Patents

Literature

610 results about "Drag coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In fluid dynamics, the drag coefficient (commonly denoted as: Cd , Cₓ or Cw ) is a dimensionless quantity that is used to quantify the drag or resistance of an object in a fluid environment, such as air or water. It is used in the drag equation in which a lower drag coefficient indicates the object will have less aerodynamic or hydrodynamic drag. The drag coefficient is always associated with a particular surface area.

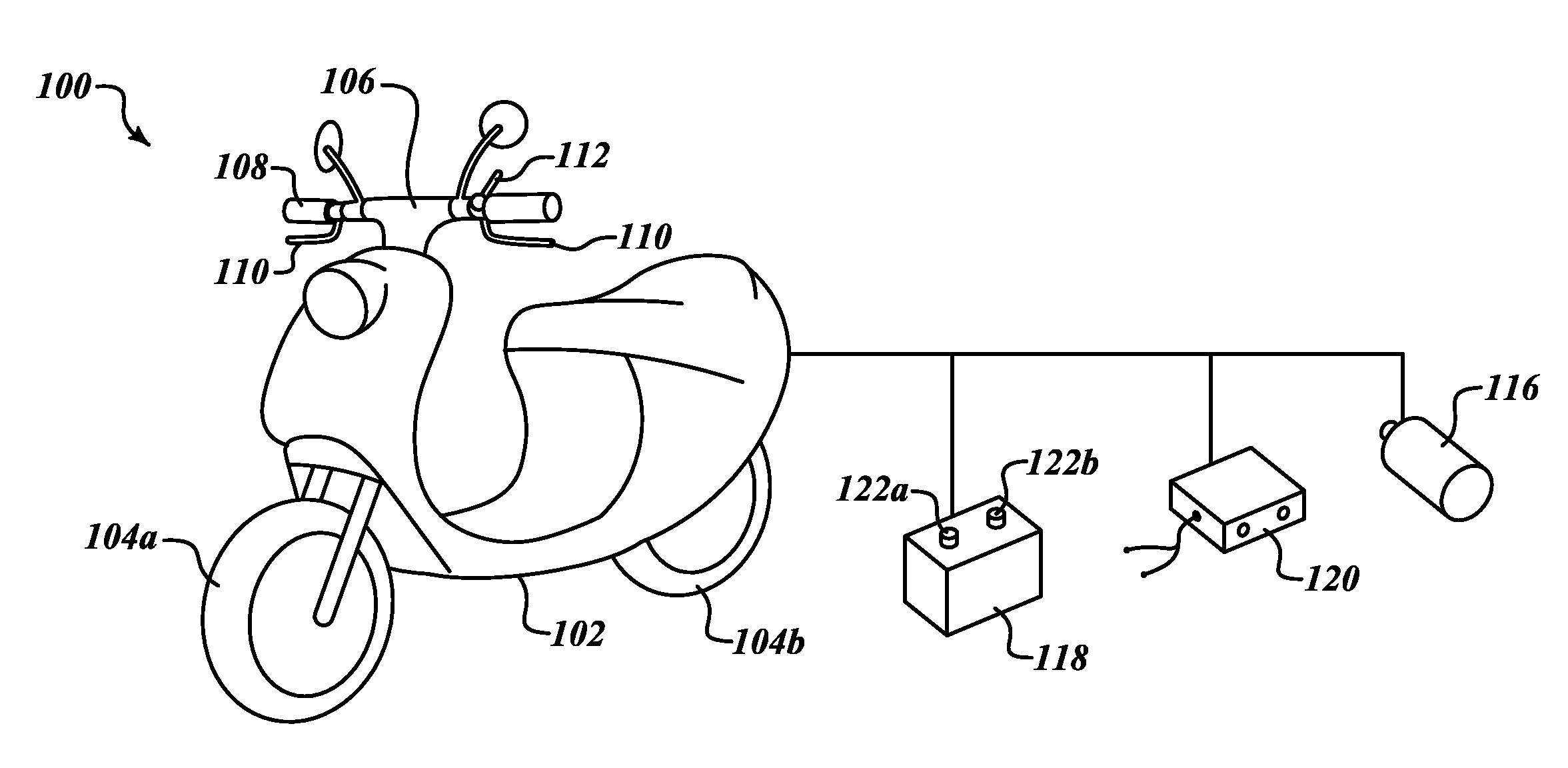

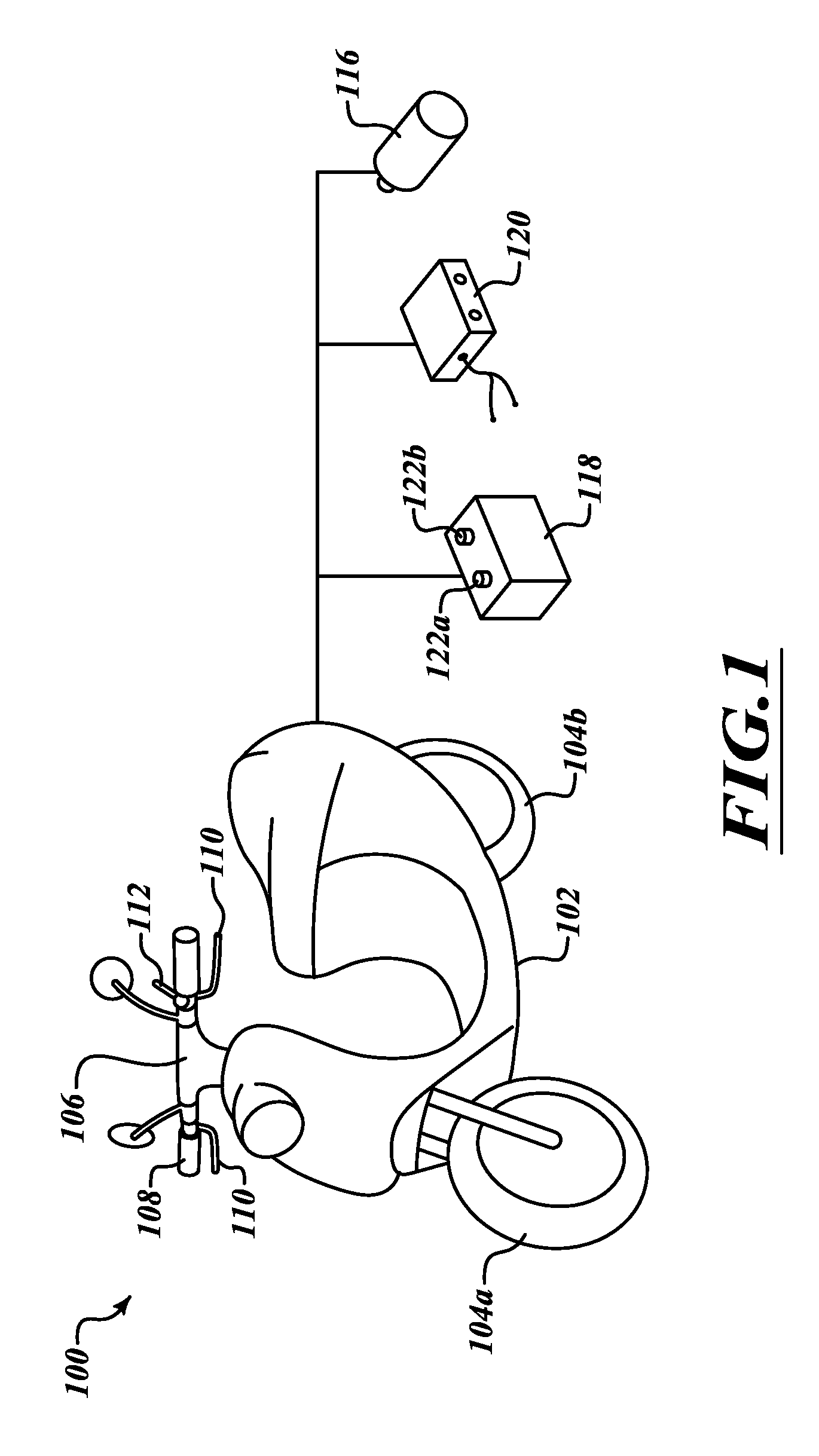

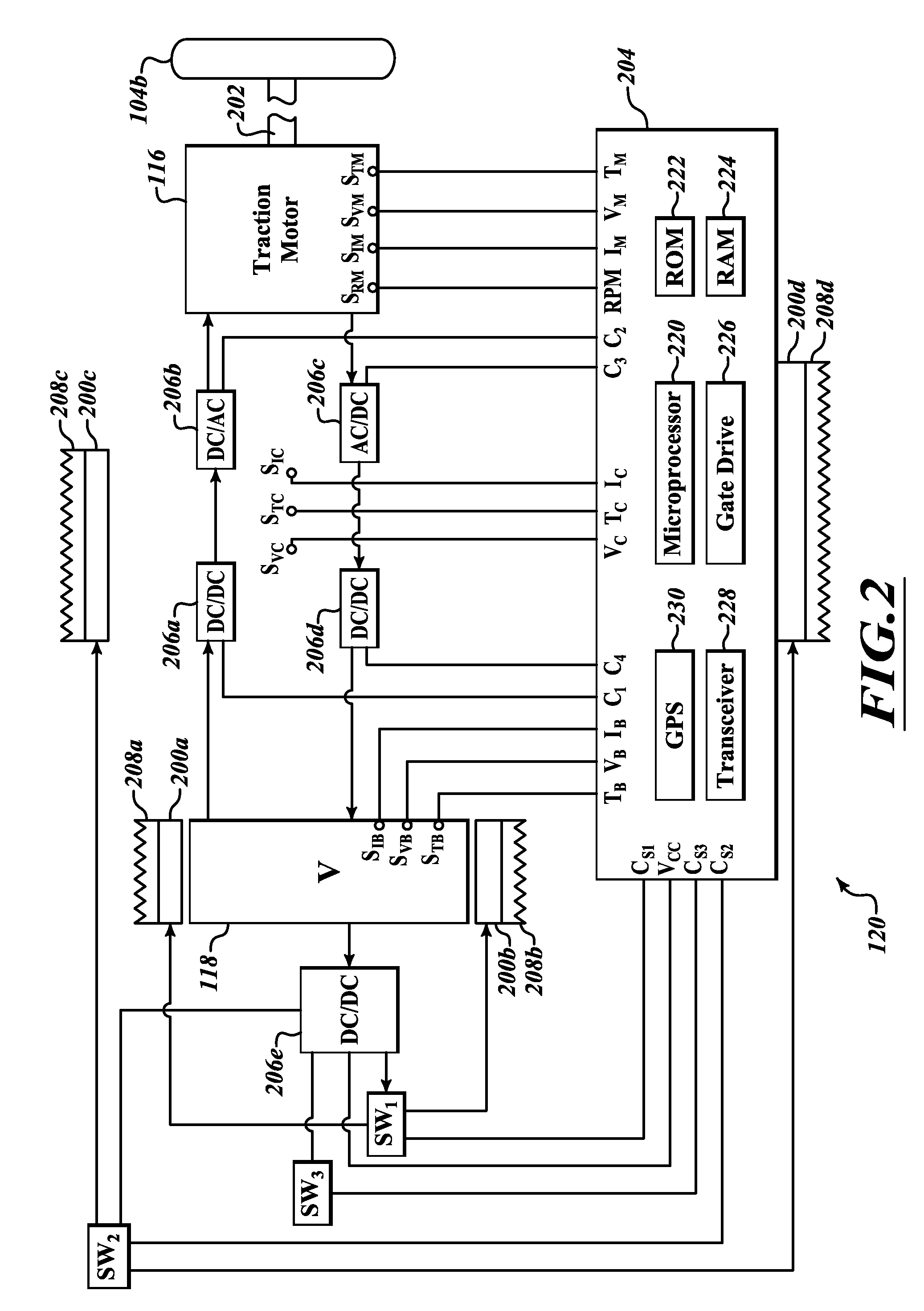

Dynamically limiting vehicle operation for best effort economy

ActiveUS20130030630A1Registering/indicating working of vehiclesCoin-freed apparatusTerrainPower flow

Vehicle operation (e.g., speed, acceleration) may be limited based on various conditions such as a current charge condition of an electrical energy storage devices (e.g., batteries, super- or ultracapacitors), history of such, conditions related to the vehicle (e.g., mileage, weight, size, drag coefficient), a driver or operator of the vehicle (e.g., history with respect to speed, acceleration, mileage) and / or environmental conditions (e.g., ambient temperature, terrain). A controller may control operation of one or more power converters to limit current and / or voltage supplied to a traction electric motor, accordingly.

Owner:GOGORO

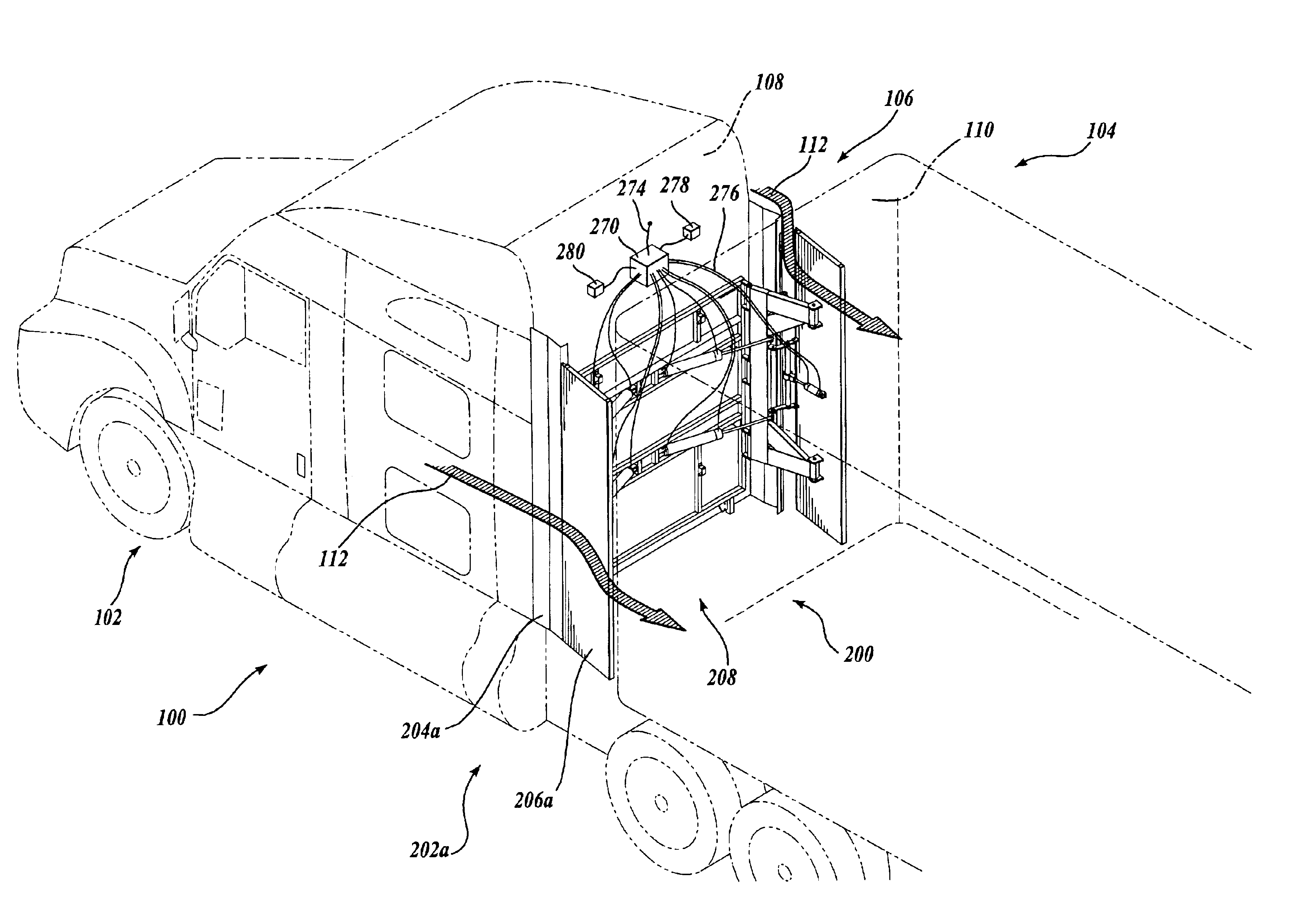

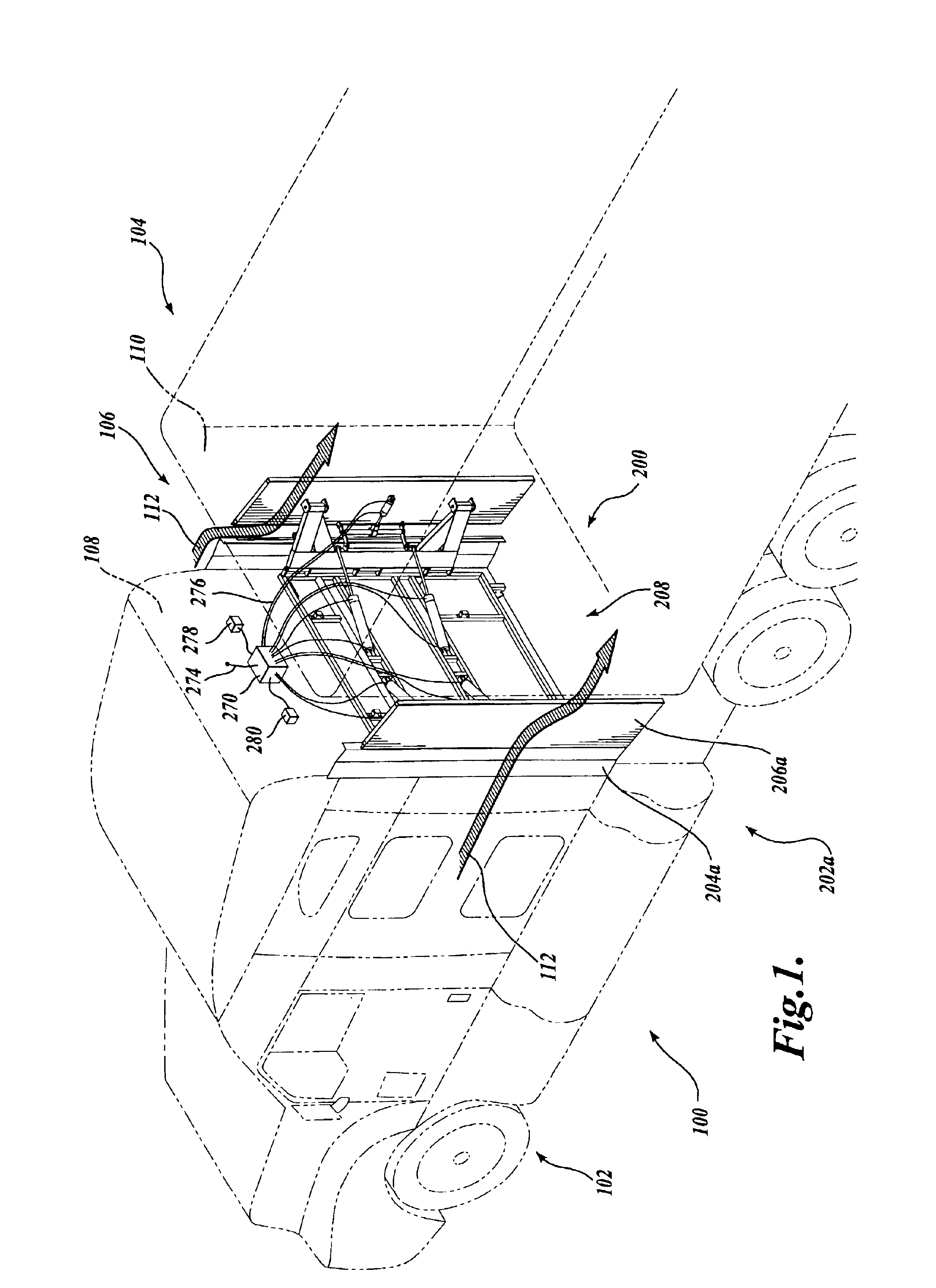

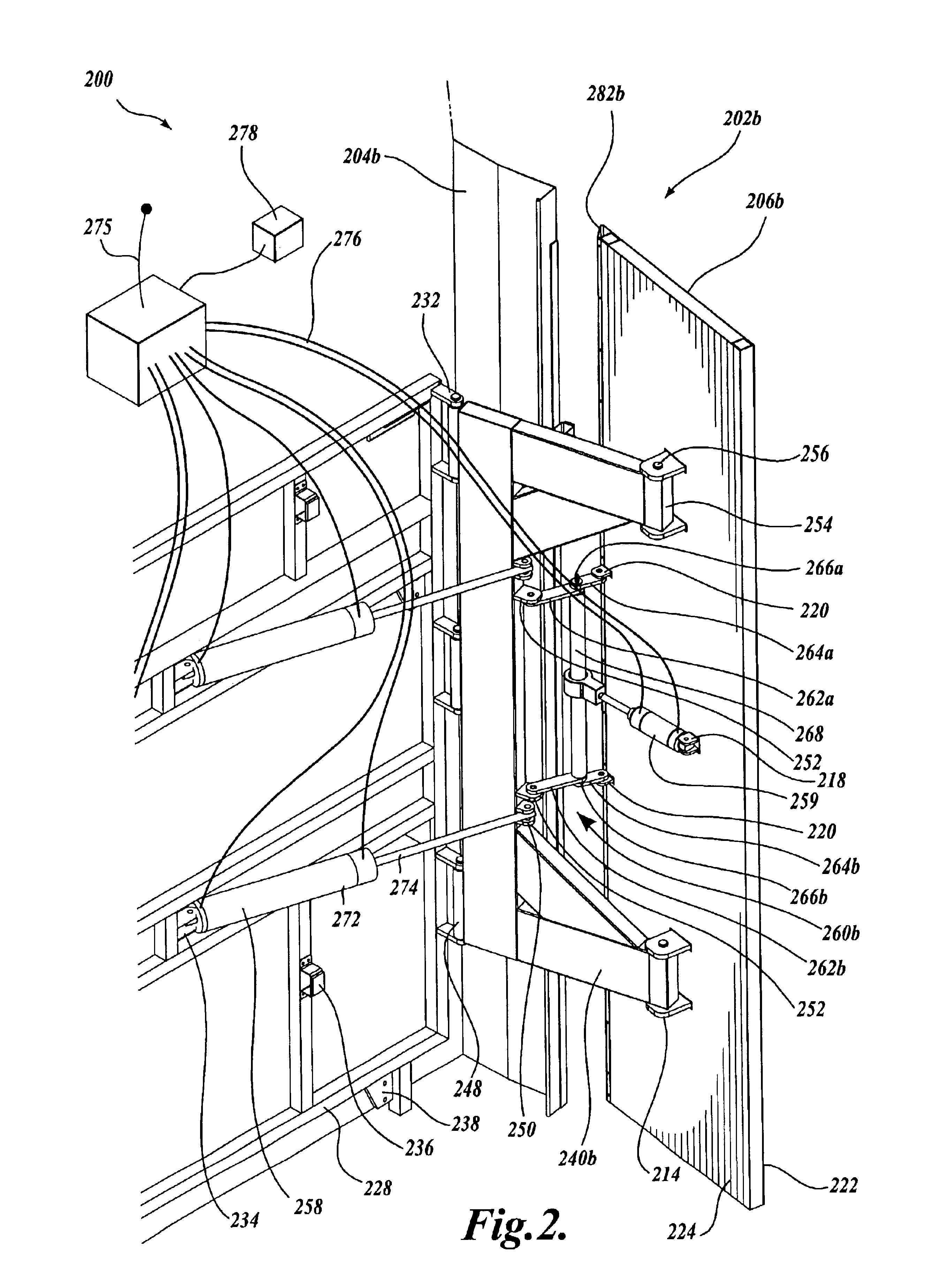

Cab extender assembly method and apparatus

InactiveUS6886882B2Improved drag coefficientSelectively manipulating an aerodynamic drag of a vehicleVehicle seatsWindowsAerodynamic dragControl system

A cab extender assembly (200) for selectively manipulating an aerodynamic drag of a vehicle (100) is provided. The cab extender assembly includes a dynamic cab extender (206a) and a control system (208) coupled to the dynamic cab extender. The control system is adapted to selectively position the dynamic cab extender between a stowed position, a deployed position in which the dynamic cab extender is substantially aligned with a side of the vehicle, and a braking position in which the dynamic cab extender is at least partially disposed into an airstream passing along the side of the vehicle to increase a drag coefficient of the vehicle. The cab extender assembly may also include a fixed cab extender (204a) substantially aligned with the dynamic cab extender when the dynamic cab extender is in the deployed position. A method of operating a cab extender assembly is also disclosed.

