Patents

Literature

523results about How to "Avoid skidding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

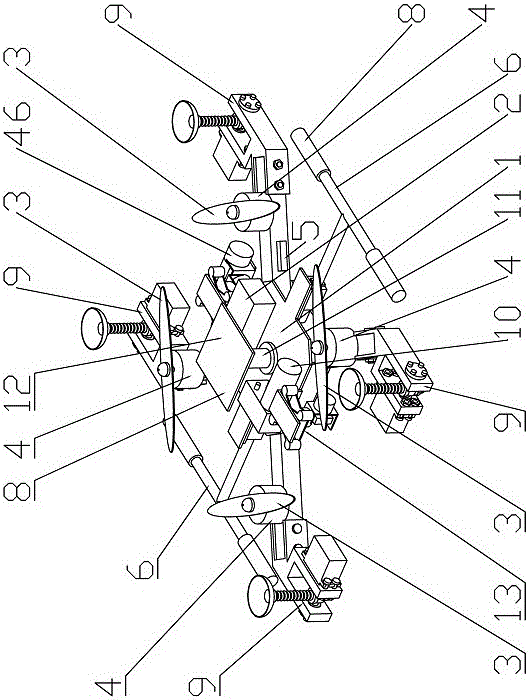

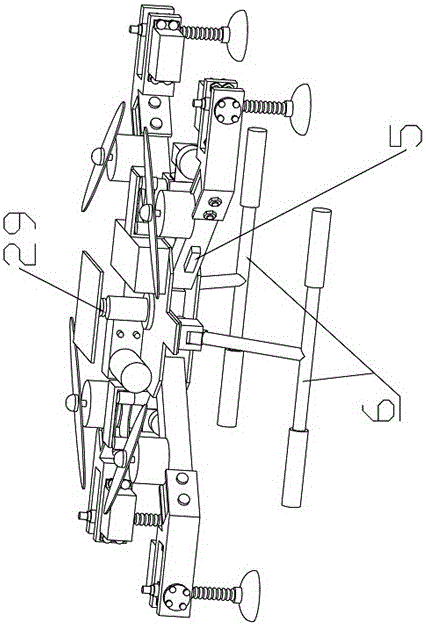

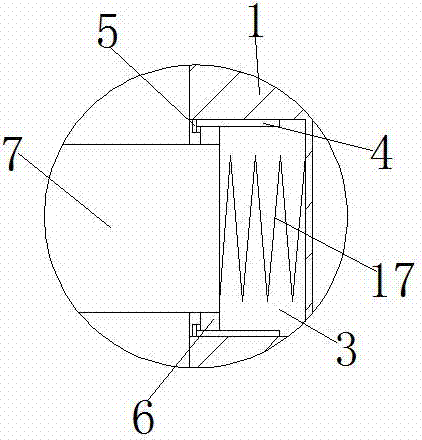

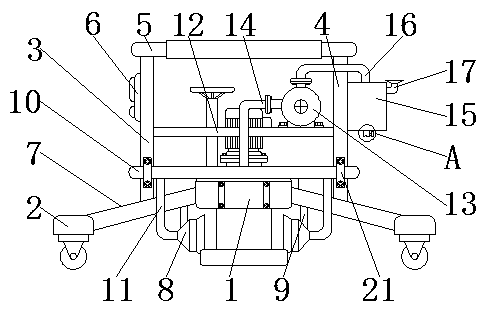

Intelligent flying robot capable of perching on walls at different inclination angles

InactiveCN105667779AExtend detection timeRealize intelligent adsorptionRotocraftControl systemEngineering

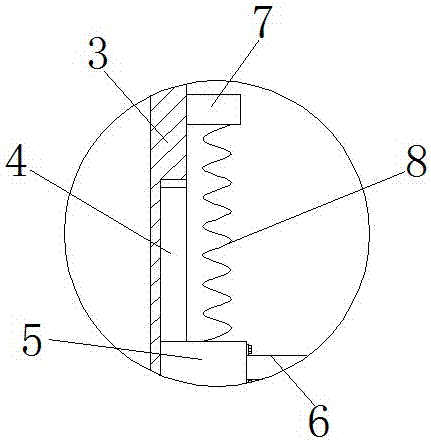

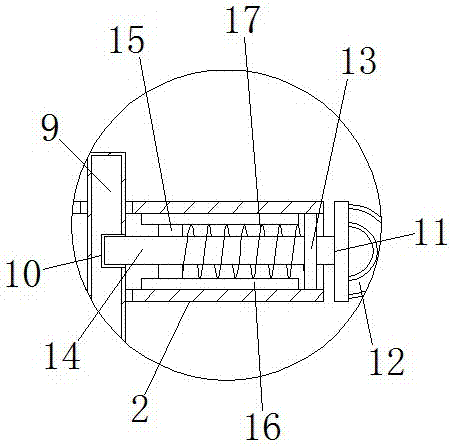

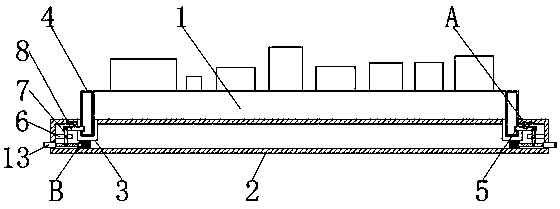

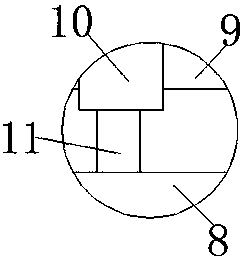

The invention relates to an intelligent flying robot capable of perching on walls at different inclination angles, and belongs to robots and aircrafts.The intelligent flying robot comprises a flying system, an adsorbing system and a control system, the flying system is a robot body, the adsorbing system is installed on the flying system, the control system controls the flying system and the adsorbing system so that the flying robot can be adsorbed on the walls at different inclination angles, and the flying state and the adsorbing state can be switched freely.The intelligent flying robot has the advantages of having the function of perching on the walls, and as perching power is far lower than flying power of the robot, the time for detecting a fixed target is substantially prolonged.Intelligent adsorption of the robot is achieved by adopting a wall inclination angle measurer, and the flying state and the adsorbing state can be switched freely.The flying robot can be adsorbed on the walls at different inclination angles, and the application range of the robot is broadened.The robot is tightly attached to the walls during adsorption, and therefore concealing performance is greatly improved.An antiskid plate and supporting legs are adopted to assist in adsorption, the adsorption effect is stable, and the robot is prevented from slipping during adsorption.

Owner:JILIN UNIV

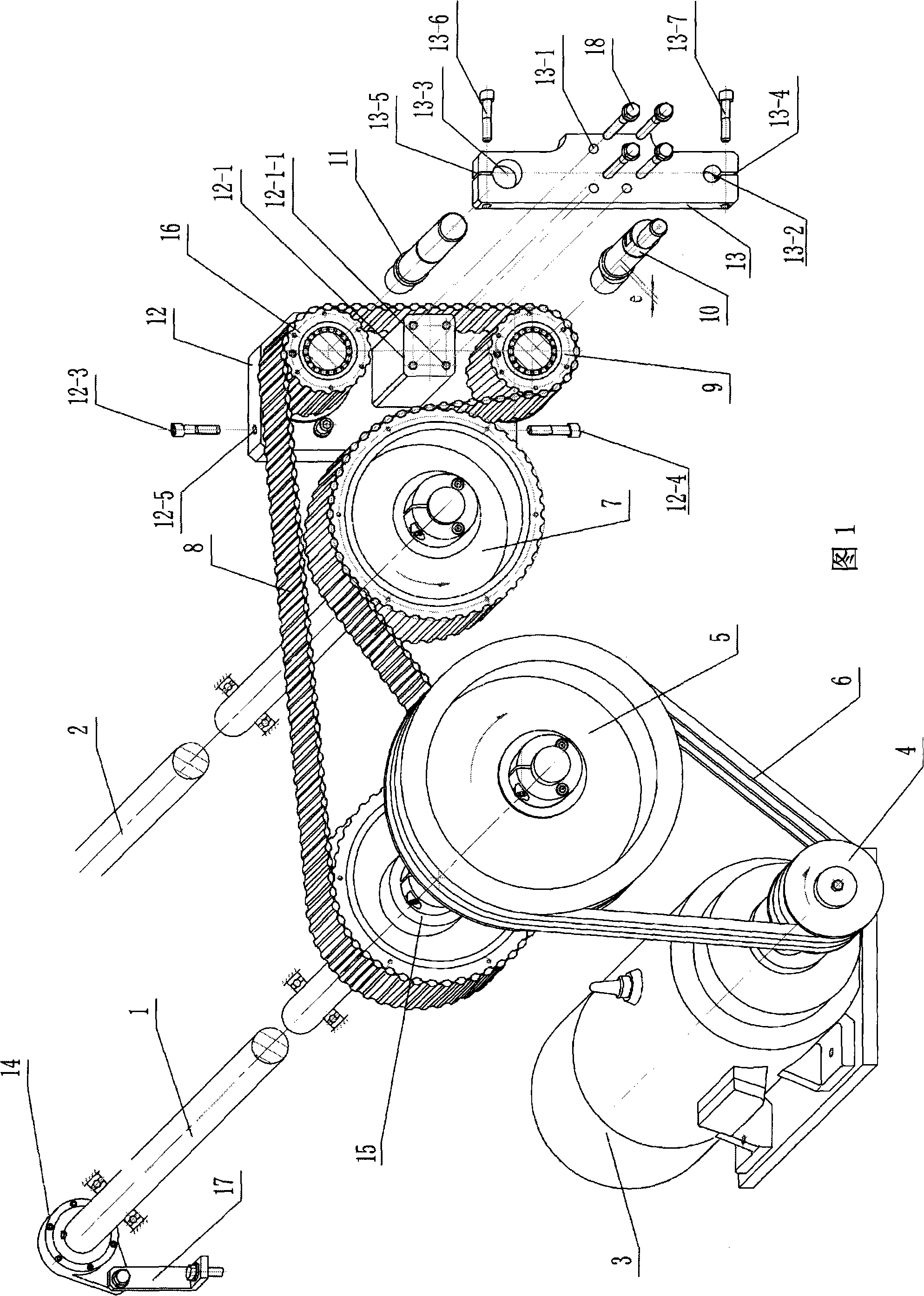

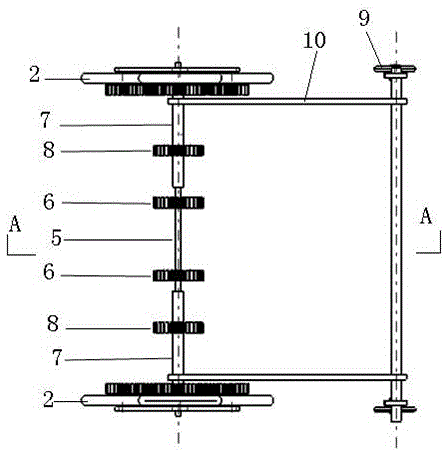

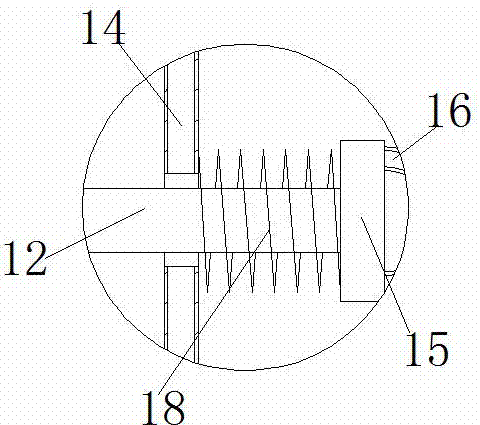

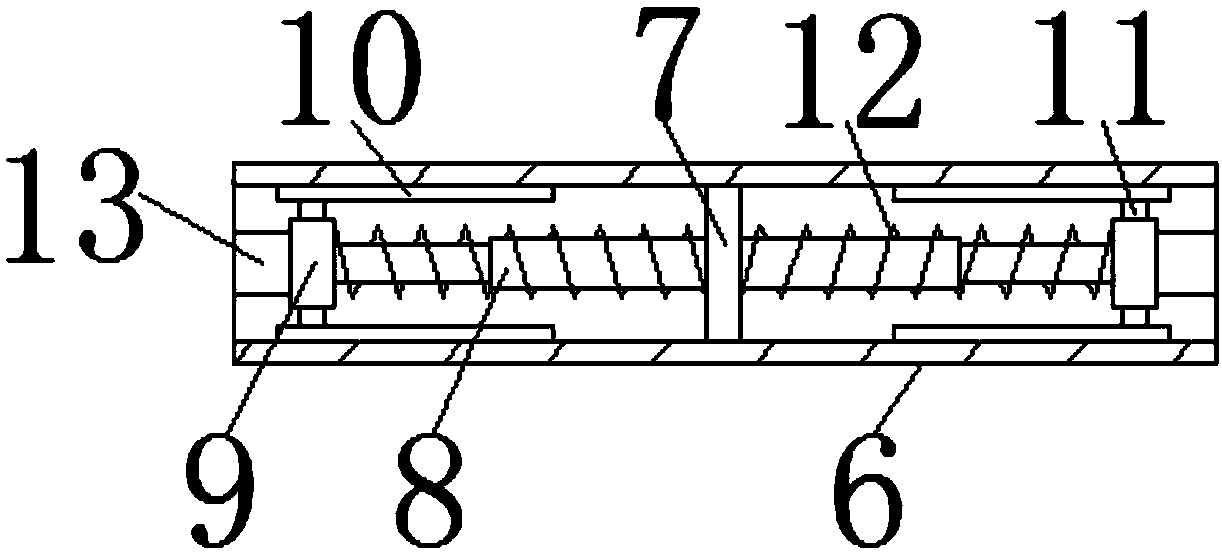

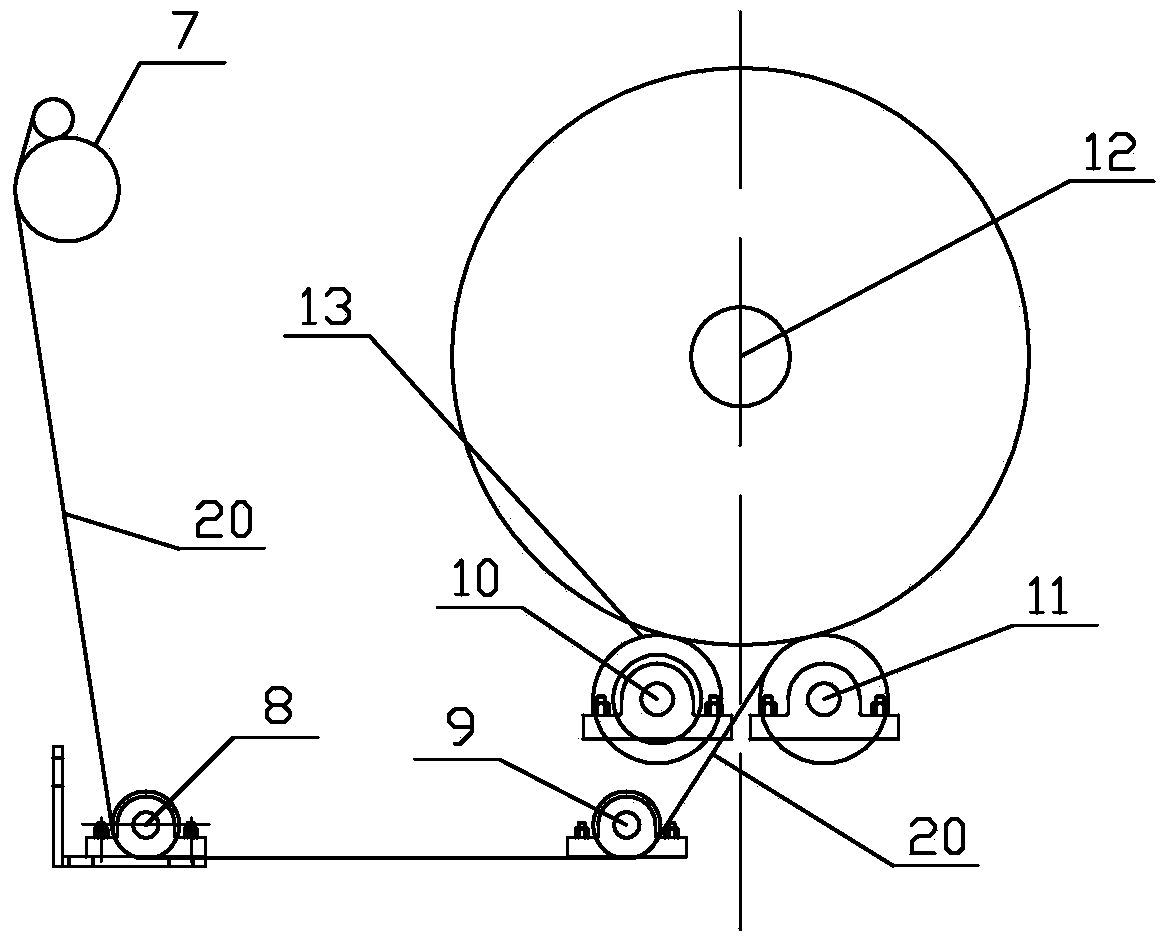

Main transmission device of double-needle warp knitting machine

InactiveCN101255633AGuaranteed to workEnsure strict synchronicityGearingFlat warp knitting machinesEngineeringPulley

To realize synchronous opposite rotation of a pair of main shafts of a double-needle warp knitted machine, the invention relates to a main driving device of the double-needle warp knitted machine, comprising: a first main shaft, a second main shaft, an electric motor, a small belt pulley fixed on an output shaft of the electric motor, a large belt pulley fixed on a front end head of the first main shaft, a first synchronous belt pulley, a second synchronous belt pulley, a guide shaft fixing pedestal, an upper guide wheel, a lower guide wheel, an upper guide shaft, a lower guide shaft and a double-surface synchronous belt; the first synchronous belt pulley is fixed on the first main shaft, the second synchronous belt pulley is fixed on the second main shaft; the upper guide wheel is supported on the upper guide shaft through a bearing, and a top point at the upper end of the upper guide wheel is higher than that at the upper end of the second synchronous belt pulley; the double-surface synchronous belt is pressed onto the second synchronous belt pulley with an outer tooth belt thereof facing downwards, and the outer tooth belt is meshed with the second synchronous belt pulley; and the double-surface synchronous belt is provided in manner of tension between the first synchronous belt pulley, the upper guide wheel, the lower guide wheel and the second synchronous belt pulley.

