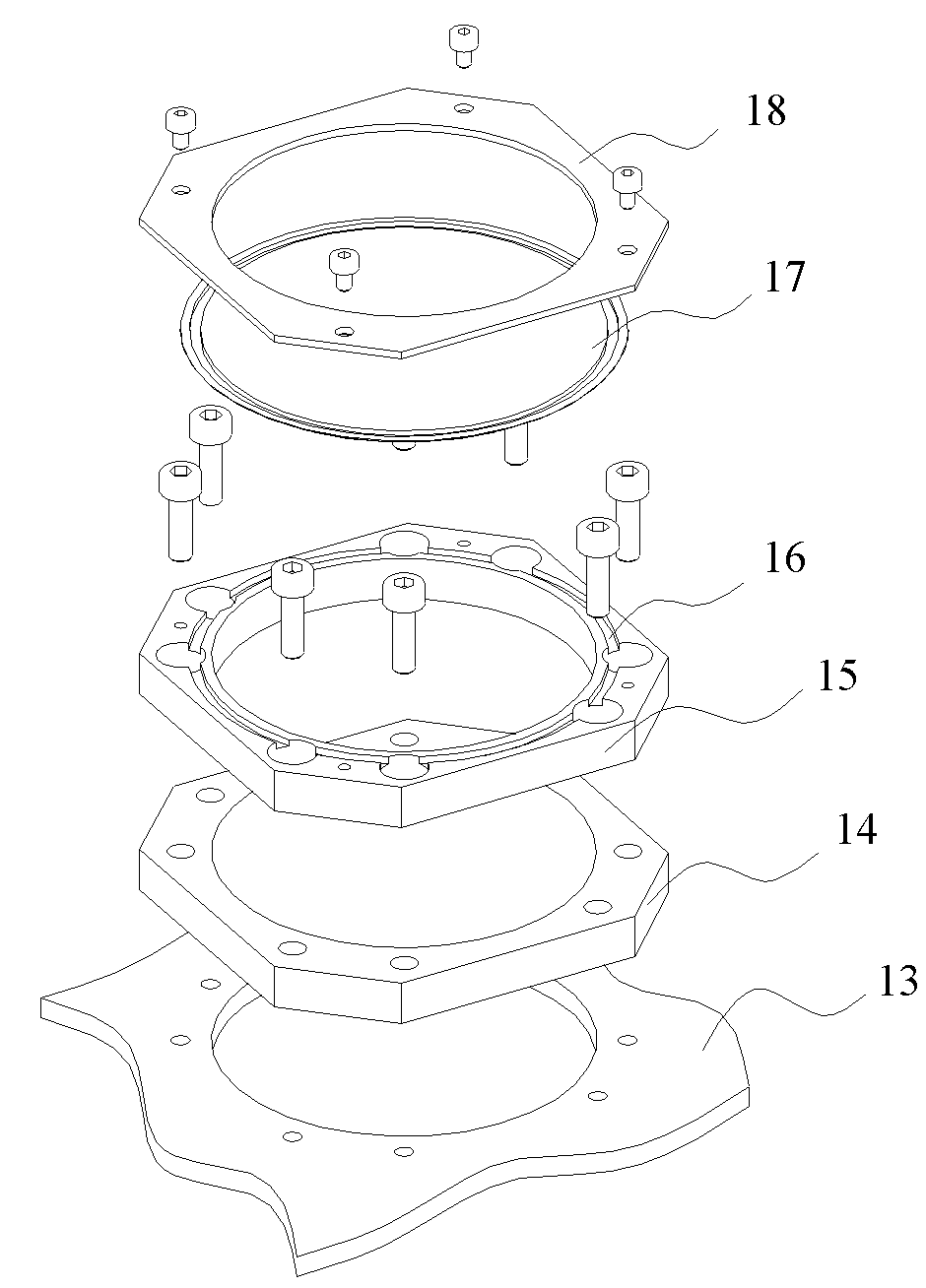

Millimeter wave multi-pixel refrigeration receiver dewar

The invention relates to a millimeter wave multi-pixel refrigeration receiver dewar. The cold shield of the dewar can effectively shield the thermal radiation without affecting the sensitivity of a receiver, thereby lowering the requirement of the refrigerating machine on refrigeration power. The millimeter wave multi-pixel refrigeration receiver dewar comprises a vacuum chamber and a cold shield arranged in the vacuum chamber, wherein the cold shield is provided with a plurality of circular windows; the circular windows are corresponding to detectors arranged in the cold shield; each circular window comprises a through hole and a dielectric lens; the through hole is arranged on the upper surface of the cold shield; the dielectric lens covers on the through hole and has certain thickness; and the edge of the dielectric lens is fixed on the upper surface of the cold shield.

Owner:ZIJINSHAN ASTRONOMICAL OBSERVATORY CHINESE ACAD OF SCI

Vacuum insulation plate and manufacturing method thereof

InactiveCN103306388AGood insulation performanceExtended service lifeClimate change adaptationInsulation improvementVacuum pressureSelf weight

The invention discloses a vacuum insulation plate and a manufacturing method thereof. The vacuum insulation panel comprises a closed hollow cavity body which is formed by casting a material slurry, wherein the interior of the cavity body is hollow; an airtight layer is arranged on the inner wall or / and the outer wall of the cavity body. After the cavity body is vacuumized, convective heat transfer caused by air movement can be avoided, so that the thermal insulation is excellent; the vacuum insulation plate is formed by casting concrete or the material slurry, so that the vacuum insulation plate is firm and reliable; a basic material adopts the concrete or the material slurry with high strength, and the strength is high enough to bear long-term effects of a vacuum pressure, a wind load, self weight and a temperature deformation stress; more than 90% of the plate structure is made of cement and other inorganic materials, so that the long service life of the vacuum insulation plate can be ensured; the vacuum insulation plate mainly uses vacuum, the cement, pottery sand and other low-cost materials, so that the cost of the vacuum insulation plate disclosed by the invention is only 1 / 3 that of the conventional vacuum insulation plate; 90% of the plate structure is made of the cement and the pottery sand, so that the fire-proof performance is class A; the vacuum insulation plate is applicable to external wall insulation and roof insulation for buildings with a shear wall structure, a framework structure and a steel structure.

