Patents

Literature

932results about How to "Does not affect strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

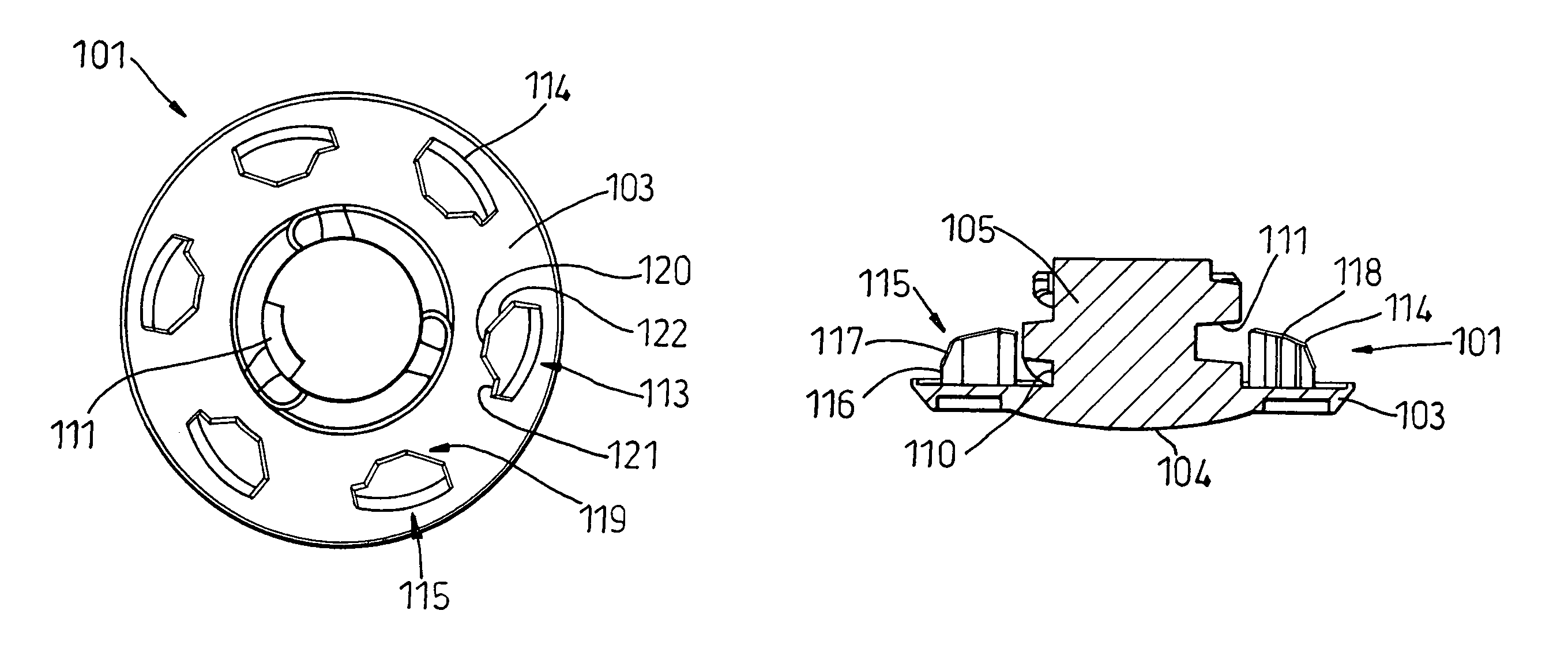

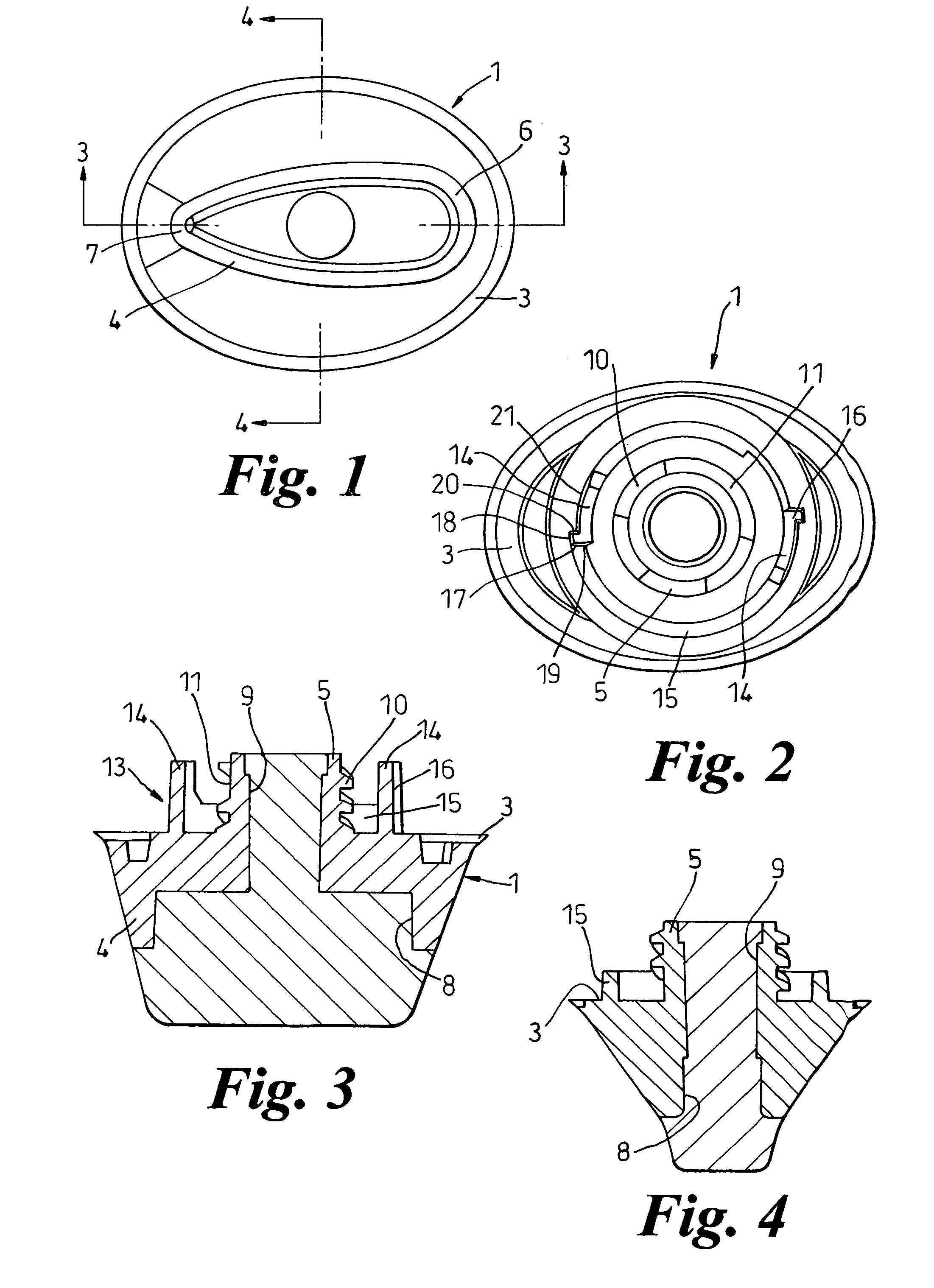

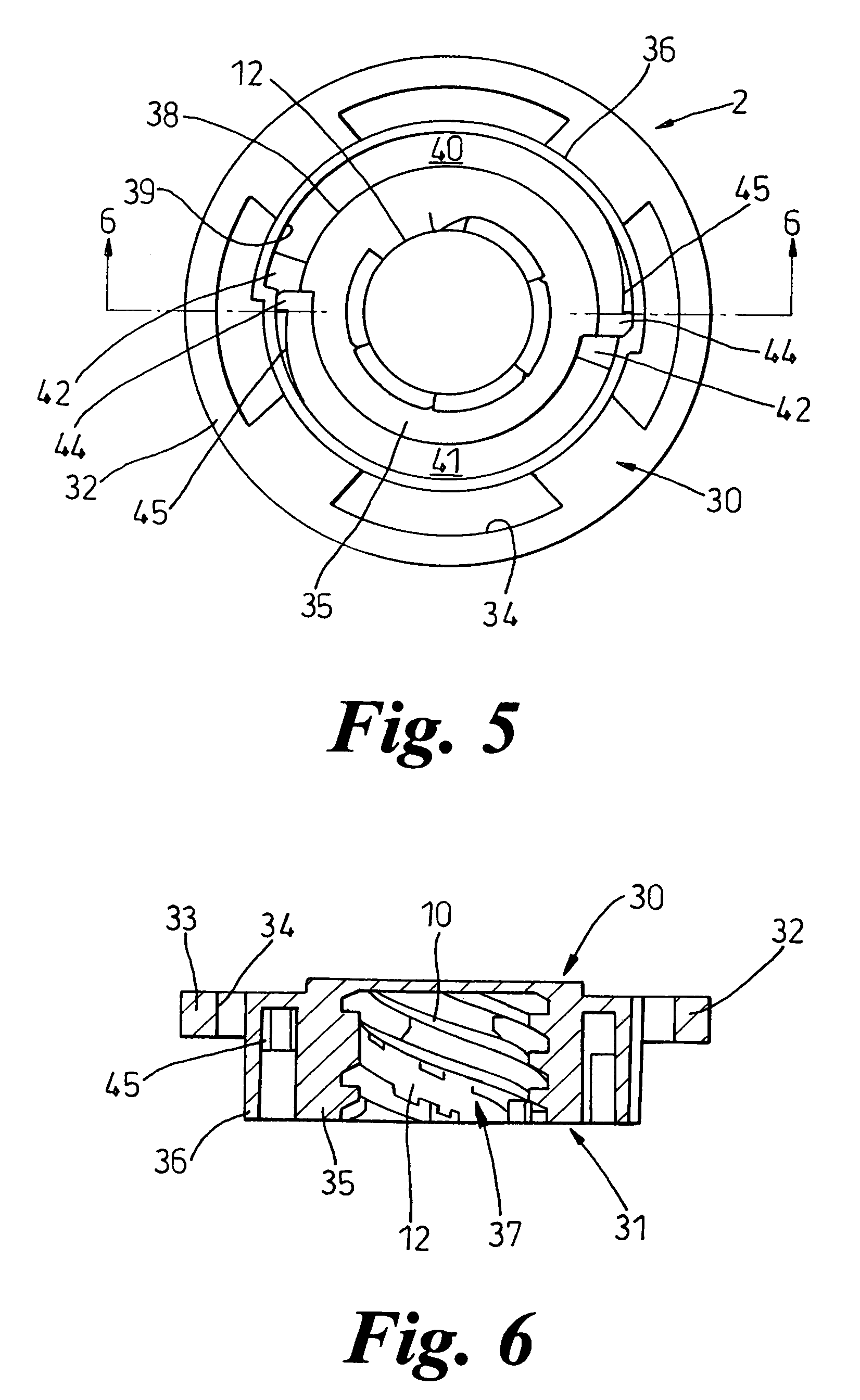

Studded footwear

A shoe stud for a sports shoe has a ground-engaging part and a multi-start threaded spigot for engagement in a complementary socket on a receptacle secured in the shoe sole or heel. The stud and receptacle also have a locking device which inter-engages when the spigot is fully inserted into the socket, to resist unscrewing. In order to ensure that the stud takes up a precise position relative to the receptacle, which may be needed if the stud is not rotationally symmetrical, the stud and receptacle have means to determine the initial position of the stud relative to the receptacle, and means to determine the final position of the stud relative to the receptacle. Determination of the initial position may be provided by a thread and complementary groove of the screw-thread connection which are of different dimensions from the others.

Owner:TRISPORT

Inorganic material in particles form

InactiveUS6165510ADoes not affect strengthPowder deliveryCosmetic preparationsInorganic materialsMaterials science

PCT No. PCT / EP97 / 00202 Sec. 371 Date Aug. 11, 1998 Sec. 102(e) Date Aug. 11, 1998 PCT Filed Jan. 15, 1997 PCT Pub. No. WO97 / 30126 PCT Pub. Date Aug. 21, 1997A cosmetic composition includes an inorganic material in granular form which, under condition of use of the cosmetic composition, breaks down to a particle size wherein less than 5% by weight, preferably less than 2% by weight, most preferably less than 1% by weight is above 45 microns, as measured by wet sieve analysis.

Owner:PQ SILICAS UK

Method for preparing anti-aging high-transparent polyurethane and graphene oxide composite microporous membrane material

ActiveCN102604137AImprove mechanical propertiesImprove wettabilityOxide compositeMicroporous membranes

The invention discloses a method for preparing an anti-aging high-transparent polyurethane and graphene oxide composite microporous membrane material. The method includes: preparing graphene oxide as filler, and uniformly mixing the graphene oxide into polyurethane emulsion by the aid of high dispersion wettability of flatting agent. Using the method can improve dispersibility and stability of the graphene oxide in the polyurethane emulsion, enhance the bonding force between the graphene oxide and an interface of a polyurethane matrix, and obtain the anti-aging high-transparent polyurethane and graphene oxide composite microporous membrane material. The method is simple and environment-friendly, the anti-aging performance and transparency of the composite microporous membrane material areevidently improved, and integral strength of the material is basically unaffected.

Owner:YANTAI UNIV

Lead paste of deep adhesive type specially-cured lead carbon battery

ActiveCN106129357AControl stratification problemHigh strengthLead-acid accumulatorsCell electrodesCapacitanceFiber

The invention relates to lead paste of a deep adhesive type specially-cured lead carbon battery. Positive electrode lead paste comprises the following constituents: 600-1,200kg of lead powder, 5-80kg of red lead, 10-60kg of 4BS seed crystal, 0.6-3.6kg of aquadag, 0.3-3.6kg of stannous sulfate, 0-3.0kg of antimonous oxide, 0.6-3.6kg of potassium phosphate, 0.5-1.8kg of fumed silica, 0.8-1.8kg of short fiber and 48-130kg of 1.40g / ml dilute sulphuric acid, and negative electrode lead paste comprises the following constituents: 600-1,000kg of lead powder, 3-12kg of barium sulfate, 1-8kg of humic acid, 0.5-2.5kg of lignin, 0.3-1.8kg of fumed silica, 0.05-1.5kg of sodium carboxymethyl cellulose (CMC), 0.5-2.5kg of PTFE emulsion, 8-10kg of graphite, 1-16kg of acetylene black / carbon black, 2-18kg of active carbon / capacitance carbon / carbon, 0.05-1.8kg of bismuth oxide / bismuth carbon sulfide bismuth, 0.01-1.2kg of graphene, 0.02-2.0kg of carbon nanofiber tube, 0.8-1.8kg of short fiber and 76-80kg of 1.40g / ml dilute sulphuric acid.

