Method for accumulated damage computation and life prediction of IGBT module used for electric car

An electric vehicle, cumulative damage technology, applied in the direction of calculation, computer-aided design, electrical digital data processing, etc., can solve the problem of deviation of the predicted value of the data processing model, the calculation of the damage degree of the IGBT module and the life prediction, and the accuracy needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

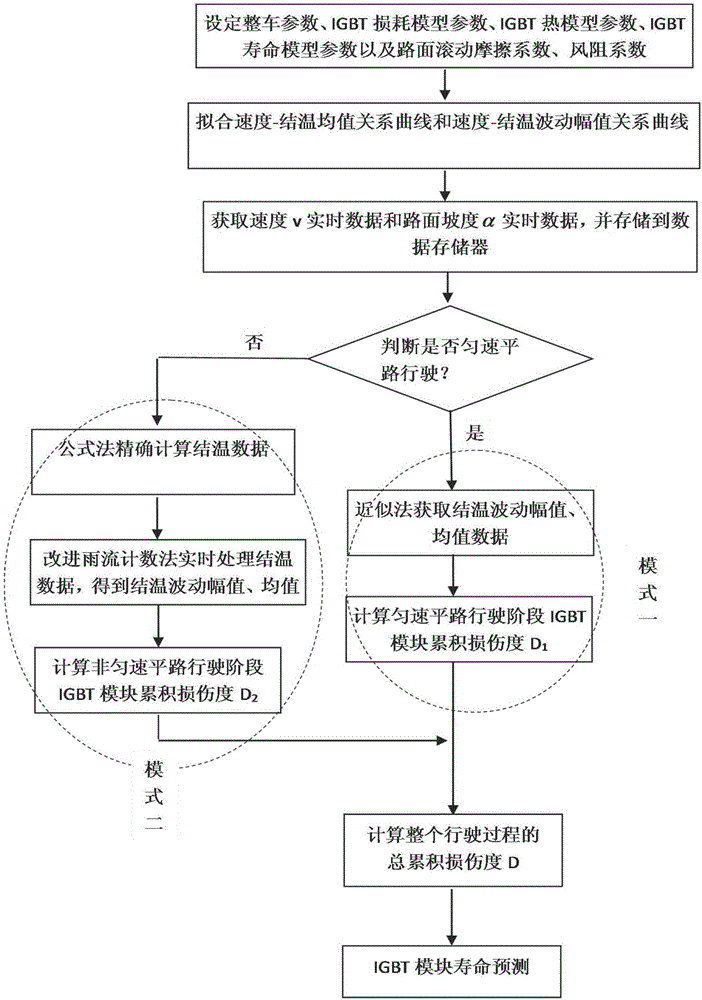

[0105] A method for calculating the cumulative damage degree and life prediction of IGBT modules for electric vehicles, such as figure 1 shown, including the following steps:

[0106] Step 1. Set vehicle parameters, IGBT module related parameters (IGBT loss model parameters, IGBT thermal model parameters, IGBT life model parameters), road rolling friction coefficient and wind resistance coefficient.

[0107] In this embodiment, among the vehicle parameters: the vehicle mass m is 1420Kg, the wheel radius r is 0.2888m, the reduction ratio k is 4, and the inverter switching frequency f sw is 10kHz, the windward area A d 2.8m 2 , the rotation mass conversion factor δ is 1.05, and the number of PMSM pole pairs n p is 4, the rotor flux linkage Ψ f is 0.1Wb.

[0108] Among the IGBT loss model parameters: turn-on energy consumption and turn-off energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com