Patents

Literature

48results about How to "Low temperature flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-staged binder for use in elastomeric coatings, caulks and sealants

InactiveUS6060532ALower Level RequirementsLow temperature flexibilityImpression capsOther chemical processesElastomerEmulsion

A method for using a thermoplastic elastomeric composition which contains a multi-staged emulsion polymer binder is provided. An elastomeric composition which contains a multi-staged emulsion polymer binder and a photosensitive composition and a method for using the elastomeric composition in elastomeric coatings, caulks, or sealants is also provided.

Owner:ROHM & HAAS CO

Filled thermoplastic olefin composition

InactiveUS20050032959A1Improve balanceGood physical propertiesOther chemical processesPigment pastesPolymer sciencePolypropylene

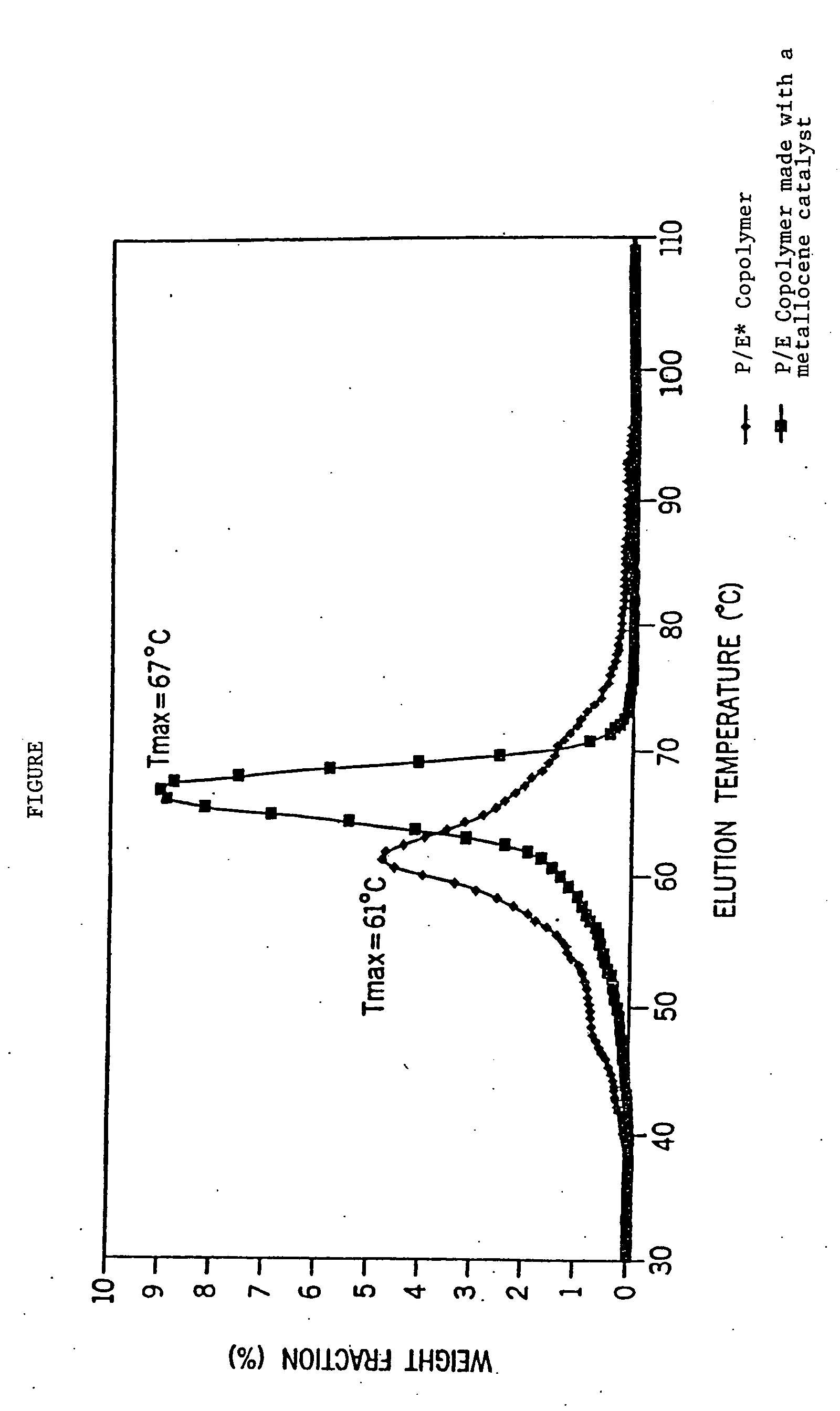

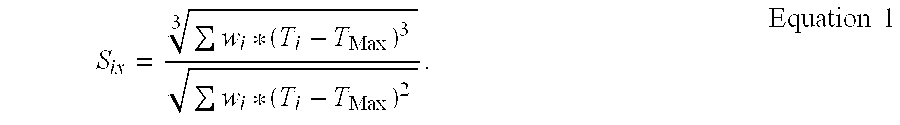

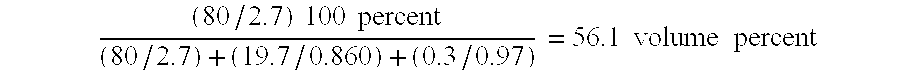

A filled thermoplastic olefin composition comprising (a) a first polypropylene having (i) substantially isotactic propylene sequences, (ii) a narrow molecular weight distribution, and (iii) a broad composition distribution, and (b) at least about 20 percent by volume filler based on the total volume of the composition. Optionally, the composition can comprise a second polypropylene different for the first polypropylene, both polypropylenes preferably propylene / α-olefin copolymers. The filler can be organic or inorganic, and the compositions are useful as, among other applications, protective coverings for wire and cable.

Owner:CHEUNG YUNWA WILSON +2

Plasticized polyvinyl chloride composition with flame retardant

InactiveUS20120142839A1Low temperature flexibilityEase the temperatureCoatingsPolyvinyl chloridePliability

A highly flame retardant plasticized polyvinyl chloride composition includes a mixture of a dialkyl or dialkenyl tetrahalophthalate and a brominated / chlorinated paraffin. The composition exhibits an absence of brittleness, and substantial flexibility at low temperatures. The composition can be used to form sheet materials, molding compositions, roofing materials, PVC formed jackets and insulation for wire and cable products.

