Biological particle purification device and purification method

A technology of biological particles and purification devices, applied in the field of biochemical analysis, can solve the problems of easy contamination, limited magnetic field action distance, low degree of automation, etc., and achieve the effect of easy derivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

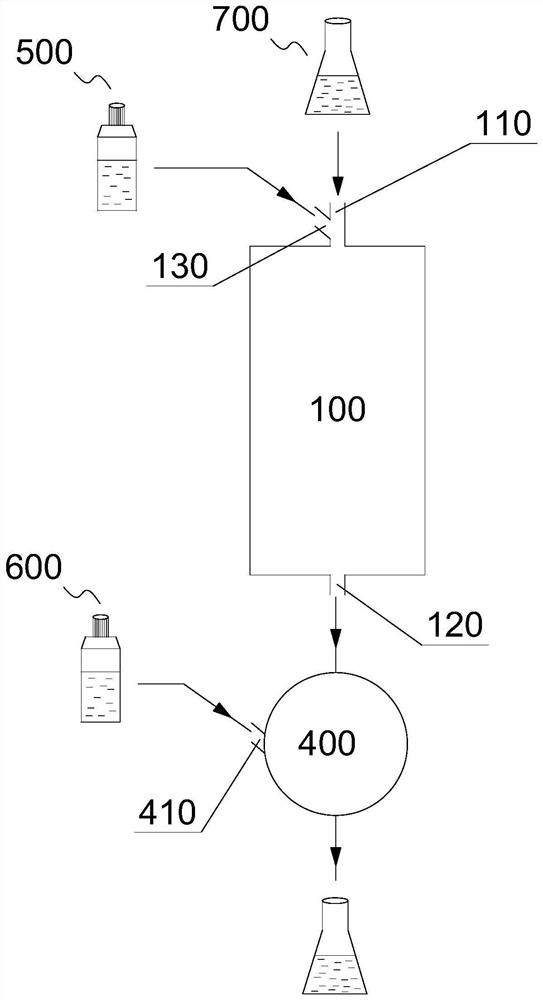

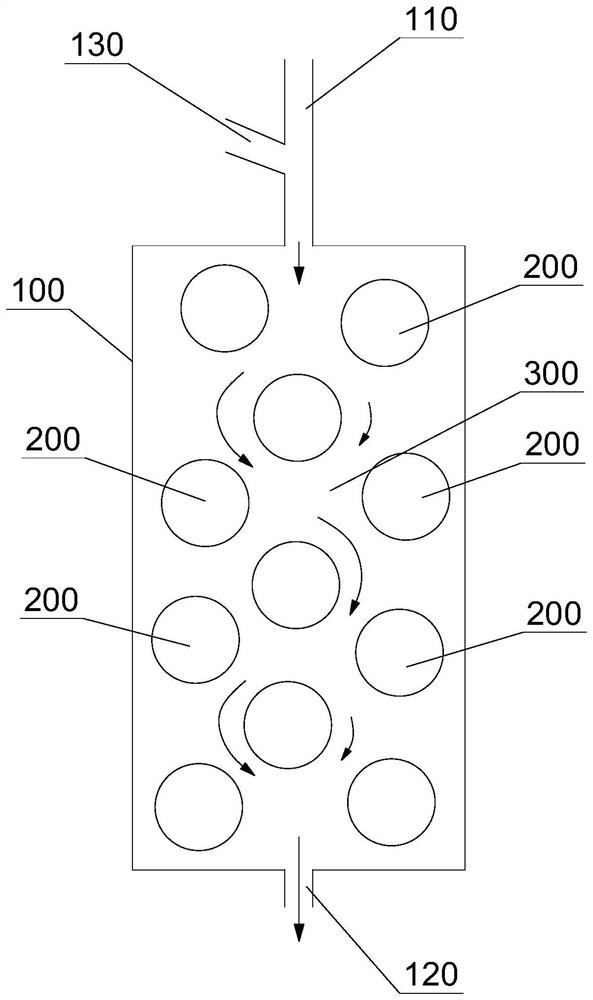

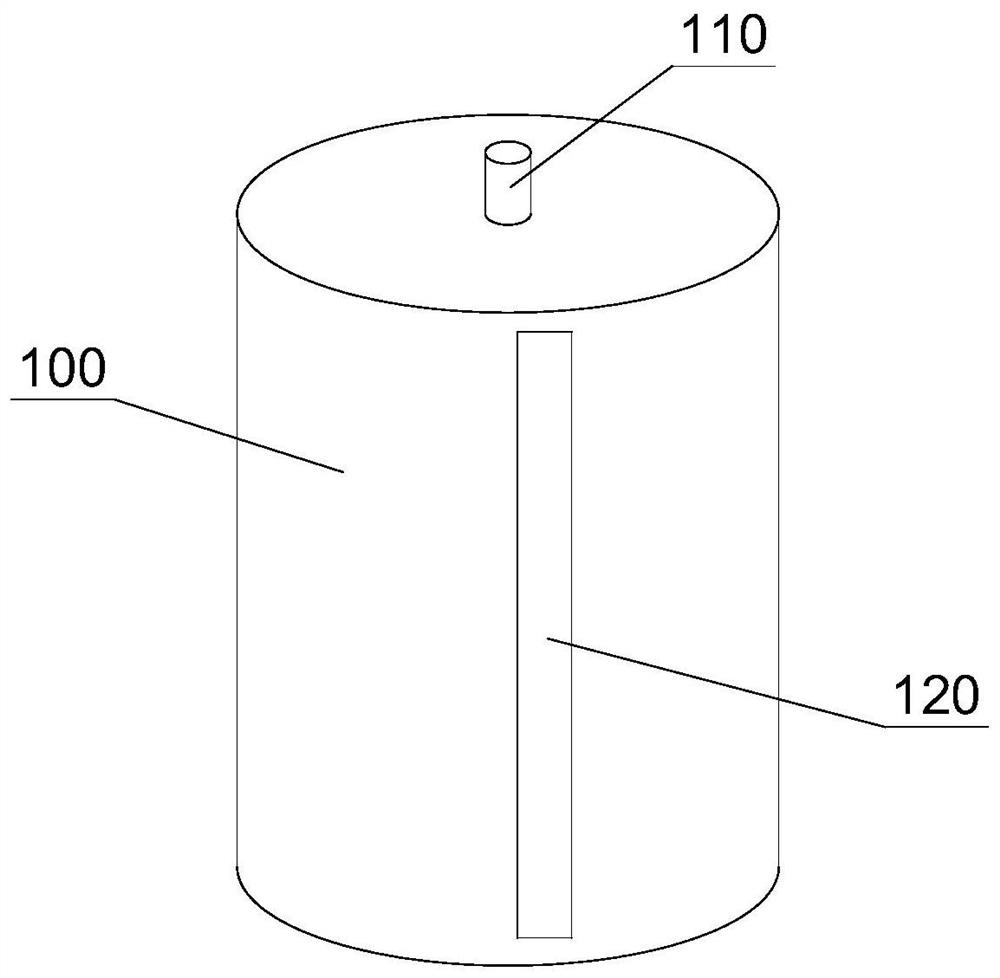

[0065] Such as figure 1 , 2 As shown, the biological particle purification device includes at least one set of affinity chromatography columns 100 and a centrifugal system. The biological particle purification device includes: a purification system and a centrifugal system. Affinity chromatography column 100 is provided with packing, and packing is used for adsorbing biological particles, and packing has chromatography channel 300, and affinity chromatography column 100 is provided with liquid inlet 110 and liquid outlet 120, and liquid inlet 110 is connected with chromatography The channel 300 communicates, the liquid outlet 120 communicates with the chromatography channel 300 , the centrifuge system includes a centrifuge and other auxiliary equipment, and the centrifuge 400 is connected to the liquid outlet 120 . The stock solution 700 to be purified enters from the liquid inlet 110 and flows through the chromatographic channel 300 for purification.

[0066] In this embod...

Embodiment 2

[0088] The difference between embodiment two and embodiment one is:

