Patents

Literature

43results about How to "Guaranteed to look good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

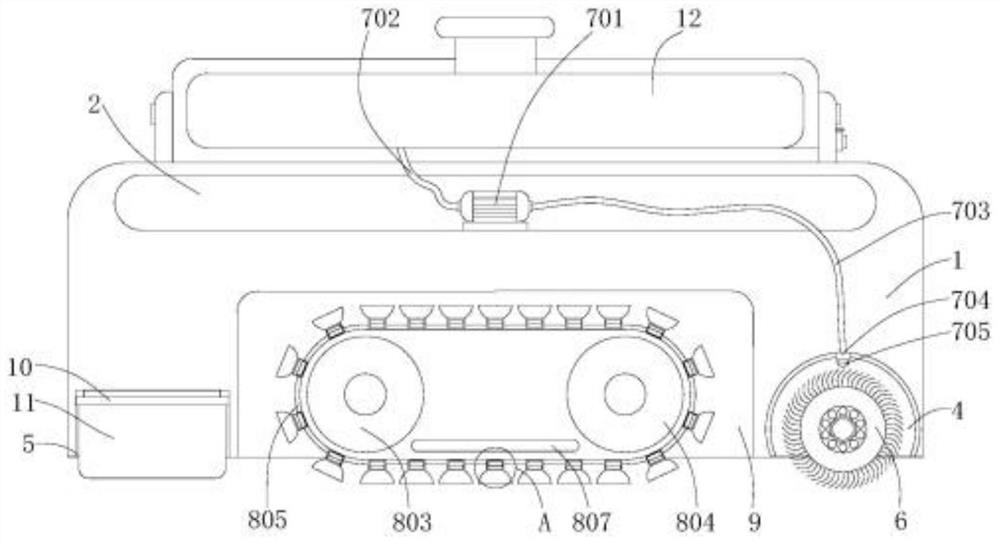

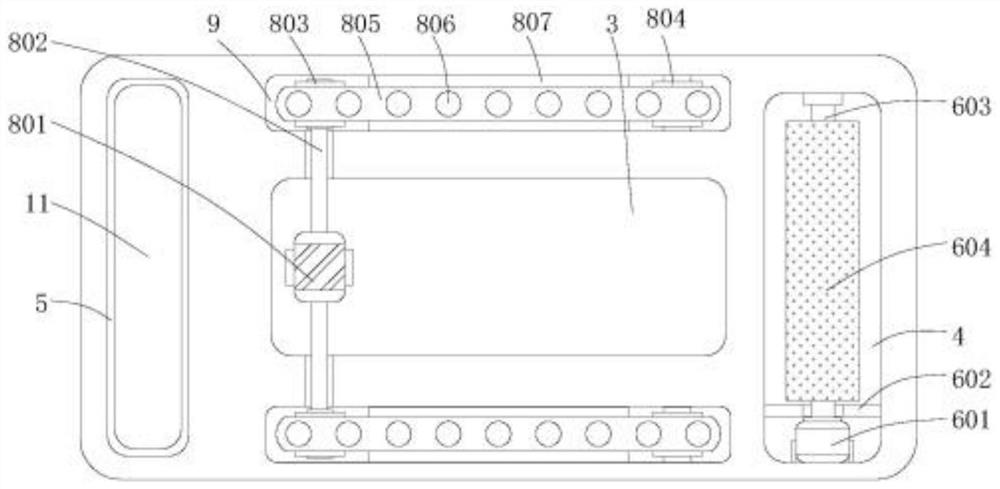

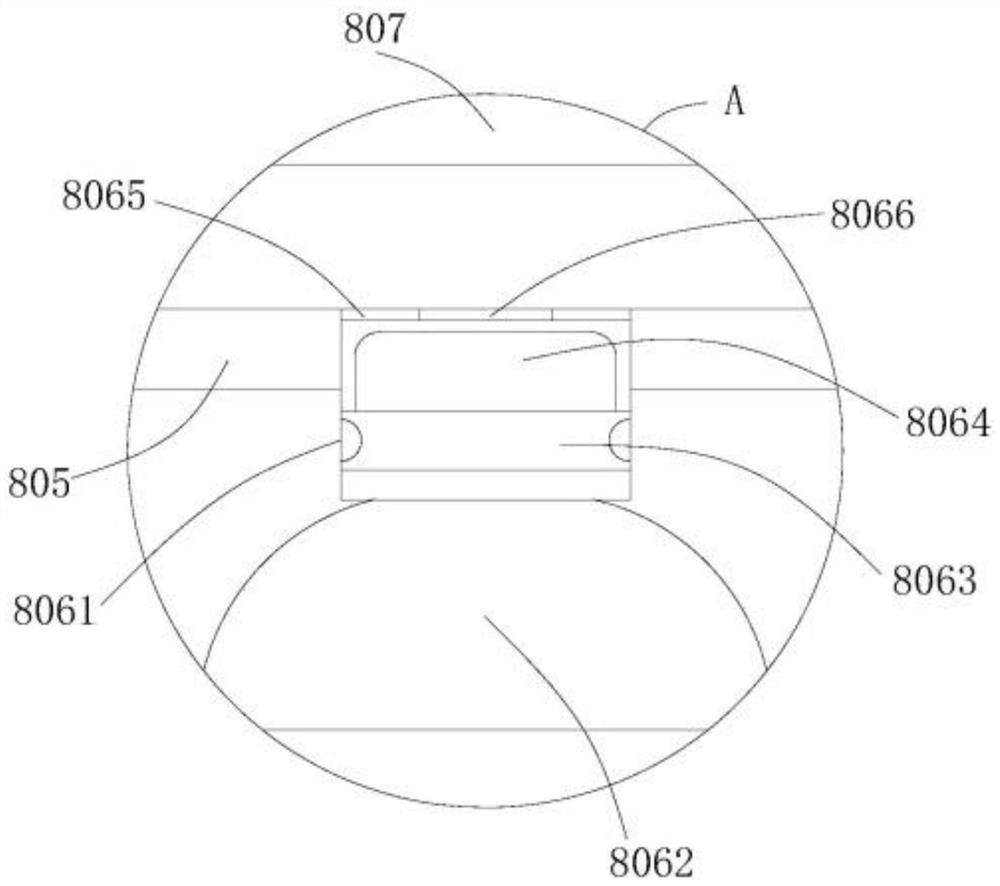

Vacuum adsorption type building glass curtain wall cleaning machine

ActiveCN109222780AEnsure stabilityAvoid skiddingCarpet cleanersFloor cleanersPulp and paper industryAtmospheric pressure