Owner:LENKSESS CORP

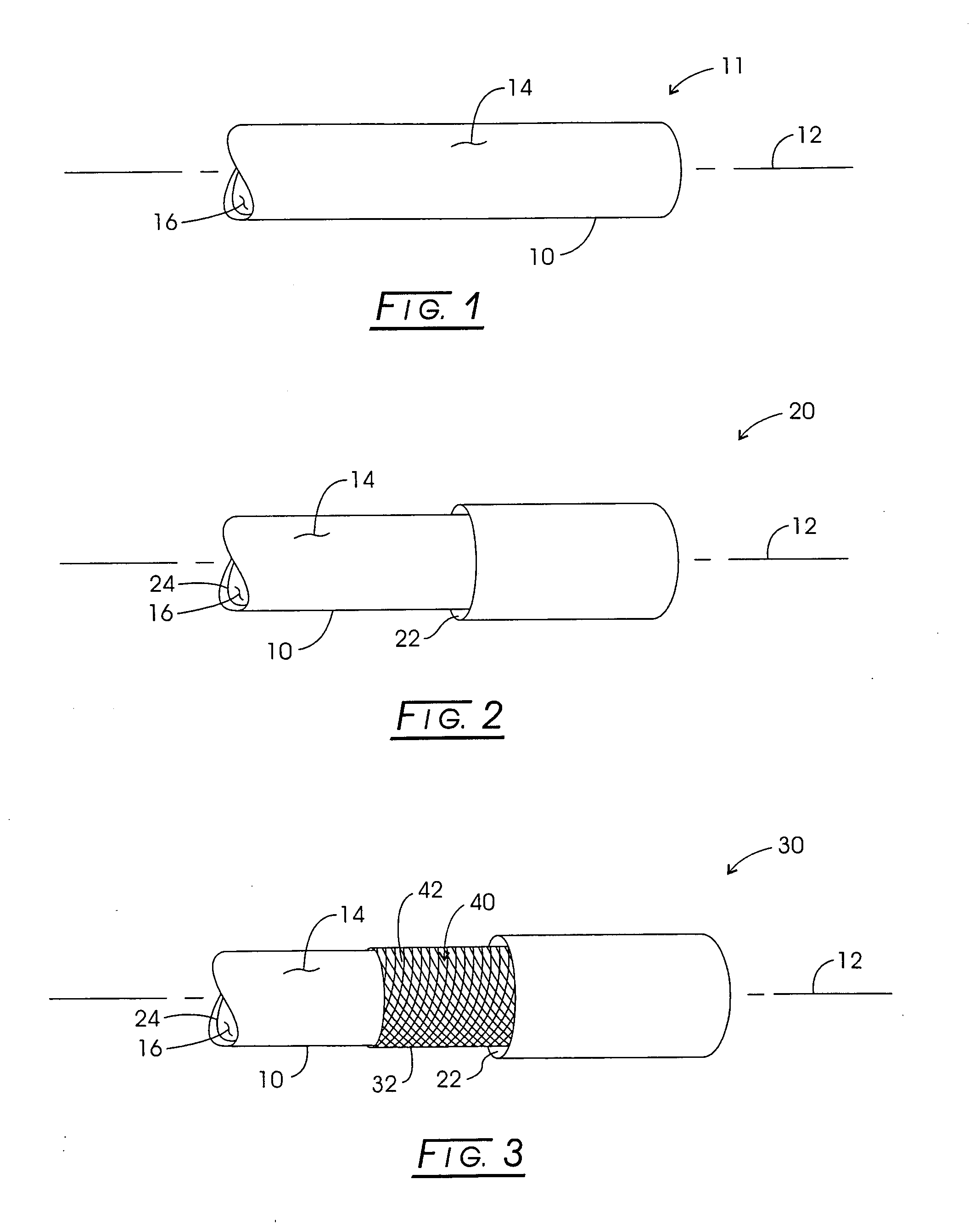

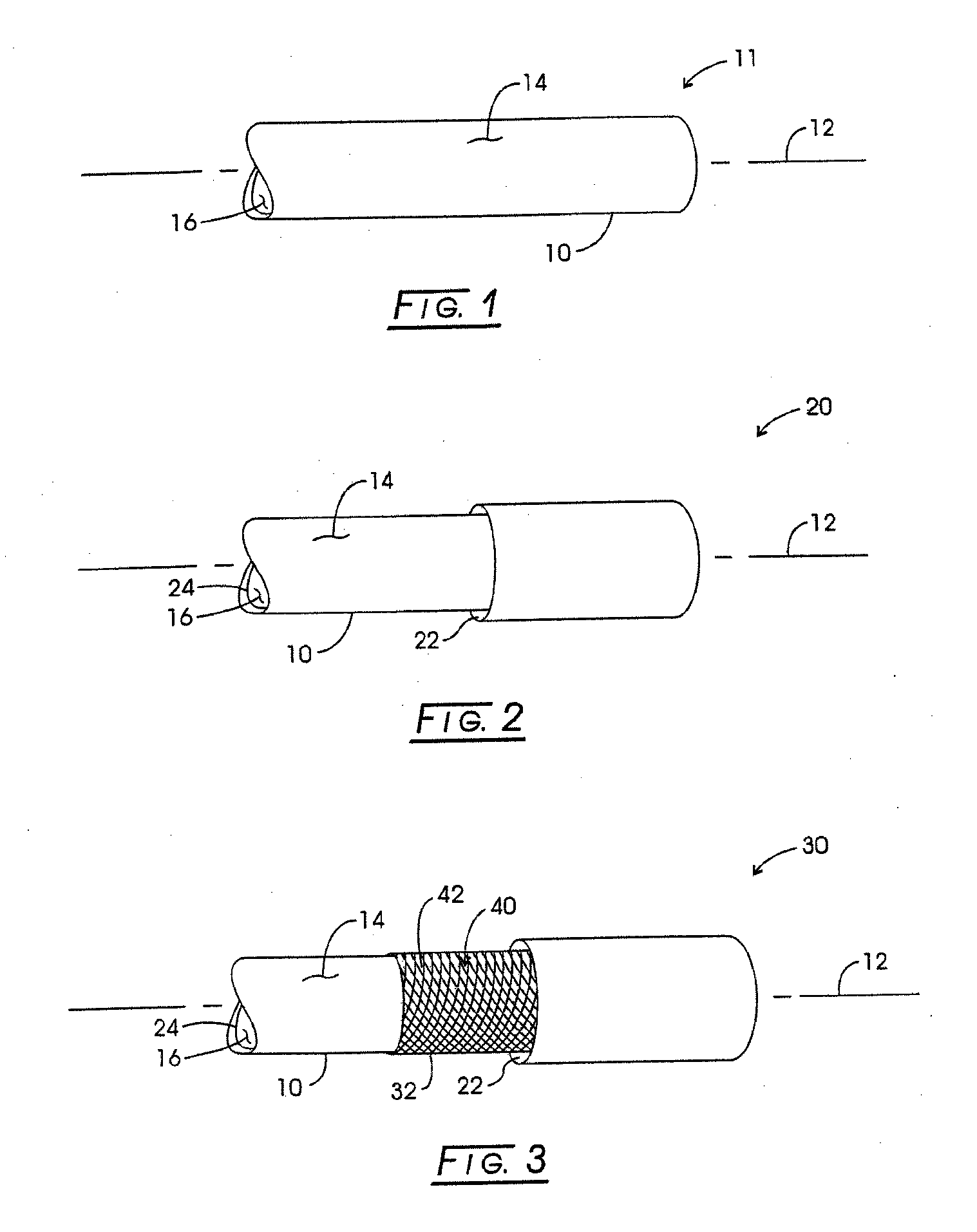

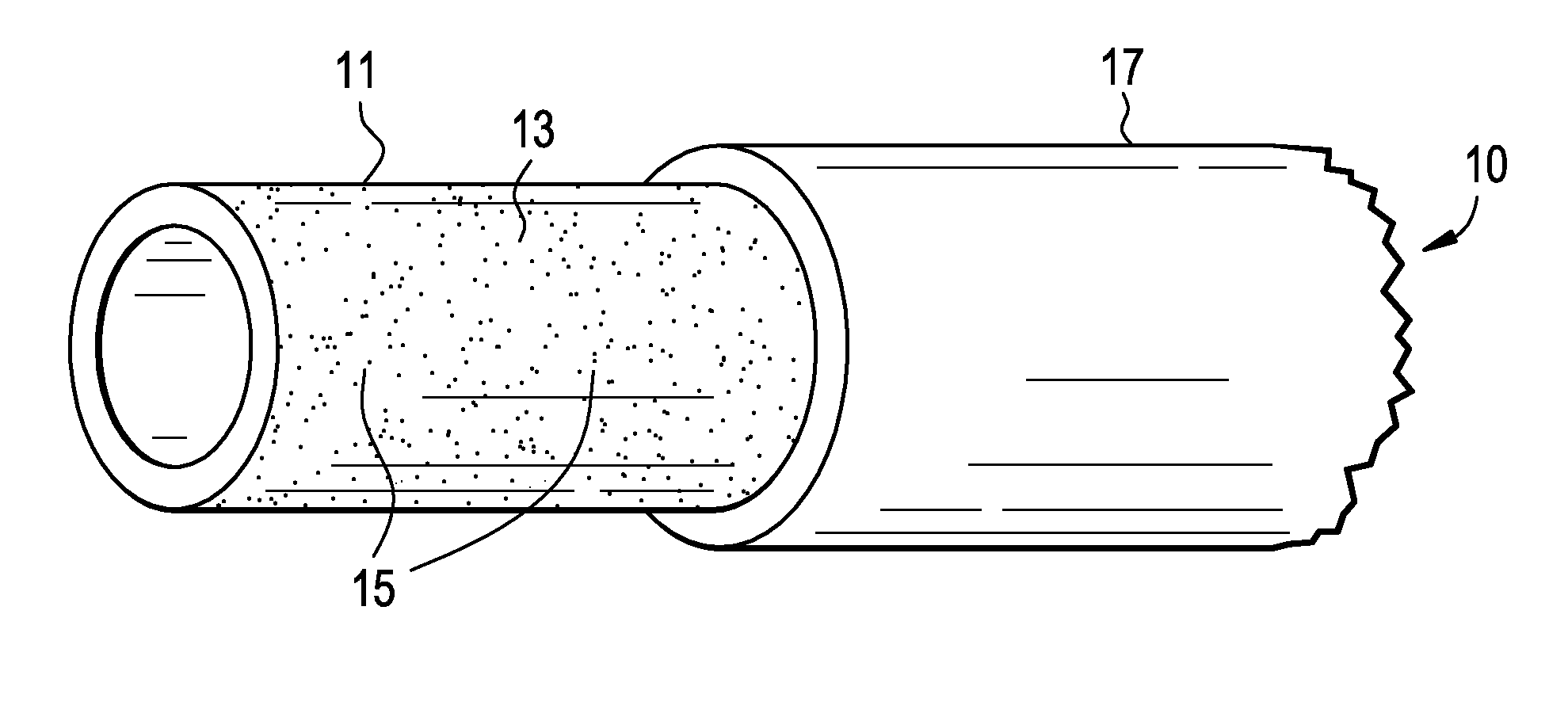

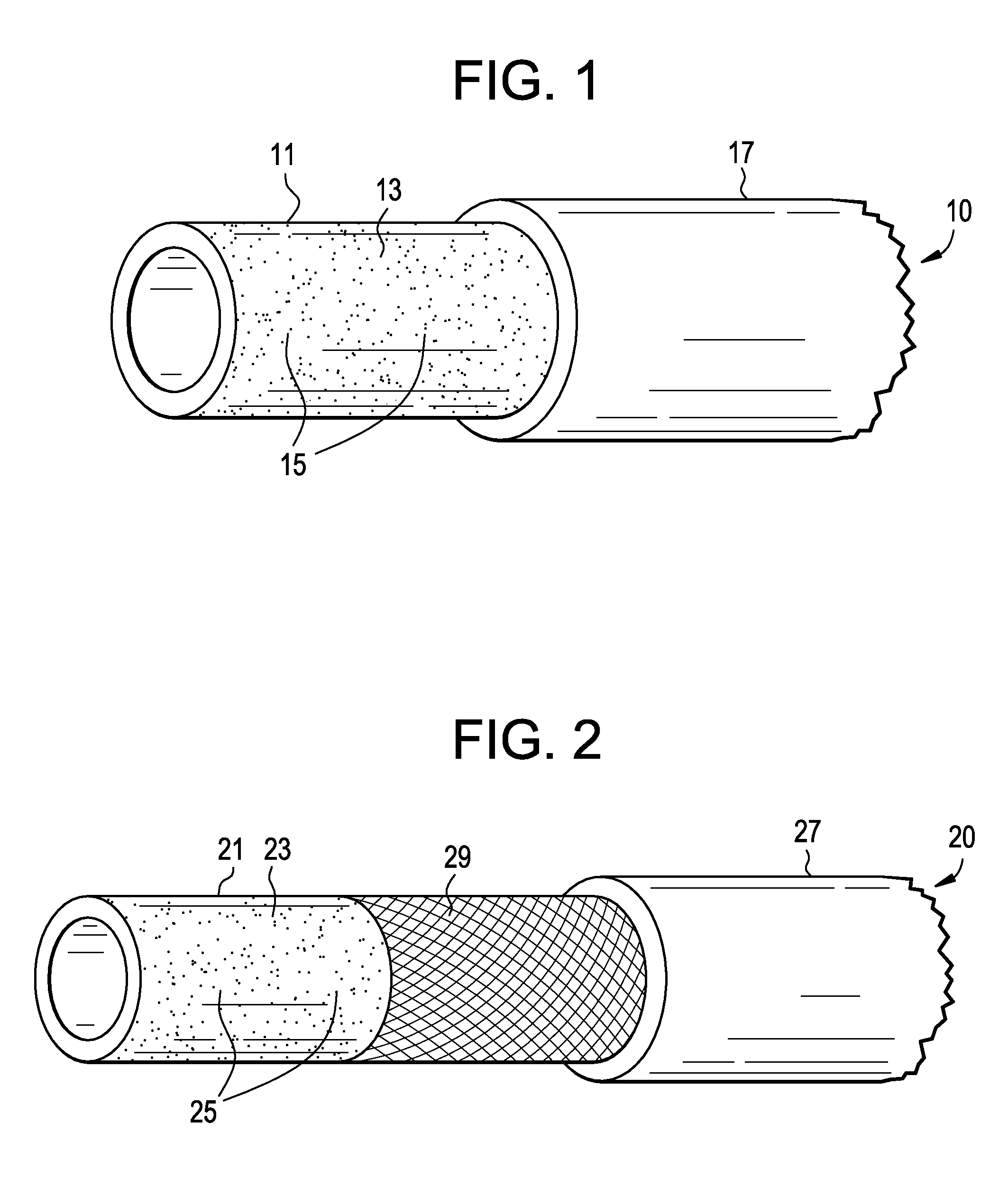

Tubular nylon alloy members for tubing and hose constructions

InactiveUS20060280889A1Easy to installReduces migratory extrudationSynthetic resin layered productsFlexible pipesPolyolefinPolyamide

Tubular polymeric member for articles such as tubing and hoses. The member is formed of an alloy which is a blend of a polyamide and a polyolefin, and a compatibilizing copolymer.

Owner:PARKER HANNIFIN CORP

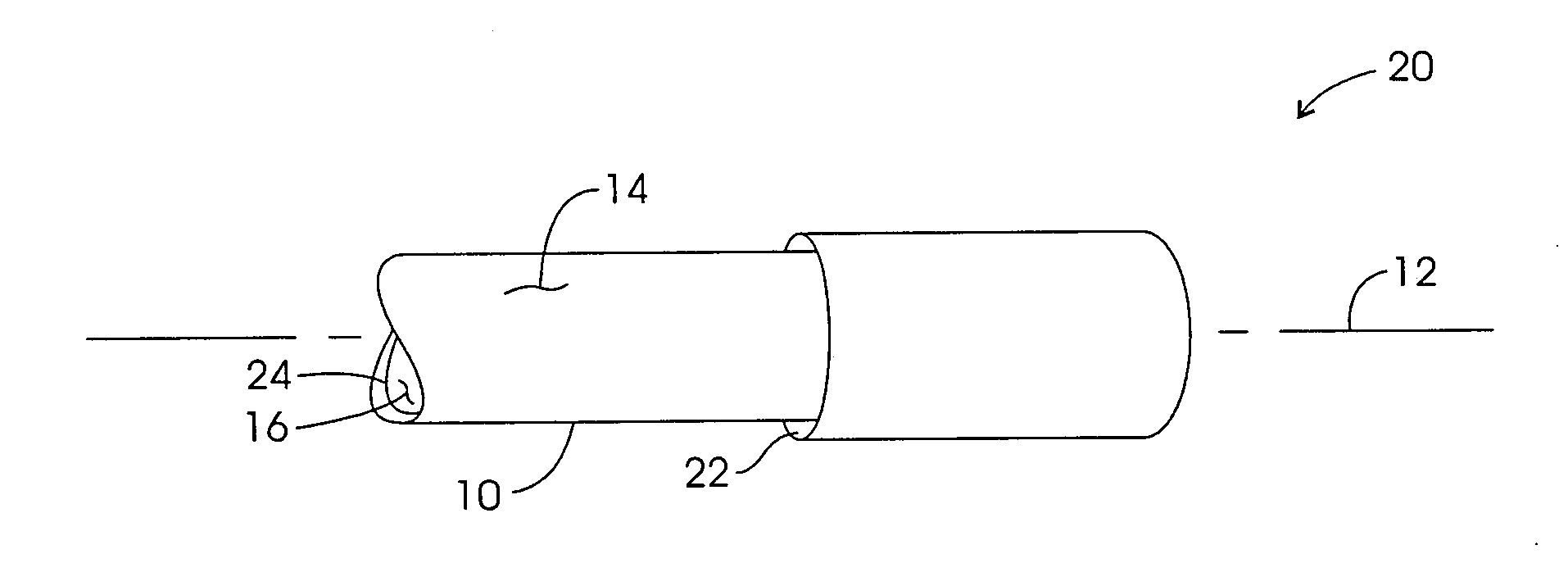

Tubular Copolyester Member for Tubing and Hose Constructions

InactiveUS20070087150A1Easy to installReduces migratory extrudationSynthetic resin layered productsFlexible pipesThermoplastic elastomerCopolyester

Tubular polymeric member for articles such as tubing and hoses. The member is formed of composition of a copolyester thermoplastic elastomer material.

Owner:PARKER HANNIFIN CORP

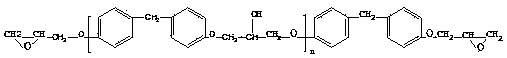

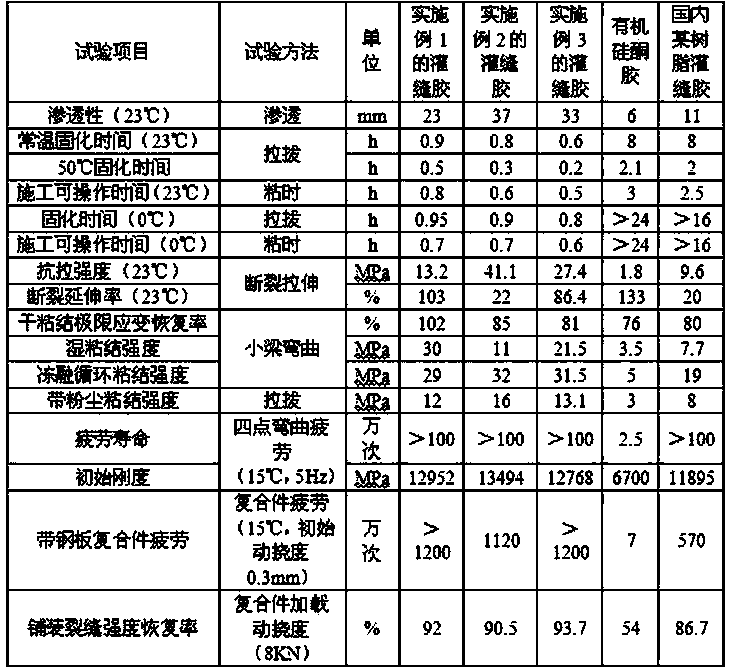

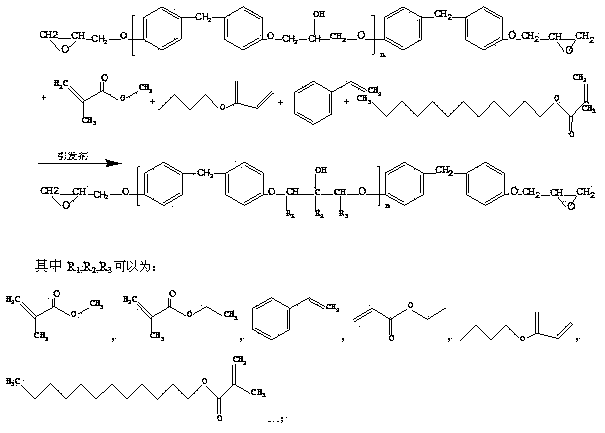

Low-temperature rapidly cured acrylic ester modified epoxy resin joint sealant used in road and bridge

ActiveCN104231995AExcellent low temperature permeabilityImprove adhesionNon-macromolecular adhesive additivesModified epoxy resin adhesivesPolymer scienceHexamethylenediamine

Owner:JIANGSU TRANSPORTATION RES INST CO LTD

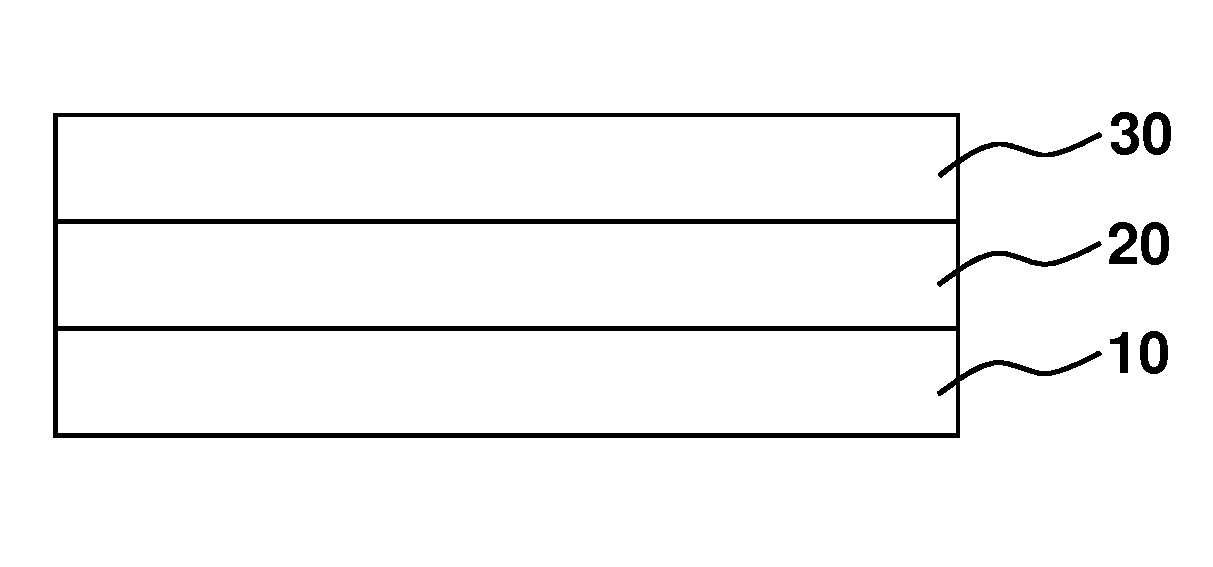

Low temperature resistant triple coextrusion composite film and preparation method thereof

ActiveCN101927591AImprove low temperature resistance and freeze resistanceLow temperature flexibilitySynthetic resin layered productsComposite filmMass ratio

The invention discloses a low temperature resistant triple coextrusion composite film and a preparation method thereof. The composite film in the invention is formed through carrying out triple coextrusion by a casting machine, and comprises an outer layer, a middle layer and an inner layer which are composited together; the materials of the middle layer adopt metallocene low-density linear polyethylene and polypropylene at the mass ratio of 1:10-1:1; and the melt index of the metallocene low-density linear polyethylene is 1-3.5. After the scheme is adopted, compared with the traditional CPP film, the low temperature resistant triple coextrusion composite film of the invention has the advantages of greatly improving the low temperature resistant and freezing resistance performance, being capable of being normally used under the environment of minus 30 DEG C, having no influence on the barrier property and strength thereof and being particularly suitable for packaging of quick frozen products such as boiled dumplings, sweet soup balls and the like.

Owner:KAIDA GRP CO LTD FJ

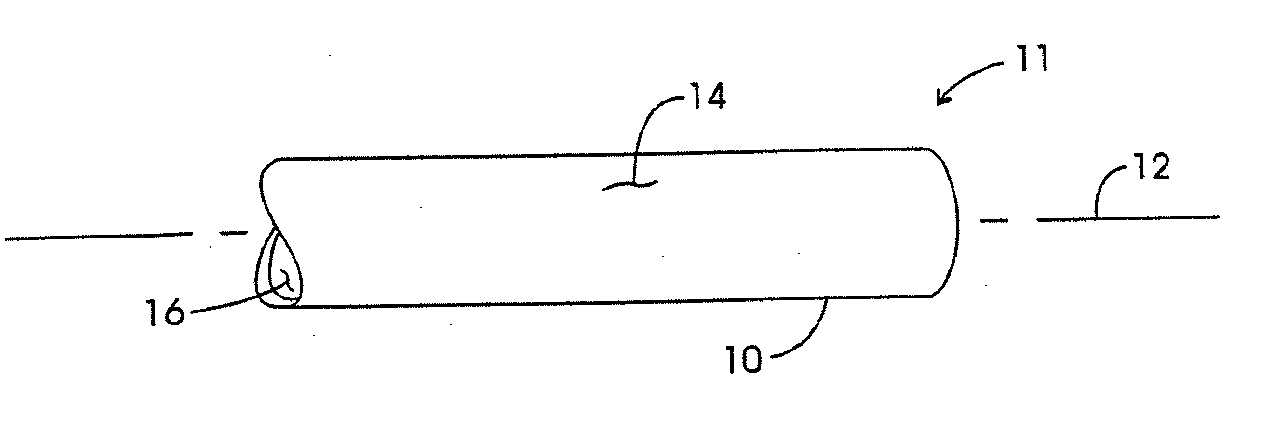

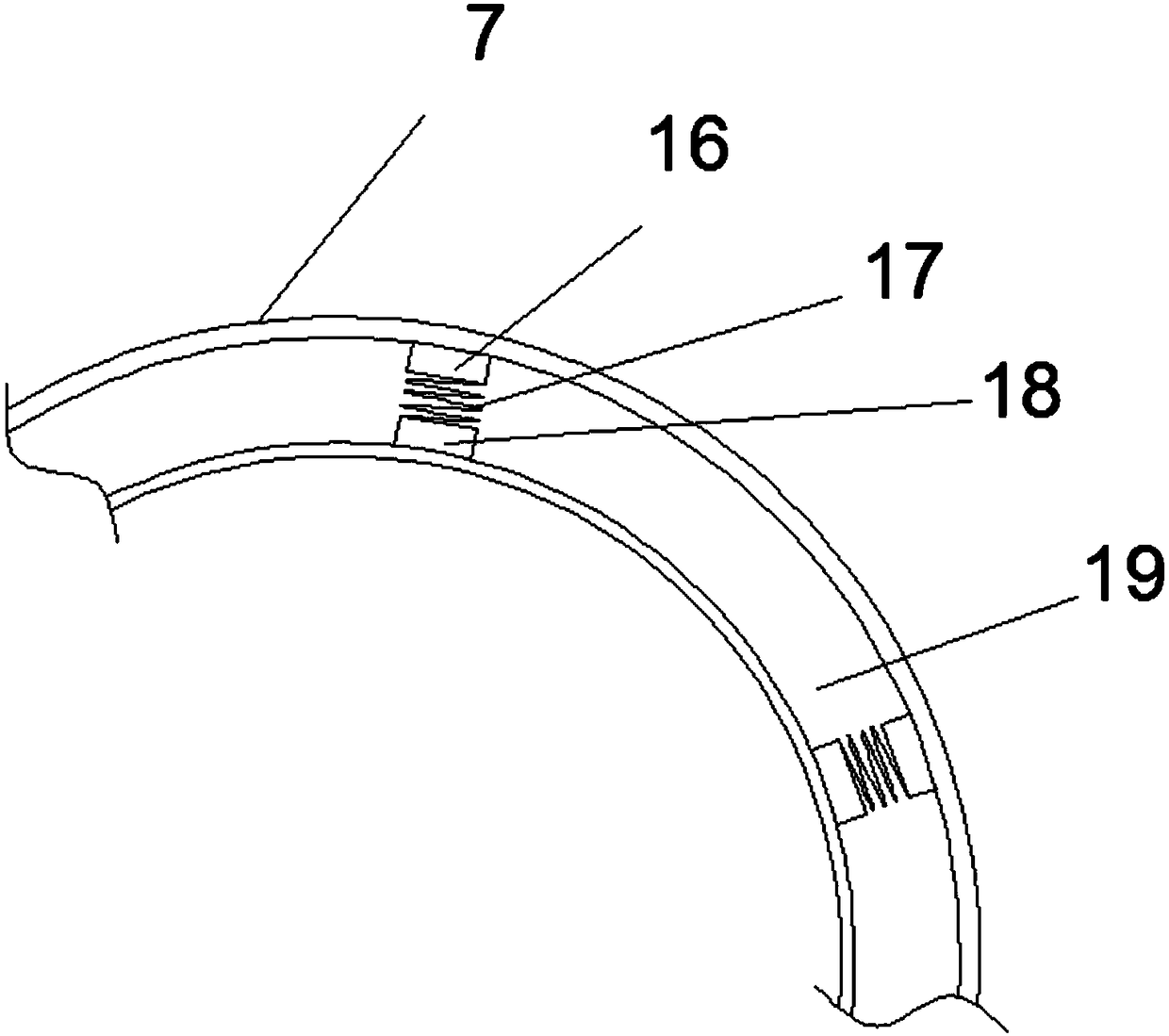

High temperature-resistant hose

InactiveUS20100018600A1High temperature resistanceImprove balanceLayered productsFlexible pipesElastomerEngineering

