Power source thermal isolation high-power LED lamp

A technology of LED lamps and thermal isolation, applied in the direction of electric light source, with built-in power supply, light source, etc., to achieve the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

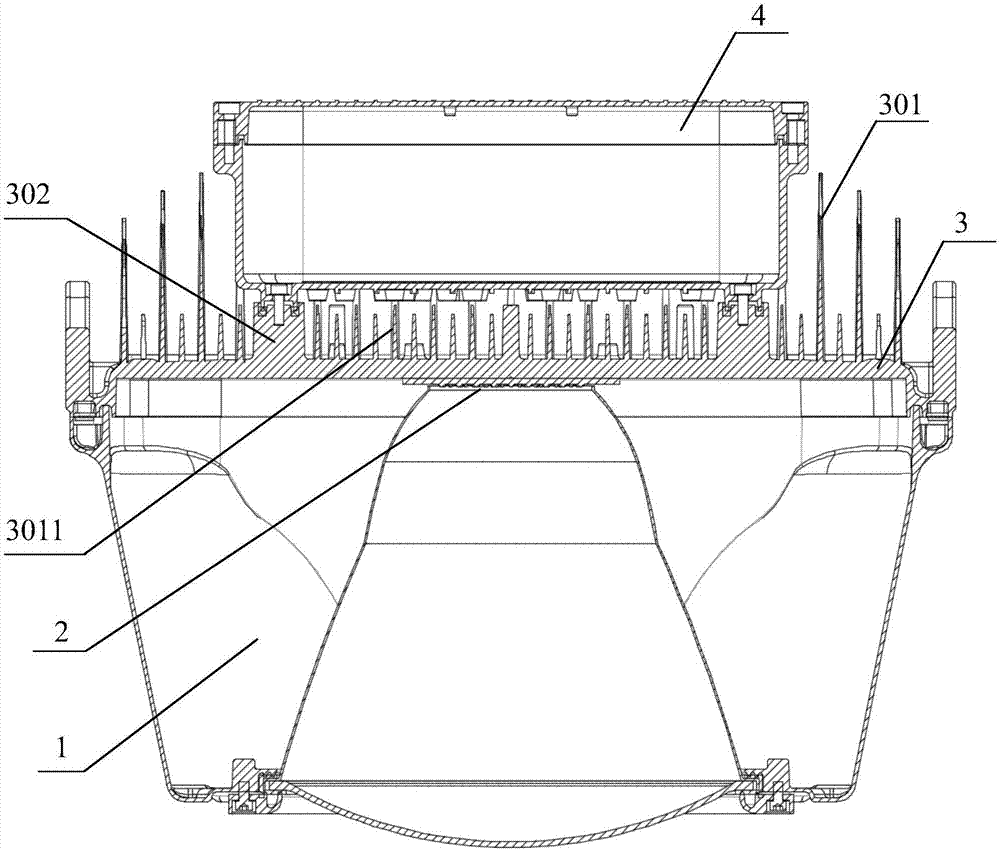

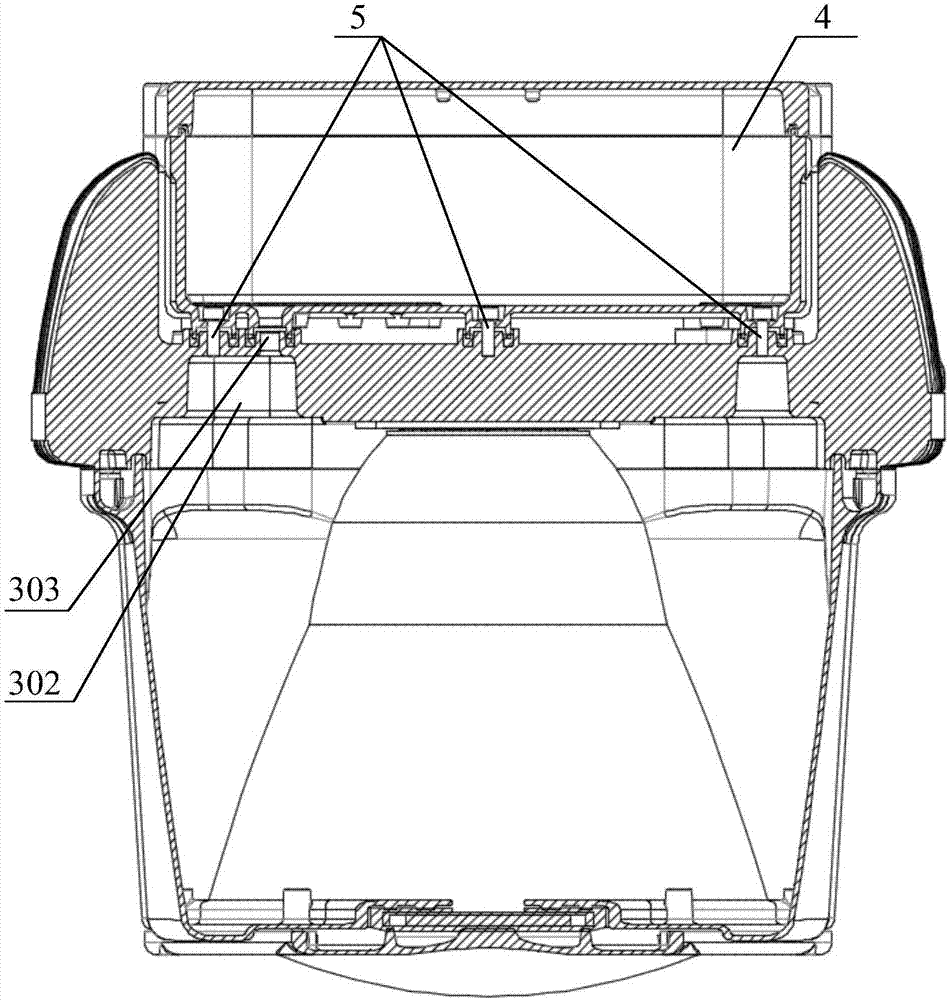

[0047] Such as figure 1 , 2 As shown, the high-power LED lamp with thermally isolated power supply includes a front cover 1, a light source board 2, a heat dissipation housing 3 and a power supply compartment 4 arranged in sequence. The front cover, the light source board and the heat dissipation housing