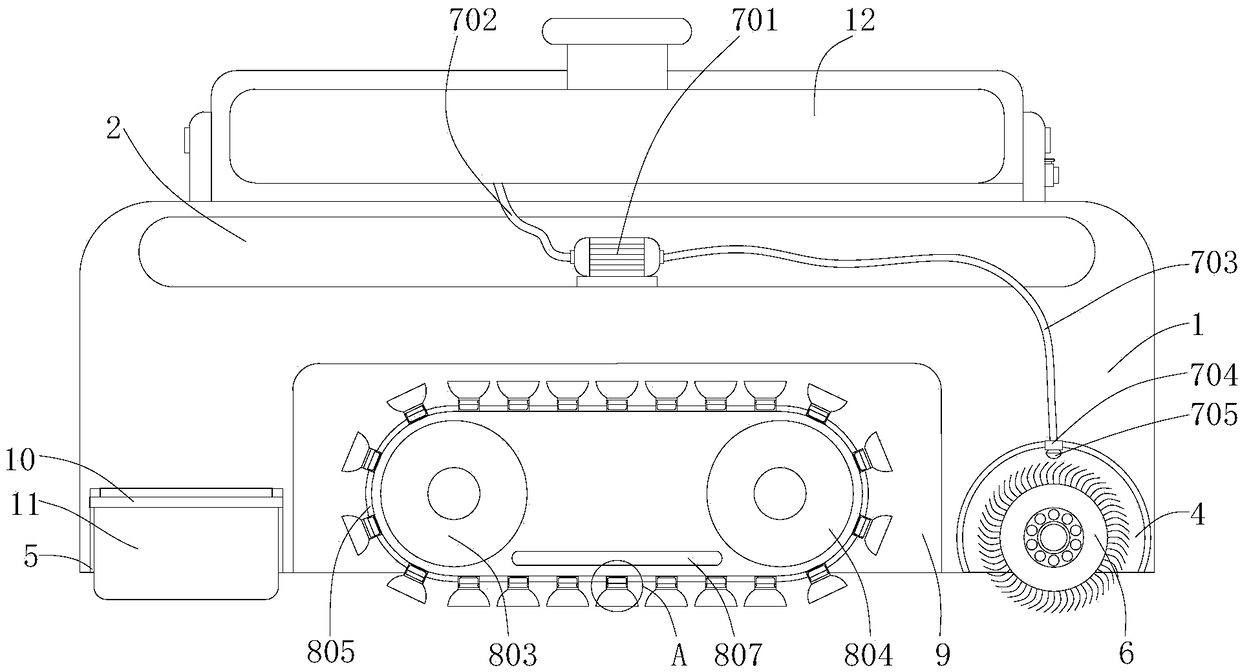

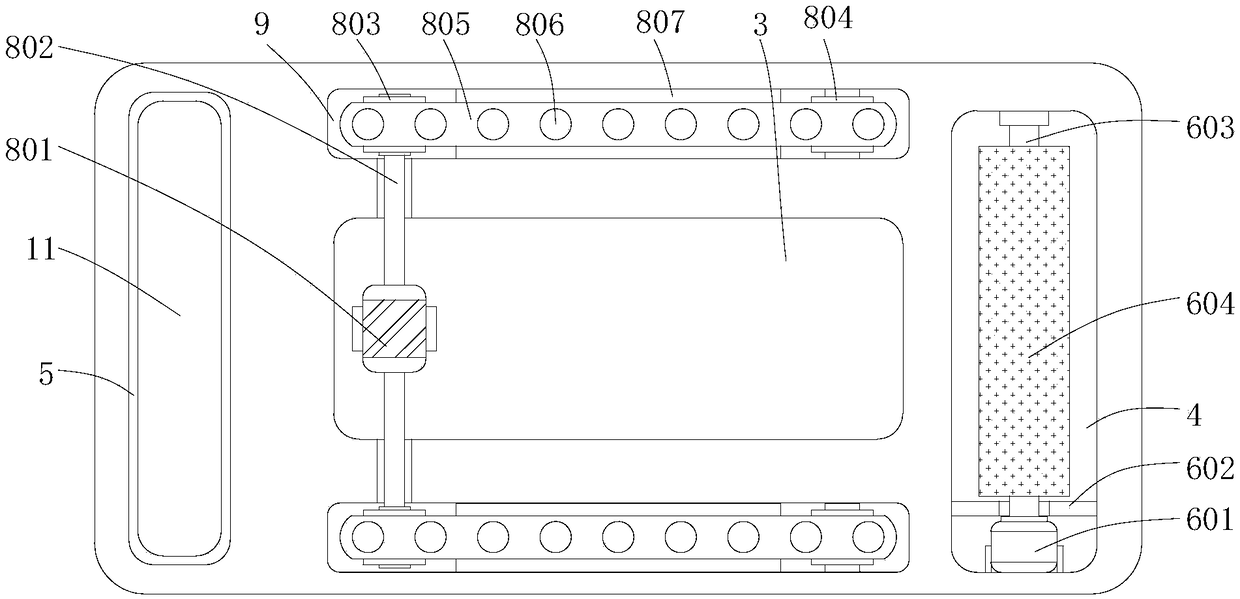

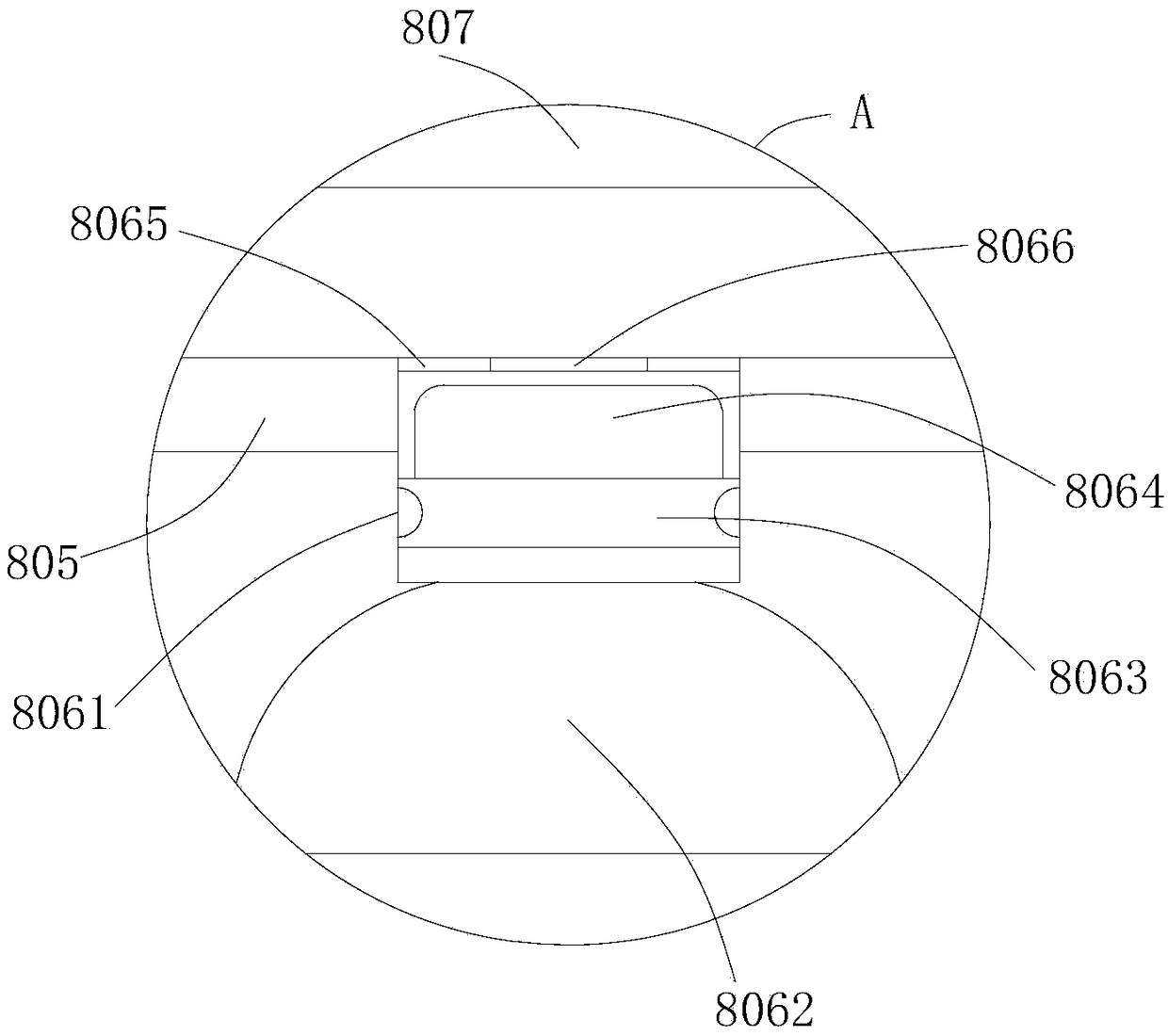

The invention relates to the technical field of glass curtain wall cleaning, and discloses a vacuum adsorption type building glass curtain wall cleaning machine. The machine includes a body, a first cavity, a second cavity, a cleaning tank, a wiping tank, a cleaning mechanism, a conveying mechanism, a vacuum suction mechanism, two fixed tanks and a water tank, wherein the first cavity is arrangedat the top of the body interior, the second cavity is arranged at the bottom of the body interior, and the first cavity is positioned directly above the second cavity, the cleaning tank is arranged atthe right end of the body bottom, and the wiping tank is arranged at the left end of the body bottom. As that track of the invention move on the surface of the glass curtain wall, so that suction cups close to the glass curtain wall are blocked, The suction cup is adsorbed on the surface of the glass curtain wall in a sealed state, and the permanent magnet block is magnetically attracted by the magnet plate, the permanent magnet block moves upward close to the magnet plate, drives the piston to move upward, and reduces the air pressure inside the suction cup, so that the machine body is firmly adsorbed on the surface of the glass curtain wall, and the stability of the machine body is ensured when the machine body moves.

Owner:日照市大东方玻璃有限公司

Manufacturing method of aluminum plate decorative picture

ActiveCN109130678AEffective surface rust removalPrevent malfunctionDecorative surface effectsSpecial ornamental structuresMetallurgyCeramic glaze

The invention relates to a manufacturing method of an aluminum plate decorative picture. The manufacturing method comprises the steps of selecting an aluminum plate, preparing a transitional glaze layer, mixing and stirring, spraying the transitional glaze layer, primary firing, spraying a surface glaze layer, secondary firing, cooling and the like. The method is reasonable and feasible, the transitional glaze layer, the aluminum plate and the surface glaze layer are combined closely, a fired product is attractive and elegant, the surface of a print is flat and does not wrinkle, the fired product is firm and durable, and can be stored for a long time, and the technical problems that jet drawing cloth of a decorative picture of an exterior wall of a building easily fades and drops, is shortin service life, and cannot be stored for a long time, the time and cost are wasted if the jet drawing cloth is changed, the cost is increased, an oxidation film of the surface of the aluminum plateis not easily combined to the glaze layer directly, coloring of the glaze layer of the surface is affected, during firing, the aluminum plate is quite easily melted, and cannot be glazed, if the aluminum plate is cooled suddenly after being fired, arched deformation of the surface of the aluminum plate is easily caused, the quality of products is affected, the production benefit of enterprises isalso affected and the like are solved. Compared with the prior art, the manufacturing method of the aluminum plate decorative picture has good market prospect and development space.

Owner:宝丰大博瓷画文化创意有限公司

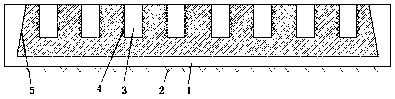

Elastic heat-preservation ceramic wall tile and manufacturing process thereof

InactiveCN108193846AImprove insulation performanceLow manufacturing costCovering/liningsStone-like material working toolsCeramic particleSilicon nitride

The invention relates to the technical field of wall tiles, in particular to an elastic heat-preservation ceramic wall tile and a manufacturing process thereof. The elastic heat-preservation ceramic wall tile comprises a ceramic bottom plate. A wedge-shaped cavity is formed in the ceramic bottom plate, and the small open end of the wedge-shaped cavity faces outwards. The wedge-shaped cavity is filled with elastic rubber, and a plurality of ceramic particles are arranged in the elastic rubber in an embedded mode. The wedge-shaped cavity is prepared from components of, by mass, 100-130 parts ofkaolin, 80-90 parts of feldspar, 40-60 parts of quartz, 10-20 parts of zirconia, 8-12 parts of silicon nitride, 10-15 parts of basalt and 5-7 parts of pure aluminum powder. The attractiveness of an original ceramic tile is ensured, the ceramic tile has elasticity, and when the body or furniture bumps against the ceramic tile, body parts and the furniture are not injured; the heat-preservation performance of the wall tile is improved; and the product manufacturing cost is low, and higher benefits are brought for factories or enterprises.

