Patents

Literature

36results about How to "Guaranteed normal printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

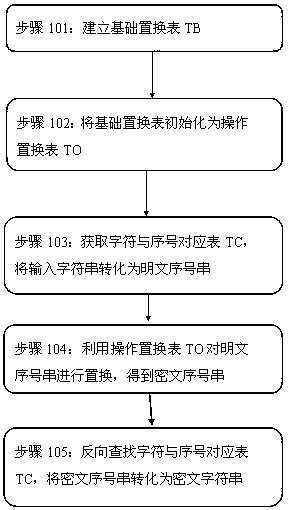

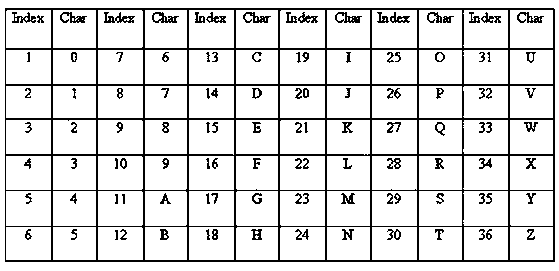

Encryption method and?device

ActiveCN103825723AAccelerateImplement encryptionEncryption apparatus with shift registers/memoriesVisibilityComputer hardware

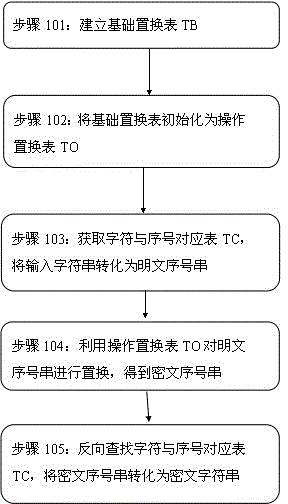

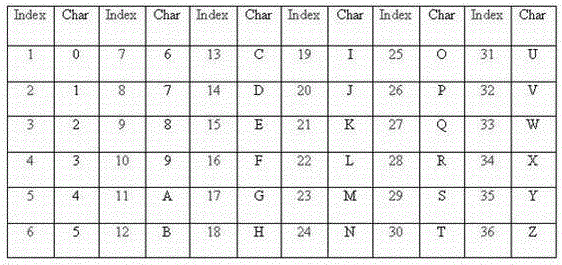

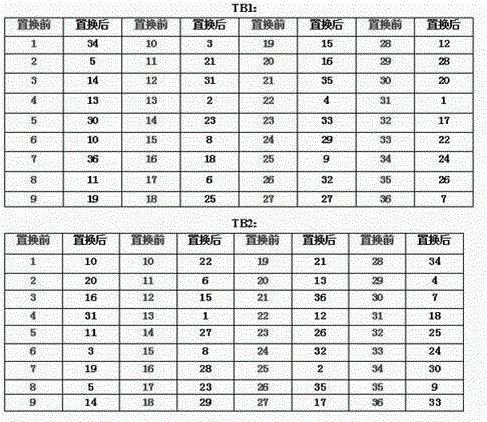

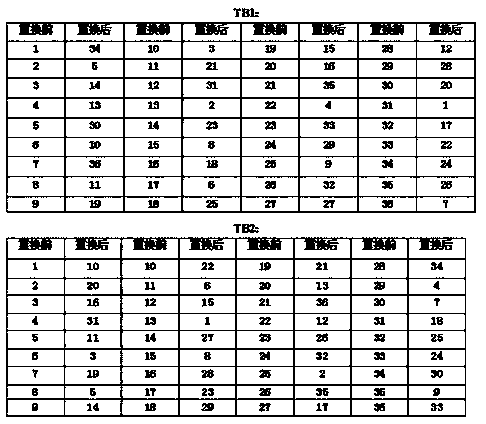

The invention discloses an encryption method based on characters. The method comprises steps of building a basic transposition table?TB and using a secret key to initialize the basic transposition table to an operation transposition table?TO, converting an input character string into a plaintext sequence number string according to a pre-defined character and sequence number corresponding?table TC, using the operation transposition table?TO for carrying out transposition on the plaintext sequence number string to obtain a ciphertext sequence number string, and converting the ciphertext sequence number string into a ciphertext character string. According to the method, a character?position services as a basic processing unit, dynamic variable data length encryption is realized, length?consistency and?visibility of the ciphertext and the plaintext can be ensured, and platform adaptability and high calculation efficiency are realized.