Owner:CHANGZHOU TIANYI TEXTILE MACHINERY

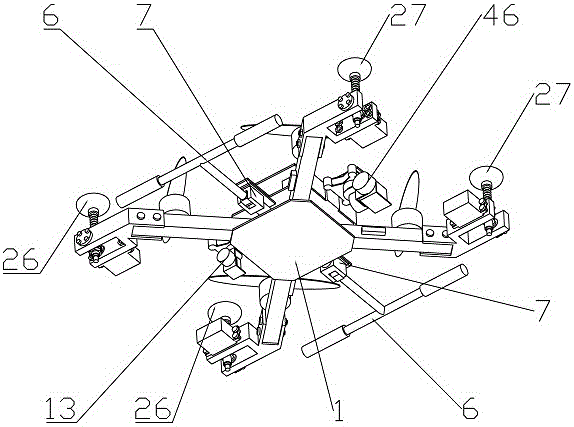

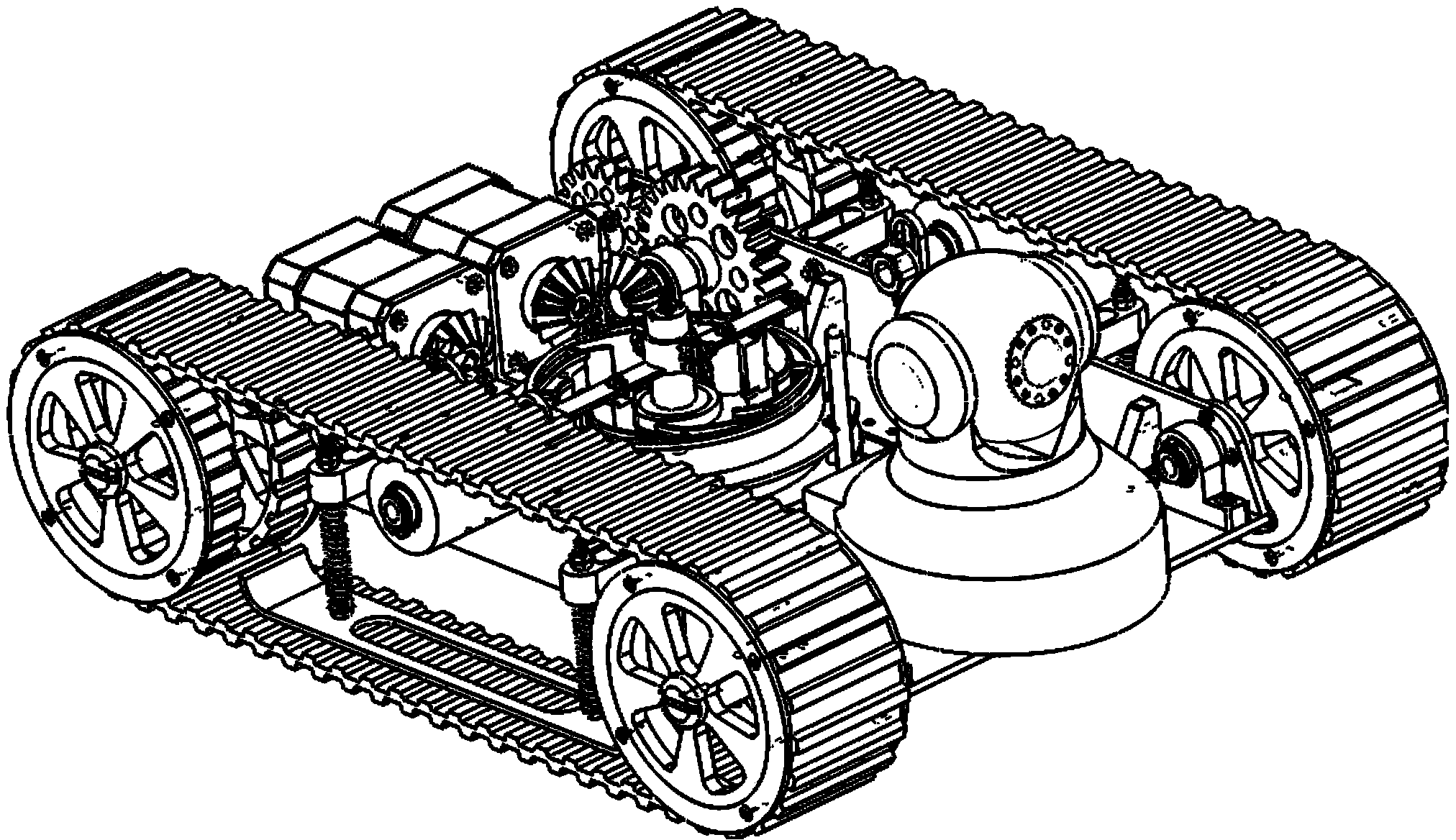

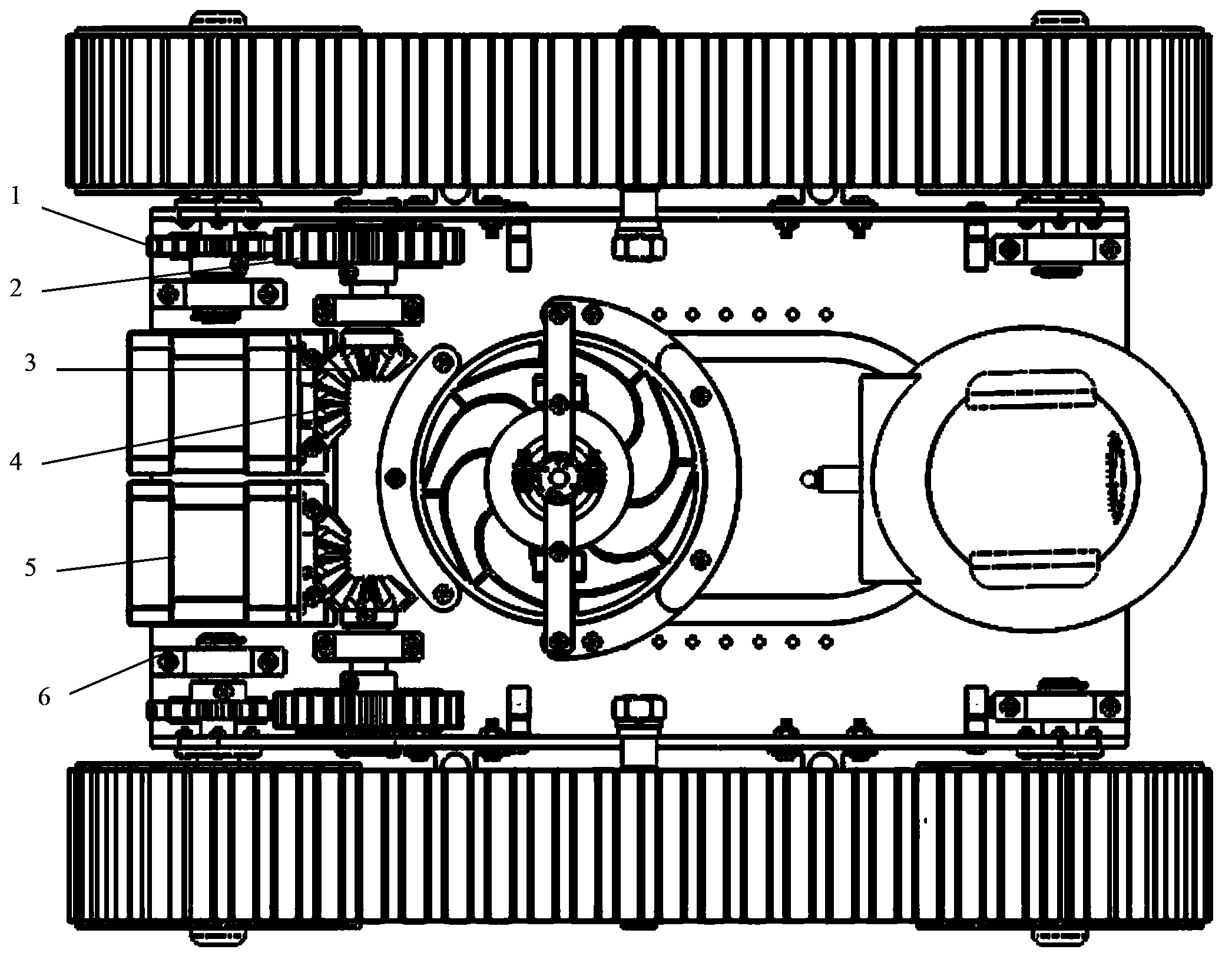

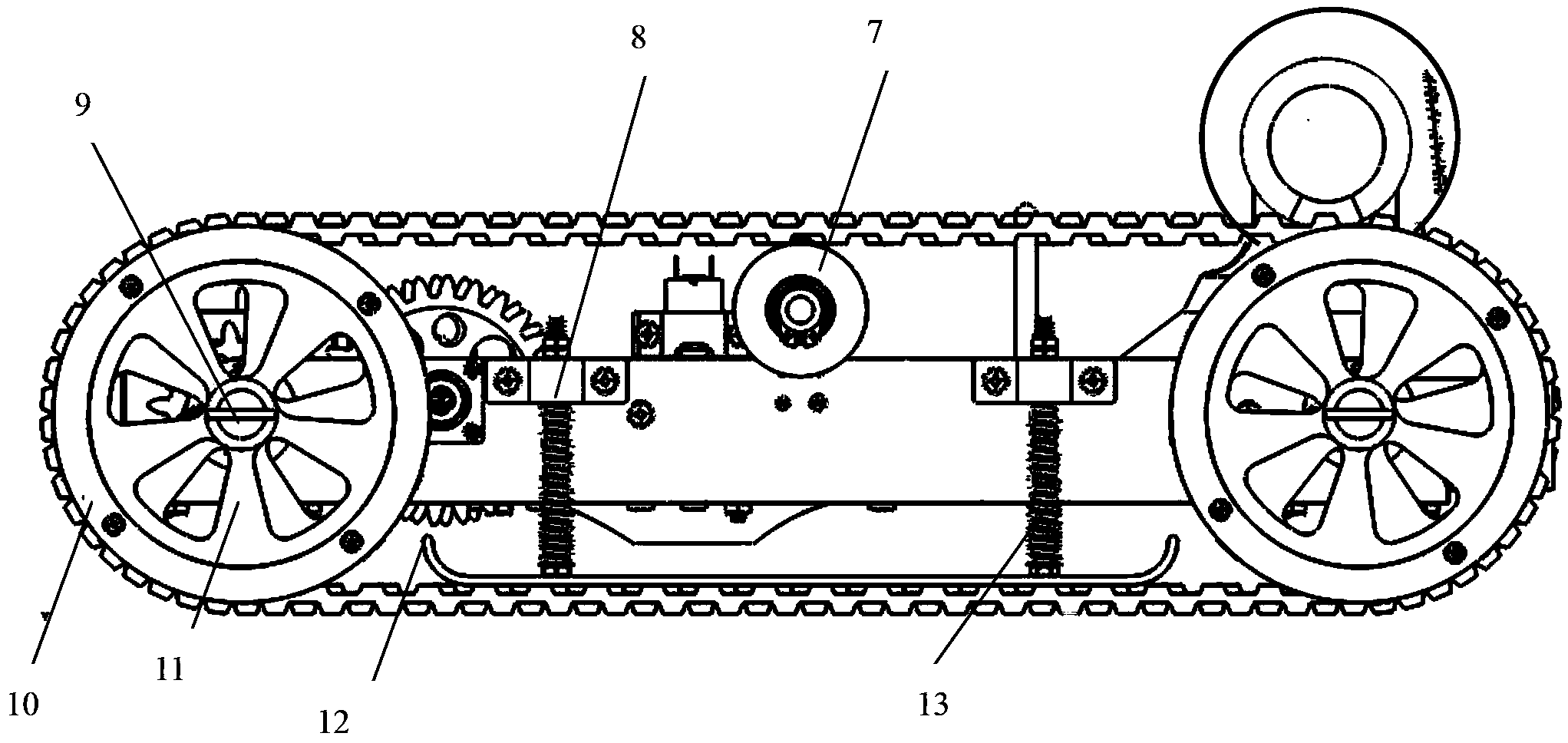

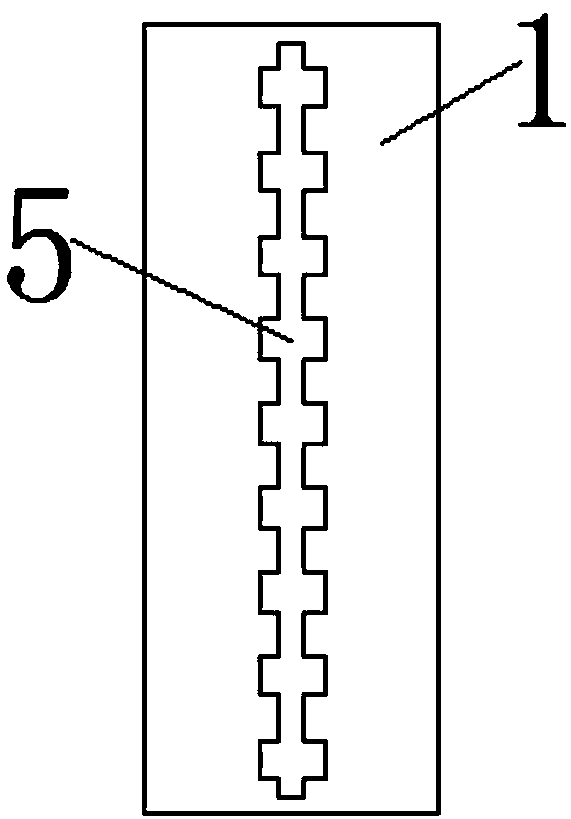

Tracked intelligent traveling-on-wall platform

InactiveCN104108431AImprove wear resistanceExtend your lifeEndless track vehiclesElectrical engineering technologyEngineering

A track intelligent traveling-on-wall platform is an innovative product of organic integration of electromechanical devices and technologies and reflects the development tendency of the mechanical-electrical integration technology. The platform mainly comprises a stepping motor driving system, a gear transmission system, a track traveling system, a track adjustment system and a vacuum absorption system, and integrates multidisciplinary knowledge and technologies of mechanical design, electronic circuits, sensing detection, program control, feedback regulation, image processing, wireless transmission and the like. The platform can be stably adsorbed and can perform stable forwarding and free turning on rough or smooth vertical surfaces such as concrete wall surfaces, ceramic exterior walls, glass curtain walls and metallic wall surfaces, and has functions of automatic obstacle avoidance, tracking, real-time monitoring, image feedback and the like. The platform has the advantages of high adsorption force, good load performance, stable traveling, convenient control and the like, and can be popularized and applied to military reconnaissance, fire detection, oil tank measurement, road deicing, industrial production, antarctic science investigation and the like after hitting, defending and grabbing and lifting devices and the like are carried on the platform.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

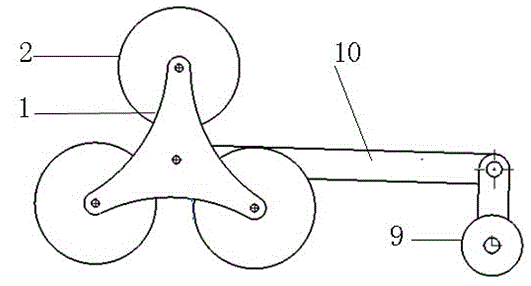

Novel electric stair climbing wheelchair chassis and design method thereof

The invention discloses a novel electric stair climbing wheelchair chassis and a design method thereof. The method comprises the steps that a star wheel mechanism is adopted as a driving walking base of an electric stair climbing wheelchair. According to the walking mode of the star wheel mechanism, a star wheel automatically rotates so that the electric stair climbing wheelchair can horizontally move on the horizontal ground, and the star wheel rotates around the rotation center line of the star wheel mechanism so that the electric stair climbing wheelchair can achieve the function of climbing stairs. According to the two walking modes, the rotation center line of the star wheel mechanism is provided with a driving center gear and a center shaft which is independent from the driving center gear, the driving center gear drives the star wheel to automatically rotate, the center shaft drives the star wheel mechanism so that the star wheel can rotate around the rotation center line of the star wheel mechanism, and the motor drives the center shaft and the center gear through an electromagnetic clutch. According to the novel electric stair climbing wheelchair chassis, the phenomenon of skid prevention of the star wheel mechanism in an existing stair climbing wheelchair chassis is avoided, the shaft and the star wheel mechanism are locked in an active mode when a user climbs stairs, and therefore the star wheel mechanism turns over to climb the stairs.

Owner:GUIZHOU UNIV

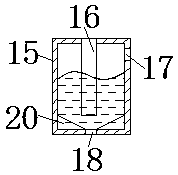

Agricultural machine fertilizer box

PendingCN107258180ASolve the inconvenience of disassemblyImprove practicalityFertiliser distributersAgricultural engineeringAgricultural machinery

The invention discloses a novel agricultural machine fertilizer box. The novel agricultural machine fertilizer box comprises a fertilizer box body, supporting rods are arranged at two sides of the fertilizer box body, grooves are arranged in two sides of the fertilizer box body, the tops and the bottoms of the grooves are fixedly connected with first slide rails, the inner walls of the two first slide rails are in sliding connection with first slide blocks, clamping blocks are fixedly connected between the two first slide blocks, and one sides, far from the supporting rods, of the clamping blocks, are fixedly connected with first springs. The mutual cooperation of the supporting rods, the grooves, the first slide rails, spacing blocks, the first slide blocks, the clamping blocks, chutes, clamping grooves, second slide rails, second slide blocks, pushing rods, bearing rods, spacing plates, connecting blocks, handles, the first springs and second springs solves the problem of inconvenient dismounting in the dismounting process, so a large amount of manpower of a dismounting person is saved, thereby the box can be conveniently used by a user.

Owner:乐陵市瑞泽农作物种植专业合作社

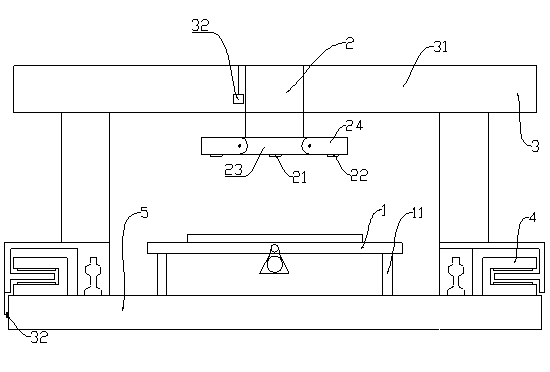

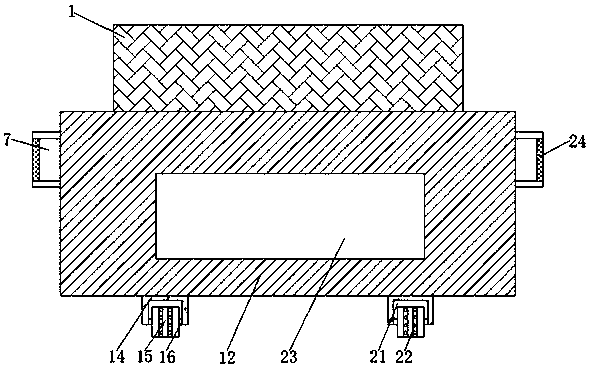

High-precision target material measurement system and method

The invention provides a high-precision target material measurement system and method. The system comprises a detection platform, an optical detection unit, a data collecting and processing unit and a control unit, wherein a hollow cavity is formed in the middle of the detection platform and provided with a detachable movable plate, the hollow cavity can be totally covered with the movable plate, at least one limiting assembly is arranged in the hollow cavity, the limiting assembly is used for fixing target materials and can drive the target materials to rotate, and the limiting assembly is connected with a driving device and is driven by the driving device; the optical detection unit comprises a lens and a raster projection device, and because the detection platform and the optical detection unit are movable, by controlling the movement direction and the movement distance of the detection platform and the optical detection unit, high-precision three-dimensional detection on any position of the target materials in different specifications and shapes can be achieved; besides, the limiting assembly can drive the target materials to rotate, and therefore the target materials do not need to be turned over in the detection process, and detection efficiency is improved.

Owner:SUZHOU JUZHEN PHOTOELECTRIC

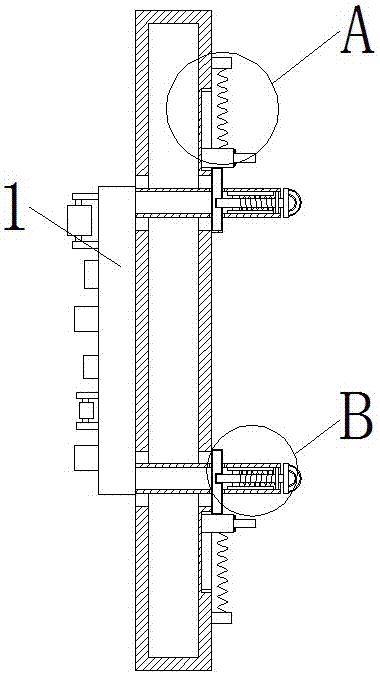

Straightening device for eliminating bending and distortion of aluminum profile

ActiveCN111790775AThe force of the roller pressure increasesReduce curvatureMetal-working feeding devicesPositioning devicesElectric machineryStructural engineering

The invention discloses a straightening device for eliminating bending and distortion of an aluminum profile, relates to the related field of aluminum profile straightening, and aims to solve the problems that for an aluminum profile with large bending degree, the feeding position slips and the bending position is stressed to be prone to generating breaking cracks in an existing straightening device. A worktable top is arranged at the upper end of a worktable; a first supporting vertical plate is fixedly connected to the rear end of one side of the upper end of the worktable top; a first rectangular long groove is formed in the first supporting vertical plate; an overturning unit is arranged on one side of the front end of the first supporting vertical plate and comprises a sliding motor,a rotating screw rod and a sliding block; a rotating motor and a speed reducer are installed on one side of the middle of the sliding block, and a turntable is installed on the other side of the middle of the sliding block; an inner driving box is arranged on one side, away from the sliding block, of the turntable; rotating connecting rods are arranged at the upper end and lower end of the front end and rear end of the inner driving box; and rotating blocks are arranged on one sides, away from the inner driving box, of the rotating connecting rods.