Owner:FOSHAN OUGE CERAMIC CO LTD

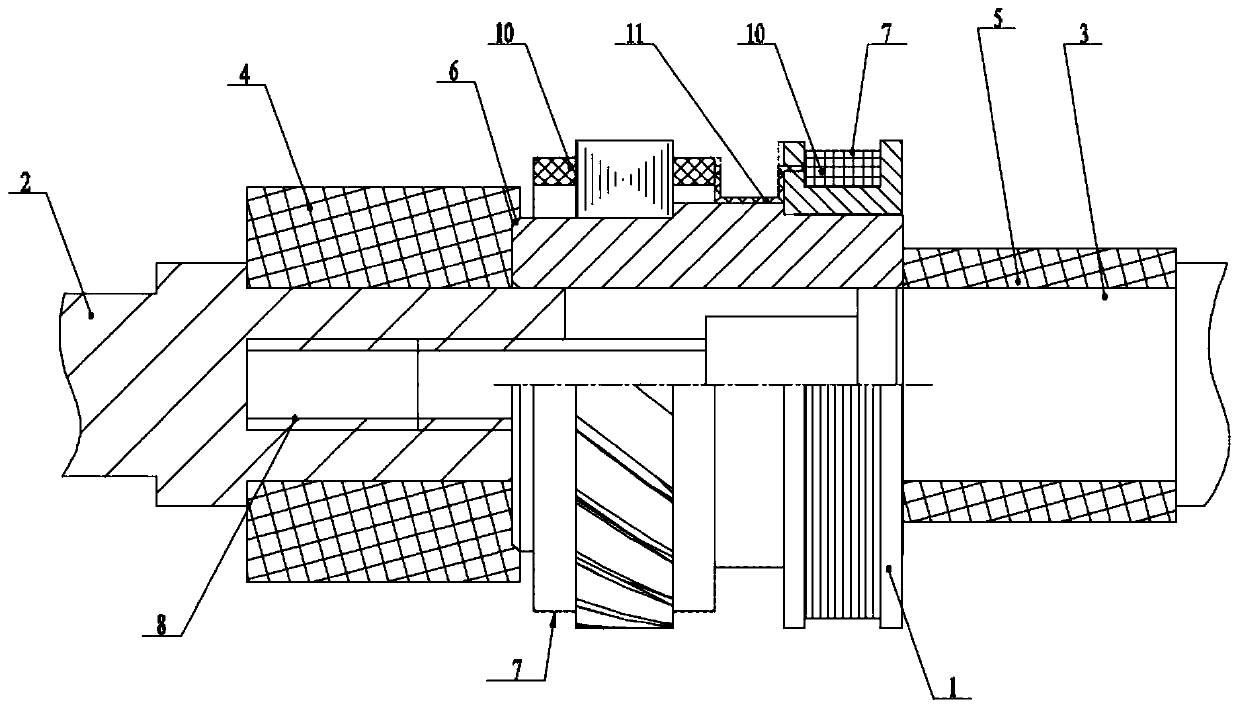

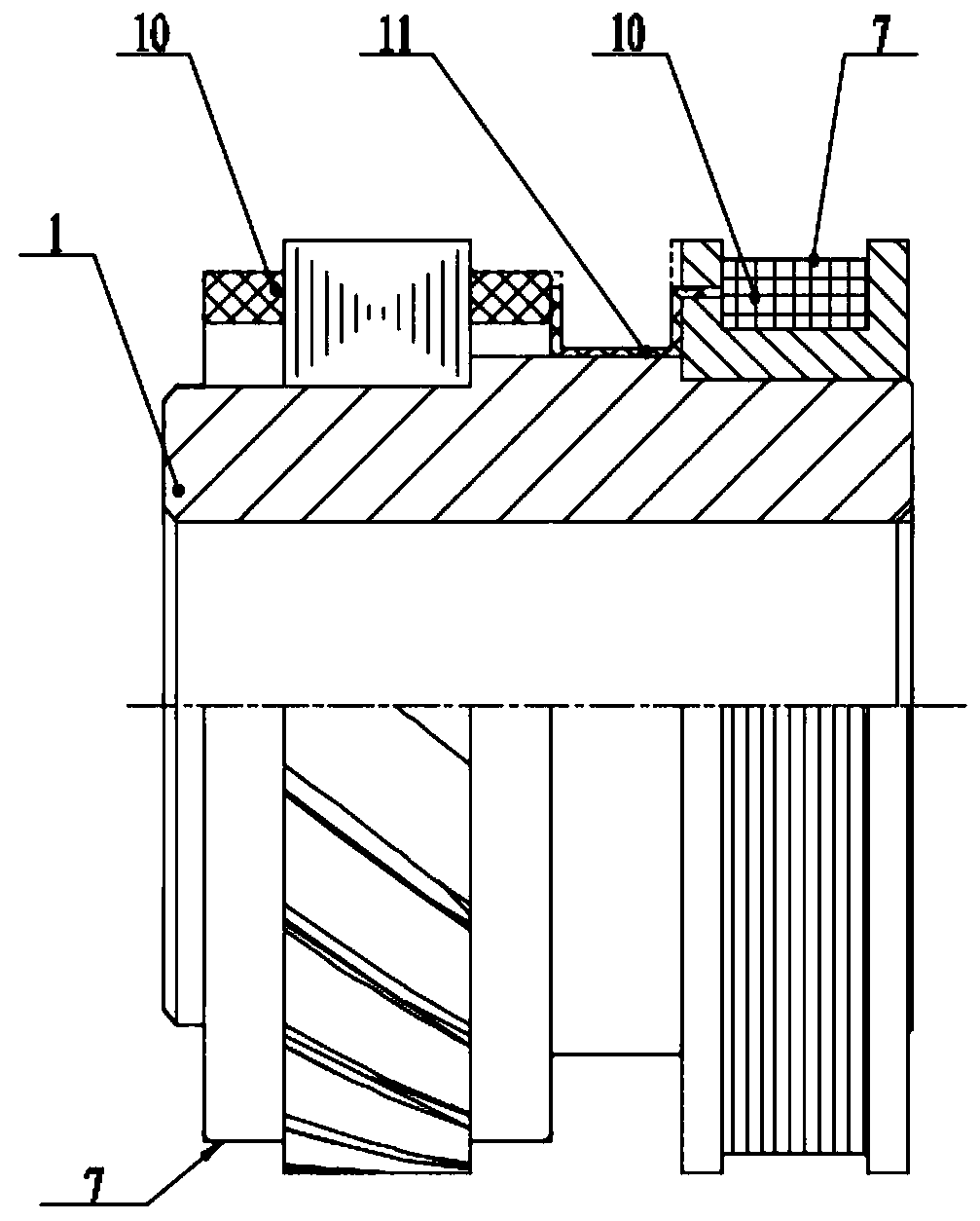

Vacuum adsorption type building glass curtain wall cleaning machine and using method

InactiveCN112545402AEnsure stabilityAvoid skiddingCarpet cleanersFloor cleanersMechanical engineeringIndustrial engineering

The invention relates to the technical field of glass curtain wall cleaning and discloses a vacuum adsorption type building glass curtain wall cleaning machine and a using method thereof. The vacuum adsorption type building glass curtain wall cleaning machine comprises a machine body, a first cavity, a second cavity, a cleaning groove, a wiping groove, a cleaning mechanism, a conveying mechanism,a vacuum adsorption mechanism, two fixing grooves and a water tank, wherein the first cavity is arranged at the top of the body, the second cavity is formed in the bottom in the machine body, the first cavity is located over the second cavity, the cleaning tank is formed in the right end of the bottom of the machine body, and the wiping tank is formed in the left end of the bottom of the machine body. The vacuum adsorption type building glass curtain wall cleaning machine is advantaged in that the caterpillar band moves on the surface of the glass curtain wall, so that the suction cups close to the glass curtain wall are blocked, the suction cups are attracted to the surface of the glass curtain wall to be in a sealed state, and due to magnetic attraction of the permanent magnet blocks andthe magnet plates, the permanent magnet blocks move upwards to be close to the magnet plates to drive the pistons to move upwards, and air pressure in the suction cups is reduced; therefore, the machine body is firmly adsorbed on the surface of the glass curtain wall, and stability of the machine body during movement is ensured.

Owner:李云魁

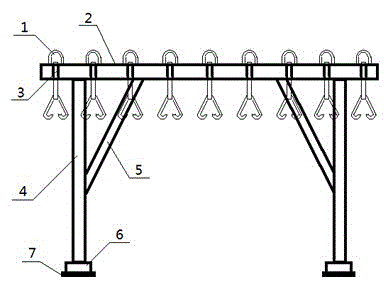

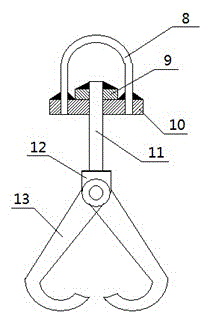

Economical and practical paint spraying rack for hydraulic cylinder

The invention discloses an economical and practical paint spraying rack for a hydraulic cylinder. The paint spraying rack comprises a rack body and hanging brackets. The hanging brackets are arranged on the rack body, and the rack body is a welded element. A main beam, supporting legs, diagonal bracings, supporting leg bases and rack body bottom plates are sequentially welded to the rack body from top to bottom. Each hanging bracket structurally and sequentially comprises a lifting handle, a small round plate, a large round plate, round steel, a U-shaped plate and a hook. The economical and practical paint spraying rack for the hydraulic cylinder is simple in structure and convenient to use, and can greatly improve work efficiency and save cost. Meanwhile, it is guaranteed that the hydraulic cylinder where paint is sprayed is attractive and elegant.