Owner:ANHUI HONGDA ELECTRICAL SOURCE

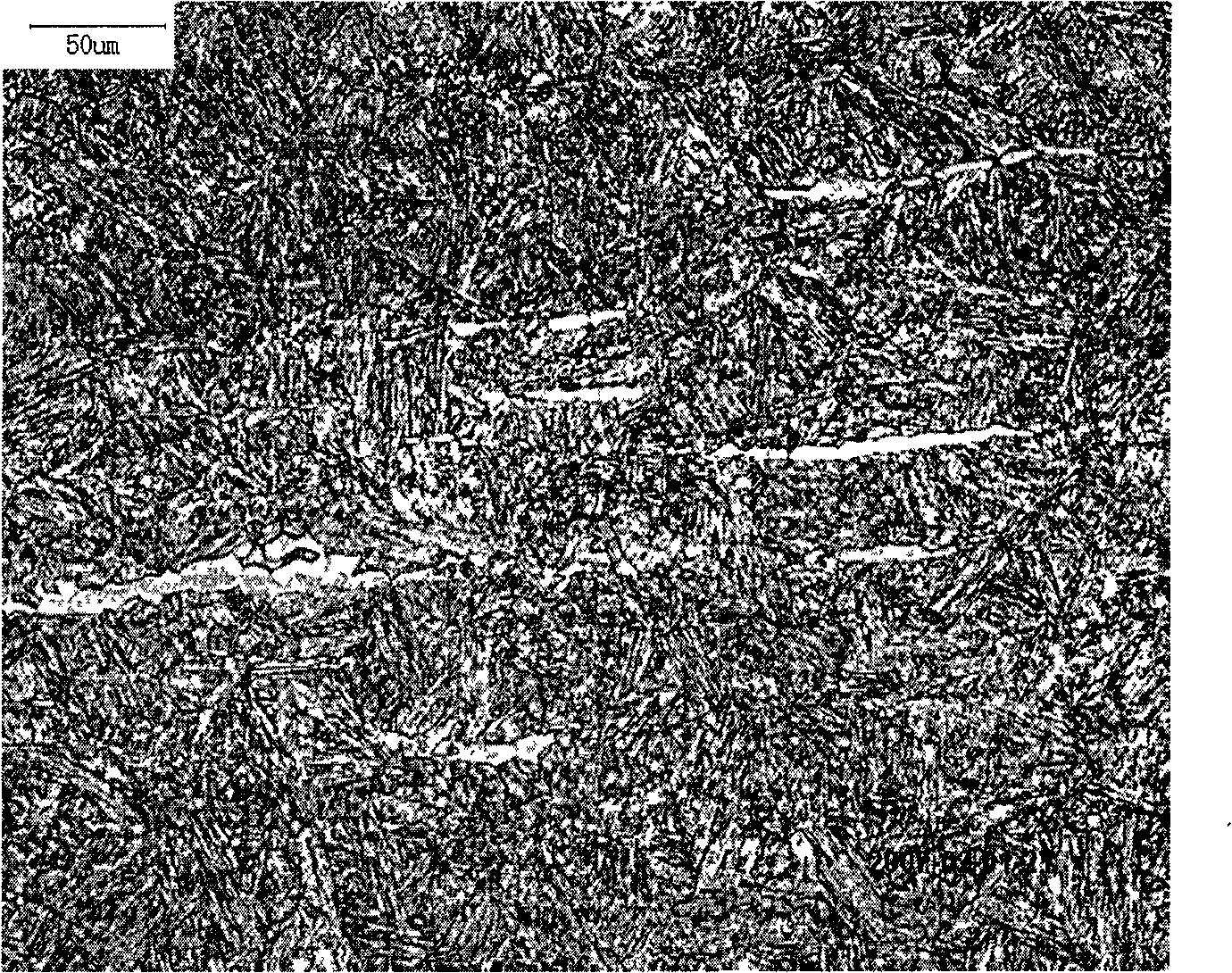

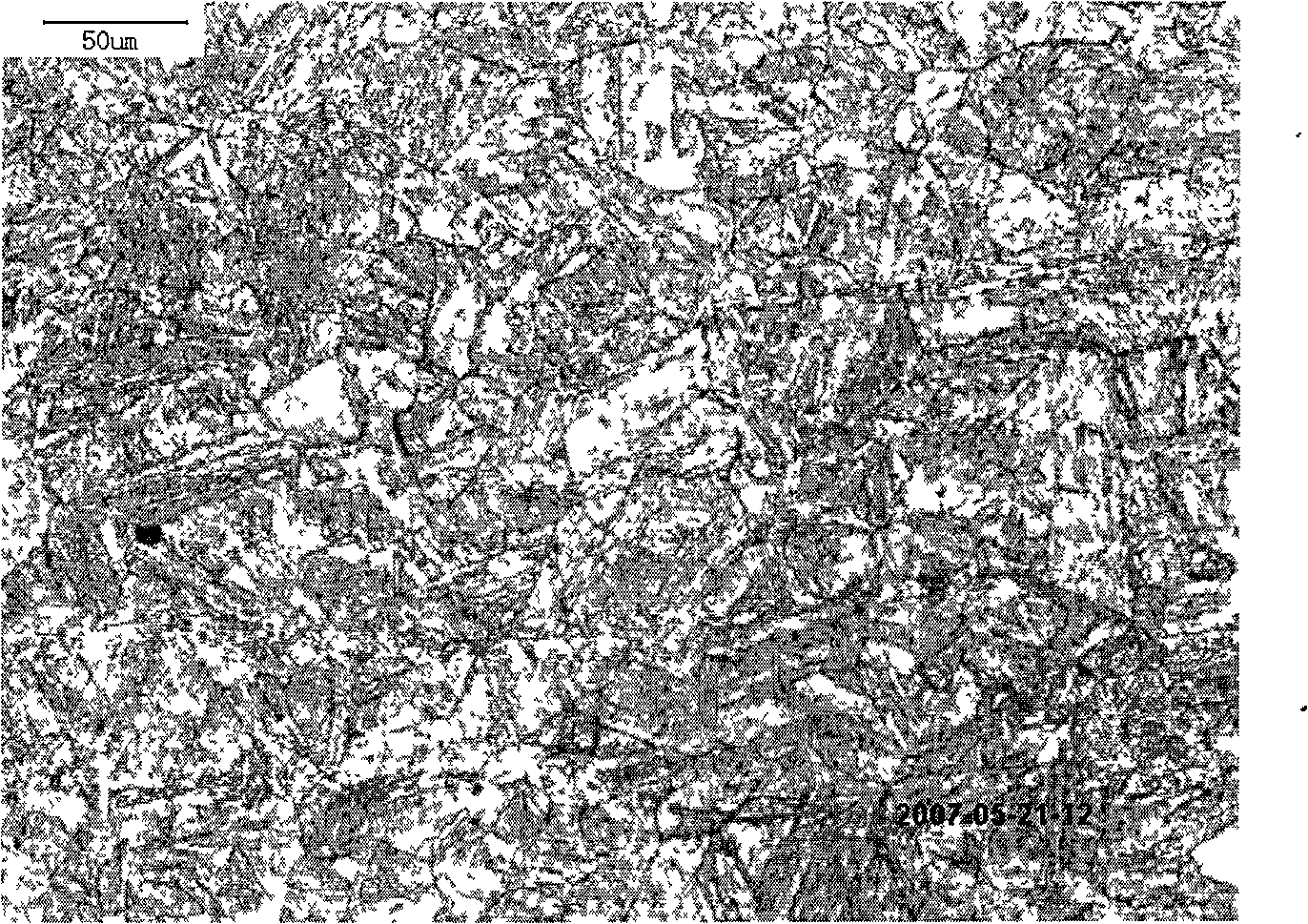

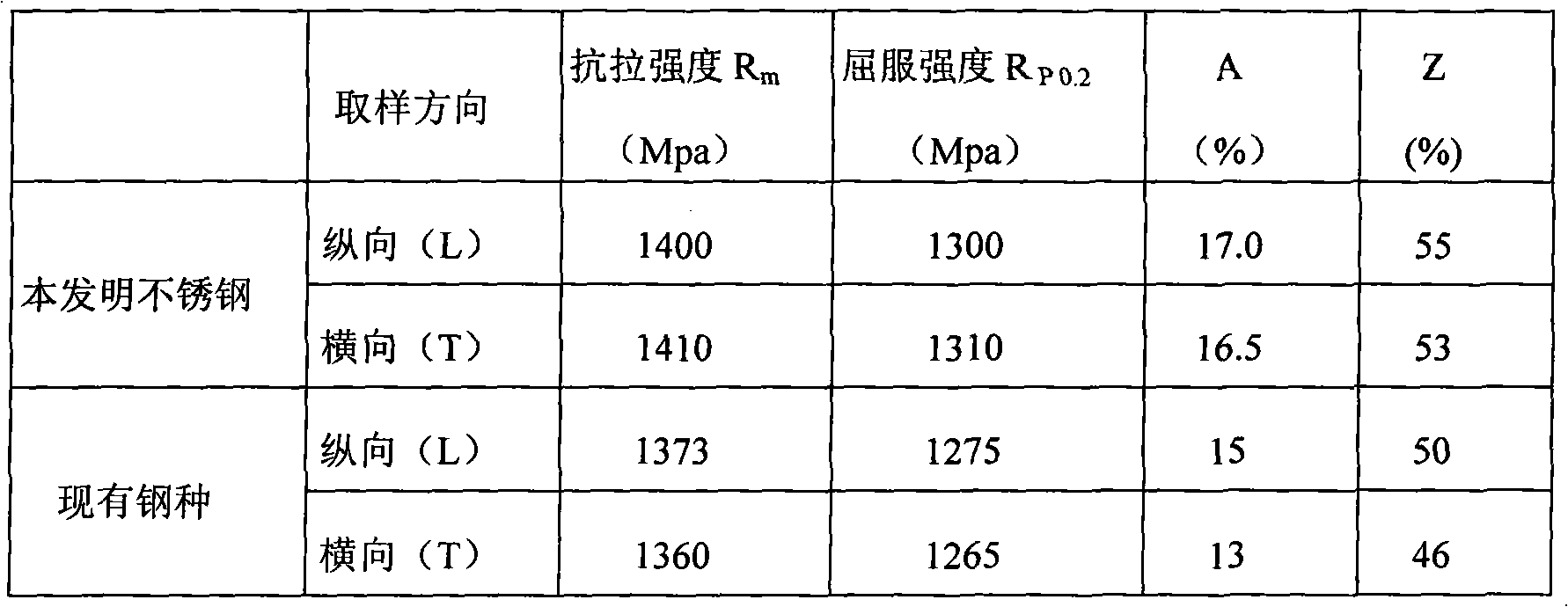

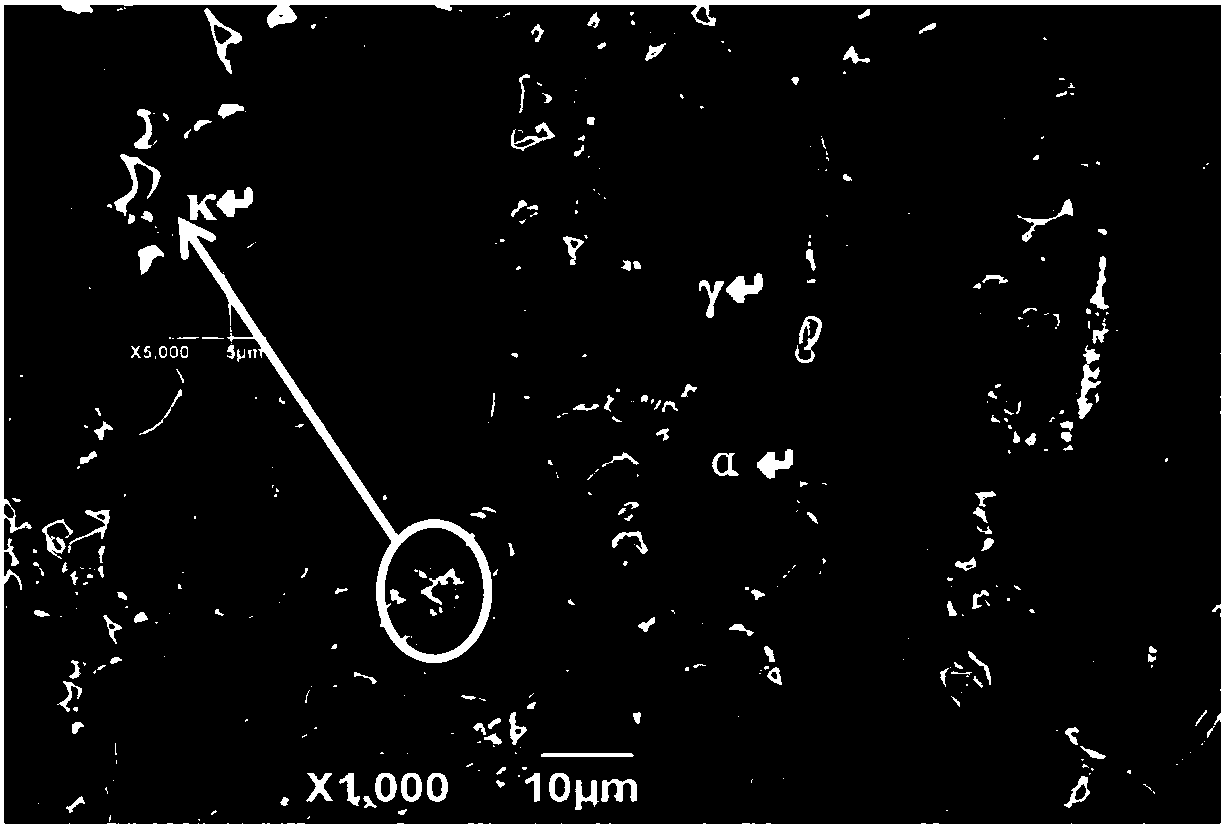

Martensite precipitation hardening stainless steel for structural member and manufacturing method thereof

The invention provides a martensite precipitation hardening stainless steel for structural member and a manufacturing method thereof. The martensite precipitation hardening stainless steel comprises the following chemical components in percentage by weight: less than or equal to 0.05 percent of C, 13.50 to 15.50 percent of Cr, 2.5 to 4.0 percent of Cu, 3.0 to 5.0 percent of Ni, 0.15 to 0.40 percent of Nb and Ta, 0.010 to 0.040 percent of N, 0.050 to 0.15 percent of V, less than or equal to 0.80 percent of Si, less than or equal to 1.00 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, and the balance of Fe and inevitable impurities. The stainless steel is smelted by combining an electric furnace, AOD refining and vacuum self-consuming technology, so the stainless steel has the characteristics of high strength, good plasticity, good corrosion resistance and the like, and can meet the requirements of high-strength components such as high-pressure values, oil drill, efficient heavy-duty machinery and the like on material performance.

