Patents

Literature

299results about How to "Expedited screening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

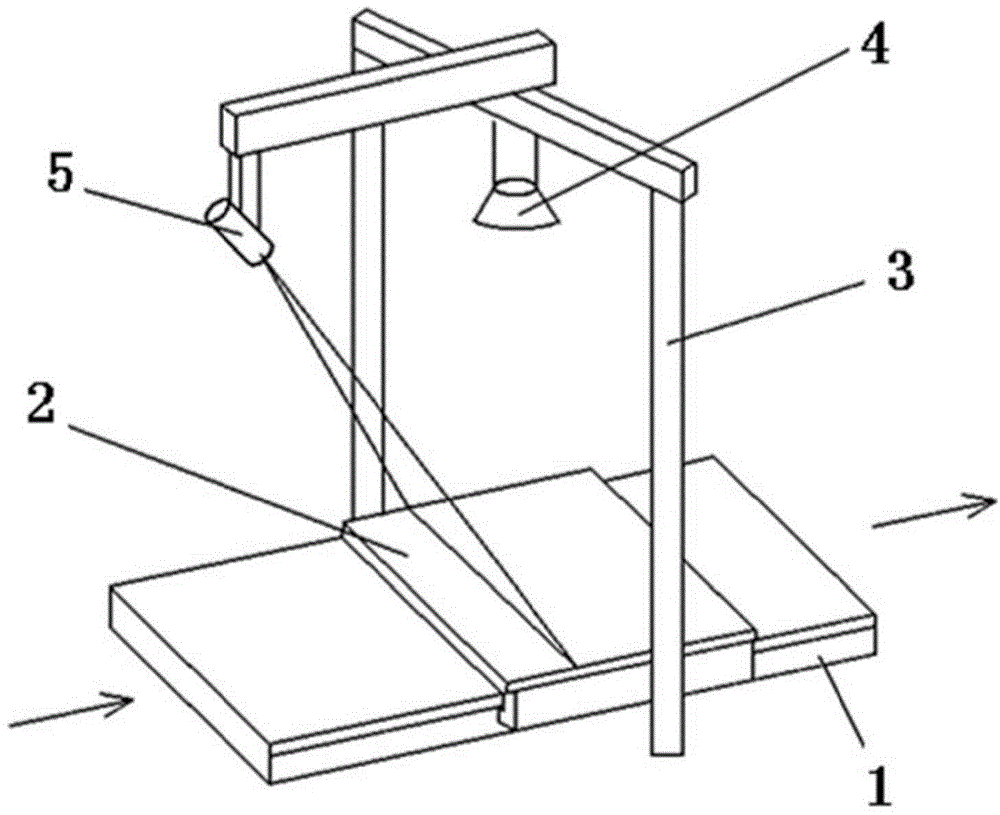

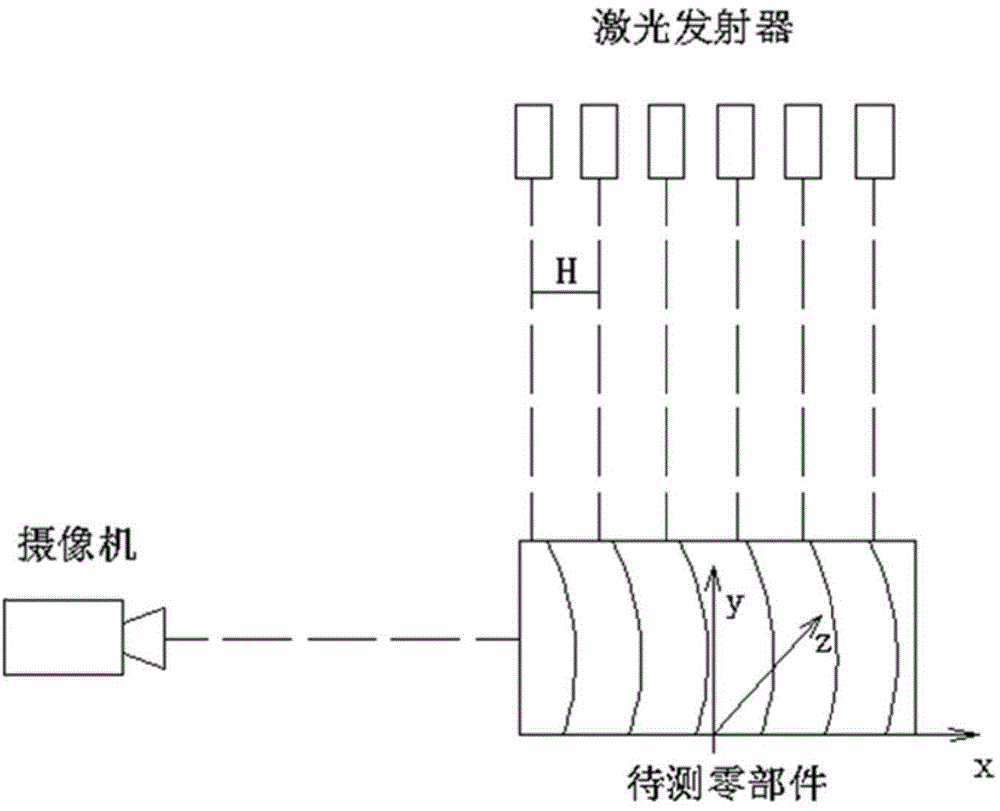

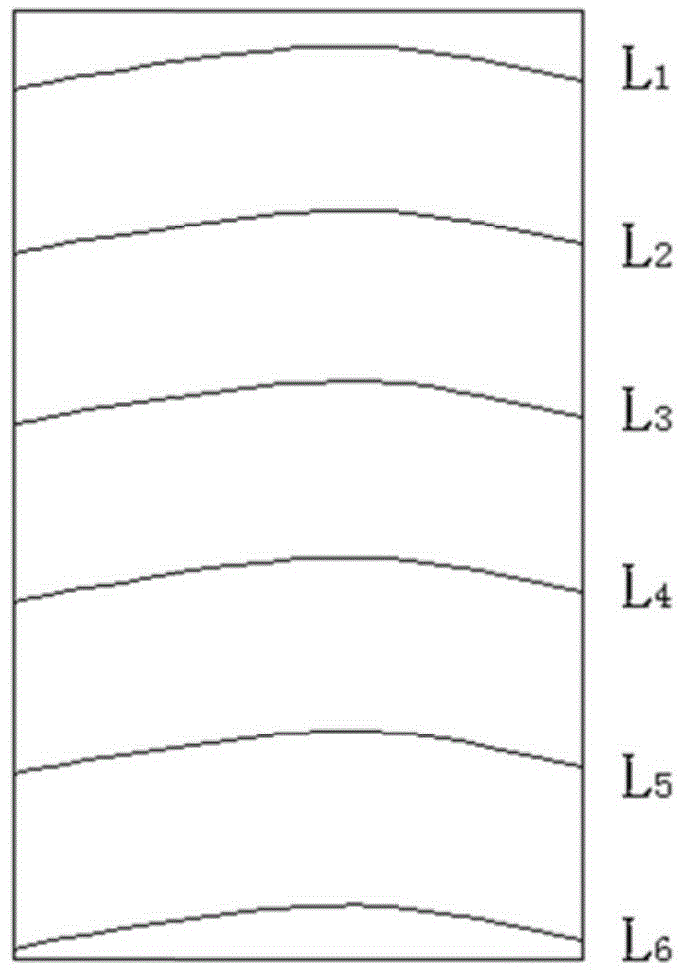

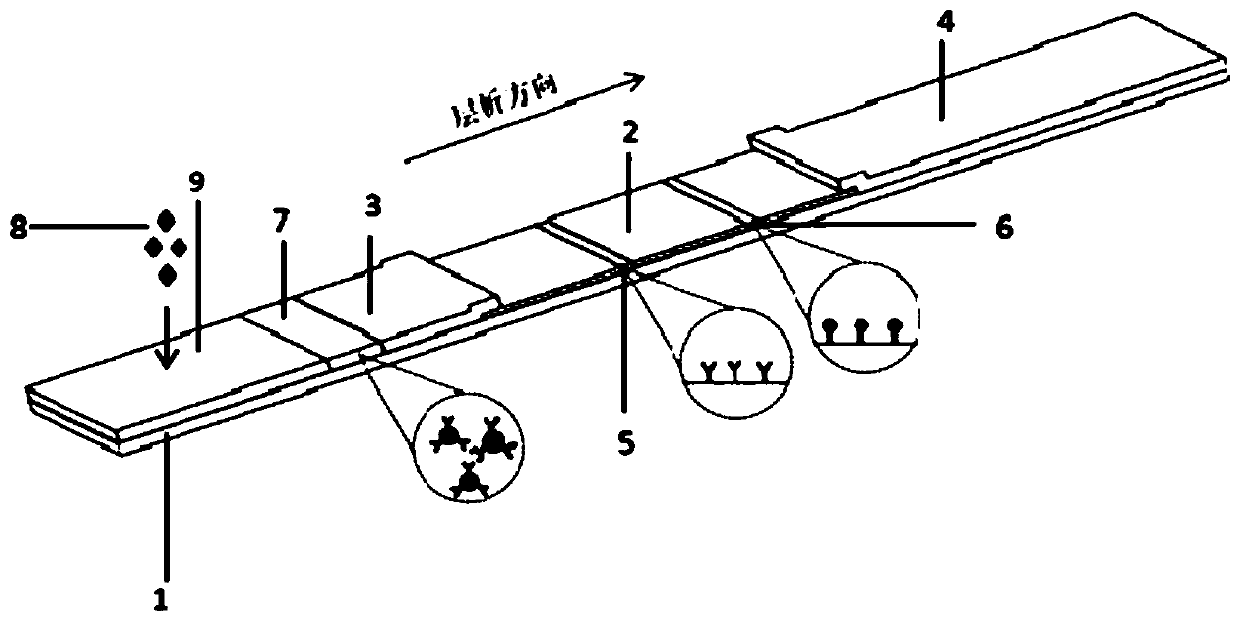

Component quality checking device based on line laser three-dimensional measurement and detection method of device

InactiveCN104913737AImprove detection efficiencyExpedited screeningUsing optical meansGraphicsMaximum error

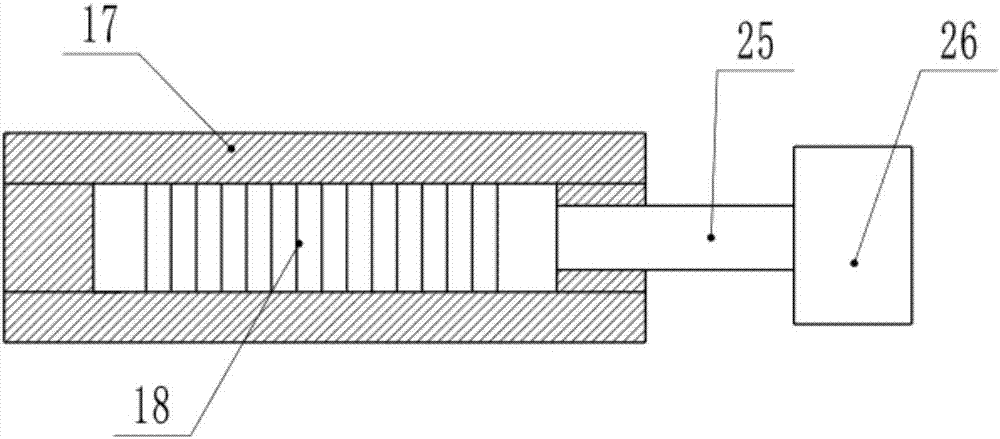

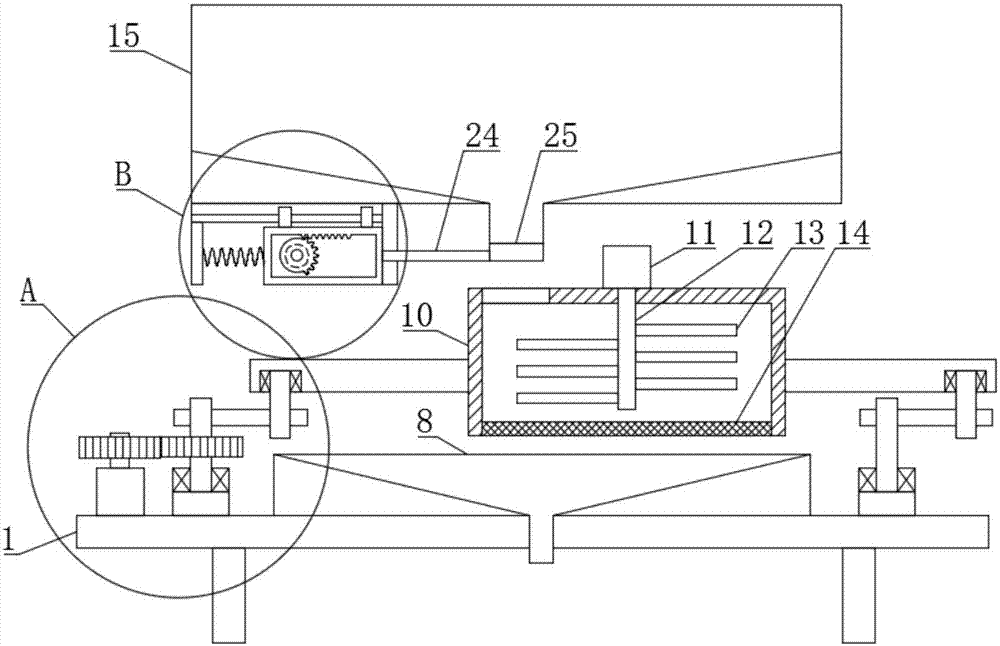

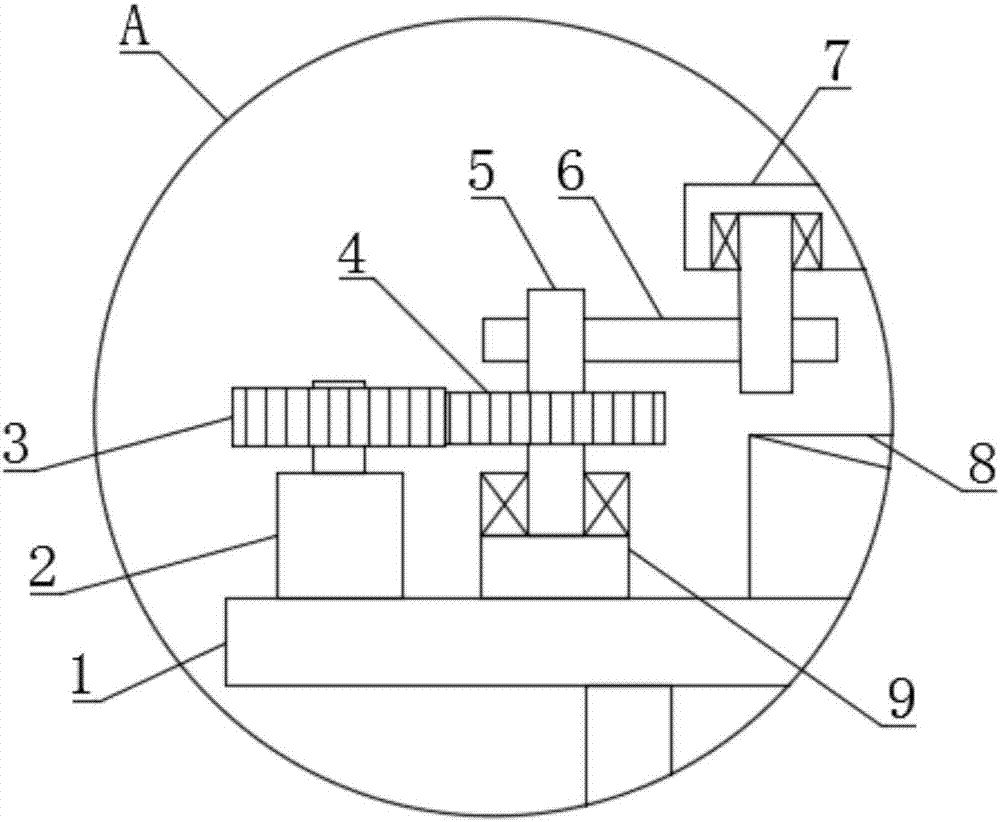

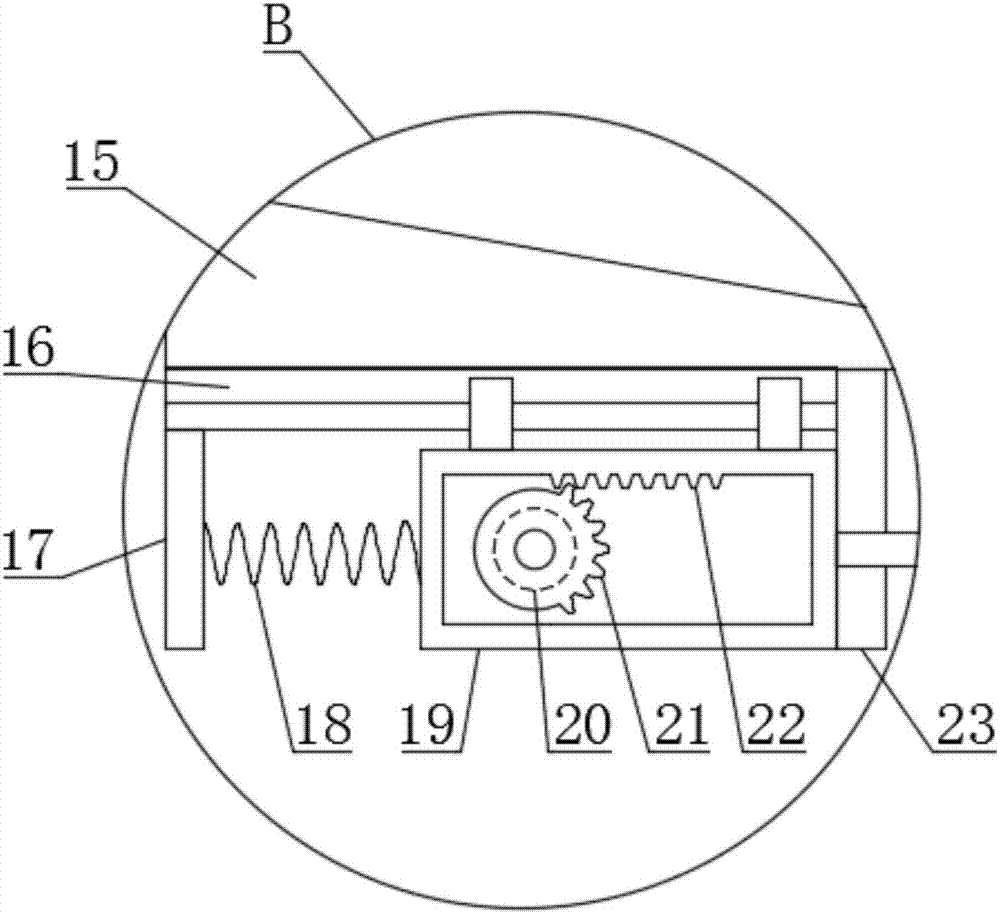

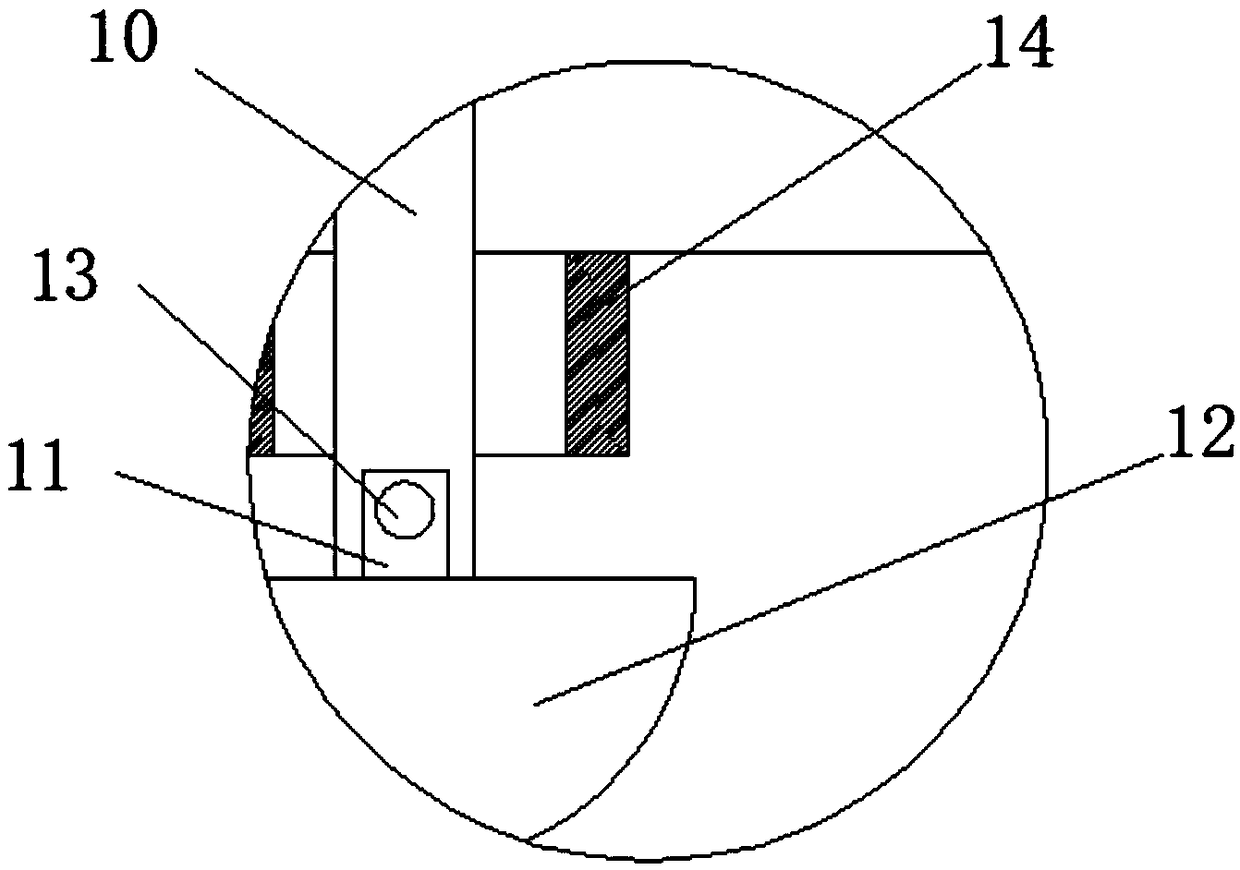

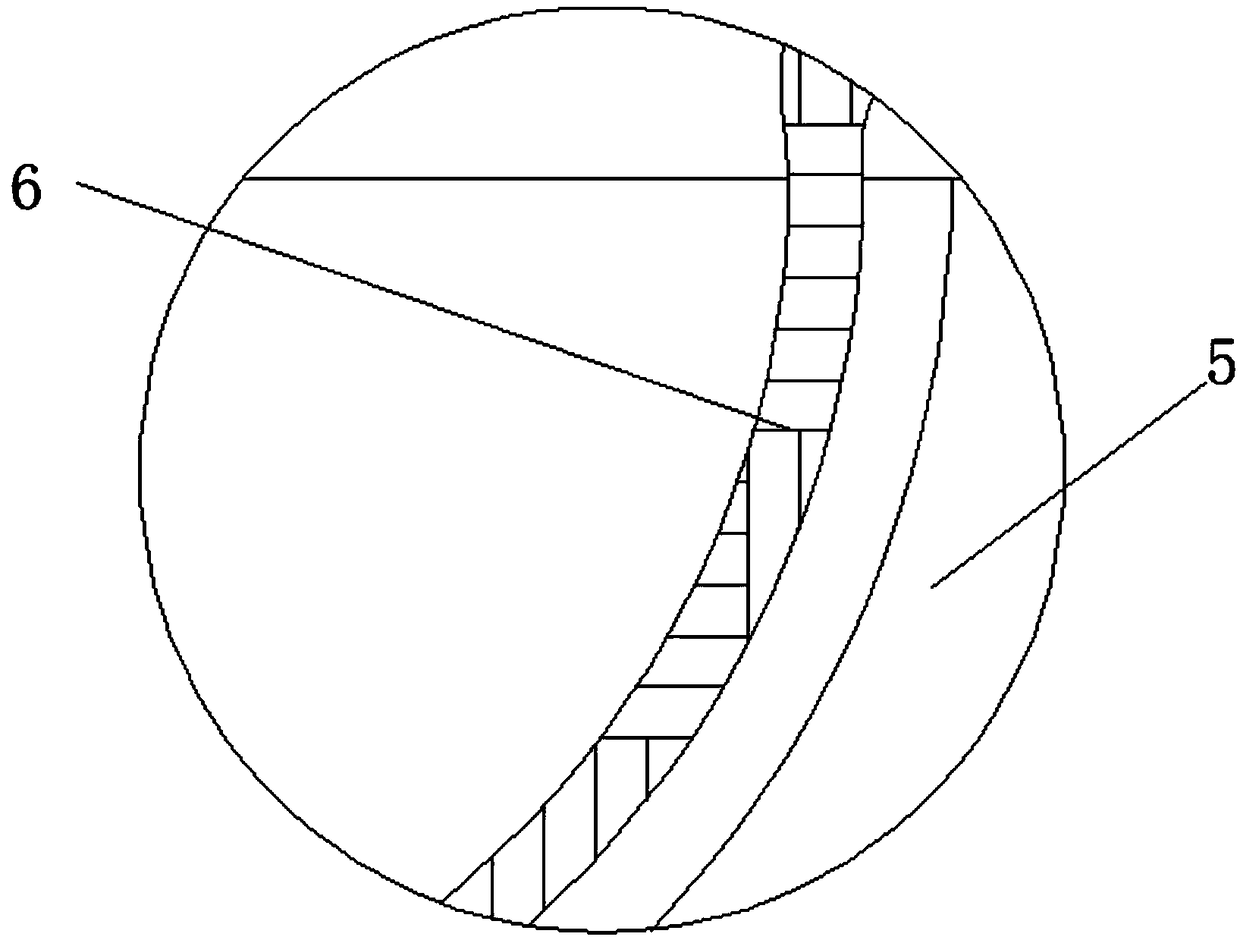

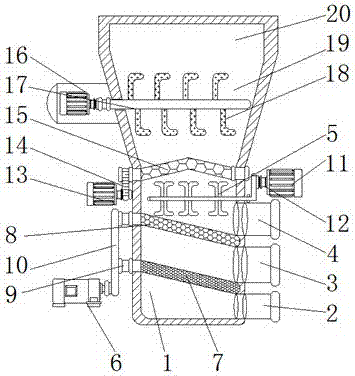

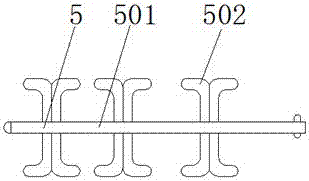

The invention provides a component quality checking device based on line laser three-dimensional measurement and detection method of the device. The quality checking device includes a mobile platform mounted on a guide rail and capable of sliding along the guide rail at a uniform speed. To-be-checked components are fixed on the mobile platform. A camera and a plurality of laser emitters are mounted above the guide rail through a mount. The camera collects images which are casted to the surfaces of the to-be-checked components by the laser emitters and deformed due to surface modulation. The camera transmits the collected image data to a computer for analysis and treatment. According to the detection method, by casting linear stripes emitted by the laser emitters to the surface of the to-be-checked components for linear scanning and by utilizing the camera for collecting image information on the to-be-checked components continuously, measured three-dimensional point cloud data and initially designed three-dimensional image are compared and analyzed in the same coordinate system for judging whether the maximum error is within the maximum permissible error range or not and screening out qualified components. The device provided by the invention is high in detection precision and realizes automatic and flow line production.

