Patents

Literature

69 results about "Nitrogen accumulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Accumulation of high levels of nitrogen is essential for high grain yields, and thus, high levels of nitrogen are commonly associated with crops having high harvest indices. Under conditions where nitrogen is limiting, a low harvest index crop is advantageous. Limited nitrogen can be partitioned into the low nitrogen concentration...

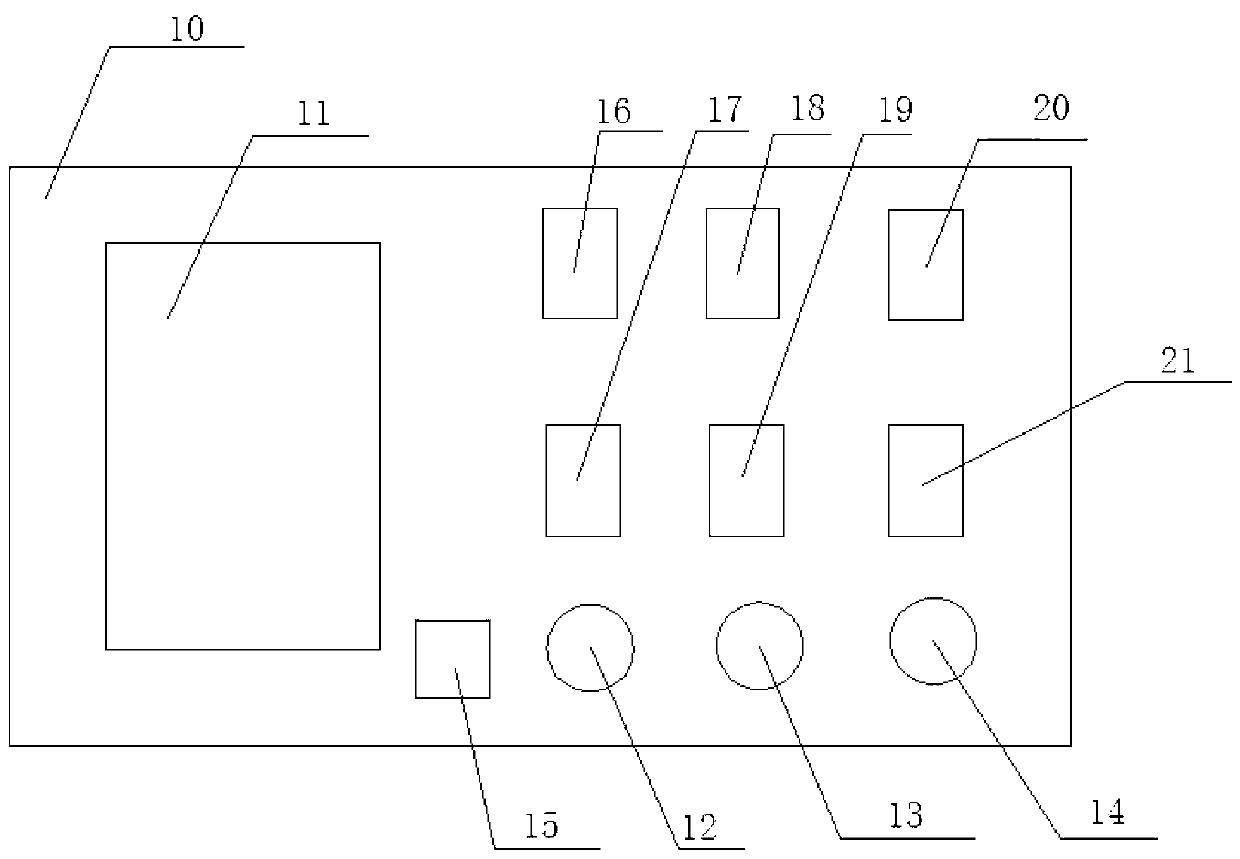

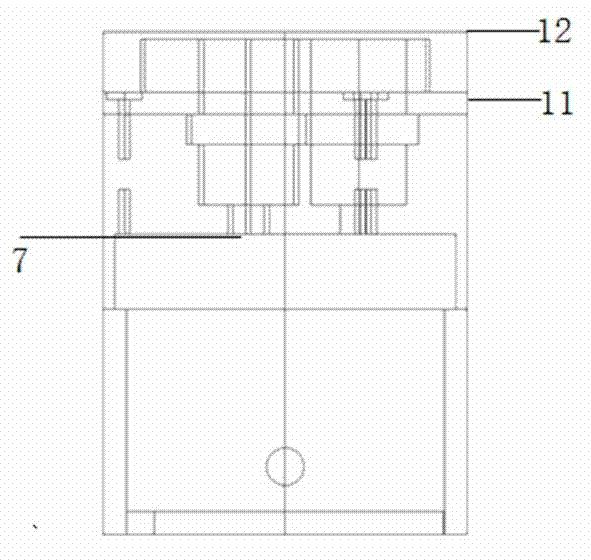

Portable multiway crop leaf nitrogen nutrient index nondestructive monitoring device

InactiveCN101021472AReduce pollutionEasy to monitor on siteColor/spectral properties measurementsSpecial data processing applicationsAgricultural scienceNitrogen accumulation

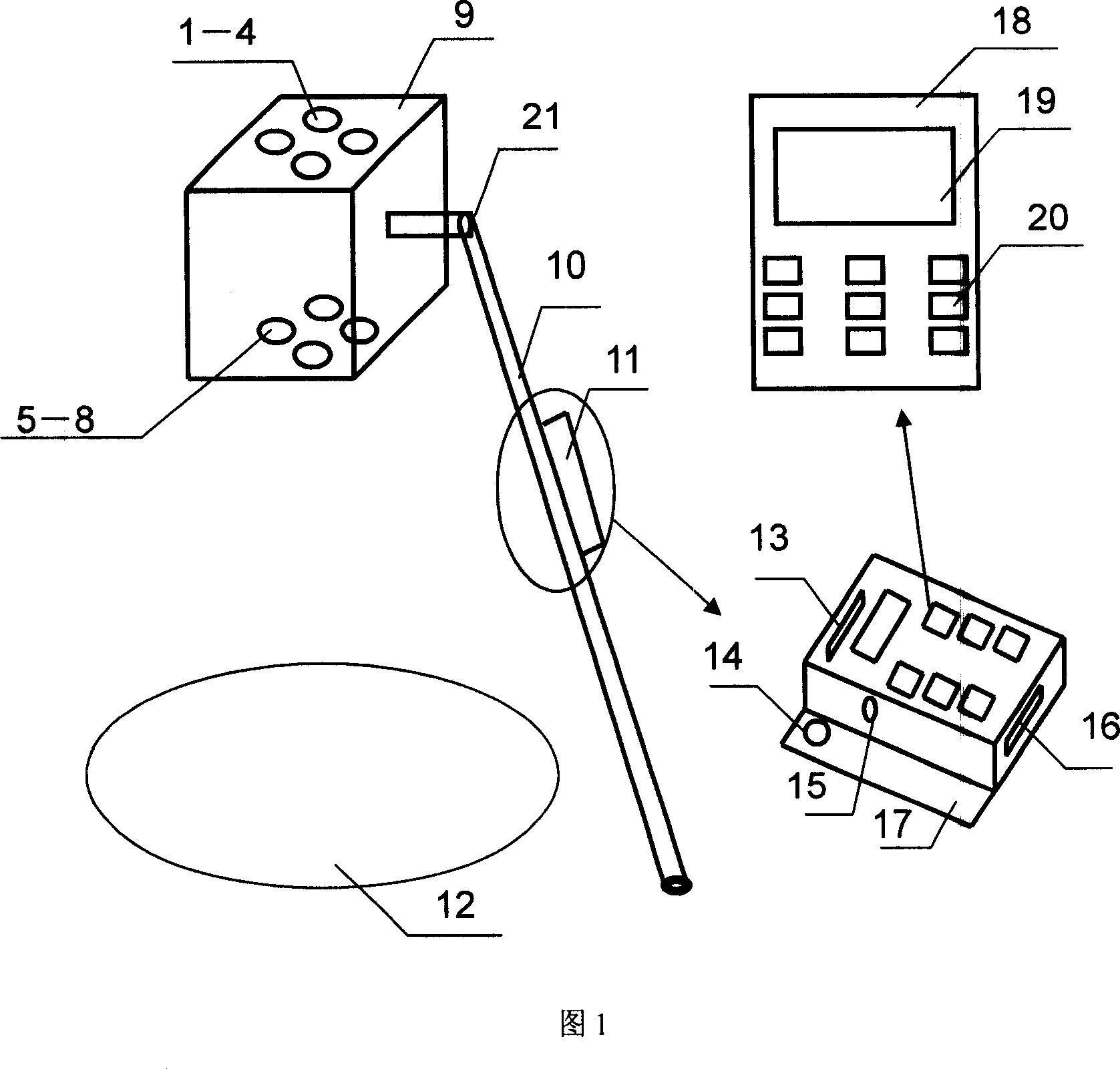

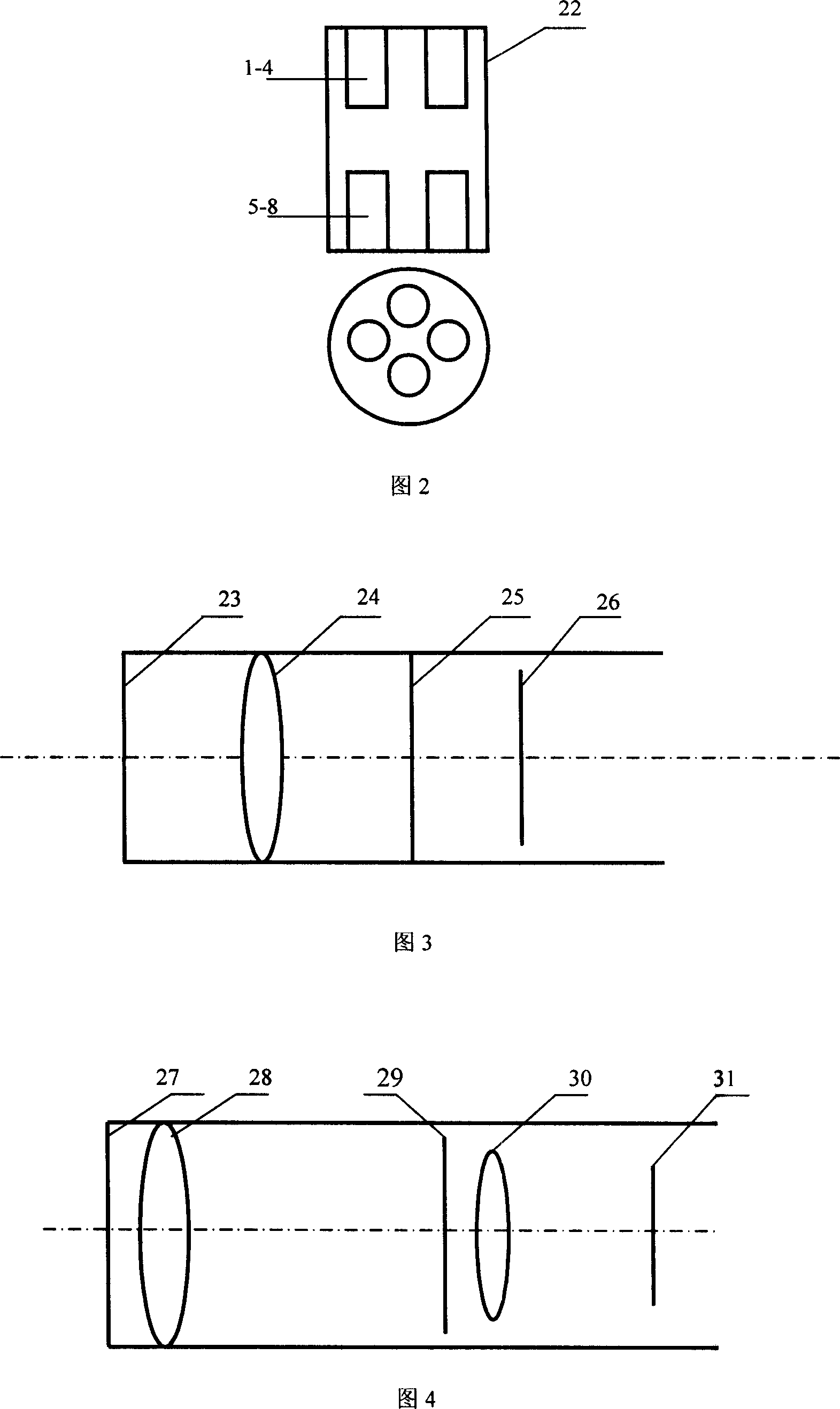

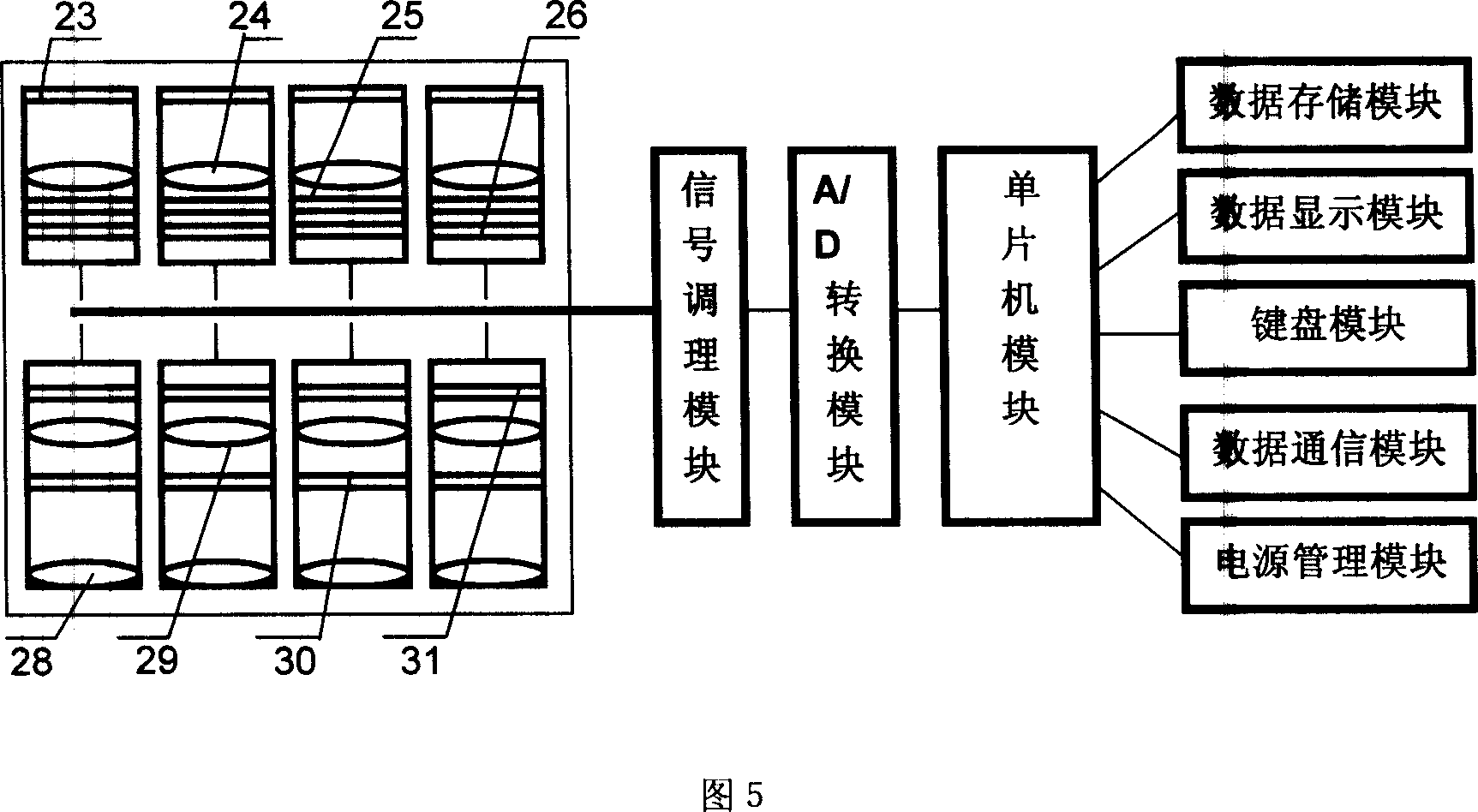

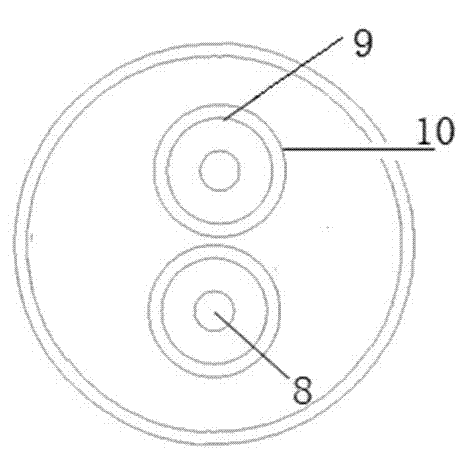

The invention relates to a lossless testing device for nitrogen nutritive index of crop leaves based on canopy reflection spectrum. It belongs to technology field of crop production, which is specially used in online detecting and precious fertilizing guidance of crop field production. It is mainly composed of bracket, spectrum signal collection and host computer. Spectrum signal collection adopts design of 4 waveband and 8 channels. Hardware system is composed of analog signals conditioning module, A / D transfer module, chip module, memory module, display module, keyboard module, communication module and power management module. Software system is programmed by C51 chip language. Detection of nitrogen content, nitrogen accumulation and leaf area index of canopy not only ensures high detecting precision, but also provides three data indexes of different facets to analyze nitrogen nutritive level of crop, which guarantees reliability and stability of detecting results. It can be applied in field operation, online lossless detecting, field online manage and guidance for agricultural production personnel.

Owner:NANJING AGRICULTURAL UNIVERSITY

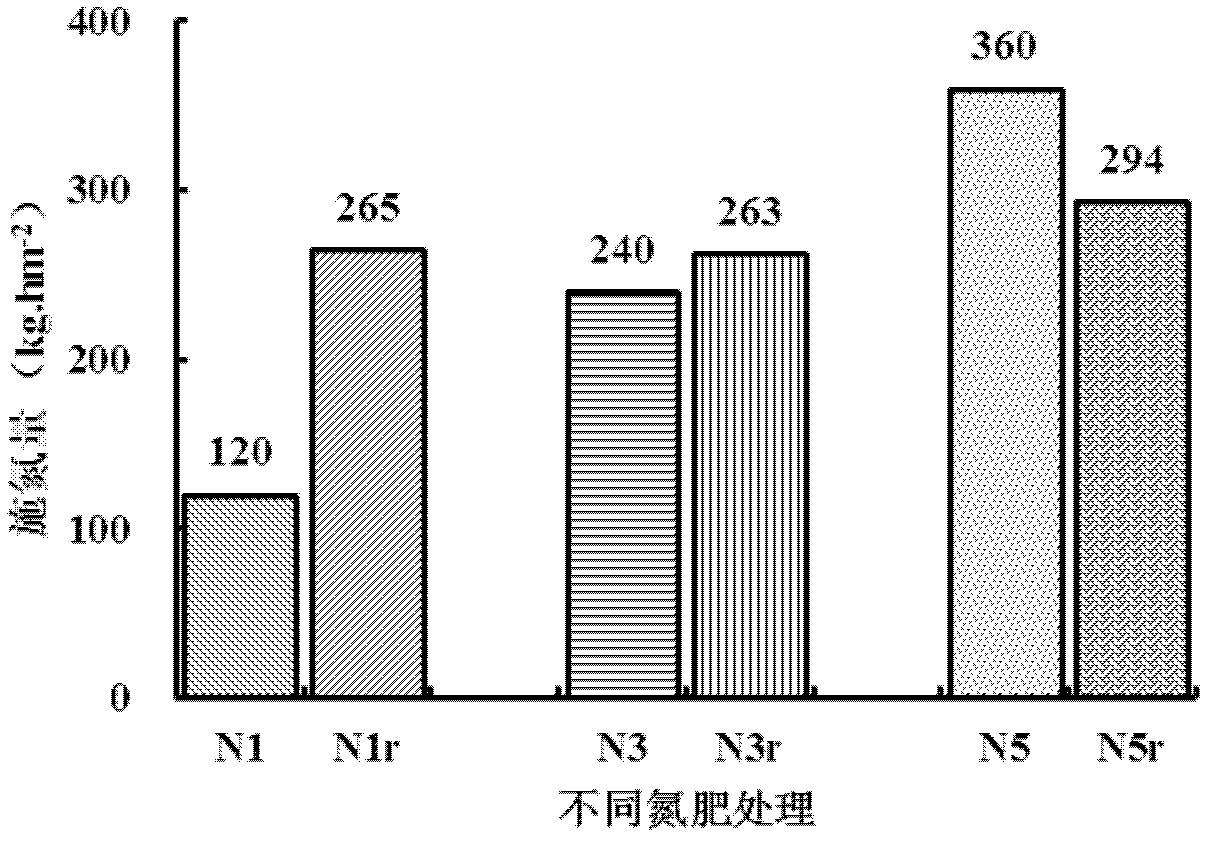

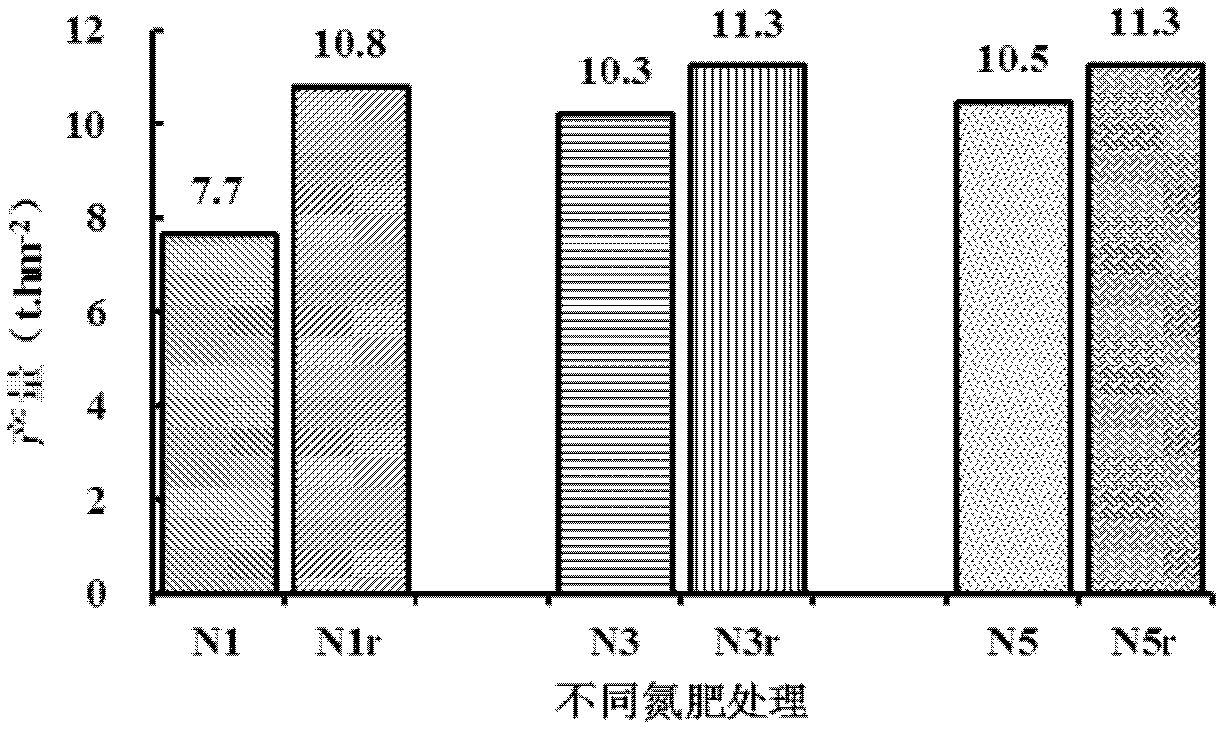

Regulation and control method for rice nitrogen topdressing based on nitrogen spectral index method

ActiveCN102318466AImprove precisionImprove the level of digital managementFertilising methodsColor/spectral properties measurementsTime informationSoil type