Owner:宝武特种冶金有限公司

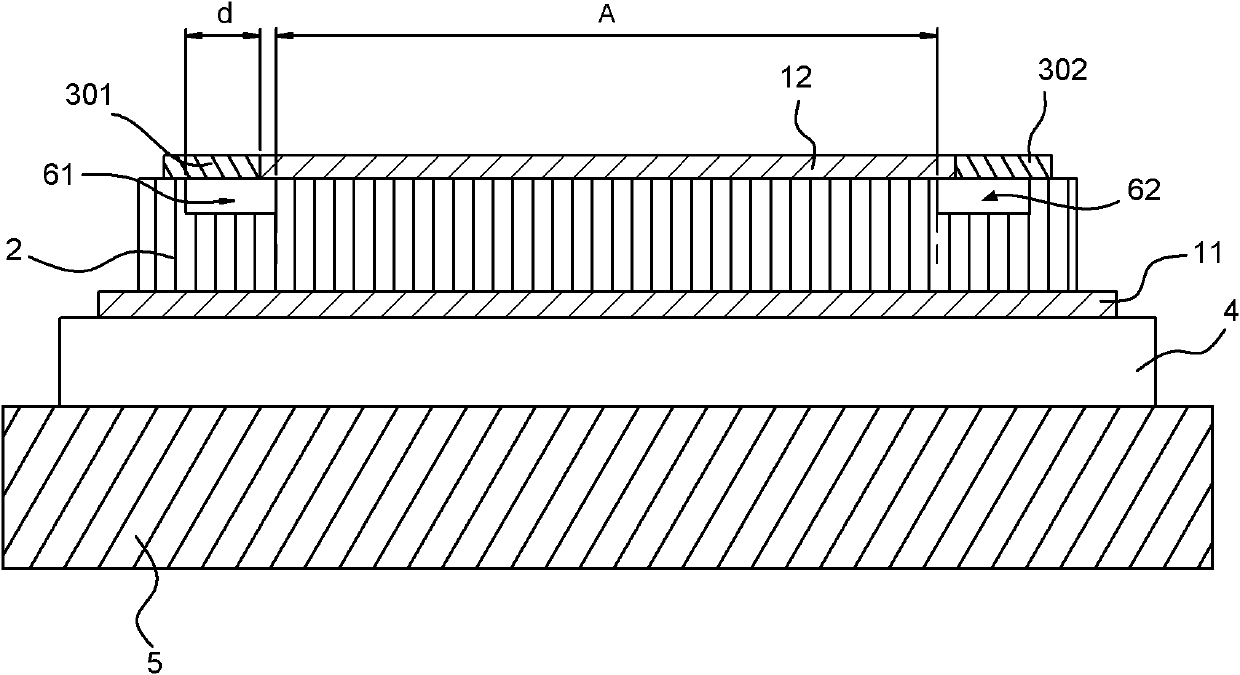

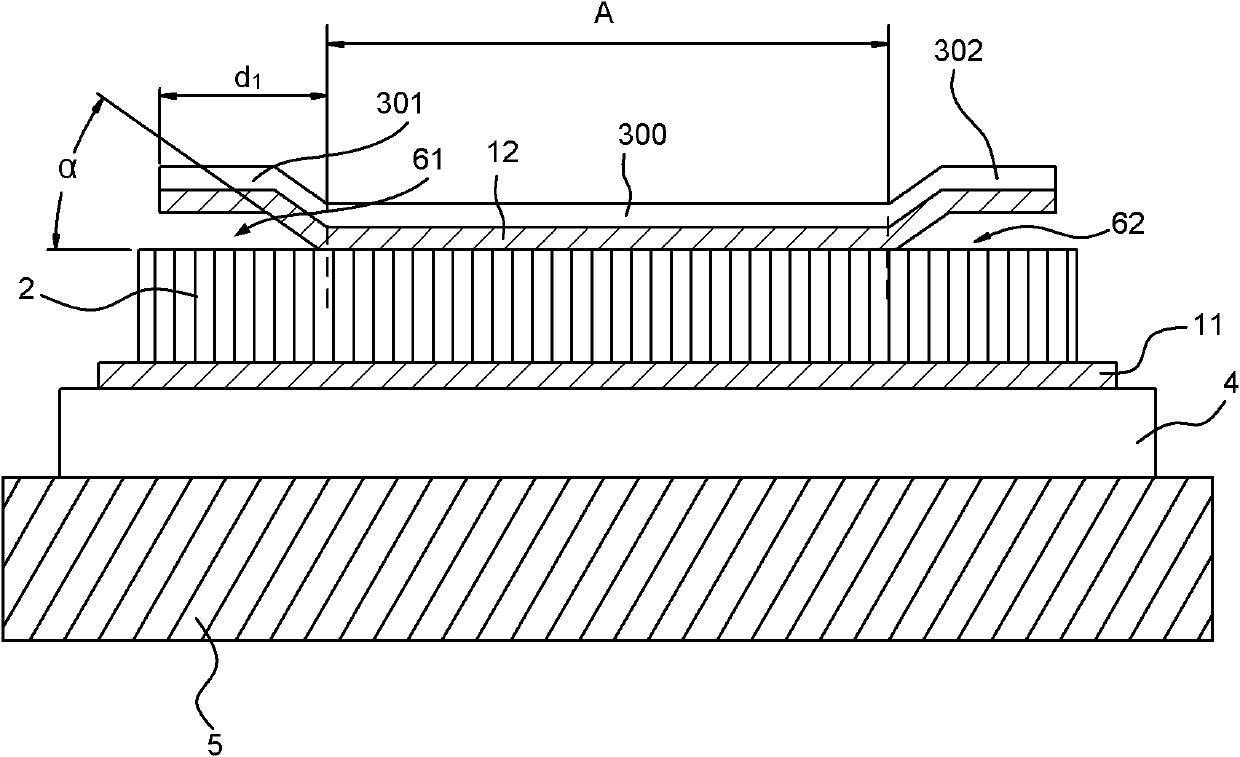

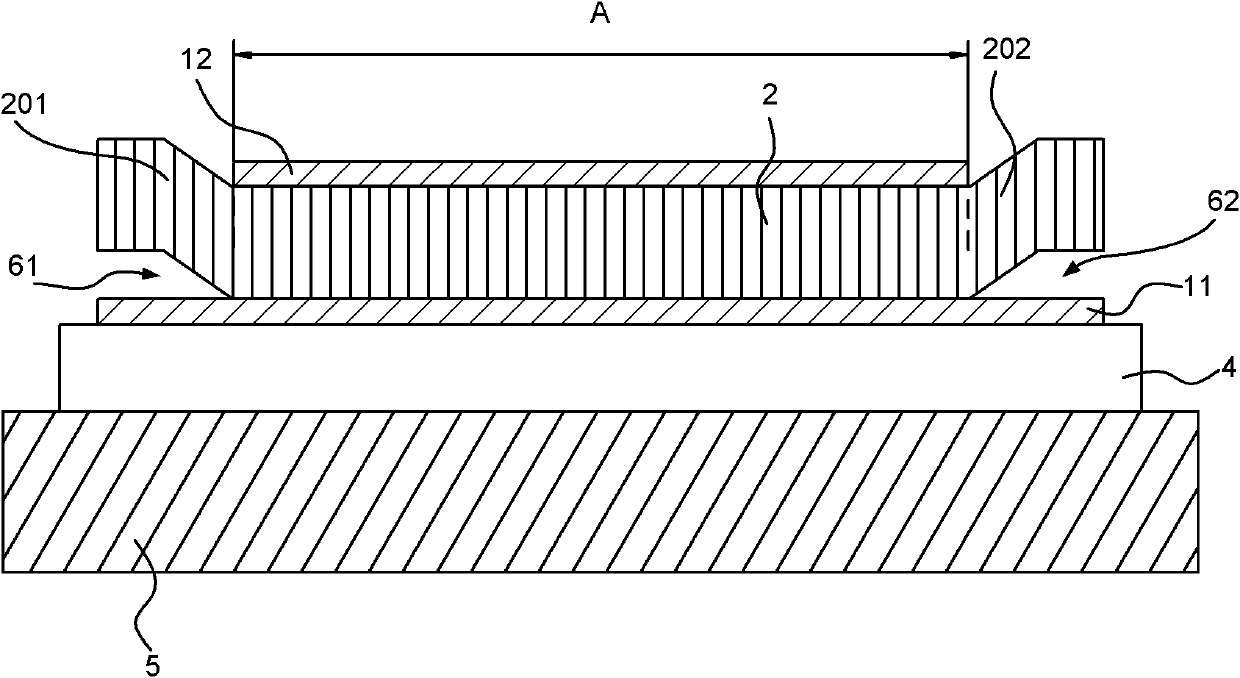

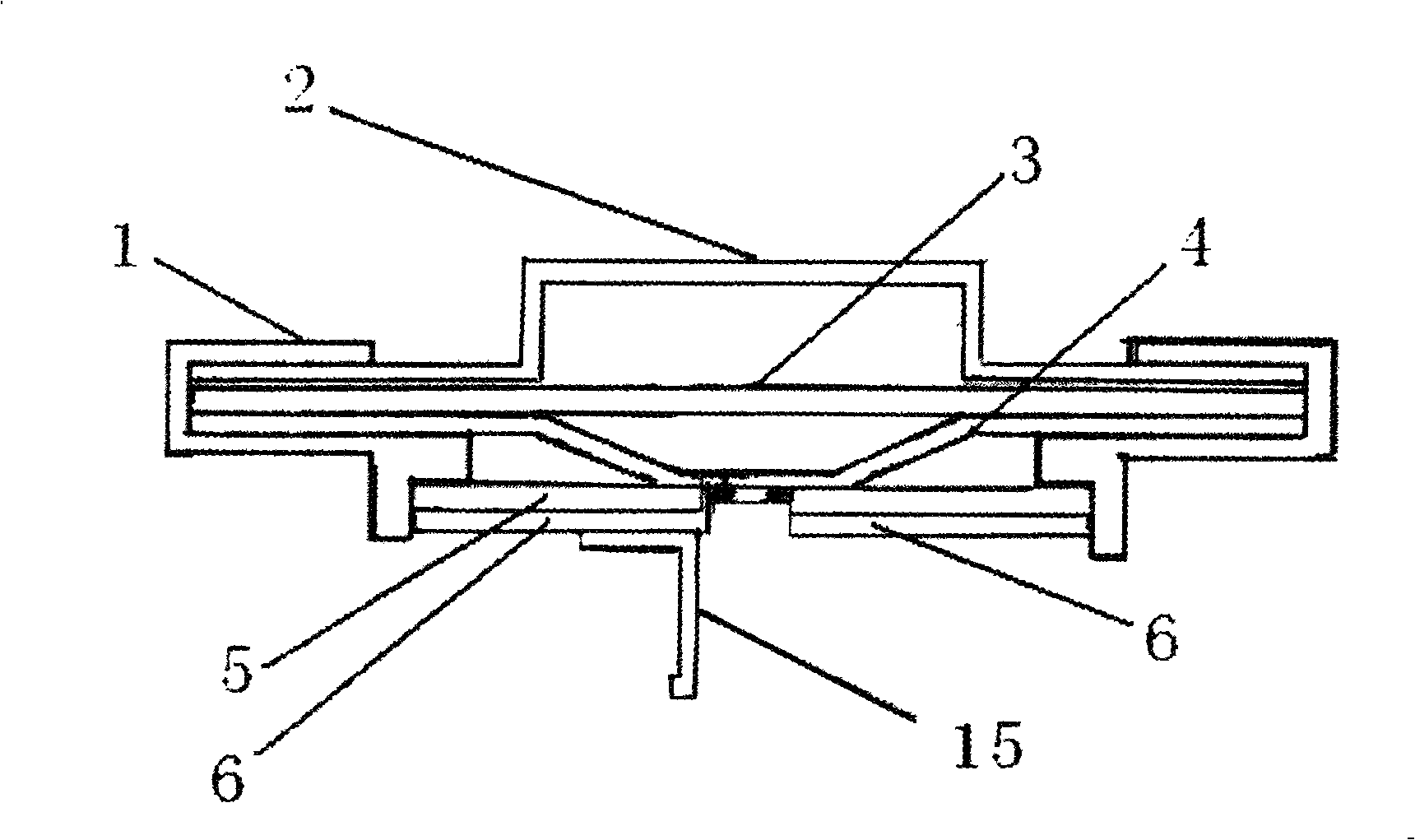

Piezoelectric resonator structure

ActiveCN101924529AHigh Q valueExcellent electrical propertiesImpedence networksAcoustic reflectionPiezoelectric resonators

The invention discloses a piezoelectric resonator structure, which comprises a substrate, an acoustic reflection layer, a first electrode, a piezoelectric layer and a second electrode, which are provided with a top surface, a bottom surface, a first tail end, a second tail end and a middle part respectively; the substrate, the acoustic reflection layer, the first electrode, the piezoelectric layer and the second electrode are arranged in turn from the bottom to the top; and an overlapping region of the substrate, the acoustic reflection layer, the first electrode, the piezoelectric layer and the second electrode is defined as an effective excitation region. A series of air gaps and interference structures are formed at the first tail ends and the second tail ends of the piezoelectric layer and the second electrode to improve the electrical performance of a resonator. The piezoelectric resonator structure greatly improves the Q value of the resonator nearby a parallel resonance frequency, meanwhile does not affect the Q value and parasitic mode strength of the resonator nearby a series resonance frequency, and does not reduce the electromechanical coupling coefficient of the resonator. A filter adopting the resonator structure has more predominant electrical properties such as lower pass-band insertion loss and the like.

Owner:ROFS MICROSYST TIANJIN CO LTD

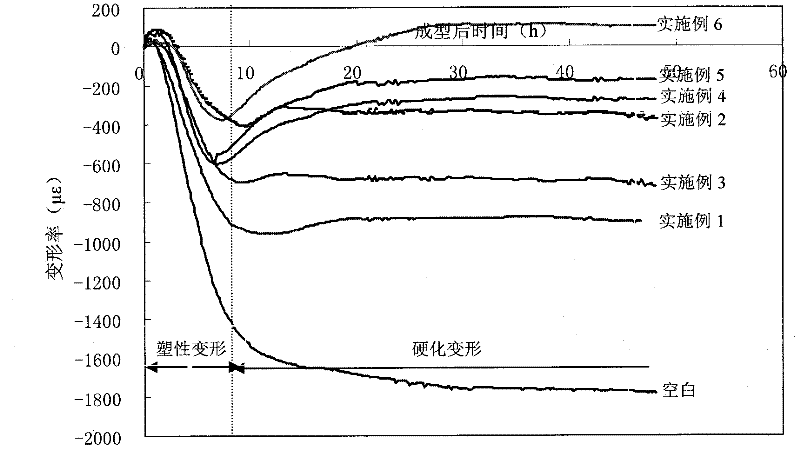

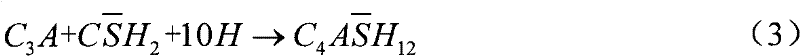

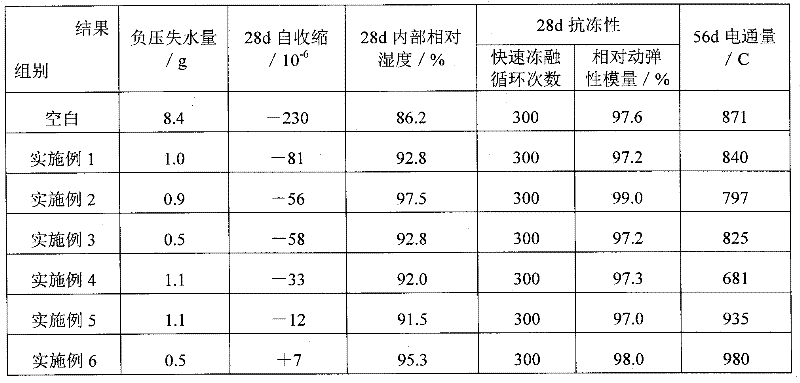

Internal curing material of high-performance concrete and preparation method thereof

The invention relates to an internal curing material of high-performance concrete and a preparation method thereof. The internal curing material comprises the following components in parts by mass: 100 parts of expanding agent, 1.0-5.0 parts of organic high water absorption material, 0-50 parts of inorganic water absorption material, 0-1.0 part of water-retaining agent and 0-10 parts of filler. The preparation method of the internal curing material comprises the following steps of: mixing a sodium hydroxide solution, acrylic acid and acrylamide according to a certain mass part, stirring, sequentially adding a cross-linking agent and an initiator, and preparing a acrylic acid / acrylamide copolymer through polymerization; drying, crushing and sieving a reaction product to obtain the organic high water absorption material; and mechanically mixing the water absorption material, the inorganic water absorption material, the expanding agent, the water-retaining agent and the filler to obtain the internal curing material of the high-performance concrete. Compared with the prior art, the concrete prepared by using the product provided by the invention has functions of water retaining, internal curing, crack resistance and the like, meanwhile, the strength and the durability of the concrete are not influenced, and the internal curing material has the main advantage that the concrete prepared by using the internal curing material still has favorable crack resistance under an extremely drought environment.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

