Patents

Literature

244results about How to "Change flow direction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

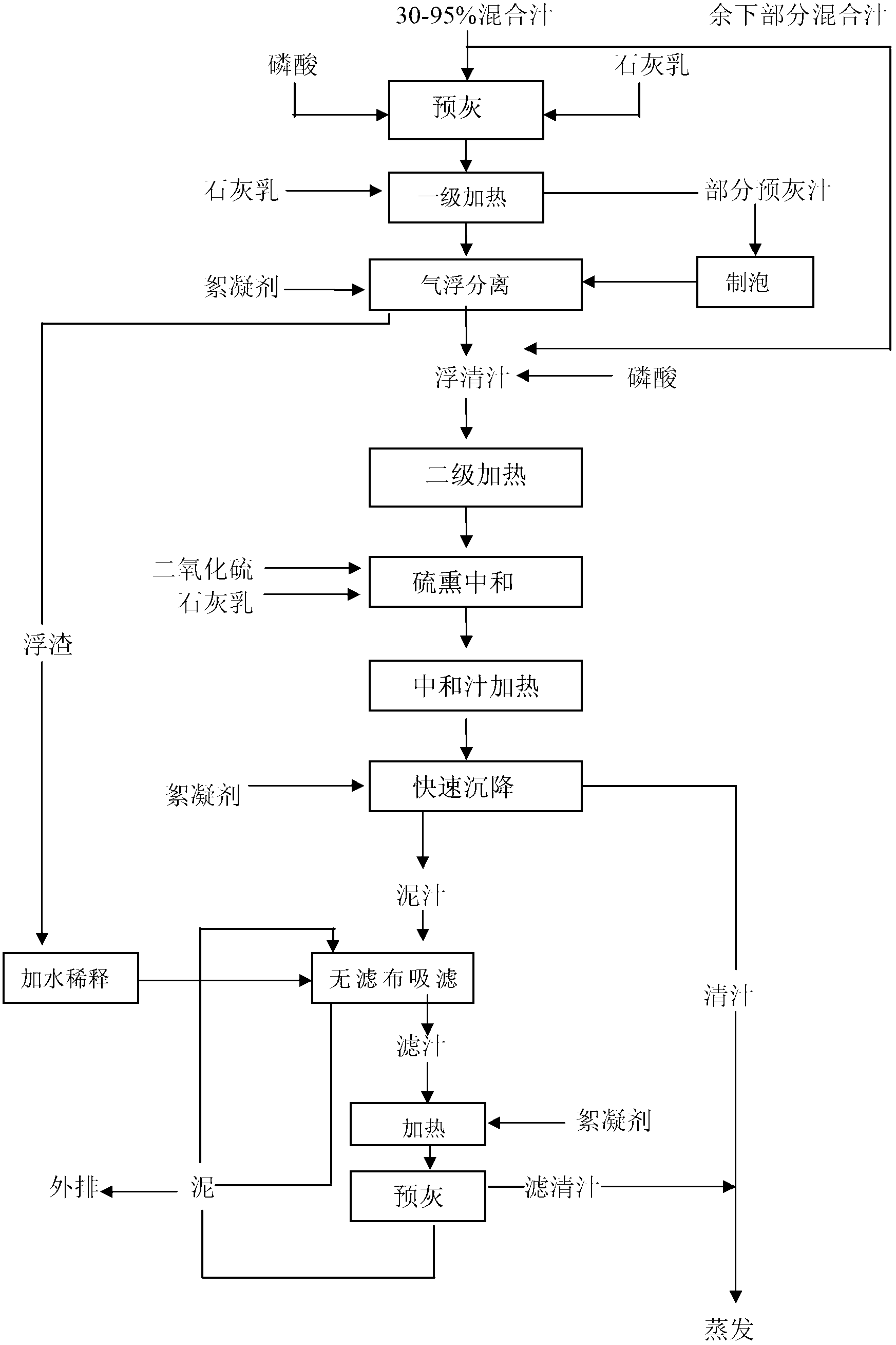

Sugarcane juice clarifying method

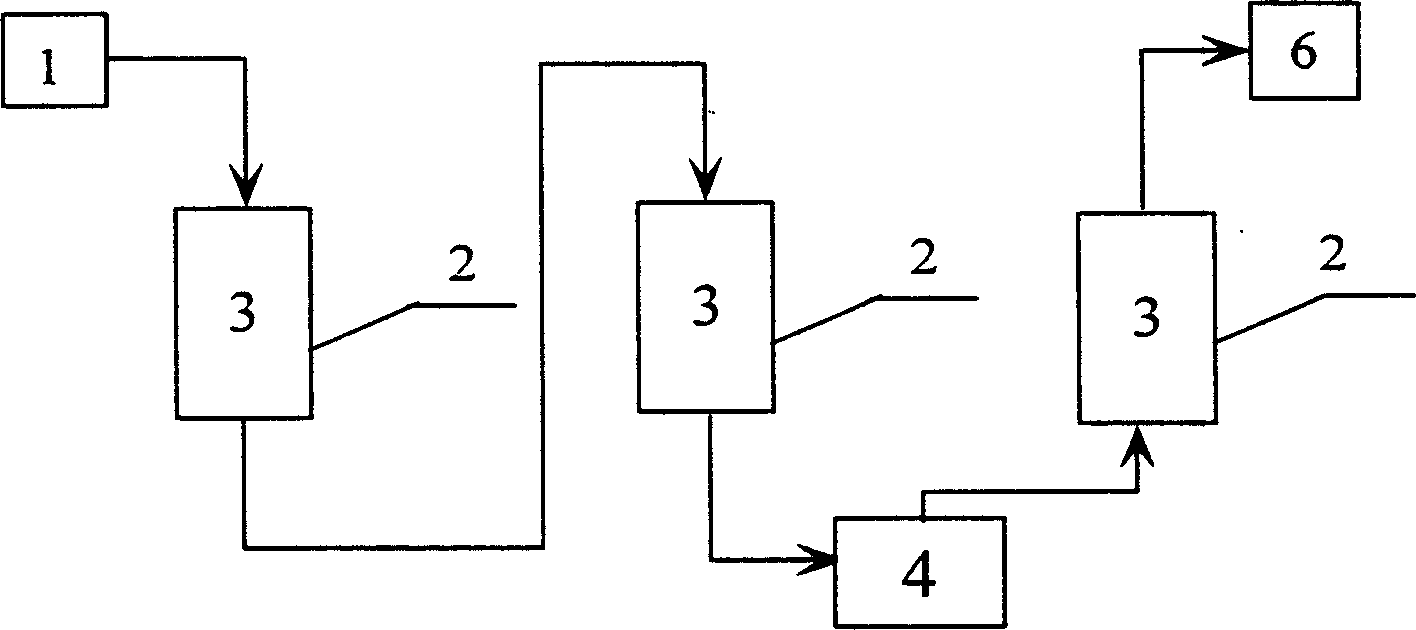

The invention discloses a sugarcane juice clarifying method. The method comprises the steps of: sequentially performing pre-liming, primary heating, foam making and air-floating separation on mixed juice which accounts for 30-95% of the total amount of mixed juice to obtain floating clear juice; mixing the rest mixed juice with the floating clear juice to obtain a mixed clear juice; and secondarily heating the mixed clear juice, stoving and neutralizing the mixed clear juice, heating the neutralized juice, and rapidly settling the neutralized juice to obtain clear juice, wherein the mixed juice is sugarcane juice obtained by the work procedure of pressing sugarcanes. The air-floating separation of part of mixed juice is combined with the rapid settlement of the rest of the mixed juice, the staying time of the sugarcane juice can be shortened, the remove rate of the non-sugar ingredient is increased, the pH value of the clear juice is stable, the phenomena of 'bottom reversing' of a settlement tank and 'cane sugar conversion' are avoided, the production cost is saved, the environment pollution is reduced and the product quality is improved.

