Package structure and method for wound-type rotary transformer rotor

A resolver and packaging structure technology, applied in transformers, magnetic circuit shape/style/structure, inductance/transformer/magnet manufacturing, etc., can solve problems such as hidden dangers, unsightly appearance, and reduced reliability of resolvers, so as to improve the use of The effect of life and reliability, high mechanical strength and three-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

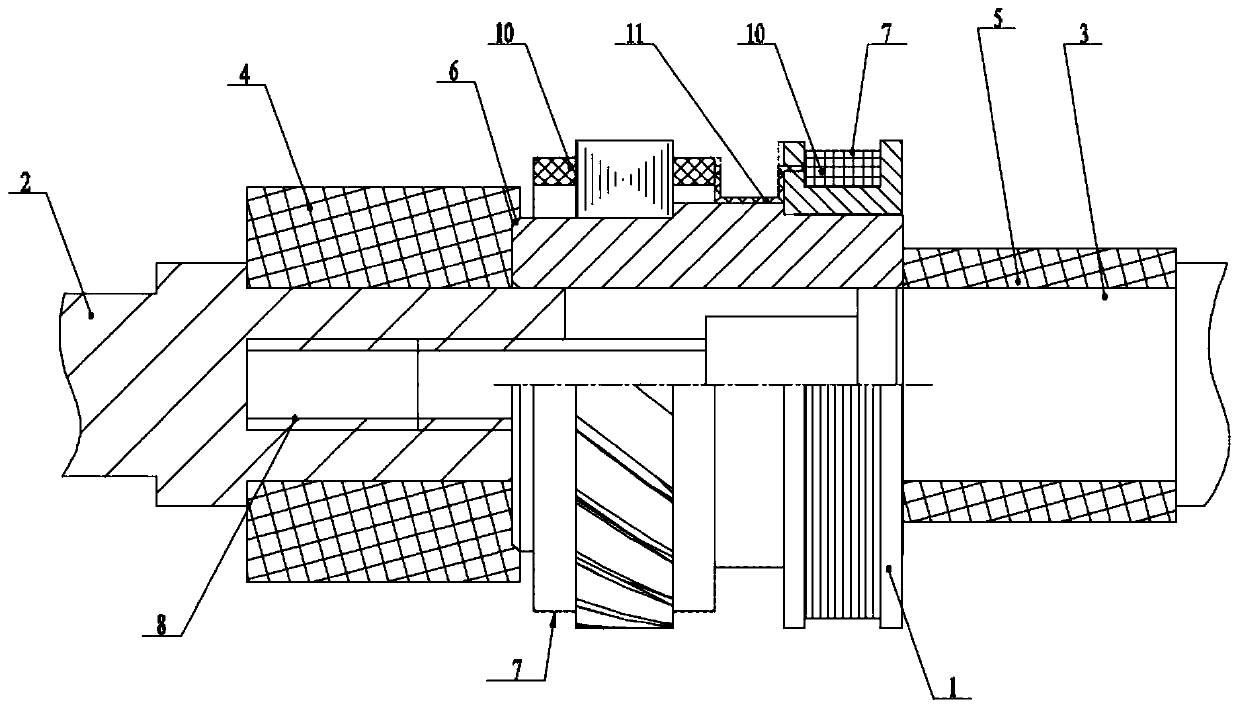

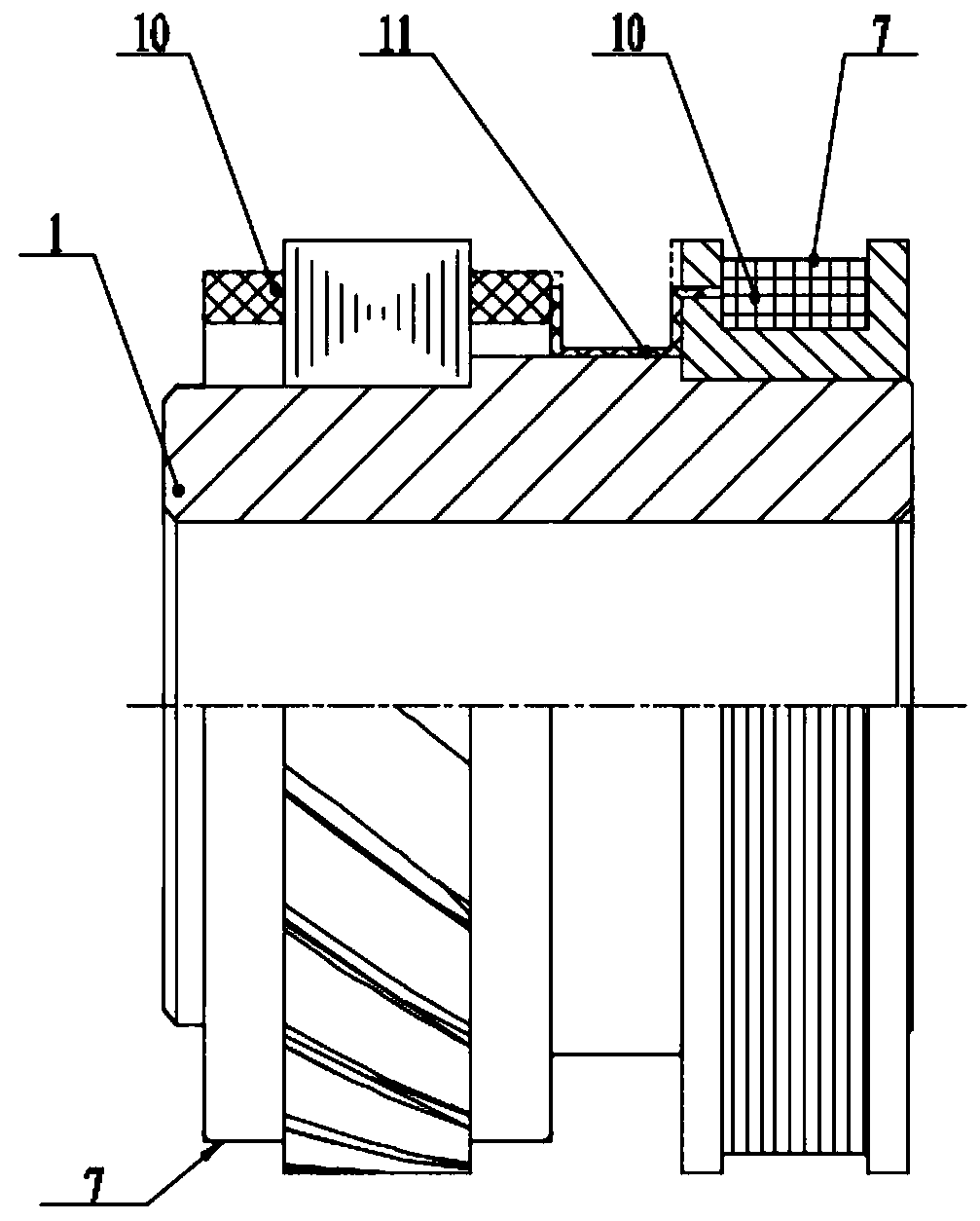

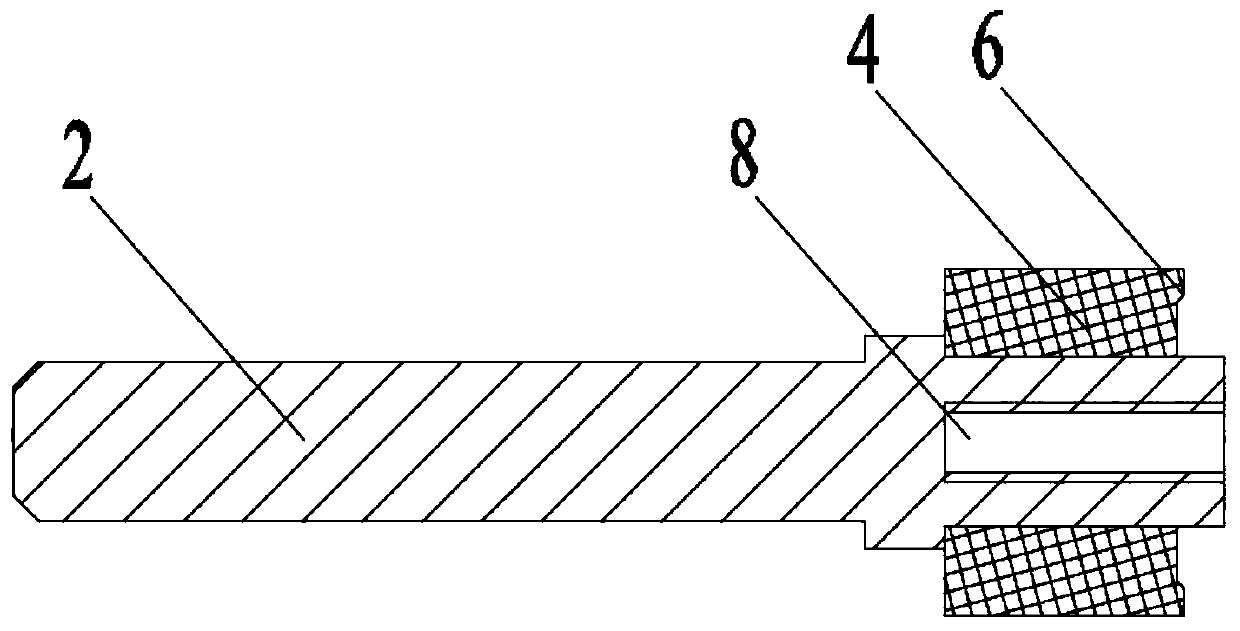

[0020] Such as Figure 1 ~ Figure 4 As shown, a packaging structure of a wound resolver rotor 1 according to the present invention includes a rotor 1, and also includes a first tooling 2 and a second tooling 3 opposite to each other. The first tooling 2 and the second tooling 3 are both It is cylindrical, and the opposite ends of the first tooling 2 and the second tooling 3 are respectively locked in the inner holes of the two ends of the rotor 1 by corresponding threads, and are locked on both ends of the rotor 1 through the first tooling 2 and the second tooling 3, so that Effectively protect the inner hole and end surface of the rotor 1 from being coated, prevent the paint from entering other places that do not need to be sprayed, and make the product beautiful; and the opposite ends of the first tooling 2 and the second tooling 3 The first locking piece 4 and the second locking piece 5 are connected with the corresponding tight fit respectively, and the ends of the first t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com