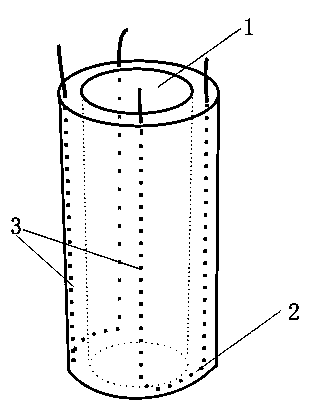

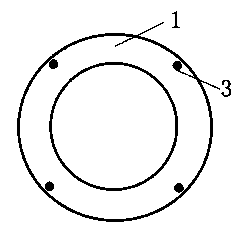

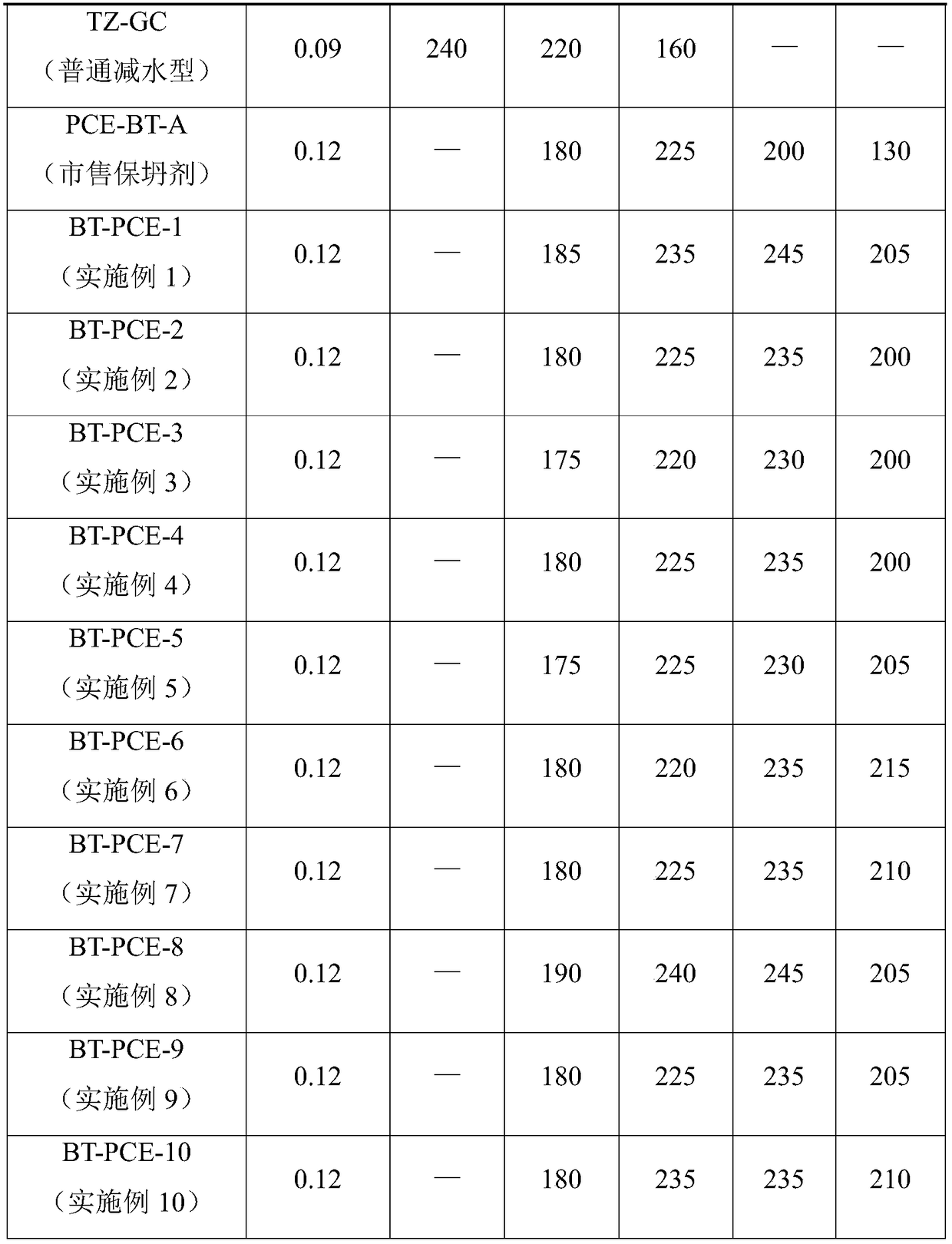

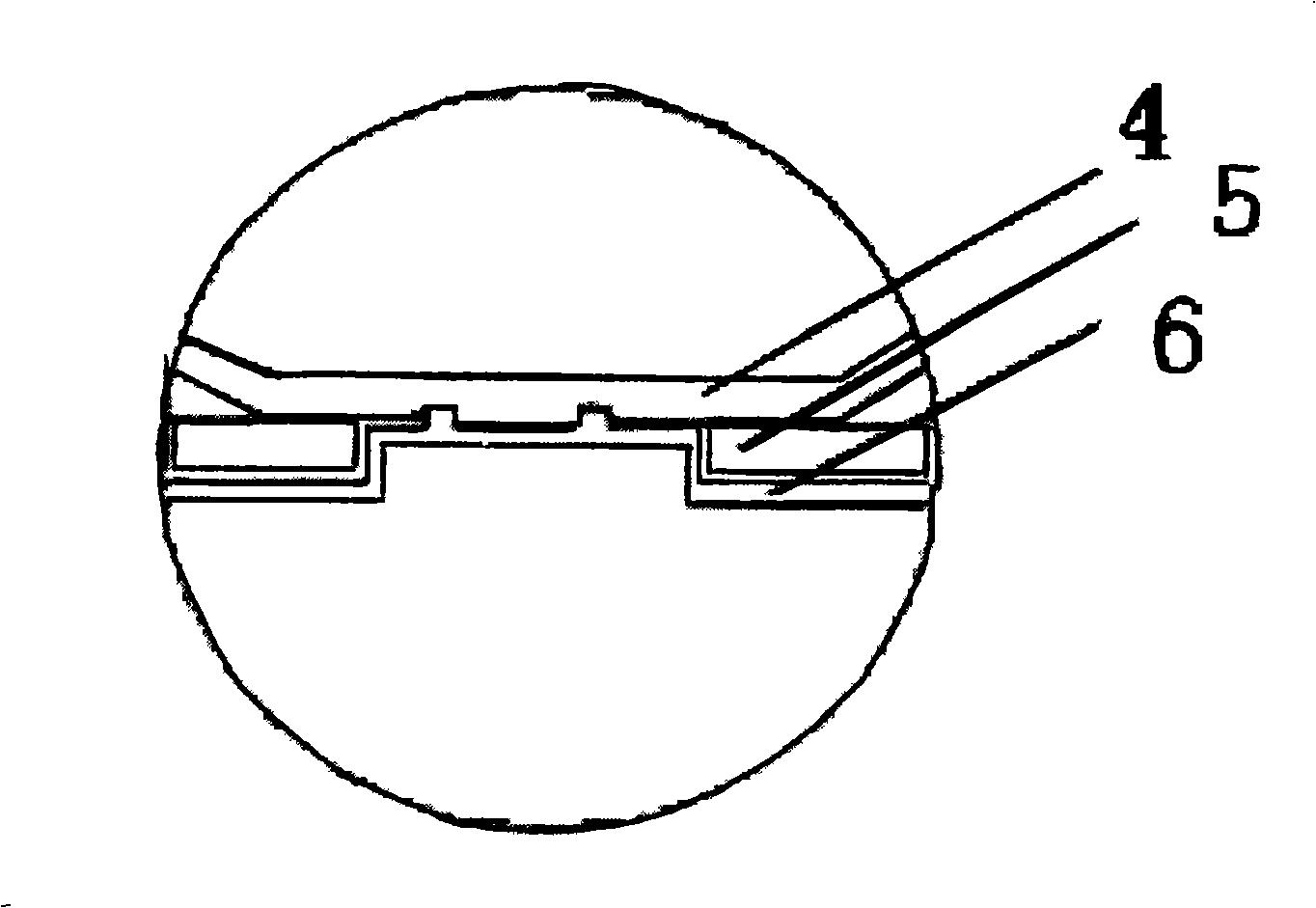

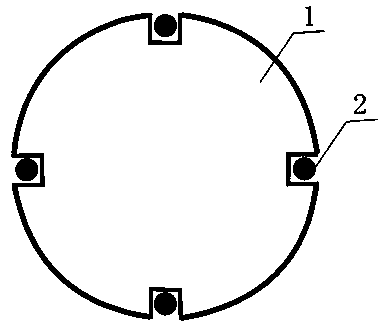

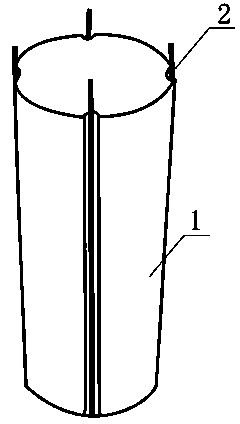

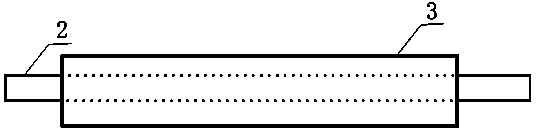

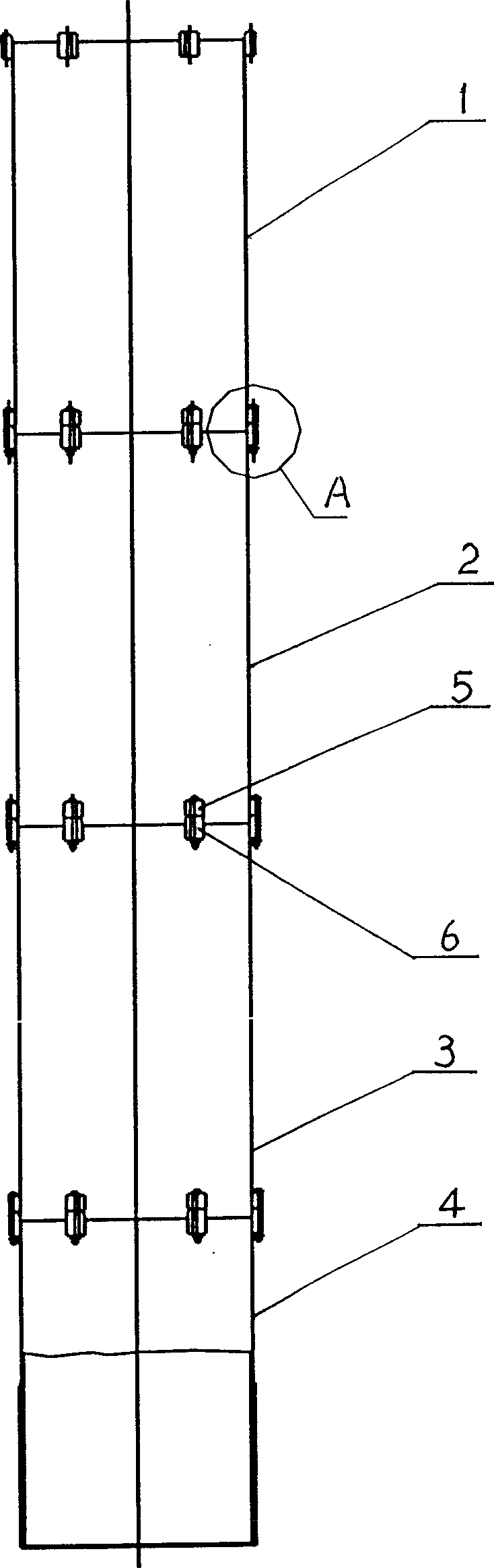

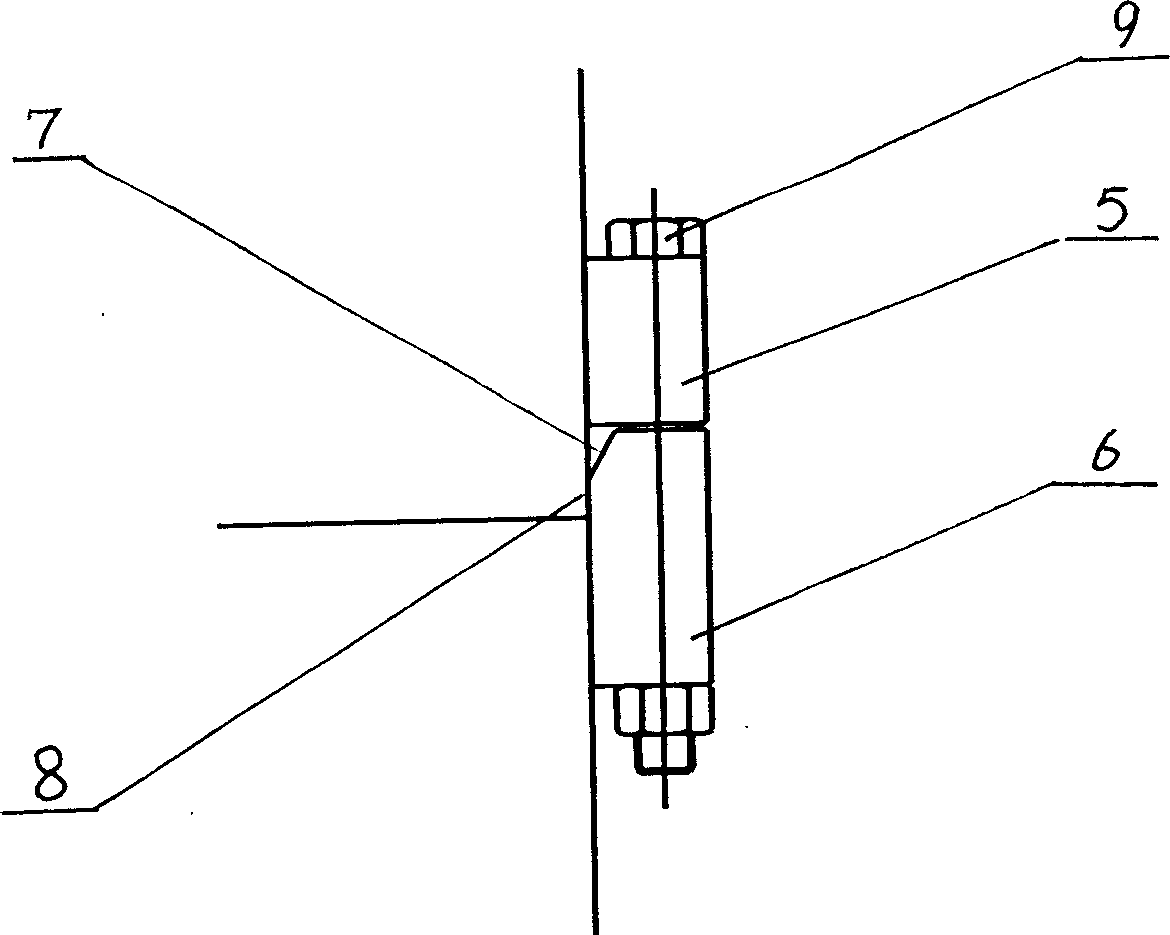

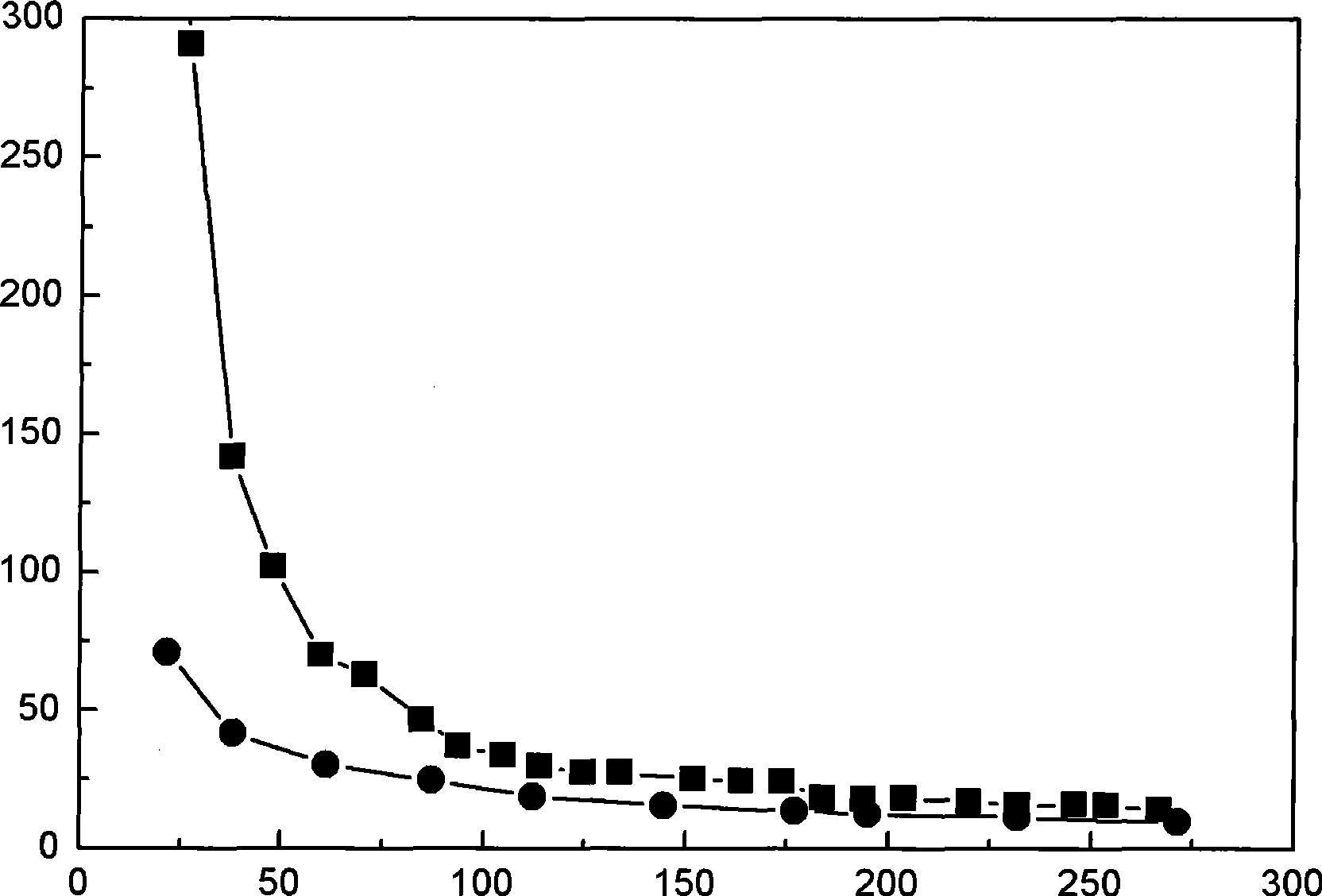

Cast-in-place concrete major-diameter pipe pile body strain monitoring method based on BOTDA

InactiveCN103673911AReduce wiringSimple wiring for constructionMaterial analysis by optical meansUsing optical meansFiberRebar

The invention discloses a cast-in-place concrete major-diameter pipe pile body strain monitoring method based on BOTDA. The cast-in-place concrete major-diameter pipe pile body strain monitoring method is characterized in that a pair of vertical reinforcing steel bars are connected with arc-shaped reinforcing steel bars with arcs which are 1 / 4 of the circumference of a pipe pile to form carrier reinforcing steel bars. Grooves are formed in the carrier reinforcing steel bars, sensor fibers are embedded in the grooves, and the grooves are filled with epoxy resin. The pair of carrier reinforcing steel bars with optical fibers in an embedded mode are embedded in the cast-in-place concrete major-diameter pipe pile. Short pulsed light and continuous probe light are injected from the two ends of the sensor fibers with the BOTDA method, and strain information of points in the axial directions of the sensor fibers is obtained by measuring frequency changes of stimulated brillouin scattering light in the sensor fibers. The cast-in-place concrete major-diameter pipe pile body strain monitoring method has the advantages of being simple in construction wiring, resisting to interference, being high in accuracy and the like.

