On-line monitoring system for mining adhesive tape operation condition based on machine vision

A technology of machine vision and operating conditions, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of inability to realize online monitoring, real-time scratching, and low sensitivity, so as to facilitate human monitoring and management, avoid accident expansion, The effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

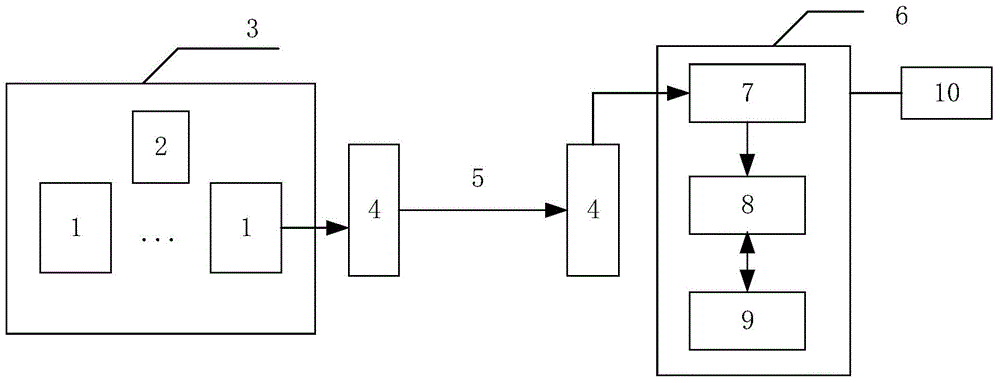

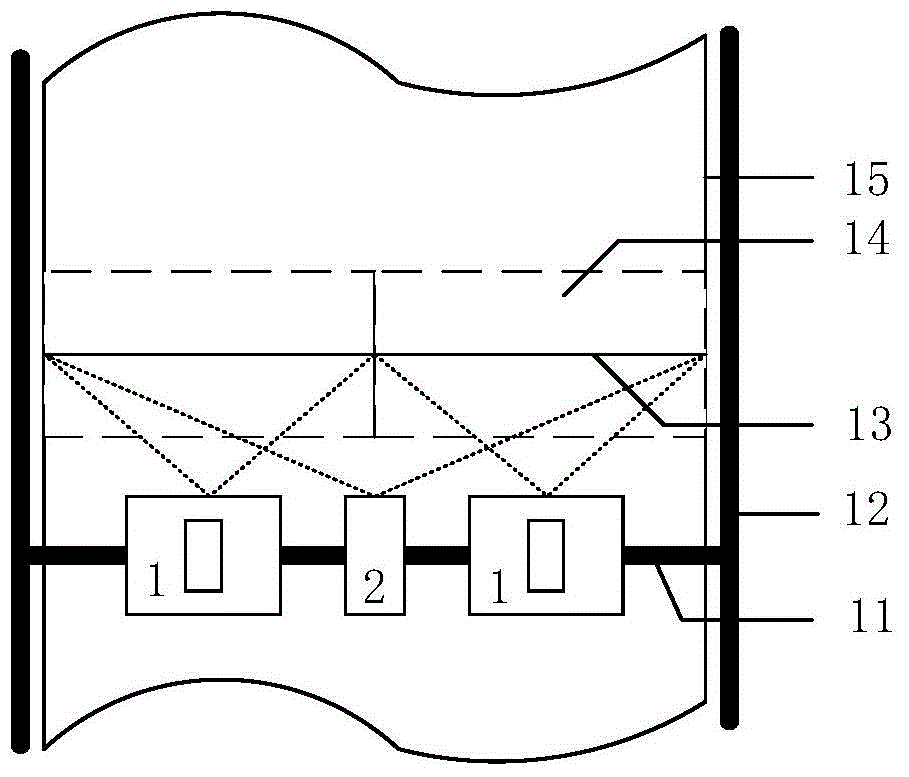

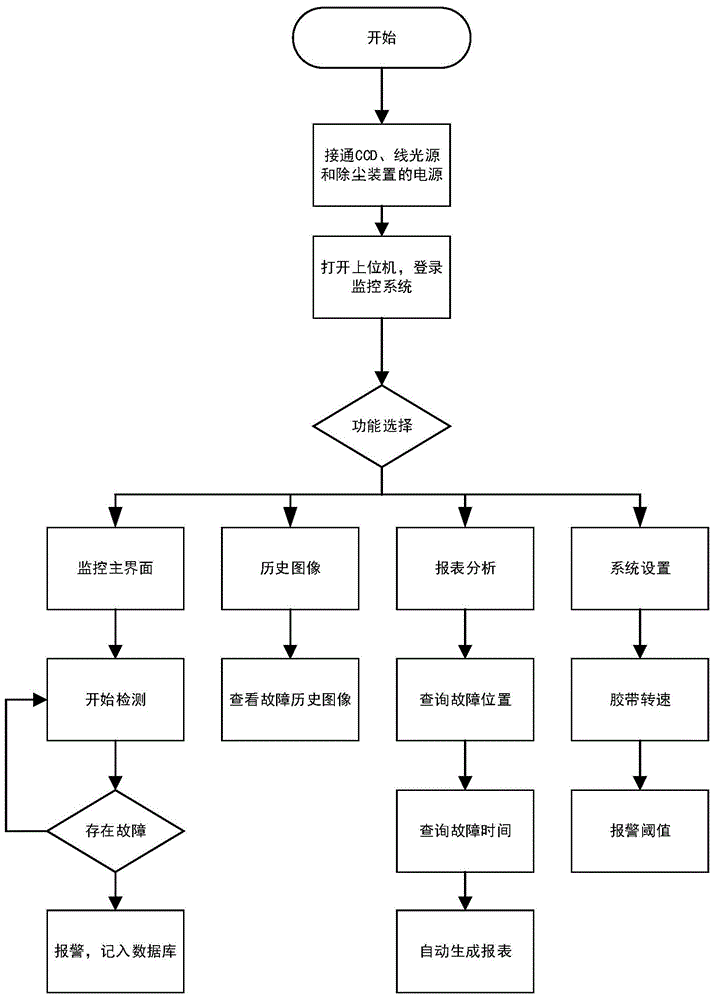

[0037] Such as figure 1 As shown, the online monitoring system for mining belt operation based on machine vision is mainly composed of industrial CCD sensor 1, laser line light source 2, dust removal device 3, optical fiber converter 4, optical fiber 5, host computer 6, video acquisition card 7, monitoring Software 8, database 9, sound and light alarm device 10 and bracket 11. Dust removal device 3 includes tempered glass roller and wiper. Industrial CCD sensor 1 and laser line light source 2 are installed in the tempered glass roller. According to the tape width of 1.2 meters, select Two industrial CCD sensors are installed side by side in the tempered glass drum, and the dust removal device 3 including the industrial CCD sensor 1 and the laser line light source 2 is installed on the large frame under the mining tape through the bracket 11. The width of the bracket 11 is adjustable. The maximum 180cm telescopic rod is used to install the dust removal device 3 containing the i...

Embodiment approach 2

[0054] The dedusting device 3 that will contain industrial CCD sensor 1, laser line light source 2 is installed on the plane with the 40cm screw rod by support 11 on the mining tape frame that is 45cm away from the mining tape lower surface. Others are the same as Embodiment 1.

Embodiment approach 3

[0056] With the 40cm screw rod, the dedusting device 3 containing the industrial CCD sensor 1 and the laser line light source 2 is installed on the mining tape frame that is positioned at a distance of 55 cm from the lower surface of the mining tape by the support 11. Others are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com