Owner:大冶市华厦铝业有限公司

Convenient-to-dismount-for-user circuit board

InactiveCN107278085ASolve the inconvenience of disassemblyImprove practicalityClamping/extracting meansComputer engineeringSurface plate

Owner:李杜娟

Computer mainboard mounting structure

InactiveCN107831861ASolve the cumbersome operationFast installationDigital processing power distributionMotherboardComputer engineering

Owner:湖南新融创科技有限公司

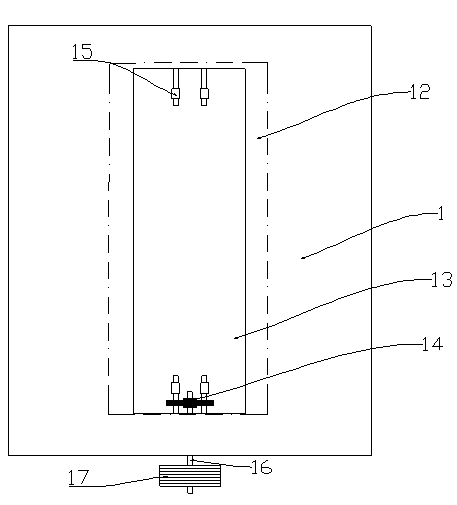

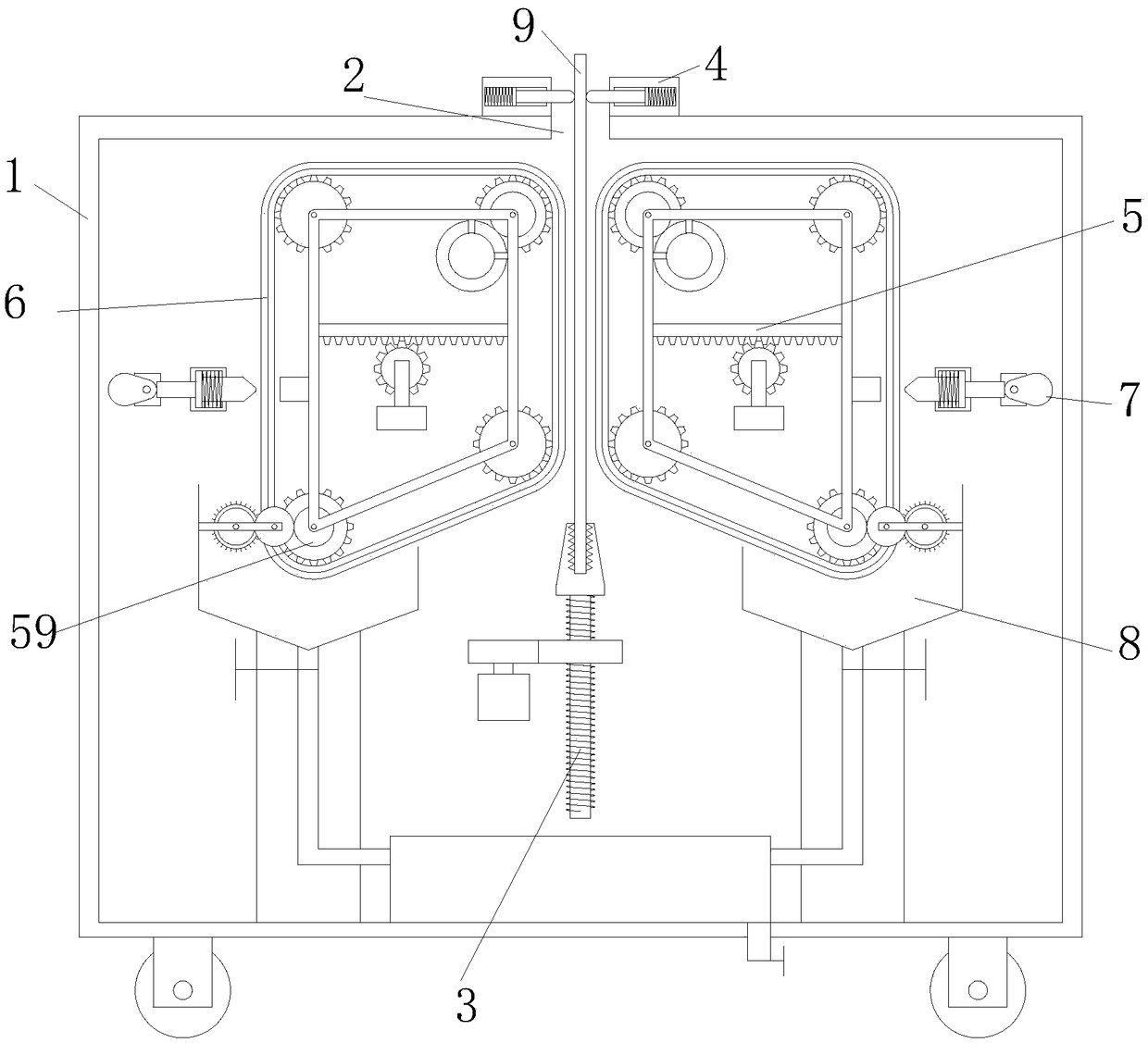

Drawing tool cleaning device

The invention discloses a drawing tool cleaning device. The drawing tool cleaning device comprises a shell, wherein a through hole is formed in the top of the shell, a clamping assembly is arranged below the through hole, fixed assemblies are symmetrically arranged on both sides of the through hole, the fixed assemblies are installed on the top of the shell, two wiping assemblies are symmetricallyarranged in the shell by using the central plane in the length direction of the through hole as a symmetrical plane, wiping cloth which is connected end to end is wound on the wiping assemblies, water wiping assemblies are arranged on one side, which is far from the clamping assembly, of the wiping assemblies, and flushing assemblies are arranged below the wiping assemblies. According to the drawing tool cleaning device, the water wiping assemblies are arranged, so that dry wiping cloth is guaranteed, and the damage to a wood drawing tool due to long-time use of wet wiping cloth is reduced; adistance adjusting motor is arranged, so that the distance between the two wiping assemblies can be adjusted, drawing tools with different thicknesses can be cleaned, and the application range of thedevice is enlarged; and a gear driving mode is adopted to drive the wiping cloth to operate, so that the condition of slipping of the wiping cloth when the water wiping assemblies are operated is avoided.

Owner:常骏驰

Front wheel driving control system and method of rubber-tyred paver and rubber-tyred paver

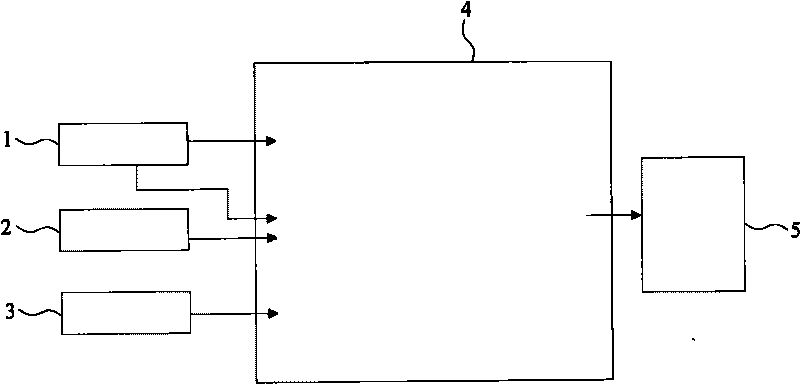

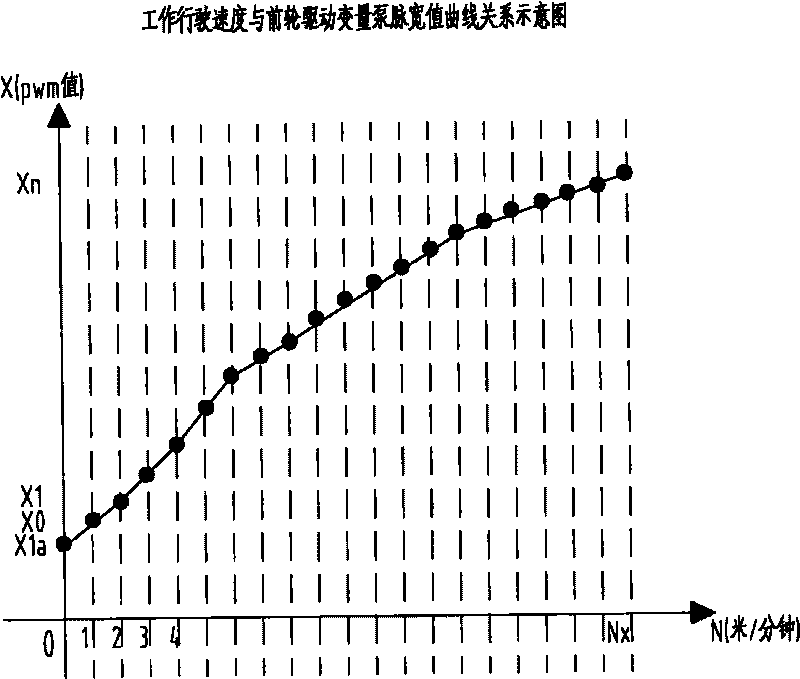

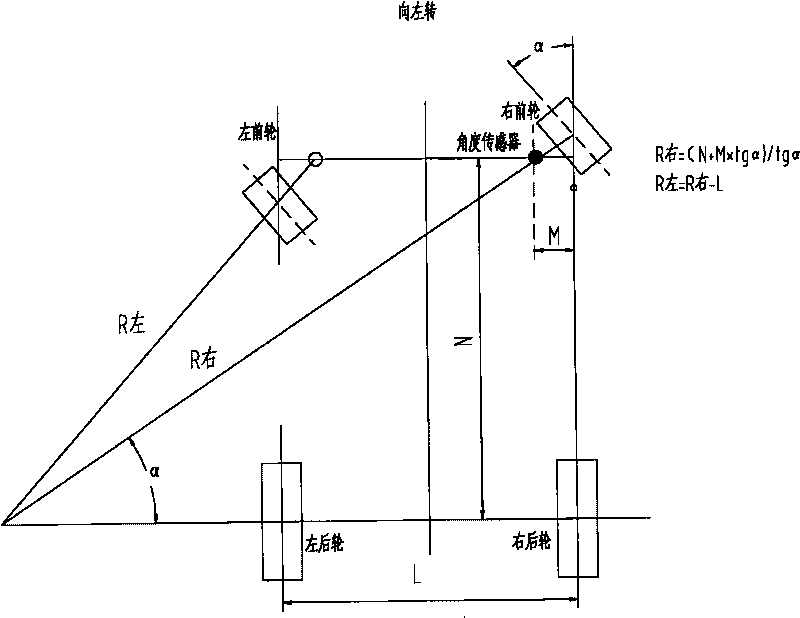

ActiveCN101696563AIncrease load capacityEnhanced load capacitySpeed/accelaration controlDeflectable wheel steeringSteering angleControl system

The invention relates to an anti-skid front wheel driving control system for a rubber-tyred paver, comprising a first detector, a second detector, a third detector and a control device. The first detector is used for detecting the working travel speed of the rubber-tyred paver; the second detector is used for detecting the steering angle of the rubber-tyred paver; the third detector is used for detecting the load pressure of the rubber-tyred paver; and the controller respectively receives signals from the first detector, the second detector and the third detector, generates and compares a first pre-output value, a second pre-output value and a third pre-output value and outputs the maximum pre-output value as the final output value to a front wheel driving hydraulic circuit of the rubber-tyred paver. Besides, the invention also relates to a rubber-tyred paver provided with the front wheel driving control system of the type and a method of the front wheel driving control system for controlling anti-skid of the rubber-tyred paver.

Owner:SANY HEAVY IND CO LTD (CN)

Electrical cabinet for electromechanical equipment and facilitating movement

InactiveCN108493777AImprove efficiencyIncrease frictionCasings/cabinets/drawers detailsSubstation/switching arrangement casingsElectric machineryPulley

The invention discloses an electrical cabinet for the electromechanical equipment and facilitating movement. The electrical cabinet includes an electrical cabinet body; a bottom surface of the electrical cabinet body is fixedly connected with a base; two symmetrical through grooves are formed in the bottom surface of the base; a cavity is formed in the interior of the base; an inner bottom wall ofthe cavity is fixedly connected with two symmetrical sleeves; the inner bottom wall of the cavity is fixedly embedded with a second bearing; and lifting plates are arranged in the sleeves. Accordingto the electrical cabinet for the electromechanical equipment and facilitating movement, a motor, a first bearing, the second bearing, a screw ring, a movable plate, lifting rods, pulley grooves, pulley rods, pulleys and the through grooves match each other, so that the pulleys can be moved down to the bottom surface of the base, the pulley can be moved up to the interior of the base when the electrical cabinet is moved to a designated working place, thereby achieving the effect of facilitating movement; the trouble of moving the existing electrical cabinets in the market can be avoided, and the problem that the existing electrical cabinets are difficult to promote can be solved.

