Ultraviolet curing ink and preparation method thereof

A technology of ultraviolet light and ink, applied in ink, household utensils, applications, etc., can solve the problems of poor yellowing resistance, excessive organic volatiles, yellowing, etc., and achieve good yellowing resistance and good folding resistance , the effect of not easy to turn yellow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

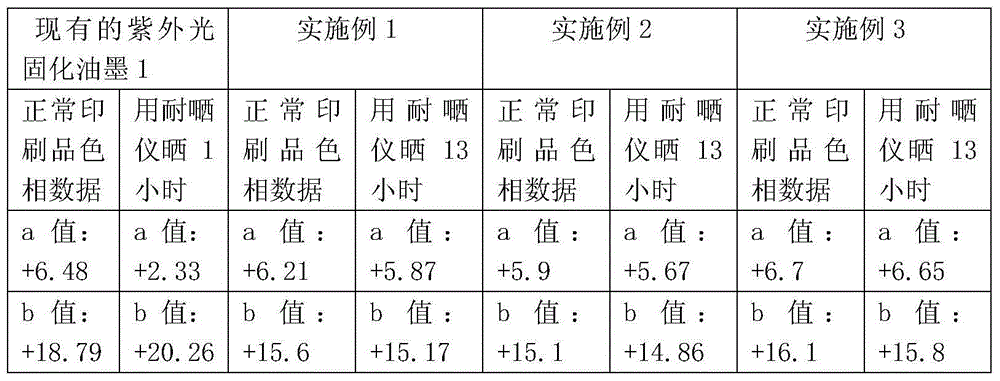

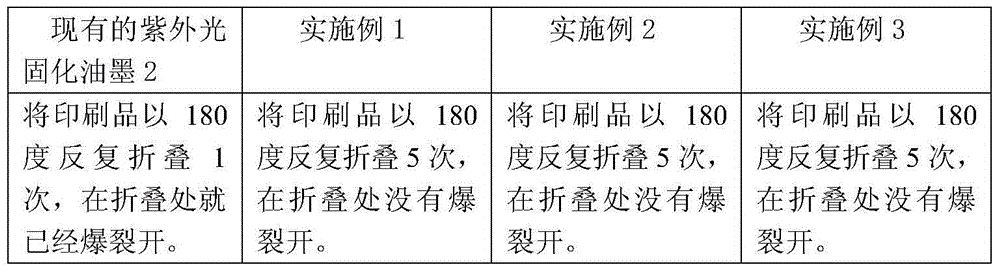

Embodiment 1

[0033] In the present embodiment, the preparation method of ultraviolet curable ink comprises the following steps:

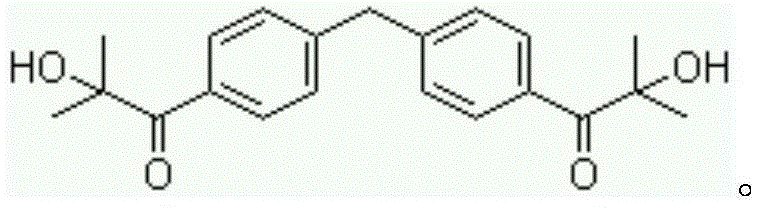

[0034] (1) Polyurethane acrylate, epoxy acrylate, tripropylene glycol diacrylate, propane trimethanol triacrylate, 1,1'-(methylenebis-4,1-phenylene base) bis[2-hydroxy-2-methyl-1-propanone], poly[2-hydroxy-2-methyl-1-[4-(1-methylvinyl)phenyl]acetone], polydi Methylsiloxane (the molecular formula of polydimethylsiloxane is (CH 3 ) 3 SiO[(CH 3 ) 2 SiO] n Si(CH 3 ) 3 , where n is a natural number from 5 to 100), polyether modified polysiloxane and polyethylene wax: 30% polyurethane acrylate, 20.5% epoxy acrylate, 20% tripropylene glycol diacrylate, propylene triacrylate Trimethylol ester 20%, 1,1'-(methylenebis-4,1-phenylene)bis[2-hydroxy-2-methyl-1-propanone] 2.5%, poly[2-hydroxy-2 -Methyl-1-[4-(1-methylvinyl)phenyl]acetone] 1%, polydimethylsiloxane 0.5%, polyether modified polysiloxane 0.5%, polyethylene wax 5 %;

[0035] (2) Put polyurethane acrylate, ...

Embodiment 2

[0041] In the present embodiment, the preparation method of ultraviolet curable ink comprises the following steps:

[0042] (1) Polyurethane acrylate, epoxy acrylate, tripropylene glycol diacrylate, propane trimethanol triacrylate, 1,1'-(methylenebis-4,1-phenylene base) bis[2-hydroxy-2-methyl-1-propanone], poly[2-hydroxy-2-methyl-1-[4-(1-methylvinyl)phenyl]acetone], polydi Methylsiloxane (the molecular formula of polydimethylsiloxane is (CH 3 ) 3 SiO[(CH 3 ) 2 SiO] n Si(CH 3 ) 3 , where n is a natural number from 5 to 100), polyether modified polysiloxane and polyethylene wax: 35% polyurethane acrylate, 15% epoxy acrylate, 18.9% tripropylene glycol diacrylate, propylene triacrylate Trimethylol ester 25%, 1,1'-(methylenebis-4,1-phenylene) bis[2-hydroxy-2-methyl-1-propanone] 1.5%, poly[2-hydroxy-2 -Methyl-1-[4-(1-methylvinyl)phenyl]acetone] 0.5%, polydimethylsiloxane 1%, polyether modified polysiloxane 0.1%, polyethylene wax 3 %;

[0043] (2) Put polyurethane acrylate,...

Embodiment 3

[0049] In the present embodiment, the preparation method of ultraviolet curable ink comprises the following steps:

[0050] (1) Polyurethane acrylate, epoxy acrylate, tripropylene glycol diacrylate, propane trimethanol triacrylate, 1,1'-(methylenebis-4,1-phenylene base) bis[2-hydroxy-2-methyl-1-propanone], poly[2-hydroxy-2-methyl-1-[4-(1-methylvinyl)phenyl]acetone], polydi Methylsiloxane (the molecular formula of polydimethylsiloxane is (CH 3 ) 3 SiO[(CH 3 ) 2 SiO] n Si(CH 3 ) 3 , where n is a natural number from 5 to 100), polyether modified polysiloxane and polyethylene wax: 25% polyurethane acrylate, 25% epoxy acrylate, 25% tripropylene glycol diacrylate, propylene triacrylate Trimethylol ester 21%, 1,1'-(methylenebis-4,1-phenylene) bis[2-hydroxy-2-methyl-1-propanone] 0.5%, poly[2-hydroxy-2 -Methyl-1-[4-(1-methylvinyl)phenyl]acetone] 1.5%, polydimethylsiloxane 0.1%, polyether modified polysiloxane 0.9%, polyethylene wax 1 %;

[0051] (2) Put polyurethane acrylate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com