Patents

Literature

169results about How to "Print clear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-layer thermal transfer ribbon and manufacturing method thereof

The invention relates to a multi-layer thermal transfer ribbon and a manufacturing method thereof, and the multi-layer thermal transfer ribbon comprises a membranous base band, a heat-resistant printing ink layer and a heat transfer printing ink layer, wherein the heat-resistant printing ink layer is coated on one side of the base band, the heat transfer printing ink layer is coated on the other side of the base band, the heat transfer printing ink layer comprises a stripping printing ink layer and an adhesive printing ink layer, the stripping printing ink layer is directly coated on the surface of the base band, the adhesive printing ink layer is coated on the stripping printing ink layer, printing ink in the striping printing ink layer is hot-melting type printing ink, and the printing ink in the adhesive printing ink layer is the hot-melting type printing ink or solvent type printing ink. The heat transfer printing ink layer of the multi-layer mixed-based ribbon can be easily completely stripped off the base band, and the great adhesive ability is realized on a smooth medium; in addition, the multi-layer thermal transfer ribbon further has the advantages of high resolution, clear printing, anti-friction property, moisture resistance, chemical corrosion resistance, environment friendliness and the like.

Owner:泉州市山水电脑耗材有限公司

High-strength wear-resistant fabric for cases and production method thereof

The invention relates to a high-strength wearable fabric for suitcases and bags and a manufacturing method thereof, which is characterized in that: the fabric is a coated fabric which is woven by adopting the high-strength polyester filament yarn with a strength indicator of more than 7.5cN / dtex and is made through a single-sided coating; the warp yarn adopts high-strength wearable polyester filament yarn air textured yarn, and the weft yarn can be in other filament yarn forms of high-strength polyester filament yarn. The high-strength wearable fabric has the advantages of high tensile strength, high tearing strength, high wear-resisting property, clear printing, good color fastness and good color tone; the fabric also has the properties of watertightness, inflaming retarding, camouflage and infrared ray prevention through the functional finishes. The overall performance of the high-strength wearable fabric is almost the same with that of foreign high-strength nylon fabric, but the price is quite low, thereby the high-strength wearable fabric has a higher cost performance.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

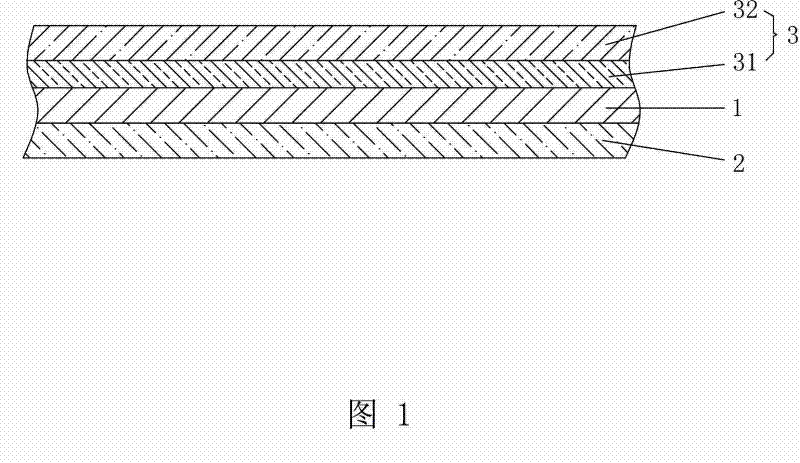

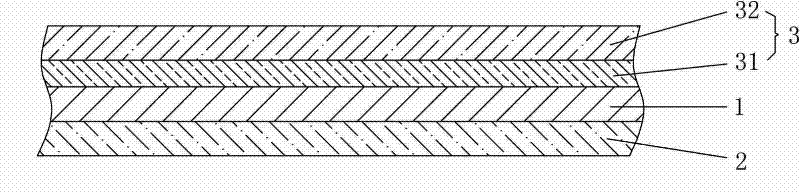

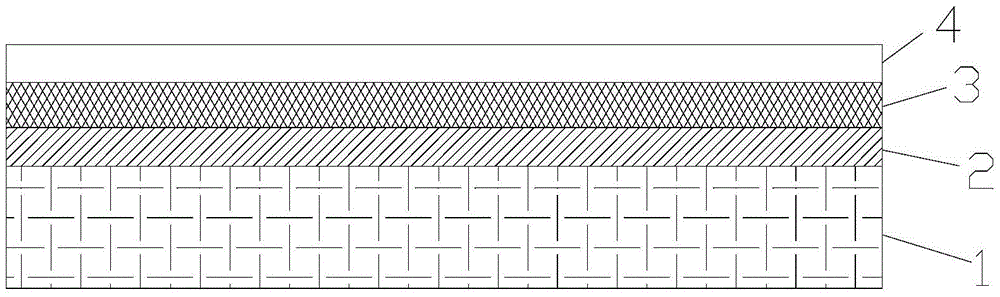

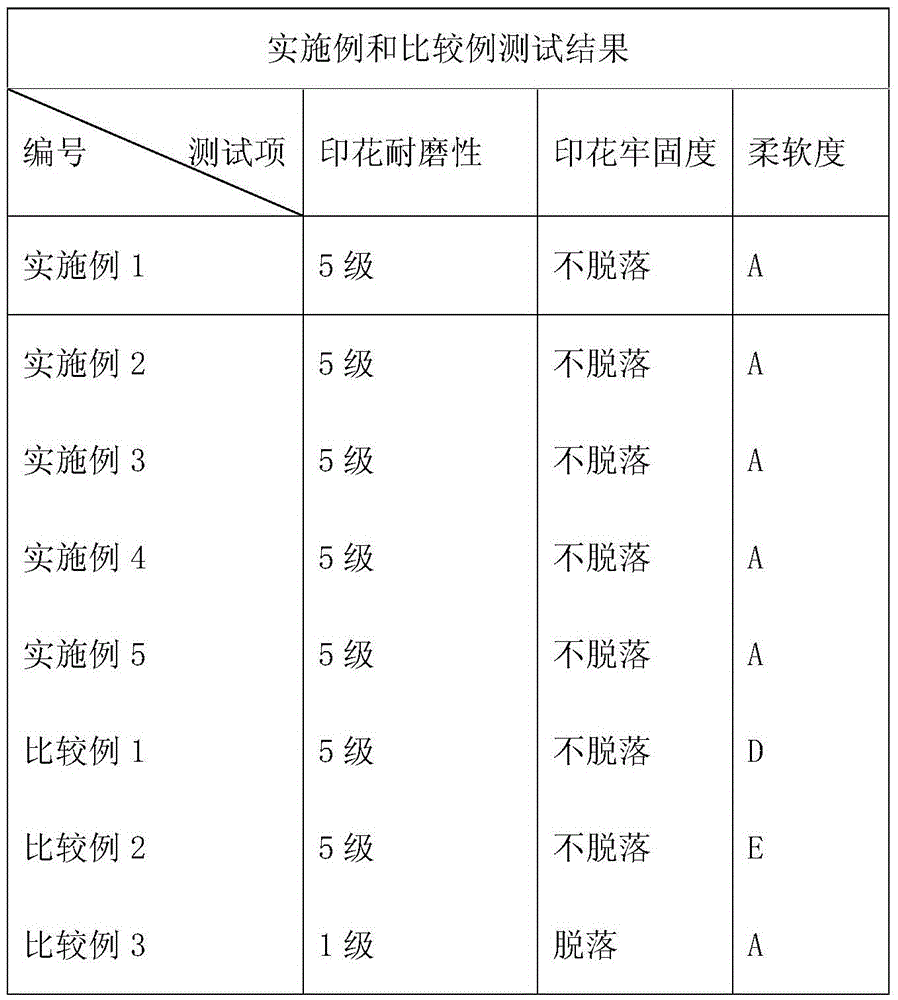

Printed organic silicone synthetic leather and preparation method thereof

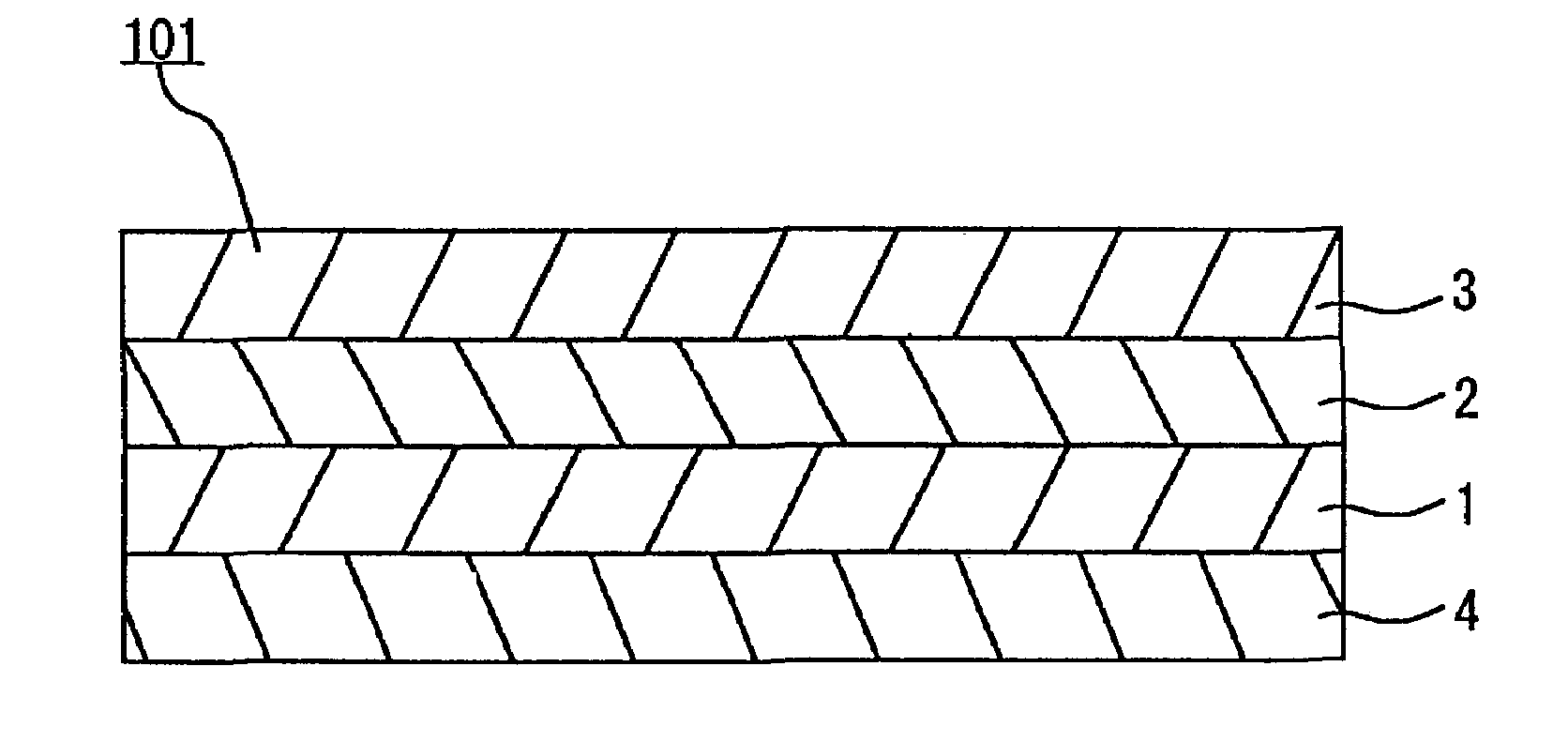

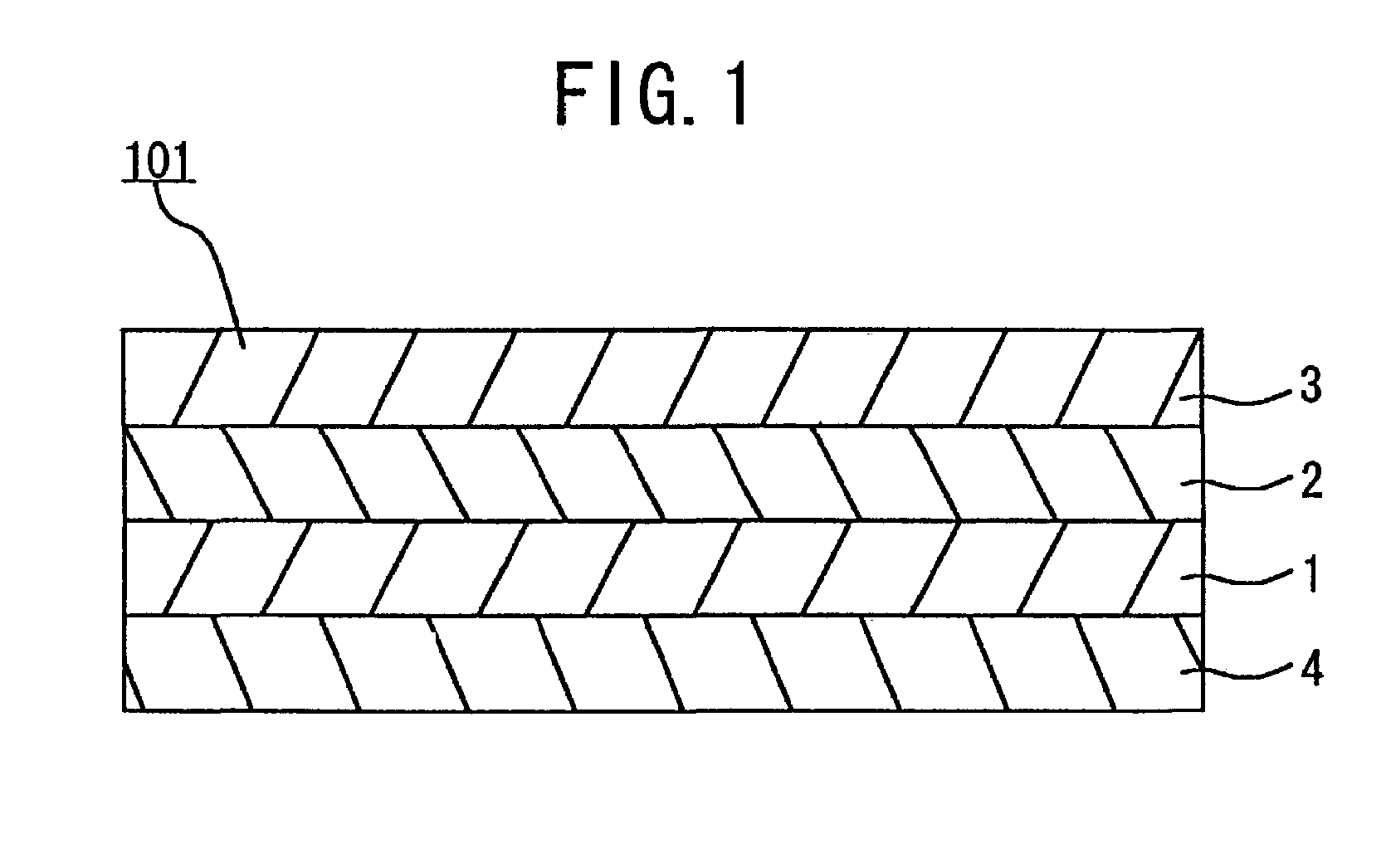

The invention discloses printed organic silicone synthetic leather and a preparation method thereof. The printed organic silicone synthetic leather comprises a silica gel layer (4), an ink layer (3), a colored silica gel layer (2) and a base material (1) in sequence from top to bottom. The preparation method includes the steps that blended silica gel layer adhesive is arranged on release paper or a release film in a coated mode and vulcanized to form the silica gel layer (4), blended ink layer adhesive is utilized to form a printed pattern on the cured silica gel layer (4) in a spraying or coating mode, blended colored silica gel layer adhesive is arranged on the vulcanized ink layer (3) in a coated mode to be attached to the base material (1), after vulcanization is conducted, the release paper or the release film is stripped, and the printed organic silicone synthetic leather is obtained. According to the printed organic silicone synthetic leather and the preparation method thereof, the release film or the release paper is utilized to cover the silica gel ink layer with a transparent layer, so that a bonding layer and a surface protection layer are additionally arranged on silica gel ink, it is difficult to remove the printed pattern from the organic silicone synthetic leather, diversity can be achieved, and the layered feeling is obvious.