Owner:CHANGAN UNIV

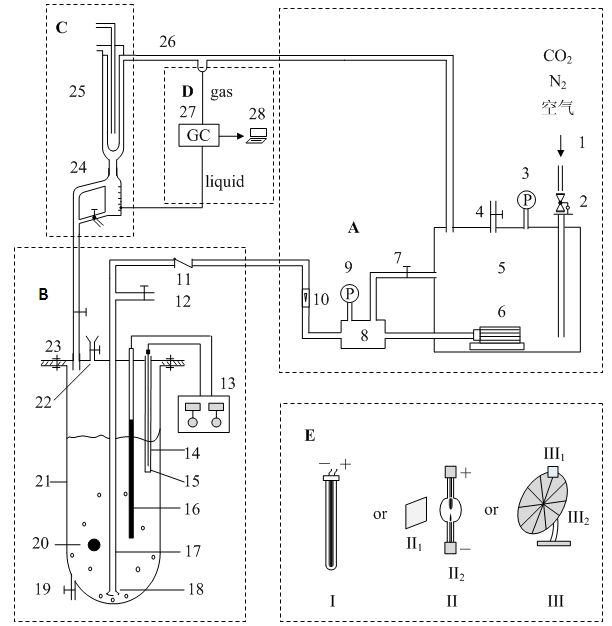

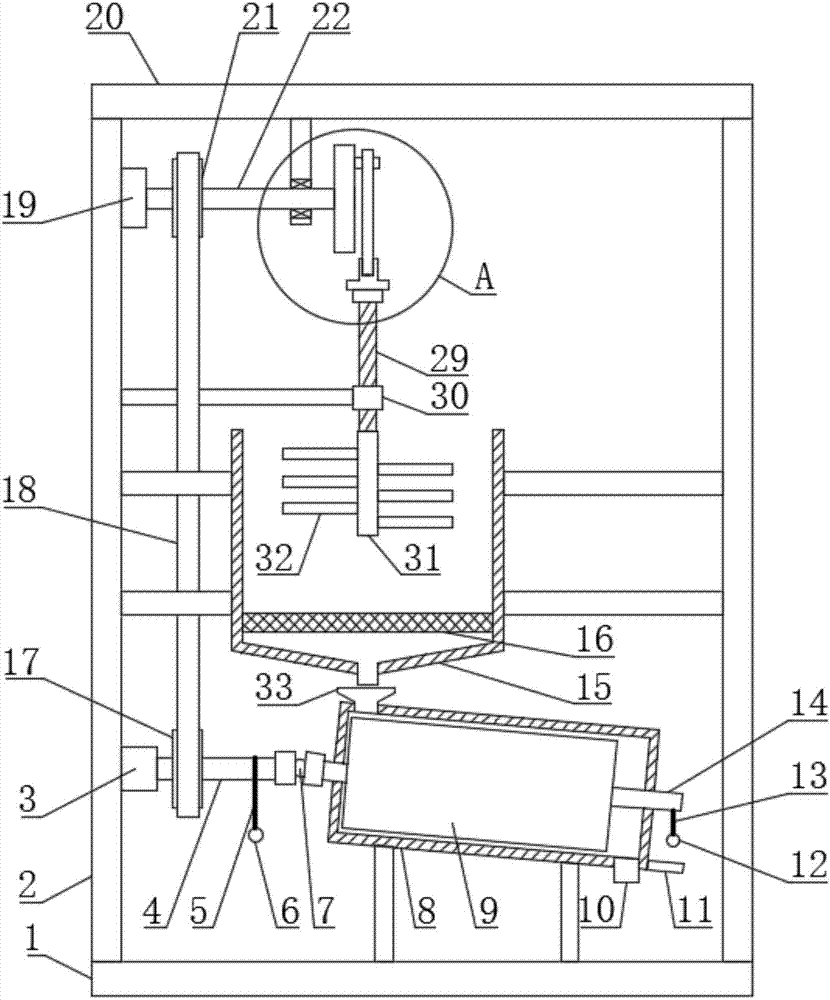

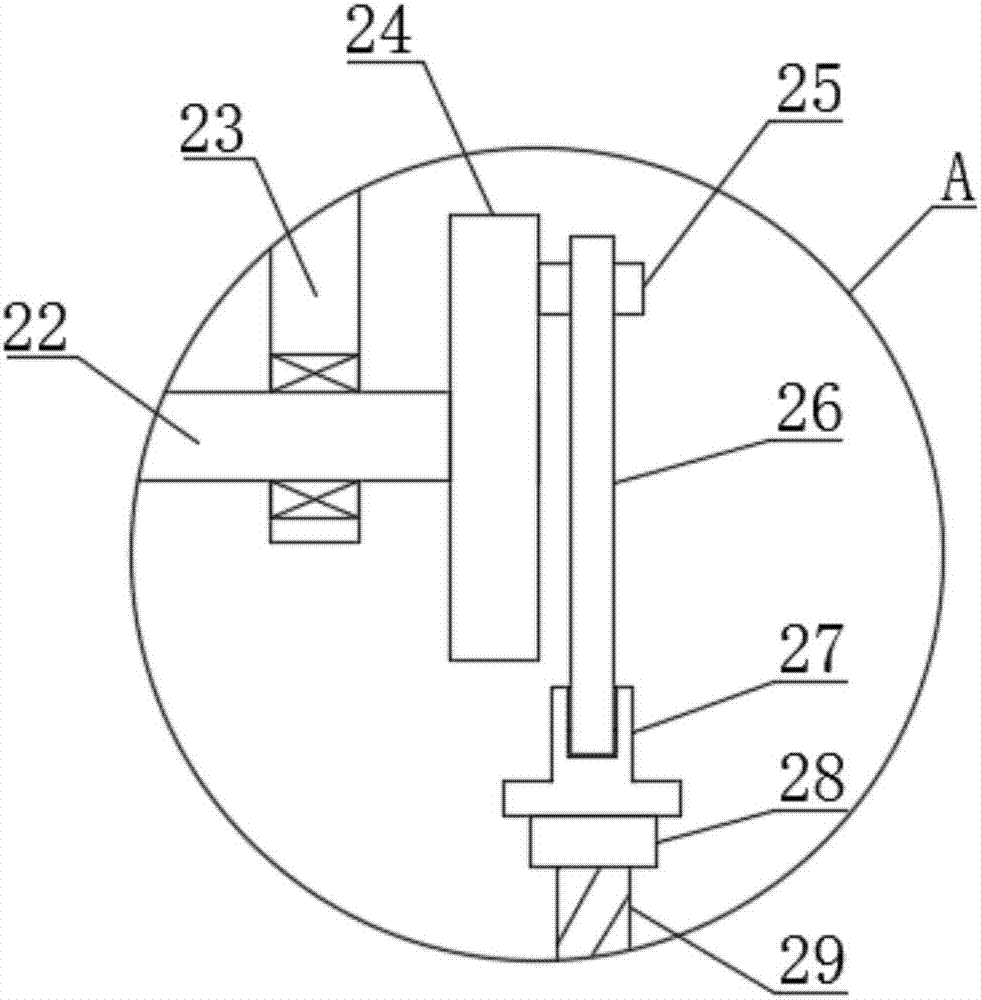

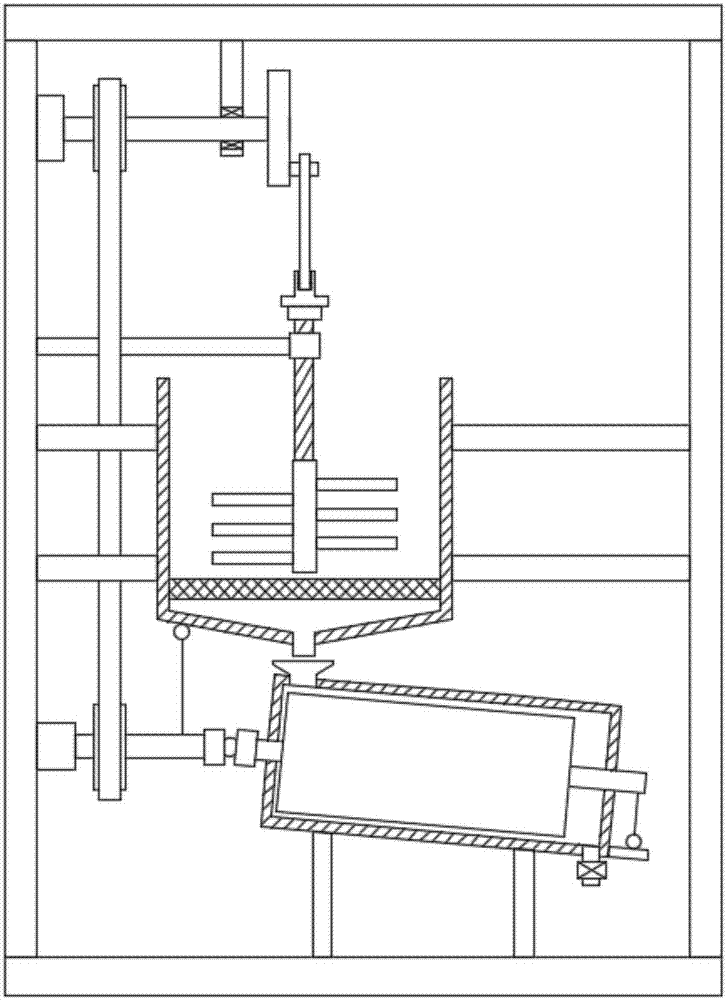

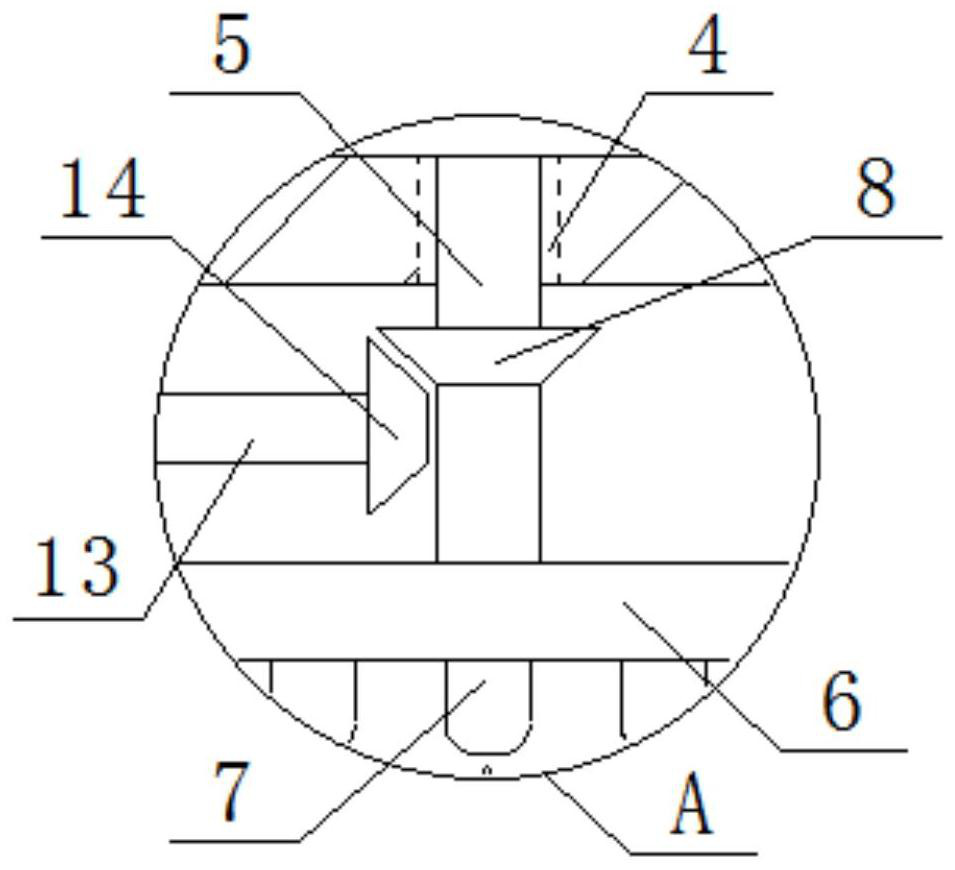

Multifunctional photocatalytic reaction device

InactiveCN102151534ASolve the separation problemWith inert gas protection functionEnergy based chemical/physical/physico-chemical processesPhotocatalytic reactionUltraviolet lights

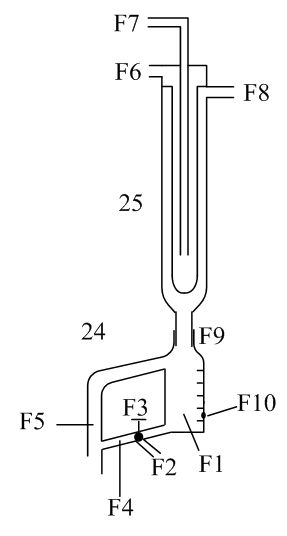

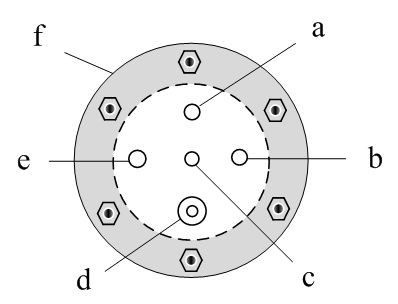

The invention discloses a multifunctional photocatalytic reaction device, which consists of a gas circulation system, a photoreaction system, a separation system, a detection system and a light source system. The light source can be ultraviolet light, visible light and sunlight and is arranged outside a quartz reactor, light penetrates through the quartz reactor to excite a photocatalyst in order to initiate photocatalytic reaction, the photocatalyst can be a thin film which is immobilized, together with a carrier, inside the reactor, or be particles suspended in reaction liquid. The reactor is suitable for liquid-solid, gas-solid and gas-liquid-solid phase photocatalytic reaction, favoring the research on photocatalytic reaction dynamics. The multifunctional photocatalytic reaction device of the invention is suitable not only for photocatalytic reduction CO2 reaction, but also for the fields such as photocatalytic degradation of organic pollutants, hydrogen production by water photolysis, photochemical synthesis and the like, besides, both intermittent operation and continuous operation can be implemented, and inert gas protection can be performed in the reaction process.

Owner:NORTHWEST UNIV(CN)

Cultivating method of tuckahoe

InactiveCN101578945AExpedited screeningGood yieldHorticultureFertilizer mixturesCuticleWolfiporia extensa

The invention discloses a cultivation method of tuckahoe, which comprises the steps of: (1) firstly, the epidermis of the tuckahoe is cut; the tuckahoe is superficially sterilized by 70 to 75% of ethanol and washed with sterile water; the water content of the tuckahoe is blotted up by disinfection cloth or a filter paper; in an aseptic inoculation box, an alcohol burner is lightened, the processed tuckahoe is sliced off by an abacterial knife near fire and the cross section is scraped into be cambered and successively scraped for twice; on the second scraping position, blocks like wheat size are connected on a pure strain culture medium, placed in a greenhouse, and cultured in the temperature of 25 to 30 DEG C till mycelial overgrows; the blocks which are white, are not infected by mixed bacterium, are villous, dense and craggy, vigorously and uniformly grow, secretes white milk pearl mycelium are pure strains; (2) a primary strain cultivation is carried out; (3) a second class strain cultivation is carried out; (4) a third class strain cultivation is carried out. The method is characterized by short production period of mycelium, excellent and stable tuckahoe quality and high yield.

Owner:贵州昌昊中药发展有限公司

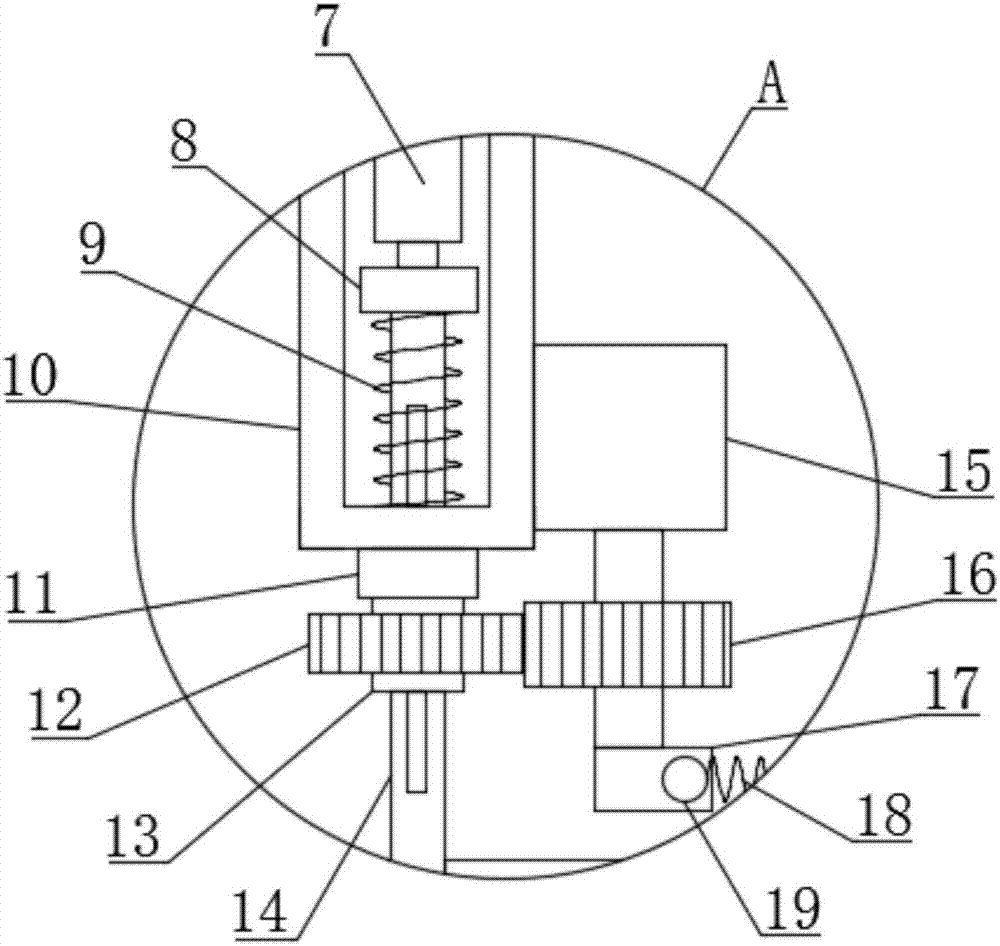

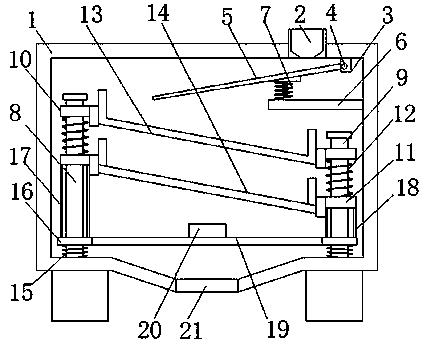

Activated carbon screening device for filter screen of purifier

The invention discloses an activated carbon screening device for a filter screen of a purifier, which comprises a base, a screening box, a first screen frame, a second screen frame, a third screen frame, a rack, a sector gear, a driving motor, a cylindrical wheel, Connecting rods, impact rods and double-axis motors, the first screen frame, the second screen frame and the third screen frame are respectively inserted and installed between the slots on the left and right sides; A toothed rack is slidably installed inside the slot, and the right end of the toothed rack is fixedly welded with an impact bar. The screening device can not only move left and right for screening, but also can vibrate up and down for screening, thereby greatly speeding up the screening speed, improving production efficiency and speeding up production tempo.

