Patents

Literature

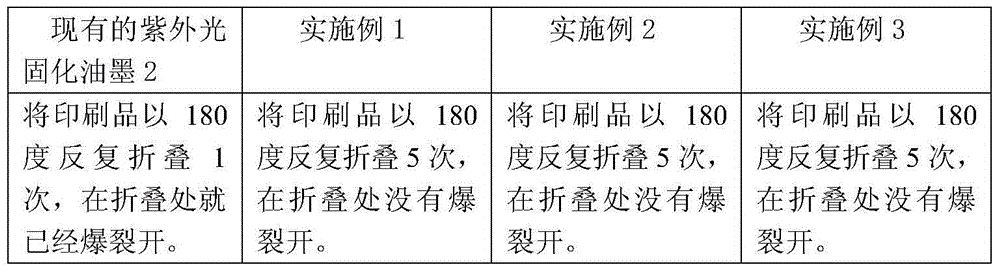

231 results about "Folding endurance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In paper testing, folding endurance is defined as the logarithm (to the base of ten) of the number of double folds that are required to make a test piece break under standardized conditions...

Acrylic Resin Films and Process for Producing the Same

InactiveUS20070243364A1Increase resistanceHigh transparencySynthetic resin layered productsOptical elementsGlutaric anhydrideFolding endurance

An acrylic resin film, in which acrylic elastic particles are mixed with an acrylic resin containing glutaric anhydride units, has a total light transmittance of 91% or more, a haze value of 1.5% or less, a folding endurance value (times) of 20 or more, and a heat shrinkage rate of less than 5% at least in either the machine direction or the transverse direction in a heat shrinkage test.

Owner:TORAY IND INC

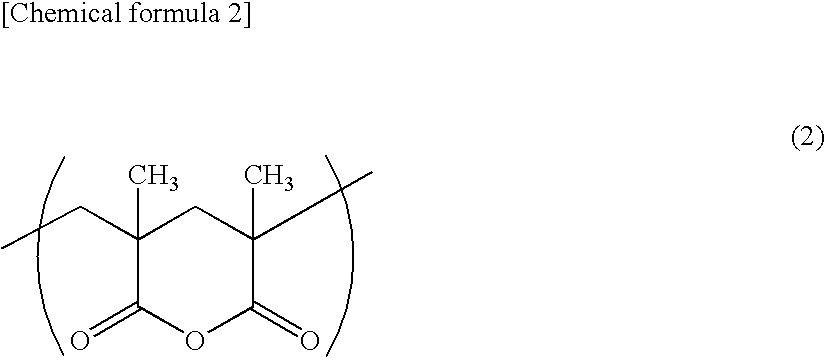

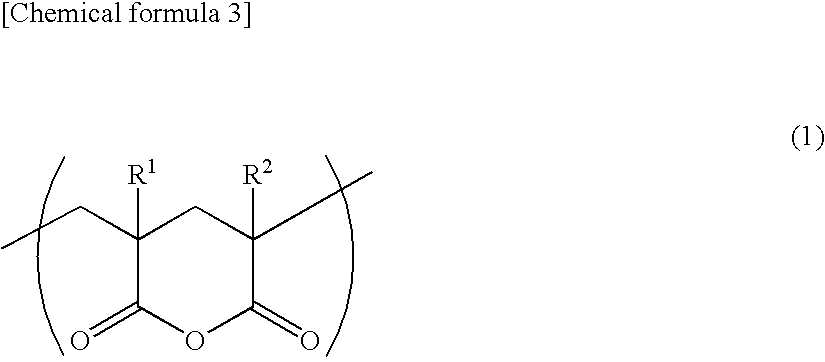

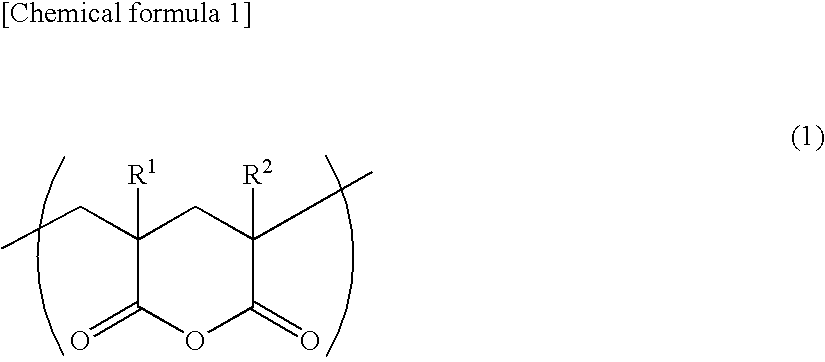

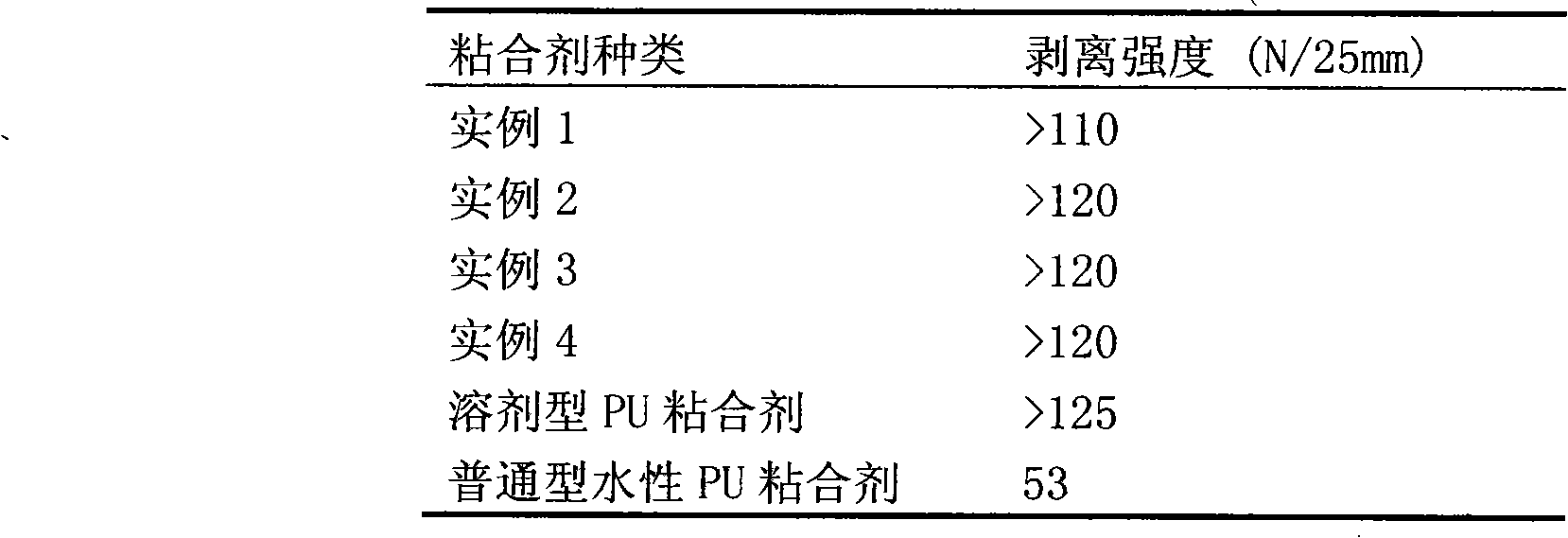

Method for preparing aqueous polyurethane adhesive and superfine fiber synthetic leather

ActiveCN101665675AHigh peel strengthIncrease elasticityPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterFolding endurance

The invention relates to a method for preparing an aqueous polyurethane adhesive and superfine fiber synthetic leather, which belongs to the technical field of chemical products and preparation methods thereof. The method is characterized by comprising the following steps: mixing polyester polyol, isocyanate, a hydrophilic chain extending agent, a micromolecule chain extending agent and an amine environment friendly catalyst to obtain a hydrophilic aqueous polyurethane prepolymer; adding a neutralizing agent to the aqueous polyurethane prepolymer to obtain an aqueous polyurethane latex; then adding an amine chain expanding agent, a thickening agent, a defoaming agent and a flatting agent to the aqueous polyurethane latex to obtain the aqueous polyurethane adhesive; coating the aqueous polyurethane latex on release paper; drying the release paper; then coating the aqueous polyurethane adhesive on the dried release paper; and pressing the release paper and base cloth together to obtain the superfine fiber synthetic leather. The high solid content aqueous polyurethane adhesive prepared by the method has better initial tack and rebound resilience and higher final strength, and the prepared superfine fiber synthetic leather has higher peel strength and low-temperature folding endurance. The preparing process of the method greatly reduces the use and the discharge of organic solvents, reduces the energy consumption and furthest reduce the environmental pollution.

Owner:HUADA CHEM GRP CO LTD

Electrically conductive adhesive composition, electrically conductive adhesive sheet and use thereof

InactiveUS6344155B1Improve rendering capabilitiesImprove conductivityCross-talk/noise/interference reductionSynthetic resin layered productsEpoxyFolding endurance

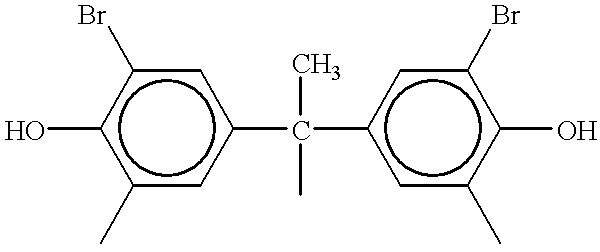

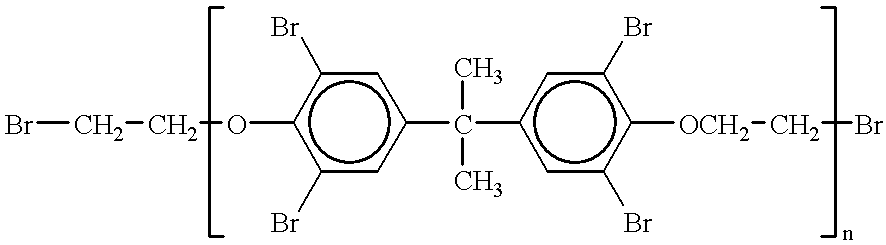

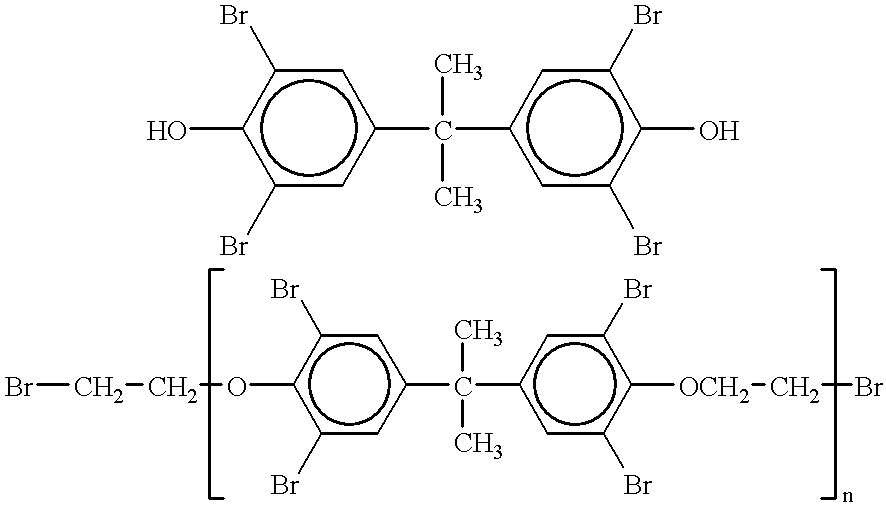

An electrically conductive adhesive composition which has flexibility and folding endurance and is feasible for use as a shield against electromagnetic waves from a flexible printed circuit, comprises 100 parts by weight of (a) an acrylonitrile-butadiene copolymer, 20 to 500 parts by weight of (b) a phenolic resin and / or an epoxy resin, 1 to 100 parts by weight, per 100 parts by weight of the components (a) and (b) in total, of (c) an electrically conductive filler and 1 to 50 parts by weight, per 100 parts by weight of the components (a) and (b) in total, of (d) a bromine-containing flame retardant.

