Patents

Literature

46results about How to "Avoid thermal convection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

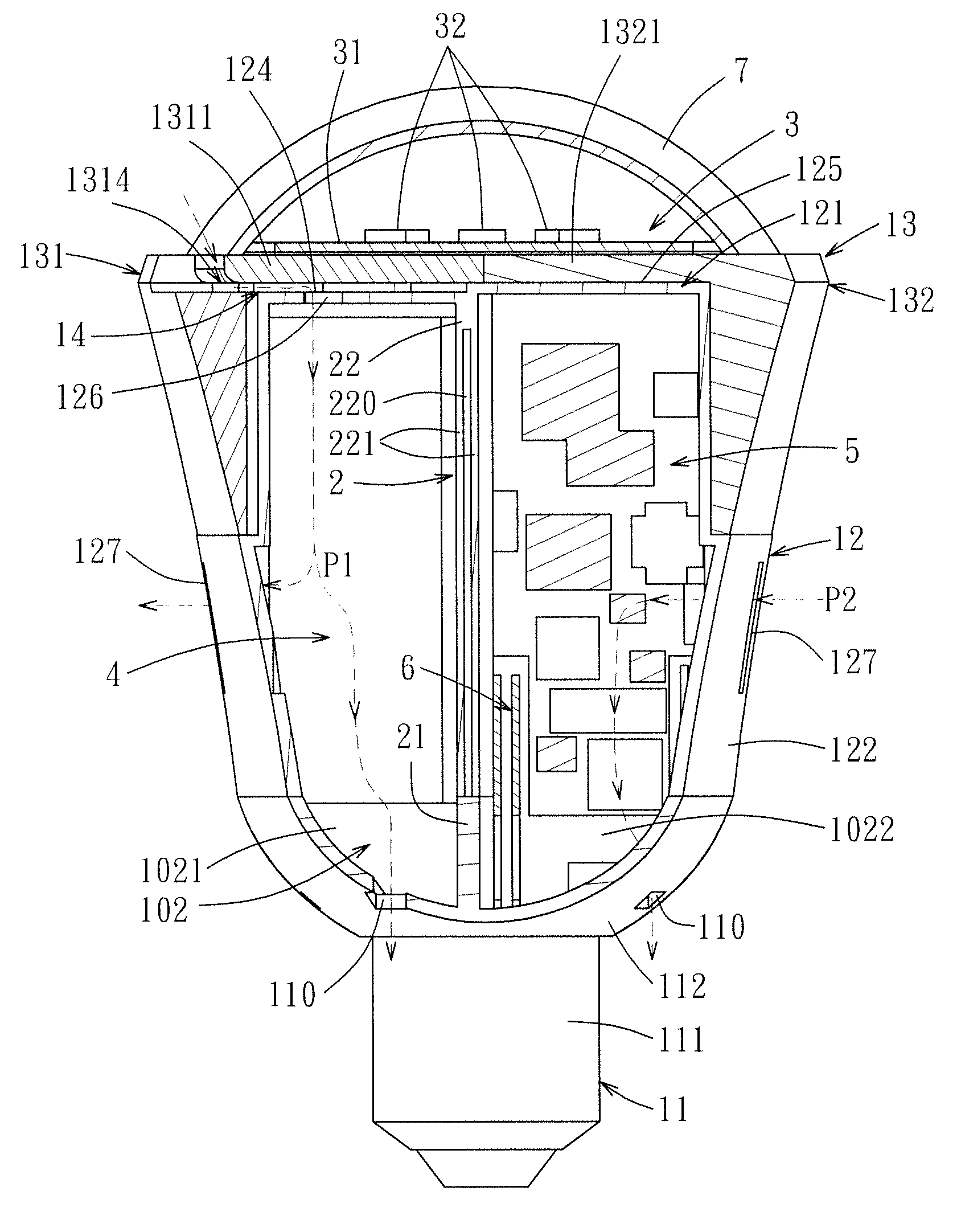

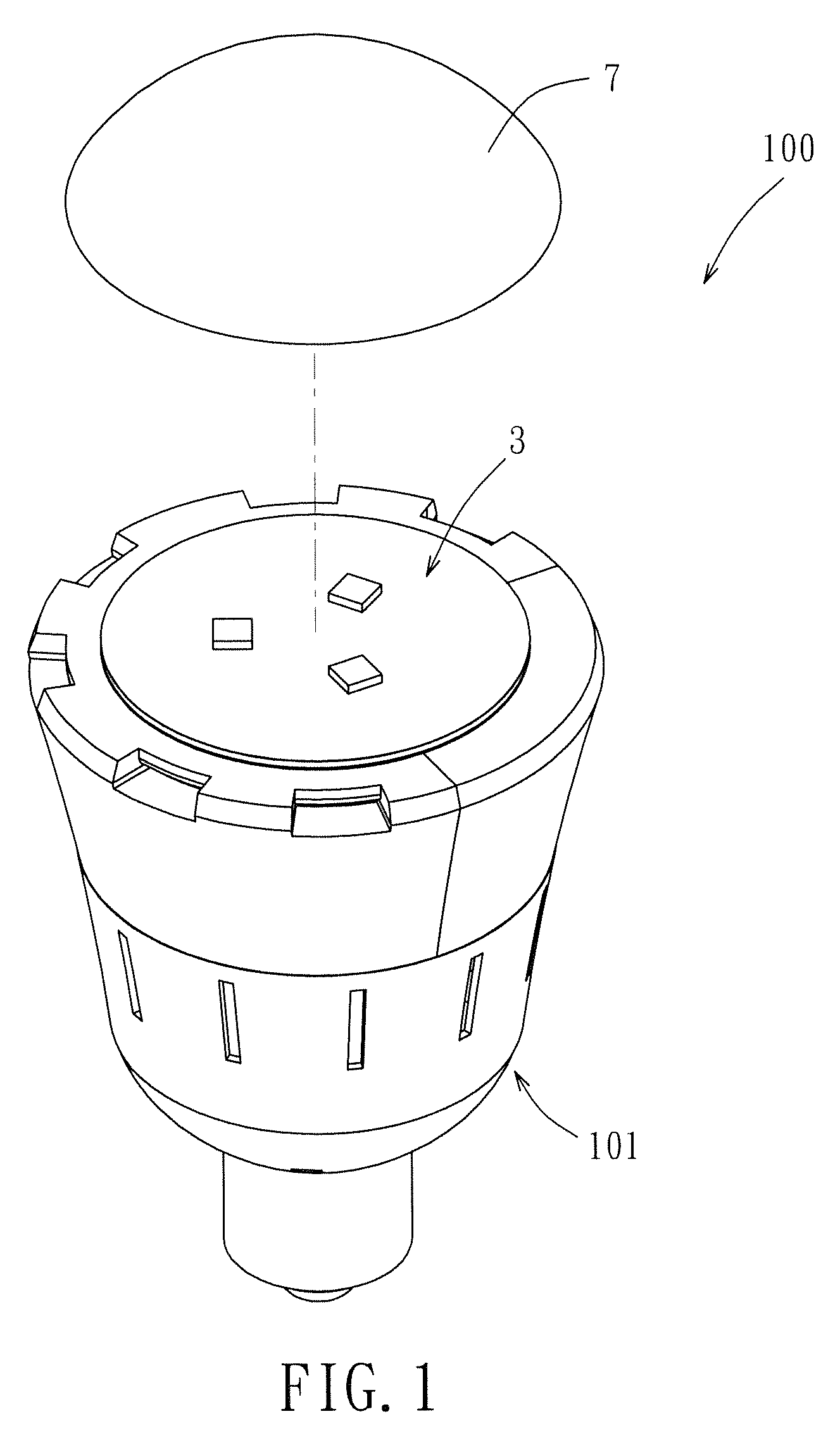

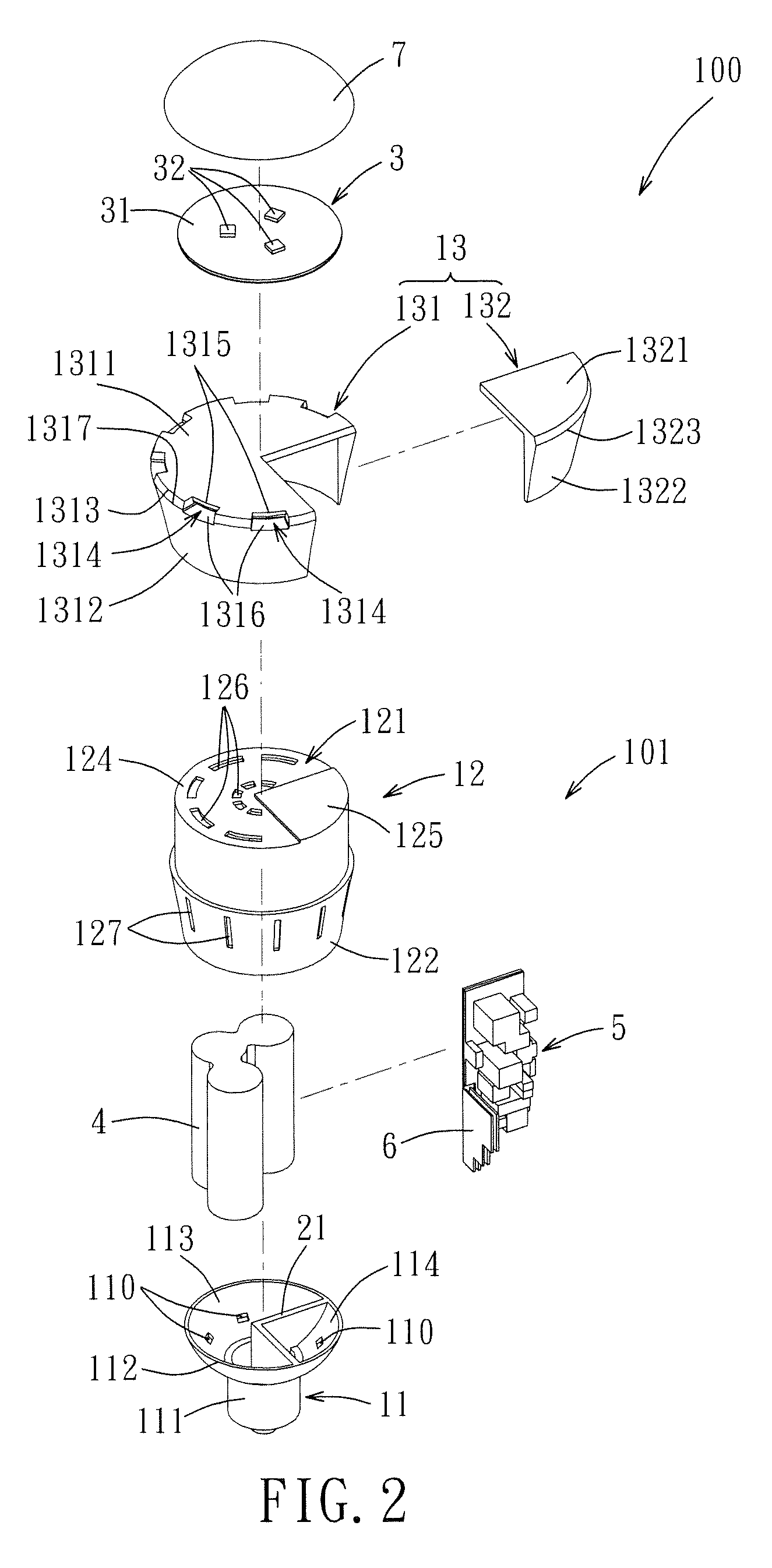

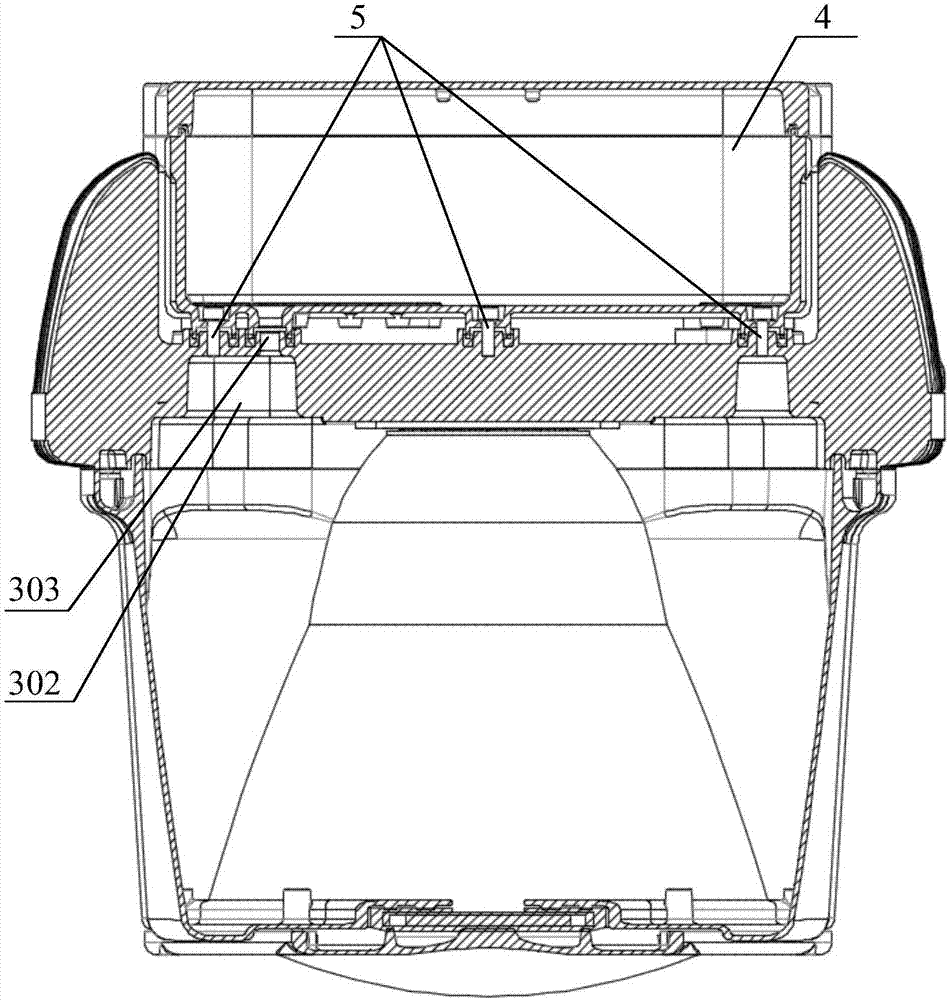

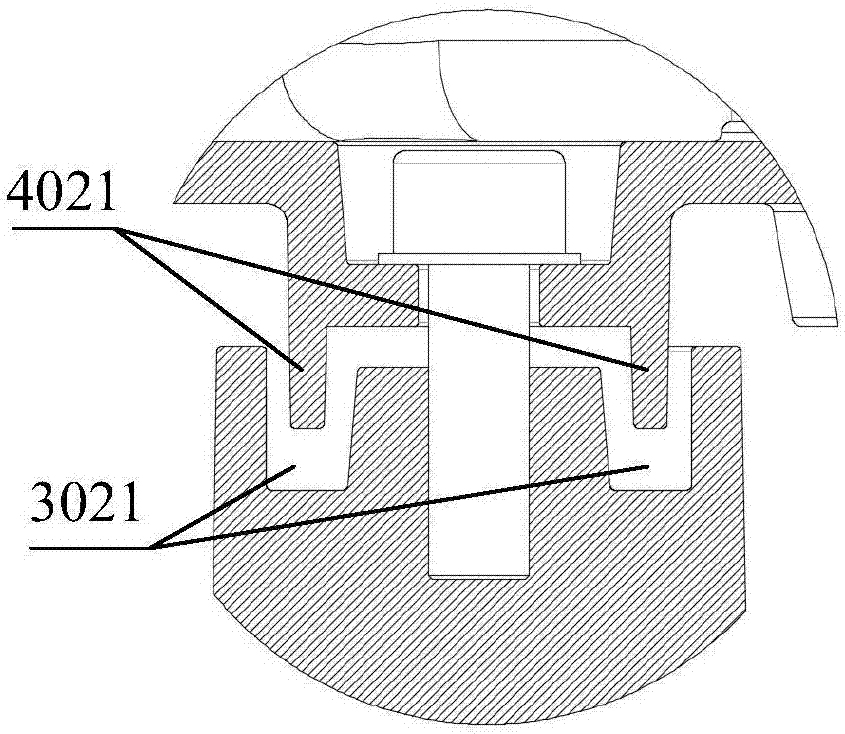

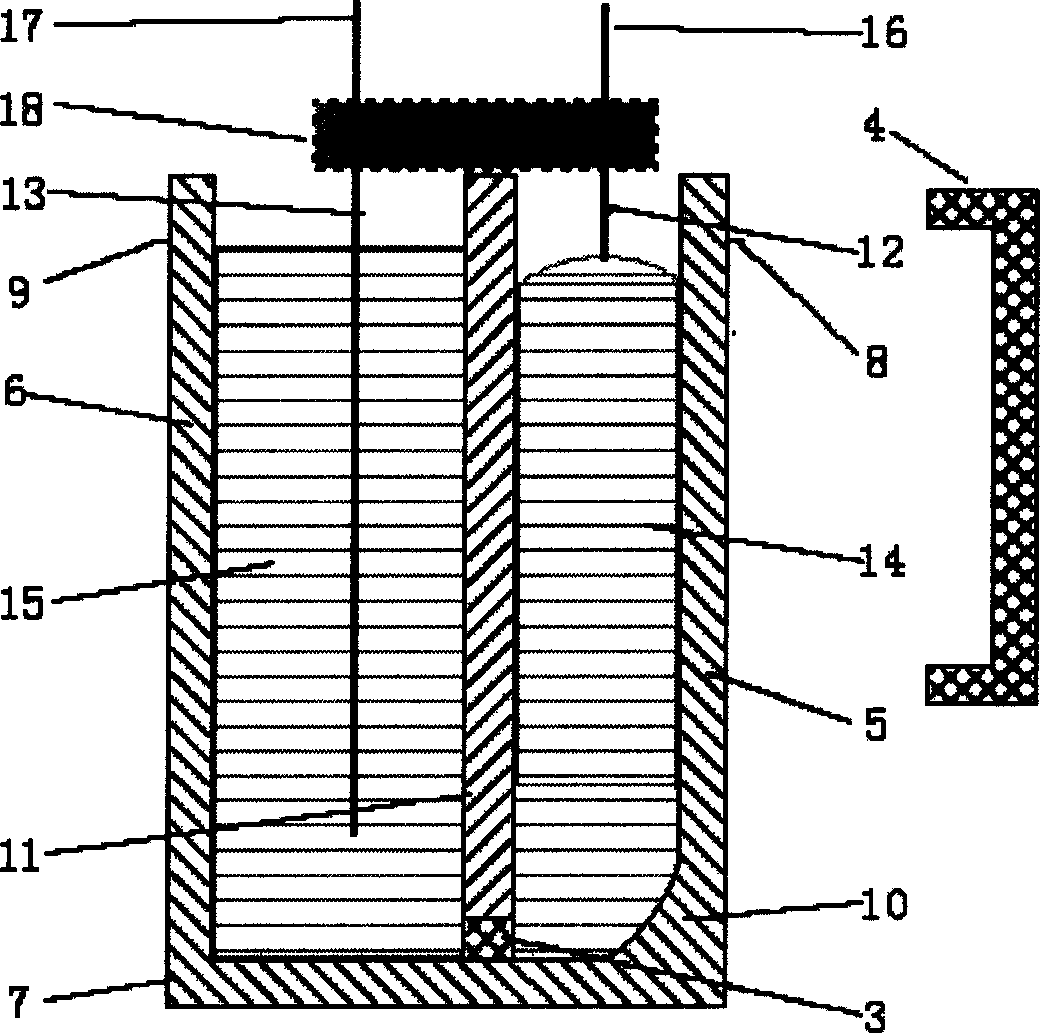

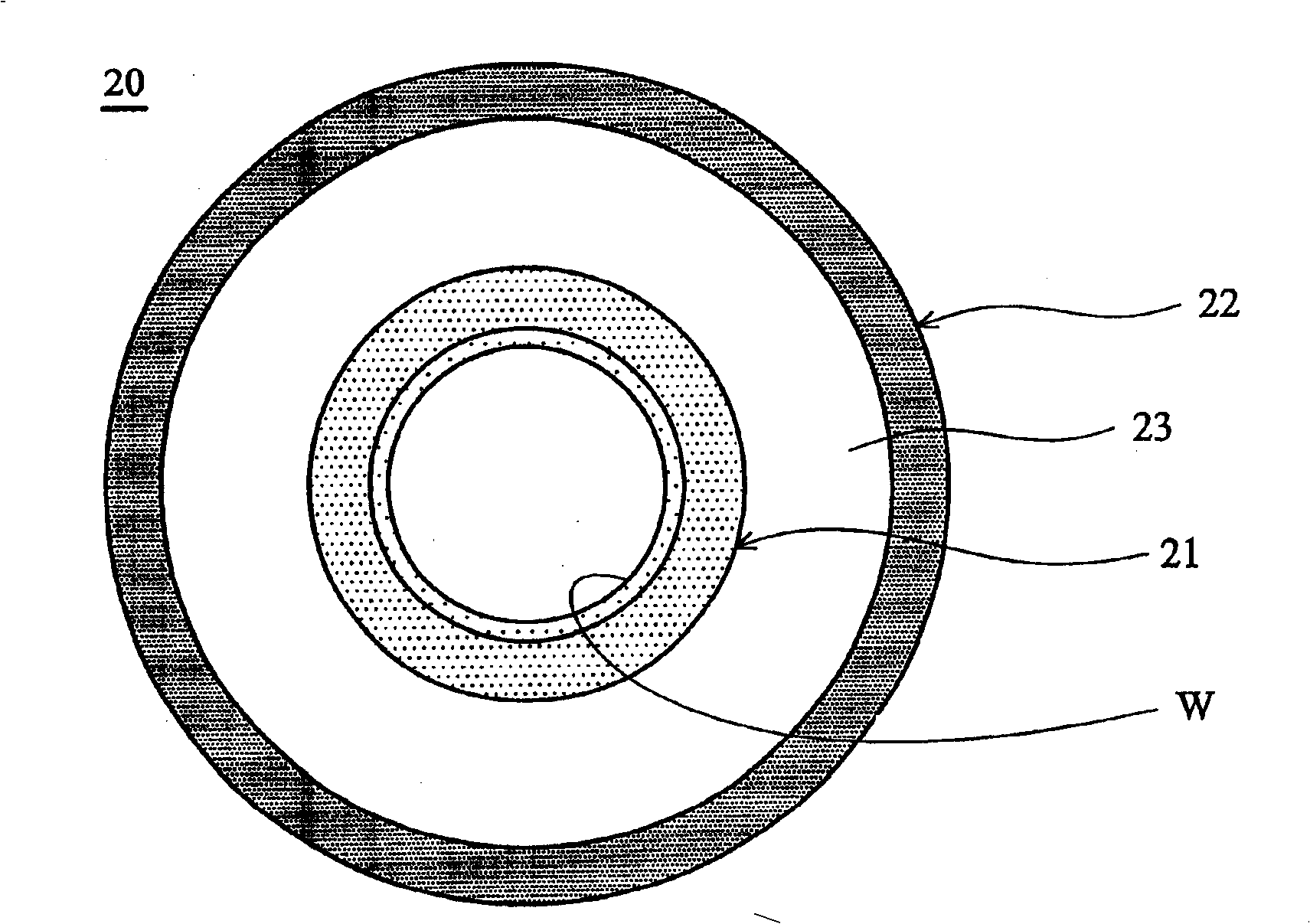

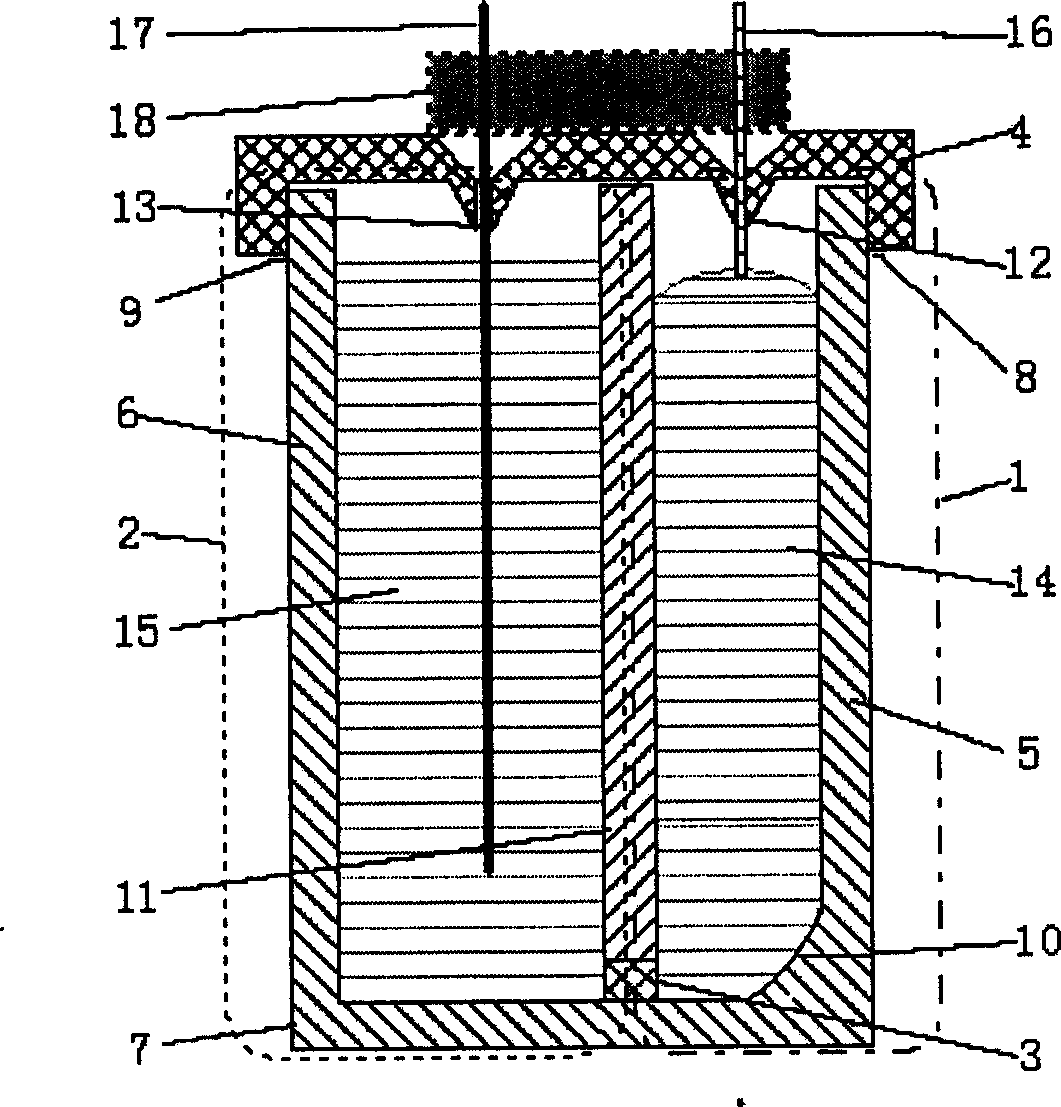

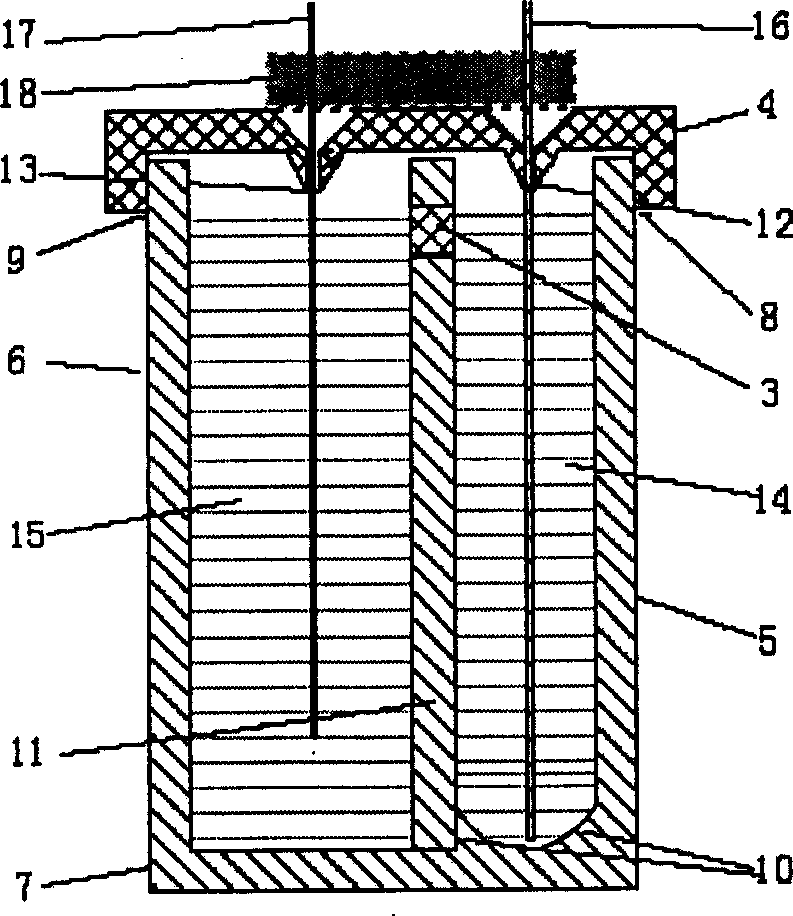

Illumination lamp

InactiveUS8556465B2Reduce adverse effectsAvoid thermal convectionLighting support devicesVehicle interior lightingConvectionElectrical and Electronics engineering

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

Water super-thin steel structure fire-proof paint and preparation method thereof

InactiveCN101125980AHigh strengthImprove fire performanceFireproof paintsPentaerythritolDiammonium phosphate

The invention relates to a waterborne super thin steel structure fireproof coating and a preparation method Which is evidently different from the solvent-typed expansion foam fireproof coating, the invention solves the problems of environmental pollution, resource waste and high cost in prior solvent-typed super thin steel structure fireproof coating. The invention takes water as solvent and comprises the components with certain weight portions: water of 5-25 weight portions, waterborne resin or mixed waterborne resin of 10-30 weight portions, waterborne expansion additive of 25-50 weight portions, pentaerythritol or dipentaerythritol or starch of 5-15 weight portions, one or two components among urea, melamine and dicyano diammonium with 6-15 weight portions, ammonium dihydrogen phosphate, ammonium polyphoste or diammonium phosphate of 15-30 weight portions, expansion regulator of 3-18 weight portions, titanium dioxide of 3-12 weight portions, dispersion agent of 0.1-1.0 weight portions.

Owner:应急管理部四川消防研究所

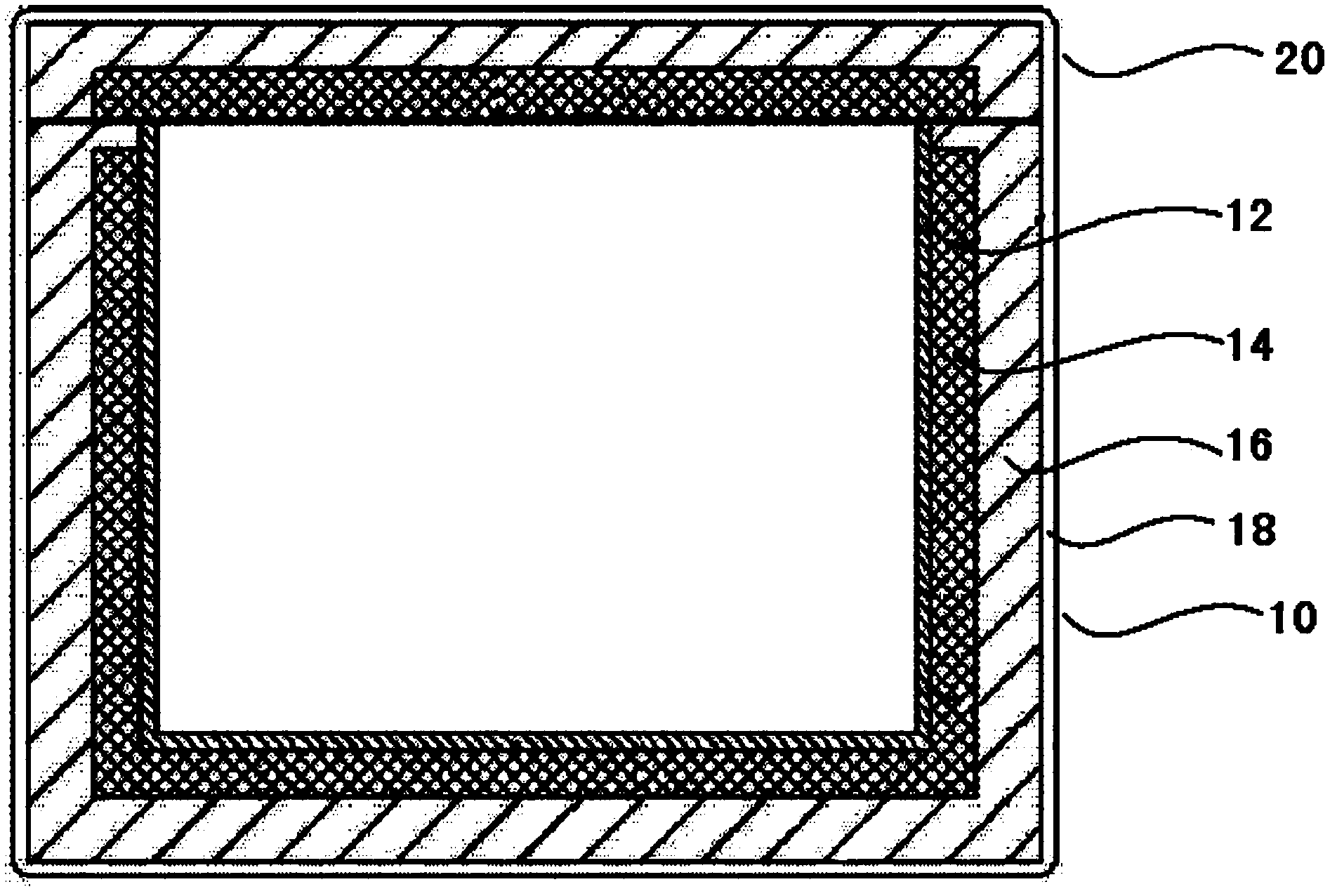

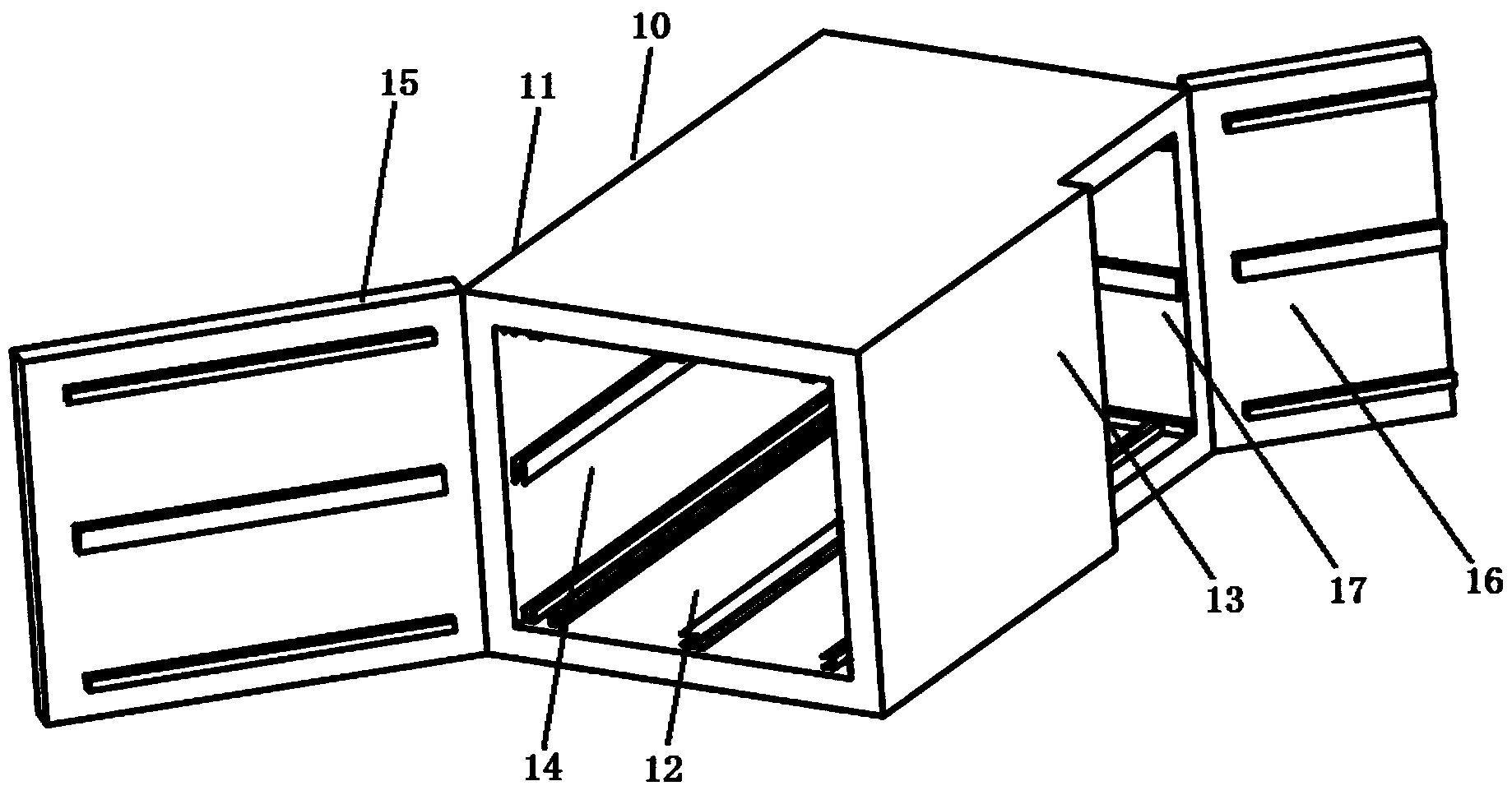

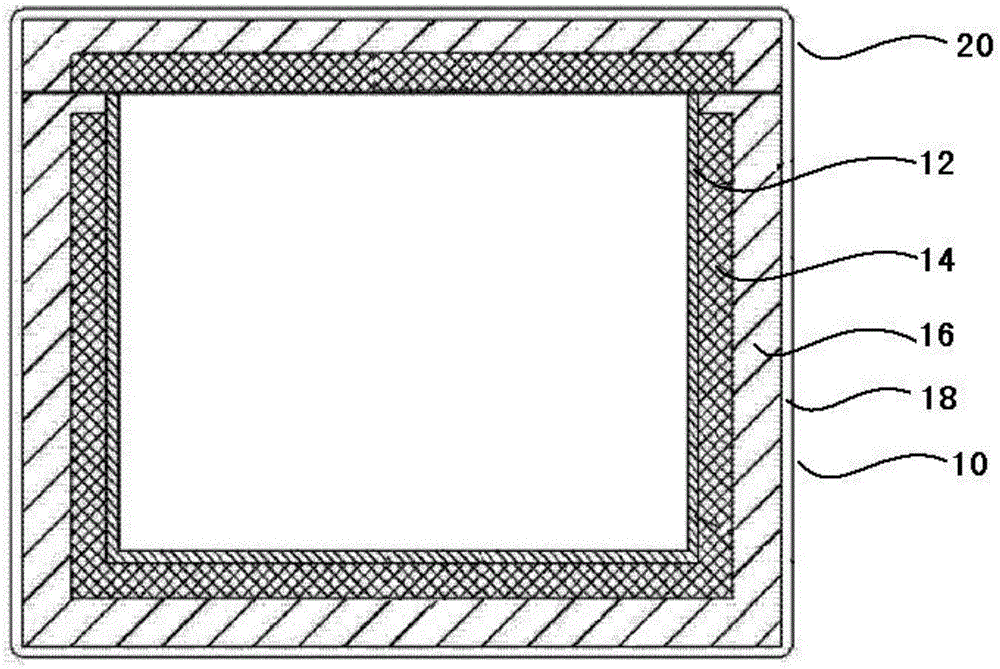

Heat insulation cold closet for medical supplies

ActiveCN103723379AReduce thicknessIncrease effective volumeLighting and heating apparatusInsulation for cooling apparatusEngineeringEffective volume