Owner:苏州市大力电器有限公司

Making method of in-glaze Ru-process jade porcelain painting

ActiveCN110625532AThe method is reasonable and feasibleIngenious designDecorative surface effectsSpecial ornamental structuresCeramic glazeAluminium

The invention relates to a making method of an in-glaze Ru-process jade porcelain painting. The method comprises the steps of cleaning for a glass plate, jade treatment, preparation of a celeste blueglaze layer, spraying of a glaze layer, direct firing, high-definition printing, continuous firing, cooling, additional arrangement of an aluminium plate and the like. The method is reasonable, feasible and ingenuous in design, internal and external pictures cannot be scratched, the pictures are high in three-dimensional sense and bright in color, the painting is high in surface jade texture, firmand durable and can be stored for a long time, and the technical problems are solved that in an existing process of making a glass porcelain plate painting, the pictures are easily scratched, the three-dimensional sense of the pictures is low, after firing, the surface jade texture is low, the artistic texture of the Ru porcelain surface cannot be formed, and the product quality and enterprise production benefit are influenced. For the prior art, the making method has great market prospects and development space.

Owner:张柳松

Formula of unsaturated polyester paint for woodenware and preparation method of formula

The invention discloses a formula of unsaturated polyester paint for woodenware and a preparation method of the formula. Acrylic resins, styrene and o-benzene type unsaturated polyester resins are main film-forming matters, wherein the styrene is a solvent and can participate in the reaction, and in the presence of an initiator, by-products are not released and can be totally transformed into solid polymers; olyethylene glycol (600) is an additive for regulating the viscosity of the coating system; zinc stearate is capable of increasing the sanding property of the coating; an anti-settling coating additive is capable of avoiding the coating from being easily settled and layered in the placement process; and after polyvinyl butyral and resins are reacted, a very stable film can be obtained,and the hardness of the coating is enhanced. The various components are reasonably matched, the solvent evaporation rate is reasonable, and the formula of the unsaturated polyester paint is an excellent unsaturated polyester coating.

Owner:闫斐斐

A formula of polyurethane paint having a modified leveling property for clarinet musical instruments and a preparing method for the paint

InactiveCN108373826AReduce evaporation rateReduce generationPolyurea/polyurethane coatingsCyclohexanoneNitrocellulose

The technical scheme of the invention provides a formula for solving the problem of poor levelling properties of the polyurethane paint for clarinet musical instruments and a preparing method for paint. The formula includes an A component and a B component, wherein the A component includes ethyl acetate, n-butyl acetate, cyclohexanone, polyketone resin, 1 / 16 second nitrocellulose, high efficiencymatting powder, hydroxy polyacrylic acid resin, wax slurry without a matting effect, and polyether modified polydimethylsiloxane; and the B component includes ethyl acetate, n-butyl acetate, hexamethylene diisocyanate, an isocyanate adduct and a matt trimer curing agent.

Owner:黄克格

Formula and preparation method of leveling-modified polyurethane paint for aluminum products

InactiveCN108373833AImprove levelingReduce evaporation ratePolyurea/polyurethane coatingsChemistrySolvent evaporation

The invention relates to a formula and preparation method of leveling-modified polyurethane paint for aluminum products. Through reduction of a solvent evaporation rate in paint volatilization, Bernadette vortexes are reduced in paint curing, the leveling effects of the polyurethane paint for aluminum products is greatly improved, orange peel phenomenon is reduced and the beauty of the product isguaranteed.