Owner:李理

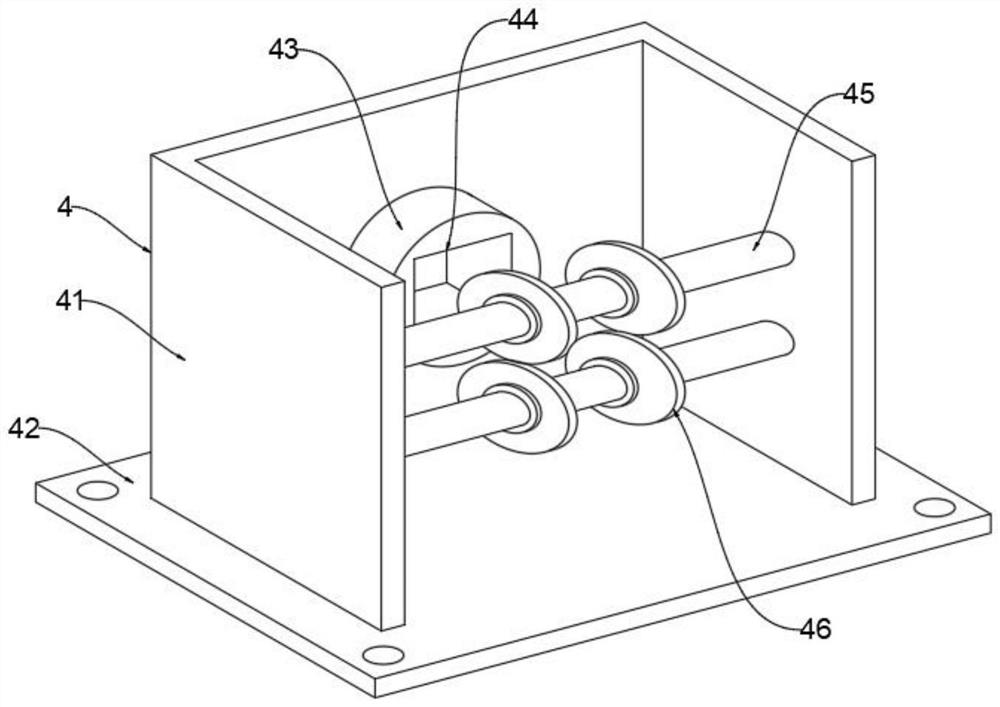

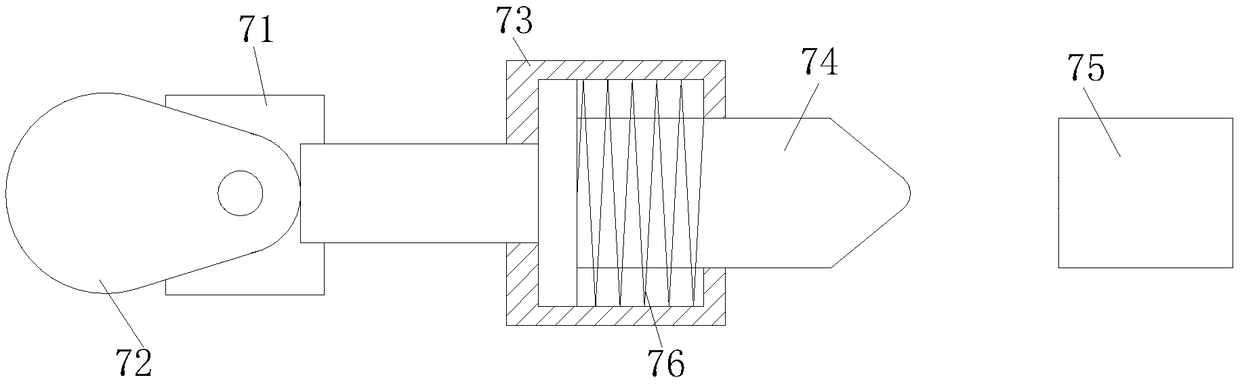

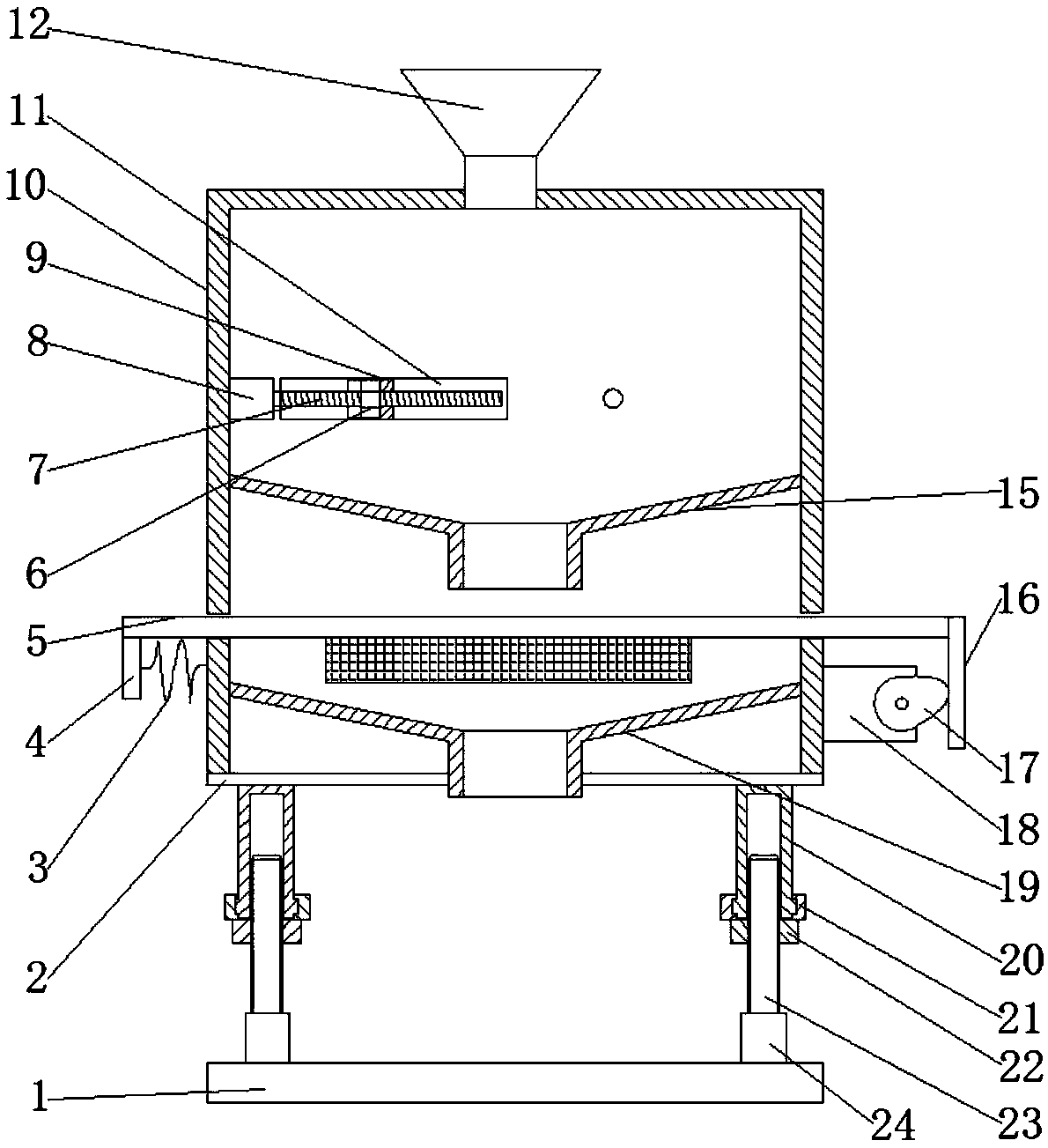

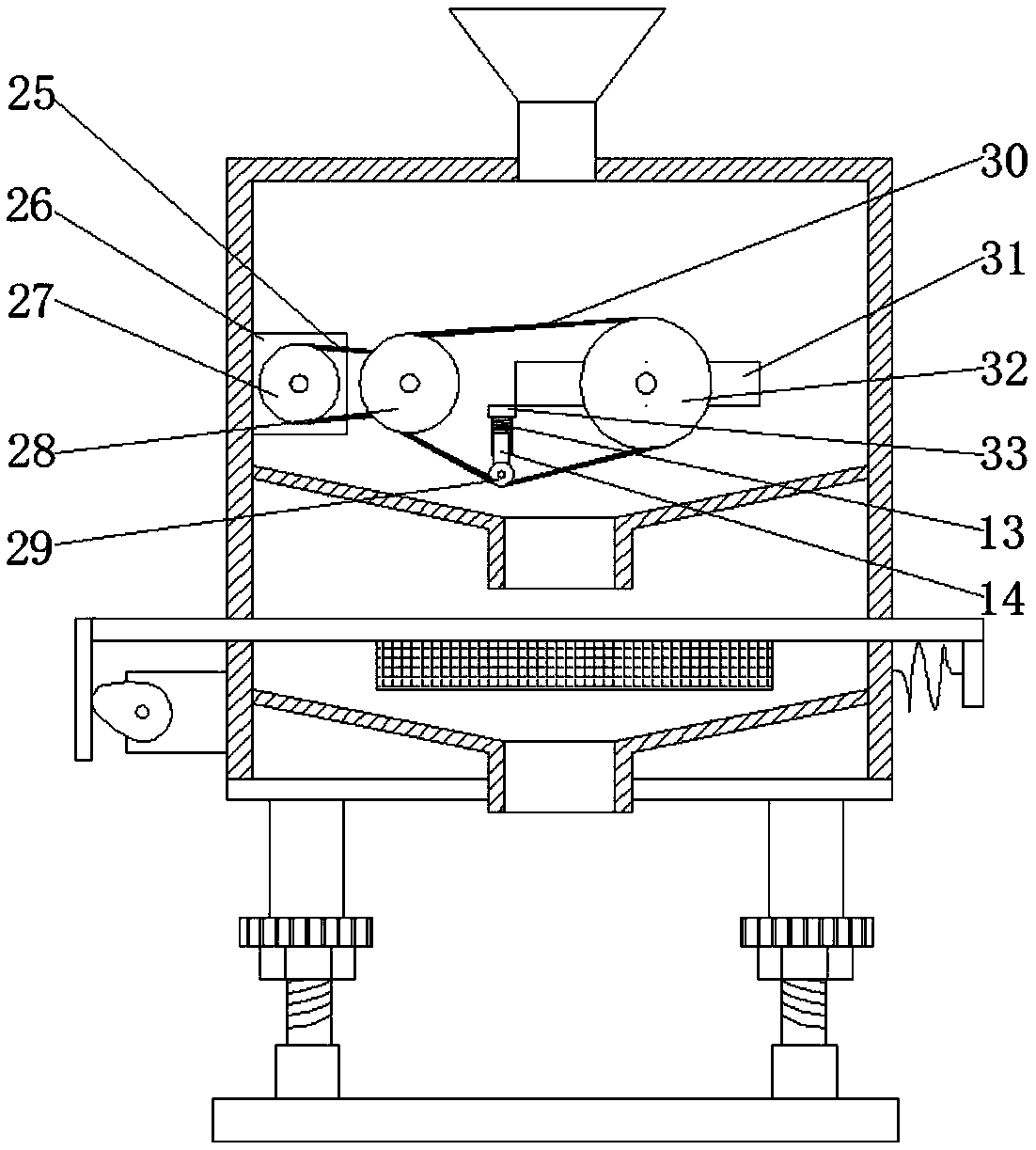

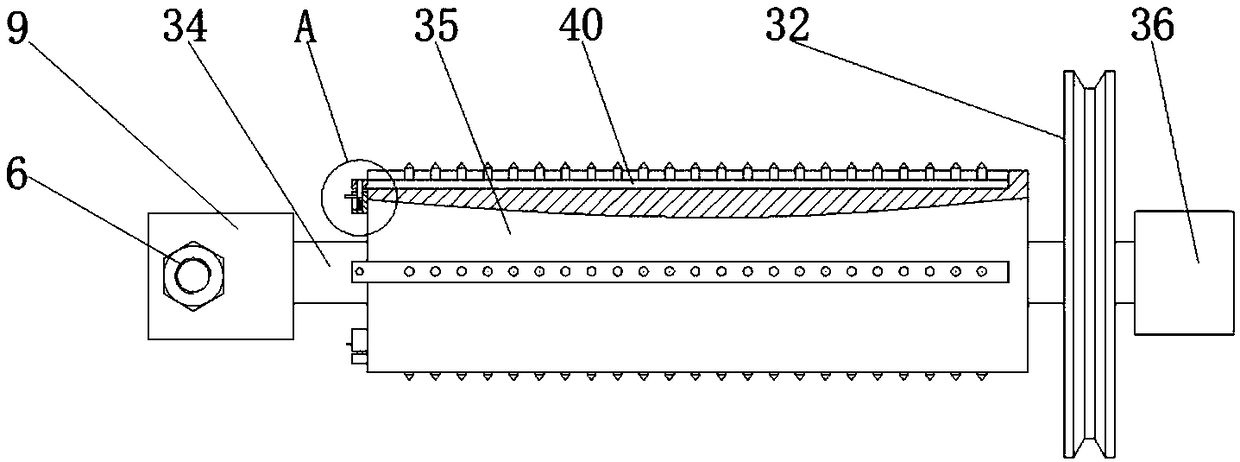

Rolling distance adjustable roller flour mill

ActiveCN108816342AAvoid skiddingEasy to disassemble and replaceGrain treatmentsEngineeringThreaded rod

The invention discloses a rolling distance adjustable roller flour mill. The rolling distance adjustable roller flour mill comprises a lifting device and a carrier plate. The upper end of the carrierplate is fixedly connected to a casing. The upper end of the casing is fixedly connected to a feeding port. The inner wall of the casing is provided with a first sliding slot. A first sliding block isslidably connected to the interior of the first sliding slot. The side of the first sliding block is provided with a groove. A first nut is fixedly connected to the interior of the groove. The innerwall of the casing is fixedly connected to a first motor. An output shaft of the first motor is fixedly connected to a first threaded rod. The first threaded rod fits to the first nut. The inner wall,symmetrical with the first sliding slot, of the casing is provided with a second sliding slot. A second sliding block is slidably connected to the interior of the second sliding slot. The rolling distance adjustable roller flour mill realizes rolling distance adjustment, can produce powder with different particle sizes, and utilizes a tooth plate to replace teeth of a round roller so that disassembly and replacement are convenient.

Owner:德州晶华集团(平原)大坝水泥有限公司

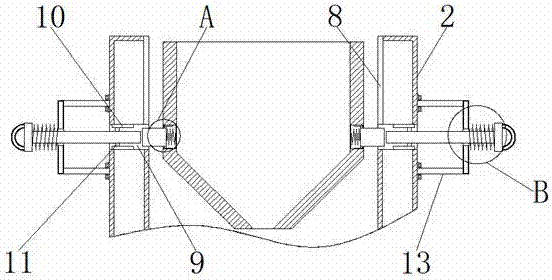

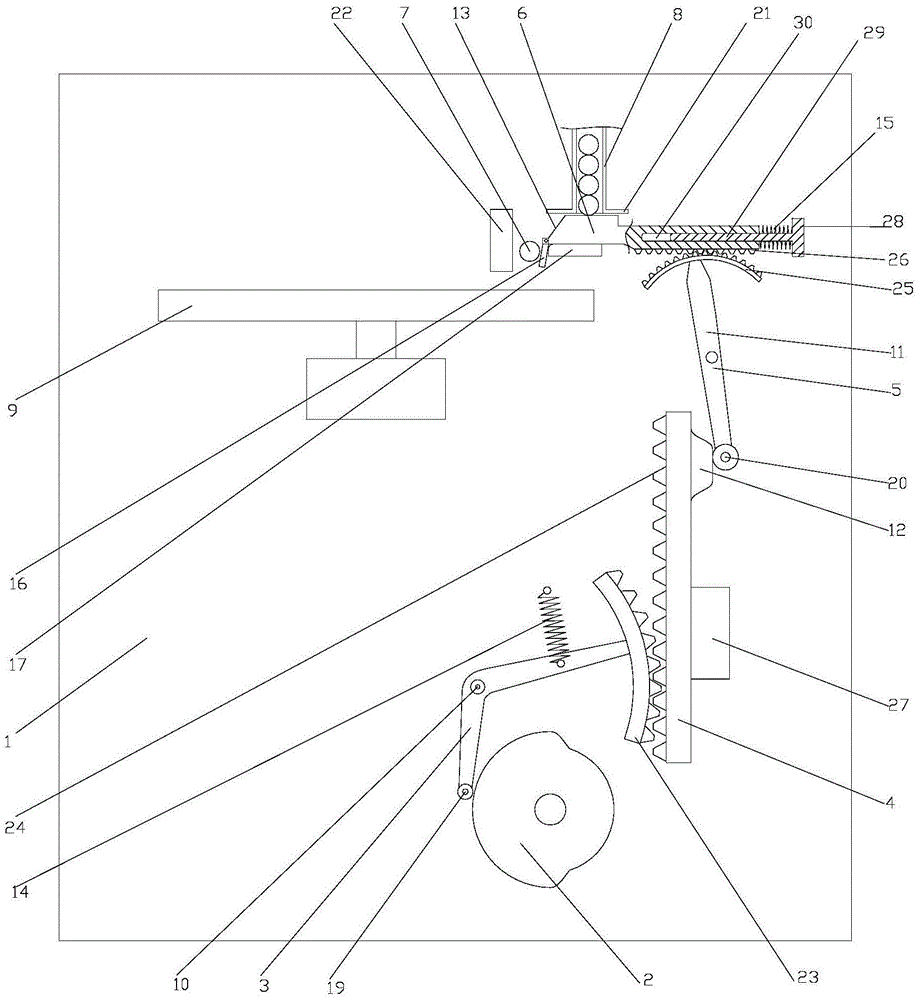

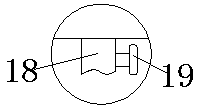

Roll ball grouping apparatus

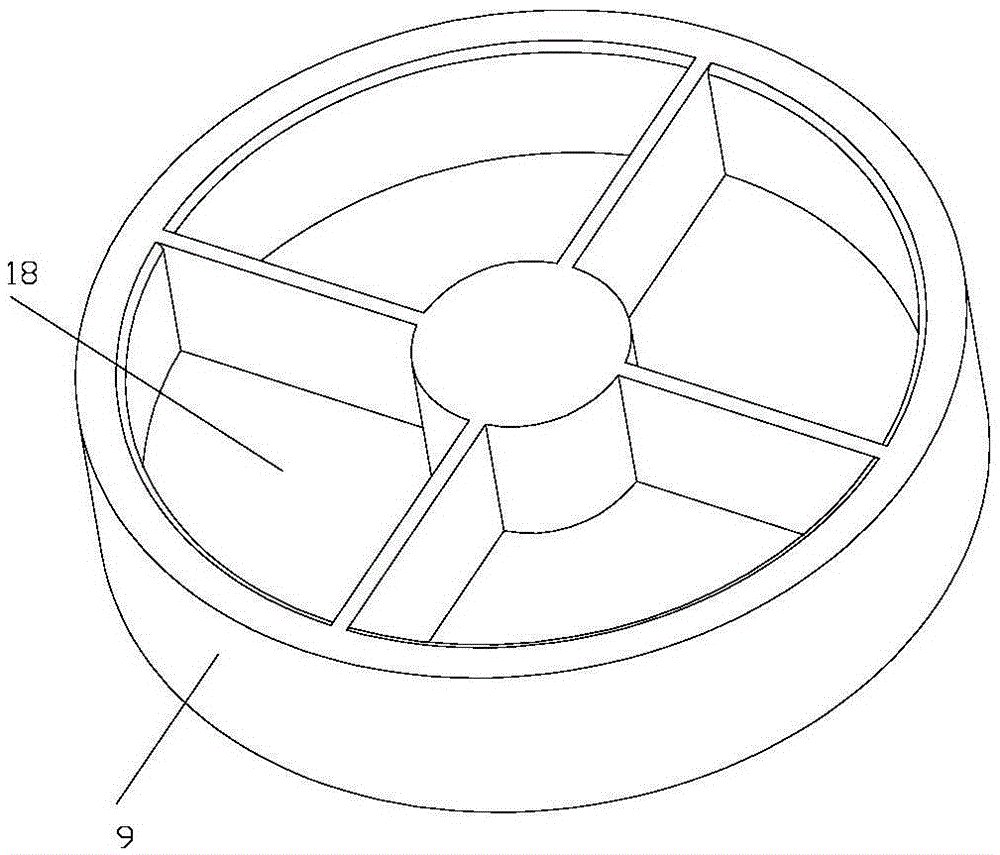

The invention discloses a roll ball grouping apparatus, comprising a base (1), a cam (2), a driving rod (3), a vertical plate (4), an oscillating rod (5), a push block (6), a charging barrel (8) and a rotating disc (9); the cam (2) is rotatably connected to the base (1) and a first motor is arranged on the base (1); the middle of the driving rod (3) is rotatably connected to the base (1) through a first hinge point (10); one end of the driving rod (3) tightly abuts against an outer contour of the cam (2); a first cambered rack (23) is arranged on the other end of the driving rod (3); the vertical plate (4) is connected to the base (1) in a sliding manner in a vertical direction; and a lug (12) is arranged on the vertical plate (4). The roll ball grouping apparatus provided has the advantages of accurate roll ball counting and reduction of labor intensity of an operator.

Owner:NEWSUN NINGBO AUTO BEARING MFG

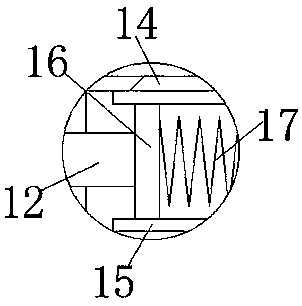

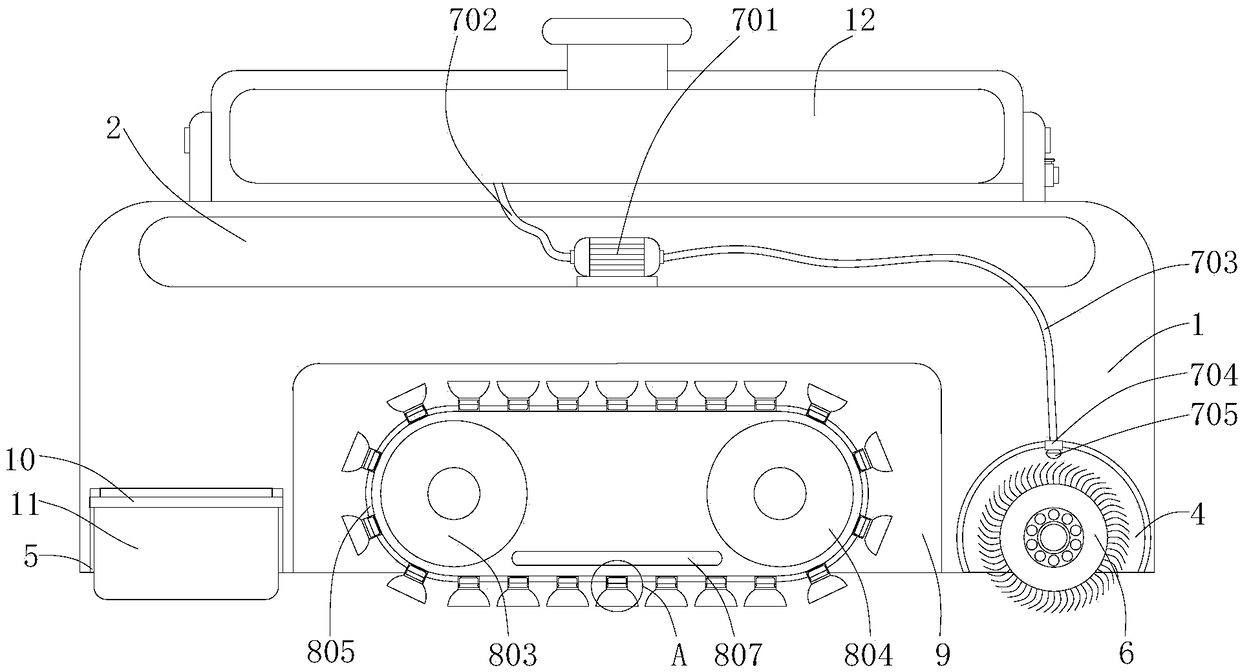

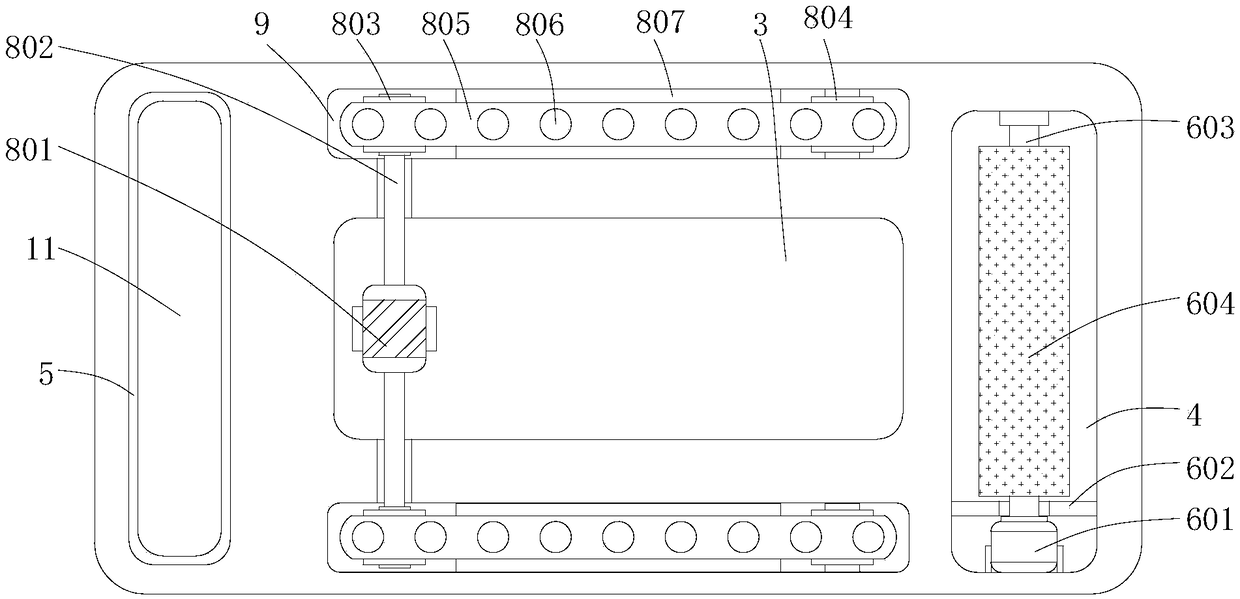

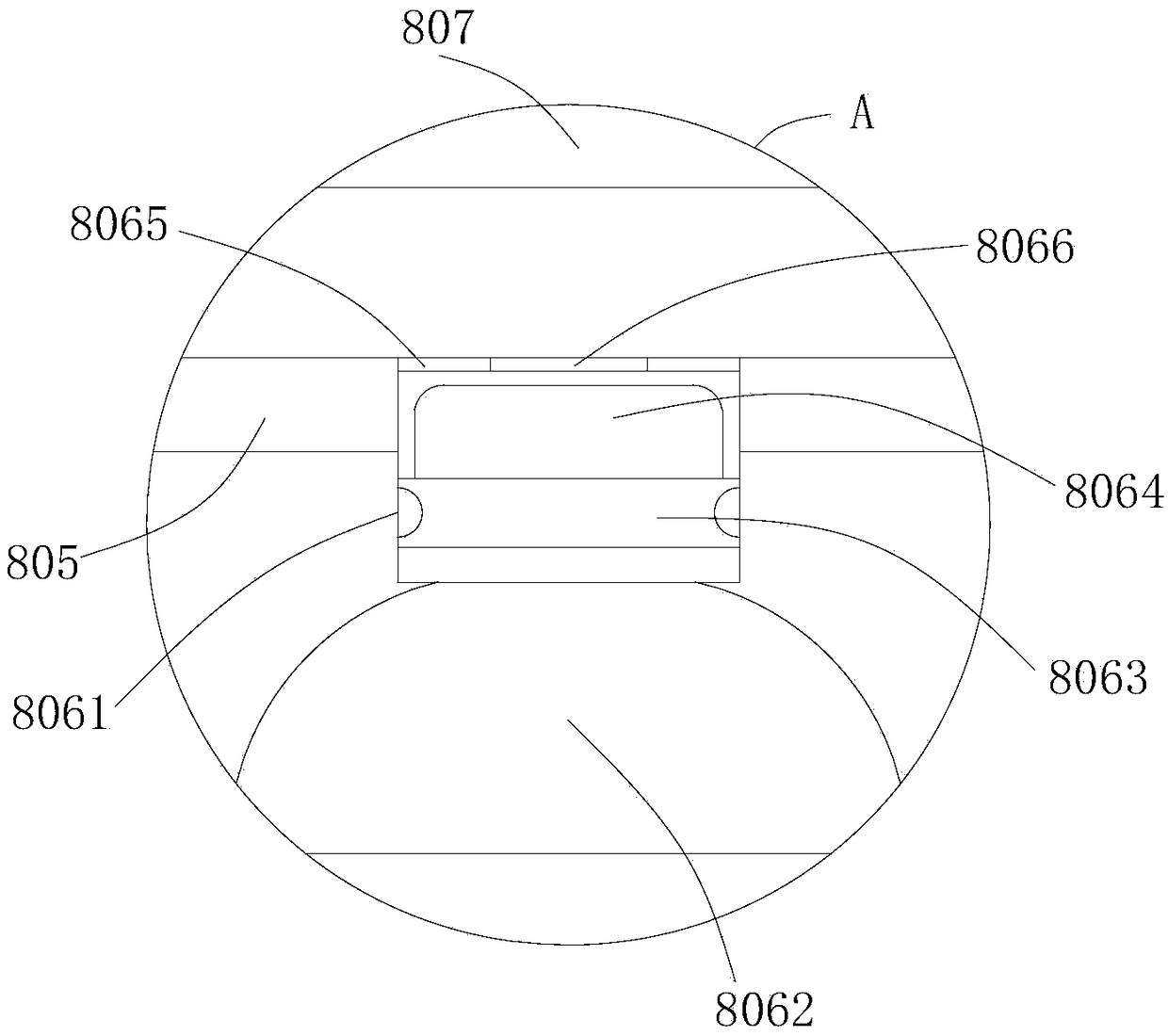

Vacuum adsorption type building glass curtain wall cleaning machine

ActiveCN109222780AEnsure stabilityAvoid skiddingCarpet cleanersFloor cleanersPulp and paper industryAtmospheric pressure

The invention relates to the technical field of glass curtain wall cleaning, and discloses a vacuum adsorption type building glass curtain wall cleaning machine. The machine includes a body, a first cavity, a second cavity, a cleaning tank, a wiping tank, a cleaning mechanism, a conveying mechanism, a vacuum suction mechanism, two fixed tanks and a water tank, wherein the first cavity is arrangedat the top of the body interior, the second cavity is arranged at the bottom of the body interior, and the first cavity is positioned directly above the second cavity, the cleaning tank is arranged atthe right end of the body bottom, and the wiping tank is arranged at the left end of the body bottom. As that track of the invention move on the surface of the glass curtain wall, so that suction cups close to the glass curtain wall are blocked, The suction cup is adsorbed on the surface of the glass curtain wall in a sealed state, and the permanent magnet block is magnetically attracted by the magnet plate, the permanent magnet block moves upward close to the magnet plate, drives the piston to move upward, and reduces the air pressure inside the suction cup, so that the machine body is firmly adsorbed on the surface of the glass curtain wall, and the stability of the machine body is ensured when the machine body moves.