The invention discloses a heat insulation cold closet. According to the heat insulation cold closet, due to the fact that a vacuum heat insulation panel layer and a rigid polyurethane layer are arranged in a polyurethane foamed plastic layer to form a composite head insulation structure, the thickness of the heat insulation cold closet is reduced so that the effective volume of a heat insulation closet in the same shape can be greatly increased; furthermore, the coefficient of heat insulation of the heat insulation cold closet is smaller than or equal to 0.004W / mK, heat radiation, heat conduction and heat convection between the interior of the closet body and the outside environment can be effectively prevented, and the heat insulation closet can guarantee that the interior temperature is controlled below 2-8 DEG C for more than 120 hours. The heat insulation cold closet is mainly used for cold storage and refrigeration during transportation and storage of medicine such as vaccine, insulin, blood products, biological products and reagents.

Owner:SUZHOU ANTEK INDAL

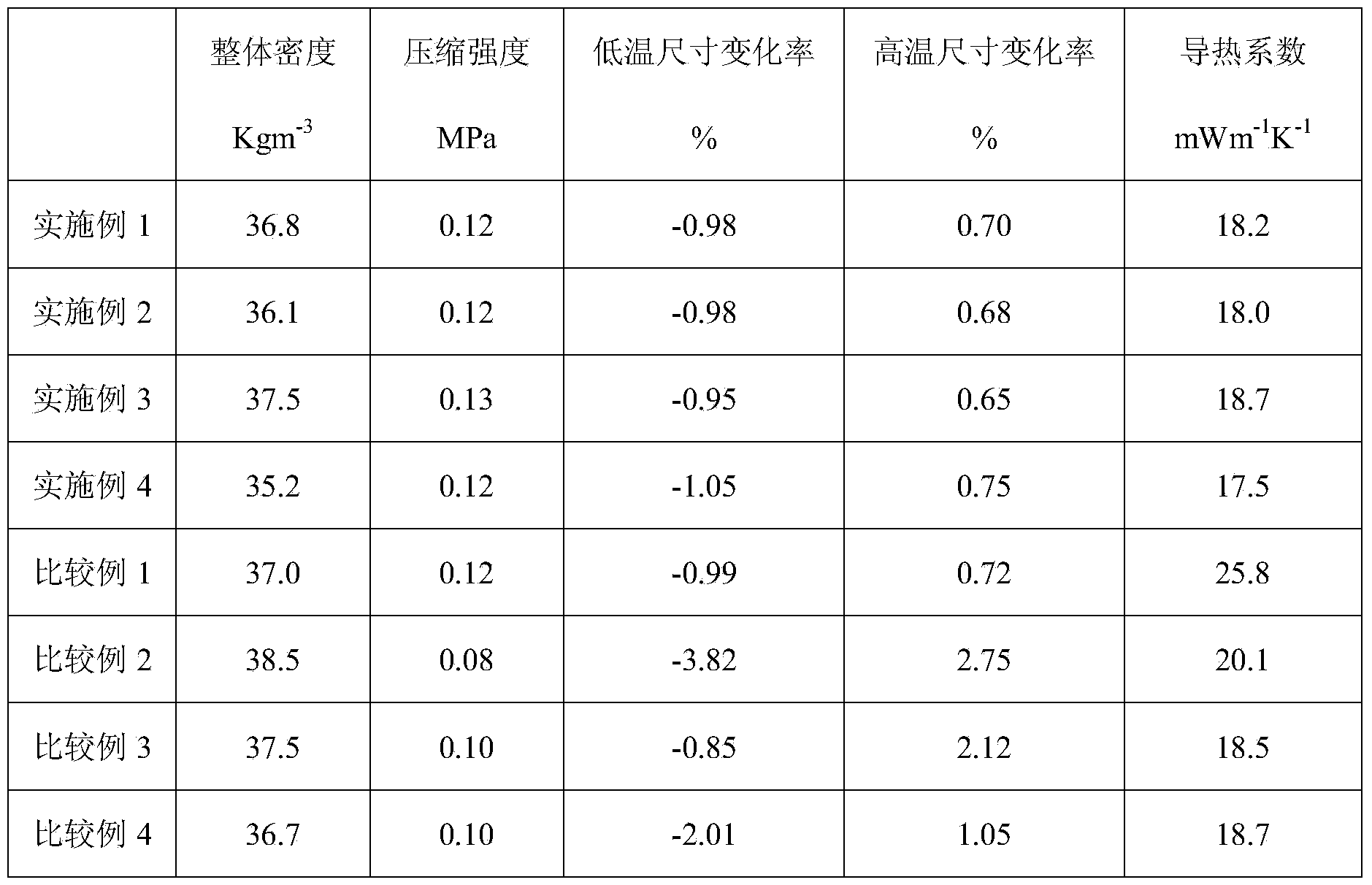

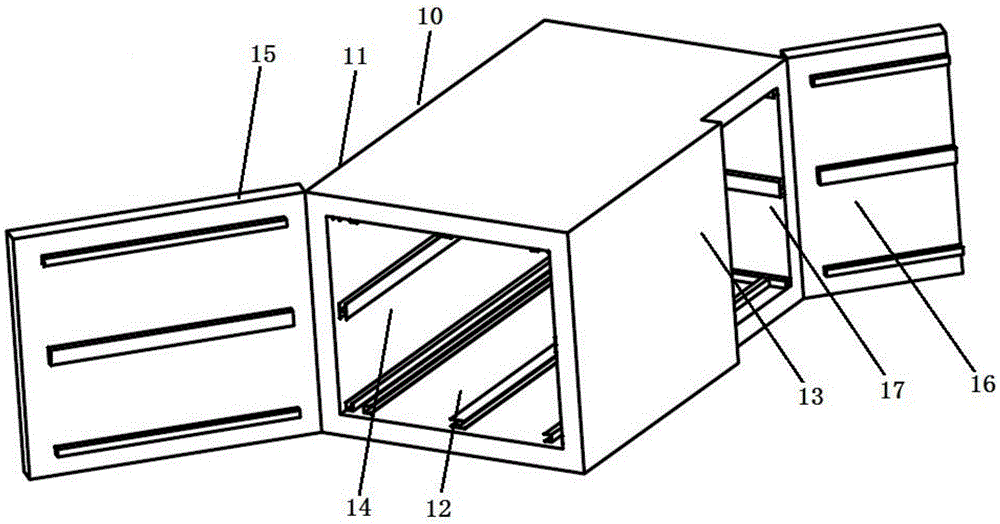

Passive vehicle-mounted chill box

ActiveCN103950645AReduce volumePrevent heat radiationDomestic cooling apparatusLighting and heating apparatusCool storageEngineering

The invention relates to a passive vehicle-mounted chill box. The passive vehicle-mounted chill box comprises a thermal insulation box body and a cool storage material arranged in the thermal insulation box body, wherein the thermal insulation box body consists of a plurality of walls forming a chill box main body; the walls comprise outer shell layers, vacuum insulated panels and inner shell layers; rigid polyurethane foam bodies fill between the outer shell layers and the vacuum insulated panels; rigid polyurethane foam bodies fill between the inner shell layers and the vacuum insulated panels; the thermal insulation box body is provided with a pressure relief device. According to the passive vehicle-mounted chill box, a direct cooling mode that the cool storage material is vaporized, absorbs heat and is diffused into the box body is adopted, and as a power supply system for supplying power to a motor compressor is not required, the size of the whole chill box can be greatly reduced, the chill box is adapted to transportation of different kinds of goods or a small number of goods, and the transportation cost can be obviously reduced when different kinds of goods or a small number of goods are transported.