Owner:深圳市太和物联信息技术有限公司

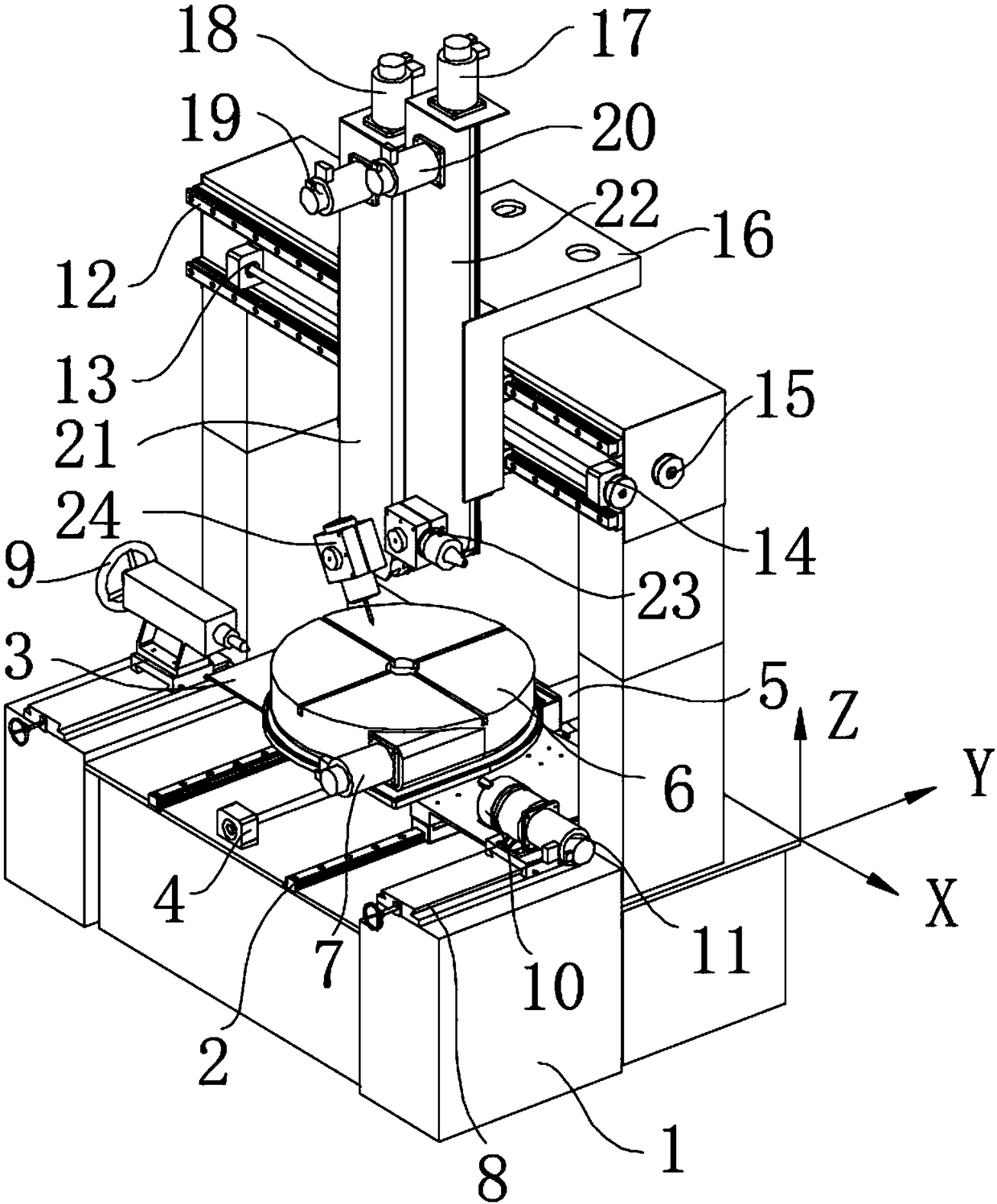

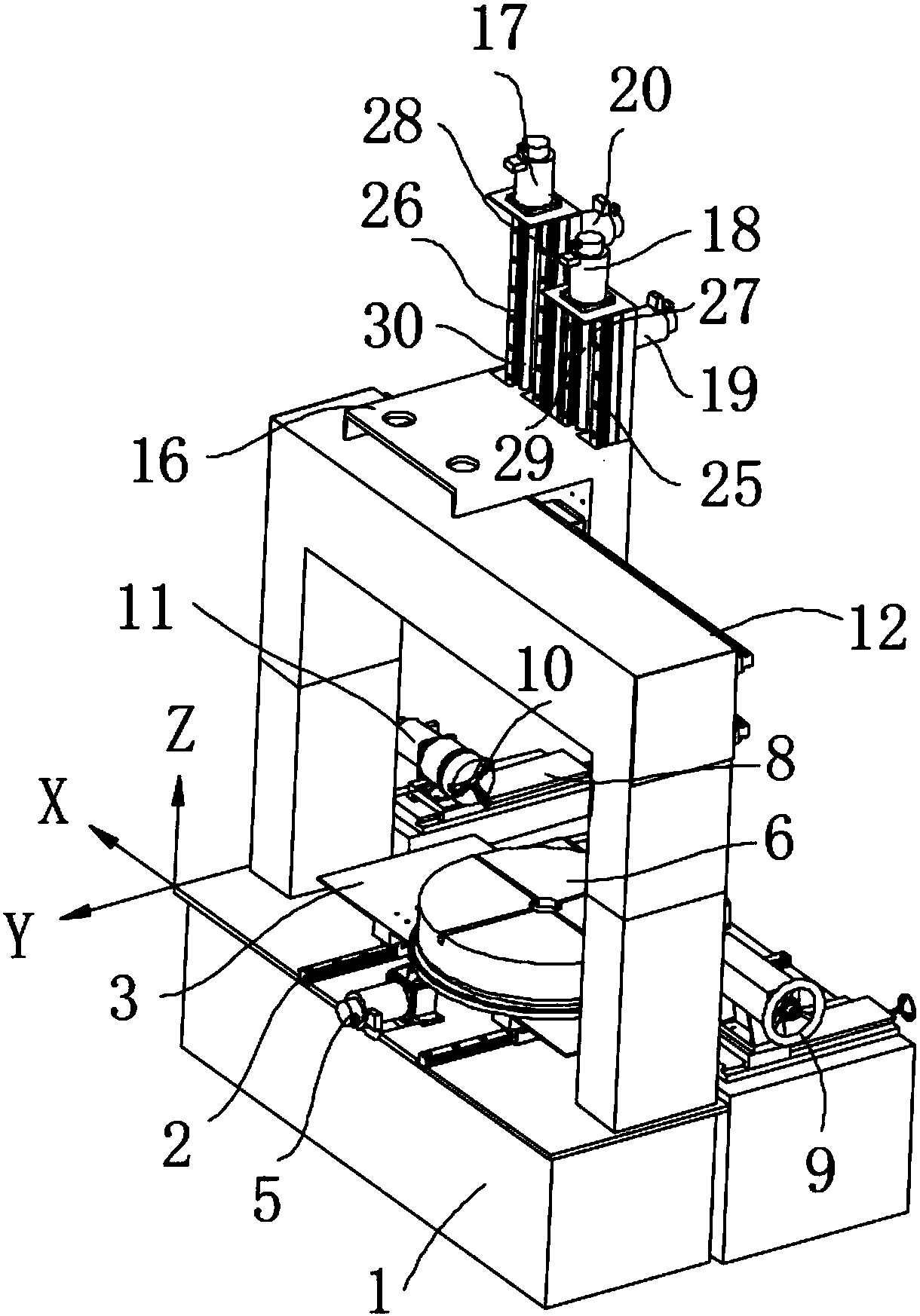

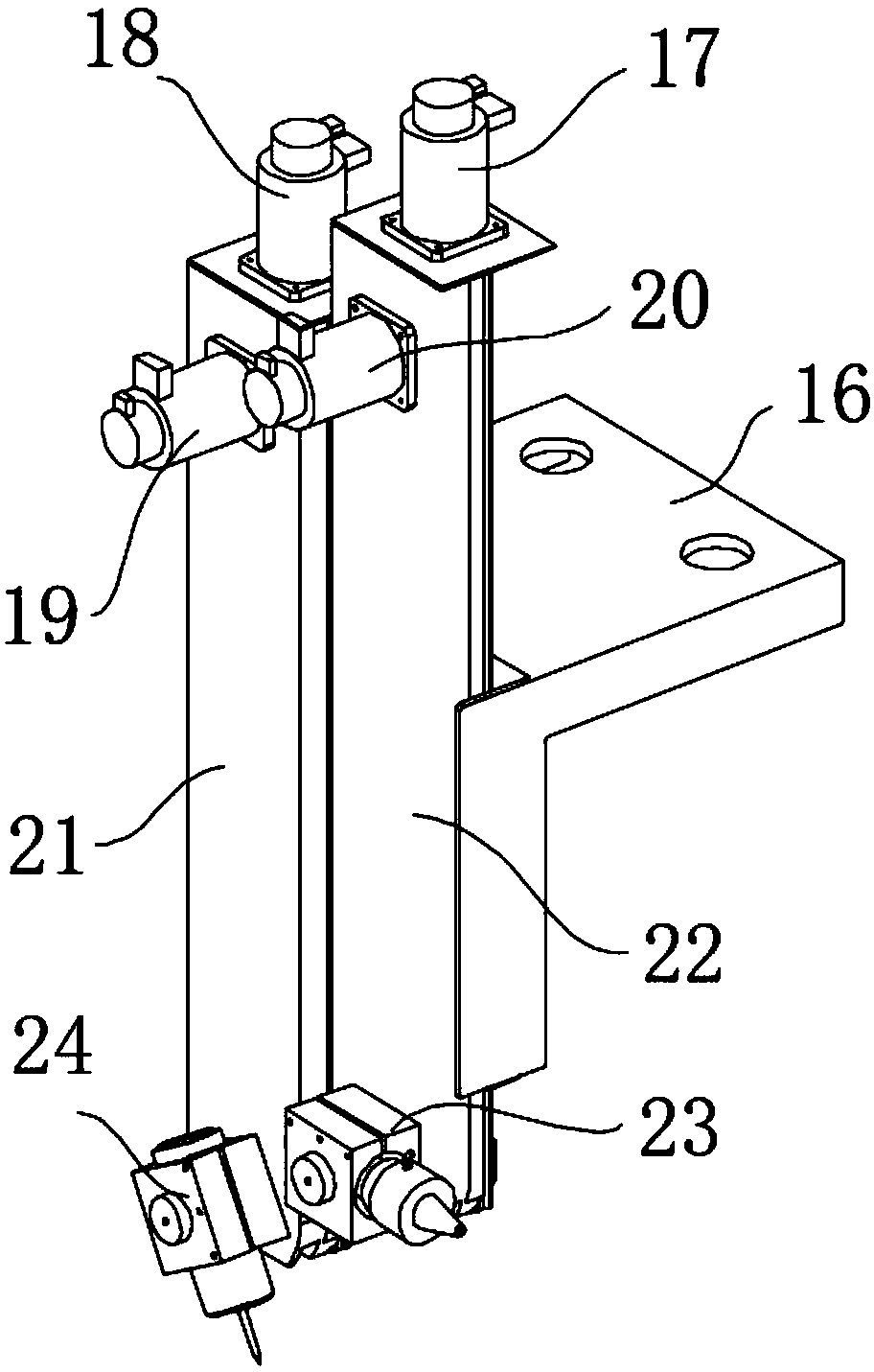

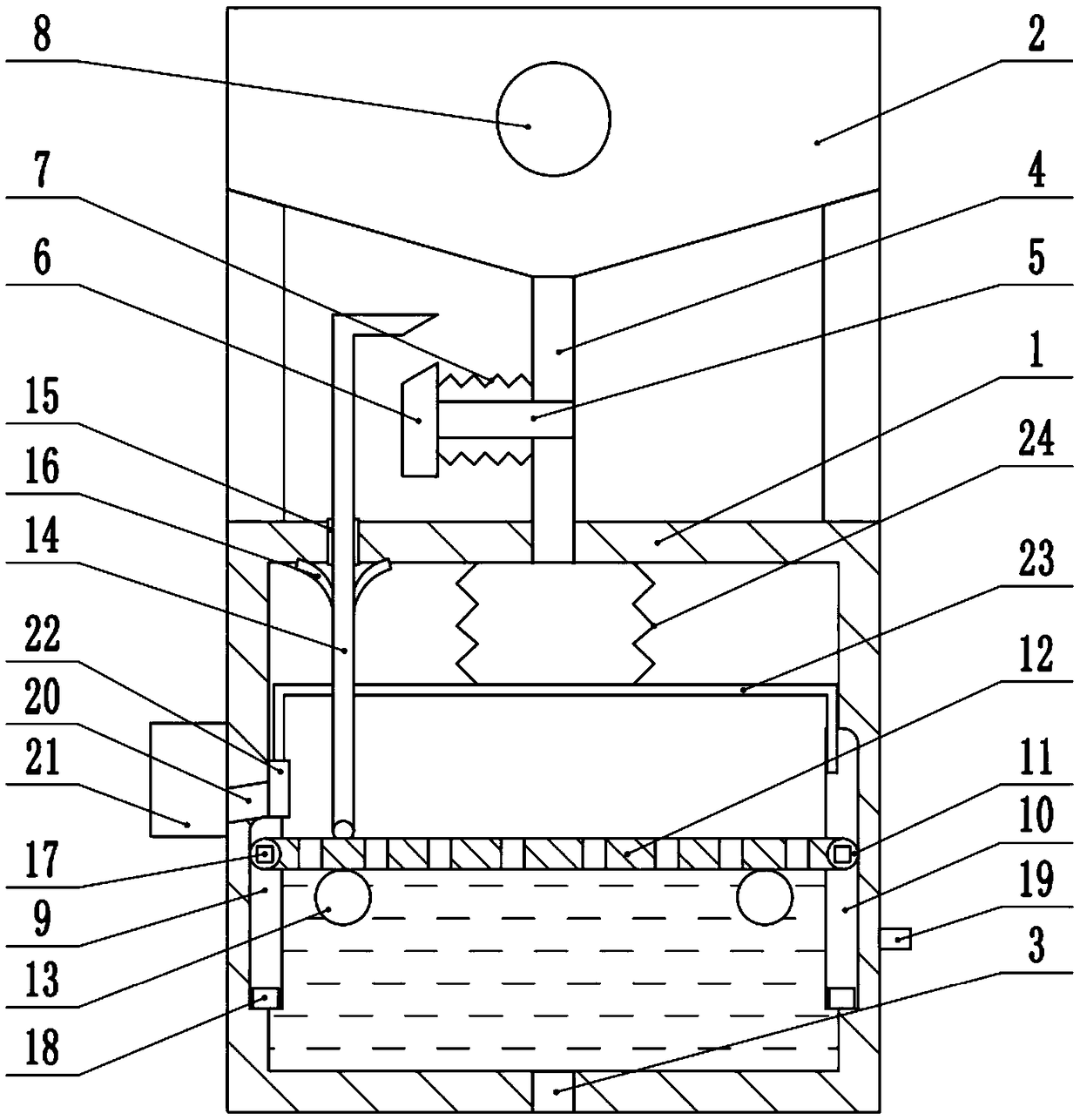

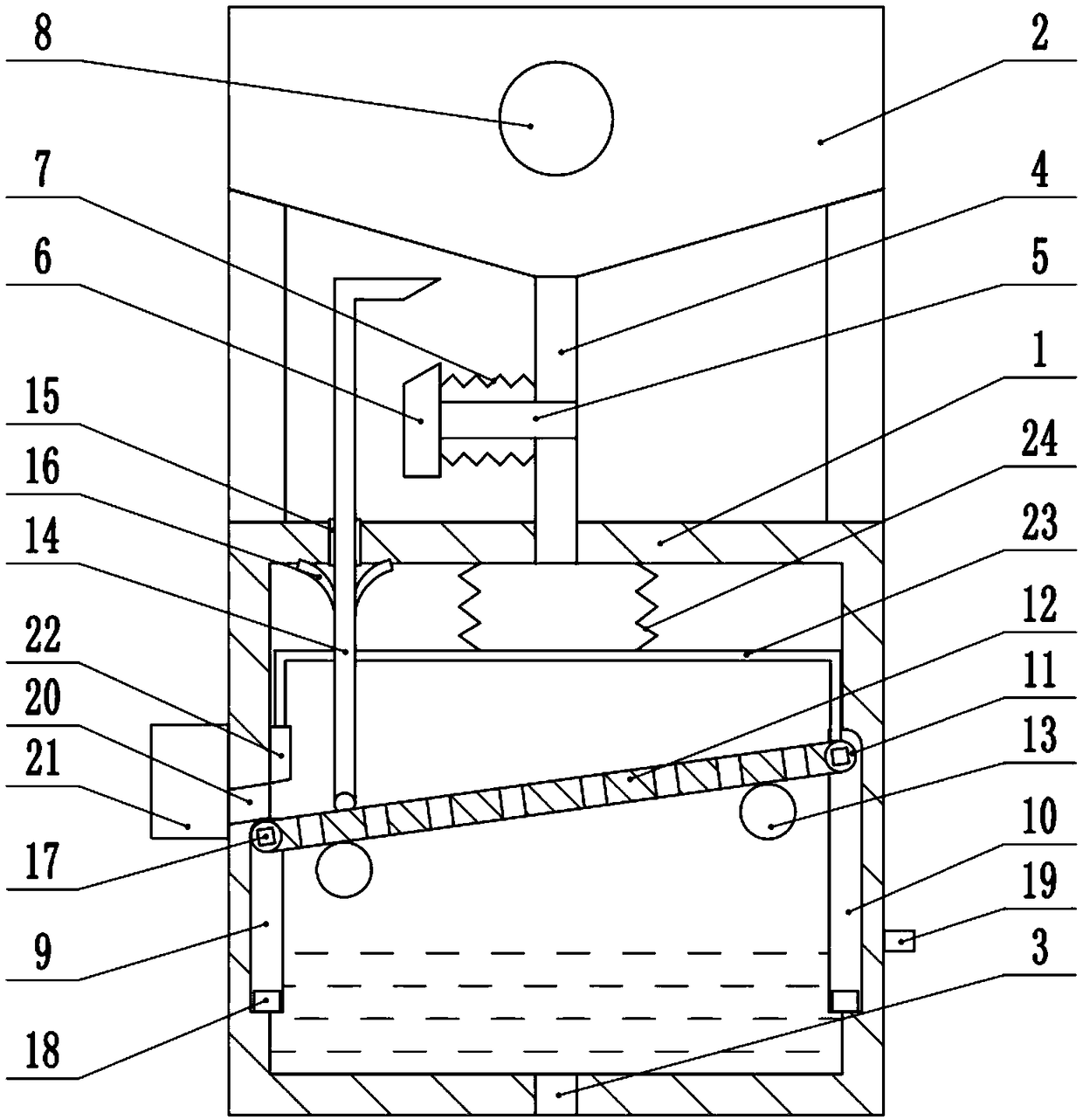

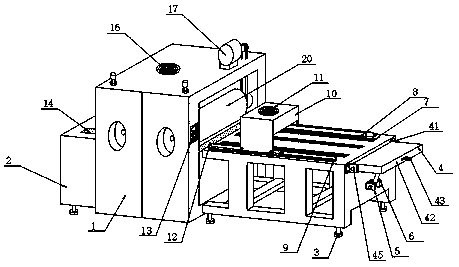

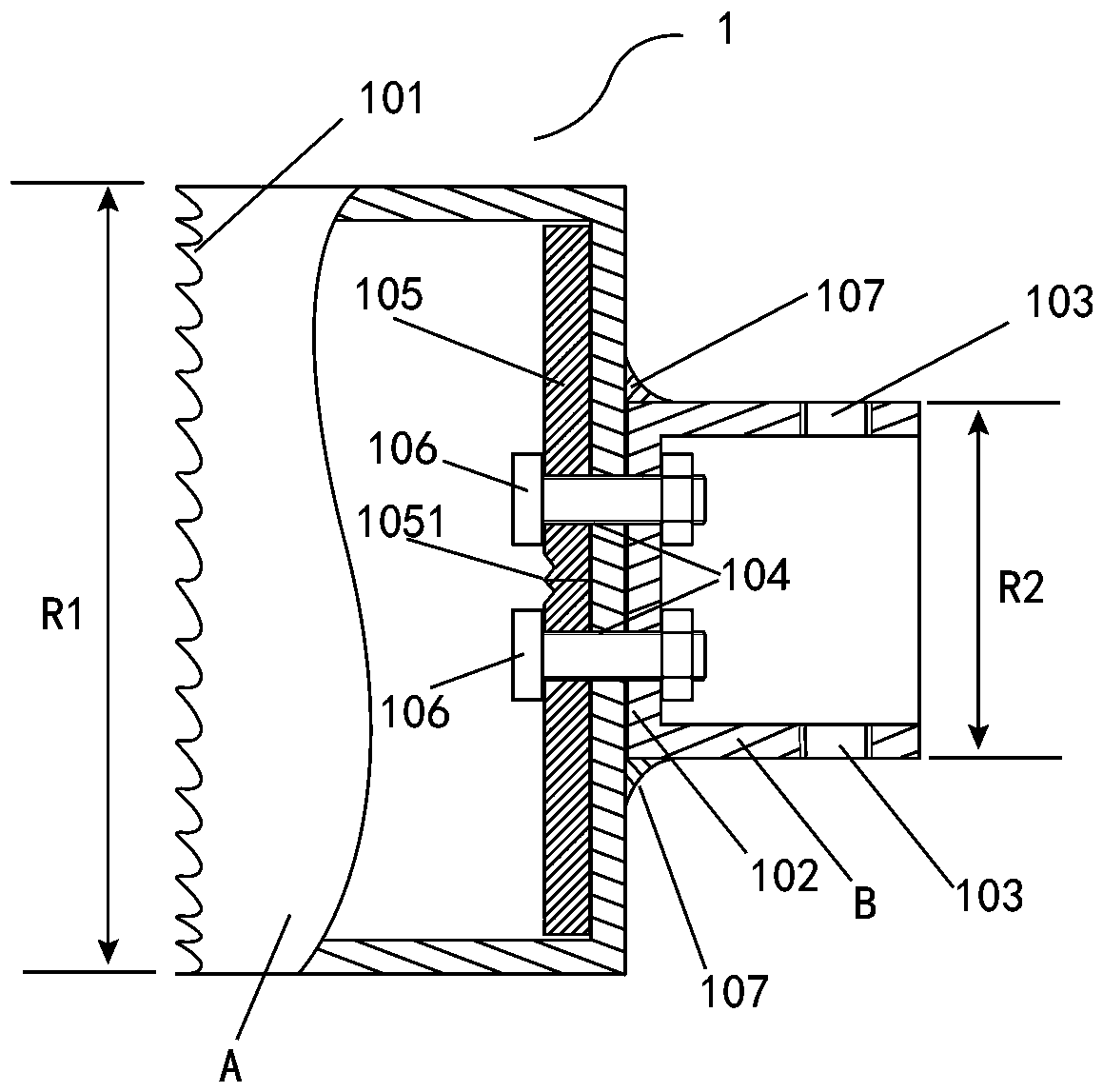

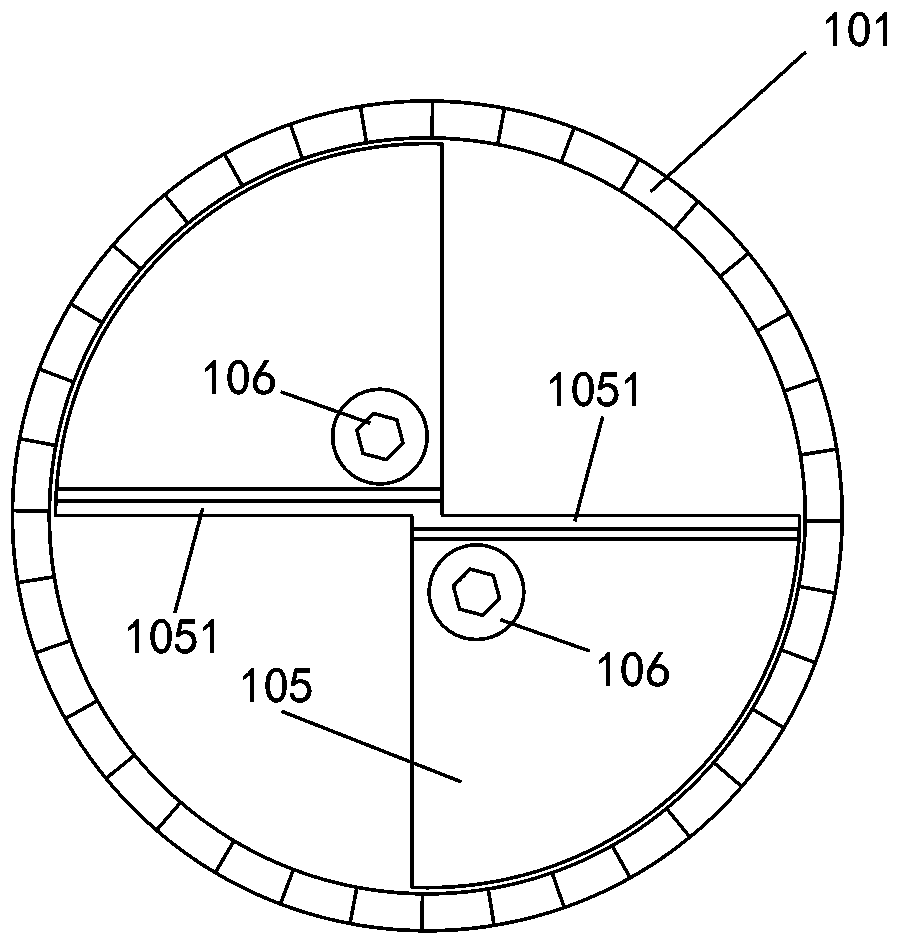

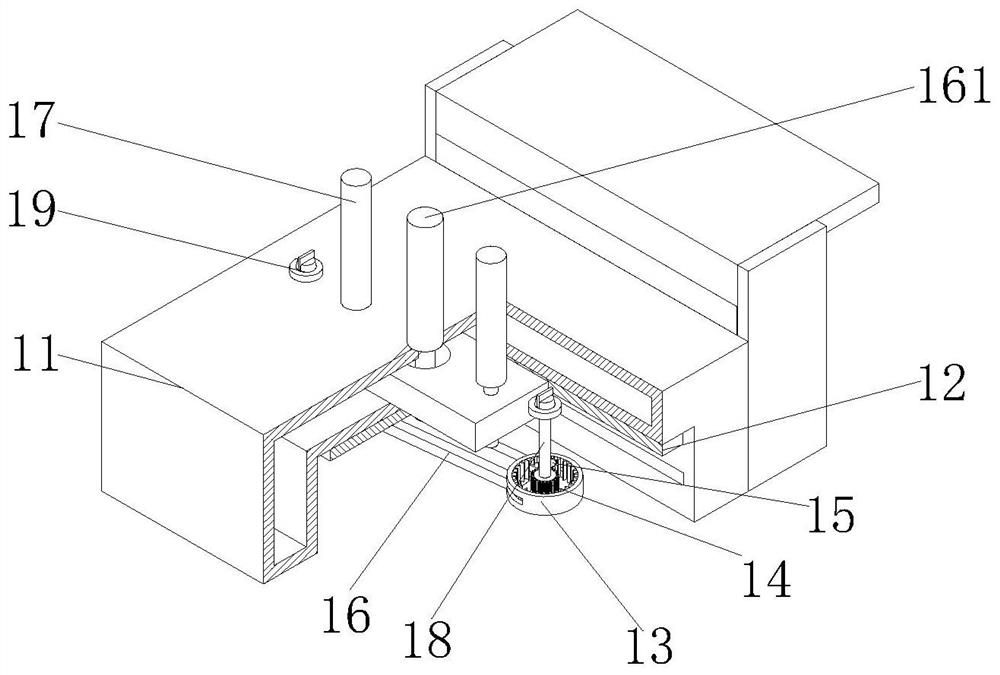

Additive and subtractive laser process machine tool and using method thereof

InactiveCN109351967AGuaranteed accuracyGuaranteed continuous supplyAdditive manufacturing apparatusIncreasing energy efficiencyMachine toolMachining

The invention discloses an additive and subtractive laser process machine tool. The laser process machine tool comprises a machine tool base, two Y-axis ball linear guide rail pairs are arranged on the left side and the right side of the top surface of the machine tool base in parallel, and a Y-axis moving platform is movably arranged on the two Y-axis ball linear guide rail pairs. The invention further discloses a using method of the additive and subtractive laser process machine tool, a first lifting servo motor and a second lifting servo motor operate in the Z-axis direction to drive a cutting machining head and a laser cladding head, the machining height of the cutting machining head and the machining height of the laser cladding head are adjusted, and the operation is coordinated to ensure the printing of the machine tool in a working region. According to the additive and subtractive laser process machine tool and the using method thereof, a first servo motor on the machine tool base operates to drive a rotary circular workbench on the Y-axis moving platform to move in the Y-axis direction to adjust printing positions; a rotary servo motor operates to drive the rotary circularworkbench to rotate angles to adjust the printing direction; and dovetail groove guide rails are installed on the machine tool base in the X-axis direction, and machine tool locking devices are arranged on the guide rails so as to lock shaft type workpieces.

Owner:江苏尤尼特激光智能装备有限公司

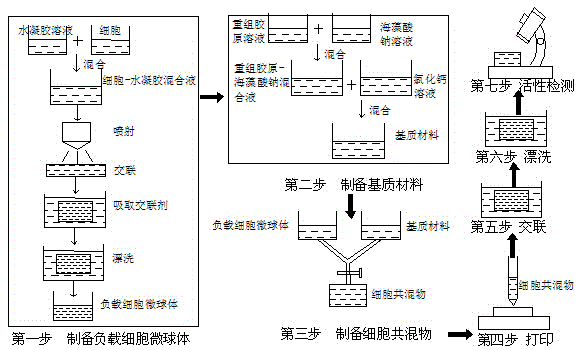

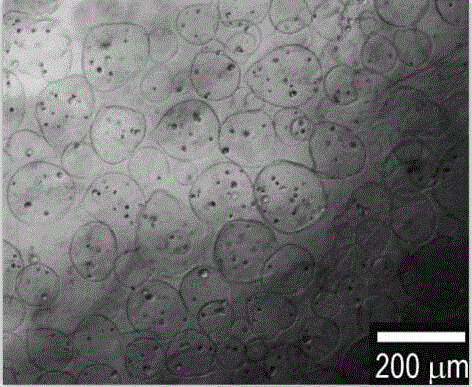

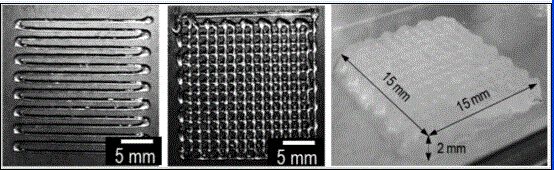

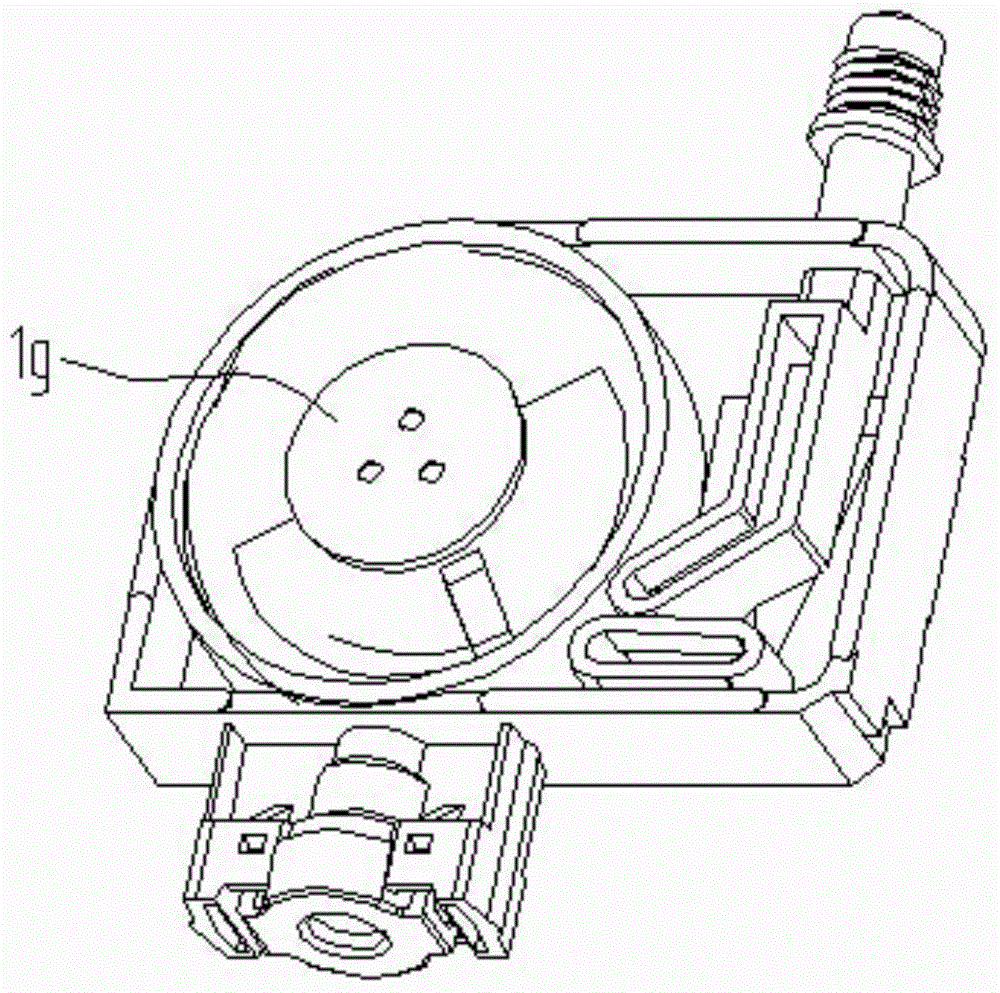

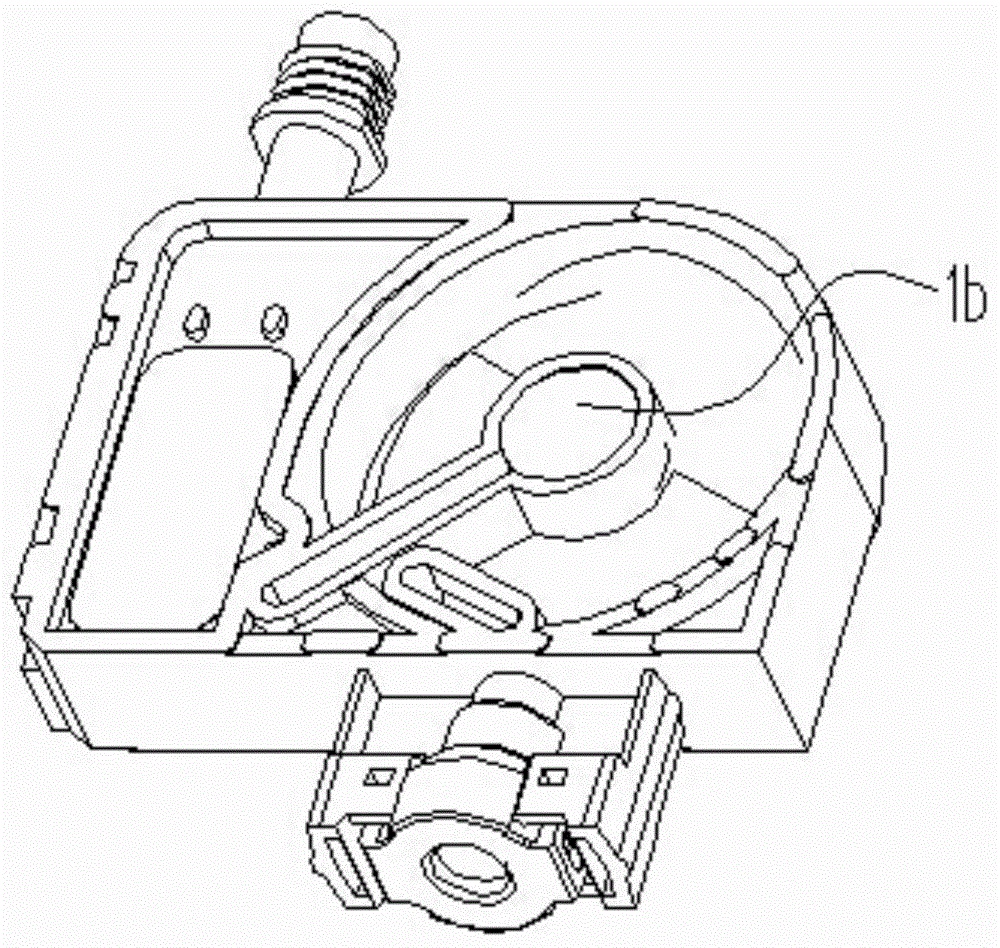

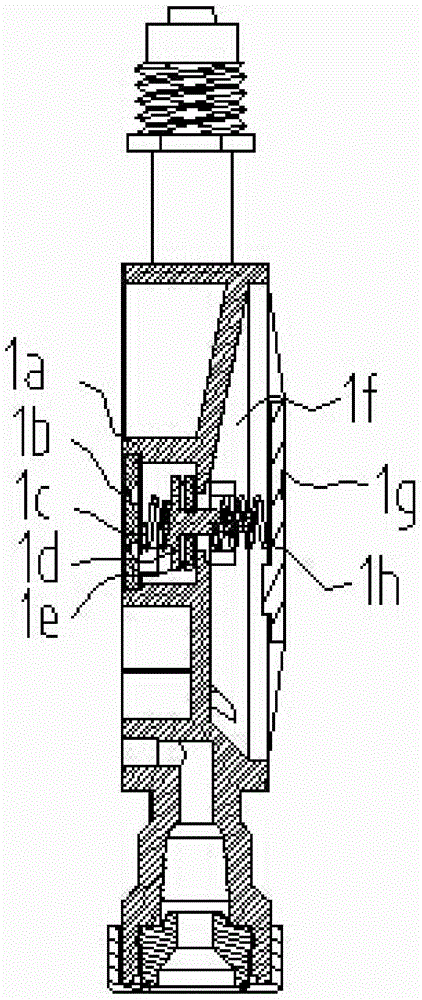

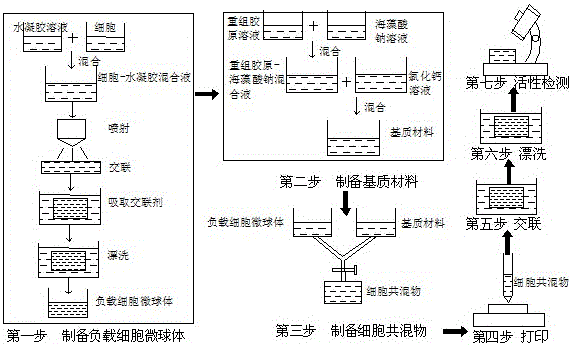

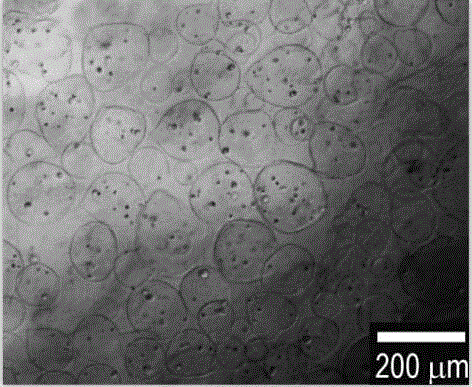

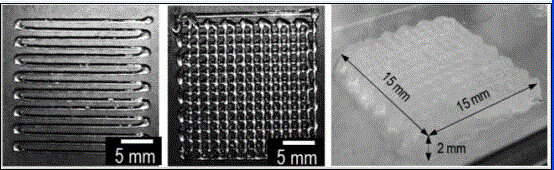

Preparation method and application of cell-loading three-dimensional support

The invention provides a preparation method of a cell-loading three-dimensional support. The preparation method of the cell-loading three-dimensional support is characterized by comprising the following steps: uniformly mixing autologous cells with a high temperature intermittently sterilized hydrogel solution to obtain mixed liquor, injecting the mixed liquor into a crosslinking agent solution, standing, then removing the crosslinking agent solution, and rinsing, so that cell-loading microspheres are obtained; mixing the cell-loading microspheres with a matrix material to obtain cell blend; and extruding the cell blend onto a three-dimensional micro-positioning platform carrying a sterile glass base plate by adopting a biological printer, and overlaying layer by layer, so that the cell-loading three-dimensional support is formed. The preparation method of the cell-loading three-dimensional support has the advantages that damage on cellular activity and bioactivity in a cell printing process is reduced, and high-activity cell printing is guaranteed.