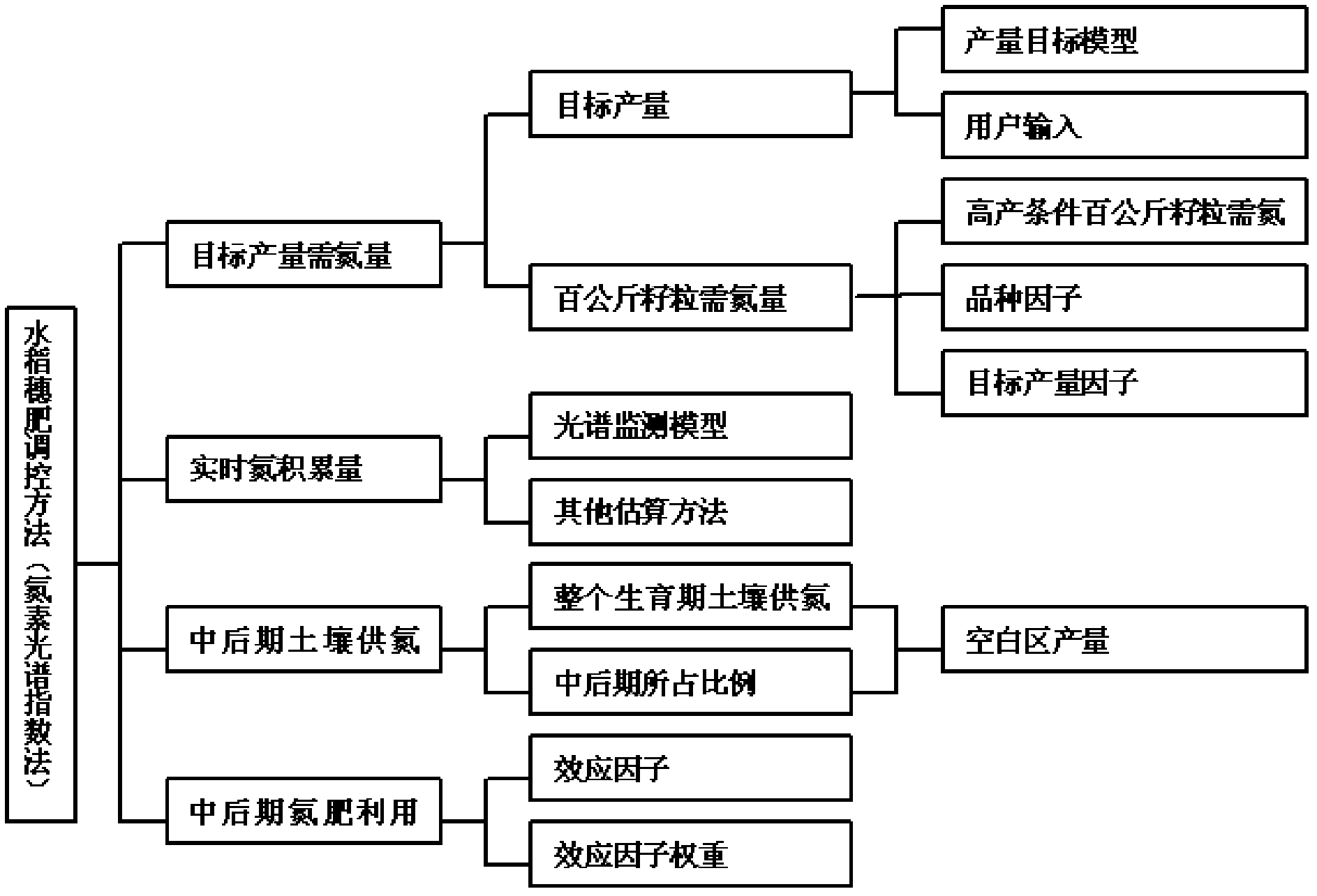

The invention belongs to the technical field of crop growing management and discloses a regulation and control method for rice nitrogen topdressing based on a nitrogen spectral index method. According to the invention, the nitrogen spectral index method is constructed according to nitrogen amount required by target rice yield, apparent utilization rate of spike fertilizer, plant real-time nitrogen accumulation amount estimated based on reflectance spectrum and soil nitrogen supplying amount while nitrogen fertilization based on a nutrient balancing principle. According to the invention, in the aspect of real-time information acquisition, plant canopy group information is utilized, thus the regulation and control method disclosed by the invention has the quicker and lossless characteristics and the like, thereby avoiding the phenomenon of point replacing surface; in the aspect of a nitrogen topdressing regulating and controlling model, the soil nitrogen supplying amount and nitrogen fertilizer utilization rate during the middle-late period are quantified, thereby enhancing the mechanism characteristic and accuracy of nitrogen topdressing amount estimation and improving the quantification level.

Owner:神农智慧农业研究院南京有限公司

Culture method of aerobic nitrosification granule sludge

ActiveCN103601287AHigh volume loadImprove removal efficiencySustainable biological treatmentBiological water/sewage treatmentSequencing batch reactorNitrogen accumulation

The invention discloses a culture method of municipal sewage nitrosification granule sludge, belonging to the field of restoration and regeneration of an aquatic environment. The invention aims to solve the problems of low carbon-nitrogen ratio, low denitrification efficiency and waste of abundant energy sources in the municipal sewage. The method comprises steps: anaerobic ammoxidation granule sludge is inoculated in an SBR (sequencing batch reactor); by using domestic sewage as raw water, the dissolved oxygen in the reactor is controlled at 4 mg / L or more, the stirring speed is controlled at 100 r / min, the temperature is controlled at 30 DEG C, the hydraulic retention time is controlled at 8 hours, and the sedimentation time is controlled at 5 minutes; the aerobic ammoxidation bacterium AOB and denitrifying bacterium can form granule sludge with anaerobic ammoxidation granule sludge as core; the shearing force generated by aeration can provide selection pressure for the formation of the granule sludge and promote the formation of the granule sludge; and the short sedimentation time is beneficial to elimination of nitrobacteria, thereby keeping the nitrosification stable. By using the method, the ammonia nitrogen removal ratio is up to 100%, and the nitrogen accumulation rate is higher than 95%.

Owner:BEIJING UNIV OF TECH

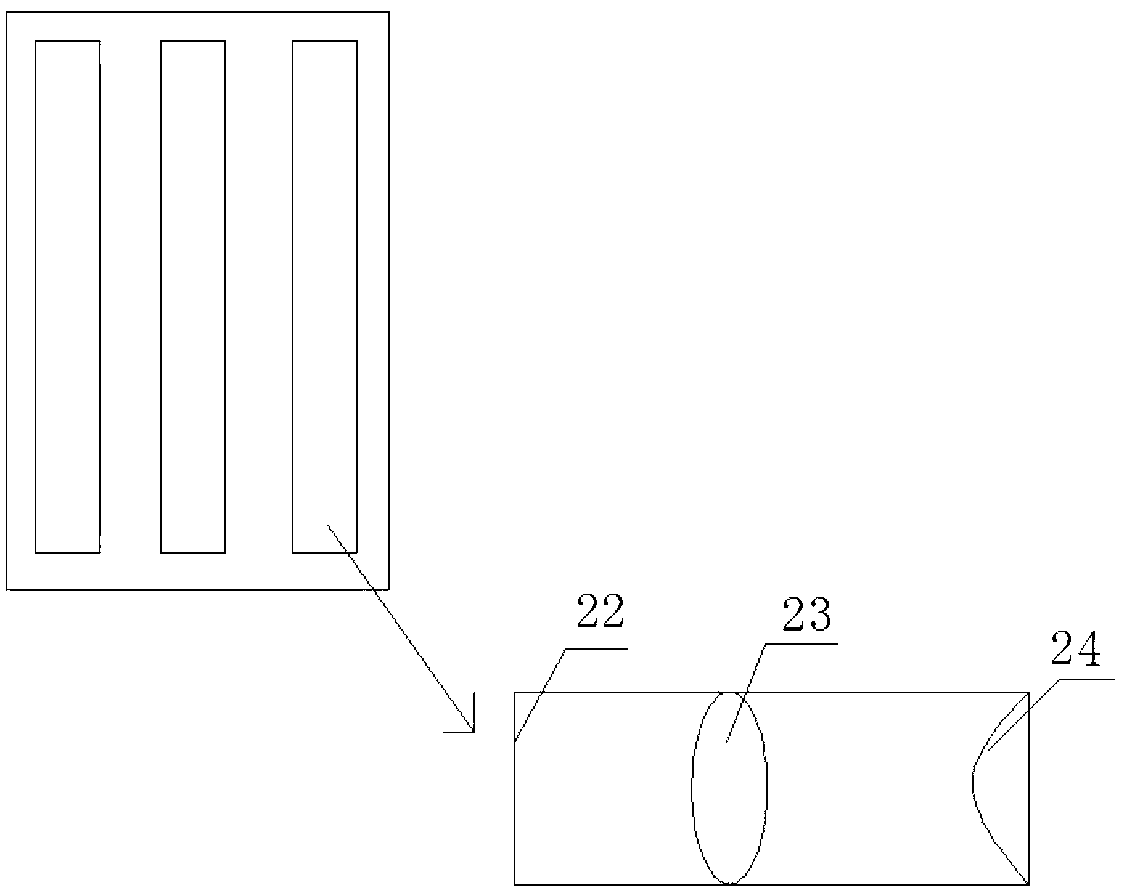

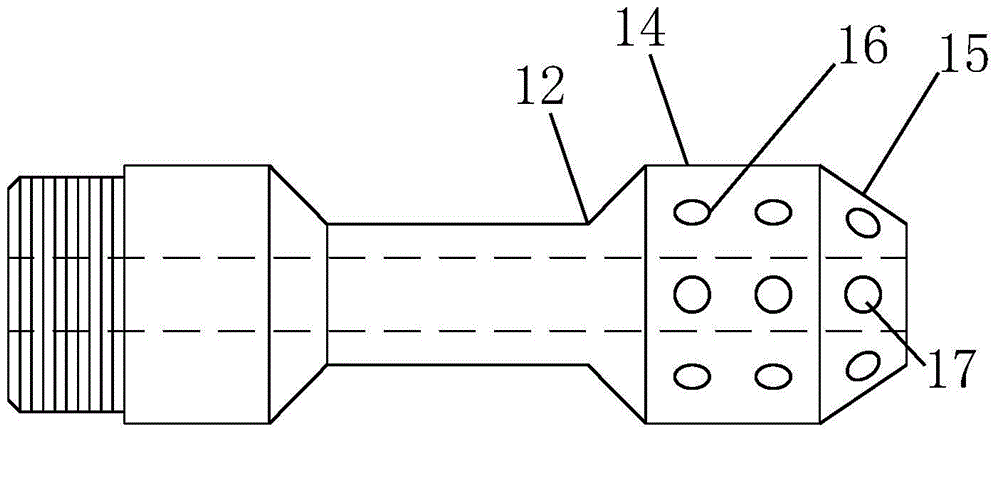

Portable crop growth information monitor based on active light source

ActiveCN103149162AWide working hoursReduce the effects of background distractionsColor/spectral properties measurementsNitrogen accumulationDry weight

Provided is a portable crop growth information monitor based on an active light source. The monitor is characterized by comprising a light source system, a spectrum signal acquisition system and a main unit system. The front end of the light source system is connected with the main unit system, the rear end of the light source system is connected with the spectrum signal acquisition system, the rear end of the spectrum signal acquisition system is connected with the main unit system, and the rear end of the main unit system is connected with the light source system. The monitor can simultaneously and comprehensively monitor and diagnose various physiology and zoology information including chlorophyll content of crops, a normalized difference vegetation index (NDVI), a leaf area index, leaf dry weight, nitrogen content, nitrogen accumulation amount, a net photosynthetic rate, a transpiration rate, leaf temperatures and the like, and has functions of data acquisition, analysis, display, storage, checking and display. By means of application of built-in electronic information techniques, the system structure is simplified, and the monitor has the advantages of being convenient to carry and low in power consumption and the like.

Owner:NANJING AGRICULTURAL UNIVERSITY

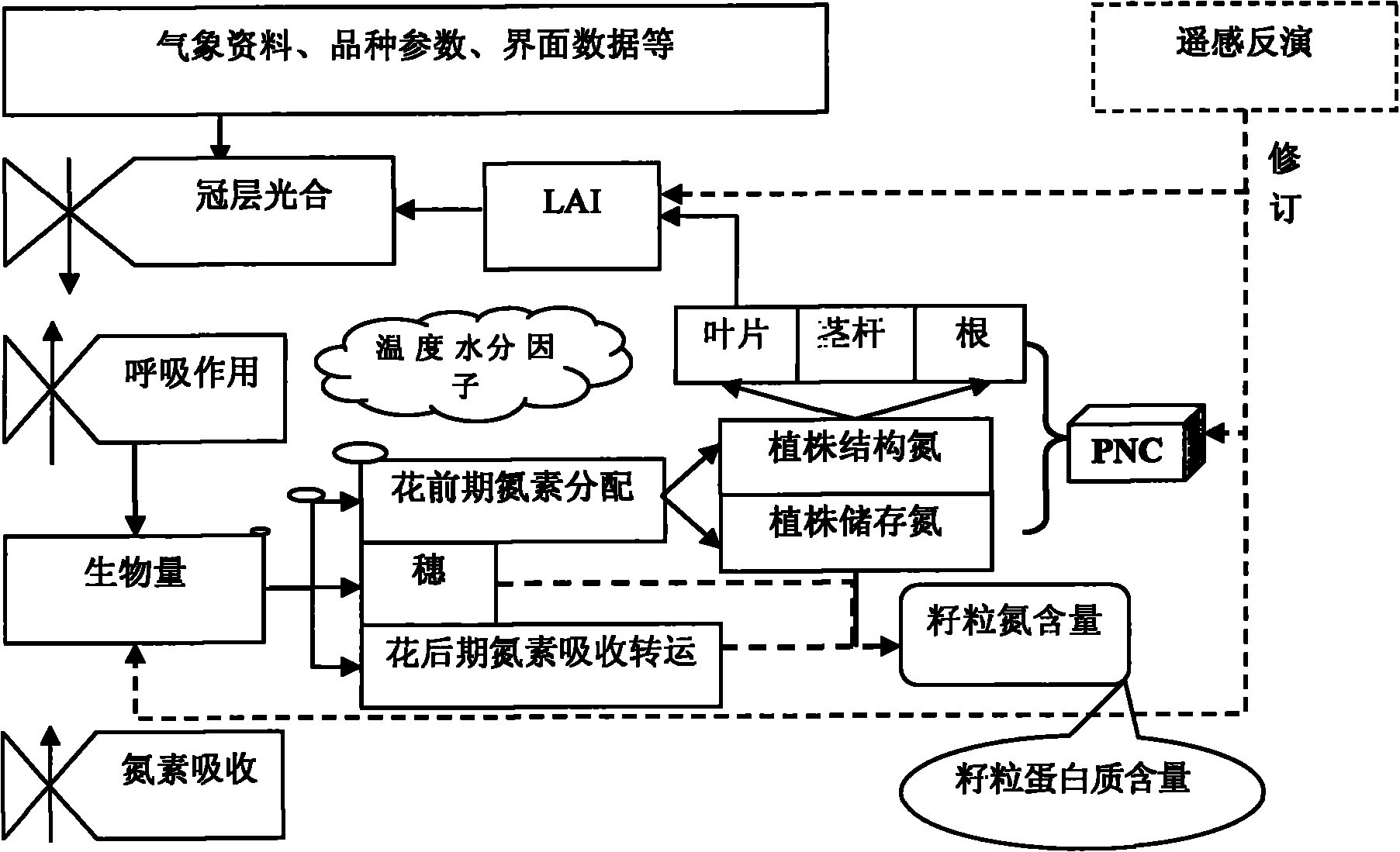

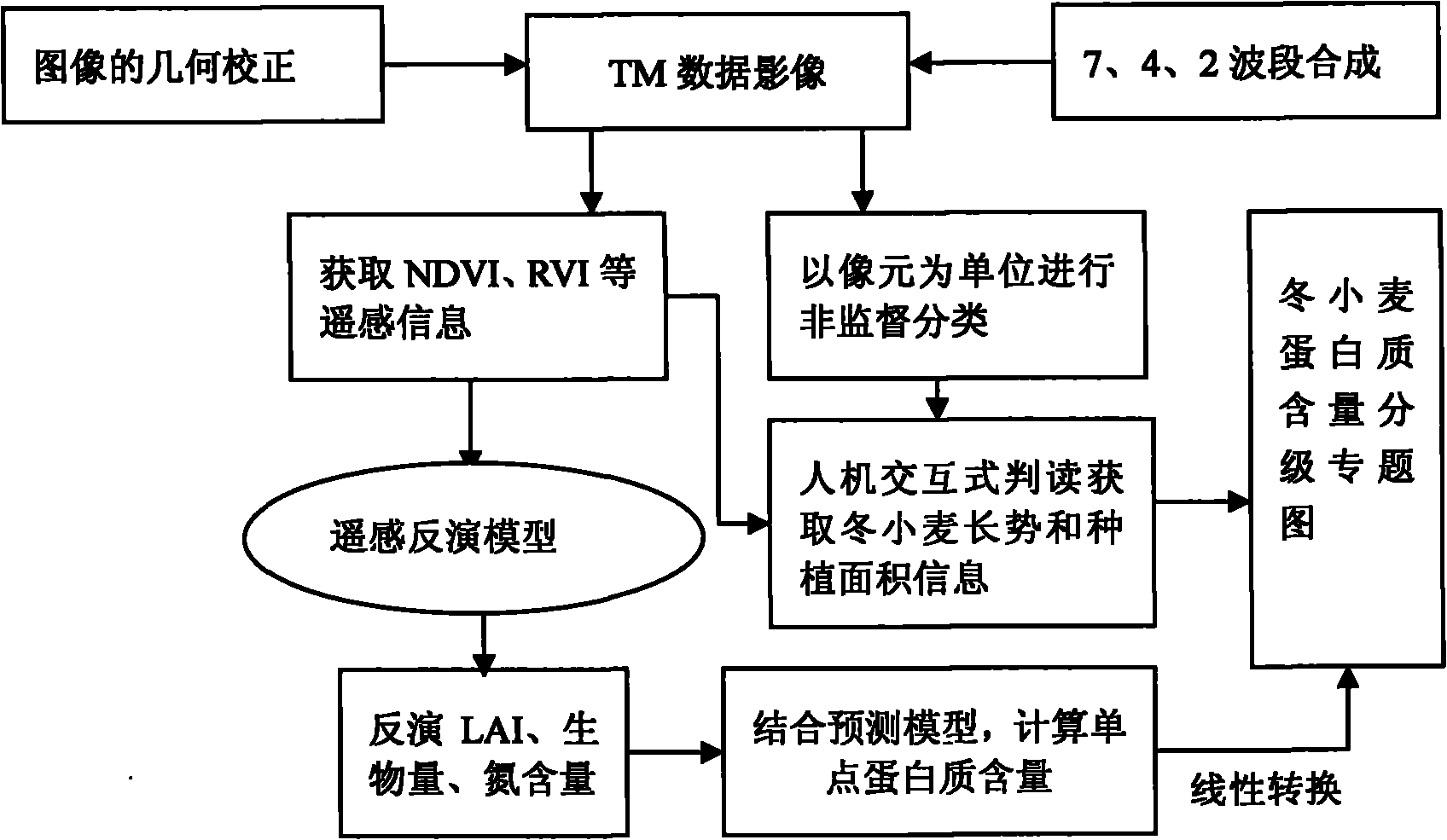

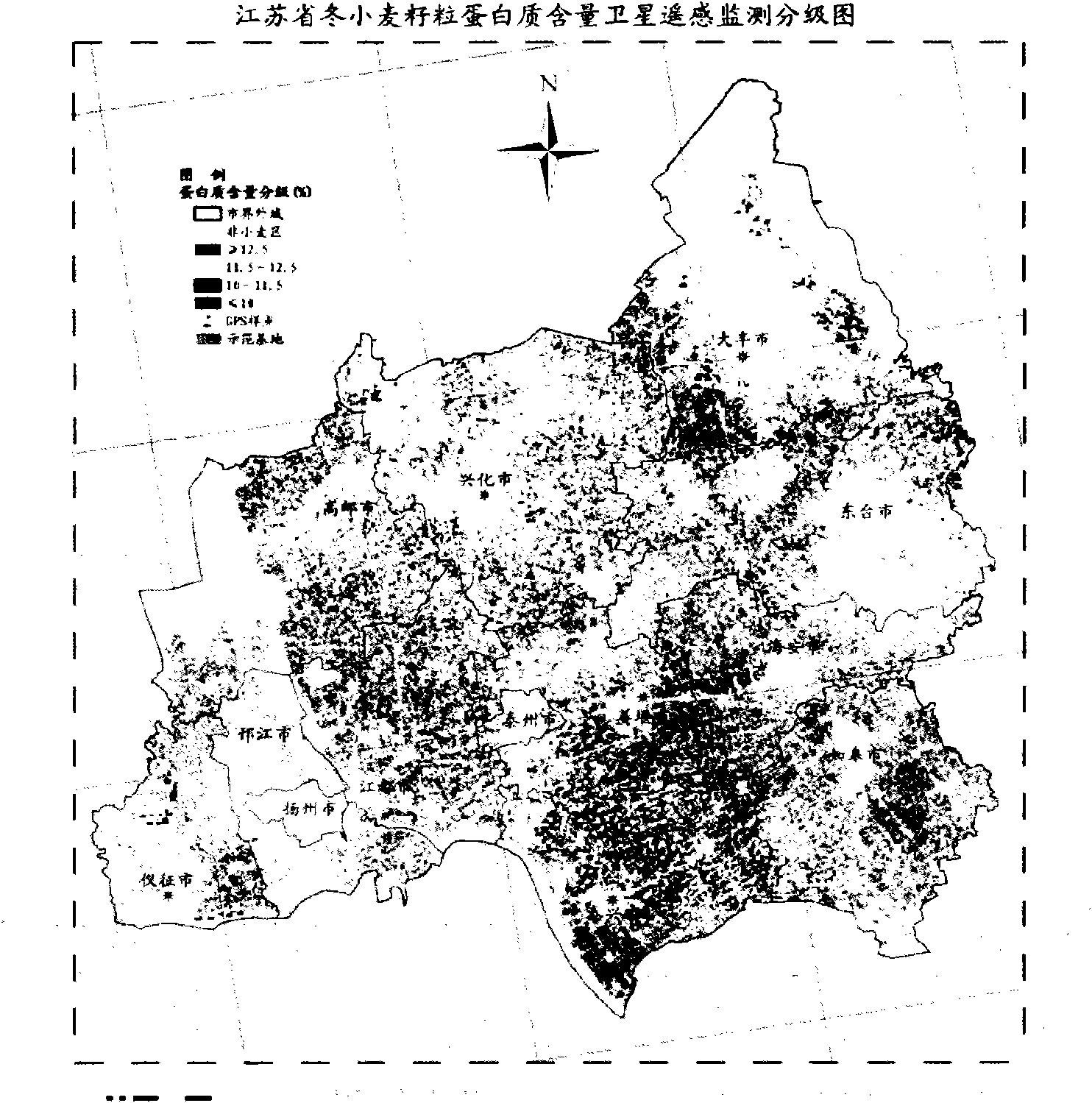

Method for remote sensing monitoring and predicting protein content of winter wheat grains

InactiveCN102156128AEasy to formulateEasy to masterMaterial analysis by optical meansSpecial data processing applicationsNitrogen accumulationSoil science

The invention provides a method, comprising the steps of: based on the instantaneity and wide regional coverage for obtaining remote sensing information, building a grain protein content prediction model based on nitrogen accumulation procedure via combining with the influencing characteristics of climatic environmental conditions in the flowering duration of wheat on the formation of grain quality; realizing the coupling of the remote sensing information and a grain protein content prediction model, namely using LAI (leaf area index), biomass and plant nitrogen content data inverted by flowering duration remote sensing images to displace the corresponding parameter variables of the wheat grain protein content prediction model, so as to realize the prediction for the protein content of single-point wheat grains, wherein the prediction precision is more than 85%; and drawing a graded monitoring and predicting thematic map for protein content of winter wheat grains by a scaling converting method of 'point' (the protein content of sample point grains) and 'face' (remote sensing images). The method has the characteristics of intuitionism and good timeliness, and has relatively good practicability for obtaining regional wheat quality information or guiding grain collection by department of agriculture.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