Owner:SUZHOU ANTEK INDAL

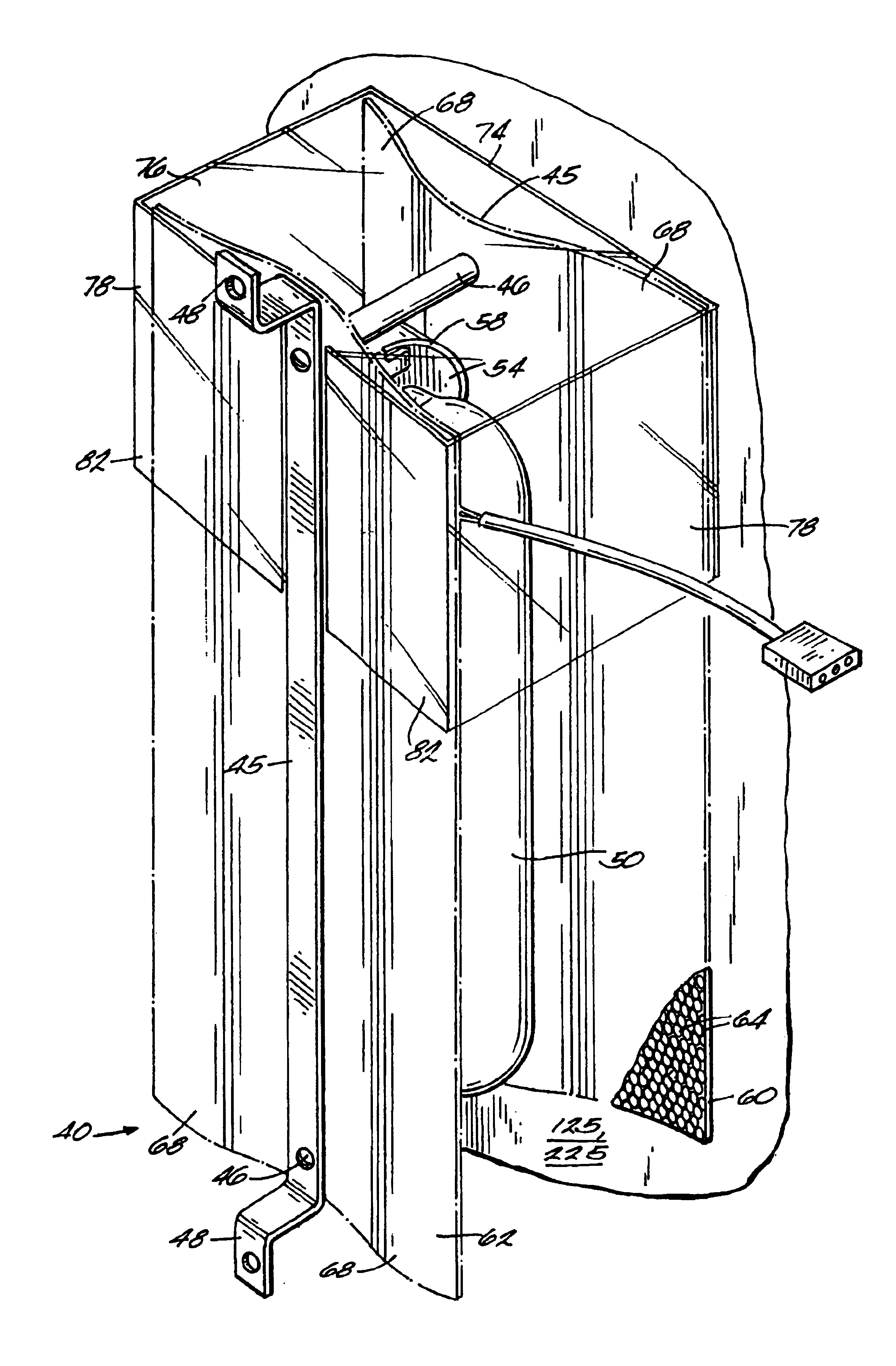

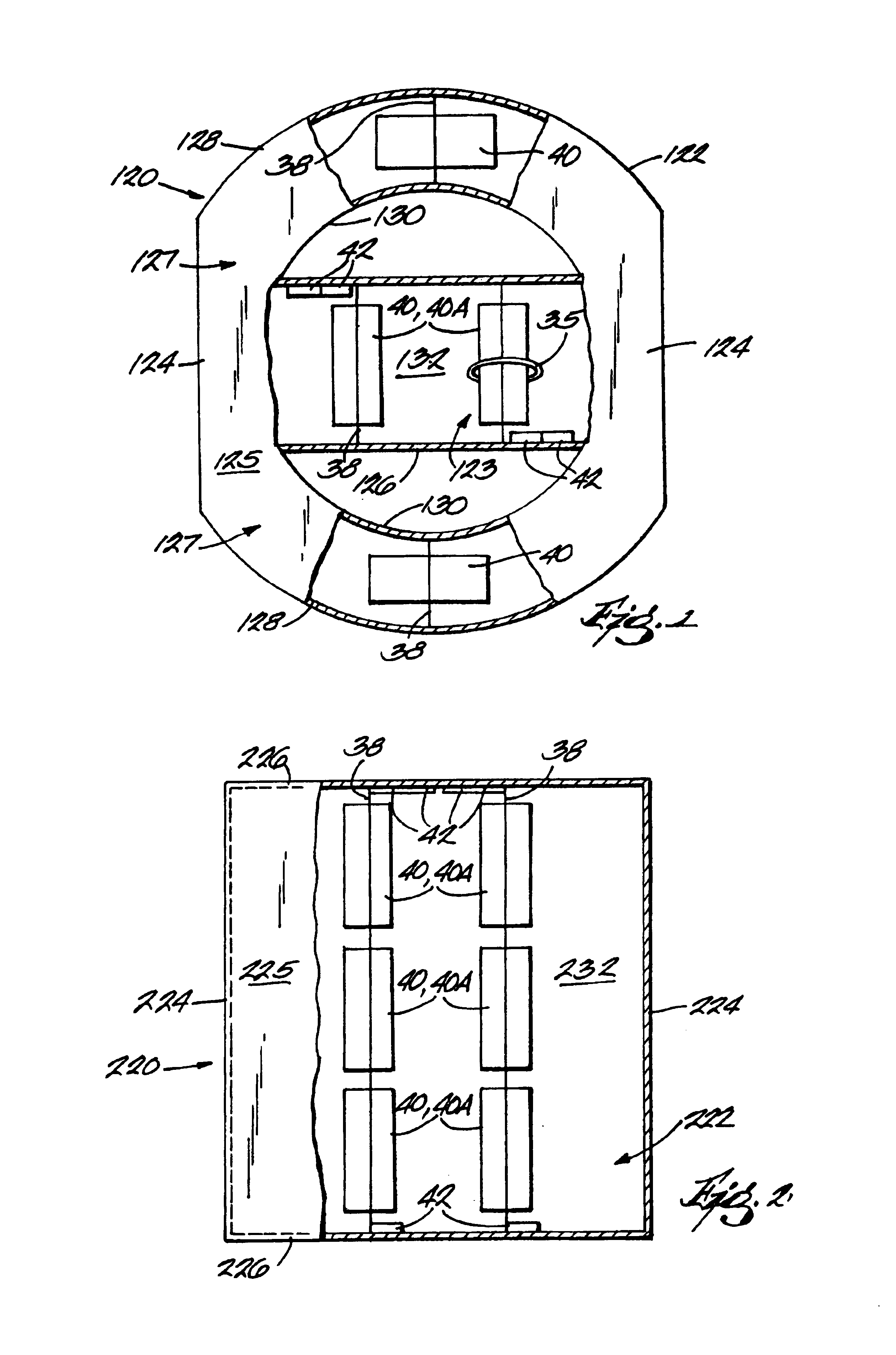

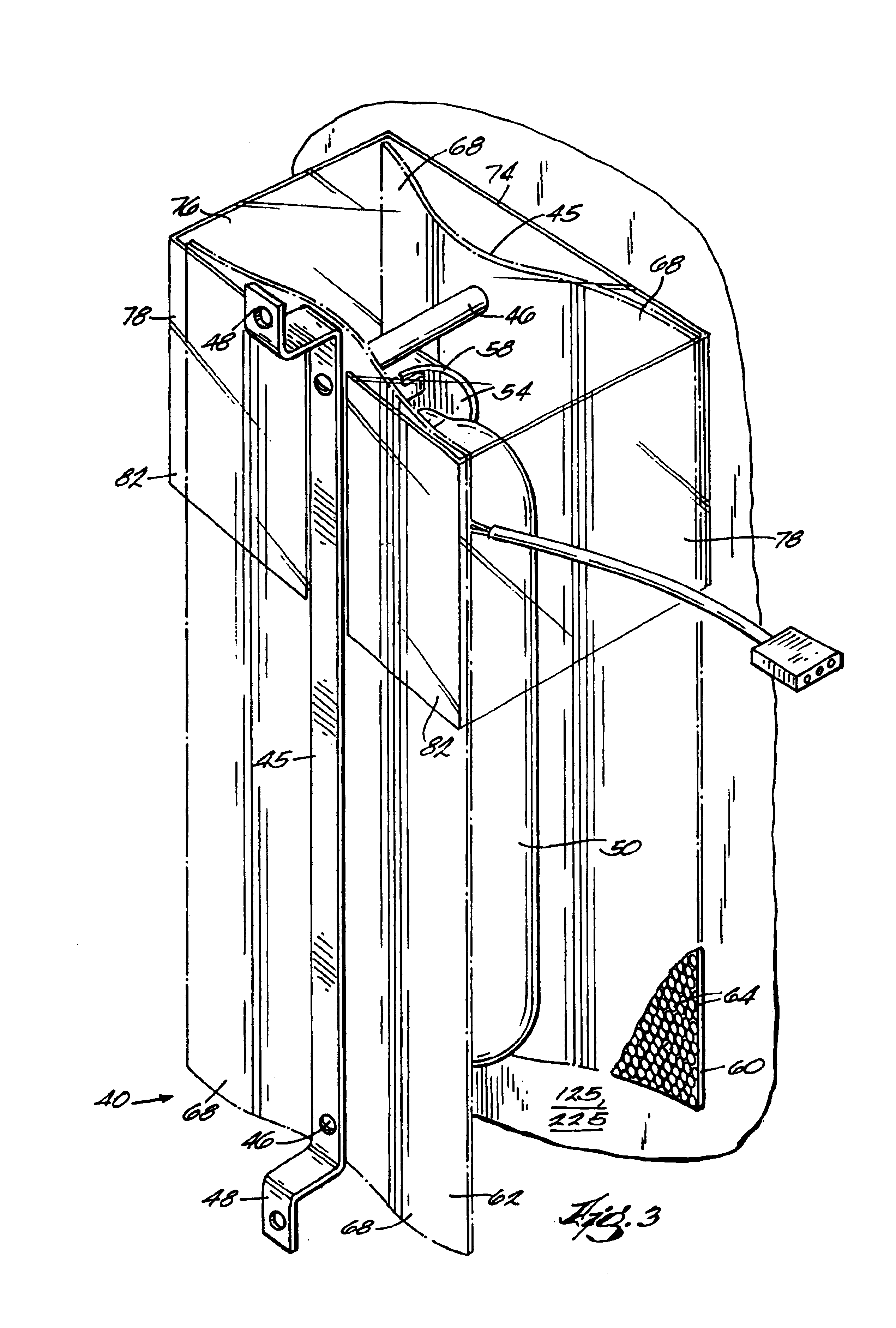

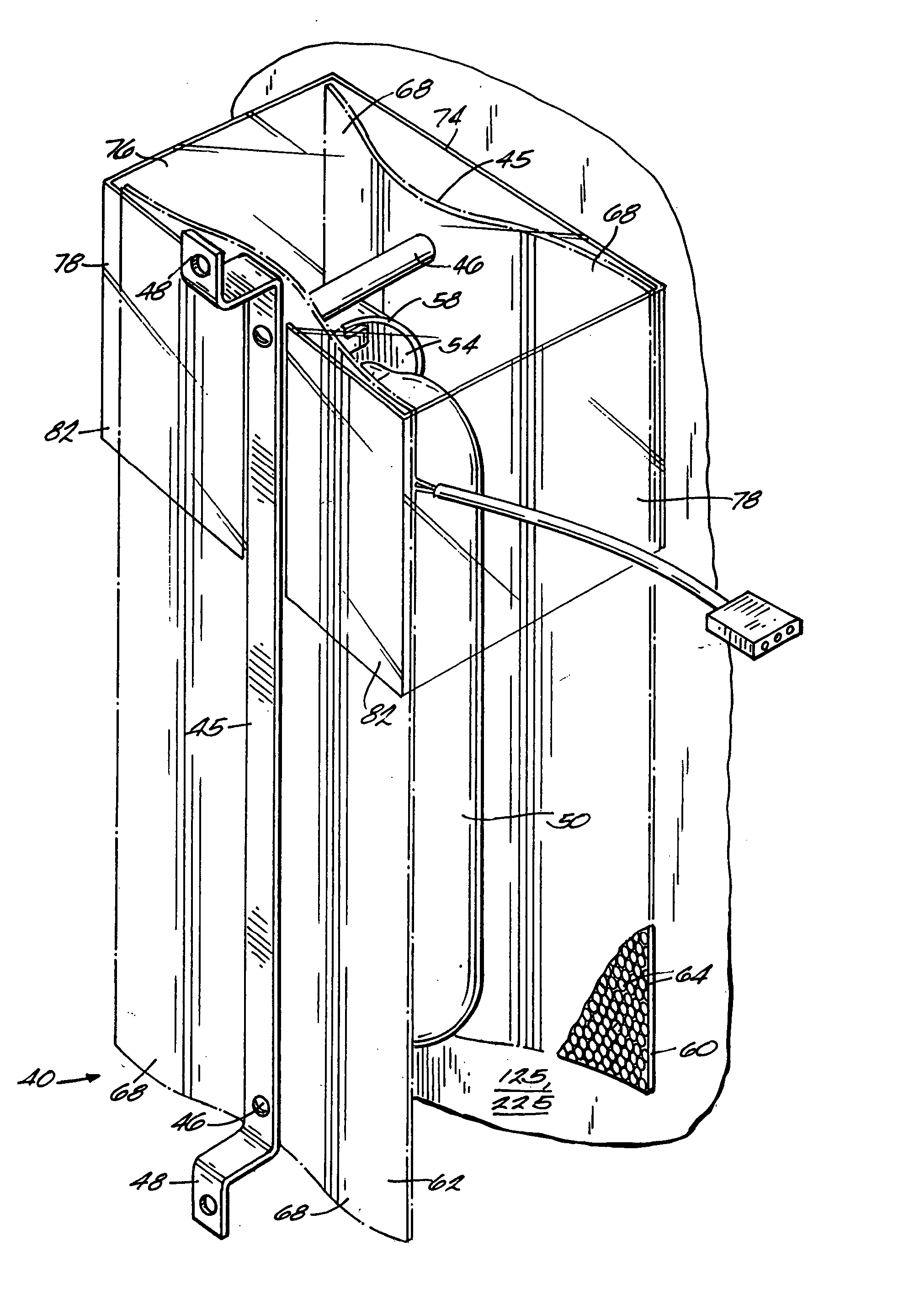

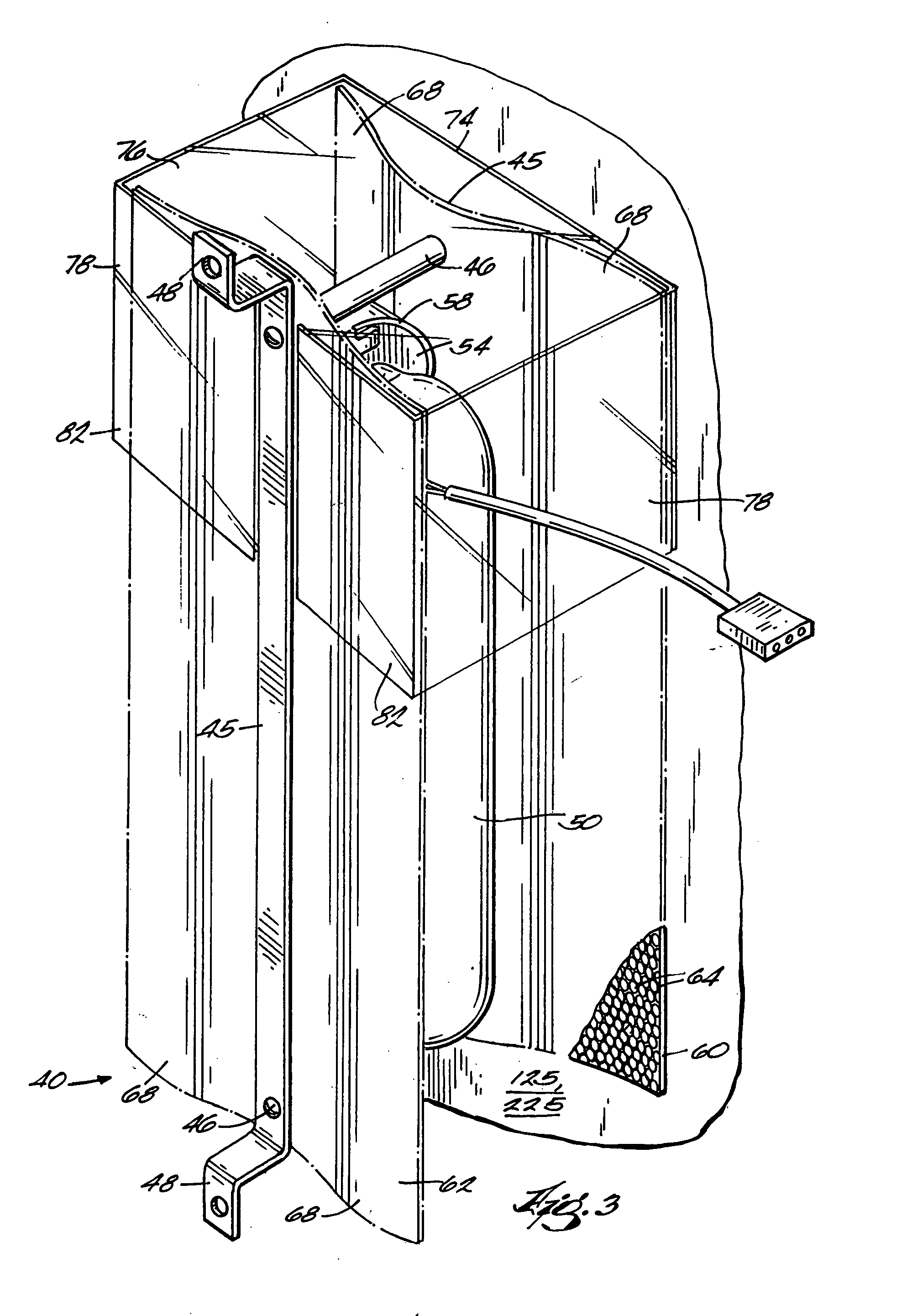

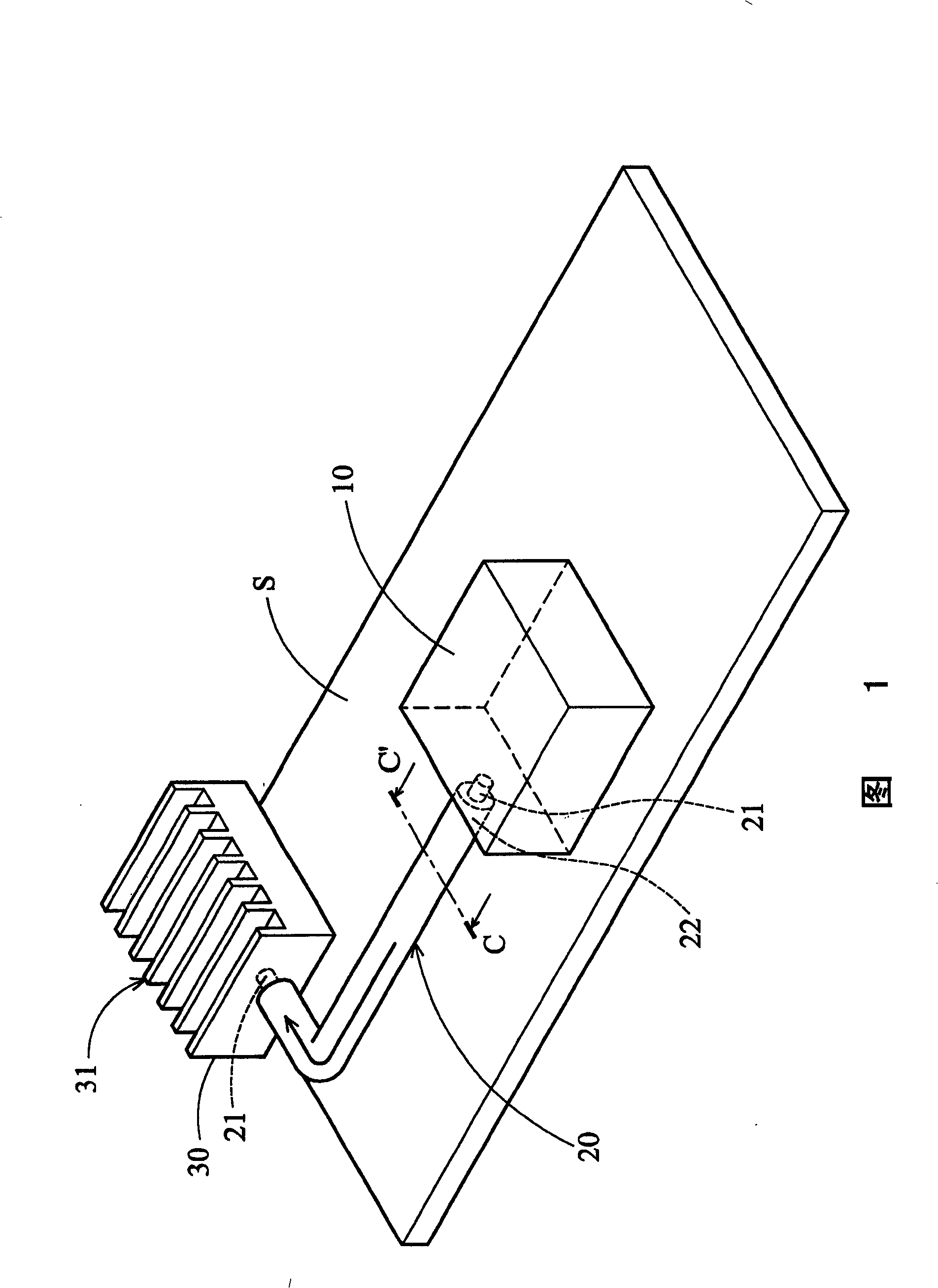

Sign illumination light fixture

InactiveUS6942366B2Uniform lightMinimal numberElectric circuit arrangementsLighting heating/cooling arrangementsSpecular reflectionPolymer

The invention provides a light fixture for illuminating a sign. The light fixture has a lamp and one or more reflectors to provide for substantially uniform illumination of a sign with a minimum number of light fixtures. One or more of the reflectors of some embodiments can formed from a material having predetermined pattern for reflecting and transmitting light from the lamp. For example, the reflectors can be made from a neutral density polymeric material consisting of a translucent or substantially transparent polymeric substrate with a pattern of reflective media disposed on or within the substrate. In some embodiments, one of the reflectors can be a specular reflector. Some embodiments of the light fixture can also include a thermal shield to at least partially prevent thermal convection along a portion of the lamp.