Owner:GUANGXI DONGTANG INVESTMENT

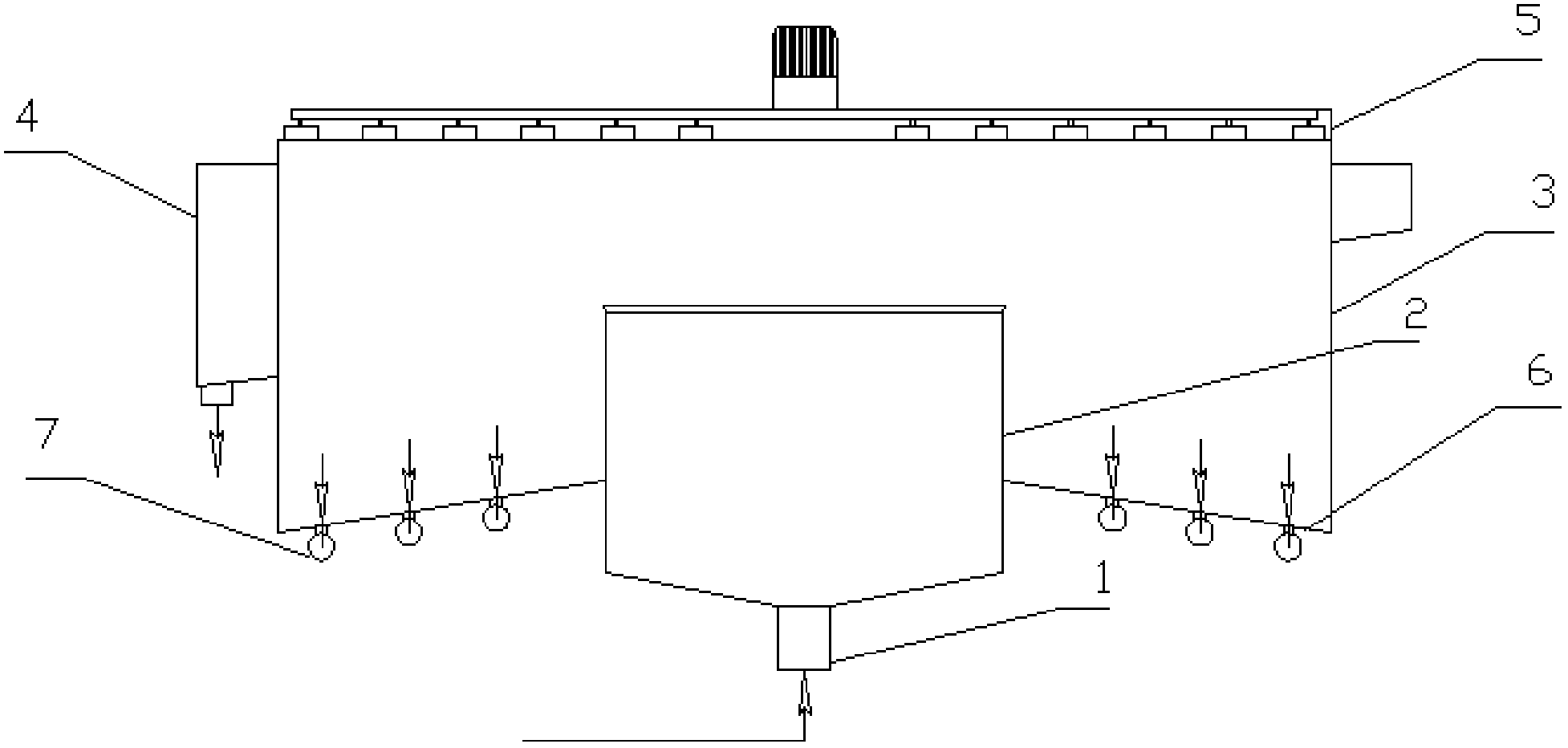

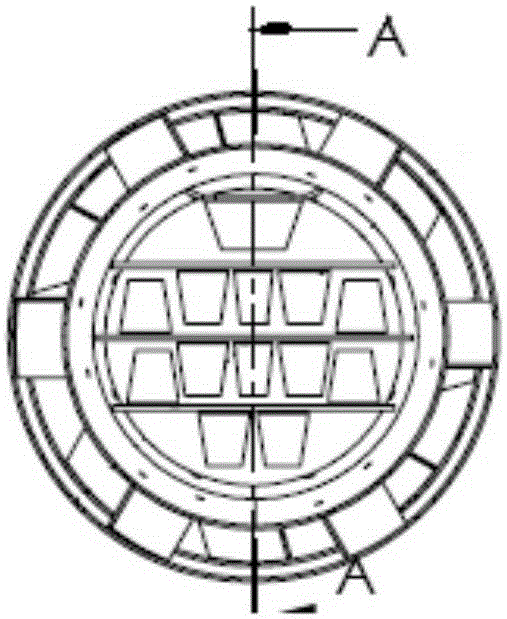

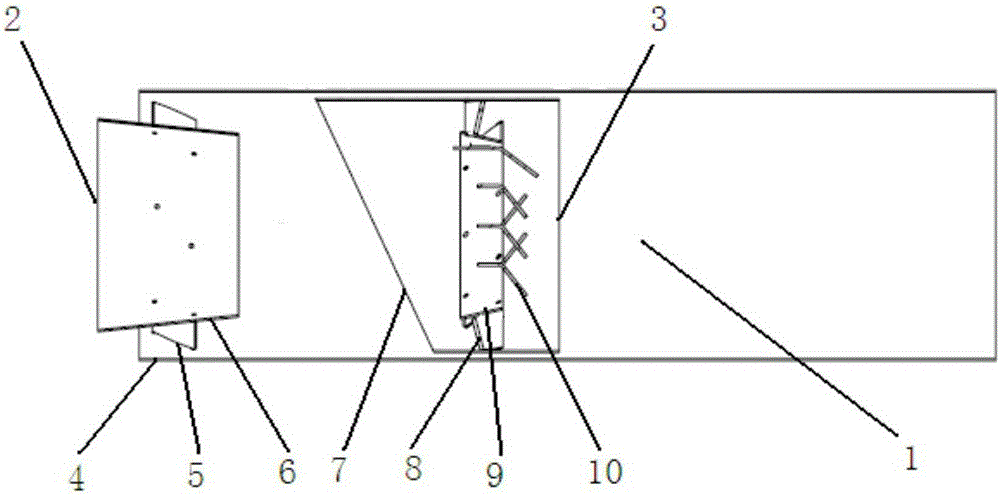

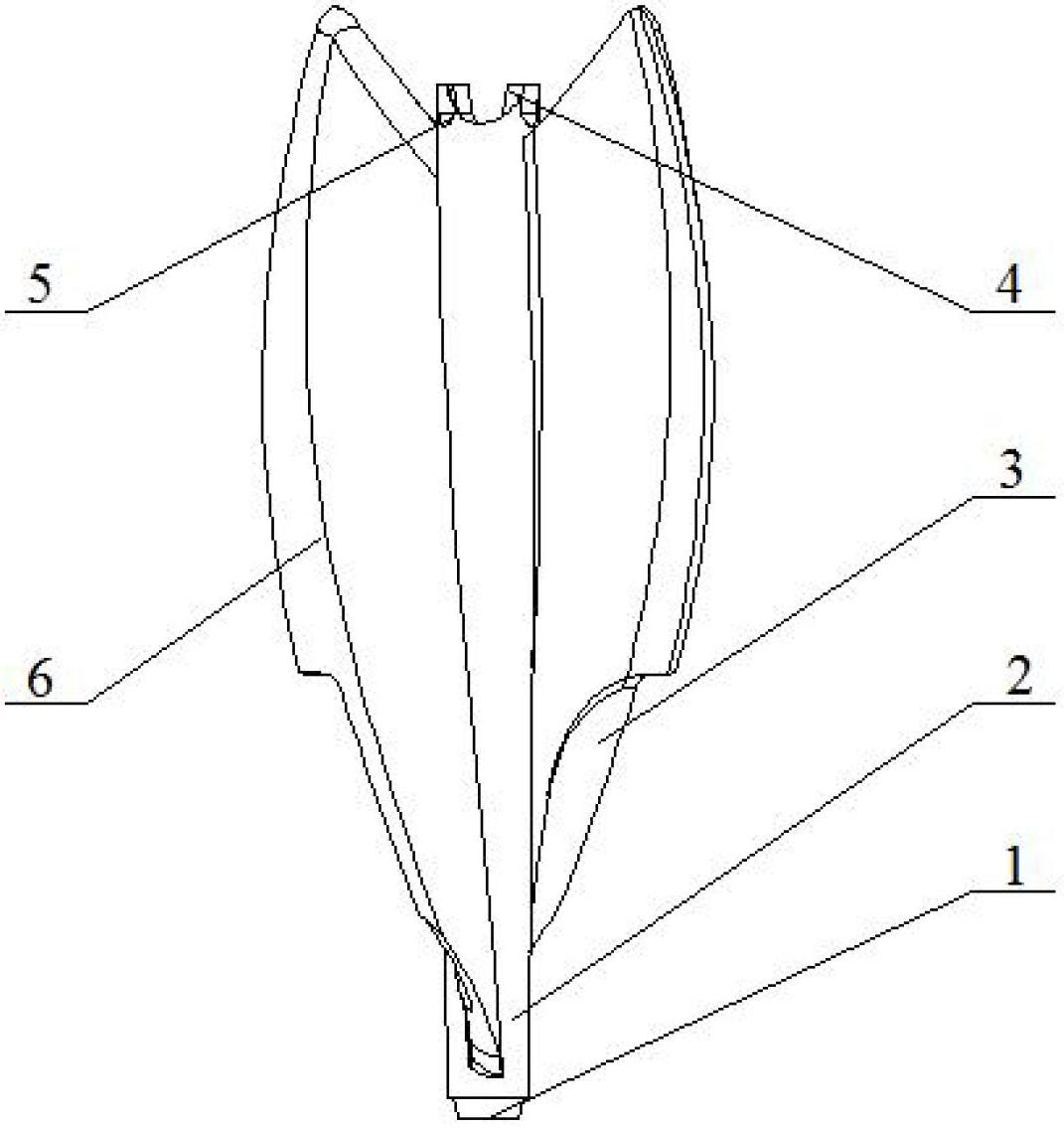

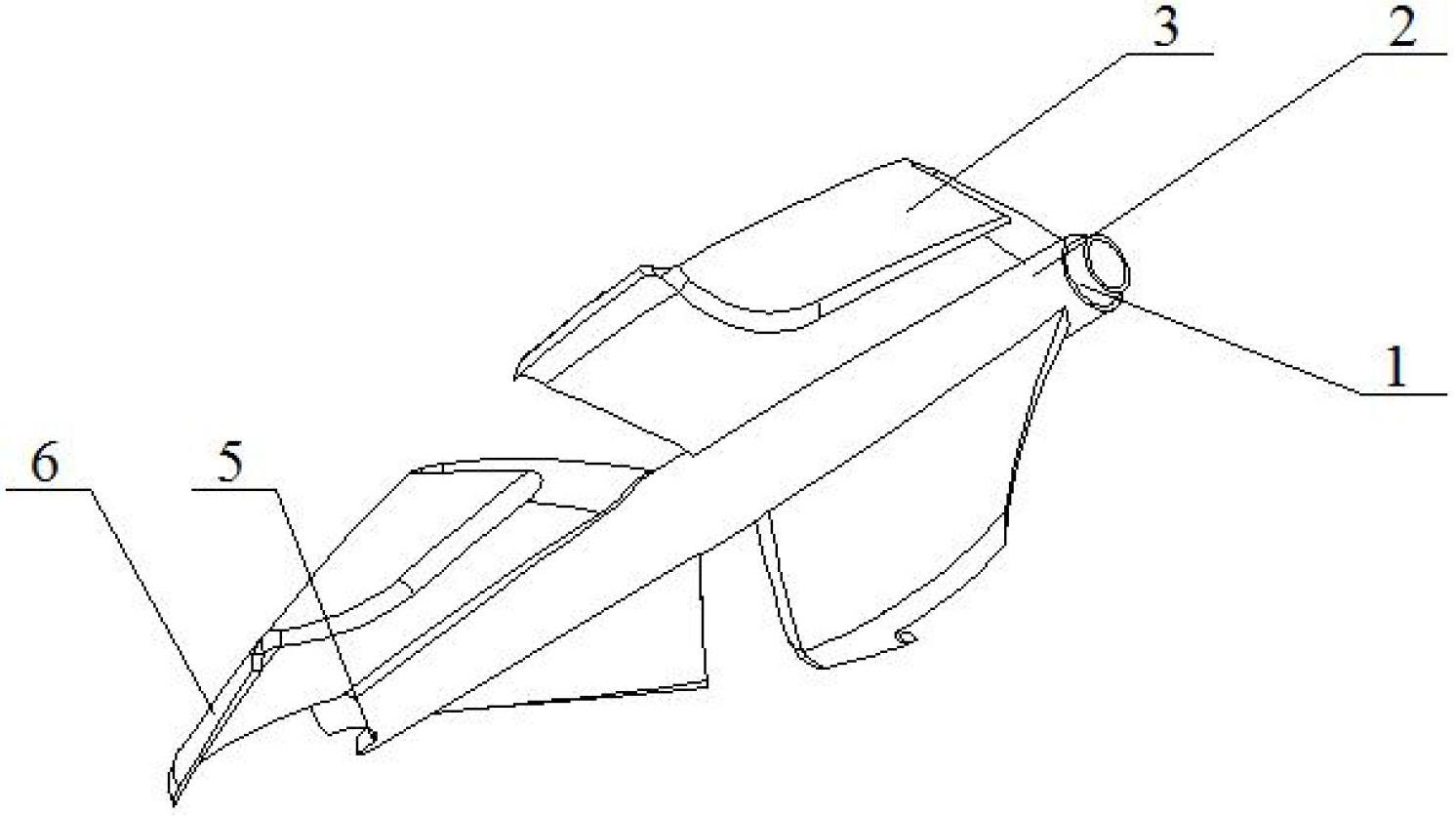

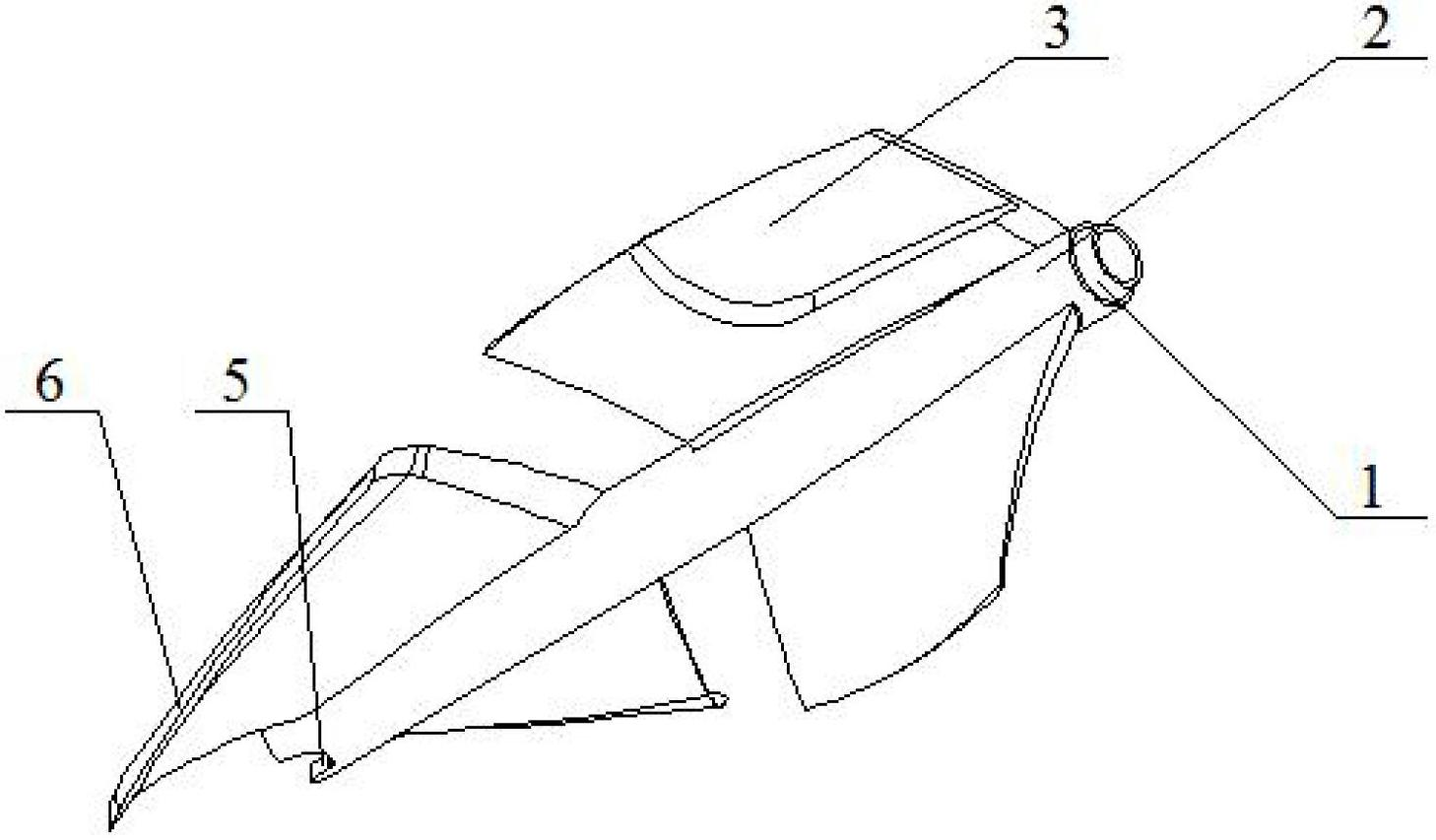

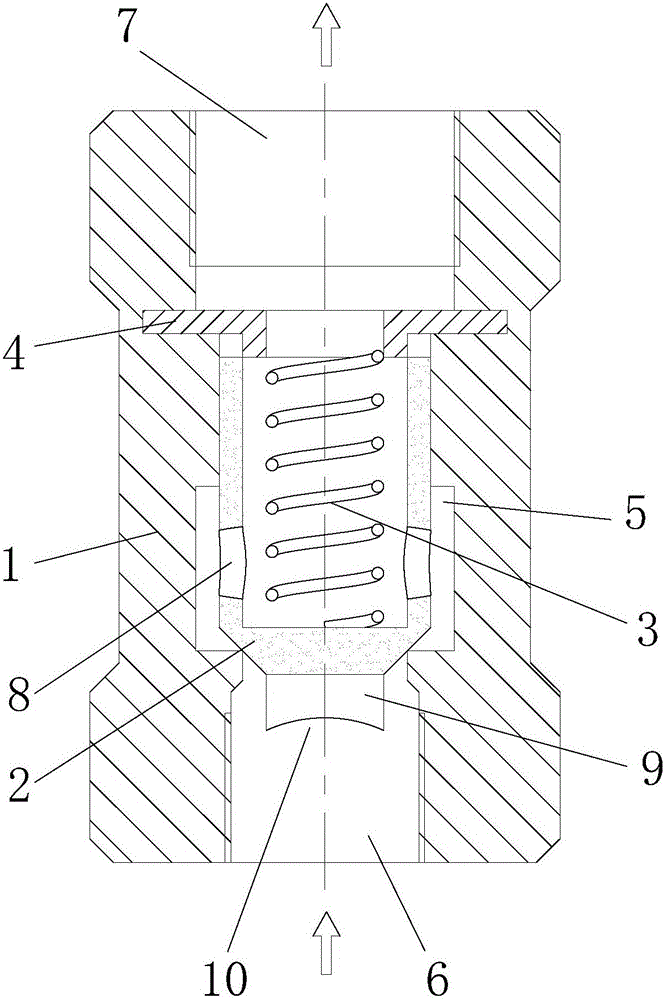

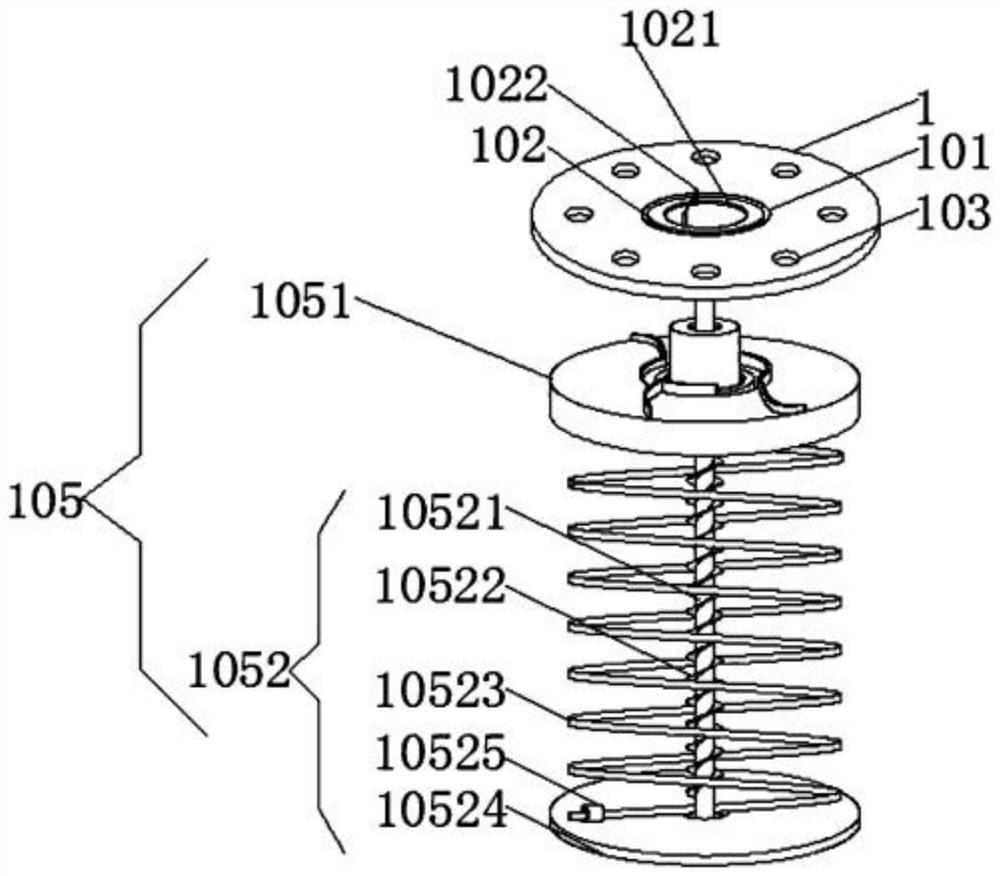

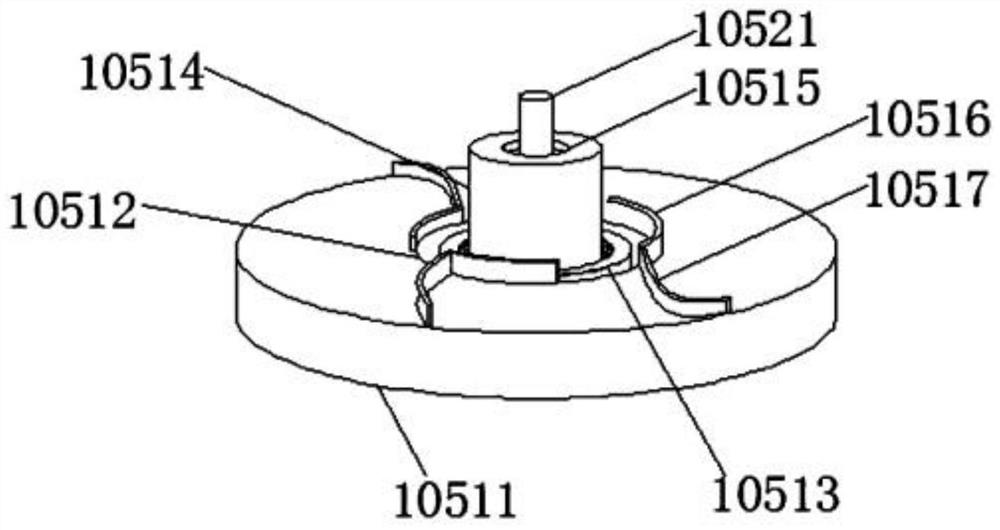

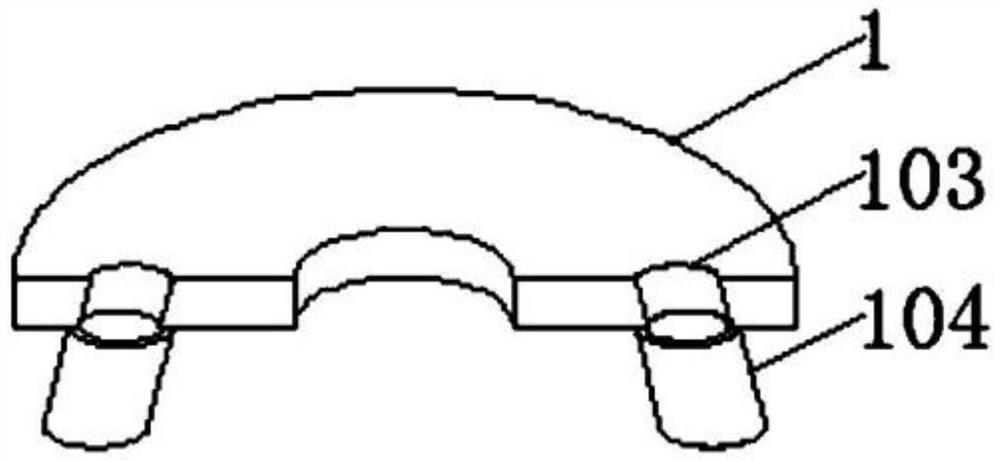

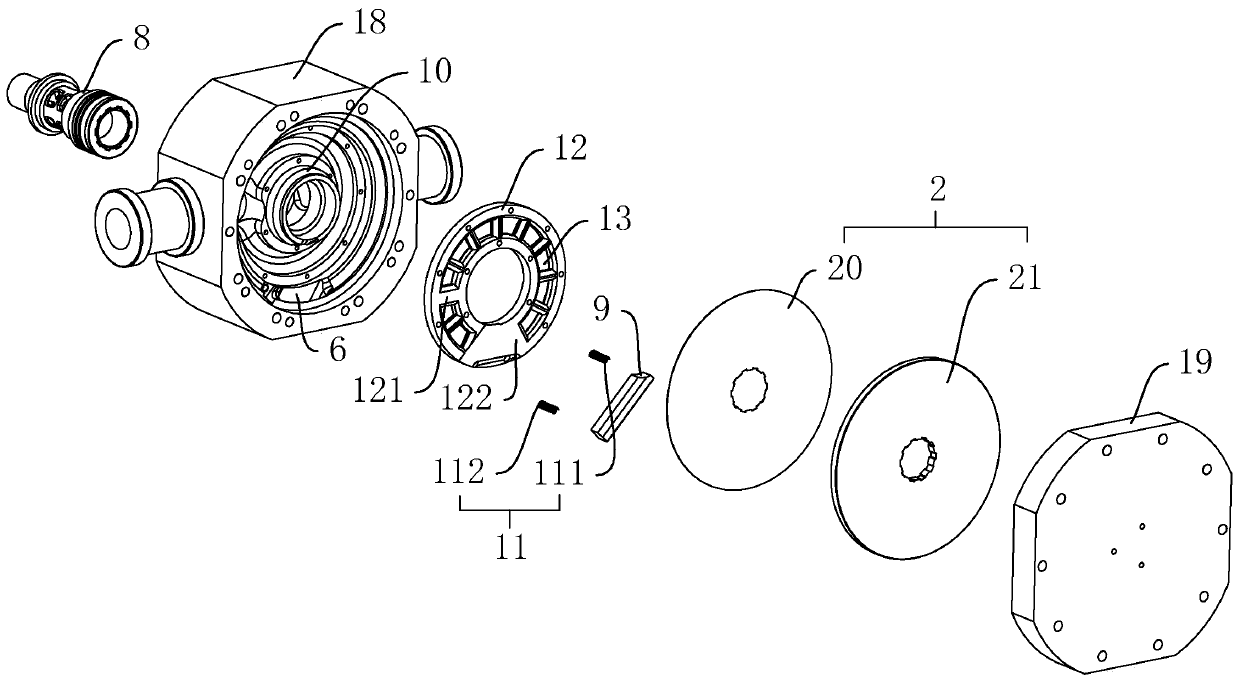

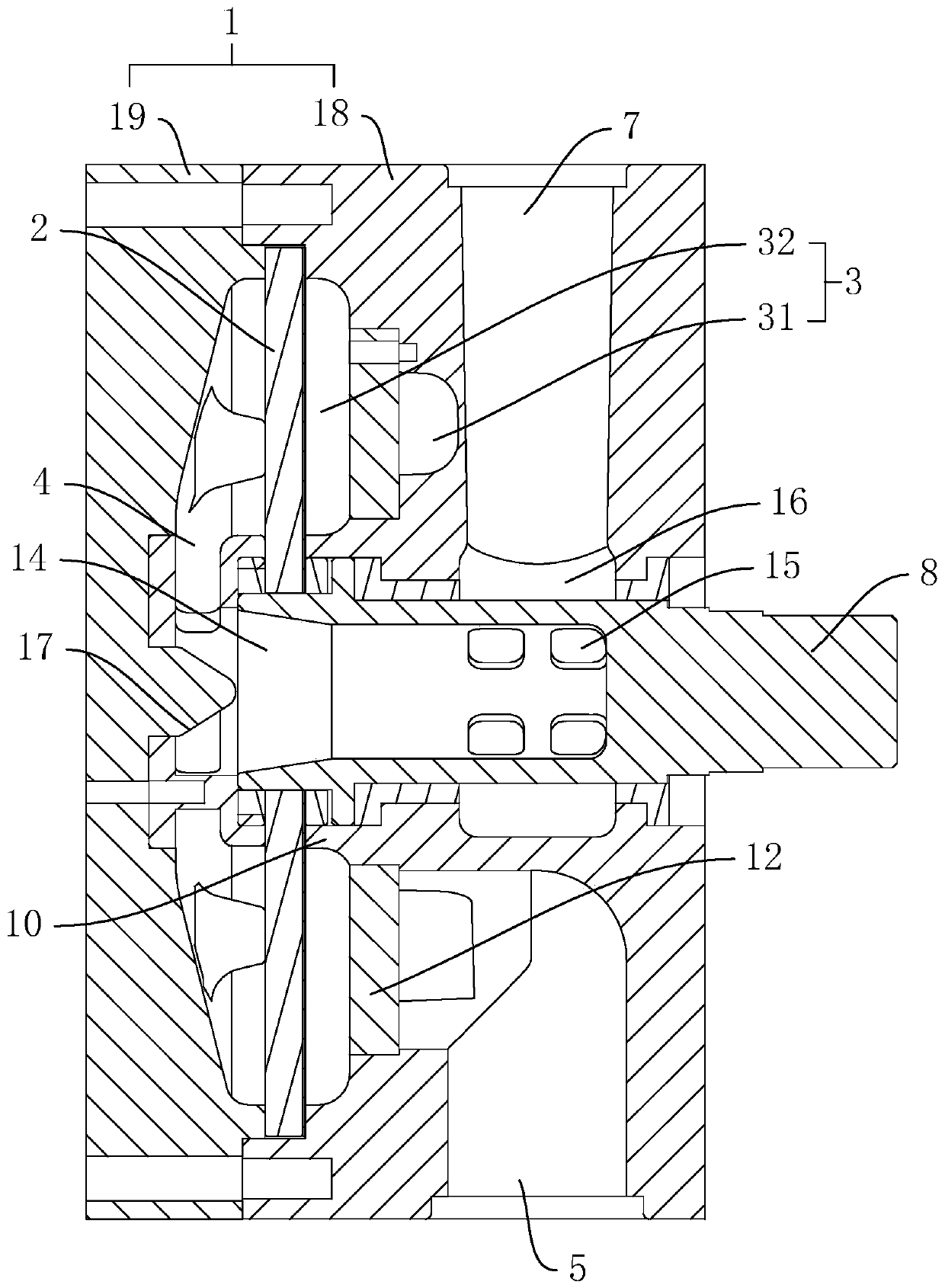

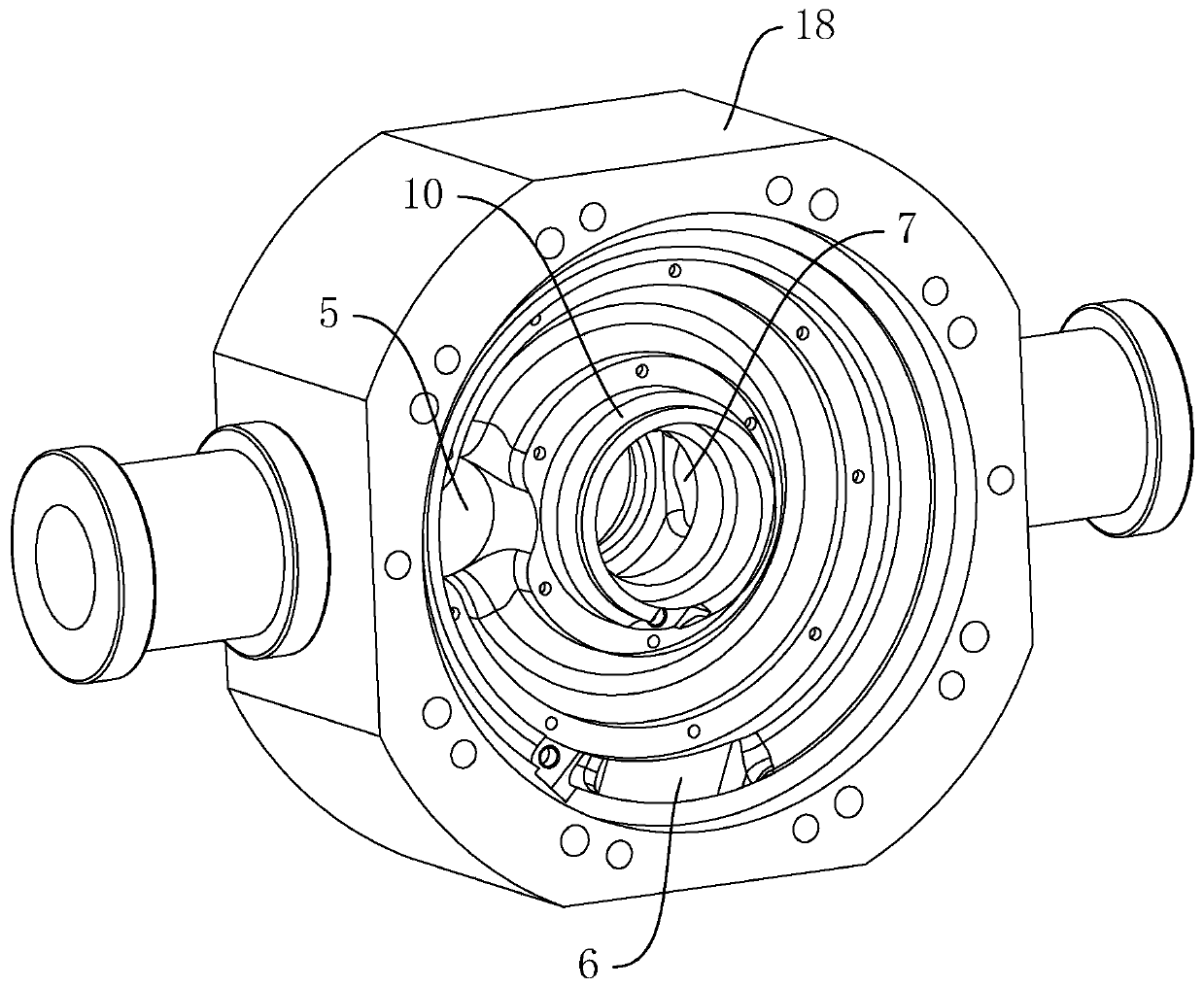

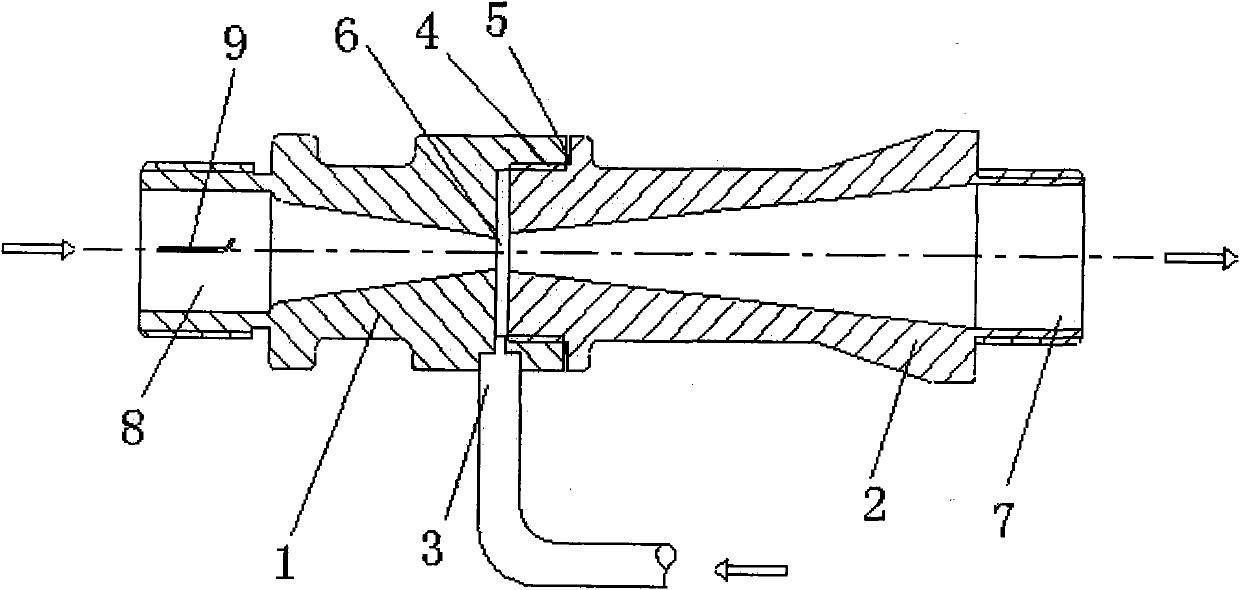

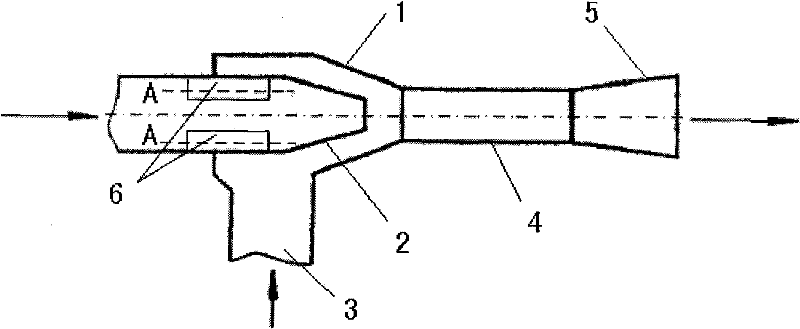

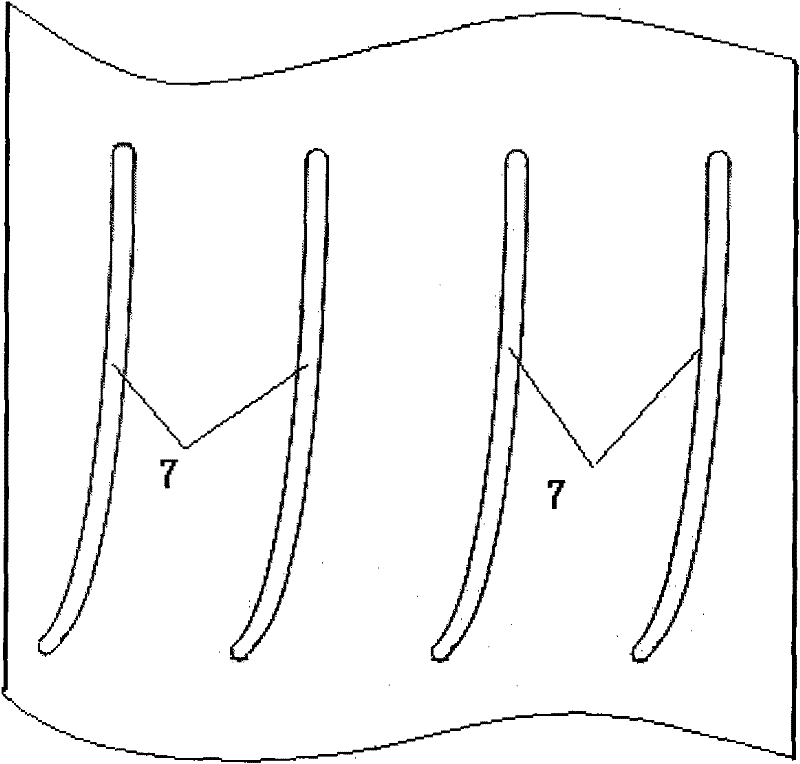

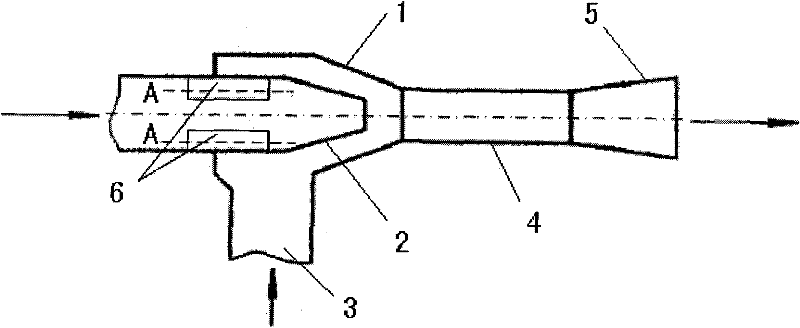

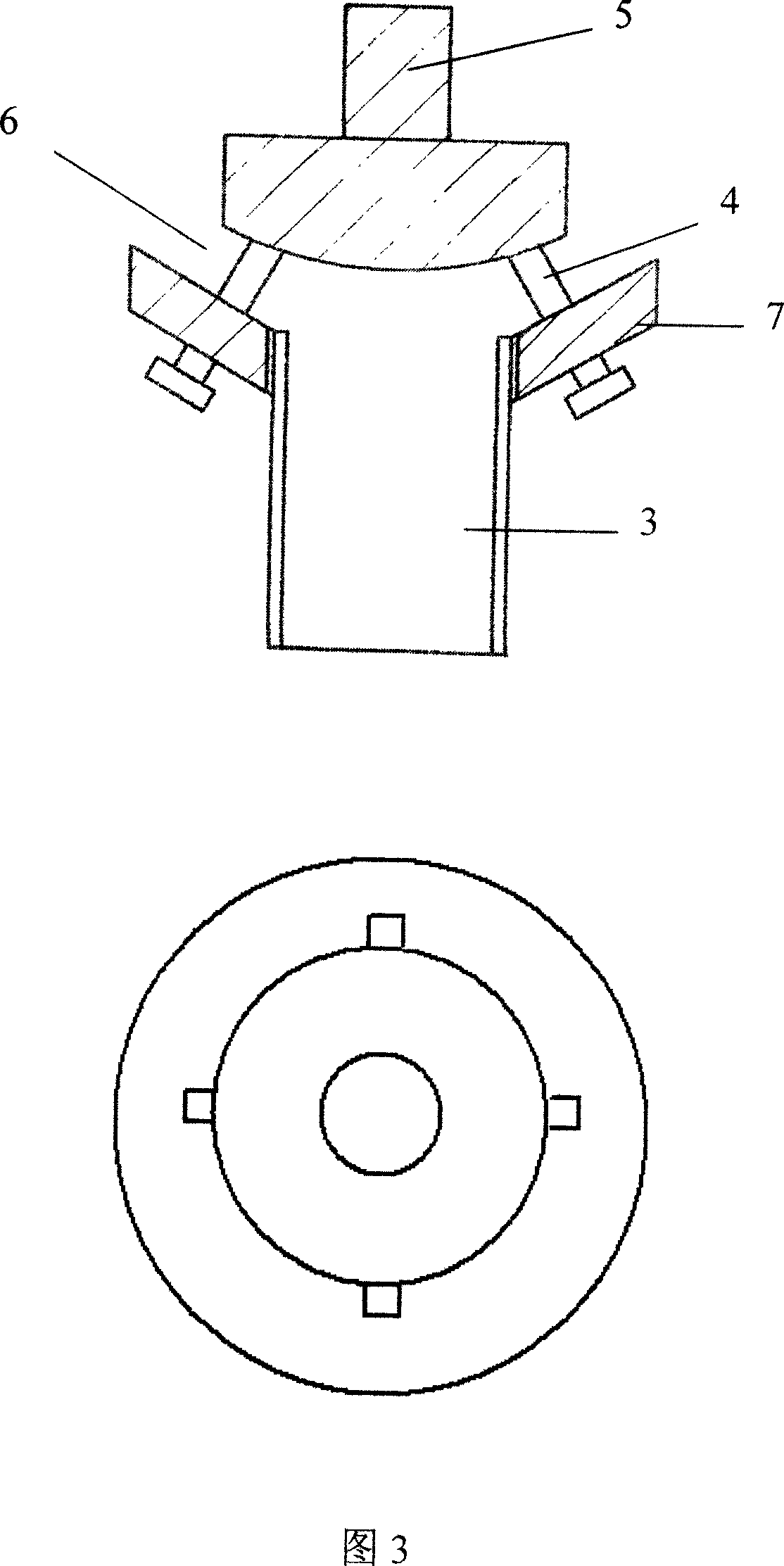

Urea mixer of SCR system

ActiveCN105201604AChange flow directionMixed changeExhaust apparatusSilencing apparatusExhaust fumesEnvironmental engineering