Owner:SALIRONE INC HUIZHOUCAMPUS

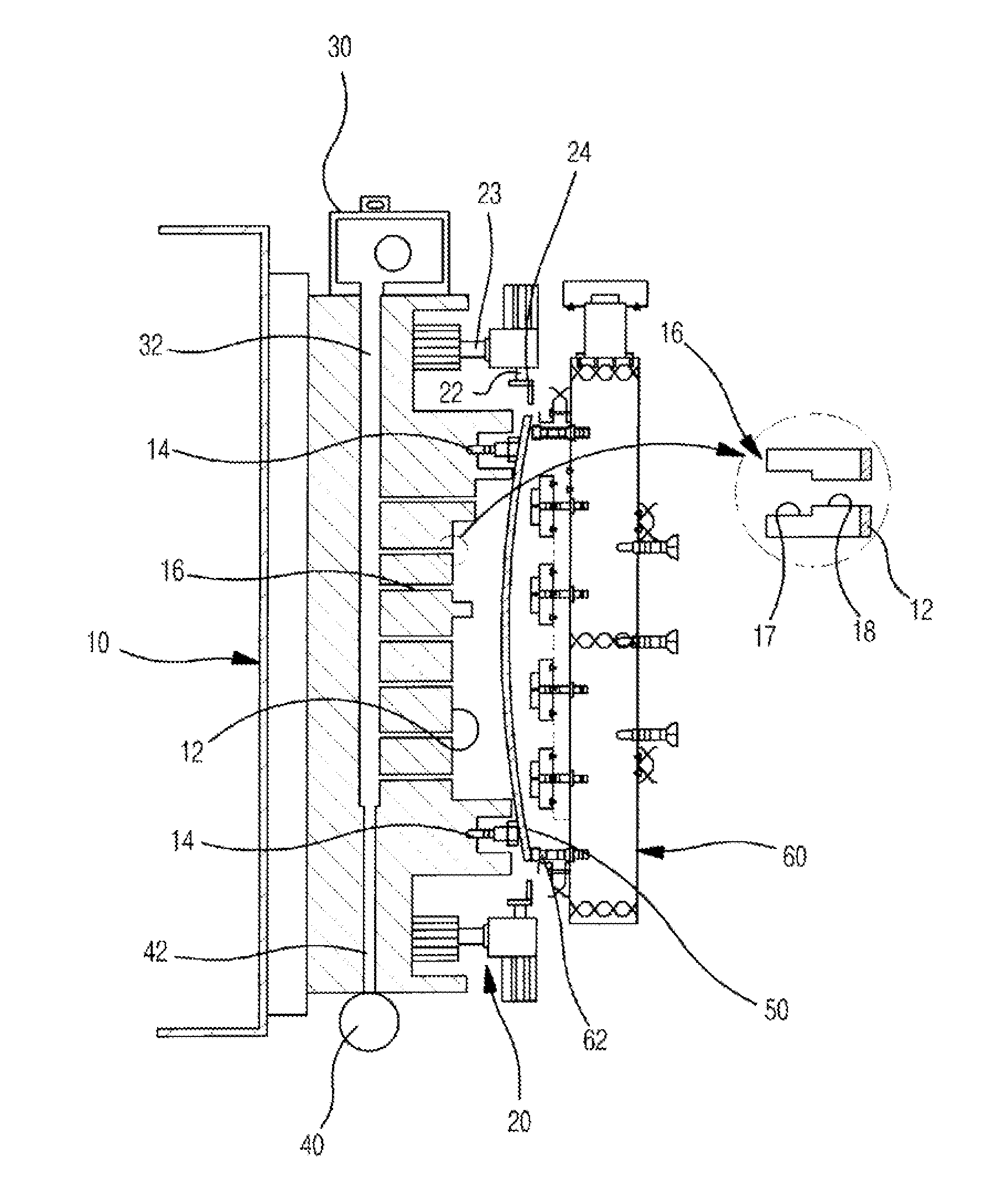

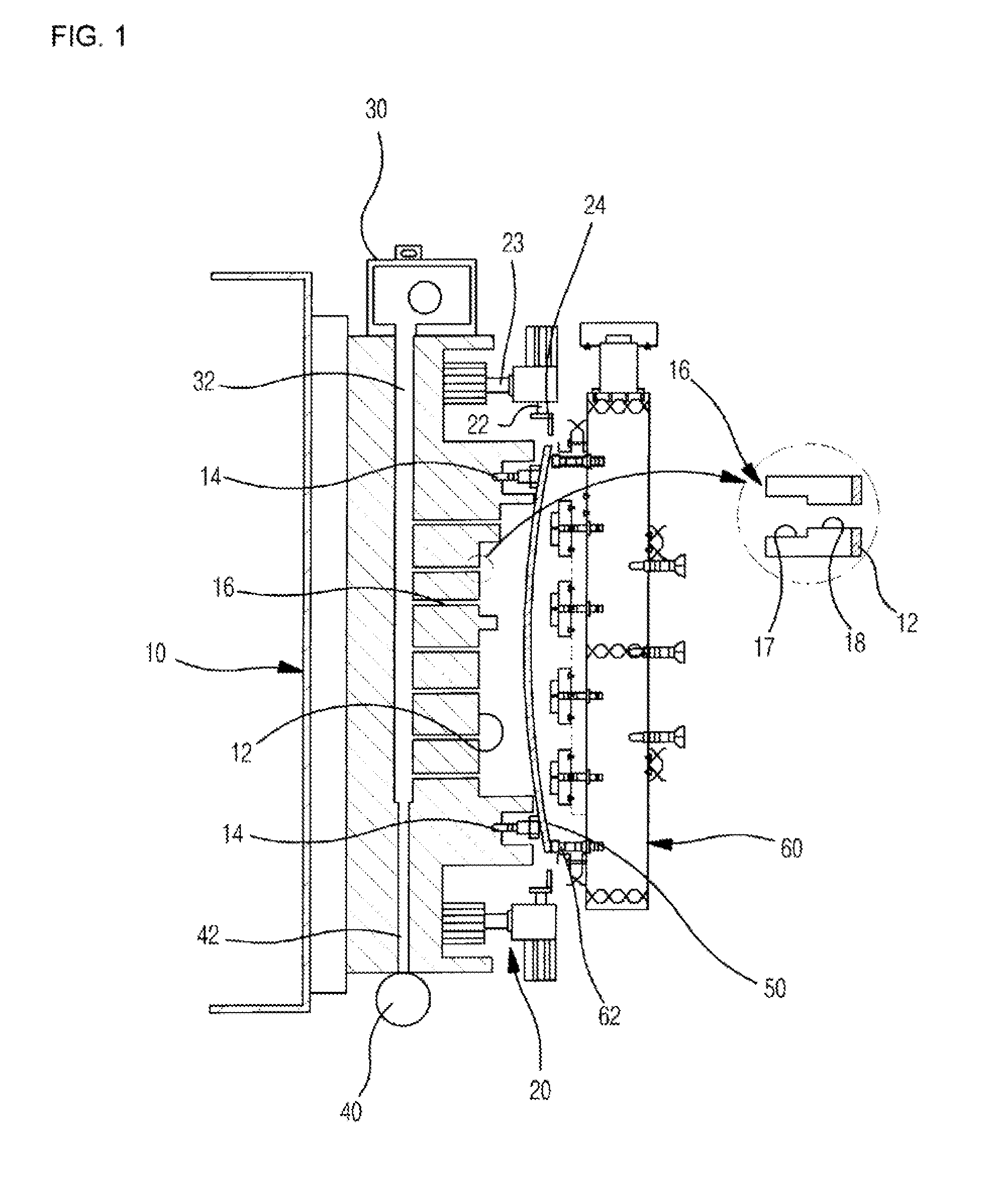

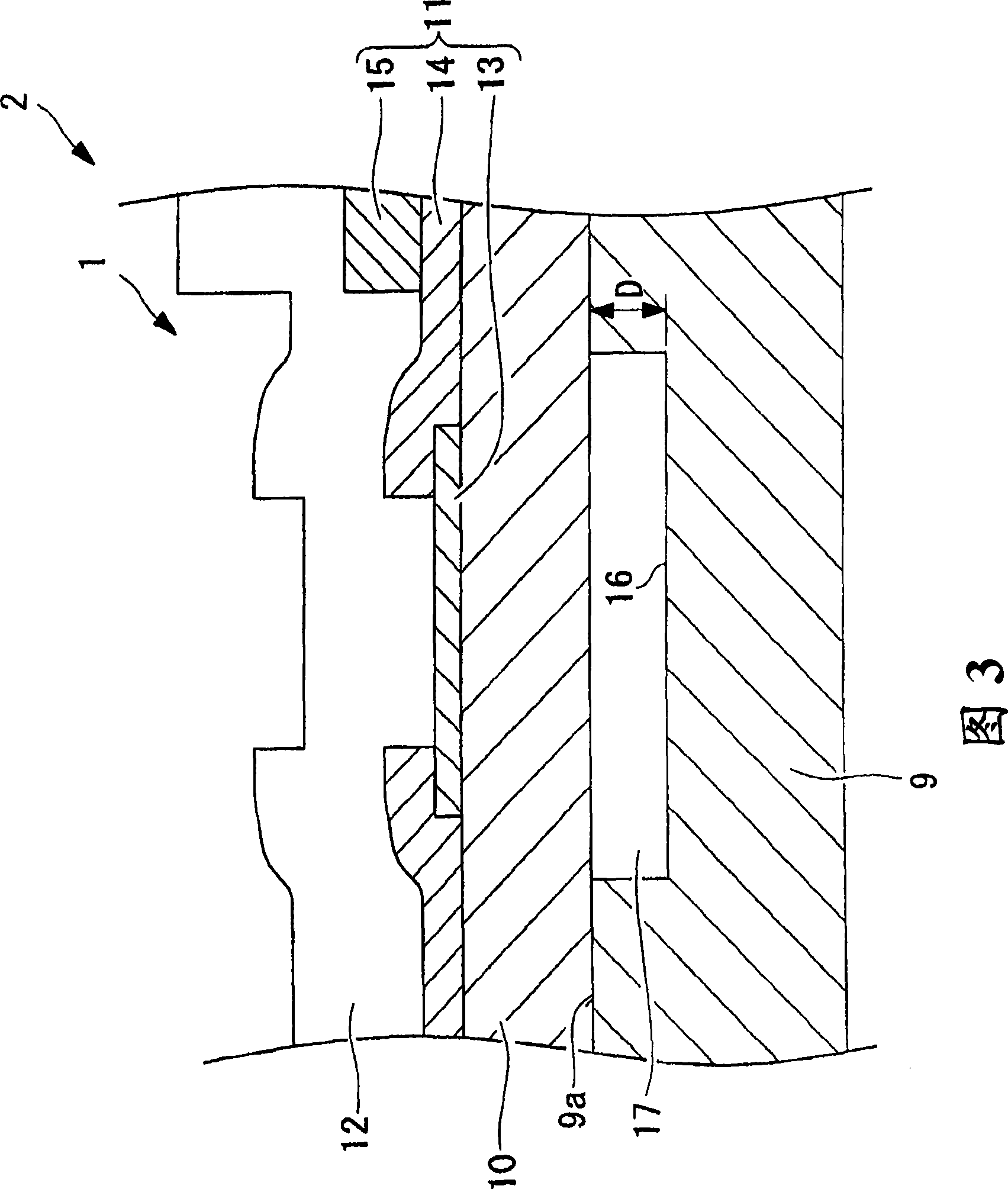

Horizontal molding method and apparatus of interior material of vehicle

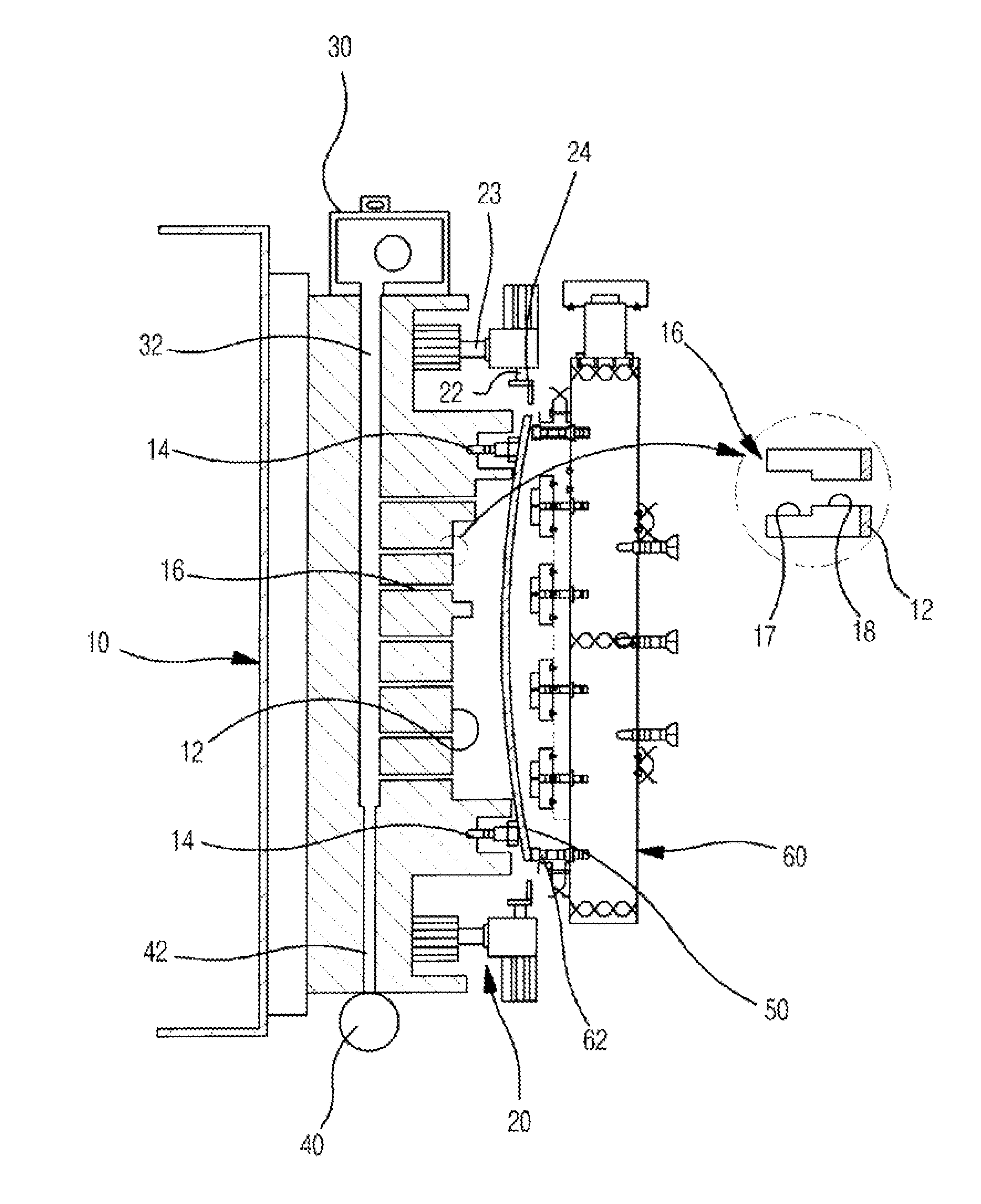

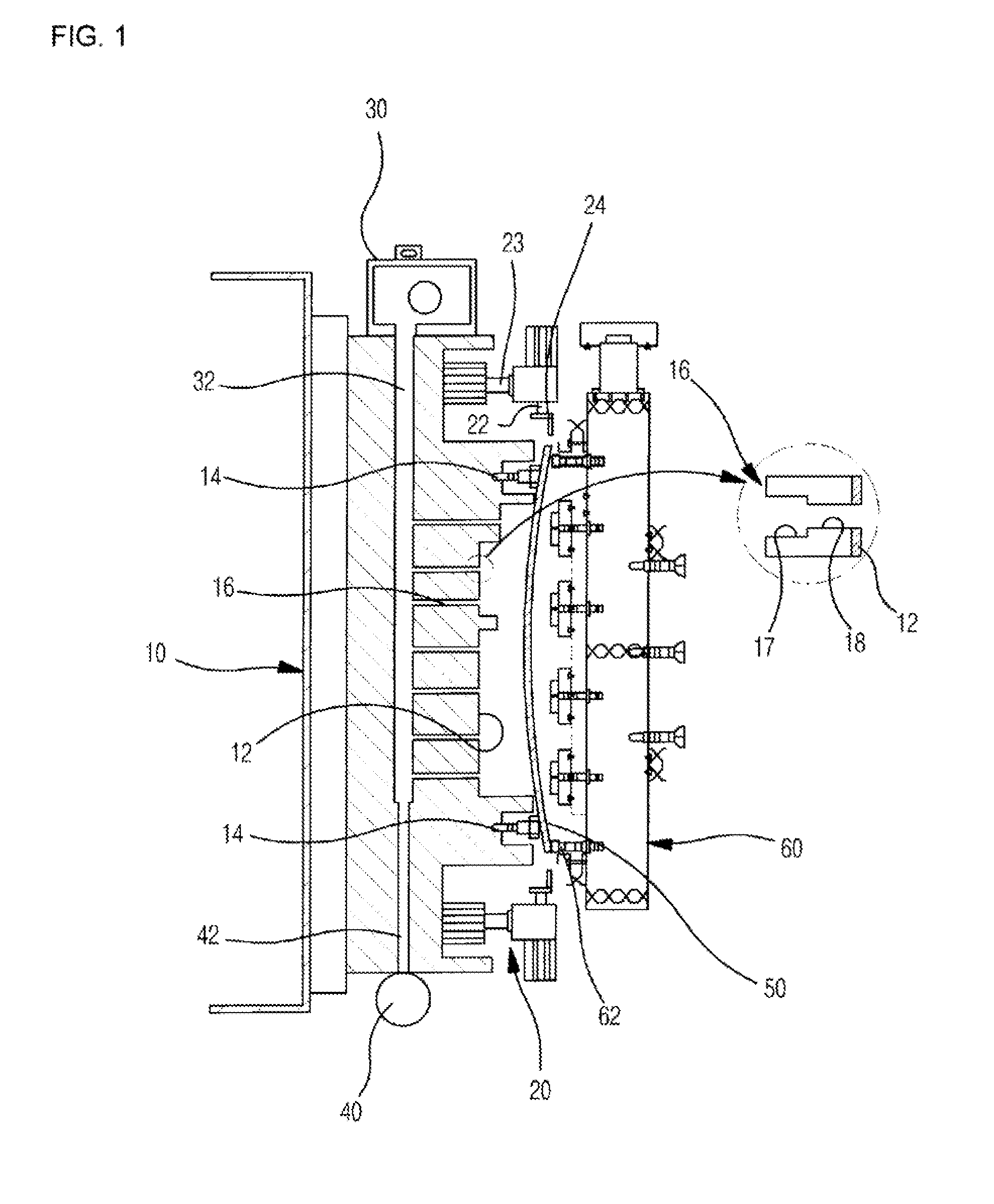

InactiveUS20110266721A1Print clearAppropriate performanceLaminationLamination apparatusShell moldingMaterial transfer

The present invention relates to a horizontal molding method and apparatus of an interior material of a vehicle. The horizontal molding apparatus includes a preheating means for preheating a skin material; a transfer unit formed to be movable and including fixing units for vertically attaching or detaching the preheated skin material on or from the transfer unit; a first mold disposed perpendicularly to a ground surface and including suction units for vacuum-sucking and fixing edges of the skin material transferred by the transfer unit, a base member having an embossed pattern to be printed on the skin material, fixing members for sealing an internal space between the skin material and the base member by clamping the edges of the skin material, and vacuum holes for vacuum-sucking the skin material onto the base member; a second mold disposed in parallel with the first mold and on which a base material is injected; and a mold moving means for horizontally moving one of the first and second molds and combining or separating the first and second molds to or from each other. According to the present invention, a skin material and a base material may be integrally molded by using horizontally moving molds, the skin material expanded in a preheating or heating process may be prevented from sagging downward due to its weight, and the skin material may be completely sealed so as not to be folded or wrinkled.

Owner:HAN IL E HWA CO LTD

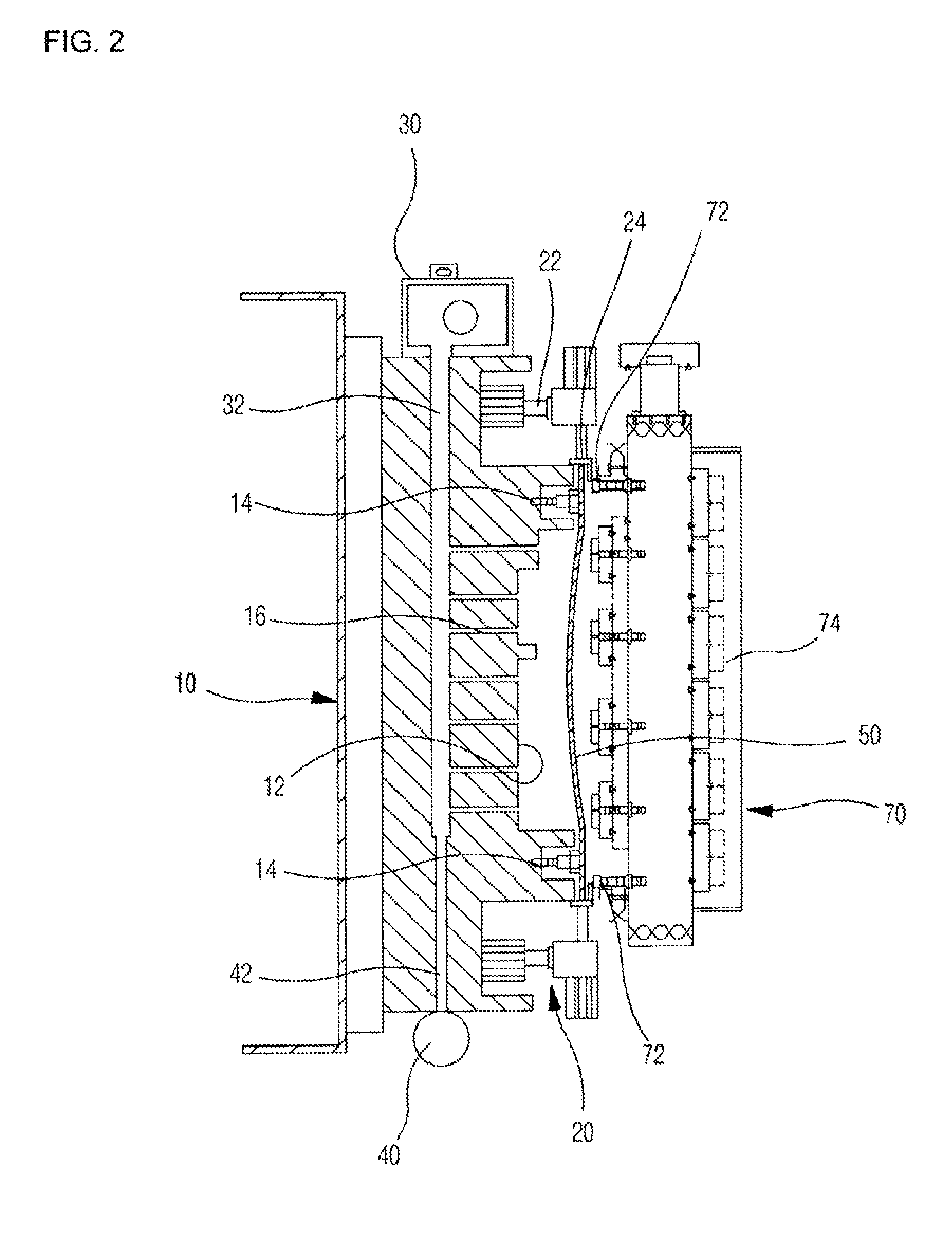

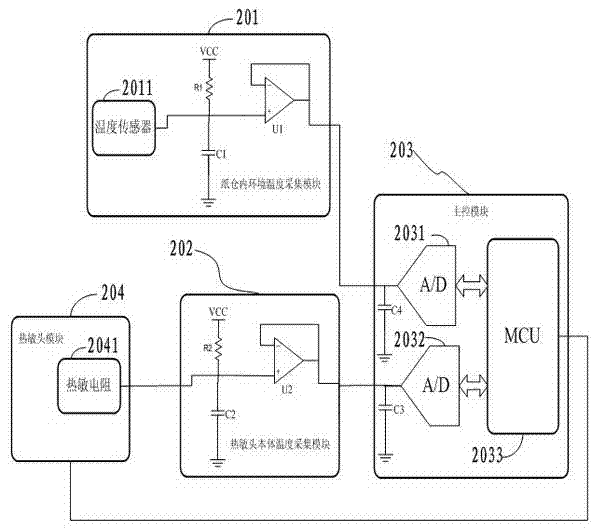

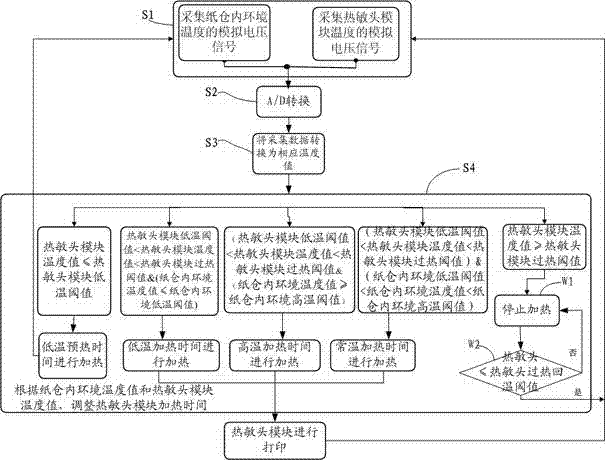

Thermal head heating adjusting device, thermal head heating adjusting method and thermal printer

The invention provides a thermal head heating adjusting device, a thermal head heating adjusting method and a thermal printer. The thermal head heating adjusting device comprises a thermal head module, a paper bin internal environmental temperature acquisition module, a thermal head body temperature acquisition module and a master control module. The thermal head heating adjusting device, the thermal head heating adjusting method and the thermal printer have the advantages that temperature sensors in a paper bin of equipment are matched with a built-in thermistor of a thermal head and are combined with the built-in thermistor of the thermal head, the design is perfect, the automatic thermal head heating control accuracy is high, and accordingly the thermal printer can clearly print data for a long time.

Owner:EDAN INSTR

Preparation method of ceramic wine bottle with printing

The invention provides a preparation method of a ceramic wine bottle with printing. The preparation method is characterized by comprising the following steps: step 1, preparing a ceramic blank body, glazing and sintering on the ceramic blank body to obtain the ceramic bottle body; step 2, printing a printing ink pattern on a paper substrate through a silk-screen printing way; printing the isolation oil on the printing ink pattern through the silk-screen printing way to form an isolation oil layer; printing a tear-off membrane on the isolation oil layer through the silk-screen printing way, and obtaining baking-free stained paper; step 3, soaking the baking-free stained paper for 5-10 min, when the paper substrate is separated from the oil printing pattern, pasting the oil printing patter on the ceramic bottle body, naturally drying for 1-2 min, tearing off the tear-off membrane, baking at 160-180 DEG C for 20-30 min, and obtaining the ceramic wine bottle with printing. The preparation method of the ceramic wine bottle only requires one-time baking technology, eliminates one baking step, saves the cost, and simplifies the technology.