Owner:EVERBRITE

Heat insulation box

InactiveCN102849349AReduce manufacturing costPrevent heat radiationDomestic cooling apparatusLighting and heating apparatusInsulation layerEngineering

The invention discloses a heat insulation box which comprises a box and a box cover. One side of the box is provided with an opening, and the box cover seals the opening. The box and the box cover comprise a first heat insulation layer, a second heat insulation layer and a shell, which are adjacent to one another sequentially from inside to outside. The first heat insulation layer is provided with a VIP (vacuum insulation panel), and the second heat insulation layer is provided with a foaming PU (polyurethane) plate. The structure of the heat insulation box can insulate a large amount of heat in external environment, heat insulation coefficient is not larger than 0.004W / m*K, and accordingly heat radiation, heat conduction and heat convection between the inside of the box and the external environment can be prevented effectively. Temperature of the heat insulation box can be kept at 2-8 DEG C continuously for more than 120 hours. The heat insulation box is mainly applied to the field of refrigeration, freezing and the like of medicaments such as vaccine, insulin, blood product, biological product and reagent in transportation and storage.

Owner:SUZHOU ANTEK INDAL

Sign illumination light fixture

InactiveUS20050018430A1Uniform illuminationUniform lightElectric circuit arrangementsLighting heating/cooling arrangementsSpecular reflectionLight fixture

The invention provides a light fixture for illuminating a sign. The light fixture has a lamp and one or more reflectors to provide for substantially uniform illumination of a sign with a minimum number of light fixtures. One or more of the reflectors of some embodiments can formed from a material having predetermined pattern for reflecting and transmitting light from the lamp. For example, the reflectors can be made from a neutral density polymeric material consisting of a translucent or substantially transparent polymeric substrate with a pattern of reflective media disposed on or within the substrate. In some embodiments, one of the reflectors can be a specular reflector. Some embodiments of the light fixture can also include a thermal shield to at least partially prevent thermal convection along a portion of the lamp.

Owner:EVERBRITE

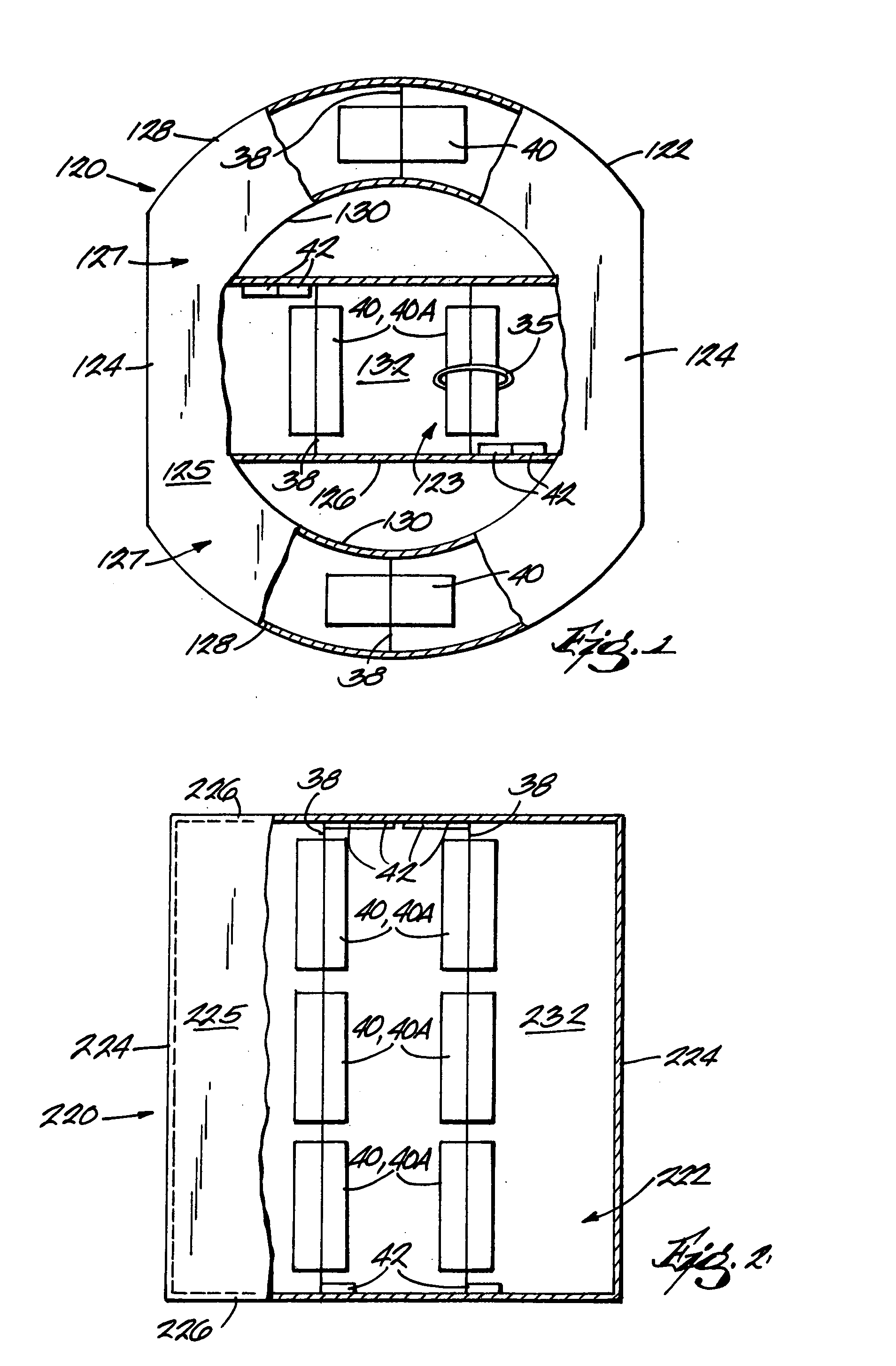

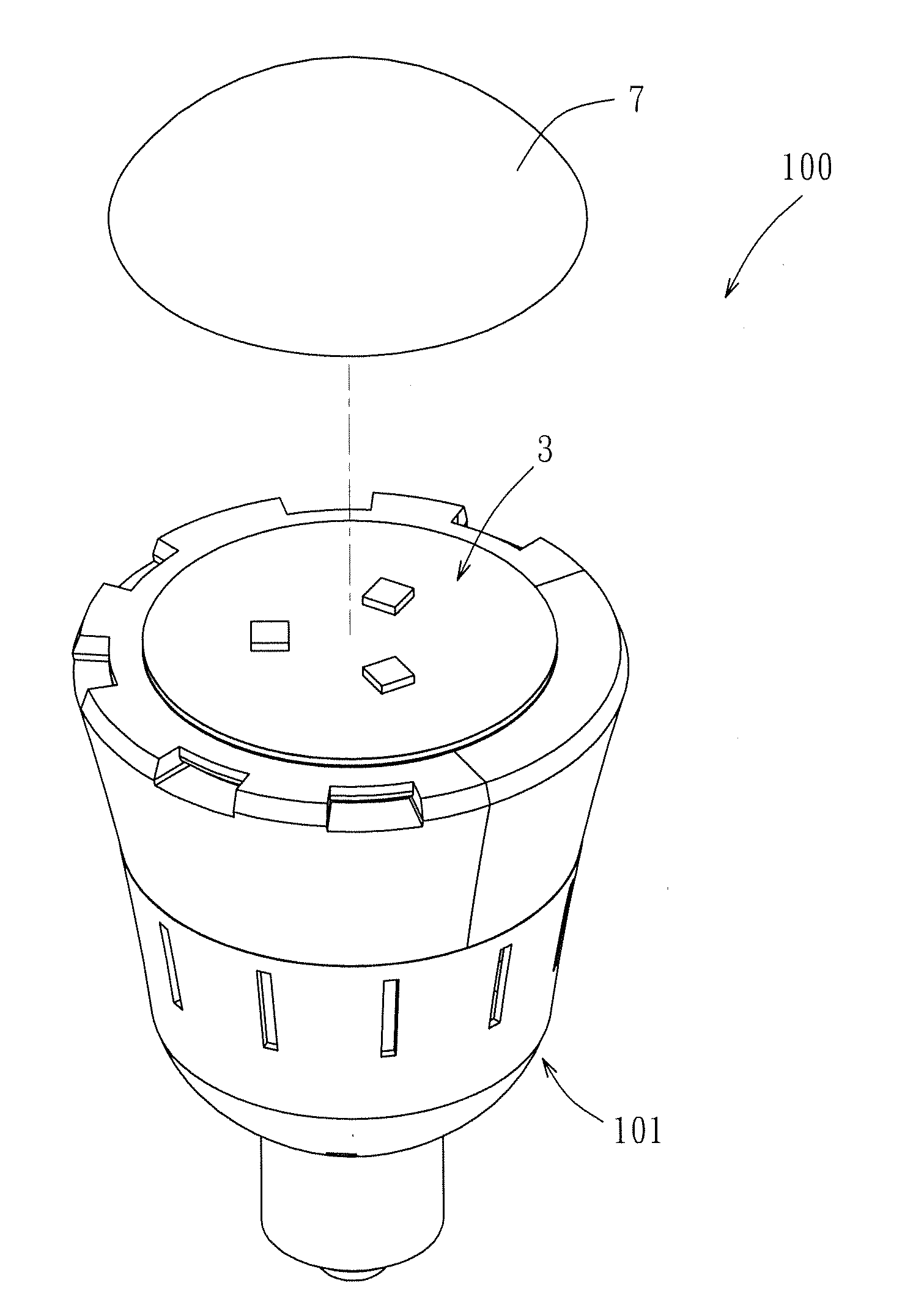

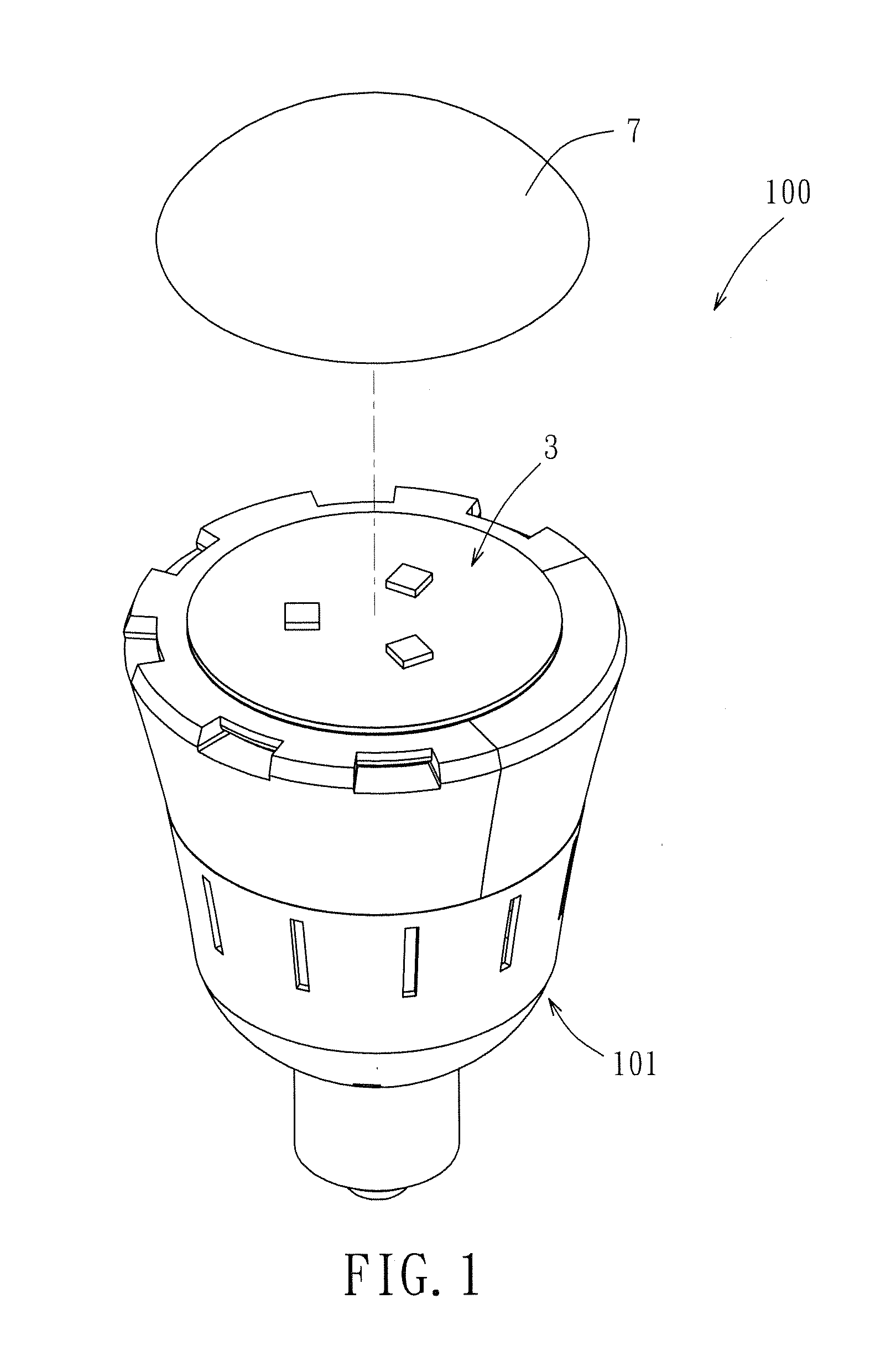

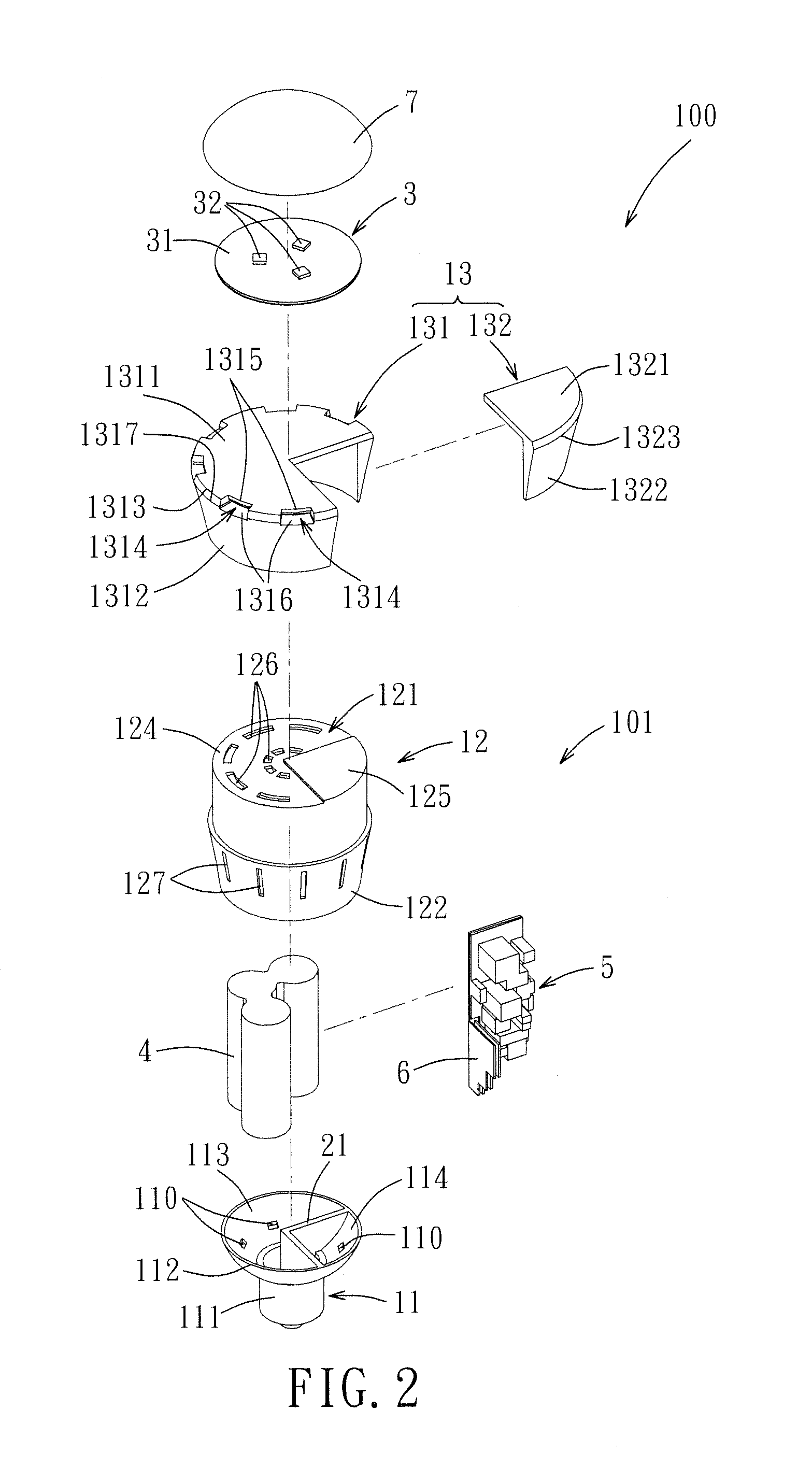

Illumination lamp

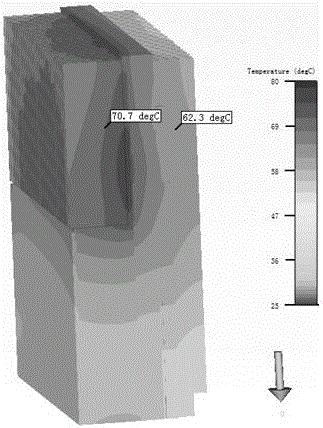

InactiveUS20120224360A1Reduce adverse effectsAvoid thermal convectionLighting support devicesVehicle interior lightingConvectionElectrical and Electronics engineering

An illumination lamp comprises a lamp body, a light-emitting module, a power supply module, and a circuit module. The lamp body defines an inner space. The partitioning unit is disposed in the lamp body for dividing the inner space into a first space for receiving the power supply module, and a second space for receiving the circuit module. Due to the presence of the partitioning unit, thermal convection between the first and second spaces is prevented to reduce adverse influence of a high temperature of the circuit module on the power supply module.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

