Patents

Literature

340 results about "Tripropylene glycol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

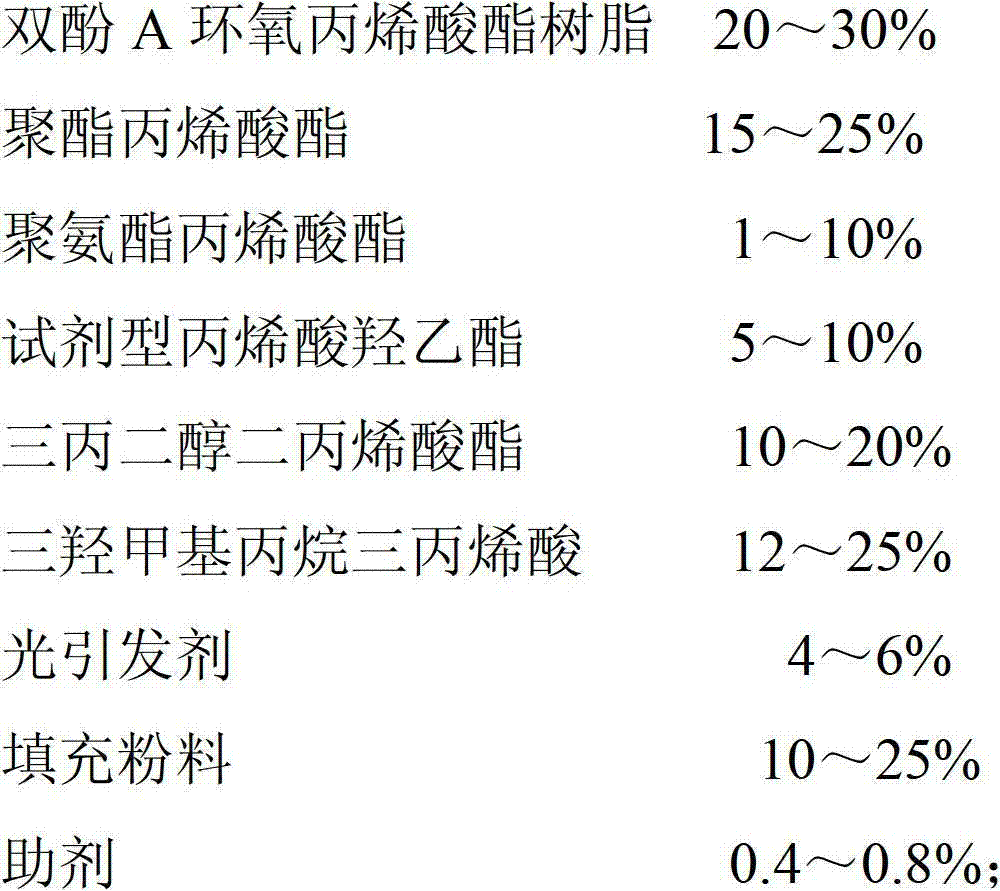

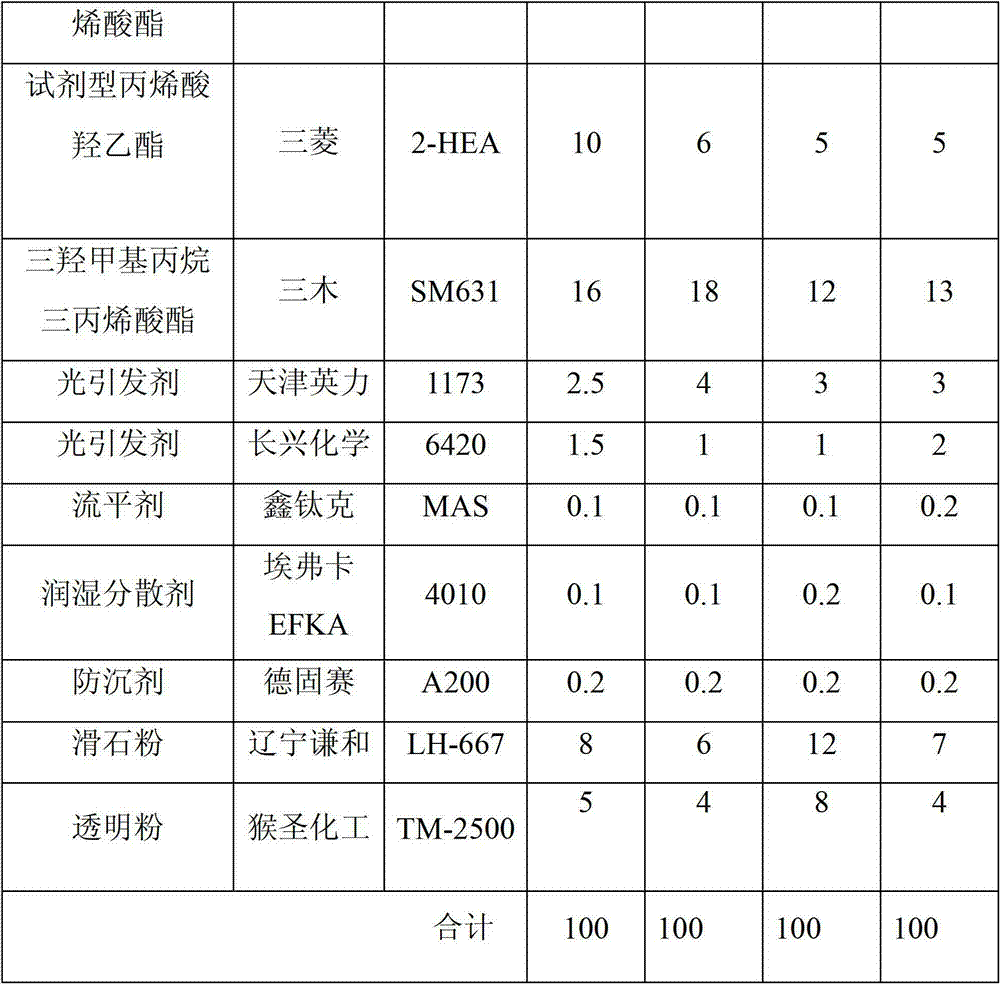

Ultraviolet light curing transparent priming paint and preparation method and use method thereof

ActiveCN102952455AReduce lossImprove product qualityPolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycolPolyester

The invention discloses an ultraviolet light curing transparent priming paint and a preparation method and a use method thereof. The ultraviolet light curing transparent priming paint comprises the following components in percentage by weight: 20-30% of bisphenol A epoxy acrylate resin, 15-25% of polyester acrylate, 1-10% of urethane acrylate, 5-10% of reagent type hydroxyethyl acrylate, 10-20% of tripropylene glycol diacrylate, 12-25% of trimethylolpropane triacrylate, 4-6% of photoinitiator, 10-25% of filling powder and 0.4-0.8% of promotor. The ultraviolet light curing transparent priming paint is suitable for laser roller construction, has good grittiness and transparency, has the characteristics that sanding is not needed for semi-curing recoating between film layers and the like, and has thick coating performance and the performance that the surface is similar to a mirror surface, and compared with conventional roller coating, the coating weight is greatly increased, roller coating processes are saved, the priming paint is sanded by a sanding machine without large pressure and with a small number of sanded films, a workpiece has no bright spots, the fullness of a product is guaranteed, the product quality is improved, the loss of the machine is smallreduced, and the use amount of sanding belts is greatly reduced.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

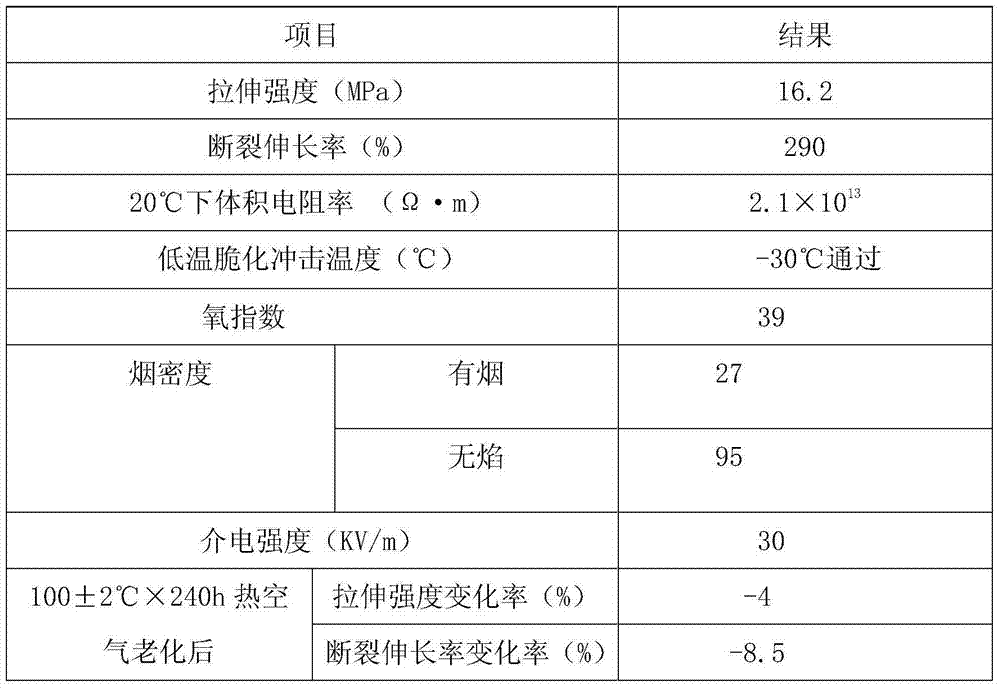

Low-smoke halogen-free flame-retardant polyolefin cable material

ActiveCN103571008AGood dispersionImprove uniformityPlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneTripropylene glycol

The invention provides a low-smoke halogen-free flame-retardant polyolefin cable material which is prepared from the following raw materials in parts by weight: 30-40 parts of ethylene-vinyl acetate copolymer (EVA), 50-70 parts of high-density polyethylene (HDPE), 4-5 parts of chlorinated polyethylene, 15-20 parts of low-density polyethylene, 40-50 parts of aluminum hydroxide (Al(OH)3), 30-40 parts of magnesium hydroxide (Mg(OH)2), 5-6 parts of amino-terminated polyol ester, 2-3 parts of tributyl phosphate, 5-8 parts of epoxy soybean oil, 5-7 parts of glycerol, 1-2 parts of antioxidant 1035, 1-2 parts of barium stearate, 1-2 parts of nano silicon carbide, 1-2 parts of tripropylene glycol diacrylate, 1-2 parts of phosphate, 1.0-3.0 parts of PE (polyethylene) wax, 1-2 parts of silane coupling agent KH-550, 1-2 parts of zinc stearate and 15-18 parts of modifying filler. Due to the adoption of the technical scheme, the dispersibility of the low-smoke halogen-free flame-retardant polyolefin cable material is obviously enhanced, and the uniformity and surface smoothness of the material system are enhanced.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

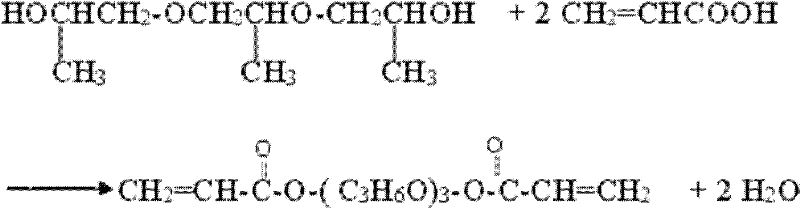

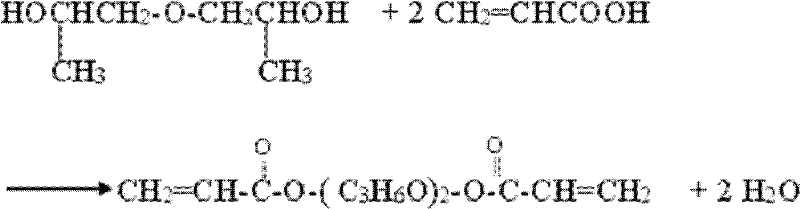

Clean production method of dipropylene glycol diacrylate (DPGDA) or tripropylene glycol diacrylate (TPGDA)

ActiveCN102491896ANo processing costsGreen and Clean Production MethodsOrganic compound preparationCarboxylic acid esters preparationTripropylene glycolDipropylene glycol diacrylate

The invention which belongs to the light-cured material field relates to a clean production method of DPGDA or TPGDA. The method concretely comprises the following steps: 1, carrying out esterification reflux dehydration on dipropylene glycol / tripropylene glycol, acrylic acid, a catalyst, a solvent, a polymerization inhibitor and an antioxidant; 2, adding sodium hydroxide and a small amount of water to neutralize; 3, adding a magnesium polysilicate adsorbent to adsorb a salt generated through neutralization; 4, carrying out reduced pressure dehydration and desolventization; 5, press-filtering to filter out magnesium polysilicate and the salt absorbed thereby; 6, adding alkaline calcium bentonit and calcium oxide to decolor, remove trace water and remove trace acids; 7, press-filtering; and 8, carrying out product index detection. The clean production method of the DPGDA or the TPGDA of the invention, which has the advantages of high yield, economic benefit possessing and environmental benefit possessing, fundamentally solves an organic wastewater pollution problem in the production process of the DPGDA or the TPGDA.