Owner:PACCAR INC

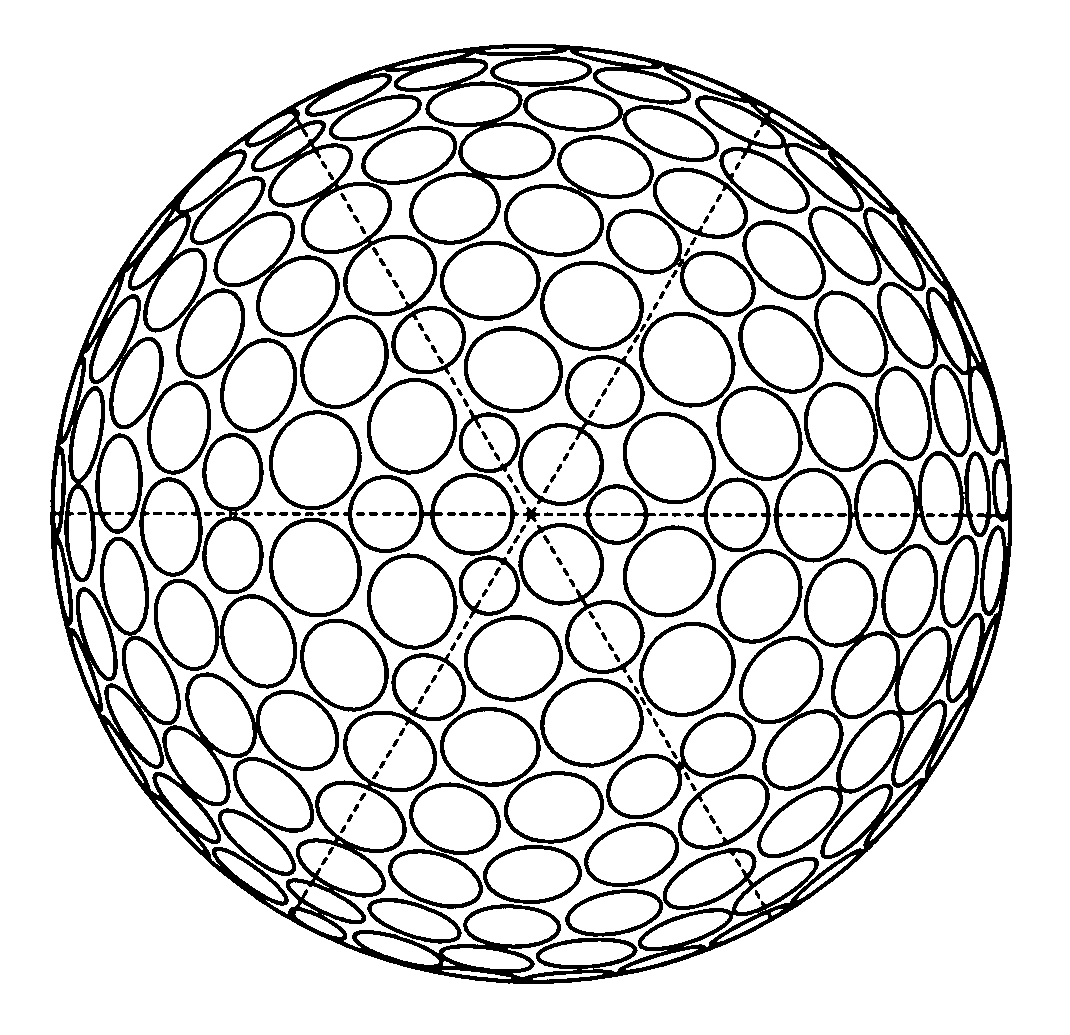

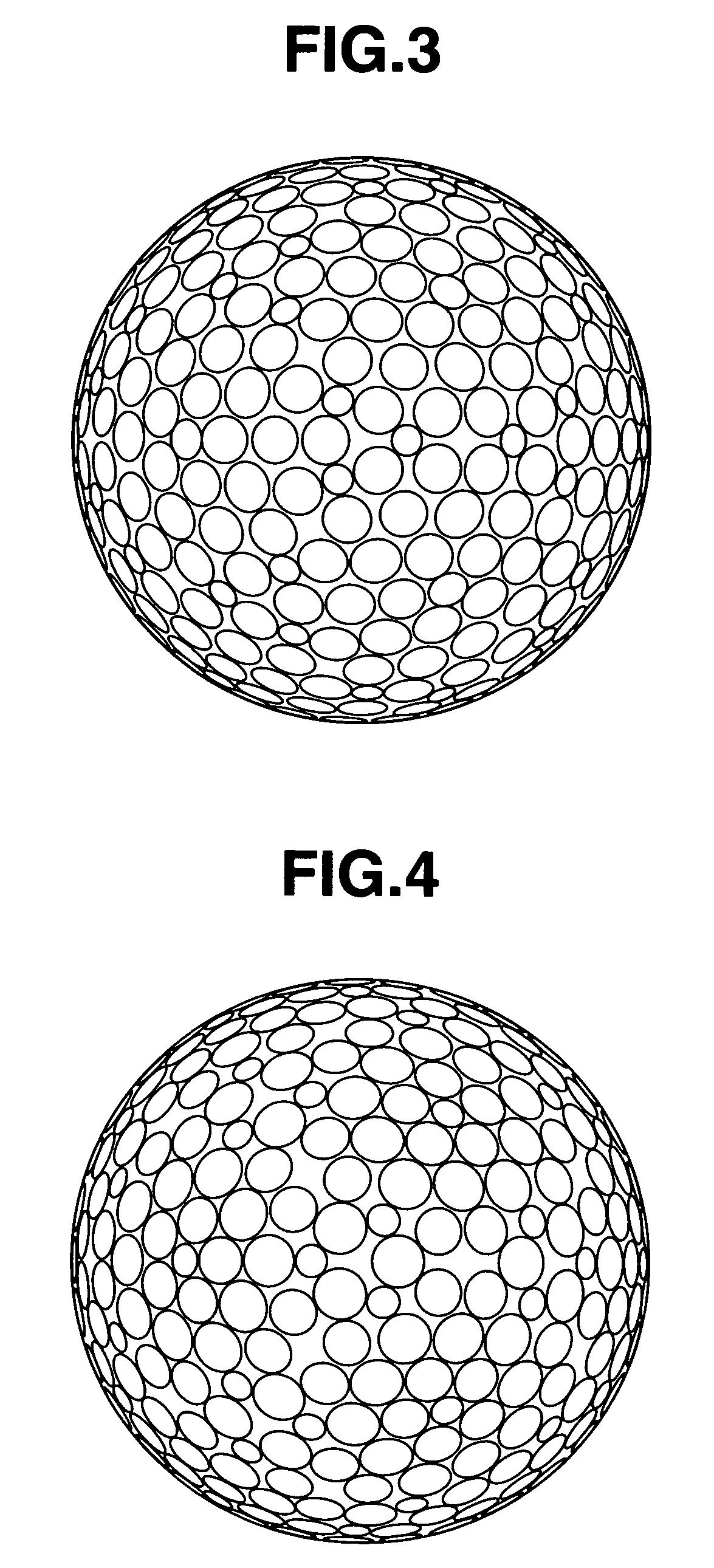

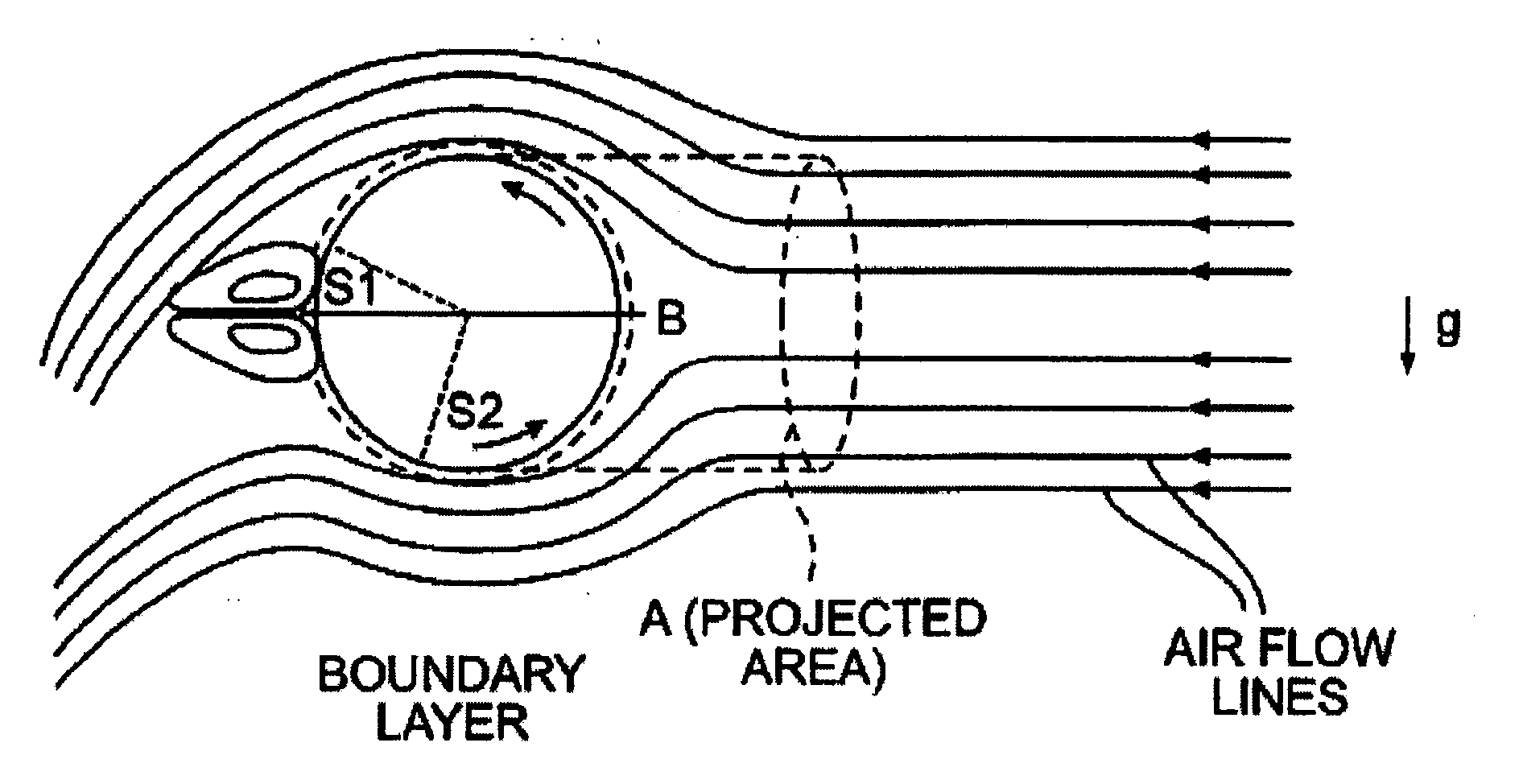

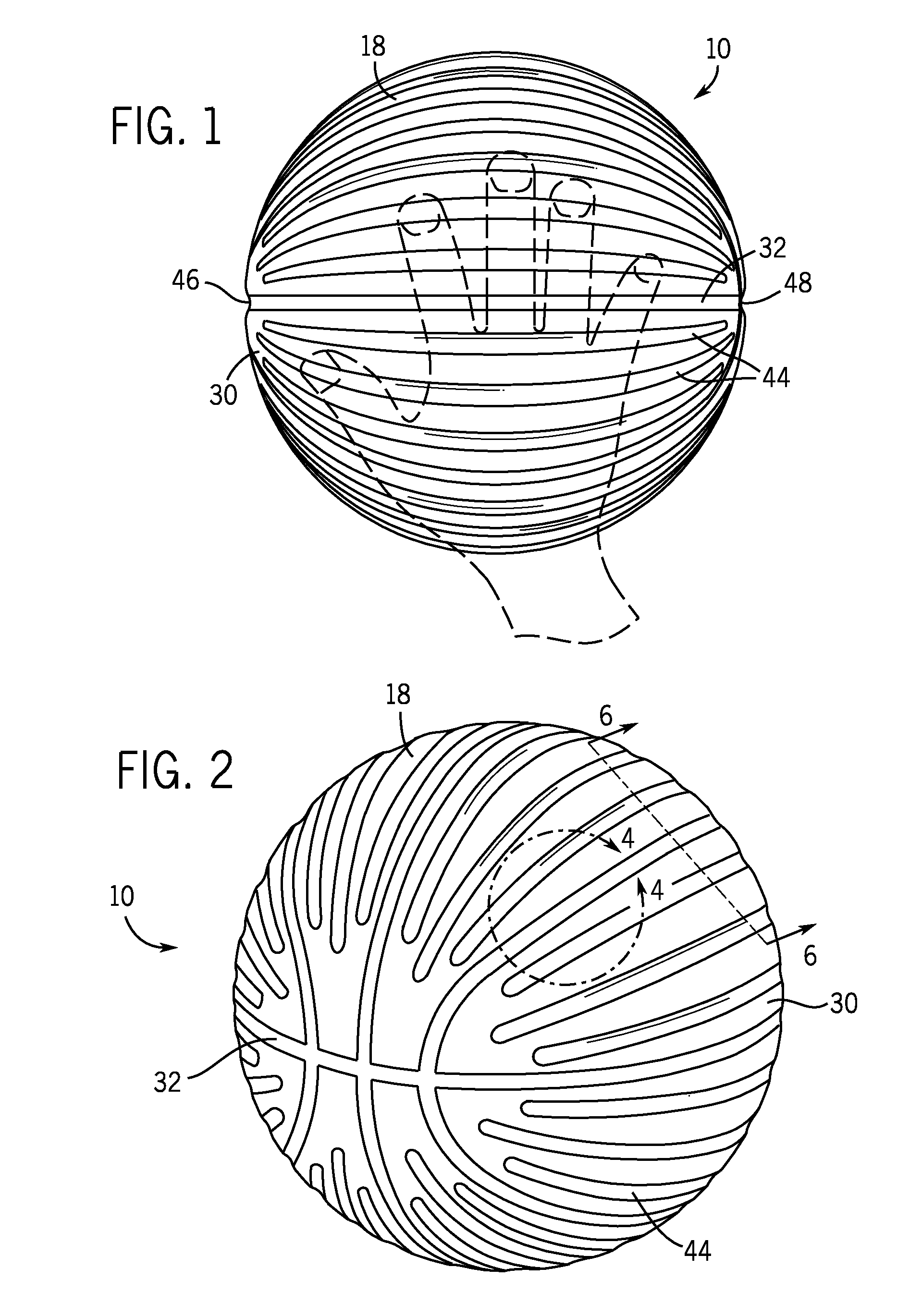

Solid golf ball

A solid golf ball is composed of a solid core and a cover of one or more layers which encloses the core and has on a surface thereof numerous dimples. The solid core has a diameter of 38.7 to 39.6 mm and a deflection hardness of 3.0 to 4.0 mm. The cover has a Shore D hardness of 59 to 70 and has 313 to 371 dimples formed thereon. The ball has an initial velocity of at least 76.8 m / s, a coefficient of lift (CL) when hit of at least 0.165 at a Reynolds number of 70,000 and a spin rate of 2,000 rpm, and a coefficient of drag (CD) when hit of not more than 0.230 at a Reynolds number of 180,000 and a spin rate of 2,520 rpm. The golf ball has a carry which is long enough to make the ball advantageous for competitive play, in addition to which it has a good feel when hit and excellent durability to cracking with repeated impact.

Owner:BRIDGESTONE SPORTS

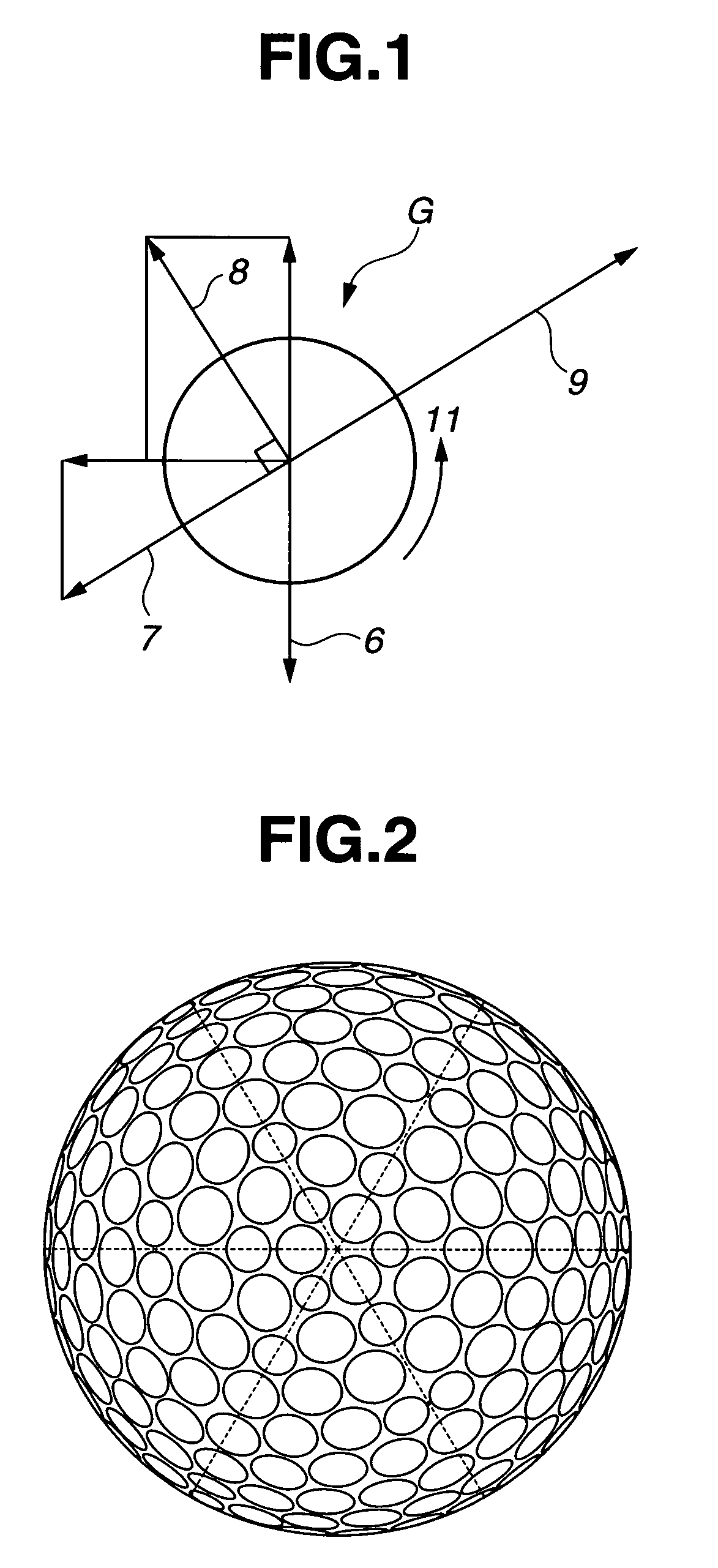

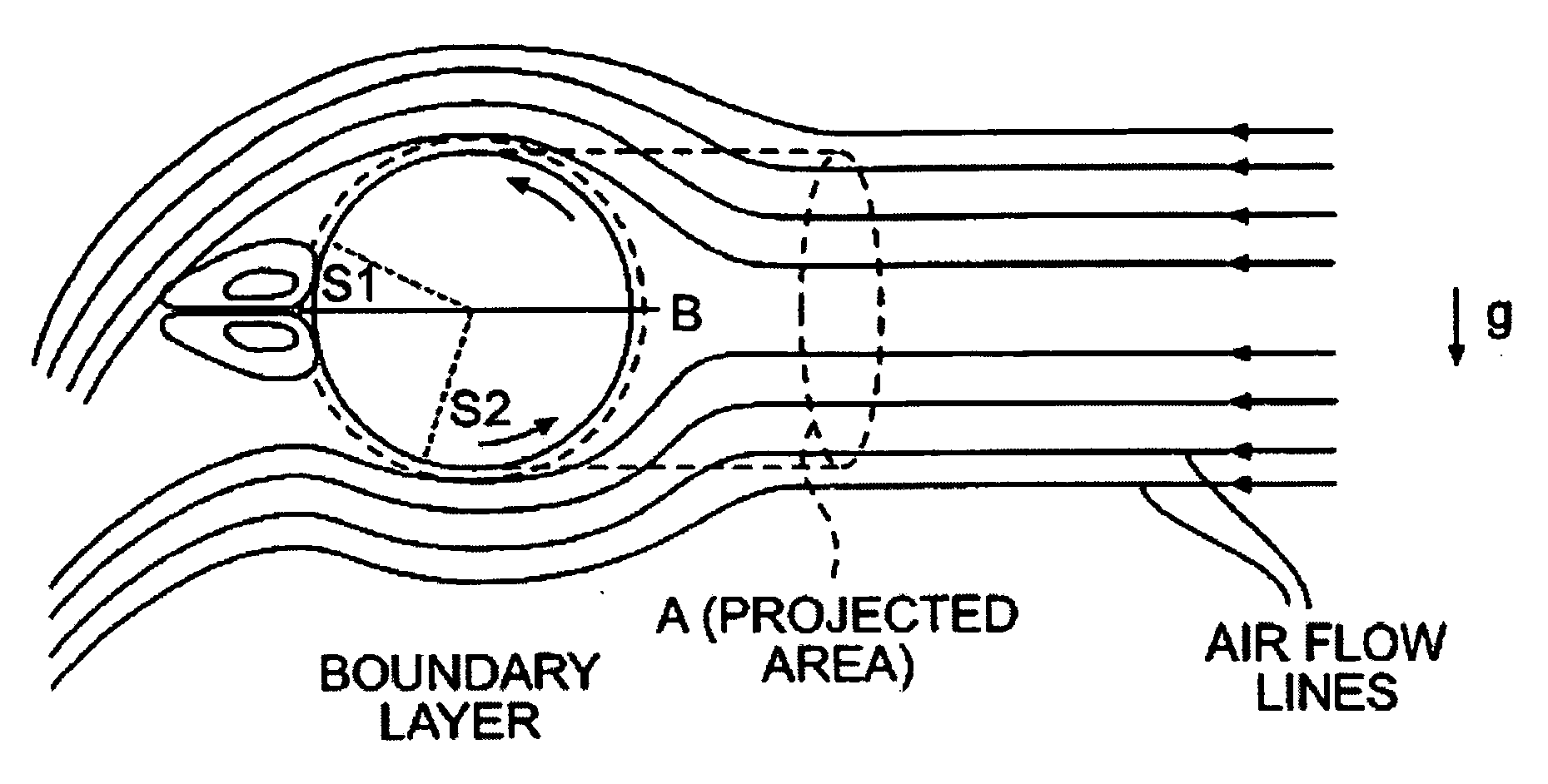

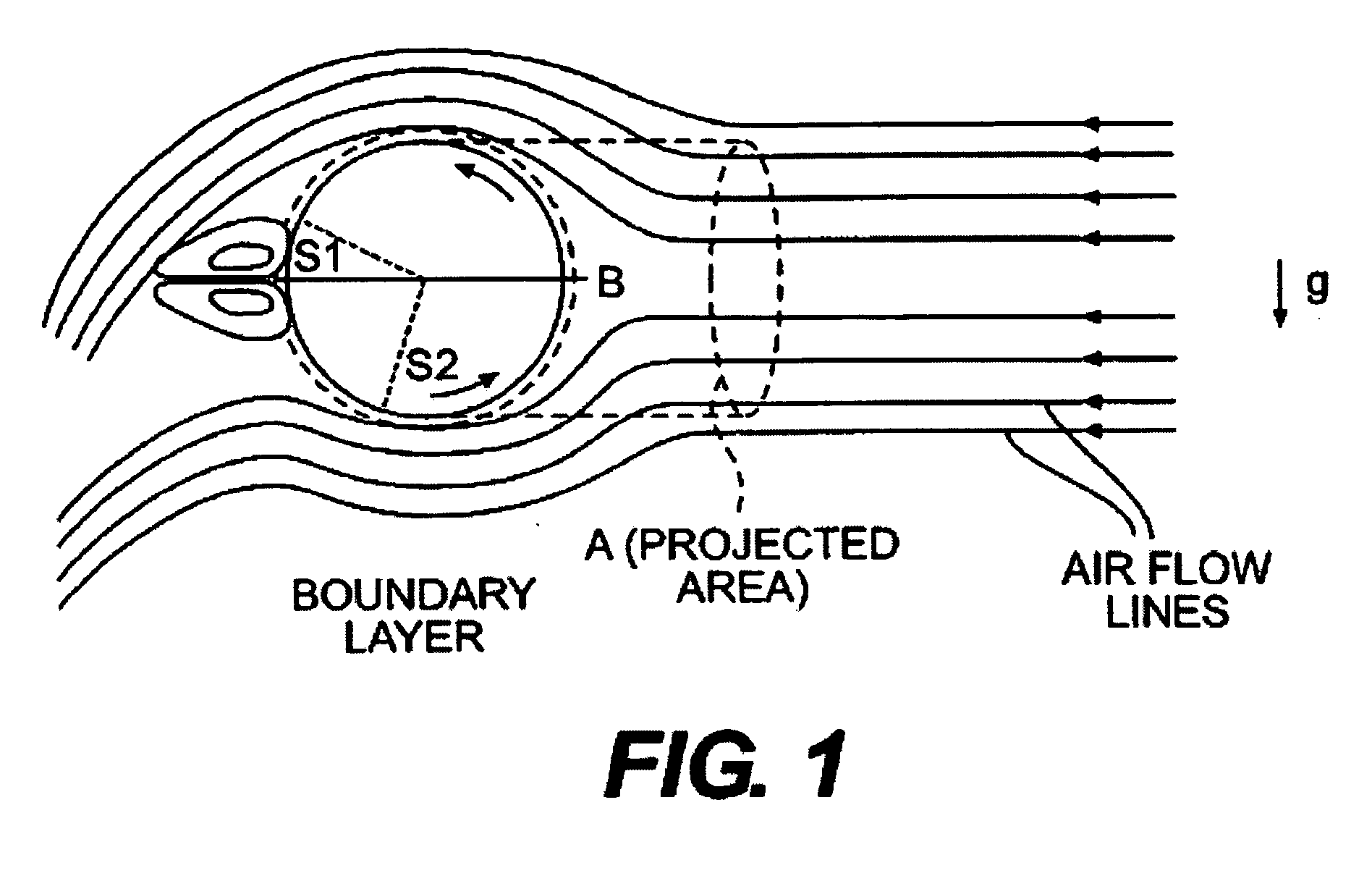

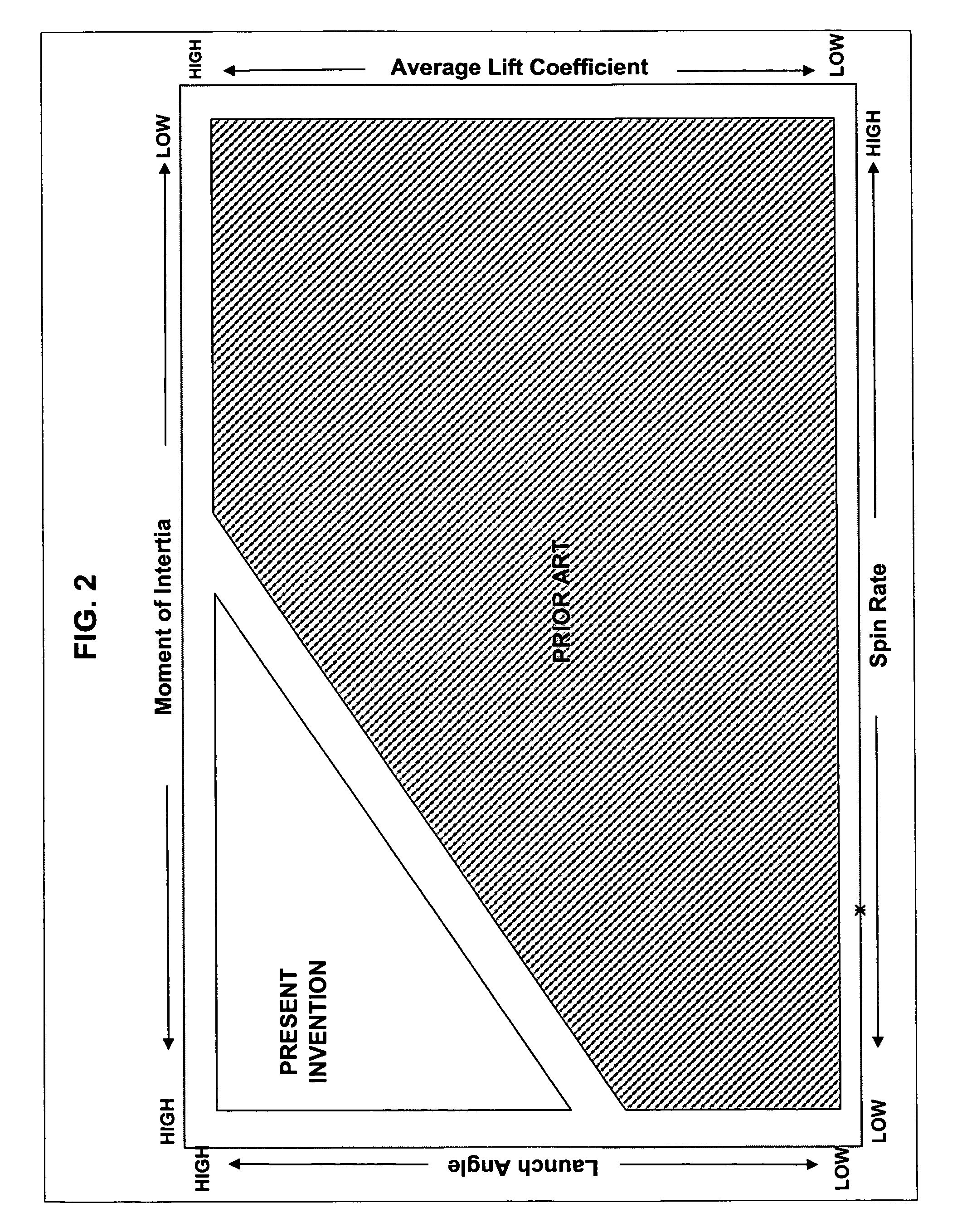

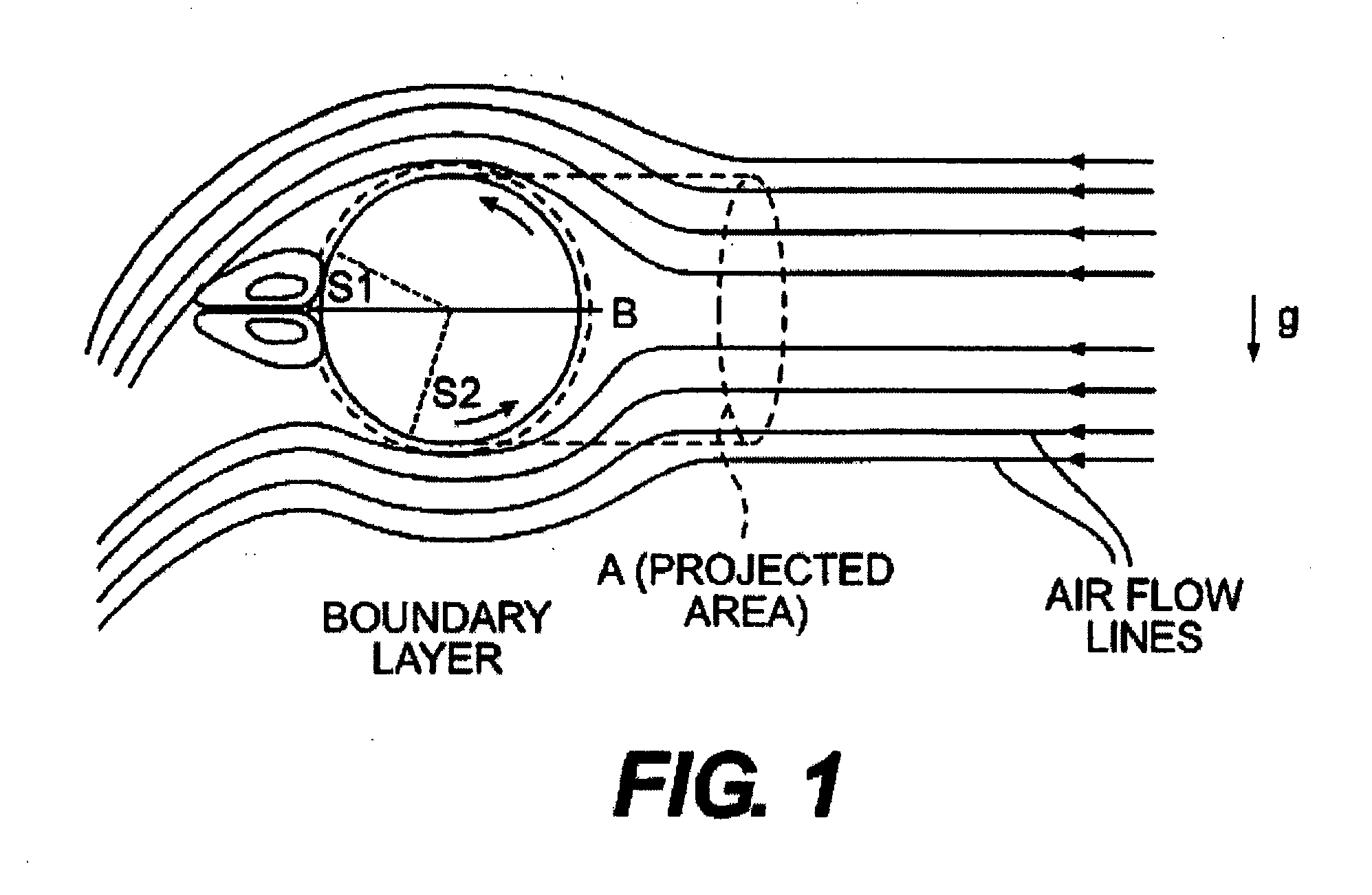

Golf ball having specific spin, moment of inertia, lift, and drag relationship

Golf ball with a novel combination of spin rate, lift coefficient, drag coefficients, and optionally moment of intertia: a golf ball with a low spin rate, a high lift coefficient, a low drag coefficient, and optionally a high moment of inertia; and a golf ball with a high spin rate, a low lift coefficient, a low drag coefficient, and optionally a low moment of inertia.

Owner:ACUSHNET CO

Golf ball having specific spin, moment of inertia, lift, and drag relationship

Golf ball with a novel combination of spin rate, lift coefficient, drag coefficients, and optionally moment of intertia: a golf ball with a low spin rate, a high lift coefficient, a low drag coefficient, and optionally a high moment of inertia; and a golf ball with a high spin rate, a low lift coefficient, a low drag coefficient, and optionally a low moment of inertia.