Owner:深圳尤尼智康医疗科技有限公司

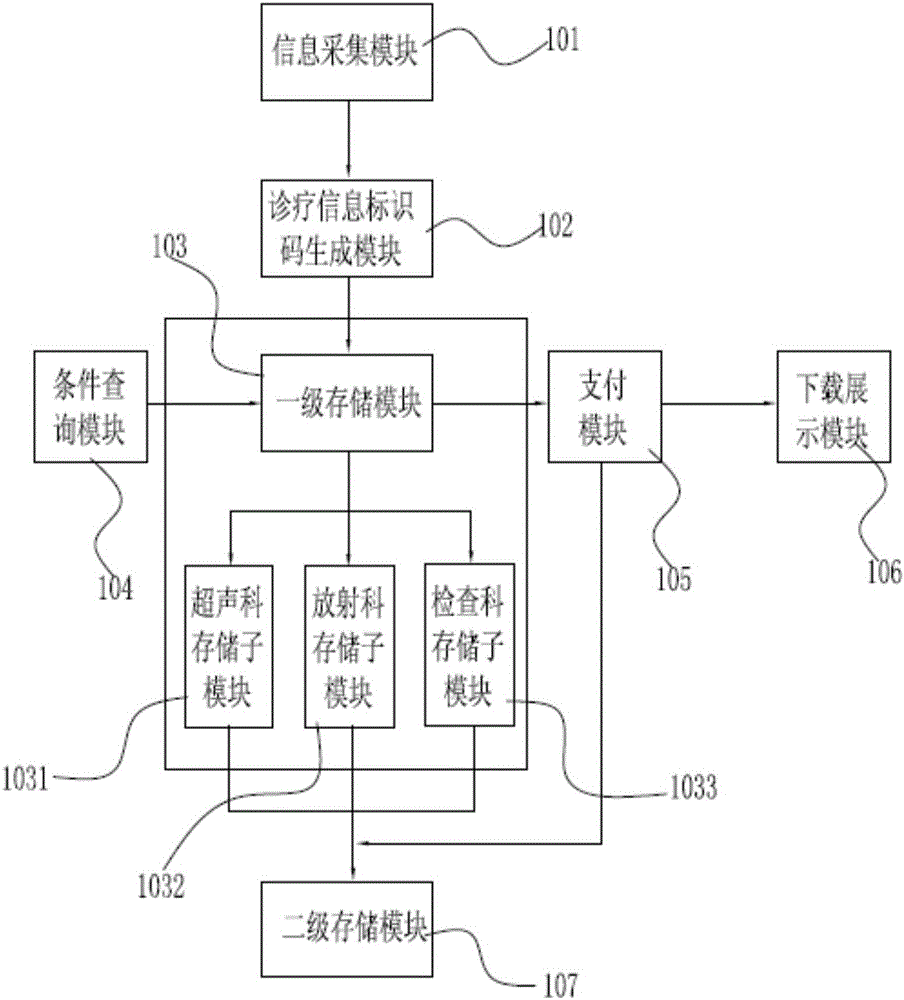

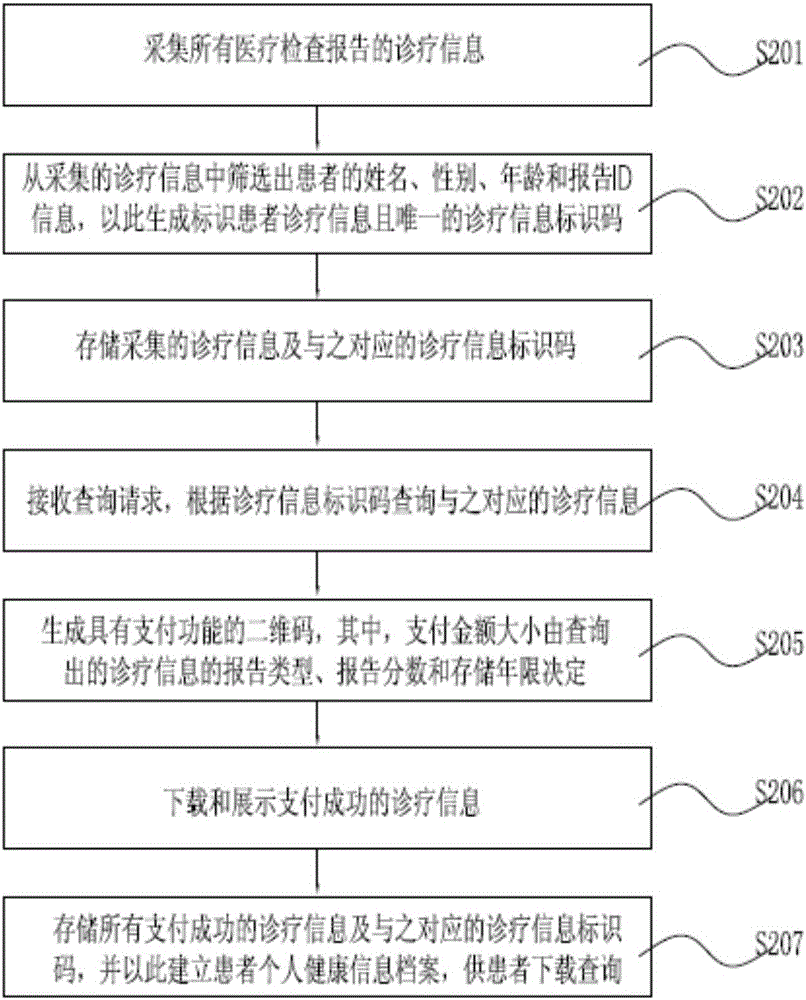

Cloud storage management system and method for medical examination reports

InactiveCN106021878AGuaranteed normal printingDo not change the operation processSpecial data processing applicationsMedical reportsPaymentCloud storage

The invention discloses a medical examination report cloud storage management system, comprising: an information collection module for collecting diagnosis and treatment information; a diagnosis and treatment information identification code generation module for generating a unique diagnosis and treatment information identification code for identifying patient diagnosis and treatment information; The storage module is used to store the collected diagnosis and treatment information and the corresponding diagnosis and treatment information identification code; the condition query module is used to query the corresponding diagnosis and treatment information according to the diagnosis and treatment information identification code; the payment module is used to generate the payment function. Two-dimensional code; download display module, used to download and display the diagnosis and treatment information of successful payment; secondary storage module, used to establish patients' personal health information files for patients to download and query. The invention also discloses a medical examination report cloud storage management method.

Owner:CHENGDU KNOT MEDICAL TECH

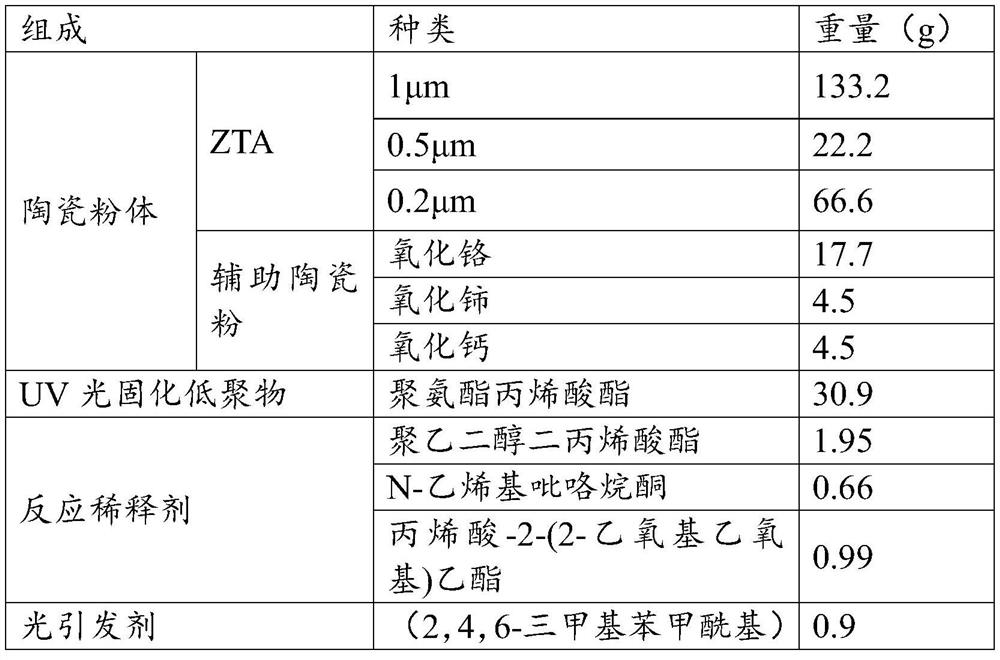

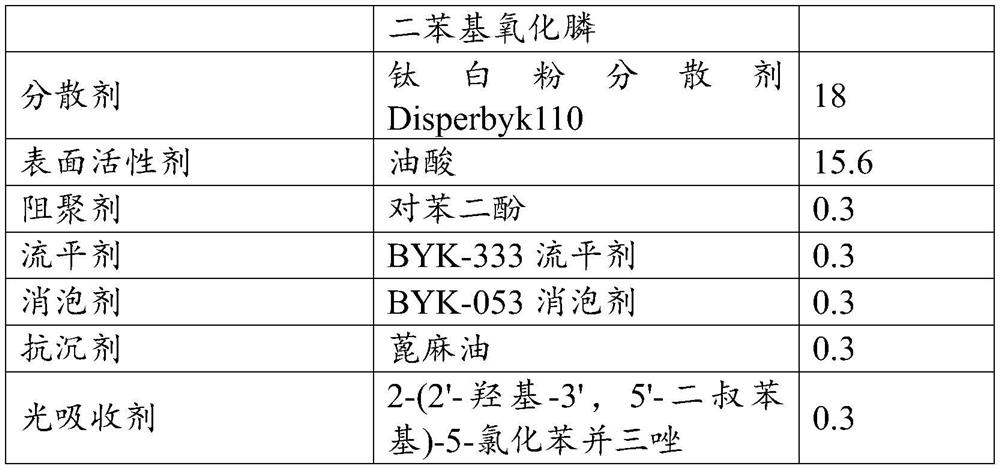

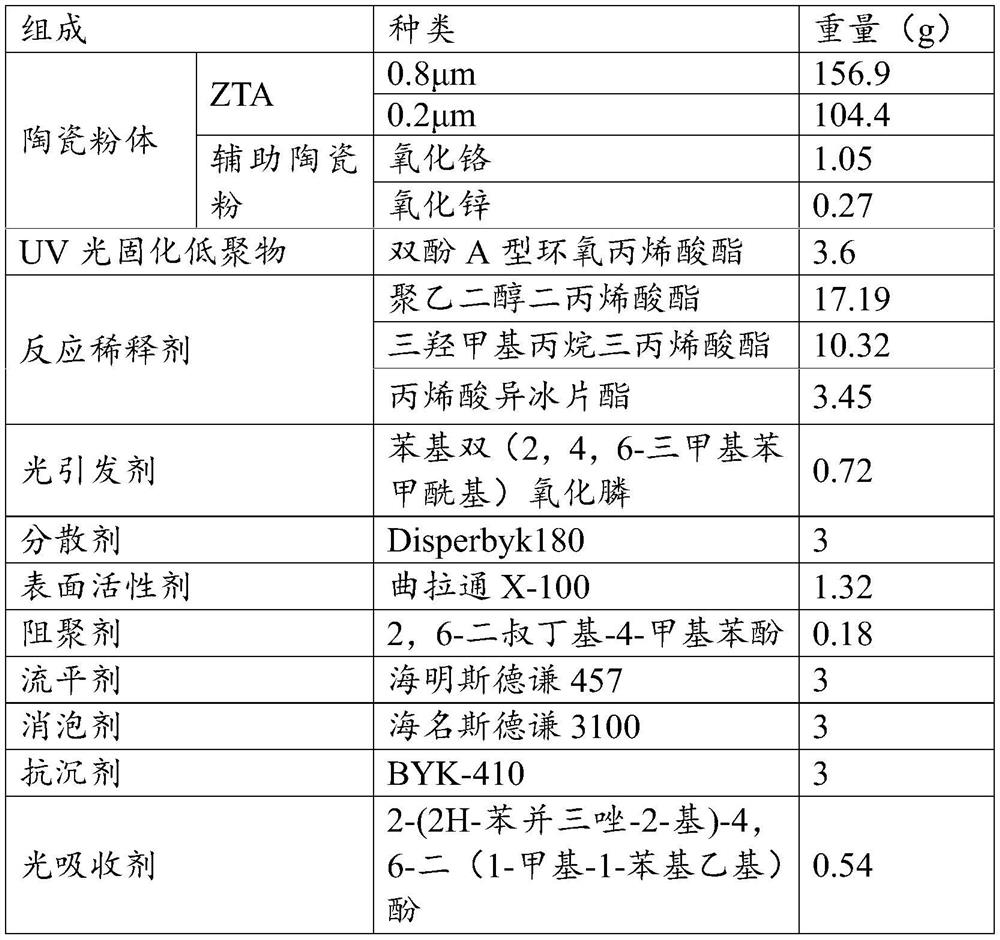

Preparation method of ceramic material

ActiveCN114380583AHigh hardnessHigh densityAdditive manufacturing apparatusCeramic shaping apparatusOxide ceramicAluminum Ion

The invention belongs to the technical field of ceramics, and provides a preparation method of a ceramic material, which comprises the following steps: degumming a zirconium oxide toughened aluminum oxide ceramic blank, pre-sintering, soaking in steeping liquor and sintering, wherein the impregnation liquid comprises a zirconium ion salt solution, an aluminum ion salt solution and urea. According to the preparation method of the ceramic material, the mixed solution of the zirconium ion salt solution, the aluminum ion salt solution and the urea is adopted as the steeping liquor to carry out post-treatment on the zirconium oxide toughened aluminum oxide ceramic green body, the compactness of the ceramic material is improved, and the defect that a ceramic product prepared through a traditional 3D printing technology is low in hardness is overcome.

Owner:重庆恩辰新材料科技有限责任公司 +1

Improved ink cartridge

InactiveCN108839441ANo need to discard frequentlyRealize automatic ink fillingPrintingEngineeringElectromagnet

The invention relates to the technical field of printer equipment, and discloses an improved ink cartridge. The improved ink cartridge comprises a main ink cartridge and an auxiliary ink cartridge. Anink outlet is formed in the main ink cartridge, an ink guide pipe is arranged between the main ink cartridge and the auxiliary ink cartridge in a communicating mode, a valve is arranged on the ink guide pipe, a wedge block is fixedly connected to the valve, and a first spring is connected between the wedge block and the ink guide pipe. The main ink box is internally provided with a first slidinggroove and a second sliding groove, the length of the second sliding groove is greater than the length of the first sliding groove, slide blocks are slidably connected into the first sliding groove and the second sling groove, filter plates are fixedly connected between the slide blocks, floating balls are fixedly connected to the filter plates, and wedge bars are hinged to the filter plates. Theslide blocks are provided with magnets, the bottoms of the first sliding groove and the second sliding groove are fixedly connected with electromagnets, the main ink cartridge is provided with a switch, the main ink cartridge is provided with a impurity outlet, the impurity outlet communicates with a waste box, a baffle is slidably connected into the main ink cartridge, a transmission rod is fixedly connected to the baffle, and a second spring is connected between the transmission rod and the main ink cartridge. The improved ink cartridge can automatically add ink and remove impurities.