Owner:JIANGSU LITIAN TECH

Ceramic pulp for photo-curable 3D printing and preparation method and application of ceramic pulp

ActiveCN110627501AHigh viscosityAdditive manufacturing apparatusCeramic shaping apparatusTripropylene glycolMeth-

The invention discloses ceramic pulp for photo-curable 3D printing and a preparation method and application of the ceramic pulp. The ceramic pulp includes ceramic powder, photo-curable resin, a photoinitiator and a dispersant, wherein the photo-curable resin comprises the components: in percent by mass, 10-60% of bisphenol A epoxy acrylate, 10-60% of trimethylolpropane triacrylate, 10-60% of tripropylene glycol diacrylate and 10-60% of isobornyl methacrylate. The rheological performance of the slurry can be adjusted through selection of reactive diluents with different functionalities and adjustment of the ratio of the diluents, needs of light curing molding can be met by the slurry, and degreasing and sintering are performed on a molded sample so as to obtain a high-density zirconia ceramic product with a relative density of up to 98.8%.

Owner:SHENZHEN RES INST CENT SOUTH UNIV +1

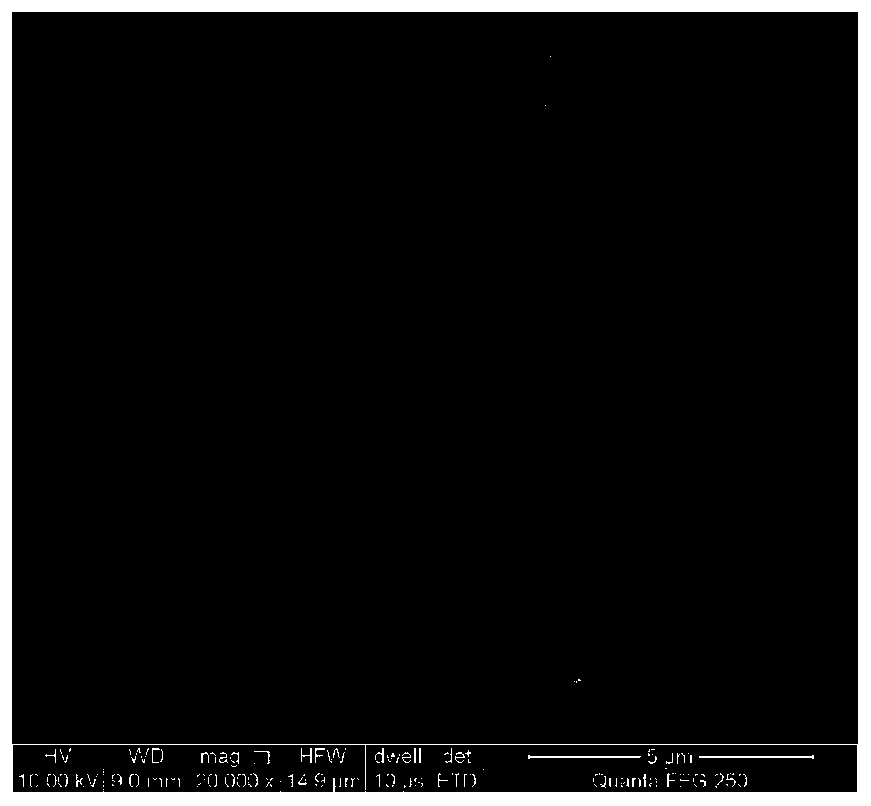

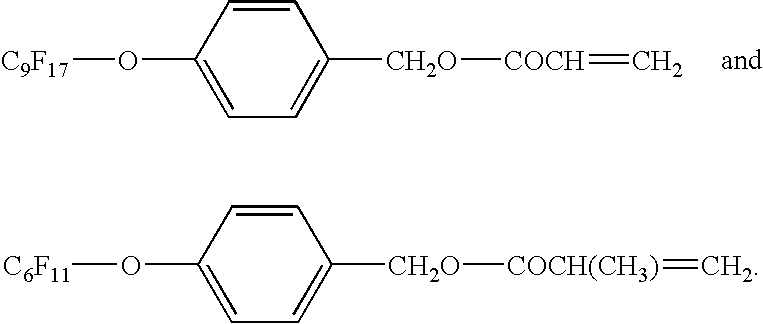

Aqueous water-and oil-repellent dispersion

An aqueous water- and oil-repellent dispersion containing: (A) a homopolymer or copolymer containing at least one polymerizable compound having a perfluoroalkyl or perfluoroalkenyl group and an acrylate or methacrylate group, or a copolymer containing said polymerizable compound and another compound copolymerizable therewith, (B) an organic solvent which is tripropylene glycol, and (C) a surfactant, has durable water- and oil-repellency and excellent storage stability.

Owner:DAIKIN IND LTD

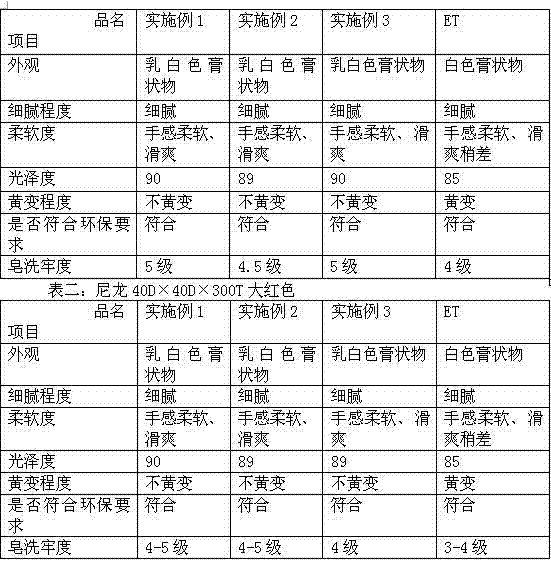

Weather-resistant leather finishing agent

InactiveCN102977764AImprove wear resistanceSolve the defect of easy yellowingPolyurea/polyurethane coatingsLeather surface finishingTripropylene glycolPolymer science

Owner:QINGDAO WINCHANCE TECH

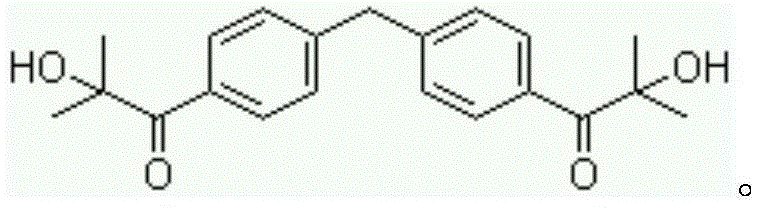

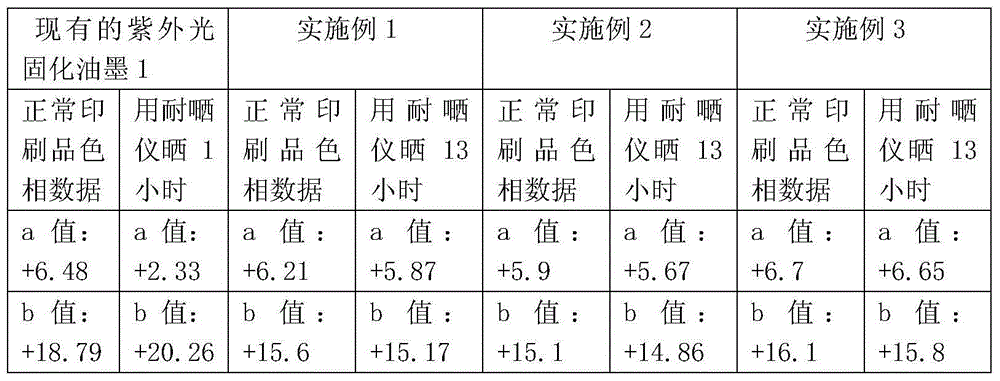

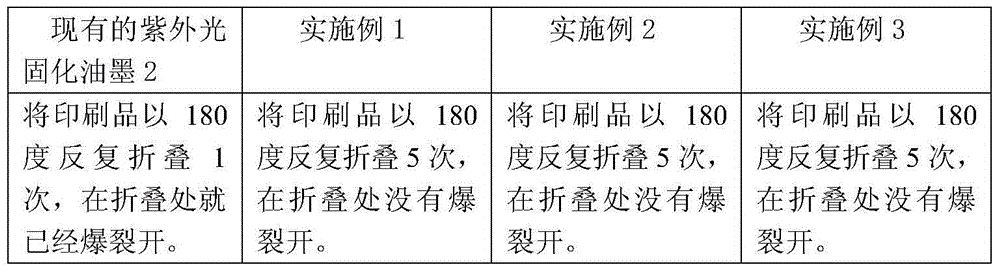

Ultraviolet curing ink and preparation method thereof

ActiveCN104804527AGood yellowing resistanceNot easy to yellowInksTripropylene glycolFolding endurance

Ultraviolet curing ink comprises the following components in weight proportion: 24-35% of polyurethane acrylate, 14-25% of epoxy acrylate, 15-25% of tripropylene glycol diacrylate, 15-25% of 1,1,1-trimethylol propane triacrylate, 0.5-2.5% of 1,1'-(methylenedi-4,1-phenylene)bis[2-hydroxyl-2-methyl-1-acetone],0.5-1.5% of Oligo[2-hydroxy-2-methyl-1-[4-(1-methylvinyl)phenyl]propanone], 0.1-1% of polydimethylsiloxane, 0.1-1% of polyether modified polysiloxane and 1-5% of polyethylene wax. The invention further provides the preparation method of the ultraviolet curing ink. According to the ultraviolet curing ink, an ink printing layer with a wrinkle effect is formed after the ultraviolet curing ink is cured after printing, and the ink printing layer has good anti-yellowing performance and good folding endurance.

Owner:SHANTOU DONGFENG PRINTING CO LTD

High temperature resistant release coating material for artificial synthetic leather release paper, and preparation method and application thereof

ActiveCN103740262AClear textureRealistic texturePolyurea/polyurethane coatingsTextiles and paperTripropylene glycolMethacrylate

The invention relates to a high temperature resistant release coating material for artificial synthetic leather release paper, and a preparation method and an application thereof. The release coating material is composed of modified urethane acrylate, modified epoxy acrylate, tripropylene glycol diacrylate, trimethylolpropane triacrylate ethoxylate, perfluoromethacrylate and gamma-methylacryloxypropyltrimethylsilane. A method for preparing the high temperature resistant release coating material for the artificial synthetic leather release paper comprises the steps of orderly putting all the components in a container, mixing and stirring so that the solid components are dissolved, and thus obtaining an even and approximately transparent coating. The release paper is clear and vivid in lines; due to the optimization of the formula, the release paper can be caused to be moderate in hardness, good and stable in release property, numerous in repeated use times, and excellent in solvent resistance and high-temperature resistance.

Owner:ZHEJIANG KAREN SPECIALTY MATERIALS

UV film-pressed yellowing-resistant topcoat gloss paint

ActiveCN103289456ADry fastImprove the decorative effectPolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycolPolymer science

The invention provides an UV (Ultra Violet) film-pressed yellowing-resistant topcoat gloss paint, comprising the following components by weight percent: 35%-45% of functional monomer, 17%-23% of polyurethane acrylate, 26%-40% of epoxy acrylic resin, 0.2-0.3% of defoamer, 0.4%-0.6% of flatting agent and 5%-7% of photoinitiator. The functional monomer is a mixture of hydroxyethyl methacrylate, dipropylene glycol diacrylate, tripropylene glycol diacrylate and trimethylolpropane triacrylate. The UV film-pressed yellowing-resistant topcoat gloss paint provided by the invention is good in adhesive force, excellent in resistance to yellowing, low cost, simple and flexible to operate, high in drying speed, free of waste and high in production efficiency.

Owner:上海展辰涂料有限公司 +1

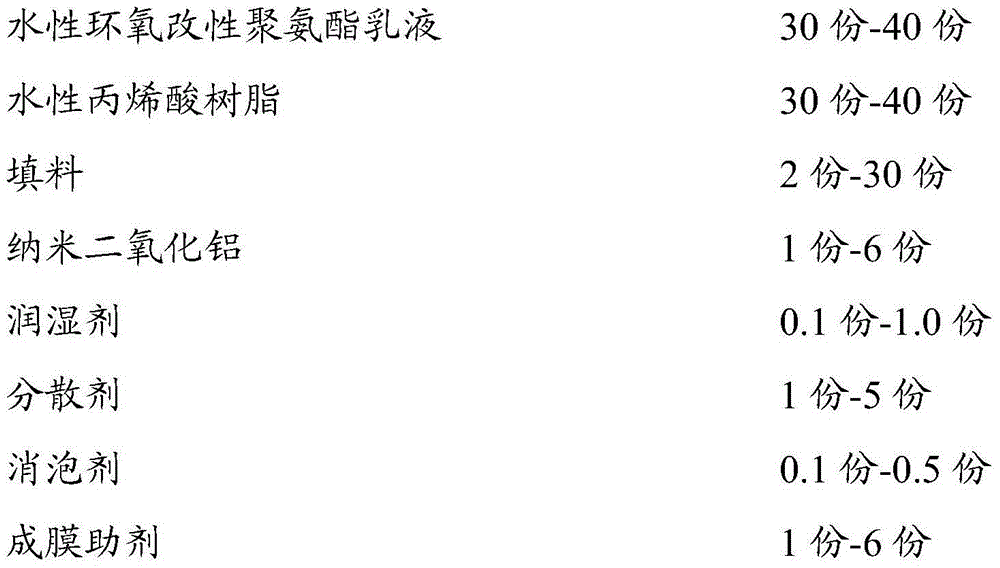

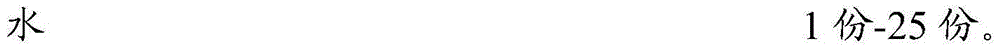

Single-component water-based wood paint

InactiveCN104817946AHigh glass transition temperatureHigh hardnessPolyurea/polyurethane coatingsTripropylene glycolEpoxy

The invention relates to a single-component water-based wood paint which comprises the following components in parts by weight: 30-40 parts of water-based epoxy modified polyurethane emulsion, 30-40 parts of water-based acrylic resin, 2-30 parts of filler, 1-6 parts of nano aluminum dioxide, 0.1-1.0 part of wetting agent, 1-5 parts of dispersing agent, 0.1-0.5 part of defoaming agent, 1-6 parts of film-forming assistant and the balance of water. The water-based acrylic resin is a hydroxy acrylic resin in which the mass content of hydroxy group is 0-2-0.4 part. The film-forming assistant is prepared by mixing the following components in parts by weight: 60-90 parts of tripropylene glycol monobutyl ether and 10-40 parts of alcohol ester-12. The single-component water-based wood paint has the advantages of excellent water resistance, excellent wear resistance, excellent adhesive force, favorable film effect, high film hardness, high drying speed and low cost.

