Patents

Literature

88results about How to "Improve ultimate tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

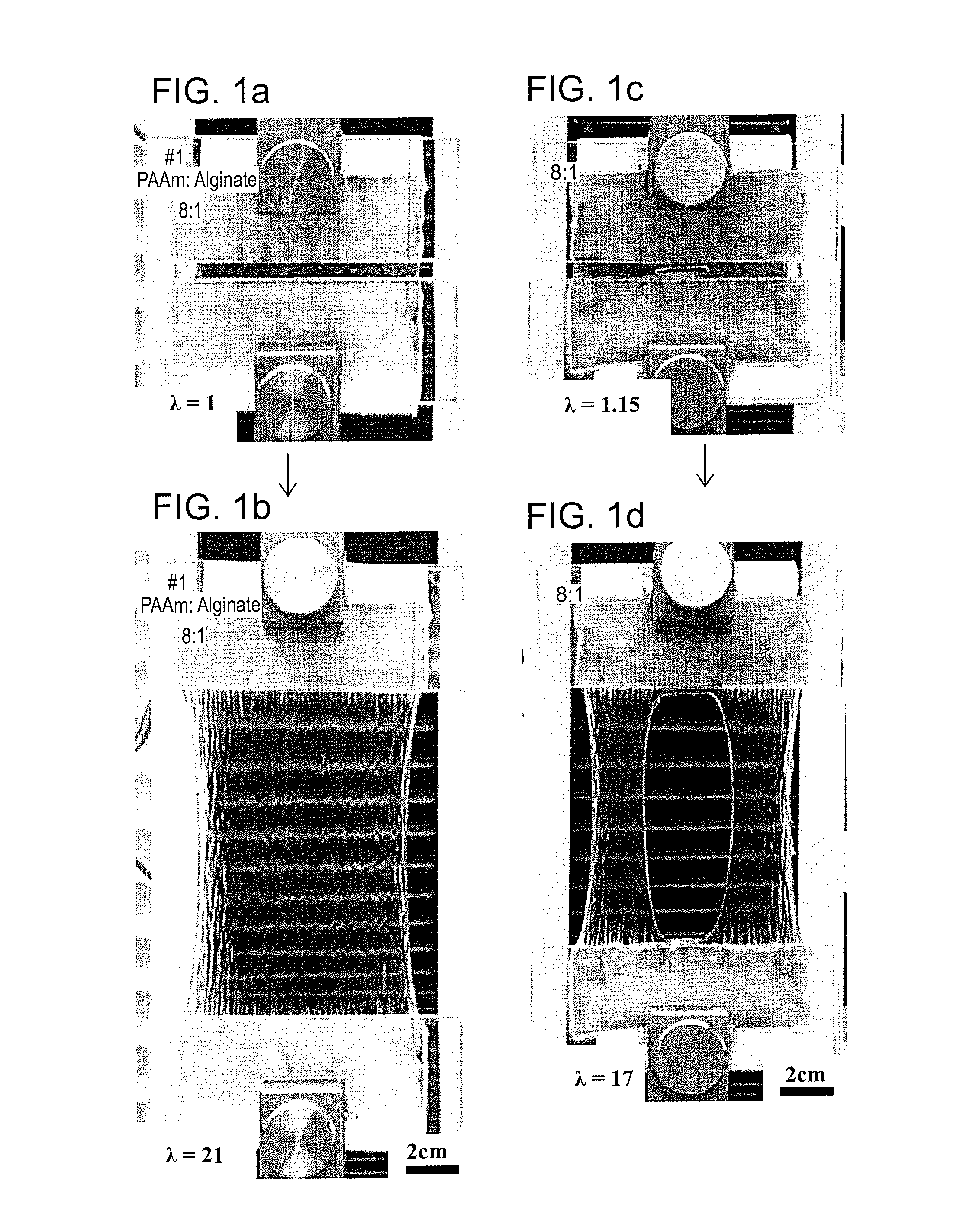

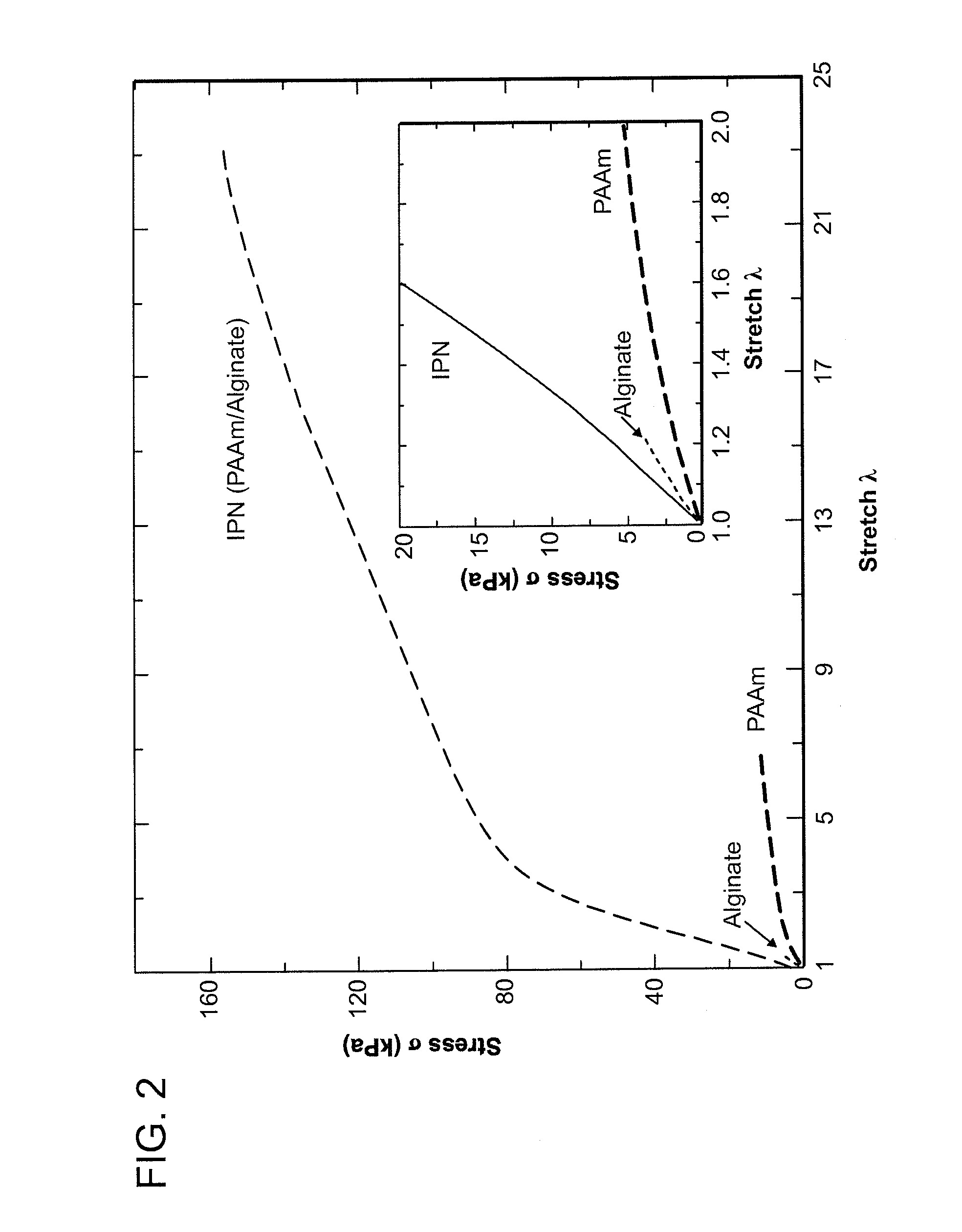

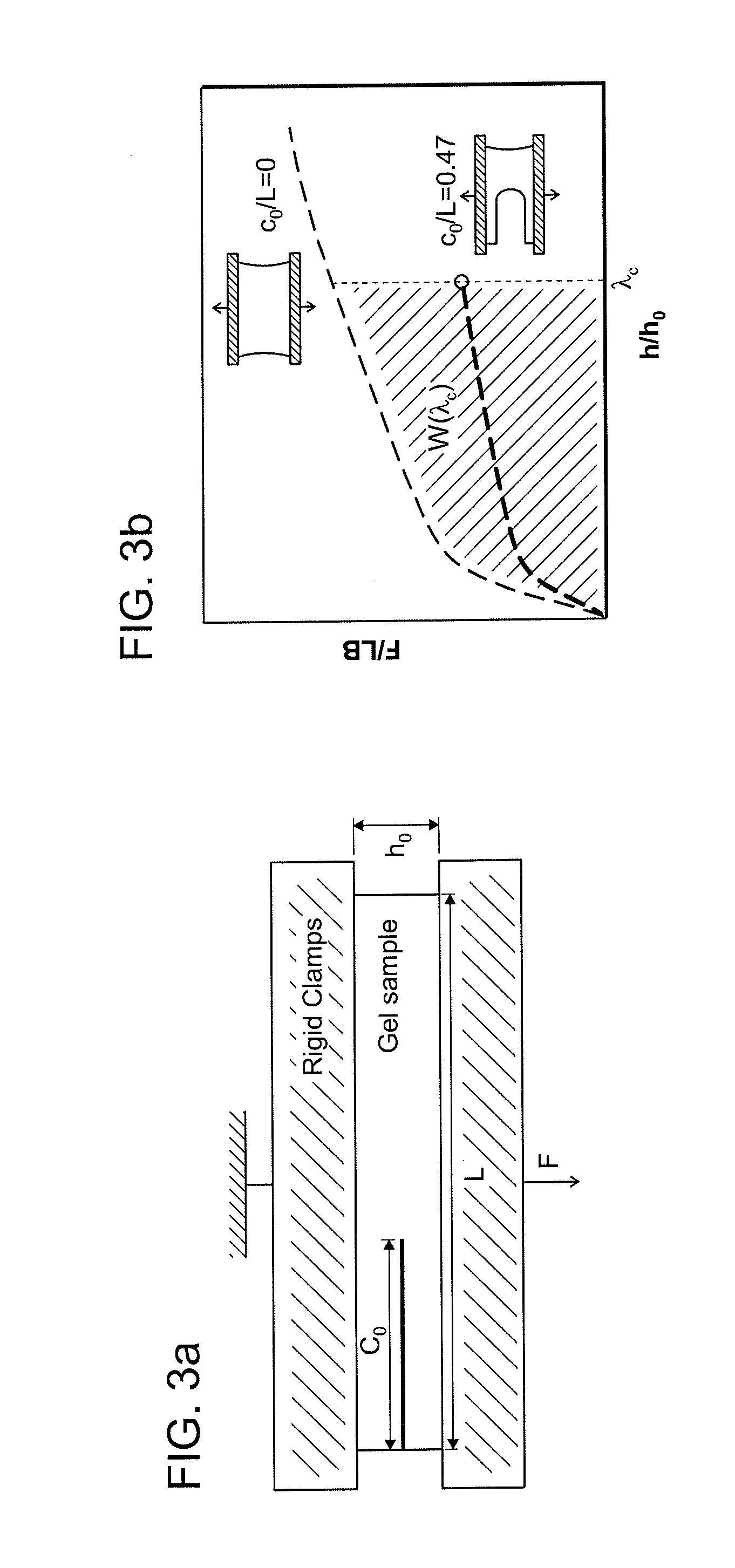

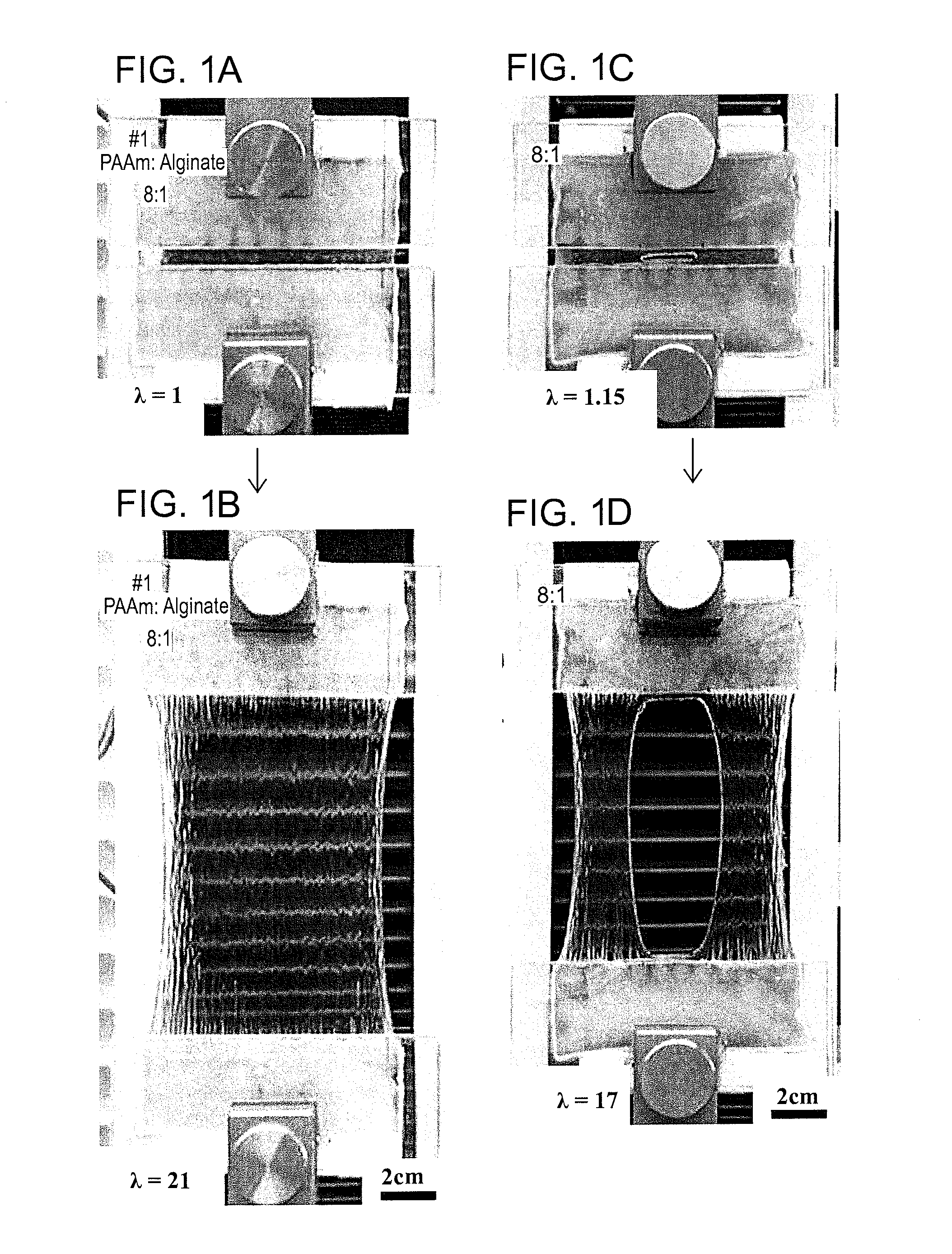

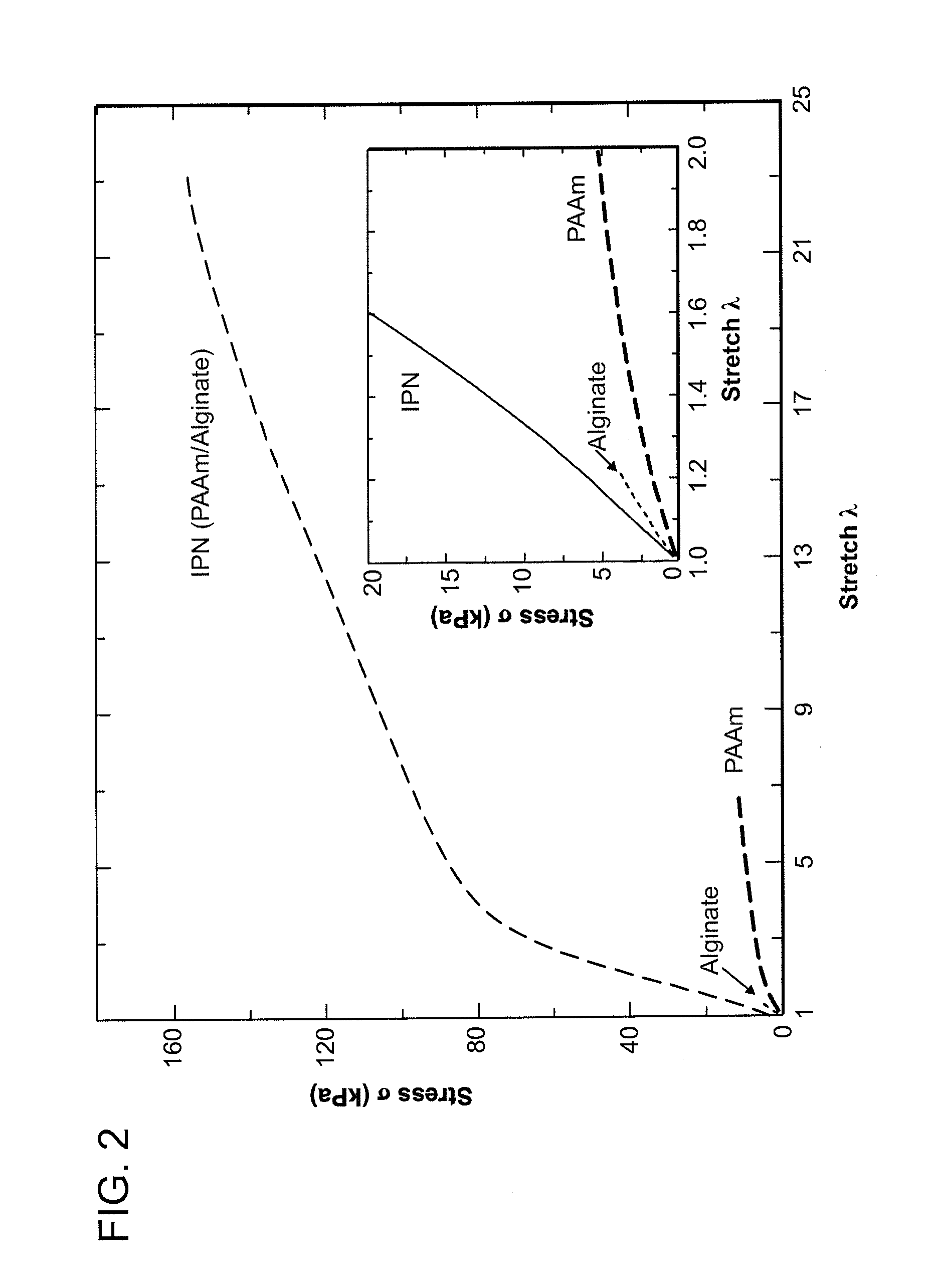

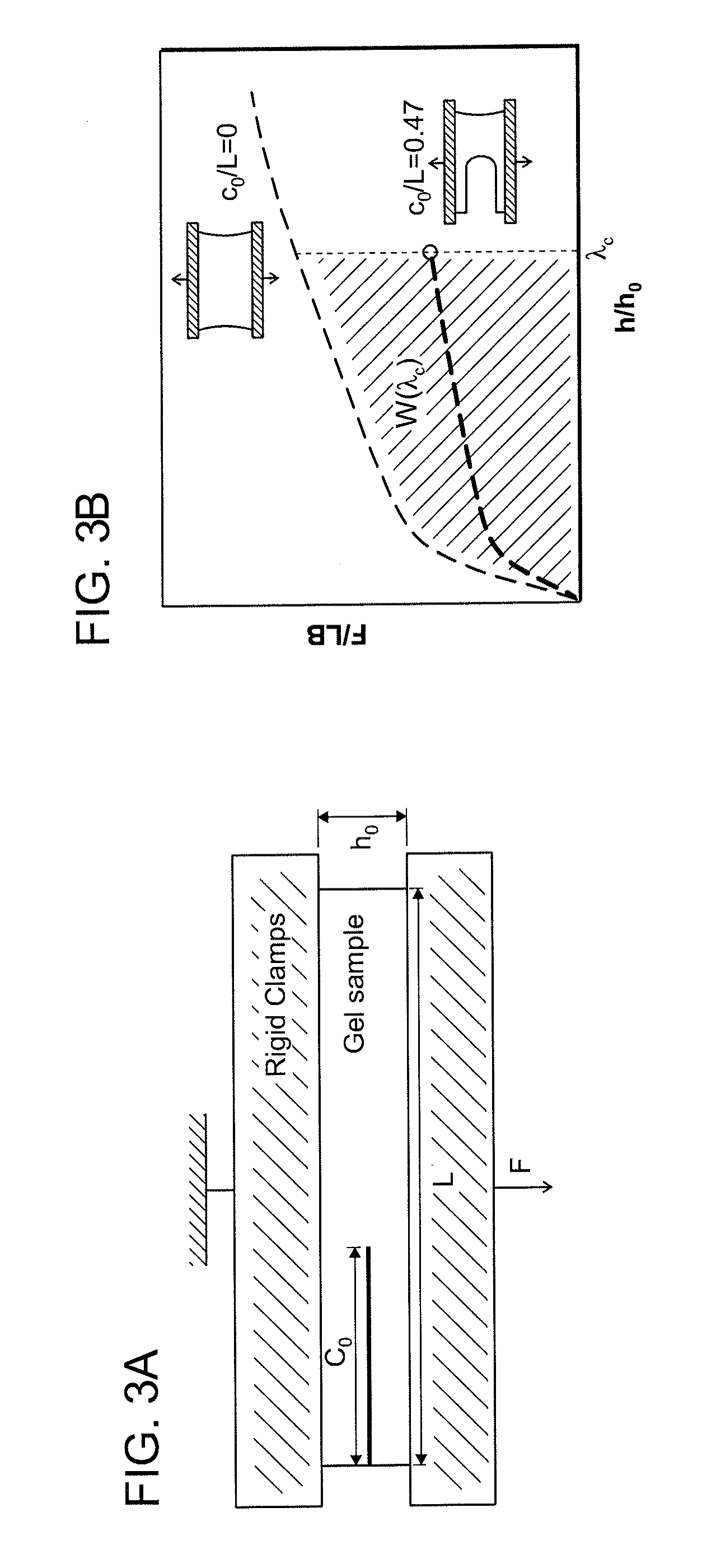

Interpenetrating Networks With Covalent and Ionic Crosslinks

ActiveUS20150038613A1Stay resilientImprove mechanical propertiesSurgical adhesivesProsthesisSelf-healingEngineering

The invention features a composition comprising a self-healing interpenetrating network hydrogel comprising a first network and a second network. The first network comprises covalent crosslinks and the second network comprises ionic or physical crosslinks. For example, the first network comprises a polyacrylamide polymer and second network comprises an alginate polymer.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE +1