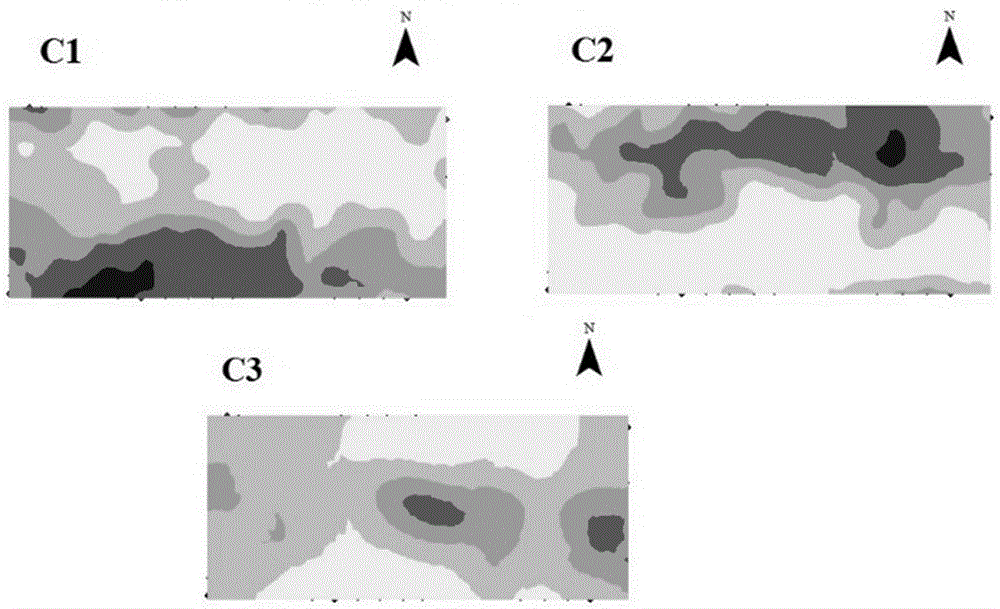

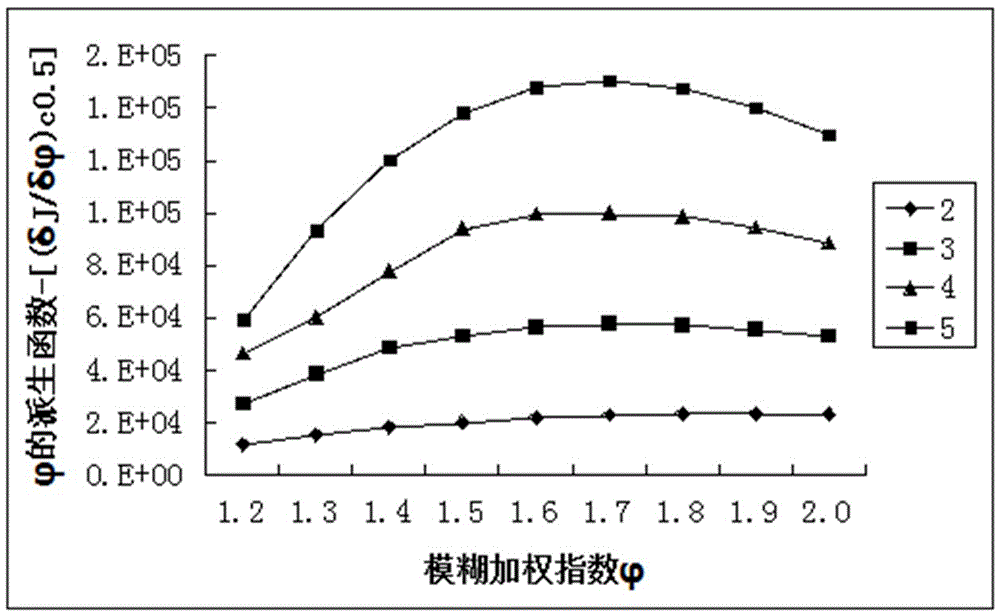

Drip irrigation cotton field nitrogen application management method based on GIS

The invention discloses a drip irrigation cotton field nitrogen application management method based on a GIS. The method comprises the steps that total nitrogen, organic matter and alkali-hydrolyzable nitrogen of soil are taken as data sources, partitioned management on drip irrigation cotton field nitrogen nutrients is achieved through a fuzzy c-mean clustering algorithm, on this basis, the application amount of nitrogen base fertilizer is determined by taking the alkali-hydrolyzable nitrogen of the soil as an index, canopy NDVI critical values of all the duration periods of cotton are determined on the basis of the nitrogen accumulation amount of leaves, and then the application amount of nitrogen topdressing is determined according to the NDVI critical values and actually measured values. The method has the advantages that the defects that due to the fact that the different nutrient contents are not taken into account in the traditional application process, application in the low nitrogen area is insufficient, and application in the high nitrogen area is excessive, and the crop growth and fertilizer waste are prevented from being influenced.

Owner:SHIHEZI UNIVERSITY

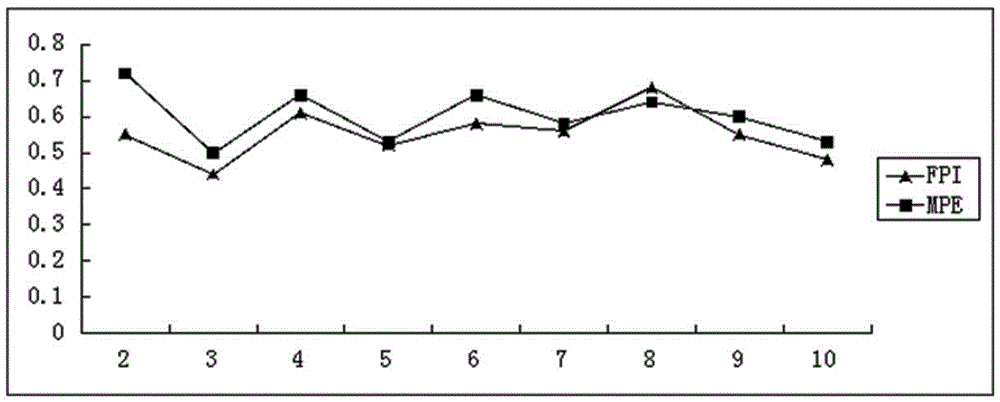

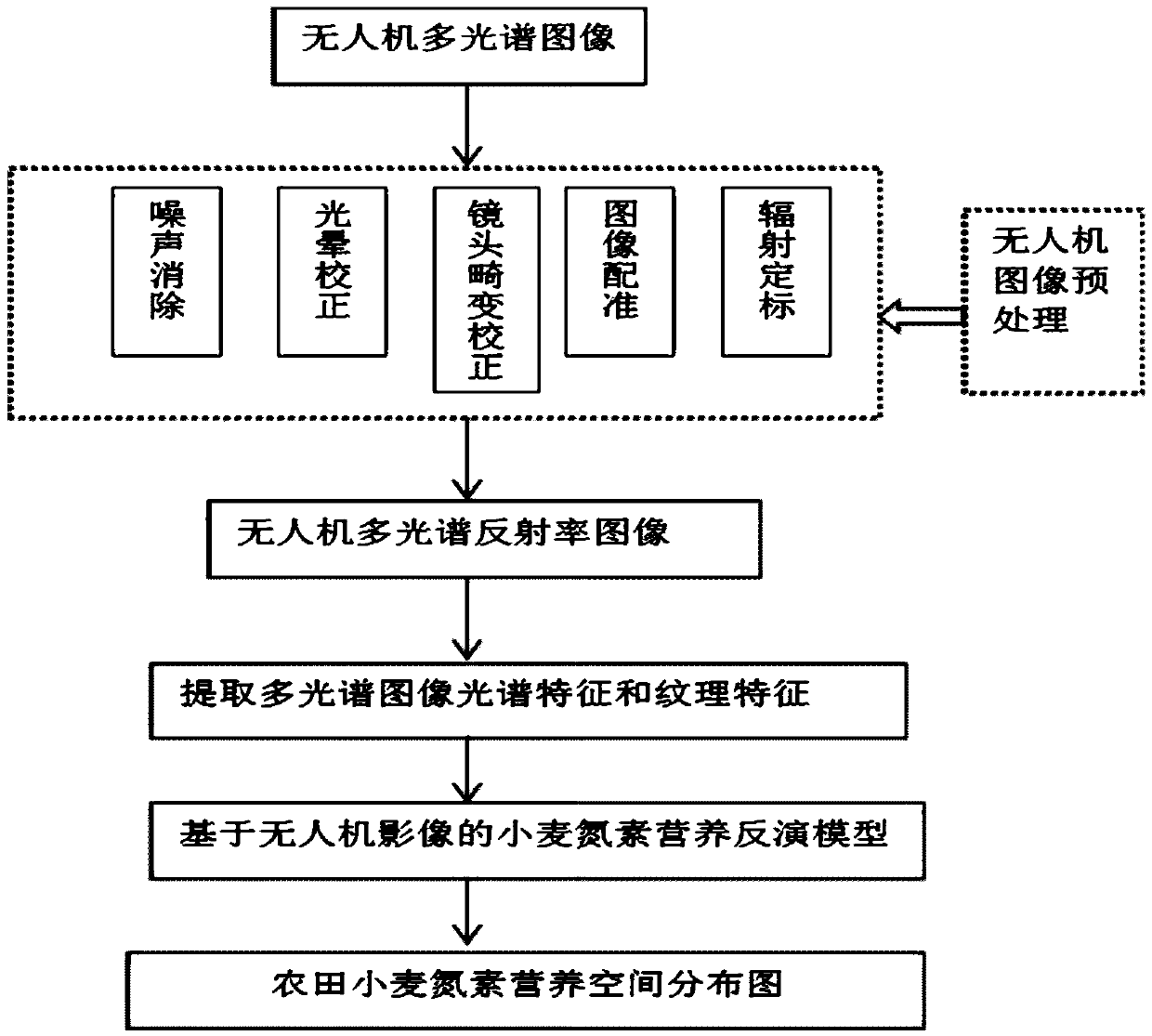

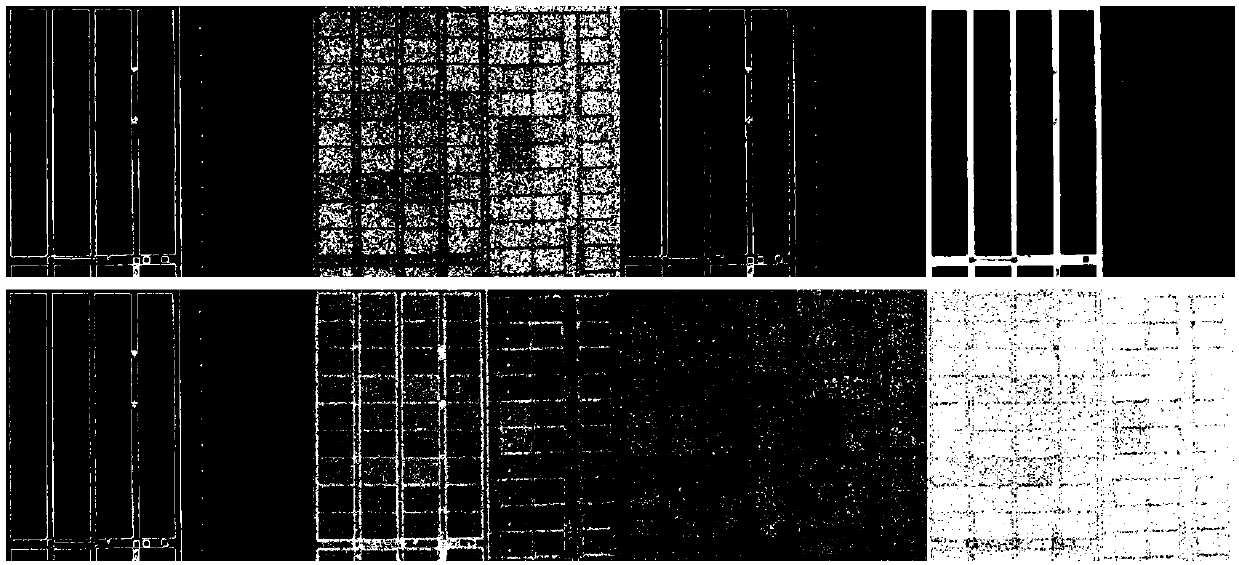

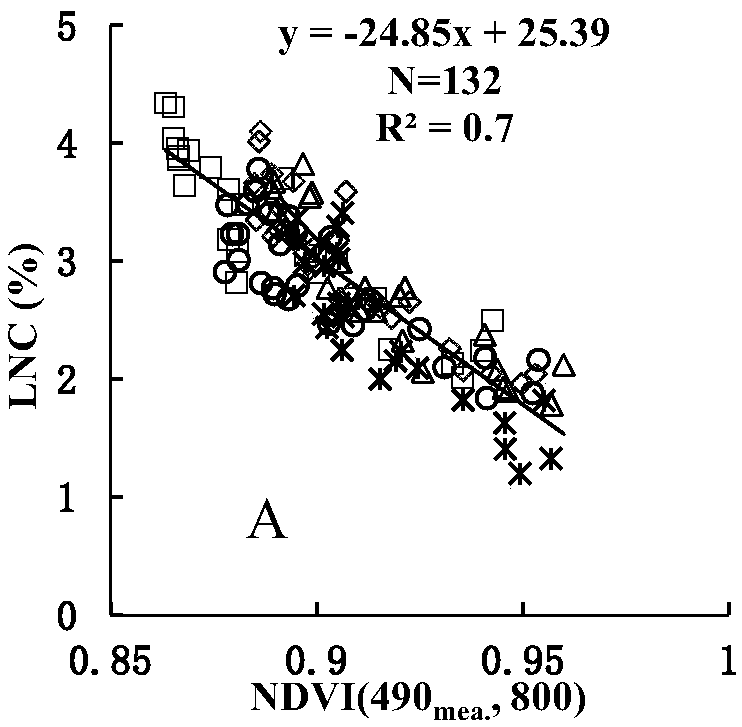

Monitoring method of wheat nitrogen nutrition based on spectral and texture features

InactiveCN109580512AOvercome being prone to \"fullness\"Disadvantages of overcoming effectColor/spectral properties measurementsNutritional statusNitrogen accumulation

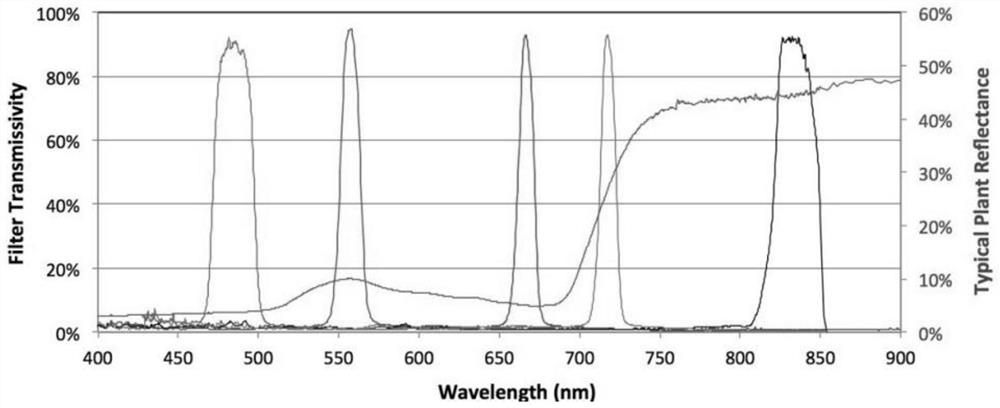

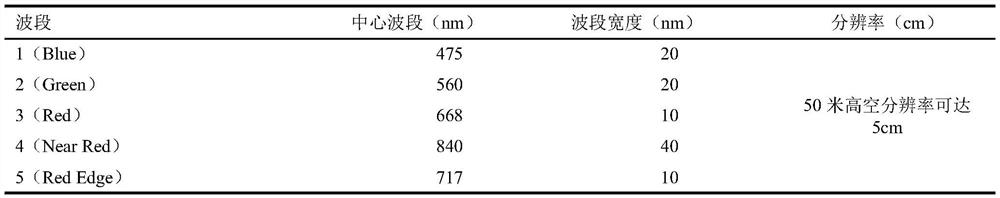

The invention provides a remote sensing monitoring method of wheat nitrogen nutrition based on spectral and texture features. The method comprises the following steps of: (1) constructing a spectral texture index for monitoring the nitrogen nutrition status of wheat by using the spectral and texture characteristics of a wheat reflectance image taken by a drone during different growth stages of thewheat; establishing a leaf nitrogen content monitoring model and a leaf nitrogen accumulation monitoring model, respectively, and then using the nitrogen nutrient data of the wheat collected from theground to test the leaf nitrogen content monitoring model and the leaf nitrogen accumulation monitoring model; obtaining the optimal leaf nitrogen content monitoring model and leaf nitrogen accumulation monitoring model of the wheat; (2) respectively inputting multi-spectral data collected by the drone into the optimal leaf nitrogen content monitoring model and leaf nitrogen accumulation monitoring model to obtain the leaf nitrogen content and leaf nitrogen accumulation of the wheat. The method of the invention comprehensively monitors the nitrogen nutrition status of the wheat canopy leaf byusing the spectral and texture features of the multi-spectral image taken by the drone, and overcomes the shortcomings of the traditional monitoring method being susceptible to the "saturation effects".

Owner:BEIJING AEROSPACE TITAN TECH CO LTD

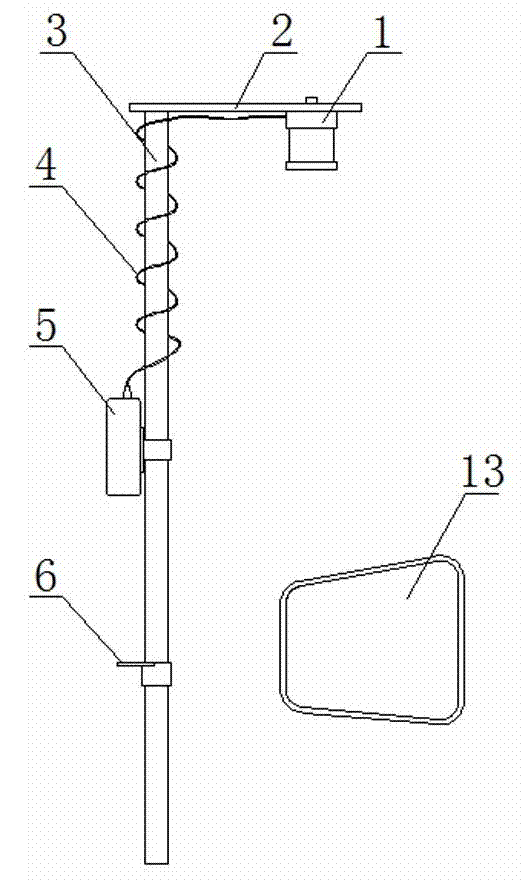

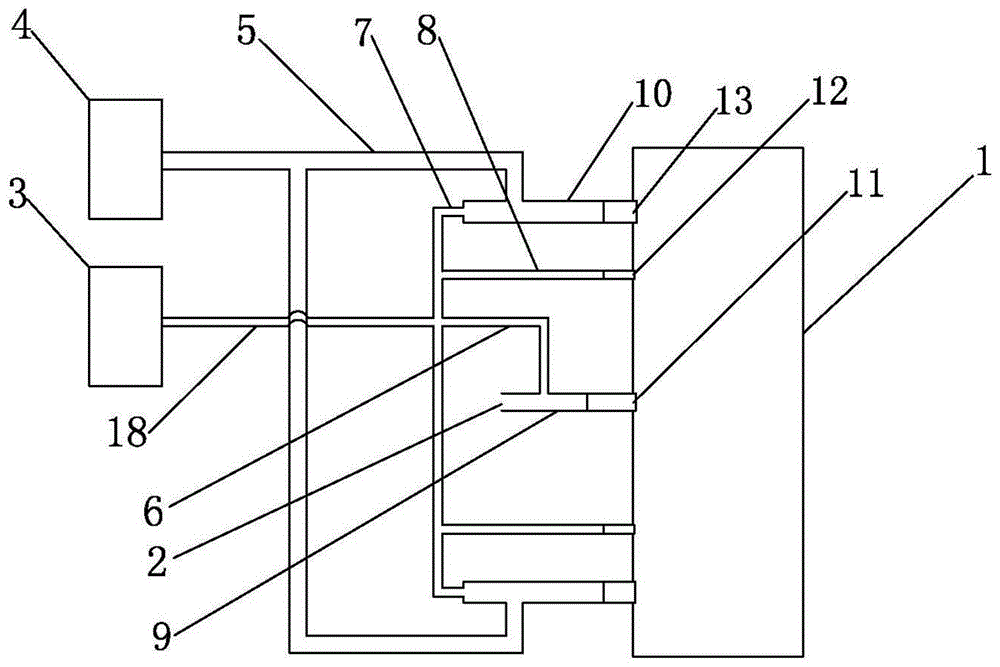

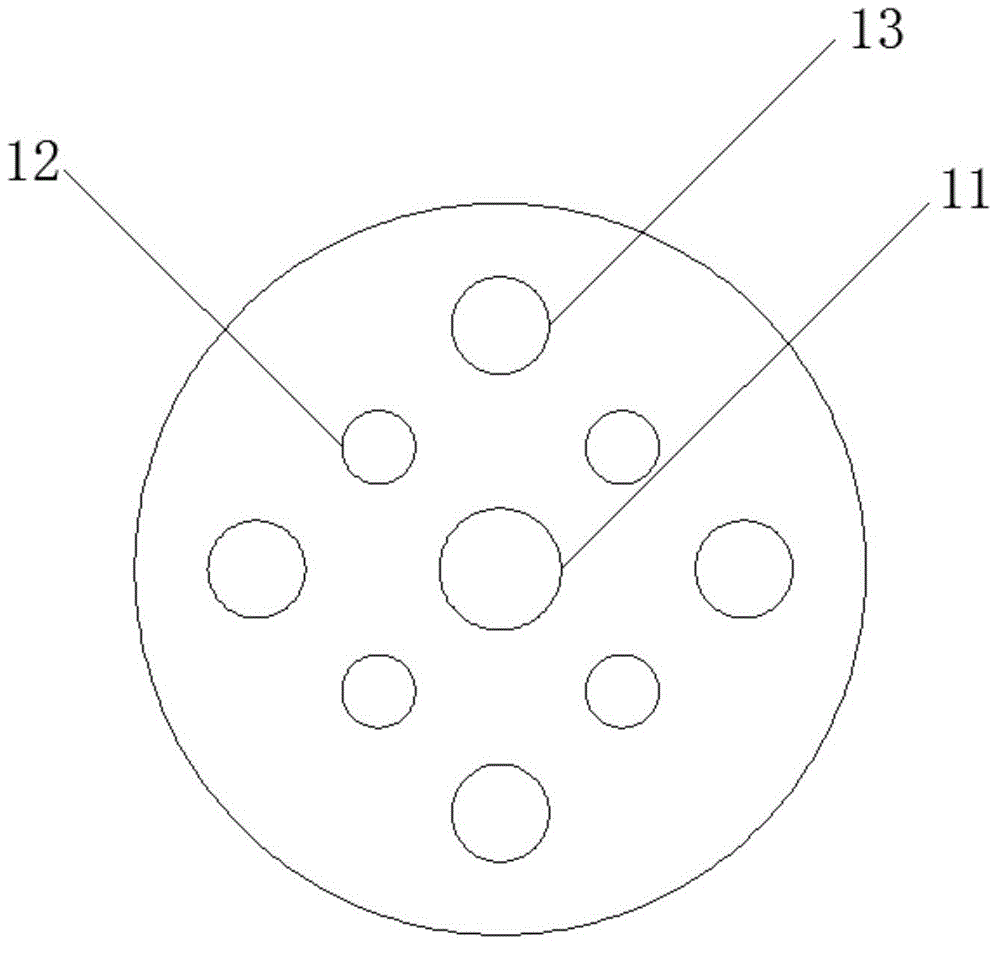

High-precision monitor for crop growth information and detection method thereof

ActiveCN102967562AMiniaturizationLow costColor/spectral properties measurementsWhiteboardNitrogen accumulation

The invention discloses a high-precision monitor for crop growth information, comprising a spectrum sensor (1), a standard reflectivity white board (13), a signal collector (5), a shielding conductor (4) and a bracket, wherein the bracket consists of a horizontal bracket (2) and a movable supporting rod (3); the spectrum sensor is fixed at one end of the horizontal bracket; the other end of the horizontal bracket is movably connected with the movable supporting rod; the signal collector is fastened on the movable supporting rod and located at a height liable to observe by human eyes; the output end of the spectrum sensor is connected with the signal collector in series through the shielding conductor; and the standard reflectivity white board is arranged below the spectrum sensor and is perpendicular to the spectrum sensor. The invention further discloses a detection method based on the high-precision monitor for crop growth information. By using the high-precision monitor for crop growth information and the detection method, multiple growth indexes of nitrogen content, nitrogen accumulation amount, leaf area index and leaf dry weight of crops can be obtained losslessly in real time, the structure is simple, and the stability and the measuring precision of the high-precision monitor are improved.