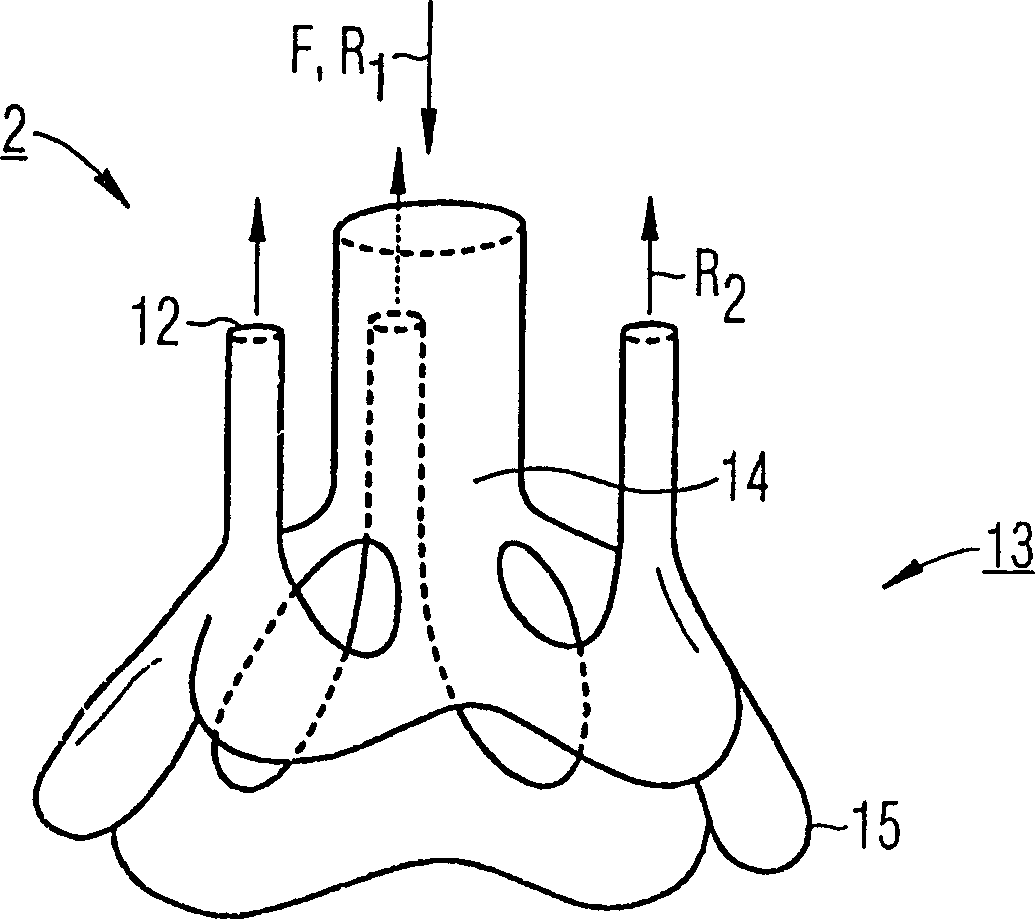

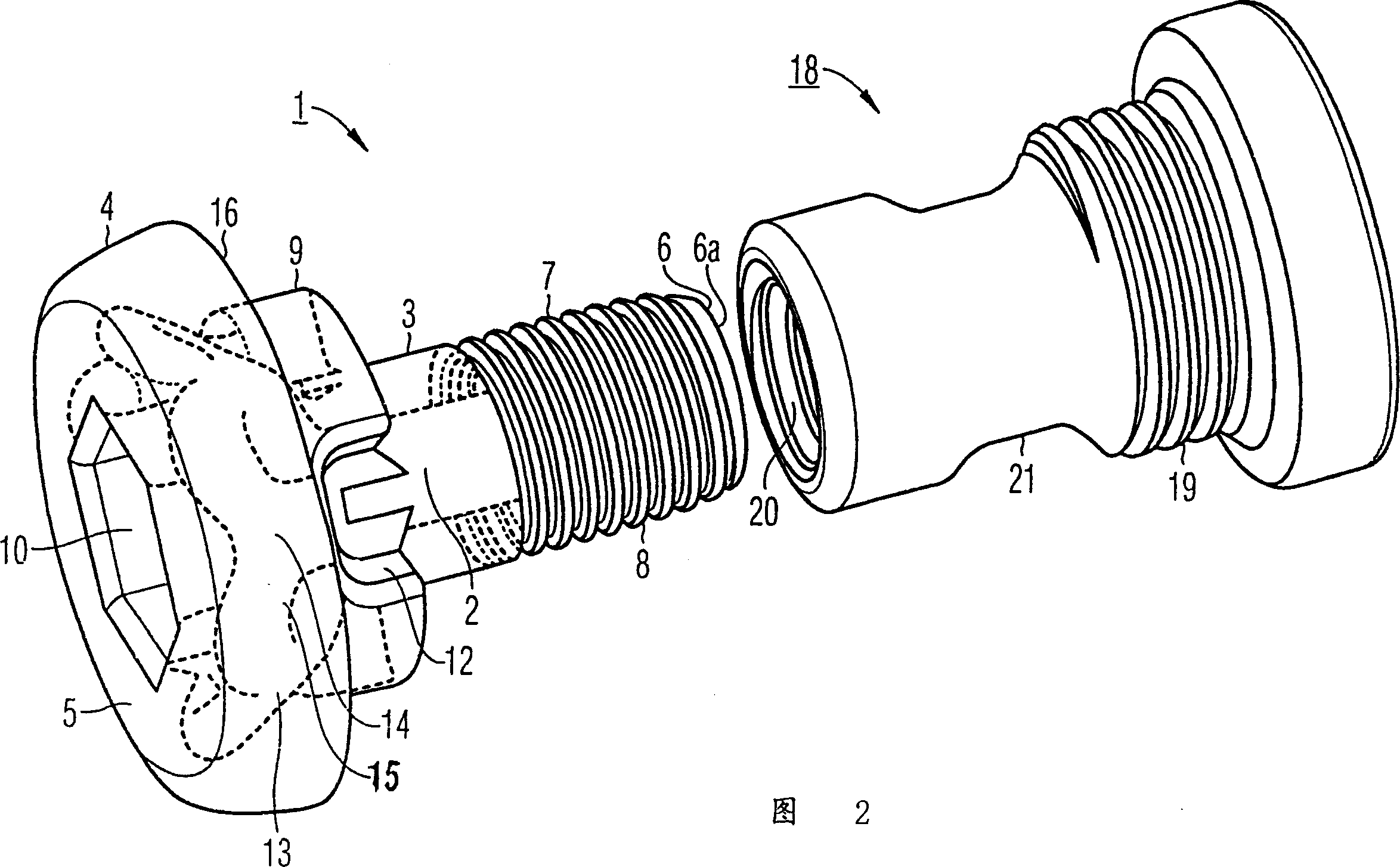

The invention provides a urea mixer of an SCR system. The mixer is capable of fully changing the flow direction of urea to make urea evenly mixed with waste gas and reducing blockages such as crystals and sediment on the urea jet breadth to avoid ammonia leakage. A blade device is installed behind a urea nozzle, the number of blades is increased, and airflow is changed by the blades to form intense perturbance so as to improve the mixing effect of a urea water solution and waste gas spray. Under the stirring action of the multiple blades, the flowing direction of the urea water solution is changed, and the urea water solution is fully mixed with the waste gas. Meanwhile, the structure of a flow guide ring in the mixer is changed, so that urea on the urea jet breadth falls off from the flow guide ring under driving of the airflow, the crystals and the sediment are reduced, and ammonia leakage is avoided.

Owner:NANJING IKAKAT EMISSIONS TECH CO LTD

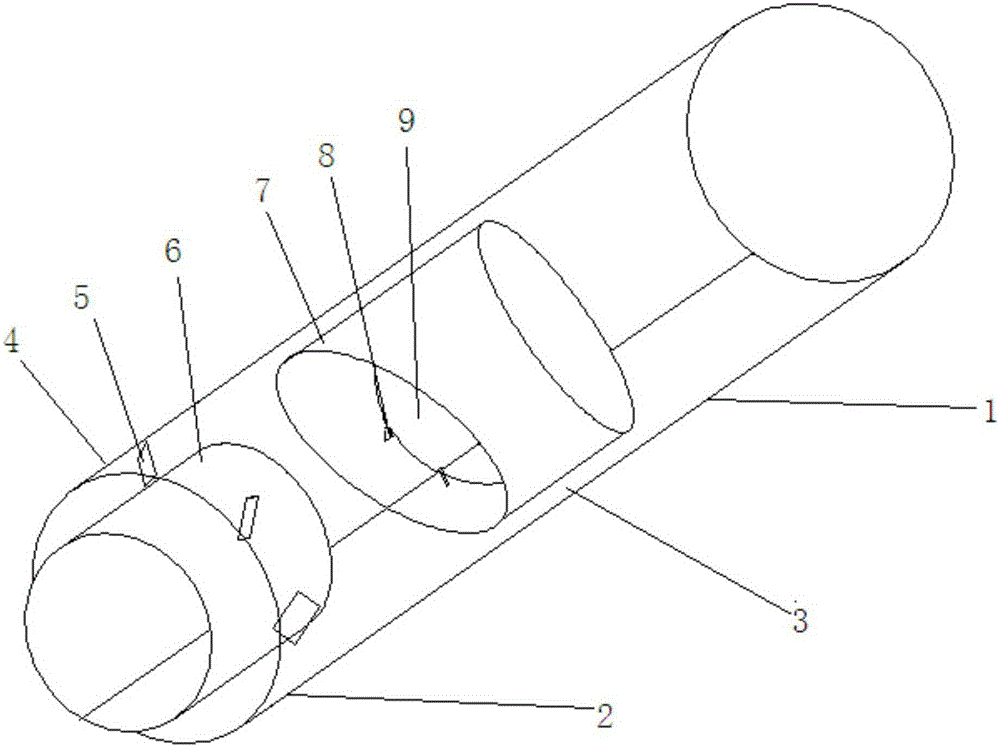

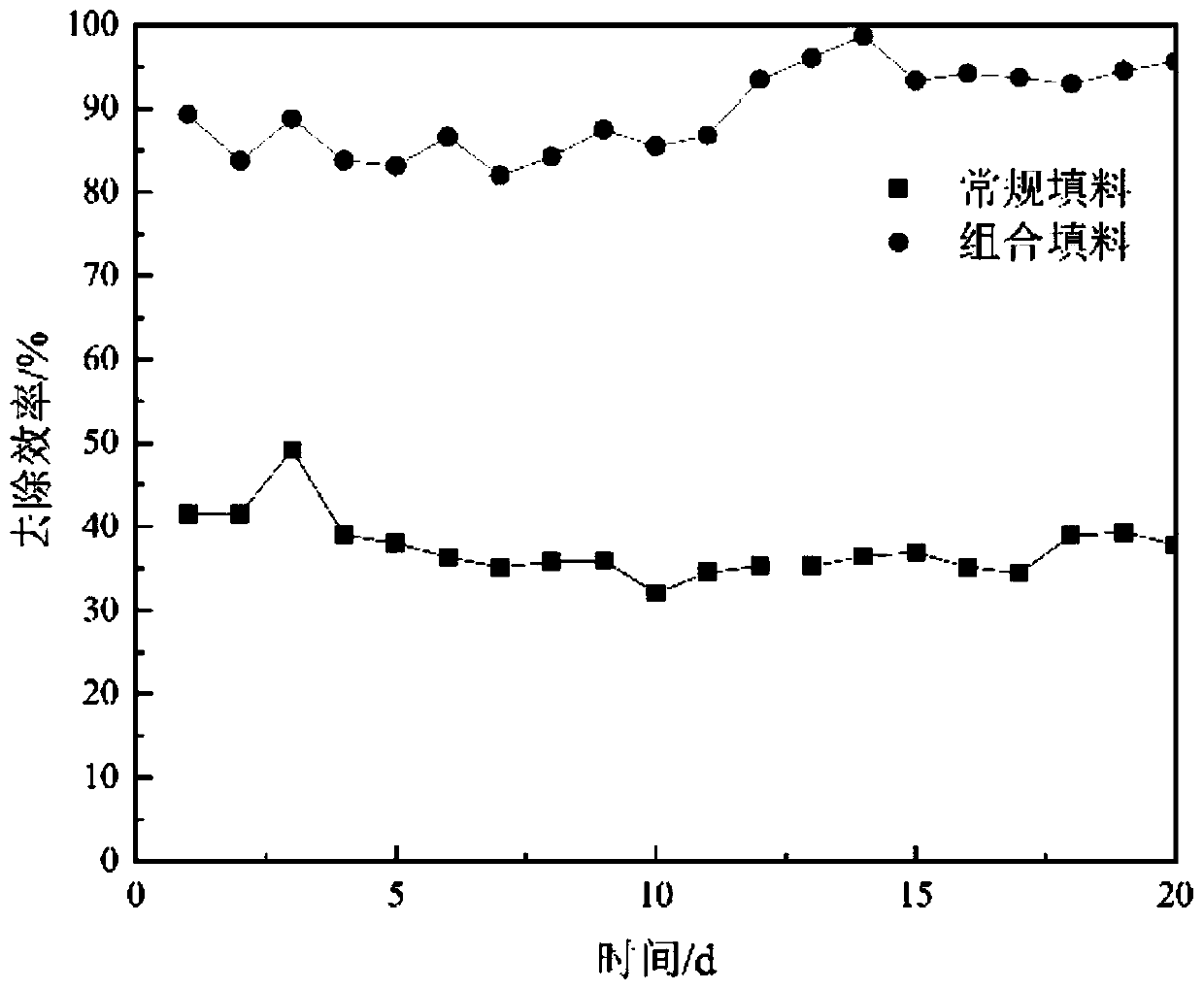

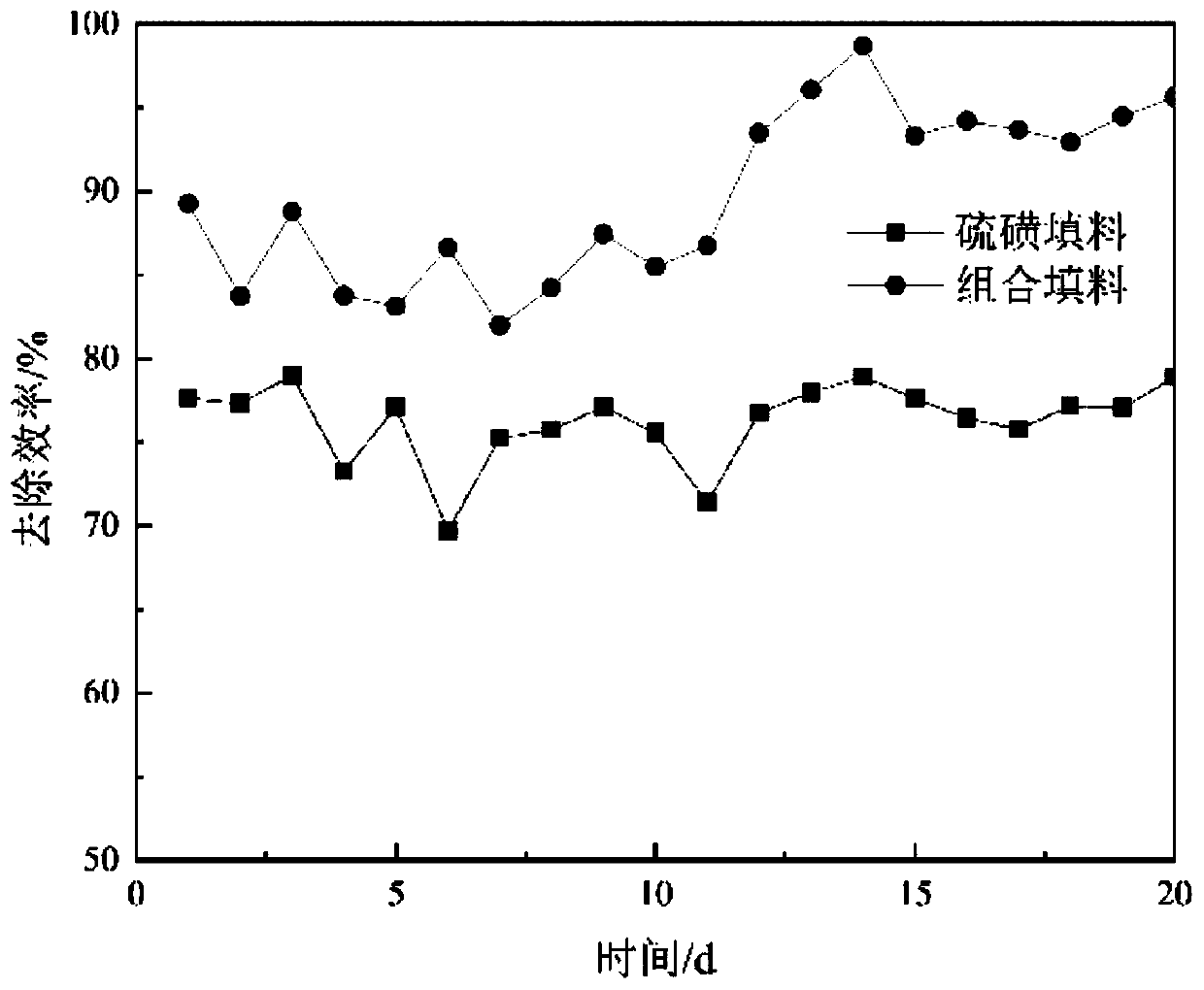

Denitrification filter combined packing and application thereof

InactiveCN109650560AChange flow directionFully contactedWater contaminantsTreatment with anaerobic digestion processesActivated carbonIron powder

The invention discloses denitrification filter combined packing and application thereof. The combined packing comprises iron-carbon packing, sulphur and a porous material. The iron-carbon packing comprises reducing iron powder, activated carbon, copper powder, a pore forming agent and a pH regulator. The iron-carbon packing, the sulphur and the porous material are sequentially arranged in a denitrification combined filter from bottom to top. Iron-carbon microelectrolysis can be generated in water through the iron-carbon packing, generated ferrous and reducing hydrogen reduce nitrate nitrogen into nitrogen, meanwhile the nitrogen and sulphur serve as electronic donors for denitrification bacteria, an organic carbon source is less added, and autotrophy denitrification is realized. Meanwhile,the combined packing is high in film culturing speed, good in denitrification performance under the optimal operation technological parameters, wide in source and low in price. By combining differenttypes of packing, the problem that the pH in a reactor is too high or too low is solved, the problem of nitrite nitrogen accumulation is solved, and a quite good removal effect is realized.

Owner:TSINGHUA UNIV

Re-use agent for polymer after driving and injecting method thereof

InactiveCN101058723AChange flow directionEnhanced overall recoveryFluid removalDrilling compositionFixation agentPolymer

The invention discloses a reusing agent of residual ground polymer driven by polymer as well as injecting method, which is characterized by the following: adopting double-liquid method fixation agent and modified calcium soil as flocculant; allocating the fixation agent with 0. 09%-0. 54% Na2Cr2O7 solution and 0. 16%-0. 96% Na2SO3 solution with bulk rate at (0. 8-1. 2):1; making the flocculant as modified calcium soil added by Na2CO3 and NaHCO3. The injecting method comprises the following steps: injecting Na2Cr2O7 solution first and insulating liquid separately; injecting Na2SO3 solution and flocculant; injecting water normally. The invention can do deep adjusting and dissect for residual ground polymer, which can change the flowing direction of ground flow effectively and improves the recovery efficiency after driving by polymer.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

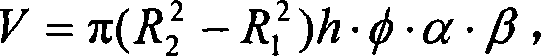

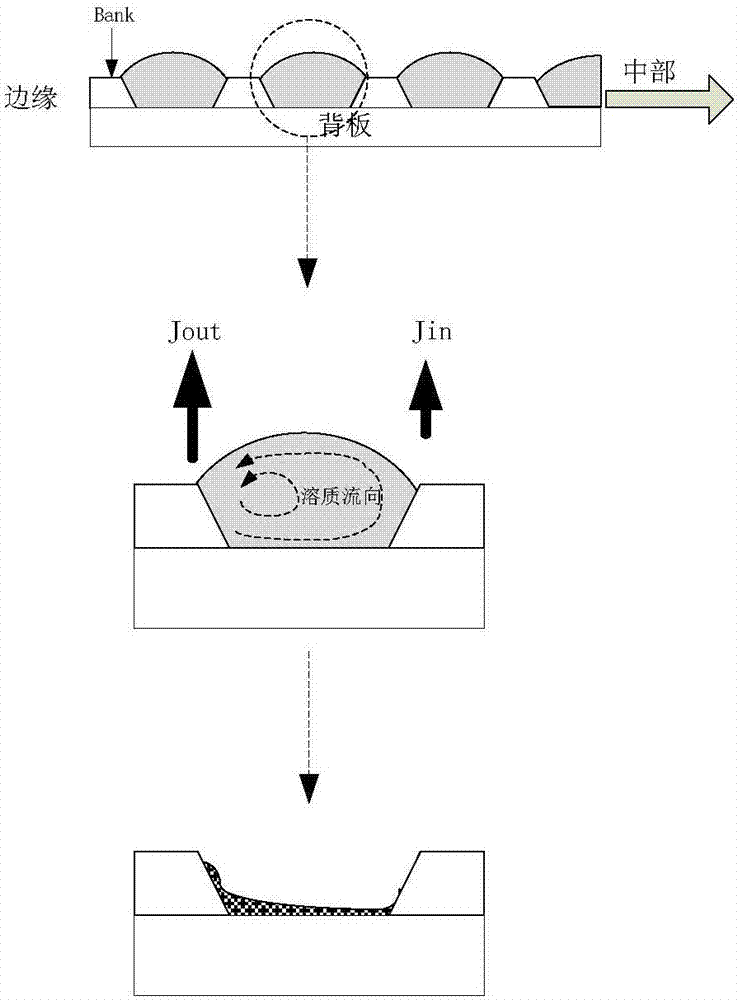

Pixel defining layer and fabrication method and application thereof

ActiveCN107968108AShort lifeChange the rate of volatilizationSolid-state devicesSemiconductor/solid-state device manufacturingNanoparticlePhotoresist

The invention relates to a pixel defining layer and a fabrication method and application thereof. The fabrication method comprises the following steps of providing a substrate, and coating photoresiston the substrate by a spin-coating process, wherein nanoparticles are added into the photoresist, the control parameters of the spin-coating process are as follows: the speed of (95-105) rotation perminute is continued for 9-11 seconds and the speed of (650-750) rotation per minute is continued for 9-11 seconds; and etching to remove the photoresist on a pixel region by a step exposure method, thereby obtaining the pixel defining layer. According to the fabrication method of the pixel defining layer, doping modification is performed on a Bank solution under the condition that an existing process is not changed, the volatilization rate of ink at different edges in the same sub-pixel is adjusted by a mode that hydrophilicity and hydrophobicity of a Bank edge in a single sub-pixel are different, so that the film formation effect is improved and optimized, and the effects of improving the yield of the device and improving the effect of the device are achieved.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

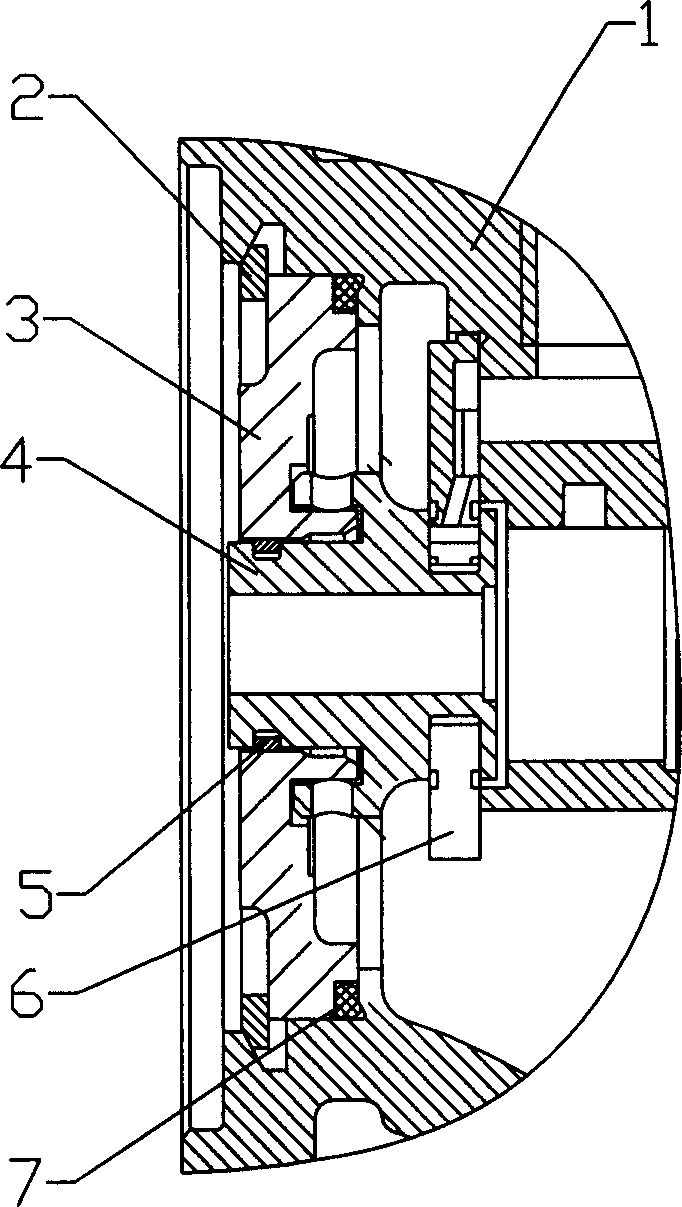

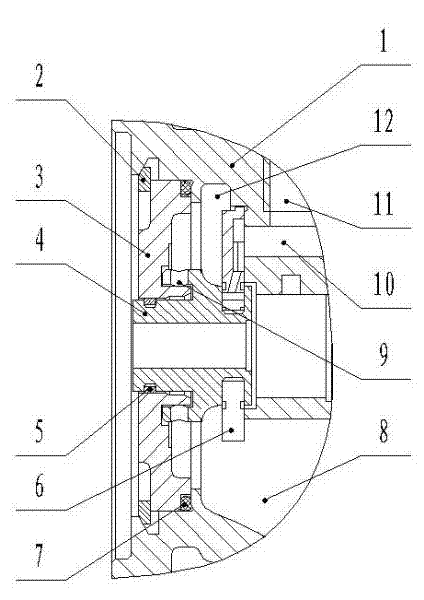

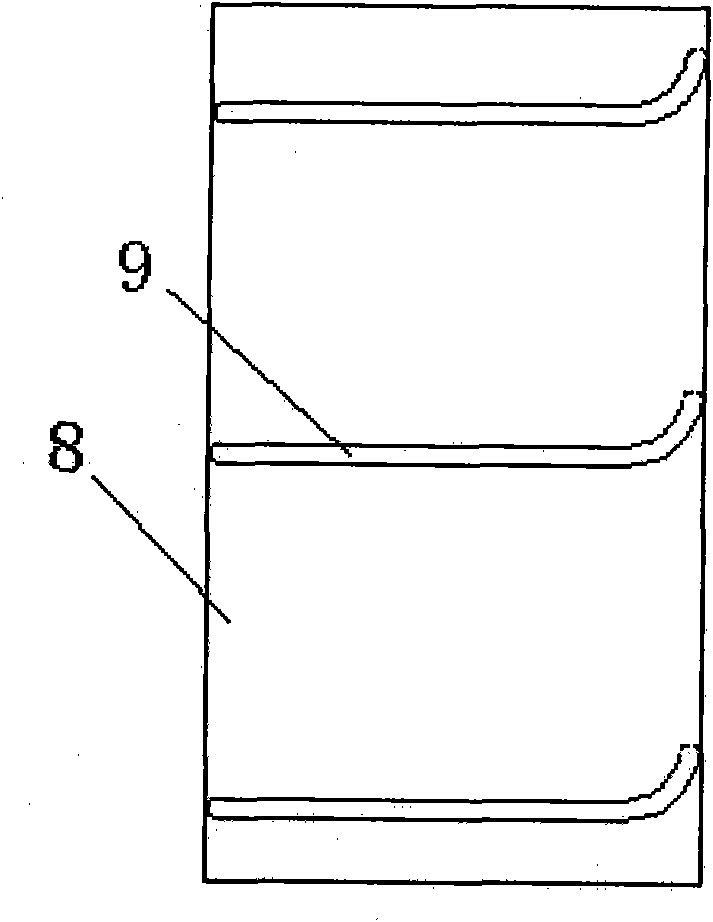

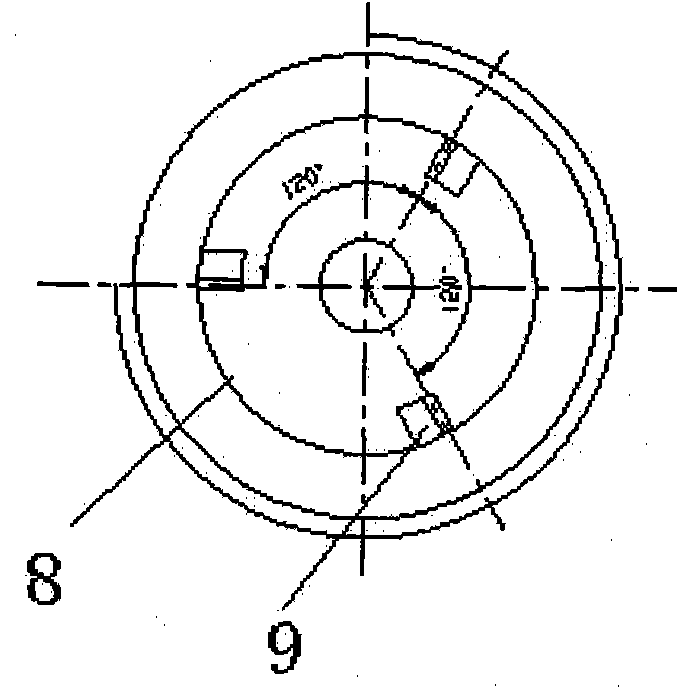

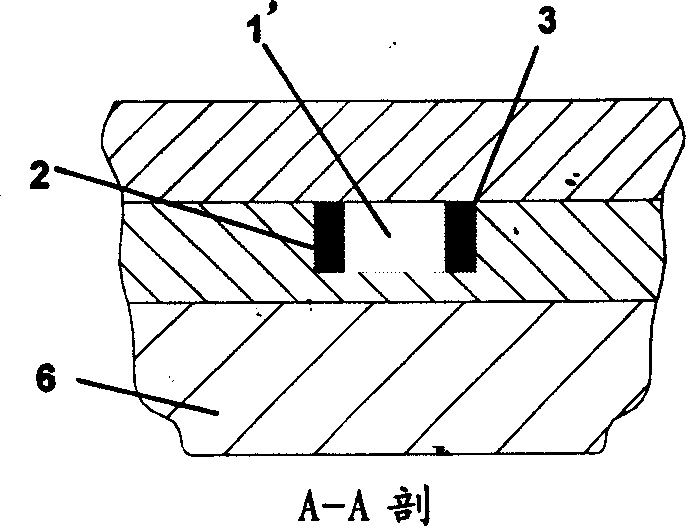

End sealing device for compressor of turbosupercharger

The invention relates to a sealing device of turbine pressurizing compressor, which comprises a middle case, a sealing ring base, a retaining oil spray disc, a retaining bearing, and an oil baffle plate between the retaining oil spray disc and the middle case. Wherein, the oil baffle plate, the middle case and the retaining bearing can form a stable sealing chamber; the oil baffle plate is mounted at the inclined surface of annular heave to limit the flowing shape of machine oil with resisting and dividing the machine oil; the case of retaining oil spray disc that connecting the oil container has a annular heave whose inner and outer sides have inclined surface to change the flowing direction; the sealing ring base has a guide groove; the guide groove and the retaining oil spray disc form a guide channel to guide the machine oil leaked from the movable sealing gap between the oil baffle plate and the retaining oil spray disc into the oil reflux cut of middle case. The invention can effectively reduce the oil leakage with wider market prospect.