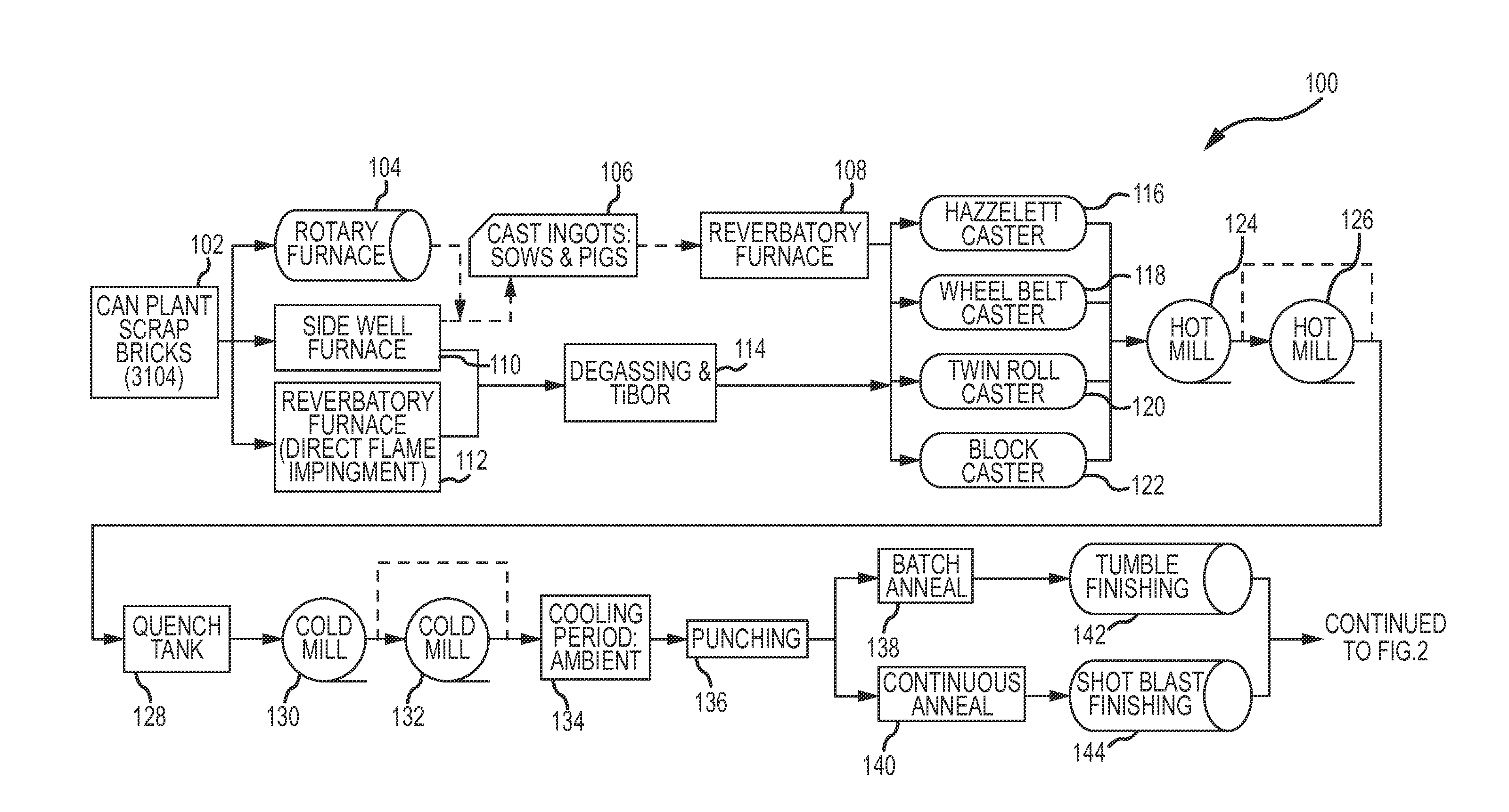

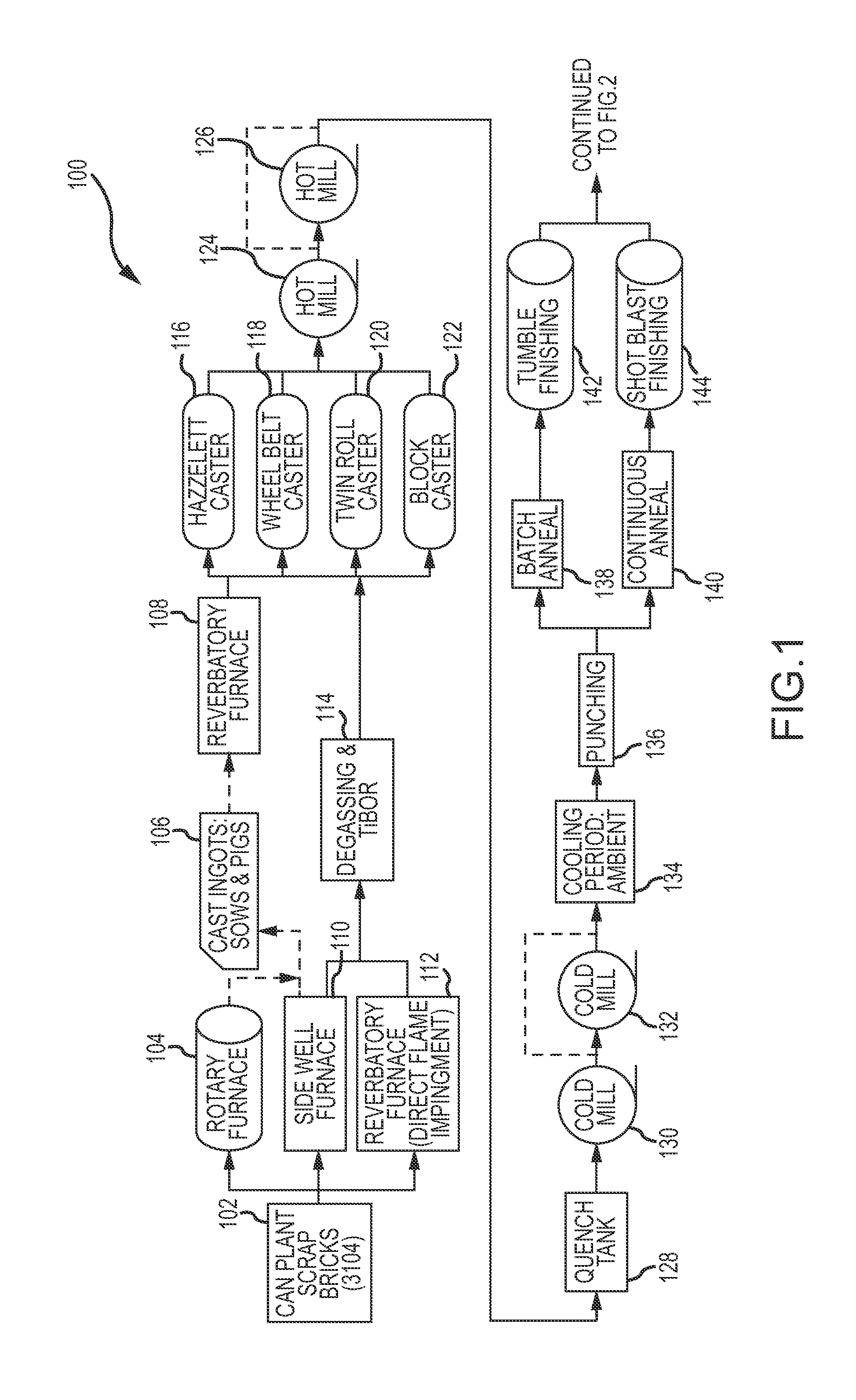

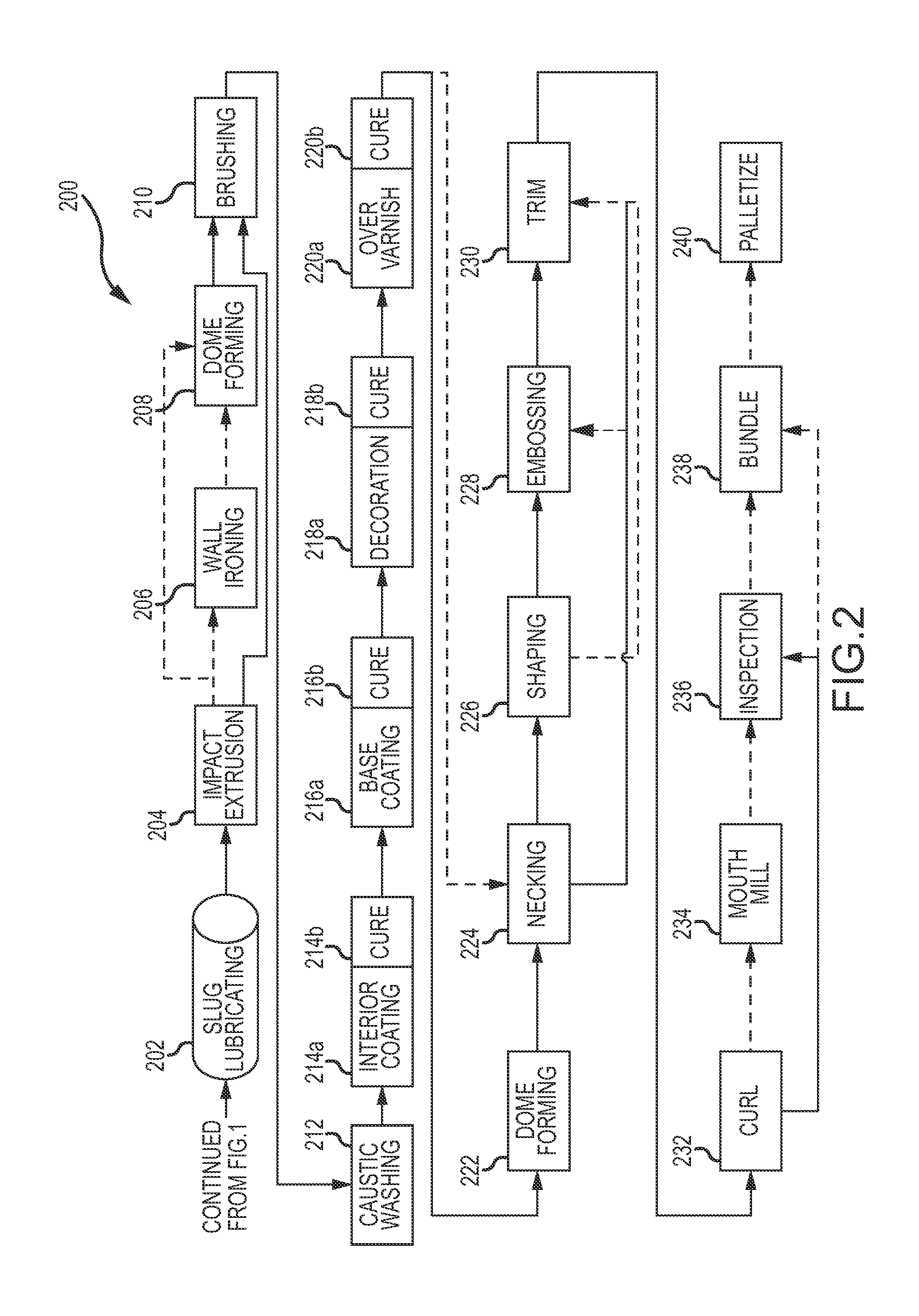

Impact extruded containers from recycled aluminum scrap

ActiveUS20130068352A1Increase resistanceReduction in weight and metal contentLiquid dispensingScrapEnvironmentally friendly

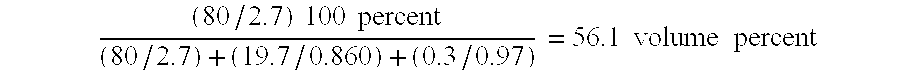

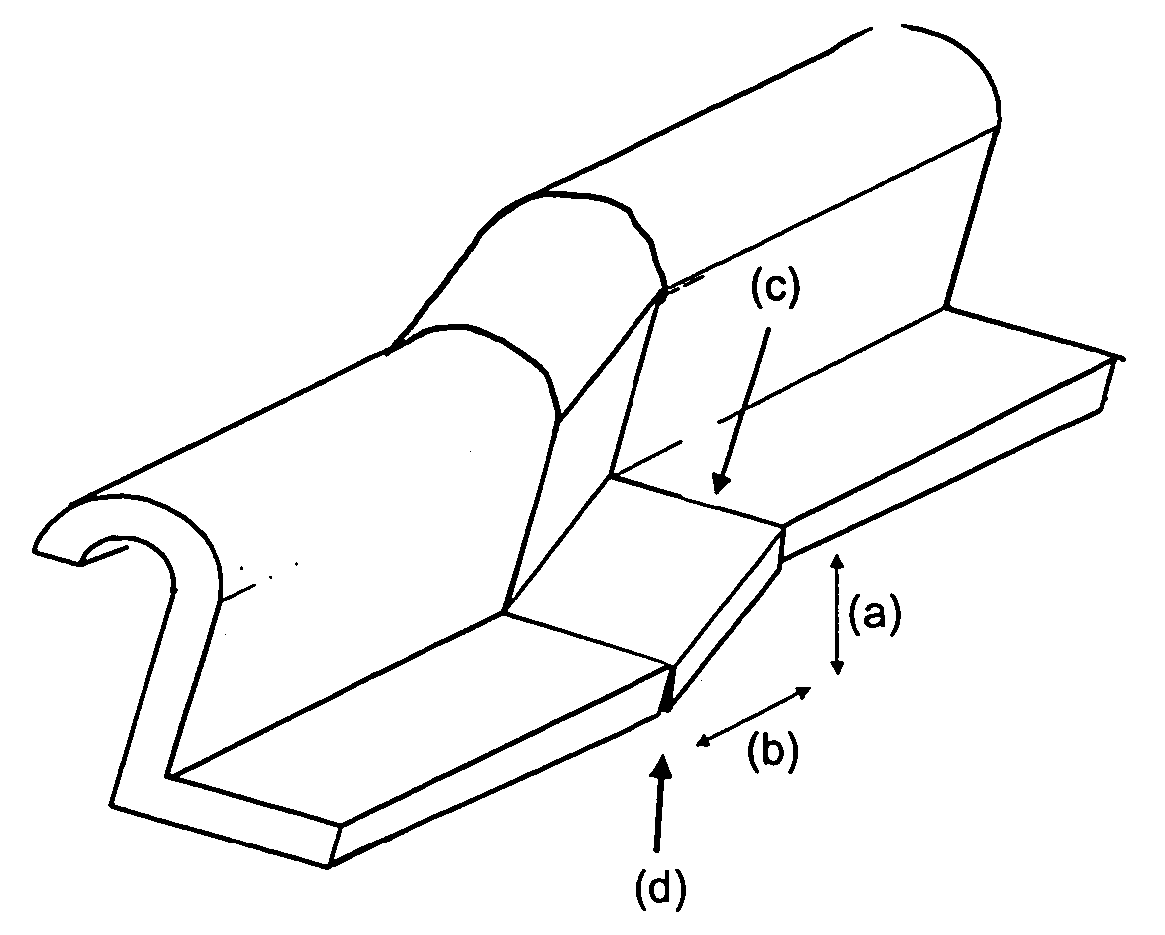

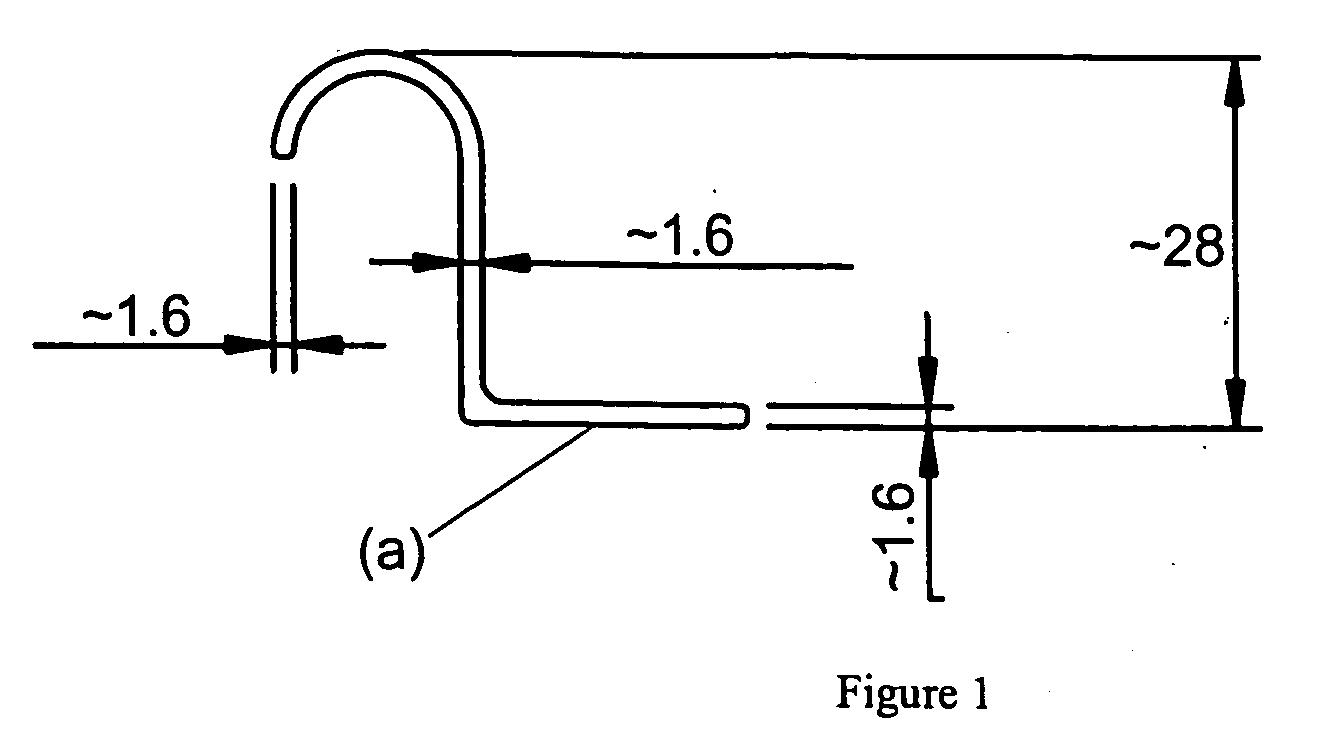

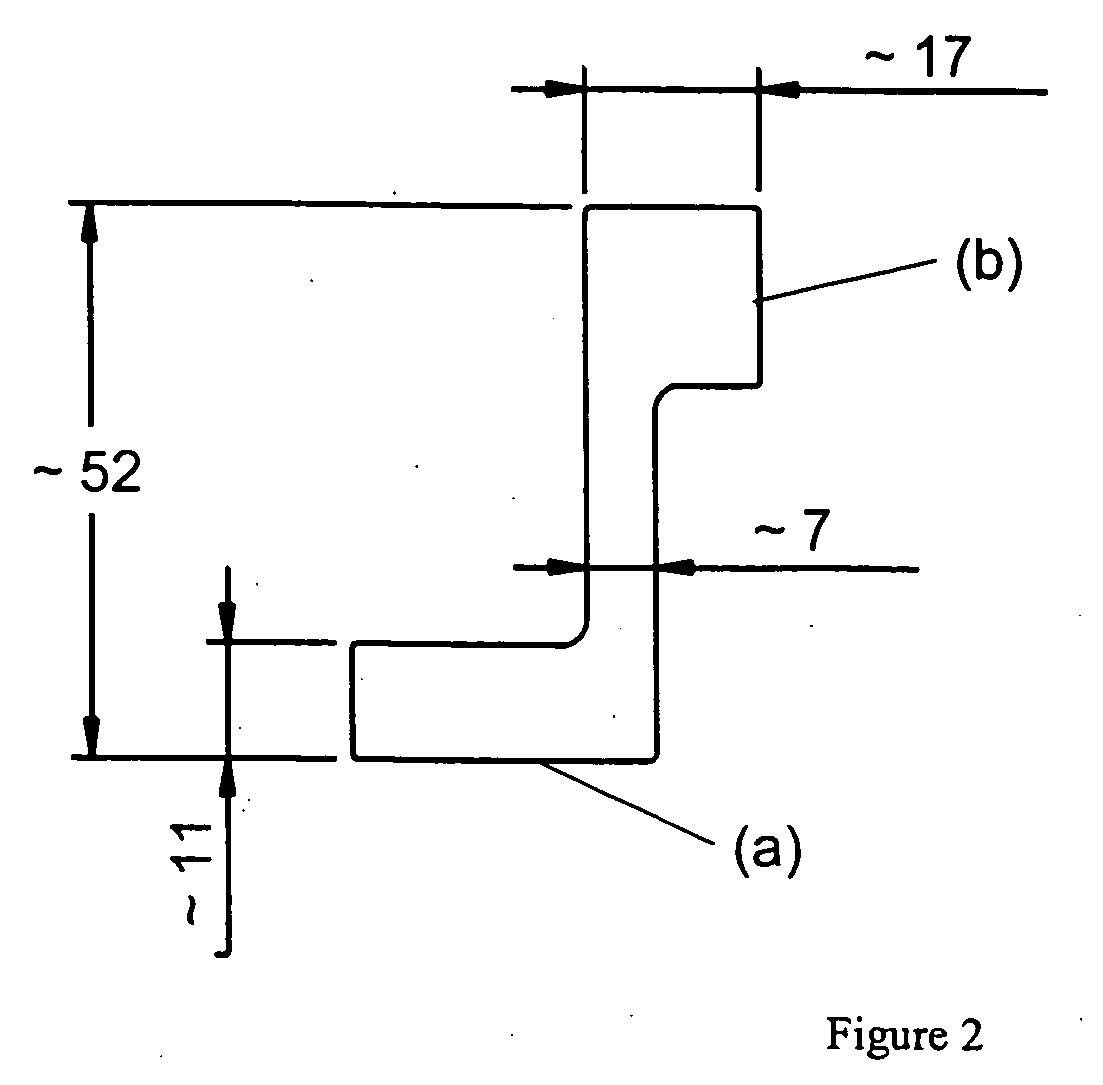

Novel aluminum alloys are provided for use in an impact extrusion manufacturing process to create shaped containers and other articles of manufacture. In one embodiment blends of recycled scrap aluminum are used in conjunction with relatively pure aluminum to create novel compositions which may be formed and shaped in an environmentally friendly process. Other embodiments include methods for manufacturing a slug material comprising recycled aluminum for use in the impact extraction process.

Owner:BALL CORP

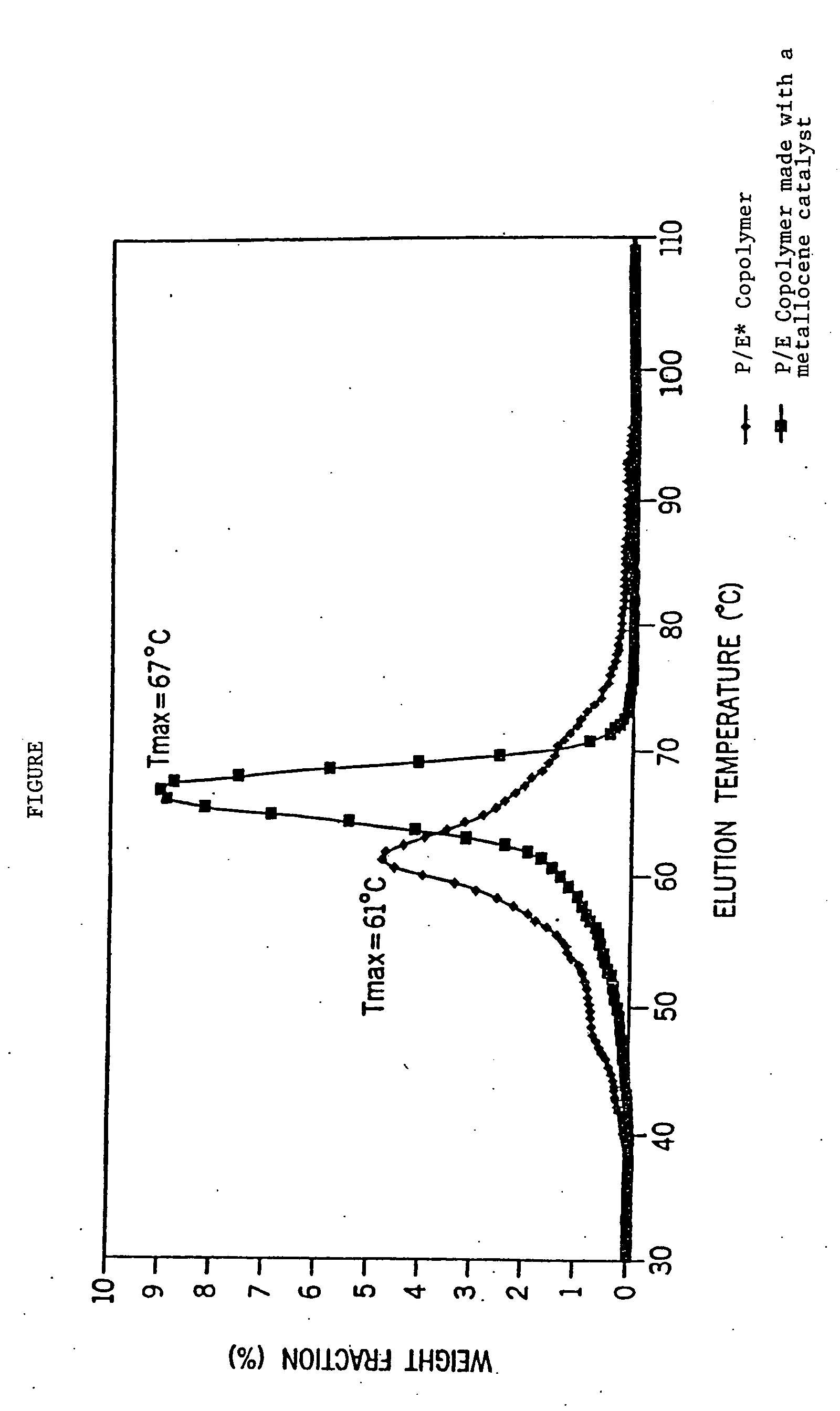

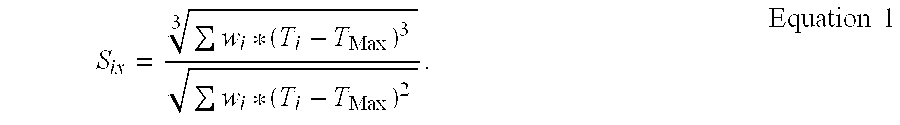

Filled thermoplastic olefin composition

InactiveUS20050032959A1Improve balanceGood physical propertiesOther chemical processesPigment pastesPolymer sciencePolypropylene

A filled thermoplastic olefin composition comprising (a) a first polypropylene having (i) substantially isotactic propylene sequences, (ii) a narrow molecular weight distribution, and (iii) a broad composition distribution, and (b) at least about 20 percent by volume filler based on the total volume of the composition. Optionally, the composition can comprise a second polypropylene different for the first polypropylene, both polypropylenes preferably propylene / α-olefin copolymers. The filler can be organic or inorganic, and the compositions are useful as, among other applications, protective coverings for wire and cable.

Owner:CHEUNG YUNWA WILSON +2

Al-Zn-Mg-Cu alloys and products with high mechanical characteristics and structural members suitable for aeronautical construction made thereof

InactiveUS20060182650A1High in zincImprove ultimate tensile strengthFuselage framesSeating arrangementsAlloyImpurity

The present invention further relates to 7xxx alloys and products produced therewith that can be flat rolled, extruded or forged, as well as associated methods. Al—Zn—Mg—Cu alloys of the present invention preferably comprise (in mass percentage): a) Zn 8.3-14.0 Cu 0.3-2.0 Mg 0.5-4.5 Zr 0.03-0.15 Fe+Si<0.25 b) at least one element selected from the group consisting of Sc, Hf, La, Ti, Ce, Nd, Eu, Gd, Tb, Dy, Ho, Er, Y and Yb, where the content of each of the elements, if selected, is between 0.02 and 0.7%, c) remainder aluminum and inevitable impurities. The present invention further is directed to products wherein Mg / Cu>2.4 and (7.9-0.4 Zn)>(Cu+Mg)>(6.4-0.4 Zn). The disclosed products can be used for example, as structural members in aeronautical construction, especially as stiffeners capable for use in fuselages of civilian and other aircrafts as well as in related applications.

Owner:EBERL FRANK +3

Al-Zn-Mg-Cu alloys and products with high mechanical characteristics and structural members suitable for aeronautical construction made thereof

InactiveUS20050072497A1High in zincAdequate resistance to corrosionFuselage framesSeating arrangementsAlloyImpurity

The present invention further relates to 7xxx alloys and products produced therewith that can be flat rolled, extruded or forged, as well as associated methods. Al—Zn—Mg—Cu alloys of the present invention preferably comprise (in mass percentage): a) Zn 8.3−14.0 Cu 0.3−2.0 Mg 0.5−4.5 Zr 0.03−0.15 Fe+Si<0.25 b) at least one element selected from the group consisting of Sc, Hf, La, Ti, Ce, Nd, Eu, Gd, Th, Dy, Ho, Er, Y and Yb, where the content of each of the elements, if selected, is between 0.02 and 0.7%, c) remainder aluminum and inevitable impurities. The present invention further is directed to products wherein Mg / Cu>2.4 and (7.9−0.4 Zn)>(Cu+Mg)>(6.4−0.4 Zn). The disclosed products can be used for example, as structural members in aeronautical construction, especially as stiffeners capable for use in fuselages of civilian and other aircrafts as well as in related applications.