Owner:NANJING AGRICULTURAL UNIVERSITY

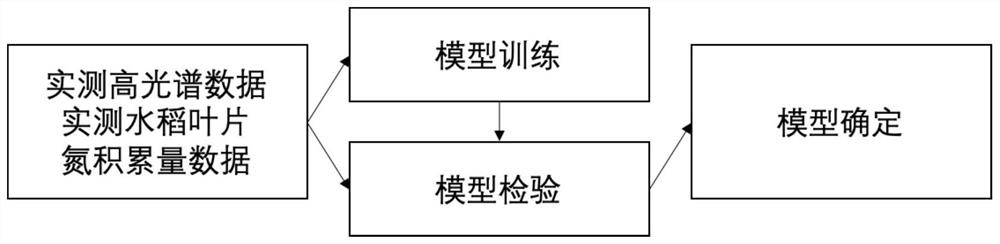

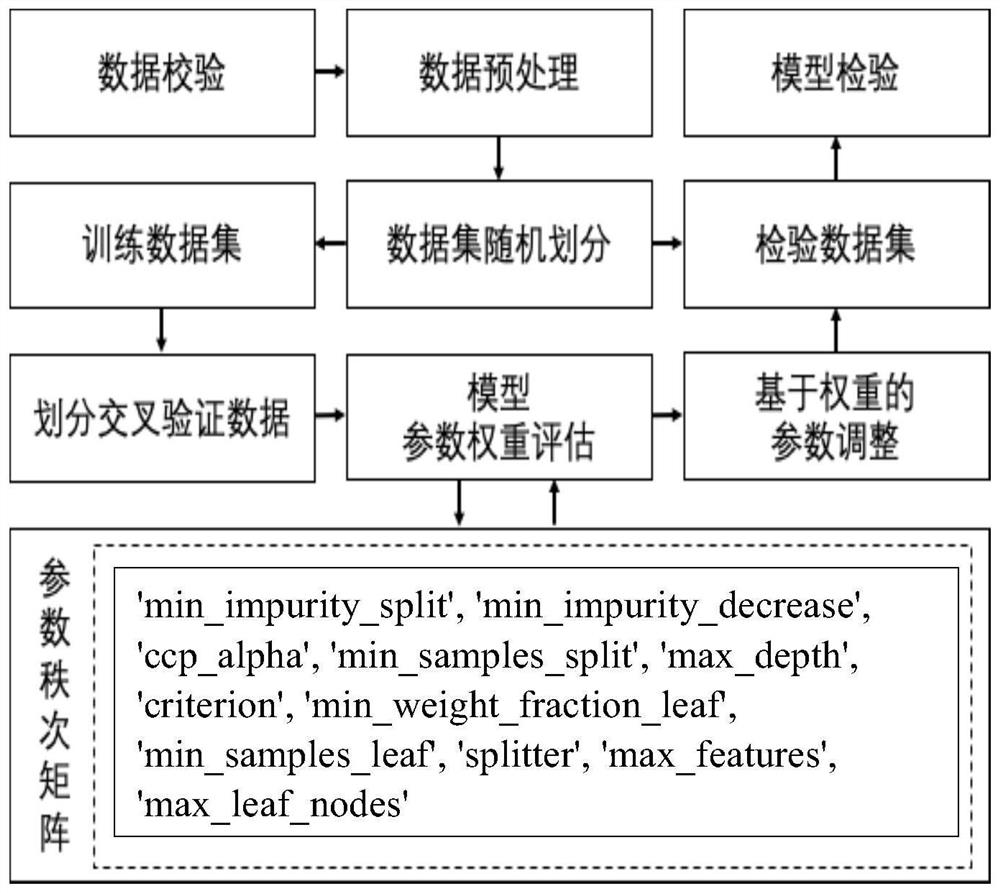

Rice leaf nitrogen accumulation remote sensing inversion model and method

PendingCN111855589AHigh precisionEasy accessScattering properties measurementsDesign optimisation/simulationSoil scienceNitrogen accumulation

The invention provides a rice leaf nitrogen accumulation remote sensing inversion model. The rice leaf nitrogen accumulation remote sensing inversion model is an extreme random tree model of Python language, and model parameters of the extreme random tree model are further provided. The invention further provides a rice leaf nitrogen accumulation remote sensing inversion method. According to the rice leaf nitrogen accumulation remote sensing inversion model, the nitrogen accumulation amount information of rice leaves can be rapidly and accurately obtained; the difficulty that the characteristic wave band of the rice leaf nitrogen accumulation amount is difficult to determine due to the spectral superposition effect caused by complex rice components is overcome, the precision of the rice leaf nitrogen accumulation amount inversion model is greatly improved, and the model is ingenious in design, simple and convenient in calculation, easy to implement and low in cost and suitable for large-scale popularization and application.

Owner:HUAIYIN TEACHERS COLLEGE

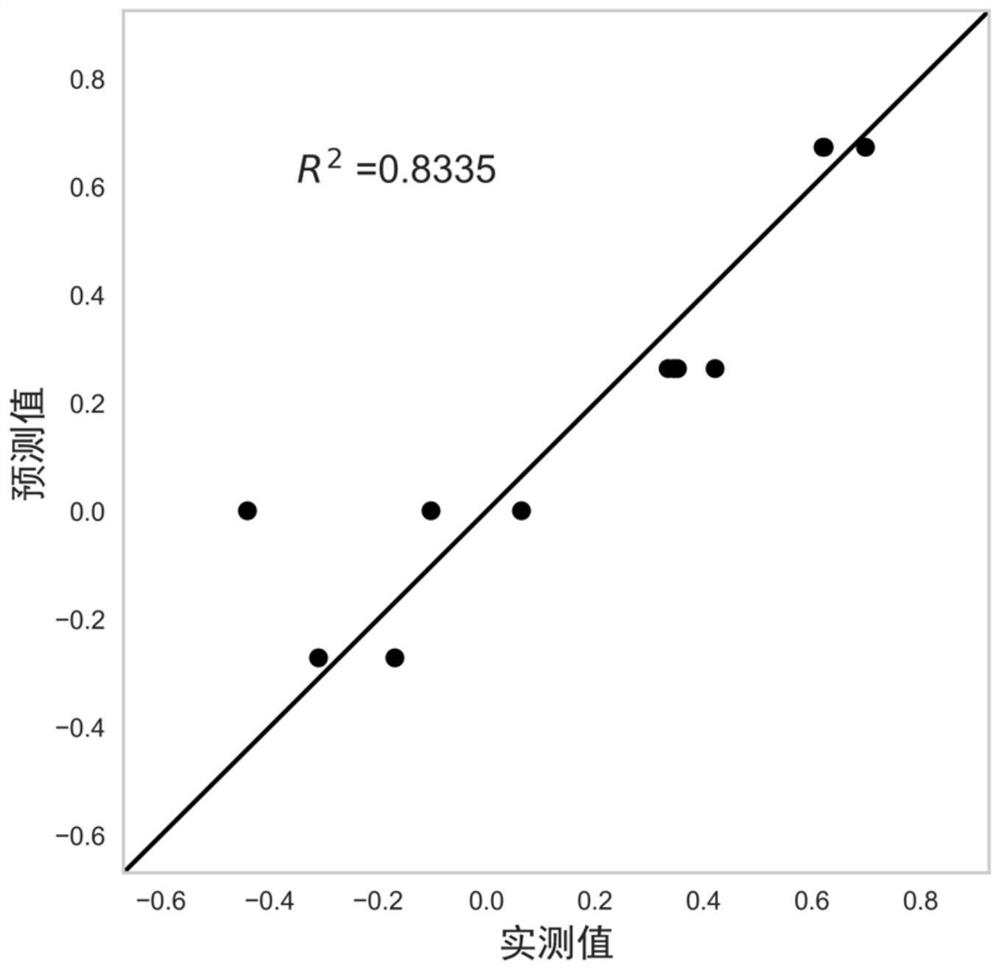

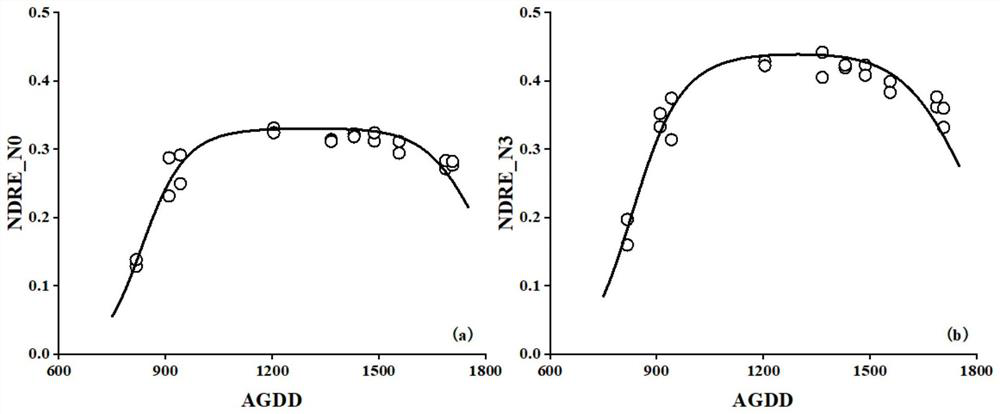

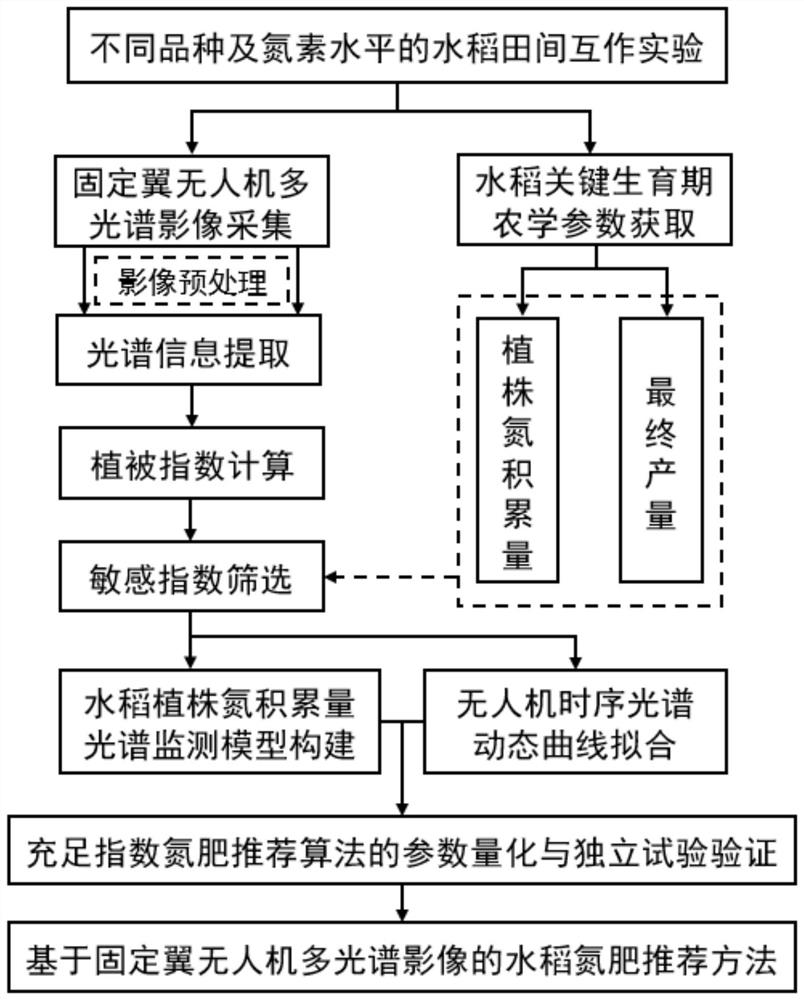

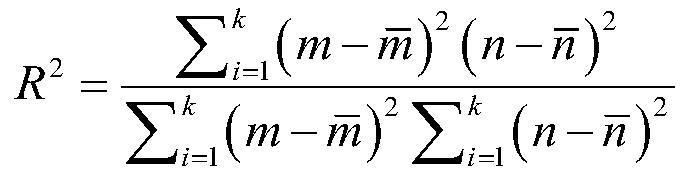

Rice nitrogen fertilizer recommendation method based on multispectral image of fixed-wing unmanned aerial vehicle

ActiveCN112903600AImprove monitoring accuracyIncrease speedColor/spectral properties measurementsAgriculture gas emission reductionNitrogen accumulationAgricultural engineering

The invention provides a rice nitrogen fertilizer recommendation method based on a multispectral image of a fixed-wing unmanned aerial vehicle based on spectral data of the image of the fixed-wing unmanned aerial vehicle, which is used for recommending the nitrogen fertilizer application amount in a key growth period of rice topdressing. Through a rice field test, a rice plant nitrogen accumulation amount monitoring model is constructed, and a time sequence spectrum dynamic curve of the unmanned aerial vehicle is fitted. And a sufficient index nitrogen fertilizer recommendation algorithm is constructed by using the model and the curve, and the algorithm is verified through an independent test. According to the method, the spectral data characteristics of an unmanned aerial vehicle platform are fully considered, the nitrogen nutrition status of the rice in the key growth period can be accurately and nondestructively monitored through sensitive vegetation index screening and optimal curve fitting methods, and finally the accurate nitrogen fertilizer recommendation amount is given through the sufficient index algorithm in combination with the monitoring result and the unmanned aerial vehicle spectral characteristics. According to the method, an optimization approach is provided for precise nitrogen management of the rice, and important theoretical basis and technical support are provided for precise agricultural management and decision-making of a regional scale.

Owner:NANJING AGRICULTURAL UNIVERSITY

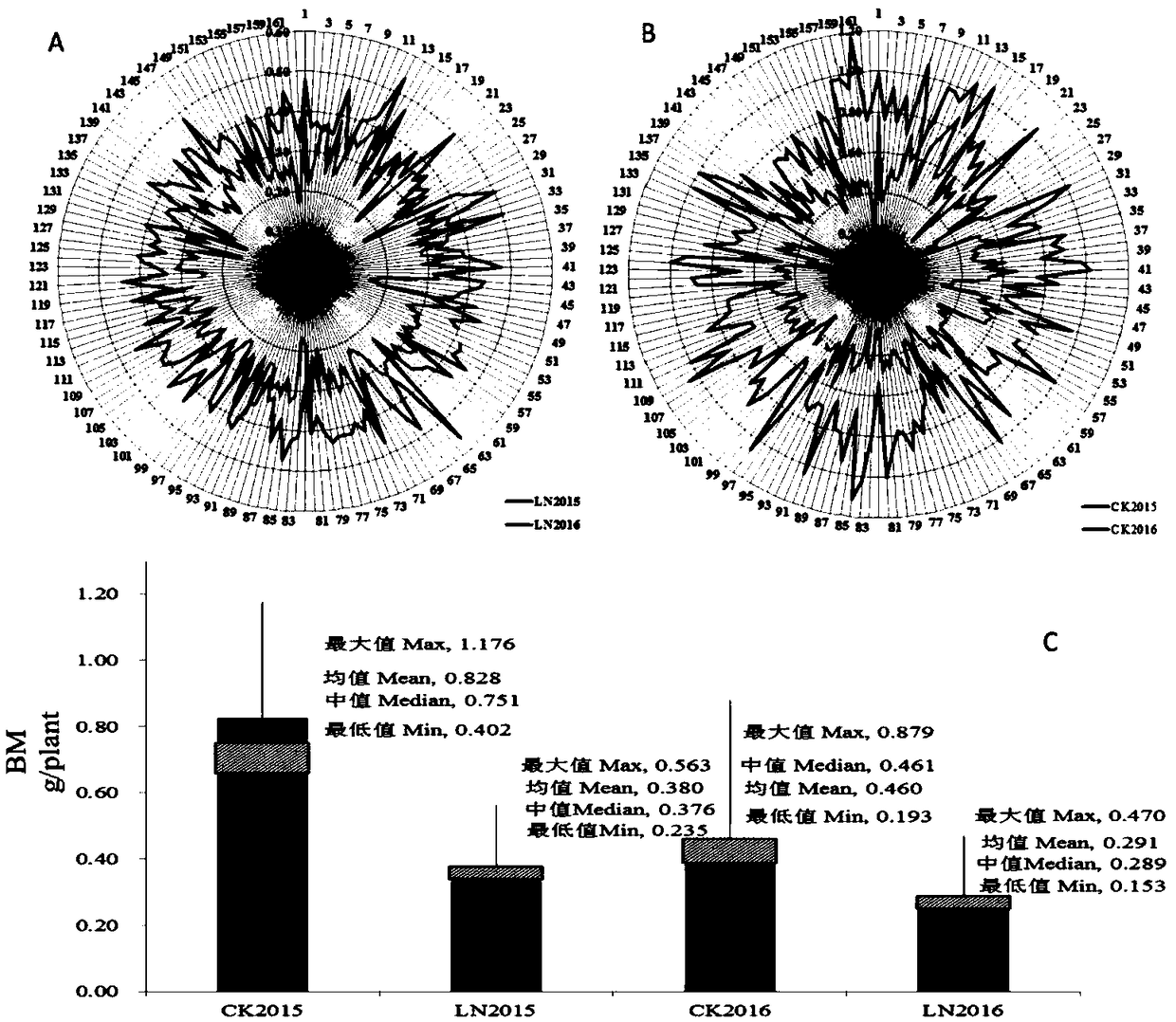

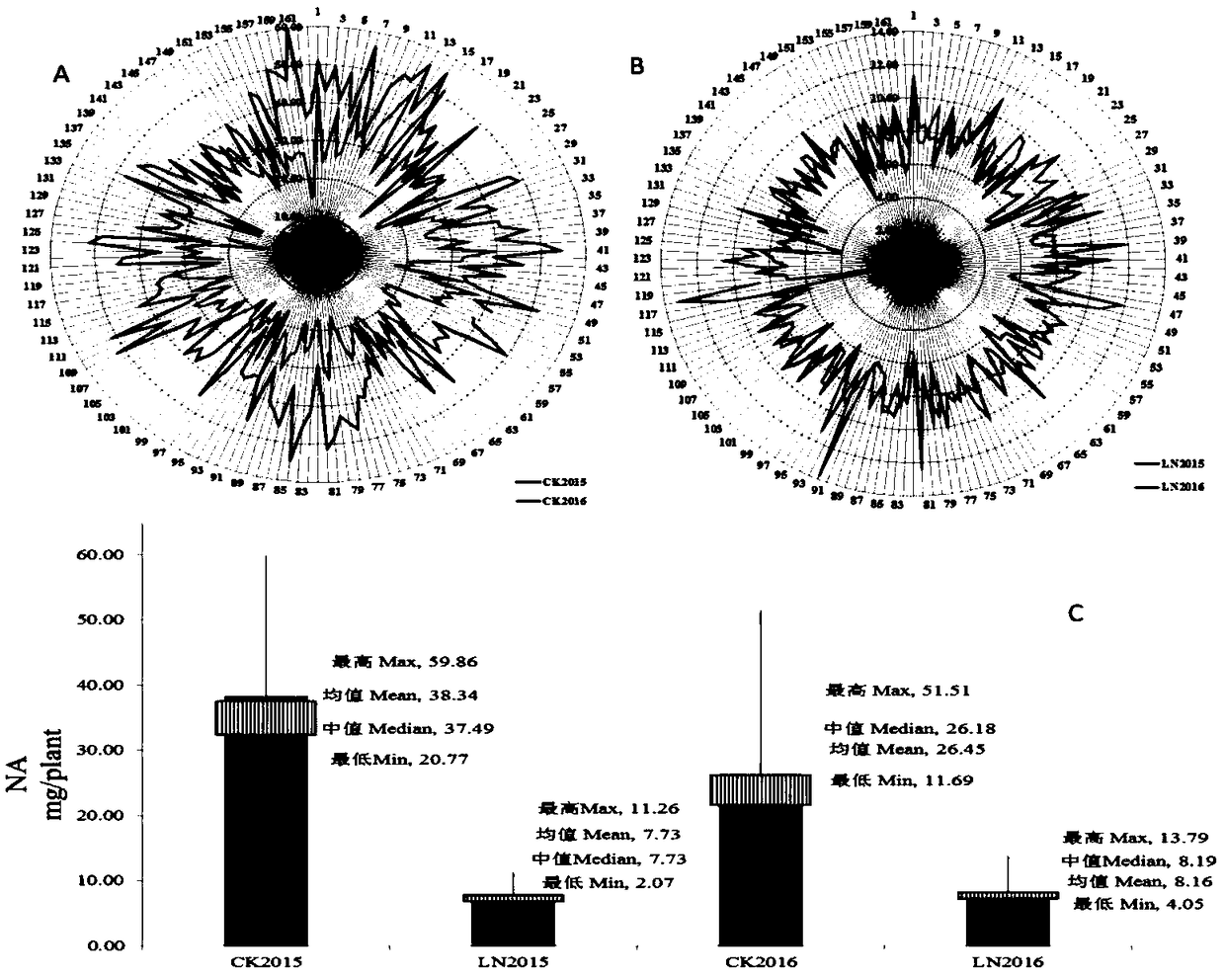

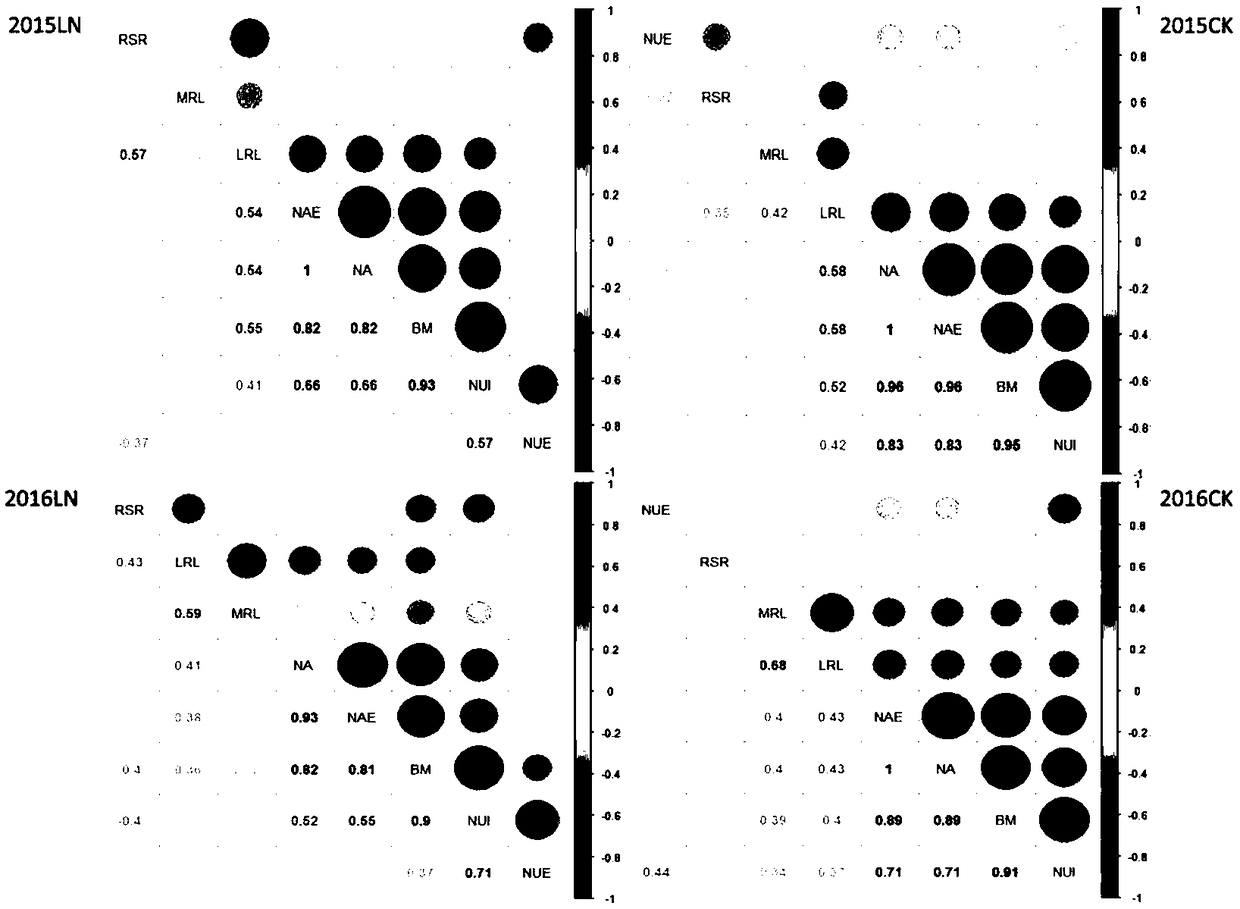

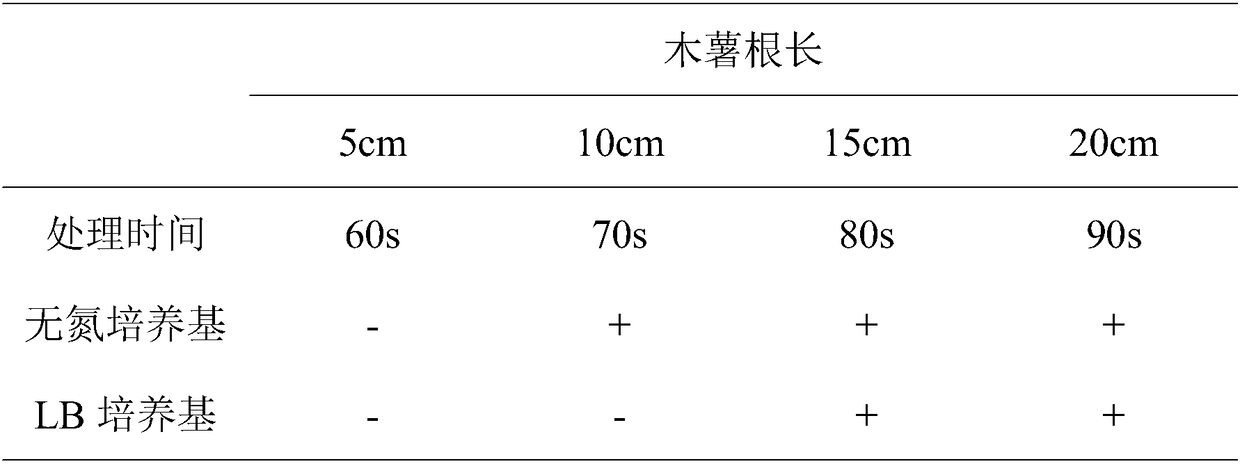

Method for screening high-nitrogen-use-efficiency rape variety by use of seedling-stage brassica napus culture experiment