Owner:KANGYUE TECH

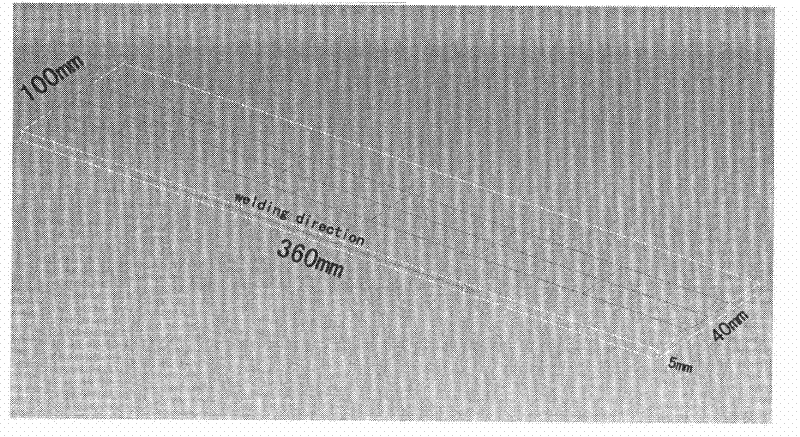

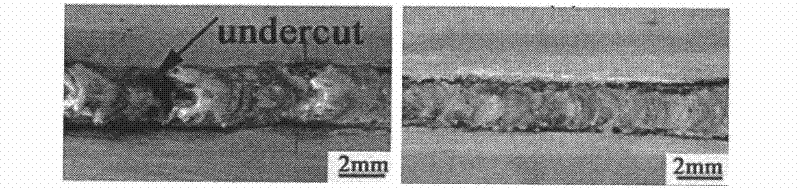

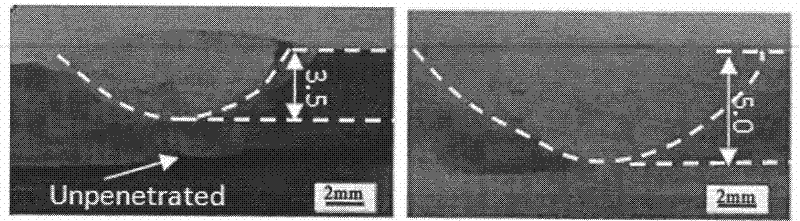

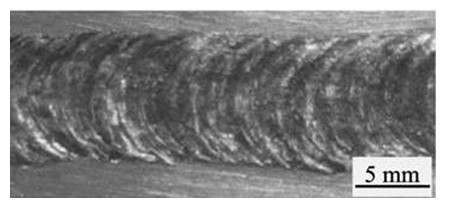

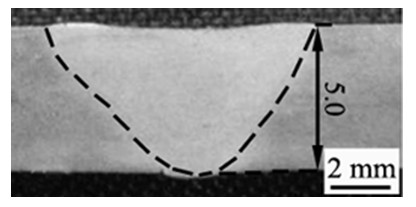

Novel active agent used for TIG (Tungsten Inert Gas) welding of magnesium alloy

InactiveCN102343489AImprove ultimate tensile strengthChanging the temperature coefficient of surface tensionArc welding apparatusWelding/cutting media/materialsPorosityHydrogen

The invention discloses a novel active agent used for TIG (Tungsten Inert Gas) welding of magnesium alloy, belonging to the active agent welding technology. The active agent is characterized in that the active agent consists of, by weight percent, 60-65 TiO2 and 35-40 CaF2, and is prepared through the following steps: first, grinding and then mixing TiO2 and CaF2 active agent powder by proportion; second, adding acetone to the mixture to enable the mixture to turn to paste; and then evenly coating the pasty active agent on the upper surface of a test sample through a flat brush, wherein the coating width is about 40mm and the coating thickness is about 0.3mm. The active agent can be used for TIG welding after the acetone volatilizes. Compared with the welding joints without being coated with the active agent in the welding process, the welding joint obtained through the welding technique disclosed by the invention has the advantages that the weld penetration is improved by 43% and the tensile property is improved by 58%. In addition, porosity in the welding line is remarkably reduced after the active agent is coated, thus solving the difficulties of the existence of hydrogen pores and shallow weld penetration.

Owner:CHONGQING UNIV

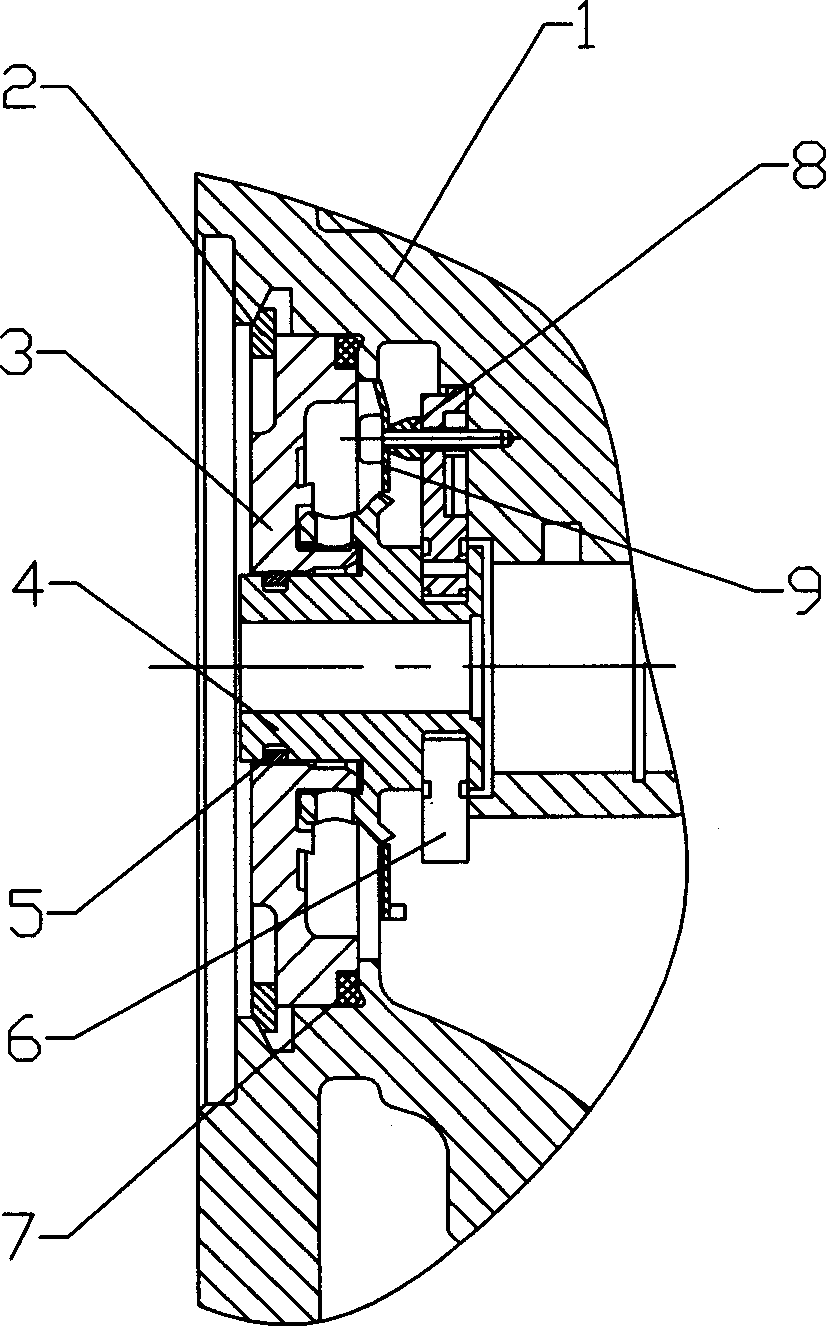

Dual-ring sealing device at gas compressor end of turbocharger

The invention discloses a dual-ring sealing device at a gas compressor end of a turbocharger. The dual-ring sealing device comprises a middle shell, wherein a thrust oil slinger is arranged in the middle shell; a sealing ring sleeve base is arranged between the thrust oil slinger and the middle shell; a gap is formed between the thrust oil slinger and the sealing ring sleeve base; two sealing devices are arranged in the gap; the gap between the two sealing devices forms a low-pressure cavity; two sealing rings are adopted; and a low-pressure cavity is formed between the two sealing rings and plays a role of buffering oil and gas on both sides. When the working condition varies, the pressure between the two sealing rings does not change immediately, and leakage is effectively prevented.

Owner:KANGYUE TECH

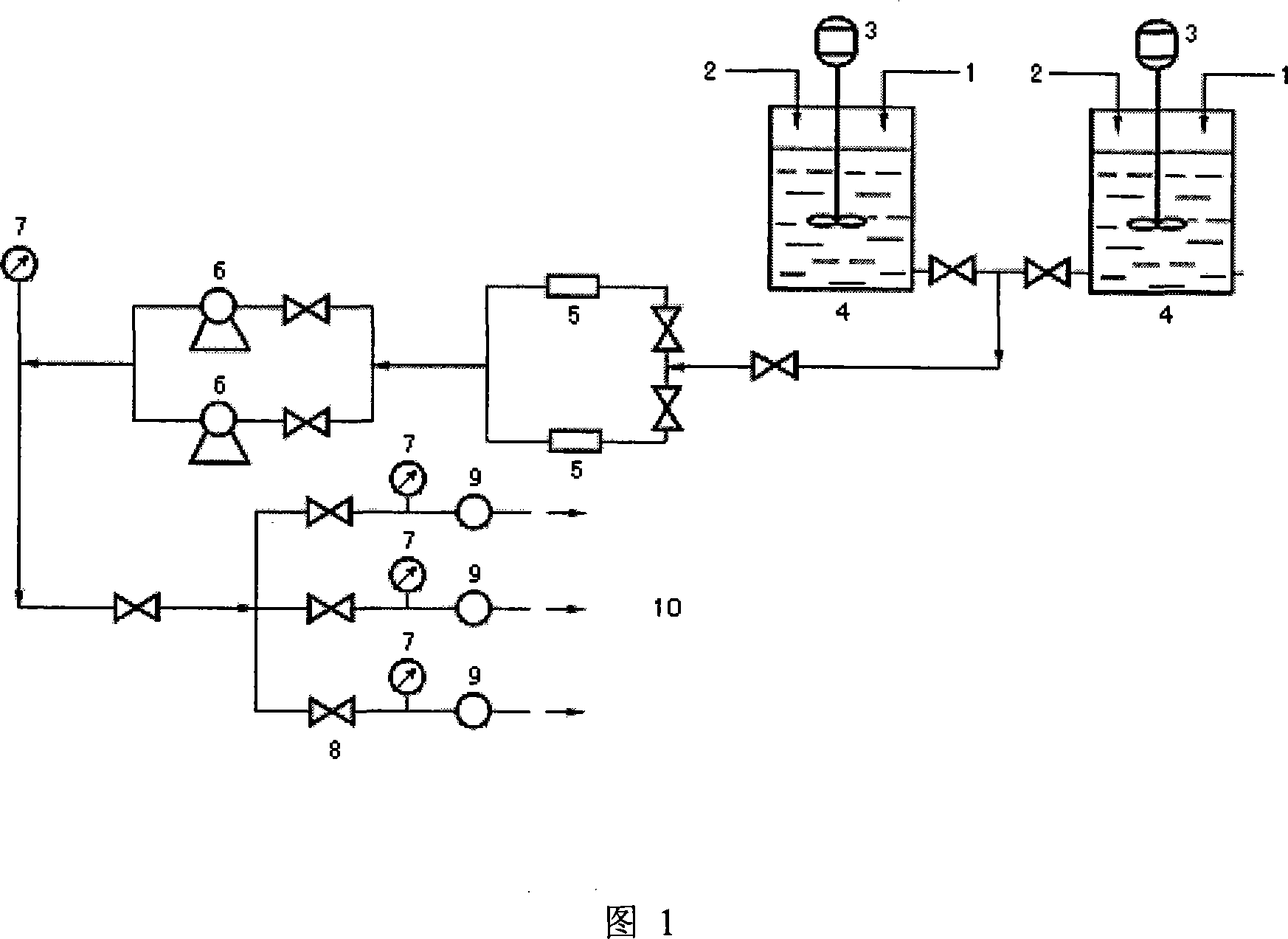

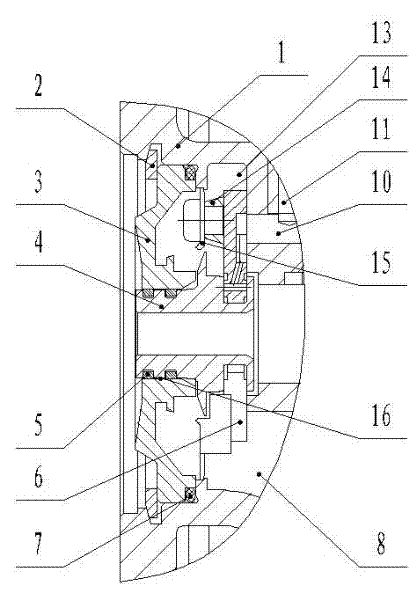

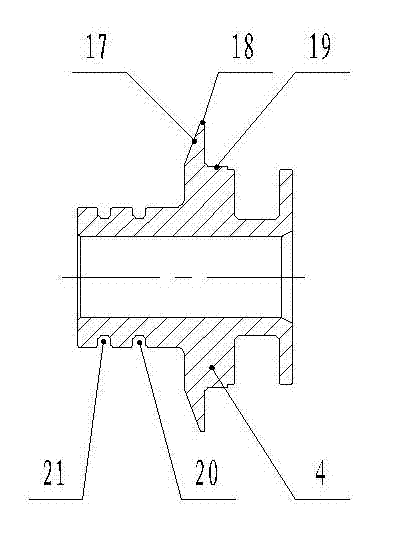

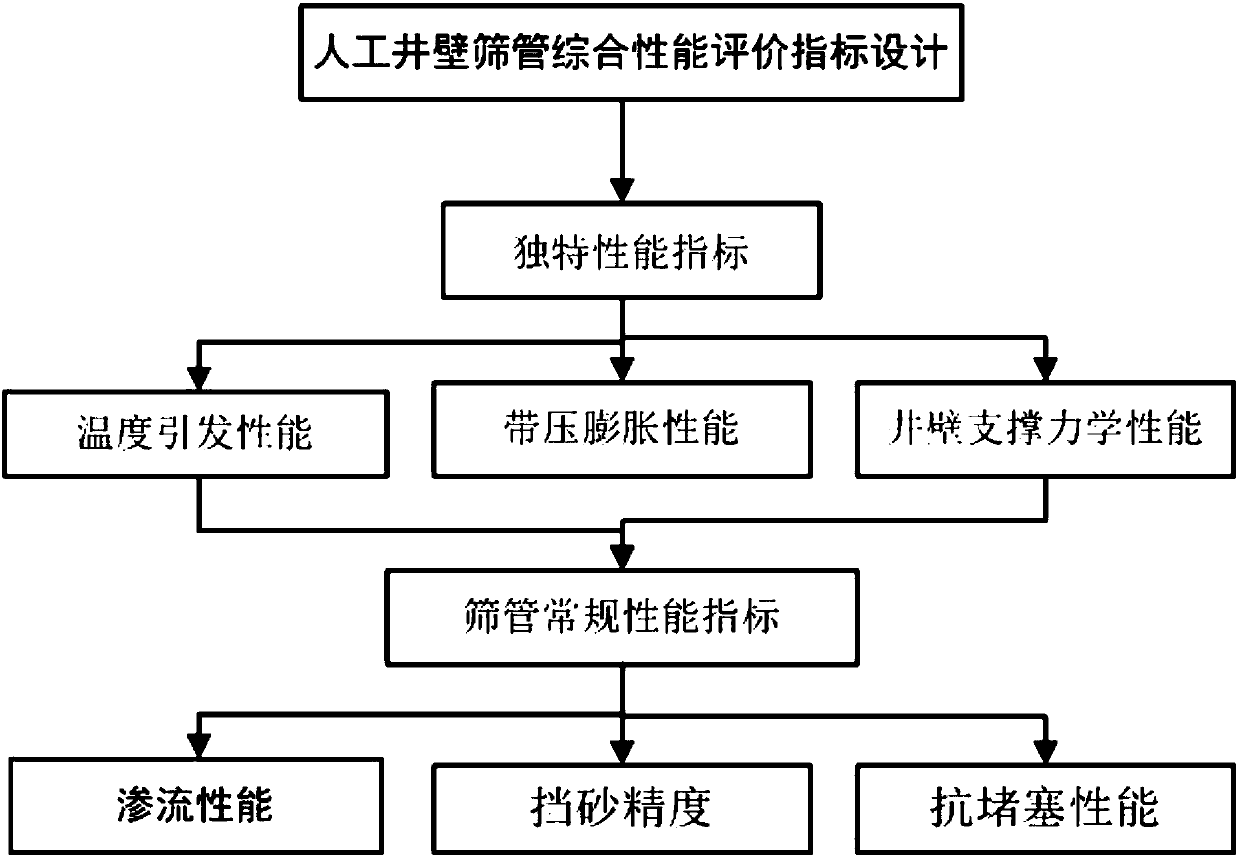

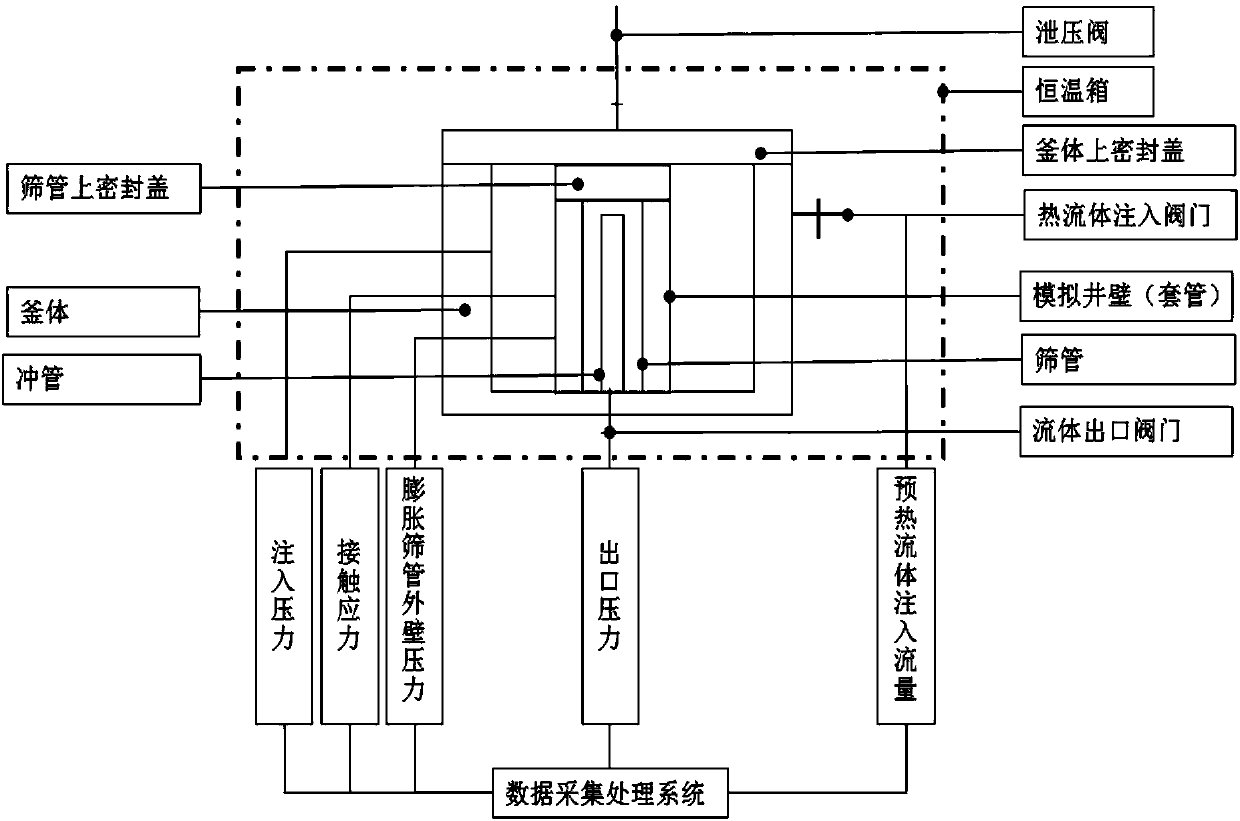

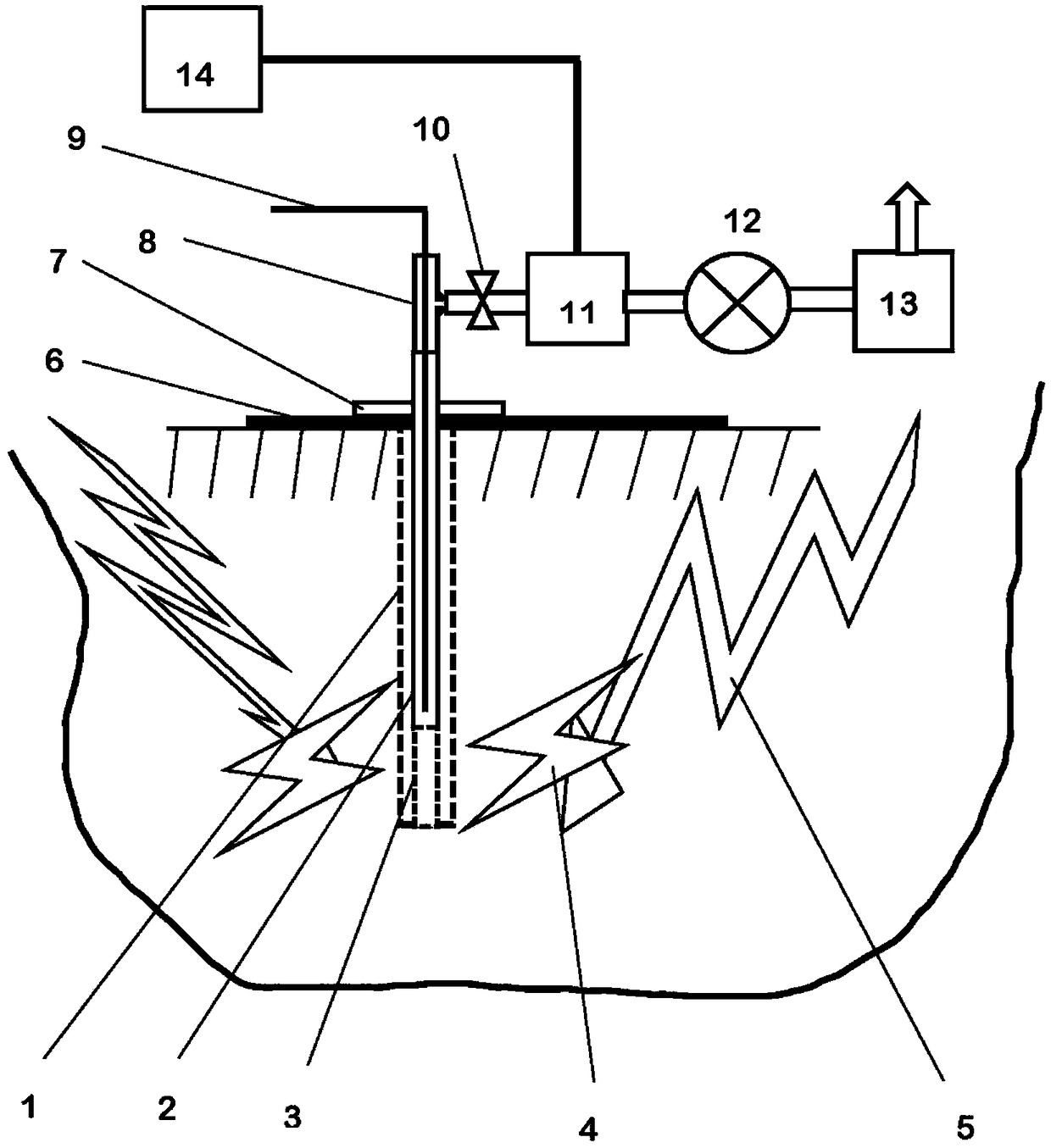

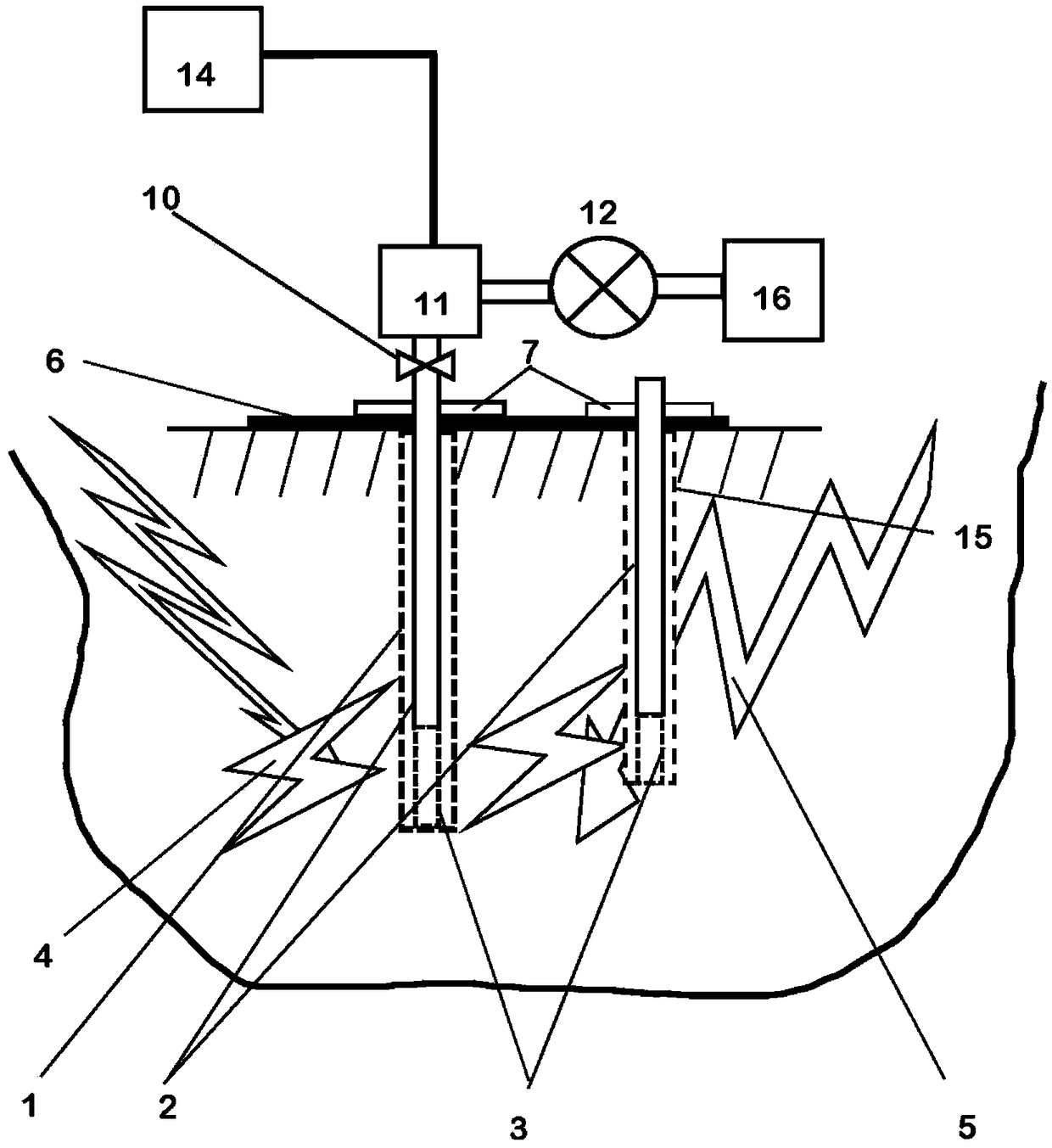

Expandable sieve pipe performance detection experiment apparatus and expandable sieve pipe performance evaluation method