Owner:ACUSHNET CO

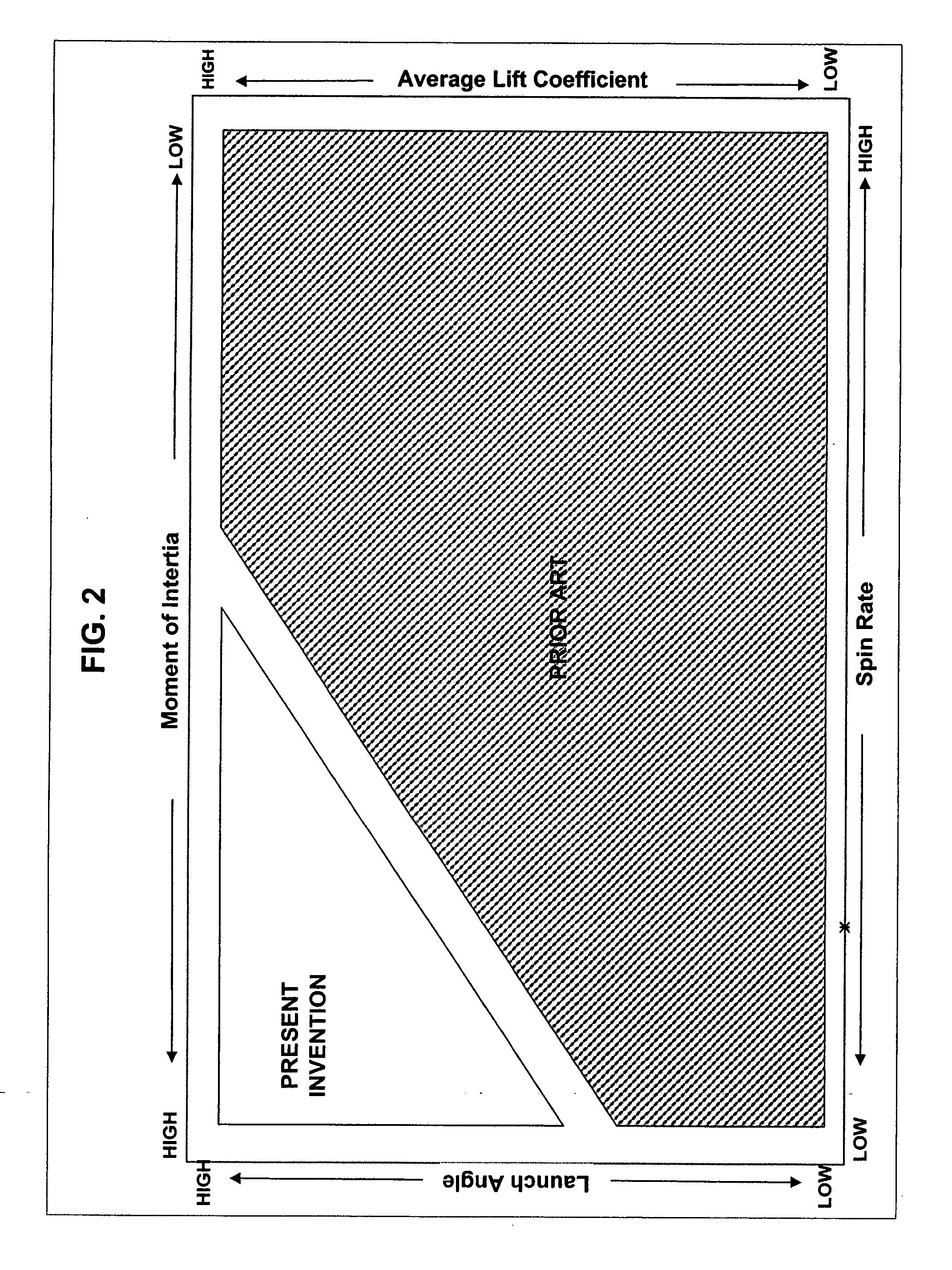

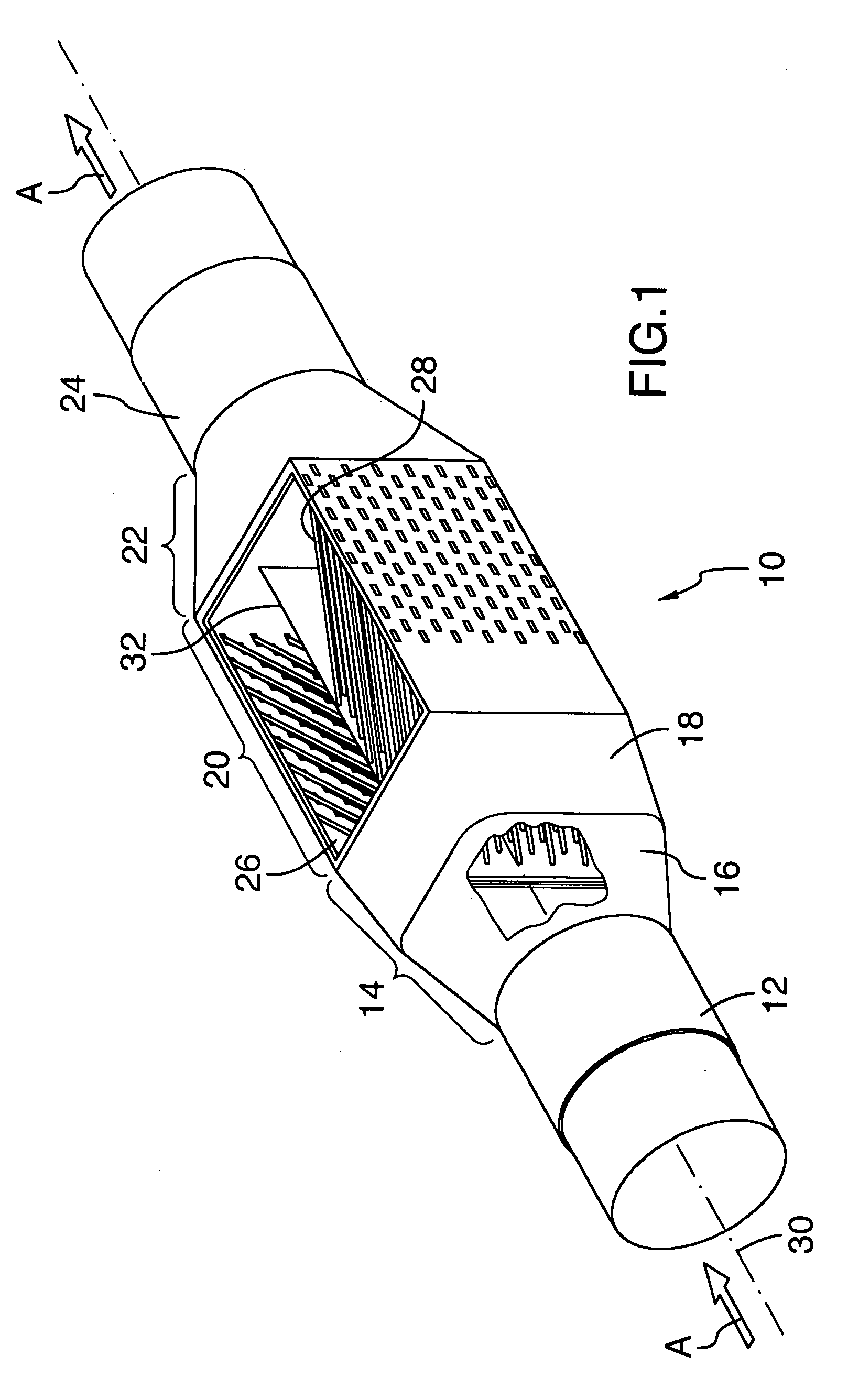

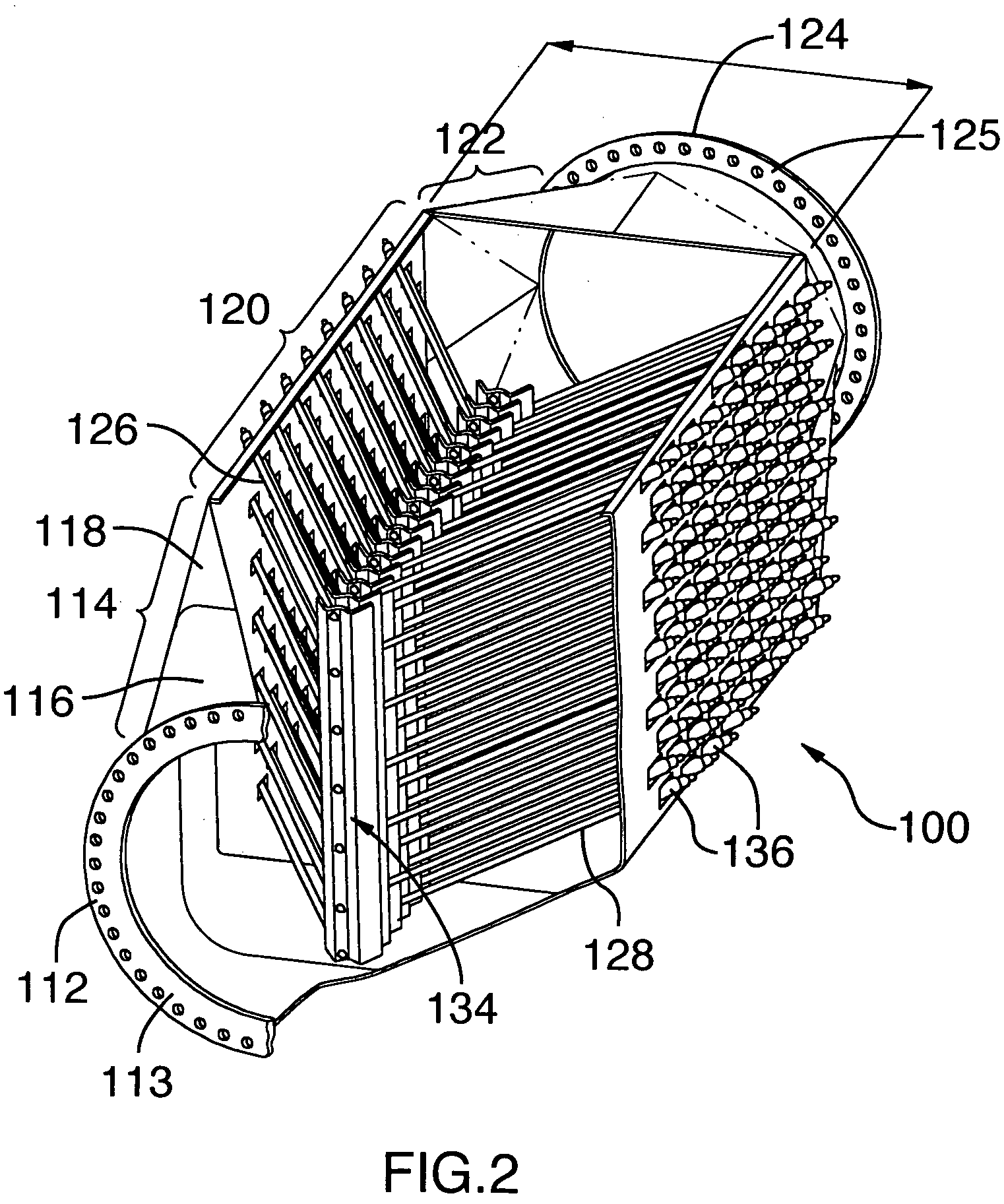

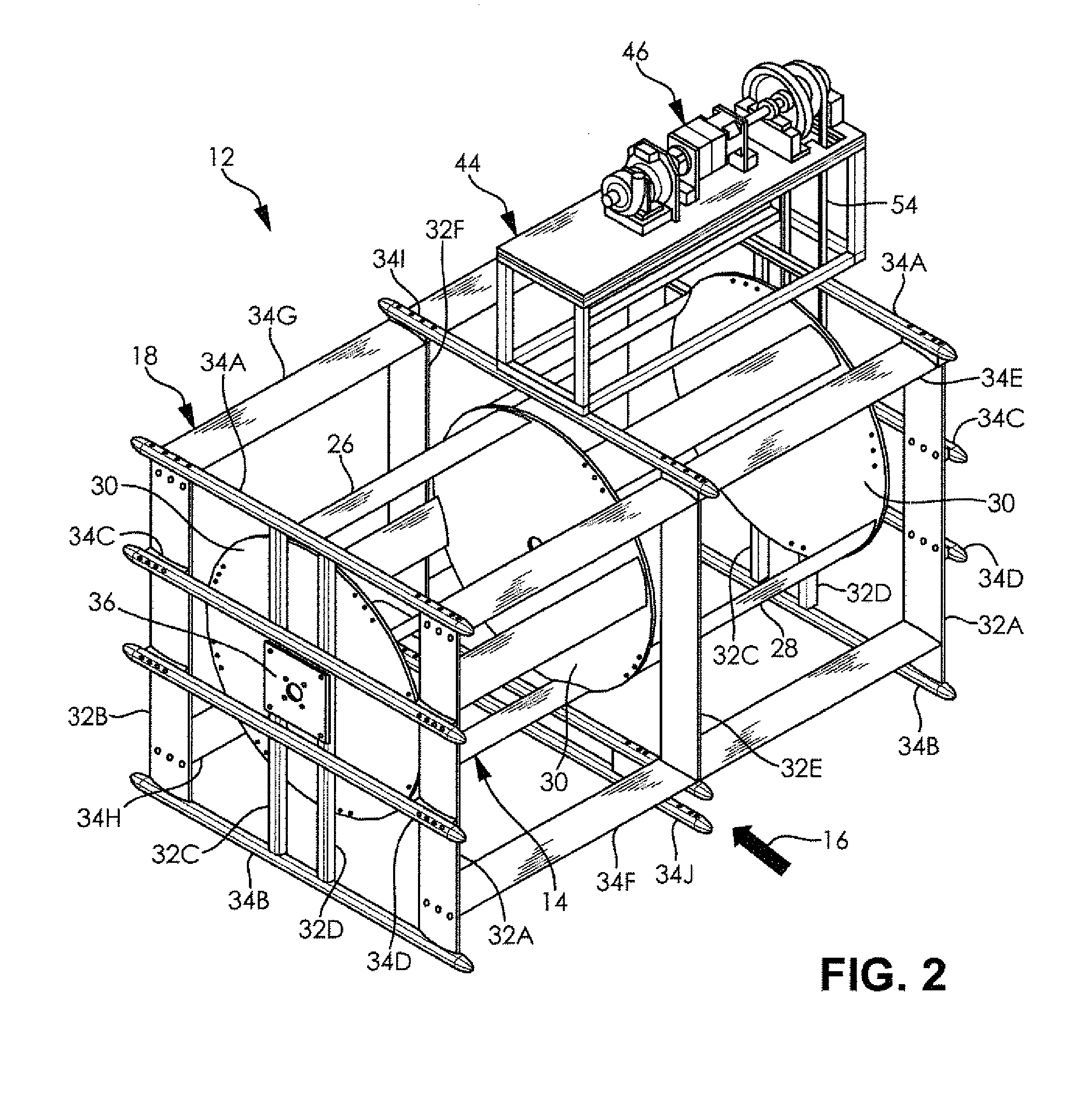

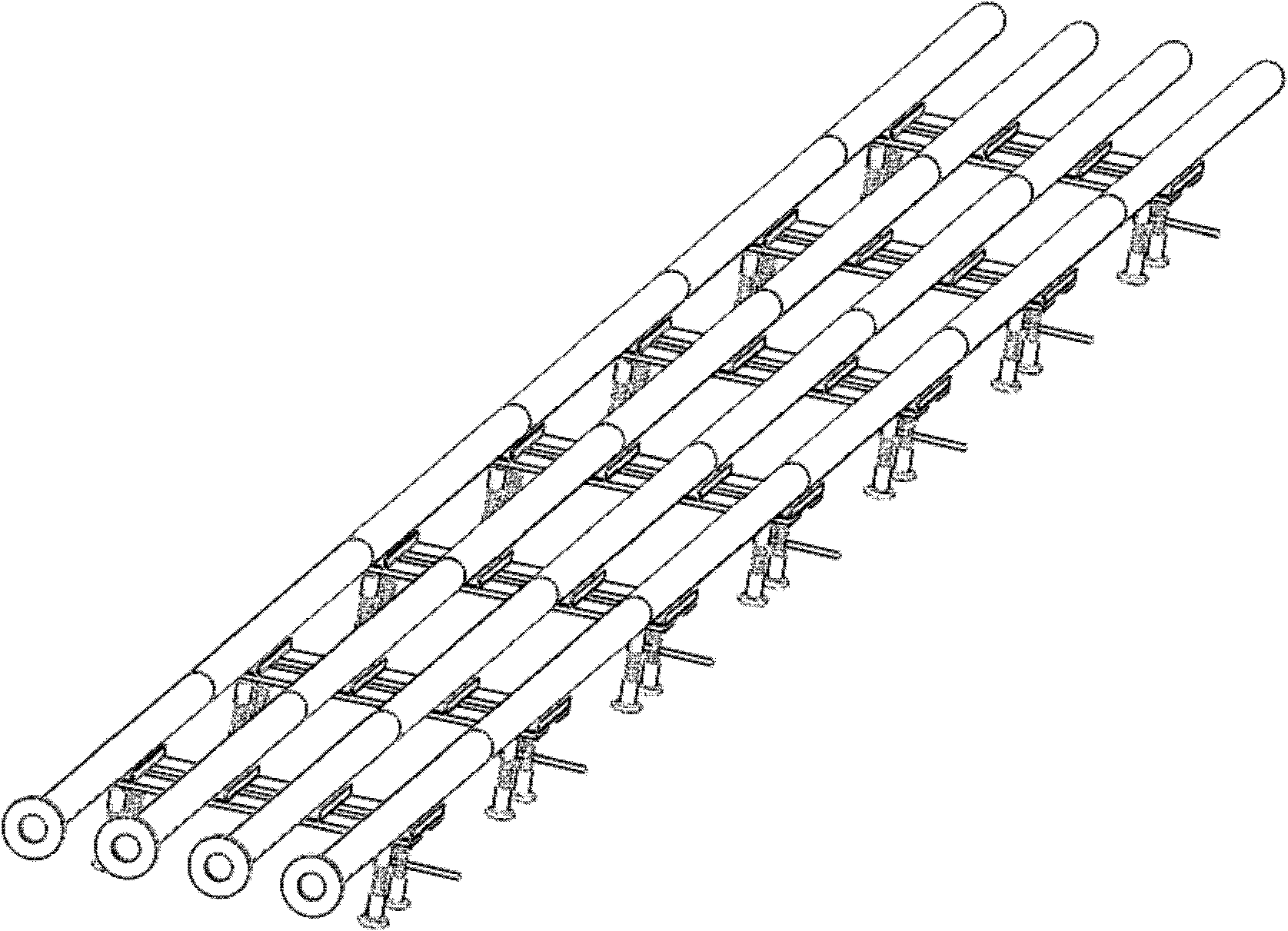

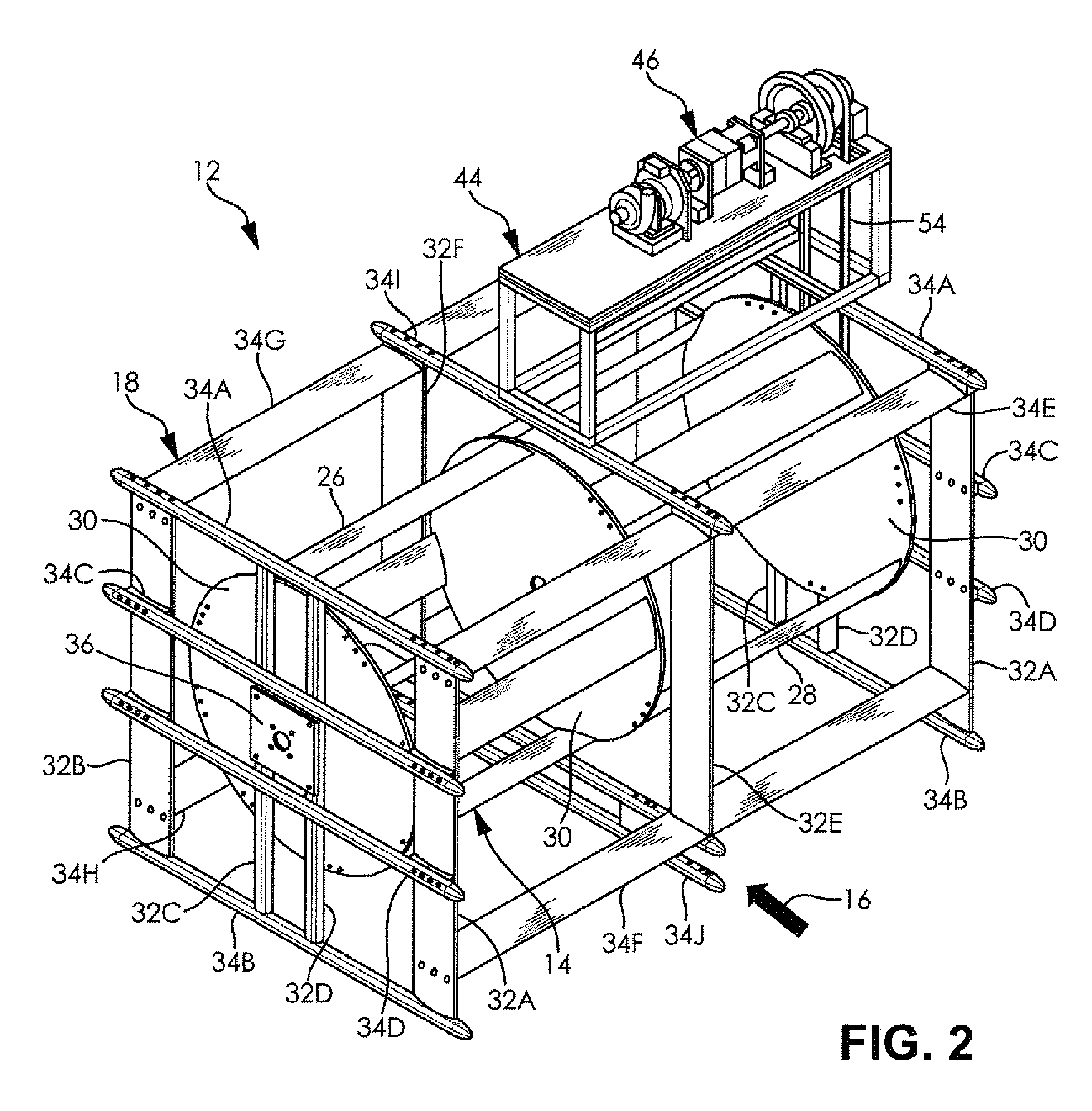

Fluid treatment system

ActiveUS20050263716A1Reducing velocity of fluid flowingIncrease fluid velocityLiquid separation by electricityWater/sewage treatment by irradiationWastewaterForced oscillation

The present invention relates to a fluid treatment system comprising: an inlet; an outlet; and a fluid treatment zone disposed between the inlet and the outlet. The fluid treatment zone has disposed therein: (i) an elongate first radiation source assembly having a first longitudinal axis, and (ii) an elongate second radiation source assembly having a second longitudinal axis. The first longitudinal axis and the second longitudinal axis are non-parallel to each other and to a direction of fluid flow through the fluid treatment zone. The present fluid treatment system has a number of advantages including: it can treat large volumes of fluid (e.g., wastewater, drinking water or the like); it requires a relatively small “footprint”; it results in a relatively lower coefficient of drag resulting in an improved hydraulic pressure loss / gradient over the length of the fluid treatment system; and it results in relatively lower (or no) forced oscillation of the radiation sources thereby obviating or mitigating of breakage of the radiation source and / or protective sleeve (if present). Other advantages are discussed in the specification.

Owner:TROJAN TECH

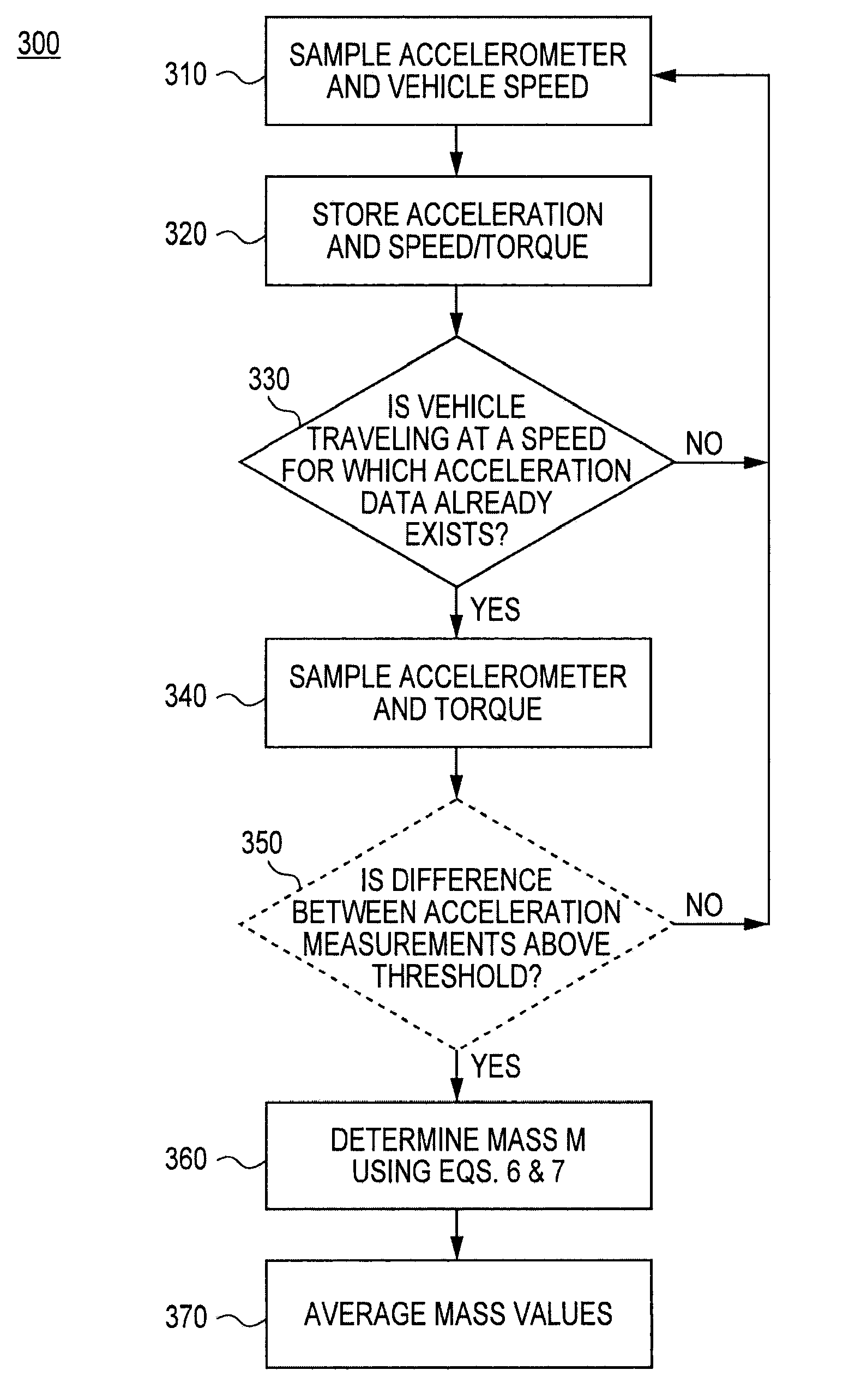

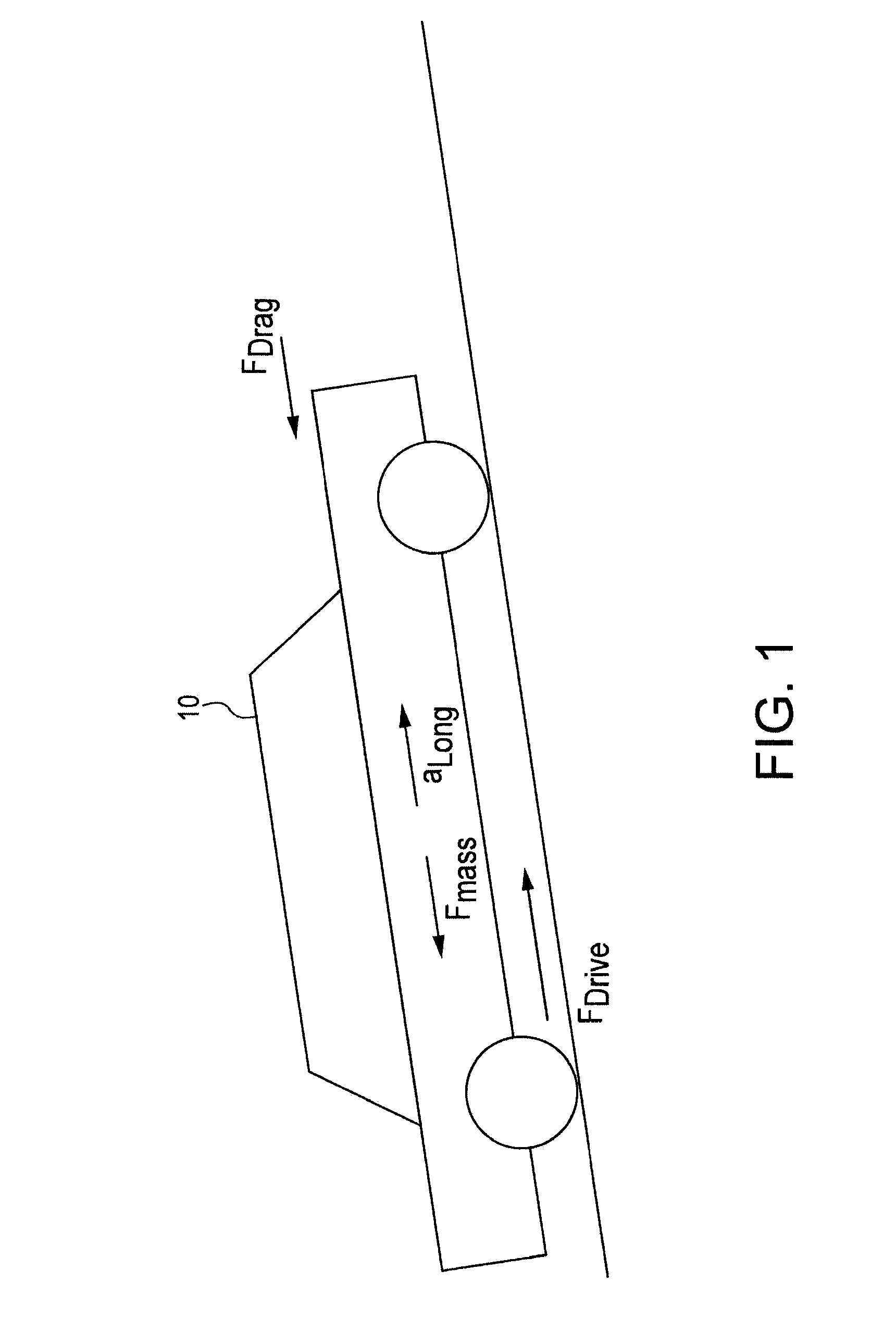

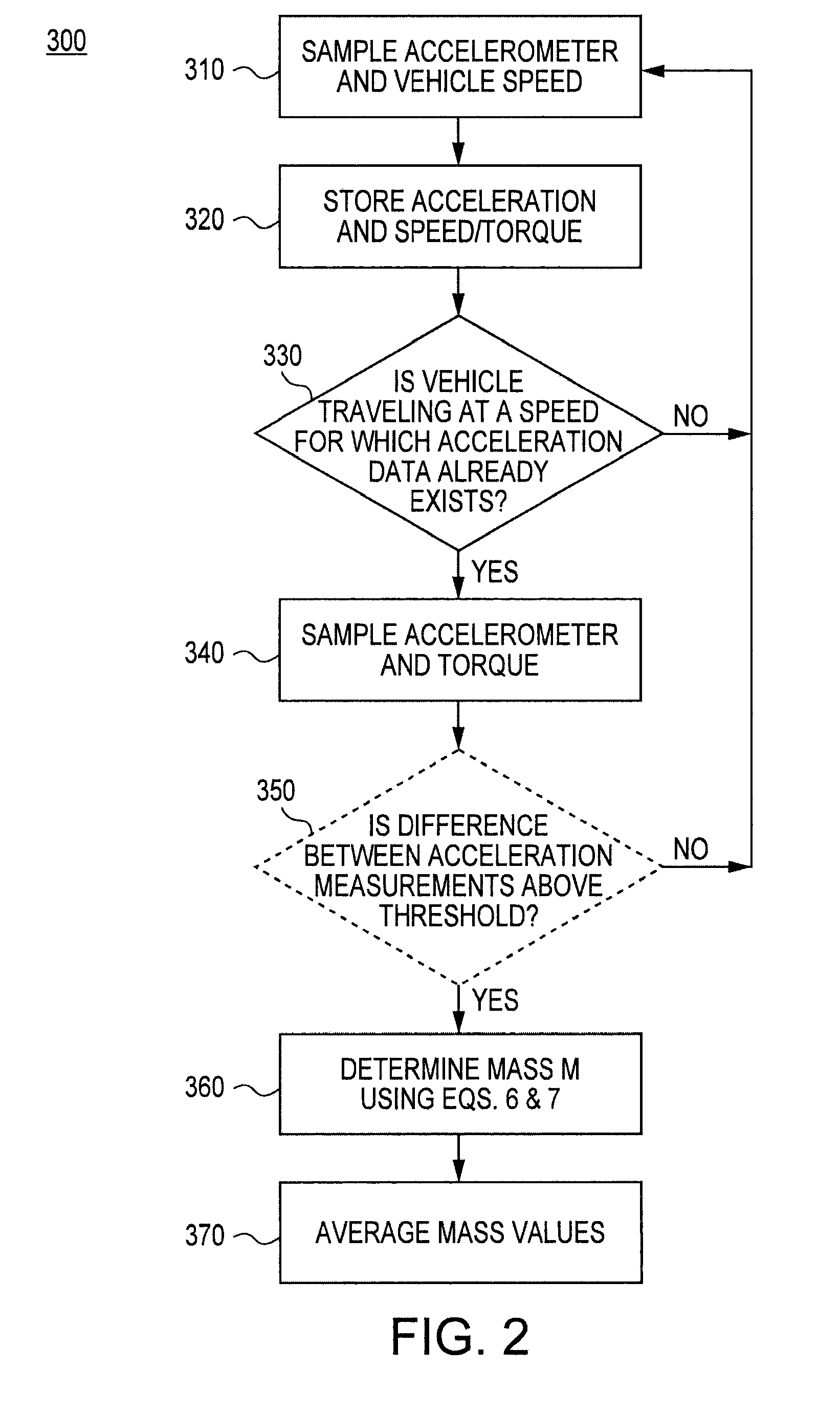

Mass, drag coefficient and inclination determination using accelerometer sensor

ActiveUS20110172877A1Vehicle testingRegistering/indicating working of vehiclesAccelerometerEngineering

A method and system of determining a vehicle's driving characteristics such as the vehicle mass, drag force coefficients and driving surface inclination. The vehicle's mass, drag force coefficients and inclination are determined using signals input from the vehicle's accelerometer.

Owner:FCA US

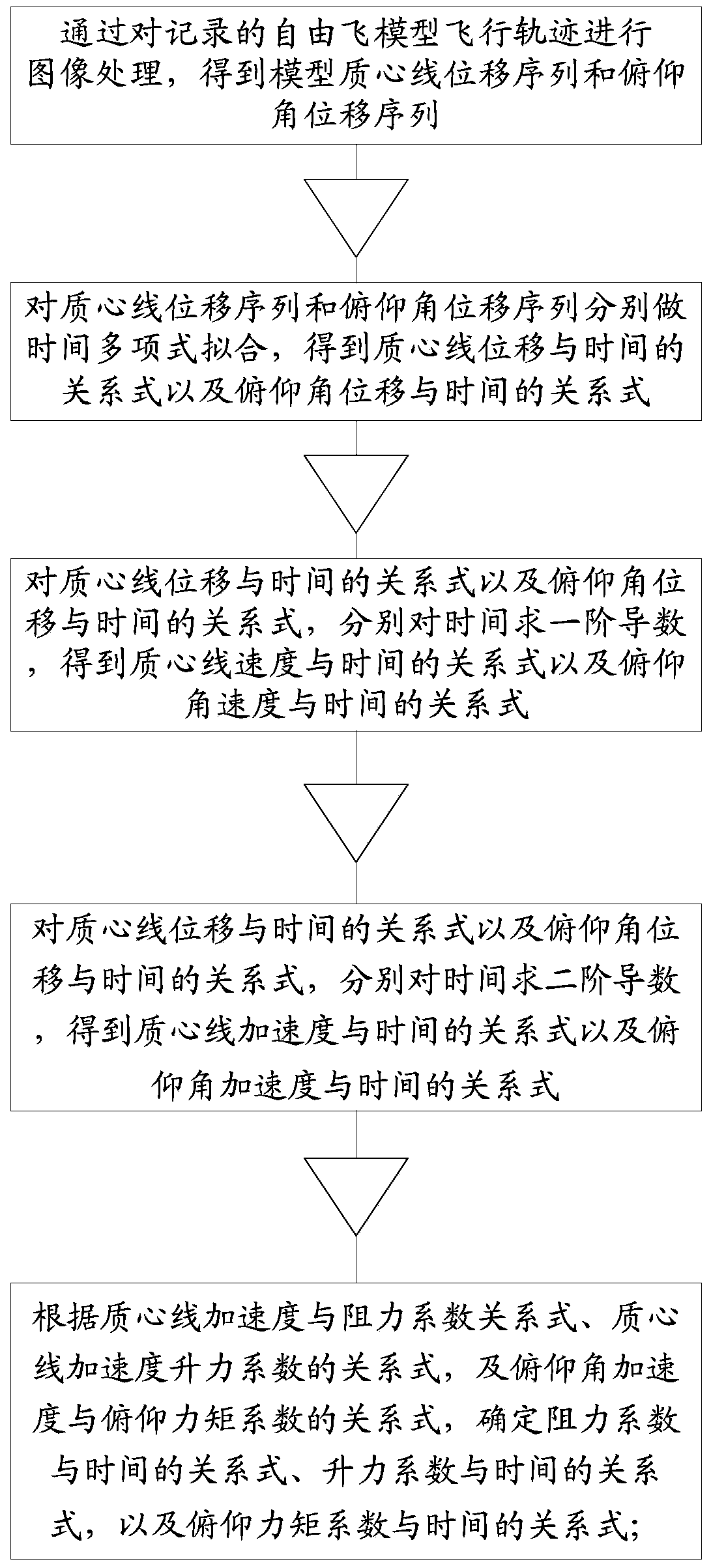

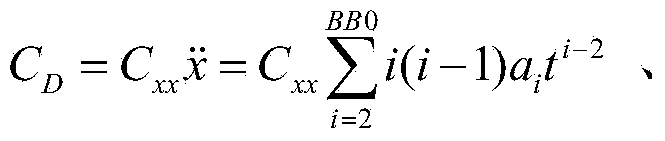

Method for determining aerodynamic parameters of model free flight tests

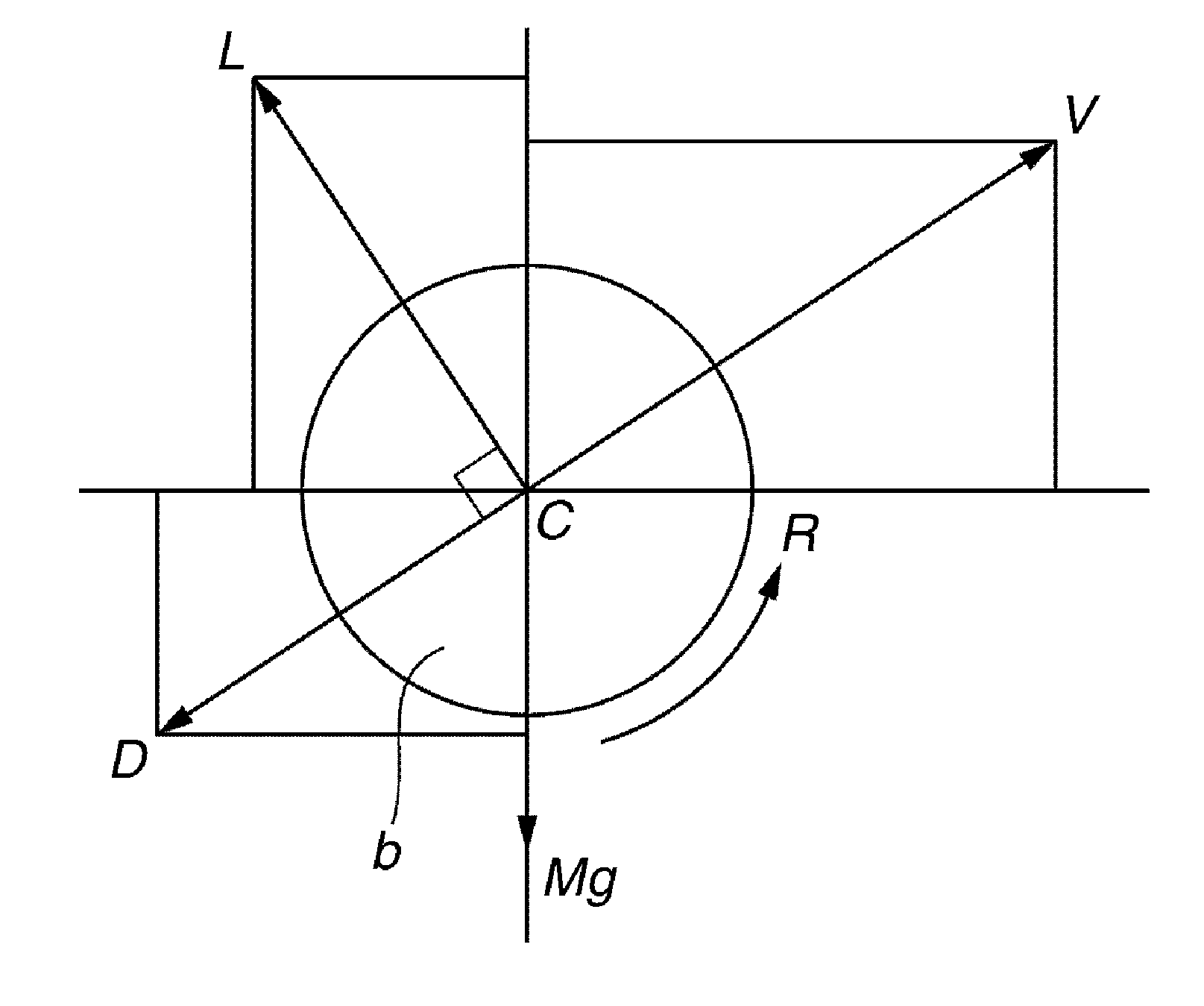

A method for determining aerodynamic parameters of model free flight tests is used in model free flight tests including a wind tunnel free flight test, an atmospheric free flight test and the like. Under the situation that a model used in wind tunnel free flight or atmospheric free flight moves in a plane, the method of polynomial time is adopted to match the linear displacement of the centroid of the model in the horizontal direction and the vertical direction and the shooting recording observing value, changing along with time, of the angle of pitch of the model, then, the time-dependent changing rule of the linear displacement, the linear velocity and the linear acceleration of the centroid of the model and the angle displacement, the angle velocity and the angle acceleration of the angle of pitch is obtained, and accordingly the time-dependent changing rule of the resistance coefficient, the lift coefficient and the pitch moment coefficient in the process of model flying is obtained. The application conditions and the range of a data processing method of the model free flight tests are expanded, and the test recorded data can be processed in wide application conditions and ranges to obtain the aerodynamic parameters and the movement rule of the model.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