Owner:SHANGHAI GAOCHENG CREATIVE TECH GRP

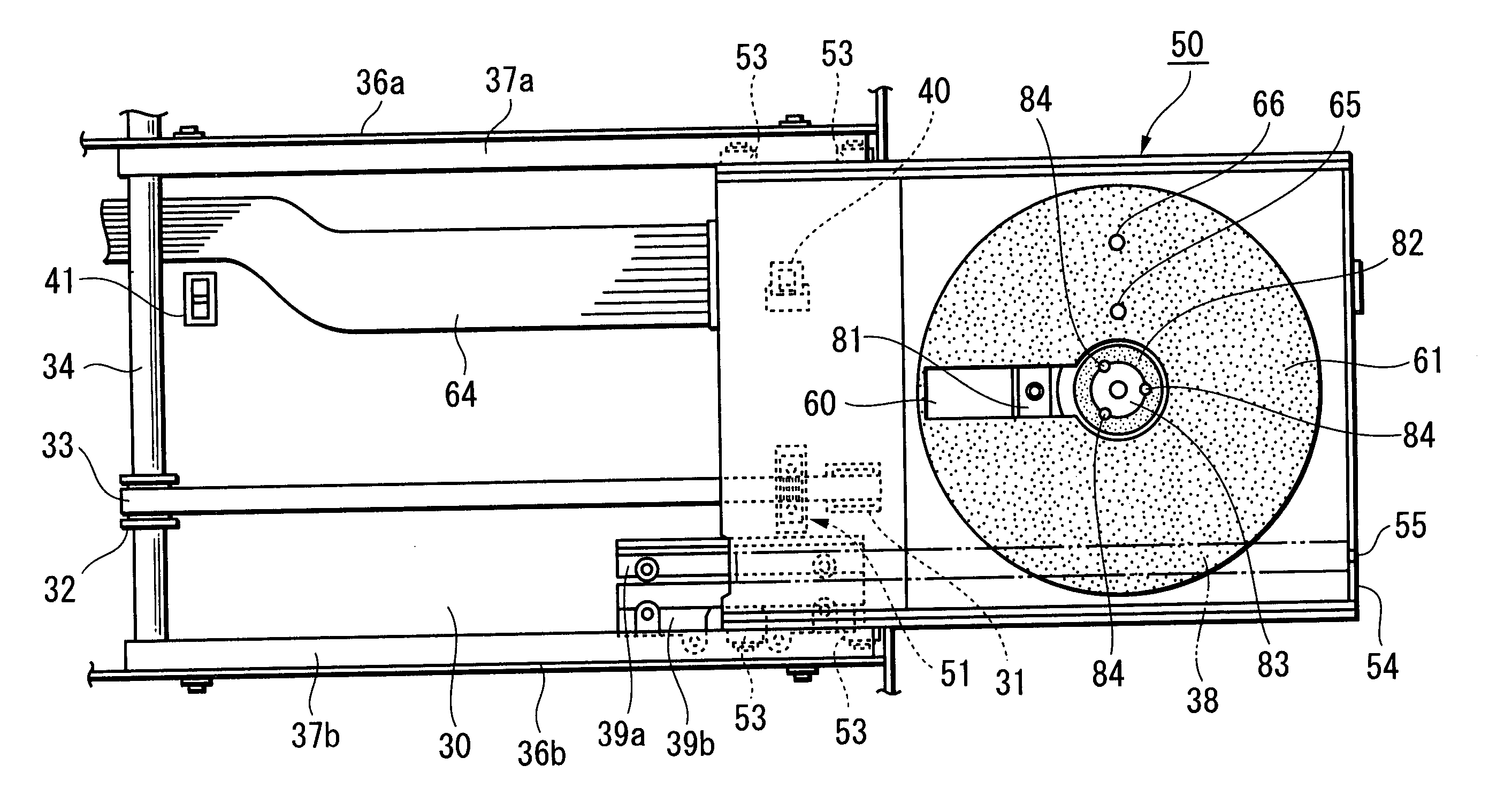

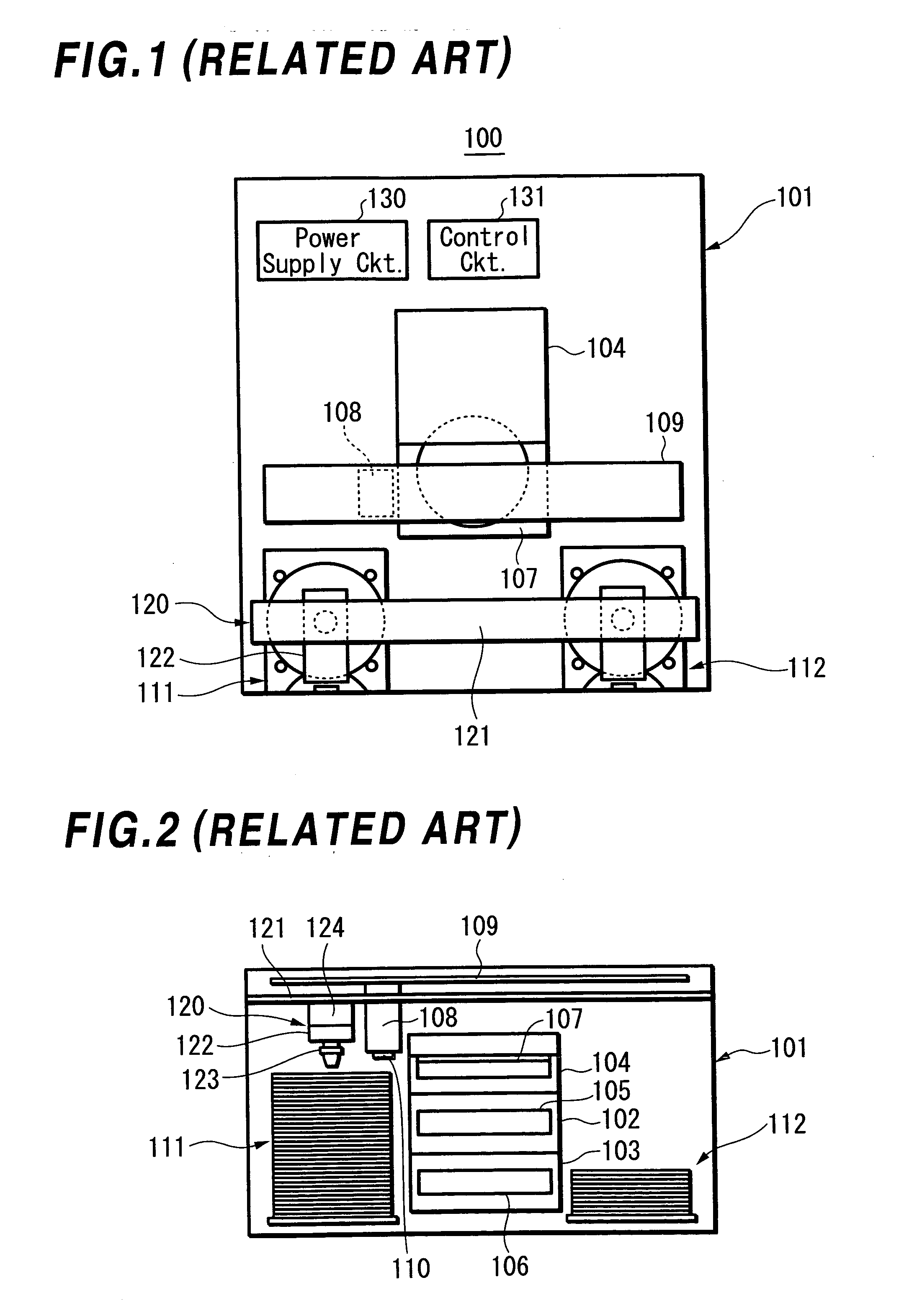

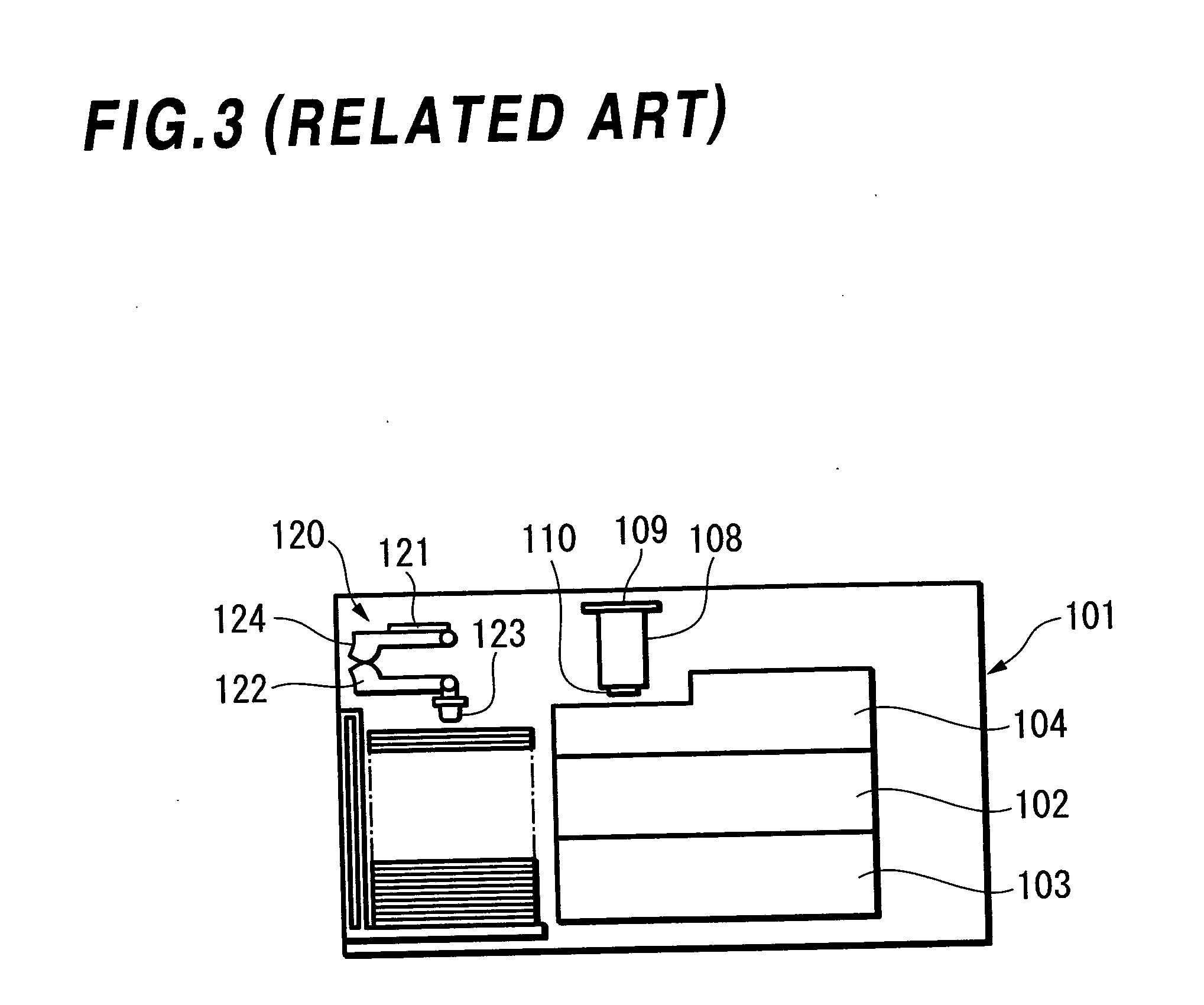

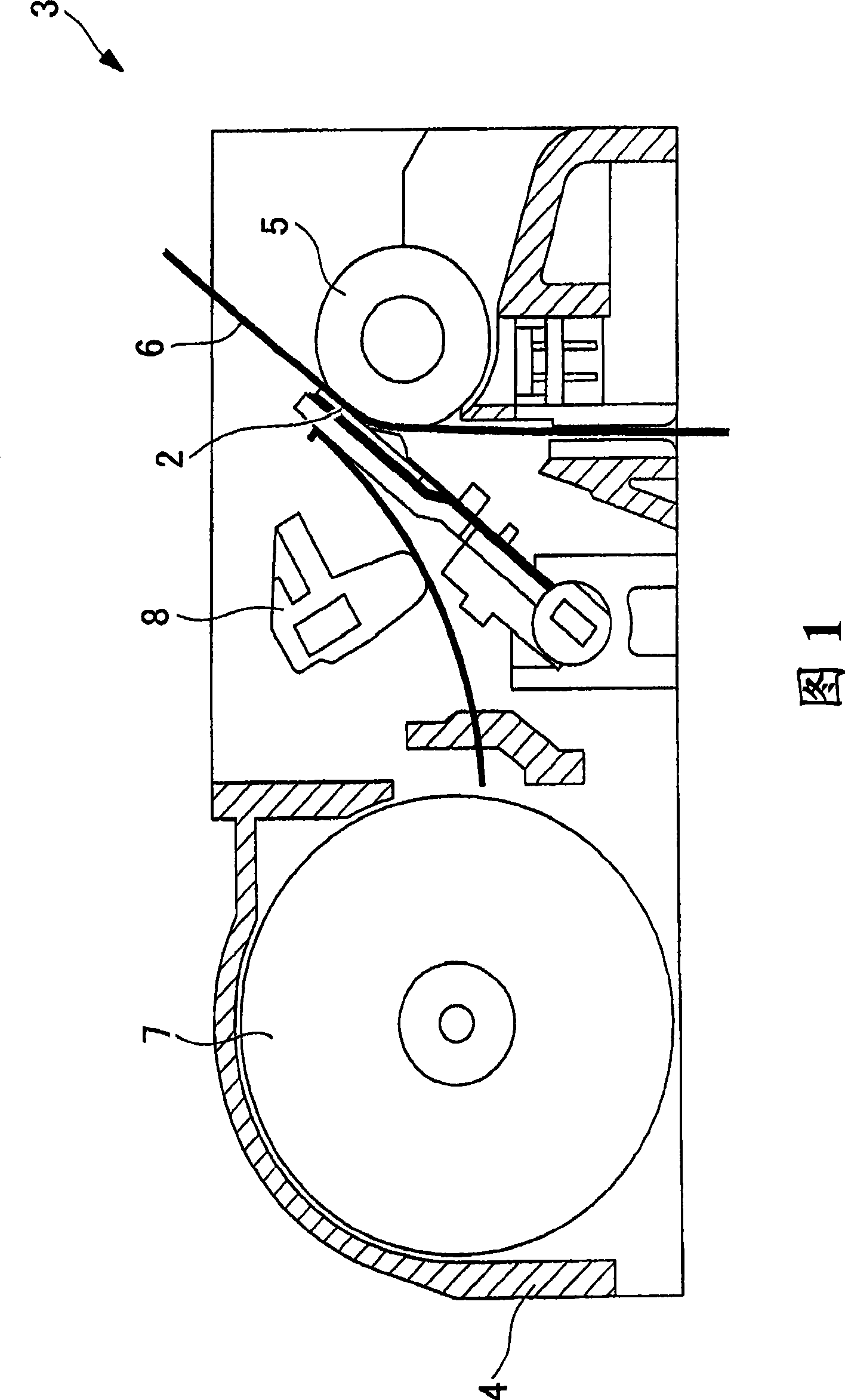

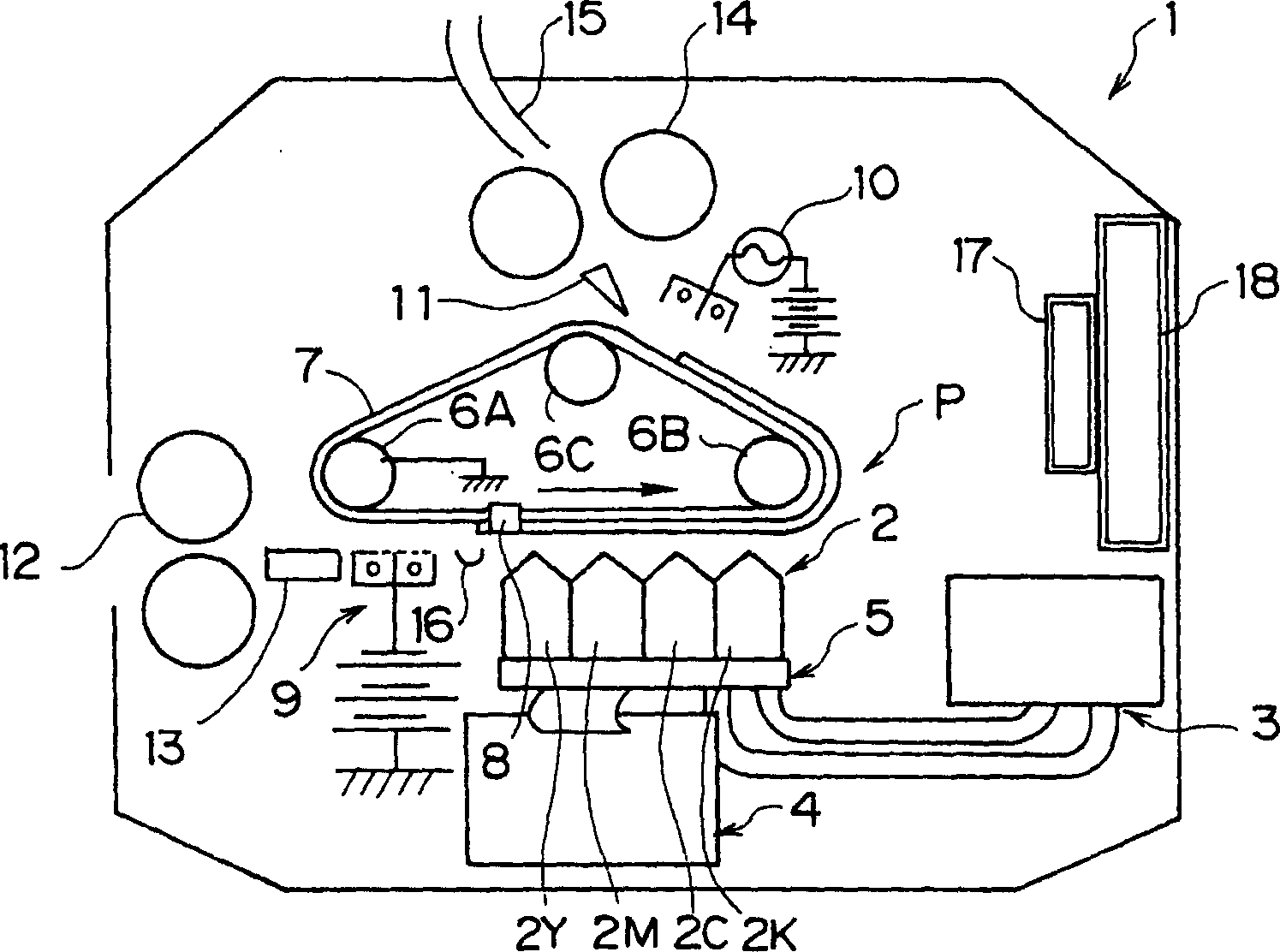

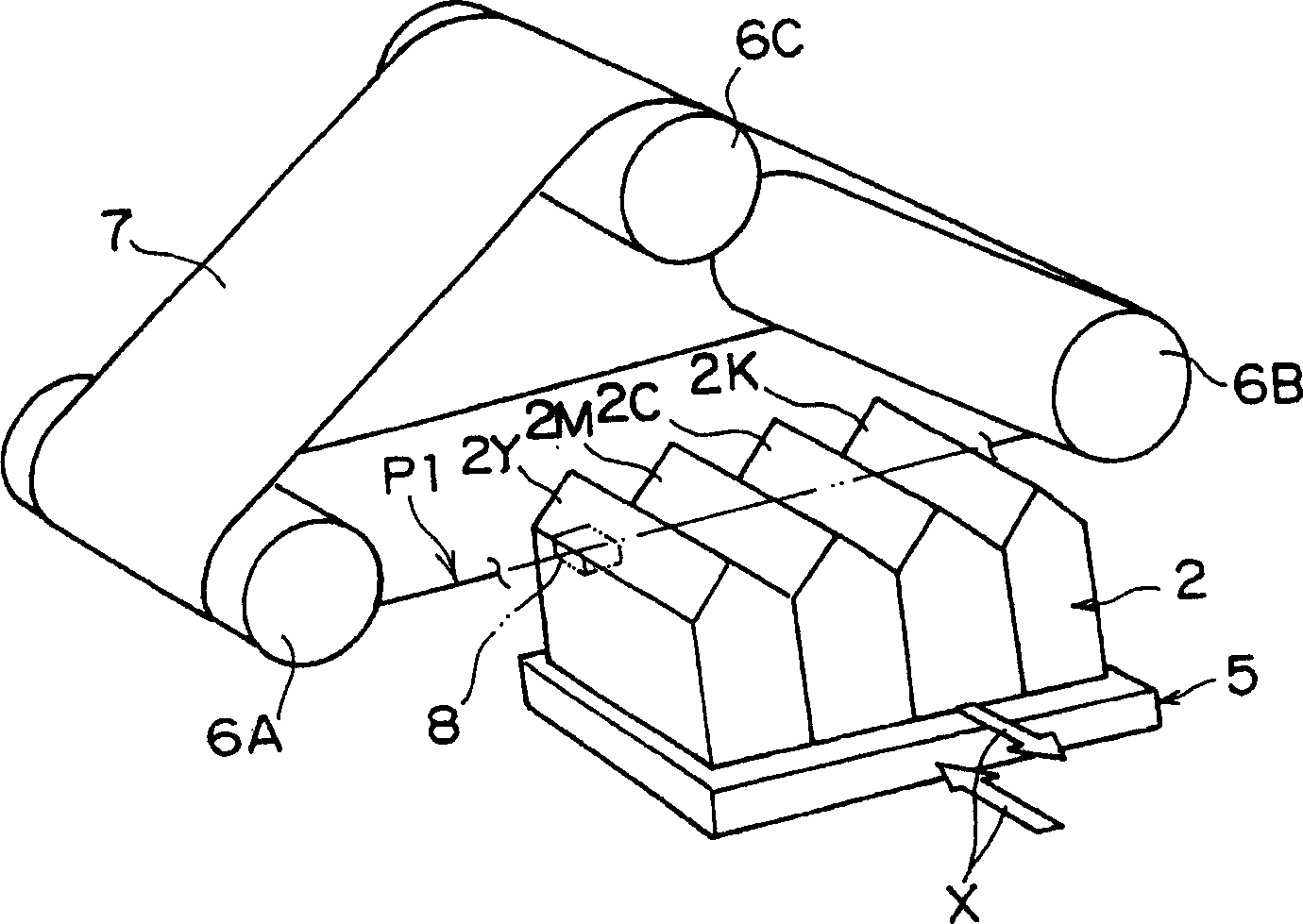

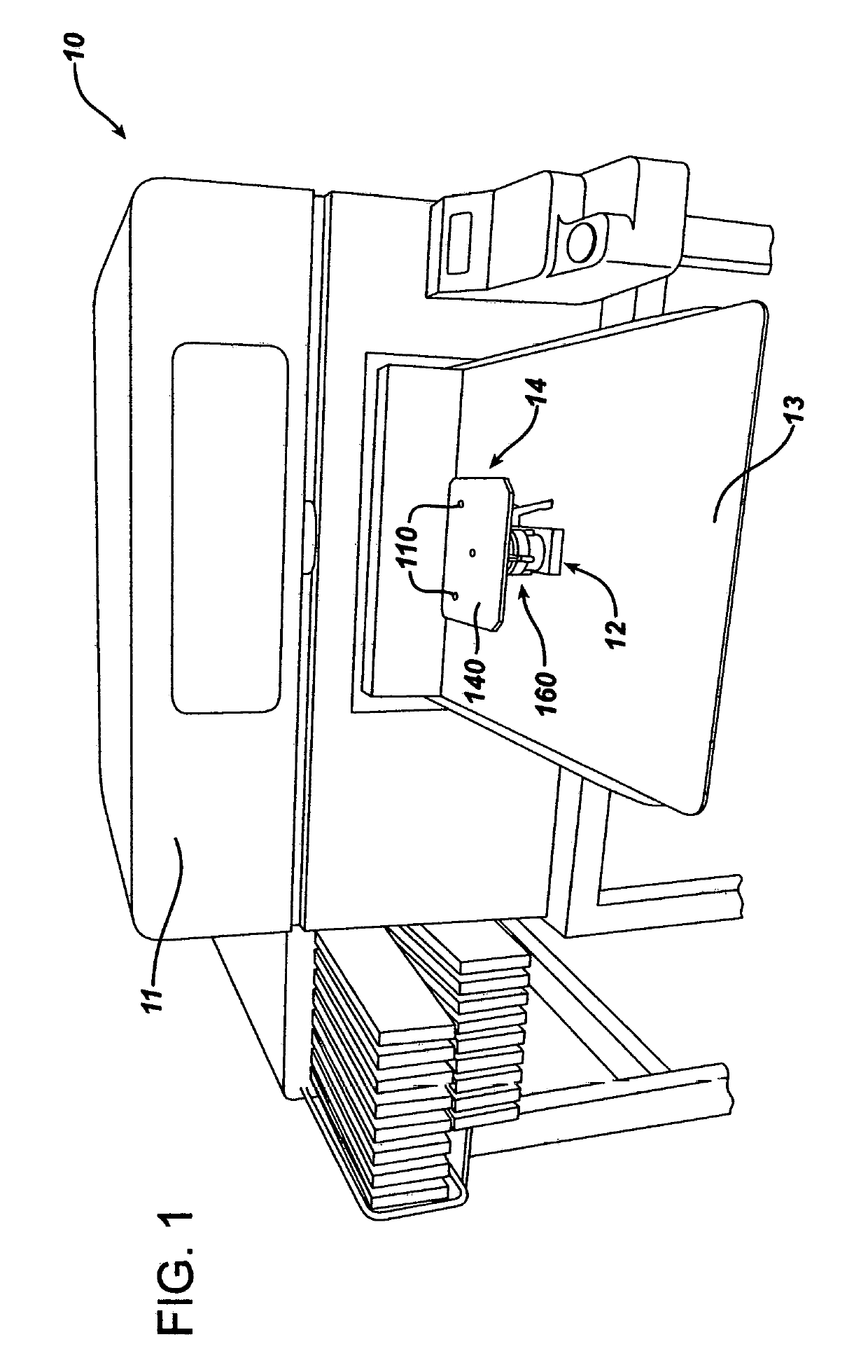

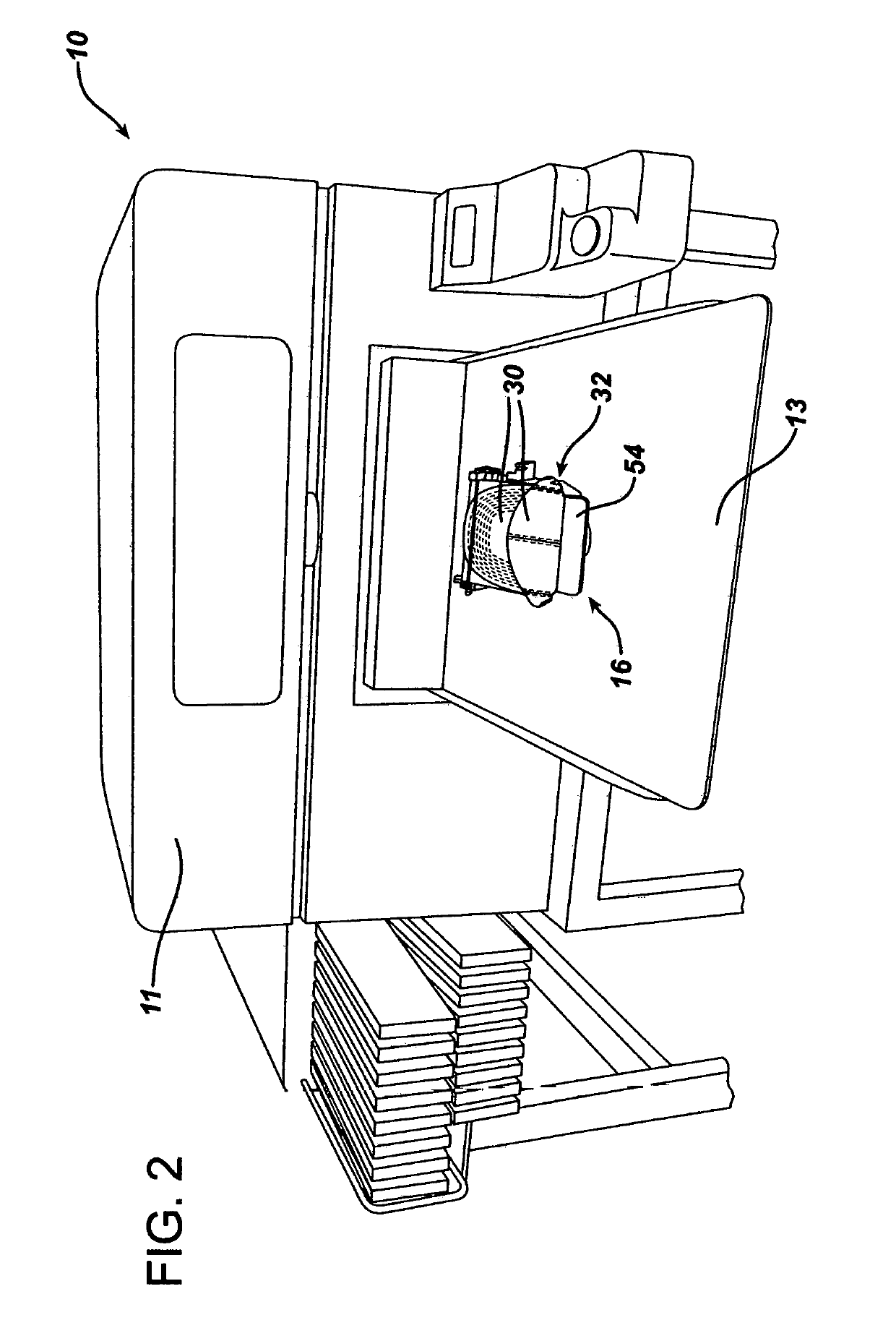

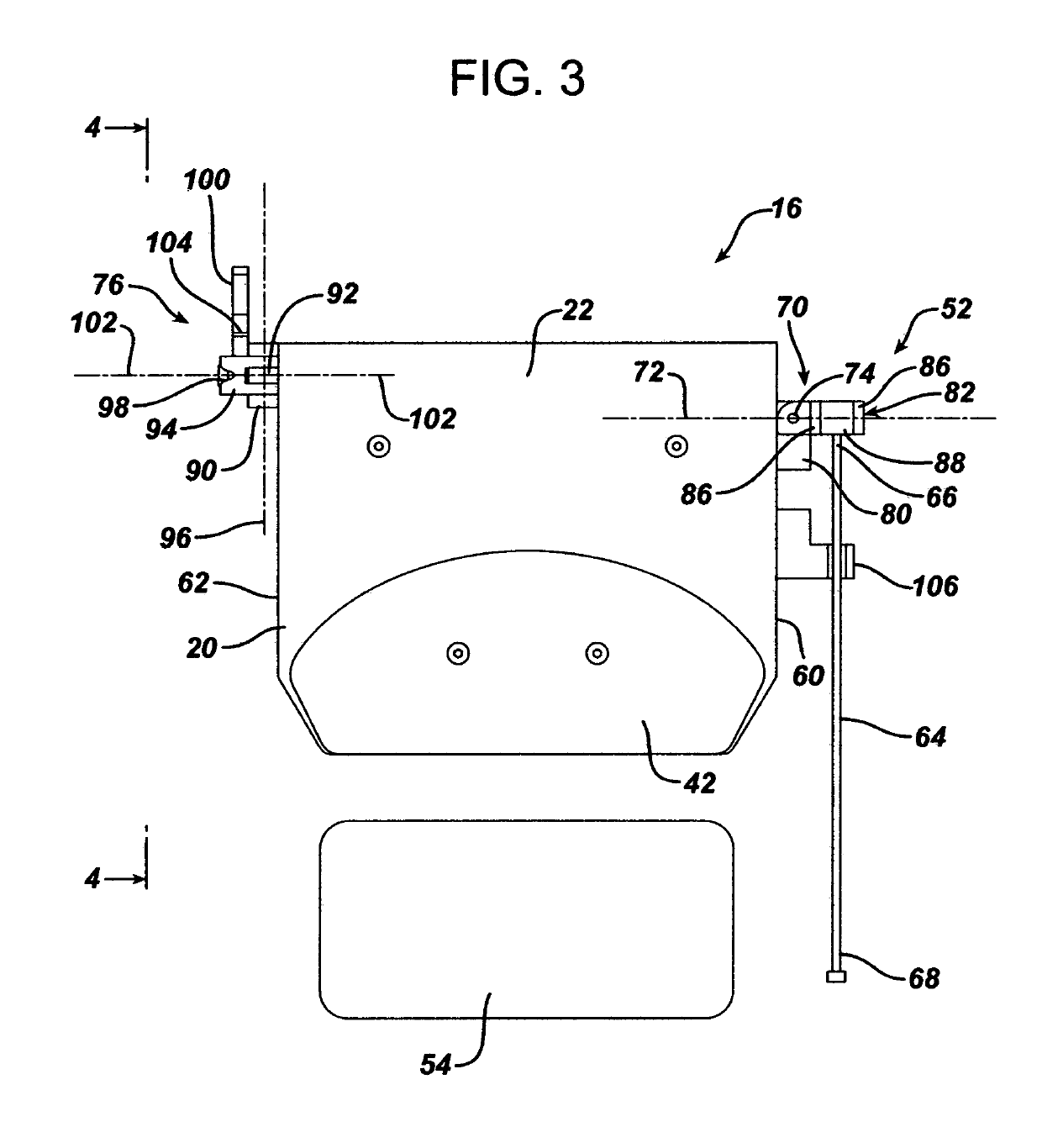

Label printing apparatus

A thermal transfer-type label printer and an optical disc apparatus are integrated to miniaturize a multi-function label printing apparatus. An information recording / reproducing unit that carries out recording or reproduction of information on a recording surface of an optical disc is incorporated within a disc tray unit of a label printing apparatus that presses a thermal transfer film ribbon, on which printing information has been formed, onto a label surface of an optical disc mounted on a disc mounting part of the disc tray unit, and transfers the printing information onto the label surface using a heat roller. The recording or reproduction of information on the recording surface of the optical disc and the transferring of the printing information on the label surface of the optical disc are carried out on the disc tray unit. When transferring the printing information, the clamping of the optical disc by a disc clamper is released and a turntable and the disc clamper are withdrawn to a non-clamping position.