Owner:HOHAI UNIV

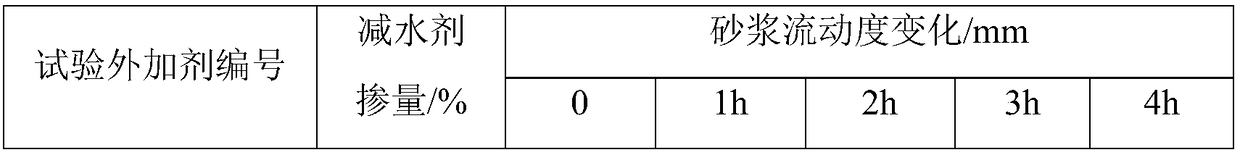

Highly adaptive ultralong-slow release slump-retaining agent and normal and low temperature preparation method thereof

The invention discloses a highly adaptive ultralong-slow release slump-retaining agent and a normal and low temperature preparation method thereof. Mainly, polyether macromonomer, unsaturated carboxylic acid monomer, unsaturated carboxylic ester monomer, unsaturated phosphate ester monomer, unsaturated amide monomer, oxidant, reducing agent, chain transfer agent and deionized water carry out freeradical polymerization by aqueous solution at the temperature of 5-25 DEG C, after sodium hydroxide solution is then added to regulate pH value, water is then replenished, and thereby the slump-retaining agent is prepared. The preparation method does not need a heat source, reaction is carried out under normal and low temperatures, equipment is simple, the operability is high, the production efficiency is high, the prepared slump-retaining agent has ultralong slow release capability, slump can be retained for a long time, the adaptability is high, and the performance is excellent.

Owner:SICHUAN TONGZHOU CHEM TECH

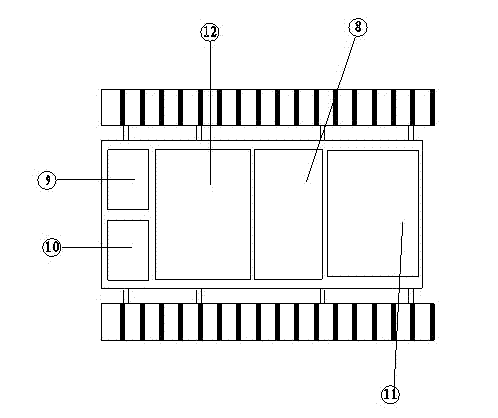

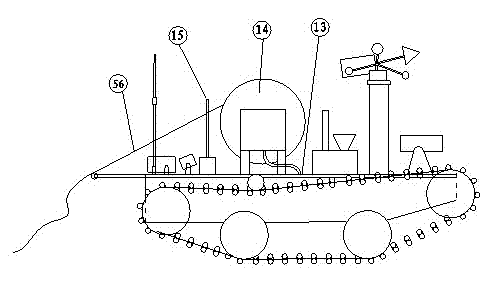

Crawler type walking robot workstation

InactiveCN102211621AHigh strengthDoes not affect strengthTelevision system detailsColor television detailsBrushless motorsProgrammable logic controller

The invention discloses a crawler type walking robot workstation, which belongs to the field of electromechanical integral robots. The crawler type walking robot workstation comprises an upper computer, a main control primary vehicle and multiple controlled secondary vehicles; the main control primary vehicle comprises a vehicle body, a crawler type walking mechanism and a PLC (Programmable Logic Controller). The crawler type walking robot workstation is characterized in that the vehicle bodies of both the main control primary vehicle and the controlled secondary vehicles are closed and inflatable boxes; the crawler type walking mechanism consists of a rubber double-sided toothed crawler, a rear driving wheel, a front guiding wheel, a front bearing wheel, a rear bearing wheel and a tension wheel; a left driving speed regulating rotor and a right driving motor are respectively driven by a storage battery as a power; the PLC is mounted on the main control primary vehicle; and the operation is executed by a speed regulating brushless motor driving module. In the invention, multiple rotor vehicles are combined together according to different functions and coordinate on the whole, thereby forming a robot workstation.

Owner:山西亚佳机电集团有限公司

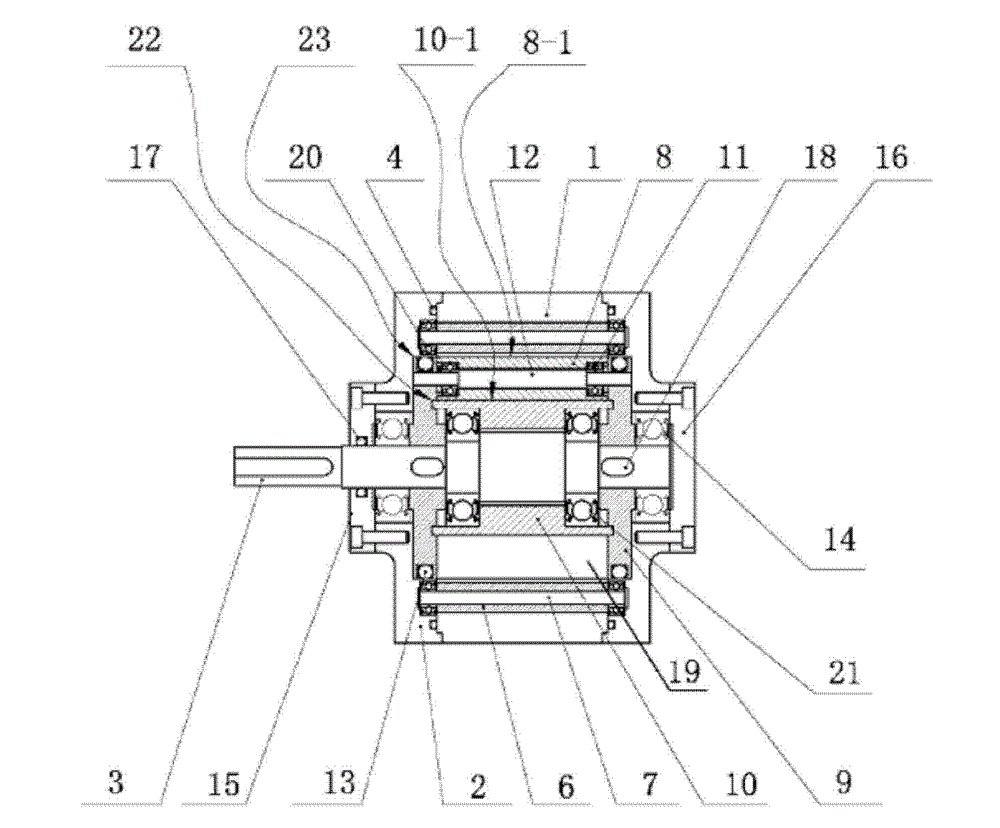

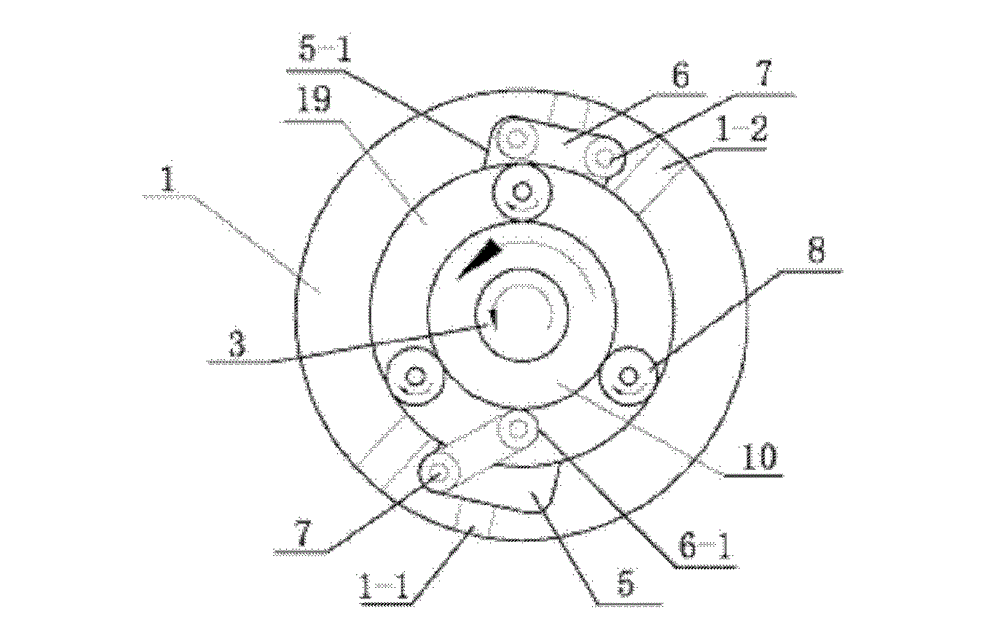

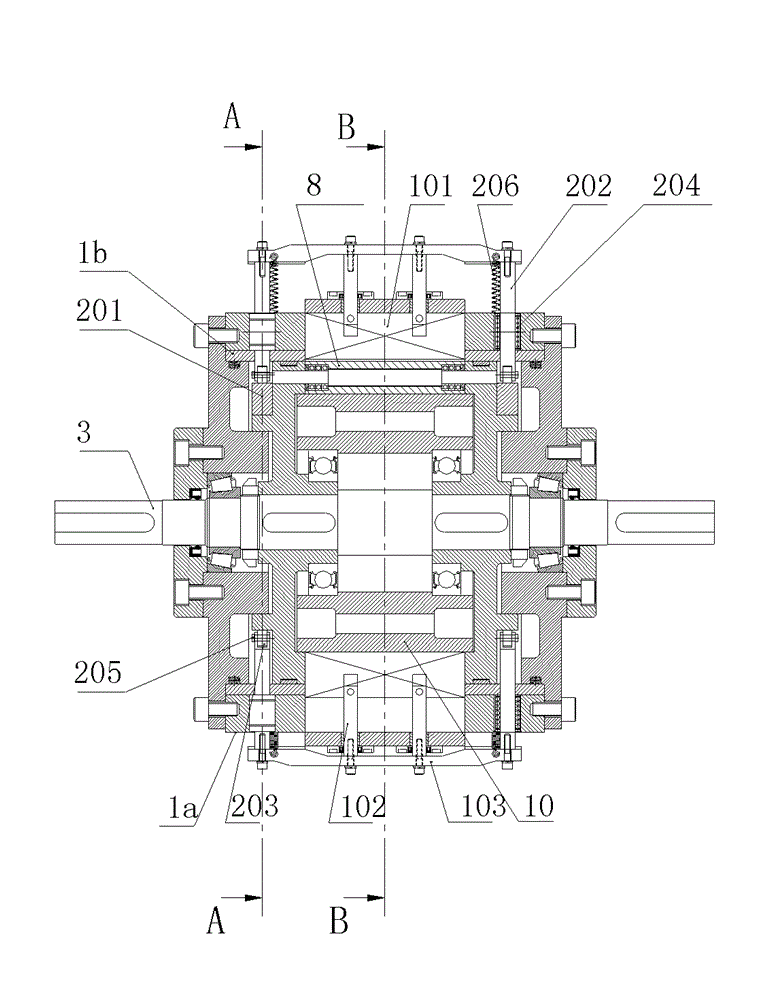

Star-rotation type rotary device adopting gate valve structure

ActiveCN103061822AReduce processing difficultyEasy to processRotary piston pumpsRotary piston liquid enginesEngineeringPiston

The invention discloses a star-rotation type rotary device adopting a gate valve structure. The star-rotation type rotary device comprises a cylinder body and a main shaft, wherein a circular-barrel-shaped cavity is formed in the cylinder body; the main shaft is supported by cylinder body sealing end covers at the two sides of the cylinder body; a centre sun gear roller is sleeved on the main shaft; a gate valve groove is formed on the cylinder body along the centre line direction of the cylinder body; a gate valve plate is arranged in the gate valve groove; the gate valve plate is switched between a withdrawing status and an extending status; an annular piston space is formed by an outer cylindrical surface of the centre sun gear roller and an inner cylindrical surface of the cylinder body; a cylindrical planetary piston wheel is arranged in the annular piston space in a rolling manner; when the gate valve plate is in the withdrawing status, the planetary piston wheel passes through the gate valve plate; and when the gate valve plate is in the extending status, the far end of the gate valve plate contacts the outer cylindrical surface of the centre sun gear roller at the inner side surface of the annular piston space. According to the star-rotation type rotary deice adopting the gate valve structure disclosed by the invention, the difficulty of machining the cylinder body can be reduced, and the integral intensity of the cylinder body is improved.

Owner:BEIJING ROSTAR TECH

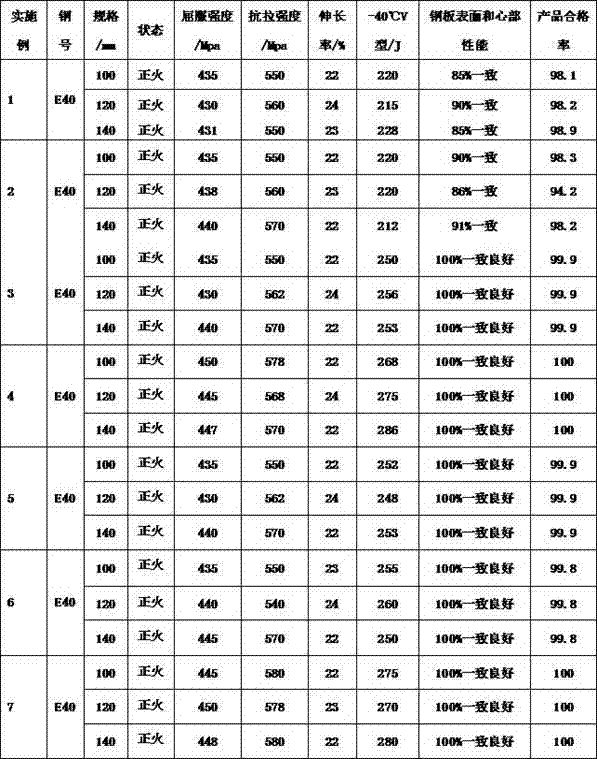

E40 high-strength ship plate steel and method for manufacturing same

The invention discloses E40 high-strength ship plate steel. The E40 high-strength ship plate steel comprises, by mass, from 0.13% to 0.16% of C, from 0.2% to 0.4% of Si, from 1.5% to 1.6% of Mn, lower than or equal to 0.03% of P, lower than or equal to 0.005% of S, from 0.30% to 0.35% of Ni, from 0.055% to 0.065% of V, from 0.035% to 0.045% of Nb, from 0.010% to 0.020% of Ti, from 0.015% to 0.035% of Als and the balance Fe. A method for manufacturing the E40 high-strength ship plate steel includes a pretreatment process for melted iron, a smelting process implemented by the aid of a converter, an argon blowing treatment process, an LF (ladle furnace) refining process, a VD (vacuum degasser) refining process, a continuous casting process, a heating process, a controlled rolling and controlled cooling process, a stack cooling process and a heat treatment process. The E40 high-strength ship plate steel and the method have the advantages that the E40 high-strength steel is successfully developed, the yield strength of the E40 high-strength ship plate steel ranges from 430MPa to 450MPa, the tensile strength of the E40 high-strength ship plate steel ranges from 550MPa to 580MPa, the elongation of the E40 high-strength ship plate steel ranges from 22% to 24%, V-type impact power of the E40 high-strength ship plate steel ranges from 210J to 280J at the temperature of minus 40 DEG C, and performance indexes of a steel plate made of the E40 high-strength ship plate steel completely meet standards and requirements of clients.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

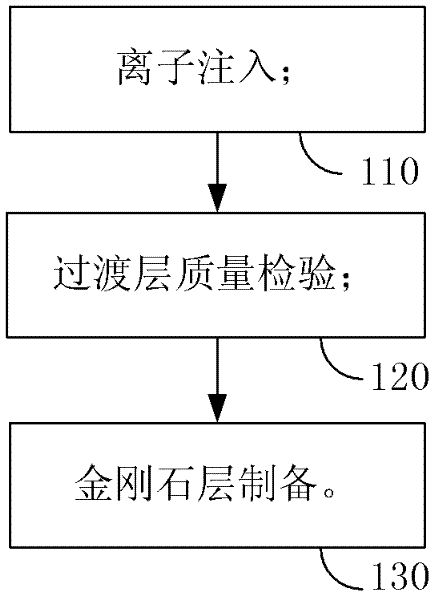

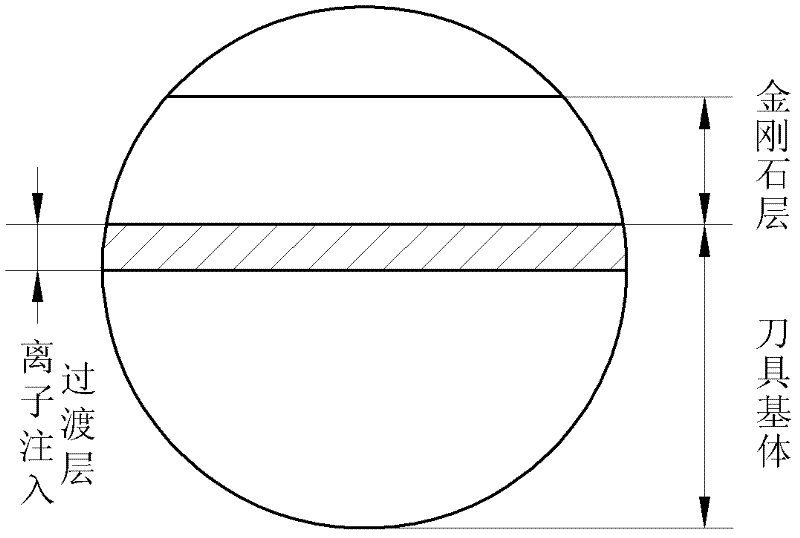

Hard alloy cutter with diamond coating and preparation method thereof

InactiveCN102248187ADoes not affect strengthIntensity will not affectVacuum evaporation coatingSputtering coatingAlloyCemented carbide

The invention discloses a hard alloy cutter with a diamond coating and a preparation method thereof. The cutter comprises a cutter matrix and the diamond coating arranged on the surface of the cutter matrix; and a transitional layer is arranged on the cutter matrix. The preparation method comprises a pretreatment step of the matrix and a diamond depositing step, wherein in the pretreatment step, the transitional layer is formed on the matrix. The cutter can be used for avoiding the adverse influence of a cobalt element on the diamond coating and has the strength of the cutter matrix.