Owner:黄莉

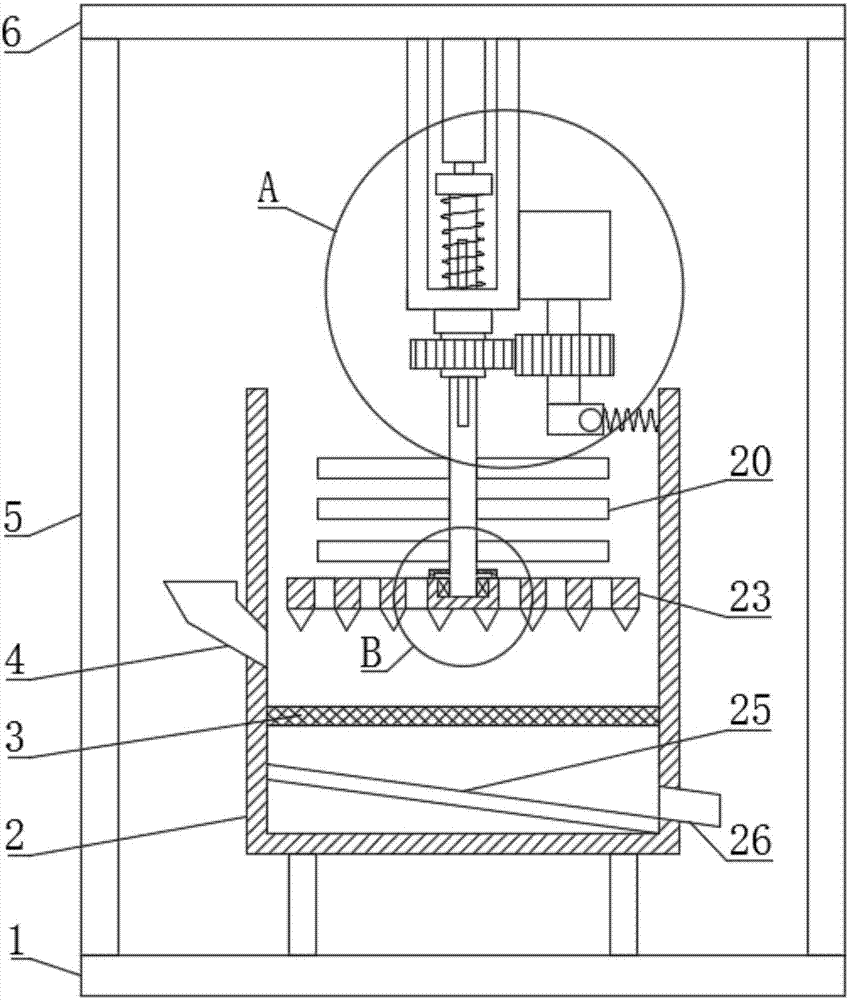

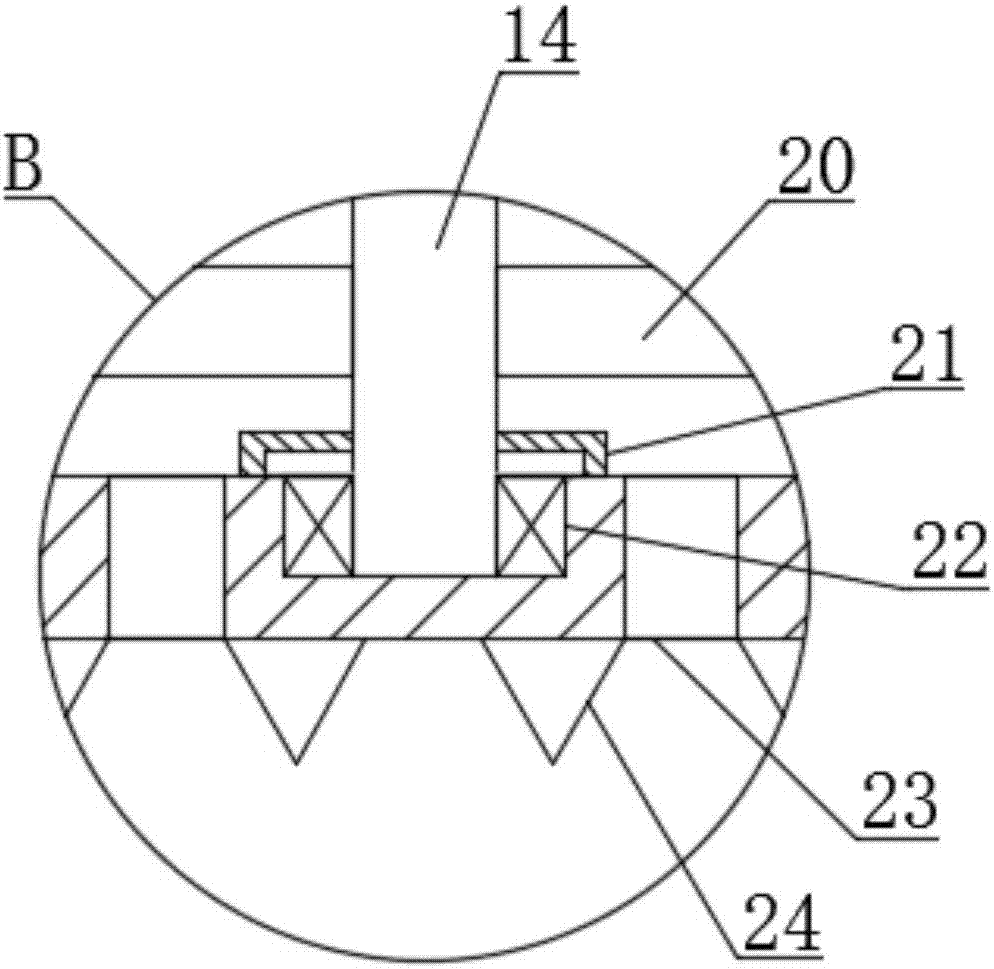

Rapid stone breaking-screening device for building

InactiveCN107377118AExpedited screeningImprove crushing qualityGrain treatmentsEngineeringMotor shaft

The invention discloses a rapid stone breaking-screening device for a building. The rapid stone breaking-screening device comprises a bottom plate and a breaking bucket, wherein a support is arranged at a bottom of the bottom plate, a plurality of support arms are connected to a sidewall of the breaking bucket, a crank mechanism is rotationally connected to a bottom of each support arm through a bearing, and a mounted bearing is connected to each crank mechanism through a first rotary shaft and arranged on the bottom plate; a driven gear is installed on a first rotary shaft at a left side, a first motor is arranged on the bottom plate, and a drive gear is installed on a motor shaft at a top end of the first motor and engaged with the driven gear; and a second motor is arranged at the centre of a top of the crushing bucket, a second rotary shaft is connected to a motor shaft at a bottom end of the second motor, a crushing blade is installed on the second rotary shaft, and a filter screen is further arranged at a bottom of the breaking bucket. According to the rapid stone breaking-screening device disclosed by the invention, the broken stone is screened through the arrangement of the filter screen; and the stone in the breaking bucket can be driven to swing to increase breaking efficiency, and stone screening can also be accelerated to prevent the filter screen from being blocked through crank structures.

Owner:泉州森泸玩具有限公司

Recommendation method and device of video data

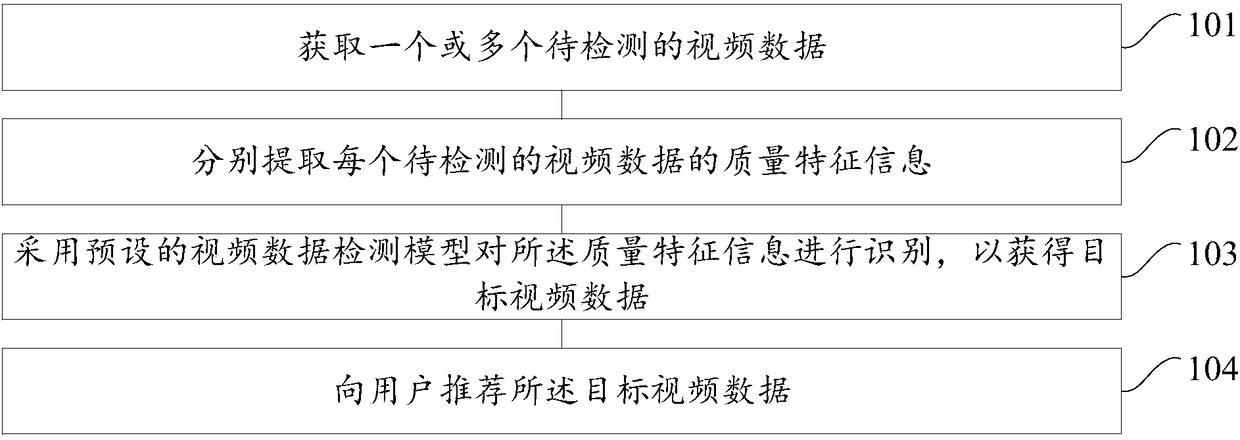

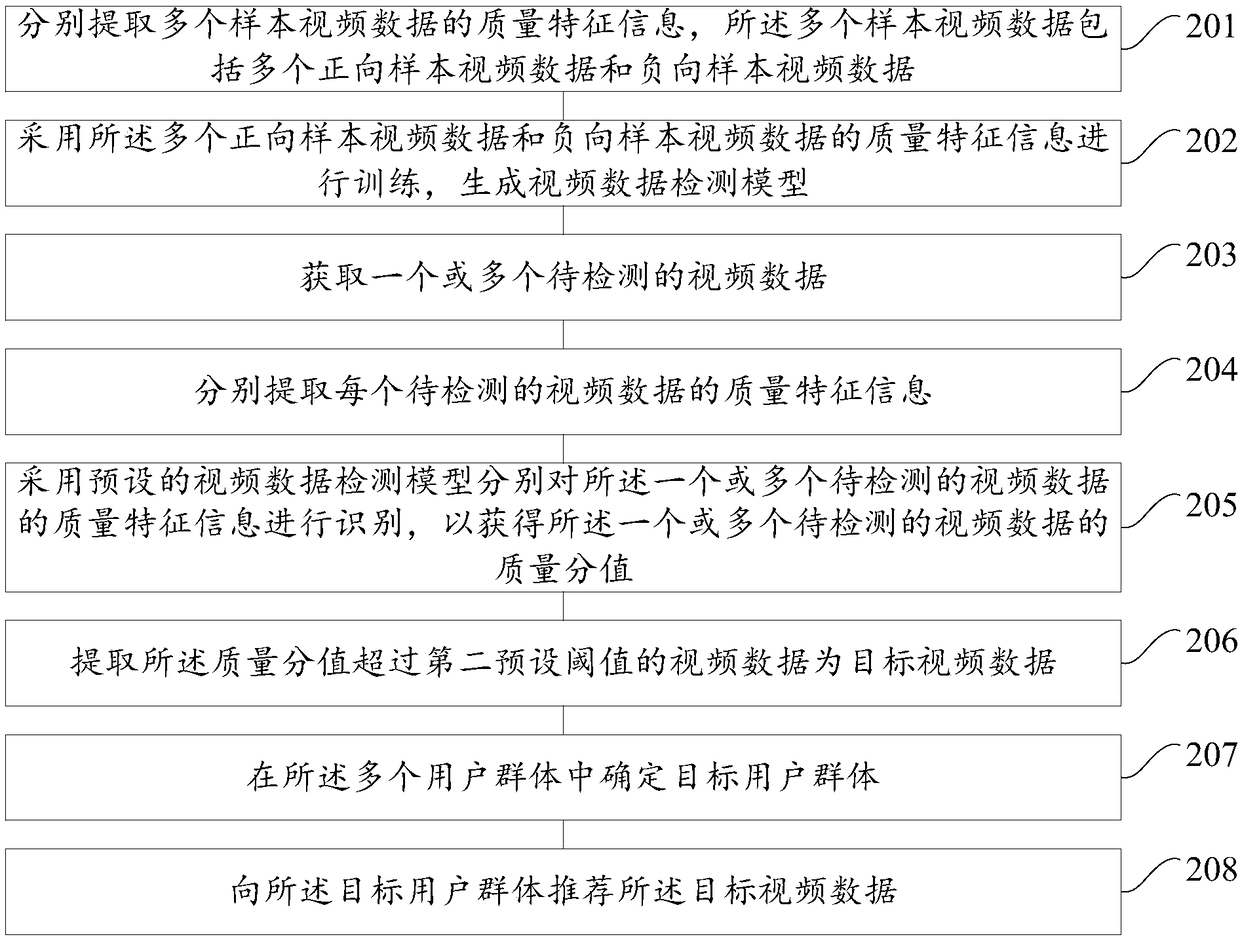

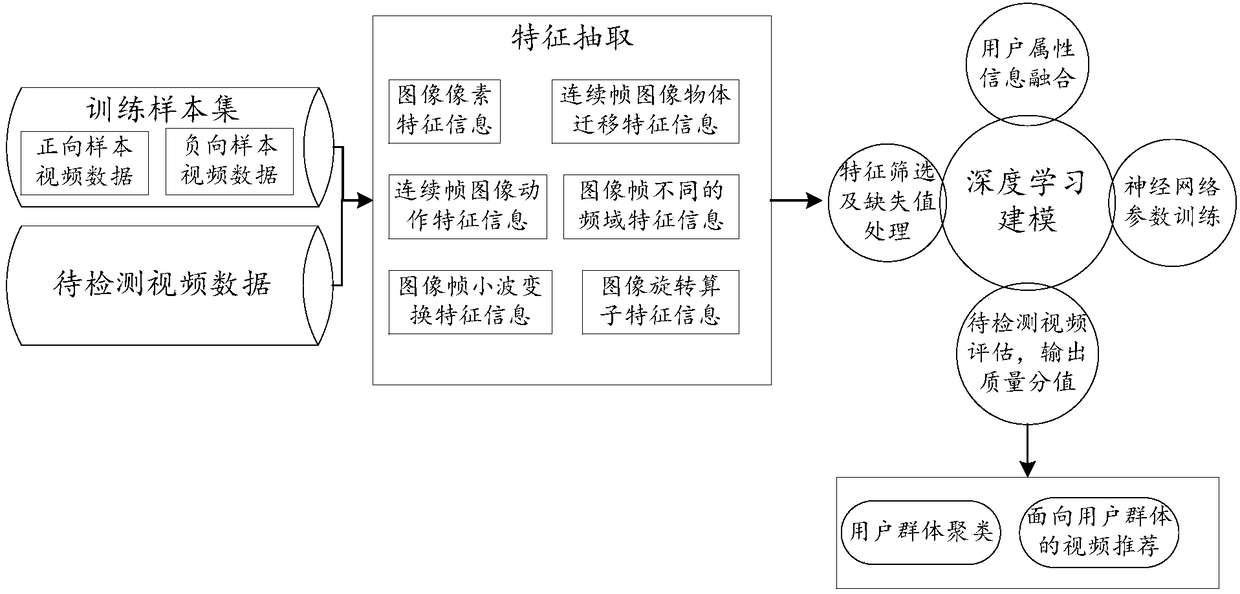

InactiveCN108509457AImprove recognition efficiencyImprove accuracyCharacter and pattern recognitionSelective content distributionPattern recognitionData detection

The embodiment of the application provides a recommendation method and device of video data. The recommendation method includes: acquiring one or more pieces of to-be-detected video data; respectivelyextracting quality feature information of each piece of to-be-detected video data; using a preset video data detection model to identify the quality feature information to obtain the target video data; and recommending the target video data to a user. According to the embodiment of the application, the high-quality video data can be quickly screened out through using the deep learning model, theproblem that in the prior art, recommendation of video fragments to users can only rely on manual identification is solved, and identification efficiency on the video data and accuracy of recommendation are improved.

Owner:ALIBABA GRP HLDG LTD

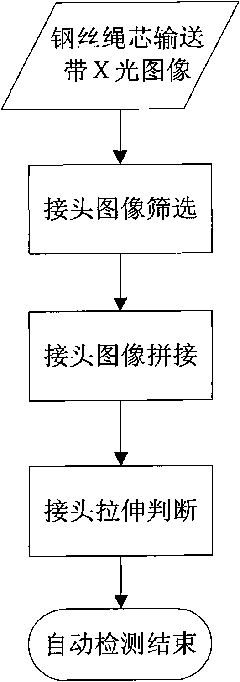

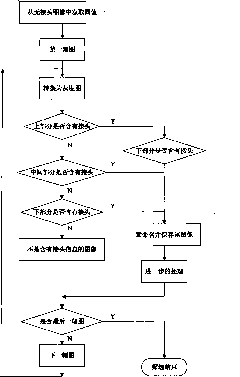

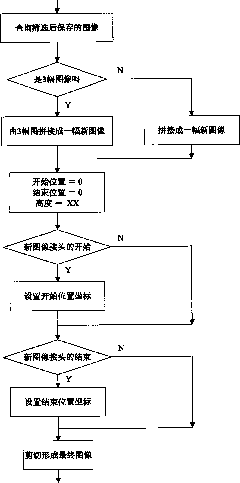

X-ray imaging stretching fault automatic detection method for steel cable core conveying belt joint

ActiveCN101825584ARealize detectionImprove use valueImage enhancementCharacter and pattern recognitionGray levelX-ray

The invention relates to an X-ray imaging stretching fault automatic detection method for a steel cable core conveying belt joint, which belongs to the field of X-ray nondestructive detection. Defects of lower reliability, poorer accuracy, non-visual display, dependence mainly on manual detection and the like exist in the current stretching fault detection of a current steel cable core conveying belt joint. The invention consists of the following three aspects: 1. on the basis of the gray level change characteristic of X-ray images of a steel cable core conveying belt, screening out images containing partial or all joint information from the X-ray images of the whole steel cable core conveying belt by adopting local histogram information; 2. splicing the screened images into the corresponding image containing the complete joint information; and 3. realizing the judgment for the stretching of each joint by adopting an improved condition Y-difference algorithm and a clustering method. The invention can automatically, rapidly and efficiently realize the stretching fault detection of the steel cable core conveying belt joint.

Owner:TIANJIN POLYTECHNIC UNIV +1

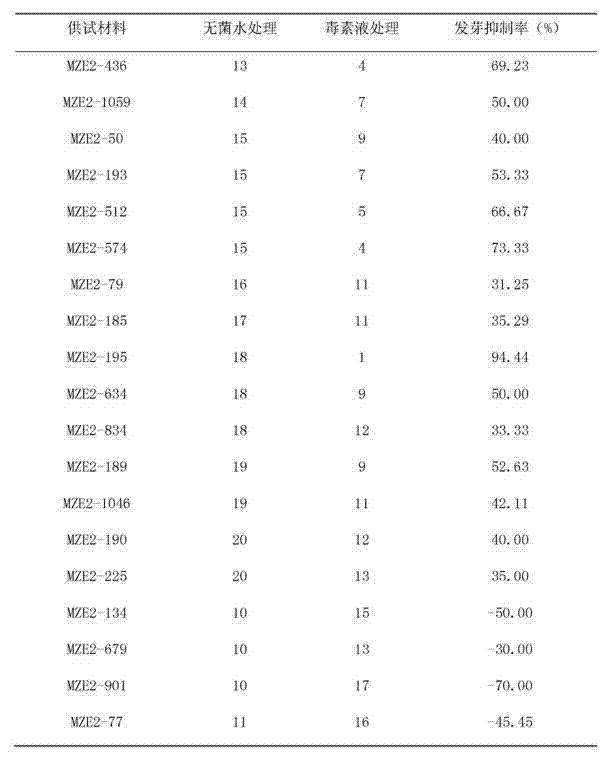

Rapid identification method of tobacco black shank resistance

ActiveCN103081678ARapid identificationHigh test costHorticultureAgricultural sciencePityophthorus nitidulus

The invention discloses a rapid identification method of tobacco black shank resistance. The rapid identification method of the tobacco black shank resistance includes the following steps of (1) sterilizing the surface of tobacco seeds to be identified; (2) cultivating tobacco blank shank germs and preparing suspension liquid of conidium of the tobacco blank shank germs; (3) extracting toxin liquid of the tobacco blank shank germs; (4) germinating the seeds after soaking seed in the toxin liquid and calculating rate of emergence of the seeds and evaluating the resistance. The rapid identification method of the tobacco black shank resistance is easy to operate, low in cost, rapid, high in accuracy, and appropriate for black shank resistance identification in tobacco breeding research.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD

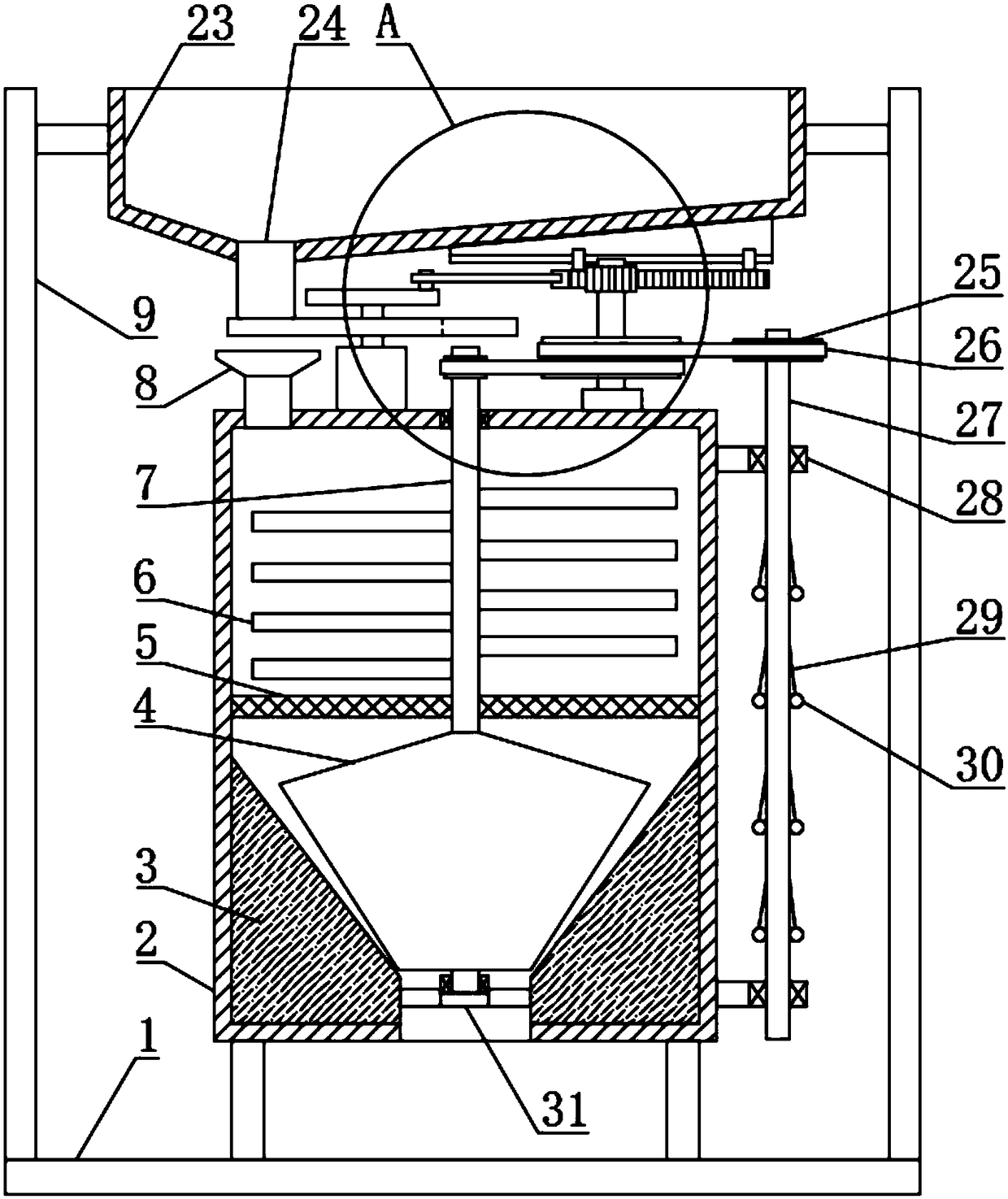

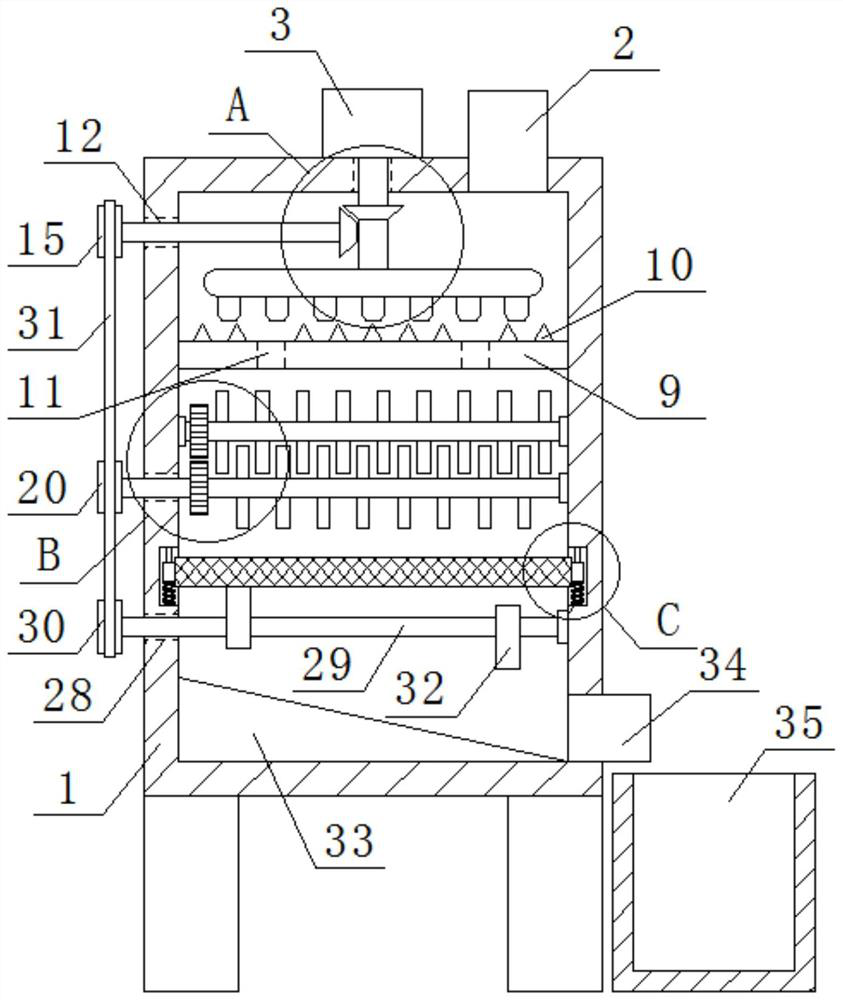

Construction waste dual-crushing and screening device

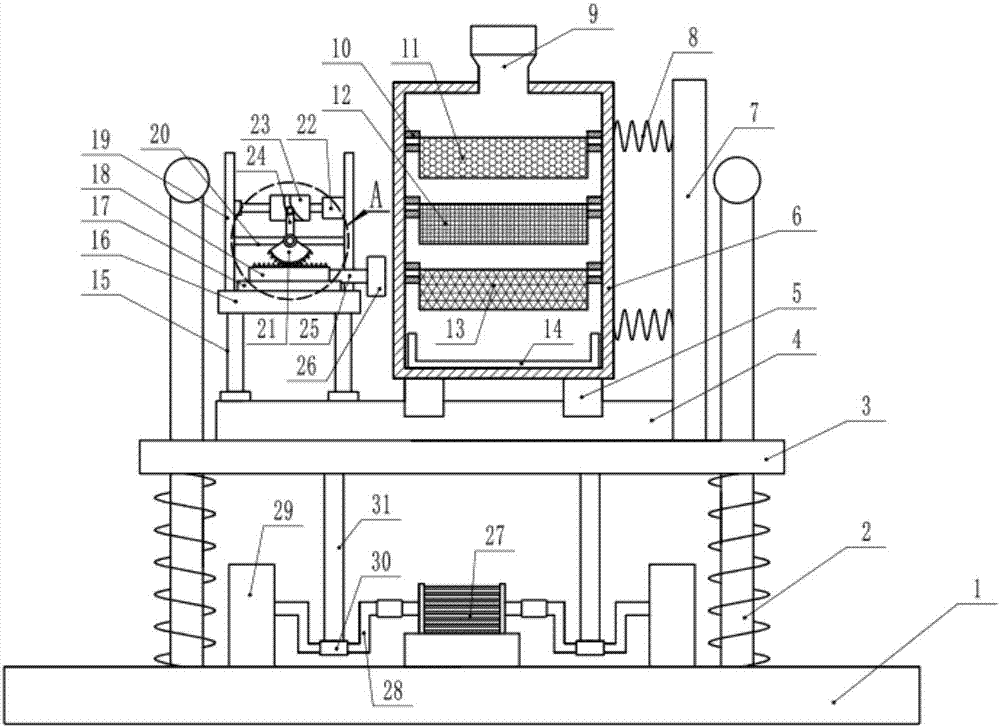

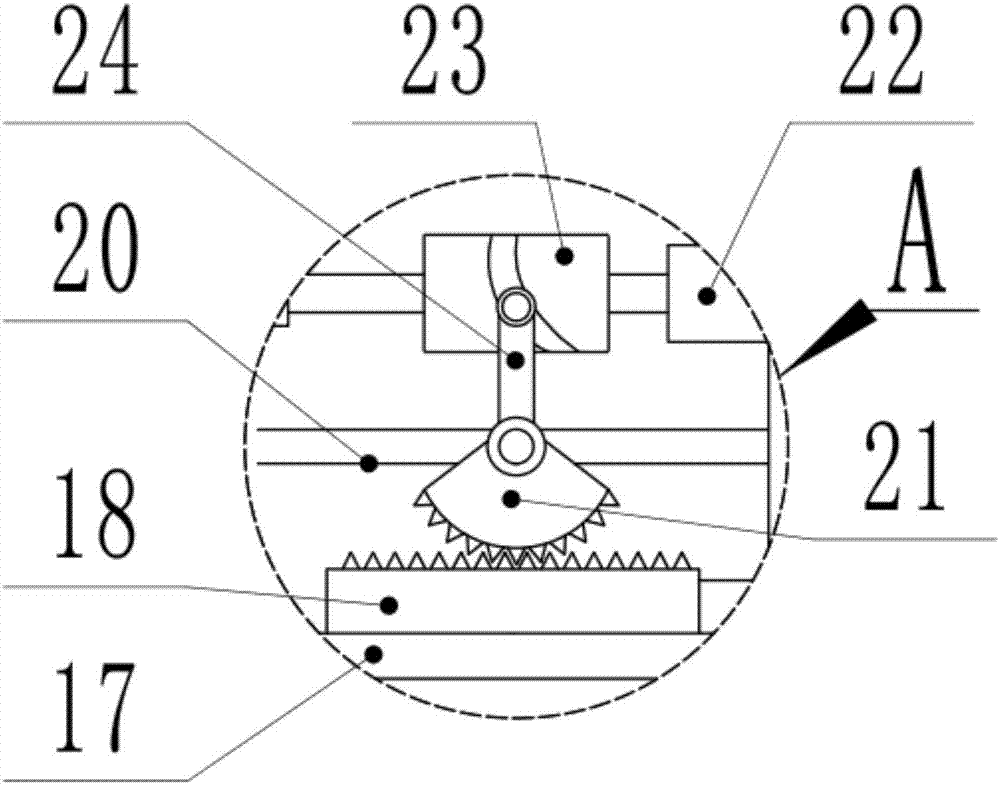

PendingCN107469940AFully brokenPromote fragmentationGrain treatmentsConstruction waste recoveryHydraulic cylinderGear wheel

The invention discloses a construction waste dual-crushing and screening device which comprises a base, wherein a crushing box is fixedly arranged on the base through a bracket; a sieve plate is fixedly arranged in the crushing box; support plates are arranged on left and right sides of the top of the base; a top plate is arranged at the tops of the support plates; a U-shaped plate is fixedly arranged at the bottom of the top plate; a hydraulic cylinder is further arranged at the bottom of the top plate; the bottom end of the piston rod of the hydraulic cylinder is rotatably connected with a first mounted bearing; a spline shaft is fixedly connected with the bottom of the first mounted bearing; a compression spring is connected onto the spline shaft in a sleeving manner; a second mounted bearing is further arranged at the bottom of the U-shaped plate; a rotary sleeve is rotatably connected below the second mounted bearing; a first gear is mounted on the rotary sleeve; smashing blades are further mounted on the spline shaft; and the bottom end of the spline shaft is rotatably connected with a crushing plate through a bearing. According to the construction waste dual-crushing and screening device, construction waste is first extruded and crushed by the crushing plate, and then, the crushed construction waste penetrates through through holes in the crushing plate to be crushed by the smashing blades rotating at a high speed, so that the construction waste is more sufficiently crushed.

Owner:ZHENGZHOU UNIV

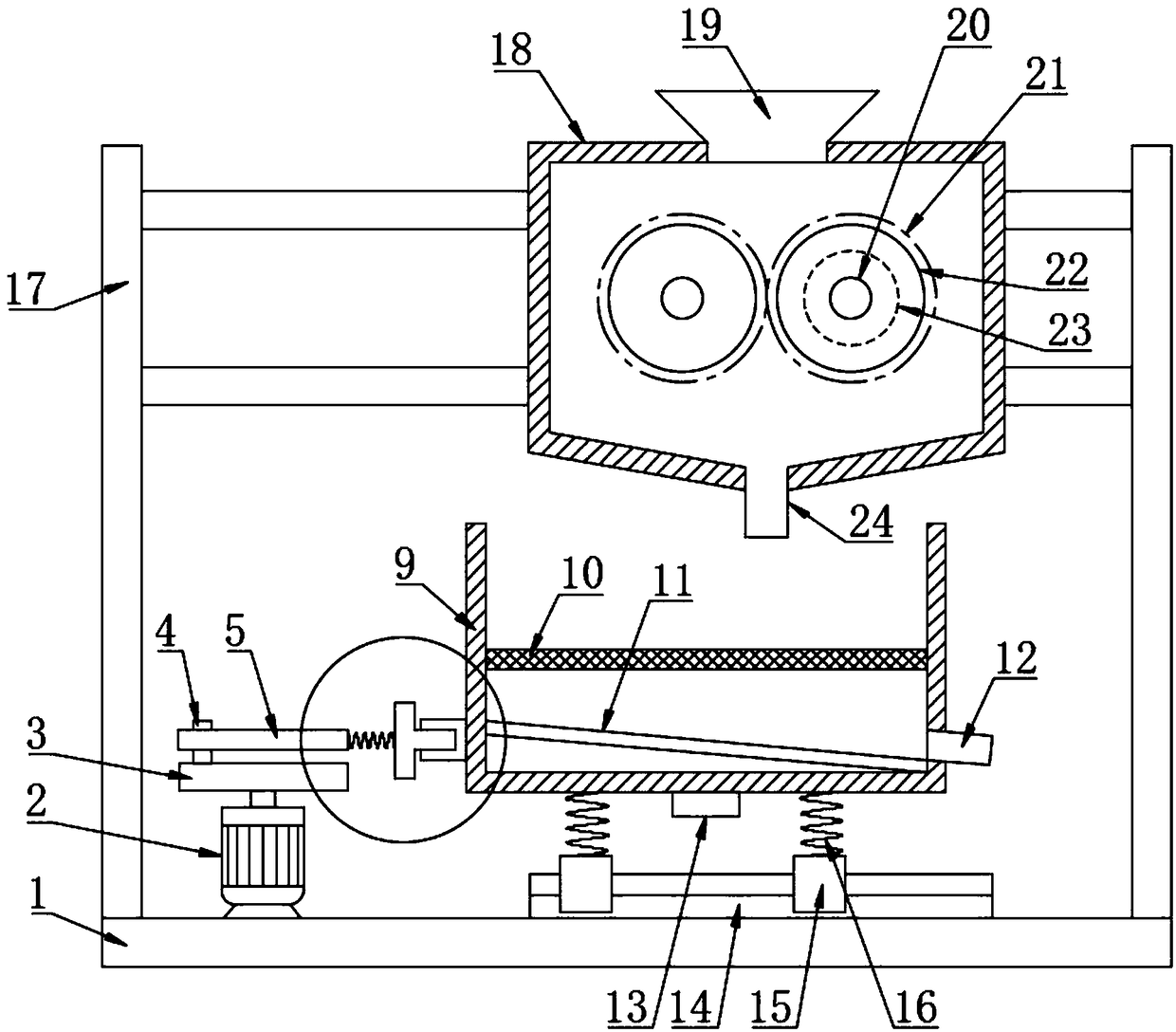

Quantitative crushing and grinding device for Chinese herbal medicines

InactiveCN108514946ANo need to add frequentlyGuaranteed qualityGrain treatmentsMedicinal herbsEngineering

The invention discloses a quantitative crushing and grinding device for Chinese herbal medicines. A working box is fixedly arranged at the top of a base through a bracket; a sieve plate is arranged atthe middle position in the working box; a grinding seat is further arranged at the bottom in the working box; the grinding seat is located below the sieve plate; a first rotary shaft is further arranged at the central position in the working box; a grinding roller and crushing blades are mounted on the first rotary shaft; supporting plates are arranged at left and right sides of the base; a medicinal material box is fixedly arranged at the tops of the supporting plates through brackets; a discharging pipe is arranged at the bottom of the medicinal material box; the discharging pipe is locatedabove a feeding funnel; a speed reducing motor is further arranged at the top of the base; a discharging disc is mounted on a motor shaft of the speed reducing motor; the top of the discharging discis fitted to the bottom of the discharging pipe. According to the quantitative crushing and grinding device disclosed by the invention, discharging is automatically controlled through rotating the discharging disc so that the amount of medicinal materials processed each time is relatively fixed and the medicinal materials do not need to be frequently added, and furthermore, the working efficiencyis improved; the medicinal materials are crushed through the crushing blades; the crushed medicinal materials are sieved and then are ground through the grinding roller, so that the quality of the medicinal materials is ensured.

Owner:童振锴

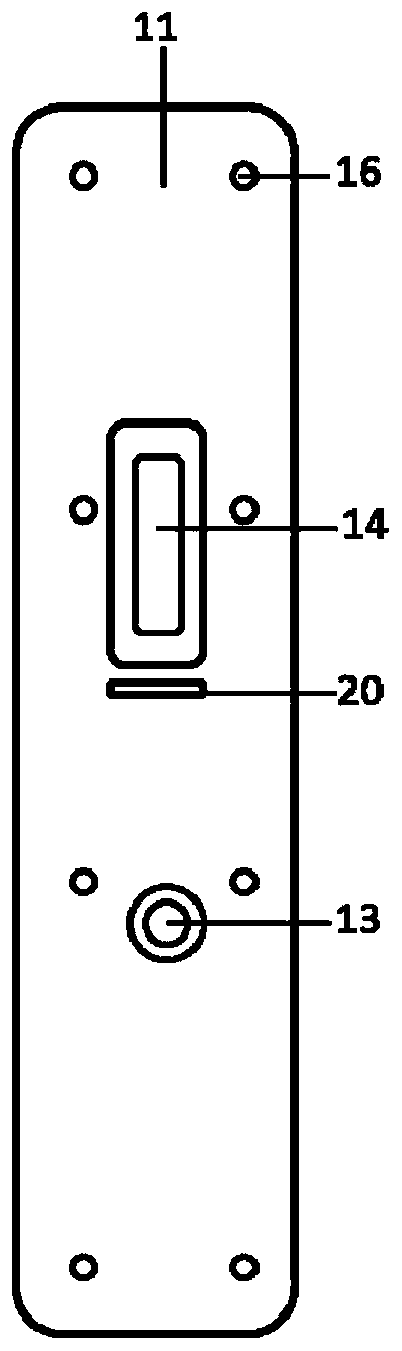

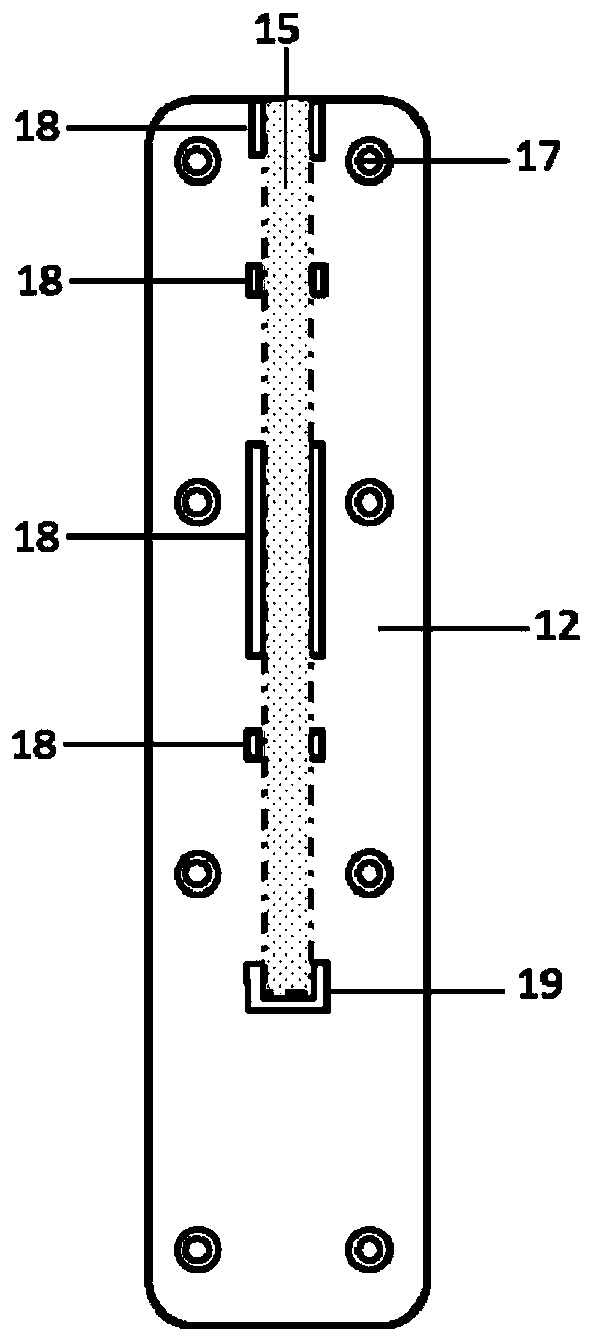

Immunochromatographic kit for rapidly detecting novel coronavirus N protein as well as preparation method and application of immunochromatographic kit

PendingCN111398589AThe detection process is fastEasy to operateImmunoassaysAlveolar lavage fluidSaliva sample

The invention relates to an immunochromatographic kit for rapidly detecting novel coronavirus N protein as well as a preparation method and application of the immunochromatographic kit. The immunochromatographic kit comprises a test strip, the test strip comprises a detection line and a quality control line, the detection line is coated with an anti-novel coronavirus N protein antibody, and the quality control line is coated with a goat anti-rabbit polyclonal antibody. The immunochromatographic kit for rapidly detecting the novel coronavirus N protein provided by the invention can be used fordetecting the novel coronavirus N protein in a nasopharynx swab, an oropharynx swab, an alveolar lavage fluid, an oral swab or a saliva sample so as to be used for diagnosing novel coronavirus pneumonia.

Owner:BEIJING ELCOTEQ BIO TECH

Waste plastic circular granulation device

InactiveCN107553785AImprove quality and efficiencyIncrease productivitySievingScreeningArchitectural engineeringProduction quality

The invention discloses a waste plastic circular granulation device. The device comprises an outer frame; the bottom end in the outer frame is fixedly connected with a moving device; the top end of the moving device is fixedly connected with a screening plate; the bottom end of a fixed hanging rod is rotationally connected with a particle crushing rotary cutter; the bottom end of the external of the outer frame is fixedly connected with a circulating outer frame; a circulating outlet is formed in one side of the top end of the circulating outer frame; the top end of the external of the outer frame is fixedly connected with a feeding device; a feed port is formed between fixed hanging rods at the top end of the outer frame; and a collecting frame is fixedly connected below the screening plate at the bottom end in the outer frame. The device relates to the technical field of plastic product machinery. The waste plastic circular granulation device solves the problems of incapability of screening in the granulation process by a plastic granulator and incapability of circularly crushing unqualified plastic particles, improves the production efficiency and the production quality, and accelerates the screening speed.

Owner:湖州骏马包装材料有限公司

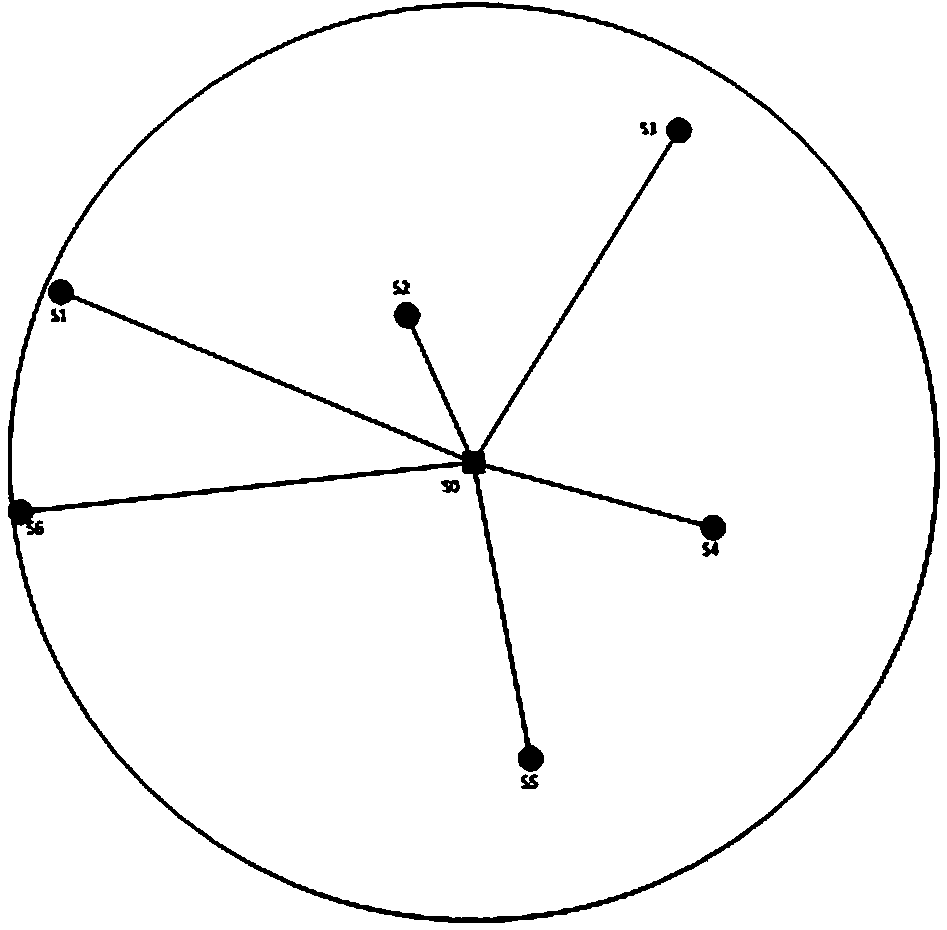

Method for rearranging information of points of interest

ActiveCN102682128AReduce redundancyAccurate exclusionSpecial data processing applicationsLongitudeComputer science

The invention relates to an information rearrangement technology. A method for rearranging information of points of interest comprises the following steps of: 1, receiving information of a point of interest A by a system; 2, inquiring names of all points of interest in a first region by taking the longitude and latitude of the point of interest A as a reference point; 3, matching and rearranging the point of interest A and other searched points of interest according to a position excursion matching method, and thus obtaining a rearrangement result and matching precision; 4, if the matching precision P1 obtained in the step 3 is greater than or equal to preset precision P', turning to the step 9, otherwise, turning to the step 5; 5, inquiring names of all points of interest in a second region range, and repeating the step 3; 6, if the matching precision P2 obtained in the step 5 is greater than or equal to the preset precision P', turning to the step 9, otherwise, turning to the step 7; 7, inquiring names of all points of interest in a third region range, and repeating the step 3; 8, if the matching precision P3 obtained in the step 3 is greater than or equal to preset precision P', turning to the step 9; and 9, outputting the rearrangement result.