Owner:黄克格

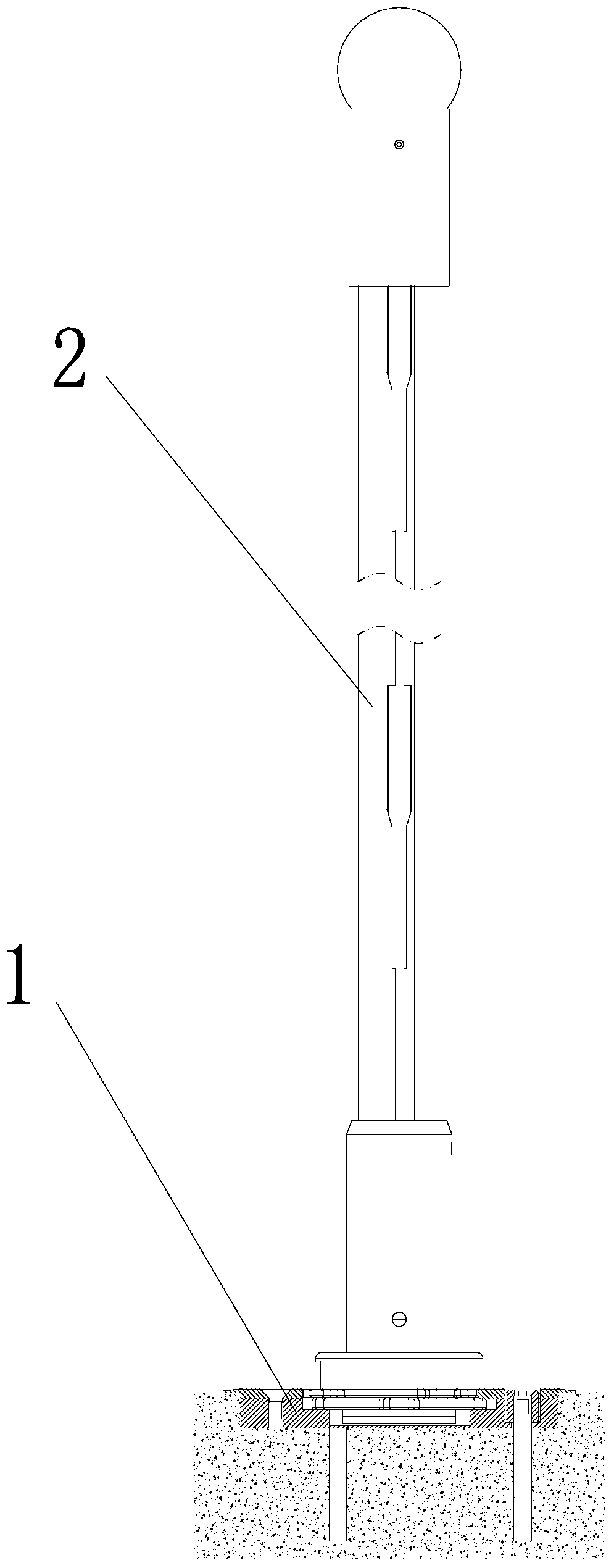

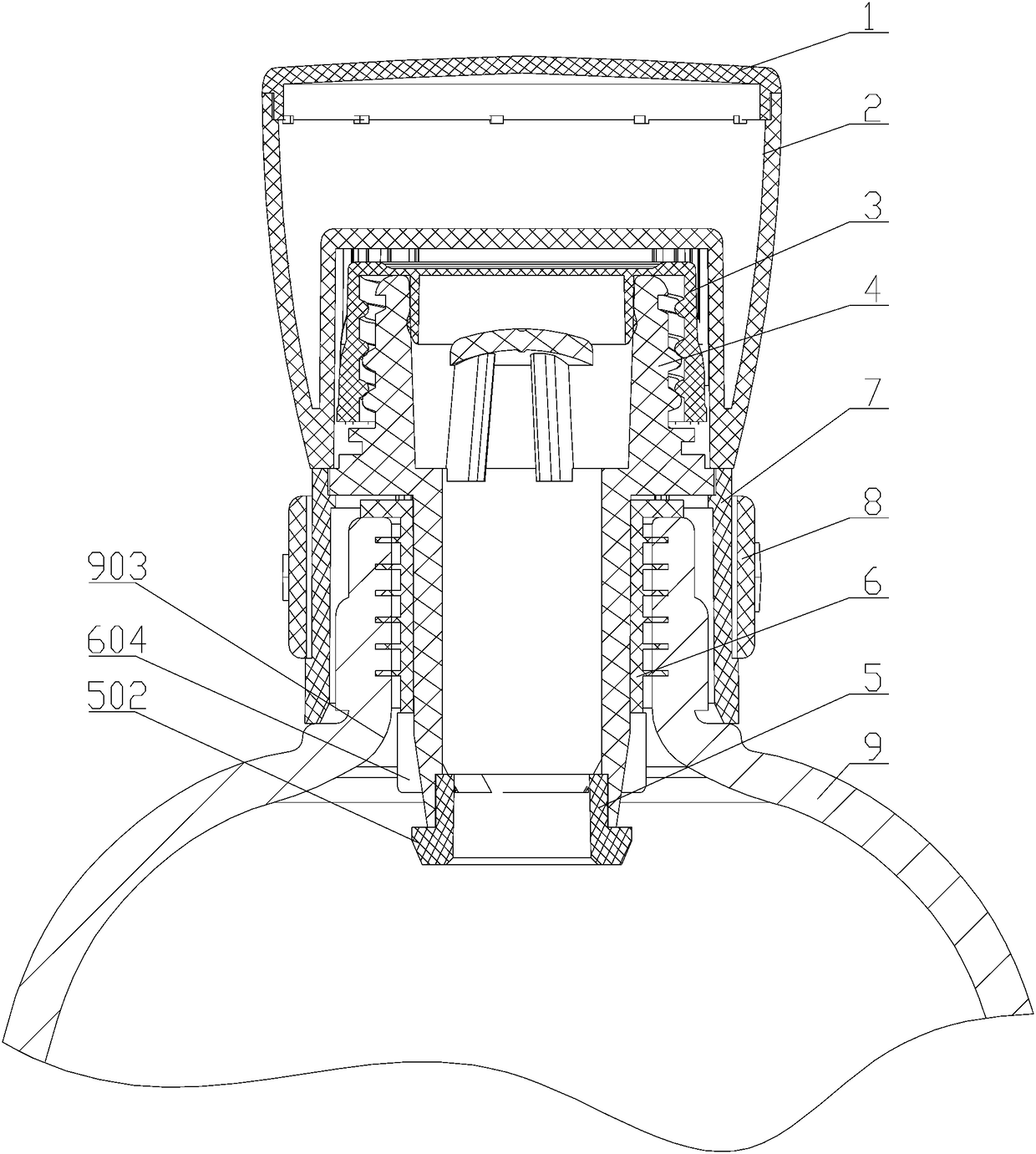

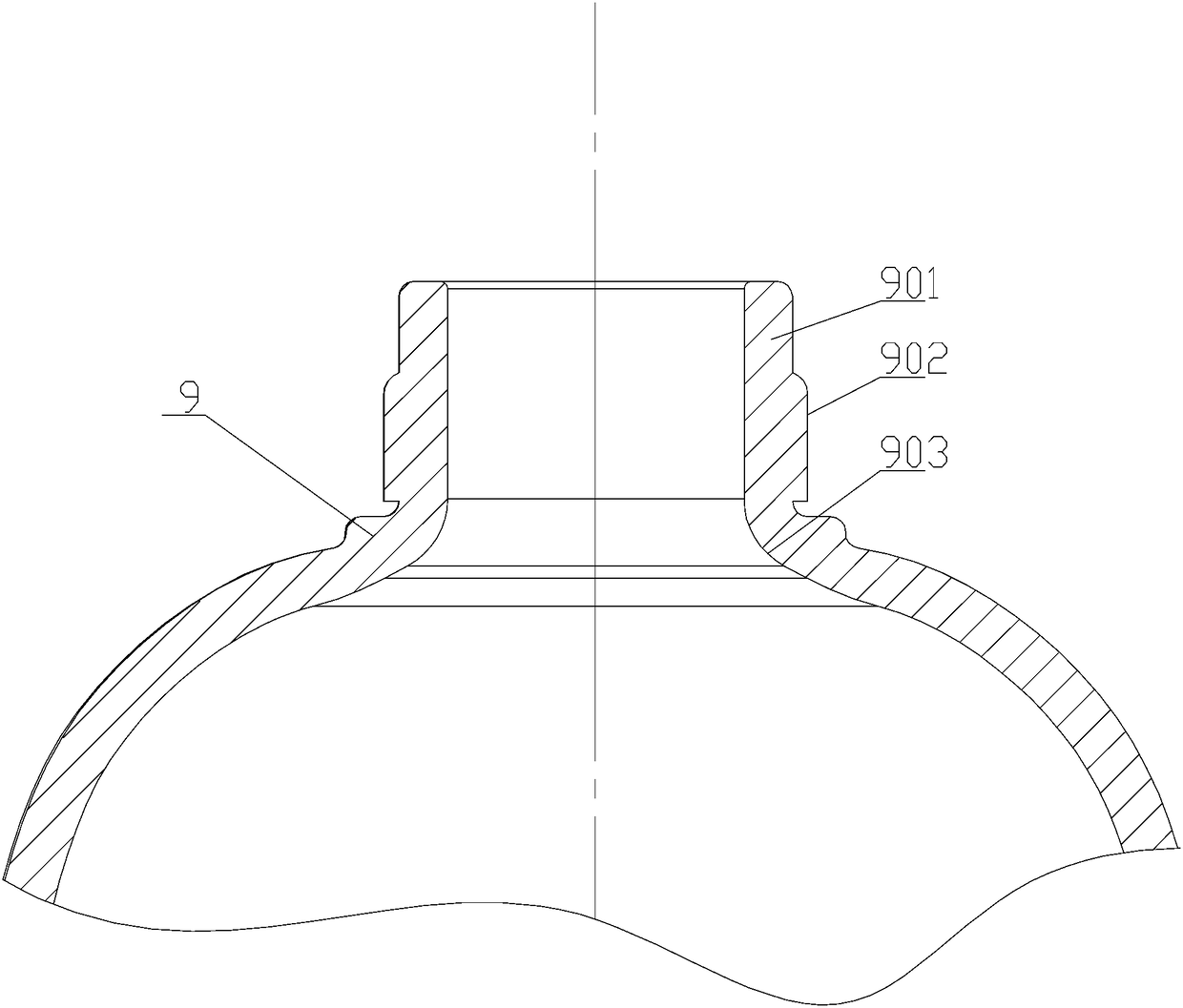

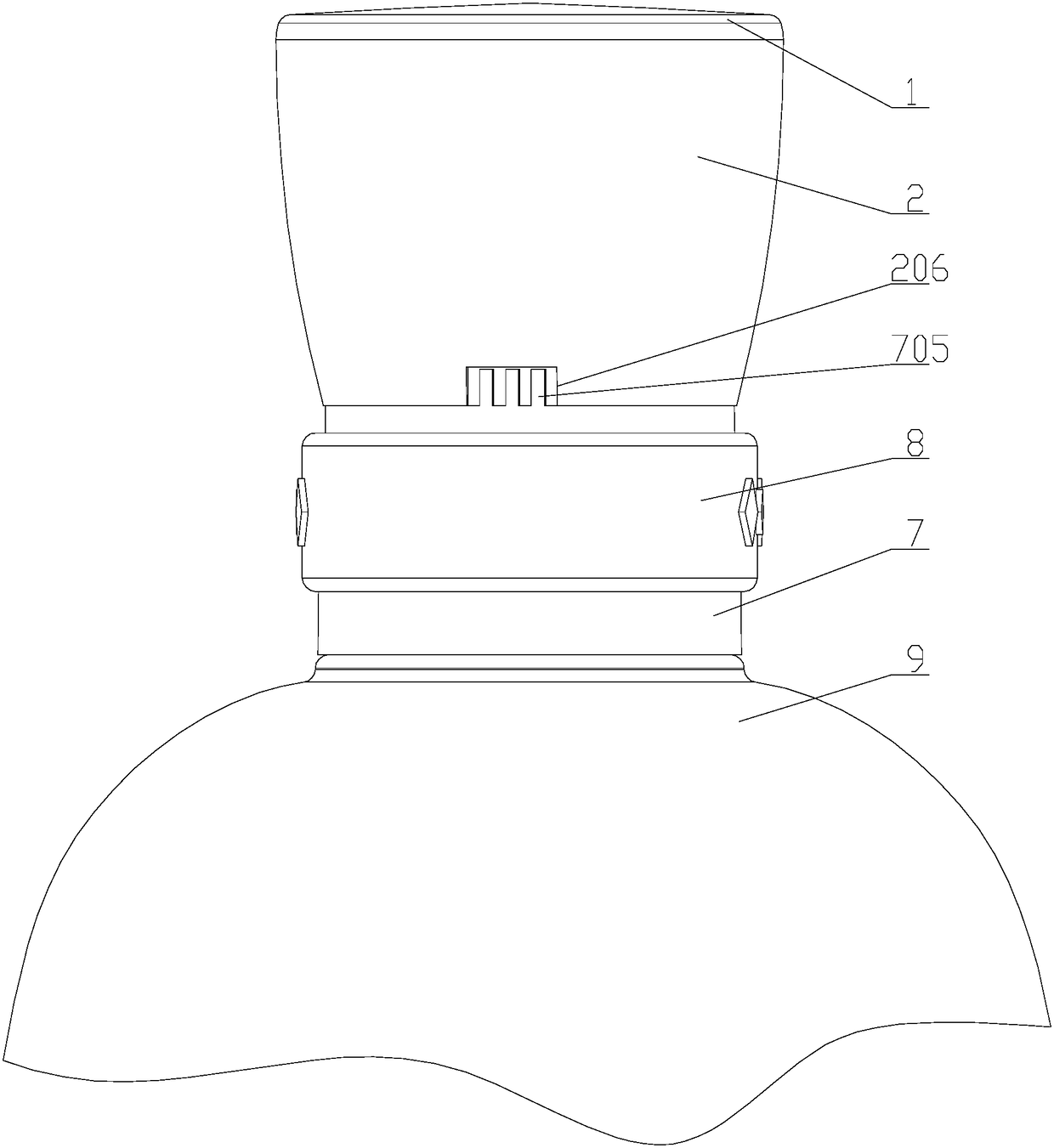

Vertical columns suitable for indoor public place and capable of being quickly demounted and mounted

PendingCN110117939AGuaranteed to look goodDoes not affect coordinationTraffic restrictionsPublic placeEngineering

The invention discloses vertical columns suitable for an indoor public place and capable of being quickly demounted and mounted. Each vertical column comprises an underground preburied device and a ground rotatable vertical column structure. According to the vertical columns, structure design is reasonable, practicality is quite high, during work, the ground rotatable vertical column structure canbe demounted (mounted) only by slightly exerting the strength upwards (downwards) to rotate the ground rotatable vertical column structure to the certain position, demounting and mounting are convenient, after complete demounting, it is ensured that the place is attractive and elegant, overall coordination of the public place is not affected, the vertical column can be used repeatedly, economization and environmental protection are achieved; the vertical column is matched with a door sill and the like for use, thus a matrix can be formed for people flow limitation, the thrust (tension) borneby each vertical column is ten times or above that of a common iron barrier with a counterweight, the structure is more stable, the vertical column can bear impact of large disorder people flow to achieve the safe flow limiting effect, the difficulty of maintaining the order by a worker is reduced, and under the effect of the underground preburied device, the phenomenon of massive collapse is avoided even if the single vertical column is damaged heavily.