[0089] Such as Figure 3-6 As shown, the filler is a membrane carrier 210, and the affinity chromatography column 100 is provided with a membrane carrier 210 to replace the microparticle carrier 200 (the technical characteristics of the microparticle carrier 200 described in Example 1 can be replaced on the membrane carrier 210 for use, in this embodiment The example will not be described in detail.), the membrane carrier 210 is curled into a loose scroll and placed in the affinity chromatography column 100, and the gap formed by the membrane carrier 210 forms the chromatography channel 300, such as Figure 4 , 5 As shown, the membrane material can be fixed into a roll shape by using commonly used brackets, buckles, welding, bonding or other methods. The affinity chromatography column 100 is provided with a liquid inlet 110 and a liquid outlet 120, the liquid inlet 110 is communicated with the chromatograp...

Embodiment 3

[0091] The difference between embodiment three and embodiment two is:

[0092] Such as Figure 7 As shown, the filler is a membrane carrier 210, and the membrane carrier 210 is provided with cavities 213, and these cavities 213 form a chromatography channel 300, and the stock solution 700 to be purified enters from the center of the reel, flows out after passing through the hollow chromatography channel 300, and the membrane carrier 210 is provided with specific antibodies, and the target biological particles in the stock solution 700 to be purified bind to the specific antibodies attached to the membrane carrier 210 . In this embodiment, the membrane carrier 210 includes a laminated lining film 211 and a microporous membrane 212, the lining membrane 211 is mesh-shaped, and the lining membrane 211 is used to provide support for the microporous membrane 212, and the stock solution 700 to be purified can easily pass through the lining membrane 211 mesh. The microporous membran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com