Owner:PECHINEY RHENALU +1

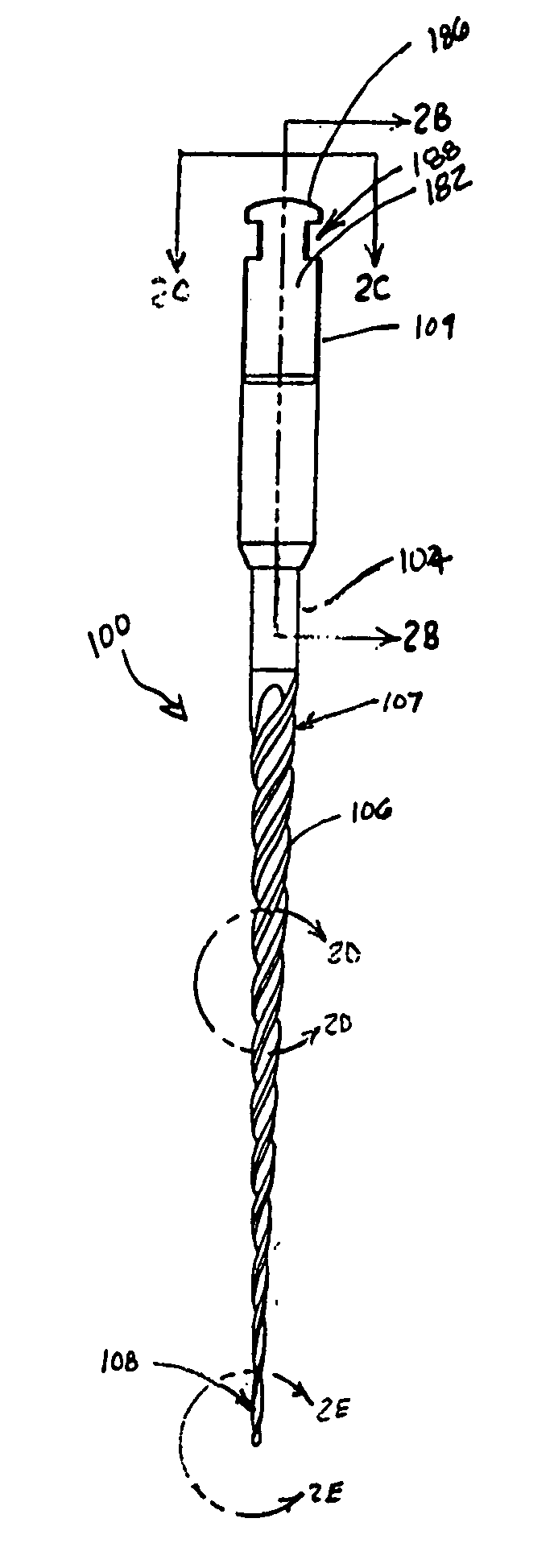

Precision cast dental instrument

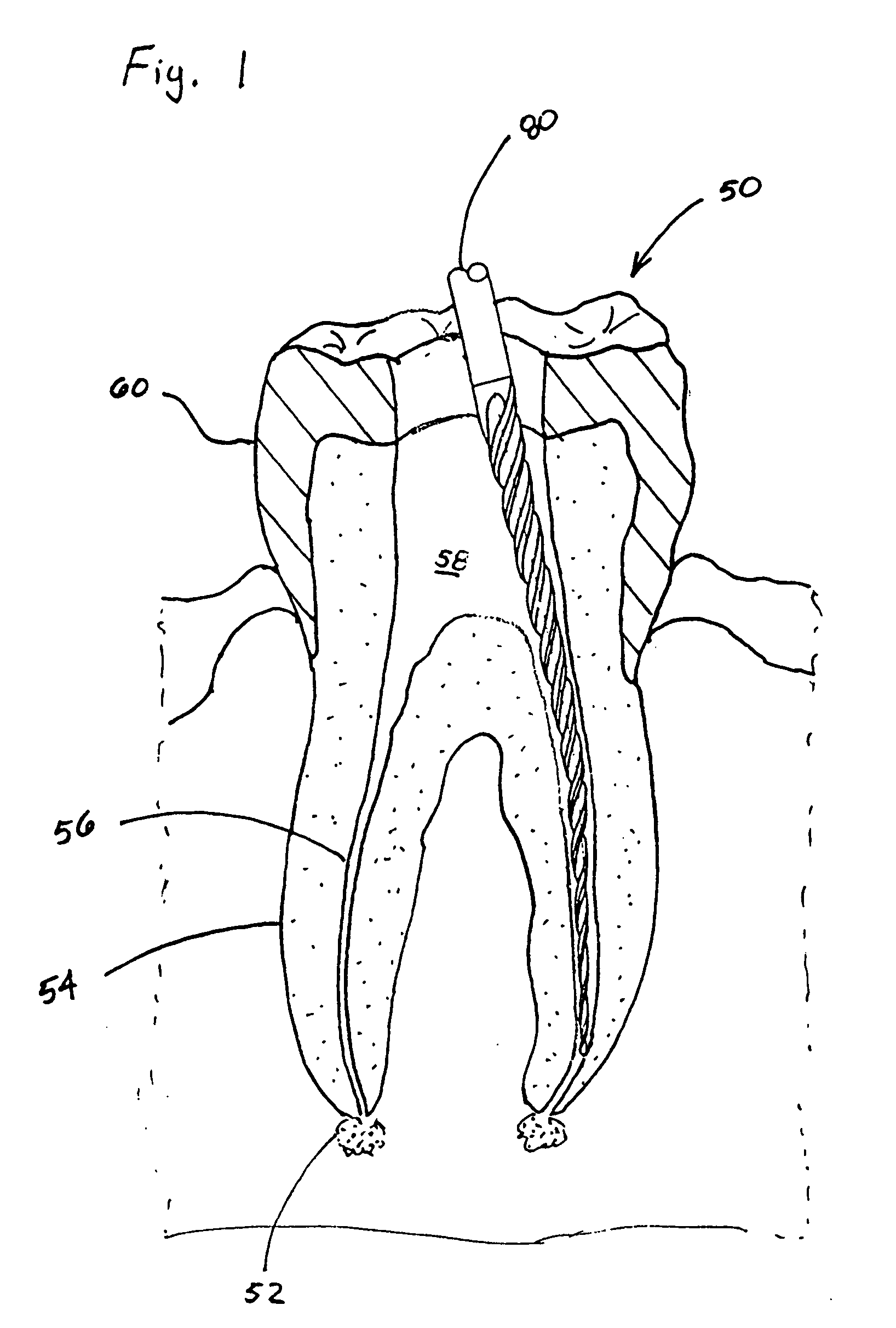

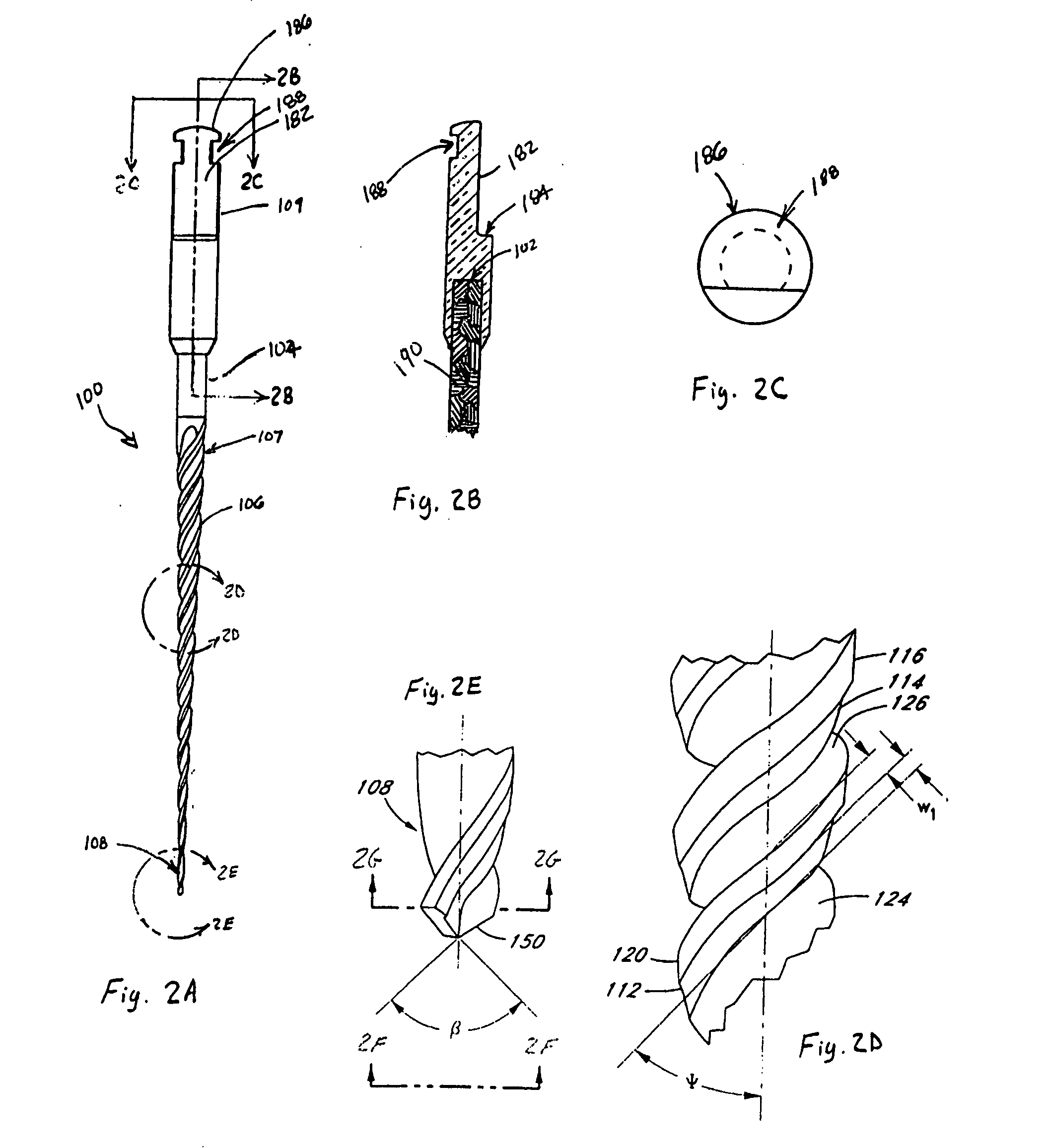

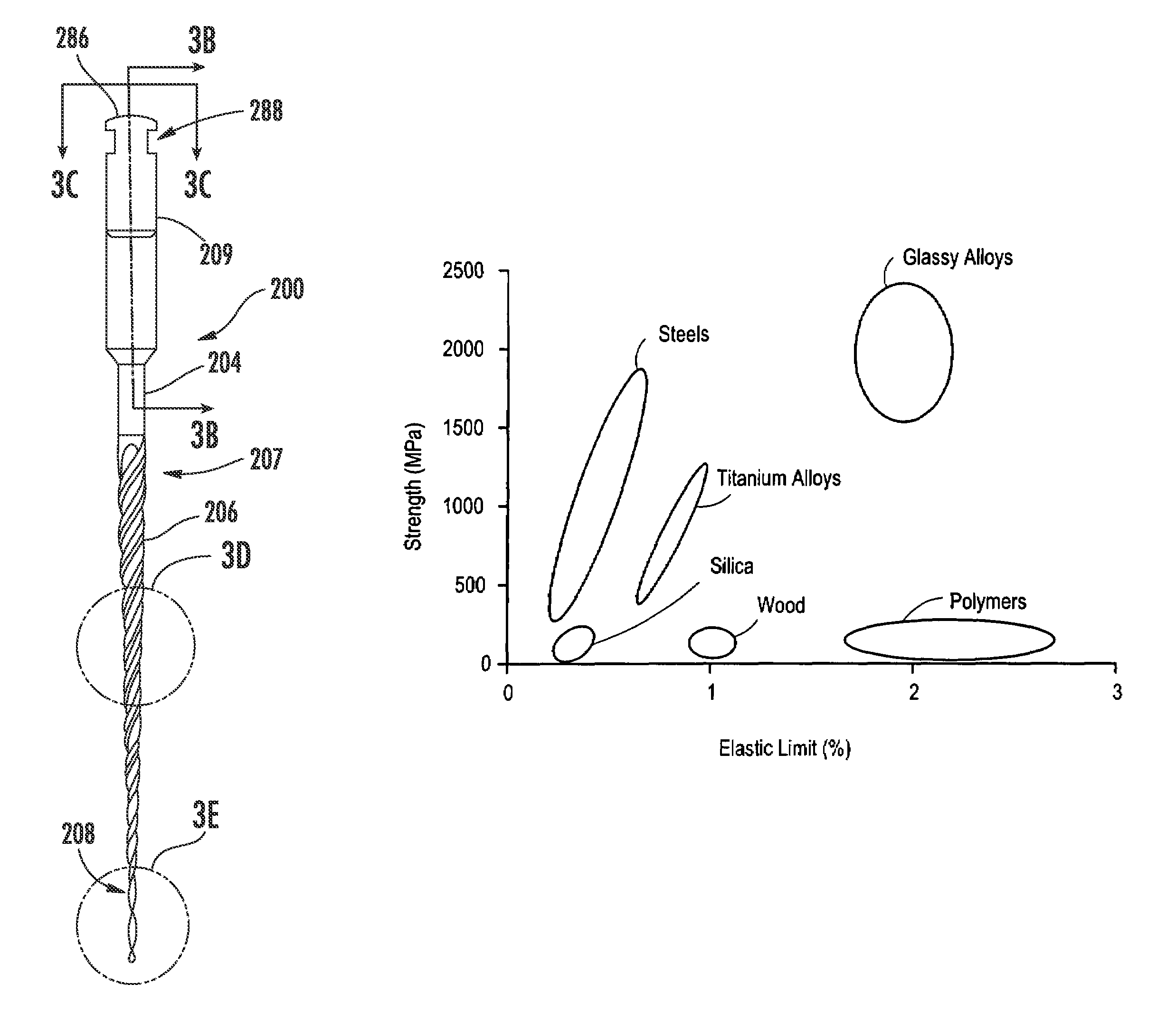

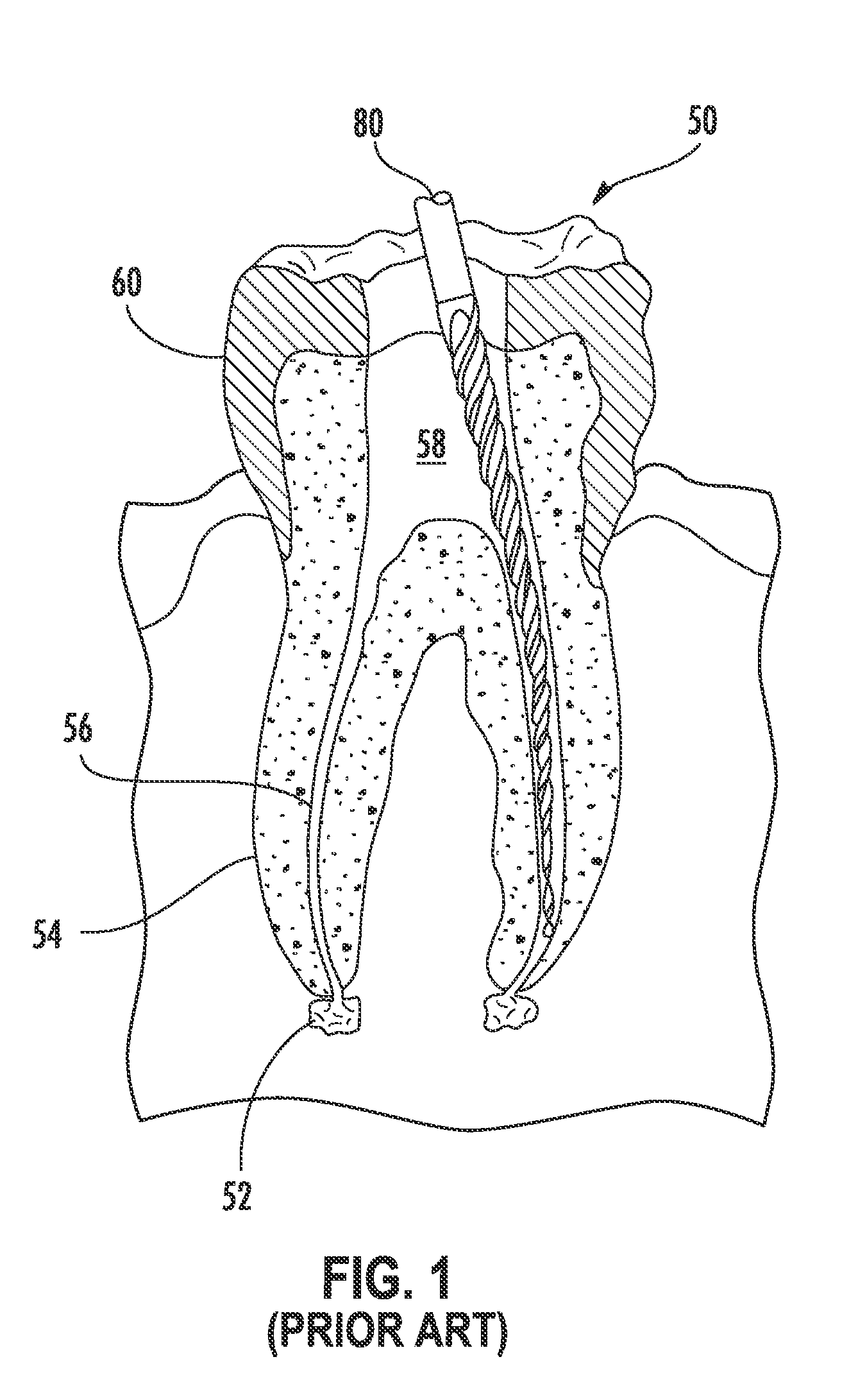

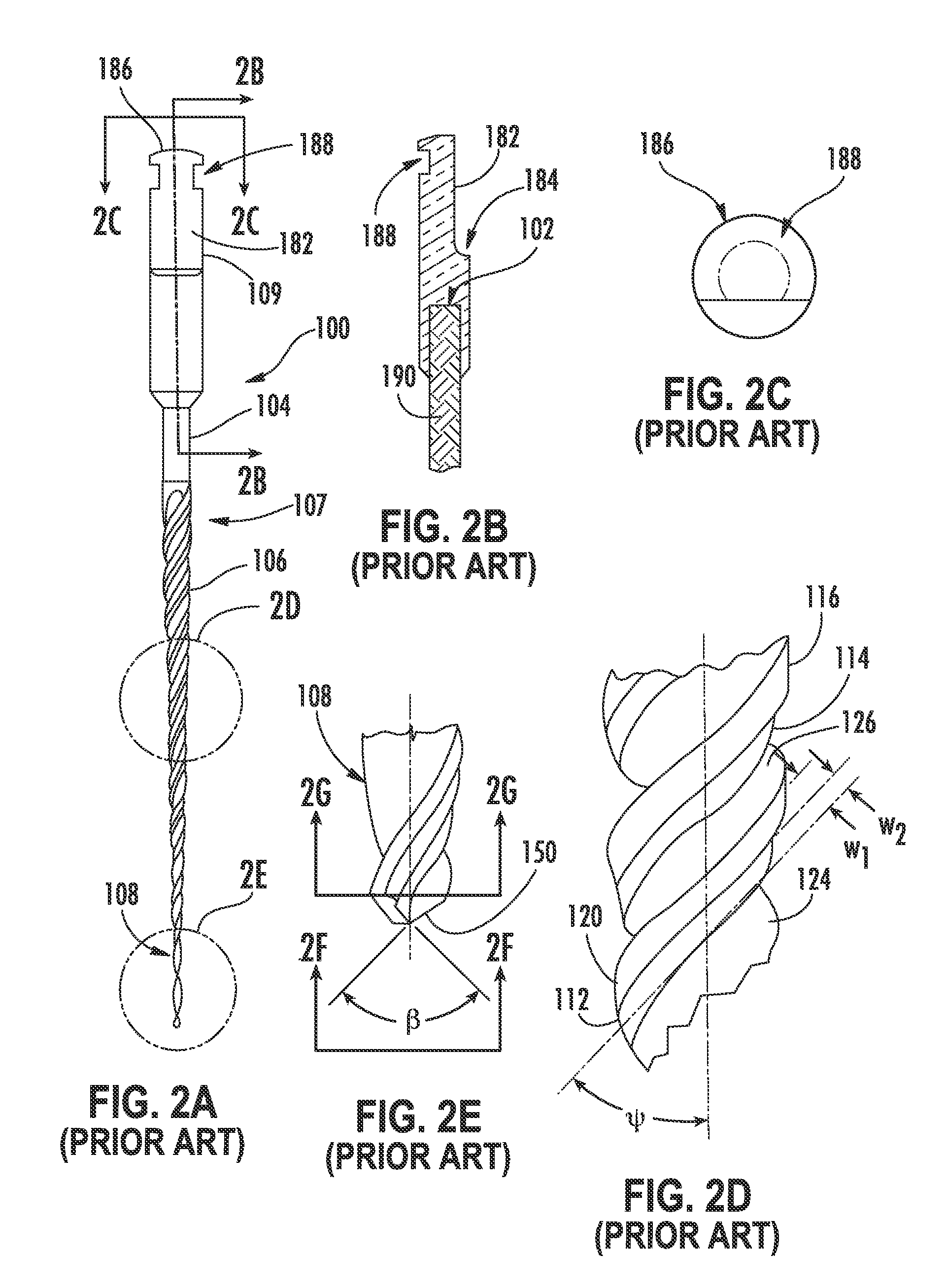

InactiveUS20070184406A1Resistance to breakageResistance to wearTransportation and packagingWristbandsDental structureInstrumentation

An endodontic file (200) is provided particularly adapted for the removal of tooth structure, decayed or damaged nerve tissues or dentine material on the interior walls of a root canal or dentine and / or enamel from the external tooth wall. The endodontic instrument includes a shaft (202) having a shank portion (204) and a generally elongated working portion (206). The working portion preferably includes cutting or abrading features (232) adapted upon rotation and / or reciprocation of the instrument to cut, abrade or remove tissue from the interior walls of a root canal or dentine and / or enamel from the external tooth wall. The working portion extends from a proximal end (207) adjacent the shank portion to a distal end (208) terminating at a tip (250). The entire instrument and / or at least the working portion thereof is formed of an amorphous or essentially amorphous material having no or essentially no detectable crystalline structure and / or from a nanocrystalline material having an average crystalline grain size less than about 1 μm. The instrument may be formed by conventional grinding operations or by direct casting, forging or molding, in a manner producing an integral as-molded instrument having one or more sharp cutting edges. The instrument is inexpensive to manufacture and exhibits improved cutting-edge sharpness, wear resistance, lubriciousness and resistance to breakage.

Owner:CLOUDLAND INST

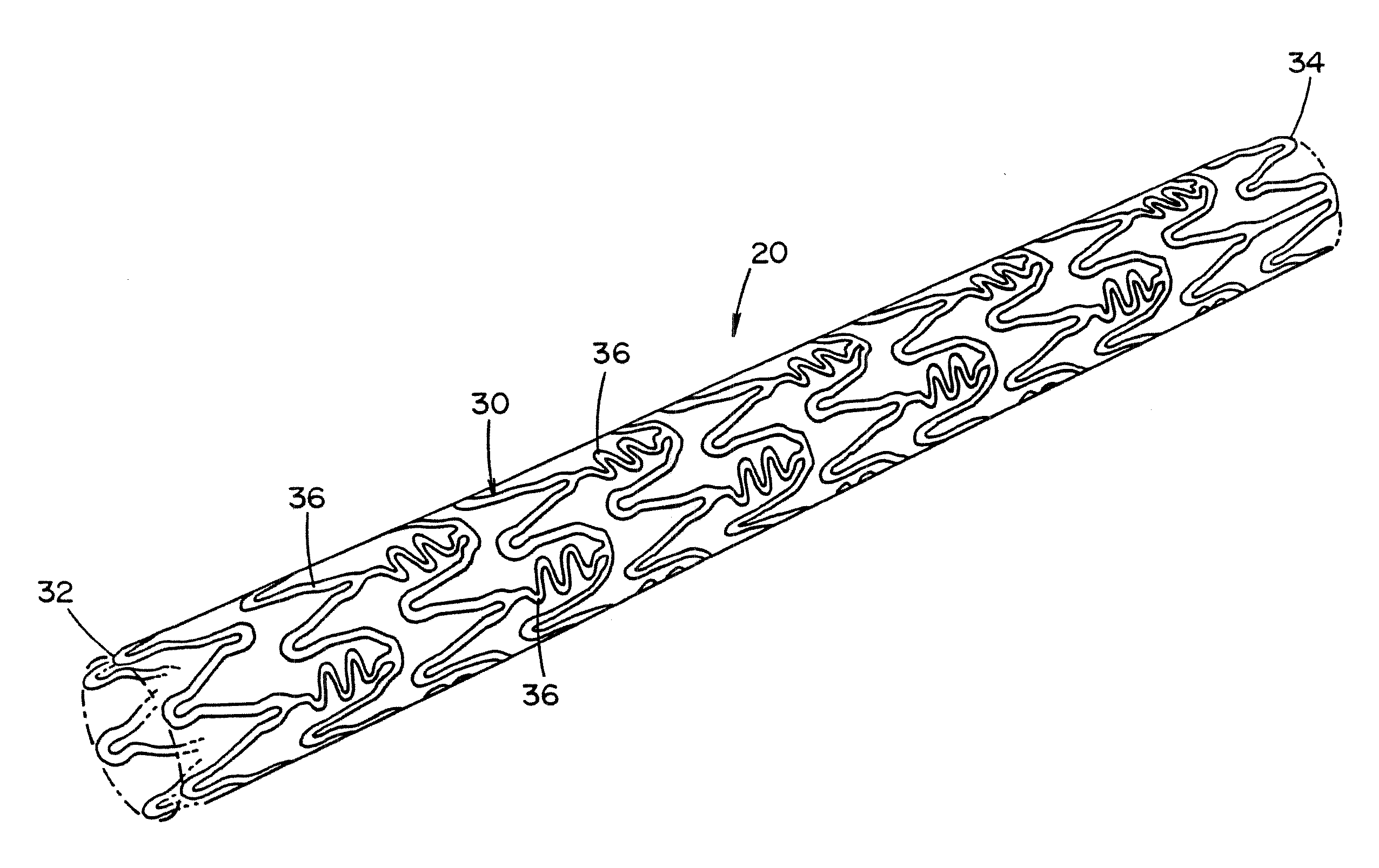

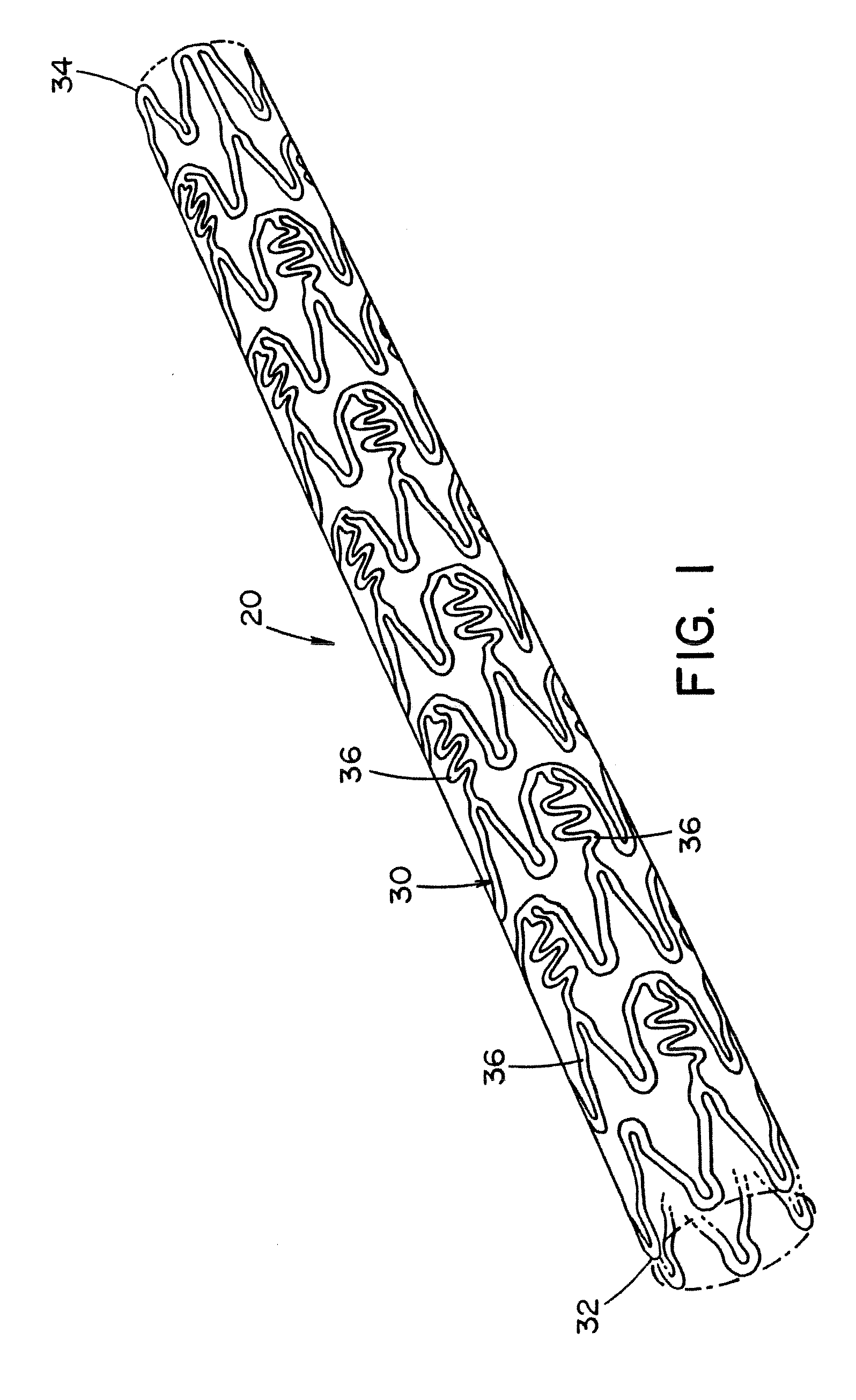

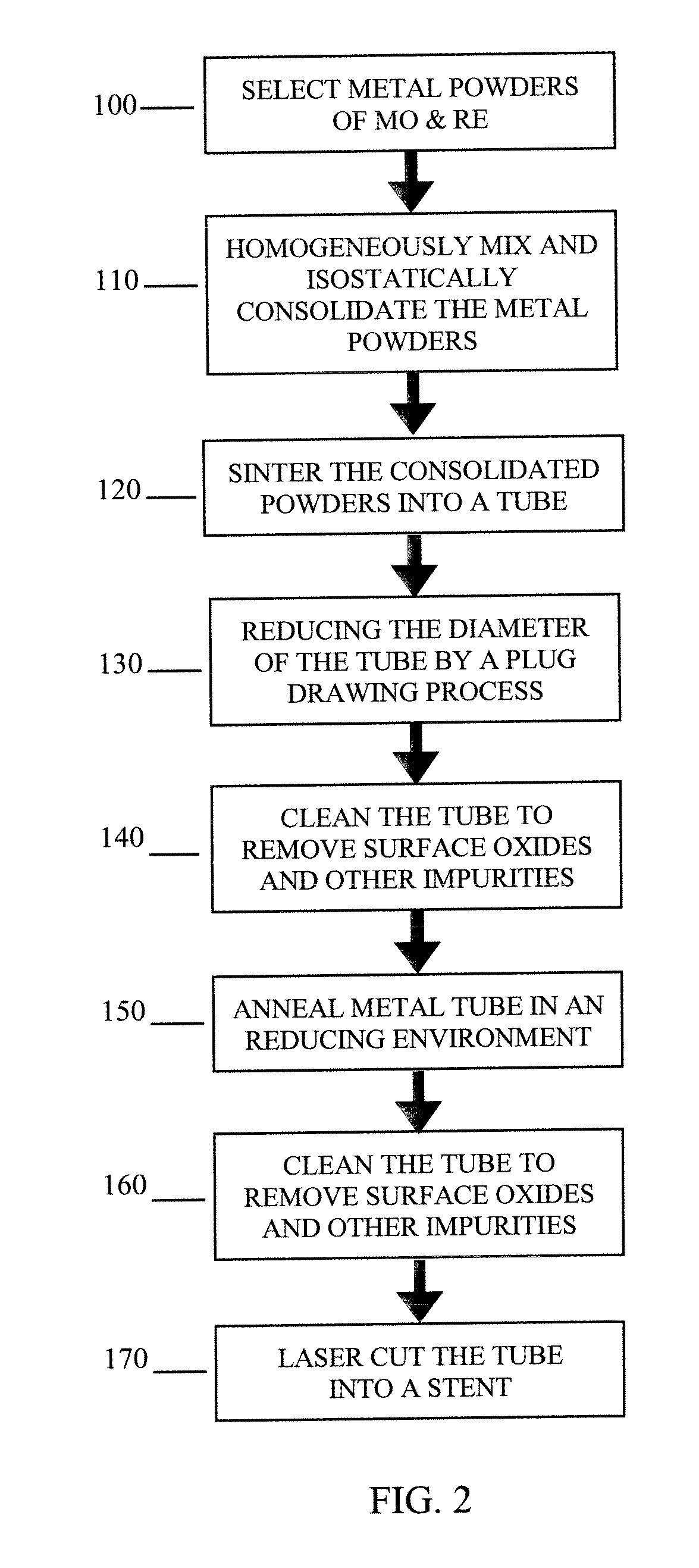

Method for forming a tubular medical device

A method and process for at least partially forming a medical device that is at least partially formed of a metal alloy which improves the physical properties of the medical device.