ActiveCN107367450AMaintain and Simulate a Constant TemperatureChange flow directionMaterial strength using tensile/compressive forcesPermeability/surface area analysisPlunger pumpEngineering

The invention provides an expandable sieve pipe performance detection experiment apparatus and an expandable sieve pipe performance evaluation method, and belongs to the field of the sand prevention well completion of oil, gas and water wells. The expandable sieve pipe performance detection experiment apparatus comprises a simulated stratum and wellbore system, a fluid circulation system, a pressure measurement system, a stress measurement system, a temperature control system and a data acquisition and processing system, wherein the simulated stratum and wellbore system comprises a constant temperature box, a kettle body arranged inside the constant temperature box, a flush pipe, an oil pipe, an expandable sieve pipe and a simulated well wall, the flush pipe, the oil pipe, the expandable sieve pipe and the simulated well wall are arranged inside the kettle body, the bottom portion of the kettle body is provided with an outlet, the side wall of the kettle body is provided with a fluid injection port and a pressure measurement hole, the fluid circulation system comprises a pre-heating device and a plunger pump, the pre-heating device pre-heats a fluid, the plunger pump injects the pre-heated fluid into the kettle body through the fluid injection port on the kettle body, and the pressure measurement system is connected to the pressure measurement hole and the outlet on the kettle body, and monitors the injection pressure, the outer wall pressure of the expandable sieve pipe and the outlet pressure.

Owner:CHINA PETROLEUM & CHEM CORP +1

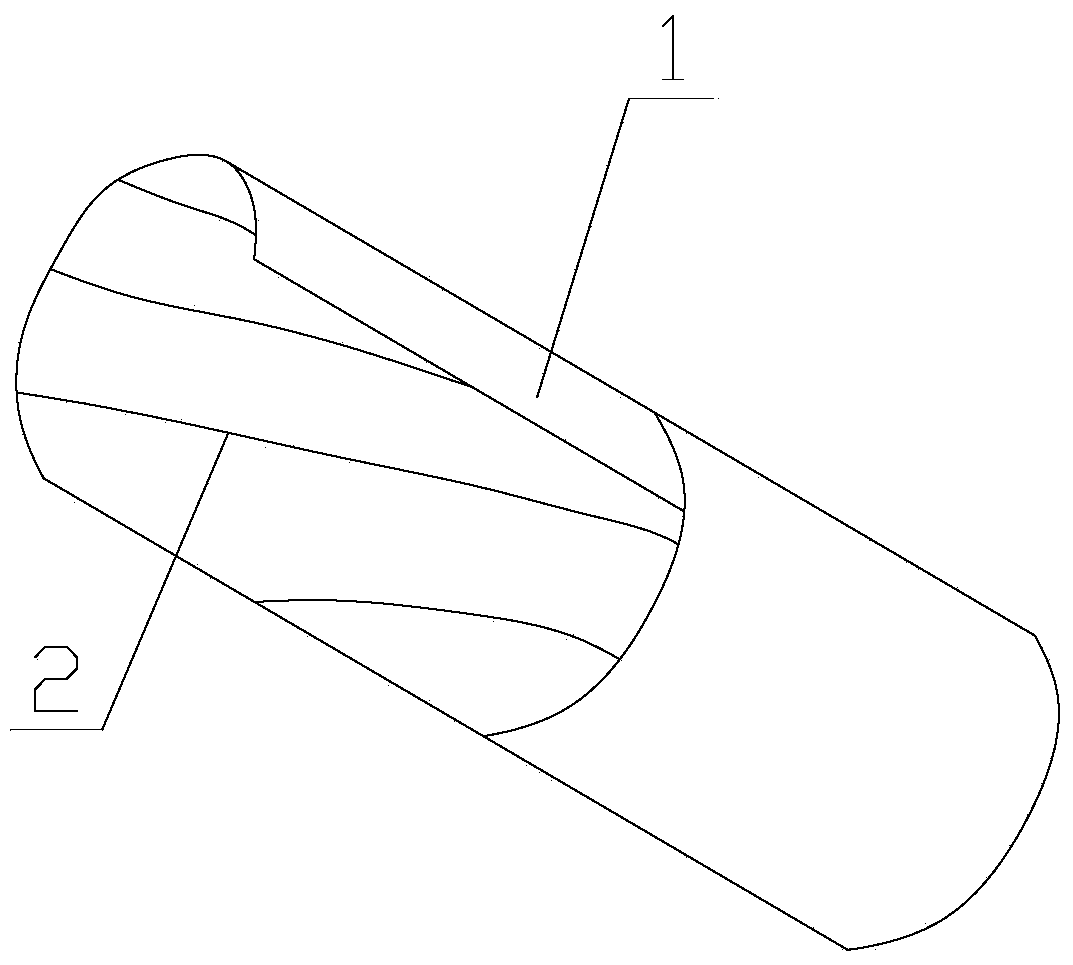

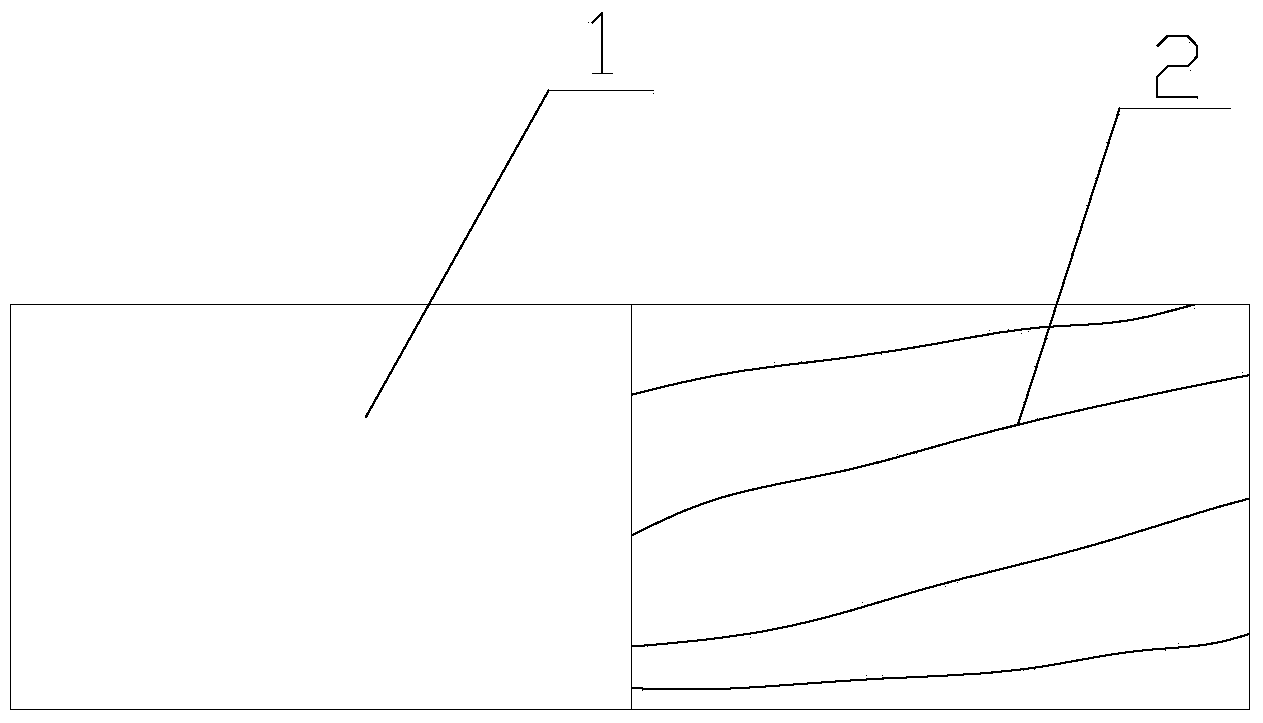

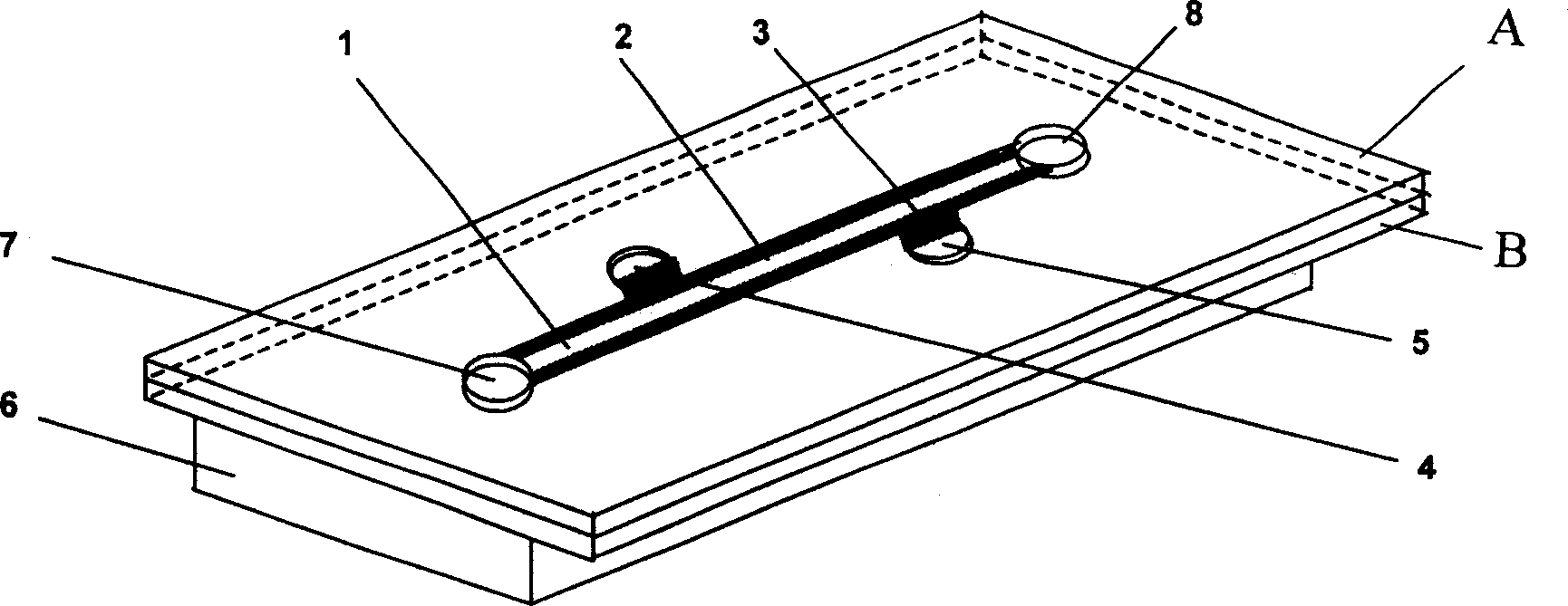

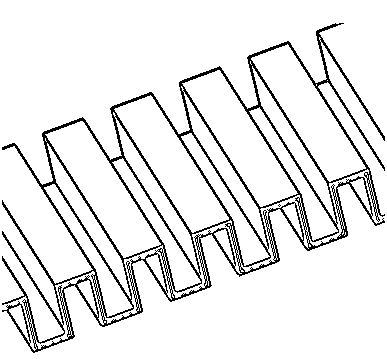

Grooving spiral curling rotor in heat exchange tube

InactiveCN102645122AAvoid depositionSave materialHeat transfer modificationRotary device cleaningEngineeringHeat transfer fluid

The invention relates to a grooving spiral curling rotor in a heat exchange tube. The rotor is composed of a hollow shaft and a blade, wherein the hollow shaft is of a tubular structure; the blade is located on the outer surface of the hollow shaft; the blade surface is smooth and spiral around the hollow shaft; the blade of the rotor is composed of a grooving blade and a curling blade; a water-facing surface of the grooving blade is provided with a diversion trench structure along the radial direction of the hollow shaft; the radial thickness of the grooving blade is reduced; a water-back surface is not provided with a diversion trench structure; the edge of the grooving blade in contact with the fluid first is subjected to beveling or rounding; and a curling structure is arranged at the top end of the curling blade and is in transition connection through a smooth curved surface. In the invention, when the grooving blade rotates, the heat transfer fluid generates centrifugal movement along the surface of the diversion trench and is thrown to the wall of the heat exchange tube; a curling structure is arranged at the top end of the curling blade; and the rotor can realize a good self-centering effect when rotating in the fluid according to the self-suspension mechanism of the curling blade so as to reduce the scraping effect between the top end of the blade and the inner wall of the heat exchange tube and increase the fluid turbulence degree.

Owner:BEIJING UNIV OF CHEM TECH

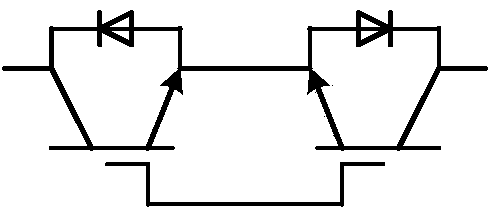

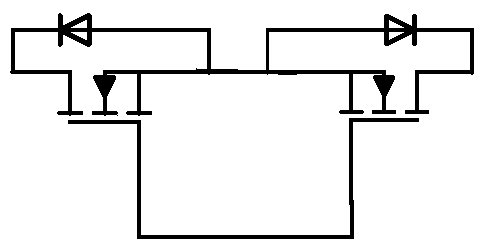

Novel storage battery pack charging control circuit and method thereof

InactiveCN104300640AExtend your lifeChange flow directionCharge equalisation circuitElectric powerCapacitanceElectronic switch

The invention discloses a novel storage battery pack charging control circuit and a method of the novel storage battery pack charging control circuit. The control circuit comprises n charging control sets. Each charging control set comprises two battery single bodies, an inductor, a capacitor, a first energy two-way controllable electronic switch and a second energy two-way controllable electronic switch, wherein the first energy two-way controllable electronic switch and the inductor are connected in series to the positive electrode and the negative electrode of one battery single body, and the second energy two-way controllable electronic switch and the inductor are connected in series to the positive electrode and the negative electrode of the other battery single body. All the charging control sets are of the same topological structure and are connected by making the first energy two-way controllable electronic switches connected with the capacitors. By means of the novel storage battery pack charging control circuit, it can be ensured that the performance of all the battery single bodies in storage battery packs can be almost the same in the later period of charging, and therefore the problem that due to the fact that distribution of energy in existing series connection storage battery packs is imbalanced, damage to storage batteries is caused is solved.

Owner:SHANGHAI DIANJI UNIV

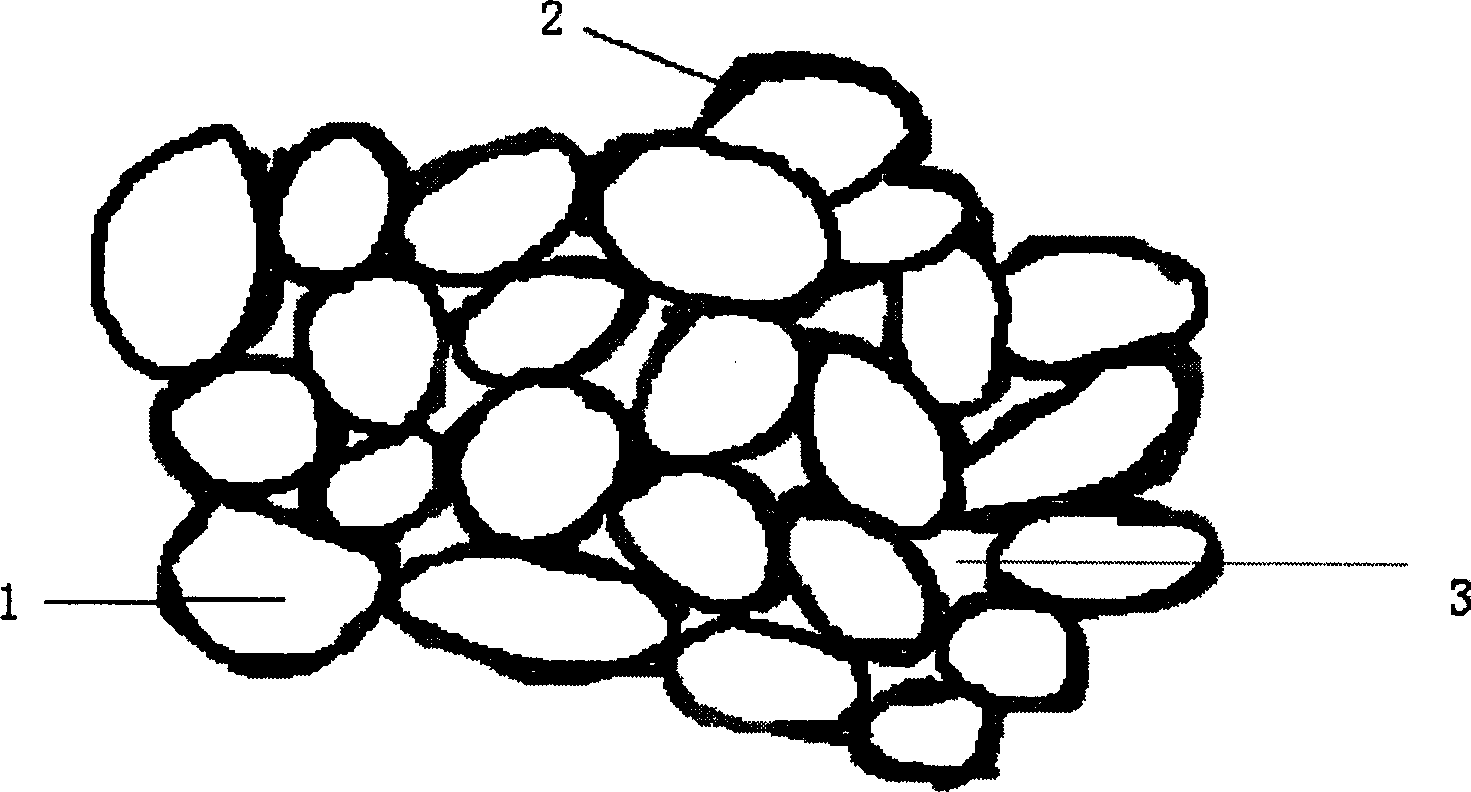

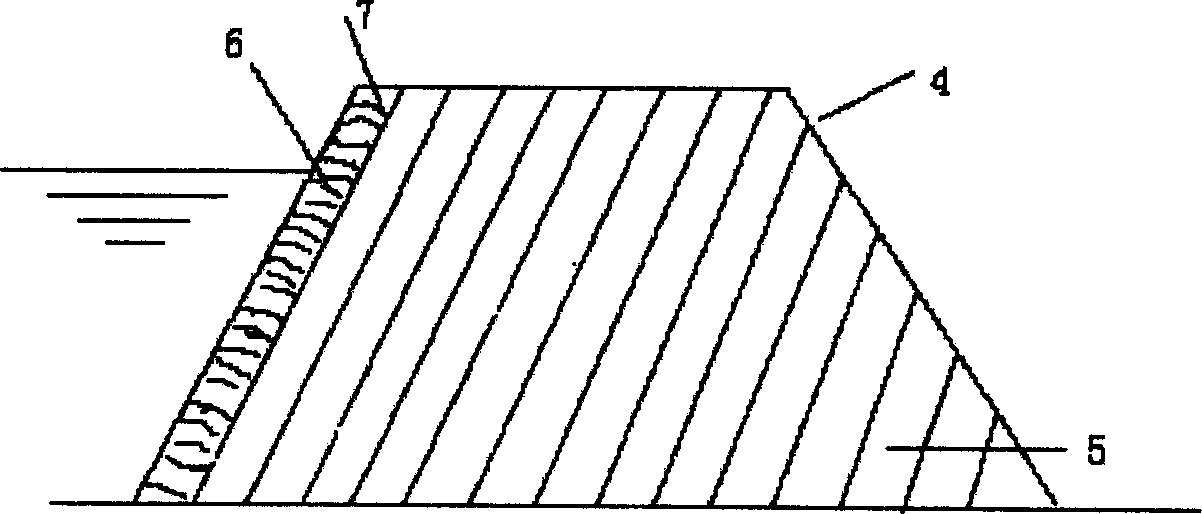

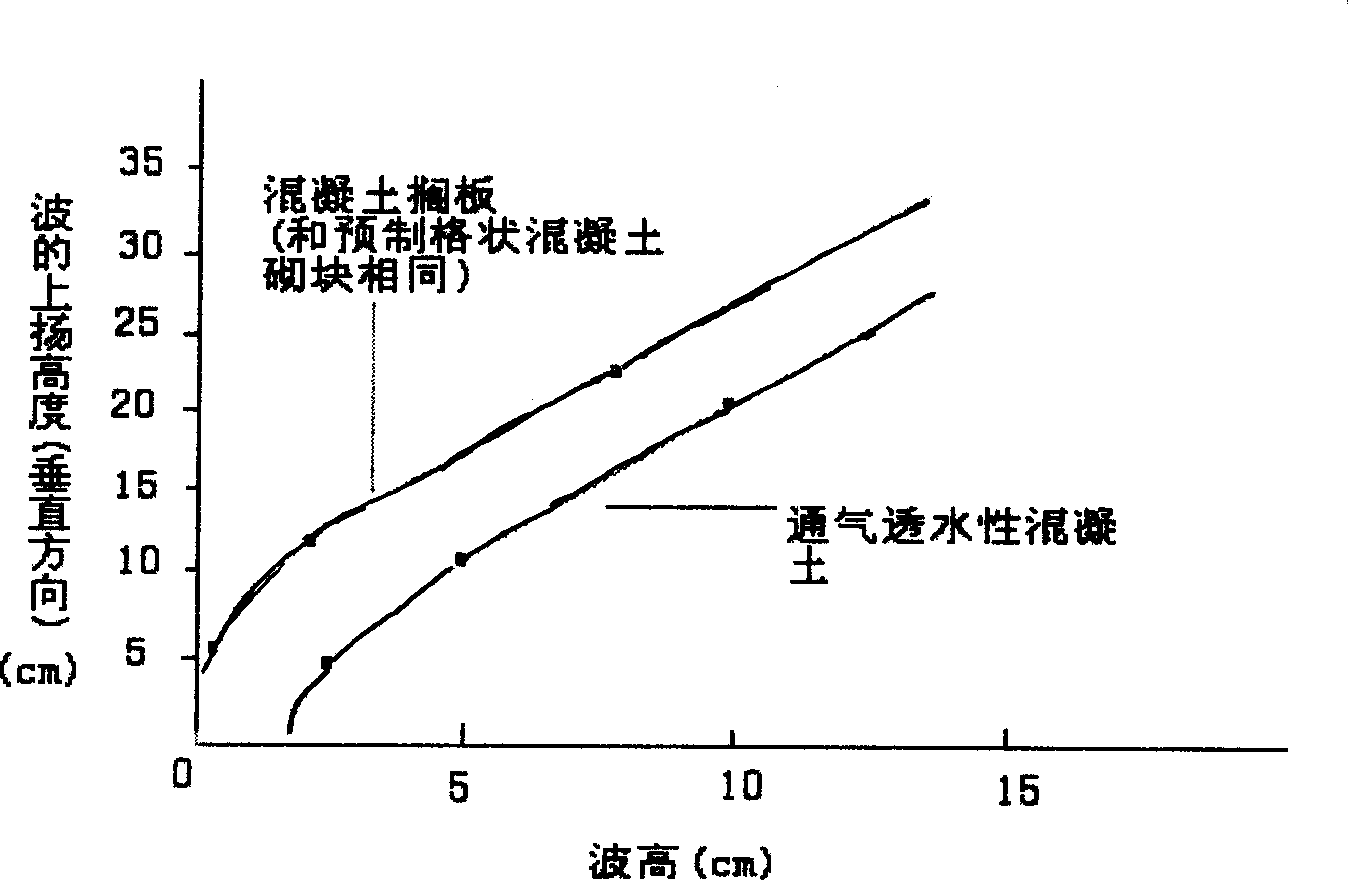

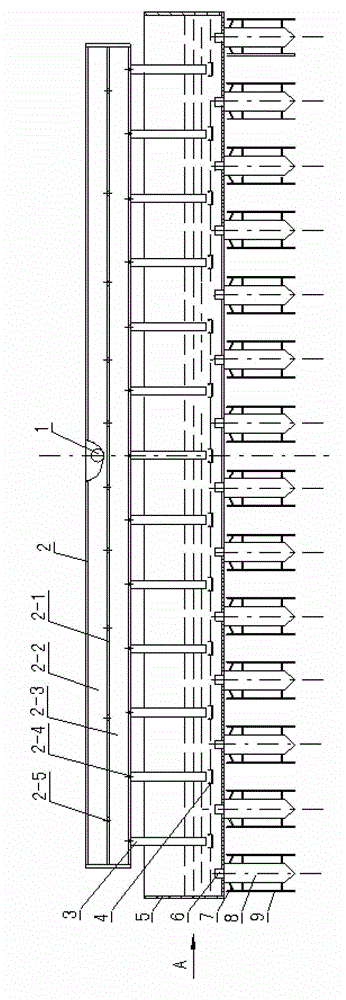

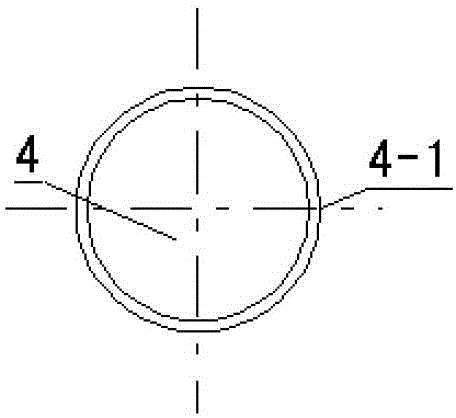

Method for constructing ventilating permeable ecological concrete water-storage side slope

The invention relates to a constructing method of aerating water penetration ecology concrete side slope. It sets an aerating water penetration ecology concrete layer constructed by graininess aggregate, concrete and the continuous clearance on the water storing side slope piling up by earth material. It has good reverse filtering effect and could effectively decrease the margin height of the water storing side slope.