Owner:TEAC CORP

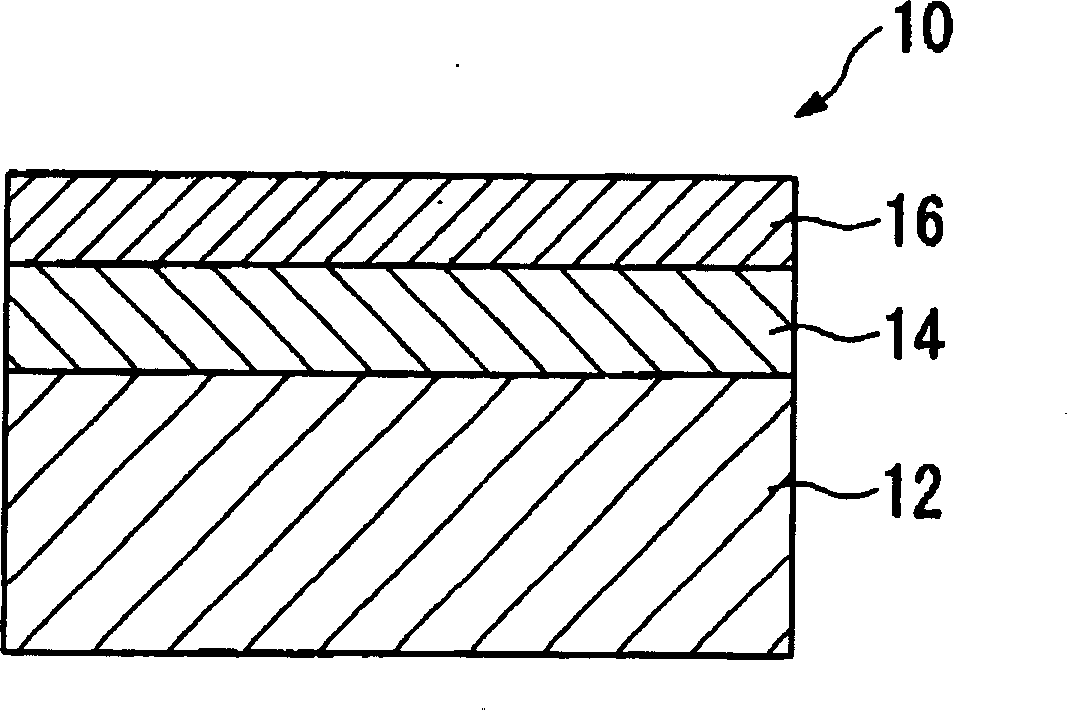

Thermal transfer film and image forming method

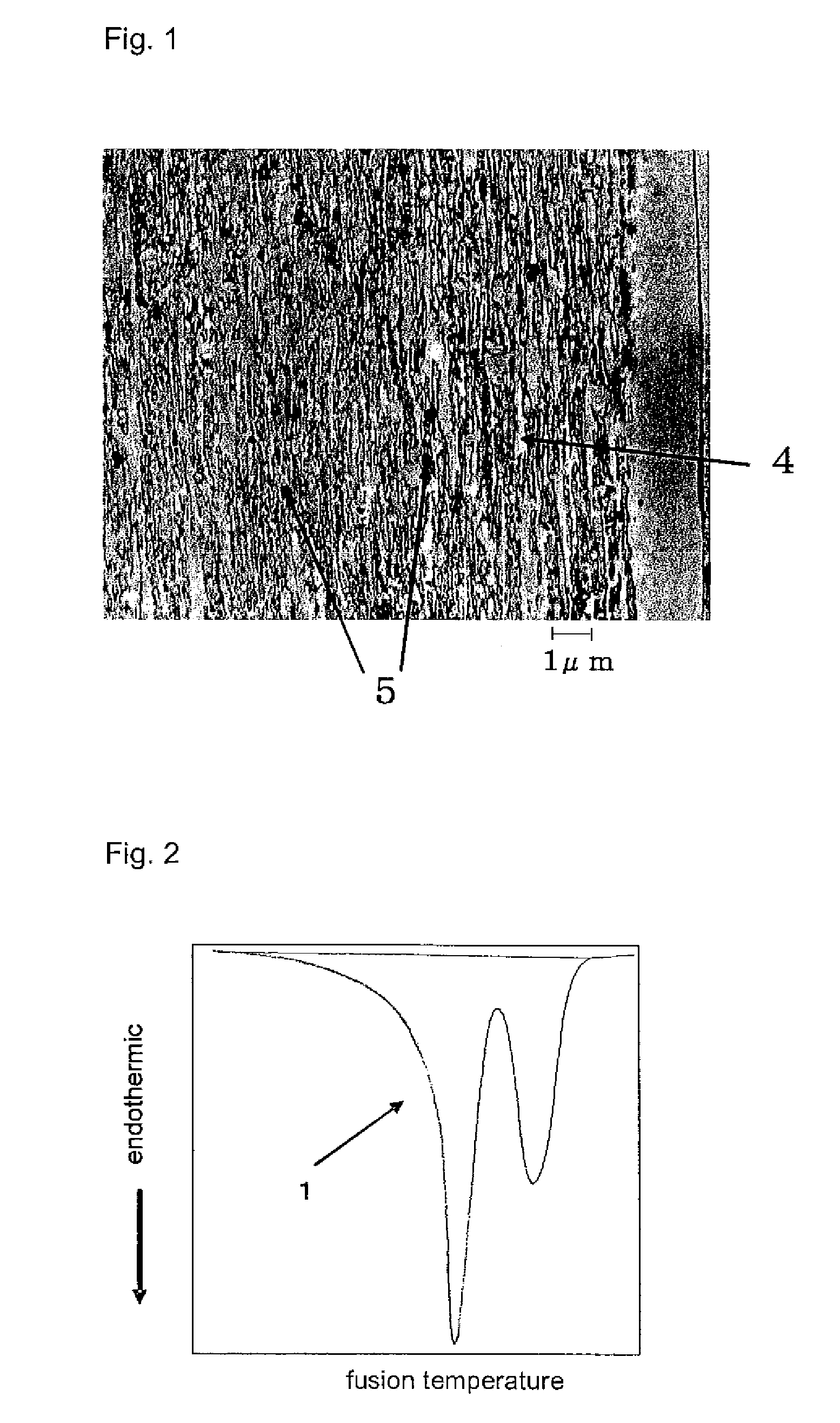

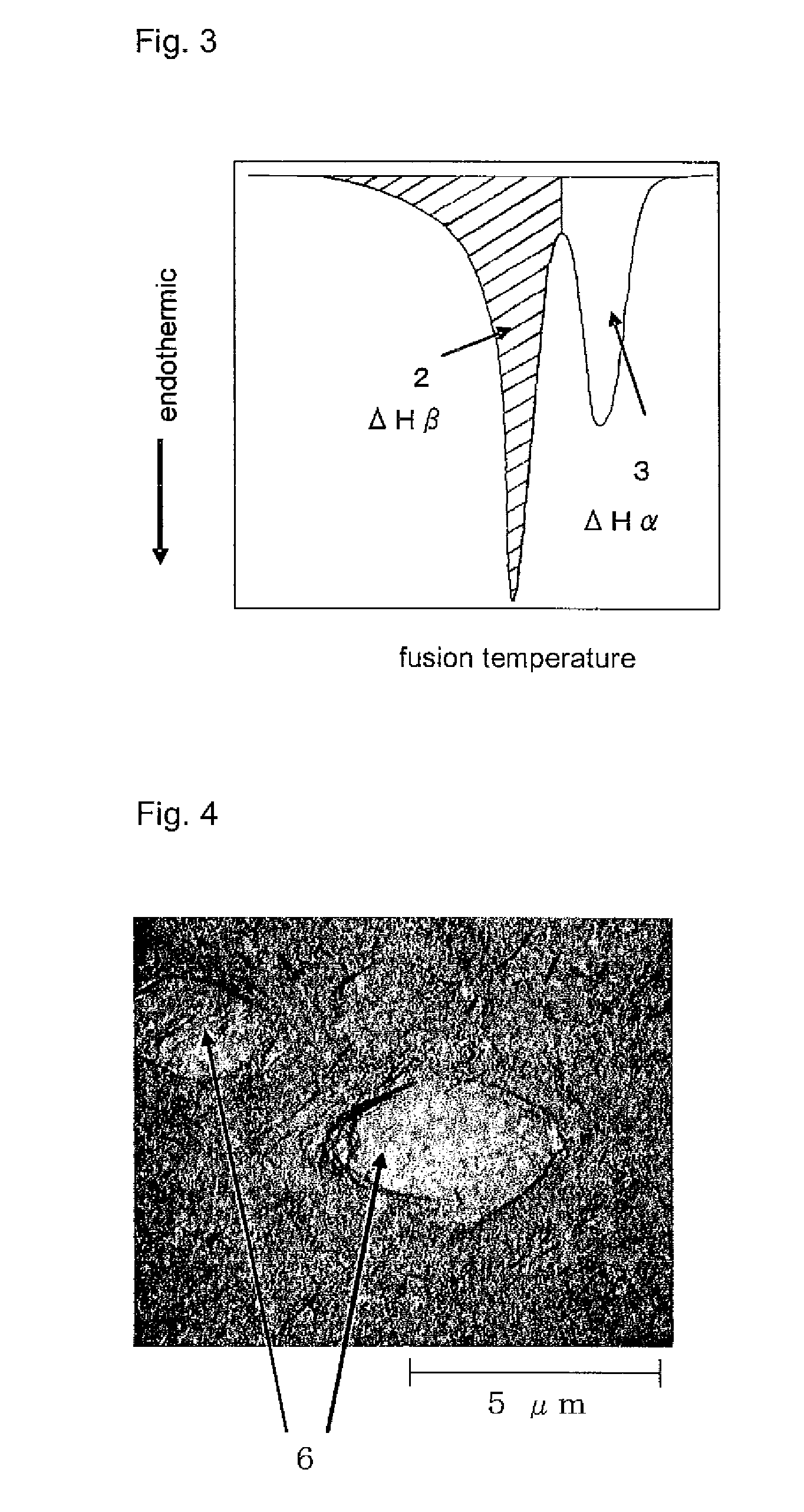

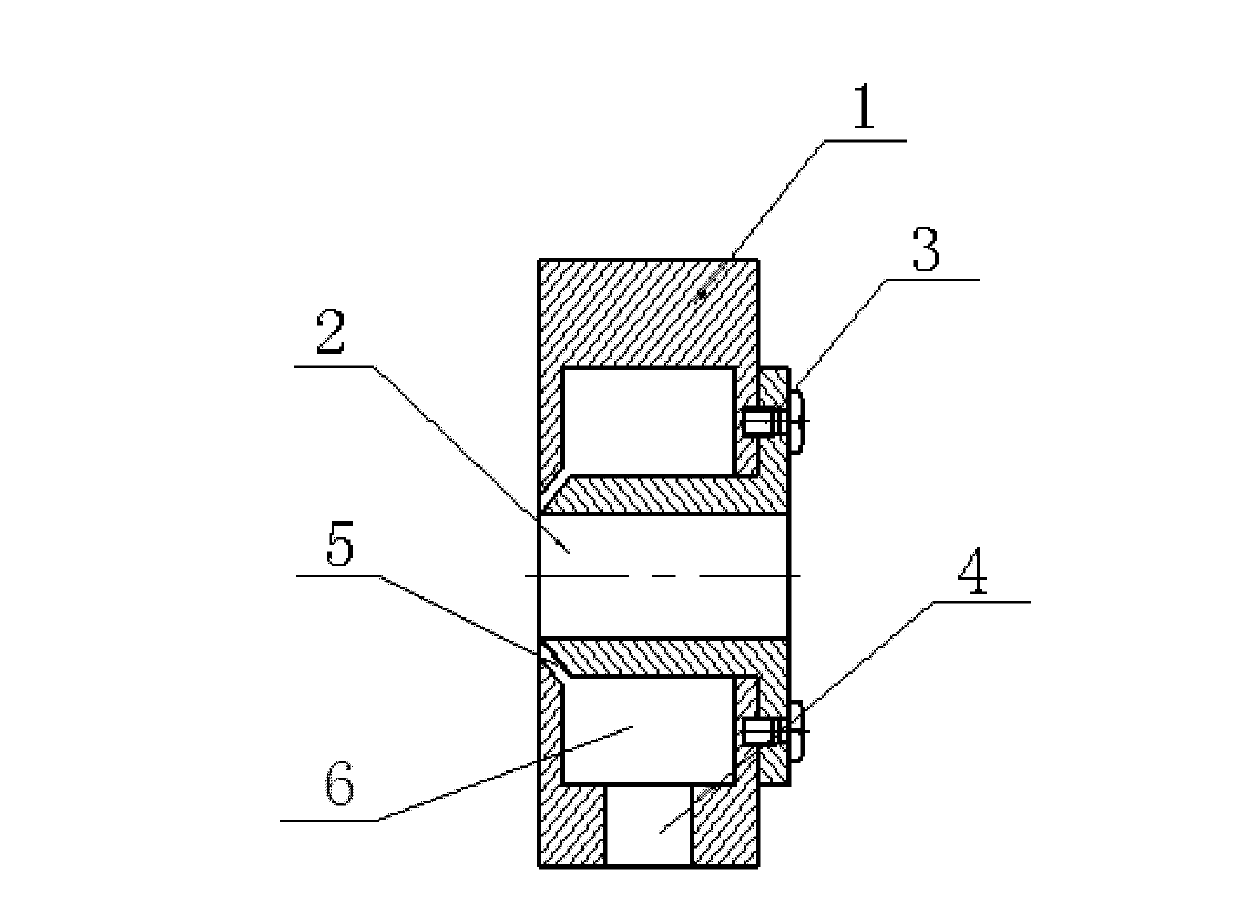

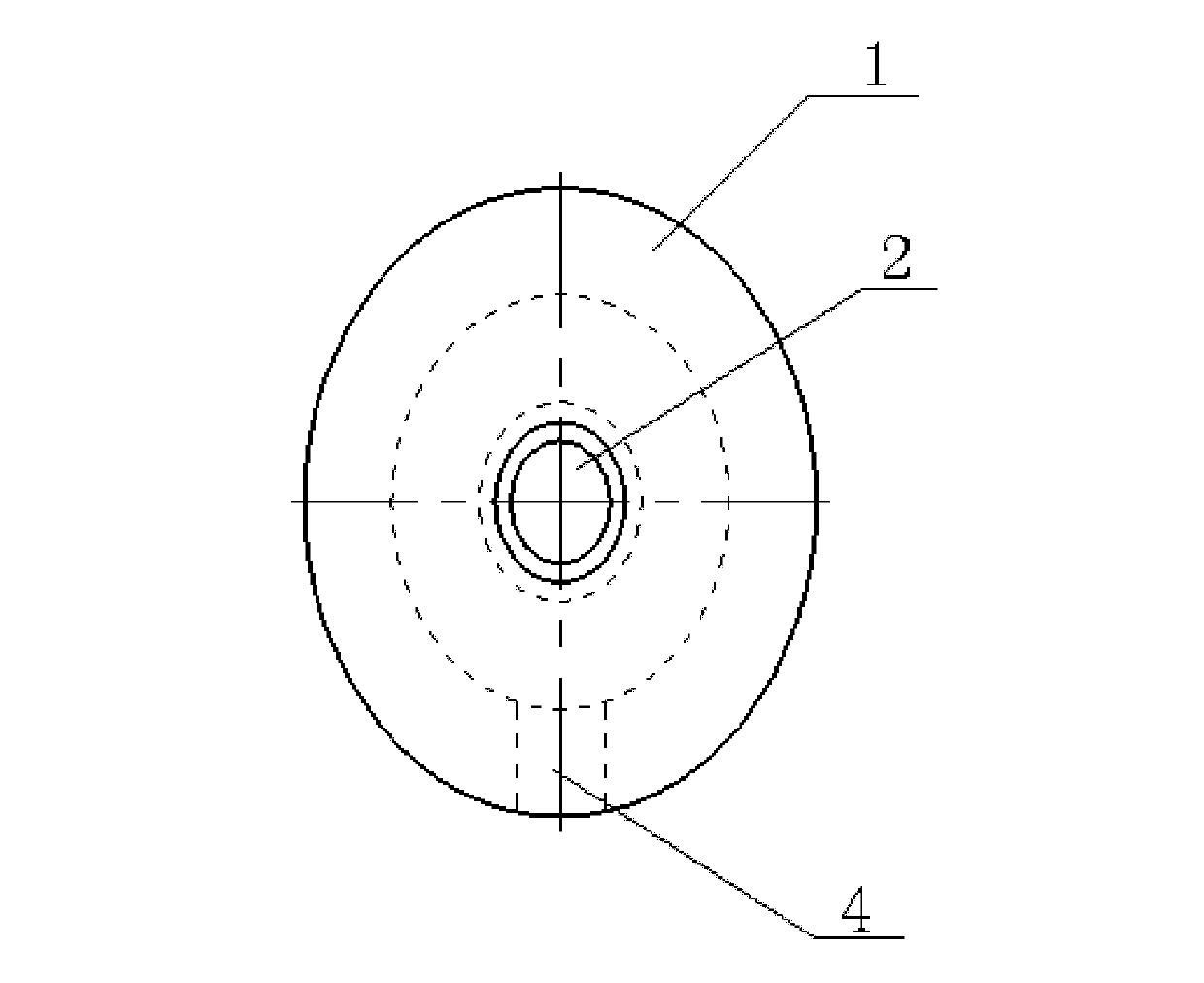

InactiveUS7011727B2Print clearReliable coatingPrinting mechanismsRecording apparatusHot meltCrystallization

A thermal transfer film comprises a coloring layer formed on a substrate film via an intermediate layer, wherein the intermediate layer contains a thermally fusible substance and a non-transferable binder resin, the melt viscosity of the thermally fusible substance in the temperature range 15 to 25° C. higher than the fuse peak temperature of the thermally fusible substance is in the range of 100 to 1000 mPa·s, the fuse peak temperature of the thermally fusible substance is in the range of 50 to 110° C., the crystallization peak temperature of the thermally fusible substance is in the range of −20 to 100 ° C., the crystallization peak temperature of the thermally fusible substance is lower than the fuse peak temperature by 10° C. or more, and the softening temperature of the binder resin measured by the ring and ball method is in the range of 130 to 400° C. This thermal transfer film is capable of forming a printed product with a good printing quality.