Owner:MIRUS LLC

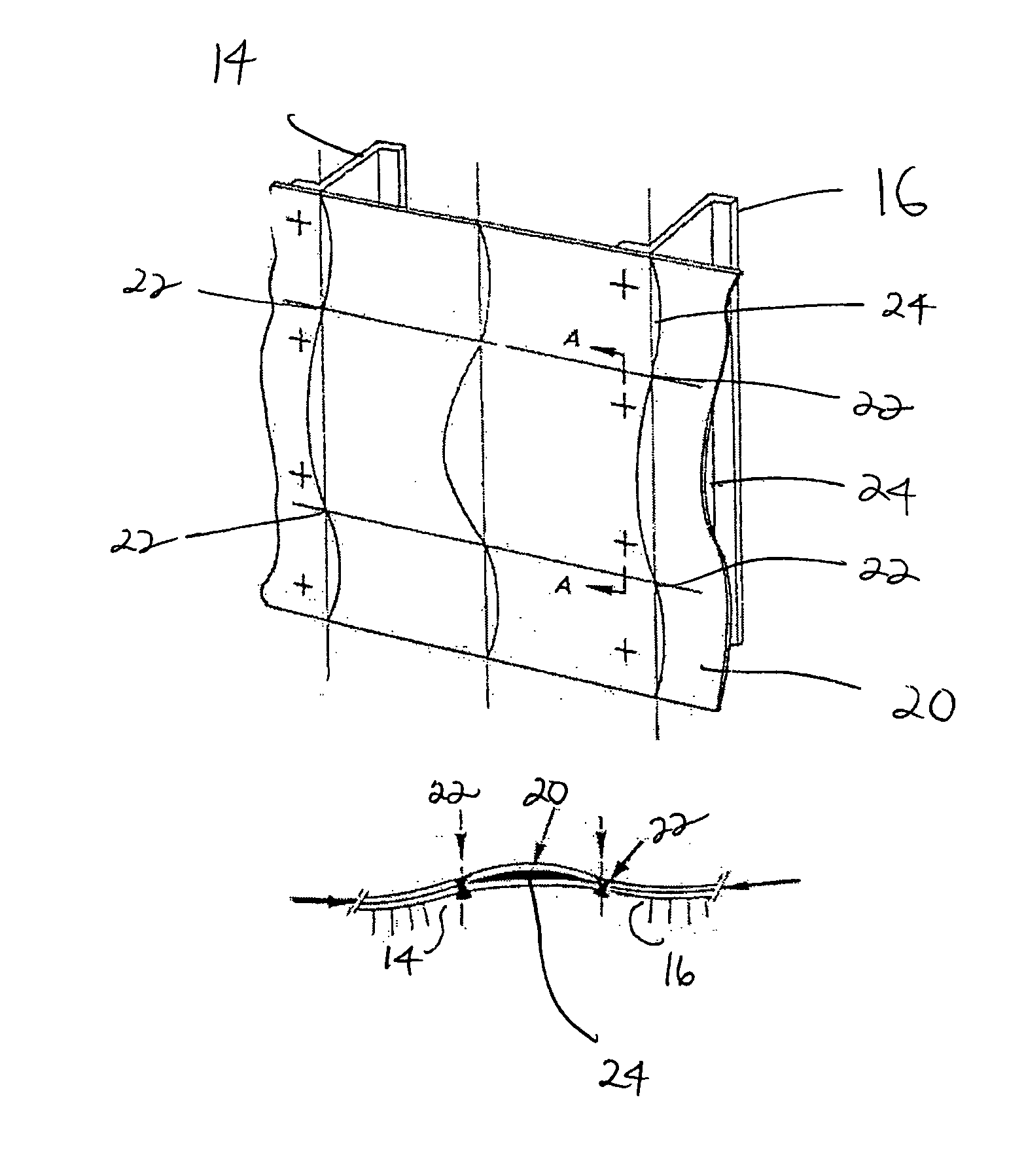

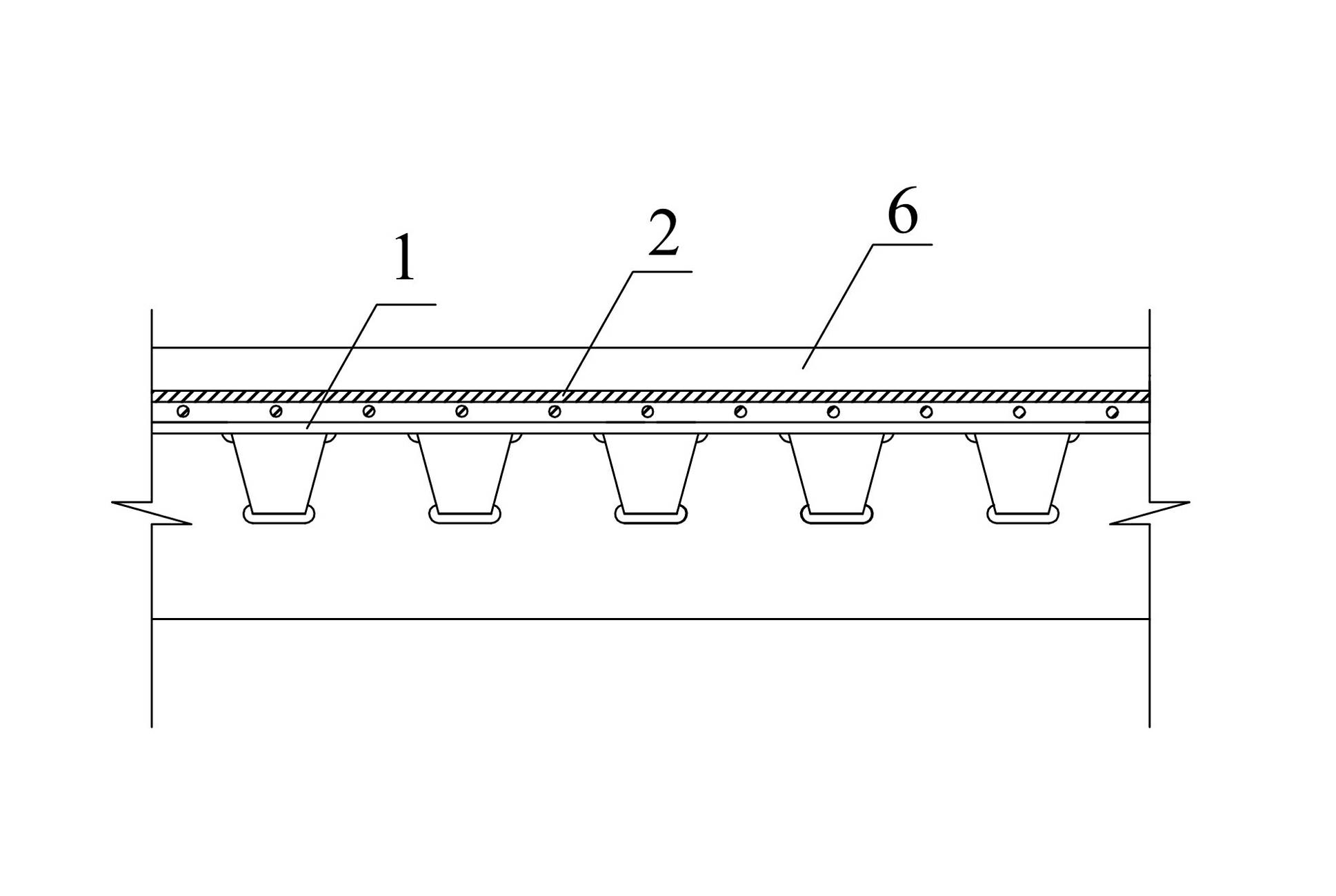

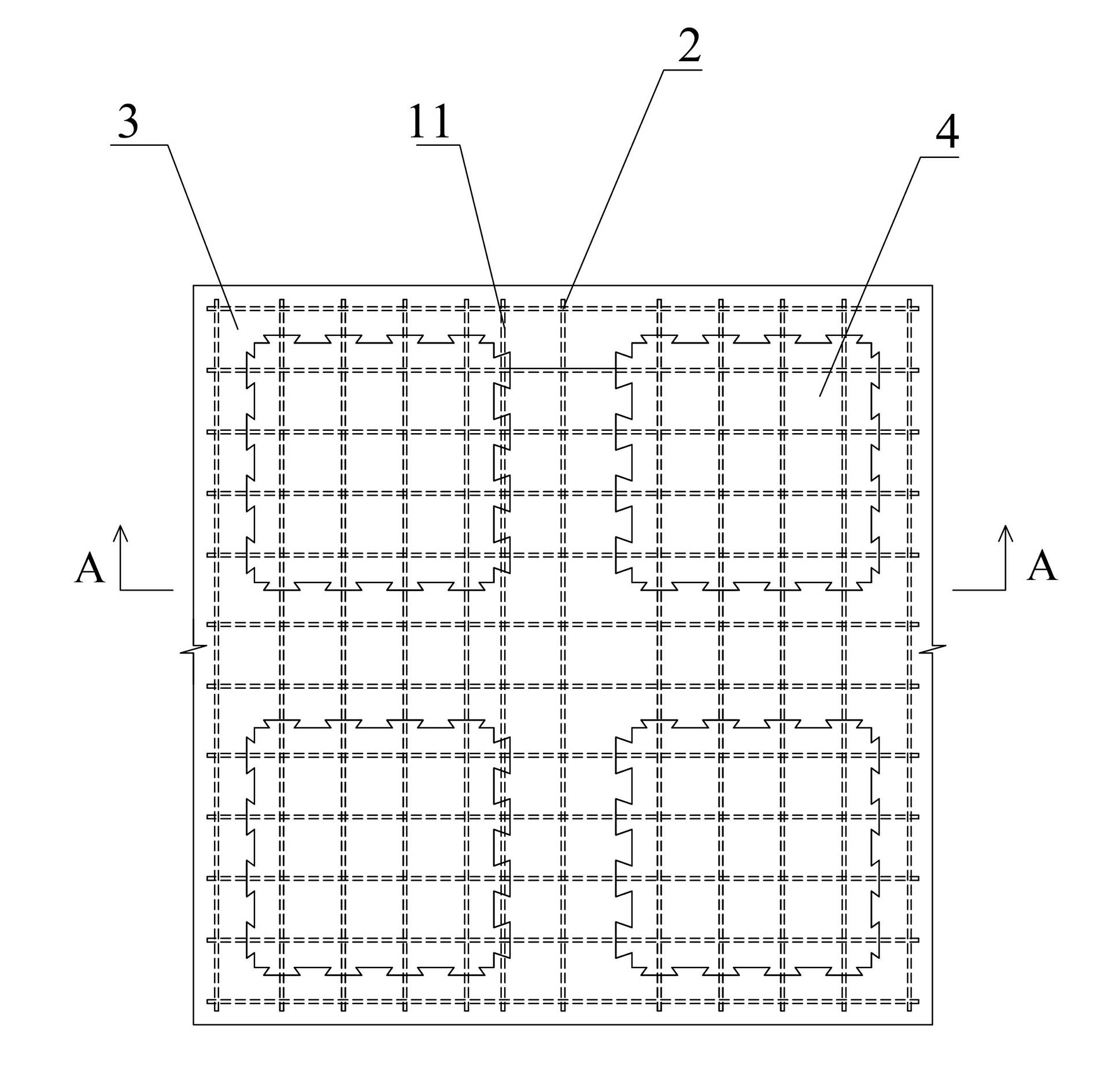

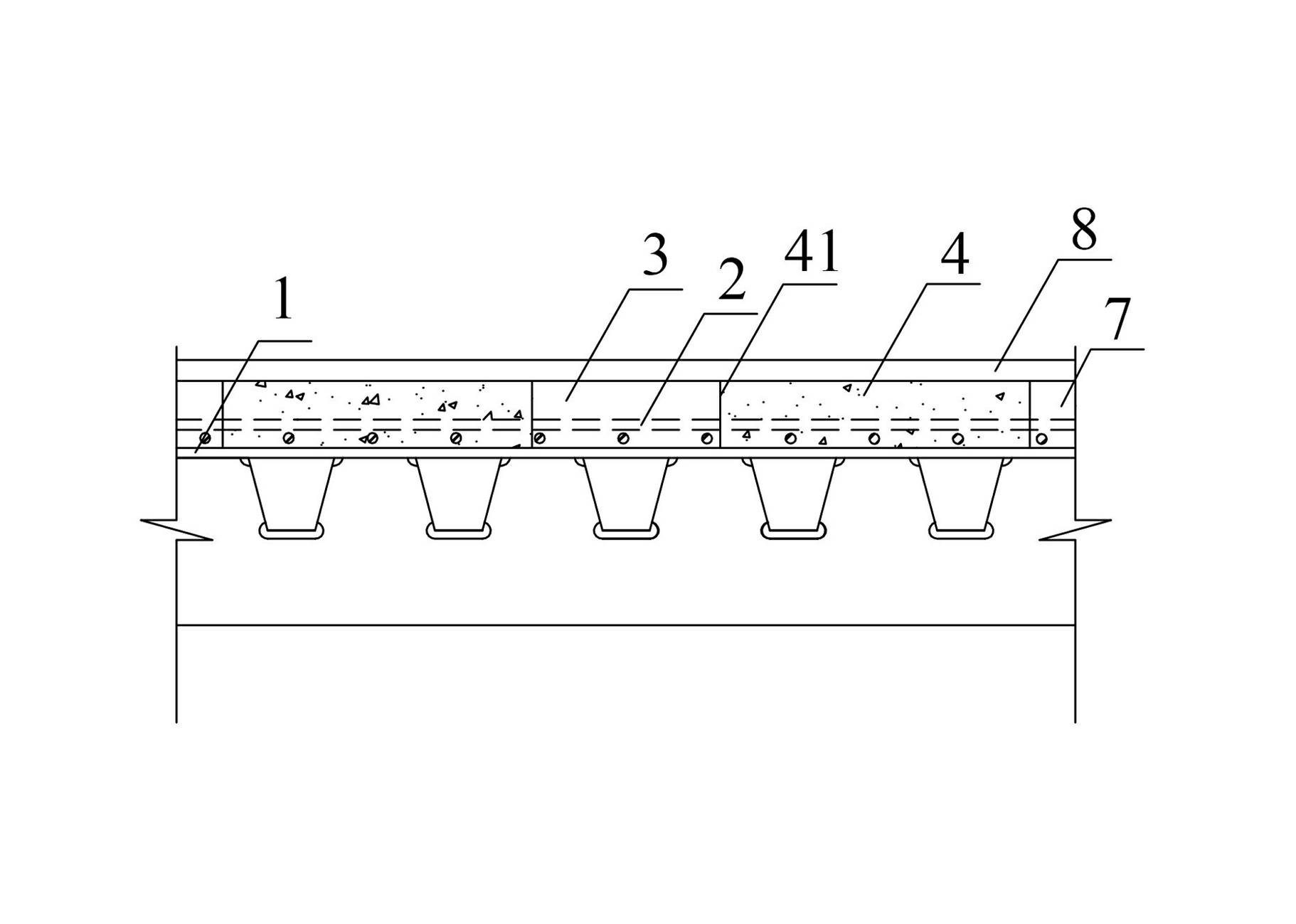

Fabricated fibrous concrete combined deck structure and construction method thereof

ActiveCN102383374AChange structureChange work statusBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention discloses a fabricated fibrous concrete combined deck structure and a construction method thereof. The combined deck structure comprises a steel bridge deck layer, wherein a fabricated fibrous concrete layer covers the upper surface of the steel bridge deck layer; the main body of the fabricated fibrous concrete layer is a cast-in-situ fibrous concrete layer; a plurality of prefabricated fibrous concrete plates are in embedded connection with the cast-in-situ fibrous concrete layer; tongue-and-groove joints articulated with the cast-in-situ fibrous concrete layer are arranged at the periphery of each prefabricated fibrous concrete plate; and the fabricated fibrous concrete layer is equipped with steel bars. The construction method comprises the following steps: the steel bridge deck layer is manufactured at first, and then the prefabricated fibrous concrete plates are manufactured and laid, or steel bridge deck blocks are prefabricated at first, and steel beams are erected and assembled; after that, the construction of the cast-in-situ fibrous concrete layer and the surface treatment are carried out in sequence; and the construction is completed finally. The combined deck structure disclosed by the invention can improve the tensile strength limit of concrete slabs and effectively prevent a pavement layer from cracks, and has good service durability, good fatigue resistance; and the construction process is simple and efficient.