Owner:ZHENJIANG JIUJIU ECOLOGICAL MATERIAL

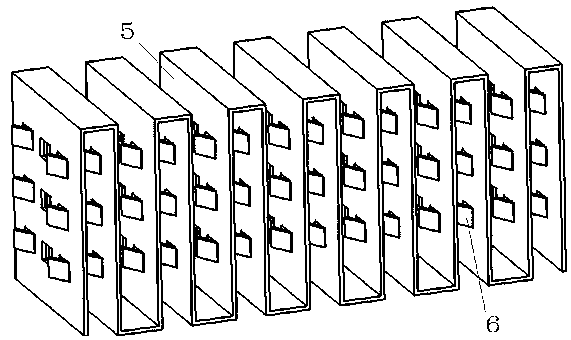

Pipe groove type liquid distributor applied to flue gas desulfurization tower

ActiveCN103143238AImprove the uniformity of liquid distributionGuaranteed separation efficiencyDispersed particle separationEngineeringDistillation

The invention relates to a pipe groove type liquid distributor applied to a flue gas desulfurization tower. The pipe groove type liquid distributor is composed of a liquid inlet tube, a liquid distributing pipe, a first-stage groove and a second-stage groove which are engaged with each other, wherein the liquid distributing pipe is divided into two stages which are engaged up and down through a middle partition board with variable interval equant liquid distributing holes; a second-stage bottom surface is provided with equal interval equant liquid distributing holes and liquid sealing pipes; the outlet end of each liquid sealing pipe is provided with a buffer; the bottom of the first-stage groove is provided with the second-stage groove vertical to the first-stage groove in a long axis direction at the middle position between corresponding adjacent liquid sealing pipes; uniform section rectangular liquid distribution liquid sealing pipes respectively inserted in each second-stage groove are arranged at the bottom of the first-stage groove; upper and lower liquid discharge holes at equal intervals are formed in both side groove boards of the second-stage groove; an anti-blocking baffle board is arranged inside each upper liquid discharge hole, and a flow guide groove board correspondingly engaged with a wire distributing board is arranged outside each upper liquid discharge hole; and a liquid distributing board is arranged at the lower part of each lower liquid discharge hole of the second-stage groove. The pipe groove type liquid distributor has the characteristics of liquid distribution uniformity, impact foam generation prevention, entrainment prevention and blockage prevention, and can be widely applied to large, middle and small containers for absorption and distillation such as flue gas desulfurization.

Owner:TIANJIN TIANDA TIANJIU TECH CO LTD

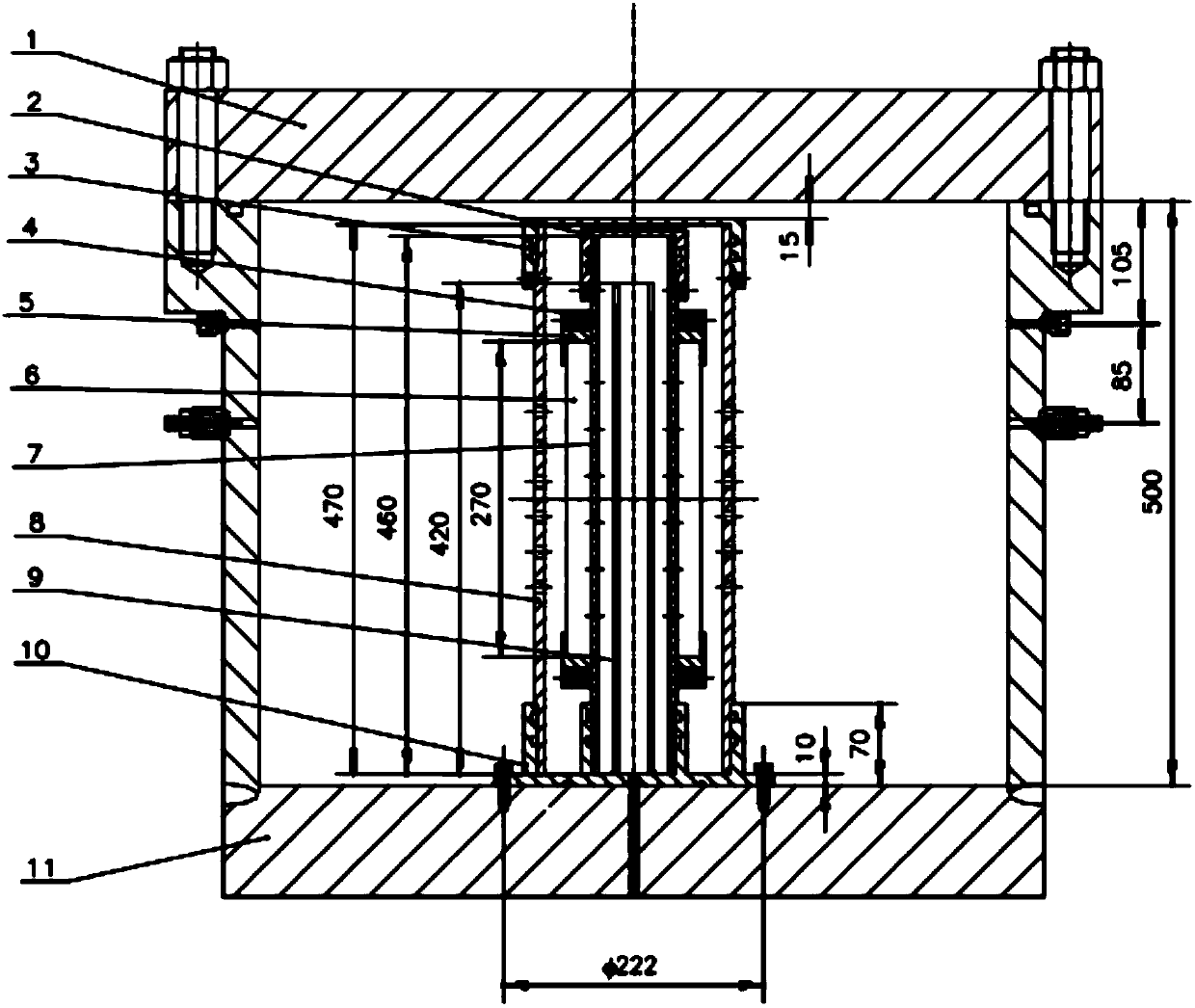

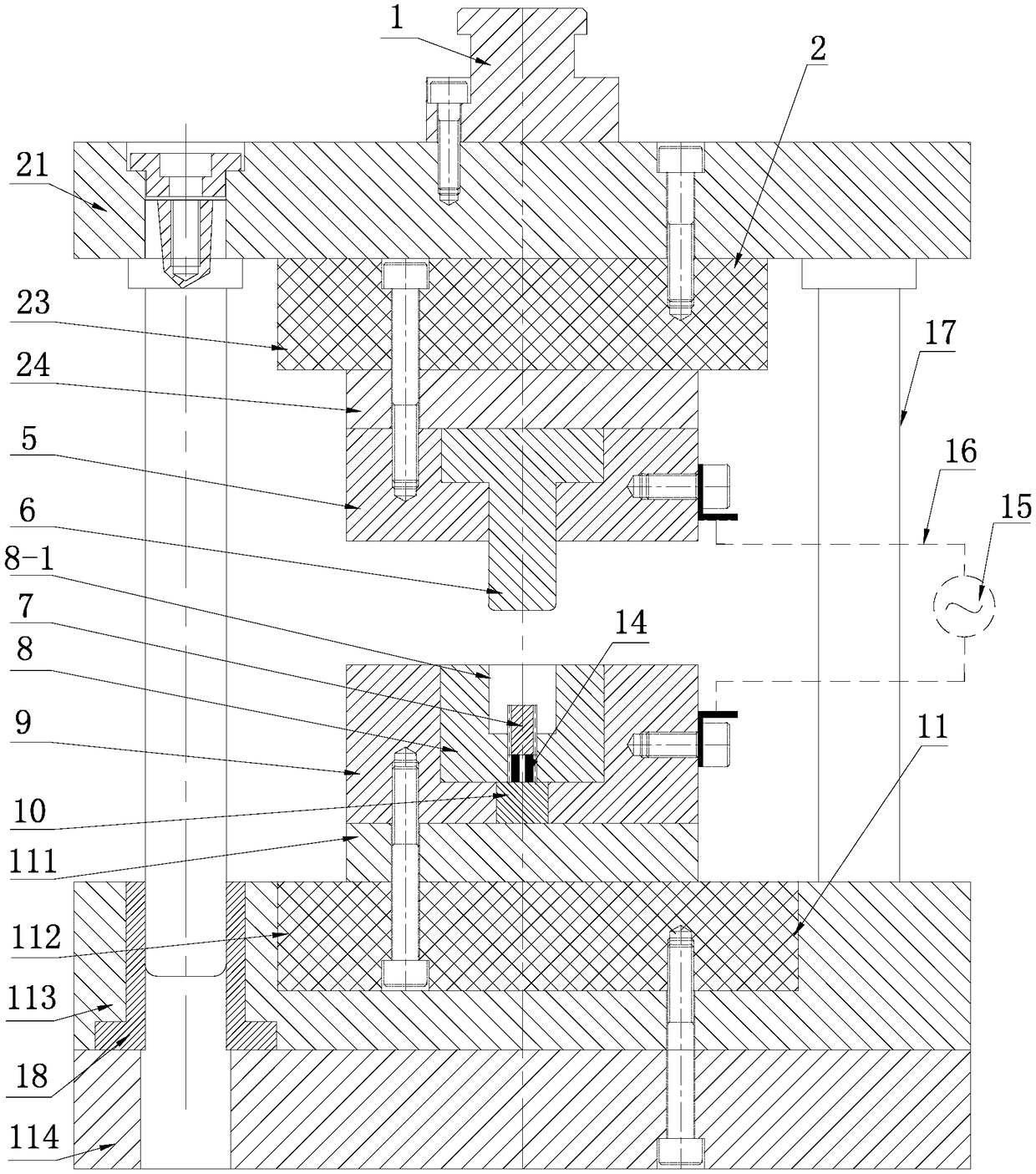

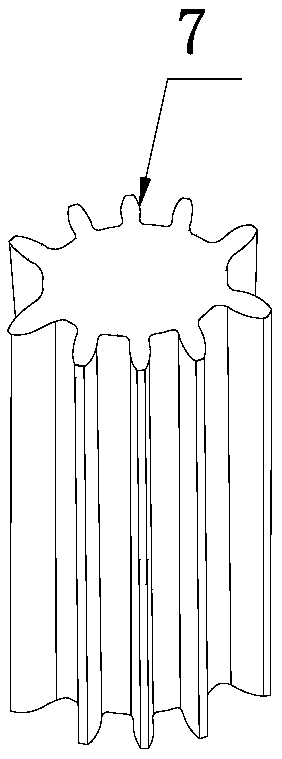

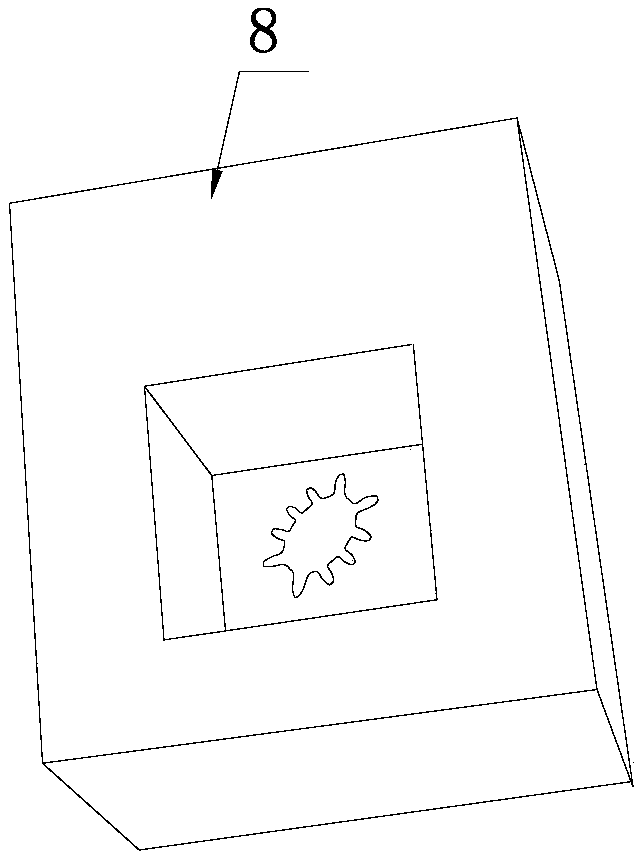

Pulse current assisted hollow shunt billet micro-forming die and method

ActiveCN108994102AImprove filling qualityHigh forming precisionExtrusion diesPulse power supplyTitanium alloy

The invention discloses a pulse current assisted hollow shunt billet micro-forming die and method and relates to a micro-forming die and method for miniature parts. In order to solve bottleneck problems that billets of miniature parts made of titanium alloy and other difficult-to-form materials have slow heating speeds, the micro die cavity is difficult to fill, the service life of the die is lowand the like, the micro-forming die comprises a die handle, an upper plate, a punch fixing plate, a punch, a female die, a female die fixing block, a demolding cushion block and a lower plate arrangedfrom top to bottom in sequence, wherein the punch is fixed in a stepped through hole which is large in top and small in bottom on the punch fixing plate. The forming method comprises the following steps: 1, die assembling, arranging the billet in the cavity of the female die, enabling pressure equipment to move downwards to drive the punch to move downwards so as to be in contact with the upper end face of the male die, continuously enabling the male die to move downwards to reach a certain pre-tightening pressure with the billet and stopping; 2, starting a pulsed power supply, heating the billets, and performing extrusion forming; 3, taking out the male die and the formed miniature parts. The invention belongs to the technical field of machine manufacturing and plastic micro-forming.