Owner:广东朗法博涂装新材料科技有限公司

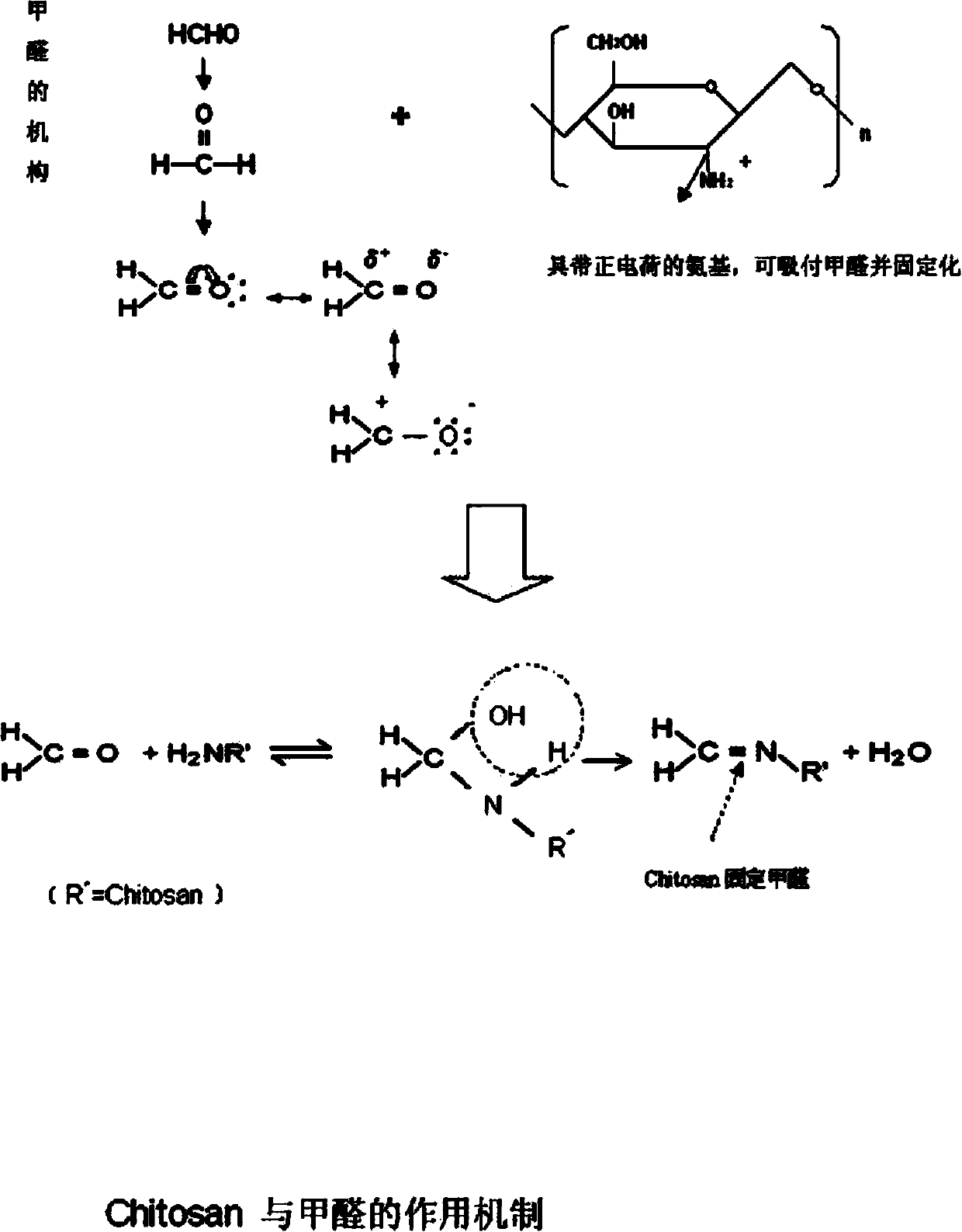

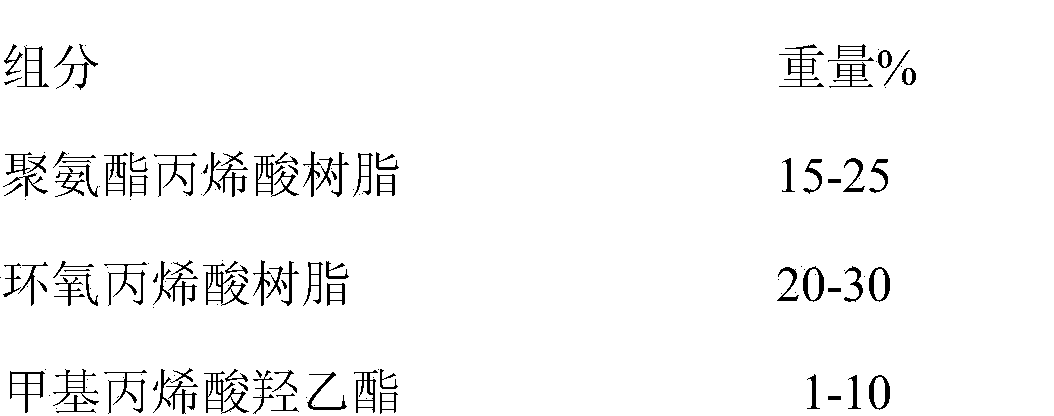

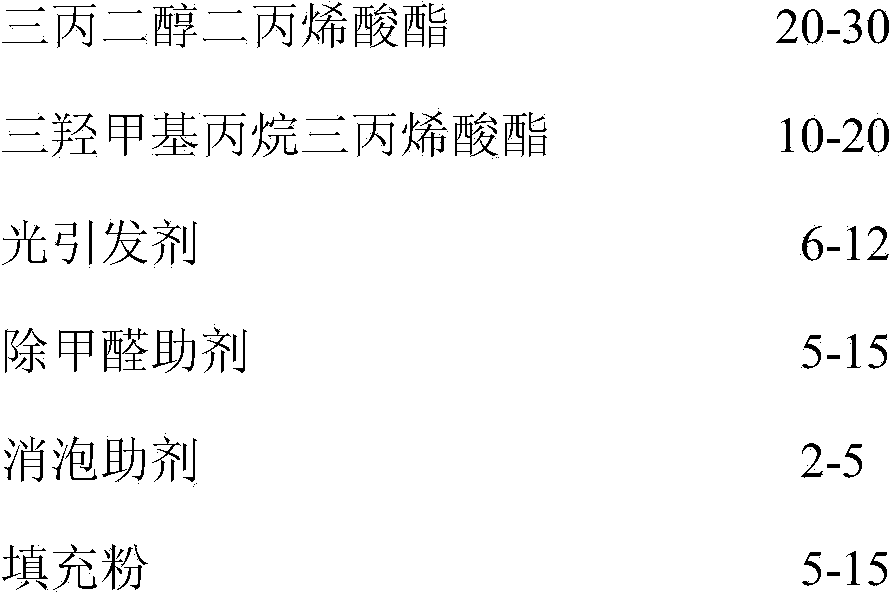

Novel photo-curing formaldehyde removing environment-friendly coating and preparation method of novel photo-curing formaldehyde removing environment-friendly coating

ActiveCN103589327AImprove toughnessImprove wear resistancePolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycol(Hydroxyethyl)methacrylate

The invention discloses a novel photo-curing formaldehyde removing environment-friendly coating and a preparation method of the novel photo-curing formaldehyde removing environment-friendly coating. The novel photo-curing formaldehyde removing environment-friendly coating comprises, by weight, 15-25% of polyurethane acrylic resin, 20-30% of epoxy acrylic resin, 1-10% of hydroxyethyl methylacrylate, 20-30% of tripropylene glycol diacrylate, 10-20% of trimethylolpropane trimethylolpropane triacrylate, 6-12% of photoinitiator, 5-15% of formaldehyde removing assistant, 2-5% of defoaming assistant and 5-15% of filling powder. The novel photo-curing formaldehyde removing environment-friendly coating prepared with the formula and the preparation method has the good formaldehyde purification performance and the good formaldehyde purification effect durability.

Owner:东周化学工业(昆山)有限公司

Cleaning method to remove flux residue in electronic assembly

InactiveUS6503874B2Surface-active detergent compositionsDetergent mixture composition preparationTripropylene glycolCleaning methods

This invention provides a method for removing flux residue and similar other residues formed on the surfaces of micro electronic components during soldering operations using solder paste and fluxing agents in electronic module assembly component fabrication by a semi-aqueous solvent cleaning process using propylene glycol alkyl ether solvents, preferably the mono alkyl ethers, as replacements for xylene. The electronic components may contain plastic components, for example, a plastic grid array (PBGA) in addition to silicon device chip(s), C4 decaps and SMTs on a ceramic chip carrier with solder columns. Preferred solvents are dipropylene glycol mono methyl ether and tripropylene glycol mono methyl ether, which are both water soluble.

Owner:IBM CORP

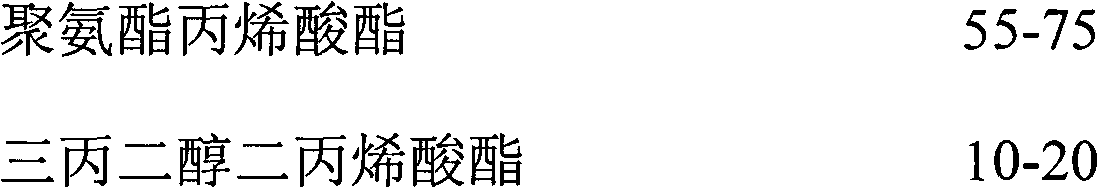

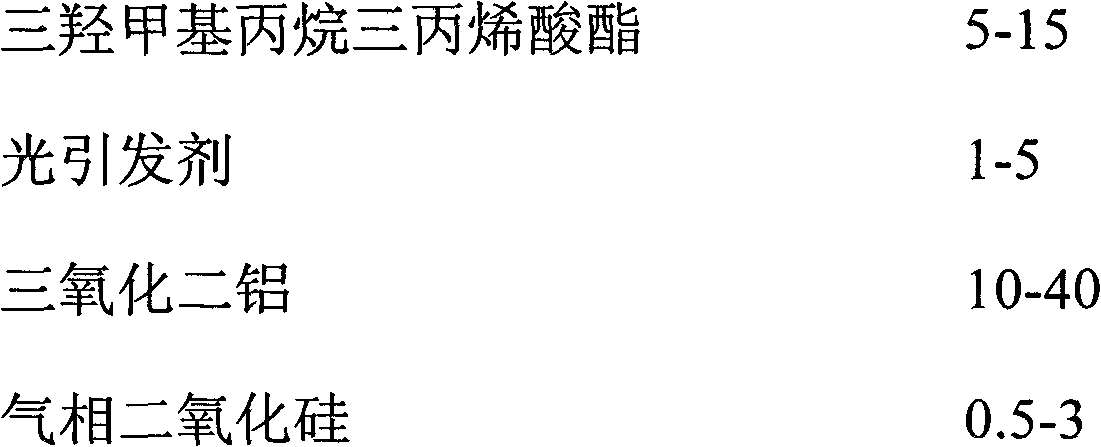

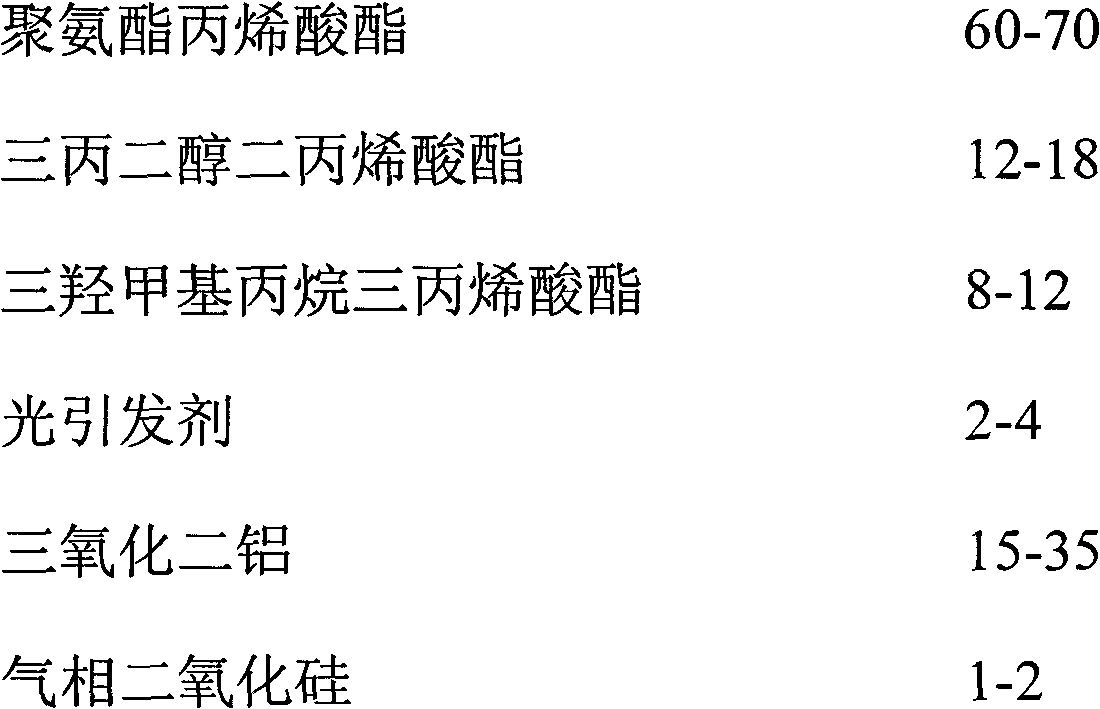

Ultraviolet wear resistant primer and preparation method thereof

ActiveCN102618163AImprove clarityImprove wear resistancePolyurea/polyurethane coatingsTripropylene glycolWear resistant