Owner:SHENZHEN JINZHOU PRECISION TECH

Concrete brick containing sludge burning ash residue

The invention discloses a concrete brick containing sludge burning ash residue, the preparation method of which comprises the following steps that: raw materials are uniformly mixed with water to be formed and to be demolded after the moisture is volatized; raw materials comprises 12 to 50 percent of cement, 0 to 30 percent of sand, 0 to 50 percent of stone, 10 to 50 percent of sludge burning ash residue and 0.1 to 0.5 percent of chemical chelating stabilizer (weight ratio); and the chemical chelating stabilizer is of complexone or organic polybasic phosphonic acid. The sludge burning ash residue which is produced in the sewage treatment plant is used for manufacturing the concrete brick, so not only the consumption of other fine aggregates is reduced without reducing the strength, but also the following processing problems of the sludge discharge reduction and sludge burning ash residue are saved, thereby saving the resource and being economical and envionrment-friendly.

Owner:SHANGHAI NORMAL UNIVERSITY +1

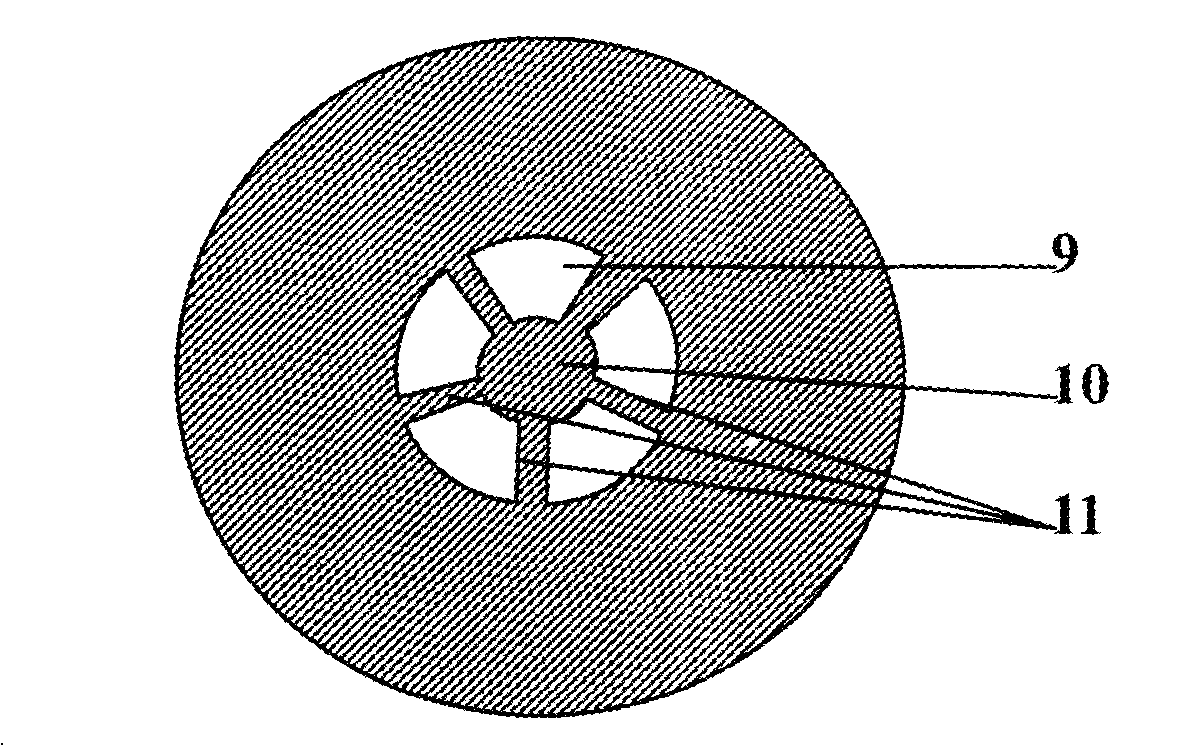

Cylindrical lithium ion cell cap and assembly method

InactiveCN101335335AExtrusion freeDoes not affect strengthVent arrangementsSecondary cellsUltrasonic weldingRechargeable cell

The invention pertains to the technical field of secondary power source (a rechargeable battery) which can be repeatedly used. The technology is applied to a lithium ion battery, in particular to a column-shaped lithium ion battery cap and an assembly method thereof. The cap includes a positive electrode external leading-out terminal, PTC, an anti-explosion aluminum plate, a supporting plate and a conductive vibration damper plate, which are sealed and arranged from top to down in sequence from a sealing ring. A lug is welded under the conductive vibration damper plate which is provided with a soldering pad welded with the anti-explosion aluminum plate. The soldering pad is connected with other parts of the conductive vibration damper plate by bars. The assembly method includes the following steps of: liquid injection, cap ultrasonic welding and sealing; or cap ultrasonic welding, liquid injection and sealing. The method mainly aims at solving technological problems in the existing structure that the vibration of ultrasonic welding causes the break of a solder joint and the failure of a cap; simultaneously, the ultrasonic welding and battery roll core assembly can be used for improving process flow and manufacturing efficiency and reducing equipment investment.

Owner:上海德朗能动力电池有限公司

Device and method for monitoring pile body strain of round solid pile

InactiveCN103759666AImprove survival rateAvoid electromagnetic interferenceForce measurement by measuring optical property variationUsing optical meansTime domainFiber

The invention discloses a device and method for monitoring pile body strain of a round solid pile. The device comprises the round solid pile, a single-mode sensor fiber, a Brillouin time domain analysis meter, glue and epoxy resin, the single-mode sensor fiber is fixed on the surface of the round solid pile through the glue and coated with the epoxy resin, and the Brillouin time domain analysis meter is respectively connected with the two ends of the single-mode sensor fiber. The method includes the steps of enabling the Brillouin time domain analysis meter to be connected to the two ends of the single-mode sensor fiber to form a measurement circuit; collecting initial data of the single-mode sensor fiber; collecting real-time data of the single-mode sensor fiber after the pile body of the round solid pile bears external loads; obtaining a difference of the real-time data and the initial data, wherein the difference is a pile body strain value under the pressure effect; further calculating a deformation value and the stress of the round solid pile according to the pile body strain value of the round solid pile. According to the method, the shortcoming that a traditional strain gage is hard in installation method and not high in rate of survival is overcome, and the distributed continuity monitoring on the pile body strain of the round solid pile is achieved.

Owner:HOHAI UNIV

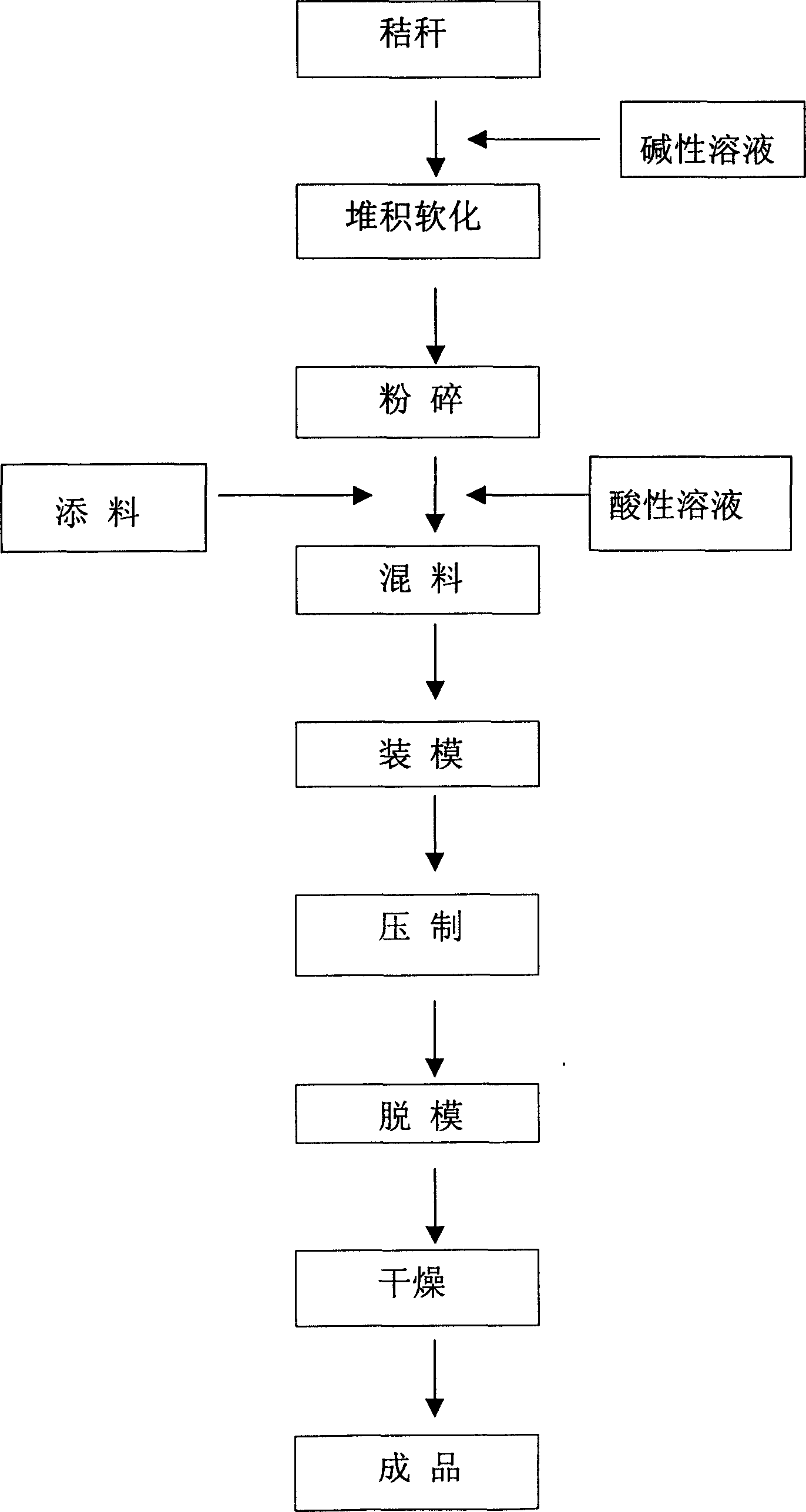

Production method of vegetable stem made pot

InactiveCN1557128AReduce energy consumptionRelieve pressureCultivating equipmentsReceptacle cultivationSeedlingRoot system

The plant stalk pot making process has simple apparatus used, less investment and low cost, and the plant stalk pot is used in cultivating and transplanting seedling and becomes fertilizer for the plant after degradation. The making process includes adopting plant stalk as main material, adding alkali solution to raise pH value to over 9, stocking for softening, crushing, adding acid solution to regulate pH to neutral, mixing with additive, molding, demolding, and drying. The weight ratio among plant stalk, alkali solution, acid solution and additive is 1 to 0.2-0.6 to 0.06-0.2 to 0.02-0.08. The present invention is suitable for cultivating seedling and pot cultivation.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

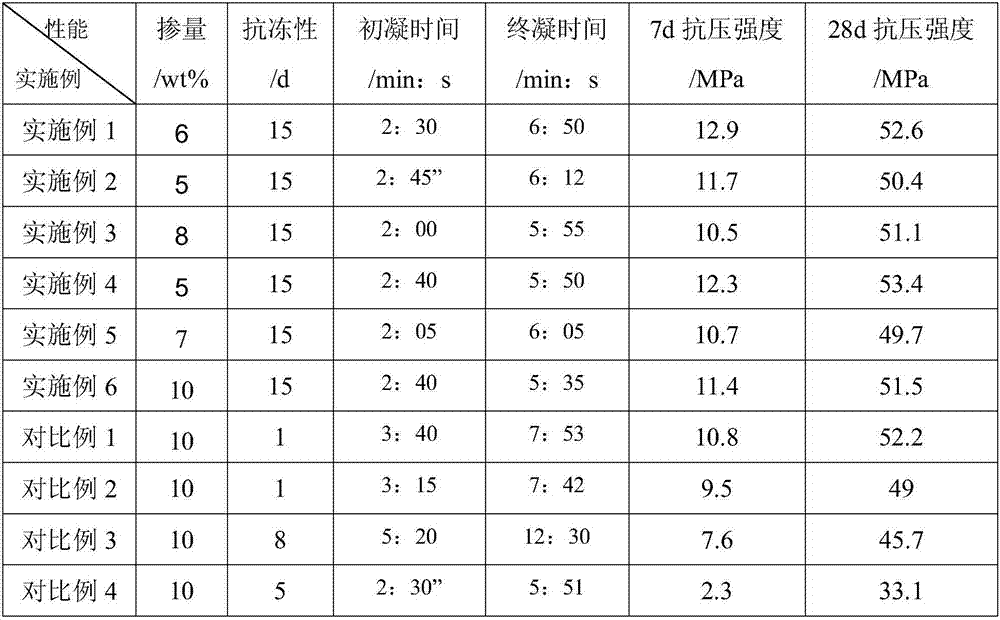

Freezing resistant type alkali-free accelerator, and preparation method and application thereof

The invention discloses a freezing resistant type alkali-free accelerator, and a preparation method and application thereof. The freezing resistant type alkali-free accelerator is prepared by the following steps: aluminum sulfate, an alcohol amine, a fluoride, a stabilizer and water are firstly mixed uniformly to prepare an alkali-free accelerator, and the product is mixed with a freezing resistant liquid containing glycine and soluble starch for reaction, thus the freezing resistant type alkali-free accelerator is obtained. The freezing resistant type alkali-free accelerator has good freezing resistant ability, so that the accelerator can be normally stored and transported in winter, and the freezing resistant type accelerator contains ingredients such as the soluble starch, so that the setting time of the accelerator can be reduced in a synergistic manner, the concrete strength is not influenced, and the practical application of the accelerator is facilitated.