Owner:CHONGQING XINGUO IND & TRADE

Self-locking anti-fake pottery jar wine cover and assembly method

PendingCN108557245ASimple structure requirementsSimple structureLocking devicesPackage recyclingSelf lockingEngineering

The invention provides a self-locking anti-fake pottery jar wine cover and an assembly method. A top cover is pressed to the top of an outer shell through a lock catch structure, an inner cover is fixedly pressed to an inner cavity of the outer shell through an inversed buckle structure and is in threaded connection to a wine outlet cover used for wine pouring, the tail end of the bottom of the wine outlet cover is provided with a stopping ring used for limiting and falling preventing of an inner plug, the inner plug is sleeved with the lower end of the wine outlet cover, the inner cavity wallis matched with the wine outlet cover, and the outer wall is matched with the inner wall of a bottle opening of a wine bottle to seal the bottle opening; and the bottom of the wine outlet cover is provided with an anti-fake sleeve used for fake preventing through a limiting step, and an inner cavity of the anti-fake sleeve is matched with the outer wall of the bottle opening of the wine bottle tolimit the bottle opening. The wine cover can be suitable for pottery jar wine bottles, is simple in manufacturing technology and has the anti-fake effect, the anti-fake structure is arranged on the wine cover body, the traditional manner is replaced for arranging the wine cover on the bottle opening of the wine bottle, the manufacturing and producing difficulty is greatly reduced, and cost is reduced.

Owner:宜昌崟锦包装有限责任公司

Manufacturing method and application of diamond jade porcelain floor free of cement concrete paving

PendingCN112456814AGood autonomyPrevent slippingFlooringMechanical engineeringIndustrial engineering

The invention relates to a manufacturing method and application of a diamond jade porcelain floor free of cement concrete paving. The manufacturing method comprises the steps of plate selection, jadeanti-skid treatment, pattern printing, primary firing, glaze sealing treatment, secondary firing, cooling and the like. According to the method, paving is convenient, decoration materials are saved, cost is reduced, indoor space is saved, the weight of a building is reduced, radiation and pollution are avoided, pictures are protected, the size can be customized, patterns can be selected autonomously, the product is attractive, elegant, firm and durable and can be stored for a long time, and the technical problems that existing floor tiles are small mounting blocks and inconvenient to mount, the weight of the building body is overweight due to the fact that cement concrete needs to be used in the laying process, the size cannot be customized according to actual needs, patterns are limited,and autonomous selection cannot be achieved are solved, and for the prior art, good market prospects and development space are achieved.