The invention discloses an ultraviolet wear resistant primer and a preparation method thereof. The ultraviolet wear resistant primer comprises the following components in parts by weight: 55-75 of urethane acrylate, 10-20 of tripropylene glycol diacrylate, 5-15 of trimethylolpropane triacrylate, 1-5 of photoinitiator, 10-40 of aluminum oxide and 0.5-3 of fumed silica. The preparation method provided by the invention comprises the following steps of: firstly mixing, dissolving and stirring the tripropylene glycol diacrylate and the trimethylolpropane triacrylate, then adding the photoinitiator and stirring, adding the urethane acrylate for blending and stirring, adding the fumed silica and the aluminum oxide while stirring, stirring for 10-20 minutes after addition, resting for 1-2h, and filtering by using a filter screen to obtain the ultraviolet wear resistant primer. The ultraviolet wear resistant primer provided by the invention has good wear-resistant performance and high hardness; after wood floors are coated by the ultraviolet wear resistant primer, and the wood floors have good whole definition; and the formula is simple and reasonable. The preparation method provided by the invention has the advantages that the technology is simple and the processing is convenient.

Owner:上海蓝宝涂料有限公司

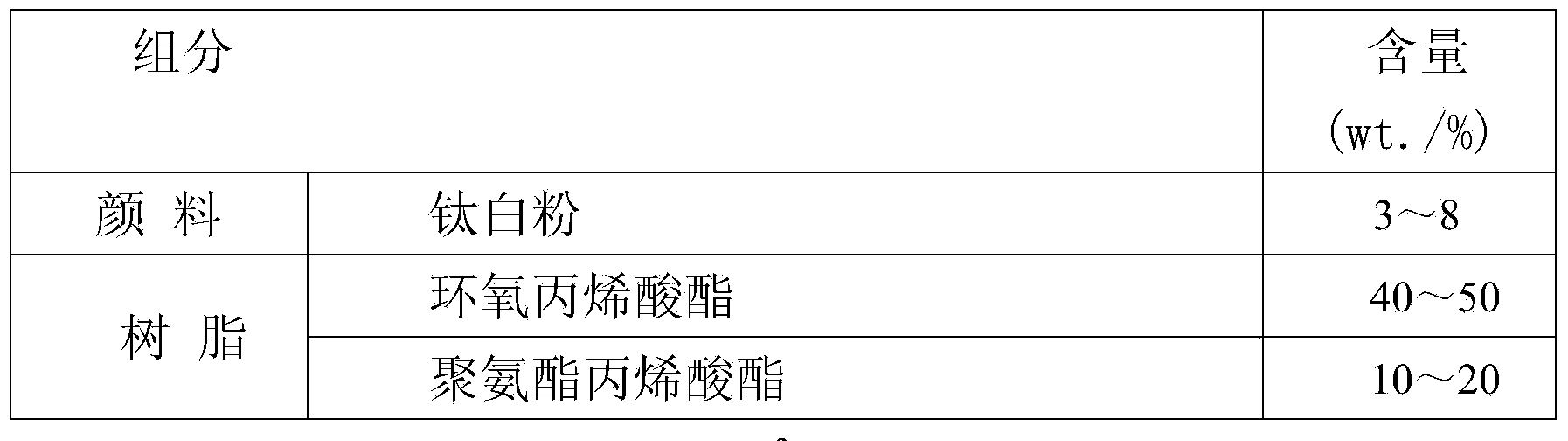

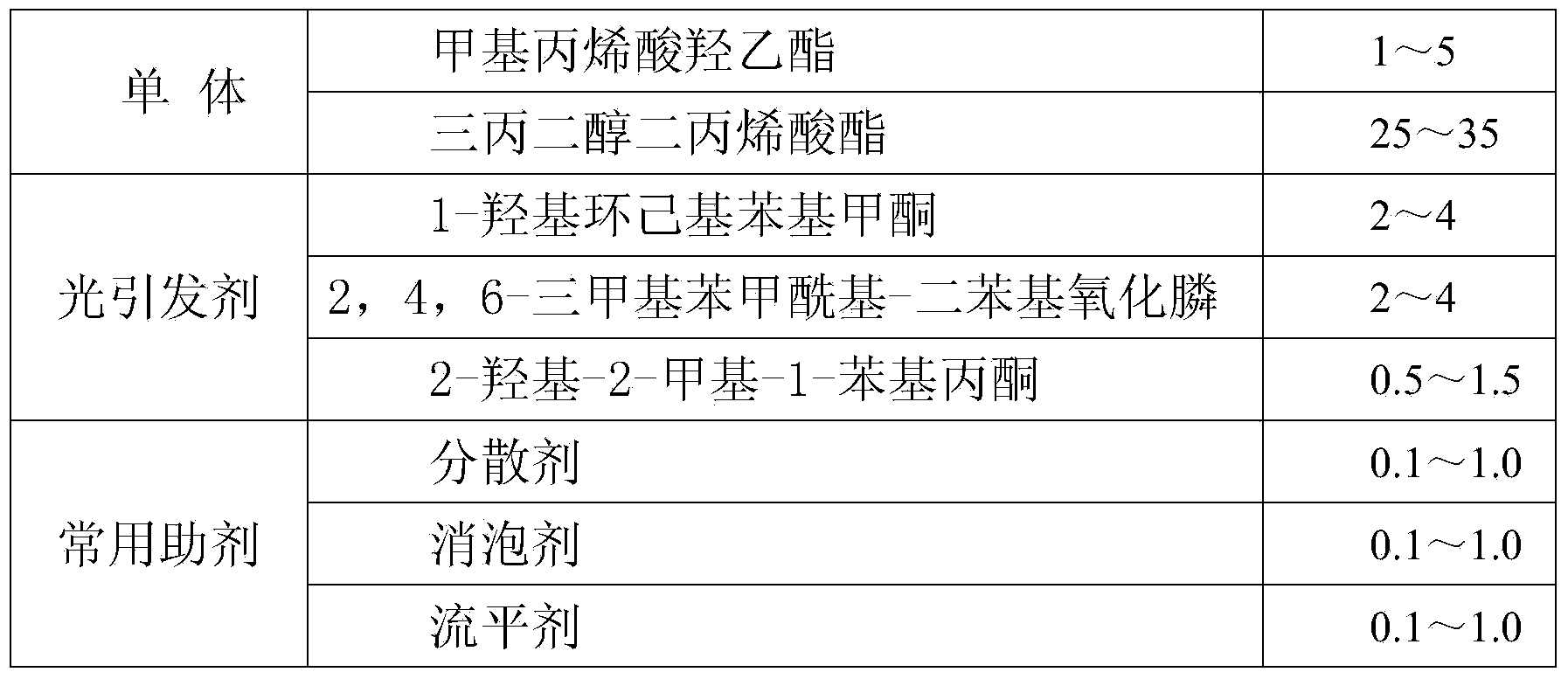

White ultraviolet curing finishing coat

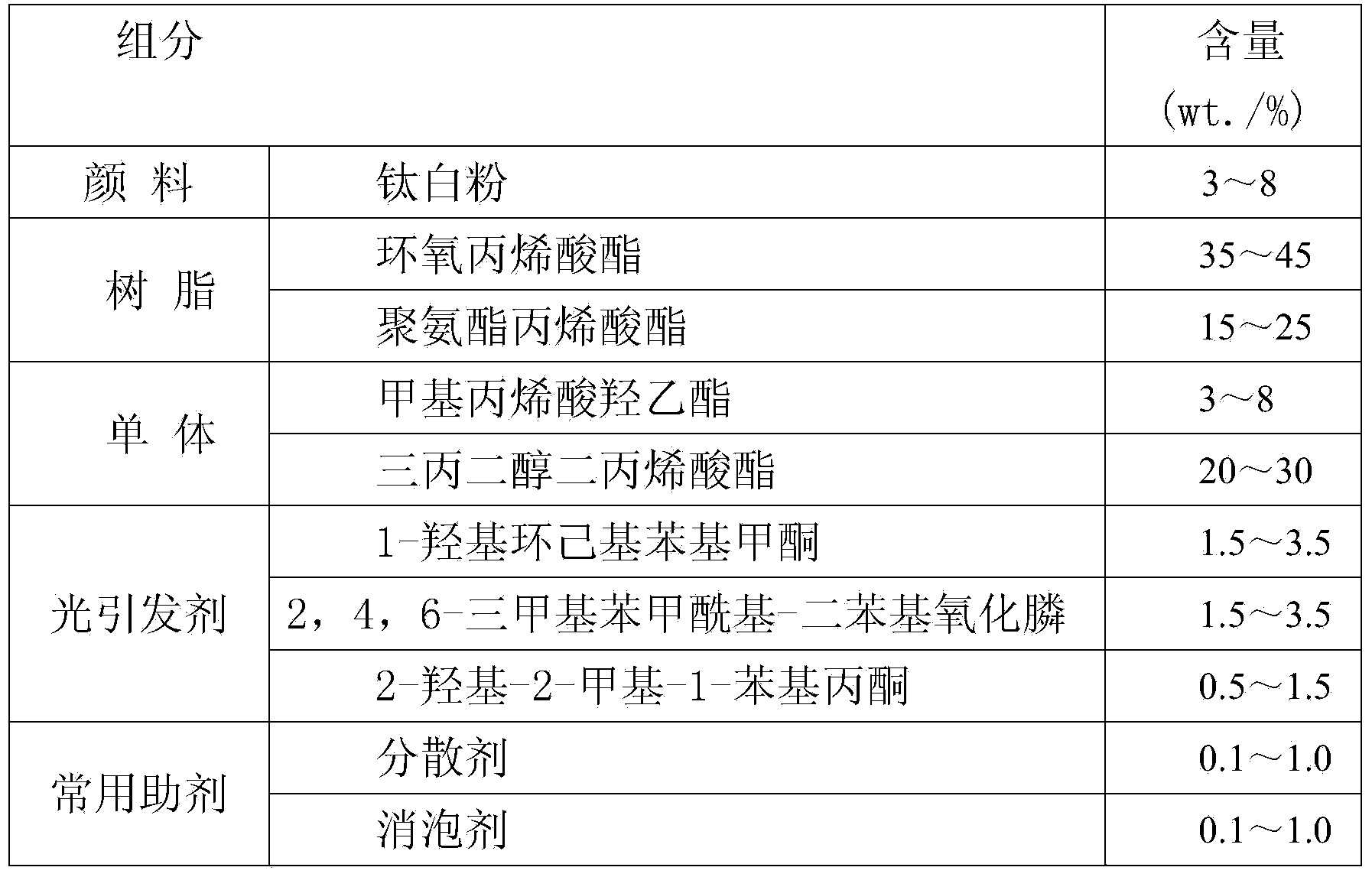

ActiveCN103709906AFast curingIncrease productivityPolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycol(Hydroxyethyl)methacrylate

The invention discloses a white ultraviolet curing finishing coat which consists of the following components by weight percent: 50-70 percent of resin, 23-40 percent of an acrylate compound monomer, 4.5-9.5 percent of a photo-initiator and 0.3-3.0 percent of an aid, wherein the resin is a mixture consisting of epoxy acrylate and urethane acrylate; the acrylate compound monomer is one or a mixture of two of hydroxyethyl methylacrylate, tripropylene glycol diacrylate, 1,6-hexanediol diacrylate, dipropylene glycol diacrylate and trimethylolpropane triacrylate. The white ultraviolet curing finishing coat can be sprayed instead of the conventional solvent based coating, and has the advantages of high curing speed, high production efficiency, lower plate production cost, energy saving, carbon reduction and the like.

Owner:东周化学工业(昆山)有限公司

Method for preparing tri(propylene glycol) diacrylate

ActiveCN101462954AWide variety of sourcesEasy to getOrganic compound preparationCarboxylic acid esters preparationTripropylene glycolSolvent

The invention belongs to a method for preparing tripropylene glycol diacrylate ester, comprising the steps as follows: (1) tripropylene glycol, acrylic acid, catalyst, solvent and polymerization inhibitor are put into a reaction kettle to be fully mixed and stirred, so as to form a mixture; (2) a steam valve of the reaction kettle is opened to slowly heat the mixture to the temperature of 70-90 DEG C for a 20-40min reaction; (3) when the temperature is continued to be increased to 80-115 DEG C, reflow is carried out for 3-5h and then the reaction is finished; (4) soda water solution and sodium chloride water solution are added into the mixture and after washing the upper organic phase is extracted; (5) the upper organic phase is separated from the solvent; (6) and then cooling and filter pressing are carried out to obtain the end product. The method is simple in process, produces few by-products or little waste water, has good activity and flexibility, low color intensity, acidity, viscosity, and shrinking percentage, high yield coefficient and good quality.