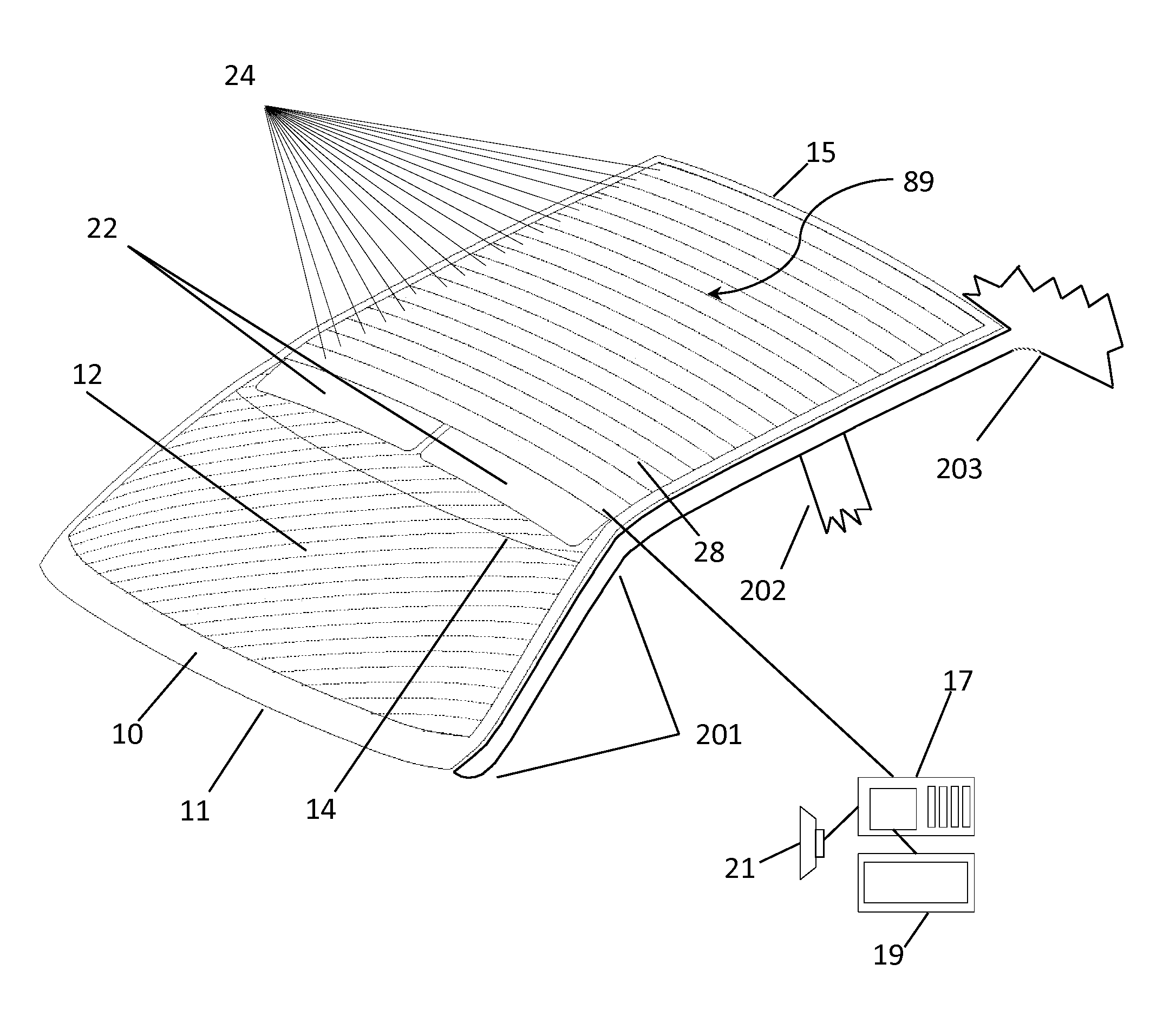

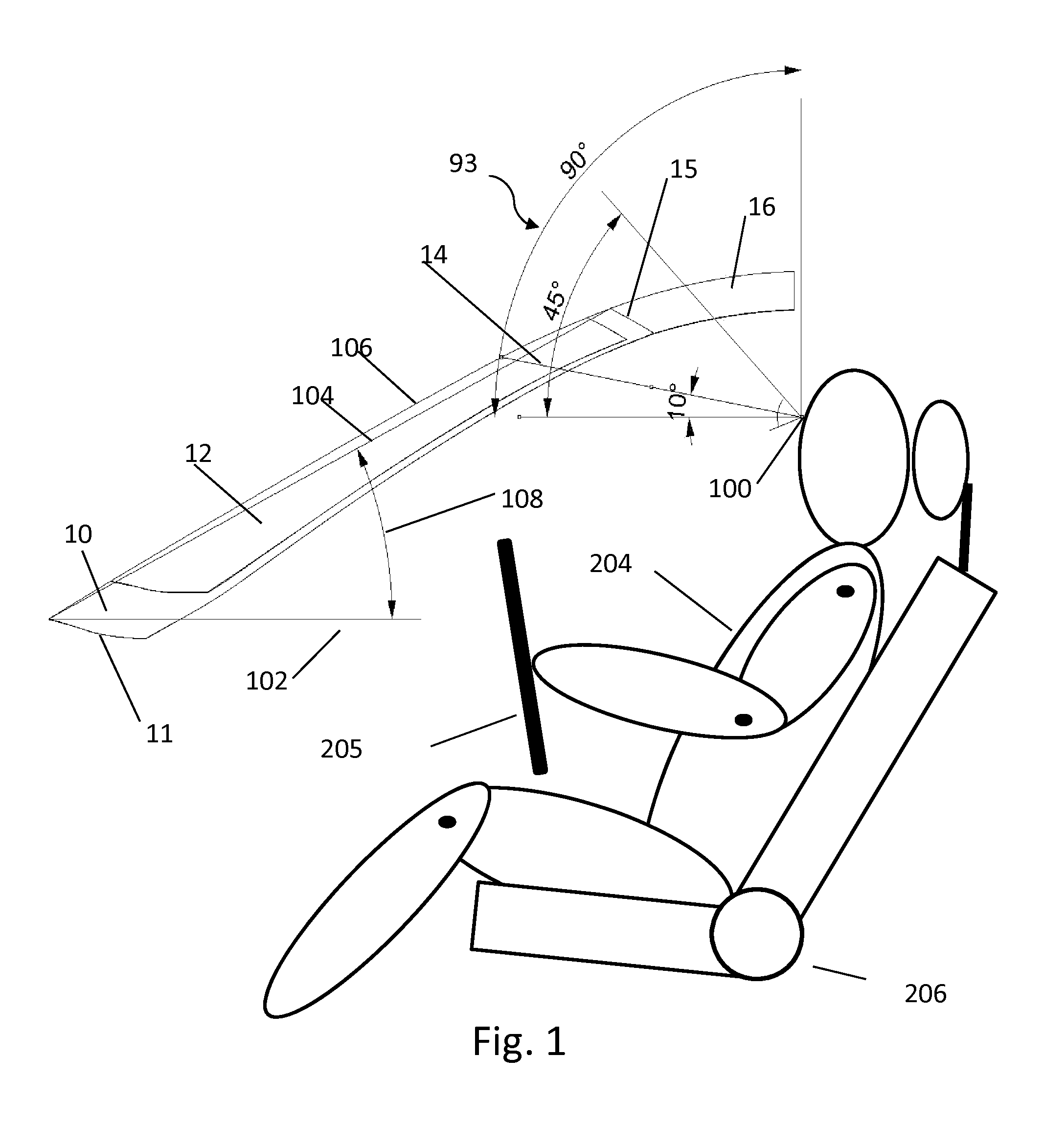

Panoramic extended windshield with integrated non-moving blind

ActiveUS20150367782A1Good opticsIncrease viewable areaAntiglare equipmentGlass/slag layered productsWindow shutterTransmittance

A vehicle windshield with a top edge extended such as to provide a lower drag coefficient and giving the driver a wider panoramic vertical viewing angle and having an integrated shading means, having no movable parts and utilizing a material which is capable changing its light transmittance electrically and with a controlling means which mimics the aesthetics of a conventional mechanical blind. Aspects of the various embodiments include: switchable segmented sun visors, integrated solid state lighting, a mounting means for attachment of a center console, mirrors, cameras and other devices, a controlling means capable of providing a variety of opening and closing sequences, a user programmable interface, a touch screen interface, touch sensitive activation, a sound emitting means to provide for the audible aesthetic of the blind, inclusion of substantially the entire roof, inclusion of substantially the entire roof and the rear window, and any combination of a tinted, heat reflecting, heat absorbing or photo-chromic coating, film or interlayer in all or a portion of the glazing area.

Owner:MANNHEIM ASTETE MARIO ARTURO

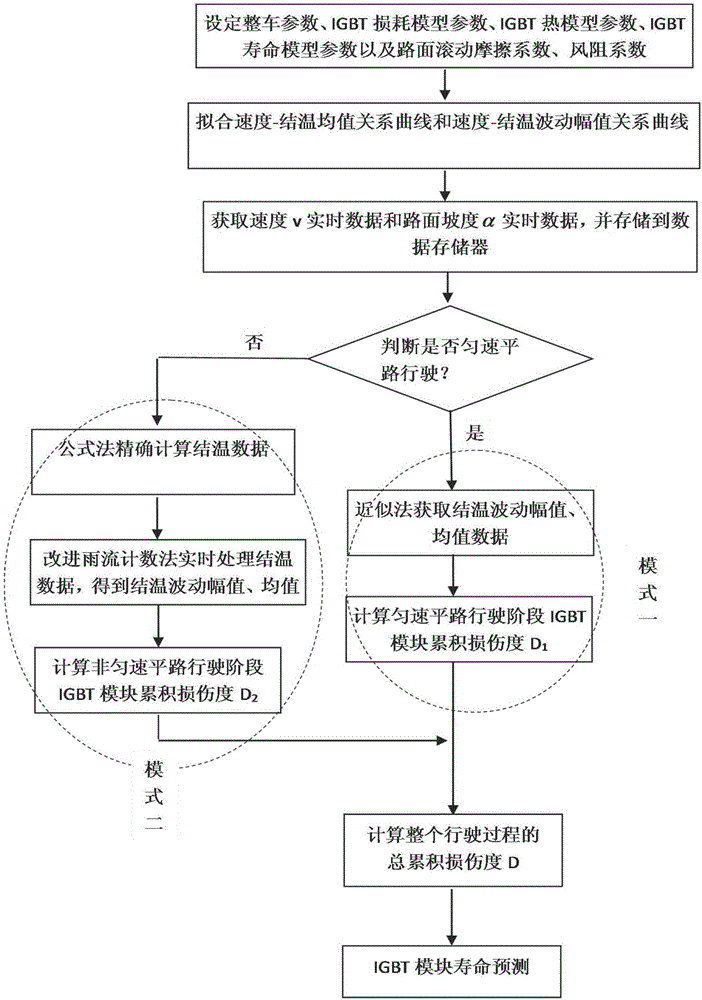

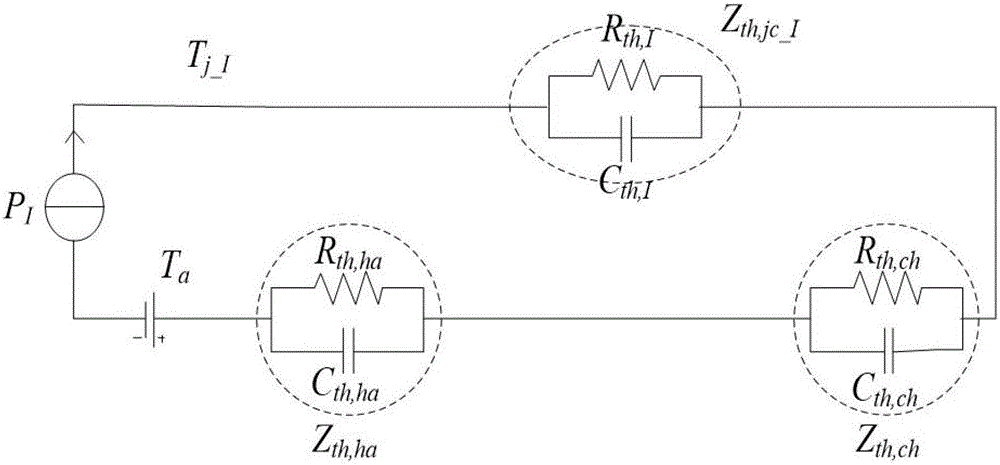

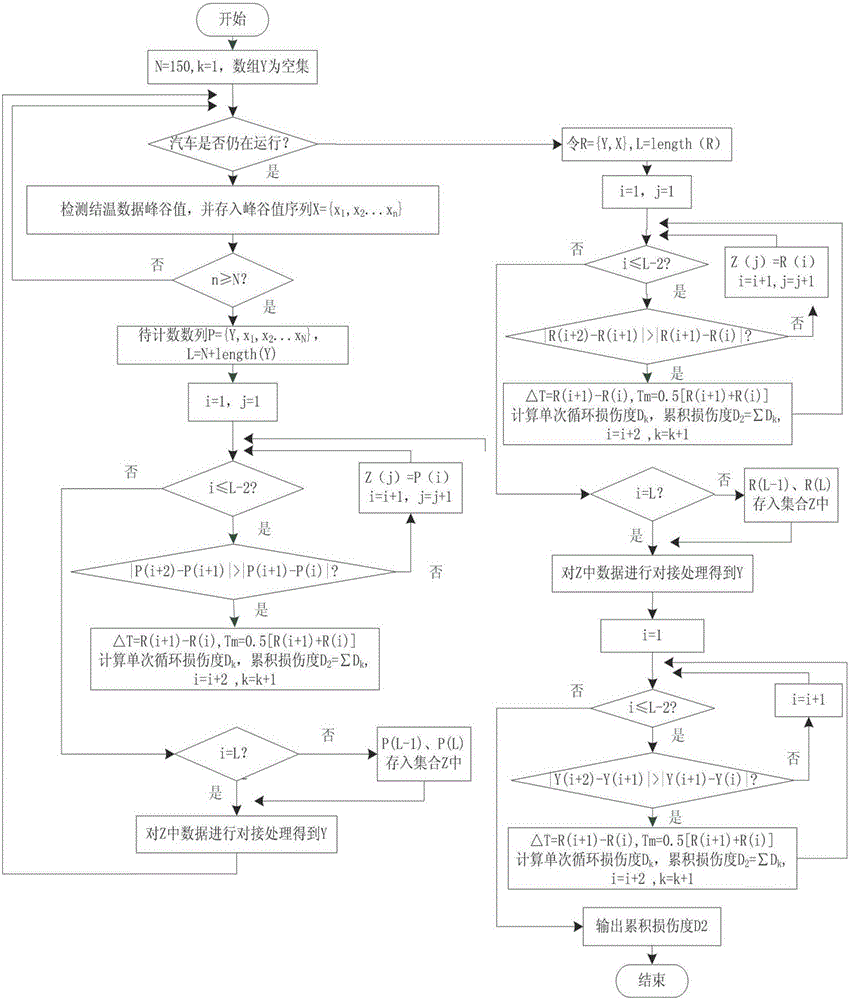

Method for accumulated damage computation and life prediction of IGBT module used for electric car

ActiveCN106528987AEasy accessSmall amount of calculationDesign optimisation/simulationSpecial data processing applicationsSimulationJunction temperature

The invention relates to a method for accumulated damage computation and life prediction of an IGBT module used for an electric car. The method is characterized by comprising the following steps of setting whole-car parameters, relative parameters of the IGBT module, a road surface rolling friction coefficient and a drag coefficient; fitting a speed-junction temperature mean value relation curve and a speed-junction temperature fluctuation amplitude relation curve; obtaining running speed-time data and road surface gradient data of the electric car in real time; judging a car running speed change condition and a climbing condition and respectively computing the IGBT accumulated damage according to two modes in order to obtain total accumulated damage of the IGBT module; and predicting the lifetime and the life mileage of the IGBT module. According to the method, the direct link is established between the running condition of the electric car and the working condition of the IGBT module, the junction temperature data and the accumulated damage of the IGBT module are directly computed, the method can be used for researching the influence of factors, such as environment temperature, road surface gradient and running acceleration, on the service life of the IGBT module used for the electric car, and the method has wide application value.

Owner:HEBEI UNIV OF TECH

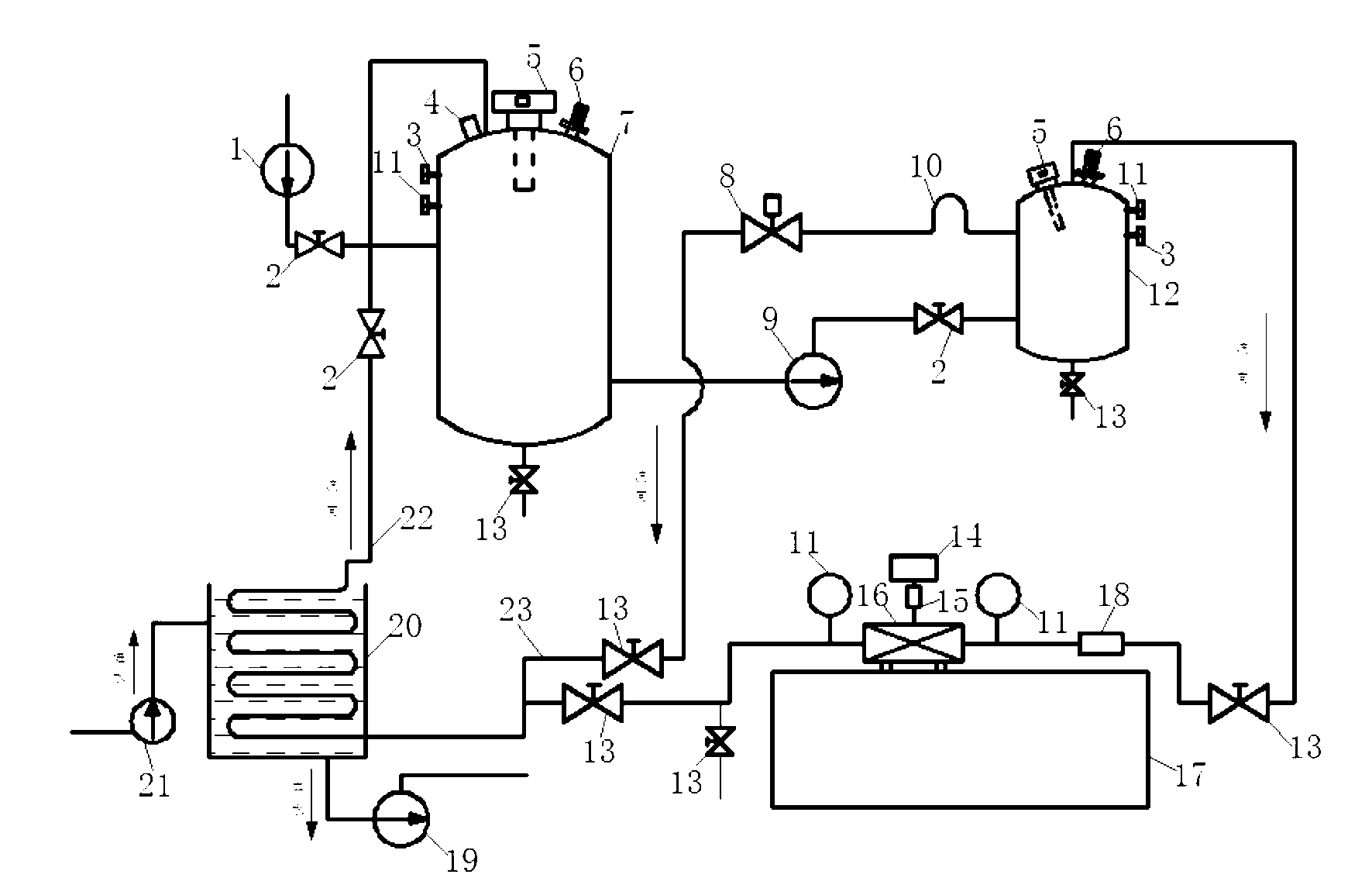

High temperature valve detecting and testing system

InactiveCN103308293ASimple structureHigh precisionMachine part testingFluid-tightness measurement using fluid/vacuumBuffer tankEngineering

The invention discloses a high temperature valve detecting and testing system, comprising an oil feed pump, an oil storage tank, a pressure pump, a buffer tank, a detecting device and a condensing device, wherein an electric heater and a pressure transmitter are installed on the top part of the oil storage tank; the bottom part of the oil storage tank is connected with the buffer tank through a third trunk pipeline; another pressure transmitter and a temperature sensor are installed on the inner side wall of the buffer tank; the buffer tank is connected with an oil inlet of a to-be-detected valve through a fourth trunk pipeline; the detecting device comprises a detecting table and a torque testing device; the valve rod of the to-be-detected valve is connected with the torque testing device; and the oil outlet of the to-be-detected valve is connected with the oil storage tank through a fifth trunk pipeline, the condensing device and a second trunk pipeline in sequence. The high temperature valve detecting and testing system is simple in structure and convenient to operate; and by the adoption of the detecting and testing system, the resistance coefficient and the torque performance of a high temperature valve and the flow characteristic can be tested, and the leakage amount can be detected.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

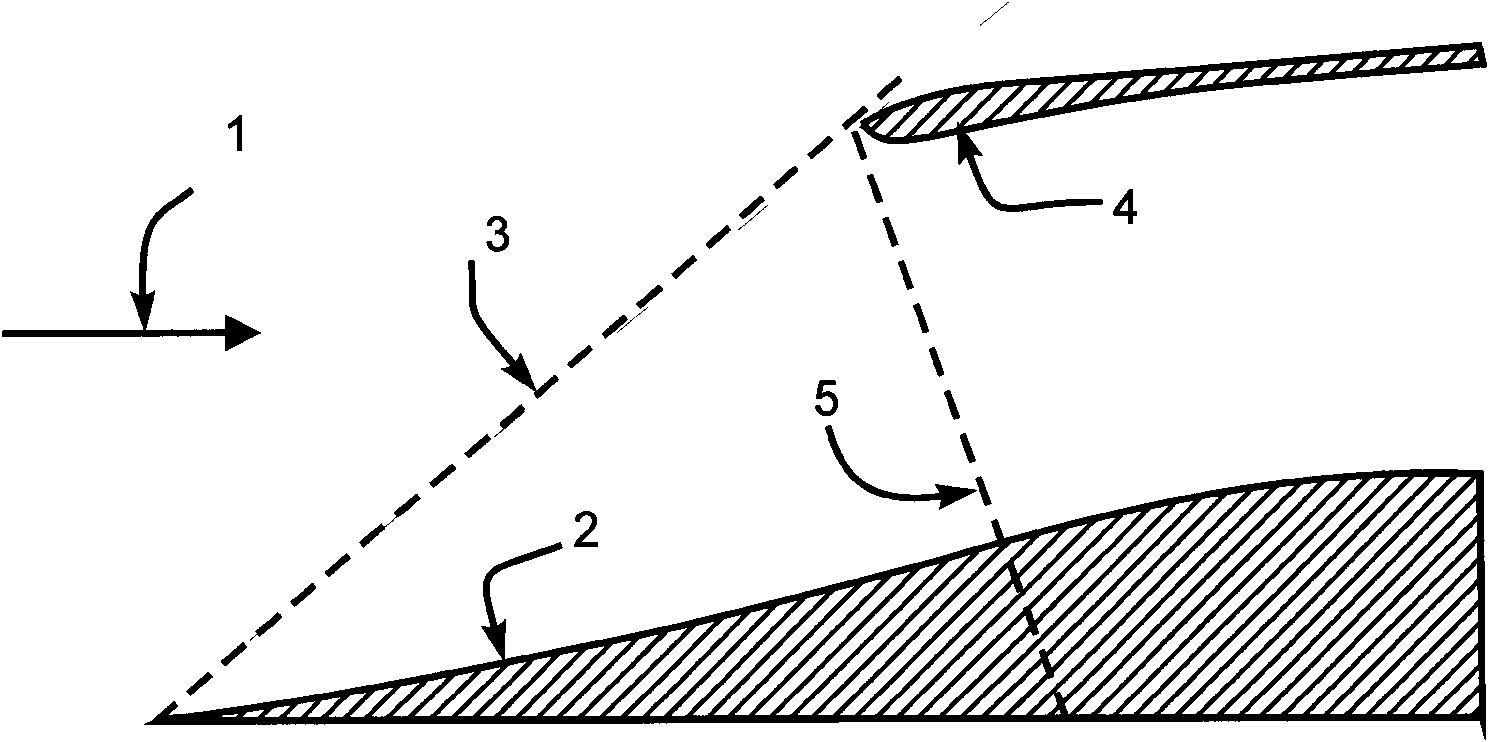

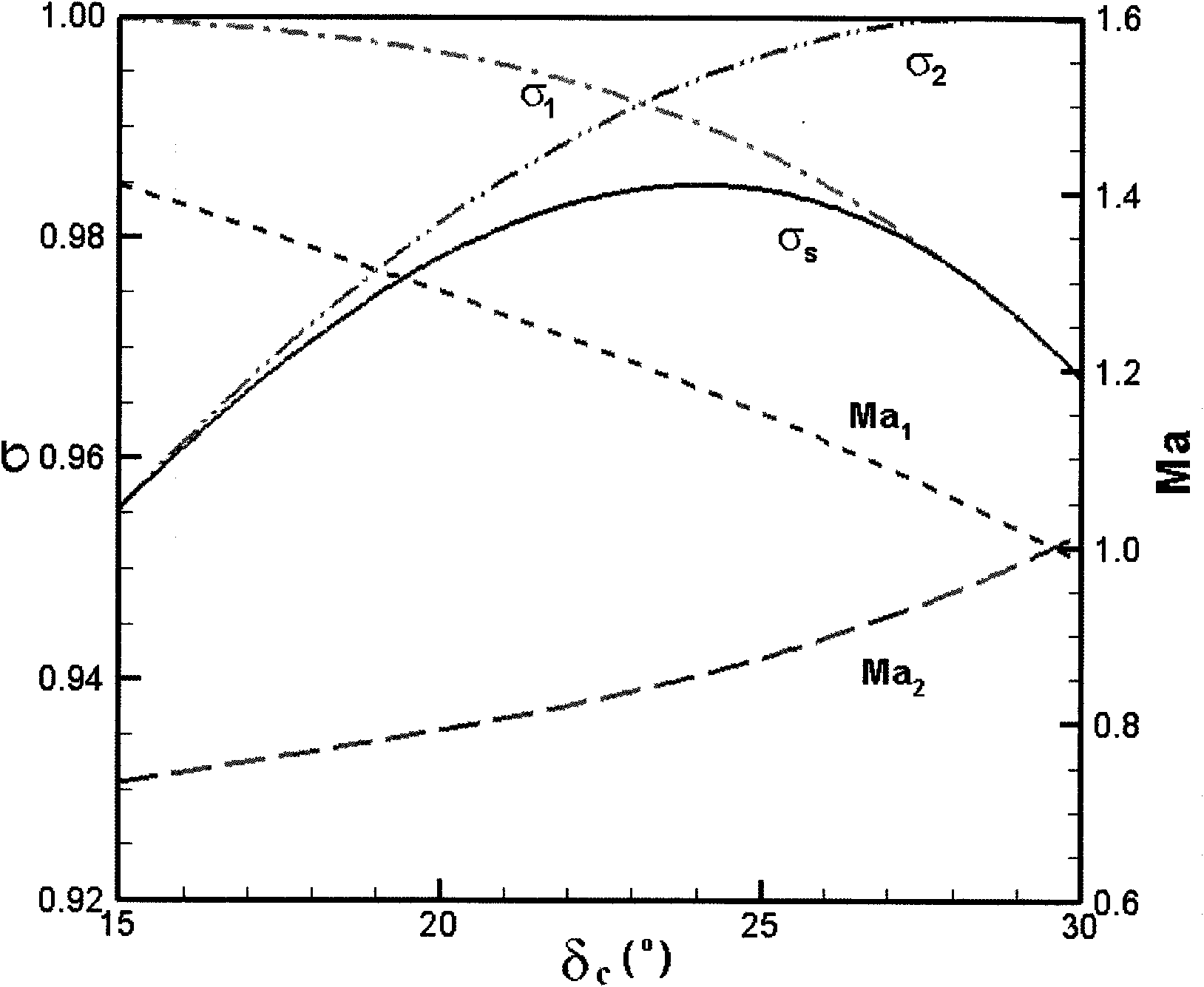

Bump air inlet method for realizing integration of unequal-strength wave system with forebody

InactiveCN101813027AReduce the Mach numberImprove performanceTurbine/propulsion air intakesShock waveEngineering

The invention provides a bump air inlet method for realizing integration of an unequal-strength wave system with a forebody, relating to the technical field of ultrasonic air inlet. The method comprises the following steps that: 1, an air inlet wave system adopts an external-compression double wave system structure based on an unequal-strength system, and the total pressure recovery coefficient sigma=sigma1*sigma2, wherein the sigma1 and the sigma2 are total pressure recovery coefficients of a conical shock wave and a normal shock wave; 2, a cone with a semi-cone angle delta c formed by the conical shock wave generates a second conical shock wave with second semi-cone angle beta in ultrasonic flow; 3, the bump height of the air inlet is h, the h / delta is 2-2.5 when the local boundary layer thickness is delta, the bump compressive plane generated in the step 2 is scaled to meet the requirement of an actual size; and 4, the lip of the air inlet adopts a conformal and sweepback lip design. The method realizes reduction of throat Mach number of the air inlet, improves the air inlet performance to ensure that the lip sweepback angle of the air inlet, the maximum turning angle of the bump compressive plane and the inlet normal shock wave angle are consistent, can increase the curve of the total pressure recovery coefficient, and reduces resistance coefficient.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