Owner:HUNAN UNIV

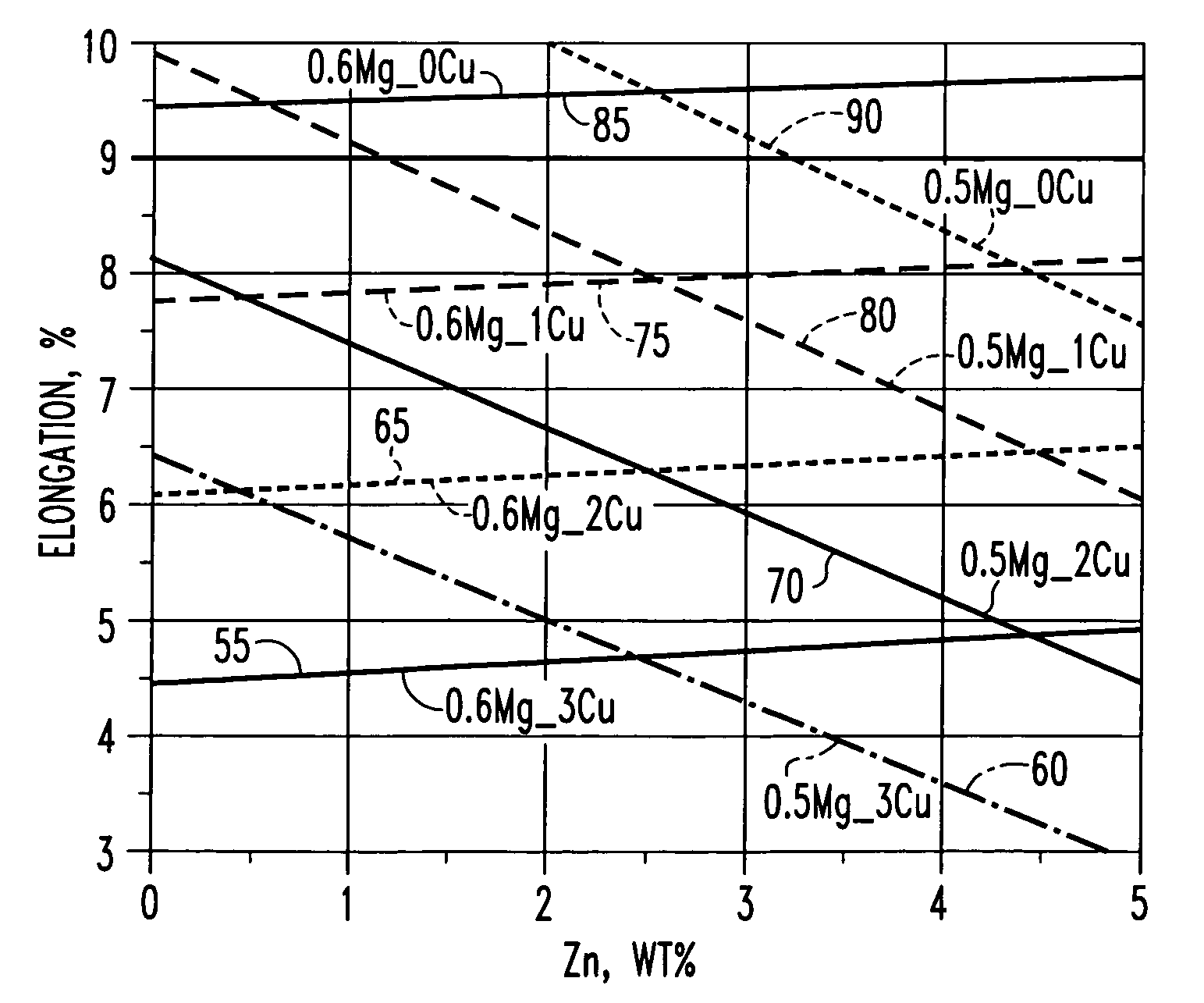

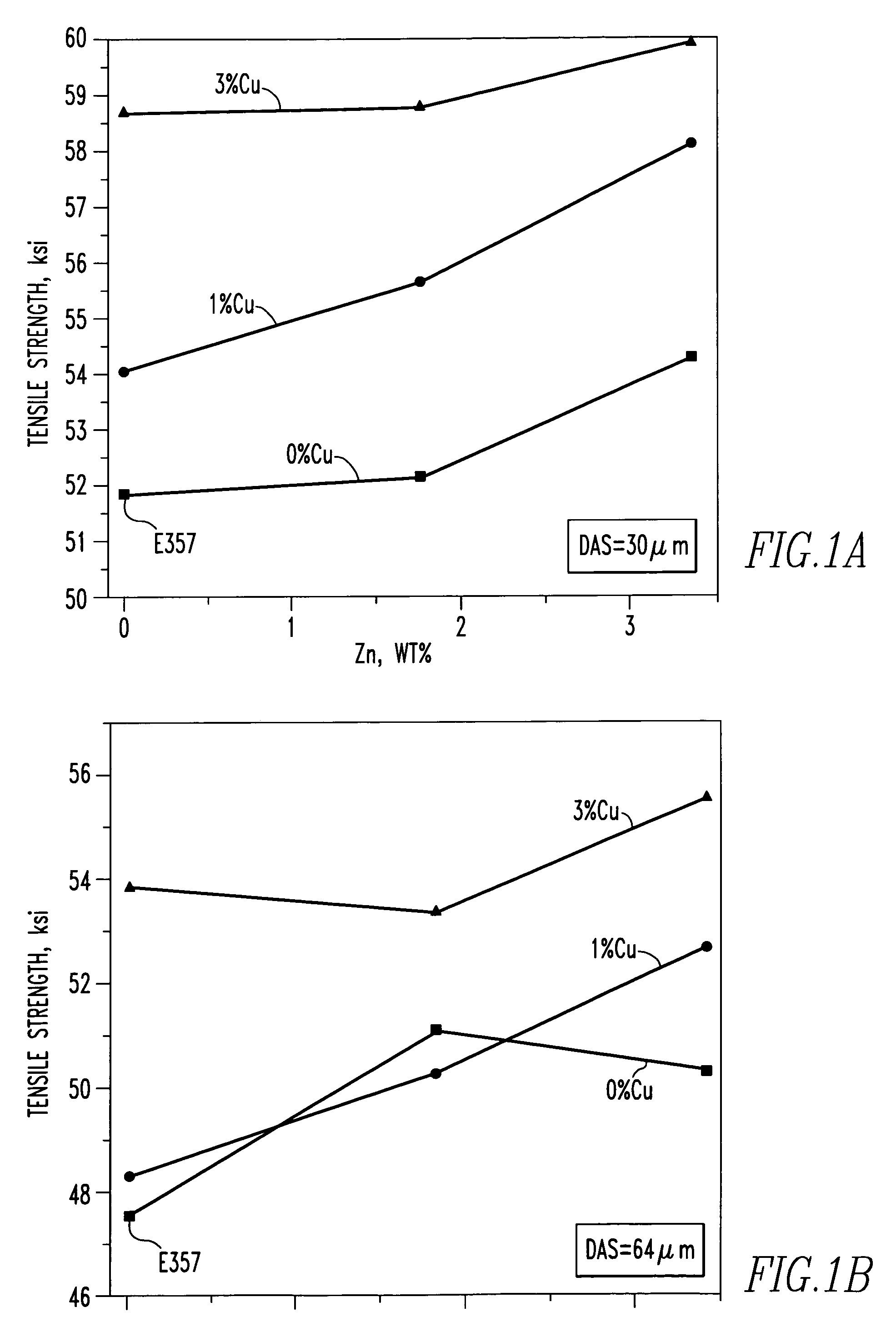

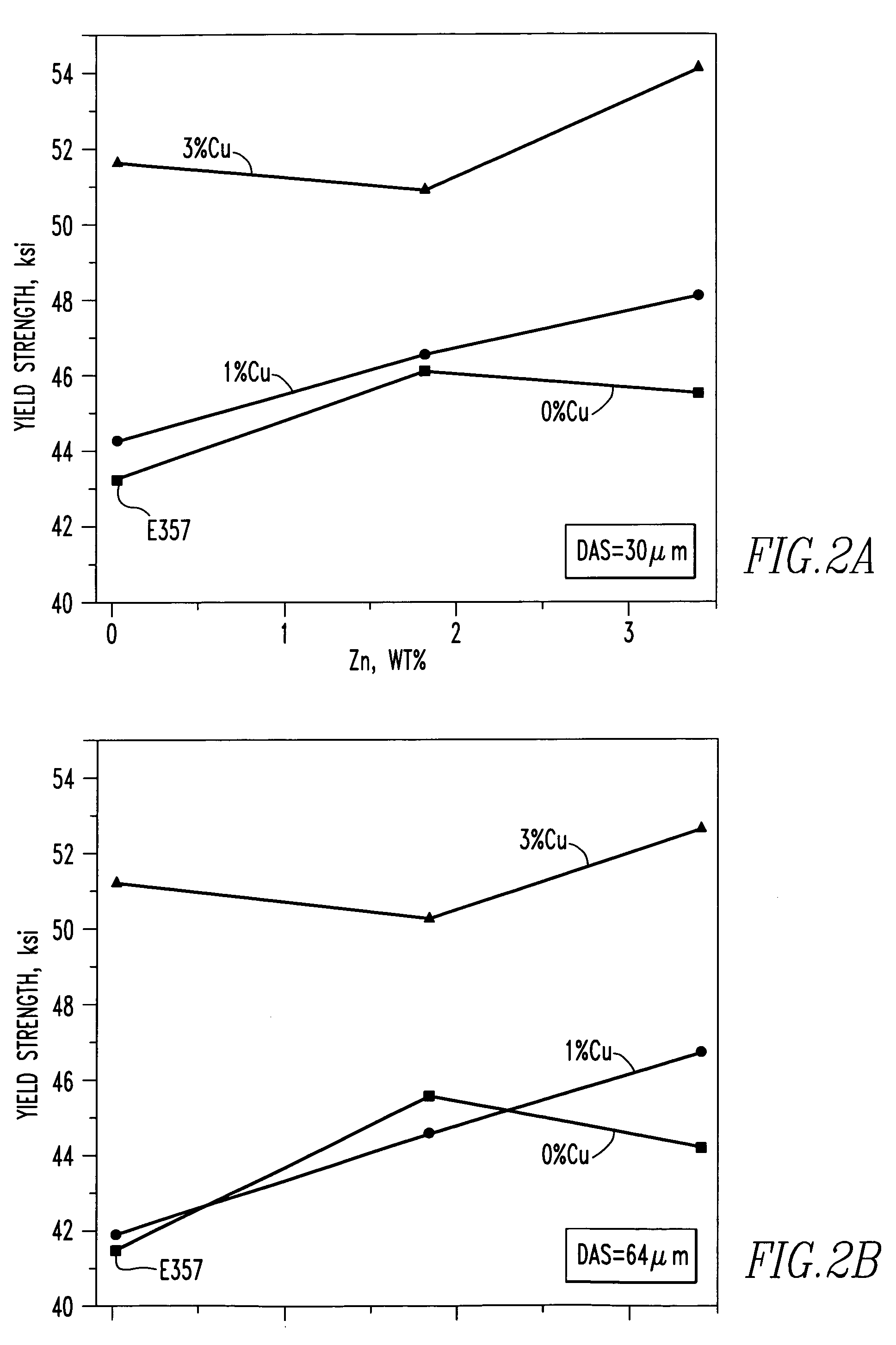

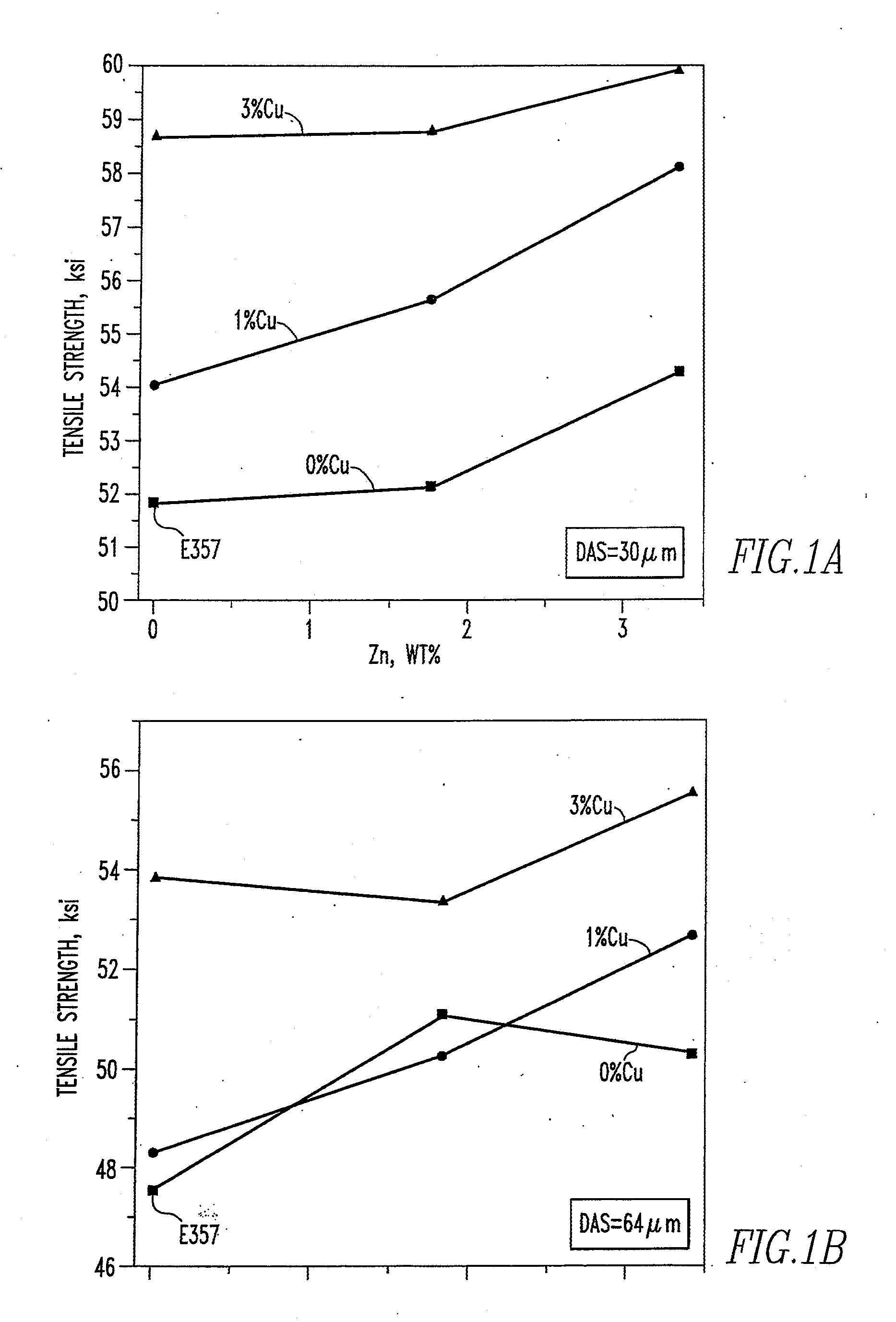

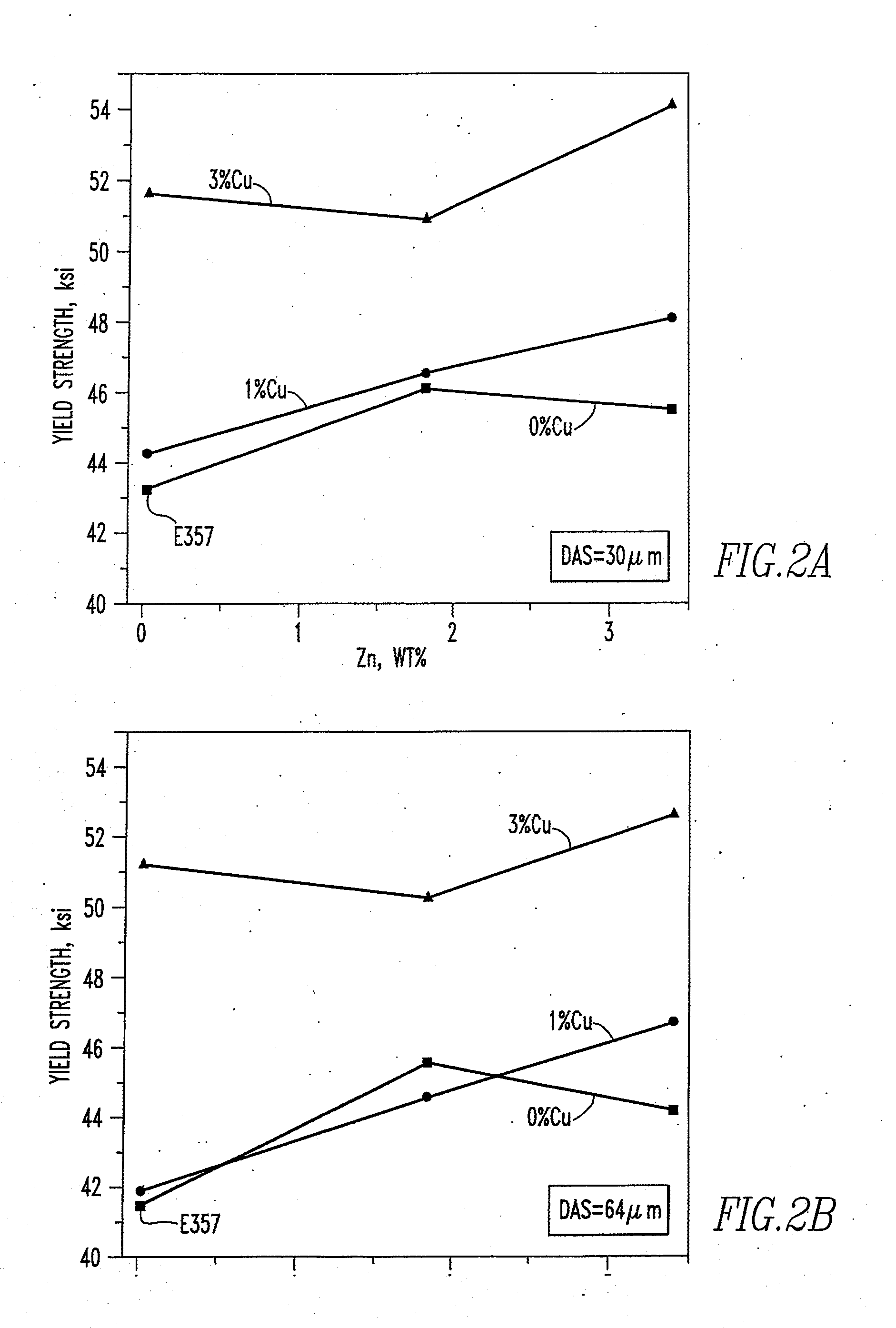

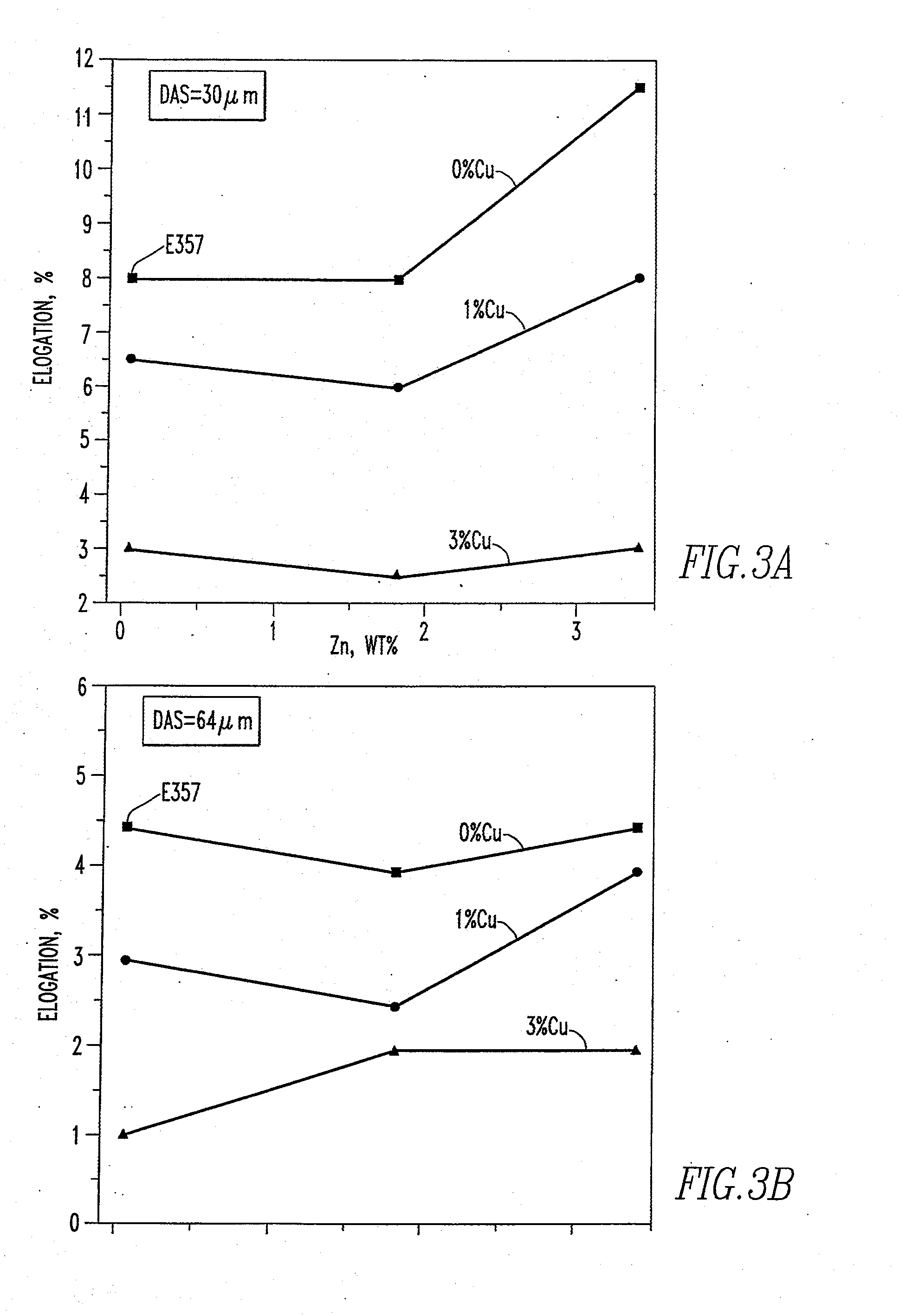

An Al-Si-Mg-Zn-Cu alloy for aerospace and automotive castings

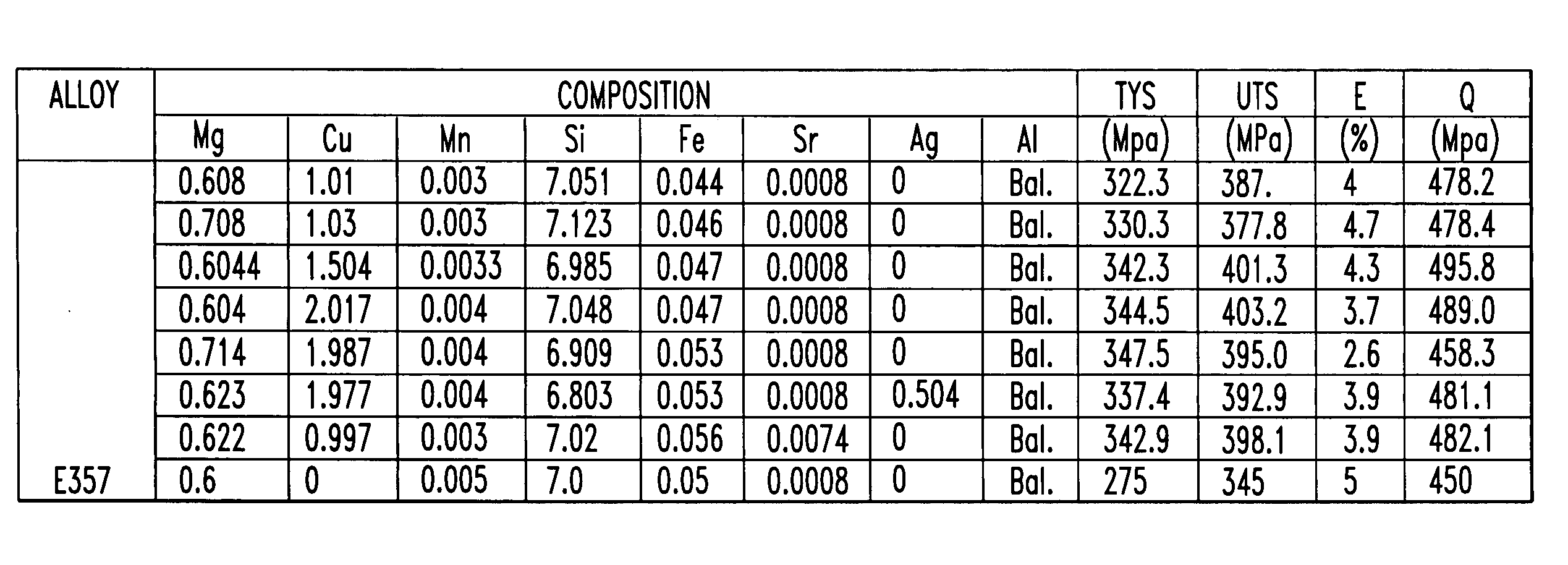

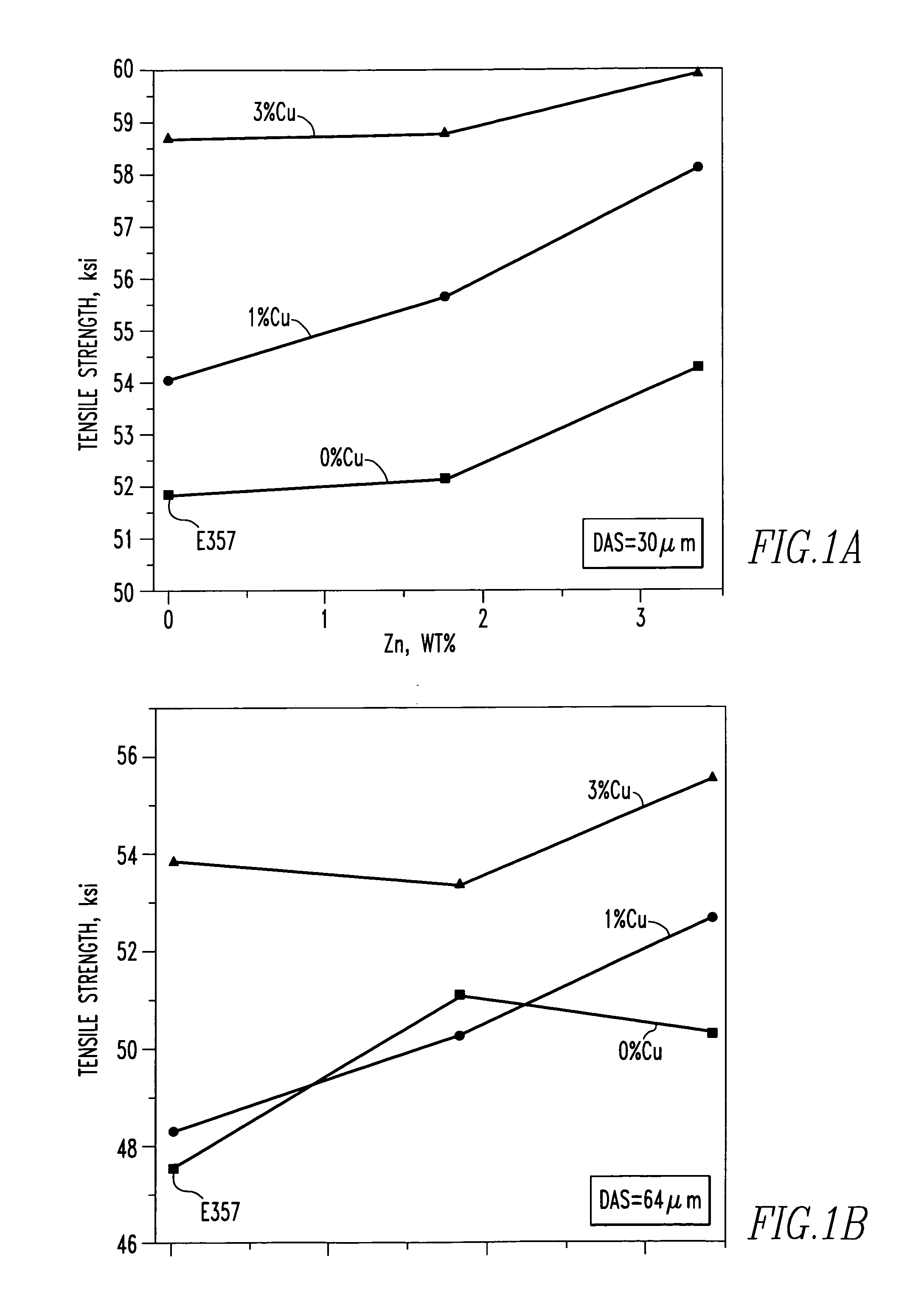

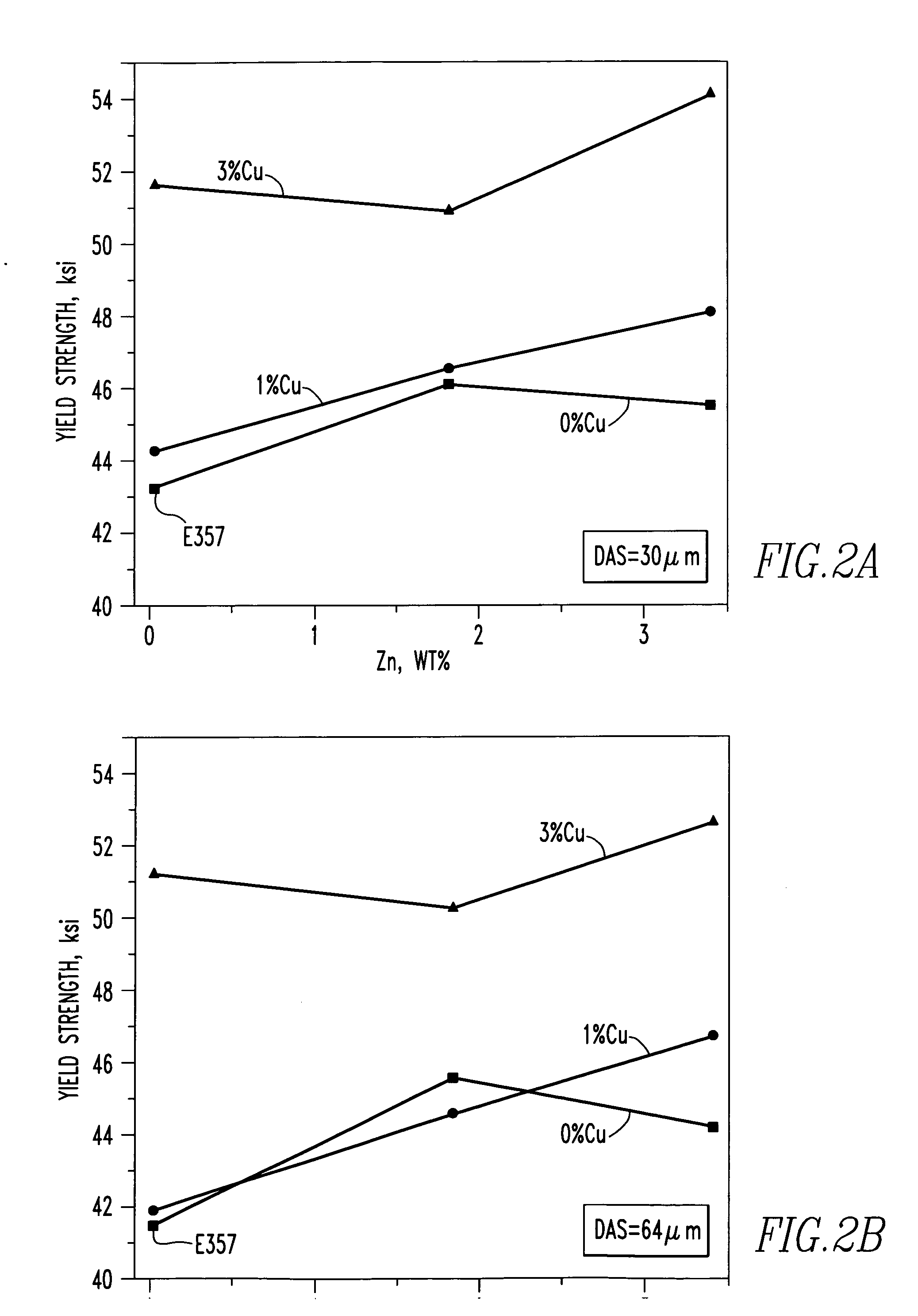

The present invention provides an aluminum casting alloy with a composition including 4%-9% Si; 0.1%-0.7% Mg; less than or equal to 5% Zn; less than 0.15% Fe; less than 4% Cu; less than 0.3% Mn; less than 0.05% B; less than 0.15% Ti; and the remainder consisting essentially of aluminum. The inventive AlSiMg composition provides increased mechanical properties (Tensile Yield Strength and Ultimate Tensile Strength) in comparison to similiarly prepared E357 alloy at room temperature and high temperature. The present invention also includes a shaped casting formed from the inventive composition and a method of forming a shaped casting from the inventive composition.