ActiveCN109042314AExpedited screeningImprove screening efficiencyPlant cultivationCultivating equipmentsBrassicaNitrogen accumulation

The invention relates to a method for screening a high-nitrogen-use-efficiency brassica napus variety by use of a seedling-stage brassica napus culture experiment. The method for screening a high-nitrogen-use-efficiency rape variety by use of the seedling-stage brassica napus culture experiment is characterized by comprising the following steps: (1) seed selection; (2) seedling culture; (3) transplantation; (4) collection of calculation indexes: biomass, nitrogen accumulation and a lateral root length; (5) comprehensive judgment on a nitrogen efficiency genotype of a rape to be evaluated by use of the calculation indexes, wherein, after the rape is transplanted and cultured for 21 days and if the total biomass is larger than 0.331 g / plant and the nitrogen accumulation is larger than 7.88 mg / plant, the rape is a high-nitrogen-use-efficiency rape; if the biomass is between 0.290 and 0.331 g / plant and the nitrogen accumulation is between 6.70 and 7.88 mg / plant, the rape is a medium-nitrogen-use-efficiency rape; if the total biomass is smaller than 0.290 g / plant and the nitrogen accumulation is smaller than 6.70 mg / plant, the rape is a low-nitrogen-use-efficiency rape. According to themethod, a high-quality rape germplasm resource screening process is effectively improved, the labor cost is reduced, the screening efficiency of a high-nitrogen-use-efficiency variety is improved, and a rape variety of a high-nitrogen-use-efficiency genotype is screened.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

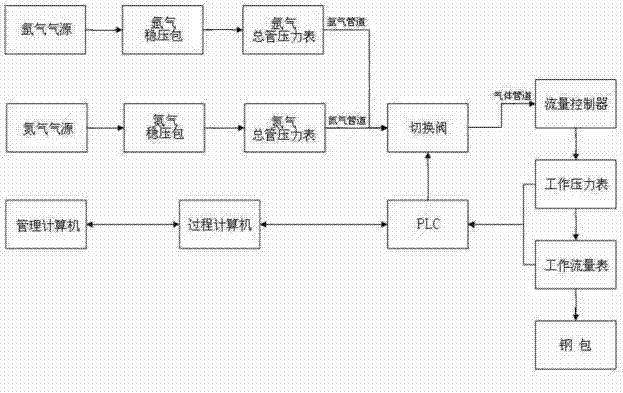

Automatic steel ladle nitrogen adding device and automatic steel ladle nitrogen adding method

InactiveCN103205531AImprove pass rateEliminate the influence of human factorsThick plateNitrogen accumulation

The invention provides an automatic steel ladle nitrogen adding device and an automatic steel ladle nitrogen adding method. On the basis of an original bottom-blowing argon system, a nitrogen source, a nitrogen stabilizing bag, a main nitrogen pressure gauge, a switching valve, a managing computer, a procedure computer, a PLC (programmable logic controller) and relative pipelines are added. When nitrogenous steel is produced, the PLC controls the switching valve according to a target nitrogen value provided by the procedure computer, when nitrogen accumulation does not reach the target nitrogen value, the switching valve is turned to a nitrogen open circuit state, when the nitrogen accumulation reaches to the target nitrogen value, the switching valve is turned to an argon open circuit state, and automatic switching between the argon and the nitrogen is realized. The defect of manual nitrogen adding is eliminated, the nitrogen content of thick nitrogenous steel plate blanks is precisely controlled within 0.008-0.015%, and the nitrogen content of thick plate products can be controlled according to the precision 0.01%, steel modifying loss is reduced, and steel grade yield and enterprise economic benefit are increased.

Owner:ANGANG STEEL CO LTD

Biomass charcoal-coated slow release fertilizer preparation technology

InactiveCN105693433AThe cumulative release process is gentleApplicable Nutritional RequirementsClimate change adaptationAgriculture gas emission reductionNitrogen accumulationAqueous solution

The invention discloses a biomass charcoal-coated slow release fertilizer preparation technology. The preparation technology comprises adding a binder into urea and bonding biomass charcoal to the urea. The coated slow release fertilizer utilizing biomass charcoal as a coating material and a polyvinyl alcohol aqueous solution with content of 5.0% as a binder has expected slow release effects, has a nutrient release speed decreased along with coating thickness increasing, has a smooth integral nitrogen accumulation release process, has a nutrient release amount of about 80% in culture for about 30 days and is suitable for nutrition demands of a crop with a short growth period.

Owner:JIANGYIN LIANYE BIOTECHOLOGY

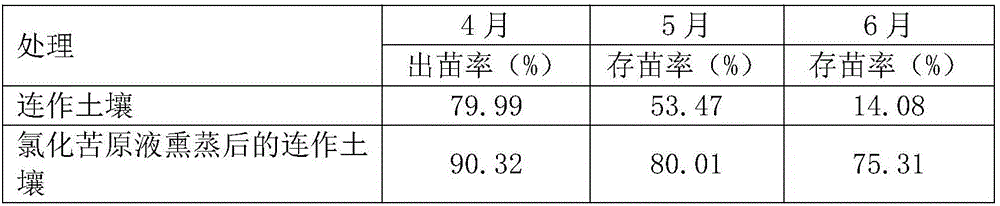

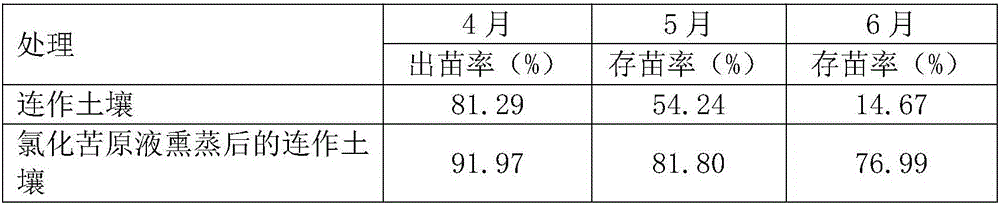

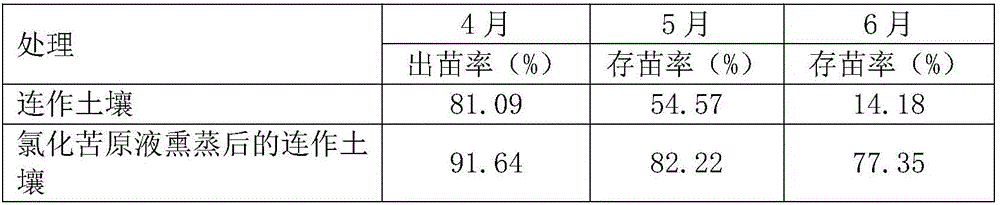

Chemical disinfection method for panax notoginseng continuous cropping soil

InactiveCN106342599APromote decompositionIncreased Nitrogen Cumulative MineralizationSteam soil sterilisationChemicalsContinuous croppingPANAX NOTOGINSENG ROOT

The invention discloses a chemical disinfection method for panax notoginseng continuous cropping soil. The method comprises the following steps of 1 treating before fumigating, 2 fumigating treating and 3 treating after fumigating. The method has the advantages that the soil is fumigated with nitrochloroform, pathogenic microorganism fungi, nematodes and underground pests in the panax notoginseng continuous cropping soil and weeds can be effectively killed, and the nitrogen accumulation mineralization amount in the soil can be significantly increased in a short time; in addition, nitrochloroform is easy to decompose in the soil, a water body and the atmosphere, and no residue exists in roots, stems, leaves and fruits of crops; the seedling emergence rate and the seedling survival rate of panax notoginseng seeds in the continuous cropping soil can be effectively increased, and meanwhile the growth vigor of panax notoginseng plants can be effectively enhanced.

Owner:文山苗乡三七科技有限公司

Free-living nitrogen fixing bacterium MBC8 and application thereof

The invention discloses a free-living nitrogen fixing bacterium MBC8 (Rhizobium galegae), which was preserved with preservation number CGMCC No.10824 on May, 19, 2015 by China General Microbiological Culture Collection Center. The strain still can exist, reproduce and have nitrogen fixing activity under drought, great temperature difference, saline-alkaline disasters and strong ultraviolet radiation. A bacterial agent prepared by using the strain can be applied to ecological systems under drought, great temperature difference, saline-alkaline disasters and strong ultraviolet radiation, can increase nitrogen accumulation of the ecological systems, can play a role of improving soil environments, can improve physiological activity of microbes and plants and can increase net primary productivity.

Owner:BEIJING FORESTRY UNIVERSITY

Pseudomonas cannabina MBC1 and application thereof

The invention discloses pseudomonas cannabina MBC1. The preservation number of the pseudomonas cannabina MBC1 is CGMCC No.10817, the preservation date is May 19, 2015, and the preservation organization is the China General Microbiological Culture Collection Center. The strain can still survive and breed and has nitrogen fixation activity under the conditions of drought, large temperature difference, salt and alkali disasters and strong ultraviolet radiation. An inoculant prepared with the pseudomonas cannabina MBC1 can be applied to ecological systems characterized in drought, large temperature difference, salt and alkali disasters and strong ultraviolet radiation to increase nitrogen accumulation of the ecological systems, improve the soil environment, improve the biological activity of microorganisms and plants, and improve net primary productivity.

Owner:BEIJING FORESTRY UNIVERSITY

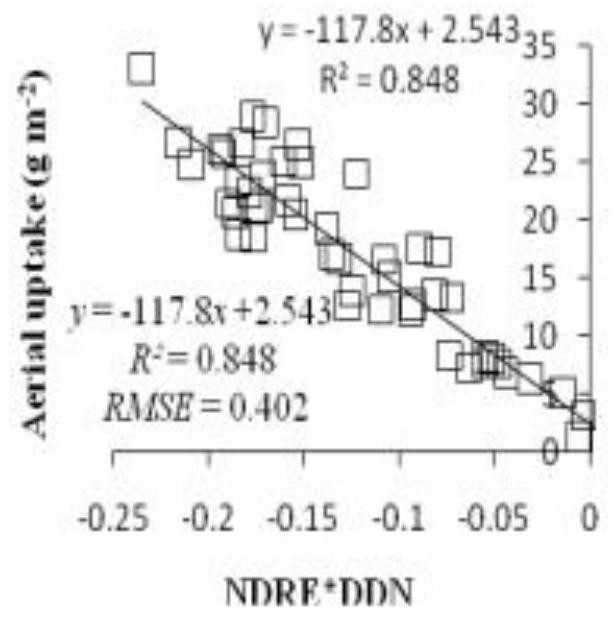

Wheat plant nitrogen accumulation amount monitoring method based on hyperspectral remote sensing technology

PendingCN113035290ASuitable reproductive periodMolecular entity identificationScene recognitionVegetationNitrogen accumulation

The invention discloses a wheat plant nitrogen accumulation amount monitoring method based on a hyperspectral remote sensing technology. The method specifically comprises the following steps: (1) collecting spectral data; (2) determining the nitrogen accumulation amount of the wheat plants; (3) constructing a new vegetation index; (4) screening out the combined vegetation index NDchl*DDN, MRER*DDI, NDRE*DDN, NDRE*DDI and NDRE*DVI with the correlation R2>0.845 to the nitrogen accumulation of wheat plants, and establishing the monitoring model of wheat plant nitrogen accumulation through regression analysis. According to the method, the effect of estimating the plant nitrogen accumulation amount by comparing and analyzing the newly constructed vegetation index and the conventional vegetation index is expected to determine a quantitative monitoring model of the wheat plant nitrogen accumulation amount, so that a technical support is provided for lossless monitoring of the wheat nitrogen nutrition state by a remote sensing technology.

Owner:INST OF PLANT NUTITUION & RESOURCE ENVIRONMENT HENAN ACADEMY OF AGRI SCI

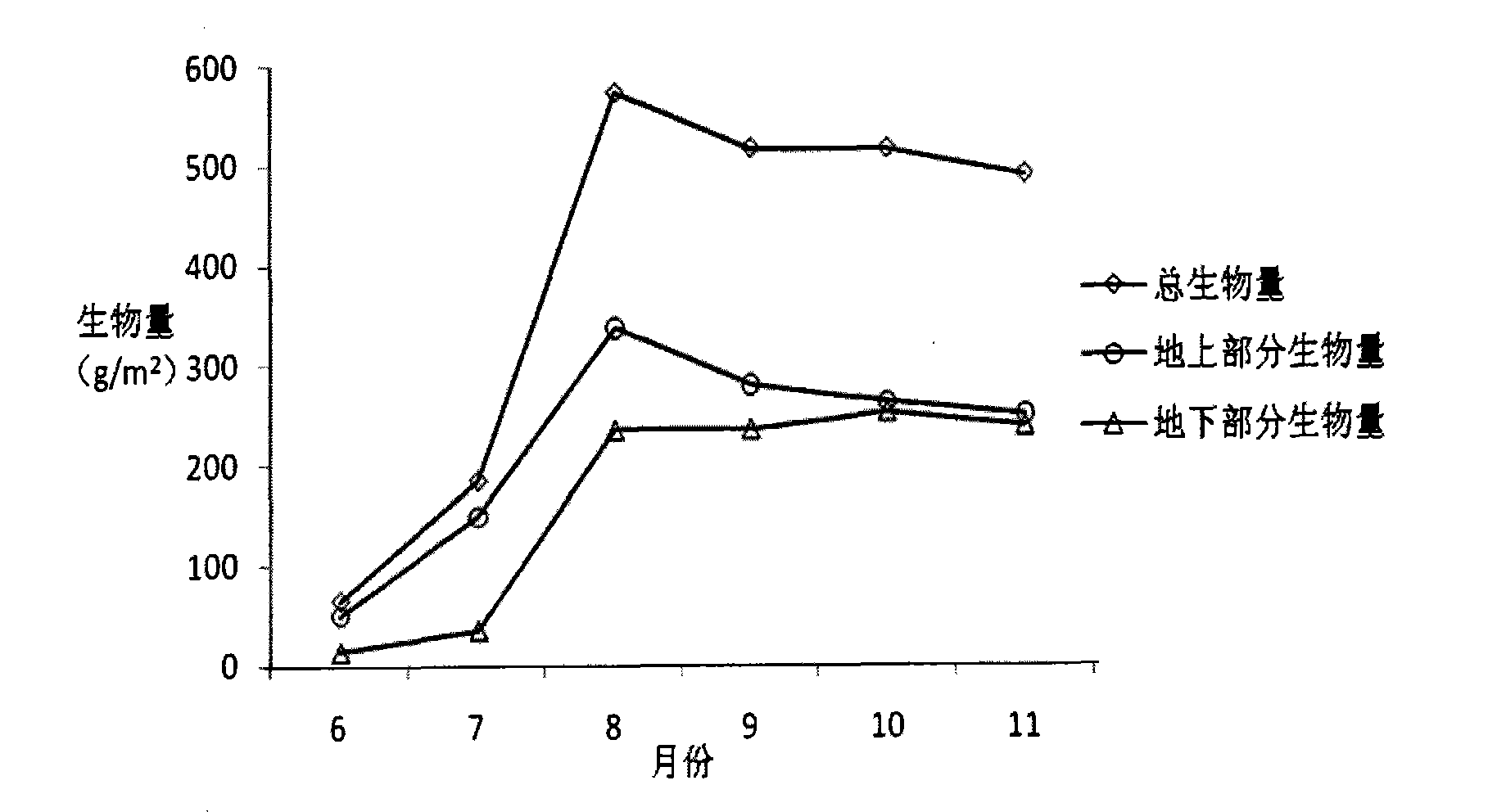

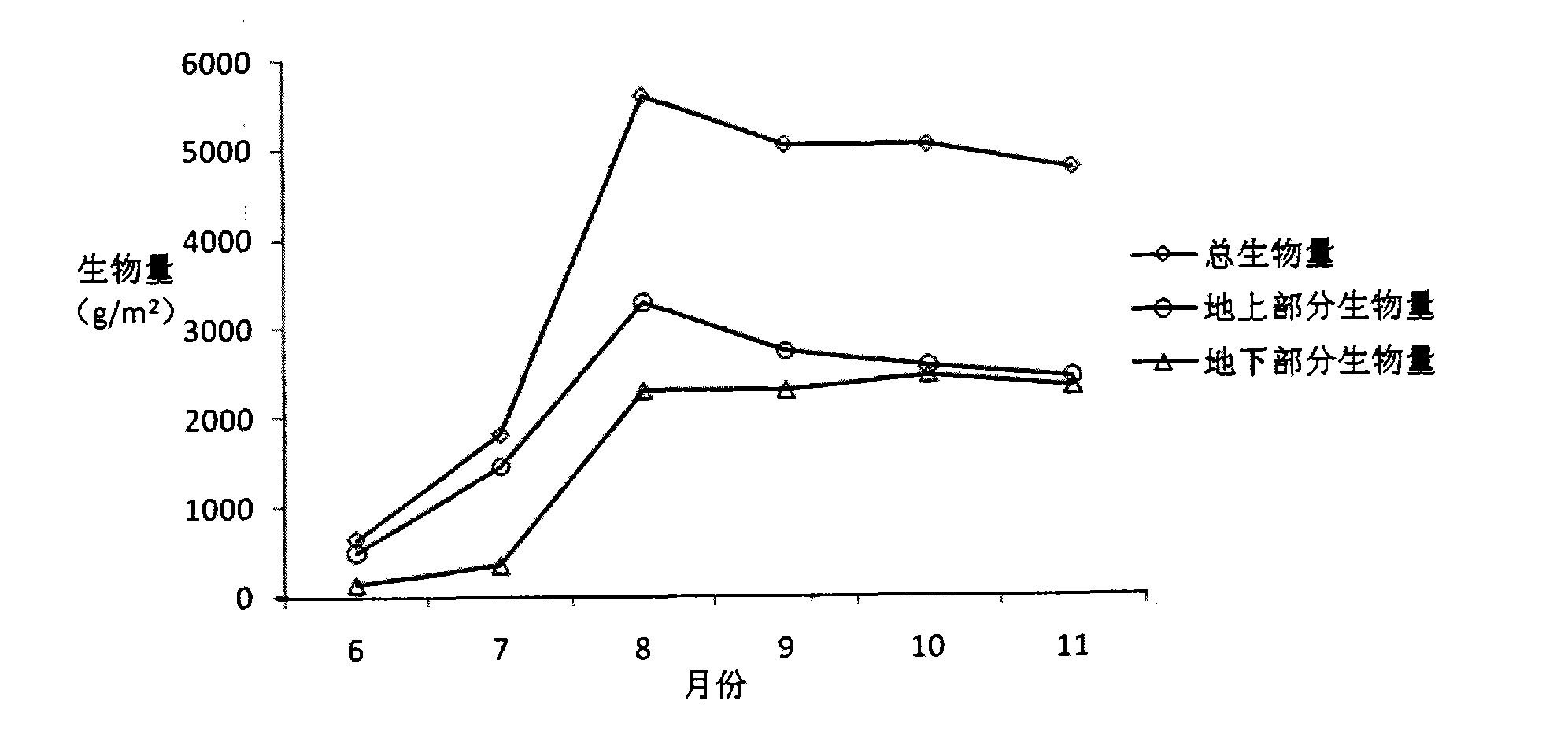

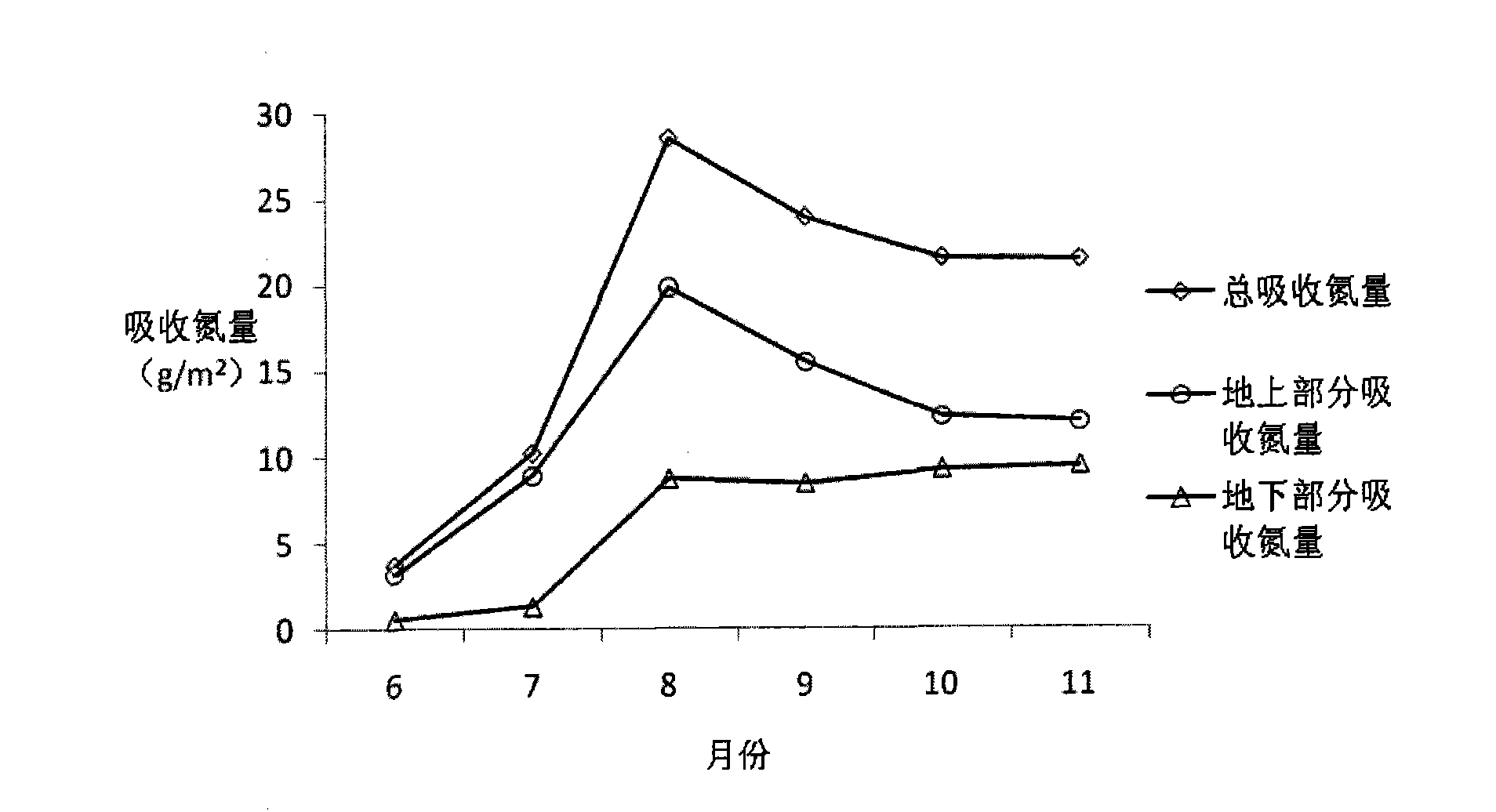

Technique for cultivating bulrush and removing total nitrogen in artificial marsh of landfill leachate

InactiveCN101781065AImprove nitrogen removal effectMultistage water/sewage treatmentSustainable biological treatmentConstructed wetlandMarsh

The invention relates to a technique for cultivating bulrush and removing total nitrogen in an artificial marsh of landfill leachate, which takes the bulrush as a marsh cultivated plant. The planting density of the bulrush is within 1000cm2 / plant, the treated landfill leachate is replenished every day, the COD concentration of the landfill leachate is controlled below 1000mg / L, the concentration of the total nitrogen is within 1000mg / L, and the bulrush is harvested at the end of August. The invention has the advantages that the absorbing capacity of the bulrush to the total nitrogen of the landfill leachate is closely related to the growth cycle, the planting density and the like, and an excellent denitrogenation effect is obtained by controlling the planting density and the clipping time; experiments prove that the highest nitrogen accumulation quantity of the parts of the stems and the leaves of the bulrush reaches 19.82g / m2 at the end of August, which shows that 3872.63g of total nitrogen can be removed from the marsh by the timely harvesting of the bulrush; and the nitrogen removal function of the artificial marsh of the landfill leachate can be best exerted by harvesting the bulrush at the end of August.

