Straight-runner low-temperature and low-voltage rectangular fuel cell

A low-temperature and low-pressure fuel cell technology, which is applied to fuel cell additives, fuel cell parts, battery electrodes, etc., can solve the problem of reducing the effective working area of the fuel cell, the contact area of the gas channel is not large, and the square groove cannot be too large. Large and other problems, to achieve the effect of solving the problem of effective working area, increasing the effective working area, and improving the utilization rate of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

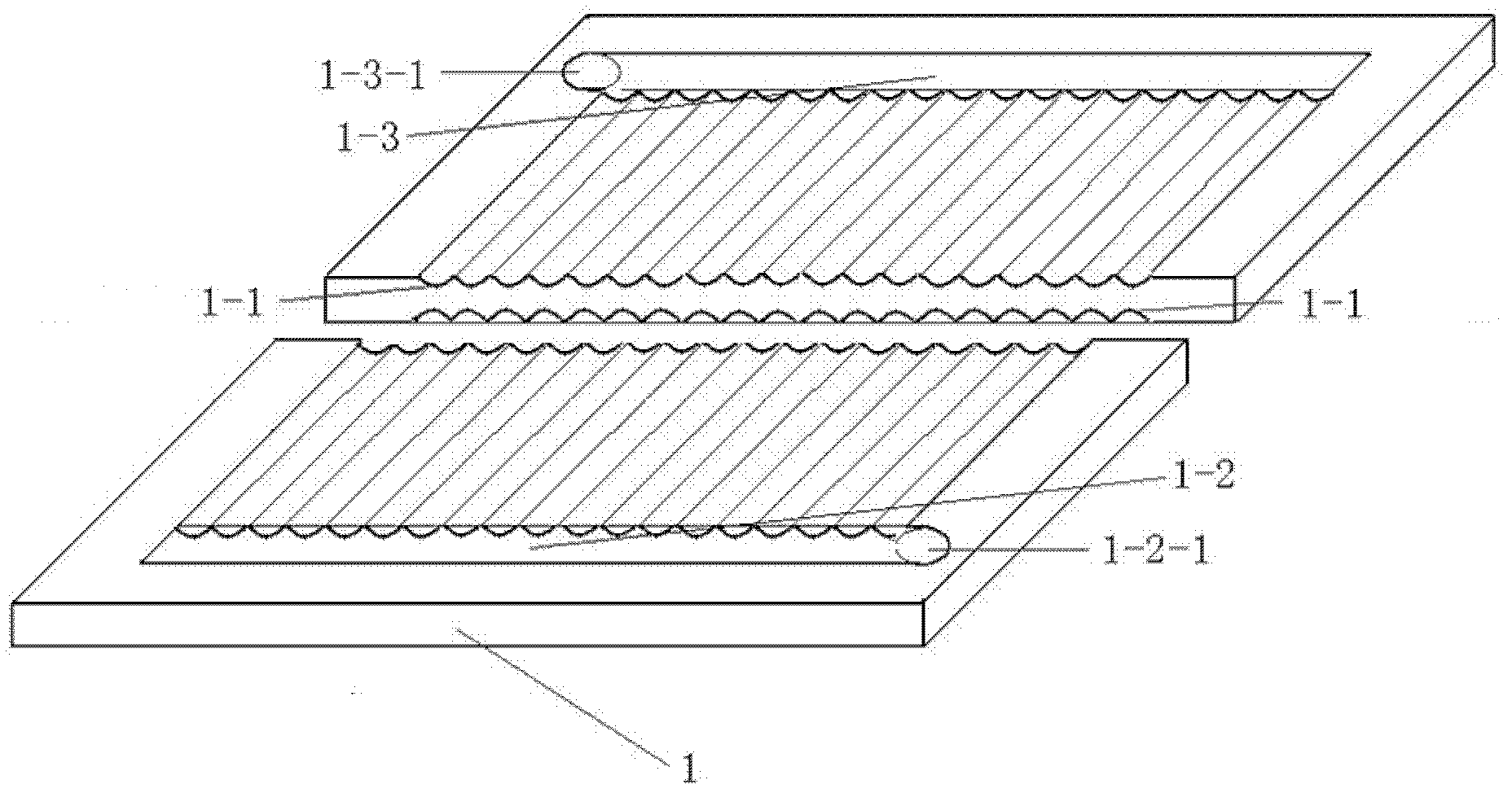

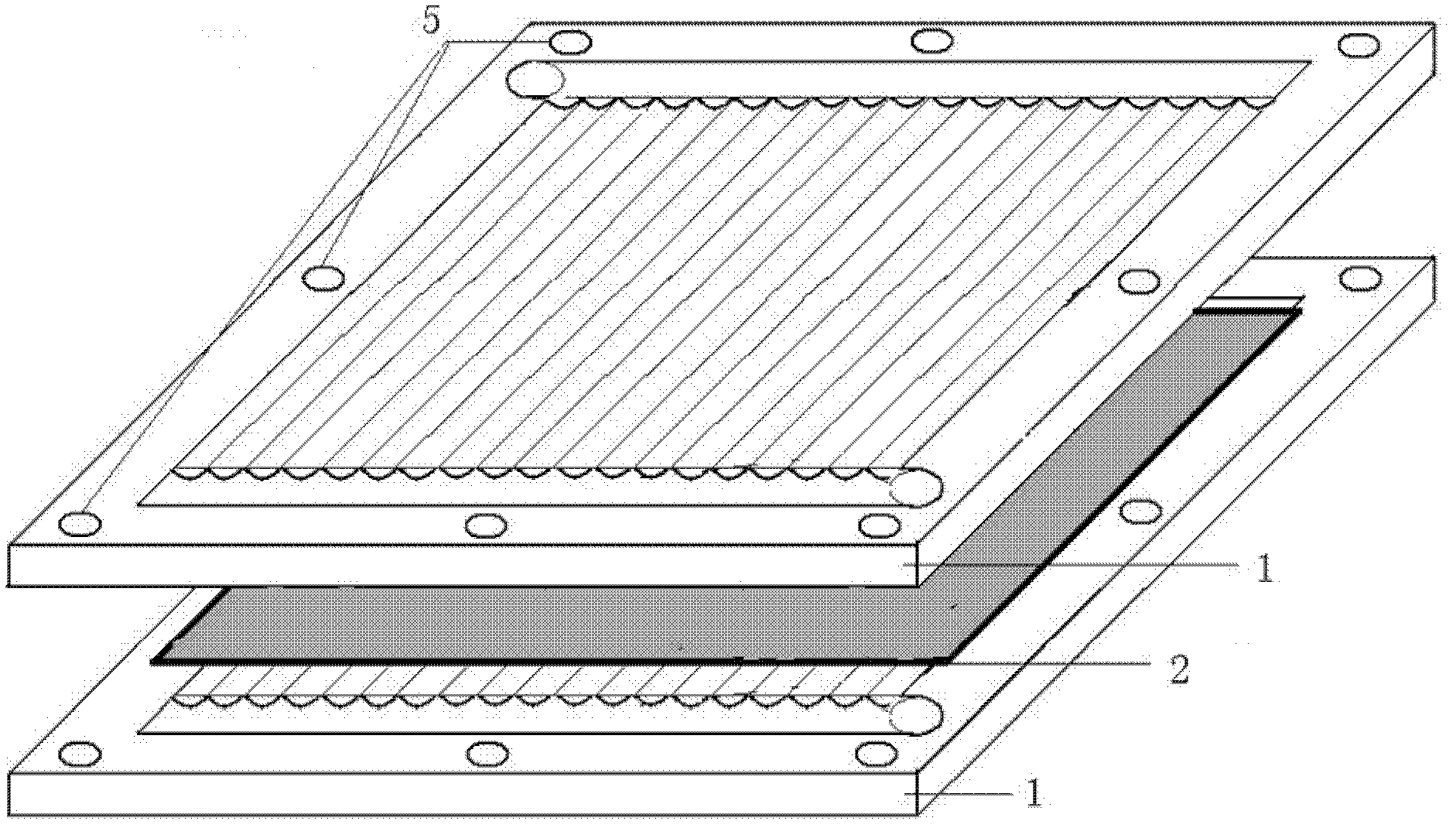

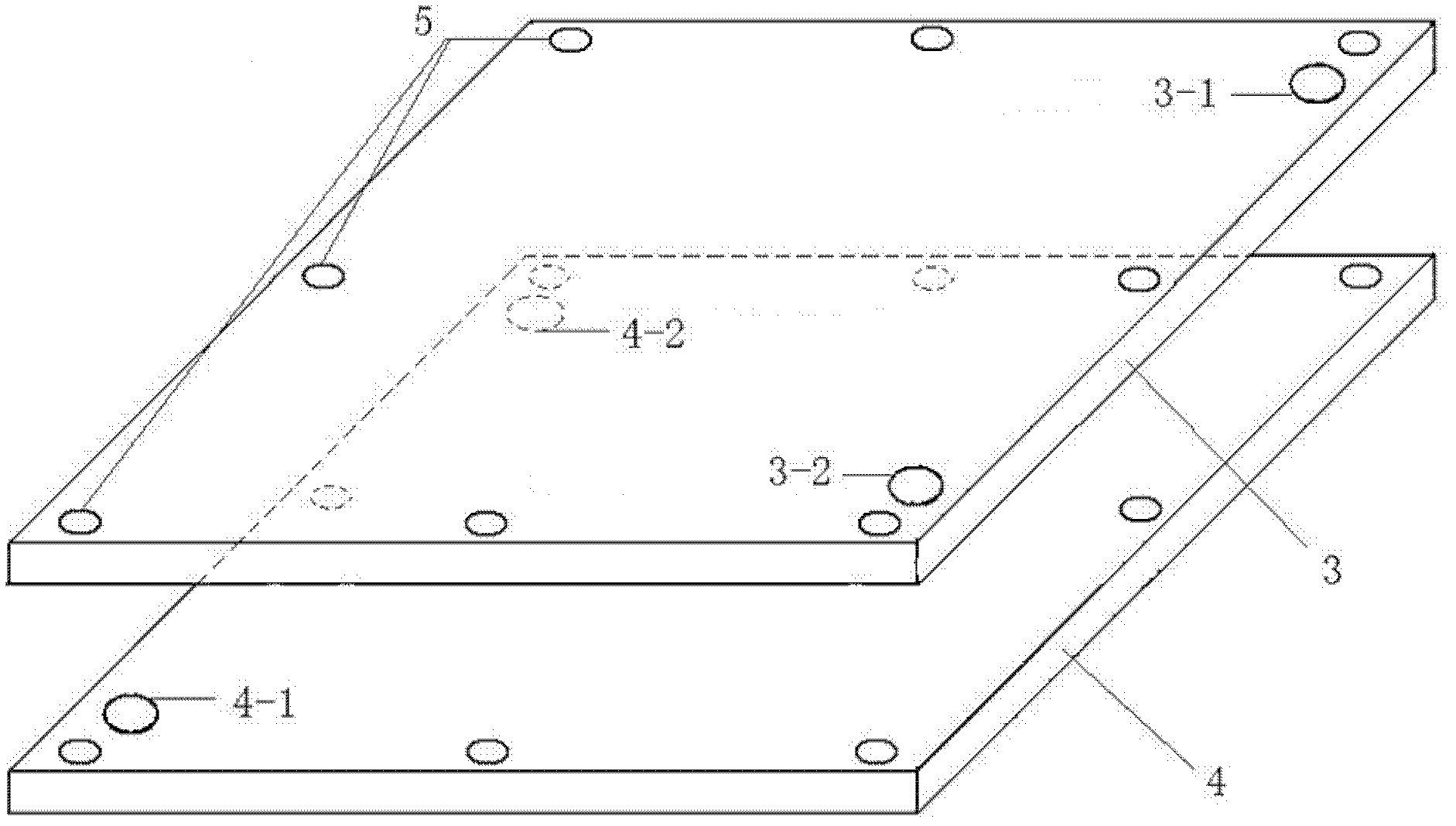

[0021] Such as figure 2 with image 3 As shown, the direct-flow low-temperature low-pressure rectangular fuel cell of this embodiment includes an intake pipe connecting plate 3 located above and an exhaust pipe connecting plate 4 located below. Press tightly with at least two pieces ( figure 1 Only two) carbon plates 1 distributed in parallel up and down are shown in the figure, and an exchange membrane 2 is sandwiched between every two adjacent carbon plates 1, and the upper surface and the lower surface of each carbon plate 1 are A plurality of channels 1-1 parallel to each other are formed, and the channels 1-1 are used as gas flow channels for gas circulation.

[0022] Eight bolt connection holes 5 are formed on the intake pipe connecting plate 3, the exhaust pipe connecting plate 4 and each carbon plate 1, so that they are connected together by bolts.

[0023] Compared with the traditional fuel cell, the biggest feature of the fuel cell in this embodiment is that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com