Owner:DAI NIPPON PRINTING CO LTD

Ink jet recording sheet

Ink jet recording sheet has excellent coloring properties for dye ink as well as pigment ink, a high degree of brightness, and excellent preservability for white paper portions. The ink jet recording sheet includes: a paper supporting medium made by machining pulp; an undercoating layer including at least a pigment and an adhesive; and an ink receiving layer including at least a pigment and an adhesive, the undercoating layer and the ink receiving layer being disposed on at least one surface of the paper supporting medium, and the ink receiving layer being located outermost thereof, wherein the undercoating layer includes titanium dioxide as the pigment and at least one emulsion type adhesive selected from acryl polymers, ethylene-vinyl acetate copolymers, or vinyl acetate polymers; and the ink receiving layer includes silica having an average secondary particle size of 3 to 11 m as the pigment, and a cationic ink fixing agent.

Owner:SEIKO EPSON CORP

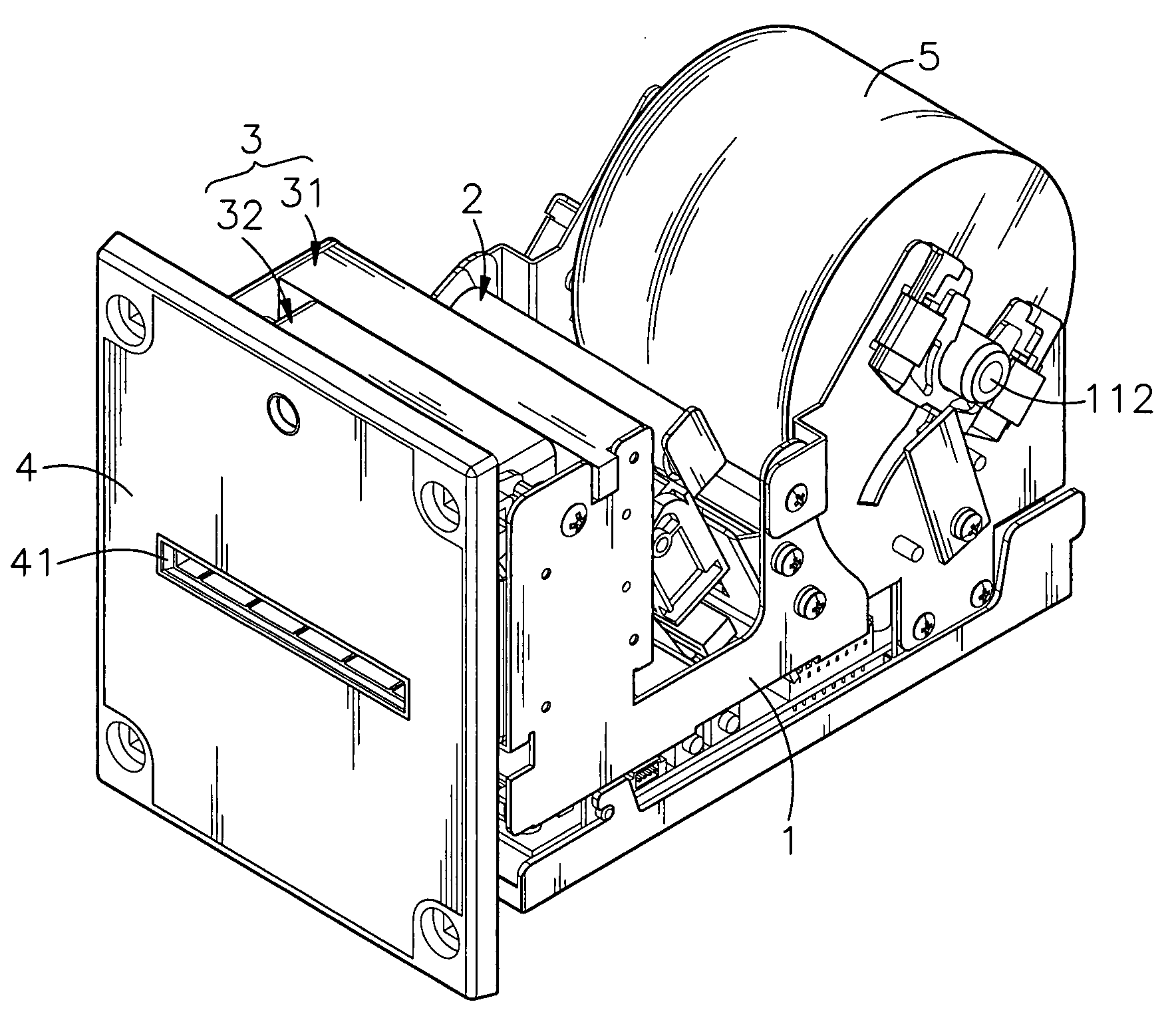

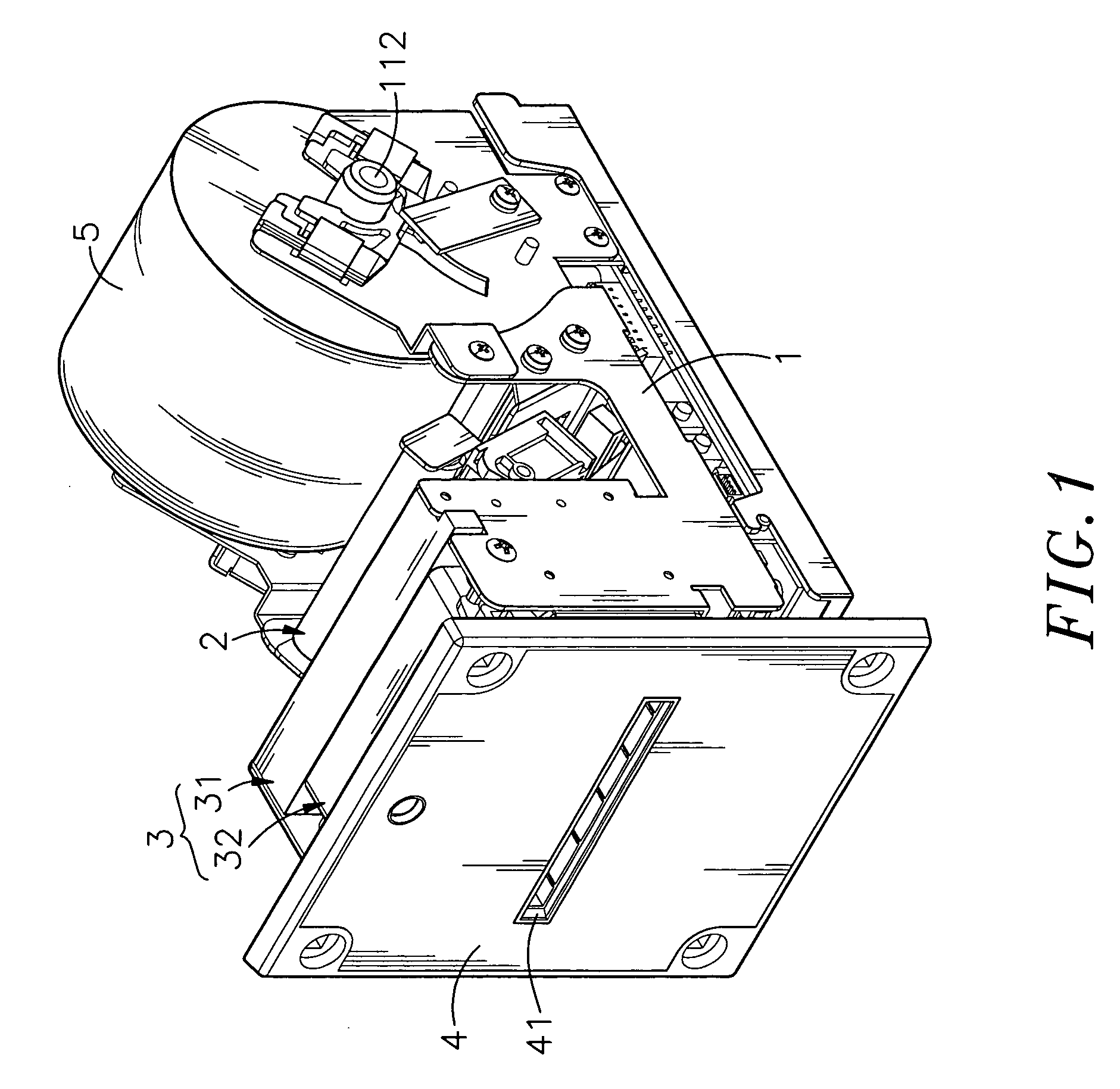

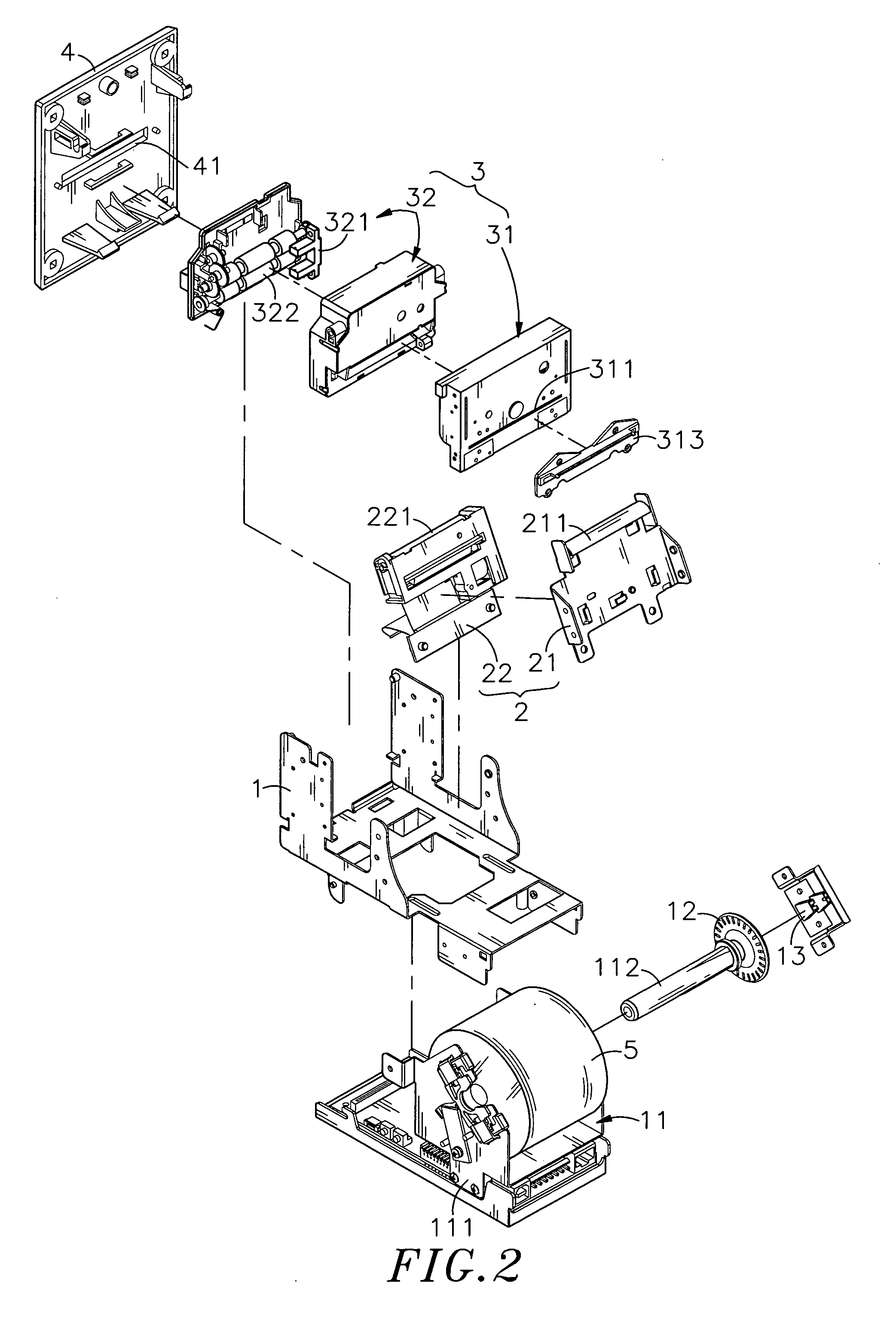

Printer module paper feed-out procedure

InactiveUS20110017795A1Avoid paper wasteAvoid damageFunction indicatorsReceipt giving machinesPulp and paper industryTransfer - action

A printer module paper feed-out procedure in which a sheet-transfer roller set transfers the paper sheet forwards during printing, and paper feed-out rollers are rotated forwards for a predetermined time period and then stopped so that the paper feed-out rollers hold down the lead end of the paper sheet when the printing action of the printing head and the paper sheet transferring action of the sheet-transfer roller set are being continued, and then a paper cutting unit is operated to cut off the printed front part of the paper sheet when the printing action is finished, and then the paper feed-out rollers are rotated to transfer the cutoff piece of paper out of a paper outlet of a face panel of the printer module and then he paper feed-out rollers are stopped to hold down the rear end of the cutoff piece of paper, avoiding falling of the cutoff piece of paper away from the paper outlet of the face panel.