Owner:贵州省仁怀市西科电脑科技有限公司

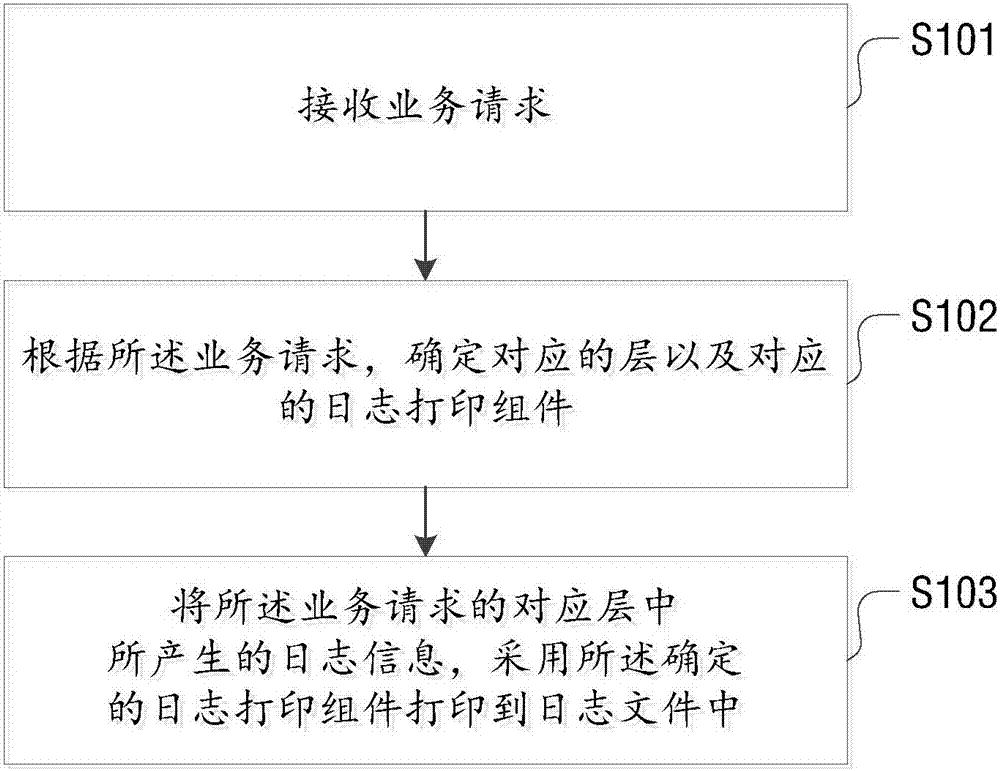

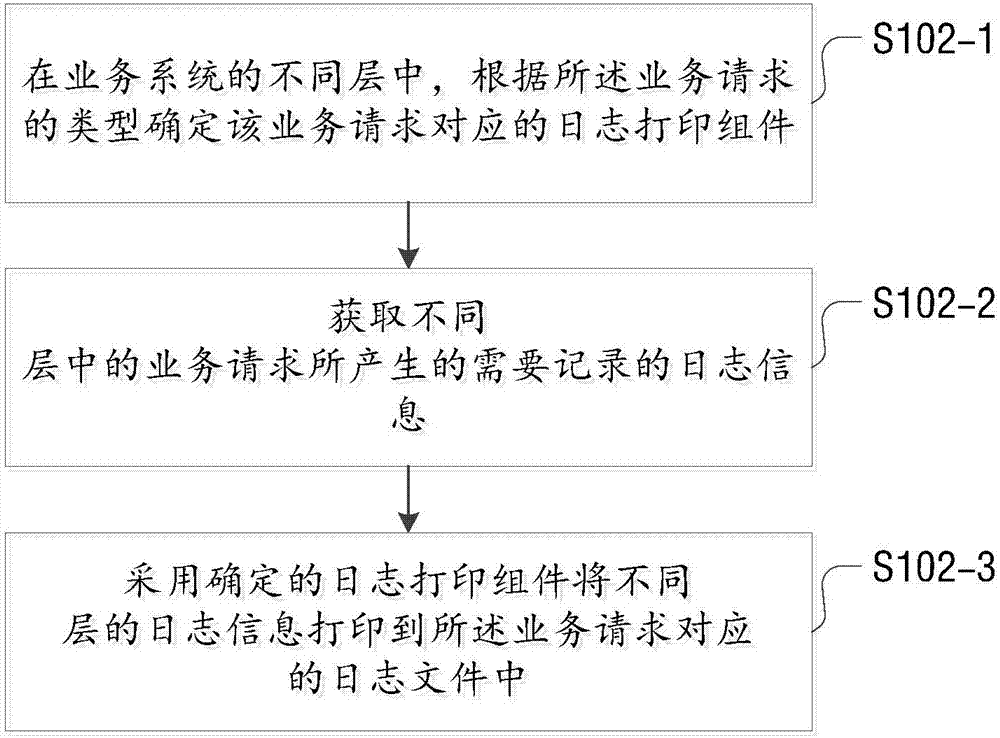

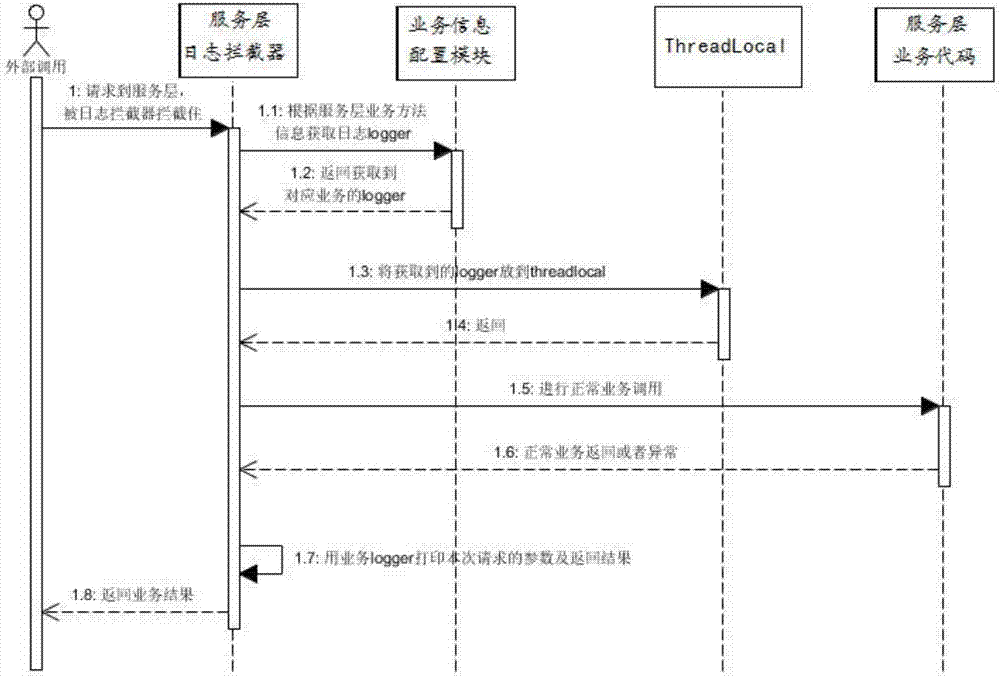

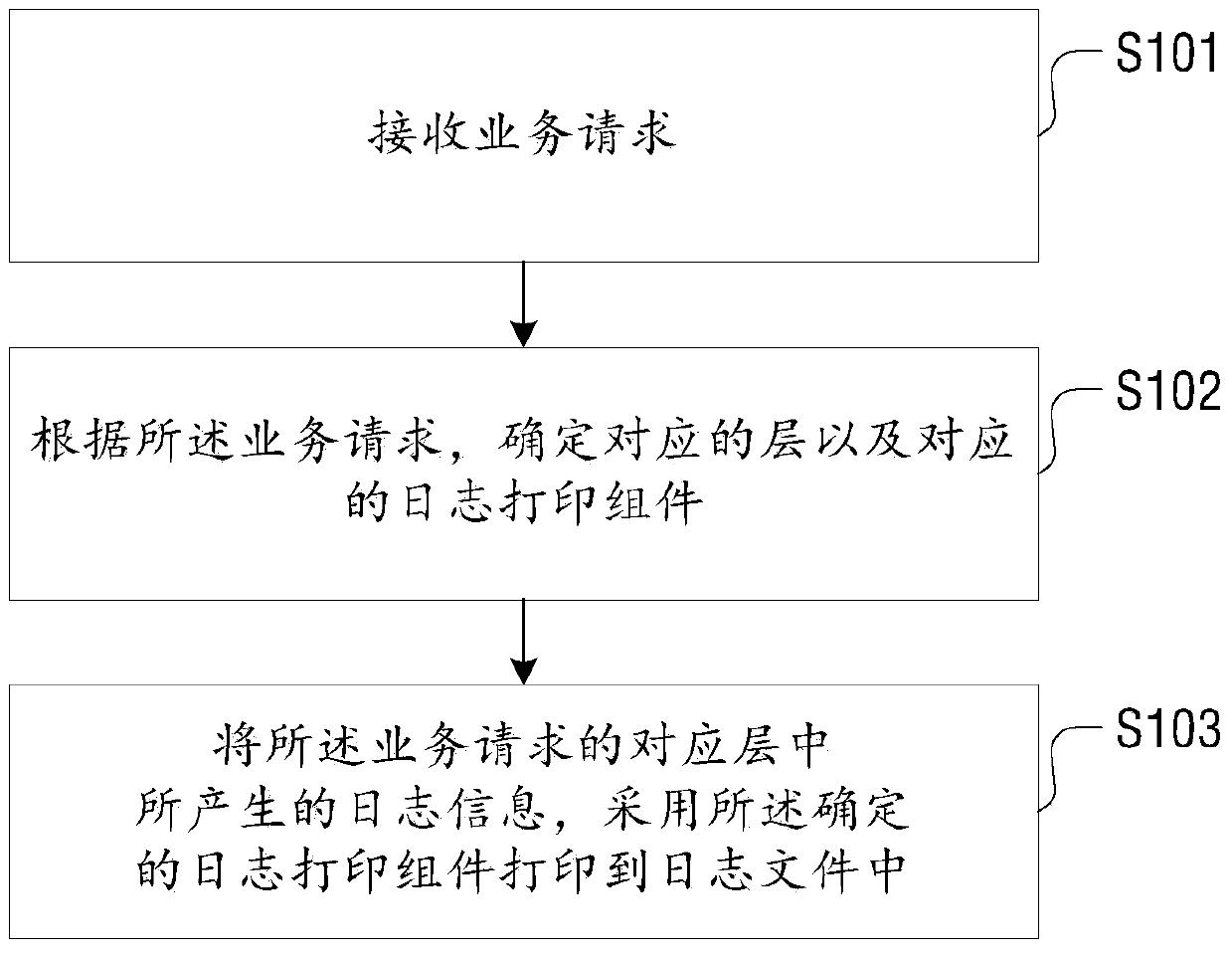

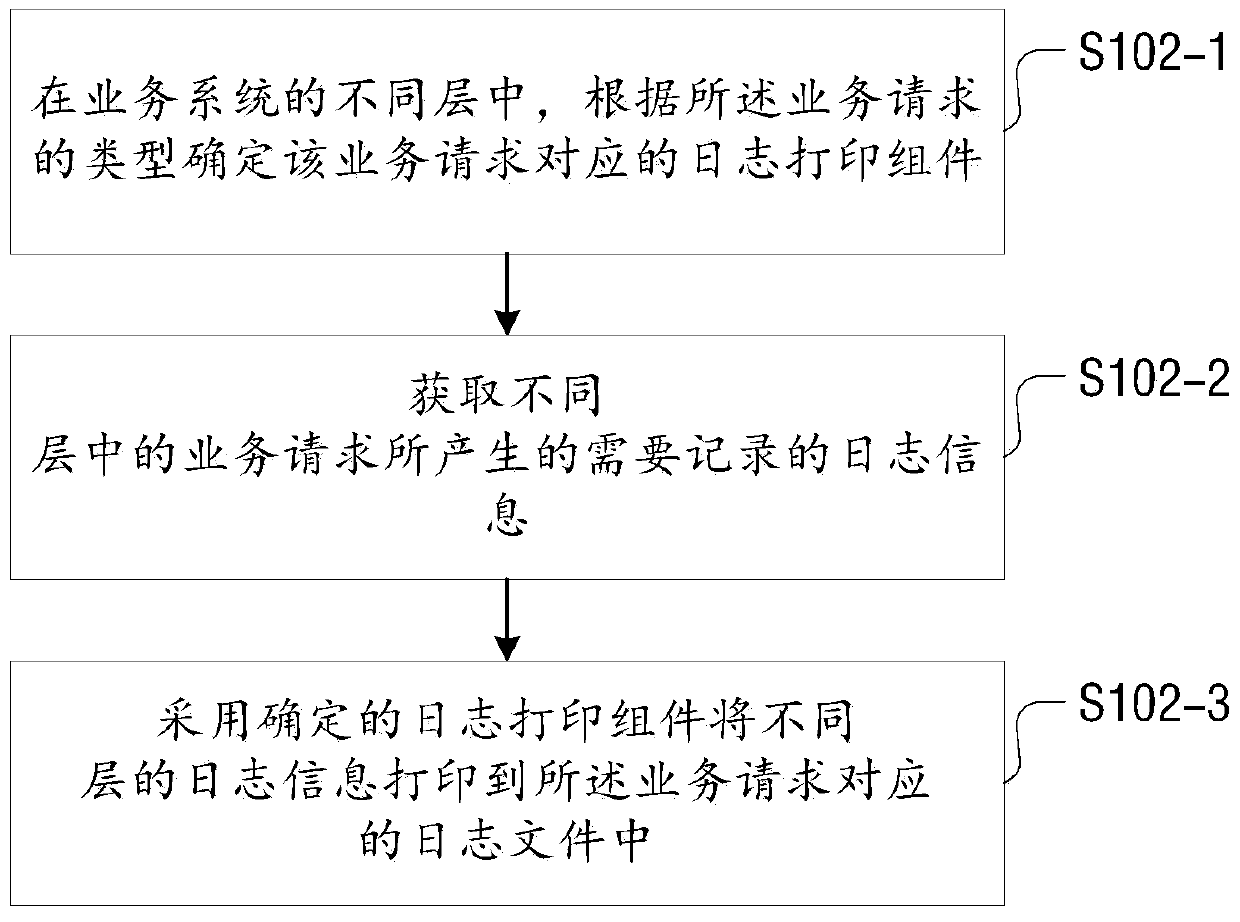

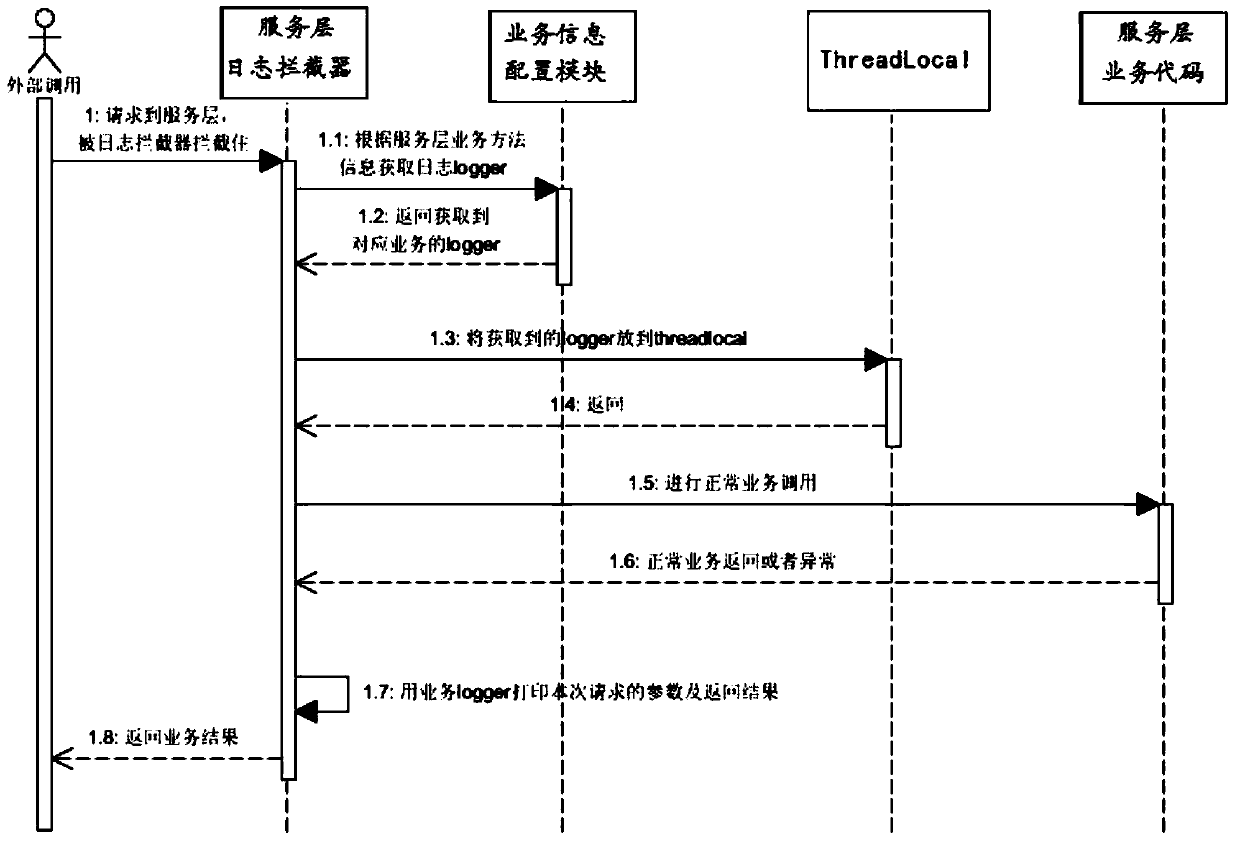

Log printing method and device and log printing system

The invention discloses a log printing method and device and a log printing system. The log printing method is used in a business system, and the business system comprises multiple layers. The method comprises the steps of receiving a business request; determining a corresponding layer and a corresponding log printing component according to the business request; adopting the determined log printing component to print log information generated in the layer corresponding to the business request into a log file. According to the method, a log framework which is simple, flexible, and does not invade a business code is built, the business system does not need to add codes, when requests from different business come, the log framework built through the method prints parameters of each layer processing method and returning values to log files corresponding to different business; meanwhile, log print in business codes can also be directly printed into the log files corresponding to the business, and thus all the logs in a business request link can be printed in the same file at one time.

Owner:ADVANCED NEW TECH CO LTD

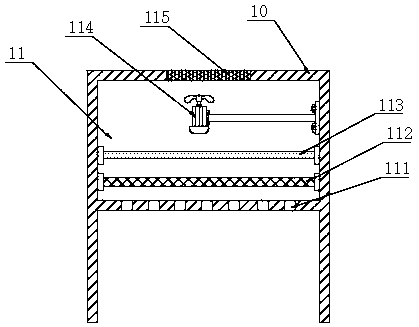

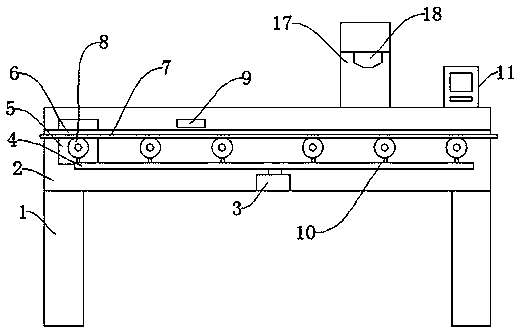

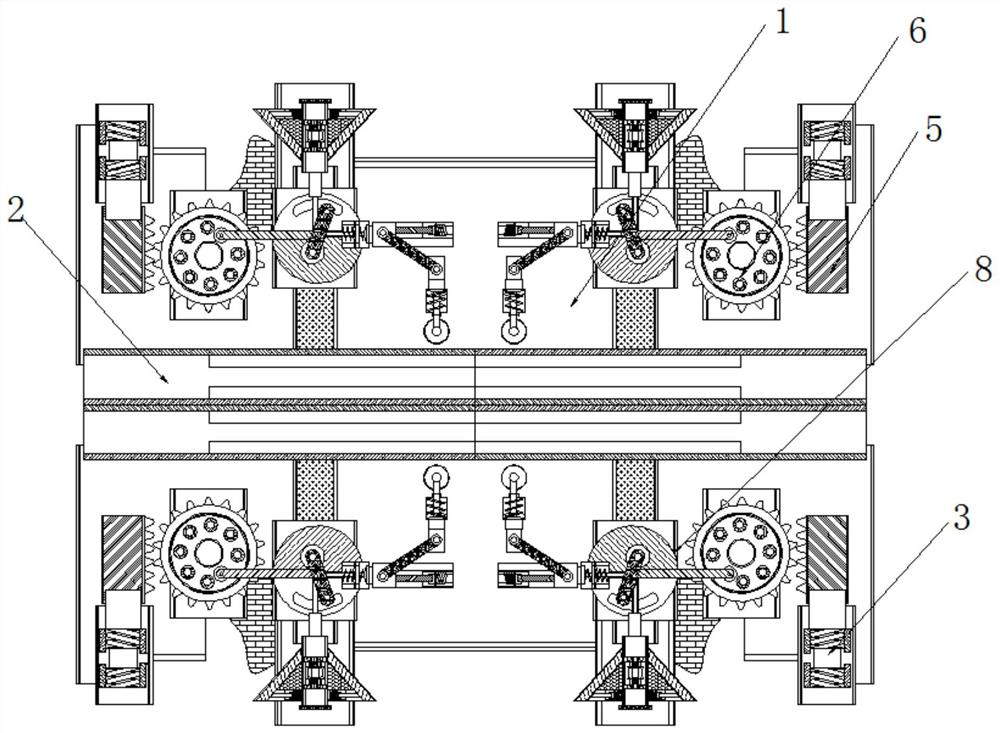

Printing device for carton production

InactiveCN109130474AIncrease working areaImprove work efficiencyDispersed particle separationRotary pressesCardboardDrive shaft

The invention discloses a printing device for carton production. The printing device comprises a printing chamber and a worktable, the worktable is arranged in the printing chamber, a control switch is arranged on the outer wall of one side of the printing chamber in an embedded manner, a servo motor is fixedly arranged on the upper surface of the printing chamber, air outlets are formed in the top end inside the printing chamber, and a transmission shaft is fixedly arranged at the position, close to the positions below the front portions of the air outlets, of the inner wall of the printing chamber. A rotating mechanism, a mounting block and a rotating rod are arranged, the work area of the worktable is increased, a purifying chamber is arranged, peculiar smell generated by paper board printing can be absorbed and purified, a heating chamber and the air outlets are arranged, blowing drying can be carried out on a paper board during printing, the paper board printing work efficiency can be improved, a limiting device is arranged, different sizes of paper boards can be limited, falling of the paper boards on a rotation chain can be avoided, and the normal printing process of the paper boards can be ensured.