Owner:TIANJIN CHEM REAGENT RES INST

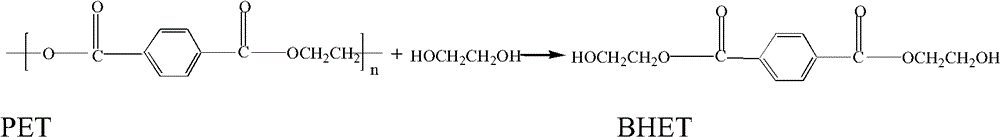

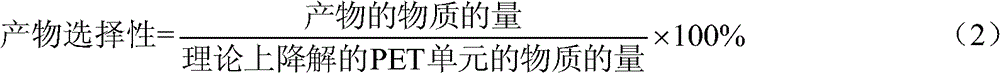

Method for catalytically alcoholizing polyethylene terephthalate

ActiveCN102796002AOrganic compound preparationCarboxylic acid esters preparationTripropylene glycolPolyethylene terephthalate glycol

The invention relates to a new method for catalytically alcoholizing polyethylene terephthalate (PET), which is characterized in that urea is taken as a catalyst, one or the mixture of ethylene glycol, diethylene glycol, propylene glycol, 1, 4-butylene glycol, pentylene glycol, hexylene glycol, 1, 7-heptandiol and triethylene glycol as a solvent, under the conditions that the catalyst usage is 0.01%-10% of the solvent by weight, the reaction temperature is 70DEG C-25 DEG C, the pressure is normal pressure and the reaction time is 1 minutes-4 hours, the polyethylene terephthalate is alcoholized. The method has the advantages of moderate reaction conditions, low-priced easily-obtained catalyst, high catalytic activity, high degradation rate, high selectivity, easily separated products, environmental friendliness, energy conservation and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Bright film printing paste and preparation method thereof

The invention provides a bright film printing paste for textiles. The bright film printing paste comprises the following raw materials in parts by weight: 20 to 21 parts of itaconic acid, 350 to 360 parts of butyl acrylate, 71 to 73 parts of hydroxyethyl acrylate, 10 to 10.5 parts of tripropylene glycol diacrylate, 42 to 44 parts of acrylonitrile, 2 to 2.3 parts of fatty alcohol-polyoxyethylene ether 23E9, 1.9 to 2.1 parts of ammonium persulfate, 550 to 600 parts of deionized water, and 20 to 22 parts of associated levelling rheological agent WT-203. The preparation method comprises the steps of emulsifying, initiating polymerization, and thickening, so as to obtain the bright film printing paste. The bright film printing paste is high in transparency, high in glossiness, free from yellowing at a high temperature, excellent in firmness, and soft in hand feel, and meets the environmental protection requirement.

Owner:LIAONING FIXED STAR FINE CHEM

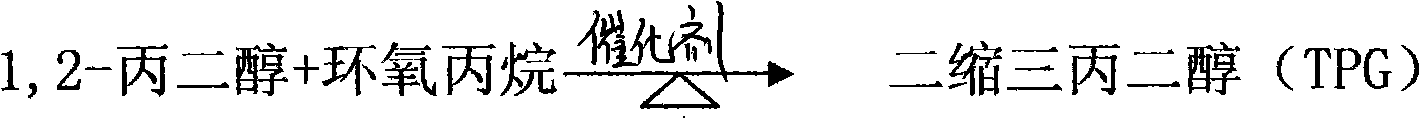

Method for synthesizing tripropylene glycol

ActiveCN101941893AHigh selectivitySmooth responseEther preparation from oxiranesTripropylene glycolTriphenylphosphine

The invention discloses a method for synthesizing tripropylene glycol. The tripropylene glycol is prepared from commercial 1,2-propylene glycol serving as a raw material and propylene oxide serving as a chain extender under the action of triphenylphosphine or barium hydroxide serving as a catalyst under the conditions of certain temperature and certain pressure, wherein the molar ratio of the 1,2-propylene glycol to the propylene oxide to the catalyst is 1:1.4:0.02-2.2:0.0005:0.02. The method has the characteristics of simple preparation, high product quality, high tripropylene glycol contentand light color.

Owner:ZHEJIANG HUANGMA TECH

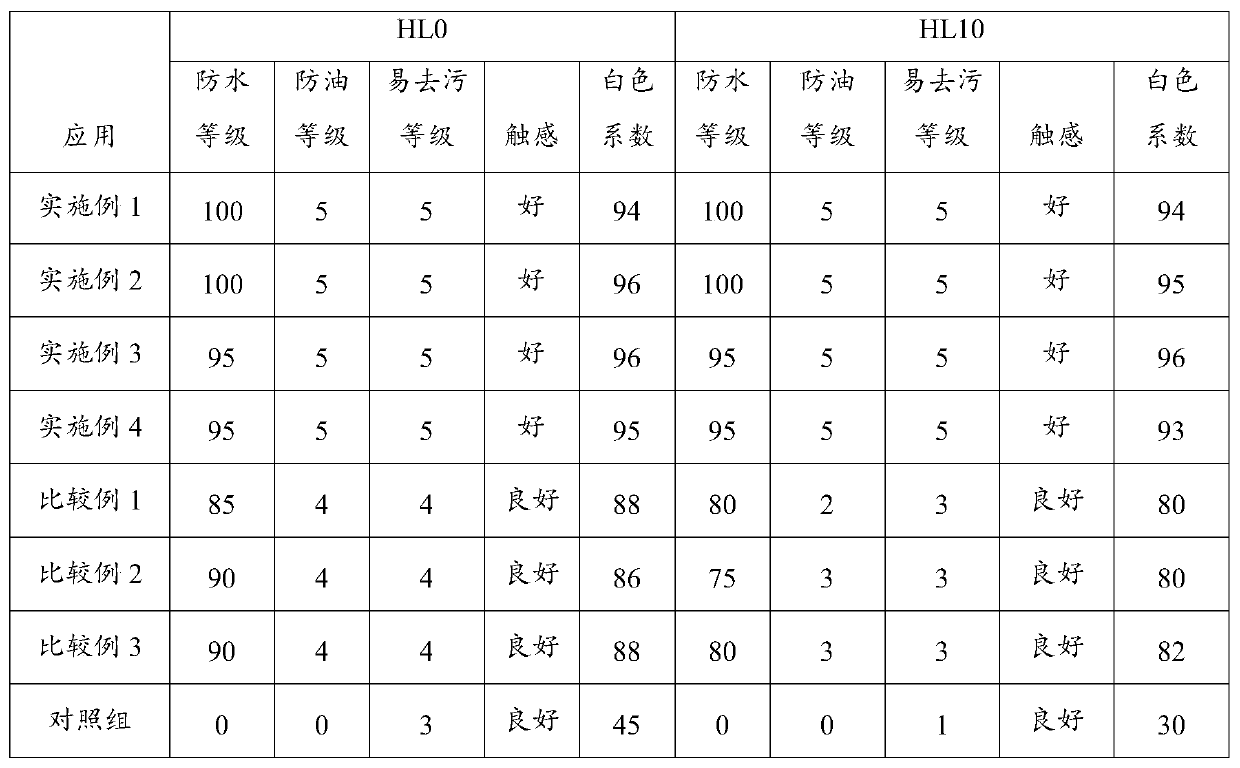

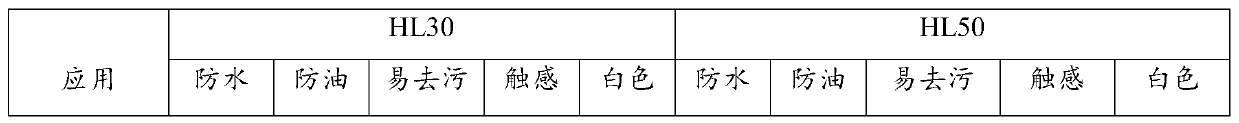

Finishing agent composition, finishing agent and preparation method and application thereof

ActiveCN110042661ALow unsealing temperatureGood flexibilityLiquid repellent fibresGrip property fibresCooking & bakingTripropylene glycol

The invention relates to the technical field of fabric function finishing agents, and provides a finishing agent composition, a finishing agent and a preparation method and application thereof. The finishing agent composition is prepared from, by mass, 40-60 parts of a three-proofing finishing agent, 20-40 parts of a silicone acrylate containing copolymerization emulsion, 20-25 parts of tripropylene glycol, 2-5 parts of water soluble silicone oil, 1-3 parts of hydroxymethyl cellulose and 1-10 parts of closed isocyanate. The closed isocyanate has the important role in balance water resistance and decontamination functions. The method for preparing the finishing agent comprises the steps of dissolving hydroxymethyl cellulose at first, then, sequentially adding water soluble silicone oil andtripropylene glycol, performing stirring for 15-25 min under the temperature of 50-55 DEG C, adding the three-proofing finishing agent and the silicone acrylate containing copolymerization emulsion, performing continuous stirring for 5-20 min, and then adding the closed isocyanate for stirring for 15-25 min. The finishing agent is good in compounding performance, the finishing agent is applied tothe woven fabric finishing process, the needed baking temperature is low, the production cost is lowered, the obtained fabric is washable, and the excellent water resistance and decontamination functions are achieved.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

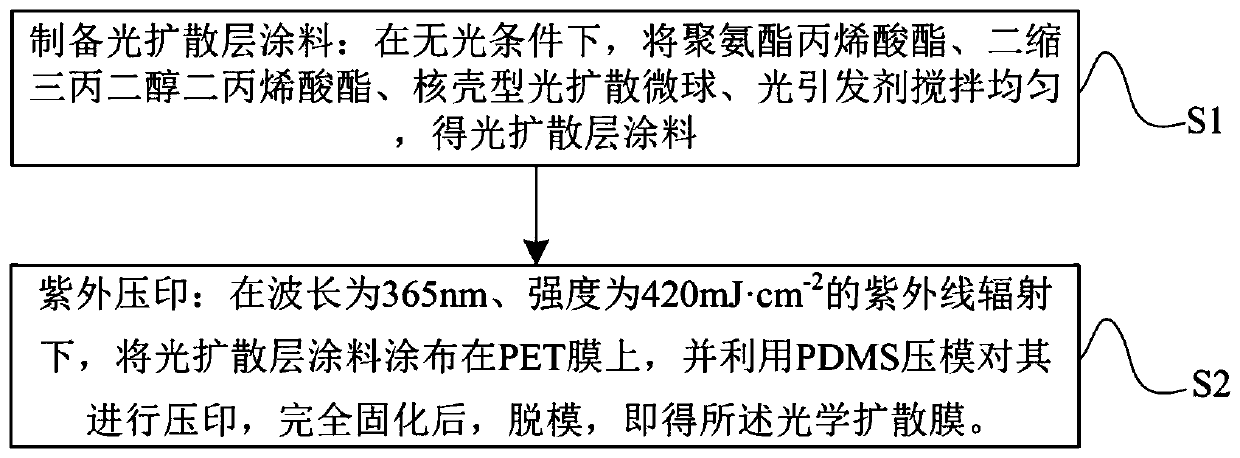

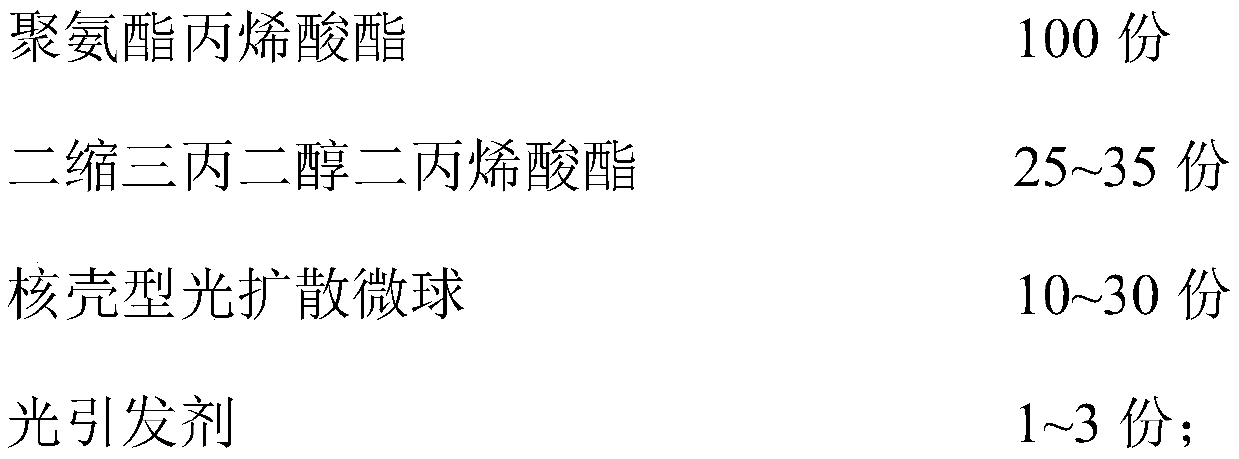

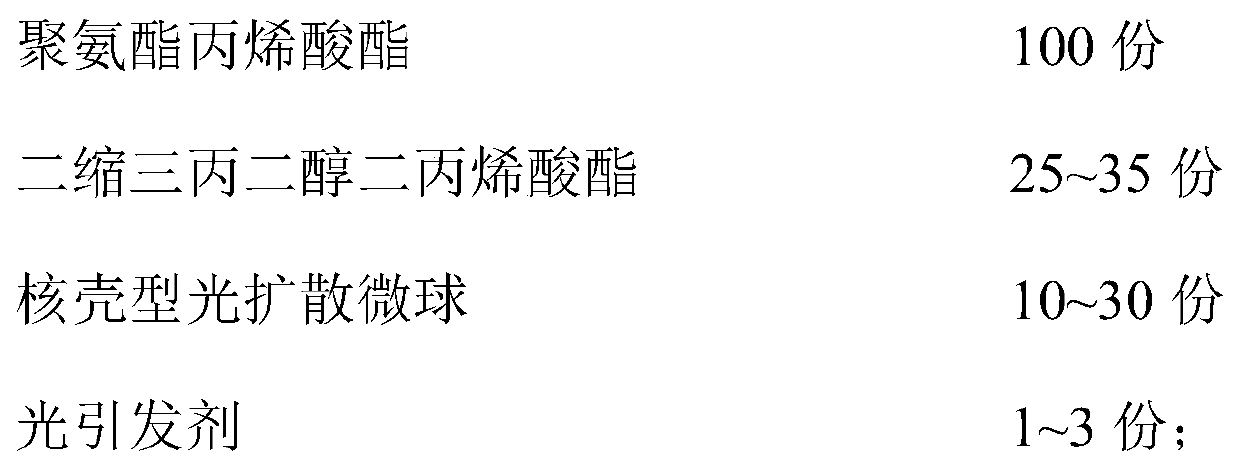

Optical diffusion film and manufacturing method thereof

ActiveCN111399096AImprove stabilityImprove diffusion abilityDiffusing elementsNon-linear opticsTripropylene glycolMicrosphere

