Radiating assembly and thermal pipe thereof

A technology of heat dissipation components and heat pipes, applied in the direction of tubular components, electrical components, heat exchange equipment, etc., can solve the problems of accelerated aging of the casing, small internal space of electronic products, and heat dissipation problems, so as to improve the service life and avoid rapid aging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

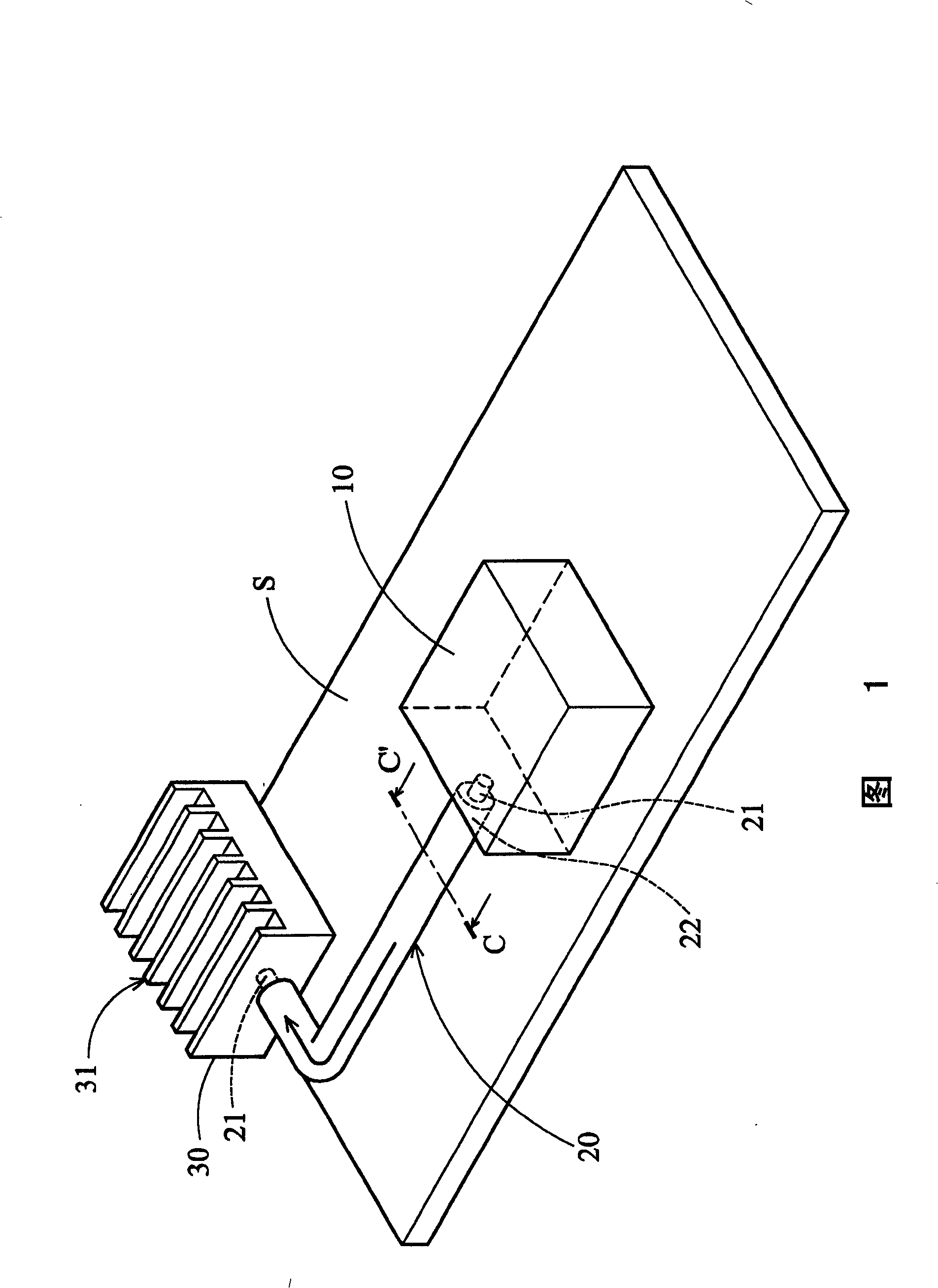

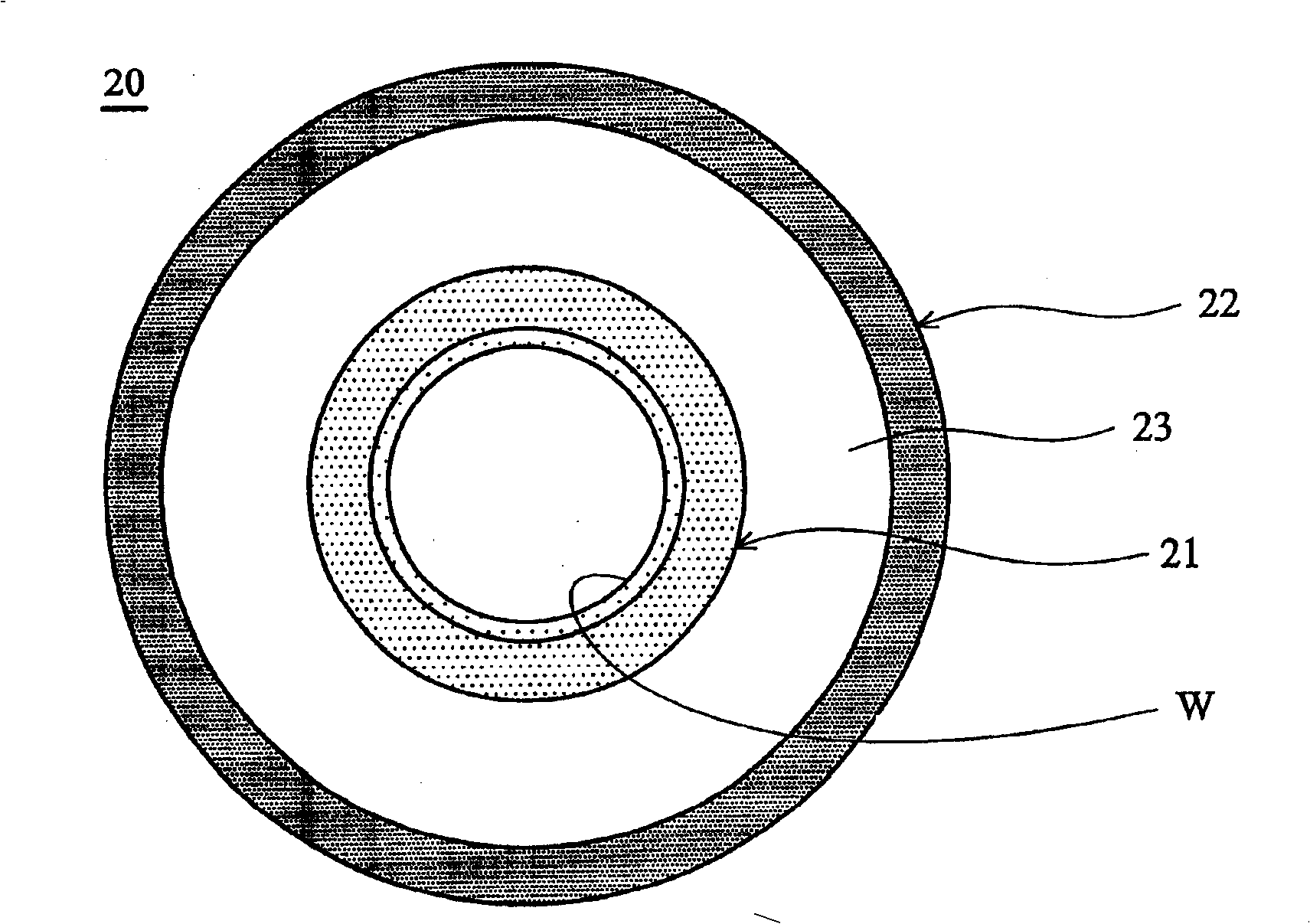

