Self-extinction skin-feeling solvent-free polyurethane waterborne matte surface treatment agent

A solvent-free polyurethane and polyurethane thickener technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as reducing surface energy, reducing film bubbles, and whitening of synthetic leather surfaces, so as to reduce surface energy and reduce Film bubbles, good skin feel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

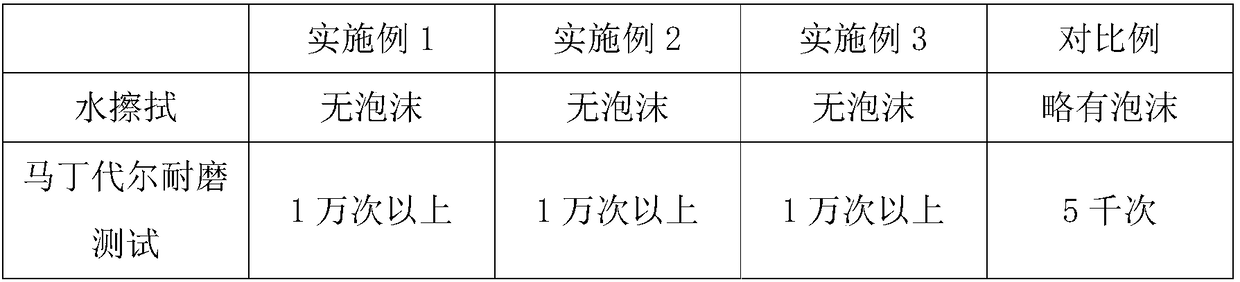

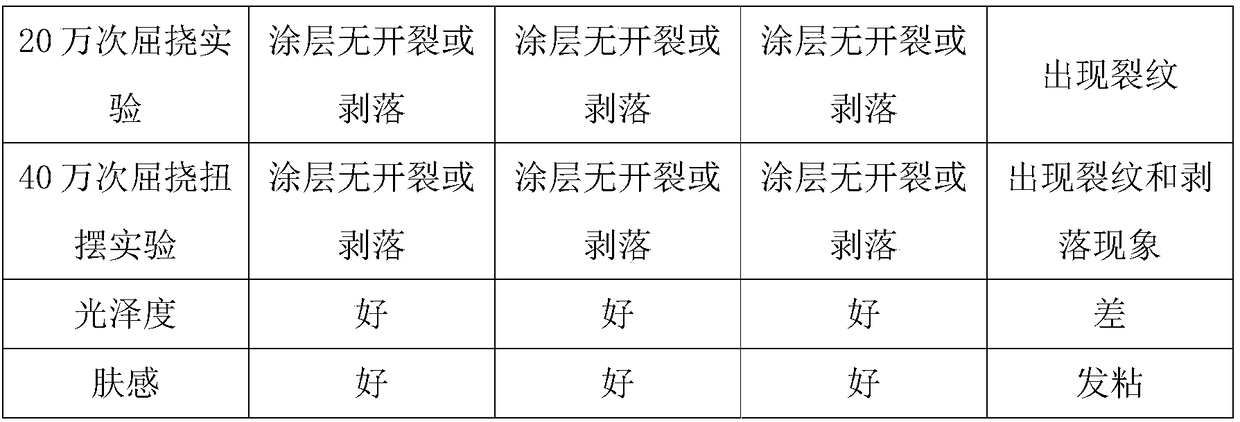

Examples

Embodiment 1

[0030] A self-dulling skin-feeling solvent-free polyurethane water-based matt surface treatment agent, prepared from the following quality formula:

[0031] Water-based matting polyurethane resin 100 parts, water 150 parts, wetting agent UL-5125: 4 parts, defoamer F-530: 0.5 parts, polyurethane thickener 8807: 5 parts; wetting agent and defoaming agent are from Jiangsu Ao Sijia Material Technology Co., Ltd., polyurethane thickener from Zhejiang Anran Technology Co., Ltd.

[0032] Preparation:

[0033] Step 1, weigh the raw materials according to the above formula, and set aside;

[0034] Step 2, adding water-based matte polyurethane resin, water, wetting agent, defoamer and polyurethane thickener to the dispersion tank in turn and stirring for 1 hour, after the end, a matte surface treatment agent is obtained, and the stirring speed of the stirring is 500r / min.

[0035] How to use: Put the matt surface treatment agent into the stirring device and stir evenly, then use QTS ...

Embodiment 2

[0049] A self-dulling skin-feeling solvent-free polyurethane water-based matt surface treatment agent, prepared from the following quality formula:

[0050] Water-based matting polyurethane resin 100 parts, water 150 parts, wetting agent UL-5125: 4 parts, defoamer F-530: 0.5 parts, polyurethane thickener 8807: 5 parts; wetting agent and defoaming agent are from Jiangsu Ao Sijia Material Technology Co., Ltd., polyurethane thickener from Zhejiang Anran Technology Co., Ltd.

[0051] Preparation:

[0052] Step 1, weigh raw materials according to the above formula, and set aside;

[0053] Step 2, adding water-based matte polyurethane resin, water, wetting agent, defoamer and polyurethane thickener to the dispersion tank in turn and stirring for 1 hour, after the end, a matte surface treatment agent is obtained, and the stirring speed of the stirring is 500r / min.

[0054] How to use: Put the matt surface treatment agent into the stirring device and stir evenly, then use QTS wire...

Embodiment 3

[0068] A self-dulling skin-feeling solvent-free polyurethane water-based matt surface treatment agent, prepared from the following quality formula:

[0069] Water-based matting polyurethane resin 100 parts, water 150 parts, wetting agent UL-5125: 4 parts, defoamer F-530: 0.5 parts, polyurethane thickener 8807: 5 parts; wetting agent and defoaming agent are from Jiangsu Ao Sijia Material Technology Co., Ltd., polyurethane thickener from Zhejiang Anran Technology Co., Ltd.

[0070] Preparation:

[0071] Step 1, weigh raw materials according to the above formula, and set aside;

[0072] Step 2, adding water-based matte polyurethane resin, water, wetting agent, defoamer and polyurethane thickener to the dispersion tank in turn and stirring for 1 hour, after the end, a matte surface treatment agent is obtained, and the stirring speed of the stirring is 500r / min.

[0073] How to use: Put the matt surface treatment agent into the stirring device and stir evenly, then use QTS wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com