The invention discloses an optical diffusion film and a manufacturing method thereof. According to the optical diffusion film, a PET film serves as a base material, and a light diffusion layer is cured on the surface. The light diffusion layer is prepared from the following raw materials in parts by mass: 100 parts of urethane acrylate, 25-35 parts of tripropylene glycol diacrylate, 10-30 parts ofcore-shell type light diffusion microspheres and 1-3 parts of a photoinitiator. The preparation method of the core-shell type photodiffusion microsphere comprises the following steps: adjusting the pH value of the 35-50% (v / v) ethanol solution to 3.0-5.0; adding APS, VTMS and phenyltriethoxysilane into the mixture; magnetically stirring at 25-40 DEG C to react for 2-6 hours; adjusting the pH value to 9-11, continuously reacting for 3-8 hours, adding Zn(NO3)2.6H2O, Ce(NO3)3.6H2O, Al(NO3)3.9H2O and HTM, magnetically stirring for 0.5-1 hour, refluxing at 80 DEG C for 3-5 hours, cooling to 40-50DEG C, dropwise adding glutaraldehyde for cross-linking modification for 1-2 hours, centrifugally washing and drying. The optical diffusion film is uniform, stable, good in weather resistance and durability, the visible light transmittance reaches 93% or above, the haze reaches 85% or above, the ultraviolet light transmittance is lower than 12%, and the 400 nm-480 nm short-wave blue light transmittance is lower than 15%.

Owner:合肥星宸新材料有限公司

Heat-preservation and thermal-insulating water-based paint for glass sliding door and preparation method of water-based paint

InactiveCN104342000AImprove antifouling performanceImprove the bactericidal effectPaints with biocidesPolyurea/polyurethane coatingsTripropylene glycolDiacetonamine

The invention discloses heat-preservation and thermal-insulating water-based paint for a glass sliding door. The water-based paint is prepared from the following raw materials in parts by weight: 48-53 parts of waterborne polyurethane resin, 16-19 parts of waterborne hydroxyl acrylic acid, 0.2-0.4 part of polypropylene oxide glyceryl ether, 1-3 parts of tripropylene glycol monobutyl ether, 0.3-0.6 part of alkylol amine titanate, 7-10 parts of modified pure acrylic emulsion, 0.2-0.5 part of polyether modified organo-polysiloxane, 0.2-0.4 part of dimethicone, 0.2-0.4 part of an accelerant TMTM, 0.3-0.6 part of butyl glycidyl ether, 0.3-0.6 part of guar gum, 0.3-0.5 part of diacetone-acryloamide, 0.4-0.9 part of zeolite powder, 1-2 parts of pigment, 1-3 parts of hollow glass microspheres, 2-3 parts of silica sol and 12-16 parts of deionized water. Due to adoption of the silica sol in the water-based glass paint disclosed by the invention, the hardness of a paint film is improved, and the paint film is not easy to peel off and is smooth and flat; due to adoption of the hollow glass microspheres, the heat preservation and thermal insulation effects are achieved, and the cost is lowered; due to adoption of the modified pure acrylic emulsion, properties such as the flouring resistance, the bactericidal activity, the scrubbing resistance and the weather resistance of the water-based paint are improved; the water-based paint is high in practicability and applicable to popularization.

Owner:凤阳徽亨商贸有限公司

Silk-screen UV glaze printing ink and preparation method thereof

The invention discloses silk-screen UV glaze printing ink and a preparation method thereof, and belongs to the technical field of printing ink and preparation thereof. The printing ink is prepared from 28-32% of epoxy modified acrylate, 18-22% of urethane acrylate, 8-12% of tri(propylene glycol)diacrylate, 18-22% of 1,6-hexamethylene diacrylate, 6-10% of a 184 macroinitiator, 3-7% of an active-amine auxiliary photoinitiator, 0.8-3% of an organosilicone flatting agent, 0.8-3% of an organosilicone antifoaming agent and 3-7% of fumed silica, and is prepared by processes of mixing, stirring at a high speed, grinding, and the like. The preparation method is simple. The printing ink prepared by the method has a transparency effect and a matte effect, thus satisfying a conceive of applying the technical quality of blue and white porcelain and other famous porcelain in history to packaging and printing, and simulating the glaze quality, of the porcelain, that is mild and humid like jade. The printing ink provided by the invention has high environmental protection property. The VOCs smell residue totally reaches requirements of the national standards.

Owner:ZHEJIANG MINONG CENTURY GRP +1

Ultraviolet light cured nail polish and production method thereof

InactiveCN102423287ASimple preparation processEasy to operateCosmetic preparationsToilet preparationsTripropylene glycolUltraviolet lights

The invention relates to an ultraviolet light cured nail polish and a production method. The ultraviolet light cured nail polish comprises the components in percentage by weight: 42-50 percent of urethane acrylate, 20-28 percent of epoxy acrylate, 7-10 percent of 1,6-hexanediol diacrylate, 8-10 percent of tripropylene glycol diacrylate, 0.3-0.4 percent of flatting agent 468, 0.1-0.3 percent of flatting agent 3080, 0.1-0.3 percent of flatting agent 333, 4-6 percent of light trigger, 1-3 percent of amine resin 5603. The preparation method of the ultraviolet light cured nail polish comprises the following steps of: feeding various materials according to the proportion of a formula; uniformly stirring the fed materials; checking; filtering; and packaging. The raw materials in the formula of the ultraviolet light cured nail polish disclosed by the invention have low cost; the production process of the ultraviolet light cured nail polish is simple and easy to operate; and in addition, the ultraviolet light cured nail polish product disclosed by the invention meets the requirement of environment friendliness and a paint film has favorable flexibility.

Owner:TIANJIN MEIJIAMEI PAINT

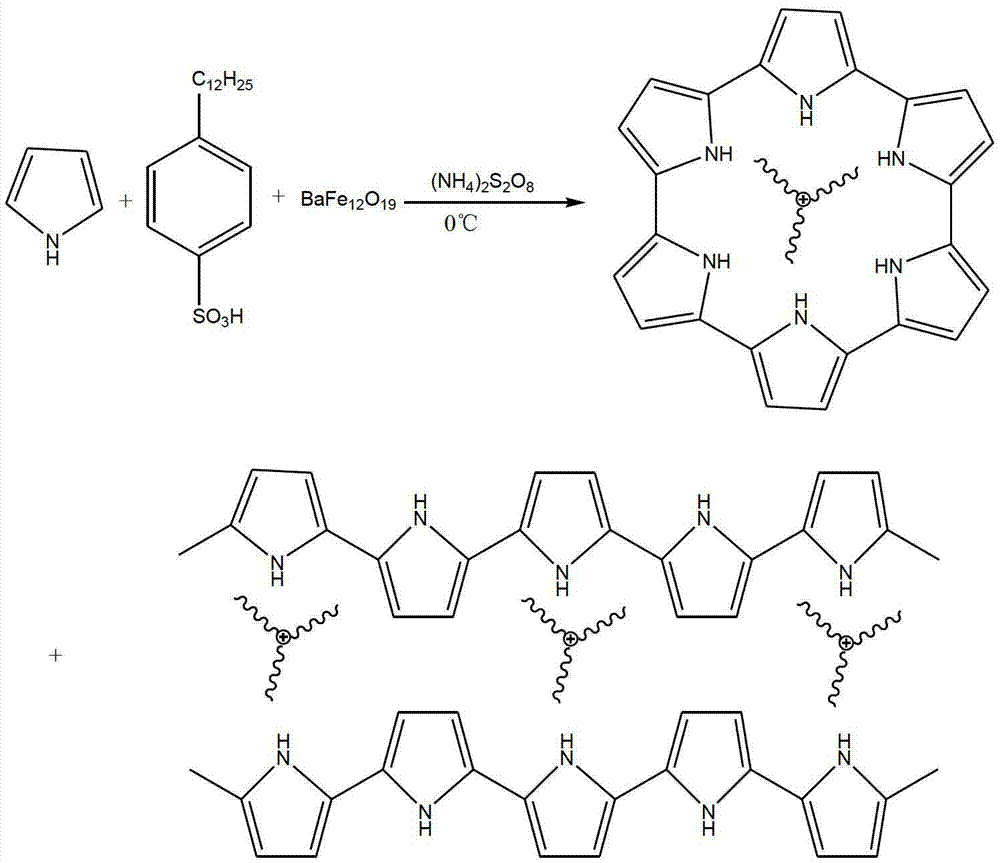

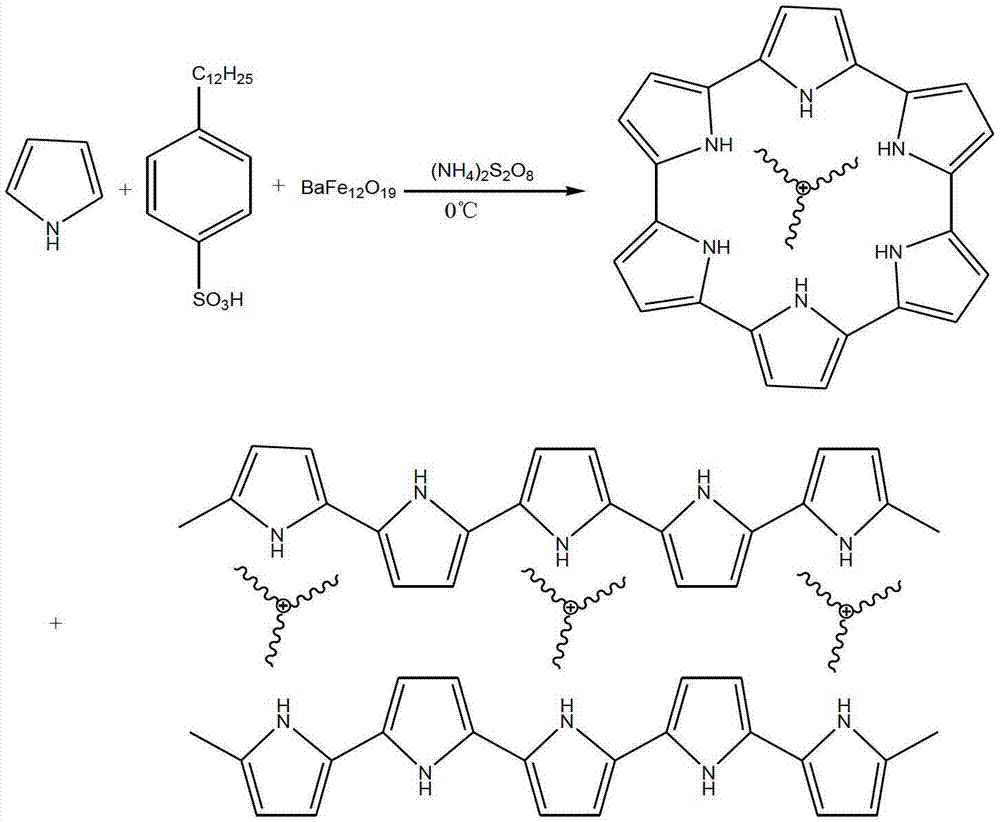

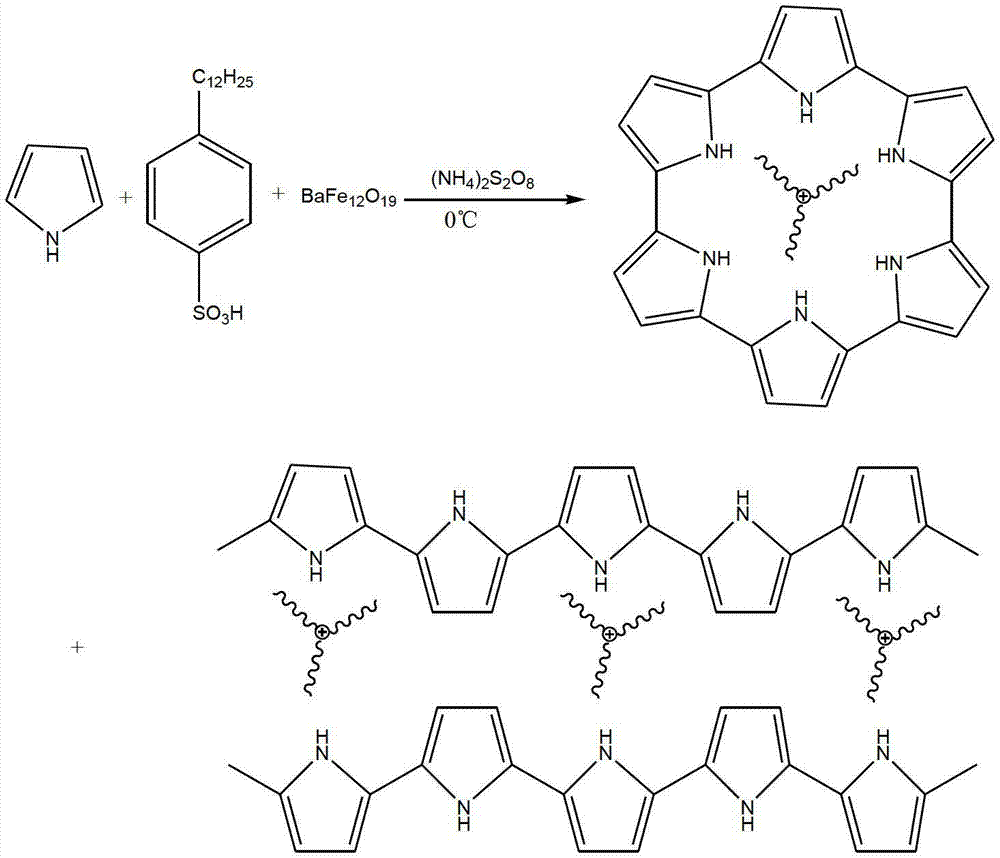

Photocuring microwave absorbing coating with barium ferrite doped with polypyrrole as wave absorber