Owner:XIAMEN YAXON NETWORKS CO LTD

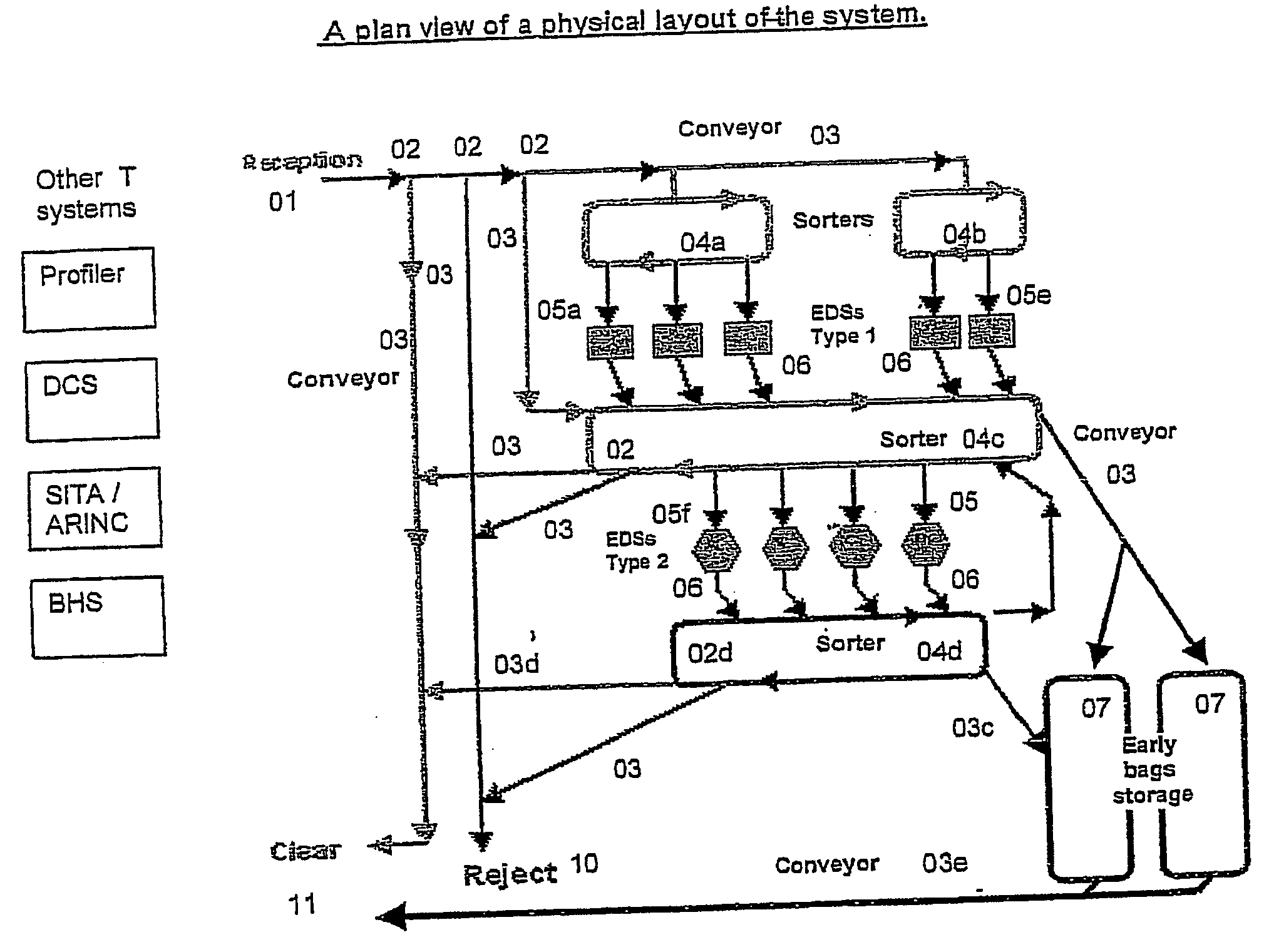

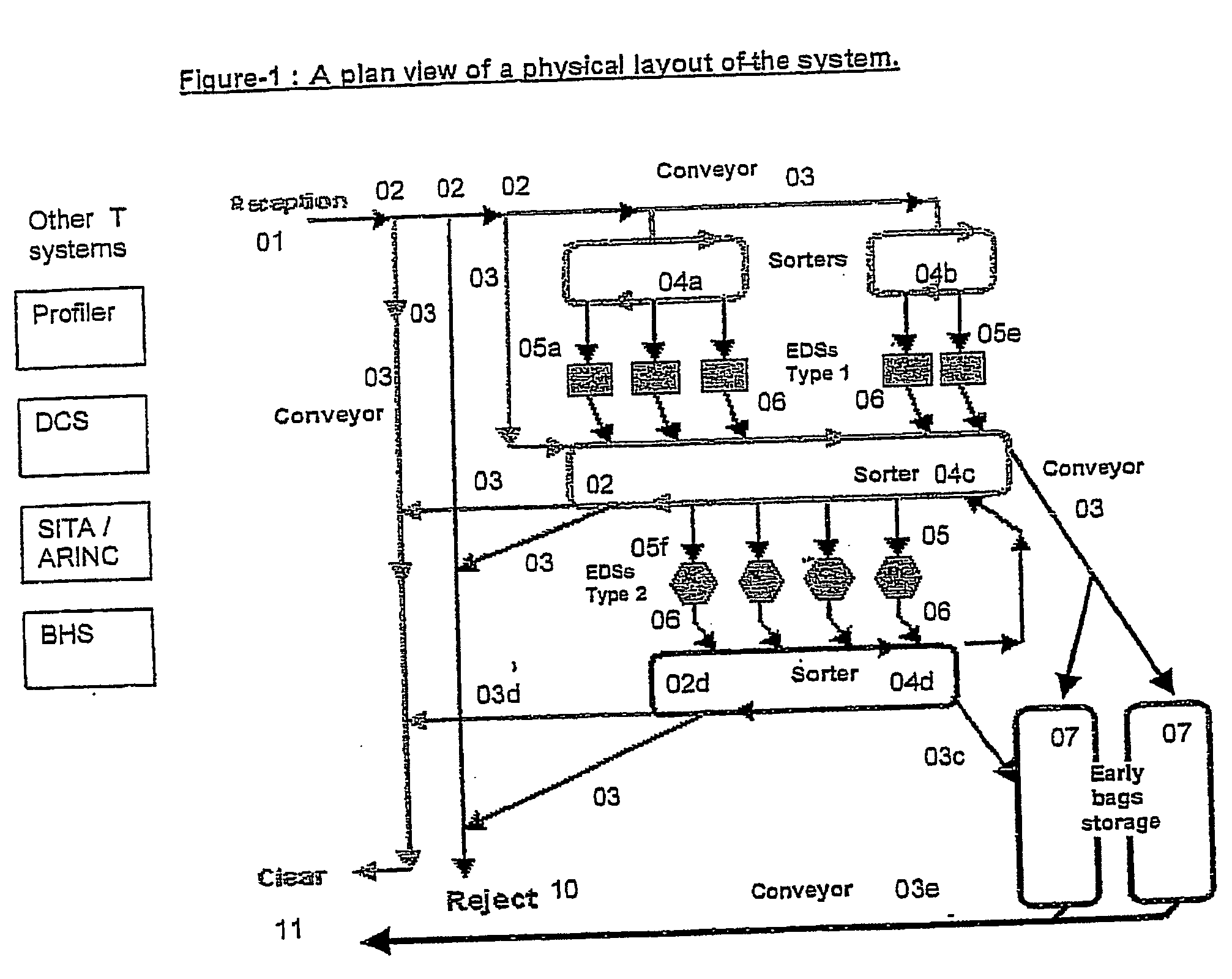

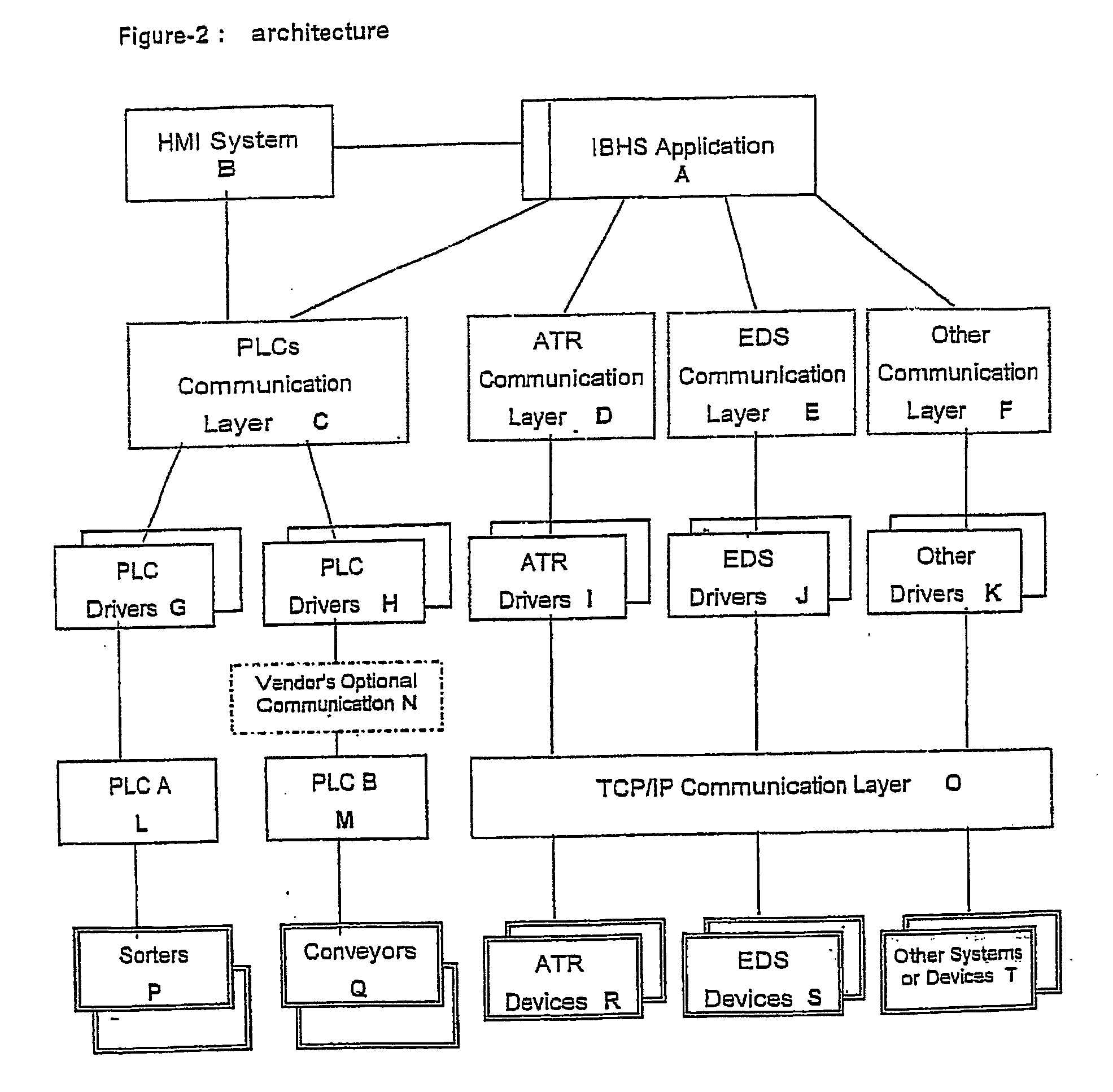

Screening system for objects in transit

InactiveUS20050177271A1Improve the detection rateMinimal labor costDigital data processing detailsFreight handling installationsBorder crossingControl system

The present invention relates to the screening of objects in-transit and materials, for security purposes (i.e. explosives detection). The invention provides an adjustable computerized system suitable for use at airports, seaports, land terminals, distribution centers, railway terminals, border crossings or other transit terminals, in order to achieve maximal efficiency and detection reliability, by adjustment of the screening process of any specific object to its risk factor in conjunction with the characteristics of the available in-line detection equipment. The invention provides an automated security inspection and conveying system for in-transit objects, comprising means for identifying the sender of each package and to profile and import the security status data relevant to the object into the system, and a plurality of various security screening machines in combination with conveying and sorting components. The system tracks each package from a reception point through the conveyors and screening machines to reach a sorting junction, via a user-adjustable screening process, the conveying and sorting components being interfaced with the security status data for assigning a risk assessment factor to the object and the sender. Each package is routed via an appropriate number of screening devices, the output of the screening devices being processed and the risk assessment factor being adjusted accordingly, the new risk assessment factor being sent to a control system of the conveying and sorting components.

Owner:SECURELOGIC

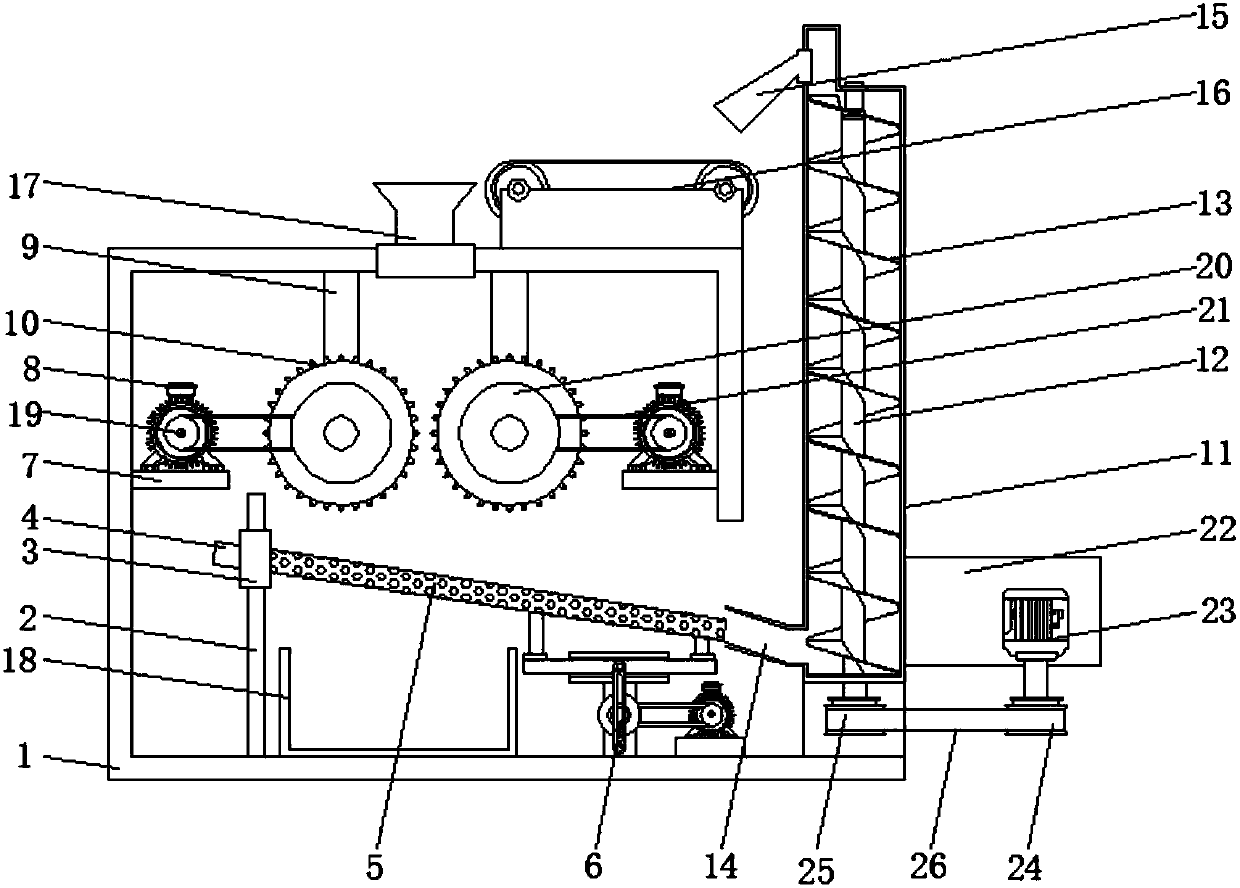

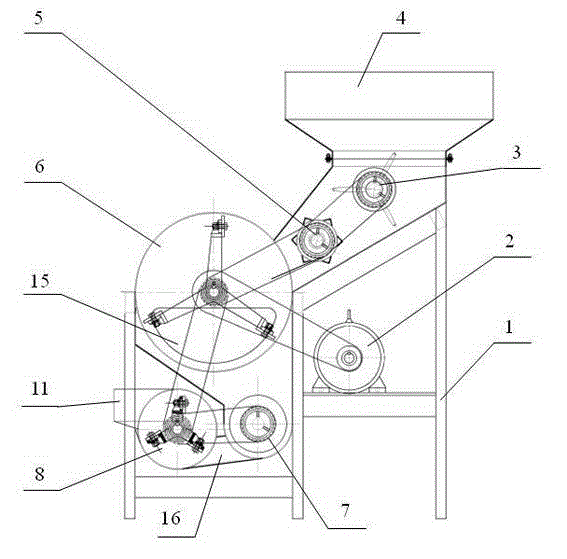

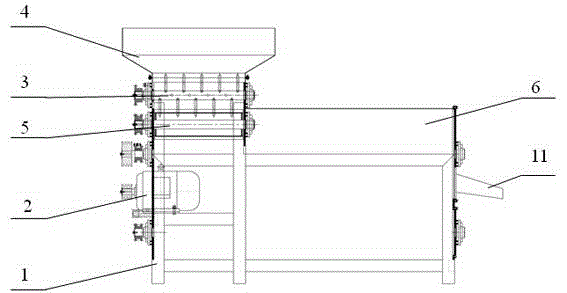

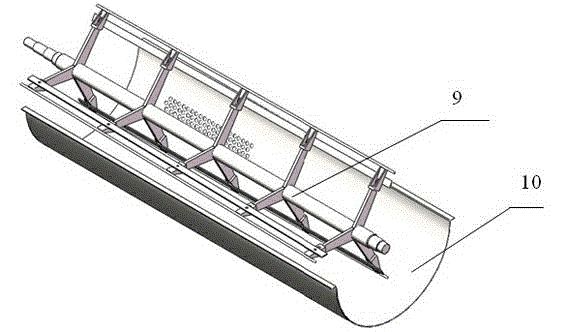

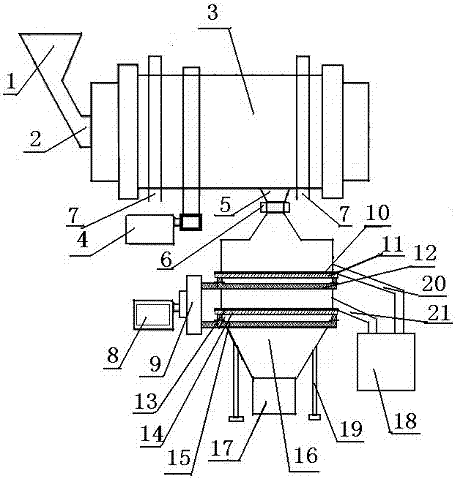

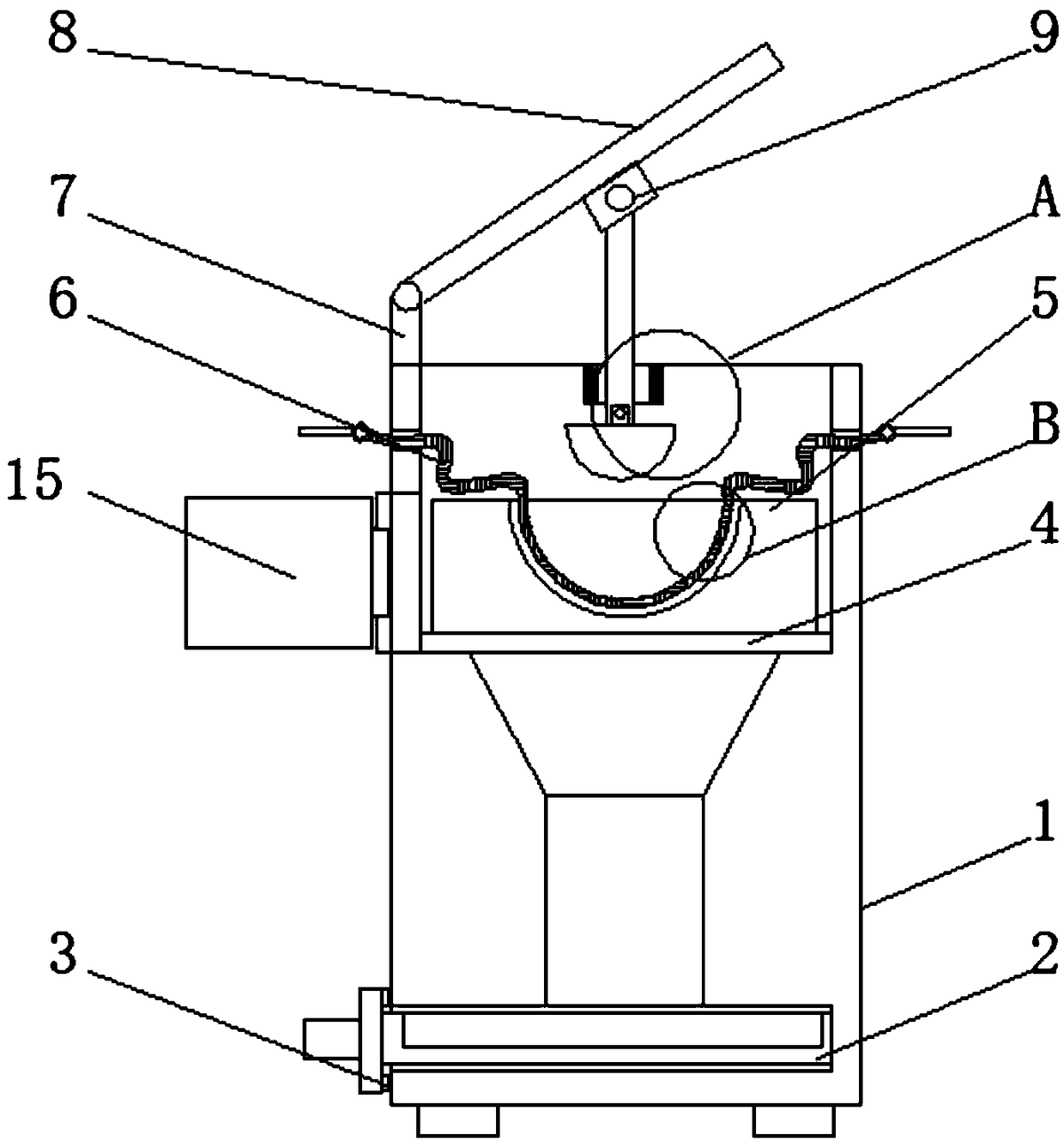

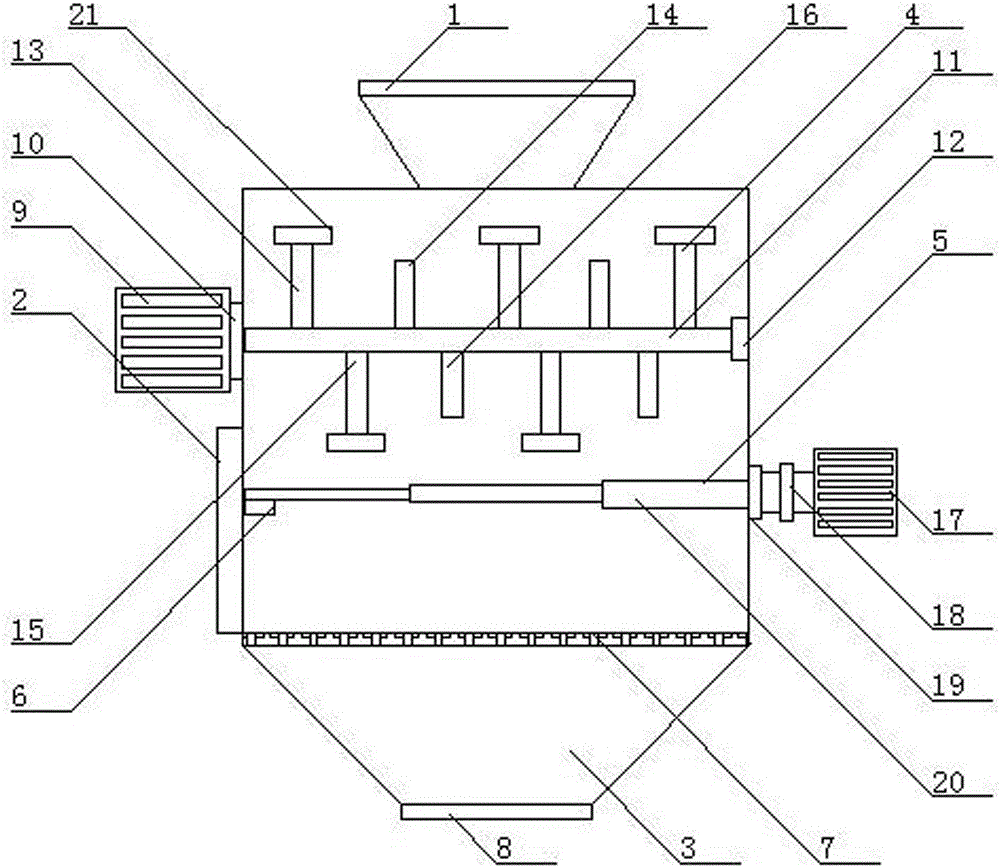

Seed melon crushing seed-taking machine

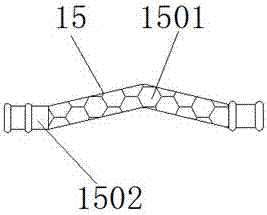

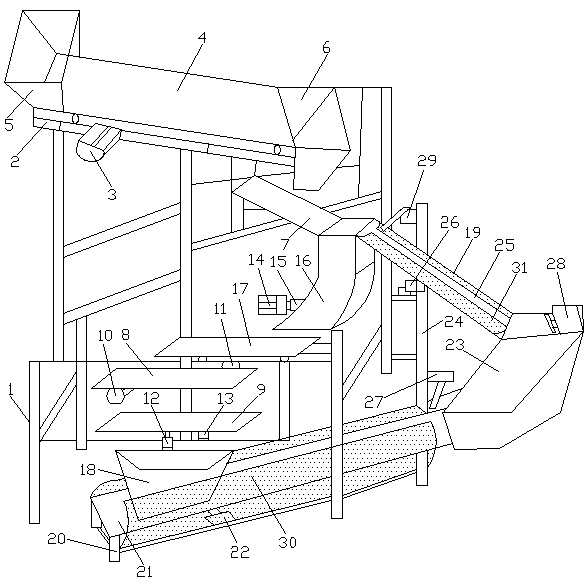

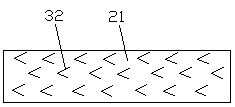

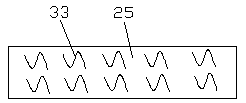

InactiveCN103329685AEffective hygienic separationNovel structureSievingScreeningProduction lineMotor drive

The invention discloses a seed melon crushing seed-taking machine, wherein a feed hopper, a motor, a crushing device, a skin and pulp separation device, a spiral crushing delivery device and a seed and pulp separation device are arranged on a rack of the seed-taking machine; the motor drives the crushing device, the skin and pulp separation device, the spiral crushing delivery device and the seed and pulp separation device; the feed hopper is arranged above an inlet of the crushing device, and an outlet of the crushing device is communicated with an inlet of the skin and pulp separation device; the bottom end of the skin and pulp separation device adopts a screen structure and communicated with the spiral crushing delivery device; an outlet of the spiral crushing delivery device is communicated with the seed and pulp separation device. According to the invention, the effective and sanitary separation of the seed melon skin, pulp and seeds is realized, and the indicators of all separated items meet various indicator requirements for the follow-up processing. The novel seed melon crushing seed-taking machine disclosed by the invention has the following characteristics: the machine is designed according to the production line for full utilization of seed melons, the structure is novel, simple and practical, the entire crushing and separation process is completed through automation, the processing efficiency is high, and the productivity reaches 10 tons per hour.