Owner:日照市大东方玻璃有限公司

Fire extinguisher holder

InactiveCN107137844AImprove practicalityAvoid the situation that the height of the limit circle cannot be adjusted according to the height of the fire extinguisherFire rescueEngineeringFire extinguisher

The invention discloses a placing frame for a fire extinguisher, which comprises a bearing rod. Both sides of the bearing rod are sequentially provided with a card groove and a slide groove from top to bottom. The inner wall of the slide groove is slidably connected with a slide block, and the slide block The side away from the inner wall of the chute is fixedly connected with a connecting block, the top of the connecting block is fixedly connected with a bracket, the inner cavity of the bracket is provided with a sleeve, and the two ends of the sleeve communicate with the outer walls on both sides of the bracket respectively. The present invention is provided with bearing bar, chute, slider, connection block, bracket, slot, casing, slide rail, limit plate, limit block, support plate, clamp rod, connection plate, handle, support rod, limit The mutual cooperation of the position ring body, the bearing plate and the spring solves the problem that the position limit ring on the existing shelf does not have the function of adjusting the height, and avoids that the height of the limit ring cannot be adjusted according to the height of the fire extinguisher when placing the fire extinguisher. The condition of the adjustment, so that the placement of the fire extinguisher is more stable.

Owner:张文华

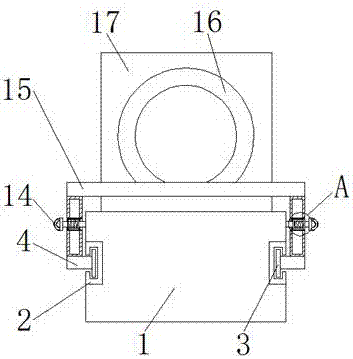

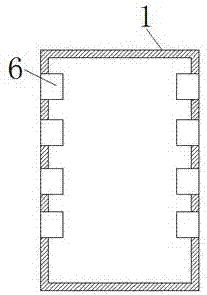

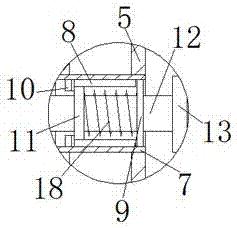

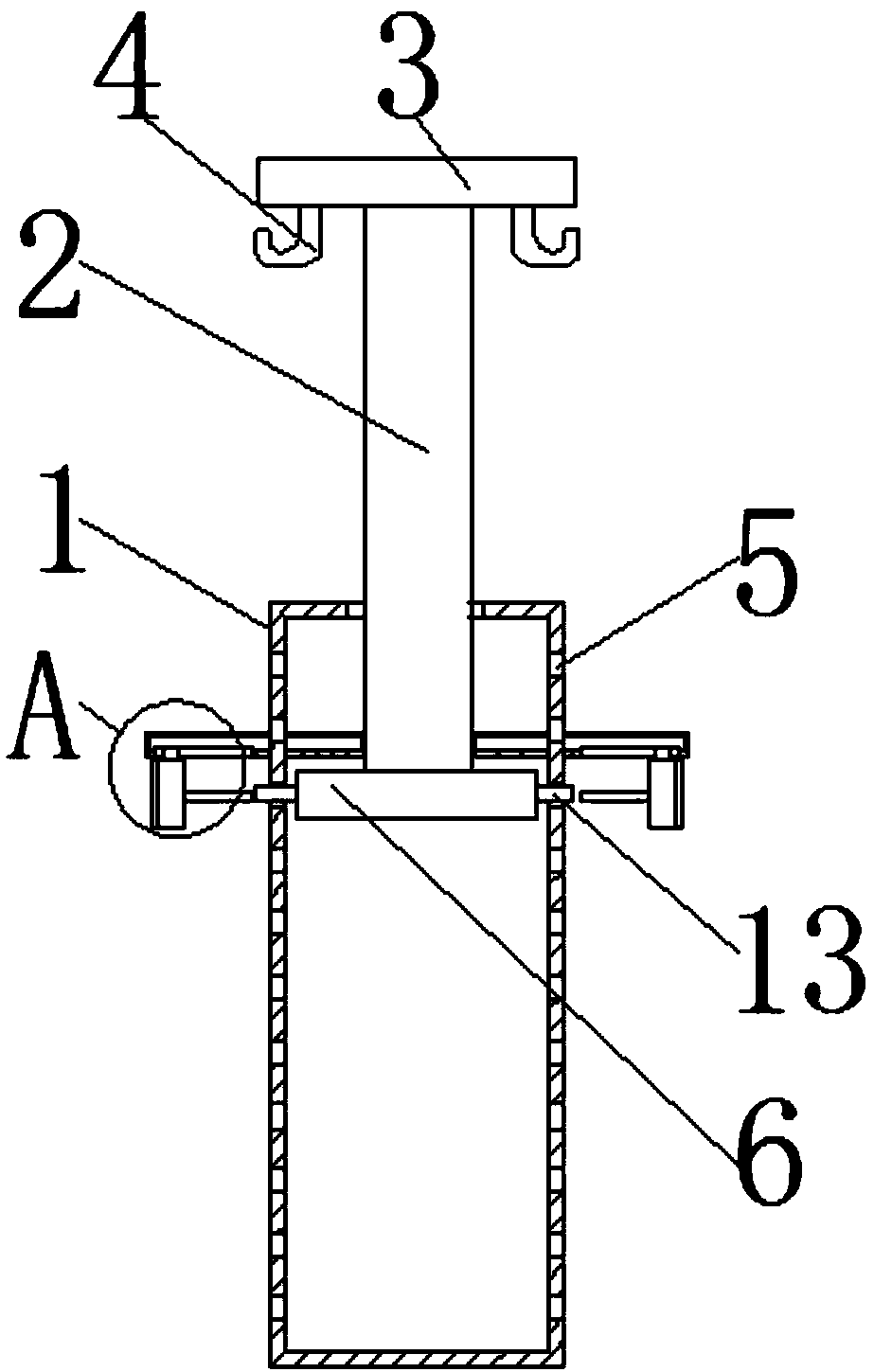

Infusion support with adjustable height

The invention discloses an infusion support with the adjustable height. The infusion support comprises a hollow rod, an inner cavity of the hollow rod is provided with a supporting rod, the top of thesupporting rod penetrates through the top of the hollow rod and is fixedly connected with a fixing plate, hooks are welded to the two sides of the bottom of the fixing plate, the two sides of the inner cavity of the hollow rod are each provided with a clamping groove, and hollow blocks are fixedly connected to the bottom of the supporting rod. By arranging the hollow rod, the supporting rod, thefixing plate, the hooks, the clamping grooves, the hollow block, a baffle, a stretchable rod, a sliding rail, a first sliding block, a spring, a clamping block, a bearing plate, a sliding groove, a second sliding block, a push plate and a push rod for cooperation, the problem that the height of an existing infusion support is not adjustable is solved, when the infusion support is in use, the height of the infusion support can be lowered, then, the infusion support is heightened after an infusion bottle is suspended, and therefore the phenomenon that due to the fact that some nurses are not tall enough, the infusion bottle needs to be suspended by means of other objects is avoided.

Owner:叶侃

Method for operating a vehicle

ActiveCN105939905AAmplify Braking DesireReach the braking effectBraking action transmissionBrake control systemsControl theoryParking brake

The invention relates to a method for operating a vehicle, wherein in order to decelerate the vehicle a braking device is activated, which comprises a parking brake as one element and a brake booster as a further element for activating a service brake of the vehicle, with the result that a braking force which decelerates the vehicle is generated by means of the braking device, wherein during the deceleration of the vehicle at least one of the elements of the braking device is controlled in such a way that the generated braking force varies over time. The invention also relates to a control device for a braking device of a vehicle, to a brake system for a vehicle, and to a computer program.

Owner:ROBERT BOSCH GMBH

Bearing clamping device facilitating replacement of bearings with different sizes

InactiveCN107052920ASolve the problem that it is not convenient to change the sizeFast replacementGrinding carriagesRevolution surface grinding machinesEngineeringMechanical engineering

The invention discloses a bearing clamping device which is convenient for size replacement, which comprises a snap ring. The top and bottom of the card slot are fixedly connected with first slide rails, the top and bottom of the first card slot are provided with a second card slot, the right side of the first card slot is provided with a card bar, and the card bar The left side penetrates to the inner wall of the first card slot. In the present invention, the first clamping groove, the first sliding rail, the second clamping groove, the clamping rod, the hollow block, the second sliding rail, the first sliding block, the limit block, the connecting rod, the push handle, the first spring, and the clamping block are arranged. , the hollow rod, the chute, the second slider, the support plate, the second spring, the push rod, the connection plate and the handle cooperate with each other, which solves the problem that the existing bearing grinding and clamping device is inconvenient to change the size, and avoids the problem of changing the size of the existing bearing grinding and clamping device. The cumbersome situation of the replacement process when grinding the inner rings of bearings of different sizes.

Owner:LEIYANG XINDAWEI TECH

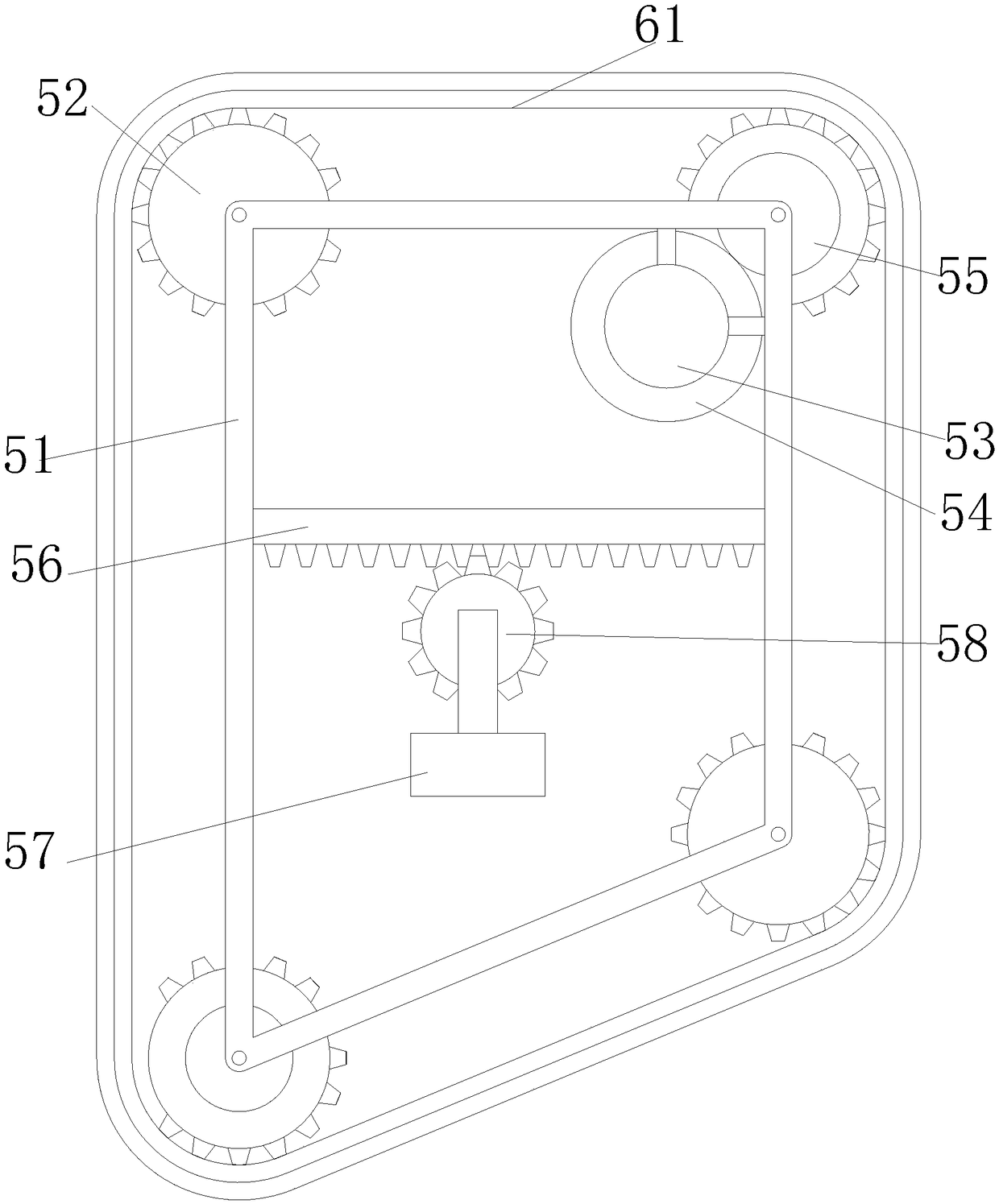

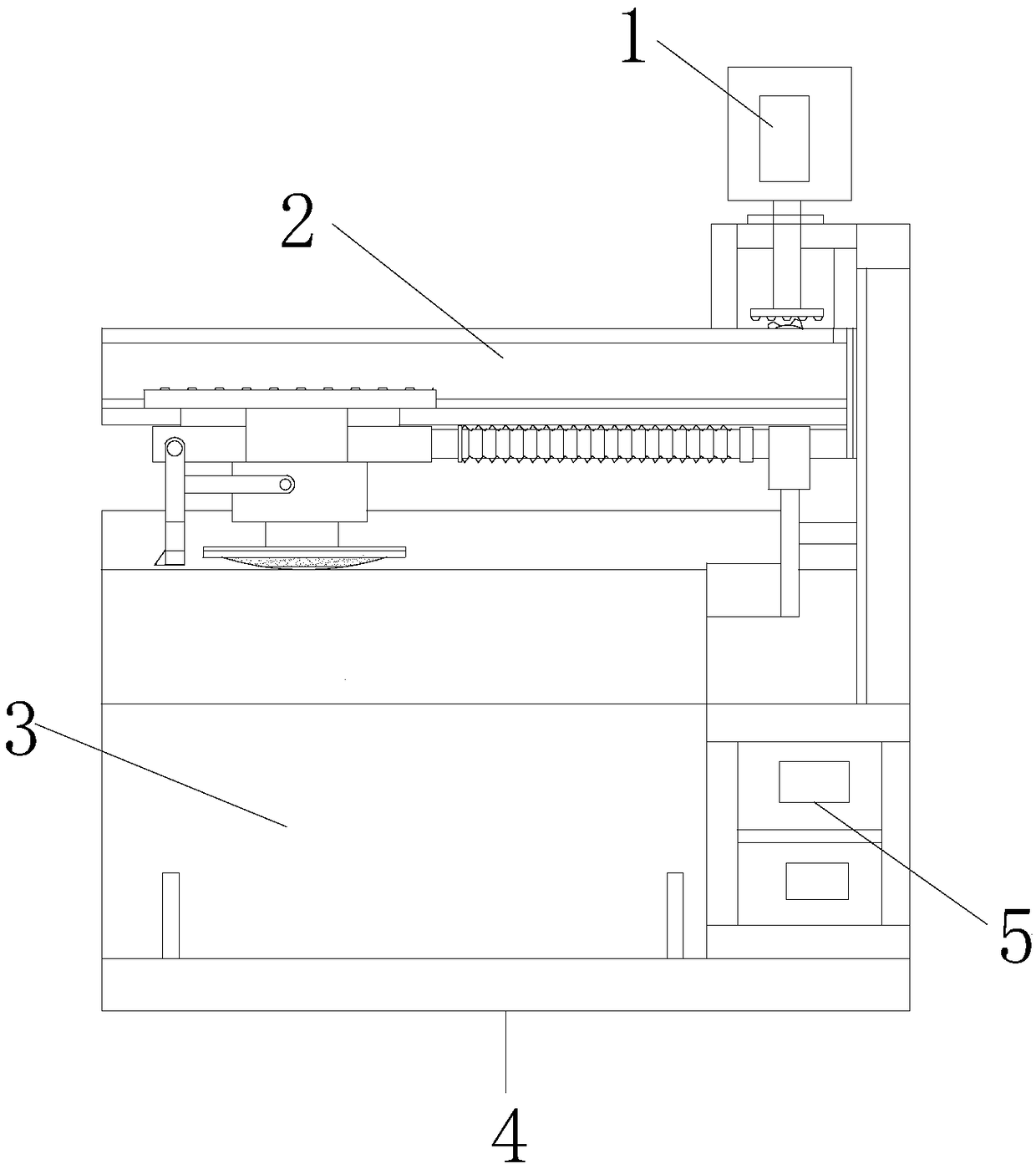

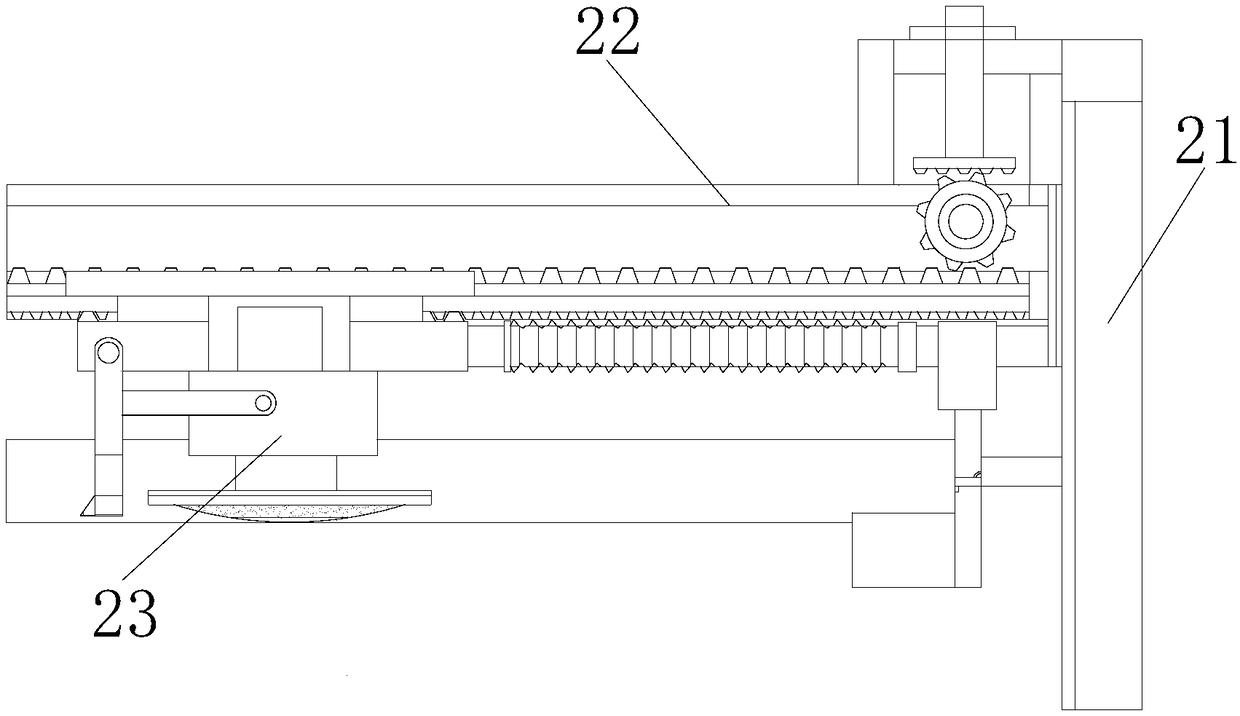

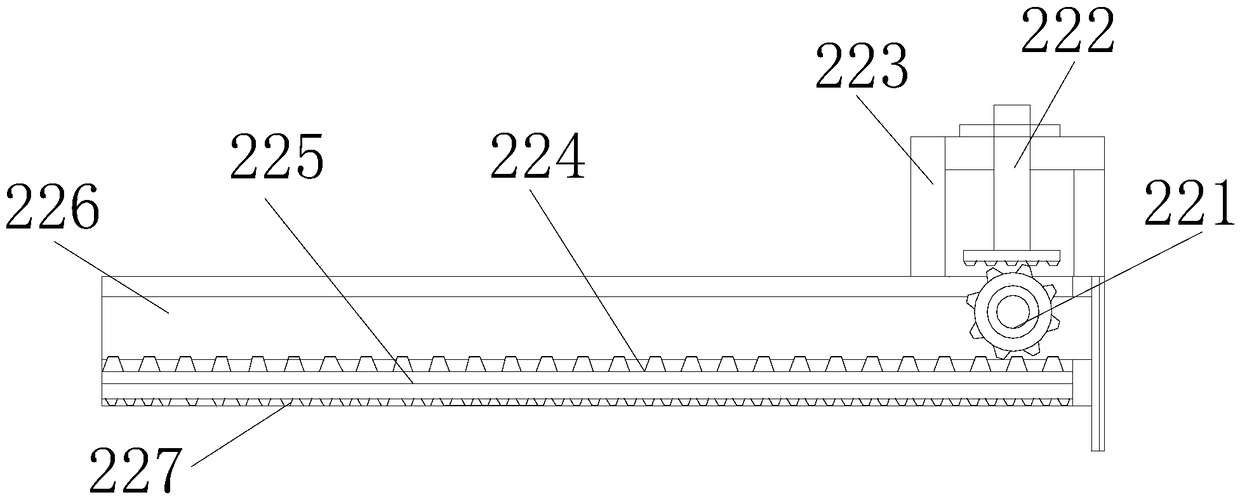

Tree annual ring sample polishing device by using cutters and convex surface type grinding wheel phased scraping

ActiveCN109366331AQuick polish jobIn case of reduced slip displacementPolishing machinesGrinding drivesGear wheelWorking environment

The invention discloses a tree annual ring sample polishing device by using cutters and convex surface type grinding wheel phased scraping. The device is structurally comprises a bi-directional motor,an intelligent flat grinding device, a fixing base, a bottom base and a motor set, wherein the motor set is located on the upper side end face of the bottom base and is movably connected with the bottom base at the same time, thus driving a gear frame in the lower part through the rotation of the gear is achieved, so that a sliding block on tooth grooves are stressed to be meshed on the sliding frame to realize stable displacement, manual pressing dynamic displacement running-in is replaced, and the slippage displacement of the equipment can be reduced; meanwhile, through the flattening of ascraping frame at the front end and the arc-shaped structure of a grinding wheel frame, the structures of bulges can be scraped in advance during displacement, and wood is polished in a layering modewith a arc-shaped structure, so that polishing work can be better and more quickly carried out on the wood, and finally, the negative pressure generated through compression caused by pulling an air bag inside a telescopic frame when displacement is carried out is used for attracting sawdust generated by the polishing, and the working environment is not influenced.