Owner:宝丰大博瓷画文化创意有限公司

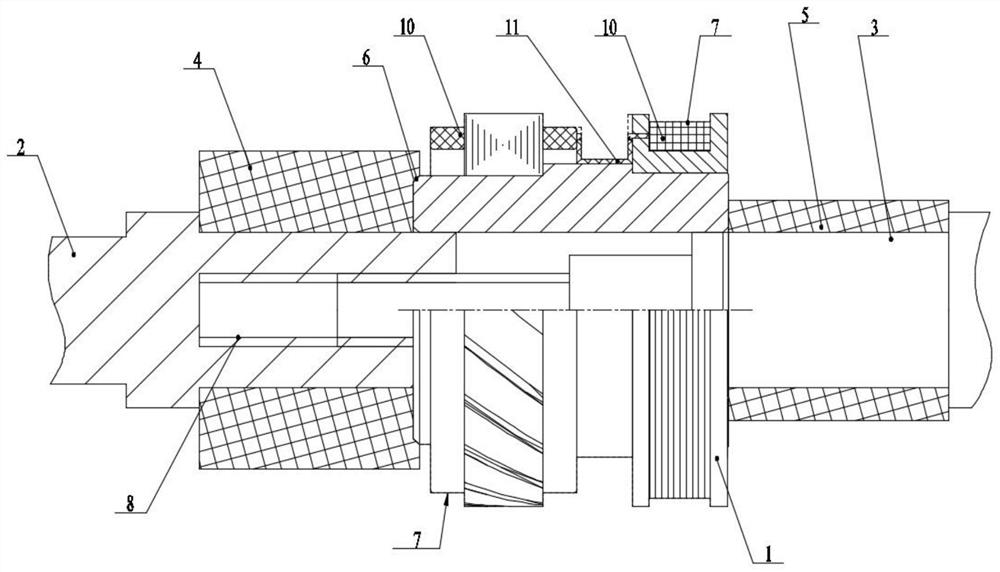

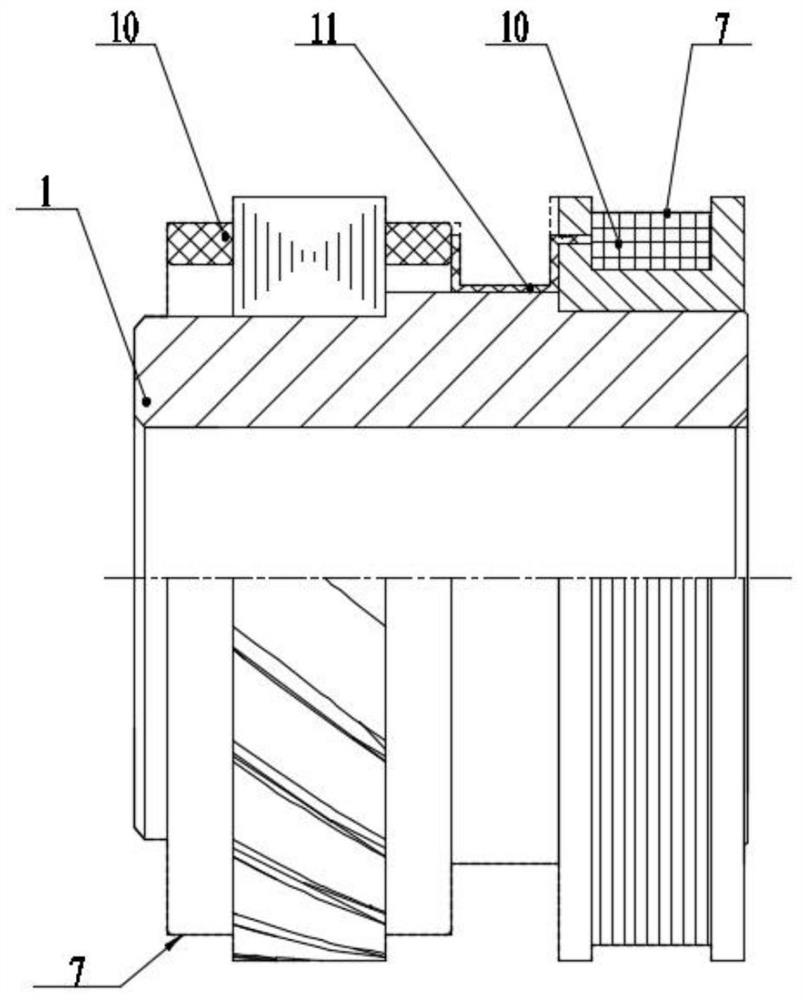

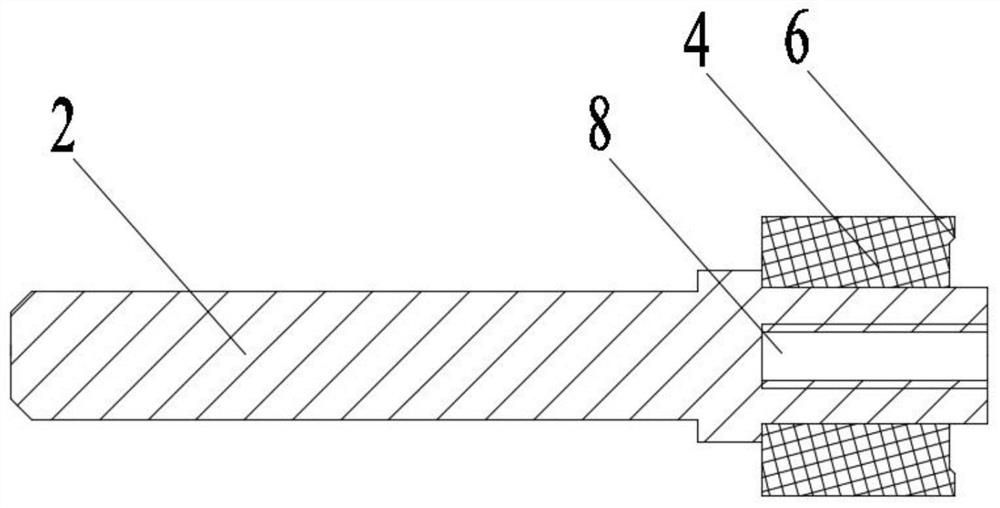

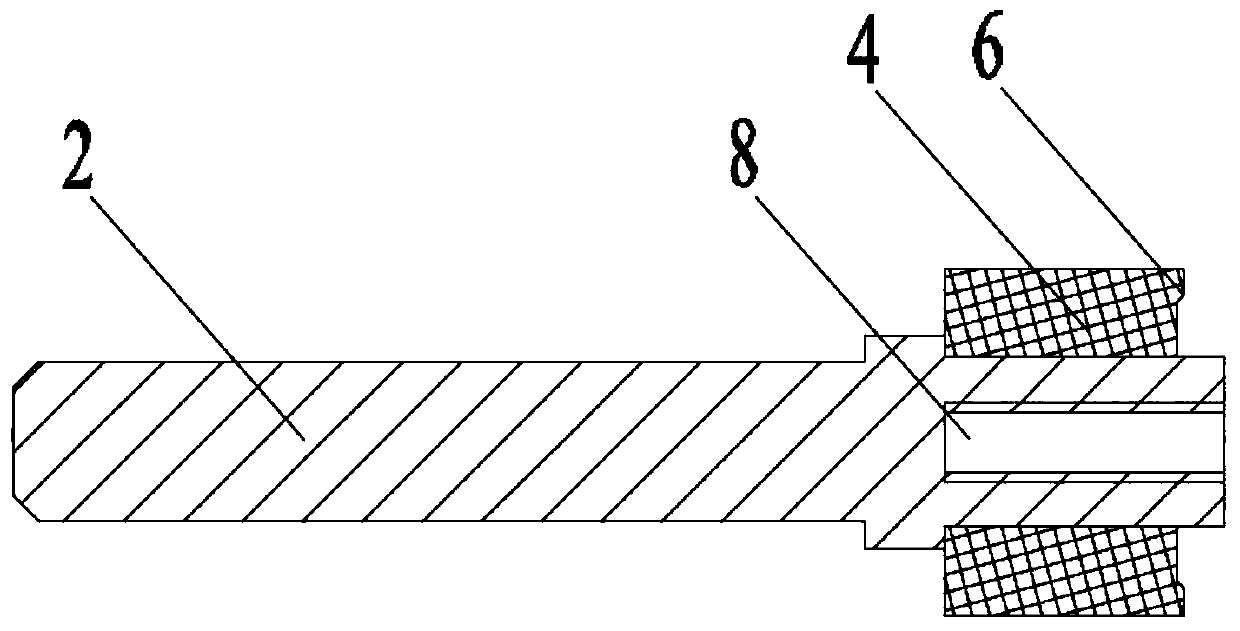

A packaging structure and method for a wound resolver rotor

ActiveCN110428961BAvoid enteringHigh mechanical strengthMagnetic circuit rotating partsTransformersControl theoryMechanical engineering

The present invention provides a package structure and method for the rotor of a wire-wound rotary transformer, which can effectively protect the rotor windings and wiring ends under the circumstances of the rotor falling to the ground, bumping, water ingress, etc., and greatly improving the service life of the rotary transformer and Reliable, and the appearance is beautiful and generous; it includes the rotor and the first and second toolings that are set oppositely. Inside, and the opposite ends of the first and second tooling are connected with the first and second locking parts in corresponding tight fit respectively, and the ends of the first and second tooling respectively protrude from the end faces of the corresponding first and second locking parts, The outer diameters of the first locking piece and the second locking piece are larger than the inner diameter of the inner hole of the rotor, and the outer diameter of the first locking piece is larger than the outer diameter of the corresponding end of the rotor. There are grooves to match the end of the rotor, and the outer circumference of the rotor is coated with epoxy.

Owner:苏州工业园区代尔塔电机技术有限公司

Method for making iron plate enamel decorative painting

ActiveCN108972352BEffective surface rust removalImprove wear resistanceDecorative surface effectsMetallurgyGlaze

The invention relates to a manufacturing method of an iron sheet enamel decoration picture. The manufacturing method comprises the following steps of selecting of an iron sheet, preparing of a transition glaze layer, mixing and stirring, spraying of the transition glaze layer, primary firing, spraying of a white glaze layer, secondary firing, cooling and the like. The manufacturing method has theadvantages that the manufacturing method is reasonable and feasible; the bottom glaze layer is tightly bonded with the iron sheet and the surface glaze layer, the fired product is attractive and elegant, the surface of the picture is flat and is free from wrinkles, the firmness and durability are realized, and the iron sheet enamel decoration picture can be restored for a long time, and can solvethe problems of easiness in fading and shedding, influence to the attractive appearance of the buildings, short service life of adhesive paper, short use time, failure in long-time storage, risk in replacement, waste of time and labor, and cost increasing of single-side adhesive paper in the existing building outer wall decoration picture, and influence to product quality and enterprise benefits due to arching and deformation of the iron sheet surface because of poor temperature control effect, flowing-down of bottom glaze layer on the iron sheet after melting, and gathering together in the production and use process of part of enamel pictures; compared with the prior art, the market prospect and development space are good.

Owner:宝丰大博瓷画文化创意有限公司

Formula and preparation method of leveling-modified selenium light plastic paint

InactiveCN108373870AReduced Bernard vortexImprove levelingRosin coatingsPolyester coatingsSolventChemistry

The invention discloses a formula and preparation method of leveling-modified selenium light plastic paint. Through reduction of a solvent evaporation rate in selenium plastic paint volatilization, Bernadette vortexes are reduced in selenium light plastic paint baking, the leveling effects of the selenium light plastic paint is greatly improved, orange peel phenomenon is reduced and the beauty ofthe product is guaranteed.

Owner:孙正国

A kind of manufacturing method of aluminum plate decorative painting

ActiveCN109130678BEffective surface rust removalEvenly combinedDecorative surface effectsSpecial ornamental structuresGlazeSurface oxidation

Owner:宝丰大博瓷画文化创意有限公司

Formula of unsaturated polyester lacquer for huqin musical instrument and manufacture method thereof

The invention relates to a formula of unsaturated polyester lacquer for the huqin musical instrument and a manufacture method thereof. The manufacture method comprises the following steps: mixing acrylic resin, styrene, polyethylene glycol (600), zinc stearate and anti-sediment coating auxiliaries, and constantly stirring for 30 minutes; and adding orthophthalic unsaturated polyester resin, polyvinyl butyral and n-butyl acetate, and keeping on stirring for 30 minutes.

Owner:闫斐斐

Formula of nitrocellulose lacquer for guitar musical instrument and manufacturing method of nitrocellulose lacquer

The invention discloses a formula of nitrocellulose lacquer for a guitar musical instrument and a manufacturing method of the nitrocellulose lacquer. The formula is prepared from the following components in percentage by weight: 10 to 15 percent of ethyl acetate, 10 to 15 percent of n-butyl acetate, 5 to 10 percent of isopropanol, 3 to 5 percent of propylene glycol methyl ether acetate, 20 to 25 percent of 1 / 16 second nitrocotton, 1 to 5 percent of efficient matting powder, 20 to 30 percent of an alkyd resin polymer with the concentration of 70 percent, and 1 to 5 percent of non-matting wax liquid.

Owner:闫斐斐

Formula and preparation method of nitrolacquer for Guqin musical instruments

The invention discloses a formula and preparation method of nitrolacquer for Guqin musical instruments. The nitrolacquer comprises, by weight, 10 to 15% of ethyl acetate, 10 to 15% of n-butyl acetate,5 to 10% of isopropanol, 3 to 5% of propylene glycol methyl ether acetate, 20 to 25% of 1 / 16s nitrocellulose, 1 to 5% of high-efficiency matting powder, 20 to 30% of 70% alkyd resin polymer, and 1 to5% of non-matt wax slurry.

Owner:孙正国

Package structure and method for wound-type rotary transformer rotor

ActiveCN110428961AAvoid enteringHigh mechanical strengthMagnetic circuit rotating partsTransformersEngineeringConductor Coil

The invention provides a package structure and a method for a wound-type rotary transformer rotor, which can effectively protect a rotor winding and a wiring wire head under the conditions of the rotor landing, bumping and water entering, greatly improve the service life and the reliability of the rotary transformer and the appearance is beautiful and elegant. The package structure comprises a rotor and first and second tools which are oppositely arranged, the first and second tools are cylindrical shapes, the opposite end portions of the first and second tools are respectively correspondinglylocked in the inner holes of the two ends of the rotor, the opposite end portions of the first and second tools are respectively, correspondingly and tightly cooperated and connected with first and second locking pieces, the first and second tool end portions are respectively extruded to the corresponding end portions of the first and second locking pieces, the outer diameters of the first locking piece and the second locking piece are larger than the inner diameters of the inner holes of the rotor, the outer diameter of the first locking piece is larger than the outer diameter of the corresponding end portion of the rotor, the end face of the first locking piece of the rotor side is provided with the groove matching with the end portion of the rotor, and the outer round surfaces of the rotor are coated with epoxy layers.