Owner:甘肃靖远银农籽瓜科技有限公司 +1

Ore pulverizing and screening device

InactiveCN108097362ASustainable additionImprove processing efficiencySievingScreeningEngineeringMotor shaft

The invention discloses an ore pulverizing and screening device which comprises a base, wherein a front slide rail and a rear slide rail are fixedly arranged at the top of the base, each slide rail isin slide connection with a left slide block and a right slide block, a screen box is arranged above the slide blocks, and the top of each slide block is respectively connected with the bottom of thescreen box through a second spring; a screen stencil fixedly connected with the inner side wall of the screen box is arranged in the screen box; a speed reducing motor is fixedly arranged at the top of the base; a disk is fixedly mounted on a motor shaft at the top end of the speed reducing motor; a hinge pin is fixedly arranged at the left side of the top of the disk; the hinge pin is rotationally connected with a connecting rod; the left side wall of the screen box is also hinged to a push plate through a connecting seat; and the right end of the connecting rod is connected with the left endof the push plate through a first spring. The ore pulverizing and screening device disclosed by the invention has the advantages that the disk rotates to drive the hinge pin to make circumferential motion so as to drive the screen box to move left and right and incline to a certain degree, thereby driving ores to sway left and right in the screen box to obtain a good screening effect.

Owner:COMMON TECH DEV CO LTD

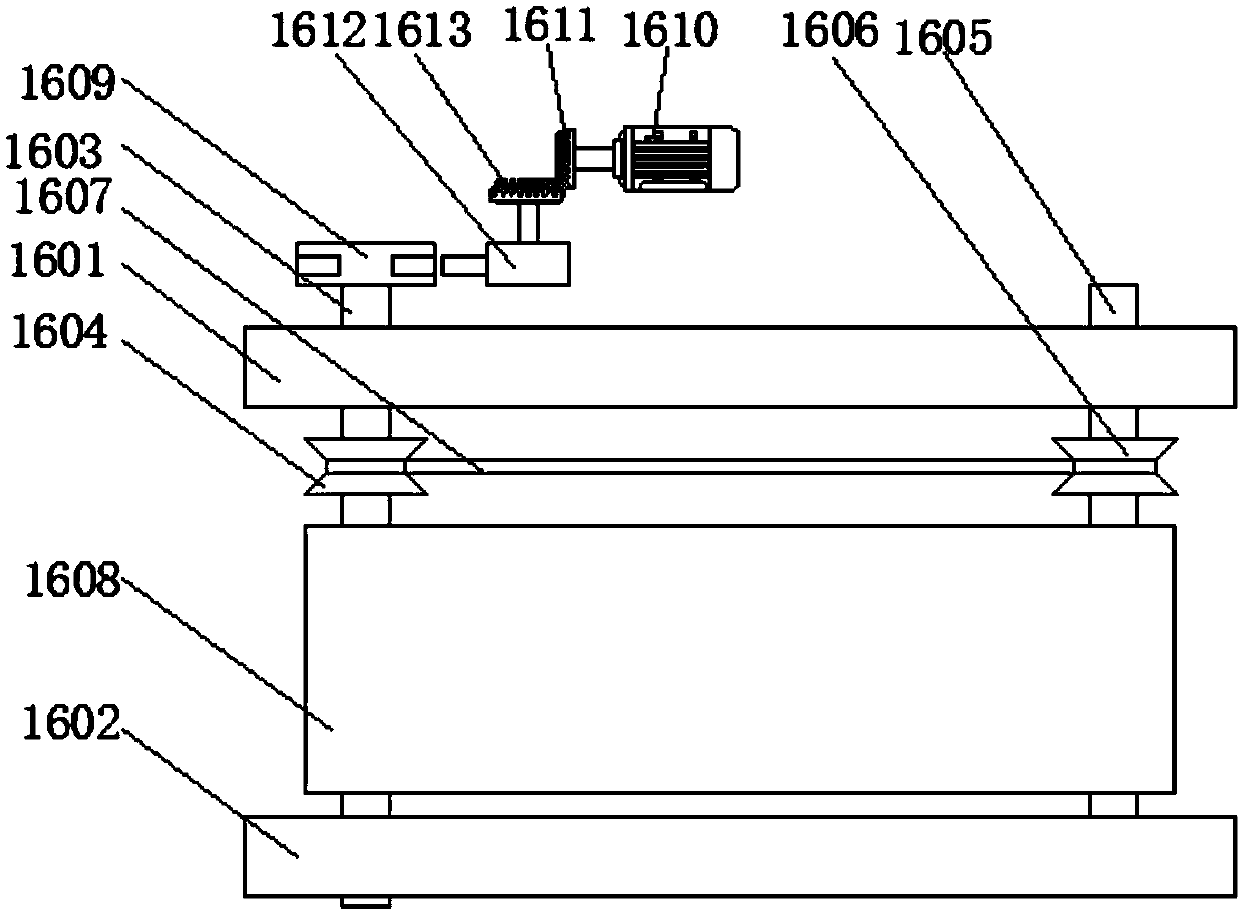

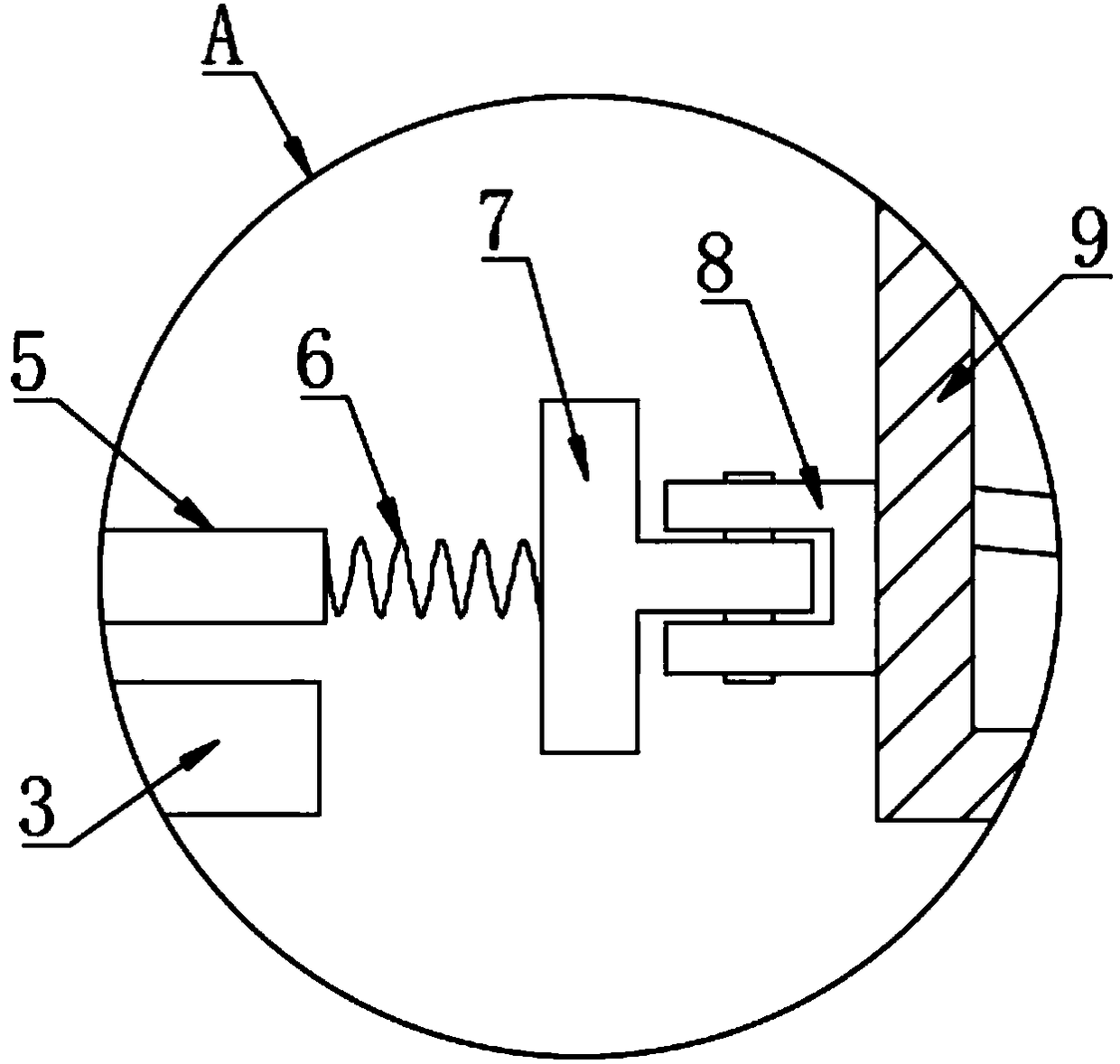

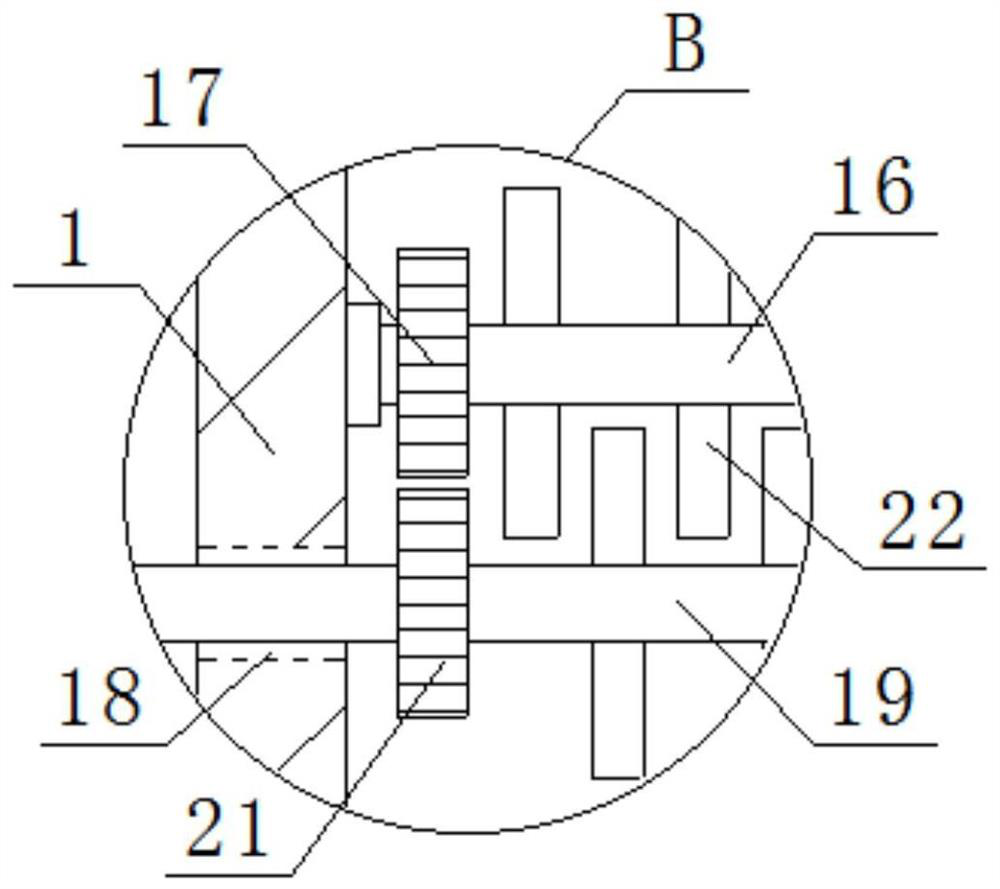

Ceramic ball mill with discharging classifying screen

InactiveCN104741174AImprove grinding efficiencyUniform finenessSievingScreeningScreening effectUltimate tensile strength

The invention discloses a ceramic ball mill with a discharging classifying screen. The ceramic ball mill comprises a hopper, a roller, a transmission mechanism and the like, wherein a first screening plate, a secondary screening plate, a first oversize material hole, a secondary oversize material hole, a first vibrating arm and a secondary vibrating arm are arranged in a classifying screen device at different heights, the first screening plate is arranged on the first vibrating arm by a connecting thread of the first vibrating arm, and a secondary buffer device is also arranged between the upside of the secondary screening plate and the classifying screen device. A ground material is accelerated to be screened through vibration of the classifying screen device, the fineness uniformity, the screening efficiency and the screening effect of a ground product are improved, the action of a vibrating mechanism on the classifying screen device replaces the manual screening operation, the labor intensity is alleviated, impact force of the vibration on the classifying screen device is alleviated due to a first buffer device and the second buffer device, production equipment cannot be damaged easily, and the service life of the production equipment is prolonged.

Owner:广西北流市红日紫砂陶瓷厂

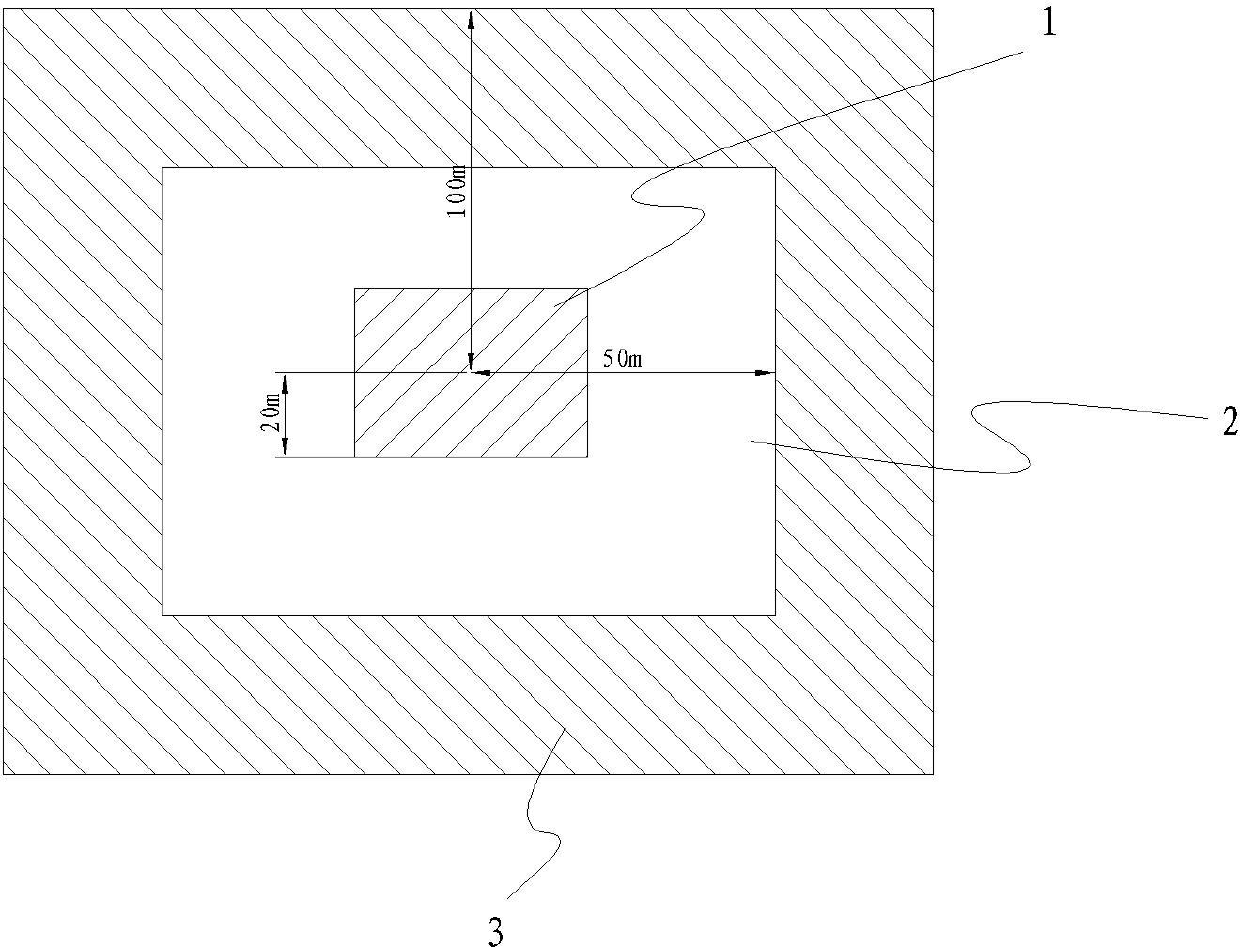

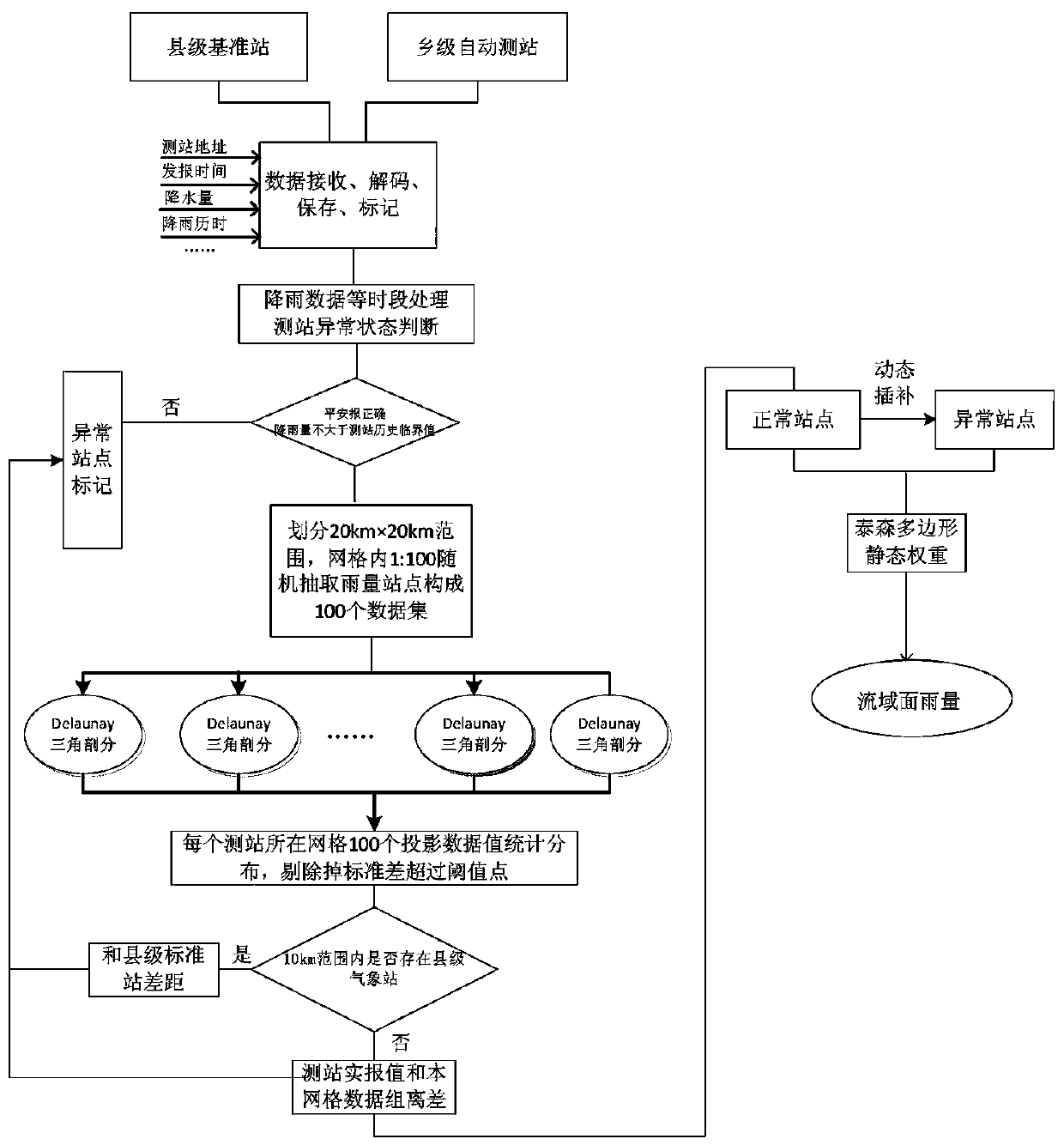

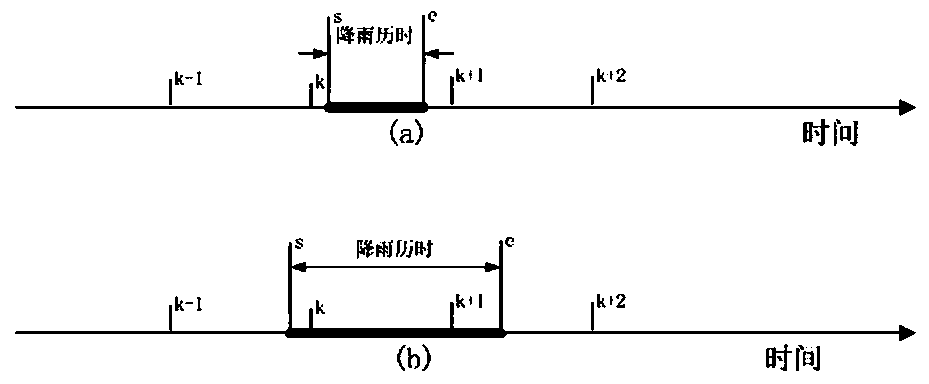

A hierarchical data processing method for a large-scale real-time rainfall automatic observation station based on dynamic interpolation

ActiveCN109840260AExpedited screeningHigh precisionForecastingDatabase modelsComputer scienceEqual time

The invention discloses a hierarchical data processing method for a large-scale real-time rainfall automatic observation station based on dynamic interpolation. The hierarchical data processing methodcomprises the following steps: step 1, receiving and processing reported data of national automatic observation stations in real time; step 2, judging an abnormal value; Step 3, equal time period processing; Step 4, screening and eliminating error values; And 5, performing interpolation calculation on the basin surface rainfall. According to the hierarchical data processing method for the large-scale real-time rainfall automatic observation station based on dynamic interpolation provided by the invention, after abnormal points are found, the abnormal points are interpolated by adopting a 'static weight + dynamic interpolation' method, so that the interpolation efficiency and effect are improved, and the accuracy of rainfall data is improved.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