Owner:INT CURRENCY TECH

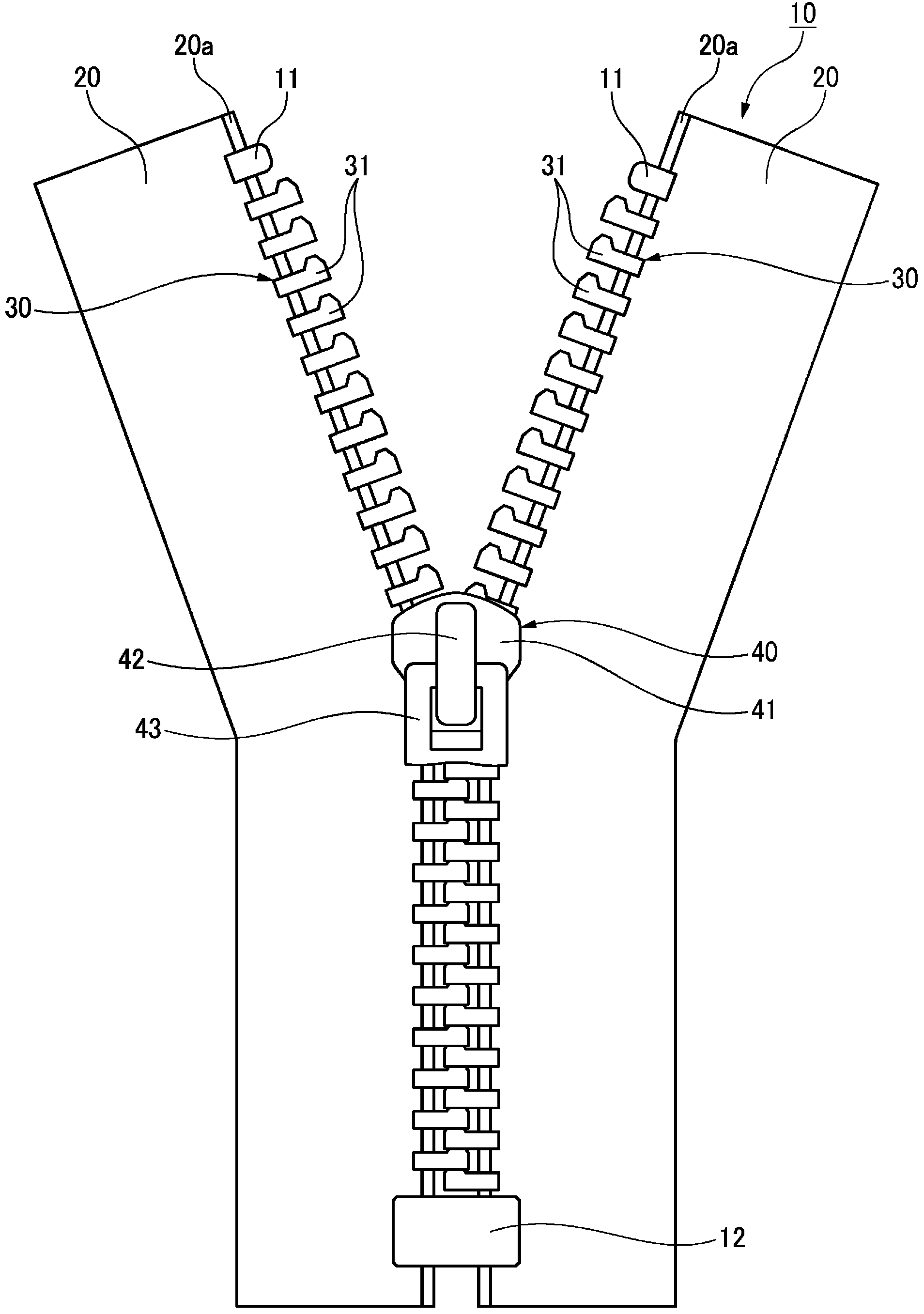

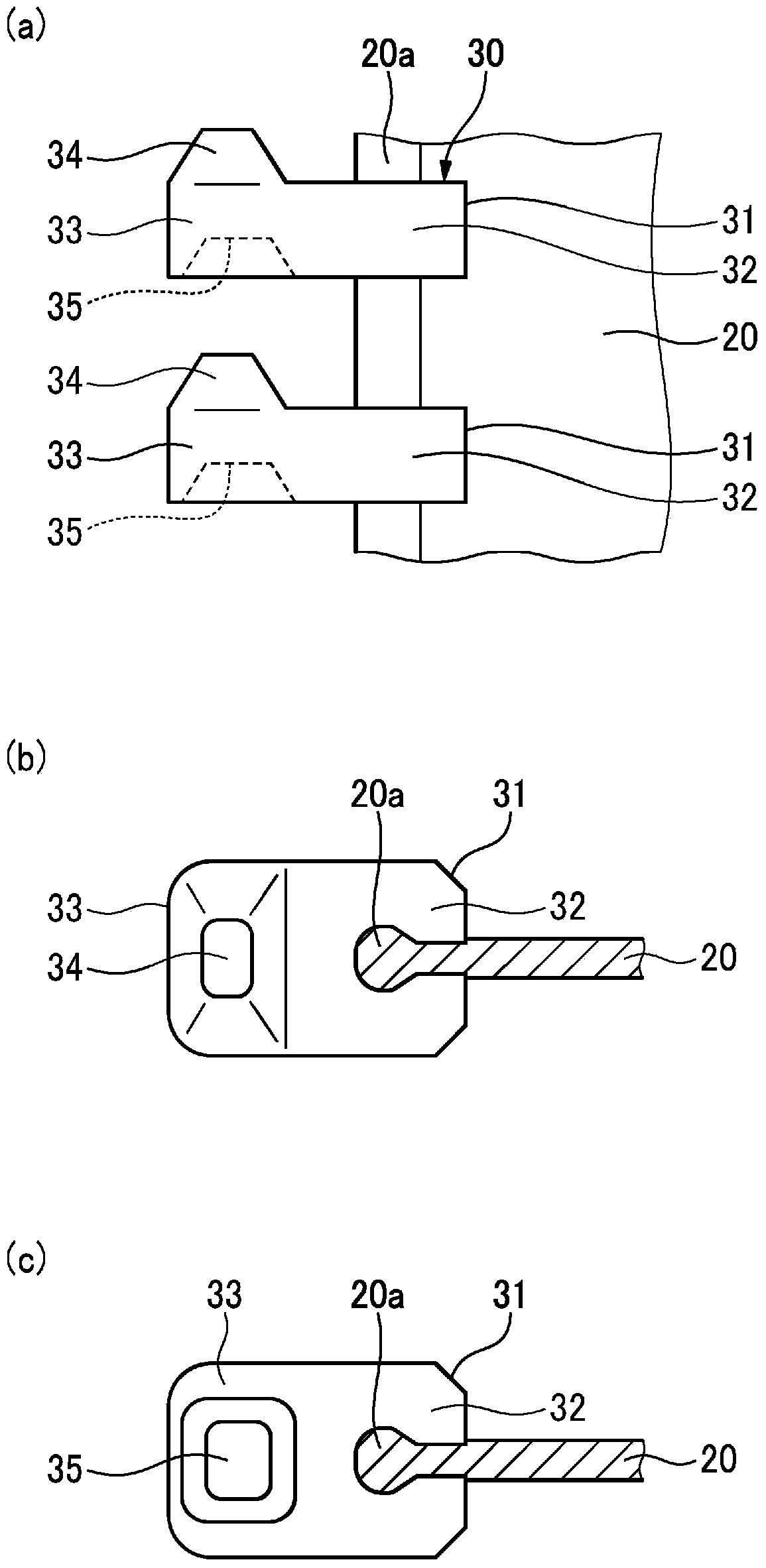

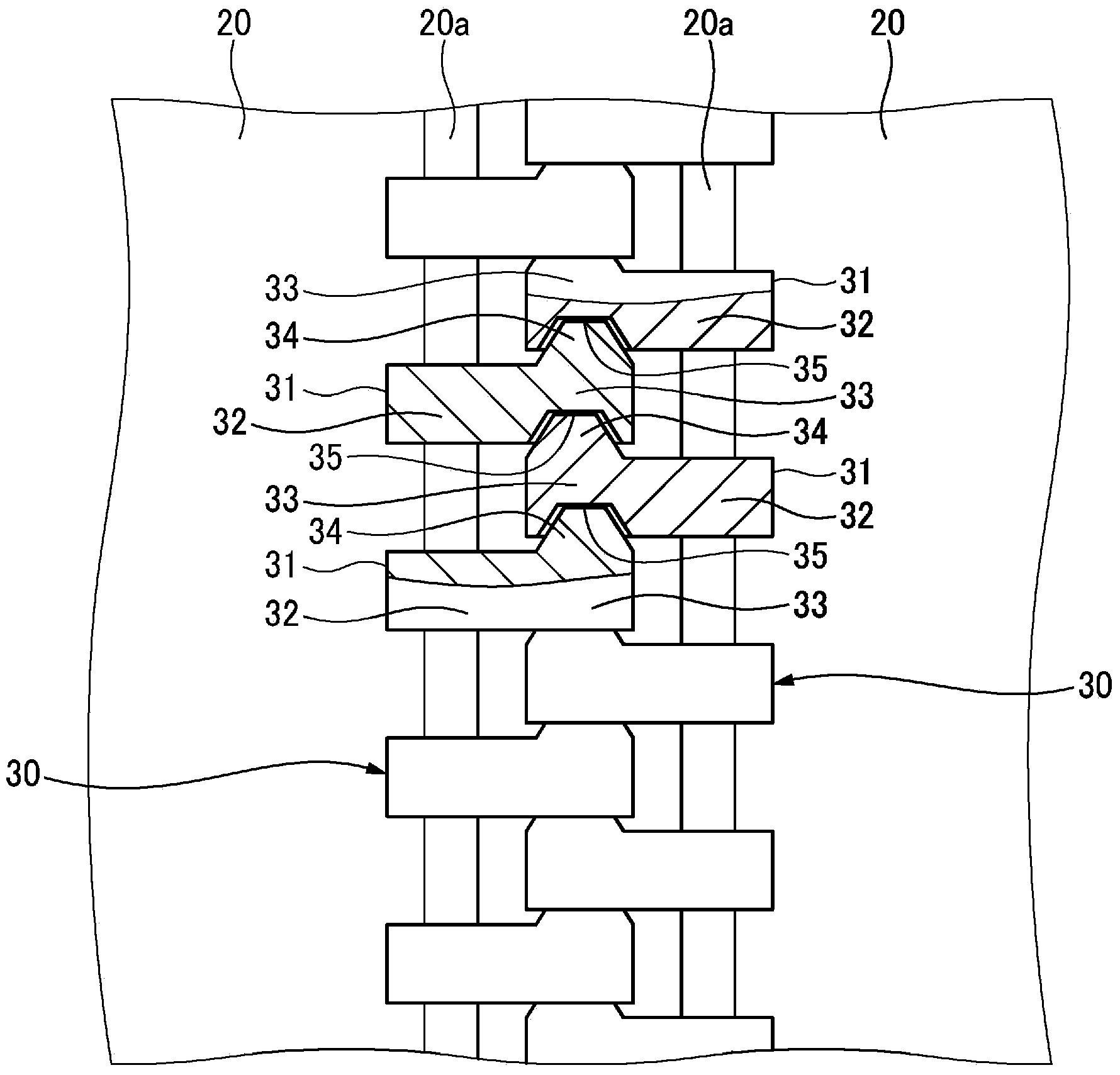

Slide fastener

ActiveCN104053377AIncrease frictionInhibit posture changesSlide fastenersBiomedical engineeringFastener

Provided is a slide fastener that is capable of maintaining the operability of a slider while improving the engagement strength of a fastener element. The present invention comprises a pair of fastener tapes (20), a pair of cores (20a) that are respectively disposed along opposing tape side edges of the pair of fastener tapes (20), and a pair of fastener element rows (30) that are respectively attached to the pair of cores (20a) and include a plurality of metallic fastener elements (31). Silica (S) is adhered to surfaces of the cores (20a) and the fastener elements (31).

Owner:YKK CORP

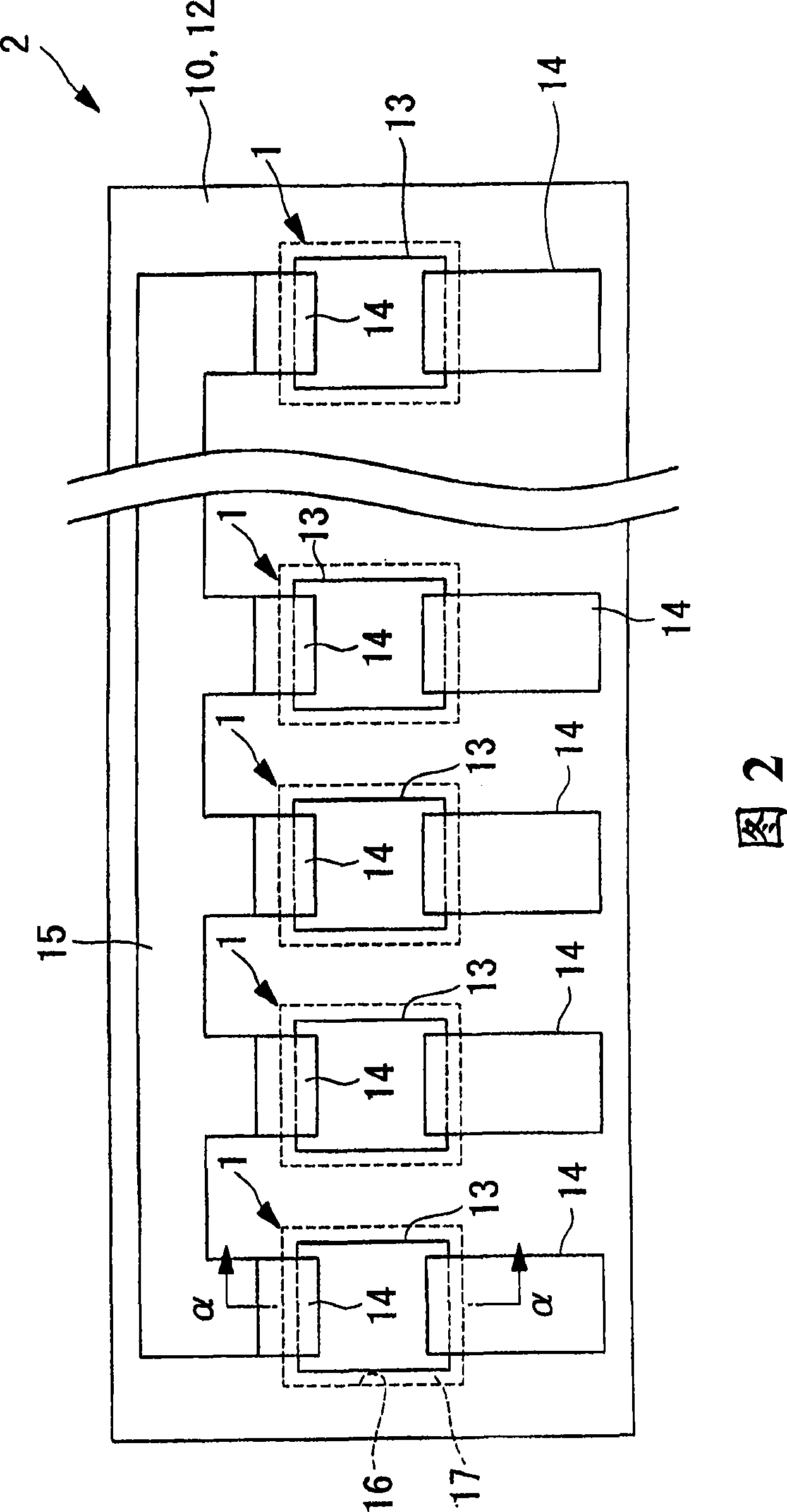

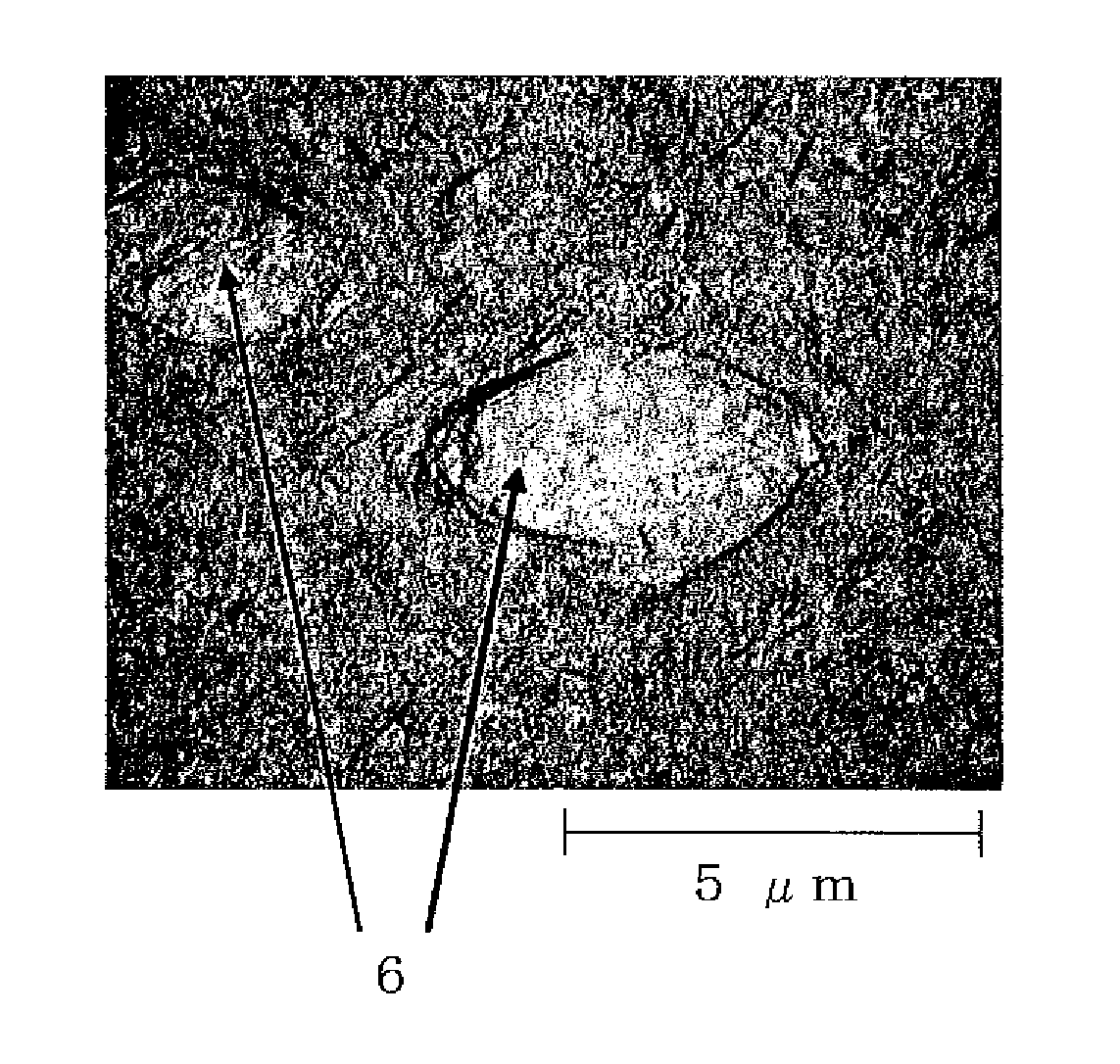

Heating resistor element, manufacturing method for the same, thermal head, and printer

InactiveCN101417545AImprove heating efficiencyImprove printing effectPrintingElectrical resistance and conductanceThermal expansion

Provided is a heating resistor element including: an insulating substrate including a glass material; a heat accumulating layer bonded to the insulating substrate through heating to temperature ranging from an annealing point to a softening point in a state of being adhered to a surface of the insulating substrate, and including the same material as the glass material of the insulating substrate; and a heating resistor provided on the heat accumulating layer, in which, on at least one of bonded surfaces between the insulating substrate and the heat accumulating layer, at least one of the insulating substrate and the heat accumulating layer is provided with a concave portion in a region opposed to the heating resistor to form a hollow portion. Accordingly, deformation caused by a difference in coefficient of thermal expansion is suppressed to improve printing quality.

Owner:SEIKO INSTR INC

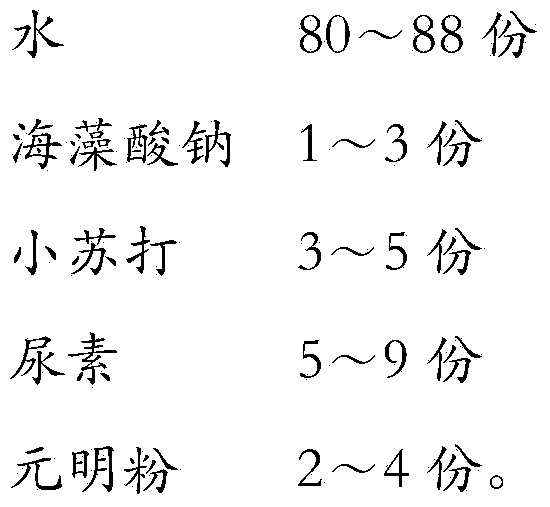

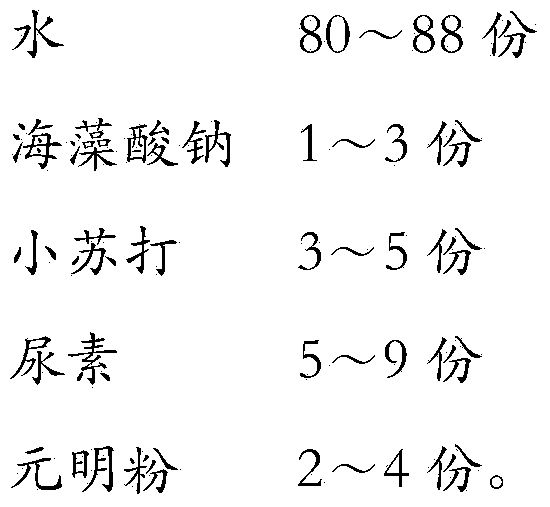

All cotton digital printing textile slurry and preparation method thereof

InactiveCN103993489APrint clearHigh color reproductionDyeing processSodium bicarbonateRoom temperature

The present invention discloses an all cotton digital printing textile slurry and a preparation method thereof, and belongs to the technical field of textile slurries. The all cotton digital printing textile slurry comprises, by weight, 80-88 parts of water, 1-3 parts of sodium alginate, 3-5 parts of sodium bicarbonate, 5-9 parts of urea, and 2-4 parts of sodium sulfate. The preparation method comprises: at a room temperature, at a rotation speed of 800-1000 rotation / min, taking 80-88 parts of water, adding 1-3 parts of sodium alginate, carrying out mixing stirring for 5-10 min, adding 5-9 parts of urea, continuously carrying out mixing stirring for 5-10 min, adding 2-4 parts of sodium sulfate, carrying out mixing stirring for 4-5 h, finally adding3-5 parts of sodium bicarbonate, carrying out mixing stirring for 2-3 h, and standing. According to the present invention, with application of the all cotton digital printing textile slurry, the printing is clear, the color reduction degree is good, the color fastness is good and can achieve more than grade 3, the whole preparation process is simple and is easy to control, the equipment investment is low, the cost is low, and the yield is high.

Owner:KUNSHAN CAIDU DIGITAL PRINTING

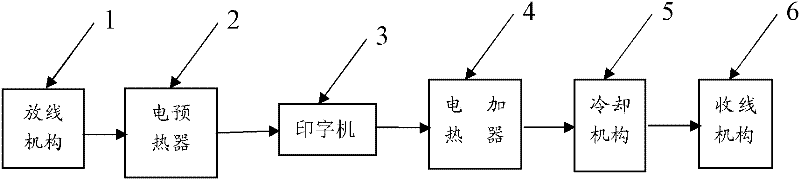

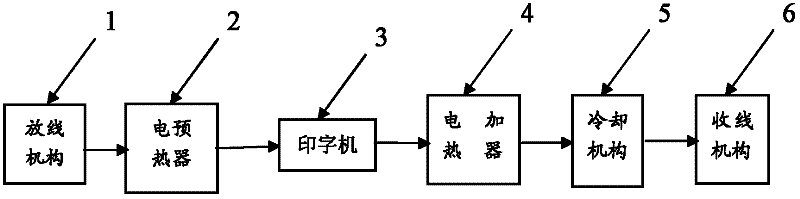

Fluoroplastic electric wire and cable surface lettering method and device

The invention provides a fluoroplastic electric wire and cable surface lettering method. The method comprises the following steps of: preheating a fluoroplastic electric wire in an electrical heating preheater, lettering on a high-temperature printing ink lettering wheel, heating the lettered electric wire in an electric heater, cooling the electric wire and the like. The invention also provides a corresponding lettering device which comprises a paying-out mechanism, the electric preheater, a high-temperature printing ink roll wheel lettering machine, the electric heater, a cooling mechanism and a cable coiling mechanism through which the electric wire successively passes. The method has the beneficial effects that the fluoroplastic surface of the electric wire is preheated to a required temperature firstly, then lettering is carried out on the fluoroplastic surface of the electric wire by use of high temperature printing ink, then the lettered fluoroplastic surface of the electric wire is heated to the required temperature so as to be firmly adhered to the fluoroplastic surface of the electric wire and cable, and subsequently, and cooling is performed, so that the lettering is firm and clear, the price is economic and cheap. Thus, the method and device provided by the invention are suitable for national conditions of China.

Owner:TIANJIN DAILY PROSPERITY SCI & TECH GROUP

Ink jet recording sheet

InactiveCN1765638AExcellent color developmentPrint clearDuplicating/marking methodsEngineeringPigment

The present invention provides an inkjet recording medium, which is provided with an ink receiving layer on a support, and is characterized in that, in the ink receiving layer, a pigment, a binder, an ink fixer, and Terpolymer of alkyl methacrylate and N-methylolacrylamide and styrene.

Owner:OJI PAPER CO LTD

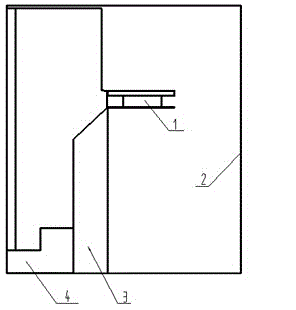

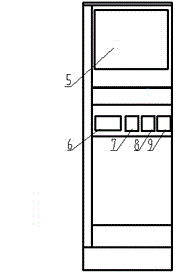

Trash intelligent recycling device

InactiveCN104609061AIncrease storage spaceReduce the burden onRefuse receptaclesRecovery methodComputer science

The invention discloses a trash intelligent recycling device. The trash intelligent recycling device comprises a hardware unit and a software unit. The hardware unit comprises a cabinet body, an industrial control computer, an electronic scale, a display, an input device and a printer. The software unit comprises a data acquisition unit, a data storage unit, a control unit and an output unit. The trash dropped by a user is recycled intelligently through an intelligent recycling cabinet, certain reward is paid to the user and the dumping motivation of the user is improved; the recycling method can recycle multiple garbage, reorganization on each kind of garbage before recycling is not needed; the time and labor are saved during a dumping work, and popularization and application are easy.

Owner:遂宁市为户利垃圾分类收集处理有限公司

Thermal dye sublimation transfer film and preparation method thereof

The invention belongs to the technical field of thermal transfer films, in particular to a thermal dye sublimation transfer film and a preparation method thereof. The thermal dye sublimation transfer film comprises a base film, wherein a printing layer is coated on the surface of the base film. The thermal dye sublimation transfer film has excellent light resistance, water resistance and scratch resistance, the transfer is extremely convenient by employing the thermal dye sublimation transfer film, and the requirement on transfer conditions is extremely low.