Owner:苏州工业园区代尔塔电机技术有限公司

A kind of making method of Ruyi jade porcelain painting in glaze

ActiveCN110625532BEffective surface removalStrong three-dimensional senseDecorative surface effectsSpecial ornamental structuresMetallurgyGlaze

The invention relates to a method for making Ruyi jade porcelain painting in glaze, which includes glass plate cleaning treatment, jade treatment, preparation of azure glaze layer, spraying glaze layer, direct firing, high-definition printing, continuous firing, and cooling , Install aluminum plate and other steps. The method of the invention is reasonable and feasible, the design is ingenious, the picture will not be scratched inside and outside, the picture has a strong three-dimensional effect, bright colors, strong jade texture on the surface, strong and durable, can be stored for a long time, and solves the problems existing in the production process of the existing glass porcelain plate painting. Scratch the picture, the three-dimensional effect of the picture is not strong, the jade texture of the surface after firing is not strong, the artistic texture of the surface of Ru porcelain cannot be formed, and technical problems such as affecting product quality and enterprise production efficiency are very good for the existing technology. market prospect and development space.

Owner:张柳松

Manufacturing method of RuYi advanced porcelain painting with pictures located under glaze layers

PendingCN110627371AEffective surface removalWon't scratchSpecial ornamental structuresCoatingsGlass sheetHigh definition

The invention relates to a manufacturing method of RuYi advanced porcelain painting with pictures located under glaze layers. The manufacturing method comprises the steps of glass plate cleaning treatment, jade-like treatment, high-definition printing, direct firing, celeste blue glaze layer preparation, glaze layer spraying, continuous firing, cooling and the like. The manufacturing method is reasonable and feasible; design is skillful; picture scratching is avoided, picture stereoscopic impression is strong, color is brilliance, surface jade-like texture feel is strong, obtained products arefirm and durable; long term storage can be realized. The technical problems that in the existing glass porcelain plate painting manufacturing process, picture scratching is easily caused, picture stereoscopic impression is not strong, surface jade-like texture feel is not strong after firing, the artistic texture feel of Ru porcelain surface cannot be formed, and product quality and enterprise production benefits are affected are solved. Compared with the prior art, the advantages of the manufacturing method are that the market prospect is promising, and development space is large.

Owner:张柳松

Formula and preparation method for unsaturated polyester paint having modified levelling property for porcelain

InactiveCN108373769AReduce evaporation rateImprove the level ofPolyester coatingsPolyesterAcrylic resin

According to the technical scheme of the invention, the invention provides a formula solving the problem that unsaturated polyester paint for porcelain has poor levelling properties and a preparationmethod of paint. The formula includes acrylic resin, styrene, polyethylene glycol (600), zinc stearate, an anti-precipitation coating auxiliary, o-benzene type unsaturated polyester resin, poly(vinylbutyral), n-butyl acetate and polyether modified polydimethylsiloxane.

Owner:闫斐斐

Leveling modified photo-plastic paint formula and manufacturing method thereof

InactiveCN106811010AReduce evaporation rateImprove the level ofPolyester coatingsPolyvinyl butyralLeveling effect

The invention solves the problem of poor leveling effect of the existing photo-plastics paint, and provides a formula using a leveling agent for improvement and a manufacturing method of the paint. The paint has the technical scheme that a formula for solving the problem of poor leveling effect of the photo-plastics paint and the manufacturing method of the paint are provided. The paint is prepared from 30 to 50 percent of glyceride maleic anhydride resin, 2 to 10 percent of propanediol, 0.01 to 0.1 percent of polyethylene glycol (600), 0.1 to 2 percent of ultra-fine silicon dioxide, 0.1 to 2 percent of polyamide wax (n-butyl alcohol and naphtha mixtures), 1 to 5 percent of 1250 meshes of talcum powder, 10 to 20 percent of phthalic unsaturated polyester resin, 0.01 to 0.1 percent of polyvinyl butyral, 5 to 15 percent of styrene, 1 to 10 percent of photo-plastics initiators (D1173) and 0.1 to 1 percent of polyether modified polydimethylsiloxane.

Owner:闫斐斐

Leveling modified guitar musical instrument nitryl paint formula and manufacturing method thereof

The invention provides the technical scheme of a formula for solving the problem of poor leveling effect of guitar musical instrument nitryl paint and a manufacturing method thereof. The paint is prepared from the following ingredients in percentage by weight: 10 to 15 percent of ethyl acetate, 10 to 15 percent of n-butyl acetate, 5 to 10 percent of isopropanol, 3 to 5 percent of propylene glycol monomethyl ether acetate, 20 to 25 percent of 1 / 16 second nitrocellulose, 1 to 5 percent of efficient extinction powder, 20 to 30 percent of 70-percent alkyd resin polymers, 1 to 5 percent of non-extinction wax liquid and 0.1 to 1 percent of polyether modified polydimethyl siloxane.

Owner:闫斐斐

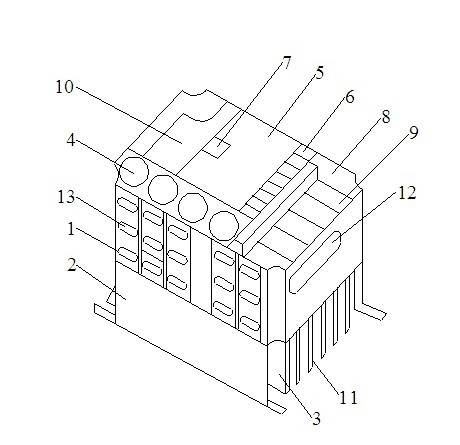

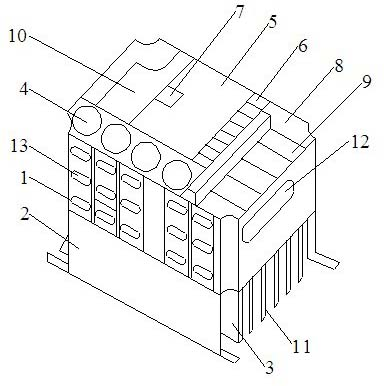

Frequency converter device

InactiveCN102638156AGuaranteed to look goodImprove cooling effectCooling/ventilation/heating modificationsPower conversion systemsCapacitanceFrequency changer

The invention discloses a frequency converter device which comprises a shell, wherein the shell is arranged on a base; a radiator and a capacitor are arranged on the base in parallel; a main control panel is arranged above the interior of the shell; a control line terminal is arranged at the front end of the main control panel; a keyboard interface is arranged at the rear end of the main control panel; an installation clearance is arranged between the main control panel and the front end of the shell; and a main circuit terminal is arranged in the installation clearance. Through the mode, the frequency converter device fully and reasonably utilizes the internal space of the shell and is compact in structures among the components, thereby ensuring the attractiveness and elegance of a frequency converter, improving the radiation effect of the frequency converter and improving the working efficiency of the frequency converter.

Owner:常州迪德奥电气技术有限公司

Formula and preparation method of automobile paint

InactiveCN106280722AGuaranteed to look goodGood spray paintWax coatingsRosin coatingsWaxNitrocellulose

A formula and a preparation method of automobile paint are disclosed. The preparation method includes the following steps: adding sec-butyl acetate, methyl ethyl ketone, isopropyl alcohol, oxidized castor oil and 1 / 16 sec nitrocellulose, continuously stirring for 30 min, adding modified rosin resin when the nitrocellulose is completely dissolved, stirring for 30 minutes, adding high-efficiency extinction powder and non-extinction wax paste, and stirring for 10 minutes. The usage method of the automobile paint includes the following steps: mixing the nitro-based paint and banana oil in a ratio of 7:3, and stirring evenly for spraying. 1 / 16 sec nitrocellulose and modified rosin resin polymer are the main film-forming materials of the automobile paint; and sec-butyl acetate, methyl ethyl ketone, isopropyl alcohol and oxidized castor oil are the main solvent for dissolving nitrocellulose. The proportion of various components is reasonable, and the solvent evaporation rate is reasonable. The automobile paint disclosed by the invention has excellent film-formation properties, and is good nitro-based paint.

Owner:孙正国

Formula and preparation method of leveling-modified nitrolacquer for Guqin instrument

InactiveCN108373801AReduce evaporation rateImprove the level ofPolyester coatingsNitrocelluloseSlurry

The invention discloses a formula and preparation method of leveling-modified nitrolacquer for a Guqin instrument. The nitrolacquer comprises, by weight, 10 to 15% of ethyl acetate, 10 to 15% of n-butyl acetate, 5 to 10% of isopropanol, 3 to 5% of propylene glycol methyl ether acetate, 20 to 25% of 1 / 16s nitrocellulose, 1 to 5% of high-efficiency matting powder, 20 to 30% of 70% alkyd resin polymer, 1 to 5% of matting-free wax slurry and 0.1 to 1% of polyether modified polydimethylsiloxane.

Owner:孙正国

Formula and production method of excellent vanadium optical plastic paint

The technical scheme of the invention is to provide a formula and a production method of an excellent vanadium optical plastic paint, wherein the excellent vanadium optical plastic paint comprises: adehydrated malic acid resin, propylene glycol, polyethylene glycol (600), ultrafine silica, polyamide wax (a n-butanol and naphtha mixture), 1250 mesh talc powder, an o-phenyl unsaturated polyester resin, polyvinyl butyral, styrene and a vanadium optical plastic initiator (D1173).

Owner:闫斐斐

Formula and production method of electric car spraying paint

The invention provides a formula and a production method of an electric car spraying paint with good effect. According to the technical scheme of the present invention, the formula and the productionmethod of the excellent electric car spraying paint are provided, wherein the electric car spraying paint comprises sec-butyl acetate, methyl ethyl ketone, o-benzene type unsaturated polyester resin,oxidized castor oil, 1 / 32 second nitrocellulose, efficient matting powder, modified rosin resin and non-matting wax slurry.

Owner:闫斐斐

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com