An automotive vehicle vacuum brake hose that resists degradation when exposed to elevated temperatures up to about 175° C. for prolonged periods of time, the automotive vehicle vacuum brake hose comprising; an inner tubular member having an elastomeric matrix selected from the group consisting of acrylic elastomer and ethylene-vinyl acetate copolymer, and a protective cover around the inner tubular member. Preferably, the high temperature-resistant vacuum brake hose includes a reinforcement member around the inner tubular member and a protective cover around the reinforcement member.

Owner:FLUID ROUTING SOLUTIONS

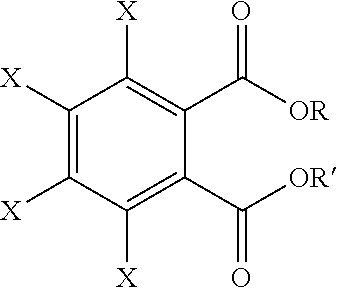

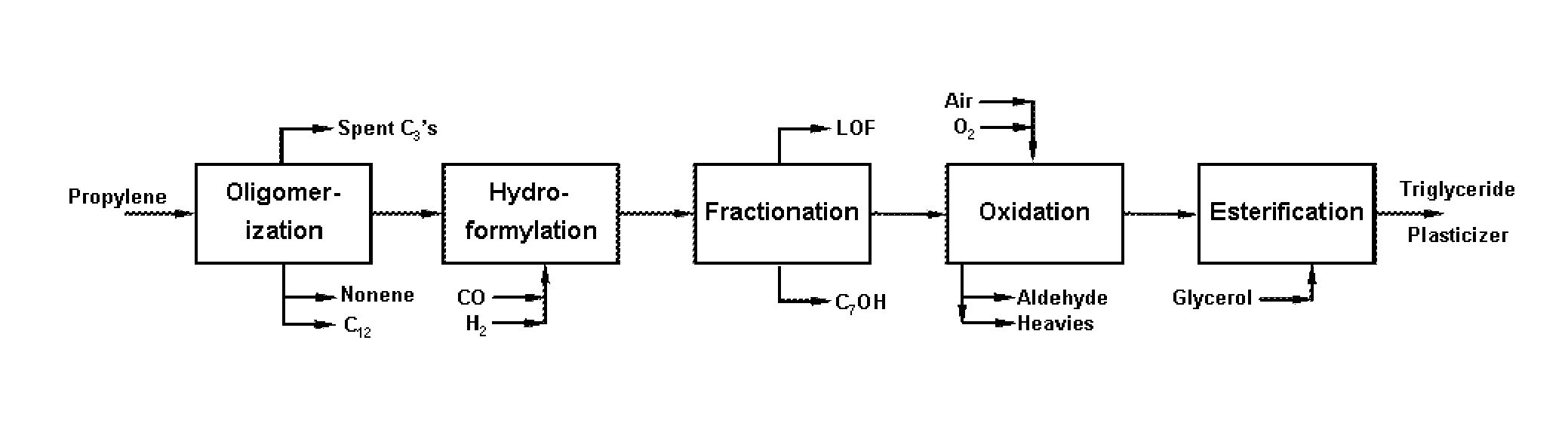

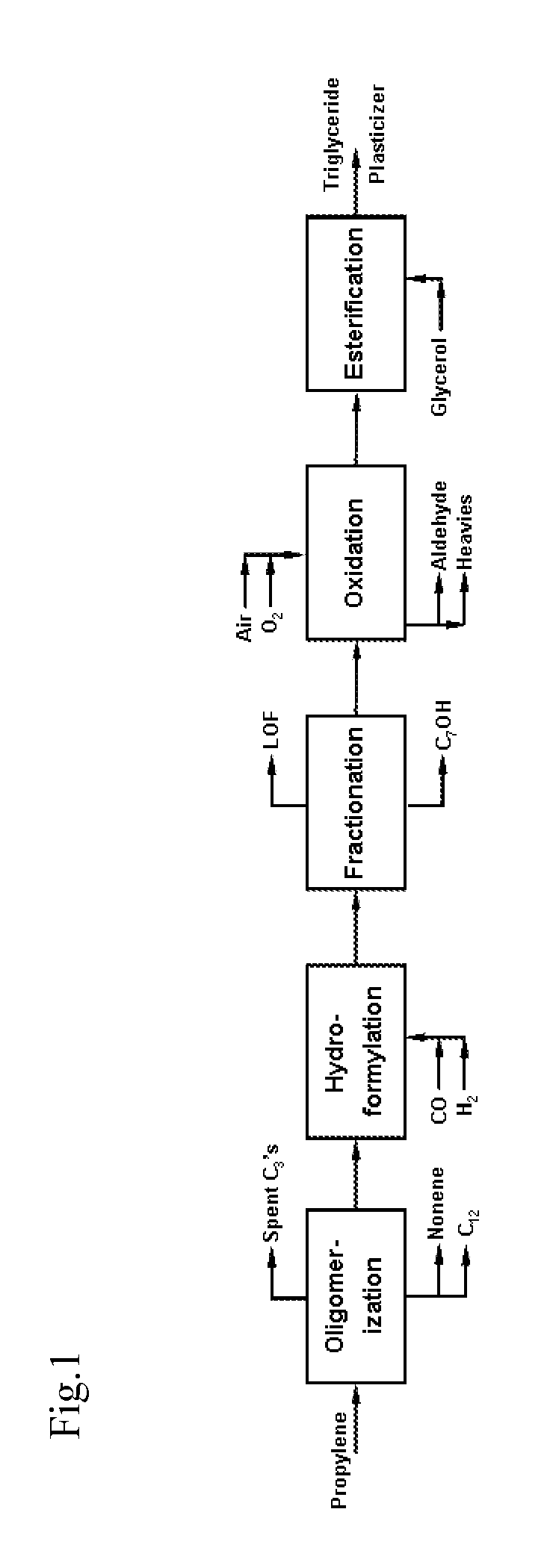

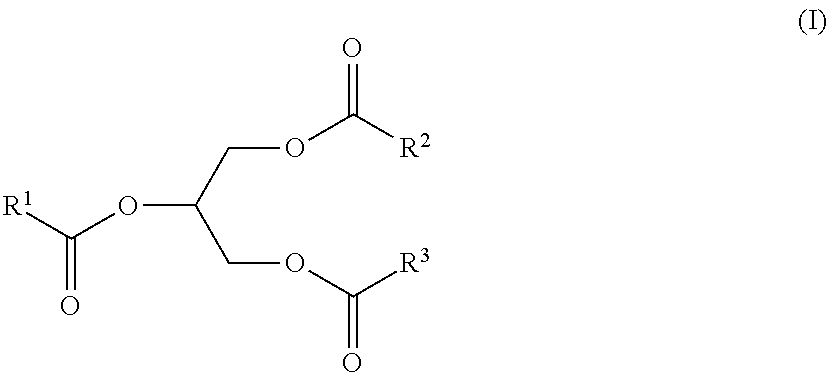

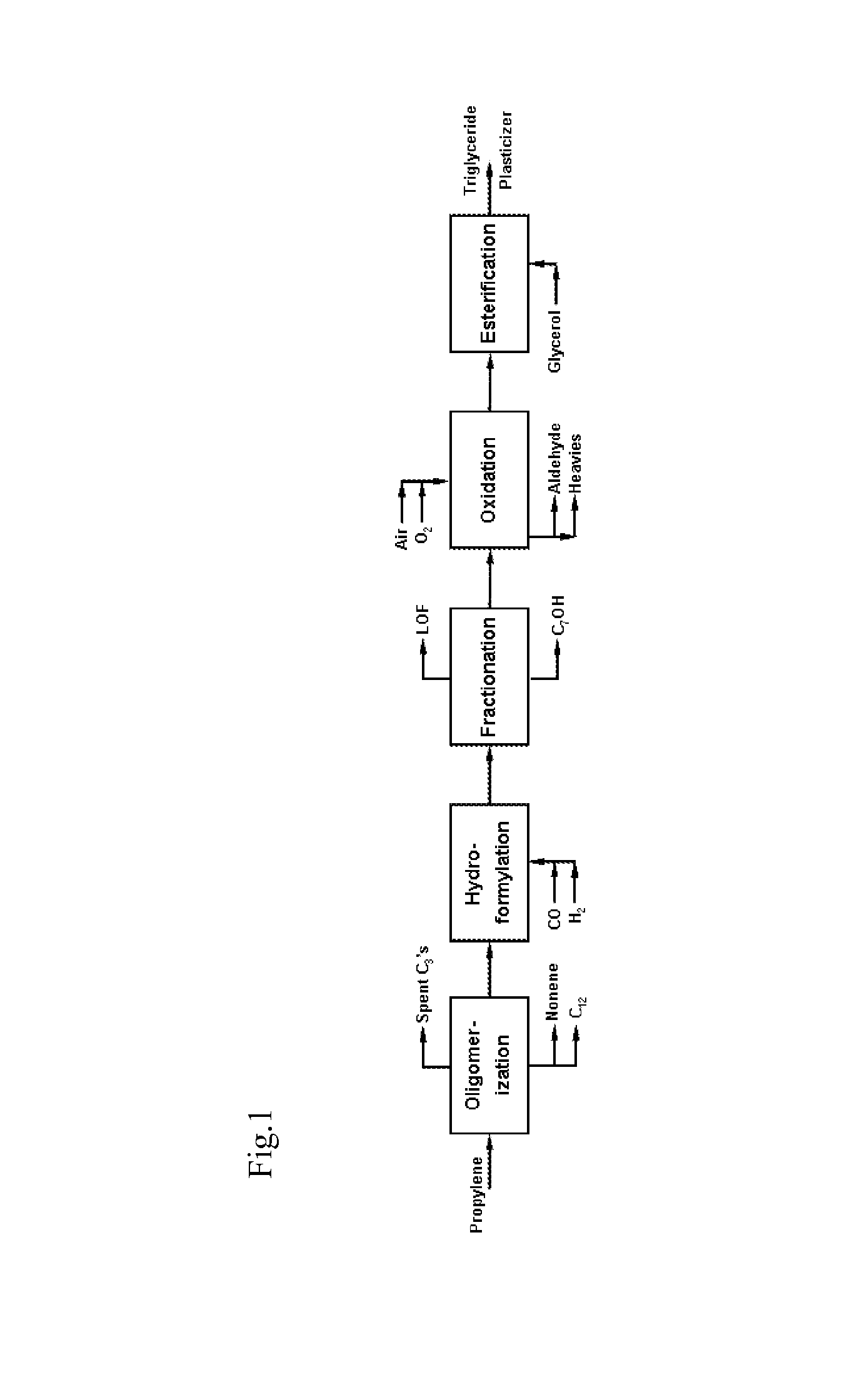

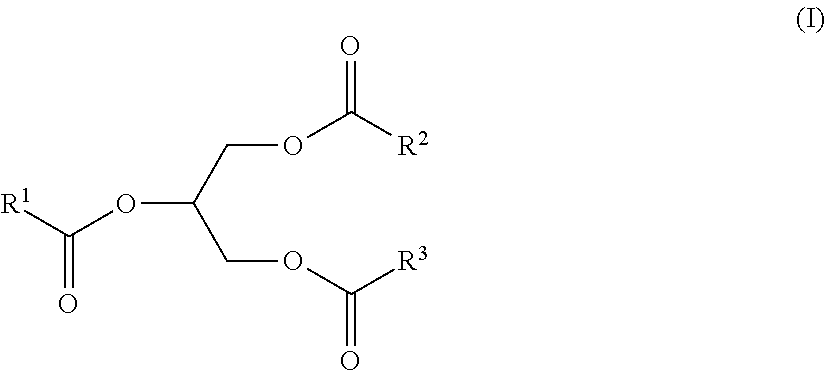

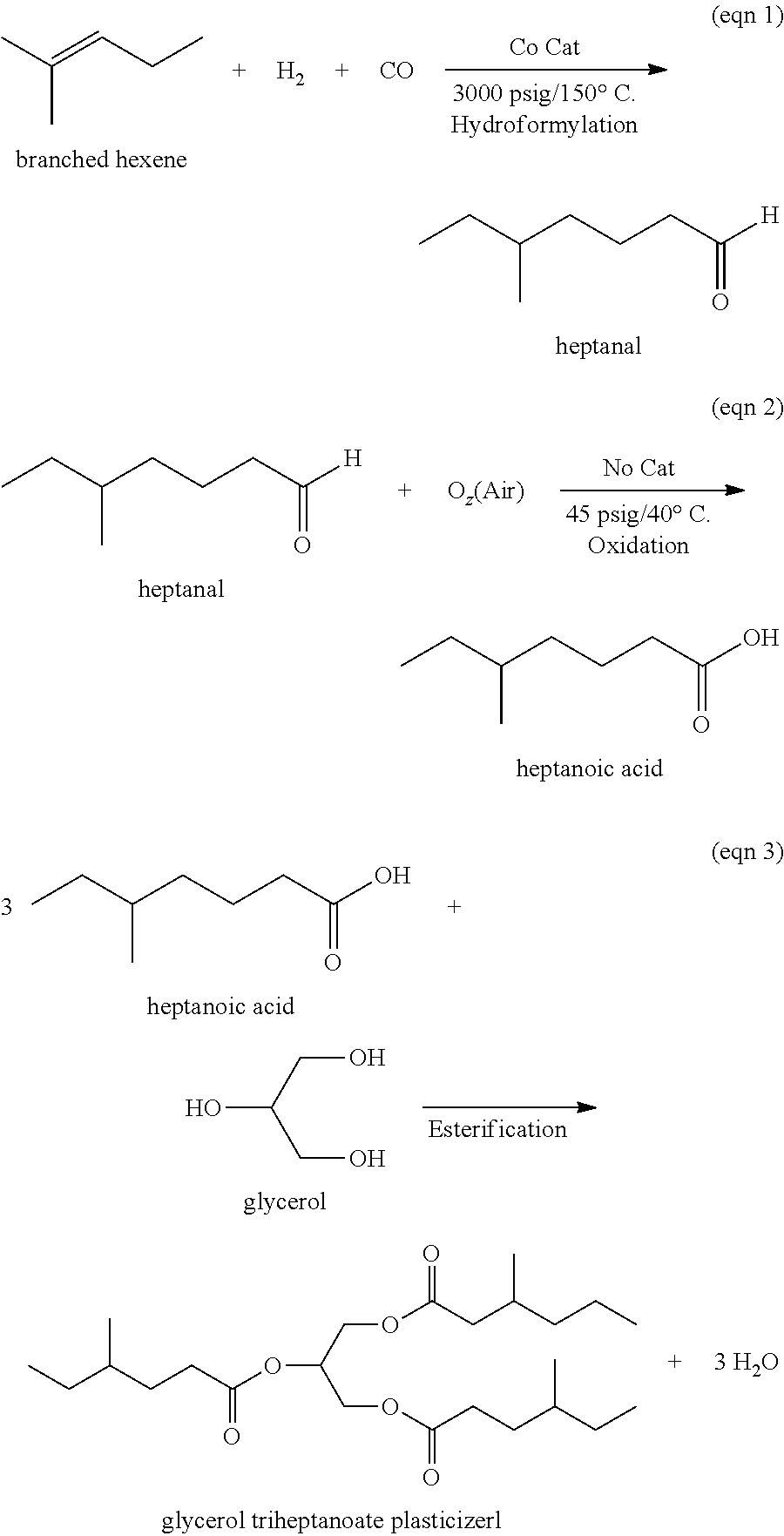

Polyol Ester Plasticizers and Process of Making the Same

InactiveUS20110021680A1Efficiency benefitLow toxicityOrganic compound preparationCarboxylic acid esters preparationCarbon numberGlycerol

Triglyceride and other polyol ester PVC plasticizers can be produced by recovery of branched C6 to C9 aldehydes from a hydroformylation product, optional hydrogenation to the alcohol, oxidation to the acid with oxygen and / or air, recovery of the resulting acid, and esterification with glycerol, ethylene glycol, propylene glycol or mixtures thereof. The branched alkyl chains comprise at least 10% methyl branching. Special triglycerides are derived from branched aliphatic acids having alkyl chains with average carbon numbers from 6 to 9 and at least 10% methyl branching. These triglycerides are fast fusing plasticisers if before esterification with glycerol, an aryl acid is introduced together with the aliphatic acids.