Owner:ZHUOLI IMAGING TECH

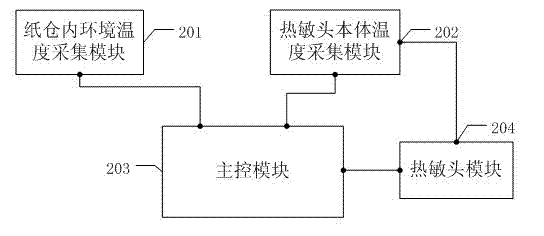

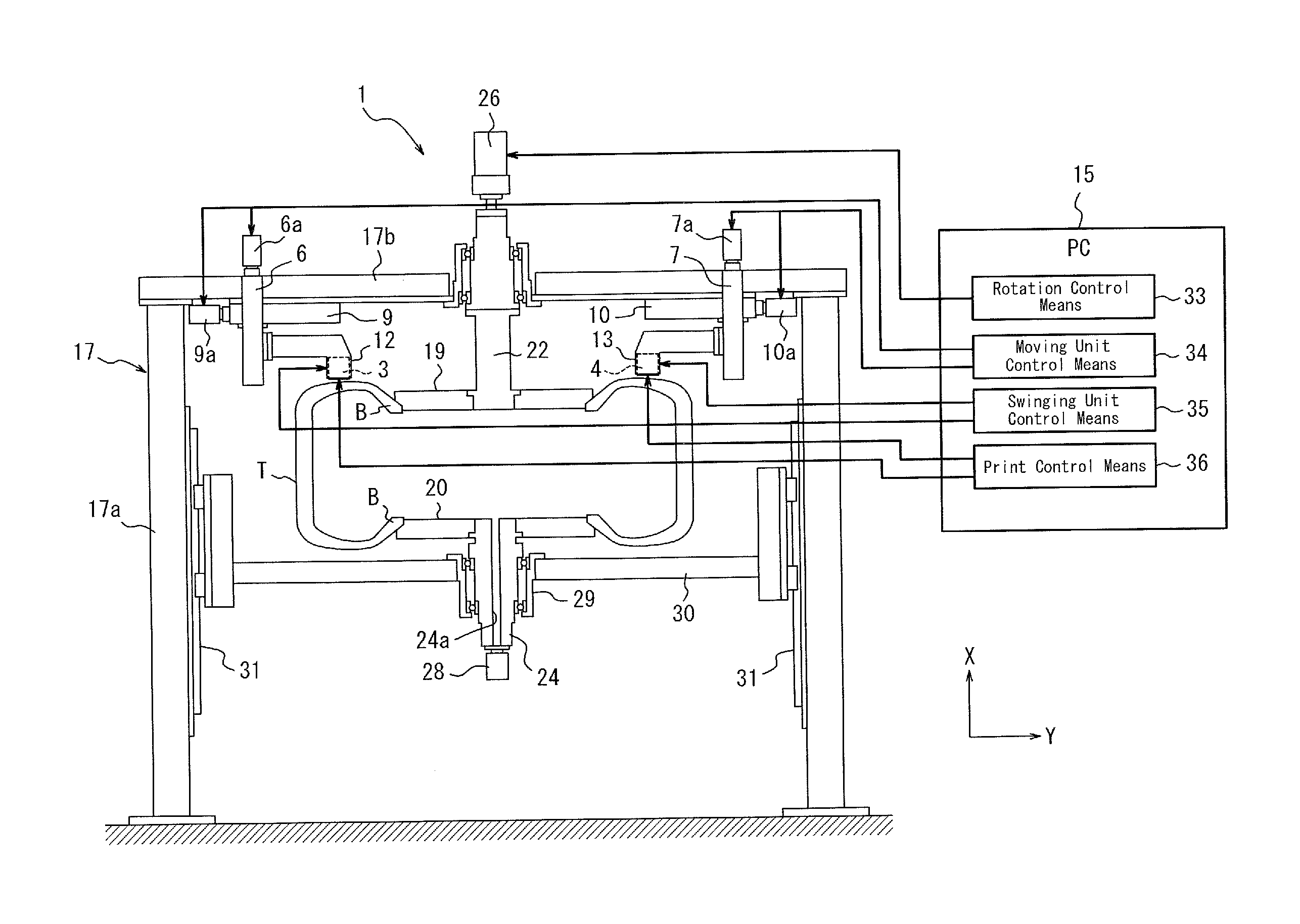

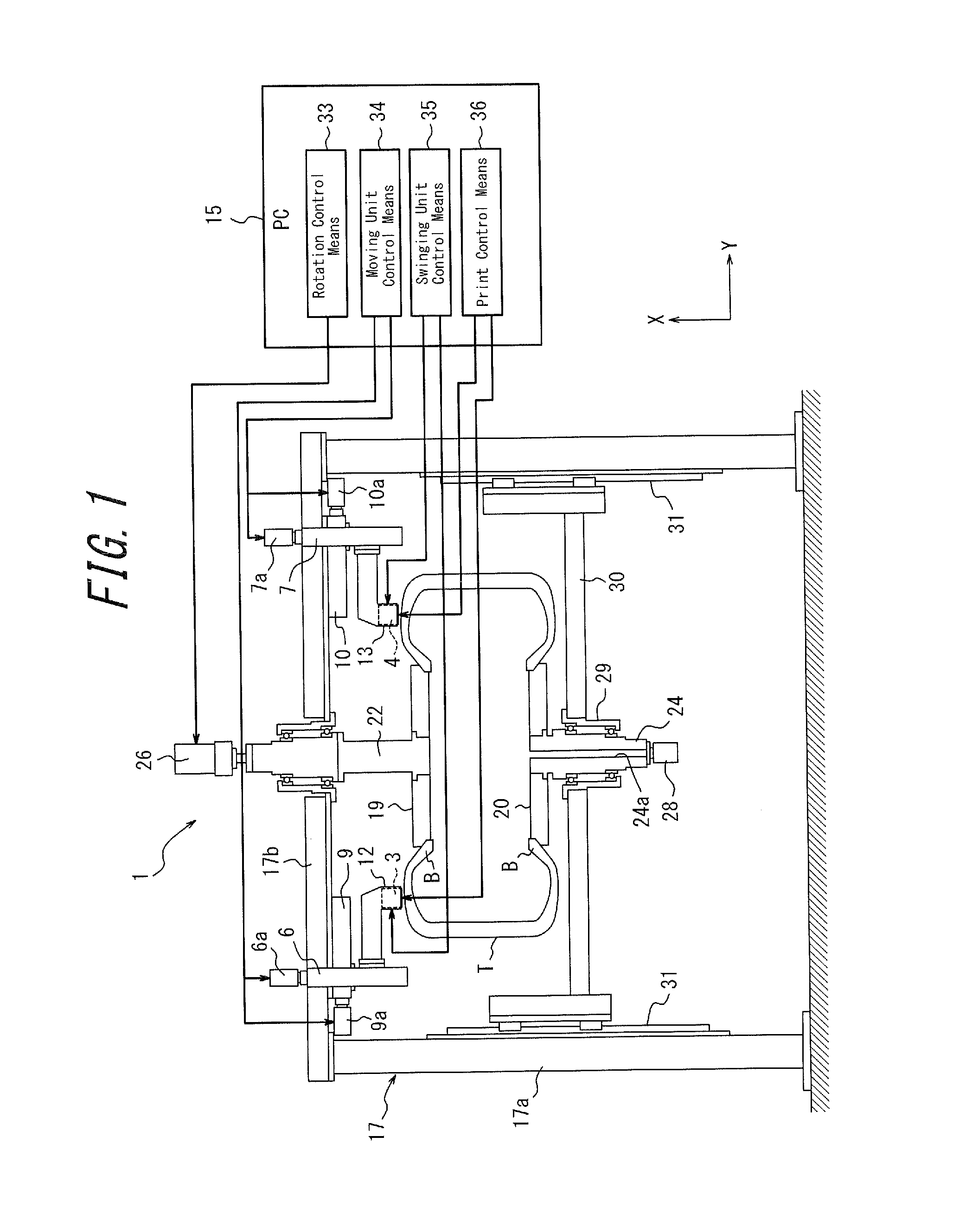

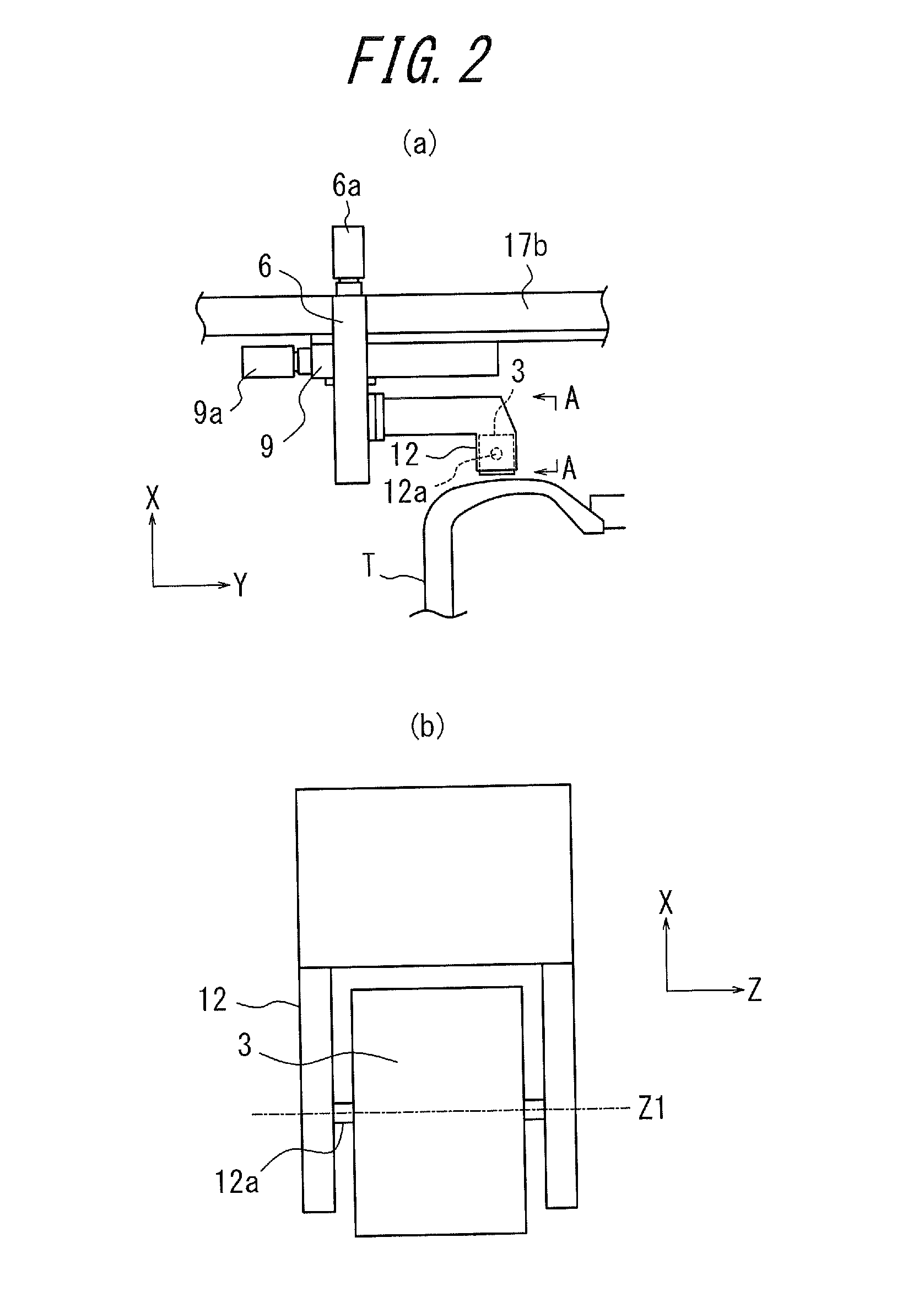

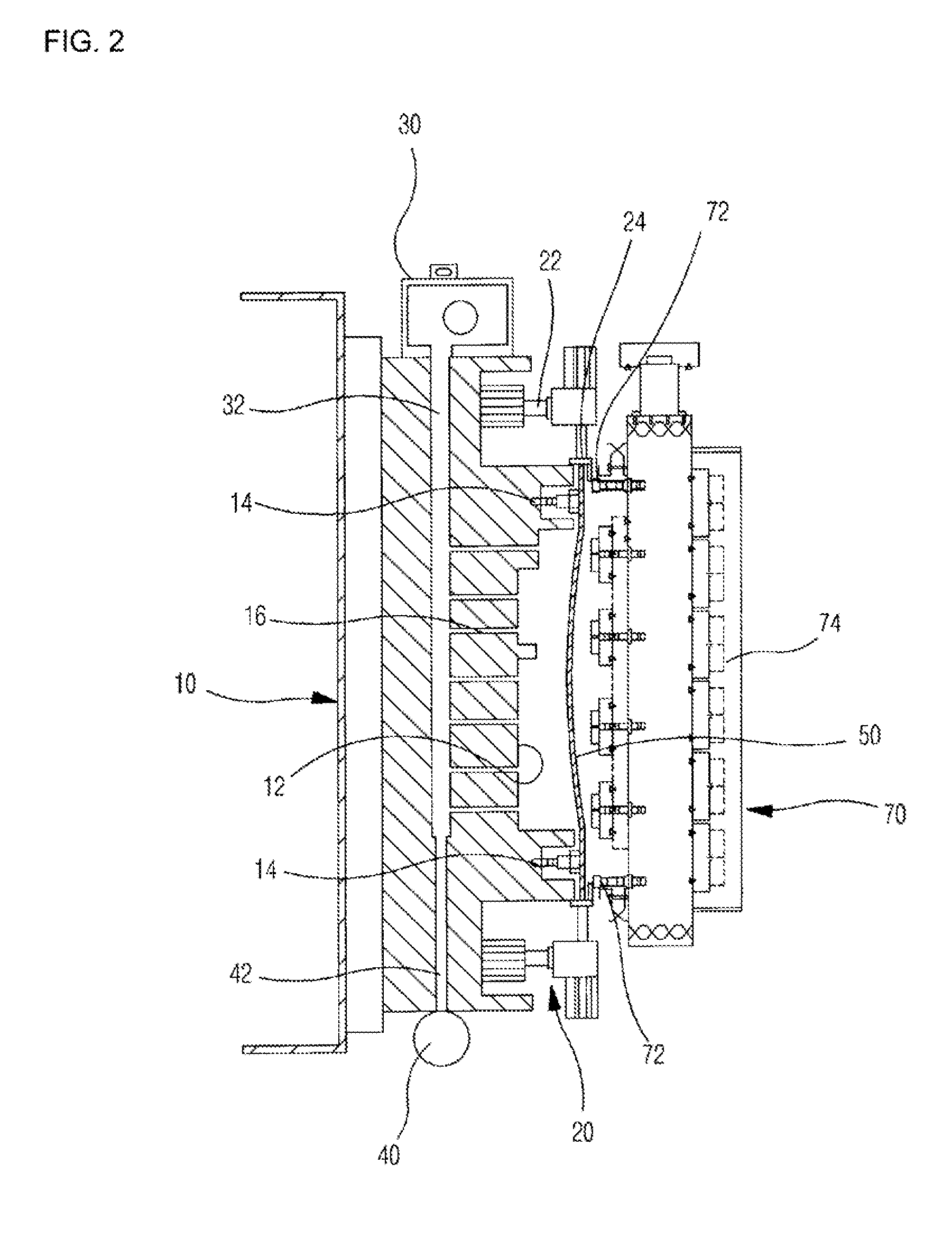

Tire printing device and method for printing onto tire surface

ActiveUS20140022302A1Without complicated operationPrint clearDuplicating/marking methodsSpraying apparatusEngineeringCoating

The present invention aims to provide a technique that prints characters and patterns clearly onto a tire surface without complicated operations. A tire printing device of the present invention includes a printer head that ejects and applies a coating material onto a tire surface, a widthwise moving unit that moves the printer head along the width direction of the tire, a radial moving unit that moves the printer head along the radical direction of the tire, and a swinging unit that swings the printer head around the axis along the circumferential direction of the tire.

Owner:BRIDGESTONE CORP

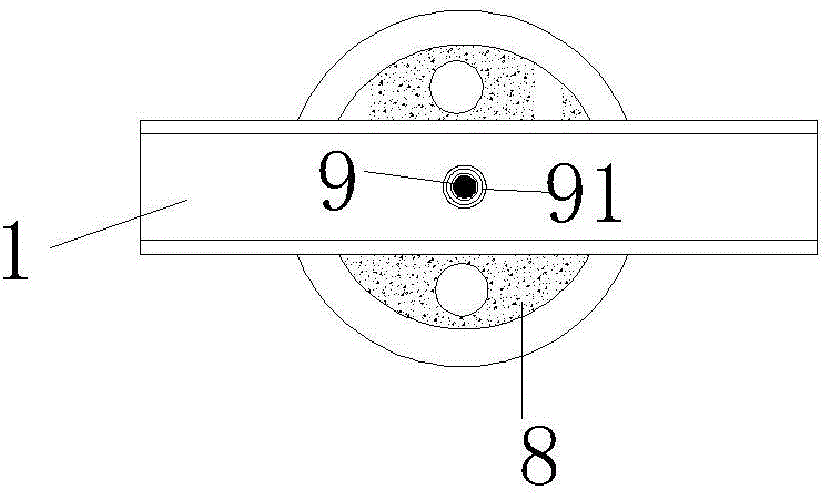

Surface printing device for coal mine cabtyre cables

The invention discloses a surface printing device for coal mine cabtyre cables, comprising a lateral base plate, a front support plate, a rear support plate, a laser generator, a control panel, and a host. The surfaces of the front support plate and the rear support plate are respectively equipped with a pulley and two positioning wheels disposed at the two ends of the pulley, and a coal mine cable is disposed between the two positioning wheels and on the pulley. A speed measuring wheel is disposed between the front support plate and the rear support plate, and the center of the speed measuring wheel is fixed to one end of a support shaft. The other end of the support shaft is equipped with a meter counting sensor. Two guide rods are fixed to the upper end face of the lateral base plate, and a slide block sleeves the guide rods. A pressure roller and a nut are respectively fixed to the outer and inner sides of the slide block. A screw embedded into the nut is installed on a fixed plate disposed on the upper ends of the two guide rods. The surface printing device of the invention adopts a new concave-convex printing technology instead of the existing ink printing technology, and the technical problem that the existing thermal printing technology cannot be implemented on a coal mine cabtyre cable is solved. Clear, firm, durable and complete printing information on the surface of a cable is ensured.

Owner:JIANGSU HENGTONG POWER CABLE

Ink-jet recording device and recording method

InactiveCN1470381AQuality improvementNo reduction in productivityInking apparatusOther printing apparatusEngineeringPosition control

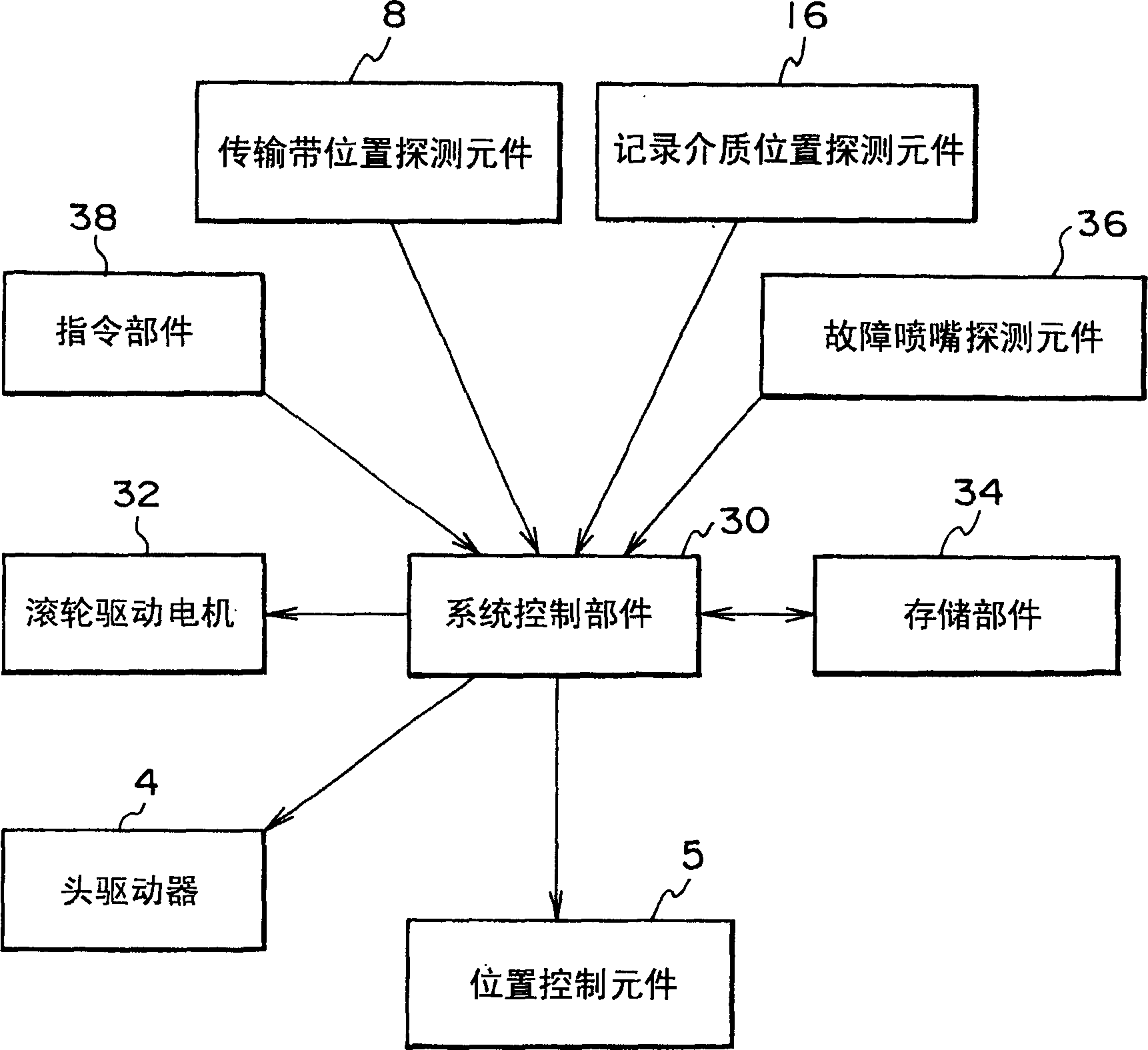

An inkjet recording device and inkjet recording method capable of forming a high quality image with a simple structure. A transport belt position detection component detects a position of an end portion of a transport belt and outputs the detected position to a system control section. A recording medium position detection component detects a position of an end portion of a recording medium and outputs the detected position to the system control section. A position control component is capable of moving on the basis of instructions from the system control section for movement across a transport direction.

Owner:FUJIFILM CORP

Transportable garment printing platen

ActiveUS20190168500A1Easy to printFacilitate rapid loadingScreen printersTypewritersCouplingEngineering

A garment printing machine is provided with a transportable platen that can be utilized to significantly decrease the delay in printing expended in loading and unloading a garment for printing in either a digitized garment printing machine or a screen garment printing machine. The platen is provided with structure that holds a print receiving area of a garment firmly in position atop a print panel support plate that forms a part of the platen. Furthermore, the invention includes a platen support structure that cooperates with the conventional couplings' on existing conventional garment printing machines. A plurality of transportable platens constructed according to the invention are utilized interchangeably so that while one garment loaded on one of the platens is being printed upon in the printing machine, the prior garment just printed upon is unloaded and the next garment to be printed is loaded onto another identical platen. This totally avoids any delay in printing due to loading and unloading of garments on the platens.