Owner:苏州心愿美电子商务有限公司

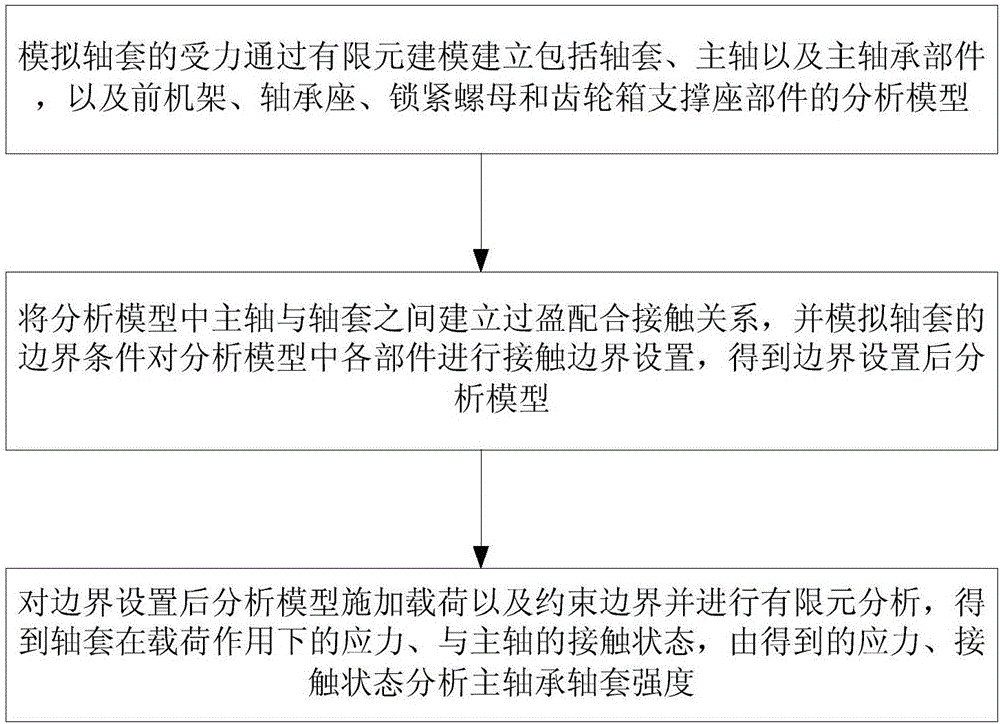

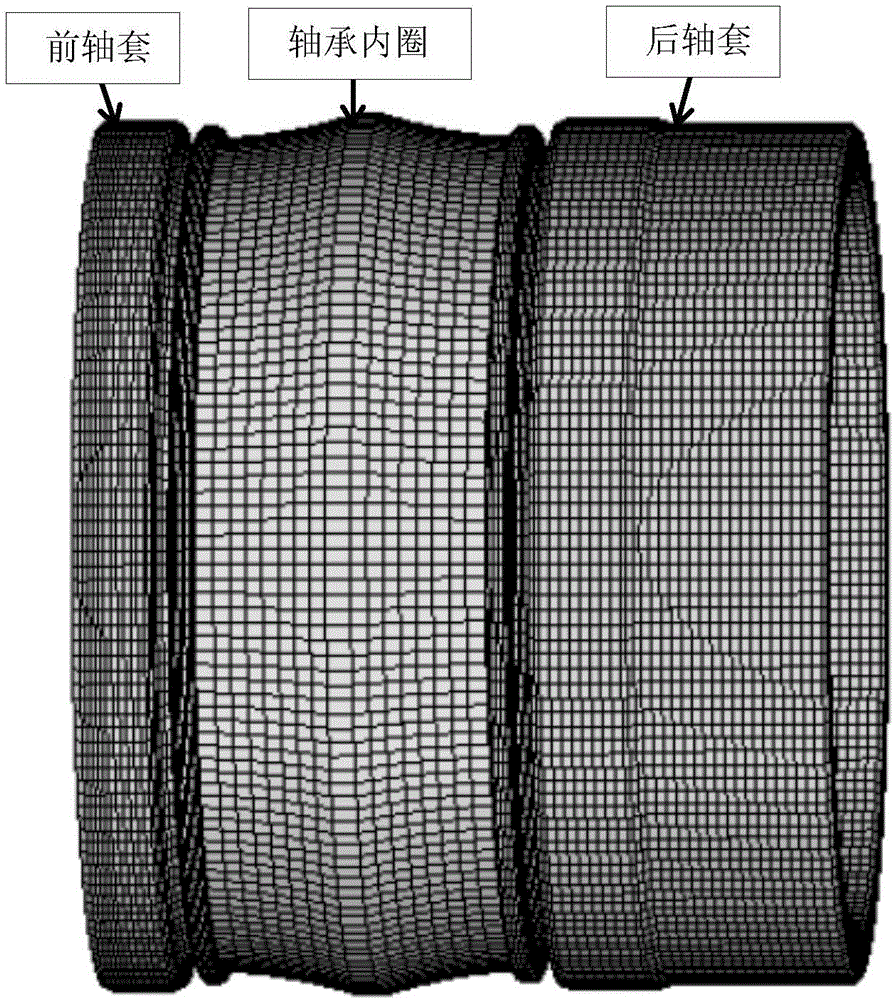

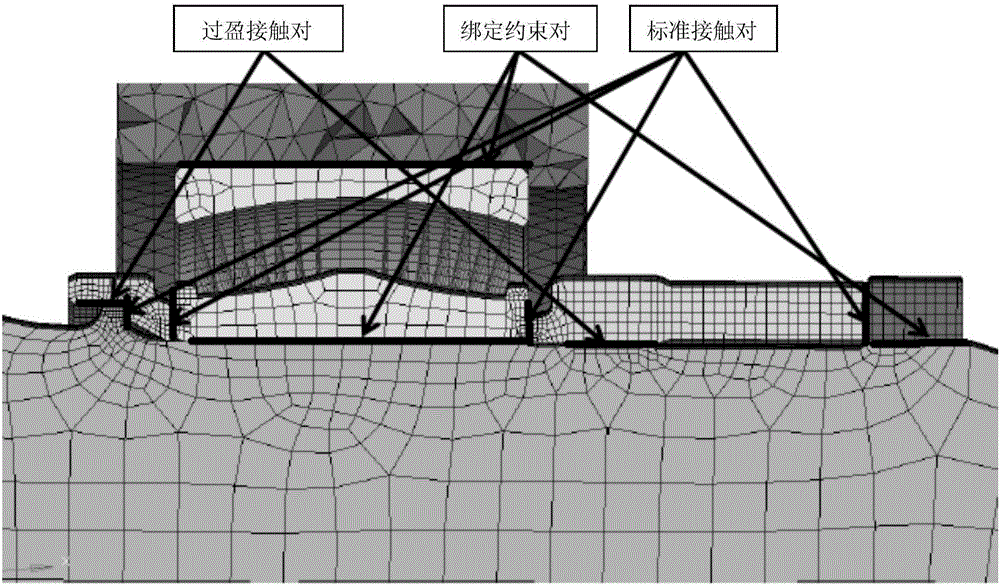

Strength analysis method and magnitude of interference analysis method of main bearing and shaft sleeve in wind turbine generator

ActiveCN106354920AGuarantee authenticityGuaranteed reliabilityGeometric CADDesign optimisation/simulationElectricityInterference fit

The invention discloses a strength analysis method and magnitude of interference analysis method of main bearing and shaft sleeve in wind turbine generator. The strength analysis method comprises the steps of 1, setting up an analytical model based on finite element modeling; 2, establishing interference fit and contact relations and simulating boundary conditions of bearing bush to arrange contact boundaries of the analytical model; 3, inflicting load and constrained boundaries and making finite element analysis to draw stress of bearing bush under load effect and contact state with main bearing and analyze strength of bearing bush of main bearing by the drawn stress and contact state; the analytical method of magnitude of interference analyzes strength of bearing bush and judges interference fit relations between bearing bush and main bearing based on analytical result of strength of bearing bush. If interference fit relations are not fulfilled in judgment, magnitude of interference shall be adjusted till interference fit relations are fulfilled and best magnitude of interference is output. The analytical methods of strength and magnitude of interference of bearing bush of main bearing in the wind turbine generator set has easy methods of realization and advantages of truthful reflection of stress of bearing bush, high analytical precision, reasonable design of magnitude of interference and so on.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

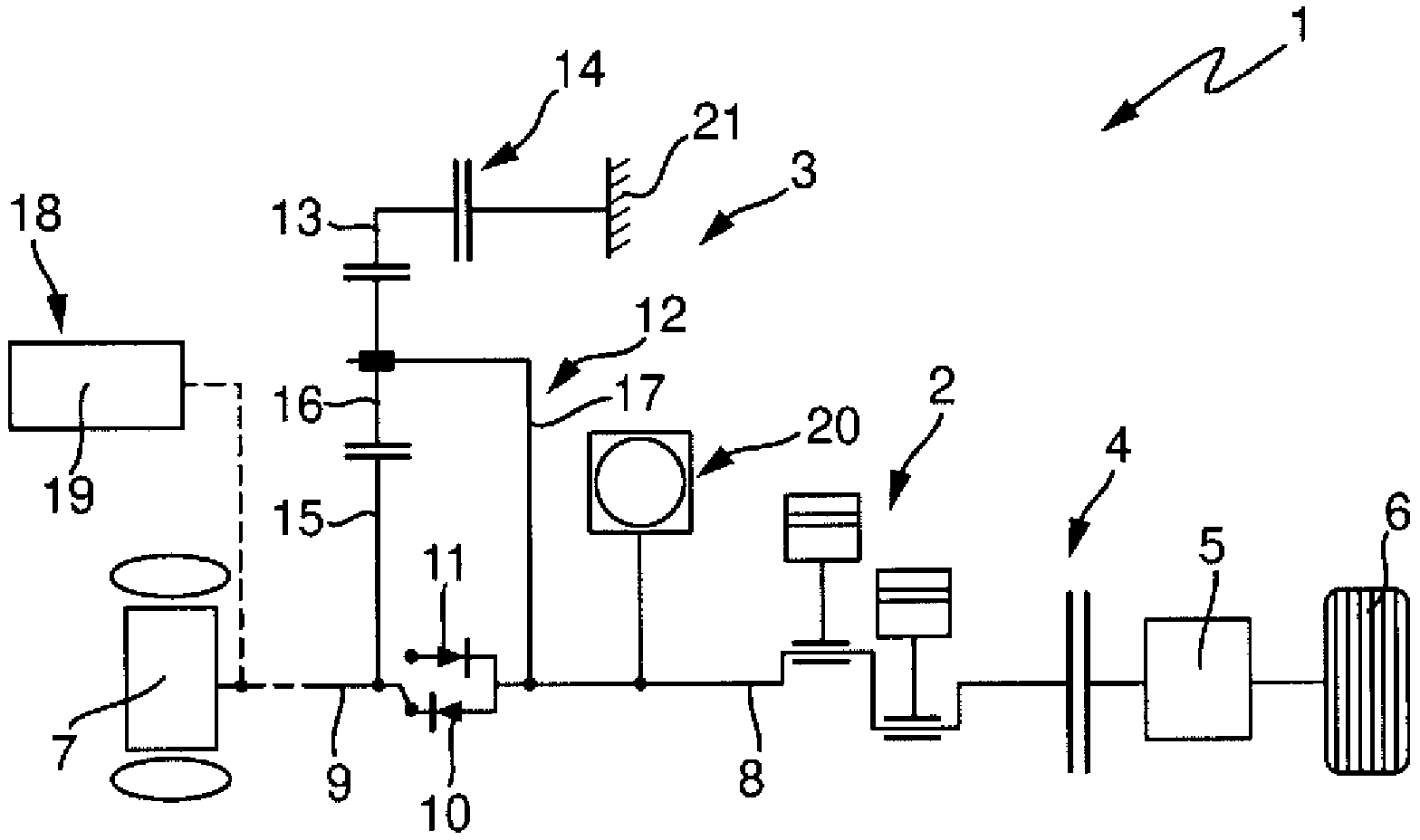

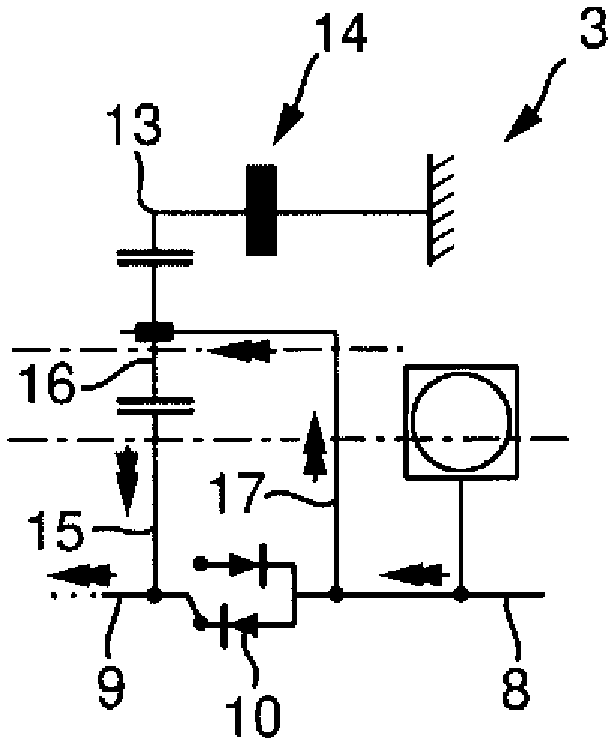

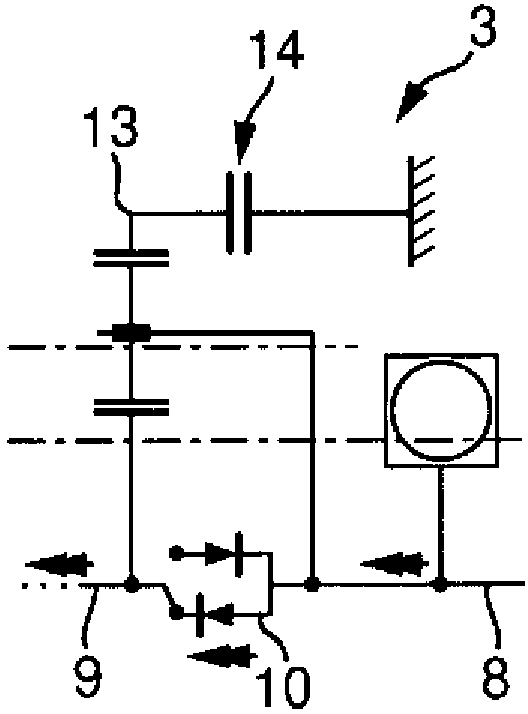

Method for controlling switchable planetary gear set in belt pulley plane of drive train

InactiveCN103261673AReliable loadingConfirmed favorableHybrid vehiclesPower operated startersStarter generatorFreewheel

The invention relates to a method for controlling a belt drive of a drive train of a motor vehicle. The belt drive is equipped with a planetary gear set which switches a transmission ratio between a starter-generator and an internal combustion engine, said planetary gear set having an internal gear which can be connected fixedly with respect to a housing by means of a brake;a web which is connected to a crankshaft of the internal combustion engine of the drive train and which has planet gears arranged over the circumference; a sun gear which is connected in a rotationally engaged manner to a rotor of the starter-generator and to at least one auxiliary unit; a first switchable freewheel which blocks in the torque direction from the rotor to the crankshaft; and a second switchable freewheel which blocks in the torque direction from the crankshaft to the rotor. In order to improve the switching accuracy of the brake and thereby avoid high torque loading during the closing of the brake, a characteristic curve of the torque that can be transmitted via the brake versus the actuating travel thereof is adapted.

Owner:SCHAEFFLER TECH AG & CO KG

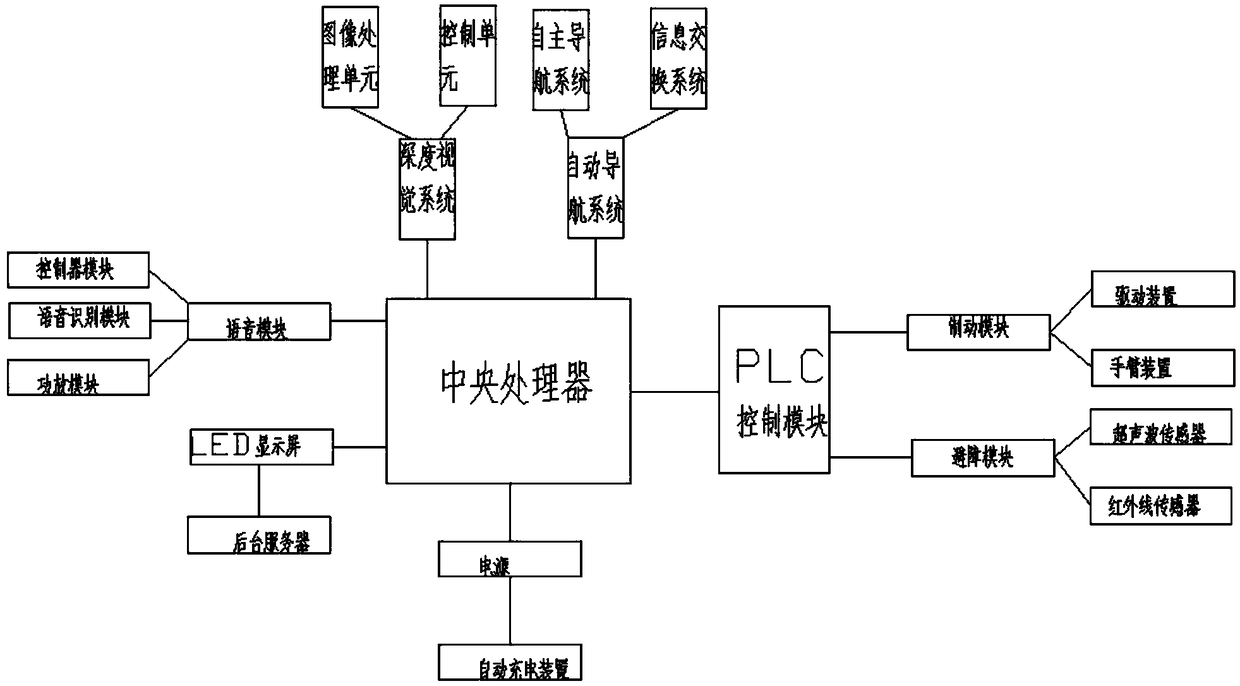

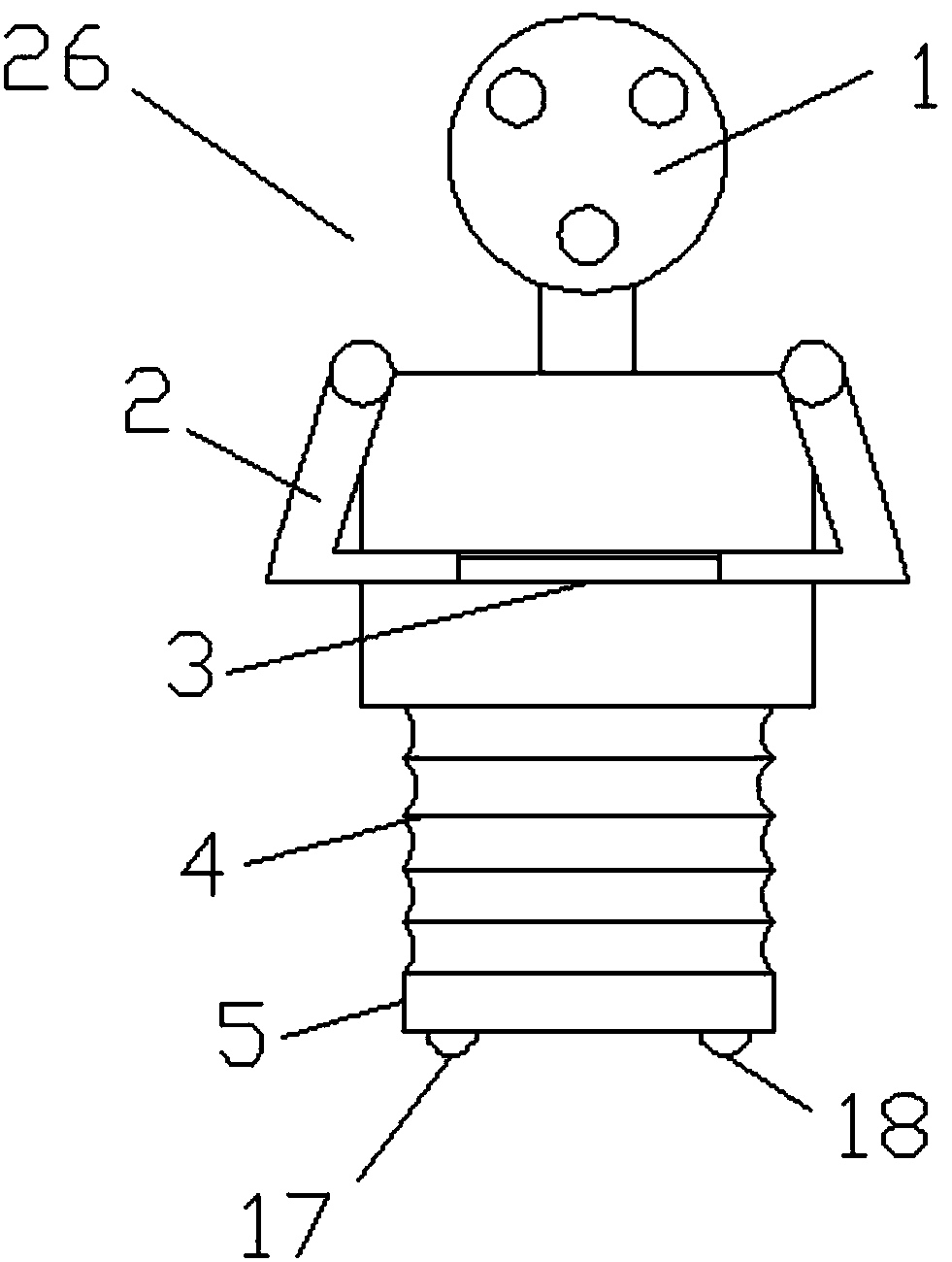

Intelligent meal delivery robot

InactiveCN108582103AImprove stabilityImprove attendance efficiencyTable equipmentsManipulatorObstacle avoidanceEngineering