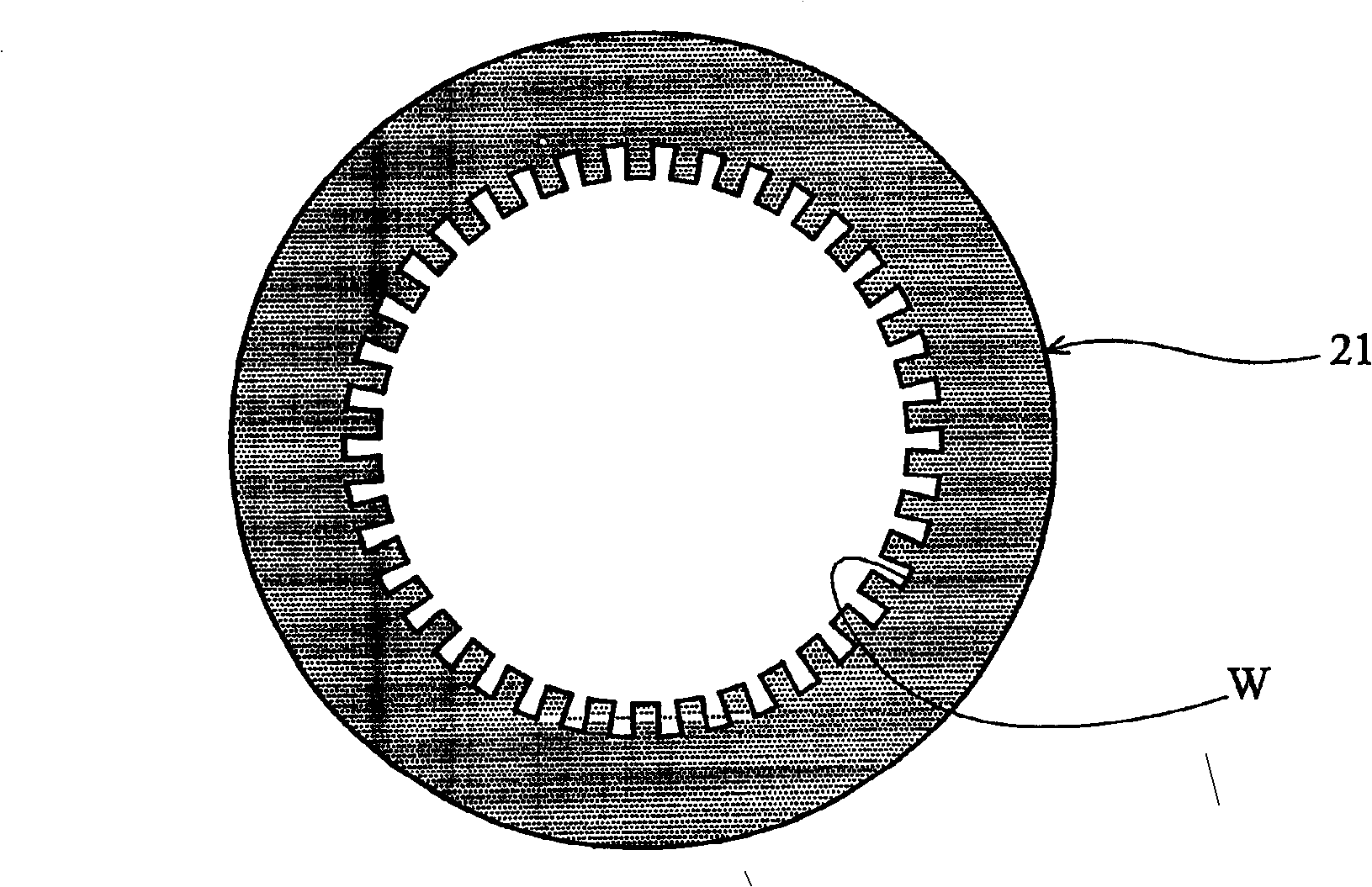

[0020] First please refer to FIG. 1 , the heat dissipation component in this embodiment is disposed on a circuit board S inside an electronic device for heat dissipation. As shown in the figure, the aforementioned heat dissipation assembly mainly includes a thermal interface material 10 (Thermal Interface Material, TIM), a heat pipe 20 and a heat sink 30 (heat sink), wherein the thermal interface material 10 is close to a heat source on the circuit board S ( For example, CPU), the heat pipe 20 connects the heat junction surface 10 and the heat sink 30, and a working fluid in the heat pipe 20 can quickly transfer heat energy from the heat junction surface 10 to the heat sink 30 to achieve the effect of heat dissipation. In a preferred embodiment, the thermal junction surface 10 can be made of a metal material with good heat conduction efficiency. In addition, a plurality of fins 31 can be arranged on the heat sink 30 to increase the heat dissipation area and enhance the heat dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com