Vibrating piling-hammer sink-pull steel protective-cylinder piling method and special steel protective cylinder

A technology of steel casing and piling hammer, which is applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problems of bad influence of pile body concrete, occupation of working time, increase of production and construction cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

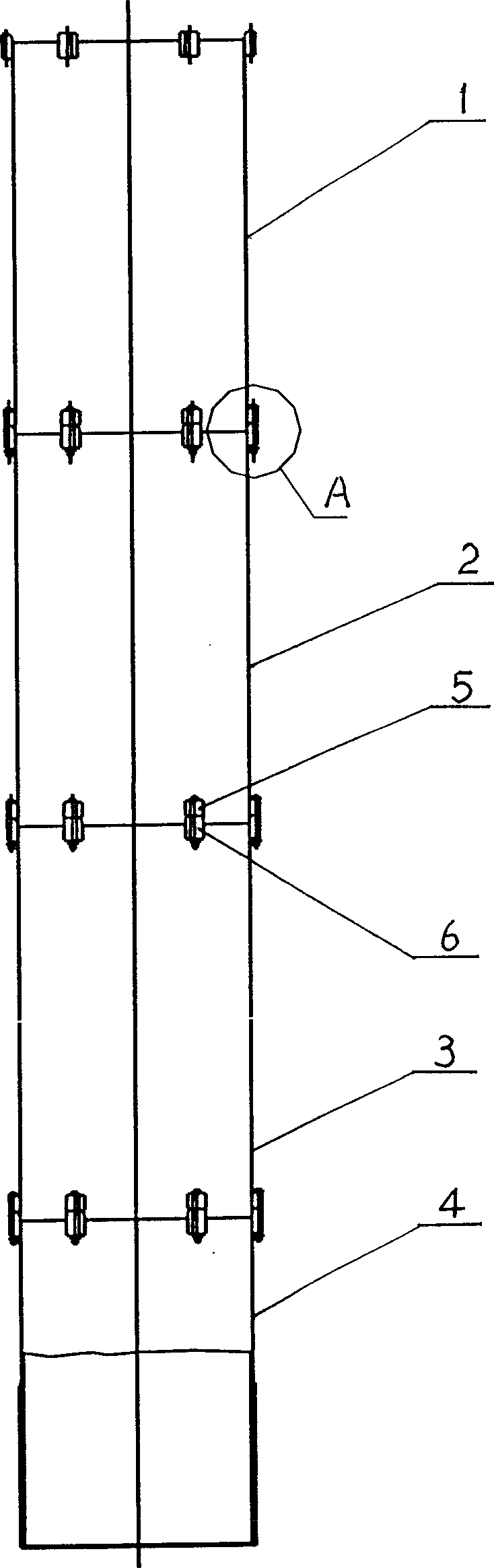

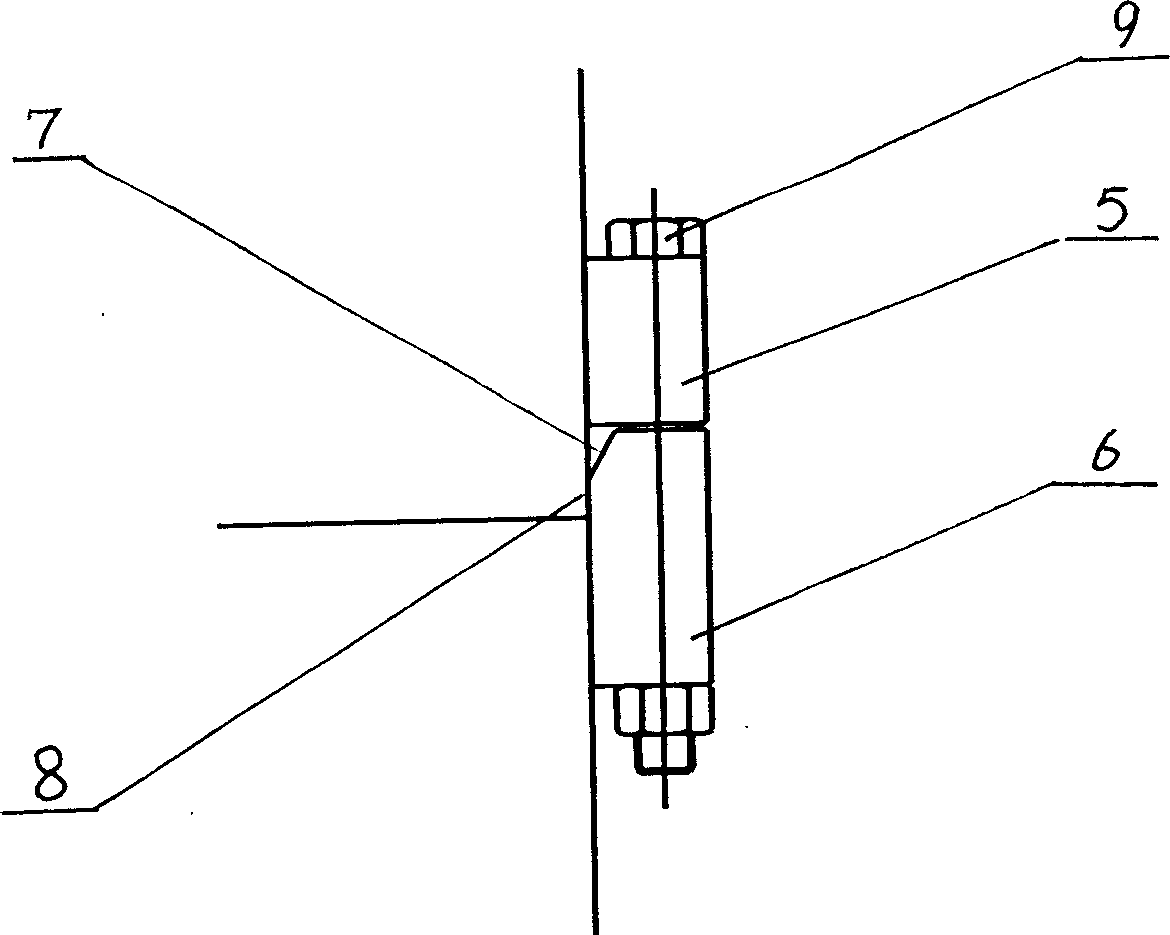

[0036] 1. The vibratory piling hammer sinking and drawing steel casing pile forming method given in this embodiment includes the following steps:

[0037] (1) Sink into steel casing

[0038] a. Set pile position control points

[0039] After placing the pile position, use four φ16-φ20 steel bars to drive into the ground no less than 0.5 meters as the control point, and the two connecting lines of the symmetrical control point intersect at the pile position point, and locate it after inspection;

[0040] b. Place the combined steel casing positioning frame at the hole, and then locate the positioning frame (simple steel frame for observing the horizontal relative position of the steel casing) according to the control pile points;

[0041] c. The pre-connected vibratory piling hammer and steel casing group (the connection length is determined according to the required sinking depth) is hoisted into the steel casing positioning frame by a crawler crane that is suitable for the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com