Thermal insulation multilayer composite material in ultra-wide sunlight greenhouse and production equipment thereof

A technology of multi-layer composite material and solar greenhouse is applied in the field of production equipment for producing the multi-layer composite material, which can solve the problems of large energy loss, high heating and ventilation cost, and failure to achieve good thermal insulation effect, improve economic benefits, The effect of reducing planting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

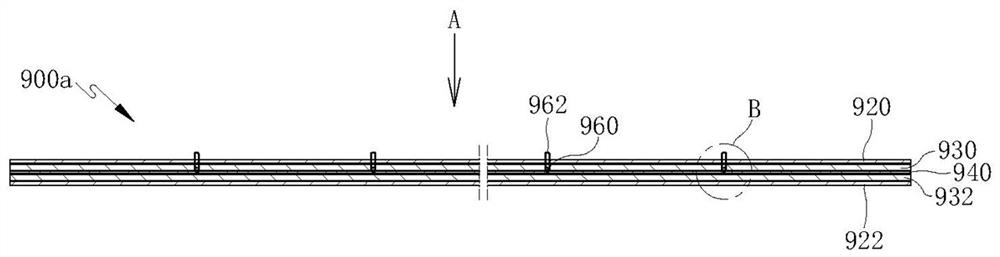

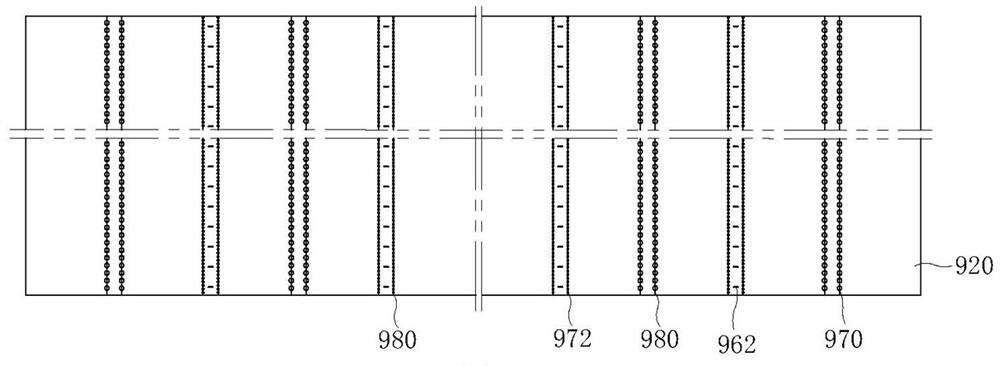

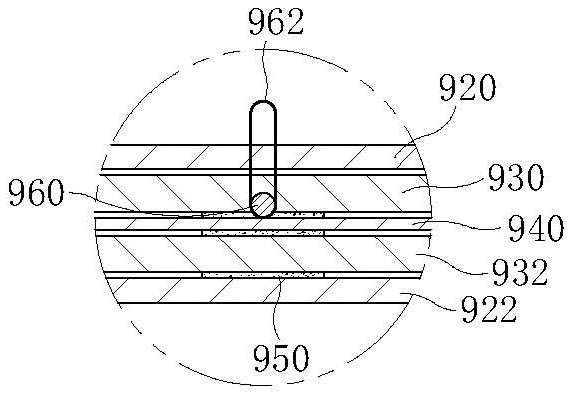

[0038] Such as figure 1 As shown, a multi-layer thermal insulation composite material 900a in an ultra-wide solar greenhouse is a flexible layered composite material structure, including a first surface material layer 920 and a second surface material layer 922 respectively located on both sides of the surface. A heat-insulating layer and an airtight layer 940 are arranged between the material layer 920 and the second surface material layer 922; The materials are combined by wire sewing to form an ultra-wide thermal insulation multi-layer composite material 900a in a solar greenhouse, with a width of 2500-6000mm, a further width of 3000-6000mm, and a total thickness of 6-30mm.

[0039] Such as figure 1 As shown, in this embodiment, the first surface material layer 920, the second surface material layer 922 and the airtight layer 940 are preferably provided with one layer, and the heat insulation layer is provided with two layers, which are respectively named as the first heat...

Embodiment 2

[0051] This embodiment is basically the same as Embodiment 1, the difference is that:

[0052] Such as Figure 4 As shown, the heat insulating layer 934 and the airtight layer 940 each have a layer. The thermal insulation multi-layer composite material 900b in the ultra-wide solar greenhouse includes the first surface material layer 920, the second surface material layer 922, the heat insulation layer 934 and the airtight layer 940, and the second surface material layer 922, the airtight layer 940 are sequentially arranged from bottom to top. The layer 940 , the heat insulating layer 934 and the first surface material layer 920 , and the hanging steel wire 960 is arranged between the heat insulating layer 934 and the airtight layer 940 .

Embodiment 3

[0054] This embodiment is basically the same as Embodiment 1, the difference is that:

[0055] The width of the thermal insulation multi-layer composite material in the ultra-wide solar greenhouse is 4500mm.

[0056] The first surface material layer and the second surface material layer are made of the same material, preferably white polyester, with a grammage of 60 g / m 2 , the width is 4600mm, the reflective rate is ≥85%, and the service life of anti-light aging is 10 years.

[0057] The material of the first heat insulation layer and the second heat insulation layer is the same, preferably EVA flexible coil, the specification is 5mm×1500mm×arbitrary length, and the density is 30kg / m 3, thermal conductivity ≤0.031w / m·k, in this embodiment, three EVA flexible coils need to be spliced together.

[0058] The airtight layer is preferably PVC, and the specification is 60mm×1500mm×arbitrary length. In this embodiment, three pieces of PVC need to be spliced together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com