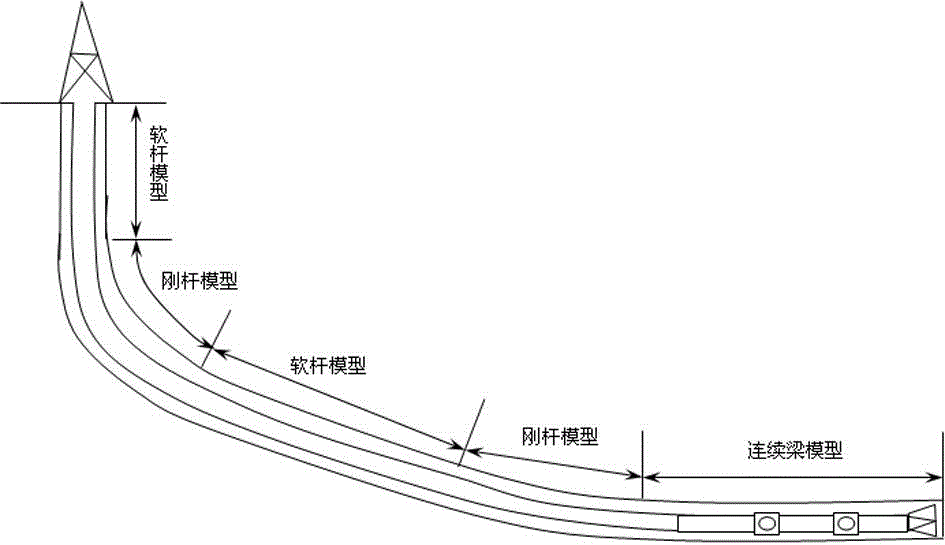

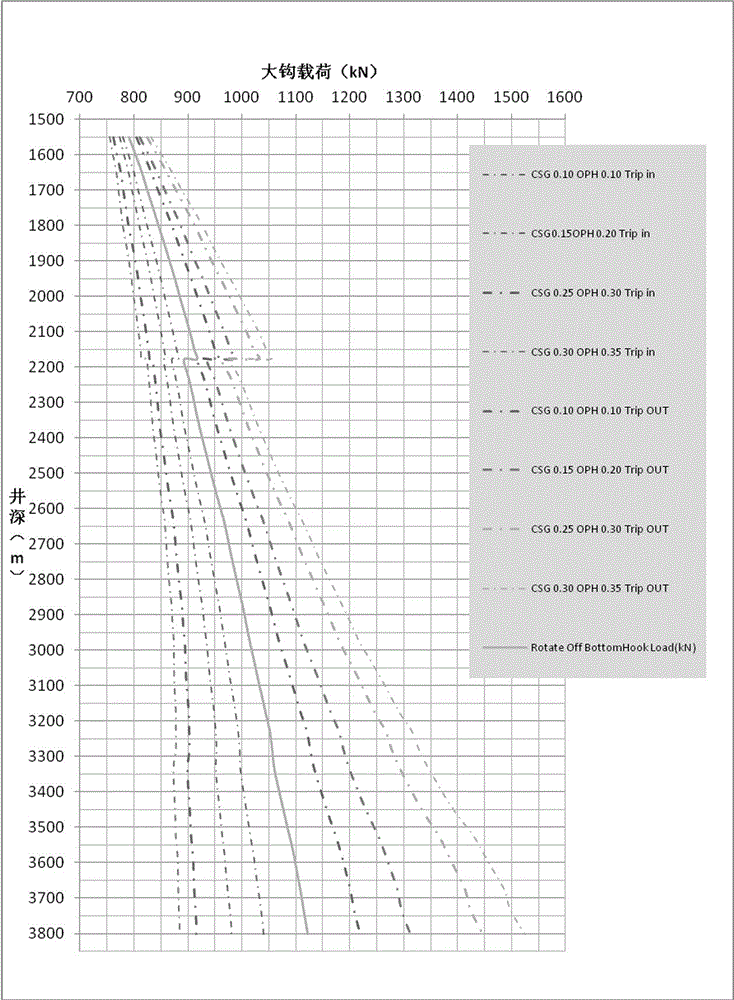

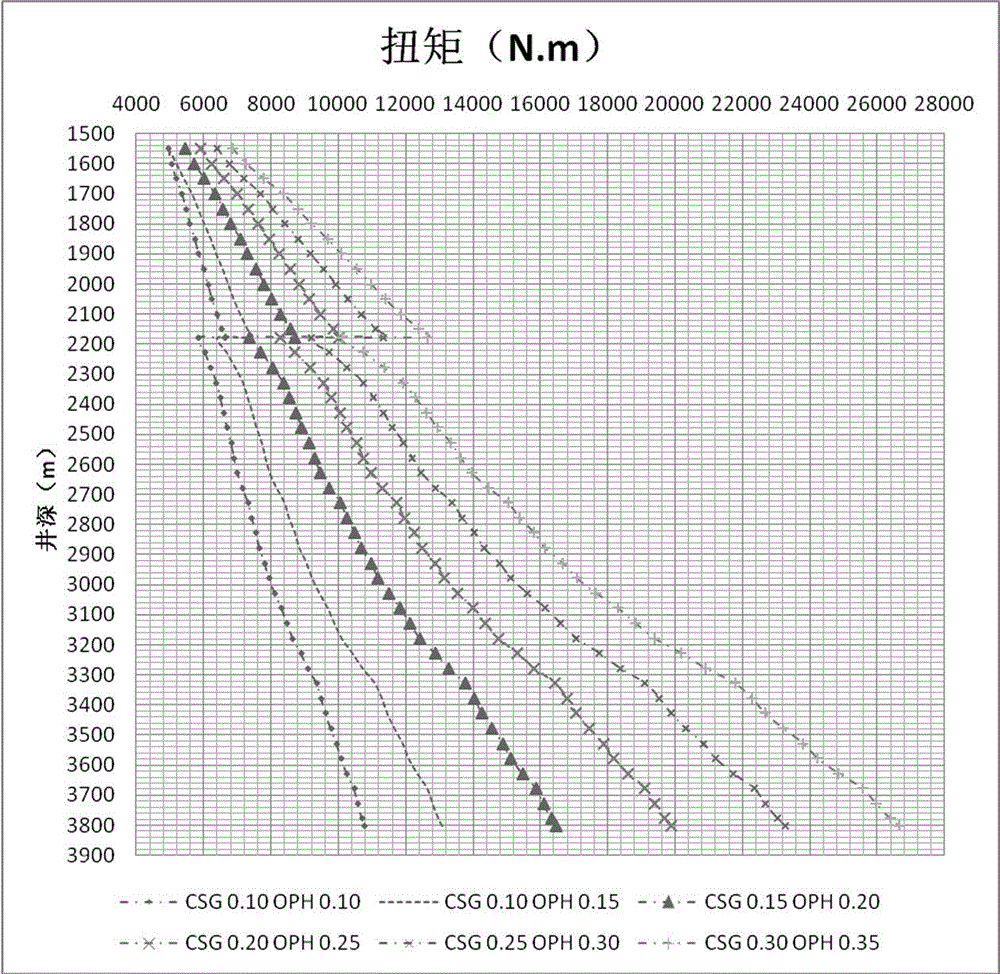

Method for monitoring friction drag and torque of large-displacement well

The invention provides a method for monitoring the friction drag and the torque of a large-displacement well. The method comprises the steps of firstly, building a friction drag and torque mechanical analysis model of the large-displacement well, and compiling an analysis program or analysis software; secondly, carrying out friction drag and torque simulation analysis computing under a track section designing condition; compiling monitoring route maps of drilling tool feed-off hook load, drilling tool lift-up hook load and idling lift-off-well bottom hook load under different friction drag coefficient conditions and route maps of rotary drilling torque along with well depth; recording the drilling tool feed-off hook load, the drilling tool lift-up hook load, the idling lift-off-well bottom hook load and the rotary drilling torque of actual drilling during site operation; finally, describing data under actual drilling record on the route maps, and comparing the data with predicted values under different friction drag coefficients and analyzing. According to the method for monitoring the friction drag and the torque of the large-displacement well, provided by the invention, the reason that causes the friction drag and the torque is deeply analyzed through real-time monitoring on the friction drag and the torque, and meanwhile, response analysis is carried out on the borehole cleanliness degree, the borehole quality, the drilling parameters, a bottom drilling tool combination, the drilling fluid performance change, the use of an anti-friction and torque-reducing tool and the like.

Owner:CHINA PETROCHEMICAL CORP +1

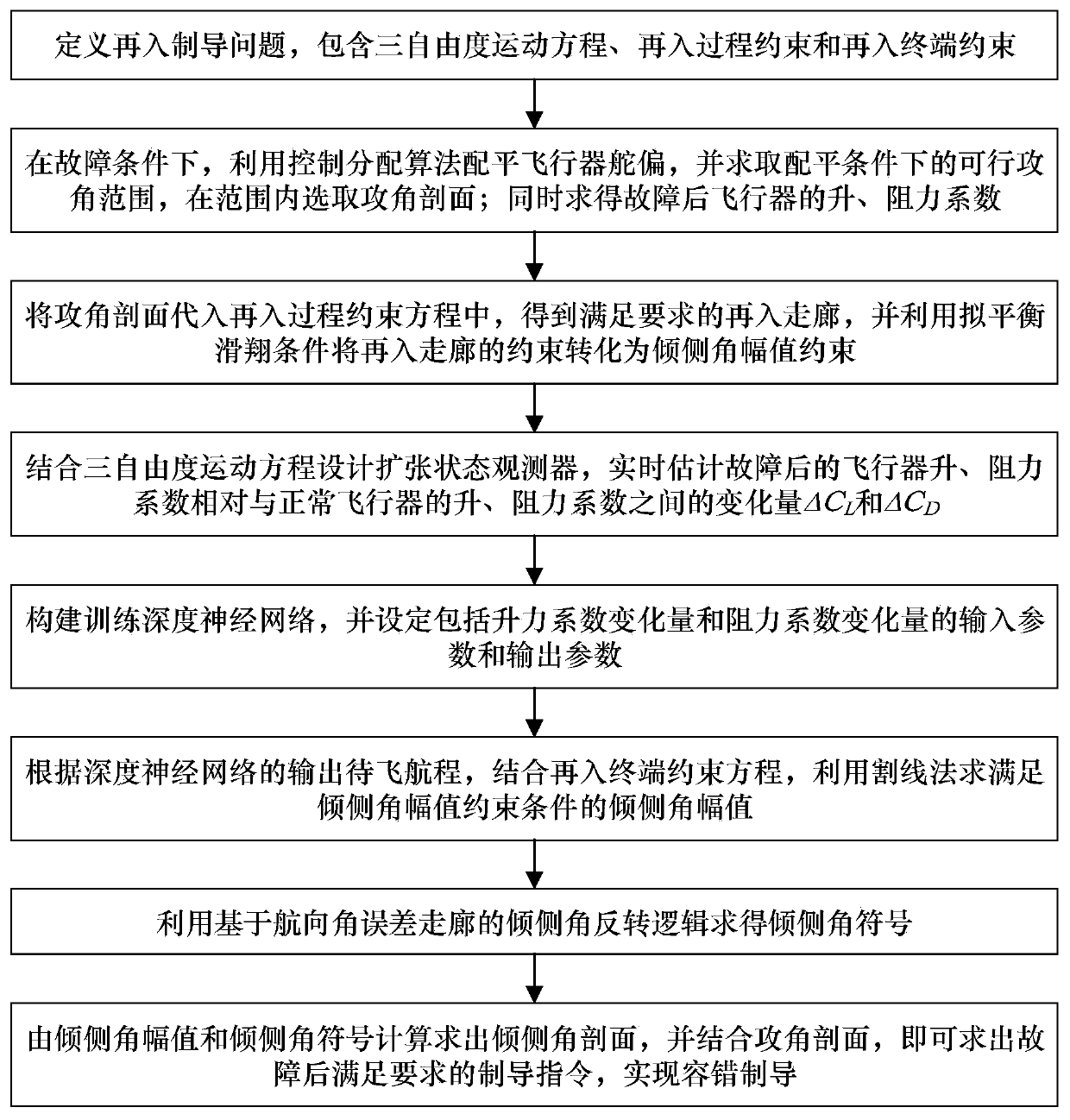

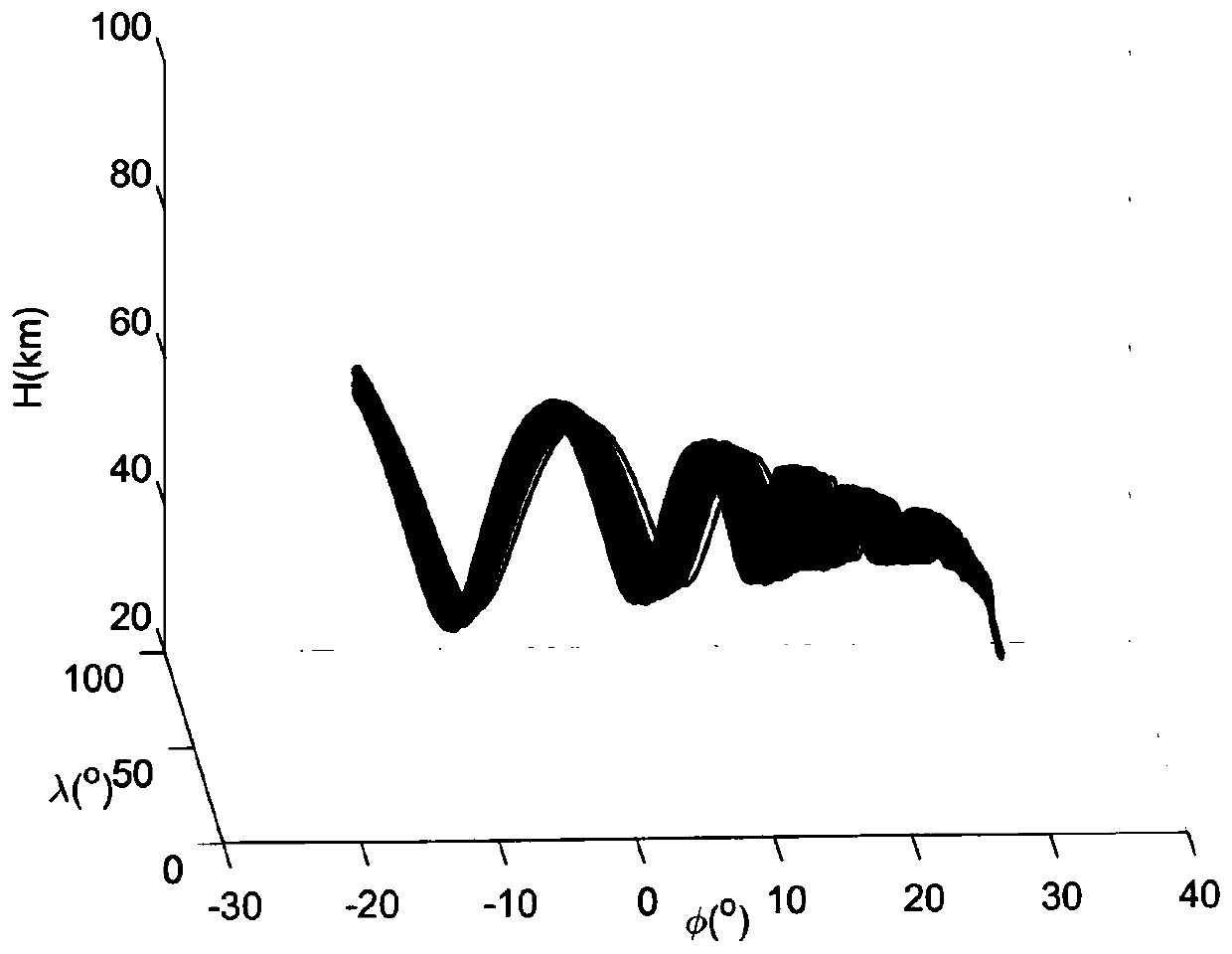

Deep learning-based reentry prediction correction fault-tolerant guidance method for hypersonic aircraft

ActiveCN110413000AImprove real-time performanceImprove Guidance AccuracyPosition/course control in three dimensionsEngineeringRudder

The invention discloses a deep learning-based reentry prediction correction fault-tolerant guidance method for a hypersonic aircraft, and belongs to the technical field of aircraft navigation guidanceand control. The method comprises the following steps of firstly, balancing the rudder deflection of an aircraft under a fault condition, selecting an attack angle profile within a feasible attack angle range, and simultaneously obtaining the lift and drag coefficients of the aircraft; then, enabling the attack angle profile to be substituted into a reentry process constraint equation to obtain areentry corridor meeting the requirements, and enabling the reentry corridor to be converted into a roll angle amplitude constraint; estimating the change amount delta CL and delta CD between the lift and drag resistance coefficient of the aircraft relative to the lift and drag coefficients of the normal aircraft, and combining the reentry terminal constraint equation to obtain an inclination angle amplitude; utilizing the inclination angle reversal logic based on the course angle error corridor to obtain an inclination angle symbol; and finally, calculating the inclination angle profile by using the inclination angle amplitude and the inclination angle symbol, and combining the attack angle profile to obtain the guidance command meeting the requirement after the fault. The method is highin guidance precision, good in algorithm instantaneity and capable of meeting the requirement of fault-tolerant guidance.

Owner:BEIHANG UNIV

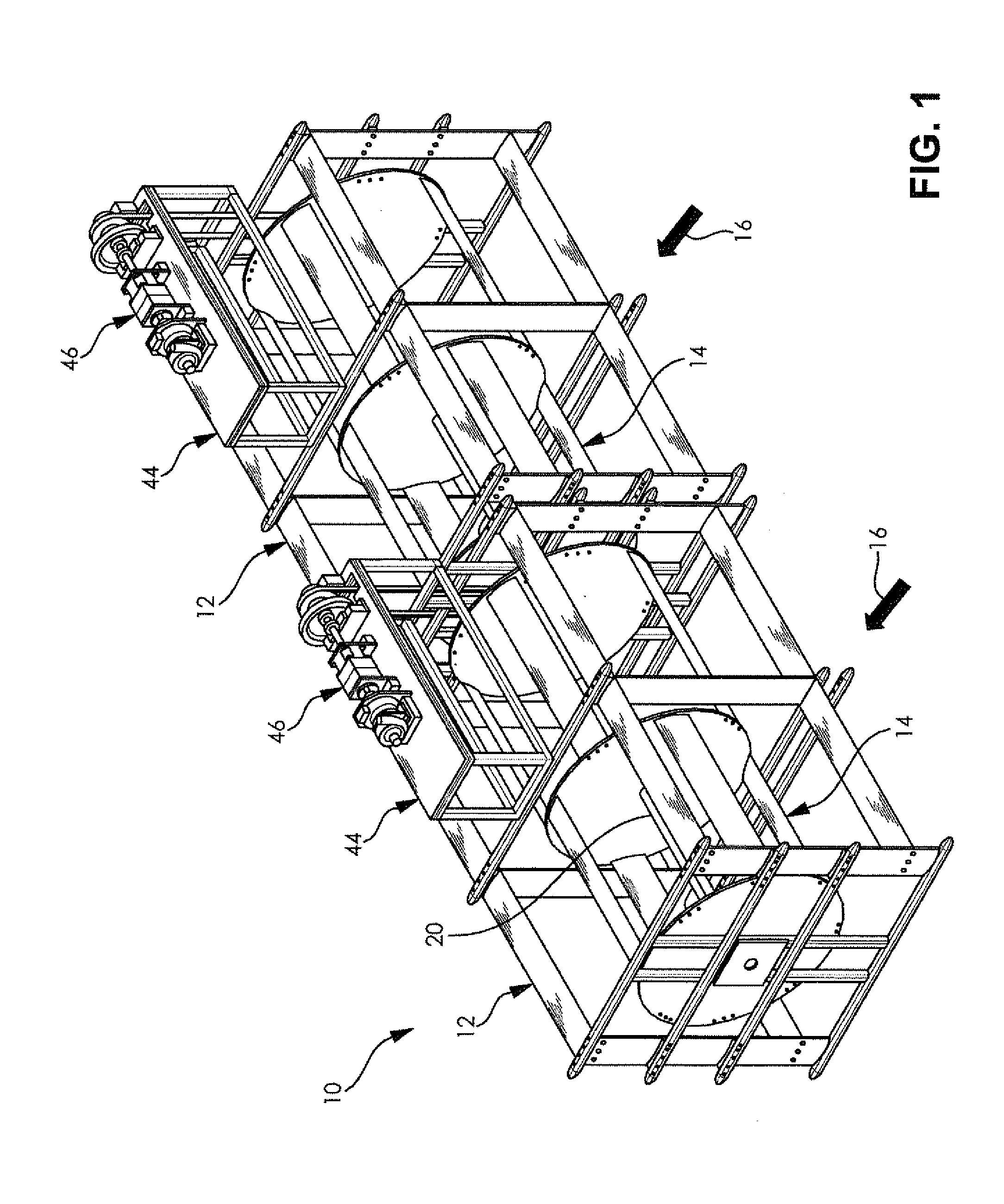

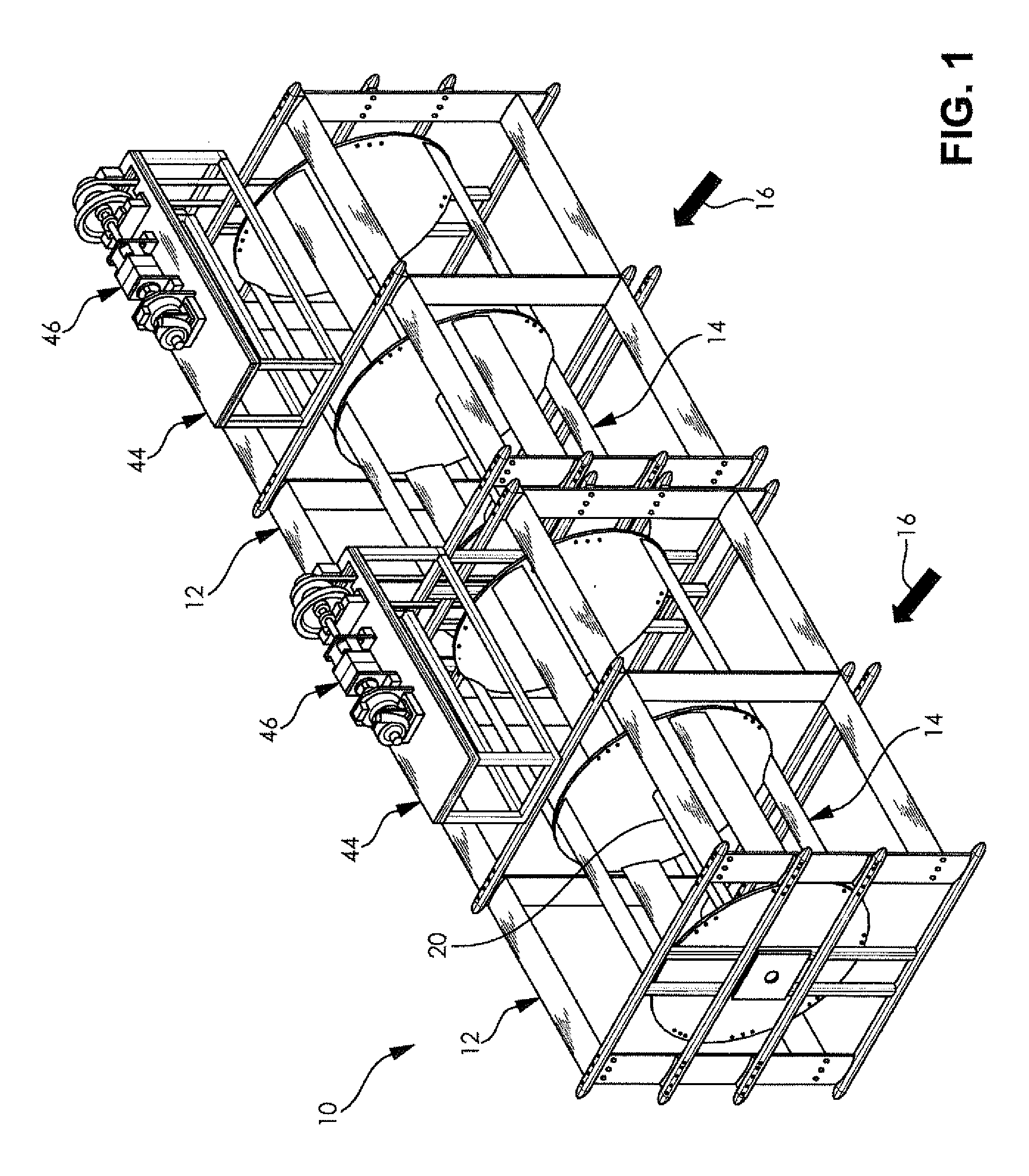

Horizontal-axis hydrokinetic water turbine system

ActiveUS20130026762A1Easy to transportEasy to installPositive displacement enginesEngine componentsRotational axisLow speed

A hydrokinetic water turbine system includes two turbine assemblies each having a frame structure, a horizontally-disposed shaft supported by the frame structure, and a rotor secured to the shaft. The rotor has a plurality of spaced-apart blades so that the flowing stream of water revolves the rotor. The blades are filled with a foam material to reduce weight and increase buoyancy. The frame structure is an open frame structure and includes frame members adapted to reduce a coefficient of drag of the frame structure. The frame members are filled with a foam material to reduce weight and increase buoyancy. The two turbine assemblies are secured side by side with shafts coaxial and the rotors rotating in opposite directions. The shafts can drive electric generators located out of the water or under the water. The underwater generators can be direct drive, low speed, high output generators.

Owner:DLZ

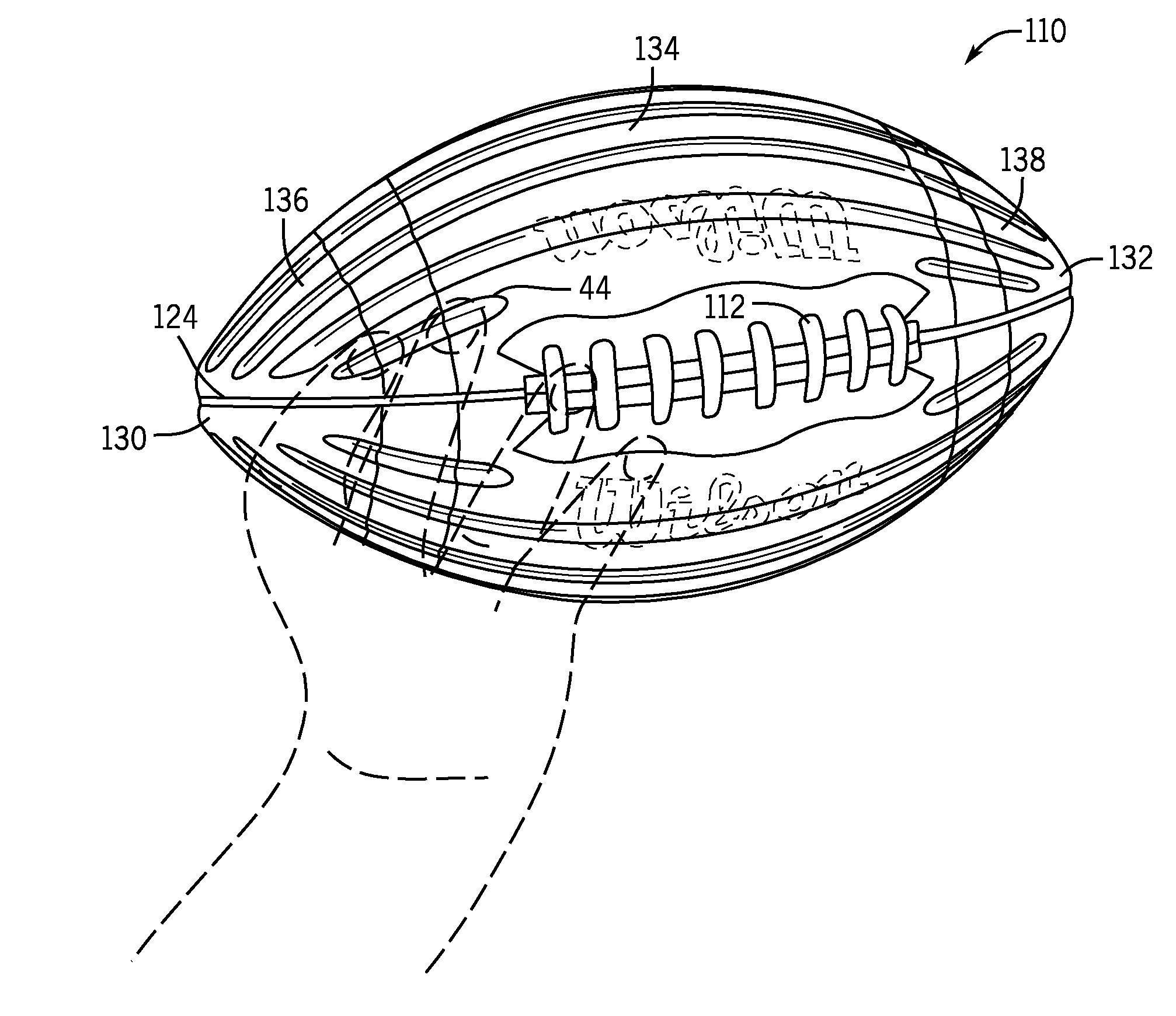

American football incorporating boundary layer trip mechanisms to reduce aerodynamic drag

A football having a prolate spheroidal shape including longitudinally spaced apart first and second ends. The football is capable of being analyzed under computational fluid dynamics analysis, and includes upper and lower central regions. Each positioned between first and second upper and lower end regions, respectively. The football further includes a bladder, a cover, a plurality of boundary layer trip mechanisms coupled to the upper and / or lower central regions, and a lacing coupled to the upper central region. The analysis includes first and second configurations. The first configuration is conducted on the football with the trip mechanisms, and the second configuration is conducted on the football without the trip mechanisms. The first and second configurations provide first and second drag coefficients, respectively. The first coefficient is at least 3 percent lower than the second coefficient. The length of the upper and lower central regions is defined by the lacing.

Owner:WILSON SPORTING GOODS

Statistical method of system resistance based on road test and bench test about car in free running at neutral position

A method for counting out system resistance of vehicle free position running in road test and platform test sets up two curve equations of vehicle road test and platform test so system equivalent resistance coefficient and system resistance of vehicle at each speed point in road test can be obtained according to vehicle type and reference mass and furthermore equivalent inertia of free position chassis driving series on vehicle in platform test can be confirmed , thus system resistance at each speed point in platform test can be detected out by only utilizing once of free position running .