Owner:TOMOEGAWA PAPER CO LTD

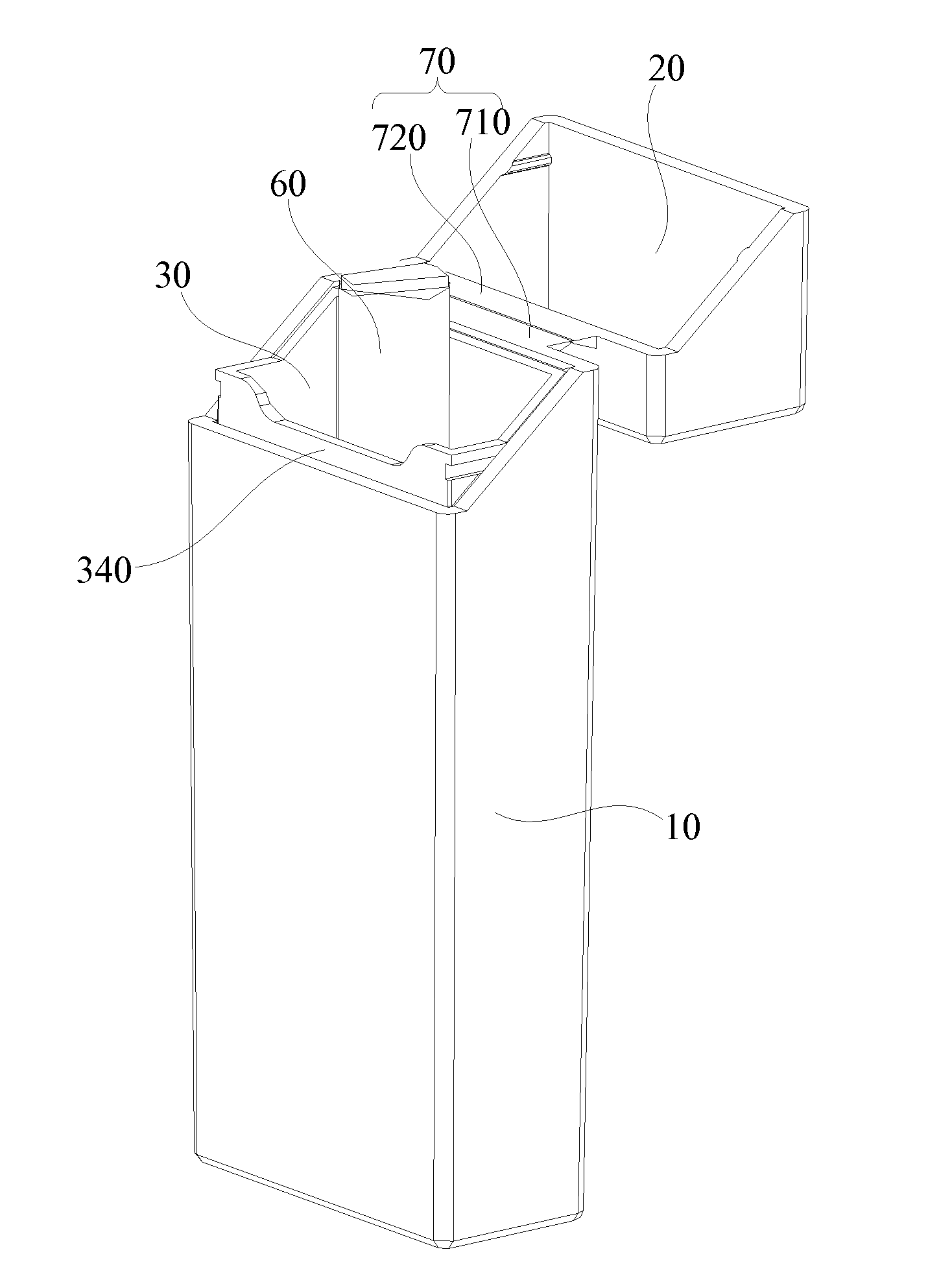

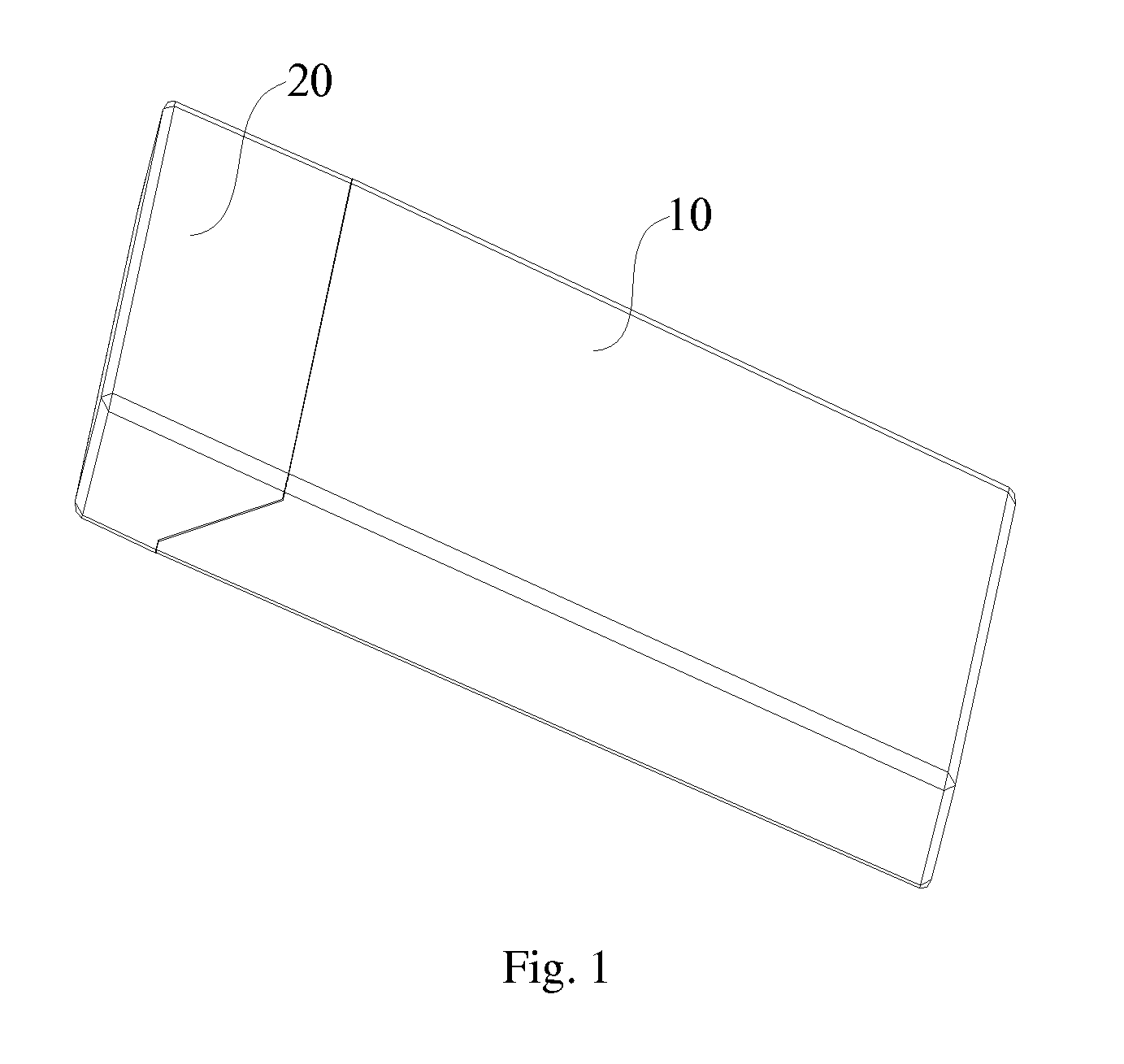

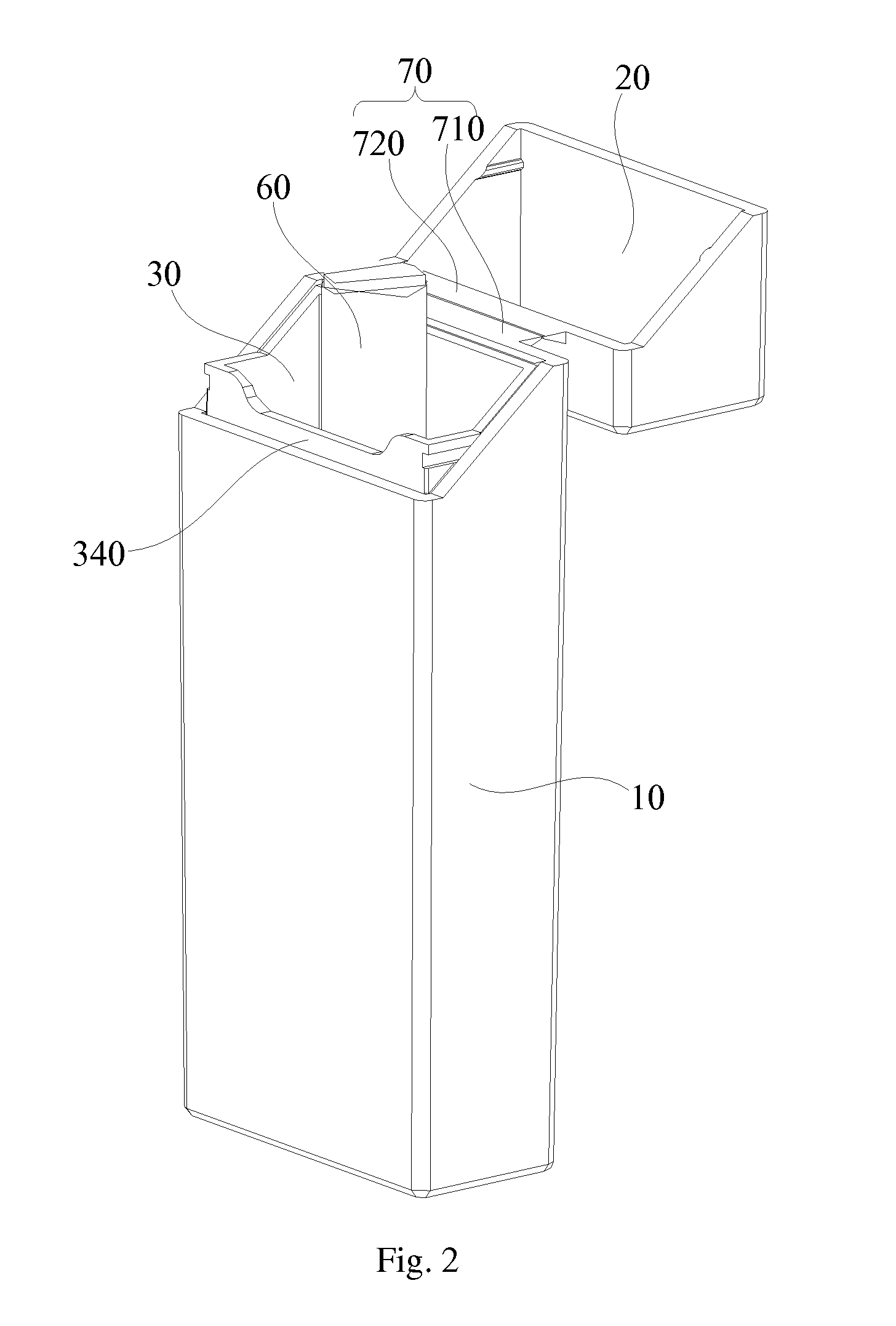

Electronic cigarette case

InactiveUS20160113323A1Good flexibilitySimple processContainers for flexible articlesCigar manufactureFolding enduranceElectronic cigarette

An electronic cigarette case comprising a cigarette case main body, a case cover, and a connection structure connected to the cigarette case main body and to the case cover is provided. The cigarette case main body, the case cover, and the connection structure are integrally formed. Since the electronic cigarette case comprising the cigarette case main body, the case cover, and the connection structure is designed to be integrally formed, and since the integrally formed cigarette main body, case cover, and connection structure are made of a material with great flexibility, the electronic cigarette case is of good folding endurance, simple processing technology, and high production efficiency, and thus production costs is reduced greatly.

Owner:KIMREE HI TECH

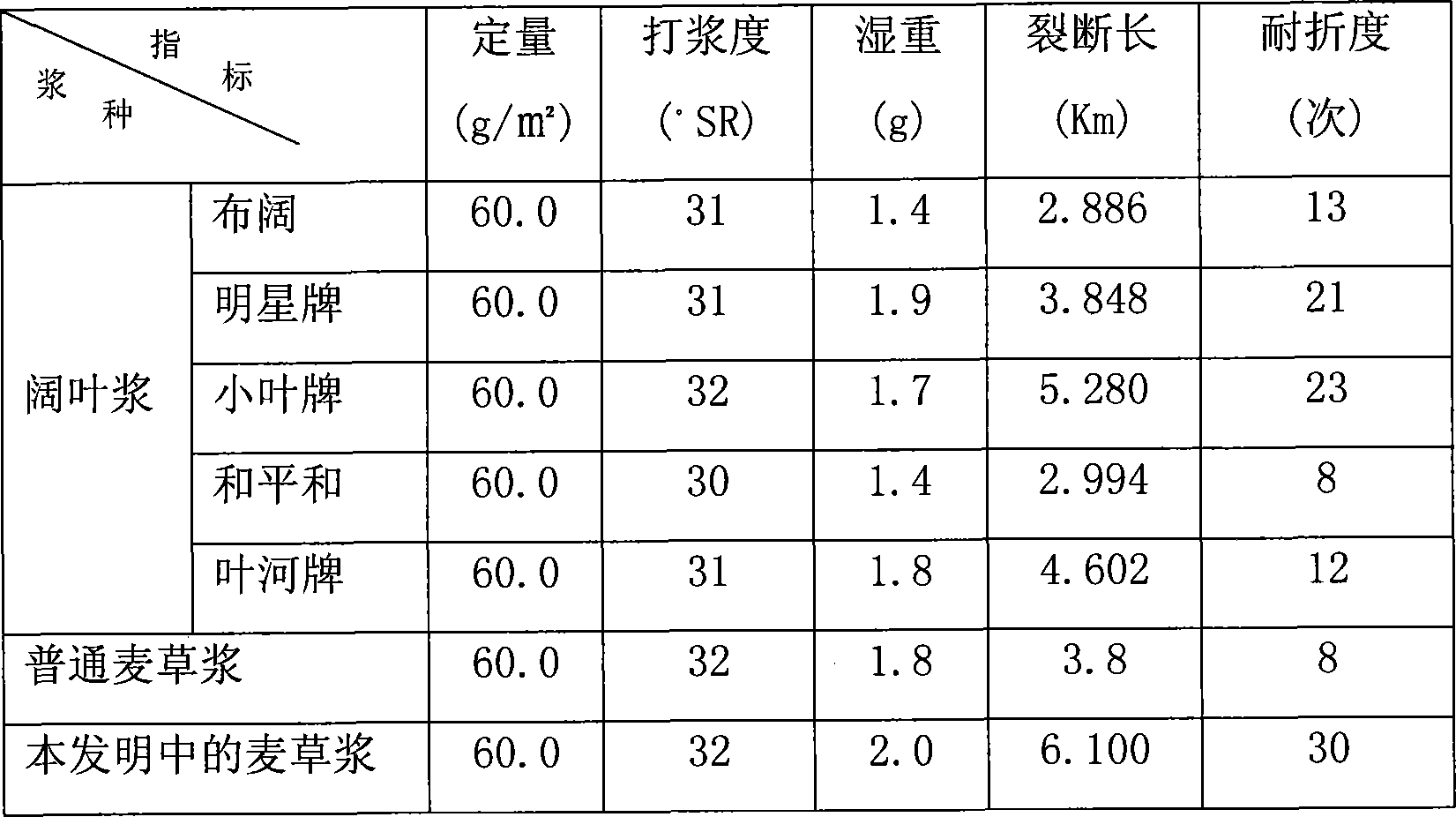

Prepared bleach chemical pulp using grass kind plant as raw material and preparation method thereof

ActiveCN101089291AReduce manufacturing costQuality improvementDigestersPulp de-wateringKappa numberFolding endurance

The present invention discloses a bleached chemical pulp prepared by using graminoid plant as raw material and its preparation method. Said invention is characterized by that it utilizes a high-hardness pulp which is obtained by using cooking process and whose permanganate number is 16-28 and equal to Kappa number 26-50 and makes said high-hardness pulp undergo the processes of pulp-washing and bleaching treatment so as to obtain the invented bleached chemical pulp whose breaking length is 4500-8000 m and folding endurance is 20-70 times.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

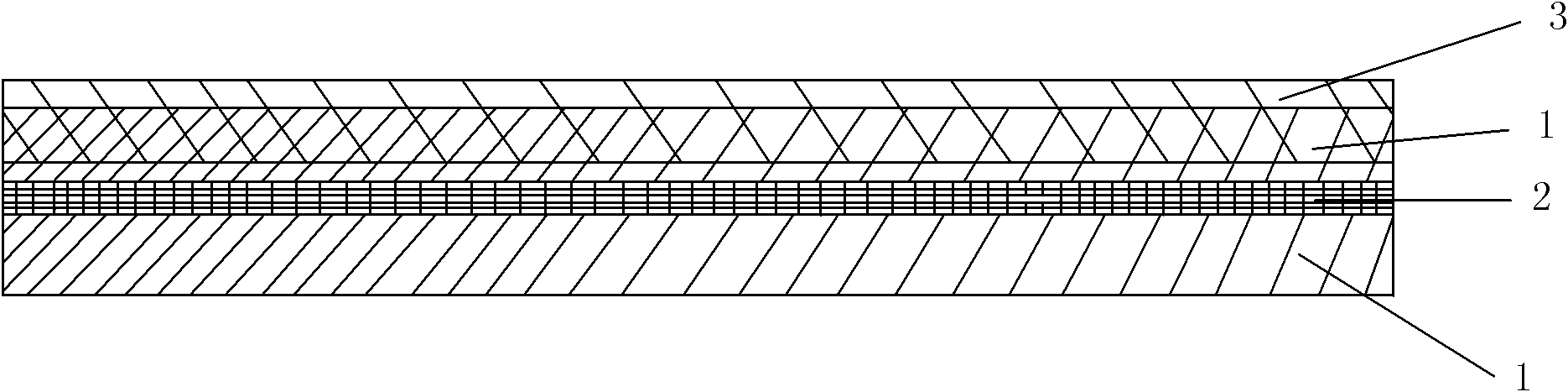

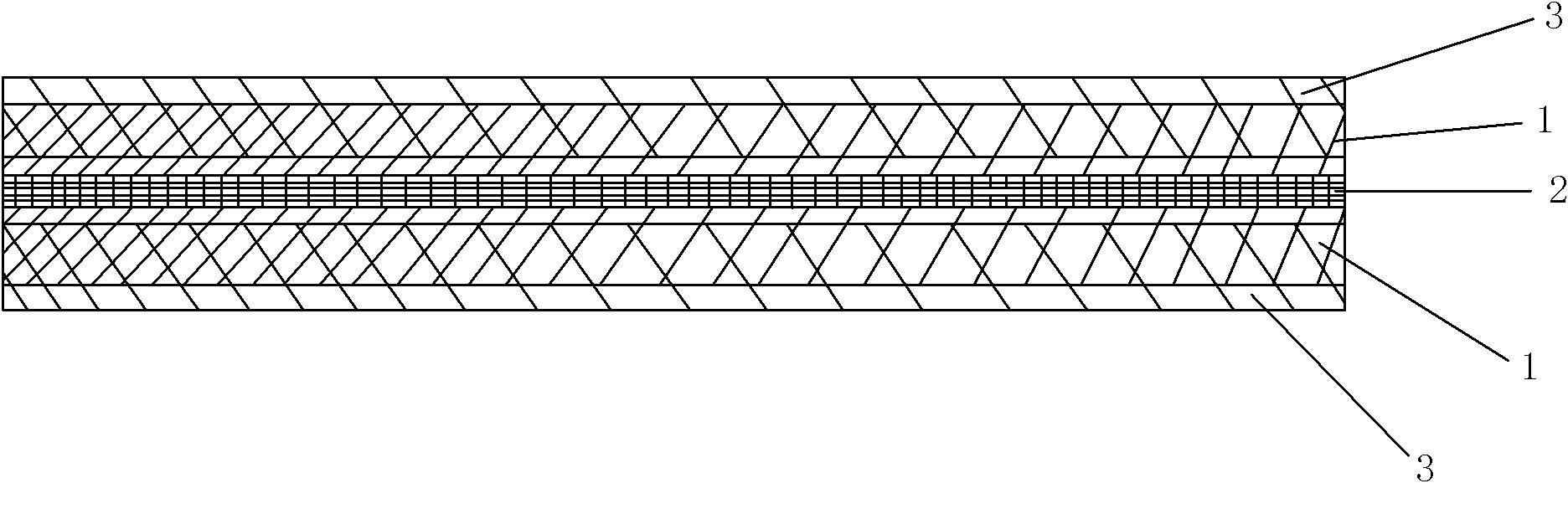

Graphite Film and Graphite Composite Film

ActiveUS20100196716A1Improve flex resistanceExcellent thermal diffusivityGraphiteSemiconductor/solid-state device detailsFolding enduranceElectronic instrument