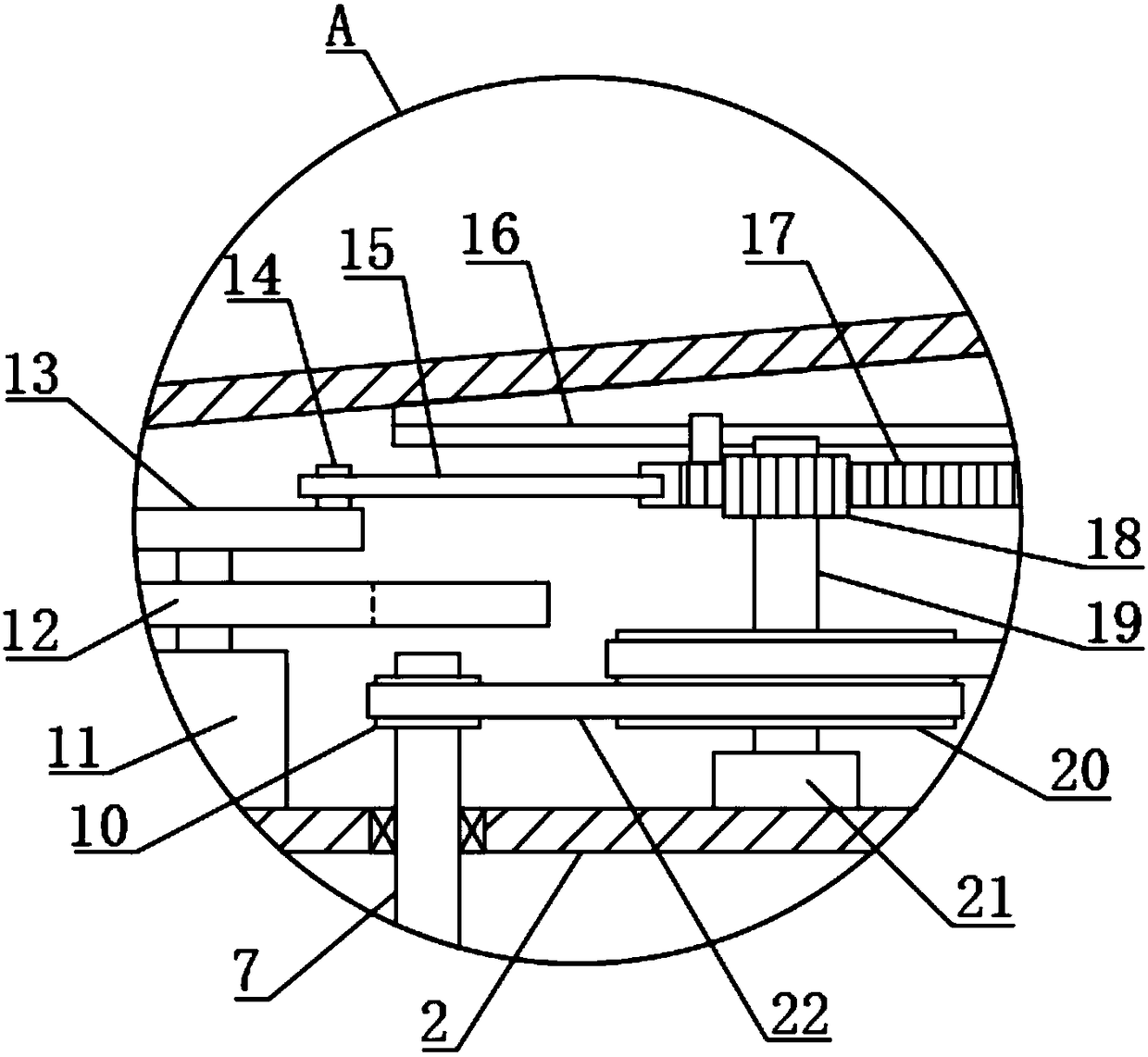

High-efficiency Chinese medicinal material smashing and grinding integrated machine

InactiveCN107457065AImprove processing efficiencyAvoid stickingGrain treatmentsEngineeringMechanical engineering

The invention discloses a high-efficiency Chinese medicinal material crushing and grinding integrated machine, which includes a base, on which support plates are arranged on the left and right sides, a crushing box is fixed between the left and right support plates through brackets, and a screen is arranged at the bottom of the crushing box; The top of the right side wall of the side support plate is also rotatably connected with a third rotating shaft through the first bearing with seat, and the right end of the third rotating shaft is also equipped with a turntable. The bottom of the connecting seat is connected to the screw rod through the second bearing with seat rotation, the right side wall of the left support plate is also fixed with a screw sleeve that matches the screw rod through the bracket, and the bottom end of the screw rod is also fixedly connected to the fourth rotating shaft. Crushing blades are installed on the rotating shaft. The invention drives the fourth rotating shaft to move up and down through the rotation of the turntable. When the fourth rotating shaft moves up and down, it will rotate due to the limit of the spiral sleeve, so that the crushing blade moves forward and backward while moving up and down, effectively improving the crushing efficiency and crushing effect.

Owner:王冠伟

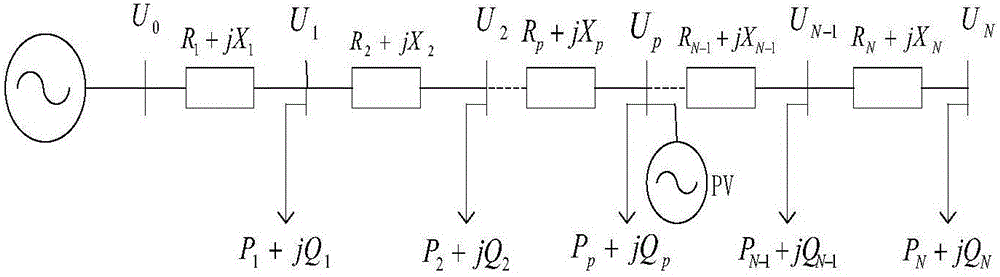

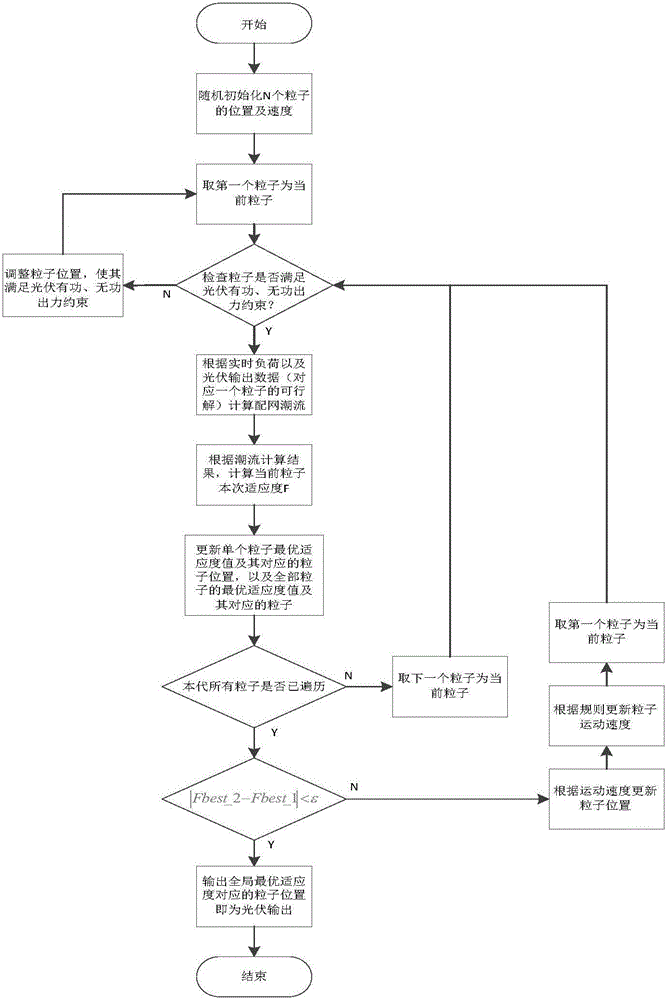

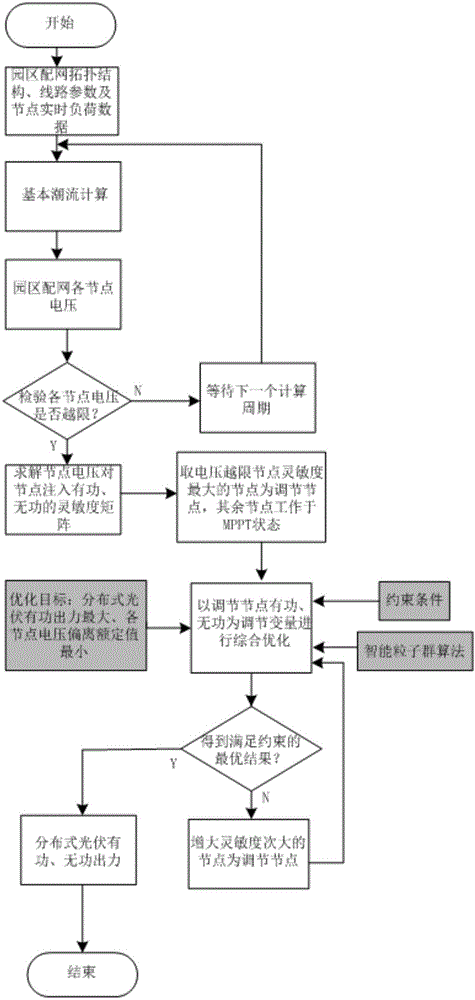

Voltage optimization method of distribution network generation predication technology based on Elman algorithm

ActiveCN106058914AExpedited screeningHigh precisionSingle network parallel feeding arrangementsPhotovoltaic energy generationNerve networkPhotovoltaic power station

The present invention discloses a voltage optimization method of a distribution network generation predication technology based on an Elman algorithm. Based on a similar day selection algorithm and an Elman nerve network, the output power predication of a distributed photovoltaic power station can be completed, a control strategy with distributed photovoltaic distribution network voltage off limitation is advanced based on active and inactive coordination control, and an improved smart particle swarm optimization algorithm is employed to perform searching optimization calculation to complete the voltage optimization control of a power distribution network line, and therefore, the voltage optimization method of the distribution network generation predication technology based on the Elman algorithm has the applicability.

Owner:NARI TECH CO LTD +5

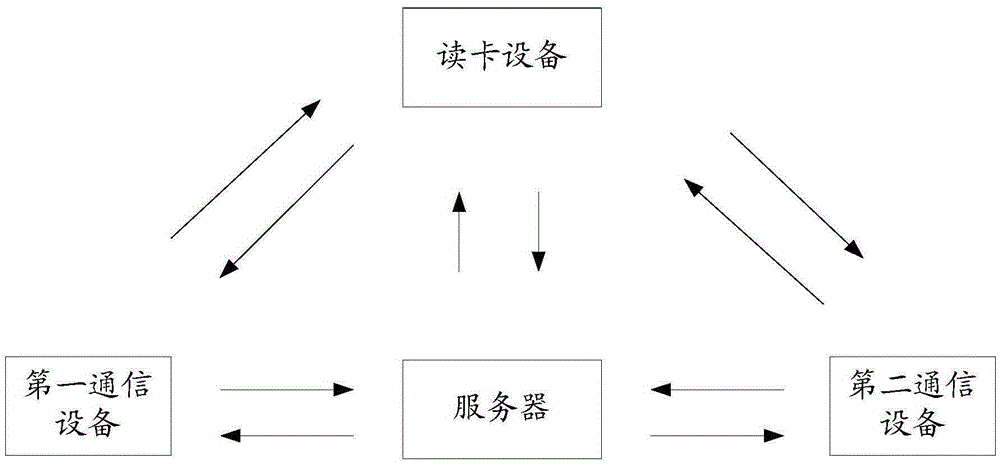

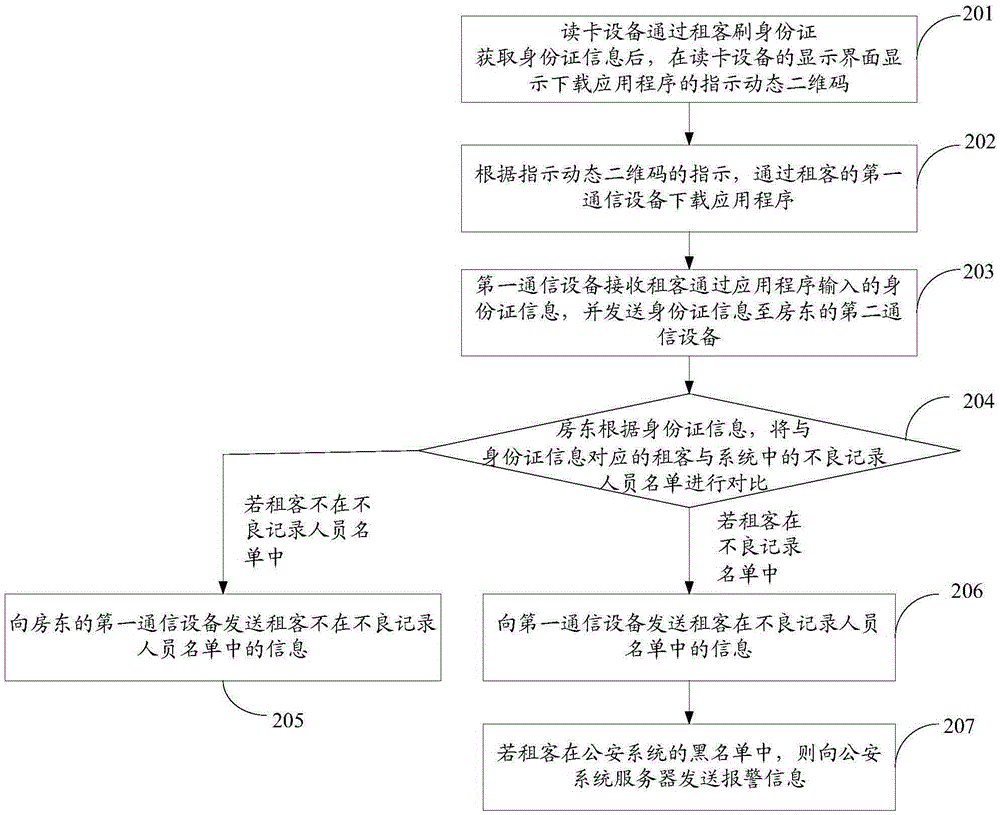

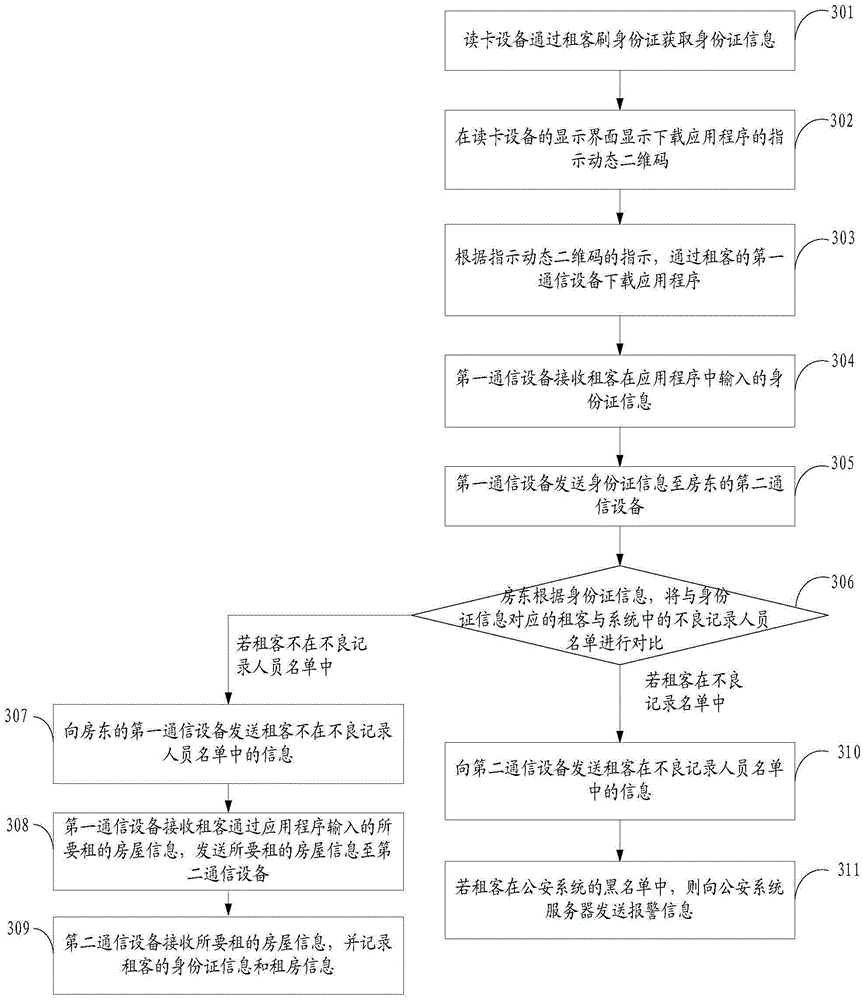

House renting information management method and system

InactiveCN105427203AImprove securityImprove discriminationData processing applicationsSensing by electromagnetic radiationApplication softwareComputer science

The invention discloses a house renting information management method and system, and belongs to the field of communication technology. The method comprises that a first communication device of a renter downloads an application according to indication of a dynamic two-dimensional code; the first communication device receives identity card information which is input by the renter via the application, and sends the information to a second communication device of a house owner; according to the identity card information, the house owner compares the renter corresponding to the identity card information with a list of persons with adverse records in the system; and if the renter does not belongs to the list, information that the renter does not belong to the list of persons with adverse record is sent to the second communication device of the house owner, and otherwise, information that the renter belongs to the list of persons with adverse record is sent to the second communication device. Thus, the renter is compared with the list, so that whether the renter is a person on the run in the police system can be timely known, the renter identity is screened more effectively, and the security of house renting is improved.

Owner:徐承柬

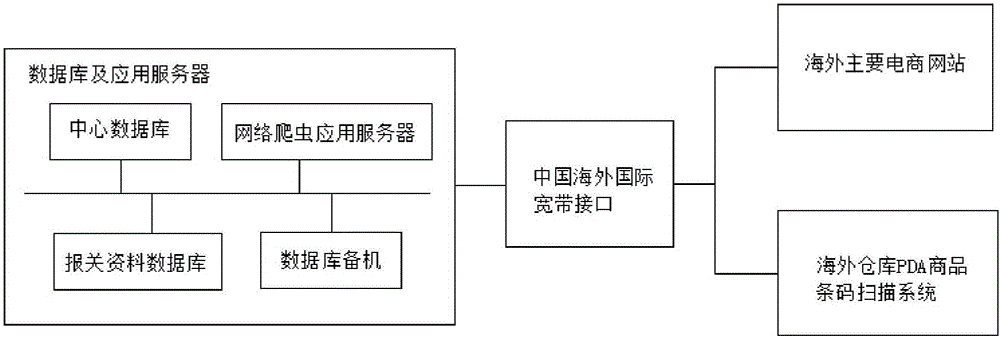

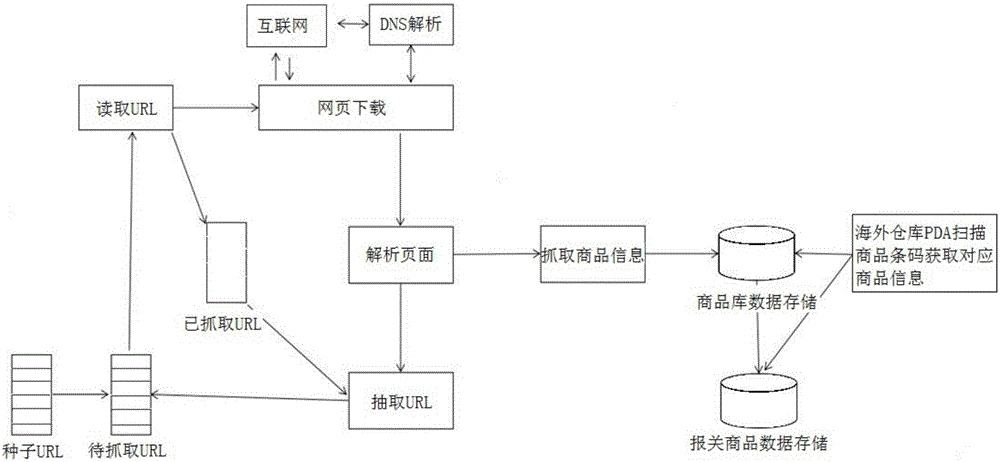

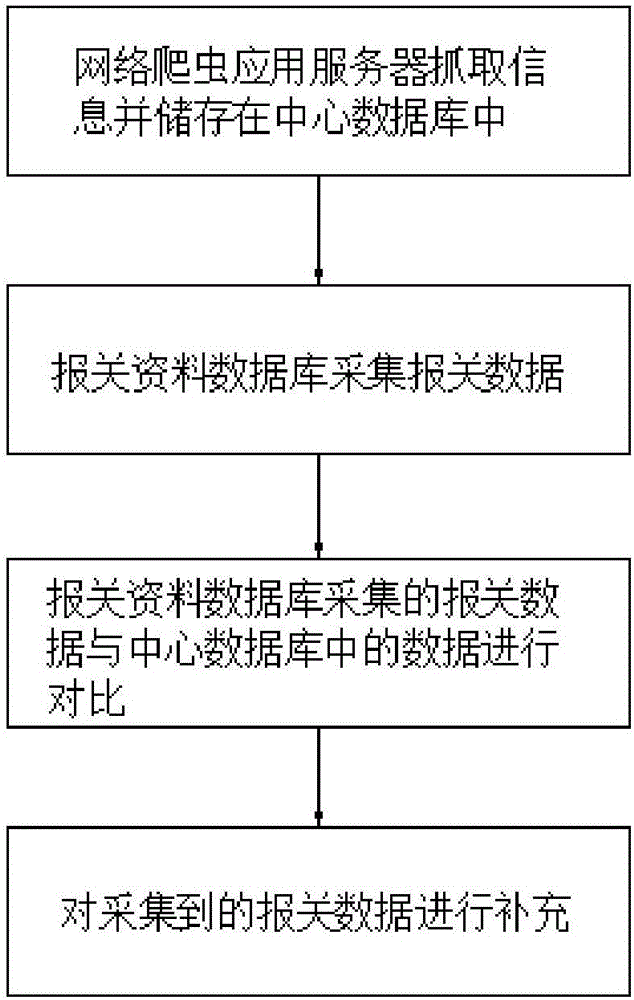

Cross-border e-commerce global commodity customs clearance system

PendingCN106803167AIntegrity guaranteedGuaranteed reliabilityWeb data indexingOffice automationWeb siteApplication server

The invention provides a cross-border e-commerce global commodity customs clearance system, which comprises a database and application server, a China overseas international broadband interface, an overseas main e-commerce website, and an overseas warehouse PDA commodity bar code scanning system. One end of the China overseas international broadband interface is connected with the database and application server arranged in a China machine room, and the other end of the China overseas international broadband interface is connected with the overseas main e-commerce website and the overseas warehouse PDA commodity bar code scanning system. The database and application server comprises a central database, a web crawler application server, a declaration data database, and a database standby machine. Through collection of commodity information around the world, a commodity database suitable for declaration and needs of daily business is established to provide big data information support for declaration and business processing. Therefore, the declaration efficiency and the declaration accuracy are greatly increased, cases of missed declaration, declaration shortage and false declaration are reduced, the accuracy of data reported to customs is guaranteed, and the customs clearance efficiency is accelerated.

Owner:深圳市海带宝网络科技有限公司

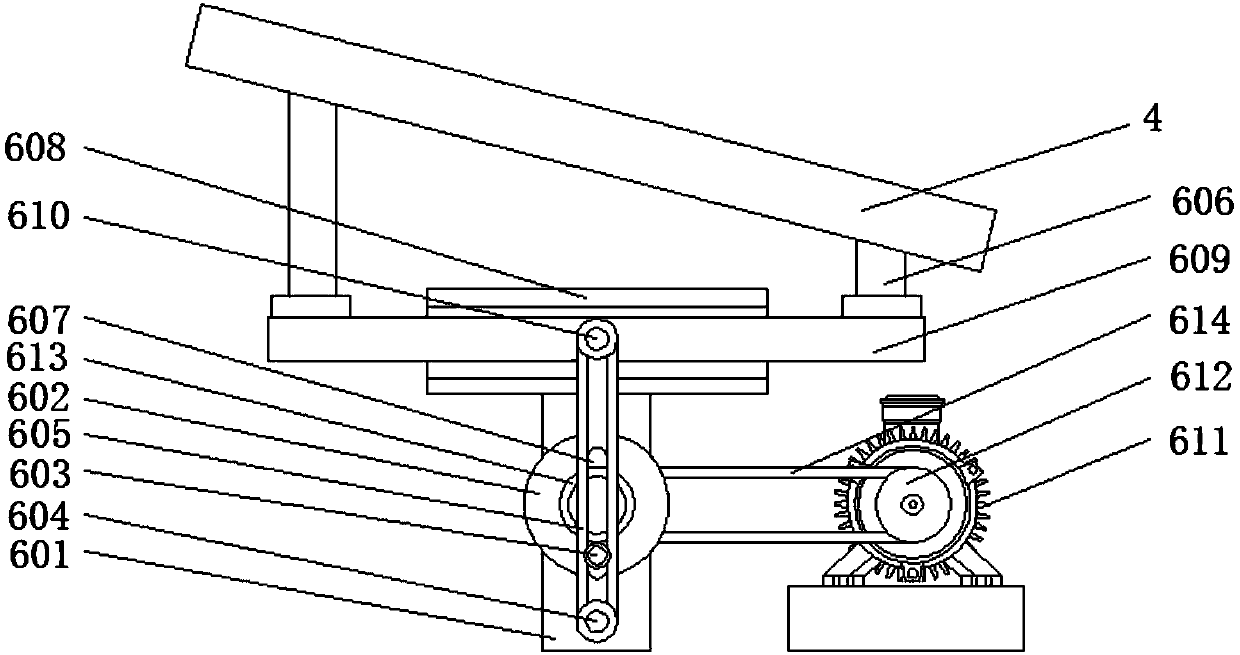

Gravel screening device for building

InactiveCN109550680AExpedited screeningImprove screening efficiencySievingNon-rotating vibration suppressionEngineeringVibration motor

The invention discloses a gravel screening device for a building. The gravel screening device for the building comprises a shell, a feeding hole is formed in the right side of the upper surface of theshell, the right side of the top of an inner cavity of the shell is fixedly connected with a fixing frame, the fixing frame is movably connected with an inclined plate through a pin shaft, a supporting plate is fixedly connected above the inner wall of the right side of the shell, a buffer spring is fixedly connected to the upper surface of the supporting plate, the other end of the buffer springis fixedly connected to the lower surface of the inclined plate through a spring base, and the left side of base of the inner cavity of the shell is fixedly connected with a first guide column. According to the gravel screening device for the building, a first screening frame, a second screening frame, the first guiding column, a second guiding column, a first guide block, a second guide block, afirst spring, a second spring and a vibration motor are arranged and cooperate with one another, so that the problem that the screening efficiency is low in a construction site is solved; and the fixing frame, the pin shaft, the inclined plate, the supporting plate and the buffer spring are arranged and cooperate with one another, so that the problem that the screening speed is low when a large amount of gravels are directly screened is solved.