Owner:EXXONMOBIL CHEM PAT INC

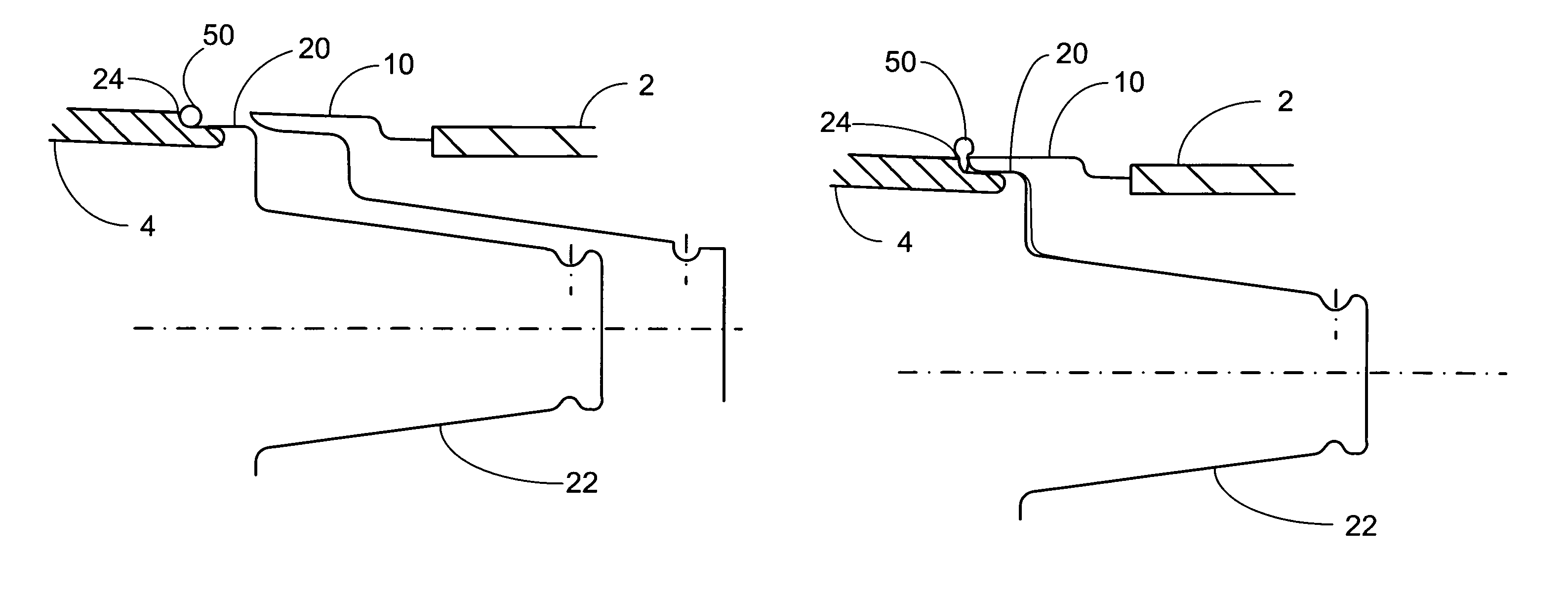

Method for waterproofing substrate

InactiveUS20140050525A1Increased durabilityLow temperature flexibilityPaving reinforcementsIn situ pavingsRoad surfaceSynthetic resin

A method for waterproofing a substrate, the method including adhering an adhesive member obtained by using an active hydrogen-containing synthetic resin, to a urethane-based waterproof layer to laminate a pavement adhesive layer; applying or spraying an isocyanate group-containing compound onto the pavement adhesive layer; and paving an asphalt mixture on the surface of the pavement adhesive layer.

Owner:DYFLEX CORP

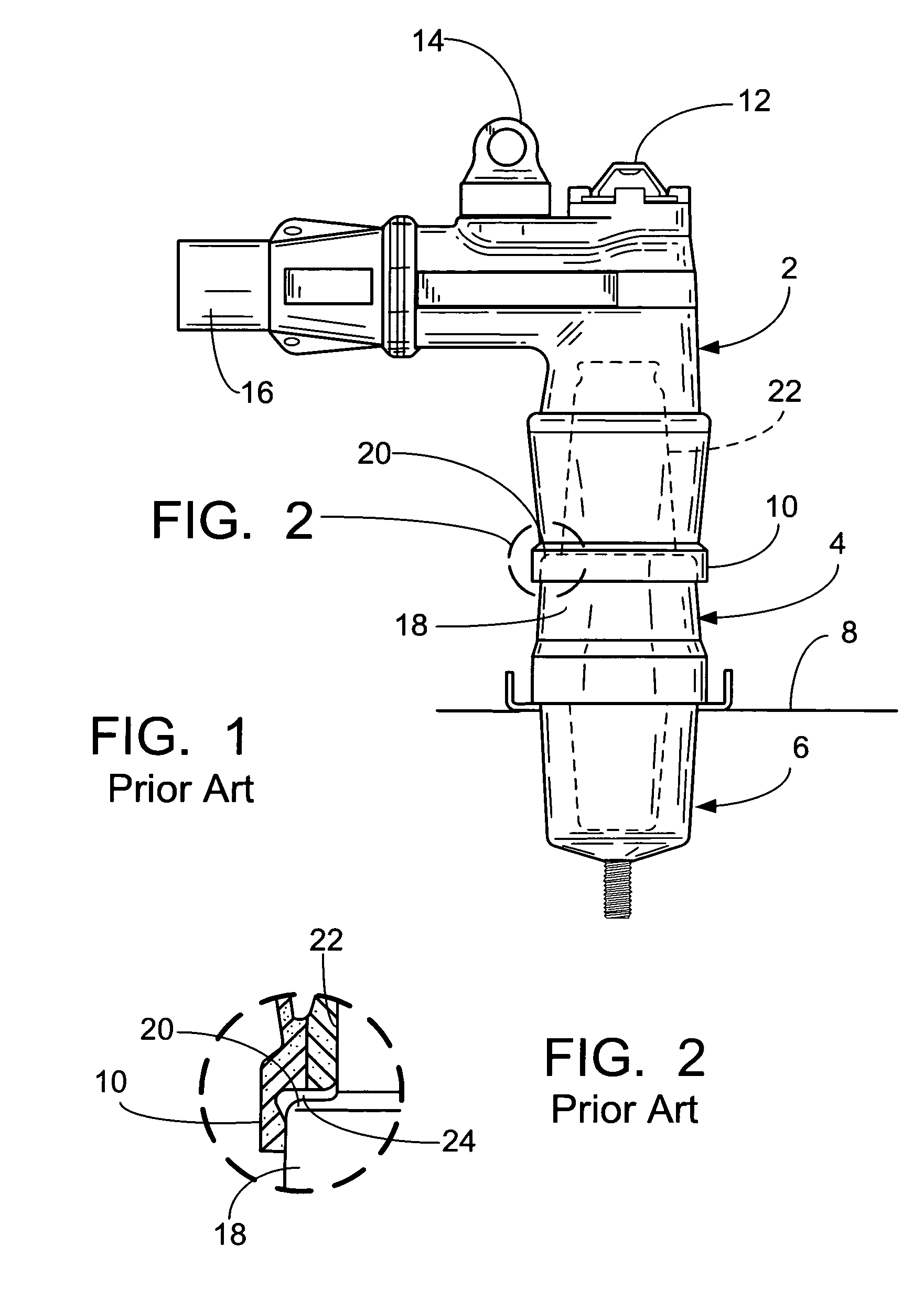

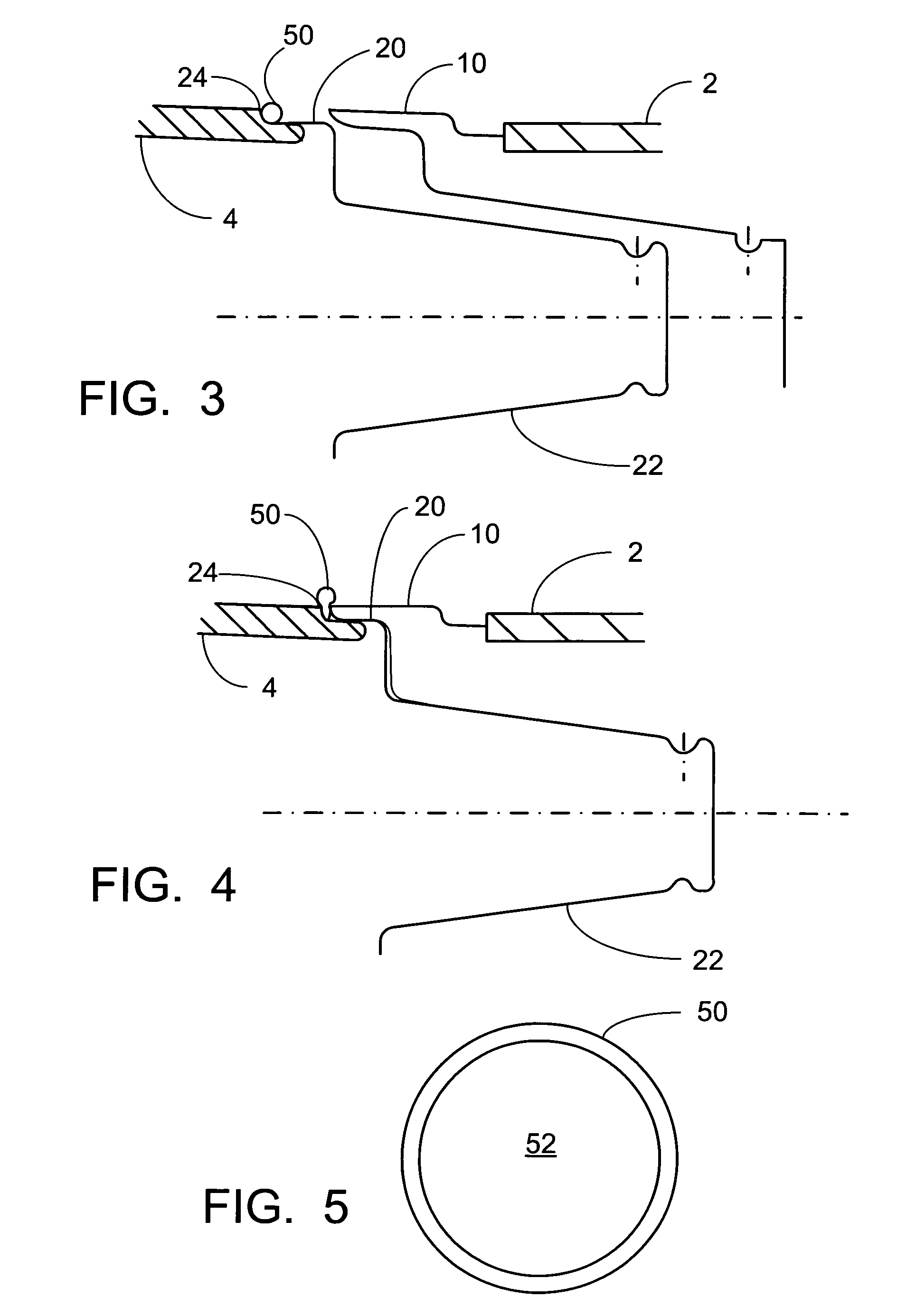

Hollow ring seating indicator

ActiveUS7758367B2Easy to transformHigh elongation resilienceOne pole connectionsElectrically conductive connectionsEngineeringMechanical engineering

Owner:THOMAS & BETTS INT INC

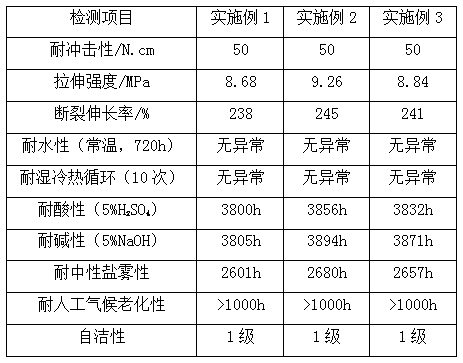

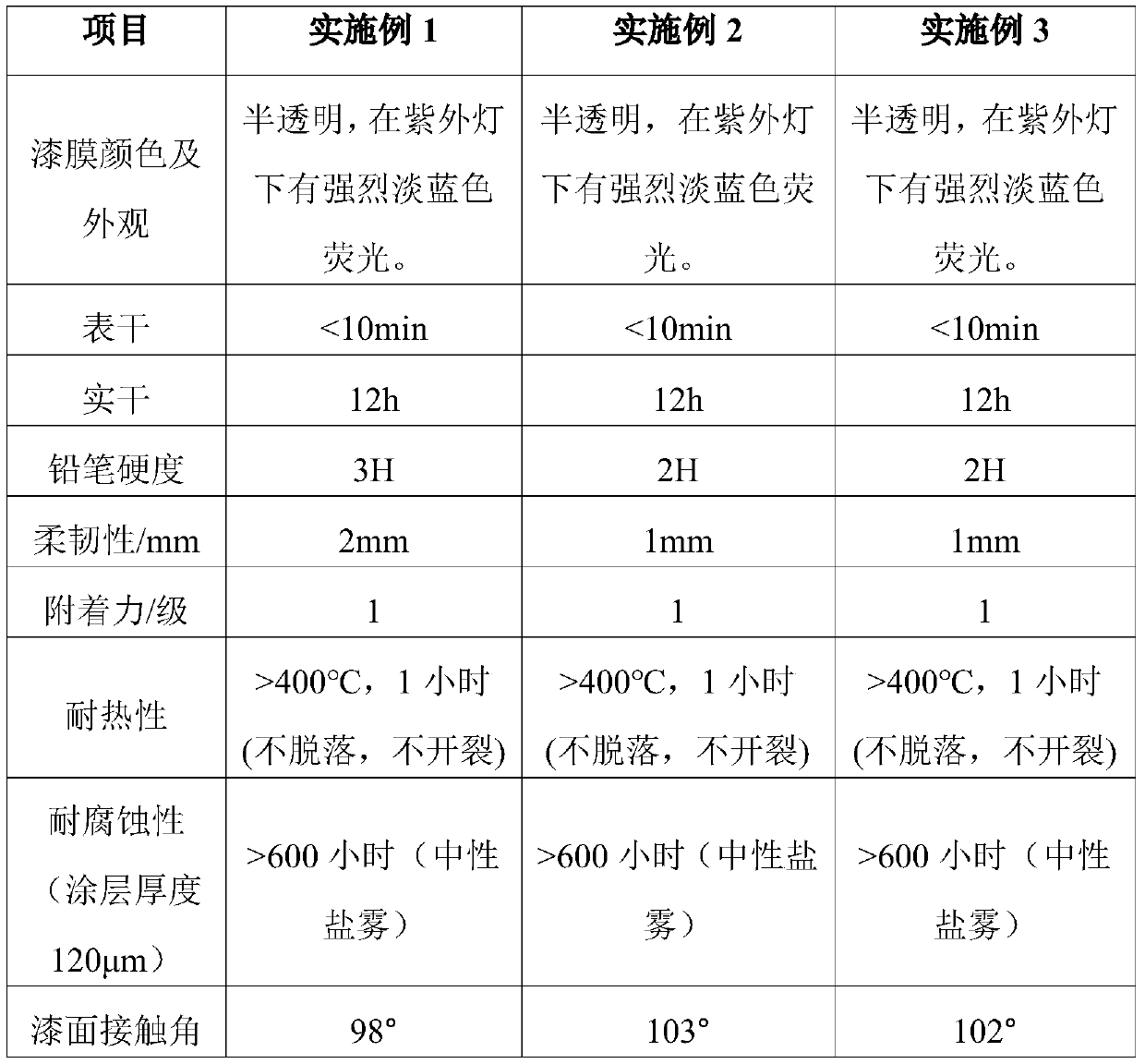

Anticorrosive tough coating material for outdoor communication tower, and preparation method thereof

InactiveCN110684440AGood dispersionGood chemical resistanceAnti-corrosive paintsEpoxy resin coatingsXylyleneFiber

The invention discloses an anticorrosive tough coating material for an outdoor communication tower, and a preparation method thereof, wherein the anticorrosive tough coating material is prepared fromthe following raw materials by weight: 12-18 parts of a polytrifluorochloroethylene resin, 35-45 parts of a bisphenol A type epoxy resin, 8-12 parts of polyphenylmethylsiloxane, 2-6 parts of alpha,omega-dihydroxy polydimethylsiloxane, 2-6 parts of amino-modified polysiloxane, 2-6 parts of hexamethyldisilazane, 2-6 parts of gas-phase nanometer silicon dioxide, 7-11 parts of silicon carbide short fibers, 12-16 parts of mica iron oxide powder, 2-8 parts of xylene, 10-20 parts of an acetone aqueous solution and 1-3 parts of a polyamine mixed curing agent. According to the invention, the prepared anticorrosive tough coating material has excellent anticorrosive performance, weather resistance and good elasticity; and by coating the communication tower with the anticorrosive tough coating material, the coating is compact, has excellent anticorrosive, anti-aging, hydrophobic, stain-resistant and impact-resistant effects, can well adapt to severe environments, and effectively prolongs the service life of the communication tower.