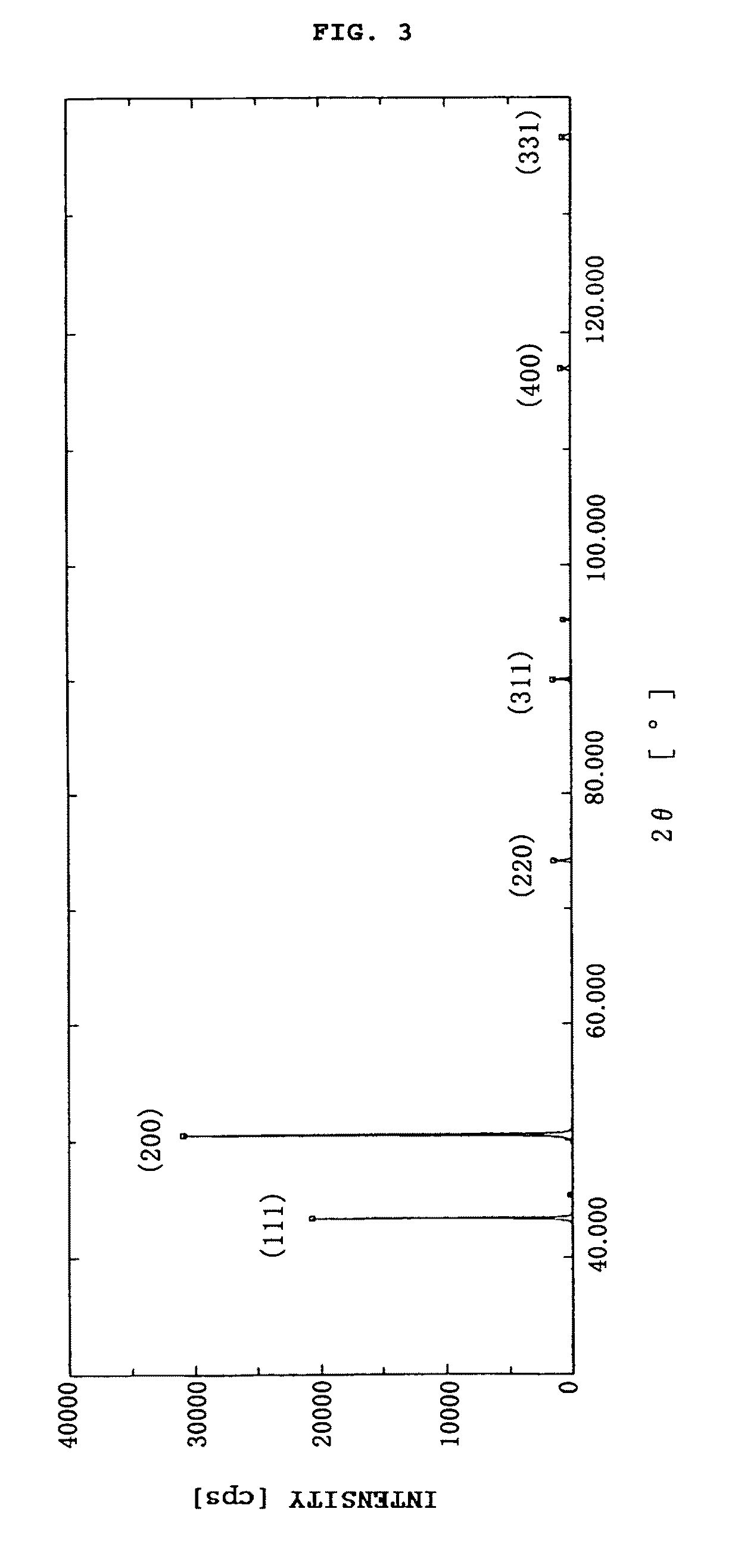

An object of the present invention is to provide a graphite film, and a graphite composite film both having an excellent thermal diffusivity which can sufficiently manage heat dissipation of electronic instruments, precision instruments and the like, along with an excellent flex resistance which can withstand application to bent portions.Means for Resolution of the present invention is a graphite film exhibiting the number of reciprocal foldings being 10,000 times or more as measured using a rectangular strip test piece having a width of 15 mm until the test piece breaks in a MIT folding endurance test under conditions of: a curvature radius R of the bending clamp being 2 mm; a left-and-right bending angle being 135°; a bending rate being 90 times / min; and a load being 0.98 N.

Owner:KANEKA CORP

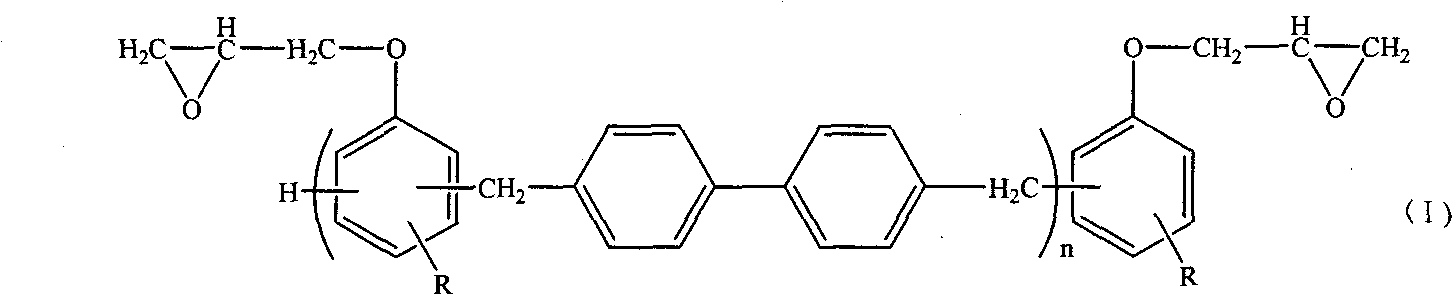

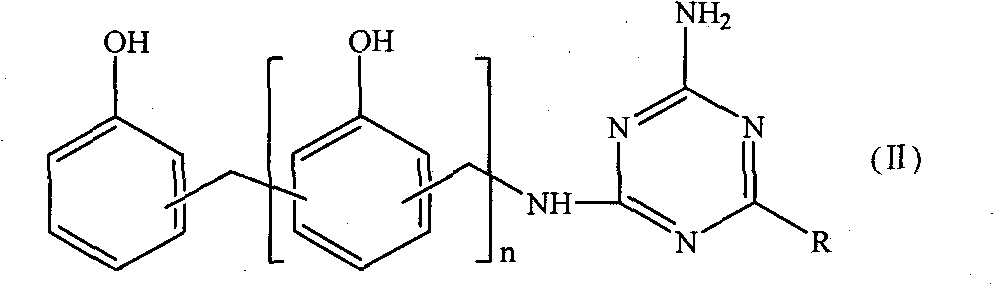

Halogen-free and phosphorous-free flame-retardant synthetic resin adhesive used for flexible copper clad laminate

InactiveCN101851480ANon-macromolecular adhesive additivesMacromolecular adhesive additivesElastomerEpoxy

The invention relates to a halogen-free and phosphorous-free flame-retardant synthetic resin adhesive used for a flexible copper clad laminate, in particular to the adhesive used for producing the flexible copper clad laminate. The adhesive comprises the following components: biphenyl epoxy resin, elastomer modified epoxy resin, a flexibilizer, a curing agent, a curing accelerator, an inorganic filler and an organic solvent. The halogen-free and phosphorous-free flame-retardant synthetic resin adhesive is halogen-free and phosphorous-free, is environmental-friendly and achieves fire retardance up to level UL94V-0; and the flexible copper clad laminate produced by using the adhesive has the characteristics of high folding endurance, high fire retardance, dip-soldering resistance, high peel strength, low water absorption and high dimensional stability.

Owner:HAISO TECH

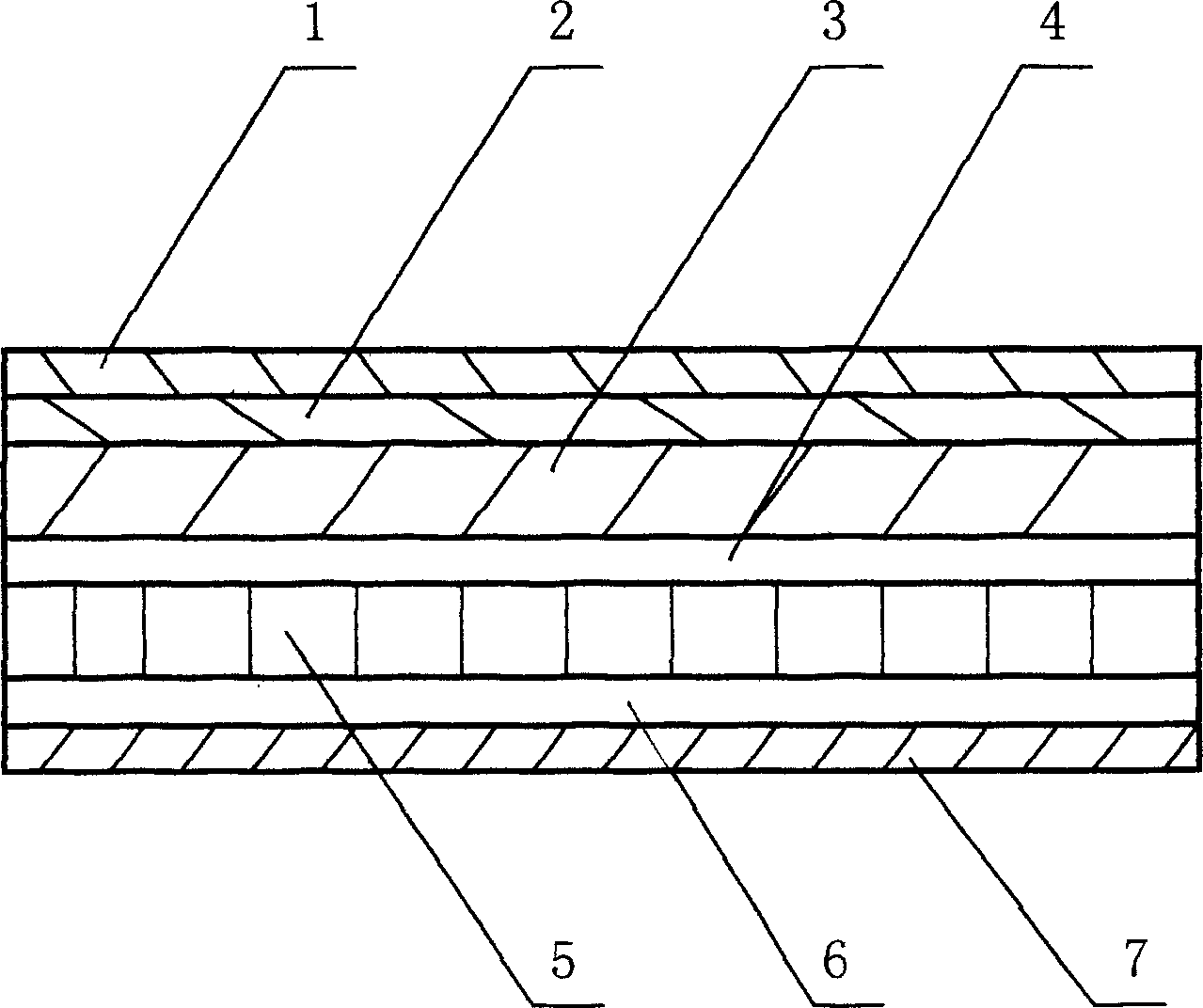

High barrier aluminum-plating composite film for packing liquid dairy product

InactiveCN1880182AHigh gas barrierImprove water resistanceFlexible coversWrappersComposite filmFolding endurance

The invention relates to a high insulated aluminum composite film used to pack liquid milk, wherein it has multilayer structure, from outer to inner, as printing layer, adhesive layer, aluminum layer, adhesive layer, baffle layer, adhesive layer and thermal sealing layer; the baffle layer is made from polyvinylidene chloride polymer or ethane-ethenol polymer. Compared with traditional plastic soft film, the invention avoids the carbon black layer and increases the aluminum layer and oxygen baffle layer, to obtain high waterproof ability and high insulated property, etc.

Owner:ZHEJIANG BILI POLYMER TECH CO LTD

Ultraviolet light-curing sand vein ink

An ultraviolet photocurable sand-texture ink consists of acrylate resin 20-60 proportion, acrylate monomer 10-50 proportion, light initiating agent 3-10 proportion, initiating improver 3-15 proportion, wax powder 3-10 proportion and auxiliary 0.3-5 proportion. It has excellent grinding effect, adhesion and folding endurance. It can be used high-level package printin.

Owner:CHINA LUCKY FILM CORP +1

Surface blackening treatment method for rolled copper foil

InactiveCN106191980AImprove acid resistanceGood alkali resistanceChromatisationSuperimposed coating processFolding enduranceSurface roughness

The invention discloses a surface blackening treatment method for a rolled copper foil. The surface blackening treatment method orderly comprises the following steps: (1) electrochemical oil removal, (2) coarsening treatment, (3) solidification treatment, (4) nickel-cobalt plating treatment, (5) zinc plating treatment, (6) passivation, (7) silicone coupling agent coating treatment, and (8) drying treatment, and obtaining the product. Current is applied in step (1) to step (6). The surface blackening treatment method for a rolled copper foil provided by the present invention has the advantage that the black appearance of the copper foil obtained after various electric plating steps meets FPC requirements. Through determination, the copper foil has a surface color blackness value of less than 30, surface roughness Ra of less than or equal to 1.0 micron and Rz of less than or equal to 2.0 microns, peel strength of more than 1.4 N / mm, and folding endurance MIT of more than 800; the copper foil has favorable acid resistance, alkali resistance, soldering resistance, and etching performance. With the blackness value RAL7016, a good extinction effect is achieved.

Owner:中铜(上海)铜业有限公司

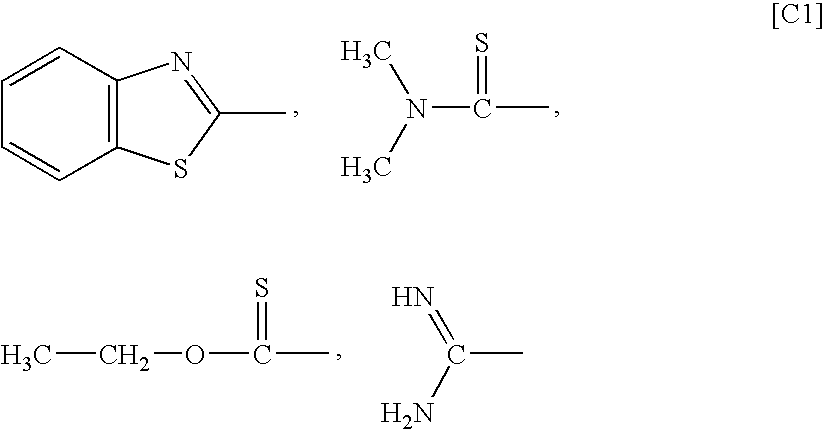

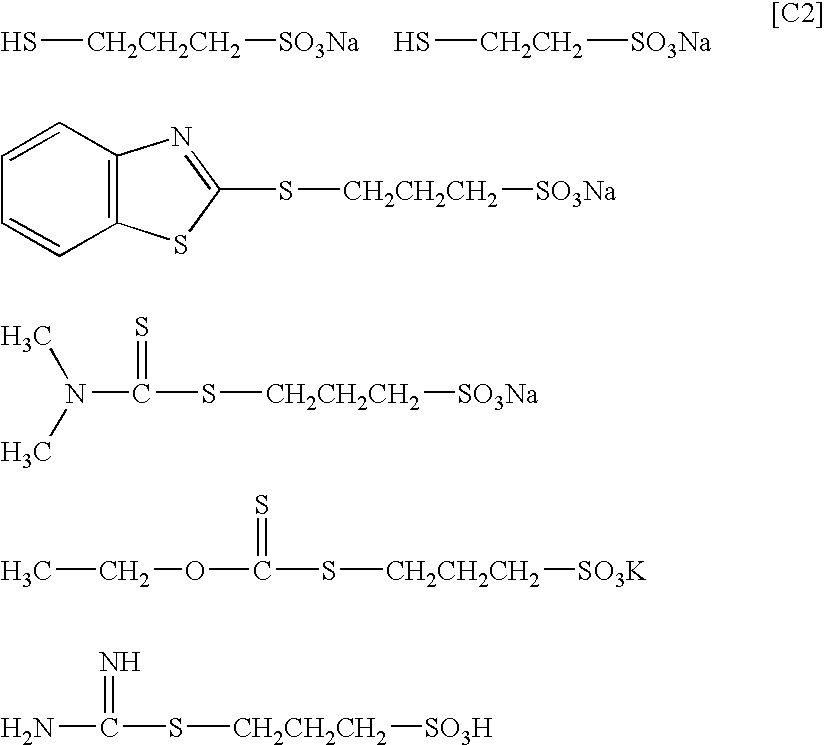

Copper electrolytic solution and two-layer flexible substrate obtained using the same

InactiveUS20100084275A1Excellent resist adhesivenessEliminate surface defectsDuplicating/marking methodsActive material electrodesFolding enduranceSulfur

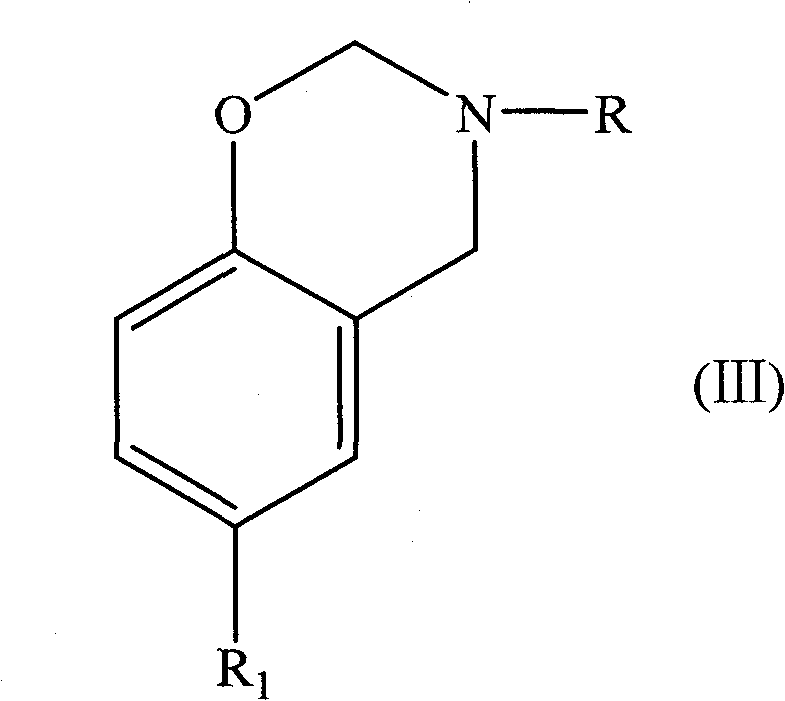

To provide a two-layer flexible substrate having excellent folding endurance, etching properties, and resist adhesiveness with no surface defects.A copper electrolytic solution containing chloride ions, a sulfur organic compound and polyethylene glycol as additives, and the copper electrolytic solution preferably contains 5 to 200 ppm of chloride ions, 2 to 1000 ppm of a sulfur organic compound and 5 to 1500 ppm of polyethylene glycol. A two-layer flexible substrate having a copper layer formed using the copper electrolytic solution, wherein the MIT folding endurance is 100 or more, and the surface roughness (Rz) of the copper layer is 1.4 to 3.0 μm.