Owner:台山市永宝工艺制造有限公司

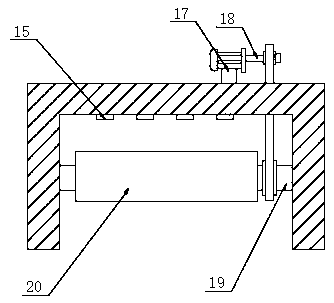

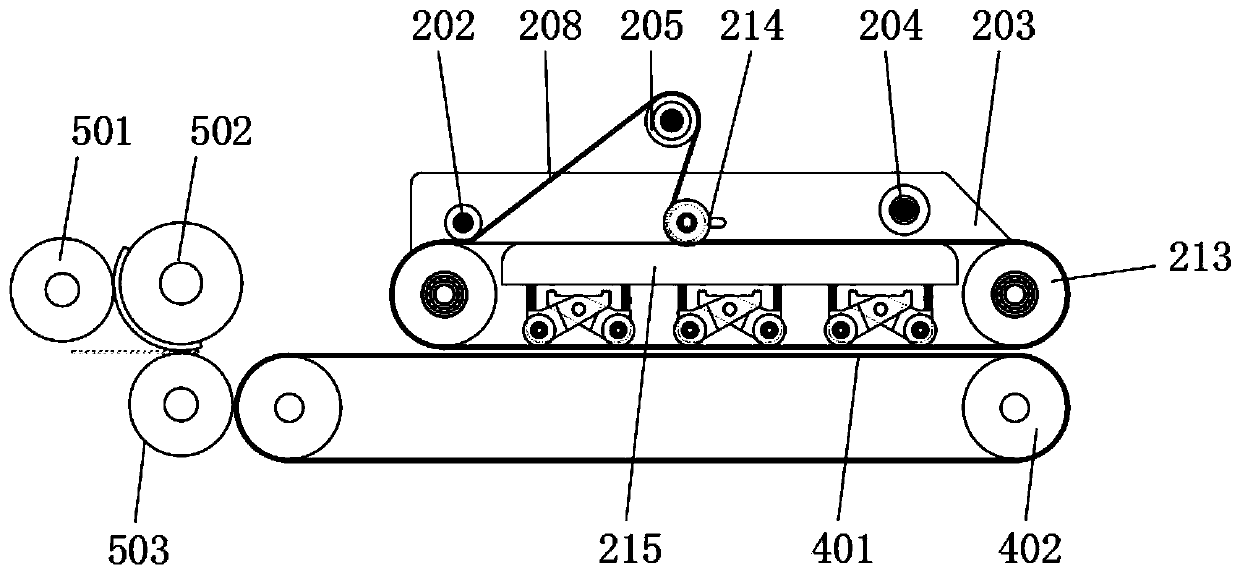

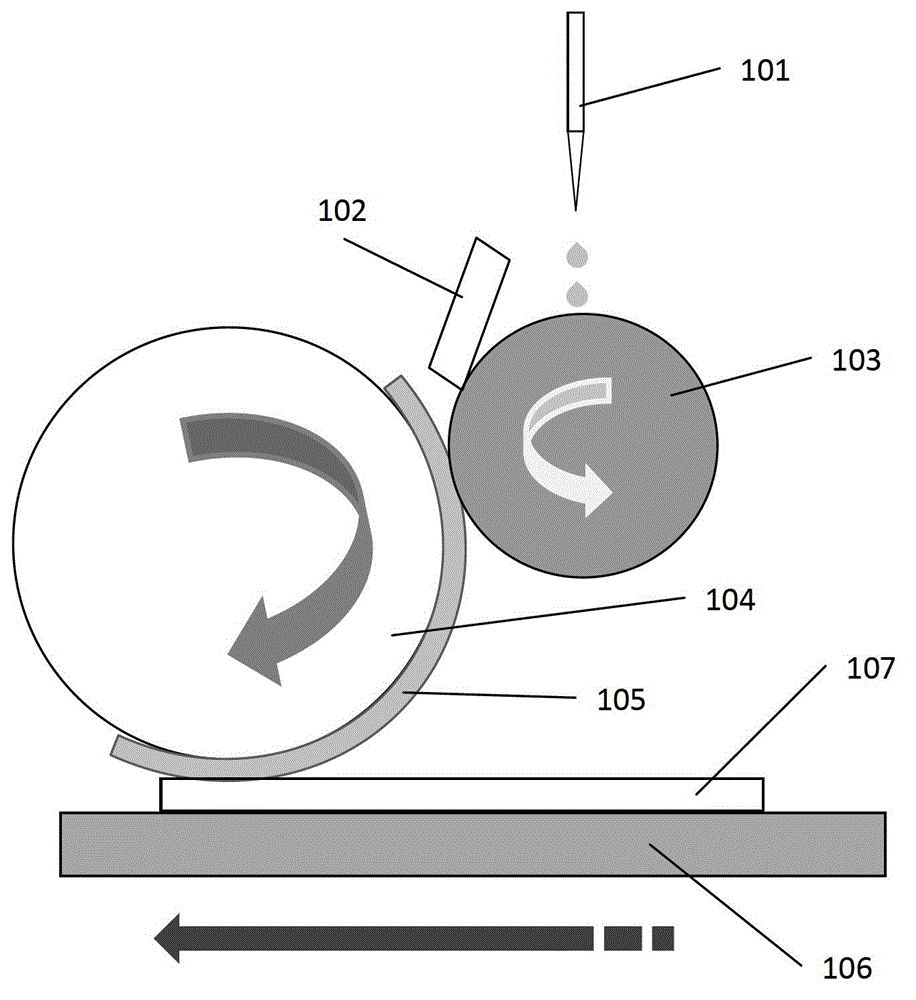

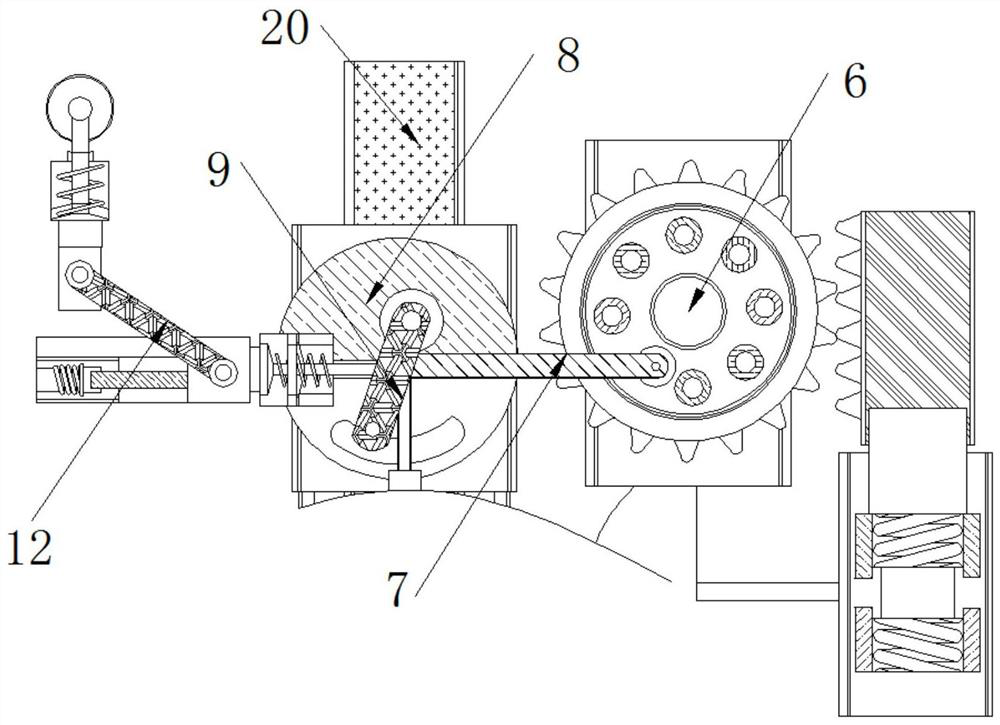

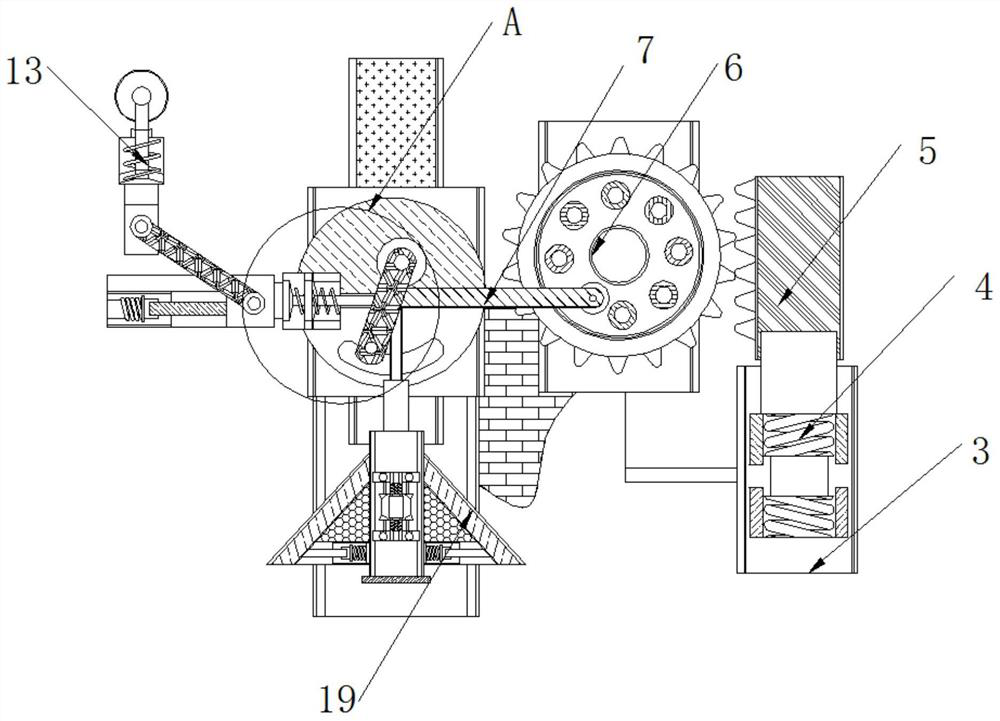

Printing machine for back flocked sand paper

ActiveCN107225852AGuaranteed normal printingAvoid print quality degradationRotary pressesPrinting press partsElectric machinerySand-paper

The invention provides a printing machine for back flocked sand paper. The printing machine sequentially comprises a feeding mechanism, a printing mechanism and a winding mechanism in the advancing sequence of the sand paper and further comprises guide rollers; the feeding mechanism comprises a feeding rack and a feeding shaft; the printing mechanism comprises a printing rack, an ink duct support, an ink duct and a printing piece; the winding mechanism comprises a winding rack, a winding motor and a winding shaft; and the guide rollers are distributed between the feeding mechanism and the printing mechanism and between the printing mechanism and the winding mechanism. With the printing machine, efficient and stable printing can be performed under the condition that the use performance of the back flocked sand paper and back flocked sand cloth is not affected; an ink transfer roller is added, so that clear printing can be guaranteed, and meanwhile, reduction of the printing quality due to relatively much ink can be avoided; the drying efficiency after printing is completed can be remarkably improved, and thus the overall printing quality can be guaranteed; and the printing machine is novel in structure and suitable for popularization and use.

Structure-enhanced photocurable resin base ceramic composite material and body degreasing method

ActiveCN108083818AIncrease penetration depthSurface crack phenomenon solutionFine structureCeramic composite

The invention discloses a structure-enhanced photocurable resin base ceramic composite material and a ceramic body degreasing method. Through optimal design of a resin system, while reaction activityof the system is maintained, the transmission depth of the ceramic slurry system is increased, and formation size errors are reduced; therefore, the interlaminar binding force of ceramic body and thebonding power between the ceramic body and a printing platform are increased, and separations of the ceramic body from the platform and cracks on the surface of the ceramic body are reduced; moreover,the tensile strength of a formed part is improved, so that the material can meet printing requirements of impending and fine structures.

Owner:深圳长朗智能科技有限公司

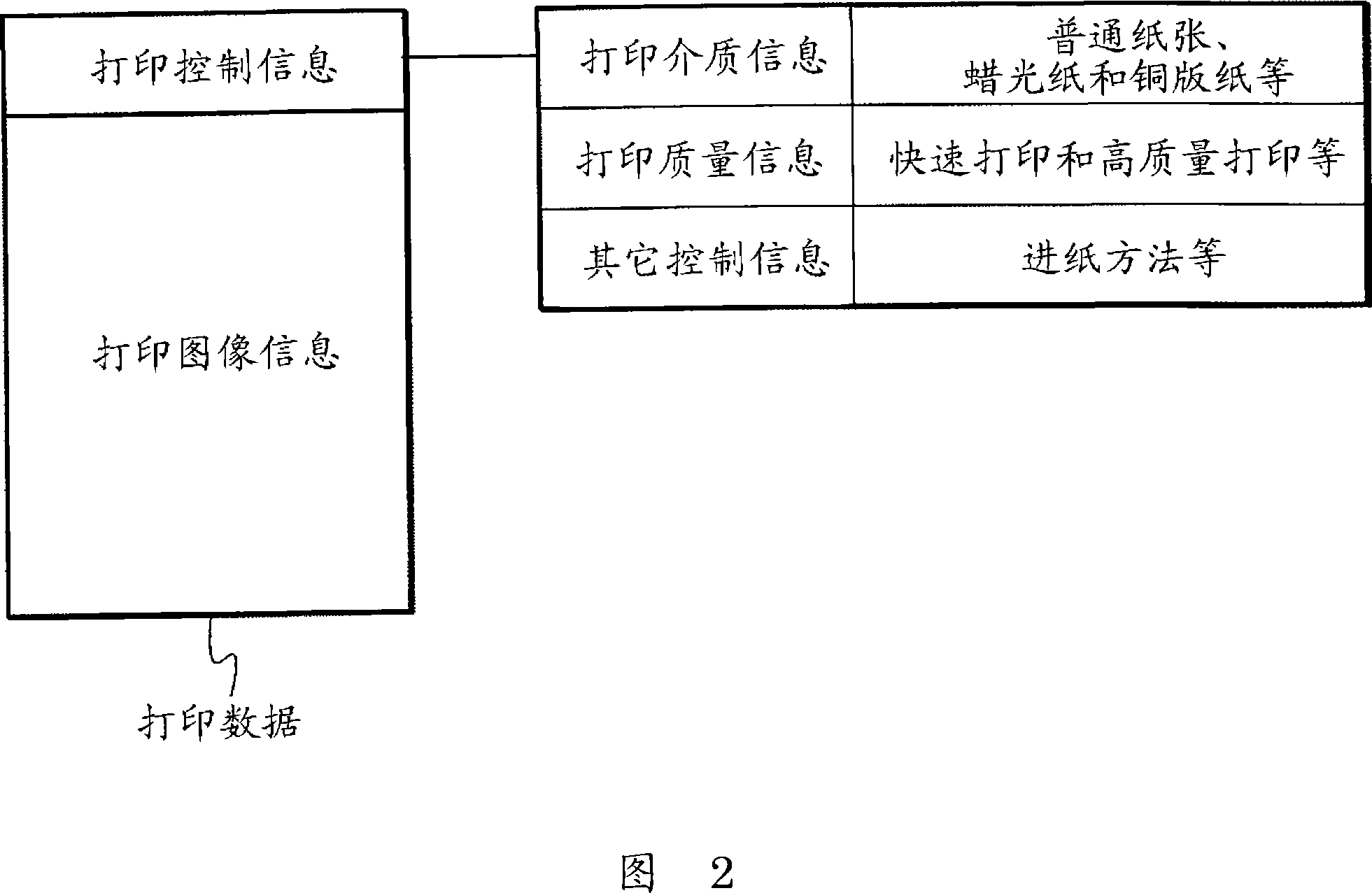

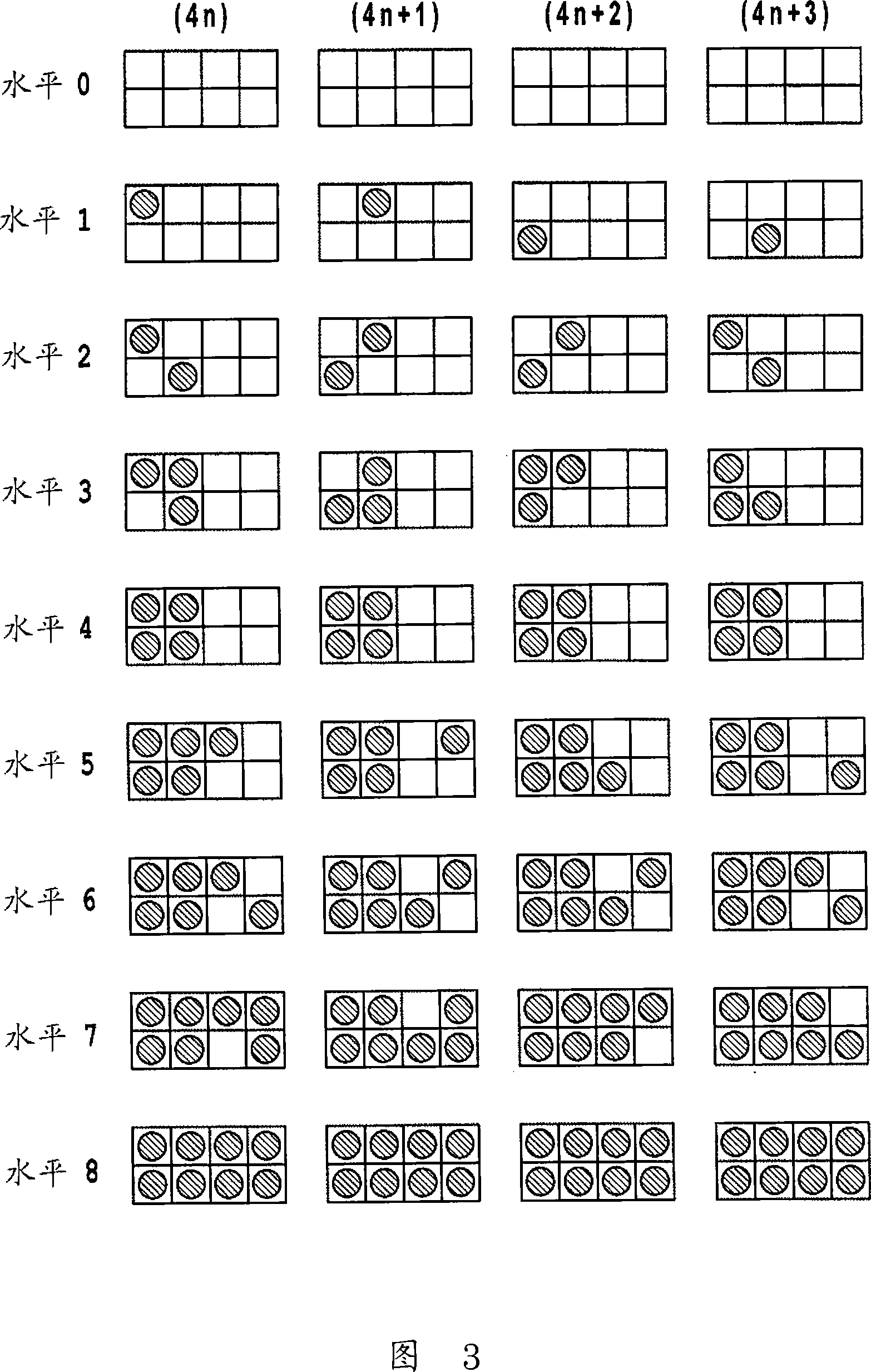

Ink jet printing apparatus and ink jet printing method

InactiveCN101088766AUniform concentrationGuaranteed normal printingSpacing mechanismsElectrical and Electronics engineeringInkjet printing

The present invention provides an ink jet printing apparatus and a method for controlling an ink jet printing apparatus which can shorten the stirring duration without losing any stirring effect by stirring ink at a required time to only a required level and still perform a printing operation with no image impairments. By a reciprocal movement of the carriage according to a mode during a non-printing operation excluding a print operation that is accompanied by a reciprocal movement of the carriage, ink in an ink tank is stirred. The stir mode is set according to the color of the ink in the ink tank mounted on the carriage.

Owner:CANON KK

Cigarette packet

ActiveCN104029883AWon't spoil the tasteWithout compromising qualityContainers for flexible articlesPackaging cigaretteEngineeringSmoke

Owner:CHINA TOBACCO GUANGDONG IND

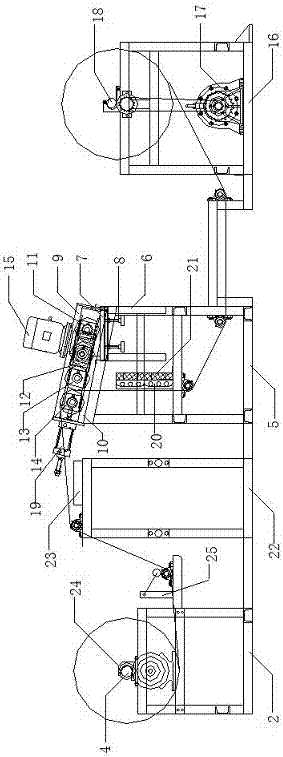

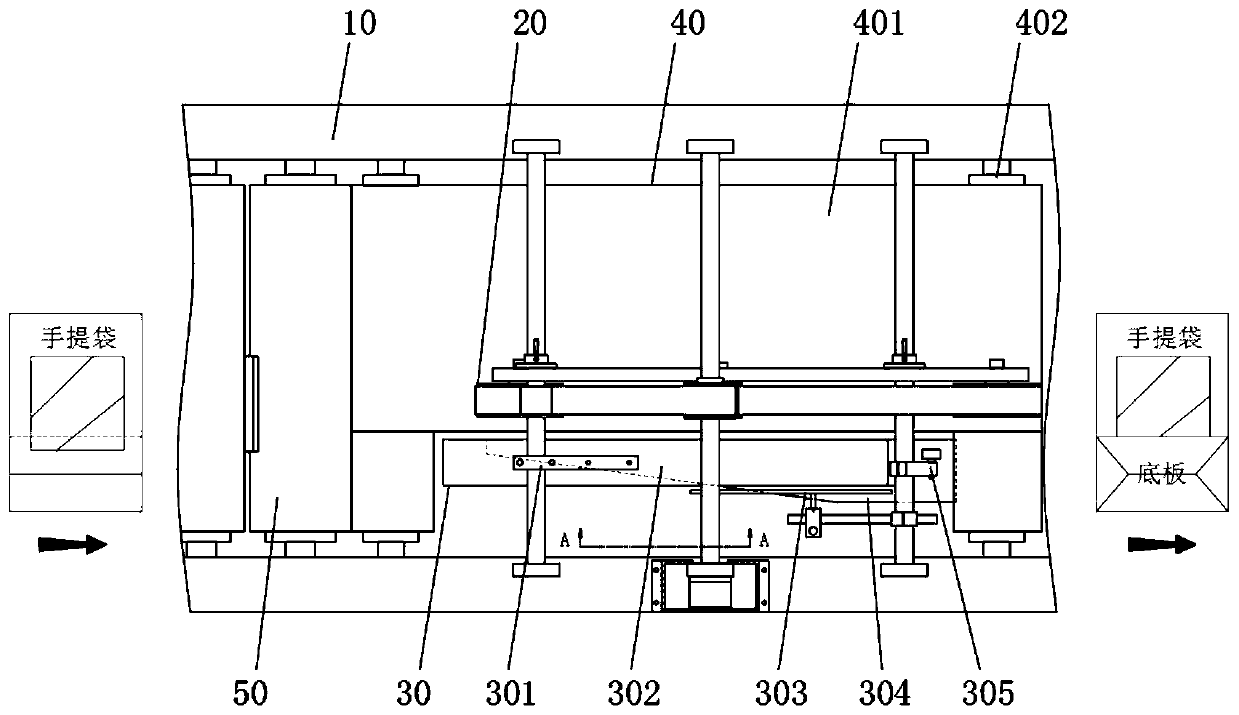

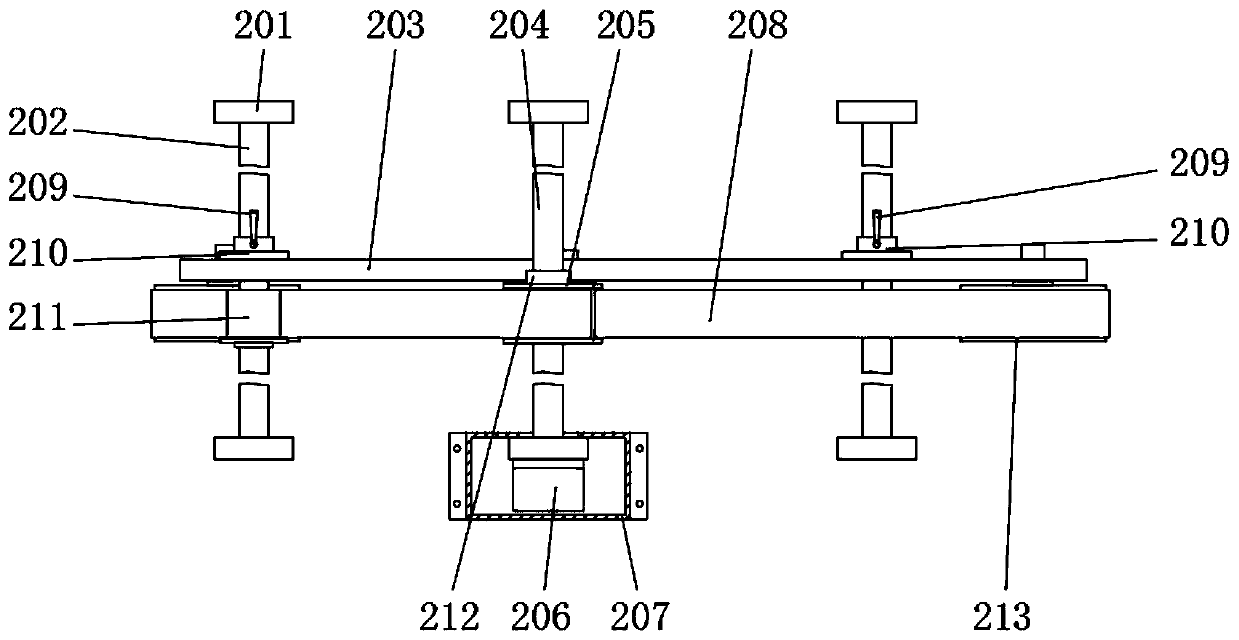

Hand bag double-sided printing and folding device

InactiveCN110641144AIncrease productivityGuaranteed normal printingOverturning articlesRotary pressesPrinting pressMechanical engineering

The invention discloses a hand bag double-sided printing and folding device. The hand bag double-sided printing and folding device comprises a frame body, a synchronous pressing assembly, a guiding assembly, a conveying assembly and a printing assembly, wherein the printing assembly and the conveying assembly are mounted inside the frame body from left to right, the synchronous pressing assembly is mounted at the front end of the conveying assembly, and the guiding assembly is arranged below the conveying assembly. According to the handbag double-sided printing and folding device, a hand bag completes printing at the upper surface by the printing assembly, is conveyed and moved under the action of the conveying assembly, and through the cooperation between the synchronous pressing assemblyand the guiding assembly, a bottom plate folded at the lower surface at the bottom of the hand bag is opened and folded to the upper surface of the hand bag, so that normal printing at the lower surface of the hand bag is guaranteed, continuous printing can be carried out on the upper surface and the lower surface of the hand bag by a printing press, and the production efficiency of hand bag printing is improved.