Owner:HARBIN INST OF TECH

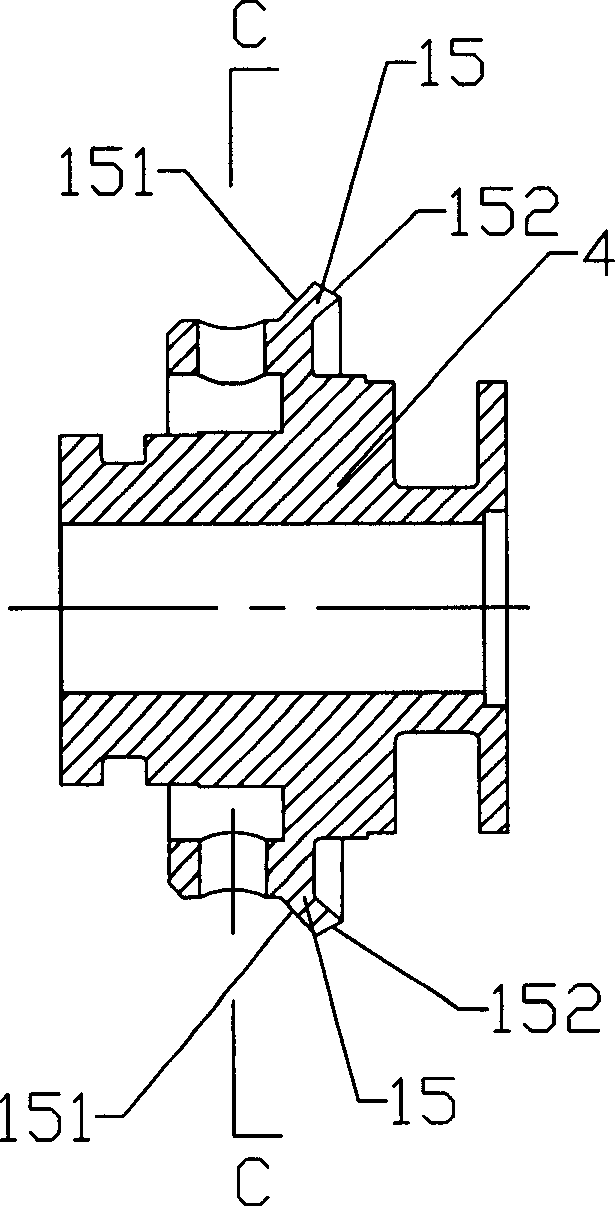

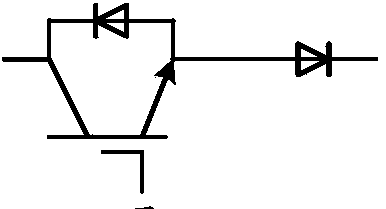

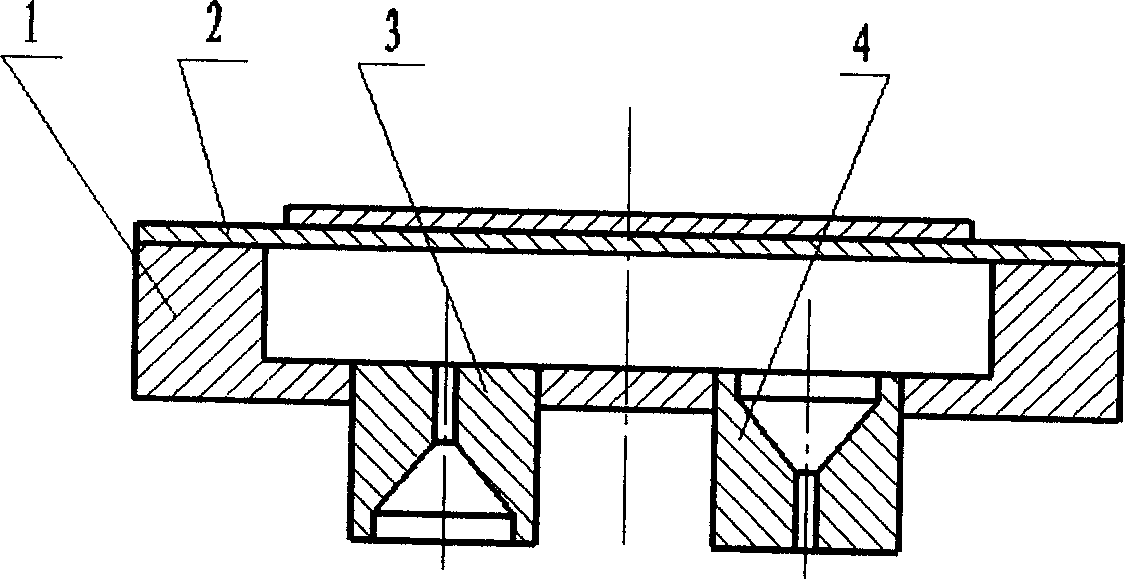

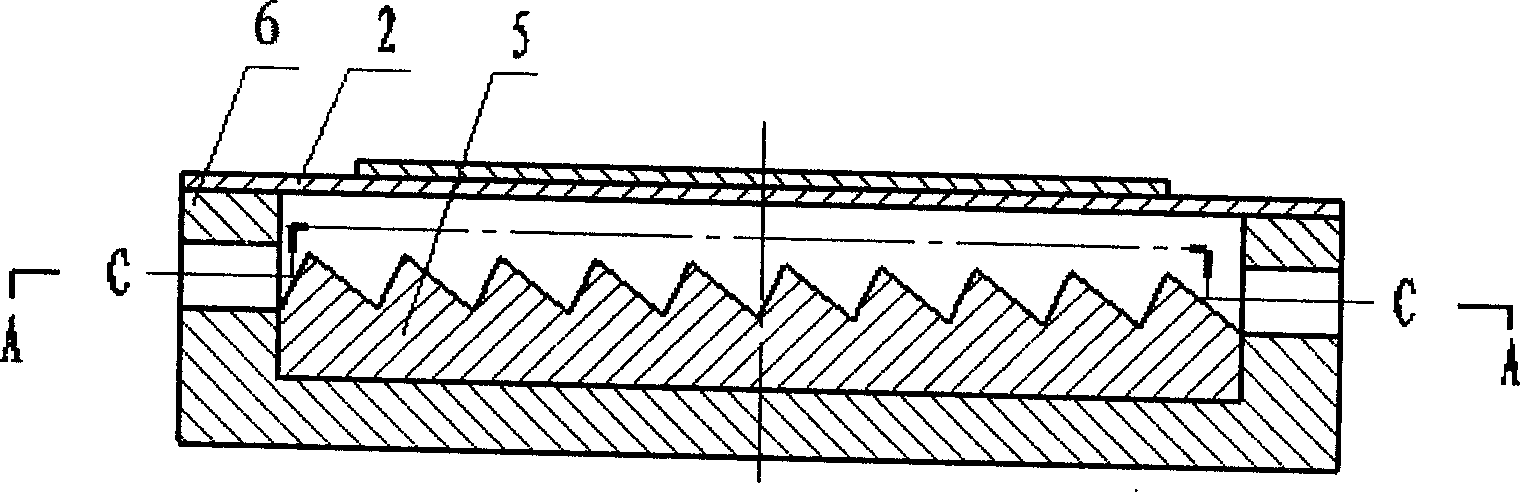

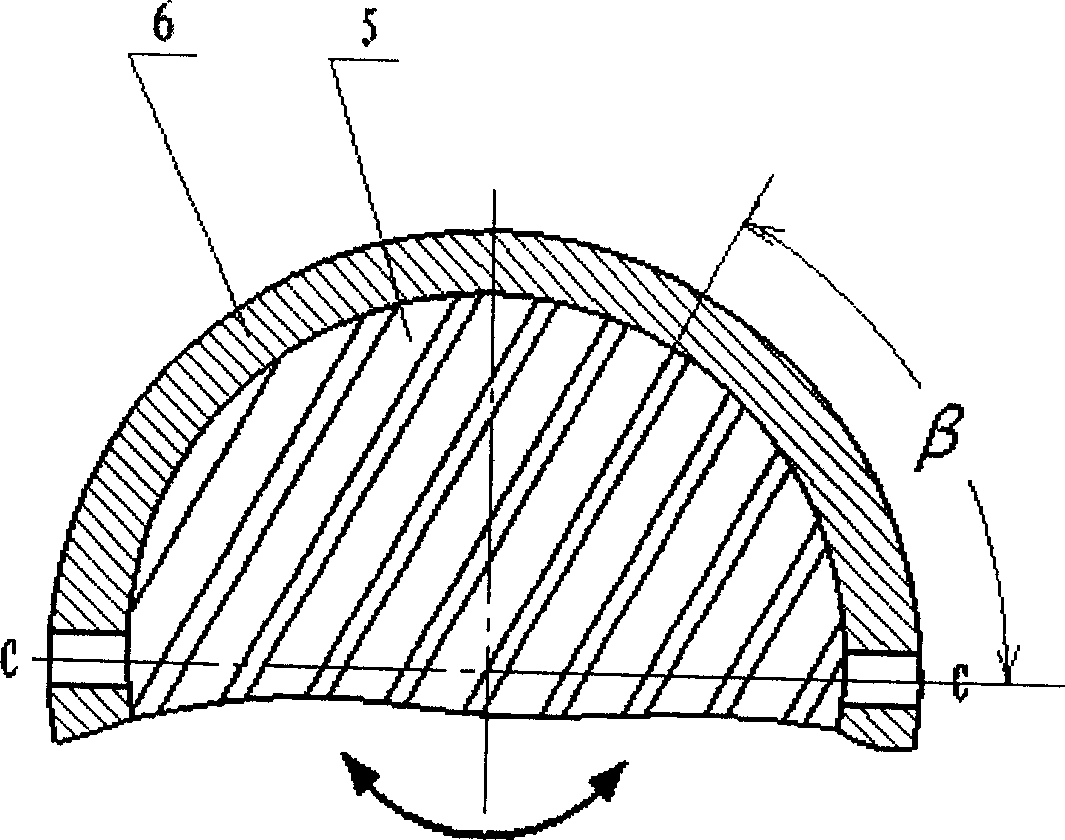

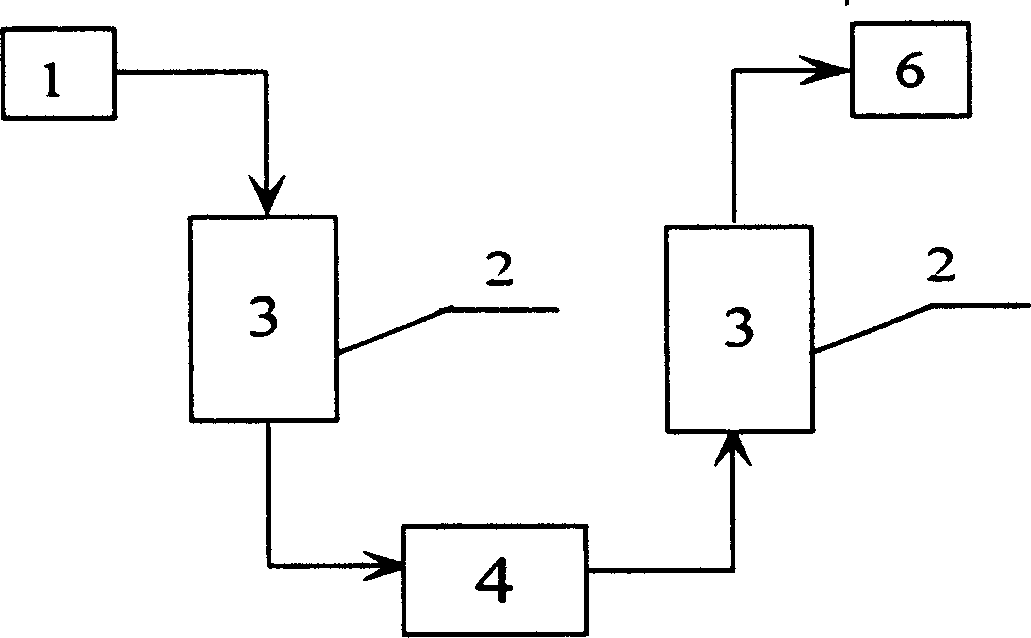

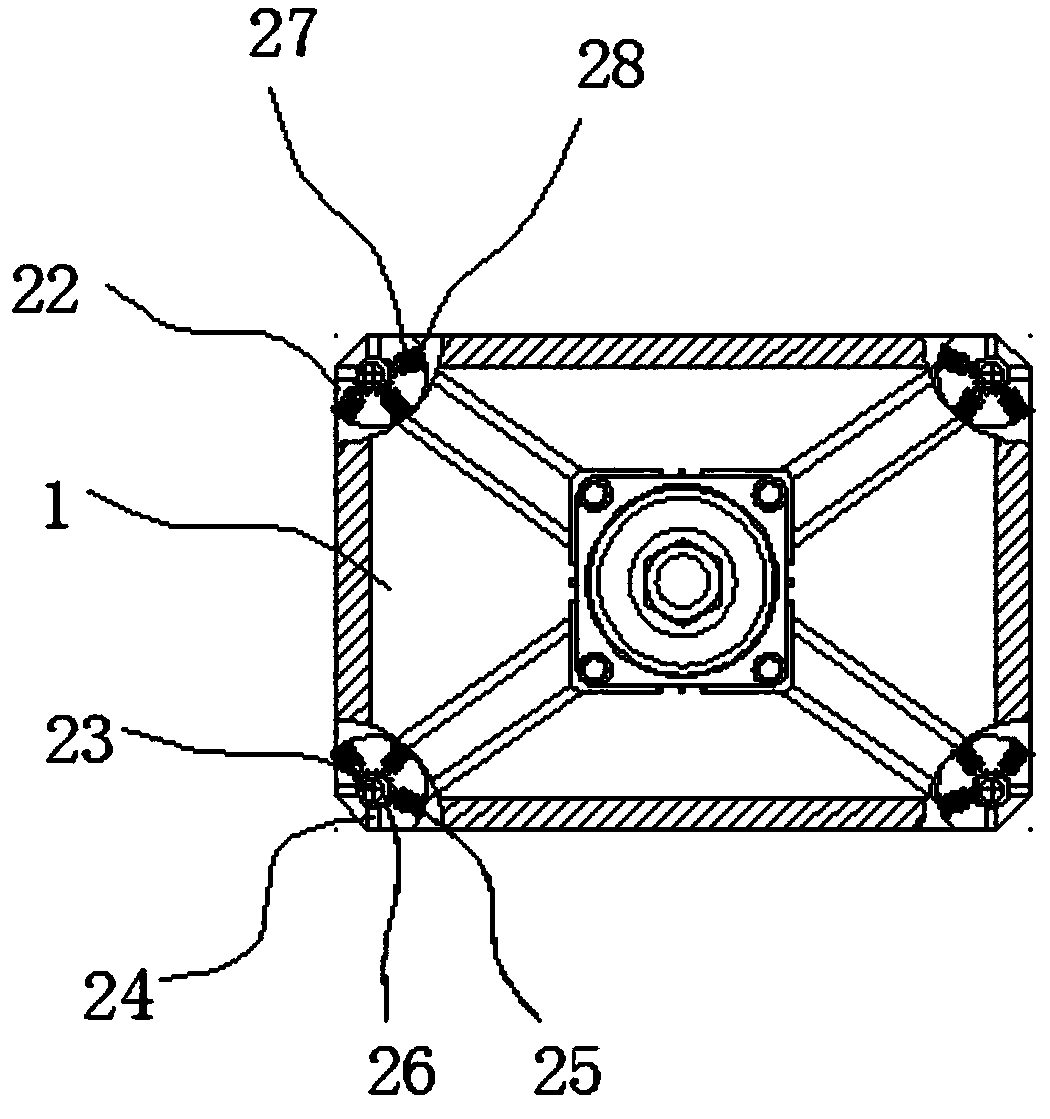

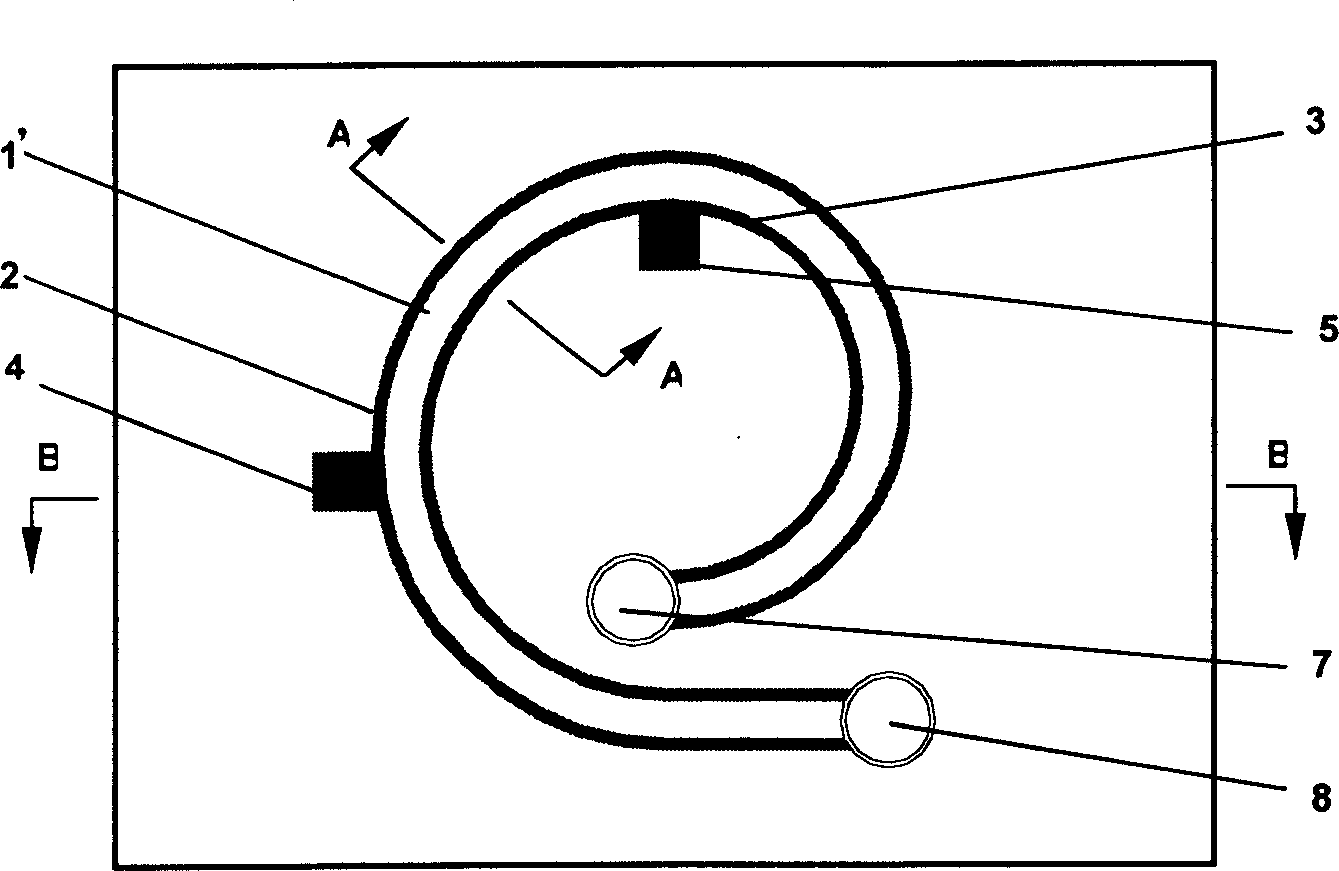

Rotary abaculus valveless piezoelectric pump

InactiveCN1743671AChange flow directionFlow adjustableFlexible member pumpsPositive-displacement liquid enginesEngineeringPiezoelectric pump

A pressure free electric pump with changeable flow and direction, which contains piezoelectric vibrator, rotary embedded block, every corrugated unit consisting of crossed planes, corrugated unit and piezoelectric vibrator constructing taper flow pipe, two planes intersecting line of corrugated unit is corrugated line paralleled each other, the embedded block rotating in cavity, the dip angle of corrugated line with suction inlet and outlet axis can be change from 0 degree to 360 degree, which resulting the taper angle of taper flow pipe changing, so the flow and direction are changed only by rotating the embedded block in pump cavity without auxiliary frequency change circuit.

Owner:BEIJING UNIV OF TECH

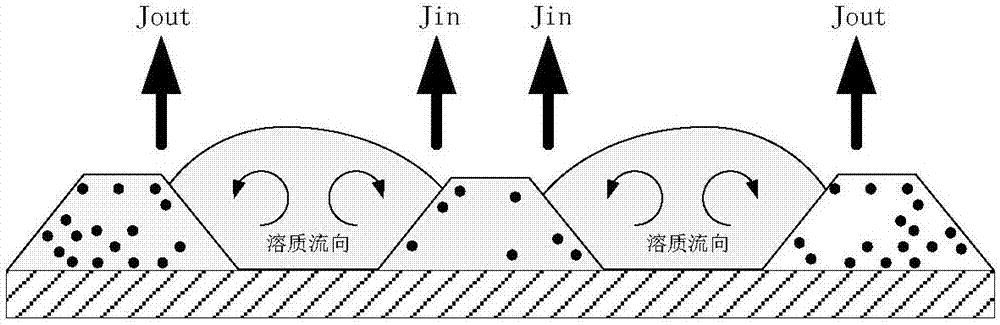

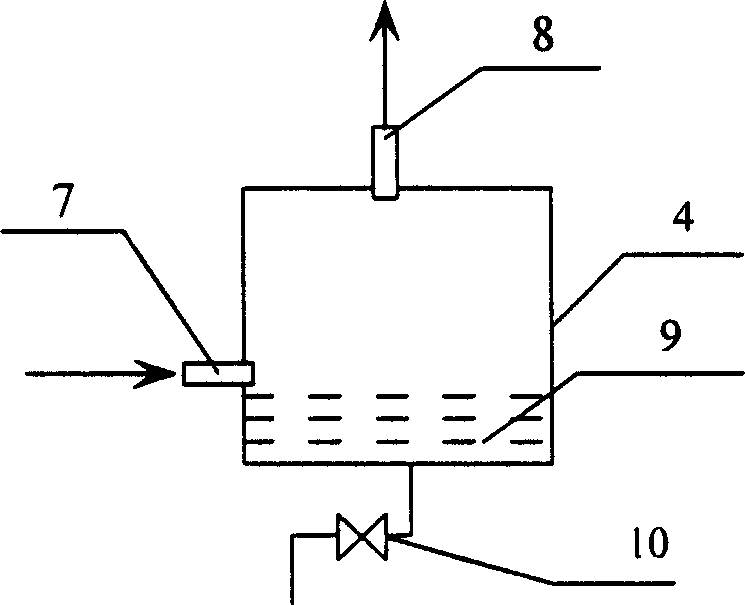

Beological filteration treatment method of wast gas containing hydrophilic and hydrophobic mixed votatile organic matter

InactiveCN1460538AReduce nutrient loss and water lossImprove degradabilityDispersed particle separationAir quality improvementChemistryVolcanic ash

The bio-filtration treatment method of waste gas containing hydrophilic and hydrophobic mixed volatile organic substances includes waste gas, bio-filtration bed with packing material, residence time and discharge. Said bio-filtration bed adopts two-stage or three-stage structure with dewatering unit, its residence time is 1-1.5 min, and its packing material is a mixture formed from compost, soil and volcanic ash, and is made up by mixing the above-mentioned compost-soil-volcanic ash mixture and activated sludge or supernatant fluid according to the volume ratio of 20:1-40:1.

Owner:DALIAN UNIV OF TECH

Hydraulic one-way valve

InactiveCN105909831ASimple structureReasonable designCheck valvesValve members for absorbing fluid energyMechanical engineeringCavitation

The invention relates to a hydraulic one-way valve. The hydraulic one-way valve comprises a valve body, a valve element, a spring and a check ring, wherein the valve body is provided with a specific internal fluid channel which extends along the axis of the valve body; the valve element is arranged in the valve body; the spring is located in the valve element and used for abutting against the valve element; and the check ring is used for limiting the spring. A water inlet is formed in the lower end of the valve body in the axis direction of the valve body. A water outlet is formed in the upper end of the valve body in the axis direction of the valve body. A valve element protection rod is arranged at the front end of the valve element, the valve element protection rod is a cylindrical rod, and an arc-shaped groove is formed in the front end face of the valve element protection rod. When the hydraulic one-way valve is in use, water flow flows from the water inlet to the water outlet; since the valve element protection rod is arranged on the front end face of the valve element, the valve element can be effectively protected against damage; and meanwhile, the arc-shaped groove is formed in the front end face of the valve element protection rod so that the flowing direction of the water flow can be changed, the momentum of the water flow is reduced, and the cavitation resistance of the valve element protection rod is improved.

Owner:刘光旭

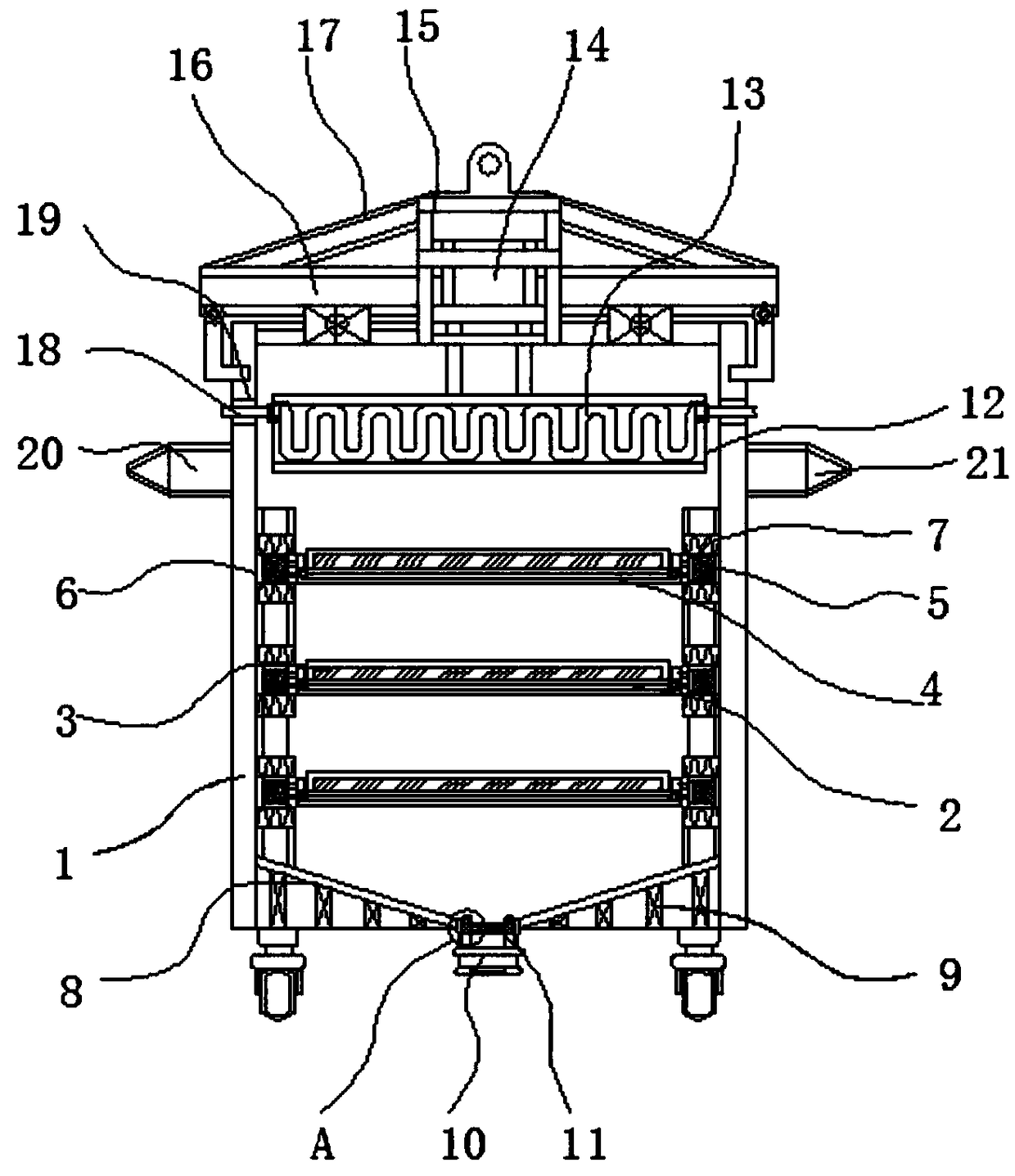

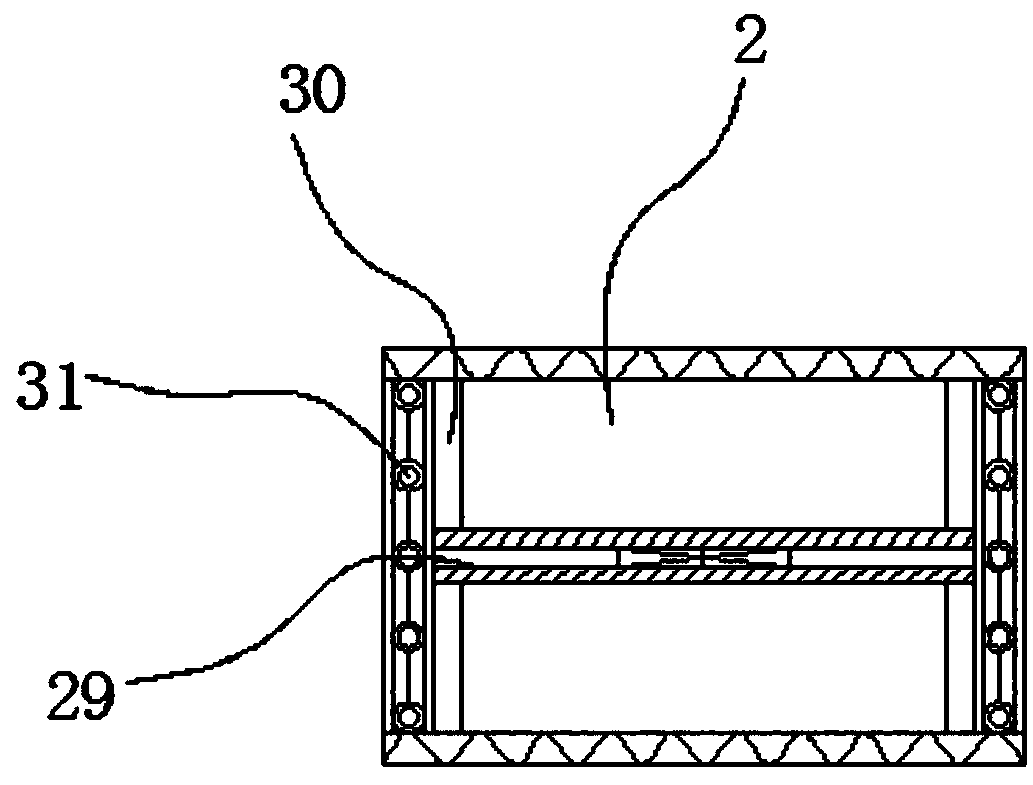

Baked food cooling box for food processing

InactiveCN109221345AAvoid damageIntegrity guaranteedPreservation by coolingCooking & bakingBaked goods

The invention discloses a baked food cooling box for food processing, and relates to the technical field of food processing. The baked food cooling box comprises a cooling box body and a cooling framework, baking trays are installed inside the cooling box body, the cooling framework is arranged over the baking trays, and the baking trays are connected with the cooling box body through grooves; guide slide wheels are installed at the left and right ends of each baking tray, a partition board is movably connected to the front of each baking tray, a cooling pipeline is installed inside the cooling framework, and the top of the cooling framework is in threaded connection with a hydraulic air cylinder. The baked food cooling box for food processing has the advantages that through the arrangement of the cooling box body, a turnover cover plate and the cooling framework, when the turnover cover plate covers the top of the cooling box body, the cover plate and the cooling box body are combinedto form a relative sealed shell. Through the cooperation of the cooling framework, food inside the cooling box body can be hermetically cooled.

Owner:FOSHAN UNIVERSITY

Hair treatment equipment and treatment method for preventing toilet floor drain from being blocked

InactiveCN111705900ANo need to worry about cloggingChange flow directionSewerage structuresDomestic plumbingWater leakageHair falling

The invention discloses hair treatment equipment and treatment method for preventing a toilet floor drain from being blocked. The hair treatment equipment comprises a water leakage top cover, whereina large through hole is formed in the middle of the top of the water leakage top cover; a top sealing cover plate is movably clamped in an inner cavity of the large through hole; a hair collection mechanism is arranged at the top of the water leakage top cover. According to the hair treatment equipment for preventing the toilet floor drain from being blocked, under the condition that normal utilization of a toilet dripping device is not influenced, the hair treatment equipment can move along with water flow to carry out shrinkage treatment on hair falling off from people; meanwhile, the hair on the ground can be directly flushed into a sewer line by utilizing the water flow; on one hand, people do not worry about treatment of the hair on the whole ground; on the other hand, people do not need to worry about the blockage of the sewer line when the hair is flushed away; and when a spring moves in a reciprocating manner by clinging to the sewer line, dirt blocks remained and attached on an inner wall of the sewer line can also be shoveled and pinched off, so that the possibility that the sewer line is prone to being blocked after being used for a long time can be avoided and the possibility that the sewer line easily generates peculiar smell can also be eliminated.

Owner:南京溧水高新产业股权投资有限公司

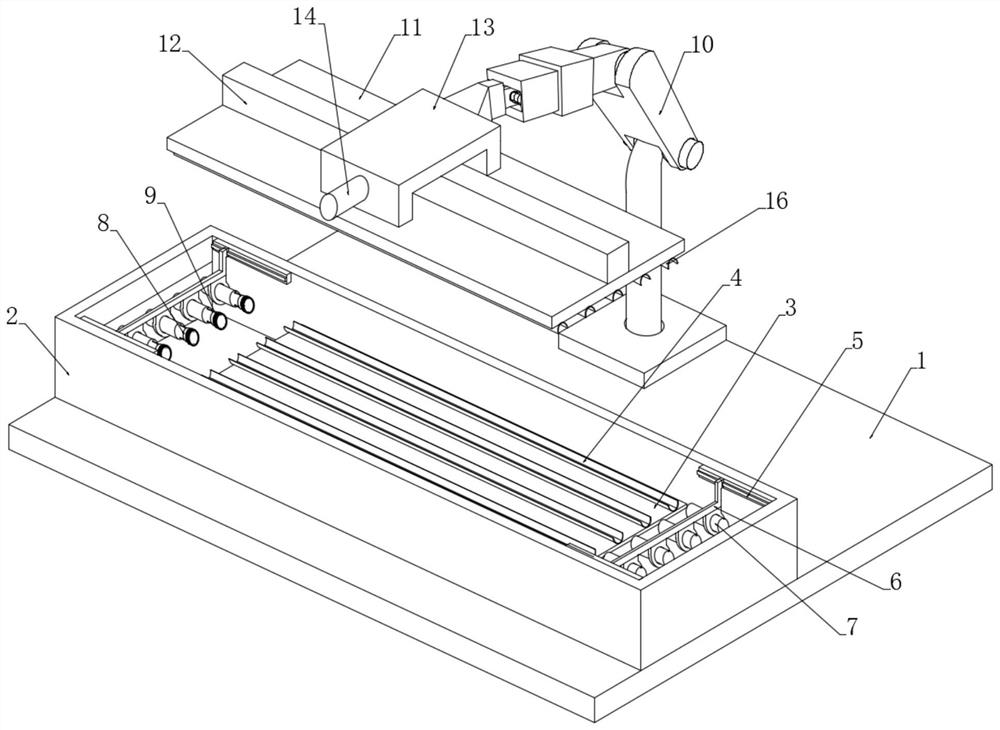

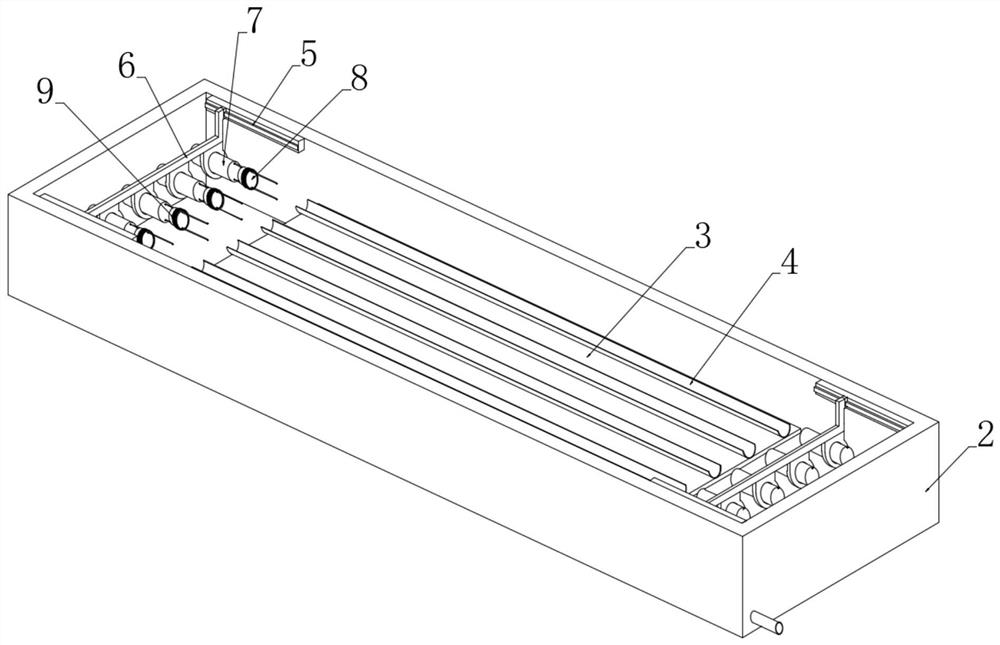

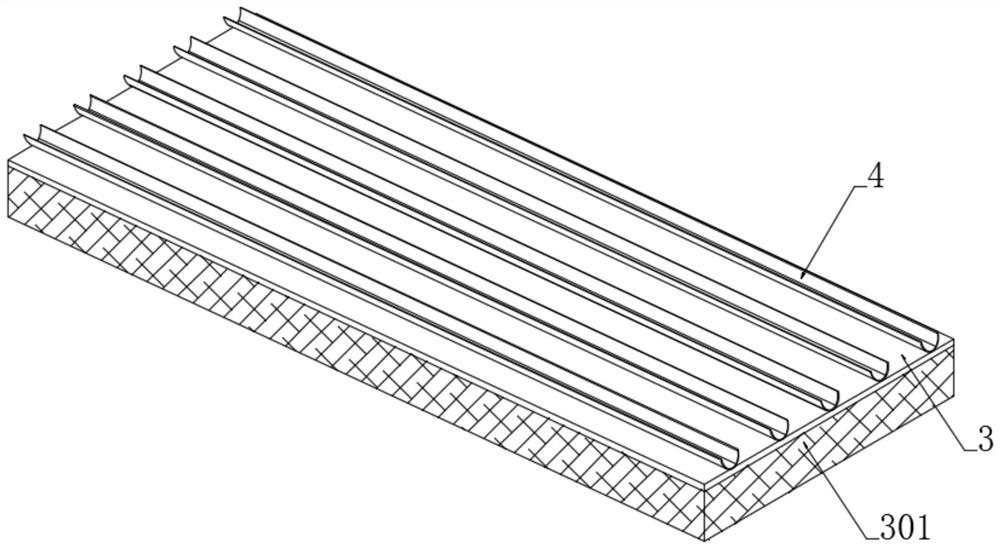

Efficient washing equipment applicable to thin-diameter thin-wall long metal tubes

ActiveCN111618034AReduce the difficulty of cleaningEasy to operateHollow article cleaningDrying gas arrangementsRobotic armProcess engineering

The invention discloses efficient washing equipment applicable to thin-diameter thin-wall long metal tubes, and belongs to the technical field of cleaning of long tubes. The efficient washing equipment applicable to the thin-diameter thin-wall long metal tubes comprises a cleaning box fixedly mounted on an operating platform; two groups of positioning magnetic absorption columns, opposite in position, are arranged at the left and right ends inside the cleaning box, second electromagnets in the two groups of positioning magnetic absorption columns are opposite in magnetism, and moving magneticabsorption columns between the two groups of positioning magnetic absorption columns can reciprocate leftwards and rightwards in the horizontal direction under the magnetic attraction-repelling effects, so that cleaning sponge sleeves on the moving magnetic absorption columns can clean the inner walls of the long tubes positioned on arc-shaped long tube limiting sleeves, a thin tube is not required to be manually connected with a cleaning sponge head to extend into the tubes for cleaning, and the cleaning difficulty is reduced effectively; and after cleaning is completed, the long tubes are adsorbed and lifted through a mechanical arm and a long tube absorbing device, drying after drainage is performed, and the operation effect is improved effectively.