Owner:JX NIPPON MINING & METALS CO LTD

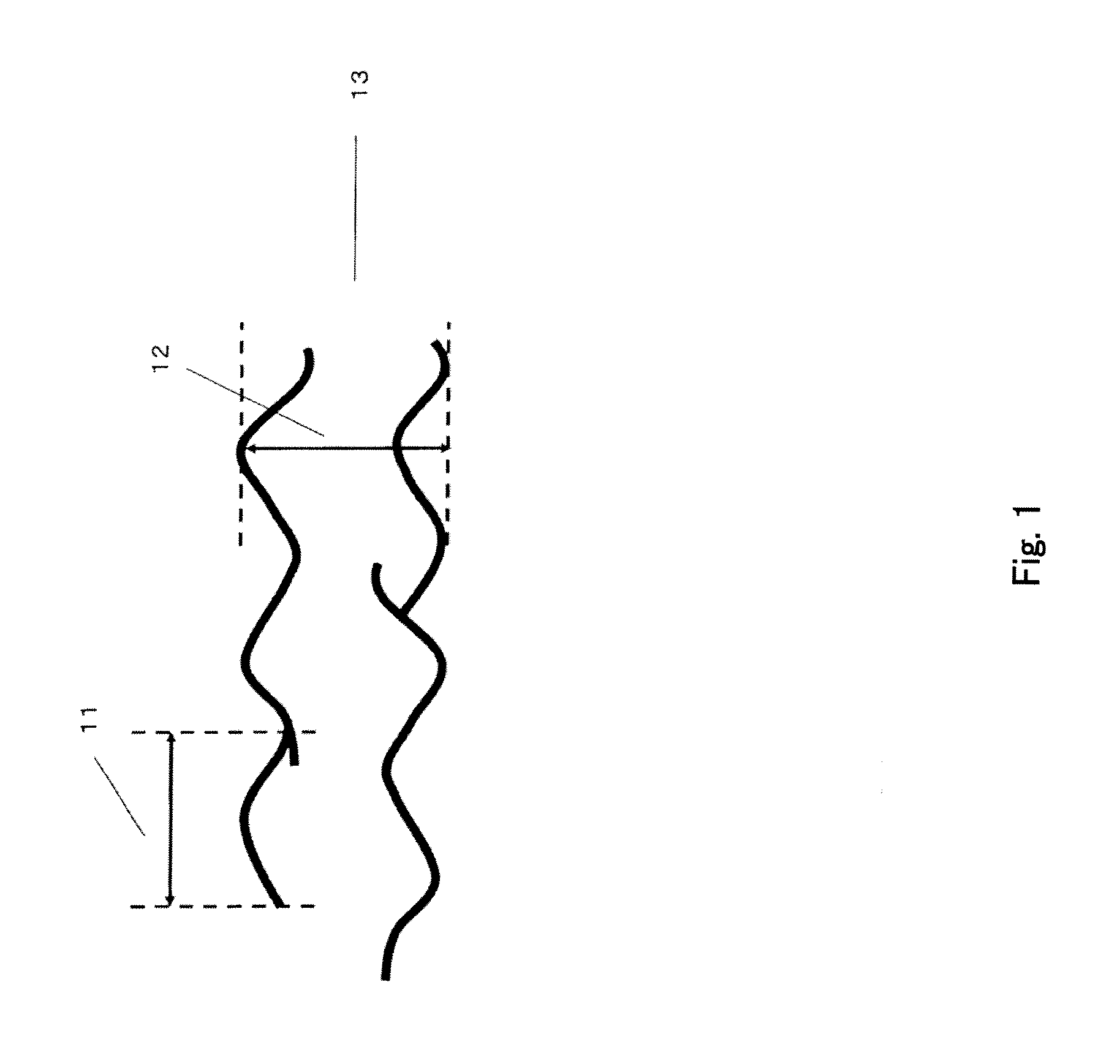

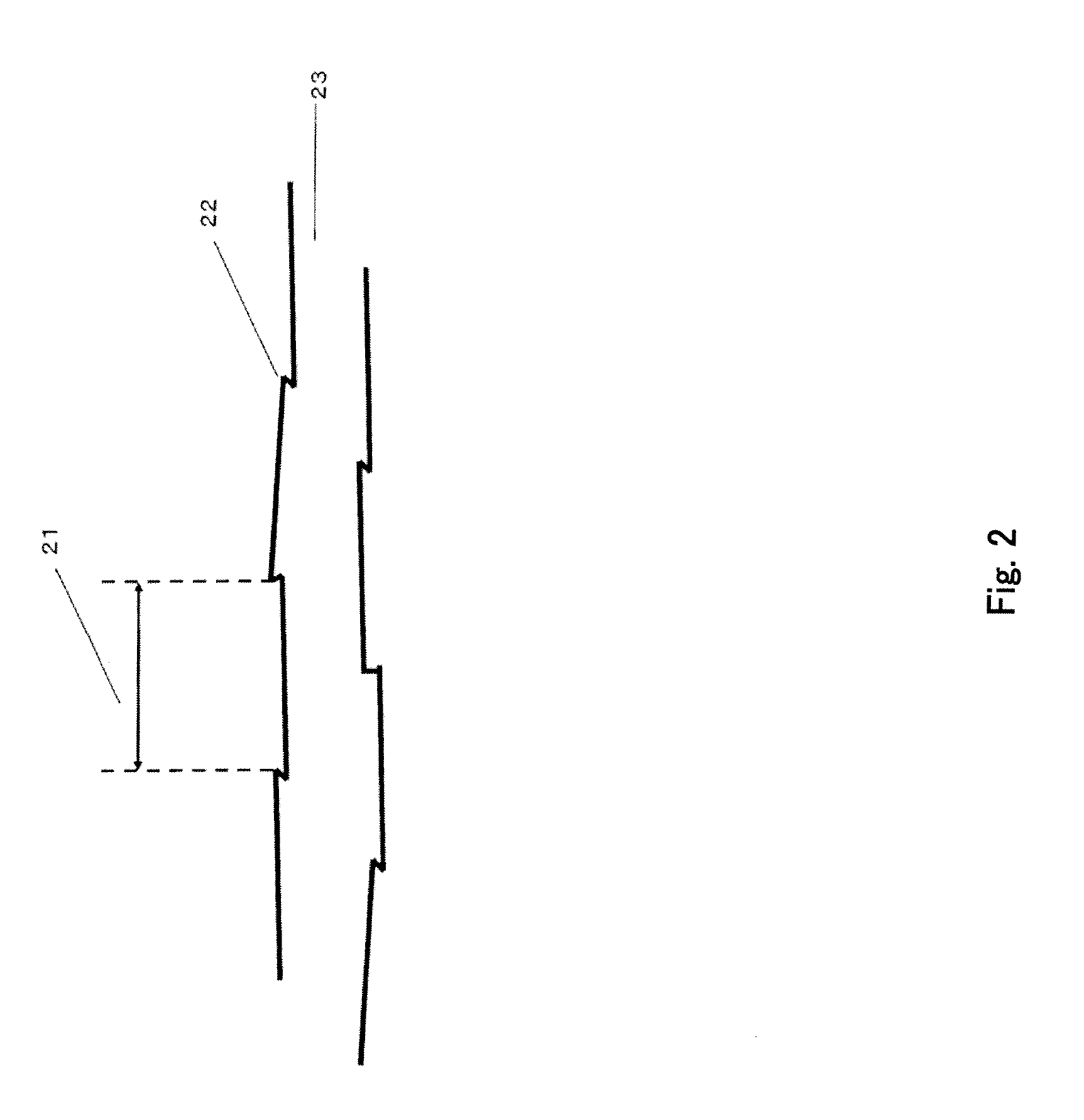

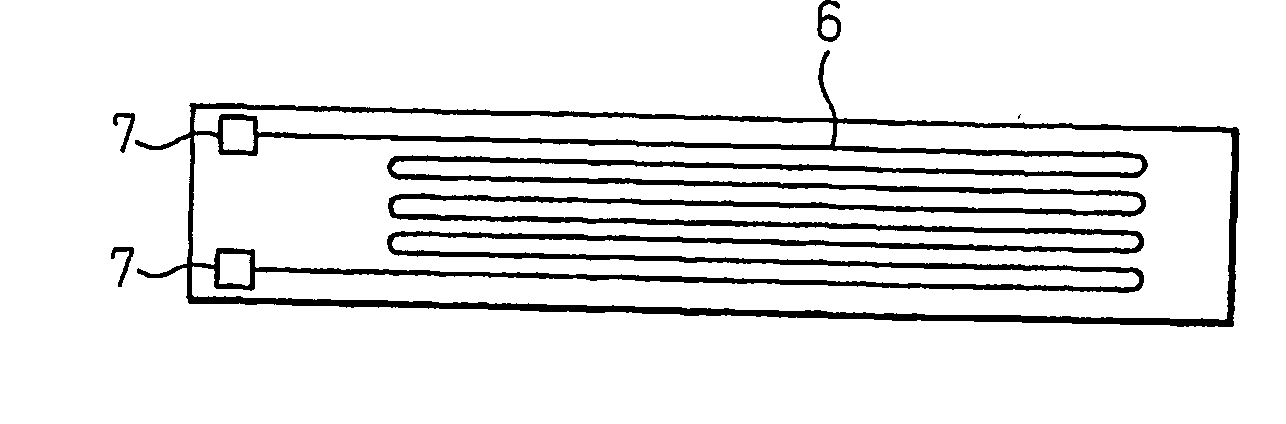

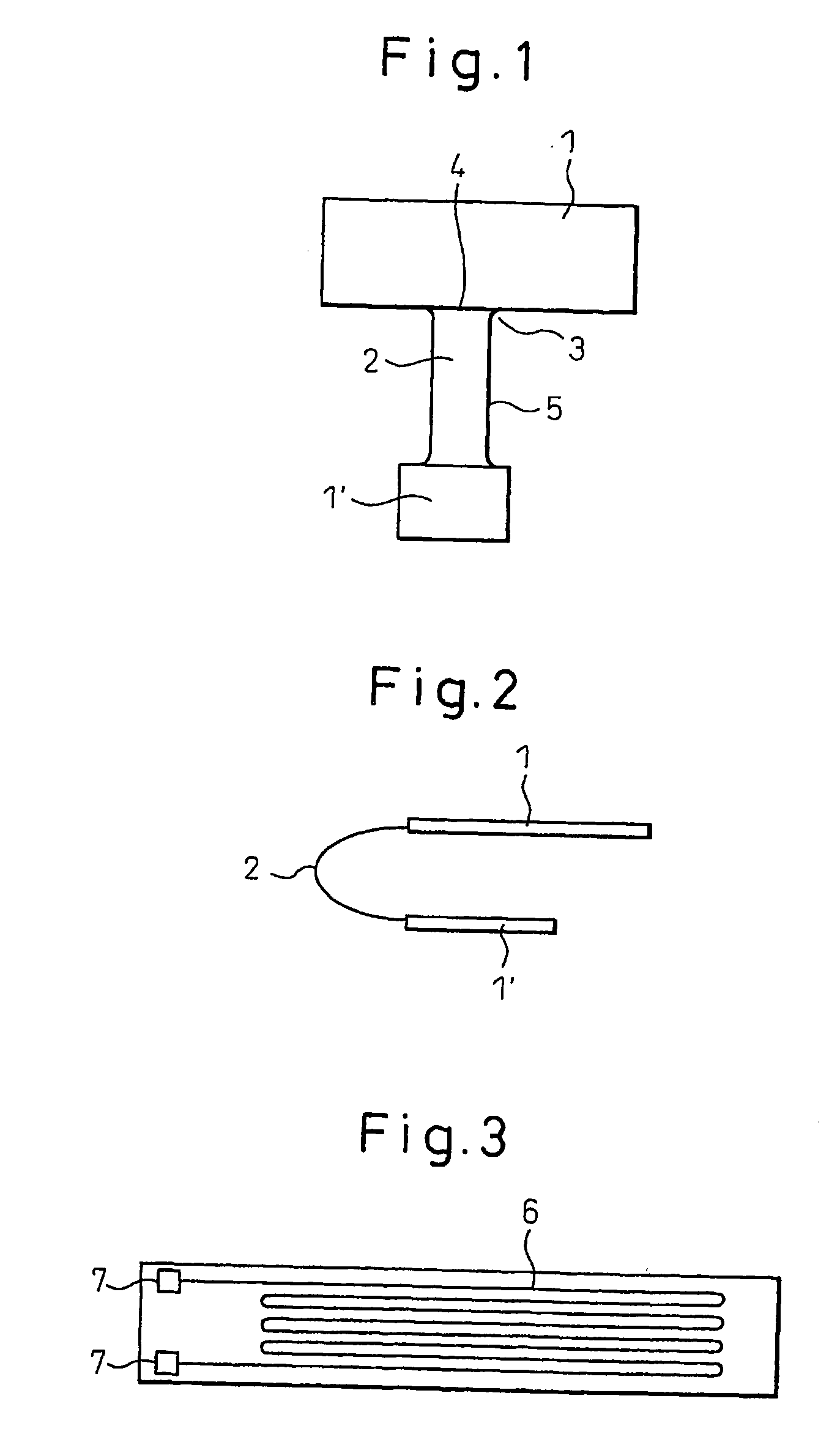

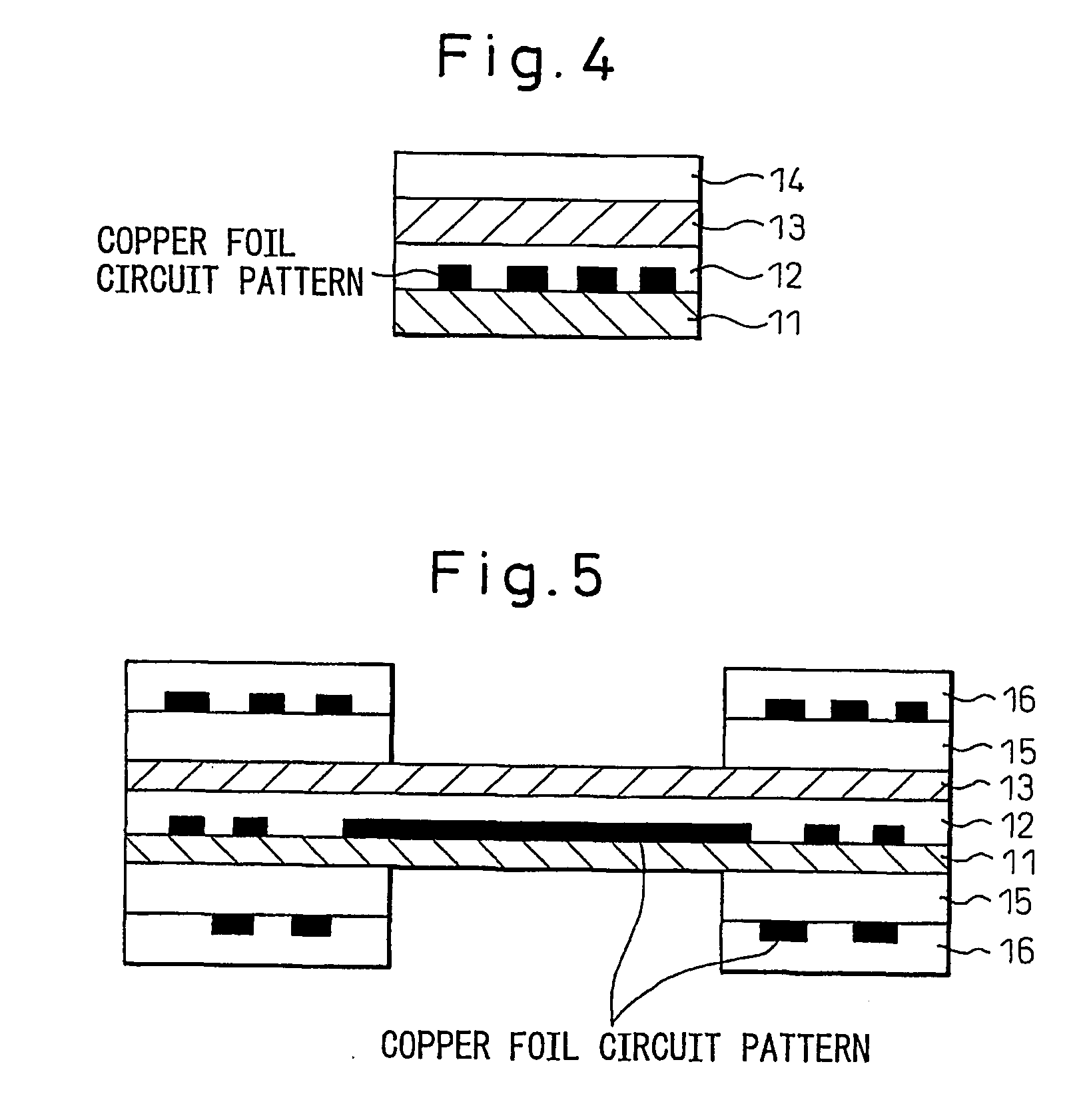

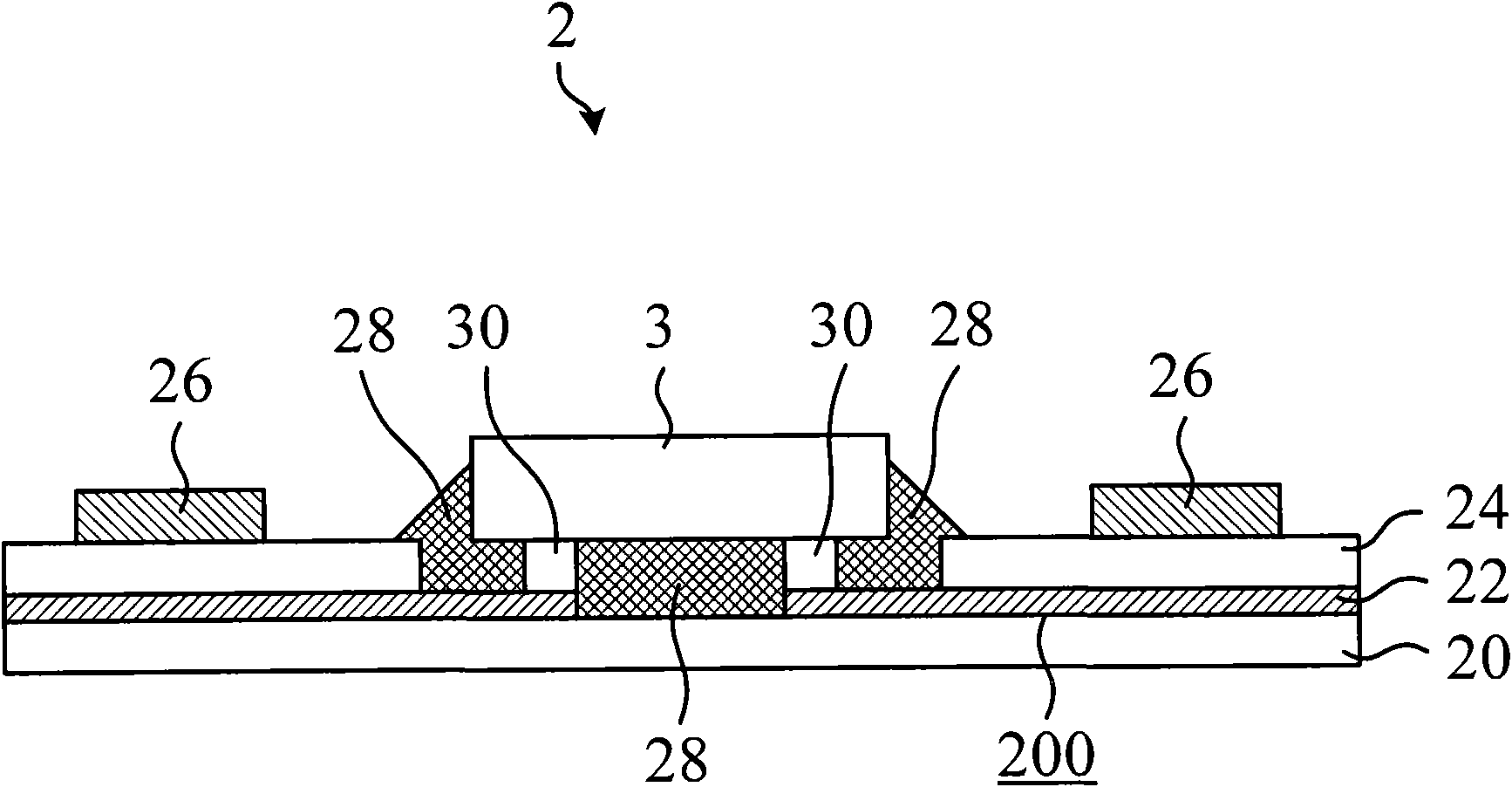

Flexible wiring board and flex-rigid wiring board

InactiveUS20070013041A1Improve folding resistanceHigh breaking strengthSemiconductor/solid-state device detailsPrinted circuit aspectsFolding enduranceEngineering

The invention provides a flexible wiring board for repeated folding sections which exhibits excellent folding endurance, and a flex-rigid wiring board comprising the flexible wiring board as a section thereof. The flexible wiring board for repeated folding sections of the invention comprises a wiring patterned base film layer (11), a flexible insulating material layer (12) covering the layer (11), and a cover film layer (13) covering the layer (12).

Owner:SHOWA DENKO KK

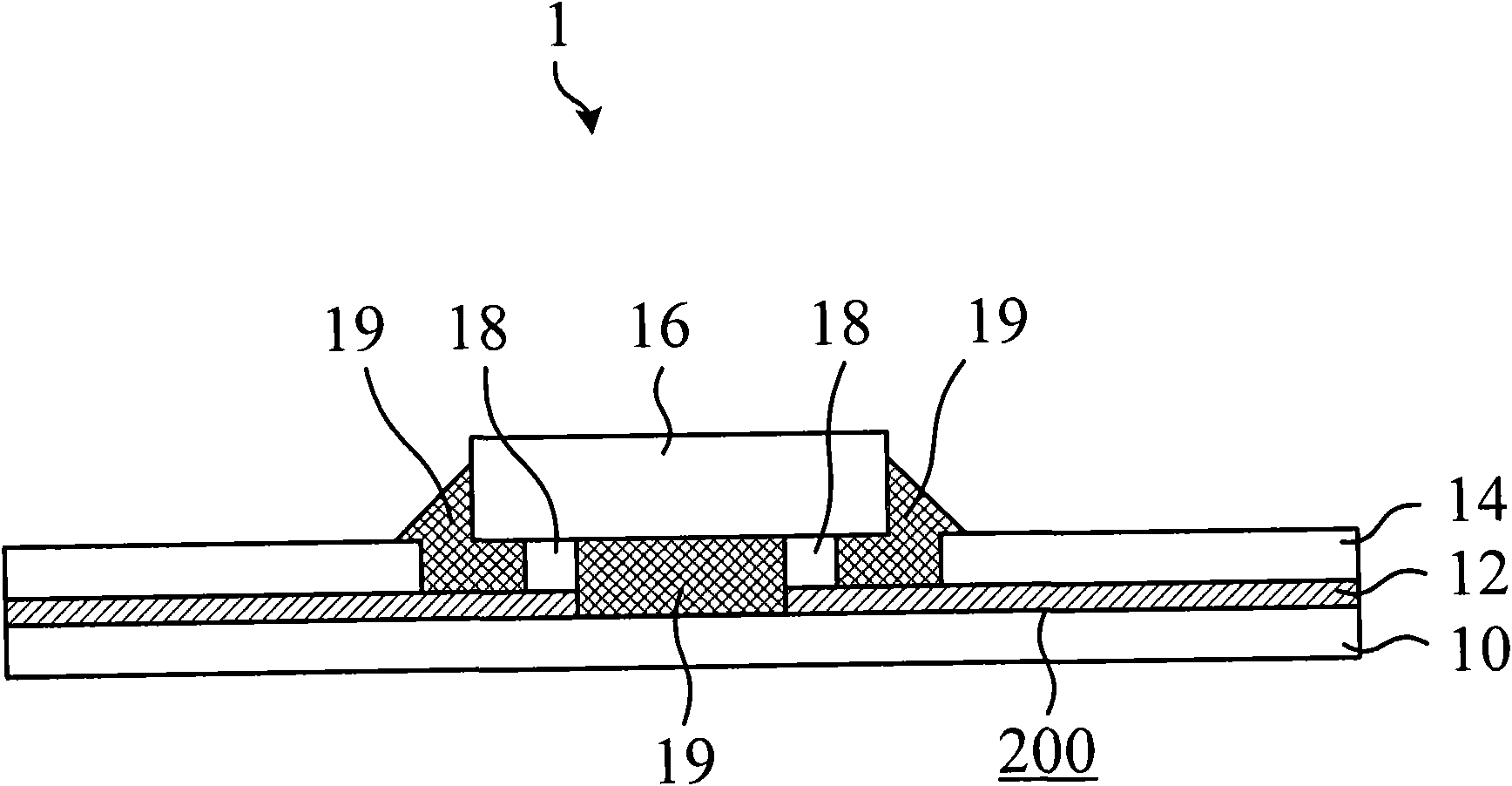

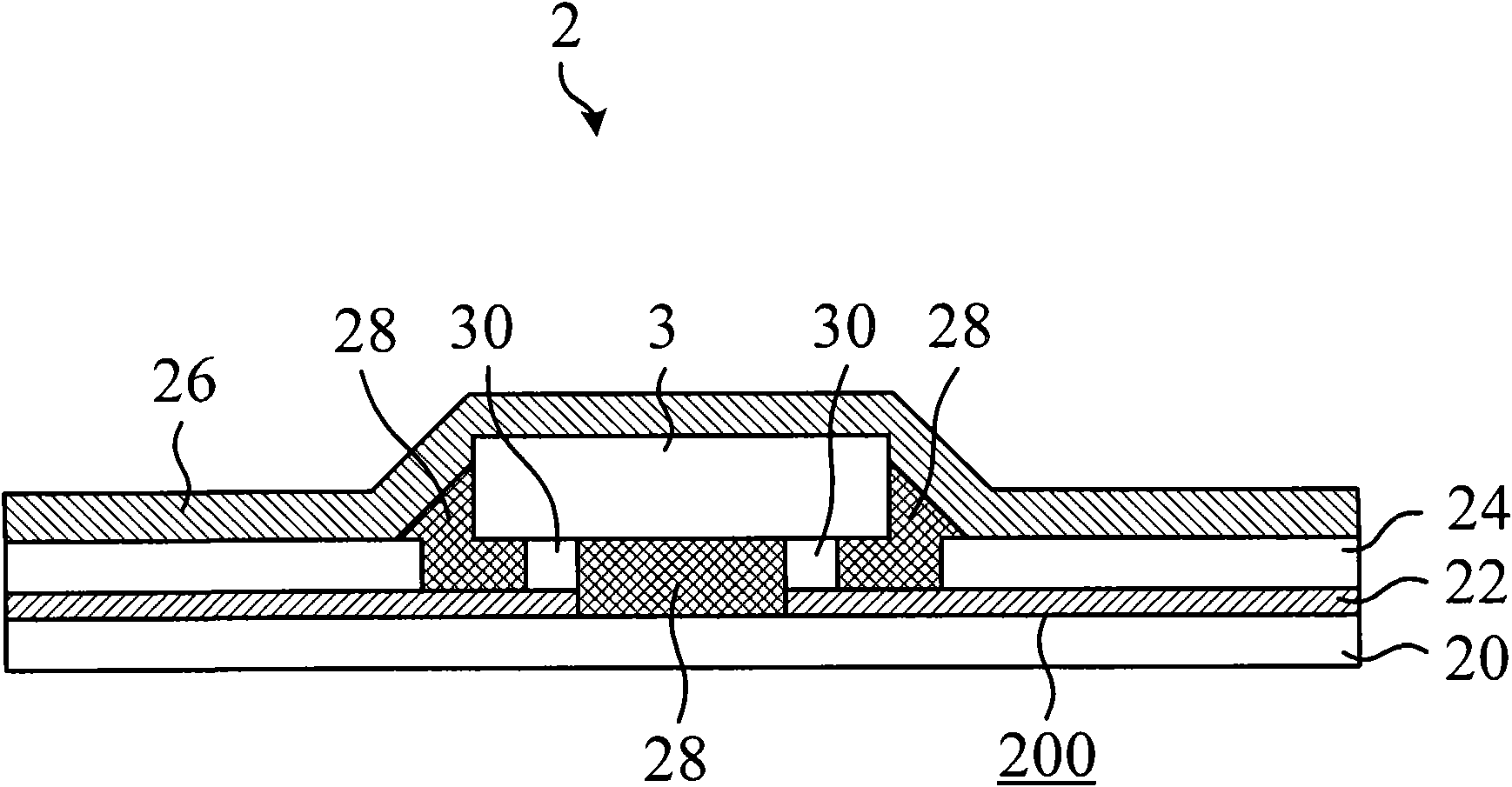

Chip on film packaging structure and chip on film packaging method

ActiveCN101626010AHigh folding resistanceSemiconductor/solid-state device detailsSolid-state devicesState of artChip on film

The invention discloses a chip on film packaging structure, which comprises a flexible substrate, a lead layer, an insulating layer and an elastic layer. The flexible substrate has a surface; the lead layer is formed on the surface and is provided with a plurality of leads; the insulating layer is formed on the lead layer; and the elastic layer is formed on the insulating layer and corresponds to at least one of the leads. When the flexible substrate is bent under the action of an external force, the elastic layer can buffer the deformation of the corresponding lead. Therefore, the rupture, caused by over deformation, of the corresponding lead can be avoided. The invention also provides a chip on film packaging method, which can improve the folding endurance of the chip on film packaging structure so as to solve the problem of the prior art.

