Novel composite active agent for magnesium alloy active tungsten-insert-gas (A-TIG) arc welding

A technology of argon tungsten arc and active agent, which is applied in welding equipment, welding medium, welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0016] The weight ratio of composite active agent is Cr 2 O 3 : 65% and SiC: 35%. First Cr 2 O 3 The active agent powder and the SiC ceramic particles are fully milled and mixed in proportion, and then acetone is added to the mixture to make it into a paste. Then use a flat brush to evenly coat the paste active agent on the upper surface of the sample with a coating width of about 40 mm and an average density of 4-5 mg per square centimeter. After the acetone volatilizes, welding is performed.

[0017] The welding specifications adopted for TIG welding of AZ31 magnesium alloy plates with a plate thickness of 5 mm are:

[0018]

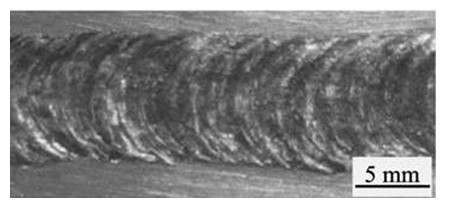

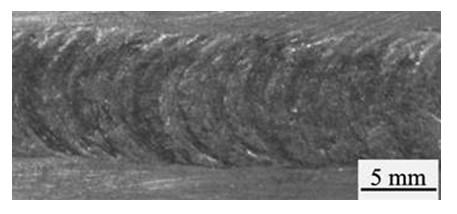

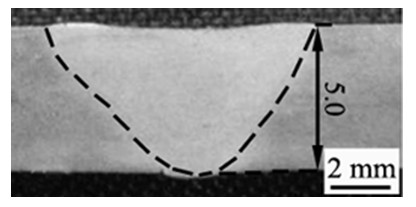

[0019] Under this welding standard condition, compared with the welded joint coated with a single component active agent, the weld width of the welded joint after the active agent has not changed significantly (such as figure 2 As shown), the penetration depth is increased by 60% (as shown in Figure 4), and the tensile performance is increased by 30% (as...

example 2

[0021] The weight ratio of composite active agent is Cr 2 O 3 : 68% and SiC: 32%. First Cr 2 O 3 The active agent powder and the SiC ceramic particles are fully milled and mixed in proportion, and then acetone is added to the mixture to make it into a paste. Then use a flat brush to evenly coat the paste active agent on the upper surface of the sample with a coating width of about 40 mm and an average density of 4-5 mg per square centimeter. After the acetone volatilizes, welding is performed. The welding parameters are the same as in Example 1.

example 3

[0023] The weight ratio of composite active agent is Cr 2 O 3 : 70% and SiC: 30%. First Cr 2 O 3 The active agent powder and the SiC ceramic particles are fully milled and mixed in proportion, and then acetone is added to the mixture to make it into a paste. Then use a flat brush to evenly coat the paste active agent on the upper surface of the sample with a coating width of about 40 mm and an average density of 4-5 mg per square centimeter. After the acetone volatilizes, welding is performed. The welding parameters are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com