Patents

Literature

578results about How to "Guaranteed levelness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

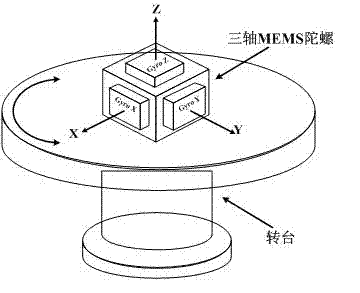

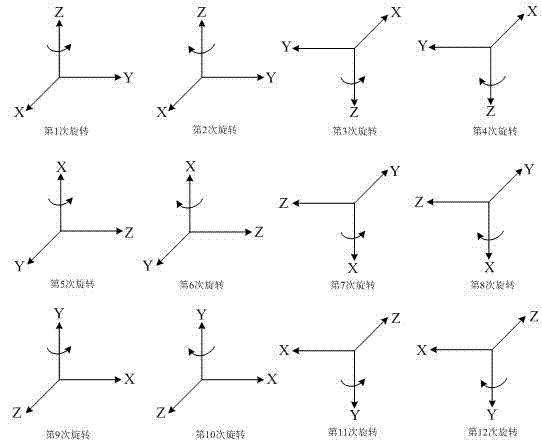

Triaxial MEMS gyroscope rotation integral calibration method based on uniaxial turntable

The invention discloses a triaxial MEMS gyroscope rotation integral calibration method based on a uniaxial turntable. According to the invention, first, a triaxial MEMS gyroscope error model is established; the triaxial MEMS gyroscope is fixed on the uniaxial turntable; MEMS gyroscope six-position rotary calibration is carried out; test data and sampling time of 12 times of rotation of the MEMS gyroscope at the 6 positions are tested and recorded; through the 12 times of rotation of the MEMS gyroscope at the 6 positions, a MEMS gyroscope error model is simplified, and an error model after gyroscope rotation is obtained; integral calculations are carried out upon two sides of the equation of the error model after gyroscope rotation, an error equation set is established, and MEMS gyroscope error coefficient is obtained by calculation. With the method provided by the invention, calibration precision is ensured; and fixed zero bias, scale factor, cross-coupling error coefficient, and acceleration sensitivity coefficient of the MEMS gyroscope can be solved rapidly, such that calibration efficiency is improved.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

Production technology of hatch coaming and hatch cover

InactiveCN101362505AReduce the number of liftingReduce workloadHull decksVessel hatches/hatchwaysManufacturing technologyHydraulic equipment

Owner:江苏熔盛重工有限公司 +1

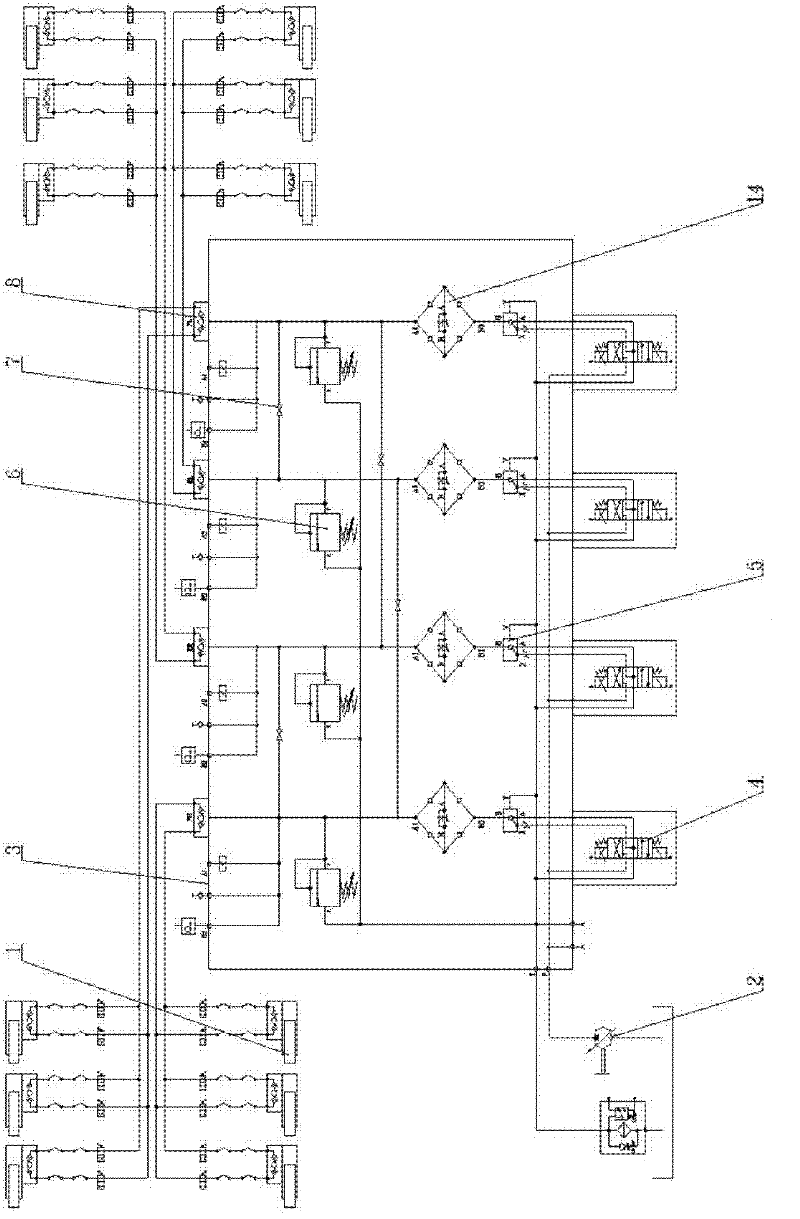

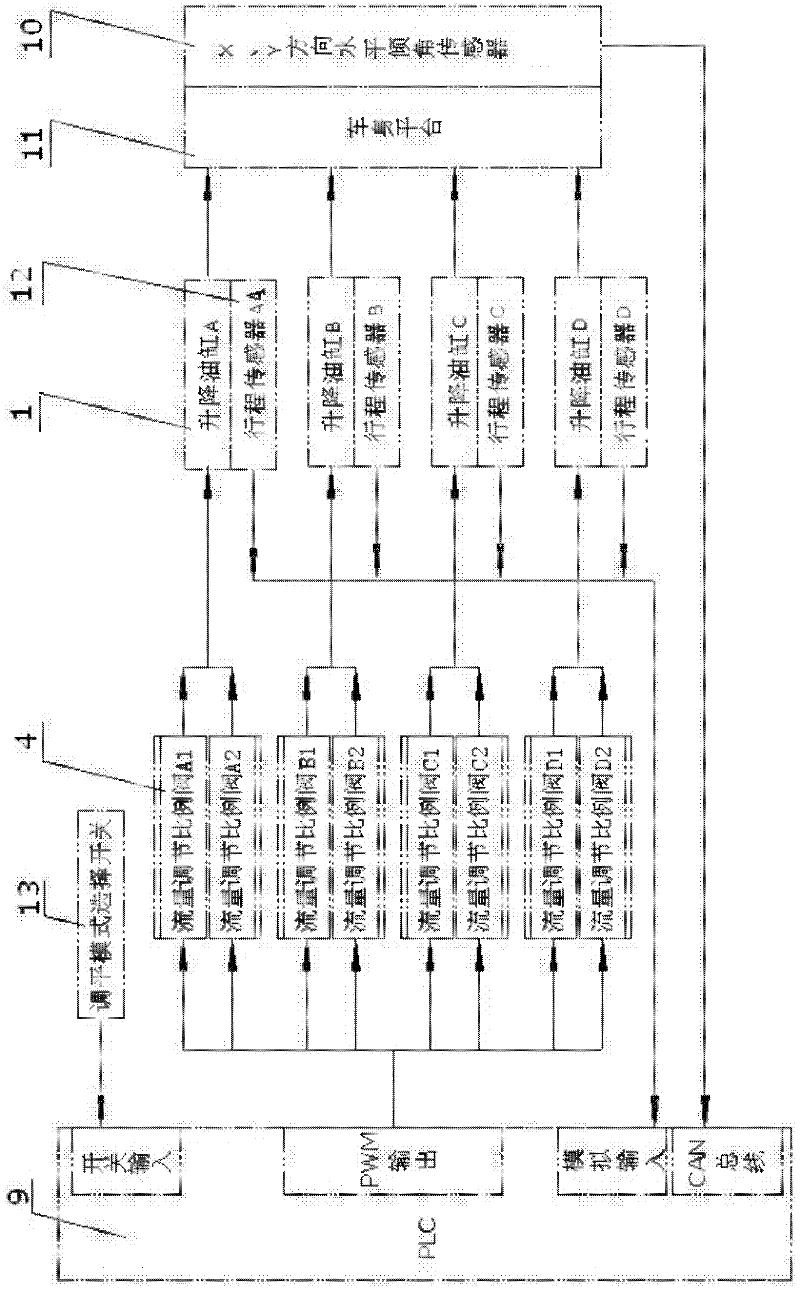

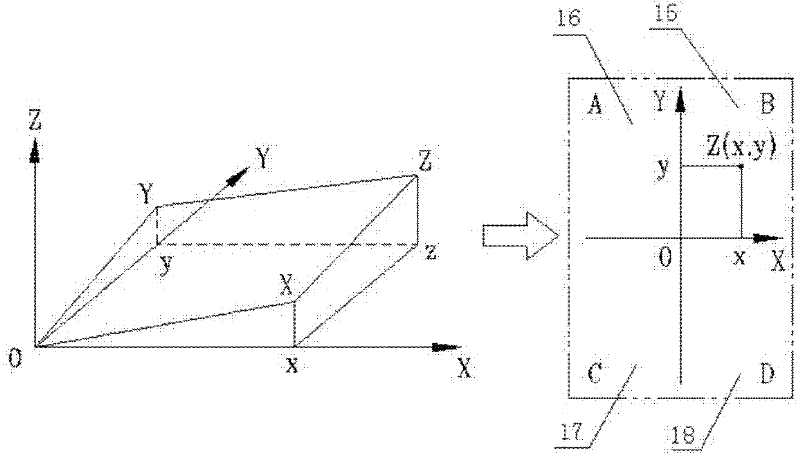

Automatic leveling system for vehicle body platform

ActiveCN102407747AGuaranteed levelnessGuaranteed smoothnessResilient suspensionsDriver/operatorProgrammable logic controller

The invention relates to the technical field of leveling systems, and discloses an automatic leveling system for a vehicle body platform. The automatic leveling system comprises a horizontality detection element, travel sensors and a programmable controller, wherein the horizontality detection element is arranged on the vehicle body platform; a lifting oil cylinder of a vehicle body platform hydraulic lifting system is divided into four groups according to areas in which four angles of the vehicle body platform are positioned; each group of lifting oil cylinder is provided with a travel sensor; and the programmable controller is connected with control valves of all the groups of lifting cylinders, the horizontality detection element and the travel sensors respectively. In the automatic leveling system, signals transmitted from the travel sensors and the horizontality detection element are subjected to operation processing through the programmable controller; when inclined, the vehiclebody platform can be appropriately leveled in time, so that the horizontality and the stability of the vehicle body platform are ensured, and vibration generated by overregulation is prevented; and various real-time regulation modes are provided, so that a driver can select the regulation modes as required according to actual road surface conditions. The system is simple, practical, safe and reliable, and has low cost and a wide application prospect.

Owner:HUBEI SANJIANG SPACE WANSHAN SPECIAL VEHICLE

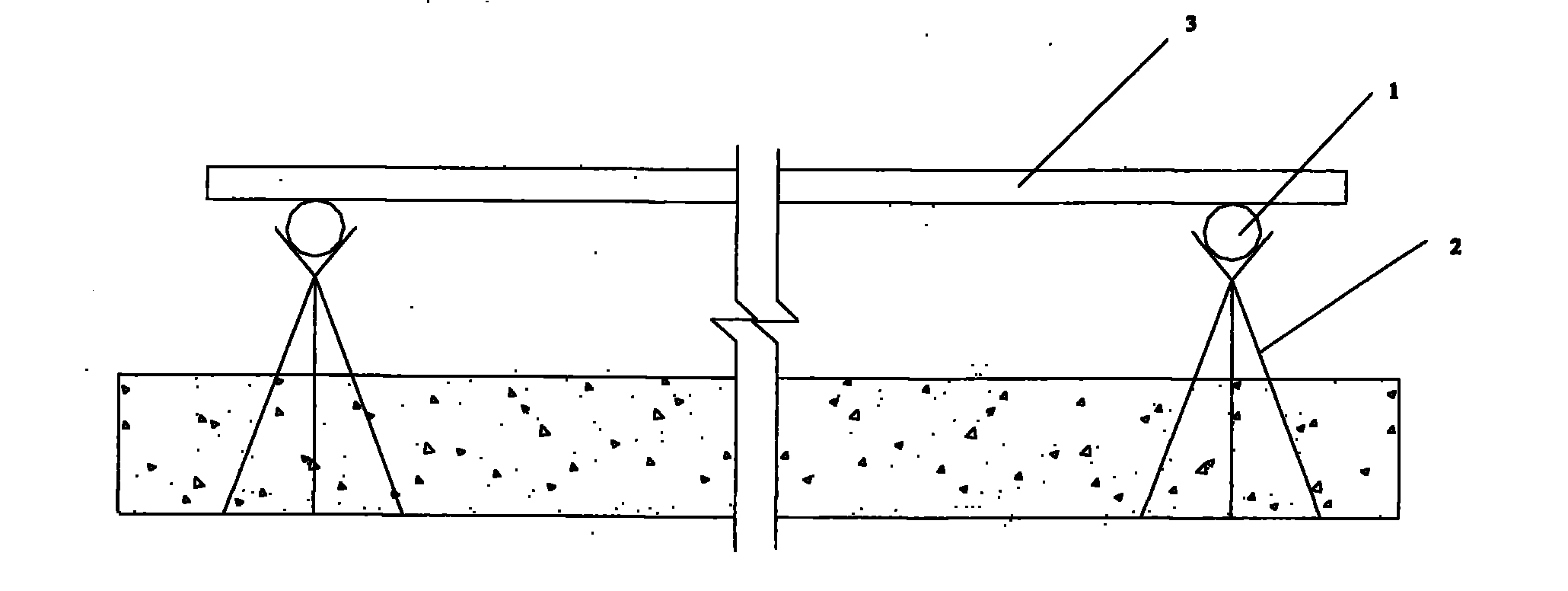

Mounting construction method of liner plates during mounting large-scale precision equipment

ActiveCN101831917AGuaranteed levelnessIncrease contactFoundation engineeringSpot weldingUltimate tensile strength

The invention provides a mounting construction method of liner plates during mounting large-scale precision equipment, which comprises the following steps of: (1) processing an equipment base; (2) setting temporary liner plates, arranging hoisting equipment, mounting the equipment base on the temporary liner plates, adjusting the coordinate position, the height and the levelness of the equipment; (3) mounting liner plates: necessarily arranging liner plates at both sides of an anchor bolt of the equipment, supporting the liner plates on the bolt which is directly supported on the equipment base, adjusting the liner plates to support the bolt so that the horizontal plate and the equipment base are stably and firmly attached and monitoring the central line, the elevation and the levelness of the equipment in a liner plate mounting process; (4) primarily grouting: making an anchor bolt die on the periphery of the anchor bolt of the equipment, grouting and fastening the anchor bolt of the equipment after grouting reaches the strength requirement; and (5) secondarily grouting: spot-welding the anchor bolt and a screw cap of the equipment when the strength of primarily grouted concrete reaches over 75 percent, dismounting the temporary liner plates, making an equipment base die below the equipment base and grouting integrally.

Owner:武汉武钢绿色城市技术发展有限公司

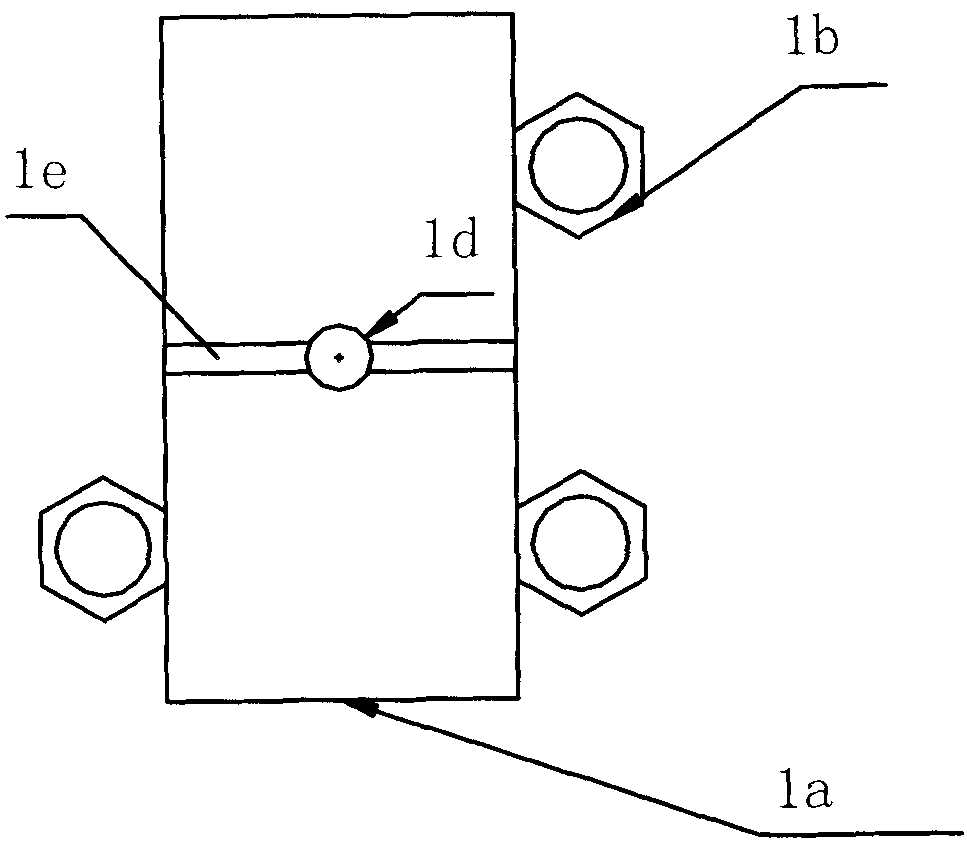

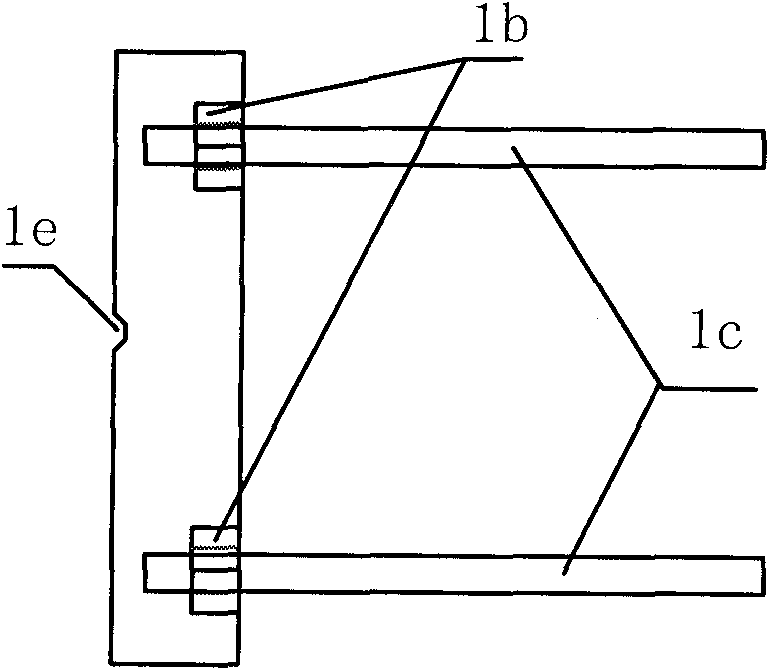

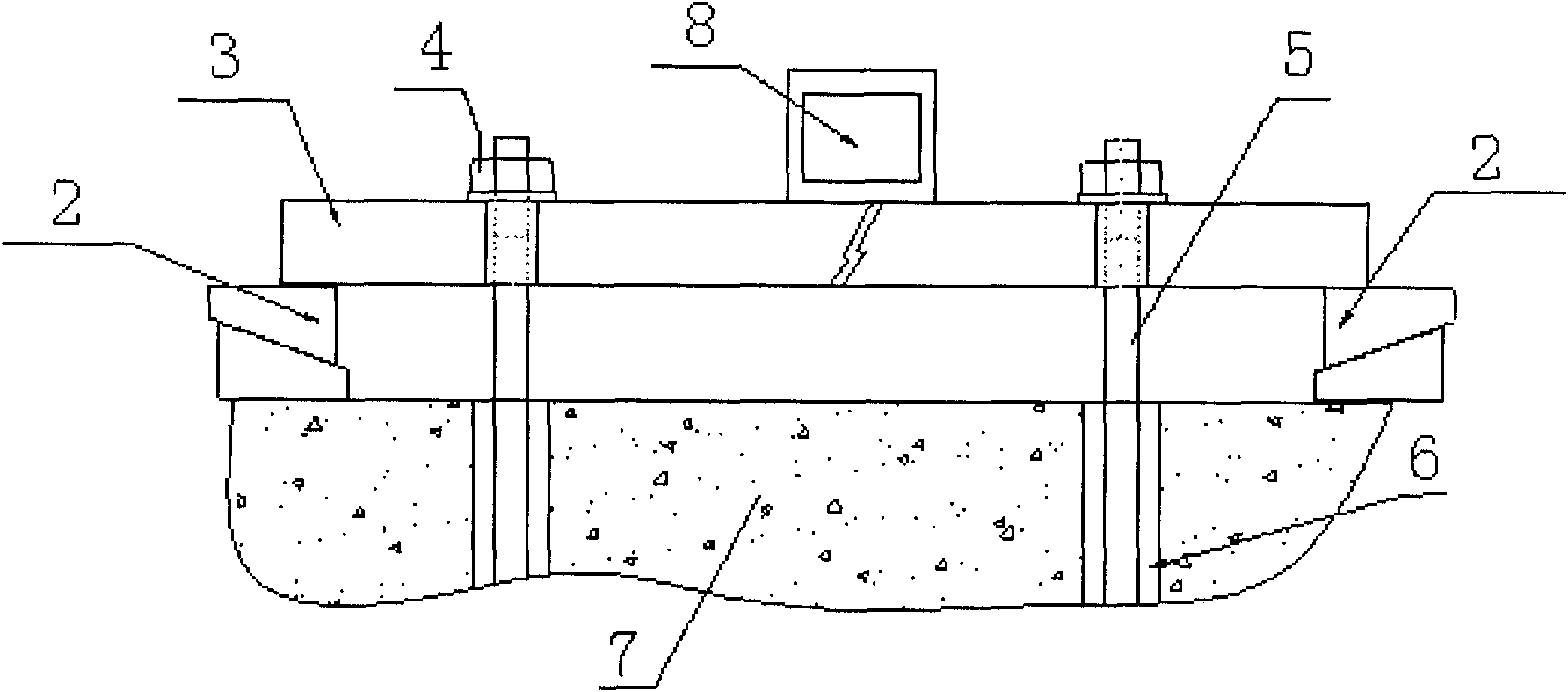

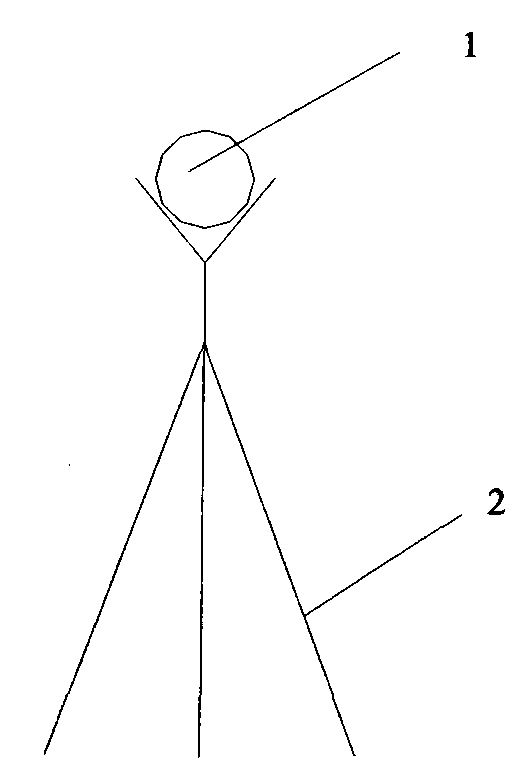

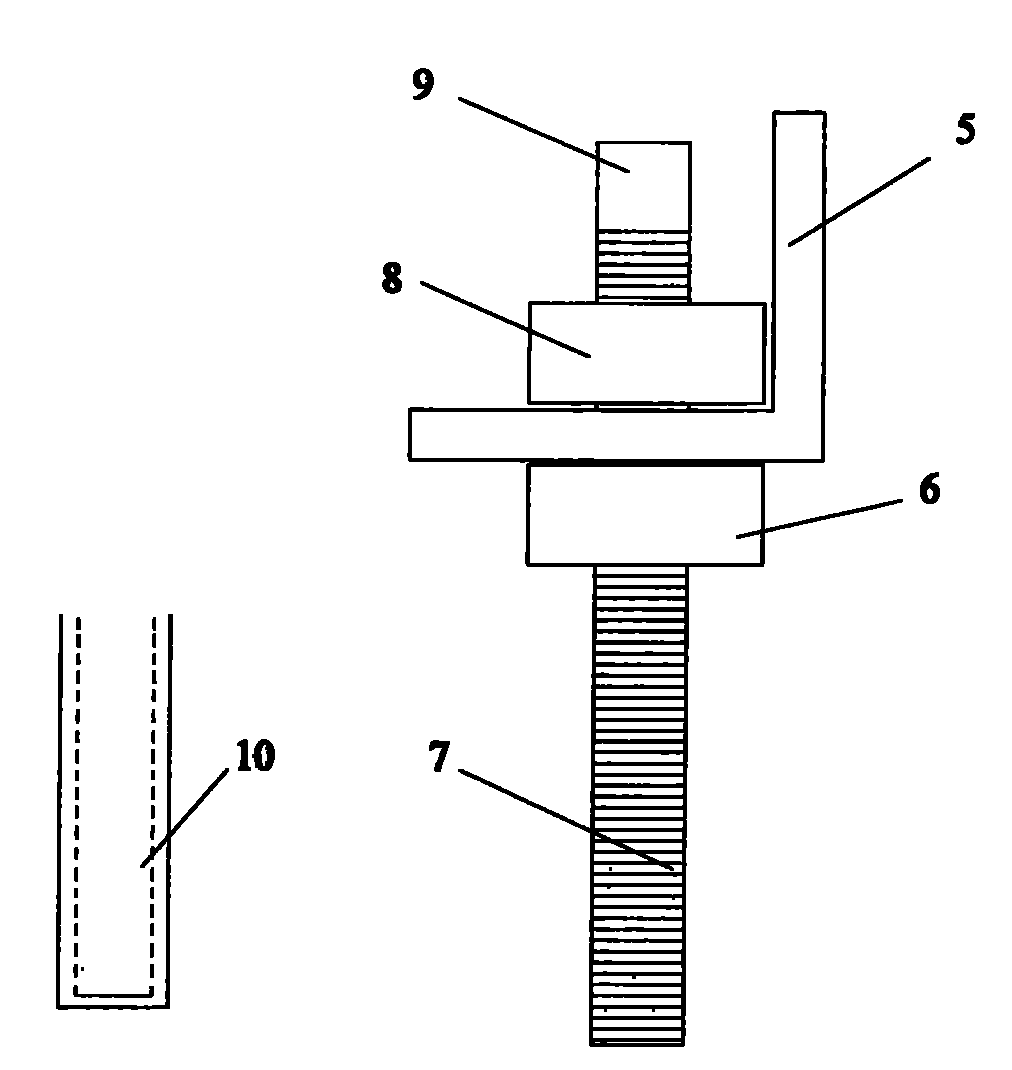

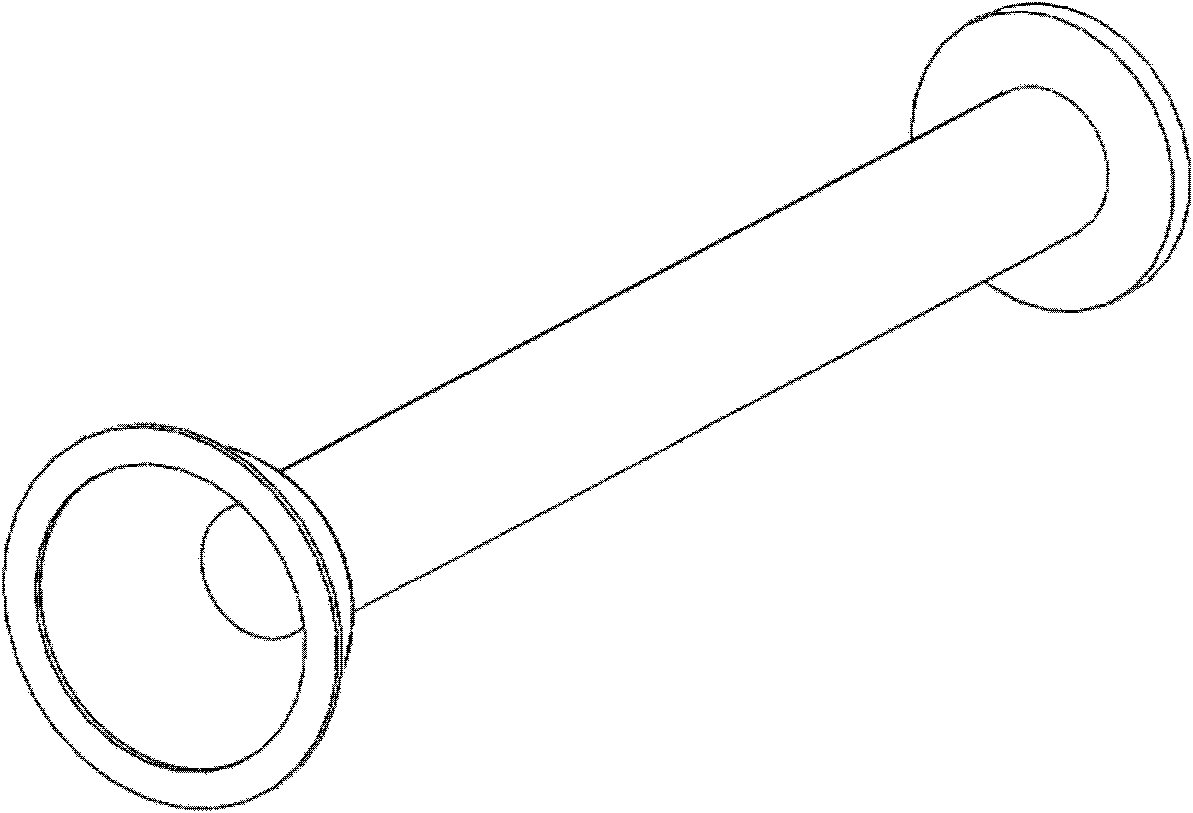

Adjustable leveling guide rail and leveling method thereof

InactiveCN101775905AHigh leveling accuracyReduce weightBuilding material handlingClean environmentEngineering

The invention provides an adjustable leveling guide rail. The adjustable leveling guide rail comprises a guide rail beam and a plurality of supporting pieces, wherein each supporting piece comprises a screw rod and a nut; the screw rod is connected with the guide rail beam through the nut; the end part of the screw rod is provided with a fixing block which is hexagonal, tetragonal or triangular; the fixing block is connected with the screw rod in an integral molding mode or the fixing block is detachably connected with the screw rod; and the supporting piece also comprises a positioning piece connected with the screw rod in a fitting mode. The invention also provides a leveling method for realizing the leveling guide rail, namely, the levelness of the leveling guide rail is adjusted by rotating a leveling nut and a positioning nut. In a construction process, instant leveling is realized by clamping the fixing block, fixing the screw rod and adjusting the levelness of the guide rail by screwing the positioning nut and the adjusting nut respectively. The adjustable leveling guide rail has high leveling accuracy, can realize instant leveling in the construction process and has the advantages of low cost, convenient detachment, easy construction, clean environment, green construction and the like.