Owner:吴明

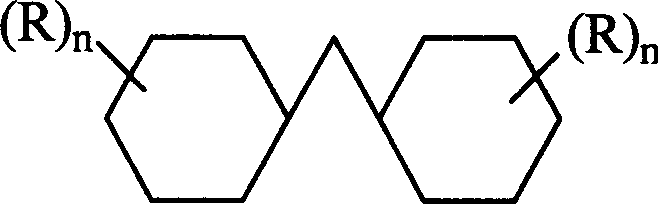

Transmission liquid composition for stepless speed gear

ActiveCN101007982AHigh viscosity indexHigh traction coefficientAdditivesAlkaline earth metalAlicyclic Hydrocarbons

The invention provides a stepless variable device transmission fluide compound. It comprises following components with their percentage on base oil weight: (1) bicyclo alicyclic hydrocarbon base oil, (2) alkali metal salt detersive, 0.05- 3%, (3) ashless dispersant 1- 15%, (4) phenol or amine anti- oxidant, 0.01- 1%, (5) antiwear agent, 0.05- 2%, (6) friction improver. 0.05- 3%, (7) viscosity index improver, 0-20%, (8) antifoam agent, 0- 1000ppm. The transmission fluide is characterized by good viscosity-temperature characteristic and low- temperature flowability, high drag coefficient at normal temperature, good comprehensive performance, and satification for CVT use requirement.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heating pipe network hydraulic simulation model identification correction method and system, method of operation

InactiveCN106682369AHigh precisionImprove computing efficiencyBiological modelsDesign optimisation/simulationPhysical systemEngineering

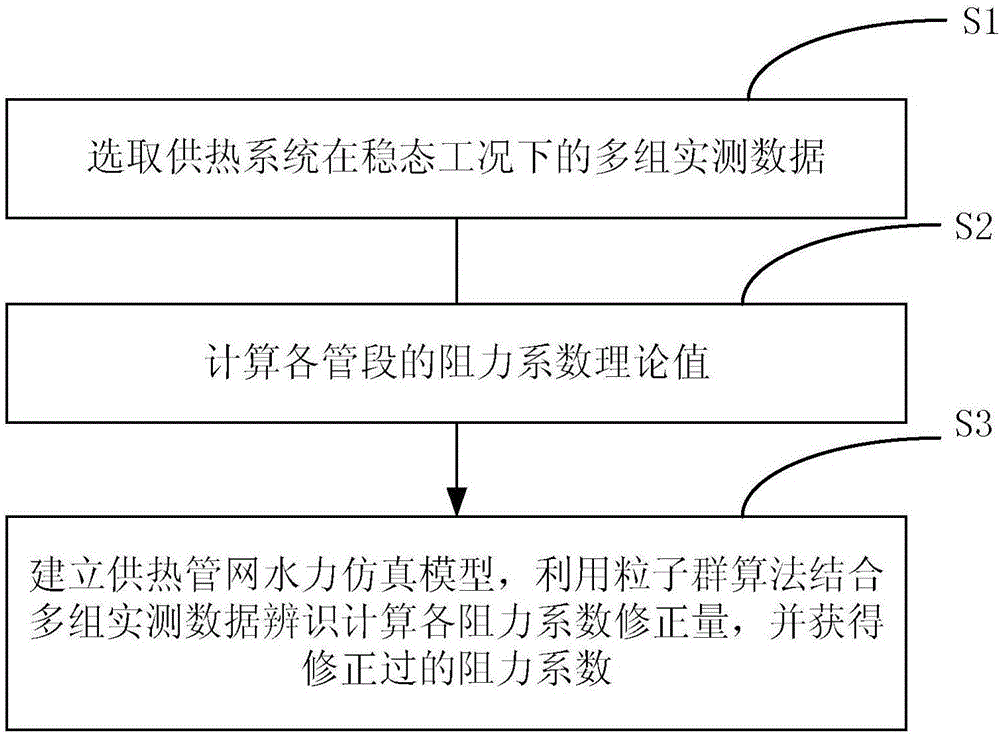

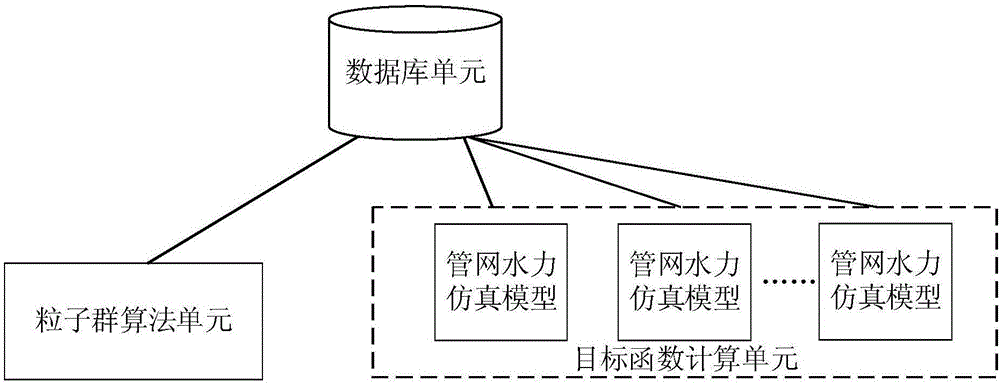

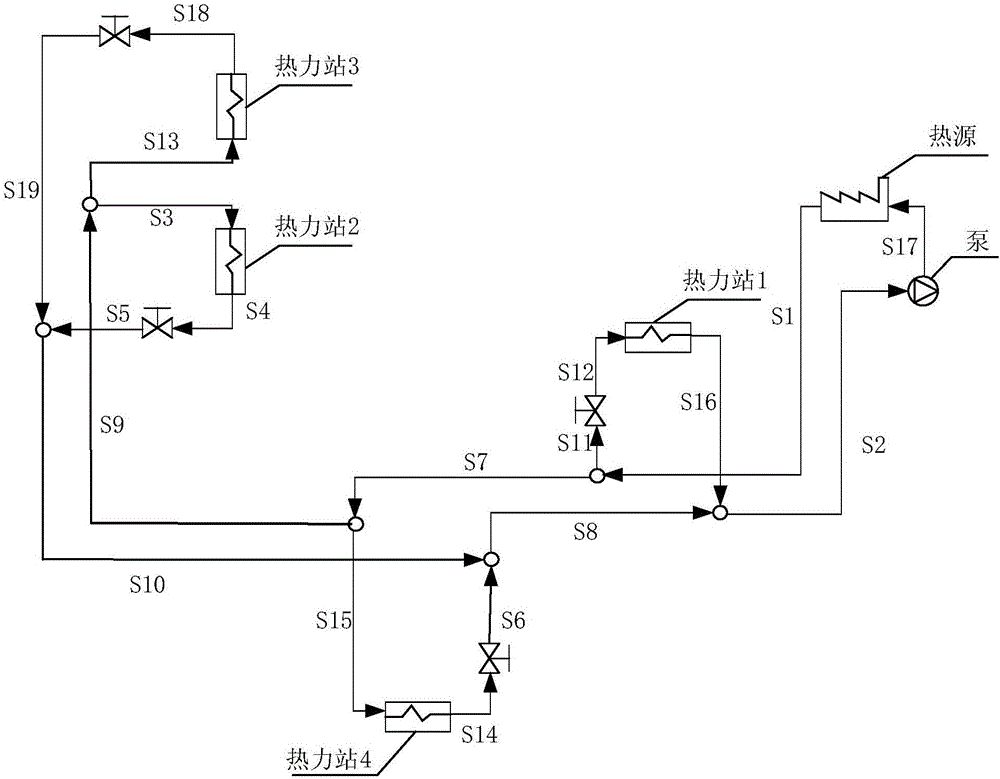

The invention relates to a heating pipe network hydraulic simulation model identification correction method and a system. The heating pipe network hydraulic simulation model identification correction method comprises the steps of S1, selecting multiple groups of actually measured data of a heating system under steady work conditions, S2, calculating theoretical values of the drag coefficient of all pipe section, and S3, establishing a hydraulic simulation model of heating pipe network, using particle swarm optimization method accompanied by multiple groups of actually measured data, identifying and calculating various resistance coefficient correction amount vectors, and through the various resistance coefficient correction amount vectors in the heating pipe network hydraulic simulation model, making the comparison between the flow conditions and the actual measured data under multiple working conditions, identifying the optimal resistance coefficient correction amount. The corrected model can better describe the actual physical system, and increase the calculation precision of the hydraulic calculation of heating pipe network. The application of a parallel computing architecture for the implementation for the identification of the particle swarm algorithm drag coefficient correction with high identification efficiency.

Owner:CHANGZHOU ENGIPOWER TECH

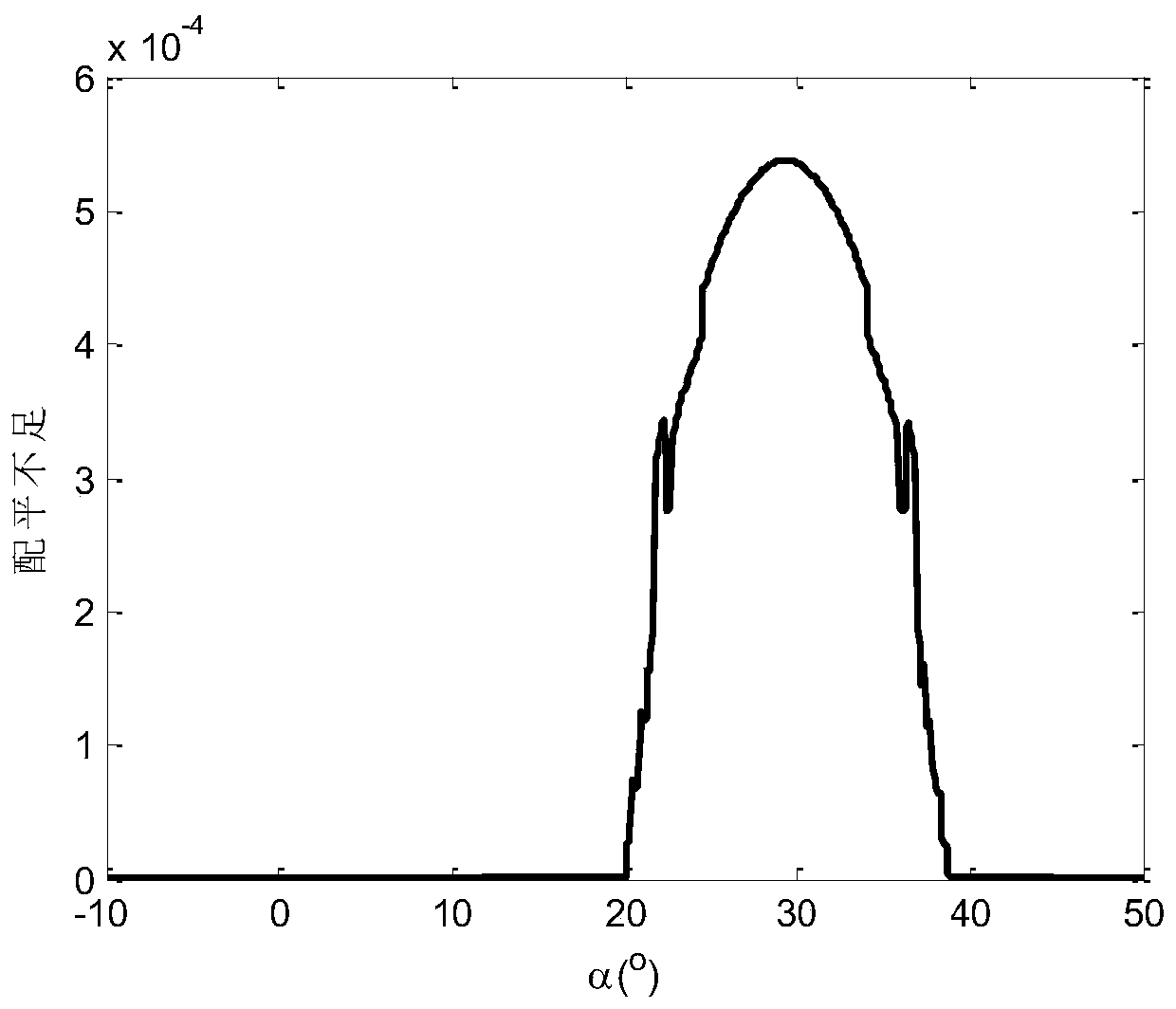

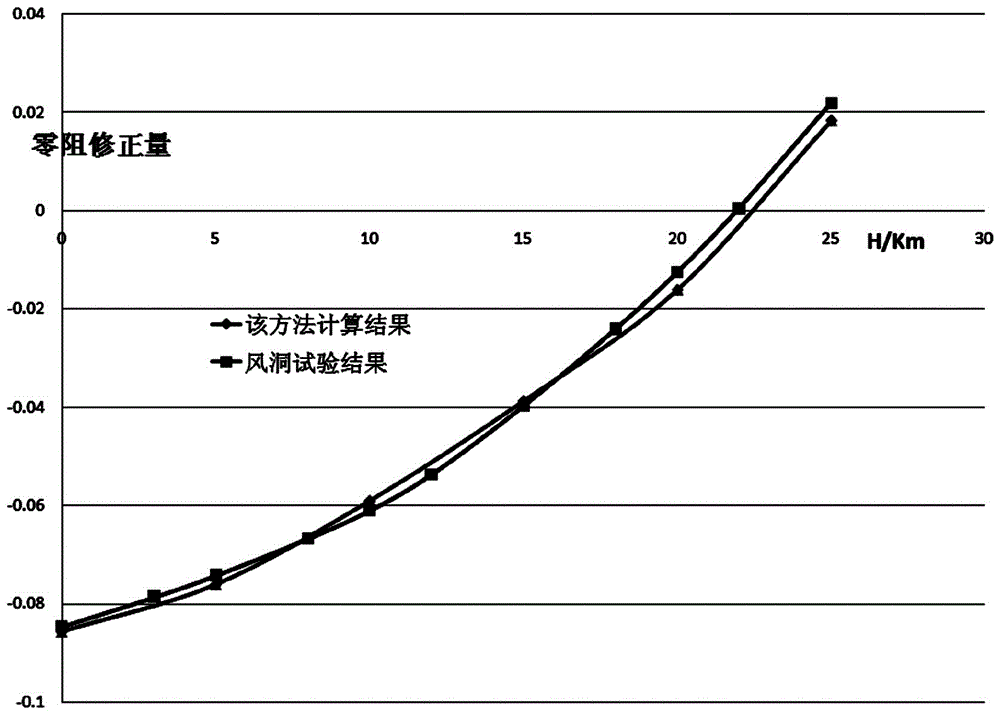

Reynolds number effect correcting method of zero lift-drag force coefficient

The invention discloses a Reynolds number effect correcting method of a zero lift-drag force coefficient. The method comprises the steps of: obtaining a zero lift attack angle [alpha]0 of an aircraft at a Mach number according to wind tunnel experiment data; calculating an actual Reynolds number ReH under each sea level altitude H based on an size and configuration of a product, and calculating a drag force coefficient CxH at the Mach number and at each altitude H when the attack angle [alpha] equals to [alpha]0, by a CFD method; increasing the Reynolds number of a blowing wind tunnel at the Mach number to the Reynolds number Re corresponding to the practical aircraft size according to a model scale, interpolating the Reynolds number Re with ReH values at different altitudes H at the step b to obtain flight altitude H wind tunnel experiment corresponding to the Re wind tunnel experiment, and calculating a drag force coefficient Cx0 of the aircraft when the attack angle [alpha] equals to [alpha]0 in the altitude H wind tunnel experiment; and obtaining a corrected value of the zero lift-drag force at the Mach number and at each flight altitude H. The Reynolds number effect correcting method of the zero lift-drag force coefficient is used for a small aspect ratio aircraft and is applicable to zero lift-drag coefficient correction.

Owner:JIANGXI HONGDU AVIATION IND GRP

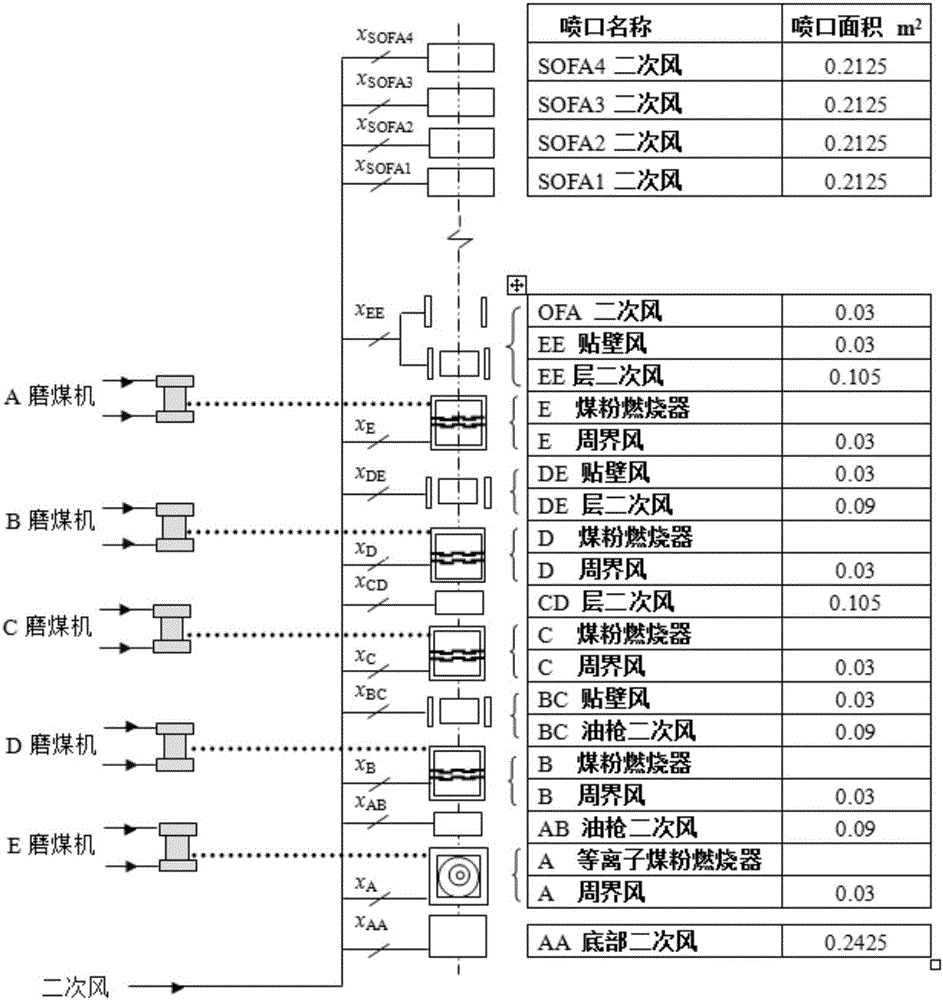

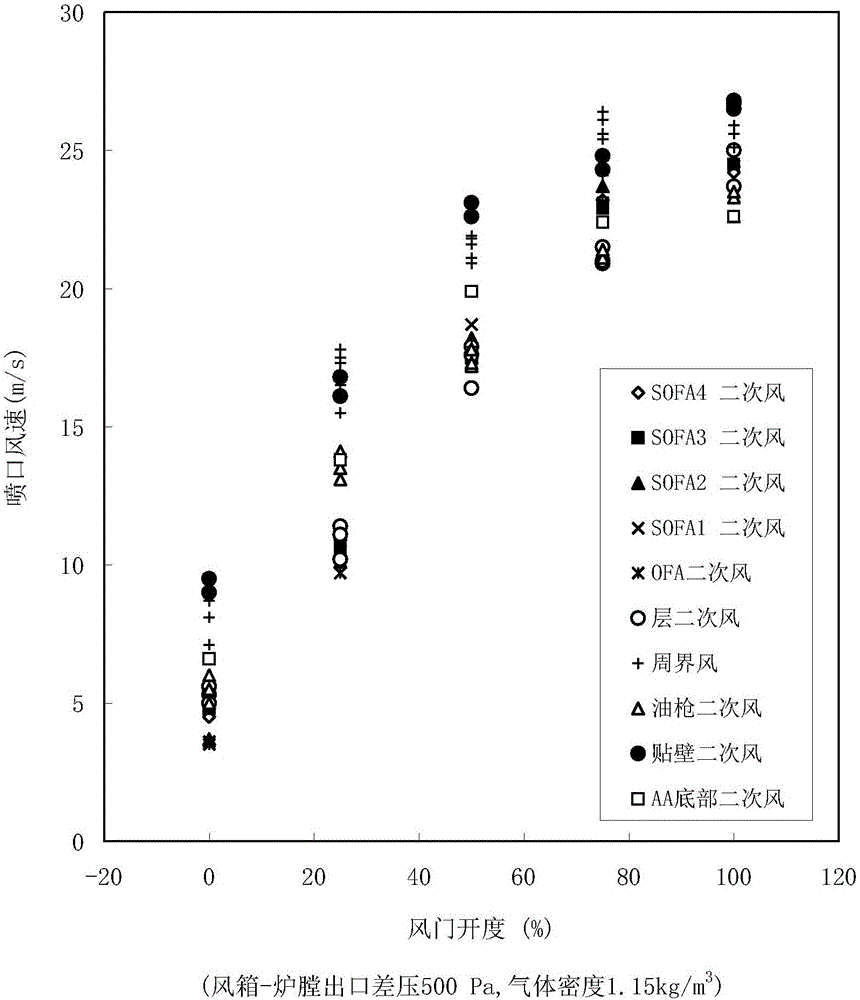

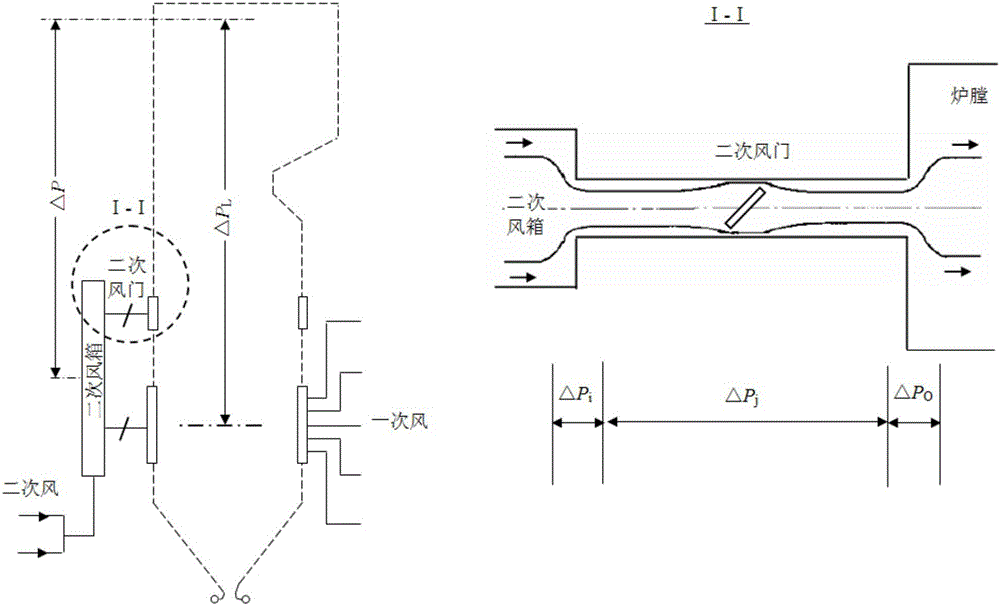

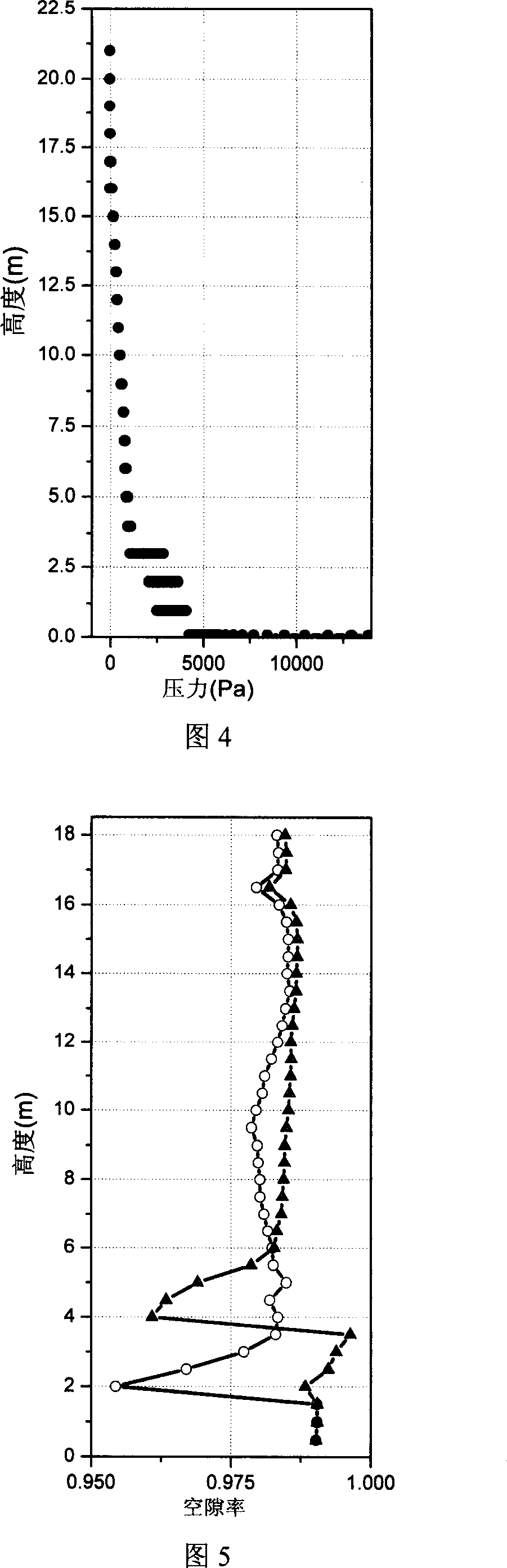

Boiler secondary air damper characteristic test data processing method

The invention discloses a boiler secondary air damper characteristic test data processing method which comprises the following steps of: dividing boiler secondary air damper characteristic test data into two groups, wherein a first group refers to test data when the opening degree of a secondary air damper is 100%, and a second group refers to test data when the opening degree of the secondary air damper is respectively a%, b%, c% and d%; processing the first group of data, thereby obtaining a hearth resistance loss coefficient; calculating resistance coefficients of the secondary air damper under each opening degree; drawing a resistance coefficient-damper opening degree relation curve; and in combination with airflow temperature and secondary air box-hearth outlet pressure difference, calculating air speed of a secondary air nozzle during heat-state operation. According to the method, the hearth resistance loss coefficient is introduced during damper characteristic test data processing, so that compared with a scheme which ignores furnace pressure loss, the scheme adopted by the method is capable of calculating the secondary air volume more accurately.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

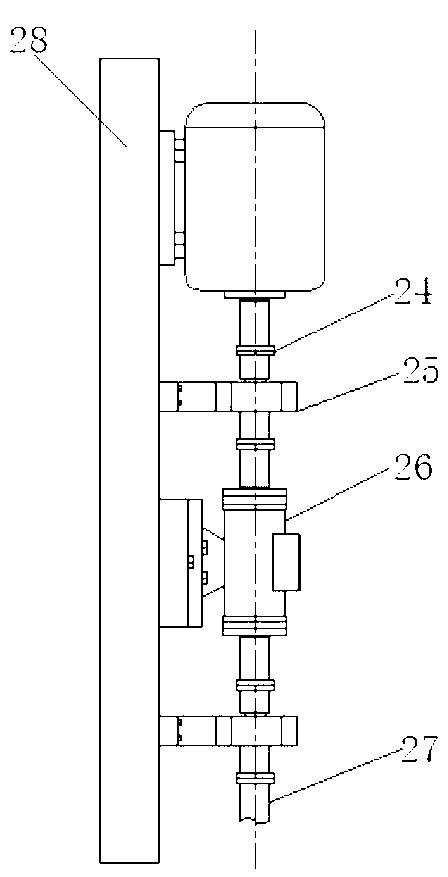

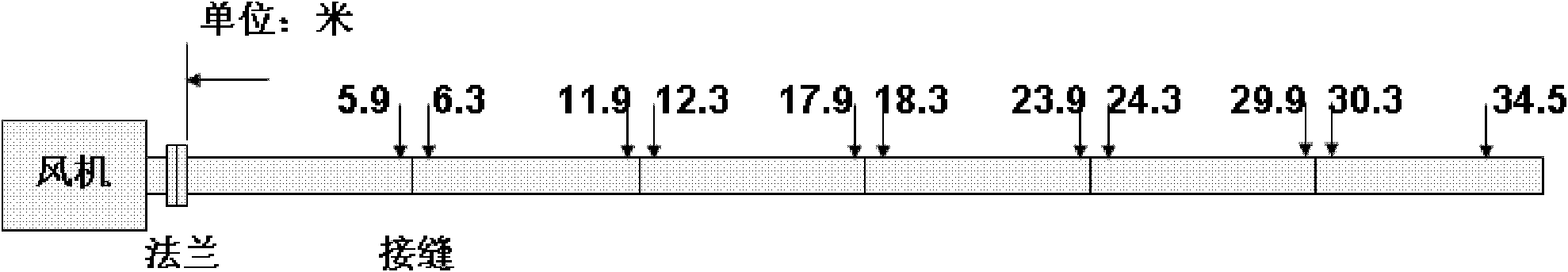

A method and device for testing the frictional resistance coefficient of the inner wall of a pipeline

InactiveCN102269690ATest the coefficient of frictional resistanceGuaranteed turbulence intensityMachine part testingUsing mechanical meansEngineeringDrag coefficient

The invention discloses a device for testing a frictional drag coefficient of an inner wall of a pipeline. The device consists of a high speed fan, a frequency converter, a turbulence smoothening section, a pipeline bracket, the pipeline, a multitube pressure gauge, a Pitot tube and a slanting leg manometer, wherein the frequency converter is connected with the high speed fan; the front end of the turbulence smoothening section is connected with the outlet of the high speed fan, and the rear end is connected with the pipeline; the pipeline is arranged on the pipeline bracket with an adjustable mechanism; pressure testing holes are processed at different positions of the pipeline and are connected with the multitube pressure gauge through tee joints and hoses; and at the tail end of the pipeline, the wind speed in the pipeline is tested by the Pitot tube, and the Pitot tube is connected with the slanting leg manometer. A method for testing the frictional drag coefficient of the inner wall of the pipeline comprises the following six steps of: 1, selecting a testing scheme; 2, selecting a testing means; 3, distributing the pressure testing holes; 4, analyzing the experimental accuracy; 5, designing and manufacturing the pipeline bracket; and 6, assembling the testing device, wiring and debugging. The invention has application value in the technical field of pipeline pressure and friction drag testing.

Owner:BEIHANG UNIV

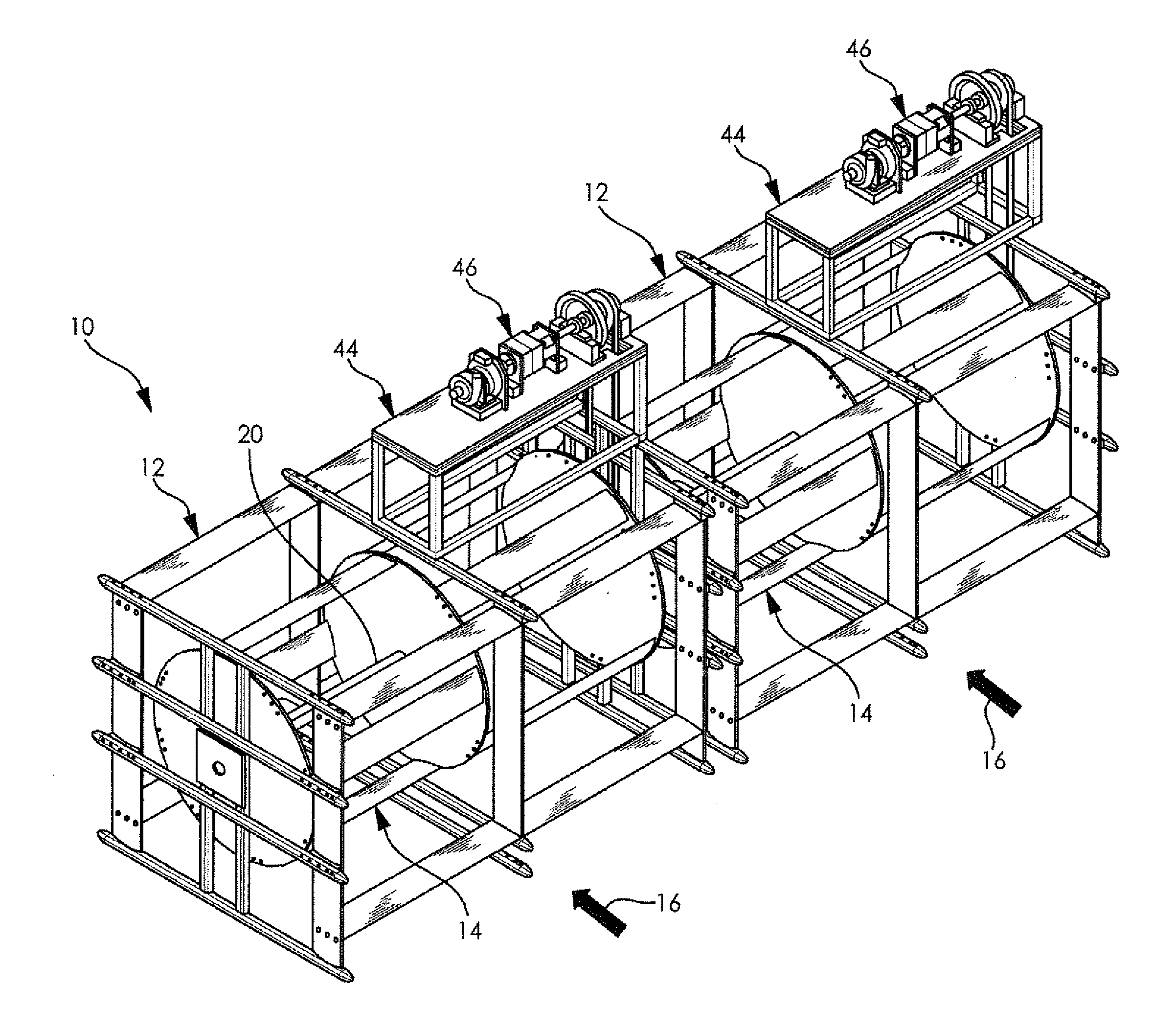

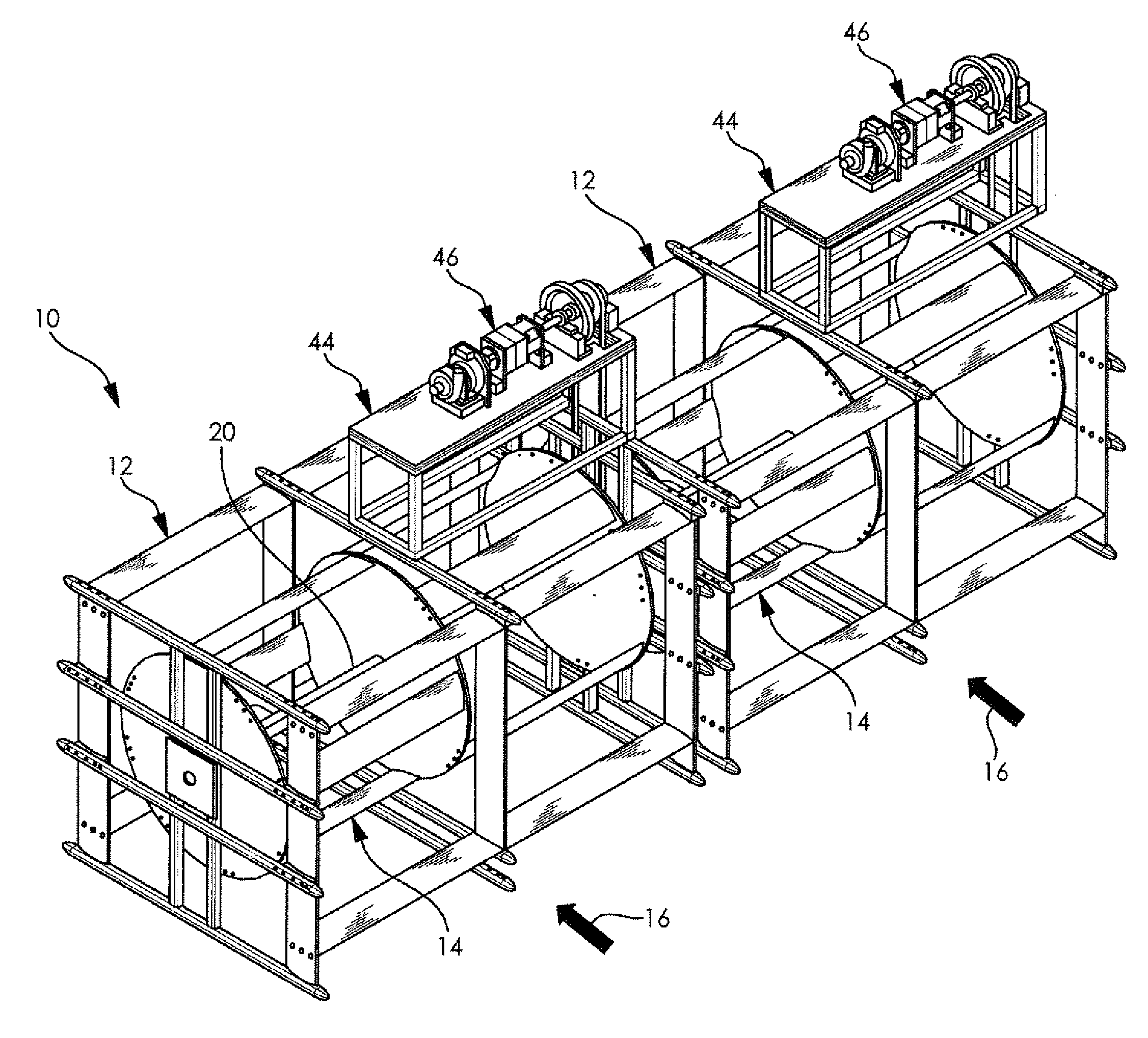

Horizontal-axis hydrokinetic water turbine system

ActiveUS20130026761A1Reduce weightReduce waterway disturbancePropellersPump componentsWater turbineHorizontal axis

A hydrokinetic water turbine system includes a frame structure, first and second shafts rotatably supported by the frame structure, and first and second rotors secured to the first and second shafts respectively and each having a plurality of spaced-apart blades so that the flowing stream of water revolves the first and second rotors about a central axis of the first and second shafts respectively. The first and second shafts are horizontally-disposed and coaxial and the first and second rotors are adapted to rotate in opposite directions. The blades are hollow and filled with a foam material to reduce weight and increase buoyancy. The frame structure is a substantially rectangular and open frame structure and includes frame members adapted to reduce a coefficient of drag of the frame structure. The frame members can be hollow and filled with a foam material to reduce weight and increase buoyancy.

