Heating pipe network hydraulic simulation model identification correction method and system, method of operation

A technology of heating pipe network and simulation model, which is applied in computational model, biological model, design optimization/simulation, etc., can solve the problem that the hydraulic simulation model of heating pipe network cannot accurately describe the operation of the pipe network.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

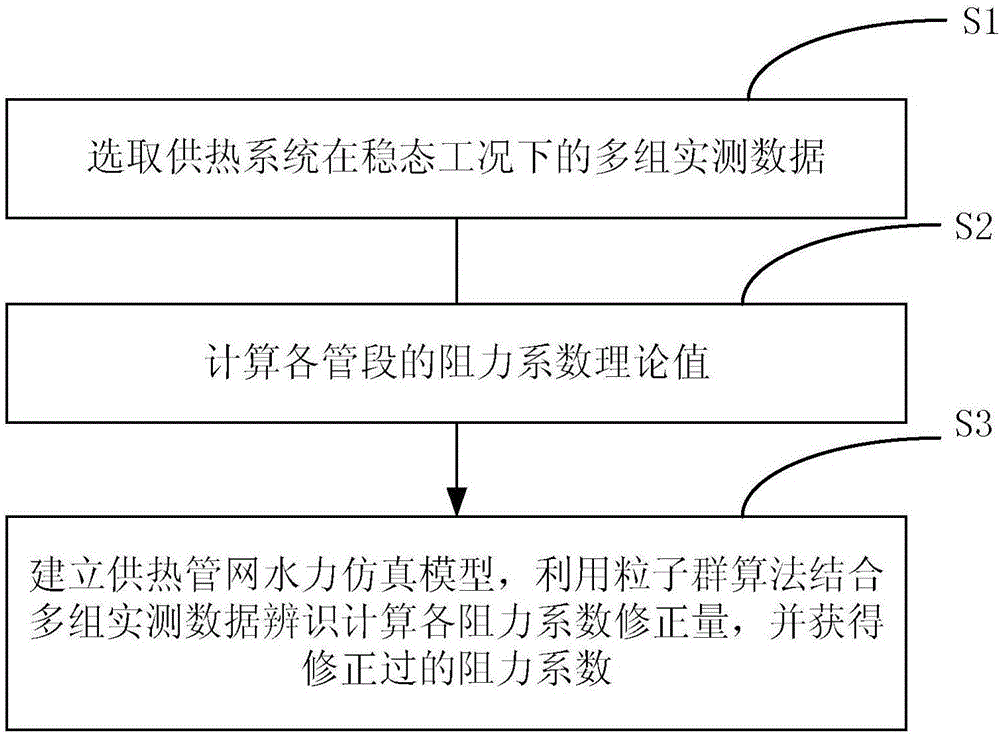

[0083] like figure 1 As shown, a method for identifying and correcting a hydraulic simulation model of a heating pipe network according to the present invention includes the following steps:

[0084] Step S1, selecting multiple sets of measured data of the heating system under steady-state conditions;

[0085] Step S2, calculating the theoretical value of the resistance coefficient of each pipe section; and

[0086] In step S3, a hydraulic simulation model of the heating pipe network is established, and a particle swarm algorithm is used in conjunction with multiple sets of measured data to identify and calculate the correction amount of each resistance coefficient, and obtain the corrected resistance coefficient.

[0087] Further, the step S1 selects multiple sets of measured data of the heating system under steady-state working conditions and selects multiple sets of measured data according to the historical operating condition data of the heating network. The historical op...

Embodiment 2

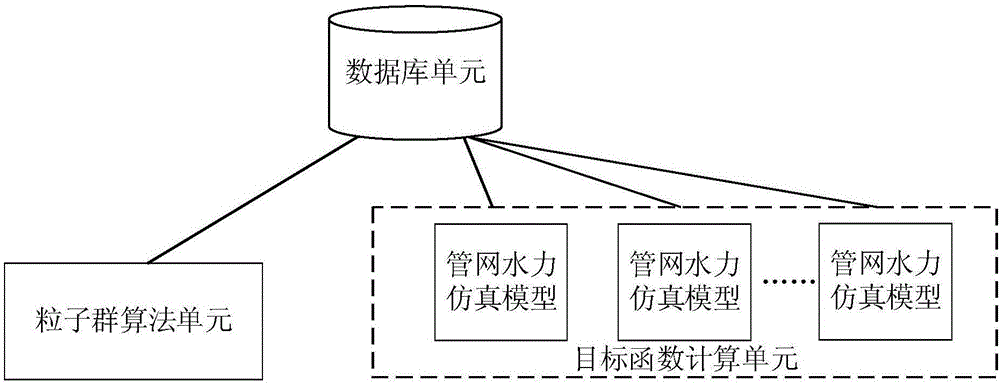

[0138] On the basis of Embodiment 1, Embodiment 2 provides a system for identifying and correcting a hydraulic simulation model of a heating pipe network, including:

[0139] The particle swarm algorithm unit generates particles corresponding to the drag coefficient correction vector of each generation, writes the particles into the database, and reads the objective function value of each particle;

[0140] The objective function calculation unit establishes the objective function for the identification of the correction value of the resistance coefficient, drives multiple hydraulic simulation models of the heating pipe network, that is, generates N simulation models for parallel simulation calculation, and obtains particles from the database, and calculates through the simulation model The objective function value of the particle is written back to the database.

[0141] The database unit stores the population of the drag coefficient correction vector and the objective functi...

Embodiment 3

[0151] On the basis of embodiments 1 and 2, this embodiment 3 provides an operation method for the identification and correction system of the hydraulic simulation model of the heating pipe network in embodiment 2, including the following steps:

[0152] Step Sa, establishing a topology model of the pipeline network to be identified, so as to generate a unique identification ID of each component of the pipeline network;

[0153] Step Sb, the preparatory work of obtaining the actual measurement data of the working conditions and calculating the theoretical value of the drag coefficient;

[0154] Step Sc, setting the algorithm parameters in the particle swarm optimization unit and starting the unit;

[0155] Step Sd, start the objective function calculation unit.

[0156] The preparatory work in the step Sb includes: correspondingly sorting the ID of the pipe section to be identified and the theoretical value of the resistance coefficient into a configuration file for the PSO u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com