Radon-resisting modified asphalt and preparation method thereof

A technology of modified asphalt and modifier, applied in building components, building insulation materials, buildings, etc., to achieve the effects of excellent compactness and airtightness, improved waterproof performance, and strong radiation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Put 40 parts of petroleum asphalt with a penetration of 120 in the reaction tank, add 5 parts of plasticizer naphthenic oil, and then add 10 parts of polymer modifier linear SBS (styrene-butadiene-styrene, styrene -butadiene-styrene block thermoplastic elastomer) and 10 parts of SBR styrene-butadiene rubber, after mixing evenly, the temperature of the material was raised to 200°C, stirred and sheared for 2 hours until the modified polymeric agent was completely dispersed in the asphalt, and the Material temperature drops to 185 ℃, add 10 parts of radon-proof radiation basic material boron ore, 10 parts of radon-proof radiation basic material barite, 10 parts of radon-proof radiation basic material magnetite powder and 5 parts of Rutile-type titanium dioxide is stirred and mixed for 1 hour to a uniform state, and a radon-proof radiation-modified asphalt product is prepared. Its radon prevention effect and radiation protection performance are shown in Table 1 and Table 2:...

Embodiment 2

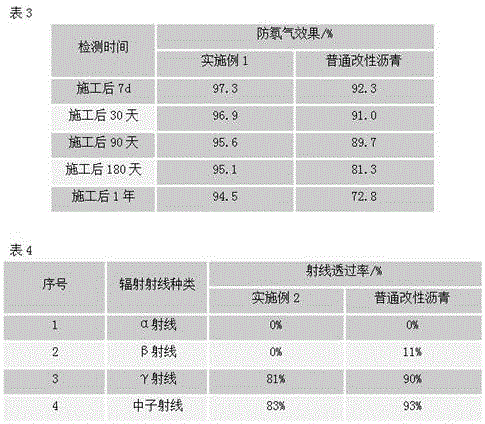

[0035] Put 55 parts of petroleum asphalt with a penetration of 70 in the reaction tank, add 15 parts of plasticizer aromatic oil, and then add 5 parts of polymer modifier linear SBS (styrene-butadiene-styrene, styrene- Butadiene-styrene block thermoplastic elastomer), after mixing evenly, raise the temperature of the material to 195°C, stir and shear and grind for 1.5h until the polymer modifier SBS is completely dispersed in the asphalt, then lower the temperature of the material to 180°C ℃, add 15 parts of radon-proof radiation basic material graphite, 5 parts of radon-proof radiation basic material clay and 5 parts of radon-proof radiation basic material magnetite powder, stir and mix for 1 hour to a uniform state, and prepare radon-proof Radiation modified bitumen finished product. Its radon prevention effect and radiation protection performance are shown in Table 3 and Table 4:

[0036]

Embodiment 3

[0038] 20 parts of natural asphalt with a penetration of 120 are placed in the reaction tank, 20 parts of plasticizer naphthenic oil are added, and 5 parts of polymer modifier SBS (styrene-butadiene-styrene, styrene-butylene Diene-styrene block thermoplastic elastomer), 5 parts of IIR butyl rubber, 5 parts of BR butadiene rubber and 10 parts of hot melt adhesive, after mixing evenly, raise the temperature of the material to 180 ° C, stir and shear Grind for 2 hours until the modified polymeric agent is completely dispersed in the asphalt, lower the temperature of the material to 180°C, add 5 parts of diatomaceous earth as the base material for preventing radon radiation, 10 parts of volcanic stone powder as the base material for preventing radon radiation, and 10 parts of Zinc ore powder, the basic element material for preventing radon radiation, and 10 parts of mica, the basic element material for preventing radon radiation, were stirred and mixed for 1.5 hours to a uniform st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com