Owner:DLZ

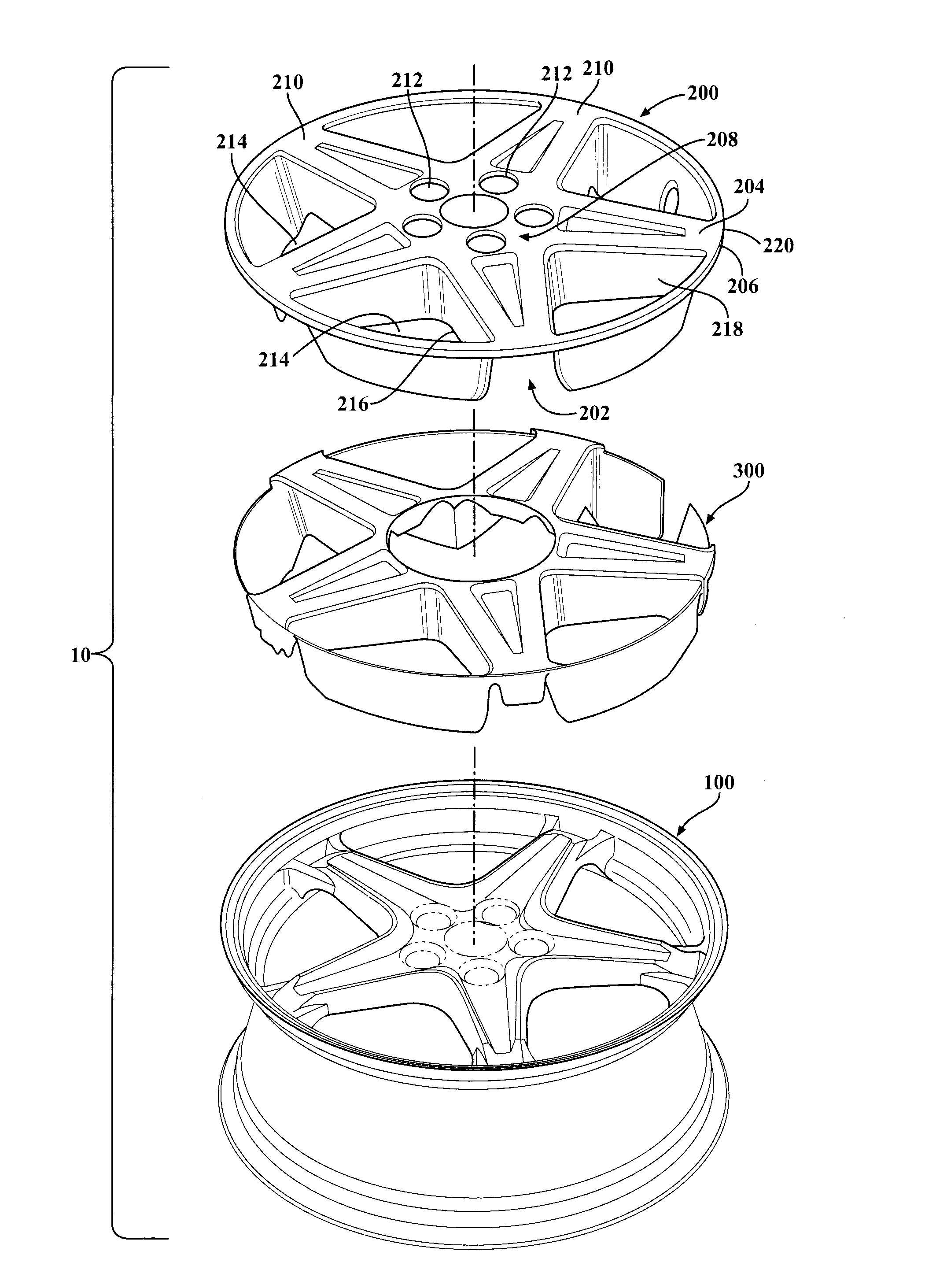

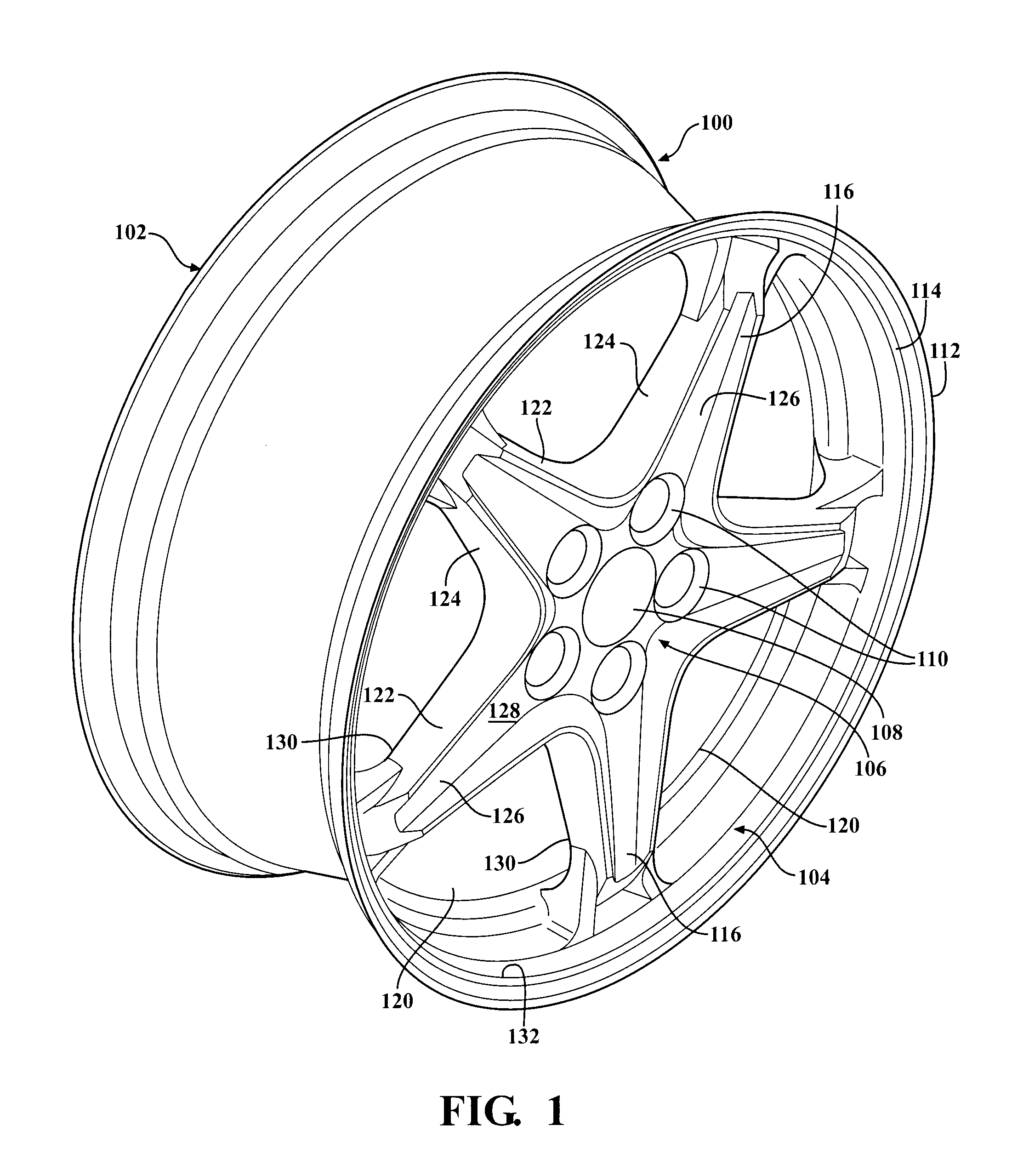

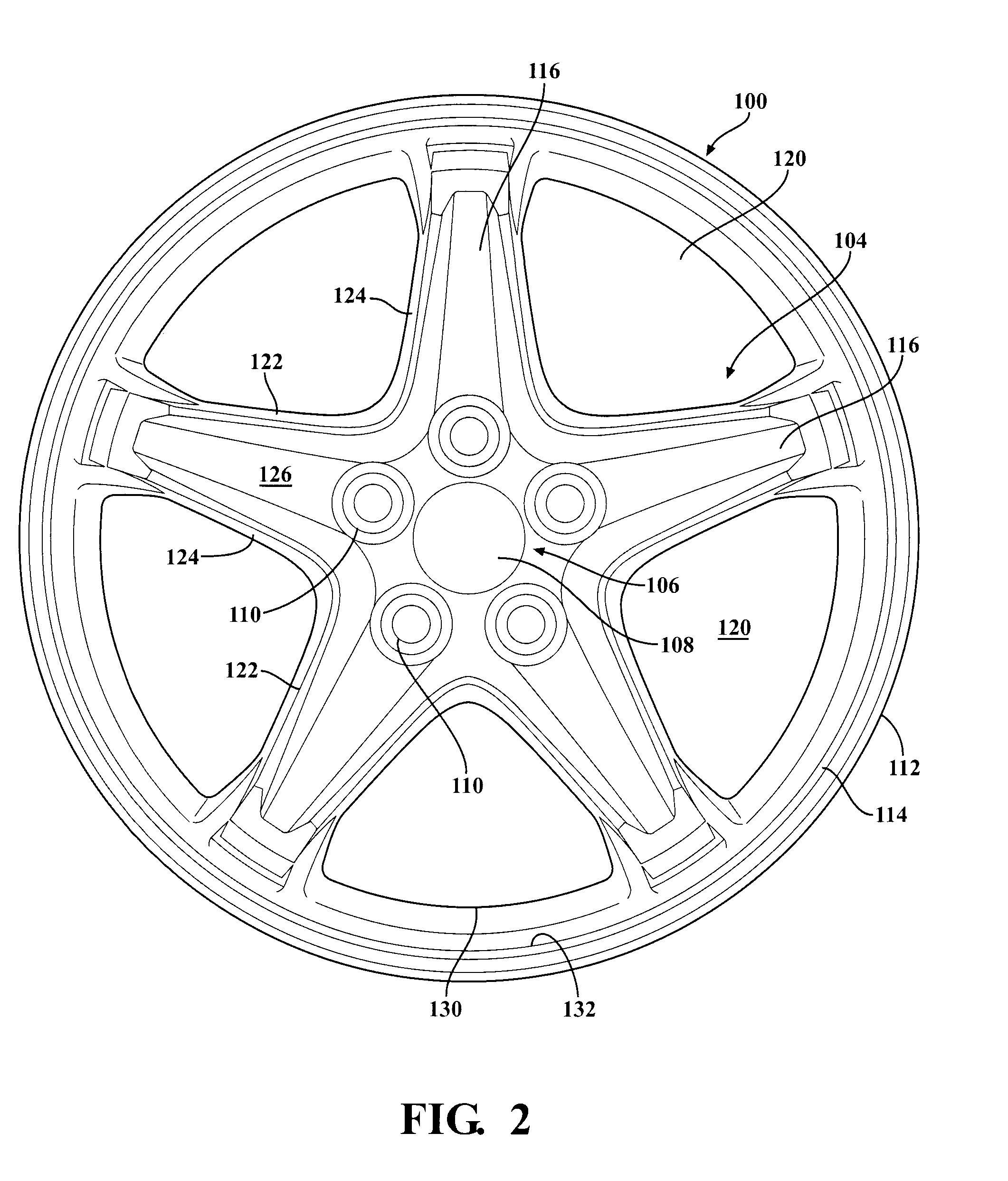

Lightweight aerodynamic wheel assembly

ActiveUS20140159469A1Improve the overall coefficientSubstantial drag coefficient improvementWheel protectionWheel manufactureTurbineDrag coefficient

A wheel assembly including a wheel and a wheel clad. The wheel includes a wheel outer rim portion, a wheel inner hub portion adapted to receive an axle therethrough, and a plurality of wheel spokes extending radially between the wheel outer rim portion and the wheel inner hub portion. The wheel has an outer surface having a plurality of wheel turbine openings therein. The wheel turbine openings have a first area. The wheel clad includes a clad outer rim portion axially aligned with at least a portion of the wheel outer rim portion, a clad inner hub portion axially aligned with at least a portion of the wheel inner hub portion, and a plurality of clad spokes extending radially between the clad outer rim portion and clad inner hub portion. The clad has a plurality of clad turbine openings each having a second area. The second area is substantially less than the first area. The clad / wheel assembly has a drag coefficient of substantially less than that of the wheel by itself.

Owner:LACKS ENTERPRISES

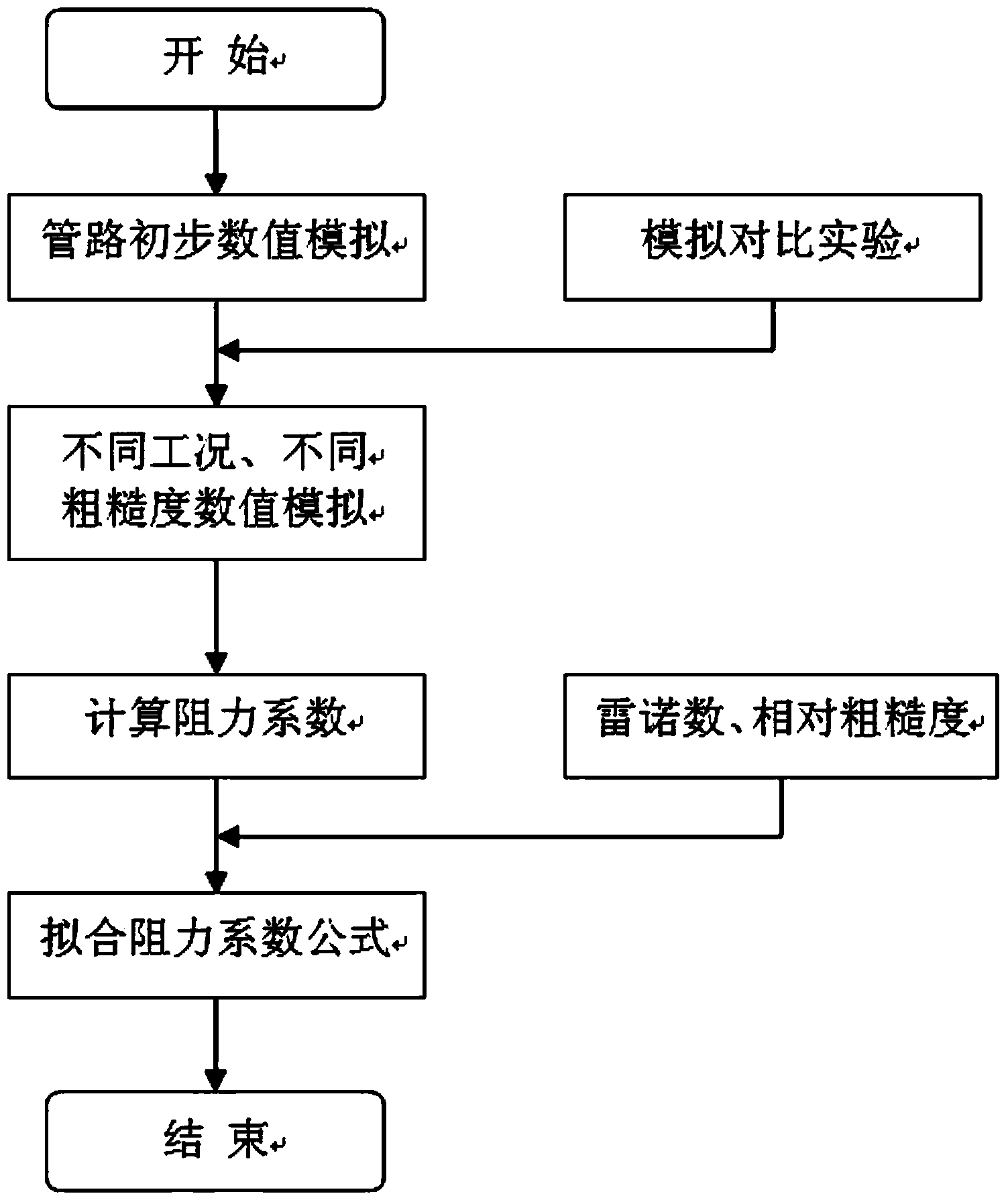

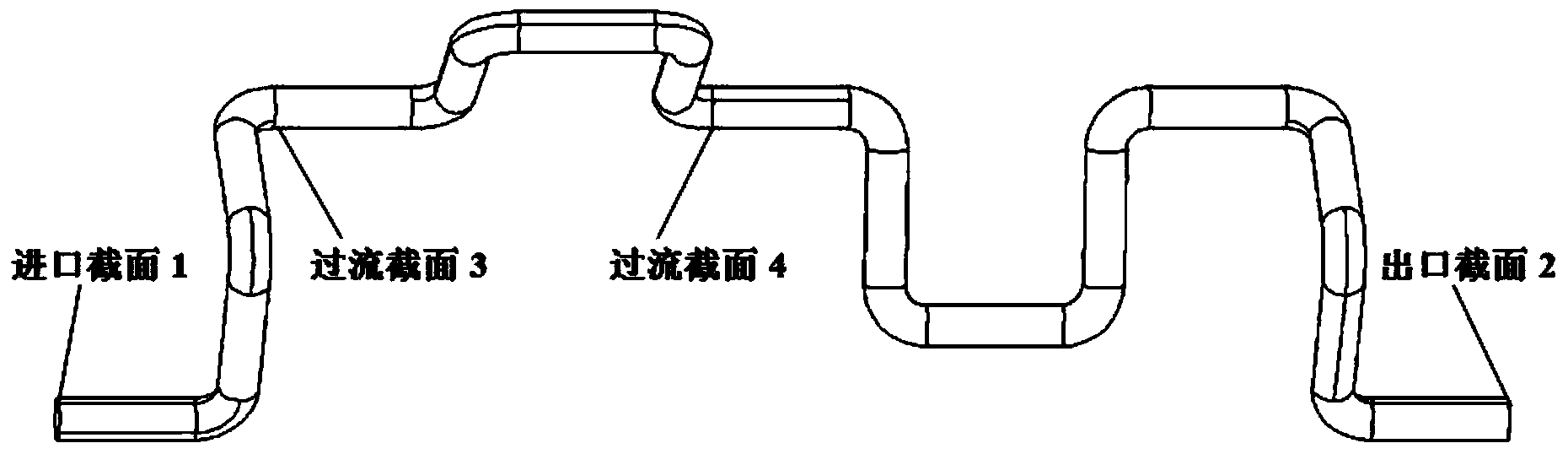

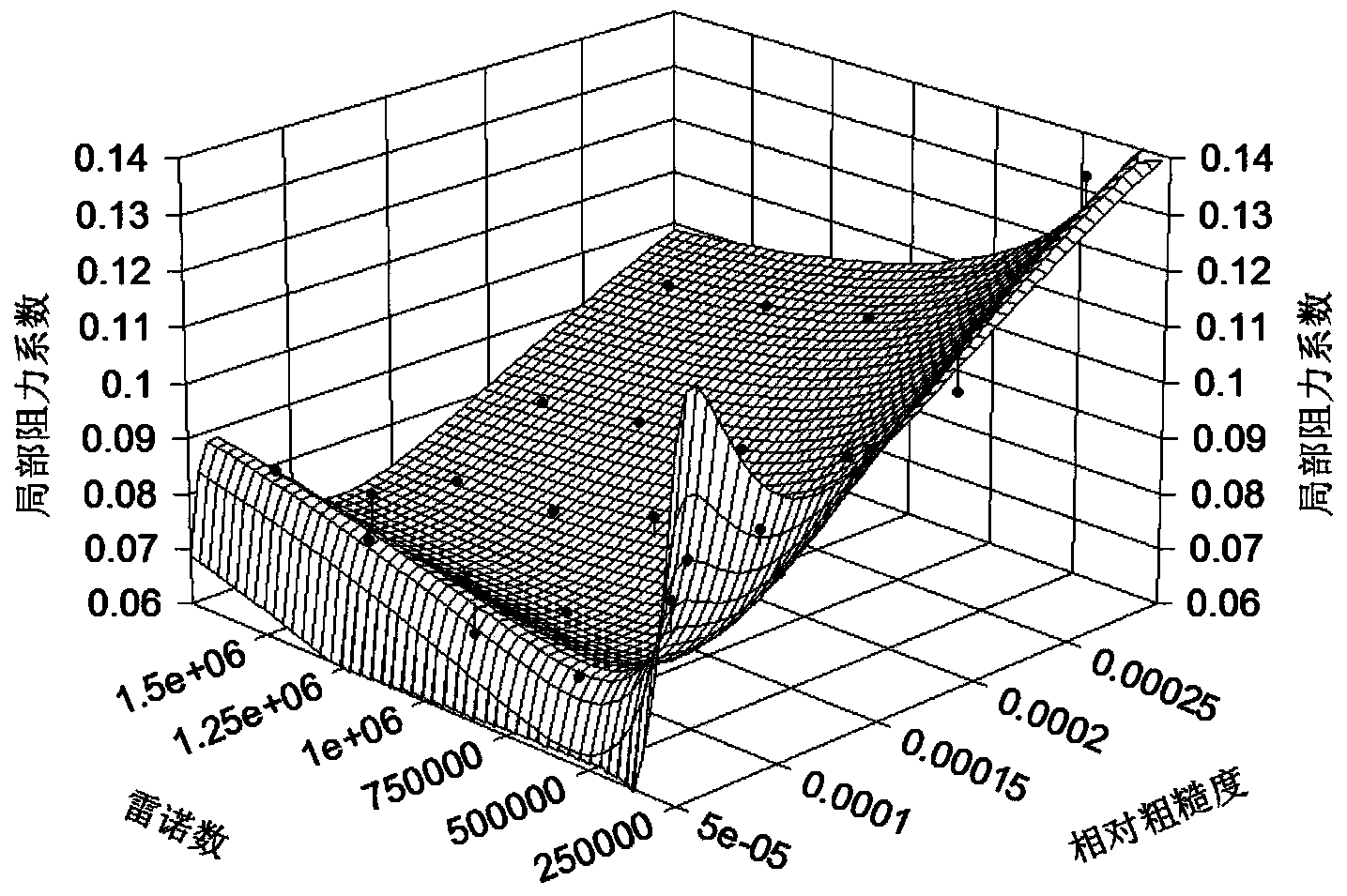

Accurate computing method used for pipeline resistance coefficient and based on numerical computation

The invention discloses an accurate computing method used for a pipeline resistance coefficient and based on numerical computation. According to the method, ANSYS-CFX is adopted to perform numerical simulation on a pipeline, and the temperature set in the numerical simulation and computed fluid energy loss per unit mass are in data comparison with the temperature obtained through experimental measurement and fluid energy loss per unit mass; and through the comparison, the temperature and the dynamic viscosity which are set in the numerical simulation are corrected, an optimal turbulence model is selected finally, and three-dimensional viscidity steady numerical simulation is performed on the pipeline under the conditions of different roughness and different flows. Each overflowing section total pressure obtained through the simulation is taken into a Bernoulli equation, and an on-way resistance coefficient and a local resistance coefficient of the pipeline under different conditions are inversely solved through the energy loss; and the data are guided into TableCurve3D for three-dimensional data curved surface fitting, and finally an optimal expression of the on-way and local resistance coefficients relative to relative roughness and Reynolds number is obtained. According to the accurate computing method, not only can the on-way and local resistance coefficients be accurately computed, but also an energy performance computation model of the pipeline system can be established on that basis, and energy-saving transformation is performed on the conventional pipeline system.

Owner:JIANGSU UNIV

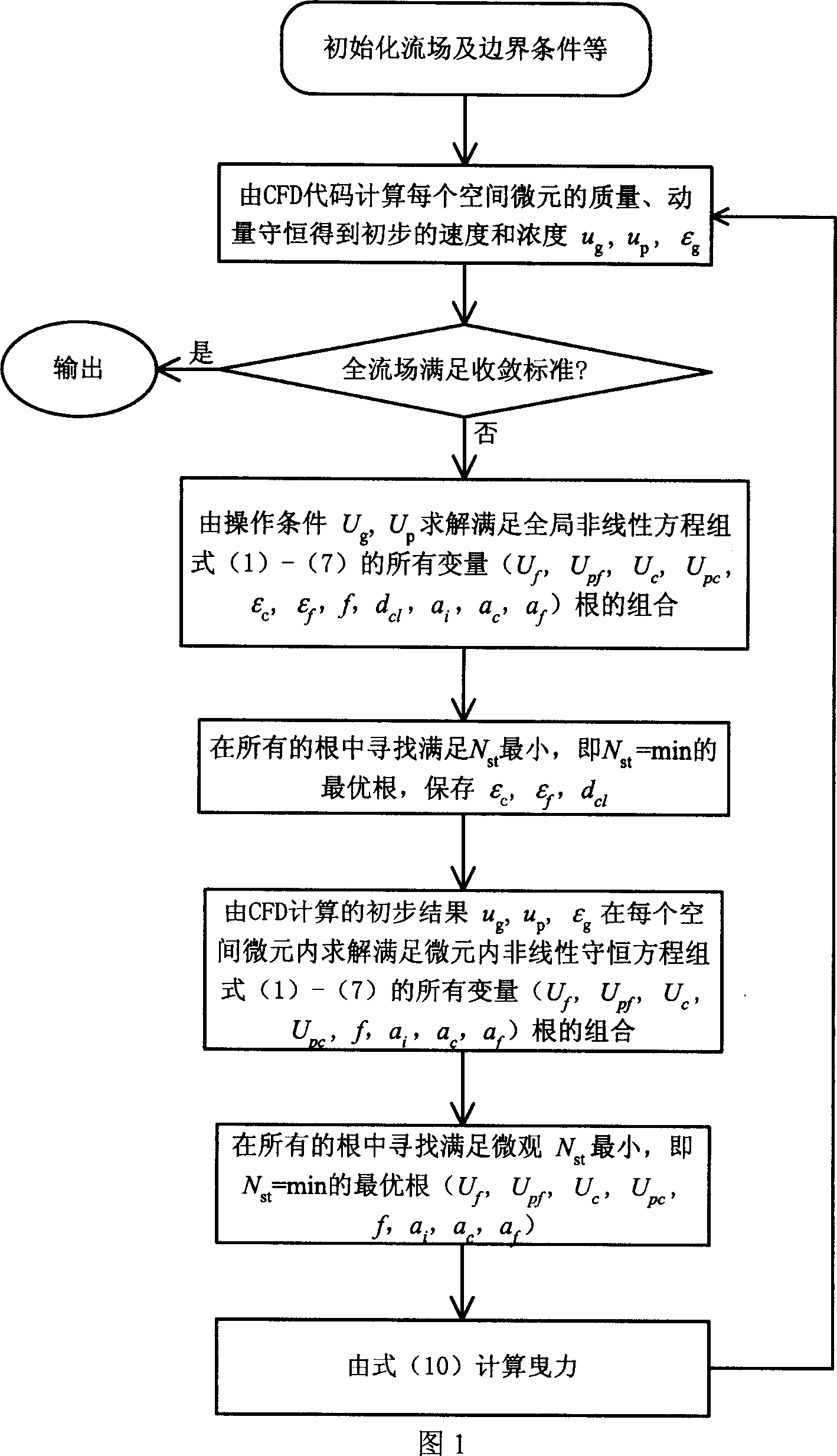

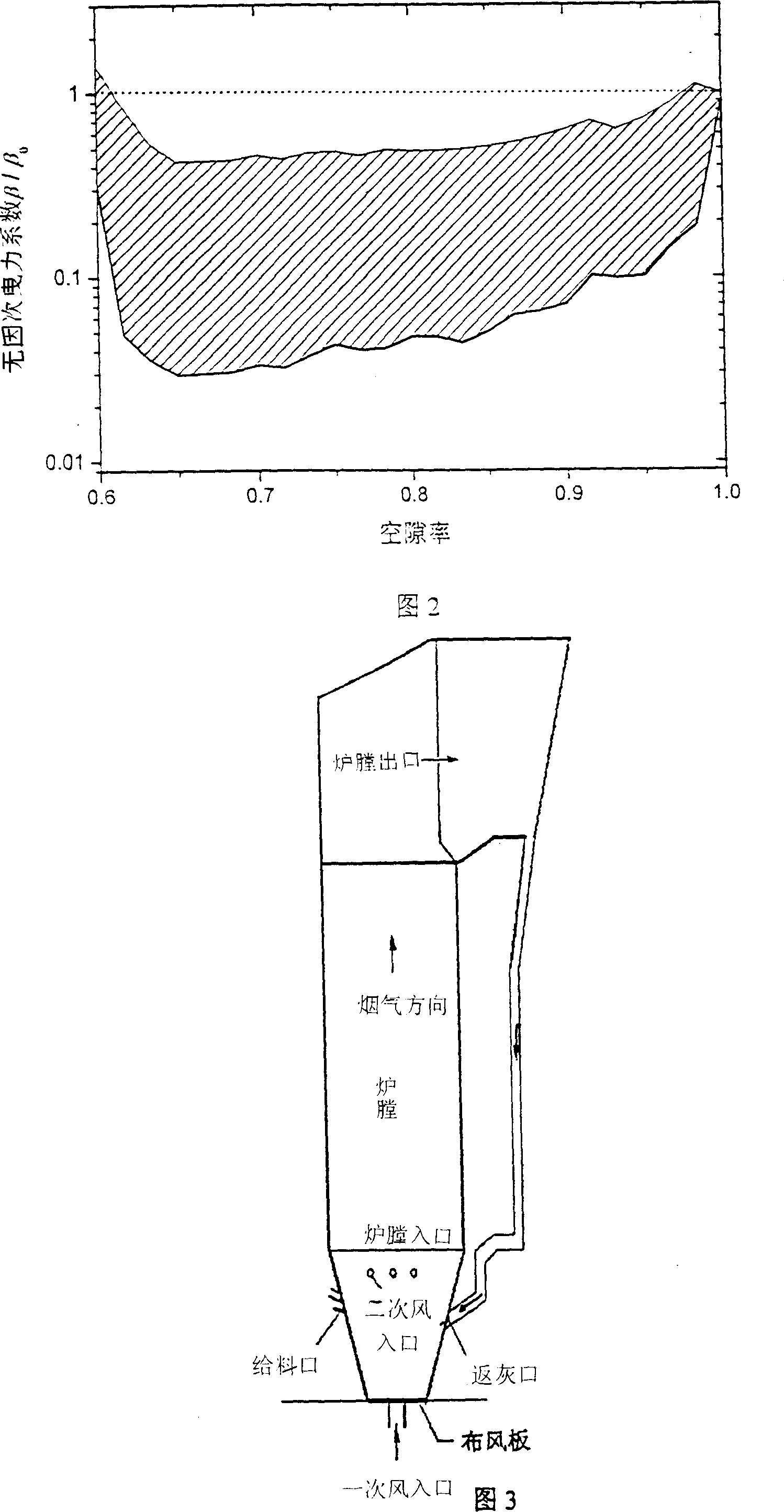

Method for measuring flow parameter distribution in particle flow two-phase flow reactor

InactiveCN1979111ACorrecting high drag coefficientsAccurately realize the calculation of reaction thermal stateHydrodynamic testingParticle flowTest flow

The invention discloses a method to testing flow parameters distribution in particle fluid two-phase flow reactor. It includes the following steps: according to the structure size and physical property, operation condition of reactor to gain speed and thickness distribution; gaining medium structure parameter; solving all the combination of variation root to seek the optimal root; calculating interlacing drag force and replacing drag force relationship of two-phase flow module to take iterative computation to gain the thickness, in random infinitesimal of reactor, and the space distribution and time evolution of speed flow field. The invention could gain drag coefficient reflecting actual situation and accurately calculate the flow, reacting, heat transferring and mass transferring process in reactor.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