Owner:义乌市港达印刷有限公司

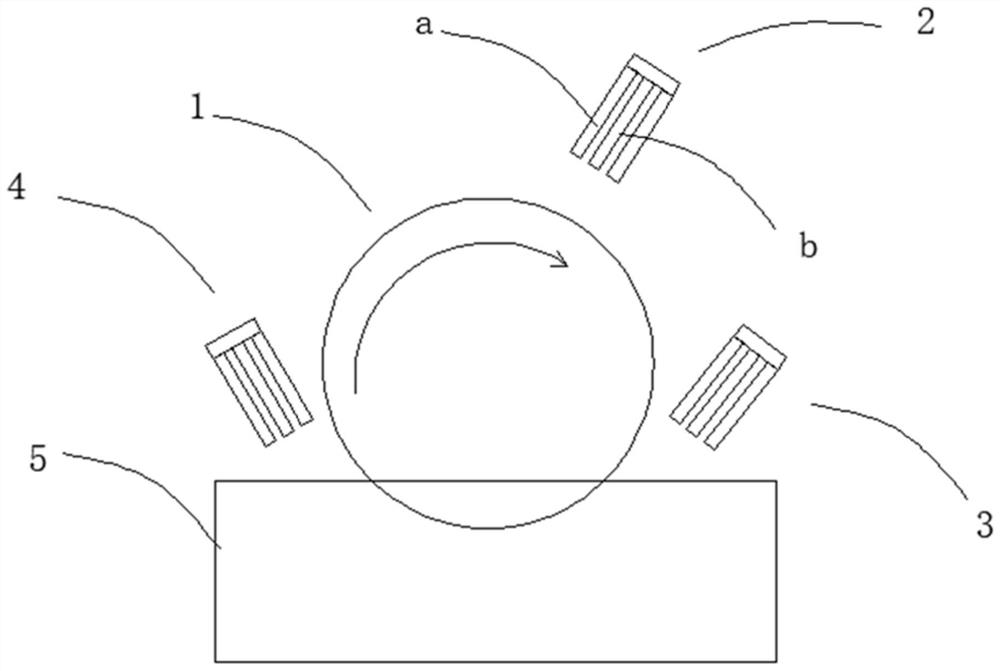

Intermittent rotary printer with cooling units

ActiveCN106113932ASimple structureGuaranteed normal printingPrinting press partsUV curingEngineering

The invention discloses an intermittent rotary printer with cooling units. The intermittent rotary printer comprises printing units, UV curing units and the cooling units; the cooling units are arranged between the printer printing units and the UV curing units; cooling transmission devices are respectively arranged between the printing units and the UV curing units; ice roller support plates are arranged on the side surfaces of support plates of the printing units; ice rollers are mounted on the ice roller support plates; one ends of the ice rollers are sleeved and linked with ice roller servo motors fixedly connected to the ice roller support plates; the ice rollers adopt a two-direction rotating drive form; the ice rollers are hollow cylinder roller bodies; water circulating devices are arranged on one side surfaces of the ice rollers; and ice roller guide rollers are mounted on the support plates below the ice rollers. The printer is added with the cooling units, is simple in structure, cools printing materials by the rice rollers in UV curing when guaranteeing normal printing, prevents the problems of material stretching and inaccurate printing positions caused by higher curing temperature of the printing materials, and improves the printing quality and the printing efficiency.

Owner:河北万杰机械科技股份有限公司

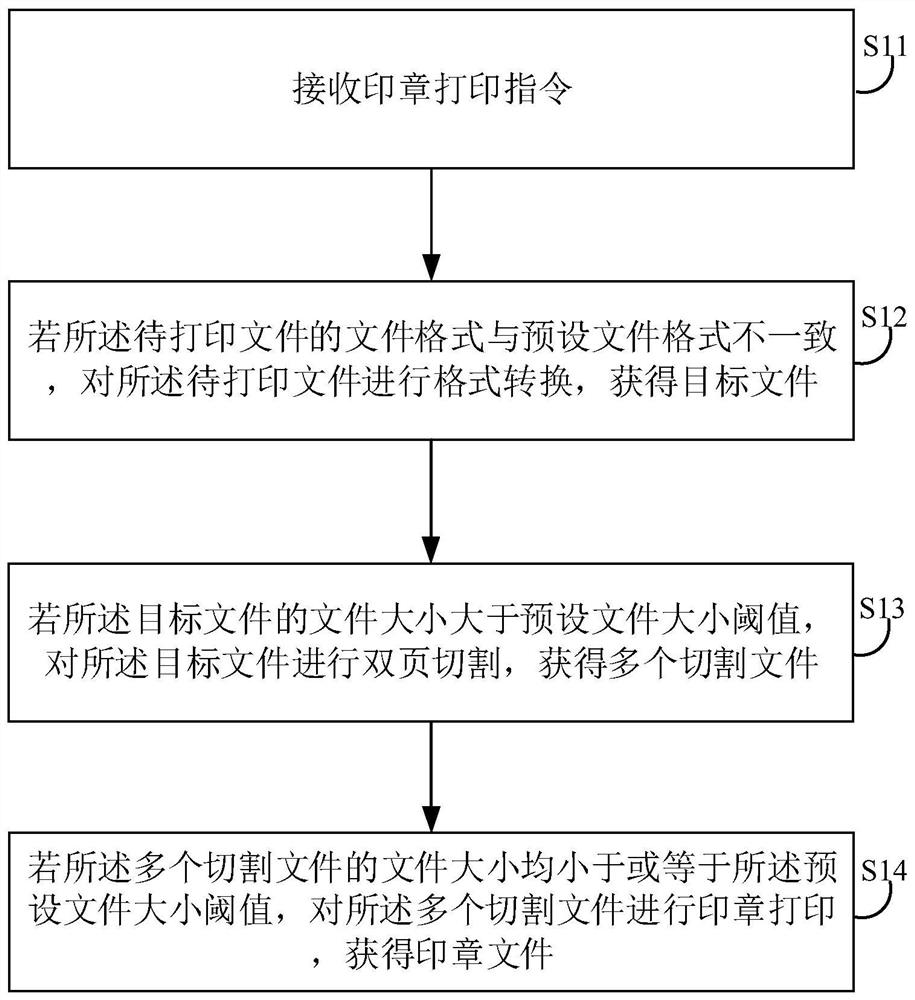

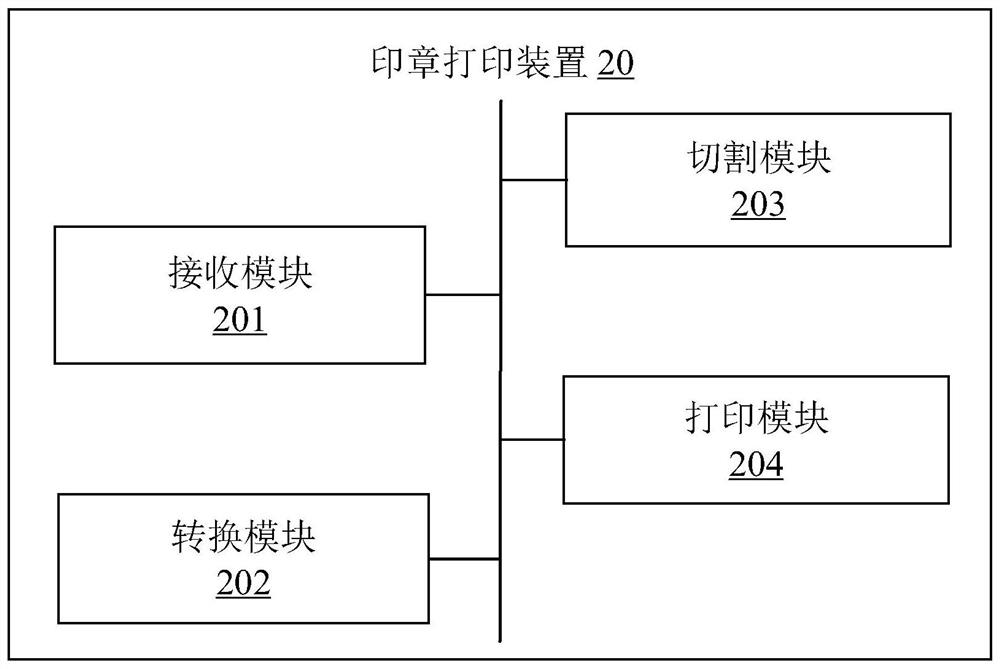

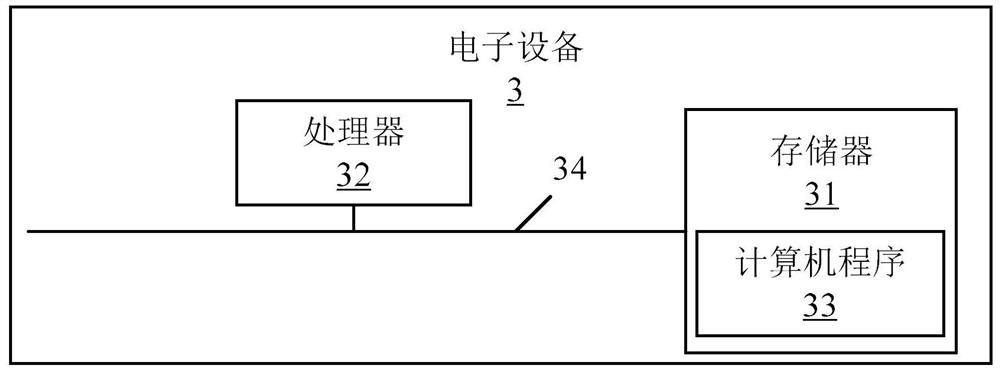

Seal printing method and device, electronic equipment and storage medium

ActiveCN111880752AImprove printing efficiencyGuaranteed normal printingDigital output to print unitsSoftware engineeringSmart government

The invention relates to the technical field of artificial intelligence, and can be applied to the field of smart government affairs, thereby promoting the construction of smart cities. The inventionprovides a seal printing method and device, electronic equipment and a storage medium, and the method comprises the steps: receiving a seal printing instruction which carries a to-be-printed file; ifthe file format of the to-be-printed file is inconsistent with a preset file format, performing format conversion on the to-be-printed file to obtain a target file; if the file size of the target fileis greater than a preset file size threshold, performing double-page cutting on the target file to obtain a plurality of cut files; and if the file sizes of the plurality of cut files are all smallerthan or equal to the preset file size threshold, performing seal printing on the plurality of cut files to obtain a seal file. The seal printing efficiency can be improved. In addition, the inventionfurther relates to a blockchain technology, and the seal file can be stored in a blockchain.

Owner:PING AN TECH (SHENZHEN) CO LTD

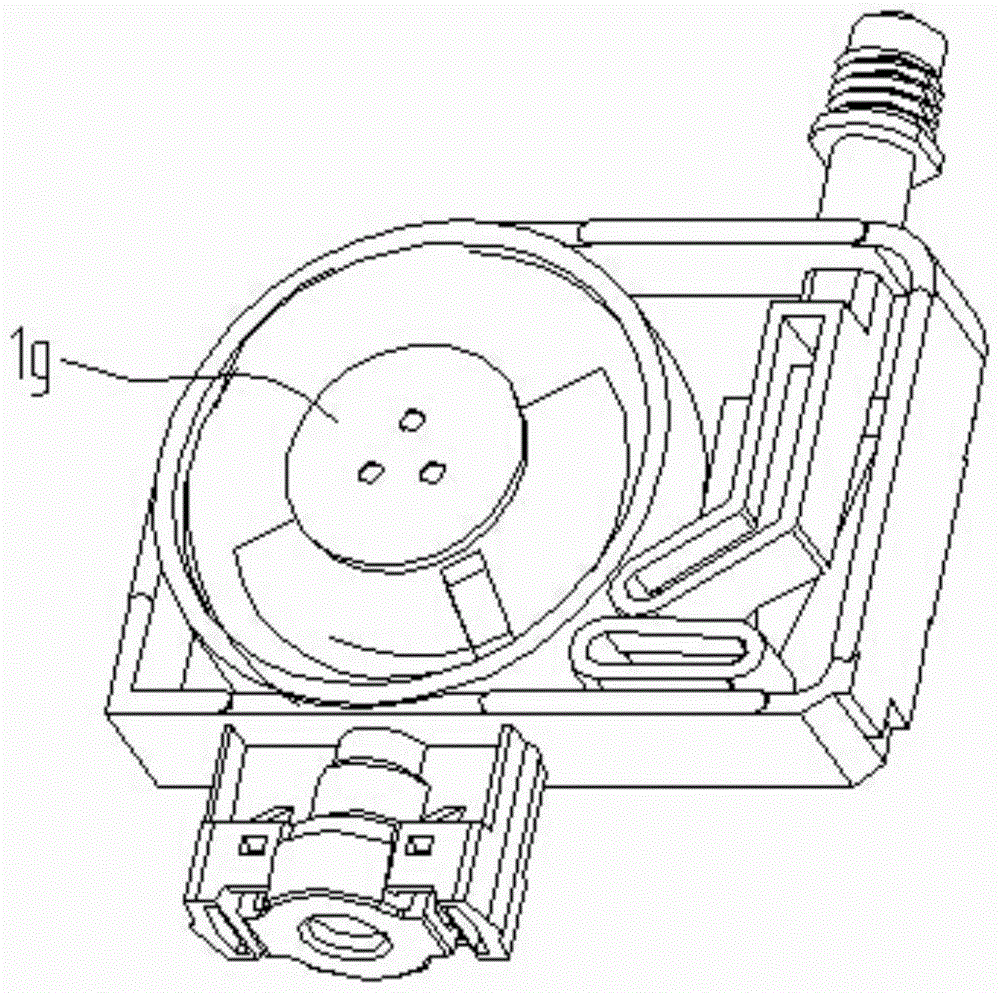

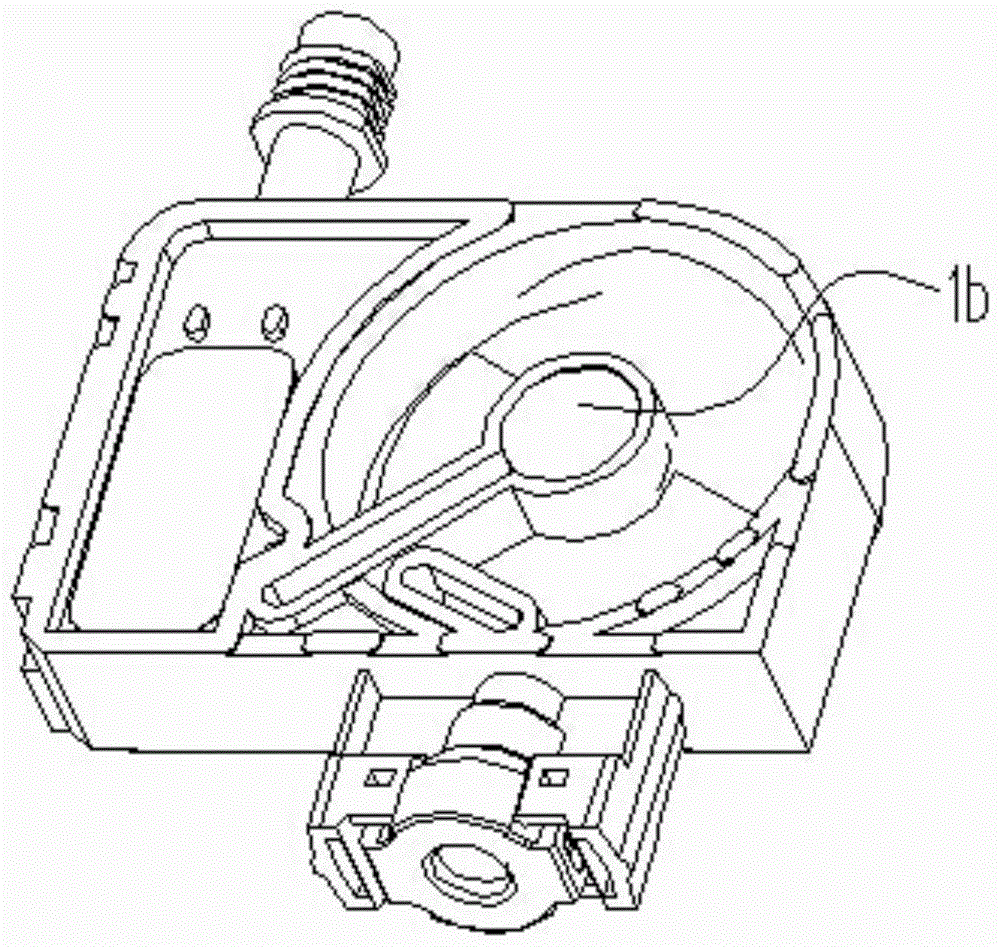

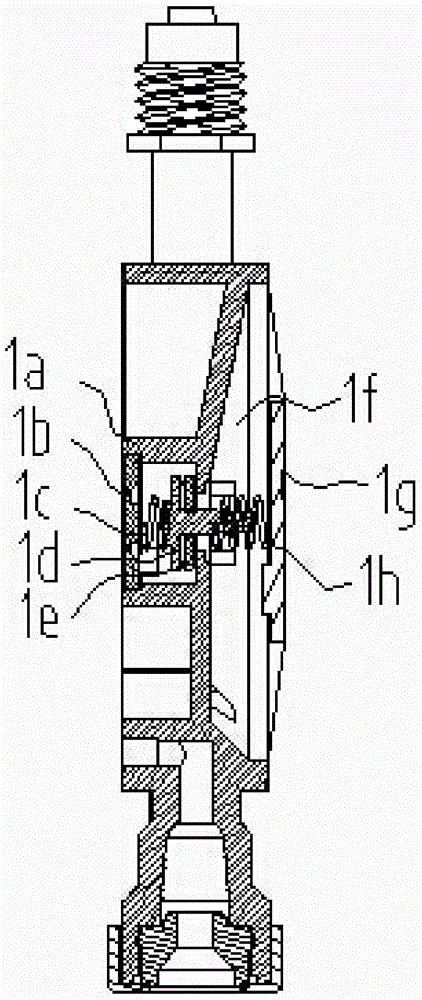

Large-capacity exhaust ink bag for large-width ink-jet printer

ActiveCN104669799AAvoid the problem of broken inkEnsure normal dischargePrintingCircular discEngineering

The invention belongs to the field of print equipment and relates to a large-capacity exhaust ink bag for a large-width ink-jet printer. The large-capacity exhaust ink bag for the large-width ink-jet printer comprises an ink bag main body, and a small plastic disc, a large plastic disc and plastic bosses, which are arranged in the ink bag main body, wherein the plastic bosses are respectively supported between the small plastic disc and the large plastic disc through a first spring and a second spring; rubber seal components are fixed at the joint of the plastic bosses and the ink bag main body; a film buffering chamber is formed by the ink bag main body, the large plastic disc and the plastic bosses, an exhaust opening is formed in the film buffering chamber, and the exhaust opening is connected with an exhaust pipe with a shutoff valve. The large-capacity exhaust ink bag for the large-width ink-jet printer, provided by the invention, easily solves the problem that the large-width printer cannot continuously print for long time in a simple manner, and greatly improves the print speed and the print quality of the large-width printer, thereby better meeting the requirements of people on the speed and the quality of the printer.

Owner:HANGZHOU WANMENG DIGITAL EQUIP

Preparation method and application of a cell-loaded three-dimensional scaffold

ActiveCN104548208BAvoid damageGuaranteed normal printingArtificial cell constructsVertebrate cellsMicrosphereThree dimensional scaffolds

The invention provides a preparation method of a cell-loading three-dimensional support. The preparation method of the cell-loading three-dimensional support is characterized by comprising the following steps: uniformly mixing autologous cells with a high temperature intermittently sterilized hydrogel solution to obtain mixed liquor, injecting the mixed liquor into a crosslinking agent solution, standing, then removing the crosslinking agent solution, and rinsing, so that cell-loading microspheres are obtained; mixing the cell-loading microspheres with a matrix material to obtain cell blend; and extruding the cell blend onto a three-dimensional micro-positioning platform carrying a sterile glass base plate by adopting a biological printer, and overlaying layer by layer, so that the cell-loading three-dimensional support is formed. The preparation method of the cell-loading three-dimensional support has the advantages that damage on cellular activity and bioactivity in a cell printing process is reduced, and high-activity cell printing is guaranteed.