Owner:广西凯威铁塔有限公司

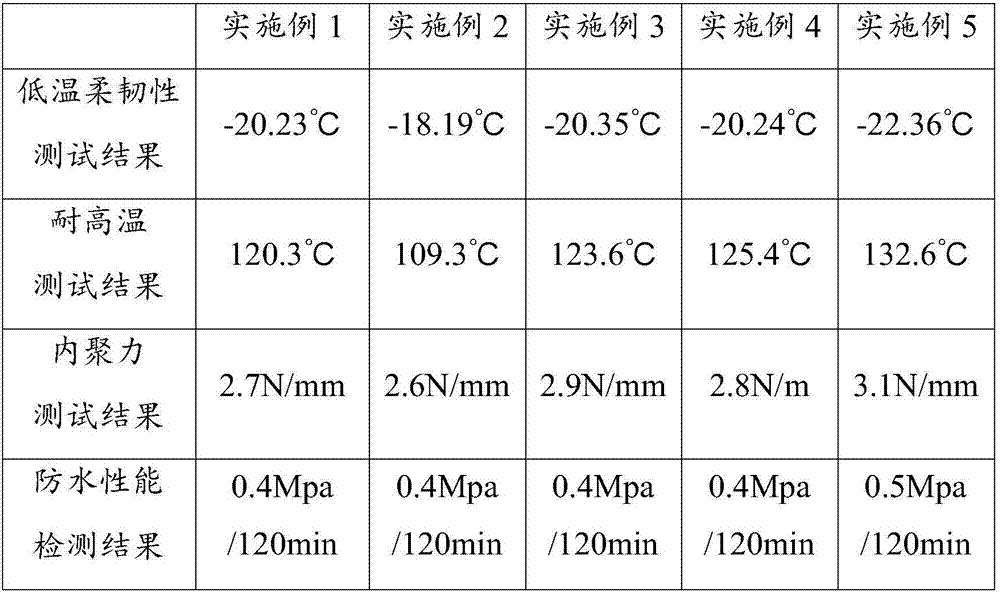

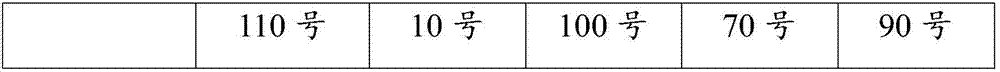

Asphalt sizing material for waterproof coiled material, preparation method of asphalt sizing material, and waterproof coiled material

InactiveCN107446366AGood low temperature flexibilityImprove high temperature resistanceBuilding insulationsDecompositionHeat stability

The invention provides an asphalt sizing material for a waterproof coiled material, a preparation method of the asphalt sizing material, and the waterproof coiled material, and relates to the technical field of the waterproof coiled material. The asphalt sizing material is mainly prepared from asphalt, butadiene styrene rubber, petroleum resin, polypropylene wax, erucyl amide, a softening agent and a stabilizer, wherein the butadiene styrene rubber can obviously improve the low-temperature flexibility and the high-temperature resistance of the asphalt sizing material; the petroleum resin can obviously improve the viscosity, the hardness and the heat stability of the asphalt sizing material; the polypropylene wax and the erucyl amide can obviously improve the high-temperature resistance and the heat stability of the asphalt sizing material; the softening agent can effectively improve the viscosity and the ductility of the sizing material; and the stabilizer can prevent decomposition and ageing of the sizing material. Therefore, the asphalt sizing material provided by the invention can obviously improve the low-temperature flexibility, the high-temperature resistance and the cohesive force through compounding of the components and the component content, and has excellent waterproof property. The asphalt sizing material can be widely applied to preparation of various types of waterproof coiled materials.

Owner:TIANJIN PENGTENG NEW BUILDING MATERIALS

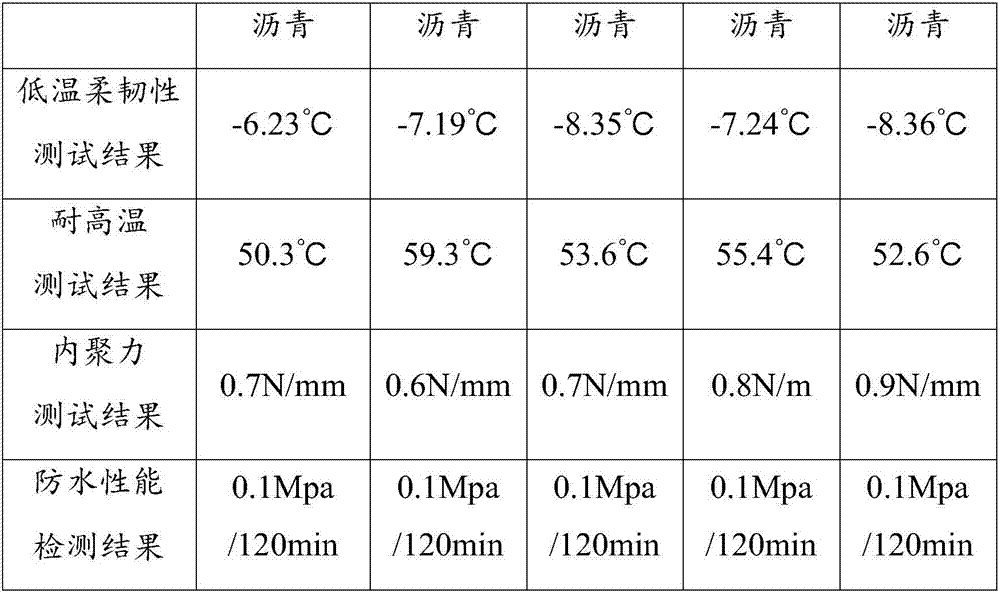

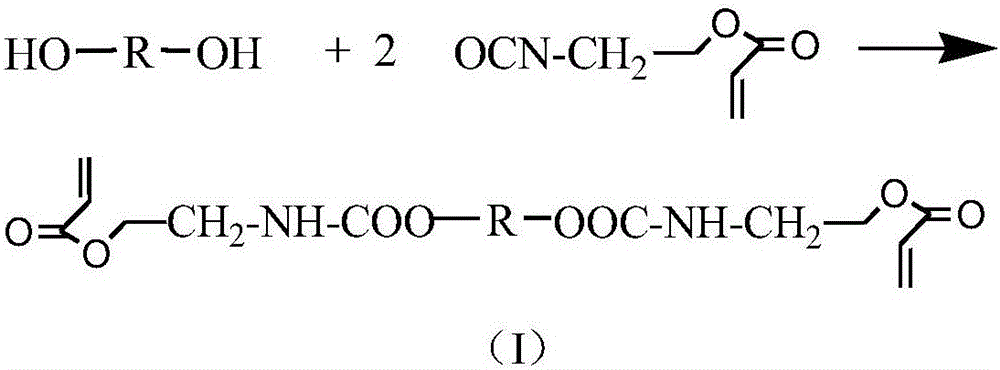

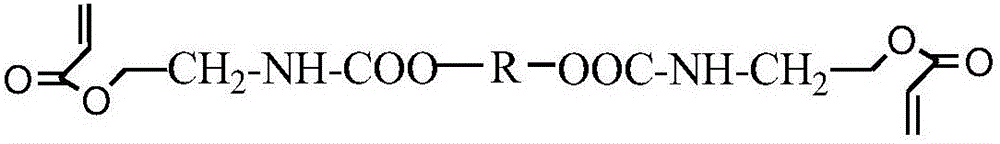

2-functionality-degree polyether urethane acrylate and preparation method and application thereof

The invention relates to 2-functionality-degree polyether urethane acrylate and a preparation method and application thereof, and discloses low-viscosity 2-functionality-degree polyether urethane acrylate. The preparation method comprises the step that polyether diol and isocyanate ethyl acrylate react to prepare 2-functionality-degree polyether urethane acrylate. The invention further discloses application of 2-functionality-degree polyether urethane acrylate to preparation of UV coatings or ink or adhesives. Isocyanate ethyl acrylate is adopted for preparing polyether urethane acrylate, the reaction steps are reduced, the reaction process is simple and easy to control, the situation that gel is generated due to side reactions is not likely to happen, the polyether urethane acrylate product is low in viscosity and beneficial to construction and application to UV formula products, when polyether urethane acrylate is used for UV spraying, no solvent or little solvent is added, and the requirement for application to the low-viscosity coatings is met. After low-viscosity 2-functionality-degree UV photocuring polyether urethane acrylate is cured, the excellent performance of low-temperature flexibility, low-temperature impacts, bacterium resistance, hydrolysis resistance and the like is achieved, and 2-functionality-degree polyether urethane acrylate can be applied as a raw material of the UV coatings, the ink and the adhesives.

Owner:JIANGSU LITIAN TECH

Polyol Ester Plasticizers and Process of Making the Same

InactiveUS20140228494A1Suitable melting and pour pointImprove compatibilityOrganic compound preparationCarboxylic acid esters preparationCarbon numberPolyolester

Triglyceride and other polyol ester PVC plasticizers can be produced by recovery of branched C6 to C9 aldehydes from a hydroformylation product, optional hydrogenation to the alcohol, oxidation to the acid with oxygen and / or air, recovery of the resulting acid, and esterification with glycerol, ethylene glycol, propylene glycol or mixtures thereof. The branched alkyl chains comprise at least 10% methyl branching. Special triglycerides are derived from branched aliphatic acids having alkyl chains with average carbon numbers from 6 to 9 and at least 10% methyl branching. These triglycerides are fast fusing plasticisers if before esterification with glycerol, an aryl acid is introduced together with the aliphatic acids.

