Activated carbon screening device for filter screen of purifier

A screening device, activated carbon technology, applied in the fields of sieves, chemical instruments and methods, solid separation, etc., can solve the problems of slow speed and poor effect, and achieve the goal of accelerating screening, speeding up screening, and improving production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

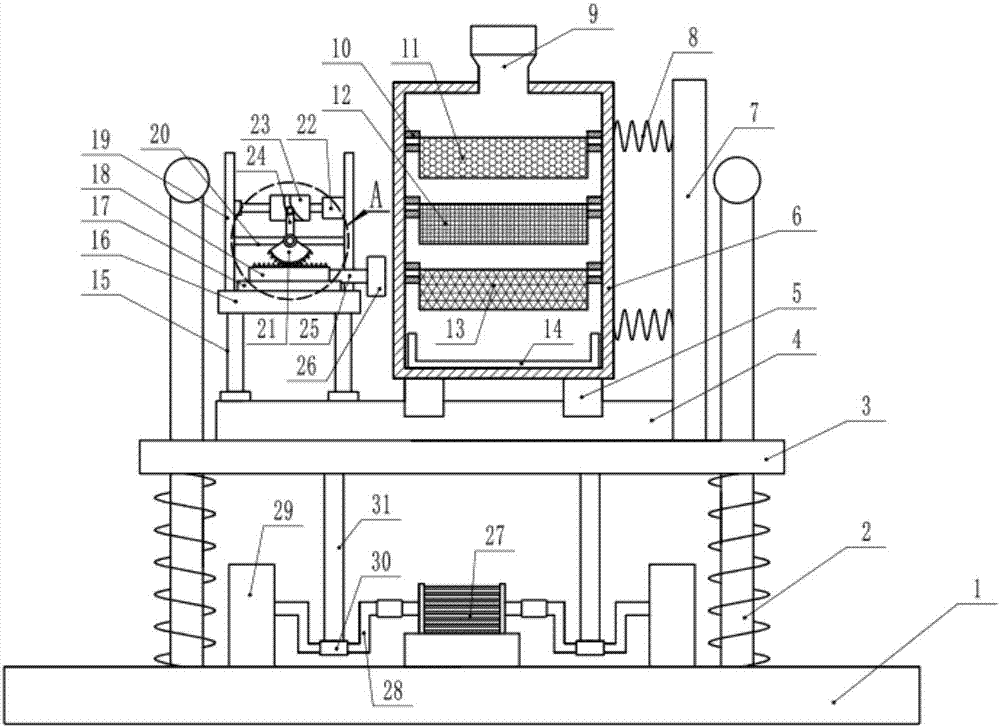

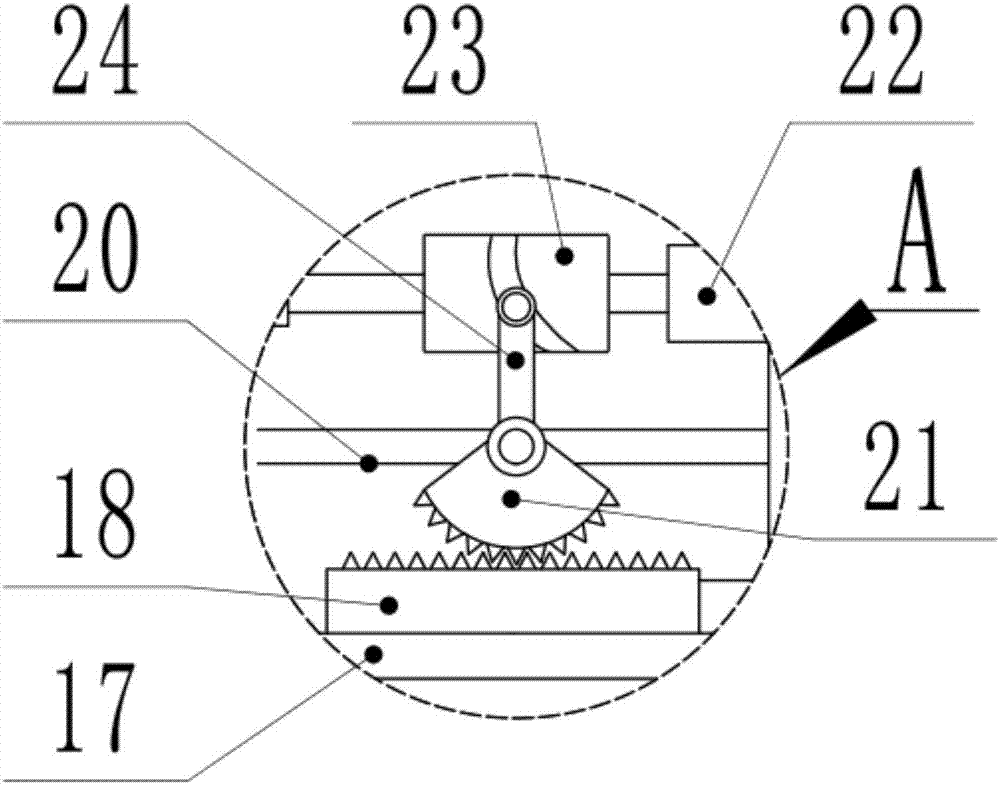

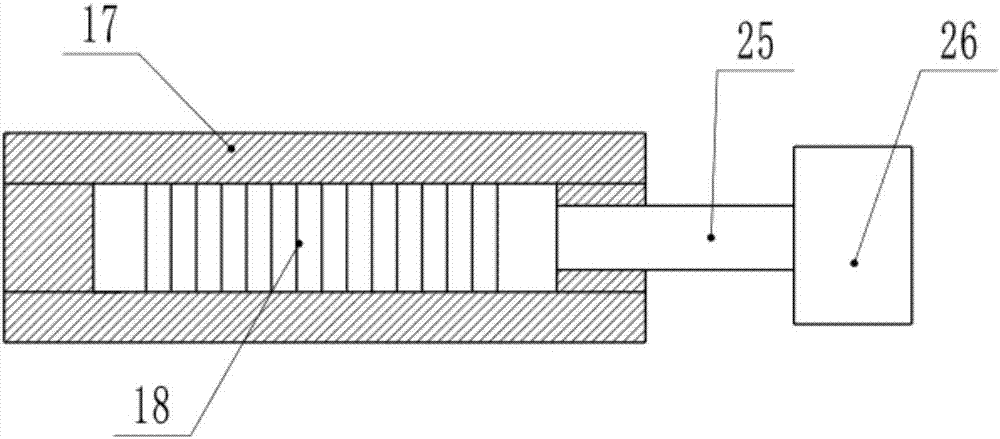

[0022] see Figure 1-3 , an activated carbon screening device for a filter screen of a purifier, comprising a base 1, a screening box 6, a first sieve frame 11, a second sieve frame 12, a third sieve frame 13, a rack 18, a sector gear 21, a driving motor 22. Cylindrical wheels 23, connecting rods 24, impact rods 25 and biaxial motors 27. The base 1 is fixedly mounted with support rods 2 through threads. There are at least four sets of support rods 2. Sliding plates are installed on the support rods 2. 3. A spring is connected between the lower side of the slide plate 3 and the upper surface of the base 1, and the support rod 2 passes through the center of the spring. The upper surface of the slide plate 3 is fixedly welded with a slideway 4, and several groups of sliders are slidably installed on the slideway 4 5. The slider 5 is fixedly installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com