The invention discloses an intelligent meal delivery robot. The intelligent meal delivery robot comprises a robot body, a head, a central processing unit, an automatic navigation system, a depth visual system, an LED display screen, a voice module, an obstacle avoidance module and a braking module, wherein the automatic navigation system, the depth visual system, the LED screen, the voice module,the obstacle avoidance module and the braking module are connected with the central processing unit and are controlled by the central processing unit. According to the intelligent meal delivery robot,food delivery can be achieved for a long time through the robot, and dish introduction for customers and online payment by the customers can be achieved through the robot, so that the seat occupancyrate of dining tables is improved, and the benefit is increased; and food delivery actions do not need to be achieved according to a fixed guide rail, higher autonomous convenience and fastness are achieved, and the meal delivery requirements of the different dining tables can be met through lifting connecting rods.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

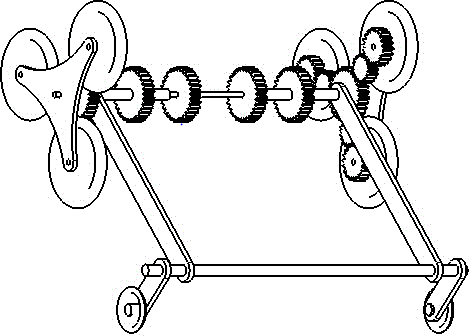

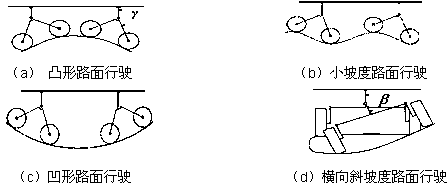

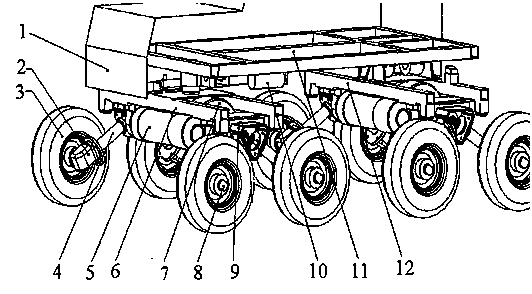

All-terrain surface adaptive relief vehicle

The invention discloses an all-terrain surface adaptive relief vehicle comprising a frame (10), four suspensions, and a control system. The suspensions the same in structure are symmetrically disposed on two sides of the frame. Every suspension set is hinged to the frame. The suspensions can freely rotate with certain degrees of freedom in a model machine longitudinal plane. The included angles between the suspensions and the frame change with changes in terrains, so that the function of contour adapting in the longitudinal plane is achieved. After disasters such as an earthquake occur, complex geographical environments and damage to roads thereby severely affect relief work; in order to focus on the limitation, the vehicle providing conveniences for work in the complex disaster sites is designed, and a powerful tool is provided for rescue and relief work and post-disaster reconstruction.

Owner:上海市闵行区知识产权保护协会

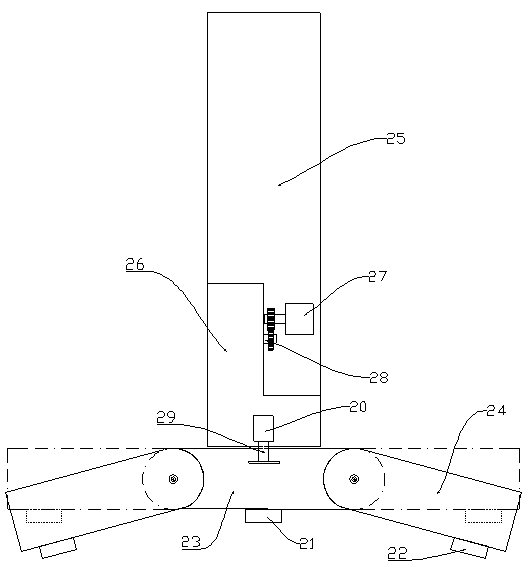

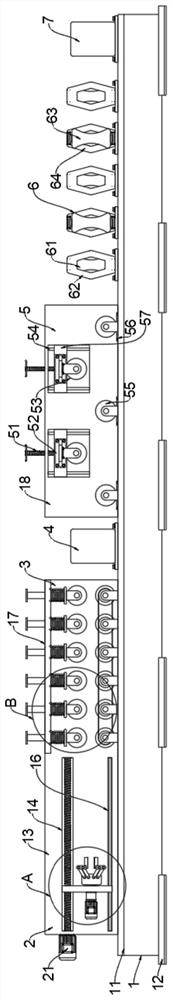

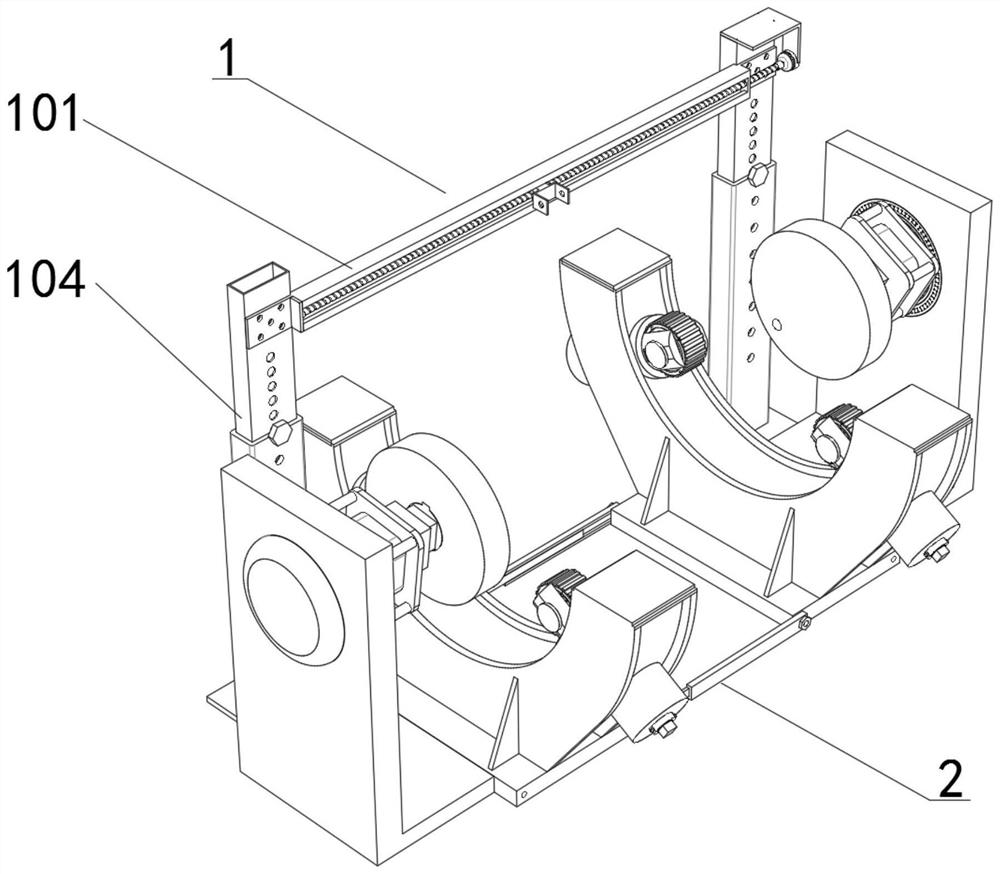

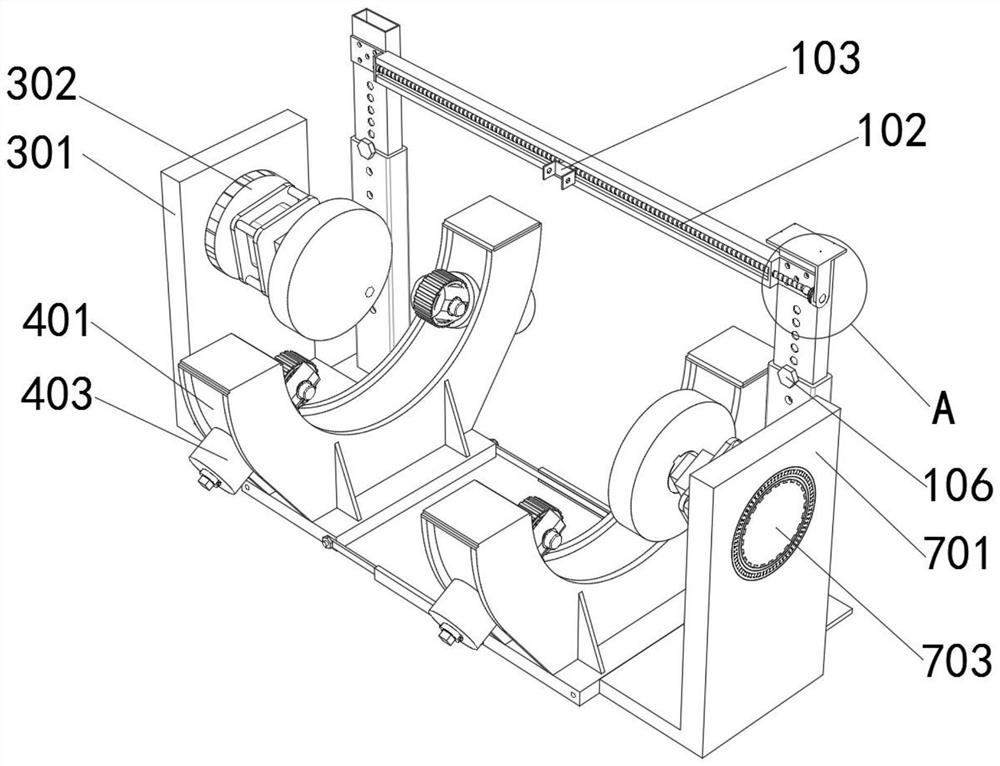

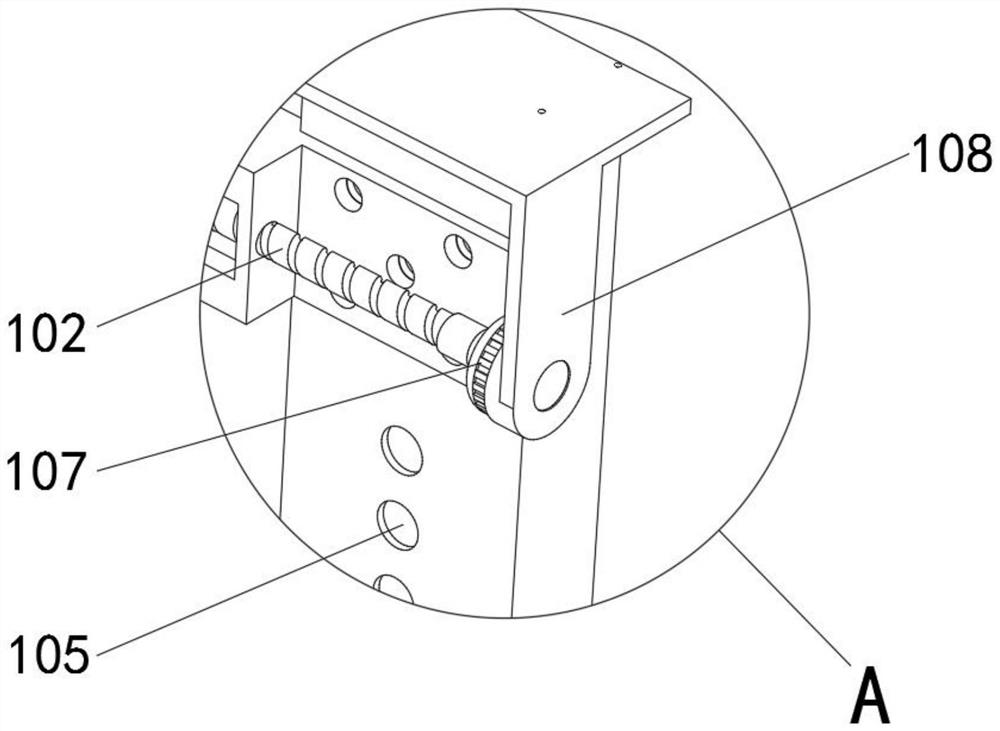

Surfacing control equipment for roller press surface repair

PendingCN112077473AAccurate surfacingReduce the hassle of manual screeningWelding/cutting auxillary devicesAuxillary welding devicesElectric machineControl engineering

The invention relates to the technical field of roller press surfacing repair, and discloses surfacing control equipment for roller press surface repair. The surfacing control equipment comprises a surfacing bracket, a roller press part clamping mechanism is arranged at one side of the surfacing bracket, the clamping mechanism comprises a driving mechanism, the driving mechanism comprises a firstfixing frame, a driving motor is fixedly arranged in the upper end of the first fixing frame, a first servo electric cylinder is fixedly arranged at the output end of the driving motor, a first auxiliary rotating device is arranged at one side of the driving mechanism, a sliding device is arranged at the other side of the first auxiliary rotating device, and the sliding device comprises a slidingrail; and a second auxiliary rotating device is arranged at the other end of the sliding device, the structure of the first auxiliary rotating device is completely consistent with that of the second auxiliary rotating device, and a driven mechanism is arranged at one side of the second auxiliary rotating device. According to the surfacing control equipment, the trouble of manual screening can be reduced, the working efficiency is improved, surfacing errors are reduced, and the surfacing efficiency is improved.

Owner:合肥中都机械有限公司

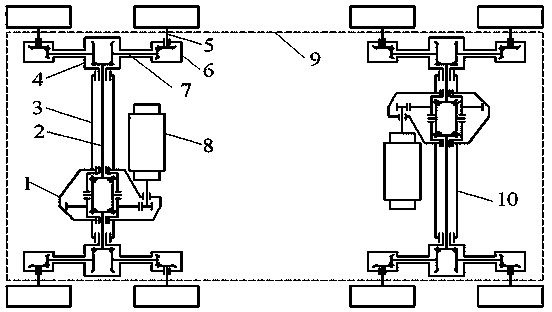

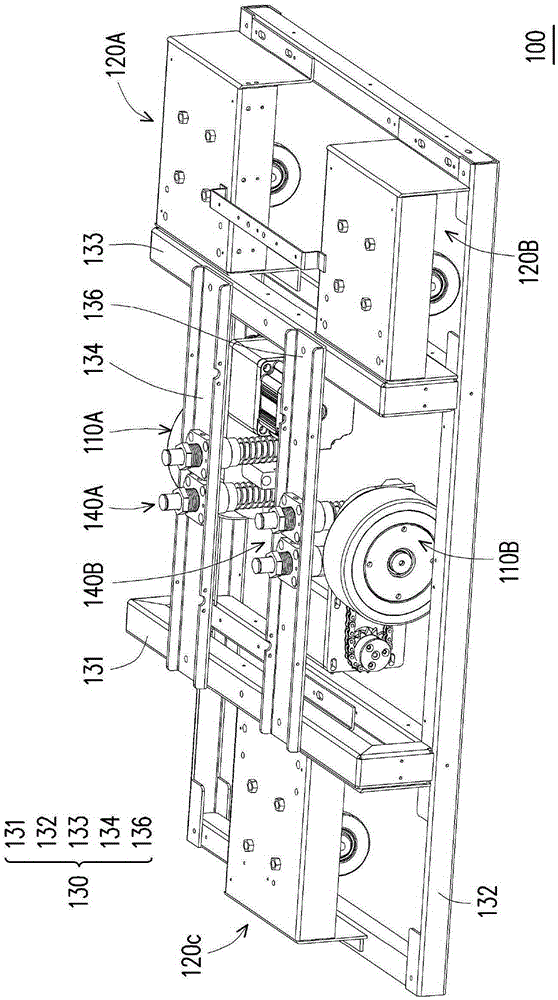

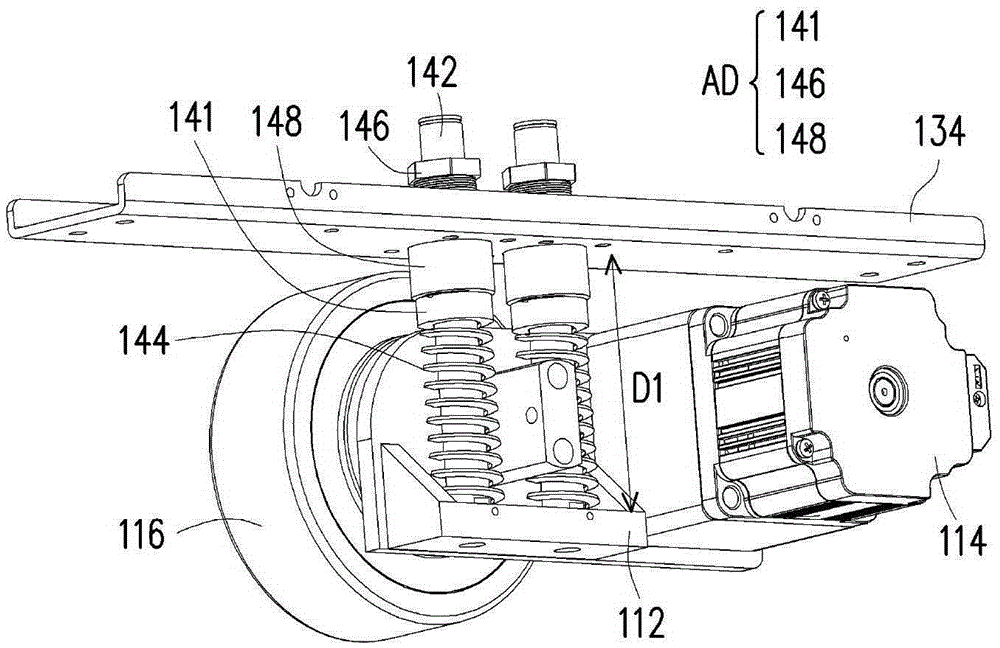

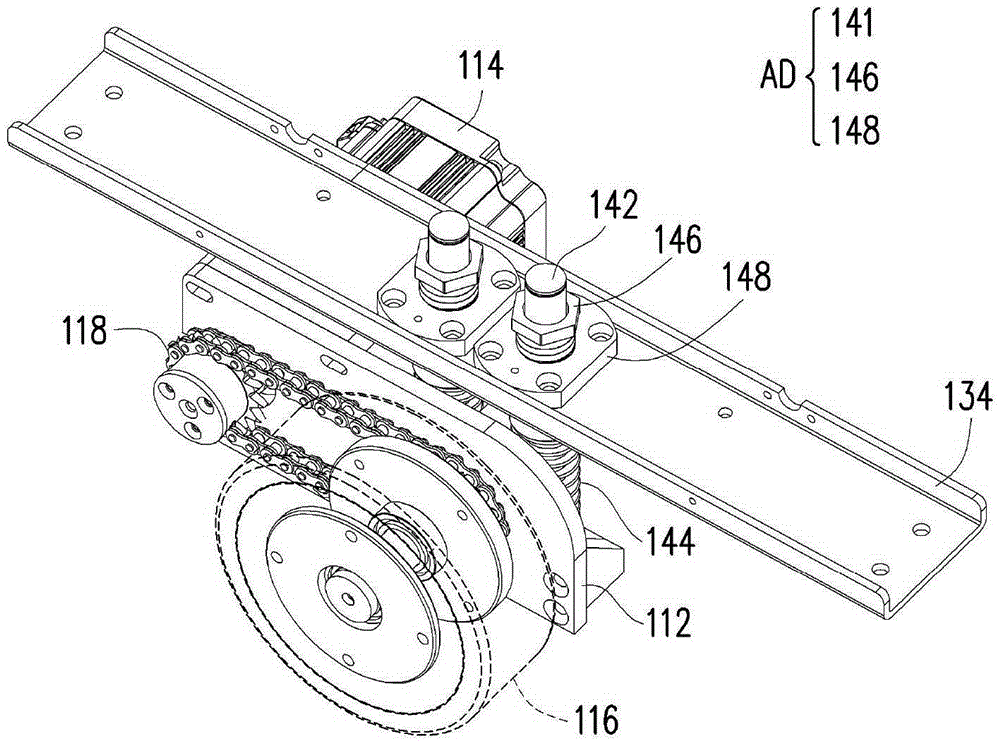

Automatic guided car

InactiveCN106627838AAvoid skiddingImprove adaptabilityResilient suspensionsVehiclesTerrainRough surface

The present invention provides an automatic guided vehicle for traveling on a floor, the vehicle comprising a vehicle body, at least one drive wheel module, at least three auxiliary wheel modules, and an adjustment module. The drive wheel module is provided in the vehicle body. The auxiliary wheel modules are freely pivotally connected to the vehicle body. The adjustment module is assembled between the body and the drive wheel module to adjust the frictional force of the drive wheel module relative to the ground. Therefore, the automatic guided vehicle changes the friction force of the drive wheel module relative to the ground by adjusting the module, and allows the automatic guided vehicle to maintain the tracking force of the drive wheel module while facing a rough surface, Wheel module slip can be prevented, and all kinds of terrain or terrain adaptability of the automatic guided car.