Owner:EXXONMOBIL CHEM PAT INC

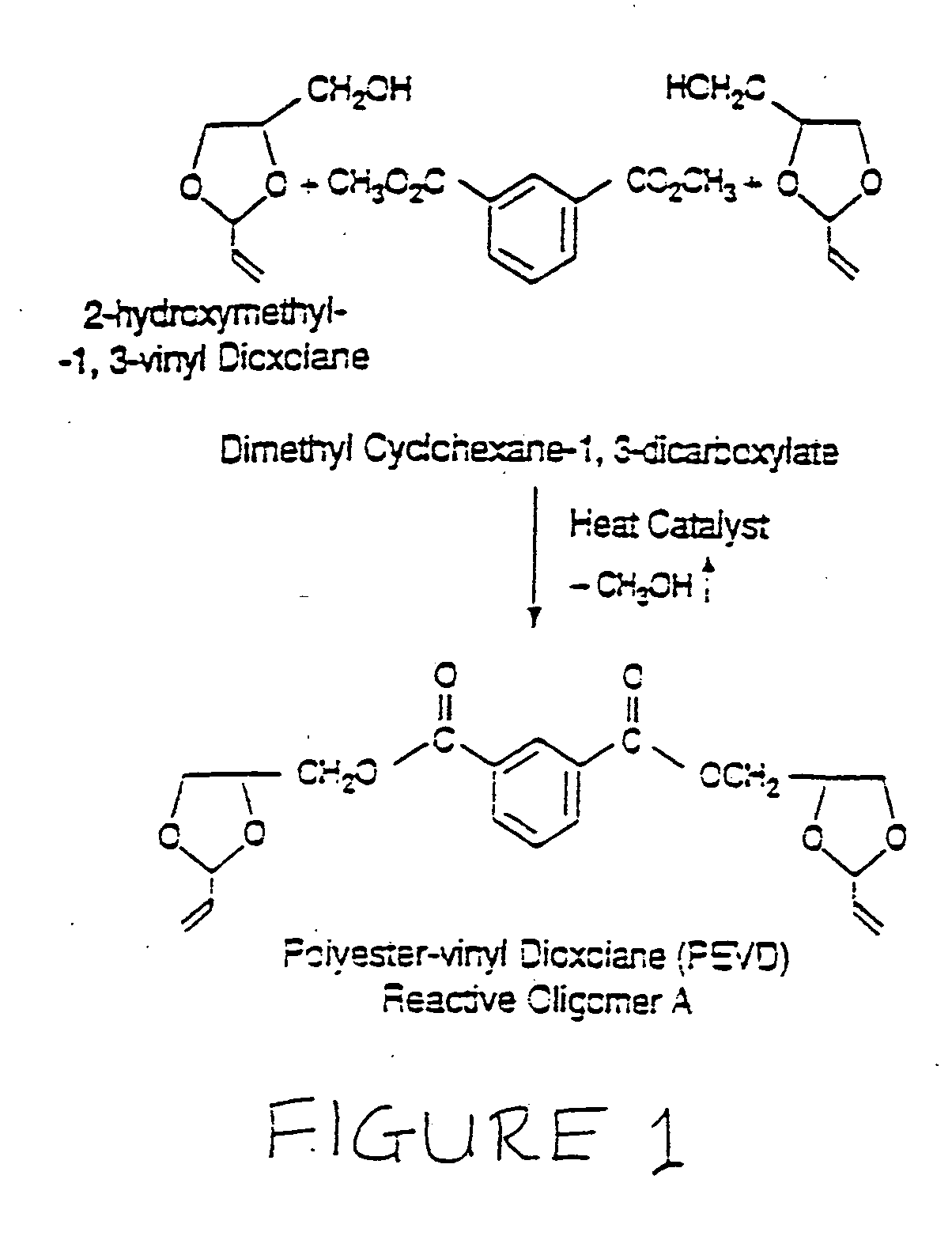

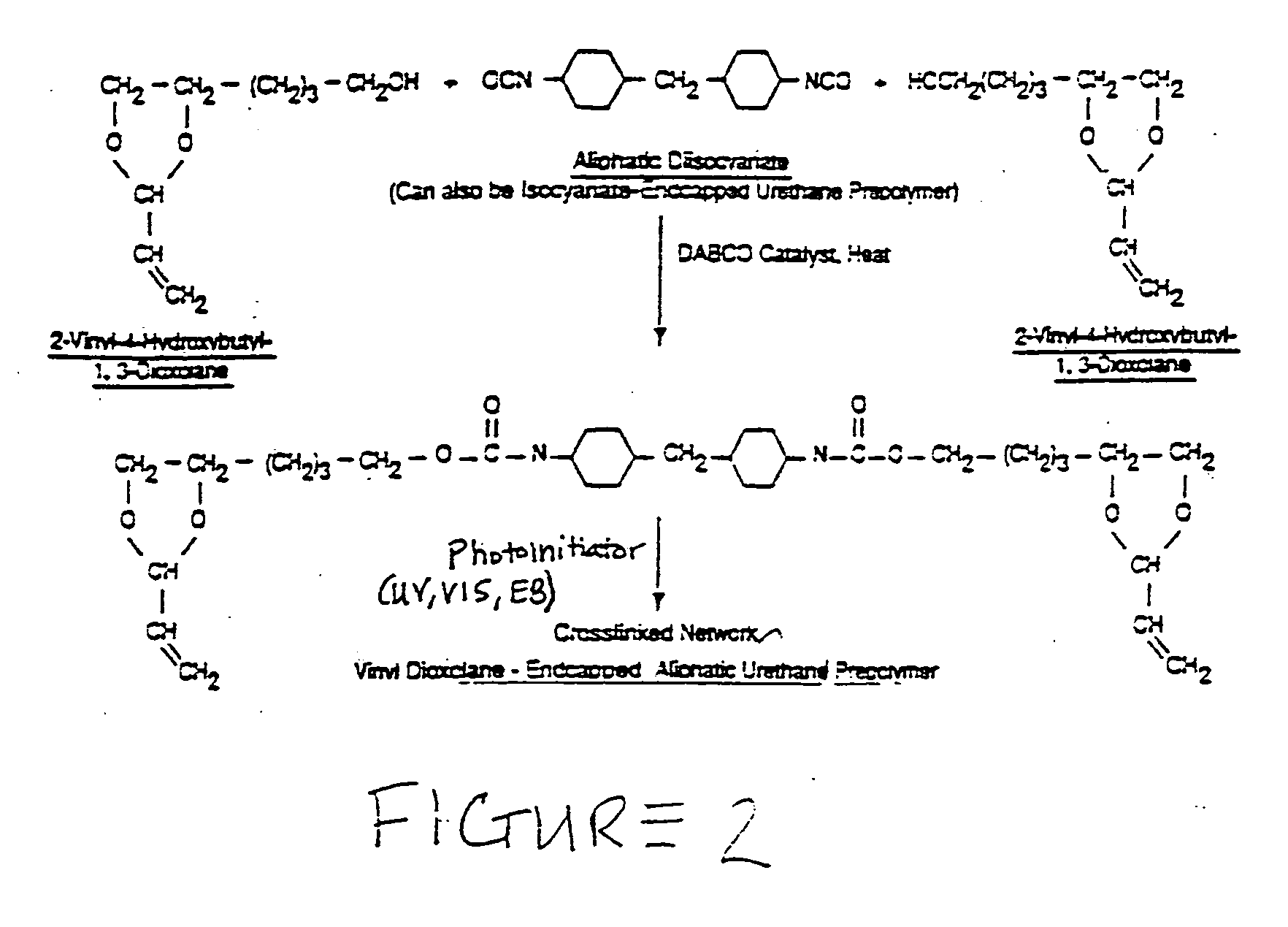

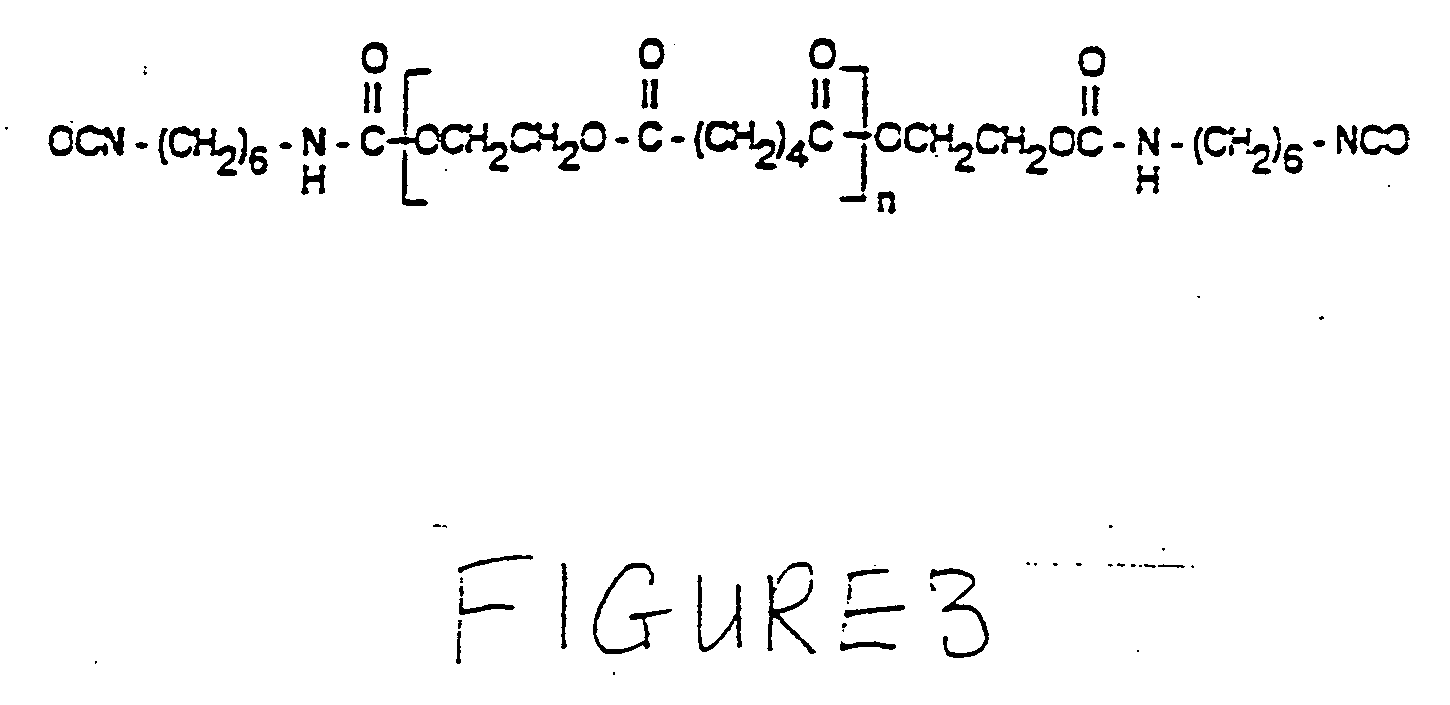

No VOC radiation curable resin compositions with enhanced flexibility

InactiveUS20060194894A1Excellent adhesion , solvent resistance and water resistanceEnhance flexibilityMixing methodsOptical articlesPhotoinitiatorPliability

The present invention provides radiation curable resin compositions having enhanced low temperature flexibility and to methods of using these compositions. The radiation curable resin compositions contain no or essentially no volatile organic components (VOCs), and find particular use as coating compositions. In particular, the radiation curable resin compositions of this invention comprise a vinyl dioxolane end-capped oligomer blended with a photoinitiator.

Owner:FOSTER-MILLER

Polymeric composition for seals and gaskets

InactiveUS7351762B2Excellent combination of propertyGood dimensional stabilitySynthetic resin layered productsThin material handlingElastomerPolymer science

The present invention relates to a polymeric composition which has an excellent combination of properties for use in making seals and gaskets for utilization in appliances, automotive applications, and building applications, such as window glazing gaskets. These polymeric compositions offer excellent dimensional stability, low compression set, outstanding sealing characteristics, low temperature flexibility, heat resistance and ultra-violet light resistance. The present invention more specifically discloses a polymeric composition having excellent characteristics for utilization in manufacturing seals and gaskets including dimensional stability, low compression set and outstanding sealing characteristics, said polymeric composition being comprised of a blend of (A) a thermoplastic resin selected from the group consisting of polypropylene, polyethylene, poly phenylene ether, polystyrene, and styrene containing copolymer resins, (B) an elastomeric polymer selected from the group consisting of block copolymer comprising a first polymeric block that is comprised of repeat units that are derived from a vinyl aromatic monomer and a second block that is comprised of repeat units that are derived from a conjugated diolefin monomer, wherein the repeat units in the second block are hydrogenated, and wherein the repeat units in the second block are elastomeric in nature, and a crosslinked olefinic elastomer, (C) a high molecular weight crosslinked diene elastomer comprised of repeat units that are derived from conjugated diene monomer selected from the group consisting of 1,3-butadiene and isoprene, wherein the high molecular weight diene elastomer has a weight average molecular weight of at least about 200,000, and (D) an oil.

Owner:THE GOODYEAR TIRE & RUBBER CO

Preparation method of low-temperature-resisting three-layer co-extruded composite thin film

ActiveCN103252955AImprove low temperature resistance and freeze resistanceLow temperature flexibilityFlexible coversWrappersLinear low-density polyethyleneAnti freezing

The invention discloses a preparation method of a low-temperature-resisting three-layer co-extruded composite thin film. The composite thin film is formed by co-extruding three layers through a casting machine and is provided with an outer layer, a middle layer and an inner layer, which are compounded together, wherein raw materials of the middle layer comprise metallocene linear low density polyethylene and polypropylene in a weight ratio of 1:10 to 1:1, and the fusion index of the metallocene linear low density polyethylene is 1-3.5. With the adoption of the scheme, when a conventional CPP (Chlorinated Polypropylene) thin film is compared with the low-temperature-resisting three-layer co-extruded composite thin film, the low-temperature-resisting and anti-freezing performance of the co-extruded three-layered composite thin film is greatly improved, the low-temperature-resisting three-layer co-extruded composite thin film can be normally used in an environment of -30 DEG C and the barrier property and the strength of the composite thin film are not influenced, and thus the low-temperature-resisting three-layer co-extruded composite thin film is particularly suitable for packaging of quick frozen products including dumplings, rice dumplings and the like.

Owner:KAIDA GRP CO LTD FJ

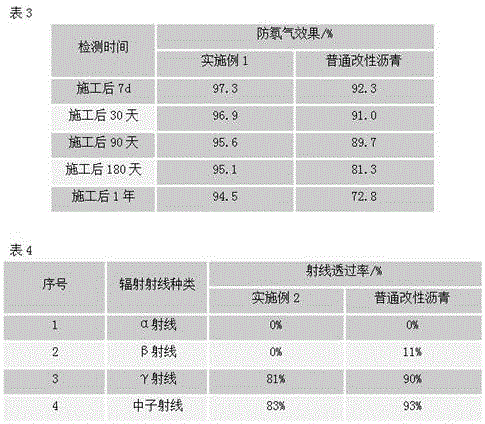

Radon-resisting modified asphalt and preparation method thereof

InactiveCN107177206AImprove waterproof performanceFunctionalBuilding insulationsPolymer modifiedAir purification

The invention relates to radon-resisting modified asphalt. The radon-resisting modified asphalt is characterized by being prepared from 20 to 90 percent of matrix asphalt, 0.1 to 30 percent of polymer modifier, 1 to 50 percent of radon radiation resisting elementary material and 0.1 to 20 percent of additive. The invention also provides a preparation method of the radon radiation resisting modified asphalt. The radon radiation resisting modified asphalt disclosed by the invention has excellent water-proof property, and the functions of radon radiation resistance, air purification and the like.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