Owner:RAYDIUM SEMICON

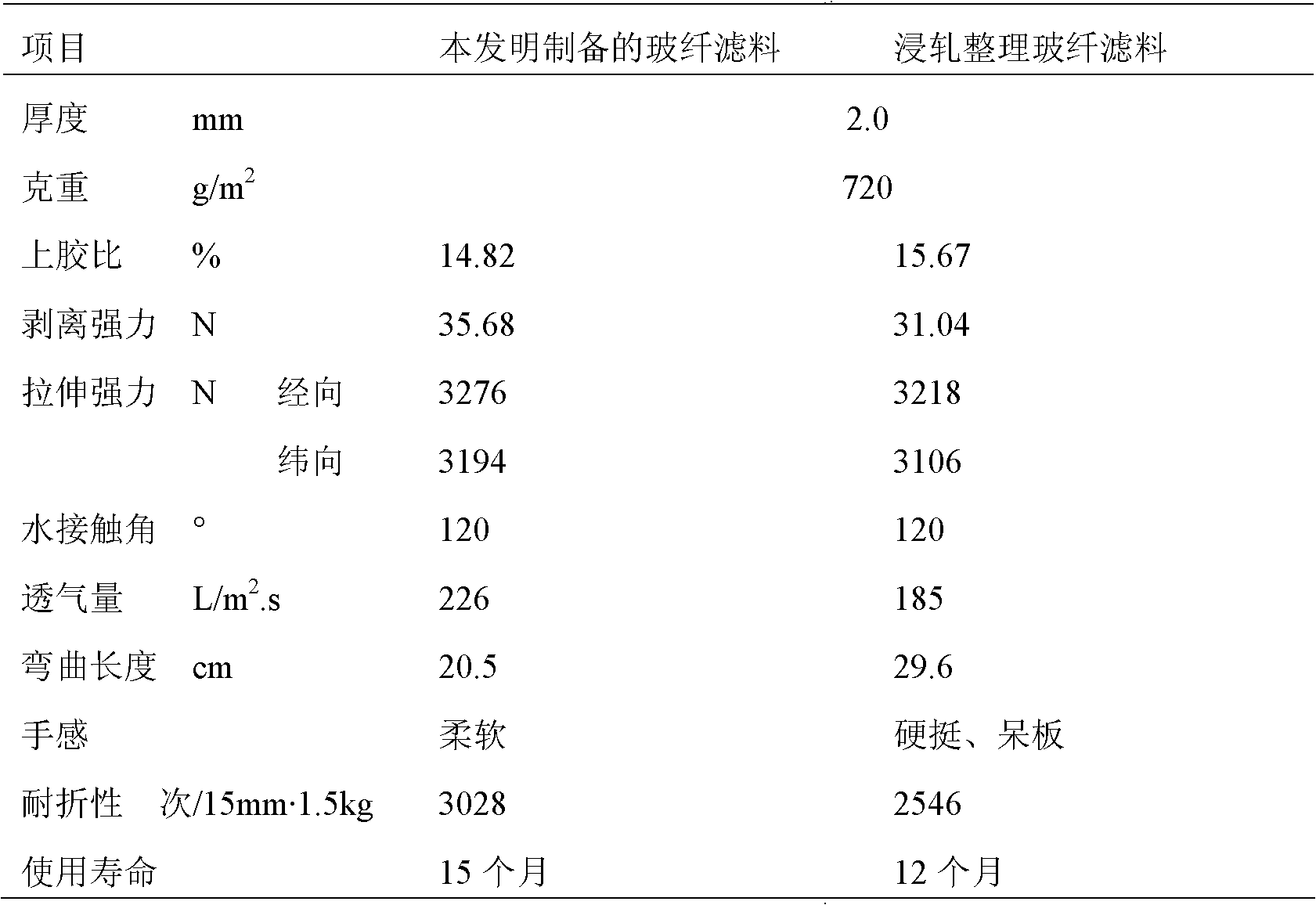

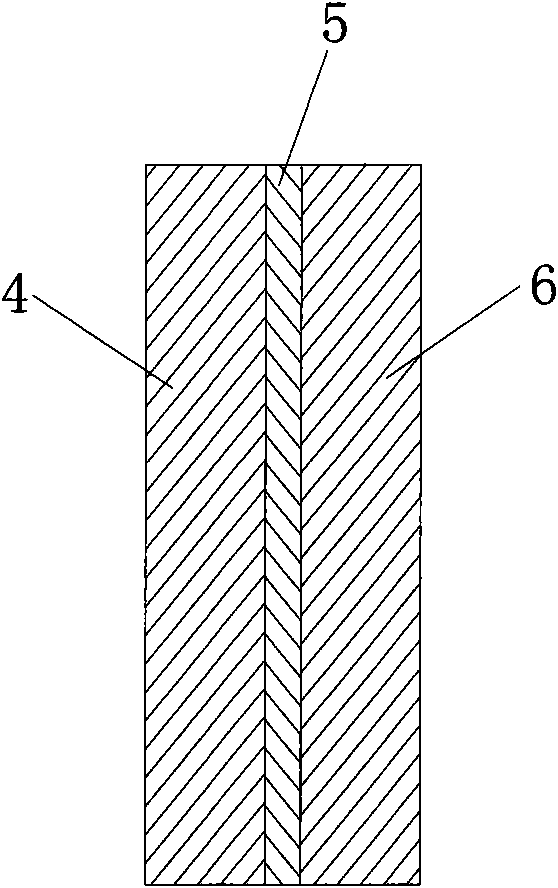

Glass fiber filter material and preparation method thereof

ActiveCN102151435AEvenly distributedReduce swimming phenomenonSynthetic resin layered productsGlass/slag layered productsGlass fiberFolding endurance

The invention discloses a glass fiber filter material and a preparation method thereof. The filter material comprises a base fabric, wherein the upper surface and the lower surface of the base fabric are respectively provided with a non-woven layer, and at least one of the non-woven layers is internally and externally provided with a foam coating layer respectively. The preparation method of the glass fiber filter material comprises the following steps of: manufacturing the glass fiber filter material, preparing finishing agent, generating foam, coating, and drying. The glass fiber filter material is subject to foaming layer arrangement, and the concentration of the finishing agent is increased, so that the finishing agent is distributed in the filter material more evenly, the migration phenomenon is reduced, and a mass of water resource, electric energy and heat energy are saved; after the glass fiber filter material is finished, and the gluing quantity of the filter material is decreased to 7-15% from 12-25% during finishing in a leaching way, so that the glass fiber filter material is even in distribution of the gluing quantity, good in flexibility, stable in quality, chemical corrosion-resistant, good in water resistance and oil resistance, easy to dedust, easy for industrial production, free of the existing water and energy-wasting step of finishing in a padding way, goodin folding endurance, and long in service life at about 15 months.

Owner:南京际华三五二一环保科技有限公司

Heat-resistant basalt fibre filter material and preparation method thereof

ActiveCN101856577AStable structureHigh filtration precisionFiltration separationNatural mineral layered productsFolding enduranceEmulsion

The invention provides a heat-resistant basalt fiber filter material and a preparation method thereof. The filter materials of the invention can be used in environment of ultra-high temperature, and has excellent folding endurance, corrosion resistance and abrasive resistance. The preparation method of the heat-resistant basalt fiber filter material has the technical scheme as follows: firstly, preparing a basalt fiber foundation and basalt fiber meshes; putting the basalt fiber foundation between the upper basalt fiber mesh and the lower basalt fiber mesh to be manufactured into the filter material; and preparing basalt fiber used for the basalt fiber foundation and then carrying out dipping treatment of teflon mix emulsion.

Owner:昆山万瑞达工业纺织品有限公司

Method for manufacturing high-performance electromagnetic wave shielding fabric

InactiveCN101302719AImprove folding resistanceImprove oxidation discolorationPhysical treatmentMagnetic/electric field screeningSputteringFolding endurance

The invention discloses a production method for a high-efficiency electromagnetic wave shielding fabric in the production of textile industries, comprises the working procedures of vacuum sputtering metallic film plating, chemical metallic film plating and protective layer applying of a fabric substrate, and is characterized in that an applied protective layer takes mixed wave absorbing materials, which comprises acrylic ester paste, carbon powder, ferrite, nano ferrite, titanium dioxide, an organic silicone softening agent and an dispersing agent, the mixed wave absorbing materials are applied onto the surface of a fabric that passes through the vacuum sputtering metallic film plating and the chemical metallic film plating through the ways of extrusion coating with a serum roller, blade coating with a knife or printing coating with a circular screen, and are solidified at high temperature. The invention has the advantages that the high-efficiency electromagnetic wave shielding fabric produced achieves the superimposed effect of electromagnetic wave reflecting and absorbing and plasma activating, improves the electromagnetic wave shielding performance further to be larger than 90 dB, simultaneously raises the combining fastness between a plated film and the fabric substrate, and improves the folding resistance of the product and the oxidative stain property of the metallic film.

Owner:SHANGHAI WEAVING SCIENCE RESEARCH INSTITUTE CO LTD

Base paper of antiflaming environment-friendly rich mineral paper and manufacturing method of the base paper

The invention provides base paper of antiflaming environment-friendly rich mineral paper and a manufacturing method of the base paper of the antiflaming environment-friendly rich mineral paper. Each 100 parts of base paper comprise the following ingredients by mass: 11-31 parts of synthetic resin, 60-80 parts of an inorganic filler, 1-2 parts of a coupling agent, 0.2 parts of an antioxidant, 0.2-0.5 parts of an antistatic agent, 1-3 parts of a lubricant, 1-5 parts of a colorant and 5-20 parts of a fire retardant. The base paper of antiflaming rich mineral wallpaper obtained in the invention is rich mineral paper with high inorganic powder content and has the characteristics of appearance, whiteness, stiffness, printing and writing performances as those of multiple types of paper; and at the same time, the obtained base paper also has the characteristics of high strength, light resistance, moisture resistance, corrosion resistance, moth resistance, stable size, folding endurance, wide application and recyclability as those of multiple types of high-grade paper (including multiple types of synthetic paper).

Owner:KUNMING IRON & STEEL HLDG CO LTD

Method for preparing cationic polyvinyl alcohol paper intensifier

InactiveCN101215807AEliminate hazardsHigh strengthReinforcing agents additionFolding enduranceSolid particle

The invention discloses a process for preparing cation polyvinyl alcohol paper reinforcing agent, which comprises: firstly charging solid particles of polyvinyl alcohol and deionized water into a reactor, heating the reactor to a certain temperature and keeping the temperature till the polyvinyl alcohol is totally melt in the reactor, cooling the reactor and charging cation etherifying agent to cationise the polyvinyl alcohol; finally charging polymer crosslinking monomer into the cation polyvinyl alcohol solution and adjusting the solution pH value to acidity and then after keeping the temperature of the solution for a while, adjusting the pH value to weak acidity to obtain transparent liquid. The invention ensures that the discharged substance contains no organic halide and formaldehyde, and the retention rate of the crosslinking product after being ionized and modified is greatly improved. The reinforcing agent of the invention not only improves paper dry and wet strength, but also improves the paper folding endurance, and if the reinforcing agent is coated on paper surface, paper surface strength can be greatly improved. Meanwhile, the process of the invention has simple process and low cost of materials and can widen the polyvinyl alcohol application range.

Owner:SHAANXI UNIV OF SCI & TECH

Compound filter material, method and application thereof

InactiveCN101596384AExtended service lifeHigh acid and alkali resistanceFiltration separationFolding enduranceAntistatic agent

The invention discloses a compound filter material, a method and application thereof, and relates to a filter material. The invention provides a compound filter material which has good folding endurance, corrosion resistance and wear resistance and can be used as a high-temperature environment filter material, a method and application thereof. The compound filter material comprises the following components in percentage by mass: 1 to 99 percent of basalt fiber and 1 to 99 percent of polytetrafluoroethylene fiber. The preparation method comprises the following steps of: mixing the basalt fiber and the polytetrafluoroethylene fiber to obtain a mixed fiber; and adding an antistatic agent to the mixed fiber for mixing to obtain the compound filter material. According to the mass percentage, the adding amount of the antistatic agent is 0.1 to 20 percent of the mixed fiber. The compound filter material can be used for directly preparing composite filter cloth with single-layer structure or multi-layer structure, and the prepared composite filter cloth with single-layer structure or multi-layer structure can be used for producing a filter device.

Owner:厦门美达斯环保工业有限公司

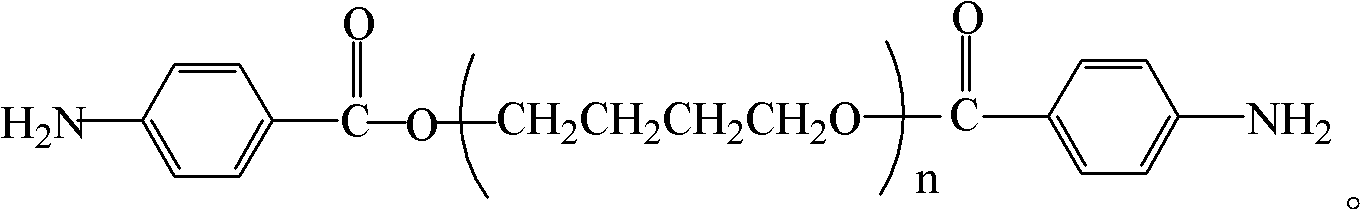

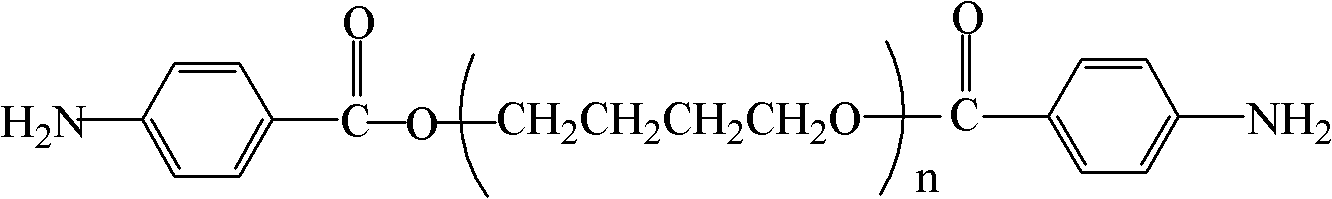

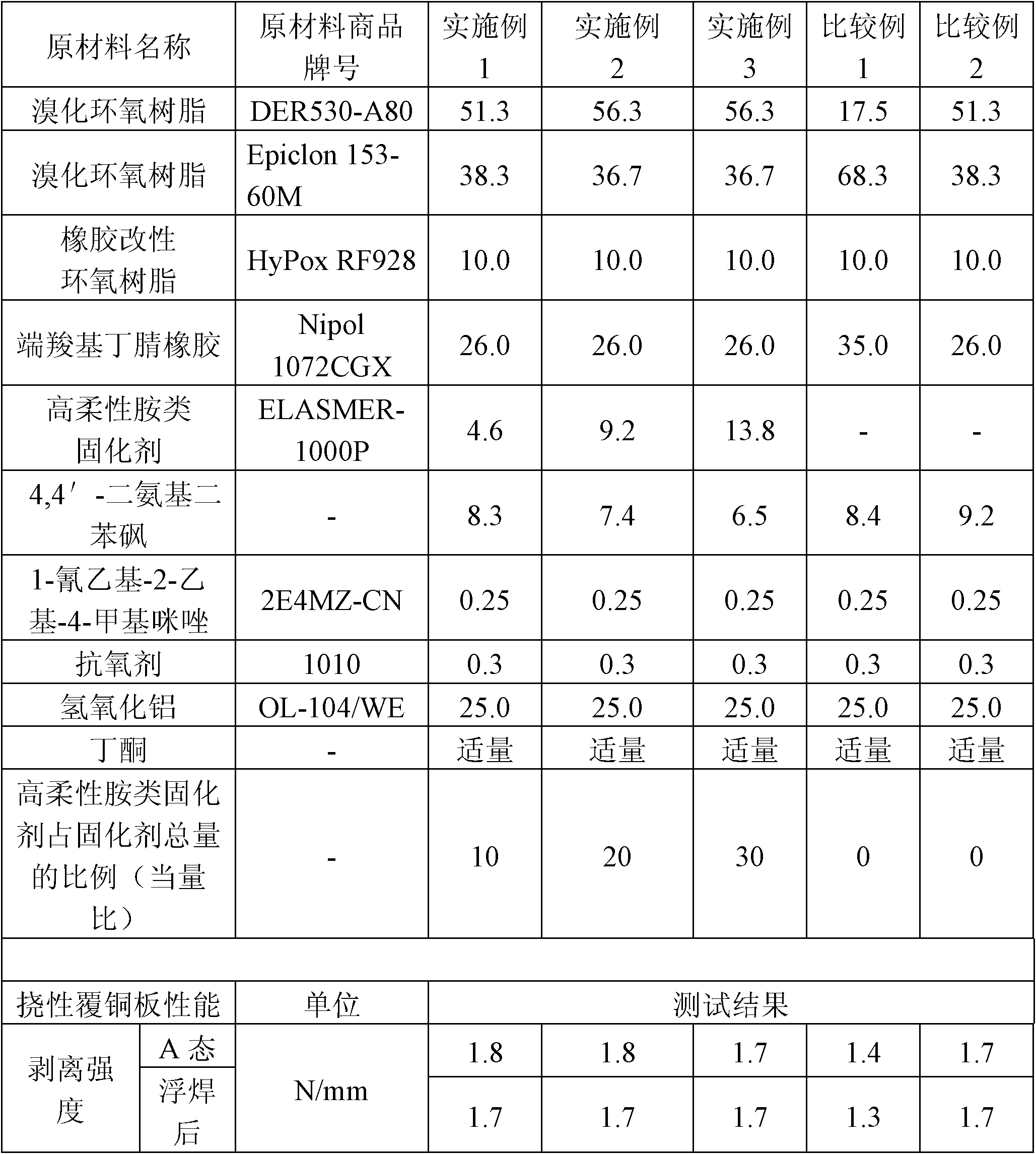

Epoxy resin composition and flexible copper-clad plate prepared from same

InactiveCN102127290AGood flexibilityLow in bromineNon-macromolecular adhesive additivesSynthetic resin layered productsEpoxyFolding endurance

The invention discloses an epoxy resin composition and a flexible copper-clad plate prepared from the same. The epoxy resin composition comprises brominated epoxy resin, rubber modified epoxy resin, butadiene-acrylonitrile rubber, a high-flexibility amine curing agent, an aromatic amine curing agent, a curing accelerator, an antioxidant, inorganic filler and an organic solvent. The flexible copper-clad plate prepared from the epoxy resin composition comprises a polyimide film, an epoxy resin composition coating coated on one or two faces of the polyimide film and a copper foil laminated on the epoxy resin composition coating. In the epoxy resin composition, the high-flexibility amine curing agent and the high-flexibility amine curing agent are taken as a composite curing system, so that the flexibility of the composition can be improved remarkably, the dosage of the butadiene-acrylonitrile rubber and the bromine content of the composition can be lowered, and the composition has high flexibility, flame retardance and heat resistance. The flexible copper-clad plate prepared from the composition has high heat resistance, peeling strength, dimensional stability, flexibility, folding endurance and processability.