Owner:KINPO ELECTRONICS +1

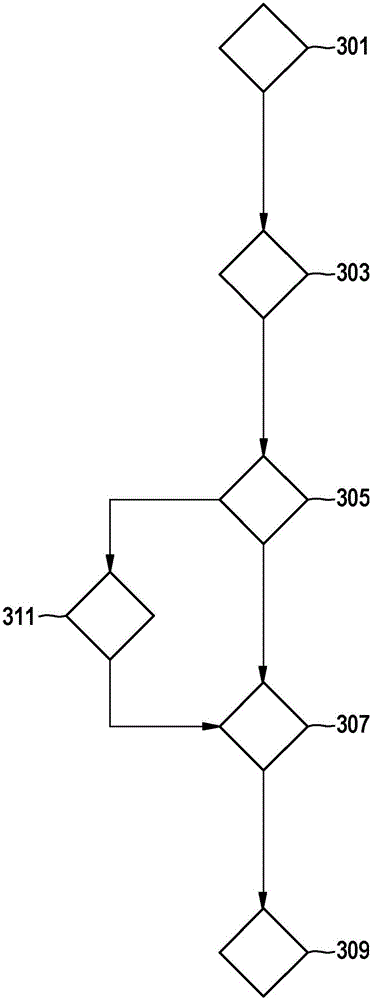

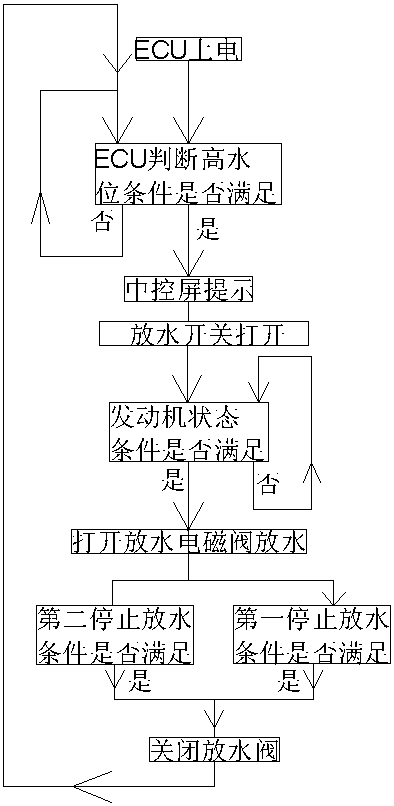

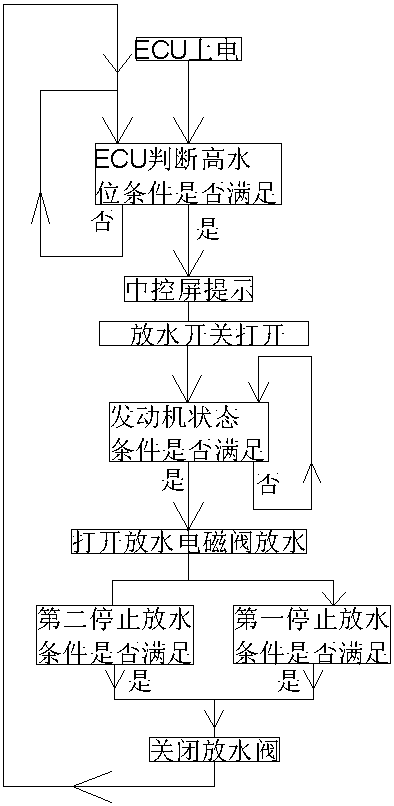

Water drainage method for fuel filter

InactiveCN111120124AClose in timeAvoid failureEngine controllersMachines/enginesIn vehicleEnvironmental engineering

The invention discloses a water drainage method for a fuel filter. The water drainage method comprises the first step of vehicle-mounted ECU powering on, the second step of high water level judgment,the third step of engine state judgment and the fourth step of water drainage. In the water drainage method, a vehicle-mounted ECU can detect the signal of the water level in a water collection cavityof the fuel filter through a water level sensor, when the water level is higher than the preset high water level, flashing prompt information is displayed on a central control screen, a worker is prompted to drive a vehicle to the proper position in time to drain water, the worker does not need to observe the water level in the fuel filter, the worker does not need to directly operate a water drainage valve, timely water drainage is guaranteed, the labor intensity of workers is reduced, the environment pollution problem and the back vehicle slip problem brought by water drainage are avoided,and the danger brought by engine starting in the water drainage process is avoided.

Owner:PINGYUAN FILTER

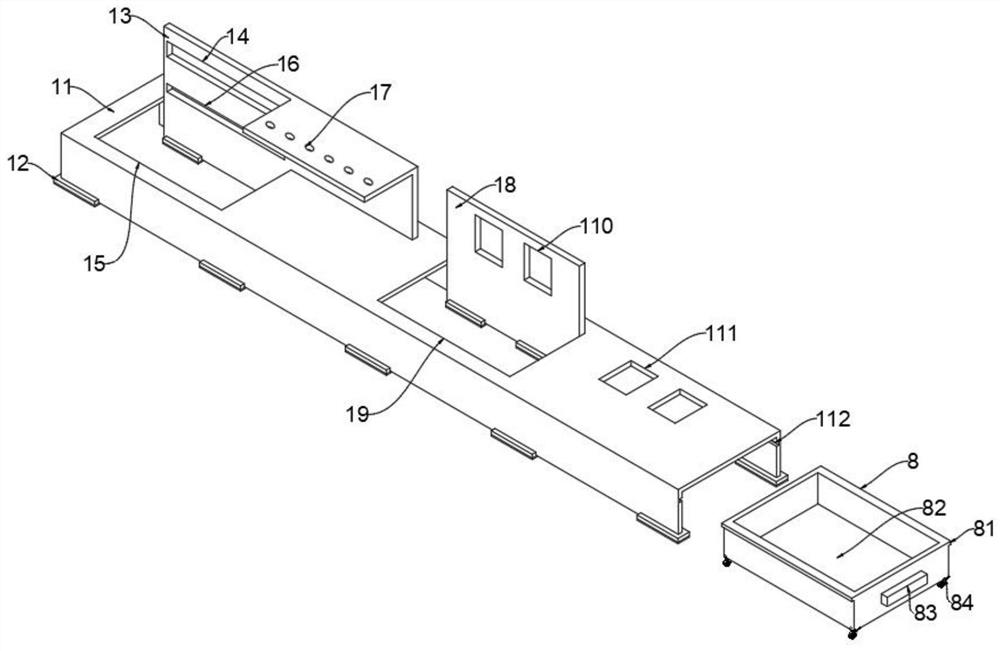

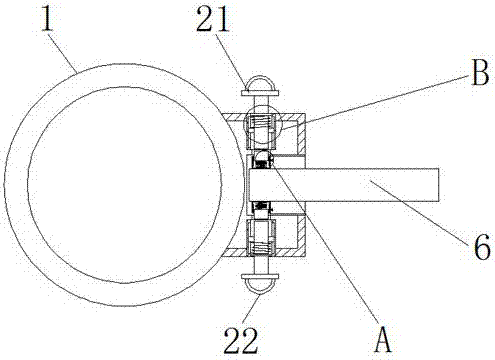

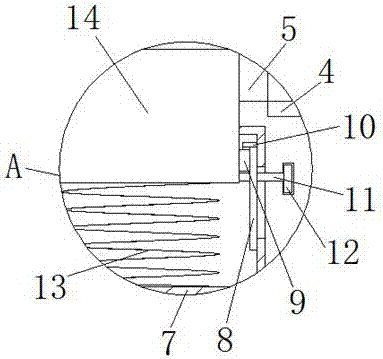

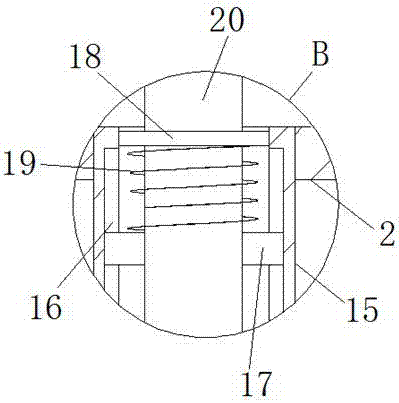

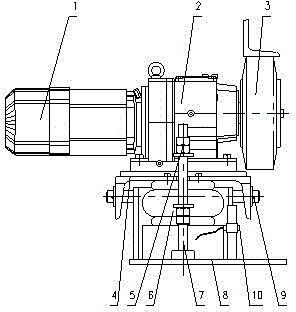

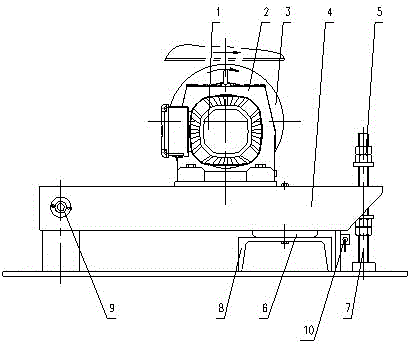

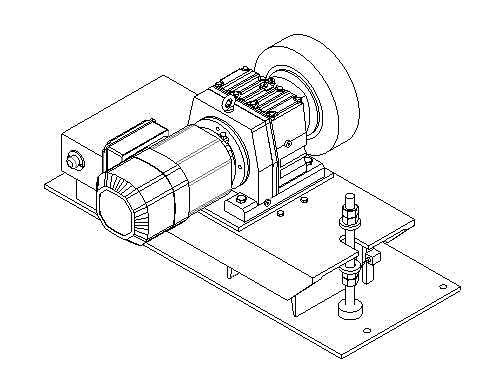

Mold table driving device with air bag

InactiveCN104015259ASmooth and continuous transmissionAvoid skiddingAuxillary shaping apparatusLow noiseProduction line

A mold table driving device with an air bag is applied to a precast concrete component flow production line and comprises a motor, a speed reducer, a rubber wheel, a speed reducer bottom plate, two sets of gasket nuts, the air bag, a stud, a support, a hinge pin and a sensor. The motor is directly connected with the speed reducer, the rubber wheel is assembled to an output shaft of the speed reducer, the speed reducer bottom plate is connected with the support through the hinge pin, and the air bag is installed between the speed reducer bottom plate and the support and connected with the speed reducer bottom plate and the support. The stud is welded to the support and provided with the gasket nuts, and the gasket nuts are installed at the proper positions above and below the speed reducer bottom plate respectively. The sensor is installed on the support. The mold table driving device is simple and reliable, overcomes the shortcoming of slip failure of a friction wheel, guarantees stable, continuous and low-noise conveying of a mold table and can ascend or descend according to the process needs.

Owner:NORTHERN HEAVY IND GRP CO LTD

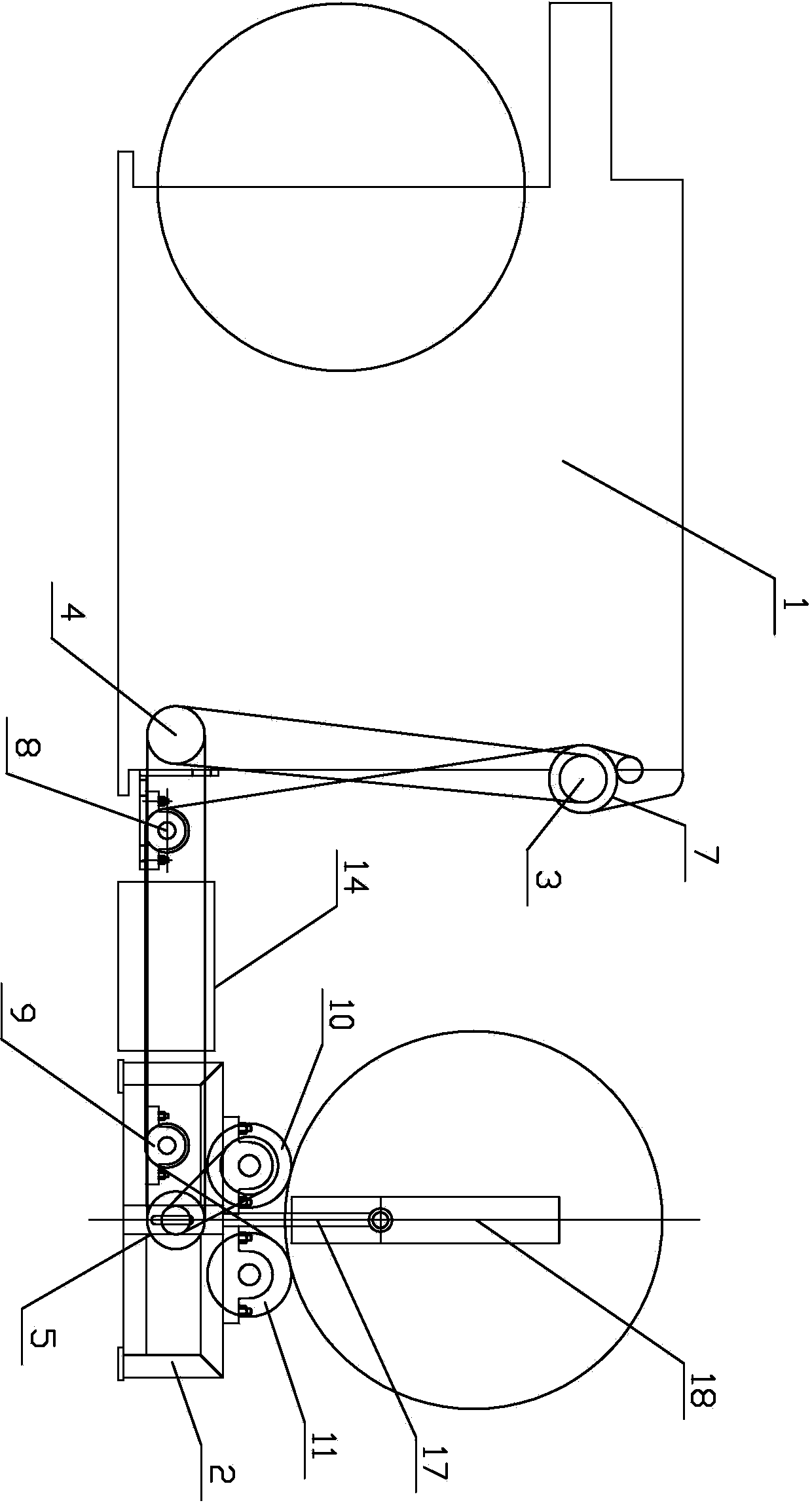

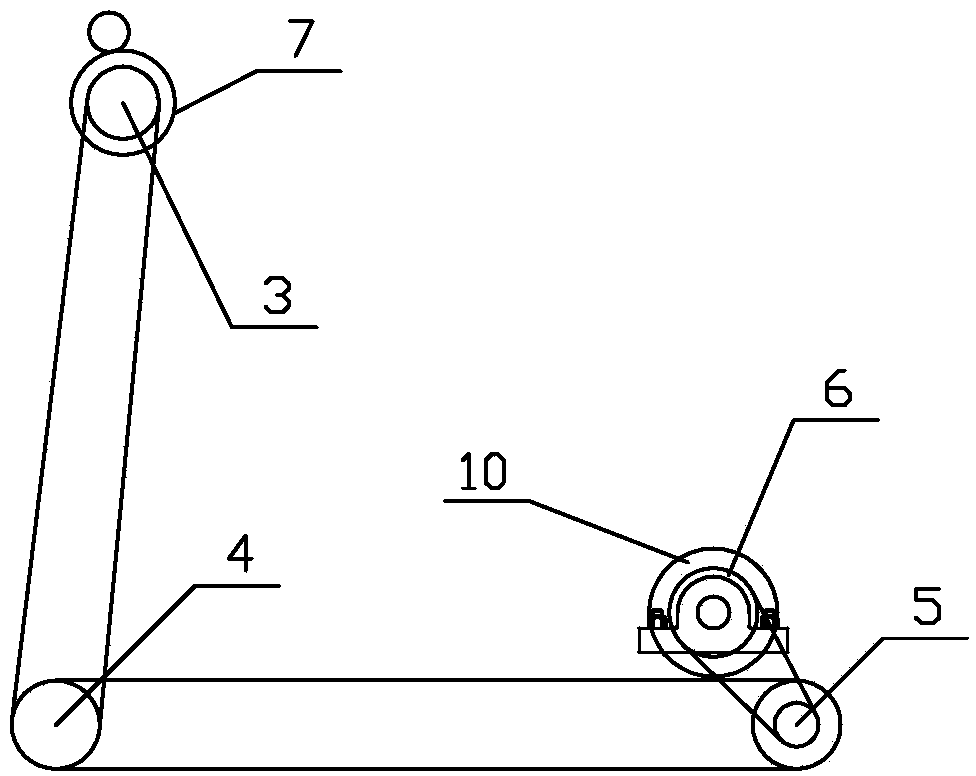

Device for batching gray fabric of loom

The invention discloses a device for batching a gray fabric of a loom. The device is characterized in that the device includes a machine base (2) arranged outside the loom, a batching mechanism arranged on the machine base (2) and a transmission mechanism for connecting the loom (1) with a batching mechanism, the transmission mechanism is a multi-stage chain transmission mechanism, and the transmission mechanism is connected with an original loom batching taker (7) on the loom. The device for batching the gray fabric of the loom has the advantages of simple structure, convenient, safe and reliable operation, low equipment failure rate and low cost; a driving shaft is capable of producing a batch, thereby reducing the number of fittings during the post processing of finished products.

Owner:ZHEJIANG SHUANGDUN TEXTILE TECH CO LTD

Rail grinding device for rail transit

InactiveCN109252427AAvoid pollutionImprove practicalityRailway track constructionEngineeringWater tanks

The invention discloses a rail grinding device for rail transit, which comprises a polishing mechanism, two sides of the polishing mechanism are fixedly installed with mounting brackets, a pulley is fixedly installed on one side of the mounting bracket away from the polishing mechanism, a first push rod and a second push rod are fixedly installed on the tops of the two mounting brackets, and a pusher is arranged on the top of the polishing mechanism. As that pulley is arranged, the first push rod, the second push rod, the push hand, the mounting bracket, a vacuum hood, a fixing rod, a vacuum line, a support plate, a blower, a dust inlet pipe, a water tank, a dust pipe, a water feeding pipe, a water outlet pipe, a control valve, a air guide plate and a limiting clasp are mutually matched, and the problem that the existing polishing device does not have the dust removing function is solved. The polishing device can collect the dust and rust ash generated when the polishing device is used, thereby avoiding the air pollution caused by the dust and rust ash and causing damage to the health of the operator.

Owner:郑州杏坛电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com