Owner:HAOHE ENG & CONSTR

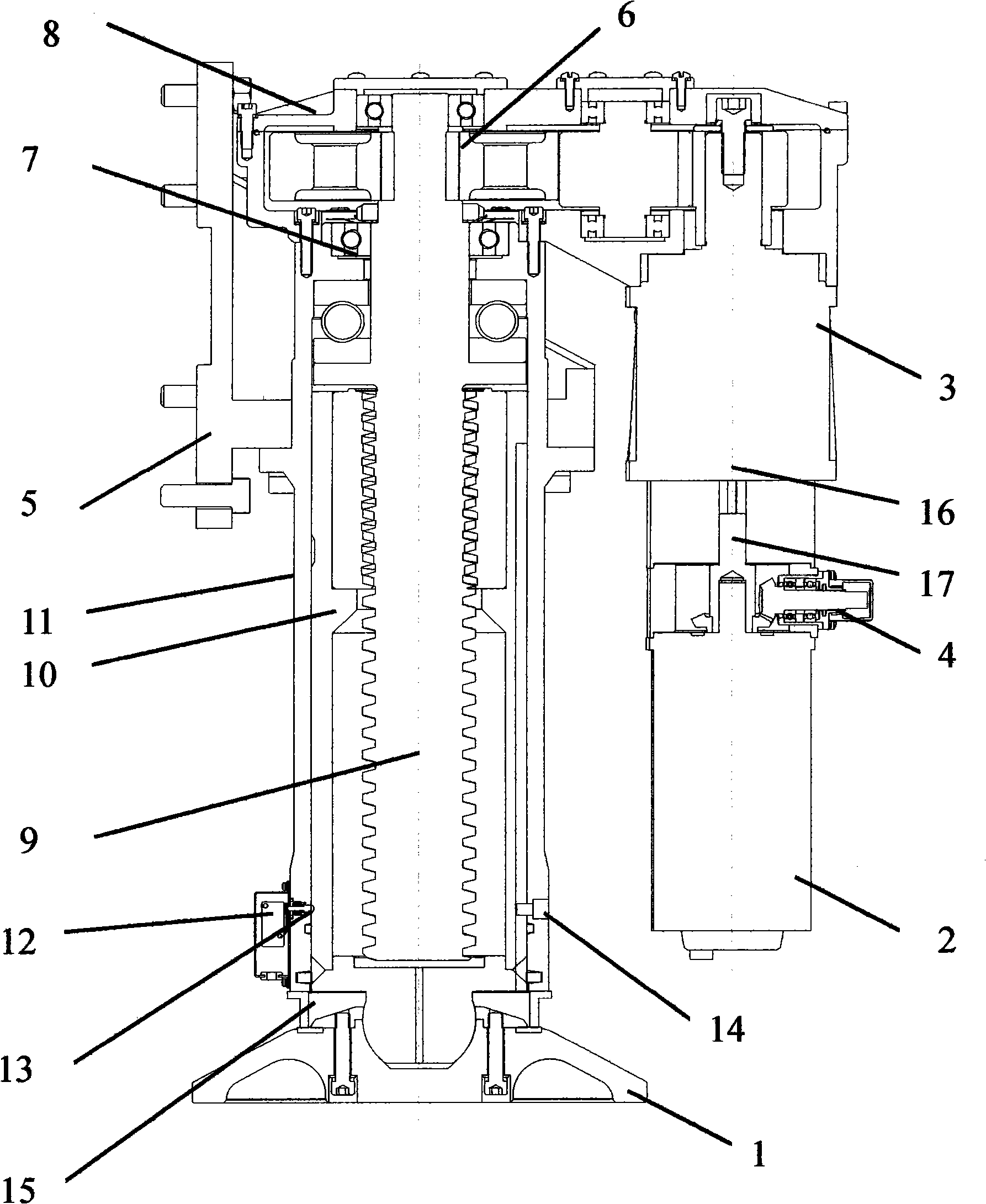

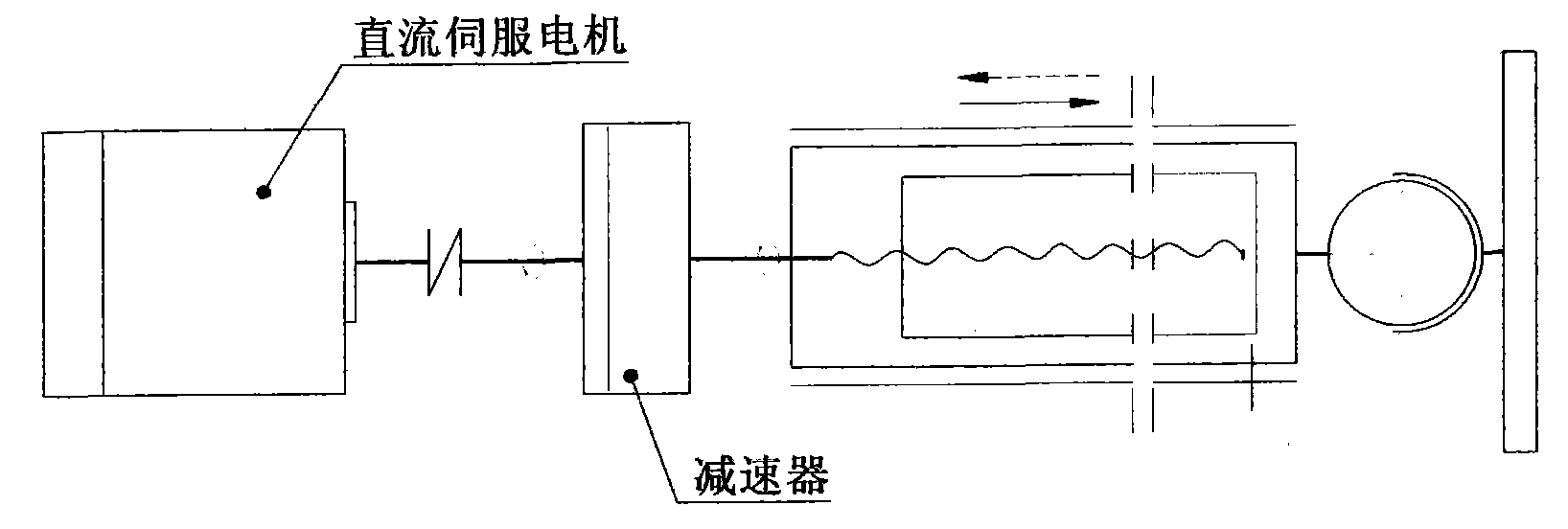

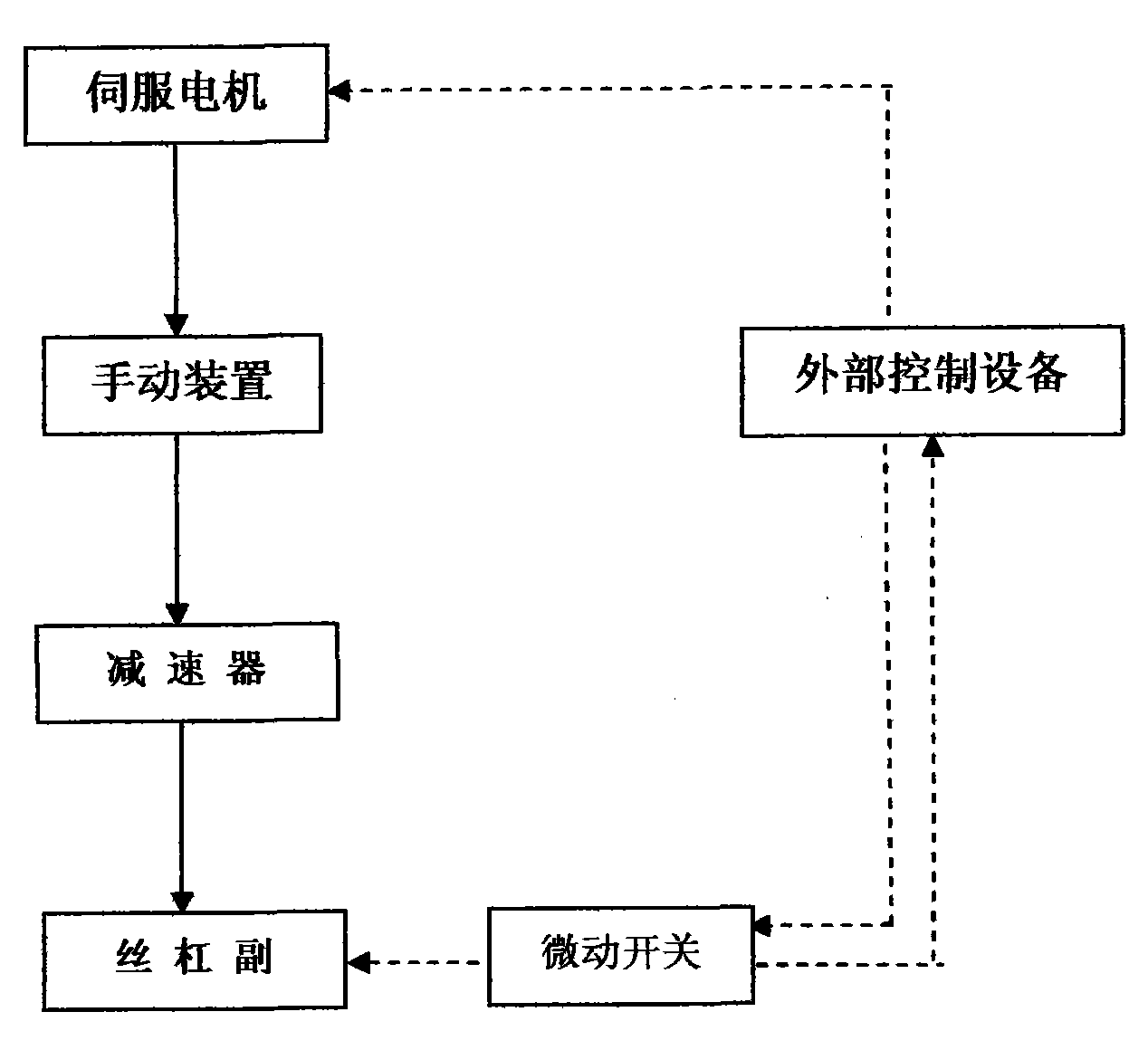

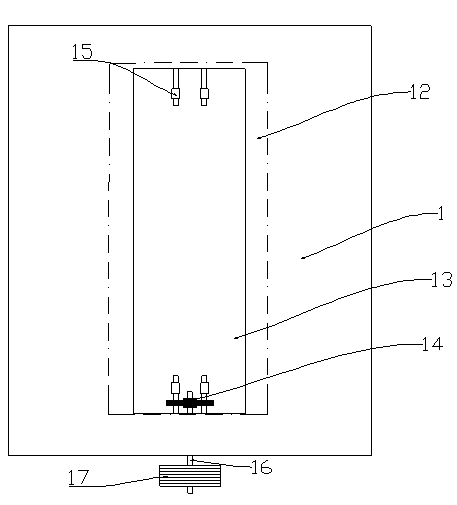

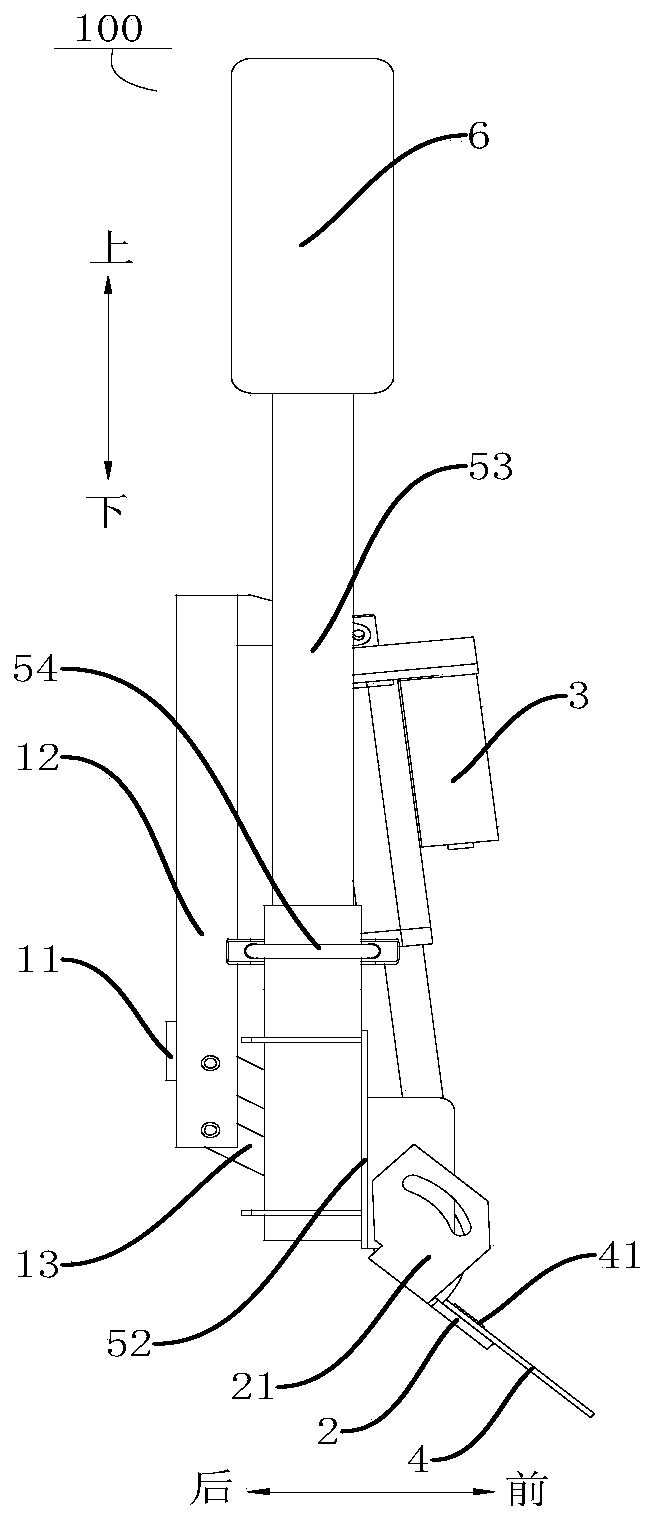

Electric automatic levelling brace

InactiveCN101561071ASmall footprintTouchdown fastStands/trestlesControl using feedbackReduction driveClosed loop

The invention relates to an electric automatic levelling brace for realizing multipoint electric automatic levelling, and aims to provide an electric automatic levelling brace with large lifting weight, rapid and reliable touchdown, good repeatability of levelling precision, high precision, safety, convenience, convenient maintenance and simple electric connection. The electric automatic levelling brace comprises a levelling bearing disc connected with a levelling brace cylinder body and a direct current servo motor with an electric control unit. The top of the levelling brace cylinder body is provided with a transmission chain which is connected with an output shaft of a speed reducer and a leading screw pair for rotary motion; the leading screw pair drives a levelling telescopic cylinder body manufactured with a screw and the levelling bearing disc fixedly connected with the leading screw pair together to do linear lifting motion; a microswitch for feeding back the lifting position to an external control system is arranged on the cylinder wall of the levelling brace cylinder body; a small displacement triggering shaft records the moving position, triggers the microswitch at a triggering point and transfers an electrical signal of the lifting position of the levelling brace to the outside; and the small displacement triggering shaft is connected external control equipment through the microswitch and forms a closed loop levelling system with the servo motor connected with the speed reducer .

Owner:LINGBAYI ELECTRONICS GRP

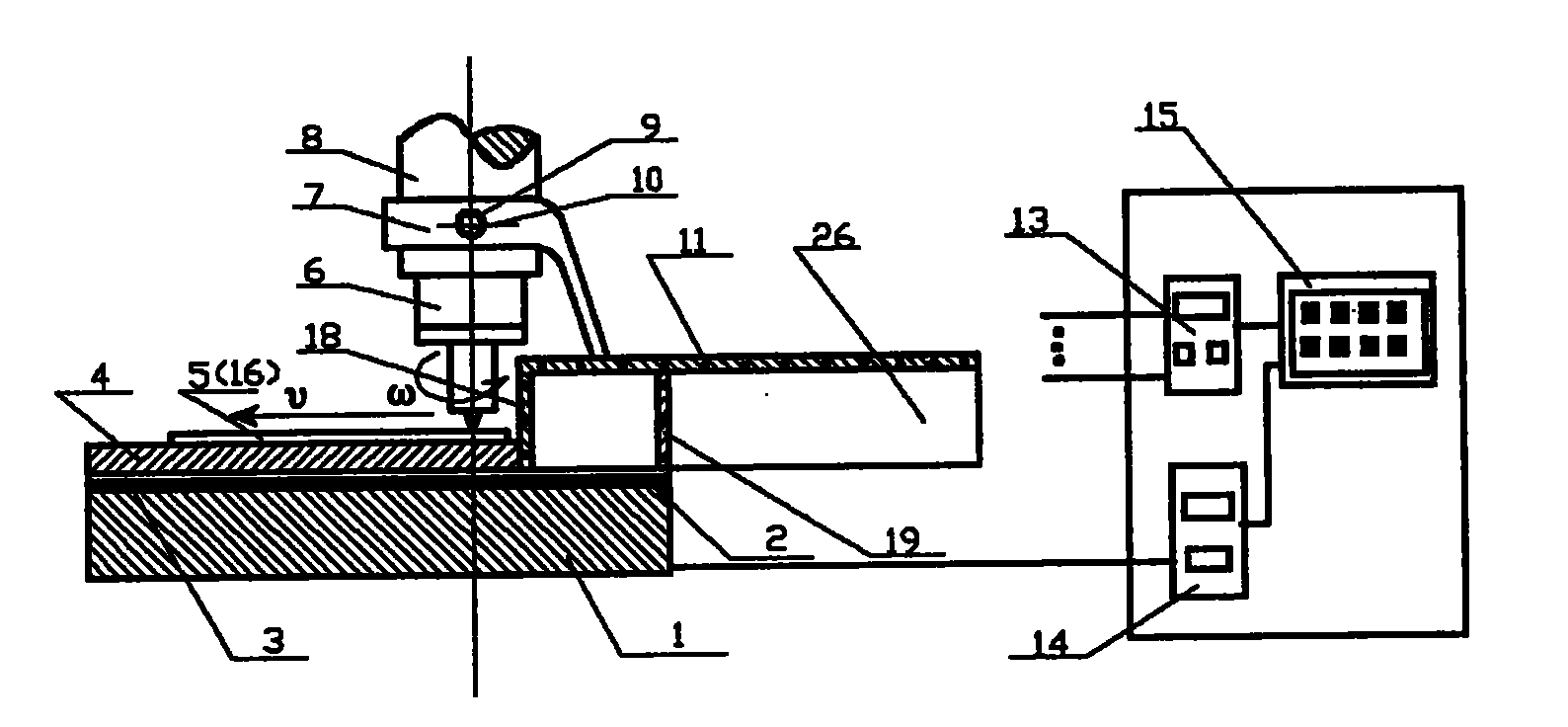

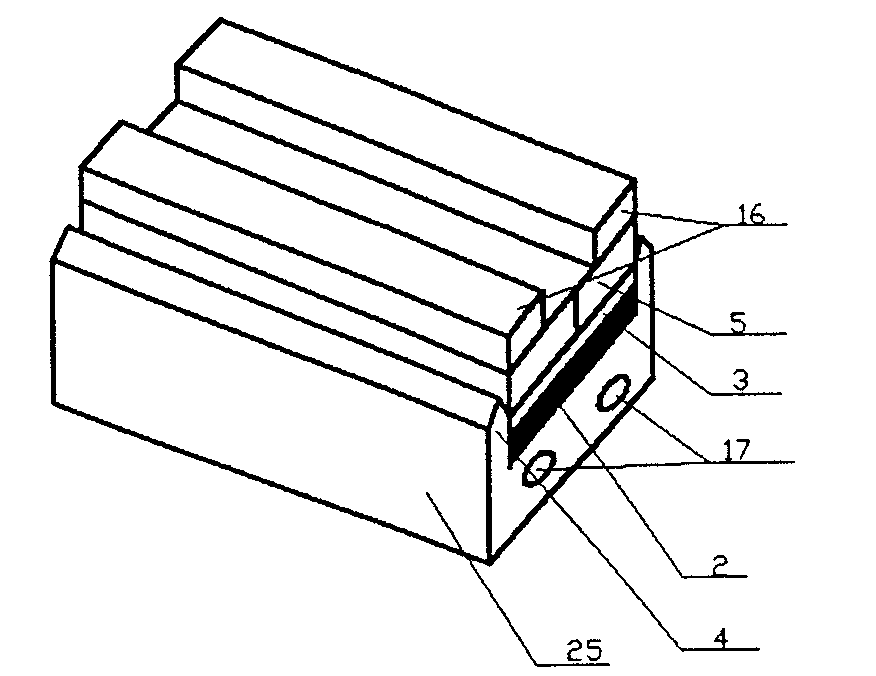

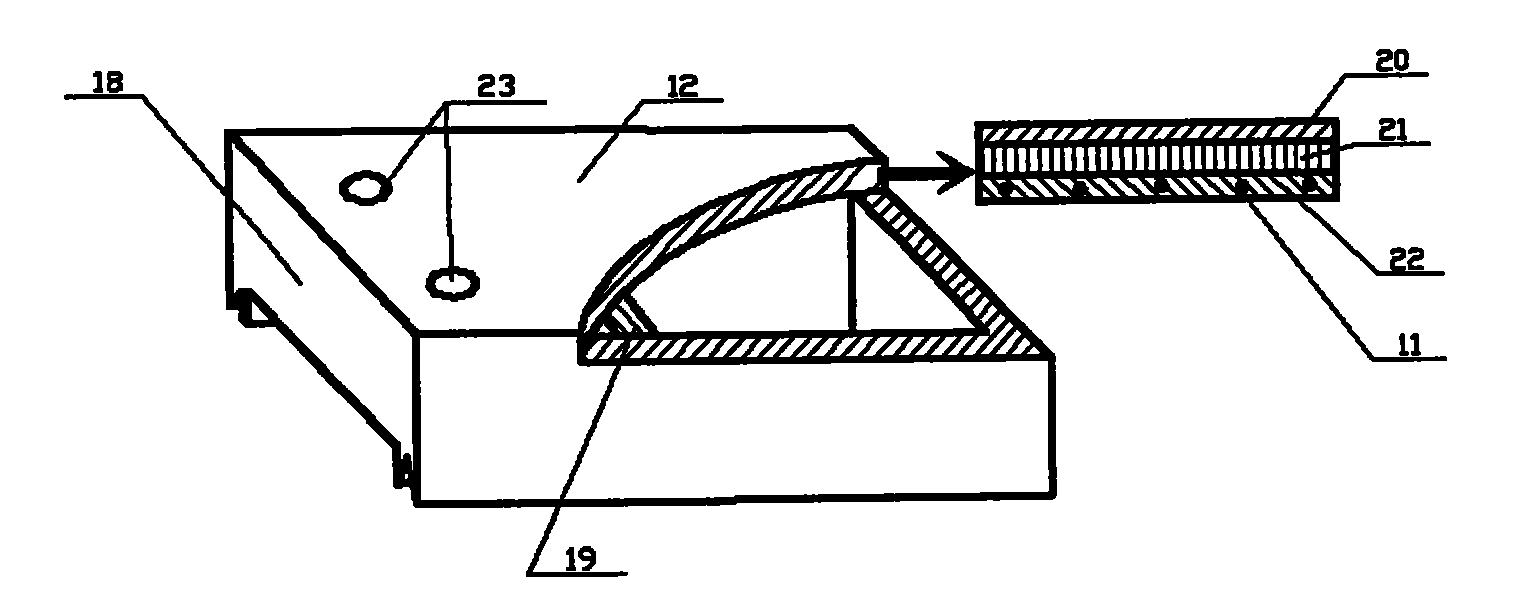

Method and device for controlling residual stress on stir friction welding surface

InactiveCN101774079AAvoid Welding Quality DeteriorationRealize full CNC controlNon-electric welding apparatusEngineeringControl equipment

The invention relates to a method and a device for controlling a residual stress on a stir friction welding surface. According to the method, an insulation box capable of moving along a stirring head is adopted to insulate the weld joint and parent metal after welding, and then furnace cooling is performed so as to reduce the residual stress on the stir friction welding surface. The device mainly comprises a sucking-disc type fixture, the insulation box and control equipment, wherein the insulation material mainly comprises fire bricks, asbestos and steel plates. During welding, the insulation box moves along the stirring head and insulates the welded workpiece continuously; and after the welding, the whole workpiece enters the insulation box to be insulated and is cooled with the furnace after being insulated for a certain time so as to control the residual stress on the welding surface and the deformation, wherein the insulating temperature is the critical temperature of the heat treatment of the materials. The device realizes full automation in the whole welding process and avoids the reduction in the welding quality due to a human factor. The method and the device have the advantages of simple device, convenient operation, high technical economic benefit, and high welding quality of the stir friction welding.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