Owner:MARTINEZ LEO JR

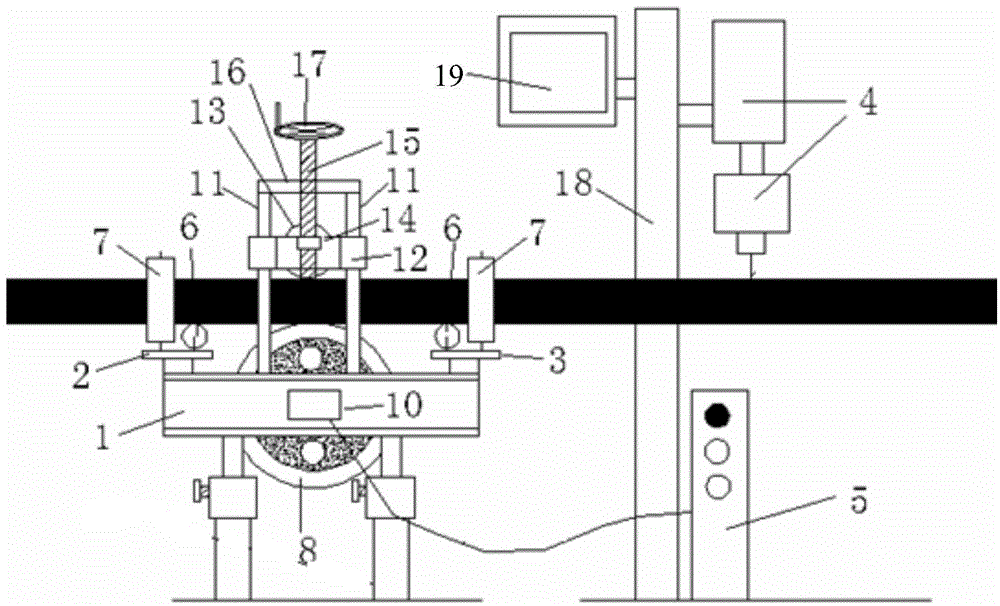

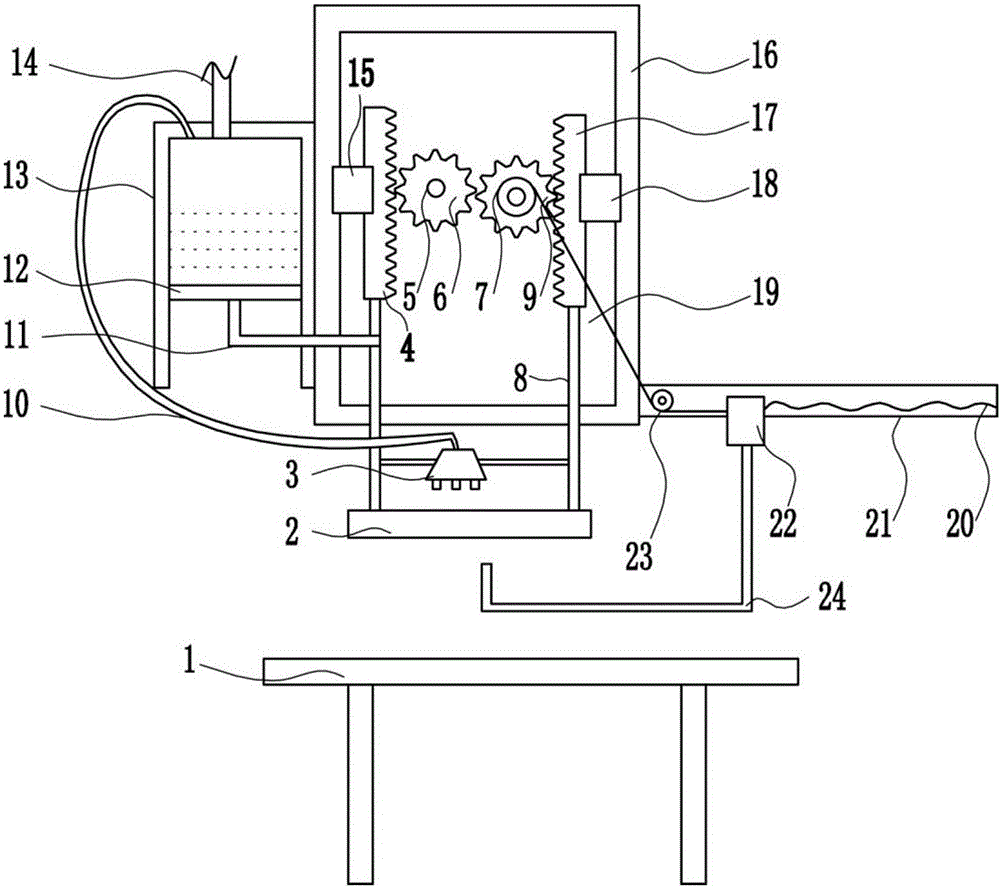

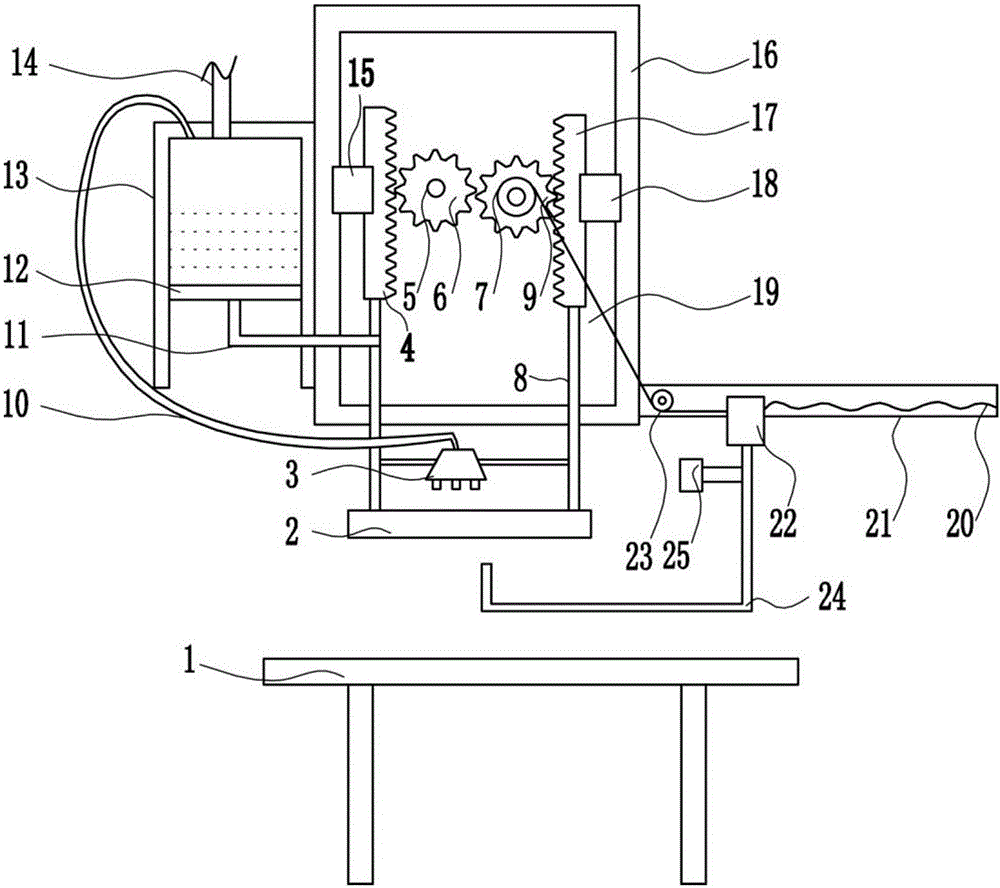

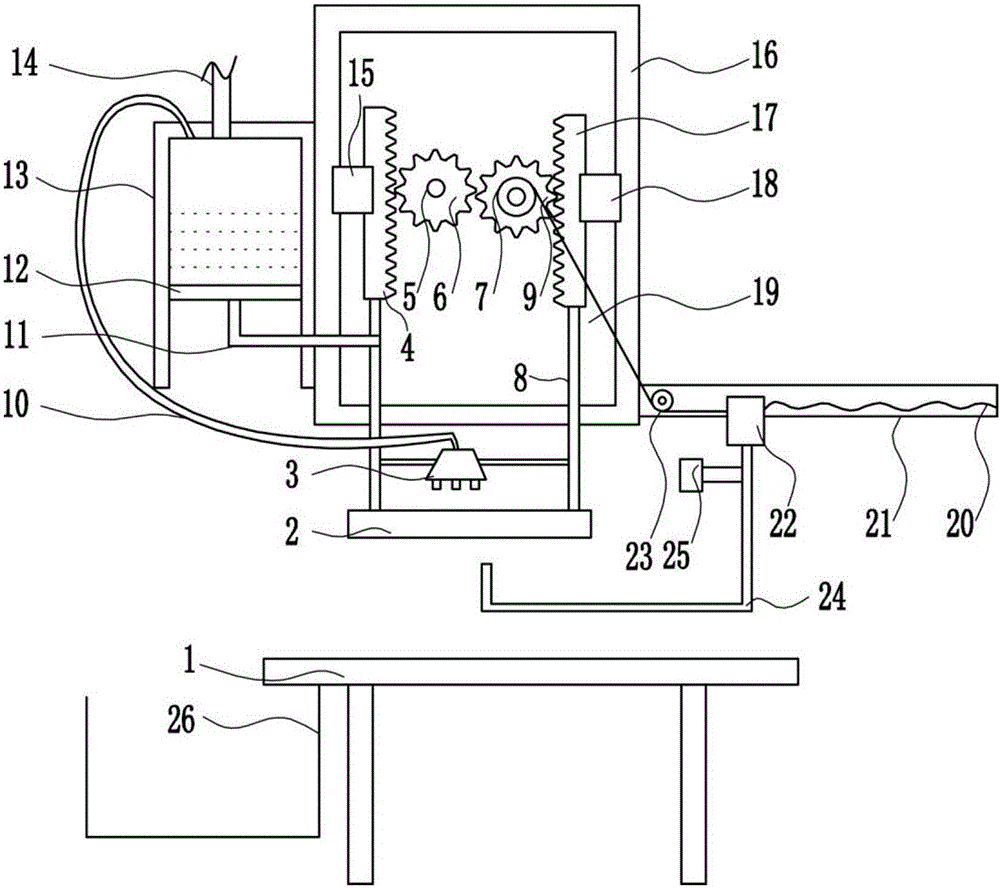

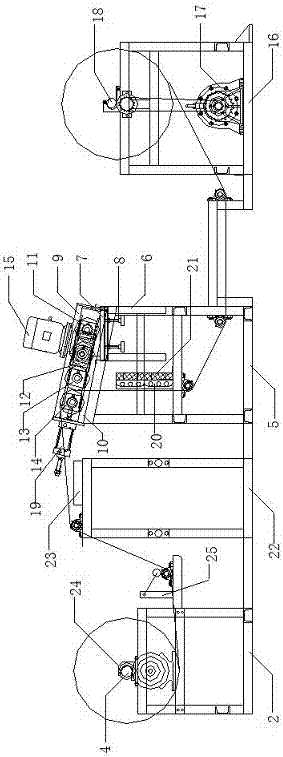

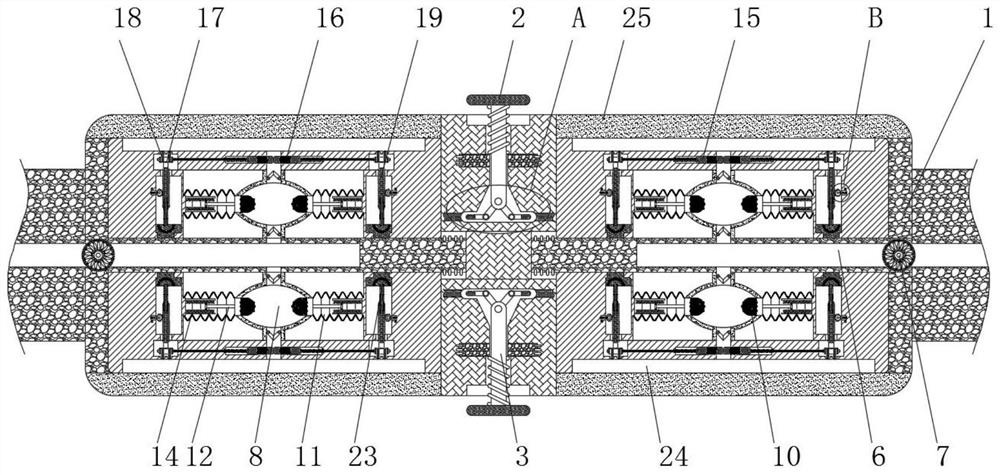

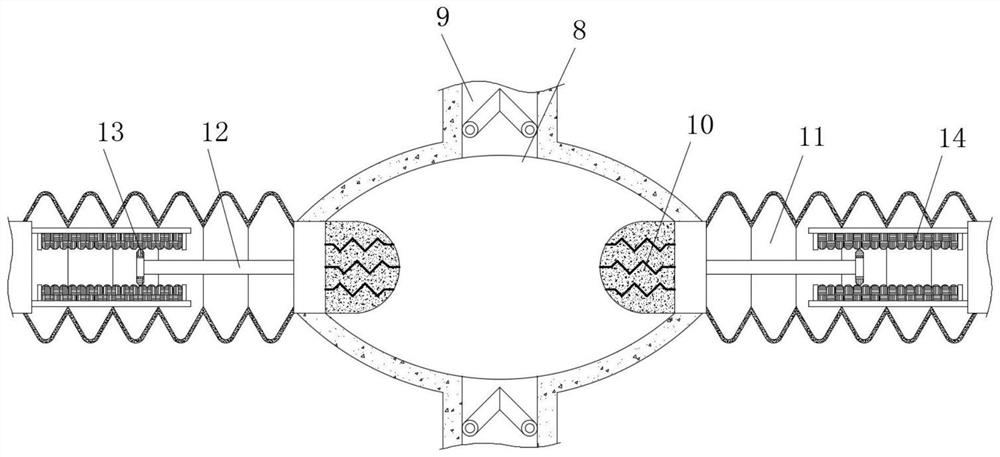

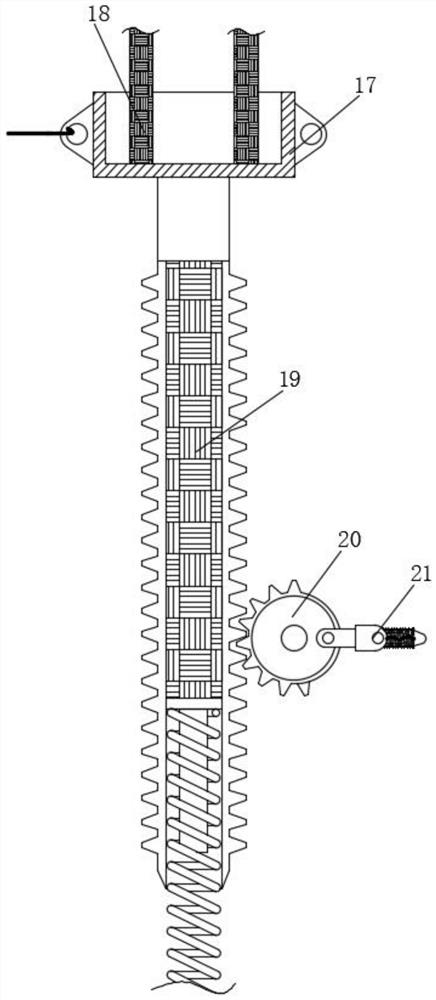

Shoe upper positioning line printing device for shoe-making

ActiveCN106476415APrinted clearlyEvenly printedInking apparatusScreen printersEngineeringConductor Coil

The invention relates to a shoe upper positioning line printing device, in particular to a shoe upper positioning line printing device for shoe-making. In order to solve the technical problems, the invention provides the shoe upper positioning line printing device for shoe-making, and the shoe upper positioning line printing device is obvious in printing, is uniform in printing and is high in printing speed. The shoe upper positioning line printing device comprises a workbench, a silk screen, a spray head, a first rack, a reduction motor, a first gear, a wire winding wheel, a first connecting rod, a second gear, a water pipe, a second connecting rod, and the like, wherein a first slide block is arranged at the left side inside a homocentric-square-shaped slide rail; the first rack is arranged at the right side of the first slide block; a second slide block is arranged at the right side inside the homocentric-square-shaped slide rail; and a second rack is arranged at the left side of the second slide block. The shoe upper positioning line printing device achieves the effects of obvious printing, uniform printing and high printing speed; and the device can be used to complete printing a shoe upper positioning line within short time, is clear in printing, and ensures product quality.

Owner:苏州盛泽科技创业园发展有限公司

Process of high-speed digital printing and interweaving of silks with gold and silver wires

ActiveCN105908498AThe effect of gold and silver is obviousPrint clearDuplicating/marking methodsBiochemical treatment with enzymes/microorganismsTextile printerEngineering

The invention discloses a process of high-speed digital printing and interweaving of silks with gold and silver wires. The process comprises the following steps of: (1) open-width scouring of a fabric; (2) sizing; (3) sizing temperature control, i.e., controlling a temperature within the range of 60-70 DEG C, in which after the temperature is within the range of 60-70 DEG C for sizing of gold and silver wires after thorough penetration of sizing of silks, a shelling effect may be produced on contact surfaces of a sizing agent with the gold and silver wires; (4) after ink-jet digital printing on the surface of the gold and silver wires, controlling an aging temperature to 80 DEG C, a humidity to 30%, a steam pressure to 2 kg and a speed per minute to 15 m / min, resulting in aggravated shelling degree due to ink jet on the surface of the gold and silver wires; (5) adding a detergent and carrying out open-width water washing at 60 DEG C to thoroughly peel a dye jetted on the gold and silver wires that is shelled by previous sizing and further shelled by aging, thus restoring the original effect of the gold and silver wires; (6) finishing and drying; and (7) tentering and softening to obtain the finished product. The process of high-speed digital printing and interweaving of silks with gold and silver wires can be used for solving the problems of unclear gold and silver wires and poor gold and silver effects after printing; the resulting silk-gold-silver wire fabric is clear in printing, lifelike, and very obvious in gold and silver effects.

Owner:ZHEJIANG QIANJIANG TEXTILE PRINTING & DYING CO LTD

Biaxially oriented white polypropylene film, reflection plate and receiving sheet for thermal transfer recording

InactiveUS20090208676A1Improve featuresIncrease production capacityMirrorsSynthetic resin layered productsProduction ratePolymer science

A biaxially oriented white polypropylene film containing a core layer (layer A) and a skin layer (layer B), said layer B is laminated at least on one surface of said layer A, wherein said layer A contains a polypropylene resin having β-crystal activity and 1 to 20 mass % particle (a) having an average dispersed diameter of 60 to 400 nm, and wherein, said layer B contains a polypropylene resin and 0.05 to 5 mass % particle (b) of an average dispersed diameter of 1 to 4 μm. The present invention provides a biaxially oriented white polypropylene film excellent in film quality and productivity and capable of making sensitivity and productivity compatible in a high level when used as a base for a receiving sheet, and a receiving sheet for thermal transfer recording made thereof.

Owner:TORAY IND INC

Water removing device for cable surface

InactiveCN103377777ASimple structureGood water removal effectConductor/cable markingAir pumpWaste management

The invention relates to a water removing device for cable surfaces. The water-removing device comprises a cable channel and a water remover. The cable channel is embedded in the water remover. An air chamber is arranged between the cable channel and the water remover. An airflow channel is arranged on the water remover, is communicated with the air chamber and is connected with an external air pump. A cable is arranged in the cable channel, and airflow is delivered into the air chamber via the airflow channel by the air pump so as to be uniformly delivered to the surface of the cable to remove water on the surface of the cable. Compared with similar products in the prior art, the water-removing device has the advantages of simple structure, convenience in application, wide application range, good water removing effect and the like.

Owner:SHANGHAI XINYI ELECTRICAL CIRCUIT EQUIP

Horizontal molding method and apparatus of interior material of vehicle

InactiveUS8568131B2Not to be folded or wrinkledPrint clearLaminationLamination apparatusEngineeringMechanical engineering

Horizontal molding method and apparatus of an interior material of a vehicle are provided. The horizontal molding apparatus includes a preheating means for preheating a skin material; a transfer unit including fixing units for vertically attaching or detaching the preheated skin material on or from the transfer unit; a first mold disposed perpendicularly to a ground surface and including suction units for vacuum-sucking and fixing edges of the skin material, a base member having an embossed pattern printed on the skin material, fixing members for sealing an internal space between the skin material and the base member, and vacuum holes for vacuum-sucking the skin material onto the base member; a second mold disposed in parallel with the first mold and on which a base material is injected; and a mold moving means for horizontally moving the first or second mold and combining or separating the first and second molds to or from each other.

Owner:HAN IL E HWA CO LTD

Printing method for plastic packaging bag

InactiveCN108081749ANot easy to fall offImprove printing effectInksRotary pressesCross-linkComposite film

The invention provides a printing method for a plastic packaging bag. The method includes the steps that a thin film A is coated with an adhesion agent under the action of a compression roller and then is put into a drying apparatus to be dried, and the drying temperature is 46-50 DEG C; the dried thin film A is bonded with a thin film B under the action of the compression roller so that a composite film can be formed, the composite film passes through the gap between a discharge tool rest and a blade, and a high-frequency and high-voltage power source is used for generating corona so that thecomposite film can be subjected to surface treatment; a printing area of the composite film is preheated, and the preheating temperature is 40-50 DEG C; a reverse image-text printing plate is adoptedto transfer printing ink onto the surface of the printing area of the composite film; ultraviolet rays are used for irradiating the printing ink of the printing area, so that the printing ink and thecomposite film are subjected to a cross-linking reaction; the composite film irradiated by the ultraviolet rays is put into a reaction still, the intensity of pressure is set to be 2-5MPa, the temperature is set to 4-8h, stable curing is performed, and the time is 3h; and the thin films are fed into a curing chamber to be subjected to a curing reaction. When the technology is adopted to produce the plastic packaging bag, the advantages of being good in printing firmness and clear in printing effect are achieved.

Owner:澧县津溥包装制品有限责任公司

Production method of building material decorating film

ActiveCN103772730AImprove flexibilityImprove waterproof performancePolyurea/polyurethane coatingsTemperature controlPolyvinyl chloride

The invention relates to a production method of a building material decorating film. The production method comprises the following steps: firstly, preparing materials; secondly, dissolving polyurethane resin and preparing separating liquid; thirdly, carrying out high-precision chromatic temperature control printing; and fourthly, coating a chemical separation layer on the bottom surface of a base film. The produced building material decorating film is of a three-layer laminated structure, wherein the middle layer which is a polyvinyl chloride and polypropylene mixed plastic film layer is used as a base film layer; a polyurethane separation liquid coating is arranged at the bottom of the base film layer; and an ink printing layer is arranged at the top of the base film layer. The building material decorating film produced by the method has strong flexibility and good water-proof performance and mildew resistance, expands varieties of building materials to which the decorating film is applied; in addition the decorating film is also adhered to woods, bamboo woods, plastics and artificial wood boards as well as metal, cement and other materials, and has the advantages of wide application range and clear printing effect; and when a coiled product is uncoiled, the front surface and the back surface of the film are not bonded together, the simulating texture is strong, and the building material decorating film is particularly as applicable to wood grain imitated boards with concavo and convex grains.

Owner:ZHEJIANG SHENGLONG DECORATION MATERIAL

Printing machine for back flocked sand paper

ActiveCN107225852AGuaranteed normal printingAvoid print quality degradationRotary pressesPrinting press partsElectric machinerySand-paper

The invention provides a printing machine for back flocked sand paper. The printing machine sequentially comprises a feeding mechanism, a printing mechanism and a winding mechanism in the advancing sequence of the sand paper and further comprises guide rollers; the feeding mechanism comprises a feeding rack and a feeding shaft; the printing mechanism comprises a printing rack, an ink duct support, an ink duct and a printing piece; the winding mechanism comprises a winding rack, a winding motor and a winding shaft; and the guide rollers are distributed between the feeding mechanism and the printing mechanism and between the printing mechanism and the winding mechanism. With the printing machine, efficient and stable printing can be performed under the condition that the use performance of the back flocked sand paper and back flocked sand cloth is not affected; an ink transfer roller is added, so that clear printing can be guaranteed, and meanwhile, reduction of the printing quality due to relatively much ink can be avoided; the drying efficiency after printing is completed can be remarkably improved, and thus the overall printing quality can be guaranteed; and the printing machine is novel in structure and suitable for popularization and use.

Printing and dyeing roller capable of avoiding color non-uniformity and liquid leakage

PendingCN112813622AAvoid uneven colorPrevent leakageTextile treatment machine arrangementsTextile treatment rollersTextile manufacturingTextile printer

The invention relates to the technical field of textile manufacturing, and discloses a printing and dyeing roller capable of avoiding color non-uniformity and liquid leakage. The printing and dyeing roller comprises a rack; a pressing plate is movably connected to the center of the side surface of the rack; a pressing rod is fixedly connected to the bottom of the pressing plate; a metal feeler lever is rotatably connected to the end, far away from the pressing plate, of the pressing rod; a metal strip is fixedly connected to the side face, close to the metal feeler lever, of the rack; a liquid inlet groove is formed in the circle center of the rack; a water pump is fixedly connected to the interior of the liquid inlet groove; and an elastic cavity is movably connected to the interior of the rack. The pressing plate is pressed, so that a dye solution in the elastic cavity in the side can enter a liquid cavity and is pad-dyed on the surface of cloth through a pressing roller; and a liquid conveying opening can be automatically closed on the non-pressed side of the pressing plate, so that the internal solution is prevented from flowing out, and the effects that a liquid outlet can be automatically closed, the surface of the cloth is prevented from being polluted due to overflow of the internal solution and printing is clearer are achieved.

Owner:海宁市骄阳旗材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com