Owner:许浒

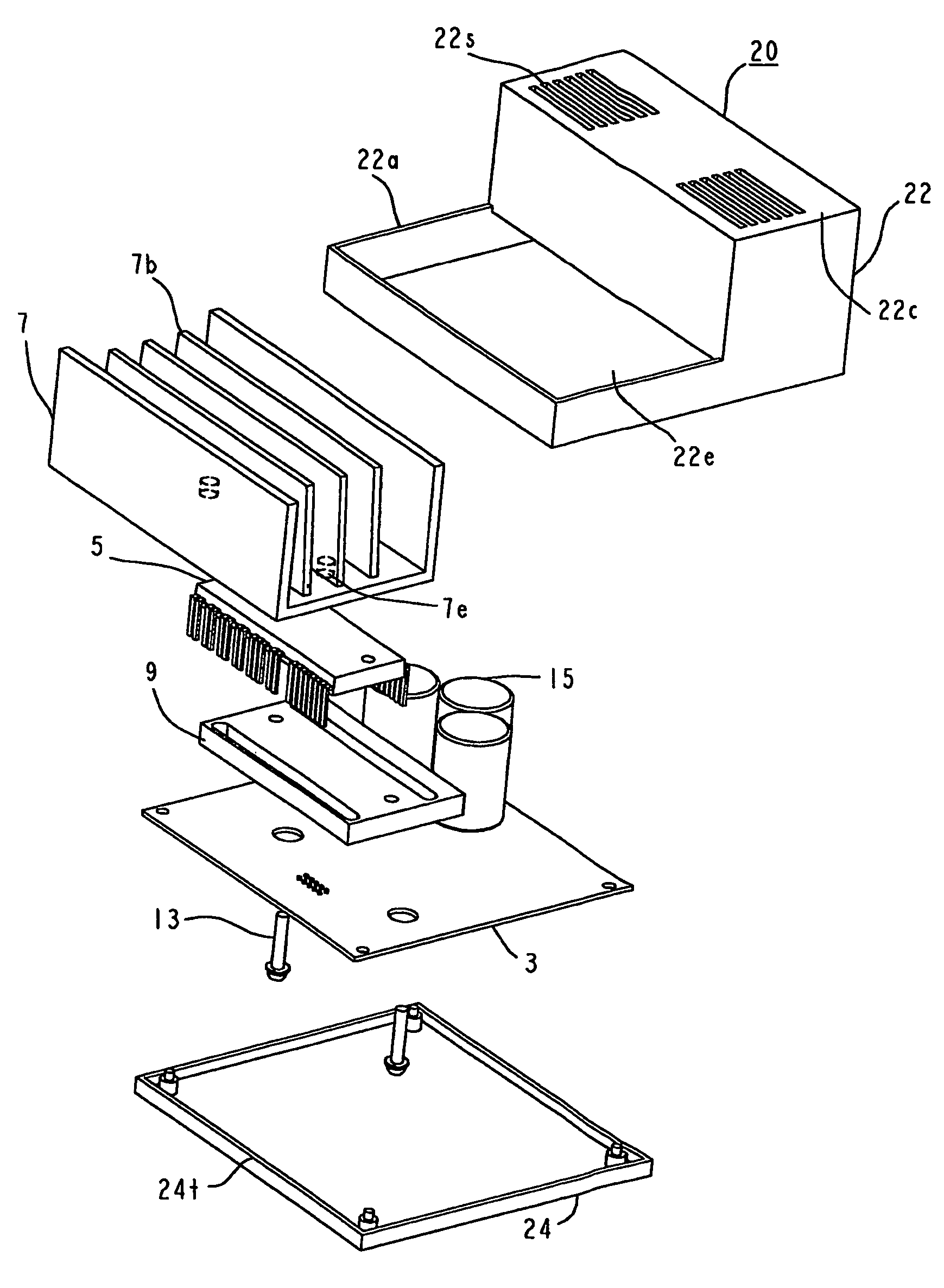

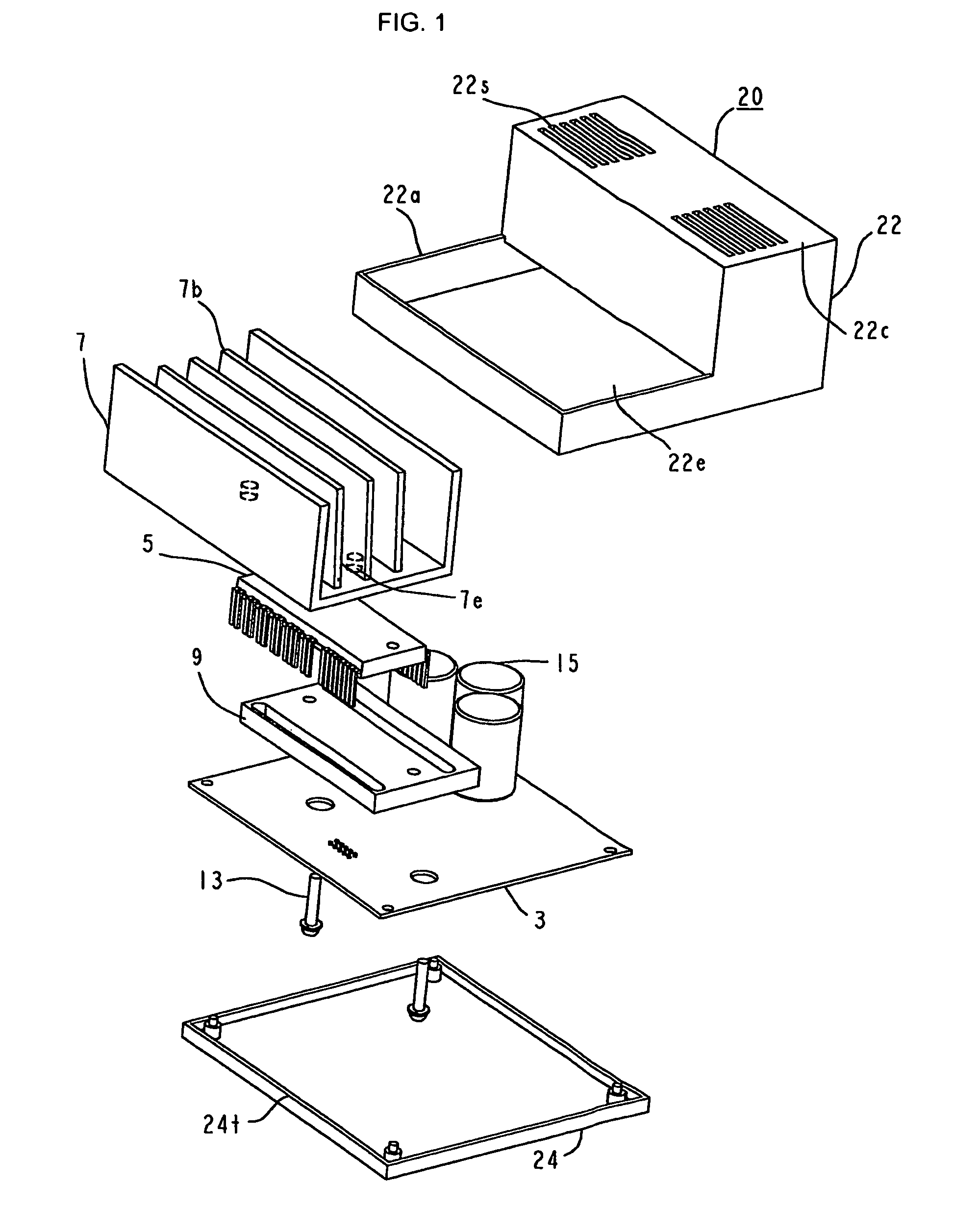

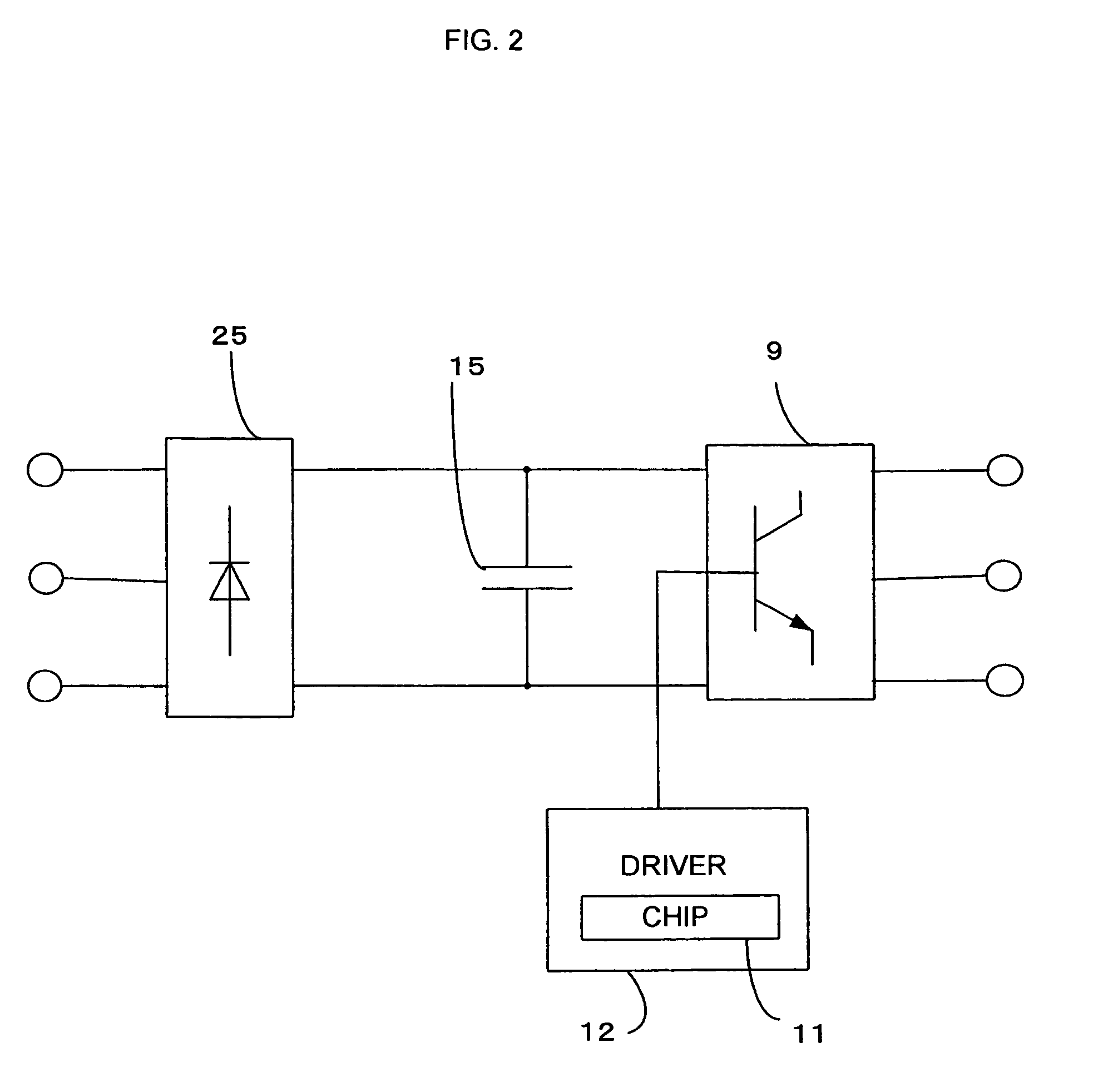

Modular heat-radiation structure and controller including the structure

InactiveUS7746648B2Avoid deformationPrevent heat radiationPrinted circuit assemblingSemiconductor/solid-state device detailsComputer moduleEngineering

A modular heat-radiation structure includes a module for generating heat, including a first main unit having a heat-radiation fin, fixed to the top face of the first main unit for radiating heat generated in the module and a resin-made and insulating heat shield inserted between the printed circuit board and the first main unit.

Owner:MITSUBISHI ELECTRIC CORP

Compact valve

InactiveUS20100139785A1Easily realizedLarge stroke of displacementOperating means/releasing devices for valvesEqualizing valvesCoil springShape-memory alloy

A compact valve using a shape memory alloy comprises: a moving valve body that contacts an inner periphery of a guide pipe having an built-in orifice, is freely movable and has a sealing portion to seal the orifice; a biasing coil provided between the orifice and the moving valve body; and a wire formed of a shape memory alloy and held between a stationary electrode of the guide pipe and a moving electrode of the moving valve body. The orifice is sealed by moving the moving valve body due to transformation of the shape memory alloy by heating the wire. The moving valve body is enabled to be elastically deformable by providing a coil spring to reduce a stress, so that an overload to the moving valve body due to contraction of the wire is absorbed by elastic deformation of the moving valve body. Thereby, the overload to the shape memory alloy is reduced to prevent deterioration of repeatability of memorized shape, to increase durability and reliability of the valve.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com