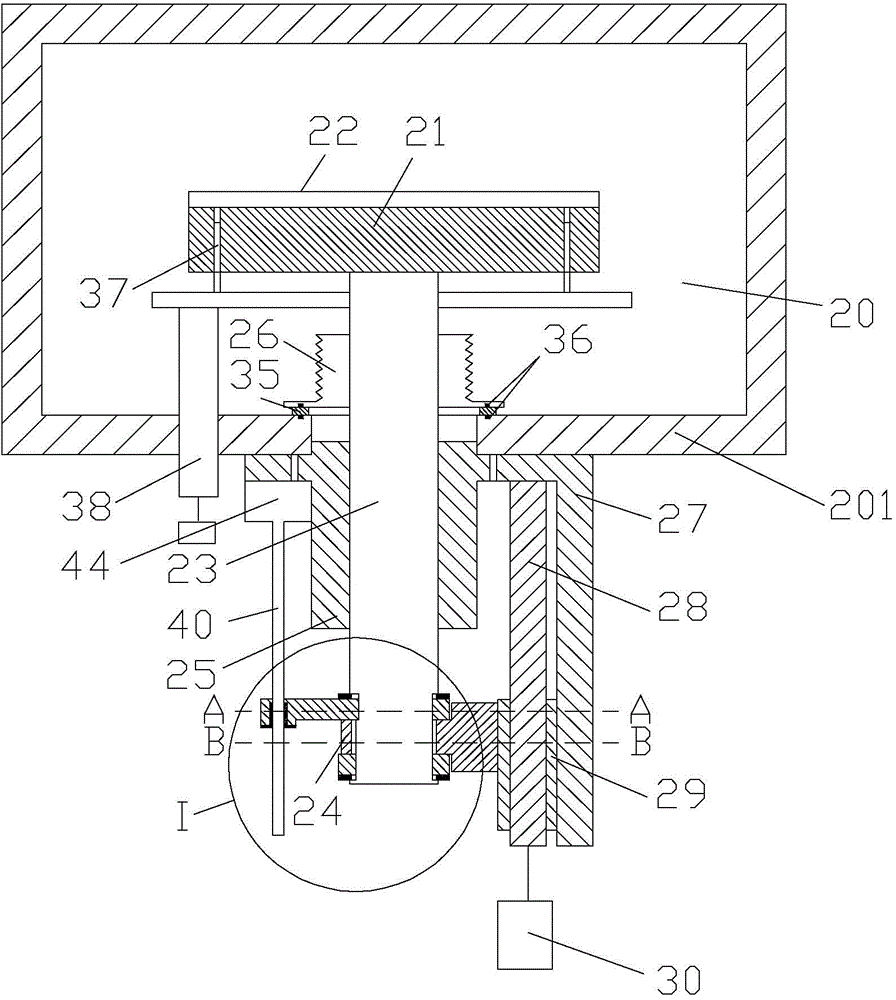

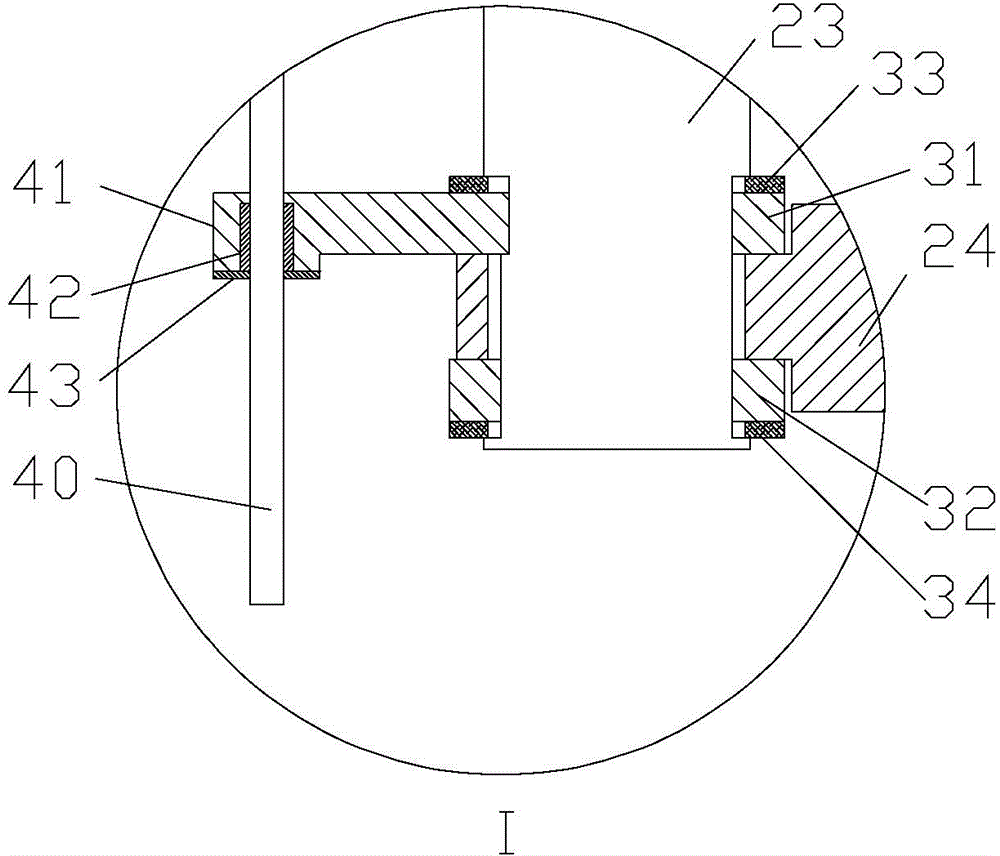

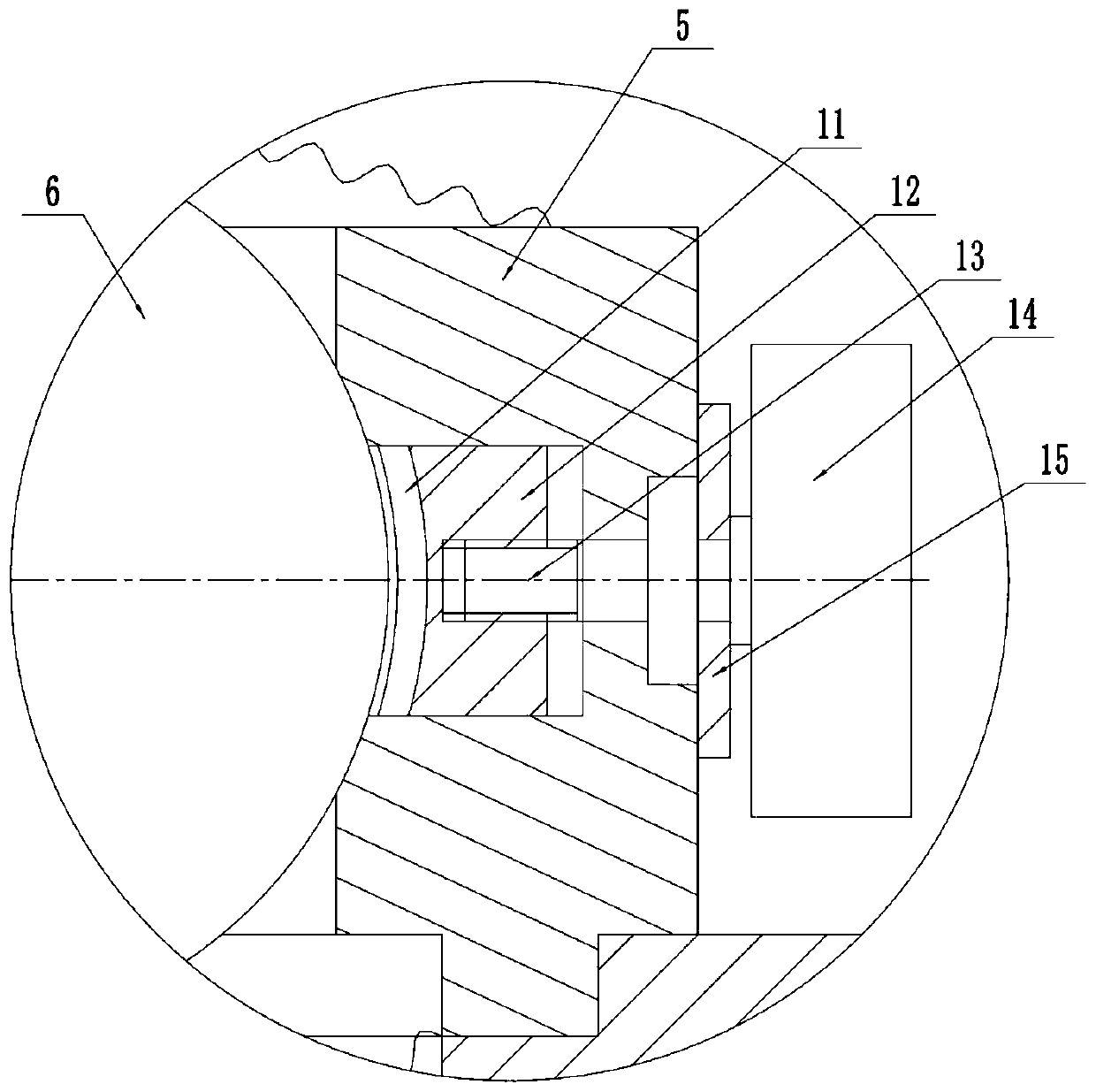

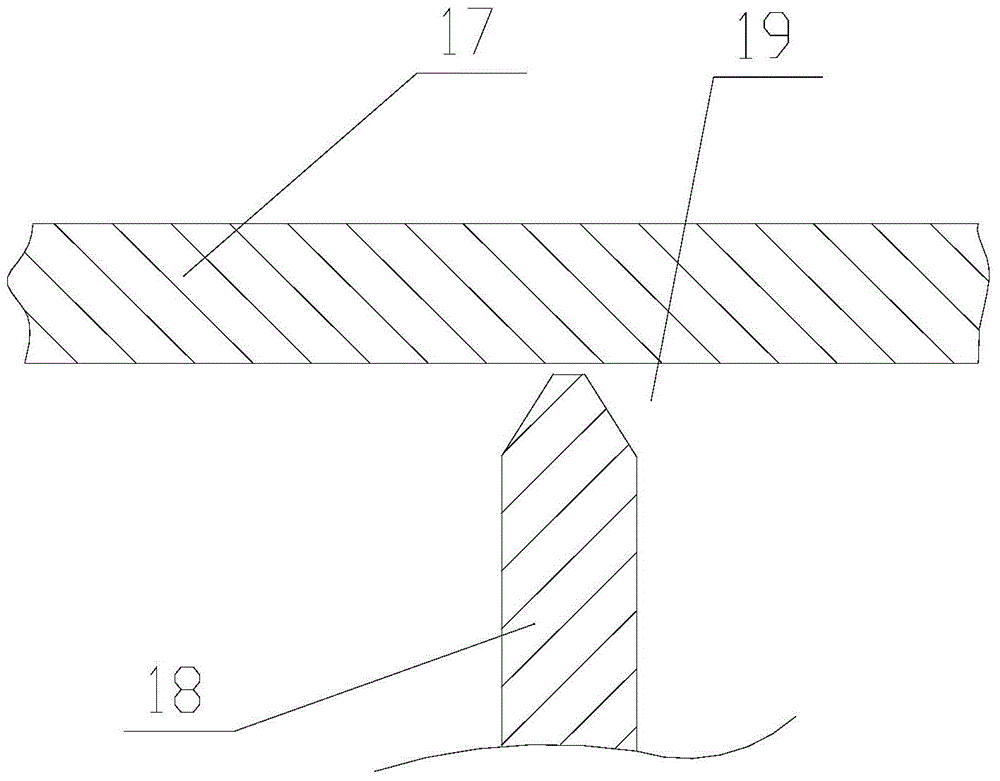

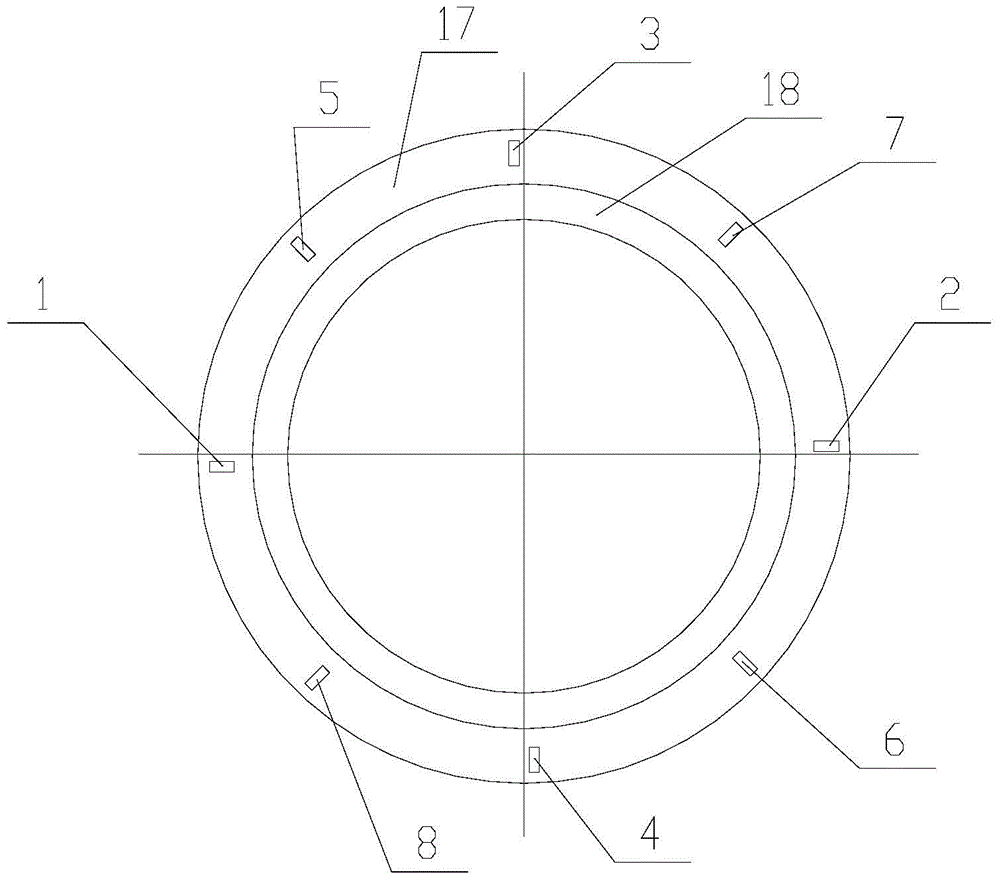

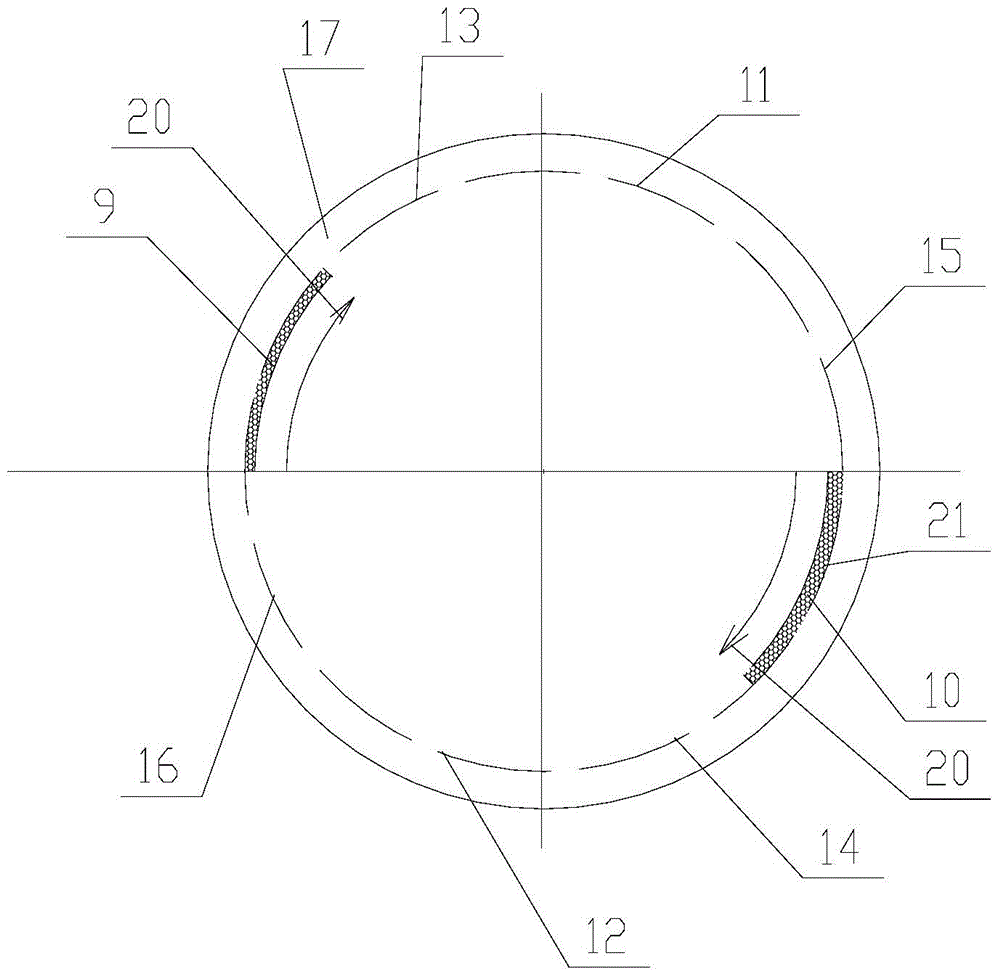

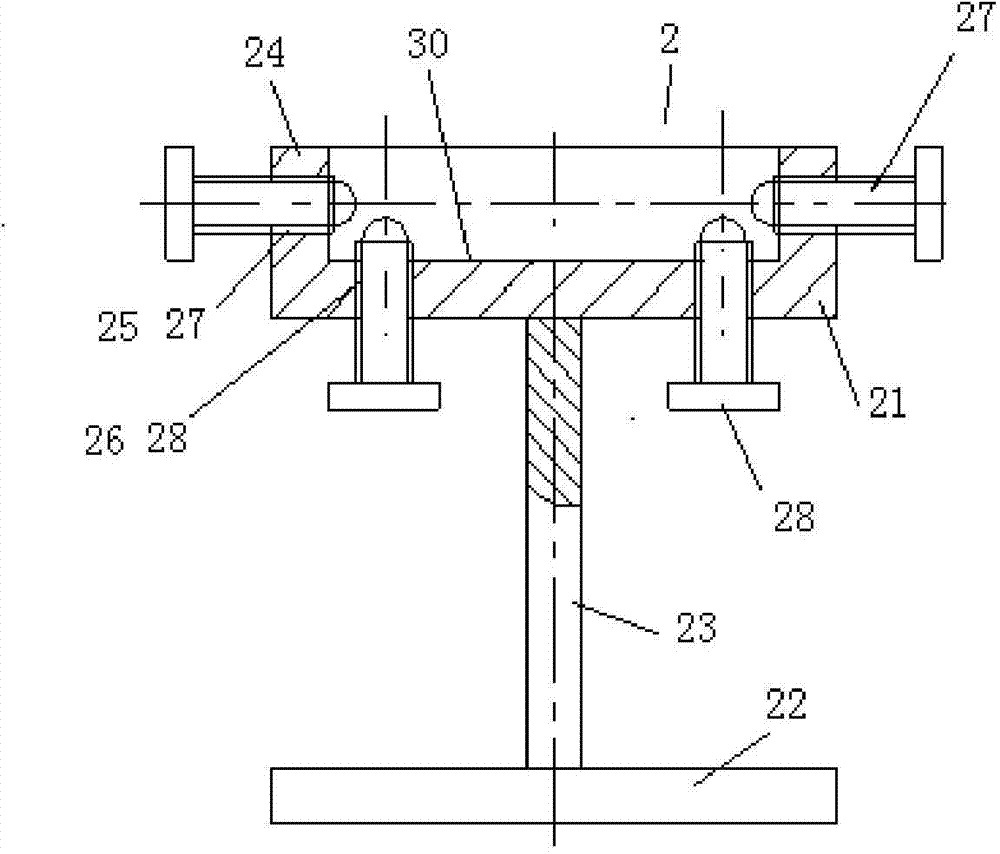

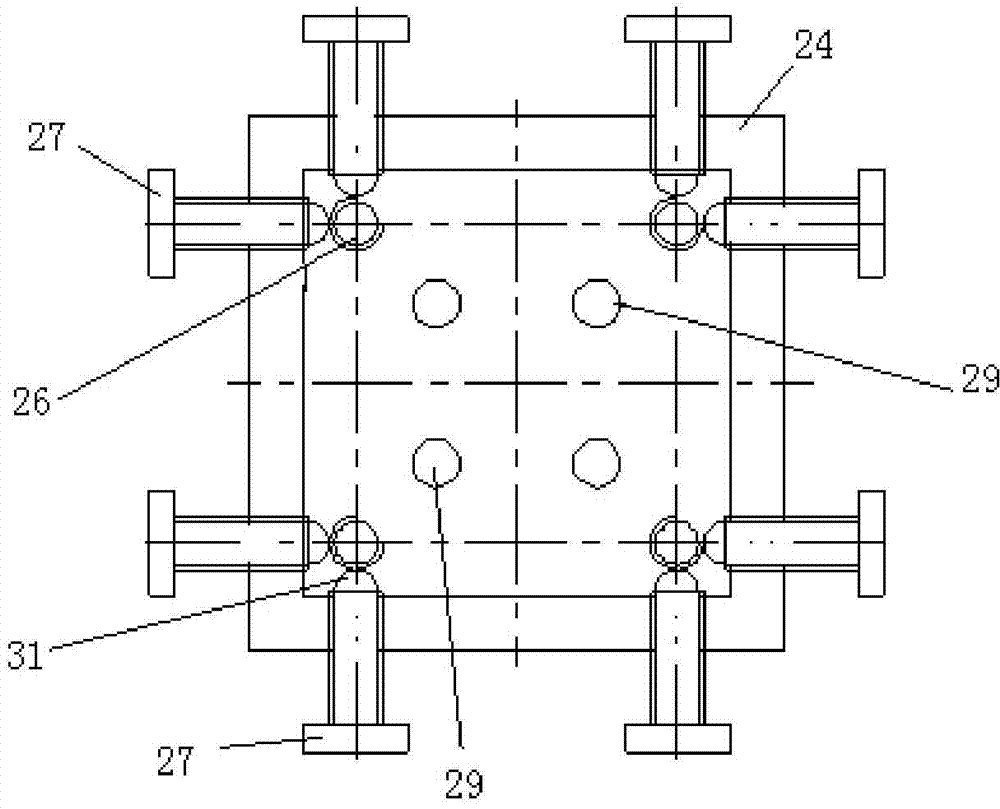

Carrying platform elevating gear, reaction cavity, and plasma processing device

ActiveCN104465447AGuaranteed levelnessEliminate redundant constraintsElectric discharge tubesVacuum evaporation coatingRotational degrees of freedomEngineering

The invention provides a carrying platform elevating gear, a reaction cavity, and a plasma processing device. A bracket driving source drives a shaft lifting bracket to do lifting motion. A bellows shaft passes through the shaft lifting bracket and is fixedly connected with the shaft lifting bracket, so as to do lifting motion with the shaft lifting bracket in a linear bearing, thereby realizing lifting motion of the carrying platform which is fixed on the bellows shaft. In the carrying platform elevating gear, a guiding mechanism is used to limit axial rotation of the bellows shaft in a lifting process. The bellows shaft passes through the linear bearing, a guiding shaft installing assembly, and a shaft lifting bracket in sequence. The guiding shaft installing assembly tightly holds the bellows shaft. The upper end of the guiding shaft is fixed on the cavity wall of the reaction cavity. The lower end of the guiding shaft passes through the guiding shaft installing assembly, so that the guiding shaft installing assembly does lifting motion with the shaft lifting bracket along the guiding shaft. The carrying platform elevating gear can limit rotation degree of freedom of a connecting rod, so as to ensure a carrying device from deflecting.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

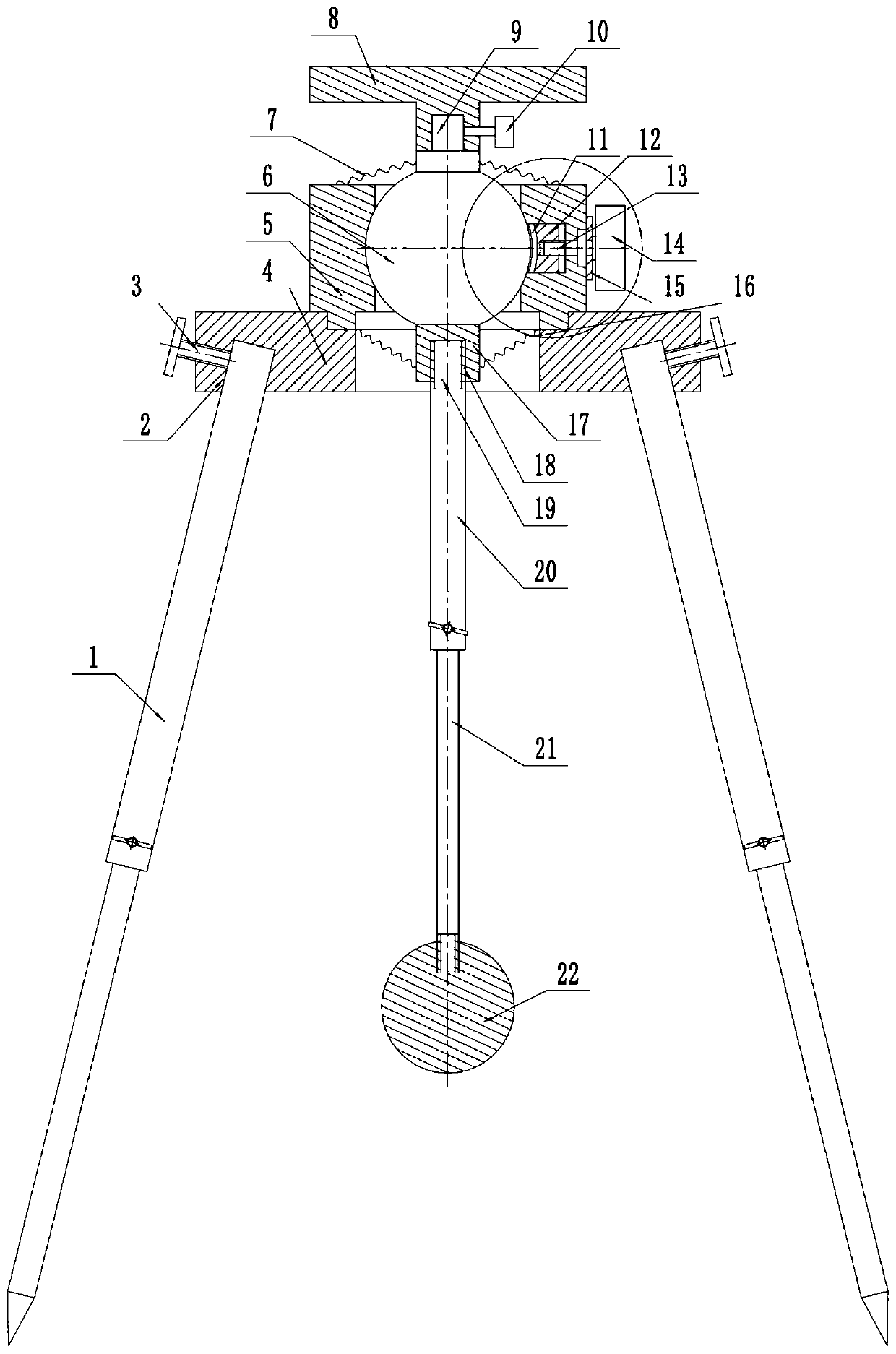

Computer surveying instrument for geological engineering construction

InactiveCN109855610AImprove stabilityImprove reliabilitySurveying instrumentsStands/trestlesSurvey instrumentEngineering

The invention discloses a computer surveying instrument for geological engineering construction. The computer surveying instrument comprises telescopic supporting feet, inserting holes, a locking screw I, a connecting seat, a fixing seat, a ball body, an upper dustproof layer, a mounting seat, an upper connecting head, a locking screw II, a pressing pad, a sliding block, a screw rod, a knob, an end cover, a lower dustproof layer, a lower connecting head, a threaded hole, external threads, a fixing sleeve, a connecting rod and a counterweight ball. The computer surveying instrument is reasonable and simple in structure, low in production cost, convenient to install and complete in function, wherein cone bodies are arranged at the bottoms of the telescopic supporting feet, and the stabilityand reliability of the support of the telescopic supporting feet are improved; according to the computer surveying instrument, the mounting seat on the upper side of the ball body is automatically adjusted to be in a horizontal state through the action of gravity; when the counterweight ball is in a static state, the knob is tightened to drive the sliding block to drive the pressing pad to press the ball body so that the ball body cannot rotate; and then an surveying instrument body can be directly mounted on the mounting seat, so that the mounting precision and efficiency are improved.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

Welding method for furnace top flange of blast furnace

ActiveCN104439740AGuaranteed levelnessReduce welding distortionArc welding apparatusShielded metal arc weldingMarking out

The invention discloses a welding method for a furnace top flange of a blast furnace. The method mainly comprises the following steps that checking and accepting; measuring and paying off; groove preparation; hoisting in position; leveling and centering; scale division and marking out, wherein even scale division and marking out are carried out on the furnace top flange through two or more diameter lines, pitch circles of rib plates arranged on the furnace top flange are equally divided into a plurality of small circular arcs, pitch circles, crossing with a furnace top steel ring, of the furnace top flange are equally divided into a plurality of small circular arcs, and pitch circle face, crossing with the furnace top steel ring, of the furnace top flange are equally divided into a plurality of congruent small sectors; rib plate welding, wherein the two sides of the rib plates are fixedly connected from the inner ends to the other ends through a symmetric welding method, and the welding speed is the same; flange welding, wherein backing weld and layered continuous bead welding are included; according to backing weld, the symmetric welding method is adopted, in the manual electric-arc welding manner, same-direction symmetric welding begins to be carried out on two sides of grooves in the centered and segmented symmetric segments at the same time, and according to the layered continuous bead welding, the number of welding layers is determined according to the thickness of the furnace top steel ring and the thickness of the furnace top flange, and the symmetric welding method is adopted, and same-direction continuous bead welding begins to be carried out on the two sides of the grooves in the centered and segmented symmetric segments at the same time.