Owner:深圳尤尼智康医疗科技有限公司

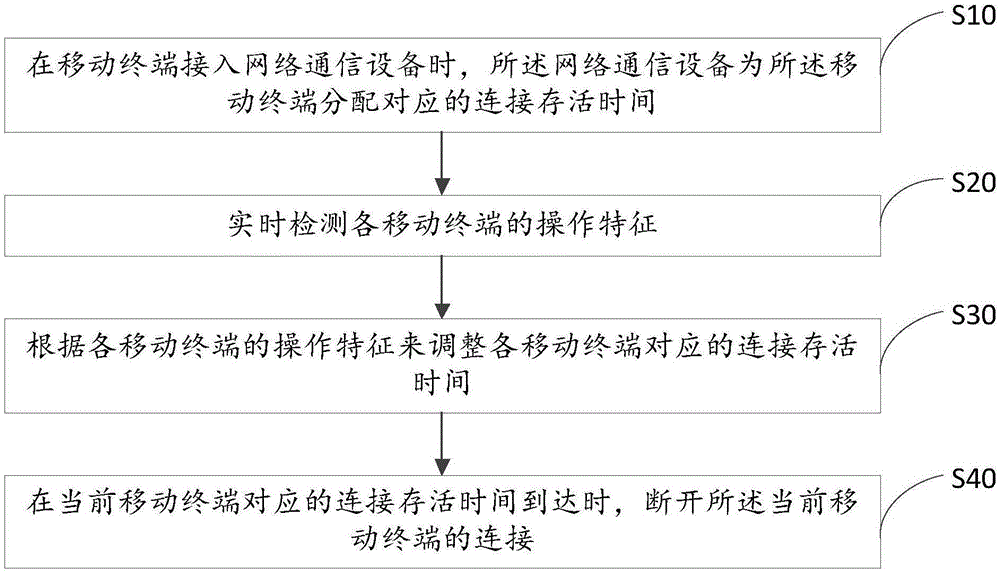

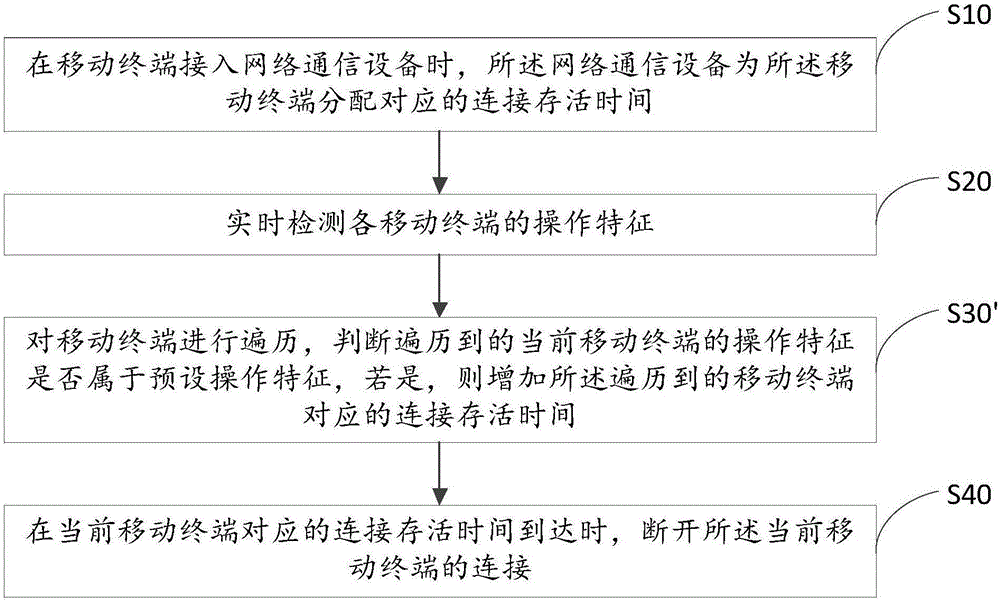

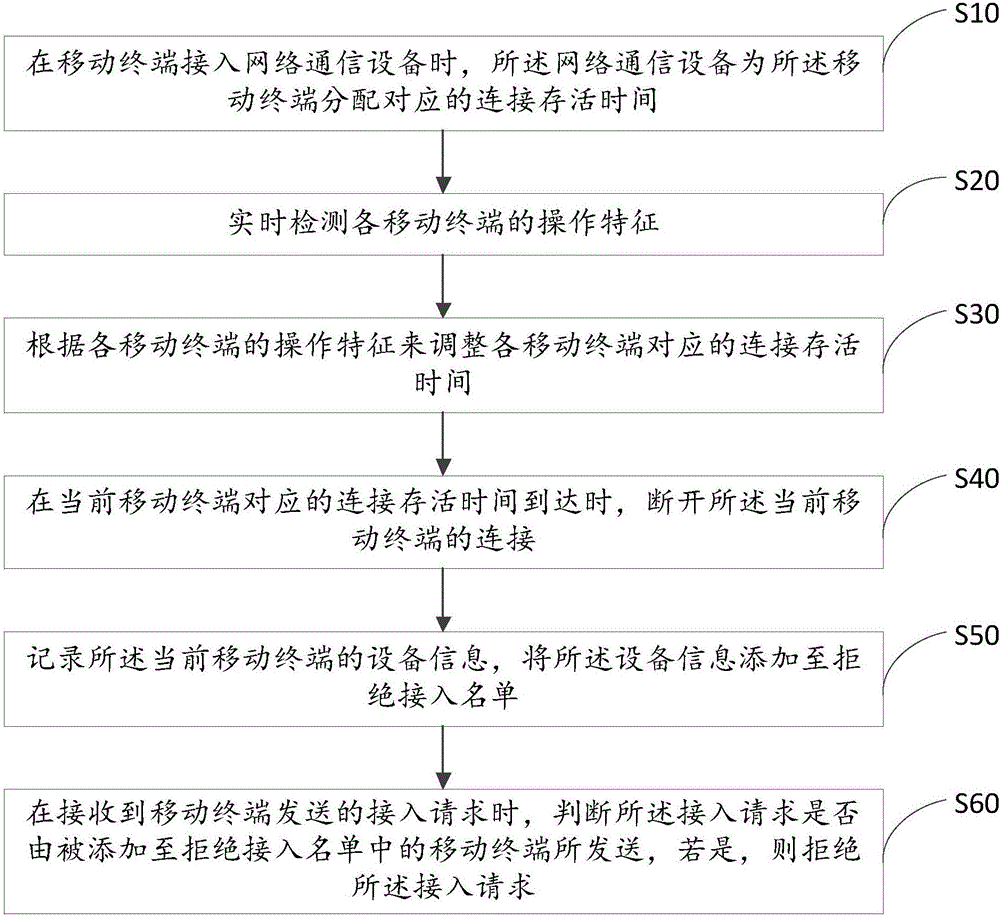

Access control method and system for network communication equipment

InactiveCN106406782AImprove experienceGuaranteed normal printingConnection managementTransmissionControl systemNetwork communication

The invention discloses an access control method for network communication equipment. The method comprises the following steps: when mobile terminals are accessed to the network communication equipment, the network communication equipment distributes corresponding connection survival times to the mobile terminals; operation characteristics of the various mobile terminals are detected in real time; according to the operation characteristics of the various mobile terminals, the corresponding connection survival times of the various mobile terminals are adjusted; and, when the corresponding connection survival times of the current mobile terminals are up, connection of the current mobile terminals is disconnected. The invention further discloses an access control system for the network communication equipment. According to the access control method and system for the network communication equipment disclosed by the invention, the corresponding connection survival times of the various mobile terminals are adjusted according to the operation characteristics of the various mobile terminals; connection of the mobile terminals used by users, who do not have printing requirements, can be disconnected; therefore, printing of users really having printing requirements can be ensured; and thus, the user experience is improved.

Owner:宜春小马快印科技有限公司

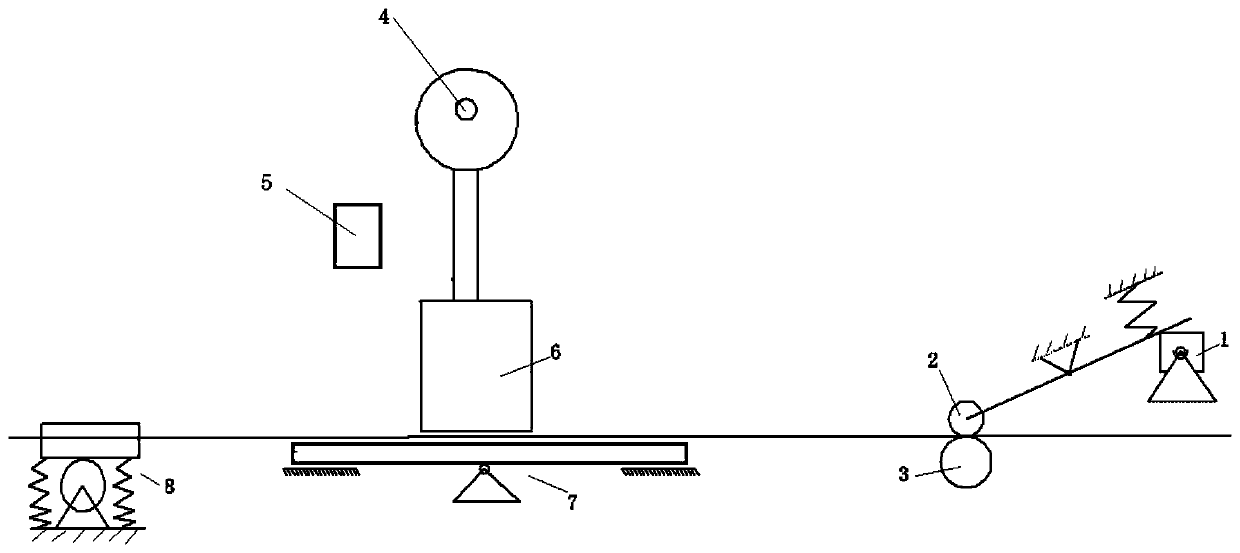

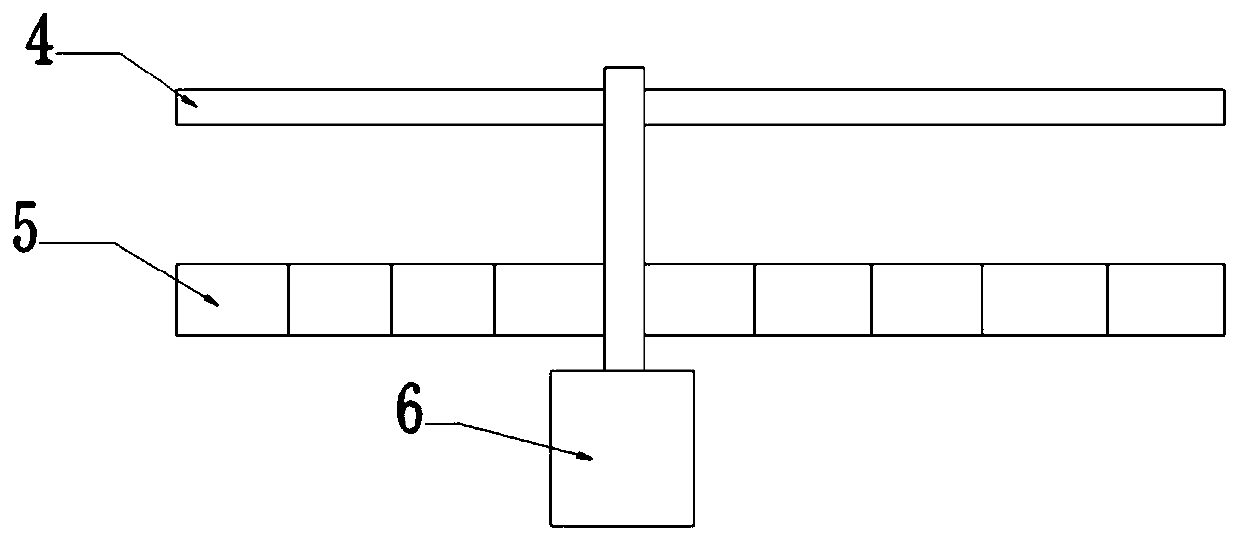

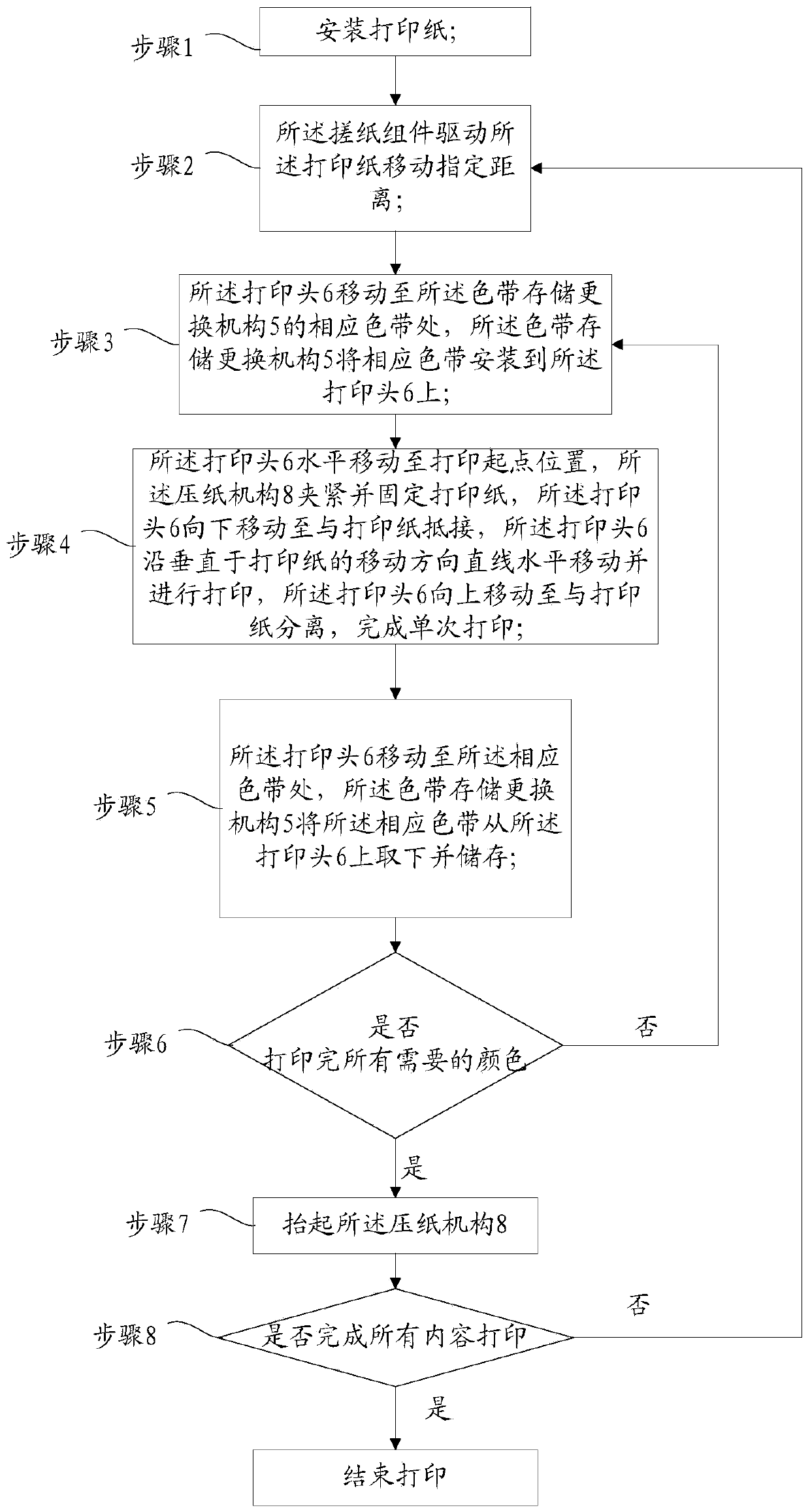

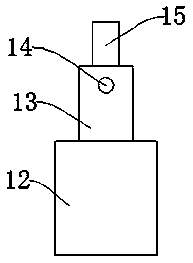

Heat transfer printing printer and printing method

PendingCN110948999ACompact structureSmall footprintTransfer printingTypewritersComputer printingMechanical engineering

The invention relates to a heat transfer printing printer and a printing method. The heat transfer printing printer comprises a paper rubbing assembly, a printing head, a colored tape storing and replacing mechanism and a paper pressing mechanism. The paper rubbing assembly and the paper pressing mechanism are successively arranged in the moving direction of printing paper, the printing head and the colored tape storing and replacing mechanism are mounted between the paper rubbing assembly and the paper pressing mechanism, the printing heat is located above the printing paper and can move linearly in a reciprocating manner horizontally in the direction perpendicular to the moving direction of the printing paper and move up and down, the colored tape storing and replacing mechanism is horizontally arranged perpendicular to the moving direction of the printing paper, and the colored tape storing and replacing mechanism is used for storing colored tapes of different colors and replacing the colored tapes to the printing head. The heat transfer printing printer has the beneficial effects that the colored tape storing and replacing mechanism replaces the colored tapes, so that the printing head can print a plurality of colors; the paper rubbing assembly drives the printing paper to move; and the paper pressing mechanism is used for fixing the printing paper when the printing head executes a printing operation to prevent the printing effect from being affected as the printing paper moves. The printer is compact in structure and small in occupied area.

Owner:湖南鼎一致远科技发展股份有限公司

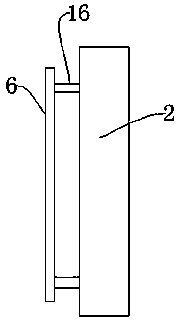

Paper feeding assembly used for printer

InactiveCN108820947APrevent disengagementFit tightlyArticle feedersPulp and paper industryPrinting press

The invention discloses a paper feeding assembly used for a printer, comprising support feet, a working table and an electrostatic generator, wherein the working table is arranged on the upper side ofthe support feet; the electrostatic generator is arranged on one side of the working table away from the support feet. According to the invention, the beneficial effects of the paper feeding assemblyare: by arranging the electrostatic generator, conductive brush heads and a discharging brush, a paper and a conveyor belt are tightly coupled, so that the separation phenomenon of the paper can be avoided; by arranging a displacement sensor, an electric stretching shaft and a side baffle, the deviation of the paper can be timely corrected, so that the normal transportation and printing of the paper can be ensured; and by arranging an ultrasonic thickness detector, the overlapping phenomenon of the paper can be avoided, so that the waste caused by wrong paper printing is reduced.

Owner:安徽轩扬包装科技有限公司

Structure-enhanced photocurable resin-based ceramic composite material and method for degreasing embryo body

ActiveCN108083818BIncrease penetration depthSurface crack phenomenon solutionCeramic compositeSlurry

The invention discloses a structure-reinforced photocurable resin-based ceramic composite material and a degreasing method for a ceramic embryo body. By optimizing the design of the resin system, it is possible to increase the penetration depth of the ceramic slurry system and reduce the molding size error while maintaining the reactivity of the system; to increase the bonding force between the ceramic body layers and the bonding force between the printing platform and reduce The detachment of the ceramic green body from the platform and the cracks on the surface of the ceramic green body; at the same time, the tensile strength of the molded part is improved, so that the material can adapt to the printing requirements of suspension and microstructure.

