High-precision target material measurement system and method

A measurement system, high-precision technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problem of only two-dimensional data collection, etc., to achieve the effect of precise control and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

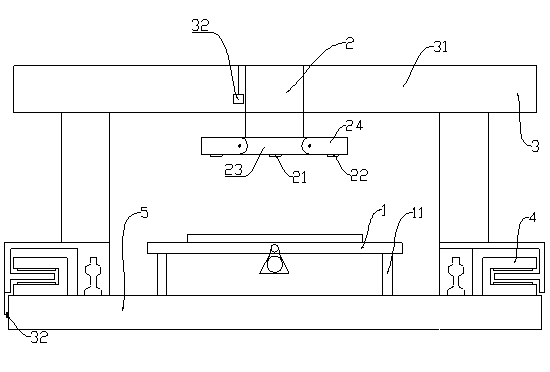

[0054] A high-precision target measurement system described in this embodiment has a structural block diagram as shown in Question 1, including: a detection platform 1 for placing targets, and the detection platform 1 can be installed on some existing detection platforms as required. On the platform 1; the optical detection unit 2 is arranged above the detection platform 1 and can move in a three-dimensional range, and the optical detection unit 2 uses a controllable moving mechanism to move in a three-dimensional space for collecting the detection The image of the target placed on the platform 1; the data collection and processing unit, which adopts the data collection and processing mechanism, is connected with the optical detection unit 2 and the detection platform 1 respectively, collects the sample detection parameters, and performs corresponding calculation and processing on them , sending; the control unit can adopt automatic control devices such as PLC, and is connected...

Embodiment 2

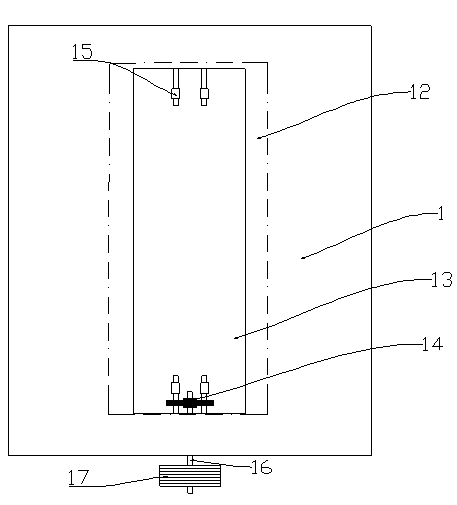

[0059] On the basis of the high-precision target measurement system described in Embodiment 1, a set of the limiting components preferably includes a first limiting member 14 and a second limiting member 15, and the first limiting member 14 is preferably two limit rods arranged in parallel, and the distance between the two limit rods is smaller than the width of the target for holding the target, such as image 3 Shown; The washer that increases friction is preferably arranged on the said limit rod, and said washer is preferably a rubber ring, and said second limit member 15 includes two limit rods arranged in parallel, and two said limit rods The distance between the rods is smaller than the width of the target material; the second limiting member 15 is independently and freely rotatable, and is fixed on its supporting column in the form of rollers. When the cylindrical target is placed on its upper part, the first limiting member 14 is driven to rotate, and at this time the ...

Embodiment 3

[0064] On the basis of a high-precision target measurement system described in the above embodiments, as figure 2 As shown, a base 5 is provided at the bottom of the detection platform 1, the detection platform 1 and the base 5 are detachably connected, the base 5 provides a stable working environment for the detection platform 1, and provides a buffer role.

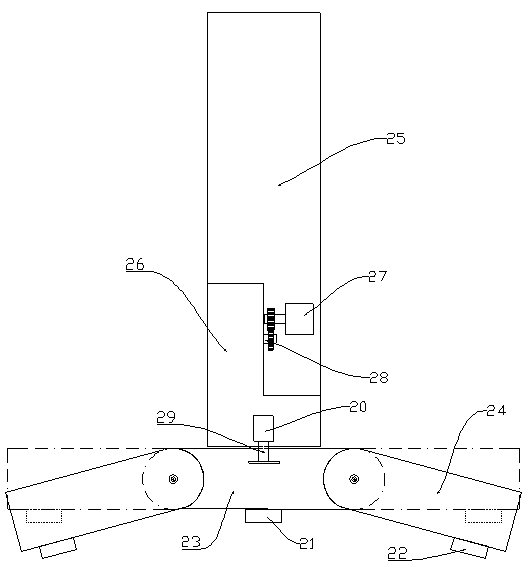

[0065] Y-axis guide rails 4 are respectively arranged on both sides of the base 5, and the two Y-axis guide rails 4 are respectively connected to the two bottom ends of a gantry 3, and the gantry 3 can be positioned on the Y-axis. Move along the Y axis on the guide rail 4, and the crossbeam of the gantry 3 is also provided with an X-axis guide rail 31; the X-axis guide rail 31 and the Y-axis guide rail 4 preferably adopt magnetic guide rails, and the magnetic rails run Accurate, to ensure the accuracy of the measurement, the optical detection unit 2 is connected with an X-axis moving mechanism 211, the X-axis moving me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com