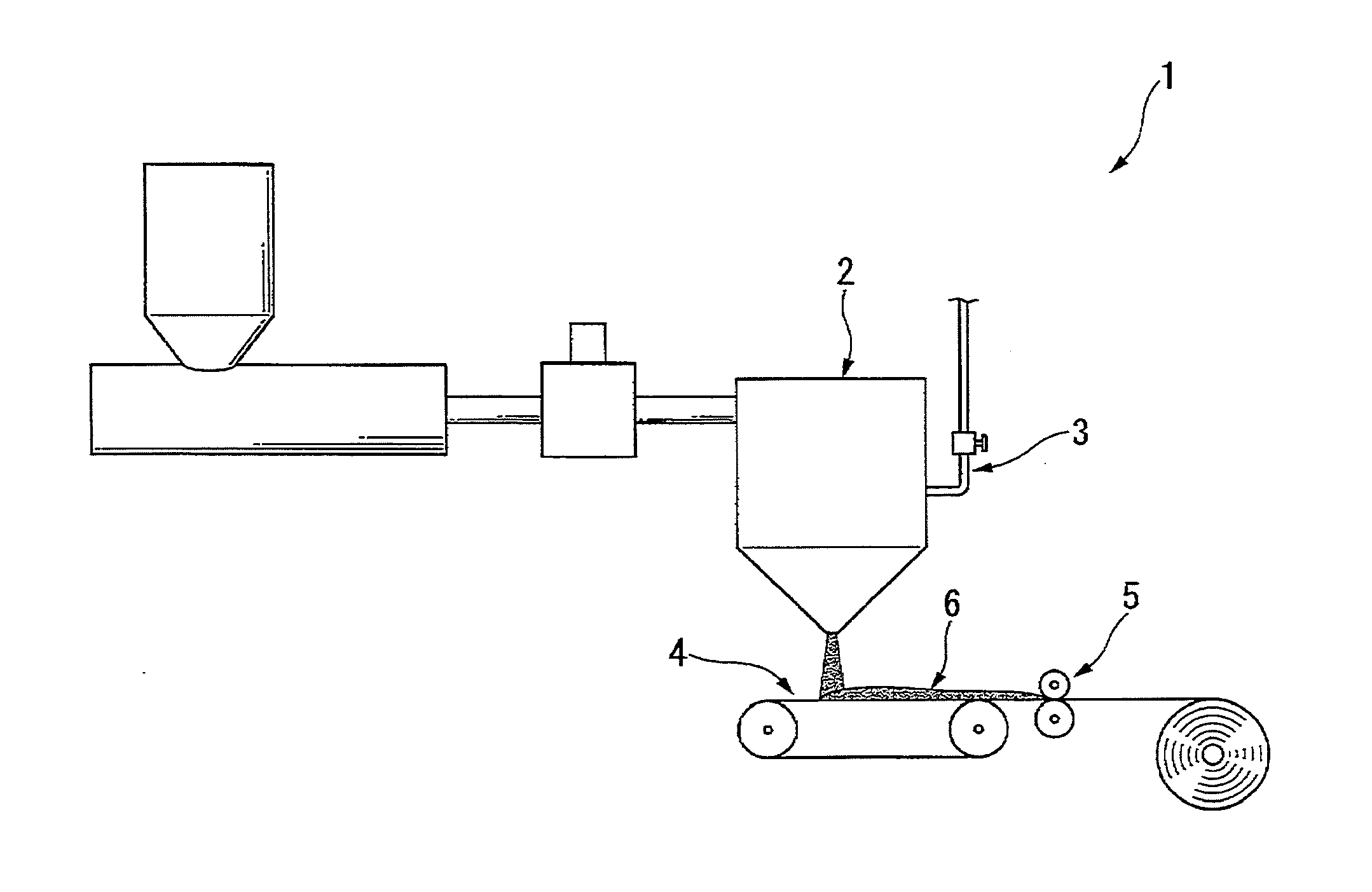

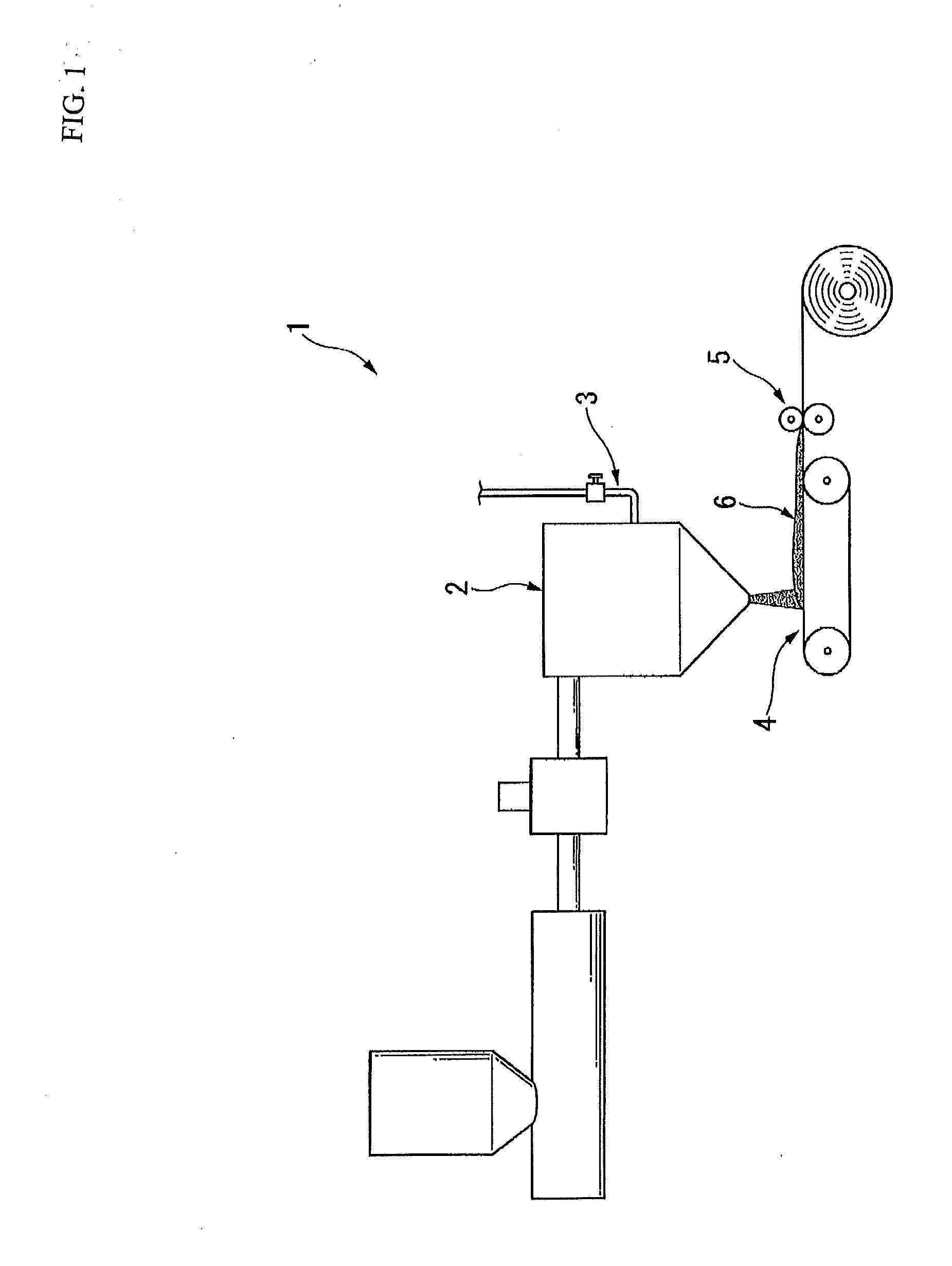

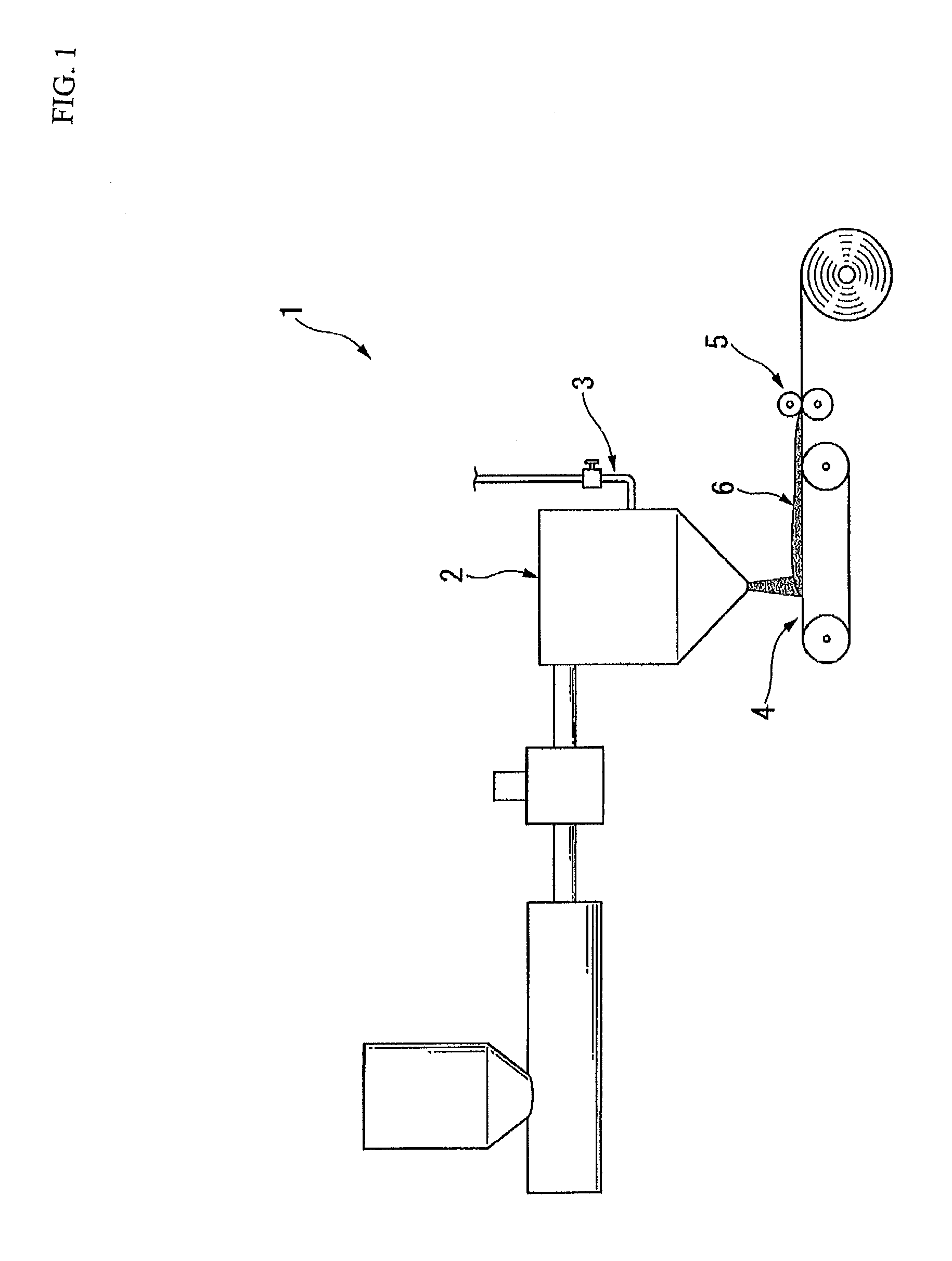

Atomizing and spraying method of sulfur modified composite anticorrosive coating

InactiveCN102755957AImprove thermal stabilityHigh viscosityLiquid surface applicatorsAnti-corrosive paintsHeat stabilityViscosity

The invention discloses an atomizing and spraying method of a sulfur modified composite anticorrosive coating, which comprises the following steps of: (1) hot-melting a sulfur raw material: adding sulfur into a reaction vessel for heating, reaching the hot-melting temperature of 135-140 DEG C of the sulfur raw material and dewatering till no air bubble exits; (2) adding modifying agents: reducing the temperate of the raw material sulfur to 120 DEG C, slowly adding the modifying agents in batch, continuously agitating, then controlling the temperature to be 140 DEG C plus or minus 5 DEG C and reacting for 5 hours; (3) adding a coupling agent, a stabilizing agent and a toughening agent and keeping the temperature of 140 DEG C for 45 minutes; (4) adding an aggregate: controlling the temperature to be 140-150 DEG C and continuously agitating; and (5) atomizing and spraying: spraying by adopting a spray gun and still keeping the temperature of 140 DEG C. By adopting the method, the thermal stability, the viscosity, the density, the liquidity and other properties of a hot-melted sulfur modified composite material are improved, so that the material has the atomizing and spraying properties.

Owner:刘岩

Anti-corrosion self-cleaning composite coating as well as preparation method and application thereof

InactiveCN112280429AAvoid corrosionGood chemical resistanceAntifouling/underwater paintsPaints with biocidesPolymer scienceMetallic materials

The invention discloses an anti-corrosion self-cleaning composite coating as well as a preparation method and application thereof. The composite coating comprises an epoxy resin layer and a polyurethane layer which are in contact with each other, an epoxy resin composition for preparing the epoxy resin layer comprises waterborne epoxy emulsion, a waterborne epoxy curing agent, filler, an aluminumcorrosion inhibitor and a coupling agent, and a polyurethane composition for preparing the polyurethane layer comprises polyurethane emulsion, a polyurethane curing agent and nano TiO2. The compositecoating combines the characteristics of chemical agent resistance and alkali resistance of epoxy resin and excellent chemical resistance, salt fog resistance, weather resistance and water resistance of the polyurethane layer, the flexibility of a coating film on the surface of a metal material can be enhanced, in addition, the aluminum corrosion inhibitor added to the epoxy resin layer can effectively inhibit corrosion of the aluminum surface, the nano TiO2 added into the polyurethane layer has a self-cleaning effect, so that the metal substrate can be prevented from being corroded by severe weather, and the stability of the composite coating in the severe weather can be enhanced.

Owner:INNER MONGOLIA POWER GRP +1

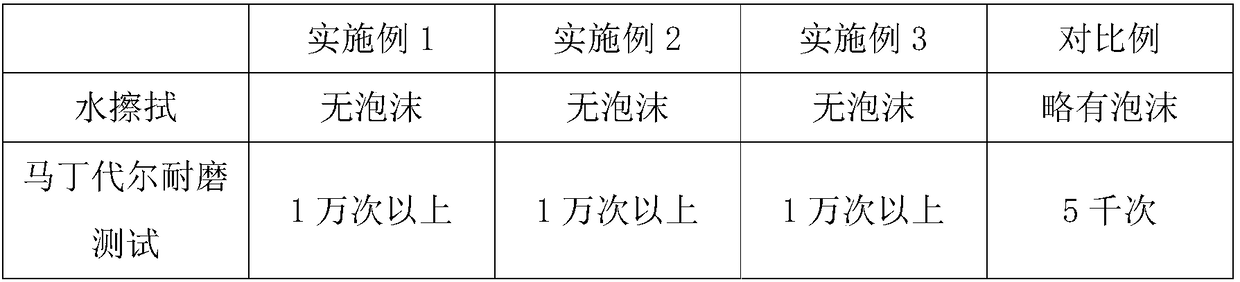

Self-extinction skin-feeling solvent-free polyurethane waterborne matte surface treatment agent

InactiveCN109054618ALower surface energyReduce film bubblesPolyurea/polyurethane coatingsSolventSurface energy

The invention belongs to the field of polyurethane surface treatment agents, and particularly relates to a self-extinction skin-feeling solvent-free polyurethane waterborne matte surface treatment agent. The self-extinction skin-feeling solvent-free polyurethane waterborne matte surface treatment agent comprises 100 parts of waterborne extinction polyurethane resin, 150 parts of water, 4 parts ofwetting agent UL-5125, 0.5 part of defoaming agent F-530, and 5 parts of polyurethane thickening agent 8807. The invention further provides a preparation method. By adopting the self-extinction skin-feeling solvent-free polyurethane waterborne matte surface treatment agent, the problem of surface whitening of synthetic leather due to the separation of an organic phase and an inorganic phase of silicon dioxide and polyurethane film-forming agent in the existing treatment agent can be solved; and by jointly using the wetting agent and the defoaming agent, not only can the surface energy be reduced, but also bubbles of the film can be reduced, and the adhesiveness of the surface treatment agent can be improved.

Owner:张家港市东方高新聚氨酯有限公司

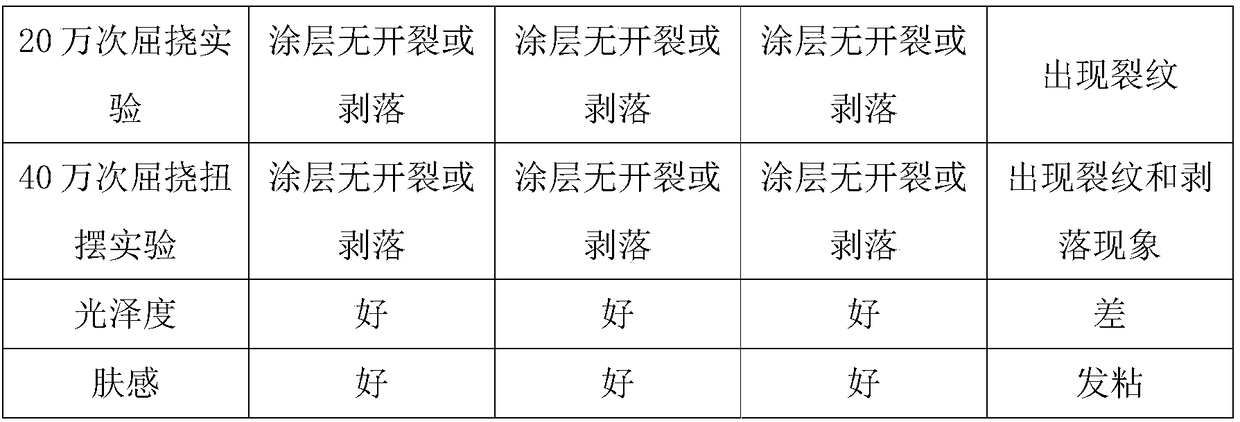

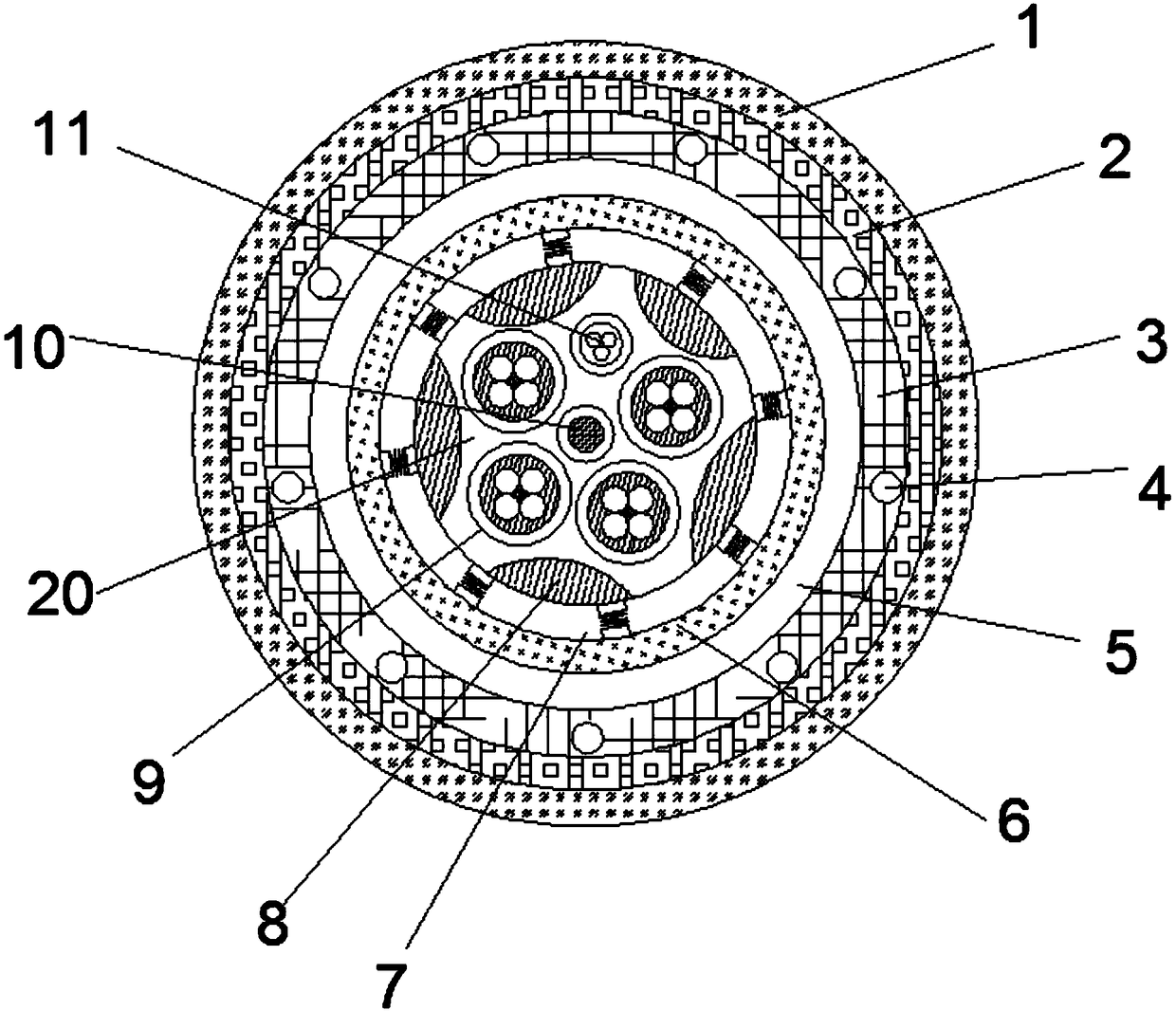

A tensile aluminum alloy power cable

InactiveCN109148018AImprove wear resistanceImprove tensile propertiesClimate change adaptationPower cables with screens/conductive layersPower cableAlloy

The invention discloses a tensile aluminum alloy power cable, include an out protective layer, Buffer layer and cable body, A metal armor lay is arranged on that inn side of the outer protective layer, A reinforcement layer is arranged on the inner side of the metal armor layer, a plurality of reinforcement ribs are arranged on the inner side of the reinforcement layer, a shielding layer is arranged on the inner side of the reinforcement layer, an insulating layer is arranged on the inner side of the shielding layer, a buffer layer is arranged on the inner side of the insulating layer, a plurality of support blocks are arranged on the inner side wall of the buffer layer, and a traction wire core is arranged on the inner side center of the buffer layer. In accordance with that present invention, through the outer protective layer, The metal armored layer, the reinforcing layer, the shielding layer, the insulating layer and the buffer layer protect the internal power cable core, and thereinforcing bars arranged inside the reinforcing layer are favorable to improve the tensile resistance of the cable, so that the abrasion resistance of the cable is stronger, and the metal armored layer enhances the protective hardness of the cable, so that the performance of the cable is improved and the service life of the cable is prolonged.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

Organic silicon modified epoxy composite resin with fluorescence characteristics

InactiveCN111116925AInhibition of intramolecular rotationAchieving Fluorescent BehaviorFireproof paintsLuminescent paintsPolymer scienceFluorescence

The invention discloses an organic silicon modified epoxy composite resin with fluorescence characteristics. The organic silicon modified epoxy composite resin is prepared from the following raw materials in percentage by mass: 10-24 wt% of amino silicon oil, 5-8 wt% of tetra-p-carboxytetraphenyl ethylene and 75-89 wt% of bisphenol A epoxy resin. According to the invention, fluorescent molecules with an aggregation-induced emission effect are connected to the composite resin through chemical bonds, and the intramolecular rotation of the fluorescent molecules is inhibited due to the combined action of polymer chain coating and chemical bond connection, so the fluorescence emission behavior of the resin is realized.

Owner:SUZHOU JIREN HIGH TECH MATERIAL CO LTD

Fireproof ceramic aluminum veneer

InactiveCN104087114AFire prevention, oxidation resistance, corrosion resistance and beautiful appearanceHeat resistantNatural resin coatingsBuilding componentsAluminum silicateElectric properties

The invention discloses a fireproof ceramic aluminum veneer which comprises an aluminum base plate layer, a chromizing film layer and a powder coating layer which are arranged from inside to outside in sequence, wherein the powder coating layer is prepared from the following raw materials in parts: 30-55 parts of epoxy resin, 45-75 parts of phenolic resin, 5-10 parts of rosin, 6-10 parts of polyethylene wax, 30-50 parts of polyester resin, 2-5 parts of diethanol amine, 1-3 parts of terephthalic acid, 2-5 parts of magnesium silicate, 2-8 parts of aluminum silicate, 3-8 parts of kieselguhr, 5-7 parts of nanosilicon dioxide, 1-2 parts of nano ferrum dioxide, 10-15 parts of silicon resin, 5-10 parts of color masterbatch powder and 2-5 parts of nanometer titania. The fireproof ceramic aluminum veneer has the advantages of fire prevention, anti-oxidation, corrosion resistance, attractiveness in appearance, and the like, also has the properties of thermal resistance, chemical resistance, cold resistance, low temperature flexibility, weather resistance and electric property, and has the properties of smoothness, fire prevention and large hardness after being sprayed.