ActiveCN103205192AImproved Magnetic Loss PerformanceImprove mechanical propertiesPolyurea/polyurethane coatingsRadiation-absorbing paintsTripropylene glycolIn situ polymerization

The invention discloses a photocuring microwave absorbing coating with barium ferrite doped with polypyrrole as a wave absorber. The barium ferrite doped with polypyrrole as the wave absorber is prepared by in situ polymerization. The wave absorbing material is uniformly mixed with six degree of functionality aliphatic polyurethane acrylate, a monomer diluent tripropylene glycol diacrylate, an accelerant, an optical initiator, a defoamer and a leveling agent to prepare the photocuring microwave absorbing material. The wave absorbing material is quickly cured through UV-irradiation, and the wave absorbing coating obtained has the properties of good adhesive force, hardness, weather fastness and the like.

Owner:GUANGZHOU SHENWEI NEW MATERIAL TECH

Firm and durable threads for plastic woven bags

ActiveCN103628170AIncrease volumeNovel structureMonocomponent polyolefin artificial filamentArtifical filament manufactureTripropylene glycolLinear low-density polyethylene

The invention discloses firm and durable threads for plastic woven bags. The firm and durable threads are characterized by being prepared from the following raw materials in parts by weight: 100 parts of polypropylene, 10-12 parts of linear low density polyethylene, 1.2-1.5 parts of white mineral oil, 0.3-0.6 part of methane dithiocyanate, 1.2-1.4 parts of silane coupling agent KH550, 0.3-0.4 part of nano-graphite, 1.2-1.5 parts of dimethylamino ethyl acrylate, 0.6-0.9 part of maleic anhydride, 0.4-0.6 part of N-hydroxymethyl acrylamide, 0.5-0.8 part of antioxidant 10100, 6-8 parts of tripropylene glycol diacrylate and 3-3.5 part of additive by adopting the following working procedures: burdening, fusing, filtering, extruding so as to obtain membranes, carrying out water cooling, thread separation and thread drawing, winding and the like. The firm and durable threads are simple in formula and low in cost; the plastic woven bags manufactured by using the threads are large in volume, novel in structure, firm, durable, anti-skidding and unlikely to be broken; and the problem that packaging bags in the prior art are short in service life is solved.

Owner:ANHUI ANYUAN PLASTIC

Electrostatically-sprayed waterborne coating

InactiveCN104419314AImprove the level ofIncrease film thicknessPolyurea/polyurethane coatingsPowdery paintsTripropylene glycolEther

The invention discloses an electrostatically-sprayed waterborne coating comprising following components, by weight, 75-85 parts of waterborne resin, 0.1-0.5 parts of a wetting agent, 0-15 parts of talcum powder, 0-10 parts of transparent powder, 0.5-1 part of an anti-settling agent, 2-5 parts of water, 1-2 parts of a thickening agent, 0.1-0.5 parts of a defoaming agent, 0.1-0.5 parts of a leveling agent, 0.1-0.3 parts of a mouldproof sterilizing agent, 0.1-0.5 parts of a pH adjusting agent, 1-3 parts of a film coalescing aid and 3-6 parts of a high-boiling-point solvent. The high-boiling-point solvent is a mixed solution composed of tripropylene glycol butyl ether and ethylene glycol hexyl ether according to a proportion of 1:1. The electrostatically-spraying waterborne coating can effectively improve a levelling property and a thickness of a paint film when the electrostatically-sprayed waterborne coating coats wood products.

Owner:展辰新材料集团股份有限公司 +4

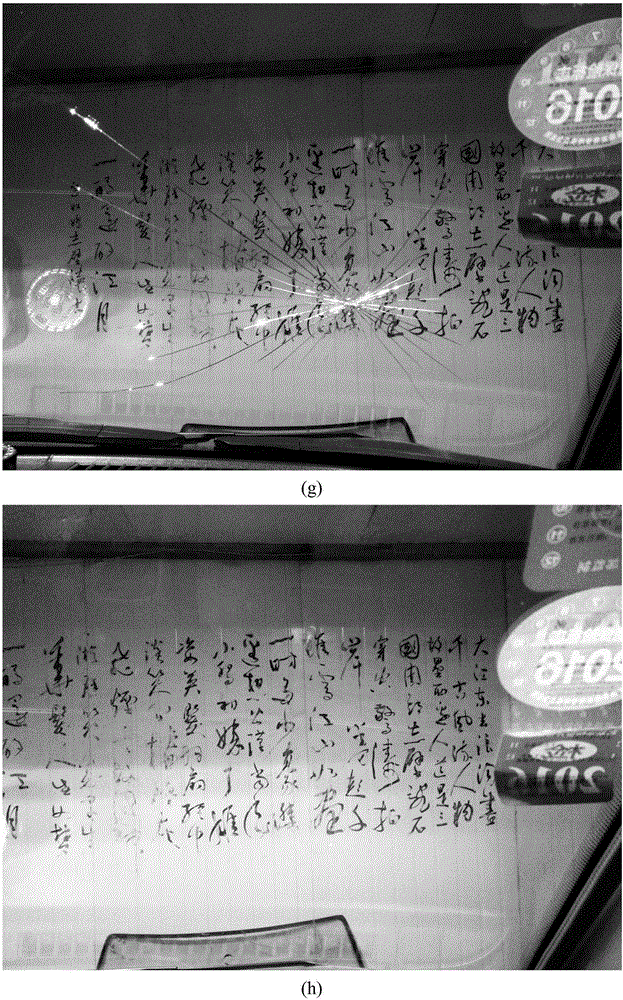

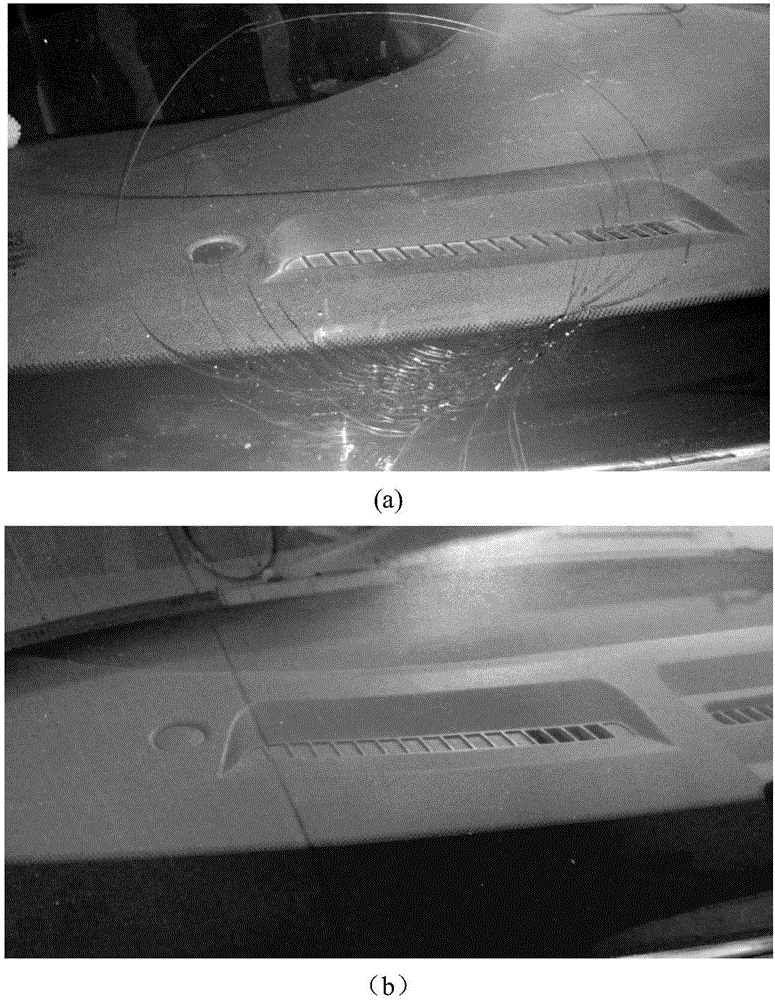

Windshield glass repairing agent and preparation method thereof

ActiveCN106281176AIntensity unchangedFast repairModified epoxy resin adhesivesEpoxyTripropylene glycol

The invention provides a windshield glass repairing agent and a preparation method thereof, aims at solving the problems of an existing glass repairing agent that the shadow property is poor and the strength cannot be kept for a long period, and belongs to the technical field of windshield glass repairing agents. The repairing agent is a product prepared by taking repairing agent mother liquid, active diluents including tripropylene glycol diacrylate and methyl methacrylate, a silane coupling agent and an initiator 2-hydroxyl-2-methyl-1-phenyl-1-acetone to react; the repairing agent mother liquid is a product prepared by taking epoxy resin, the tripropylene glycol diacrylate, ethyl acrylate, acrylic acid, hydroquinone, pentaerythritol triacrylate and the 2-hydroxyl-2-methyl-1-phenyl-1-acetone to react. The refractive index of the product is similar with that of windshield glass; the repaired windshield glass has no cracks when being observed from a plurality of angles; a repairing speed is rapid and the strength of the repairing agent at a repaired part can keep unchanged; the utilization strength of the windshield glass is the same as that of undamaged windshield glass.

Owner:孙涛

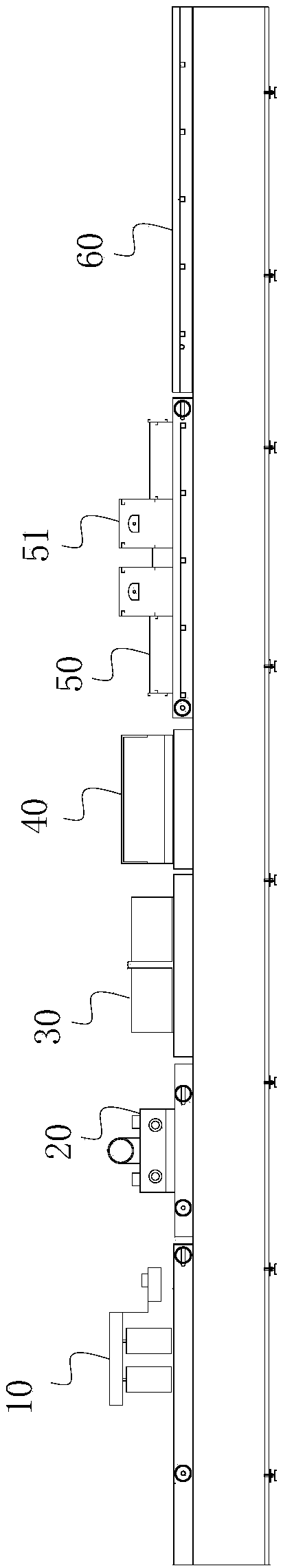

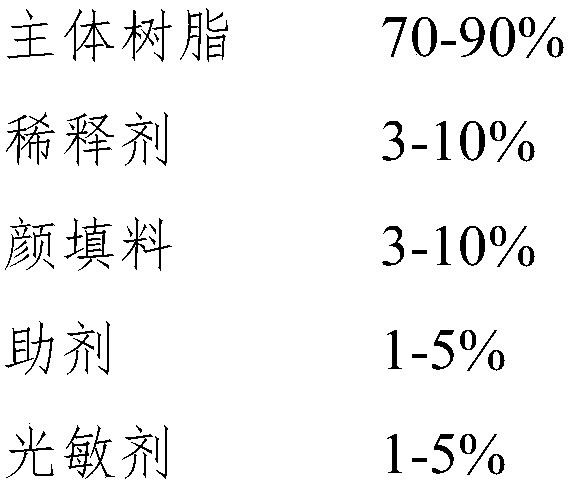

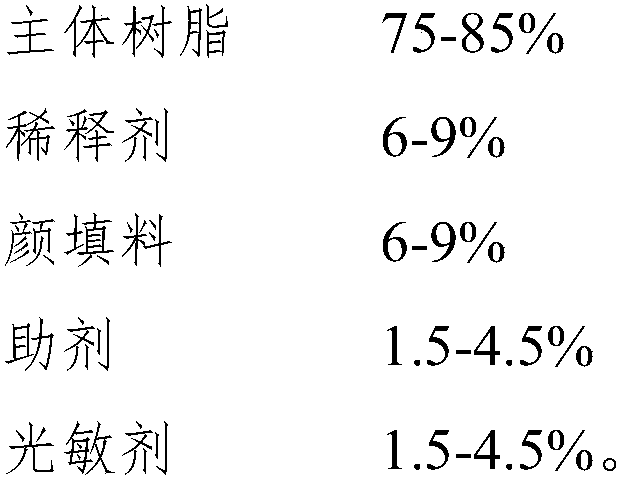

Metal template coating, preparation method thereof and coating production line thereof

ActiveCN107652871ANo side effectsImprove bindingLiquid surface applicatorsAntifouling/underwater paintsTripropylene glycolSodium Bentonite

The invention discloses a metal template coating which is composed of, by weight, 70-90% of main resin, 3-10% of diluent, 3-10% of pigment and filler, 1-5% of auxiliary and 1-5% of photosensitive agent. The main resin is selected from one or multiple of aliphatic polyurethane acrylate, acrylate or aromatic methyl semi-acrylate, the diluent is selected from one or multiple of isobornyl acrylate, 1,6-hexanediol diacrylate or tripropylene glycol diacrylate, the pigment and filler comprises 20-30% of zinc stearate, 20-30% of bentonite, 20-30% of calcium carbonate and 20-30% of talcum powder, theauxiliary is selected from one or multiple of polysiloxane, unsaturated polyamide and hydroxyl acid salt or propylene glycol methyl ether, and the photosensitive agent is selected from one or multipleof 1-hydroxy cyclohexylphenyl ketone, 2-isopropyl thioxanthone or 2-benzyl-dimethyl amino-1-(4-morpholine phenyl) butanone.The preparation method does not need a curing agent, and momentary drying within 10s can be realized through ultraviolet curing. The metal template coating is powerful in bonding with an aluminum alloy template and less prone to shedding.

