Preparation method of ceramic material

A technology of ceramic materials and alumina ceramics, applied in the field of ceramics, can solve the problems of low hardness of ceramic materials, and achieve the effects of improving density, increasing hardness and overcoming low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

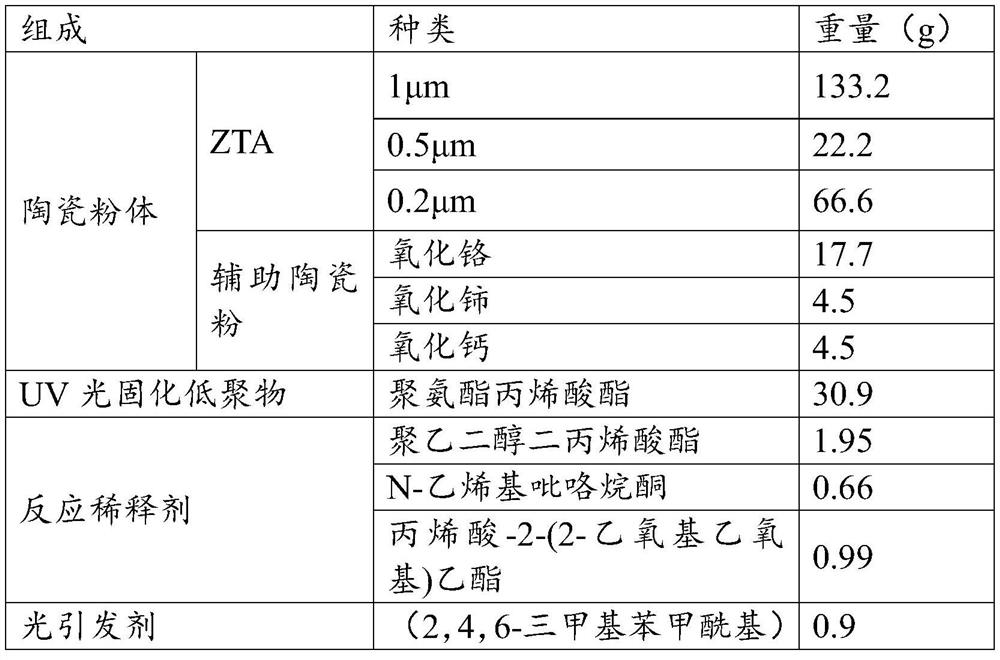

[0070] This embodiment provides a preparation method of a ceramic material, comprising the following steps:

[0071] (1) Preparation of ceramic green body slurry:

[0072] Step S1: Mix 1 μm, 0.5 μm and 0.2 μm ZTA (the mass ratio of zirconia and alumina in ZTA is 1:8) and mix with auxiliary ceramic powder (chromium oxide, cerium oxide, calcium oxide), add surface active Agent (oleic acid) and 50g dehydrated ethanol, after 500r / min ball milling 6h, dry to constant weight, grind, cross 200 mesh sieves, obtain the ceramic powder body of surfactant modification;

[0073] S2 step: UV photocurable oligomer (polyurethane acrylate), reaction diluent (polyethylene glycol diacrylate, N-vinylpyrrolidone, acrylate-2-(2-ethoxyethoxy) ethyl ester ), photoinitiator ((2,4,6-trimethylbenzoyl) diphenylphosphine oxide), polymerization inhibitor (hydroquinone), light absorber (2-(2'-hydroxyl-3 ', 5'-di-tert-phenyl)-5-chlorinated benzotriazole), stirred evenly at 60°C on a heating platform covere...

Embodiment 2

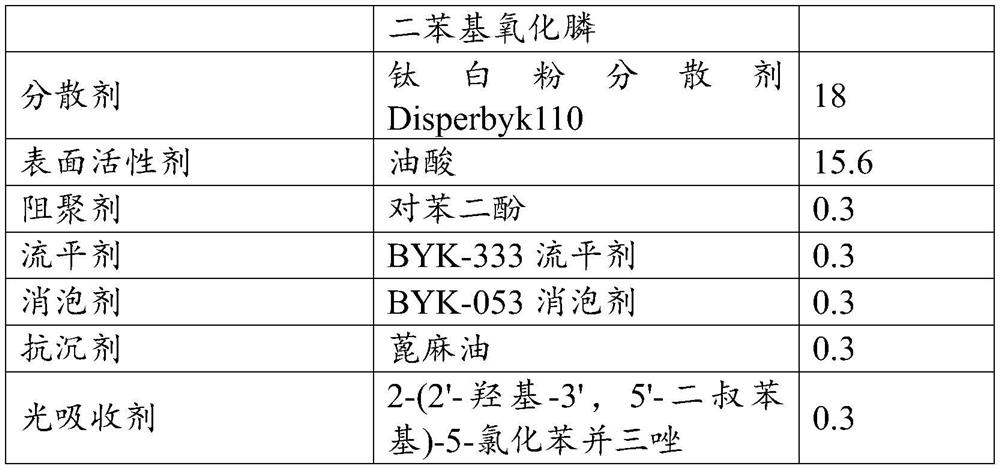

[0087] This embodiment provides a preparation method of a ceramic material, comprising the following steps:

[0088] (1) Ceramic body slurry preparation:

[0089] S1 step: mix 0.8 μm and 0.2 μm ZTA (mass ratio of zirconia and alumina in ZTA is 1:9) and mix with auxiliary ceramic powder (chromium oxide, zinc oxide), add surfactant (triton X-100) and 55g of absolute ethanol, dried to constant weight after ball milling at 500r / min for 6h, ground, and crossed a 200-mesh sieve to obtain a surfactant-modified ceramic powder;

[0090] Step S2: UV photocurable oligomer (bisphenol A type epoxy acrylate), reaction diluent (polyethylene glycol diacrylate, trimethylolpropane triacrylate, isobornyl acrylate), photoinitiated Agent (phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide), polymerization inhibitor (2,6-di-tert-butyl-4-methylphenol), light absorber (2-( 2H-benzotriazol-2-yl)-4,6-bis(1-methyl-1-phenylethyl)phenol), stirred evenly at 80°C on a heating platform covered with a black l...

Embodiment 3

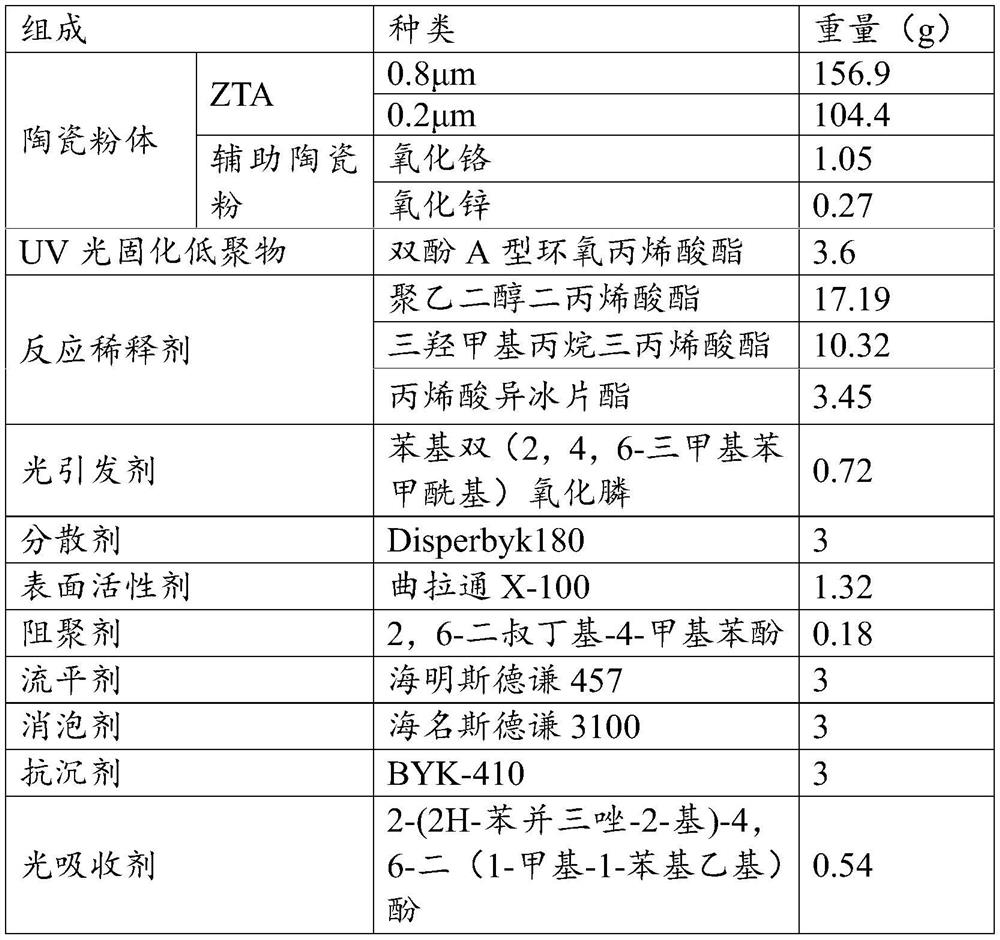

[0103] This embodiment provides a preparation method of a ceramic material, comprising the following steps:

[0104] (1) Preparation of ceramic green body slurry:

[0105] Step S1: Mix 1 μm, 0.5 μm and 0.2 μm ZTA (the mass ratio of zirconia and alumina in ZTA is 1:10) and mix it with auxiliary ceramic powder (chromium oxide, zinc oxide), add surfactant (oil acid) and 50g of absolute ethanol, dried to constant weight after ball milling at 500r / min for 6h, ground, and passed through a 200-mesh sieve to obtain a surfactant-modified ceramic powder;

[0106] S2 step: UV photocurable oligomer (bisphenol A type epoxy acrylate), reaction diluent (tripropylene glycol diacrylate, 1,6-hexanediol diacrylate, ditrimethylol propane tetraacrylic acid ester), photoinitiator ((2,4,6-trimethylbenzoyl) diphenylphosphine oxide), polymerization inhibitor (hydroquinone), light absorber (2-(2H-benzotri Azol-2-yl)-4,6-di-tert-amylphenol), stirred evenly at 55°C on a heating platform covered with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com