Owner:四川苏博特新材料有限公司 +1

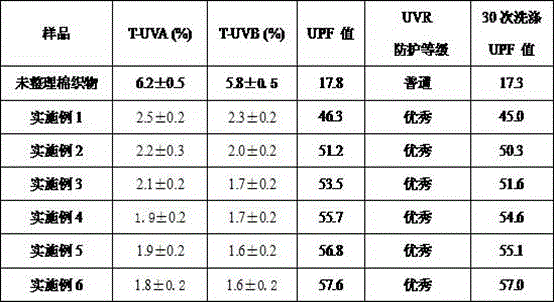

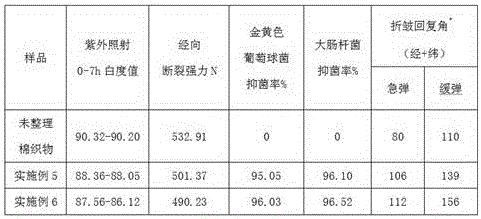

Modified-chitosan-containing anti-ultraviolet finishing agent for cotton fabric and anti-ultraviolet cotton fabric obtained by aid of anti-ultraviolet finishing agent

The invention provides a modified-chitosan-containing anti-ultraviolet finishing agent for cotton fabric and anti-ultraviolet cotton fabric obtained by aid of the anti-ultraviolet finishing agent. The modified-chitosan-containing anti-ultraviolet finishing agent for the cotton fabric is a uniformly mixed solution of 3,4,5-trimethoxybenzoyl chitosan, a crosslinking agent, a penetrant and an acetic acid or lactic acid solution, wherein the crosslinking agent is organic polycarboxylic acid or amino-modified silicone oil emulsion; the penetrant is either JFC or peregal O. The anti-ultraviolet cotton fabric with anti-ultraviolet, anti-bacterial and anti-crease finishing functions is obtained through double-dip double-nip, water washing and drying, the anti-ultraviolet, anti-bacterial and anti-crease finishing functions are high in durability, the cotton fabric still maintains the original style of the fabric after finishing, the hand feel, the strength, the whiteness and the color of the cotton fabric are not affected, and the original human body affinity is maintained; the finishing agent is simple in composition and easy to prepare, and a finishing process is simple and environment-friendly.

Owner:EASTERN LIAONING UNIV

Method for printing multi-component intrinsic flame-retardant fabric

ActiveCN104313924AColor point clearFull colorSucessive textile treatmentsLiquid/gas/vapor treatment of propelled fabricsFiberTextile printer

The invention belongs to the technical field of textile printing and dyeing, and particularly relates to a method for printing multi-component intrinsic flame-retardant fabric. The method comprises the following steps: selecting and matching cloth, pretreating the fabric, performing rotary screen printing, steaming at high temperature, rapidly performing wet steaming, oxidizing, soaping, performing softening and color fixing, and performing steam sanforizing. The invention provides the printing technology and method which can realize clear colorizing points, full color and high printing fastness of multi-component intrinsic flame-retardant printed fabric, do not influence the flame retardance, do not damage flame-retardant fibers, and do not influence the strength; the industrial production and application of the multi-component intrinsic flame-retardant printed fabric are realized; indeed, the multi-component intrinsic flame-retardant printed fabric is popularized and applied.

Owner:SHANDONG WOYUAN NEWFASHIONED FABRIC

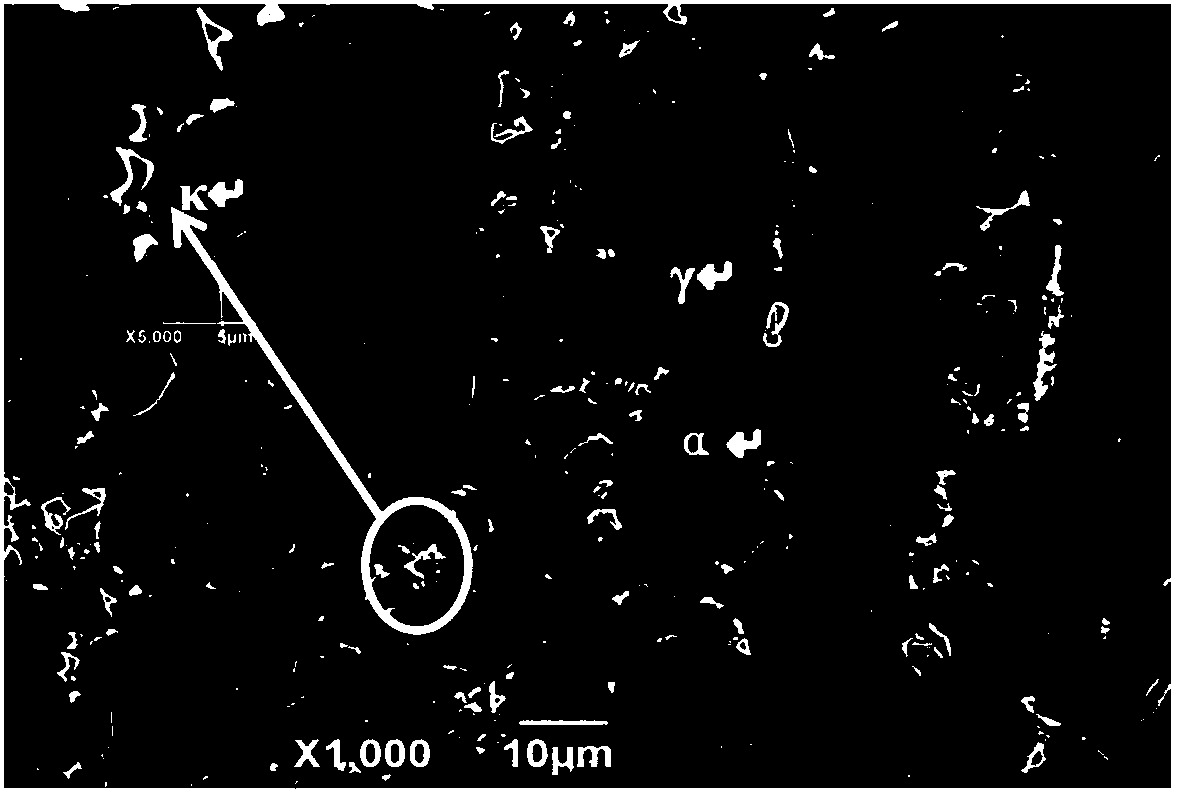

Low-density high manganese steel with high product of strength and elongation

InactiveCN107641763AHigh strengthImprove plasticityProcess efficiency improvementSolution treatmentCarbide

The invention provides low-density high manganese steel with high product of strength and elongation, and belongs to the field of low-density steel. The sum of the mass percents of Mn and Al in low-density steel exceeds 28%. The low-density high manganese steel is prepared through the following steps: smelting, namely, smelting on the basis of the alloy component system; casting; hot rolling, namely, heating a casting blank to be 1150-1250 DEG C; maintaining the temperature; then performing hot rolling at least twice; performing solution treatment, namely, maintaining the temperature of 1000-1100 DEG C of the casting blank, and then quenching; cold rolling, namely, performing cold rolling on the obtained low-density steel at least twice; annealing and then cooling to obtain the low-densitysteel. According to the low-density high manganese steel with high product of strength and elongation, a certain amount of Al is added to the steel, and the alloy component and the processing technology are adjusted, so as to obtain Fe-Mn-Al-C series low-density steel; the low-density steel is of an appearance of an austenite, ferrite and k carbide multi-phase structure, so that the low-density steel is high in strength and high in plasticity.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

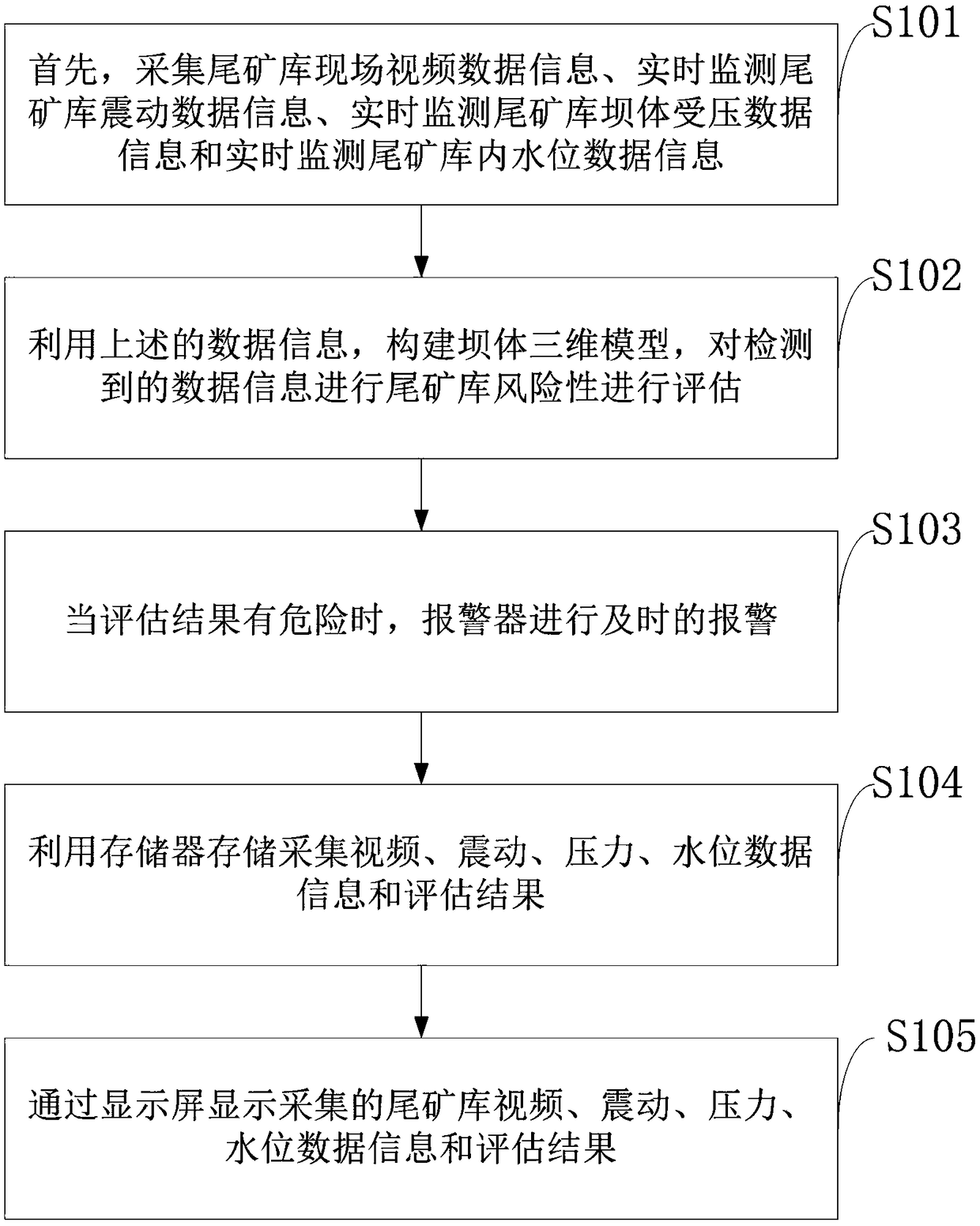

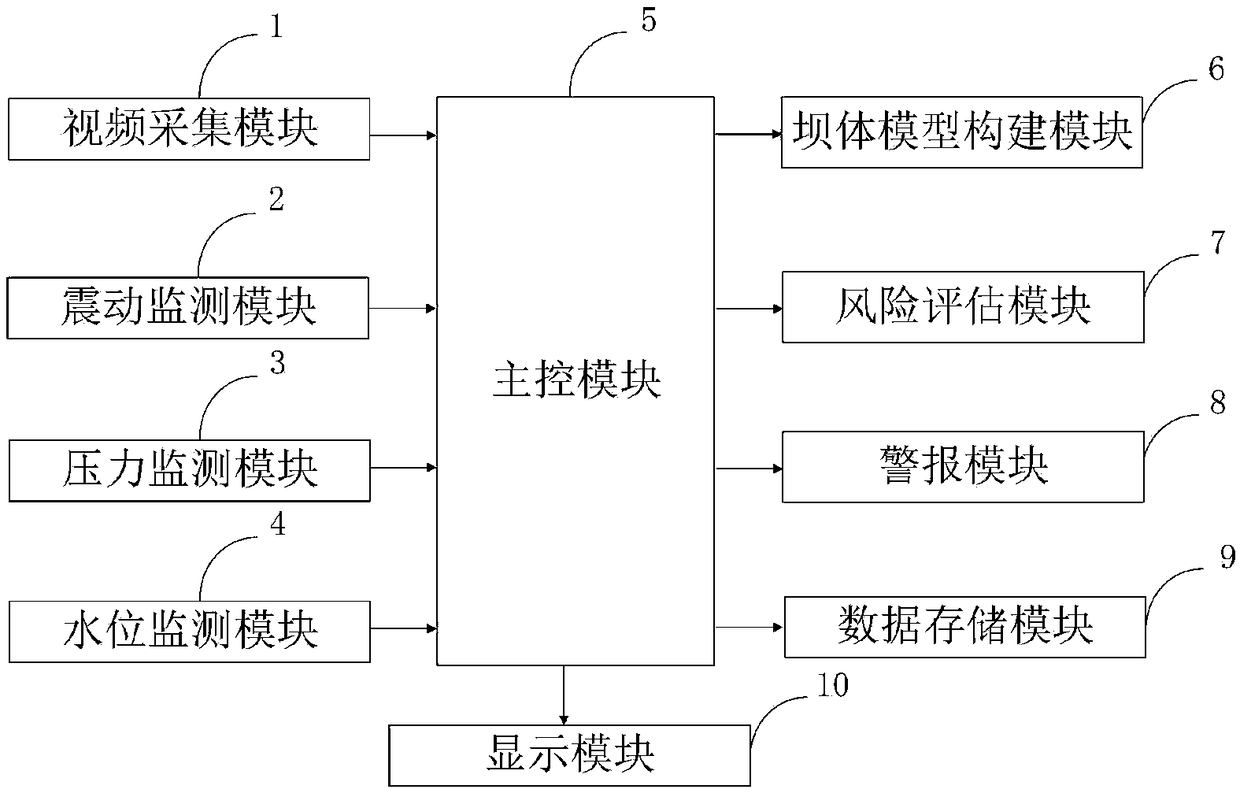

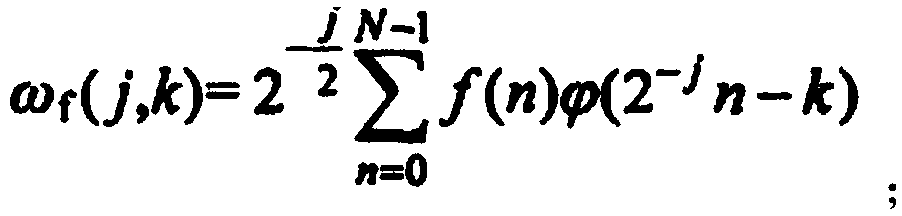

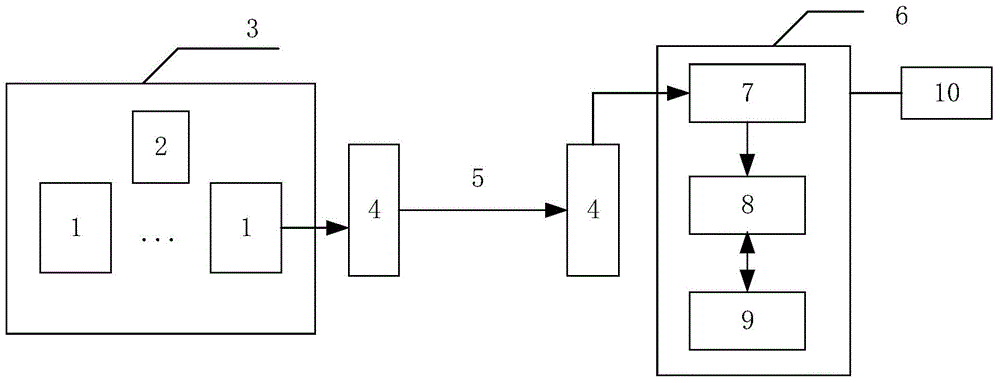

Information-based intelligent control system and control method for safety monitoring of tailing ponds

PendingCN109341778ADoes not affect strengthReduce the impact of stabilityMeasurement devicesCharacter and pattern recognitionInformatizationEngineering

The invention belongs to the technical field of tailing pond monitoring, and discloses an information-based intelligent control system and control method for safety monitoring of tailing ponds. The information-based intelligent control system for safety monitoring of tailing ponds includes a video acquisition module, a vibration monitoring module, a pressure monitoring module, a water level monitoring module, a main control module, a dam body model building module, a risk assessment module, an alarm module, a data storage module and a display module. The shape and distribution characteristicsof the saturation line in model test can be controlled through the dam body model building module, so that the similarity between an experimental dam body model and an actual dam body can be improved,and the accuracy of the experiment can be improved. Meanwhile, through the risk assessment module, the safety status of a tailing pond can be evaluated based on historical data, and moreover, spatialinformation can be increased to further refine the tailing pond evaluation system, and real-time warning and risk investigation can be carried out for tailing ponds to contain disasters in the bud.