Owner:深圳长朗智能科技有限公司

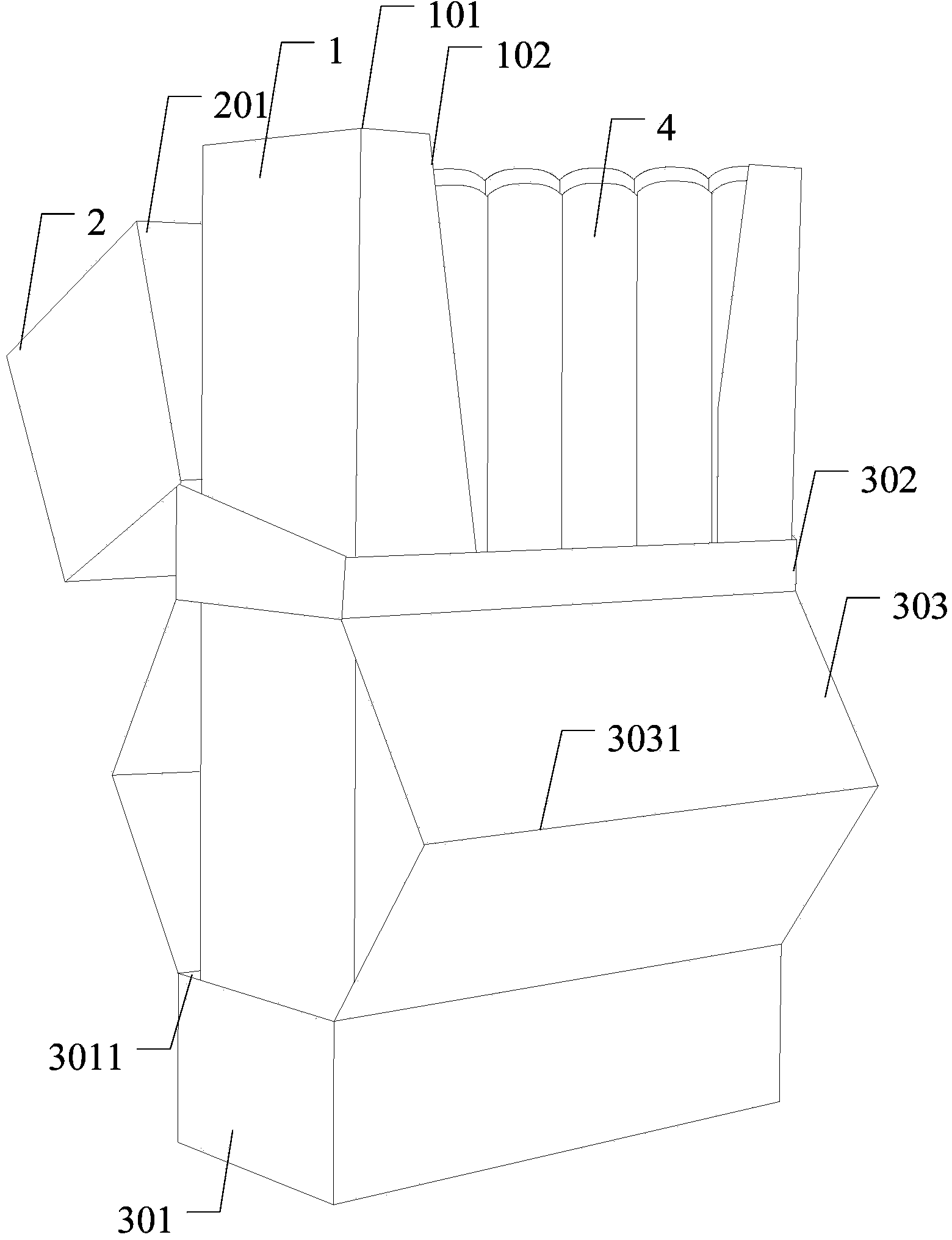

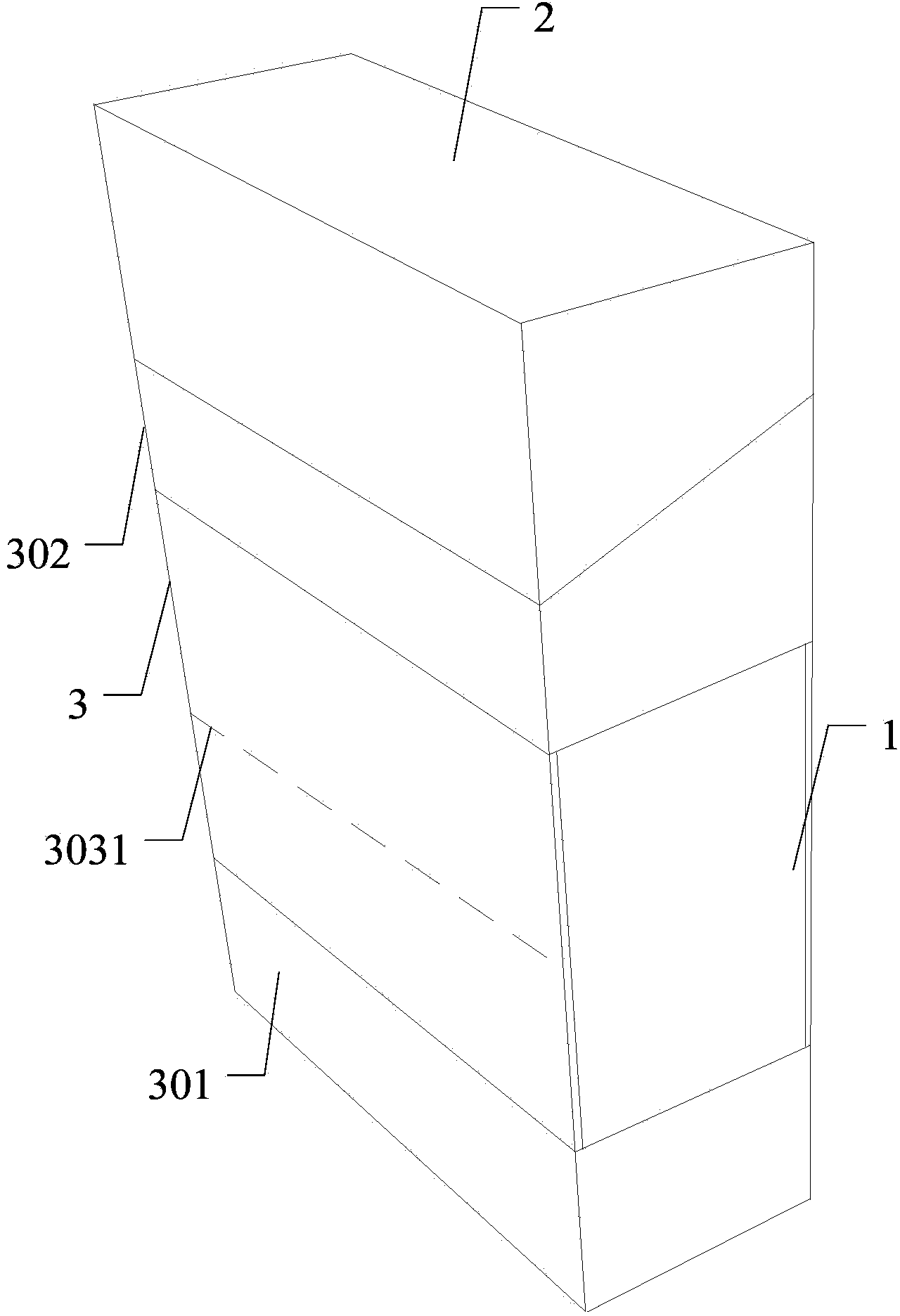

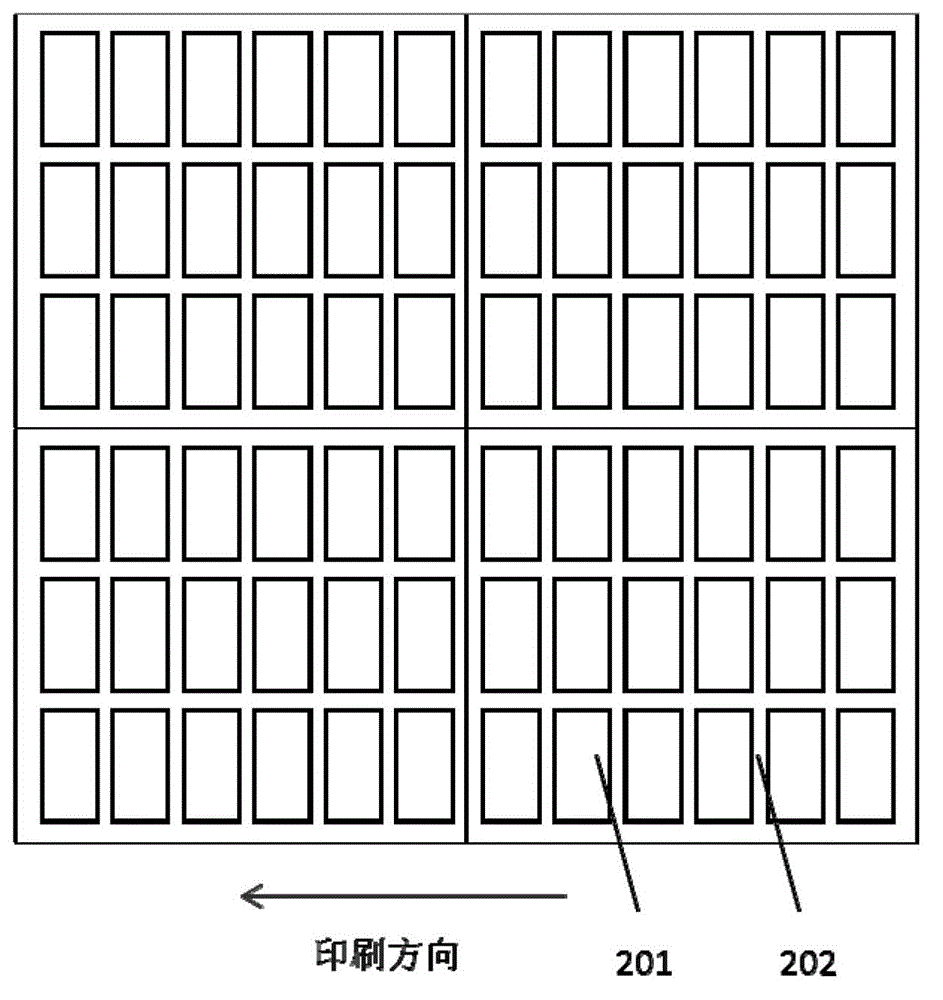

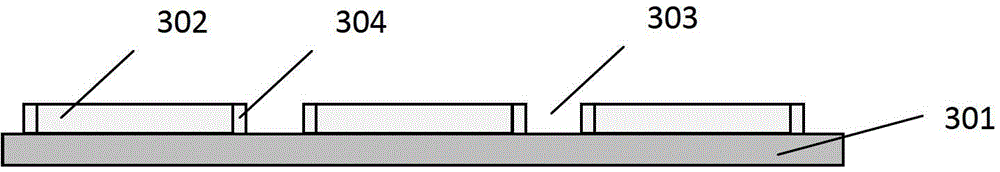

Relief printing plate structure

InactiveCN102774127BReduce vibrationRelieve pressurePlate printingFoil printingLiquid-crystal displayEngineering

A relief printing plate comprises a bearing base plate (301) and a plurality of printing patterns arranged on the bearing base plate. A space area is arranged between adjacent printing patterns. The printing pattern comprises a middle area (302) corresponding to a display area and a boundary area (304) corresponding to a non-display area, the boundary area being arranged on two sides of the middle area, and an inclined slope (404) being arranged on the boundary area along the printing direction. The relief printing plate can effectively reduce shock and boundary pressure during printing, and print an orientation material on a glass base plate evenly, so as to improve the width and the thickness of an HALO area, prevent the HALO area from affecting the liquid crystal display area, and effectively guarantee printing and display effects of an orientation film.

Owner:BOE TECH GRP CO LTD +1

A kind of encryption method and device

ActiveCN103825723BImplement encryptionGuaranteed normal printingEncryption apparatus with shift registers/memoriesVisibilityComputer hardware

The invention discloses an encryption method based on characters. The method comprises steps of building a basic transposition table?TB and using a secret key to initialize the basic transposition table to an operation transposition table?TO, converting an input character string into a plaintext sequence number string according to a pre-defined character and sequence number corresponding?table TC, using the operation transposition table?TO for carrying out transposition on the plaintext sequence number string to obtain a ciphertext sequence number string, and converting the ciphertext sequence number string into a ciphertext character string. According to the method, a character?position services as a basic processing unit, dynamic variable data length encryption is realized, length?consistency and?visibility of the ciphertext and the plaintext can be ensured, and platform adaptability and high calculation efficiency are realized.

Owner:深圳市太和物联信息技术有限公司

Large-capacity exhaust ink bag for large format printer

ActiveCN104669799BEnsure normal dischargeIsolate volatilizationPrintingMechanical engineeringExhaust pipe

The invention belongs to the field of print equipment and relates to a large-capacity exhaust ink bag for a large-width ink-jet printer. The large-capacity exhaust ink bag for the large-width ink-jet printer comprises an ink bag main body, and a small plastic disc, a large plastic disc and plastic bosses, which are arranged in the ink bag main body, wherein the plastic bosses are respectively supported between the small plastic disc and the large plastic disc through a first spring and a second spring; rubber seal components are fixed at the joint of the plastic bosses and the ink bag main body; a film buffering chamber is formed by the ink bag main body, the large plastic disc and the plastic bosses, an exhaust opening is formed in the film buffering chamber, and the exhaust opening is connected with an exhaust pipe with a shutoff valve. The large-capacity exhaust ink bag for the large-width ink-jet printer, provided by the invention, easily solves the problem that the large-width printer cannot continuously print for long time in a simple manner, and greatly improves the print speed and the print quality of the large-width printer, thereby better meeting the requirements of people on the speed and the quality of the printer.

Owner:HANGZHOU WANMENG DIGITAL EQUIP

Intelligent office energy-saving auxiliary device capable of avoiding paper jamming of printer

InactiveCN113002190AGuaranteed normal printingTo achieve the effect of automatic guidanceOther printing apparatusComputer printingGear wheel

Owner:广州丰晁玩具贸易有限公司

Log printing method and device, and log printing system

The invention discloses a log printing method and device and a log printing system. The log printing method is used in a business system, and the business system comprises multiple layers. The method comprises the steps of receiving a business request; determining a corresponding layer and a corresponding log printing component according to the business request; adopting the determined log printing component to print log information generated in the layer corresponding to the business request into a log file. According to the method, a log framework which is simple, flexible, and does not invade a business code is built, the business system does not need to add codes, when requests from different business come, the log framework built through the method prints parameters of each layer processing method and returning values to log files corresponding to different business; meanwhile, log print in business codes can also be directly printed into the log files corresponding to the business, and thus all the logs in a business request link can be printed in the same file at one time.

Owner:ADVANCED NEW TECH CO LTD

Packaging Box Printing Process to Prevent Excessive Emulsification and Residue of Ink

ActiveCN109677119BCooling effectReduce emulsificationRotary pressesPrinting press partsProcess engineeringMagnetic stirrer

The invention discloses a packaging box printing technology for preventing ink over emulsification and residue generation. The packaging box printing technology comprises the steps that after a printcylinder of a printing machine is separated from paper, the surface of the print cylinder is blown through a first air supply device; the ink surface is blown through a second air supply device at a border just in contact with ink when the print cylinder of the printing machine dips ink; the ink surface is blown through a third air supply device at a part separated from ink after the print cylinder of the printing machine dips ink; and a plurality of rotors which can fill the inner bottom of an ink pond are put into the ink pond of the printing machine, and the rotors are driven to rotate through a magnetic stirrer at the bottom of the outer side of the ink pond. According to the packaging box printing technology, mixing of substances like fountain solutions during ink printing is effectively reduced during the printing stage, over emulsification and generation of large-particle substances which affect the printing effect in ink are prevented, printing quality can be guaranteed, printing efficiency is greatly improved, and residual ink after printing can be normally utilized in a relatively long time.

Owner:苏州恒辰印刷科技有限公司

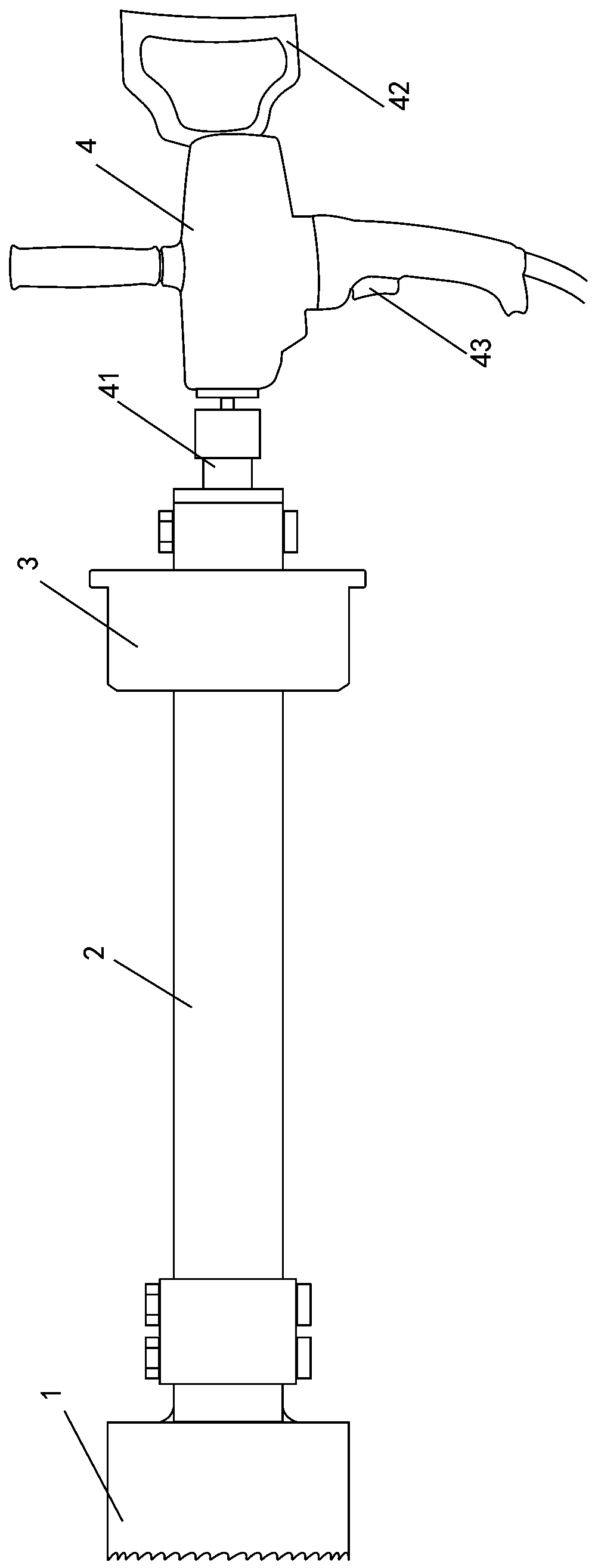

High-effectively production roll paper core deformation repair device and method

PendingCN110253965AGuaranteed normal printingRepair inner diameterMechanical working/deformationRolling paperDrive shaft

The invention provides a high-efficiency production roll paper core deformation repair device and method. The device comprises a drill bit, a transmission shaft, a locating sleeve and a handheld electric drill. The drill bit is composed of a section A and a second B. The section B is provided with sawteeth. The section B serves as the connecting end. The transmission shaft is a hollow cylindrical tube. The ends C and D of the transmission shaft are both provided with fixing screw holes. The section B of the drill bit is connected and fixed to the end C of the transmission shaft through a fixing sleeve. The locating sleeve is arranged on the transmission shaft and can move back and forth on the portion, between the screw holes of the two ends C and D of the transmission shaft, of the cylindrical tube. The end D of the transmission shaft is further provided with a connector. The handheld electric drill clamps the connector through a drill chuck to provide rotating power for the repair device. After deforming, a roll paper core tube can be quickly repaired through the device and method provided by the invention so that a paper core shaft can smoothly and rapidly penetrate through the roll paper core tube. The high-efficiency production roll paper core deformation repair device ensures normal use of roll paper, is easy to operate and fast and convenient to maintain and greatly improves the production efficiency.

Owner:长沙晚报利德印务有限公司

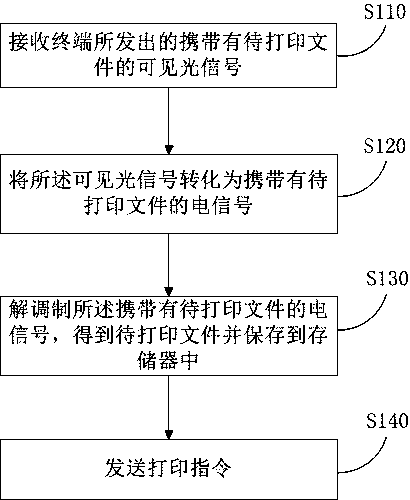

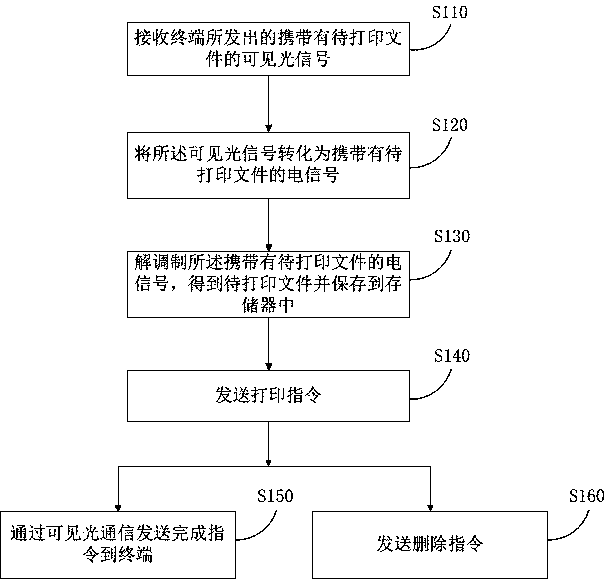

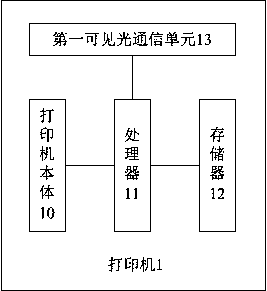

Self-service printing method, self-service printer and system

PendingCN108257324APrevent leaksIncrease printing speedApparatus for meter-controlled dispensingElectric signalComputer engineering

The invention provides a self-service printing method. The method comprises the steps that a visible optical signal which carries a to-be-printed file and is sent by a terminal is received; the visible optical signal is converted into an electric signal carrying the to-be-printed file; the electric signal carrying the to-be-printed file is demodulated, and the to-be-printed file is obtained and saved in a storage; a printing instruction is sent, wherein the printing instruction is used for printing the to-be-printed file. Accordingly, the problem that in the prior art, self-printing has security risks is solved, and the self-service printing method, a self-service printer and a system which can prevent privacy file leakage and are high in security are provided.

Owner:FOSHAN HUANYUN TECH CO LTD

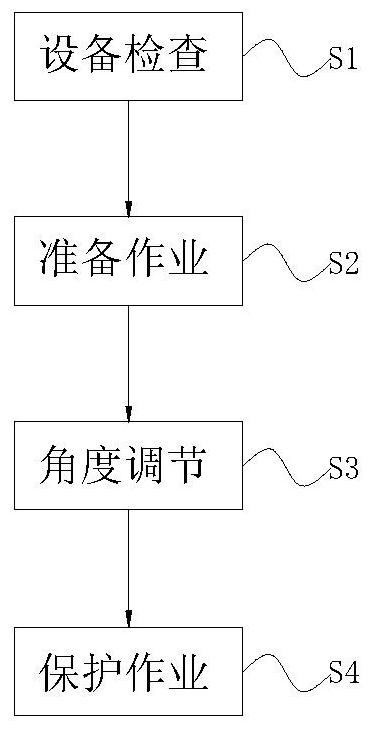

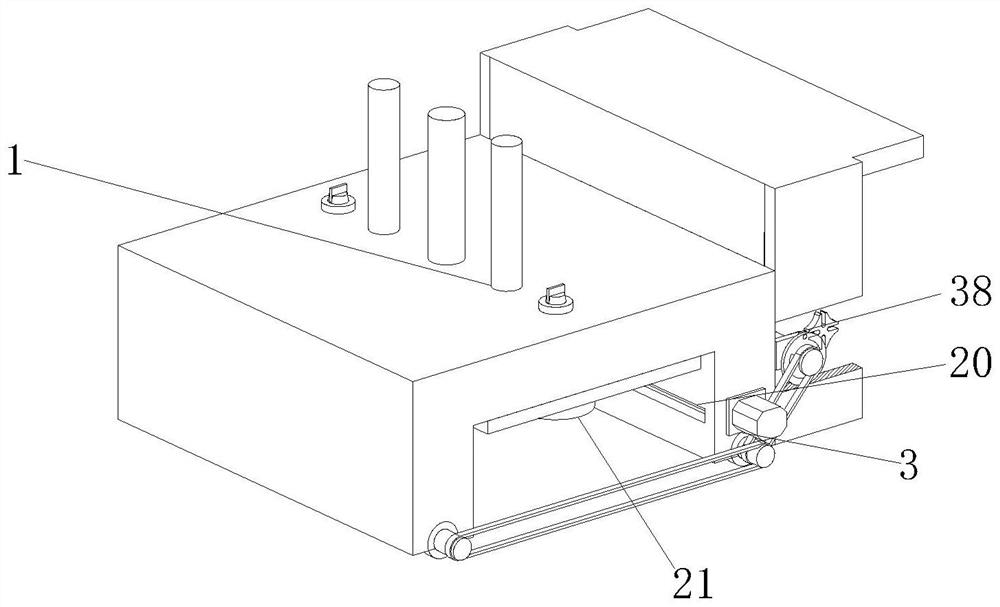

Municipal road building construction method

ActiveCN112878165AImprove convenienceGuaranteed normal printingRoad cleaningRoads maintainenceArchitectural engineeringBuilding construction

The invention provides a municipal road building construction method, and relates to the field of municipal highways. Equipment comprises an angle adjusting device and a moving device, and the angle adjusting device is fixedly connected to the moving device. According to the method, automatic municipal road marking construction can be achieved, manual participation is reduced, and cost consumption is reduced; and secondly, multi-angle road marking construction can be carried out, the problem that marking construction is single is solved, meanwhile, the equipment can carry out inclined line construction only in the moving process, tedious manual operation on the equipment is avoided, and the construction efficiency is improved.

Owner:武汉金涛本顺市政工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com