Owner:CHINA 19TH METALLURGICAL CORP

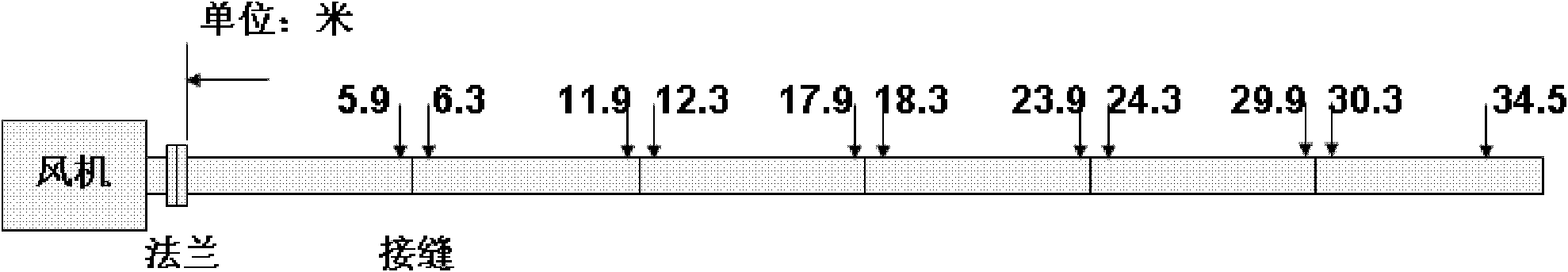

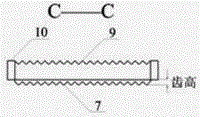

A method and device for testing the frictional resistance coefficient of the inner wall of a pipeline

InactiveCN102269690ATest the coefficient of frictional resistanceGuaranteed turbulence intensityMachine part testingUsing mechanical meansEngineeringDrag coefficient

The invention discloses a device for testing a frictional drag coefficient of an inner wall of a pipeline. The device consists of a high speed fan, a frequency converter, a turbulence smoothening section, a pipeline bracket, the pipeline, a multitube pressure gauge, a Pitot tube and a slanting leg manometer, wherein the frequency converter is connected with the high speed fan; the front end of the turbulence smoothening section is connected with the outlet of the high speed fan, and the rear end is connected with the pipeline; the pipeline is arranged on the pipeline bracket with an adjustable mechanism; pressure testing holes are processed at different positions of the pipeline and are connected with the multitube pressure gauge through tee joints and hoses; and at the tail end of the pipeline, the wind speed in the pipeline is tested by the Pitot tube, and the Pitot tube is connected with the slanting leg manometer. A method for testing the frictional drag coefficient of the inner wall of the pipeline comprises the following six steps of: 1, selecting a testing scheme; 2, selecting a testing means; 3, distributing the pressure testing holes; 4, analyzing the experimental accuracy; 5, designing and manufacturing the pipeline bracket; and 6, assembling the testing device, wiring and debugging. The invention has application value in the technical field of pipeline pressure and friction drag testing.

Owner:BEIHANG UNIV

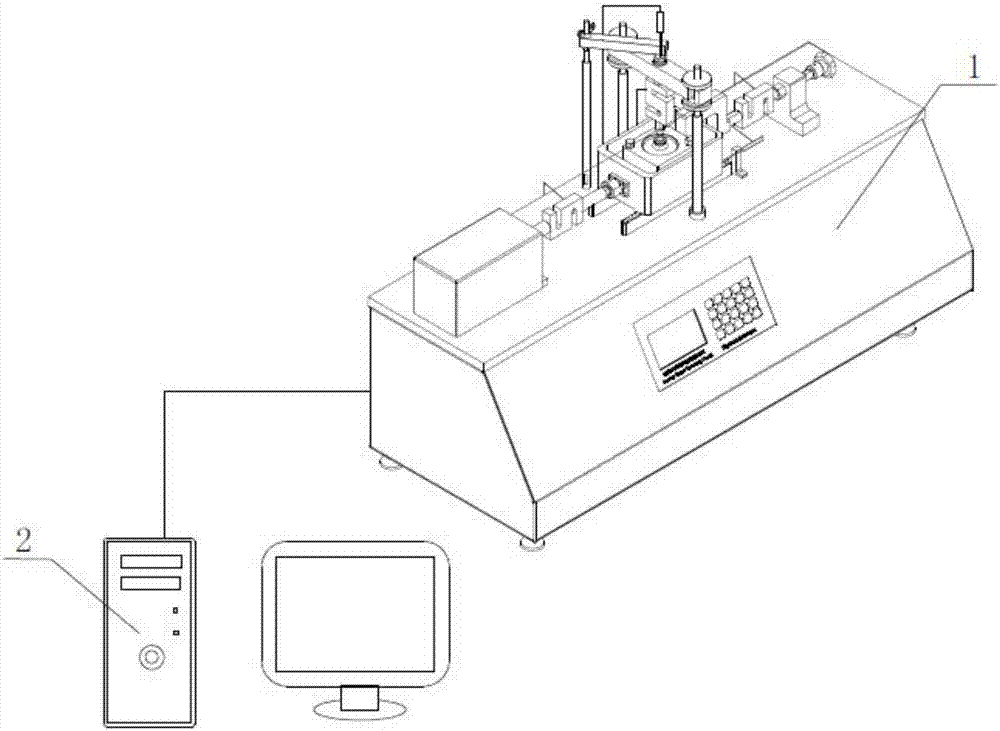

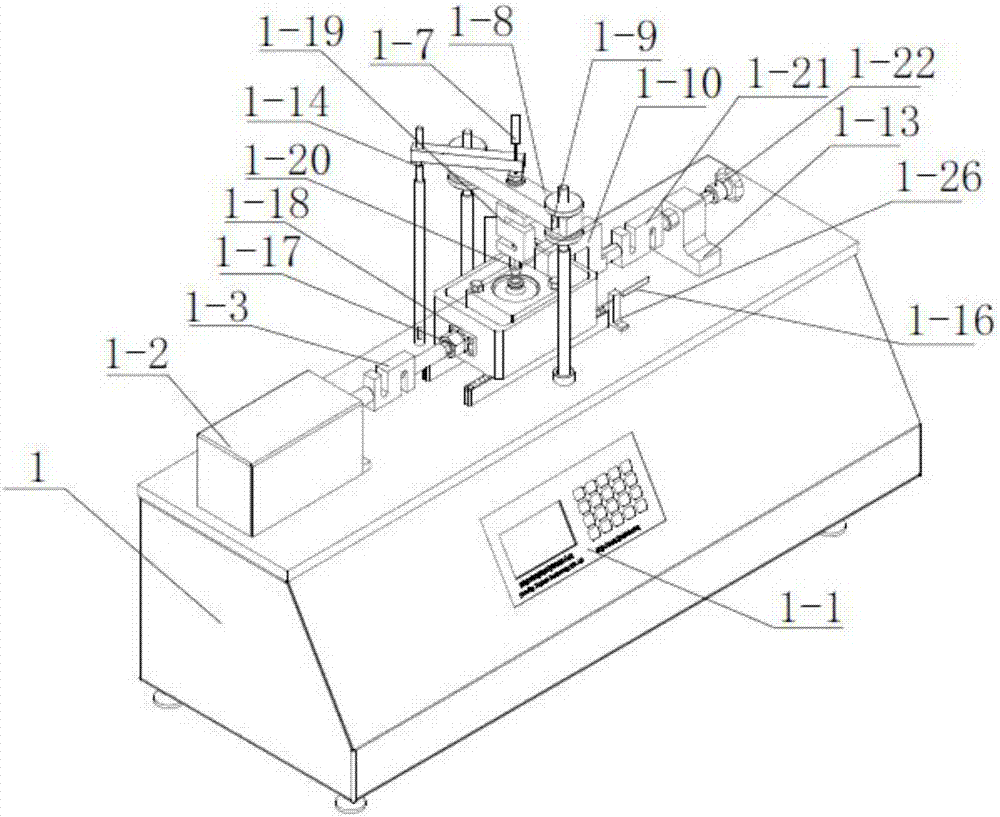

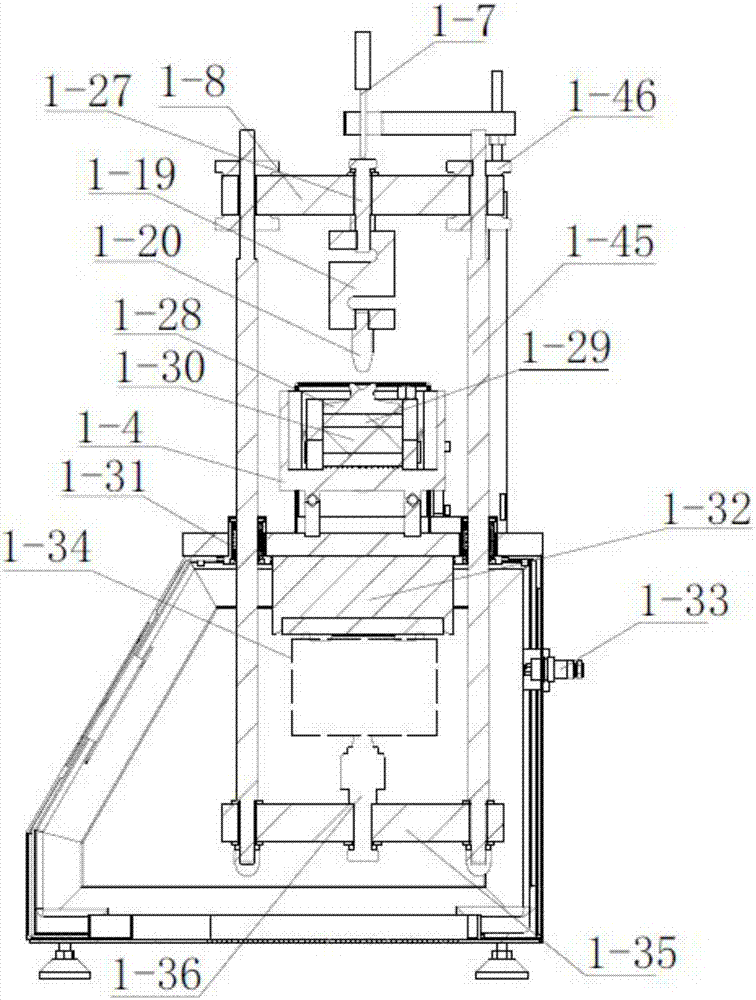

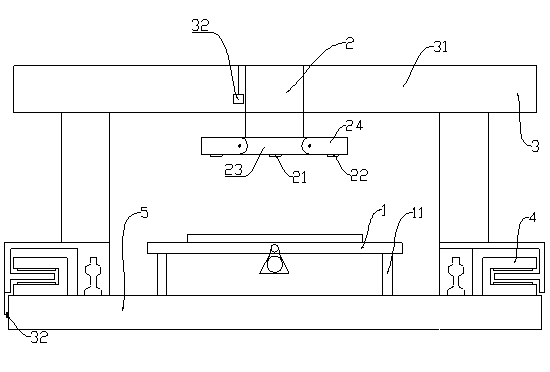

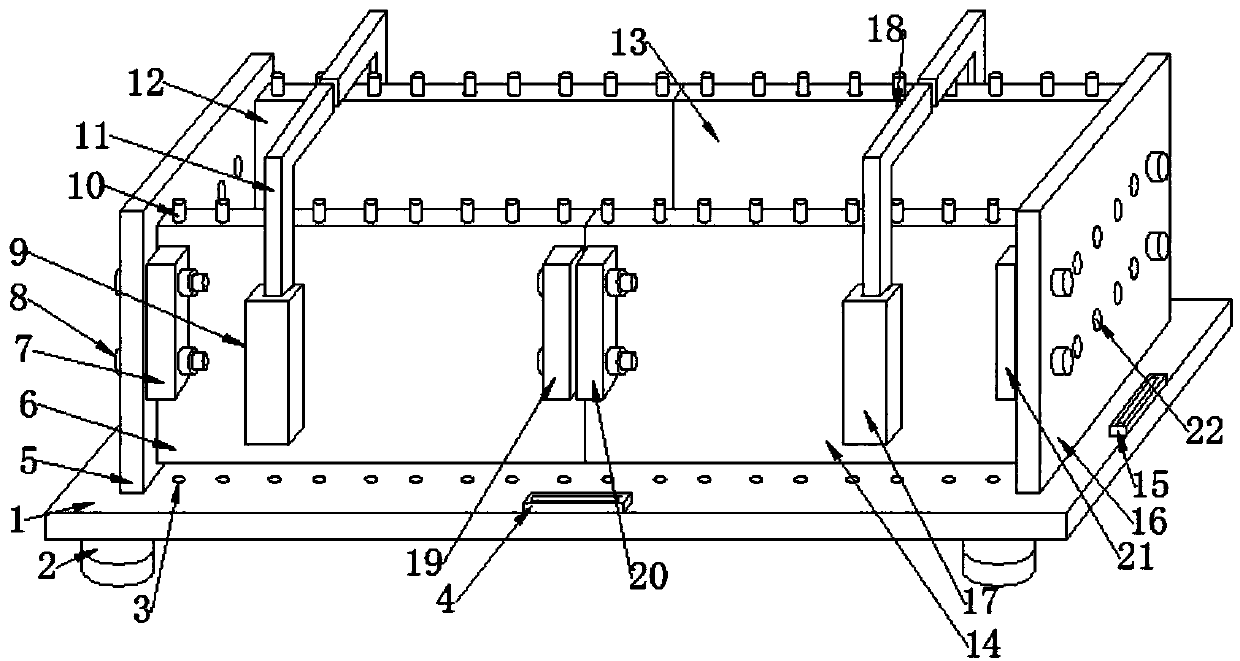

Automatic rheological direct-shear apparatus and experimental operation method thereof

PendingCN106940274AHigh control precisionVersatileMaterial strength using steady shearing forcesMechanical pressure/force controlDirect shear testRelaxation test

The invention discloses an automatic rheological direct-shear apparatus and an operation method thereof. The automatic rheological direct-shear apparatus comprises a rheological direct-shear instrument (1) and a computer (2). The rheological direct-shear instrument (1) is under servo closed-loop control, a vertical load sensor (1-19) in a vertical servo loading system is employed for adjusting and controlling axial stress applied on a sample (1-30), and meanwhile, a first horizontal load sensor (1-3) arranged in a horizontal shear driving system and connected with a horizontal shear driving device is used for applying a constant a horizontal shear force on the sample (1-30), so direct-shear creep test of soil is realized; and at the same time, a horizontal displacement sensor (1-16) is employed for accurate control of the horizontal shear amount of the sample (1-30), so direct-shear strain relaxation test of soil is realized. The automatic rheological direct-shear apparatus provided by the invention can carry out both conventional direct-shear test and rheological direct-shear test on soil, has high stability and can realize accurate control of testing and whole-process automation of acquisition.

Owner:南京泰克奥科技有限公司

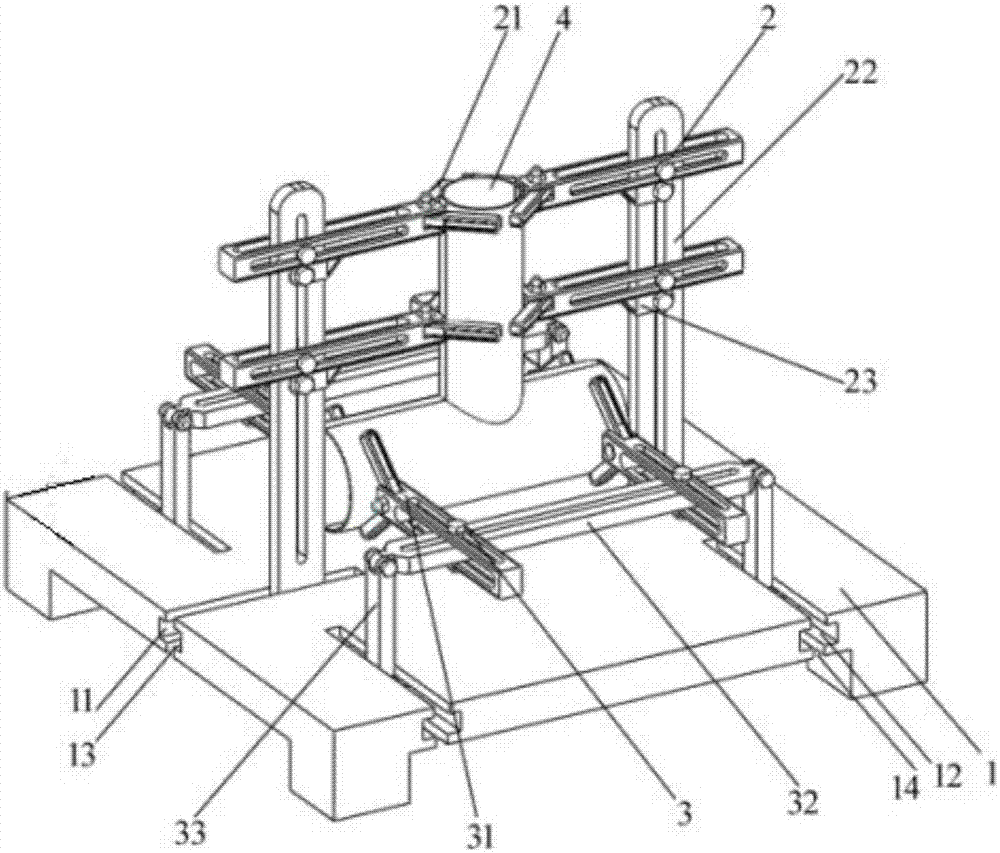

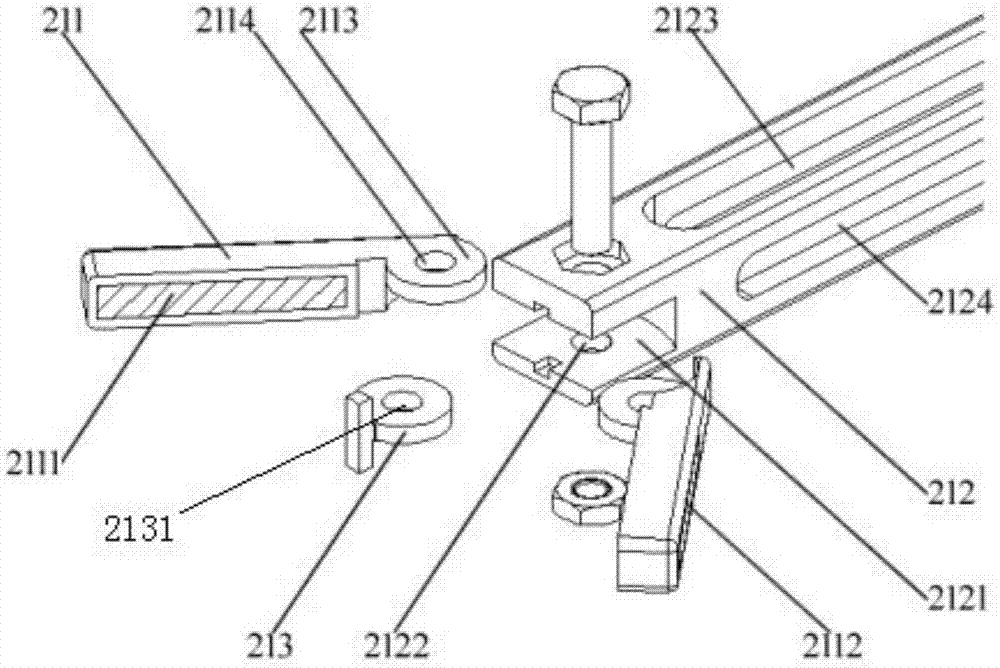

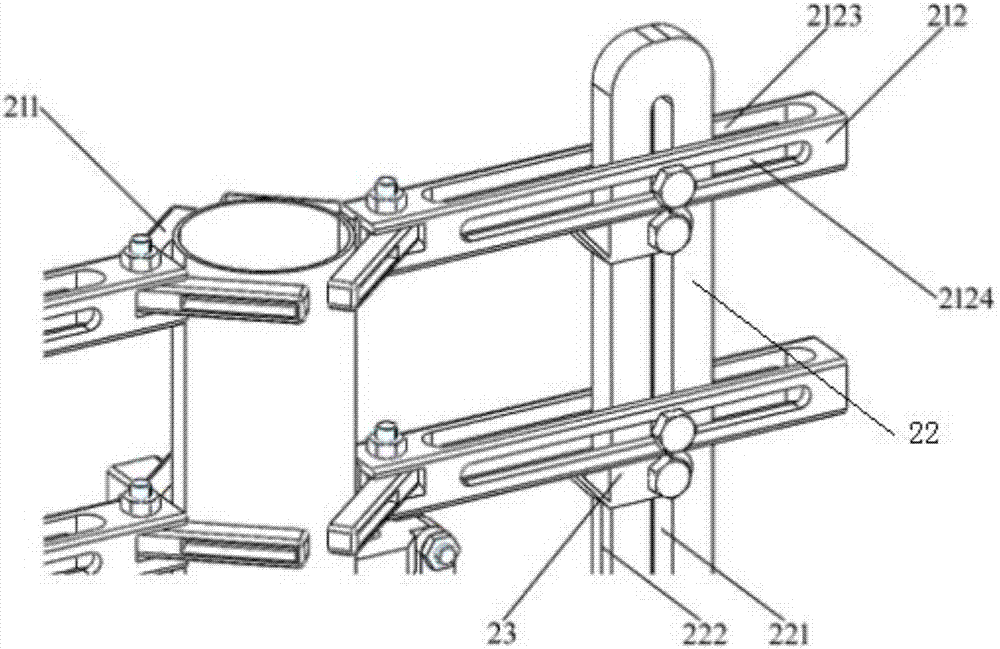

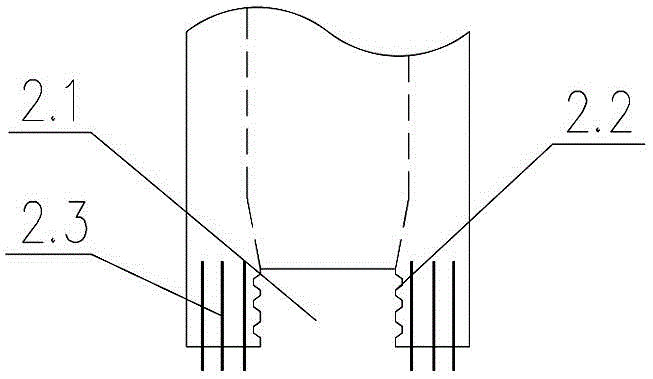

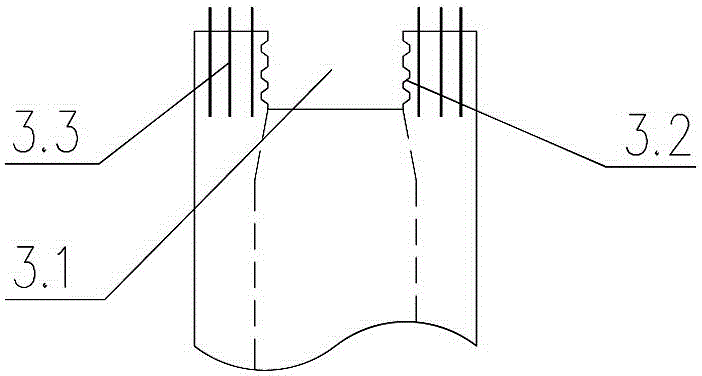

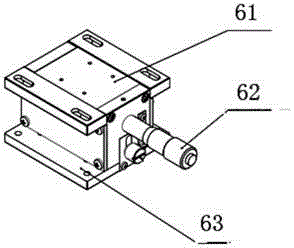

Thin-wall three-way pipe clamping device

PendingCN108000047AImprove stabilityAvoid pinchingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThin walled

The invention discloses a thin-wall three-way pipe clamping device. The thin-wall three-way pipe clamping device comprises a base plate. A thin-wall three-way pipe vertical segment clamping module anda thin-wall three-way pipe horizontal segment clamping module are mounted on the base plate. The thin-wall three-way pipe vertical segment clamping module comprises vertical sliding rods which are movably mounted on the base plate. Vertical segment V-shaped clamping mechanisms are movably mounted on the vertical sliding rods. A trapezoids support frame for locating is mounted between each vertical sliding rod and each vertical segment V-shaped clamping mechanism. The thin-wall three-way pipe horizontal segment clamping module comprises a horizontal sliding rod support frame which is movably mounted on the base plate. A horizontal sliding rod is mounted on the horizontal sliding rod support frame. Horizontal segment V-shaped clamping mechanisms are movably mounted on the horizontal slidingrod. The thin-wall three-way pipe clamping device has universality and is precise in locating and capable of improving welding precision and operation efficiency.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

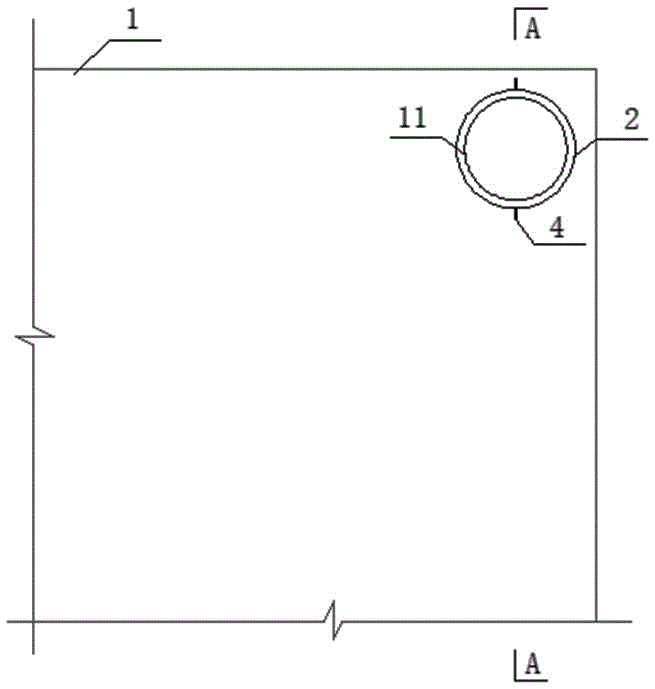

Accurately embedded water supply or water drainage casing pipe based on BIM and aluminum alloy formwork and construction method

ActiveCN106481880AGuarantee the verticality of the installationGuaranteed one-time successful installationPipe laying and repairPipesStructure of the EarthProduction drawing

Provided is a construction method for accurately embedding a water supply or water drainage casing pipe based on BIM and an aluminum alloy formwork. The construction method comprises the operation steps that 1, a model is built through the BIM technology, position collision checking of the water supply or water drainage casing pipe is conducted, and a water supply or water drainage casing pipe production drawing is deeply optimized and designed; 2, the aluminum alloy formwork of a floor or a wall or a beam where a pipeline passes through is designed through the BIM technology, and pipeline position information data are recorded and stored through a two-dimensional code; 3, the aluminum alloy formwork with a positioning clamp ring is produced according to the information model; 4, the aluminum alloy formwork of the floor or the wall or the beam is installed; and 5, concrete is poured into the floor or the wall or the beam, when the concrete strength meets the requirement, the aluminum alloy formwork is dismounted, and the water supply or water drainage casing pipe is accurately embedded in the concrete structure. The effect that pipelines on the floor are on the same straight line is ensured, and perpendicularity of later pipeline installation is ensured; pipelines on the beam or the wall can be on the same proper slope line, and gradient of later pipeline installation is ensured; and the pipelines can be installed at a time successfully, and rework caused by dimensional deviation is avoided.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