Owner:ARCONIC INC

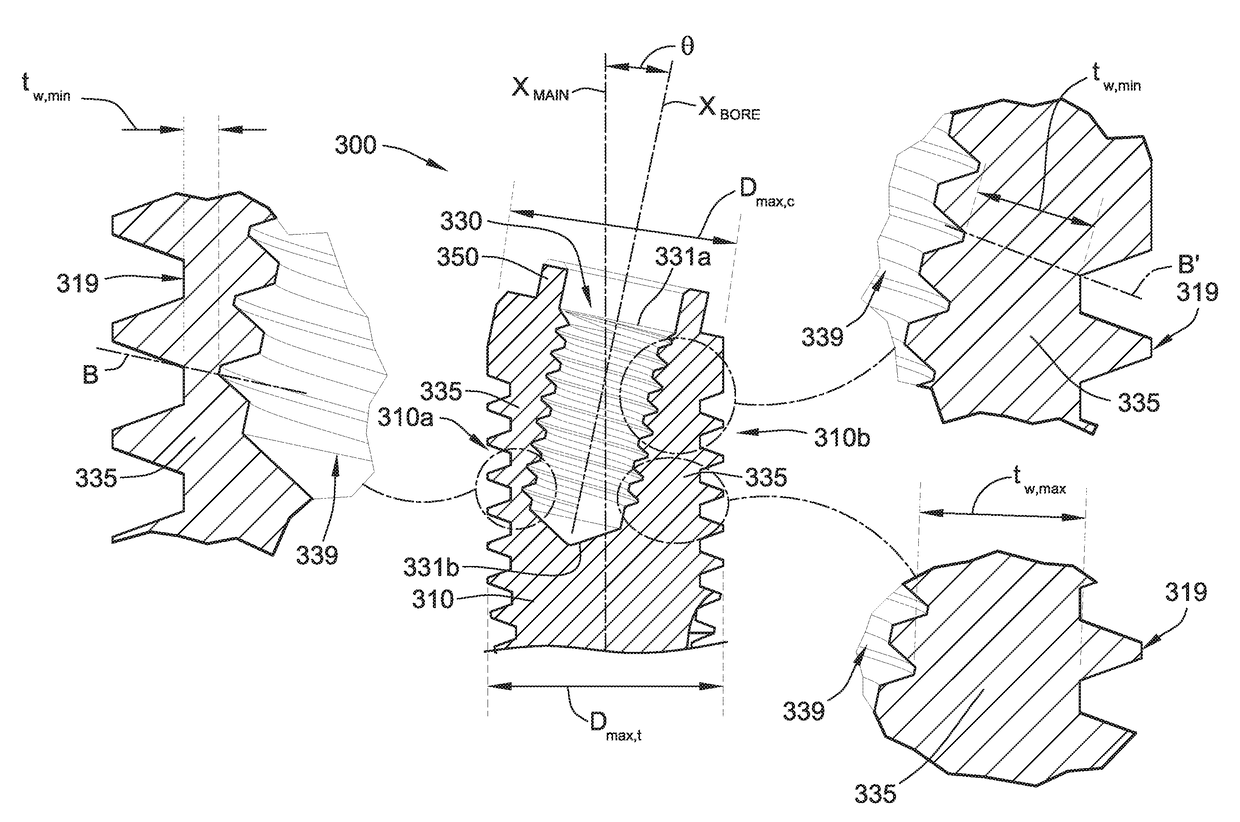

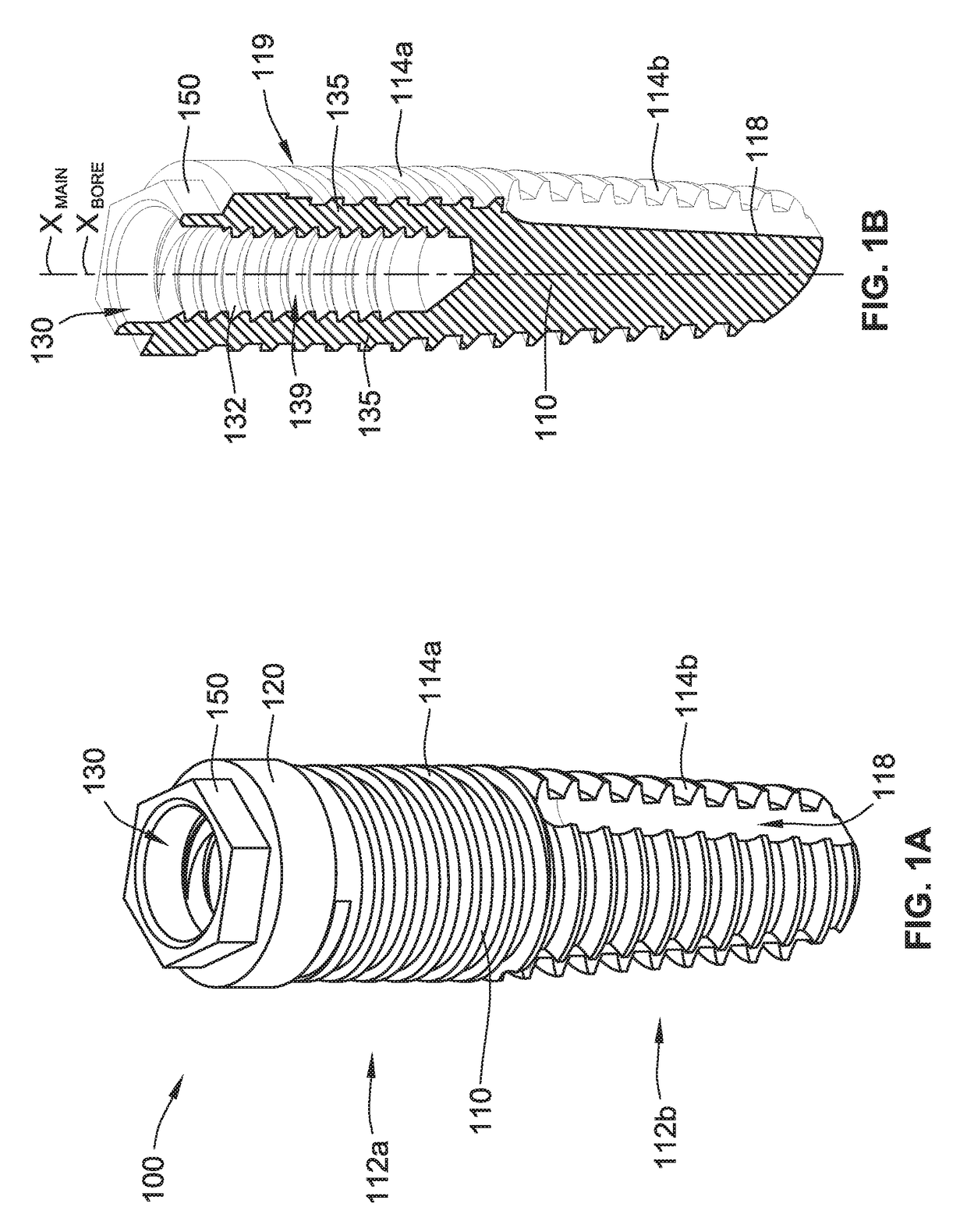

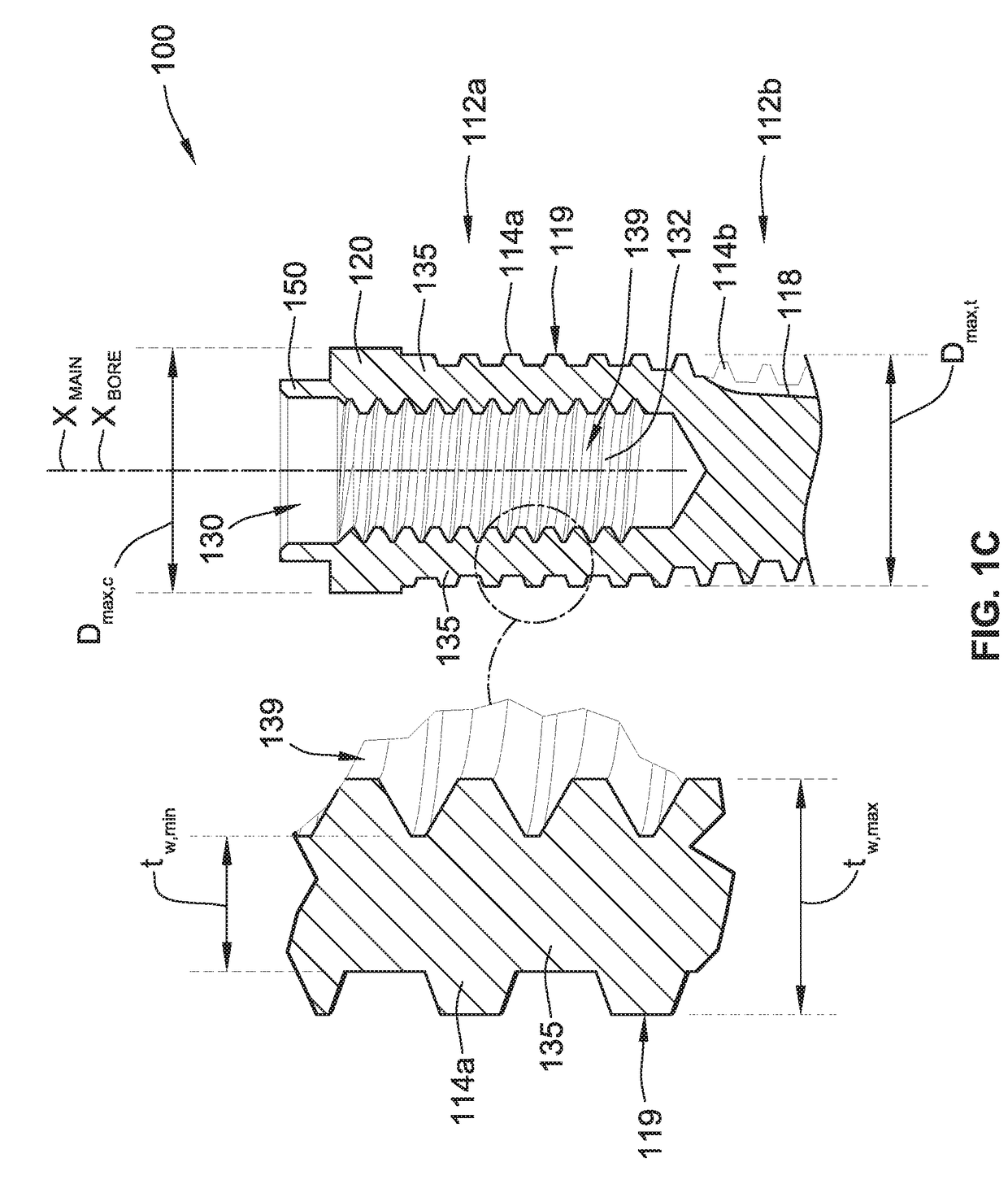

Angulated dental implant

A dental implant includes a generally cylindrical body, an interior bore, and a non-rotational feature. The generally cylindrical body has a main-central axis and is formed from cold-worked, high strength, commercially pure titanium having an ultimate tensile strength of at least about 900 MPa. The generally cylindrical body has a proximal portion and an opposing distal portion for anchoring the dental implant in bone of a patient. The interior bore is formed in the generally cylindrical body and has (i) a bore-central axis and (ii) a threaded portion for receiving a screw that is configured to removable hold an abutment in engagement with the dental implant. The non-rotational feature is configured to engage the abutment in a non-rotational fashion.

Owner:SOUTHERN IMPLATS (PTY) LTD

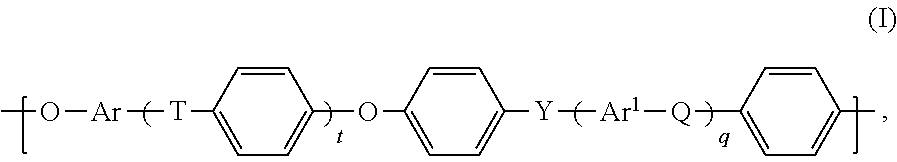

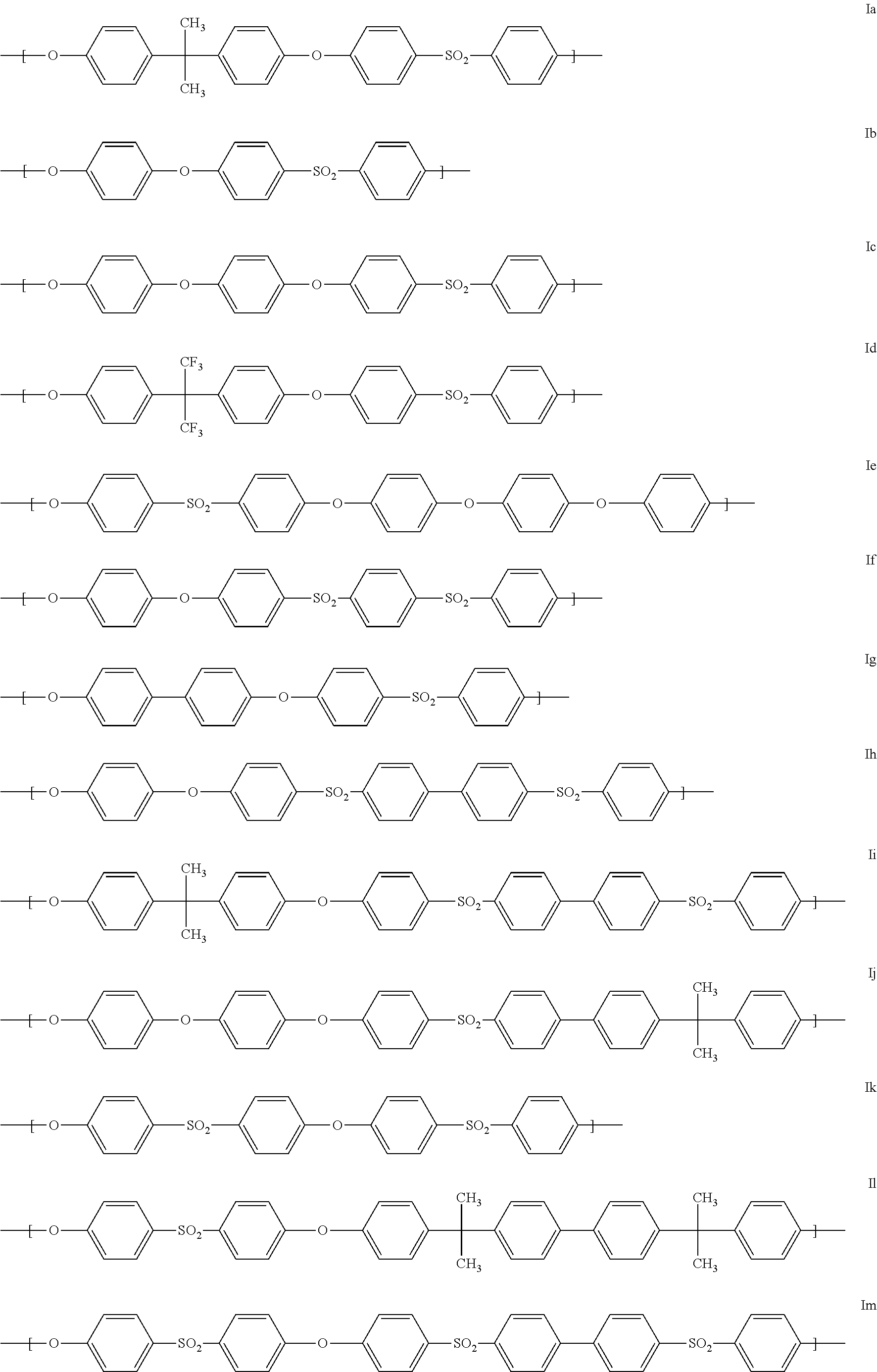

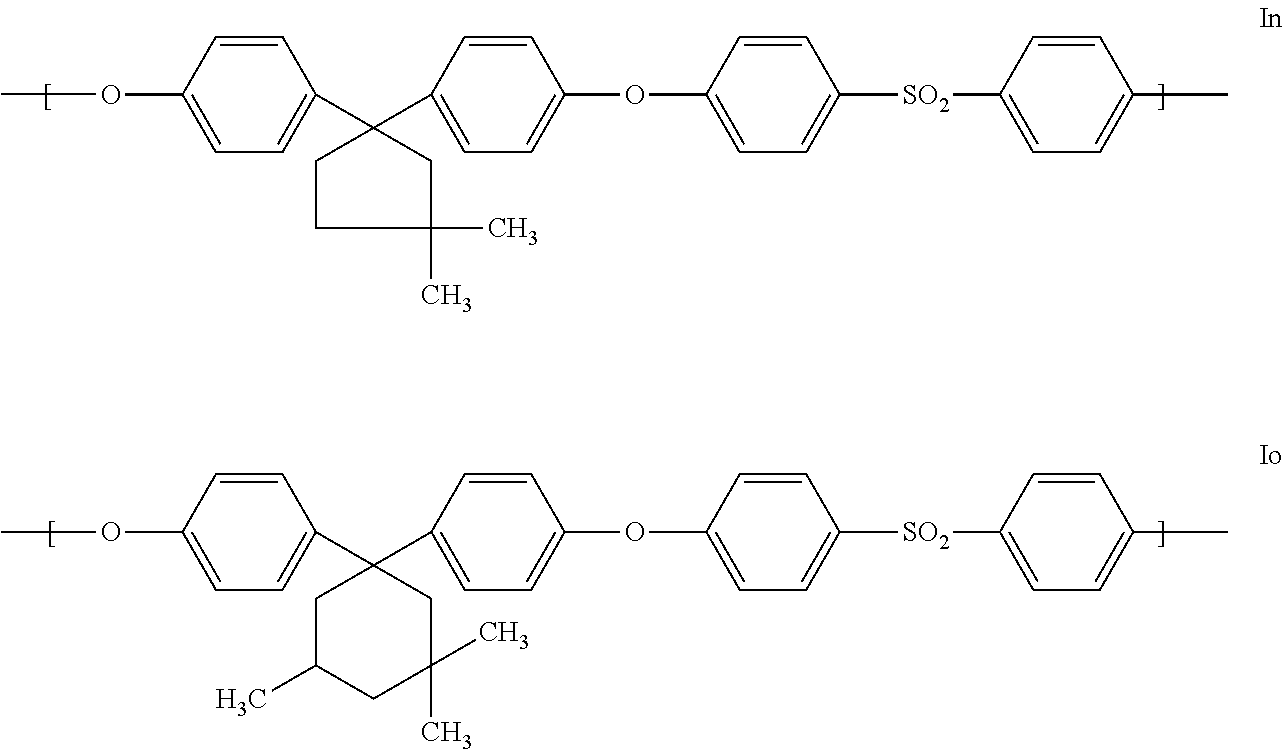

Blends of polyarylene ethers and polyarylene sulfides

The present invention relates to thermoplastic molding compositions comprising the following components:(A) at least one polyarylene ether (A1) having an average of at most 0.1 phenolic end group per polymer chain and at least one polyarylene ether (A2) having an average of at least 1.5 phenolic end groups per polymer chain,(B) at least one polyarylene sulfide,(C) at least one functionalized polyarylene ether comprising carboxy groups,(D) at least one fibrous or particulate filler, and(E) optionally further additives and / or processing aids.The present invention further relates to a process for producing the thermoplastic molding compositions of the invention, to the use of these for producing moldings, fibers, foams, or films, and to the resultant moldings, fibers, foams, and films.

Owner:BASF AG

Al-Si-Mg-Zn-Cu alloy for aerospace and automotive castings

The present invention provides an aluminum casting alloy with a composition including 4%-9% Si; 0.1%-0.7% Mg; less than or equal to 5% Zn; less than 0.15% Fe; less than 4% Cu; less than 0.3% Mn; less than 0.05% B; less than 0.15% Ti; and the remainder consisting essentially of aluminum. The inventive AlSiMg composition provides increased mechanical properties (Tensile Yield Strength and Ultimate Tensile Strength) in comparison to similiarly prepared E357 alloy at room temperature and high temperature. The present invention also includes a shaped casting formed from the inventive composition and a method of forming a shaped casting from the inventive composition.

Owner:ALCOA USA CORP

Moisture-curable, polyether urethanes with reactive silane groups and their use as sealants, adhesives and coatings

InactiveUS6844413B2Improve ultimate tensile strengthLow modulusPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsSilanesAdhesive

A moisture-curable, alkoxysilane-functional polyether urethanes containinga) 20 to 90% by weight, of a polyether urethane containing two or more reactive silane groups and one or more polyether segments, where the polyether segments have a number average molecular weight (Mn) of at least 3000 and a degree of unsaturation of less than 0.04 milliequivalents / g, and the sum of Mn of all of the polyether segments per molecule averages 6000 to 20,000, and the reactive silane groups are incorporated by the reaction of an isocyanate group with a compound of formulaH2N—Y—Si—(X)3 (I)b) 10 to 80% by weight, of a polyether urethane containing one reactive silane group and one or more polyether segments having Mn of 1000 to 15,000, where the reactive silane groups are incorporated by the reaction of an isocyanate group with a compound of formula