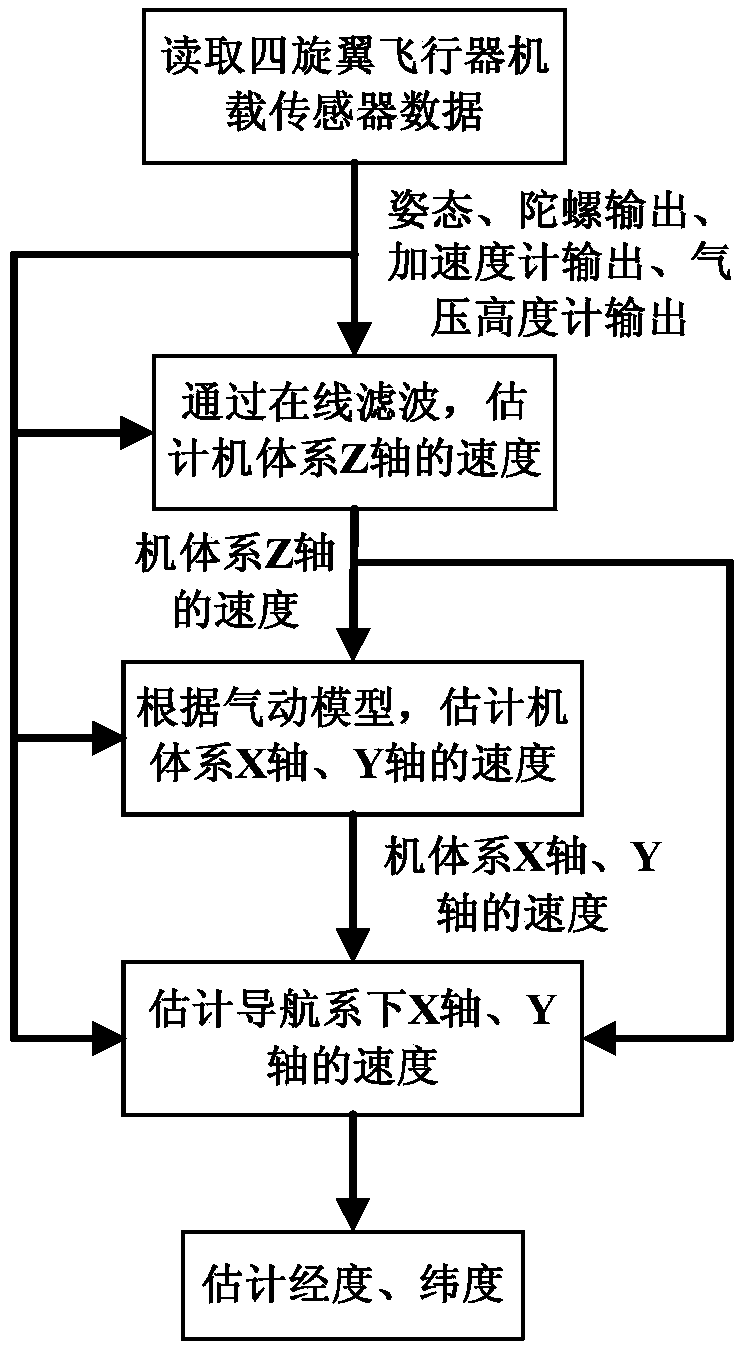

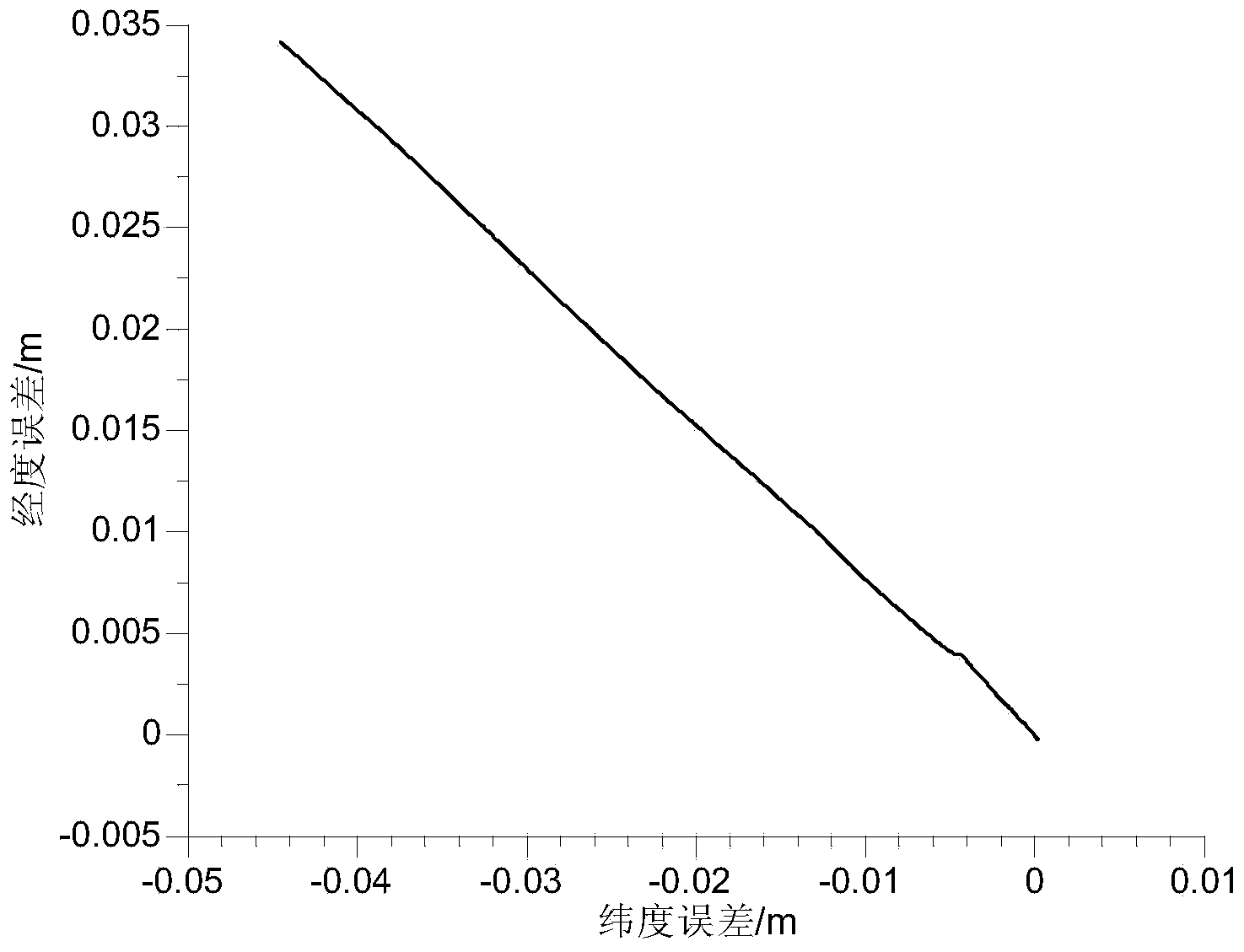

Pneumatic model-assisted navigation method for four-rotor-wing air vehicle

ActiveCN103837151AQuick testHigh positioning accuracyNavigational calculation instrumentsFlight vehicleRotary wing

The invention discloses a pneumatic model-assisted navigation method for a four-rotor-wing air vehicle and belongs to the field of combined navigation and autonomous navigation. A pneumatic model of the four-rotor-wing air vehicle is combined with an airborne sensor, so that the speed and the position information of the four-rotor-wing air vehicle can be estimated. According to the pneumatic model-assisted navigation method for the four-rotor-wing air vehicle, parameters of the adopted pneumatic model comprise the radiuses of rotor wings, the air density, the solidness of the rotor wings, the lifting slope, the resistance coefficient and a rotor wing mounting angle; information of the adopted airborne sensor comprises rotating speeds of the rotor wings, the acceleration, the angle speed, the attitude and the height. Any external equipment does not need to be additionally arranged; the speed and position estimation precision of the four-rotor-wing air vehicle during flying without a GNSS (global navigation satellite system) can be improved; the pneumatic model-assisted navigation method has the characteristics of low cost, zero load, high autonomy and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

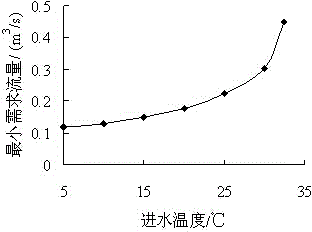

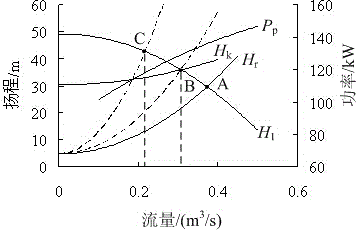

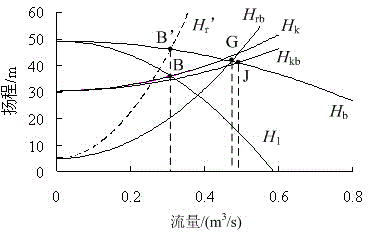

Method for determining optimal combination operation scheme of circulating cooling water system water pump units and adjusting valves of petrochemical enterprise

ActiveCN104131983AReduce consumptionSave energyPump controlPump installationsPetrochemicalEngineering

The invention provides a method for determining an optimal combination operation scheme of circulating cooling water system water pump units and adjusting valves of a petrochemical enterprise. According to the method, maximum critical flow points of different combinations of the system water pump units during operation and required water power resistance coefficients of the water return pipe adjusting valves are determined; according to the minimum demand flow of a system at different water inlet temperatures, a system flow range corresponding to the various operation combinations, with the smallest the energy consumption, of the water pump units is determined, and the operation combinations of the circulating cooling water system water pump units can be optimized; for the determined optimal operation combination, corresponding to a certain minimum demand flow range of the system, of the water pump units, the minimum demand flow of the system is in the flow range but generally smaller than the maximum of the flow range, then by reducing the opening degrees of the adjusting valves, the operation flow of the system is reduced to be equal to the minimum demand flow of the system, the resistance coefficients of the adjusting valves and added values of the coefficients are determined, power of a water pump shaft is further reduced, and therefore the optimal operation combination of the circulating cooling water system water pump units and the adjusting valves can be achieved.

Owner:YANGZHOU UNIV

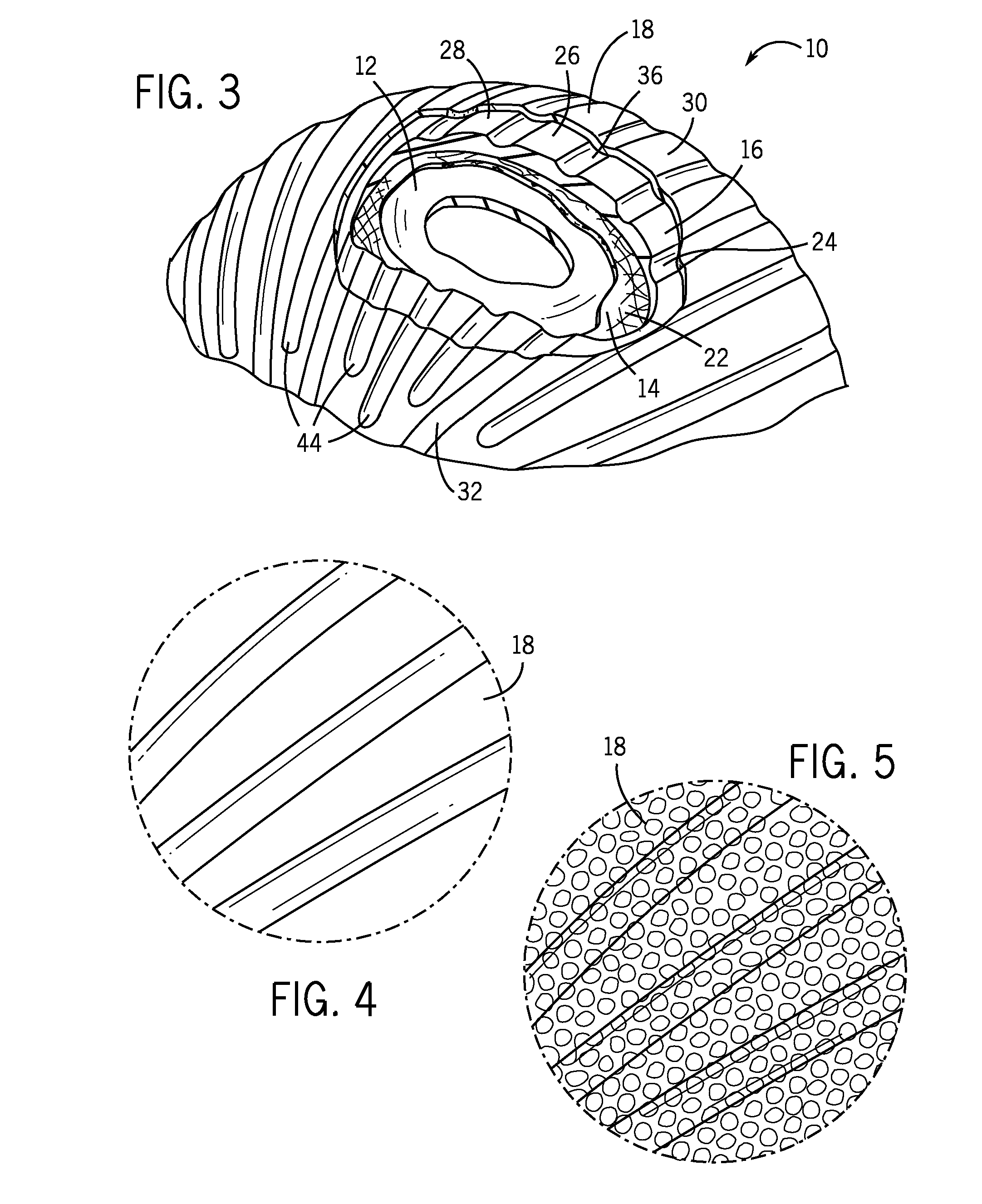

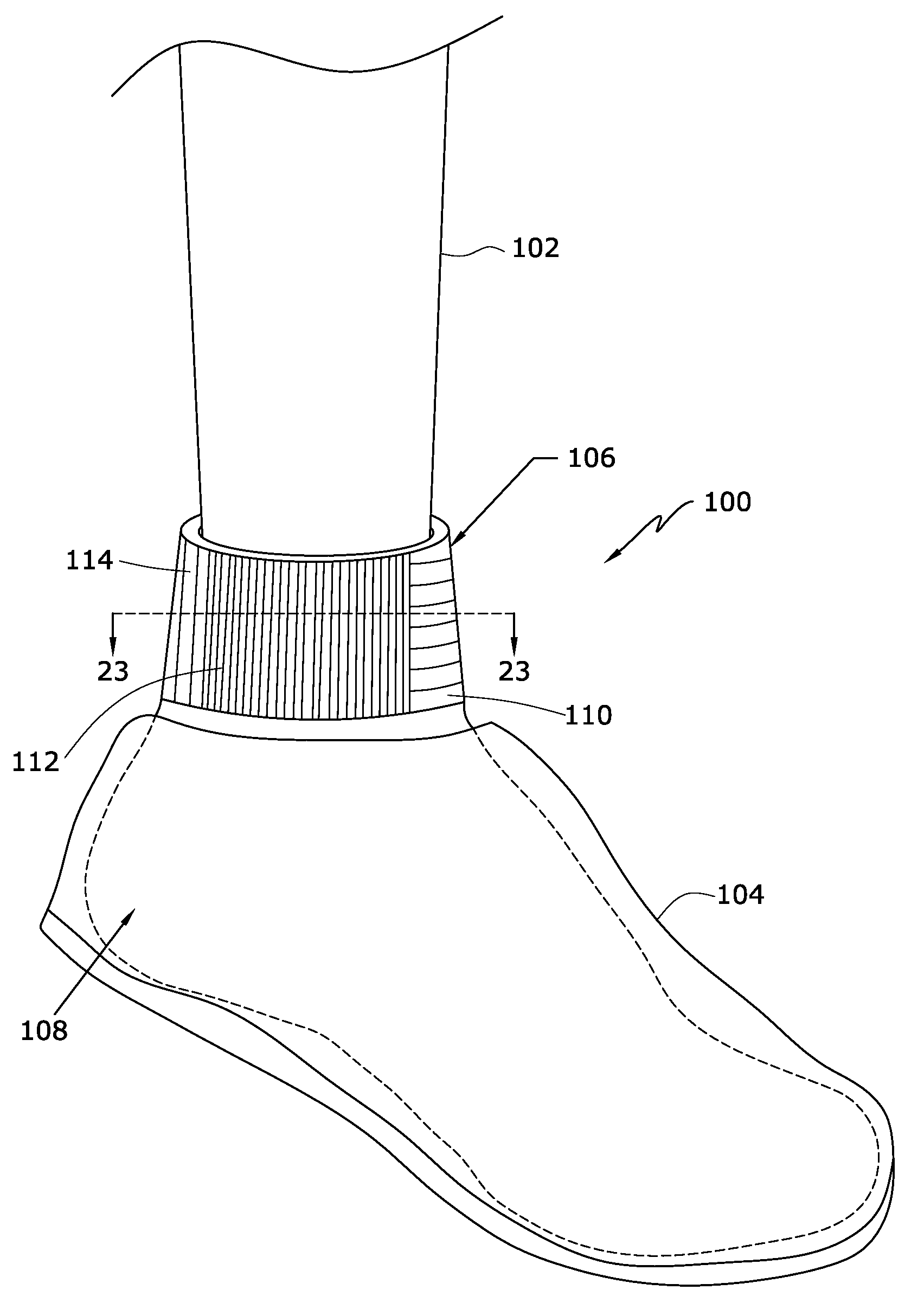

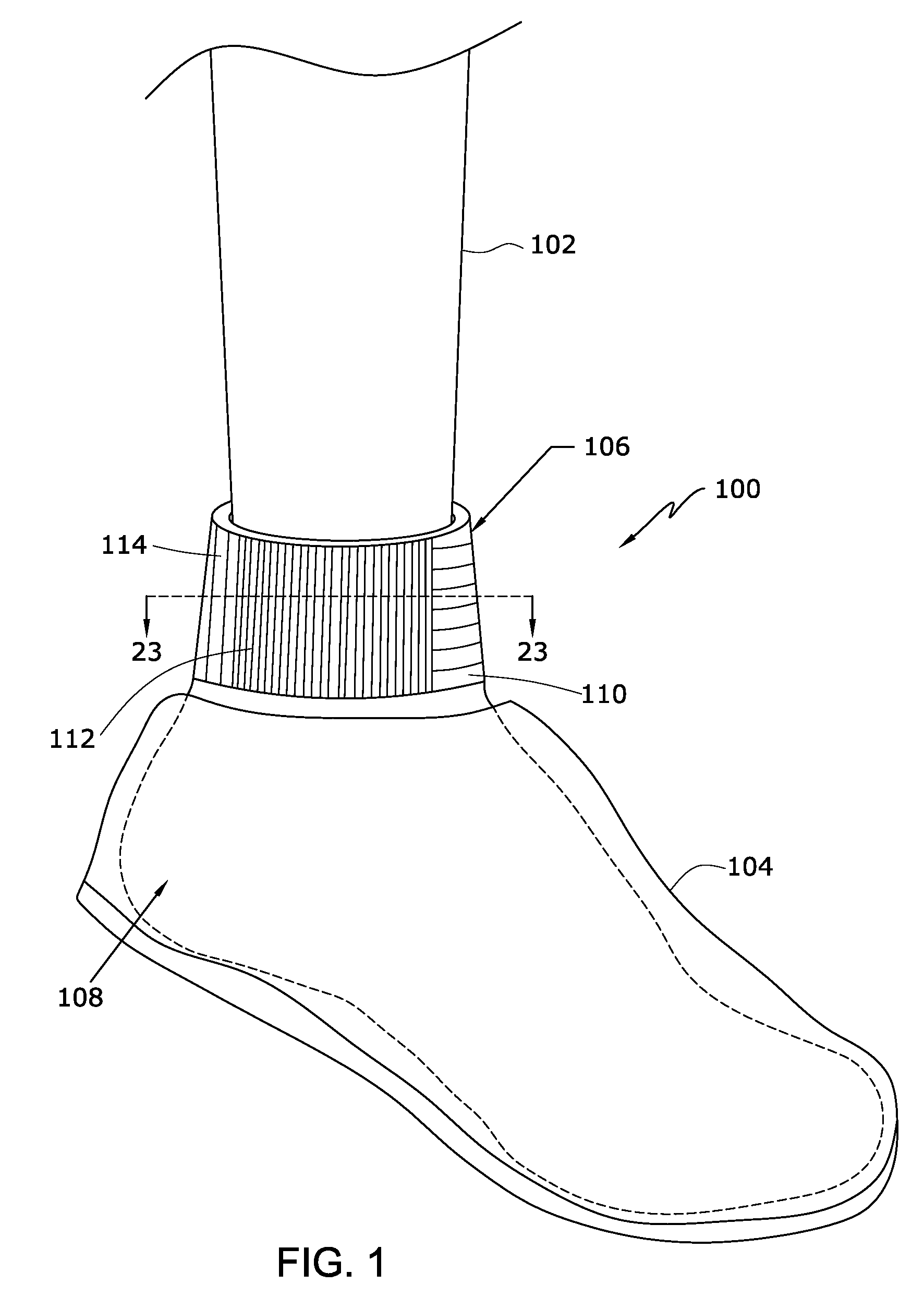

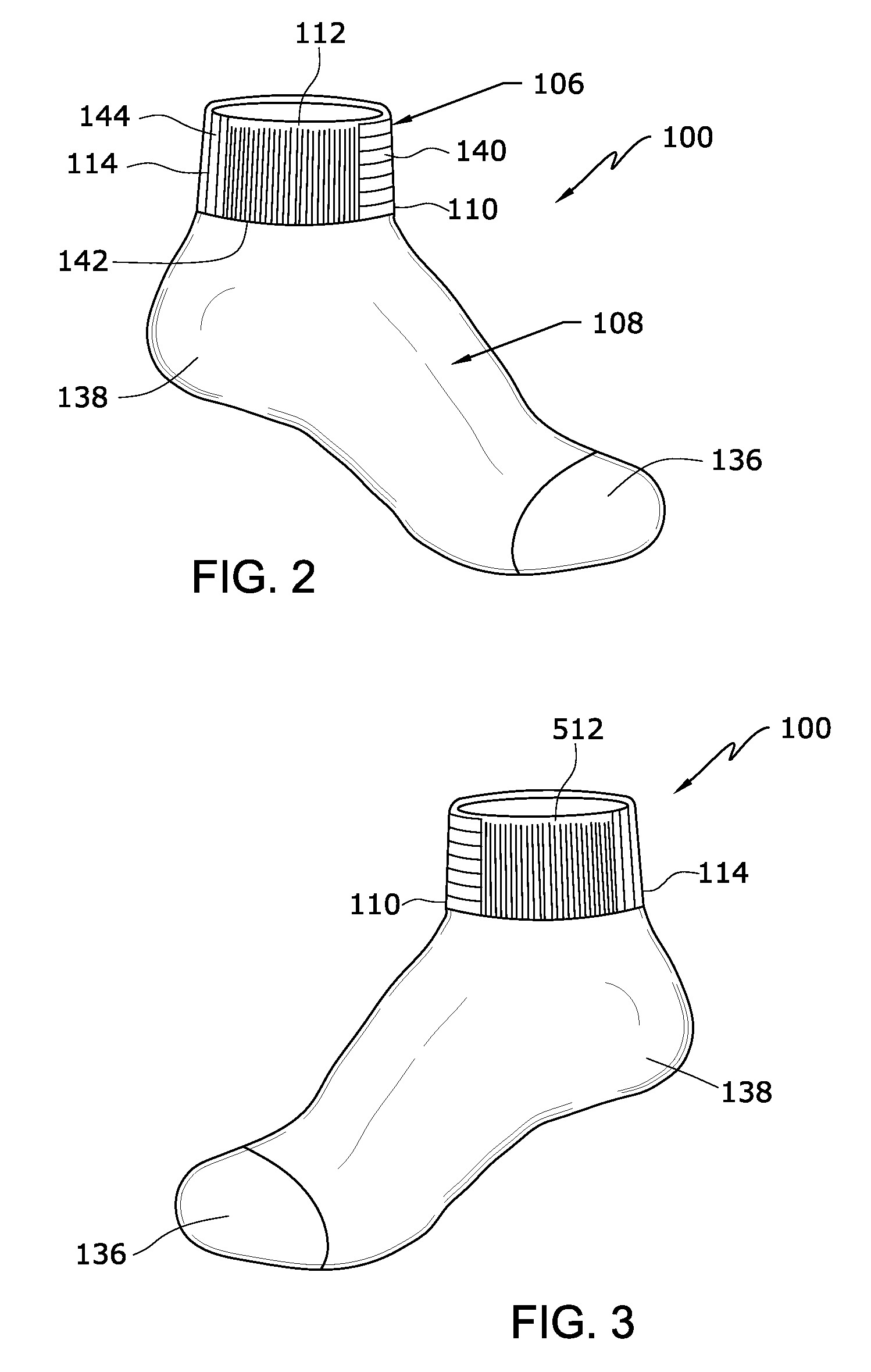

Apparel with reduced drag coefficient

Owner:NIKE INC

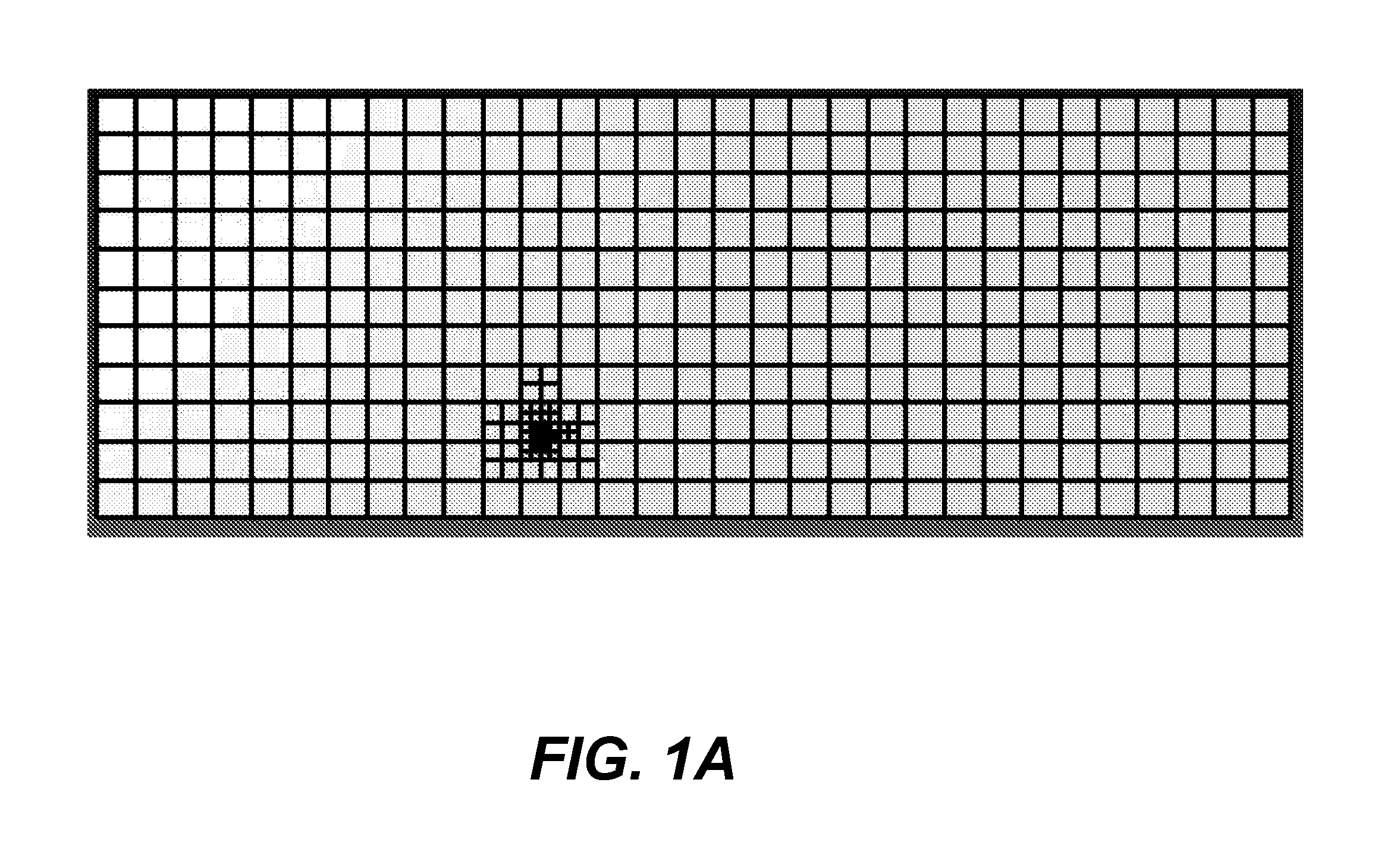

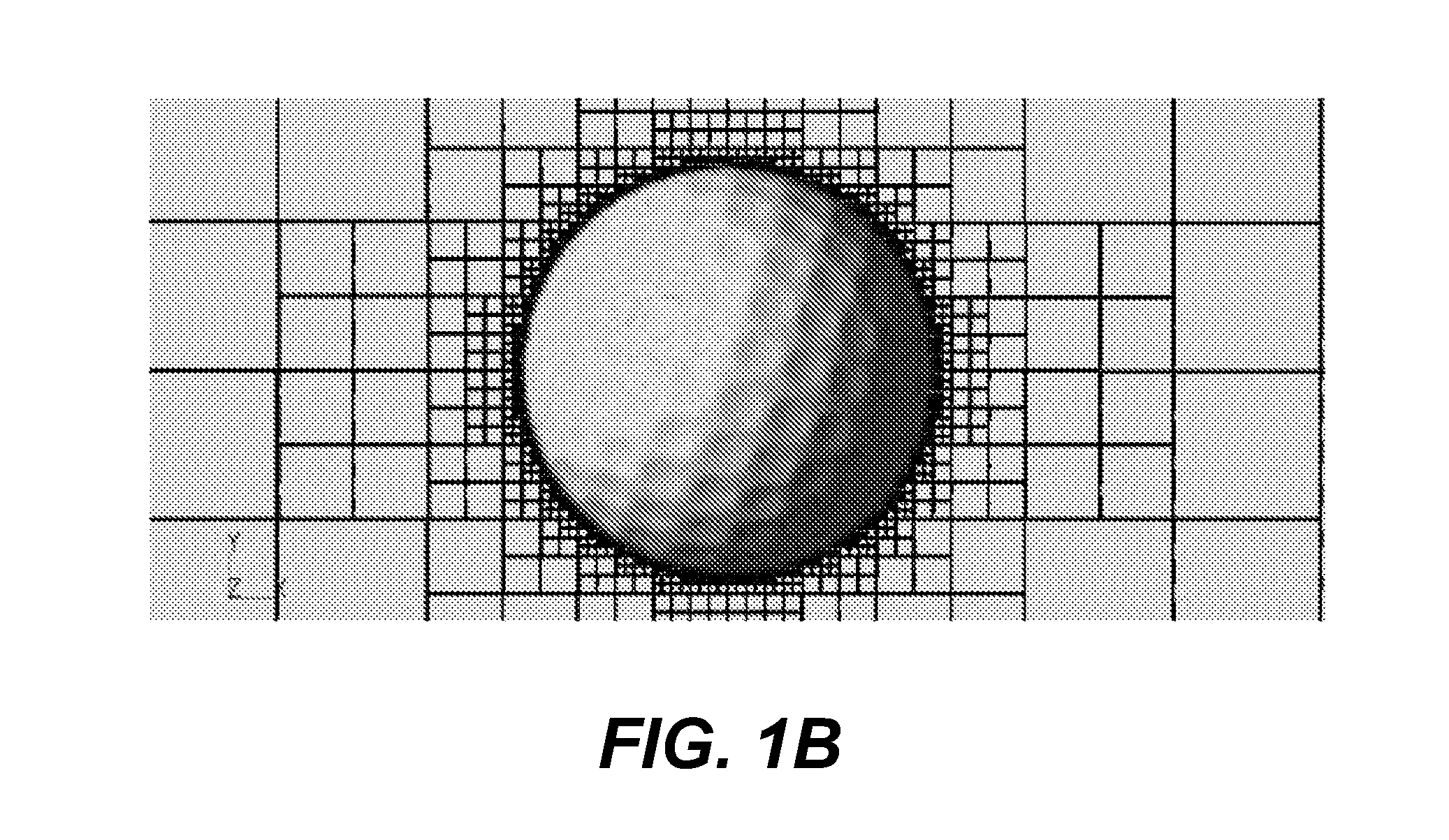

Golf ball trajectory simulation method

InactiveUS20110257945A1Efficient developmentReduce computing timeBall sportsComputation using non-denominational number representationEngineeringGolf Ball

The invention is directed at a golf ball trajectory simulation method which sets up a golf ball model within a virtual airflow space where a grid has been generated, sets a weight for the ball model and applies initial conditions (initial velocity, launch angle, spin rate) to the ball model so as to cause the model to fly within the virtual airflow space, then calculates the lift coefficient and the drag coefficient for the golf ball from the air stream velocity, direction and pressure calculated in each grid cell, and calculates the flight distance and left-to-right dispersion for the golf ball from launch until landing by calculating the change in height, change in lateral direction, change in velocity and change in spin rate for the golf ball during flight. The trajectory simulation method divides the flight path of the golf ball model into two or three regions based on the criteria that Re=250,000 to 170,000 is a high-velocity region, Re=170,000 to 100,000 is a medium-velocity region and Re=100,000 and below is a low-velocity region, and sets up a height for the grid adjacent to the golf ball model surface in the high-velocity region (grid height A), a height for the grid adjacent to the golf ball model surface in the medium-velocity region (grid height B) and a height for the grid adjacent to the golf ball model surface in the low-velocity region (grid height B) such that grid height A<grid height B<grid height C.

Owner:BRIDGESTONE SPORTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com