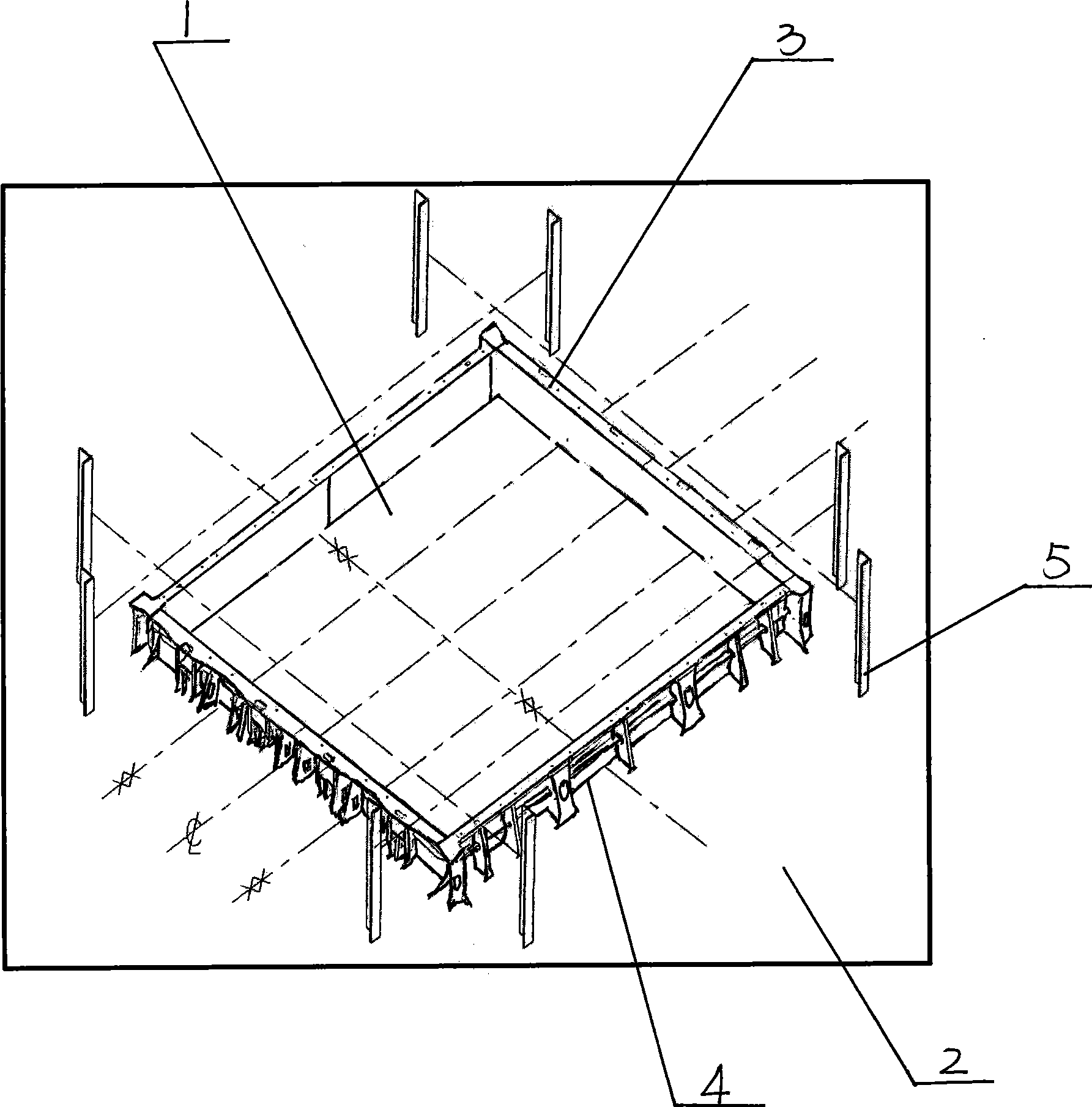

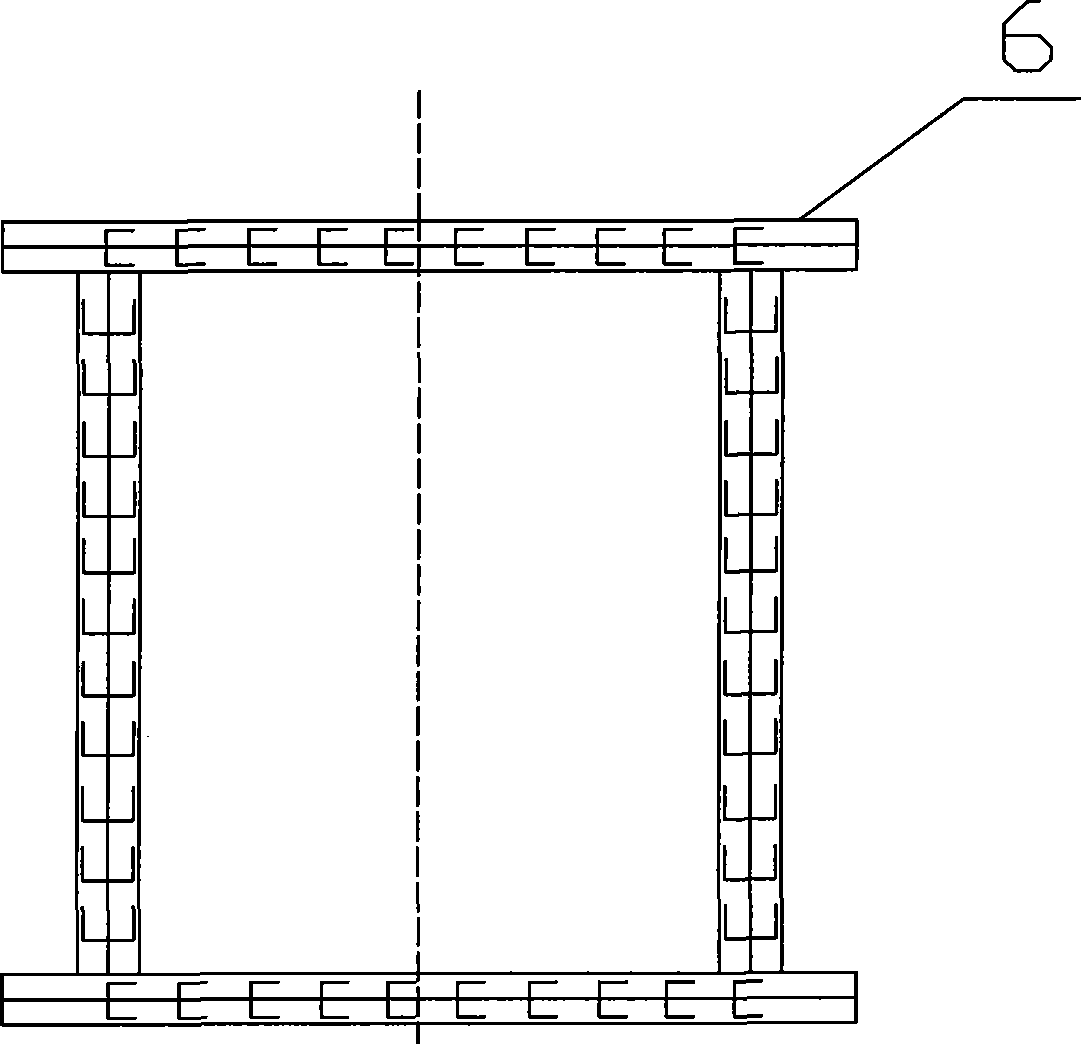

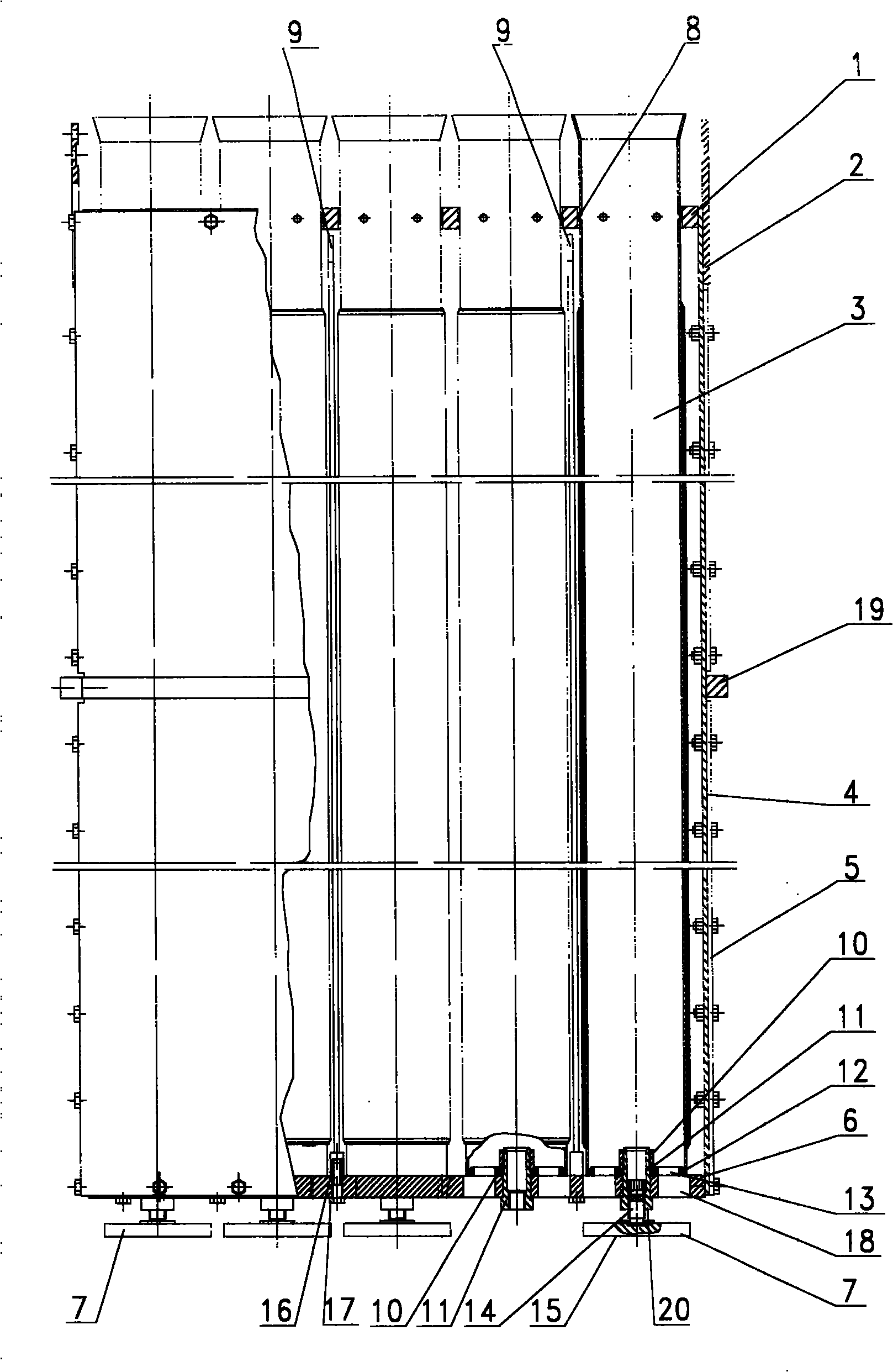

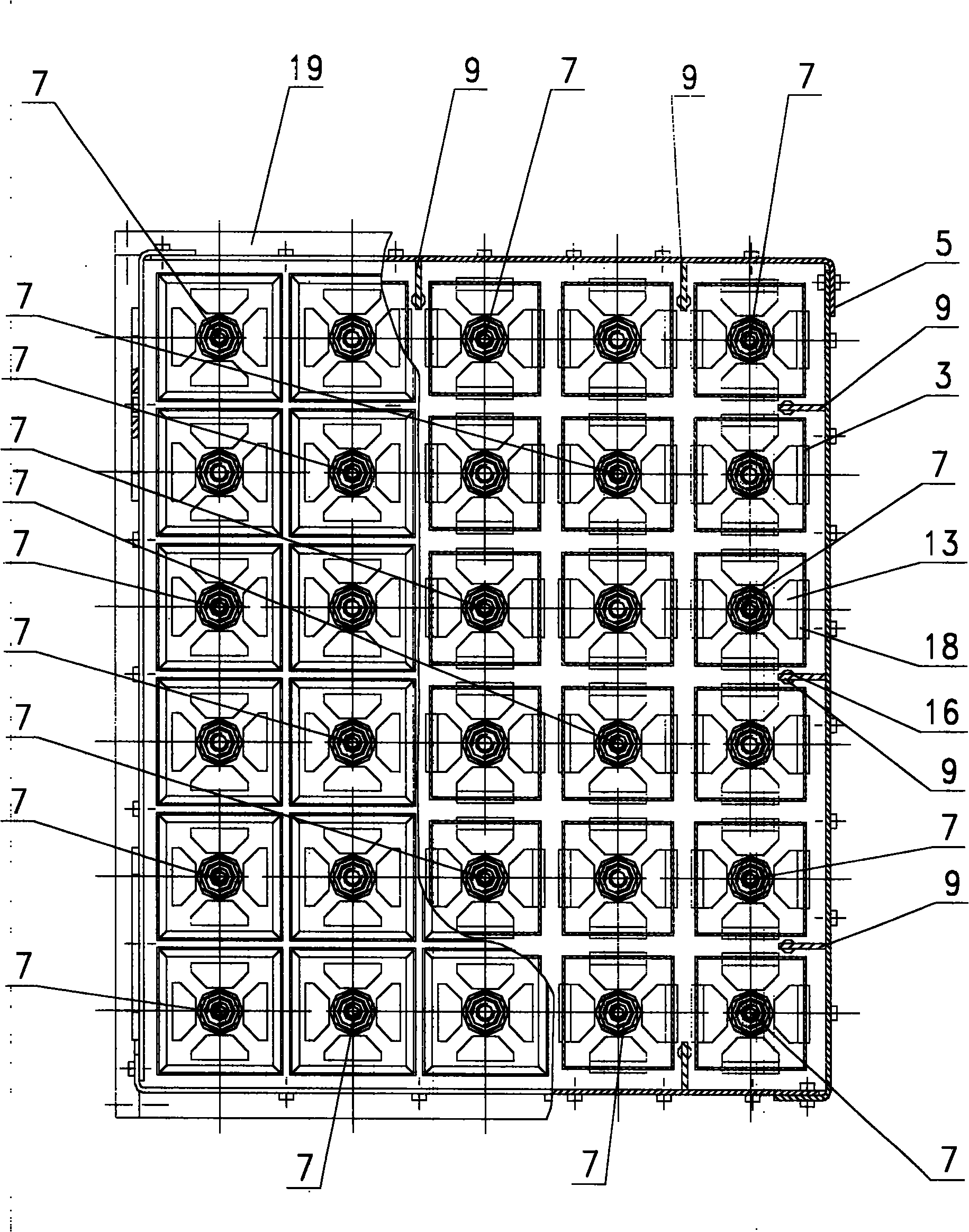

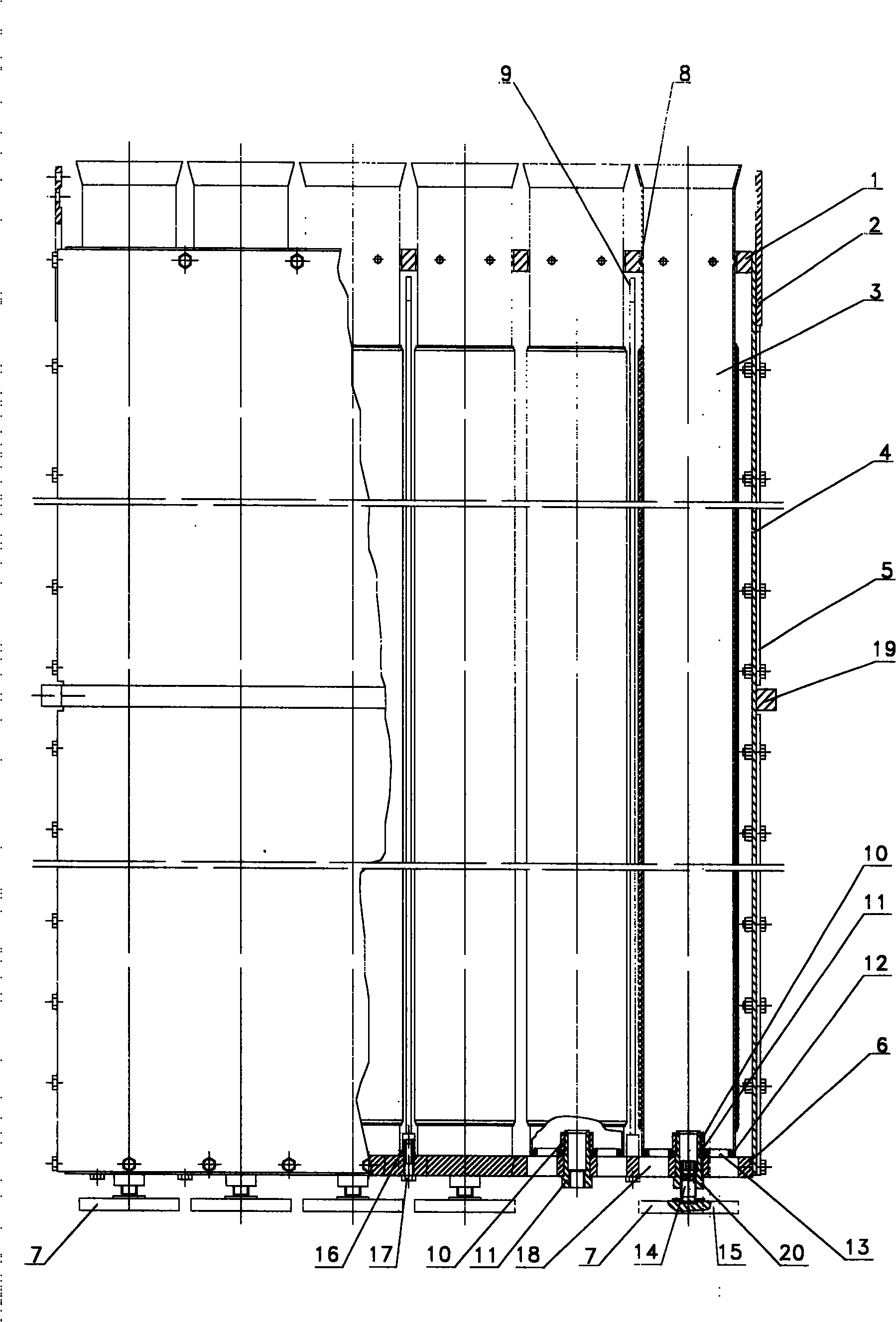

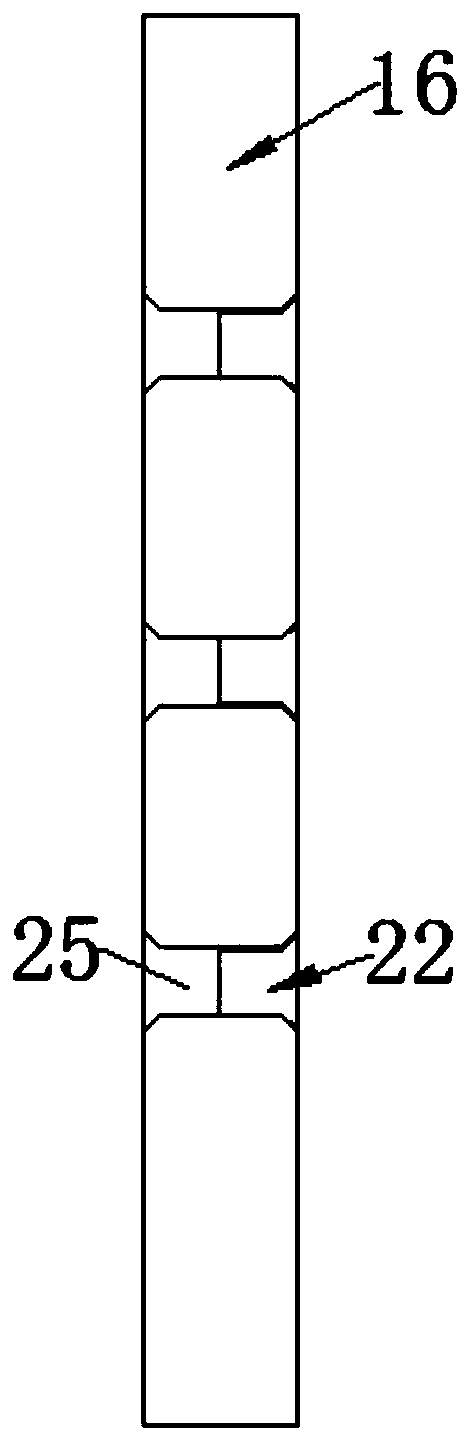

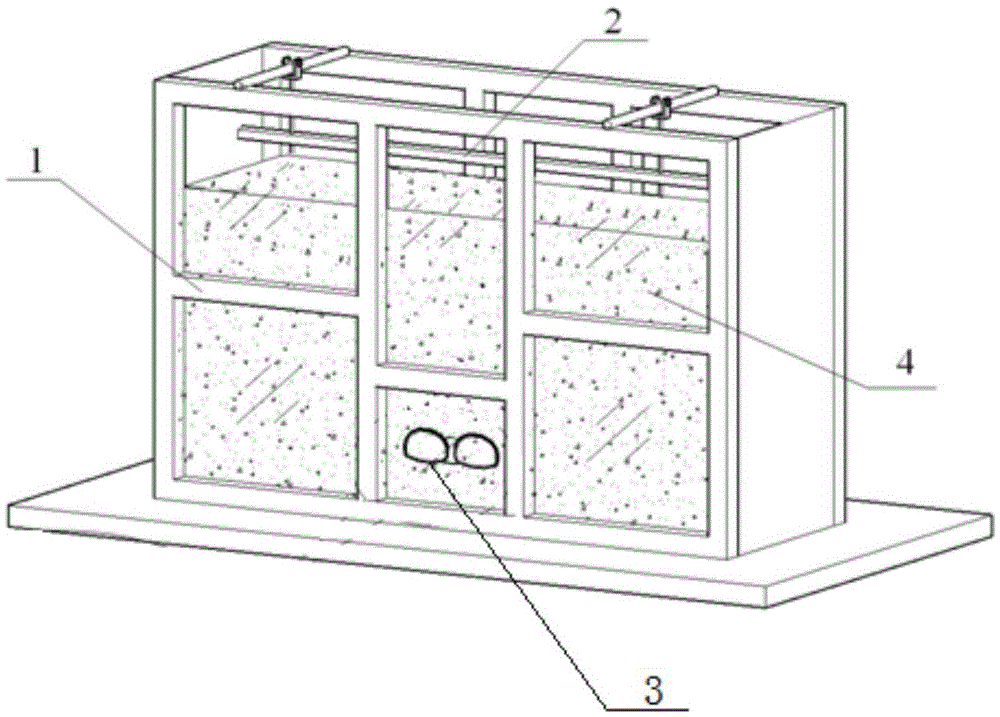

Spent fuel storage rack in pressurized water reactor nuclear power station

InactiveCN101783189AGuaranteed levelnessGuaranteed stabilityNuclear energy generationReactor fuel elementsPressurized water reactorNuclear power

The invention relates to a spent fuel storage rack and in particular discloses a spent fuel storage rack in a pressurized water reactor nuclear power station. The storage rack comprises four enclosing plates, an upper bearing plate positioned at the tops of the enclosing plates, and a lower bearing plate and a storage sleeve which are positioned at the bottoms of the enclosing plates, wherein the enclosing plates, the upper bearing plate and the lower bearing plate form a cubic cavity; the storage sleeve is positioned in the square holes on the upper bearing plate and the lower bearing plate; base plates of the storage sleeve are positioned on the lower bearing plate; legs are fixedly connected with the lower bearing plate; thread sleeves on the legs are welded with the lower bearing plate; cylindrical convex plates are arranged at the bottoms of the thread sleeves; the upper ends of the thread sleeves are fastened with the lower bearing plate and the base plates by nuts; adjusting screws are arranged in and in threaded connection with the thread sleeves; the bottoms of the adjusting screws are freely positioned in the spherical recesses of bottom backing plates; and the base plates are provided with through holes communicated with the inside of the storage sleeve and the through holes are communicated with the through holes on the bearing plates. The storage rack has high storage capacity and good shock resistance.

Owner:CHINA NUCLEAR POWER ENG CO LTD

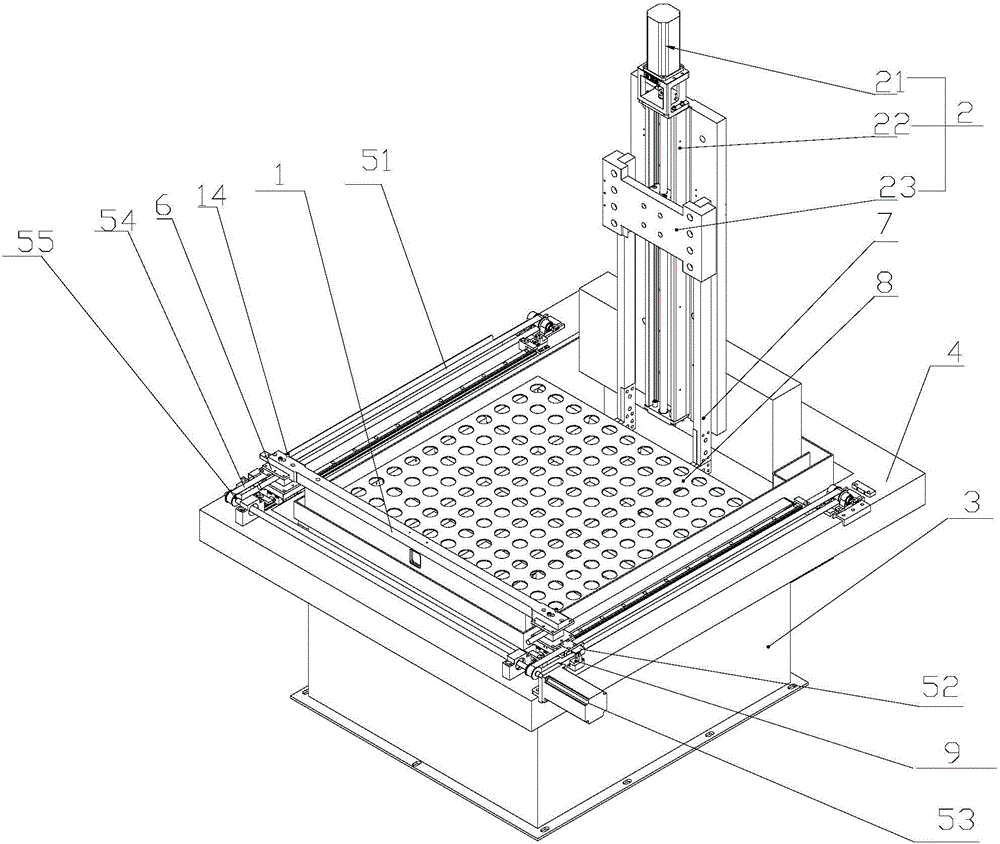

High-precision target material measurement system and method

The invention provides a high-precision target material measurement system and method. The system comprises a detection platform, an optical detection unit, a data collecting and processing unit and a control unit, wherein a hollow cavity is formed in the middle of the detection platform and provided with a detachable movable plate, the hollow cavity can be totally covered with the movable plate, at least one limiting assembly is arranged in the hollow cavity, the limiting assembly is used for fixing target materials and can drive the target materials to rotate, and the limiting assembly is connected with a driving device and is driven by the driving device; the optical detection unit comprises a lens and a raster projection device, and because the detection platform and the optical detection unit are movable, by controlling the movement direction and the movement distance of the detection platform and the optical detection unit, high-precision three-dimensional detection on any position of the target materials in different specifications and shapes can be achieved; besides, the limiting assembly can drive the target materials to rotate, and therefore the target materials do not need to be turned over in the detection process, and detection efficiency is improved.

