Surface printing device for coal mine cabtyre cables

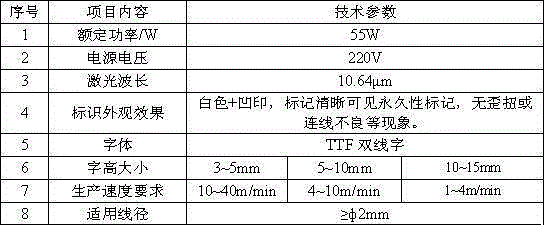

A technology for cables and coal mines, which is applied in the field of surface printing devices for rubber-sheathed cables used in coal mines. It can solve the problems that thermal embossing printing technology cannot be realized, and achieve the effects of low cost of use, clear printing content, and clear and complete printing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

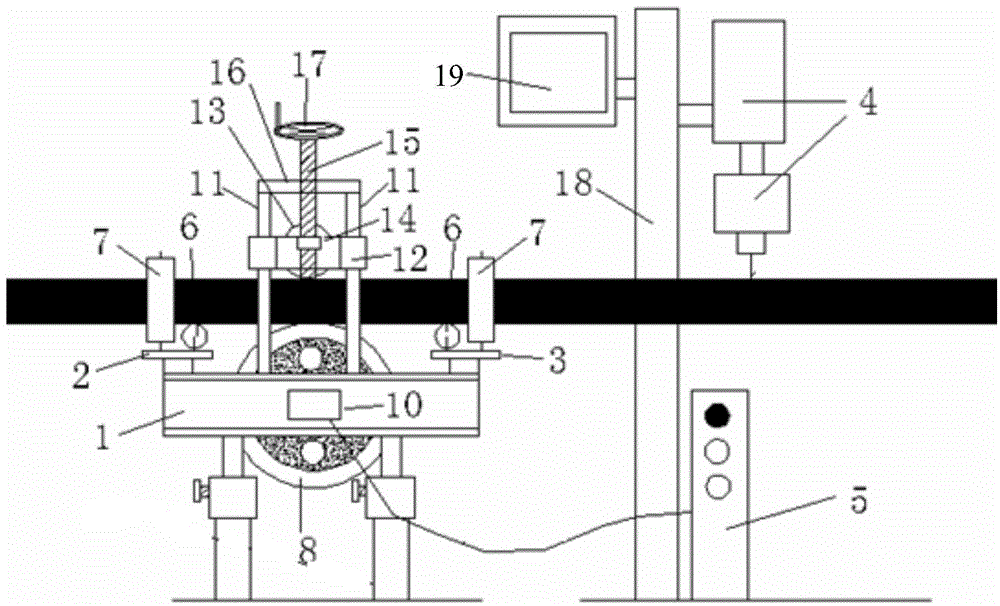

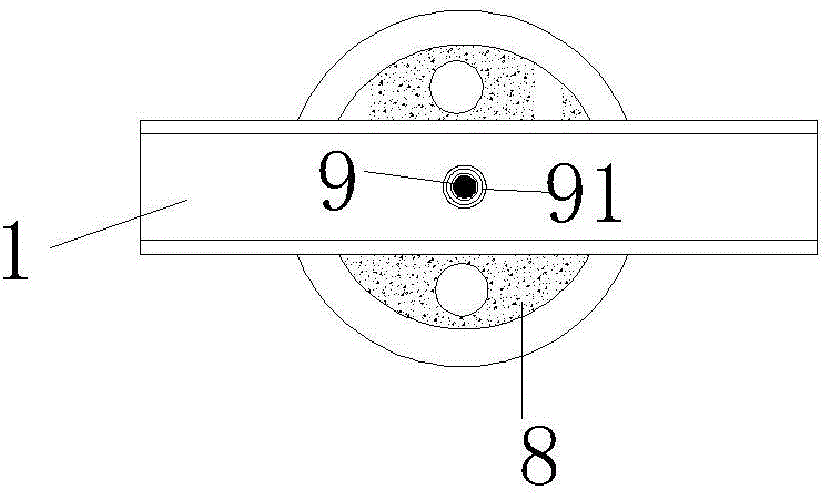

[0014] Embodiment: A surface printing device for rubber-sheathed cables used in coal mines, including a side base plate 1, a front support plate 2, a rear support plate 3, a laser generator 4, a control panel 19 and a host 5, and the side base plate 1 is left Front support plate 2 and rear support plate 3 are respectively fixed on the front end and rear end of the side. Pulleys 6 and 2 positioning pulleys 7 are respectively located at the two ends of pulley 6 on the upper surfaces of front support plate 2 and rear support plate 3. Between the two positioning wheels 7 and on the pulley 6, a tachometer wheel 8 is located between the front support plate 2 and the rear support plate 3 and its center is fixed on one end of the support shaft 9, and the support shaft 9 is installed on the On the side substrate 1, a meter sensor 10 is installed at the other end of the support shaft 9, and the meter sensor 10 is used to convert the speed of the tachometer wheel 8 into a length electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com