Owner:COVESTRO LLC

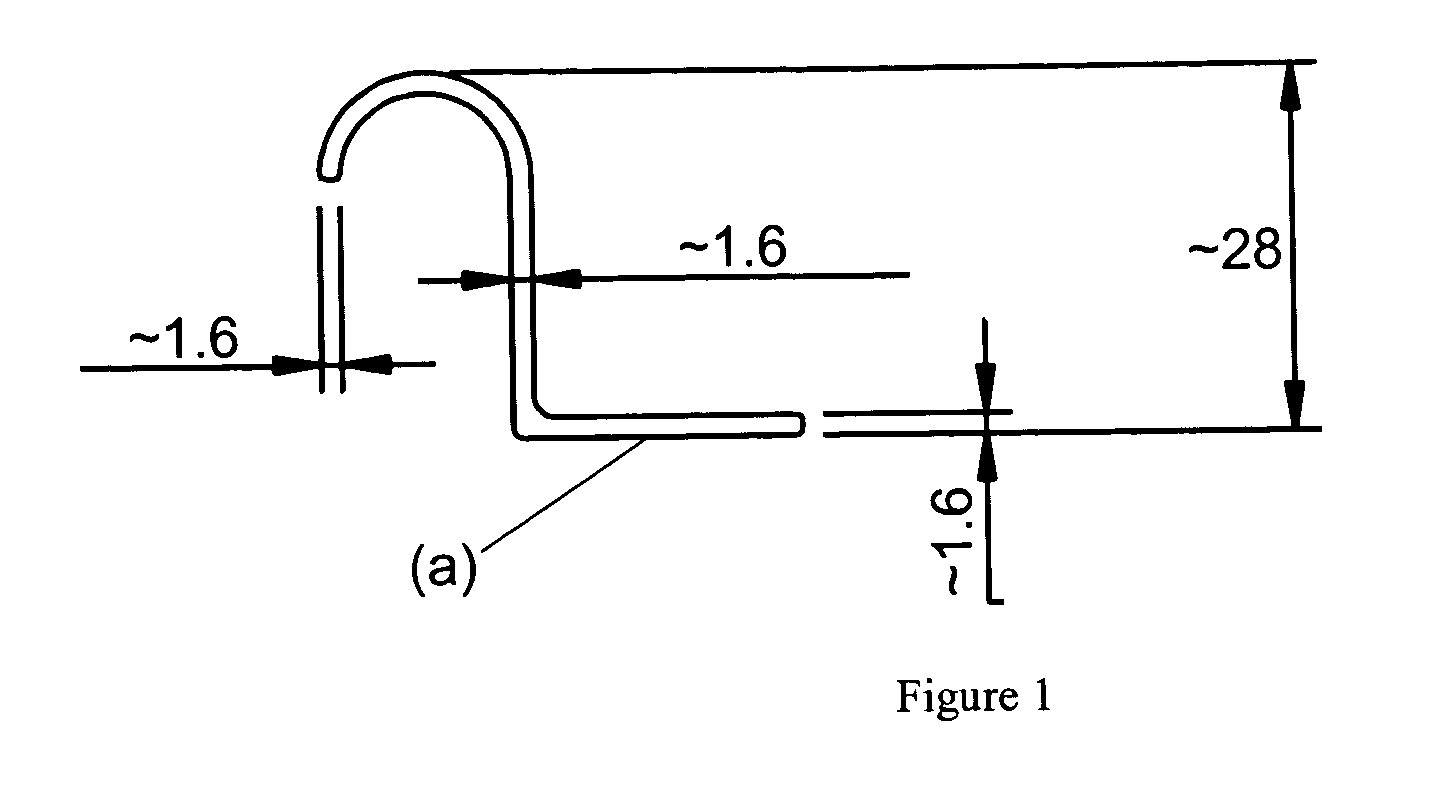

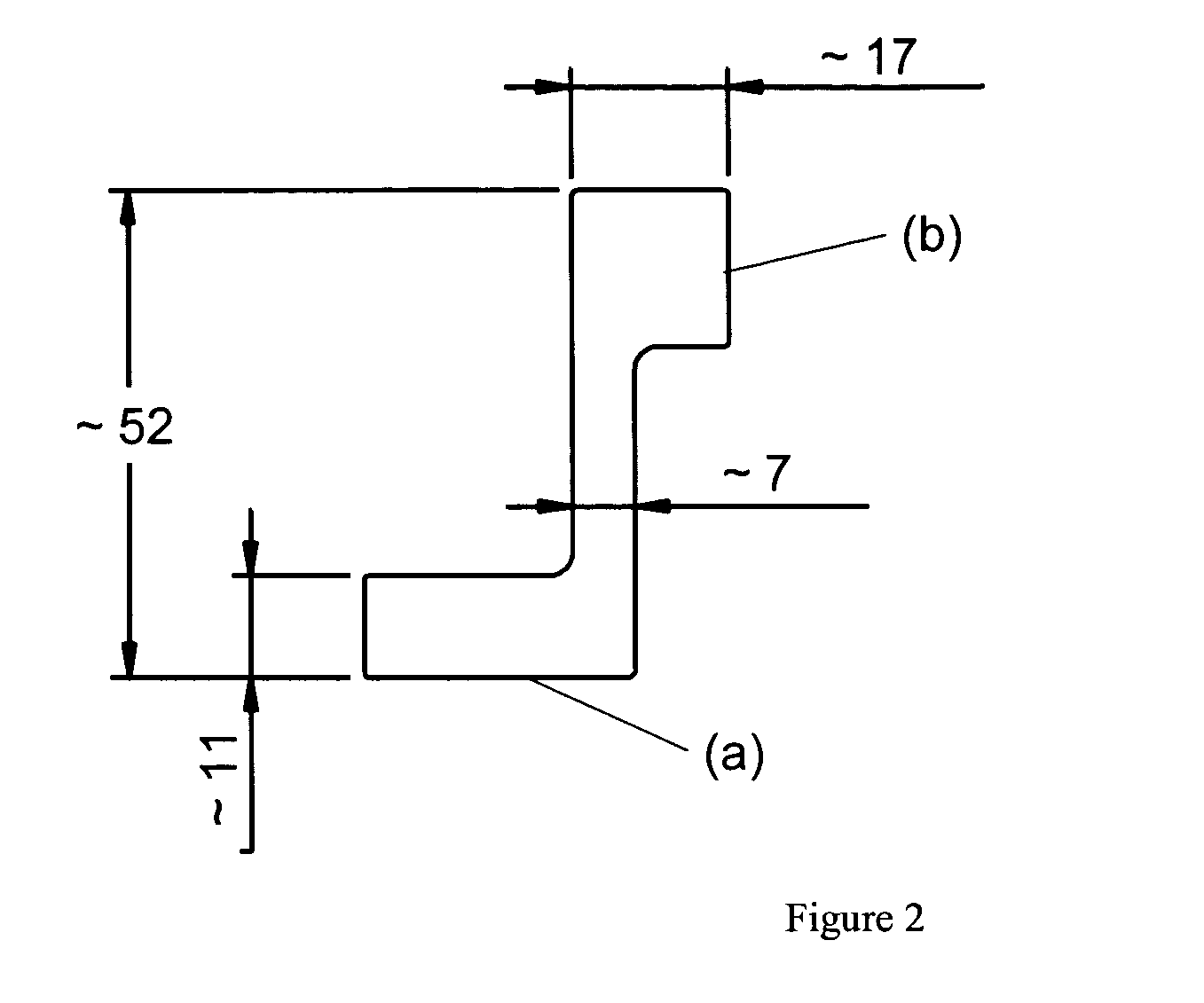

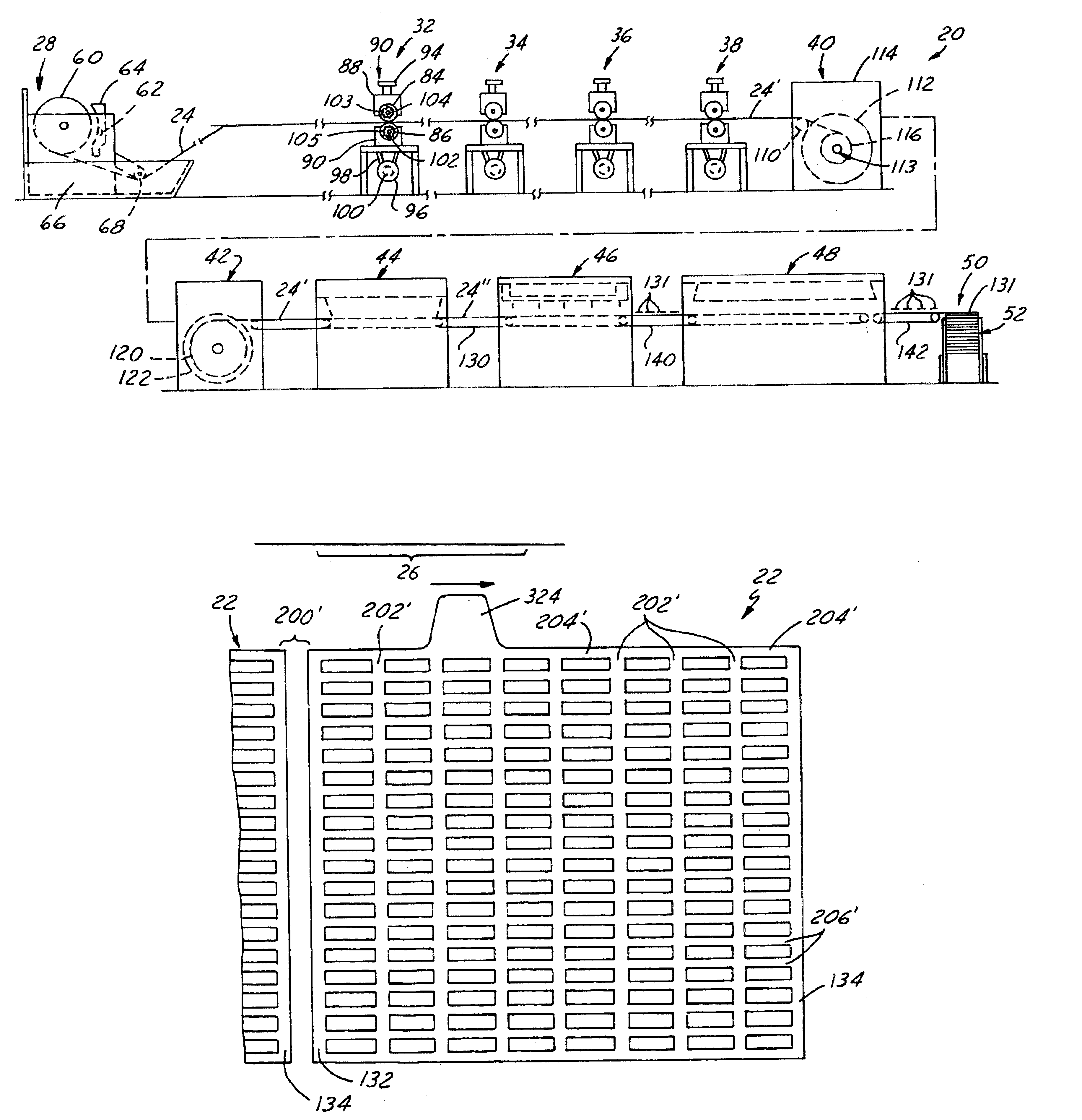

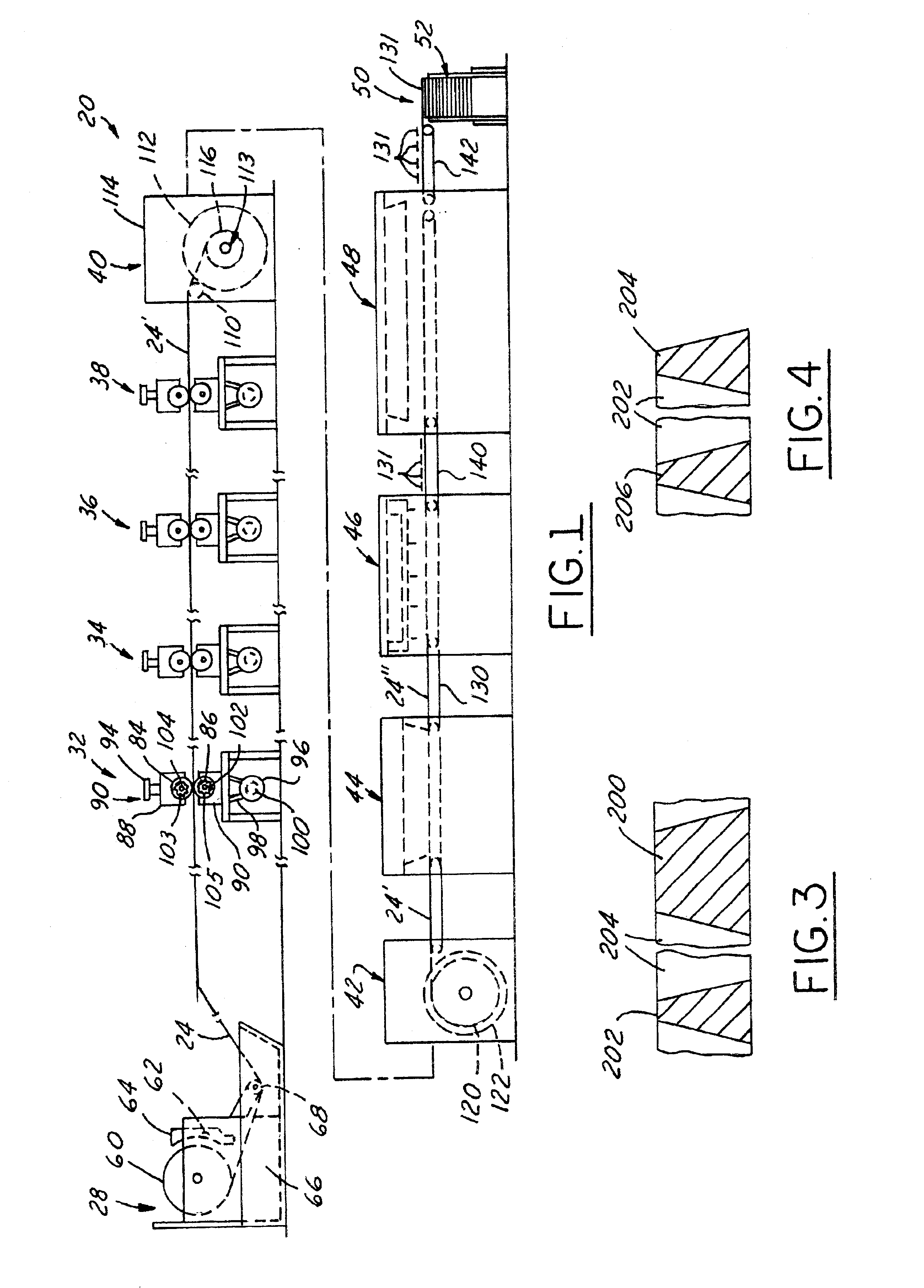

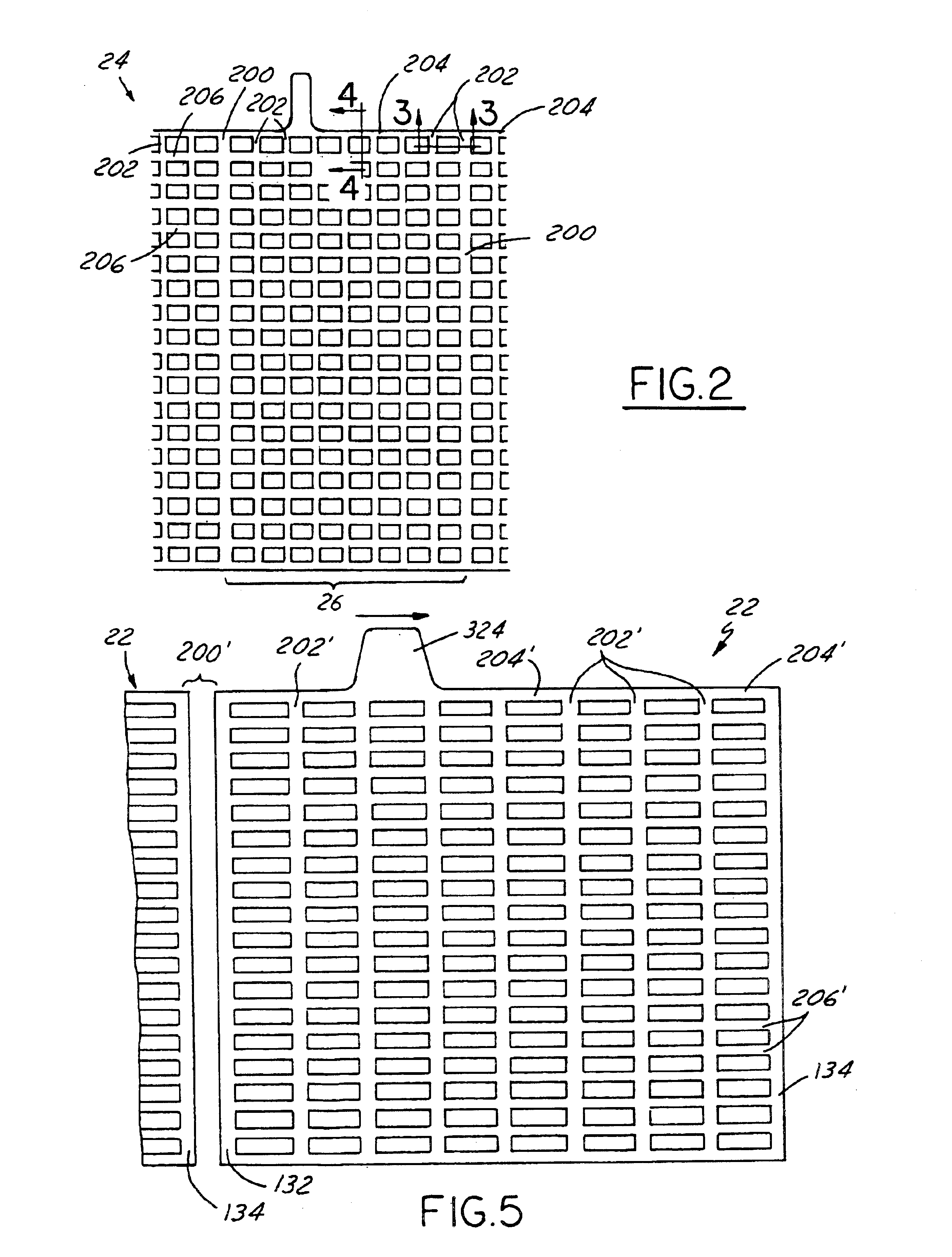

Battery grids

InactiveUS6895644B2Reduce thicknessReduction in thickness of webFinal product manufactureElectrode carriers/collectorsGramEngineering

A battery positive grid is continuously cast of lead and thereafter cold worked to reduce its cross sectional thickness to change the microstructure of the lead and provide enhanced corrosion resistance and other properties needed for positive grids. The as cast thickness is reduced by not more than ½ or 2 to 1, to produce a positive grid with a lead weight of 0.5 to 2.1 grams per square inch of the area of the plan of the cold worked grid which improves the life of a battery in which it is used. A battery negative grid is continuously cast of lead and thereafter cold worked to reduce its cross sectional thickness 1.2:1 to less then 1.5:1 to increase the ultimate tensile strength needed for a lighter negative grid with a lead weight of 0.3 to 0.9 of a gram per square inch of the area of its plan.

Owner:WIRTZ MFG CO INC

Interpenetrating networks with covalent and ionic crosslinks

ActiveUS20160354520A1Improve mechanical propertiesImprove fracture toughnessProsthesisSelf-healingEngineering

The invention features a composition comprising a self-healing interpenetrating network hydrogel comprising a first network and a second network. The first network comprises covalent crosslinks and the second network comprises ionic or physical crosslinks. For example, the first network comprises a polyacrylamide polymer and second network comprises an alginate polymer.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE +1

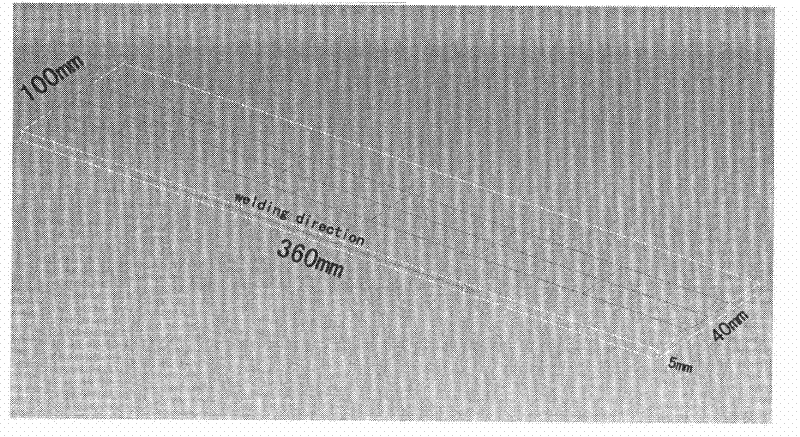

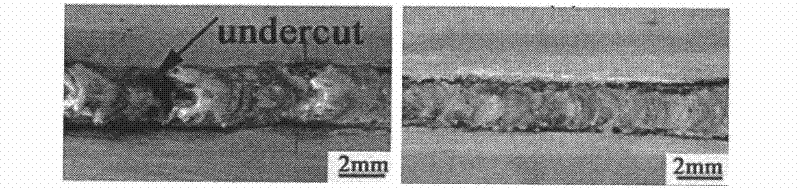

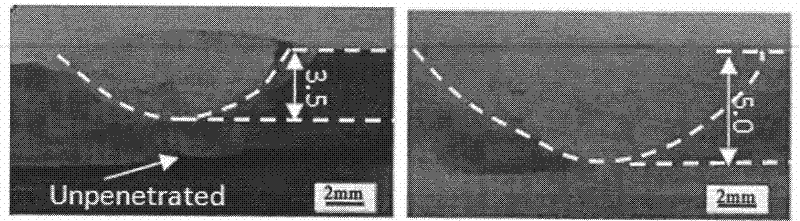

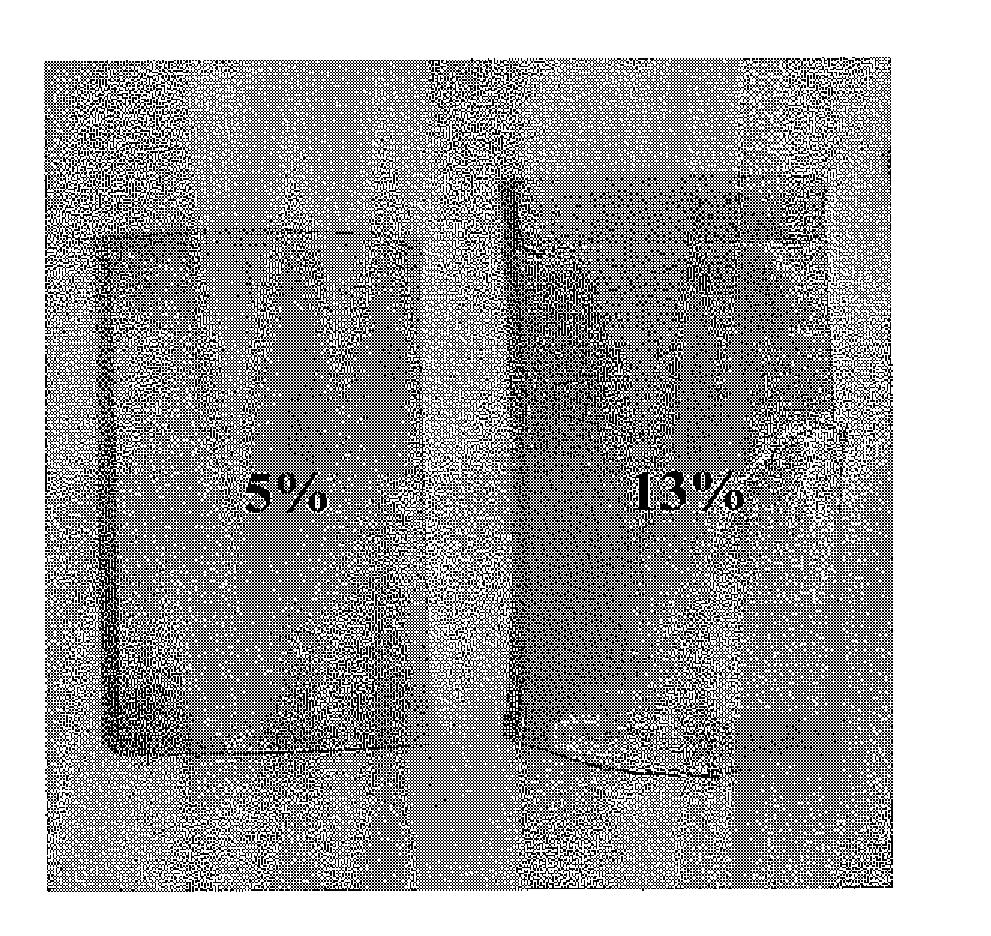

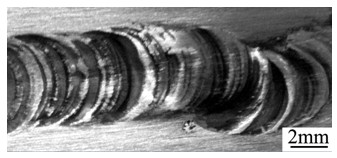

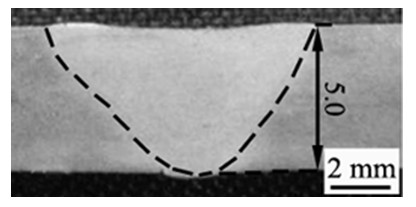

Novel active agent used for TIG (Tungsten Inert Gas) welding of magnesium alloy

InactiveCN102343489AImprove ultimate tensile strengthChanging the temperature coefficient of surface tensionArc welding apparatusWelding/cutting media/materialsPorosityHydrogen

The invention discloses a novel active agent used for TIG (Tungsten Inert Gas) welding of magnesium alloy, belonging to the active agent welding technology. The active agent is characterized in that the active agent consists of, by weight percent, 60-65 TiO2 and 35-40 CaF2, and is prepared through the following steps: first, grinding and then mixing TiO2 and CaF2 active agent powder by proportion; second, adding acetone to the mixture to enable the mixture to turn to paste; and then evenly coating the pasty active agent on the upper surface of a test sample through a flat brush, wherein the coating width is about 40mm and the coating thickness is about 0.3mm. The active agent can be used for TIG welding after the acetone volatilizes. Compared with the welding joints without being coated with the active agent in the welding process, the welding joint obtained through the welding technique disclosed by the invention has the advantages that the weld penetration is improved by 43% and the tensile property is improved by 58%. In addition, porosity in the welding line is remarkably reduced after the active agent is coated, thus solving the difficulties of the existence of hydrogen pores and shallow weld penetration.

Owner:CHONGQING UNIV

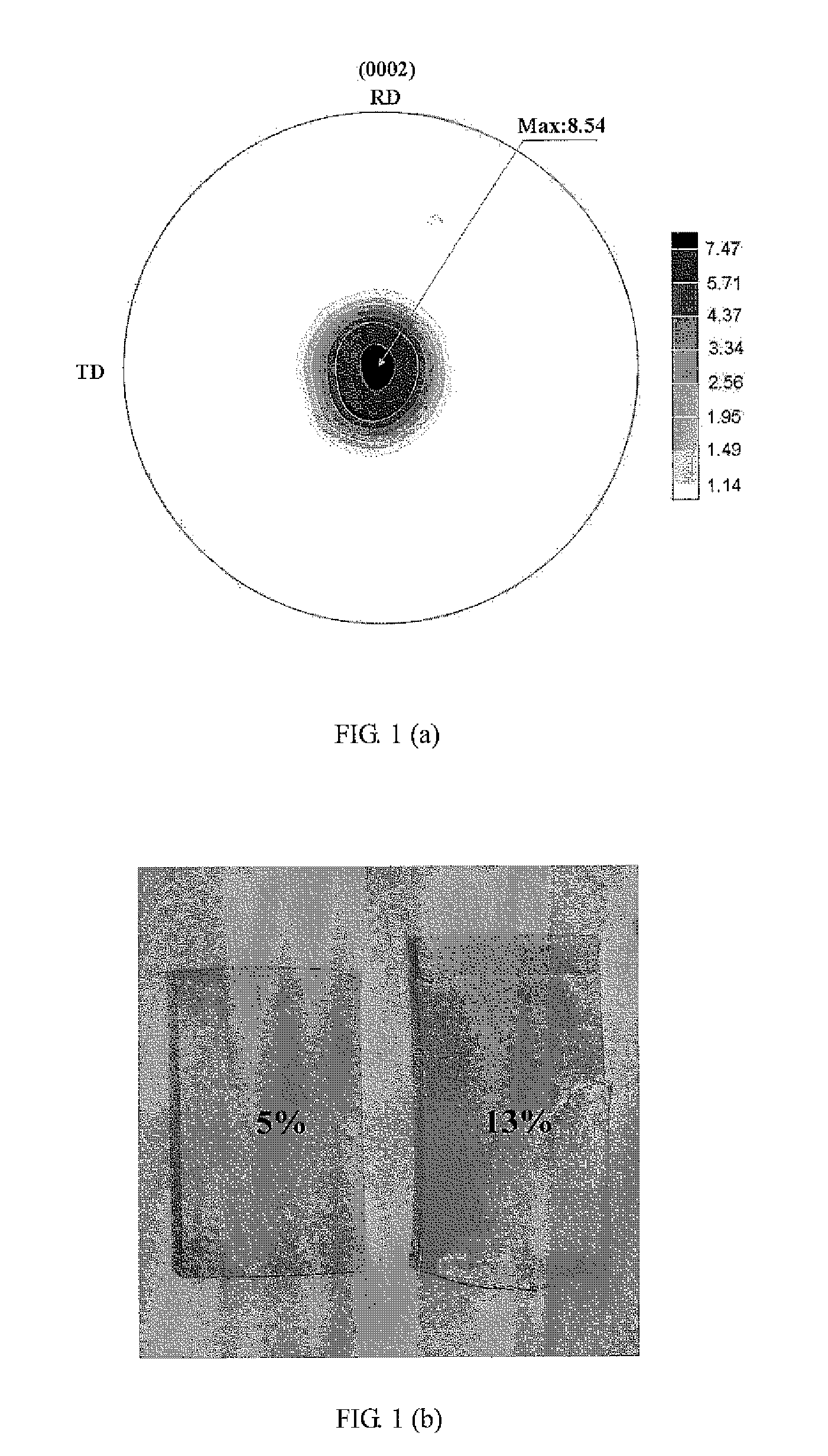

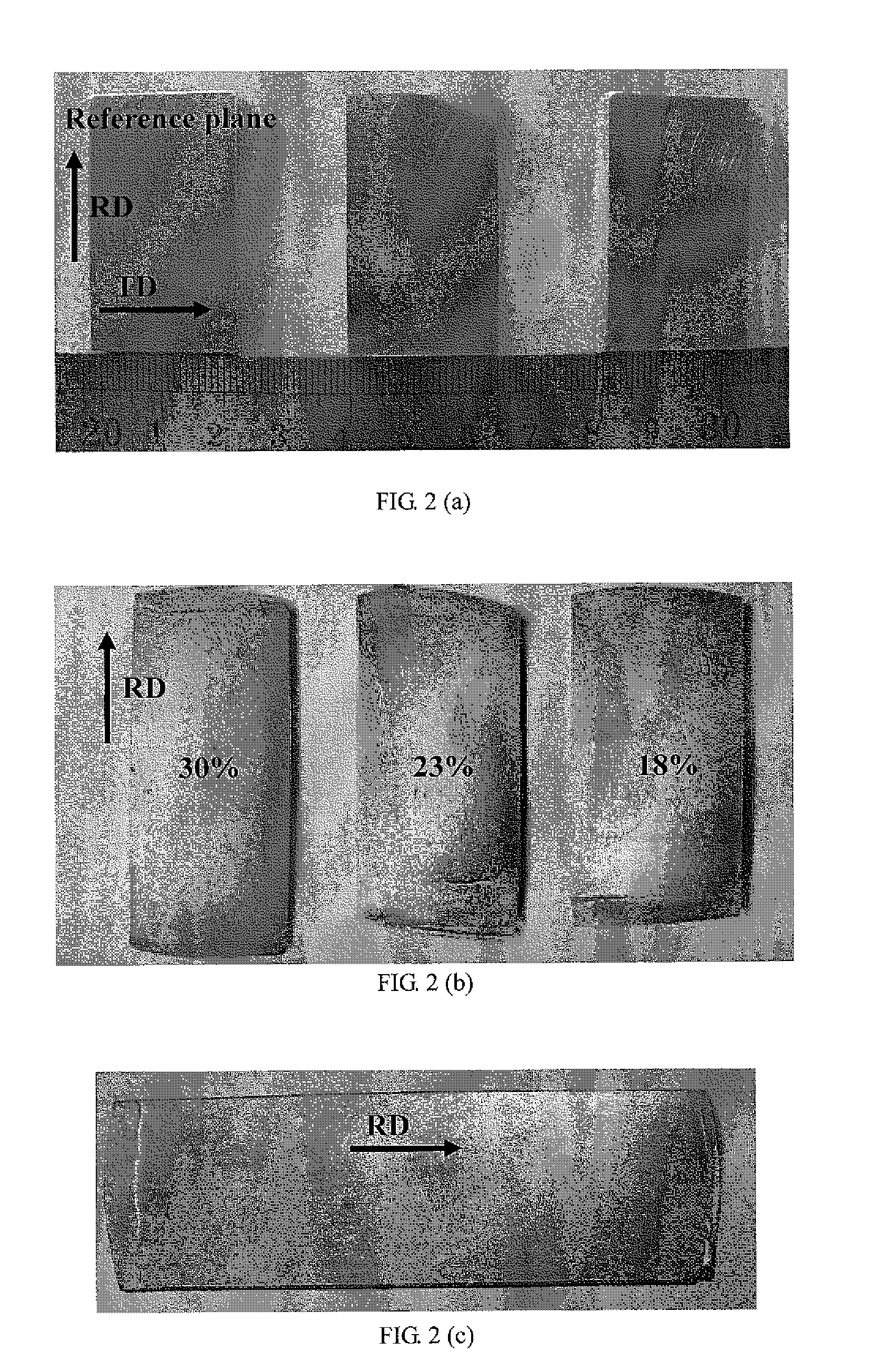

Cold-rolling method for a wrought mg alloy with weak/non-basal texture and a cold rolled sheet

InactiveUS20120288398A1Easy to manipulateEasy to controlMetal rolling arrangementsRoom temperatureSingle pass

The present invention relates to a cold-rolling method for cold-rolling a wrought Mg alloy with a weak or non-basal texture as well as a cold-rolled sheet, the method comprising the steps of: pre-treating a billet of the wrought Mg alloy with a weak or non-basal texture, and then cold rolling it; wherein the weak or non-basal texture plane of said billet is selected as a rolling plane, and the rolling direction is parallel to the rolling plane; and said billet is cold rolled at room temperature to a sheet or foil with a thickness of 0.1 to 100 mm, wherein single-pass or multi-pass rolling is used, and the cold rolling is followed by an annealing at 200 to 400° C. for 10 min to 48 h.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Precision cast dental instrument

InactiveUS7677296B2Resistance to breakageResistance to wearTransportation and packagingWristbandsInstrumentationPrecision casting

An endodontic file (200) is provided particularly adapted for the removal of tooth structure, decayed or damaged nerve tissues or dentine material on the interior walls of a root canal or dentine and / or enamel from the external tooth wall. The endodontic instrument includes a shaft (202) having a shank portion (204) and a generally elongated working portion (206). The working portion preferably includes cutting or abrading features (232) adapted upon rotation and / or reciprocation of the instrument to cut, abrade or remove tissue from the interior walls of a root canal or dentine and / or enamel from the external tooth wall. The working portion extends from a proximal end (207) adjacent the shank portion to a distal end (208) terminating at a tip (250). The entire instrument and / or at least the working portion thereof is formed of an amorphous or essentially amorphous material having no or essentially no detectable crystalline structure and / or from a nanocrystalline material having an average crystalline grain size less than about 1 μm. The instrument may be formed by conventional grinding operations or by direct casting, forging or molding, in a manner producing an integral as-molded instrument having one or more sharp cutting edges. The instrument is inexpensive to manufacture and exhibits improved cutting-edge sharpness, wear resistance, lubriciousness and resistance to breakage.

Owner:CLOUDLAND INST

Al-si-mg-zn-cu alloy for aerospace and automotive castings

The present invention provides an aluminum casting alloy with a composition including 4%-9% Si; 0.1%-0.7% Mg; less than or equal to 5% Zn; less than 0.15% Fe; less than 4% Cu; less than 0.3% Mn; less than 0.05% B; less than 0.15% Ti; and the remainder consisting essentially of aluminum. The inventive AlSiMg composition provides increased mechanical properties (Tensile Yield Strength and Ultimate Tensile Strength) in comparison to similiarly prepared E357 alloy at room temperature and high temperature. The present invention also includes a shaped casting formed from the inventive composition and a method of forming a shaped casting from the inventive composition.

Owner:ARCONIC INC

Transparent polyamide moulding compositions with high tensile strain at break

A polyamide moulding composition with particularly good tensile strain at break consisting of the following constituents: (A) 50 to 100% by weight of at least one transparent polyamide composed of: (a1) 55 to 77 mol % of acyclic, aliphatic diamine having 5-10 carbon atoms; (a2) 23 to 45 mol % of cycloaliphatic diamine having 6-36 C atoms, where the proportions of (a1) and (a2) are based on the entirety of the diamines used; (a3) 40 to 80 mol % of aromatic dicarboxylic acid or a mixture of such dicarboxylic acids; and (a4) 20 to 60 mol % of acyclic, aliphatic dicarboxylic acid having 8 to 16 carbon atoms, or a mixture of such dicarboxylic acids, where the proportions of (a3) and (a4) are based on the entirety of the dicarboxylic acids used; and (B) 0-50% by weight of additives,; where the entirety of components (A) and (B) gives 100% by weight.

Owner:EMS PATENT AG

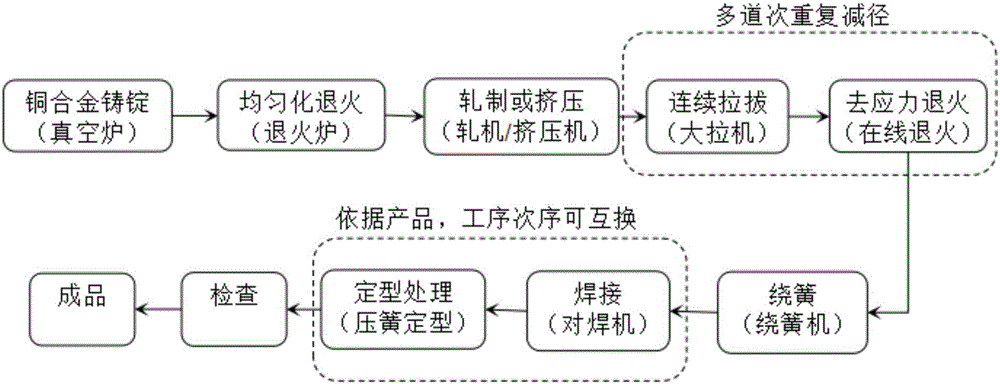

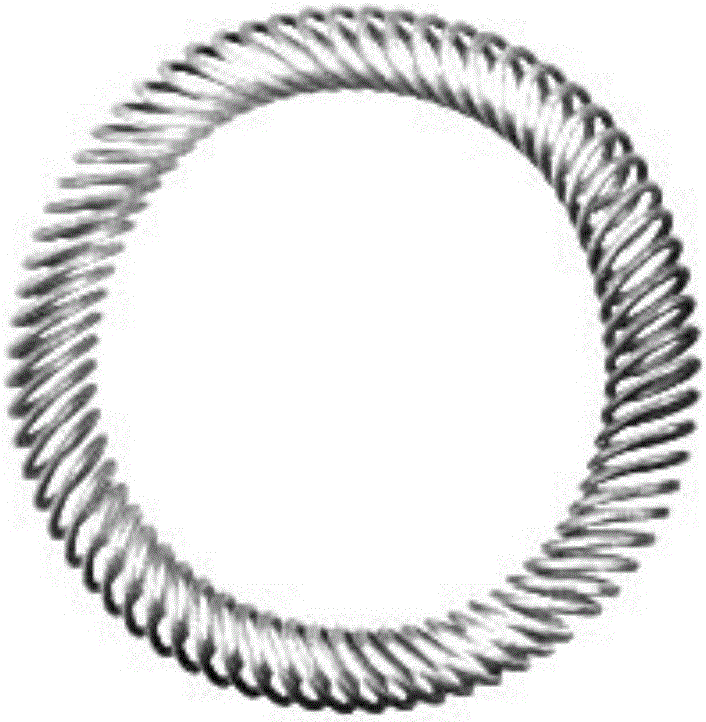

High-strength and high-conductivity rare-earth chromium-zirconium-copper spring contact finger and manufacturing method thereof

ActiveCN106350697AHigh ultimate tensile strengthHigh conductivityCoupling contact membersContactsMagnesiumHigh intensity

The invention discloses a high-strength and high-conductivity rare-earth chromium-zirconium-copper spring contact finger and a manufacturing method thereof. The spring contact finger is manufactured from, by weight, 99.95% of metallic copper, 99.9% of metallic zirconium, 99.9% of metallic chromium and industrial rare-earth materials (cerium-rich rare earth and silicon magnesium), and alloys include, by weight, 8-15% ofzirconium, 0.2-1.5% of chromium, 3-8% of rare earth and the balance of the copper. The manufacturing method mainly includes the steps of vacuum melting, homogenizing annealing, extrusion breakdown of cast ingot (an extruded rod is phi18-phi30mm in size), multi-pass continuous drawing and intermediate stress relief annealing, wire winding spring, sizing pressure spring, butt welding of the contact finger and the like. The spring contact finger has the advantages of high ultimate tensile strength, high electric conductivity, good rebound resilience, no pollution and the like, the mechanical property of the spring contact finger is comparable to that of beryllium copper while the physical performance and environmental index of the same are obviously superior to the beryllium copper, and the spring contact finger can take the place of the beryllium copper in majority of occasions where the spring contact finger is used.