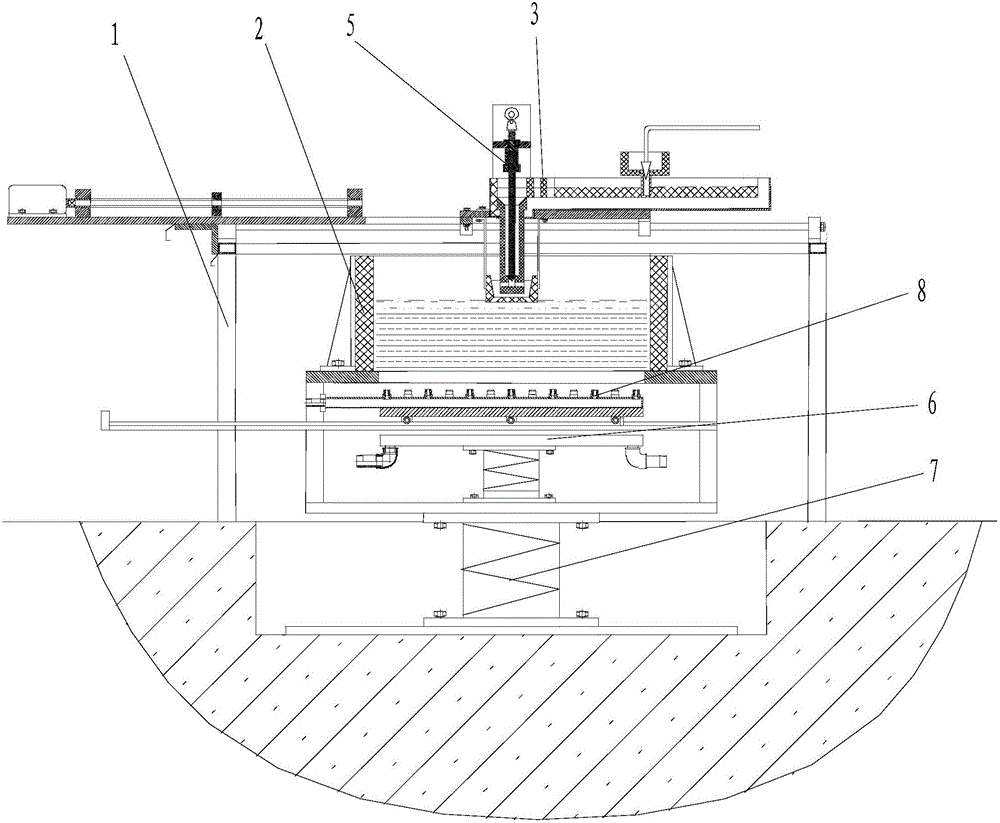

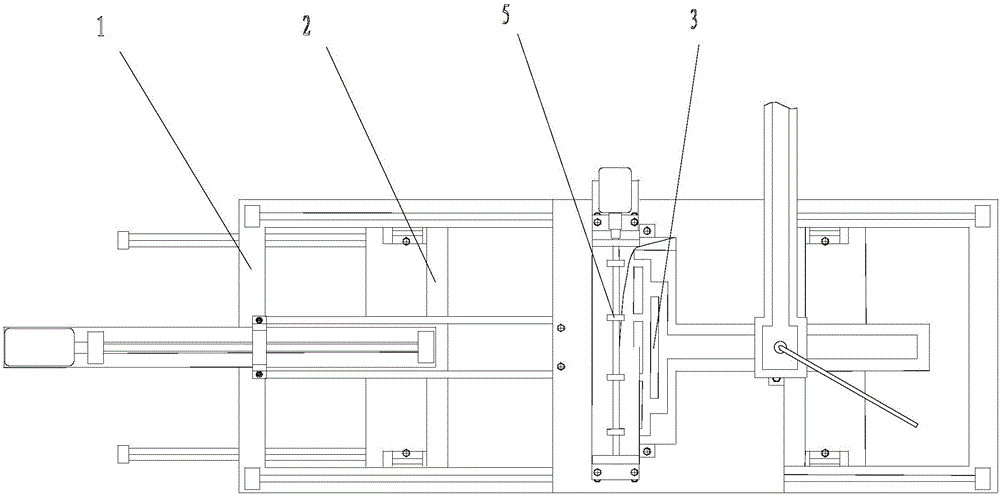

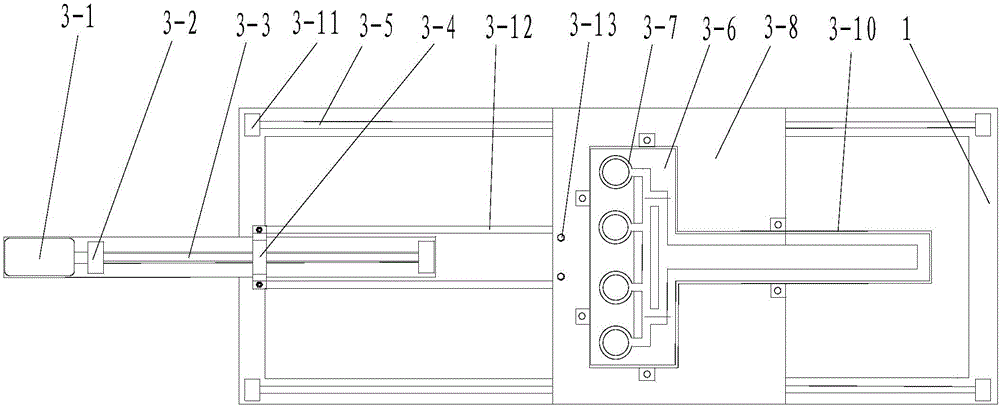

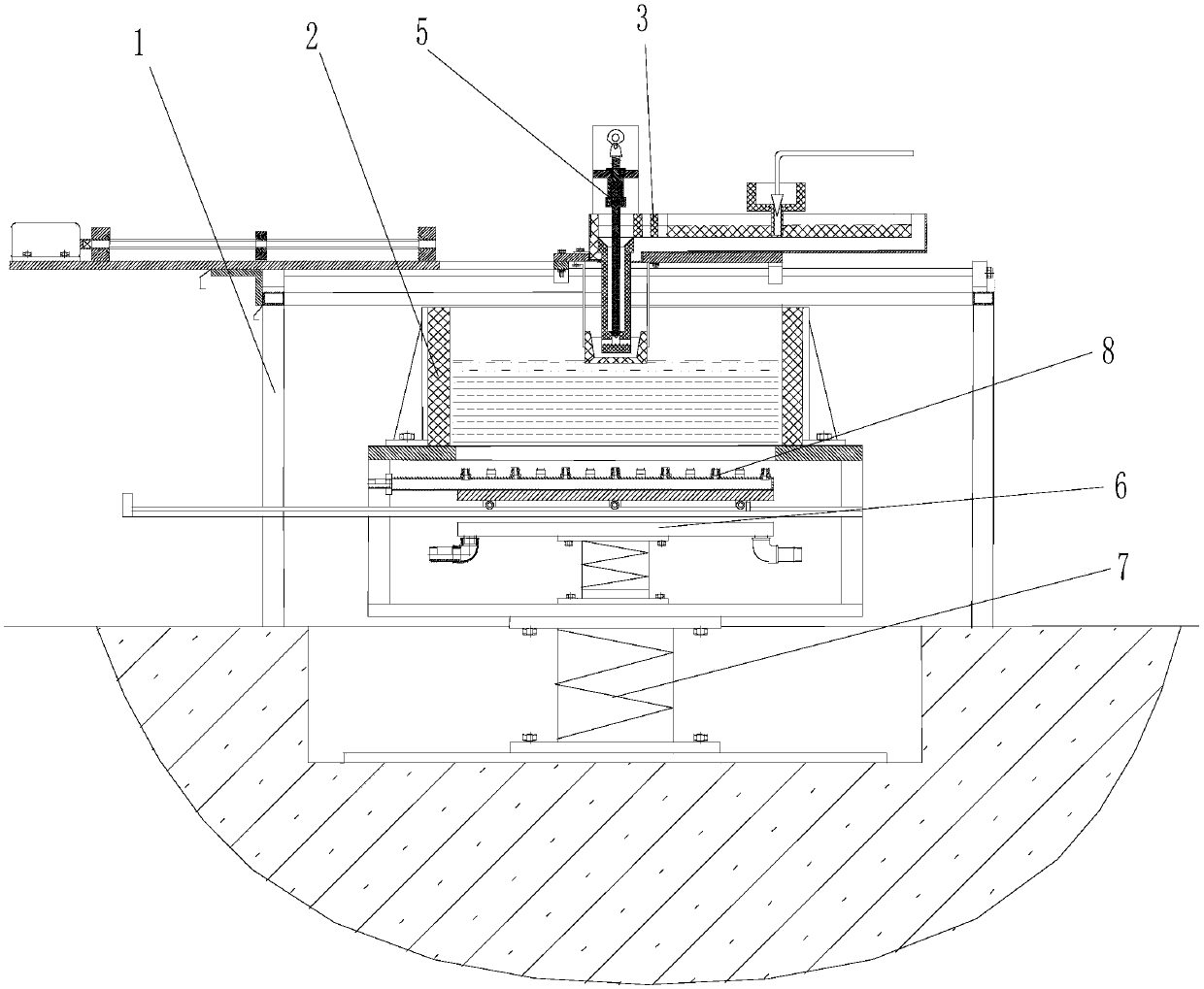

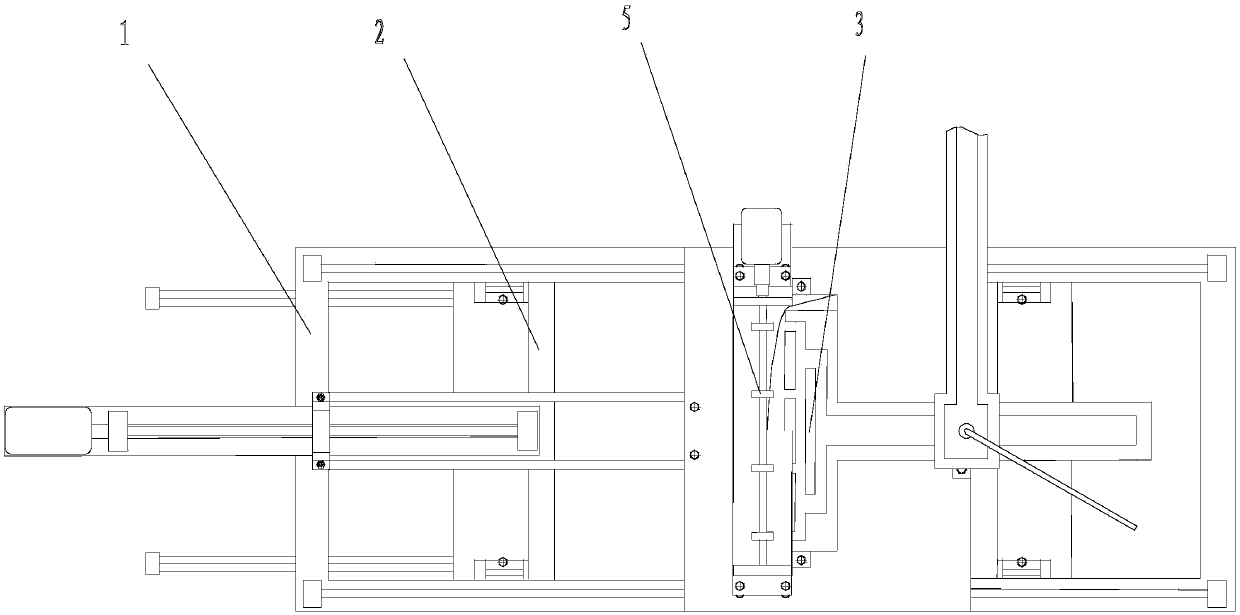

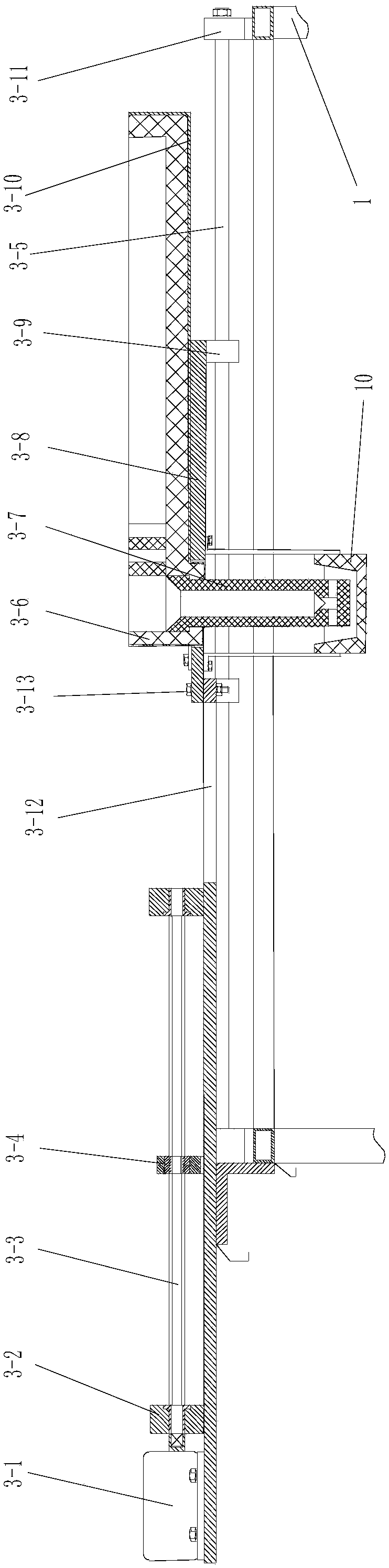

Aluminum alloy laminar flow distribution plane solidification casting device and casting method thereof

ActiveCN106238716AAchieve laminar distributionAvoid local overheatingMolten metal pouring equipmentsIngot castingWater spray

The invention discloses an aluminum alloy laminar flow distribution plane solidification casting device and a casting method thereof, and belongs to the technical field of aluminum alloy ingot blank casting. The device comprises a support. A translation flow distribution mechanism capable of moving horizontally is arranged on the upper portion of the support. A flow control mechanism is arranged at an outlet of the translation flow distribution mechanism. A casting tank is arranged below the translation flow distribution mechanism. A water spraying system and a cooling plate system are arranged below the casting tank. The method includes the steps that the cooling plate system rises into the casting tank, and molten aluminum alloy enters a flow distribution groove and then enters a guide rod sleeve; a second motor is started to control flow of the molten aluminum alloy; a first motor is started, a movable plate drives the flow distribution groove to move horizontally, and the molten aluminum alloy flows to a cooling plate upper plate body in a laminar mode; when an aluminum alloy solidification layer can be supported, a cooling plate oil cylinder is started, and thus the cooling plate system descends; then the water spraying system is pushed in, and sprayed water is cooled; the descending speed of a main oil cylinder is controlled until casting reaches a preset thickness; and after all the cooling is completed, water spraying is stopped, the water spraying system is extracted, ingot castings are taken out, and accordingly casting is completed.

Owner:NORTHEASTERN UNIV

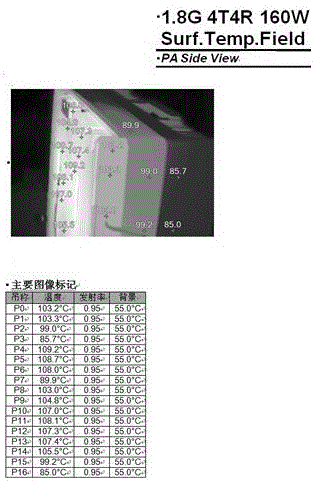

Power source thermal isolation high-power LED lamp

PendingCN108006548AReduce physical contact areaImproved thermal isolationElectric circuit arrangementsLighting heating/cooling arrangementsThermal isolationRubber ring

The invention provides a power source thermal isolation high-power LED lamp. Safety and reliability of a power source of the high-power LED lamp can be improved, and adverse effects on a power sourcebin due to heat dissipation are lowered. In the power source thermal isolation high-power LED lamp, a front face cover, a light source plate and a heat dissipation shell form a light source bin. The power source bin is fixedly connected with the back of the heat dissipation shell. The power source bin and the heat dissipation shell are relatively independent, and a space is kept. A set of bosses are formed on the back of the heat dissipation shell and between heat dissipation fins. The bottom face of the power source bin is fixedly connected with the set of bosses through a set of screws, a space is kept between the bottom face of the power source bin and the heat dissipation fins below the bottom face of the power source bin, and fixed installation of the power source bin is achieved. Atleast one connecting column is further formed on the back of the heat dissipation shell. The connecting column is provided with a center channel communicating with the light source bin so as to achieve penetrating and connecting of circuits. The bottom face of the power source bin is provided with a connector matched with the connecting column, and a seal thermal isolation rubber ring is arrangedon the joint.

Owner:西安锐泽克斯光电科技有限公司

Electric sample introduction multiunit tube for capillary electrophoresis

InactiveCN1570621AEliminate convectionConvection is inevitableComponent separationMaterial analysis by electric/magnetic meansPlatinumPorosity

This invention relates to an electric sampling multiple tubes for capillary tube electrophoresis, which employs double-tube structure with diaphragm, wherein one is designed for sampling tube, the other is for electrode tube and they are used separately to receive electric sampling capillary tube and platinum electrode. And at the same time a porous diaphragm is located in the common inner tube wall between sampling tube and electrode to avoid the fluid flow between them. The diaphragm porosity is good at conductivity. The bottom of sampling tube is curved connected with its outer wall so as to effectively eliminate electric field blind angle. The invention effectively solves the problem of bubbling on electrode surface and fluid flow caused by heat diversity in traditional electric sampling, including field enlarging sampling.

Owner:SHANGHAI JIAO TONG UNIV

Insulated refrigerators for medical and pharmaceutical products

InactiveCN103723379BReduce thicknessIncrease effective volumeLighting and heating apparatusInsulation for cooling apparatusThermal coefficientEngineering

The invention relates to a heat-insulated refrigerator for medical medicine, comprising a box body with an opening, and a cover body sealingly fitted with the opening; the box body is sequentially composed of a hard polyurethane layer and a vacuum insulation board layer , foamed polyurethane board and shell. In the heat-insulating refrigerated box of the present invention, since the vacuum insulation board layer and the rigid polyurethane layer are arranged in the polyurethane foam plastic layer to form a composite heat-insulating structure, not only the thickness of the heat-insulated refrigerated box is reduced, but also the same appearance The effective volume of the insulation box is greatly improved, and its thermal insulation coefficient is less than or equal to 0.004W / mK, which can effectively prevent heat radiation, heat conduction and heat convection between the inside of the box and the external environment. The heat insulation box can ensure that the temperature inside the box is within At 2-8°C, the duration is more than 120 hours; the insulated refrigerator of the present invention is mainly used for refrigeration and freezing of vaccines, insulin, blood products, biological products, reagents and other medicines during transportation and storage.

Owner:SUZHOU ANTEK INDAL

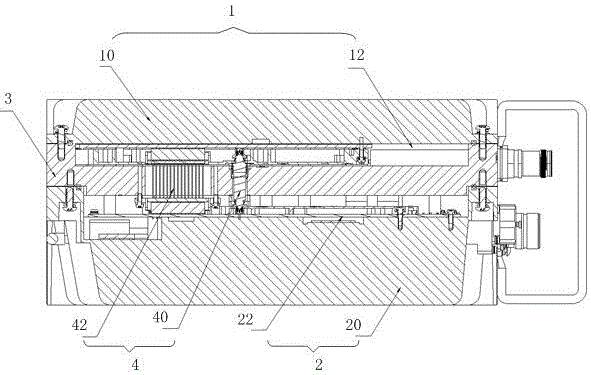

Radio frequency remote module and radio frequency base station

ActiveCN106330236AReduce interactionPrevent heat radiationTransmissionModifications by conduction heat transferTransceiverRadio frequency

According to the embodiment of the invention, a radio frequency remote module is provided, comprising a filter module, a power amplifier module and a transceiver module. The power amplifier module and the transceiver module are arranged respectively on the two sides of the filter module. The filter module communicates with the transceiver module through a digital signal connector adapter; the filter module communicates with the power amplifier module through a radio frequency adapter. The invention also provides a corresponding radio frequency base station. According to the invention, it is possible to reduce the influence of the power amplifier module on the temperature of the transceiver module. The module of the invention is highly integrated.

Owner:SHENZHEN SAMSUNG COMM TECH RES +1

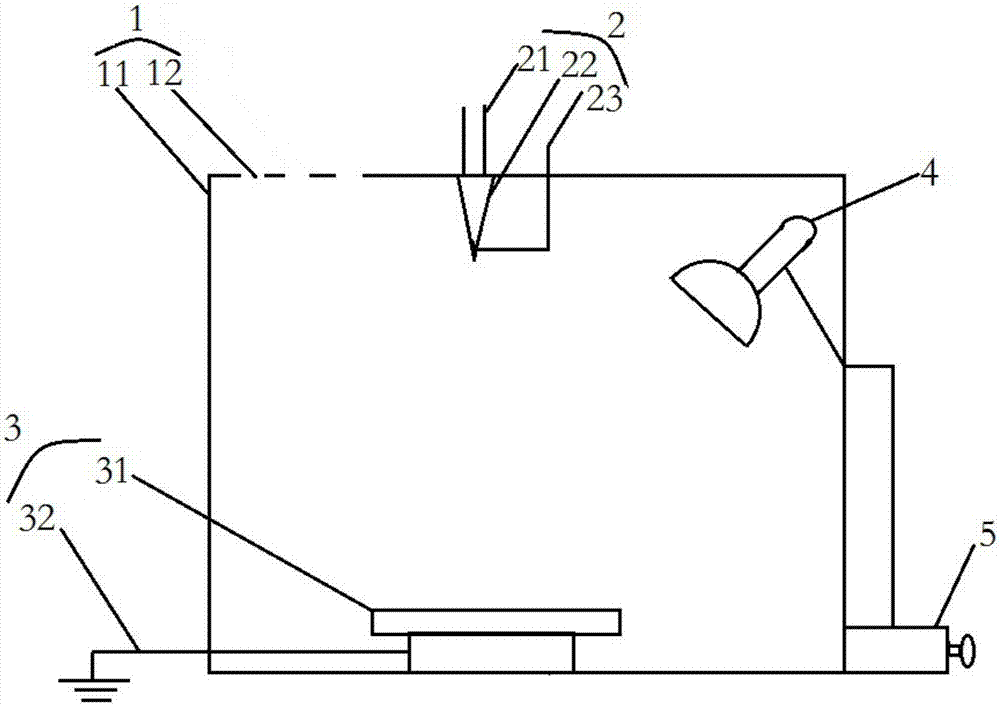

Thermal radiation heating type electrostatic spinning machine

InactiveCN107099863AAccelerate evaporationHigh yieldFilament/thread formingVoltage regulator moduleFiber

The invention provides a thermal radiation heating type electrostatic spinning machine. The upper end face of a tank body is provided with an air through hole, a spinning solution jetting device is arranged above the inside of the tank body. The hot radiation heating type electrostatic spinning machine comprises a solution conduit, a nozzle connected with the solution conduit and a high voltage power source anode binding post connected with the nozzle, a high voltage power source anode binding post connected with the nozzle is connected with a high voltage power source anode, the upper end of the solution conduit extends outside the tank body, a thermal radiation heating device is a heating source arranged above the inside of the tank body, a voltage adjustment module is connecting with the heating source, and the heating temperature is adjusted by adjusting thermal radiation heating device power; a fiber receiving device comprises a receiving table arranged on the bottom in the tank body and a high voltage cathode connecting binding post connected with the receiving table, the receiving table is located under the nozzle, and the high voltage cathode connecting binding post is connected with a high voltage power source cathode. In the hot radiation heating type electrostatic spinning machine, through thermal radiation, jet flow in the electrostatic spinning process is heated, volatilization of a spinning solvent is promoted, and the finished silk efficiency and fiber quality of nanofiber are improved.

Owner:HARBIN ENG UNIV

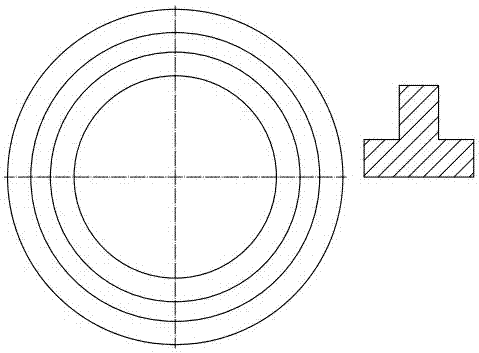

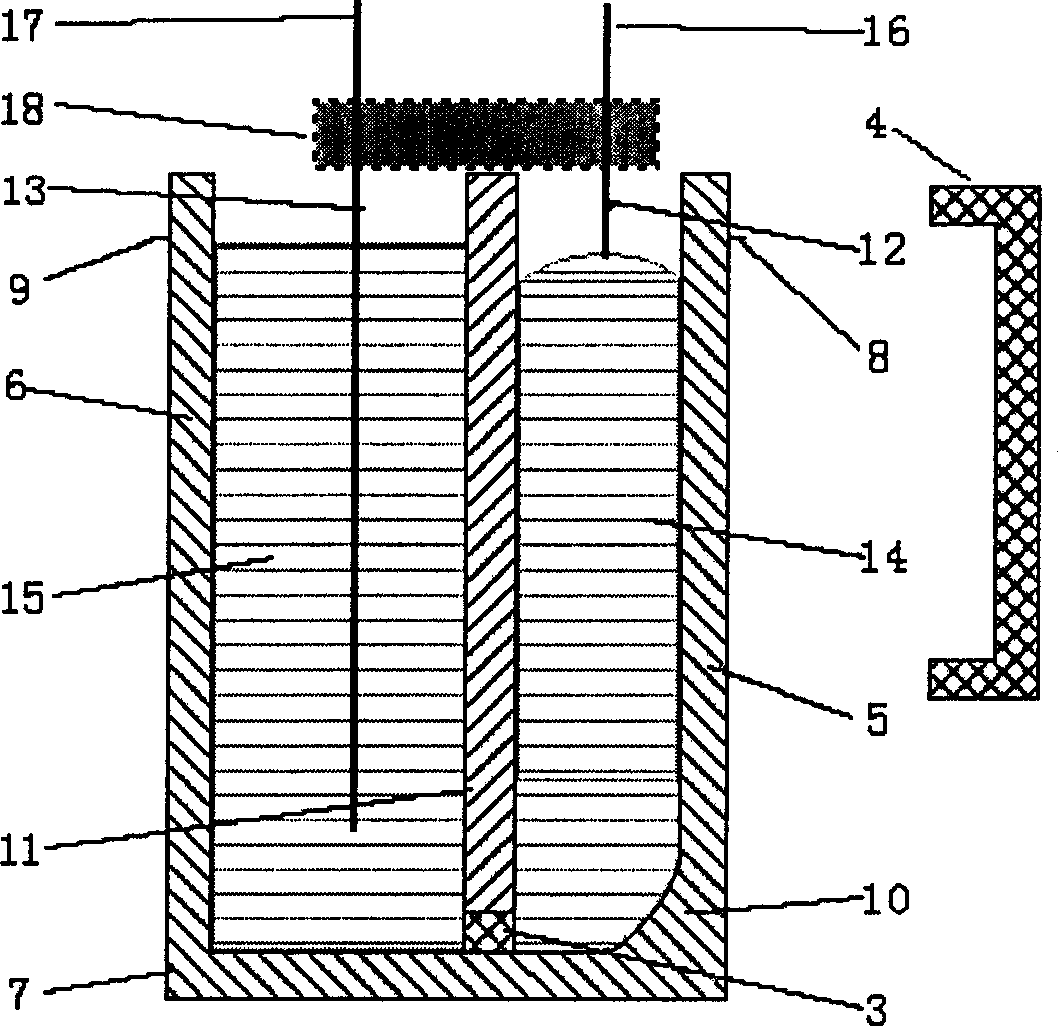

Method for reducing splashing of silicon liquid in polycrystalline silicon electron beam smelting process

InactiveCN103570024AReduce uneven heatingAvoid thermal convectionSilicon compoundsMaterials preparationCrucible

The invention belongs to the field of electron beam smelting, and in particular relates to a method for reducing the splashing of silicon liquid in a polycrystalline silicon electron beam smelting process. The method comprises the steps of material preparation, vacuumizing, pretreatment and smelting, wherein after the pretreatment step, the following steps are performed: (1) adjusting electron beam current, and heating and melting a silicon material; (2) adjusting electron beam spots to spirally move towards the circle center of a crucible along the upper edge of the inner wall of the crucible, causing the electron beam spots to reversely spirally move after the electron beam spots move to the circle center of the crucible, and repeating the spiral movement; (3) after the movement of the electron beam spots is completed, performing electron beam smelting. The method has the remarkable effects that silicon material loss caused by the splashing of the silicon liquid can be reduced, ablation in a vacuum cavity can be reduced, the hidden danger of stopping of an electron gun in case of sudden changes in pressure in the vacuum cavity caused by the splashing of the silicon liquid can be avoided, and a process is simple and easy to operate.

