Vacuum adsorption type building glass curtain wall cleaning machine

A technology of vacuum adsorption and glass curtain wall, which is applied in the direction of cleaning machinery, cleaning equipment, carpet cleaning, etc., can solve the problems of time-consuming and laborious, slow work efficiency, and affect the appearance, and achieve the effects of reducing labor intensity, preventing slipping, and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

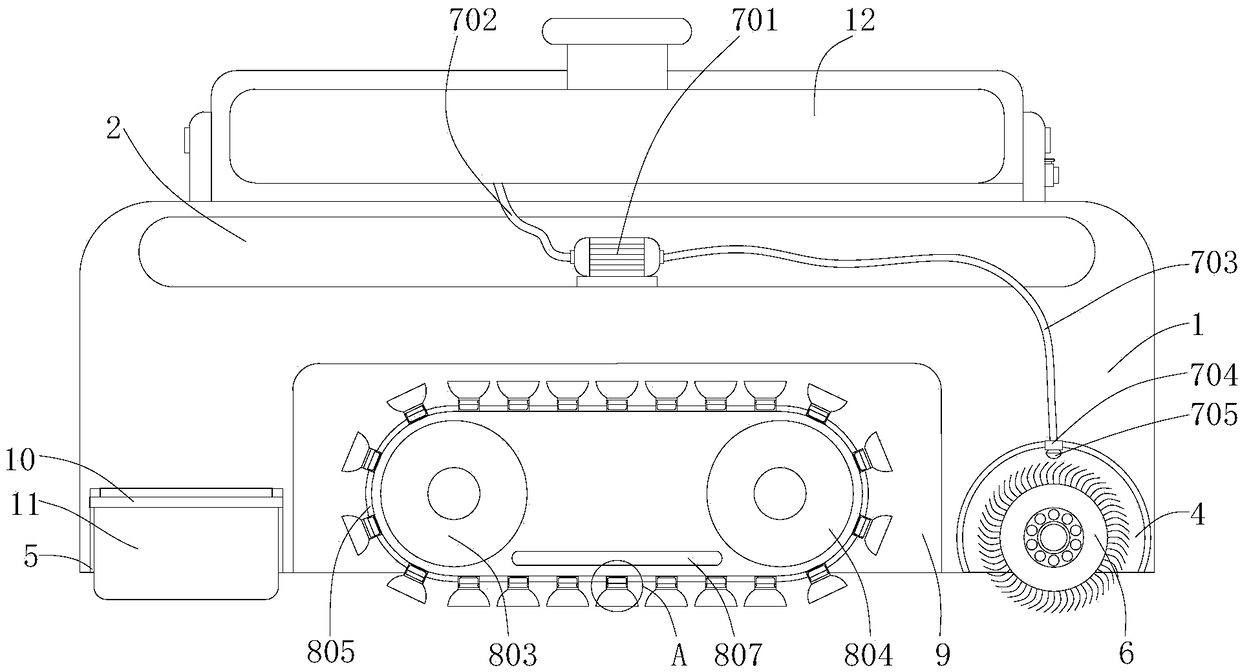

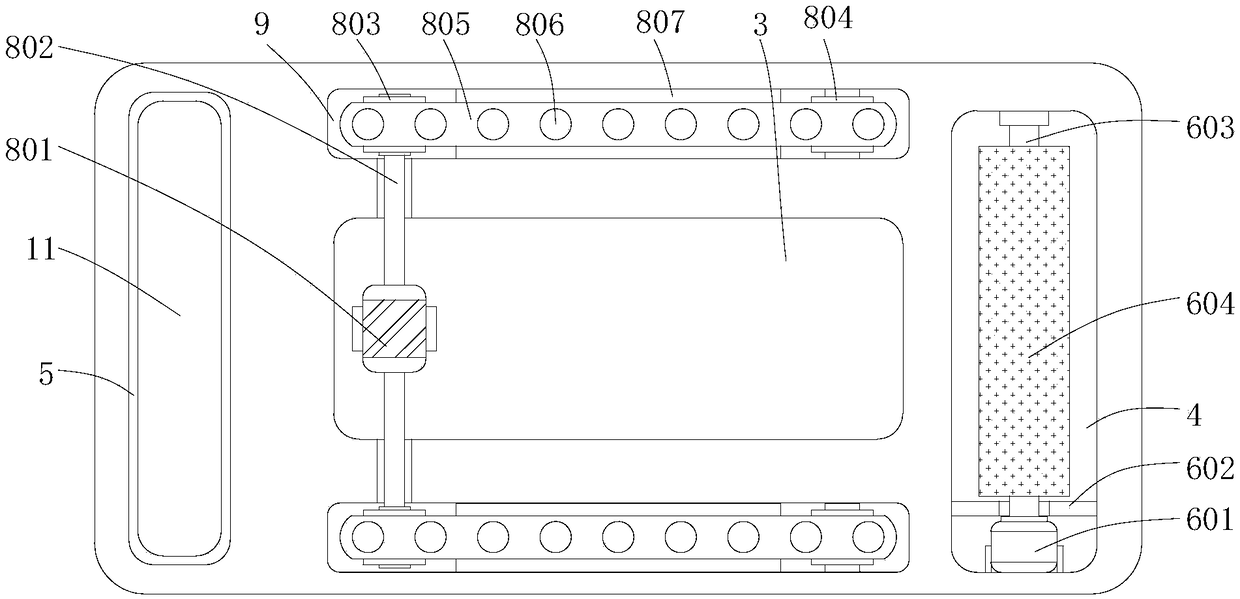

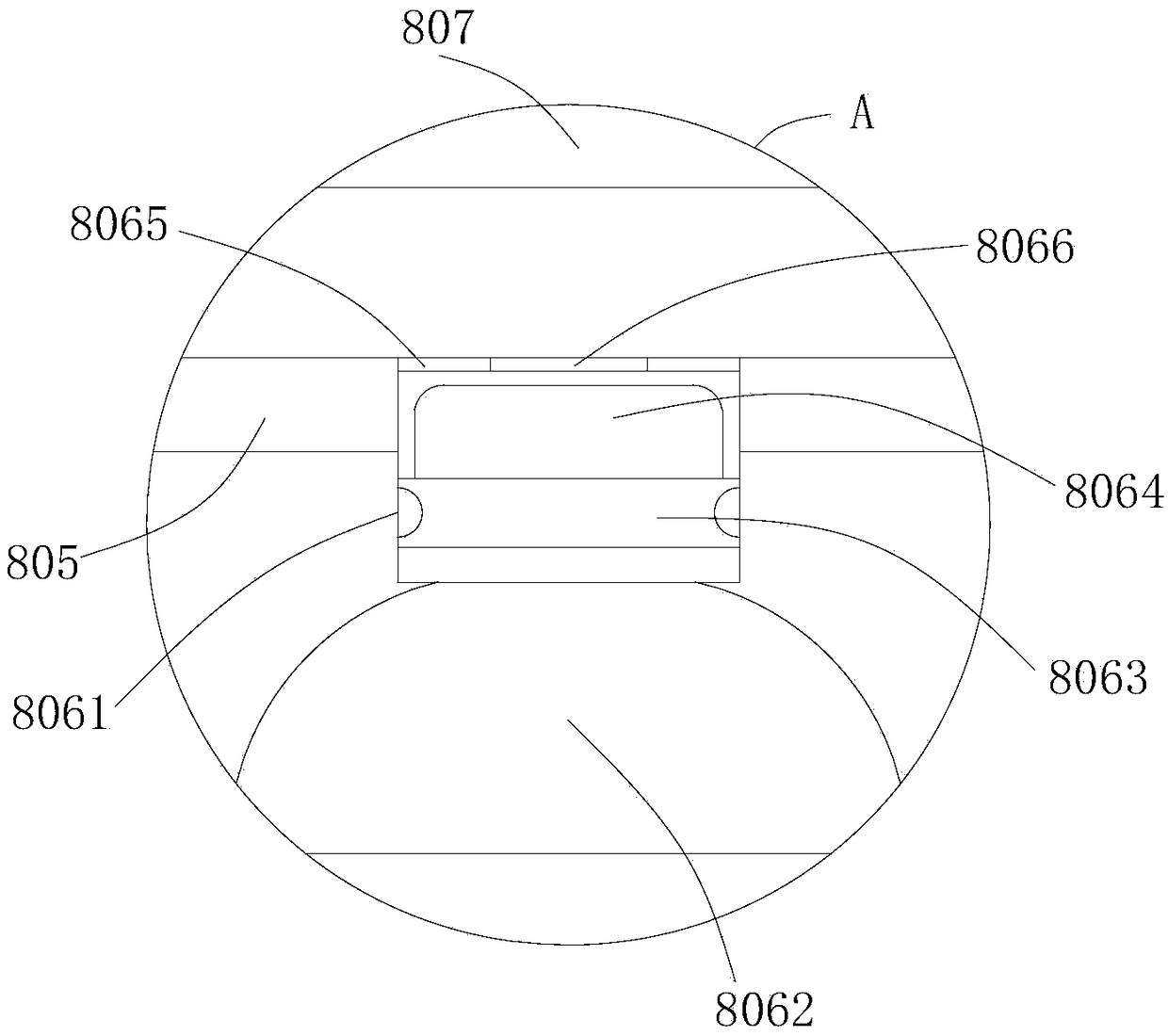

[0027] see Figure 1-4 , a vacuum adsorption type building glass curtain wall cleaning machine, including a body 1, a first cavity 2, a second cavity 3, a cleaning tank 4, a wiping tank 5, a cleaning mechanism 6, a conveying mechanism 7, a vacuum adsorption mechanism 8, two A fixed groove 9 and a water tank 12, the first cavity 2 is set on the top inside the body 1, the second cavity 3 is set on the bottom inside the body 1, and the first cavity 2 is located directly above the second cavity 3, The setting of the first cavity 2 and the second cavity 3 facilitates the installation and fixing of the micro-water pump 701 and the biaxial motor 801, reduces the weight of the body 1 at the same time, facilitates the movement of the body 1 on the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com