Owner:BEIJING GREEN CHINA TECHNOLOGIC DEV

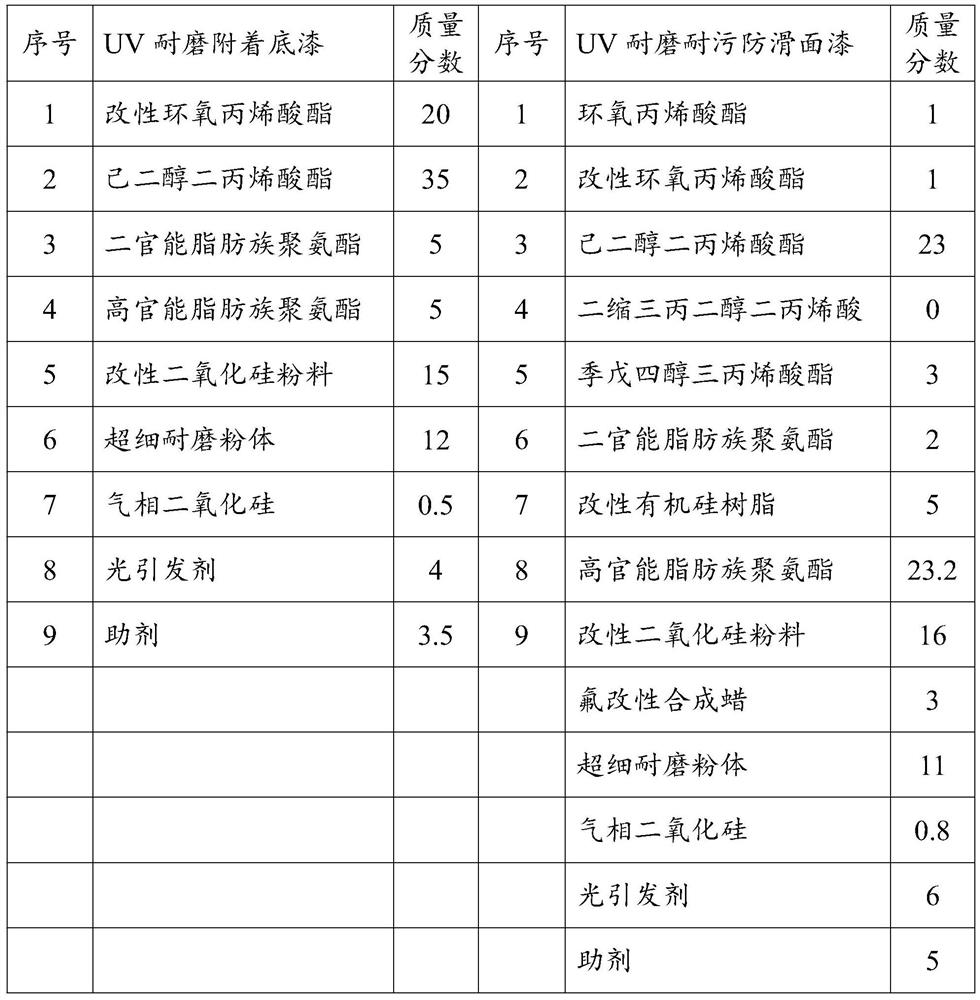

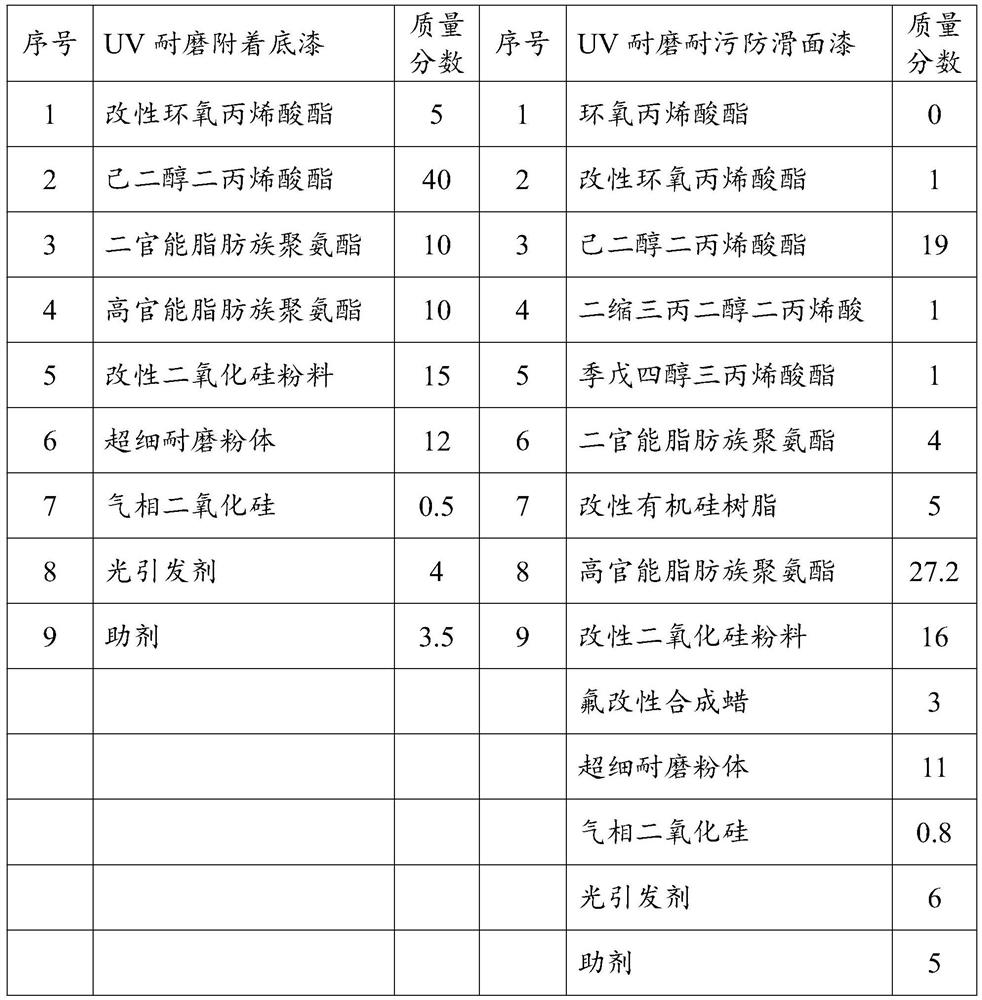

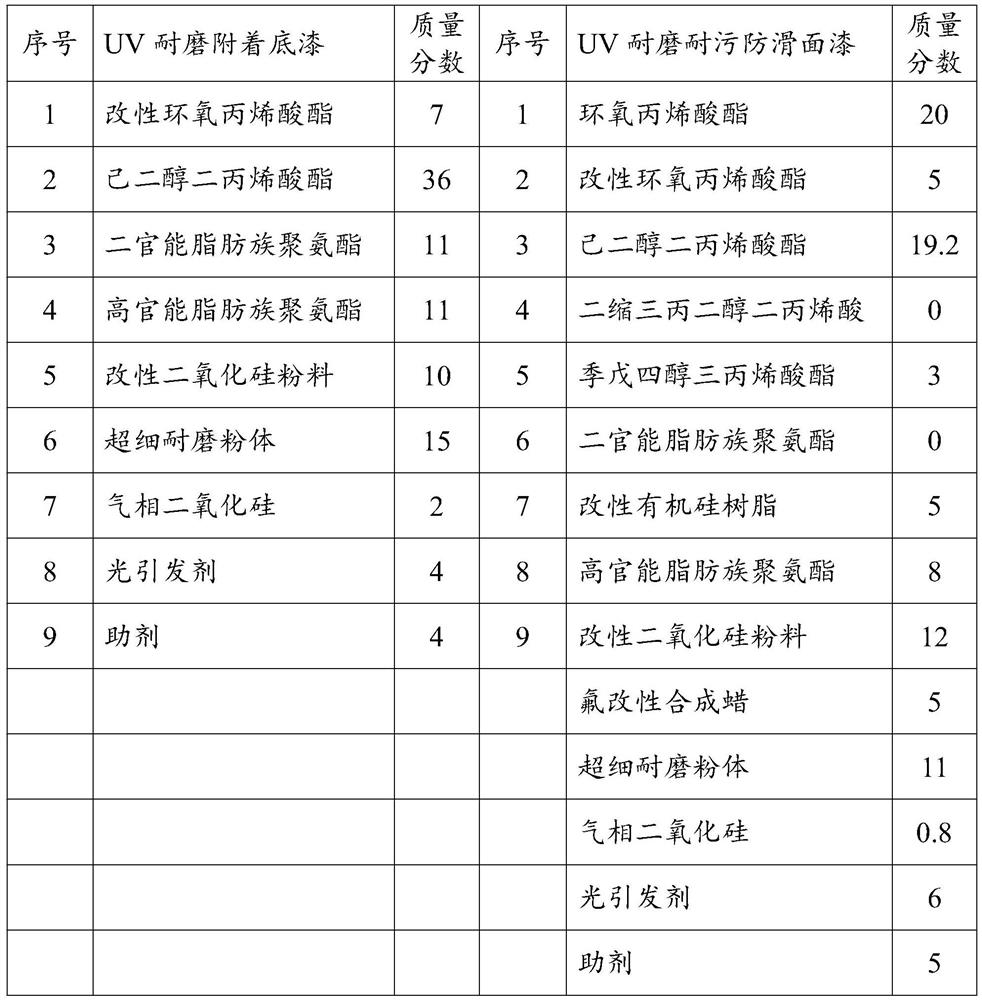

Super wear-resistant, anti-skid and stain-resistant floor ultraviolet curing coating system

PendingCN113527992AReduce surface tensionReduce surface abrasionPolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycolPolymer science

The invention provides a super wear-resistant, anti-skid and stain-resistant floor ultraviolet curing coating system, which comprises a UV wear-resistant, anti-skid and stain-resistant finish paint, wherein the UV wear-resistant, anti-skid and stain-resistant finish paint comprises the following components in percentage by mass: 0-20% of epoxy acrylate, 0-20% of modified epoxy acrylate, 0-10% of tripropylene glycol diacrylic acid, 0-10% of pentaerythritol triacrylate, 0-5% of bifunctional aliphatic polyurethane, 15-30% of hexanediol diacrylate, 5-30% of high-functional aliphatic polyurethane, 1-10% of modified organic silicon resin, 10-20% of modified silicon dioxide powder, 1-10% of fluorine modified synthetic wax, 10-20% of superfine wear-resistant powder, 0-2% of fumed silica, 3-10% of a photoinitiator and 1-10% of an auxiliary agent. According to the invention, the physical indexes of paint films on SPC, PVC or wood all reach expectations, and the stain resistance, wear resistance and skid resistance are excellent.

Owner:上海展辰涂料有限公司

Ultraviolet-curing antifouling anti-doodling bactericidal finishing paint and preparation method thereof

InactiveCN104530963AEfficient killingEfficient reproductionAntifouling/underwater paintsPaints with biocidesTripropylene glycolUltraviolet

The invention relates to an ultraviolet-curing antifouling anti-doodling bactericidal finishing paint and preparation method thereof. The finishing paint comprises the following components in percentage by weight: 10%-40% of low-surface-tension antifouling resin, 10-40% of polyurethane acrylate, 2%-7% of diphenyl ketone, 2%-7% of 2-hydroxy-2-methyl-1-phenyl-1-propanone, 5%-15% of trihydroxymethylpropane triacrylate, 10-30% of tripropylene glycol diacrylate, 5%-10% of 1,6-hexanediol diacrylate, 3%-15% of matte powder and 0.1%-0.5% of a fungicide. The finishing paint is environment-friendly and non-toxic and is easy to clean, can effectively kill bacteria or control the growth of bacteria and has the characteristics of scratching resistance, impact resistance and the like; and since the finishing paint is free of solvent, harmful heavy metals and pesticide-like organic fungicides, the finishing paint is environment-friendly and harmless and is suitable for interior decorations of kitchens, bathrooms, kitchens, children rooms and the like.

Owner:东周化学工业(昆山)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com