A method and device for testing the frictional resistance coefficient of the inner wall of a pipeline

A technology for friction resistance and testing of pipelines, which is used in measuring devices, mechanical devices, and testing of mechanical components. , verticality, deflection and deformation requirements are very high, to achieve the effect of stable airflow

Inactive Publication Date: 2011-12-07

BEIHANG UNIV

View PDF3 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The high-speed wind tunnel is a method to test the frictional resistance coefficient of the inner wall of the pipeline, but the cost of the wind tunnel is very high, and in the process of the test, the straightness, roundness, cylindricity, verticality, deflection, etc. The requirements are very high, and the frictional resistance coefficient of the inner wall of the pipeline cannot be tested quickly and accurately. Therefore, new testing methods and means need to be developed, researched and discussed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0071] Step 1: Test plan selection

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

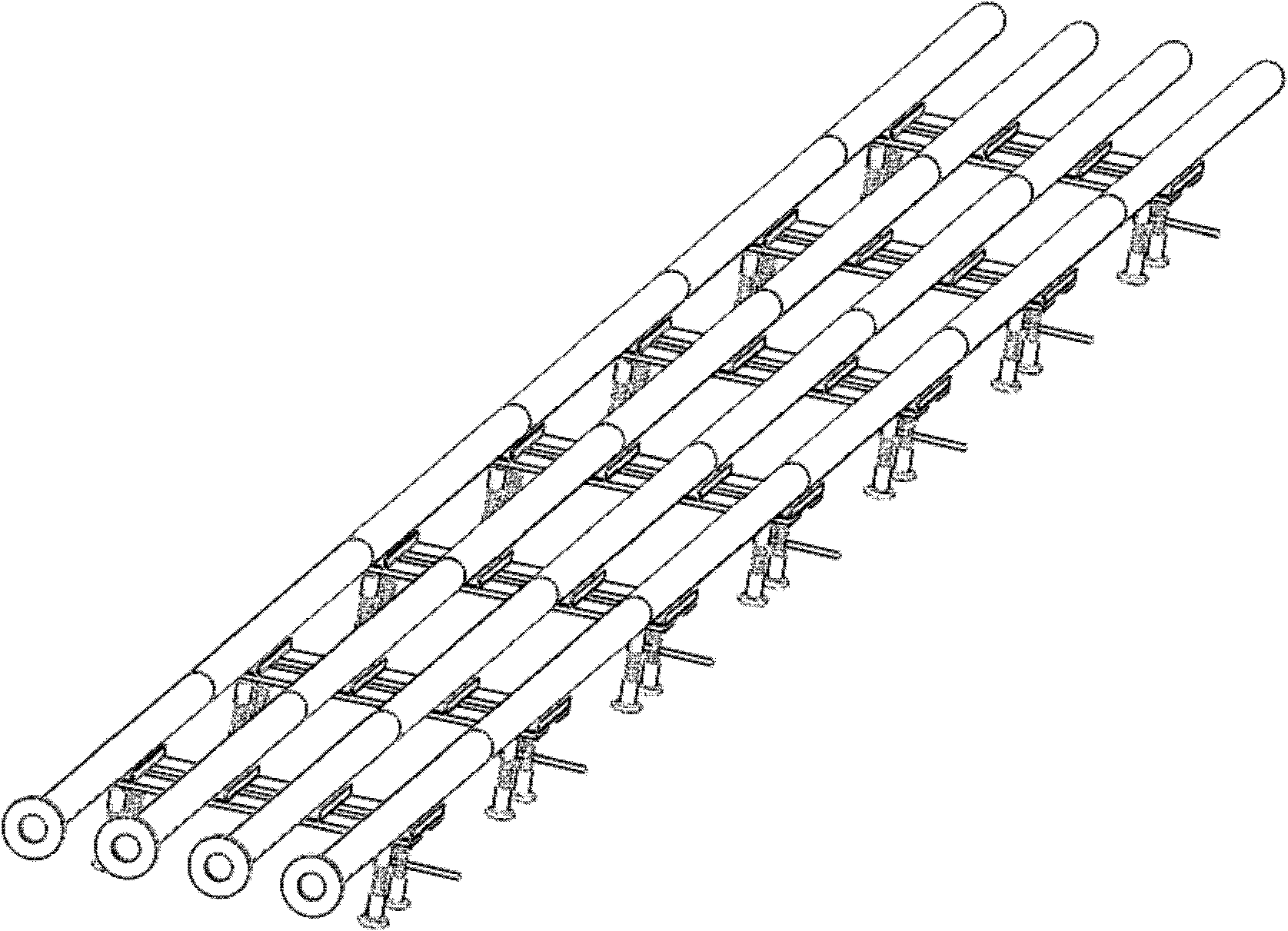

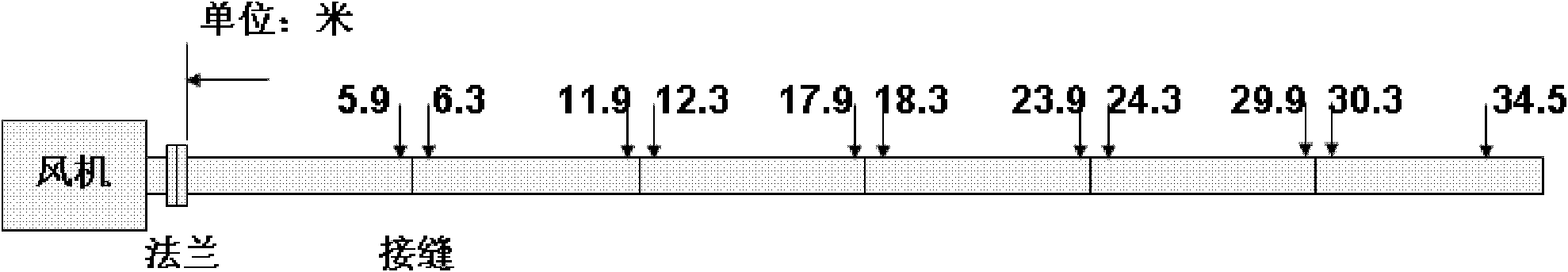

Abstract

The invention discloses a device for testing a frictional drag coefficient of an inner wall of a pipeline. The device consists of a high speed fan, a frequency converter, a turbulence smoothening section, a pipeline bracket, the pipeline, a multitube pressure gauge, a Pitot tube and a slanting leg manometer, wherein the frequency converter is connected with the high speed fan; the front end of the turbulence smoothening section is connected with the outlet of the high speed fan, and the rear end is connected with the pipeline; the pipeline is arranged on the pipeline bracket with an adjustable mechanism; pressure testing holes are processed at different positions of