Owner:CHINA XIDIAN GRP CO LTD

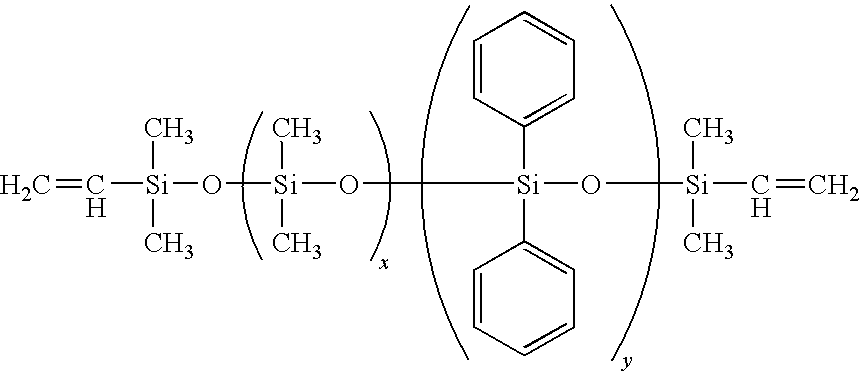

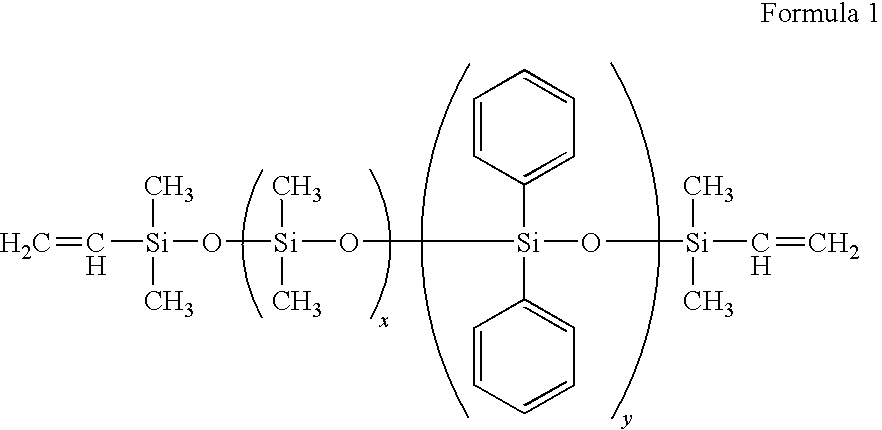

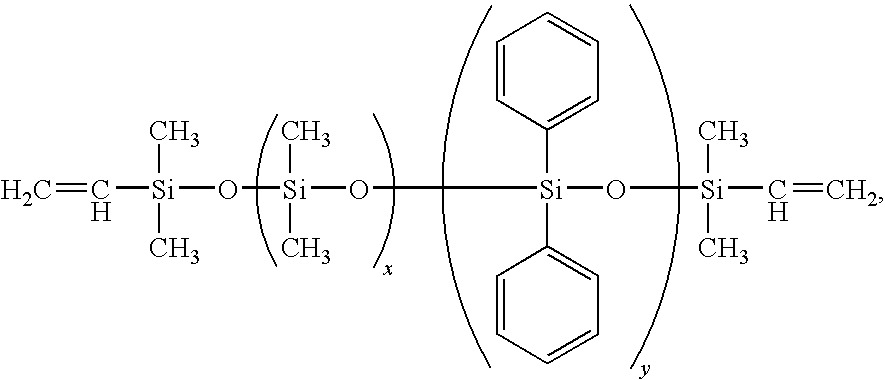

Hybrid intraocular lens materials for small incision surgery

ActiveUS7763682B2Low modulusHigh modulusSurgical adhesivesTissue regenerationIntraocular lensMedicine

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

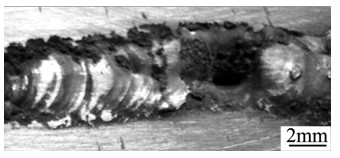

Novel nano-particle reinforced active tungsten argon arc welding method

InactiveCN103008845AImprove ultimate tensile strengthPromote nucleation and crystallizationArc welding apparatusWelding/cutting media/materialsAcetoneCrystallite

The invention discloses a novel nano-particle reinforced active tungsten argon arc welding method, and belongs to the active welding technology. The method is characterized by comprising the following steps of: before welding, mixing oxide activator powder and nano ceramic particles in proportion, and then adding acetone into the mixture so that the mixture is in pasty; then uniformly coating the pasty activator on the surface of samples by a flat brush, wherein the coating width is about 40mm, and the average coating amount is 5.mg.cm<-2>; and carrying out tungsten argon arc welding after the acetone is volatilized. The external waviness of the welding joints obtained by adopting the nano-particle reinforced active tungsten argon arc welding is smooth; compared with the welding joints obtained by the traditional tungsten argon arc welding, the fusion depth is increased by 110%; the crystal particles of the welding joint fusion region are obviously reduced compared with the active tungsten argon arc welding; and the tensile property of the welding joint is improved by 64.6% compared with the active tungsten argon arc welding. The problems that the tungsten argon arc welding fusion depth of magnesium alloy is shallow and the crystal particles of the active tungsten argon arc welding are thick are solved.

Owner:CHONGQING UNIV

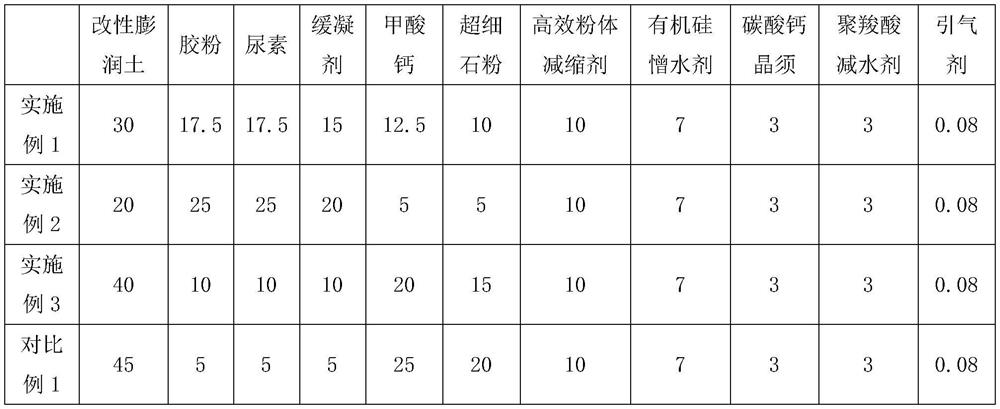

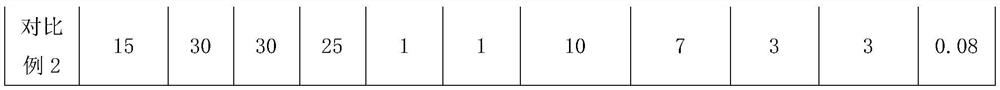

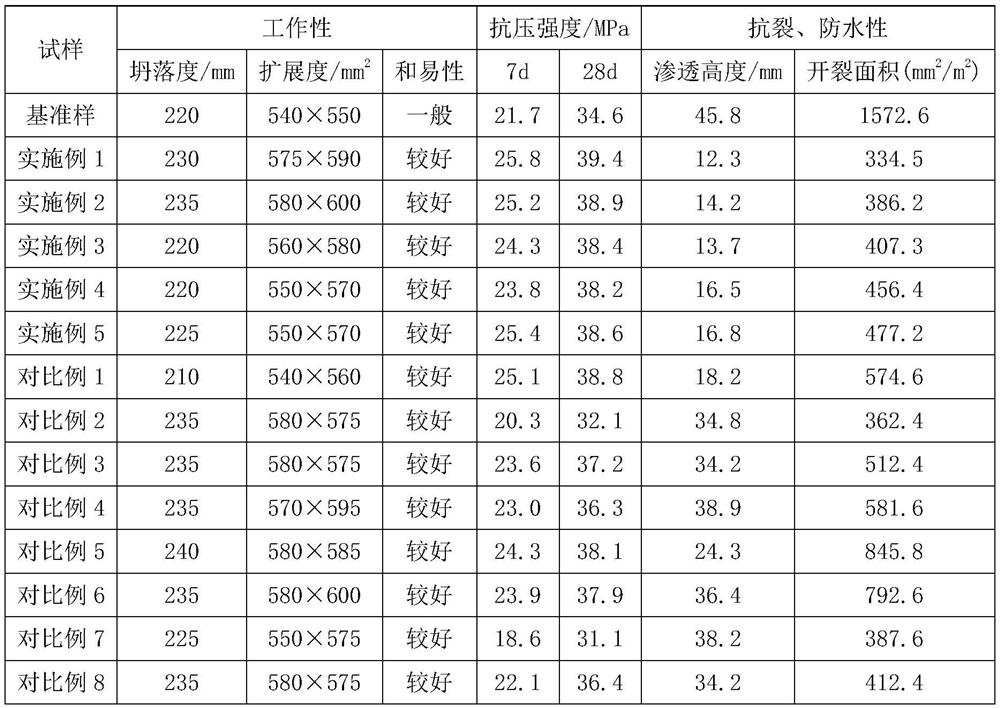

Compact anti-cracking waterproof agent capable of inhibiting early cracking of concrete and preparation method of dense anti-cracking waterproof agent

ActiveCN112851191AImprove mechanical propertiesImprove pore structureSolid waste managementSodium BentoniteCrack resistance

The invention discloses a dense anti-cracking waterproof agent for inhibiting early cracking of concrete. The dense anti-cracking waterproof agent comprises the following components in parts by weight: 20-40 parts of modified bentonite, 10-25 parts of rubber powder, 10-25 parts of urea, 10-20 parts of a retarder, 5-20 parts of calcium formate, 5-15 parts of superfine stone powder, 5-15 parts of an efficient powder shrinkage reducing agent, 4-10 parts of an organic silicon water repellent, 1-5 parts of calcium carbonate whiskers, 1-5 parts of a polycarboxylate superplasticizer and 0.05-0.1 part of an air entraining agent; wherein the modified bentonite is prepared by mixing sodium bentonite and a Fe2(SO4)3 solution in proportion, carrying out standing aging treatment at normal temperature, filtering the mixture, washing the mixture with water, and drying, grinding and sieving the mixture. On the premise that the original working performance of concrete is not influenced, the anti-crack waterproof agent can slightly improve the mechanical property of the concrete, improve the pore structure of the concrete, improve the compactness of the concrete, enhance the impermeability of the concrete, greatly reduce the risk of early cracking of the concrete and improve the ultimate tensile strength of the concrete; therefore, the anti-seepage and waterproof performance of the concrete is comprehensively improved from two aspects of compactness and crack resistance.

Owner:WUHAN YUANJIN BUILDING MATERIALS TECH CO LTD

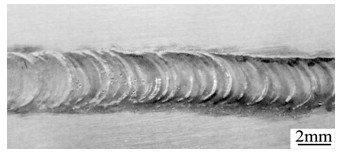

High-performance magnesium alloy welding active agent

InactiveCN102689111AImprove ultimate tensile strengthImprove mechanical propertiesArc welding apparatusWelding/cutting media/materialsActive agentTungsten

The invention discloses a novel active agent for improving the welding performance of magnesium alloy argon tungsten-arc welding, belonging to the welding technology of active agents. The novel active agent is characterized by consisting of MnCl2 and ZnO, wherein the active agent has the weight ratio of MnCl2 to ZnO of (65%-75%); (25%-35%). A preparation method of the novel active agent comprises the following steps of: grinding MnCl2 and ZnO active agent powder, mixing in proportion, and adding acetone into a mixture, so that the active agent is pasty; evenly coating the pasty active agent on the surface of a sample by a flat hair bush, wherein the coating width is about 40mm, and the average coating quantity of the active agent is 6mg / cm<-2>; and carrying out argon tungsten-arc welding after the acetone is volatilized. Compared with the welding joint which is uncoated with the active agent, the tensile property of the welding joint obtained by the welding technology is improved by 22.8%. Compared with the welding joint which is coated with the single active agent, the tensile property of the welding joint is improved by 60.7%. The difficulties of the high possibility of the narrow melting depth in the magnesium alloy TIG (tungsten-arc welding) welding and the high possibility of the coarse crystalline grains in the A-TIG (argon tungsten-arc welding) welding can be solved.

Owner:CHONGQING UNIV

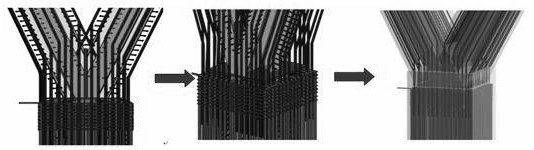

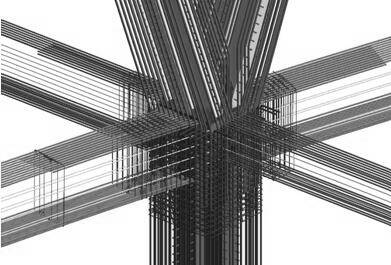

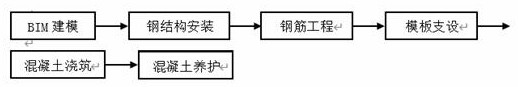

Cross construction method for complex V-shaped stiff columns and irregular ring beams of large stadium

ActiveCN112627434AImprove ultimate tensile strengthHydration goes wellStrutsGirdersArchitectural engineeringRebar

The invention relates to the field of construction of large public stadiums, and particularly relates to a cross construction method for complex V-shaped stiff columns and irregular ring beams of a large stadium. The method comprises the steps of 1, BIM modeling; 2, steel structure hoisting; 3, steel bar binding engineering; 4, formwork erecting; 5, concrete pouring; and 6, concrete curing. According to the principle of the construction method, due to the fact that adjacent V-shaped columns have a corner of a certain angle, bottom projections of the V-shaped columns are staggered and overlapped. According to the method, coordinate points are extracted through the BIM technology, on-site corner point positioning is conducted through a total station, and then V-shaped column bottom edge lines are popped up according to positioning points for construction. The construction method for complex cross of the V-shaped super-complex stiff columns and the irregular ring beams of the stadium is achieved in a focused mode, flexibility is achieved, and the concept of sustainable development is met.

Owner:SHANGHAI BAOYE GRP CORP

Gearbox for tillage machine

InactiveCN104195394AReduce consumptionPrevent oxidationGearingUltimate tensile strengthMaterials science

The invention relates to a gearbox for a tillage machine. The process of manufacturing a gearbox body comprises the following steps: adding Al, Ca, Mn, Si and RE into a magnesium alloy material, adding MgCl, MgO, KCl and BaCl2 in a melting process, increasing the wall thickness of a die, enlarging the feeder head, mounting a resistive heater and a water-cooling device, and vacuumizing. The product mechanical ultimate tensile strength, the yield strength and the elongation of the gearbox can be improved, the gearbox has relatively strong corrosion resistance and relatively high stability, and the service life of the gearbox body of the tillage machine can be prolonged, and the quality of the gearbox body of the tillage machine can be improved.

Owner:CHONGQING CITY FULING DISTRICT BAOXIANG MACHINERY CO LTD

Agglomerated material containing recycled silicon

InactiveUS20060051598A1Improve featuresGreat degreeSolid waste managementConductive materialColoring agentsMaterials science

An agglomerate material, advantageously used for the production of sheets or slabs or blocks for flouring and / or cladding or furnishing items consists of a mixture comprising between 1% and 75% of a raw material being IT industry recycled silicon tablets in the form of powders, grit or the like, between 5% and 20% of a binder, a colorant and a filler aggregate.

Owner:STONE ITAL

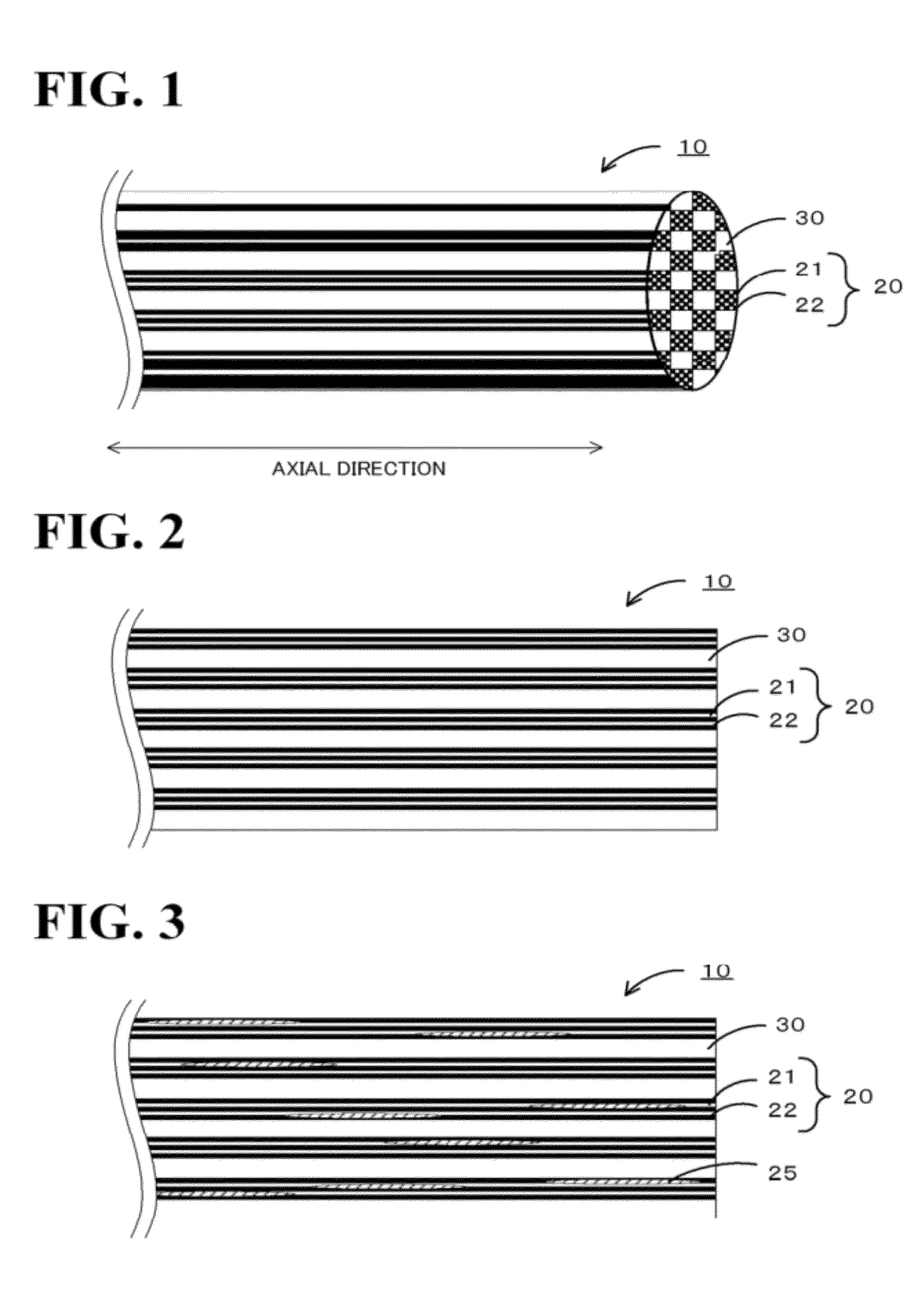

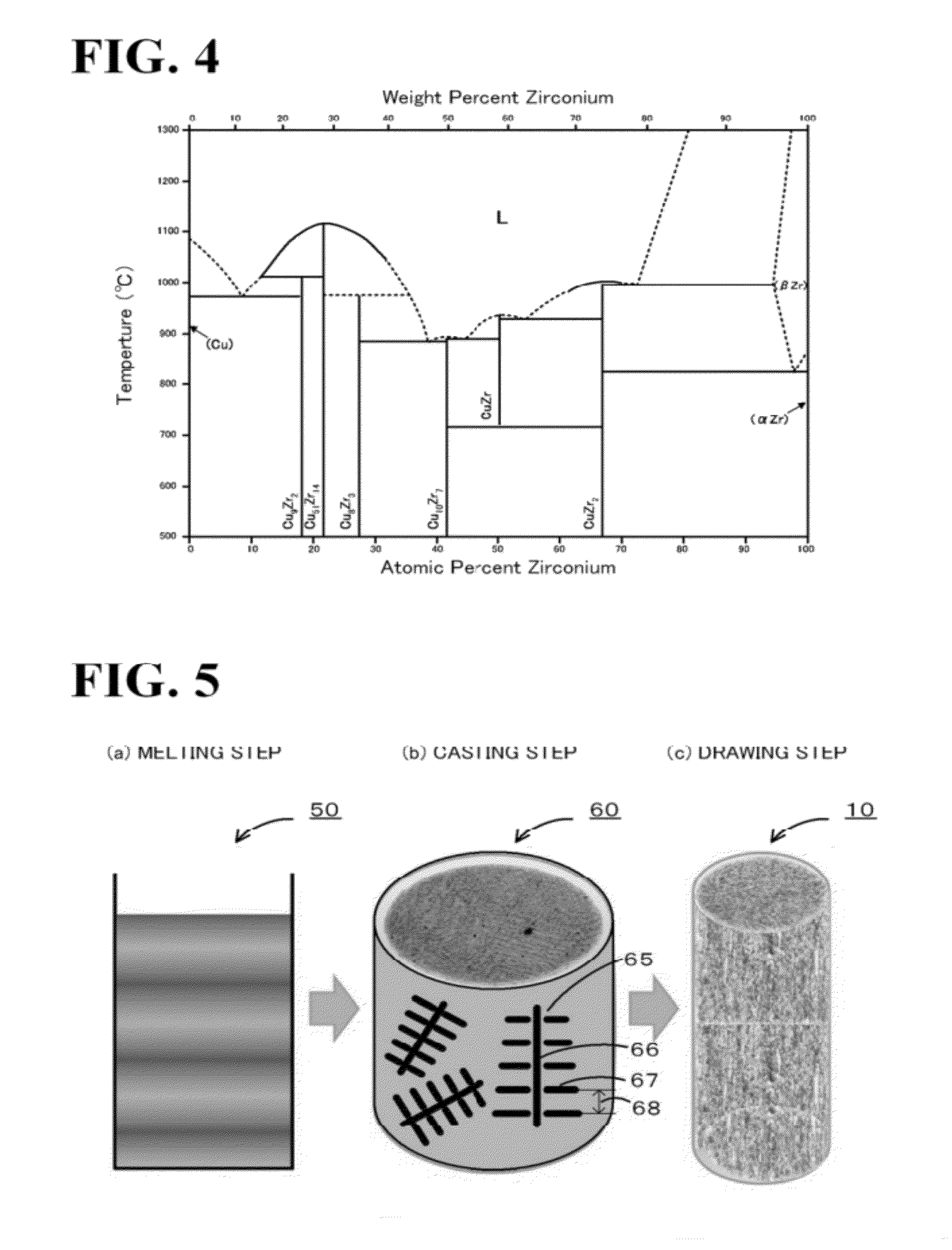

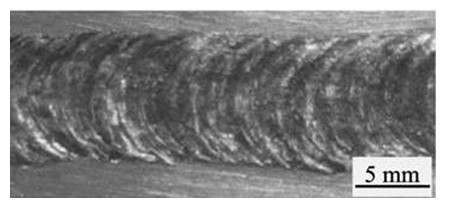

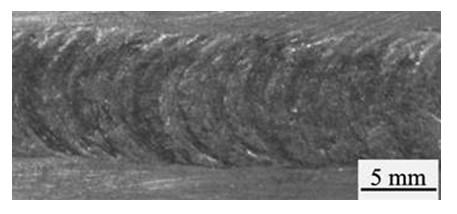

Copper alloy wire and method for producing the same

ActiveUS20120148441A1Improve ultimate tensile strengthHigh strengthConductive materialFoundry mouldsFiber-reinforced compositeFiber structure

The zirconium content of the alloy composition of a copper alloy wire is 3.0 to 7.0 atomic percent; and the copper alloy wire includes copper matrix phases and composite phases composed of copper-zirconium compound phases and copper phases. The copper matrix phases and the composite phases form a matrix phase-composite phase fibrous structure and are arranged alternately parallel to an axial direction as viewed in a cross-section parallel to the axial direction and including a central axis. The copper-zirconium compound phases and the copper phases in the composite phases also form a composite phase inner fibrous structure and are arranged alternately parallel to the axial direction at a phase pitch of 50 nm or less as viewed in the above cross-section. This double fibrous structure presumably makes the copper alloy wire densely fibrous to provide a strengthening mechanism similar to the rule of mixture for fiber-reinforced composite materials.

Owner:NGK INSULATORS LTD +1

Novel composite active agent for magnesium alloy active tungsten-insert-gas (A-TIG) arc welding

InactiveCN102689112AImprove ultimate tensile strengthChanging the temperature coefficient of surface tensionArc welding apparatusWelding/cutting media/materialsActive agentCeramic particle

The invention discloses a novel composite active agent for magnesium alloy active tungsten-insert-gas (A-TIG) arc welding, and belongs to an active agent welding technique. The novel composite active agent for magnesium alloy active tungsten-insert-gas arc welding provided by the invention is characterized in that the active agent is Cr2O3, and the weight proportion of the active agent is 65-70%; and a ceramic additive particle is SiC, and the weight proportion of the ceramic additive particle is 30%-35%. The novel composite active agent for magnesium alloy active tungsten-insert-gas arc welding is prepared through the following steps of: firstly grinding Cr2O3 active agent powder and the SiC ceramic particle, and mixing in proportion; then adding acetone into the mixture, so that the mixture becomes pasty; then coating the pasty active agent on the upper surface of a test sample uniformly by a flat brush, wherein the coating width is about 40mm, and the average density per square centimeter is 4-5mg; and carrying out tungsten-insert-gas (A-TIG) arc welding after the acetone is volatilized. Compared with a welding joint which is not coated with the active agent, the welding joint obtained through the welding technology has the advantages that the fusion depth is improved by 60%, an the tensile property is improved by 30%; and in addition, after the active agent is coated, crystal particles in the welding line are thinned obviously, and the difficulties that the fusion depth is shallow in the TIG arc welding, and the crystal particles of the welding line in the traditional active TIG arc welding are toughened seriously are solved.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com