Owner:GUANGDONG SHENGYI SCI TECH

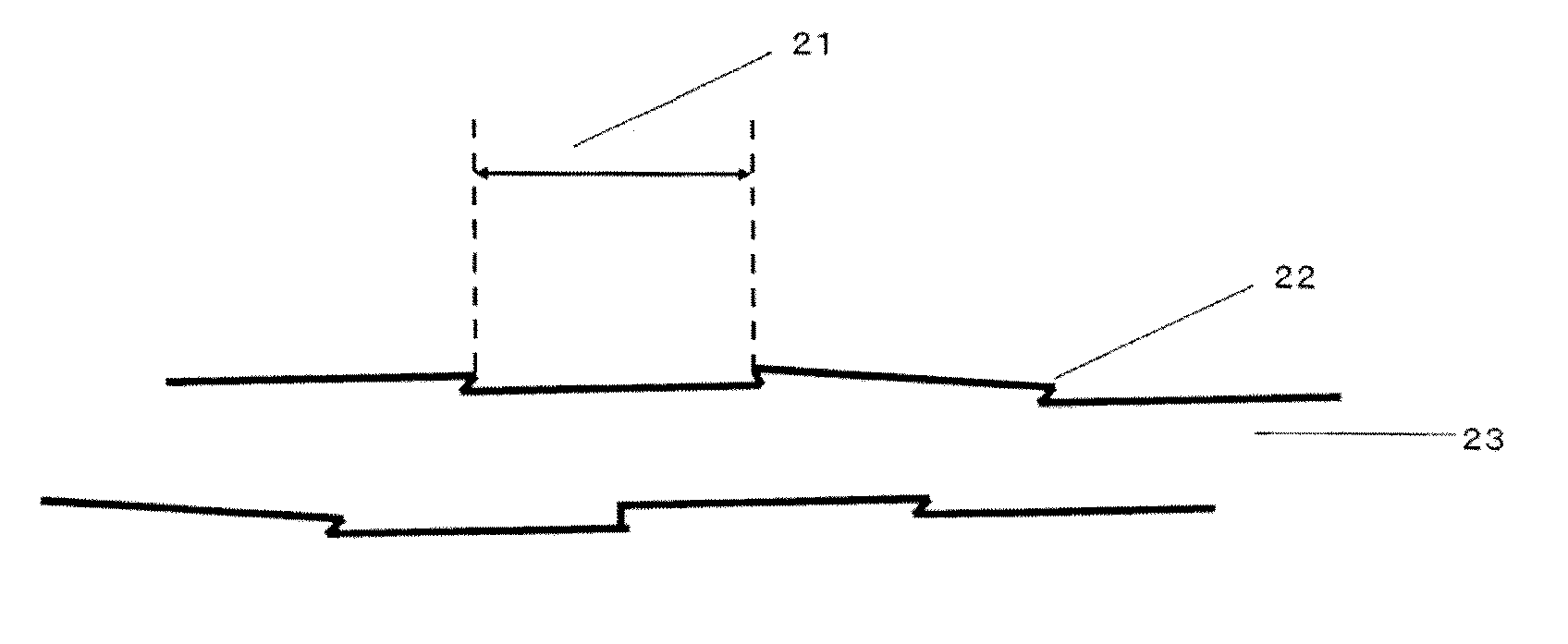

Raw paper and production method and application thereof

A raw paper prepared by a mixed pulp including straw pulp, which can be used to prepare textbooks, writing papers and office paper with good performance, and the producing method of said raw paper are provided. The weight proportion of the straw pulp in the mixed stock is from 10% to 100%, and the straw pulp has a hardness of KMnO4 value 10-17, an average fiber length of 0.1-2.5 mm, a tensile index of 23-57 Nm / g, a tearing index of 3.0-6.0 mN·m2 / g, a folding endurance index of 2-6 kPa·m2 / g and a whiteness of 28-50%. Either, the L value of the hue of said raw paper is 65-95, a value is 0-5, and b value is 0-40. The KMnO4 value of hardness of the pulp after oxygen delignification is 10-14. The method includes: adding grass-series raw material into a digester, then adding cooking liquor, heating the cooking liquor to 100-200°, pressurizing to 0.3-0.9 MPa, cooking for 150-250 min, extruding the pulp, washing and obtaining the straw pulp. The amount of the ammonium sulfite of the cooking reagent is 5-20% of the absolute dry material, and the amount of the sodium hydroxide is 0-15% of the absolute dry material, the liquor ratio is 1:2-15.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Method for making high-filtering and electrostatic resistance overlay film compound punched felt

The invention relates to a manufacturing method of a high-filtration anti-static tectorial membrane composite needled felt, which is characterized in that the composite needled felt is formed by that after being treated with anti-static processing, a composite needled felt plain felt is treated with hot pressing draping with a polyfluortetraethylene microporous membrane. The composite needled felt has good anti-static performance, high filtration efficiency and strong folding endurance, and the service life of the composite needled felt is greatly prolonged.

Owner:中材科技膜材料(山东)有限公司

Decorating material

ActiveUS20060204729A1Improve surface propertiesSimple materialDecorative surface effectsDuplicating/marking methodsFolding enduranceElectron

There is provided a decorative material which hardly undergoes deterioration of a substrate even when irradiated with an electron beam, and is excellent in surface properties such as stain resistance, abrasion resistance and marring resistance. The decorative material of the present invention comprises a substrate, and a pattern layer and / or a colored layer, and a surface protective layer which are successively laminated on the substrate, wherein the surface protective layer is obtained by crosslinking and curing an electron beam-curable resin composition, and a rate of reduction in a folding endurance of a material obtained by applying the electron beam-curable resin composition onto the substrate and then irradiating an electron beam to the electron beam-curable resin composition, relative to a folding endurance of the substrate before applying the electron beam-curable resin composition thereonto is 70% or lower as measured in the CD direction (lateral direction) of the substrate.

Owner:DAI NIPPON PRINTING CO LTD

Powerful breathable fiber mid-sole material and manufacturing method

The invention discloses a powerful breathable fiber mid-sole material and a manufacturing method. The material is manufactured by taking polyester staple fibers, high-strength stretch yarns, polypropylene fibers and ES fibers as raw materials; loosening, mixing, carding, lapping, needling, ironing and reinforcing to form a non-woven substrate; and afterfinishing and processing the substrate, wherein (1) a blend fiber comprises the following components: 40 to 60 parts of 7.0D polyester staple fibers, 50 to 100 parts of 15D polyester staple fibers, 0 to 10 parts of POY staple fibers, 2 to 8 parts of the polypropylene fibers and 2 to 8 parts of the ES fibers; (2) padding finishing liquid for afterfinishing comprises the following components: 0 to 50 parts of modified butyronitrile latex (H), 0 to 50 parts of modified butyronitrile latex (S), 50 to 100 parts of carboxylic styrene butadiene latex, 25 to 75 parts of ground calcium carbonate, 50 to 100 parts of precipitated calcium carbonate, 10 to 25 parts of tapioca flour, 0 to 25 parts of titanium pigment and 0 to 1 part of seaweed powder. The material has the advantages of high folding endurance, powerfulness, breathability and the like, short production process flow, simple operation, high efficiency and low product cost.

Owner:福建鑫华股份有限公司

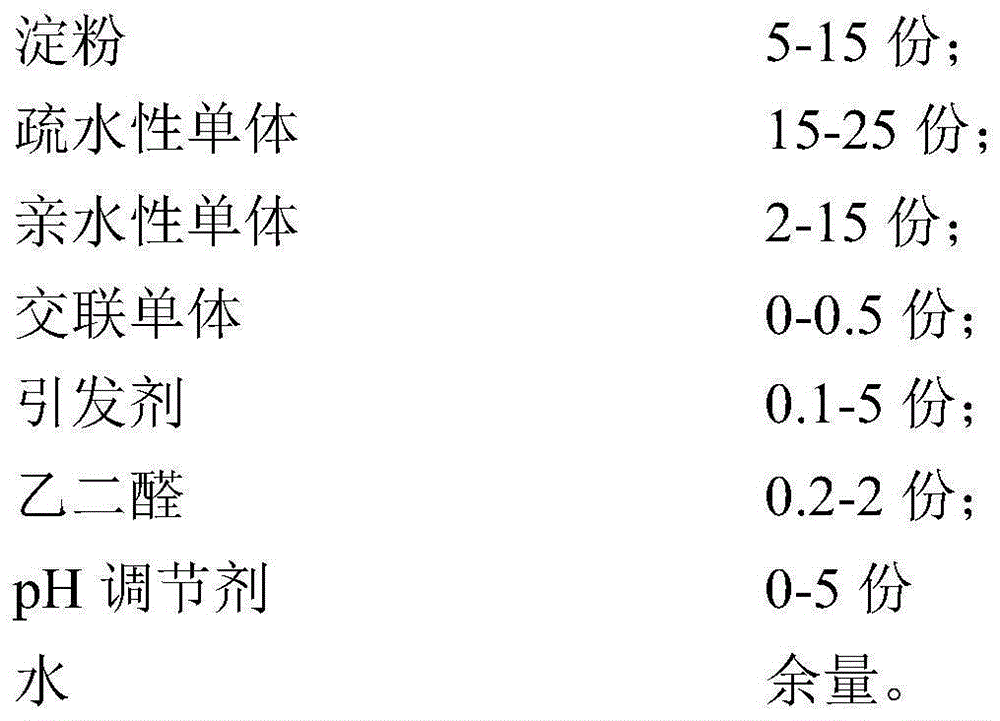

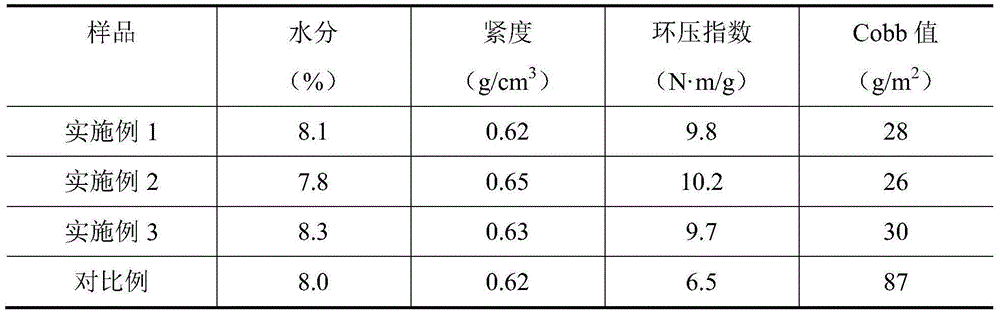

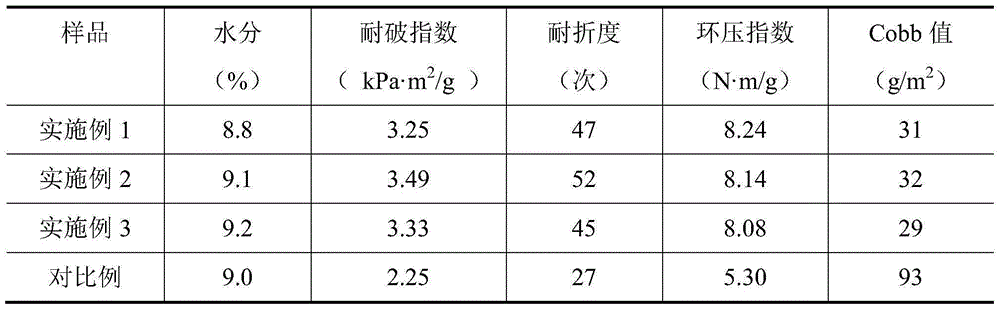

Enhanced multifunctional surface sizing assistant for papermaking and preparation method thereof

InactiveCN104988796AImprove stabilityHigh reactivityWater-repelling agents additionPaper coatingHydrophilic monomerBursting strength

The invention discloses a production formula of an enhanced multifunctional surface sizing assistant for papermaking and a preparation process. Specifically, the production formula involves: 5-15 parts of starch, 15-25 parts of a hydrophobic monomer, 2-15 parts of a hydrophilic monomer, 0-0.5 part of a crosslinking monomer, 0.1-5 parts of an initiator, 0.2-2 parts of glyoxal, 0-5 parts of a pH regulator, and the balance water. The sizing assistant prepared by the preparation process provided by the invention can enhance the strength indexes of paper and paper boards (like enhancing ring crush strength, bursting strength, folding endurance, moisture resistance and the like), also can endow paper and paper boards with good water resistance, meet the multipurpose sizing demands of paper and paper boards, and have good market prospects.

Owner:浙江弘利新材料有限公司

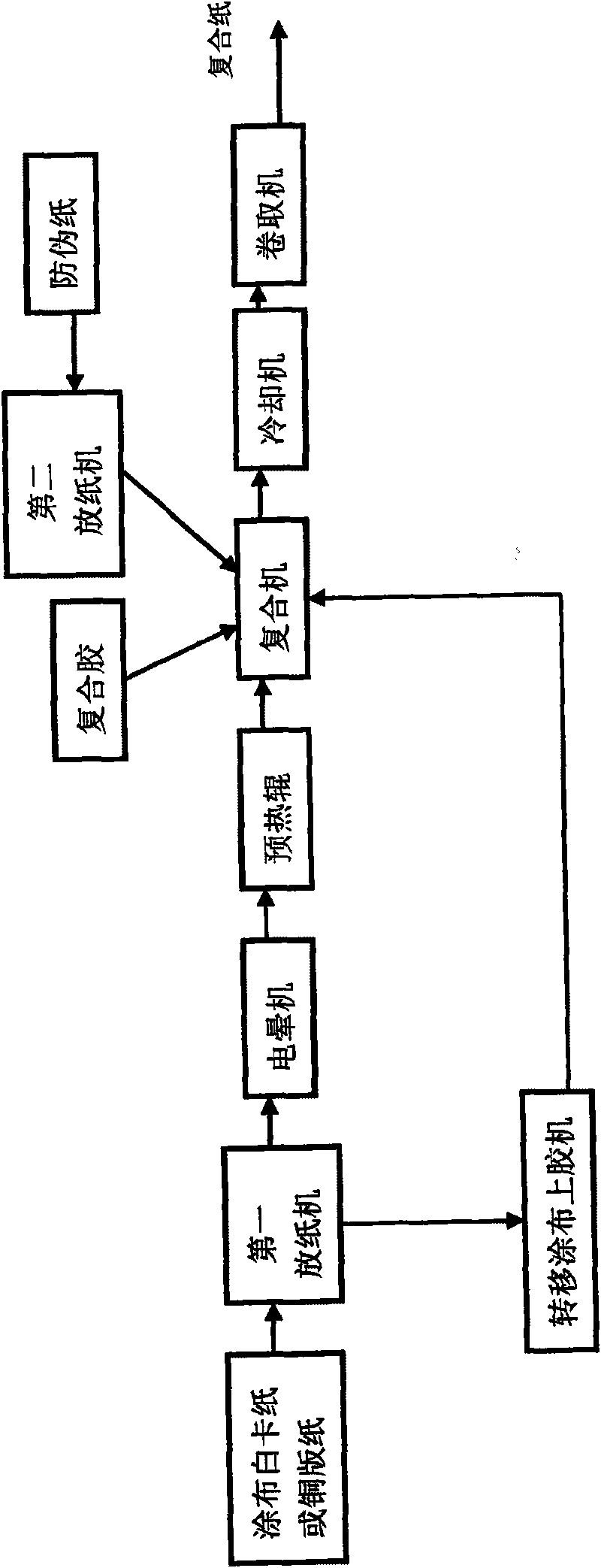

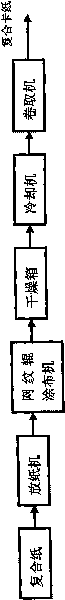

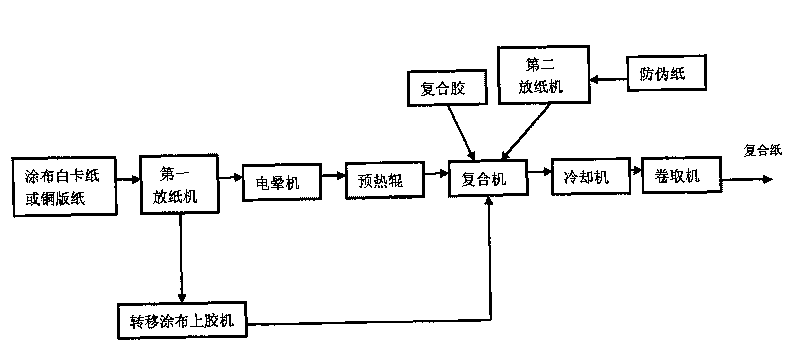

Forgery-prevention composite cardboard used for packaging cigarettes and processing method thereof

ActiveCN101701432AGood printabilityMeet the machine requirementsPaper coatingPaper/cardboardCardboardFolding endurance

The invention provides a forgery-prevention composite cardboard used for the external packaging of cigarettes and a processing method of the forgery-prevention composite cardboard. The forgery-prevention composite cardboard for packaging the cigarettes is provided with a basal layer and a forgery-prevention layer compounded on the basal layer, wherein the basal layer and the forgery-prevention layer are bonded and compounded by composite glue, and the surface of the forgery-prevention layer is also provided with a coating layer. The processing method of the forgery-prevention composite cardboard comprises the following steps: respectively preprocessing a coating white cardboard or copper printing paper used as the basal layer and forgery-prevention paper used as the forgery-prevention layer, then compounding the basal layer and the forgery-prevention layer into a whole and finally, applying the coating layer to the surface of the forgery-prevention layer, wherein the preprocessing comprises the preheating treatment steps of tension control, corona treatment and the like. The forgery-prevention composite cardboard has favorable printing performance, also has very strong forgery-prevention property and folding endurance and very good stiffness and meets the mounting requirement of a cigarette packaging machine completely; the forgery-prevention composite cardboard is especially suitable for serving as paper used for the external packaging of the cigarettes.