Owner:QINGDAO XINSHIJI SOLAR ENERGY TECH CO LTD

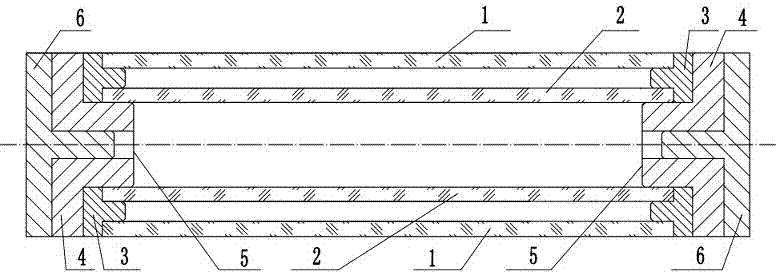

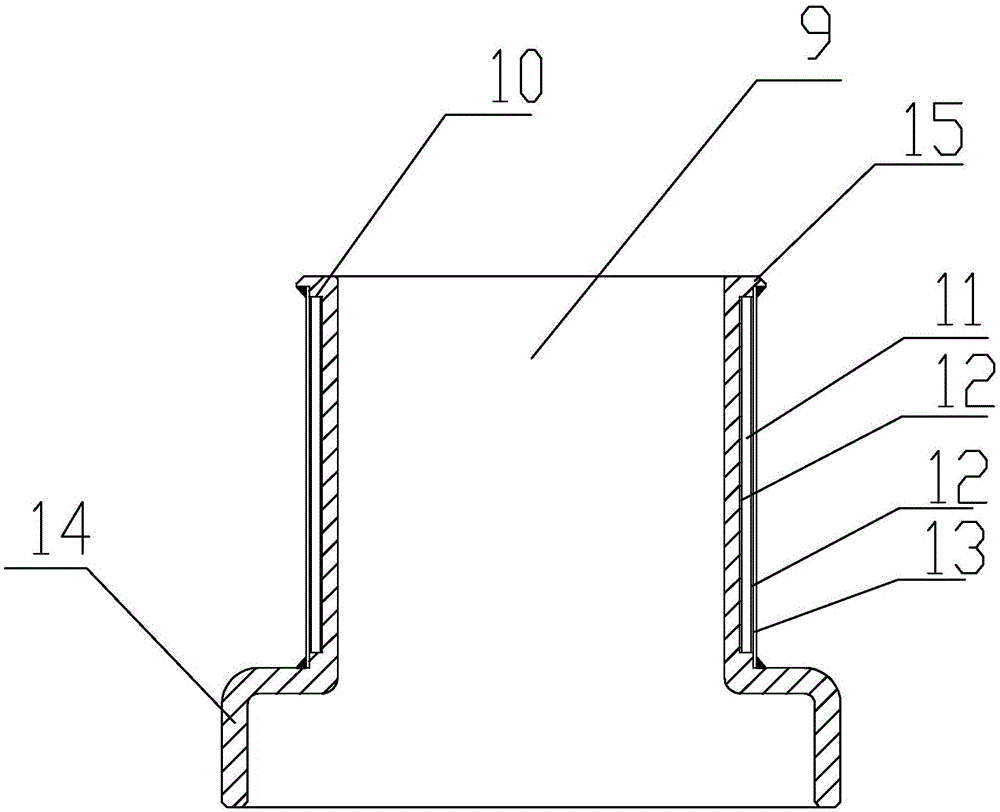

Disposable thermal-stable micro-reactor

InactiveCN107413286AWide variety of sourcesSimple structureChemical/physical/physico-chemical microreactorsSingle useInterference fit

The invention provides a micro-reactor, which can maintain thermal stability, is low in cost and is disposable after use. The micro-reactor includes: a reactor outer tube, a reactor inner tube, two supporting rings, two seal caps, two filter screens and two sealing plugs. The reactor inner tube is sleeved with the reactor outer tube to form an air gap. Bulge rings of the supporting rings are embedded into the air gap at the two ends of the reactor outer tube and the reactor inner tube through interference fit. Holes are formed in the seal caps along axial lines and serve as an inlet and an outlet of the disposable thermal-stable micro-reactor. The filter screens are respectively located at the inner sides of the seal caps. The micro-reactor has good heat insulation property and simple structure, is easy to manufacture, is low in cost, has high adaptability, and can be applied to biochemical analysis, especially calorimetric principle detection of environmental toxins.

Owner:QINGDAO UNIV

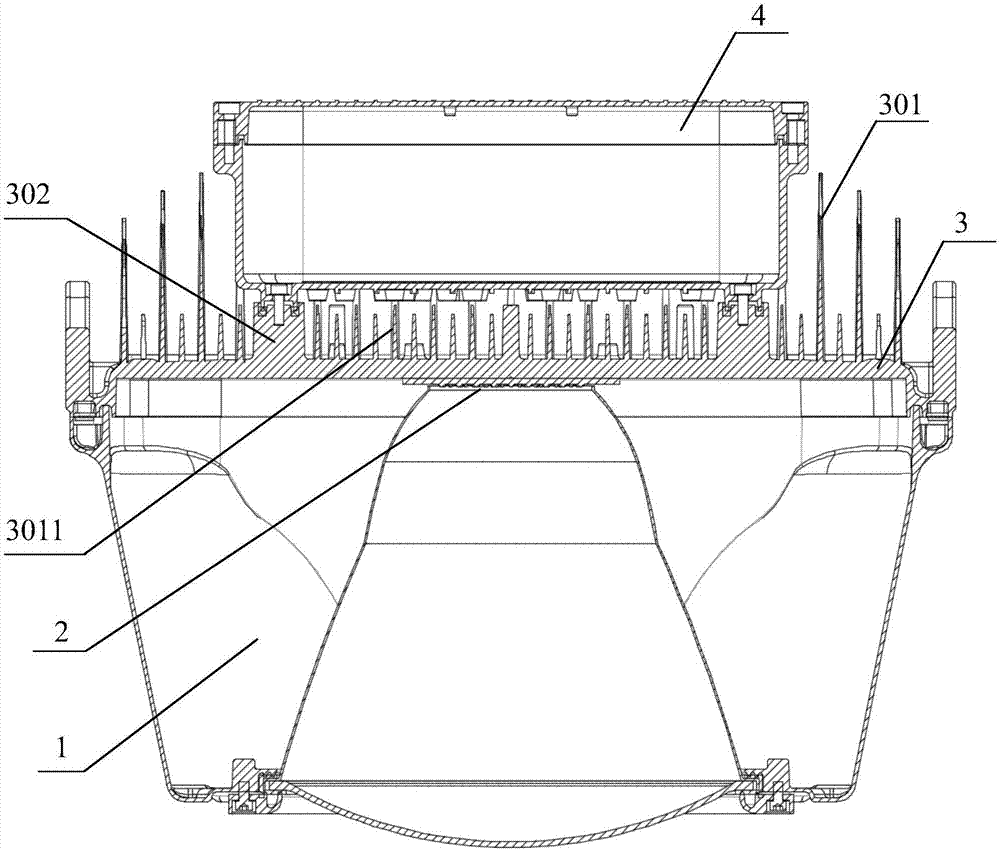

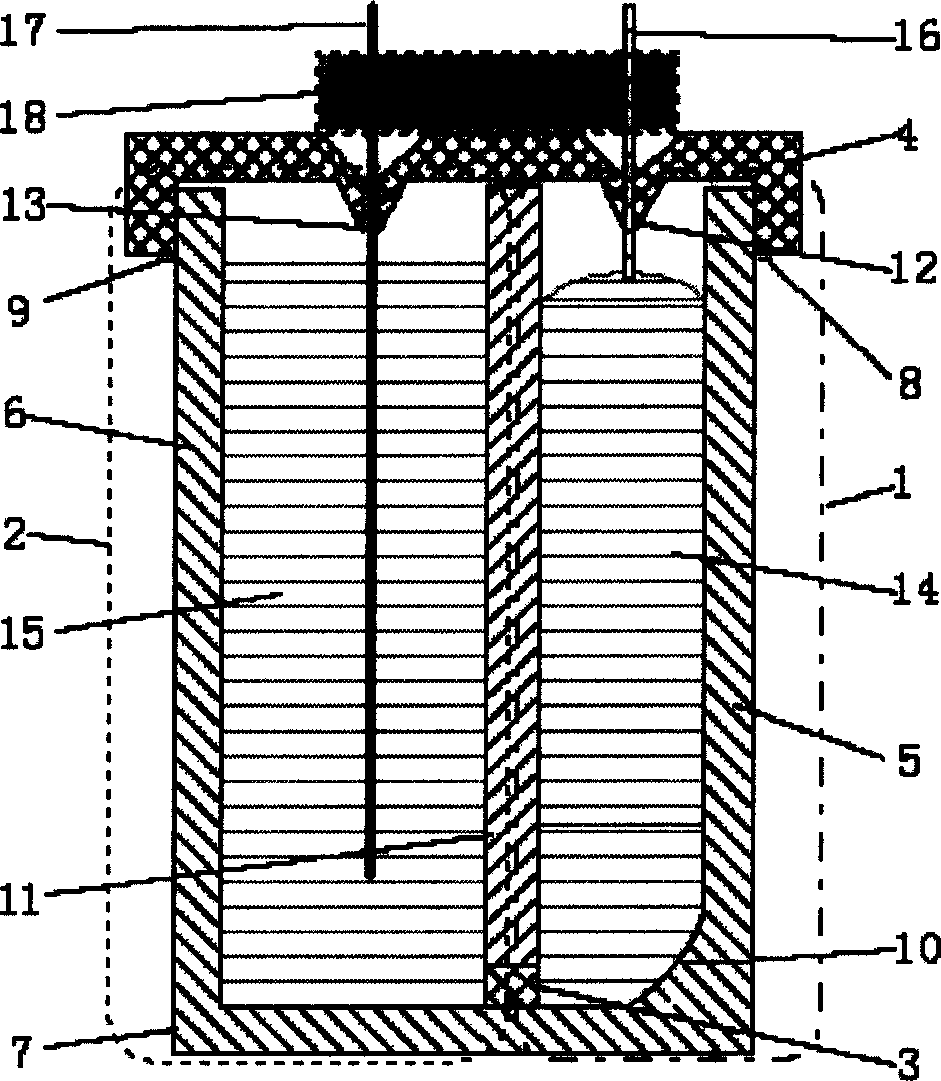

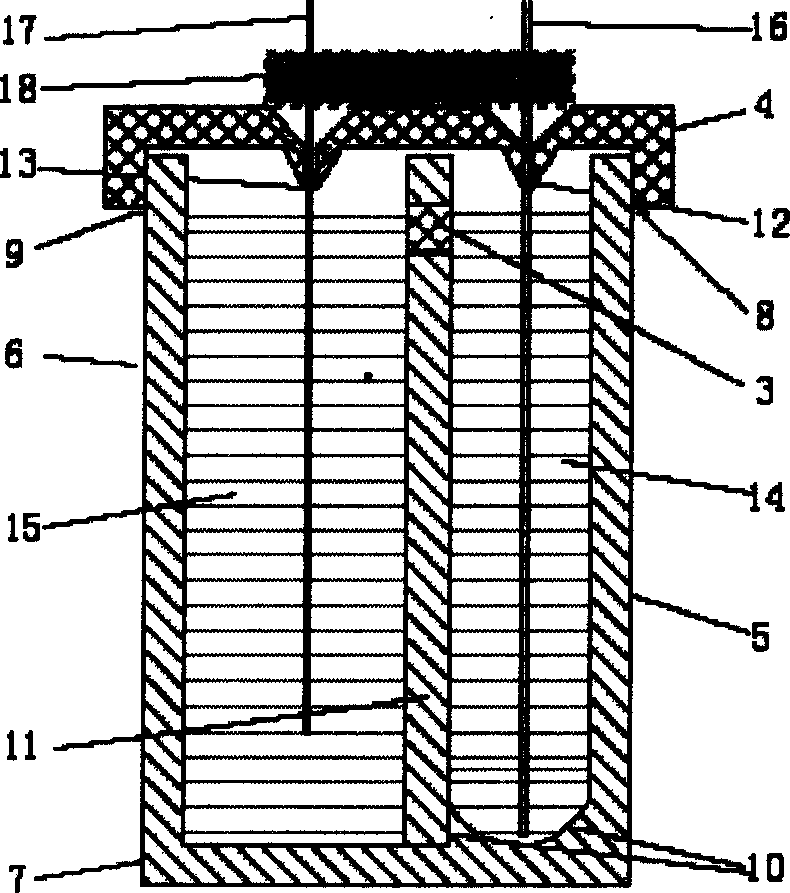

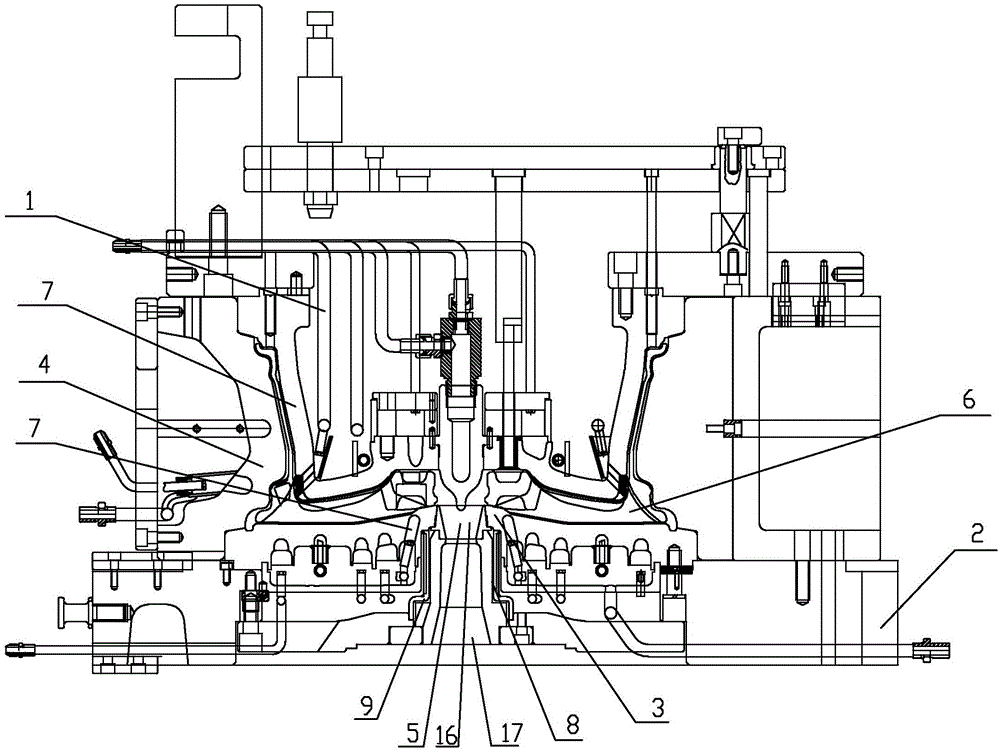

Water-cooled wheel hub mould

ActiveCN104999042AIncrease temperatureFast coolingFoundry mouldsFoundry coresThermal insulationHigh pressure water

The invention discloses a water-cooled wheel hub mould. The water-cooled wheel hub mould comprises an upper mould (1), a lower mould (3), a side mould (4), a pedestal (2), a sprue gate (5), a product (6), and a high pressure water cooling device; a casting cavity of wheel hubs to be casted is formed via combination of the upper mould (1), the lower mould (3), and the side mould (4); the lower mould (3) and the side mould (4) are both fixed on the pedestal (2); the high pressure water cooling device comprises cooling pipelines (7) arranged on the upper end, the lower end, and the side surface of the product (6); the sprue gate (5) is arranged on the bottom of the lower mould (3); and a thermal insulation device used for thermal insulation of the sprue gate (5) is arranged between the side surface of the sprue gate (5) and the lower mould (3). The water-cooled wheel hub mould is high in cooling speed, and is capable of realizing progressive solidification, reducing casting rejection rate, and increasing production efficiency.

Owner:佛山市灿东模具技术有限公司 +1

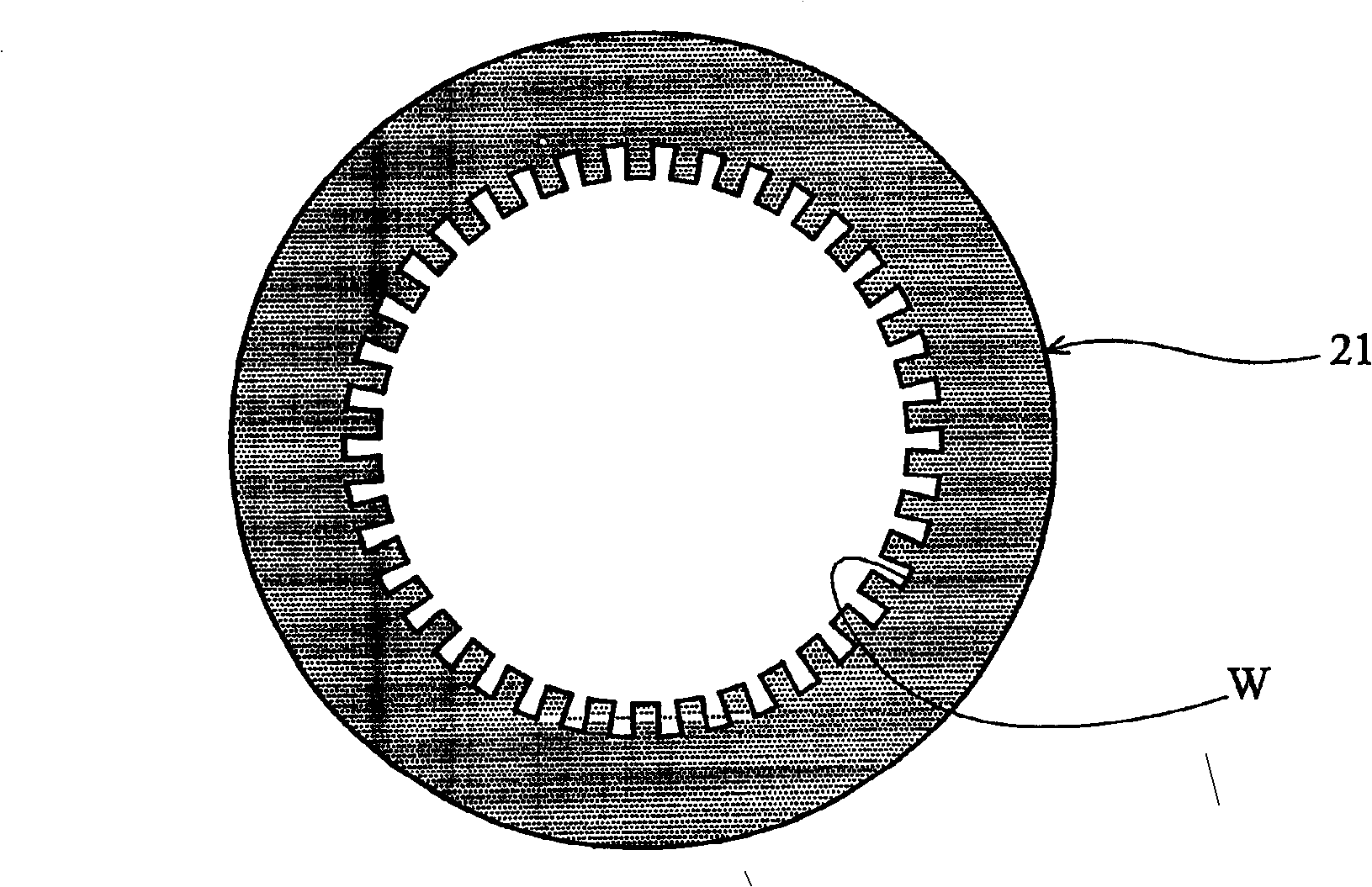

Radiating assembly and thermal pipe thereof

InactiveCN101257778AAvoid thermal conductivityAvoid thermal convectionDigital data processing detailsSemiconductor/solid-state device detailsEngineeringHeat pipe

The invention discloses a radiating assembly, which is suitable for an electronic device, includes a thermojunction, a radiator and a heat pipe. The thermojunction closes to a heat source in the electronic device. The heat pipe is connected with the thermojunction and the radiator, wherein the heat pipe includes a tubular body and a casing which wraps around the tubular body, a vacuum layer is formed between the casing and the tubular body to prevent insulation conduction and thermal convection.

Owner:ASUSTEK COMPUTER INC

Electric sample introduction composite tube for capillary electrophoresis

InactiveCN1238714CEliminate convectionConvection is inevitableComponent separationMaterial analysis by electric/magnetic meansPlatinumPorosity

This invention relates to an electric sampling multiple tubes for capillary tube electrophoresis, which employs double-tube structure with diaphragm, wherein one is designed for sampling tube, the other is for electrode tube and they are used separately to receive electric sampling capillary tube and platinum electrode. And at the same time a porous diaphragm is located in the common inner tube wall between sampling tube and electrode to avoid the fluid flow between them. The diaphragm porosity is good at conductivity. The bottom of sampling tube is curved connected with its outer wall so as to effectively eliminate electric field blind angle. The invention effectively solves the problem of bubbling on electrode surface and fluid flow caused by heat diversity in traditional electric sampling, including field enlarging sampling.