Owner:SUZHOU JUZHEN PHOTOELECTRIC

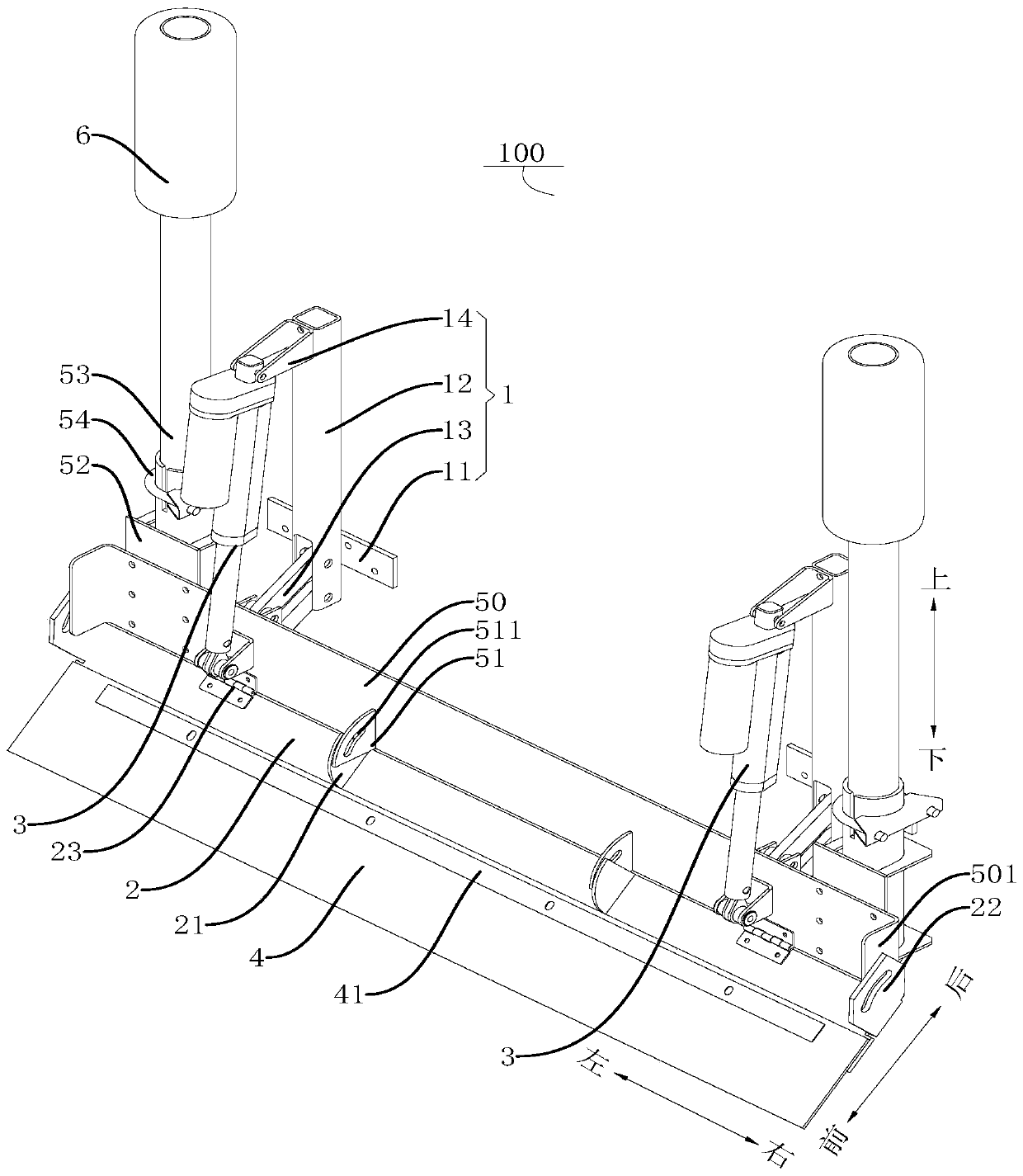

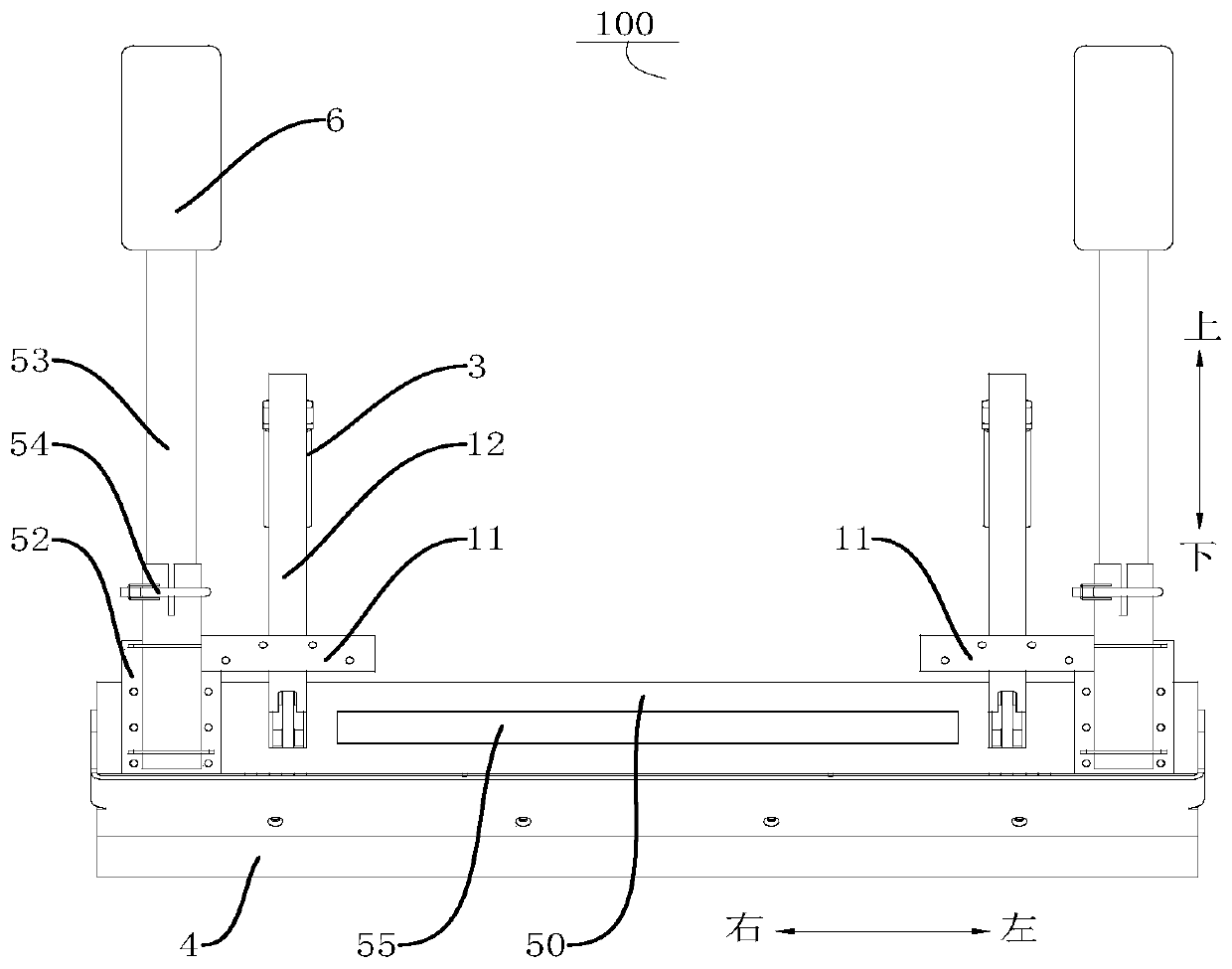

Leveling device and leveling robot with leveling device

ActiveCN110565964AGuaranteed levelnessEven by forceBuilding material handlingComputer engineeringRobot

The invention discloses a leveling device and a leveling robot with the leveling device. The leveling device comprises mounting racks, a scraping plate, drive devices and a leveling sheet. The scraping plate is movably connected to the mounting racks and is arranged in a manner of inclining relative to the horizontal plane. The two sets of drive devices are arranged and are arranged at the two ends of the scraping plate correspondingly. One end of each set of drive device is connected to the corresponding mounting rack, and the other end of each set of drive device is connected to the scrapingplate. When doing telescopic motion, each set of drive device drives the scraping plate to do lifting motion. The leveling sheet is connected with the scraping plate and is used for leveling the surface of a building. According to the leveling device, through the scraping plate and the drive devices arranged on the leveling device, when the drive devices operate, the height and inclination degreeof the scraping plate relative to the surface of the building can be rapidly adjusted according to the condition of the surface of the building; and levelness generated after the leveling sheet on the rear side of the scraping plate and the surface of the building are in contact is guaranteed, so that the surface of the building is smoothed and leveled. Adjusting is flexible, work efficiency is high, and a smooth effect can be formed.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Adjustable type concrete precast block mold wide in application range

The invention discloses an adjustable type concrete precast block mold with in application range. The adjustable type concrete precast block mold with in application range comprises supporting seats,leveling bolts and bearings. The upper sides of the supporting seats are provided with the leveling bolts. The upper sides of the leveling bolts are provided with the bearings. Rotating rods are arranged in the bearings. The adjustable type concrete precast block mold with in application range has the beneficial effects that through arrangement of insertion holes, insertion rods, a first fixing block, a second fixing block, a third fixing block, a fourth fixing block, a first side plate, a second side plate, a third side plate and a fourth side plate, the mold can produce concrete precast blocks of different sizes, and mold resource waste is avoided; through arrangement of a first horizontal pipe, a second horizontal pipe, the leveling bolts, the supporting seats, the rotating rods and thebearings, the levelness of the mold can be adjusted, the levelness of the mold is guaranteed, so that the quality of the concrete precast block is guaranteed; through arrangement of reinforcing steelbar holes and rubber plugs, reinforcing steel bars can be laid on the mold according to use demands of the reinforcing steel bars, and more use demands can be met.

Owner:HUNAN WUXIN MACHINERY

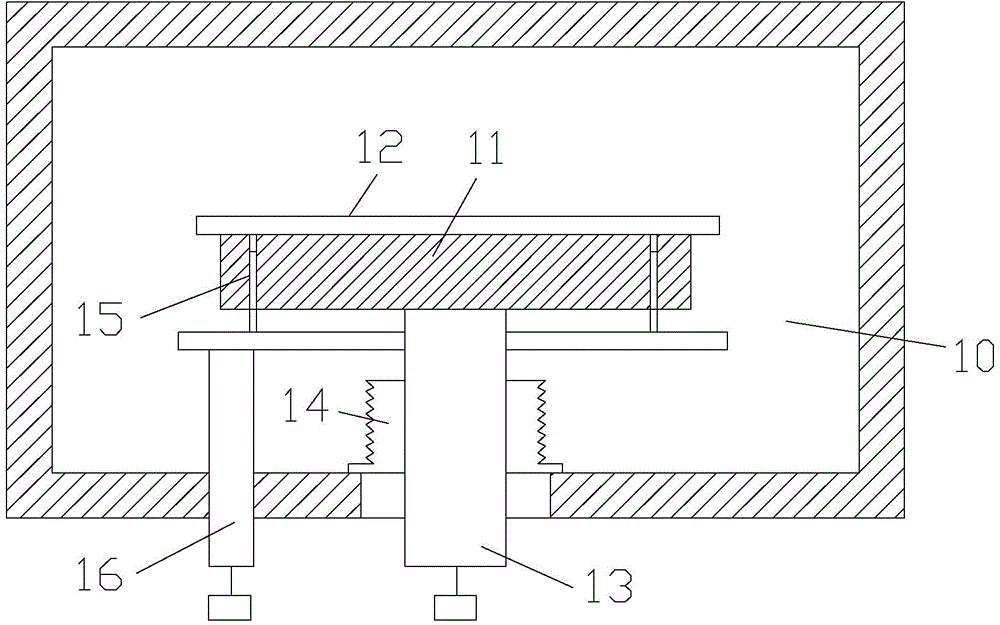

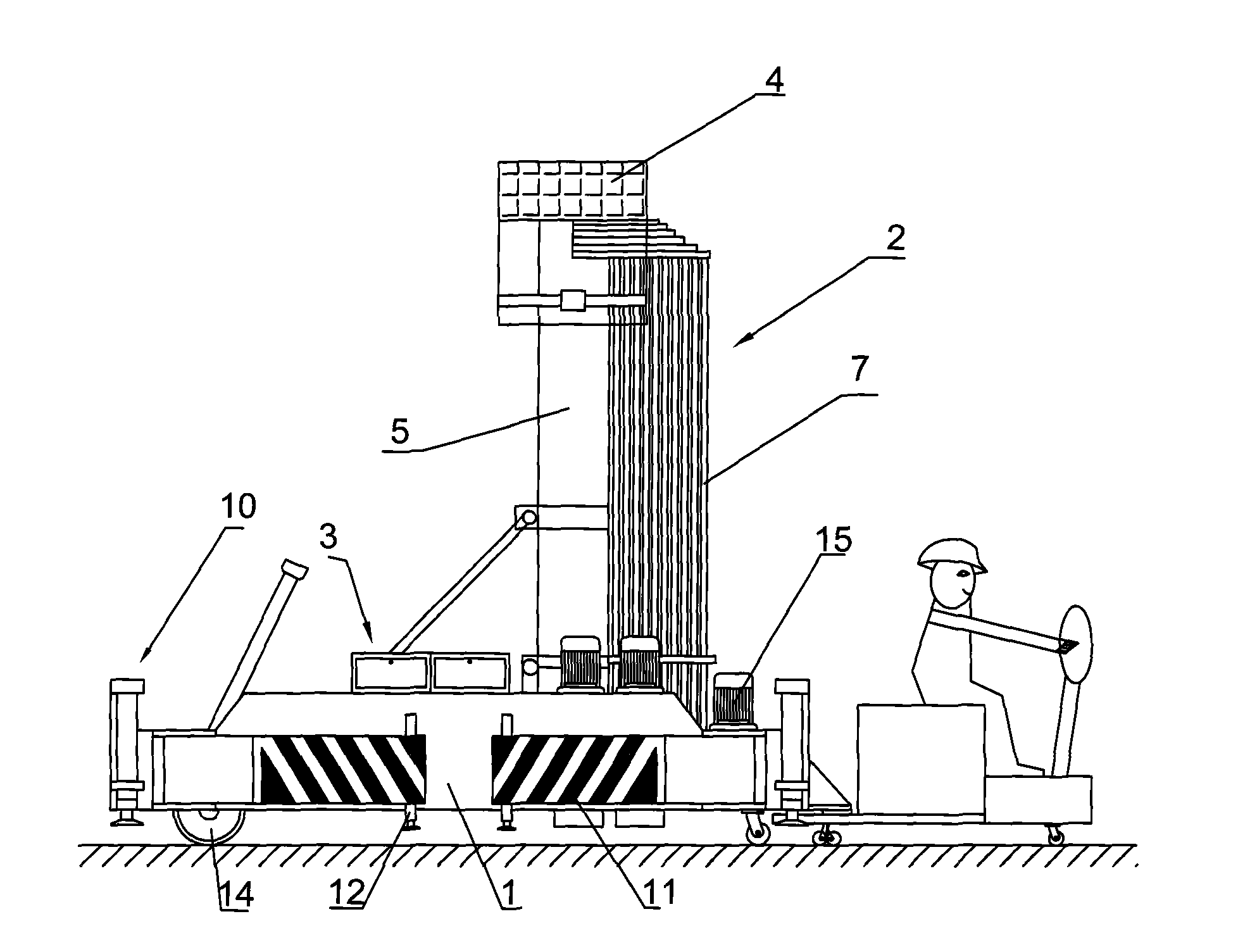

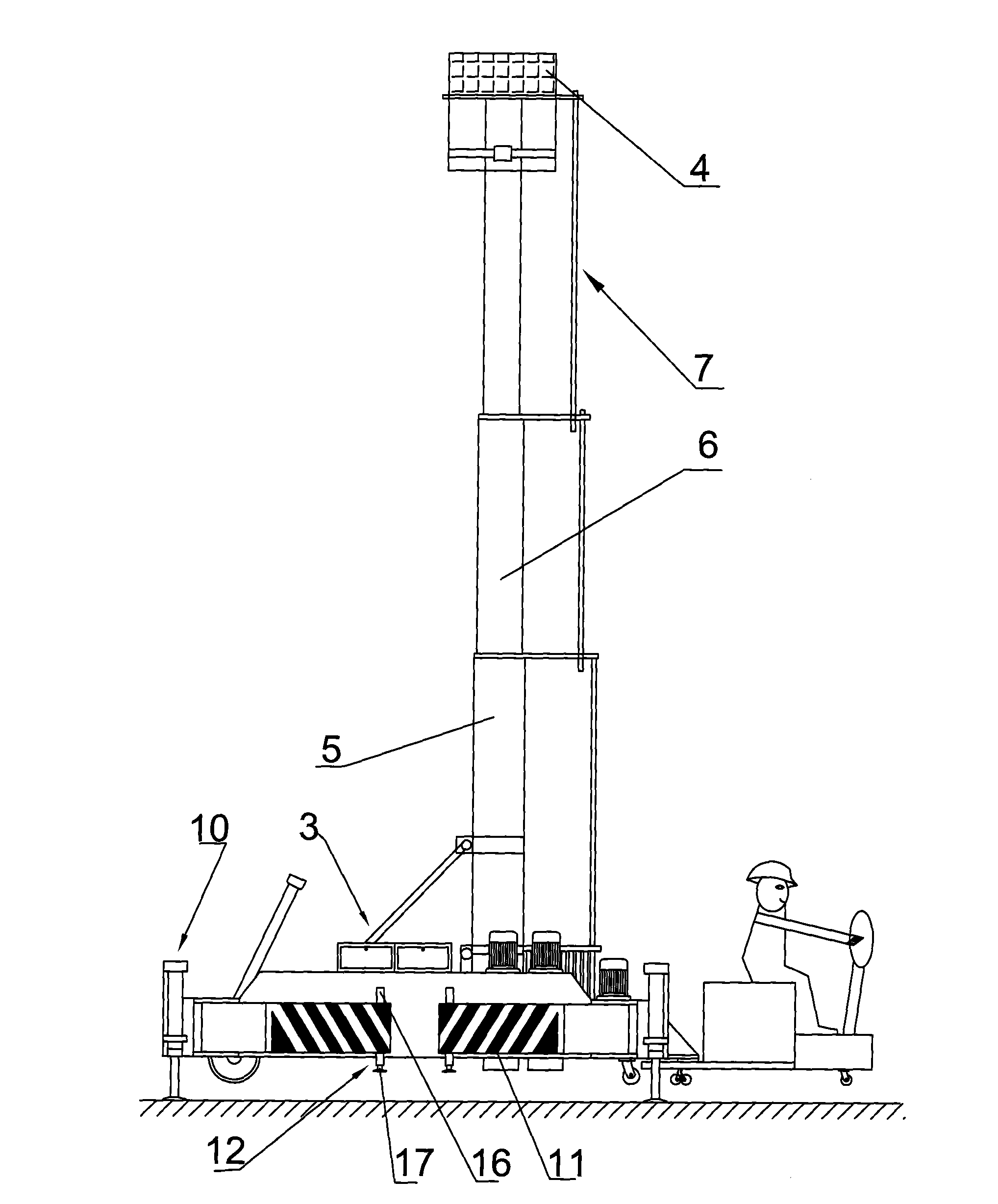

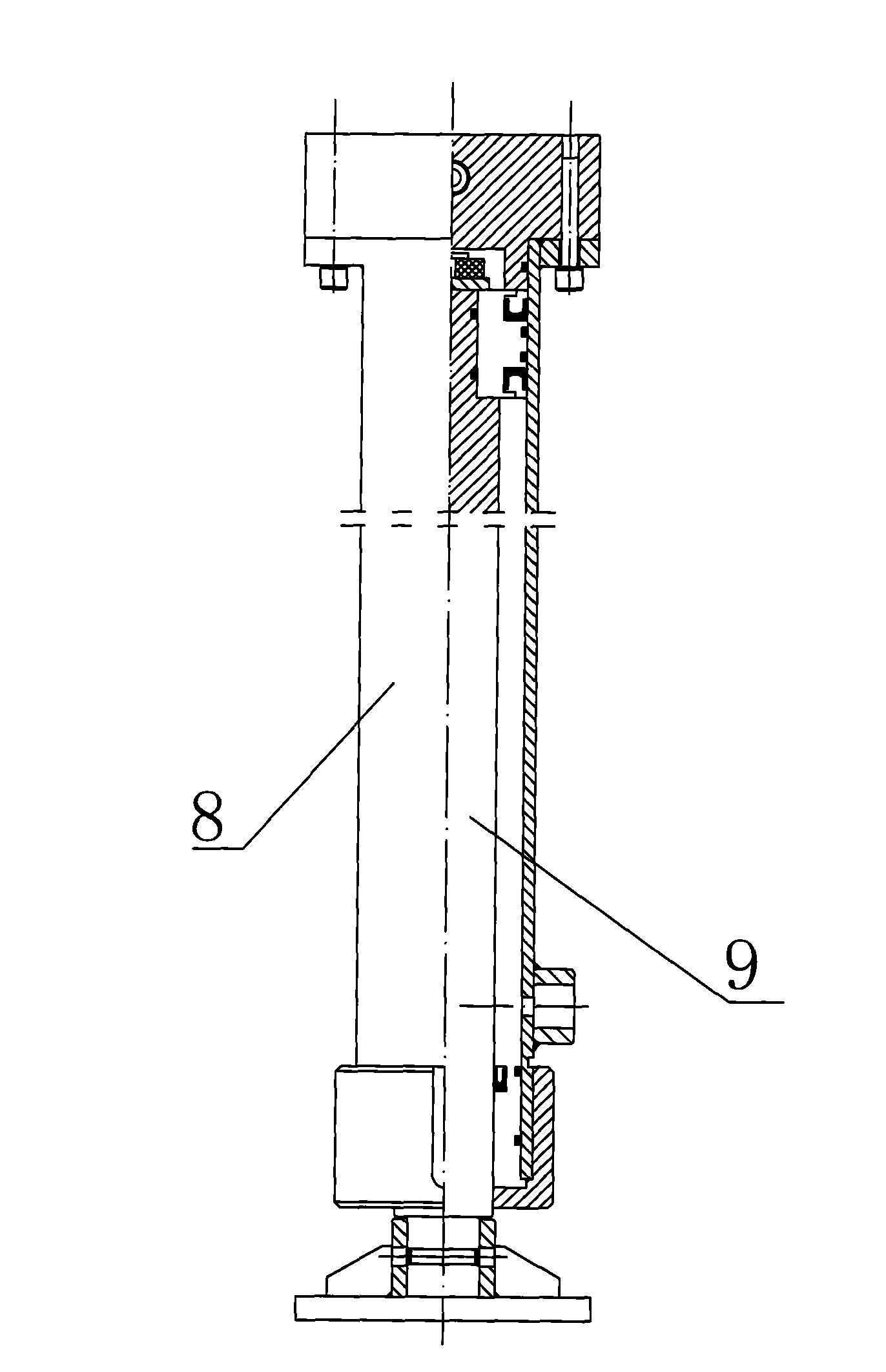

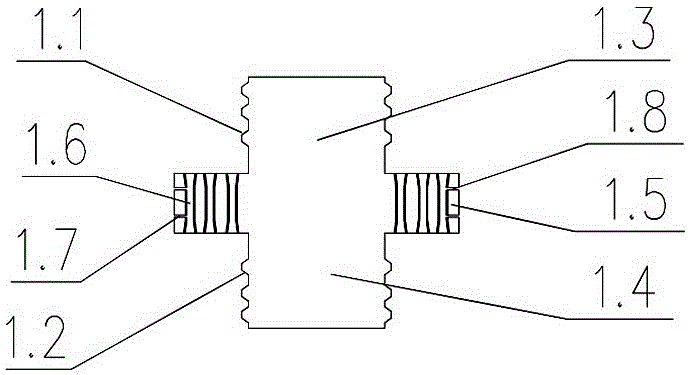

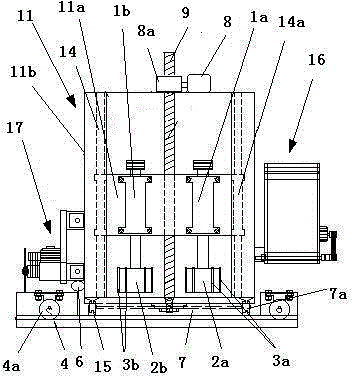

Hydraulic lifter

InactiveCN101670996AGuaranteed levelnessAvoid the problem of partial plantingLifting devicesPiston rodIndustrial engineering

The invention relates to a hydraulic lifter comprising a base, a lifting mechanism, a working platform and an electrohydraulic controlling mechanism. The lifting mechanism is provided with a multistage telescopic oil cylinder; the working platform is arranged on the top of the lifting mechanism; and the electrohydraulic controlling mechanism is used for driving the lifting mechanism. The hydrauliclifter is characterized in that the base is provided with a balancing device used for keeping the base horizontal; the balancing device comprises at least three base balancing oil cylinders which arefixed on the balancing device; the sleeves of the base balancing oil cylinders are fixedly arranged on the base; and piston rods of the base balancing oil cylinders are arranged towards the ground. The balancing device can be in two working states. When the balancing device is in the first working state, the piston rods of all the base balancing oil cylinders tough the ground, and the base leavesthe ground. When the balancing device is in the second working state, the base touches the ground, and the piston rods of all the base balancing oil cylinders are folded in the sleeves of the base balancing oil cylinders. Because the base balancing oil cylinders of the invention can support the base, the unbalanced loading of the hydraulic lifter, which is resulted from the uneven construction ground, can be avoided.

Owner:太仓高德升降机有限公司

Construction method of prefabricated segment type pier

ActiveCN106592440ALow costAccurate structural positioningBridge structural detailsBridge erection/assemblyConnection typePre stress

The invention discloses a construction method of a prefabricated segment type pier. Firstly, prefabricating a positioning block, an upper segment and a lower segment; secondly, assembling the positioning block and the lower segment; the third step, assembling the positioning block and the upper segment; the fourth step, grouting; and the fifth step, installing annular stirrups on the periphery of an annular wing plate. Compared with the existing pier construction technology, the prefabricated pier segments can be prefabricated in a large scale and transported conveniently; as the size is smaller, large-scale lifting equipment is not needed; the prefabricated pier segments are connected by adopting the way of combining the body socket and spigot joint and the socket and spigot joint of a grouting casing pipe and stress column bar splices, the prestressed connection type is avoided, no additional temporary connection measures are needed, the structure is accurate in positioning and reliable in stress, the construction period is shortened, and the construction cost is lowered; and the perpendicularity of the prefabricated pier is guaranteed through the way of arranging the annular wing plate on the positioning block and the way of arranging spacers between the annular wing plate and the upper segment and between the annular wing plate and the lower segment.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD +1

Multifunctional wood machining equipment

ActiveCN104890063AMove fastReduce resistance to movementMulti-purpose machinesBark-zones/chip/dust/waste removalWood machiningEngineering

The invention discloses multifunctional wood machining equipment and belongs to the field of wood machining equipment. A running vehicle comprises a movement and driving devices moving along X-axis direction, Y-axis direction and Z-axis direction, at least two rotating spindles taking vertical direction as axis are arranged at the front end of the movement, a knife is arranged at the lower end of each spindle, and multiple rows of blades are arranged around each knife, distances between the blades on different spindles and cut wood are difference, the spindles are rotatably connected with a motor respectively, multiple top discs different in diameter are arranged on a top tip seat and a top tip of a tail seat, a rolling device along the X-axis direction is arranged on the lower portion of the tail seat, and a control panel is arranged on the multifunctional wood machining equipment. By the multifunctional wood machining equipment, production efficiency can be improved, labor intensity of operating personnel can be lowered, machining diameter can be expanded, machining variety can be increased, and sales market can be expanded.