Owner:QUANZHOU INST OF EQUIP MFG

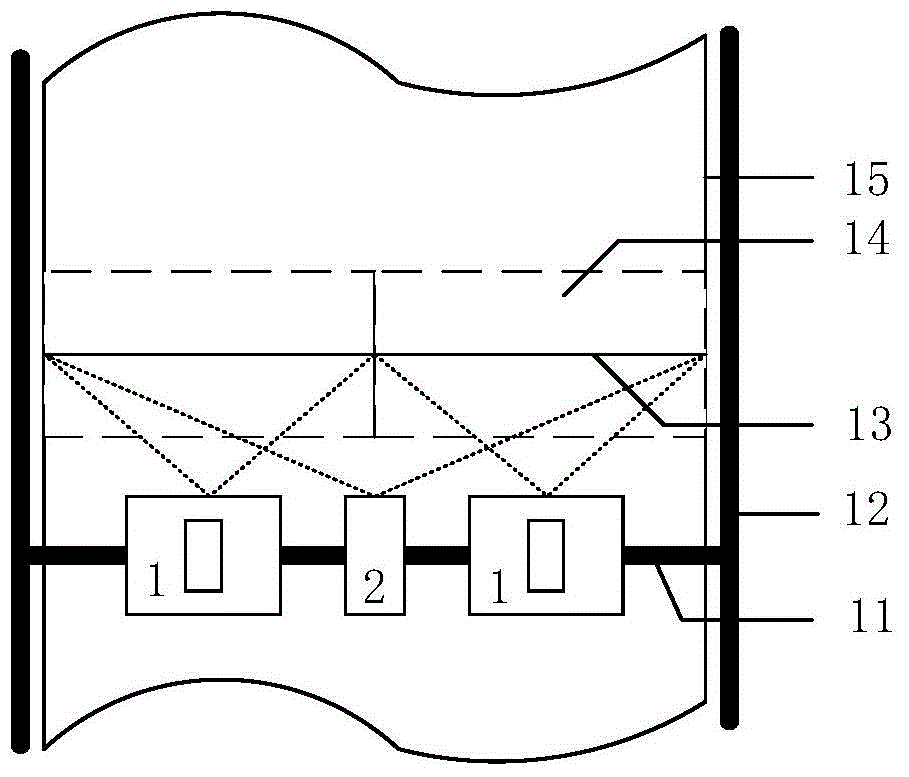

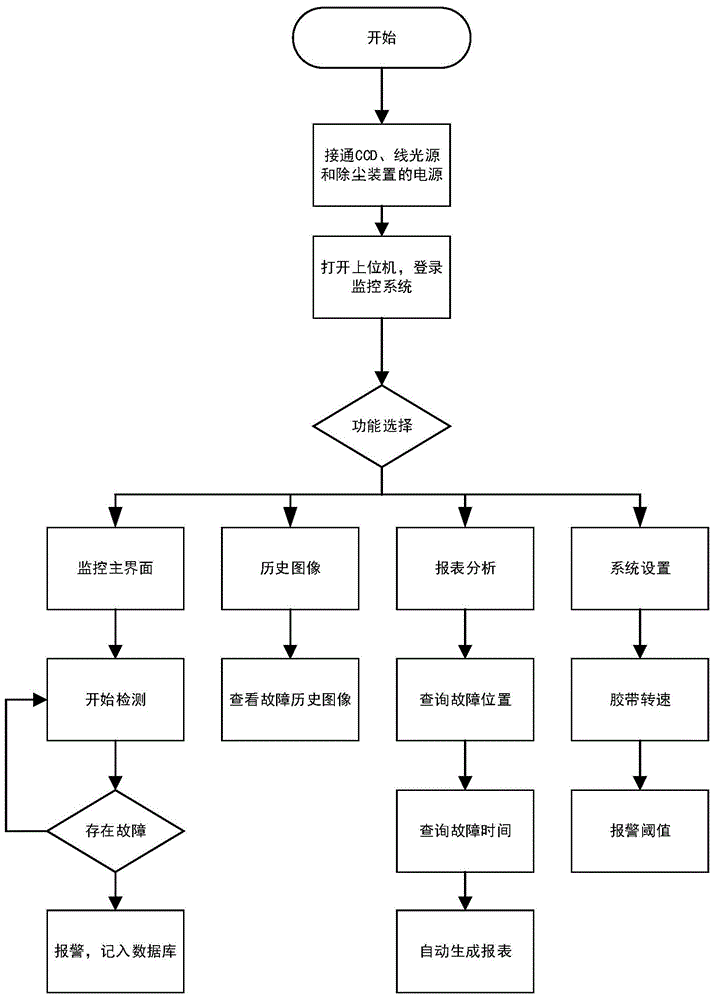

On-line monitoring system for mining adhesive tape operation condition based on machine vision

InactiveCN104792796ADoes not affect strengthEasy to monitor and manageMaterial analysis by optical meansUsing optical meansMachine visionMonitoring system

The invention discloses an on-line monitoring system for the mining adhesive tape operation condition based on machine vision, and belongs to the technical field of coal mining equipment on-line testing. The system is characterized in that an industrial CCD sensor is adopted to be matched with a laser line source to collect feature information of a mining adhesive tape image, the feature information of the mining adhesive tape image is positioned by a non-contact speed sensor, data of tine features in the dark is amplified by the laser line source through the effect of brightness contrast, and the feature information of abnormal points on the mining adhesive tape are effectively, accurately and quickly captured and analyzed, so that the longitudinal tearing, scratching, abrasion, deviation and the like of the mining adhesive tape can be subjected to on-line monitoring.

Owner:TAIYUAN UNIV OF TECH

Vacuum infusion process capable of producing wind turbine blade samples

InactiveCN101767458AAnalytical mechanical propertiesDoes not affect strengthDomestic articlesEpoxyGlass fiber

The invention relates to a vacuum infusion process capable of producing wind turbine blade samples, which comprises: cleaning the upper half blade mound and the lower half blade mould, applying release agent, and orderly laying a glass fiber layer, bamboo and PVC foam in the lower layer, and a glass fiber layer and a release material layer in the upper layer; laying a sample glass fiber layer on the release material layer; evenly laying release cloth, vacuum membrane and the like on the sample glass fiber layer to form a forming chamber; form a finished upper half blade and a finished lower half blade after vacuum pumping, pressure maintaining, epoxy resin infusion and taking out samples after curing; and heating, curing, cooling and lifting the upper half blade mound and the lower half blade mould. The vacuum infusion process can provide the traceable basis for technicians and quality inspectors; the mechanical properties of the blade can be analyzed under the premise of not damaging finished blades, and the tests for the properties of the blade samples are only needed; and the difficulty of material selection and testing is lowered, but the strength properties of the blades are not influenced; and the test results can present the true properties of the blades.

Owner:无锡天奇竹风科技有限公司

Specially shaped wood fiber molded product enclosed forming method

InactiveCN103737699AImprove thermal conductivityQuality improvementWood working apparatusDomestic articlesCompression moldingTO-18

The invention discloses a specially shaped wood fiber molded product enclosed forming method. The method sequentially includes processes of drying, blending, mat formation, pre-pressing and hot press molding. By means of the method, the moisture content of wood fibers is kept in 8% to 18%, during hot press molding, the temperature is controlled between 95 DEG C to 130 DEG C, the hot-press pressure is controlled between 30kg / cm2 to 110kg / cm2, and the hot-pressing time is controlled between 2.5 minutes to 28 minutes. According to the method, the moisture content in the wood fibers is increased so as to increase heat transfer rate in products, the time consumed by a heated object core layer which reaches curing temperature in a glue process is shortened, the producing efficiency is increased, moreover, the heating temperature is properly lowered so as to eliminate phenomena of product layering and surface bulging in the compression molding process, and qualities of wood fiber molded products are improved.

Owner:宁波新缅新材料研发有限公司

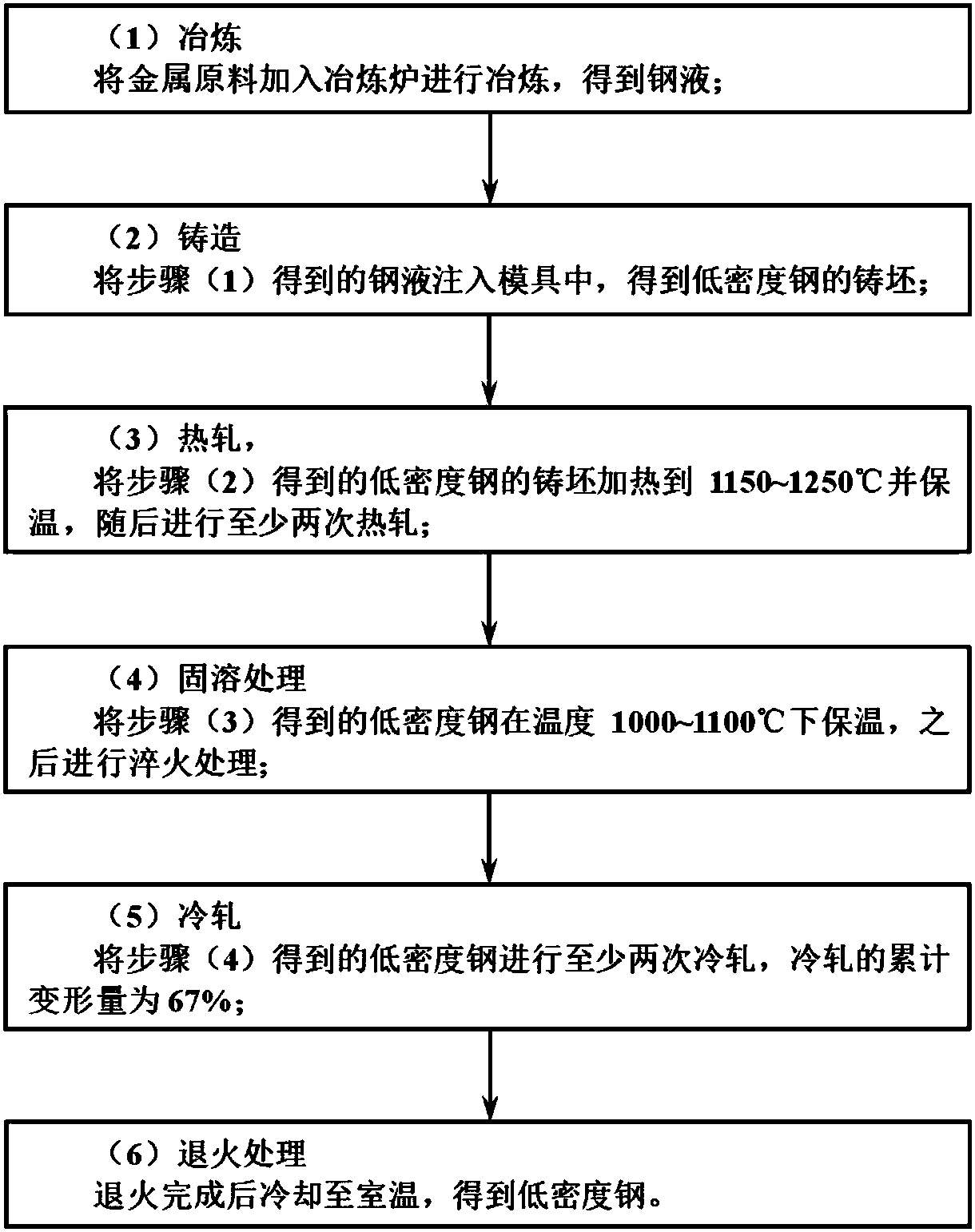

Preparation method for low-density steel with strength and elongation product larger than 50 GPa.%

The invention relates to a preparation method for low-density steel with the strength and elongation product larger than 50 GPa.%, and belongs to the field of low-density steel. The preparation methodincludes the following steps of smelting, specifically, raw materials are put into a smelting furnace for smelting; casting, specifically, obtained molten steel is poured into a mold, and low-densitysteel ingots are obtained after cooling; hot rolling, specifically, the obtained low-density steel ingots are heated to 1150-1250 DEG C, heat preservation is carried out, and then at least two timesof hot rolling are carried out; solution treatment, specifically, the obtained low-density steel is subjected to heat preservation at the temperature of 1000-1100 DEG C, and quenching treatment is carried out; cold rolling, specifically, the obtained low-density steel is subjected to at least two times of cold rolling; and cooling after annealing treatment. In this way, the low-density steel is obtained. Through regulation of alloy elements and the machining process, the Fe-Mn-Al-C system low-density steel is obtained, and the morphology of the low-density steel is of a multi-phase structure including austenite, ferrite and kappa carbide, so that the low-density steel has high strength and good plasticity, and the strength and elongation product is larger than 50 GPa.%.

Owner:马鞍山学院

Wicker product anti-pest and anti-mildew method capable of enhancing wicker knitting capacity

InactiveCN106003333ALoose organizational structureLow ash contentWood treatment detailsCane mechanical workingHigh humidityEngineering

The invention discloses a wicker product anti-pest and anti-mildew method capable of enhancing wicker knitting capacity. The method includes the following steps of (1) wicker peeling, (2) softening treatment, (3) wicker knitting and (4) anti-pest and anti-mildew treatment. By the adoption of the method, all the steps are matched scientifically and reasonably, and wicker products manufactured are good in anti-pest and anti-mildew effect. Compared with the prior art, the service life under the conventional using condition can be prolonged by about 20%, and the service life under the high-humidity condition can be prolonged by over 50%. Moreover, using stability is good, anti-deformation capacity is high, and the use value is good.

Owner:阜南县猛发工艺品有限公司

Vibrating piling-hammer sink-pull steel protective-cylinder piling method and special steel protective cylinder

This invention discloses a method for piling including 1, sinking a steel fender drum, 2, holing, 3, pulling up the steel fender drum. After the concrete is filled, a vibration hummer is used to pull the steel fender up first and then stops working when a hoist can pull up the steel fender directly. This invented fender drum is composed of at least two sections of drum units, connection ears are distributed on the outside walls of both ends and those on the two adjacent units are symmetric and connected by bolts.

Owner:HEBEI CONSTR & INVESTIGATION RES INST

Metal double polar plates of polymer electrolyte film fuel cell and method of manufacturing the same

InactiveCN101369667AImprove corrosion resistanceGood electrical conductivity and corrosion resistanceCell electrodesFinal product manufacturePlasma nitridationVoltage

A metal bipolar plate of a polymer electrolyte membrane battery and manufacturing method thereof, being manufactured via plasma nitridation process on pure titanium or titanium alloy plate with thickness of 0.1 to 3.0mm, comprising: in-furnace nitriding temperature is 400 to 500 centigrade, nitriding time is 0.5 to 30 hours, glow voltage for heat preservation is 500V to 700V, current density is 0.5 to 15mA / cm2, in-furnace vacuum temperature is 133Pa to 1330Pa, reaction gas is ammonia gas or mixed gas of nitrogen-hydrogen. The surface thickness of the product is a titanium nitride with thickness of 1 to 50mum(TiN and / or Ti2N). After plasma nitride membrane process, interface contact resistance is apparently reduced, little greater than graphite, passivation current density is less than 10muA / cm2. The surface according to the invention is thin metal bipolar plate of titanium nitride, capable of increasing mass ratio power and volume ratio power of battery banks.

Owner:DALIAN JIAOTONG UNIVERSITY

Low temperature resistant triple coextrusion composite film and preparation method thereof

ActiveCN101927591AImprove low temperature resistance and freeze resistanceLow temperature flexibilitySynthetic resin layered productsComposite filmMass ratio

The invention discloses a low temperature resistant triple coextrusion composite film and a preparation method thereof. The composite film in the invention is formed through carrying out triple coextrusion by a casting machine, and comprises an outer layer, a middle layer and an inner layer which are composited together; the materials of the middle layer adopt metallocene low-density linear polyethylene and polypropylene at the mass ratio of 1:10-1:1; and the melt index of the metallocene low-density linear polyethylene is 1-3.5. After the scheme is adopted, compared with the traditional CPP film, the low temperature resistant triple coextrusion composite film of the invention has the advantages of greatly improving the low temperature resistant and freezing resistance performance, being capable of being normally used under the environment of minus 30 DEG C, having no influence on the barrier property and strength thereof and being particularly suitable for packaging of quick frozen products such as boiled dumplings, sweet soup balls and the like.

Owner:KAIDA GRP CO LTD FJ

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com