Owner:上海环境工程技术有限公司

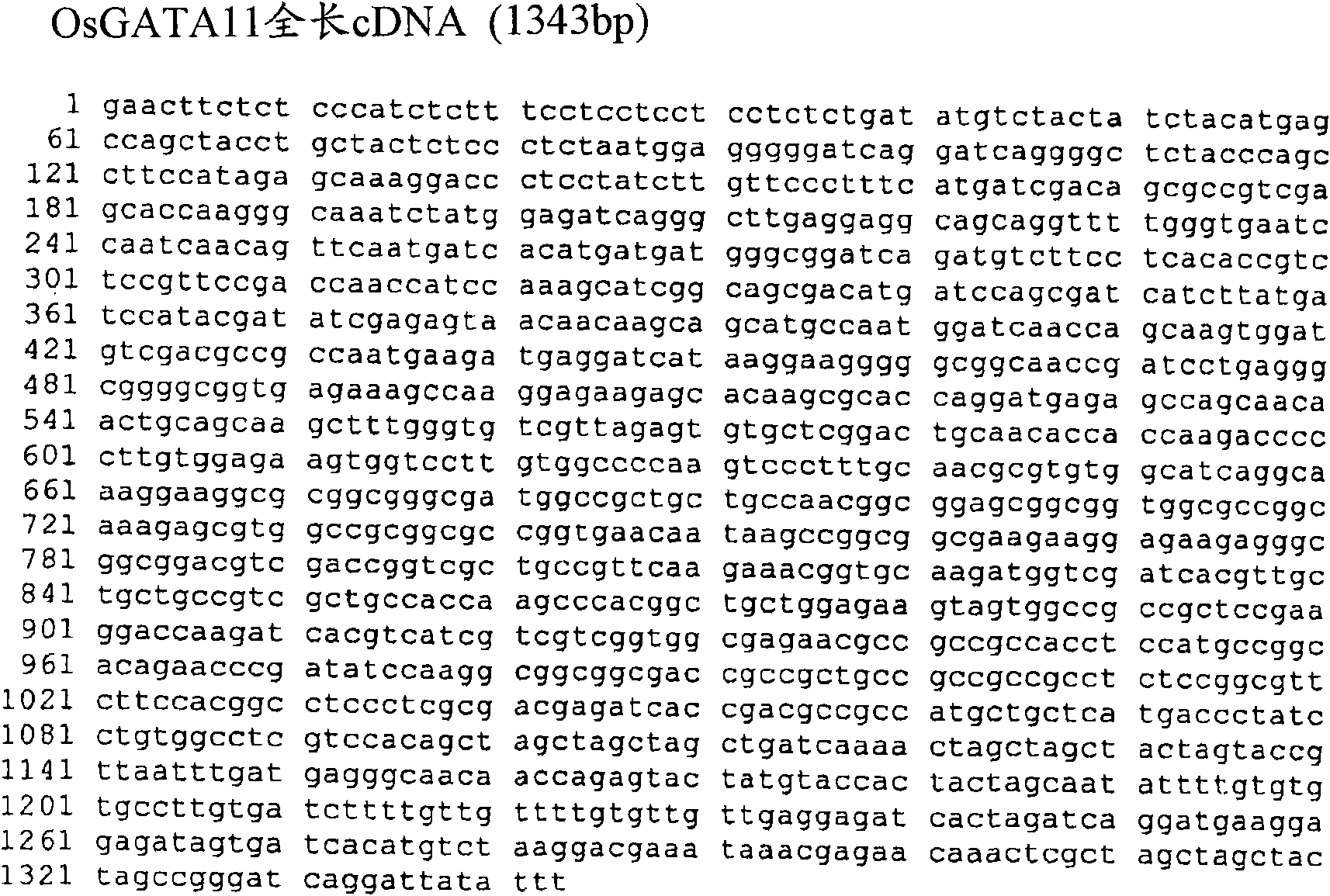

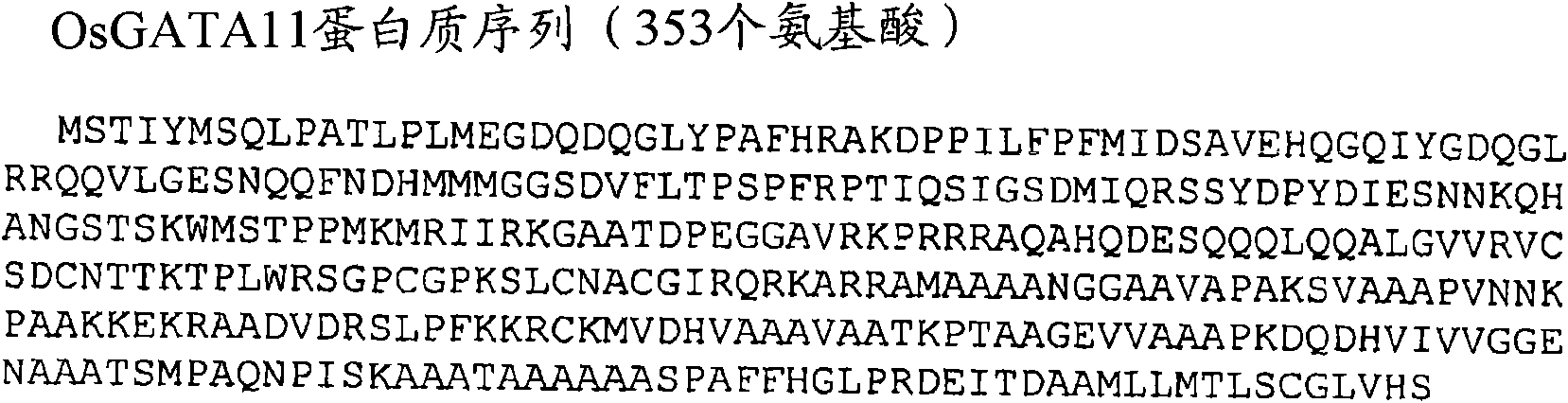

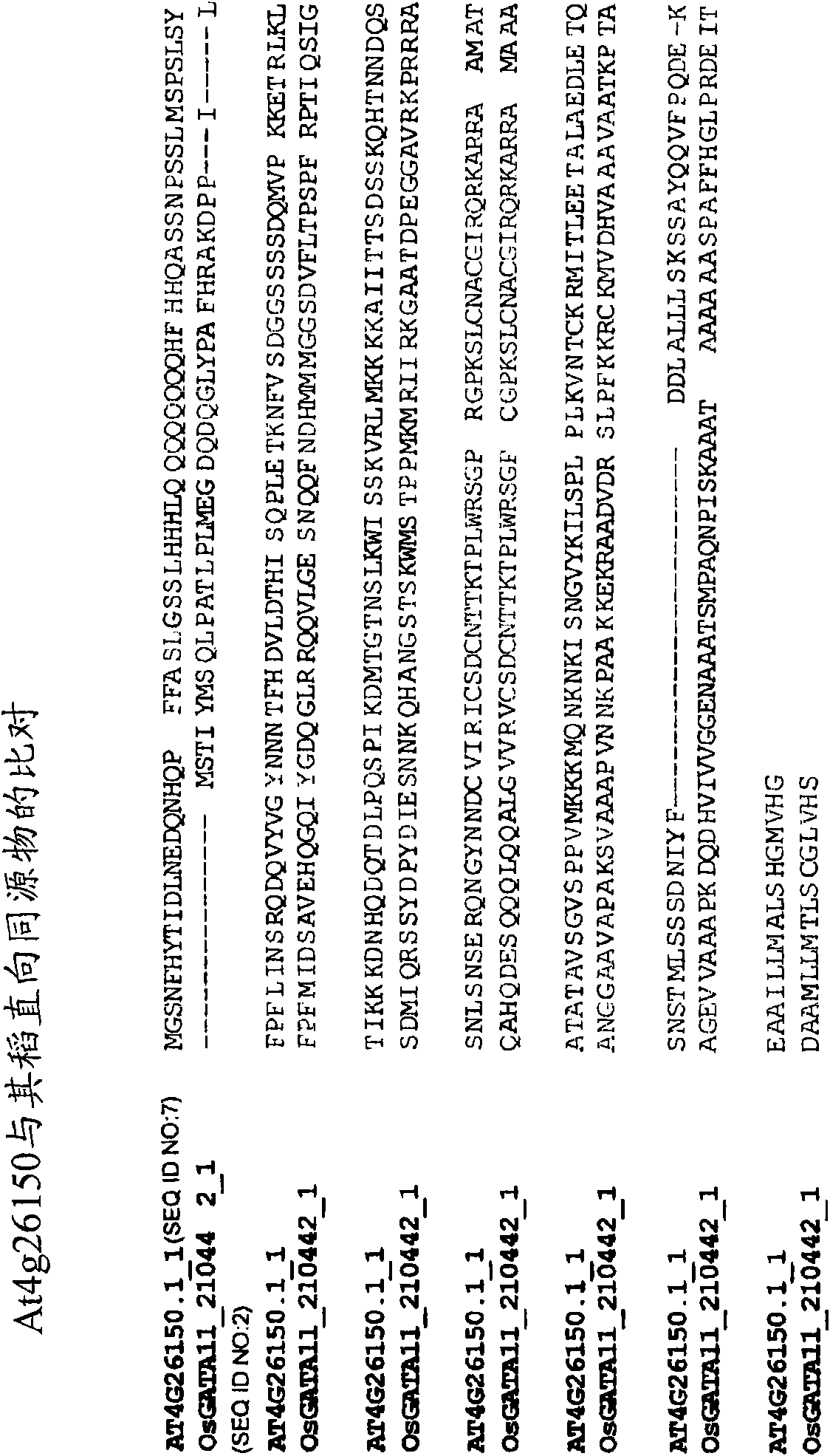

Carbon and nitrogen-regulating gene and protein and modulation thereof

The present invention relates to a nitrogen-regulated GATA transcription factor gene required for sugar and nitrogen accumulation and the modulation of the expression of this gene to modulate a characteristic in a plant. The GATA transcription factor of the present invention is involved in regulating sugar and nitrogen accumulation in plants. Increased expression of this or substantially similar genes can produce plants with improved nitrogen utilization and increased yield and increased stress tolerance.

Owner:UNIVERSITY OF GUELPH

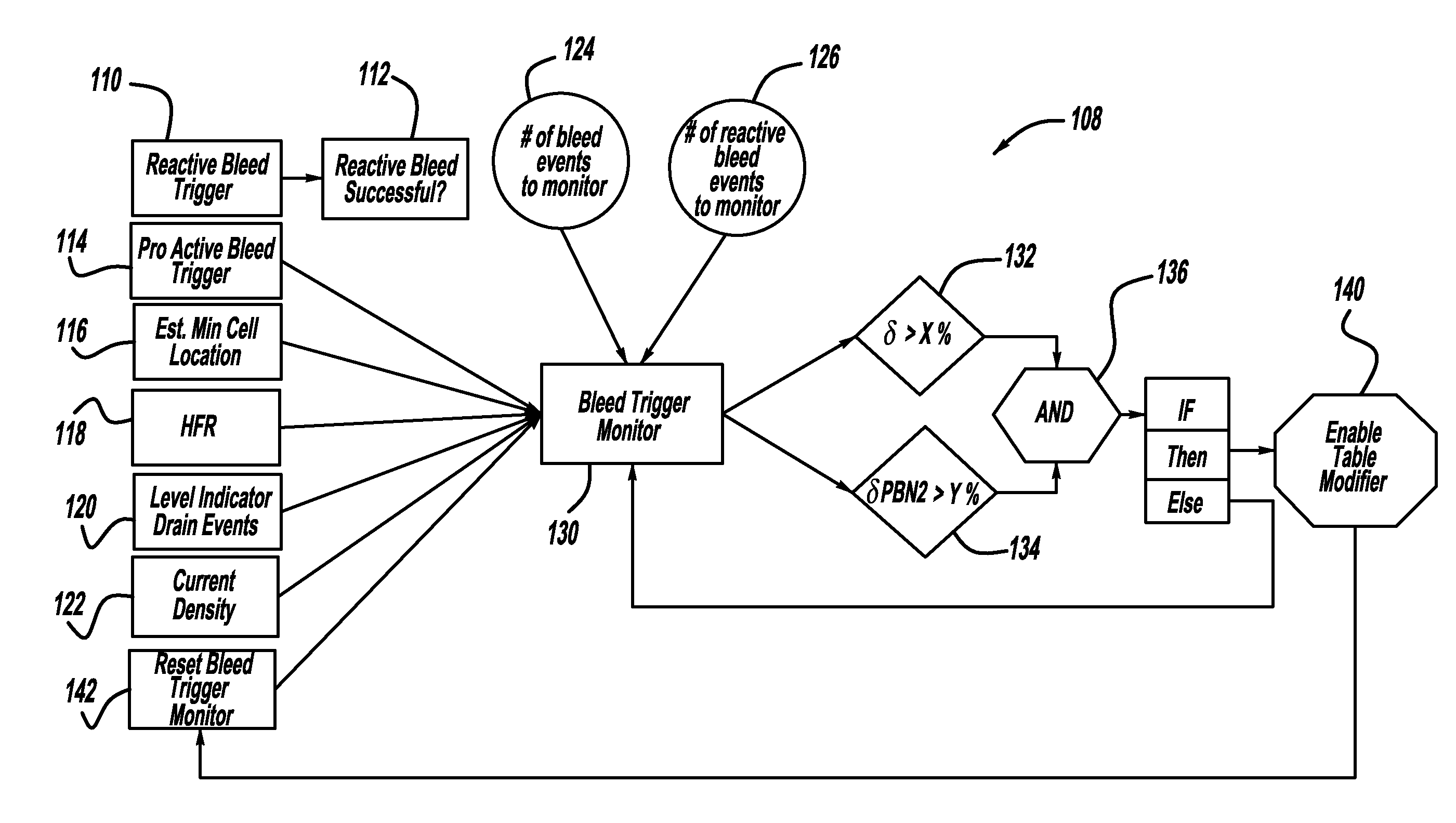

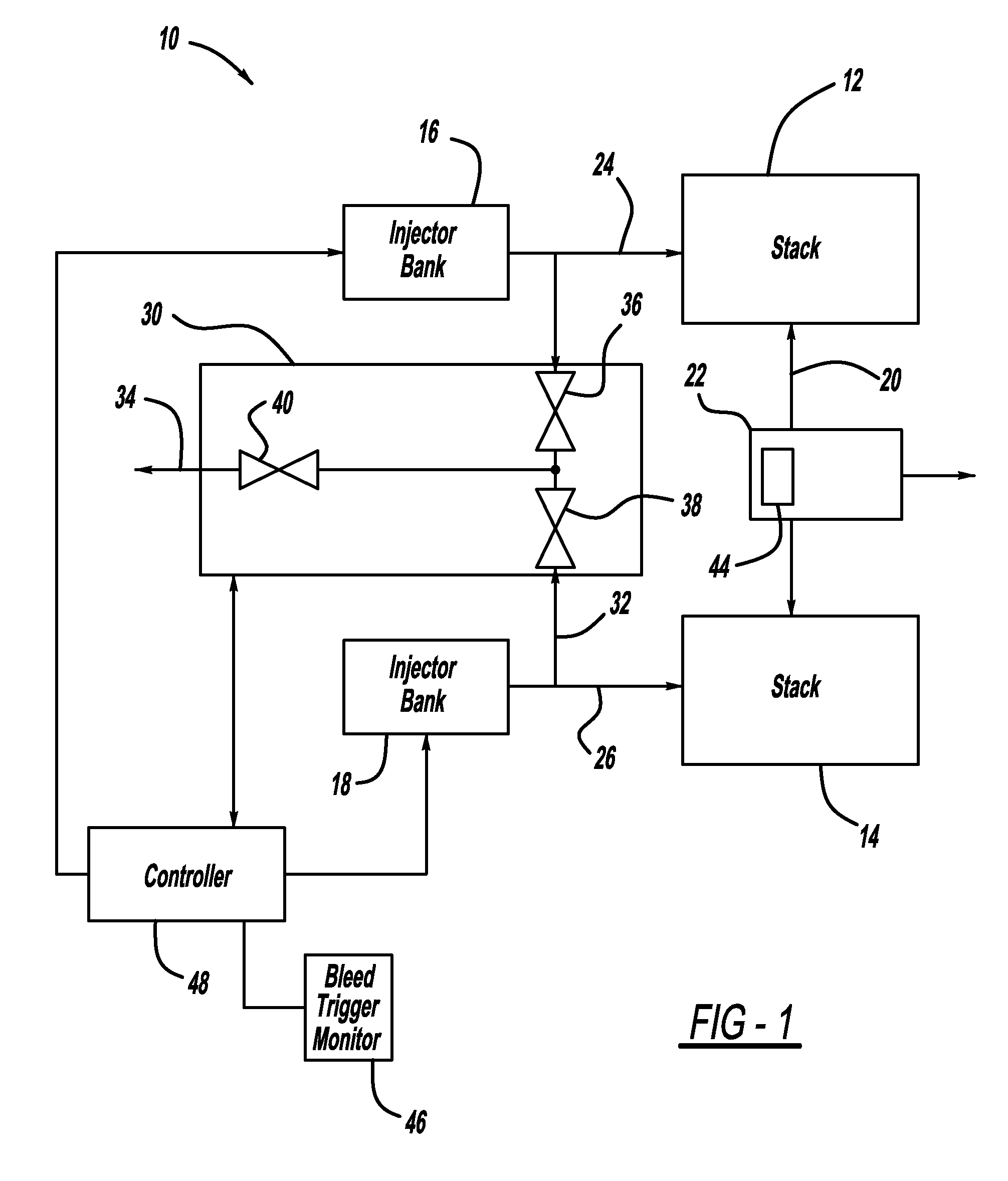

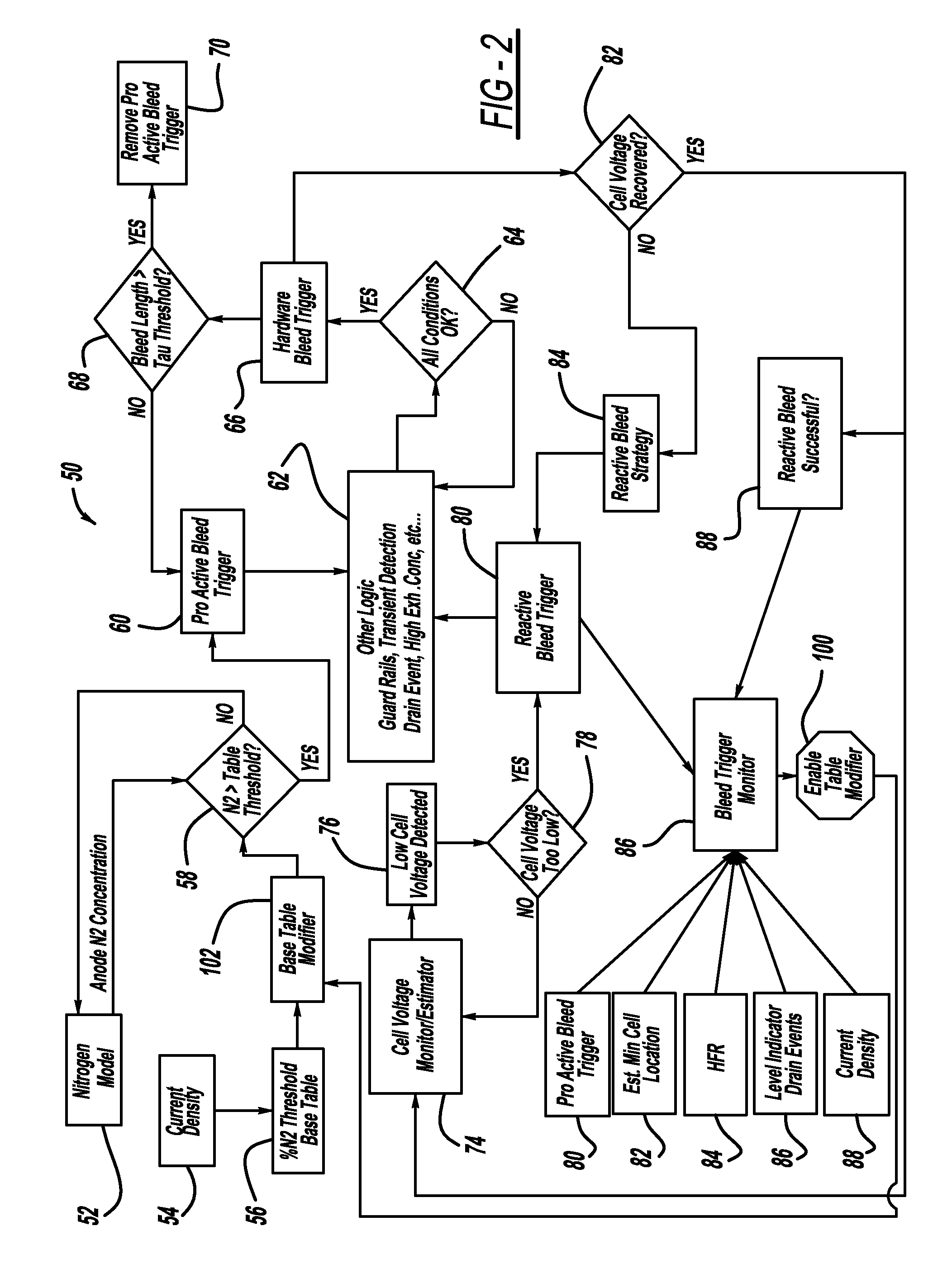

Bleed trigger monitor used in fuel cell system

A system and method for monitoring anode bleed trigger events and determining when to adjust a proactive bleed schedule in a fuel cell system. The system employs a bleed trigger monitor algorithm for monitoring proactive bleed and reactive bleeds that determines whether the reactive bleeds are caused by excess nitrogen in the anode. The algorithm monitors the number of reactive bleeds that are cause by nitrogen accumulation in the anode side of the fuel cell stack and changes the proactive bleed schedule in response thereto, if necessary.