Owner:ZHEJIANG JINFA BEARING

Method for controlling spontaneous combustion of underground coal and developing and utilizing

ActiveCN109339788AAvoid pollutionRealize environmental pollution controlDisloding machinesUnderground miningThermal energySpontaneous combustion

The invention belongs to the technical field of underground resource development and utilization, and relates to a method for controlling spontaneous combustion of underground coal and developing andutilizing. After clearly surveying spontaneous combustion of the underground coal and the geological conditions, a spontaneous combustion area is divided into a plurality of blocks; drill holes are formed from the blocks to an underground spontaneous combustion area to form a production well, high temperature flue gas from underground coal combustion is extracted to the ground by an induced draftfan through the production well, and a certain negative pressure is formed in the underground combustion area; the ground of a certain area near the production well is blocked off, air is forced fromthe periphery of the sealing area into the underground to participate in combustion, and the volume of a combustion bed is controlled; and the high temperature flue gas extracted to the ground is exchanged into thermal energy through a heat exchanger to generate electricity or supply heat, and the flue gas is treated centrally. In addition, water and other raw materials can be sent to the underground combustion area artificially to adjust the carbon hydrogen ratio of high temperature flue gas, and producing qualified synthetic gas is extracted to the ground for chemical production. According to the method for controlling spontaneous combustion of the underground coal and developing and utilizing, the process is simple, comprehensive utilization of resources is achieved, pollution is controlled, economic and social benefits are good, and industrialized development can be achieved.

Owner:杨昌玮

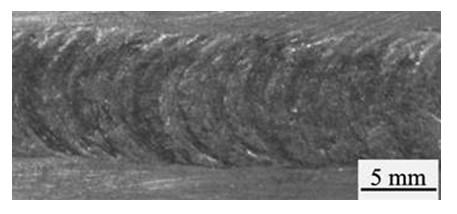

Novel composite active agent for magnesium alloy active tungsten-insert-gas (A-TIG) arc welding

InactiveCN102689112AImprove ultimate tensile strengthChanging the temperature coefficient of surface tensionArc welding apparatusWelding/cutting media/materialsActive agentCeramic particle

The invention discloses a novel composite active agent for magnesium alloy active tungsten-insert-gas (A-TIG) arc welding, and belongs to an active agent welding technique. The novel composite active agent for magnesium alloy active tungsten-insert-gas arc welding provided by the invention is characterized in that the active agent is Cr2O3, and the weight proportion of the active agent is 65-70%; and a ceramic additive particle is SiC, and the weight proportion of the ceramic additive particle is 30%-35%. The novel composite active agent for magnesium alloy active tungsten-insert-gas arc welding is prepared through the following steps of: firstly grinding Cr2O3 active agent powder and the SiC ceramic particle, and mixing in proportion; then adding acetone into the mixture, so that the mixture becomes pasty; then coating the pasty active agent on the upper surface of a test sample uniformly by a flat brush, wherein the coating width is about 40mm, and the average density per square centimeter is 4-5mg; and carrying out tungsten-insert-gas (A-TIG) arc welding after the acetone is volatilized. Compared with a welding joint which is not coated with the active agent, the welding joint obtained through the welding technology has the advantages that the fusion depth is improved by 60%, an the tensile property is improved by 30%; and in addition, after the active agent is coated, crystal particles in the welding line are thinned obviously, and the difficulties that the fusion depth is shallow in the TIG arc welding, and the crystal particles of the welding line in the traditional active TIG arc welding are toughened seriously are solved.

Owner:CHONGQING UNIV

Silk-screen-free plastic melt filter

PendingCN110370497AChange flow directionSmooth entryPlastic recyclingEngineeringMechanical engineering

The invention provides a silk-screen-free plastic melt filter which comprises a hollow box body. A filter screen plate is connected into the box body in a rotating manner. The filter screen plate partitions an inner cavity of the box body into a feeding cavity and a discharging cavity. A feeding opening, an impurity discharging opening and a discharging opening are formed in the box body. The boxbody is provided with a rotating shaft. The rotating shaft is connected with the filter screen plate. A scraper is fixed into the feeding cavity. The scraper abuts against the filter screen plate andscrapes off impurities on the filter screen plate. Meanwhile, the scraper can block the scraped impurities and guide the scraped impurities to the impurity discharging opening. The rotating shaft is driven by drive parts like a motor and drives the filter screen plate to rotate. The impurities attached to the filter screen plate are scraped off by the scraper, and move to the impurity dischargingopening under guiding of the scraper. The scraper blocks the impurities scraped off, and thus the situation that the impurities pass by the scraper easily and flow back to a treated area is avoided. Moreover, the scraper is fixedly connected into the feeding cavity, the impurities scraped off will not rotate around the rotating shaft in the feeding cavity, and the impurities can be discharged outrapidly from the impurity discharging opening.

Owner:ZHEJIANG LEENY TECH

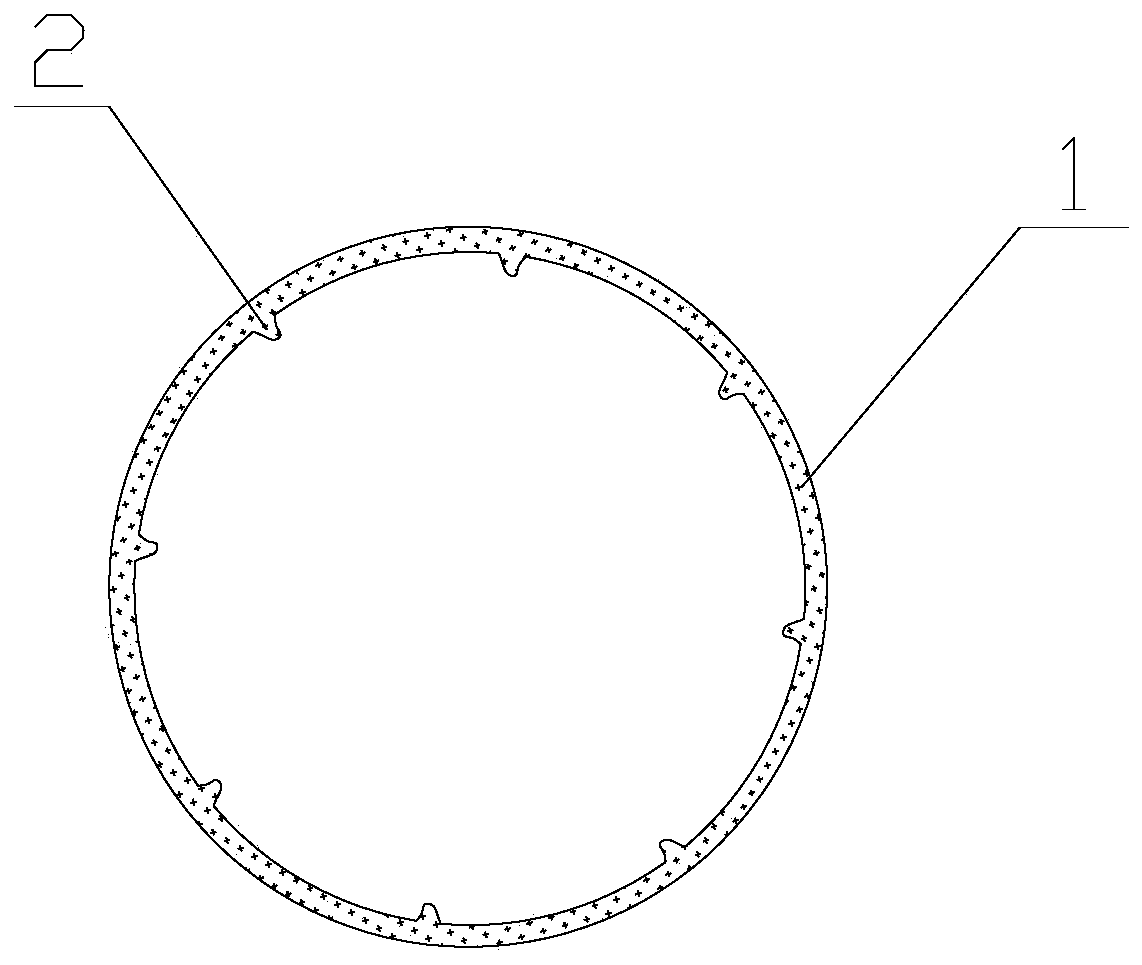

Inside spin type high-temperature-resisting ultra-quiet drainage pipe and manufacturing method thereof

InactiveCN103883812AFalling water noise reductionLow costFlexible pipesRigid pipesElastomerHeat resistance

The invention discloses an inside spin type high-temperature-resisting ultra-quiet drainage pipe and a manufacturing method thereof to solve the problem that existing drainage pipes are high in noise, not resistant to high temperature and high in cost and relates to the technical field of drainage. The inside spin type high-temperature-resisting ultra-quiet drainage pipe comprises a denoising layer, wherein spiral ribs are arranged on the inner wall of the denoising layer, the denoising layer is manufactured from, by weight, 20-35 percent of block co-polypropylene, 5-10 percent of viscous elastic bodies, 50-70 percent of barium sulfate, 2-3 percent of dispersing agents, 1-2 percent of coupling reagents, and 1-2 percent of lubricants, and a high-temperature-resistant polypropylene resin layer is further arranged on the outer surface of the denoising layer. According to the spin type high-temperature-resisting ultra-quiet drainage pipe and the manufacturing method thereof, by means of the denoising layer and the spiral ribs on the inner wall of the denoising layer, water falling noise of a building plastic pipeline system can be reduced to a level below 35 decibel, the heat-resistance temperature of a pipeline can reach 90 DEG C, the manufacturing cost of the drainage pipe is 10% less than that of a flexible cast-iron pipe, the service life of the pipe can reach 50 years, and the drainage pipe is easy to install, low in cost, economical and practical.

Owner:QINGDAO HENGRUI PLASTIC TECH

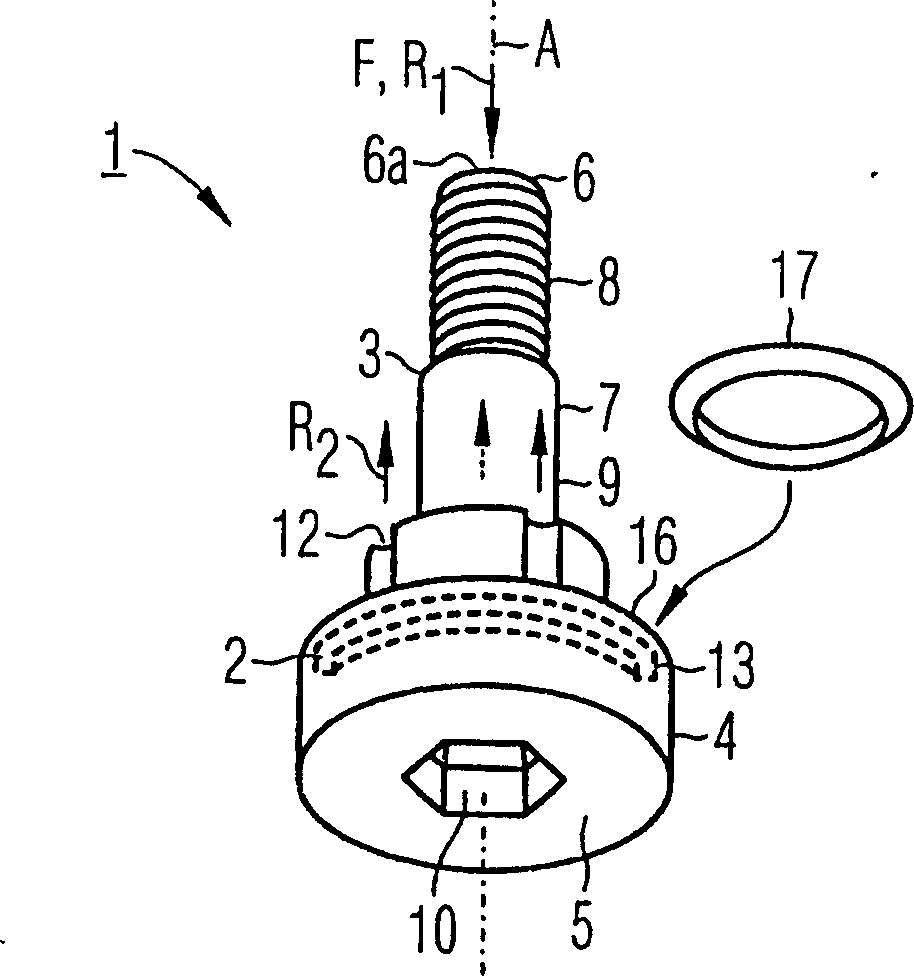

Venturi fertilizer applicator

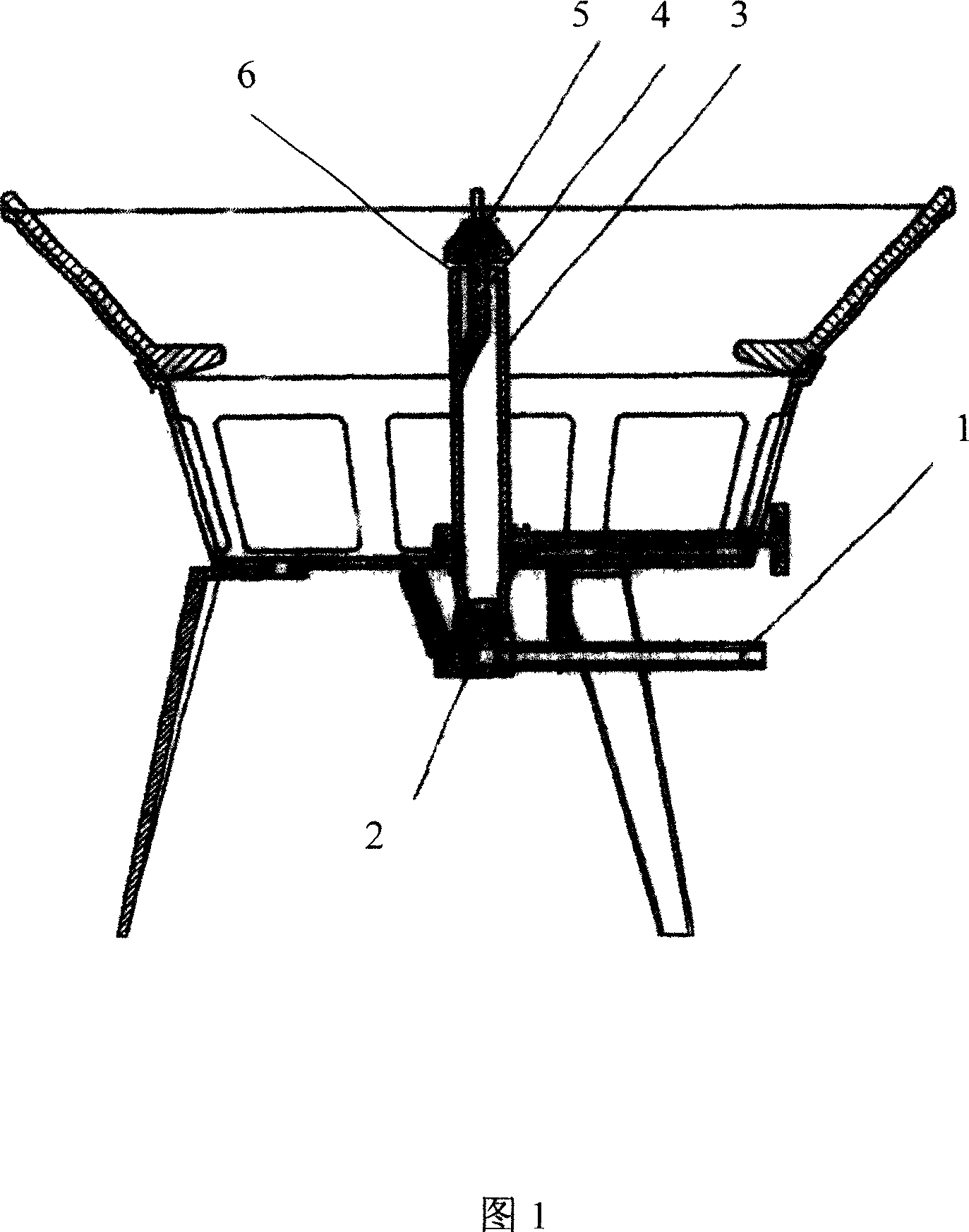

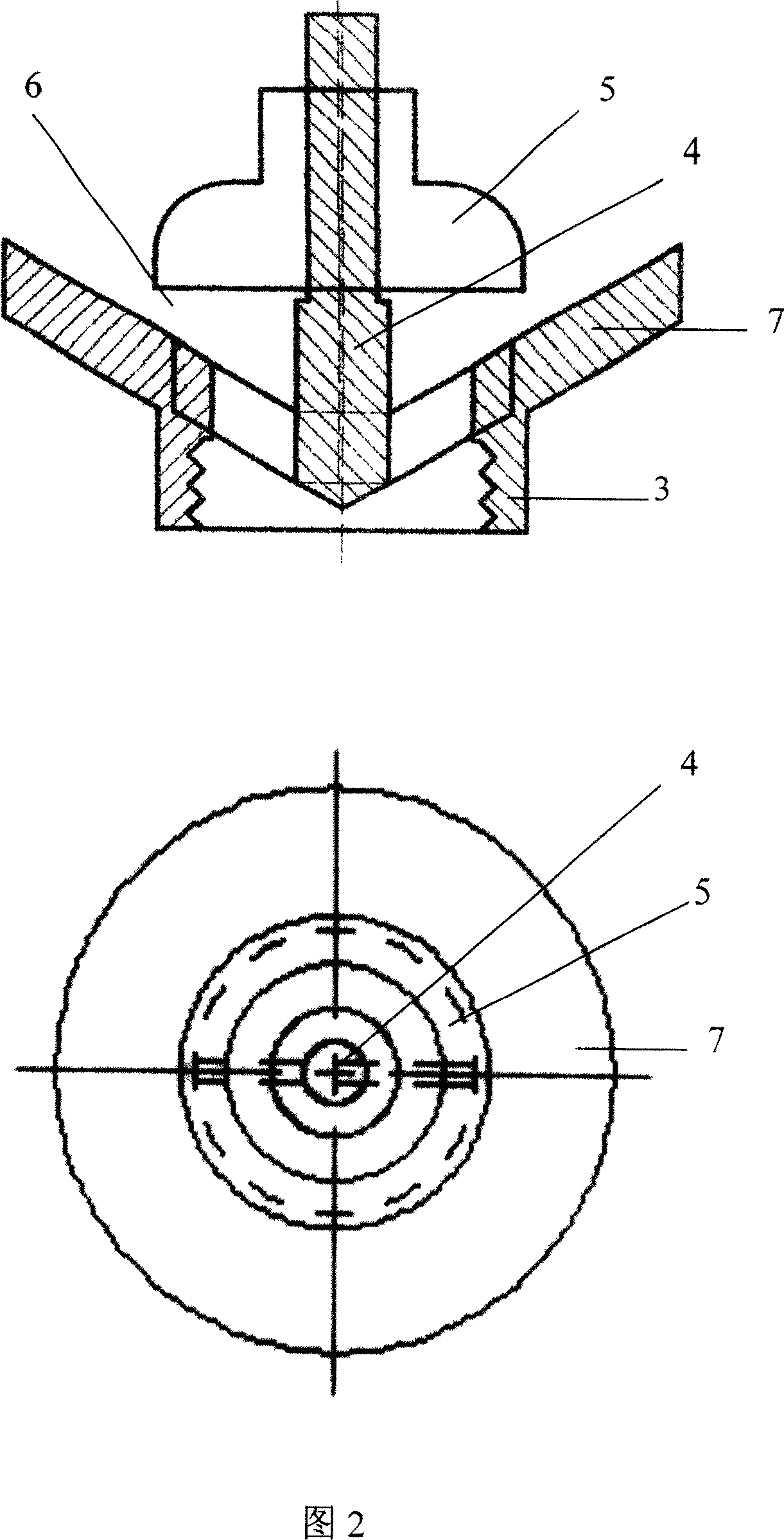

InactiveCN101946581AChange flow directionImprove energy exchange efficiencyLiquid fertiliser distributionStraight tubeEngineering

The invention relates to a venturi fertilizer applicator which comprises a contracting section, a diffusing section and a suction tube, wherein the contracting section and the diffusing section are connected through threads in a sealing mode; the transition section between the contracting section and the diffusing section is the throat; and the suction tube is connected to the joint of the contracting section and the diffusing section in a sealing mode and communicated with the throat. The invention is characterized in that a set of guide blades, which are evenly arranged in circumferential direction, are arranged in an inlet straight tube section at the front part of the contracting section; the guide blades are divided into an inflow section and an outflow section; the inflow section is flat; and the outflow section is bent in a circular arc of 60-90 degrees. The invention has the advantages of simple and ingenious structural design, high fertilizer suction efficiency and low overflow head loss, and can be widely used in the fertilizer application process of an irrigation system.

Owner:CHINA AGRI UNIV

Magnetic fluid impulse type minipump

InactiveCN1540163ASimple structureGood chemical stabilityPumpsPositive-displacement liquid enginesSputteringEngineering

A magnetic fluid driven miniature pump is composed of the first substrate with two electric electrodes and the tube inlet and outlet, the second substrate with etched microtube, liquid torages and the electrodes formed on the two side walls of microtube by sputtering, and a permanent magnet installed onto lower surface of the second substrate. After two substrates are aligned and boand and the electrolyte is filled in said microtube, said electrodes are connected to positive and negative electrodes of power supply to generate current in the electrolyte. Under the action of said permanent magnet, a lorentz force is generated in the electrolyte to drive it to flow from one liquid storage to another.

Owner:ZHEJIANG UNIV

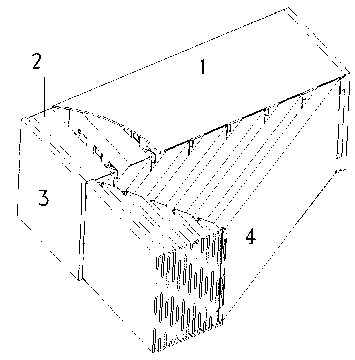

Plate-fin crotch structure heat exchange device for enhancing heat transfer

InactiveCN103267436ASolve temperature non-uniformity problemsEnhanced turbulence effectLaminated elementsStationary plate conduit assembliesEngineeringPlate fin heat exchanger

The invention discloses a plate-fin crotch structure heat exchange device for enhancing heat transfer. The plate-fin crotch structure heat exchange device comprises two end sockets, a partition board, flow deflectors and fins. Fluid enters the plate-fin crotch structure heat exchange device through the flow deflector on one side. After being subjected to heat exchange with the fins, the fluid flows out from the other side. The plate-fin crotch structure heat exchange device is characterized in that the fins are crotch-shaped fins, wherein each crotch-shaped fin is composed of a trunk part and a crotch part, and each crotch-shaped fin comprises at least two crotches which are evenly distributed on two side faces of a trunk. The crotches are arranged in a staggered mode on two sides of each trunk in the flowing direction of the fluid. The open direction of each crotch-shaped fin is consistent with the flowing direction of the fluid. The range of an open angle is 10-30 degrees. By means of the plate-fin crotch structure heat exchange device for enhancing the heat transfer, the problem that the temperatures of the fluid in different flow paths of a heat exchanger are not uniform is solved; the turbulence performance of the fluid in the heat exchanger is improved, a thermal boundary layer of the fluid is damaged, the flowing directions of the fluid in the different flow paths are changed, and therefore the heat exchange efficiency is improved; due to a crotch-shaped fin structure of the plate-fin heat exchanger, the thermal boundary layer of the fluid is damaged, and the heat transfer effect of the heat exchanger is enhanced.

Owner:ZHEJIANG UNIV

A guide vane type rotary jet pump

InactiveCN102297165AImprove energy exchange efficiencyChange flow directionJet pumpsMachines/enginesRotary pumpWorking fluid

The invention relates to a guide vane type rotary jet pump, which is characterized in that it comprises a head, a nozzle is arranged in one end along the horizontal direction of the head, and an inlet is arranged in the bottom along the vertical direction of the head; The other end of the head in the horizontal direction is connected to a diffuser through a throat; a group of guide vanes capable of providing peripheral speed are arranged on the inner wall of the nozzle. Since the present invention adopts a set of guide vanes on the inner wall of the nozzle, the working fluid flowing in from the nozzle passes through the guide vanes, so that the working fluid flows out of the nozzle and has a certain circumferential speed around the axis of the nozzle, thus changing the flow rate of the working fluid. The turbulent flow structure of the mixed layer with the absorbed fluid improves the energy exchange efficiency between the operating fluid and the absorbed fluid. The invention can be widely applied under various complicated working conditions.

Owner:CHINA AGRI UNIV

Backlight assembly and liquid crystal display device using the same

InactiveCN1485571AEfficient use ofReduce usageContinuous combustion chamberTurbine/propulsion engine coolingLiquid-crystal displayEntire head

A screw includes a head and a shank, and includes a coolant passage which has an inflow opening and an outflow opening. The cooling pasage does not pass axially through the entire head and shank. By avoiding a coolant flow which passes axially through the entire screw, especially effective utilization of a coolant is achieved, in particular by coolant which also flows on the outer surface of the screw.

Owner:SIEMENS AG

Intense fire gas cooker manufacturing method and product thereof

InactiveCN1995830AChange flow directionChange the way of beingDomestic stoves or rangesLighting and heating apparatusCombustible gasProduct gas

The invention relates to a method for gas range. When combustible gas is sprayed into the mixed pipe from nozzle, wind resistance in the mixed pipe decreases the flow speed of high-pressure combustible gas and changes the flow direction of gas. As the position of added wind pipe is adjusted up and down, inlet quantity of air is adjusted so that the mixing proportion of combustible gas and air achieves the optimum. When the combustible gas is sprayed out form air outlet port, under the effect of fire distributing head it is distributed round in balance and fire guide groove on the bottom face or spherical face of fire distributing head can change the flow direction effectively so that the combustible gas generates rotating flow. Fire guide ring outside of air outlet port of mixed pipe can make the combustible gas be distributed upwards on the slope face of fire guide ring in radiation and uniformity. As the distance between fire distributing head and fire guide ring is adjusted the flame distributing area is adjusted. The thermal efficiency of strong fire furnace produced by the invention can improves to 55% or so and prior technology is 25% or so. It can save energy by more than 50%.

Owner:张兵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com