form a light source compartment. The back of the heat dissipation housing is fixedly connected, and the short heat dissipation fins 3011 are located below the power supply compartment.

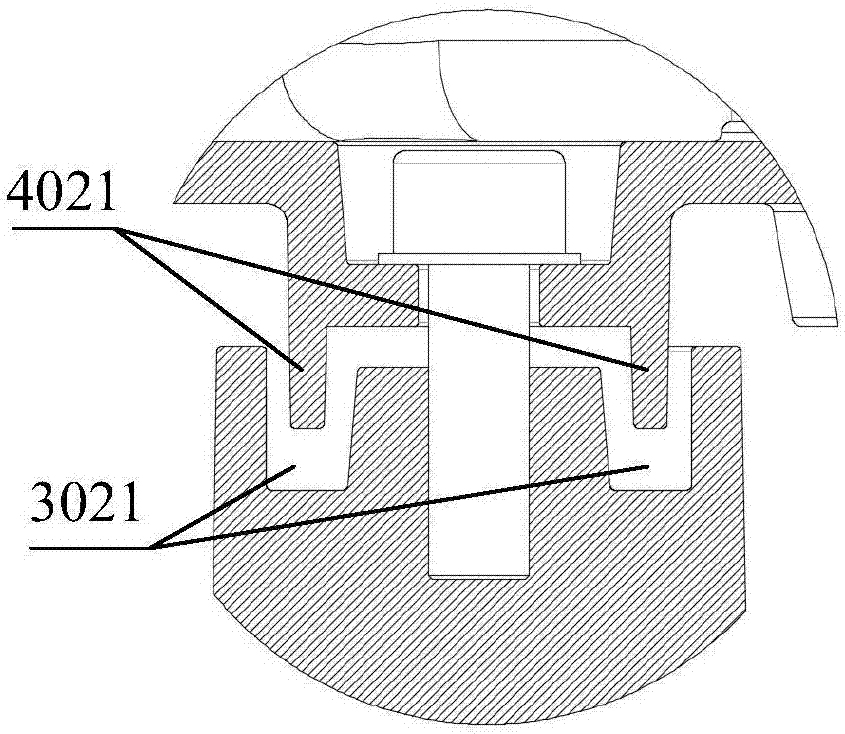

[0048] The power supply compartment 4 is relatively independent from the heat dissipation housing 3 and keeps a distance; the back of the heat dissipation housing forms a group of bosses 302 (usually distributed at four corners) between the heat dissipation fins 301, and the bottom surface of the power supply compartment is connected to the protrusions by a group of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com