Owner:GM GLOBAL TECH OPERATIONS LLC

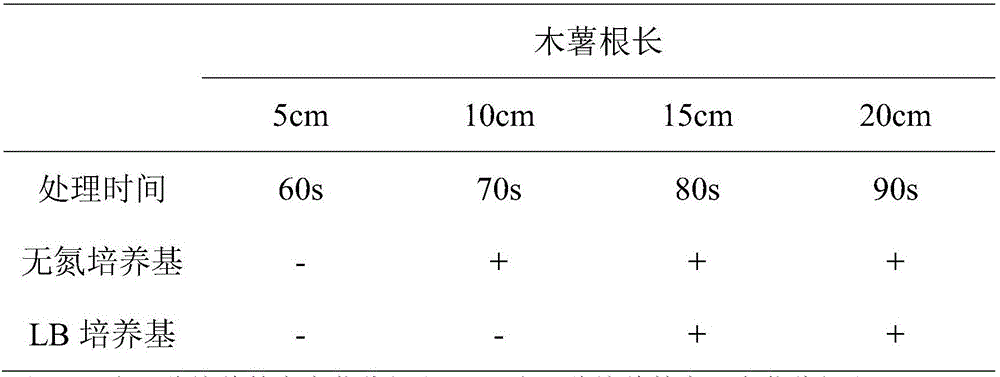

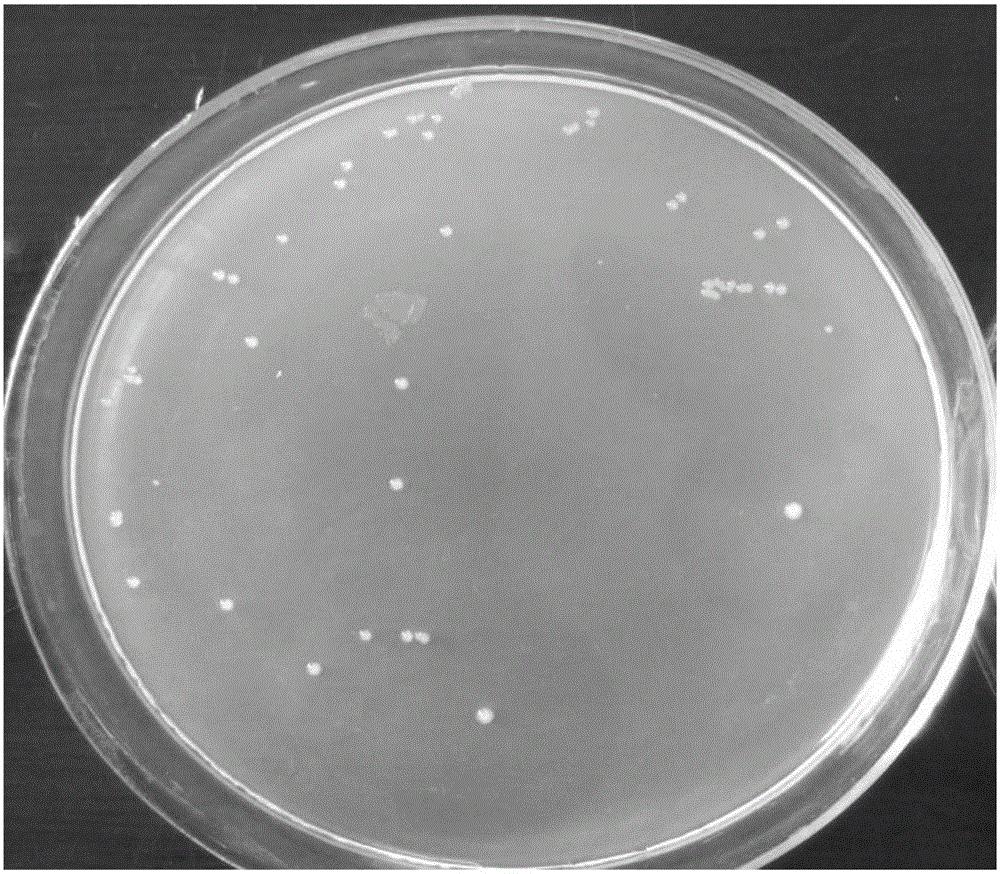

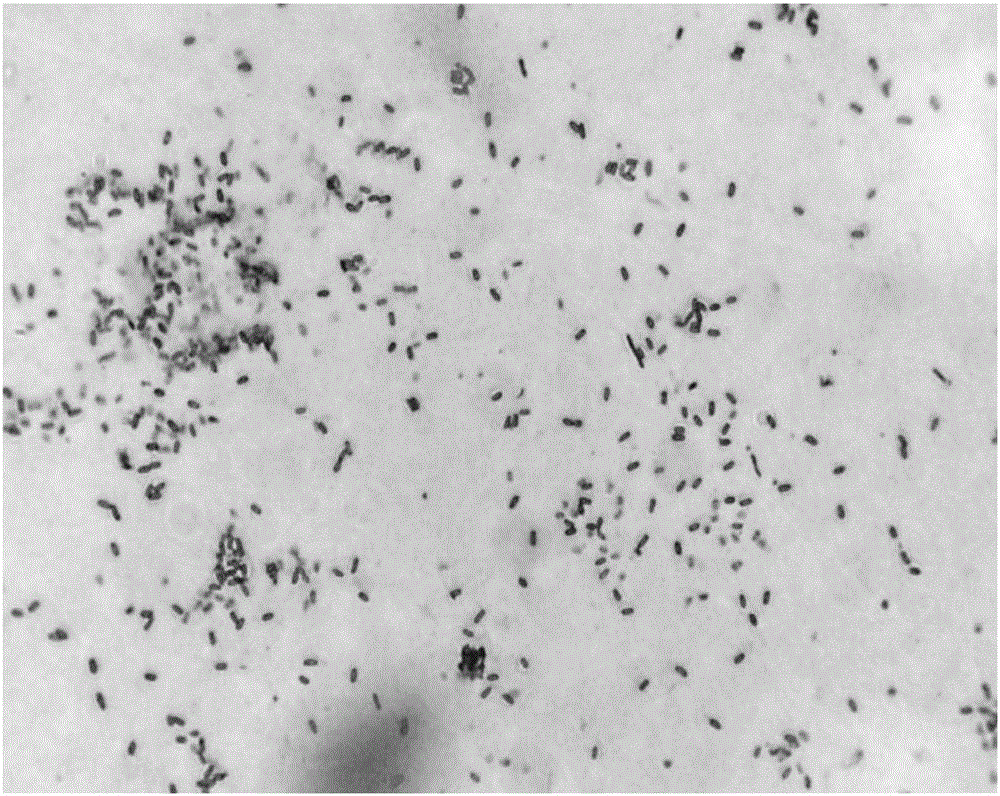

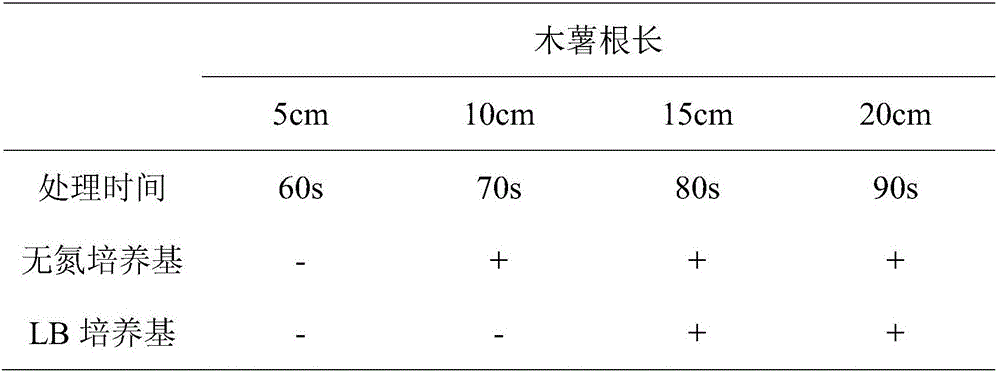

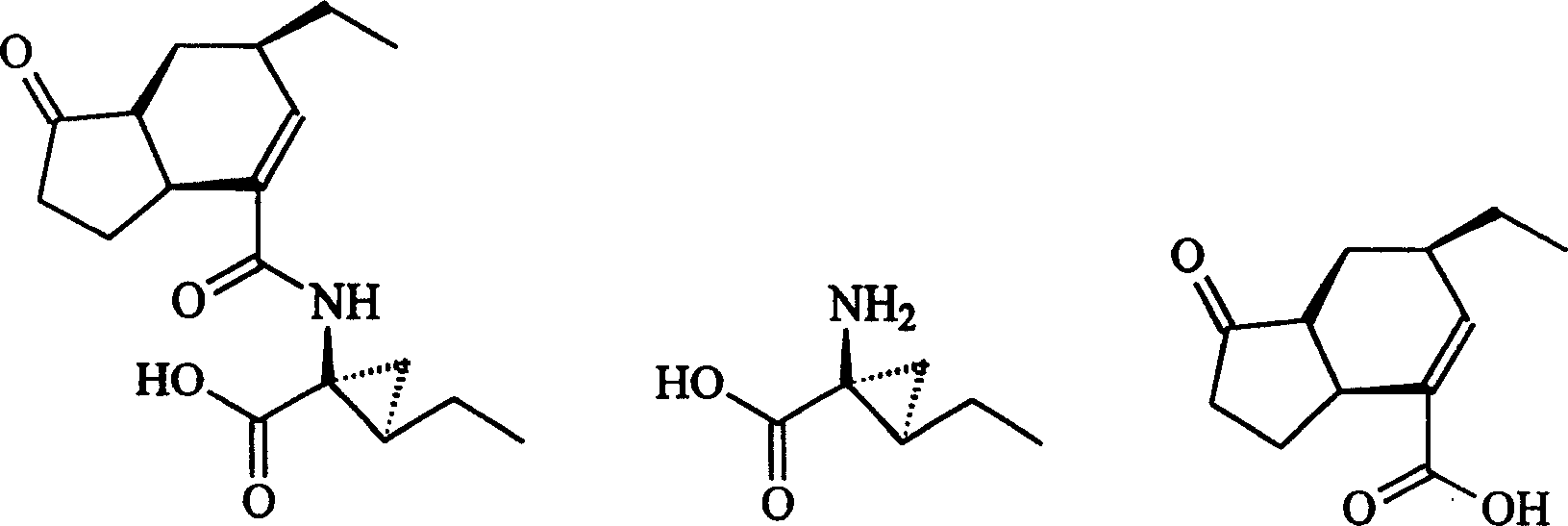

Microbacterium for cassava nitrogen fixation and preparation method and application thereof

ActiveCN105907670APromote accumulationBacteriaMicroorganism based processesNitrogen accumulationFermentation

The invention discloses microbacterium for cassava nitrogen fixation and a preparation method and application thereof. The microbacterium belongs to Microbacterium sp. and is preserved in CGMCC (China General Microbiological Culture Collection Center) on March 7, 2016, and a preservation serial number is CGMCC NO.12182. A biological agent with the microbacterium as an active component is prepared by tube culture and liquid fermentation culture. By application of the microbacterium and the biological agent thereof, nitrogen contents of roots, stems and leaves of cassava seedlings can be remarkably increased, nitrogen accumulation in an early growth stage of cassava is benefited, and high application value in cassava production is achieved.