Owner:安阳市涵缘机械设备有限公司

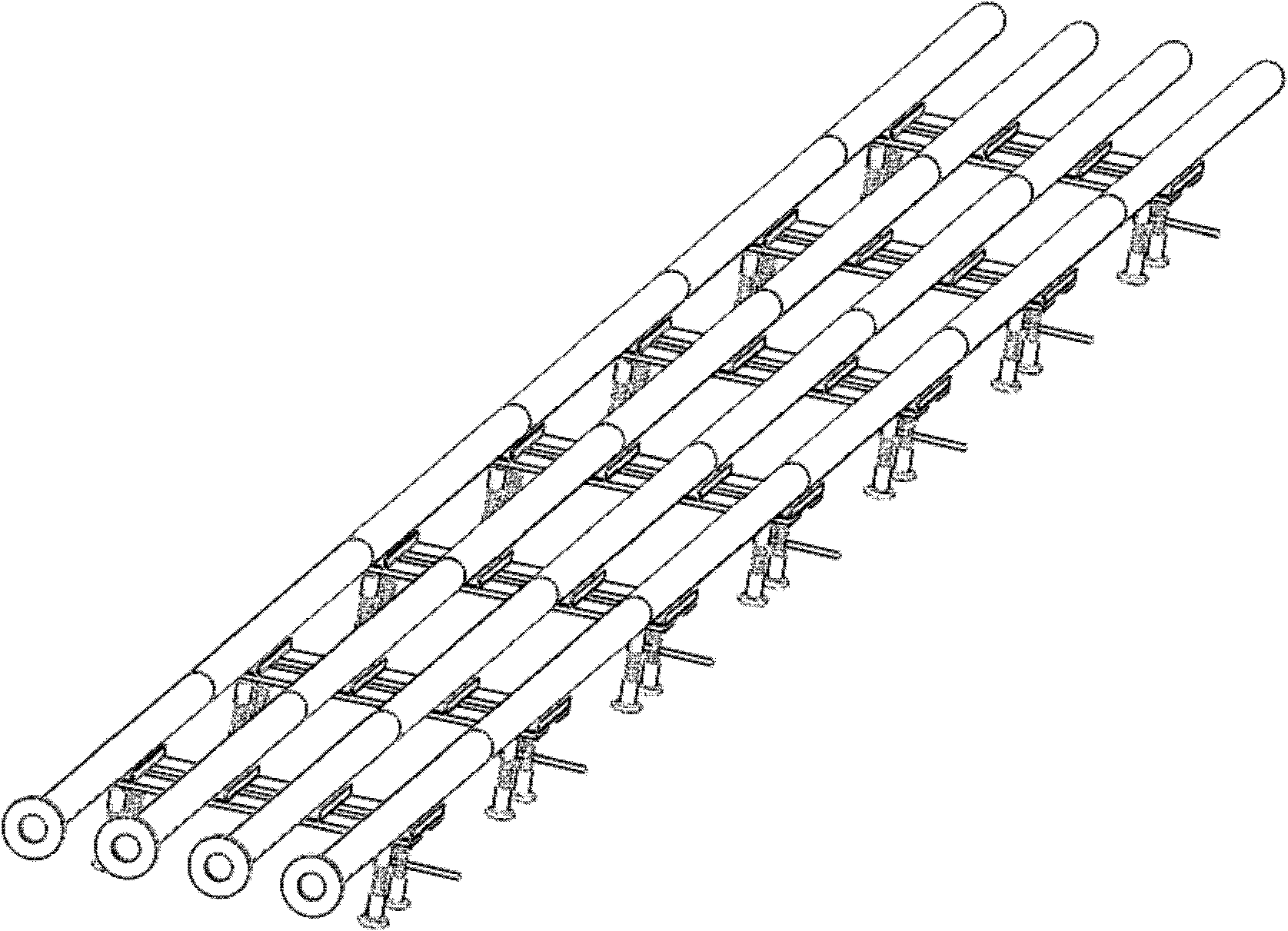

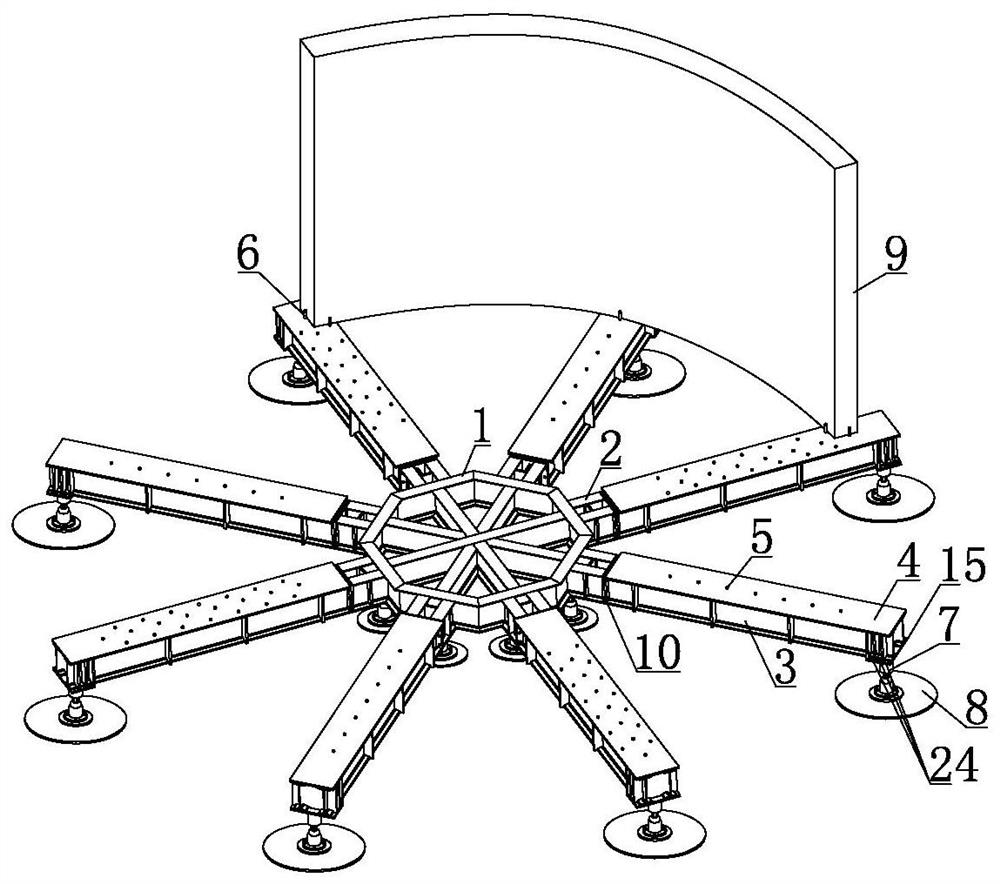

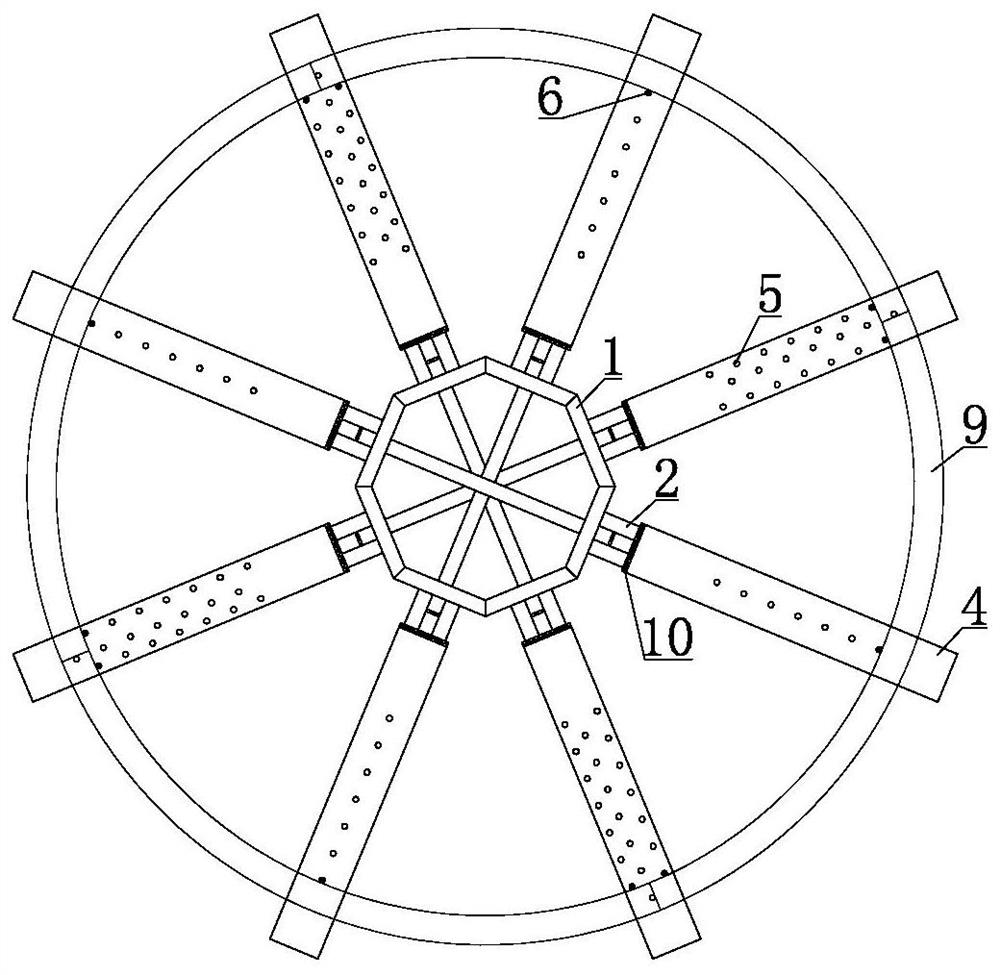

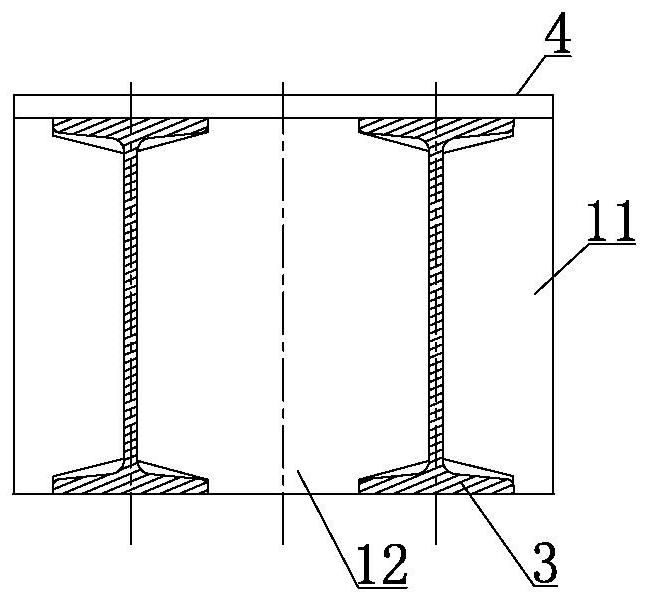

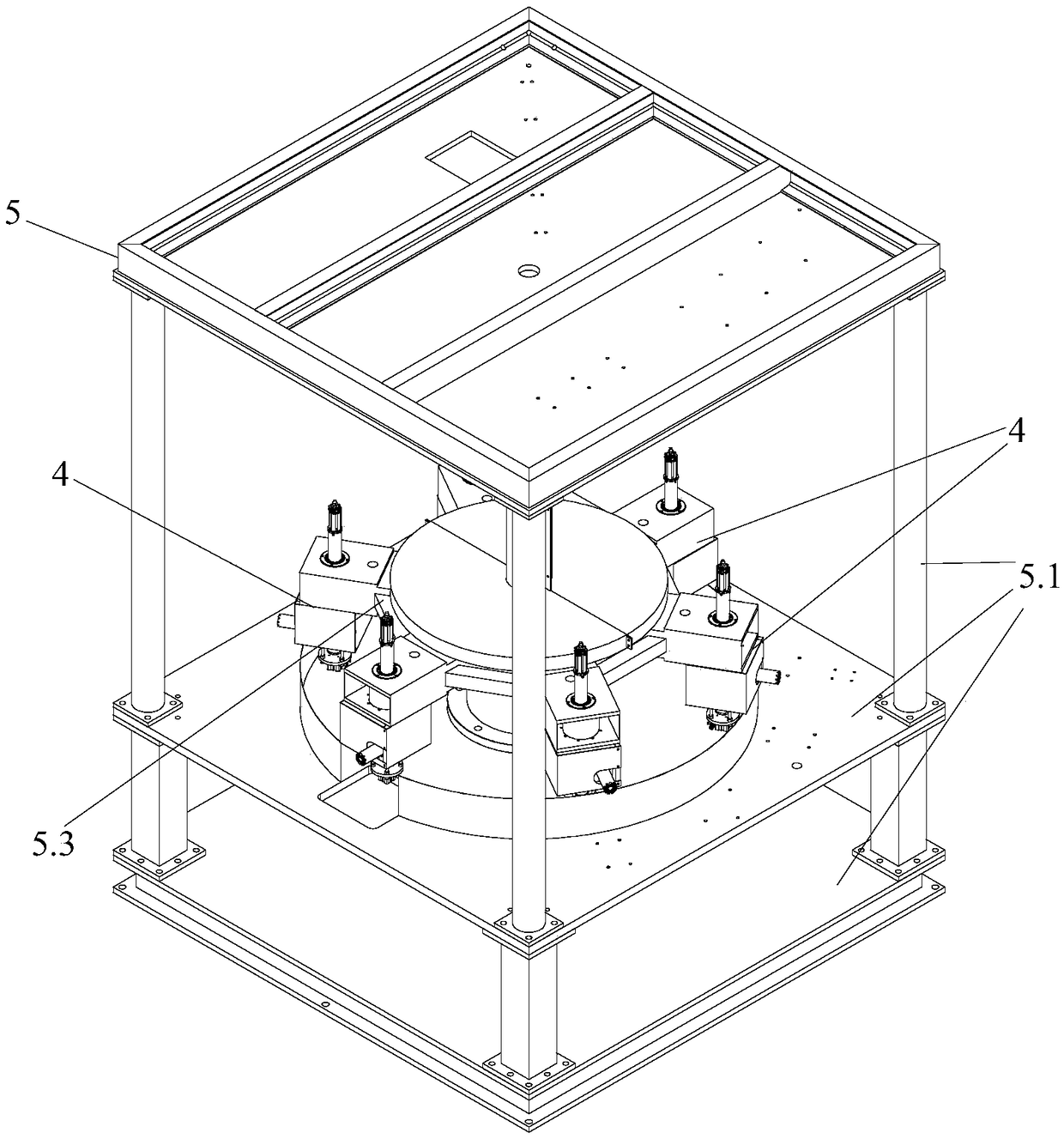

Fabricated concrete tower tube piece assembly platform and assembly method

ActiveCN111946555AReasonable structural designRealize precise positioning splicingWind motor assemblyWind motor supports/mountsArchitectural engineeringTower

The invention provides a fabricated concrete tower tube piece assembly platform and assembly method. The fabricated concrete tower tube piece assembly platform comprises a center frame, connecting sections, supporting beams, supporting panels, limiting positioning pin holes, positioning pins, leveling supporting feet, base plates and the like. The octagonal center frame and the eight supporting beams are connected through the connecting sections to form a spliced platform body structure. The supporting panels are welded to the top faces of the supporting beams, a series of limiting positioningpin holes are formed in the supporting panels, and the positioning pins are inserted to achieve rapid and accurate positioning of concrete tower tube pieces. The leveling supporting feet are arrangedat the bottoms of edge beams of the center frame and the bottoms of the outer ends of the supporting beams and serve as supporting supports and leveling devices of the platform. The base plates are arranged at the bottoms of the leveling supporting feet and used for dispersing upper concentrated loads and reducing local settlement of a foundation. According to the fabricated concrete tower tube piece assembly platform and assembly method, rapid and accurate assembly of the fabricated concrete tower tube pieces in the technical field of wind power can be realized, the concrete tower rapid construction concept of instant assembly and instant hoisting is embodied, and a quite excellent technical scheme for assembly construction of the fabricated concrete tower tube pieces prefabricated in afragmentation manner is achieved.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

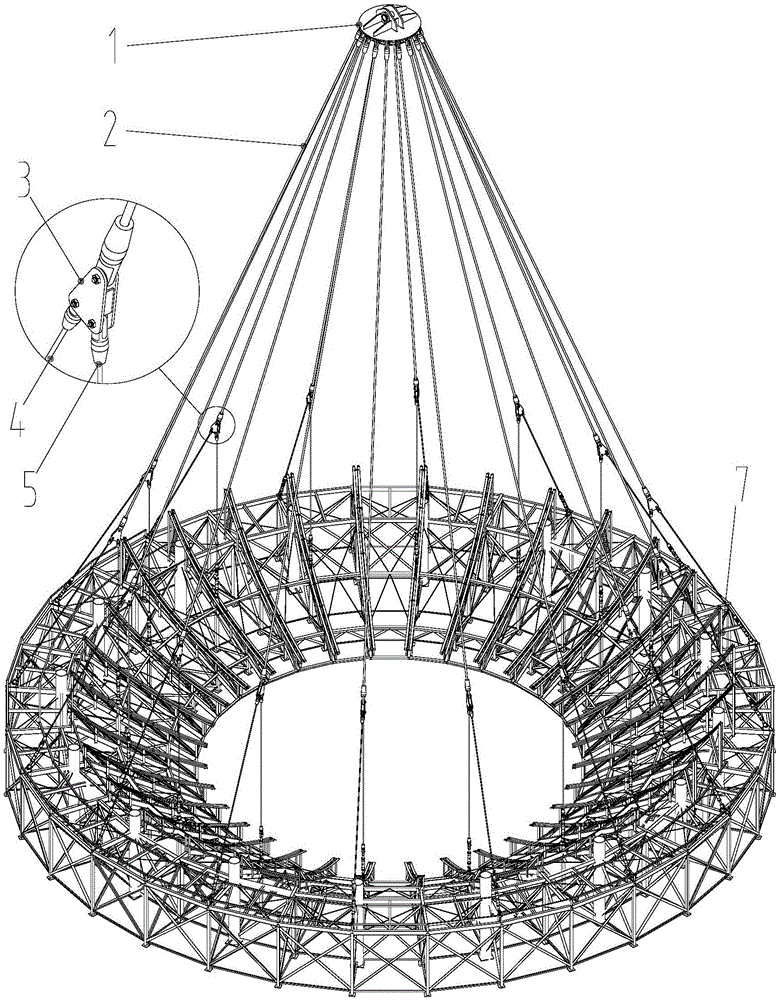

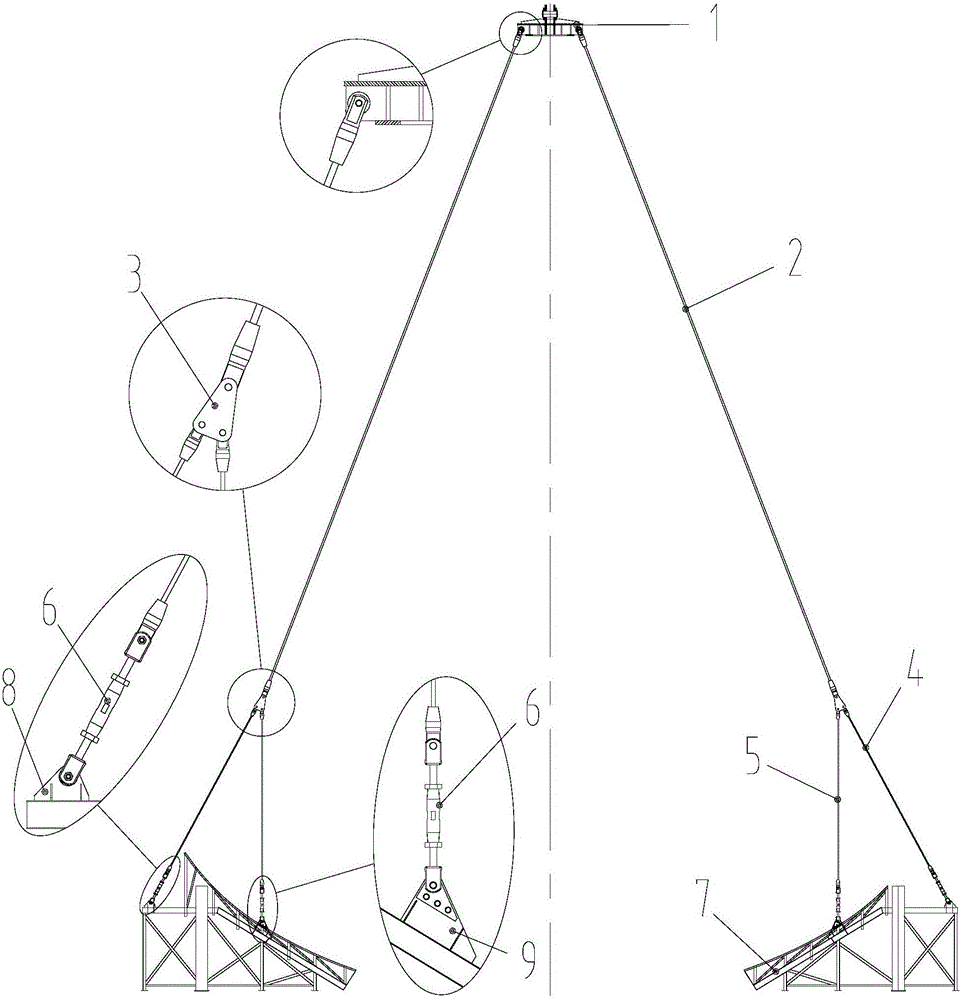

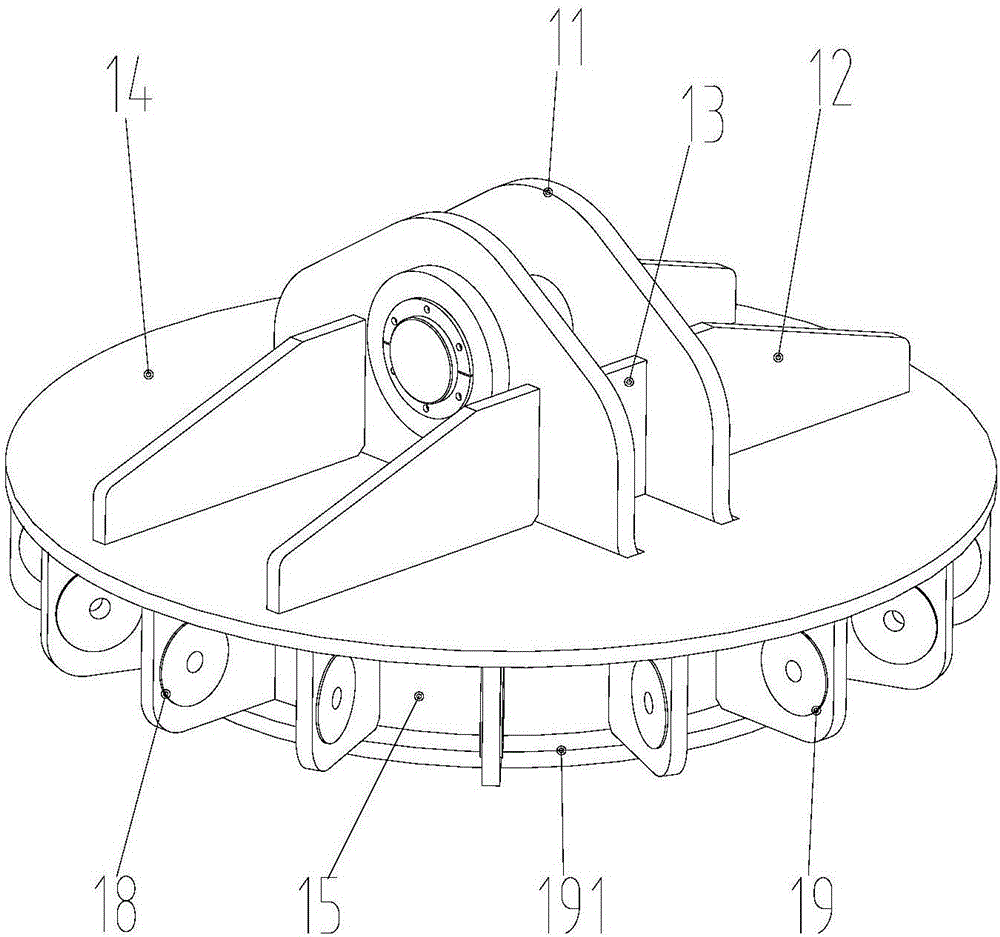

Special hoisting sling and hoisting method for nuclear power station CR10 and reinforcing steel bar composite module

ActiveCN106429791ASimple structureReasonable structureLoad-engaging elementsNuclear powerEngineering

The invention relates to a special hoisting sling and a hoisting method for a nuclear power station CR10 and reinforcing steel bar composite module. The special hoisting sling comprises a transition beam, main slings, sling distributors, outside auxiliary slings, inside auxiliary slings and adjustable pull rods. According to the special hoisting sling and the hoisting method for the nuclear power station CR10 and reinforcing steel bar composite module provided by the invention, the special hoisting sling is adopted as connection between a hoist and the CR10 and reinforcing steel bar composite module, the special hoisting sling is connected before hoisting, the transition beam is connected with the hoist, and the adjustable pull rods are connected with inside and outside lifting lugs on the CR10 and reinforcing steel bar composite module. A center-of-gravity position of the CR10 and reinforcing steel bar composite module is adjusted through applying balance weight and adjusting the adjustable pull rods, so that the level degree of a lower port is ensured. The CR10 and reinforcing steel bar composite module is in position through hook-lifting, rotating, walking and hook-dropping of normal hoisting. According to the special hoisting sling and the hoisting method provided by the invention, the deformation of the CR10 and reinforcing steel bar composite module during a hoisting process can be effectively reduced, the level degree of the lower port of the CR10 and reinforcing steel bar composite module is ensured, and the construction safety is ensured.

Owner:DALIAN YILIY CONSTR MACHINERY

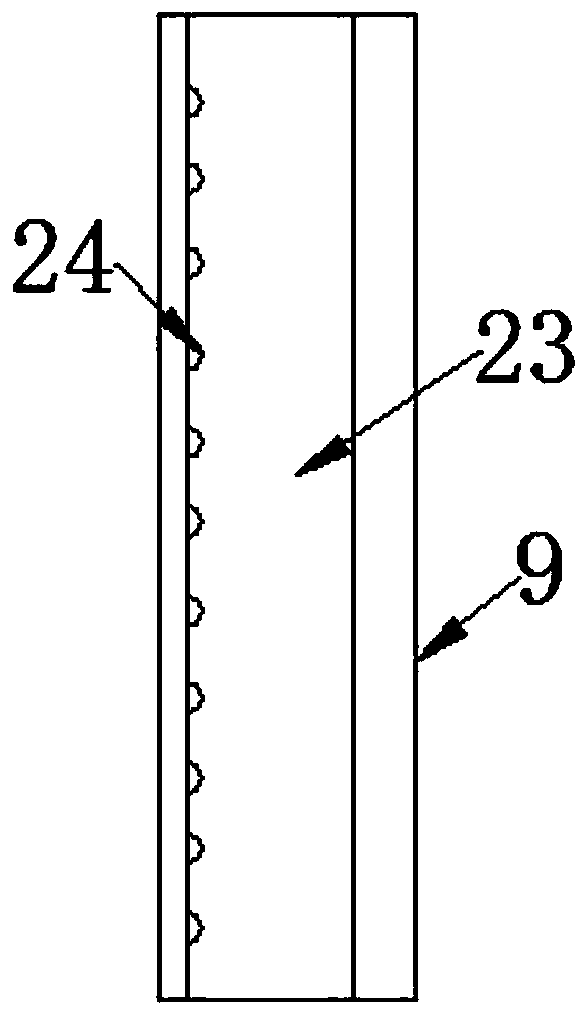

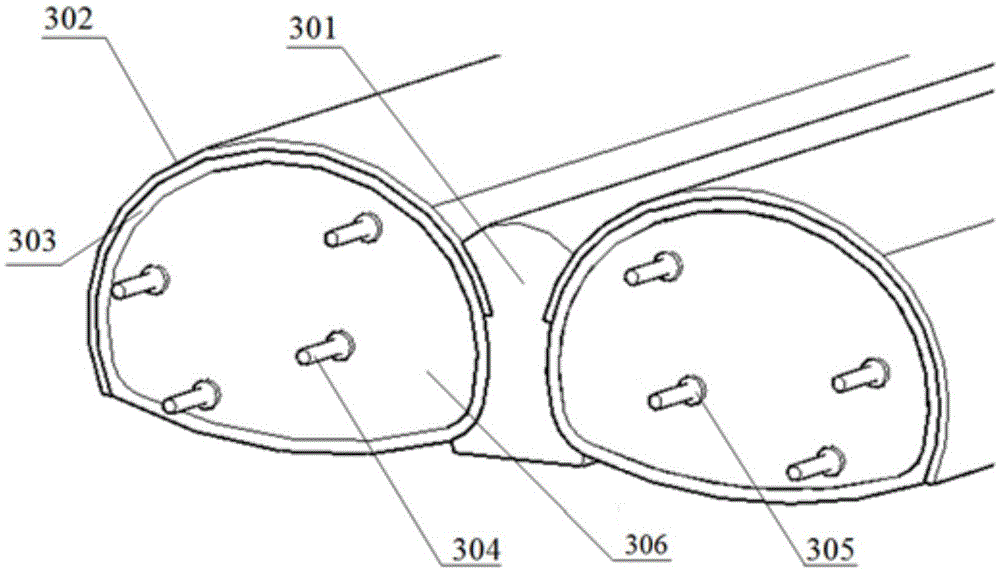

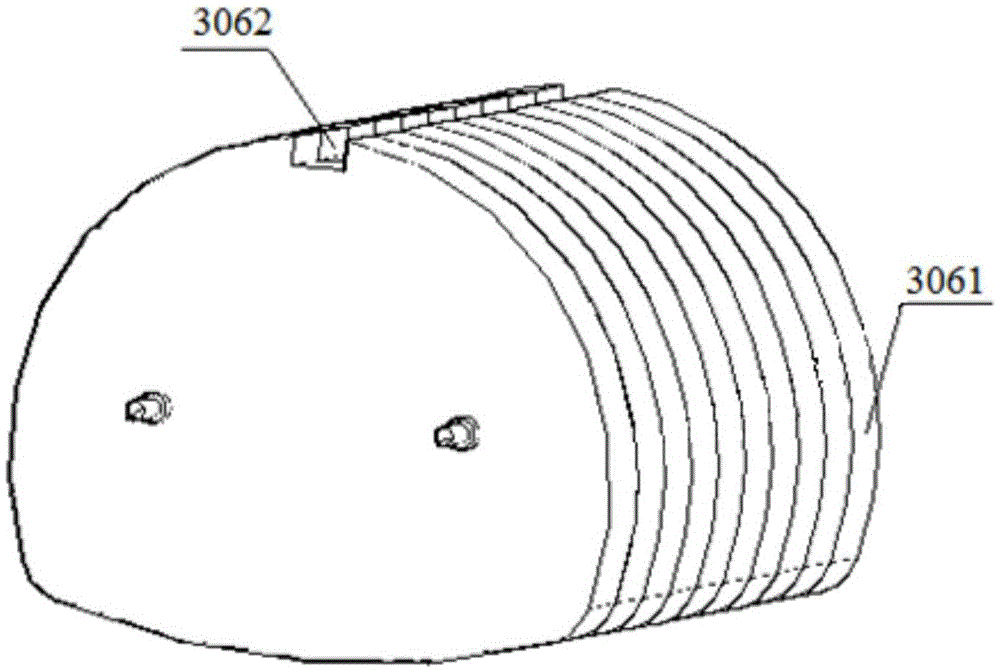

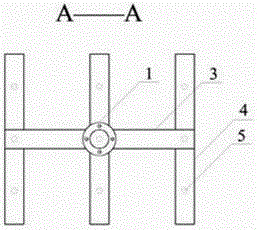

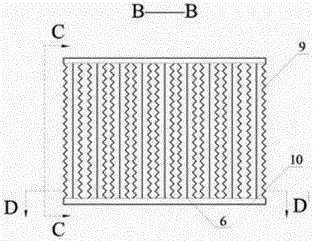

Test device for simulating tunnel excavation process

InactiveCN105572308AComprehensive collectionEasy to disassembleMaterial analysisSurface deformationMental detachment

The invention discloses a test device for simulating the tunnel excavation process. The test device comprises a test box. A dial indicator rack is suspended on the top of the test box. An embedded body is embedded in the bottom of the test box. The test box is filled with a soil mass simulation material. The embedded body comprises a first tunnel excavation test body, a middle partition test body and a second tunnel excavation test body. The first tunnel excavation test body and the second tunnel excavation test body are of the same structure. The first tunnel excavation test body sequentially comprises a primary support simulation layer, a secondary lining simulation layer and a mountain simulation piece from outside to inside. The mountain simulation piece comprises a plurality of plates which are arranged in parallel and detachably connected. By means of the test device, ground surface deformation data can be collected, stress data of a middle partition, a primary support and a secondary lining is collected at the same time, the process of simulating mountain excavation is changed into the process of taking out the simulation piece in a layered mode piece by piece through the platy layered mountain simulation piece, detachment is convenient, and the contour left after detachment is smoother.