Owner:陈欢娟

Propylene-based amorphous poly-alpha-olefins (APAOs) formulated with hexene-1 monomer containing amorphous poly-alpha-olefins for use in hot melt adhesives

ActiveUS10160888B2Excellent initialControllable open time and set timeNon-macromolecular adhesive additivesButeneMetallurgy

Owner:REXTAC

A kind of water-in-water multicolor paint and preparation method thereof

The invention relates to a water-in-water colorful paint and a preparation method thereof. The water-in-water colorful paint includes a color toning emulsion and a granulation emulsion, wherein the granulation emulsion is in a continuous phase and is prepared by adding sodium tetraborate into a synthetic resin silicone acrylic emulsion with stirring uniformly; and the color toning emulsion is in a dispersed phase and is prepared by adding hydroxyethyl cellulose into a polyvinyl acetate co-polymer emulsion with stirring uniformly. The preparation method includes the steps of preparing the color toning emulsion, the granulation emulsion and elastic latex paints in various colors, adding the elastic latex paints into the color toning emulsion with stirring uniformly, and adding a mixture of the color toning emulsion and the elastic latex paints into the granulation emulsion with stirring uniformly. The water-in-water colorful paint is prepared with the granulation emulsion as the continuous phase and the color toning emulsion as the dispersed phase to form a two-phase emulsion. The preparation method is simple and is controllable in hardness of prepared granules. The paint is clear in color and is excellent in storage stability.

Owner:YANTAI ANJIALI COATINGS TECH CO LTD

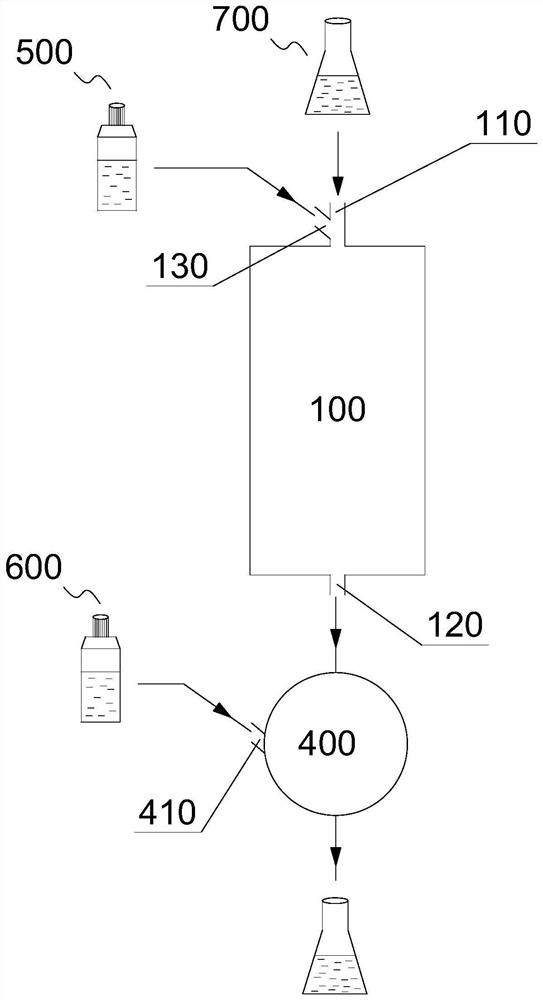

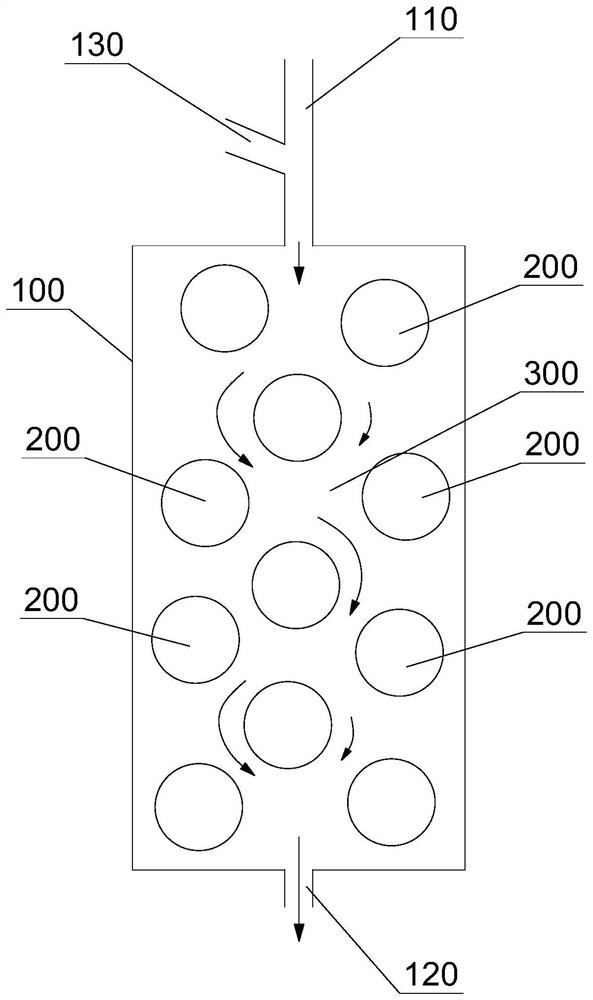

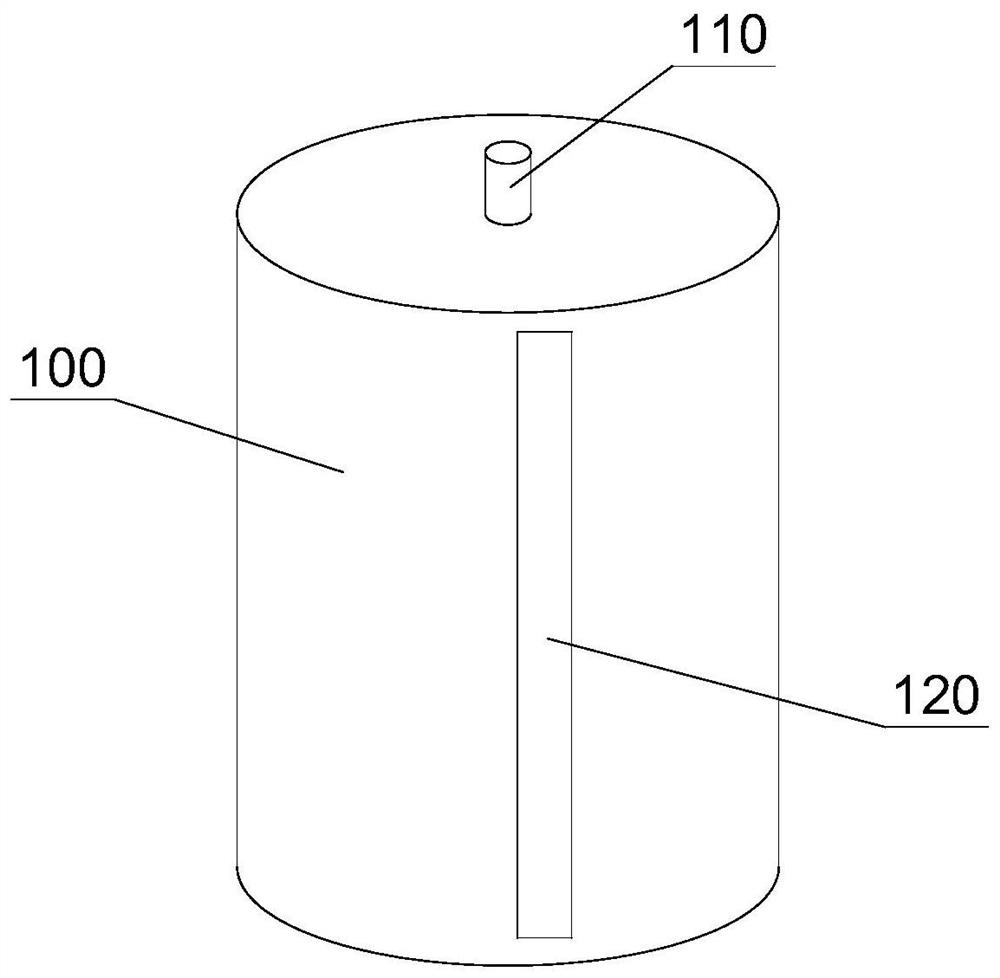

Biological particle purification device and purification method

PendingCN112251320ALow temperature flexibilityResilientCell dissociation methodsBioreactor/fermenter combinationsCentrifugationBiological particles

The invention relates to a biological particle purification device and a purification method. The biological particle purification device comprises the following parts: a purification system, and a centrifugation system. The purification system consists of at least one group of affinity columns, wherein the affinity columns are filled with fillers used for adsorbing biological particles and have chromatography channels; the affinity columns are provided with liquid inlets and liquid outlets; the liquid inlets are communicated with the chromatography channels; and the liquid outlets are communicated with the chromatography channels. The centrifugal system is in butt joint with the liquid outlets. The biological particle purification device forms a closed automatic process, so that pollutioncan be avoided; and moreover, continuous automatic purification operation can be achieved so as to ensure high production efficiency of the purification method.

Owner:GUANGZHOU GUANGLI BIOTECH

Method for waterproofing substrate

InactiveUS9121142B2Increased durabilityLow temperature flexibilityPaving reinforcementsIn situ pavingsHydrogenSynthetic resin

Owner:DYFLEX CORP

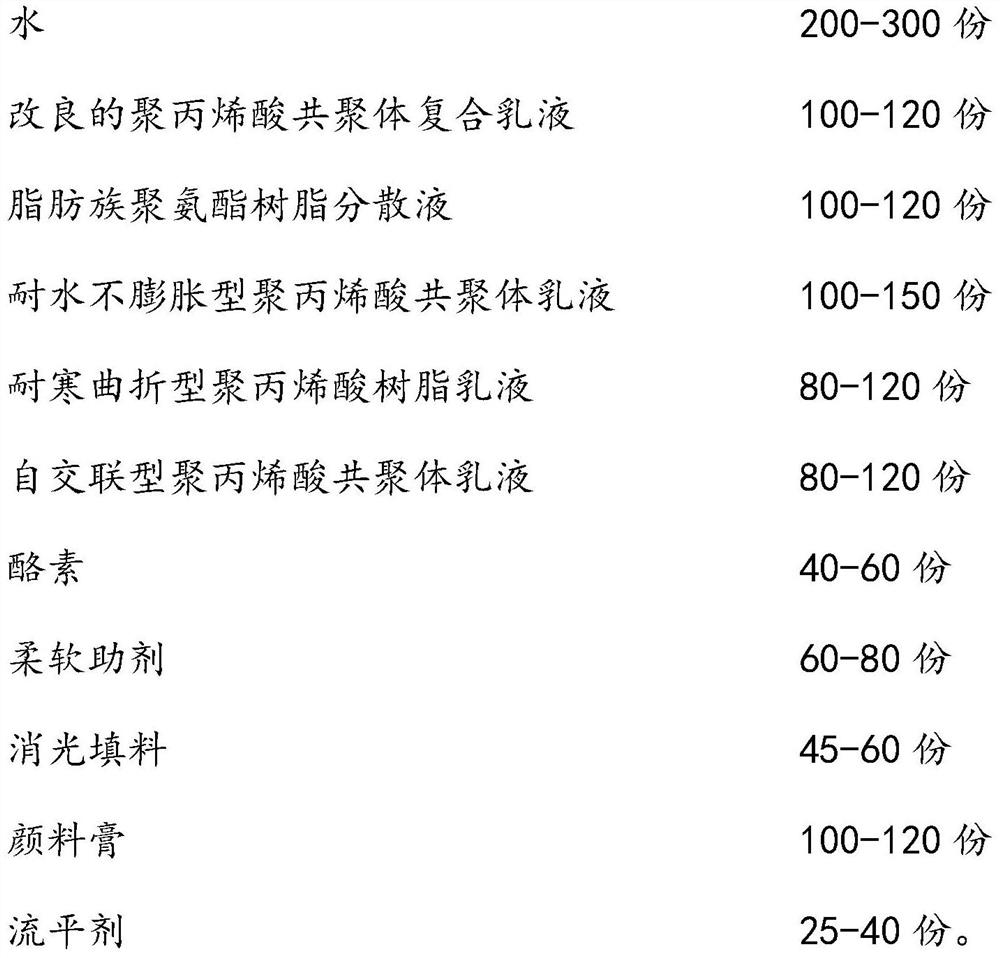

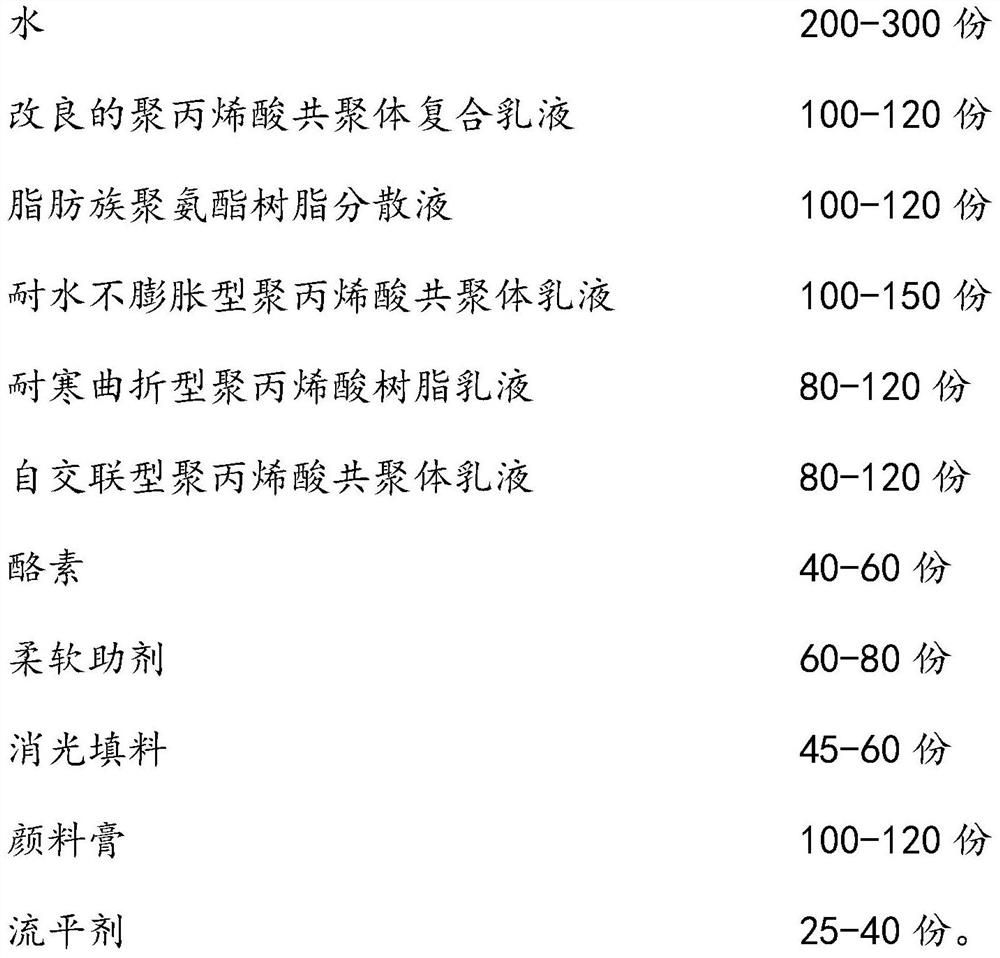

Green coating method based on heavy-metal-free tanned cow crust leather

PendingCN113969097AGood heat stabilityImprove coating hydrophobicityLeather stretching/tensioningLeather softeningComposite materialEmulsion

The invention discloses a green coating method based on heavy-metal-free tanned cow crust leather. The method comprises the following procedures: to-be-coated crust leather preparation, first milling, toggling, pre-priming coat spraying, priming coat spraying, ironing, intermediate coat spraying, isolation layer spraying, ironing, standing, second milling, oscillation staking, top coat spraying, ironing, oscillation staking, hand feeling layer spraying and finished leather obtaining, wherein the coating agent components in the priming coat spraying process and the intermediate coat spraying process are the same, each coating agent component comprises an improved polyacrylic acid copolymer composite emulsion, an aliphatic polyurethane resin dispersion liquid, a water-resistant non-expansive polyacrylic acid copolymer emulsion, a cold-resistant zigzag polyacrylic acid resin emulsion and a self-crosslinking polyacrylic acid copolymer emulsion, and the coating agent in the top coat spraying process comprises a resin film-forming agent. According to the invention, the water absorption of the heavy-metal-free tanned cow finished leather is greatly reduced, the heavy-metal-free tanned cow finished leather has good waterproof and antifouling properties, and the coating has good dry / wet rubbing resistance, wear resistance, bending resistance and gluing resistance.

Owner:XINGYE LEATHER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com