Owner:GUANGXI UNIV

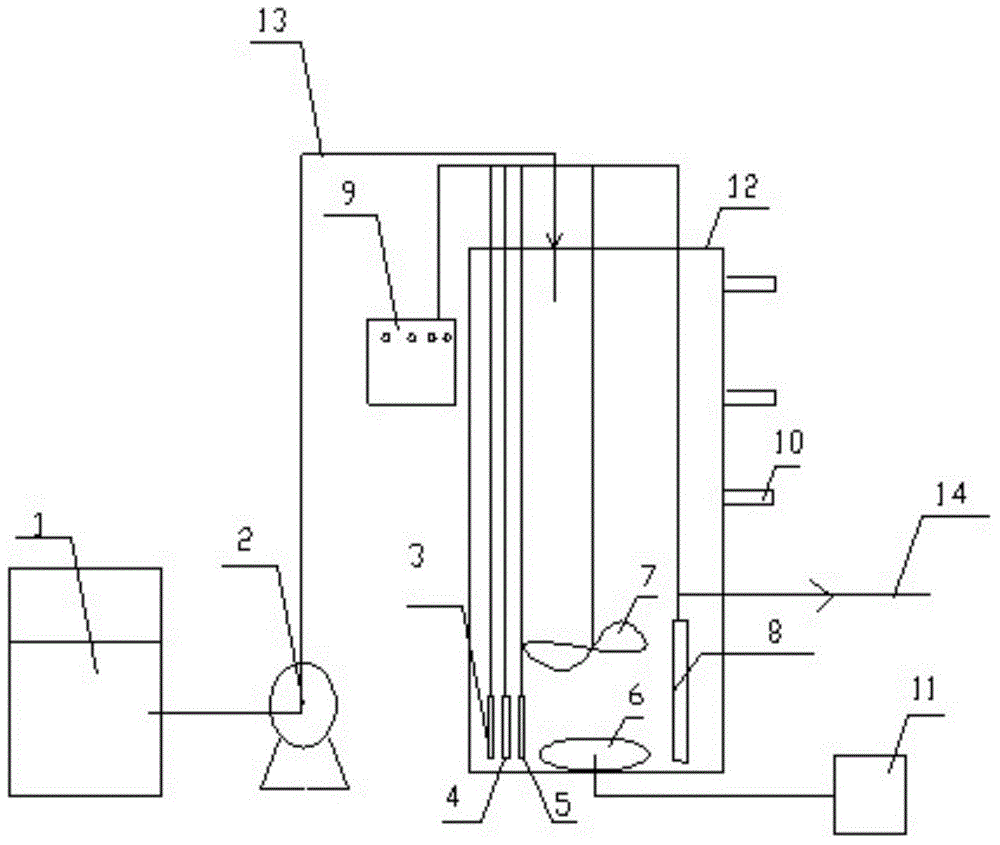

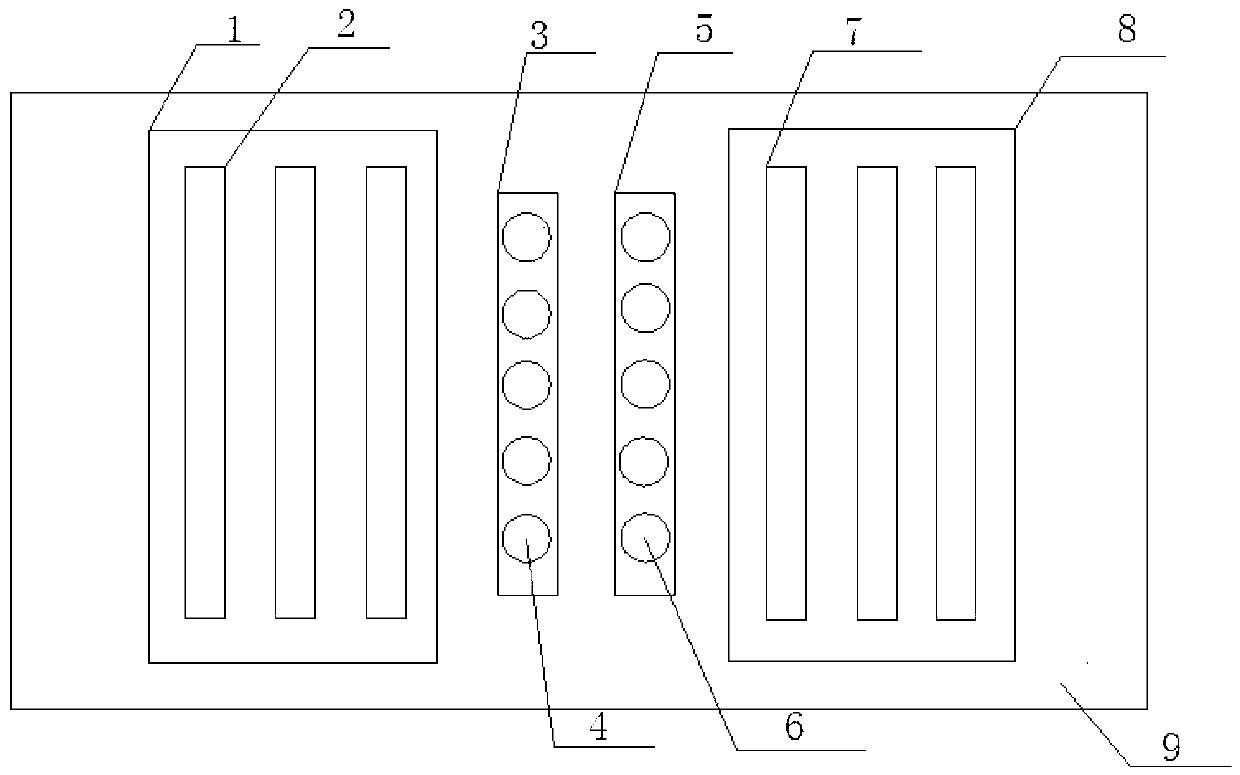

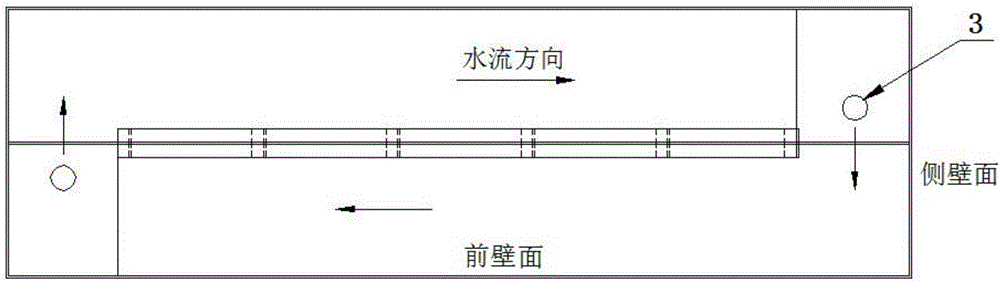

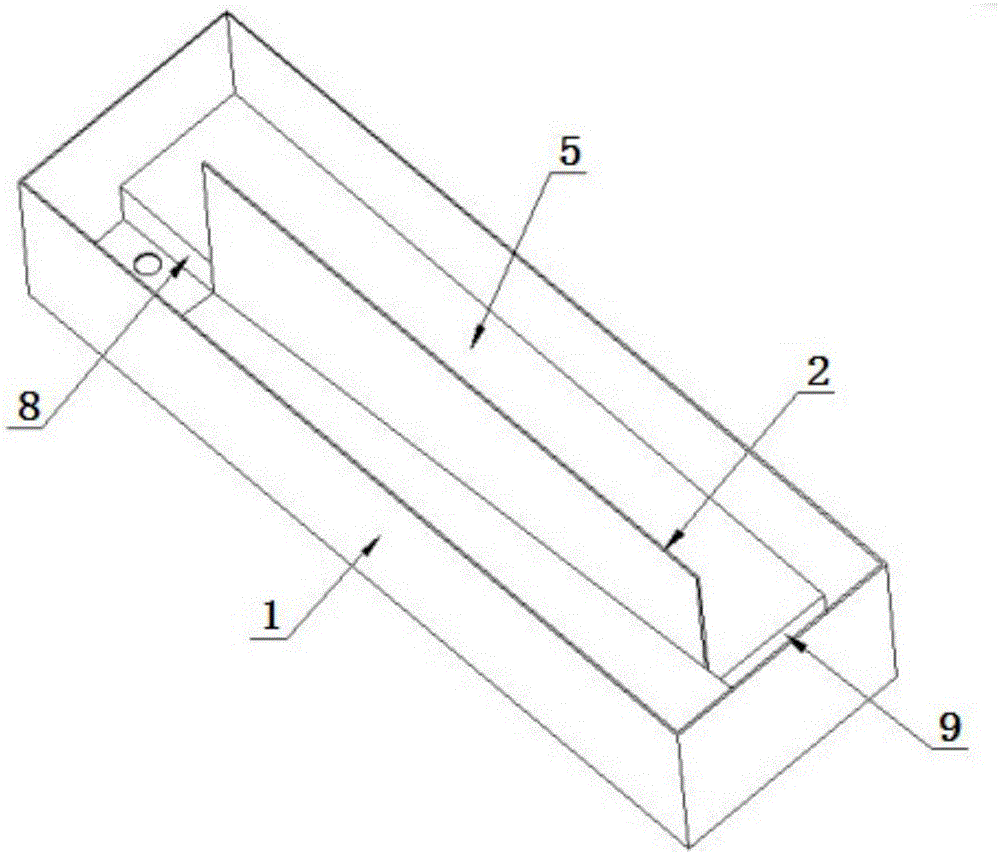

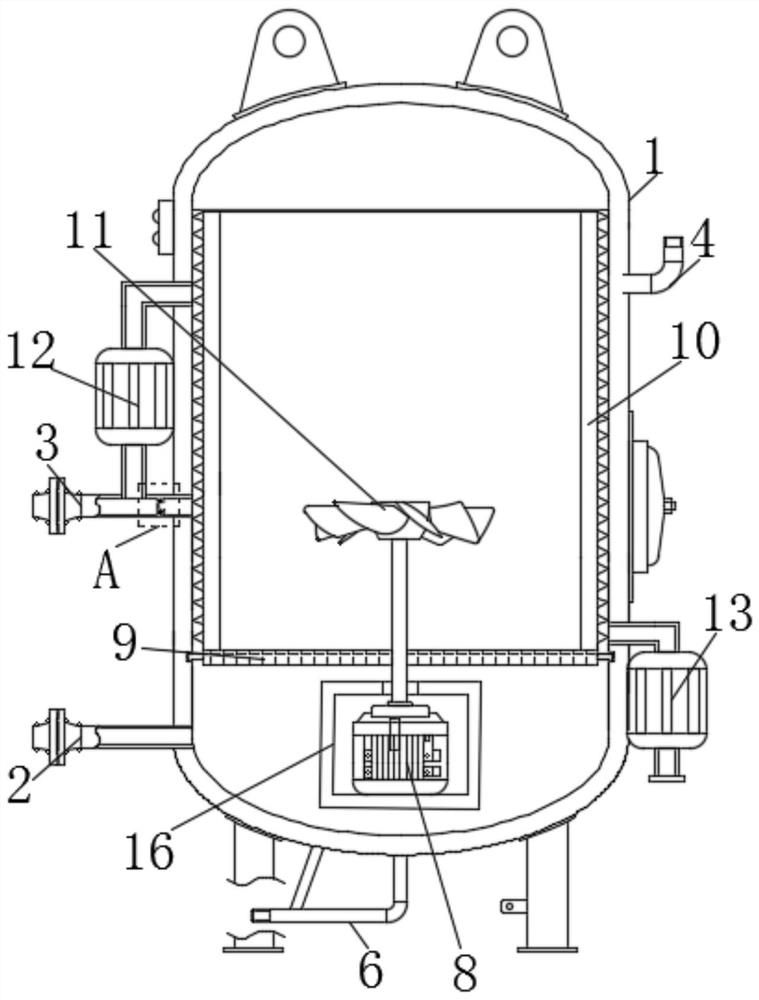

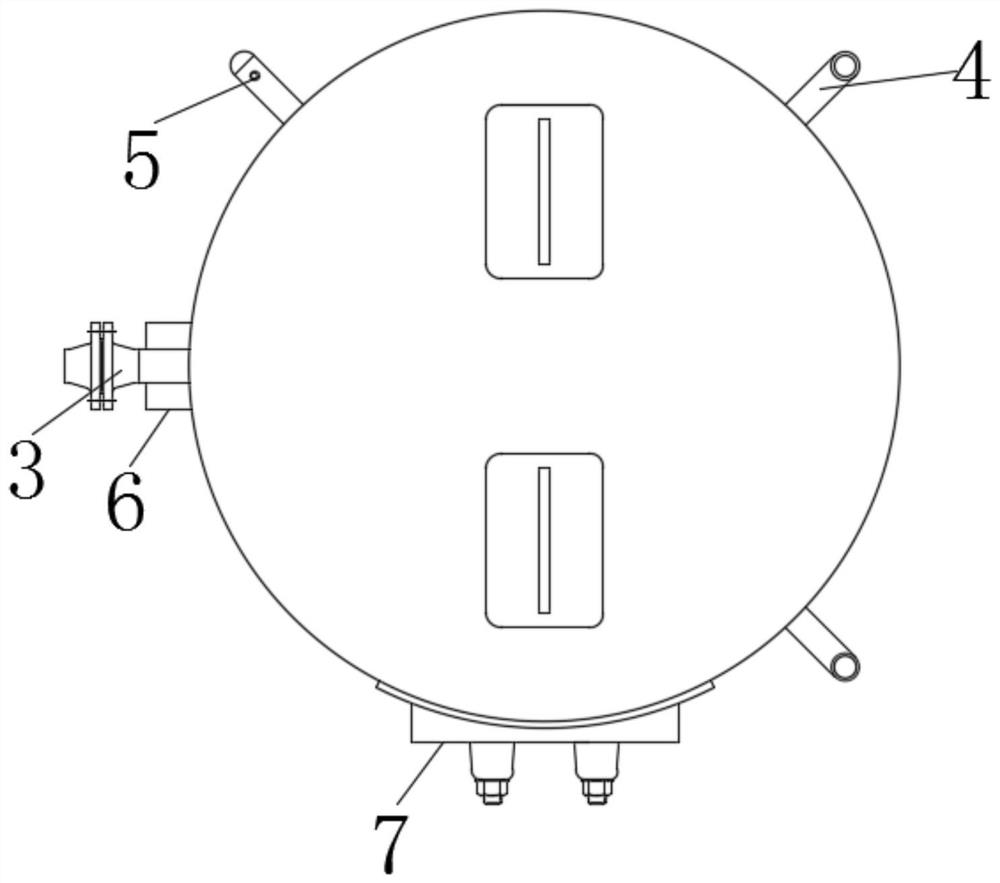

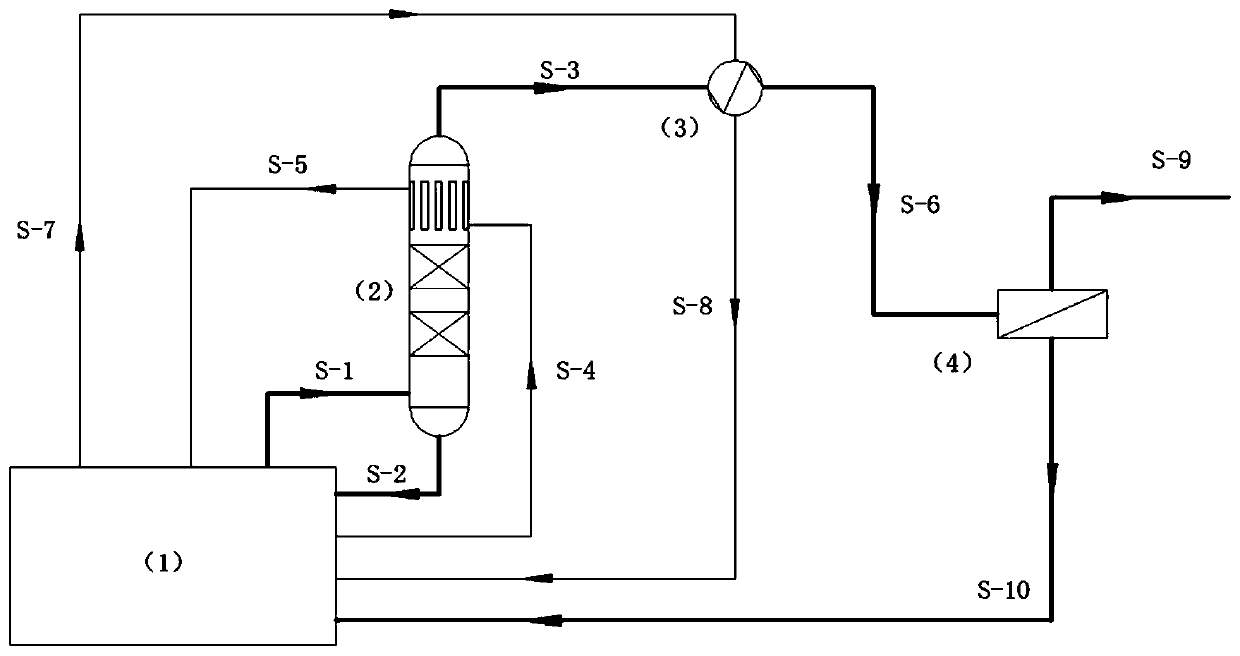

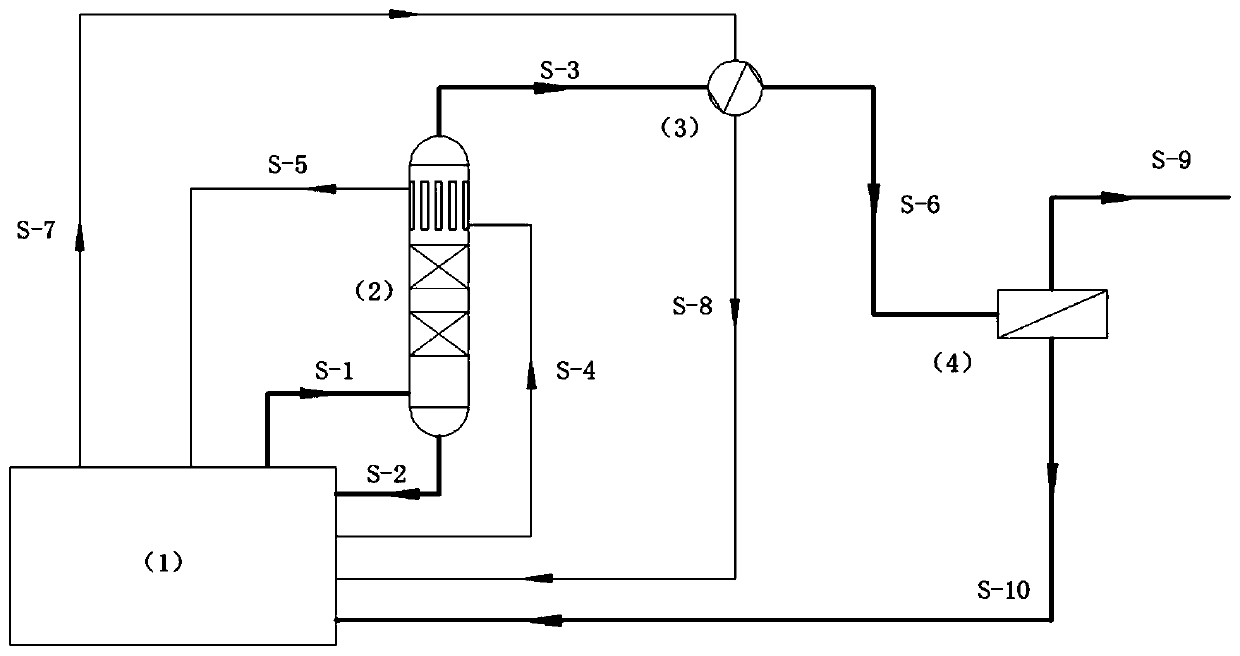

Efficient excrement separation runway type circulating water culture device

ActiveCN106614233ASolve the problem of deteriorating water qualityIngenious structural designPisciculture and aquariaGlass fiberNitrogen accumulation

The invention relates to an efficient excrement separation runway type circulating water culture device. The efficient excrement separation runway type circulating water culture device is characterized in that a separation plate is vertically mounted in a glass fiber reinforced plastic square tank and the length of the separation plate is smaller than the length of the glass fiber reinforced plastic square tank; two plugging plates II are vertically arranged on opposite sides of two ends of the separation plate respectively and are vertical to the separation plate; two inclined plates are arranged on two sides of the separation plate respectively, upper ends of the two inclined plates are fixed on side walls of the glass fiber reinforced plastic square tank respectively and lower ends of the two inclined plates are mounted at tops of the plugging plates II; and side faces of the inclined plates are sealed by the plugging plates I. An excrement deposition cabin is formed by the plugging plates I, the plugging plates II and wall faces of the glass fiber reinforced plastic square tank; and a blow-off hole is formed in the bottom surface of the excrement deposition cabin. The efficient excrement separation runway type circulating water culture device is simple in structure and can be used for discharging residual feed and excrement in a culture pond; and problems that ammonia and nitrogen accumulation and harmful pathogenic bacterium breeding are caused by residual feed and excrement deposition so that normal growth of culture objects is influenced, even the death is caused are effectively solved.

Owner:ZHEJIANG UNIV

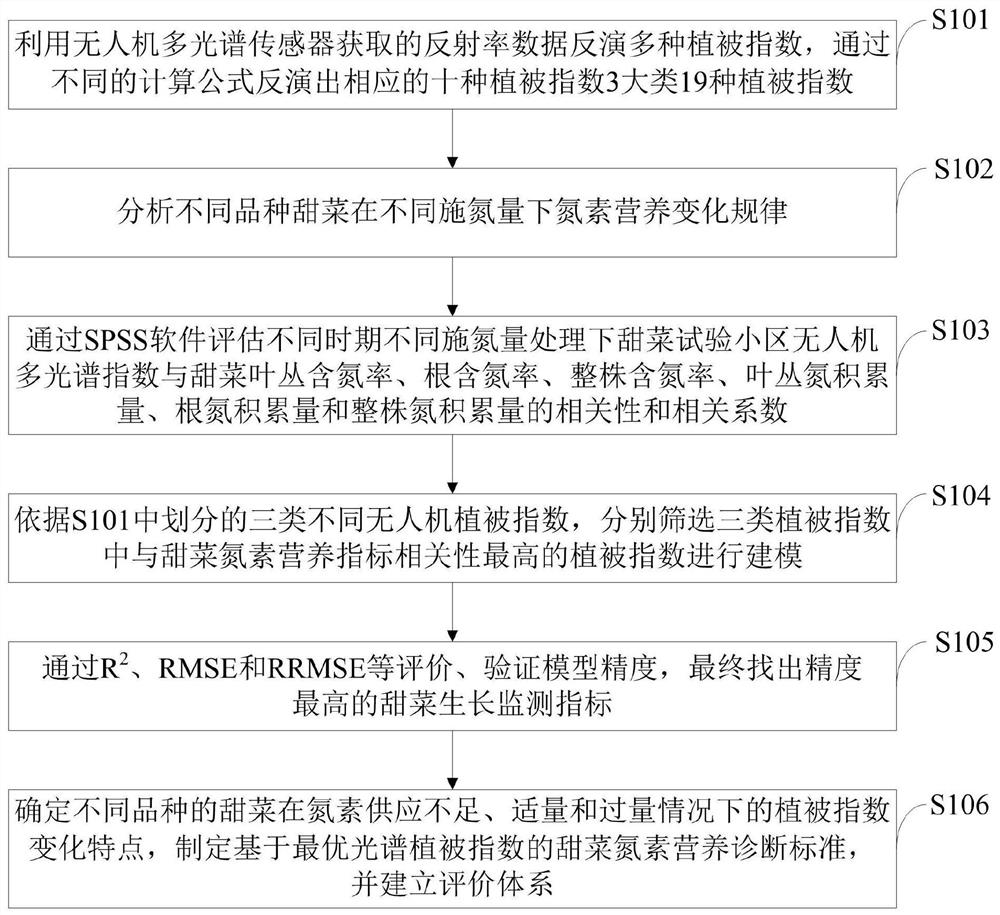

Beet nitrogen nutrition detection method and system based on unmanned aerial vehicle multispectral data

ActiveCN112986158AHigh precisionWeight factor reductionColor/spectral properties measurementsAgriculture gas emission reductionNutritional IndicesNutrition Indexes

The invention belongs to the technical field of nutrition diagnosis, and discloses a beet nitrogen nutrition detection method and system based on unmanned aerial vehicle multispectral data, and the method comprises the steps: carrying out the inversion to obtain ten vegetation indexes and three major classes 19 vegetation indexes; analyzing a nitrogen nutrition change rule of different varieties of beets under different nitrogen application amounts; evaluating correlation and correlation coefficients between the unmanned aerial vehicle multispectral index of the beet test plot and the nitrogen content of the leaf clump, the nitrogen content of the root, the nitrogen content of the whole plant, the nitrogen accumulation amount of the leaf clump, the nitrogen accumulation amount of the root and the nitrogen accumulation amount of the whole plant of the beet; screening the vegetation index with the highest correlation with the beet nitrogen nutrition index in the three types of vegetation indexes for modeling; finding out a beet growth monitoring index with the highest precision; and formulating a beet nitrogen nutrition diagnosis standard based on the optimal spectral vegetation index, and establishing an evaluation system. Experiments show that the unmanned aerial vehicle can diagnose the leaf cluster nitrogen accumulation amount NWL, the root nitrogen accumulation amount NWT and the whole plant nitrogen accumulation amount NWP in unit area, and diagnosis results have statistical significance.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Pulverized coal low-NOx and oxygen-enriched combustion device

ActiveCN104896501ALow combustion reaction rateEvenly distributedIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyNitrogen accumulationOxygen tank

The invention discloses a pulverized coal low-NOx and oxygen-enriched combustion device. The pulverized coal low-NOx and oxygen-enriched combustion device comprises a hearth, an oxygen tank, an oxidizing agent nozzle, a central nozzle, a steam nozzle and a steam generator, wherein the central nozzle is mounted on one side of the hearth; the lateral wall of a primary air pipeline is connected with the outlet of the steam generator through a primary steam inlet pipeline; the oxidizing agent nozzle is mounted on the side, with the central nozzle, of the hearth; the outlet of the oxidizing agent nozzle extends into the hearth, the inlet of the oxidizing agent nozzle is connected with a secondary air pipeline, the secondary air pipeline is connected with the primary steam inlet pipeline through a secondary steam inlet pipeline, and the lateral wall of the secondary air pipeline is connected with the oxygen tank through an oxygen inlet pipe; the steam nozzle is mounted on the side, with the central nozzle, of the hearth. The pulverized coal low-NOx and oxygen-enriched combustion device has the advantages steam is added to lower the temperature peak in a furnace, the temperature field distribution in the hearth is allowed to be even, smoke circulating equipment is reduced, constant nitrogen accumulation in smoke circulation is eliminated, NOx emission is lowered, combustion efficiency is increased, and cost is saved.

Owner:HUAZHONG UNIV OF SCI & TECH

Curtobacterium citreum for cassava nitrogen fixation and preparation method and application thereof

ActiveCN105754907APromote accumulationBacteriaMicroorganism based processesBiotechnologyNitrogen accumulation

The invention discloses curtobacterium citreum for cassava nitrogen fixation and a preparation method and application thereof.The preservation number of the curtobacterium citreum is CGMCC No.12181.A biological microbial agent with the curtobacterium citreum as an active ingredient is prepared after the curtobacterium citreum is subjected to strain culture and liquid fermenting cultivation.When the strain and the biological microbial agent containing the same are used at the seedling stage of cassava growth, the nitrogen content of the roots, stem and leaves of cassava can be remarkably increased, nitrogen accumulation at the early stage of cassava growth is promoted, and high application value is achieved with respect to cassava production.

Owner:GUANGXI UNIV

Multi-section buffer tank

InactiveCN112963651AImprove the quality of workAvoid wastingContainer filling methodsHollow article cleaningNitrogen accumulationBuffer tank

The invention discloses a multi-section buffer tank. The buffer tank comprises a buffer tank body, an air inlet pipe is arranged at the bottom end of the left side of the buffer tank body, an inspection hole is formed in the front face of the buffer tank body, a buffer net is arranged in the buffer tank body, and a first air pump is installed at the left side of the buffer tank body; and an air outlet of the first air pump is connected with the interior of an air outlet pipe, a second air pump is installed at the bottom end of the left side of the buffer tank body, a sealing plate is arranged in the air outlet pipe, and supporting blocks are welded in the right sides of the upper end and the lower end of the air outlet pipe. The buffer effect of the multi-section buffer tank is improved, the purity of nitrogen absorbed by gas equipment is improved, the working quality of the gas equipment is indirectly improved, nitrogen waste is avoided, cost is saved, benefits are improved, and potential safety hazards caused by more and more nitrogen accumulation in the buffer tank main body are avoided.

Owner:秦德贤

Preparation method of microbacterium for cassava nitrogen fixation

InactiveCN108587977APromote accumulationBacteriaMicroorganism based processesMicroorganismNitrogen accumulation

The invention discloses a preparation method of microbacterium for cassava nitrogen fixation. The microbacterium belongs to Microbacterium sp.. The microbacterium is collected at the CGMCC on March 07th, 2016 under the number of CGMCC No.12182. A biological agent taking the microbacterium as an active substance is prepared through tube seed culture and liquid fermentation culture. By applying thestrain and the biological agent thereof in the seedling period of cassava growth, nitrogen content of cassava roots, stems and leaves can be increased remarkably, nitrogen accumulation at the early stage of cassava growth is facilitated, and the preparation method has great application value in cassava production.

Owner:GUANGXI UNIV

Free living nitrogen fixing bacterium MBC9 and application thereof

The invention discloses a free living nitrogen fixing bacterium massilia plicata MBC9. The preservation number of the free living nitrogen fixing bacterium massilia plicata MBC9 is CGMCC No.10825, the preservation date is May 19, 2015, and the preservation institution is China General Microbiological Culture collection Center. The strain can still live, breed and have nitrogen fixation activity under drought, large temperature differences, salt and alkali disasters and strong ultraviolet radiation. A microbial agent prepared from the free living nitrogen fixing bacterium massilia plicata MBC9 can be applied to ecological systems with drought, large temperature differences, salt and alkali disasters and strong ultraviolet radiation, can increase nitrogen accumulation in the ecological systems and can perform the function of improving soil environments and the physiological activity of microorganisms and plants and increasing net primary productivity.

Owner:BEIJING FORESTRY UNIVERSITY

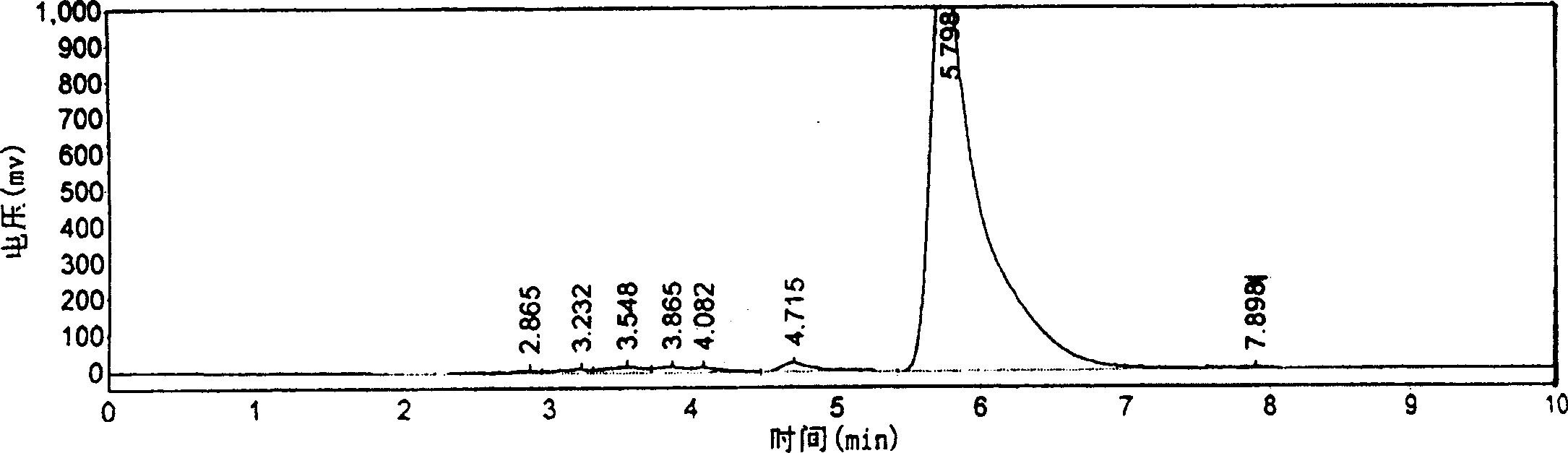

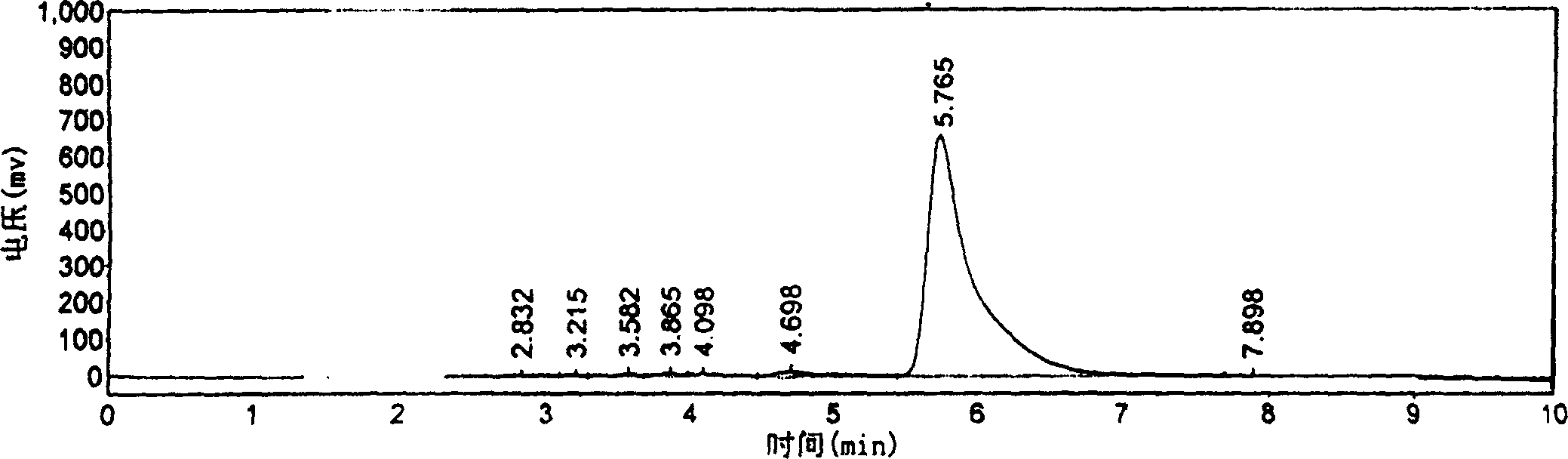

High proportion psendomonas syringae production strain and its fermentation method to produce psendomonas syringae

InactiveCN1259414CIncrease productionOvercoming the weakness of low temperature to accumulate coronatinBacteriaFermentationBiotechnologyNitrogen accumulation

Owner:蔡祝南 +1

Deep cooling and film coupled ethylene cyclic refrigeration system non-condensed effluent gas separating and recycling technology

ActiveCN110006216AAvoid accumulationEfficient separation and recovery processSolidificationLiquefactionNitrogen accumulationPetrochemical

The invention provides a deep cooling and film coupled ethylene cyclic refrigeration system non-condensed effluent gas separating and recycling technology, and belongs to the technical field of petrochemical engineering. According to the technology, starting from the characteristics of an ethylene cyclic refrigeration system, deep cooling conditions formed through ethylene throttling expansion areutilized for conducting liquidation and rectification on non-condensed effluent gas, most of ethylene is recycled in the form of the liquid state, then, a gas film is used for separating and enriching ethylene left in deep cooling tail gas, and low-pressure ethylene-rich gas obtained on the permeation side returns to a compressor of the ethylene cyclic refrigeration system. Deep cooling and filmseparation coupling is adopted for treating the non-condensed effluent gas, and ethylene losses are obviously reduced while oxygen and nitrogen accumulation is avoided. Taking a butyl rubber device of60,000 tons / year as an example, by adoption of the provided efficient non-condensed effluent gas separating and recycling technology, the ethylene content of the tail gas exhausted towards a torch islower than 5.0 vol%, the ethylene recycling rate reaches 99%, about 210 tons of ethylene can be recycled every year, and the annual economic benefits exceed 2 million yuan.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com