Owner:CHANGAN UNIV

Uniform overflow type liquid distributor

InactiveCN104307192AAvoid effusionEasy to overflowEvaporator accessoriesEvaporators with horizontal tubesButt jointEngineering

The invention relates to a liquid distribution device, and particularly relates to a uniform overflow type liquid distributor used for uniformly distributing liquid on a horizontal heat exchange pipe. The liquid distributor comprises a flange, a feeding pipe, a horizontal branch pipe, a spray pipe, a folded-plate type overflow groove, a connecting channel and liquid distributing teeth, wherein the flange is arranged at a feeding opening; one end of the feeding pipe is connected with the flange, and the other end of the feeding pipe is connected with horizontal branch pipe; the spray pipe and the horizontal branch pipe are not in central butt joint, and occurrence of liquid accumulation in the spray pipe can be avoided; liquid in the overflow groove slowly increases by using the spray pipe, so that liquid overflows stably and has small fluctuation.

Owner:SHENYANG AEROSPACE UNIVERSITY

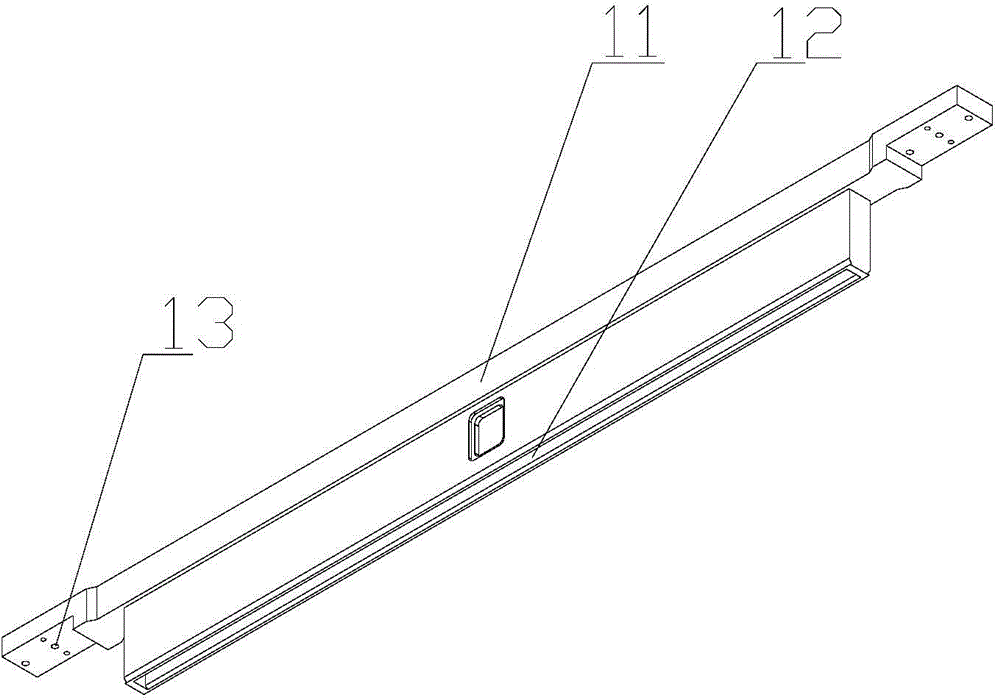

Coating scraper and coating apparatus for photocuring rapid prototyping

ActiveCN105437541AReduce weightEasy to adjustLiquid surface applicatorsCoatingsEngineeringRapid prototyping

The present invention provides a coating scraper and a coating apparatus for photocuring rapid prototyping, the coating scraper is an integrated structure, and includes a mounting beam and a scraper body connected with the mounting beam, the scraper body is provided with a downwardly-opening long groove, and edges are arranged on two sides along the longitudinal direction of the long groove. The integrated-structure coating scraper is light in weight, easy to adjust and easy to assemble and reduces the cost.

Owner:SHANGHAI UNION TECH

Adjusting device for equipment installing alignment

InactiveCN104723094AReduce labor intensitySimple structureMetal working apparatusStructural engineering

Owner:SHANDONG IRON & STEEL CO LTD

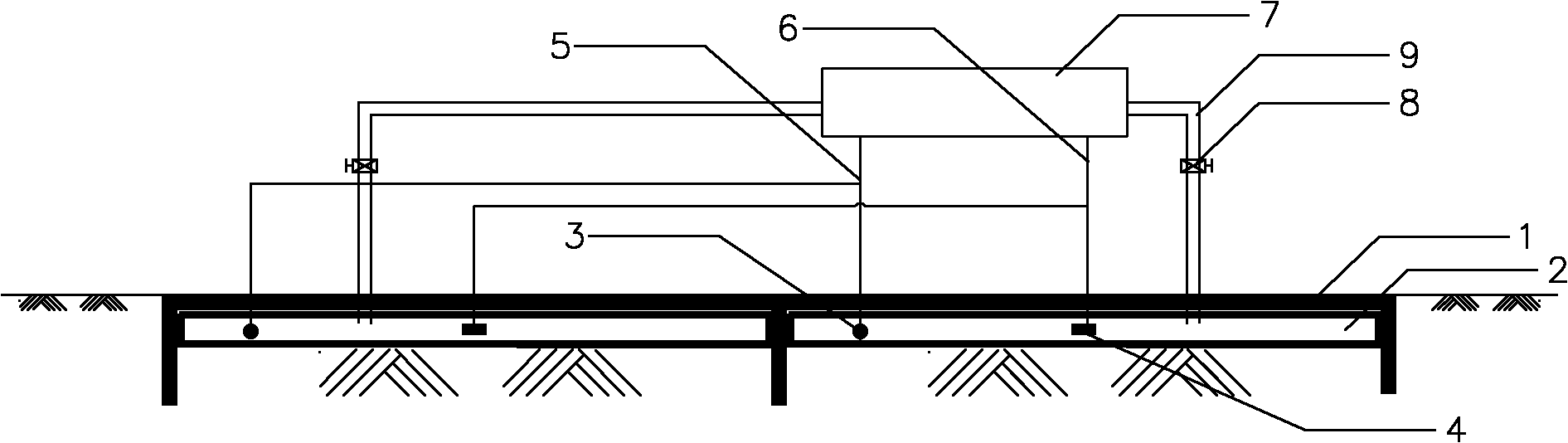

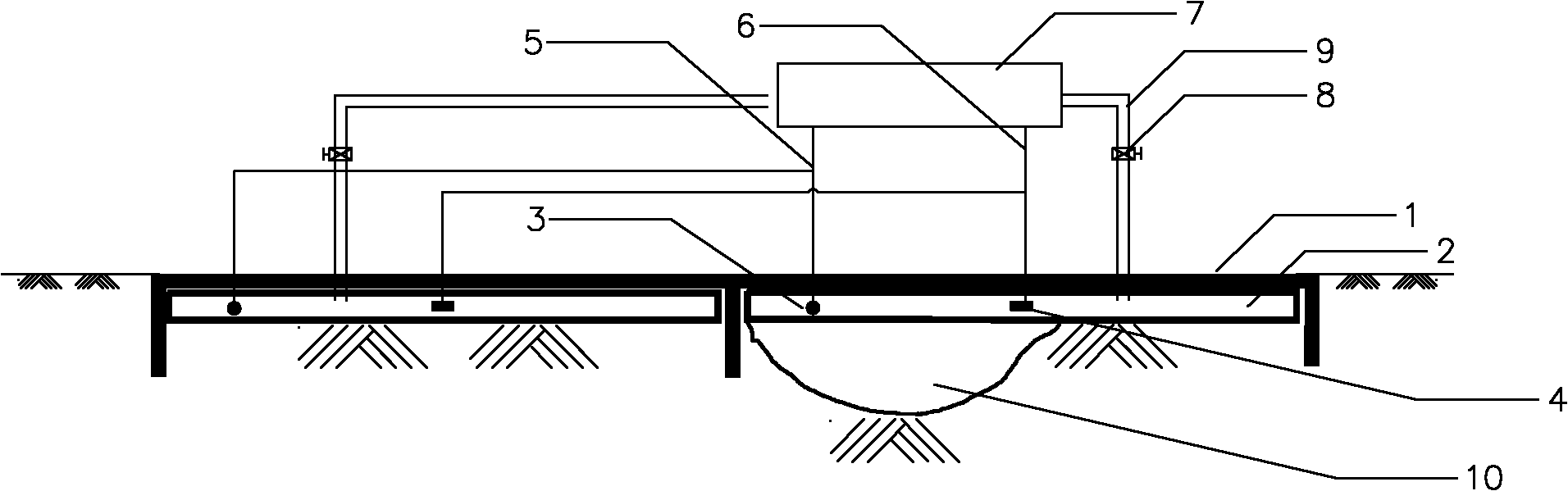

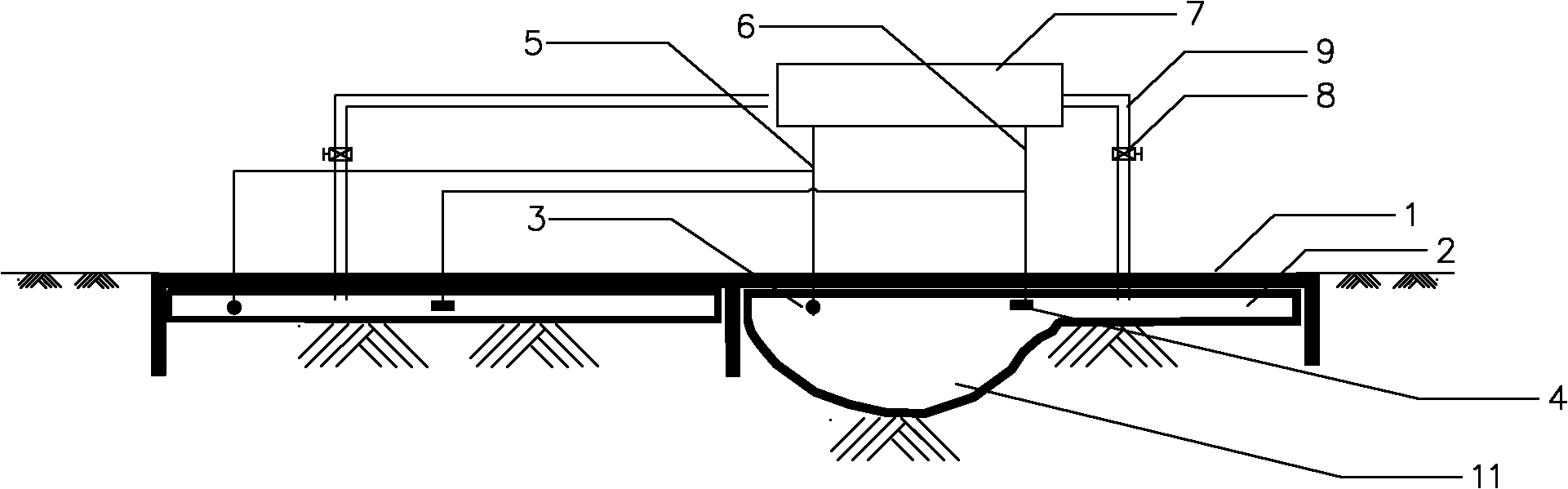

Sedimentation-controllable foundation system

InactiveCN102108712AImprove reliabilityImprove bearing capacityFoundation testingBridge engineeringControl system

The invention discloses a sedimentation-controllable foundation system, comprising a foundation, wherein the foundation comprises a top plate, a deformable capsule made of an elastic material is arranged under the top plate and connected with a water pipe, and the water pipe is provided with a valve; a pressure sensor and a displacement sensor are arranged in the capsule, the pressure sensor and the displacement sensor are connected with a control system, and the valve is controlled by the control system. In the sedimentation-controllable foundation system, the capsule is arranged between the groundwork and the top plate of the foundation, and deformation of the groundwork is filled by the capsule which is injected with water, so that the levelness and the stability of the foundation are improved; automation of the system is implemented through the sensors and the control system, so that the reliability of the foundation can be effectively increased, the bearing capacity and the stability of the foundation are further improved; the sedimentation of the foundation is controlled well; the device used in the system is simple; and the construction is simple and convenient, economic benefit is obvious, and the total cost of the project is low. The sedimentation-controllable foundation system is suitable for building engineering, port engineering, ocean engineering, water conservancy engineering and bridge engineering.

Owner:TIANJIN UNIV

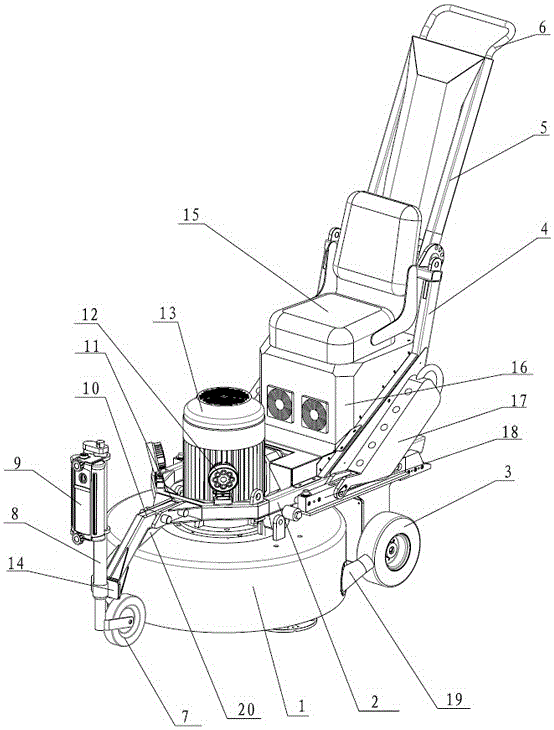

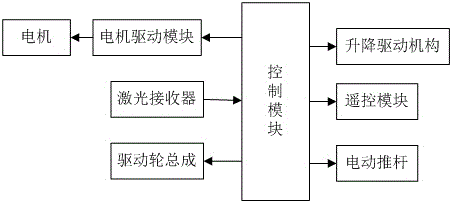

Grinding machine with laser positioning function and control method of grinding machine

The invention relates to a grinding machine with a laser positioning function and a control method of the grinding machine. The grinding machine comprises a grinding assembly and a rack; the grinding assembly is arranged on the rack; a grinding base is arranged at the bottom of the front end of a supporting frame and is connected with the supporting frame through a lifting driving mechanism; the two sides of the bottom portion of the rear end of a supporting rod are each provided with a rear wheel, and the rear wheels are driven through a driving wheel assembly; a universal wheel is arranged at the front end of the supporting rod and is fixedly connected with the front end of the supporting frame through a front support; an electric push rod for controlling the universal wheel to ascend and descend is further arranged on the universal wheel, and a pushing rod of the electric push rod is fixedly connected with the universal wheel; and a laser receiver is further arranged at the front end of the electric push rod, and the laser receiver, a motor, the lifting drive mechanism, the electric push rod and the driving wheel assembly are all electrically connected with a control module. The grinding machine has the beneficial effects that the grinding height is controlled through the laser receiver, and it is ensured that the parallelism degree of a grinding plane is consistent.

Owner:JINJIANG XINGYI POLISHING MACHINERY

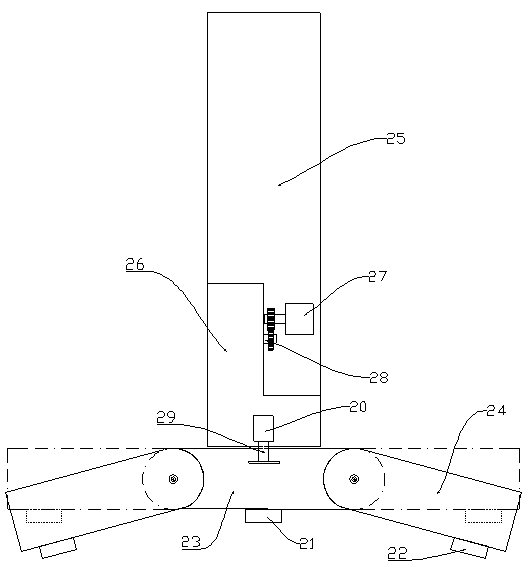

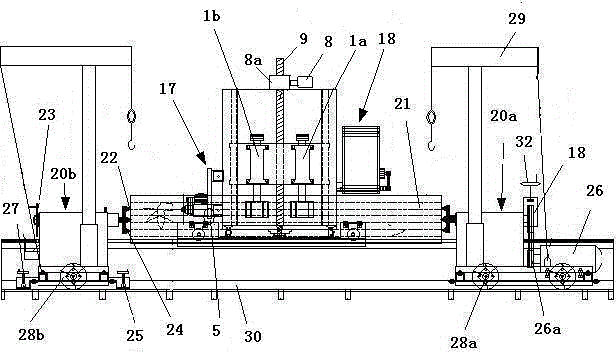

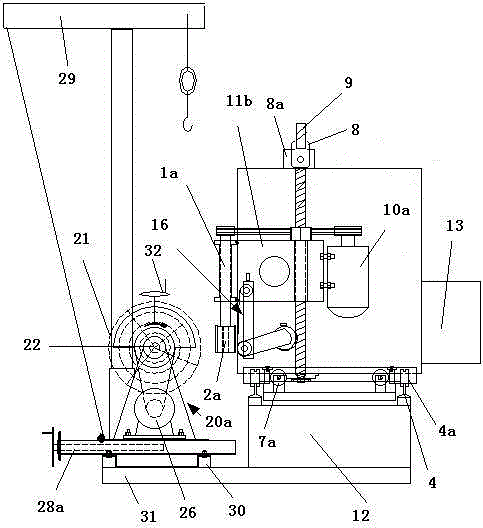

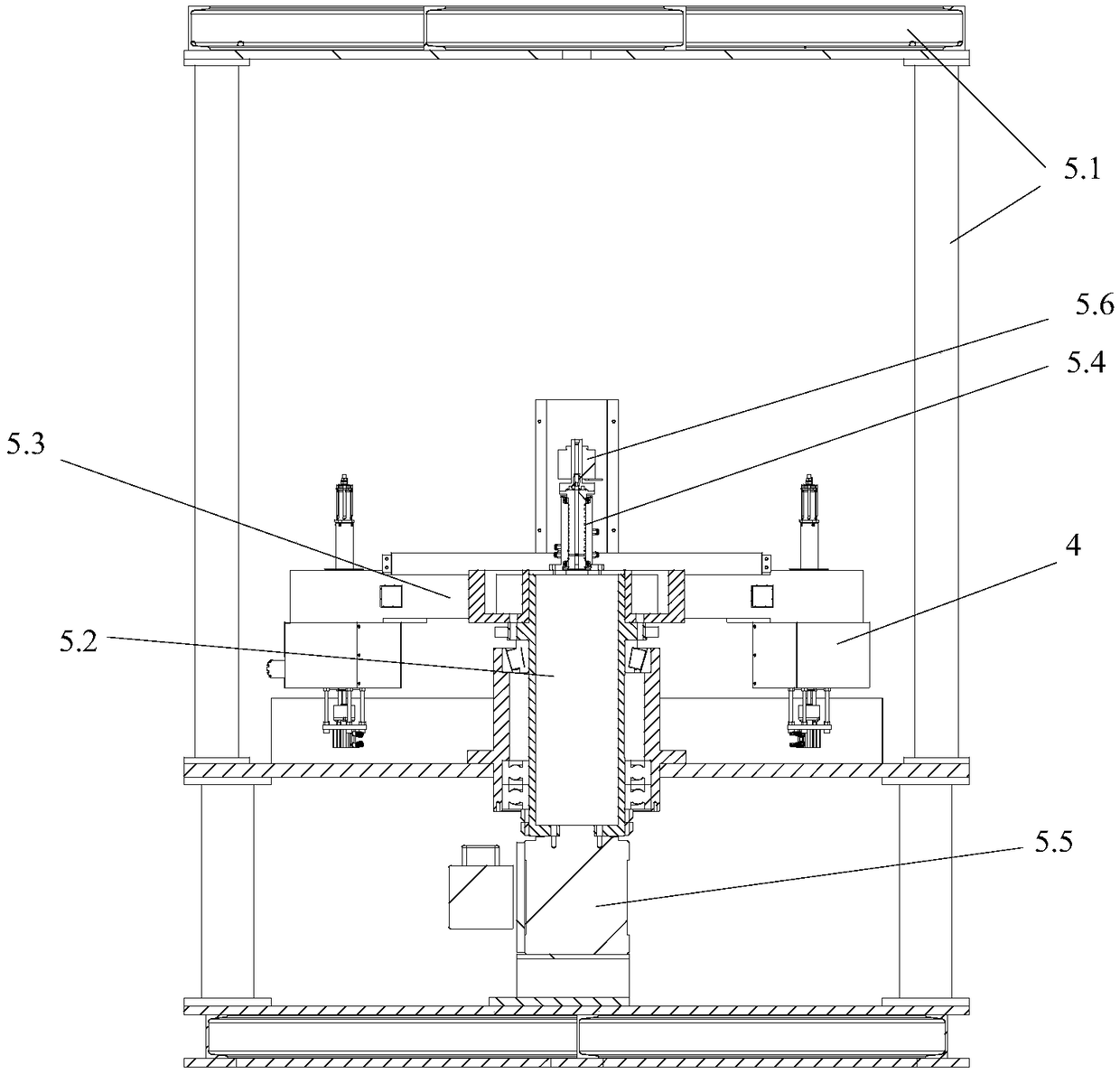

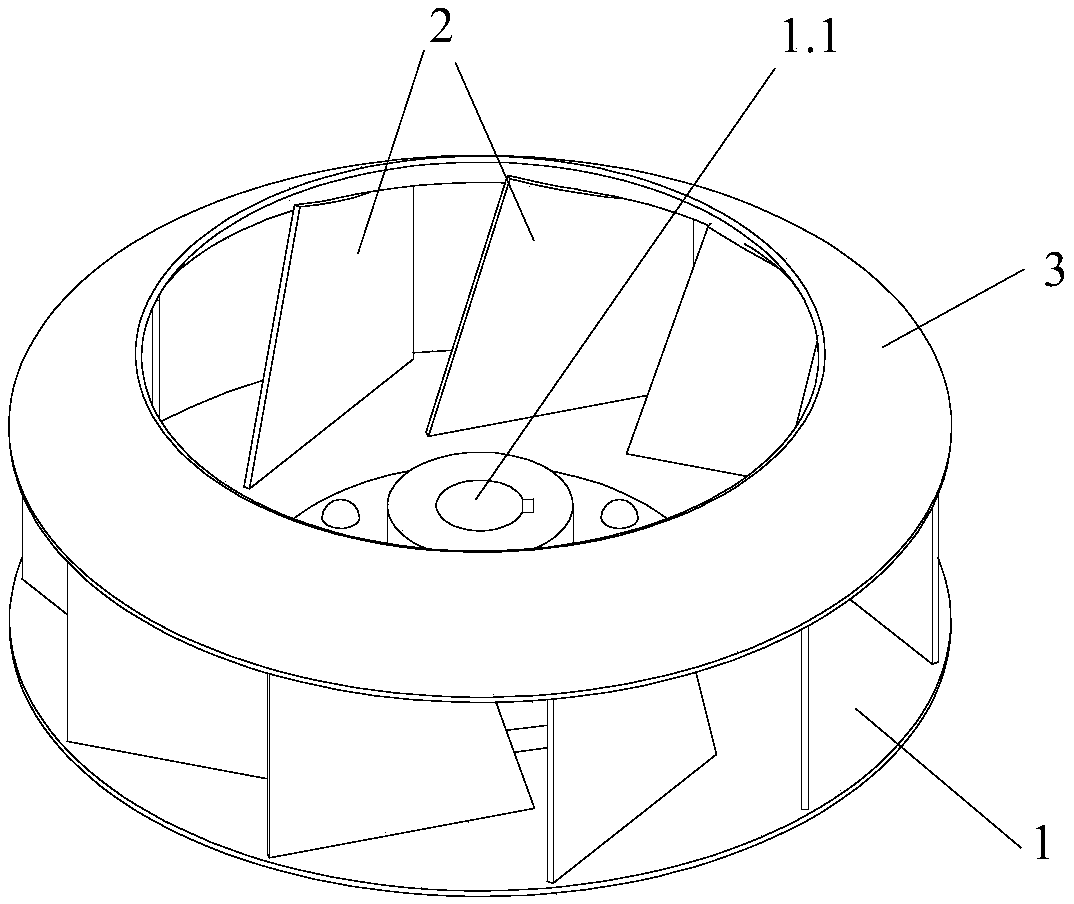

Multi-station full-automatic welding equipment for fan impeller machining

PendingCN109262189ASolve efficiency problemsImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesImpellerWork in process

The invention provides multi-station full-automatic welding equipment for fan impeller machining. The multi-station full-automatic welding equipment comprises chassis positioning mechanisms, a main frame mechanism, a blade and chassis assembling positioning mechanism located at a second machining station, a first welding mechanism used for welding blades and a chassis at a second machining station, a top cover feeding mechanism located at a third machining station, a second welding mechanism used for conducting spot welding on top covers and the blades on the third machining station, a turningmechanism located on a fifth machining station, a third welding mechanism used for conducting all welding on the turned top cover welding semi-finished products and turned blade welding semi-finishedproducts on the fifth machining station, so that a fan impeller finished product is obtained and a discharging mechanism. The chassis positioning mechanisms are separately connected with the main frame mechanism. According to production demands, full-automatic welding can be conducted on the fan impeller to replace a traditional manual welding technology, and therefore welding efficiency, weldingquality and welding precision are improved.

Owner:FOSHAN GOOGOL AUTOMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com