the pipeline and are connected with the multitube pressure gauge through tee joints and hoses; and at the tail end of the pipeline, the wind speed in the pipeline is tested by the Pitot tube, and the Pitot tube is connected with the slanting leg manometer. A method for testing the frictional drag coefficient of the inner wall of the pipeline comprises the following six steps of: 1, selecting a testing scheme; 2, selecting a testing means; 3, distributing the pressure testing holes; 4, analyzing the experimental accuracy; 5, designing and manufacturing the pipeline bracket; and 6, assembling the testing device, wiring and debugging. The invention has application value in the technical field of pipeline pressure and friction drag testing.

Description

technical field [0001] The present invention relates to a method and device for testing the frictional resistance coefficient of the inner wall of a pipeline, more particularly, it refers to a method for calculating the frictional resistance coefficient of the inner wall of the pipeline by using the method of testing the pressure at different positions of the pipeline and the gas flow velocity at the end of the pipeline method, and designed and processed a whole set of test equipment, which belongs to the technical field of pipeline pressure and friction resistance testing. Background technique [0002] During the transportation of natural gas pipelines, almost all the power of the pumping station is used for the frictional resistance of the inner wall of the pipeline. Therefore, in the process of power design of the pumping station, the frictional resistance coefficient of the inner wall of the pipeline is the key factor in the design. How to quickly, efficiently and accurat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N19/02G01M13/00

Inventor 张德远张景建雒悦豪陈华伟姜兴刚

Owner BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com