Owner:浙江京华新材料科技有限公司

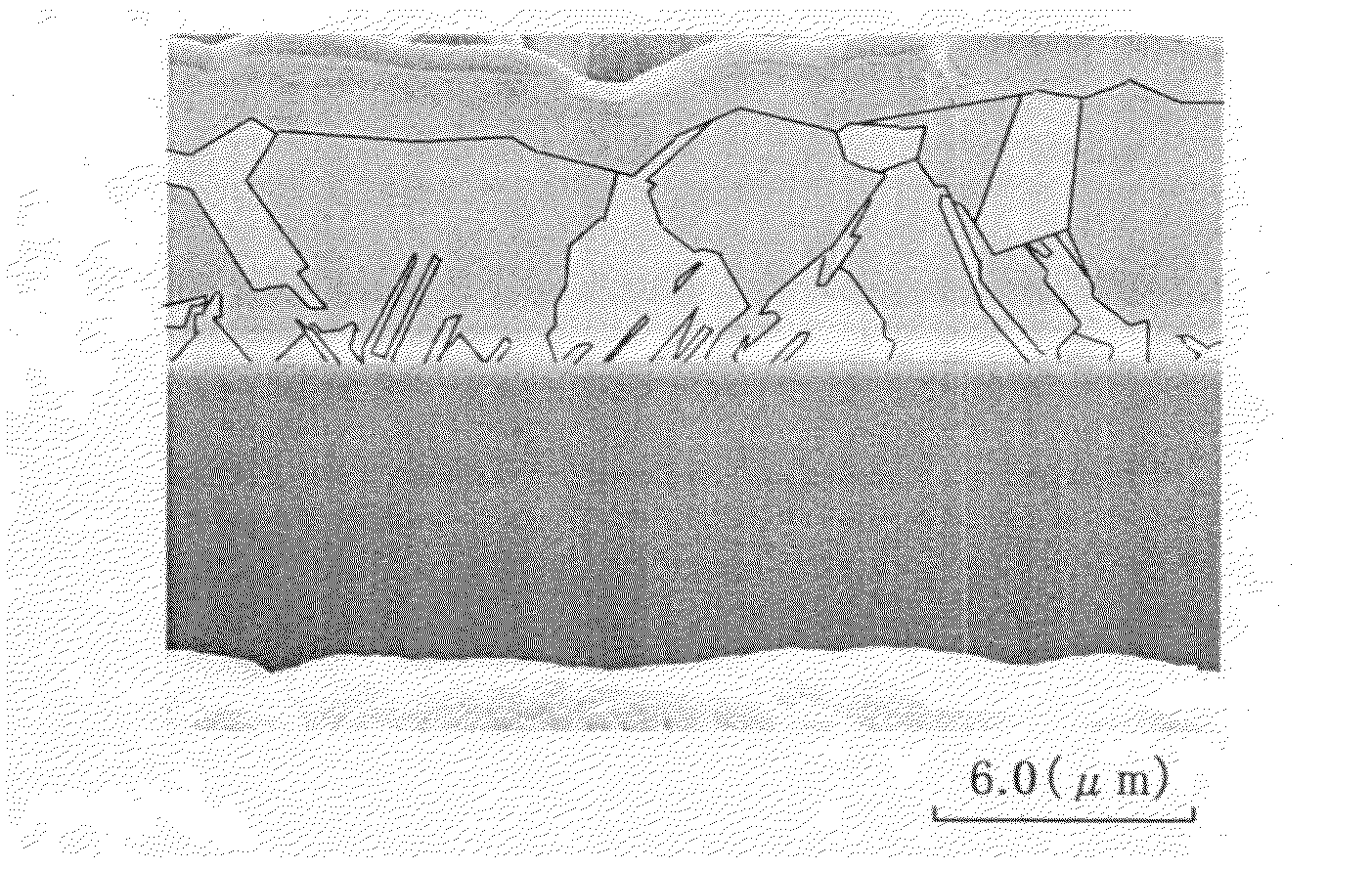

Two-layer flexible substrate, and copper electrolytic solution for producing same

InactiveUS20110311834A1Polycrystalline material growthFrom normal temperature solutionsFolding enduranceThiourea

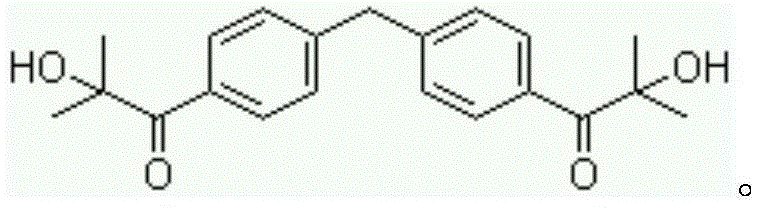

It is an object of the invention to provide a two-layer flexible substrate that excels in folding endurance and free from occurrence of Kirkendall voids or the like even when lead portions of COF are plated with tin and heat treatment is performed. The present invention is directed to a two-layer flexible substrate in which a copper layer is provided on one or both faces of an insulating film by using a copper electrolytic solution, wherein an average size of copper crystal grains constituting the copper layer is equal to or greater than 1 μm and equal to or less than a thickness of the copper layer, and a ratio of peak intensity of (200) to a sum total of intensities of six principal peaks {[peak intensity of (200)] / [sum total of peak intensities of (111), (200), (220), (311), (400), (331)]} in the X-ray diffraction of the copper layer is equal to or greater than 0.4. The above copper electrolytic solution for forming the copper layer contains a chloride ion and one or more of thiourea, thiourea derivatives, and thiosulfuric acid as additives.

Owner:JX NIPPON MINING& METALS CORP

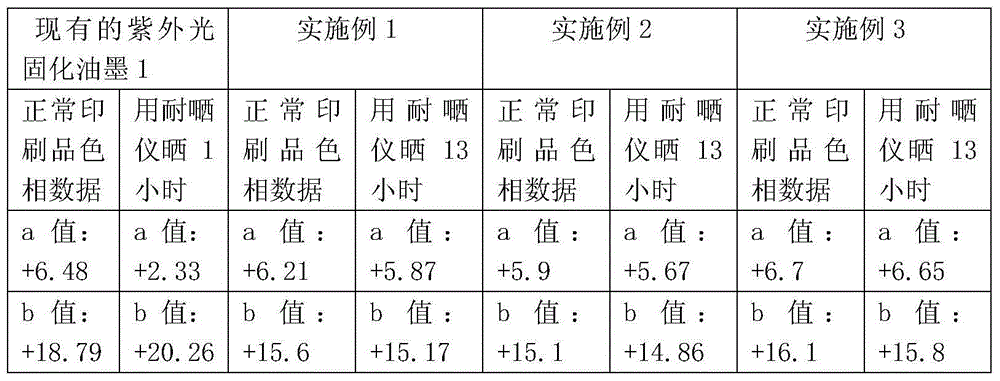

Ultraviolet curing ink and preparation method thereof

ActiveCN104804527AGood yellowing resistanceNot easy to yellowInksTripropylene glycolFolding endurance

Ultraviolet curing ink comprises the following components in weight proportion: 24-35% of polyurethane acrylate, 14-25% of epoxy acrylate, 15-25% of tripropylene glycol diacrylate, 15-25% of 1,1,1-trimethylol propane triacrylate, 0.5-2.5% of 1,1'-(methylenedi-4,1-phenylene)bis[2-hydroxyl-2-methyl-1-acetone],0.5-1.5% of Oligo[2-hydroxy-2-methyl-1-[4-(1-methylvinyl)phenyl]propanone], 0.1-1% of polydimethylsiloxane, 0.1-1% of polyether modified polysiloxane and 1-5% of polyethylene wax. The invention further provides the preparation method of the ultraviolet curing ink. According to the ultraviolet curing ink, an ink printing layer with a wrinkle effect is formed after the ultraviolet curing ink is cured after printing, and the ink printing layer has good anti-yellowing performance and good folding endurance.

Owner:SHANTOU DONGFENG PRINTING CO LTD

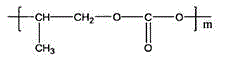

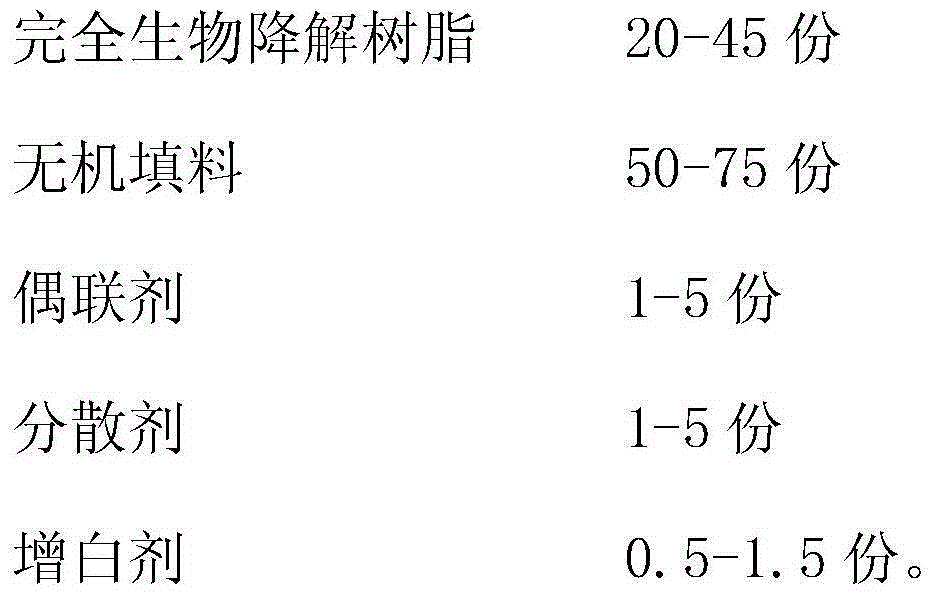

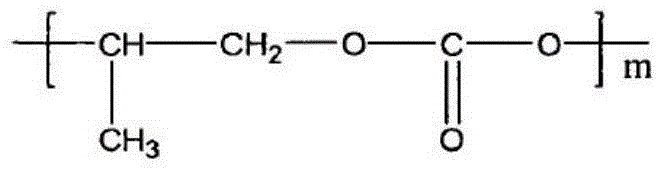

Biodegradable stone paper and preparation method thereof

InactiveCN104693710ASolve the problem of non-biodegradableTo achieve the purpose of environmental protectionFolding endurancePapermaking

The invention discloses biodegradable stone paper and a preparation method thereof, and belongs to the technical field of light industrial papermaking. Main ingredients of the stone paper comprise, 50-75 parts of inorganic filler, 20-45 parts of full biodegradable resin, 1-5 parts of coupling agent, 1-5 parts of dispersing agent and 0.5-1.5 parts of brightening agent, wherein the full biodegradable resin is a mixture of carbon-dioxide-based full-degradable plastic and biodegradable polyester. The stone paper prepared by the preparation method is a full-degradable material, and the problem that existing stone paper regards polyethylene as a base body, and resin is not degradable is solved. The stone paper has a series of advantages that the strength is higher, the folding endurance is high, and the whiteness is high.

Owner:SUN YAT SEN UNIV +1

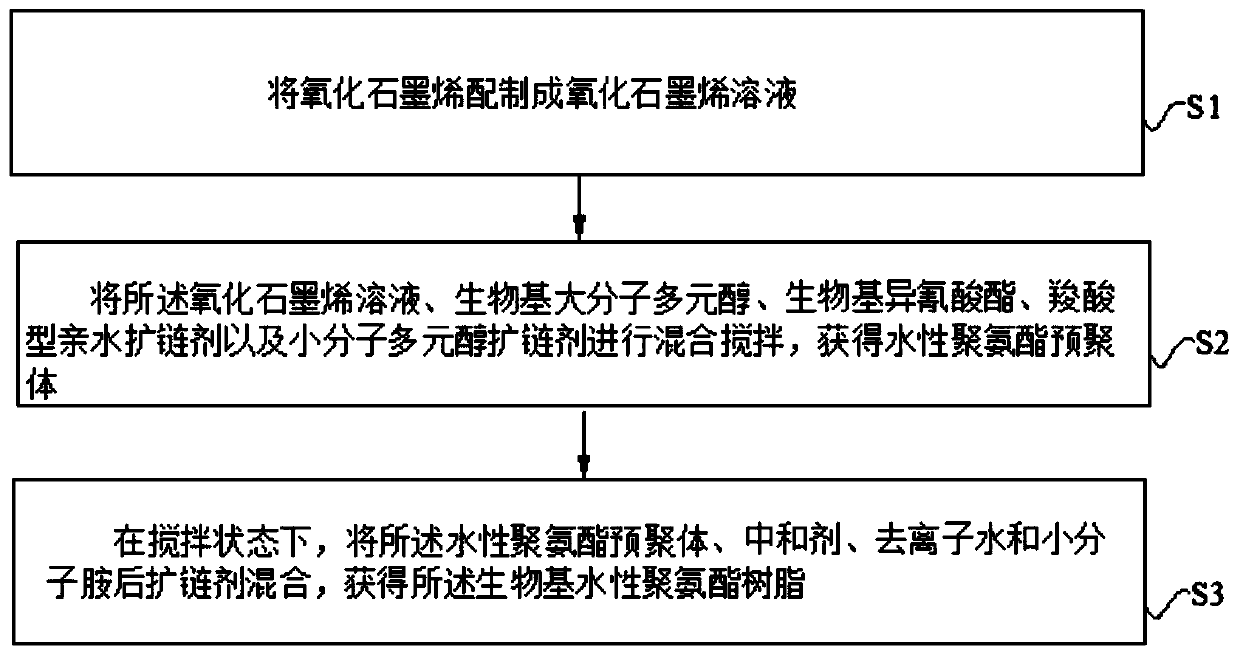

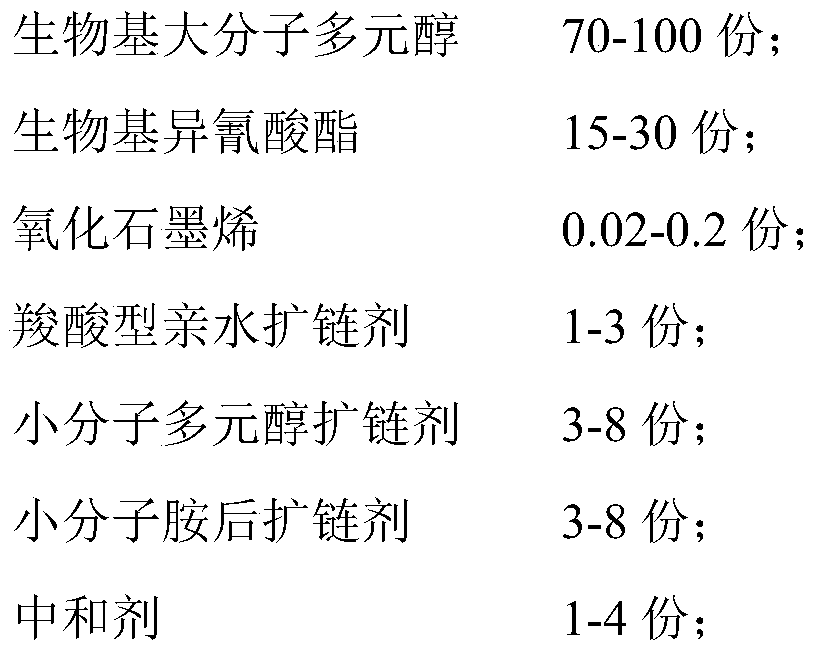

Biological aqueous polyurethane resin, preparation method therefor and application of biological aqueous polyurethane resin

The invention discloses biological aqueous polyurethane resin, a preparation method therefor and an application of the biological aqueous polyurethane resin. The biological aqueous polyurethane resinat least comprises the following ingredients in parts by mass: 70-100 parts of biological macromolecular polyol, 15-30 parts of biological isocyanate, 0.02-0.2 part of graphene oxide. According to thebiological aqueous polyurethane resin, the preparation method therefor and the application of the biological aqueous polyurethane resin, properties such as folding endurance, wear resistance and mechanical properties of the biological aqueous polyurethane resin can be improved.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com