Owner:SHANGHAI JIAO TONG UNIV

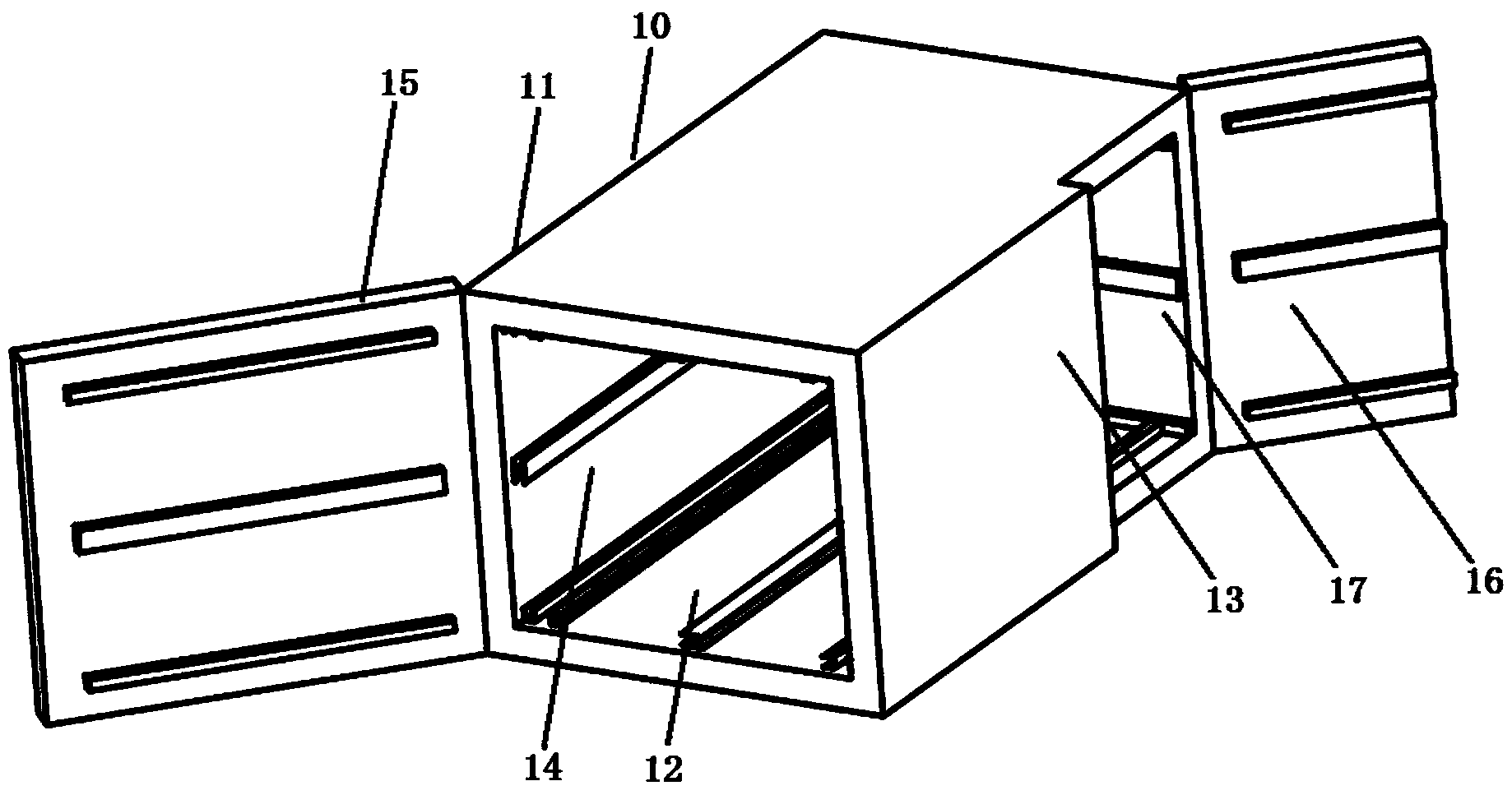

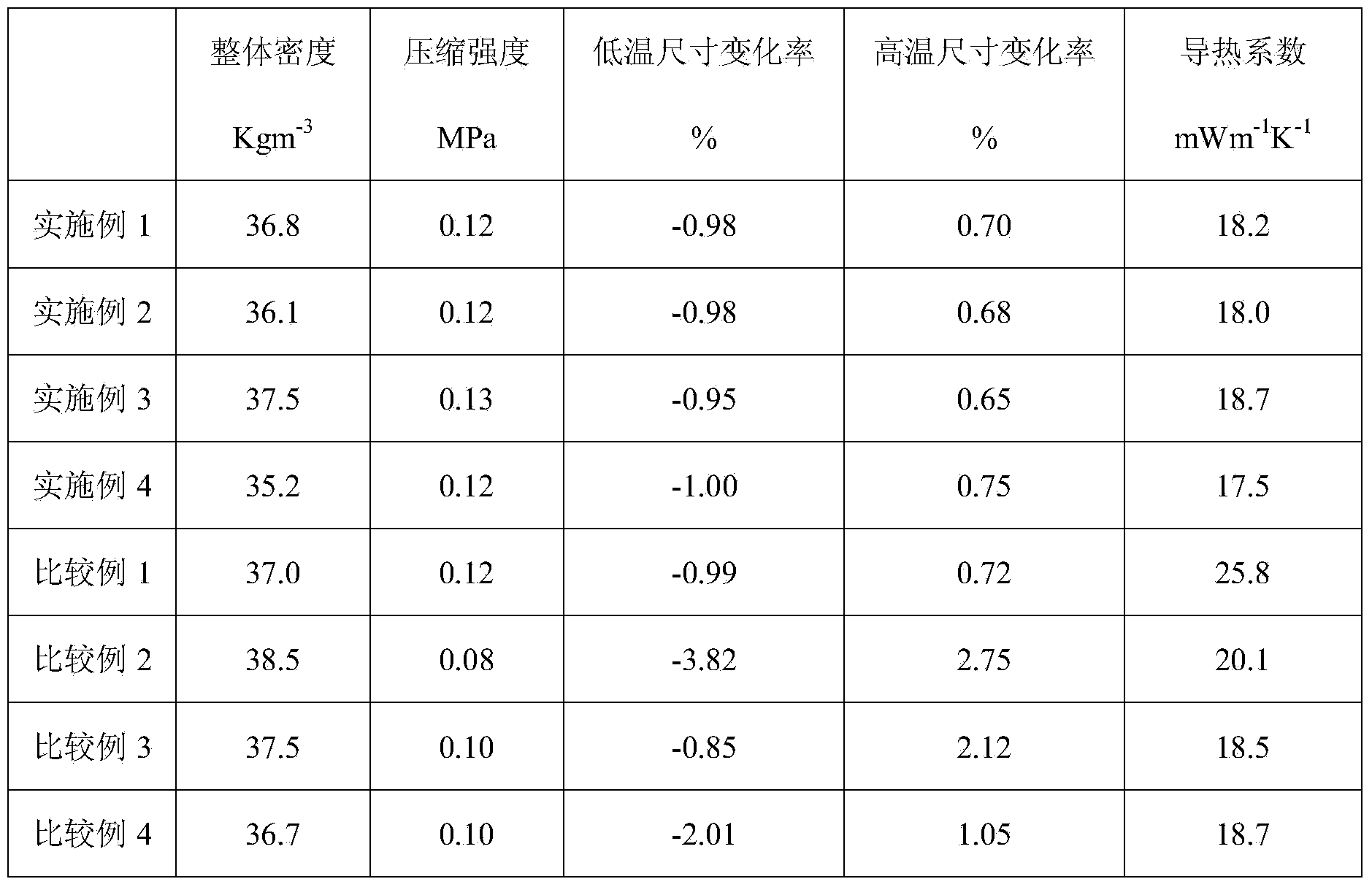

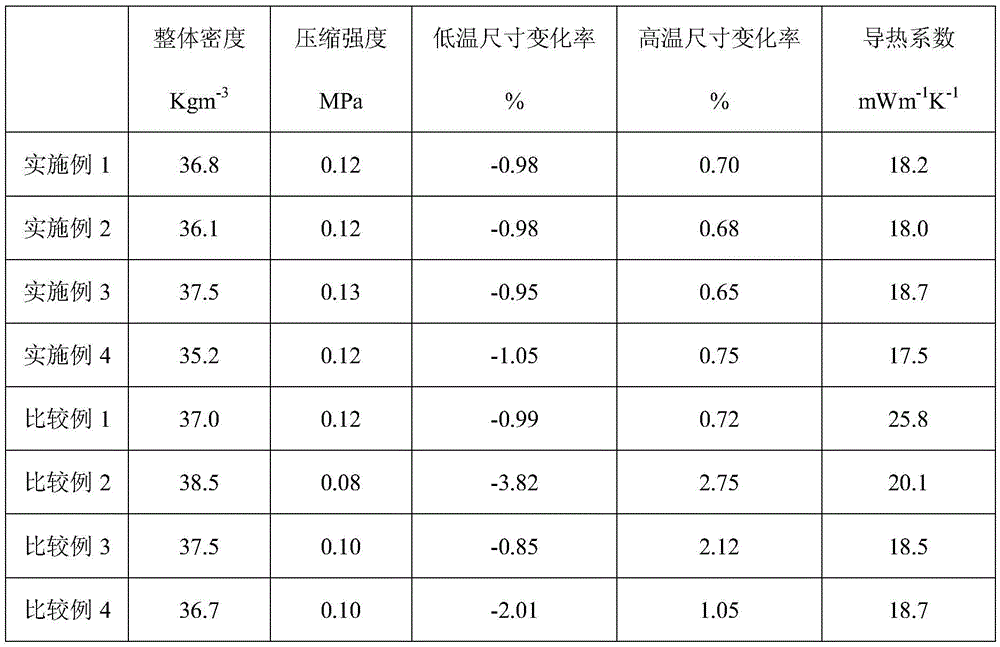

Passive car refrigerator

ActiveCN103954089AImprove cooling efficiencyIncrease floor area ratioDomestic cooling apparatusLighting and heating apparatusRefrigerantEngineering

The invention relates to a passive car refrigerator, which comprises a heat insulation box body and refrigerants contained in the heat insulation box body, wherein the heat insulation box body consists of a plurality of wall parts, each wall part comprises an outer wall layer, an inner wall layer and a vacuum heat insulation plate core layer, in addition, a hard polyurethane foam body is filled between each outer wall layer and the corresponding inner wall layer, in addition, the vacuum heat insulation plate core layers are cladded inside the hard polyurethane foam bodies, the integral density of each hard polyurethane foam body is 35 to 40Kg / m<3>, the compression intensity is 0.10 to 0.15MPa, and the dimension change rate is not higher than 1.0 percent when each hard polyurethane foam body is placed in the air at a temperature between -20 DEG C and 50 DEG C for 24 hours. The passive car refrigerator provided by the invention has the advantages that a direct refrigeration mode of refrigerant vaporization heat absorption and diffusion to the box body is adopted, and a power supply system for supplying power to an electric compressor is not needed, so the capacity rate of the whole car refrigerator can be obviously improved, and the transportation cost is obviously reduced.

Owner:SUZHOU ANTEK INDAL

Heat-insulating material used in ultrahigh vacuum

InactiveCN107160794ARigidSmall heat capacitySynthetic resin layered productsCoatingsUltra-high vacuumHeat losses

The invention discloses a thermal insulation material used in ultra-high vacuum, which comprises alternately stacked plastic foam layers and metal layers, and the metal layer is vacuum plated on the plastic foam layers. The invention is a heat insulation material used in ultra-high vacuum, which has ultra-high vacuum compatible characteristics, can prevent heat conduction, heat radiation and heat convection; has the characteristics of lightness and low heat capacity; can be folded and is convenient for cutting; the The heat insulation material itself has a certain rigidity, and no additional support is needed during use, which reduces the cost of use and avoids heat loss caused by the support.

Owner:苏州衡微仪器科技有限公司

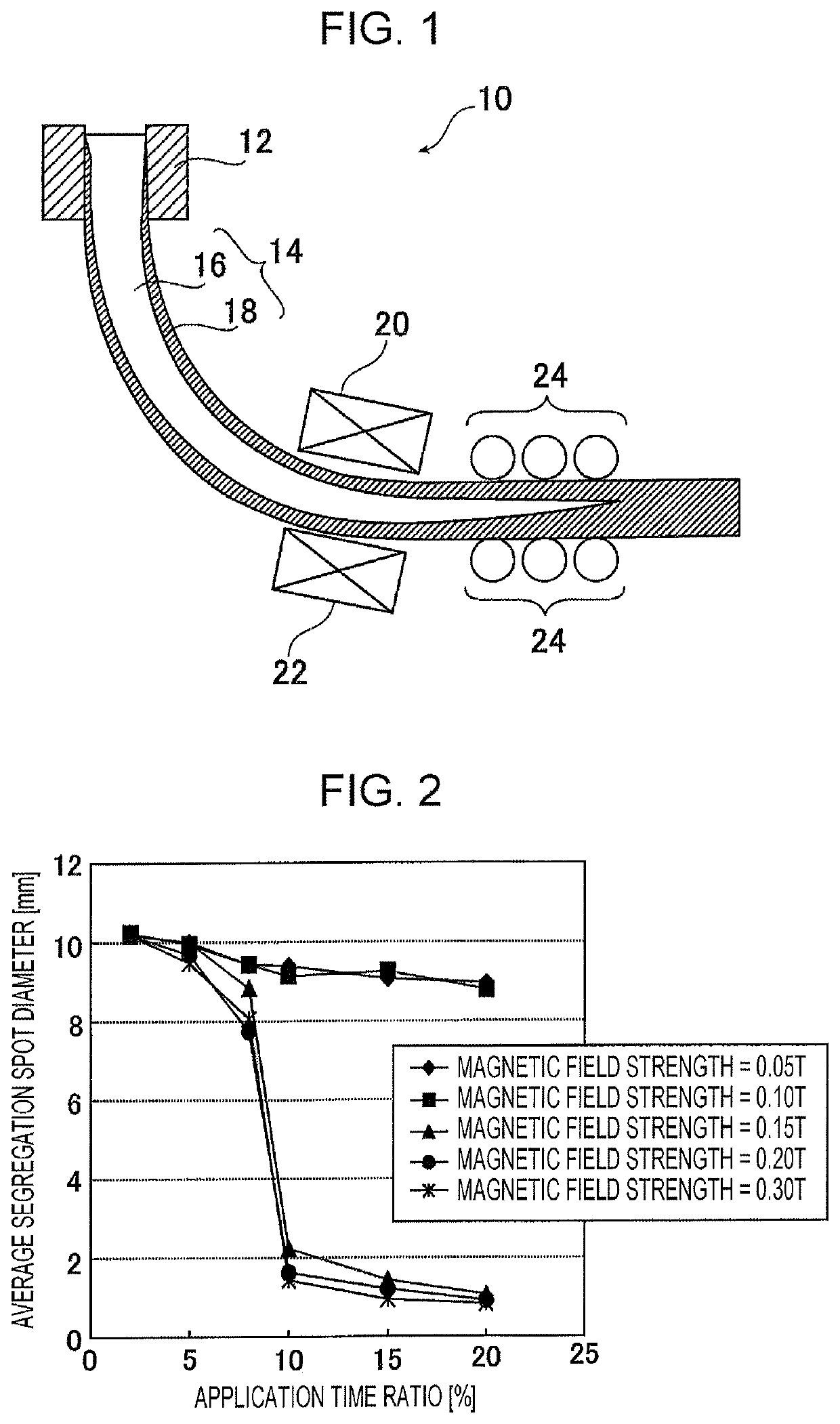

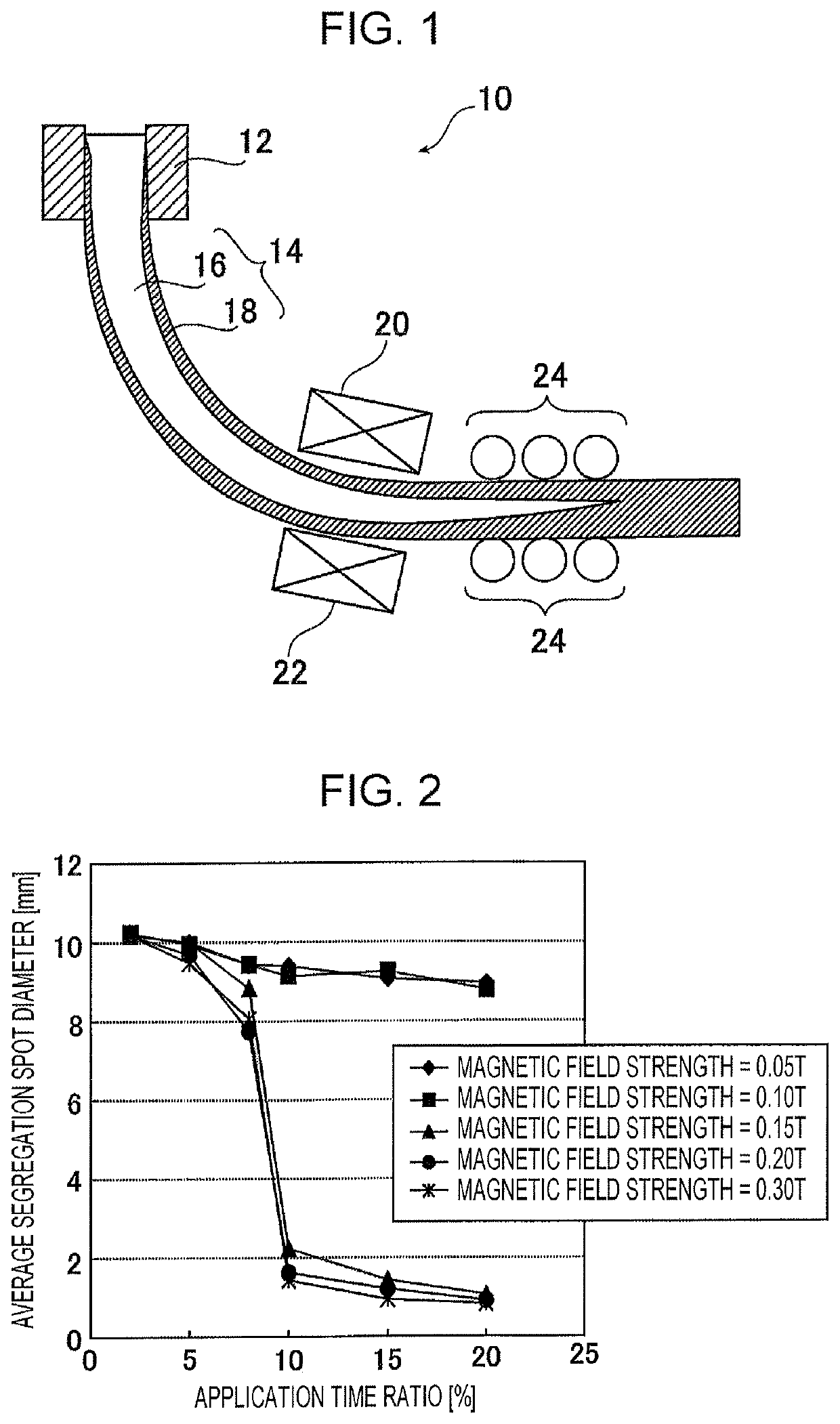

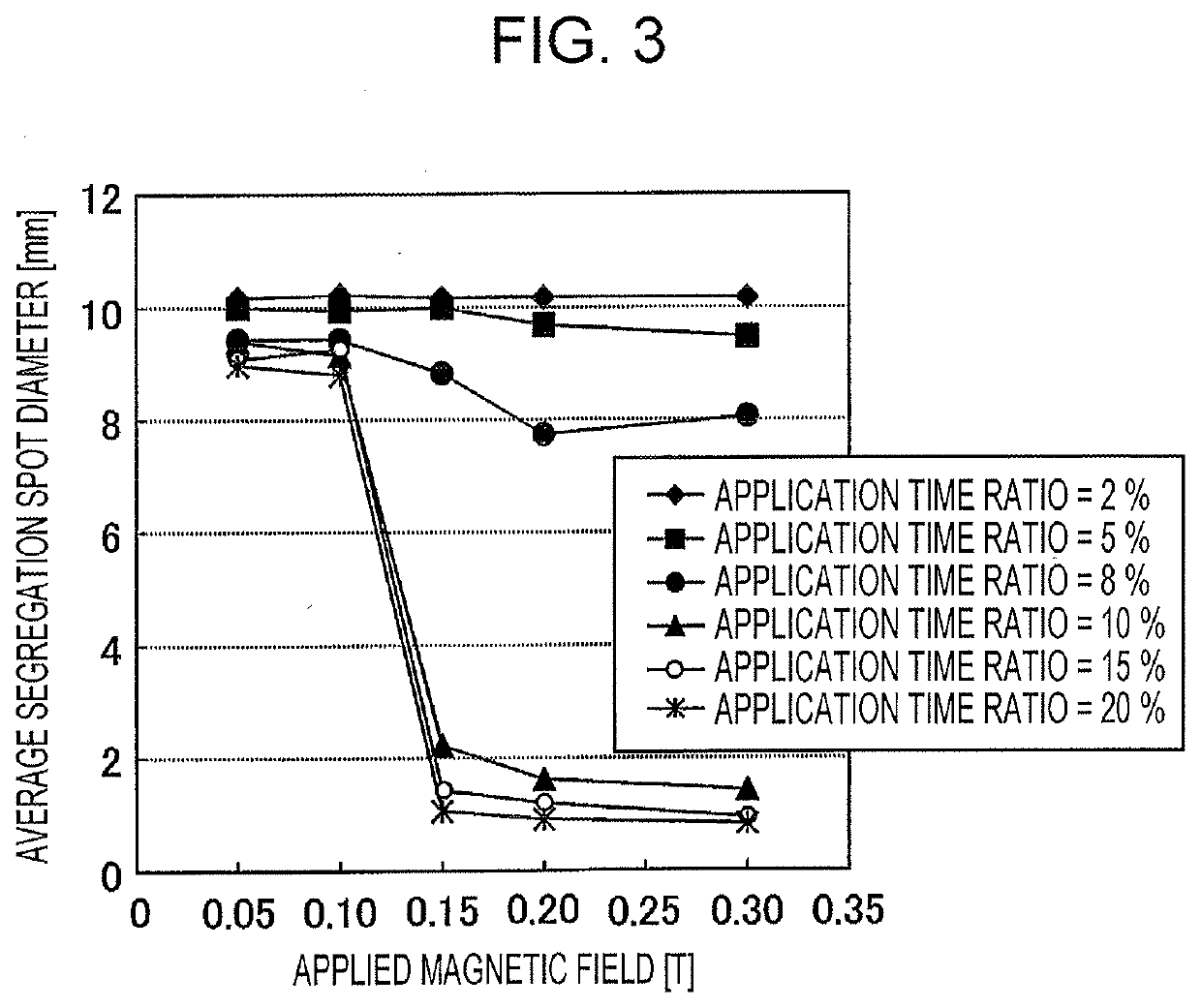

Continuous steel casting method

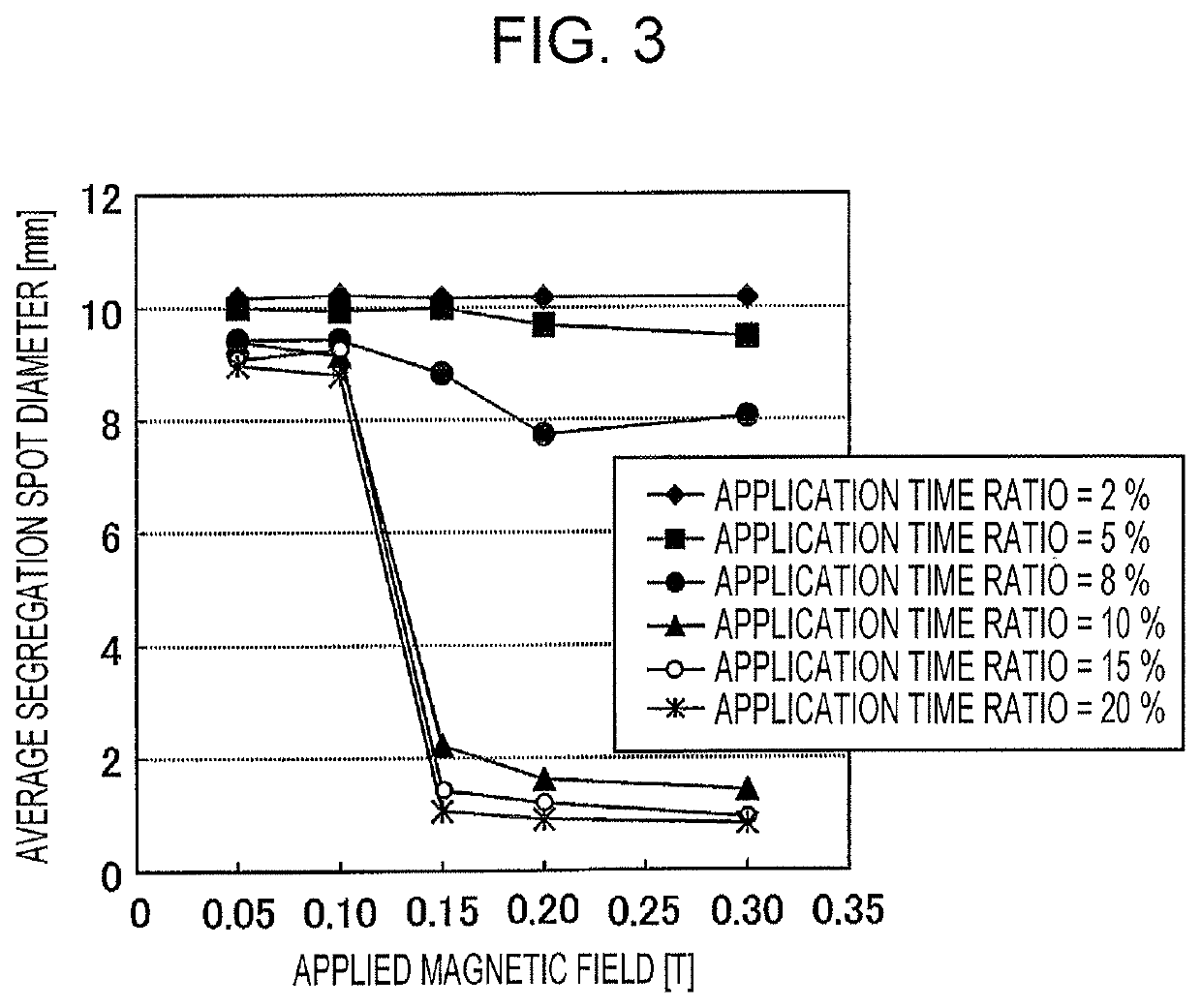

A continuous steel casting method includes producing a strand. The producing of the strand includes pouring molten steel into a mold of a continuous casting machine and withdrawing a solidified shell from the mold, the solidified shell being a solidified portion of the molten steel. The method includes applying a static magnetic field to at least a portion of a region of the strand, the strand being in the continuous casting machine, the region being a region where a solid fraction fs at a thickness-wise middle position of the strand is in a given range, the static magnetic field having a magnetic field strength of greater than or equal to 0.15 T and being in a direction orthogonal to a direction in which the strand is withdrawn, the static magnetic field being applied at an application time ratio of greater than or equal to 10%.