Owner:扬州市三祥机械制造有限公司

Fast pugging equipment in ceramic technology and application method thereof

ActiveCN109262828AImprove work efficiencyNaturalClay processing apparatusDual purposeMaterials science

The invention discloses fast pugging equipment in a ceramic technology and an application method thereof, and belongs to the technical field of ceramic production. The fast pugging equipment in the ceramic technology comprises a pugging dual-purpose base, wherein a mineral powder shift sliding chute is formed in the lower end of the pugging dual-purpose base; a purple sand mineral powder collection box is in slip connection in the mineral powder shift sliding chute; a bevel funnel is dug at the middle of the pugging dual-purpose base; a mineral powder falling hole is dug in the lower end of the bevel funnel. During traditional manual pugging of a purple sand work, the working efficiency of manual pugging is remarkably improved, the obtained purple sand work has the specific water absorption and structural naturalness of traditional manual pugging, and the output of the purple sand works can be greatly increased; moreover, part of the processes of traditional manual pugging are simplified, thus the protection and inheritance of manual pugging in the traditional cultural heritage of China are promoted; the purple sand works also can be developed into a series of tourist products of the manual pugging project.

Owner:临沂晶华陶瓷有限公司

Automated pulverizer with screening function

InactiveCN107051678AExpedited screeningGuarantee product qualitySievingFeeding-stuffEngineeringProduction quality

The invention discloses an automatic pulverizer with screening function, which comprises a screening box, a stirring device, a first motor, a second motor and a crushing box, and the right side of the screening box is respectively installed with first discharge port, the second discharge port and the third discharge port, the first screen and the second screen are respectively installed under the stirring device, the first motor is connected to the stirring device through a rotating shaft, and the second The motor is rotatably connected to the screening device through a belt, a crushing shaft is installed inside the crushing box, a third motor is installed on the left side of the crushing box, and a feeding port is arranged above the crushing box. The automatic pulverizer with screening function can automatically screen materials while crushing materials, so that materials of different qualities can be collected by classification, ensuring the quality of production, high degree of automation, and greatly reducing the required manpower. Thereby reducing production costs.

Owner:SUZHOU YUXI NEW MATERIAL TECH

Gravel material multistage screening and crushing method

PendingCN109663637AThe crushing process is easy to controlImprove crushing efficiencySievingFouling preventionPrimary screeningContinuous production

The invention discloses a gravel material multistage screening and crushing method, and belongs to the technical field of gravel crushing. The gravel material multistage screening and crushing methodis characterized by comprising the following steps that a, gravel materials are conveyed to a screening work station; b, primary screening is carried out through a first-grade screening net, the gravel materials with the large particle size fall into a crushing station, the crushed gravel materials are conveyed to a second-grade screening net for horizontal swinging and screening, the screened gravel materials fall into a third-grade stage screening net, and the screened gravel materials are vibrated and screened through the third-grade screening net; and c, the gravel materials subjected to the third-stage screening fall into a material returning bin, the gravel materials falling from the material returning bin are conveyed into a crushing cylinder of a material crushing device through amaterial returning conveying part for circulation crushing. According to the method, the whole crushing process is easy to control, materials with different particle sizes can be crushed just by one material crushing device, the materials are conveyed into the material crushing device to be crushed through multistage screening, continuous production can be carried out, the crushing efficiency andthe yield are improved, and popularization and application are facilitated.

Owner:四川高路远长集团有限公司

Magnetic separating device for rice processing

InactiveCN106513167AQuality assuranceImprove adsorption capacityMagnetic separationGrain millingMetal adsorptionMagnetic separator

The invention discloses a magnetic separating device for rice processing. The magnetic separating device comprises a machine body; a feeding funnel is arranged in the middle of the top end of the machine body; a clearing door is arranged at the lower end at the left side of the machine body; a tapered discharge hopper is arranged at the bottom end of the machine body; a stirring magnetic separator is arranged at the upper end inside the machine body; a telescopic baffle plate mechanism is arranged at the middle lower end inside the machine body; a fixed blocking part is arranged at the middle lower end at the left side inside the machine body; and a metal adsorption net is arranged at the lower end inside the machine body. The magnetic separating device for rice processing solves the problems that magnetic separating equipment in the prior art is generally not good in magnetic separating effect, is low in working efficiency and is inconvenient to use; a stirring magnetic-separating design is adopted to carry out magnetic separating processing while stirring; and the metal adsorption net is arranged, so that dual adsorption effects are achieved, rice can be quickly and comprehensively subjected to magnetic separating processing, the magnetic separating effect is better, and magnetic separating efficiency is extremely high.

Owner:HARBIN MIMI RICE IND TECH CO LTD

Efficient smashing device for pesticide production

The invention belongs to the technical field of pesticide production, and particularly relates to an efficient smashing device for pesticide production. Aiming at the problems that an existing mode isunthorough in smashing, and the screening efficiency is low, the following scheme is provided, specifically, the efficient smashing device comprises a smashing box, and a feeding pipe is fixedly installed on one side of the top of the smashing box and communicates with the smashing box; a motor is fixedly installed in the center position of the top of the smashing box; the center position of thetop of the smashing box is provided with a first through hole, a rotary rod is rotationally installed in the first through hole, the top end of the rotary rod extends to the upper portion of the smashing box and is fixedly installed on an output shaft of the motor, and the bottom end of the rotary rod extends into the smashing box and is fixedly sleeved with a rotary disc. The efficient smashing device is compact in structure, reasonable in design and convenient to operate, raw materials can be smashed more thoroughly on the premise that no driving device is added, in addition, the screening speed is increased, the production cost is reduced, and the efficient smashing device is suitable for application and popularization.

Owner:ANHUI YINONG CHEM

High-yield coenzyme Q10 rhodobacter sphaeroides and mutation breeding and application thereof

ActiveCN109762757AQuadruple resistantIncrease productionBacteriaMicroorganism based processesBacteroidesHigh-Throughput Screening Methods

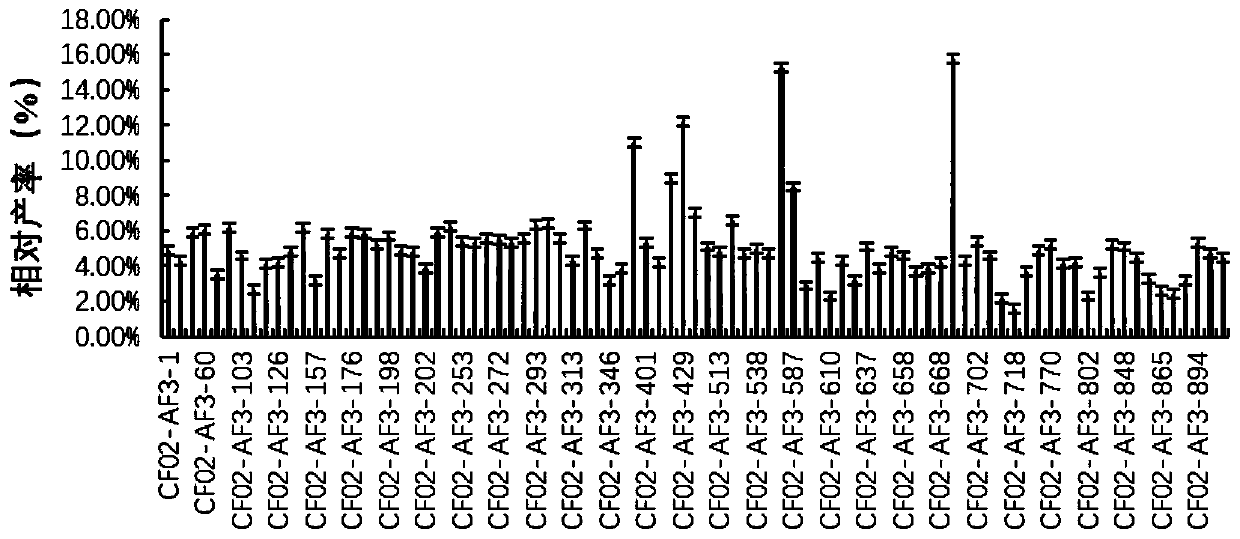

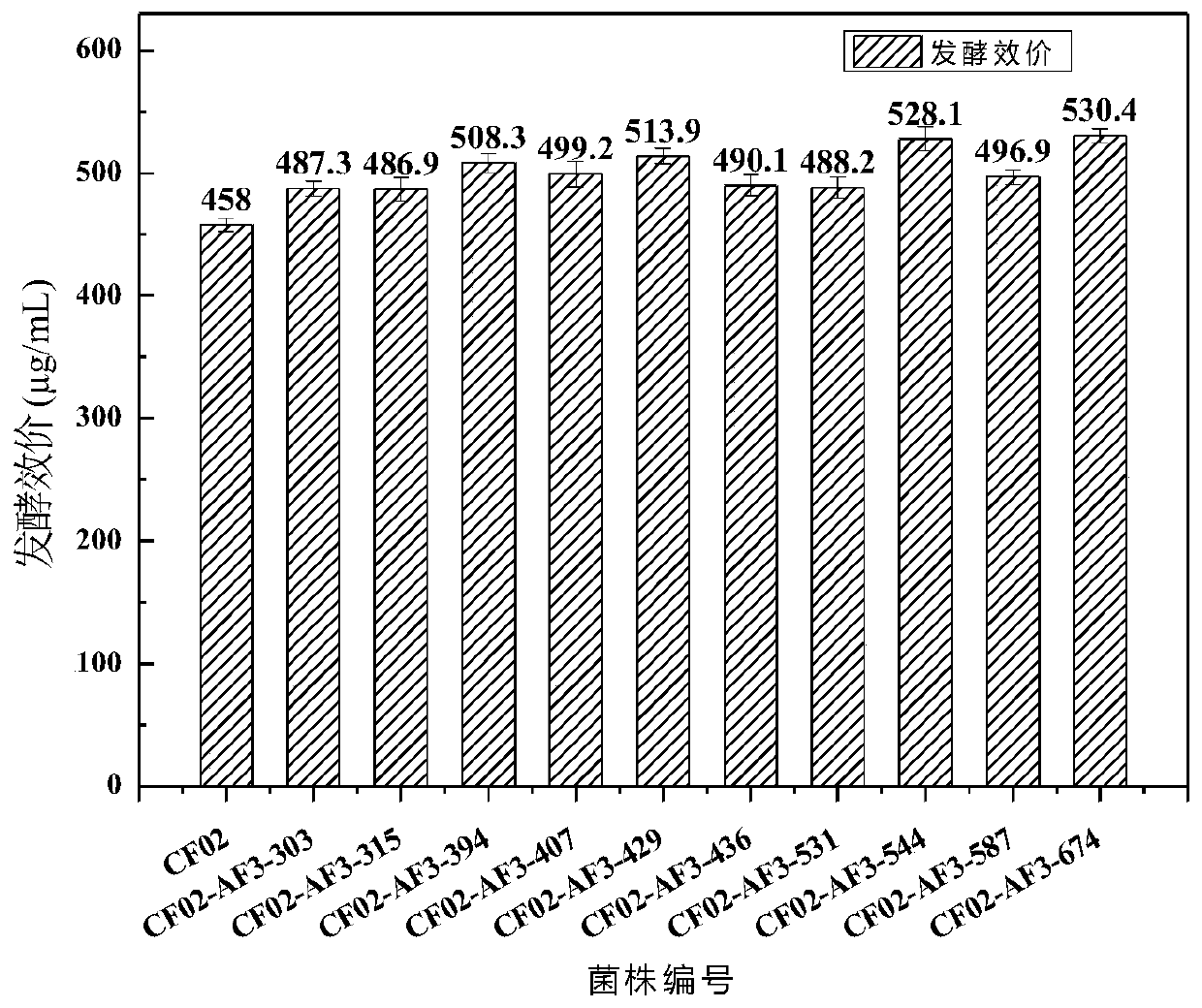

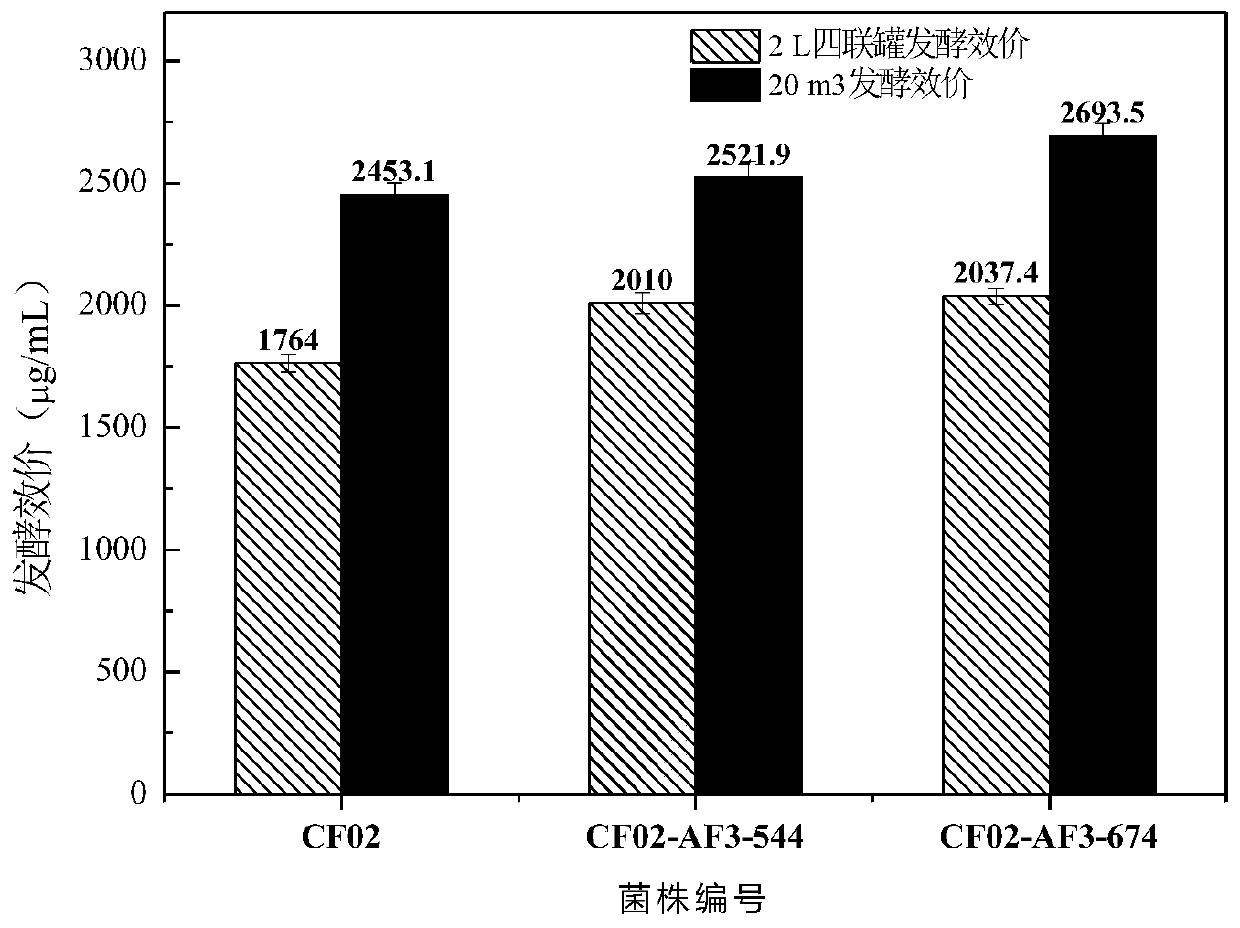

The invention provides high-yield coenzyme Q10 rhodobacter sphaeroides and mutation breeding and application thereof, and relates to the field of microbial mutation breeding. Strains screened by spacemutagenesis are used as starting bacteria and subjected to plasma mutagenesis at normal pressure and room temperature. The high-yield coenzyme Q10 rhodobacter sphaeroides are obtained after multi-resistance screening, high-throughput screening and step-by-step amplification verification, and are deposited in China General Microbiological Culture Collection Center with the deposit number of CGMCCNo. 16625. The average titer of a mutant strain of the rhodobacter sphaeroides can reach 2694[mu] / mL according to 20m<3> fermentation production verification, and the yield of the coenzyme Q10 is significantly improved. In addition, the strain has quadruple resistance and broad application prospects.

Owner:SHENZHOU BIOLOGY & TECH CO LTD +1

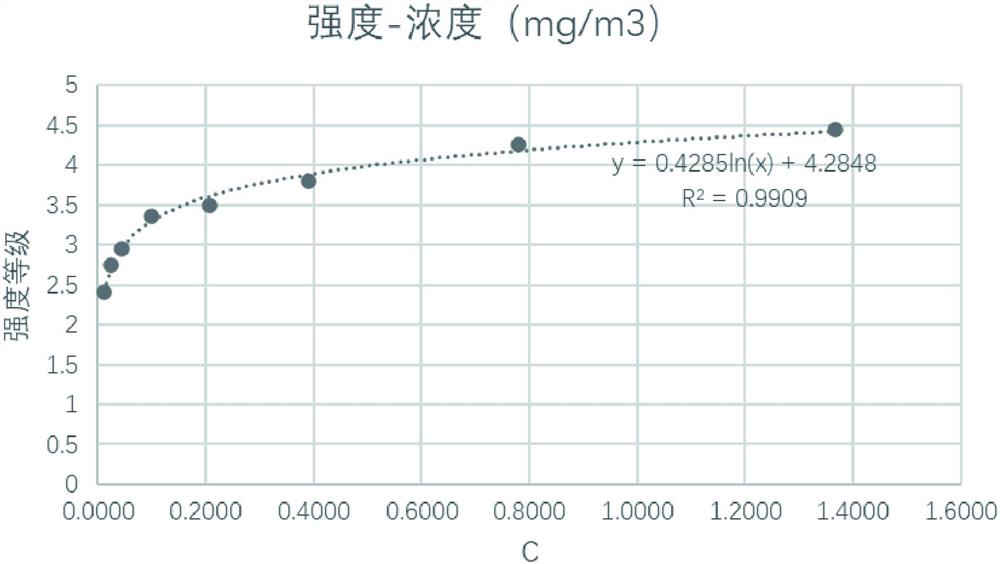

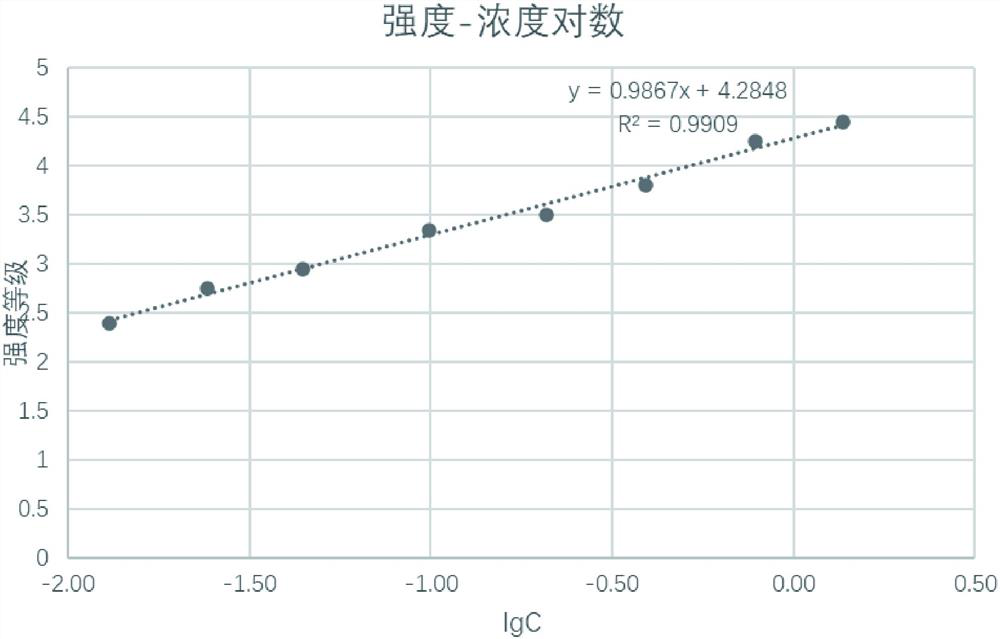

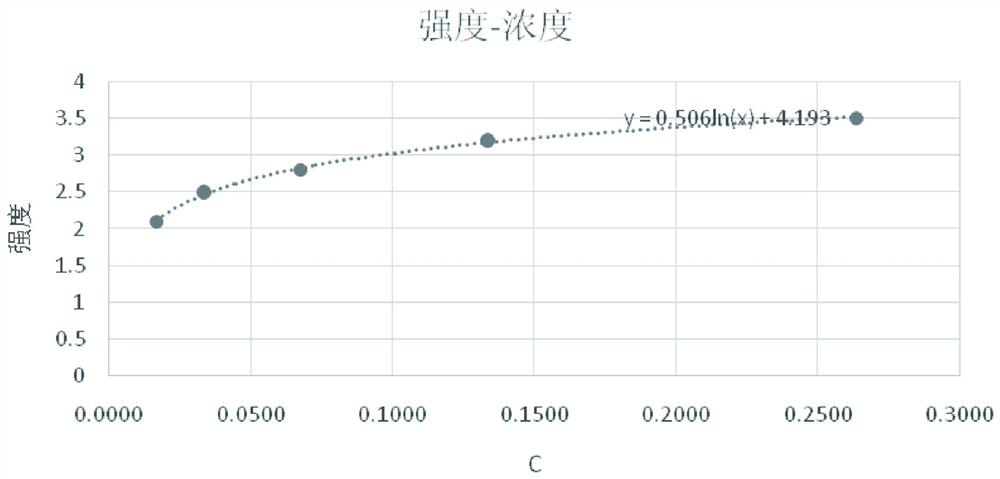

Odor evaluation method for automobile part material by threshold method

PendingCN111693649AImprove screeningEnsure capability consistency and stabilityMaterial analysisBlind SampleData mining

The invention discloses an odor evaluation method for an automobile part material by a threshold method, which is characterized in that firstly, sampling evaluation methods of the part material are counted, the difference of odor evaluation modes of the part material is solved, odor difference comparison of products of different levels is facilitated, and the transfer of odor intensity among the products of different levels is facilitated to be obtained; secondly, sampling and environmental treatment refer to original conditions and can be compared with an original method, meanwhile, samplingand environment treatment conditions can be adjusted as required at any time without influencing the use of the method; thirdly, the odor evaluation personnel can use the method to train, so that thecapability screening of the odor evaluation personnel is increased, and the capability consistency and stability of the odor evaluation personnel are ensured; fourthly, the original rating descriptionwith difficulty in multi-language description and sensory definition is converted into the judgment whether the smell can be identified or not, so that the evaluation difficulty is reduced, and the data reliability is improved; and fifthly, a blank blind sample is used in the test, so that the credibility of experimental data is improved.

Owner:中汽研汽车零部件检验中心(宁波)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com