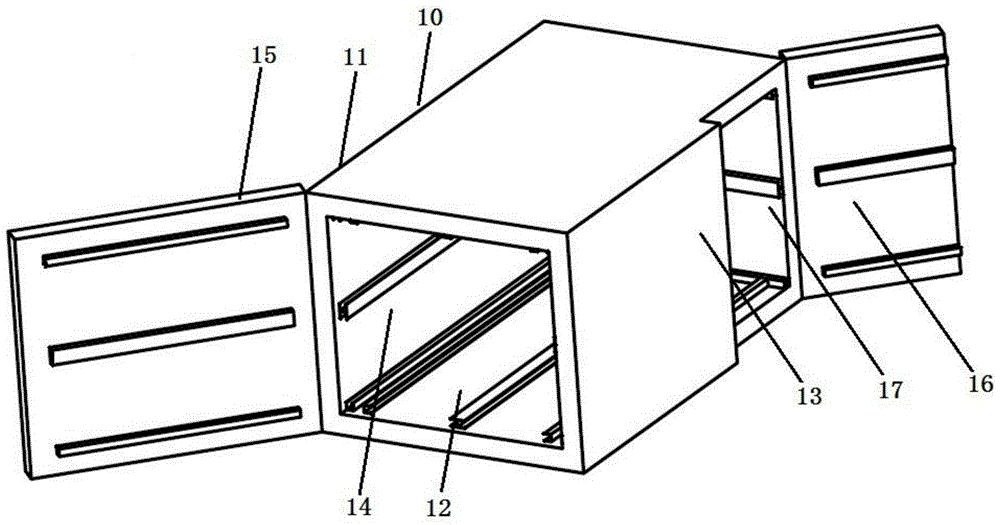

Passive car refrigerator

A technology for refrigerated boxes and insulated boxes, which is applied to household refrigeration devices, insulated containers, and impact-sensitive items. It can solve the problems of increasing transportation costs and achieve the effects of reducing transportation costs, high refrigeration efficiency, and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

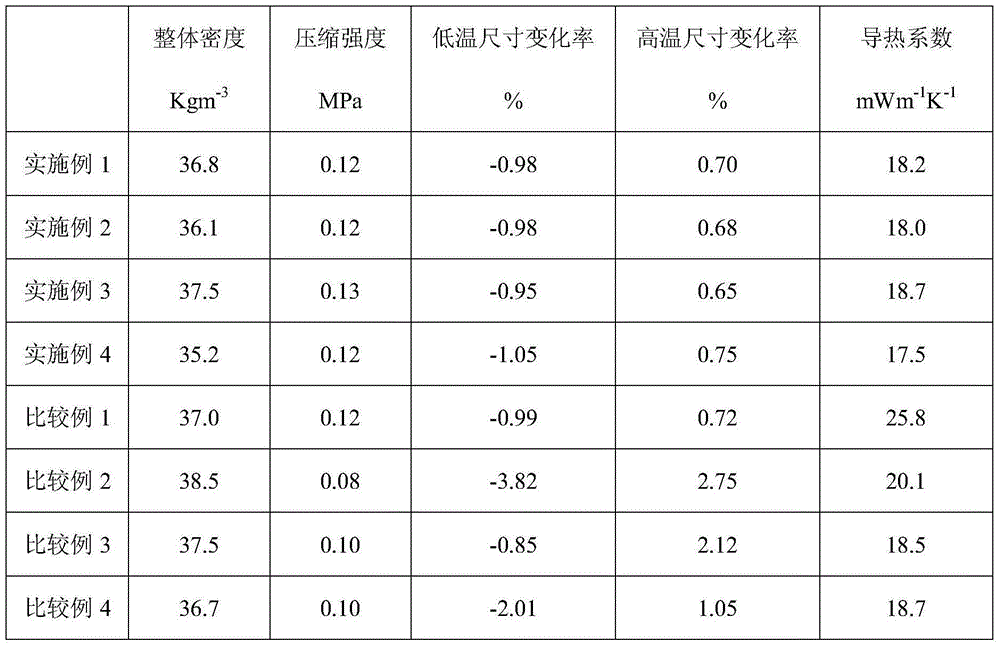

Embodiment 1

[0017] In this embodiment, the shell layer and the shell layer are both made of carbon steel, and the thickness of the shell layer and the shell layer is 2-20 mm; the thickness of the vacuum insulation panel layer is 10 mm, and the first hard The thickness of the first rigid polyurethane foam is 25mm, and the thickness of the second rigid polyurethane foam is 25mm. And, the first rigid polyurethane foam and the second rigid polyurethane foam are made of 22.0wt% carbodiimide modified MDI, 18.0wt% PEA-1000, 7.5wt% PEBA-1000, 2.5 wt% of hydroxyl-terminated polybutadiene, 3.0wt% of polyvinylamine resin (molecular weight is 800), 1.6wt% of polydimethylsiloxane, 0.20wt% of triethylenediamine, 12.0wt% of The composition of cyclopentane, 1.2wt% of water and the rest of ethyl acetate is uniformly mixed and poured.

Embodiment 2

[0019] In this embodiment, the shell layer and the shell layer are both made of carbon steel, and the thickness of the shell layer and the shell layer is 2-20 mm; the thickness of the vacuum insulation panel layer is 10 mm, and the first hard The thickness of the first rigid polyurethane foam is 25mm, and the thickness of the second rigid polyurethane foam is 25mm. And, the first rigid polyurethane foam and the second rigid polyurethane foam are made of 22.0wt% carbodiimide modified MDI, 18.0wt% PEA-1000, 7.5wt% PEBA-1000, 2.0 wt% of hydroxyl-terminated polybutadiene, 3.0wt% of polyvinylamine resin, 1.6wt% of polydimethylsiloxane, 0.20wt% of triethylenediamine, 12.0wt% of cyclopentane, 1.2 It is obtained by uniformly mixing the composition of wt% water and the balance of ethyl acetate and pouring.

Embodiment 3

[0021] In this embodiment, the shell layer and the shell layer are both made of carbon steel, and the thickness of the shell layer and the shell layer is 2-20 mm; the thickness of the vacuum insulation panel layer is 10 mm, and the first hard The thickness of the first rigid polyurethane foam is 25mm, and the thickness of the second rigid polyurethane foam is 25mm. And, the first rigid polyurethane foam and the second rigid polyurethane foam are made of 22.0wt% carbodiimide modified MDI, 18.0wt% PEA-1000, 7.5wt% PEBA-1000, 2.5 wt% of hydroxyl-terminated polybutadiene, 3.0wt% of polyvinylamine resin, 1.6wt% of polydimethylsiloxane, 0.20wt% of triethylenediamine, 12.0wt% of cyclopentane, 0.8 It is obtained by uniformly mixing the composition of wt% water and the balance of ethyl acetate and pouring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com