Owner:JFE STEEL CORP

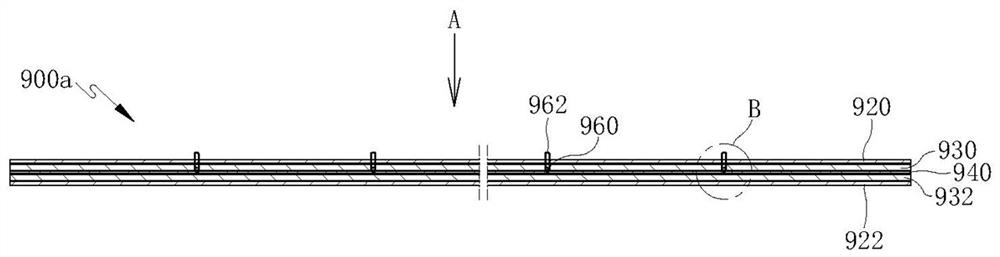

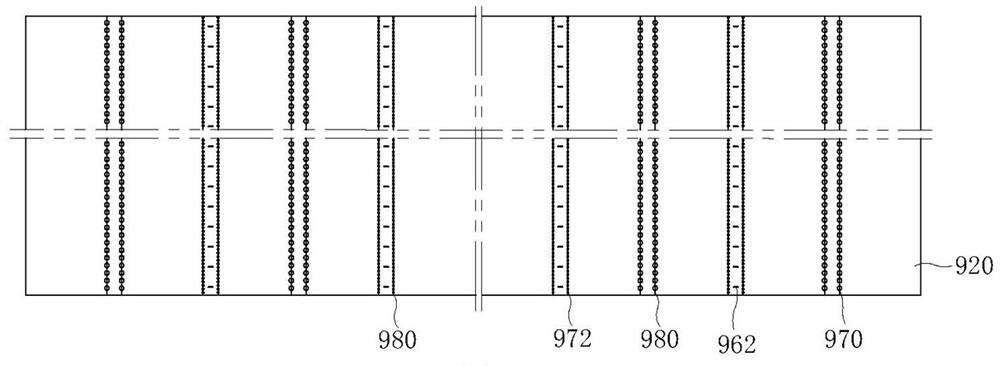

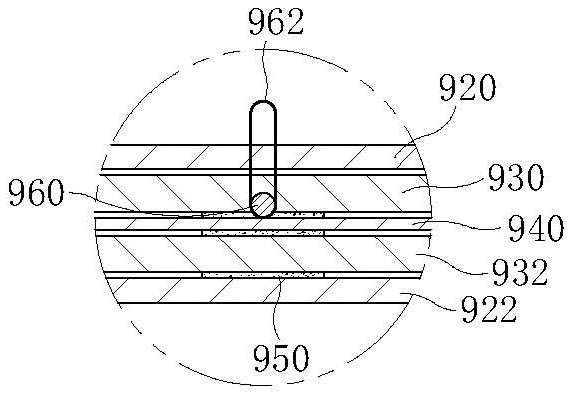

Thermal insulation multilayer composite material in ultra-wide sunlight greenhouse and production equipment thereof

PendingCN114347599ASolve the problem of "half a year's leisure"Reduce breeding costsLamination ancillary operationsClimate change adaptationInsulation layerThermal insulation

The invention discloses an ultra-wide sunlight greenhouse internal heat preservation multilayer composite material and production equipment thereof, and relates to the technical field of agricultural facilities, the ultra-wide sunlight greenhouse internal heat preservation multilayer composite material comprises a first plane material layer and a second plane material layer which are respectively located on two side surfaces, and a heat insulation layer and an airtight layer are arranged between the first plane material layer and the second plane material layer; the breadth of the ultra-wide thermal insulation multilayer composite material in the solar greenhouse is 2500-6000 mm. According to the ultra-wide sunlight greenhouse internal heat preservation multilayer composite material and the production equipment, the technical problem that in the prior art, a multi-span greenhouse and a glass curtain wall greenhouse are poor in heat preservation is solved, and the heat preservation performance of the multi-span greenhouse and the glass curtain wall greenhouse can be enhanced; the method effectively solves the problem of half-year leisure, can effectively promote the development of facility agriculture in China, and has good popularization value.

Owner:山东农圣恒昌农业科技有限公司

Passive car refrigerator

ActiveCN103983064BIncrease floor area ratioPrevent heat radiationDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigeration

The invention relates to a passive vehicle-mounted refrigerator, comprising an insulation box body and a refrigerant; the main body of the insulation box body is formed by a top wall part, a bottom wall part, a front wall part, a rear wall part, a left wall part and a right wall part; the left wall part is an openable structure; the front wall is provided with a front side door; each wall part comprises an outer shell layer, a vacuum thermal insulation panel and an inner shell layer; first hard polyurethane foam bodies are injected between the outer shell layers and the vacuum thermal insulation panels; second hard polyurethane foam bodies are injected between the inner shell layers and the vacuum thermal insulation panels. The passive vehicle-mounted refrigerator adopts the direct refrigeration mode that the refrigerant is vaporized to absorb heat and is diffused into the thermal insulation box body, and a power supply system powered by an electrical compressor does not need to be adopted, so the plot ratio of the whole cold storage refrigerator is greatly improved. Compared with the prior art, the passive vehicle-mounted refrigerator has the advantages that the investment is low and the transportation cost for the transportation of a few or different types of objects is obviously reduced.

Owner:SUZHOU ANTEK INDAL

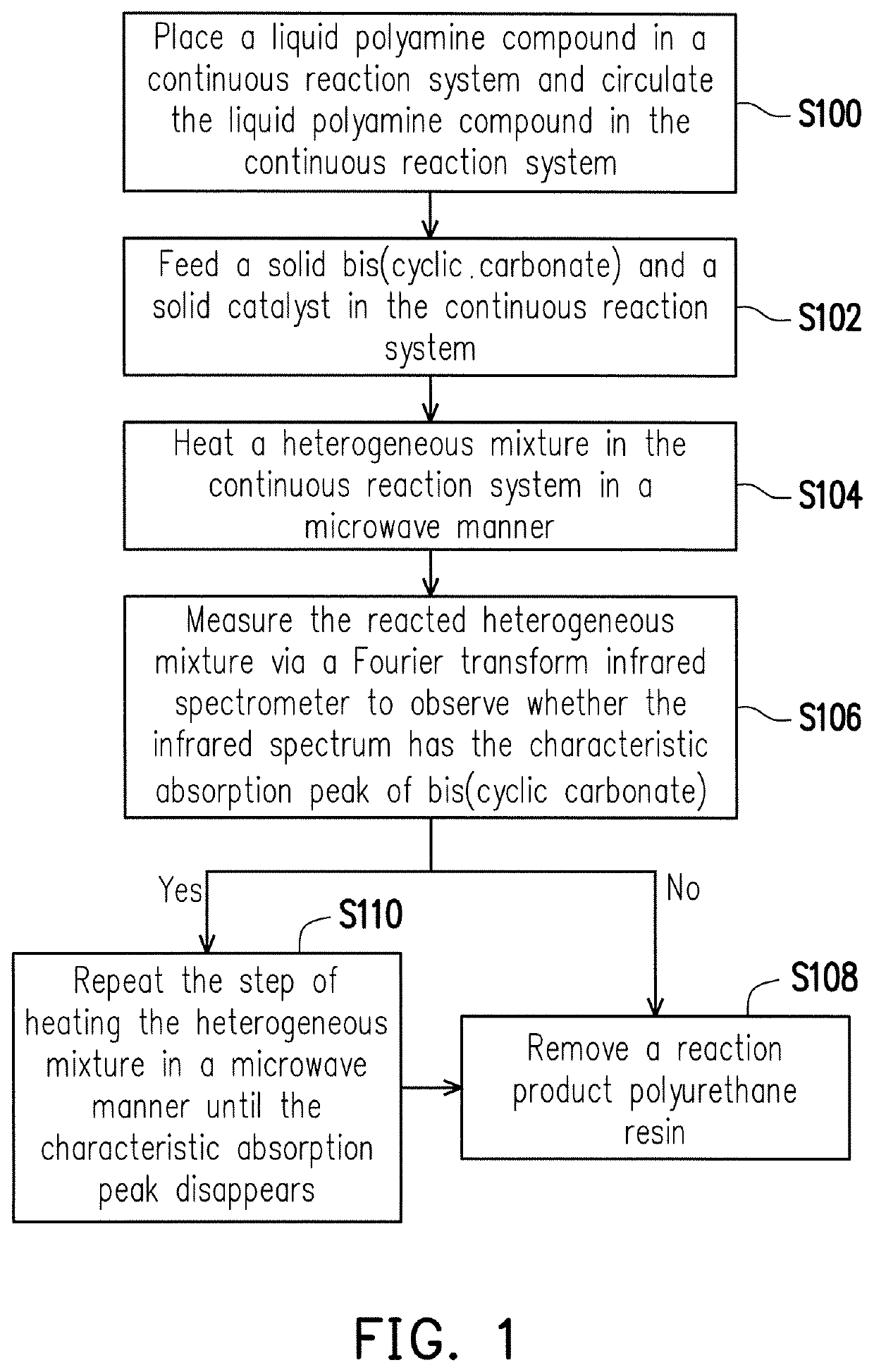

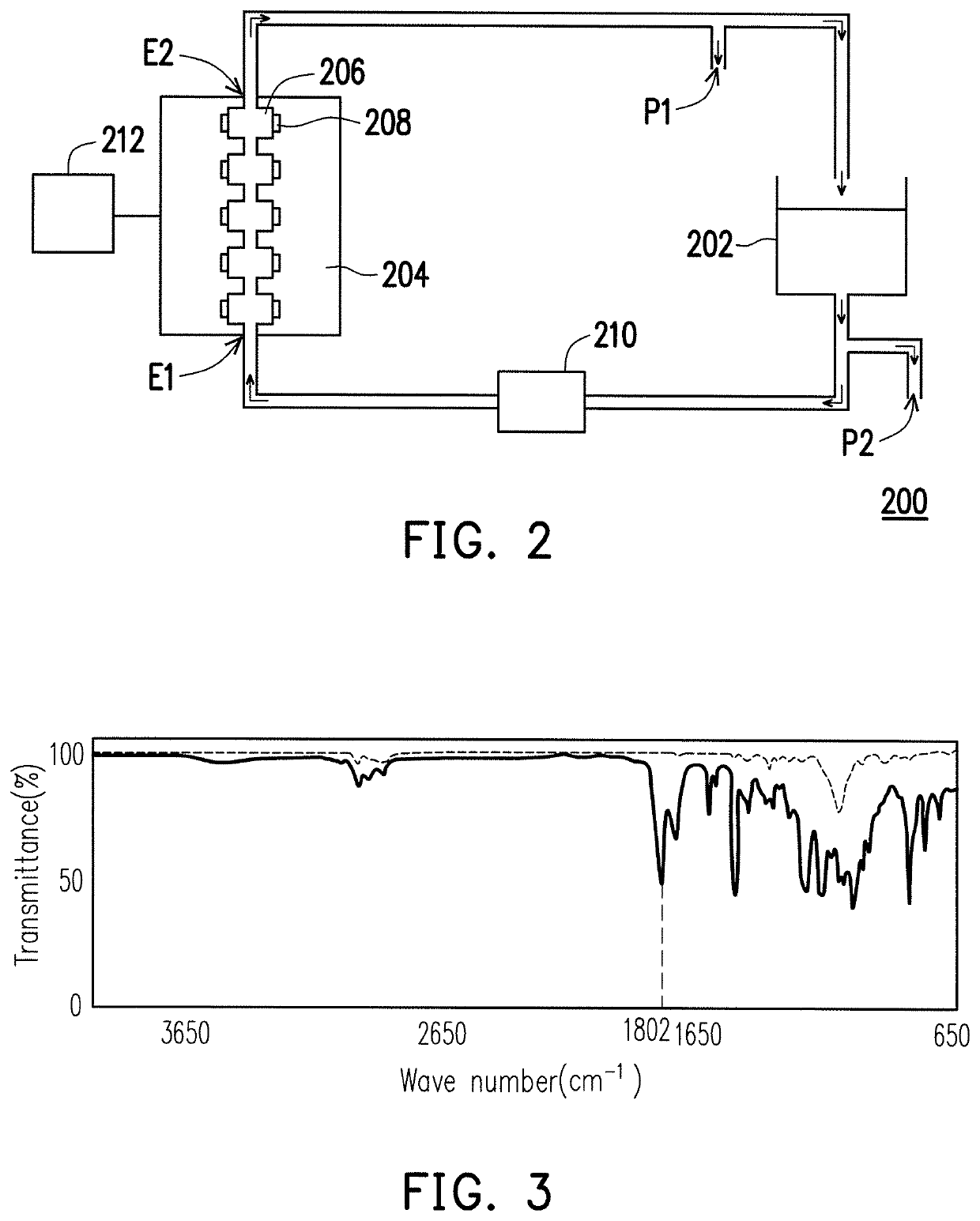

Preparation method of polyurethane resin

ActiveUS10570254B2Reduce manufacturing costAvoid thermal convectionEnergy based chemical/physical/physico-chemical processesPolyamine CompoundPolymer science

A preparation method of a polyurethane resin including the following steps is provided. A liquid polyamine compound is placed in a continuous reaction system, and the liquid polyamine compound is circulated in the continuous reaction system. A solid bis(cyclic carbonate) and a solid catalyst are placed in the continuous reaction system to mix the solid bis(cyclic carbonate), solid catalyst, and liquid polyamine compound to form a heterogeneous mixture. The heterogeneous mixture is heated in the continuous reaction system in a microwave manner, such that the heterogeneous mixture reacts to form a polyurethane resin.

Owner:NATIONAL TSING HUA UNIVERSITY +2

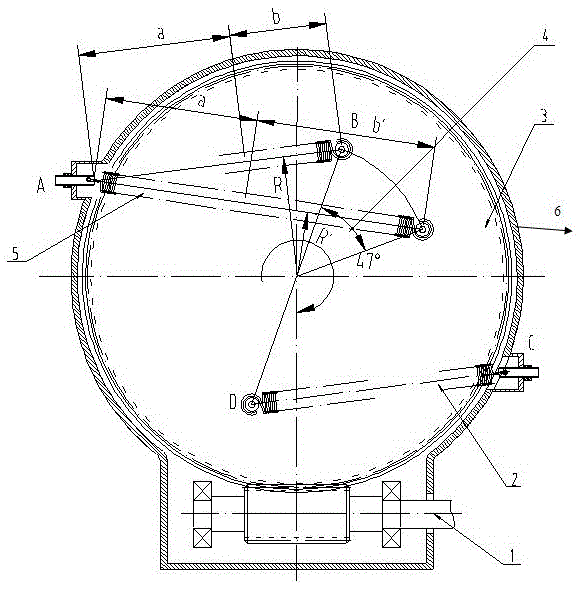

Small rotation angle transmission device with anti-backlash mechanism for astronomical machinery

The invention provides a small-rotation-angle transmission device with a gap eliminating mechanism, which can be taken as a small-rotation-angle transmission system with a small rotation stroke, such as a declination axis. The small-rotation-angle transmission device comprises a transmission case and a rotating shaft, wherein the rotating shaft is externally provided with a shaft sleeve which is fixedly connected with the transmission case; a transmission shaft is provided with a pre-stretched spring; one end of the spring is fixed on the end face of the transmission shaft, and the other end of the spring is fixed on the shaft sleeve; when the rotating shaft rotates to any angle, rotating torque output from the spring is same. The small-rotation-angle transmission device provided by the invention adopts the spring to output the constant torque so as to implement transmission gap elimination, so that a motor and a drive circuit are omitted, the device cost and power consumption are saved, the motor is prevented from heating, and imaging quality is prevented form being reduced by thermal convection. The small-rotation-angle transmission device is simple in structure, reliable in performance, and not easy to be damaged.

Owner:NANJING ZHONGKE ASTROMOMICAL INSTR

Method for Reducing Splash of Liquid Silicon During Electron Beam Melting of Polysilicon

InactiveCN103570024BReduce uneven heatingAvoid thermal convectionSilicon compoundsMaterials preparationSmelting process

The invention belongs to the field of electron beam smelting, and in particular relates to a method for reducing the splashing of silicon liquid in a polycrystalline silicon electron beam smelting process. The method comprises the steps of material preparation, vacuumizing, pretreatment and smelting, wherein after the pretreatment step, the following steps are performed: (1) adjusting electron beam current, and heating and melting a silicon material; (2) adjusting electron beam spots to spirally move towards the circle center of a crucible along the upper edge of the inner wall of the crucible, causing the electron beam spots to reversely spirally move after the electron beam spots move to the circle center of the crucible, and repeating the spiral movement; (3) after the movement of the electron beam spots is completed, performing electron beam smelting. The method has the remarkable effects that silicon material loss caused by the splashing of the silicon liquid can be reduced, ablation in a vacuum cavity can be reduced, the hidden danger of stopping of an electron gun in case of sudden changes in pressure in the vacuum cavity caused by the splashing of the silicon liquid can be avoided, and a process is simple and easy to operate.

Owner:QINGDAO XINSHIJI SOLAR ENERGY TECH CO LTD

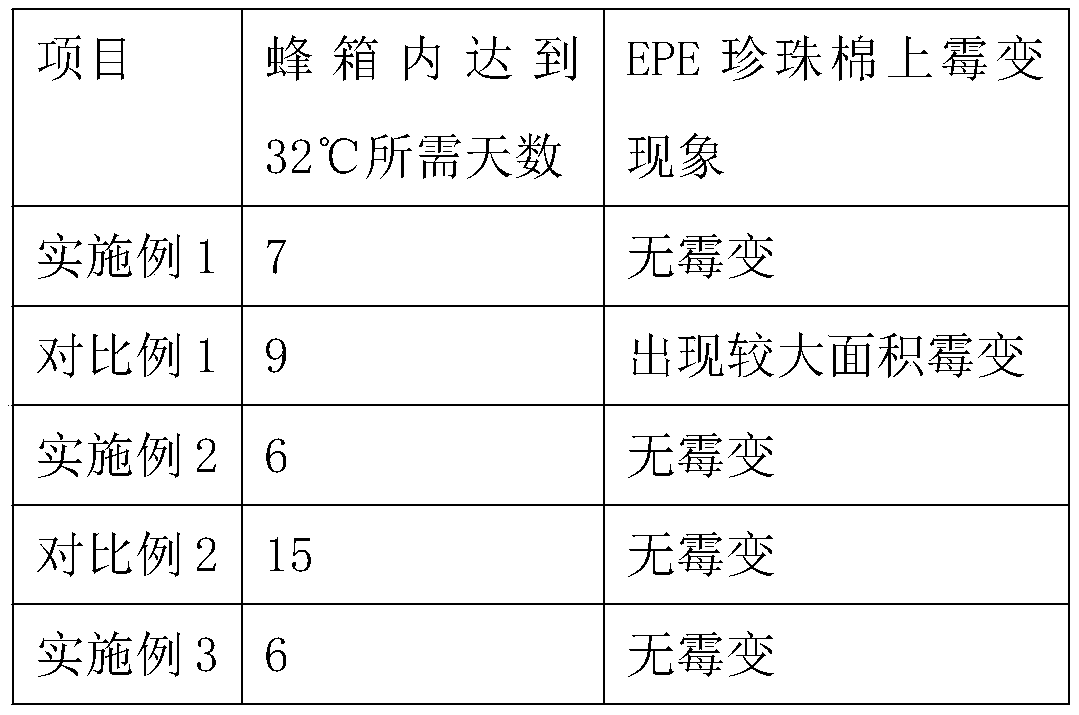

Preparation method of EPE pearl wool for swarm heat preservation

InactiveCN111574742AImprove insulation effectImprove antibacterial propertiesFoaming agentThermal insulation

The invention discloses a preparation method of EPE pearl wool for swarm heat preservation, which comprises the following operation steps: (1) adding epsilon-polylysine and aminated multi-walled carbon nanotubes into deionized water, and mixing and stirring to obtain an antibacterial agent; (2) adding shellac into an ethanol aqueous solution until the shellac is completely dissolved, adding the antibacterial agent into the solution, and performing ultrasonic water bath to obtain a modified antibacterial agent; (3) uniformly mixing and stirring coconut shell powder, white carbon black and diatomite, and adding an internal lubricant into the mixture to obtain a thermal insulation filler; and (4) feeding a modified polyethylene master batch, the modified antibacterial agent and the thermal insulation filler into a foaming machine for heating treatment, then adding a foaming agent to form a porous structure, and performing extruding, cooling, extending, and finally rolling to obtain the EPE pearl wool for swarm heat preservation. The prepared EPE pearl wool for swarm heat preservation has excellent heat preservation performance and excellent antibacterial performance, and bacteria canbe effectively prevented from breeding and reproducing on the surface of the EPE pearl wool.

Owner:合肥市兴烨包装材料有限公司

Aluminum Alloy Layered Distribution Plane Solidification Casting Device and Casting Method

ActiveCN106238716BAchieve laminar distributionAvoid local overheatingMolten metal pouring equipmentsIngot castingElectric machinery

An aluminum alloy layered flow planar solidification casting device and a casting method thereof belong to the technical field of aluminum alloy ingot casting. The device includes a bracket, a horizontally movable translational diverting mechanism is provided on the upper part of the bracket, a flow control mechanism is provided at the outlet of the translational diverting mechanism; a casting box is provided below the translational diverting mechanism, and a water spray is provided below the casting box systems and cooling plate systems. Method, the cooling plate system is raised into the casting box, and the aluminum alloy liquid enters the shunt trough and enters the guide rod sleeve; the second motor is started to control the flow of the aluminum alloy liquid; the first motor is started, and the moving plate drives the shunt trough to move horizontally, and the aluminum alloy The liquid flows to the top of the cooling plate in a laminar manner; when the aluminum alloy solidified layer can support it, start the cooling plate cylinder to lower the cooling plate system; then push the water spray system in to spray water for cooling; control the descending speed of the main oil cylinder , until the casting reaches the predetermined thickness; after all cooling, stop spraying water, pull out the water spray system, take out the ingot, and the casting is completed.

Owner:NORTHEASTERN UNIV LIAONING

Continuous steel casting method

A continuous steel casting method includes producing a strand. The producing of the strand includes pouring molten steel into a mold of a continuous casting machine and withdrawing a solidified shell from the mold, the solidified shell being a solidified portion of the molten steel. The method includes applying a static magnetic field to at least a portion of a region of the strand, the strand being in the continuous casting machine, the region being a region where a solid fraction fs at a thickness-wise middle position of the strand is in a given range, the static magnetic field having a magnetic field strength of greater than or equal to 0.15 T and being in a direction orthogonal to a direction in which the strand is withdrawn, the static magnetic field being applied at an application time ratio of greater than or equal to 10%.

Owner:JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com